Page 1

SERVICE MANUAL

…

…

…

…

…

…

…

…

…

…

…

…

LED BACKLIGHT TV

S84O3LC23LE44

20-08-2014

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

LC-23LE448RU

CONTENTS

Page

• SERVICING NOTICES ON CHECKING ……………………………………………………………………………………A1-1

• HOW TO ORDER PARTS …………………………………………………………………………………….……………

• IMPORTANT ……………………………………………………………………………………………...…………………

• ABOUT LEAD FREE SOLDER (PbF) ……………………………………………………………..………………………

• CAUTION WHEN REMOVE THE REAR CABINET…………………………………………………………..…………

• HOTEL MODE FUNCTION ……………………………………………………………..…………………………………

• GENERAL SPECIFICATIONS ……………………………………………………………………………………………

• DISASSEMBLY INSTRUCTIONS ………………………………………………………………….……………………… B1-1~B2-2

• HOW TO UPGRADE SOFTWARE ………………………………………………………………………………………

• ELECTRICAL ADJUSTMENTS……………………………………………………………………..……………………… D-1, D-2

• TROUBLESHOOTING GUIDE ……………………………………………………………………….……………………

• BLOCK DIAGRAM …………………………………………………………………………………..………………………

• PRINTED CIRCUIT BOARDS ……………………………………………………………………….……………………

• SCHEMATIC DIAGRAMS …………………………………………………………………………..……………………… H-1, H-2

• WAVEFORMS ……………………………………………………………………………………….………………………

• MECHANICAL EXPLODED VIEWS ……………………………………………………………………… ……………… J1-1, J1-2

• REPLACEMENT PARTS LIST ……………………………………………………………………..……..………………

A1-1

A1-1

A1-2

A1-2

A1-3

A2-1~A2-6

C-1

E-1~E-5

F-1, F-2

G-1

I-1

K1~K3

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

!

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

required.

SERVICING NOTICES ON CHECKING

1. KEEP THE NOTICES 6. PERFORM A SAFETY CHECK AFTER

SERVICING

As for the places which need special attentions,

they are indicated with the labels or seals on the Confirm that the screws, parts and wiring which

cabinet, chassis and parts. Make sure to keep the were removed in order to service are put in the

indications and notices in the operation manual. original positions, or whether there are the

portions which are deteriorated around the

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an external metal and the AC cord plug blades.

electric shock while the electric current is And be sure the safety of that.

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific 2. Remove the antenna terminal on TV and turn

characters of incombustibility and withstand on the TV.

voltage for safety. Therefore, the part which is 3. Insulation resistance between the cord plug

replaced should be used the part which has terminals and the eternal exposure metal

the same character.

Especially as to the important parts for safety using the 500V insulation resistance meter

which is indicated in the circuit diagram or the

table of parts as a ! mark, the designated 4. If the insulation resistance is less than 1M

parts must be used. ohm, the inspection repair should be

serviced places serviced or not. Check the

insulation between the antenna terminal or

(INSULATION CHECK PROCEDURE)

1. Unplug the plug from the AC outlet.

[Note 2] should be more than 1M ohm by

[Note 1].

4. BE CAREFUL WITH THE

LCD PANEL [Note 1]

If you have not the 500V insulation

Avoid a shock to the panel while servicing. resistance meter, use a Tester.

Take enough care to deal with it.

[Note 2]

5. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

External exposure metal: Antenna terminal

HOW TO ORDER PARTS

Please include the following informations when you order parts.

1. MODEL NUMBER

The MODEL NUMBER can be found on the back of each product and can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

IMPORTANT

When you exchange IC and Transistor with a heat sink, apply silicon grease (YG6260M) on the contact

section of the heat sink. Before applying new silicon grease, remove all the old silicon grease.

(Old grease may cause damage to the IC and Transistor).

A1-1

Page 3

All products with the printed circuit board with PbF printing must be serviced with lead free solder.

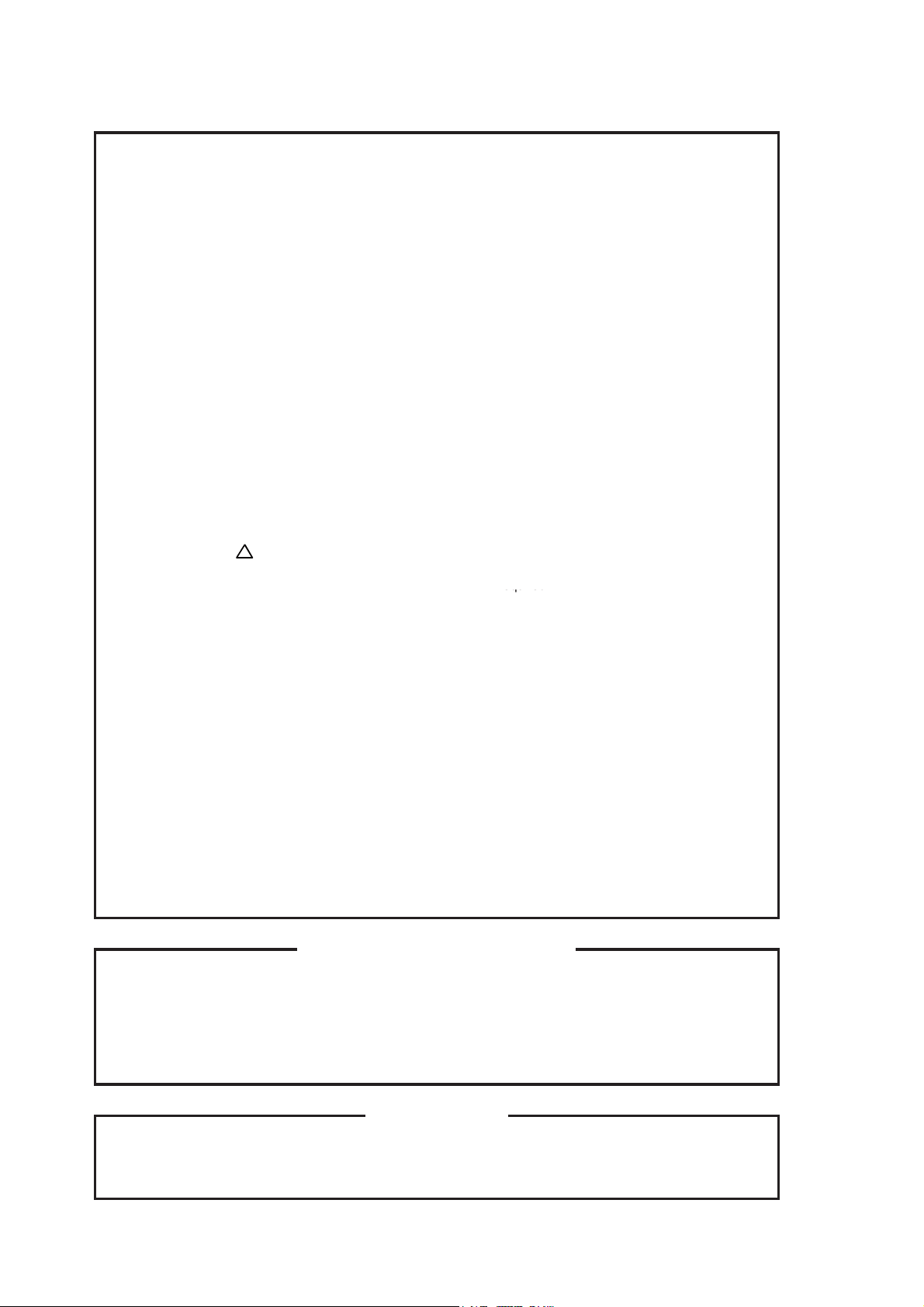

ABOUT LEAD FREE SOLDER (PbF)

Distinction of PbF PCB:

PCBs (manufactured) using lead free solder will have a PbF printing on the PCB.

(Please refer to figures.)

Caution:

• Pb free solder has a higher melting point than standard solder;

Typically the melting point is 86

Please use a soldering iron with temperature control and adjust it to 650

In case of using high temperature soldering iron, please be careful not to heat too long.

•

Pb free solder will tend to splash when heated too high (about 1100

•

When soldering or unsoldering, completely remove all of the solder from the pins or solder area,

and be sure to heat the soldering points with the lead free solder until it melts sufficiently.

o

F~104oF(30oC~40oC) higher.

o

F ± 20oF (350oC ± 10oC).

o

F/ 600oC).

Recommendations

Recommended lead free solder composition is Sn-3.0Ag-0.5Cu.

CAUTION WHEN REMOVE THE REAR CABINET

1. Remove SCREWs from COVER BACK ASS'Y and hold the COVER BACK ASS'Y as the below Picture.

2. Remove connector of CD2201䇮CD2202䇮CD301 from MAIN PCB BOARD.

In doing so, take care the space NOT to touch T-CON PCB , COVER BACK ASS'Y must be held off the T-CON PCB

( as NOT over dashed line in below picture).

3. And then, also take care for cables NOT to be fallen down from RIBs on COVER BACK ASS'Y side.

COVER BACK

SPACE

T-CON PCB

A1-2

Page 4

/

pp

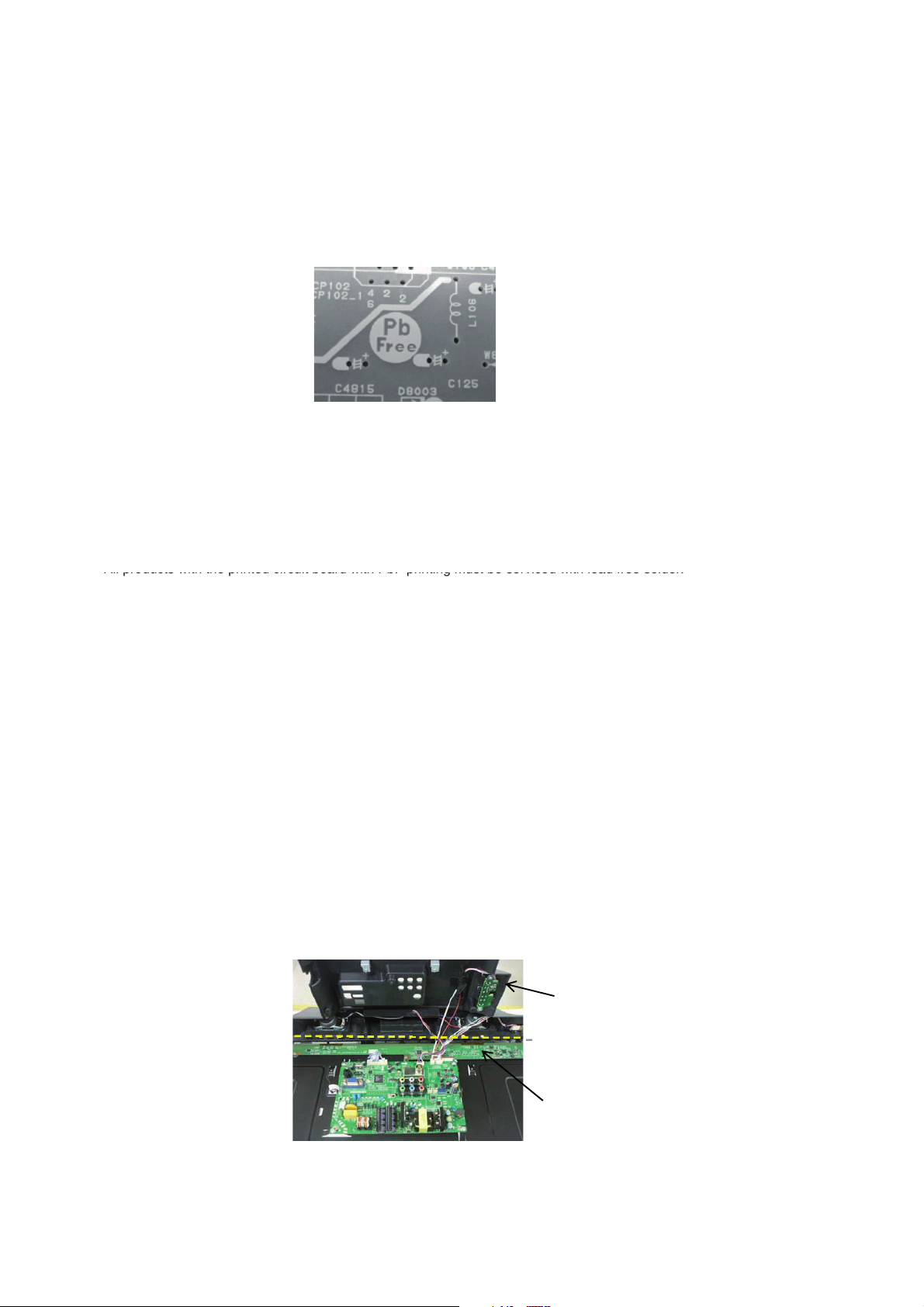

HOTEL MODE FUNCTION

To set the Hotel mode, please follow the steps below.

1. Press the MENU---> 1147 button on the remote control.

2. Press the DOWN button on the remote control,

3. Select the "GENERAL SETTING" menu , then press ENTER button.

Select the "Hotel Mode " menu, Select "ON",Then press the RETURN button.

4.

Using the LEFT/RIGHT button on the remote control, please select " ".

5.

Then press the ENTER button.

6.

Please input the password "0000". Then press the ENTER button.

7.

The Hotel mode setting menu will appear.

8.

9. Using the UP/DOWN button on the remote control,

select the desired mode. Then press the ENTER button.

10. Using the LEFT/RIGHT button on the remote control,

set the mode to desired setting.

11. The Hotel mode has now been set up.

To reset the Hotel mode, please follow the steps below.

1. Press the MENU---> 1147 button on the remote control.

2. Press the DOWN button on the remote control,

3. Select the "GENERAL SETTING" menu , then press ENTER button.

4. Select the "Hotel Mode " menu.

5. Using the LEFT/RIGHT button on the remote control, please select " ".

6. Then press the ENTER button.

7. Please input the password "0000". Then press the ENTER button.

8. The setting items has now been returned to initial value.

Hotel Mode

On

Setting item Setting value Initial value

TV/AV/

Source Lock COMPONENT/ Setting Input skip, combine with "Default Source".

HDMI/PC/MEDIA

Default Source

Default Prog

Maximum volume 0~100 100

Default Volume 0~100 20 Setting volume at Power on.

Clear Lock Setting of the Hotel Mode return factory setting.

Set Password Setting of the Password.

TV/AV

COMPONENT/ Setting Input Source, combine with "Source Lock"

HDMI/PC/MEDIA If select "Source Lock" for this function disa

0~199 1 Setting of the CH if select "Default Source" to TV input.

OFF

Setting of the maximum volume value.

