Page 1

SERVICE MANUAL

ELECTRONIC

CASH REGISTER

MODEL ER-A320

SRV Key : LKGIM7113RCZZ

PRINTER: CR-812A

(For "U" version)

CONTENTS

CHAPTER 1. SPECIFICATIONS ....................................................................... 1

CHAPTER 2. OPTIONS.....................................................................................4

CHAPTER 3. SRV. RESET AND MASTER RESET.......................................... 5

CHAPTER 4. HARDWARE DESCRIPTION ...................................................... 5

CHAPTER 5. TEST FUNCTION ......................................................................10

CHAPTER 6. CIRCUIT DIAGRAM & PWB LAYOUT ......................................13

PARTS GUIDE

Parts marked with " " are im portan t fo r main tain ing t he safet y of t he set. Be sure t o replace these parts wit h specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

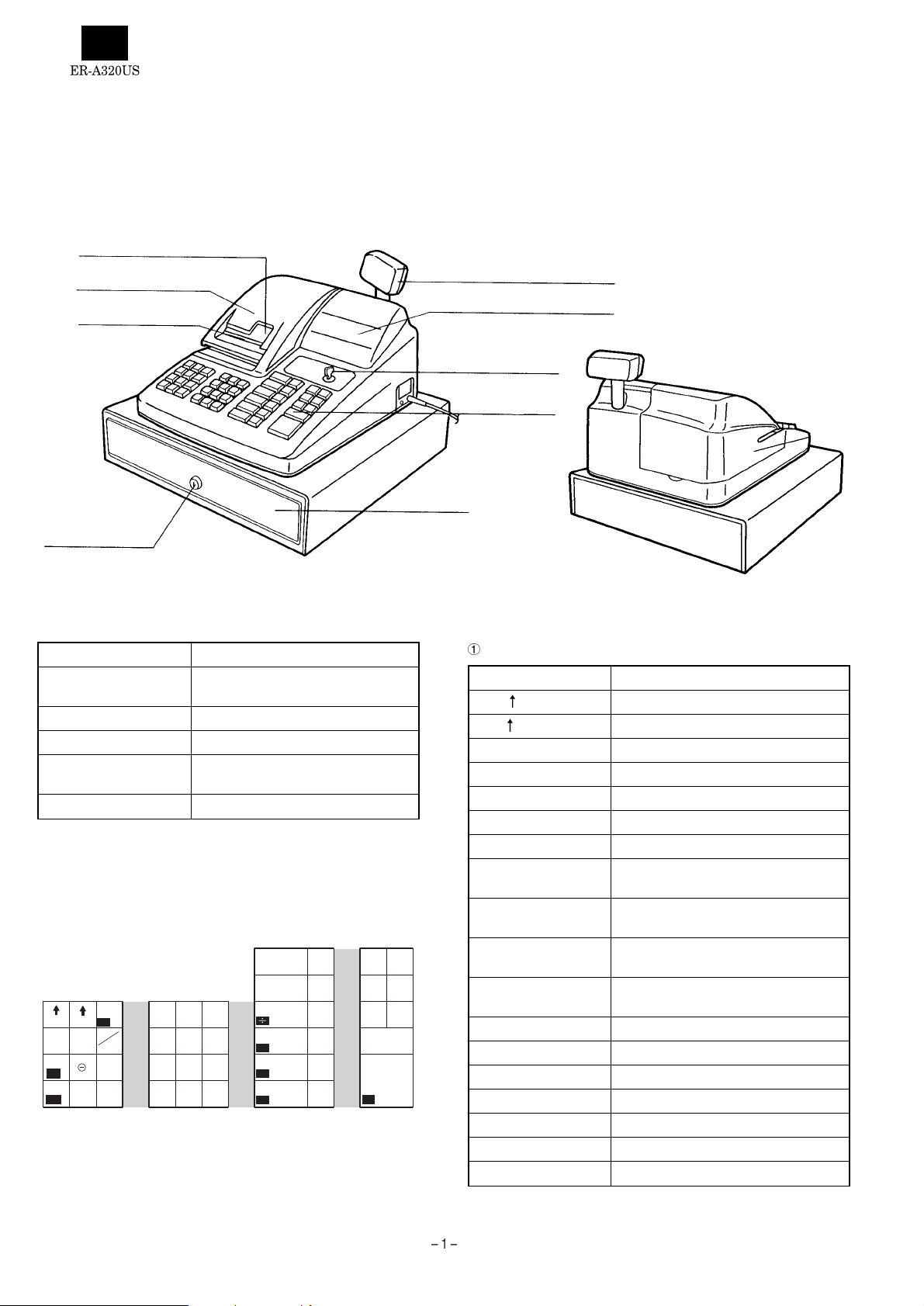

CHAPTER 1 . SPECIFICATIONS

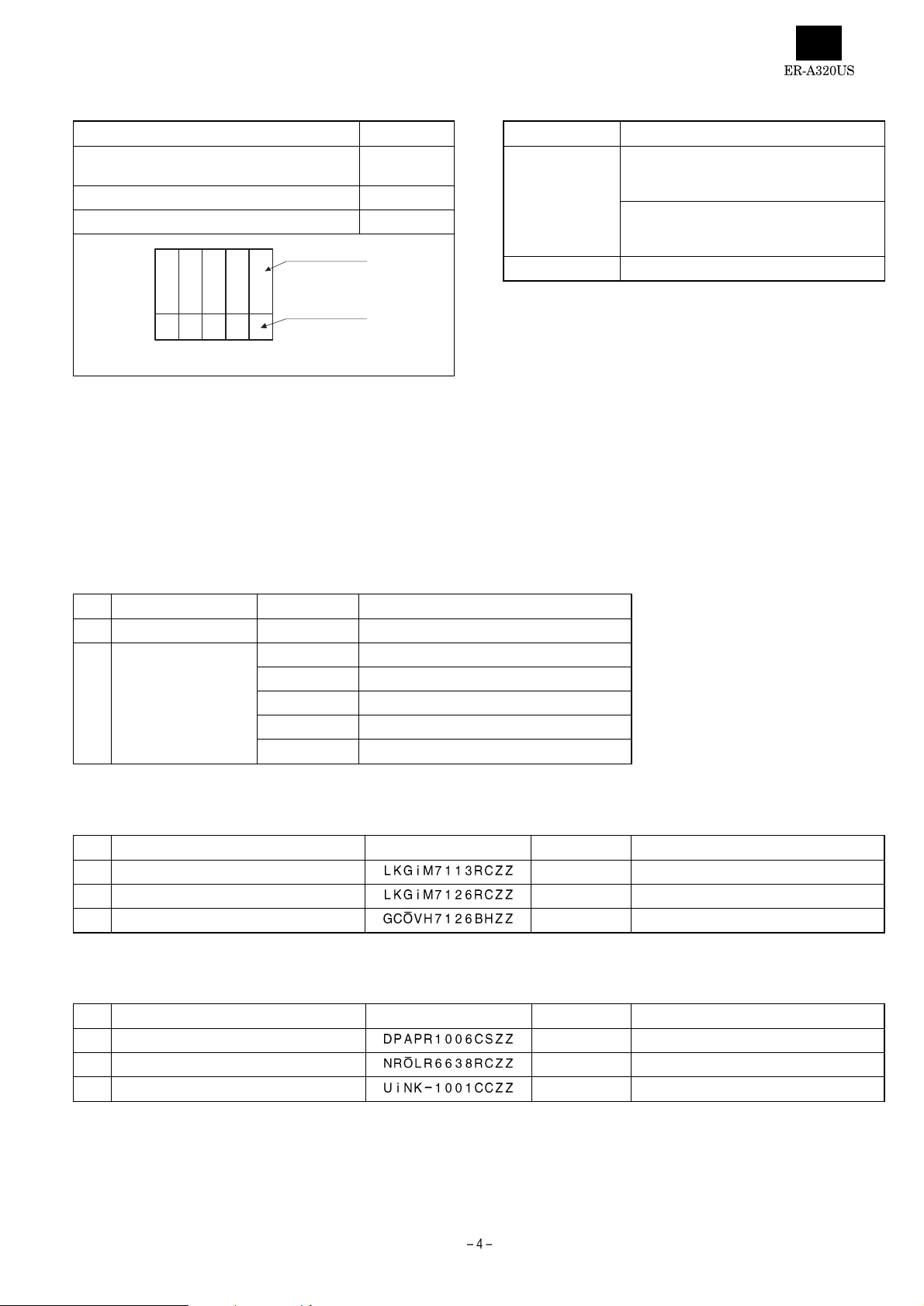

1. Appearance/Rating

1) Appearance

Journal paper

Printer cover

Receipt paper

Drawer lock

2) Rating

Power source 120V AC m 10%, 60 Hz

Power consumption Stand-by: 9W

Operating: 35W (Max.)

Operating temperature 32°F to 104°F (0°C to 40°C)

Operating humidity 10% to 90% (RH)

Physical dimensions

including the drawer

420 (W) x 423 (D) x 304 (H) mm

(16.5 (W) x 16.7 (D) x 12.0 (H) in.)

Weight 13.0 kg (28.7 lbs.)

2. Keyboard

1) Standard keyboard layout

PLU/SUB NS

5 10

Receipt

Journal

RCPT PRINT

RA

RM

PO

%

CAL

CL

C

@

FOR

RFND

VOID

0 00 •

987

654

321

4

3

X

-

2

+

1

Customer display (Pop-up type)

Operator display

Mode switch

Keyboard

Drawer

2) Key top name

Standard key top

KEY TOP DESCRIPTION

RECEIPT Receipt paper feed key

JOURNAL Journal paper feed key

0~9, 00 Numeric keys

. Decimal point key

@/FOR Multiplication key

CL/C Clear key

PRINT Validation print key

Dept.1/+ Department 1/

Dept.2/– Department 2/

Dept.3/

TAX1

AUTO

SHIFT

CONV

CH

MDSE

CHK

SBTL

9

#/TM/SBTL

8

7

CA/AT

=

6

u Department 3/

Dept.4/

v Department 4/

Dept.5~10 Department 5~10 keys

PLU/SUB PLU/Subdepartment key

RCPT Receipt print key

- Discount key

AUTO Automatic sequencing key

% Percent ke y

NS No-sale key

Plus key (Calc. mode)

Minus key (Calc. mode)

Multiplication key (Cal c. mode)

Division key (Calc. mode)

Page 3

KEY TOP DESCRIPTION

RA/RM Received on account/

Recall memory key (Calc. mode)

PO/CAL Paid out/Calculation mode key

RFND Refund key

VOID Void key

CH Charge key

CHK Check key

CONV Conversion key

MDSE SBTL Merchandise subtotal key

#/TM/SBTL Non-add code/Time display/Subtotal key

CA/AT/= Cash/Amount tendered/

Equals key (Calc. mode)

TAX1 SHIFT TAX1 shift key

DISPLAY DEVICE LED

NUMBER OF LINE 1 line

NUMBER OF POSITIONS 10 positions

COLOR OF DISPLAY Green

CHARACTER SIZE 14.2mm (H) x 8.0mm (H)

2) Customer display (Pop-up type)

