Page 1

TopPage

LC-37AD5E

SERVICE MANUAL

No. S77K9LC37AD5E

LCD COLOUR TELEVISION

CONTENTS

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRE-

CAUTION ............................................................i

Precautions for using lead-free solder ...............ii

CHAPTER 1. OPERATION MANUAL

[1] SPECIFICATIONS ......................................... 1-1

[2] OPERATION MANUAL .................................. 1-2

[3] DIMENSIONS ................................................ 1-7

CHAPTER 2. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS ................... 2-1

CHAPTER 3. ADJUSTMENT PROCEDURE

[1] After replacement of any PWB and/or IC for

repair, note the following. ............................... 3-1

[2] SOFTWARE UPDATING................................ 3-1

[3] Entering and exiting the adjustment pro-

cess mode.................................................... 3-16

[4] Remote controller key operation and de-

scription of display in adjustment process

mode. ........................................................... 3-16

[5] Adjustment process mode menu.................. 3-17

[6] Special features............................................ 3-18

[7] Video signal adjustment procedure.............. 3-19

[8] White Balance Adjustment ........................... 3-20

[9] Initialization to factory settings ..................... 3-21

[10] Lamp error detection .................................... 3-21

[11] Public Mode (Hotel Mode)............................ 3-22

MODEL

CHAPTER 5. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS .........................5-1

CHAPTER 6. OVERALL WIRING DIAGRAM/BLOCK

DIAGRAM

[1] OVERALL WIRING DIAGRAM ......................6-1

[2] MAIN BLOCK DIAGRAM...............................6-2

[3] SYSTEM BLOCK DIAGRAM .........................6-3

[4] POWER BLOCK DIAGRAM ..........................6-4

CHAPTER 7. PRINTED WIRING BOARD

[1] MAIN UNIT PRINTED WIRING BOARD........7-1

[2] AV UNIT PRINTED WIRING BOARD............7-5

[3] POWER UNIT PRINTED WIRING

BOARD.......................................................... 7-8

[4] D-TUNER UNIT PRINTED WIRING

BOARD........................................................7-10

[5] KEY UNIT PRINTED WIRING BOARD ....... 7-10

[6] DIGITAL UNIT PRINTED WIRING

BOARD........................................................ 7-11

[7] R/C, LED UNIT PRINTED WIRING

BOARD........................................................7-15

CHAPTER 8. SCHEMATIC DIAGRAM

[1] DESCRIPTION OF SCHEMATIC DIA-

GRAM............................................................8-1

[2] SCHEMATIC DIAGRAM................................8-2

Parts Guide

LC-37AD5E

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROBLESHOOTING TABLE ......................... 4-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

LC-37AD5E

LC37AD5E

SAFETY PRECAUTION

Service Manual

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CAUTION:

FOR CONTINUED PROTECTION AGAINST A

RISK OF FIRE REPLACE ONLY WITH SAME

TYPE FUSE.

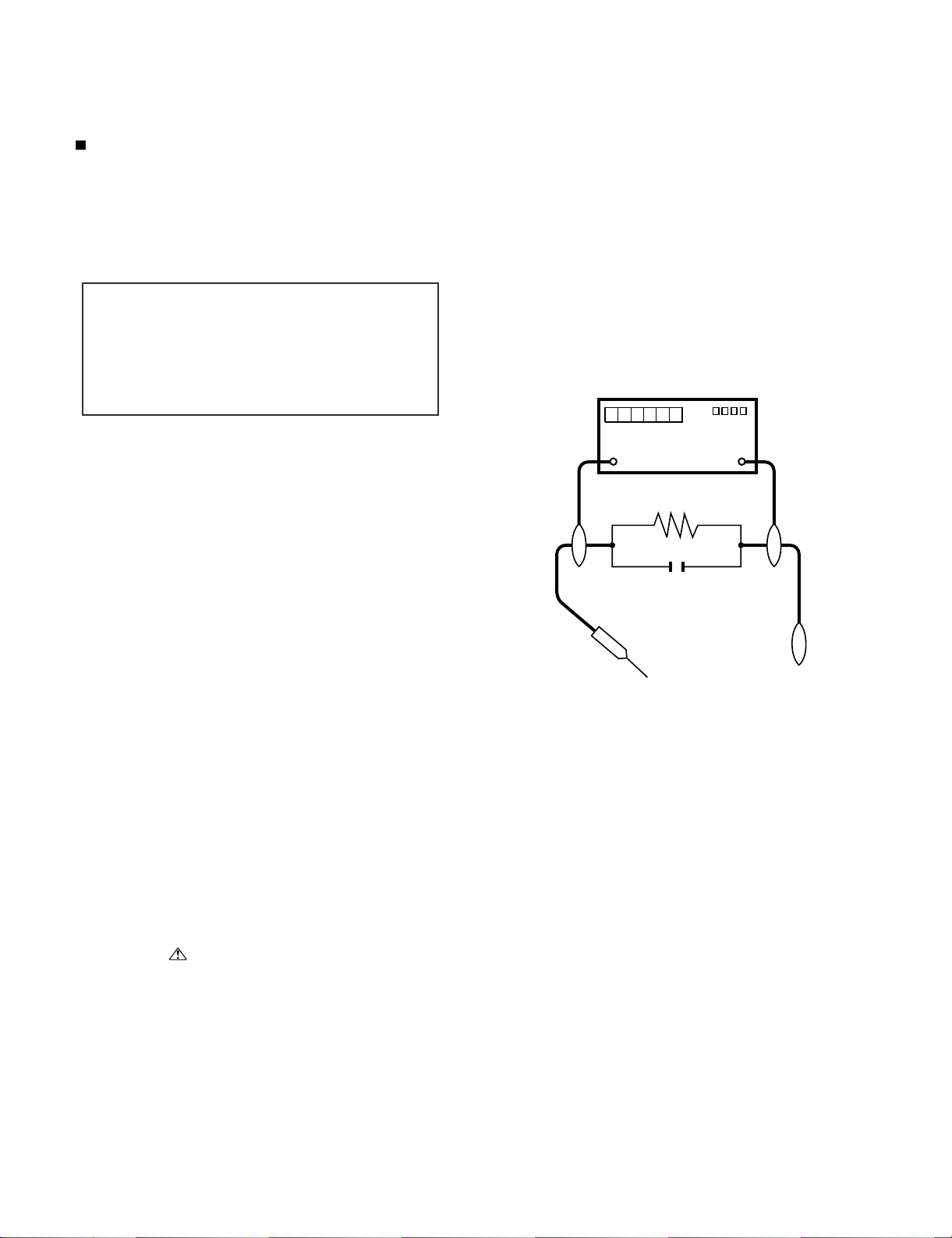

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 1.05 V peak (this corresponds to 0.7 mA peak AC.)

or more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

F701 (T4AL/AC250V)

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

• Plug the AC cord directly into a 220~240 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15µF capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

SAFETY NOTICE

Many electrical and mechanical parts in LCD color television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by “ ” and shaded areas in the Replacement Parts