FUNCTION

ear.

A1-3

A1-3

Page 5

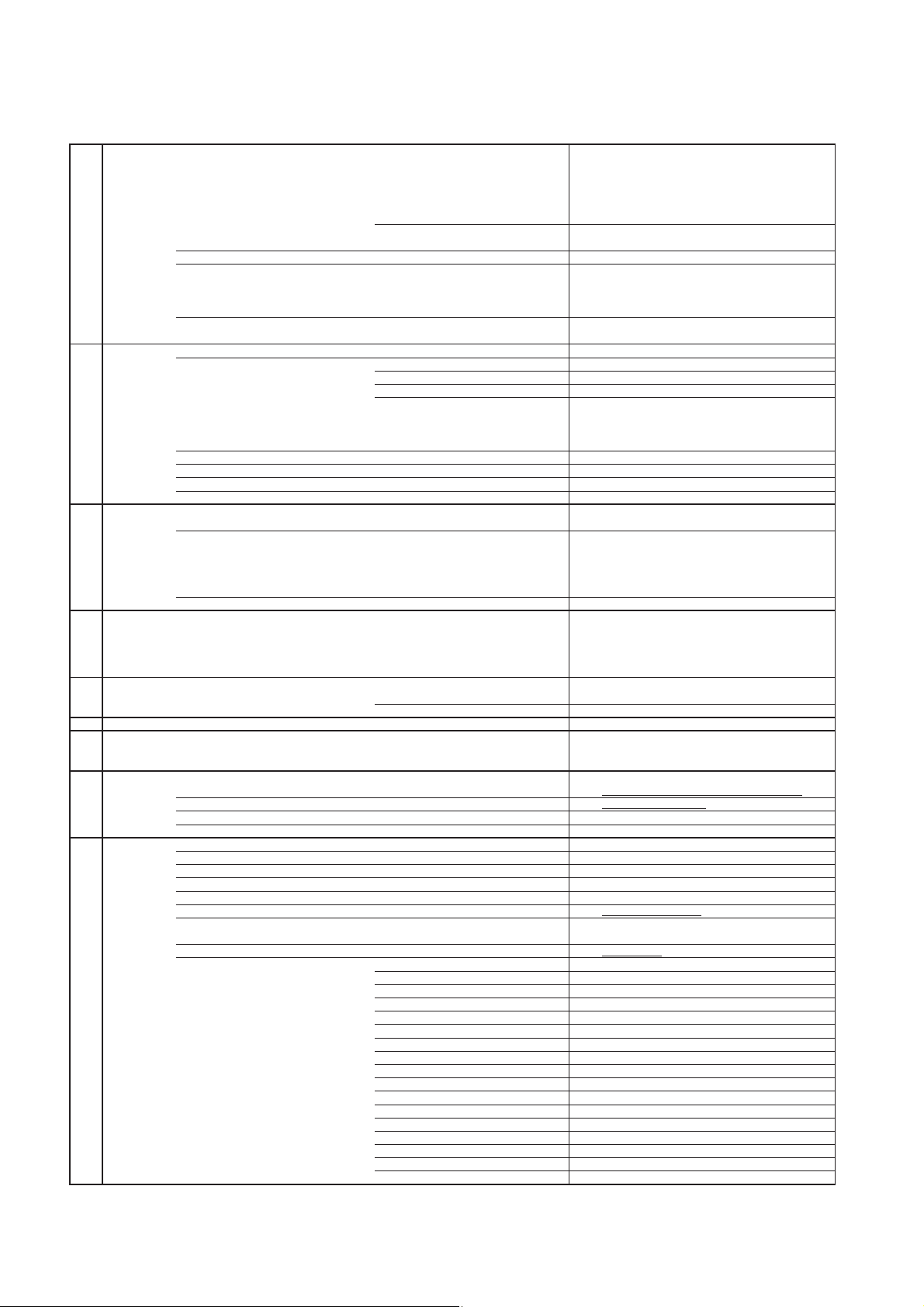

GENERAL SPECIFICATIONS

G-1 TV

System

G-2 Tuning

System

G-3 Power

G-4 Regulation

G-5 Temperature

G-6 Operating Humidity

G-7 OSD Language

G-8 Clock and

Timer

G-9 Remote

Control

LCD LCD Size / Visual Size 22.95 inch / 583.0mmV

Color System PAL / SECAM / NTSC3.58 / NTSC4.43 / PAL60

Speaker 2 Speaker

Sound Output MAX 5W + 5W

Broadcasting System Analog

Tuner and System 1Tuner (Analog)

Receive CH Destination UK, I.R., CCIR Hyper

CH Coverage Analog 44.25MHz~863.25MHz

Intermediate Analog

Frequency Picture(FP) 38.9 / 38.9 / 38.9 / 45.75MHz

Auto Tuning Method

Preset CH Analog 199 Carrier

Stereo/Dual TV Sound Nicam / A2 Dual / US Stereo(w/ SAP)

Tuner Sound Muting Yes

Power Source AC 220-240V AC 50/60Hz

Power Consumption at AC 33 W at AC 220 V 50 Hz

Protector Power Fuse Yes

Sleep Timer Max Time 240 Min

On/Off Timer Program(On Timer / Off Timer) -- Program / -- Program

Timer Back-up (at Power Off Mode) more than -- Min Sec

EPG Timer Events -Unit RC-UW

Case Color Black

Glow in Dark Remocon No

Remocon Format SHARP

Format SHARP

Custom Code 10000 / 10001 / 01111

Power Source Voltage(D.C) 3V

Total Keys 43 Keys

Keys Power (Stand By) Yes

LCD Type Color TFT LCD

Number of Pixels 1366(H) x 768(V)

Double Scan No

View Range Left/Right 85/85 degree

Up/Down 85/85 degree

Bright Dot

Zero Bright Dot Ratio --

Position Bottom

Size 1.0 x 2.5 inch

Impedance 4 ohm

10%(Typical) ---

Sound(FS)

FP-FS

DC ---

at DC --

Stand by (at AC) w/ EPG Timer --

w/o EPG Timer 1 W at AC 230 V 50 Hz

Per Year -- kWh/Year

Safety

Radiation EN55013,EN55020,EN55022

X-Radiation Operation

Storage

Space Around Unit 100mm (4inch)

Step 10 / 20 / 30 / 60 / 90 / 120 / 180 / 240 Min

UM size x pcs UM-4 x 2 pcs

Information Yes

Analog Menu No

Digital Menu No

Input Select Yes

TV/DVB-T No

Guide No

Picture Size Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

n҇0

PAL(B/G, D/K, I), SECAM(B/G, D/K)

BG / II / DK / M

33.4 / 32.9 / 32.4 / 41.25MHz

5.5 / 6.0 / 6.5 / 4.5MHz

ALL Band (Not C.C.I.R. CH Plan)

IEC60065 Ed.7:2001+Amd.1:2005, EAC(applied by

Sharp)

IEC61000-3-2, IEC61000-3-3

o

0

C ~ +40oC

o

-20

C ~ +60oC

Less than 80% RH

English, Simplified Chinese, Arabic, Thai, Persian

French, Vietnam, Russian, Malay, Portuguese,

Spanish, Indonesian

A2-1

A2-1

Page 6

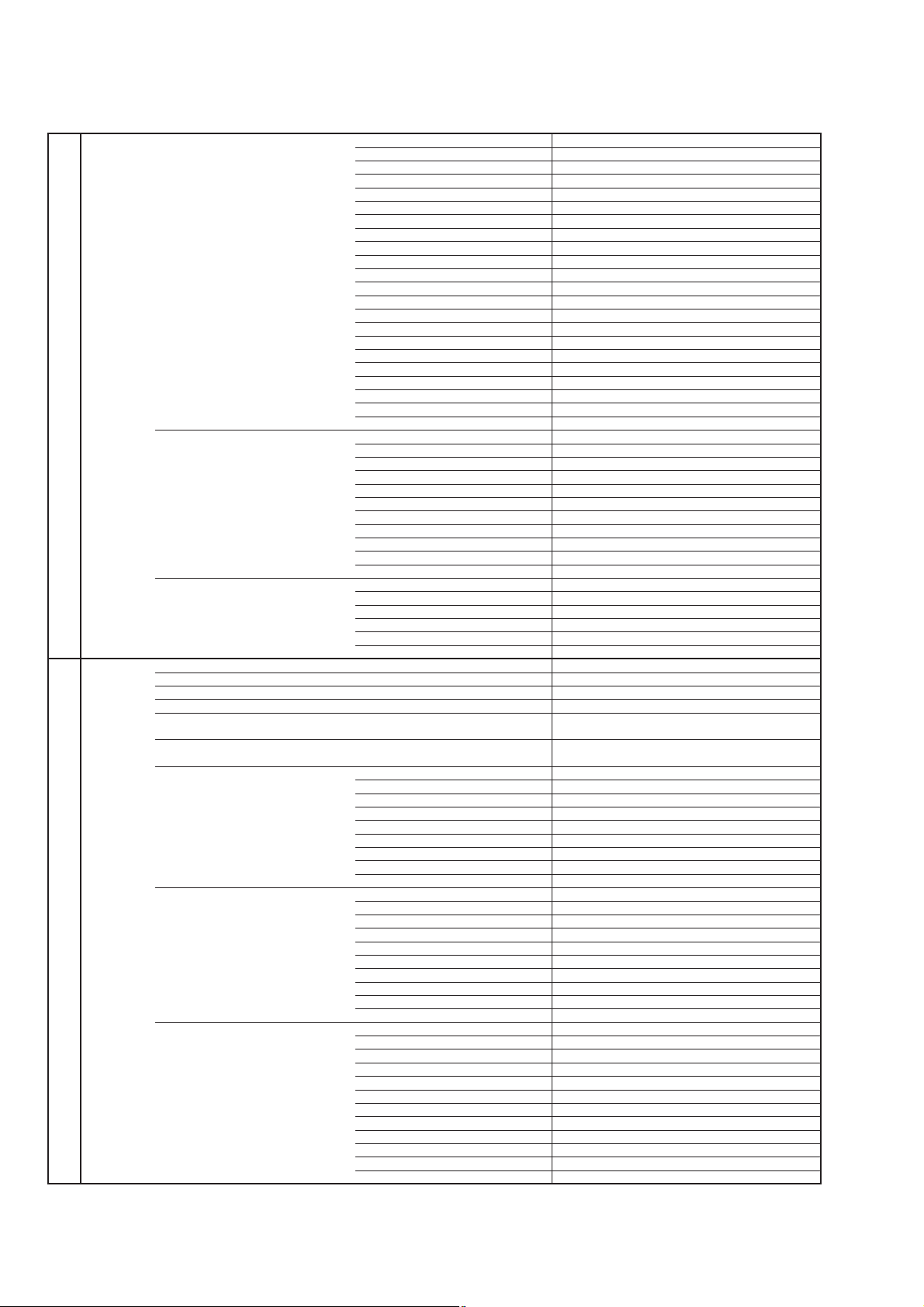

GENERAL SPECIFICATIONS (continued)

0 Yes

Sleep No

Mute Yes

Volume Up / ń

Volume Down / ł

Volume Up Yes

Volume Down Yes

CH Down Yes

CH Up Yes

Menu Yes

㸡

㸣

㸠

㸢

MEDIA Yes

Enter / CH List Yes

Return / Index Yes

Freeze frame Yes

Quick View Yes

Audio 1/2 Yes

TV/Radio No

Subtitle No

Reveal Yes

HOLD Freeze Frame enable

Red Yes

Green Yes

Yellow Yes

Cyan Yes

F/T/B(Expand) Yes

Sub Page Quick View enable

Page Up CH Up enable

Page Down CH Down enable

STOP Yes

SEARCH > Yes

SEARCH < Yes

SKIP >> Yes

SKIP << Yes

Country No

TV Location No

Auto Power Off Yes

Auto tuning Yes

Auto clock (Digital tuner) No

Plug in start Yes

Brightness , Contrast , Color Yes

Tint Yes

Sharpness Yes

DNR Yes

Color Temperature Yes

Backlight Control Yes

DBC (Dynamic Backlight Control) No

Motion 100/120Hz No

Film Mode No

Brightness , Contrast , Color Yes

Sharpness No

HOR POSITION , VER POSITION Yes

PHASE , CLOCK Yes

AUTO ADJUST Yes

RED , GREEN , BLUE No

DNR No

Color Temperature Yes

Backlight Yes

WXGA INPUT No

WVGA INPUT No

G-10 Features

T'TEXT Keys TV / TEXT / MIX Yes

USB MEDIA Keys PLAY / PAUSE Yes

Power On Memory Yes

Auto Shut Off Yes

Just Clock Function No

Game Position No

DNR Yes

Comb Filter Yes

Auto Set Up (Fast installation) Language Yes

Picture Setting(TV) Picture Mode Yes

Picture Setting(PC) Picture Mode Yes

No

No

Yes

Yes

Yes

Yes

3D

3D

CH sort No

ATS No

A2-2

Page 7

GENERAL SPECIFICATIONS (continued)

Audio Sound Mode Yes

Tuning Auto Tuning Yes

Lock Key Lock Yes

Screen Saver

T'Text Yes

Text and Picture No

Wide Mode (4:3/16:9/CINEMA/REAL) Yes

CH Label Yes

Reset to Default Yes

HD Zoom No

Picture Scroll (Vertical Position) No

PFC(Power Factor circuit) No

Freeze frame Yes (ATV/CVBS in Only)

Plug and Play No

Power Management Yes

Hearing Impaired No

Audio Description No

Power On LED No

HDMI Mode No

Blue Back Yes

Scart Spec Scart1 AV in No

Scart2 AV in No

Digital Text (VBI teletext)

MHEG-5

MHP

EPG (BBC type 8Days Digital tuner only)

OAD (Over Air Download)

Common Interface (Digital tuner only)

Rec Screen Status

Ch sorting based on Ch List (Digital/Germany only)

Rename Carrier (Digital)

Edit Event Timer

Software Update via CI Slot

Preference Language (Audio/Subtitle/Digital Service)(Digital)

DVB Subtitle (Digital)