Optional key top

KEY TOP DESCRIPTION

Dept. 11~40 Department 11~40 keys

DEPT# Department number entry key

TAX2 SHIFT~TAX4

SHIFT

AUTO2 Automatic sequencing 2 key

CONV2~4 Conversion 2~4 keys

CA2 Cash total 2 key

CH2 Charge 2 key

Tax2~Tax4 shift keys

- 2 Discount 2 key

%2 Percent 2 key

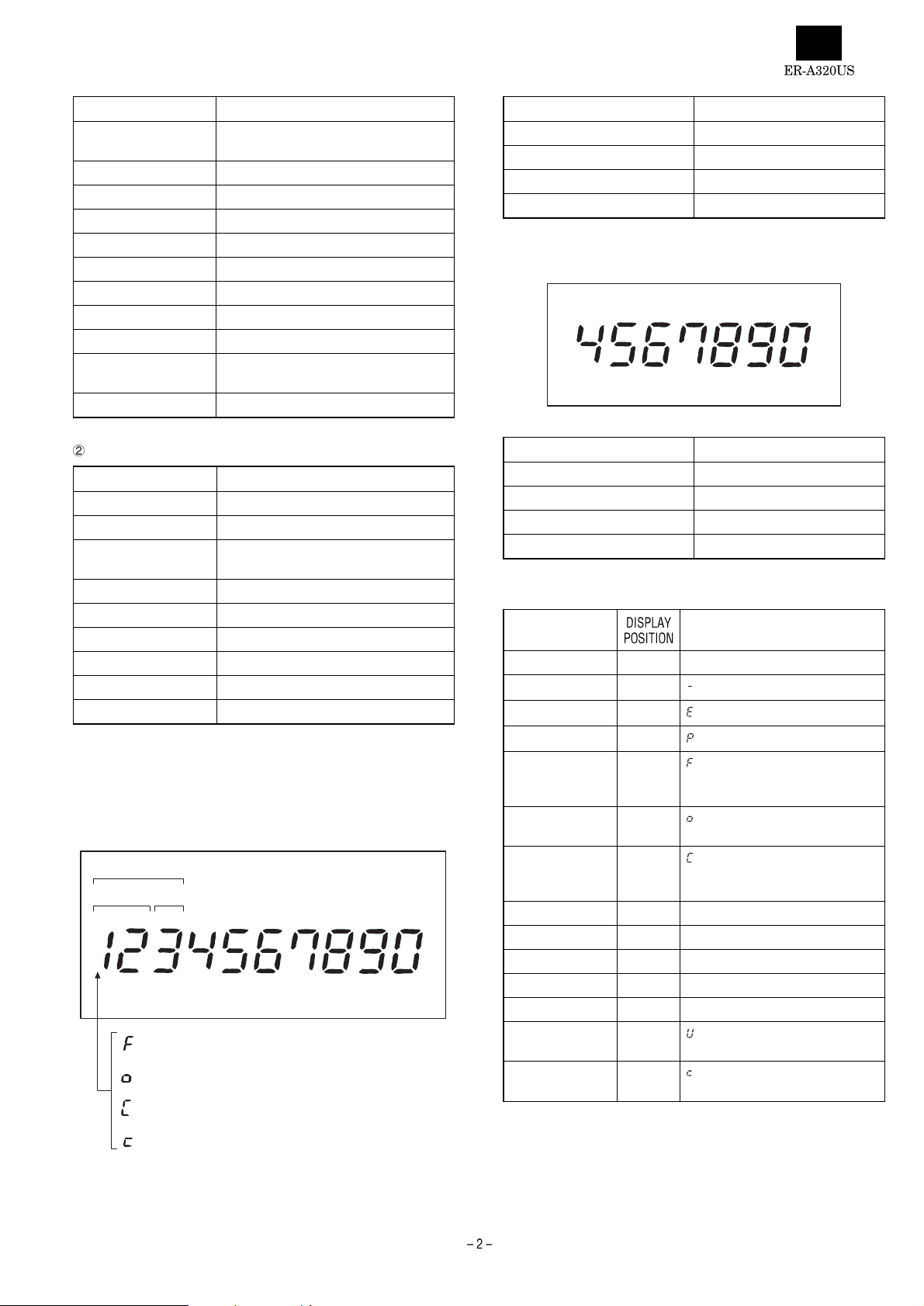

3. Display

1) Operator display

PLU/SUB

DEPT REPEAT

RCPT

OFF

: This appears when a transaction is finalized.

: This appears when the cash register computes the subtotal.

: This appears when the change due amount is displayed.

DISPLAY DEVICE LED

NUMBER OF LINE 1 line

NUMBER OF POSITIONS 7 positions

COLOR OF DISPLAY Green

CHARACTER SIZE 14.2mm (H) x 8.0mm (H)

3) Lamps

DESCRIPTION

AMOUNT 1~8

MINUS SIGN 2~10 : Floating

ERROR 10

PGM MODE 10

CA/AT

CH

CHK

SUBTOTAL/

SHORT TENDER

CHANGE 10 : Lights up whenever the

DEPARTMENT 9~10 No zero-suppressed.

PLU 8~10 No zero-suppressed.

REPEAT 8 Endless count, starting from 2.

DECIMAL POINT 5~1 TAB (4~2)

RECEIPT OFF 9 —

VALIDATION 10 : Light up when the validation

CONVERSION or

CALC. MODE

10 : Lights up when a registration

is finalized by dep r essing

CA/AT, CH or CHK key

10

change due amount appears

in the display.

printing is compulsory.

10

: This appears when for the calculator mode.

Page 4

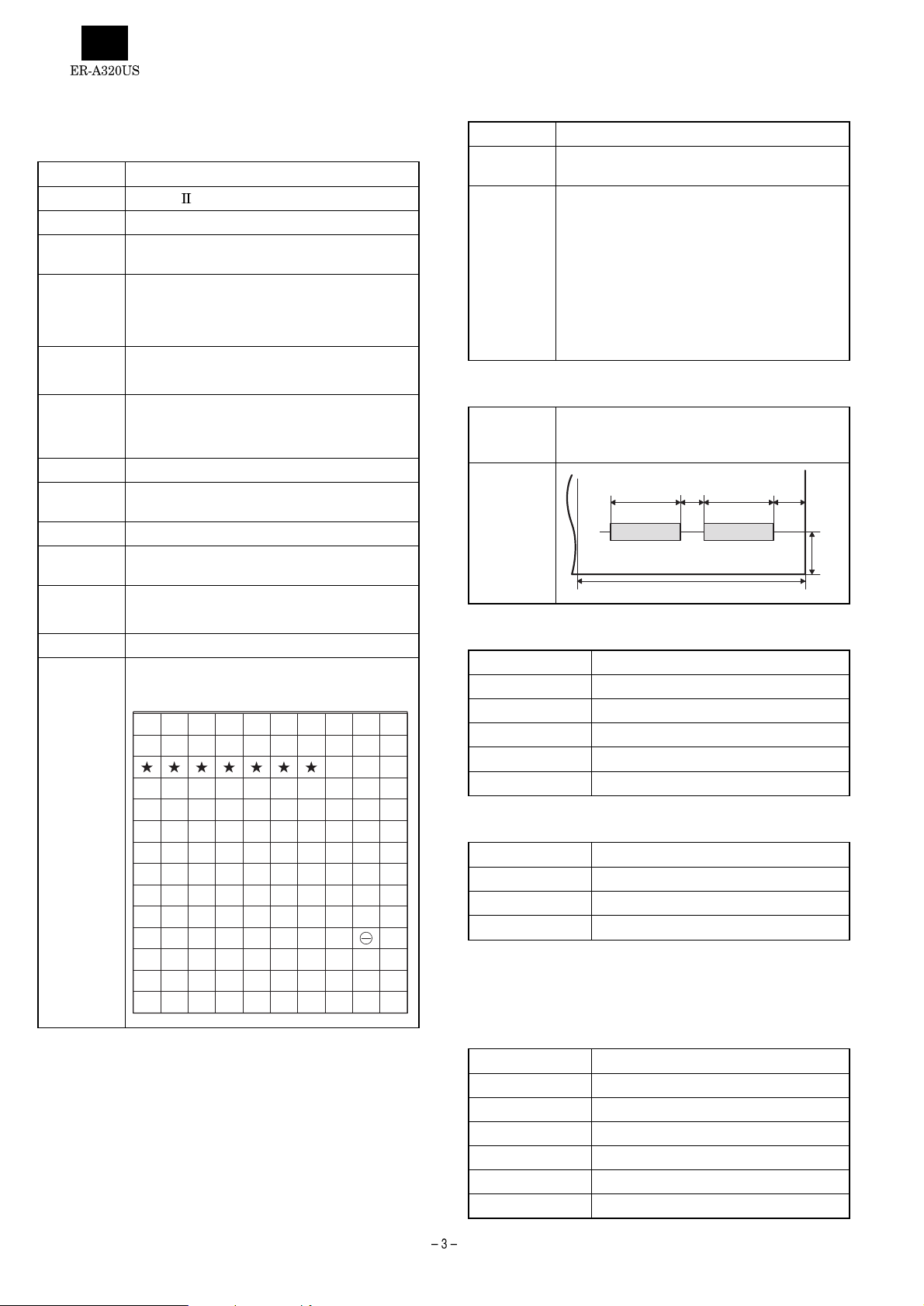

4. Printer

1) Printer specifications

ITEMS

Model name

No. of station 2 (Receipt/Journal)

Printing

system

Printing

capacity

Character

size

Print pitch Column distance : 3.35mm for between 1st and 2nd

Print speed Approx. 2.5 lines/sec.

Paper feed

speed

Reliability MCBF 2.5 million lines

Validation

form sensor

Near end

sensor

Cutter Manual

Print wheel

layout

CR-812A

Print wheel select ive type

Receipt : Max. 10 chr.

Journal : Max. 10 chr.

Validation : Max. 20 chr./1 line

Figure : 1.7mm (W) x 3.2mm (H)

Symbol : 2.4mm (W) x 3.2mm (H)

column 3.0mm for after 3rd column

Row distance : 5.1mm

Approx. 17 lines/sec. at receipt issued.

No

Journal side: No

Receipt side: No

Parts code: 00BM731002300

10198765432

PL

Z

TX

.

.

.

.

GT

CA

CK

-

-

-

-

-

-

#

CH

%

CG

@

Q

2) Roll paper

Parts code DPAPR1006CSZZ

Dimension 44.5

Paper quality Journal/Receipt

m 0.5 mm in width

Max. 80mm in diamet er

Fine quality paper

Paper thickness : 0.0 6 to 0.09 mm

Paper weight : 52.3 to 64g/m

Validation form

Normal paper only

Thickness : 0.08 to 0.19 mm

Size : 115mm or more, 210mm or

under (W) x 70mm or more (H)

2

3) Validation paper

Paper quality Normal paper and pressure sensitive paper only

Thickness : 0.07 to 0.14 mm

Size : 115 mm or more (W) x 70 mm or more (H)

Printing area

19.1

29.4 29.4

10Dig.

Wide over 115mm

10Dig.

16

4) Inkin g

Parts code NROLR6638RCZZ

Ink supply system Ink roller

Form Roller

Specification Material-rubber

Roller life Approx. 0.6 million lines

Print color Purple

16.6

0

RA

PO

VD

NS

TX

FS

X

EX

RF

TD

½

ST

TL

1

2

3

4

5

6

5) Logo stamp

Material Porous rubber

Size 30mm (W) x 20mm (H)

Color Purple

Parts code for ink UINK1001CCZZ

5. Drawer

0

0

0

0

0

0

0

1

1

1

1

1

1

2

2

2

2

2

2

3

3

3

3

3

3

4

4

4

4

4

4

5

5

5

5

5

5

6

6

6

6

6

6

7

7

7

7

7

7

8

8

8

8

8

8

9

9

9

9

9

9

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

1) Drawer b o x an d dr aw er

Model name SK423

Size 420(W) x 423(D) x 112(H) mm

Color Gray 368

Material Metal

Bell —

Release lever Standard equipment; Situated at the bottom

Drawer open sensor Standard equipm ent

Page 5

2) Money ca se

3) Lock

Separation from the drawer Allowed

Separation of the coin compartments from the

money case

Bill separator —

Number of compartments 5B/5C

Bill compartments

Coin compartments

5B/5C

Disallowed

CHAPTER 2. OPTIONS

1. Sales options

Location of th e lock Front

Method of locking

and unlocking

Key No. SK1-1

Locking : lnsert the drawer lock key into th e

Unlocking : lnsert the drawer lock key into the

lock and turn it 90 degrees

counterclockwise.

lock and turn it 90 degrees

clockwise.

No. NAME MODEL DESCRIPTIONS

1 COIN CASE ER-55CC2 5B/5C (For "U" version)

2 KEY TOP KIT ER-11KT7 1 x 1 key top

ER-12KT7 1 x 2 key top

ER-22KT7 2 x 2 key top

ER-11DK7G 1 x 1 dummy key

ER-51DK7G 5 x 1 dummy key

2. Service options

No. NAME PARTS CODE PRICE RANK DESCRIPTIONS

1 SRV KEY

2 MODE KEYGRIP COVER

3 DRIP-PROOF KEYBOARD COVER

AK

AL OP key only

BE

3. Supplies

No. NAME PARTS CODE PRICE RANK DESCRIPTIONS

1 ROLL PAPER

2INK ROLLER

3 INK FOR STAMP

AR

AY

AK

Page 6

CHAPTER 3. SRV RESET AND MASTER RESET

The SRV key is used for operating in the SRV mode.

1. SRV reset (Program Loop Reset)

Used to return the machine back to its operational state after a lockup

has occurred.

Procedure

· Method 1

1) Unplug the AC cord from the wall out let.

2) Set the mode switch to (SRV’) position.

3) Plug in the AC cord to the wall outlet.

4) Turn to (SRV) position from (SRV’) position.

· Method 2

1) Set the mode switch to PGM position.

2) Unplug the AC cord from the wall out let.

3) While holding down JOURNAL FEED key and RECEIPT FEED

key, plug in the AC cord from the wall outlet.

Note: 1. The ER-A320 printer will cycle and print the following on the

journal

2

CHAPTER 4. HARDWARE DESCRIPTION

2. Master reset (All memory clear)

Used to clear all memory contents and return machine back to initial

settings.

(Returns keyboard back to the de fault keyboard layout.)

Procedure

1) Unplug the AC cord from the wall out let.

2) Set the MODE switch to the (SRV’) position.

3) Plug in the AC cord to the wall outlet.

4) While holding down JOURNAL FEED key, turn from (SRV’) position to the (SRV) position.

Note: 1. The ER-A320 display will flash the "." decimal point at the

right most position and will bee p 3 times.