List and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

DVM

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

i

Page 3

LC-37AD5E

Precautions for using lead-free solder

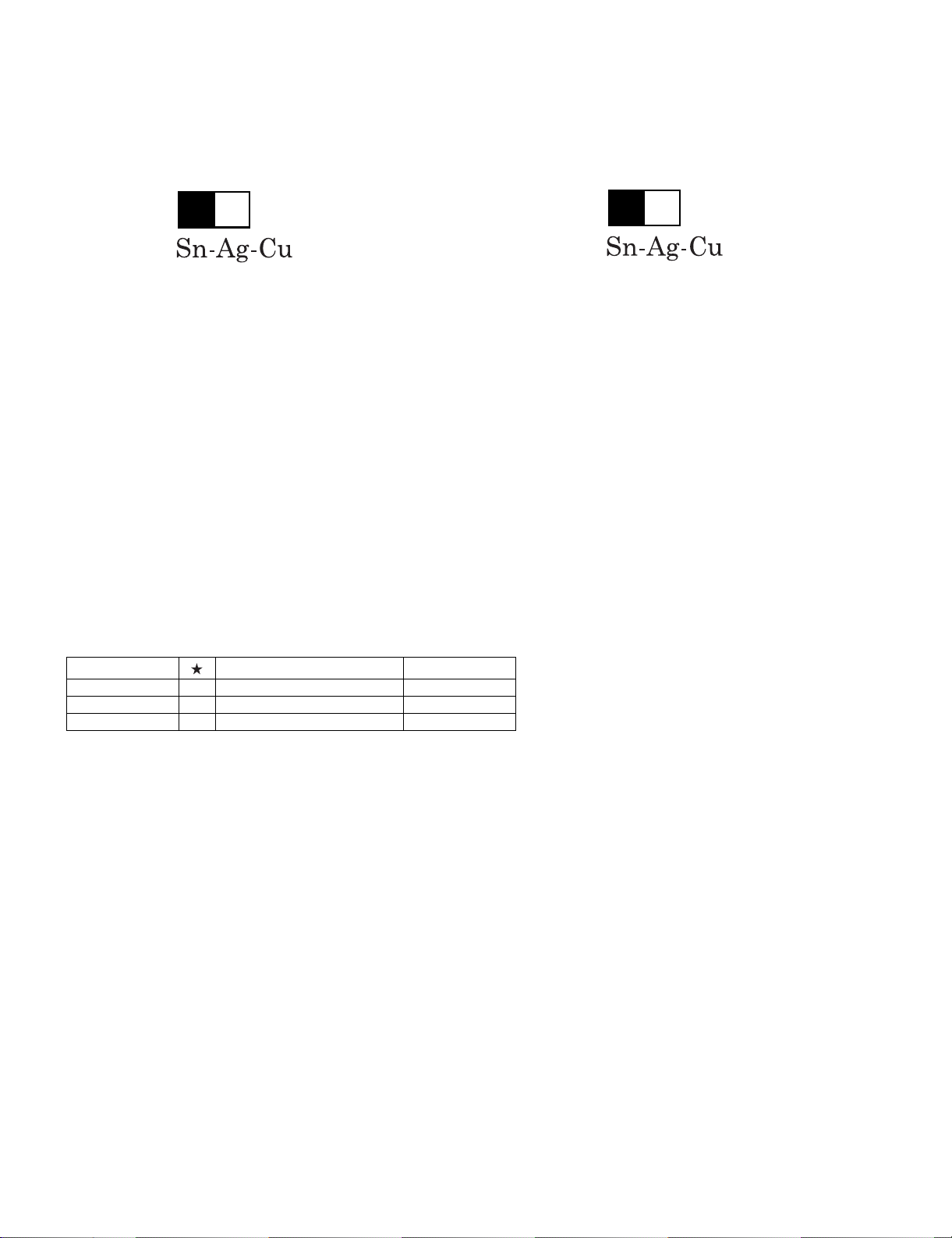

Employing lead-free solder

• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

ii

Page 4

LC-37AD5E

LC37AD5E

CHAPTER 1. OPERATION MANUAL

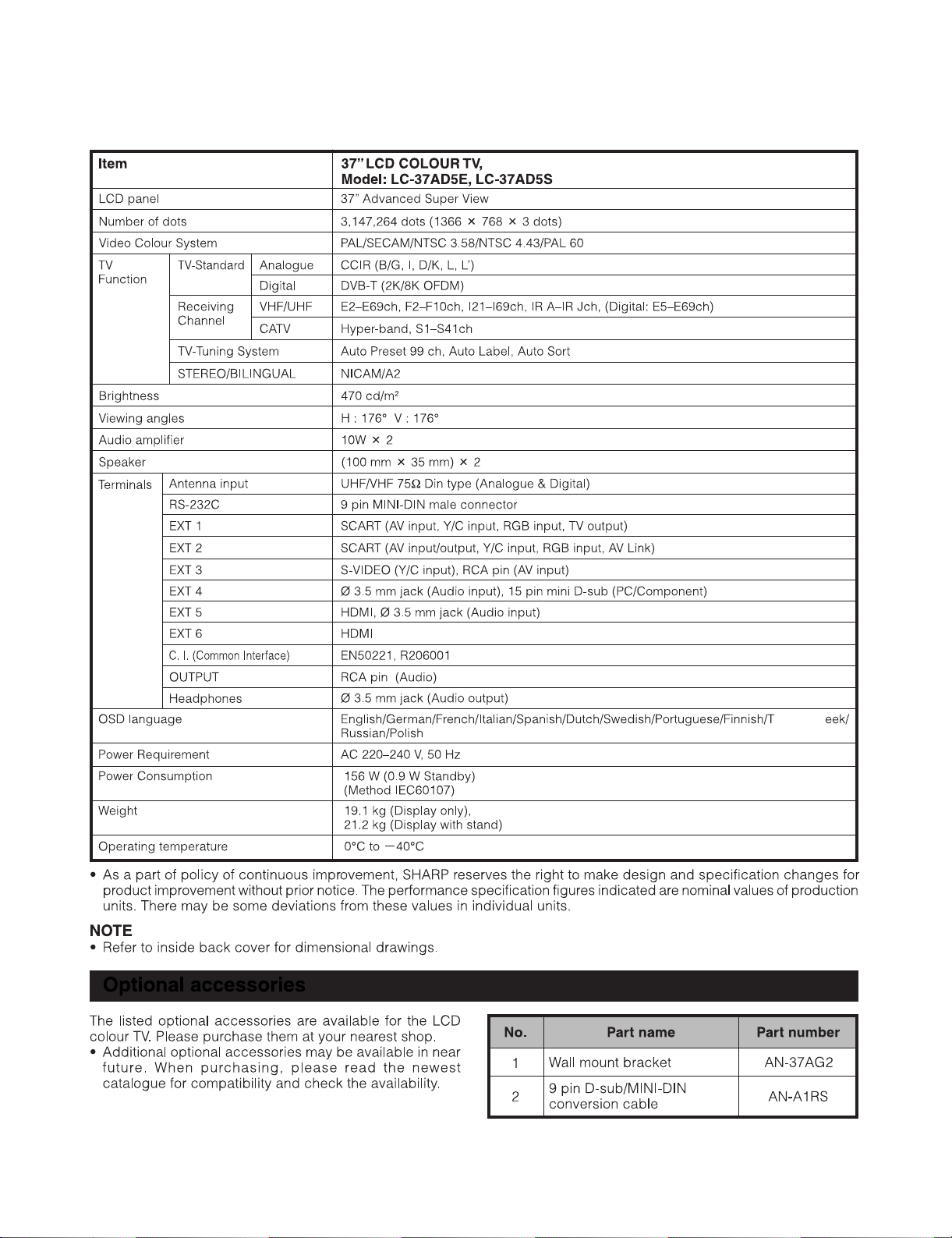

[1] SPECIFICATIONS

Service Manual

urkis h/Gr

1 – 1

Page 5

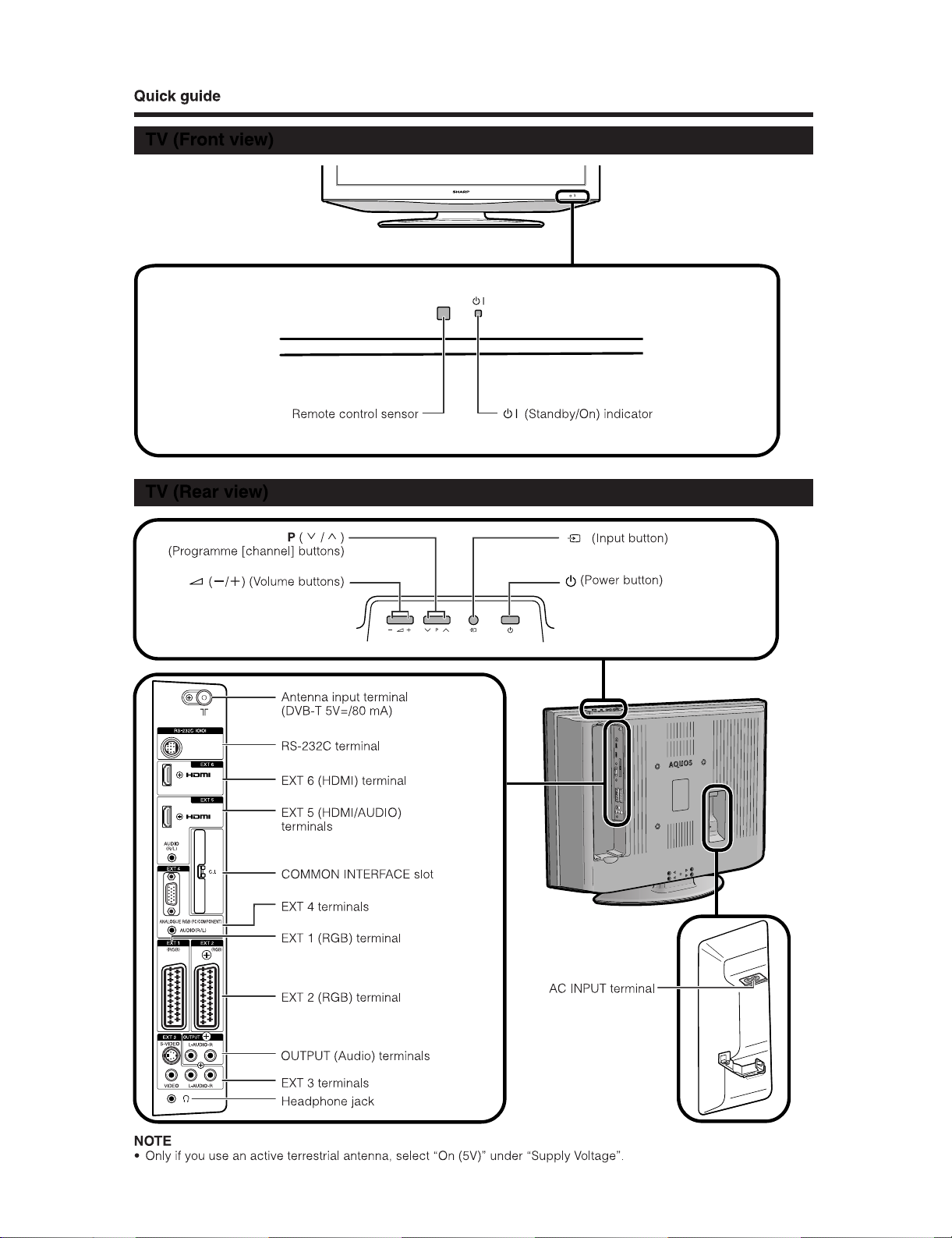

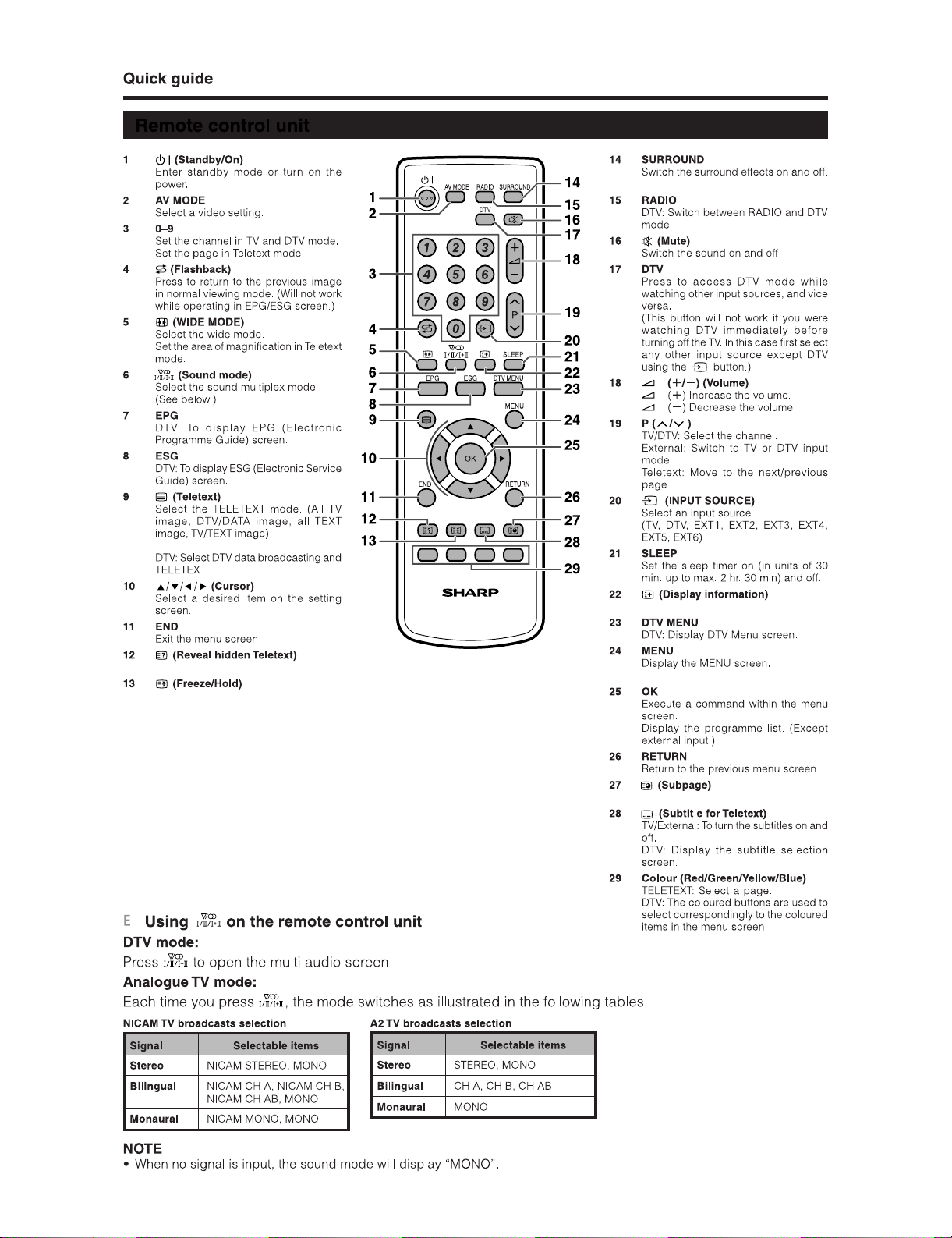

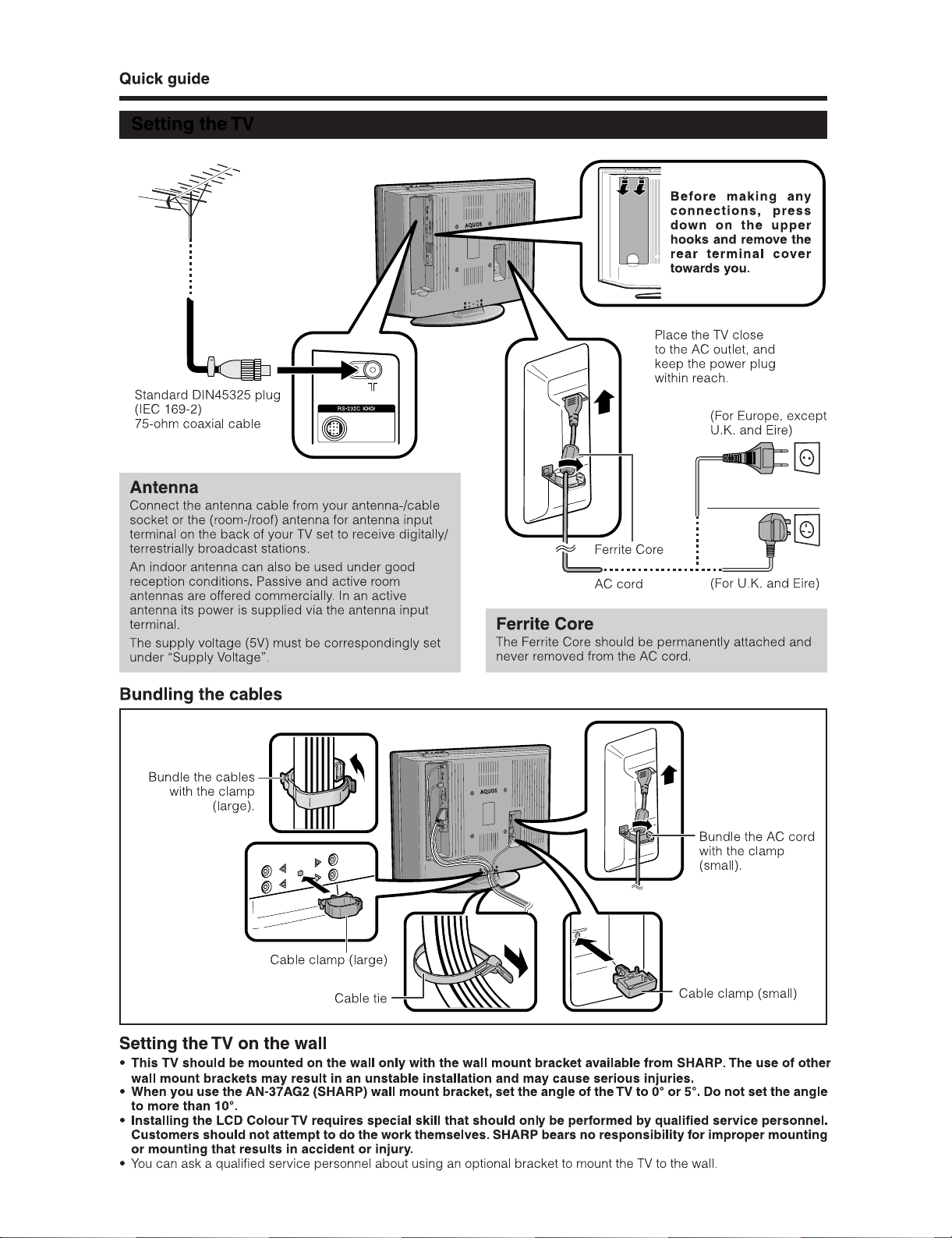

[2] OPERATION MANUAL

LC-37AD5E

1 – 2

Page 6

LC-37AD5E

1 – 3

Page 7

LC-37AD5E

1 – 4

Page 8

LC-37AD5E

1 – 5

Page 9

LC-37AD5E

1 – 6

Page 10

LC-37AD5E

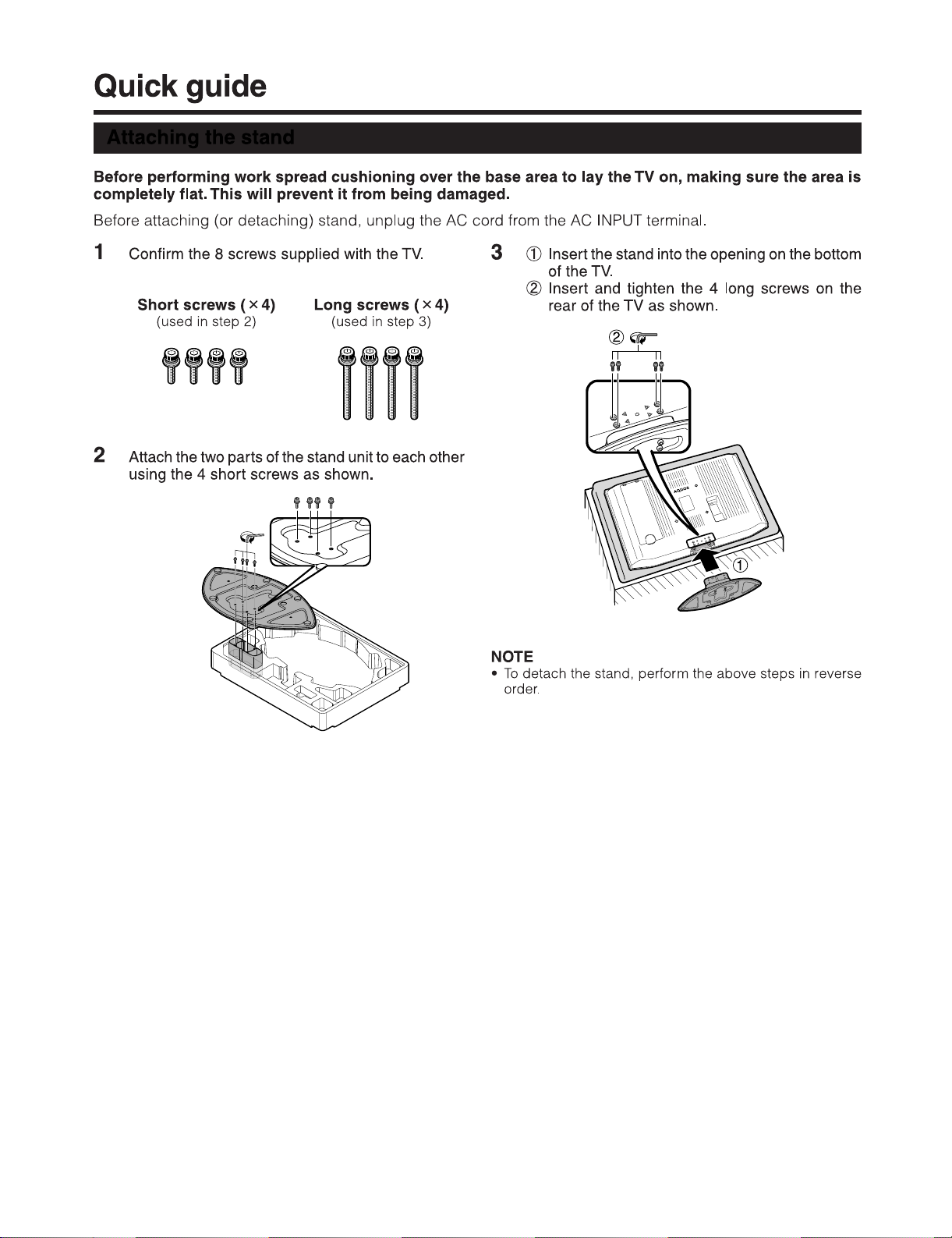

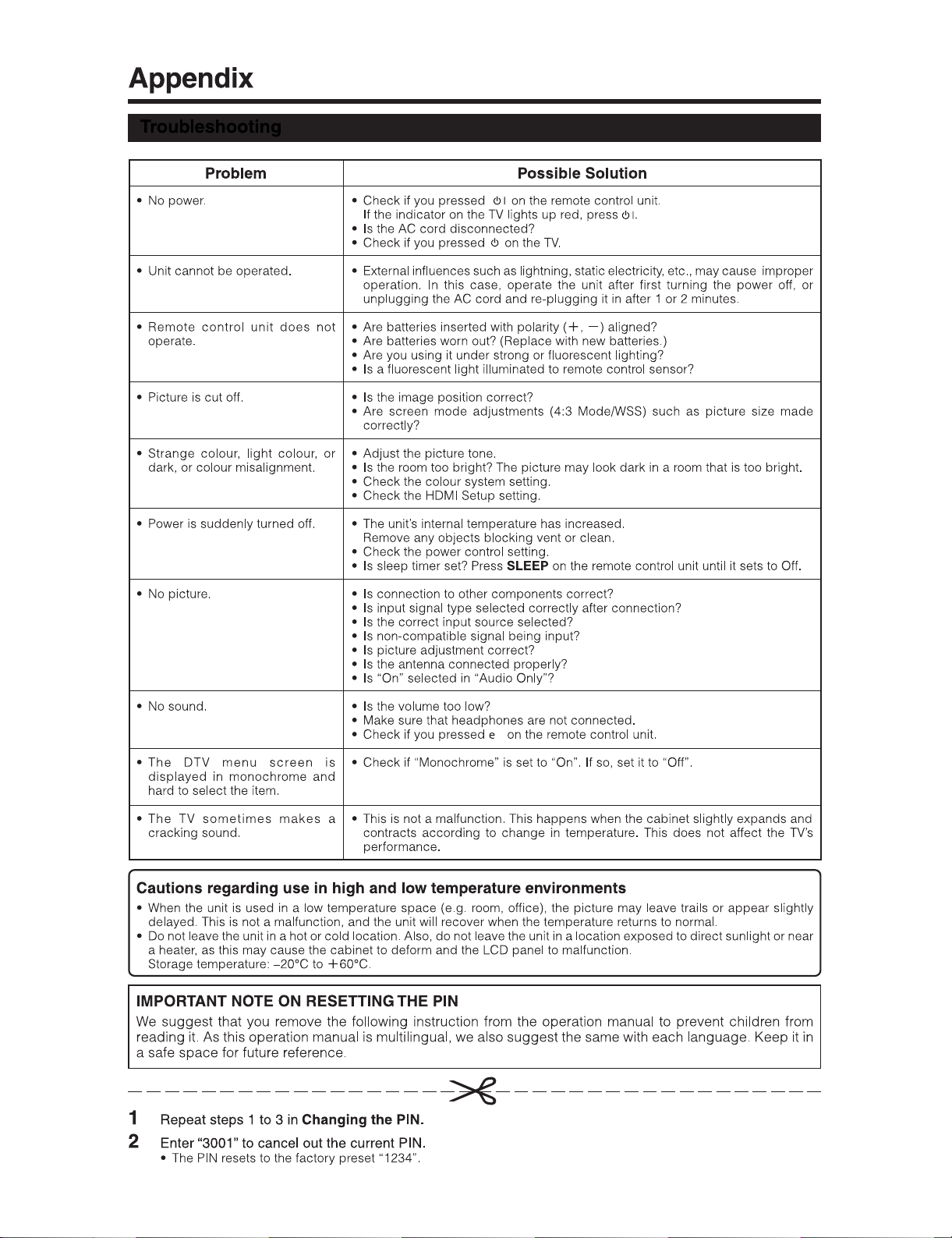

[3] DIMENSIONS

Units: inches (mm)

919.0

822.6

650.5

601.5

463.8

370.4

49.0

547.0

200.0

293.0

116.5114.8

85.0

200.0

1 – 7

Page 11

Set each holder like this way.

Others are omitted .

