Page 1

SERVICE MANUAL LCD COLOUR TELEVISION

LC-10A3E

TENTATIVE

SERVICE MANUAL

S51T1LC-10A3H

LCD COLOUR TELEVISION

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

» IMPORTANT SERVICE SAFETY PRECAUTION................................................................................. 2

» SPECIFICATIONS ................................................................................................................................ 3

» OPERATION MANUAL ......................................................................................................................... 4

» DIMENSIONS ....................................................................................................................................... 5

» DISASSEMBLY OF THE SET............................................................................................................... 6

» ADJUSTING PROCEDURE OF EACH SECTION ............................................................................... 9

» TROUBLE SHOOTING TABLE ........................................................................................................... 12

» CHASSIS LAYOUT ............................................................................................................................. 16

MODEL LC-10A3E

» BLOCK DIAGRAM.............................................................................................................................. 18

» DESCRIPTION OF SCHEMATIC DIAGRAM ..................................................................................... 19

» SCHEMATIC DIAGRAM ..................................................................................................................... 20

» PRINTED WIRING BOARD ASSEMBLIES........................................................................................ 27

» PARTS LIST

» PACKING OF THE SET ...................................................................................................................... 40

MODEL

LC-10A3E

CONTENTS

Ë

ELECTRICAL PARTS..................................................................................................................... 31

MAIN UNIT ..................................................................................................................................... 31

TERMINAL UNIT............................................................................................................................ 35

OPERATION UNIT ......................................................................................................................... 36

LED UNIT ....................................................................................................................................... 37

Ë

ACCESSORIES PARTS ................................................................................................................. 37

Ë

PACKING PA RTS ........................................................................................................................... 37

Ë

CABINET PARTS LOCATION ........................................................................................................ 38

Ë

CABINET AND MECHANICAL PARTS.......................................................................................... 39

Page

SHARP CORPORATION

1

Page 2

LC-10A3E

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

1

2

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212

Ë

IMPORTANT SERVICE SAFETY PRECAUTION

Service work should be perfomed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before ser vicing.

CAUTION: FOR CONTINUED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE. F3701 (1.25A, 250V), F3702

(1.25A, 250V), F3751 (2.0A, 250V) FUSE.

BEFORE RETURNING THE RECEIVER

(Fire & Shock Hazard)

Before returning the receiver to the user, perform

the following safety checks:

1. Inspect all lead dress to make certain that leads are

not pinched, and check that hardware is not lodged

between the chassis and other metal parts in the

receiver.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators and etc.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

• Plug the AC cord directly into a 110~240 volt A C outlet,

and connect the DC power cable into the receiver's

DC jack. (Do not use an isolation transformer for this

test).

• Using two clip leads, connect a 50k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all

exposed metal cabinet parts and a known earth ground,

such as electrical conduit or electrical ground connected

to an earth ground.

• Use an AC voltmeter ha ving with 5000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resisor.

• Connect the resistor connection to all exposed metal

parts having a return to the chassis (antenna, metal

cabinet, screw heads, knobs and control shafts,

escutcheon and etc.) and measure the AC voltage drop

across the resistor.

All checks must be repeated with the AC cord plug

connection reversed. (If necessary, a nonpolarized

adaptor plug must be used only for the purpose of

completing these checks.)

Any reading of 35V peak (this corresponds to 0.7

milliamp. peak A C .) or more is e xcessive and indicates

a potential shock hazard which must be corrected

before returning the monitor to the owner .

DVM

AC SCALE

50k ohms.

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD television

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage and etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

and shaded areas in the

Schematic Diagrams

For continued protection, replacement parts must be

identical to those used in the original circuit.

The use of a substitute replacement parts which do not

have the same safety characteristics as the factory

recommended replacement parts shown in this service

manual, may create shock, fire or other hazards.

components having such features are identified by “ å”

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

2

Replacement Parts Lists

.

and

Page 3

Specifications

LCD panel...............................................................................................10.4" TFT LCD

Number of dots ..................................................................................921,600 dots VGA

Video colour systems.......................................................................PAL/NTSC/SECAM

TV FUNCTION

TV Standard (CCIR) .....................................................................................I/DK/BG

TV Tuning System.......................................................................Auto preset 100 ch.

STEREO/BILINGUAL ............................................................................ NICAM, IGR

AUTO PRESET...................................................................................................YES

CATV.....................................................................................................~Hyper Band

4-LINE COMB FILTER.............................................................................................. Yes

Luminance ......................................................................................................400 cd/m

Lamp life ................................................................................................... 60,000 Hours

Viewing angles................................................................................................... H : 120°

Audio amplifier .................................................................................................1.0 W × 2

Speakers................................................................................................ 3 × 4 cm, 2 pcs

Terminals

AV1 .......................................................................................... AV-IN 1, S-VIDEO-IN

AV2 ................................................................................................................AV-IN 2

AV OUT .........................................................................................................AV-OUT

ANT......................................................................................................................DIN

H/P ...........................................................................................3.5 mm ø jack (Rear)

OSD Language .......................English/German/Dutch/French/Italian/Spanish/Swedish

Power supply.............................................................. DC 12 V, AC110-240 V, 50/60 Hz

Weight........................................................................................ 1.9 kg w/o accessories

Accessories ............................ R/C, Batteries, Wall mount parts, AC adaptor, AC cord,

........................................... AV cable for mini-jack

LC-10A3E

2

V : 100°

Design and specifications are subject to change without notice.

3

Page 4

LC-10A3E

Operation Manual

Main unit (front view)

Remote sensor window

(The actual location is not visible)

Power/standby indicator

A green indicator lights when the power is on and a red indicator

lights when in the standby mode (the indicator will not light when

the power is off).

Main unit (rear view)

Top control panel

BRIGHT

BRIGHT

Ë

The MUTE, DISPLAY, MENU, Volume (+)/(–), CH (')/("), and TV/VIDEO buttons provide the same

functions as the buttons on the remote control.

(The MENU button has a slightly different function from the remote control button.)

DISPLAY

MENU

MENU

MUTE

Volume (+)/(–)

TV/VIDEO

TV/VIDEO

CH

CH (')/(")

Adjust the set stand to an angle so that

the screen is easily visible. The set

stand can be opened up to 80°.

MAIN POWER

MAIN POWER

Remote control

(POWER)

TV/VIDEO

CHANNEL SELECT

TV/VIDEO

VOL

–

123

456

8

7

/

0

LCDTV

Rear terminal section

AV input 1 terminal

• S-Video input

VS

RL

AUDIO

AUDIO

V

AUDIO

V

HEADPHONE

POWER

MENU

CH

CH

9

MENU

CH (')/("), Cursor control Up/Down

VOL

'

+

Selects next higher channel

"

Selects next lower channel

VOL (+)/( ), Cursor control Right/Left

FLASHBACK

Returns to previous channel

DISPLAY

Press...Displays receiving channel for 10 seconds.

Channel indication reduces in size after

about 10 seconds.

Press again...Removes display.

MUTE

Press...Stops sound.

Press again...Returns sound to previous level.

SOUND MODE SELECTOR

Switching audio mode.

INPUT

DC12V

• Video input

• Audio R/L

AV-IN1

AV-IN2

AV input 2 terminal

AV-OUT

AV output terminal

Headphone output

terminal

DC input terminal

Antenna input terminal

4

Page 5

Dimensions

LC-10A3E

Front View

267

213.2

193

Side View

63.5

47.5

43.5

35

1

81.279.2

1

107.8

22

123

126.5 105.5

49.5

65

Rear View

88.5

72 12.5 14 14 14 15

90.1

15.5 103

30.5

60

177

243.8

(Units: mm)

5

Page 6

LC-10A3E

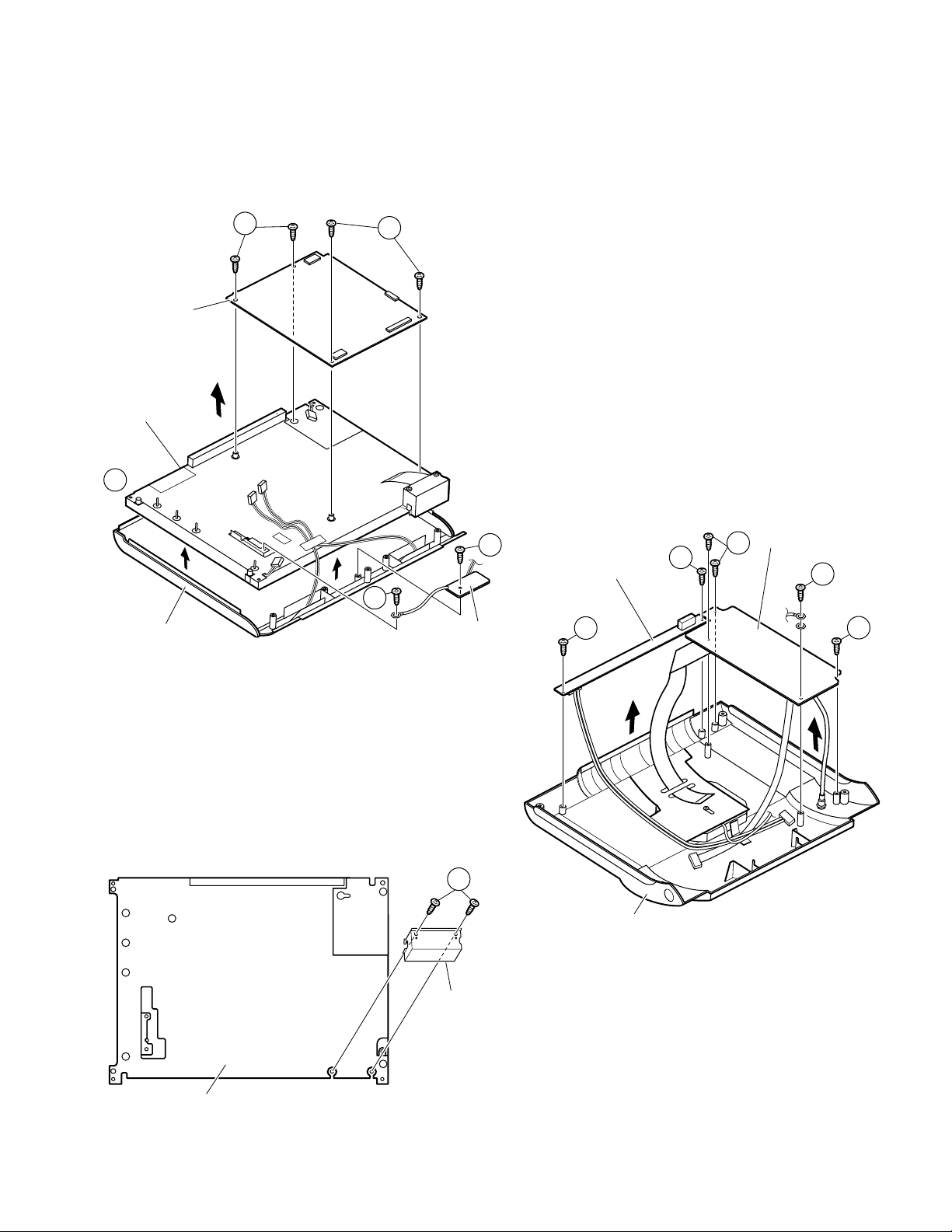

1. Remove the five lock screws (1) off the cabinet B.

2. Push on the six hooks (2) of the cabinet B and open it slightly.

3. Disconnect all the connectors (3) from the terminal and operation PWBs. Detach the cabinet B.

4. Disconnect all the connectors (4) from the main PWB.

DISASSEMBLY OF THE SET

1

1

1

2

2

1

1

2

2

Cabinet B

2

2

3

P3203

P3204

3

P701

P2001

SC401

3

3

P301

P2001

(Main PWB)

4

P752

P401 SC1201

P701

P2002

4

P751

SC1203

4

Cabinet A

4

6

Page 7

5. Remove the four lock screws (5) off the main PWB.

6. Peel off the one piece of tape (6) and detach the LC display unit.

7. Remove the two lock screws (7) off the remote control PWB.

8. Remove the four lock screws (8) off the terminal PWB.

9. Remove the two lock screws (9) off the operation PWB.

10.Remove the two lock screws (10) off the flexible shield.