Clock

DST

Signal Status

Digital Out Dolby Digital No

Decode(Down Mix) Dolby Digital No

Tone Control (Bass/Treble/Balance) Yes

Surround Yes

Equalizer No

Speaker No

Auto Volume Yes

BBE No

SRS WOW (SRS 3D/Focus/Tru Bass) No

Variable Audio Out No

Manual Tuning Yes

Update Scan No

CH Skip Yes

CH Move Yes

CH Del Yes

Fine Tuning Yes

Channel Lock No

Parental Lock (Digital) No

Hotel Lock Yes

USB Clone (Hotel Lock) Yes

Inversion No

Full White No

Screen Saver No

Static Image No

Text type Fastext / Toptext

Text Language English, German, Swedish, Finnish, Hungarian,

AV out No

S-Video in No

RGB in No

AV out No

S-Video in No

RGB in No

Dolby Digital Plus No

MPEG No

HE AAC No

Dolby Digital Plus No

Italian, French, Portuguese, Spanish, Czech,

Slovak, Polish, Estonian, Lettish, Lithuanian,

Slovenian, Rumanian, Russian,

Ukrainian, Turkish, Greek, Hebrew, Farisi

Arabic, Serbian, Croatian, Bulgarian

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

A2-3

Page 8

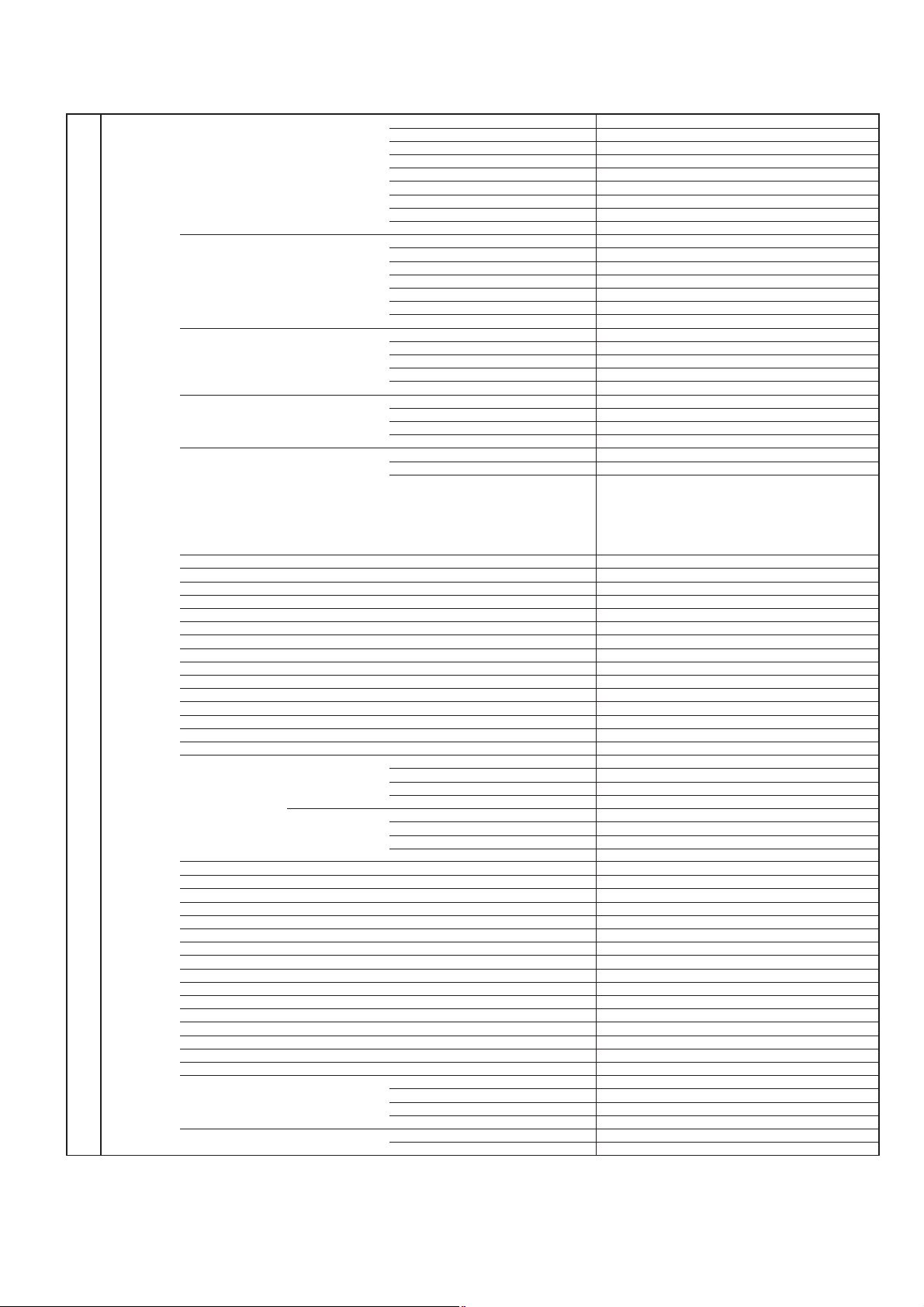

GENERAL SPECIFICATIONS (continued)

MPEG No

HE AAC No

USB Media Player Photo JPEG (.jpg/.jpeg), BMP (.bmp), PNG (.png)

Music MP3 (.mp3), WMA (.wma), AAC (.aac/.m4a)

Video Container AVI (.avi), MKV (.mkv), MP4 (.mp4),

Video Codec Xvid, MPEG1, MPEG2, MPEG4 SP/ASP,

Audio Codec MPEG2, MP3, PCM/ADPCM, WMA, AC-3, AAC

Text Text (.txt)

PC Monitor Input Yes

VGA (640x480) Yes (60Hz)

VGA (720x400) No (Possible to Display)

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) Yes (60Hz)

WXGA+ (1440x900) Yes (60Hz)

WSXGA+ (1680x1050) No (Possible to Display)

FULL HD (1920x1080) Yes (60Hz)

HDMI Input Yes

VGA (640×480)

VGA (720x400) No (Possible to Display)

WVGA (848x480) No

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

SXGA (1280x1024) Yes (60Hz)

WXGA+ (1440x900) Yes (60Hz)

WSXGA+ (1680x1050) No (Possible to Display)

FULL HD (1920x1080) Yes (60Hz)

720×480i (4:3)

720×480i (16:9)

720×480p (4:3)

720×480p (16:9)

720×576i (4:3)

720×576i (16:9)

720×576p (4:3)

720×576p (16:9)

1280×720p

1920×1080i

1920×1080p

CEC(ORION Standard)

Deep Color

xvYCC

Component Input Yes

720×480i (4:3)

720×480i (16:9)

720×480p (4:3)

720×480p (16:9)

720×576i (4:3)

720×576i (16:9)

720×576p (4:3)

720×576p (16:9)

1280×720p

1920×1080i

1920×1080p

Wall Mount Size W x H(mm) Yes (100 x 100)

Screw Size M4 x 10

Stand Tilt No

Swievel No

PS (.mpg), TS (.ts/.trp), VOB (.vob)

DIVX(.div/.divx/.avi/.mp4), MOV(.mov)

MJPEG, H.264, DIVX

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50/60Hz)

Yes (50/60Hz)

Yes (24/50/60Hz)

No

No

No

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (60Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50Hz)

Yes (50/60Hz)

Yes (50/60Hz)

No (Possible to Display)

A2-4

Page 9

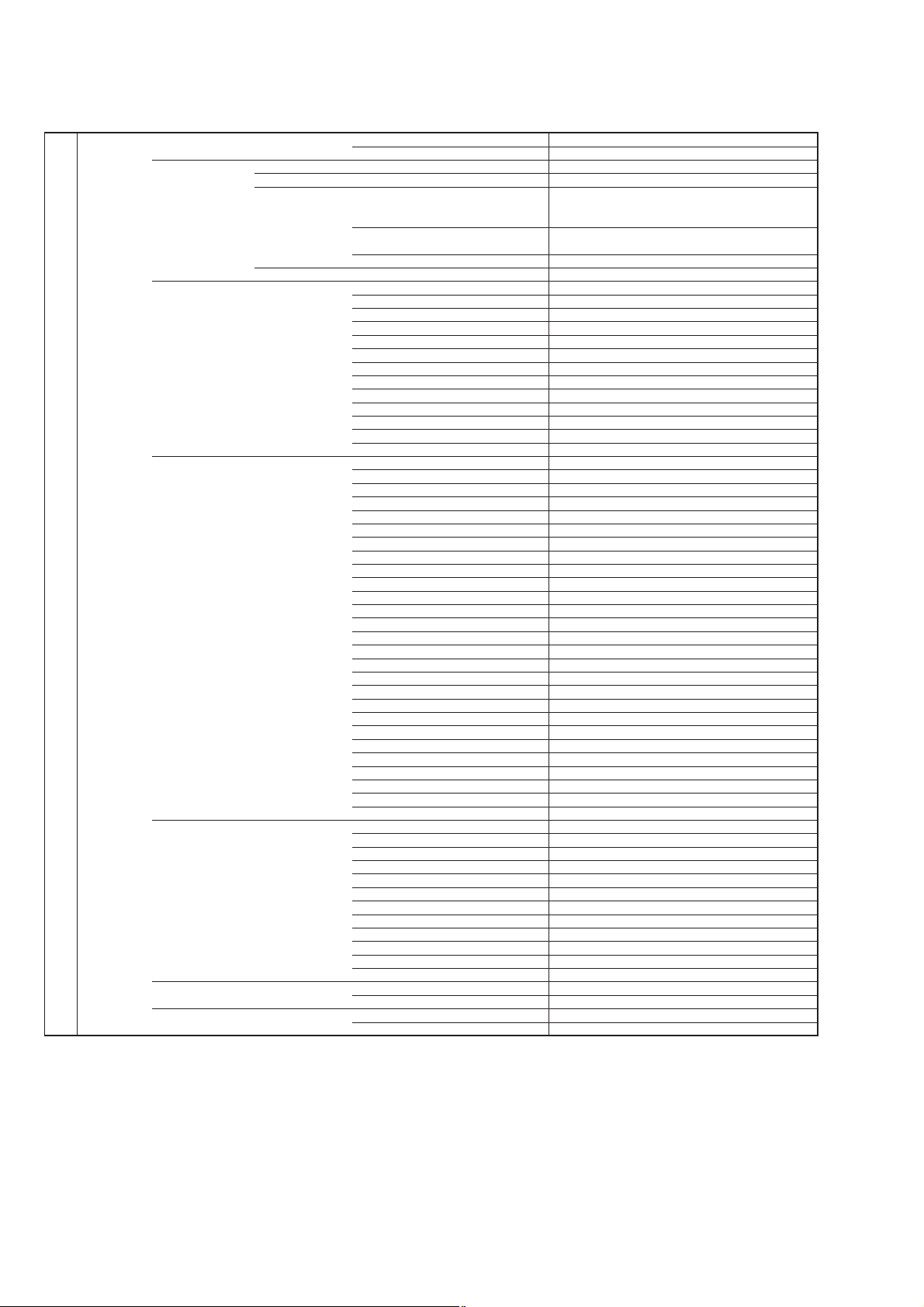

GENERAL SPECIFICATIONS (continued)

G-11 Accessories

G-12 Interface

G-13 Set Size

G-14 Weight

Owner's Manual Language Russian/Kazak (w/EAC number)

Remote Control Unit Yes

DVB-T Antenna No

U/V Mixer No

Information Sheet (VESA) No

DC Car Cord (Center+) No

Warranty card Yes(w/Serial No, Model No. label)

EAC Safety sheet Yes ( for AUG'14 O/R only)

Warning Sheet No

Circuit Diagram No

Antenna Change Plug No

Service Facility List No

Important Safeguard No

Quick Set-up Sheet No

Battery Yes

AC Adapter No

AC Cord (for AC Adapter) No

AC Cord No

AV Cord (2Pin-1Pin) No

HDMI-DVI Cable No

Registration Card No

300 ohm to 75 ohm Antenna Adapter No

Stand Screw??? Yes (4pcs)

Stand Yes

Frame Stand No

Switch Side Power (Tact) Yes

Indicator Power/Stand-by Yes(Green / Red)

Terminals Rear Video Input 1

w/Guarantee Card No

UM size x pcs UM-4 x 2 pcs

OEM Brand No

System Select No

Main Power SW No

Channel Up/Menu Up Yes

Channel Down/Menu Down Yes

Volume Up/Menu > Yes

Volume Down/Menu < Yes

Input Select/Enter Yes

Menu No ("Vol-"+"Vol+" 1sec)

On Timer No

Audio Input 1

S- Input 1 No

Video Input 2 No

Audio Input 2 No

S- Input 2 No

Video Output No

Audio Output No

Digital Audio Out (Coaxial) No

Euro Scart (21Pin) No

Component In

Audio Input (Component In use)

HDMI Input 1

Audio Input (HDMI/DVI In use) PC Monitor Audio Input enable

HDMI Input 2 No

Audio Input (HDMI/DVI In use) No

PC Monitor Input (D-Sub)

Audio Input

USB

Sub Woofer Output No

Diversity No

Ext Speaker No

DC Jack 12V(Center +) No

VHF/UHF Antenna Input

Headphone No

CI Card Slot No

AC Inlet No

Approx. W x D x H (mm) 542 x 136.9 x 350.5

w/o Stand,Handle Approx. W x D x H (mm)

Net Approx. 3.0 kg (6.6lbs)

Net w/o Stand,Handle Approx. 2.8 kg (6.2lbs)

Gross Approx. 4.1 kg (9.1lbs)

Gross w/Master Carton (Approx.) --- kg ( --- lbs)

RCA x 1

RCA x 2(L, R)

RCA x 3

Audio Input1 enable

Yes

Yes

Mini Pin Jack(Ǘ3.5), STEREO

Yes

DIN Type

542 x 57.5 x 326.5

A2-5

Page 10

GENERAL SPECIFICATIONS (continued)

G-15 Carton

G-16 Material

G-17 Environment

Master Carton No

Gift Box Yes

Drop Test Natural Dropping At 1 Corner / 3 Edges / 5 Surfaces

Container Stuffing 2400 Sets/40' hi-cub container

w/Pallet No

w/Wrapping No

Cabinet Cabinet Front PS 94HB (Piano)

PCB Non-Halogen No

Environmental standard requirement Green procurement of SHARP

Pb- Free Phase3(PHASE3A)

WEEE No

Content ---- Sets

Material -- /-Dimensions W x D x H(mm) -- x -- x --

Description of Origin No

Material Single/Full Color

W/Color Photo Label No

W/Handle

Dimensions W x D x H(mm) 589 x 113 x 390

Design As per Buyer's

Description of Origin Yes

Height (cm) 48 (ES:+15%, PP:+5%)

Cabinet Rear PS 94V0 NON-DECABROM

Speaker Box -Stand PS 94HB (Piano)

Eyelet Yes

Measures for Whisker Yes

Yes

A2-6

Page 11

(A)

g

g

(

)

(

)

y

(

)

y

(1)

g

(

(2)

