Page 1

SERVICE MANUAL VCR/DVD COMBINATION MODEL

DV-NC55U/C/M

SERVICE MANUAL

S61U2DV-NC55U

VCR/D VD COMBINATION MODEL

REW PLAY

EJECT/ STOP

POWER

/

L(MONO)-AUDIO-RAV 2 IN VDEO

1. IMPORTANT SERVICE NOTES........................................................................................................ 2

2. FEATURES........................................................................................................................................ 4

3. SPECIFICATIONS ............................................................................................................................. 4

4. PART NAMES.................................................................................................................................... 6

MODELS DV-NC55U/C/M

5. MAINTENANCE CHECK ITEMS AND EXECUTION TIME ............................................................... 9

6. DISASSEMBLY METHOD ............................................................................................................... 10

7. OPERATION OF PICKUP ............................................................................................................... 14

8. ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS ............................ 15

9. TEST MODE .................................................................................................................................... 38

10. TROUBLESHOOTING..................................................................................................................... 41

11. IC FUNCTION LIST ......................................................................................................................... 52

12. BLOCK DIAGRAMS......................................................................................................................... 76

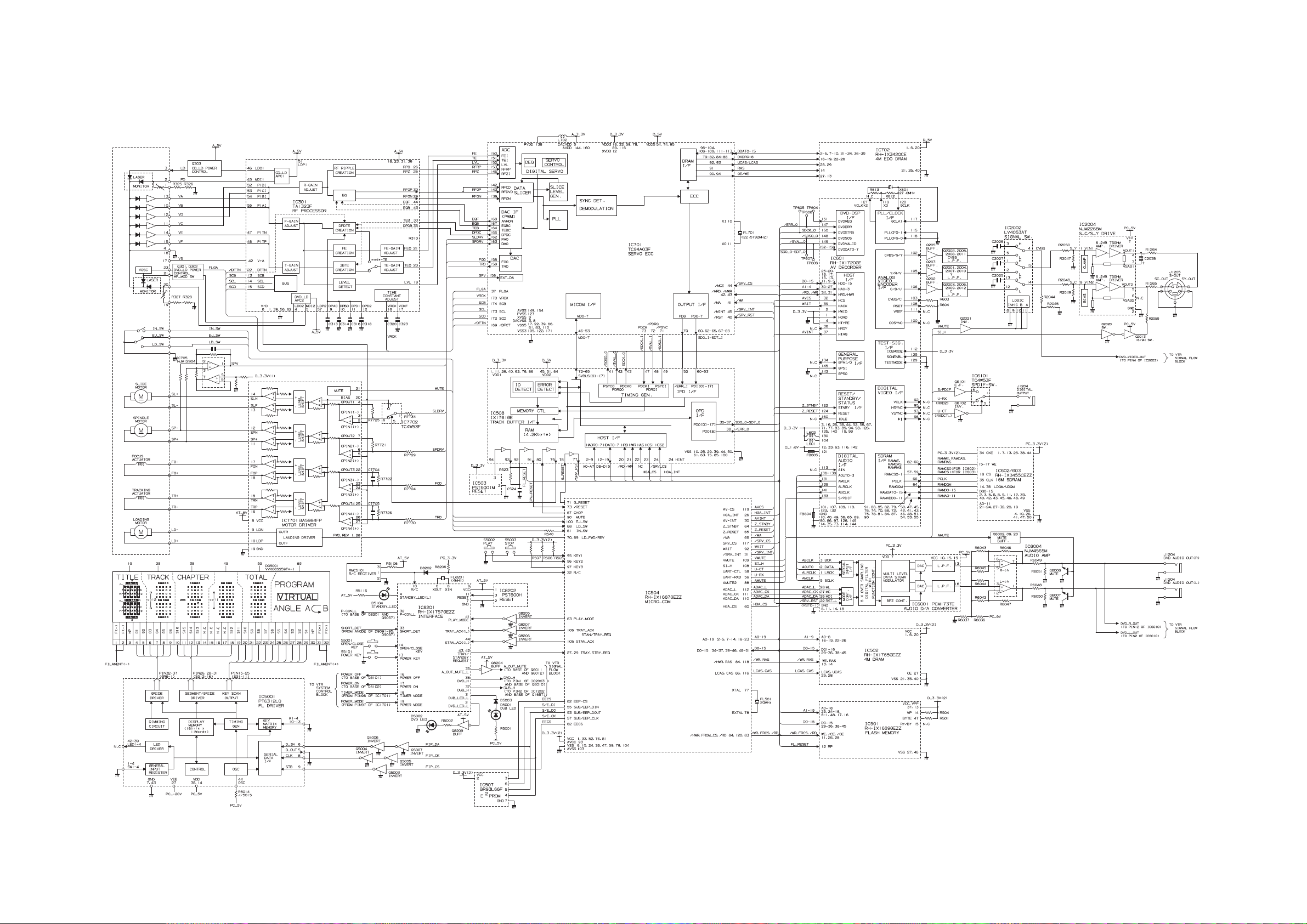

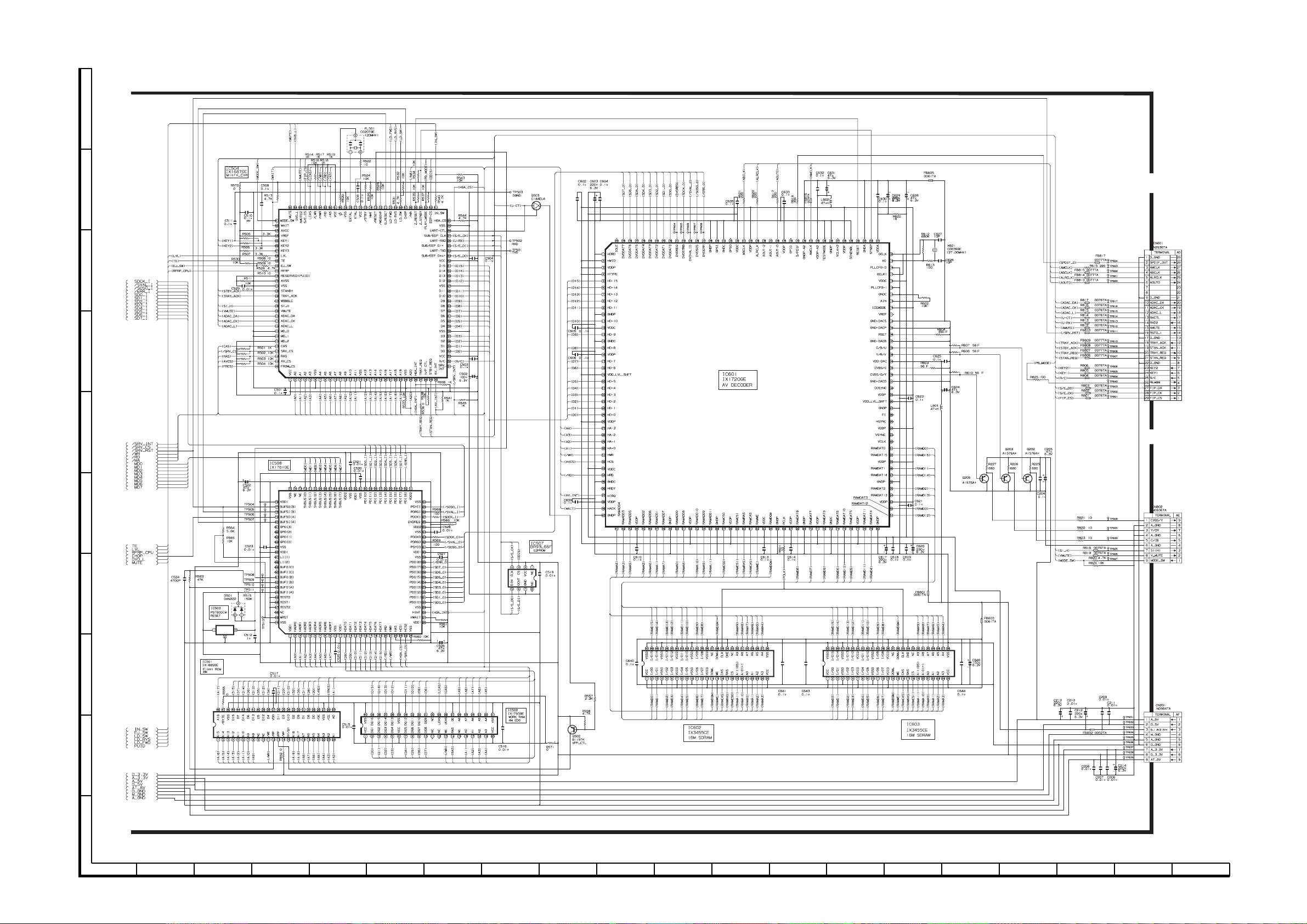

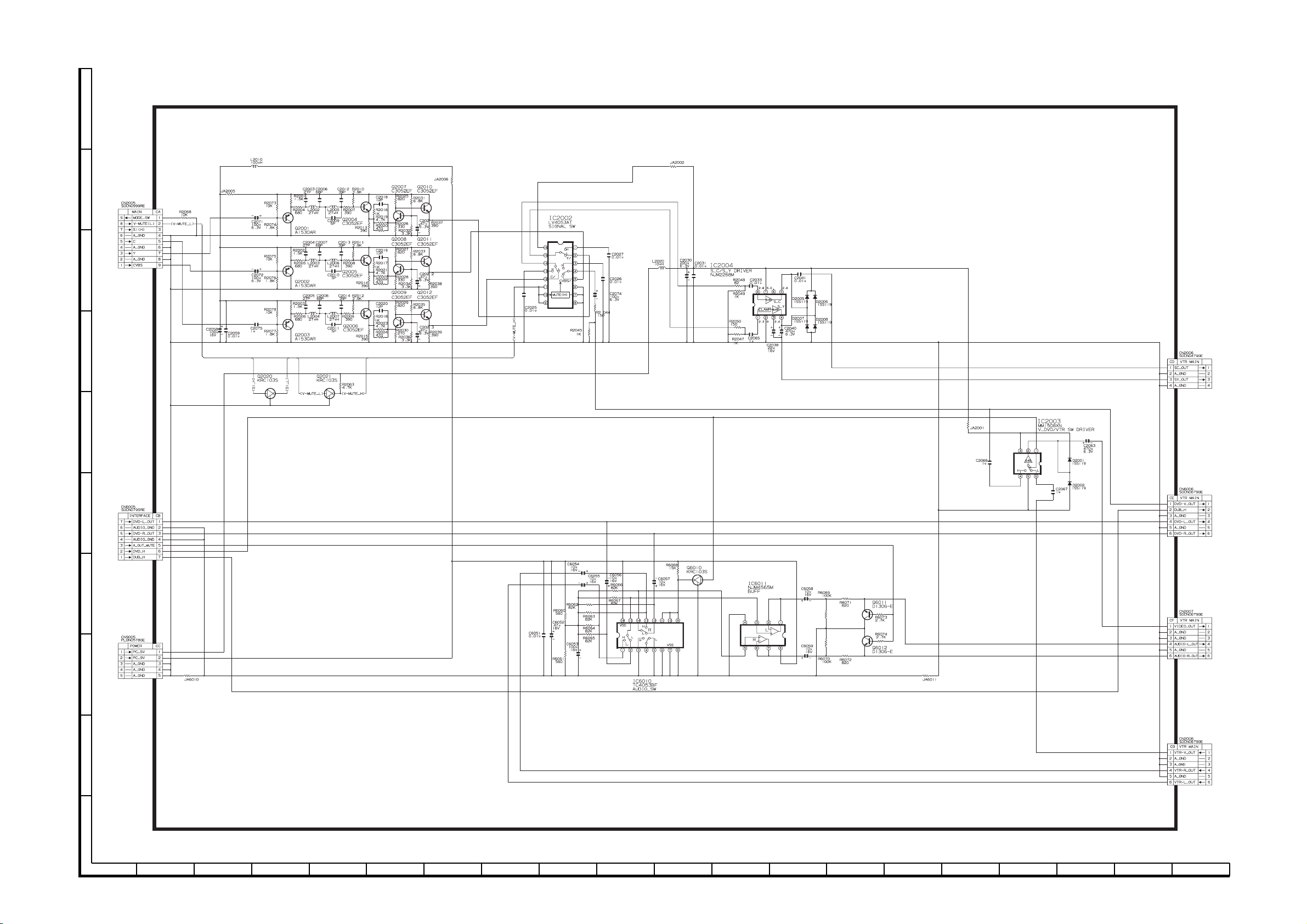

13. SCHEMATIC DIAGRAMS................................................................................................................ 84

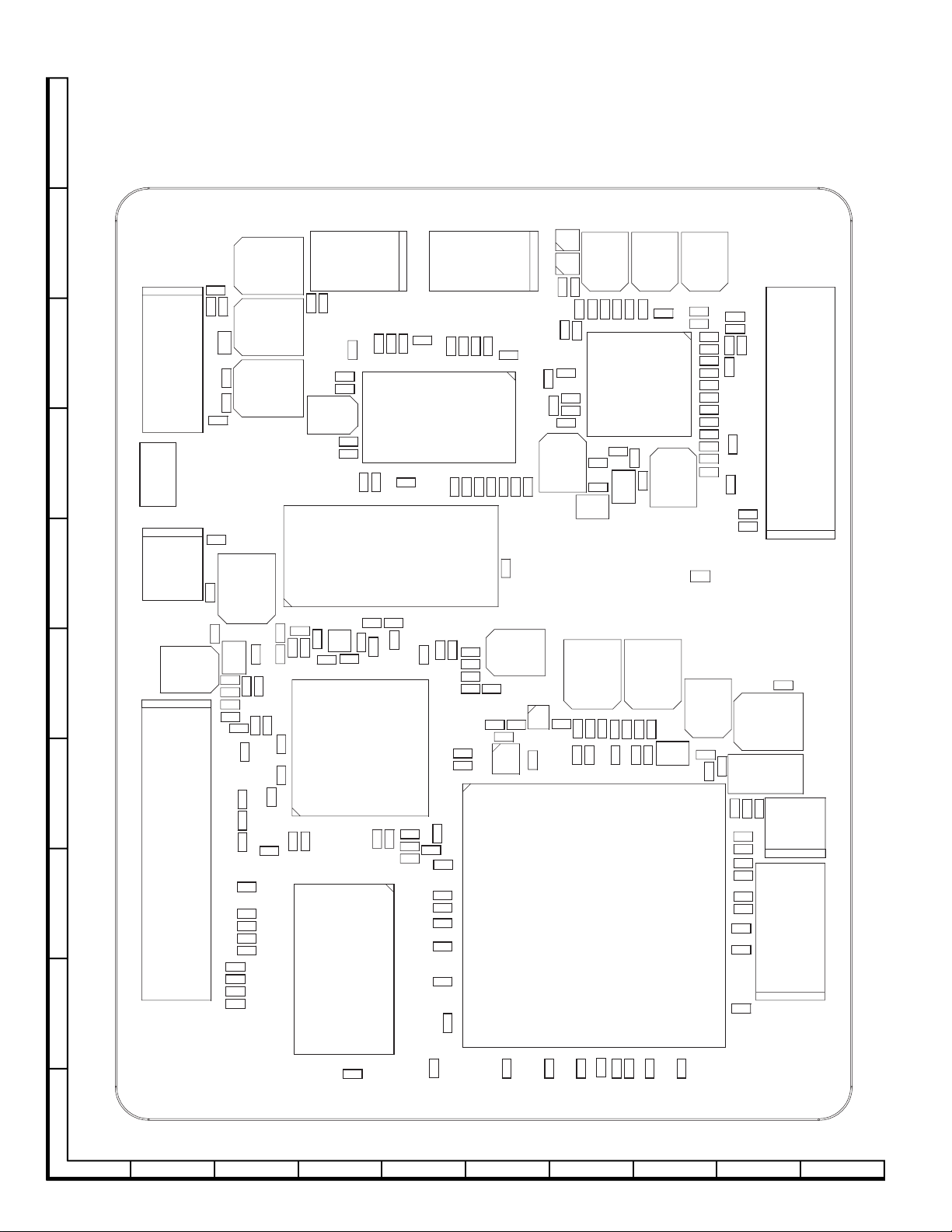

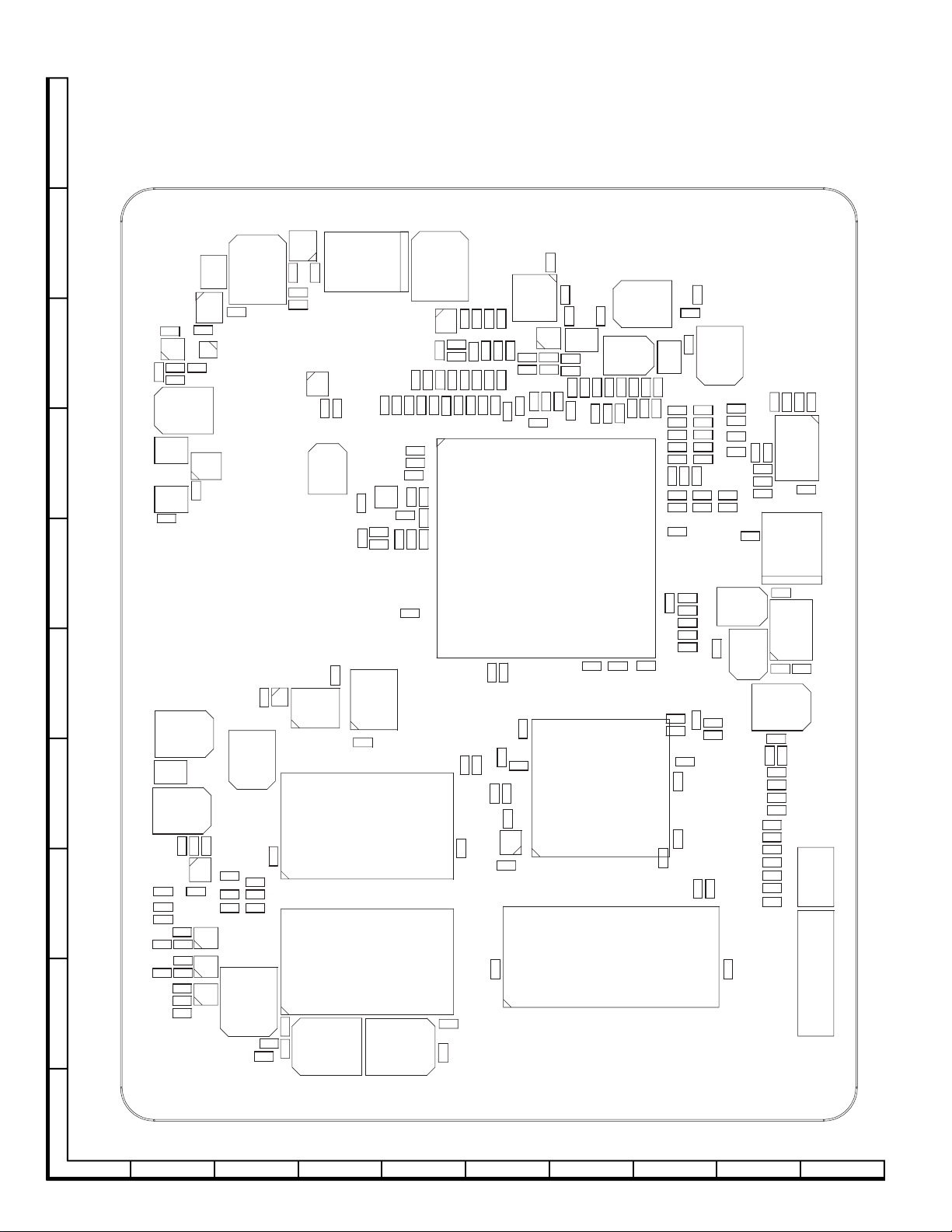

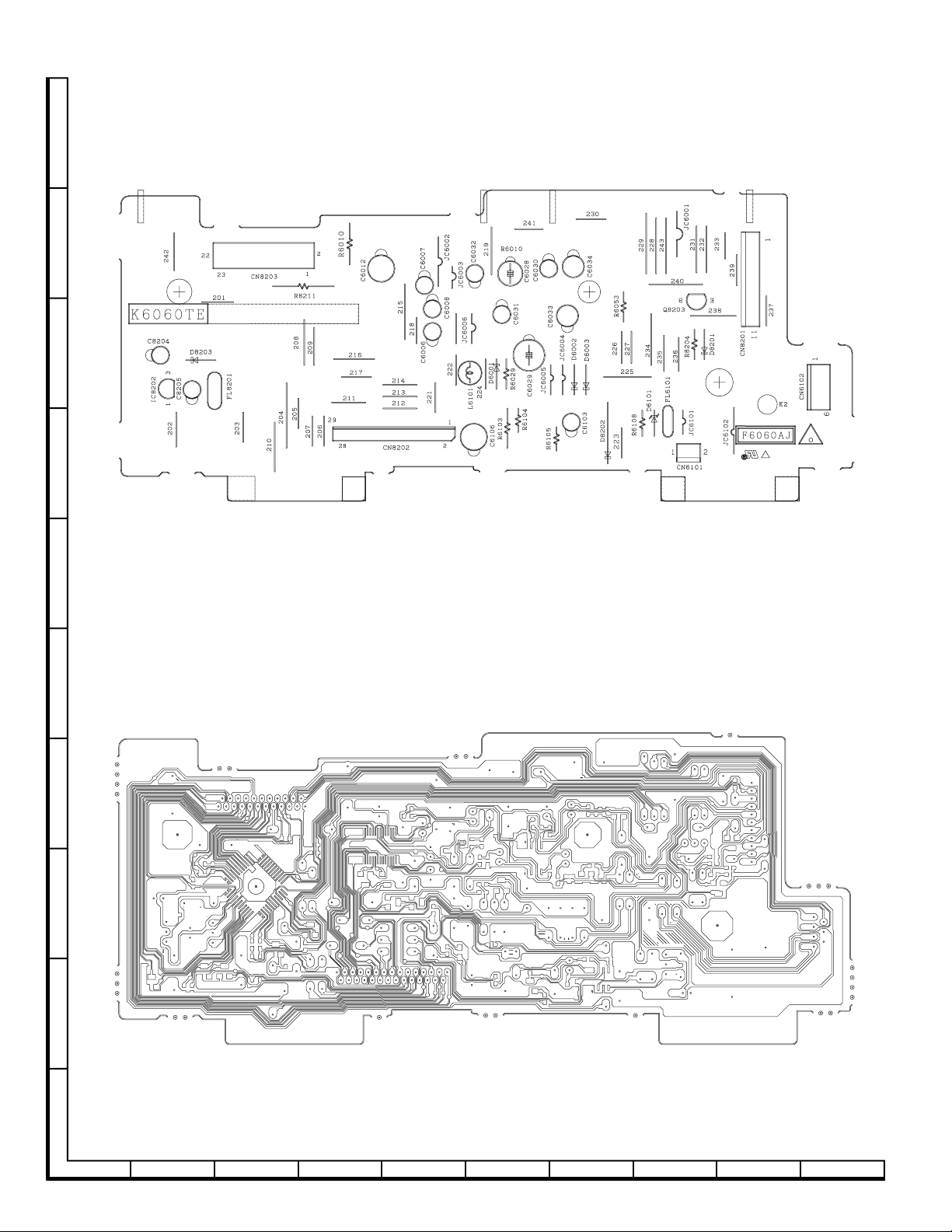

14. PRINTED WIRING BOARD ASSEMBLIES ................................................................................... 102