LC-10A3E

Main PWB

LC display unit

6

Cabinet A

5

5

Terminal PWB

7

Operation PWB

7

LED PWB

9

9

8

8

8

LC display unit

(rear view)

10

Cabinet B

Flexible shield

7

Page 8

LC-10A3E

11.Undo the seven hooks (11) to release the unit frame.

12.Detach the fluorescent lamp (12).

12

11

11

11

11

Panel holder

11

11

11

8

Page 9

LC-10A3E

ADJUSTING PROCEDURE OF EACH SECTION

The best adjustment is made before shipping. If any position deviation is found or after part replace is performed, adjust

as follows.

1.Preparation for Adjustments

(1)Use the exclusive-use AC adapter or stable DC power supply.

AC adapter: UADP-0225CEPZ

DC power supply: 12 ± 0.5V

2.Special mode setting procedure

(1)Adjustment mode

[Procedure]

• Short-circuit TP2001 to GND, and turn on the power.

• Or short-circuit TP2002 to GND, and turn on the power.

• Or holding down the [TV/VIDEO] key and [MENU] key, turn on the main power, and simultaneously press the

(inspection process) [CH "] key and [VOL– ] key to change the mode to the adjustment mode.

• Each adjustment item is chosen with the [MENU] key, and adjusted with the [VOL] key.

[Description]

The manual adjustment or adjustment through communication with the automatic machine is performed.

(2)Inspection mode

[Procedure]

Holding down the [TV/VIDEO] key and [MENU] key, turn on the power.

[MENU] key is pushed and made inspection mode.

[Description]

• In the ordinary menu select with the [CH] key, and decide with the [VOL] key. Then select “PICTURE”, “TINT (only

NTSC)”, “COLOUR”, “BLACK LEVEL”, “SHARPNESS”, “RED-BLUE”, “GREEN” and “COLOUR SYSTEM” with the

[CH] key, and decide with the [VOL] key. After that, adjust values with the [VOL] key.

• VOLUME, PICTURE, TINT (only NTSC), COLOUR, BLACK LEVEL, SHARPNESS, RED-BLUE, GREEN change as

follows.

(3)Shipping setting mode

[Procedure]

Holding down the [TV/VIDEO] key and [MENU] key, turn on the main power, and simultaneously press the (inspection

process) [CH '] key and [VOL+] key to change the mode to the shipping setting mode.

[Description]

User adjustment and other values are taken as defaults.

If TV is indicated as SETTING COMPLETE, setting has been completed.

ûMin.Û ûCenterÛ ûMax.Û

3.Cancel of special mode

Turn off the main unit power.

4.Initialization

Here is the procedure of initializing the EEPROM and making model number and size settings.

4-1. Get Pins (81) and (82) of the IC2001 (microprocessor) grounded and turn on the power.

4-2. Select a model number (A1, A2H, A2U, A3E). For Model LC-10A3E select A3E.

4-3. Select a size in inches (10, 12, 15, 20). For Model LC-10A3E select 10.

4-4. Get Pins (81) and (82) of the IC2001 (microprocessor) back to normal.

9

Page 10

LC-10A3E

5.Reset of lamp error

6.Adjustments

If the power LED remains red and the power is not turned on, or if repair has been perf ormed, enter the adjustment

mode to reset the lamp error.

For the resetting procedure, refer to " No power" in the "Trouble shooting Table" section.t remote controller:

6-1. +B adjustment

V ary the “+B-ADJ” setting on Page 1 of the adjustment process so that the voltage at pin 49 of SC401 be 5.00

±0.02 V.

Note : Adjust precisely to 5.0 V because this level will be used as supply voltage reference.

6-2. Counter-bias adjustment

Vary the “COM BIAS” setting on Page 2 of the adjustment process so that the contrast be sharpest (black

looks most sinking). The adjustment guideline is around 114 for Model LC-10A3E.

6-3. TAMP adjustment

1) Receive the colour bar signal.

2) See if the "Y" reading on page 2 of the adjustment process is somewhere between BO and BA. If not, make

the "PAL TAMP" adjustment to get the "Y" reading in the range of BO thru BA.

(Adjustment process menu on-screen display on page 2)

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

0

2

1

2

3

4

5

6

7

8

9

10

11

12

13

COM BIAS 117

PAL 27TAMP

TV H- PEAK ING 3

RCUTOFF 0

GCUTOFF 0

BCUTOFF –1

TA PMH AB

TAMP L B0

G3 B3 R3 00 00 00

G1 B4 Y 00 00 B5

Y Data (75% white )

6-4. White balance adjustment

Vary the “RCUTOFF” and “BCUTOFF” settings to achieve optimum white balance.

Note : For the “RCUTOFF” and “BCUTOFF” settings, keep the readings in the range of -10 to +10. If out of

this range, the user-adjustable range is reduced.

10

Page 11

7.OSD Menu (for pages 1 and 2)

LC-10A3E

Page Item MIN MAX Remarks

1 +B-ADJ 0 255 160 Refer to 5-1

MODEL A3E Refer to 4-2

INCH SIZE 10 Refer to 4-3

TIMER 1

SYSTEM PAL

NTSC PWM FREQ 000 FFF 0C0

PAL PWM FREQ 000 FFF 0BD

TV GAIN OFF

ERROR NO RESET 0

PMUTE 00

2 COMBIAS 0 255 117 Refer to 5-2

PAL TAMP 0 63 27

TV H-PEAKING 0 63 27

R CUT OFF 0 7 0 Refer to 5-3 (around -5)

Initial

Setting

G CUT OFF -15 +15 0

B CUT OFF -15 +15 -1 Refer to 5-3

TAMP H 00 FF BA

TAMP L 00 FF B0

G3 -15 +15 0

B3 00 FF 00

R3 00 FF 00

G1 00 FF 00

B4 00 FF 00

Y00FF00

11

Page 12

LC-10A3E

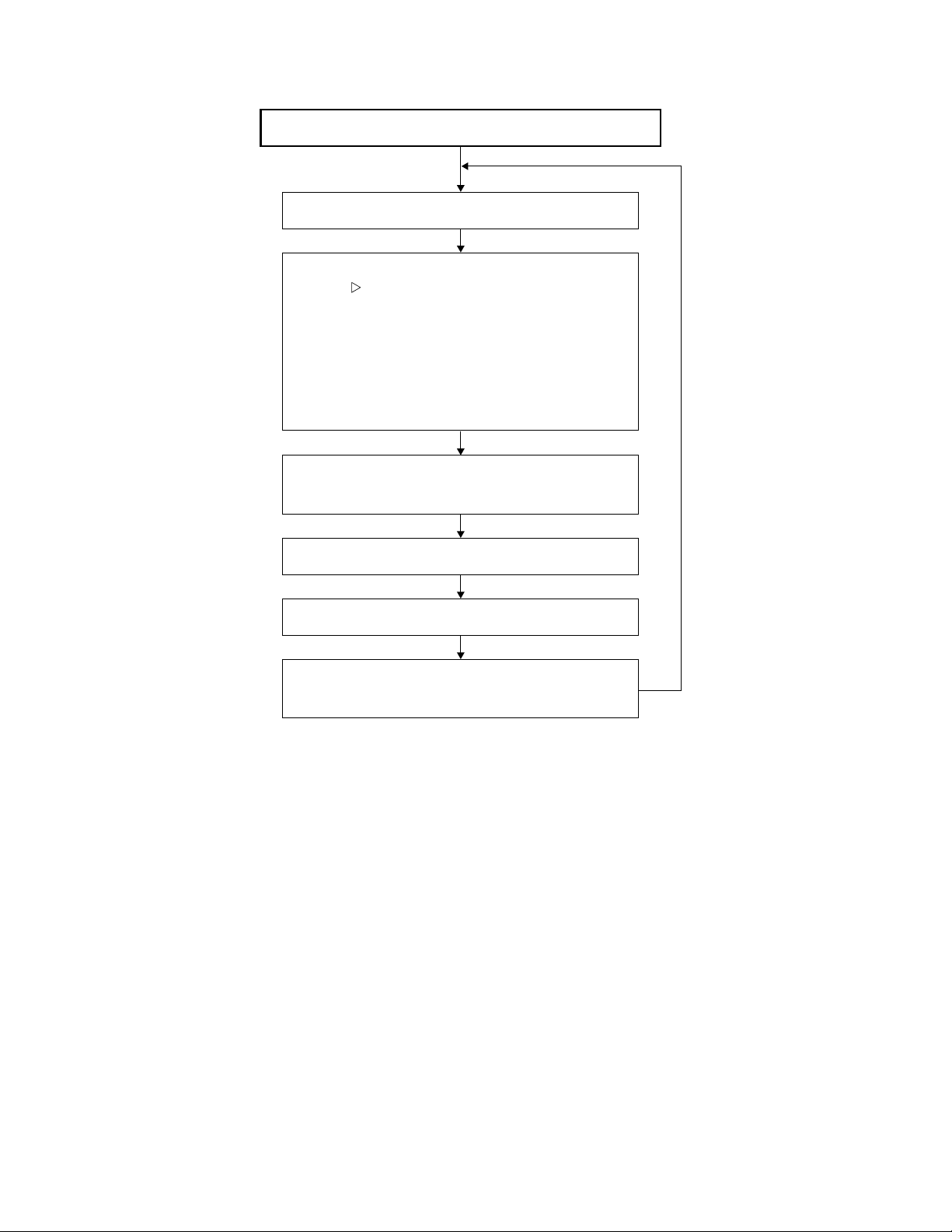

TROUBLE SHOOTING TABLE

No Power (Power LED indicator still in red)

Go to the adjustment process mode.

