Page 1

SERVICE MANUAL PORTABLE DVD VIDEO PLAYER

DV-L88U

SERVICE MANUAL

S21P2DV-L88U/

PORTABLE D VD VIDEO PLAYER

MODEL DV-L88U

10. SCHEMATIC DIAGRAMS................................................................................................................ 32

11. PRINTED WIRING BOARD ASSEMBLIES ..................................................................................... 52

12. REPLACEMENT PARTS LIST ........................................................................................................ 63

13. PACKING OF THE SET................................................................................................................... 77

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

D V-L88U

CONTENTS

Page

1. IMPORTANT SAFEGUARDS AND PRECAUTIONS ........................................................................ 2

2. FEATURES........................................................................................................................................ 5

3. SPECIFICATIONS ............................................................................................................................. 5

4. PART NAMES.................................................................................................................................... 7

5. DISASSEMBLY METHOD ................................................................................................................. 8

6. ADJUSTMENT METHOD ................................................................................................................ 11

7. TEST MODE .................................................................................................................................... 18

8. TROUBLESHOOTING..................................................................................................................... 21

9. BLOCK DIAGRAMS......................................................................................................................... 24

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

DV-L88U

1. IMPORTANT SAFEGUARDS AND PRECAUTIONS

1. IMPORTANT SERVICE NOTES

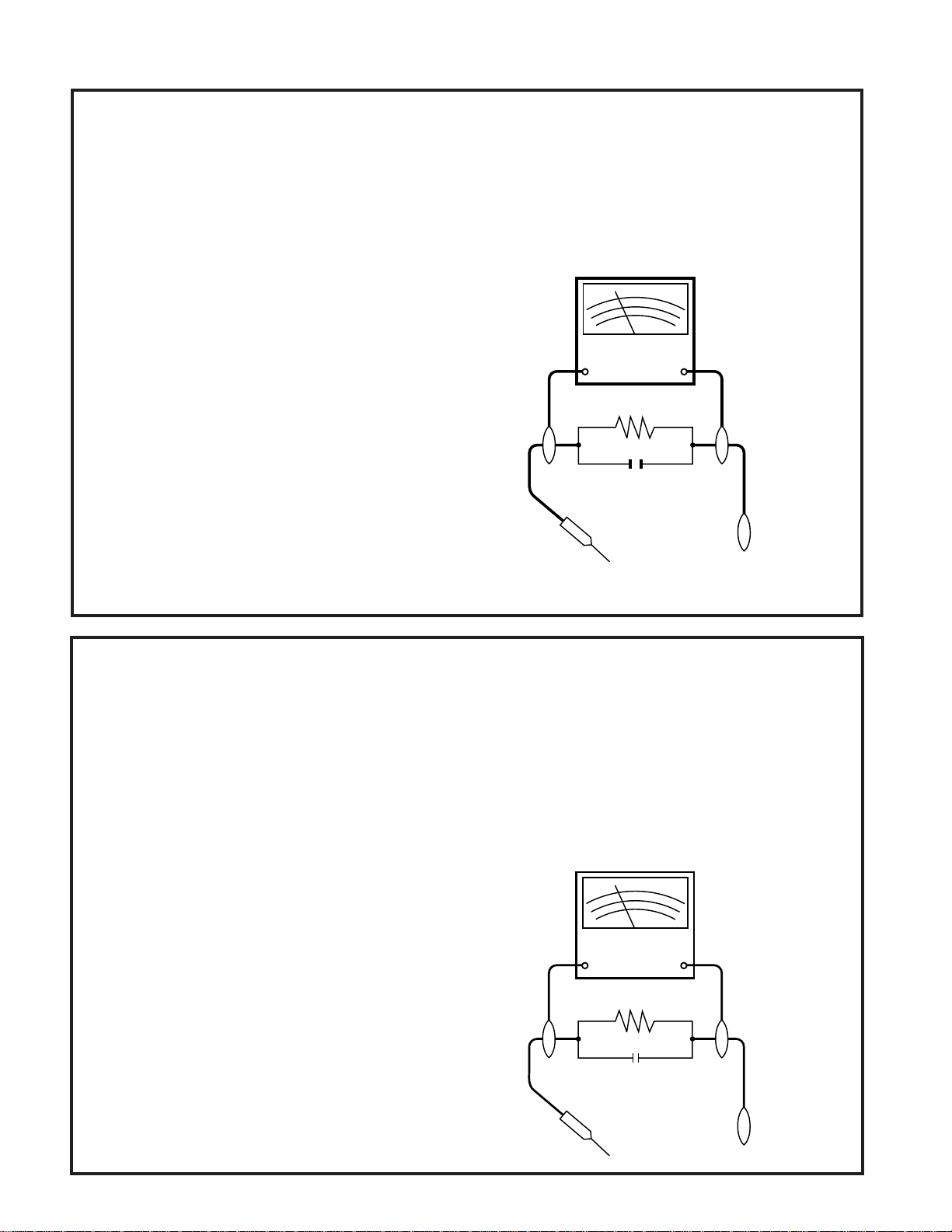

BEFORE RETURNING THE DVD VIDEO PLAYER

Before returning the DVD video player to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the DVD video

player.

2. Inspect all protective devices such as non-metallic

control knobs, insulation materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

3. To be sure that no shock hazard exists, check for

current in the following manner.

● Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

● Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series with

all exposed metal cabinet parts and a known earth

ground, such as a water pipe or conduit.

● Use an DVM or VOM with 1000 ohm per volt, or higher,

sensitivity or measure the AC voltage drop across the

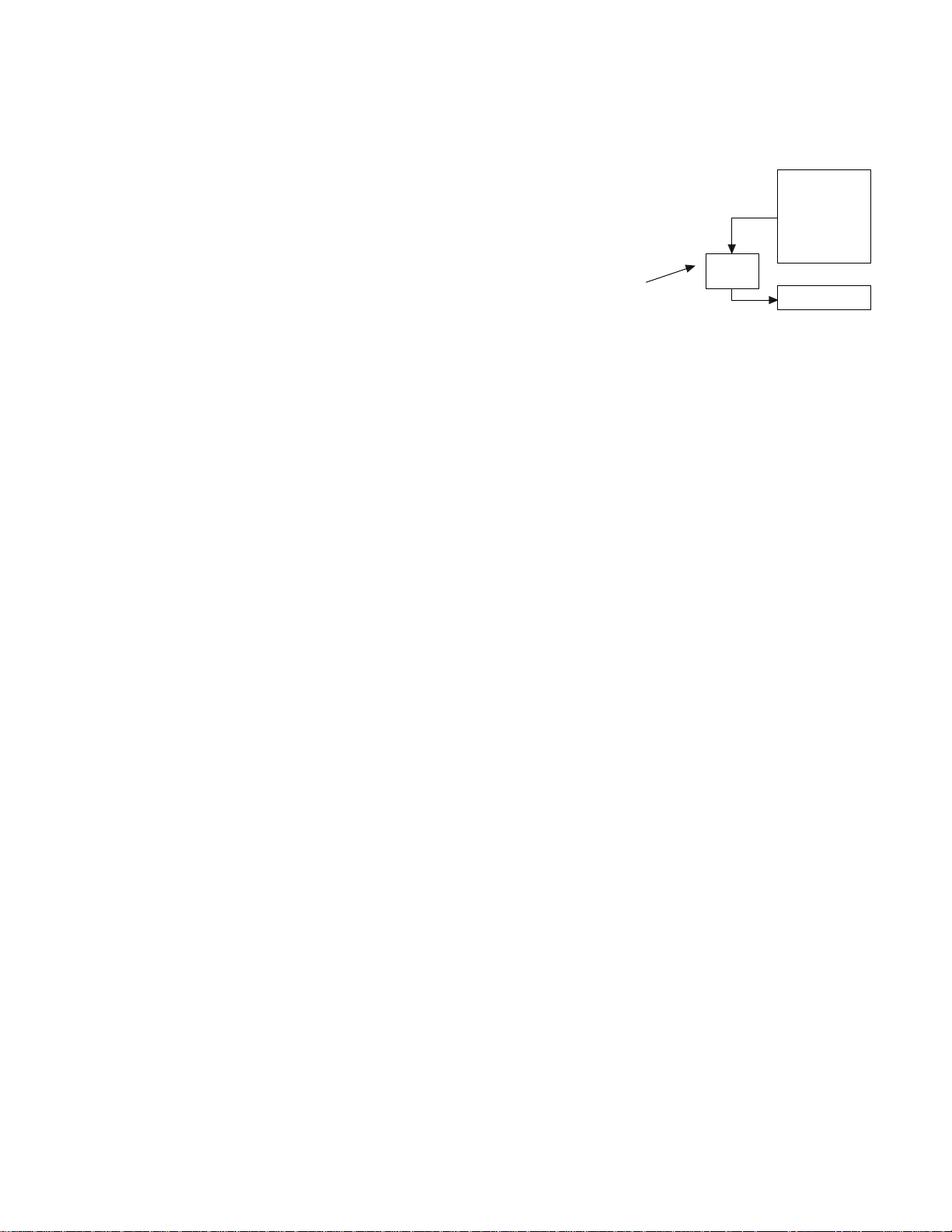

resistor (See Diagram).

● Move the resistor connection to earth exposed metal

part having a return path to the chassis (metal cabinet,

screw heads, knobs and control shafts, etc.) and

measure the AC voltage drop across the resistor.

Reverse the AC plug on the set and repeat AC voltage

measurements for each exposed part. Any reading of

0.45V rms (this corresponds to 0.3mA rms AC.) or

more is excessive and indicates a potential shock

hazard which must be corrected before returning the

DVD video player to the owner.

SSVM

AC SCALE

1.5k ohms.

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE REPRODUCTOR DE VíDEO

DVD

Avant de rendre le reproductor de vídeo DVD à l’utilisateur,

effectuer les vérifications de sécurité suivantes.

1. Vérifier toutes les gaines de fil pour être sûr que les fils

ne sont pas pincés ou que le matériel n’est pas coincé

entre le châssis et les autres pièces métalliques dans le

reproductor de vídeo DVD.

2. Vérifier tous les dispositifs de protection tels que les

boutons de commande non métalliques, les matériaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

réseaux de résistance / condensateur d’isolement, Ies

isolateurs mécaniques, etc.

3. Pour être sûr qu’il n’y a aucun risque de choc électrique,

vérifier le courant de fuite de la maniére suivante.

● Brancher le cordon d’alimentation secteur directement

dans une prise de courant de 120 volts. (Ne pas utiliser

de transformateur d’isolement pour cet essai).

● Utiliser deux fils à pinces et connecter une résistance

de 10 watts 1,5 kohm en parallèle avec un condensateur

de 0,15 µF en série avec des pièces du coffret métallique

exposées et une masse de terre connue telle qu’un

tuyau ou un conduit d’eau.

● Utiliser un DVM ou VOM avec une sensibilité de 1000

ohms par volt ou plus ou mesurer la chute de tension

CA entre la résistance (voir diagramme).

● Déposer la connexion de la résistance à toutes les

pièces métalliques exposées ayant un parcours de

retour au châssis (coffret métallique, tétes de vis, boutons et arbres de commande, etc.) et mesurer la chute

de tension CA entre la résistance. Inverser la fiche CA

(une fiche intermédiaire non polarisée doit être utilisée

à seule fin de faire ces vérifications.) sur l’appareil et

répéter les mesures de tension CA pour chaque piéce

métallique exposée. Toute lecture de 0,45 V rms (ceci

correspond à 0,3 mA rms CA) ou plus est excessive et

signale un danger de choc qui doit être corrigé avant de

rendre le reproductor de vídeo DVD à son utilisateur.

VTVM

AC SCALE

1.5k ohms

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

2

Page 3

WARNING :TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NO T EXPOSE

THIS APPLIANCE TO WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USER·SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user of uninsulated

voltage within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instructions in the literature accompanying this unit.

CAUTION

This symbol mark means following.

For continued protection against fire hazard, replace only with same type fuse

F901 (4A, 63V)/F902 (4A, 63V) on Power

PWB.

F9901 (1.75A, 32V) on CCFT INV. PWB.

CP9001 (1.6A, 72V)/CP9002 (2A, 72V)

on Power PWB.

1.5A 250V

DV-L88U

ATTENTION:POUR REDUIRE LES RESQUES D'INCENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L'HUMIDITE.

ATTENTION

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

ATTENTION: AFIN DE REDUIRE LES RISQUES DE

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L'UTIUSATEUR, CONFIER L'APPAREIL A

UN DEPANNEUR QUALIFIE.

Ce symbole signale à l'utilisateur la présence

d'une tension non isolée à l'intérieur de l'appareil

qui peut être la cause de secousses électriques

dangereuses.