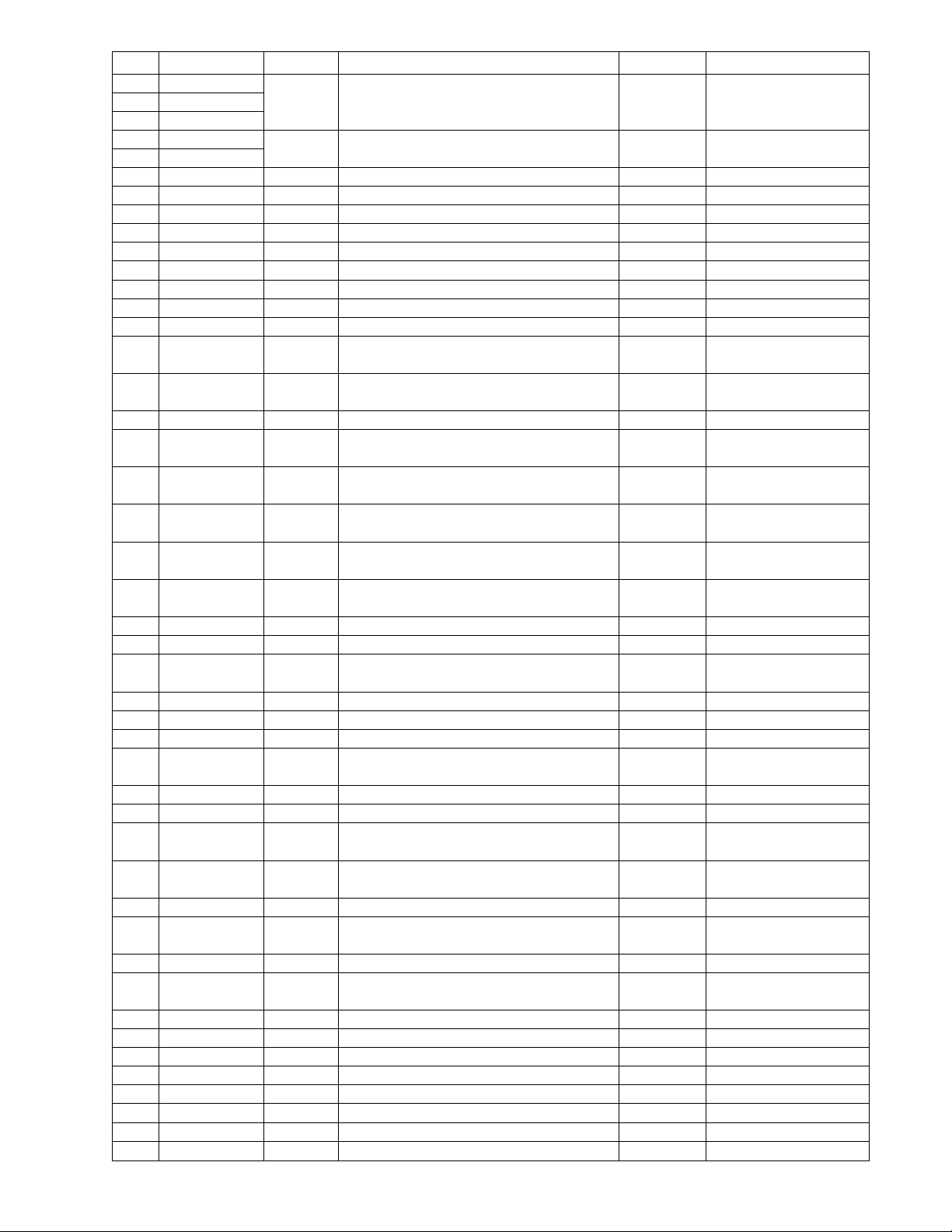

15. REPLACEMENT PARTS LIST ...................................................................................................... 123

16. PACKING OF THE SET................................................................................................................. 142

PLAY STOP

OPEN/

VCR DVD

STANDBY

CH(

TRACKING

)

CLOSE

(AV 1 )

D V-NC55C

D V-NC55U

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

QSURROUND

CONTENTS

D V-NC55M

Page

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

DV-NC55U/C/M

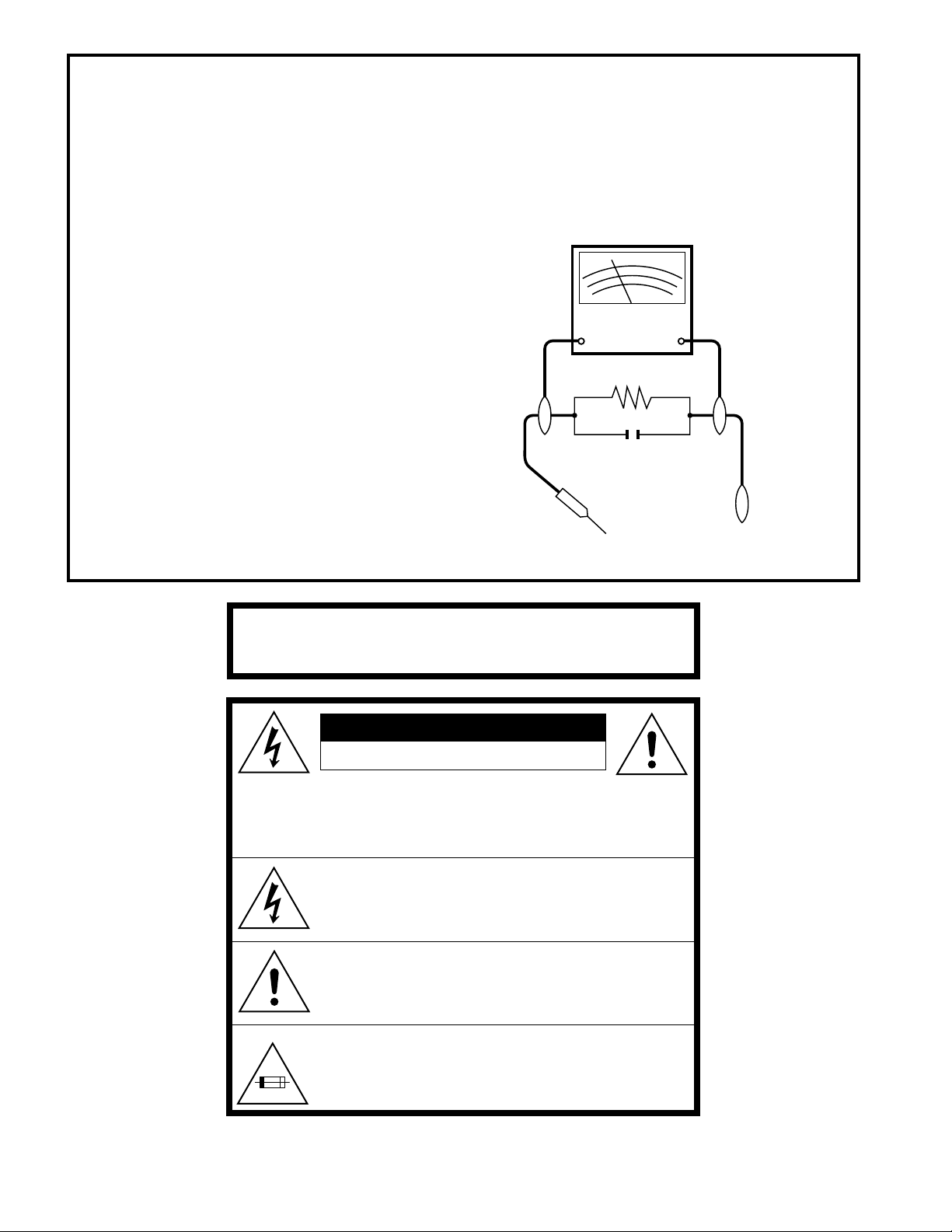

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VCR/DVD COMBINATION MODEL

Before returning the video cassette recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the VCR/DVD

combination model.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

current in the following manner.

● Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

● Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as a water pipe or conduit.

● Use an SSVM or VOM with 1000 ohm per volt, or

higher, sensitivity or measure the AC voltage drop

across the resistor (See Diagram).

● Move the resistor connection to earth exposed metal

part having a return path to the chassis (antenna,

metal cabinet, screw heads, knobs and control shafts,

etc.) and measure the AC voltage drop across the

resistor. Reverse the AC plug on the set and repeat

AC voltage measurements for each exposed part.

Any reading of 0.45V rms (this corresponds to 0.3mA

rms AC.) or more is excessive and indicates a potential shock hazard which must be corrected before

returning the VCR/DVD combination model to the

owner.

SSVM

AC SCALE

1.5k ohms.

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

WARNING :TO REDUCE THE RISK OF FIRE OR ELEC-

TRIC SHOCK, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

CA UTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK. DO

CAUTION:

3.0A 125V

NOT REMOVE COVER. NO USER-SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED

SERVICE PERSONNEL.

This symbol warns the user of uninsulated voltage

within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are important

operating and maintenance instructions in the literature

accompanying this unit.

This symbol mark means fast operating fuse.

For continued protection against risk of fire, replace

only with same type fuse F901 (3.0A, 125V).

2

Page 3

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE VCR/DVD MAGNETOSCOPE

Avant de rendre le magnétoscope à l’utilisateur, effectuer

les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans

le VCR/DVD magnétoscope.

2. Vérifier tous les dispositifs de protection tels que les

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement, Ies

isolateurs mécaniques, etc.

3. Pour être sûr qu’il n’y a aucun risque de choc électrique,

vérifier le courant de fuite de la maniére suivante.

● Brancher le cordon d’alimentation secteur directement

dans une prise de courant de 120 volts. (Ne pas utiliser

de transformateur d’isolement pour cet essai).

● Utiliser deux fils à pinces et connecter une résistance

de 10 watts 1,5 kohm en parallèle avec un condensateur

de 0,15 µF en série avec des pièces du coffret

métallique exposées et une masse de terre connue

telle qu’un tuyau ou un conduit d’eau.

● Utiliser un VTVM ou VOM avec une sensibilité de 1000

ohms par volt ou plus ou mesurer la chute de tension

CA entre la résistance (voir diagramme).

● Déposer la connexion de la résistance à toutes les

DV-NC55U/C/M

pièces métalliques exposées ayant un parcours de

retour au châssis (connexions d’antenne, coffret

métallique, tétes de vis, boutons et arbres de

commande, etc.) et mesurer la chute de tension CA

entre la résistance. Inverser la fiche CA (une fiche

intermédiaire non polarisée doit être utilisée à seule fin

de faire ces vérifications.) sur l’appareil et répéter les

mesures de tension CA pour chaque piéce métallique

exposée. Toute lecture de 0,45 Vrms (ceci correspond

à 0,3 mArms CA) ou plus est excessive et signale un

danger de choc qui doit être corrigé avant de rendre le

VCR/DVD magnétoscope à son utilisateur.

VTVM

ECHELLE CA

1,5 KOHMS

10W

0,15 µF

SONDE D'ESSAI

VERS PIECES

METALLIQUES

EXPOSEES

CANNECTER A

UNE MASSE DE

TERRE CONNUE

ATTENTION: POUR REDUIRE LES RESQUES D'IN-

CENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A

LA PLUIE OU A L'HUMIDITE.

ATTENTION

RISQUE DE CHOC ELECTRIQUE

ATTENTION: AFIN DE REDUIRE LES RISQUES DE CHOC

ELECTRIQUE, NE PAS RETIRER LE COUVERCLE,

AUCUN ORGANE INTERNE NE PEUT ETRE

REPARE PAR L'UTILISATEUR. CONFIER

L'APPAREIL A UN DEPANNEUR QUALIFIE.

Ce symbole signale à l'utilisateur la présence d'une

tension non isolée à l'intérieur de l'appareil qui peut être

la cause de secousses électriques dangereuses.

Ce symbole avertit l'utilisateur que des instructions

importantes relatives à l'utilisation et àl'entretien se

trouvent dans le manuel accompagnant l'appareil.

PRECAUTION:

Cette marque indique le fusible à action in stantansée.

Pour la protection continue contre le risque d'incendie,

3,0A 125V

ne remplacer que par le fusible type F901 (3,0A, 125V).

NE PAS OUVRIR

3

Page 4

DV-NC55U/C/M

2. FEATURES

ËË

Ë Common Features

ËË

• A DVD, CD player and VCR all in one.

• Simultaneous VCR recording and DVD playback.

ËË

Ë VCR

ËË

• Hi-Fi Stereo Sound/Double-Azimuth 4-Heads

• Built-in MTS (Multi-channel TV Sound) Decoder

• 400 Times Rewind Speed to Fast Forward and Rewind.

• EZ Set Up (Auto Channel/Clock Set Up)

• S-VHS Quasi Playback

• 19µ Clear Picture System (in EP mode)

• Simple Recording Timer

• Sharp Super Picture

• Exact Rec/Tape Remaining

ËË

Ë DVD

ËË

• Plays DVD, CD (Digital Audio) discs as well as CD-R/CD-RW discs recorded in MP3 file format

• Virtual Dolby Surround (QSURROUND*1) provides high-quality surround sound

• Digital Gamma correction and Digital Super Picture functions

• Dolby Digital*2/DTS*3 digital out capability

• High-quality digital images

• High-quality digital sound

*1QSURROUNDTM is a trademark of QSound Labs, Inc.

*2Manufactured under license from Dolby Laboratories. "Dolby", "Pro Logic" and the double-D symbol are trademarks of

Dolby Laboratories.

*3"DTS" and "DTS Digital Surround" are trademarks of Digital Theater Systems, Inc.

3. SPECIFICATIONS

Signal System: NTSC

INPUT/OUTPUT JACKS

DVD/VCR shared output jacks: VIDEO jack: RCA Pin-jack

AUDIO jack: RCA Pin-jack

DVD output jacks: VIDEO jack: S-Video jack

AUDIO jack: RCA Pin-jack

DIGITAL AUDIO IF: Coaxial digital

AUDIO output jack: RCA Pin-jack

VIDEO input jacks: VIDEO jack: RCA Pin-jack

AUDIO jack: RCA Pin-jack

VCR

Video Recording System: Rotary Two-Head Helical Scanning

Number of Video Heads: 4

Video Signal Standard: NTSC Color System

Audio Recording System: 1 Stationary Head for Linear Audio

2 Rotary Heads for Hi-Fi stereo

Tape Width: 12.7 mm (1/2 inch)

Tape Speed: (SP) 33.35 mm/sec (1.31 i.p.s.)

(LP) 16.67 mm/sec (0.66 i.p.s.) (playback only)

(EP) 11.12 mm/sec (0.44 i.p.s.)

Maximum Recording Time: (SP) 160 min (T-160)

(EP) 480 min (T-160)

4

Page 5

Channel Coverage: VHF 2-13

UHF 14-69

CATV 1-125

Antenna Input: 75Ω

Video Input: Input level: 0.5 to 2.0 Vp-p (75Ω)

Video Output: Output level: 1.0 Vp-p (75Ω)

Audio Output: Input level: –8 dBs (47kΩ)

(0 dBs = 0.775 Vrms)

Audio Output: Output level: –8 dBs (1kΩ)

(0 dBs = 0.775 Vrms)

Hi-Fi Audio: Dynamic Range: 90 dB

Frequency Response: 20 Hz-20 kHz

Memory Backup: 60 seconds

DVD

DVD/VCR shared Video output: Output level: 1 Vp-p (75Ω)

S video output: Y output level: 1 Vp-p (75Ω)

C output level: 0.286 Vp-p (75Ω)

Audio output: Output level: 2 Vrms (1 kHz, 0 dB)

Video signal horizontal resolution: 500 lines

S/N ratio: 60 dB

Audio signal frequency characteristics: For DVD linear PCM playback:

4 Hz to 22 kHz (48 kHz sampling)

4 Hz to 44 kHz (96 kHz sampling)

CD playback: 4 Hz to 20 kHz (JEITA)

S/N ratio: CD: 100 dB, 1 kHz (EIAJ)

Dynamic range: DVD linear PCM: 96 dB

CD: 96 dB (JEITA)

Total harmonic distortion ratio: CD: 0.006% (JEITA)

Pickup: Wave length: 650 nm

Laser output: Max. 0.7 mW

DV-NC55U/C/M

Operating temperature: 5°C to 35°C (41°F to 95°F)

Storage temperature: –20°C to 55°C (–4°F to 131°F)

Power supply: 120 V AC, 60 Hz

Power consumption: 30 W

Dimensions: 430 mm × 99 mm × 346.5 mm (W × H × D)

(including attachments) (16 15/16" × 3 29/32" × 13 21/32")

Weight: 5.1 kg (11.3 lbs)

Specifications are subject to change without notice.

Weight and dimensions are approximate.

3-1. ACCESSORIES

Accessories: Remote Control Unit x 1, Battery x 2, VIDEO/AUDIO Cable x 1, 75 Ohm Coaxial Cable x 1

5

Page 6

DV-NC55U/C/M

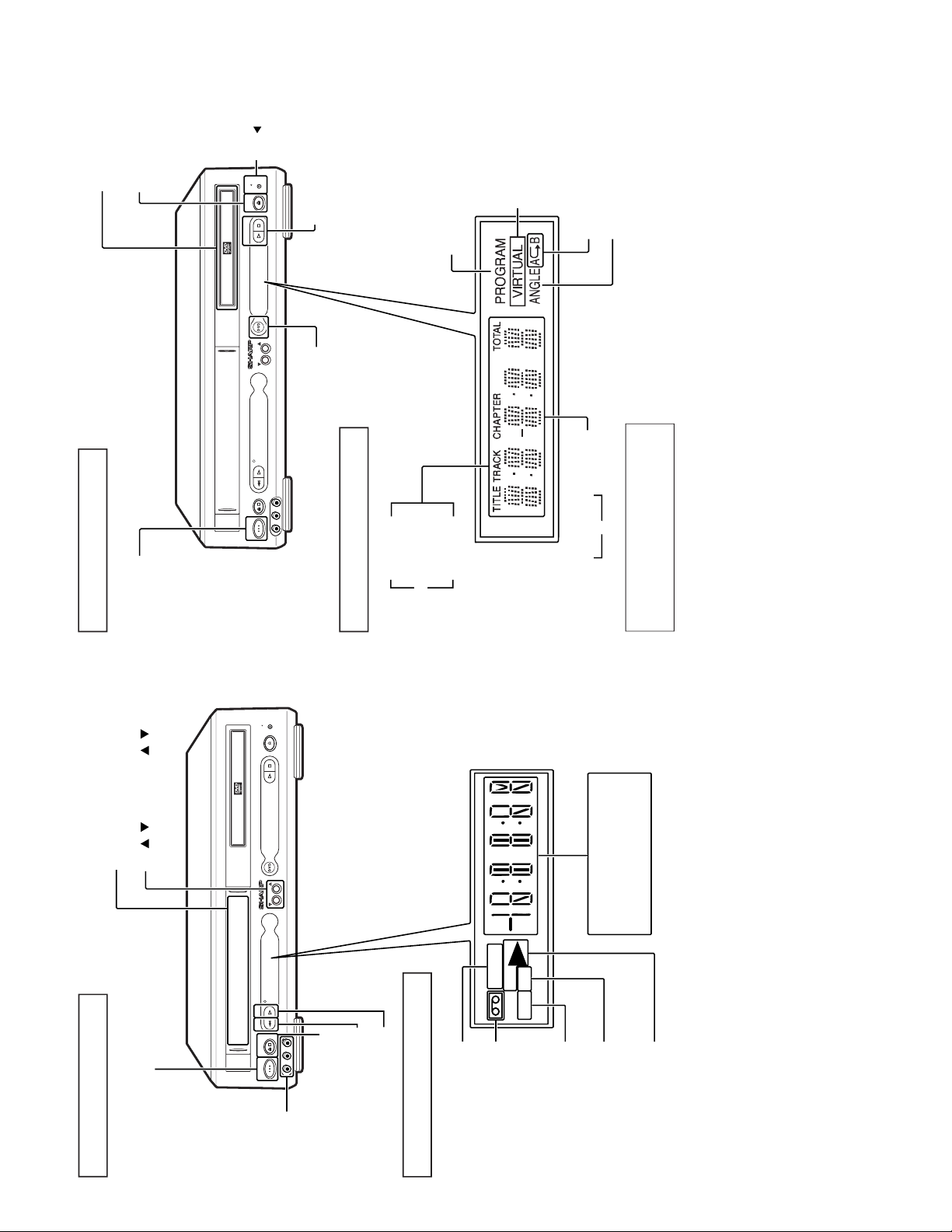

VCR Main Unit (Front)

REW PLAY

STANDBY

CH(

TRACKING

)

/

POWER

EJECT/ STOP

PLAY STOP

OPEN/

CLOSE

VCR DVD

(AV 1 )

L(MONO)-AUDIO-RAV 2 IN VDEO

TIMER

REC

VCR

SPEP

CH / , TRACKING

POWER

PLA Y

EJECT/STOP

Clock Indicator

Channel Indicator

Tape Counter Indicator

REW

Front AUDIO/

VIDEO input

jack

Cassette-in

Indicator

Timer Recording

Indicator

/

Tape Speeds

Indicator

VCR Mode

Indicator

Operation status

Indicator

Cassette compartment

VCR Front Panel Display

DVD Main Unit (Front)

DVD Front Panel Display

REW PLAY

STANDBY

CH(

TRACKING

)

/

POWER

EJECT/ STOP

PLAY STOP

OPEN/

CLOSE

VCR DVD

(AV 1 )

L(MONO)-AUDIO-RAV 2 IN VDEO

Disc tray

OPEN/CLOSEPOWER

TITLE

indicator

Operation status/Time indicator

TRACK

indicator

CHAPTER

indicator

Disc operation buttons

(PLA Y, STOP)

PROGRAM indicator

REPEAT indicator

ANGLE indicator

VIRTUAL surround

indicator

1

2

DVD Output indicator

VCR DVD

indicator

You can toggle between 1 and 2 by

pressing the remote control unit’s

DISPLAY button .