1

+B-ADJ 160

MODEL A3E

INCH SIZE 10

TIMER 1

NTSC PWM FREQ OCO

PAL PWM FREQ OBD

TV GAIN OFF

ERROR NO RESET 5

PMUTE 00

Move the cursor to ERROR NO RESET

and click on it (to reset to zero).

Turn off the power.

Is the power turned on again?

No

Check the back light lamp, D753, D754, Q757,

Q3600-2 and their peripheral parts as well as pin

(42) of IC2001.

Note:

This model is equipped with the lamp error detection function

that detects the current flowing into the fluorescent lamp and

protects the backlight lamp drive circuit.

If a lamp error is detected, the microprocessor interrupts the

unit and the ERROR NO RESET setting will go up.

When the ERROR NO RESET setting has reached "5", the

microprocessor turns and keeps off the unit's power. To

resume the power, take the above procedure to clear the

ERROR NO RESET setting.

12

Page 13

No picture

at all

Yes

No

Are inputs

and outputs

of IC802 as

specified?

Check all the settings on the microprocessor’s adjust process menu.

No picture

Check IC802

and its

peripheral

parts.

Yes

No

Are inputs

and outputs

of IC1201 as

specified?

Check

IC1201 and

its peripheral

parts.

Check LCD

panel voltage

and

waveform.

No TV and

VIDEO 1

output

Yes

No

Are inputs

and outputs

of IC402 as

specified?

Check IC402

and its

peripheral

parts.

NO

Is input at Pin

(73) of IC802

as specified?

Check IC802,

AV1 line and

their

peripheral

parts.

No TV

output

Yes

No

Are voltages

at Pins (6),

(7) and (9) of

tuner as

specified?

Check the

power line.

Yes

No

Is output at

Pin (19) of

tuner as

specified?

Check the

tuner and its

peripheral

parts.

No

Is input at Pin

(1) of IC402

as specified?

Check the

line in

question.

Yes

Check IC402

and its

peripheral

parts.

Yes

No

Are Pins (2)

and (4) of

IC402 at “H”

and “L”

respectively?

Are Pins (65)

and (66) of

IC2001 at “H”

and “L”

respectively?

No VIDEO

1 output

YES

No

Is input at Pin

(1) of IC402

as specified?

Check the

line in

question.

Yes

No

Are Pins (1)

and (4) of

IC402 both at

“L”?

No VIDEO

2 output

No

Is input at Pin

(74) of IC802

as specified?

Check J3404,

AV line and

their

peripheral

parts.

No S

VIDEO

output

No

Are inputs at

Pins (71) and

(72) of IC802

as specified?

Check

J3301, SY

line, SC line

and

peripheral

parts.

Are Pins (65)

and (66) of

IC2001 both

at “L”?

Check IC402

and its

peripheral

parts.

Yes

Check the

line in

question.

Yes

Check the

line in

question.

TROUBLE SHOOTING TABLE

LC-10A3E

13

Page 14

LC-10A3E

No picture and sound

No colour

No TV colour

No S-VIDEO colour

Yes

No

Do F3701 and F3702

function?

Check all the settings on the microprocessor’s adjust process menu.

No

Are secondary outputs

(+38V, +16V, +9V, +5V, -8V)

of T701 as specified?

Yes

Are the oscillation waveform

at T701’s primary side as

specified?

Yes

No

Disconnect F3701 and

F3702. Is the load side

short-circuited?

Yes

No

Is any of T701’s primary side,

Q701, Q710 and S4701

short-circuited?

Check J3701, its peripheral

parts and connection cable.

Replace F3701 and F3702.

Check S4701 and

connection cable.

Check the secondary-side

load of T701.

Fluorescent lamp failure

Yes

No

Does F3751 function?

Yes

No

Is Pin (34) of IC1201 at “H”?

Yes

No

Are the oscillation waveforms

at the primary side of T751

and T752 as specified?

Yes

Replace F3751.

No

Is input at Pin (71) of IC802

as specified?

Check J3301, SC line and

peripheral parts.

Yes

Check the line, IC1201 and

its peripheral parts.

Check Q751, Q752, T751,

T752, Q753 and their

peripheral parts.

Replace the fluorescent lamp

and check the oscillation

waveform again.

No VIDEO colour

Check all the settings on the microprocessor’s adjust process menu.

TROUBLE SHOOTING TABLE (Continued)

14

Page 15

TROUBLE SHOOTING TABLE (Continued)

No sound

from

speakers

Yes

No

Is Pin (53) of

IC2001 at “L”?

Check all the settings on the microprocessor’s adjust process menu.

No sound

No

Are outputs at

Pins (1) and (7)

of IC903 as

specified?

Yes

No

Are inputs and

outputs of

IC303 as

specified?

Yes

No

Are inputs at

Pins (5) and (8)

as well as

outputs at Pins

(2) and (11), all

of IC301, as

specified?

Muting effect is

on. Check the

FSMU line.

Check IC901,

IC903 and their

peripheral

parts.

Check IC303

and its

peripheral

parts.

Check the line

in question,

IC303 and its

peripheral

parts.

Yes

Check the

speakers and

their peripheral

parts.

No sound

from

headphone

Yes

No

Is Pin (55) of

IC2001 at “L”?

Check the

headphone and

its peripheral

parts.

Check Q306,

J3404 and their

peripheral

parts.

No sound

from output

line

Yes

No

Is Pin (52) of

IC2001 at “L”?

No

Are outputs at

Pins (1) and (7)

of IC902 as

specified?

Yes

Check the line

in question.

Check the

LMUTE line.

Check IC902

and its

peripheral

parts.

TV sound

failure

Yes

No

Is output at Pin

(16) of tuner as

specified?

No

Is input at Pin

(60) of IC901

as specified?

Check the

tuner and its

peripheral

parts.

Check IC901,

Q3301, Q3204,

Q3205 and

their peripheral

parts.

LC-10A3E

15

Page 16

LC-10A3E

CHASSIS LAYOUT

MAIN Unit (Side-A)

J

I

H

G

F

MAIN Unit (Side-B)

E

D

C

B

A

12345678910

16

Page 17

TERMINAL Unit

J

I

H

G

LC-10A3E

F

OPERATION Unit (Side-A)

E

OPERATION Unit (Side-B)

D

LED Unit

C

B

A

10 11 12 13 14 15 16 17 18 19

12345678910

17

Page 18

LC-10A3E

BLOCK DIAGRAM

J

I

H

G

F

E

D

C

B

A

12345678910

18

Page 19

DESCRIPTION OF SCHEMATIC DIAGRAM

VOLTAGE MEASUREMENT CONDITION:

1. When the exclusive-use AC adapter is used, the colour

bar signal of colour bar generator for service is input to

get the normal screen. When the audio is minimized,

the voltage value is measured with the 20 kΩ/V tester.

WAVEFORM MEASUREMENT CONDITION:

1. When the exclusive-use AC adapter is used, the colour

density, lightness and colour hue are set to the center

position, and the signal of colour bar generator for

service is observed to get waveform.

The wave for m test point is indicated with the mark

( ) in the wiring diagram.

INDICATION OF RESISTOR & CAPACITOR:

RESISTOR

1. The unit of resistance “Ω” is omitted.

(K=kΩ=1000 Ω, M=MΩ).

2. All resistors are ± 5%, unless otherwise noted.

(J= ± 5%, F= ± 1%, D= ± 0.5%)

3. All resistors are Carbon type, unless otherwise noted.

C : Solid W : Cement

S : Oxide Film T : Special

N : Metal Coating

LC-10A3E

CAPACITOR

1. All capacitors are mF, unless otherwise noted.

(P=pF=mmF).

2. All capacitors are Ceramic type, unless otherwise

noted.

(ML) : Mylar (TA) : Tantalum

(PF) : Polypro Film (ST) : Styrol

CAUTION:

This circuit diagram is original one, therefore there may be a

slight difference from yours.

IMPORTANT SAFETY NOTICE:

PARTS MARKED WITH “å” ( )ARE

IMPORTANT FOR MAINTAINING THE SAFETY OF

THE SET. BE SURE TO REPLACE THESE PARTS

WITH SPECIFIED ONES FOR MAINTAINING THE

SAFETY AND PERFORMANCE OF THE SET.

10 11 12 13 14 15 16 17 18 19

19

Page 20

LC-10A3E LC-10A3E

Ë

MAIN Unit -1/2

J

I

H

å AND SHADED COMPONENTS=SAFETY RELATED PARTS

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

20~21

Page 21

LC-10A3E LC-10A3E

Ë

MAIN Unit -2/2

J

I

H

å AND SHADED COMPONENTS=SAFETY RELATED PARTS

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

22~23

Page 22

LC-10A3E LC-10A3E

Ë

TERMINAL Unit

J

I

H

å AND SHADED COMPONENTS=SAFETY RELATED PARTS

G

F

E

D

C

å

B

A

1234567891011 12 13 14 15 16 17 18 19 20

24~25

Page 23

LC-10A3E

J

I

H

G

Ë

OPERATION and LED Unit

OPERATION UNIT

F

LED UNIT

E

D

C

B

A

12345678910

26

Page 24

PRINTED WIRING BOARD ASSEMBLIES

J

I

H

G

LC-10A3E

F

E

D

C

B

Main Unit (Side-A)

A

12345678910

27

Page 25

LC-10A3E

J

I

H

G

F

E

D

C

B

Main Unit (Side-B)

A

12345678910

28

Page 26

LC-10A3E

J

LED Unit (Side-A)

I

H

G

F

E

D

C

B

A

Operation Unit (Side-A) Terminal Unit (Side-A)

12345678910

29

Page 27

LC-10A3E

J

I

H

G

LED Unit (Side-B)

F

E

D

C

B

A

Operation Unit (Side-B) Terminal Unit (Side-B)

12345678910

30

Page 28

LC-10A3E

Ref. No. Part No. ★ Description Code

PARTS LIST

PARTS REPLACEMENT

Replacement parts which have these special safety characteristics identified in this manual: electrical components having

such features are identified by

Replacement Parts Lists and schematic diagrams.

The use of a substitute replacement part which does not have

the same safety characteristics as the factory recommended

replacement parts shown in this service manual may create

shock, fire or other hazards.

“

HOW TO ORDER REPLACEMENT PARTS

To have your order filled promptly and correctly, please furnish

the following informations.