Ce symbole avertit l'utilisateur que des instructions importantes relatives à l'utilisation

et àl'entretien se trouvent dans le manuel

accompagnant l'appareil.

ATTENTION

Ce symbole signifie que l'on devra utiliser un fusible de même type F901 (4A,

63V)/F902 (4A, 63V) on Power PWB .

F9901 (1.75A, 32V) on CCFT INV. PWB.

CP9001(1.6A, 72V)/ CP9002 (2A, 72V)

on Power PWB.

1.5A 250V

Fuse Replacement Marking

4A 63V

On Power PWB Inside of Enclosure LCD front

1.75A 32V

1.6A 72V 2A 72V

On Power PWB

3

Page 4

DV-L88U

åå

åCAUTION

åå

BEFORE BATTERY DESTROY

The RBRCTM Seal

SHARP participates in the RBRCTM* Nickel-Cadmium Battery Recycling Program in the United States. The RBRCTM

Seal on our battery pack contained in our product indicates that SHARP is voluntarily participating in an industry

program to collect and recycle these batteries. The RBRCTM program provides you with a convenient alternative

to placing spent Nickel-Cadmium battery packs into the trash or municipal waste stream, which is illegal in some

areas. At the end of their useful life, the Nickel-Cadmium battery can be dropped off at the nearest collection center

for recycling. For information on the nearest collection center, call 1-800-8-BATTERY or your local recycling

center. If you are located outside the United States, contact your local authorities for information concerning proper

disposal and/or recycling of this battery. SHARP's involvement in this program is part of our commitent to protecting

our environment and conserving natural resources.

[Footnote] *RBRC

TM is a trademark of the Rechargeable Battery Recycling Corporation.

ËË

Ë NICKEL-METAL HYDRIDE BATTERY

ËË

ËË

Ë LITHIUM or LITHIUM-ION BATTERY

ËË

ËË

Ë SEALED LEAD BATTERY

ËË

Battery disposal

Contains the above Rechargeable Battery. must be recycled or disposed of properly.

Remove the Battery from the products and contact Federal or State Environmental Agencies for information on

recycling and disposal options.

4

Page 5

2. FEATURES

This DVD video player can play back DVD video discs and Audio CDs.

• CD-R/CD-RW recorded in MP3 file format can also be played.

8" LCD Screen and Stereo Speakers

• A big 8" LCD screen and built-in stereo speakers provide exciting DVD viewing, even without connecting to a TV.

2-WAY Power Supply

• A 2-way power supply allows operation using the supplied AC adapter for indoor play, or the battery pack (supplied)

for outdoor play.

Compact, Lightweight Design

• Your DVD video player is designed to go along just about anywhere.

High-Resolution Images, High-Quality Sound

• A high-resolution 336,960-pixel LCD screen produces images of outstanding quality.

• DIGITAL GAMMA correction and DIGITAL SUPER PICTURE provide more realistic image detail.

• VIRTUAL DOLBY (*1QSURROUND) ensures richer sound from two built-in speakers.

AV input/output, optical digital output jack equipped as standard

• An optical digital output jack (which doubles as the phones jack) can be used to output a stream of *2Dolby Digital 5.1

channel audio and *3DTS digital audio. Connecting a Dolby Digital/DTS digital surround processor or amplifier to this

jack creates an environment of amazingly powerful surround sound.

• The AV input/output jack can be used to connect a VCR or camcorder to your DVD video player. Or you can use these

jacks to connect to a TV for big-screen viewing.

DV-L88U

*1QSURROUNDTM is a trademark of QSound Labs, Inc.

*2Manufactured under license from Dolby Laboratories. "Dolby", "Pro Logic" and the double-D symbol ( ) are

trademarks of Dolby Laboratories.

*3"DTS" and "DTS Digital Surround" are trademarks of Digital Theater Systems, Inc.

3. SPECIFICATIONS

Product: Portable DVD Video Player

Model: DV-L88U

Signal System: NTSC

Supported Disc Types: DVD (Region Number 1, ALL), Audio CD, CD-R, CD-RW

Video Input/Output: Input/Output Jack: Pin jack × 1

Input/Output Levels: 1Vp-p (75Ω)

S-Video Input/Output: Y Input/Output Level: 1Vp-p (75Ω)

C Input/Output Level: 0.286Vp-p (75Ω)

Input/Output Jack: S connector × 1

Audio Input/Output: Input /Output Jack: Pin jack × 1

Input/Output Levels: 1.7Vrms (1kHz, 0dB)

Digital Audio Interface: Optical Digital Output: Mini jack (shared with Headphones Output)

Audio Output: 0.8W + 0.8W

Headphones Output: Output Jack: Mini jack (stereo) (shared with Optical Digital Output)

Display: Screen Size: 8 inches (99.2 (357/64") (H) × 176.4 (615/16") (W) mm)

Type: Transmissive TN liquid crystal panel

Drive: TFT (thin transistor) active matrix

Pixels: 336,960 (234 (H) × 480 (W) × 3),

Effective Pixel Rate: 99.99% minimum

Speakers: Two 28mm round speakers

Light Source: Internal (fluorescent)

Video Signal: Horizontal Resolution: 500 lines

S/N Ratio: 60 dB

5

Page 6

DV-L88U

AC Adapter Specifications

Audio Signals: Frequency Characteristics:

Linear PCM DVD: 4Hz to 22kHz (48kHz sampling)/

4Hz to 44kHz (96kHz sampling)

CD: 4Hz to 20kHz (EIAJ)

S/N Ratio: CD: 96dB 1kHz (EIAJ)

Dynamic Range: Linear PCM DVD: 96dB (EIAJ)

CD: 96dB (EIAJ)

Total Harmonic Distortion Ratio: 0.006% maximum (EIAJ)

Power Requirements: AC Adapter: 10V DC

Battery Pack: 7.4V DC

Power Consumption: Main Power On: 12W average (10W without AC Adapter)

(AC Adapter) Main Power Off: 0.6W (standby) (0.1W without AC Adapter)

Dimensions: 211 (W) × 174 (D) × 42.3 (H) mm (85/16" × 655/64" × 143/64")

(except for projections)

Weight (approx.): 930g (2.05 lbs)

Operating Temperature: 5°C to 35°C (41°F to 95°F)

Operating Humidity: 80% RH maximum

Storage Temperature: -20°C to 40°C (-4°F to 104°F)

Power Requirements: 110 to 240V AC, 50/60Hz

Rated Output: DVD Operation: 10V DC

Charging: 10V DC

Dimensions: 54 (W) × 98 (D) × 26.5 (H) mm

(21/8" × 355/64" × 13/64")

Weight (approx.): 170g (0.38 lbs)

Battery Pack Specifications

Model: BT-L300U

Type: Lithium-ion type

DC output: 7.4V

Capacity: 5100mAh

Operating temperature: 0°C to 40°C (32°F to 104°F) (charging: 10°C to 30°C (50°F to 86°F))

Max. Dimensions: 59 (W) × 142.5 (D) × 20.5 (H) mm

(221/64" × 55/8" × 13/16") without protruding parts

Weight (approx.): 285g (0.63 lbs)

Specifications are subject to change without notice.

Weight and dimensions are approximate.

Digital Output (Linear PCM)

· The digital output format used in this DVD video player is Linear PCM audio sampled at 44.1kHz or 48kHz.

Linear PCM sound for DVD discs sampled at 96kHz cannot be output digitally.

Check the disc jacket for information on the audio sampling used.

3-1. ACCESSORIES

Accessories: AC Cord x 1, CR2025 type lithium battery x 1, Remote Control Unit x 1, AC Adapter x 1,

Lithium-ion Battery Pack x 1

6

Page 7

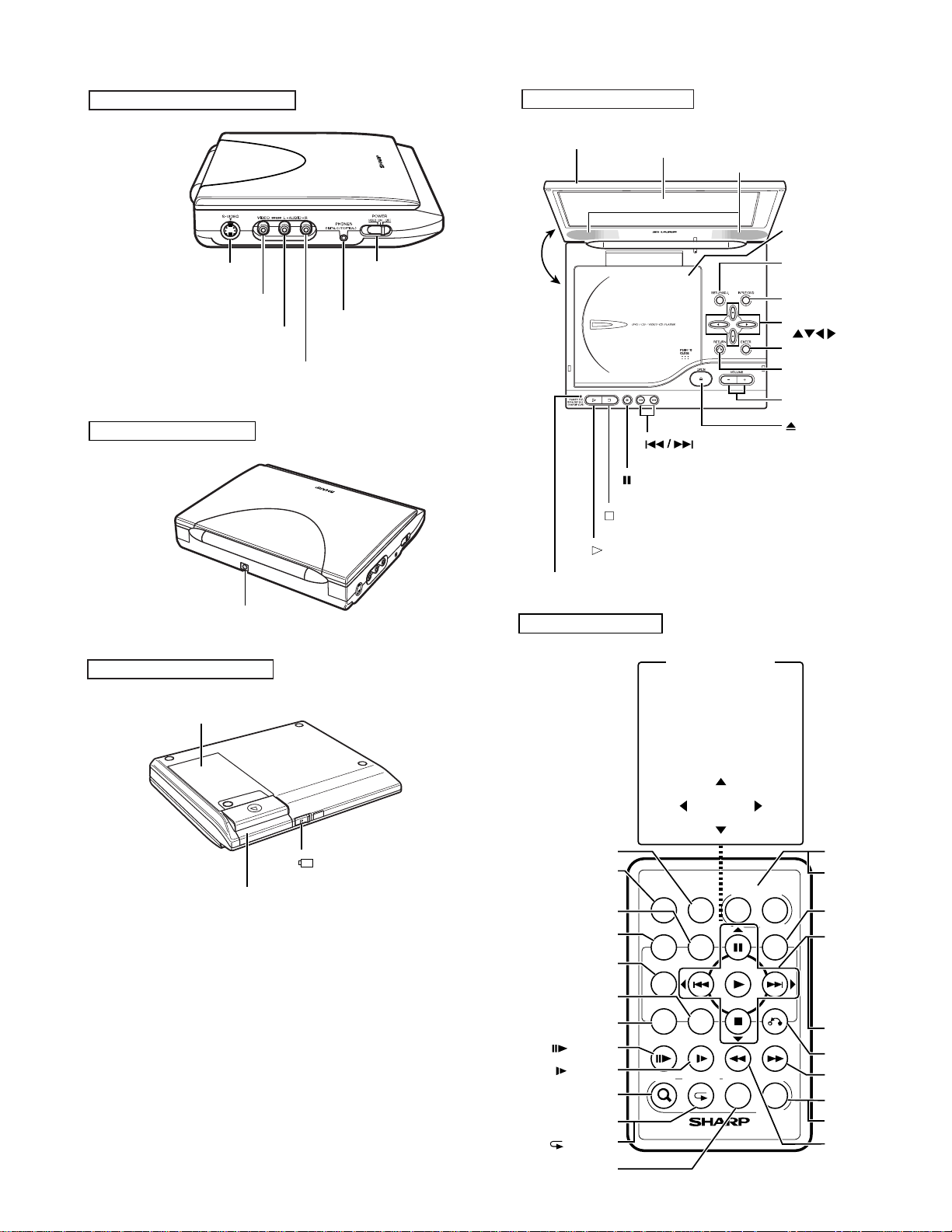

4. PART NAMES

DV-L88U

DVD Video Player - Right side

S-VIDEO

input/output jack

VIDEO

input/output jack (yellow)

AUDIO (L)

input/output jack (white)

AUDIO (R)

input/output jack (red)

DVD Video Player - Rear

POWER switch

DIGITAL OUT (OPTICAL)/

PHONES jack

DVD Video Player - Front

Display panel

angle range: 0°-180°

180°

0°

(SKIP)

(STILL/PAUSE)

(STOP)

(PLA Y)

LCD screen

Speakers

Disc compartment

cover

SETUP/ADJ.

INPUT/DVD

Cursor buttons

( )

ENTER

RETURN

VOLUME –/

+

OPEN

DC IN jack

DVD Video Player - Bottom

Battery pack compartment (inside)

Battery pack compartment cover

.

“ RELEASE” tab

Indicator lamp

Remote Control Unit

INPUT/DVD

POWER

FUNCTION

TITLE

MENU

VIDEO ADJ.

SETUP

(F.ADV)

(SLOW)

ZOOM

PROGRAM

(REPEAT)

DISPLAY

Select/Enter Mode

• The operation buttons

have the following

Select/Enter functions

when Setup screen,

Function control screen or

another type of setting

screen is on the display.

ENTER

INPUT

–

/DVD

POWER

FUNCTION

TITLE

MENU

SETUP

VIDEO ADJ.