2. The ER-A320 printer will cycle and print the following on the

journal

1

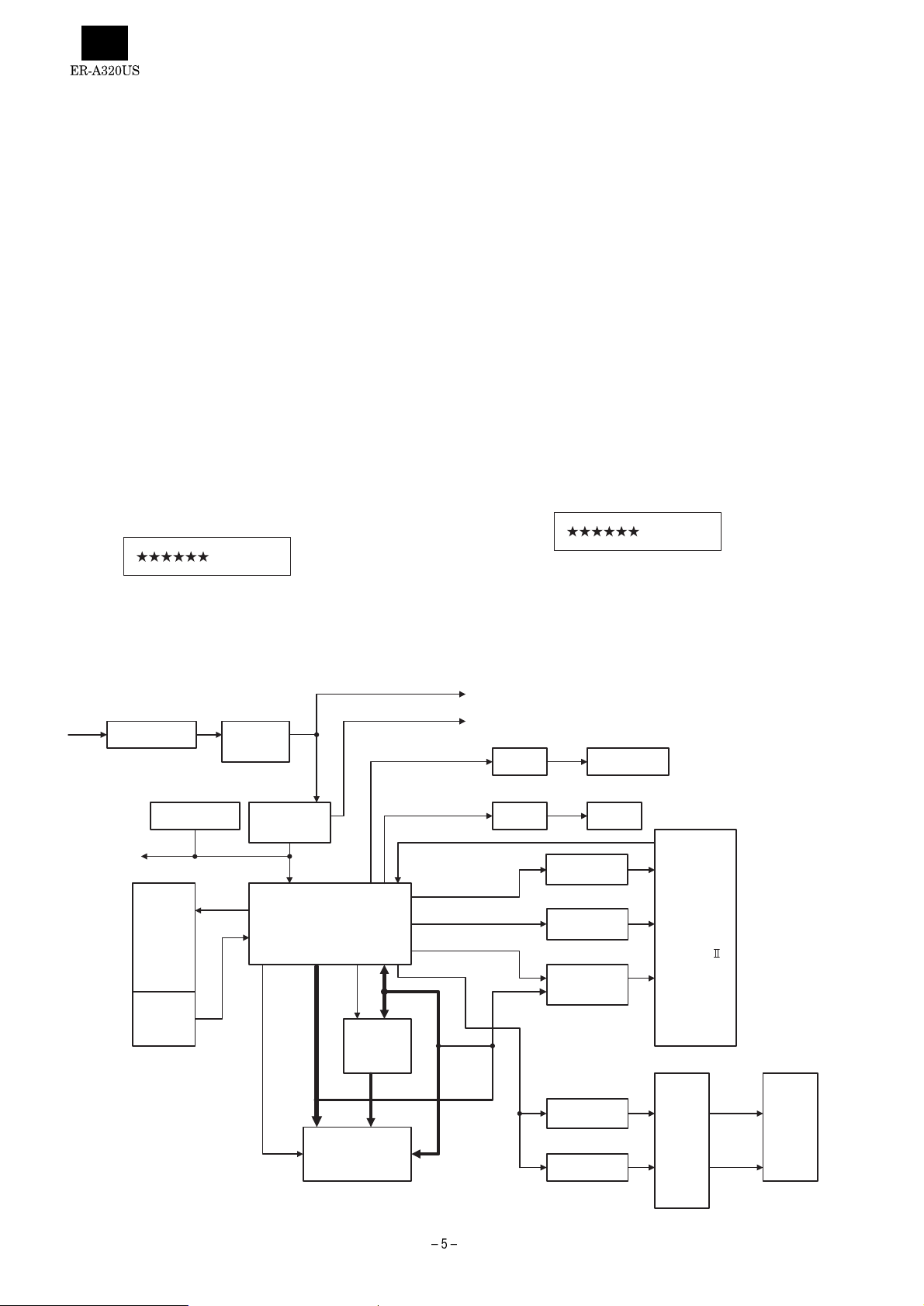

1. Block diagram

TRANSFORMER

NI-MH BATTERY

KEYBOARD

8X9 72KEY

MODE

SWITCH

8SIGNAL

CHIP SELECTSIGNAL

VOLTAGE

REGULATOR

STROBE

SIGNAL

RETURN

SIGNAL

DC-DC

CONVERTER

µPD78045

ADDRESS

BUS

CPU

LATCH

SIGNAL

ADDRESS

BUS

ADDRESS

LATCH

S-RAM

256 kbit

DRIVE SIGNAL

DRIVE SIGNAL

TIMING SIGNAL

DRIVE SIGNAL

DRIVE SIGNAL

HAMMER COMMON SIGNAL

DATA BUS

PRINTER POWER SOURCE : +18V

DISPLAY POWER SOURCE : +5.5V

DRIVER DRAWER

DRIVER

DRIVE SIGNAL

DIGIT SIGNAL

BUZZER

MOTOR

DRIVER

STAMP, PAPER

FEED DRIVER

PRINT WHEEL

MG DRIVER

SEGMENT

DRIVER

DIGIT DRIVER

PRINTER

CR-812A

OP.

DISPLAY

7SEG LED

10DIG

POP-UP

DISPLAY

7SEG LED

7DIG

Page 7

2. CPU (UPD78045F) pin configuration

PIN

No.

NAME

1 P94 DIG7 Di splay digit 7 O H

2 P93 DIG6 Dl splay digit 6 O H

3 P92 DIG5 Di splay digit 5 O H

4 P91 DIG4 Di splay digit 4 O H

5 P90 DIG3 Di splay digit 3 O H

6 P81 DIG2 Di splay digit 2 O H

7 P80 DIG1 Di splay digit 1 O H

8VDD VDD+5V

9 P27 AD7 RAM Address & Data bus 7

10 P26 AD6 RAM Address & Data bus 6

11 P25 AD5 RAM Address & Data bus 5

12 P24 AD4 RAM Address & Data bus 4

13 P23 AD3 RAM Address & Data bus 3

14 P22 AD2 RAM Address & Data bus 2

15 P21 AD1 RAM Address & Data bus 1

16 P20 AD0 RAM Address & Data bus 0

17 /RESET /RESET Reset signal I L

18 P74 NU NU O H

19 P73 NU NU O H

20 AVSS AVSS GND

21 P17 KR11 Key return signal 11 I H

22 P16 KR10 Key return signal 10 I H

23 P15 KR9 Key return signal 9 I H

24 P14 KR8 Key return signal 8 I H

25 P13 KR7 Key return signal 7 I H

26 P12 KR6 Key return signal 6 I H

27 P11 KR5 Key return signal 5 I H

28 P10 VB Battery voltage I

29 AVDD AVDD +5V

30 AVREF AVREF +5V (VCC)

31 XT1 P04 Sub clock: 32.768 kHz I

32 XT2 XT2 O

33 VSS VSS GND

34 X1 X1 Main clock: 4.19 MHz I

35 X2 X2 O

36 P37 MD Printer mo tor ON signal O H

37 P36 BUZ Buzzer ON signal O H/L

38 P35 RF Receipt paper feed signal O H

39 P34 JF Journal paper feed signal O H

40 P33 STAMP Stamp ON signal O H

41 P32 /ALE Address latch signal O

42 P31 /CE Chip select signal O L

SIGNAL

NAME

DESCRIPTION I/O

I/O H

Printer magnet 8

I/O H

Printer magnet 7

I/O H

Printer magnet 6

I/O H

Printer magnet 5

I/O H

Printer magnet 4

I/O H

Printer magnet 3

I/O H

Printer magnet 2

I/O H

Printer magnet 1

PIN

No.

NAME

43 P30 /WE Write signal O L

44 P03 RMS NU I

45 P02 JMS Drawer open sensor I

46 P01

47 P00 PE Power enable signal I H

48 IC IC VSS

49 P72 P72 NU O H

50 P71 MG10 Printer magnet 10 O H

51 P70 MG9 Printer magnet 9 O H

52 VDD VDD +5V

53 P127 R-COM Prin t er receipt common

54 P126 J-COM Printer journal common

55 P125 VDD Mode signal (VDD) I H

56 P124 DR1 Standard drawer drive signal O H

57 P123 KR4 Key return signal 4 I H

58 P122 KR3 Key return signal 3 I H

59 P121 KR2 Key return signal 2 I H

60 P120 KR1 Key return signal 1 I H

61 P117 A14 RAM Address 14 O

62 P116 A13 RAM Address 13 O

63 P115 A12 RAM Address 12 O

64 P114 A11 RAM Address 11 O

65 P113 A10 RAM Address 10 O

66 P112 A9 RAM Address 9 O

67 P111 A8 RAM Address 8 O

68 P110 DR2 Option drawer drive signal O H

69 P107 DP/ST8 Display segment signal DP

70 P106 G/ST7 Display segment signal G

71 VLOAD VLOAD GND

72 P105 F/ST6 Display segment signal F

73 P104 E/ST5 Display segment signal E

74 P103 D/ST4 Display segment signal D

75 P102 C/ST3 Display segment signal C

76 P101 B/ST2 Display segment signal B

77 P100 A/ST1 Display segment signal A

78 P97 DIG10 Display digit signal 10 O H

79 P96 DIG9 Display digit sign al 9 O H

80 P95 DIG8 Display digit sign al 8 O H

SIGNAL

NAME

DESCRIPTION I/O

a Printer timing signal I H

OH

signal

OH

signal

Key strobe signal 8

Key strobe signal 7

Key strobe signal 6

Key strobe signal 5

Key strobe signal 4

Key strobe signal 3

Key strobe signal 2

Key strobe signal 1

OH

OH

OH

OH

OH

OH

OH

OH

Page 8

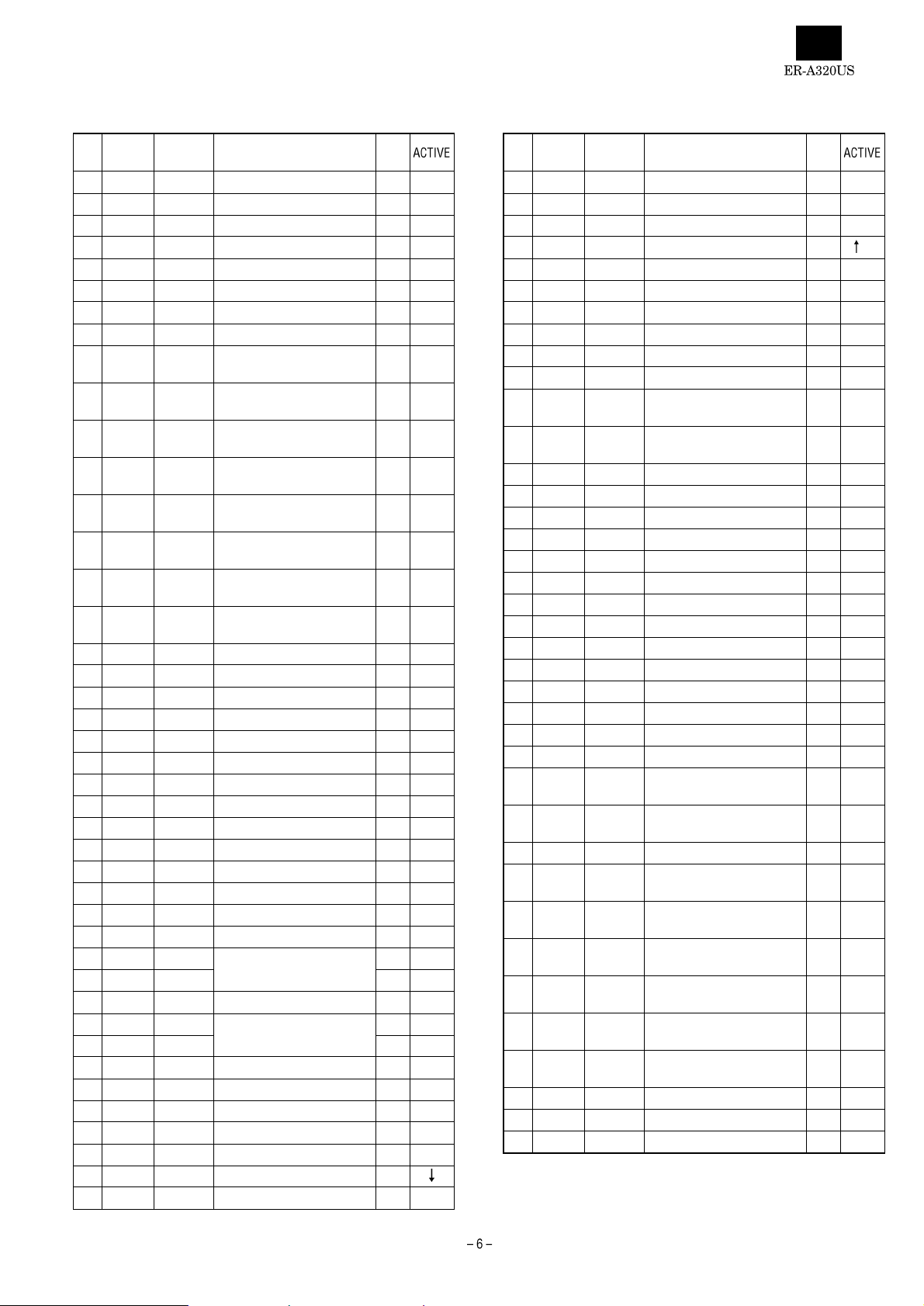

3. RAM control

/CE

/WE

A8~A14

(WRITE)

As shown in the attached time chart, address signals are output from

P20-P27, P111-P117, and the lower address is latched with P32. The

write enable signal (P30) is output. The write data to the RAM are

output from P20-P27. Then the chip enab le signal (P3 1) is output to

write the data .

IC2

CPU

/ALE

AD0~AD7

IC3

74HC373

A0~A7

AD0~AD7

IC14

S-RAM

/WE: Write signal

When the si gnal is low , writing i s perform ed. When t he sig-

nal is high, reading is performed.