#LCD HOLDER Set to gide lib of CAB-A

Push untill Locked

LC37AD5E

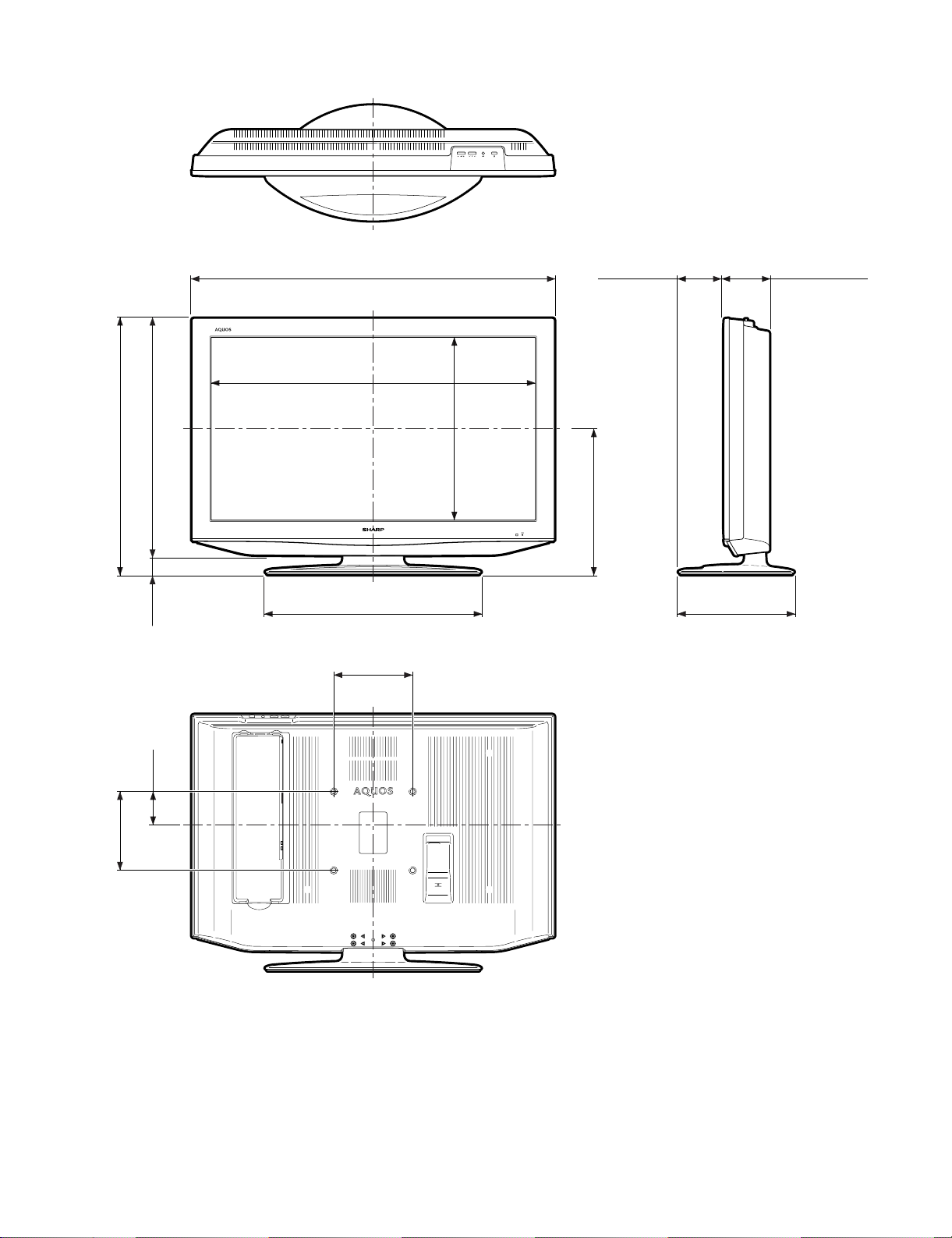

CHAPTER 2. REMOVING OF MAJOR PARTS

Service Manual

[1] REMOVING OF MAJOR PARTS

LC-37AD5E

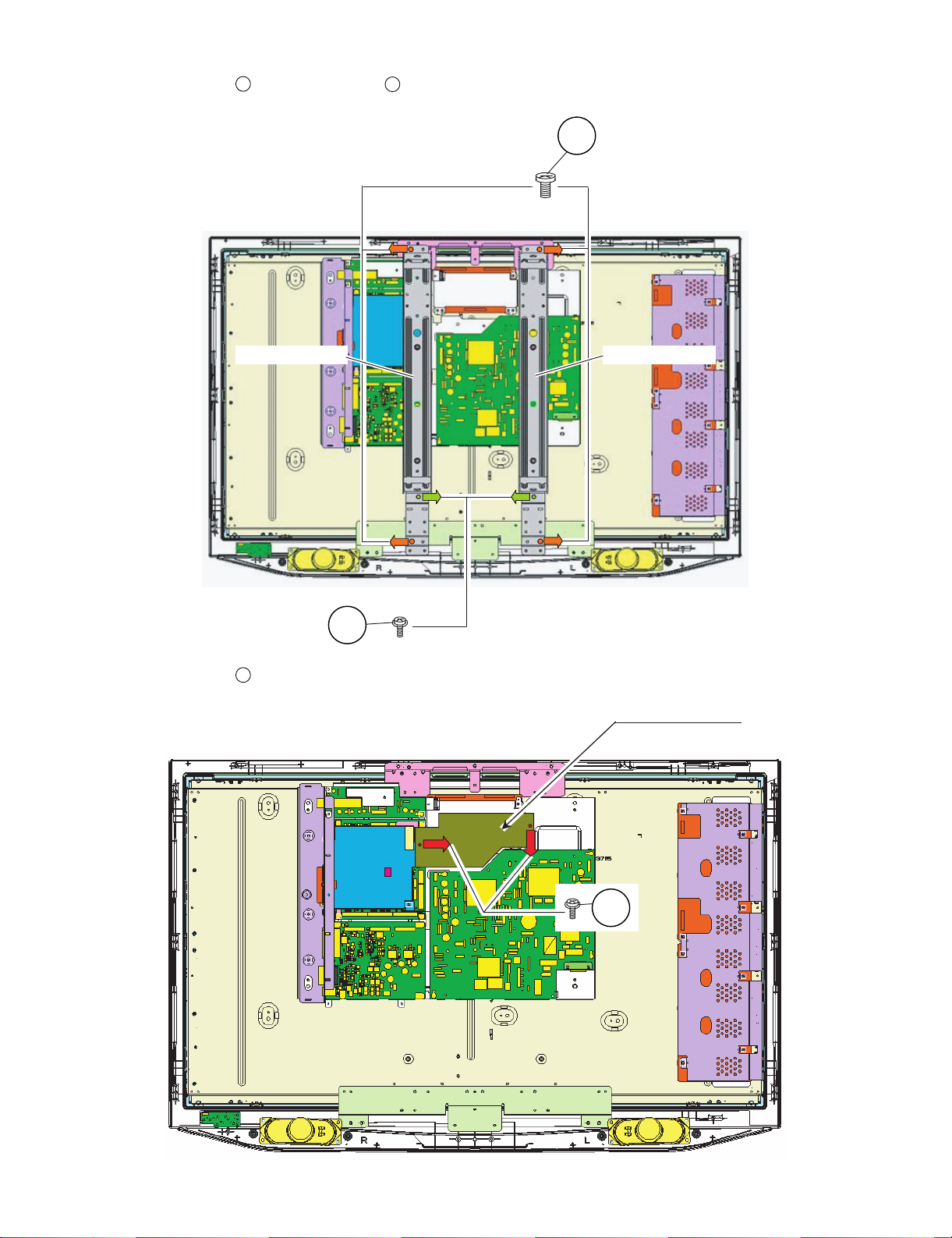

1. Remove the 4 lock screws , and the 12 lock screws . Detach the Rear Cabinet.

1

2

2

1

Rear Cabinet

2. Remove the 6 lock LCD Side Holders .

3

3

3

3

3

3

3

2 – 1

Page 12

LC-37AD5E

STAND ANGLE UNIT

Wire "KM" to WH

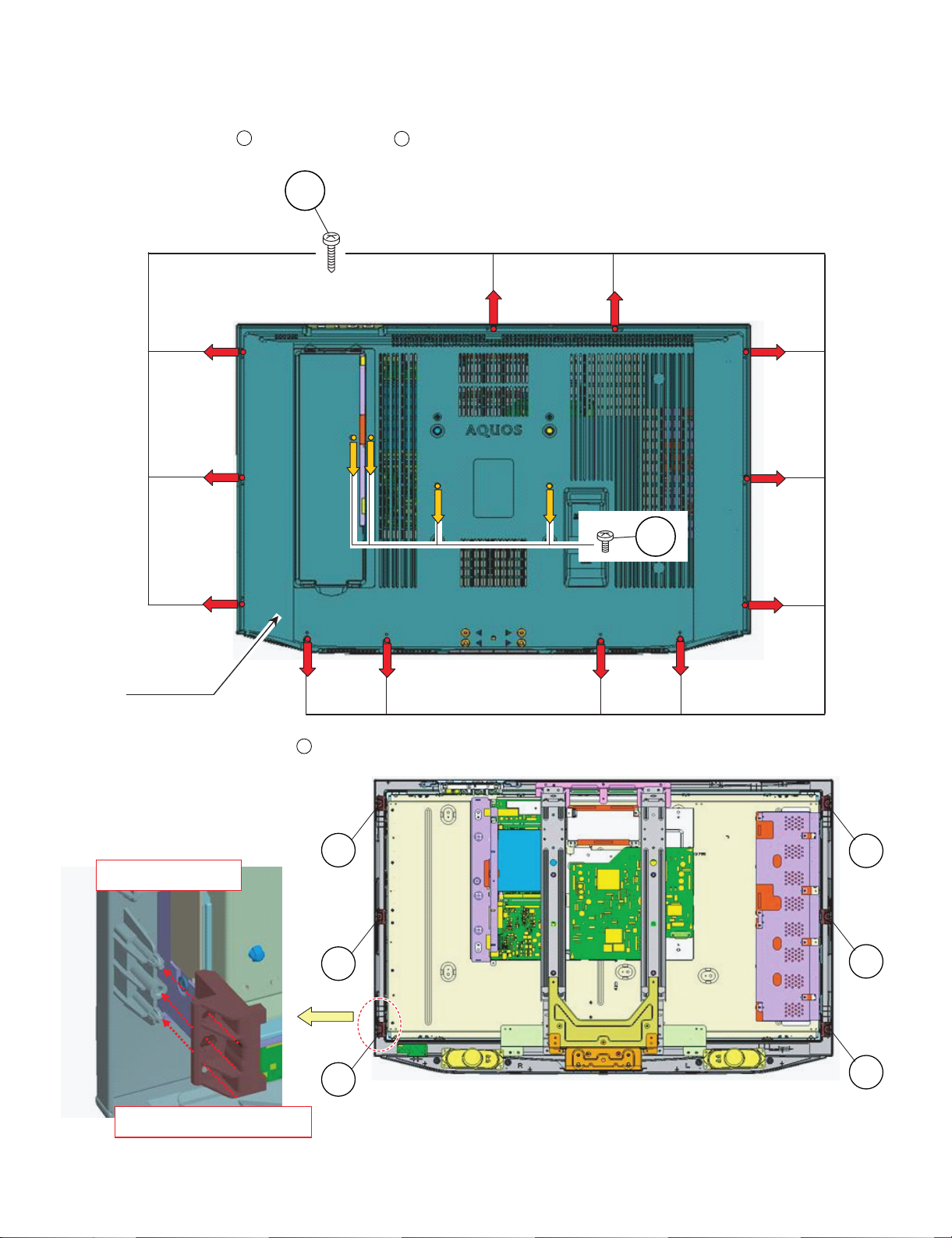

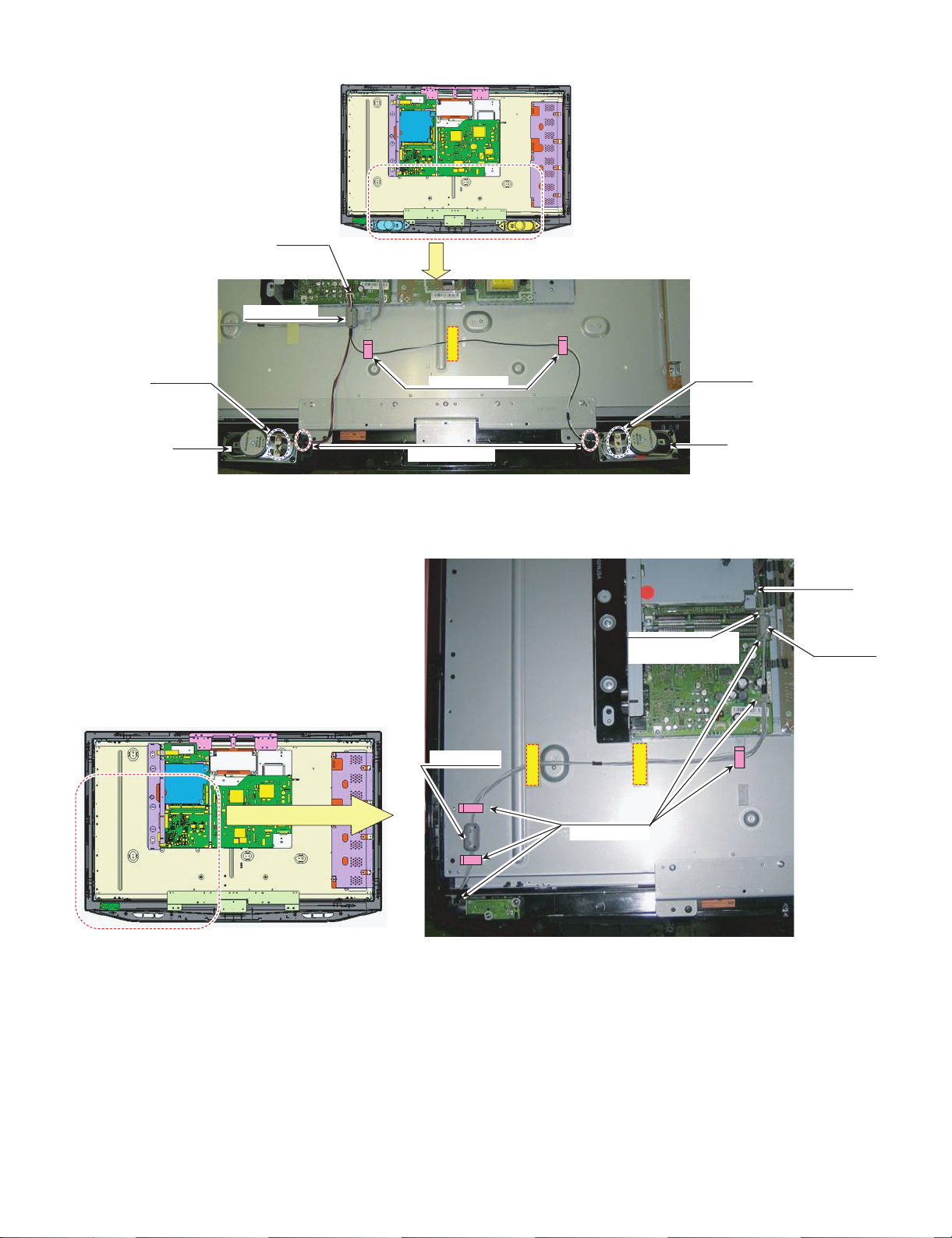

3. Remove the 9 lock screws . Detach the Stand Angle Unit.

4

4

4. Remove the 2 lock screws . Detach the Top Control Cover Ass'y.

TOP CONTROL COVER

Wire "KM"

5

TOP CONTROL COVER ASS'Y

5

2 – 2

Page 13

LC-37AD5E

5. Remove the 2 lock scrwes , and the 4 lock screws . Detach the Center Angle-L/R.

6

7

7

CENTER ANGLE LCENTER ANGLE R

6

6. Remove the 2 lock scrwes . Detach the Digital Shield.

8

DIGITAL SHIELD

8

2 – 3

Page 14

LC-37AD5E

FOR Wire "SP"

Wire "SP" to SP Lib

Wire "SP" to WH

FOR Wire "RA"

#StoptomoveCore,

No shape to Shield A ngle

Wire "RA" to WH

7. Remove all the connectors from PWBs.

Wire "SP"

Wire "SP-R"

SP-R

Wire "SP-L"

SP-L

Wire "RA"

for "RA" wire

2 – 4

Page 15

LC-37AD5E

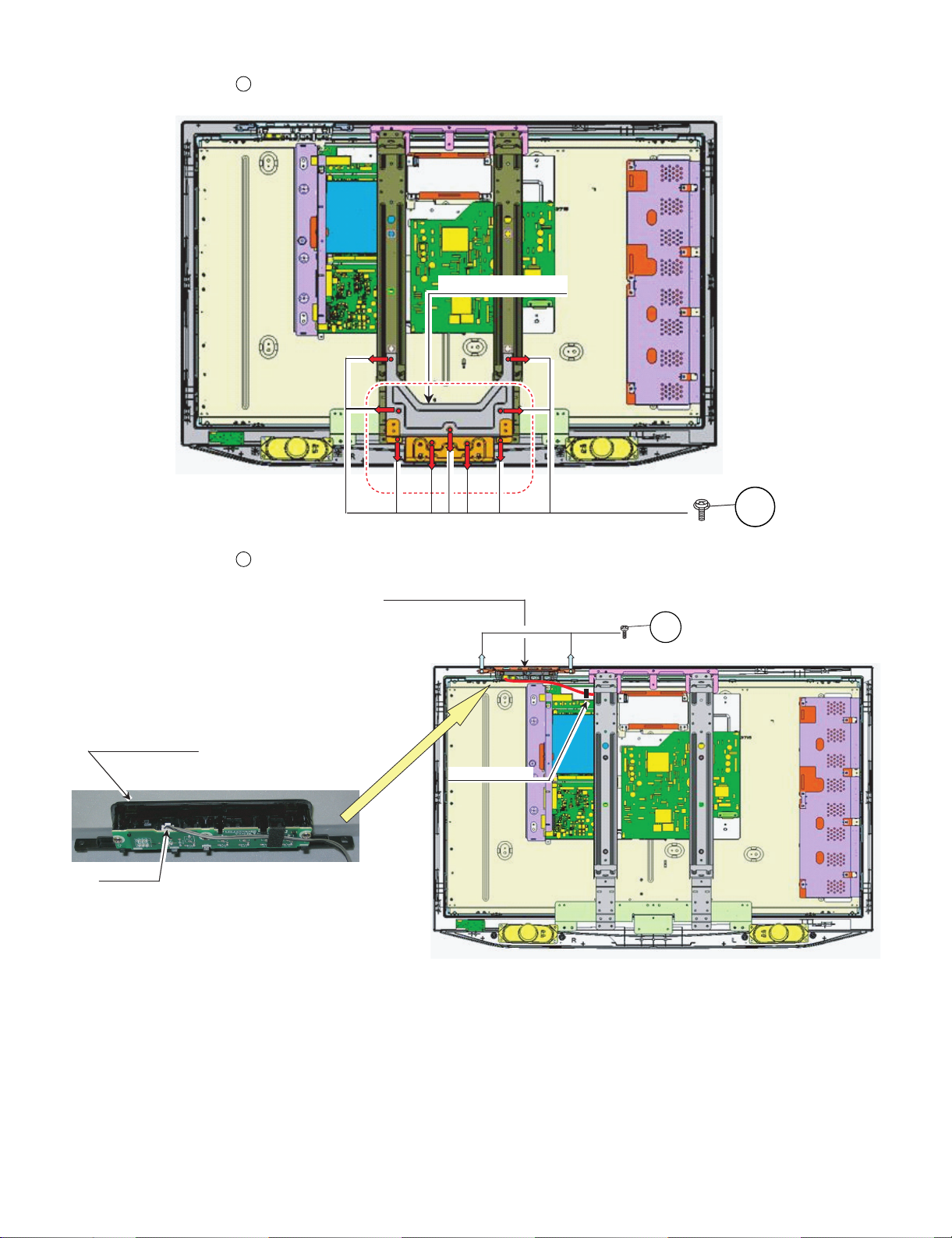

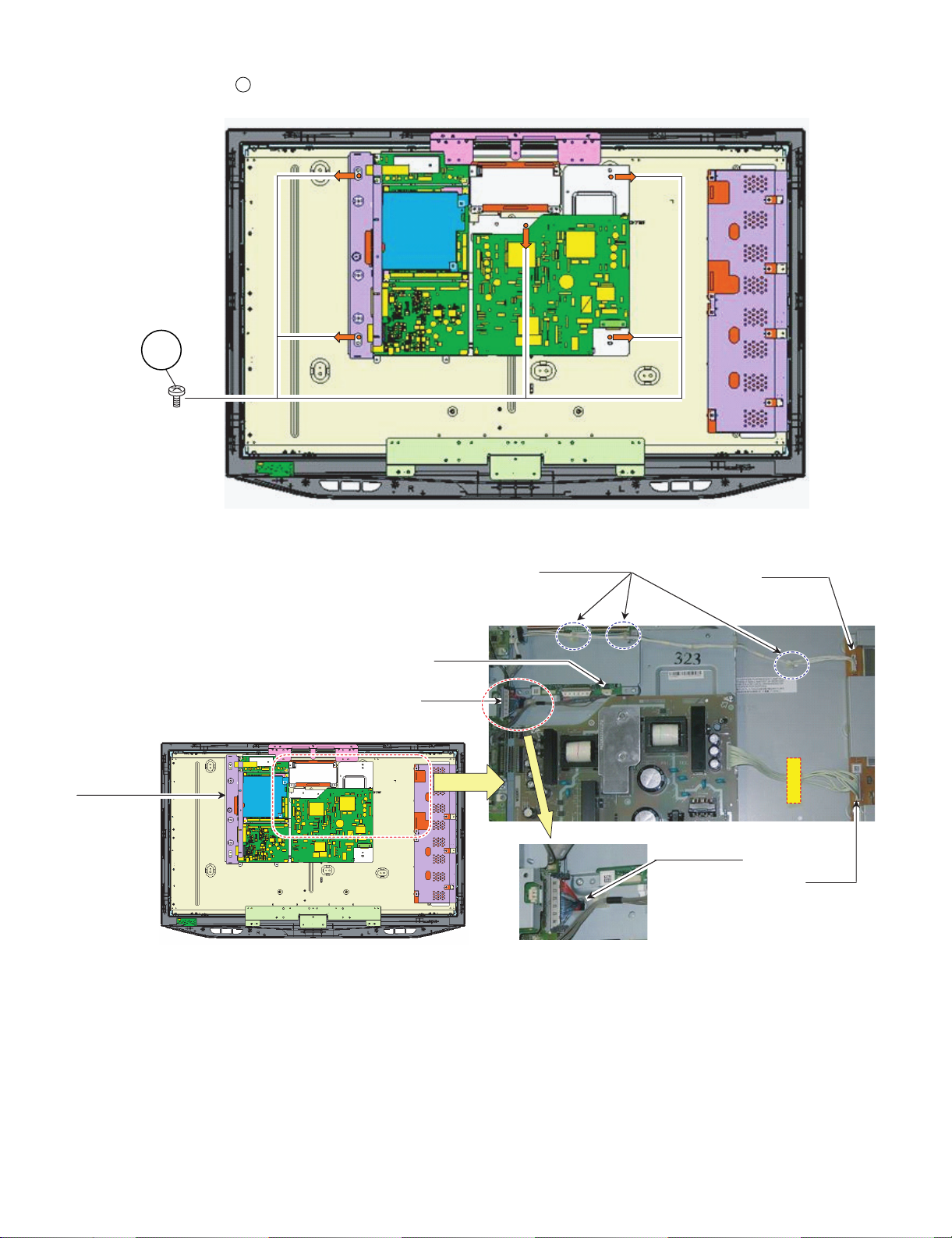

8. Remove the 5 lock screws . and detach the Chassis Tray Unit.

9

9

9. Remove all the connectors from PWBs.

Chassis Tray Unit

Wire "SH"

Wire "LV"

Wire "LB" to WH

Wire "LB"

Wire "LV" to WH

Wire "LA"

2 – 5

Page 16

LC-37AD5E

Tuner Unit

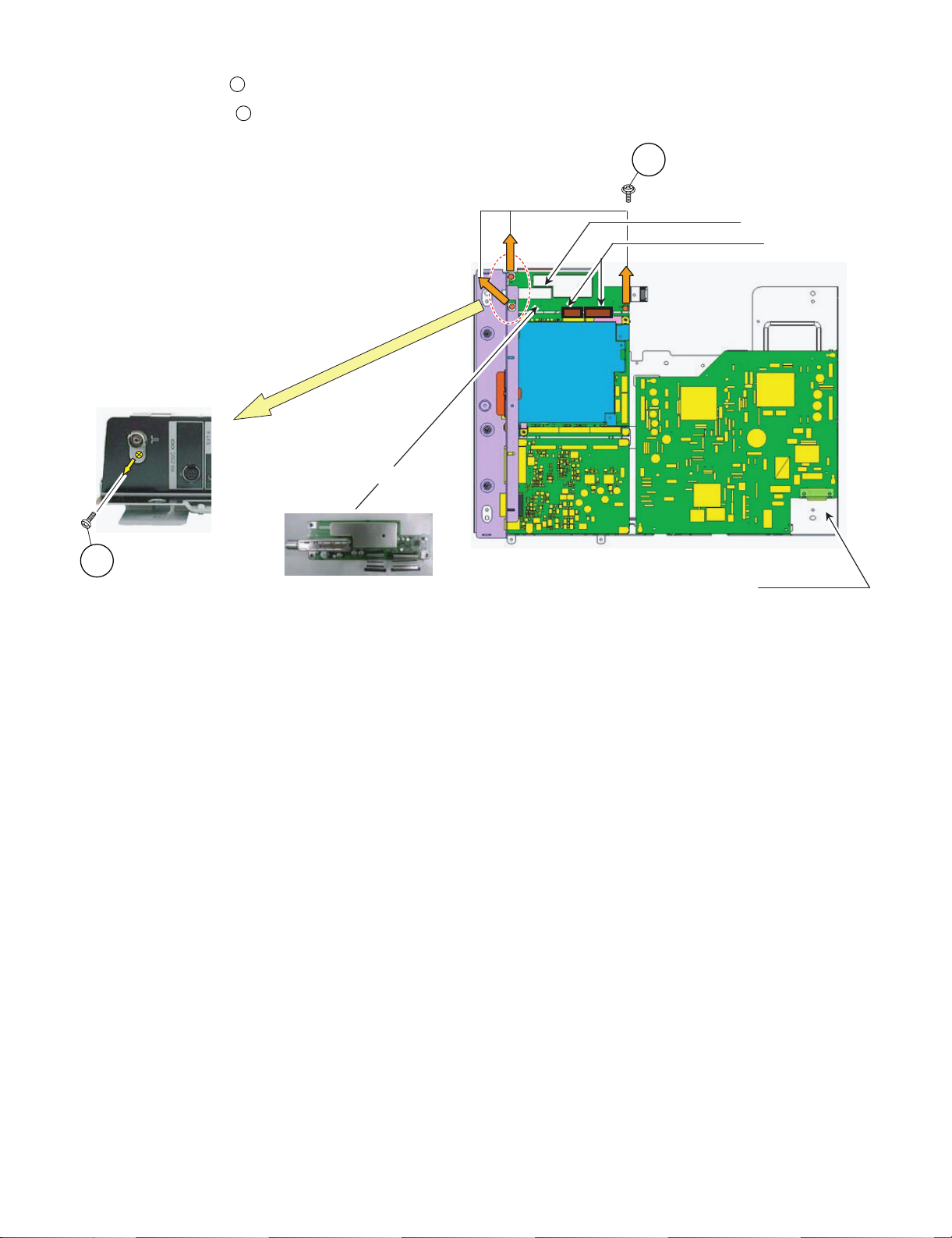

10.Remove the 1 lock screw . Detach the Terminal Cover.

11.Remove the 2 lock screws . Detach the D-Tuner Unit.