PROGRAM DISPLAY VIEW MODE

ZOOM

DVD VIDEO PLAYER

VOLUME

ENTER

+

SHIFT

RETURN

LCD ON/OFF

–

VOLUME

VOLUME

+

SHIFT

â (STILL/

PAUSE)

à (SKIP)

û (PLAY)

Ë (STOP)

À (SKIP)

RETURN

è (FWD)

VIEW MODE

LCD ON/OFF

È (REV)

7

Page 8

DV-L88U

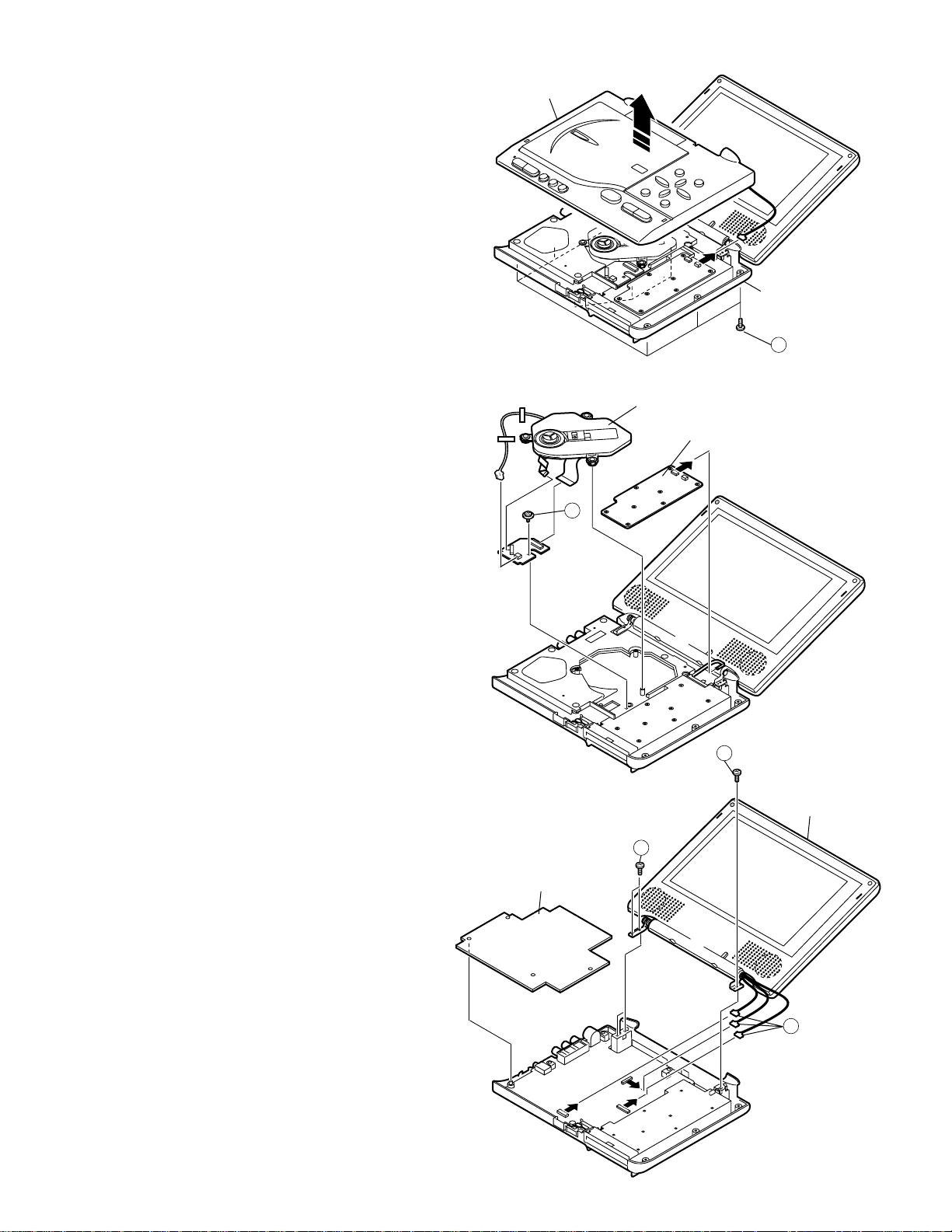

5. DISASSEMBLY METHOD

5-1. DISASSEMBLY METHOD

1. Remove the nine screws 1.

2. Remove the six screws and remove the battery cover.

3. Six screws of the operate PWB fixed are removed from

the cabinet B bottom.

4. Lift the cabinet A, remove the connector.

Cabinet A

Cabinet B

1

5. Remove the mechanism ass'y and operate PWB.

6. Remove the one screw 2.

7. Remove the three connectors 3.

8. Remove the three screws 4.

9. Remove the LCD unit.

10. Remover the main PWB.

Mechanism Ass'y

Operate PWB

2

4

LCD Unit

4

Main PWB

3

8

Page 9

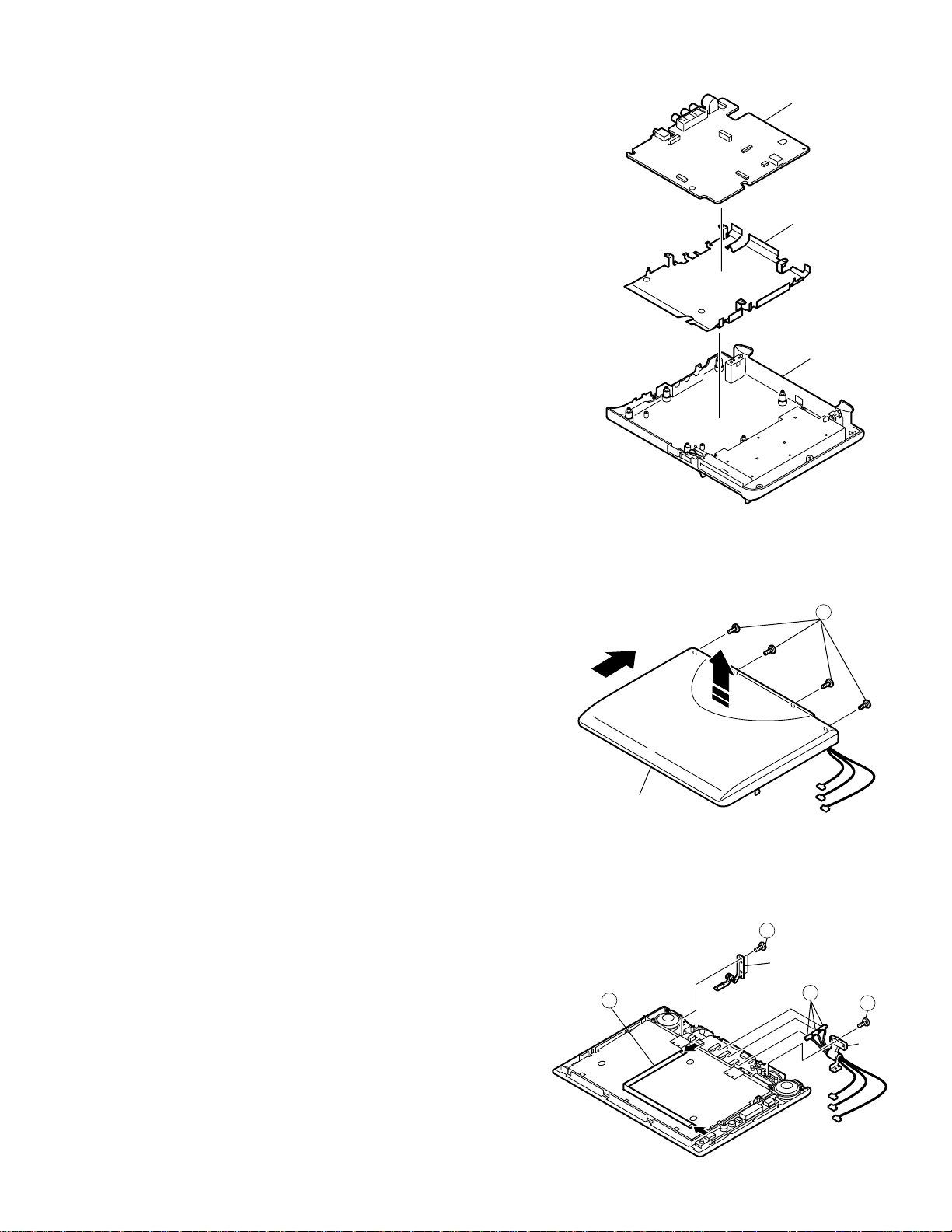

11. Remove the shield plate and power PWB from cabinet B.

Power PWB

Shield Plate

Cabinet B

Hinge L

Hinge R

7

8

7

6

12. Remove the power PWB and shield plate.

(Partly fixed with solder.)

DV-L88U

13. Remove the four screws 5.

14. Cabinet C is slided in the direction of ¤, and lifted in the arrow

direction of ⁄, and removed.