1. MODEL NUMBER 2. REF. NO.

3. PART NO. 4. DESCRIPTION

5. CODE

MARK★: SPARE PARTS-DELIVERY SECTION

Ref. No. Part No. ★ Description Code

“å”

and shaded area in the

”

LCD MODULE UNIT

RLCDT0067CEZZ J LCD Module Unit

LAMP UNIT

å KLMP-0116CEZZ J Lamp AZ

PRINTED WIRING BOARD ASSEMBLIES

(NOT REPLACEMENT ITEM)

DUNTKA077DE16 – MAIN Unit —

DUNTKA645DE01 – TERMINAL Unit —

DUNTKA646DE01 – OPERATION Unit —

DUNTKA647DE01 – LED Unit —

Ref. No. Part No. ★ Description Code

DUNTKA077DE16

MAIN UNIT

INTEGRATED CIRCUITS

IC201 VHiNJM2147M-1 J NJM2147M AF

IC301 VHiLA4227//-1 J LA4227 AG

IC303 VHiNJM2283F-1 J NJM2283F AF

IC402 VHiNJM2235M-1 J NJM2235M AE

IC701 VHiAN8005M/-1 J AN8005M AD

IC702 VHiNJM2377M-1 J NJM2377M AK

IC704 VHiBA033FP/-1 J BA033FP AG

IC802 VHiVPC3230D-1 J VPC3230D BG

IC901 RH-iX3371CEZZ J IX3371CE BD

IC902 VHiNJM4560M-1 J NJM4560M AG

IC903 VHiNJM4560M-1 J NJM4560M AG

IC1101 VHiMB8346BV-1 J MB8346BV AN

IC1102 VHiNJM4565V-1 J NJM4565V AF

IC1103 VHiNJM4565V-1 J NJM4565V AF

IC1104 VHiNJM4565V-1 J NJM4565V AF

IC1105 VHiBU4053V/-1 J BU4053V AE

IC1106 VHiNJM4580V-1 J NJM4580V AE

IC1107 VHiNJM4580V-1 J NJM4580V AE

IC1108 VHiNJM4580V-1 J NJM4580V AE

IC1109 VHiNJM353M/-1 J NJM353M AG

IC1110 VHiBU4053V/-1 J BU4053V AE

IC1201 RH-iX3378CEZZ J IX3378CE AY

IC1202 VHiPD485505-2 J PD485505 AY

IC2001 RH-iX3606CEZZ J IX3606CE

IC2002 VHiPST529DM-1 J PST529DM AE

IC2003 VHiTC4W66F/-1 J TC4W66F AE

IC2004 VHiBR24C08F-1 J BR24C08F AF

IC2005 VHiBA7046F/-1 J BA7046F AF

TRANSISTORS

Q201 VS2SC2712Y/-1 J 2SC2712Y AB

Q202 VS2SC2712Y/-1 J 2SC2712Y AB

Q203 VSFMY3/////-1 J FMY3 AB

Q204 VS2SC2712Y/-1 J 2SC2712Y AB

Q302 VS2SA1162Y/-1 J 2SA1162Y AB

Q303 VSDTC314TK/-1 J DTC314TK AC

Q304 VSDTC314TK/-1 J DTC314TK AC

Q306 VSDTC144EE/-1 J DTC144EE AA

Q308 VSDTC144EE/-1 J DTC144EE AA

Q701 VS2SA1162Y/-1 J 2SA1162Y AB

Q702 VS2SK2503//-1 J 2SK2503 AE

Q703 VS2SC2712Y/-1 J 2SC2712Y AB

Q707 VSDTC144EE/-1 J DTC144EE AA

Q708 VSFMMT718//-1 J FMMT718 AE

Q709 VSDTC144EE/-1 J DTC144EE AA

Q710 VS2SA1162Y/-1 J 2SA1162Y AB

Q751 VSFZT1053A/-1 J FZT1053A AG

Q752 VSFZT1053A/-1 J FZT1053A AG

Q753 VS2SA1162Y/-1 J 2SA1162Y AB

Q754 VSDTC114YE/-1 J DTC114YE AB

Q757 VSUPA606T//-1 J UPA606T AD

Q1101 VS2SA1729//-1 J 2SA1729 AF

Q1102 VS2SC4520//-1 J 2SC4520 AE

Q1201 VSDTC144EE/-1 J DTC144EE AA

Q2003 VS2SC2712Y/-1 J 2SC2712Y AB

Q2004 VSDTC144EE/-1 J DTC144EE AA

Q2005 VSDTA144EE/-1 J DTA144EE AA

Q2006 VSDTC144EE/-1 J DTC144EE AA

D201 VHDDAN222//-1 J DAN222 AA

D702 VHDSFPB56//2E J SFPB56 AC

D703 VHD1SS250//1E J 1SS250 AB

D704 VHD1SS250//1E J 1SS250 AB

D705 VHDDAN222//-1 J DAN222 AA

D706 VHDSFPB74//2E J SFPB74 AD

D707 VHDDAN222//-1 J DAN222 AA

D709 VHDDAN222//-1 J DAN222 AA

D710 VHDDAN222//-1 J DAN222 AA

D712 VHDDAN222//-1 J DAN222 AA

D753 VHDiMN10///-1 J IMN10 AB

31

DIODES

Page 29

LC-10A3E

Ref. No. Part No. ★ Description Code

DUNTKA077DE16

MAIN UNIT(Continued)

D754 VHDiMN10///-1 J IMN10 AB

D1101 VHD1SS250//1E J 1SS250 AB

D1102 VHDDAN222//-1 J DAN222 AA

D1201 VHDDAN222//-1 J DAN222 AA

D1202 RH-EX0227CEZZ J Zener Diode, 5.1V AB

PACKAGED CIRCUITS

X801 RCRSC0012CEZZ J Crystal, CRSC0012CE AH

X901 RCRSB0250GEZZ J Crystal, CRSB0250GE AG

FILTER

X2002 RFiLA0107CEZZ J Filter, FiLA0107CE AD

COILS

L701 RCiLC0130CEZZ J Coil, CiLC0130CE AG

L705 RCiLC0057CEZZ J Coil, CiLC0057CE AD

L706 RCiLC0130CEZZ J Coil, CiLC0130CE AG

L752 RCiLC0110CEZZ J Coil, CiLC0110CE AF

L803 VP-1M3R3JR93N J Peaking, 3.3µHAB

L804 RCiLC0055CEZZ J Coil, CiLC0055CE AD

L805 RCiLC0055CEZZ J Coil, CiLC0055CE AD

L806 VP-1M4R7J1R2N J Peaking, 4.7µHAB

L807 VP-1M4R7J1R2N J Peaking, 4.7µHAB

L901 VP-1M4R7J1R2N J Peaking, 4.7µHAB

L902 VP-1M101J7R7N J Peaking, 100µHAC

L1202 VP-1M470J5R4N J Peaking, 47µHAC

L1203 VP-1M220J2R9N J Peaking, 22µHAC

L1204 VP-1M220J2R9N J Peaking, 22µHAC

L1205 VP-1M220J2R9N J Peaking, 22µHAC

TRANSFORMERS

å T701 RTRNZ0778CEZZ J Transformer AM

å T751 RTRNZ0764CEZZ J Transformer AM

å T752 RTRNZ0764CEZZ J Transformer AM

CAPACITORS

C201 VCKYTV1HF104Z J 0.1 50V Ceramic AA

C202 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C203 RC-KZ1025CEZZ J 1 10V Ceramic AB

C204 RC-KZ1025CEZZ J 1 10V Ceramic AB

C205 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C206 VCKYCY1HF103Z J 0.01 50V Ceramic AA

C207 VCEAKM1HW225M J 2.2 50V Electrolytic AB

C301 VCEAPF1CN106M J 10 16V Electrolytic AD

C302 VCEAPF1CN107M J 100 16V Electrolytic AD

C303 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C304 VCEAPF1CN476M J 47 16V Electrolytic AD

C305 VCKYCY1EB223K J 0.022 25V Ceramic AA

C306 VCEAPW1CN477M J 470 16V Electrolytic AE

C307 VCEAPF1HN225M J 2.2 50V Electrolytic AD

C308 VCEAPF1HN225M J 2.2 50V Electrolytic AD

C309 VCKYCY1EB223K J 0.022 25V Ceramic AA

C310 VCEAPF1CN476M J 47 16V Electrolytic AD

C311 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C312 VCEAPF1CN107M J 100 16V Electrolytic AD

C313 VCKYTV1CF105Z J 1 16V Ceramic AB

C314 VCEA4U1CN228M J 2200 16V Electrolytic AE

C316 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C317 VCEAPF1HN105M J 1 50V Electrolytic AD

C318 VCEAPF1HN105M J 1 50V Electrolytic AD

C319 VCEAPF0JW226M J 22 6.3V Electrolytic AB

C403 VCKYTV1AB105K J 1 10V Ceramic AD

C404 VCKYTV1AB105K J 1 10V Ceramic AD

C406 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C408 VCCCCY1HH331J J 330p 50V Ceramic AA

C409 VCCCCY1HH331J J 330p 50V Ceramic AA

C411 VCCCCY1HH331J J 330p 50V Ceramic AA

C701 VCCCCY1HH471J J 470p 50V Ceramic AA

C702 VCKYTV1CF105Z J 1 16V Ceramic AB

C703 VCEAPF1CN226M J 22 16V Electrolytic AD

C704 VCKYTV1CF105Z J 1 16V Ceramic AB

Ref. No. Part No. ★ Description Code

C706 VCKYCY1HB562K J 5600p 50V Ceramic AA

C707 VCKYCY1CF334Z J 0.33 16V Ceramic AA

C708 VCEAPF0JN226M J 22 6.3V Electrolytic AD

C710 VCKYTV1CF105Z J 1 16V Ceramic AB

C711 VCKYCY1EB103K J 0.01 25V Ceramic AA

C712 VCEAPT1CN226M J 22 16V Electrolytic AC

C713 RC-EZ1176CEZZ J 100 16V Electrolytic AK

C716 VCKYTV1CF105Z J 1 16V Ceramic AB

C719 RC-EZ0420CEZZ J 100 25V Electrolytic AE

C721 VCEASD1HN336M J 33 50V Electrolytic AD

C722 VCKYTV1HF104Z J 0.1 50V Ceramic AA

C728 VCKYTV1HF104Z J 0.1 50V Ceramic AA

C729 VCKYTV1CF105Z J 1 16V Ceramic AB

C731 VCCCCY1HH181J J 180p 50V Ceramic AA

C733 RC-EZ0538CEZZ J 330 16V Electrolytic AE

C734 VCKYTV1CF105Z J 1 16V Ceramic AB

C735 RC-EZ0416CEZZ J 330 6.3V Electrolytic AD

C736 RC-EZ0416CEZZ J 330 6.3V Electrolytic AD

C737 RC-EZ1339CEZZ J 220 16V Electrolytic AD

C738 RC-KZ1025CEZZ J 1 10V Ceramic AB

C740 VCEAPF1EN475M J 4.7 25V Electrolytic AC

C741 VCKYTV1CF105Z J 1 16V Ceramic AB

C746 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C747 VCKYTV1HB562K J 5600p 50V Ceramic AA