4. PART NAMES

6

Page 7

DV-NC55U/C/M

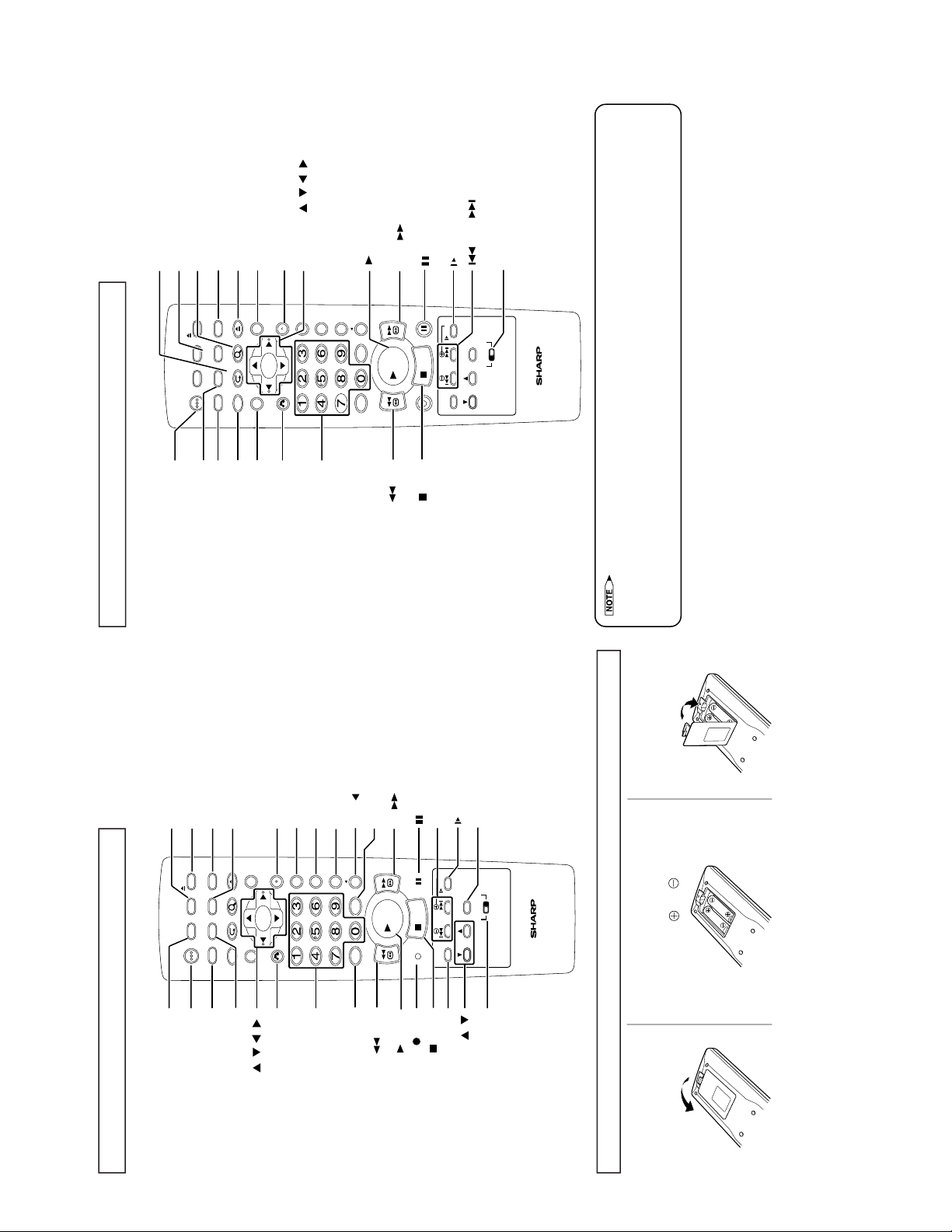

REV FWD

PLAY

STOP

100

OPEN/

CLOSE

VCR/DVD

SELECTOR

VCR MENU

DVD SETUP

TAPE

SPEED

ON

SCREEN

TITLE

DVD MENU

DISPLAY

FUNCTION

CONTROL

PROGRAM ZOOM

CANCEL

RETURN

POWER

ON/OFF

TV/ VCR EJECT

SET

ENTER

ZERO BACK

SKIP SEARCH

REPLAY

VCR DVDAM/PM INPUT

PAUSE/STILL

REC

SLOW

CH

VCR DVD

SKIP

DPSS

AUDIO

OUTPUT

VCR/DVD COMBINATION

ON SCREEN

TIMER ON/OFF

POWER

DISPLAY

CANCEL

CURSOR ( / / / )

Number buttons

100, AM/PM

PLAY

REV

REC

STOP

TAPE SPEED

VCR/DVD CHANGE Switch

TV/VCR

VCR/DVD SELECTOR

EJECT

VCR MENU

SET

ZERO BACK

SKIP

REPLAY

VCR DVD

PAUSE/STILL

SLOW

±

/

—

, DPSS

±

/

—

INPUT

SLOW

AUDIO OUTPUT

CH /

FF

Remote Control Unit (VCR Operation Buttons)

• The explanations on this page use the VCR/DVD CHANGE Switch in the VCR position.

Loading the

1

Open the battery cover

by pulling the lid in the

direction of the arrow.

2

Load the batteries.

Load the two batteries (R6 UM/SUM-3 or AA)

supplied with the remote control unit so that

the battery poles

and are positioned

as indicated.

3

Close the battery cover

by lowering the lid in the

direction of the arrow.

• Do not subject the remote control unit to shock, water or excessive humidity.

• The remote control unit may not function if the Unit sensor is in direct sunlight or any other strong light.

• Incorrect use of batteries may cause them to leak or burst. Read the battery warnings and use the batteries properly.

• Do not mix old and new batteries, or mix brands in use.

• Remove the batteries if you do not use the remote control unit for an extended period of time.

Remote Control Unit (DVD Operation Buttons)

• The explanations on this page use the VCR/DVD CHANGE Switch in the DVD position.

REV FWD

PLAY

STOP

100

OPEN/

CLOSE

VCR/DVD

SELECTOR

VCR MENU

DVD SETUP

TAPE

SPEED

ON

SCREEN

TITLE

DVD MENU

DISPLAY

FUNCTION

CONTROL

PROGRAM ZOOM

CANCEL

RETURN

POWER

TIMER

TV/ VCR EJECT

SET

ENTER

ZERO BACK

SKIP SEARCH

REPLAY

VCR DVDAM/PM INPUT

PAUSE/STILL

REC

SLOW

CH

VCR DVD

SKIP

DPSS

AUDIO

OUTPUT

VCR/DVD COMBINATION

ON SCREEN

POWER

DISPLAY

FUNCTION CONTROL

RETURN

TITLE

CURSOR ( / / / )

Number buttons

REV

STOP

VCR/DVD SELECTOR

REPEAT, PROGRAM

ZOOM

PLAY

DVD MENU

OPEN/CLOSE

DVD SETUP

ENTER

PAUSE/STILL

FWD

SLOW

VCR/DVD CHANGE Switch

SKIP

7

Page 8

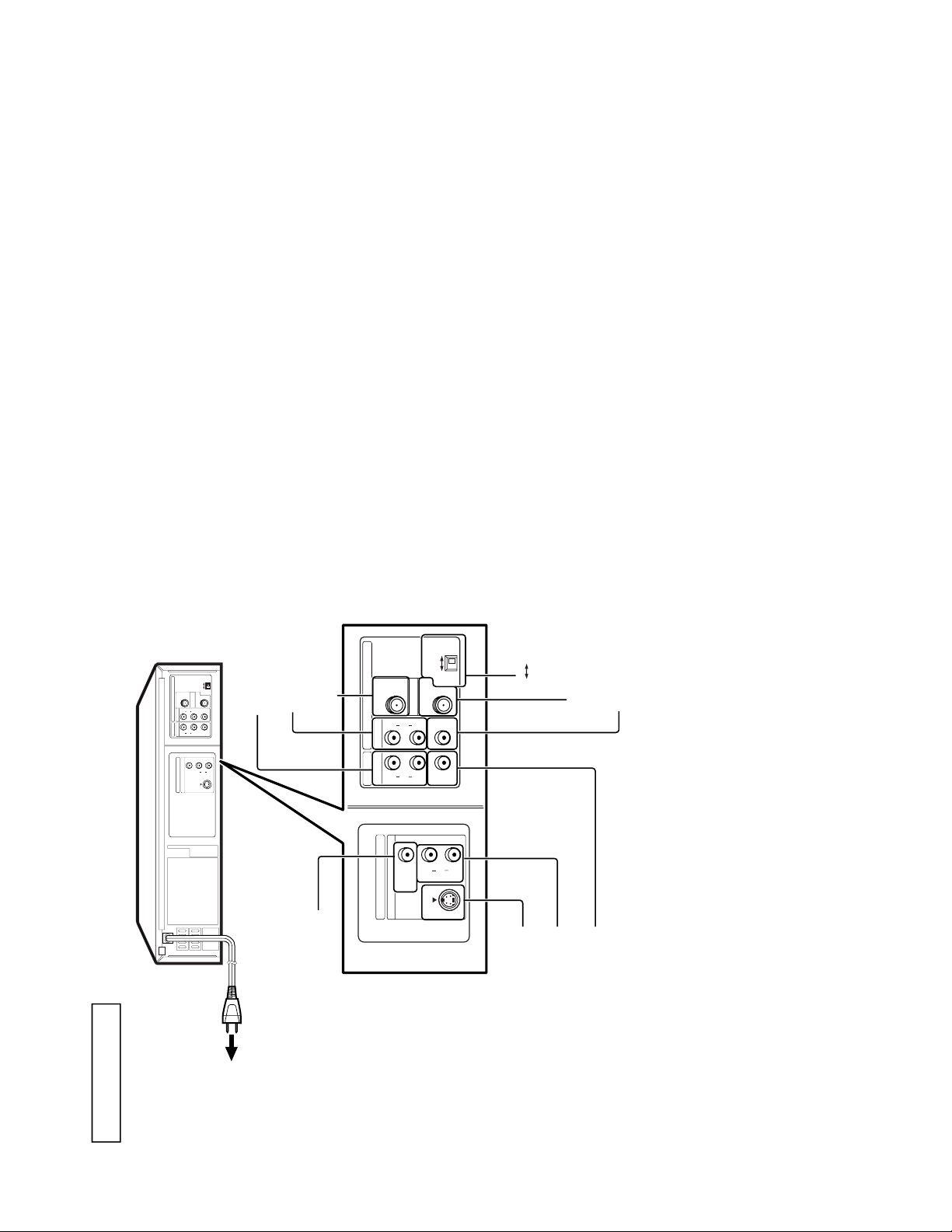

DV-NC55U/C/M

Main Unit (Rear)

DVD OUT

AV 2 OUT

DIGITAL

AUDIO

AUDIO

R

L

S-VIDEO

DVD/VCR

AV 1 OUT

AUDIO

R

L

VIDEO

VCR

AV 1 IN

AUDIO

R

L

(

MONO

)

VIDEO

IN FROM

ANTENNA

UHF/VHF

CATV

OUT TO TV

OUTPUT

CHANNEL

34

DVD OUT

AV 2 OUT

DIGITAL

AUDIO

AUDIO

R

L

S-VIDEO

DVD/VCR

AV 1 OUT

AUDIO

R

L

VIDEO

VCR

AV 1 IN

AUDIO

R

VIDEO

IN FROM

ANTENNA

UHF/VHF

CATV

OUT TO TV

OUTPUT

CHANNEL

3

4

L

(

MONO

)

VCR AUDIO input jacks

ANTENA IN (antena or

cable input)

VCR VIDEO input jack

ANTENA OUT

3 4 OUTPUT

CHANNEL select

DVD/VCR shared AUDIO

output jacks

DVD Coaxial DIGITAL

output jack

DVD S-VIDEO output jack

DVD AUDIO output jacks

DVD/VCR shared VIDEO

output jack

To an AC outlet

8

Page 9

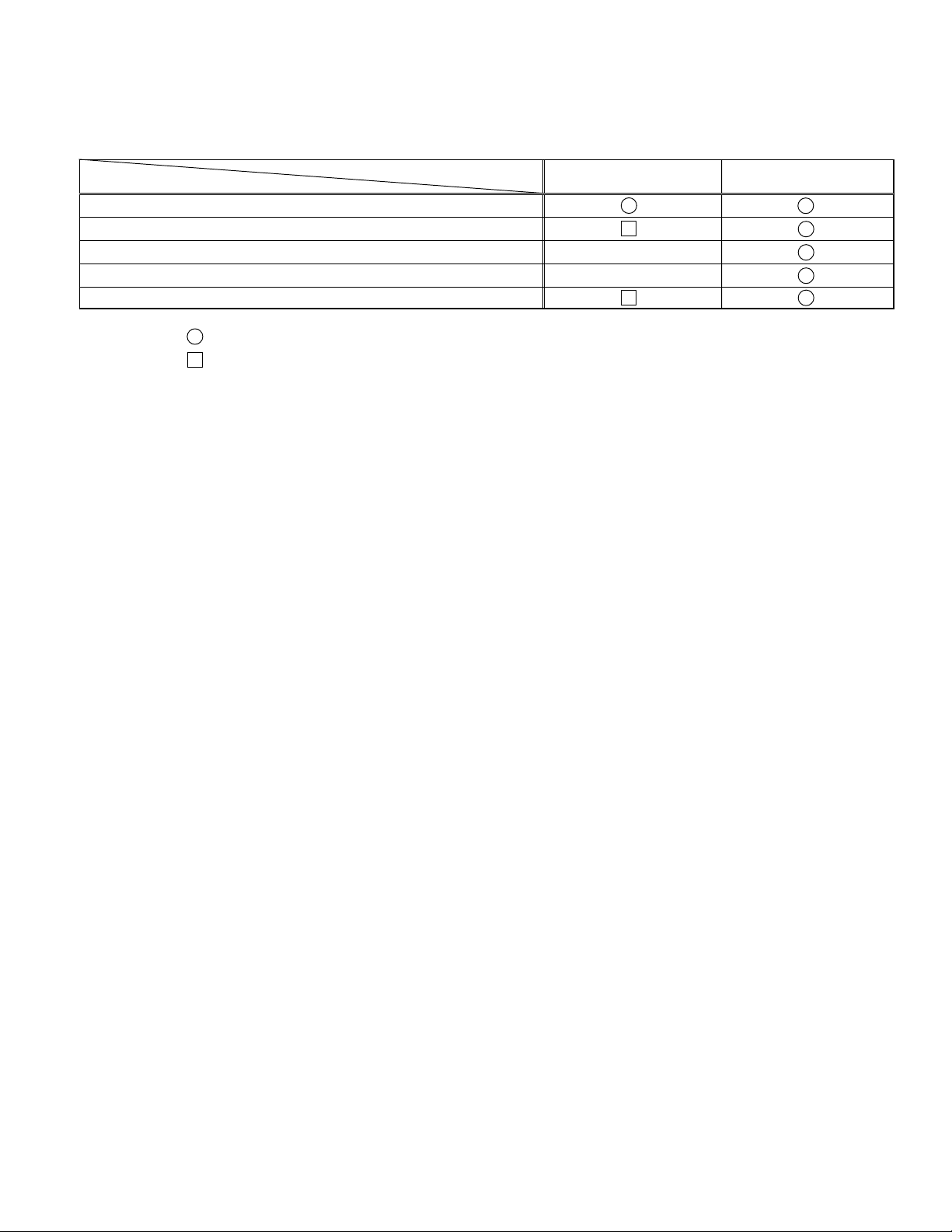

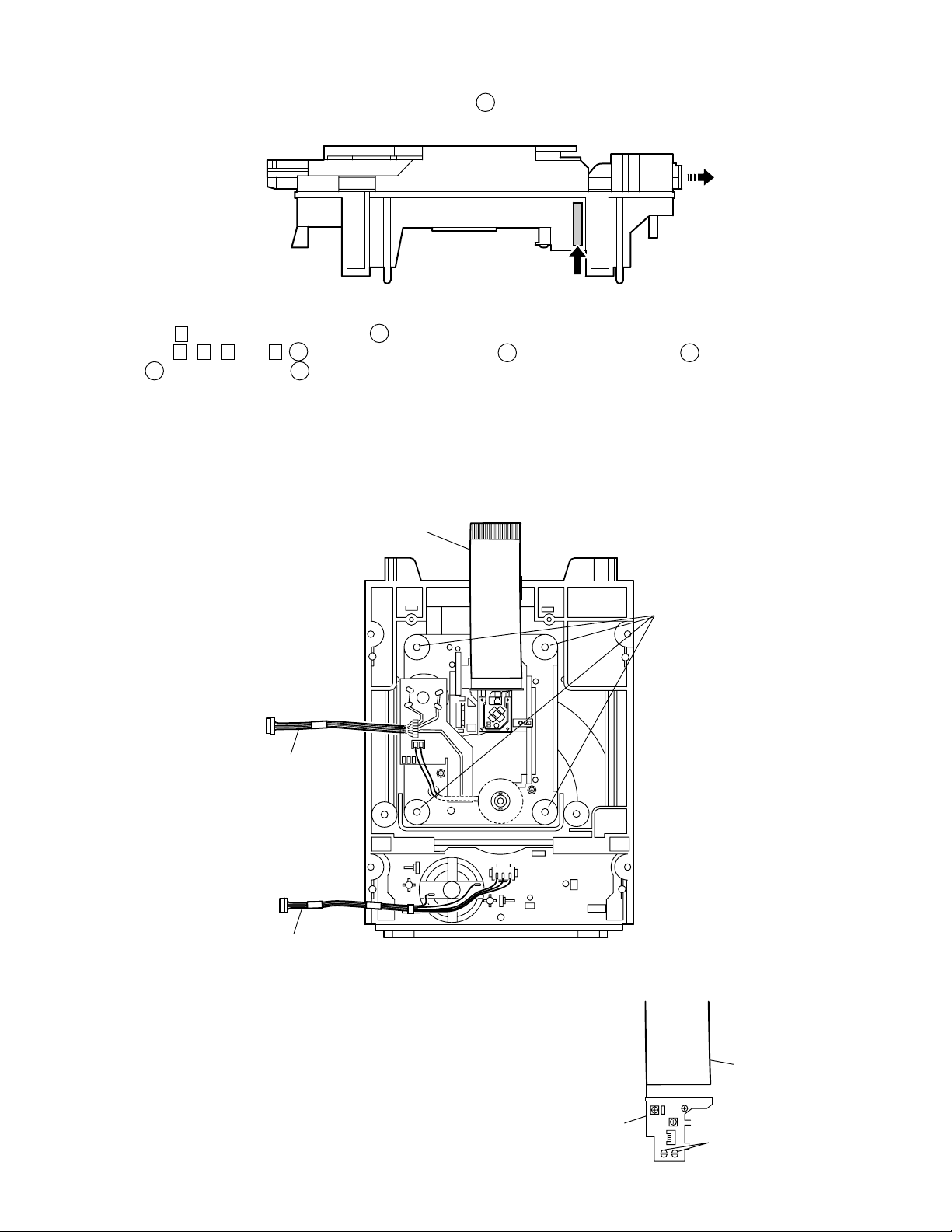

5. MAINTENANCE CHECK ITEMS AND EXECUTION TIME

MECHANICAL PARTS REGUIRING PERIODICAL INSPECTION

Use the following table as a guide to maintain the mechanical parts in good operating condition.

DV-NC55U/C/M

Parts

Pickup

Spindle Unit

Sled Motor

Loading Motor

Belt

Note : Part Replacement

: Cleaning

(For cleaning, use a lint-free cloth danpened with pure isopropyl alcohol.)

Maintained

1,000 hrs.

2,000 hrs.

CARES WHEN USING THE PICKUP

1. The laser light having wavelength 650 nm is emitted from the objective lens. BE CAREFUL SO THAT THE LASER

LIGHT DOES NOT ENTER DIRECTLY INTO YOUR EYE.

2. The semiconductor laser may be easily damaged by electrostatic charges. When handling the pickup, take care so that

the electrostatic charge is not generated.

3. The semiconductor laser may be easily damaged by overcurrent. Use the power supply unit which does not give any

spike current when the power is turned on and off.

4. Carefully remove the dust and dirt from the objective lens with the lens blower.

When handling the objective lens, take due care so that it is not contaminated with fingerprint, etc. If the objective lens

is contaminated, impregnate the cleaning paper with a small quantity of solvent (isopropyl alcohol), and gently wipe to

clean.

5. The ozone layer depleting components (ODC) are not used in the production process for the product.

9

Page 10

DV-NC55U/C/M

9

9

10

12

12

11

12

22

21

20

15

16

14

17

16

18

19

23

24

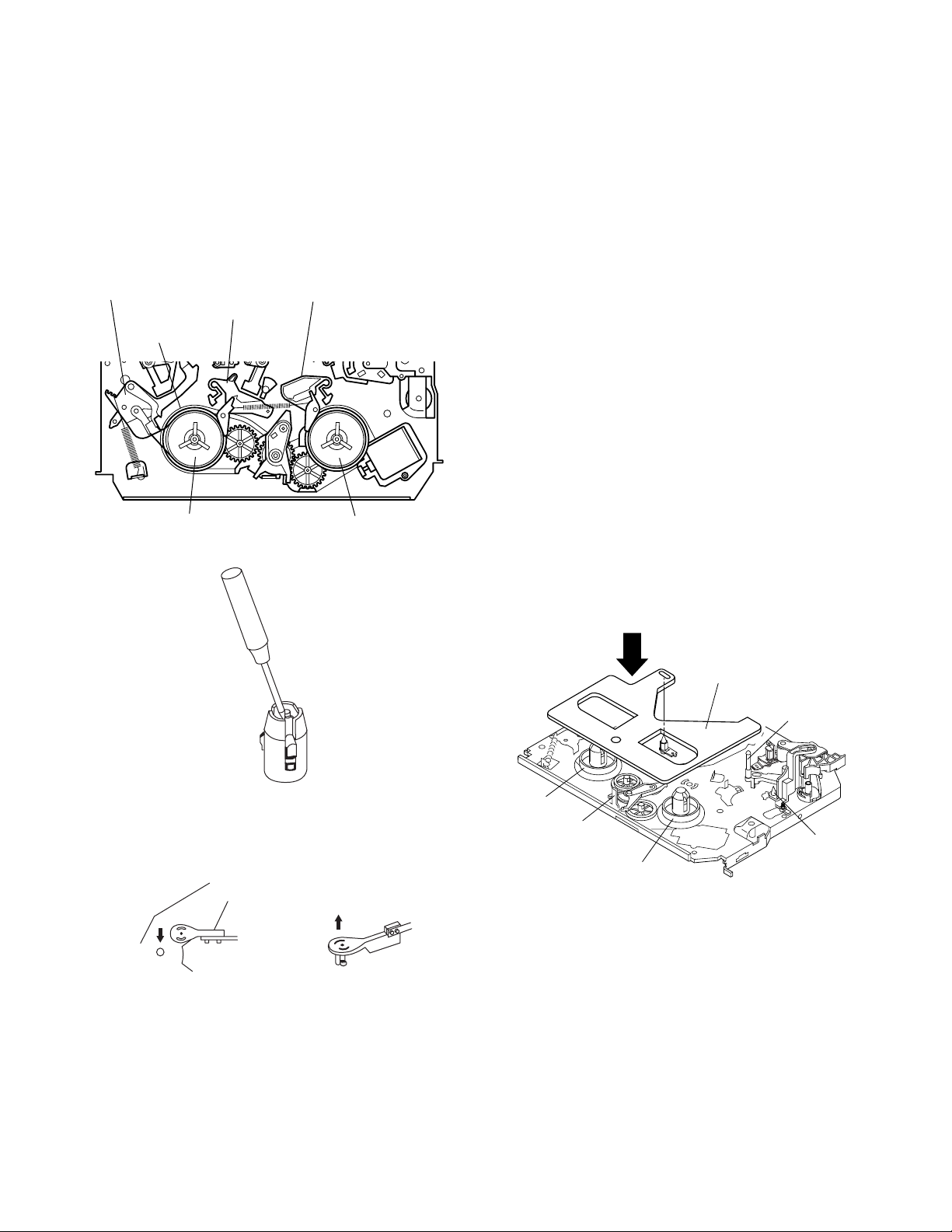

6. DISASSEMBLY METHOD

6-1. DISASSEMBLY METHOD

1)Removing the cabinet.