15. Remove the connectors 6 from the LCD PWB.

16. Remove the FFC 8 from the connector.

17. Remove the three screws 7, and remove the hinge L, R.

5

¤

⁄

Cabinet C

9

Page 10

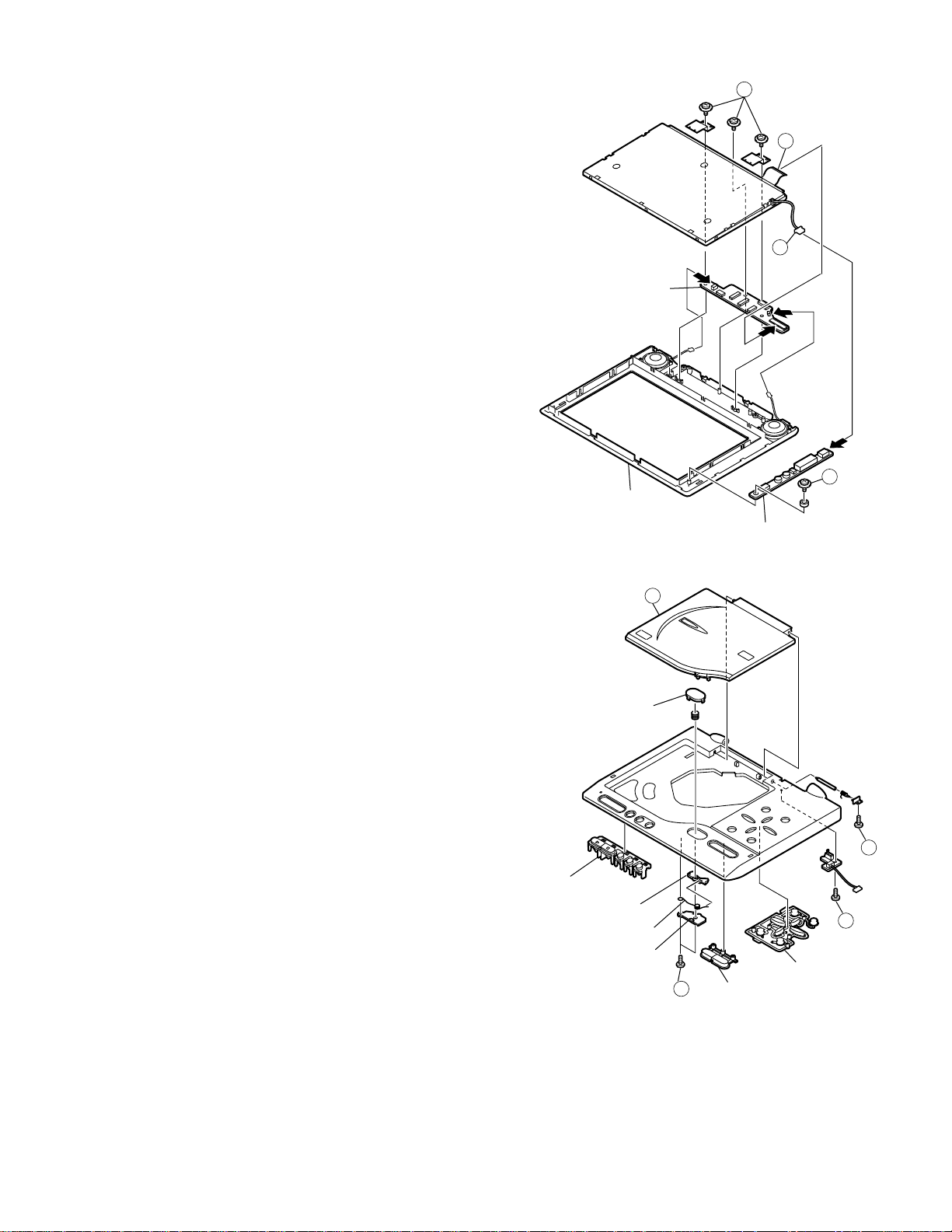

DV-L88U

18. Remove the connectors 9 and 0.

19. Remove the three screws q, and remove the LCD fixing angle.

20. Remove the LCD from the cabinet D.

21. Remover the LCD CTL PWB.

22. Remove the screw w.

23. Remove the inverter unit.

11

9

10

LCD CTL PWB

12

Cabinet D

Inverter Unit

24. Remove the disc cover e by pressing open button.

25. Remove the one screw r.

26. Remove the one screw t.

27. Remove the two screws y.

28. Remover the lock holder, button lock spring and D. cover lock.

29. Remove the mode key, volume key, cursor buttons and open button.

Mode Key

Button Lock Spring

Open Button

D. Cover Lock

Lock Holder

13

16

Volume Key

14

15

Cursor Buttons

10

Page 11

DV-L88U

6. ADJUSTMENT METHOD

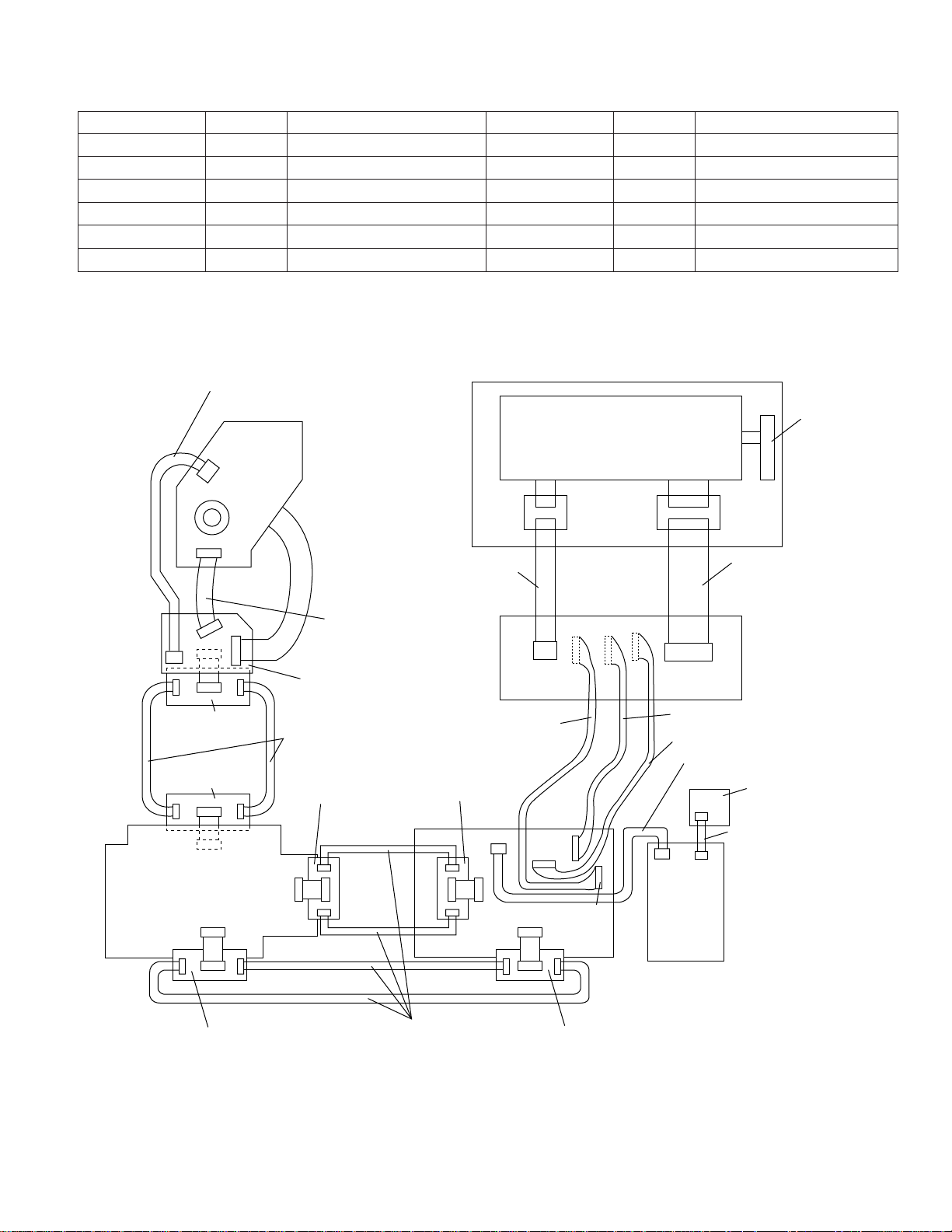

6-1. HARNESS LIST FOR SERVICE PARTS

Parts Code Price Code Remarks Parts Code Price Code Remarks

QCNW-8557GEZZ AE Spindle extension, 13-pin QCNW-8566GEZZ AD Operate PWB extension, 2-pin

QCNW-8558GEZZ AE Sled extension, 2-pin QCNW-8623GEZZ AZ

QCNW-8562GEZZ AK Power-LCD extension, 9-pin QCNW-8624GEZZ AX Main-Power extension, 15-pin

QCNW-8563GEZZ AK Power-LCD extension, 10-pin

QCNW-8564GEZZ AK Power-LCD extension, 12-pin

QCNW-8565GEZZ AE Operate PWB extension, 6-pin

99GFCKWB90751A BX —————

QCNW-8151GEZZ

QCNW-8152GEZZ

AQ Inverter extension, 6-pin

AQ LCD panel extension, 32-pin

Drawing for service jigs

QCNW-8558GEZZ

Mechanism

Panel

Main-RF&Motor extension, 25-pin

Inverter PWB

99GFCKWB90751A

99GFCKWB90751A

CN301

MAIN PWB

CN801

B

to

CN85

B

CN84

QCNW-8557GEZZ

RF&MOTOR

PWB

QCNW-8623GEZZ x2

99GFCKWB90751A

B

to

CN802

B

QCNW-8151GEZZ

QCNW-8562GEZZ

99GFCKWB90751A

CN5001

CN9901

CN82CN86

CN1901

CN1800

CN1802

CN6601

B

to

B

CN81

F

F

C

CN1903

12

10

POWER

CN83

9

CN1801

PWB

CN1902

12

9

CN1904

10

CN1900

QCNW-8564GEZZ

OPERATE

PWB

F

QCNW-8152GEZZ

F

C

LCD CTL PWB

QCNW-8563GEZZ

QCNW-8565GEZZ

DET LCD

CLOSE PWB

QCNW-8566GEZZ

CN4402CN4401

99GFCKWB90751A

QCNW-8624GEZZ x4

11

99GFCKWB90751A

Page 12

DV-L88U

ADJUSTMENT PROCEDURE AND METHOD OF LCD PWB SIDE

Connect it by using the jig and so on that a LCD PWB is packaged in the set or with the body.

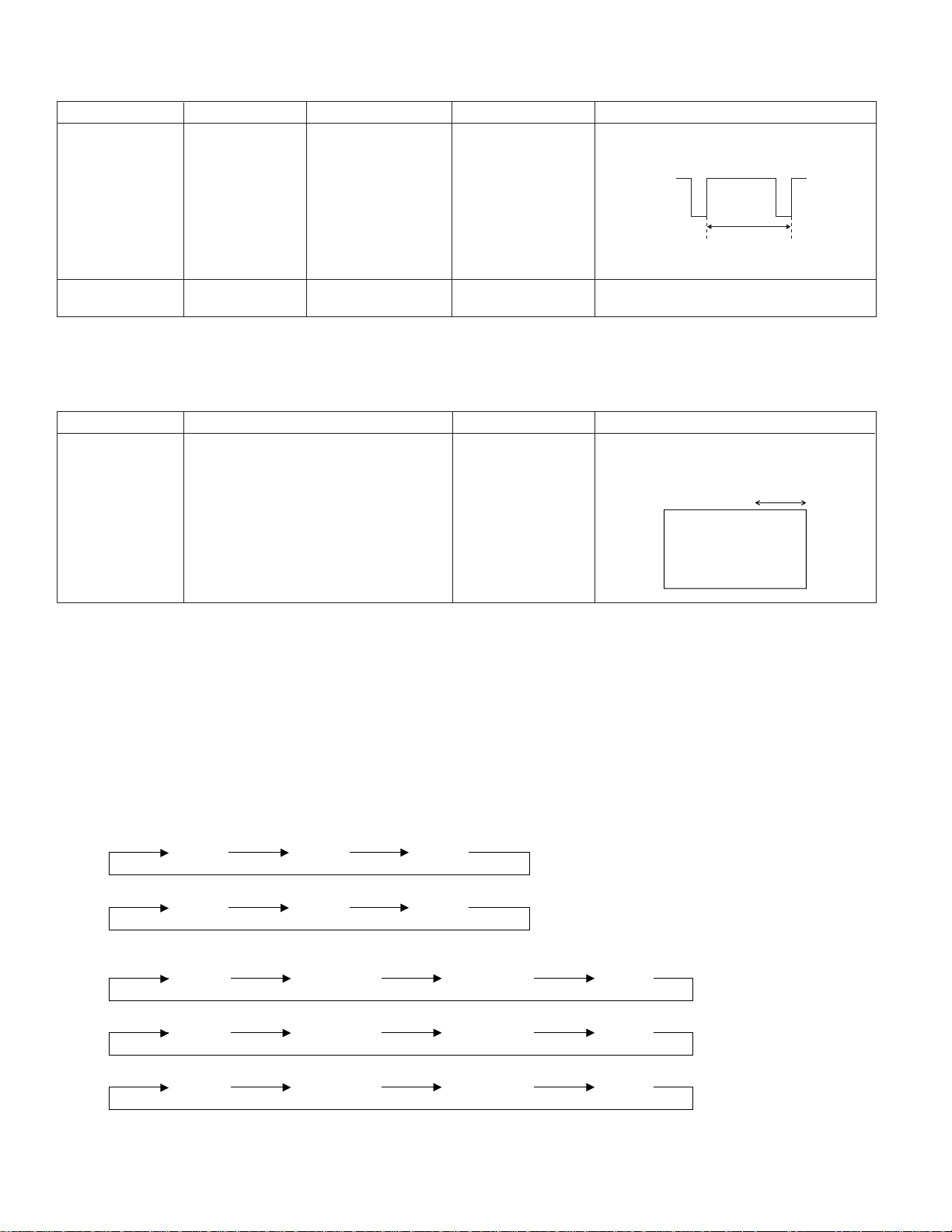

Adjustment Item Adjustment Menu Adjustment Point Signal/Setting Adjustment Contents

1Free run R1933 Observe the 5PIN of No input Adjust so that the frequency becomes

adjustment (VR) TP1900 (HSY) with a 15.73±0.1kHz (63.6µS).

frequency counter.

HSY

15.73kHz

(63.6µS)

2Screen center R1914(VR) Visual observation of Monoscope full Adjust the screen so that it is located in the

adjustment the panel. screen. (525/30) center.

[Caution] Do the image plane center adjustment of 2 after you surely do free run adjustment of 1.

Image plane center deviates when adjustment is done in the reverse order.

CHECK ITEMS OF LCD PWB SIDE

Adjustment Item Adjustment Point Input Signal/Setting Adjustment Contents

1Free run check Check the panel visually by connecting External input Check that the horizontal movement of OSD

to the checker. (525/30) is 2 mm or less when inputting a signal in

the external input mode with no signal input.

INPUT

POWER PWB SIDE ADJUSTING PROCEDURE AND METHOD.

Connect it by using the jig and so on that a POWER PWB is packaged in the set or with the body.

Supply the power in the condition that the “ENTER” and “STILL” keys are pressed at the same time and move to the special

mode (SP MODE).

After that, get the initialize set by pressing the “PLAY” key. After setting, turn off the power once.

Supply the power again in the condition that the “ENTER” and “STILL” keys are pressed at the same time and after moving

to the special mode (SP MODE), get the adjustment mode by pressing “INPUT/DVD” key.

Each operation in the adjustment mode changes as follows:

(1) Switch the adjustment block with the "VOLUME+" key input.

TV1

(2) Perform paging of each adjustment block with the "RETURN" key.

TV1

(3) Switch each adjustment item with the "VOLUME–" key input.

TV1 adjustment

GAM0

OPT

TV2

SBRIGHT GPOS CONT

BAT

TV3

TV2 adjustment

WB-R WB-B SCOLOR STINT

TV3 adjustment

COM OSDH BBRIGHT GAIN

(4) Change each adjustment value with the left or right cursor key.