/CE: Chip select signal

A8-A14: Address bus

AD0-7: Address/Data bus

A0-1: Address bus signal

/ALE: Address latch signal

Address signals A0-A7 are used commonly with the data bus. When

the address latch signal /ALE is input to IC3, the address/data bus

signal AD0-AD7 access the RAM as a dd ress signals A0-A7.

(READ)

As shown in the attached time chart, address signals are outputted

from P20-P27, P111-P117, and the lower address is latched with P32.

The modes at P20-P27 are changed to the input mode. The chip

enable signal (P31) is output for the RAM. Then the output data from

the RAM are read from P20-P27.

RAM control

(READ cycle)

P111~P117

P20~P27

Lower address

P32

latch signal

P30

RAM /WE

RAM /OE

Fixed to LOW

P31

RAM /CS

P20~P27

READ timing

P20~P27

Select

Hammer common

30ns or above

Upper address

Lower address RAM data output

15ns or above

Fixed to HIGH.

Input

Output

15ns or

above

70ns or above

70ns or above

5. Printer motor drive circuit

0ns or above

RAM control

(WRITE cycle)

P111~P117

P20~P27

Lower address

P32

latch signal

RAM /WE

P30

RAM /OE

P20~P27

P20~P27

P20~P27

Select

RAM Data IN

Hammer common

30ns or above

Fixed to LOW.

RAM /CS

READ timing

Upper address

Lower address Input data to RAM

15ns or above

Input

Output

15ns or

above

30ns or above

50ns or above

0ns or

above

60ns or

above

0ns or above

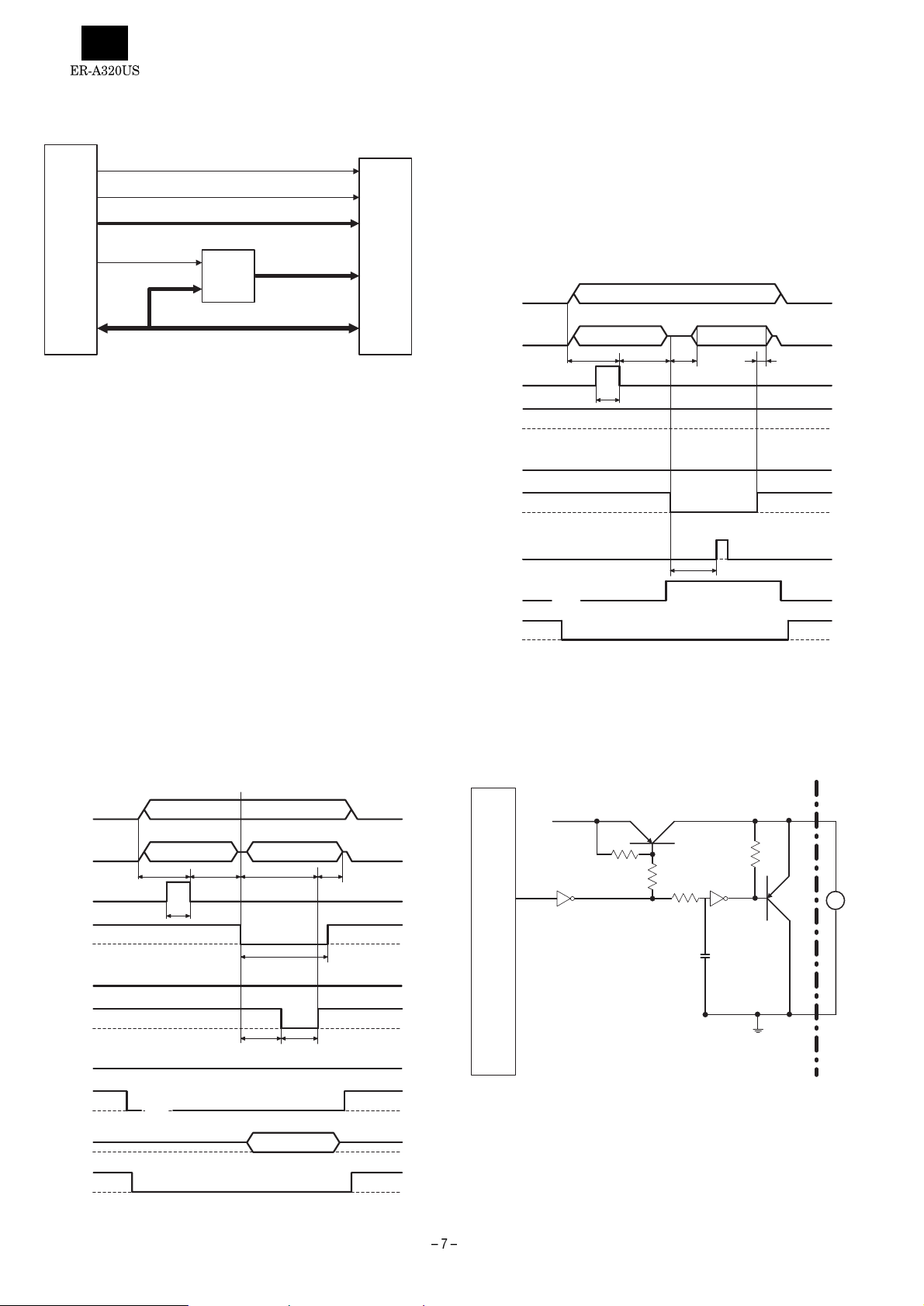

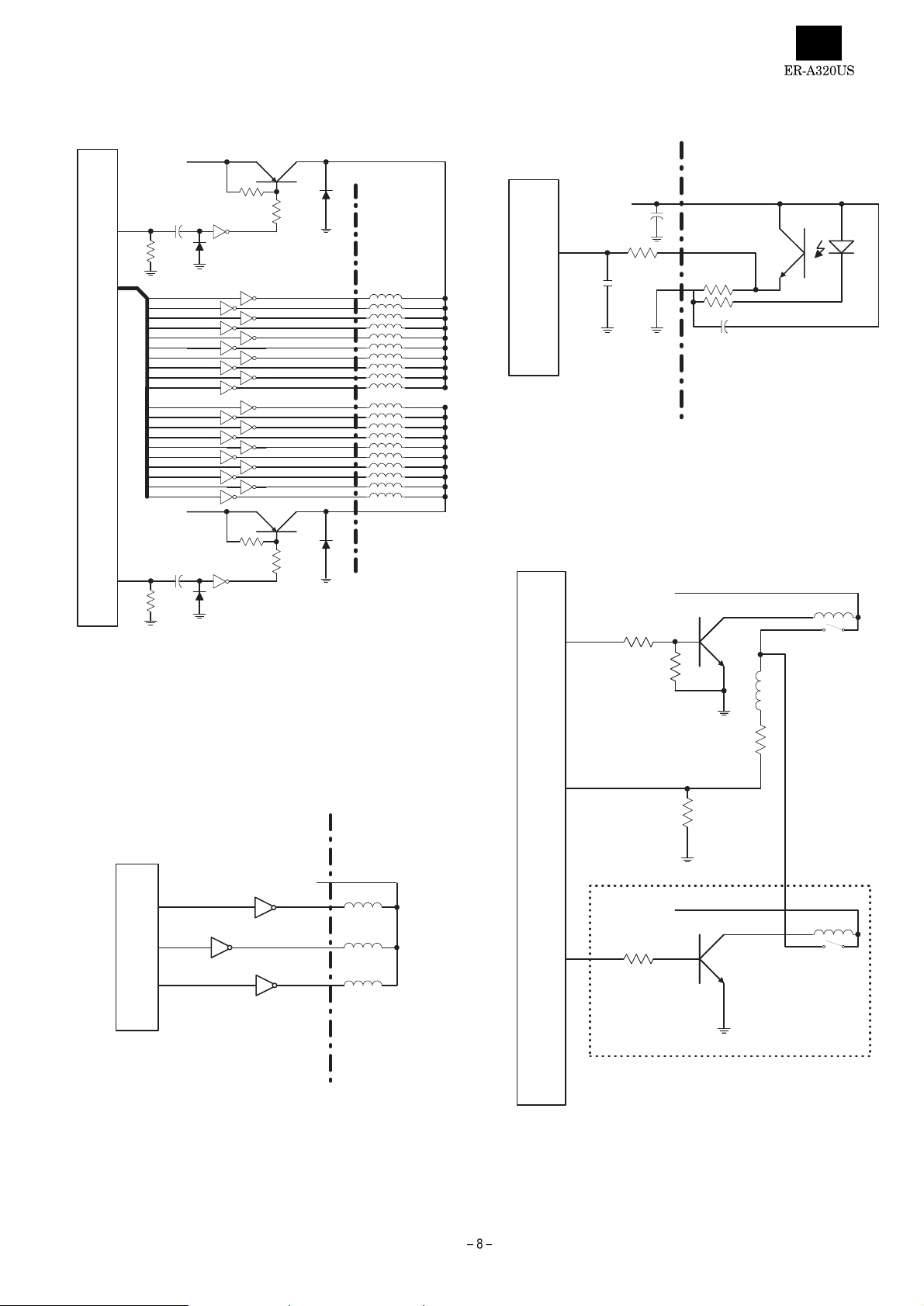

1) Printer motor drive and brake circuit

Q17

B1340

R81

C32

220P

2.7K

R78

470

R79

2.7K

R80

22K

CPU

VP : +18V

IC6B

KID65003P

MD

IC2

The printer motor is operated by switching operation of transistor Q17

with the motor drive signal MD from the CPU.

VM

Q18

M

B926

Page 9

2) Print solenoid drive circuit

4) Timing signal circuit

VJ

D28

1N4002

R83

JM1

JM2

JM3

JM4

JM5

JM6

JM7

JM8

JM9

JM10

RM1

RM2

RM3

RM4

RM5

RM6

RM7

RM8

RM9

RM10

VR

D29

1N4002

R85

CPU

2.7K

R82

2.7K

R84

IC7B

IC7D

IC7F

IC8A

IC8C

IC8E

IC8G

IC9B

IC9D

IC9F

Q19

B926

Q20

B926

220/2W

220/2W

VP : +18V

IC6D

C40

KID65003P

100µF/16V

J-COM

IC2

R-COM

R136

R137

+

D30

C41

100µF/16V

+

IC7C

IC7E

IC7G

IC8B

IC8D

IC8F

IC9A

IC9C

IC9E

IC9G

KID65003P

RB441Q

IC6C

D31

RB441Q

1K

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

MG9

MG10

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

MG9

MG10

VP : +24V

1K

Since the address bus is used to drive the print solenoid, an access to

the RAM can not be pe rfor me d d uri ng pr int ing . The c omm on v olt age of

the print solenoid is supplied by switching operations of transistors

Q20 and Q19 with the J-COM signal and the R-COM signal.

3) Paper feed solenoid and stamp solenoid drive

circuit

VCC:+5V

C29

10U/16V

α

R133

IC2

CPU

C37

1000P

50V

1K

The timing si gnal a is delivered to the CPU by the photo transistor

attached to the printer.

5. Drawer drive circuit

DR1

JMS

R53

1K

VP : +18V

Q21

C3784

STANDARD DRAWER

R54

15K

L2

R55

15K

VM

CPU

RF

JF

IC2

STAMP

1

7A

7

6G

1

6F

RF: Paper feed solenoid drive signal (Receipt side)

JF: Paper feed solenoid drive signal (Journal side)

STAMP: Stamp solenoid drive signal (Receipt side)

CPU

IC2

DR2

R89

1K

VP : +18V

4.7K

R57

Q14

C3784

OPTION DRAWER

The solenoid is dr iven by switching operation of transistor Q21 with the

drive signal DR1 fr om the CPU.

When an option drawer is used, the parts enclosed with the dotted line

must be attached to the PWB.

Page 10

6. Keyboard circuit

/RESET

KR10

ST1~ST8

C11

M104

R40

56K

D17

1SS133

MODE SWITCH

7. Display circuit

+6V

DIG1-DIG10

DIG1'DIG9'DIG10' DIG2'

DIG1'-7'

CPU

ST8

ST7

ST6

ST5

ST4

ST3

IC2

ST2

ST1

KR1

KR2

KR3

KR4

KR5

KR6

KR7

KR8

KR9

D9

D10

D11

D12

D13

D14

D15

D16

RA2

56K X 8

R102

56K

KEY MATRIX

The keyboard performs key scanning with the eight strobe signals

ST1-ST8, and returns a signal on KR1-KR9 to the CPU.

The mode switch performs scanning with the eight strobe signals ST1ST8, and returns the return signal KR10 to the CPU. When the mode

switch is at SRV position, the reset sig na l /R ESET is outputted.

IC2

CPU

FND5 FND1FND4,3,2

A',B',C',D',E',F',G',DP'

DP~A

Operator Display

A,B,C,D,E,F,G,DP

A',B',C',D',E',F',G',DP'

DP' G' F' E' D' C' B' A'

POP UP

DISPLAY

The 7-segment LED is used in the display. The operator display uses

10 digit signals, and the pop-up display uses 7 digit signals.