(1) Remove the five screws 1 and 2.

1

2

2)Removing the front panel.

(1) Remove the earth plate.

(2) Remove the three screws 3.

(3) Remove the three hooks 4.

3)Removing the front PWB.

(1) Remove the shild plate.

(2) Remove the four FFCs 5 and 6.

(3) Release the two hooks 7 and tilt the PWB toward you to

remove it.

(4) Release the two hooks 8 and tilt the PWB toward you to

remove it.

4)Removing the DVD mechanism.

(1) Remove the six screws 9.

(2) Remove the DVD REINF. angle 0.

(3) Remove the connector q.

(4) Remove the two FFCs w.

3

Shild Plate

4

1

7

6

8

5

6

(5) Peel the FFC w off the DVD mechanism.

(6) Remove the FFC r.

(7) Remove the shield (lower) t.

(8) Remove the two FFCs y, and at two connectors u, and

at four screws i.

(9) Remove the wire from the wire holder o.

(10)Remove the DVD main PWB p.

(11)Remove the FFC cover a.

(12)Remove the two interface PWB holders s, and remove

the interface PWB d.

(13)Remove the two screws f.

10

Page 11

(14)Remove the connector.

(15)Remove the three screws g and h.

DV-NC55U/C/M

Connector

26

25

5)Removing the cassette housing control/VTR mechanism.

(1) Remove the two screws k.

(2) Remove the two screws l.

(3) Remove the one screw ;.

(4) Remove the H/A shield case (upper) .

31

6)Removing the terminal plate/VTR main PWB.

(1) Remove the four screws .

(2) Remove the one screw .

32

33

7)Removing the bottom plate.

(1) Remove the six screws .

34

28

31

29

30

32

33

11

32

34

Page 12

DV-NC55U/C/M

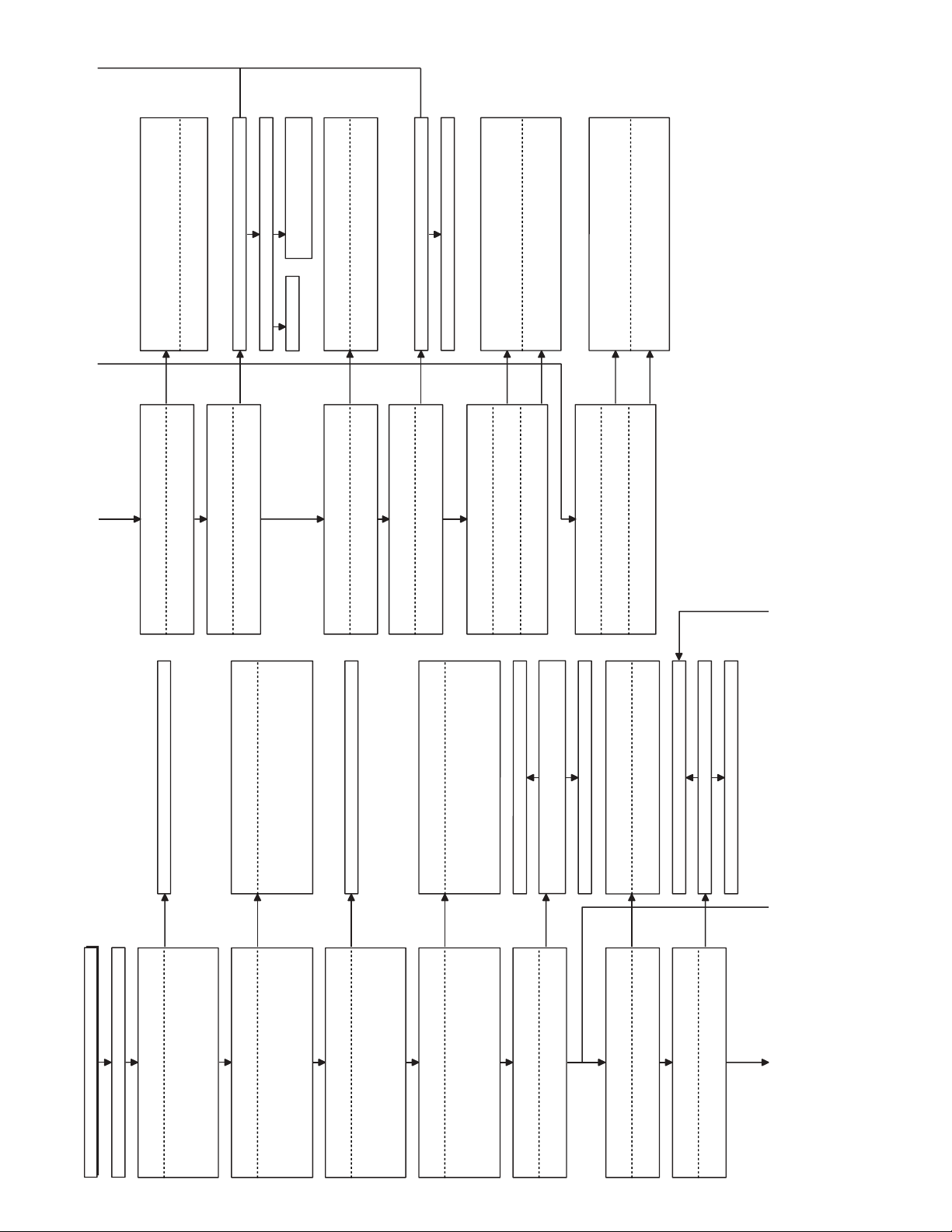

6-2. EXTENSION CABLE USE POINT (FOUR PLACES)

Parts Code Price Code Name/Description

QCNW-8570GEZZ AV Extension cable (FFC), 29pin 500mm

DVD main CN801–I/F CN8202

QCNW-8571GEZZ AN Extension cable (wire), 9pin 500mm

DVD main CN201–power P9001

QCNW-8601AJZZ AE Extension cable (FFC), 23pin

I/F CN8203–DVD display CN5001

QCNW-8605AJZZ AE Extension cable(FFC), 9pin

DVD main CN802– AV CN2005

Extension Cable Diagram

Tuner

CN2005

Power PWB

Audio/Video PWB

VTR Main PWB

VTR Mechanism

CN8203

VTR Display PWB DVD Display PWB

Interface

PWB

CN8202

P9001

CN5001

QCNW-8601AJZZ

23pin

DVD Mechanism

QCNW-8571GEZZ

9pin

CN201

DVD main PWB

CN802

CN801

QCNW-8570GEZZ

29pin

QCNW-8605AJZZ

9pin

12

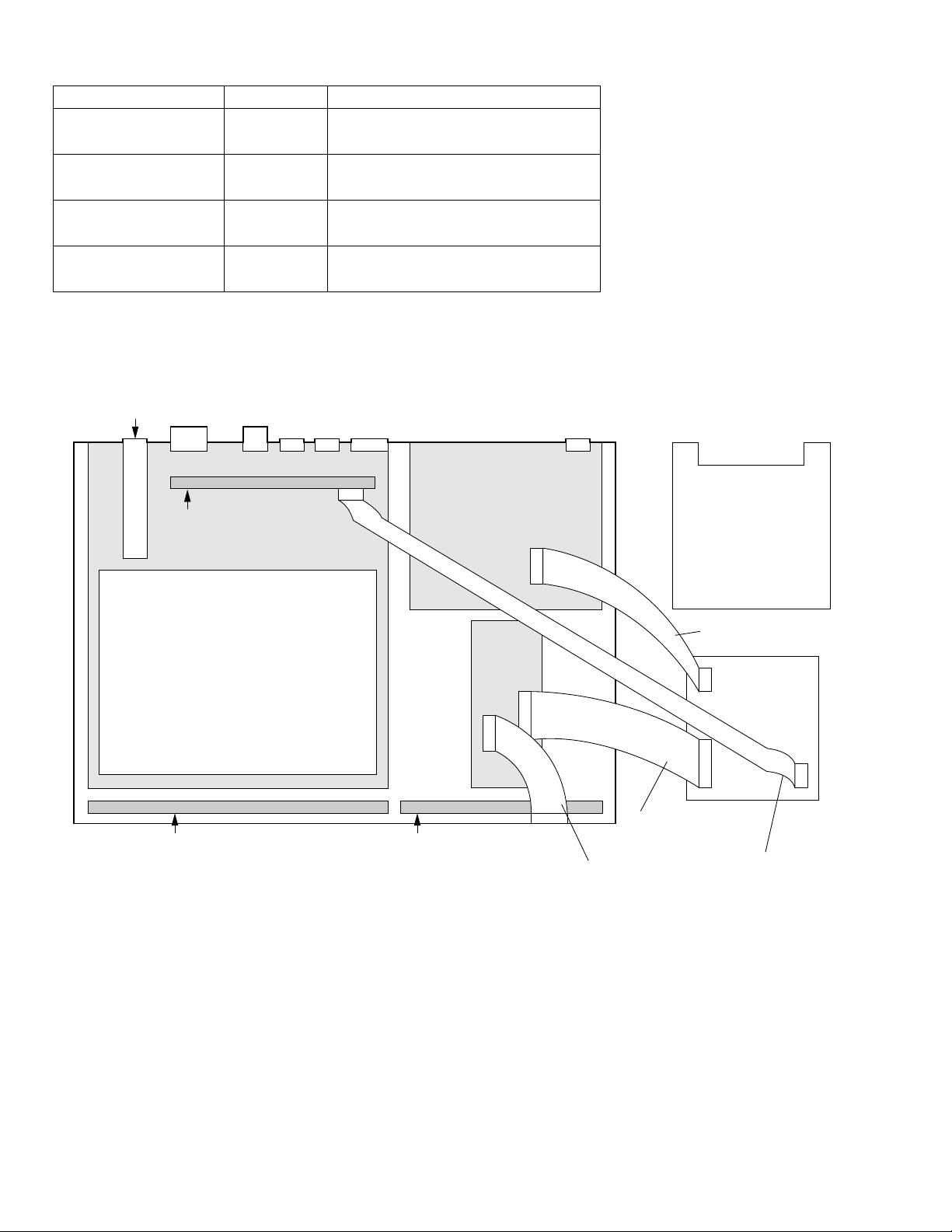

Page 13

DV-NC55U/C/M

6-3. REPLACEMENT OF MAIN PARTS

<Take out disk>

1. Remove the mechanism with angle from the set (refer to 35 on page 140).

2. It is in such cases as the thin driver, and it is pushed in slowly, and a tray is drawn in the arrow direction the slide rack on the

left of the base chassis.

3. Take out disk.

Front Side

<Disassembling and assembling the mechanism chassis>

1. After setting the mechanism chassis to the angle state, ground it to prevent the electrostatic discharge damage of the pickup .

2. Remove S and the DVD shield (lower) 56 (refer to the illustration on page 140).

3. Remove P , Q , Z and R 83 from the DVD main PWB unit 68 , and loosen the 4 screws 45 to remove the DVD main PWB

unit 68 . (Pickup relay FFC 74 isn't removed.) (refer to the illustration on page 140)

4. Remove screws fixing the base chassis (located at the back right and at front left when facing the set).

5. With the pickup FFC connected, turn over the base chassis and short (solder) two short lands on the pickup interface PWB in

order to prevent the electrostatic discharge damage of the pickup.

6. Remove the pickup FFC from the main PWB.

7. Remove the pickup FFC from the pickup interface PWB.

8. Remove the traverse mounting screws to remove the traverse chassis ass'y.

Note: After assembly and wiring, remove the solder joint of the short land. If short-circuited, a disk is not played back.

Pickup FFC

Traverse Fixing Screw

Sled Motor Lead Wire

Loading Motor Lead Wire

<Replacing the pickup and the spindle motor>

Since the pickup optical axis and turntable inclination of DVD are adjusted with higher accuracy than of CD/MD, make a replacement

as a mechanism service chassis ass'y (refer to Parts List).

13

Pickup interface PWB

Pickup FFC

Short Land

Page 14

DV-NC55U/C/M

2-focus objective lens

Actuator assembly

7. OPERATION OF PICKUP

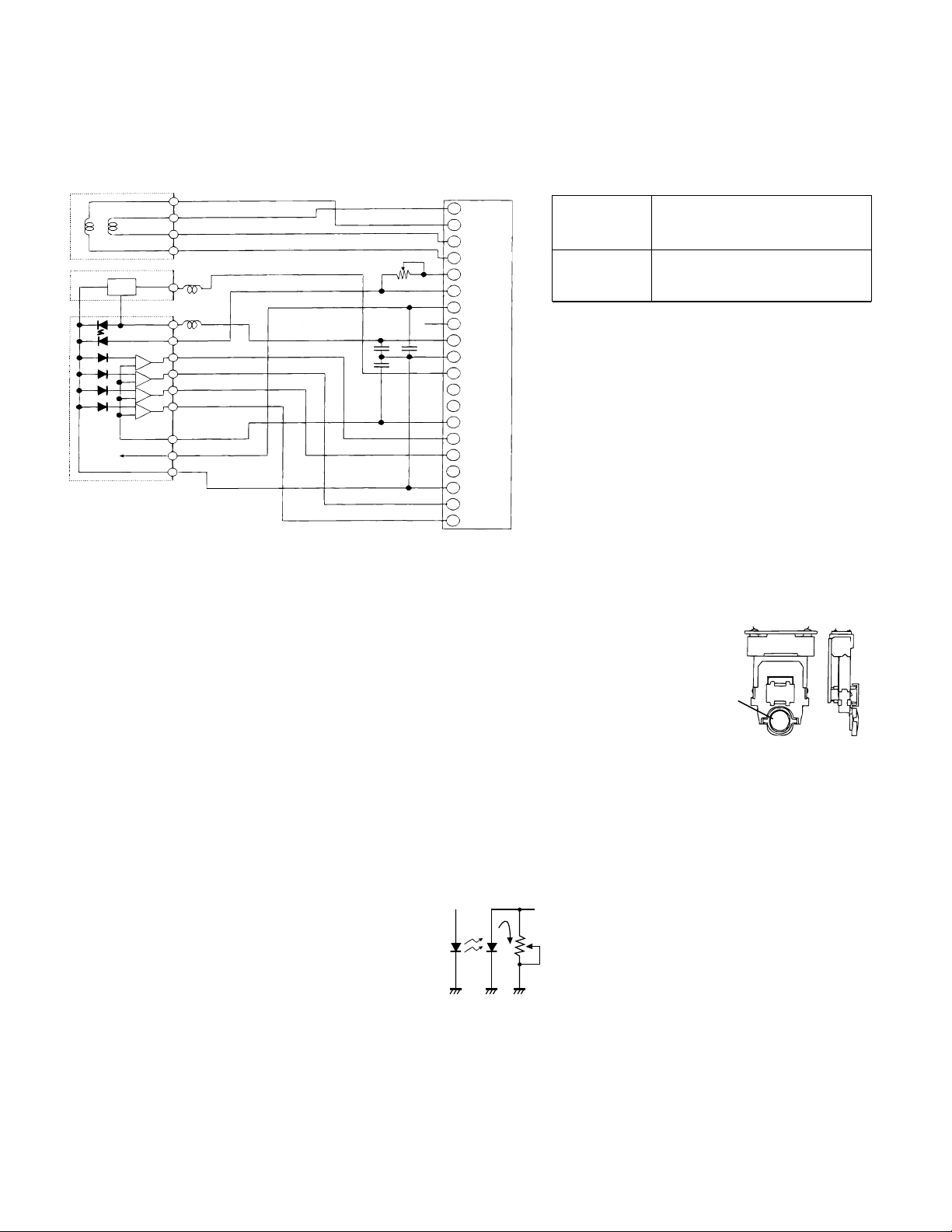

7-1. CIRCUIT CONFIGURATION OF PICKUP

The pickup unit reads signals from the disk, and the flexible cable is connected to the board. The following signals flow through the

cable.

7-2. EQUIVALENT CIRCUIT OF PICKUP

FO+

TR–

TR+

OSC

FO–

OS

V

LD

PD

VA

–

+

VB

–

+

VC

–

+

VD

–

+

ref

V

Vcc

GND

Power adjust

ACTUATOR

HIGH-FREQUENCY CONVOLUTION

HOLOGRAM LASER UNIT

TR–

1

FO+

2

TR+

3

FO–

4

VR

5

PD

6

CC

V

7

GND

8

(NC)

LD

9

GND

10

OS

V

11

NC

12

NC

13

ref(VCC/2)

V

14

VA

15

VD

16

NC

17

GND

18

VB

19

VC

20

7-3. POLARITIES OF SIGNAL

Focus When electric current is flowed

FO+, FO- from FO+ to FO-, the lens comes

to near the disk.

Tracking When electric current is flowed

TR+, TR- from TR+ to TR-, the lens goes

toward the outer circumference.

1

7-4. SIGNALS OF PICKUP

7-4-1. Tracking drive signal (TR+, TR-)

The signal drives the tracking servo mechanism which projects the beam on the track by moving the objective lens (OL) to the outer

or inner circumference (at a right angle against the track) of the disk.

7-4-2. Focus drive signal (FO+, FO-)

The signal drives the focus servo mechanism which aligns the focus on the pit of the disk

by elevating OL (vertically against the disk surface.)

The VR terminal is connected to GND.

7-4-3. Monitor Diode (PD)

Since the laser diode largely varies output of the laser light even if the flowing current is slightly varied, the projection

light is detected with the monitor diode to control the laser light to be equally output.

Since the current varies on the monitor diode according to the intensity of the received light of the laser diode, the drive current of

the laser diode is reduced if the current of the monitor diode increases. On the contrary, the drive current of the laser diode is increased

if the current of the monitor diode decreases.

As the projection light of the laser diode becomes stronger, the current of the monitor diode increases to increase the current which

flows into the monitor diode output (PD). This is input to the pin 44 of IC301 and is compared with the reference voltage to control

the drive current of the laser diode.

The circuit is called ALPC (Automatic Laser Power Control).

LD

PD

When the quantity of laser light increases, the

current shown in figure increases and the PD

terminal voltage rises.

7-4-4. Laser diode drive current control (LD)

Power supply to drive the laser diode

IC301 is used to control. The LD terminal voltage

lowers, and the quantity of light reduces. (IC301 is

actuated by voltage input.)

7-4-5. High-frequency convolution module power supply (VOSC)

The high-frequency convolution imposes the high-frequency signal on the DC current to impose the high frequency on the drive

current of the laser. Thus, the interference of outgoing light and reflected light is prevented.

7-4-6. HF Signal (VA, VB, VC, VD)

Signals recorded in the disk

14

Page 15

DV-NC55U/C/M

8. ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS

The explanation given below relates to the on-site general service (field service) but it does not relates to the adjustment

and replacement which need high-grade equipment, jigs and skill. For example, the drum assembling, replacement and

adjustment service must be performed by the person who have finished the technical courses.

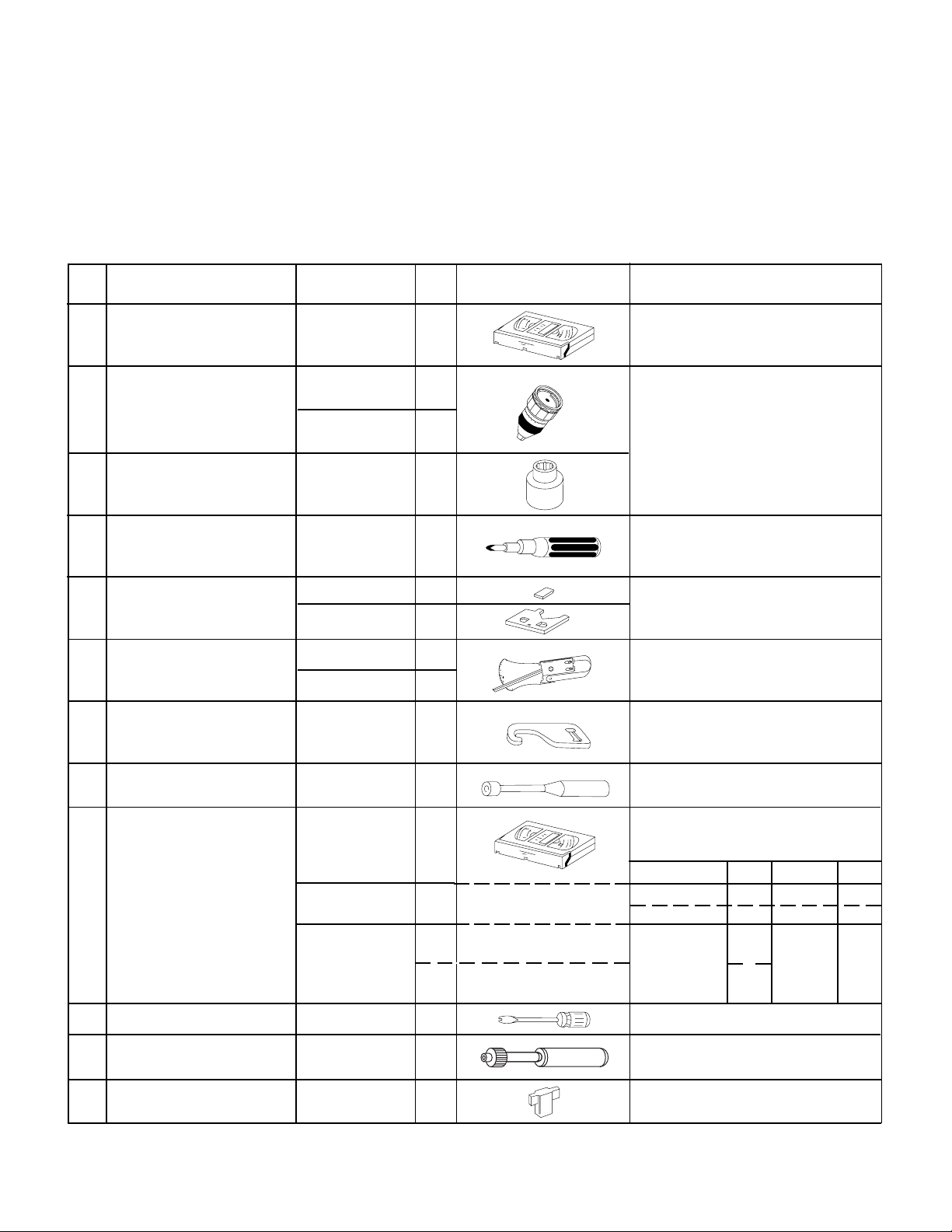

8-1. MECHANISM CONFIRMATION ADJUSTMENT JIG

So as to perform completely the mechanism adjustment prepare the following special jigs. So as to maintain the initial

performance of the machine the maintenance and check are necessary. Utmost care must be taken so that the tape is

not damaged. If adjustment needs any jig, be sure to use the required jig.