C748 RC-EZ1339CEZZ J 220 16V Electrolytic AD

C749 RC-EZ1177CEZZ J 150 6.3V Electrolytic AH

C751 VCEA4U1CN228M J 2200 16V Electrolytic AE

C752 RC-FZ0173CEZZ J Capacitor AG

C755 VCKYCY1HB103K J 0.01 50V Ceramic AA

C757 VCKYCY1CB273K J 0.027 16V Ceramic AA

C758 VCKYCY1CB273K J 0.027 16V Ceramic AA

C759 VCEAPF0JN107M J 100 6.3V Electrolytic AD

C760 VCKYTV1HB103K J 0.01 50V Ceramic AA

C761 VCKYTV1HB103K J 0.01 50V Ceramic AA

C762 RC-FZ0174CEZZ J 0.12 100V Mylar AG

C763 VCKYCY1HB562K J 5600p 50V Ceramic AA

C764 VCKYTV1CF105Z J 1 16V Ceramic AB

C765 VCKYTV1CF105Z J 1 16V Ceramic AB

C801 VCEAPF1CN106M J 10 16V Electrolytic AD

C802 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C803 VCCCCY1HH7R0D J 7p 50V Ceramic AA

C804 VCCCCY1HH7R0D J 7p 50V Ceramic AA

C805 RC-KZ1025CEZZ J 1 10V Ceramic AB

C806 RC-KZ1025CEZZ J 1 10V Ceramic AB

C807 VCKYCY1HB331K J 330p 50V Ceramic AA

C808 VCKYCY1HB331K J 330p 50V Ceramic AA

C809 VCEAPK1CN107M J 100 16V Electrolytic AD

C810 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C811 VCKYCY1HB331K J 330p 50V Ceramic AA

C812 RC-KZ1025CEZZ J 1 10V Ceramic AB

C813 RC-KZ1025CEZZ J 1 10V Ceramic AB

C814 VCKYCY1HB102K J 1000p 50V Ceramic AA

C815 VCKYTV1CF684Z J 0.68 16V Ceramic AB

C816 VCKYTV1CF684Z J 0.68 16V Ceramic AB

C817 VCKYTV1CF684Z J 0.68 16V Ceramic AB

C818 RC-KZ1025CEZZ J 1 10V Ceramic AB

C819 RC-KZ1025CEZZ J 1 10V Ceramic AB

C820 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C821 VCEAPW1CN477M J 470 16V Electrolytic AE

C822 RC-KZ1025CEZZ J 1 10V Ceramic AB

C825 RC-KZ1025CEZZ J 1 10V Ceramic AB

C826 VCKYCY1CF224Z J 0.22 16V Ceramic AA

C827 VCKYCY1CF224Z J 0.22 16V Ceramic AA

C830 VCEAPF0GW107M J 100 4V Electrolytic AC

C831 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C835 VCKYCY1CF224Z J 0.22 16V Ceramic AA

C839 VCKYCY1CF224Z J 0.22 16V Ceramic AA

C840 VCKYCY1CF224Z J 0.22 16V Ceramic AA

C841 VCKYCY1CF224Z J 0.22 16V Ceramic AA

C842 VCEAPF0GW107M J 100 4V Electrolytic AC

C844 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C848 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C874 RC-KZ1025CEZZ J 1 10V Ceramic AB

C875 RC-KZ1025CEZZ J 1 10V Ceramic AB

C876 VCEAPF0GW107M J 100 4V Electrolytic AC

32

Page 30

LC-10A3E

Ref. No. Part No. ★ Description Code

DUNTKA077DE16

MAIN UNIT(Continued)

C878 RC-KZ1025CEZZ J 1 10V Ceramic AB

C879 VCKYTV1CF684Z J 0.68 16V Ceramic AB

C902 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C905 VCEAPF1CW106M J 10 16V Electrolytic AB

C906 VCEAPF1CW106M J 10 16V Electrolytic AB

C909 VCKYCY1HB682K J 6800p 50V Ceramic AA

C910 VCKYCY1HB682K J 6800p 50V Ceramic AA

C911 VCEAPF1CW106M J 10 16V Electrolytic AB

C912 VCEAPF1CW106M J 10 16V Electrolytic AB

C913 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C914 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C915 VCEAPF0JW336M J 33 6.3V Electrolytic AB

C916 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C919 RC-KZ1025CEZZ J 1 10V Ceramic AB

C920 RC-KZ1025CEZZ J 1 10V Ceramic AB

C921 RC-KZ1025CEZZ J 1 10V Ceramic AB

C922 RC-KZ1025CEZZ J 1 10V Ceramic AB

C923 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C924 VCEAPF1CW106M J 10 16V Electrolytic AB

C925 RC-KZ1025CEZZ J 1 10V Ceramic AB

C927 VCCCCY1HH560J J 56p 50V Ceramic AA

C928 VCCCCY1HH560J J 56p 50V Ceramic AA

C929 VCCCCY1HH560J J 56p 50V Ceramic AA

C930 VCCCCY1HH5R0C J 5p 50V Ceramic AA

C931 VCCCCY1HH5R0C J 5p 50V Ceramic AA

C932 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C933 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C935 VCEAPF1CW226M J 22 16V Electrolytic AB

C937 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C938 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C939 VCKYCY1HB561K J 560p 50V Ceramic AA

C940 VCKYCY1HB152K J 1500p 50V Ceramic AA

C941 VCKYCY1HB152K J 1500p 50V Ceramic AA

C942 VCKYCY1HB561K J 560p 50V Ceramic AA

C943 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C944 VCEAPF1CW106M J 10 16V Electrolytic AB

C945 VCEAPF1HW225M J 2.2 50V Electrolytic AB

C946 VCEAPF1HW225M J 2.2 50V Electrolytic AB

C954 VCEAPF1CW106M J 10 16V Electrolytic AB

C955 VCKYTV1CF105Z J 1 16V Ceramic AB

C956 VCKYTV1CF105Z J 1 16V Ceramic AB

C957 VCEAPF1EW475M J 4.7 25V Electrolytic AB

C958 VCEAPF1EW475M J 4.7 25V Electrolytic AB

C961 VCKYCY1HB102K J 1000p 50V Ceramic AA

C962 VCKYCY1HB102K J 1000p 50V Ceramic AA

C963 VCKYCY1HB102K J 1000p 50V Ceramic AA

C964 VCKYCY1HB102K J 1000p 50V Ceramic AA

C1101 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1102 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1103 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1104 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1105 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1106 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1107 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1108 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1109 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1110 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1111 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1112 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1113 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1114 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1115 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1116 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1117 VCCCCY1HH560J J 56p 50V Ceramic AA

C1118 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1119 VCKYTV1CF105Z J 1 16V Ceramic AB

C1120 VCKYTV1EF104Z J 0.1 25V Ceramic AB

C1122 VCKYTV1CF105Z J 1 16V Ceramic AB

C1123 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1124 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1127 VCEAPF1CN107M J 100 16V Electrolytic AD

C1128 VCE9PF1CN106M J 10 16V Electrolytic AD

Ref. No. Part No. ★ Description Code

C1201 VCCCCY1HH220J J 22p 50V Ceramic AA

C1202 VCKYCY1HB103K J 0.01 50V Ceramic AA

C1203 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1204 VCCCCY1HH220J J 22p 50V Ceramic AA

C1205 VCCCCY1HH220J J 22p 50V Ceramic AA

C1206 VCEAPF1HN106M J 10 50V Electrolytic AD

C1207 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1209 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C1210 VCEAPF0GW107M J 100 4V Electrolytic AC

C1211 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1212 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C1213 VCEAPF0JW107M J 100 6.3V Electrolytic AC

C1214 VCEAPF0GW107M J 100 4V Electrolytic AC

C1215 RC-KZ1025CEZZ J 1 10V Ceramic AB

C1217 VCEAPF1CW226M J 22 16V Electrolytic AB

C1218 VCEAPF1CN106M J 10 16V Electrolytic AD

C2001 VCKYCY1HB102K J 1000p 50V Ceramic AA

C2002 VCCCCY1HH221J J 220p 50V Ceramic AA

C2003 VCEAPF1HW105M J 1 50V Electrolytic AB

C2006 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C2007 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C2009 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C2010 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C2017 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C2018 VCCCCY1HH101J J 100p 50V Ceramic AA

C2019 VCKYTV1AB105K J 1 10V Ceramic AD

C2020 VCKYCY1HB102K J 1000p 50V Ceramic AA

C2021 VCEAPF1AW476M J 47 10V Electrolytic AB

C2022 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C2023 VCKYTV1AB105K J 1 10V Ceramic AD

C2024 VCKYCY1HB222K J 2200p 50V Ceramic AA

RESISTORS

R201 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R202 VRS-CY1JF103F J 10k 1/16W Metal Oxide AA

R203 VRS-CY1JF102F J 1k 1/16W Metal Oxide AA

R204 VRS-CY1JF473F J 47k 1/16W Metal Oxide AA

R205 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R206 VRS-CY1JF103F J 10k 1/16W Metal Oxide AA

R207 VRS-CY1JF622F J 6.2k 1/16W Metal Oxide AA

R208 VRS-CY1JF473F J 47k 1/16W Metal Oxide AA

R209 VRS-CY1JF123F J 12k 1/16W Metal Oxide AA

R210 VRS-CY1JF242F J 2.4k 1/16W Metal Oxide AA

R211 VRS-CY1JF332F J 3.3k 1/16W Metal Oxide AA

R212 VRS-CY1JF332F J 3.3k 1/16W Metal Oxide AA

R213 VRS-CY1JF682F J 6.8k 1/16W Metal Oxide AA

R214 VRS-CY1JF122F J 1.2k 1/16W Metal Oxide AA

R215 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R216 VRS-CY1JF153J J 15k 1/16W Metal Oxide AA

R217 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R218 VRS-CY1JF391J J 390 1/16W Metal Oxide AA

R219 VRS-TV1JD103J J 10k 1/16W Metal Oxide AA

R220 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R301 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R302 VRS-TX2HF8R2J J 8.2 1/2W Metal Oxide AA

R303 VRS-CY1JF561J J 560 1/16W Metal Oxide AA

R304 VRS-CY1JF561J J 560 1/16W Metal Oxide AA

R305 VRS-TX2HF8R2J J 8.2 1/2W Metal Oxide AA

R308 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R309 VRS-TW2ED222J J 2.2k 1/4W Metal Oxide AA