(B)

pp

p

(D)

y

Fig.1

3

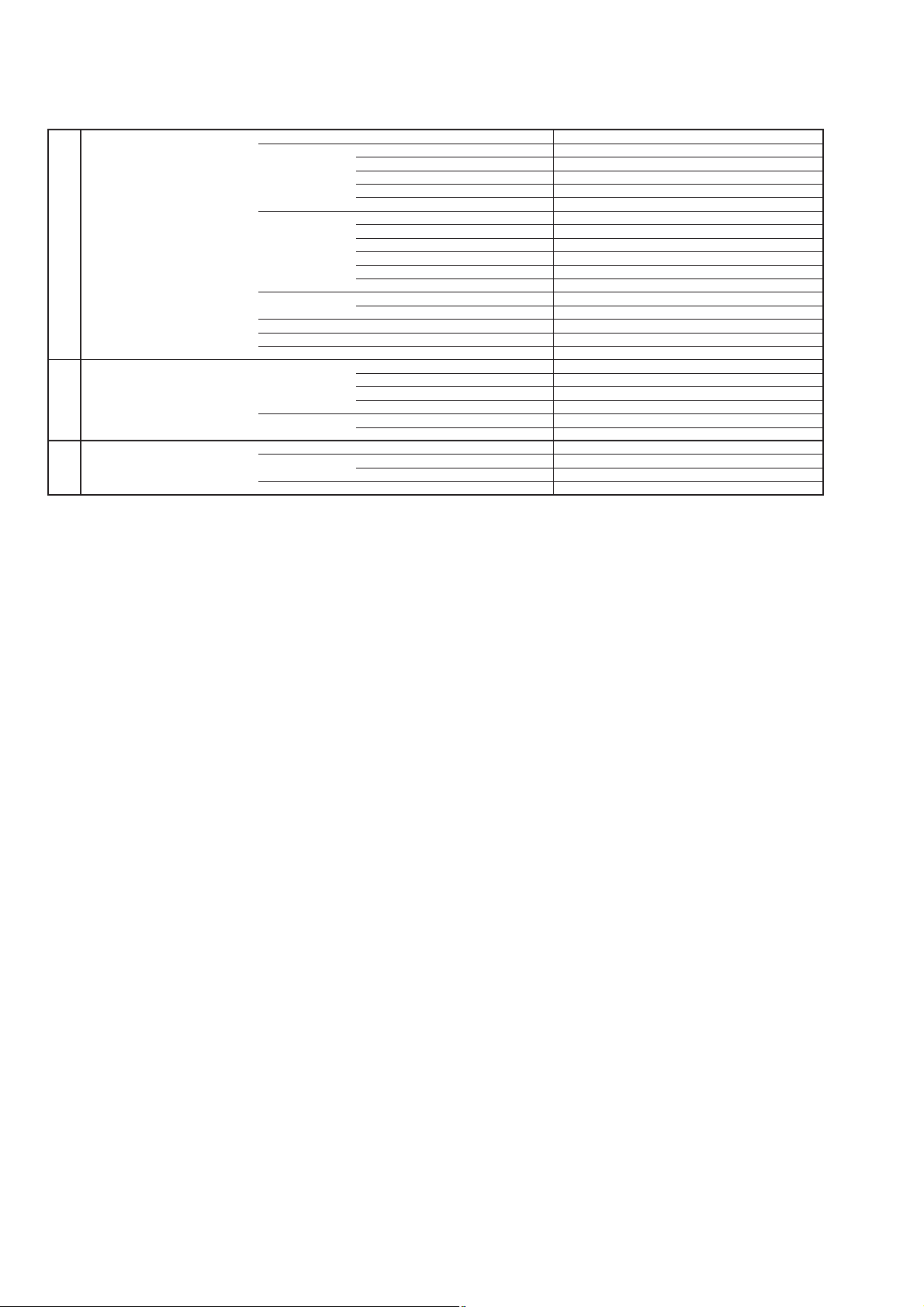

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF MECHANICAL PARTS

1-3: MAIN UNIT (Refer to Fig. 1-3)

AND P.C. BOARDS

1. Remove the 5 screws (1).

2. Remove the Shield Main in the direction of arrow

CAUTION

Parts removal shuld be perform in clean room cause 4. Remove the Main Unit in the direction of arrow (B).

•

the unit will be dero

Be careful not to remove the LVDS cable forcibly, because

•

the LVDS cable may be damaged.

To wear the gloves each time.

•

1-1: STAND ASS'Y

Remove the 4 screws (1).

1.

Remove the Stand Ass'y in the direction of arrow.

2.

1-2: COVER BACK ASS'Y

1. Remove the 11 screws

2. Disconnect the followin

ate by dust.

Refer to Fig. 1-1

Stand Ass'y

Refer to Fig. 1-2

.

connectors:

(1)

(1)

(1)

Fig. 1-1

(1)

CD301, CD2201 and CD2202).

3. Remove the Cover Back Ass'y in the direction of arrow (A).

4. Remove the 2 screws

5. Remove the Sheet PC in the direction of arrow

6. Unlock the su

7. Remove the O

eration PCB in the direction of arrow (C).

.

.

ort (3).

8. Unlock the 2 supports (4).

9. Remove the Remocon PCB in the direction of arrow

(1)

(1)

(1)

(1)

Cover Back Ass'y

(A)

Operation PCB

(1)

(1)

(1)

(1)

(3)

(1)

(1)

(C)

(D)

(B)

Remocon PCB

.

(1)

(4)

3.

Disconnect the followin

Shield Main

Main Unit

1-4: LED MODULE ASS'Y

connectors: (CN12 and CNB802).

(1)

(1)

(1)

(A)

(1) (1)

(B)

Refer to Fig. 1-4

1. Unlock the 14 supports (1).

2. Remove the LED Module Ass'

in the direction of

arrow (A) -> (B) -> (C) -> (D), Please remove carefully

(1)

(1)

.

(A)

(B)

(D)

(1)

(1)

Front Cabi Ass'y

LED Module Ass'y

.

and slowl

• Do not touch LED Module Ass'

.

-

(C)

(1)

(1)

Fig. 1-4

(2)

(2)

Sheet PC

Fig. 1-2

B1-1

Page 12

Fig.2-1

DISASSEMBLY INSTRUCTIONS (continued)

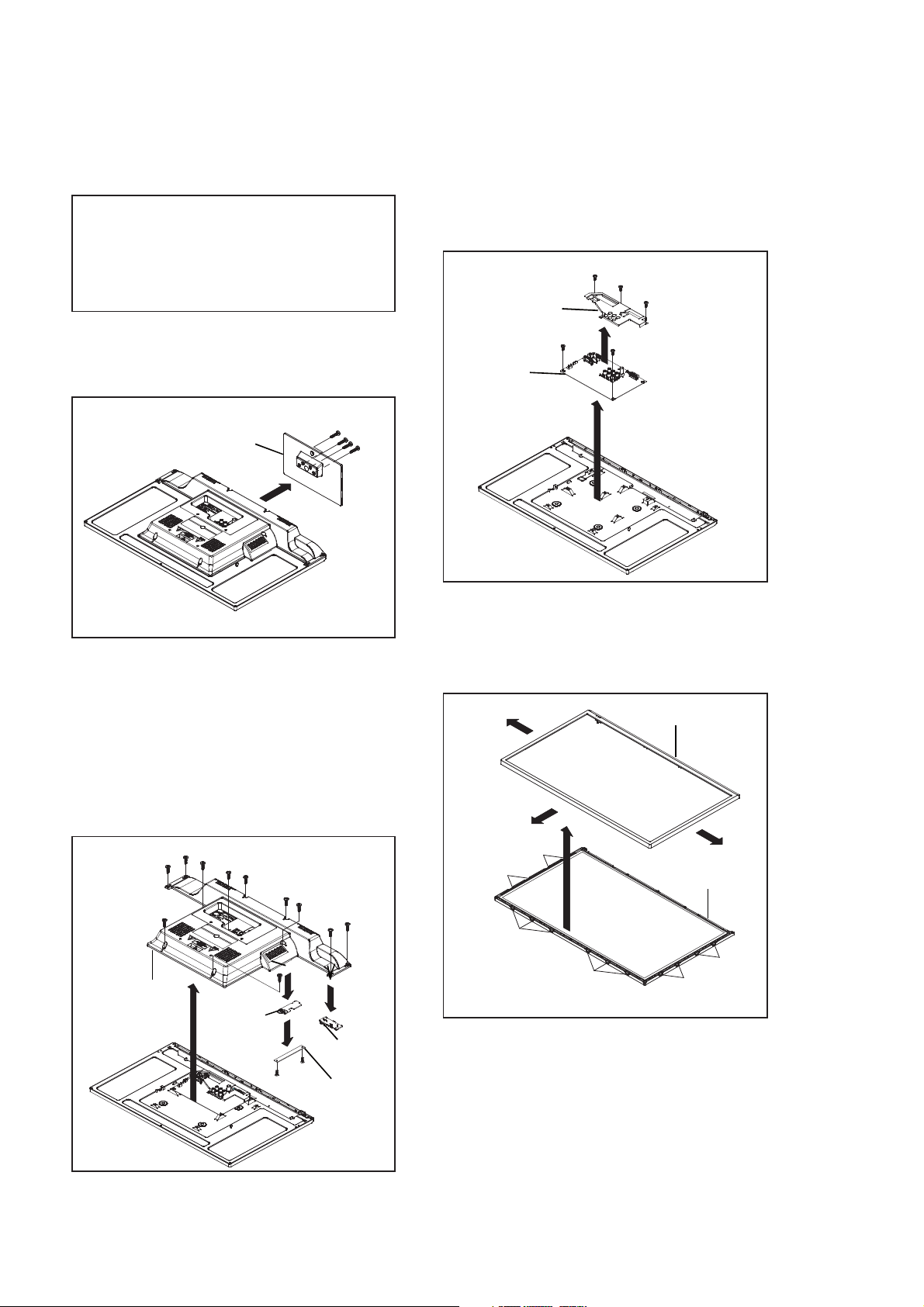

2. REMOVAL AND INSTALLATION OF

FLAT PACKAGE IC

3. When IC starts moving back and forth easily after

desoldering completely, pickup the corner of the IC using

tweezers and remove the IC by moving with the IC

REMOVAL desoldering machine. (Refer to Fig. 2-3.)

1. Put Masking Tape (cotton tape) around the Flat Package

NOTE

IC to protect other parts from any damage.

(Refer to Fig. 2-1.)

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

NOTE

leads or solder lands under the IC when removing it.

Masking is carried out on all the parts located within

10 mm distance from IC leads.

Masking Tape

(Cotton Tape)

IC

Tweezers

Blower type IC

desoldering machine

2. Heat the IC leads using a blower type IC desoldering

machine. (Refer to Fig. 2-2.)

IC

NOTE

Fig. 2-3

Do not rotate or move the IC back and forth , until IC 4. Peel off the Masking Tape.

can move back and forth easily after desoldering the

leads completely. 5. Absorb the solder left on the pattern using the Braided

Shield Wire. (Refer to Fig. 2-4.)

Blower type IC

desoldering machine

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Braided Shield Wire

Soldering Iron

IC

Fig. 2-2

IC pattern

Fig. 2-4

B2-1

Page 13

damaged. So, always be sure to replace the IC

s

damaged. So, always be sure to replace the IC in this

DISASSEMBLY INSTRUCTIONS (continued)

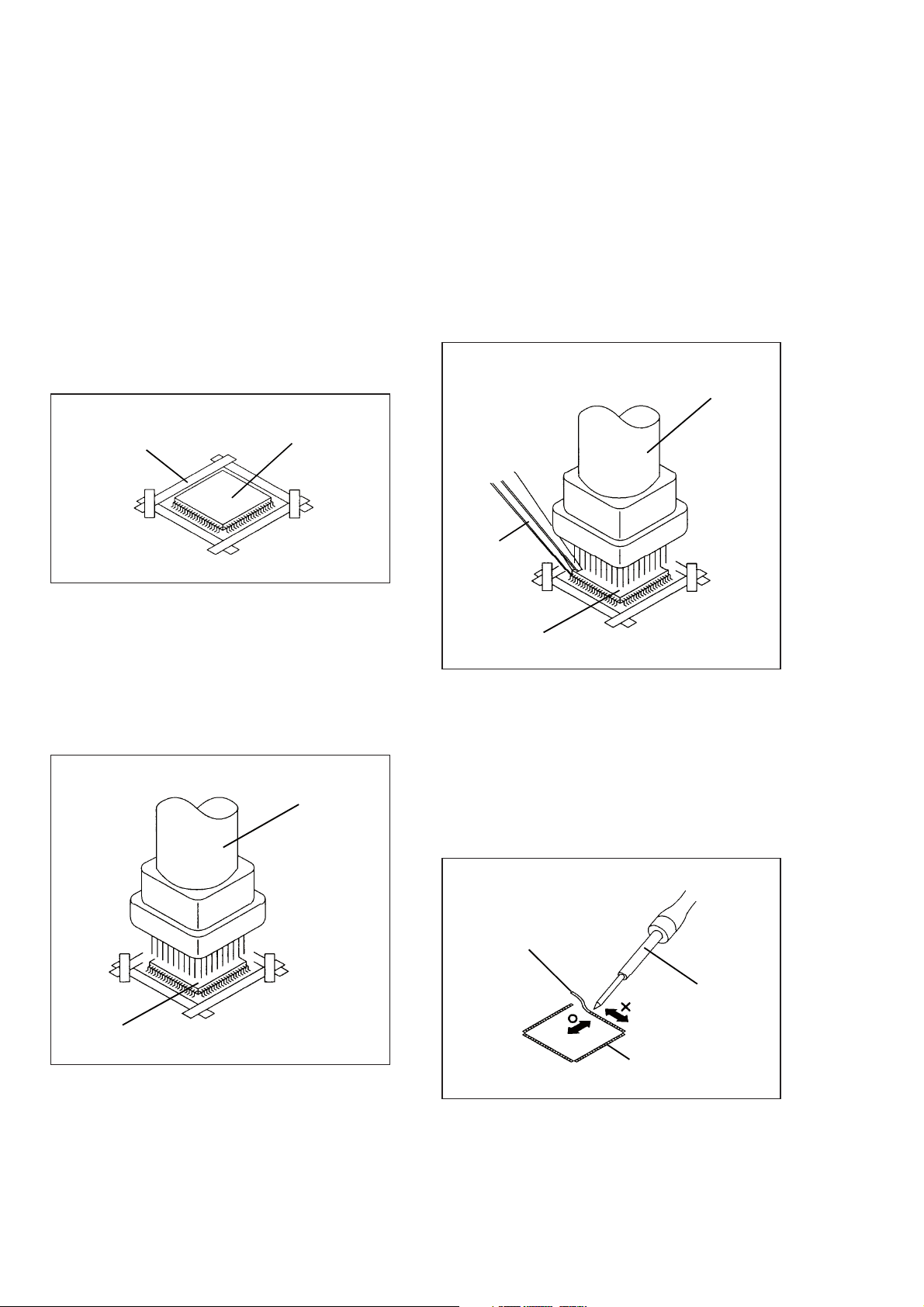

INSTALLATION

4. When bridge-soldering between terminals and/or the

soldering amount are not enough, resolder using a

1. Take care of the polarity of new IC and then install the

Thintip Soldering Iron. (Refer to Fig. 2-8.)