No. Jig ltem Part No. Code Configuration Remarks

This cassette torque meter is used for check-

1. Torque Cassette Meter JiGVHT-063 CZ

JiGTG0090 CM

2.

Torque Gauge

JiGTG1200 CN

3. Torque Gauge Head JiGTH0006 AW

ing and adjusting the torque of take-up for

measuring tape back tension.

These Jigs are used for checking

and adjusting the torque of take-up

and supply reel disks.

4. Torque Driver JiGTD1200 CB

Master Plane Jig and

Reel Disk Height

5.

Adjusting Jig

JiGRH0002 BR

JiGMP0001 BY

JiGSG2000 BS

Tension Gauge

6.

JiGSG0300 BF

Pinch pressing force

7. JiGADP0003 BK

measuring jig

Reverse guide height

8.

adjustment box driver

9.

Alignment Tape

JiGDRiVER11055

VROATSV CD

AR

VROEFZCS BG

OR

VROEFZHS BH

When fixing any part to the threaded

hole using resin with screw, use the

jig. (Specified torque 5 kg)

These Jigs are used for checking

and adjusting the reel disk height.

There are two gauges used for the

tension measurements, 300 g and

2.0 kg.

This Jig is used with the tension

gauge. Rotary transformer clearance

adjusting jig.

This Jig is used for height adjustment of the

reverse guide (for reverse guide height adjustment).

These tapes are especially used for

electrical fine adjustment.

Video Audio HiFi Audio Track

525 Monoscope 7k — 58µm

NTSC Color Bar 1k — 58µm

Black Level

(only SYNC) signal

1k

—19µm

2.3k

Guide roller height

10. JiGDRiVERH-4 AP

adjustment driver

X value adjustment

11. JiGDRiVER-6 BM

gear driver

Reverse Guide Height

12. JiGRVGH-F18 BU

Adjusting Jig

This screwdriver is used for adjusting the

guide roller height.

For X value adjustment

This Jig is used for height

adjustment of the reverse guide.

15

Page 16

DV-NC55U/C/M

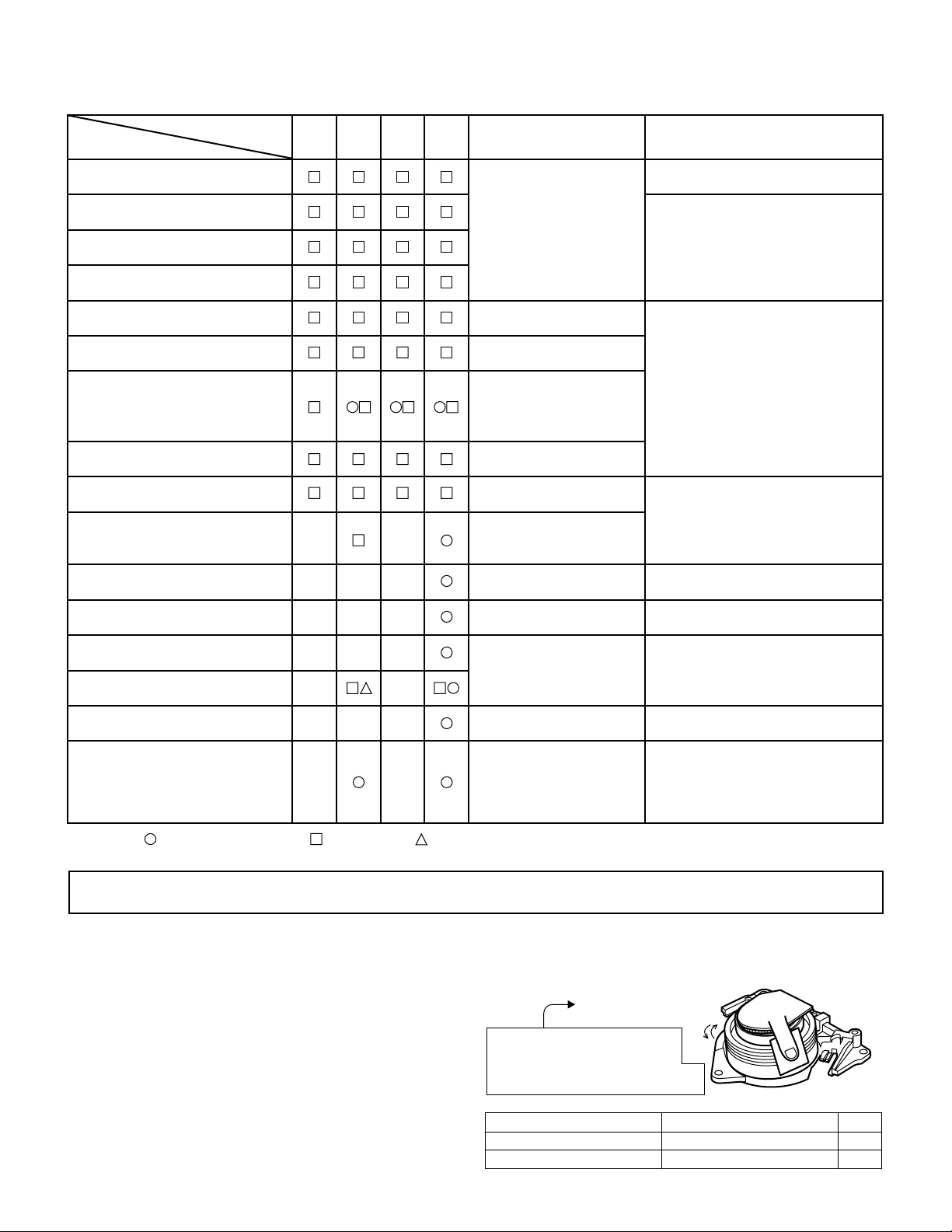

8-2. MAINTENANCE CHECK ITEMS AND EXECUTION TIME

Perform the maintenance with the regular intervals as follows so as to maintain the quality of machine.

Parts

Guide roller ass’y

Maintained

500

hrs.

1000

hrs.

1500

hrs.

2000

hrs.

Possible symptom

encountered

Remarks

Abnormal rotation or significant

vibration requires replacement.

Sup guide shaft

Reverse guide

Slant pole on pole base

Full erase head

A/C head

Upper and lower drum ass’y

Capstan D.D. motor

Pinch roller

Reel belt

Tension band ass’y

Loading motor

Idler ass’y

Limiter pulley

Lateral noises Head

occasionally blocked

Color and beating

Small sound or sound

distortion

Poor S/N ratio, no color

Poor flatness of the

envelope with alignment

tape

No tape running,

uneven color

No tape running, tape

slack

No tape running, tape

slack, no fast forward/

rewind motion

Screen swaying

Cassette not loaded or

unloaded

No tape running, tape

slack

Clean tape contact part with the

specified cleaning liquid.

Clean tape contact area with the

specified cleaning liquid.

Clean rubber and rubber contact

area with the specified cleaning

liquid.

Supply/take-up main brake levers

Tape slack

Replace the roller of the cleaner

AHC (Automatic head cleaner)

when it wears down.

Just change the AHC roller

assembly for new one.

NOTE : Part replacement. : Cleaning : Apply grease

<Specified> Cleaning liquid Industrial ethyl alcohol

* This mechanism does not need electric adjustment with variable resistor. Check parts. If any deviation is found,

clean or replace parts.

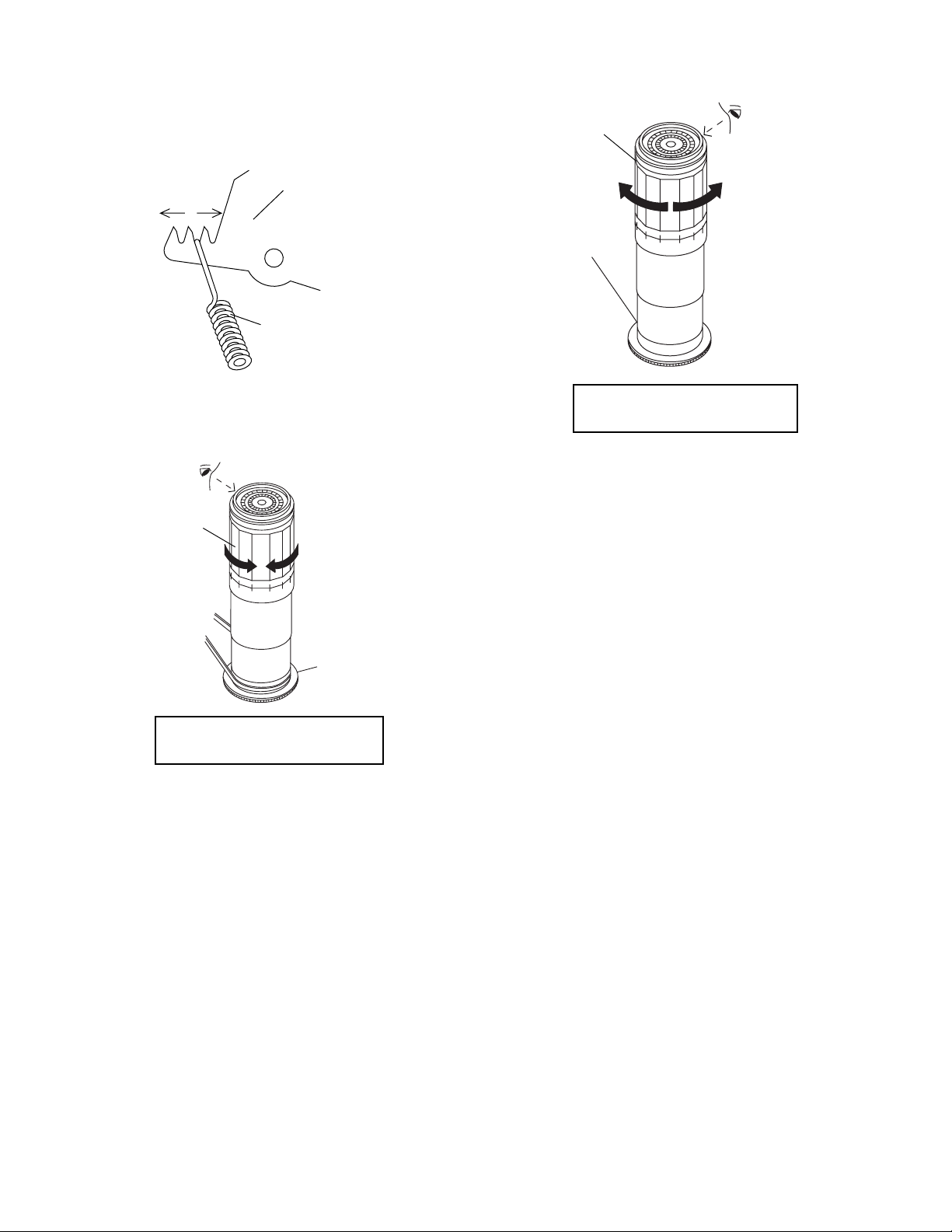

Video head cleaning procedure

1. Apply one drop of cleaning liquid to the cleaning paper with the baby oiler.

2. Gently press the cleaning paper against the video head to fix your finger, and move the upper drum so that each head

is passed to and fro 5 times (do not move the cleaning paper).

3. Wipe with the dry cleaning paper.

Notes :

• Use the commercially available ethanol of Class 1 as

cleaning liquid.

• Since the video head may be damaged, do not move up

and down the cleaning paper.

Gently press the cleaning paper to

fix with your finger, and rotate the

upper drum to clean.

Move to and fro 5 times for each head.

(Do not move the cleaning paper.)

Rotate the upper drum

with one hand.

• Whenever the video head is cleaned, replace the cleaning paper.

• Do not apply this procedure for the parts other than the

video head.

Parts Code Description Code

ZPAPRA56-001E Cleaning Paper AW

ZOiLR-02-24TE Babe Oiler (Spoit) AH

16

Page 17

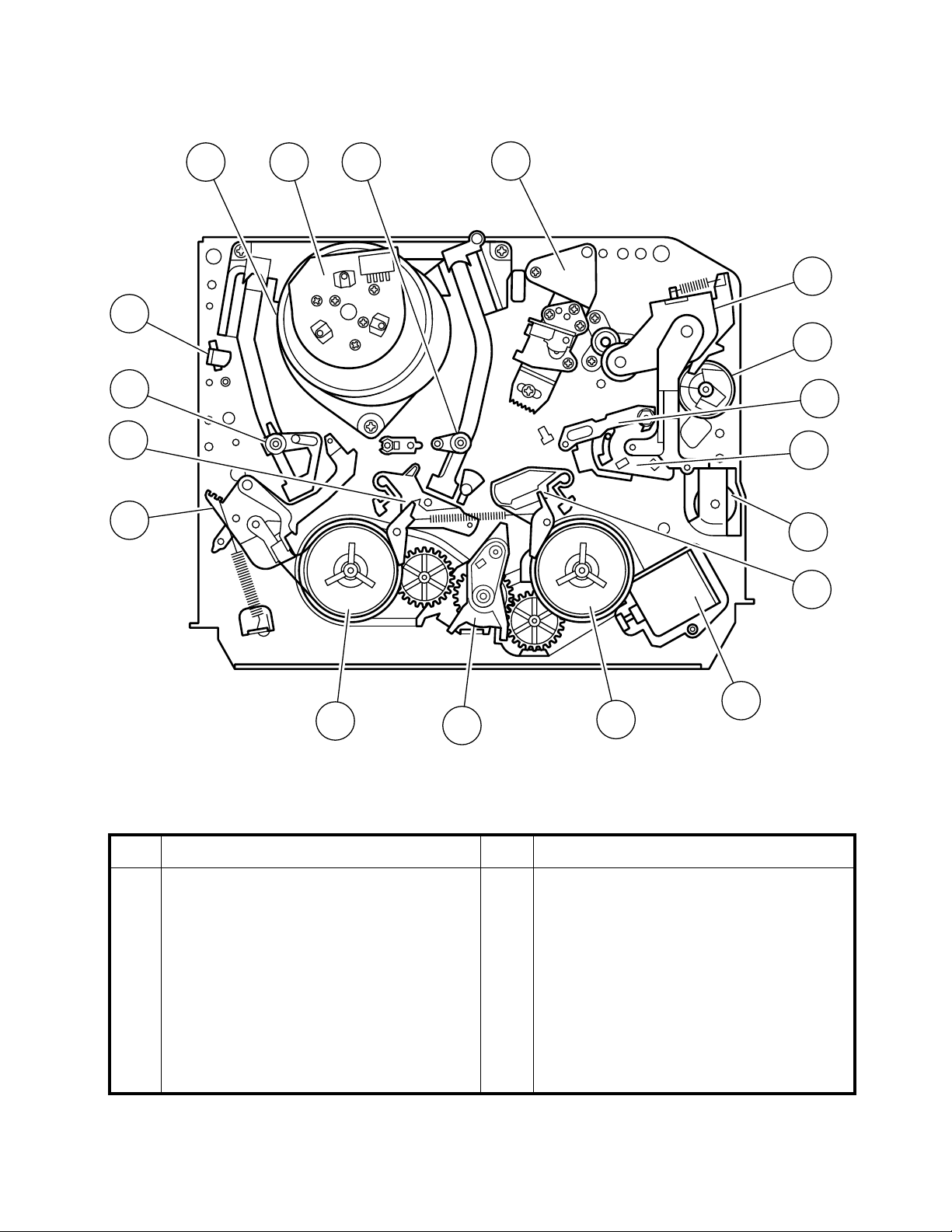

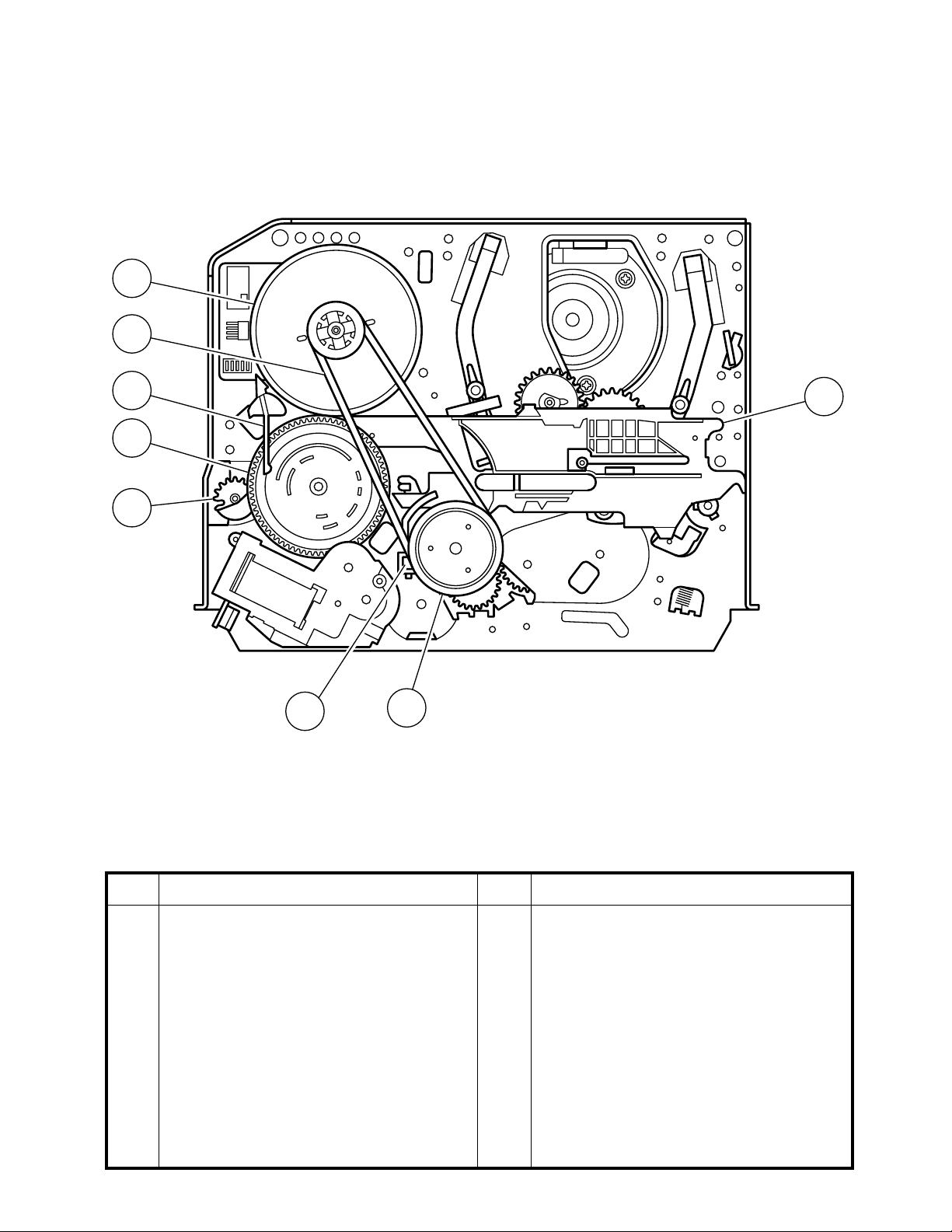

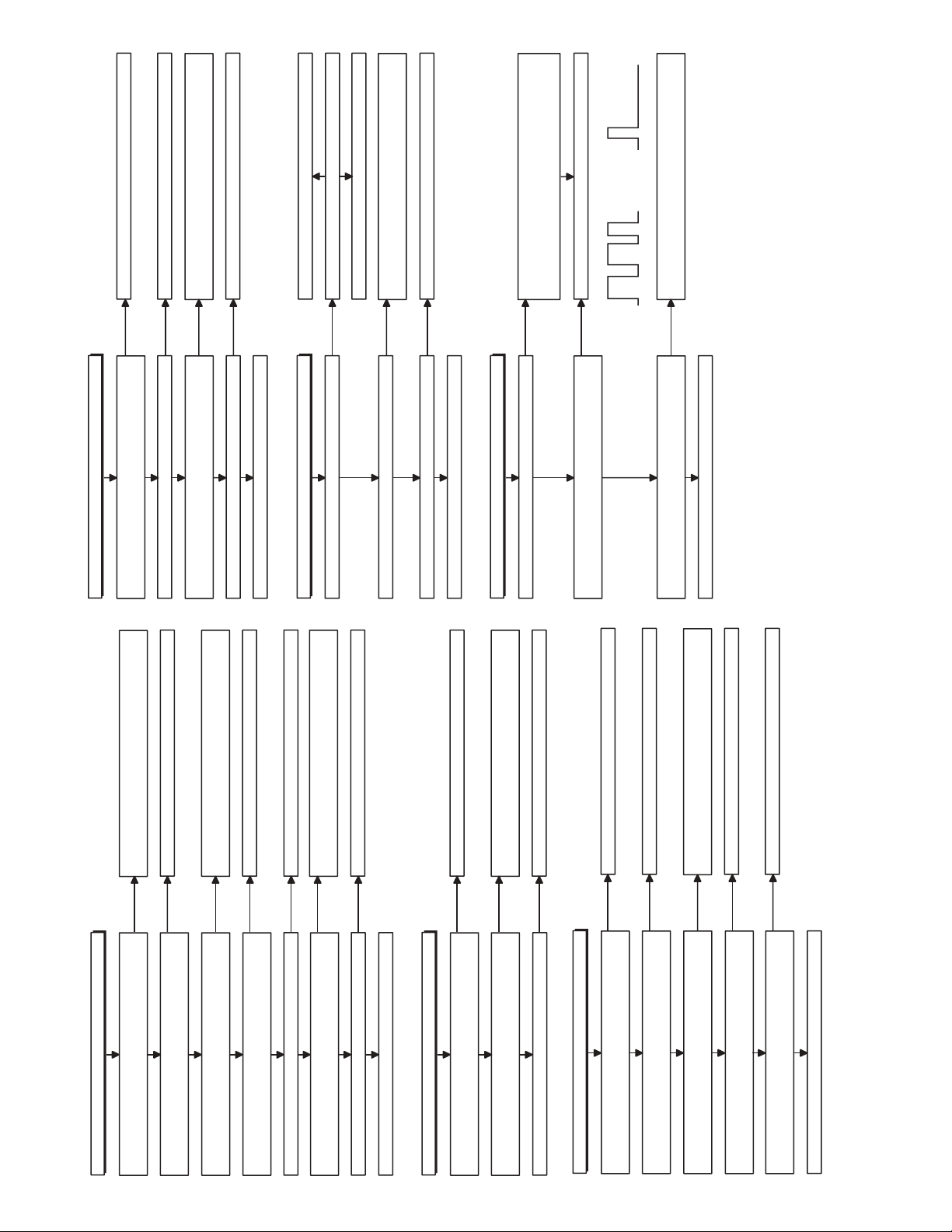

8-3. FUNCTION OF MAJOR MECHANICAL PARTS (TOP VIEW)