8. Power supply circuit

POWER

TRANSFOR

MER

P-OFF

CIRCUIT

T1AL/250V

PE

REGULATOR

CIRCUIT

BATTERY

CIRCUIT

VP:+18V

REGULATOR

CIRCUIT

VB

: CPU,RAM

: PRINTER, DRAWER

+6v

: DISPLAY

VCC:+5V

VDD:+5V

F1

9. Clock generator circuit

C16

P04

22P

X1

32.768KHz

XT2

R51

IC2

CPU

330K

X2

R93

1M

X1

X2: 4.19MHz is inputted as the CPU main clock.

X1: 32.768KHz is inputted as the time renew al clock.

C14

33P

X2

4.19MHz

Page 11

10. Buzzer circuit

/RESET

IC2

CPU

10U/50V

/RESET

C19

CHAPTER 5. TEST FUNCTION

VDD

R58

1K

Q16

C3198

+

C11

0.1µ

R59

MODE SWITCH

C18

22U/16V

+

VCC

D24

1K

1SS133

1. Start of test function

The following key operation is required in the SRV mode to start the

test.

XXXX ST

Test command

Master reset is required when the system is to be started for the first

time.

This circuit sounds buzzer with the BUZ signal from the CPU.

11. Reset circuit

VDD

R58

C11

Q16

C3198

1K

MODE SWITCH

R59

C18

22U/16V

+

VCC

1K

D24

1SS133

/RESET

IC2

CPU

C19

10U/50V

/RESET

+

M104

The reset signal is formed with VCC and VDD. The /RESET signal is

also outputted when the mode switch is at SRV position.

2. List of test commands

No. Test contents Key operations

1 Mode switch test 1

2 Keyboard test XXXX02

3 Display and Buzzer test 3

4 Standard Drawer test 4

5 Option Drawer test 14

6 Printer test 5

7 RAM test 6

ST

ST

ST

ST

ST

ST

ST

NOTE-1: Test message is printed on the journal

NOTE-2: The contents of the totalizer and the preset values are not

erased by the test.

3. Test function

1) Test No. 1: Mode switch test

Key operation

1

ST

Then, turn the mode switches in the following order.

In the mode switch test, turn the switch rhythmically.

MODE: SRV

DISPLAY:

Description

As the mode switch position number is displayed, check the num-

ber.

Termination

The test can be terminated when the mode switch is turned to the

SRV side from other position .

Termination print at normal end

Termination print and error

PGM VOID OFF OP X/Z REG

MGR X1/Z1 X2/Z2 SRV

(1) (2) OFF (3) (4)

(5) (6) (7) (0)

Page 12

2) Test No. 2: Keyboard test

Key operation

XXXX 02 ST

Sum check data Test command

(1) Enter the test command in succession to the sum check data

of the model.

Model name

ER-A320 2518

NOTE: Sum check data

The check sum is a decimal number obtained by

converting the hard code hexadecimal total of all

keys.

The

CA/AT key are the exception.

(2) Next, push every key on the keyboard except for the receipt

and journal keys.

When the

immediately produced assuming that all keys have been

pressed.

There is no order in w hich the keys have to be depressed.

Display:

[Keyboard position code of model vs. key to be pressed]

[All key position code]

R

J

41

70

21

10

11

00

[ER-A320 standard keyboard layout]

R

J

41

70

21

10

11

00

CA/AT key is pressed, the termination printout is

02 XX XX=position code.

54

43

23

13

54

43

23

13

53

33

73

53

33

73

03

61

64 63

31

44

34

20

24

74

01 14 04 03

63

31

20

01 04

34

74

Sum check data

(Standard keyboard data)

65 68 67 58 77 78

66

55

56

57

62

42

45

35

46

52

32

76

75

36

22

72

15

05

16

0212

26

25

06

68

67

58

56

35

75

05

25

57

46

36

16

06

55

45

76

15

26

48

47

28

17

07

77

48

4761

38

37

27

18

08

78

38

37

27

08

3) Test No.3: Display and buzzer test

Key operation

3

ST

Description

Continuous beeps and the display are tested.

1. 2. 3. 4. 5. 6. 7. 8. 9. 0.

State of display

The decimal point is shifted digit by digit from the lowest digit

(every 200 msec).

Then all segments are lighted (for about 1 sec).

8. 8. 8. 8. 8. 8. 8. 8. 8. 8.

State of display

Pressing any key will terminate the test.

Check items

Check that each position display is correct.

Check that the display is even and uni form.

Check that the buzzer sound is normal. (No interruption and vibrations of sounds.)

Test end

End print

4) Test No. 4: Drawer open test

Key operation

4

ST : For standard drawer

Description

With this test, the drawer opens and its state is displayed in the

following manner:

Drawer open

Drawer closed

When the model that has no drawer sensor switch, displayed is

"C".

Termination

With depression of any key

Termination print 04 (For standard drawer)

XX 0

XX C

XX=04

Description

Until the depression of the

is compared with the sum check da ta, except for the

Termination

The test terminates with the depression of the

the termination printout is produced.

Termination print at normal end

Termination print at error

ST key, the sum of key position codes

CA/AT key and

CA/AT key.

Page 13

5) Test No. 5: Continuous print test

Key operation

5

ST

Description

The continuous printing as shown below is performed.

Termination

After pressing any key, one-cycle of printing is performed before

completing the operation.

Print format

PL

-

Z

TX

.

.

.

.

GT

-

-

-

-

-

-

#

%

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

5

6

6

6

6

6

6

6

6

7

7

7

7

7

7

7

7

8

8

8

8

8

8

8

8

9

9

9

9

9

9

9

9

0

1

2

3

4

5

6

7

CA

CK

CH

RA

PO

VD

NS

TX

FS

EX

RF

EX

@

Q

CG

TD

1

2

3

4

5

6

½

X

ST

TL

TL

6) Test No.6: RAM test

Key operation

6

ST

Test content

The RAM of 256Kbit (standard provision) is checked.

Read and write of each data are made to the addresses shown in

the table below to compare the data. If there is no error, the normal

print is made and the machine returns to the key wait state. If an

error occurs, the error print is made and the machine returns to the

key wait state.

[Test data]

Address 00000001000200040008001000200040

Data 00 01 02 04 08 10 20 40

Address 00800100020004000800100020004000

Data 80 EF FD FB F7 EF DF BF

Check item

Check the end print.

Test end

Normal end print

Error print

AAAA : Address No.

Page 14

R102

A

56K

D

C

B

CN9P

12345678

VCC

VDD

C10

+6V

R9

120

R138

D7 1SS133

D6 1N4002

VP

330u

C4

Q1

2SC4153

HEAT SINK

F1

UL CSA 2.0A/125V

UL CSA 4.0A/125V

Q42

KTC1027

Q15

2SB1243

R2

3.9K

1

4

BD1

DI102

3

C1

M 0.033u

F2

GND

50v

ZD1

R1

12K

MTZ20D

C2

50V

6800uF

2

ZD5

MTZ6.2B

C8

R7

3.6KF

L1

220uH

R6

10

Q2

KTD1414

56

1 2

IC1

PE

VCC

R5

100K

R3

56K

D3

1SS133

ZD2

MTZJ18B

GND

330u

16V

C34

C9

330u

16V

BT

100

1000u

16V

R8

1KF

D4

PS102R

C7

220P

KA34063A

3

4

C6

50V

C 0.1u

C36

3300P

C5

50V

3.3u

R4

2.7K

0.1u/50V

R101 1M

VB

CN2

ST1~ST8

R121~R130: 12K

R130

R128 R129

Q36 Q37 Q38 Q39 Q40

R126 R127

CN5

BT CN

D9

D10

ST8

ST7

Q31~Q33: A1271

R111~R120: 220

R11,13,15,17,19,21,

23,25,27,29 : 2.2K

Q3~Q12:C3198

R117 R118 R119 R120

Q8 Q9 Q10 Q11 Q12

R21 R23 R25 R27 R29

R116

CN8P

D15

D11

D12

D13

D14

D16

1SS133*8

ST1

ST2

ST3

ST4

ST5

ST6

Q34~Q40: B926

CN15

FND2 FND1

DIG5' DIG4' DIG3' DIG2' DIG1'

CN8

KEY72

CN7

GND

/RESET

POP UP LED CN * 1

PM CN

R30

R31

R32

R33

R34

R35

RA2

56KX8

2 1

KR1~KR9

IC5

KID65003P

C11

1SS133

50V

C 0.1u

D17

56K

R40

ST1~ST8

12K

R132

KR10

CA1

2200P

161

A'B'C'D'

5

30

E'

F'G'DP'

152

143

134

125

116

30

30

30

30

30

A

5

B

5

C

5

D

5

E

5

F

3

DIG8' DIG7' DIG6'

R111

R15 R17 R19

Q4 Q5 Q6 Q7Q3

DIG9'

R13

R112 R113 R114 R115

220

DIG10'

R11

FND5 FND4 FND3

2.2K

B

CN1

PS CN

CN14/CN14-1

Q32 Q33 Q34 Q35Q31

FM CN

R122 R123 R124 R125

1. POWER

DIG1~10

+6V

R121

CHAPTER 6. CIRCUIT DIAGRAM & PWB LAYOUT

D

C

12K

107

5

30

R36

30

R37

SEGA~DP

MAIN LED PWB

G

C33

2200P

Q13

12k

R39

C3198

R38

2.2k

8 7 6 5 4

DP

A

Page 15

|link

|popup.sch

16V

VDD

22K

AD7

AD6

AD5

AD4

/CE

20D719D618D517D416D315

/CE

AD0

AD1

AD2

A

|power.sch

2 1

C28

330P

AD3

S-RAM28P

14

3

VRVMGND

12 5

8E

8C

13 4

8D

AD0

12V

A7

AD7

AD6A6A5

20Q719D718D617Q616Q515D514D413Q412

VCC

/OE

IC3

1Q0 2D0 3D1 4Q1 5Q2 6D2 7D3 8Q3 9

A0

AD0

AD1A1A2

B

PRINTER

1

PRCN30P

30

N.U.

10 79G12 59E14 39C16 19A11 6

MG 10

C30

R135

1K

R133

50V

C37

1000pF

a

VDD

0.1u

R71

22K

C25

IC4

4.7K

10u

C29

VCC

VDD

C27

10u

16V

R68

C39

10uF/16V

12V

C26

330P

A13A8A9

A11

A10

28

27

26A825A924

23

22

21

/OE

A13

A11

A10

/WE

VDD

A141A122A73A64A55A46A37A28A19A010D011D112D213GND

A14

A12A7A6A5A4A3A2A1A0

11 6

13 4

15 2

10 7

9F

9D

9B

8G

8F

AD1

AD2

AD3

AD4

AD5

AD6

AD7

MG 9

C24

1000P

AD5

AD4A4/ALE

11

/LE

GND

74HC373

10

AD2

AD3

A3

D

VM

VJ

D28

Q18

12345678

Q17

2SB1340

VP

CN11

VP

B926

R81

2.7K

12 5

6E

220P

C32

22K

R80

R79

2.7K

15 2

R78

470

6B

MD

VP

C35

50V

C 0.1u

L2

B CORE

Q21

C3784

R54

15K

R53

1K

DR1

1N4002

Q19

B926

2.7K

R83

R82

220/2W

13 4

6D

RB441Q

D30

C40

100uF/16V

1k

R136

J-COM

VP

CN16

R55

15K

U:X

Q14

C3784

1K

R89

DR2

4.7K(H)

3.3K(L)