12

Page 13

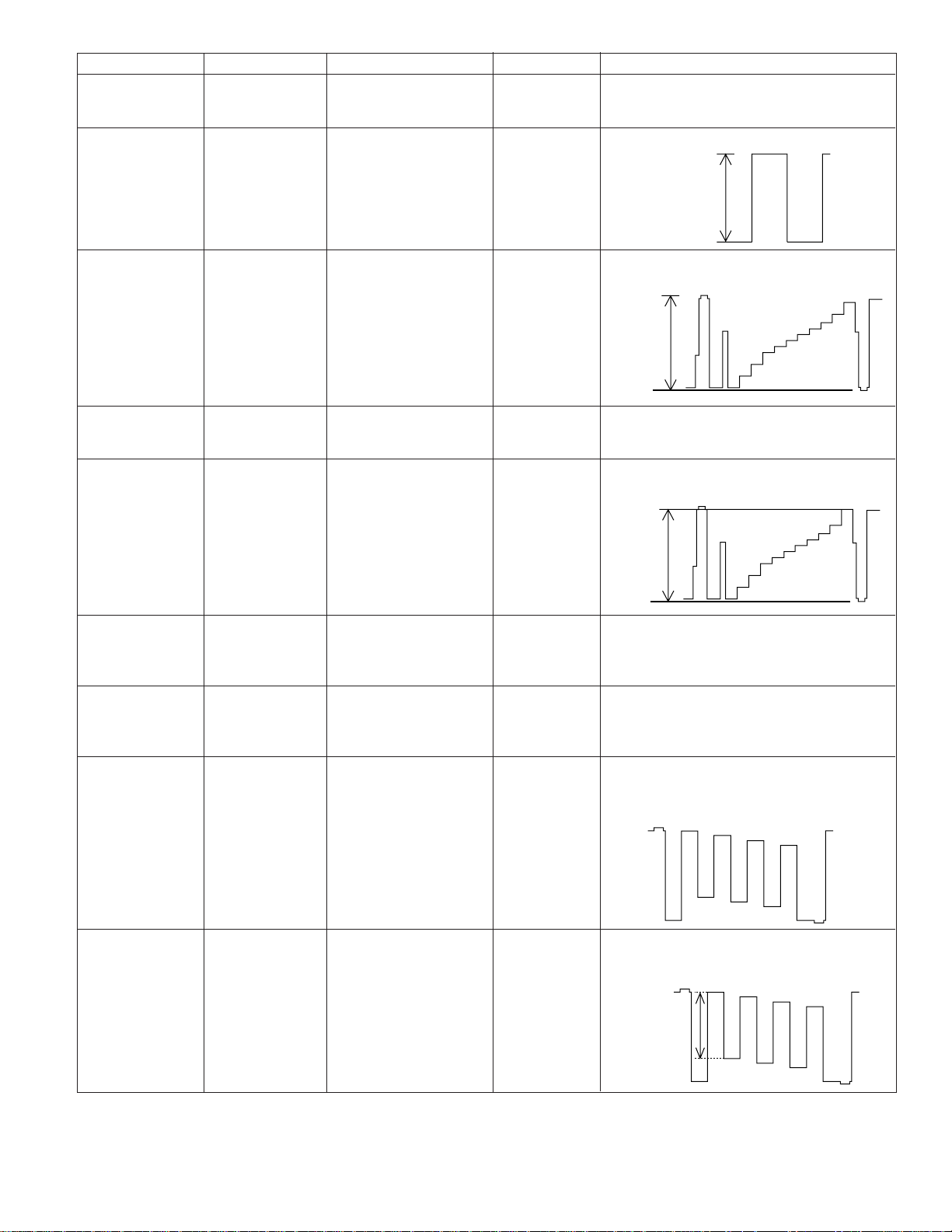

Adjustment Item Adjustment Menu Adjustment Point Signal/Setting Adjustment Contents

8.0V±0.1

Blue

Black

Red

Green

Yellow

Magenta

Cyan

White

1Sub-bright SBRIGHT Check that the SBRIGHT is “56”.

check

DV-L88U

2Common GPOS

amplitude

Connect the synchroscope

to 1 pin (COM) of TP1900.

Black-and-white Adjust the common amplitude to 8.0±0.1V.

10STEP

adjustment

3RGB amplitude GAIN

adjustment

Connect the synchroscope

to 2PIN (VG) of TP1900.

Black-and-white Adjust the Vpp(SYNC-SYNC) of VG to

10STEP 4.0±0.1V.

4.0V±0.1

4Gamma0 check GAM0 Check that the GAM0 is “50”.

5Contrast CONT

adjustment

Connect the synchroscope

to 2PIN (VG) of TP1900.

Black-and-white Adjust the 100% white part(SYNC-white100%)

10STEP to 3.8±0.1V.

3.8V±0.1

6White balance WB-R(Red)

adjustment

(Red)

7White balance WB-B(Blue)

adjustment

(Blue)

8Sub tint STINT

adjustment

9Sub color SCOLOR

adjustment

Connect the synchroscope

to 2PIN (VG) and 3PIN

(VR) of TP1900.

Connect the synchroscope

to 2PIN (VG) and 4PIN

(VB) of TP1900.

Connect the synchroscope

to 4PIN (VB) of TP1900.

Connect the synchroscope

to 4PIN (VB) of TP1900.

Black-and-white Adjust the white balance (red) so that black level

10STEP the equal of green and red output become equal.

Black-and-white Adjust the white balance (blue) so that black level

10STEP the equal of green and blue output become

equal.

100% color bar Make the peak to peak of the yellow, green

and red of the color bar signals stepwise or

same. Place green between yellow and red.

100% color bar Adjust the yellow amplitude of the color bar

signal (white level to yellow peak level) to

3.2±0.1Vpp.

White

3.2V

±0.1

Yellow

13

Page 14

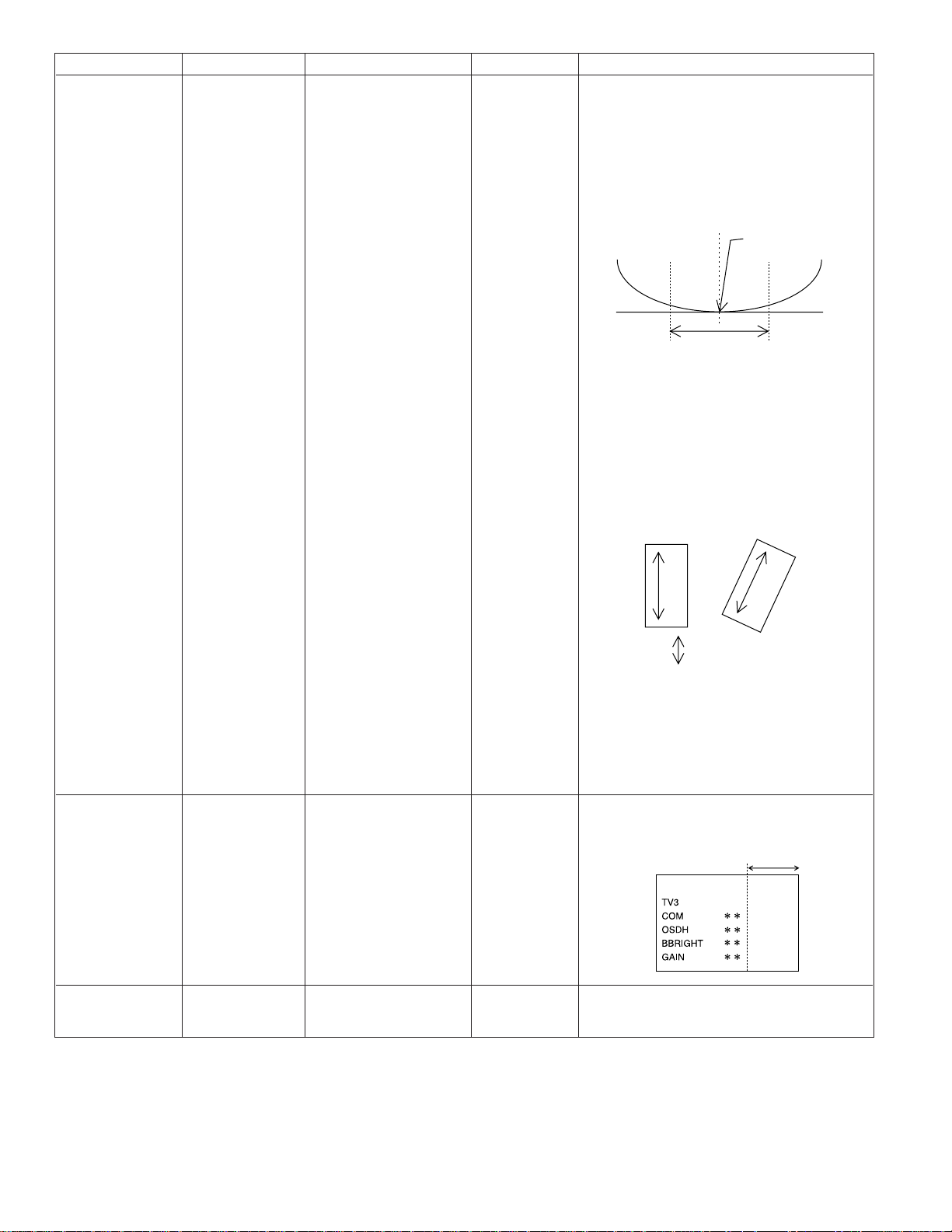

DV-L88U

Direction of stripe

Adjustment Item Adjustment Menu Adjustment Point Signal/Setting Adjustment Contents

0Confrontation COM Specified adjustment jig No input state When using the specified adjustment jig

bias adjustment (illuminometer) or visual

observation Perform it in a and adjust the waveform to the minimum

Brightness: Center

combination of point.

PWB and the At this time, perform the adjustment several

liquid crystal times to fix the optimal point because the

panel which will measuring value hardly changes around the

be supplied as optimal point.

products finally.

Connect the output of jig to the oscilloscope

(Type drawing)

Adjust within the above

range to fix the optimal point

In case of visual adjustment Stand or tilt the

panel as shown in the figure and check by

shaking your head and seeing whether stripes

appear.

If the adjustment is improper, you will see

stripes in the longitudinal direction.

Perform the adjustment so that they

do not appear.

Optimal point

[Another method] [Another method]

Flicker signal Externally input the signal shown left and

generator adjust so that the cross bars become minimum

“Example: by visually checking the screen.

BP1018 made

by JFC”

qOSD position OSDH OSD character The position of the adjustment value on the

adjustment visual observation right end of the OSD character is adjusted to

15mm ± 2mm from the right end of the image

plane.

wLighting control BBRIGHT Check that the BBRIGHT is “76”.

standard check

15mm

14

Page 15

CHECK AND READJUSTMENT

Adjustment Item Adjustment Menu Adjustment Point Signal/Setting Adjustment Contents

1Free run R1933 OSD character External input Check that the horizontal movement of OSD

check (VR) visual observation (525/30) position is 2mm or less when inputting a signal

in the external input mode with no signal input.

If it is more than 2 mm, adjust it so as to get

2 mm or less

INPUT

2Screen positon R1914 Visual observation of Monoscope full 95% of the scales for the overcoat scanning

check (VR) panel screen confirmation confirm whether it can be seen

(525/30) with the right and left as well in the monoscope

image plane. Center adjustment is done when

a scale can't be seen.

3Luminance/ GPOS Comparison with the 10STEP signal Check whether the luminance and gradation

gradation check standard set of 10STEP signal are not different in compar-

ison with the standard set. If they are different,

adjust them so as to get equal to the standard

set.

DV-L88U

4Sub color check SBRIGHT Comparison with the Check whether the depth of color is not diffe-

standard set rent in comparison with the standard set. If it is

different, addjust it so as to get equal to the

standard set.

5Sub tint check STINT Comparison with the Check wheter the tone is not different in co-

standard set mparison with the standard set. If it is different,

adjust it so as to get equal to the standard set.

6OSD positon OSDH OSD character External input Check the outside input mode, and it confirms

check visual observation that the character of INPUT of OSD is 15mm

± 2mm from the right end of the image plane.

When it deviates, it is confirmed.

15mm

INPUT

15

Page 16

DV-L88U

BATTERY END VOLTAGE ADJUSTMENT

1. Initial setting

(1) Power supply

Input 6.15V±0.05V to the DVD battery.

Note1) Set the voltage on the DC input jack PWB of the main unit to the value specified above in the condition of

DVD start-up (LCD lit).

Note 2) Check the voltage with a calibrated measuring instrument. In case that drift is worried, check the voltage

periodically.

2. Battery end voltage adjusting procedure and method

(1) Select the battery detection error compensation adjustment mode.

1 Turn on the main power switch on while pressing the “UP” “DOWN” keys of the main unit at the same time.

2 Press the mode selection key.

3 Press the sound volume down button twice to enter the battery adjusting screen.

4 With button changing button, make the cross key to the cursor mode. (With 70 type remote controller, the cursor

key can be used for operation as it is.)