DV-NC55U/C/M

15

17

18

10

14

1

9

2

7

3

11

5

12

8

6

No. Function

1 Full erase head

2 Supply pole base ass’y

3 Tension arm

4 Idler wheel ass’y

5 Pinch drive lever ass’y

6 Supply reel disk

7 Supply main brake

4

No. Function

8 Take-up main brake

9 Pinch drive cam

10 A/C head ass’y

11 Reverse guide lever ass’y

12 Casecon drive gear

13 Take-up reel disk

14 Pinch roller lever ass’y

13

16

17

Page 18

DV-NC55U/C/M

FUNCTION OF MAJOR MECHANICAL PARTS (BOTTOM VIEW)

21

22

19

20

12

23

26

24

No. Function

15 Upper and lower drum ass’y

16 Loading motor

17 Drum drive motor

18 Take-up pole base ass’y

19 Slow brake lever

20 Master cam

21 Capstan D.D. motor

No. Function

22 Reel belt

23 Clutch lever

24 Limiter pulley ass’y

26 Shifter

18

Page 19

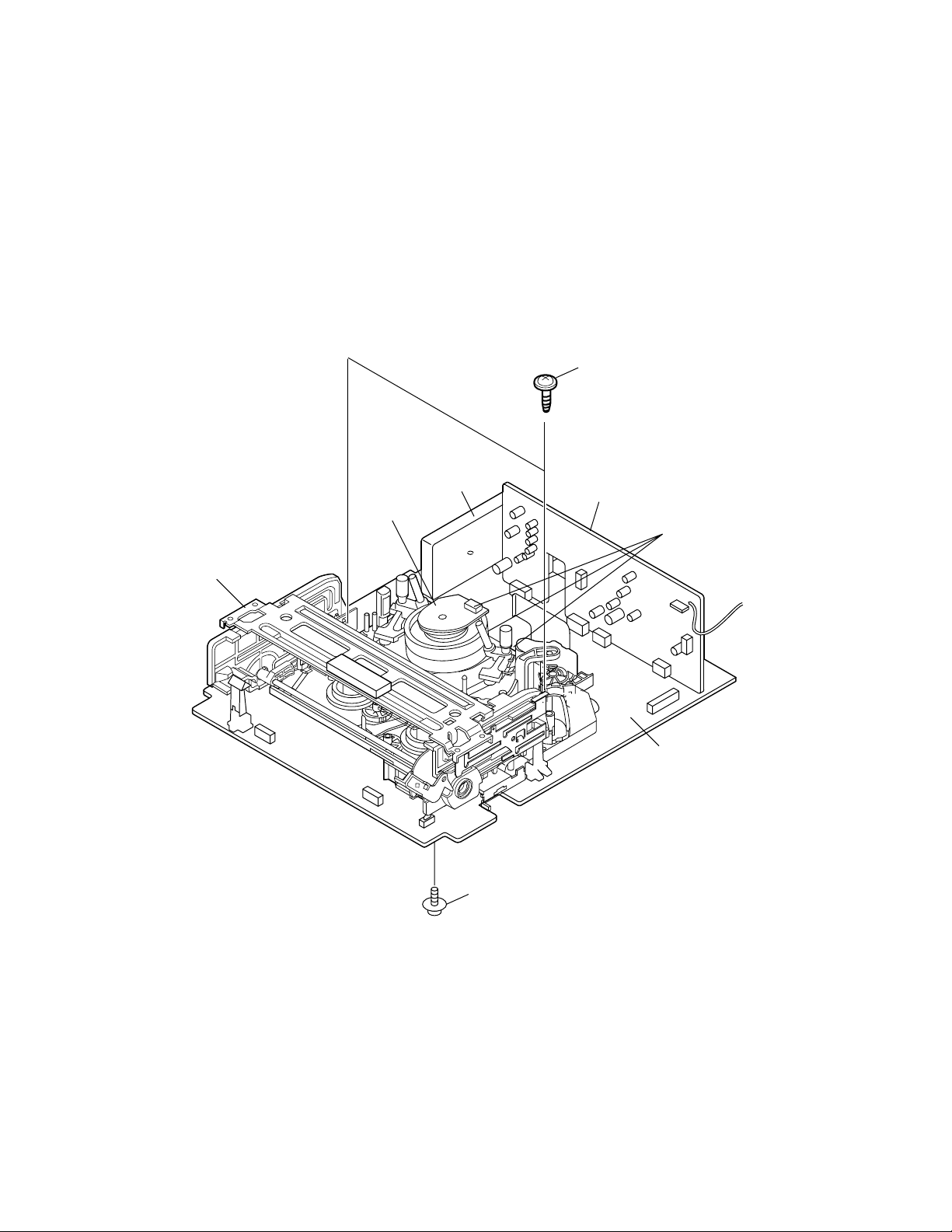

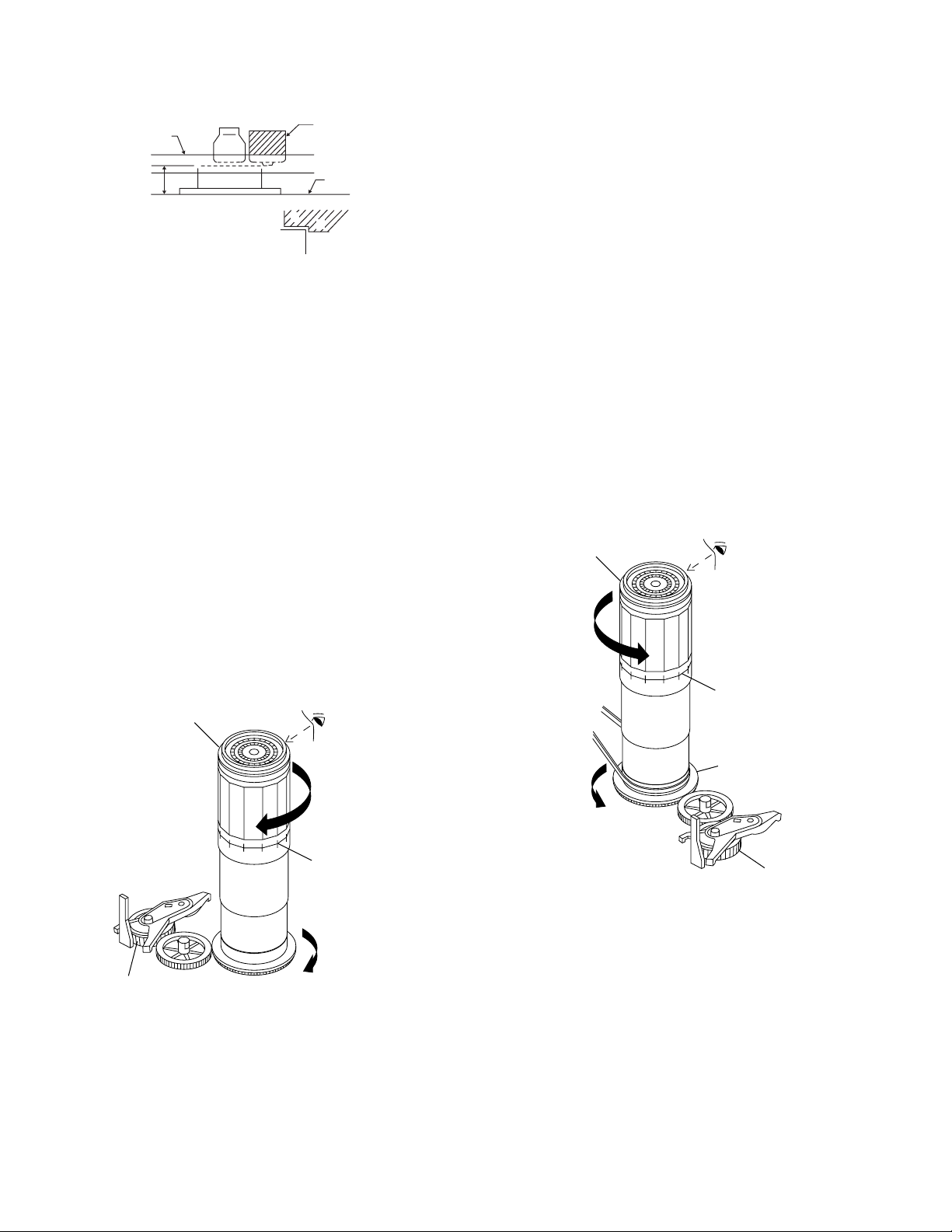

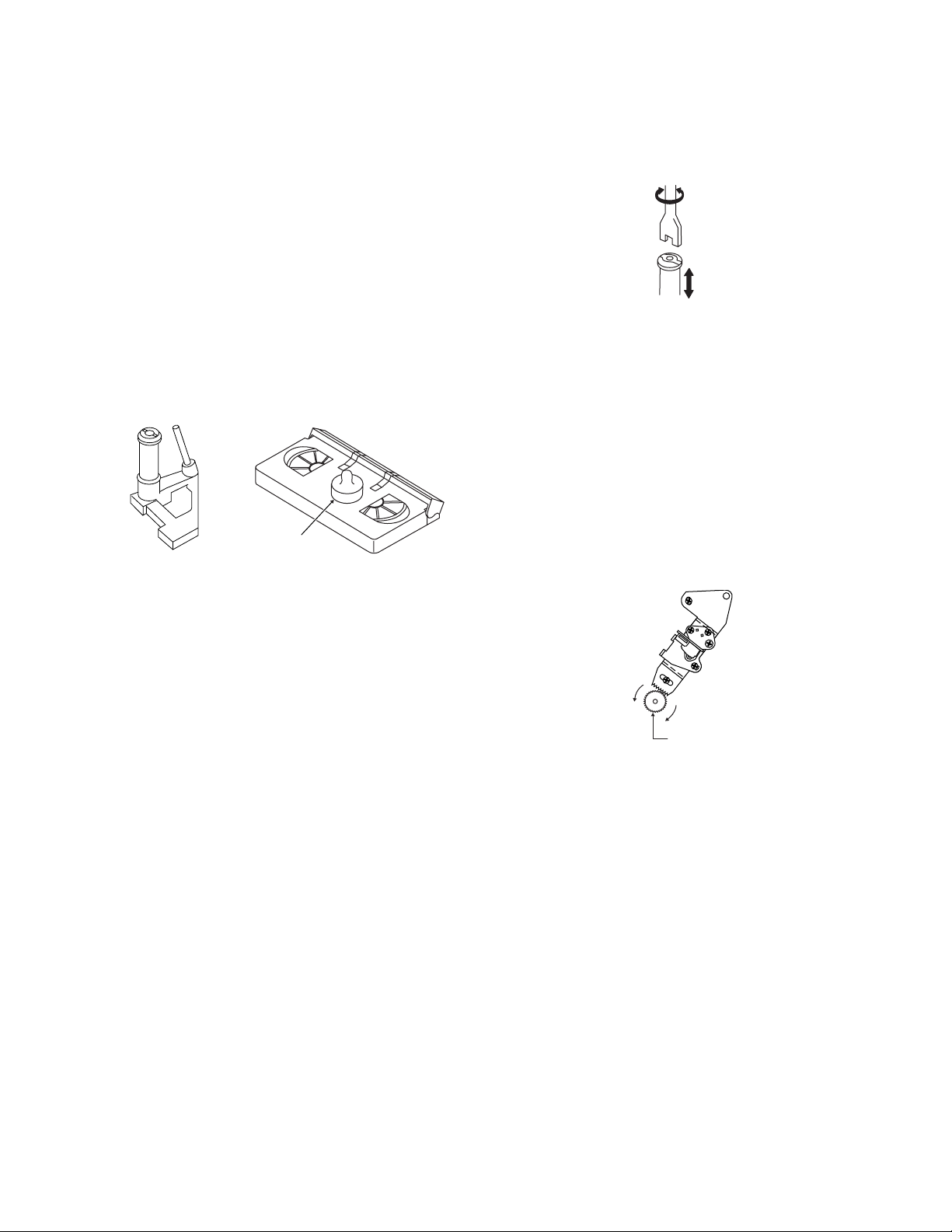

8-4. DISASSEMBLING THE MECHANISM/MAIN PWB ASSEMBLY

DV-NC55U/C/M

1. When removing the mechanism from the main PWB.

Remove the PWB bottom plate 1 screw 1.

Remove the FFC cable (AA, AD, AH) 2 which connect-

ing the PWB and the mechanism.

Take out vertically the mechanism so that it does not

damage the adjacent parts.

MECHANISM

CHASSIS

CASSETTE

HOUSING

Tuner

2. Removing the mechanism and cassette housing.

Remove 2 screws 3 fixing the cassette housing to the

mechanism, and remove the cassette housing.

3

AUDIO/VIDEO PWB

2

1

MAIN PWB

19

Page 20

DV-NC55U/C/M

1

AUDIO/VIDEO PWB

MAIN PWB

START SENSOR

END SENSOR

REC TIP SW

TUNER

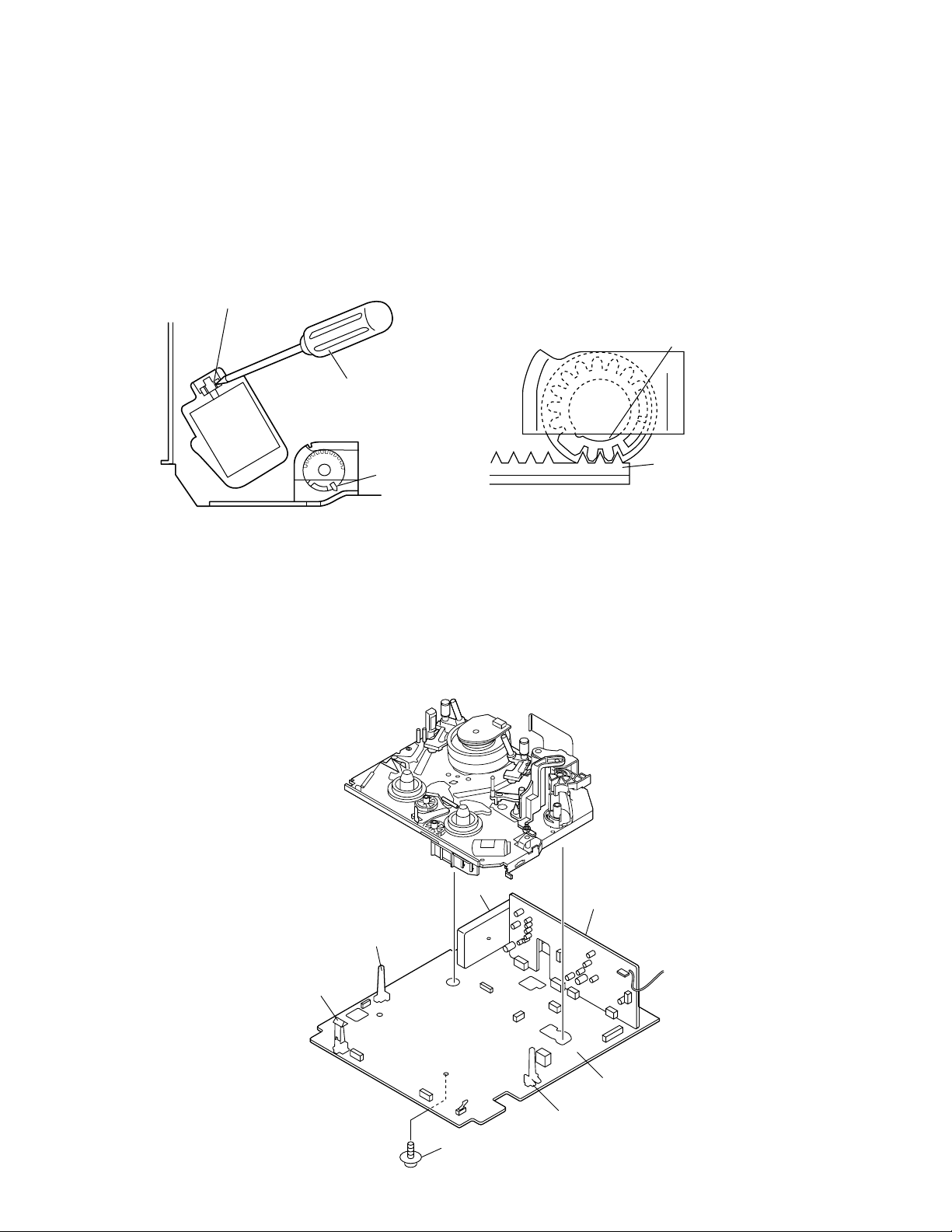

8-5. CARES WHEN REASSEMBLING

INSTALLING THE CASSETTE HOUSING

When the cassette housing is installed on the mechanism,

the initial setting is essential condition.

There are two initial setting methods, namely electrical and

mechanical.

1. Electrical initial setting

So as to perform initial setting of mechanism execute the

Step 1 of Installation of cassette housing. After ascertaining

the return to the initial setting position (*1) install the

Pulley feed gear

Screwdriver

Tilt mark (*1)

INSTALLING THE MECHANISM ON PWB

Lower vertically the mechanism, paying attention to the

mechanism edge, and install the mechanism with due care

so that the parts are not damaged. So as to fix the mechanism to the main PWB install 1 screw 1. For other, fix the

vicinity of loading motor and solder joint side of main PWB.)

Connect again the FFC cable (AA-MH, AD-ME, AH-MH)

between the mechanism and the main PWB.

cassette housing. (Conditions: When mechanism and PWB

have been installed)

2. Mechanical initial setting

Feed the pulley feed gear of loading motor with screw

driver. After ascertaining the return to the initial set position

(*1) install the cassette housing in the specified position.

(This method is applied only for the mechanism.)

Casecon

drive gear

Drive angle of

cassette housing

PARTS WHICH NEED PARTICULAR CARE

When installing the mechanism chassis on the PWB unit,

take care so as to prevent deformation due to contact of

mechanism chassis with REC TIP SW.

20

Page 21

DV-NC55U/C/M

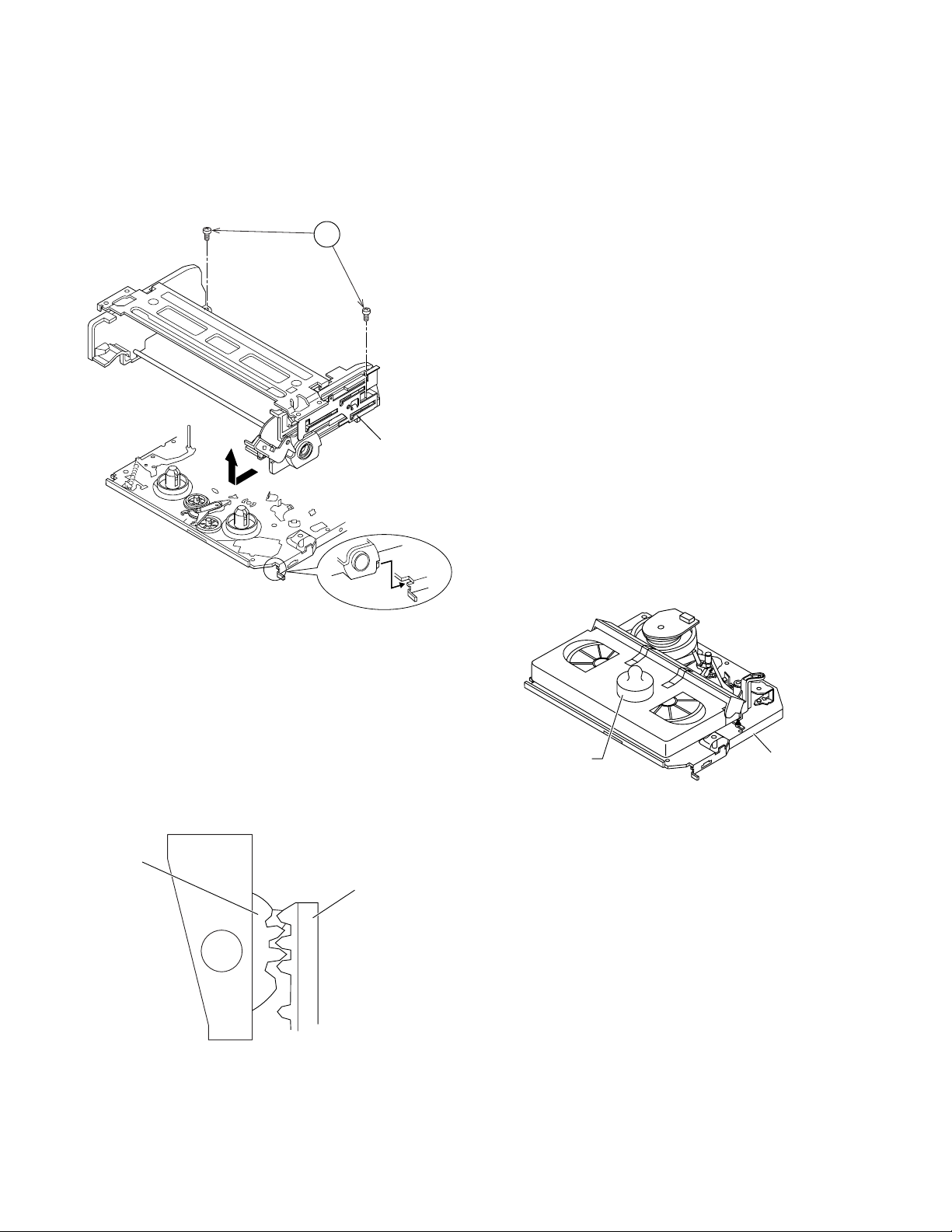

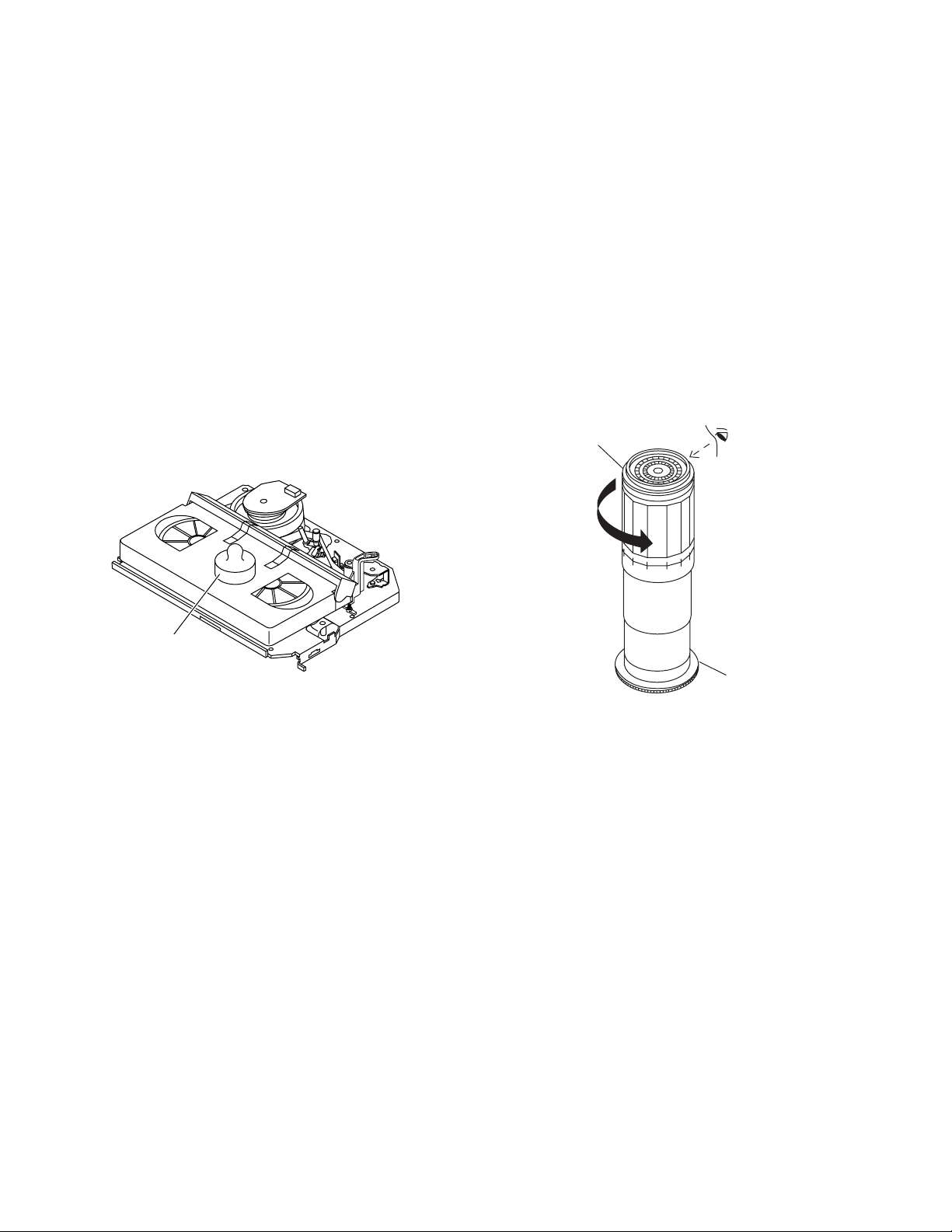

8-6.REMOVING AND INSTALLING THE CAS-

SETTE HOUSING

• Removal

1. In the cassette removing mode, remove the cassette.

2. Unplug the power cord.

3. Remove in the following numerical order.

a) Remove two screws 1.

b) Slide and pull up the cassette housing control.