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 2-5.)

Thin-tip Soldering Iron

Soldering Iron

IC

Fig. 2-8

5. Finally, confirm the soldering status on four sides of the

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

Solder temporarily

Solder temporarily

Fig. 2-5

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

2. Supply the solder from the upper position of IC leads When the IC leads are bent during soldering and/or

sliding to the lower position of the IC leads. repairing, do not repair the bending of leads. If the

(Refer to Fig. 2-6.)

bending of leads are repaired, the pattern may be

in thi

case.

Solder

Soldering Iron

Supply soldering

IC

from upper position

to lower position

Fig. 2-6

3. Absorb the solder left on the lead using the Braided

Shield Wire. (Refer to Fig. 2-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 2-7

B2-2

Page 14

p

HOW TO UPGRADE SOFTWARE

Turn off and Unplug the AC cord.

1

Connect the USB storage device into the Media input terminal while turning off.

2

Insert the AC cord plug and press hold Power untill the flashing.

3

If the LED light is flashing, Power Key is leaved, Then wait 50 sec. after that let update data.

4

(Do not be closed the light while updating. If it closes, please update data again.)

Power on at Power key then the OSD will appear on the screen It is finished updating data.

5

Unplug and remove the USB.

6

Unplug the Ac cord and disconnect the USB, then insert plug.

7

Power on and check version to follow that "MENU ---> 1147 ---> FACTORY SETTING --->VERSION".

8

To process the "FACTORY SETTING" "INIT TV" and to set the first time installation bofore dirivery.

9

CHECK FOR THE FIRMWARE VERSION

This unit is

CAUTION

1.

rovided with the following SERVICE MODES so you can repair, examine and adjust easily.

Do not adjust other items except " SW INFORMATION".

Check of the SUM DATA and VERSION on the screen.

1-1: Press the MENU ---> 1147 button on the remote control.

1-2:

The "Factory Setting" menu on the screen as shown in Fig. 1-1.

Factory Setting

GENERAL SETTING

PICTURE

SOUND

DEBUG

ADC ADJUST

EMC SETTING

SW INFORMATION

Software Update (USB)

INIT FAC CHANNEL >>>

INIT TV >>>

BURN MODE OFF

BUILD TIME 2014-07-18 11:53:45

VERSION M3SS-05X

LSC230AN01

23_SH_M3SS_05X_V59_DivX

BD_VST59_P901A

Checksum 9CB6

Fig. 1-1

1-3: Press the DOWN button on the remote control, Select the "SW INFORMATION" menu,

then press ENTER button.

1-4:

The SW INFORMATION menu on the screen as shown in Fig. 1-2.

SW INFORMATION

BUILD TIME

VHF_L_H 163

VHF_H_UHV 467

WDT ON

MANTIS NO.

AT:V2.72

LCD ON TIME 6

HDCP INFO: 0x000EF905

AT Tested Status CHECKED

LSC230AN01

23_SH_M3SS_05X_V59_DivX

BD_VST59_P901A

Checksum

CS55400

9CB6

Fig. 1-2

1-5: After the confirmation of each check sum. Turn off power.

C-1

Page 15

.

ELECTRICAL ADJUSTMENTS

1. ADJUSTMENT PROCEDURE

Prepare the following measurement tools for electrical

adjustments.

1. Pattern Generator 2. Please select input About mode to adjust COLOR TEMP

On-Screen Display Adjustment

1. Press the MENU---> 1147 button on the remote control. to set to the AV mode.

2. Press the DOWN button on the remote control. 5. Using the remote control, set the brightness and

3. Select the "PICTURE SETTING" menu, then press contrast to normal position.

ENTER button on the remote control. 6. Press the MENU---> 1147 button on the remote control.

4. Select the "COLOR TEMP" menu , then press 7. Press the DOWN button on the remote control.

ENTER button on the remote control. 8. Select the "PICTURE SETTING" menu, then press

5.

On the screen as shown in Fig. 1-1.

SOURCE < HDMI >

COLOR TEMP < COOL >

R GAIN 149

G GAIN 128

B GAIN 149

R OFFSET

G OFFSET

B OFFSET

COPR ALL

RESET

1005

1010

990

2. BASIC ADJUSTMENTS

2-1: WHITE BALANCE

1. Place the set in Aging Test for more than 15 minutes.

3. Receive the gray scale pattern from the Pattern

Generator.

4. Press the INPUT SELECT button on the remote control

ENTER button on the remote control.

9. Select the "COLOR TEMP" menu , then press

ENTER button on the remote control.

10. Press the UP/DOWN button on the remote control

to select the "R GAIN", "B GAIN", "R OFFSET",

"B OFFSET".

11. Adjust the LEFT/RIGHT button on the remote control

to whiten the R GAIN, B GAIN, R OFFSET, B OFFSET

at each step tone sections equally.

12. Perform the above adjustments 8 and 9 until the white

color is achieved.

BD_VST59_P901A

-

D-1

Page 16

ELECTRICAL ADJUSTMENTS (continued)

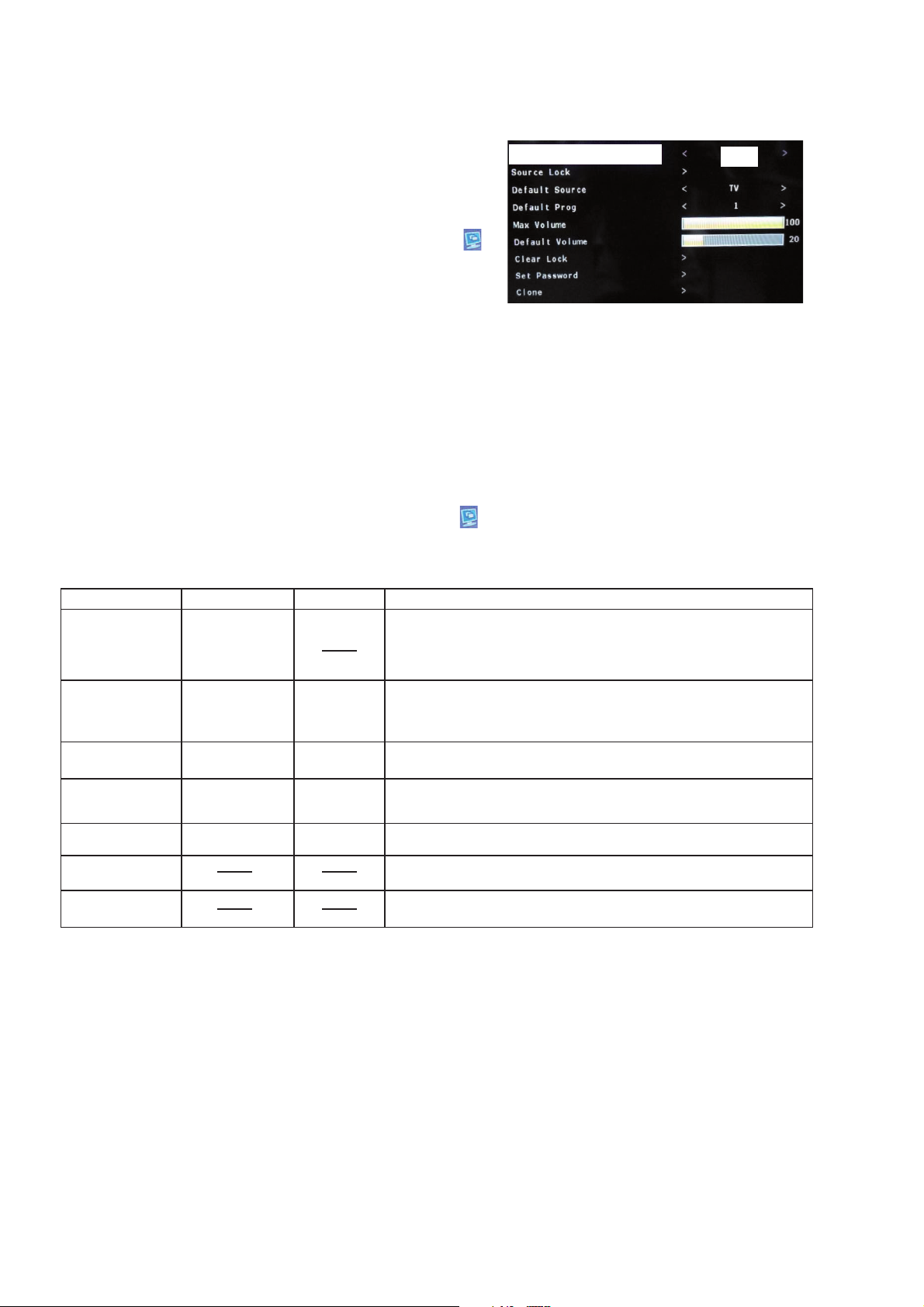

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

LCD PANEL

CN5

MAIN UNIT

CN6

CN18

SP301

SPEAKER

CD2202

CP2202

OPERATION PCB

CN12

CNB1

CNB802

CD503

AC IN

CD2201

OS2201

CP2201

REMOCON PCB

D-2

Page 17

(LCD SECTION)

Y

Power does not turn on

AC cord is connected

to the CNB1?

Check FB1 Broken.

TROUBLESHOOTING GUIDE

No

Connect AC Cord to CNB1

㪰㪼㫊

No

Change FB1

es

Does 2 pins of DB101 have

the voltage of 12V?

Yes

Does 2 pins of DB102

have the voltage of 6.5V?

Yes

No

Change DB101

No

Change DB102

Change Main board.

E-1

Page 18

N

TROUBLESHOOTING GUIDE (continued)

The Picture appears,

but the audio does not appears

No

Is Speaker connected?

Yes

Is there signal at pins 1

and 4 of CN18?

o

Change Main board

Connect Speaker

Yes

Change Speaker

E-2

Page 19

TROUBLESHOOTING GUIDE (continued)

Panel does not light.

No

CP2000 is connected

to the CNB802?

㪰㪼㫊

Connect CP2000 to CNB802

Does 1䌾3 pins of CNB802

have the voltage of 11V?

No

Does 1 pins of UB801 have

the voltage of 12V?

No

Change Main board

Yes

Change Panel

Yes

Change UB801

E-3

Page 20

TROUBLESHOOTING GUIDE (continued)

The picure does not appear

No

CD2801 is connected

to the CN12?

Yes

Connect CD2801 to CN12

CD2801 is

connected

to the Panel?

No

CN12 have signal and

voltage of 12V?

No

Change Main board

Yes

Connect CD2801 to Panel

Yes

Change panel

E-4

Page 21

TROUBLESHOOTING GUIDE (continued)

The color does not appear

No

Is Setting of color Normal?

Yes

Is the color signal received?

No

Is there color signal at IC U9?

No

Adjust the color setting

Yes

Receive the color signal.

Yes

Check U9(TSUMV59XE) and

peripheral circuit.

Change Main board

E-5

Page 22

BLOCK DIAGRAM

Audio

Component

In Jack

HDMI

Connector

HDMI

Audio Mini Jack

PC In

PC & DVI Audio

Analog RGB

Component

Video In

(D-Sub 15 pin)

Pr

PC Input

Pb

Y

HSYNC/VSYNC

CVBS In

R

V

䌌

UBS

Silicon Tuner

R620D2

Speaker

SOUND AMP

TPA3110LD2PWP

R

Key A

Key B

Key A/Key B

<Operation PCB>

SCALER+LVDS+AUDIO DECORDER

Mstar

TSUMV39LE or TSUMV59XE

<MAIN >

Remocon In

Serial FLASH 32Mbit

GD25Q16BSIG

(GIGA)

ฃశㇱ

Remocon

Remocon

<Remocon PCB>

Speaker OUT

<LCD Panel>

F-1

Page 23

PCB

102

PCB

101

+

EB

106

GND

PCB

102

PCB

101

+

EB

106

GND

BLOCK DIAGRAM (continued)

Power

TB101

DB102

6

䋱

6.5V

+ +EB102 EB103

7

DB101

11

3

QB101

12V

10

EB101

+

5

9

4

DB104

8

SGND

DB2

LCB1

FB1CNB1

6

5

5

VCC

OTP

3

COMP

2

+ +EB1 EB2

SGND

DB1

DB3

UB101

OUT

OUT

CS

4

GND

1

DB4

3

2

䋱

4

AC_IN

F-2

Page 24

PRINTED CIRCUIT BOARDS

OPERATION (INSERTED PARTS)

SOLDER SIDE

SW2204

SW2202

CEM844A

SW2205

SW2206

SW2201

SW2203

CP2202

OPERATION (CHIP MOUNTED PARTS)

SOLDER SIDE

C2202

C2201

R2202

R2201

R2204

CEM844A

R2203

REMOCON (INSERTED PARTS)

SOLDER SIDE

CEM846A

D2201

CP2201

OS2201

REMOCON (CHIP MOUNTED PARTS)

SOLDER SIDE

R2210

R2209

CEM846A

R2208

C2203

C2204

G-1

Page 25

SCHEMATIC DIAGRAMS

2

C2208 *

123

GND

3

PCB270

CEM844

KEYB

KEYA

CD2202

06EH232202

KEY‑A

KEY‑B

4

CP2202

FROM/TOMICON

A2001WR‑3A

B

PCBDA0

5

CEM846

FROM/TOMICON

CP2201

7

A2001WR‑5A

12345

GND

REMOCONIN

AT+5VAT+3.3V

STANDBYLED

POWERONLED

8

CD2201

6

CH252005

GND4

1

WASRECEIVEDINGOODCONDITIONANDPICTUREISNORMAL.