R310 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R311 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R314 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R315 VRS-CY1JF392J J 3.9k 1/16W Metal Oxide AA

R316 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R317 VRS-CY1JF392J J 3.9k 1/16W Metal Oxide AA

R324 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R327 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R328 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R329 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R331 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R401 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R402 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R403 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R404 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

33

Page 31

LC-10A3E

Ref. No. Part No. ★ Description Code

DUNTKA077DE16

MAIN UNIT(Continued)

R405 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R406 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R407 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R408 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R409 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R410 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R411 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R418 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R420 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R424 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R430 VRS-CA1JF101J J 100 1/16W Metal Oxide AA

R434 VRS-CY1JF105J J 1M 1/16W Metal Oxide AA

R435 VRS-CY1JF105J J 1M 1/16W Metal Oxide AA

R436 VRS-CY1JF105J J 1M 1/16W Metal Oxide AA

R437 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R701 VRS-CY1JF1R0J J 1 1/16W Metal Oxide AA

R702 VRS-CY1JF154J J 150k 1/16W Metal Oxide AA

R703 VRS-CY1JF274J J 270k 1/16W Metal Oxide AA

R704 VRS-TQ2BD000J J 0 1/8W Metal Oxide AA

R705 VRS-TX2HF000J J 0 1/2W Metal Oxide AA

R706 VRS-CR3AD821J J 820 1W Metal Oxide AC

R707 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R708 VRS-CY1JF272F J 2.7k 1/16W Metal Oxide AA

R709 VRS-CY1JF123F J 12k 1/16W Metal Oxide AA

R711 VRS-CY1JF184J J 180k 1/16W Metal Oxide AA

R712 VRS-CY1JF683F J 68k 1/16W Metal Oxide AA

R713 VRS-CY1JF133F J 13k 1/16W Metal Oxide AA

R715 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R716 VRS-TX2HF000J J 0 1/2W Metal Oxide AA

R717 VRS-CY1JF152F J 1.5k 1/16W Metal Oxide AA

R718 VRS-CY1JF274J J 270k 1/16W Metal Oxide AA

R719 VRS-CY1JF563F J 56k 1/16W Metal Oxide AA

R720 VRS-CY1JF473J J 47k 1/16W Metal Oxide AA

R721 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R722 VRS-CY1JF105J J 1M 1/16W Metal Oxide AA

R723 VRS-CY1JF682J J 6.8k 1/16W Metal Oxide AA

R724 VRS-TQ2BD000J J 0 1/8W Metal Oxide AA

R725 VRS-CY1JF1R0J J 1 1/16W Metal Oxide AA

R726 VRS-CY1JF1R0J J 1 1/16W Metal Oxide AA

R729 VRS-TQ2BD000J J 0 1/8W Metal Oxide AA

R731 VRS-TQ2BD000J J 0 1/8W Metal Oxide AA

R732 VRS-TW2ED222J J 2.2k 1/4W Metal Oxide AA

R733 VRS-TQ2BD683J J 68k 1/8W Metal Oxide AA

R734 VRS-CY1JF393J J 39k 1/16W Metal Oxide AA

R735 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R736 VRS-CY1JF1R0J J 1 1/16W Metal Oxide AA

R737 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R738 VRS-TW2ED102J J 1k 1/4W Metal Oxide AA

R739 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R740 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R741 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R742 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R747 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R748 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R751 VRS-TW2ED392J J 3.9k 1/4W Metal Oxide AA

R752 VRS-TW2ED392J J 3.9k 1/4W Metal Oxide AA

R753 VRS-CY1JF333J J 33k 1/16W Metal Oxide AA

R754 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R765 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R766 VRS-CA1JF821J J 820 1/16W Metal Oxide AA

R768 VRS-CA1JF104J J 100k 1/16W Metal Oxide AA

R770 VRS-CA1JF562J J 5.6k 1/16W Metal Oxide AA

R772 VRS-CY1JF563J J 56k 1/16W Metal Oxide AA

R773 VRS-TW2ED000J J 0 1/4W Metal Oxide AB

R774 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R801 VRS-CB1JF221J J 220 1/16W Metal Oxide AC

R802 VRS-CB1JF220J J 22 1/16W Metal Oxide AC

R803 VRS-CB1JF220J J 22 1/16W Metal Oxide AC

R804 VRS-CA1JF101J J 100 1/16W Metal Oxide AA

R806 VRS-CY1JF221J J 220 1/16W Metal Oxide AA

R809 VRS-CY1JF750J J 75 1/16W Metal Oxide AA

R810 VRS-CB1JF220J J 22 1/16W Metal Oxide AC

Ref. No. Part No. ★ Description Code

R811 VRS-CY1JF222J J 2.2k 1/16W Metal Oxide AA

R812 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R813 VRS-CB1JF220J J 22 1/16W Metal Oxide AC

R814 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

R815 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R816 VRS-CA1JF470J J 47 1/16W Metal Oxide AB

R819 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R826 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R831 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R832 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R833 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R834 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R852 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R860 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R861 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R901 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R902 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R903 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R905 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R909 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R910 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R913 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R914 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R915 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R916 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R917 VRS-CY1JF105J J 1M 1/16W Metal Oxide AA

R918 VRS-CY1JF822F J 8.2k 1/16W Metal Oxide AA

R919 VRS-CY1JF822F J 8.2k 1/16W Metal Oxide AA

R920 VRS-CY1JF822F J 8.2k 1/16W Metal Oxide AA

R921 VRS-CY1JF822F J 8.2k 1/16W Metal Oxide AA

R922 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R923 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R924 VRS-CY1JF473J J 47k 1/16W Metal Oxide AA

R925 VRS-CY1JF473J J 47k 1/16W Metal Oxide AA

R951 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R954 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R958 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R959 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R960 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R961 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R962 VRS-CY1JF153J J 15k 1/16W Metal Oxide AA

R963 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R964 VRS-CY1JF473J J 47k 1/16W Metal Oxide AA

R965 VRS-CY1JF473J J 47k 1/16W Metal Oxide AA

R966 VRS-CY1JF152J J 1.5k 1/16W Metal Oxide AA

R967 VRS-CY1JF152J J 1.5k 1/16W Metal Oxide AA

R968 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R969 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1101 VRS-CA1JF333J J 33k 1/16W Metal Oxide AA

R1102 VRS-CA1JF103J J 10k 1/16W Metal Oxide AA

R1103 VRS-CA1JF103J J 10k 1/16W Metal Oxide AA

R1104 VRS-CA1JF333J J 33k 1/16W Metal Oxide AA

R1105 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1106 VRS-CA1JF333J J 33k 1/16W Metal Oxide AA

R1107 VRS-CA1JF103J J 10k 1/16W Metal Oxide AA

R1108 VRS-CA1JF103J J 10k 1/16W Metal Oxide AA

R1109 VRS-CA1JF333J J 33k 1/16W Metal Oxide AA

R1110 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1111 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R1112 VRS-CY1JF103F J 10k 1/16W Metal Oxide AA

R1113 VRS-CA1JF333J J 33k 1/16W Metal Oxide AA

R1114 VRS-CY1JF103F J 10k 1/16W Metal Oxide AA

R1115 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R1116 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R1117 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R1118 VRS-CY1JF823F J 82k 1/16W Metal Oxide AA

R1119 VRS-CY1JF472F J 4.7k 1/16W Metal Oxide AA

R1120 VRS-TW2ED5R6J J 5.6 1/4W Metal Oxide AA

R1121 VRS-CY1JF181J J 180 1/16W Metal Oxide AA

R1123 VRS-CY1JF181J J 180 1/16W Metal Oxide AA

R1124 VRS-CY1JF472F J 4.7k 1/16W Metal Oxide AA

R1125 VRS-TW2ED101J J 100 1/4W Metal Oxide AA

R1126 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1127 VRS-TX2HF000J J 0 1/2W Metal Oxide AA

R1129 VRS-CY1JF563F J 56k 1/16W Metal Oxide AA

34

Page 32

LC-10A3E

Ref. No. Part No. ★ Description Code

DUNTKA077DE16

MAIN UNIT(Continued)

R1130 VRS-TW2ED5R6J J 5.6 1/4W Metal Oxide AA

R1132 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1133 VRS-CY1JF223F J 22k 1/16W Metal Oxide AA

R1134 VRS-CY1JF822F J 8.2k 1/16W Metal Oxide AA

R1135 VRS-CY1JF561J J 560 1/16W Metal Oxide AA

R1136 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1137 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1138 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1143 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1144 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1145 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1146 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1147 VRS-CY1JF100J J 10 1/16W Metal Oxide AA

R1149 VRS-CY1JF562J J 5.6k 1/16W Metal Oxide AA

R1150 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1202 VRS-CB1JF220J J 22 1/16W Metal Oxide AC

R1203 VRS-CA1JF220J J 22 1/16W Metal Oxide AA

R1204 VRS-CB1JF220J J 22 1/16W Metal Oxide AC

R1205 VRS-CA1JF220J J 22 1/16W Metal Oxide AA

R1206 VRS-CB1JF220J J 22 1/16W Metal Oxide AC

R1207 VRS-CA1JF220J J 22 1/16W Metal Oxide AA

R1208 VRS-CY1JF560J J 56 1/16W Metal Oxide AA

R1209 VRS-CA1JF220J J 22 1/16W Metal Oxide AA

R1210 VRS-CY1JF220J J 22 1/16W Metal Oxide AA

R1211 VRS-CY1JF221J J 220 1/16W Metal Oxide AA

R1212 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1214 VRS-CB1JF101J J 100 1/16W Metal Oxide AA

R1217 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1218 VRS-CA1JF101J J 100 1/16W Metal Oxide AA

R1220 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R1221 VRS-CB1JF332J J 3.3k 1/16W Metal Oxide AC

R1222 VRS-CB1JF101J J 100 1/16W Metal Oxide AA

R1223 VRS-CA1JF101J J 100 1/16W Metal Oxide AA

R1225 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R1228 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R1229 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R1230 VRS-CY1JF562J J 5.6k 1/16W Metal Oxide AA

R1232 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1233 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R1234 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R1235 VRS-CB1JF473J J 47k 1/16W Metal Oxide AC

R1236 VRS-CB1JF473J J 47k 1/16W Metal Oxide AC

R2001 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R2002 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R2003 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R2004 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R2007 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R2008 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2009 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R2010 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2011 VRS-CB1JF101J J 100 1/16W Metal Oxide AA

R2014 VRS-CA1JF103J J 10k 1/16W Metal Oxide AA

R2016 VRS-CA1JF223J J 22k 1/16W Metal Oxide AA

R2018 VRS-CA1JF101J J 100 1/16W Metal Oxide AA

R2019 VRS-CB1JF331J J 330 1/16W Metal Oxide AC

R2025 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R2028 VRS-CB1JF102J J 1k 1/16W Metal Oxide AA