10

11

11

D-TUNER Unit

B to B connector

10

Chassis Tray Unit

2 – 6

Page 17

LC-37AD5E

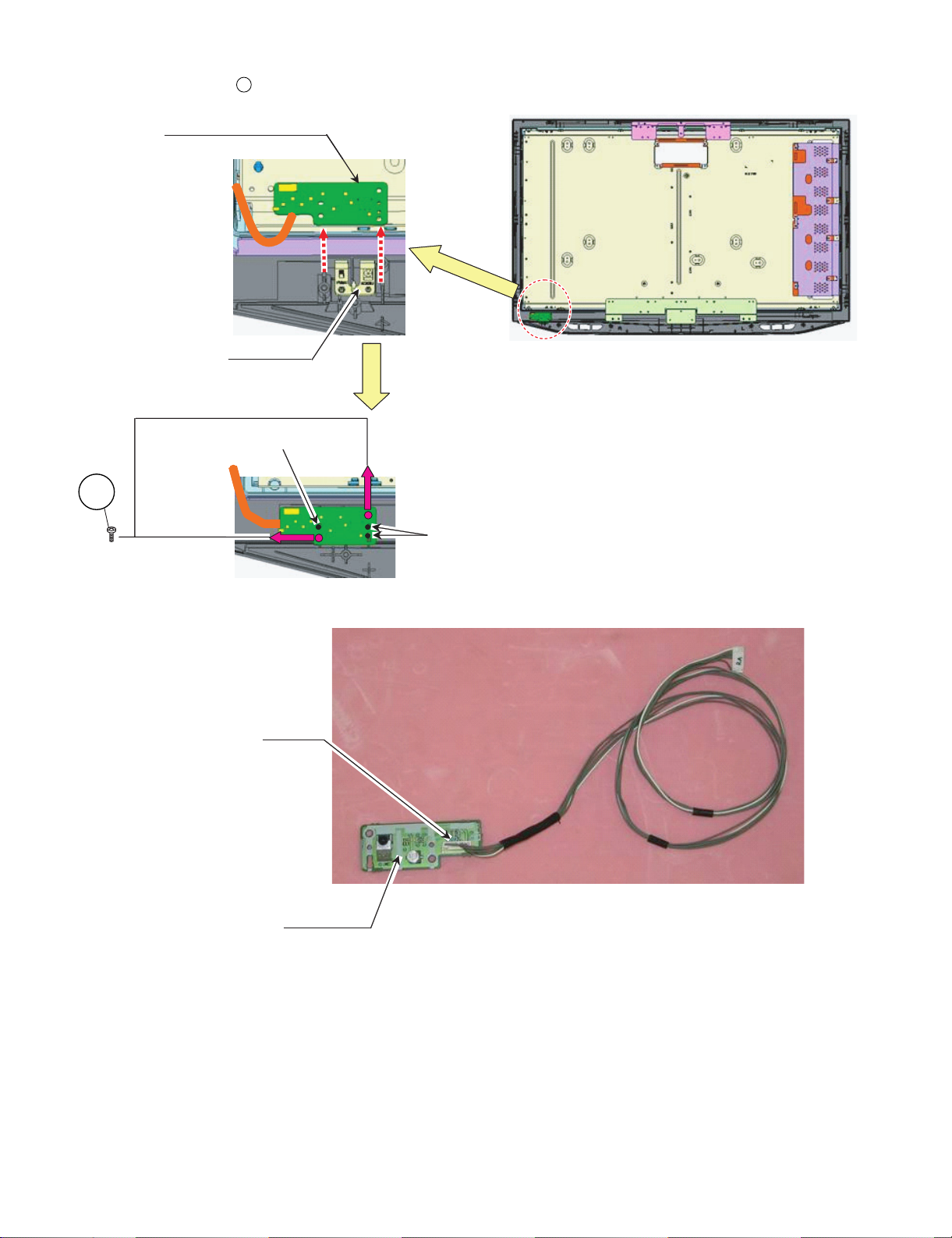

12.Remove the 2 lock screws . Detach the R/C, LCD Unit.

R/C LED UNIT With Wire "RA"

Wire "RA"

#R/C LED PWB Set to gide lib of CAB-A

Wire "RA"

12

LED COVER

12

Wire "RA"

R/C, LED UNIT

#R/CLEDPWBSettogidelibofCAB-A

2 – 7

Page 18

LC-37AD5E

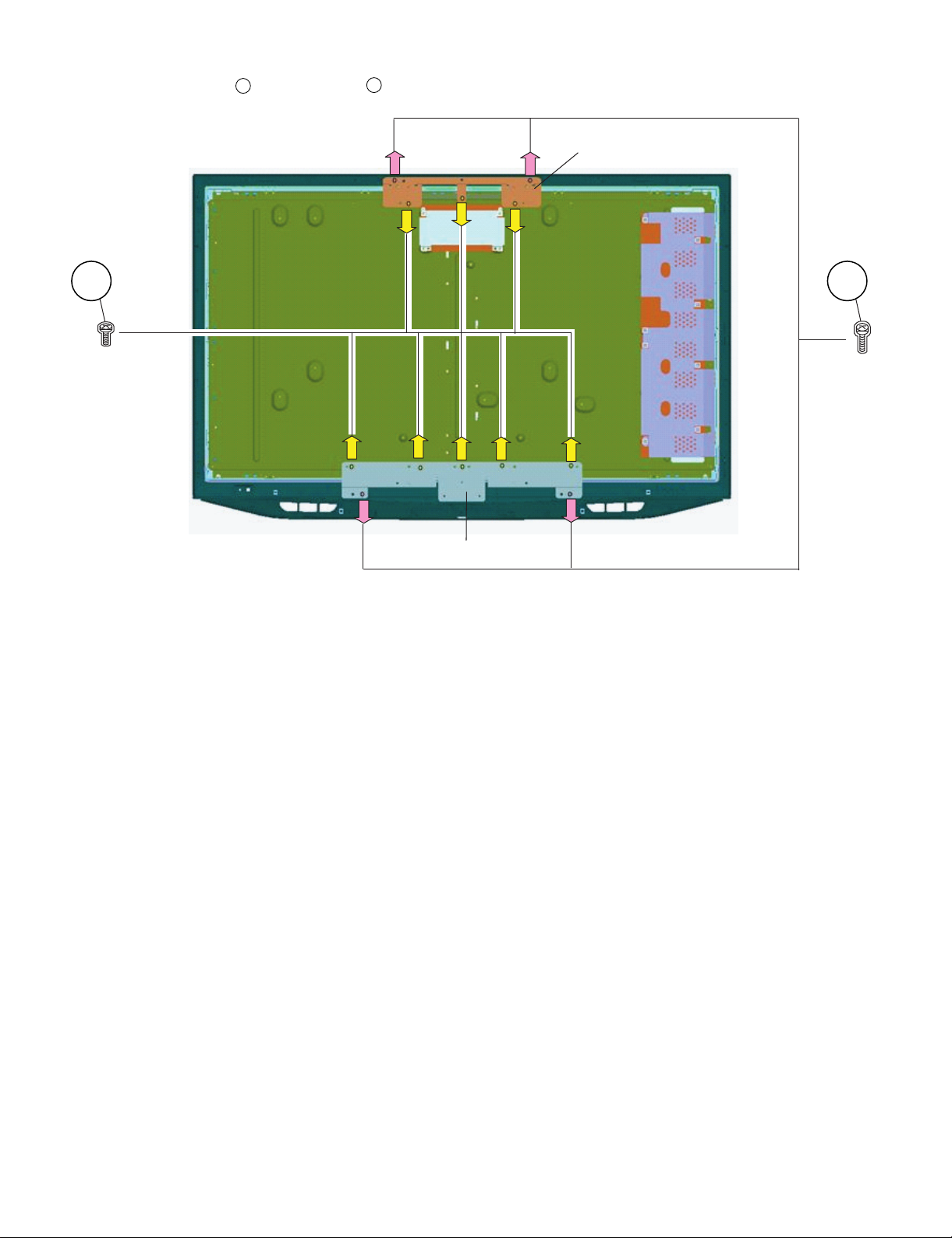

13.Remove the 4 lock screws , and 8 lock screws . Detach the LCD Angle.

13

14

LCD ANGLE TOP

14 13

LCD ANGLE BOTTOM

2 – 8

Page 19

LC37AD5E

CHAPTER 3. ADJUSTMENT PROCEDURE

Service Manual

[1] After replacement of any PWB and/or IC for repair, note the following.

When replacing the following units, be sure to prepare the new units loaded with updated software.

MAIN-UNIT: DUNTKD890FM32

• Note that an IC into which ROM data is written is available for MAIN-UNIT servicing (see below)

IC1901 VHi24LC2BiNEES EDID (HDMI)

IC1902 RH-iXC023WJZZS EDID (HDMI)

IC2303 RH-iXB731WJZZS EDID (PC)

[2] SOFTWARE UPDATING

There are 2 methods to update software in the VCTp: I2C method, RS-232C HyperTerminal and RS-232C Tera Term method.

• RS-232C method is allowed when the TV is working properly and the action should be only software upgrade.

1. RS-232C Method Description (HyperTerminal).

The hardware tools requirement are:

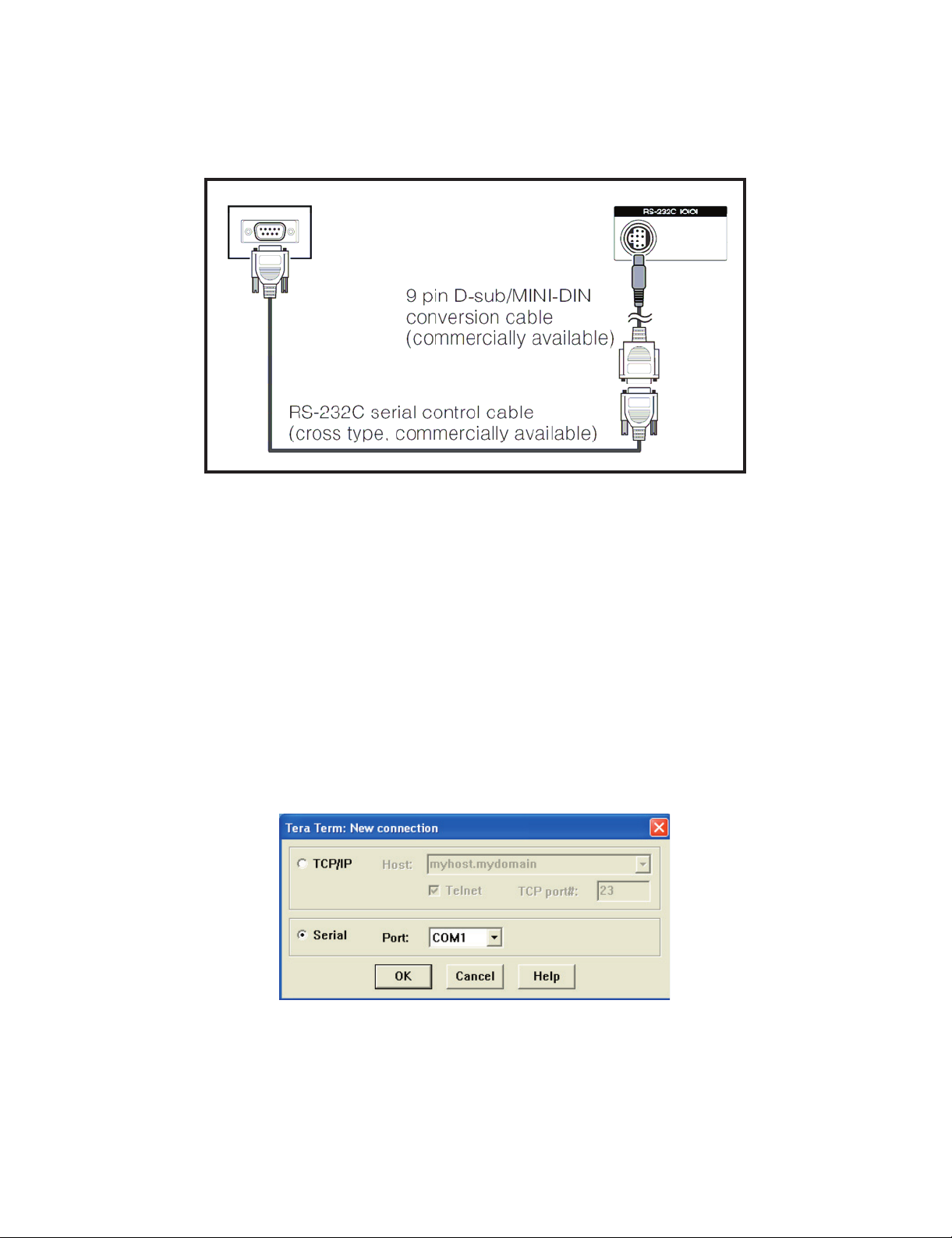

1. A Modem-null (Cross type) DB9 female to DB9 female cable.

2. An adaptor DB9 male to mini-Din 9 pin male cable (Sharp Code: QCNWGA015WJPZ)

3. Make the connections as indicated in the figure:

LC-37AD5E

Computer TV set

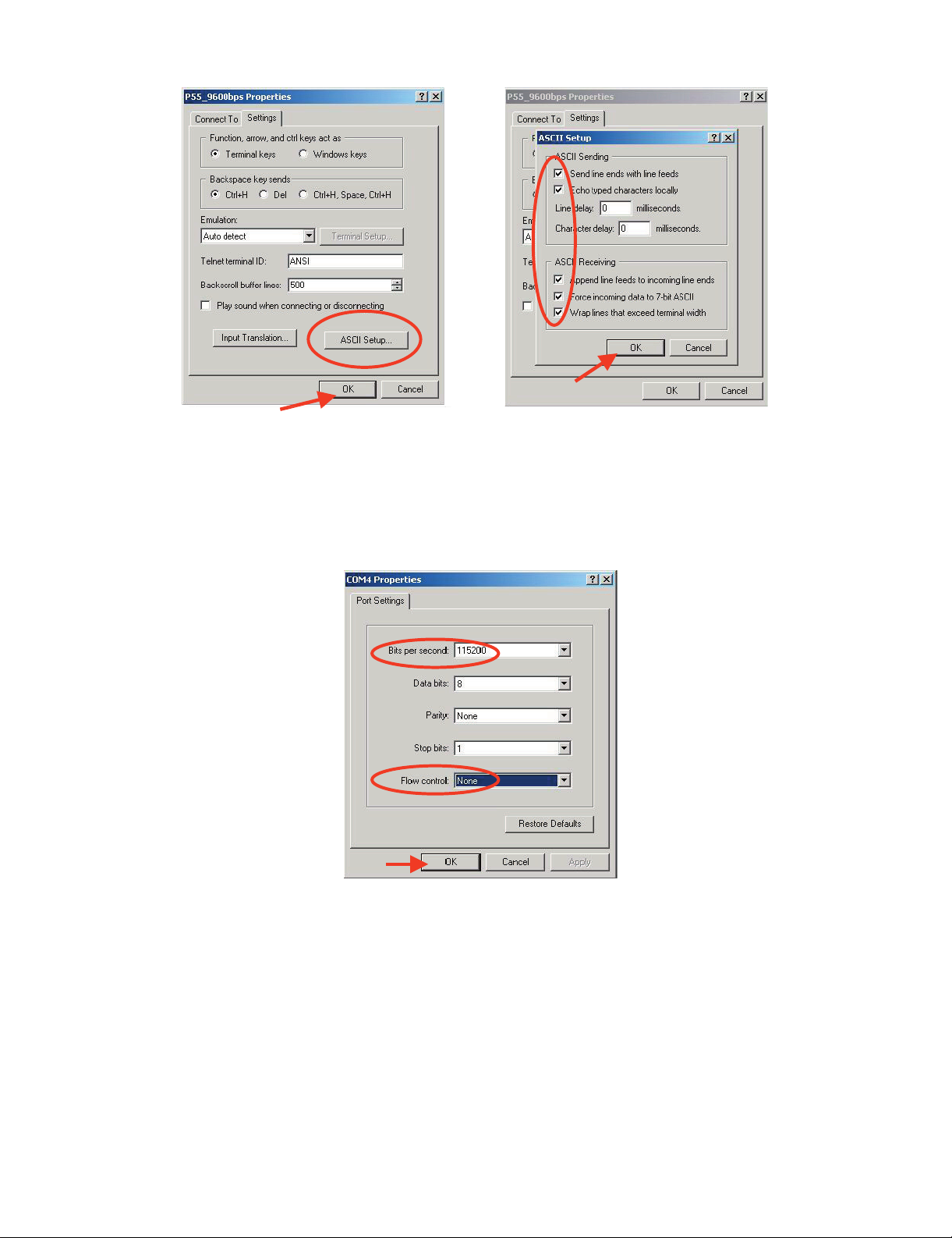

Before using RS-232C updating method is necessary to configure a Terminal PC software. HyperTerminal has been selected as a Terminal software because it’s include in all Windows versions as an accessory, and you can find it inside “Accessories\Communications” folder. For this reason, please follow carefully the next steps:

1) First time HyperTerminal is used, it’s necessary to configure some settings. Follows next action to configure two connection: low speed

(9600bps) and high speed (115200bps).

2) Create a New Connection file with name “P55_9600bps”.

3) Select a free COM port and select the Port Settings properties as follows:

3 – 1

Page 20

LC-37AD5E

4) Click on “File\Properties” menu for selecting the General and ASCII properties as follows:

5) Select “New Connection” in the File Menu.

6) Answer “Yes” to close current connection and “Yes” to save session “P55_9600bps”.

7) Create a new connection with the name “P55_115200bps”.

8) Select a the same COM port used in item 2 and select the Port Settings properties as follows:

9) Select the same General and ASCII properties as item 3.

10)Close HyperTerminal session, answering “Yes” to close current connection and “Yes” to save session “P55_115200bps”.

To start updating session, click over “P55_9600bps” icon that you can find in the “START\All programs\Accessories\ Communications\HyperTerminal\HyperTerminal” folder and follow next procedure:

3 – 2

Page 21

LC-37AD5E

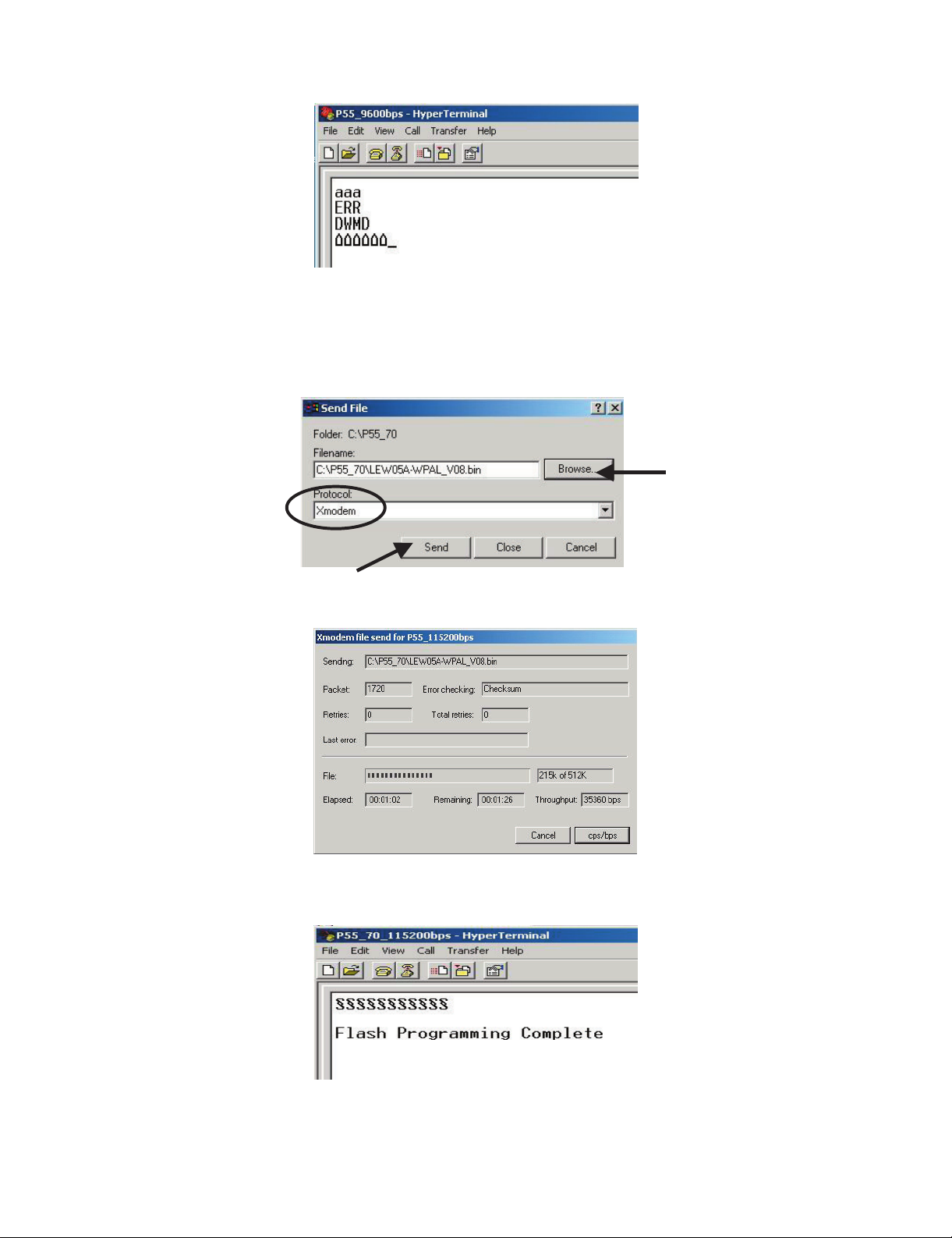

1) Check the connection between TV set and PC, sending a wrong command, as for example: “aaa”. TV set returns an “ERR” label as an syntaxis

ERROR (Not correct order or sequence).