1

Cassette

housing

control

Notes:

1. When fitting the S/E sensor holder to the cassette

controller frame L/R, take care.

2. Misengagement of teeth of casecon drive gear and drive

angle gear causes malfunction. (The cassette cannot be

set, load and ejection are repeated).

3. In the case when you use the magnet screw driver, never

approach the magnet driver to the A/C head, FE head,

and drum.

4. When installing or removing, take care so that the

cassette housing control and tool do not contact the

guide pin or drum.

5. After installing the cassette housing control once perform cassette loading operation.

8-7.TO RUN A TAPE WITHOUT THE CASSETTE

HOUSING CONTROL ASSEMBLY

1. Remove the full-surface panel.

2. Short-circuit between TP5102 and TP5103.

3. Plug in the power cord.

4. Turn off the power switch.

(The pole bases move into U.L.position.)

5. Open the lid of a cassette tape by hand.

6. Hold the lid with two pieces of vinyl tape.

7. Set the cassette tape in the mechanism chassis.

8. Stabilize the cassette tape with a weight (500g) to

prevent floating.

9. Turn on the power switch.

10. Perform running test.

Figure 8-1.

• Reassembly

1. Before installing the cassette housing control, shortcircuit between TP5102 and TP5103 provided goes left

at VTR display PWB, press the eject button. The casecon

drive gear turns and stops when the positioning mark

appears. Engage two teeth of casecon drive gear with

the three teeth of casecon drive angle gear, and set on

the mechanism chassis as shown below.

Casecon

drive gear

Casecon drive

angle gear

Figure 8-2.

500g

Weight to prevent

float (500g)

Mechanism chassis

Figure 8-3.

Note:

The weight should not be more than 500g.

To take out the cassette tape.

1. Turn off the power switch.

2. Take out the cassette tape.

2. Install in the reverse order of removal.

Power source plug is pulled out after the mounted

completion, and it comes.

21

Page 22

DV-NC55U/C/M

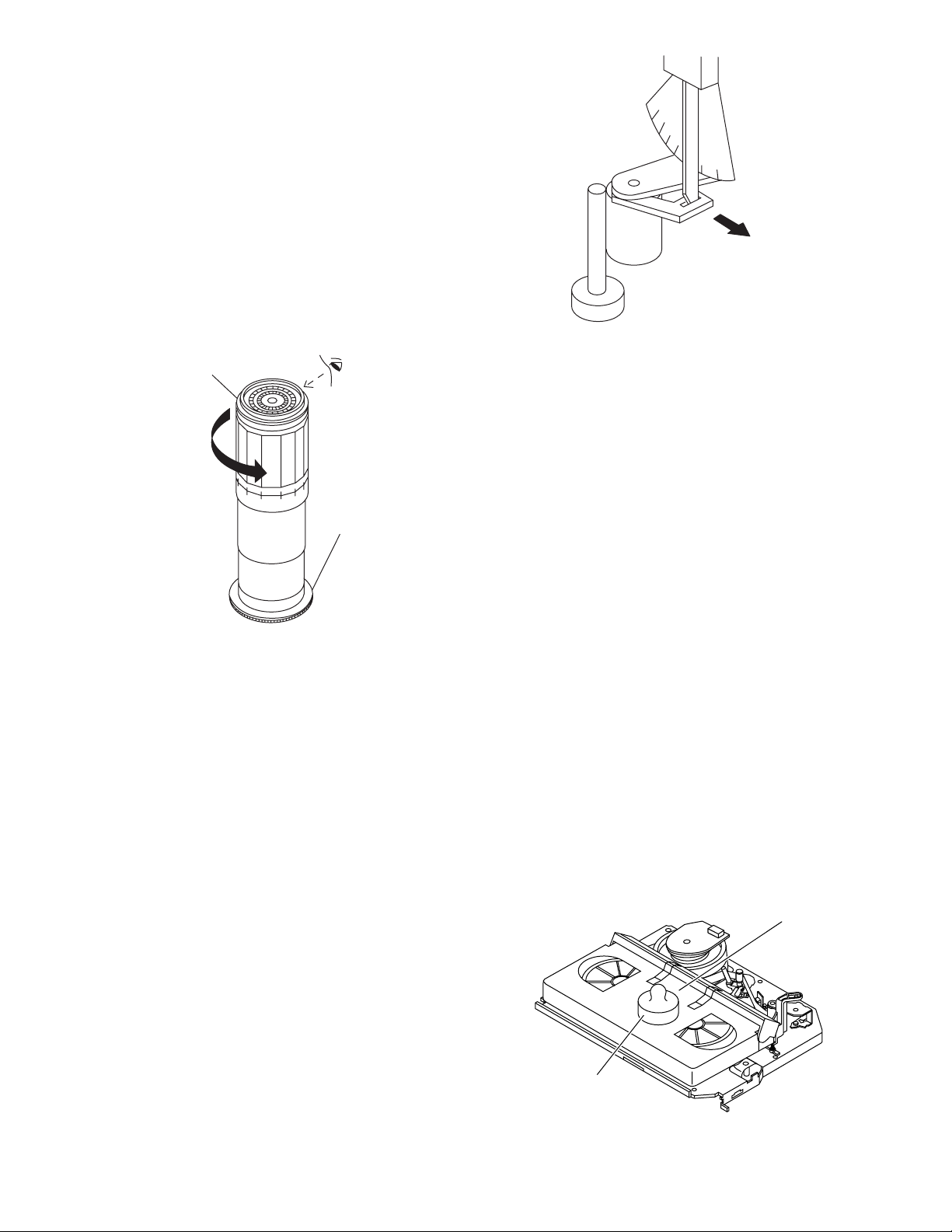

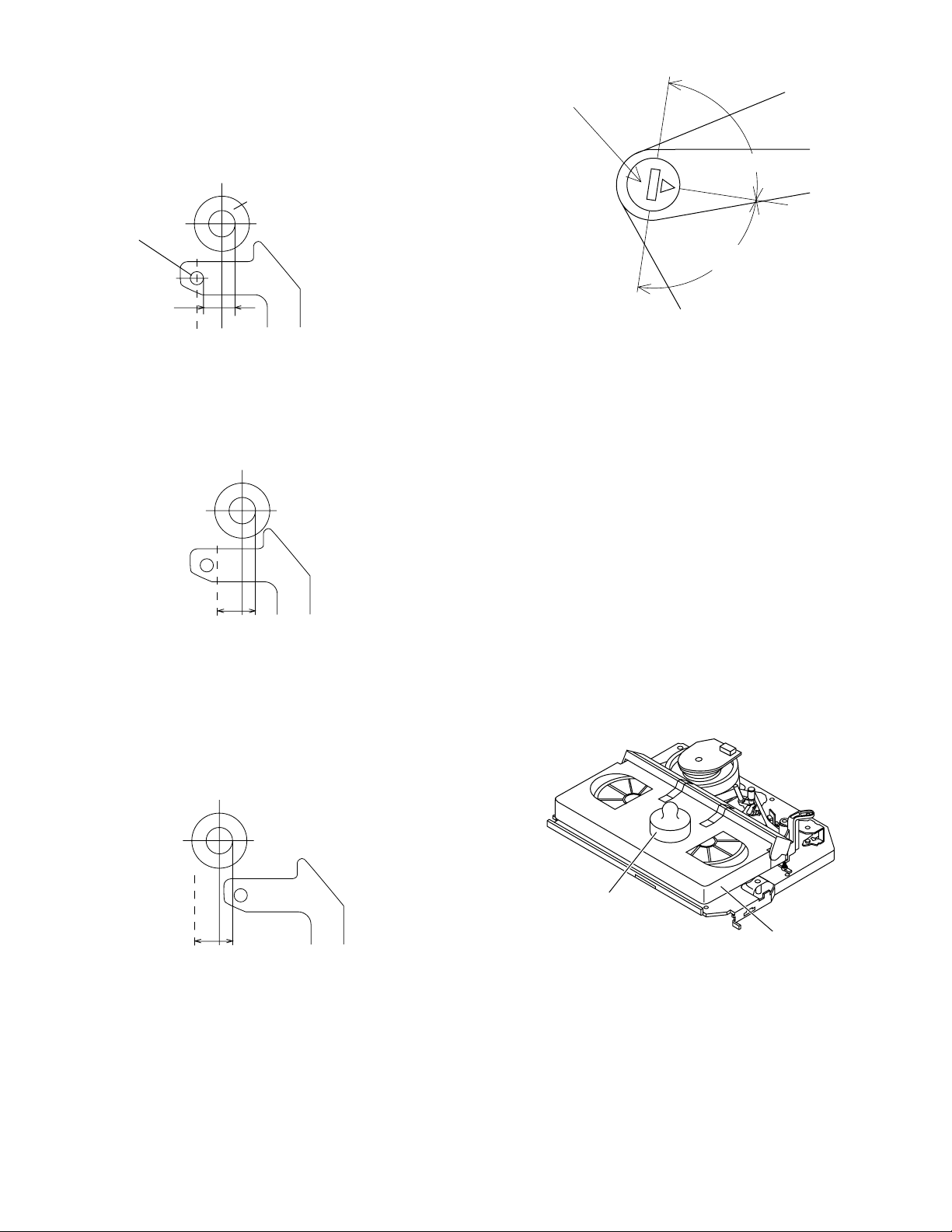

8-8.REEL DISK REPLACEMENT AND HEIGHT

CHECK

• Removal

1. Remove the cassette housing control assembly.

2. Pull the tension band out of the tension arm ass'y.

3. Remove the Supply/Take-up main brake ass'y.

4. Open the hook at the top of the reel disk, and remove the

reel disk.

Note:

Take care so that the tension band ass'y and main brake

ass'y (especially soft brake) are not deformed.

Tension arm ass'y

Supply main brake ass'y

Tension band ass'y

Supply reel disk

Take-up main brake ass'y

Take-up reel disk

Notes:

1. When installing the reel disk, take due care so that the

tension band ass'y is not deformed and grease does no

adhere.

2. Do not damage the Supply main brake ass'y. Be careful

so that grease does not adhere to the brake surface.

• Reassembly (Take-up reel disk)

1. Clean the reel disk shaft and apply grease (SC-141) to

it.

2. Align the phase of the reel disk to that of the reel relay

gear and to install a new take-up reel disk onto the shaft.

3. Check the reel disk height and reassemble the take-up

main brake ass'y.

Note:

1. Take care so that the Take-up main brake ass'y is not

damaged. Take care so that grease does not adhere the

brake surface.

2. After reassembly, check the video search rewind back

tension (see 8-13), and check the brake torque (see 8-

17).

• Height checking and adjustment

Note:

1. Set the master plane with due care so that it does not

contact the drum.

2. When putting the master plane, shift the reverse guide

a little in the loading direction. Care must be taken since

excessive shift results in damage.

Figure 8-4.

Note:

When the tension band ass'y is pressed in the direction of

the arrow for removal, the catch is hard to be deformed.

Figure 8-5.

• Reassembly (Supply reel disk)

1. Clean the reel disk shaft and apply grease (SC-141) to

it.

2. Match the phases of reel disk and reel relay gear, and set

the new reel disk.

3. After checking the reel disk height, wind the tension

band ass'y around the reel disk, and insert into the hole

of tension arm ass'y.

4. Assemble the Supply main brake ass'y.

Master plane

Reverse

guide

Supply reel disk

Cassette lock

release shaft

Take-up reel disk

Position

pin

Figure 8-6.

Note:

1. Check that the reel disk is lower than part A but higher

than part B. If the height is not correct, readjust the reel

disk height by changing the poly-slider washer under the

reel disk.

22

Page 23

DV-NC55U/C/M

2. Whenever replacing the reel disk, perform the height

checking and adjustment.

Master plane

10 ± 0.2mm

Reel disk

Reel disk

Reel disk height

adjusting jig

Mechanism chassis

A

B

Figure 8-7.

8-9. CHECKING AND ADJUSTMENT OF TAKE-

UP TORQUE IN FAST FORWARD MODE

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

take-up reel disk.

2. Press the FF button.

3. To calculate the remaining capacity of the play back

mode, slowly rotate the supply reel disk, and then shift

it into the forward mode.

• Checking

1. Turn the torque gauge slowly (one rotation every 2 to 3

seconds) by hand in the CW direction.

2. Make sure that the indication of torque gauge is not less

than 30mN·m (306gf·cm).

Torque gauge

Notes:

1. Hold the torque gauge by hand so that it is not moved.

2. Do not keep the reel disk in lock state. Do not allow longtime measurement.

8-10.CHECKING AND ADJUSTMENT OF TAKE-

UP TORQUE IN REWIND MODE

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Setting

1. Set a torque gauge to zero on the scale. Place it on the

supply reel disk.

2. Press the rewind button.

3. To calculate the remaining capacity, slowly rotate the

take-up reel disk, and then shift it into the rewind mode.

• Checking

1. Turn the torque gauge slowly (one rotation every 2 to 3

seconds) by hand in the CCW direction.

2. Make sure that the indication of torque gauge is not less

than 30mN·m (306gf·cm).

Torque gauge

30mN·m (306gf·cm)

or more

CCW

The gauge is held at

its maximum value.

(Red mark)

30mN·m (306gf·cm)

or more

Idler ass'y

CW

The gauge is held at

its maximum value.

(Red mark)

Figure 8-8.

• Adjustment

1. If the FF winding-up torque is less than the specified

value, clean the capstan D.D. motor pulley, drive belt,

and limiter pulley with cleaning liquid, and check again.

2. If the torque is less than the set value, replace the reel

belt.

Supply reel disk

Idler ass'y

Figure 8-9.

• Adjustment

1. If the rewind winding-up torque is less than the specified

value, clean the capstan D.D. motor pulley, drive belt,

and limiter pulley with cleaning liquid, rewind again, and

check the winding-up torque.

2. If the winding-up torque is still out of range, replace the

drive belt.

23

Page 24

DV-NC55U/C/M

Notes:

1. Hold the torque gauge by hand so that it is not moved.

2. Do not keep the reel disk in lock state. Do not allow longtime measurement.

8-11.CHECKING AND ADJUSTMENT OF

TAKE-UP TORQUE IN RECORD/

PLAYBACK MODE

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Turn off the power switch.

• Open the cassette torque meter lid, and fix it with

tape.

• Load the cassette torque meter into the unit.

• Put the weight (500g) on the cassette torque meter.

• Turn on the power switch.

• Press the picture record button, and set EP picture

record mode (x3).

Set value EP6.9 ± 2.5mN⋅m (70 ± 25gf⋅cm)

8-12.CHECKING AND ADJUSTMENT OF TAKE-

UP TORQUE IN VIDEO SEARCH REWIND

MODE

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Setting

Press the playback button and rewind button to set the

video search rewinding mode.

• Checking

Place the torque gauge on the supply reel disk, and turn it

counterclockwise very slowly (one rotation every 1 to 2

seconds) and check that the torque is within the set value

14.0 ± 3.9mN⋅m. (144 ± 40gf⋅cm)

Torque gauge

CCW

500g

Cassette torque meter

Figure 8-10.

• Checking

1. Make sure that value is within the setting 6.9 ± 2.5mN·m

(70 ± 25gf·cm).

2. The winding-up torque fluctuates due to variation of

rotation torque of limiter pulley ass'y. Read the center

value of fluctuation as setting.

3. Set the EP record mode (x3) and make sure that the

winding-up torque is within setting.

• Adjustment

If the playback winding-up torque is not within the setting,

replace the limiter pulley assembly.

Note:

When the torque cassette is set, put a weight (500g) to

prevent rise.

When the cassette torque meter is taken out.

Turn off the power switch.

Supply reel disk

Figure 8-11.

Note:

Surely put the torque gauge on the reel disk to measure. If

the torque gauge is raised, accurate measurement is

impossible.

• Adjustment

If the rewinding playback winding-up torque is not within the

setting, replace the limiter pulley assembly.

Note:

The winding-up torque fluctuates due to variation of rotation torque of supply reel disk. Read the center value of

fluctuation as setting.

24

Page 25

8-13.CHECKING THE VIDEO SEARCH REWIND

BACK TENSION

• Remove the cassette housing control assembly.

DV-NC55U/C/M

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Checking

1. After pressing the play button, press the rewind button,

and set the video search rewind mode.

2. Place the torque gauge on the take-up reel disk, and turn

it counterclockwise very slowly (one rotation every 2 to

3 seconds) and check that the torque is within the set

value 3.4 ± 1.5mN⋅m (35 ± 15gf⋅cm).

Torque gauge

CCW

Take-up reel disk

Pinch roller

Capstan shaft

Tension gauge adapter

Tension gauge

900 - 1,200gf

Figure 8-13.

1. Detach the pinch roller from the capstan shaft.

Do not separate excessively. Or the pinch lever and

pinch double action lever may disengage.

2. Engage the tension gauge adapter with the pinch roller

shaft, and pull in the arrow direction.

3. Gradually return the pinch roller, and measure the

pulling force when the pinch roller contacts the capstan

shaft.

4. Make sure that the measured value is within setting 9.0

N to 11.8 N (900 to 1,200gf).

Figure 8-12.

Notes:

Set the torque gauge securely on the take-up reel disk.

If it is not secure, the measurement will be incorrect.

8-14.CHECKING THE PINCH ROLLER

PRESSURE

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Checking

Press the play button to set the playback mode.

8-15.CHECKING AND ADJUSTMENT OF

TENSION POLE POSITION

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Turn off the power switch.

• Setting

1. Open the cassette tape (T-120), and fix with tape.

2. Set the cassette tape in loading state.

3. Put the weight (500g) on the cassette tape.

4. Turn on the power switch.

5. Make the adjustment with the beginning of a T-120 tape.

(T-120)

500g

Weight to prevent

float (500g)

25

Figure 8-14.

Page 26

DV-NC55U/C/M

• Checking

1. Set a cassette tape, push the REC button to place the

unit in the SP record mode. Now check the tension pole

position.

2. Visually check to see if the right edge of the tension pole

is within the 2.3 ± 0.25 from the right edge of the Sup

guide shaft.

Sup guide shaft

Tension pole

2.3 ± 0.25

Make the adjustment with the beginning of a T-120 tape.

Figure 8-15.

At left side from the center line

Tension pole adjuster adjusting range

Tension pole adjuster

90°

90°

Figure 8-18.

Adjust so that the delta mark of tension pole adjuster is

within 90° range (left, right).

8-16.CHECKING AND ADJUSTMENT OF

RECORD/PLAYBACK BACK TENSION

• Remove the cassette housing control assembly.

2.3 ± 0.25

Figure 8-16.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate counterclockwise.

At right side from the center line

2.3 ± 0.25

Figure 8-17.

Insert the slotted screwdriver in the tension pole adjuster,

and rotate clockwise.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Turn off the power switch.

• Setting

1. Open the torque cassette meter and fix with tape.

2. Set the cassette tape in loading state.

3. Put the weight (500g) on the cassette torque meter.

4. Turn on the power switch.

500g

Weight to prevent

float (500g)

Cassette torque

meter

Figure 8-19.

• Checking

1. Push the REC button to place the unit in the SP record

mode.

2. At this time ascertain that the back tension is within the

setting (36.5 to 52g·cm) by seeing the indication of

torque cassette meter.

26

Page 27

DV-NC55U/C/M

• Adjustment

1. If the indication of torque cassette meter is lower than

the setting, shift the tension spring engagement to the

part A.

2. If the indication of torque cassette meter is higher than

the setting, shift the tension spring engagement to the

part B.

A

B

Tension arm

Tension spring

Figure 8-20.

8-17. CHECKING THE BRAKE TORQUE

• Checking the brake torque at the supply side

Torque gauge

CCW CW

• Checking the brake torque at the take-up side

Torque gauge

CW

Take-up reel

disk

CCW: 4.9~13.7mN⋅m (50~140gf⋅cm)

CW: 3.9~10.8mN⋅m (40~110gf⋅cm)

CCW

Figure 8-22.

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

Supply reel disk

CCW: 2.9~9.8mN⋅m (30~100gf⋅cm)

CW: 4.9~13.7mN⋅m (50~140gf⋅cm)

Figure 8-21.

• Remove the cassette housing control assembly.

• After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

• Setting

1. Switch from the FF mode to the STOP mode.

2. Disconnect the power cord.

3. Set a torque gauge to zero on the scale. Place it on the

supply reel disk.

• Checking

Turn the torque gauge at a rate of about one turn/2 sec

in the CW direction/CCW direction with respect to the

supply reel disk so that the reel disk and torque gauge

pointer rotate at equal speed, and make sure that the

value is within the setting (CW direction: 4.9 to 13.7mN·m

(50 to 140gf·cm); CCW direction: 2.9 to 9.8mN·m (30 to

100gf·cm).