R2031 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2035 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R2041 VRS-CA1JF101J J 100 1/16W Metal Oxide AA

R2042 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2045 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R2047 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R2048 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

R2049 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

R2050 VRS-CY1JF562J J 5.6k 1/16W Metal Oxide AA

R2051 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2052 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2053 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R2054 VRS-CY1JF333J J 33k 1/16W Metal Oxide AA

R2055 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R2056 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

Ref. No. Part No. ★ Description Code

R2057 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

R2058 VRS-CY1JF474J J 470k 1/16W Metal Oxide AA

R2059 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R2061 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R2062 VRS-CY1JF333J J 33k 1/16W Metal Oxide AA

R2063 VRS-CY1JF333J J 33k 1/16W Metal Oxide AA

R2067 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2068 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R2074 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R2075 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R2076 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R2083 VRS-CY1JF103J J 10k 1/16W Metal Oxide AA

BALUNES

FB702 RBLN-0051TAZZ J Balun, BLN-0051TA AC

FB703 RBLN-0051TAZZ J Balun, BLN-0051TA AC

FB704 RBLN-0051TAZZ J Balun, BLN-0051TA AC

FB705 RBLN-0095CEZZ J Balun, BLN-0095CE AD

FB706 RBLN-0051TAZZ J Balun, BLN-0051TA AC

FB708 RBLN-0095CEZZ J Balun, BLN-0095CE AD

FB709 RBLN-0090CEZZ J Balun, BLN-0090CE AD

FB801 RBLN-0090CEZZ J Balun, BLN-0090CE AD

FB802 RBLN-0090CEZZ J Balun, BLN-0090CE AD

FB901 RBLN-0006TAZZ J Balun, BLN-0006TA AB

FB1201 RBLN-0090CEZZ J Balun, BLN-0090CE AD

FB1202 RBLN-0006TAZZ J Balun, BLN-0006TA AB

FB1203 RBLN-0076TAZZ J Balun, BLN-0076TA AC

MISCELLANEOUS PARTS

P701 QPLGN1178GEZZ J Plug, 11Pin AC

P751 QPLGN0155FJZZ J Plug, 3Pin(HV) AE

P752 QPLGN0155FJZZ J Plug, 3Pin(HU) AE

P2002 QPLGN1320REZZ J Plug, 13Pin AC

P2003 QPLGN0520REZZ J Plug, 5Pin AB

P2004 QPLGN0420REZZ J Plug, 4Pin AA

SC401 QSOCN0464FJZZ J Socket, 50Pin AH

SC1201 QSOCN0461FJZZ J Socket, 53Pin AH

SC1203 QSOCN0199FJZZ J Socket, 20Pin AE

LHLDW1077GEZZ J Holder AA

DUNTKA645DE01

TERMINAL UNIT

TUNER

NOTE: THE PARTS HERE SHOWN ARE SUPPLIED AS AN

ASSEMBLY BUT NOT INDEPENDENTLY.

TU3201 VTUVT2U5CD553 J VHF Tuner BD

TRANSISTORS

Q3201 VSDTC144EE/-1 J DTC144EE AA

Q3202 VSDTC144EE/-1 J DTC144EE AA

Q3203 VSDTC144EE/-1 J DTC144EE AA

Q3204 VS2SC2712Y/-1 J 2SC2712Y AB

Q3205 VS2SC3928AR-1 J 2SC3928AR AB

Q3301 VS2SC3928AR-1 J 2SC3928AR AB

Q3302 VS2SC2712Y/-1 J 2SC2712Y AB

Q3303 VSDTC314TK/-1 J DTC314TK AC

Q3304 VSDTC314TK/-1 J DTC314TK AC

Q3401 VS2SC3928AR-1 J 2SC3928AR AB

Q3402 VS2SC3928AR-1 J 2SC3928AR AB

Q3403 VSDTC144EE/-1 J DTC144EE AA

Q3404 VS2SK1467//-1 J 2SK1467 AE

Q3405 VS2SK1467//-1 J 2SK1467 AE

DIODES

D3301 VHDDE5SC4M/-1 J DE5SC4M AF

D3401 RH-EX1271CEZZ J Zener Diode, 12V AB

D3402 RH-EX1271CEZZ J Zener Diode, 12V AB

D3403 RH-EX1271CEZZ J Zener Diode AB

35

Page 33

LC-10A3E

Ref. No. Part No. ★ Description Code

DUNTKA645DE01

TERMINAL UNIT(Continued)

COILS

L3201 VP-1M220J2R9N J Peaking, 22µHAC

L3202 RCiLC0141CEZZ J Coil, CiLC0141CE AF

L3401 VP-1M101J7R7N J Peaking, 100µHAC

CAPACITORS

C3201 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C3202 VCEA4U0JN338M J 3300 6.3V Electrolytic AE

C3203 VCKYCY1HB103K J 0.01 50V Ceramic AA

C3204 VCKYCY1HB102K J 1000p 50V Ceramic AA

C3205 VCCCCY1HH330J J 33p 50V Ceramic AA

C3207 VCCCCY1HH330J J 33p 50V Ceramic AA

C3208 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C3209 VCKYCY1HB102K J 1000p 50V Ceramic AA

C3210 VCEAPF1HW225M J 2.2 50V Electrolytic AB

C3301 VCE9PF1AW106M J 10 10V Electrolytic AE

C3302 VCE9PF1AW106M J 10 10V Electrolytic AE

C3303 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C3304 VCKYTV1CB105K J 1 16V Ceramic AC

C3305 VCKYTV1CB105K J 1 16V Ceramic AC

C3306 VCKYCY1HB102K J 1000p 50V Ceramic AA

C3308 VCEAPF1CW106M J 10 16V Electrolytic AB

C3311 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C3312 RC-EZ0417CEZZ J 150 16V Electrolytic AD

C3313 RC-KZ1025CEZZ J 1 10V Ceramic AB

C3314 VCKYTV1CB105K J 1 16V Ceramic AC

C3315 VCKYTV1CB105K J 1 16V Ceramic AC

C3402 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C3403 VCEAPW1CN477M J 470 16V Electrolytic AE

C3404 VCKYCY1EF104Z J 0.1 25V Ceramic AA

C3405 VCEAPF0JW336M J 33 6.3V Electrolytic AB

C3406 RC-KZ1025CEZZ J 1 10V Ceramic AB

C3407 VCEAPF0JW226M J 22 6.3V Electrolytic AB

RESISTORS

R3201 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3202 VRS-CA1JF561J J 560 1/16W Metal Oxide AA

R3203 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3204 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3205 VRS-CY1JF153J J 15k 1/16W Metal Oxide AA

R3206 VRS-CY1JF332J J 3.3k 1/16W Metal Oxide AA

R3207 VRS-CY1JF152J J 1.5k 1/16W Metal Oxide AA

R3208 VRS-CY1JF331J J 330 1/16W Metal Oxide AA

R3209 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3210 VRS-TQ2BD000J J 0 1/8W Metal Oxide AA

R3301 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3302 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3303 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3304 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3305 VRS-TQ2BD750J J 75 1/8W Metal Oxide AA

R3306 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3307 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3308 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3309 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3310 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3313 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3314 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3315 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3316 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3319 VRS-TQ2BD750J J 75 1/8W Metal Oxide AA

R3320 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3321 VRS-CY1JF822J J 8.2k 1/16W Metal Oxide AA

R3323 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3324 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3326 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3327 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3328 VRS-CY1JF562J J 5.6k 1/16W Metal Oxide AA

R3329 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3330 VRS-TX2HF331J J 330 1/2W Metal Oxide AB

R3331 VRS-TX2HF331J J 330 1/2W Metal Oxide AB

R3332 VRS-CR3AD3R9J J 3.9 1W Metal Oxide AC

R3333 VRS-CR3AD3R9J J 3.9 1W Metal Oxide AC

Ref. No. Part No. ★ Description Code

R3334 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R3401 VRS-TQ2BD750J J 75 1/8W Metal Oxide AA

R3402 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3404 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3405 VRS-CY1JF000J J 0 1/16W Metal Oxide AA

R3409 VRS-CY1JF104J J 100k 1/16W Metal Oxide AA

R3410 VRS-TQ2BD750J J 75 1/8W Metal Oxide AA

R3411 VRS-CY1JF680J J 68 1/16W Metal Oxide AA

R3412 VRS-CY1JF680J J 68 1/16W Metal Oxide AA

R3413 VRS-CY1JF223J J 22k 1/16W Metal Oxide AA

R3414 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

R3415 VRS-CY1JF562J J 5.6k 1/16W Metal Oxide AA

R3416 VRS-CY1JF272J J 2.7k 1/16W Metal Oxide AA

R3417 VRS-CY1JF750J J 75 1/16W Metal Oxide AA

R3701 VRS-TW2ED000J J 0 1/4W Metal Oxide AB

R3702 VRS-TW2ED000J J 0 1/4W Metal Oxide AB

BALUNES

FB3401 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3402 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3403 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3404 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3405 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3406 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3407 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3408 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3409 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3410 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3411 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3412 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3413 RBLN-0059CEZZ J Balun, BLN-0059CE AB

FB3414 RBLN-0059CEZZ J Balun, BLN-0059CE AB

MISCELLANEOUS PARTS

å FH3701 QFSHD1002CEZZ J Fuse Holder AA

å FH3702 QFSHD1002CEZZ J Fuse Holder AA

å FH3703 QFSHD1002CEZZ J Fuse Holder AA

å FH3704 QFSHD1002CEZZ J Fuse Holder AA

å FH3751 QFSHD1002CEZZ J Fuse Holder AA

å FH3752 QFSHD1002CEZZ J Fuse Holder AA

å F3701 QFS-C1223CEZZ J Fuse, 1.25A AD

å F3702 QFS-C1223CEZZ J Fuse, 1.25A AD

å F3751 QFS-C2023CEZZ J Fuse, 2A AD

J3301 QSOCD0406GEZZ J Socket, AV Input 1 AF

J3302 QJAKJ0080CEZZ J Jack, AV Output AF

J3303 QJAKE0166CEZZ J Jack, AV Input 1 AE

J3304 QJAKE0167CEZZ J Jack, AV Input 1 AE

J3305 QJAKJ0080CEZZ J Jack, AV Input 2 AF

J3401 QJAKJ0080CEZZ J Jack, AV Input 2 AF

J3402 QJAKE0168CEZZ J Jack, AV Input 1 AE

J3403 QJAKJ0080CEZZ J Jack, AV Output AF

J3404 QJAKJ0080CEZZ J Jack, Head Phone AF

J3701 QJAKE0165CEZZ J Jack, Power Input AE

P3203 QPLGN0280GEZZ J Plug, 2Pin AB

P3204 QPLGN0280GEZZ J Plug, 2Pin AB

P3701 QPLGN1178GEZZ J Plug, 11Pin AC

SC3401 QSOCN0464FJZZ J Socket, 50Pin AH

DUNTKA646DE01

OPERATION UNIT

DIODES

D4016 RH-EX1271CEZZ J Zener Diode AB

D4017 RH-EX1271CEZZ J Zener Diode AB

D4018 RH-EX1283CEZZ J Zener Diode AB

D4019 RH-EX1283CEZZ J Zener Diode AB

CAPACITORS

C4001 VCCCCY1HH471J J 470p 50V Ceramic AA

C4002 VCCCCY1HH471J J 470p 50V Ceramic AA

36

Page 34

LC-10A3E

Ref. No. Part No. ★ Description Code

DUNTKA646DE01

OPERATION UNIT(Continued)