R57

JMS

C

VR

D29

1N4002

Q20

B926

2.7K

R84

C41

100uF/16V

VP

C42

/RESET

OS

R58

1K

C3198

Q16

VDD

C18

VCC

PRCN30P

30292827262524232221201918171615141312111098765432

R85

220/2W

PR CN12

14 3

6C

1234567891011121314151617181920212223242526272829

RB441Q

D31

R137

R-COM

22uF/16V

STAMP

C19

10uF/10V

R59

1K

D24

22u

16V

1SS133

VJ

15 2

11 67F16 18A14 3

1k

D32

RB441Q

13 4

16 1

7B

11 6

7D

7A

6F

10 7

6G

AD0

JF

RF

15 2

14 3

10 7

12 5

8B

7C

7G

7E

AD1

AD2

AD3

AD4

AD5

AD6

AD7

C23

0.1u

VCC

KR1~KR11

DIG1~DIG10

2. CPU

A10

A

A

DR2

DP/ST

G/ST7

F/ST6

E/ST5

D/ST4

C/ST3

B/ST2

A/ST1

DIG10

DIG

DIG

VDD

C13

10u

16V

A

B

1

DR1

RA1

12K*8

A12

A13

A14

KR1

KR2

KR3

KR4

A11

P11

P11

P11

P11

P10

P10

VLOAD

P10

P10

P10

P10

P10

P10

P97

P96

P95

3

2

1

0

7

6

5

4

3

2

1

0

P11464P11563P11662P11761P12060P12159P12258P12357P12456P12555P12654P127

P94

P93

P92

P91

P90

P81

P80

VDD

P27

1

2

3

4

5

6

7

8

9

DIG 6

DIG 5

DIG 4

DIG 3

DIG 2

DIG 1

DIG 7

AD7

VDD

IC2

6

5

6

6

9

6

7

8

6

8

6

9

8

7

0

7

1

7

2

7

3

7

4

7

5

7

6

7

7

7

8

7

9

9

8

0

8

R87,88

12k*3

R134

PP:O

MP:X

12V

C12

0.1u

3

2

a

PE

RMS

JMS

MG 10

MG 9

R-COM

J-COM

R76

R77

53

52

P7051P7150P72

VDD

P26

P25

P24

P23

P22

10

11

12

13

14

15

AD6

AD5

AD4

AD3

AD2

AD1

NU

49IC48

P21

P20

16

17

AD0

P0047P0146P0245P0344P3043P3142P32

/RESET

P74

P73

AVSS

18

19

20

NU

NU

/RESET

/WE

P17

P16

21

22

23

KR11

KR10

KR9

VCC

+

16 1

BZ1

/CE

/ALE

41

P33

P34

P35

P36

P37

X

X

VSS

XT2

P04

AVREF

AVD

P10

P11

P12

P13

P15

P14

24

KR8

6A

UPD78045

STAMPJFRF

MD

R93

1M

4.19MHz

4

0

3

9

3

8

3

7

BUZ

3

6

3

5

2

3

4

1

3

3

3

2

3

1

3

0

2

9

D

2

8

2

7

KR5

2

6

KR6

2

5

KR7

R51

X2

33P

C16

C14

330K

X1

32.768KHz

330K

R50

VCC

VB

VDD

R131

12K

/WE

/ALE

CN10

NE CN

VCC

R92

4.7K

22P

CN9

D21

D18

D19

D20

KR11

ST3

ST4

ST1

ST2

C31

1000P

RMS

V:O

U:X

1HCKEY

1SS133*4

R52

56K

/CE

U:X

V:X

VCC

TEXT3

TEXT2

TEXT1

IC6,7,8,9

KID65003P

VP

A/ST1~DP/ST8

8 7 6 5 4

D

C

B

A

Page 16

D

C

B

A

12345678

2 1

POP UP LED CN * 1

CN1

PM CN

3

DIG1'DIG2'DIG3'DIG4'DIG5'DIG6'DIG7'

A'B'C'D'E'F'G'DP'

27

R24

27

R22

27

R20

27

R18

27

FND3 FND2 FND1

R16

3. POP-UP DISPLAY

D

FND4

27

R14

27

R12

27

R10

8 7 6 5 4

C

B

A

Page 17

4. PWB LAYOT

MAIN PWB LAYOUT

POP-UP PWB LAYOUT

Page 18

PARTS GUIDE

MODEL ER-A320

SRV key : LKGiM7113RCZZ

PRINTER : CR-812AII

(For "U" & "A" Version)

CONTENTS

ER-A320U/A

1 Exteriors

2 Keyboard unit

3 Packing material & Accessories

4 Drawer box unit(SK-423type)

5 Main PWB unit

6 Pop up PWB unit

7 Articles for consumption

8 Service route options

■ Index

Because parts marked with "!" are indispensable for the machine safety maintenance and poeration, it

must be replaced with the parts specific to the product specification.

SHARP CORPORATION

This document has been published to be

used for after sales service only.

The contents are subject to change without

notice.

Page 19

ER-A320U/A

1Exteriors

NO. PARTS CODE

GCOVA7128BHSA AZ

1

PCUT-6654BHZZ AE

2

LX-BZ6788BHZZ AD

3

GCOVH7124BHSD AF

4

PFILW6962BHZZ AU

5

GCABB7861BHZZ AN

6

CPWBF7504BH01 BC

7

QCNW-7815BHZZ AR

8

PFILW6961BHZZ AP

9

XHPSD30P06K00 AA

10

XBBSC30P08000 AA

11

HDECP2368BHZZ AN

12

TCAUZ6684BHZA AE

13

TCAUZ6685BHZB AF

GCABB7236BHZF BE

14

GFTAF6921BHSC AH

15

XEBSD30P08000 AA

16

QCNW-7805BHZZ AF

17

CPWBF2845BH01 BV

18

GCOVH7125BHSD AQ

19

XNESD30-24000 AA

20

XHBSD40P06000 AA

21

XBPBZ40P08K00 AA

22

! QACCD8411BHZZ AV

23

XJPSD30P16X00 AB

24

! RTRNP2411BHZZ BF

25

RCORF6698BHZZ AR

27

PCUSG1220BHZZ AE

29

XBPSD30P10KS0 AB

30

KI-OB2367RCZZ BX

31

LBNDJ2003SCZZ AA

32

QCNW-3066BHZZ AE

33

PSTM-6658RC01 AR

34

LX-BZ6769BHZZ AA

35

LX-BZ6781BHZZ AB

36

UBATZ6661BHZZ BA

37

PCUSG7017BHZZ AC

38

LBNDJ6636BHZZ AD

39

QCNW-3065BHZZ AE

40

QCNW-3057BHZZ AN

41

QCNW-3044BHZZ AE

42

QCNW-7451BHZZ AG

43

XJPSD30P12X00 AB

44

00B1009882/// AC

45

QTANP0004BHZA AE

46

LHLDW6841BHZZ AD

47

RCORF6712BHZZ AG

48

RCORF6704BHZZ AK

49

RCORF5029SCZZ AL

50

LHLDW6821BHZZ AD

51

PRICE

RANK

NEW

PART

MARK

RANK

N D Printer cover

C Paper cutter

CScrew

N D Battery cover

D Display filter

D Pop up cabinet

E Pop up LED PWB unit(NORMAL)

C P-Flat cable (15p)

D Pop up filter

CScrew (M3´6K)

CScrew (3´8)

N D Deco panel

D Caution label [U.S.A]

D Caution label [Canada]

N D Top cabinet

D Clerk cover A

CScrew (3´8)

C GND wire (PWB-K/B-DR)

N E Main PWB unit [include No.17]

N D Trans cover

C Nut (M3)

CScrew (4´6)

CScrew (4´8K)

B AC cord (SP-035)

CScrew (3´16X)

N B Power transformer (120V)

C Core (SC18B)

C Printer cushion

CScrew (3´10KS)

N E Prunter unit (CR812A2) [include No.45]

C Cable band

N C Earth wire

C Stamp(YOUR RECEIPT THANK YOU)

CScrew

CScrew (M3´16)

B Battery

C Battery cushion

C Battery band

N C GND wire

N C Printer cable (30P)

C Battery cable (NI-MH)

C Trans cable (2pin)

CScrew (3´12X)

C C.C.S. Screw (M3´5.5)

C Earth terminal

C Holder (11N)

C Core (OP14C)(RCORFOP14CHZZ)

N C Core (OP-16C)

C Core (SSC-452-12H)

C Q-clamp (S)

DESCRIPTION

– 1 –

Page 20

1Exteriors

ER-A320U/A

34

30

29

30

2

32

49

45

1

5

6

7

8

4

10

40

35

11

51

3

48

21

12

14

9

13

15

35

29

33

31

30

29

32

44

25

39

24

41

50

46

38

19

23

37

22

27

47

36

44

20

42

43

16

16

16

16

17

16

16

18

16

– 2 –

RCP00301

Page 21

ER-A320U/A

2 Keyboard unit

NO. PARTS CODE

LANGQ7604BHZZ AG

1

LKGIW0001BHZZ AS

2

QCNW-7804BHZZ AL

3

PHOG-1060CCZZ AA

4

XJPSD30P08000 AA

5

LKGIM7110BHZZ AE

6

LKGIM7111BHZZ AE

JKNBZ6897BHZZ AG

7

JKNBZ6896BHZA AG

8

JKNBZ6899BHZZ AH

9

JKNBZ6898BHZZ AH

10

JKNBZ6905BHZZ AF

JKNBZ6908BHZZ AK

JKNBZ6911BHZZ AK

JKNBZ6912BHZZ AK

JKNBZ6913BHZZ AK

JKNBZ6914BHZZ AK

11

JKNBZ6915BHZZ AK

JKNBZ6916BHZZ AK

JKNBZ6917BHZZ AK

JKNBZ6918BHZZ AK

JKNBZ6919BHZZ AK

JKNBZ6920BHZZ AK

JKNBZ6901BHZA AL

12

JKNBZ6900BHZA AN

13

LFRM-6700BHZZ BB

14

PGUMM6725BHZZ AZ

15

PSHEP6844BHZZ BC

16

LPLTM6705BHZZ AX

17

XEBSD30P06000 AA

18

LHLDZ6837BHZZ AE

19

LHLDZ6836BHZZ AE

20

CLABH2516BHZZ AX

101

DUNTK3986BHZZ BP

501

PRICE

RANK

NEW

PART

MARK

RANK

C Mode sw angle

B Mode switch(Body)

C Mode cable

C Display cushion

CScrew (3´8)

B MA key (MA)

B OP key (OP)

C Key cap (1´1)

C Key top (1´1)

C Key cap (1´2)

C Key top (1´2)

C Key top (0)

C Key top (.)

C Key top (1)

C Key top (2)

C Key top (3)

C Key top (4)

C Key top (5)

C Key top (6)

C Key top (7)

C Key top (8)

C Key top (9)

C Key top (00)

C Key cap (2´2)

C Key top (2´2)

D Key frame

C Key rubber

C Key sheet unit

C Key plate

CScrew (3´6)

C Holder L (YELLOW)

C Holder R (WHITE)

N D Key label

N E Keyboard [include No.7~17,19,20,101]

DESCRIPTION

3 Packing material & Accessories

PRICE

NO. PARTS CODE

SPAKA8367BHZZ AT

1

PSHEP6681BHZZ AF

2

SPAKA8366BHZZ AT

3

SPAKC3114BHZZ BB

4

SSAKH4231CCZZ AA

5

SSAKH3015CCZZ AA

6

TINSE2400BHZZ AV

7

TINSK2401BHZZ AZ

UINK-1001CCZZ AK

8

SSAKH3012CCZZ AA

10

LKGIM7331BHZZ AE

11

LKGIM7110BHZZ AE

12

LKGIM7111BHZZ AE

TCADH6795BHZZ AC

13

TCADH6788BHZA AC

UBNDA6630BHZZ AK

14

00BF703301010 AQ

15

RANK

NEW

MARK

N D Packing case

N D Instruction book [U.S.A]

N D Instruction book [Canada]

PART

RANK

D Packing add L

C Packing sheet

D Packing add R

D Vinyl bag (140´500mm)

D Vinyl bag (260´360 30U)

S Ink for stamp (5cc)

D Vinyl bag (80´120mm)

B Lock key (1pc)

B MA key (MA)

B OP key (OP)

D Caution card (Red) [U.S.A]

D Caution card (Black) [Canada]

C AC cord band

C Paper rolling shaft

DESCRIPTION

– 3 –

Page 22

2 Keyboard unit

ER-A320U/A

6

5

5

1

2

3

7

8

19

9

10

20

12

11

13

4

14

20

19

19

15

20

16

17

18

501

18

3 Packing material & Accessories

6

7

8

15

12

1

10

18

18

2

RCP00302

3

14

5

13

11

– 4 –

4

RCP00303

Page 23

ER-A320U/A

4 Drawer box unit(SK-423type)

PRICE

NO. PARTS CODE

CCABM7245BH03 BL

1

CCABM7251BH04 BL

PGUMM6695BHZZ AE

3

NROLP6650BHZZ AP

4

XUBSD30P08000 AA

5

LBRC-6666BHZZ AQ

6

MSPRT6714BHZZ AE

7

MLEVF6695BHZZ AK

8

PSKR-6629BHZZ AL

9

SSAKA5004CCZZ AA

10

PSKR-6628BHZZ AG

11

GCAS-6682BHZZ AZ

12

LX-BZ6776BHZZ AA

13

QSW-M6872BHZZ AR

14

CPLU-6647BH01 AY

15

CFRM-6683BH01 AW

16

LX-BZ6775BHZZ AA

17

MSPRT6713BHZZ AD

18

XRESJ50-06000 AA

20

MCAMM6633BHZA AE

21

LFRM-6682BHZZ AN

22

XWSSD40-10000 AA

23

XNESD40-32000 AA

24

PGUMM6696BHZZ AE

25

XHBSD30P12000 AA

26

MSPRC6712BHZZ AF

27

NROLP6650BHZZ AP

28

XNESD60-50000 AA

29

XWSSD60-15000 AA

30

GDRW-6680BHZZ BE

31

GDRW-6678BHZZ BF

GCOVA7146BHZZ AV

32

LKGIW7330BHZZ AY

33

PRNGT6637BHZZ AA

34

LKGIM7331BHZZ AE

35

MSPRK6718BHZZ AF

36

LPLTM6674BH01 AX

37

LPLTM6674BHZE AZ

SPAKA8255BHZZ AC

38

XHBSD40P12000 AA

39

MSPRB6711BHZZ AD

40

XHPSC30P08000 AA

41

DUNT-1306BHZA AX

42

GCAS-6678BHZZ BC

57

LBRC-6663BHZZ AQ

58

CCAS-6682BH01 BF

501

GDRW-6682BHZZ BH

502

GDRW-6684BHZZ BH

CLOK-6676BH01 BH

503

CFRM-6682BH02 AQ

504

CCAS-6678BH01 BF

505

(Unit)

GBOXD7139BH01 BX

901

GBOXD7144BH01 BY

RANK

NEW

MARK

N D Cabinet frame unit [U.S.A]

N D Cabinet frame unit [Canada]

N E Drawer box unit (SK-423 5B/5C) [U.S.A]

N E Drawer box unit (SK-423 4B/8C) [Canada]

PART

RANK

C Stopper gum

C Roller

CScrew (3´8)

C Bracket (for 5B) [U.S.A]

C Bill spring

C Bill lever

C Bill separator [Canada]

D Vinyl bag (100´300mm) [Canada]

C Separator [Canada]

D Money case (5B/5C) [U.S.A]

CScrew

B Micro switch

B Solenoid + Drawer cable

E Lock frame unit

CScrew (3´5)

C Open lever spring

C E type ring (5mm)

C Lock cam

D Bell frame

C Washer

C Nut (M4)

C Gum leg

CScrew (3´12)

C Push out spring

C Roller

C Nut (M6)

C Washer (6mm)

D Drawer case frame unit [U.S.A]

D Drawer case frame unit [Canada]

D Front cover

B Lock key (body)

C Key ring

B Lock key (1pc)

C Lock key spring

D Bottom plate [U.S.A]

D Bottom plate [Canada]

D Paper pad

CScrew (4´12)

C Earth spring

CScrew (3´8)

E Lock key unit

D Money case (4B/8C) [Canada]

C Bill bracket (for4B) [Canada]

E Money case unit (5B/5C) [U.S.A]

E Drawer case unit (for 5B/5C) [U.S.A]

E Drawer case unit (for 4B/8C) [Canada]

E Lock unit

E Bell frame unit (include No.22,26,27)

E Money case unit [Canada]

DESCRIPTION

– 5 –

Page 24

4 Drawer box unit(SK-423type)

ER-A320U/A

15

1

22

17

18

28

16

24

25

23

26

30

29

29

27

15

30

20

504

13

14

28

503

21

3

5

5

58

5

7

8

5

9

10

11

57

for CANADA

31

36

33

34

35

32

501

505

502

5

38

42

5

5

5

for U.S.A.