(2) Adjust with the right and left key so that the “BAT” value displayed on the LCD becomes “0”.

No. Item Checked place Checking method Standard, condition Remarks

1 S image Y output S terminal 1. Play the test disc TDV - 581A.

2. Check the Y output with an 1Vp-p ± 0.15Vp-p S terminal Y output

oscilloscope. Measure at 75Ω

termination.

2 S image C output S terminal 1. Play the test disc TDV - 581A.

2. Check the C output with an 0.286Vp-p ± 0.15Vp-p S terminal C output

oscilloscope. Measure at 75Ω

termination.

3 Error rate check Display 1. Press the STOP key and the V-CD:TDV-581A When playing back.

PLAY key of the main unit key 20/4

at the same time and check

the error rate displayed on the

display.

DVD:TV-501

38/76

4 Flash memory Display 1. Press the return key and the Model name of the When NO DISC.

check VOL-UP key of the main unit software

key at the same time. Region code

Transmit the numeric number Software Ver.

key of R/C (1), next transmit

play to check the model name

and the region code, and

transmit play again to check

the software Ver.

Sound level check

5

Audio output

L/R

Play the title 49, chapter 1AC - 320

mode of the test disc TV - 501 to

check the sound output level.

1.35Vrms ± 0.3Vrms

6 Digital sound Digital sound Connect the digital surround The sound from the digital

output check output processor to the digital sound surround processor must

output and play the VCD to check be played properly.

the sound output from the digital

surround processor.

7 Distorted disc Played image Play the test disc TDV - 533 to It must be normally played.

playback check check the played image on the * No EJECT, rickety play

monitor screen. or staying in LOAD

condition are allowed.

16

Page 17

No. Item Checked place Checking method Standard, condition Remarks

8 Battery display Main unit LCD 1. Supply 8V to the battery

check terminal. Get the DVD start-up

screen.

2. Change the battery voltage to

7V. → Check the battery half

display.

3. Change the battery voltage to

6.5V. → Check the battery alarm

display.

4. Change the battery voltage to

5.9V. → Check the power is

turned off.

9 Charging action Main unit LED 1. Supply power from an

check AC adapter.

2. Connect 15Ω supplied a 6.5V

DC to the battery terminal → Check the LED for

or connect the empty battery. charging orange lights on.

DV-L88U

17

Page 18

DV-L88U

7. TEST MODE

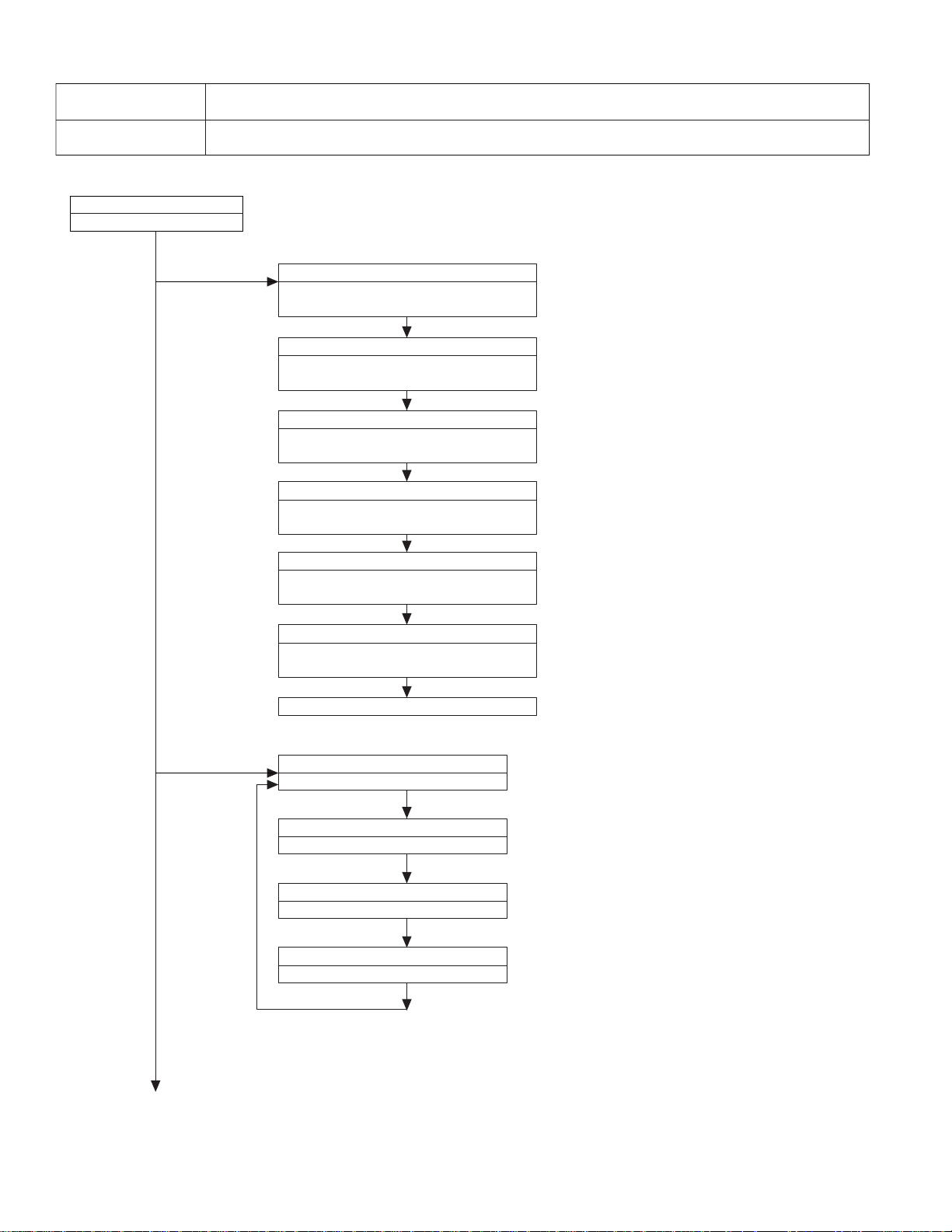

Test Mode A power source is put, and a Skip/Forward key and a Volume Up key are pushed after the "NO DISC" display

ROM Renewal Mode A power source is put with pushing a Skip/Forward key and Volume Down key at the same time.

[TEST MODE]

Test mode initial image plane

F0000000 00000000

at the same time. (It keeps pushing it for about three seconds.)

(It keeps pushing it for about three seconds.)

<The "1" key of the remote controller is pushed.>

The preparation date display of the program

10000000 ********

(Last updata)

The "PLAY" key of the remote controller is pushed.

Model number display

10000001 00007604

(Model number)

The "PLAY" key of the remote controller is pushed.

The version display of the program

10000002 ********

(Program ver.)

The "PLAY" key of the remote controller is pushed.

Reagion number display

10000003 00000008

(Region code:Binary display)

The "PLAY" key of the remote controller is pushed.

Micro-code number display

10000004 ********

(Microcode ver.)

The "PLAY" key of the remote controller is pushed.

The preparation date display of the servo program

10000005 ********

(Servo ver.)

The "PLAY" key of the remote controller is pushed.

It is returned to the test mode initial image plane.

Micro-code is the thing of the process

program of the system integrated circuit.

<The "2" key of the remote controller is pushed.>

Color bar display

20000001 00000000 (FIP)

Color bar display

20000002 00000000 (FIP)

Color bar display

20000003 00000000 (FIP)

Color bar display

20000003 00000000 (FIP)

<The "3" key of the remote controller is pushed.>

To (1)

There is no copy guard signal.

What is the symptom at the time of dubbing to VTR?

The "PLAY" key of the remote controller is pushed.

AGC only

What is the symptom at the time of dubbing to VTR?

The "PLAY" key of the remote controller is pushed.

AGC+Color stripe1

What is the symptom at the time of dubbing to VTR?

The "PLAY" key of the remote controller is pushed.

AGC+Color stripe2

What is the symptom at the time of dubbing to VTR?

The "PLAY" key of the remote controller is pushed.

18

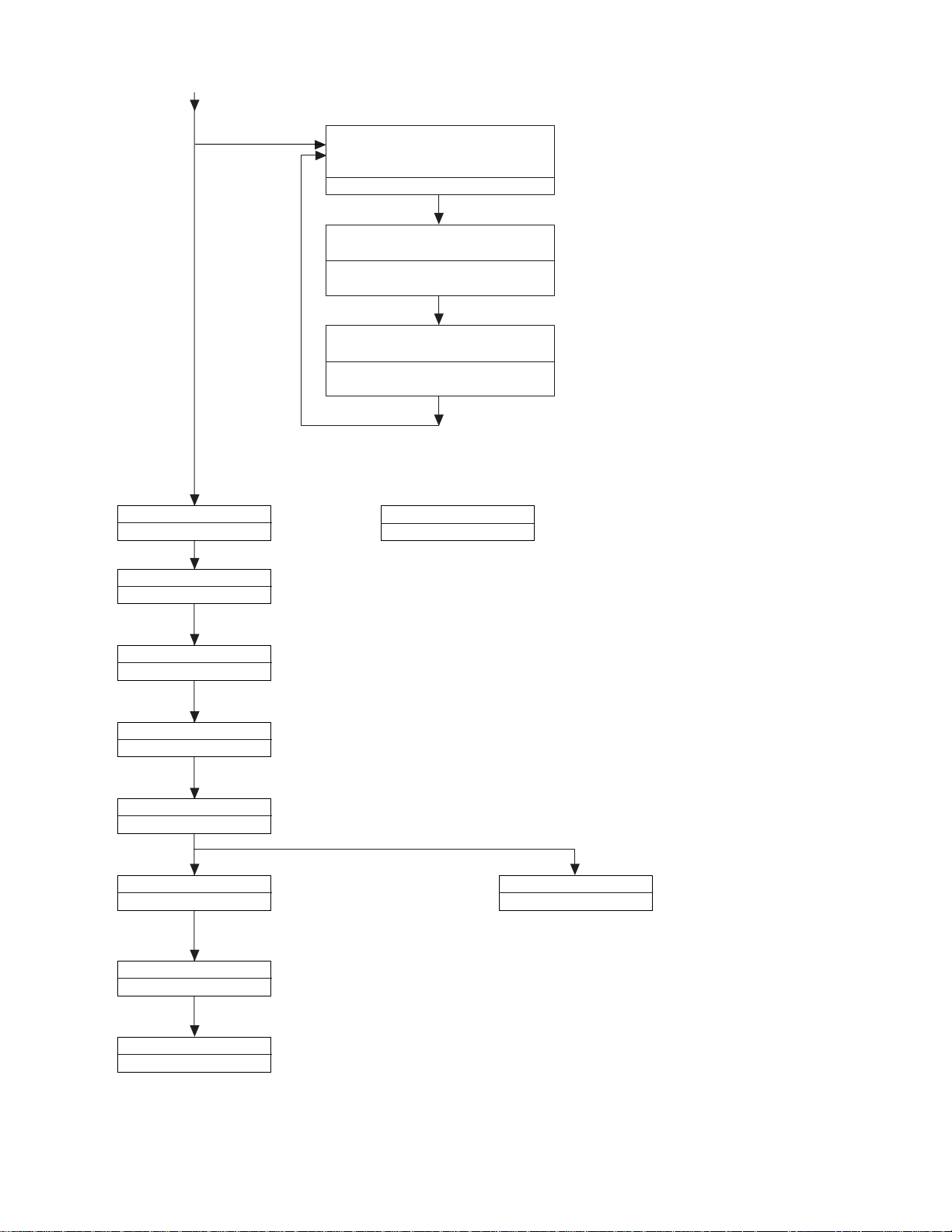

Page 19

From (1)

<The "1" key of the remote controller is pushed.>

<Disk is put, and the "2" key of the remote controller is pushed.>

*It is usually returned in power source off for the state.

STEP TEST

30000201 00000000

DVD laser lights, the spindle motor

rotates and the pickup moves to the

outer periphery.

30000001 000000DD

DVD laser off, CD laser on, spin kick,

sled outer periphery feed

ErrDisplay0 ErrDisplay1

30000001 000000CD

Laser off, spin kick, sled outer periphery

feed

ErrDisplay0 ErrDisplay1

30000001 00000000

Focus on

The "PLAY" key input.

<The "1" key of the remote controller is pushed.>

<The "1" key of the remote controller is pushed.>

<The "1" key of the remote controller is pushed.>

STEP TEST

DD00E210 EEEEEEEE

DV-L88U

Note:Not to face the light of the laser squarely,

caution!

When a disk is not in.

STEP TEST

30000202 00000000

STEP TEST

30000203 00000000

STEP TEST

30000204 00000000

STEP TEST

30000205 00000000

STEP TEST

DD000210 00000000

STEP TEST

DD000211 00000000

RF gain adjustment, Track on

The "PLAY" key input.