RESISTORS

R4080 VRS-CY1JF822J J 8.2k 1/16W Metal Oxide AA

R4081 VRS-CY1JF123J J 12k 1/16W Metal Oxide AA

R4082 VRS-CY1JF273J J 27k 1/16W Metal Oxide AA

R4083 VRS-CY1JF563J J 56k 1/16W Metal Oxide AA

R4084 VRS-CY1JF822J J 8.2k 1/16W Metal Oxide AA

R4085 VRS-CY1JF123J J 12k 1/16W Metal Oxide AA

R4086 VRS-CY1JF273J J 27k 1/16W Metal Oxide AA

SWITCHES

S4009 QSW-K0088GEZZ J Switch, MENU AD

S4010 QSW-K0088GEZZ J Switch, CH(+) AD

S4011 QSW-K0088GEZZ J Switch, CH(–) AD

S4012 QSW-K0088GEZZ J Switch, MUTE AD

S4013 QSW-K0088GEZZ J Switch, BRIGHT AD

S4014 QSW-K0088GEZZ J Switch, VOL(–) AD

S4015 QSW-K0088GEZZ J Switch, VOL(+) AD

S4016 QSW-K0088GEZZ J Switch, TV/VIDEO AD

S4017 QSW-K0088GEZZ J Switch, DISPLAY AD

S4701 QSW-S0213CEZZ J Switch, MAIN POWER AE

MISCELLANEOUS PART

P4004 QPLGN0564TAZZ J Plug, 5Pin AC

DUNTKA647DE01

LED UNIT

Ref. No. Part No. ★ Description Code

SUPPLIED ACCESSORIES

LANGU9053CE01 J Wall Mount Parts AS

å QACCB0016TAZZ J AC Cord(LC-10A3E(K)) AV

å QACCK0002TAZZ J AC Cord(LC-10A3E) AM

QCNW-5685CEZZ J AV Cable for Mini-jack AY

RRMCG1618CESA J Infrared R/C Unit AV

TiNS-7449CEZZ J Operation Manual

å UADP-0225CEPZ J AC Adaptor

PACKING PARTS

(NOT REPLACEMENT ITEM)

SPAKC5591CEZZ – Packing Case —

SPAKF4002CEZZ – Packing Material —

SPAKP1000CEZZ – Wrapping Paper —

SPAKX2056CEZZ – Buffer Material —

SPAKX2060CEZZ – Buffer Material —

SSAKA0160CEZZ – Operation Manual —

Polyethylene Bag

TLABK0001TAZZ – No. Label —

Q4106 VSDTC144EE/-1 J DTC144EE AA

Q4107 VSUMG4/////-1 J UMG4 AC

DIODES AND LED

TRANSISTORS

D4120 RH-EX1271CEZZ J Zener Diode AB

D4121 RH-EX1271CEZZ J Zener Diode AB

D4122 RH-PX0368CEZZ J PhotoDiode AE

CAPACITOR

C4120 VCKYTV1CF105Z J 1 16V Ceramic AB

RESISTORS

R4187 VRS-CY1JF331J J 330 1/16W Metal Oxide AA

R4188 VRS-CY1JF102J J 1k 1/16W Metal Oxide AA

R4189 VRS-CY1JF472J J 4.7k 1/16W Metal Oxide AA

R4190 VRS-CY1JF101J J 100 1/16W Metal Oxide AA

MISCELLANEOUS PARTS

RMC4101

SC4102 QPLGN0464TAZZ J Plug, 4Pin AC

SLD4101

RRMCU0239CEZZ J Remote Receiver AG

PSLDM4646CEFW J Shield AD

37

Page 35

LC-10A3E

Ref. No. Part No. ★ Description Code

CABINET PARTS LOCATION

1 CCABA2425CE05 J Front Cabinet Ass’y

1-1

1-2 GCOVA2018CEKA J Cover, for R/C Receiver

1-3 GCOVA1817CESA J Cover, for LED AE

1-4 HBDGB3133CESM J Badge, ”SHARP”

1-5 HDECA0200CESG J Decoration Plate

1-6 LANGS0101CEFW J Speaker Punching (R), x2 AD

1-7 LANGS0102CEFW J Speaker Punching (L), x2 AD

1-8 XEBSD20P05000 J Screw, for Speaker, x4 AA

1-9 VSP4030P-428D J Speaker, x2 AR

1-10 MSPRP0200CEFW J Spring, for Punching Earth AD

1-11 PSPAP0052CEZZ J Spacer AA

1-12 PSPAG2002CEZZ J Spacer, x4 AA

1-13 PSPAG2003CEZZ J Spacer, x2 AA

1-14 PSPAH1002CEZZ J Spacer, x2 AB

1-15 PSPAH1003CEZZ J Spacer AB

1-16 PSPAH1004CEZZ J Spacer AB

1-17 PSPAH0704CEUZ J SP Spacer

2 CCABB2324CE01 J Rear Cabinet Ass’y

2-1

2-2 GDAi-1084CESD J Set Stand AX

2-3 JKNBP1166CEKA J Knob, Power AE

2-4 JBTN-2075CEKA J Button, Control

2-5 LANGF9600CEFW J Set Stand Angle AG

2-6 XBPSF30P10KS0 J Screw, x4 AB

2-7 PZETZ0015CEZZ J Insulator, Set Stand AG

2-8 PMLT-0316CEZZ J Absorber AB

2-9 QCNW-6047CEZZ J Earth Cable AB

2-10 XEBSD30P08000 J Screw AA

2-11 PMLT-0318CEZZ J Absorber, x2 AB

2-12 PMLT-0356CEZZ J Absorber AB

2-13 PSPAG2004CEZZ J Spacer AB

2-14 PSPAH1001CEZZ J Spacer AD

2-15 QCNCW0129CEZZ J PAL-RCA Convert

3 RLCDT0067CEZZ J LCD Module Unit

5 PSHEP0271CEZZ J Diffusion Sheet AH

6 PSHEP0271CEZZ J Diffusion Sheet AH

å 7 KLMP-0116CEZZ J Lamp AZ

8 PGiDM0100CEZZ J Light Guide Plate AV

9 PSHEP0272CEZZ J Diffusion Sheet AF

10 LHLDZ2141CEKZ J Panel Holder AS

11 PSLDM4602CEFW J Shield AK

12 PZETK0101CEZZ J Insulator AF

13 PSPAG2000CEZZ J Light Shielding Spacer AC

14 PSLDM4674CEFW J Shield AF

15 XEBSD30P08000 J Screw, x14 AA

16 XEBSF30P12000 J Screw, x5 AA

17 HiNDP5844CESA J Model Label

18 QCNW-5538CEZZ J Power Cable AG

19 QCNW-5279CEZZ J Key Cable AF

20 QCNW-5539CEZZ J Main-Terminal FFC AK

22 QCNW-5285CEZZ J RC/LED Cable AF

24 PSPAK0035CEZZ J Spacer AA

25 QCNW-4941CEZZ J Gate FFC AE

26 PSPAG2001CEZZ J Spacer AE

28 LHLDW1173CEZZ J Wire Holder AD

29 QCNW-5710CEZZ J Earth Wire AC

30 QCNW-5951CEZZ J Source FFC AF

31 RCORF0064CEZZ J Core AL

32 QCNW-6049CEZZ J ANT Cable

33 LX-NZ3047GEZZ J Nut AA

34 TLABN0369CEZZ J Serial No. Label

34 TLABN0370CEZZ J Serial No. Label

Not Available

Not Available

– Front Cabinet —

– Rear Cabinet —

(LC-10A3E)

(LC-10A3E(K))

Ref. No. Part No. ★ Description Code

38

Page 36

LC-10A3E

Ref. No. Part No. ★ Description Code

CABINET AND MECHANICAL PARTS

H

2-8

2-14

2

2-12

G

OPERATION Unit

19

18

F

15

2-13

20

2-11

2-3

2-10

TERMINAL Unit

15

A

2-1

2-7

A

32

Ref. No. Part No. ★ Description Code

2-5

2-9

10

2-15

2-4

2-2

2-6

34

17

33

16

12

15

11

13

14

E

D

C

B

A

25

MAIN Unit

3

31

6

5

30

15

8

7

24

9

28

1-16

1-13

1-12

1-1

1-17

1-14

1-4

1

1-2

1-15

1-7

1-11

1-8

1-9

1-5

1-6

1-3

1-10

1-7

1-9

1-14

22

LED Unit

1-8

1-6

1-17

26

15

29

123456

39

Page 37

LC-10A3E

Ref. No. Part No. ★ Description Code

★SSAKA0160CEZZ

(Operation Manual Polyethylene Bag)

TiNS-7449CEZZ

(Operation Manual)

Batteries (2 pcs.)

PACKING OF THE SET

★SPAKX2060CEZZ

(Buffer Material)

Ref. No. Part No. ★ Description Code

QCNW-5685CEZZ

(AV Cable for Mini-jack)

å

UADP-0225CEPZ

(AC Adaptor)

RRMCG1618CESA

(Infrared R/C Unit)

å

QACCB0016TAZZ(LC-10A3E(K))

QACCK0002TAZZ(LC-10A3E)

(AC Cord)

LANGU9053CE01

(Wall Mount Parts)

★SPAKX2056CEZZ

(Buffer Material)

★SPAKP1000CEZZ

(Wrapping Paper)

★SPAKF4002CEZZ

(Packing Material)

★TLABK0001TAZZ

(No. Label)

★SPAKC5591CEZZ

(Packing Case)

★ Not Replacement Item

40

Page 38

LC-10A3E

Ref. No. Part No. ★ Description Code

Ref. No. Part No. ★ Description Code

COPYRIGHT © 2001 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical,

photocopying, recording, or otherwise, without

prior written permission of the publisher.

D Japan P Japan TQ1129-S

Jun. 2001 Printed in JAPAN

NA. DS

SHARP CORPORATION

AV Systems Group

Quality & Reliability Control Center

Yaita, Tochigi 329-2193, Japan

42

Loading...

Loading...