2) Send the command “DWMD” to enter TV set in Download Mode. The TV set answer sending same symbol continuosly. If this symbol character

doesn’t appear, please don’t worry and pass to next step.

3) Close this connection and open “P55_115200bps” connection clicking over the “P55_115200bps” that you can find in “START\All pro-

grams\Accessories\ Communications\HyperTerminal\HyperTerminal” folder.

4) Using “Transfer\Send file...” menu, select desired file (.bin format) and the transmission protocol (Xmodem) as show below.

5) After press “Send” button the updating process starts as follows:

6) When flash update process finishes, the “Flash Programming Complete” label appears in the screen, the device automatically go to switch off,

and in a few seconds go to switch on again.

VERY IMPORTANT NOTE:

During the updating time, please don’t use the PC for other purpouses, in order to abolish communication problems between TV set and

PC. If TV set was not updated properly, the TV won’t have the software to startup again, and you must follow the “I2C method” to update

another time the TV set.

3 – 3

Page 22

LC-37AD5E

2. RS-232C Method Description (Tera Term)

The hardware tools requirement are:

1. A Modem-null (Cross type) DB9 female to DB9 female cable.

2. An adaptor DB9 male to mini-Din 9 pin male cable (Sharp Code: QCNWGA015WJPZ)

3. Make the connections as indicated in the figure:

Computer TV set

Software requirements:

To upgrade VCTp software from RS-232C external connector is necessary to use a Tera Term (Pro) free software.

The URL of Tera Term home page is:

http://hp.vector.co.jp/authors/VA002416/teraterm.html

(The address may be changed in future)

Tera Term (Pro) supported operating systems:

MS-Windows 95 or upper

MS-Windows NT 3.5 and 4.0 or upper

Note.- For Windows 3.1 use Tera Term version 1.X.

Copy all the distribution files to an empty floppy disk or temporary directory (for example C:\ TEMP).

Run SETUP.EXE and follow the instruction given by it.

After the installation, the distribution? les are no longer needed, you can delete them or may keep them in the floppy disk.

Ho w to us e Tera Te r m Pro:

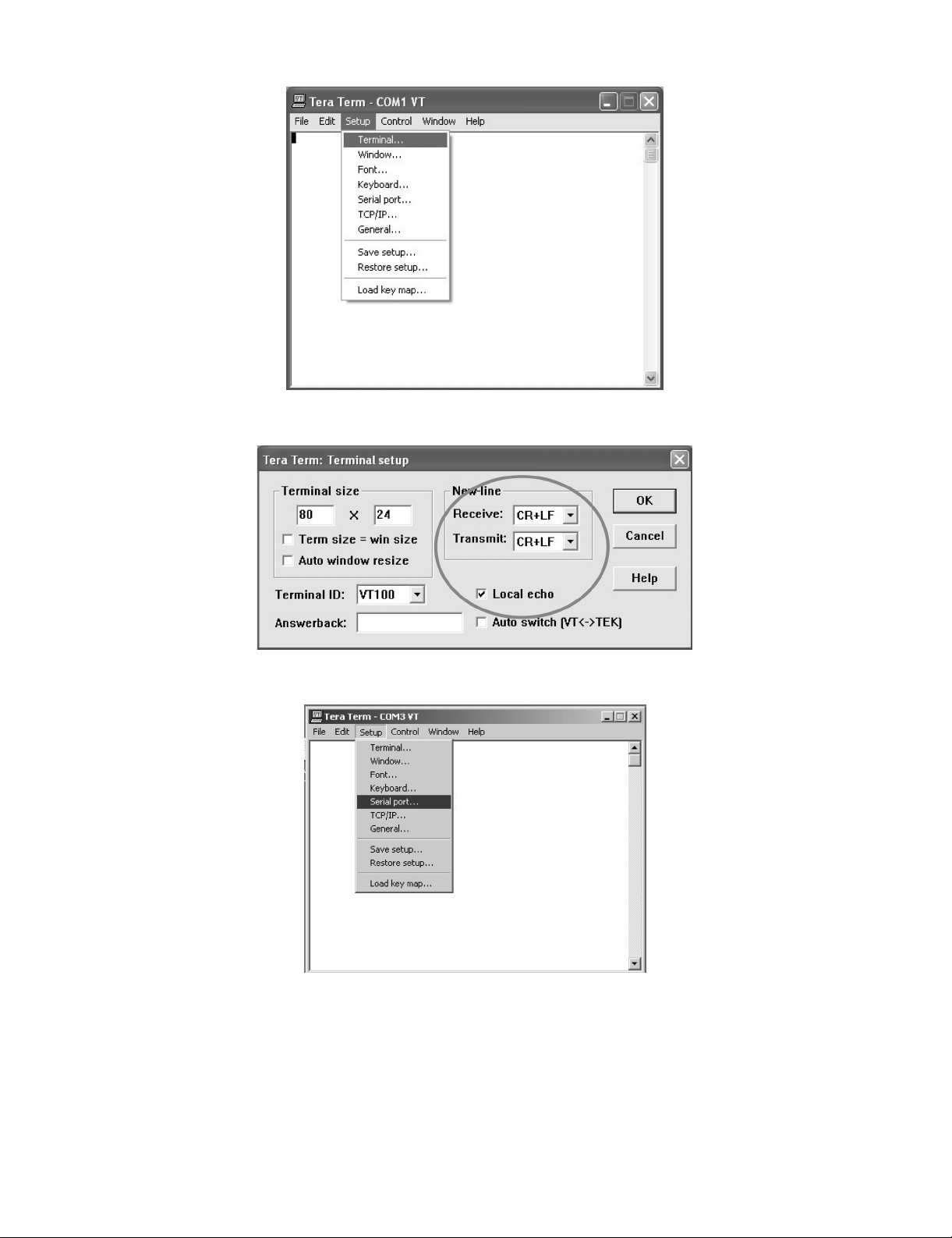

When the Tera Term (Pro) program is used, it’s necessary to shape some settings. Follows next action to configure the connection:

3 – 4

Page 23

1) Select: Serial→COM X→ O.K.

2) Select: Term inal

LC-37AD5E

3) Choose the same options as the above picture.

3 – 5

Page 24

LC-37AD5E

4) Select: Setup → Serial port → O.K. Appear the follow screen:

5) Select follows settings:

Serial port to use: COM x

Baud rate: 9600

Data: 8 bits

Parity: none

Stop: 1 bit

Flow control: none

Enter O.K.

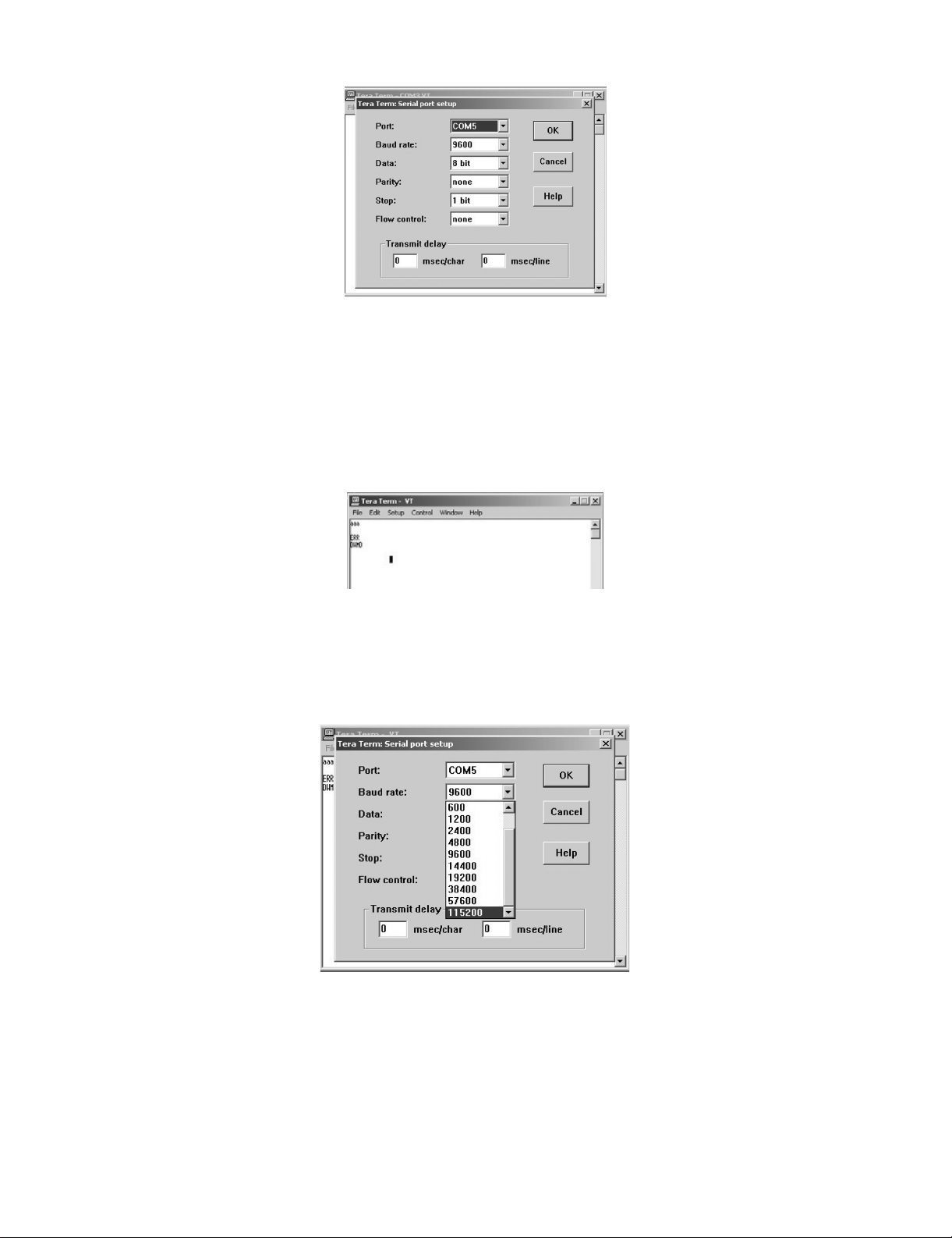

6) Check the connection between TV set and PC, sending a wrong command, as for example: “aaa”. TV set returns an “err” label as an syntaxes

ERROR (Not correct order or sequence).

Send a “DWMD” (capital letters) command to enter TV set in Download Mode.

Change a baud rate to 115200.

Select: Setup → Baud rate → 115200 → O.K.

3 – 6

Page 25

7) Select: File → Transfer → XMODEM → Sent

8) Choose the file for upgrade and click “Open”.

LC-37AD5E

9) After select “Open” the upgrade process starts as follows:

3 – 7

Page 26

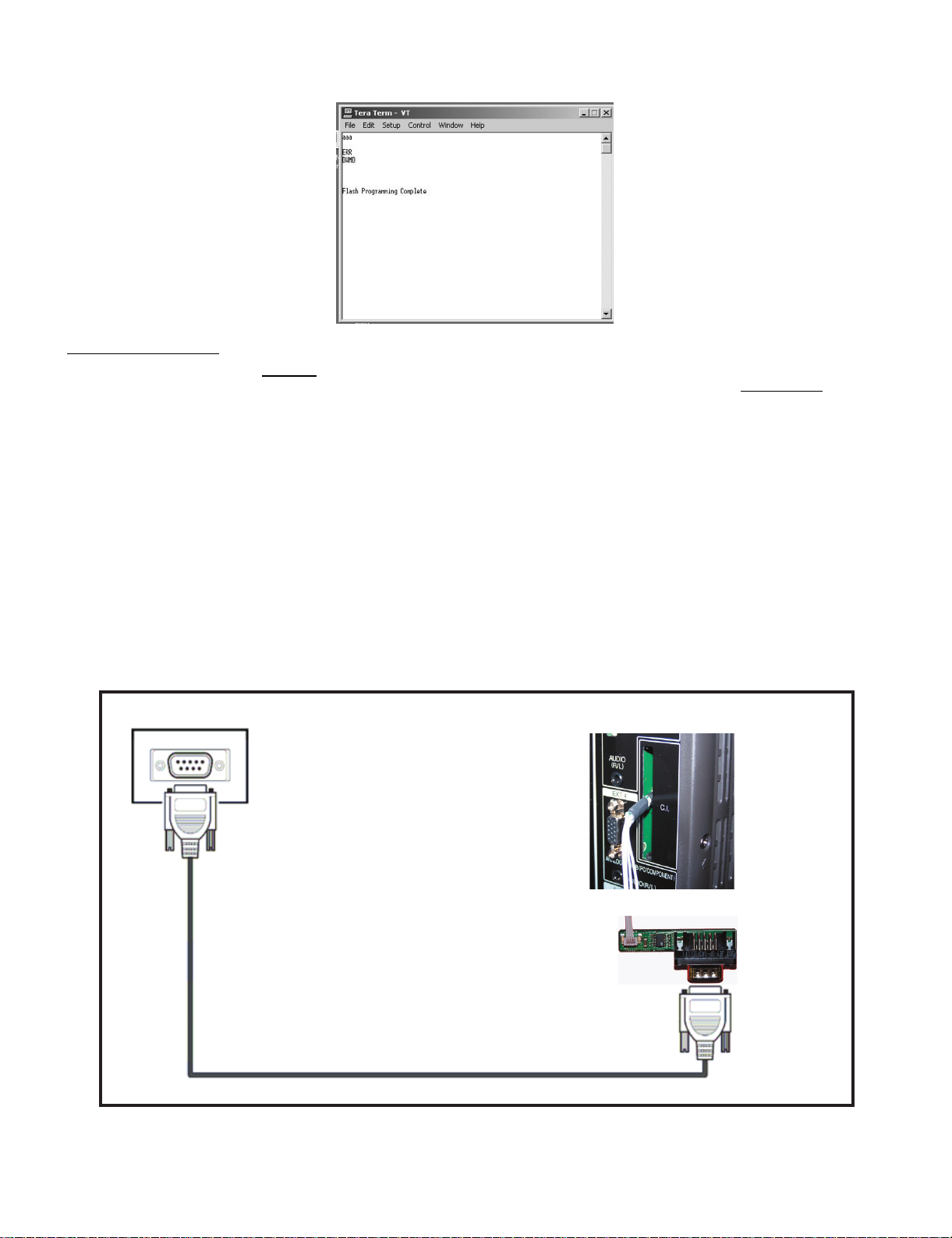

LC-37AD5E

10)When flash update process finishes, the “Flash programming complete” label appear in the screen, the device automatically go to switch off, and

in a few seconds go to switch on again.

VERY IMPORTANT NOTE:

During the updating time, please don’t use the PC for other purposes, in order to abolish communication problems between TV set and PC.

If TV set was not updated properly, the TV won’t have the software to startup again, and you must follow the “I2C method”

another time the TV set.

3. How to update the Digital Board Software.

There are 2 methods to update the Digital Board Software on Flash Memory (IC4203) thought the Digital Processor (IC4001).

• Jig RS-232 Method (From PC trough RS-232C COM port).

• PCMCIA CARD (Compact Flash Memory) Method.

NOTE: The PCMCIA method is only compatible with those PCs running XP Windows Version.

to update

3.1. Jig RS-232 Method Description

• Hardware requirements:

1. A modem null (Cross type) DB9 female to DB9 female cable.

2. The Jig Kit (Sharp Code: QCNWKA012WJZZ)

3. Make the connections as in the below figure.

Computer

TV Set

(CI Terminal)

~

~

Jig

RS-232C serial control cable

(cross type, commercially available)

• Software requirements:

1. “Winupload” application software on PC.

3 – 8

Page 27

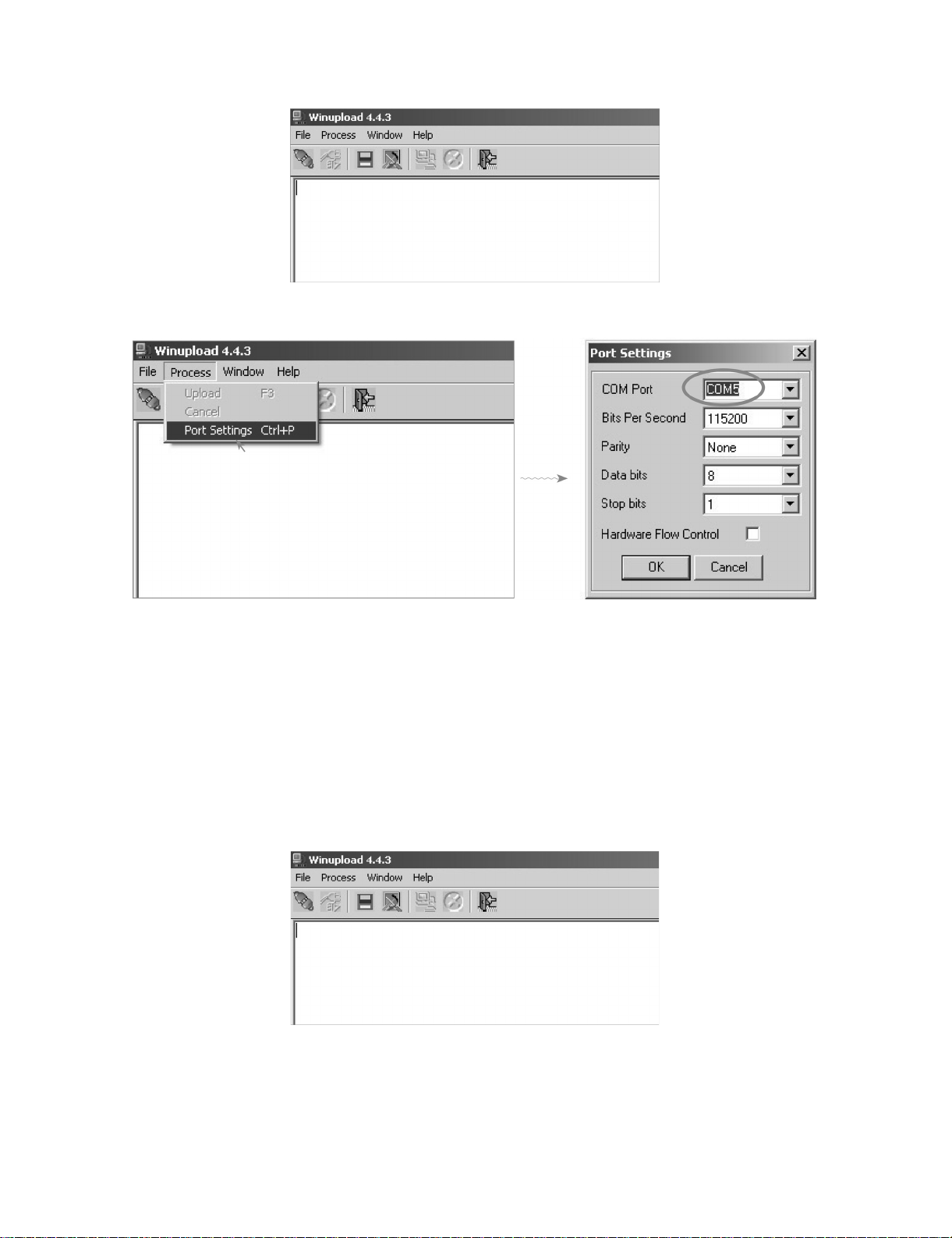

• How to setup the “Winupload” software for the first time:

1. Start “Winupload”. It will appear the following picture.

2. Select the most suitable RS232 Serial Port from “Port Setting” - “Process” Menu.

LC-37AD5E

3. Select the following settings from “Port Settings” Menu.

Bits Per Second: 115200

Parity: None

Data bits: 8

Stop bits: 1

Hardware Flow Control: OFF

• Procedure for updating the TV set.