Focus gain adjustment

The "PLAY" key input.

Track gain adjustment

The "PLAY" key input.

Focus balance adjustment

The "PLAY" key input.

(In case of CD)

STEP TEST END

CD000210 ********

(******** is sub-Q.)

After TOC Reading,

Follow-up play condition

STEP TEST END

DD000212 ********

(******** is the sector ID.)

Focus balance of the layer 1,

follow-up play condition after focus gain adjustment

19

Page 20

DV-L88U

Personal computer

(DOS)

DVD itself

Connect to the video input

terminal.

Connect the “red” audio cable to jig.

Fixture for the ROM renewal

[ROM RENEWAL MODE]

1. Connect the DVD main unit and the computer as shown on the right. And then start-up the software for rewriting.

2. Turn on the power while the Skip/Forward key and the Volume Down key of the DVD main unit are kept pressed at the same time.

(Keep pressing about 3 second.)

The red LED flickers 5 - 6 times with the 0.5 second cycle and then the green LED flickers with 0.1 second cycle.

3. According to the computer display, data transfer prompt is issued by inputting “Y” and

pressing ENTER key, and when the rewriting starts normally,

The LED in green lights on from flickering.

4. When the rewriting is completed normally,

The green LED lights on.

5. After completing the rewriting and checking the display of No. 4 shown above,

always press the “RETURN” key. After that turn off the POWER.

6. Treatment in case of rewriting error

1 The red LED flickers with 0.1 second cycle (When the stop key is pressed it

return to the condition of “2” so write again.)

2 The red/green LED flickers by turns (When the stop key is pressed it becomes

the condition of “5” so write again from “1”.)

20

Page 21

DV-L88U

Check AC adapter or battery-pack.

No

Voltage on DC JACK (Approx. 10V) or battery

terminal (8.4 - 6V)?

Yes

The power cannot be turned on.(1)

•When using the AC adapter ------check circuit

around F901, Q904, Q905.

•When using battery------check circuit around

F902, Q906, Q913.

No

Voltage specified above (Approx.6 - 10V) on

TP9002, TP9003?

Yes

Voltage of approx. 6 - 11V supplied on 4 pin of

IC5503?

No

Voltage of approx. 5V supplied on 72 pin of

IC5502 (TV microcomputer)?

Yes

Yes

29 pin of IC5502 still “L”?

No

Oscillation signal of 32kHz checked on 23, 24 pins

of IC5502?

Yes

Check the IC5502 and X5502.

Check the Q5503 and Q5504.

No

No

No

Yes

Circuit protector CP9001 is actuated (disconnection)

replace. Check LCD inverter circuit, INV-V line,

D5510, D5511, D5512, Q5506 and Q5507.

Refer to “The key operation is disabled.” or

“No operation is possible from the infrared remote

control.”.

No

•Approx. 5V outputted to 45 pin of IC5502?

•Approx. 5V outputted to 46 pin of IC5502?

(DVD mode)

No

Yes

Check PCON-H line between IC5502 - IC9001.

•Approx. 4.5 V supplied to 20 - 21 pins of IC9001?

•Approx. 4.5 V supplied to 22 pin of IC9001?

(DVD Mode)

Yes

Appropriate voltage outputted on each B line

(TP9005 - 9012)?

No

No

Yes

Triangle oscillation of approx. 0.6V p-p checked on

17 pin of IC9001?

Circuit protector CP9002 cut?

Yes

Check short circuit of each SWITCHING TR and

each B line.

* All the B lines cannot be outputted for short

circuit of even 1postion (1 line).

Replace IC5503.

Replace IC9001.

FLOW CHART NO.1

Attach junction line properly or replace junction line.

No

Wire between operation PWB and Power PWB

connected properly?

Yes

Yes

The key operation is disabled.

No

Slide switch does not function.

No

When slide switch is placed "ON", 5 pin of IC5502

is "L"?

Yes

Is the control voltage normally into the pins(78)

and (80) of IC5502? (78pin→KEY)

Replace S5501.

Yes

Replace operation pwb or S4001~S4005.

Replace IC5502.

No

Replace IC5502.

FLOW CHART NO.2

Check TVMI_5V line.

Replace the remote control receiver.

FLOW CHART NO.3

Operation is possible from the body, but no

operation is possible from the infrared remote

control.

Replace the remote control receiver or replace the

remote control transmitter is necessary.

Is 5V voltage supplied to the pin 2 terminal of

remote control receiver?

Is the "L" pulse sent out pin 3 terminal of receiver

when the infrared remote control is activated?

(Actuated with power button)

DVD cannot be operated but TV can be operated.

(DVD is actuated with play, stop button.)

To 2

1“L” pulse signal is generated from 79 pin of

IC5502?

(Actuated with power button)

No

No

No

Yes

No

To 1

Replace IC5502.

No

Yes

Check line of 2 pin of IC4001.

2“L” pulse signal is generated from 32 pin of

IC502?

(DVD is actuated with play, stop button.)

Replace IC502.

No

Yes

Check D512 line.

Yes

Yes

Yes

No operation is possible from the infrared remote control.

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

PLAY

STOP

STILL

SKIP/BACK

SKIP/FORWARD

DVD/INPUT

SETUP/ADJUPRIGHT

LEFT

DOWN

ENTER

RETURN

VOL-UP

VOL-DOWN

8. TR OUBLESHOOTING

21

Page 22

DV-L88U

FLOW CHART NO.4

Is the tray lid open?

When S802 is pressed, are the pins 3 and 4

short-circuited?

Check the connection between pins 2 or 4 of S802

and pin 27 of IC502.

Does the pickup move in the direction of inner

periphery?

No

No

No

No

Check the cable connecting to the CN7302.

(Check the CN7302 and line of pins 2 and 4 of IC705.)

Check the cable connecting to the CN7303.

Replace the S802.

Yes

No

Yes

After moving in the direction of inner periphery,

does the pickup move in the direction of outer

periphery?

Yes

Check the M_4.8V line.

Is 4.8V being applied to the pins 16 and 17 of

IC7701?

Yes

Replace the IC7701.

Yes

The disc does not rotate.

No

Is FE signal inputted into the pin 150 of IC701.

Check or replace IC701.

Check the line between the IC301 and IC701.

FLOW CHART NO.5

When removing disc and applying load to spin

motor (by stopping with hand, etc.), objective lends

moves up and down? (Checking item to symptom)

Note) If load is not applied to spin, lens does not

move and becomes NO DISC immediately.

See FLOW CHART NO.6<The [No Disc] indication.

(In case focus servo does not function.)>

Replace IC301.

Is there input signal on the pins(50,55) and (49,54)

of IC301?

Is FE signal output to the pin 21 of IC301 when

the disc is set?

No

No

Check the connection of optical pickup cable.

If it is normal, replace the optical pickup.

Yes

No

Yes

Yes

Yes

The [No Disc] indication. (In case of focus error)

In case of CD For DVD, 58, 59, 63, and 64

FLOW CHART NO.6

Is the focus control signal output to the pin 14 of

IC701?

Check the IC701 DAC power source periphery

circuit. If it is normal, replace IC701.

Check M_5V line.

Is 8V voltage applied to the pins 8 and 27 and

25 and 24 of IC705?

Replace IC705.

Is the focus control signal from the pin 158 of

IC701 input into the pin 20 of IC705?

Check the focus control signal (DA0) line between

the IC705 and IC701.

Is the focus control drive voltage output from the

pins 29 and 30 of IC705?

No

No

No

Yes

Yes

Yes

No

Yes

The [No Disc] indication. (In case focus servo does not function.)

Check the line between the IC705 and the focus

actuator.

Focus control drive voltage applied to 27, 29 pin

of CN7301 (focus actuator terminal)?

Check the connection of optical pickup cable.

If it is normal, replace the optical pickup.

FLOW CHART NO.7

Check the D_3.1V line and A_5V line.

Is the drive signal (SEL) of Q301 (LD POWER

ON) being output to the pin 37 of IC701?

Is the drive signal (LDO1) of Q302 (LD POWER

CTL) being output to the pin 45 of IC301?

When S801 is pressed, is the base of Q303 0.8V?

Is the voltage of 3.3V being applied to the emitter

of Q301? And, is the voltage of 3.4V being applied

to the emitter of Q302?

Is the voltage of 3.1V and 2.3V being applied to

the pins 14 and 23 of CN7301, respectively?

Check the connection of optical pickup cable.

If it is normal, replace the pickup.

Check the Q301 and line between Q302 and

CN301.

Check the line from the pin 37 of IC701, through

Q305, to the base of Q301.

Check the line between the pin 45 of IC301 and

base of Q302.

Check the line between S801 and R323.

No

No

No

No

No

No

Yes

Yes

Yes

Yes

The DVD disc is not recognized.

(When the laser beam does not go on)

FLOW CHART NO.8

Check the A_5V line.

Is the drive signal (LDO2) of Q304 (LD POWER

CTL) being output to the pin 4 of IC301?

When S801 is pressed, is the base of Q304 0.8V?

Is the voltage of 3.4V being applied to the emitter

of Q303?

Is the voltage of 2.3V being applied to the pin 9

of CN7301?

Check the connection of optical pickup cable.

If it is normal, replace the pickup

Check the line between Q304 and CN7301.

Check the line between the pin 4 of IC301 and

base of Q303.

Check the line between S801 and R323.

No

No

No

No

Yes

Yes

Yes

The CD disc is not recognized.

(When the laser beam does not go on)

FLOW CHART NO.9

Check tray switch. S801, 802

No

Check for contamination of objective lens of

optical pickup.

Replace the optical pickup unit.

When cover is closed, disc starts rotating?

Check the main PWB unit.

Set disc to mechanism.

Replace the main PWB unit.

Is the level of RF signal which is output from

pin 28 of IC301, normal?

No

No

No

Yes

Yes

Yes

Yes

Both picture and sound do not operate normally.(1)

22

Page 23

DV-L88U

FLOW CHART NO.10

Check or replace Q2201.

Set the disc on the disc tray.

Check the V-MUTE line.(Pin3 of D2204)

5V applied to 1 pin of IC2201?

Are the video signals shown above input into

the pins of IC2201?

IC2201 2PIN Y/CR

IC2201 15PIN C/CB

Are the video signal outputted to each pins of

IC2201?

(1)When S1-OUT/VIDEO OUT is selected with the

signal selection switch(Q2201).

IC2201 11PIN CVBS

IC2201 6PIN S-Y

IC2201 12PIN S-C

Check the line between the pins of main unit

IC601 and the pins of IC2201.

IC601 105PIN → IC2201 2PIN Y/CR

IC601 106PIN → IC2201 15PIN C/CB

No

No

No

Yes

No

Yes

Yes

Picture do not operate normally.

FLOW CHART NO.11

Check or replace IC6801.

Set disc to DISC tray and play.

Digital sound signal inputted to each pin of

IC6801?

IC6801 5PIN AMCLK

IC6801 3PIN ABCLK

IC6801 1PIN ALRCLK

IC6801 2PIN AOUT0

Check each line between each pin of IC601 and

each input pin of IC6801.

IC601 131PIN → IC6801 5PIN AMCLK

IC601 141PIN → IC6801 3PIN ABCLK

IC601 139PIN → IC6801 1PIN ALRCLK

IC601 136PIN → IC6801 2PIN AOUT0

System control signal inputted to each pin of

IC6801?

IC6801 26PIN DAC DA

IC6801 27PIN DAC CK

IC6801 28PIN DAC L

IC6801 22PIN RSTO I

Check or replace IC6801.

Check each line between each pin of IC504 and

IC251 and each input pin of IC6801.

IC504 110PIN → IC6801 26PIN DAC DA

IC504 111PIN → IC6801 27PIN DAC CK

IC504 112PIN → IC6801 28PIN DAC L

IC251 77PIN → IC6801 22PIN RSTO I

No

No

Yes

Yes

Yes

Check or replace IC6610.

Yes

Yes

Sound is not given properly from speaker.

Control signal inputted to each in of IC6610?

IC6610 2PIN VOL_UP

IC6610 3PIN VOL_DOWN

Check from each pin of IC5502 to each input pin

of IC6610.

IC5502 33PIN → IC6610 2PIN VOL_UP

IC5502 4PIN → IC6610 3PIN VOL_DOWN

No

Yes

Is 15 pin of IC6610 low?

Check the Q6609, D6601, R6001, J6001.

No

Yes

Sound signal inputted to each pin of IC6610?

IC6610 5PIN Lch Input

IC6610 23PIN Rch Input

Check the IC6604, IC6605 and IC6607 and

peripheral circuit.

No

Yes

Charge troubleshooting

Go to item 4.

Charge LED (orange) lights on?1.