5

6

7

8

25

39

37

25

39

40

25

39

41

– 6 –

38

12

RCP00304

Page 25

ER-A320U/A

5 Main PWB unit

NO. PARTS CODE

LX-BZ6644RCZZ AA

1

PRDAF6666BHZZ AN

2

QCNCM1101BHZZ AC

3

QCNCM7057BHZZ AB

4

QCNCW2822BH3J AH

5

QCNCW6882BH1A AG

6

QCNCW7081BHZZ AB

7

QCNCW7118BH0H AG

8

QCNCW7118BH0I AG

9

QCNCW7201BH1E AK

10

QCNW-7805BHZZ AF

11

QCNW-7811BHZZ AM

12

QCNW-7824BHZZ AE

13

! QFS-H0001QCZZ AG

14

! QFS-B0323QCZZ AC

15

QFSHD2109AFZZ AC

16

RALMB6646BHZZ AQ

17

RC-EZ106ARC1A AD

18

RC-KZ1054CCZZ AB

19

RC-Z1N104RCZZ AA

20

RCILC6647RCZZ AE

21

RCRM-7001BHZZ AH

22

RCRSP6676RCZZ AG

23

RMPTC8563QCJB AC

24

VCCCPU1HH220J AA

25

VCCCPU1HH330J AB

26

VCEAGA1CW106M AA

27

VCEAGA1CW107M AC

28

VCEAGA1CW226M AB

29

VCEAGA1CW337M AB

30

VCEAGA1HW335M AB

31

VCEAGD1CW108M AE

32

VCEAGD1HW337M AF

33

VCEAGU1HC688M AY

34

VCKYPU1HB102K AA

35

VCKYPU1HB221K AB

36

VCKYPU1HB331K AA

37

VCKYPU1HB332K AA

38

VCQYNA1HM333K AA

39

VHD1N4002G/-1 AA

40

VHD1D4B42//-1 AD

41

VHDDSS133HV-1 AA

42

VHDPS102R//-1 AD

43

VHDRB441Q40-1 AD

44

VHEMTZ20D//-1 AA

45

VHERD6.2EB/-1 AD

46

VHEMTZJ18B+-1 AC

47

VHID78045F097 AY

48

VHILH52B256N9 AW

49

VHIMC34063AM1 AG

50

VHIKID65003AP AE

51

VHIMC74HC373N AK

52

VHPHDSP5621-1 AM

53

VRD-RC2EY000J AA

54

VRD-RC2EY000J AA

VRD-RC2EY100J AA

55

VRD-RC2EY101J AA

56

VRD-RC2EY102G AA

57

VRD-RC2EY102J AA

58

VRD-RC2EY104J AA

59

VRD-RC2EY105J AA

60

VRD-RC2EY121J AA

61

VRD-RC2EY123J AA

62

VRD-RC2EY153J AA

63

VRD-RC2EY221J AA

64

VRD-RC2EY222J AA

65

VRD-RC2EY223J AA

66

VRD-RC2EY272J AA

67

VRD-RC2EY300J AA

68

VRD-RC2EY334J AA

69

VRD-RC2EY362G AA

70

VRD-RC2EY392J AA

71

VRD-RC2EY471J AA

72

VRD-RC2EY472J AA

73

VRD-RC2EY563J AA

74

VRS-RE3DA221J AB

75

VSKTA1271//-1 AE

76

VS2SB1243++-1 AG

77

VS2SB1340//-1 AL

78

VS2SB926-S/TC AD

79

PRICE

RANK

NEW

PART

MARK

RANK

C Screw (3.5´8S)(LX-BZ6644BHZZ) [for HEAT SINK fixed]

C Hheat sink [HEAT SINK]

C Connector (5273-02A)(2P) [CN1]

C Connector (5045-3)(3pin) [CN11]

N C Connector (PR)(MLX 52045-3045) [CN12]

C Connector (11P)(52011-1110)(ST TYPE) [CN7]

C Connector (2P)(5267-02A)(Blue) [CN2]

C Connector (8P)(5229-08CPB) [CN5]

C Connector (K/B)(9P)(5229-09CPB) [CN8]

C Connector (15P)(52806-1510) [CN15]

C GND wire (PWB-K/B-DR)

C F-LED cable (18P) [CN14,14-1]

C GND wire

N A Fuse (UL/CSA 4.0A 125V 52SB) [F2]

A Fuse (UL125V 2A) [F1]

C Fuse holder (HD2109AF) [F1]

B Buzzer [BZ1]

C Capacitor (10WV 10mF) [C19]

C Capacitor (10WV 0.1mF) [C6,11,34,35]

C Capacitor (12WV 0.1mF)(RC-Z1N104BHZZ) [C12,23,26]

C Coil (220mH)(RCH-110)(RCILC6647BHZZ) [L1]

B X-TAL (4.19MHz) [X2]

B Crystal (DT38 32.768KHz) [X1]

B Block resistor (56KW´8 1/8W ±5%) [RA2]

C Capacitor (50WV 22PF)(VCCCPA1HH220J) [C16]

C Capacitor (50WV 33pF)(VCCCPA1HH330J) [C14]

C Capacitor (16WV 10mF) [C13,27,29,39]

C Capacitor (16WV 100mF) [C40,41]

C Capacitor (16WV 22mF) [C18,42]

C Capacitor (16WV 330mF) [C9,10]

C Capacitor (50WV 3.3mF) [C5]

C AL Capacitor (1000mF/16V) [C8]

C Capacitor (50WV 330mF) [C4]

N C Capacitor (50WV 6800mF) [C2]

C Capacitor (50WV 0.001mF)(VCKYPA1HB102K) [C24,31,37]

C Capacitor (50WV 220pF)(VCKYPA1HB221K) [C7,32]

C Capacitor (50WV 330pF)(VCKYPA1HB331K) [C25,28]

C Capacitor (50WV 3300pF)(VCKYPA1HB332K) [C36]

C Capacitor (50WV 0.033mF) [C1]

B Diode (1N4002G) [D6,28,29]

B Diode (1D4B42)(VHDDI102/BH-1) [BD1]

B Diode (DSS133HV) [D3,7,9~17,24]

B Diode (PS102R) [D4]

B Diode (RB441Q-40) [D30,31,32]

B Zener diode (MTZ20D) [ZD1]

B Zener diode (RD6.2EB)(VHEMTZ6.2B/-1) [ZD5]

B Zener diode (MTZJ18B) [ZD2]

N B CPU (D78045F097) [IC2]

B IC (SRAM 256K 8´32K 100ns)(VHIG76C256F70) [IC4]

B IC (MC34063AM1)(VHIKA34063A-1) [IC1]

B IC (KD65003AP) [IC5~9]

B IC (MC74HC373)(VHISN74HC373N) [IC3]

B LED (2SEG)(HDSP5621) [FND1~5]

C Resistor (1/4W 0W ±5%) [R139,141]

C Resistor (1/4W 0W ±5%) [R140]

C Resistor (1/4W 10W ±5%) [R6]

C Resistor (1/4W 100W ±5%) [R9]

C Resistor (1/4W 1KW ±2%)(VRD-RC2EY102F) [R8]

C Resistor (1/4W 1.0KW ±5%) [R53,58,59,76,77,133,136,137]

C Resistor (1/4W 100KW ±5%) [R5]

C Resistor (1/4W 1.0MW ±5%) [R93,101]

C Resistor (1/4W 120W ±5%) [R138]

C Resistor (1/4W 12KW ±5%) [R1,39,121~132]

C Resistor (1/4W 15KW ±5%) [R54,55]

C Resistor (1/4W 220W ±5%) [R111~120]

C Resistor (1/4W 2.2KW ±5%) [R11,13,15,17,19,21,23,25,27,29,38]

C Resistor (1/4W 22KW ±5%) [R68,71,80]

C Resistor (1/4W 2.7KW ±5%) [R4,79,81,82,84]

C Resistor (1/4W 30W ±5%) [R30~37]

C Resistor (1/4W 330KW ±5%) [R50,51]

C Resistor (1/4W 3.6KW ±2%)(VRD-RC2EY362F) [R7]

C Resistor (1/4W 3.9KW ±5%) [R2]

C Resistor (1/4W 470W ±5%) [R78]

C Resistor (1/4W 4.7KW ±5%) [R57,92,135]

C Resistor (1/4W 56KW ±5%) [R3,40,52,102]

C Resistor (2W 220W ±5%) [R83,85]

B Transistor (KTA1271)(VS2SA1271-/-1) [Q31,32,33]

N B Transistor (2SB1243) [Q15]

B Transistor (2SB1340) [Q17]

B Transistor (2SB926-S/TC)(KA1270)(VSKTA1270//-1) [Q18,19,20,34~40]

DESCRIPTION

– 7 –

Page 26

5 Main PWB unit

NO. PARTS CODE

VSDSC001-//-1 AA

80

VS2SC3784-/-1 AD

81

VS2SC4153-/-1 AG

82

VSKTC1027//-1 AG

83

VSKTD1414//-1 AL

84

XBPSD30P06000 AA

85

(Unit)

CPWBF2845BH01 BV

901

PRICE

RANK

6 Pop up PWB unit

NO. PARTS CODE

QCNCW7202BH1E AK

1

VHPHDSP5621-1 AM

2

VRD-RC2EY270J AA

3

CPWBF7504BH01 BC

901

PRICE

RANK

7 Articles for consumption

NO. PARTS CODE

DPAPR1006CSZZ AR

1

NROLR6638RCZZ AY

2

UINK-1001CCZZ AK

3

PRICE

RANK

ER-A320U/A

NEW

PART

MARK

RANK

B Transistor (2SC3198)(VS2SC3198-/-1) [Q3~13,16]

B Transistor (2SC3784) [Q21]

B Transistor (2SC4153) [Q1]

N B Transistor (KTC1027) [Q42]

B Transistor (KTD1414) [Q2]

CScrew (3´6) [for TR fixed]

N E Main PWB unit

NEW

PART

MARK

RANK

C Connector (52807-1510) [CN1]

B LED (2SEG)(HDSP5621) [FND1,2,3,4]

C Resistor (1/4W 27W ±5%) [R10,12,14,16,18,20,22,24]

E Pop up PWB unit (NORMAL)

NEW

PART

MARK

RANK

S Roll paper (5roll/pack)

S Ink roller (purple)

S Ink for stamp (5cc)

DESCRIPTION

DESCRIPTION

DESCRIPTION

8 Service route options

NO. PARTS CODE

LKGIM7113RCZZ AK

1

LKGIM7126RCZZ AL

2

GCOVH7126BHZZ BE

3

PRICE

RANK

NEW

MARK

PART

RANK

S Service key

S Mode key grip cover [OP key only]

S Drip-proof keyboard cover

DESCRIPTION

– 8 –

Page 27

ER-A320U/A

■ Index

PARTS CODE NO.