1. Switch off the TV set to be updated, in DTV mode.

2. Start “Winupload”. It will appear the following picture on PC.

3 – 9

Page 28

LC-37AD5E

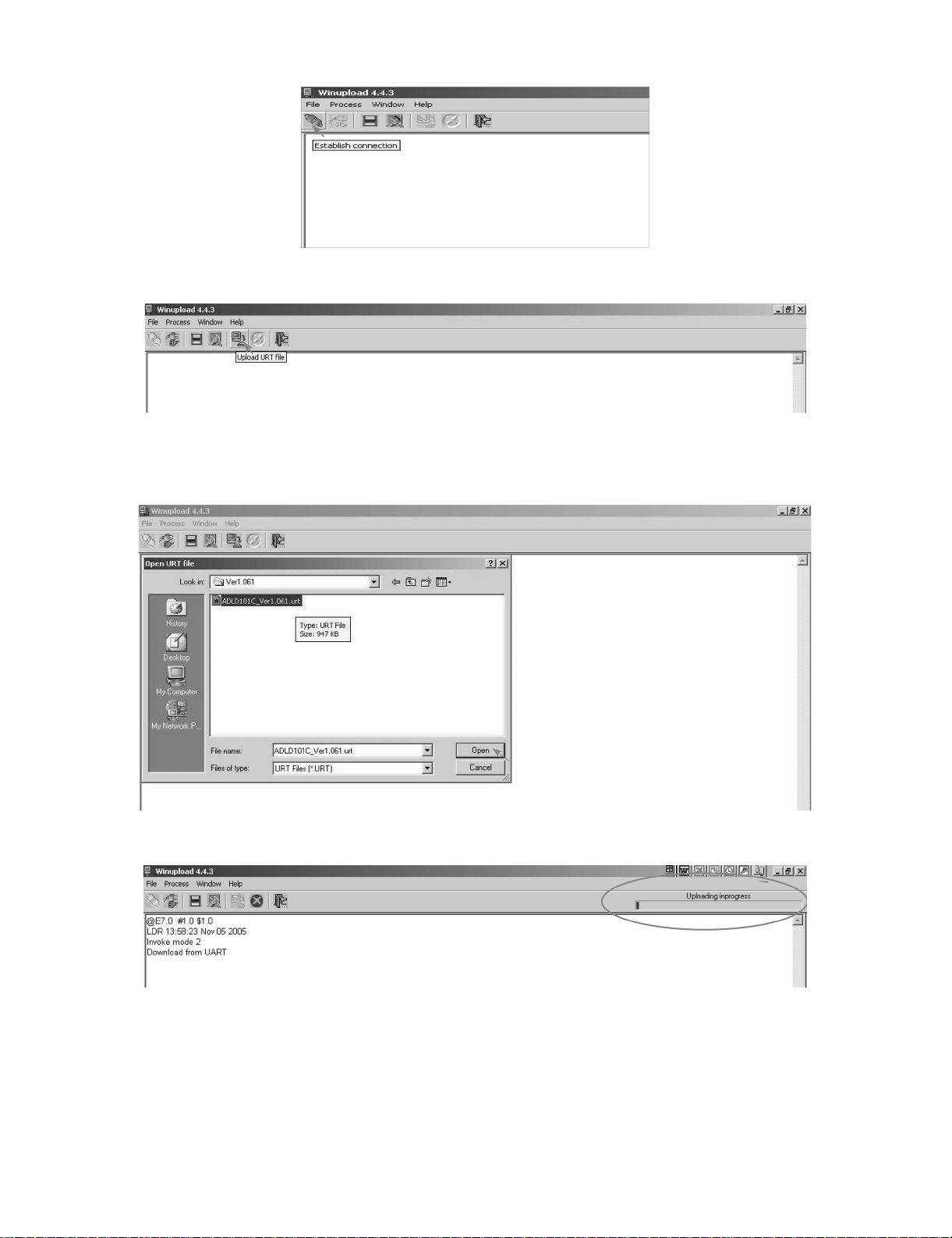

3. Establish connection on Winupload Software.

4. Select “Upload URT file”

5. Select and open the “.urt” data file from data directory

NOTE: Consider the version shown below just an example, may be is not the latest one, and could be different depending on the TV set destination

(market/Country) or model.

6. Switch On the TV Set (previously in DTV Mode). The Uploading Process starts automatically.

3 – 10

Page 29

LC-37AD5E

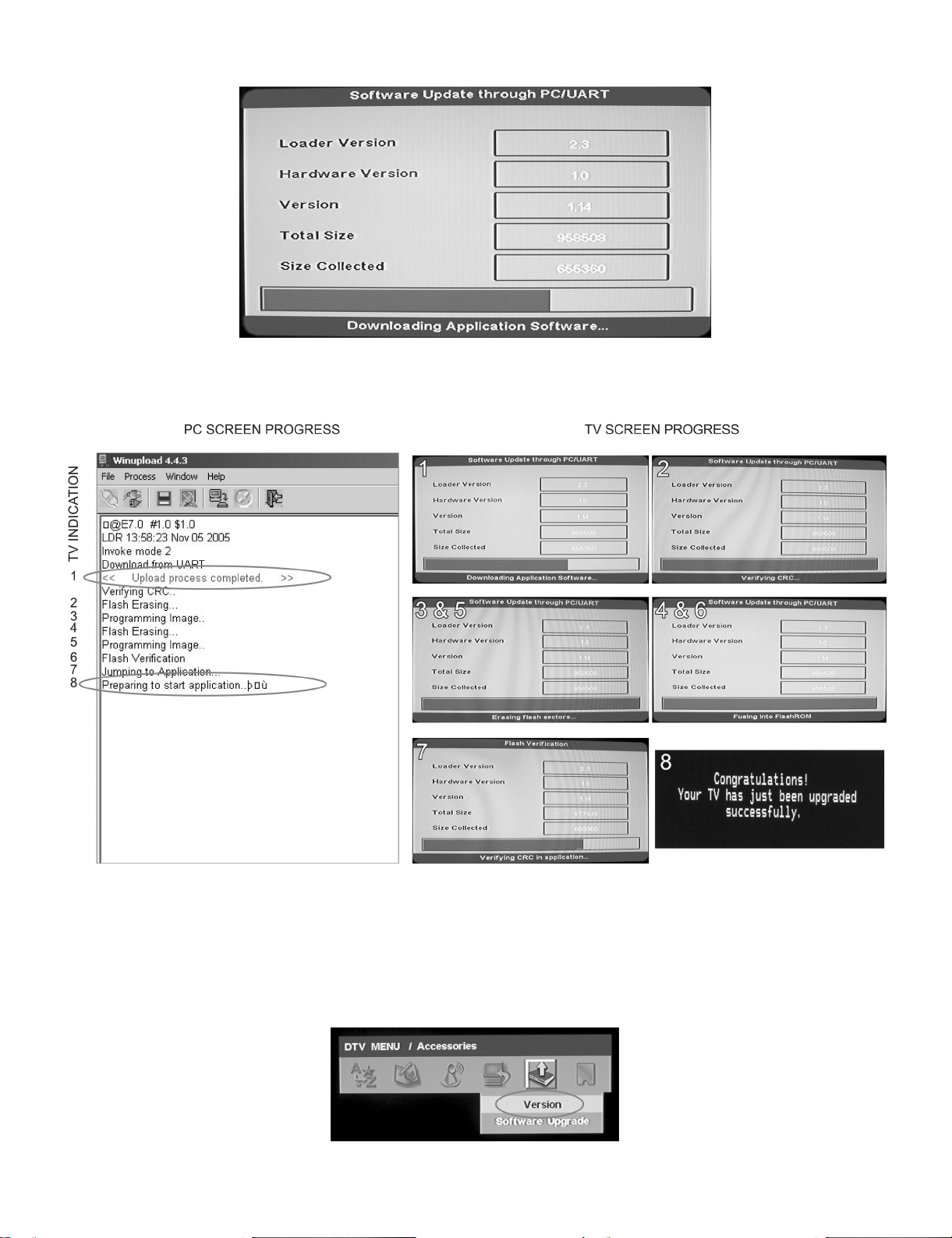

While the TV set is uploading the software, the following information is shown on the TV set screen.

Then, data transfer from PC to TV set finishes when the “Upload progress completed” label appears in the “Winupload” screen. Now, the TV set made

some additional verification (Items #2 to #7). When the full uploading process is finished, in the “Winupload” window appears the label “Preparing to

start application” for a new TV Set, and just now, in the TV screen of the updated set, appears a congratulations label (Item #8).

NOTE: Do not turn off the TV set while the software updating was in progress.

7. Unplug the AC cord.

8. Disconnect the Jig from TV Set.

• Software Version verification procedure.

1. Connect the AC cord and Switch On the TV Set.

2. Select DTV Menu on TV Set. The following On Screen Display will appear.

3 – 11

Page 30

LC-37AD5E

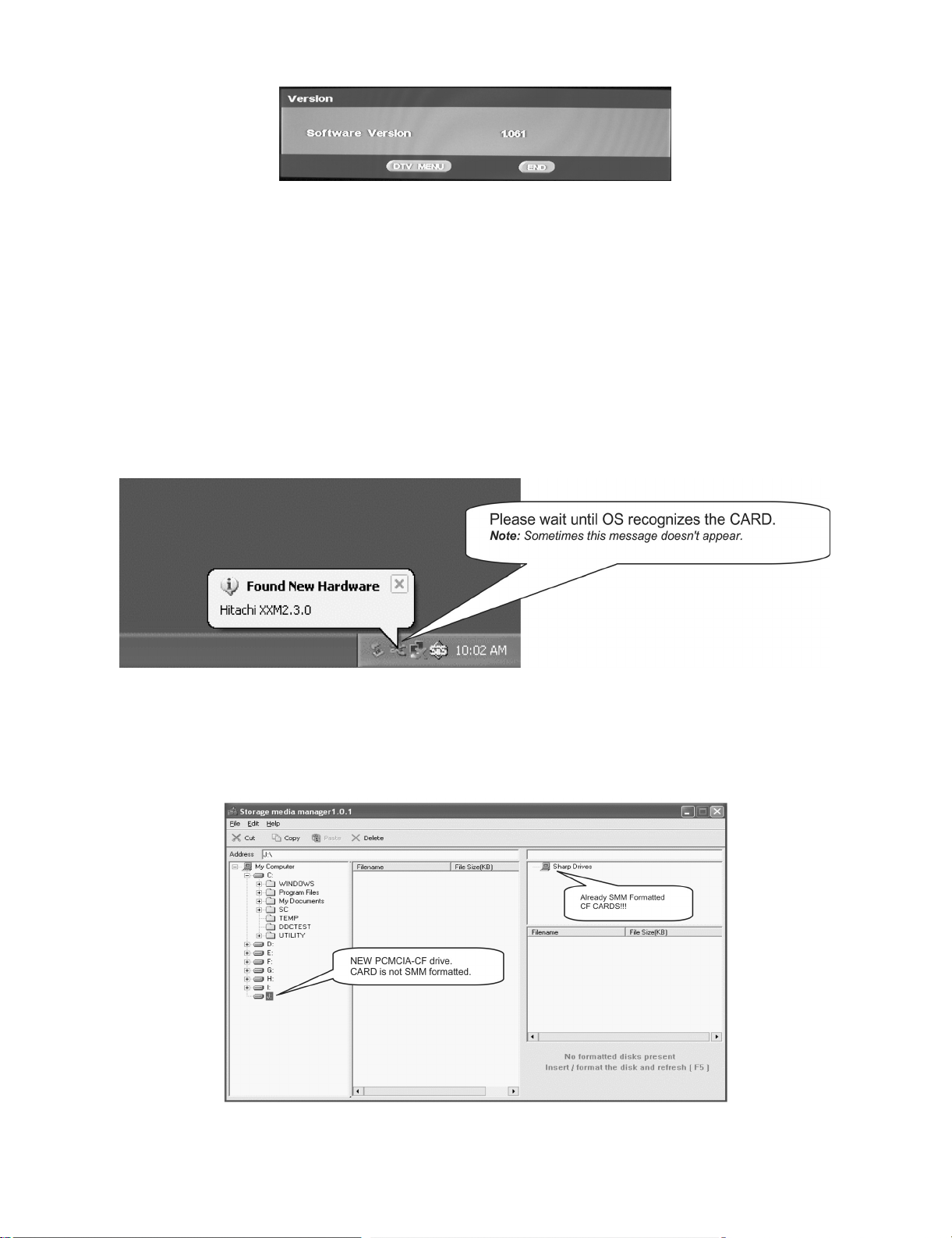

3. Select “Version”. The updated version can be verified.

NOTE: Consider the version shown above just as example, may be is not the latest one, and could be different depending on the TV set destination

(market/Country) or model.

3.2. PCMCIA Card (Compact Flash) Method.

• Hardware requirements:

1. Compact Flash Memory Card.

2. PCMCIA Compact Flash Adapter or USB Multi Card Reader.

• Software requirements:

1. “StorageMediaManager1.0.1” application software, installed on PC.

2. “Loader 1.1” or higher application software, installed on DTV Set.

NOTE: Storage Media Manager only for Windows XP.

• How to prepare the CF Card using the “Storage Media Manager 1.0.1” (SMM):

1. Insert PCMCIA (Compact Flash (CF) + CF-Adapter)

2. Execute SMM. If SMM does not appear or a Windows Error Box appears, please verify there are no USB media drives connected to the PC.

NOTE: Consider that it's recommended remove unnecessary media during SMM execution. Probably, If you try to use an USB Multi Card Reader

with SMM doesn't work fine.

3. If the CF card has never been formatted for the SMM (is not same format type used in Windows), the SMM will show you the PCMCIA-CF drive as

a Windows Media Drives, hanged of the “My Computer” tree (“J” Drive in the picture showed below).

But, if the PCMCIA-CF card had been formatted previously by SMM, directly the PCMCIA-CF drive will appear in the SMM formatted Drives box

(Sharp Drives). Please go to Item #6.

3 – 12

Page 31

4. In case of not SMM formatted card, select PCMCIA-CD Drive and using the Right-Click Pop up Menu please format the Drive.

5. Formatting the CF card. Select “Yes” to confirm the action.

NOTE: All FC’s data of the inside are erased.

LC-37AD5E

6. If SMM formatted card already appears under SHARP DRIVES box please continue, if not try to repeat from item #1. Select origin folder and “.img”

data file to be written in the CF card.

3 – 13

Page 32

LC-37AD5E

7. First of all, select copy target drive and then use Drag & drop for the “.img” file.

8. Wait, copy is in process.

9. Copy is finished, when the Copying progress bar disappears and the name of data file appears in the File Box.

3 – 14

Page 33

LC-37AD5E

10. Close SMM application.

11. Remove PCMCIA safely using the Windows Task bar pop up menu (Right-click over the Tray Icon).

12. Now, the PCMCIA-CF card is prepared to update the TV set.

Procedure to update the TV Set using PCMCIA-CF Card:

1. Switch Off the LCD TV Set in DTV mode.

2. Insert PCMCIA Card (already prepared according the details before given at “How to prepare the CF Card using the “Storage Media Manager

1.0.1 “(SMM))”.

3. Switch On the LCD TV Set (it starts automatically the updating, Items #1 to #4).

4. Wait till the finishing indication is shown.

5. For checking the correct update, please Select DTV Menu on TV Set. The following On Screen Display will appear.

6. Select “Version”. The updated version can be verified.

3 – 15

Page 34

LC-37AD5E

[3] Entering and exiting the adjustment process mode

1) Unplug the AC power cord of running TV set to force off the power.

2) While holding down the “VOL (-)” and “INPUT” keys on the set at once, plug in the AC power cord to turn on the power.

The letter appears on the screen.

3) Next, hold down the “VOL (-)” and “P ( )” keys on the set at once.

Multiple lines of orange characters appearing on the screen indicate that the set is now in the adjustment Process mode.

If you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC power cord to force off the power. (When the power is turned off

with the remote controller, once unplug the AC power cord and plug it in again. In this case, wait 10 seconds or so before plugging.)

K

Caution: Use due care in handling the information described here lest the users should know how to enter the adjustment process mode.

If the settings are tampered with in this mode, unrecoverable system damage may result.

[4] Remote controller key operation and description of display in adjustment process mode.

1. key operation

Remote controller key Main unit key Function

P ( / )

(+ / –) (+ / –)

Cursor ( / )

Cursor ( / )

on remote controller button

OK —————— Executing a function

* Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

P ( / )

—————— Turning a page (PREVIOUS/NEXT)

—————— Changing a selected line setting (+10/–10)

Moving an item (line) by one (UP/DOWN)

Changing a selected item setting (+1/–1)

Input source switching (toggle switching)

(TV→DTV→EXT1→EXT2→EXT3→EXT5→EXT6)

2. Description of display

(1) Current page/Total pages (3) Currently selected input

(4) Current colour TV system

(2) Current page title

(5) Destination

1/11

[INFO] TV AUTO XX:EURO

Main Version

Dev Version

Dev Loader Version

Pic Version

TEMP SENSOR

NORMAL STANDBY CAUSE

ERROR STANDBY CAUSE

LEW07 01.XX (XX/XX/XXX)

XX

XX

XX

XX

XX

XX

Adjustment process

menu header

(7) Parameters

3 – 16

Page 35

[5] Adjustment process mode menu

The character string in brackets [ ] will appear as a page title in the adjustment process menu header.

Page Line Item Description Remarks (adjustment detail, etc.)

1/11 [INFO]

1 Main Version LEW07 01. XX (XX/XX/XX) Main microprocessor version

2 Dev Version XX DTV microprocessor version

3 Dev Loader Version XX DTV microprocessor-Loader version

4 Pic Version xxxxxx Pic MICON version

5 TEMP SENSOR xxxxxx

6 NORMAL STANDBY CAUSE RC_STANDBY

7 ERROR STANDBY CAUSE [1] 00H 00M Error standby cause Total operating time before error

[2] 00H 00M

[3] 00H 00M

[4] 00H 00M

[5] 00H 00M

2/11 [INIT]

1 Factory Init [EURO/RUSSIA/SWEDEN] ENTER Initialization to factory settings execution

2 Inch Setting XX Inch present setting

3 Public Mode OFF/ON HOTEL MODE flag setting

4 Center Acutime xxH xxM Main operating hours

5 RESET OFF/ON Main operating hours reset

6 Backlight Acutime xxH xxM Backlight operating hours

7 RESET OFF/ON Backlight operating hours reset

8 Picture Read Pos X 0-xxx x-axis setting of picture data

9 Picture Read Pos Y 0-xxx y-axis setting of picture data

10 Picture Read ON/OFF Start/stop of picture data

3/11 [PAL.SECAM.N358]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL+TUNER ADJ ENTER PAL TUNER auto adjustment execution

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 32 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 32 TUNER DAC adjustment

9 RF AGC 16 RF AGC adjustment

4/11 [COMP 15K]

1 COMP 15K ADJ ENTER COMP15K auto adjustment execution

2 COMP 15K CONTRAST 40 Contrast adjustment

5/11 [HDTV]

1 HDTV CONTRAST 41 HDTV Contrast adjustment

6/11 [SMPTE]

1 RF-AGC ADJ ENTER RF-AGC auto adjustment execution

2 PAL-TUNER ADJ ENTER PAL TUNER auto adjustment execution

3 PAL ADJ ENTER PAL auto adjustment execution

4 TUNER ADJ ENTER TUNER auto adjustment execution

5 CONTRAST SD 32 PAL contrast adjustment

6 SECAM CB OFFSET 1 SECAM offset adjustment

7 SECAM CR OFFSET 1 SECAM offset adjustment

8 TUNER A DAC 32 TUNER DAC adjustment

9 RF AGC 16 RF AGC adjustment

7/11 [M GAMMA INFO]

1 M GAMMA IN 1 160 W/B adjustment, gradation 1 input setting

2 M GAMMA IN 2 320 W/B adjustment, gradation 2 input setting

3 M GAMMA IN 3 480 W/B adjustment, gradation 3 input setting

4 M GAMMA IN 4 640 W/B adjustment, gradation 4 input setting

5 M GAMMA IN 5 800 W/B adjustment, gradation 5 input setting

6 M GAMMA IN 6 960 W/B adjustment, gradation 6 input setting

7 M GAMMA WRITE OFF/ON EEP writing of adjustment values

8 M GAMMA RESET OFF/ON Initialization of adjustment values

LC-37AD5E

3 – 17

Page 36

LC-37AD5E

Page Line Item Description Remarks (adjustment detail, etc.)