• Setting

1. Switch from the FF mode to the STOP mode.

2. Disconnect the power cord.

3. Set a torque gauge to zero on the scale. Place it on the

take-up reel disk.

• Checking

1. Turn the torque gauge at a rate of about one turn/2 sec

in the CCW direction/CW direction so that the reel disk

and torque gauge pointer rotates at equal speed and

make sure that the value is within the setting (CCW

direction: 4.9 to 13.7mN·m (50 to 140gf·cm), CW direction: 3.9 to 10.8 mN·m (40 to 110gf·cm).

2. Adjustment of the brake torque at the supply side and the

take-up side

• Unless the supply side brake torque or take-up side

brake torque is within the setting, clean the felt surface

of reel disk (supply, take-up) brake lever, check again

the brake torque.

• If value cannot be set within the setting yet, replace the

main brake ass'y or main brake spring.

27

Page 28

DV-NC55U/C/M

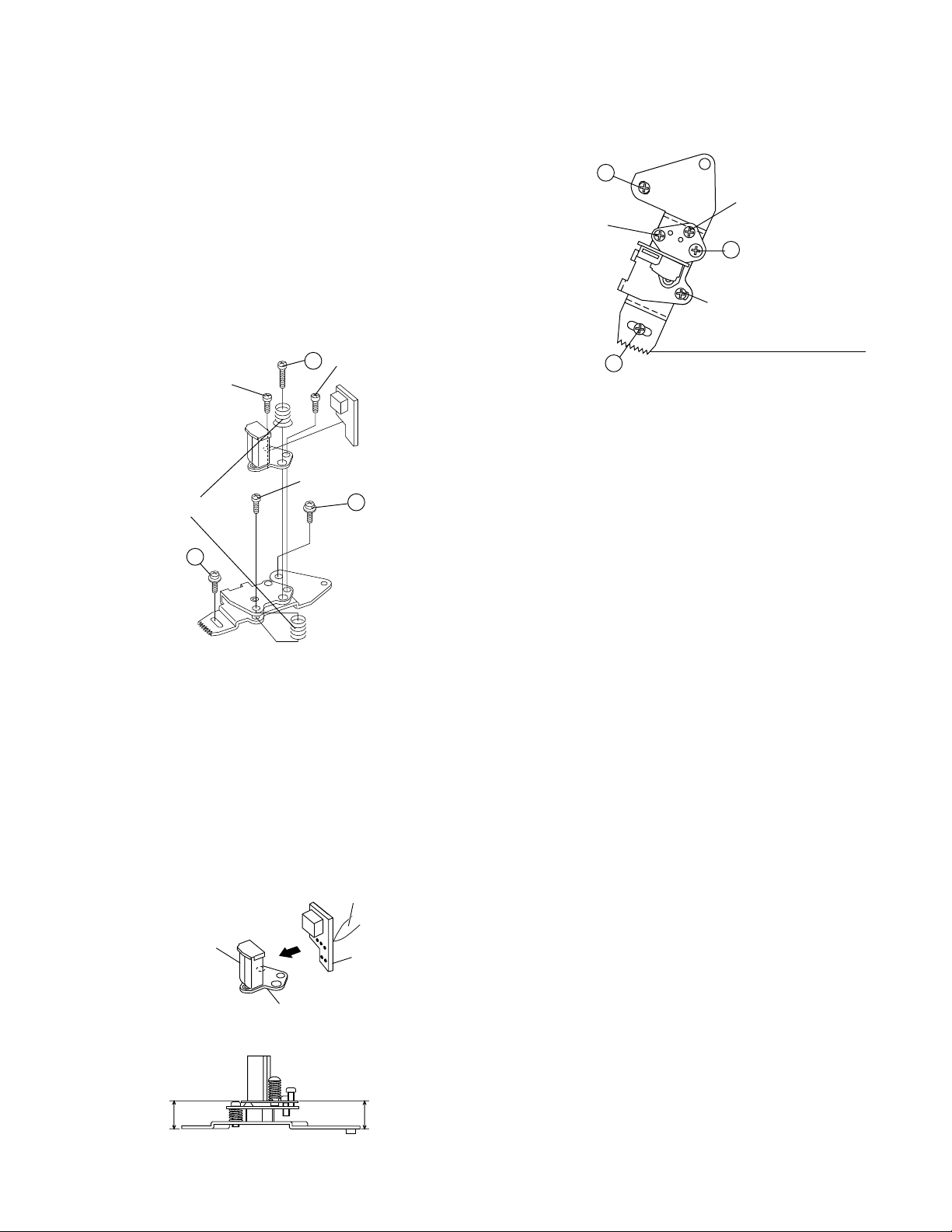

8-18. REPLACEMENT OF A/C (AUDIO/CONTROL)

HEAD

1. Remove the cassette housing control assembly.

2. In unloading state unplug the power cord.

• Removal

1. Remove the screws 123, Azimuth screw, Tilt screw.

2. Unsolder the PWB fitted to the A/C head.

Notes:

1. When replacing, never touch the head. If you touched,

clean with the cleaning liquid.

2. When removing the screw 3, take care so that the

spring may out.

Tilt screw

3

Azimuth screw

Height screw

Spring

1

3. Align the left end of gear of A/C head arm with the

punched mark of chassis, tentatively tighten the screws

1 and 2 so as to ensure smooth motion of A/C head

arm. Tentative tightening torque must be 0.15 to 0.20

N·m (1.5 to 2.0kgf·cm).

1

Tilt screw

Azimuth screw

3

Height screw

Left end of A/C head arm gear

2

Punched line mark on chassis

Figure 8-25.

Note:

1. If the screws 1 and 2 are tighten tentatively too loose,

the azimuth and height of A/C head may change when

they are finally tightened. Therefore care must be taken.

2. After completion of A/C head be sure to adjust tape

running. (Execute the running adjustment by the method

described in 8-21.)

2

Figure 8-23.

• Replacement

1. Solder the removed PWB to the new head assembly.

2. Adjust the height from the A/C head arm (lower surface)

to the A/C head plate to 10.8mm with slide calipers. (3

places of azimuth screw section, tilt screw section and A/

C head front section) (See the figure below.)

Solder

New A/C head ass'y

A/C head PWB

Never touch the head

A/C head plate

Figure 8-24.

10.8mm10.8mm

28

Page 29

DV-NC55U/C/M

8-19. A/C HEAD HEIGHT ROUGH ADJUSTMENT

• Setting

Height screw

Weight to prevent

float (500g)

Azimuth screw

Tilt screw

Cassette tape

500g

Mechanism chassis

Figure 8-26.

8-20.HEIGHT ADJUSTMENT OF REVERSE

GUIDE

1. Adjust the height from the mechanism chassis to the

reverse guide lower flange to 13.38 mm, using the

reverse guide height adjustment jig, in tape loading

state. (Refer to Figure 8-28 (a) (b).)

Reverse guide

Reverse guide height

adjusting jig

Mechanism

chassis

(a)

Figure 8-28.

2. Rotate counterclockwise the reverse guide height adjustment nut 1/10 turn. (For height adjustment use the

reverse guide height adjustment box driver (JiGDRiVER

11055)).

Reverse guide height

adjusting jig

13.38mm

(b)

Box driver

1. Turn off the power switch.

2. Set the cassette tape in the unit.

3. Turn on the power switch.

4. Press the PLAY button to put the unit in the playback

mode.

5. Roughly adjust the height of the A/C head by turning the

height screw until the tape is in the position shown

below.

A/C head

Tape

0.3mm

Figure 8-27.

• Adjustment

Adjust the height screw visually so that the control head is

visible 0.3mm below the bottom of the tape.

CCW

Height adjusting nut

Figure 8-29.

3. Set the tape, and check for tape crease near the reverse

guide in the playback mode.

If crease is found, turn the reverse guide adjustment nut

to remove crease. (As for crease check refer to Figure 8-

30.)

500g

Weight to

prevent float (500g)

A

Mechanism

chassis

Reverse guide

Capstan

motor shaft

Fixing guide

An example of

crease near the

reverse guide

* Check for crease from the A direction.

Figure 8-30.

29

Page 30

DV-NC55U/C/M

8-21. ADJUSTMENT OF TAPE DRIVE TRAIN

1. Tape run rough adjustment

1 Remove the cassette housing control assembly.

2 After short-circuiting between TP5102 and TP5103

provided goes left at VTR display PWB, plug in the

power cord.

3 Check and adjust the position of the tension pole.

(See 8-15.)

4 Check and adjust the video search rewind back

tension. (See 8-13.)

5 Connect the oscilloscope to the test point for PB

CHROMA signal output (TP1201). Set the synchronism of the oscilloscope to EXT. The PB CHROMA

signal is to be triggered by the head switching pulse

(TP1202).

6 Set the alignment tape (VROATSV) to play. (Put a

500g weight on the cassette tape to prevent lift of

cassette tape.)

Guide roller

Cassette Tape

500g

Weight of 500g

Figure 8-31.

Notes:

1. Previously set the tracking control in the center position,

and adjust the ATR signal waveform to maximum with X

value adjustment nut. Thereby the tape run rough adjustment is facilitated.

2. Especially the outlet side ATR signal waveform must

have higher flatness.

Figure 8-32.

2. Adjustment of A/C head height and azimuth

1 Perform the initial setting of A/C head position by the

method stated in "8-18 Replacement 3".

2 Connect the oscilloscope to the audio output termi-

nal.

3 Using the alignment tape in which 1 kHz linear audio

signal has been recorded, adjust the height screw so

as to get max audio output.

4 Using the alignment tape in which 7 kHz linear audio

signal has been recorded, adjust the azimuth screw

so as to get max audio output.

5 The adjustment of 3 and 4 twice or three times

repeat, and finally adjust 4.

7 Press the tracking button (+), (–) and change the

ATR signal waveform from max to min and from min

to max. At this time make sure that the ATR signal

waveform changes nearly parallel.

8 Unless the ATR signal waveform changes nearly

parallel, adjust the height of supply side and take-up

side guide roller so that the envelope waveform

changes nearly parallel. (For ATR signal adjustment

procedure refer to Figure 8-35.)

9 Turn the tilt screw to remove the tape crease at the

fixing guide flange.

Playback the tape and check for tape crease at the

fixing guide flange.

(1)If there is no tape crease

Turn the tilt screw clockwise so that tape crease

appears once at the flange, and then return the tilt

screw so that the crease disappears.

(2)If there is tape crease

Turn counterclockwise the tilt screw so that the

tape crease disappears.

(Reference) If the tilt screw is turned clockwise

crease appears at the lower flange.

For X value adjustment

Adjust the X value, turning the geartype screwdriver.

Figure 8-33.

3. Tape run adjustment

1 Connect the oscilloscope to PB CHROMA signal

output test point, set oscilloscope sync to EXT,

trigger-input the PB CHROMA signal (head switching pulse).

2 Rough adjustment of X value

Tentatively fix A/C head arm screws 1 and 2 by the

method described in 8-18 "Replacement 3".

Playback the alignment tape (VROATSV) and

shortcircuit between TP5101 and TP5103. As a

result the auto-tracking is automatically cancelled,

so that the X value adjustment mode is set.

Move the A/C head with the X value adjustment gear

driver (JiGDRiVER-6) by the method shown in Figure 8-33, and adjust the A/C head so as to get the

maximum ATR signal waveform. (Note: When the A/

C head is adjusted, adjust so that the maximum ATR

signal waveform is obtained nearest the position of

initial setting made in 8-18.)

30

Page 31

3 Next, press the tracking button (+), (–) and change

the ATR signal waveform from max to min and from

min to max. At this time adjust the height of supply

and take-up side guide roller with the adjustment

driver (JiGDRiVER-4) so that the ATR signal waveform changes nearly parallel.

4 If the tape is lifted or sunk from the helical lead

surface, the PB CHROMA signal waveform appears

as shown in Figure 8-35.

5 Press the tracking button (+), (–) and make sure that

the ATR signal waveform changes nearly parallel.

6 Finally check tape crease near the reverse guide. If

tape crease is found, remove it as stated in 8-20

"HEIGHT ADJUSTMENT OF REVERSE GUIDE"

item 3.

Supply side

Take-up side Supply side Take-up side

DV-NC55U/C/M

PB CHROMA

Signal

Head switching pulse

Figure 8-34.

4. A/C head X value adjustment

1 Tentatively fix A/C head arm screws 1 and 2 by the

method described in 8-18 "Replacement 3".

2 Playback the alignment tape (VROEFZCS or

VROEFZHS), and shortcircuit between TP5101 and

TP5103. As a result the auto-tracking is automatically cancelled, so that the X value adjustment mode

is set.

When the tape is below the helical lead.When the tape is above the helical lead.

Adjustment

Supply side guide roller

rotated in clockwise

direction (lowers guide

roller) to flatten

ATR signal.

Take-up side guide roller

rotated in clockwise

direction (lowers guide

roller) to flatten

ATR signal.

Figure 8-35.

3 Move the A/C head with the X value adjustment gear

driver by the method shown in Figure 8-33, and

adjust the A/C head so as to get the maximum ATR

signal waveform. (Note: At this time adjust so as to

get the maximum ATR signal waveform nearest the

A/C head position which has been set in case of X

value rough adjustment as stated in 8-21, 3- 2.)

4 Tighten finally the screws 1 and 2. Be sure to tighten

at first the screw 1 and then the screw 2. Final

tightening torque is 0.6N·m (If the screw 2 is tightened

first, the X value may deviate.)

5 Adjust the playback switching point (Refer to the

electric adjustment method.)

6 Playback the self-picture-recorded tape, and check

the flatness of ATR signal waveform and sound.

Supply side guide roller

rotated in counterclockwise direction (raises

guide roller) to make the

tape float above the helical

lead. The supply

side guide roller is then

rotated in the clockwise

direction to flatten the

ATR signal.

Take-up side guide roller

rotated in counterclockwise direction (raises

guide roller) to make the

tape float above the

helical lead. The take-up

side guide roller is then

rotated in the clockwise

direction to flatten the

ATR signal.

Notes:

When the A/C head X value adjustment is performed, be

sure to perform at first X value rough adjustment (refer to 8-

21, 3-2).

2

1

Figure 8-36.

31

Page 32

DV-NC55U/C/M

8-22.REPLACEMENT OF THE CAPSTAN D.D.

(DIRECT DRIVE) MOTOR

• Remove the mechanism from the main PWB (refer to 84 item 1 When removing the mechanism from the main

PWB ).

• Removal (Follow the order of indicated numbers.)

1. Remove the reel belt 1.

2. Remove the slow brake lever 2.

3. Remove the three screws 3.

3

Capstan D.D. motor

Capstan D.D.

motor

control PWB

8-23. REPLACEMENT OF DRUM D.D. MOTOR

1. Set the ejection mode.

2. Withdraw the main power plug from the socket.

• Removal (Perform in numerical order.)

1. Disconnect the FFC cable 1.

2. Unscrew the D.D. stator assembly fixing screws 2.

3. Take out the D.D. stator assembly 3.

4. Unscrew the D.D. rotor assembly fixing screws 4.

5. Take out the D.D. rotor assembly 5.

Notes:

1. In removing the D.D. stator assembly, part of the drum

earth spring pops out of the pre-load collar.

Be careful not to lose it.

2. Install, so that the D.D. rotor ass'y and upper drum ass'y

mounting direction check holes align.

(Align the upper drum dent with the rotor hole.)

3. Be careful not to damage the upper drum or the video

head.

4. Protect the hole elements from shock due to contact with

D.D. stator or D.D. rotor ass'y.

5. After installation adjust the playback switching point for

adjustment of servo circuit.

1

Reel belt

2

Slow Blake Lever

Figure 8-37.

• Reassembly

1. Taking care so that the capstan shaft does not contact

the mechanism chassis, set its position on the mechanism chassis, and then install with the three screws 3.

2. Install the slow brake lever 2.

3. Install the reel belt 1.

Notes:

1. Before installing the capstan D.D. motor, confirm whether

an acetate tape (ZTAPEN120020E) is drawn on the

back of mechanism chassis.

Stick an acetate tape on the projection part of

the chassis.

Capstan Motor Installation position.

Mechanism Chassis from the back.

2

D.D. stator ass'y

3

4

5

4

D.D. rotor ass'y

1

FFC

Upper drum

Figure 8-39.

Figure 8-38.

2. After installing the capstan D.D. motor, be sure to rotate

the capstan D.D. motor and check the movement.

3. Set the tape, and check for the tape crease near the

reverse guide in the playback mode. Adjust the A/C

head and azimuth as stated in 8-21 item 2. If crease is

found, adjust as stated in 8-21 item 3.

32

Page 33

DV-NC55U/C/M

1

6

4

3

2

5

7

8-24.REPLACING THE UPPER AND LOWER

DRUM ASSEMBLY

• Replacement (Perform in the numerical order)

1 Remove the motor as stated in 8-23 D.D. motor replace-

ment.

2 Remove the drum earth brush ass’y 2.

3 Remove the drum base 3 from the upper and lower

drum assembly 1.

[Cares when replacing the drum]

1. Be careful so that the drum earth brush is not lost.

2. Do not touch directly the drum surface.

3. Fit gently the screwdriver to the screws.

4. Since the drum assembly is an extremely precise as-

sembly, it must be handled with utmost care.

5. Make sure that the drum surface is free from dust, dirt

and foreign substances.

6. After replacing the drum be sure to perform the tape

running adjustment.

After that, perform also the electrical adjustment.

• Playback switching point adjustment

• X-position adjustment and check

• Standard and x-3 slow tracking adjustment

7. After replacing the drum clean the drum.

8-25.ASSEMBLING OF PHASE MATCHING

MECHANISM COMPONENTS

• Assemble the phase matching mechanism components in the following order.

1. Assemble the pinch roller assembly and pinch drive

cam.

2. Mounting the shifter (on the back of the mechanism

chassis).

3. Mounting the master cam (on the back of the mechanism chassis).

4. Assemble the connection gear, slow brake and loading

motor parts.

• PINCH DRIVE CAM AND PINCH ROLLER

ASSEMBLING METHOD.

(Place the following parts in position in numerical order.)

(1)Reverse drive lever 1

(2)Reverse guide spring 2

(3)Reverse guide lever ass’y 3

(4)Reverse guide height adjusting nut 4

(5)Pinch drive cam 5

(6)Pinch roller ass’y 6

(7)Open lever 7

2

1

3

Figure 8-41.

Figure 8-40.

33

Page 34

DV-NC55U/C/M

1Insert Reverse Guide Lever Ass’y

Insert reverse guide lever ass'y

2 Insert pinch drive cam

Turn the reverse guide lever

assembly counterclockwise

to the stopper.

Fit the pinch drive cam so that the notch of

pinch drive lever assembly aligns with the

half-round notch of chassis.

Pinch drive lever ass'y

Figure 8-42-1.

2Insert Pinch Roller/Pinch Double Action Lever Ass’y.

Pinch Roller Double

Action Lever Ass'y

Phase Matching Point 2

Align here.

Fit the pinch drive cam so that the notch of pinch

drive cam aligns with the dent of pinch drive lever

assembly.

3Insert Open Lever.

Open lever

Figure 8-42-2.

Figure 8-42-3.

34

Page 35

DV-NC55U/C/M

8-26. INSTALLING THE SHIFTER

Capstan

D.D. motor

Reel pulley

(Bottom side of mechanism chassis)

Figure 8-43.

Insert

point 3

Drum

1. Make sure that the loading gear is at the Phase-Matching point 1 as shown below.

2. Install, paying attention to insert point 5 and release

point 3.

3. For the phase matching at the insert point 1, see the

Phase-Matching point 2 as shown below.

4. Finally fix the inserts 1 and 4.

Phase-Matching

point 2

Loading gear (T)

Round mark

Sifter

Half round notch

Insert

point 1

Shaft 1

Insert

point 2

Rotation

point 2

Shaft 1

Insert

point 4

Shaft 4

Insert

point 5

Phase-matching

point 1

Shaft 1

Figure 8-44.

Release

point 3

35

Page 36

DV-NC55U/C/M

8-27.INSTALLING THE MASTER CAM (AT

REAR SIDE OF MECHANISM CHASSIS)

1. Make sure beforehand that the shifter is at the point as

shown below.

2. Place the master cam in the position as shown below.

E ring

(XRESJ30-06000)

Master cam

Fully turn

clockwise

Fully turn counterclockwise

Face the wide tooth side ward

Figure 8-45-1.

8-28. REPLACEMENT OF LOADING MOTOR

• Removal

Apply grease

Apply grease

No grease

Note:

See the figure below for the phase matching between the

master cam and the casecon drive gear.

3. Finally fix with the E ring.

Master cam

Casecon drive gear

Half-round notch

Round mark

When installing the master cam,

align the casecon drive gear

round mark with the half-round

notch of master cam.

Figure 8-45-2.

Figure 8-46.

• Replacement

Remove the loading motor, and install the replacement

loading motor as shown below.

+0.2

10.2 mm

–0.2

Figure 8-47.

The loading motor pressing-in must be less than 14.7 N

(1,500 gf).

Adjust the distance between motor and pulley to 10.2

+0.2

mm).

–0.2

36

Page 37

8-29. ASSEMBLY OF CASSETTE HOUSING

1. Drive Gear and R Drive angle ass’y

Apply grease

Apply grease

Figure 8-48.

DV-NC55U/C/M

MSPRT0381AJFJ

Apply grease

2. Synchro Gear, Drive Gear L and Drive Gear R

Top surface should be free from scratches or soil.

Drive angle

LANGF9592AJFW

Drive gear R

Frame

Figure 8-49.

37

Page 38

DV-NC55U/C/M

9. TEST MODE

F0000000 00000000

"NO DISC" state

"F0" key input (Press the "play" key and the "stop" key for 5 seconds.)

<Press the "1" key on the remote control or "stop" key on the main unit.>

The preparation date display of the program

10000000 ~~~~~~~~

(Last updata)

The "playback" key of the remote controller is pushed.

Model number display

10000001 00000552

(Model number)

The "playback" key of the remote controller is pushed.

The version display of the program

10000002 ~~~~~~~~

(Program ver.)

The "playback" key of the remote controller is pushed.

Reagion number display

10000003 00000002

(Region code:Binary display)

The "playback" key of the remote controller is pushed.

Micro-code number display

10000004 ~~~~~~~~

(Microcode ver.)

The "playback" key of the remote controller is pushed.

The preparation date display of the servo program

10000005 ~~~~~~~~

(Servo ver.)

The "playback" key of the remote controller is pushed.

It is returned to the test mode initial image plane.

Micro-code is the thing of the process

program of the system integrated circuit.

<The "2" key of the remote controller is pushed.>

Color bar display

00001 (FIP)

The "playback" key of the remote controller is pushed.

Color bar display

00002 (FIP)

The "playback" key of the remote controller is pushed.

Color bar display

00003 (FIP)

The "playback" key of the remote controller is pushed.

Color bar display

00004 (FIP)

The "playback" key of the remote controller is pushed.