[C]

CCABM7245BH03

CCABM7251BH04

CCAS-6678BH01

CCAS-6682BH01

CFRM-6682BH02

CFRM-6683BH01

CLABH2516BHZZ

CLOK-6676BH01

CPLU-6647BH01

CPWBF2845BH01

"

CPWBF7504BH01

"

[D]

DPAPR1006CSZZ

DUNT-1306BHZA

DUNTK3986BHZZ

[G]

GBOXD7139BH01

GBOXD7144BH01

GCABB7236BHZF

GCABB7861BHZZ

GCAS-6678BHZZ

GCAS-6682BHZZ

GCOVA7128BHSA

GCOVA7146BHZZ

GCOVH7124BHSD

GCOVH7125BHSD

GCOVH7126BHZZ

GDRW-6678BHZZ

GDRW-6680BHZZ

GDRW-6682BHZZ

GDRW-6684BHZZ

GFTAF6921BHSC

[H]

HDECP2368BHZZ

[J]

JKNBZ6896BHZA

JKNBZ6897BHZZ

JKNBZ6898BHZZ

JKNBZ6899BHZZ

JKNBZ6900BHZA

JKNBZ6901BHZA

JKNBZ6905BHZZ

JKNBZ6908BHZZ

JKNBZ6911BHZZ

JKNBZ6912BHZZ

JKNBZ6913BHZZ

JKNBZ6914BHZZ

JKNBZ6915BHZZ

JKNBZ6916BHZZ

JKNBZ6917BHZZ

JKNBZ6918BHZZ

JKNBZ6919BHZZ

JKNBZ6920BHZZ

[K]

KI-OB2367RCZZ

[L]

LANGQ7604BHZZ

LBNDJ2003SCZZ

LBNDJ6636BHZZ

LBRC-6663BHZZ

LBRC-6666BHZZ

LFRM-6682BHZZ

LFRM-6700BHZZ

LHLDW6821BHZZ

LHLDW6841BHZZ

LHLDZ6836BHZZ

LHLDZ6837BHZZ

LKGIM7110BHZZ

"

LKGIM7111BHZZ

"

LKGIM7113RCZZ

LKGIM7126RCZZ

LKGIM7331BHZZ

"

LKGIW0001BHZZ

4- 1

4- 1

4-505

4-501

4-504

4- 16

2-101

4-503

4- 15

1- 18

5-901

1- 7

6-901

7- 1

4- 42

2-501

4-901

4-901

1- 14

1- 6

4- 57

4- 12

1- 1

4- 32

1- 4

1- 19

8- 3

4- 31

4- 31

4-502

4-502

1- 15

1- 12

2- 8

2- 7

2- 10

2- 9

2- 13

2- 12

2- 11

2- 11

2- 11

2- 11

2- 11

2- 11

2- 11

2- 11

2- 11

2- 11

2- 11

2- 11

1- 31

2- 1

1- 32

1- 39

4- 58

4- 6

4- 22

2- 14

1- 51

1- 47

2- 20

2- 19

2- 6

3- 12

2- 6

3- 12

8- 1

8- 2

3- 11

4- 35

2- 2

PRICE

RANK

BL

BL

BF

BF

AQ

AW

AX

BH

AY

BV

BV

BC

BC

AR

AX

BP

BX

BY

BE

AN

BC

AZ

AZ

AV

AF

AQ

BE

BF

BE

BH

BH

AH

AN

AG

AG

AH

AH

AN

AL

AF

AK

AK

AK

AK

AK

AK

AK

AK

AK

AK

AK

BX

AG

AA

AD

AQ

AQ

AN

BB

AD

AD

AE

AE

AE

AE

AE

AE

AK

AL

AE

AE

AS

NEW

PART

MARK

RANK

ND

ND

E

E

E

E

ND

E

B

NE

NE

E

E

S

E

NE

NE

NE

ND

D

D

D

ND

D

ND

ND

S

D

D

E

E

D

ND

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

NE

C

C

C

C

C

D

D

C

C

C

C

B

B

B

B

S

S

B

B

B

PARTS CODE NO.

LKGIW7330BHZZ

LPLTM6674BH01

LPLTM6674BHZE

LPLTM6705BHZZ

LX-BZ6644RCZZ

LX-BZ6769BHZZ

LX-BZ6775BHZZ

LX-BZ6776BHZZ

LX-BZ6781BHZZ

LX-BZ6788BHZZ

[M]

MCAMM6633BHZA

MLEVF6695BHZZ

MSPRB6711BHZZ

MSPRC6712BHZZ

MSPRK6718BHZZ

MSPRT6713BHZZ

MSPRT6714BHZZ

[N]

NROLP6650BHZZ

"

NROLR6638RCZZ

[P]

PCUSG1220BHZZ

PCUSG7017BHZZ

PCUT-6654BHZZ

PFILW6961BHZZ

PFILW6962BHZZ

PGUMM6695BHZZ

PGUMM6696BHZZ

PGUMM6725BHZZ

PHOG-1060CCZZ

PRDAF6666BHZZ

PRNGT6637BHZZ

PSHEP6681BHZZ

PSHEP6844BHZZ

PSKR-6628BHZZ

PSKR-6629BHZZ

PSTM-6658RC01

[Q]

QACCD8411BHZZ

QCNCM1101BHZZ

QCNCM7057BHZZ

QCNCW2822BH3J

QCNCW6882BH1A

QCNCW7081BHZZ

QCNCW7118BH0H

QCNCW7118BH0I

QCNCW7201BH1E

QCNCW7202BH1E

QCNW-3044BHZZ

QCNW-3057BHZZ

QCNW-3065BHZZ

QCNW-3066BHZZ

QCNW-7451BHZZ

QCNW-7804BHZZ

QCNW-7805BHZZ

"

QCNW-7811BHZZ

QCNW-7815BHZZ

QCNW-7824BHZZ

QFS-B0323QCZZ

QFS-H0001QCZZ

QFSHD2109AFZZ

QSW-M6872BHZZ

QTANP0004BHZA

[R]

RALMB6646BHZZ

RC-EZ106ARC1A

RC-KZ1054CCZZ

RC-Z1N104RCZZ

RCILC6647RCZZ

RCORF5029SCZZ

RCORF6698BHZZ

RCORF6704BHZZ

RCORF6712BHZZ

RCRM-7001BHZZ

RCRSP6676RCZZ

RMPTC8563QCJB

RTRNP2411BHZZ

4- 33

4- 37

4- 37

2- 17

5- 1

1- 35

4- 17

4- 13

1- 36

1- 3

4- 21

4- 8

4- 40

4- 27

4- 36

4- 18

4- 7

4- 4

4- 28

7- 2

1- 29

1- 38

1- 2

1- 9

1- 5

4- 3

4- 25

2- 15

2- 4

5- 2

4- 34

3- 2

2- 16

4- 11

4- 9

1- 34

1- 23

5- 3

5- 4

5- 5

5- 6

5- 7

5- 8

5- 9

5- 10

6- 1

1- 42

1- 41

1- 40

1- 33

1- 43

2- 3

1- 17

5- 11

5- 12

1- 8

5- 13

5- 15

5- 14

5- 16

4- 14

1- 46

5- 17

5- 18

5- 19

5- 20

5- 21

1- 50

1- 27

1- 49

1- 48

5- 22

5- 23

5- 24

1- 25

PRICE

RANK

AY

AX

AZ

AX

AA

AA

AA

AA

AB

AD

AE

AK

AD

AF

AF

AD

AE

AP

AP

AY

AE

AC

AE

AP

AU

AE

AE

AZ

AA

AN

AA

AF

BC

AG

AL

AR

AV

AC

AB

AH

AG

AB

AG

AG

AK

AK

AE

AN

AE

AE

AG

AL

AF

AF

AM

AR

AE

AC

AG

AC

AR

AE

AQ

AD

AB

AA

AE

AL

AR

AK

AG

AH

AG

AC

BF

NEW

PART

MARK

RANK

B

D

D

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

S

C

C

C

D

D

C

C

C

C

C

C

C

C

C

C

C

B

C

C

NC

C

C

C

C

C

C

C

NC

NC

NC

C

C

C

C

C

C

C

A

NA

C

B

C

B

C

C

C

C

C

C

NC

C

B

B

B

NB

– 9 –

Page 28

PARTS CODE NO.

[S]

SPAKA8255BHZZ

SPAKA8366BHZZ

SPAKA8367BHZZ

SPAKC3114BHZZ

SSAKA5004CCZZ

SSAKH3012CCZZ

SSAKH3015CCZZ

SSAKH4231CCZZ

[T]

TCADH6788BHZA

TCADH6795BHZZ

TCAUZ6684BHZA

TCAUZ6685BHZB

TINSE2400BHZZ

TINSK2401BHZZ

[U]

UBATZ6661BHZZ

UBNDA6630BHZZ

UINK-1001CCZZ

"

[V]

VCCCPU1HH220J

VCCCPU1HH330J

VCEAGA1CW106M

VCEAGA1CW107M

VCEAGA1CW226M

VCEAGA1CW337M

VCEAGA1HW335M

VCEAGD1CW108M

VCEAGD1HW337M

VCEAGU1HC688M

VCKYPU1HB102K

VCKYPU1HB221K

VCKYPU1HB331K

VCKYPU1HB332K

VCQYNA1HM333K

VHD1D4B42//-1

VHD1N4002G/-1

VHDDSS133HV-1

VHDPS102R//-1

VHDRB441Q40-1

VHEMTZ20D//-1

VHEMTZJ18B+-1

VHERD6.2EB/-1

VHID78045F097

VHIKID65003AP

VHILH52B256N9

VHIMC34063AM1

VHIMC74HC373N

VHPHDSP5621-1

"

VRD-RC2EY000J

VRD-RC2EY100J

VRD-RC2EY101J

VRD-RC2EY102G

VRD-RC2EY102J

VRD-RC2EY104J

VRD-RC2EY105J

VRD-RC2EY121J

VRD-RC2EY123J

VRD-RC2EY153J

VRD-RC2EY221J

VRD-RC2EY222J

VRD-RC2EY223J

VRD-RC2EY270J

VRD-RC2EY272J

VRD-RC2EY300J

VRD-RC2EY334J

VRD-RC2EY362G

VRD-RC2EY392J

VRD-RC2EY471J

VRD-RC2EY472J

VRD-RC2EY563J

VRS-RE3DA221J

VS2SB1243++-1

VS2SB1340//-1

VS2SB926-S/TC

VS2SC3784-/-1

VS2SC4153-/-1

VSDSC001-//-1

4- 38

3- 3

3- 1

3- 4

4- 10

3- 10

3- 6

3- 5

3- 13

3- 13

1- 13

1- 13

3- 7

3- 7

1- 37

3- 14

3- 8

7- 3

5- 25

5- 26

5- 27

5- 28

5- 29

5- 30

5- 31

5- 32

5- 33

5- 34

5- 35

5- 36

5- 37

5- 38

5- 39

5- 41

5- 40

5- 42

5- 43

5- 44

5- 45

5- 47

5- 46

5- 48

5- 51

5- 49

5- 50

5- 52

5- 53

6- 2

5- 54

5- 55

5- 56

5- 57

5- 58

5- 59

5- 60

5- 61

5- 62

5- 63

5- 64

5- 65

5- 66

6- 3

5- 67

5- 68

5- 69

5- 70

5- 71

5- 72

5- 73

5- 74

5- 75

5- 77

5- 78

5- 79

5- 81

5- 82

5- 80

PRICE

RANK

AC

AT

AT

BB

AA

AA

AA

AA

AC

AC

AE

AF

AV

AZ

BA

AK

AK

AK

AA

AB

AA

AC

AB

AB

AB

AE

AF

AY

AA

AB

AA

AA

AA

AD

AA

AA

AD

AD

AA

AC

AD

AY

AE

AW

AG

AK

AM

AM

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AA

AB

AG

AL

AD

AD

AG

AA

NEW

PART

MARK

RANK

D

D

D

ND

D

D

D

D

D

D

D

D

ND

ND

B

C

S

S

C

C

C

C

C

C

C

C

C

NC

C

C

C

C

C

B

B

B

B

B

B

B

B

NB

B

B

B

B

B

B

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

NB

B

B

B

B

B

PARTS CODE NO.

VSKTA1271//-1

VSKTC1027//-1

VSKTD1414//-1

[X]

XBBSC30P08000

XBPBZ40P08K00

XBPSD30P06000

XBPSD30P10KS0

XEBSD30P06000

XEBSD30P08000

XHBSD30P12000

XHBSD40P06000

XHBSD40P12000

XHPSC30P08000

XHPSD30P06K00

XJPSD30P08000

XJPSD30P12X00

XJPSD30P16X00

XNESD30-24000

XNESD40-32000

XNESD60-50000

XRESJ50-06000

XUBSD30P08000

XWSSD40-10000

XWSSD60-15000

[0]

00B1009882///

00BF703301010

5- 76

5- 83

5- 84

1- 11

1- 22

5- 85

1- 30

2- 18

1- 16

4- 26

1- 21

4- 39

4- 41

1- 10

2- 5

1- 44

1- 24

1- 20

4- 24

4- 29

4- 20

4- 5

4- 23

4- 30

1- 45

3- 15

PRICE

RANK

AE

AG

AL

AA

AA

AA

AB

AA

AA

AA

AA

AA

AA

AA

AA

AB

AB

AA

AA

AA

AA

AA

AA

AA

AC

AQ

NEW

PART

MARK

RANK

B

NB

B

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

ER-A320U/A

– 10 –

Page 29

ER-A320U/A

COPYRIGHT C 1999 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Information Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-11, Japan

1999 September Printed in Japan S

Page 30

COPYRIGHT ã 1999 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Information Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 September Printed in Japan

Loading...

Loading...