8/11 [M GAMMA 1-3]

1 M GAMMA R 1 0 W/B adjustment, gradation 1R adjustment value

2 M GAMMA G 1 0 W/B adjustment, gradation 1G adjustment value

3 M GAMMA B 1 0 W/B adjustment, gradation 1B adjustment value

4 M GAMMA R 2 0 W/B adjustment, gradation 2R adjustment value

5 M GAMMA G 2 0 W/B adjustment, gradation 2G adjustment value

6 M GAMMA B 2 0 W/B adjustment, gradation 2B adjustment value

7 M GAMMA R 3 0 W/B adjustment, gradation 3R adjustment value

8 M GAMMA G 3 0 W/B adjustment, gradation 3G adjustment value

9 M GAMMA B 3 0 W/B adjustment, gradation 3B adjustment value

10 M GAMMA WRITE OFF/ON EEP writing of adjustment values

9/11 [M GAMMA 4-6]

1 M GAMMA R 4 0 W/B adjustment, gradation 4R adjustment value

2 M GAMMA G 4 0 W/B adjustment, gradation 4G adjustment value

3 M GAMMA B 4 0 W/B adjustment, gradation 4B adjustment value

4 M GAMMA R 5 0 W/B adjustment, gradation 5R adjustment value

5 M GAMMA G 5 0 W/B adjustment, gradation 5G adjustment value

6 M GAMMA B 5 0 W/B adjustment, gradation 5B adjustment value

7 M GAMMA R 6 0 W/B adjustment, gradation 6R adjustment value

8 M GAMMA G 6 0 W/B adjustment, gradation 6G adjustment value

9 M GAMMA B 6 0 W/B adjustment, gradation 6B adjustment value

10 M GAMMA WRITE OFF/ON EEP writing of adjustment values

10/11 [ETC]

1 EEP CLEAR OFF/ON Clear of all adjustment value

2 EEP CLEAR B OFF/ON Clear of adjustment value of B mode

3 STANDBYCAUSE RESET OFF/ON Reset of STANDBY CAUSE

4 AUTO INSTALLATION SW 0/1 1: * * * 0: * * *

5OPTION 0

6 COUNTRY EURO/RUSSIA/SWEDEN Destination setting

7 L ERR RESET 0 LAMP ERR RESET Initializatio of L_ERR

8 L ERR STOP 0/1 LAMP ERR Inhibit L_LRR detection

9 DTV CLR ENTER Clear of DTV Setting

10 I2C-OFF ENTER I2C DATA execution

11/ 11 [L CD]

1 OSC FREQ50 144 INVERTER drive frequency setting

2 OSC FREQ60 144 INVERTER drive frequency setting

3 PWM FREQ50 1 Frequency setting for INVERTER dimmer

4 PWM FREQ60 1 Frequency setting for INVERTER dimmer

5 PWM FREQ 424 Dimmer frequency adjustment

6 PWM DUTY 227 Dimmer DUTY adjustment

7 PWM CTRL 0 Dimmer CONTROL adjustment

[6] Special features

* ERROR STANDBY CAUSE (Page 1/11)

The total time when the unit enters the standby due to operational error and cause of error are recorded on EEPROM as much as possible.

The values can be used to locate the fault for repair.

* EEP CLEAR (Page10/11)

Clear of process adjustment EEP value.

3 – 18

Page 37

[7] Video signal adjustment procedure

* The adjustment process mode menu is listed in Section 5.

1. Signal check

1. Signal generator level adjustment check (Adjustment to the specified level)

• Composite signal PAL : 0.7Vp-p ±0.02Vp-p (Pedestal to white level)

2. Entering the adjustment process mode

1. Enter the adjustment process mode according to Section 3.

3. RF AGC adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

PAL

Sprit Field Colour Bar

RF signal UV

[Terminal]

TUNER

• Feed the PAL Sprit Field colour bar signal to TUNER.

LC-37AD5E

Signal level: 55 dB µV + 1dB, -1dB (75Ω LOAD)

[E-12CH]

2 Auto adjustment

performance

4. Tuner adjustment

Adjustment point Adjustment Conditions Adjustment procedure

1 Setting [Signal]

2 Auto adjustment

performance

Adjustment process

Page3

PAL

Full Field Colour Bar

RF signal

Adjustment process

Page3

㸡100% white

Bring the cursor on [ RF AGC ADJ] and press [OK]

[ RF AGC ADJ OK] appears when finished.

• Feed the RF signal (PAL colour bar) to TUNER.

• Make sure the PAL colour bar pattern has the sync level of 7:3 with

the picture level.

[RF Signal]

㸡100% white

Bring the cursor on [ TUNER ADJ] and press [OK]

[ TUNER ADJ OK] appears when finished.

3 – 19

Page 38

LC-37AD5E

[8] White Balance Adjustment

Adjustment gradation values (IN) appear on page 7/11 of process adjustment, and adjustment initial values (offset value) appear on pages 8/11 and

9/11. For white balance adjustment, adjust the offset values on pages 8/11 and 9/11.

[Condition of the unit for inspection] Modulated light: MAX (+8)

[Adjustment reference device] Minolta CA-210

[Adjustment]

Check that the values on page 7/11 of process adjustment are set as below. If not, change them accordingly.

M GAMMA IN 1 160 M GAMMA IN 2 320

M GAMMA IN 3 480 M GAMMA IN 4 640

M GAMMA IN 5 800 M GAMMA IN 6 960

1) Display the current adjustment status at point 6. (Page 8/11 of process adjustment)

The display for checking the adjustment status is toggled by pressing the “6” button on the remote control.

(Normal OSD display → “6”→ display for check (OSD disappears) → “6” →normal OSD display → • • •)

2) Read the value of the luminance meter.

3) Change M GAMMA R6/M GAMMA B6 (Adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

(Basically, G is not changed. If adjustment fails with R and B, change G. When G is lowered, the weaker of R and B must be fixed.)

4) If G is changed in step 3), change the values of M GAMMA G1-M GAMMA G5 on pages 8/11 and 9/11 of process adjustment as follows. When not

changed, go to step5).

Offset value of M GAMMA G1 = (Offset value of M GAMMA G6) * (160/960)

Offset value of M GAMMA G2 = (Offset value of M GAMMA G6) * (320/960)

Offset value of M GAMMA G3 = (Offset value of M GAMMA G6) * (480/960)

Offset value of M GAMMA G4 = (Offset value of M GAMMA G6) * (640/960)

Offset value of M GAMMA G5 = (Offset value of M GAMMA G6) * (800/960)

5) Display the adjustment status of the current point 5. (Each time the “5” button on the remote control is pressed, the adjustment status check display is toggled.)

(Normal OSD display → “5” → Check display (OSD disappears) → “5” → Normal OSD display → • • •)

Change M GAMMA R5/M GAMMA B5 (adjustment offset value) on page 9/11 of process adjustment so that the values of the luminance meter

approach x = 0.272 and y = 0.277.

6) Repeat step 5) for points 4, 3, 2, and 1.

[Adjustment reference standard value]

Adjustment spec ±0.004 Inspection spec ±0.006 (point 1)

Adjustment spec ±0.002 Inspection spec ±0.004 (Excluding the above-mentioned)

3 – 20

Page 39

[9] Initialization to factory settings

LC-37AD5E

Caution: When the factory settings have been made, all user setting data, including the channel settings, are initialized.

After adjustments, exit the adjustment process mode.

To exit the adjustment process mode, unplug the AC power cord from the outlet to forcibly turn off the power.

When the power is turned off with the remote control, unpulug the AC power cord and plug it back in (wait apporximately 10 seconds before plugging in the AC power cord).

(The adjustments done in the adjustment process mode are not initialized.) Keep this in mind when initializing these settings.

Adjustment item Adjustment conditions Adjustment procedure

1 Factory settings Forcibly turn off the power

(See to below caution)

• Enter the adjustment process mode.

• Move the cursor to [Factory Init] on page 2/11.

• Use the R/C key to select a destination [EURO/RUSSIA/

SWEDEN]. And, press the [OK] key.

• “EXECUTING...” appears and initialization starts.

• After a while, “*** OK ***” appears and the setting is complete.

NOTE: Never turn the power off during initialization.

When performing factory settings (while displaying page 2 of adjustment

process), confirm that the item “Inch Setting” or the panel size displayed

in the upper right corner corresponds to each panel size.

The following settings will be back to their factory ones.

1. User settings

2. Channel data (e.g. broadcast frequencies)

3. Maker option setting

4. Password data

[10] Lamp error detection

1. Function description

This LCD colour television has a function (lamp error detection) to be turned OFF automatically for safety when the lamp or lamp circuit is abnormal.

If the lamp or lamp circuit is abnormal, or some other errors happen, and the lamp error detection is executed, the following occur.

1- The main unit of television is turned OFF 5 seconds after it is turned ON. (The power LED on the front side of TV turns from green to red.)

2 - If the situation “1” happens 5 times sequentially, the power is turned on (relay is turned ON).

However, the backlight is not turned on, and then the relay is turned OFF after 5 to 6 seconds. (The power LED turns from green to red.)

2. Countermeasures

When television is turned OFF by the lamp error detection mentioned above, it enters the adjustment process with the power LED red. Entering the

adjustment process turns OFF the error detection and turns ON TV. This enables the operation check to detect errors in the lamp or lamp circuit

Check whether “L ERROR RESET” on point 7, page 10/11 of the adjustment process is 1 or more. If it is 1 or more, it indicates the lamp error detection was executed. After confirming that the lamp or lamp circuit is normal, reset the lamp error counter pushing “OK” in the R/C. After resetting

counter the label “***OK***” appears on Screen.

3. Reset standby cause error list

After confirming that the lamp error counter has been erased, select “STAND BY CAUSE RESET” on point 3, page 10/11 of the adjustment process

and select ON using the right cursor. For execute press “OK” in the R/C and the label “***OK***” appears on Screen.

3 – 21

Page 40

LC-37AD5E

[11] Public Mode (Hotel Mode)

1. How to Enter in the Public Mode (Hotel Mode).

Turn on the power and enter in the Adjustment Process mode (ADJ1 or Service Mode) as usual.

In the [INIT], Page 2/11 of Service, turns ON the Public Mode option.

Turn off TV by pressing Main Power switch.

While pressing “VOL+” and “P^” keys at the same time, press Main Power switch for more than 2 seconds.

After this sequence the TV will turn on showing the Public Mode setting screen as follows:

Is possible to select each item of function by pressing cursor UP/DOWN keys on the remote control or CH( )/( ) keys on the LCD TV. (Except

DTV)

The setting position of each item of functions is made by pressing cursor RIGHT/LEFT keys on the remote control or VOL (+)/(-) keys on the LCD TV.

Select EXECUTE position after you set all function, and press cursor RIGHT/LEFT keys on the remote control or VOL (+)/(-) keys on the LCD TV for

confirmation.

2. Public Mode Settings.

1. POWER ON FIXED [VARIABLE FIXED]

When it is set to “FIXED” the TV is impossible to be switch off by Main Switch or Remote Control.

2. MAXIMUM VOLUME [0 60]

Is possible to set the maximum volume at limited level.

3. VOLUME FIXED [VARIABLE FIXED]

Is possible to fix the sound volume at limited level.

When “FIXED” is selected the sound volume before limited is fixed.

4. VOLUME FIXED LEVEL [0 60]

If “FIXED” has been selected, is possible to set a fixed volume at the level that is chosen.

5. RC BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” is selected, the remote control keys are inoperative.

6. PANEL BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” has been selected, the set’s keys remain deactivated (Except POWER key).

7. MENU BUTTON [RESPOND NO RESPOND]

If “NO RESPOND” has been selected, “MENU” key, of remote control, is inoperative.

8. ON SCREEN DISPLAY [YES NO]

If “NO” has been selected, the On Screen Display does not appear.

9. INPUT MODE START [NORMAL → TV (X) → DTV → INPUT1 → INPUT2 → INPUT3 → INPUT4 → INPUT5 ]

When any other item than “NORMAL” has been selected, the sets will start in a selected input mode at the next power-on.

10.INPUT MODE FIXED [VARIABLE → FIXED]

“FIXED” has been selected, any channels and input modes other than those selected at the start mode cannot be picked up.

11.RESET

Cancel all Public Mode settings. (It returns to the factory settings)

12.EXECUTE

Select this item, and press cursor RIGHT/LEFT keys on the remote control or VOL (+)/(-) keys on the LCD TV for confirmation the functions settings.

3 – 22

Page 41

LC-37AD5E

LC37AD5E

CHAPTER 4. TROUBLESHOOTING TABLE

Service Manual

[1] TROBLESHOOTING TABLE

Power unit operation check.

Are the power cord and harness in the unit properly connected? NO Connect the power cord and harness properly, and turn on the

power.

YES

Is F701 normal? NO Are both ends of C704, C705 and C706 short-circuited when

checking their resistance values?

NO

Replace F701.

YES

Is a voltage of BU5V applied to pin (20, 21) of P701?

(Set the main power SW to OFF.)

NO

Is a voltage of approx. 8 - 15V to pin (4) of IC705? NO Check IC705, IC708, D725 and Q724.

YES

Check short circuit of 5V line (D737, C752, etc.).

YES

Is it a symptom that the relay clatters twice as soon as the main

power SW is set to ON and the power is not supplied?

NO

Does the same symptom appear even if R858 (2.7k)

is removed and the power is supplied again?

YES

Check Q724, D731, D734, IC707, D751, D753,

D754, D741, D759 and D746.

YES

Does a relay noise sound? (Once) NO Are PCON1 and 2 [pins (1) and (2) of P702] at Hi (3V or more)?

YES

Check peripheral circuits of D738, R828 and D735. Check peripheral circuits of Q712, Q713,

NO Check IC704, D728, D762 and D736.

C704 • • • Check VA701, VA702 and D701.

C705 • • • Check IC704 and IC705.

If there are no problems, check the resistance value between

pins (1) and (5) of P704.

When the value is low (several Ω - several hundred Ω), disconnect P704.

If the value is still low, the parts of 24V line are defective.

When the resistance value is several kΩ, check the inverter unit.

NO

There is a possibility that control by P-CON is not performed

properly. Check whether the “P-CON1” and “PCON2” signals are

sent from pins (97) and (91) of IC1710 (FPGA) of MAIN-UNIT.

Q721, Q723 and RY701.

YES

YES

4 – 1

Page 42

LC-37AD5E

No sound from speakers

No sound output in all modes.

Is the audio signal properly sent from pins (28) (L-ch) and (27)

(R-ch) of IC3002?

YES

Is the audio signal of pins (3) (L-ch) and (5) (R-ch) of IC303 (OP-

AMP) sent properly?

YES

Is the audio signal of pin (4) of IC301 (R-ch)/IC302 (L-ch)

(AUDIO-AMP) sent properly?

YES

Is the audio signal output of pins (2, 1) (L-ch) and (4, 3) (R-ch) of

P301 (AUDIO-CONNECTOR) normal?

YES

Check Speaker Box (right and left) and wire harness.

NO Check IC3002 or peripheral circuits.

NO Check SC2704 and P1201 or peripheral circuits. Is the S-MUTE

signal “L”?

NO Check HEAD-PHONE (J1301) or peripheral circuits.

NO Check P301 (AUDIO-CONNECTOR) and peripheral circuits.

No sound (during the reception of TV broadcasting)

No audio output during UHF/VHF reception

Checklist:

1) Is the volume set to MIN or MUTE on the remote control? ••• Set the desired volume.

2) Are headphones connected to HEADPHONE (J1301)? ••• Disconnect them.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

NO

Refer to “No sound output in all modes”.

NO

Is the SIF signal (SIF_IN+) sent to pin (31) of IC3002 (VCT)? YES Check whether +5V and +8V are supplied to pins (33) and (18) of

IC3002 respectively. Or, check peripheral circuits.

NO

Is the audio signal (SIF) sent from pin (1) of CONNECTOR

(SC2705)?

(TUNER) NO

Is the audio signal (SIF) sent from pin (12) of IC201 (IFDEMOD)?

YES Check pin (31) of IC3002 (VCT) and peripheral circuits.

YES Check Q203 (AMP) and peripheral circuits.

(TUNER) NO

Is the SIF signal sent to pins (23) and (24) of IC201 (IFDEMOD)?

(TUNER) NO

Is the IF signal sent from pin (17) of TUNER (TU201)? YES Check FL202 and peripheral circuits.

NO

Check whether 5V (CONT) and 5V are supplied to pins (1) and

(2) of TUNER (TU201) respectively. Check SDA/SCL and AGC

signal.

YES Check IC201 and peripheral circuits.

YES Replace TUNER (TU201).

4 – 2

Page 43

No sound from external input devices (1)

No sound from an external input device connected to EXT1

(SCART1).

<EXT1>

Is IN1-L audio signal sent from pin (6) of SCART1 terminal

(J1101) to pin (14) of IC3002 (VCT)?

Is IN1-R audio signal sent from pin (2) of SCART1 terminal

(J1101) to pin (13) of IC3002 (VCT)?

YES

Refer to “No sound output in all modes”.

No sound from external input devices (2)

No sound from an external input device connected to EXT2

(SCART2).

<EXT2>

Is IN2-L audio signal sent from pin (27) of SCART2 terminal

(J1101) to pin (12) of IC3002 (VCT)?

Is IN2-R audio signal sent from pin (23) of SCART2 terminal

(J1101) to pin (11) of IC3002 (VCT)?

NO

NO

LC-37AD5E

Check pins (6) and (2) of SCART1 and connection to an external

input device.

Check pins (27) and (23) of SCART2 and connection to an external input device.

YES

Refer to “No sound output in all modes”.

No sound from external input devices (3)

No sound from an external input device connected to EXT3.

<EXT3>

Is IN3-L audio signal sent from pin (3) of J1201 terminal to pin

(16) of IC3002 (VCT)?

Is IN3-R audio signal sent from pin (5) of J1201 terminal to pin

(15) of IC3002 (VCT)?

YES

Refer to “No sound output in all modes”.

No sound from external input devices (4)

No sound from EXT4 (AUDIO) connecting an external input

device.

<EXT4>

Is D-SUB-L audio signal sent from J2702 to pin (15) of IC2704

(SW)?

Is D-SUB-R audio signal sent from J2702 to pin (2) of IC2704

(SW)?

NO

NO

Check pins (3) and (5) of EXT3 (J1201) and connection to an

external input device.

Check the line between J2702 and IC2704.

(Q2703, Q2706, etc.)

YES

Is D-SUB-L audio signal sent to pin (10) of IC3002?

Is D-SUB-R audio signal sent to pin (9) of IC3002?

YES

Refer to “No sound output in all modes”.

NO Check the line between IC2704 and IC3002.

4 – 3

Page 44

LC-37AD5E

No sound from external input devices (5)

No sound from EXT5 (AUDIO) connecting an external input

device.

Check that Option-HDMI Setup-Audio select is set to “Analog”.

<EXT5> OK

Is HDMI-L audio signal sent from J2701 terminal to pin (14) of

IC2704 (SW)?

Is HDMI-R audio signal sent from J2701 terminal to pin (5) of

IC2704 (SW)?

YES

Is HDMI-L audio signal sent to pins (10) of IC3002?

Is HDMI-R audio signal sent to pins (9) of IC3002?

YES

Refer to “No sound output in all modes”.

NO

NO Check the line between IC2704 and IC3002.

Check the line between J2701 and IC2704.

(Q2704, Q2705, etc.)

4 – 4

Page 45

LC-37AD5E

No sound except from speakers (1)

No audio output from EXT1 (SCART) terminal.

Checklist:

1) Is the MUTE button on the remote control set to ON? ••• Set to OFF.

2) Check the connection to external devices. ••• Is there any improper connection?

Is audio signal sent to pins (3) (L-ch) and (1) (R-ch) of EXT1

(J1101)?

NO

Is S-MUTE-LINE [IC1710 (100)] at H? YES Check IC1710 and its peripheral circuit, and S-MUTE line.

NO

Is audio signal sent from pins (24) (L-ch) and (23) (R-ch) of

IC3002?

YES

Check the audio signal output line from pins (24) (L-ch) and (23)

(R-ch) of IC3002 to pins (3) (L-ch) and (1) (R-ch) of EXT1.

(Q1108, Q1107, etc.)

YES Check the connection to EXT1 (J1101) and external devices.

(Q1105, Q1106, etc.)

NO Check IC3002 or peripheral circuits.

No sound except from speakers (2)

No audio output from EXT2 (SCART) terminal.

Checklist:

1) Is the MUTE button on the remote control set to ON? ••• Set to OFF.

2) Check the connection to external devices. ••• Is there any improper connection?

Is audio signal sent to pins (24) (L-ch) and (22) (R-ch) of EXT2

(J1101)?

NO

Is S-MUTE-LINE [IC1710 (100)] or S2-MUTE-LINE [IC3003 (25)]

at H?

NO

Is audio signal sent from pins (22) (L-ch) and (21) (R-ch) of

IC3002?

YES

Check the audio signal output line from pins (22) (L-ch) and (21)

(R-ch) of IC3002 to pins (24) (L-ch) and (22) (R-ch) of EXT2.

(Q1104, Q1103, etc.)

YES Check the connection to EXT2 (J1101) and external devices.

YES Check IC1710/IC3003 and its peripheral circuit.

NO Check IC3002 or peripheral circuits.

(S-MUTE_LINE, S2-MUTE_LINE, Q1101, Q1102, D309, D310,

etc.)

4 – 5

Page 46

LC-37AD5E

No sound except from speakers (3)

No audio output from AUDIO_OUTPUT terminal.

Checklist:

1) Is the MUTE button on the remote control set to ON? ••• Set to OFF.

2) Check the connection to external devices. ••• Is there any improper connection?

Is audio signal sent to pins (13) (L-ch) and (15) (R-ch) of

AUDIO_OUTPUT (J1201)?