WITHTHEDIGITALTESTERWHENTHECOLORBROADCAST

NOTE:THEDCVOLTAGEATEACHPARTWASMEASURED

D2201

STANDBY/POWER

330 1/16W

LTL‑1BEFJ‑002A

G

R2210

(REMOCONPCB)

330 1/16W

R2209

R

3

(OPERATION/REMOCONPCB)

R2208

47 1/16W

OPERATION/REMOCONSCHEMATICDIAGRAM

123

B+

GND

OS2201

Vout

S‑R531F‑H451‑B

6.3V

22

B

C2203

226.3V B

C2204

12

(OPERATIONPCB)

CH‑

SW2206

SW2205

VOL+

SW2204

POWER

SW2203

VOL‑

CH+

EVQ21505R

EVQ21505R

EVQ21505R

EVQ21505R

EVQ21505R

SW2202

EVQ21505R

SW2201

INPUT/ENTER

R2204

11K 1/16W

R2203

1.8K 1/16W

R2202

2.7K 1/16W

OFPRINTINGANDSUBJECTTOCHANGEWITHOUTNOTICE

NOTE: THISSCHEMATICDIAGRAMISTHELATESTATTHETIME

R2201

6.8K 1/16W

ABC D E F GH

8

ABC D E F GH

7

6

5

4

3

2

1

H-1

Page 26

SCHEMATIC DIAGRAMS (continued)

8

7

6

5

4

3

2

1

ARE

VFM1

LCDPANEL

DESCRIBEDINPARTSLISTONLY

CRITICALFORSAFETY,USEONES

CD2801

1

45678

9

GND

GND

GND

ORX1‑

ORX0+

ORX0‑

101112131415161718

ORX2+

ORX2‑

ORX1+

CP12

VCC

VCC

CEC

HOTPLUG

DDCGND

DDCSDA

DDCSCL

+5VPOWER

RESERVED

TMDSCLK‑

TMDSCLK+

TMDSDATA1‑

TMDSDATA2‑

TMDSDATA1+

TMDSDATA0+

TMDSDATA0‑

TMDSCLKSH

TMDSDATA0SH

TMDSDATA1SH

TMDSDATA2SH

9

19

CN14

5

6

E

HH

3

4

AV1

E

YPbPr

1

2

H

E

101112131415161718

2345678

TMDSDATA2+

1

VCC

GND

GND

ORX3+

ORX3‑

OCLK+

OCLK‑

192202122232425262728

GND

GND

ERX2+

ERX2‑

ERX1+

ERX1‑

ERX0+

ERX0‑

29330

MAINPCB

ERX3+

ERX3‑

ECLK+

ECLK‑

TP.VST59.PA901

:SINCETHESEPARTSMARKEDBY

CAUTION

5

6

E

HH

3

4

AV4

E

AVIN

1

2

H

E

123

4

VS

SCL

GND

+5V

USBP

USBN

INTERCONNECTIONDIAGRAM

CN10

15

CN9

1

3

21

CD503 CNB1

HS

CNB802

CP2000

9

1011121314

LED+

LED+

LED+

12345

12345

VLED

VLED

VLED

LED‑FB

GNDNCGNDNCSDA

GND

LED‑FB

LED‑FB

6

6

PCBXX0

LEDBARPCB

12V

12V

GND

GND

NC

LED+

LED‑FB

PWM‑DIM

CNB801

1

2

CN5

CD2201

CP2201

OS2201

123

CNT1

GND

IR

AT+3.3V

54312

1REMOCONIN

GND

AT+3.3V 3

12345

VoutB+GND

123

TM101

AT+3.3V

LEDG

LEDR

12345

542

STANDBYLED

POWERONLED

COMMANDTRANSMITTER

123

4

CNB2

123

CN6

GND

KEYB

KEYA

321

CD2202

321

GND

KEYA

CEM846

PCBDA0

REMOCONPCB

G

1 2

R

D2201

3

STANDBY/POWER

KEYB

PCB270

CEM844

OPERATIONPCB

123

CP2202

123

4

CN18

SPOUTL+

SPOUTL‑

SPOUTR‑

SPOUTR+

4

3

2

1

SP301

SPEAKER

SPEAKER

NC

GND

GND

VGAR

VGAG

VGAB

1

2345678

T5

1

N1N1N1

CEN948

ABC D E F GH

8

ABC D E F GH

7

6

5

4

3

2

1

H-2

Page 27

SCHEMATIC DIAGRAMS (continued)

Main Unit

8

7

6

5

4

3V3 TEST

+5V M_5V

+3.3V_STB

5V-M

+3.3V_STB

U1

+5V

TEST

2

VO

VI

3

Q4

C13

CL1

4

VO

ADJ

1

C40.1uF-0402-Y5V-+80%-20%-16V

CL2

LC1117CLTR33

10uF-0603-X5R-20%-6. 3V

NC/10uF-0805-Y5V-+80%-20%-10V

C5

CM4

R12

R9

R89

0.1uF-0402-Y5V-+80%-20%-16V

100Kohm-0402-1%-1/ 16W

4K7ohm-0402-5%-1/ 16W

0.1uF-0402-X5R-20%-16V

Q5

R14

10Kohm-0402-5%-1/ 16W

PWR-ON/OFF

4K7ohm-0402-5%-1/ 16W

0.1uF-0402-Y5V-+80%-20%-16V

WPM2341A-3/TR

LMBT3904LT1G

TEST

2V5/1V8

UL41

M_5V DDR-2.5V/1.8V

VCC_P

TEST

C40

Q8

C39

0.1uF-0402-Y5V-+80%-20%-16V

200Kohm-0402-1%-1/ 16W

AO3407A

DM1

R38

R36

PVCC+5V

PVCC12V

R12V

R5V

CL43

CL44

2

4

VO

VO

ADJ

VI

3

CL42

CL41

PVCC VCC-Panel

Q10

+

ED10

0ohm-0805-5%-1/ 8W

NC/0ohm-0805-5%-1/ 8W

GND

1

GNDGND

0.1uF-0402-Y5V-+80%-20%-16V

10uF-0603-X5R-20%-6. 3V

0.1uF-0402-Y5V-+80%-20%-16V

NC/10uF-0805-Y5V-+80%-20%-10V

LC1117CLTR18

4K7ohm-0402-5%-1/ 16W

0.22uF-0402-X5R-10%-16V

R101

R39

PWR-ON/OFF

PMLL4148L-F

ć-XF

4K7ohm-0402-5%-1/ 16W

100uF-16V-20%-6 7-105

ADJ/Vs-ON

LMBT3904LT1G

2K2ohm-0402-5%-1/ 16W

TEST

R4

BL-ADJ PWM-DIM

510ohm-0402-5%-1/ 16W

8

7

6

5

4

+5V

CD121

TEST

TEST

LD12

3

BS

NC

2

12V

CD15

CD14

+5V

SW

IN

+

ED11

RD12

CD1

RC13

UD11

5

FB

COMP

6

GND

4

EN

7

RD11

+

ED1

ć-XF

3K3ohm-0402-1%-1/ 16W

100uF-16V-20%-6 7-105

18Kohm-0402-1%-1/ 16W

NC/22pF-0402-NPO-5%-50V

CD16

RD14

CD17

ć-XF

220pF-0402-X7R-10%-50V

RT7257GHZSP

3300pF-0402-X7R-10%-50V

0.1uF-0402-Y5V-+80%-20%-16V

100Kohm-0402-1%-1/ 16W

470uF-16V-20%-8 12-105

1uF-0603-X5R-10%-25V

B B

10uF-0805-Y5V-+80%-20%-10V

0.1uF-0402-Y5V-+80%-20%-16V

10uF-0805-Y5V-+80%-20%-10V

22Kohm-0402-1%-1/ 16W

RD6

CD3

CD42

3

SCD54TL-4R7M

10ohm-0402-5%-1/ 16W

0.1uF-0402-Y5V-+80%-20%-16V

2

12V 12V

PWM-DIM PWM-DIM

1

+3.3V_STB +3.3V_STB

A A

RD1

CD13

1

8

CD12 0.1uF-0402-Y5V-+80%-20%-16V

CD18

CD11

+12V

SCD54TL-4R7M

0.1uF-0402-Y5V-+80%-20%-16V

10ohm-0402-5%-1/ 16W

LD2

1

8

UD1

CD41

CD48

TEST

1V2

+

ED42

+1.2V_VDDC

CD44

CD45

RD2

CD20

RD43

5

3

FB

SW

BS

NC

IN

EN

2

7

CD6

COMP

6

GND

4

ć-XF

0.1uF-0402-Y5V-+80%-20%-16V

100uF-16V-20%-6 7-105

12K4ohm-0402-1%-1/ 16W

NC/22pF-0402-NPO-5%-50V

22Kohm-0402-1%-1/ 16W

10uF-0603-X5R-20%-6. 3V

RD4

CD7

3

2

ć-XF

RD41

+

+5V

ED41

C C

100uF-16V-20%-6 7-105

RT7237CHGSP

10Kohm-0402-5%-1/ 16W

220pF-0402-X7R-10%-50V

0.1uF-0402-Y5V-+80%-20%-16V

3300pF-0402-X7R-10%-50V

20Kohm-0402-5%-1/ 16W

0.1uF-0402-Y5V-+80%-20%-16V

10uF-0805-Y5V-+80%-20%-10V

1

D D

H-3

Page 28

SCHEMATIC DIAGRAMS (continued)

Main Unit

8

XTALO

XTALI

Y1

R77

1Mohm-0402-5 %-1/16W

30pF-0402-NPO-5 %-50V

30pF-0402-NPO-5 %-50V

C68

24MHz-2 0PPM-20PF-HC-49S-SMD-TKD

C72

7

D13

System-RST

A K

C140

+1.2V_VDDC

AVDD33-DMPLL

CL12

LL47

C78

RF70

+3.3V-STB/VS1

C98

C80

NC/0ohm-0402-5 %-1/16W

0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

+3.3V_STB

0.1uF-0402-Y5V-+80%-20%-16V

FCM1005KF-121T06(120ohm-500mA)

C67

C66

C65

1uF-0402-X5R-2 0%-10V

1uF-0402-X5R-2 0%-10V

1uF-0402-X5R-2 0%-10V

C79

C75

C74

10uF-0603-X5R-2 0%-6.3V

0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

C70

+3.3V_STB

C181

C178

GND

GND

RXOC+

RXO1+

VCC-PanelVCC-Panel

RXO0+

CN12

1 2

3 4

5 6

7 8

9 10

GND

RXO0-

RXO1-

VCC-Panel

RXE3+

RXEC+

RXE1+

RXE2+

RXE0+

RXO2+

RXO3+

GND

GND

䱢-B

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

NC/5pF-0402-NPO-5 %-50V

NC/5pF-0402-NPO-5 %-50V

21 5PIN-2.0-D-H-G-

NC/5pF-0402-NPO-5 %-50V

NC/5pF-0402-NPO-5 %-50V

RXEC-

RXE1-

RXE2-

RXE3-

RXO3-

RXE0-

RXO2-

RXOC-

GND

GND

C177

C180

C139

L6

L26

+3.3V_STB

C3

C136

C133

0.1uF-0402-Y5V-+80%-20%-16V

10uF-0603-X5R-2 0%-6.3V

FCM1005KF-121T06(120ohm-500mA)

NC/FCM1005KF-121T06(120ohm-500mA)