NO

Is S-MUTE-LINE [IC1710 (100)] at H? YES Check IC1710 and its peripheral circuits, and S-MUTE line.

NO

Is audio signal sent from pins (22) (L-ch) and (21) (R-ch) of

IC3002?

YES

Check the audio signal output line from pins (22) (L-ch) and (21)

(R-ch) of IC3002 to pins (13) (L-ch) and (15) (R-ch) of

AUDIO_OUTPUT. (Q1202, Q1201, etc.)

YES Check the connection to AUDIO_OUTPUT external (J1201) and

external devices.

(Q1204, Q1203, etc.)

NO Check IC3002 or peripheral circuits.

DTV troubleshooting

The unit does not enter the DTV mode. Or, the DTV menu does

not appear.

NO

No video output during DTV reception. YES Go to “No video output during DTV reception. Colour of image

NO

No audio output during DTV reception. YES Go to “No audio output during DTV reception. Sound is low”

YES Go to “The unit does not enter the DTV mode. Or, the DTV menu

does not appear.”

are not right.”

4 – 6

Page 47

The unit does not enter the DTV mode. Or, the DTV menu does not appear.

Digital UNIT:

Is a voltage supplied from IC4701 (3.3V-REG)/IC4704 (1.8VREG)/IC4702 (5V-REG)?

YES

Do X4001(32.768kHz)/ X4002(27MHz) oscillate? NO Check peripheral circuits of X4001/X4002.

D-TUNER UNIT: YES

Does each REG [IC206 (REG), IC208 (REG) and IC205 (REG)]

driving IC202 work normally?

YES

Is a voltage applied to pin (20) (I2CSEL) of P202?

(High=3.3V)

YES

Is FESCL/FESDA signal sent to pins (22) and (21) of P202 and

pins (1) and (13) of IC204 (SW).

YES

Does X202 (27MHz) oscillate? NO Check peripheral circuits of X202.

NO Check peripheral circuits of IC4701/IC4704 of IC4702.

(IC4701, IC4704, IC4702, Q4703 and POW-ON_LINE, etc.)

NO Check peripheral circuits of IC206/IC208/IC205.

NO MAIN UNIT:

Check around the pin (1) of IC1710.

NO Check peripheral circuits of IC202 (COFDM)/ IC4001 (D-Proces-

sor).

LC-37AD5E

YES

Check IC202 (COFDM)/IC4001 (D-Processor).

4 – 7

Page 48

LC-37AD5E

No video output during DTV reception. Colour of Images are not right.

D-TUNER UNIT:

Is digital signal fed from pins (20) and (21) of TU201 (TUNER) to

pins (11) and (10) of IC202 (COFDM)?

YES

Is data FED[0:7] sent from pins (3), (4), (5), (6), (8), (9), (10) and

(11) of P202?

DIGITAL UNIT: YES

Are video signals (R/G/B, CVBS) sent from C4639/C4640/C4641/

C4625?

YES

Are video signals (R/G/B, CVBS) send from the C4636/C4637/

C4638 and emitters of Q4607?

MAIN UNIT: YES

Is video signal (CVBS) sent from pin (2) of IC2705 (SW). NO Check IC2705 and its peripheral circuits.

YES

Are video signals (R/G/B, CVBS) fed from pins (179), (180), (181)

and (184) of IC3002?

NO Check TU201 and its peripheral circuits and if I2C is accessed

between TU201 and IC202.

NO Check between IC202 and P202.

NO Check R4011 (AC8pin), R4013 (AC9pin) and IC4001 (D-Proces-

sor).

NO Check Q4601-Q4607 and their peripheral circuits.

NO Check peripheral circuits of IC3002.

YES

Are scrambled images not displayed? YES DIGITAL UNIT:

NO

Refer to “No video output in all modes”.

No audio output during DTV reception. Sound is low.

DIGITAL UNIT:

Is audio signal fed to pins (5) (L-ch) and (10) (R-ch) of IC4604

(OP-AMP)?

YES

Is audio signal sent from pins (7) and (8) of IC4604 (OP-AMP)? NO Check power supply of IC4604 (OP-AMP) and its peripheral cir-

MAIN UNIT: YES

Is audio signal sent to pins (11) and (4) of IC2704 (SW)? NO Check the line between IC4604 and IC2704.

YES

Is AIN1L audio signal sent to pins (10) of IC3002?

Is AIN1R audio signal sent to pins (9) of IC3002?

NO Check R4002 (AD2pin) and IC4001 (D-Processor).

NO Check output of pins (13) and (3) of IC2704 and peripheral cir-

Check 5V output of pin (1), (2), (5) and (6) of IC4702.

Check 5V of pin (6) of Q4401.

cuits.

cuits.

YES

Refer to “No sound output in all modes”.

4 – 8

Page 49

No picture on the display (1)

No video output in all modes.

YES

Is LVDS video signal (LVDS_0N/0P-3N/3P) sent to pins (141)/

(140)-(129)/(128) of IC3002 (VCT), and is CLK signal (LVDS_CN/

CP) sent to pins (132)/(131)?

YES

Is LVDS video signal (LVDS_0N/0P-3N/3P) sent to pins (20)/(19)(8)/(7) of connector (P2305), and is CLK signal (LVDS_CN/CP)

sent to pins (11)/(10)?

YES

Is power (LCD5V) supplied to pins (28-31) of connector (P2305)? NO Check LCD5V_LINE and its peripheral circuits.

YES

Check the panel module.

<On input of the tuner (U/V)> No picture on the display (2)

No picture appears on LCD during the tuner (U/V) reception.

NO Check IC3002 and its peripheral circuits.

NO Check the line between IC3002 and P2305.

(Q1706, Q1704, etc.)

LC-37AD5E

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “TV”.

2) Is MENU-PICTURE-Contrast/Brightness set to “MIN”? ••• Set it to an appropriate level.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

Is level of pins (15) and (14) of tuner (TU201) and pins (10) and

(11) of IC201 (IF-DEMOD) at H?

YES

Is the video signal (IF) sent from pin (17) of tuner (TU201)? NO Check the tuner (TU201) and peripheral circuits.

YES

Is video signal sent from pin (17) of IC201 (IF-DEMOD)? NO Check FL201 (SAW-FIL), IC201 and peripheral circuits.

YES

Is the video signal VIN1 (ATUNER-CVBS) sent to pin (191) of

lC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO These are communications lines for control (I2C). Follow the

path and check whether they are forced to L (PULL_DOWN).

NO Check IC201 (IF-DEMOD), CONNECTOR (P201/SC2705) and

peripheral circuits. (Q204, etc.)

4 – 9

Page 50

LC-37AD5E

<When EXT1 is used for external input> No picture on the display (3)

No EXT1-Composite output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT1”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is composite video signal sent to pin (20) of SCART1 (J1101)? NO Check external connection, input setting, SCART1 and periph-

eral circuits.

YES

Is composite video signal (VIN_1) sent to input terminal pin (6) of

IC2702 (SW)?

YES

Is composite video signal (VIN1) sent to input terminal pin (190)

of IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO Check CONNECTOR (P1101/SC2702), SCART1 (J1101) and

peripheral circuits.

NO Check IC2702 (SW) and peripheral circuits.

<When EXT1 is used for external input> No picture on the display (4)

No EXT1-RGB output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT1”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is RGB signal sent to pins (15)/R, (11)/G and (7)/B of SCART1

(J1101)?

YES

Is RGB signal (R1/G1/B1=VIN_6/5/9) sent to input terminal pins

(187), (175) and (182) of IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO Check external connection, input setting, SCART1 (J1101) and

peripheral circuits.

NO Check CONNECTOR (P1101/SC2702), SCART1 (J1101) and

peripheral circuits.

4 – 10

Page 51

LC-37AD5E

<When EXT1 is used for external input> No picture on the display (5)

No EXT1-Y/C output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT1”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is Y/C signal sent to pins (20) and (15) of SCART1 (J1101)? NO Check external connection, input setting, SCART1 (J1101) and

peripheral circuits.

YES

Is Y/C signal (VIN1=Y1/C1) sent to input terminal pins (190) and

(187) of IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

<When EXT2 is used for external input> No picture on the display (6)

NO Check CONNECTOR (P1101/SC2702), IC2702 (SW) and

peripheral circuits.

No EXT2-Composite output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT2”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is composite video signal sent to pin (41) of SCART2 (J1101)? NO Check external connection, input setting, SCART2 (J1101) and

YES

Is composite video signal (VIN-2) sent to input terminal pin (4) of

IC2702 (SW)?

YES

Is composite video signal (VIN2) sent to input terminal pin (190)

of IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO Check CONNECTOR (P1102/SC2703), SCART2 (J1101) and

NO Check IC2702 (SW) and peripheral circuits.

peripheral circuits.

peripheral circuits.

4 – 11

Page 52

LC-37AD5E

<When EXT2 is used for external input> No picture on the display (7)

No EXT2-RGB output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT2”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is RGB signal sent to pins (36)/R, (32)/G and (28)/B of SCART2

(J1101)?

YES

Is RGB signal (R2/G2/B2=VIN_15/16/17) sent to Input terminal

pins (178), (177) and (176) of IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

<When EXT2 is used for external input> No picture on the display (8)

NO Check external connection, input setting, SCART2 (J1101) and

peripheral circuits.

NO Check CONNECTOR (P1102/SC2703), SCART2 (J1101) and

peripheral circuits.

No EXT2-Y/C output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT2”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is Y/C signal sent to pins (41) and (36) of SCART2 (J1101)? NO Check external connection, input setting, SCART2 (J1101) and

YES

Is Y/C signal (VIN2=Y2/C2) sent to input terminal pins (190) and

(178) of IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO Check CONNECTOR (P1102/SC2703), IC2702 (SW) and

peripheral circuits.

peripheral circuits.

4 – 12

Page 53

LC-37AD5E

<When EXT3 is used for external input> No picture on the display (9)

No EXT3 output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT3”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is composite video signal sent to pin (1) of A/V-IN-TERMINAL

(J1201)?

YES

Is composite video signal (IN3-CVBS) sent from pins (2) of

IC1201 (SW)?

YES

Is composite video signal (IN3-CVBS) sent to input terminal pin

(4) of IC2705 (SW)?

YES

Is composite video signal (IN3-CVBS=VIN7) sent to input terminal pin (184) of IC3002 (VCT)?

NO Check external connection, input setting, A/V-IN-TERMINAL

(J1201) and peripheral circuits.

NO Check IC1201 and peripheral circuits.

NO Check CONNECTOR (P1102/SC2703), and peripheral circuits.

NO Check IC2705 (SW) and peripheral circuits.

YES

Refer to “No video output in all modes”.

<When EXT3 is used for external input> No picture on the display (10)

No EXT3-Y/C output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT3”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is Y/C signal sent to pins (11) and (7) of S-TERMINAL (J1201)? NO Check external connection, input setting, S-TERMINAL (J1201)

and peripheral circuits.

YES

Is Y3 signal (IN3-Y) sent from pin (2) of IC1201 (SW)? NO Check IC1201 and peripheral circuits.

YES

Is Y3 signal (IN3-Y) sent to input terminal pin (4) of IC2705 (SW)? NO Check CONNECTOR (P1102/SC2703), and peripheral circuits.

YES

Is Y/C signal (VIN7/VIN8) sent to input terminal pins (184) and

(183) of IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO Check IC2705 (SW) and peripheral circuits.

4 – 13

Page 54

LC-37AD5E

<When EXT4 is used for external input> No picture on the display (11)

No EXT4 (15pin-D-SUB terminal) output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXIT4”.

2) Is MENU-PICTURE-CONTRAST/BRIGHTNESS set to “MIN”? ••• Set it to an appropriate level.

3) Check the connection to the external device ••• Connect it correctly as per the operation manual for the device.

Is “EXT4” selected with “INPUT SOURCE” button on the remote

control?

YES

Is D-SUB-COMPONENT signal (PCV_R/G/B) sent to pins (1), (2)

and (3) of EXT4-TERMINAL (SC2303)?

YES

Is D-SUB-COMPONENT signal

(PCV_R/G/B=VIN19/20/21) sent to pins (174), (173) and (172) of

IC3002 (VCT)?

NO Select “EXT4” with “INPUT SOURCE” button on the remote con-

trol.

NO Check D-SUB-adaptor and external connection.

NO Check EXT4-TERMINAL and peripheral circuits.

YES

Refer to “No video output in all modes”.

4 – 14

Page 55

LC-37AD5E

<When EXT5 is used for external input> No picture on the display (12)

No EXT5 (HDMI) output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXT5”.

2) Have you checked the type video signal sent from HDMI-connected external device? ••• Confirm the type (it should “RGB”, “YCbCr 4:4:4” or

“YCbCr 4:2:2”).

3) Have you checked the type of Color Matrix sent from HDMI-connected external device? ••• Confirm the type (it should be “ITU601” or

“ITU709”.)

4) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

Is “EXT5” selected with “INPUT SOURCE” button on the remote

control?

YES

Is the type of video signal (Signal Type) from HDMI-connected

external device set?

YES

Is the type of color signal (Color Matrix) from HDMI-connected

external device set?

NO Select “EXT5” with “INPUT SOURCE” button on the remote con-

trol.

NO From MENU-Option-HDMI Setup-Signal Type, select a signal

type (“RGB”, “YCbCr 4:4:4” or “YCbCr 4:2:2”).

NO From Option-HDMI Setup-Color Matrix, select a color signal type

(“ITU601” or “ITU709”)

YES

Is TMDS data (RX*±signal) sent to pins (1) - (12) of EXT5 (HDMI)

terminal (SC1901)?

YES

Is 8bit-DIGITAL signal (HDMI- R/G/B) sent from pins (110) - (144)

of IC1905 (HDMI-RECEIVER)?

YES

Is 8bit-DIGITAL signal (HDMI- R/G/B) sent to pins (73) - (50) of

IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO Is I2C signal (SDA/SCL signal) sent to pins (16) and (15) of

EXT5 (HDMI) terminal?

Check external connection and peripheral circuits.

NO Check power supply (3.3/1.8V) pins (99) and (74) of IC1905,

SDA/SCL signal pins (29) and (30), and peripheral circuits.

NO Check SDA3/SCL3 signal pins (27) and (28), interface between

IC1905 and lC3002, and peripheral circuits.

4 – 15

Page 56

LC-37AD5E

<When EXT6 is used for external input> No picture on the display (13)

No EXT6 (HDMI) output of the external input system.

Checklist:

1) Is “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and set “INPUT SOURCE” to “EXT6”.

2) Have you checked the type video signal sent from HDMI-connected external device? ••• Confirm the type (it should “RGB”, “YCbCr 4:4:4” or

“YCbCr 4:2:2”).

3) Have you checked the type of Color Matrix sent from HDMI-connected external device? ••• Confirm the type (it should be “ITU601” or

“ITU709”.)

4) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

Is “EXT6” selected with “INPUT SOURCE” button on the

remote control?

YES

Is the type of video signal (Signal Type) from HDMI-connected

external device set?

YES

Is the type of color signal (Color Matrix) from HDMI-connected

external device set?

NO Select “EXT6” with “INPUT SOURCE” button on the remote con-

trol.

NO From MENU-Option-HDMI Setup-Signal Type, select a signal

type (“RGB”, “YCbCr 4:4:4” or “YCbCr 4:2:2”).

NO From Option-HDMI Setup-Color Matrix, select a color signal type

(“AUTO”, “ITU601” or “ITU709”)

YES

Is TMDS data (RX*±signal) sent to pins (1) - (12) of EXT6 (HDMI)

terminal (SC1902)?

YES

Is 8bit-DIGITAL signal (HDMI- R/G/B) sent from pins (110) - (144)

of IC1905 (HDMI-RECEIVER)?

YES

Is 8bit-DIGITAL signal (HDMI- R/G/B) sent to pins (73) - (50) of

IC3002 (VCT)?

YES

Refer to “No video output in all modes”.

NO Is I2C signal (SDA/SCL signal) sent to pins (16) and (15) of

EXT6 (HDMI) terminal?

Check external connection and peripheral circuits.

NO Check power supply (3.3/1.8V) pins (99) and (74) of IC1905,

SDA/SCL signal pins (31) and (32), and peripheral circuits.

NO Check SDA3/SCL3 signal pins (27) and (28), interface between

IC1905 and lC3002, and peripheral circuits.

4 – 16

Page 57

LC-37AD5E

<During external connection> No picture on the monitor (1)

SCART1:

No picture appears on EXT1 - connected monitor during the tuner

(U/V) reception.

Checklist:

1) Are input terminal on back of TV and “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and

set “INPUT SOURCE” appropriately.

2) Is the Signal Type (item) in MENU-Option-Input Select equal to Signal Type of an external device? ••• Set it to “CVBS”, “Y/C” or “RGB”.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

4) The picture is sent to the monitor in a CVBS signal if the source during display is TV, CVBS or Y/C of EXT1-3.

When sent by component, etc., that signal is not sent to the monitor.

5) When the monitor picture is not sent and is not displayed on the monitor, refer to “No picture” for each terminal.

6) The video output from EXT1 is not the monitor output (output of the picture now watching).

The picture of the last selected TV channel is always sent to EXT1. (Specification)

Is video signal sent to pin (19) of SCART1 (J1101)? YES Check SCART1, external connection or input setting.

NO

Is video signal (V-OUT1) sent from pin (2) of IC1102 (SW)? YES Check SCART1 (J1101) and peripheral circuits.

NO

Is video signal (V-OUT1) sent from pin (195) of IC3002 (VCT)? YES Check IC1102 (SW), Connector (SC2702, P1101) and peripheral

circuits.

NO

Is video signal (CVBS) sent to pin (191) of lC3002? YES Check power supply of IC3002 and peripheral circuits.

NO

Is video signal (CVBS) sent from pin (17) of IC201 (IF-DEMOD)? YES Check CONNECTOR (P201, SC2705) and peripheral circuits.

NO

Is video signal (IF) sent from pin (17) of tuner (TU201)? YES Check IC201, FL201 (SAW-FIL), Q211 and peripheral circuits.

NO

Check +5V (CONT) power supply pins (1) and (2), I2C line pins

(15) and (14) of tuner (TU201) and peripheral circuits.

4 – 17

Page 58

LC-37AD5E

<During external connection> No picture on the monitor (2)

SCART2:

No picture from EXT1 appears on EXT2-connected monitor.

NOTE: Normally, if the screen during display is sent to EXT2, no

picture is sent to EXT2.

Checklist:

1) Are input terminal on back of TV and “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and

set “INPUT SOURCE” appropriately.

2) Is the Signal Type (item) in MENU-Option-Input Select equal to Signal Type of an external device? ••• Set it to “CVBS”, “Y/C” or “RGB”.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

4) The picture is sent to the monitor in a CVBS signal if the source during display is TV, CVBS or Y/C of EXT1-3.

When sent by component, etc., that signal is not sent to the monitor.

5) When the monitor picture is not sent and is not displayed on the monitor, refer to “No picture” for each terminal.

6) The video output from EXT1 is not the monitor output (output of the picture now watching).

The picture of the last selected TV channel is always sent to EXT1. (Specification)

Is video signal sent to pin (40) of SCART2 (J1101)? YES Check SCART2, external connection or input setting.

NO

Is video signal (V-OUT2) sent from pin (2) of IC1101 (SW)? YES Check SCART2 (J1101) and peripheral circuits.

NO

Is video signal (V-OUT2) sent from pin (194) of IC3002 (VCT)? YES Check IC1101 (SW), Connector (SC2702, P1101) and peripheral

circuits.

NO

Is video signal (VIN2) from EXT1 sent to pin (190) of IC3002

(VCT)?

NO

Check whether video signal is sent to pin (20) of SCART1. YES Check SCART1, IC2702 (SW), CONNECTOR (SC2702, P1101)

NO

Check SCART1, external connection or input setting.

YES Check power supply of IC3002 (VCT) and peripheral circuits.

and peripheral circuits.

4 – 18

Page 59

LC-37AD5E

<During external connection> No picture on the monitor (3)

SCART2:

No picture from EXT3 appears on EXT2- connected monitor.

Checklist:

1) Are input terminal on back of TV and “INPUT SOURCE” button on the remote control set up correctly? ••• See the operation manual and

set “INPUT SOURCE” appropriately.

2) Is the Signal Type (item) in MENU-Option-Input Select equal to Signal Type of an external device? ••• Set it to “CVBS”, “Y/C” or “RGB”.

3) Is ANT-CABLE disconnected or connected improperly? ••• Connect it correctly as per the operation manual.

4) The picture is sent to the monitor in a CVBS signal if the source during display is TV, CVBS or Y/C of EXT1-3.

When sent by component, etc., that signal is not sent to the monitor.

5) When the monitor picture is not sent and is not displayed on the monitor, refer to “No picture” for each terminal.

6) The video output from EXT1 is not the monitor output (output of the picture now watching).