0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

0.01uF-0402-X7R-1 0%-50V

DDR-2.5V/1.8V AVDD-2.5V/3.3V

8

7

R79

+3.3V_STB

+3.3V_STB

U8

R74

R80

Q13

C71

NC/SGM810-SXN3L

NC/100Kohm-0402-5 %-1/16W

C69

8

7

VDD

HOLD#

CE#1SO2WP#3VSS

FLASH_CS0N

SPI_Flash-SDO

R83

PWR-ON/OFF

RXO0+

RXO1+

RXO1-

RXO0-

RXOC-

RXO2+

RXOC+

RXO2-

RXO3+

RXO3-

RXE0-

RXE0+

RXE1-

RXE1+

RXE2-

61

60

LVBCKM

RIN1P

15

+3.3V-STB/VS1

YPbPr_Pr_IN

RXE2+

+3.3V_STB

54

56

52

51

53

55

57

59

58

LVB3P

LVA1P

LVA0P

LVA2P

LVB3M

LVA2M

LVA1M

LVA0M

LVBCKP

AVDD_MOD

LVACKM

LVACKP

LVA3M

LVA3P

VDD

AVDD_PLL

GPIO57

GPIO56

GPIO55

VDDIO_CMD

RFAGC

VIFM

VIFP

AVDD_REF

AVDD_DMPLL

XIN

XOUT

AUOUTR1

AUOUTL1

AUOUTR0

AUOUTL0

AUR5

AUL5

AUR4

AUL4

AVDD_AU33

23

25

22

VCOM0

AV_OUT

AV1_CVBS_IN

DVD-CVBS

AUVAG

PC_ARI

PC_ALI

+3.3V_STB

SCART_AV_IN

RXEC-

50

RXEC+

49

48

RXE3RXE3+

47

+1.2V_VDDC

46

+3.3V_STB

45

AMP_MUTE

44

TUNER_SDA

43

TUNER_SCL

42

DDR-2.5V/1.8V

41

TAGC

40

VIFM

39

VIFP

38

37

AVDD-2.5V/3.3V

36

AVDD33-DMPLL

XTALI

35

34

XTALO

33

SCR_OUT/

32

SCL_OUT/

AMP_RO

31

AMP_LO

30

SCART_RI

29

SCART_LI

28

AV1_R_IN

27

AV1_L_IN

26

C82100pF-0402-NPO-5 %-50V

R104

AMP_LO

200Kohm-0402-1 %-1/16W

USB_DM

USB_DP

5R1ohm-0402-5 %-1/16W

R135

R130

USB0_DM

USB0_DP

C87100pF-0402-NPO-5 %-50V

R110

AMP_RO

200Kohm-0402-1 %-1/16W

L23

5R1ohm-0402-5 %-1/16W

C77

C14

AUVAG

AUVAG

0.1uF-0402-Y5V-+80%-20%-16V

10uF-0603-X5R-2 0%-6.3V

0ohm-0402-5 %-1/16W

SPI_Flash-SCK

SPI_Flash-SDI

SPI_Flash-SDO

FLASH_CS0N

+1.2V_VDDC

LED_R/

U9

TSUMV59XE-V1

74

75

SCZ

NC/1Kohm-0402-5 %-1/16W

NC/NC/AVLC18S02003

NC/1uF-0402-X5R-2 0%-10V

SPI_Flash-SCK

SPI_Flash-SDI

5

6

SI

SCK

GD25Q32BSIG

4

FLASH_WP0N

R91

UART-TX

GND

DD4

A K

DD3

A K

USB0_DM

USB_DM

76

USB0_DP

USB_DP

77

TESTPIN

78

BL-ADJ

79

SPI_WP0N

80

DDCA_CK

UART-RX

81

DDCA_DA

UART-TX

82

DDR-2.5V/1.8V

83

SAR0

KEYA

84

SAR1

KEYB

85

IRIN

IRIN

86

CEC

LED_CTL

87

HWRESET

System-RST

88

89

HDMI_HPD

90

RXCKN

HDMI_RXC-

91

RXCKP

HDMI_RXC+

92

RX0N

HDMI_RX0-

93

RX0P

HDMI_RX0+

94

DDCD_DA

HDMI_SDA

95

RX1N

HDMI_RX1-

96

RX1P

HDMI_RX1+

97

DDCD_CK

HDMI_SCL

98

RX2N

HDMI_RX2-

99

RX2P

HDMI_RX2+

100

EPAD

101

AVDD_33

1

+1.2V_VDDC

+3.3V_STB

+3.3V_STB

68

69

73

71

64

63

66

70

62

67

65

72

SDI

SCK

SDO

VDD

GPIO0

LVB2P

LVB0P

LVB1P

LVB2M

LVB1M

LVBOM

INT/GPIO65

AVDD_MOD

PWM0/GPIO26

PWM1/GPIO25

AVDD_DDR

GND_EFUSE

HOTPLUGD

TSUMV29LU

SOGIN112BIN1P11GIN1M14GIN1P13CVBS217AVDD_3316AUL0

GIN0P

GIN0M

SOGIN0

VDDC2HSYNC03BIN0P4RIN0P8VSYNC09AVDD_2510CVBS118CVBS019VCOM20CVBSOUT21AUR024AUVAG

6

7

5

GIN0M

GIN1M

AVDD-2.5V/3.3V

YPbPr_Pb_IN

YPbPr_SOG

YPbPr_Y_IN

PC_RIN

PC_SOG

PC_BIN

PC_GIN

PC_VSIN

PC_HSIN

C73

10Kohm-0402-5 %-1/16W

4K7ohm-0402-5 %-1/16W

R86

NC/10Kohm-0402-5 %-1/16W

NC/0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

R87

RXDTEST

TXDTEST

100ohm-0402-5 %-1/16W

100ohm-0402-5 %-1/16W

NC/AVLC18S02003

VGA_SDA

VGA_SCL UART-RX

NC/AVLC18S02003

6

5

4

+3.3V_STB

+3.3V_STB

6

5

4

3

IRTEST

3V3_IRTEST

LED_RTEST

KEY_ATEST

KEY_BTEST

GND

KEY_A

KEY_B

0.01uF-0402-X7R-1 0%-50V

510ohm-0402-5 %-1/16W

2

0.1uF-0402-Y5V-+80%-20%-16V

+3.3V_STB

CK5

RK12 22ohm-0402-5 %-1/16W

LED_R LED_CTLRK13

3V3_STB/

1

0.01uF-0402-X7R-1 0%-50V

NC/AVLC18S02003

4K7ohm-0402-1 %-1/16W

4K7ohm-0402-1 %-1/16W

1Kohm-0402-5 %-1/16W

1Kohm-0402-5 %-1/16W

KEYA

KEYB

CK1

CK2

+3.3V_STB

RK10

RK8

+3.3V_STB

AK

AK

DK1

DK2 NC /AVLC18S02003

RK11

RK9

KEY_A

KEY_B

LED_G

LMBT3904LT1G

10Kohm-0402-5 %-1/16W

1Kohm-0402-5 %-1/16W

R81

M_5V

Q14

R97

R95

4K7ohm-0402-5 %-1/16W

LED_CTL

C6

22pF-0402-NPO-5 %-50V

123

CN6

3PIN-2.0-D-H-G-B

+3.3V_STB

LED_GTEST

R107

IR

GND

LED_R

LED_G

3V3_STB/

12345

CN5

5PIN-2.0-D-H-G-B

IRIN

GND

C2

R1

IR R6

1Kohm-0402-5 %-1/16W

4K7ohm-0402-5 %-1/16W

22pF-0402-NPO-5 %-50V

R103

C84

C81

C85

VCOM0

GIN1M R109

0.047uF-0402-X7R-1 0%-16V

0.047uF-0402-X7R-1 0%-16V

0.047uF-0402-X7R-1 0%-16V

68ohm-0402-5 %-1/16W

68ohm-0402-5 %-1/16W

68ohm-0402-5 %-1/16W

4K7ohm-0402-5 %-1/16W

4K7ohm-0402-5 %-1/16W

R197

R199

SPI_WP0N

BL-ADJ GIN0M

3

2

1

+3.3V_STB

A A

B B

C C

D D

H-4

Page 29

SCHEMATIC DIAGRAMS (continued)

Main Unit

8

PC_ALI

CH14

CH12

CH13

HDMI_SCL

HDMI_SDA

HDMI_HPD

22pF-0402-NPO-5 %-50V

10pF-0402-NPO-5 %-50V

10pF-0402-NPO-5 %-50V

PC_ARI

C62

C61

12Kohm-0402-5 %-1/16W

8K2ohm-0402-5 %-1/16W

8K2ohm-0402-5 %-1/16W

1uF-0402-X5R-2 0%-10V

1uF-0402-X5R-2 0%-10V

12Kohm-0402-5 %-1/16W

R62

8

R65

7

AK

AK

DH2

DH1

AK

AK

HDMI-SCL/

HDMI-SDA/

RH5

RH4

6

5

SHELL1

CN14

4

20

HDMI_RX2+

RPH1

HDMI_RX2+'

1

HDMI_5V

300ohm-0402-2 5%

300ohm-0402-2 5%

33ohm-0402-5 %-1/16W

33ohm-0402-5 %-1/16W

4*10ohm-0402-5 %-1/16W

4*10ohm-0402-5 %-1/16W

HDMI_RXC-

HDMI_RXC+

HDMI_RX0-

HDMI_RX0+

HDMI_RX1-

HDMI_RX1+

HDMI_RX2-

135

78

135

78

642

642

RPH2

GND

GND

GND

GND

2

D2+

HDMI_RXC-'

HDMI_RXC+'

HDMI_RX0-'

HDMI_RX0+'

HDMI_RX1-'

HDMI_RX1+'

HDMI_RX2-'

3

D2 Shield

CEC1

12

4

7

10

6

9

5

8

13

11

D2-

D1-

D0-

CK-

D1+

D0+

CK+

D1 Shield

D0 Shield

CK Shield

SHELL2

21

DH3

10pF-0402-NPO-5 %-50V

10pF-0402-NPO-5 %-50V

HOTPLUG1

4K7ohm-0402-5 %-1/16W

4K7ohm-0402-5 %-1/16W

HDMI_SCL

HDMI_SDA

RH16

RH15

GND

HDMI-SDA/

100pF-0402-NPO-5 %-50V

RH6

RH7

RH17

GND

HDMI_5V

ARC

HOTPLUG1

HDMI_SDA'

HDMI_SCL' HDMI-SCL/

15

14

NC

CE Remote

HDMI_5V

17

18

19

16

+5V

GND

HP DET

DDC CLK

DDC DATA

SHELL3

HHF-33B001-2SB

22

AK

DH5

DH6

CEC1

ARC

22pF-0402-NPO-5 %-50V

22pF-0402-NPO-5 %-50V

22pF-0402-NPO-5 %-50V

PC_R

HDMI_HPD

RH1

HDMI_5V

RH2

10Kohm-0402-5 %-1/16W

LMBT3904LT1G

1Kohm-0402-5 %-1/16W

10Kohm-0402-5 %-1/16W

QH1

RH3

HOTPLUG1

PC_RIN

C105

R144

VGA_Rin'

NC/AVLC18S02003

R42 75ohm-0402-5 %-1/16W

VGA_Rin'

D3

TEST

WLHK-015A

4K7ohm-0402-5 %-1/16W

4K7ohm-0402-5 %-1/16W

M_5V

PC_GIN

PC_SOG

C107

C106

0.047uF-0402-X7R-1 0%-16V

33ohm-0402-5 %-1/16W

R149

VGA_Gin'

75ohm-0402-5 %-1/16W

R47

VGA_Gin'

A K

PC_G

TEST

CN9

162738495

1716

1112131415

R46

VGA_SDA

R45

PC_BIN

C108

0.047uF-0402-X7R-1 0%-16V

1000pF-0402-X7R-1 0%-50V

0.047uF-0402-X7R-1 0%-16V

33ohm-0402-5 %-1/16W

R150

33ohm-0402-5 %-1/16W

VGA_Bin'

NC/AVLC18S02003

75ohm-0402-5 %-1/16W

R51

VGA_Bin'

D7

A K

D5 NC/AVLC18S02003

PC_B

A K

TEST

10

PC_VS

TEST

VGA_SCL

A K

DI5

A K

DI6

R64

R63

PC_ALIN

PC_ARIN

PC_AR

TEST

PC_AL

TEST

5341267

CN8

PJ-1061

100ohm-0402-5 %-1/16W

100ohm-0402-5 %-1/16W

2K2ohm-0402-5 %-1/16W

2K2ohm-0402-5 %-1/16W

NC/AVLC18S02003

D9

PC_VSIN

R53

VS_VGA

NC/AVLC18S02003

NC/AVLC18S02003

NC/AVLC18S02003

D10

PC_HSIN

A K

A K

R56

R59

R57

PC_HS

TEST

HS_VGA

7

6

5

4

YPbPr_SOG

C58

33ohm-0402-5 %-1/16W

75ohm-0402-5 %-1/16W

A K

YPBPR_PB

TEST

YPbPr1-Y

21436

AV1

YPbPr_Y_IN

C59

1000pF-0402-X7R-1 0%-50V

R60

YPbPr1-Y

NC/ICVL0518030FR

YPbPr1-Y

YPbPr1-Pb

75ohm-0402-5 %-1/16W

C48

D4

YPBPR_PR

TEST

YPbPr_Pr_IN

C60

0.047uF-0402-X7R-1 0%-16V

NC/100pF-0402-NPO-5 %-50V

R44

0.047uF-0402-X7R-1 0%-16V

33ohm-0402-5 %-1/16W

33ohm-0402-5 %-1/16W

R61

YPbPr1-Pr

NC/ICVL0518030FR

R55

75ohm-0402-5 %-1/16W

D8

YPbPr1-Pr

A K

A K

USB_5V

)

㔯ǃ㬍ǃ㓒

YPbPr1-Pr

5

AV3-8.4-46A(

C C

-XF

ć

MSMD110

NC/ICVL0518030FR

100uF-16V-2 0%-67 -105

NC/ICVL0518030FR

NC/10uF-0805-Y5V-+80%-20%-10V

USB0_DP

USB0_DM

M_5V

A K

DI8

USB5V

2

1

3

GND5GND

DM

POWER

A K

DI7

+

EF41

CE42

4

6

DP

GND

GND

F2

TEST

CN10

USB-A-110A-EP

D D

3

2

1

YPbPr_Pb_IN

YPbPr1-Pb

C56

R58

YPbPr1-Pb

D6

YPBPR_Y

0.047uF-0402-X7R-1 0%-16V

NC/ICVL0518030FR

R49

TEST

3

AV1_R_IN

C45

R41

AV1_IN/ AV1_CVBS_IN

C50

NC/ICVL0518030FR

75ohm-0402-5 %-1/16W

33ohm-0402-5 %-1/16W

0.047uF-0402-X7R-1 0%-16V

R48

C47 NC/100pF-0402-NPO-5 %-50V

R43

D11

AV1-RIN

A K

AV1_L_IN

C54

1uF-0402-X5R-2 0%-10V

8K2ohm-0402-5 %-1/16W

R50 12Kohm-0402-5 %-1/16W

D1 NC/AVLC18S02003

A K

1uF-0402-X5R-2 0%-10V

8K2ohm-0402-5 %-1/16W

R52

R54 12Kohm-0402-5 %-1/16W

D2 NC/AVLC18S02003

A K

AV1-LIN

2

CVBS_IN

TEST

AV4

AV_L

TEST

AV1_IN/

AV1-LIN

21436

AV_R

)

TEST

哴ⲭ㓒

AV1-RIN

5

AV3-8.4-46A-H(

1

A A

B B

H-5

Page 30

SCHEMATIC DIAGRAMS (continued)

Main Unit

4

0.47uF-0603-X5R-10% -16V

0.47uF-0603-X5R-10% -16V

NC/1000pF-0402-X7R-10% -50V

NC/1000pF-0402-X7R-10% -50V

ć-XF

LOUT+

CA10

CA9

CA17

CA11

LOUT-

ROUT-

+

CA18

CA14

CA23

CA19

ROUT+

+

0.47uF-0603-X5R-10% -16V

0.47uF-0603-X5R-10% -16V

NC/1000pF-0402-X7R-10% -50V

NC/1000pF-0402-X7R-10% -50V

TEST

CN18

TEST

123

LOUT+

LOUT-

LOUT+

ROUT-

LOUT-

ROUT-

4

ROUT+

ROUT+

A2504A-04-A1MA-P

TEST

TEST

4

LA1

SCD54TL-220M

SCD54TL-220M

3

NC/470uF-16V-20% -812-105

1000pF-0402-X7R-10% -50V

+

EA1

12V

CA3

CA2

28

12V

2

RA2

AVCC

10ohm-0402-5% -1/16W

RA5

UA1

RA8

+

1uF-0603-Y5V-+80%-20%-16V

0.22uF-0402-X5R-10% -16V

0.22uF-0402-X5R-10% -16V

CA7

25

27

26

24

BSPL

PGND

OUTPL

PVCCL

PVCCL

SD1FAULT2LINP3LINN4GAIN05GAIN16AVCC7AGND8GVDD9PLIMIT10RINN11RINP12NC13PBTL

CA8

GAIN0

CA6

AMP-STB/

AGND

+

LA3

23

OUTNL

CA35

CA12

22

BSNL

AVCC

CA13

21

LA4

BSNR

SCD54TL-220M

0.22uF-0402-X5R-10% -16V

20

19

PGND

OUTNR

RA11

RA12

CA15

LA5

SCD54TL-220M

0.22uF-0402-X5R-10% -16V

CA22

18

17

BSPR

OUTPR

CA20

CA21

AGND

CA4

1uF-0603-Y5V-+80%-20%-16V

1000pF-0402-X7R-10% -50V

12V

CA25

CA24

15

16

PVCCR

PVCCR

TPA3110D2PWPR

14

NC/0ohm-0402-5% -1/16W

RA02

10Kohm-0402-5% -1/16W

GND AGND

GAIN0

RA1

M_5V

NC/0ohm-0402-5% -1/16W

3

GAIN0

NC/0ohm-0402-5% -1/16W

RA3

GND

2

RA01

GND AGND

0.22uF-0402-X5R-10% -16V

0.22uF-0402-X5R-10% -16V

AMP_MUTE

RA4

1

A A

510ohm-0402-5% -1/16W

10Kohm-0402-5% -1/16W

AMP_LO

B B

3300pF-0402-X7R-10% -50V

1Kohm-0402-5% -1/16W

0.1uF-0402-Y5V-+80%-20%-16V

CA29

AGND

CA30

3300pF-0402-X7R-10% -50V

1Kohm-0402-5% -1/16W

0.22uF-0402-X5R-10% -16V

0.22uF-0402-X5R-10% -16V

RA7

1

AMP_RO

C C

1uF-0402-X5R-20% -10V

3K9ohm-0402-1% -1/16W

1uF-0402-X5R-20% -10V

1K2ohm-0402-5% -1/16W

D D

H-6

Page 31

SCHEMATIC DIAGRAMS (continued)

Main Unit

8

IF-AGC/

6800pF-0402-X7R-10%-50V

0.1uF-0402-Y5V-+80%-20%-16V

VIFM

RT4

DIF2-OUT1

R194

IF-AGC

TAGCIF-AGC/

R108

TUNER_SDA

R193

TUNER-SDA/

R30

10Kohm-0402-5%-1/ 16W

C127

0.047uF-0402-X7R-10%-16V

10Kohm-0402-5%-1/ 16W

100ohm-0402-5%-1/ 16W

C86

TUNER_SCL

100ohm-0402-5%-1/ 16W

100ohm-0402-5%-1/ 16W

30pF-0402-NPO-5%-50V

30pF-0402-NPO-5%-50V

R195

C129

C128

TUNER-SCL/

VIFP

C143

300ohm-0402-25%

300ohm-0402-25%

C142

C144

RT3

DIF2-OUT2

220ohm-0402-5%-1/ 16W

220ohm-0402-5%-1/ 16W

10Kohm-0402-5%-1/ 16W

10Kohm-0402-5%-1/ 16W

680ohm-0402-5%-1/ 16W

0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

56pF-0402-NPO-5%-50V

56pF-0402-NPO-5%-50V

5pF-0402-NPO-5%-50V

LT7

LT8

CT12

7

6

R106

TUNER-VCC

5

R192

TUNER-VCC

R191

4

3

C132

C131

2

C130

R620D2

150nH-0603-5%-C

150nH-0603-5%-C

5R1ohm-0402-5%-1/ 16W

0.01uF-0402-X7R-10%-50V

LT3

LT6

AVDD3V

1000pF-0402-X7R-10%-50V

5pF-0402-NPO-5%-50V

HQ1005C8N2JT

SDCL1005C47NJTDF

SDCL1005C22NJTDF

CT15

LT2

CT2

CT11

0.1uF-0402-Y5V-+80%-20%-16V

0.1uF-0402-Y5V-+80%-20%-16V

330pF-0402-NPO-5%-50V

1K8ohm-0402-5%-1/ 16W

AVDD3V

RT2

CT13

CT7

CT10

CT14

LT5

CT4

LT9

DT1

LT4

T15

1234567

T5

CT16

15

1234567

CT17

UT2

19

20

21

22

23

24

25

18

vcc

tf2n

tf2p

tf1n

tf1p

vcc

rf_in1

rf_in2

gnd

1

1011121314

CT19

17

16

vdd-pll

open_d2det14det25sclk

3

AVDD3V

亪㔌)

SDCL1005CR22JTDF(

亪㔌)

SDCL1005CR22JTDF(

8 9

CT21

RT1

IF-AGC

14

15

13

cp

avss

vagc

ifp_p

ifp_n

12

dvss

11

dvdd

10

xtal_o

9

xtal_i

8

sda

6

CT26

CT25

CT20

RT5

10pF-0402-NPO-5%-50V

7

0.01uF-0402-X7R-10%-50V

0ohm-0402-5%-1/ 16W

1uF-0402-X5R-20%-10V

avdd

亪㔌)

SDCL1005CR22JTDF(

47pF-0402-NPO-5%-50V

150pF-0402-NPO-5%-50V

120pF-0402-NPO-5%-50V

BAV99-BR

68pF-0402-NPO-5%-50V

˄ᇶሱ˅-LHD

T-31.9 15.89 9-IEC14.5

NC/31.9 15.89 9.0-IEC14.5

DIF2-OUT2

AVDD3V

TUNER-SCL/

0.1uF-0402-Y5V-+80%-20%-16V

0ohm-0402-5%-1/ 16W

TUNER-VCC

+3.3V_STB

CT29

YT1

DIF2-OUT1

CT31

RT7

CT30

0.1uF-0402-Y5V-+80%-20%-16V

33pF-0402-NPO-5%-50V

16MHz-20PPM-20PF-H C-49S-TKD

33pF-0402-NPO-5%-50V

0ohm-0402-5%-1/ 16W

TUNER-SDA/

CT8

AVDD3V

CT5

CT1

10uF-0603-X5R-20%-6. 3V

10uF-0603-X5R-20%-6. 3V

0.1uF-0402-Y5V-+80%-20%-16V

LT1

FCM1005KF-121T06(120ohm-500mA)

RT6

M_5V

CT3

2

4

VO

VO

ADJ

1

VI

UT1

3

CT9

NC/0.1uF-0402-Y5V-+80%-20%-16V

NC/LC1117CLTR33

NC/0.1uF-0402-Y5V-+80%-20%-16V

8

7

6

5

4

3

2

1

A A

B B

C C

D D

1

H-7

Page 32

WAVEFORMS

㪰

I-1

Page 33

MECHANICAL EXPLODED VIEW

PCBXX0

(LED BAR ASS'Y)

104

202

205

103B

103B

205

206

103B

205

102B

102G

103B

103A

103

102A

102H

203

203

201

207

111

112

108

111

203

111

110

111

203

MAIN001

(MAIN UNIT)

PCBDA0

113

113

106

PCB270

(OPERATION PCB ASS'Y)

105

206

205

206

206

102G

111

112

102G

111

111

110

111

102G102G

102D

102C

102E

201

201

102F

201

102

J1-1

107

101E

204

101D

101C

101A

(REMOCON PCB ASS'Y)

101D

101E

101B

109

101

Page 34

MECHANICAL EXPLODED VIEW (continued)

TM101

PACKAGE TOP

FILM BAG

(9JD791WHAA549)

PACKAGE BOTTOM

SCREW ASS'Y,

POLYBAG INSTRUCTION (RED CAUTION),

GUARANTEE CARD,

INSTRUCTION BOOK(RU/KZ),

EAC SAFETY SHEET

FILM BAG

(9JD791WHAA558)

PACKAGE BOTTOM

GIFT BOX

HANDLE STOPPER

HANDLE

J1-2

Page 35

K

PARTS GUIDE

PRICE NEW

RAN

MARK Delivery

Part

DESCRIPTIONPARTS CODENo.

MECHANICAL REPLACEMENT PARTS LIST

101 9JD7A7080106C AU * FRONT CABI ASS'Y

101A 9JD708WPD0085 AR * CABINET FRONT

101B 9JD711WPD0826 AK * PALTE FRONT

101C 9JD713WPA0478 AD * GLASS LED

101D 9JD92P20A023A AD * CUSHION BEZEL

101E 9JD92P200042A AD * CUSHION BEZEL

102 9JD7A7020450A AU N * COVER BACK ASS'Y

102A 9JD702WPAC172 AR * COVER BACK

102B 9JD7210000173 AD * SHEET BUTTON

102C 9JD752WPA0003 AD * SHEET PC

102D 9JD761WSAA556 AD * ANGLE BACK

102E 9JD761WSA0971 AD * ANGLE BACK L

102F 9JD761WSA0972 AD * ANGLE BACK R

102G 9JD800WQ0A218 AD * FELT SHEET

102H 9JD800WQ0A268 AD * FELT SHEET

103 9JD7A704A501B AM * STAND ASS'Y

103A 9JD704WPAA370 AM * STAND

103B 9JD800WFAA082 AD * CUSHION LEG

104 9JD93P300091A AD * DOUBLE FACE TAPE

105 9JD7225270061 AD N * SHEET RATING

106 9JD725000A125 AD * SHEET CAUTION

107 9JD752WPA0002 AD * SHEET PC

108 9JD752WSA0836 AG N * SHIELD MAIN

109 9JD7230008691 -- N * ENERGY LABEL

110 9JD800WQ0A230 AD * FELT SHEET

111 9JD800WQ0A268 AD * FELT SHEET

112 9JD800WRA0032 AD * CUSHION

113 9JD800WQ00233 AD N * FELT SHEET

201 9JD8110K26A0U AD * SCREW TAP TITE(P)LAMI HEAD 2.6x10

202 9JD8109230A0S AD * SCREW TAP TITE(B) BIND 3x10

203 9JD810923060U AD * SCREW TAP TITE(B) BIND 3x6

204 9JD8110E2680U AD * SCREW TAP TITE(P) WH10 M2.6x8

205 9JD811022680S AD * SCREW TAP TITE(P)BIND 2.6x8

206 9JD8154D3080S AD * SCREW TAP TITE(B) WH8 3x8

207 9JD810272635U AD * SCREW PLANE M M2.6x3.5

PACKING DIAGRAM

--- 9JD791WHA0225 AD * GIFT SHEET

--- 9JD791WHAA549 AD * FILM BAG

--- 9JD791WHAA558 AD * FILM BAG

--- 9JD792WHA0910 AF * PACKAGE TOP

--- 9JD792WHAA641 AF * PACKAGE BOTTOM

--- 9JD793WCD2167 -- N * GIFT BOX

--- 9JD794WHAA010 -- * HANDLE

--- 9JD794WHAA011 -- * HANDLE STOPPER

--- 9JD7G8900007A AD * SCREW ASS'Y

--- 9JDJ3SS0502A -- N * GUARANTEE CARD

--- 9JDJ3SS0521A -- N * INSTRUCTION BOOK(RU/KZ)

--- 9JDJB5ND001 AD * POLYBAG INSTRUCTION(RED CAUTION)

--- 9JDJ3SS0529A -- N * EAC SAFETY SHEET

K-1

Page 36

A

(

)

)

PARTS GUIDE (continued)

No. PARTS CODE DESCRIPTION

PRICE NEW Part

RANK MARK Delivery

ELECTRICAL REPLACEMENT PARTS LIST

REMOCON PCB ASS'Y

*** PCB ***

PCBDA0 9JDA3SS05XDA0 AL N * REMOCON PCB ASS'Y CEM846

*** RESISTORS ***

R2208 9JDR803R9470J AD * RC, 47 OHM 1/16W

R2209 9JDR803R9331J AD * RC, 330 OHM 1/16W

R2210 9JDR803R9331J AD * RC, 330 OHM 1/16W

*** CAPACITORS ***

C2204 9JDCS0RB0PH7M AD * CC, 22 UF 6.3V B

*** DIODES ***

D2201 9JD0021E9Q010 AD * LED, LTL-1BEFJ-002A

*** OTHERS ***

CP2201 9JD06GG250019 AD * CONNECTOR PCB SIDE A2001WR-5A

OS2201 9JD077T038018 AE * REMOTE RECEIVER S-R531F-H451-B

OPERATION PCB ASS'Y

*** PCB ***

PCB270 9JDA3SS05X270 AL N * OPERATION PCB ASS'Y CEM844A

*** RESISTORS ***

R2201

R2202

R2203

R2204

C2201 9JDCS0PB0315K AD * CC, 0.1 UF 25V B

C2202 9JDCS0PB0315K AD * CC, 0.1 UF 25V B

SW2201 9JD0504101T34 AC * SWITCH,TACT, EVQ21505R

SW2202 9JD0504101T34 AC * SWITCH,TACT, EVQ21505R

SW2203 9JD0504101T34 AC * SWITCH,TACT, EVQ21505R

SW2204 9JD0504101T34 AC * SWITCH,TACT, EVQ21505R

SW2205 9JD0504101T34 AC * SWITCH,TACT, EVQ21505R

SW2206 9JD0504101T34 AC * SWITCH,TACT, EVQ21505R

CP2202 9JD06GG230019 AD * CONNECTOR PCB SIDE, A2001WR-3A

CD503 9JD120H6HD003 AL N * CORD AC BUSH, A2A7B20061216700-R2

BT001 9JD141U004021 AD * BATTERY,MANGAN, AAA

BT002 9JD141U004021 AD * BATTERY,MANGAN, AAA(R03

CD2201 9JD06EH252005 AF * CORD CONNECTOR, EH252005

CD2202 9JD06EH232202 AD * CORD CONNECTOR, EH232202

MAIN001 9JD1564000040 BP N * MAIN UNIT, TPVST59.PA901_V59_DIVX_RU

SP301 9JD070Y035001 AP * SPEAKER, S0307F38-A

TM101 9JD076K0UW011 AP * TRANSMITTER, 001.A43.K0UW011R

V7201 9JDA3SS05XFM0 CC * LED MODULE ASS'Y LSC230AN01-LED OR2

9JDR803R9682J AD * RC, 6.8K OHM 1/16W

9JDR803R9682F AD * RC, 6.8K OHM 1/16W

9JDR803R9272J AD * RC, 2.7K OHM 1/16W

9JDR803R9272F AD * RC, 2.7K OHM 1/16W

9JDR803R9182J AD * RC, 1.8K OHM 1/16W

9JDR803R9182F AD * RC, 1.8K OHM 1/16W

9JDR803R9113J AD * RC, 11K OHM 1/16W

9JDR803R9113F AD * RC, 11K OHM 1/16W

*** CAPACITORS ***

*** SWITCHES ***

*** OTHERS ***

*** AC CORD ***

*** OTHERS ***

R03

LED MODULE ASS'Y

9JDA3SS05XXX0 AV N * LED BAR ASS'Y

9JD09LB123001 BX * LCD CELL LSC230AN01

K-2

Page 37

K

K

y

PARTS GUIDE (continued)

No. PARTS CODE DESCRIPTION

NTCB1 9JD080XU05006 AE * FUSE, SCK15056MBY502

QB101 9JDTKF04N60B0 AG * FET, MDF4N60BTH

QB102 9JDTTFA3906L0 AB * FET, LMBT3906LT1G

UB101 9JDIM2F975370 AG * IC, LD7537RGL

UB801 9JDIM2F933500 AG * IC, OB3350CPA

QB801 9JDTKFTOD4420 AH * Transistor, AOD442

UD11 9JDIM2F0275G0 AG * IC, RT7257GHZSP

U1 9JDIM2F911170 AF * IC, LC1117CLTR33

UL41 9JDIM2F9117C0 AD N * IC, LC1117CLTR18

UD1 9JDIM2F0237C0 AE * IC, RT7237CHGSP

U8 9JDIN7J032BS0 AH * IC, GD25Q32BSIG

U9 9JDIN7J059XE1 BC N * IC, TSUMV59XE-V1

UA1 9JDIN7J031100 AM * IC, TPA3110D2PWPR

UT2 9JDIN7J0620D0 AM * IC, R620D2

PRICE NEW Part

RAN

MAR

MAIN PARTS IN MAIN UNIT

Deliver

K-3

Page 38

COPYRIGHT © 2014 BY SHARP CORPORATION

ALL RIGHTS RESERVED

.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

SHARP CORPORATION

Loading...

Loading...