Yes

No

No

No

Yes

No

No

Yes

Yes

Yes

No

Power supplied from AC adapter?

Power of main unit can be turned on and off?

Power of main unit OFF?

F901 fuse is not cut?

Voltage of battery alone is 2V or more?

Replace fuse.

Failure of battery.

Cannot be charge.

Failure other than charging.

Cannot be charged when power is ON.

Turn off power and check.

Breakdown of IC5502.

44 pin of IC5502 is H?4.

No

No

No

No

Yes

Yes

Yes

2 pin of IC901 oscillating at approx. 200kHz?

19 pin of IC901 oscillating at approx. 200kHz?

Voltage on C901?

Yes

Yes

Investigate CHG_ON line.

Investigate from C901 to battery terminal.

Check around IC901 or breakdown of IC901.

Check around IC901 or breakdown of IC901.

Investigate Q908, D906, L901, and R915.

In the condition that power is supplied from AC adapter and power is off, nothing is connected to battery terminal.2.

Yes

No

Yes

No

Yes

No

Voltage of 0V/8.4V generated to battery terminal

cyclically.

"H" voltage on 8 pin of IC5502?

Yes

Investigate CHG_ON line. Charging circuit must

function accompanied by CHG_ON cyclically.

Voltage on 77 pin of IC5502?

44 pin of IC5502 repeating H/L cyclically?

If certain voltage is on, investigate BAT_V line.

When battery is not connected, voltage of 0V/4.2V

is outputted cyclically.

Study on other items.

Investigate line of DCIN_H.

Only battery is connected. (Assume herein that battery with voltage of 7.4 V is connected.)3.

Yes

No

No

No

Yes

Voltage of 3.7V on 77 pin of IC5502?

Voltage on 6 pin of Q905?

Yes

1V or less on 4 pin of D5509?

Investigate around Q905.

No problems with this item.

Investigate around IC5505.

Investigate around IC5505.

23

Page 24

DV-L88U DV-L88U

9. BLOCK DIAGRAMS

9-1. MAIN BLOCK DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

24~25

Page 25

DV-L88U DV-L88U

9-2. MAIN/LCD BLOCK DIAGRAM

VSS (-16V)

Q6603

R1929

R1930

R1941

R2254

R6657

R6658

R6651

R6652

Q6609

15

23

12

13

(SP-MUTE)

VGH(+13V)

5

6

23

20

15

9

4

14

11

J2001

TPA0152

IC6610

23

4

9

21

16

Q6606Q6605

D_3V

Q6601

J6001

J2002

IC1806(1/2)

J

AT_A_5V

R1809

R1813

(GAMMA 0)

+

Q1838

Q1802

Y/VIDEO

AT_A_5V

R1816

Q1807

R1831

DVD_L

C1842 C1825

R1855

TH5501

R5529

LED-R, G

D5503

C5510

C5516

57

37

56

54

22

55

21

38

36

60 LED_R

61 LED_G

AT_A_5V

R1810R1805

R1807

Q1800

R1803

I

C1846

R1889

R1853

R1854

C1848

R1870

R1847

C1828

C1831

X1800

AT_A_5V

A_7.5V

R1899

D1803 1/2

H

Q1804

D1803 1/2

DVD_L

AT_A_5V

G

F

AT_A_5V

IC3201

MB8346BV

E

D

IC5501

C

B

A

_1

_1

_1

R/C

MICS

TV_KEY1

TV_KEY2

PCON_H

DVD_PCON

TU_PCON

LED_G

LED_R

HOLD

POWER

R1812

C1803

C1807

R1808

6867666970

_1

_1

19

2018164579

C1805

IC1802

IC1804

IR3Y29AM

D1800

62

_1

R1804

PCON_M

IC1801

MIRST

DVD_PCON

46

154759

C1809

S803

D5504

R1811

C1806

IC1800

SNT1G08C

AT_A_5V

Q1801

AT_A_5V

Q2222

IC5502

IX1751GE

LCD MICON

POWER5HOLD6TV_KEY178TV_KEY280TU_PCON

48

R1846

C1827

R1850

R1806

DVD_LDVD_L

C1821

C1819

C1815

13

634950

CSYNC

DVD_L35DEF

32KHZ 8MHZ

X5502

MainSTNBY

X5501

42

OUTV_MUTE

VOL_DOWN

VOL_UP

TV_H

A_MUTE

VCC

RESET

C1946

Q1900

Y/ VIDEO

D2204

4

33

17

34

41

72

RXDCTL

29

RXD2

A_MUTE

SPDIF

R1939

AT_A_5V

R2204

Q5513 Q2217

D_3V

Q2218Q2219

2

416

IC5503

Reg

RESET

R1882

Q2202

AT_A_5V

Q2216

+

R1918

R1938

R1936

R1164

C1949

5

IC6606

5

3

C2214

C2204

C2207

VOL_DOWN

VOL_UP

Q1805

Q1806

L1904

C1945

Q5506

Q5507

ADAPTER_10V

D1902

C1943

IC1900

LZ9GK21

AT_A_5V

IN_H

A_MUTE

R1932

9

2

15

Q2201

BATT_V

C1938

C1939

CLAMP

CLAMP

BIOS

A_5V

A_5V

R6611

R6614

R6627

1 VCC2

12

13

R1928

R1927

IC1901

R1934

R1933

LPF

6TH ORDER

LPF

6TH ORDER

Q6607

Q6608

11

14

R1926

R1923

R1925 R1924

R1922

(-16V)

R1935

D1903

SELECT

6dB

AMP

6dB

AMP

IC6605

BU4053V

IC6604

BU4053V

R1914

C1913

R1921 L1903 R1955

C1935 C1936

D1900

VCC1 16

6dB

AMP

6dB

AMP

6dB

AMP

6dB

AMP

TVMI_5V

Q6602

Q6601

D_3V

7

6

5

11

10

12

TP1900

HSY

AT_A_5V

IC2201

TK15430V

C2210

+

C2212

+

C2213

+

C2211

+

IC6607

NJM4560M

AUDIO AMP.

351

D6601

D1904

R1956

R1943

IC1999

R1944

C1937

R2242

R2237

R2249

C2209

From a

AT_A_5V

Q2250

R6634

7

R6635

Q6604

1234567891011 12 13 14 15 16 17 18 19 20

26~27

Page 26

DV-L88U DV-L88U

9-3. POWER 1 BLOCK DIAGRAM

J

I

H

G

F

E

D

C

DC JACK

BATTERY TERMINAL

BATT 1

BATT 2

GND 3

GND 4

F901 L9801

D901

1

2

C921

F902

AC POWER

Q904

S11D1

R932

D9 04

R933

4

C922

3

R951

3

R9 03

R9 04

OPEN

2

1

Q907

R906

D902

Q906

5,6

D2

D1

7,8

S1

1

D2 S2 3

7,8

5,6

G1

24

4

G2

G1

2

G

D1

7,8

G1

2

G2

D905

26

3

S2

S1

1

D

Q913

S

Q901

S2

D2

5,6

3

G2

4

Q905

35

D901

R925

R927

R923

R916

R941

C910

R922

FB2

–IN2

+IN2

C911

FB1

R921

–IN1

R926

+IN1

DTC

R920

C908

CSCP

C909

R918

R924 R928

15

14

13

6

7

8

16

1µA

5

D

G

S

Q911

Error

Amp.2

–

+

Error

Amp.1

–

+

SCP

Comp.

–

–

+

2.1 V 1.1 V

Q912

D

G

S

Q910

62

1

35

4

COUT –INC +INC

–

+

bias

SR

Latch

+

+

+

–

DTC

Comp.

Current

Amp.

UVLO

PWM

Comp.

X25

–

+

R917

IC901

10912

Out 100kΩ

1V

1.9V

1.3V

bias Vcc

OSC Ref CTL

2.5V

24 3 1 11

RT CT VREF

C907

C905

18

Vcc

19

OUT

20

VE

CTL

17

C903 C904

2

R919

R931

R930

R929

2,3,6,7

+

–

D909

D910

L902

+

C912

–

Q908

5

3

1

R912

1,5,8

R940

L901

GD4

+

D906

C901

–

Q909

DC. V out

A-Amp 4.5V

BATTERY-i (AD)

Charge On Control

Trickle (H)

Power-H

DC-IN (H)

BAT. V (AD)

INV. V out

SWITCH (L)

B

A

1234567891011 12 13 14 15 16 17 18 19 20

28~29

Page 27

DV-L88U DV-L88U

9-4. POWER 2 BLOCK DIAGRAM

J

Q9907

DC IN

I

VREF

VREF

1.2V

Low input

voltage,

protection circuit

IC9001

PWM Comp.1

–

–

+

PWM Comp.2

–

–

+

PWM Comp.3

+

+

–

100Ω

PWM Comp.4

+

+

–

100Ω

14 4215 16

R9007

OFF Electric

current setting

OFF Electric

current setting

OFF Electric

current setting

OFF Electric

current setting

–1.9V

–1.3V

17

C9003

2.5V

Ref.

19

OSC.

RT CT VREF GND

2.5V

2.5V

2.5V

2.5V

VCC ON/OFF

CTL

48

45

46

47

3

2

44

43

34

35

40

41

38

37

39

38

21

22

18

20

1

Ca1

Cb1

Vcc2

OUT1

VE1

Ca2

Cb2

OUT2

VE2

Ca3

Cb3

OUT3

VE3

Ca4

Cb4

OUT4

VE4

CTL2

CTL3

Vcc1

CTL1

C9019

C9021

R9035

C9015

C9023

R9036

C9016

C9024

R9037

C9020

C9025

R9038

R9025

SCP

7

6

5

8

4

12

11

10

13

9

25

26

27

24

28

30

31

32

29

33

SCP Comp.

23

CH1

Error Amp.1

+

–

Comp.1

VREF

+

–

CH2

Error Amp.2

+

–

Comp.2

VREF

+

–

CH3

Error Amp.3

+

–

Comp.3

+

0.6V

–

CH4

Error Amp.4

+

–

Comp.4

+

0.6V

–

–

–

–

–

+

1µA

Low input voltage, protection circuit

2.1V

DTC Comp.1

DTC Comp.2

DTC

Comp.3

VREF

SR

Latch

+

–

2V

+

–

2V

–

–

+

R9027

A

H

R9021

R9009

B

G

R9001

R9023

R9020

R9012

R9006

R9005

R9017

R9003

R9004

C

F

R9008

R9018

R9030

R9011

R9024

R9010

D

E

R9019

R9026

R9022

R9028

R9031

R9013

R9015

R9014

R9029

+IN1(E)

–IN1(E)

FB1

–IN1(C)

DTC1

+IN2(E)

–IN2(E)

FB2

–IN2(C)

DTC2

+IN3(E)

–IN3(E)

FB3

–IN3(C)

DTC3

+IN4(E)

–IN4(E)

FB4

–IN4(C)

DTC4

R9032

D

C9004

C

D

CP9002

C9027

C9028

C9030

SWITCHING

Q9001

C9030

Q9004

3.3V SWITCHING

Q9003

1.8V SWITCHING

Q9002

5V SWITCHING

1

10

2

9

3

8

4

7

5

6

T9001

C

L9007

D9003

L9006

D9002

A

L9004

D9001

+

–

+

–

C9049

C9050

+

–

C9048

D9004

213

431

D9005

C9031

4

2

B

C9033

C9032

DVD_PCON

D9007

D9006

D9008

5V

13V

7.5V

–5V

–16V

3.3V

1.8V

P-CON-H

Q9903

6

1

2

3

4

5

Q9913

M_5V

D_5V

A_5V

AT_A_5V

A_3.3V

D_3.3V

D_1.8V

Q9914

DVD P-CONTROL

B

A

1234567891011 12 13 14 15 16 17 18 19 20

30~31

Page 28

DV-L88U DV-L88U

10. SCHEMATIC DIAGRAMS 10-1. MAIN (1) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

32~33

Page 29

DV-L88U DV-L88U

10-2. MAIN (2) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

34~35

Page 30

DV-L88U DV-L88U

10-3. LCD CTL CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

36~37

Page 31

DV-L88U DV-L88U

10-4. POWER (1) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

38~39

Page 32

DV-L88U DV-L88U

10-5. POWER (2) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

40~41

Page 33

DV-L88U DV-L88U

10-6. POWER (3) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

42~43

Page 34

DV-L88U DV-L88U

10-7. POWER (4) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

å AND SHADED COMPONENTS=SAFETY RELATED PARTS

å

å

å

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

44~45

Page 35

DV-L88U DV-L88U

10-8. POWER (5) CIRCUIT SCHEMATIC DIAGRAM

J

I

H

å

G

å AND SHADED COMPONENTS=SAFETY RELATED PARTS

å

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

46~47

Page 36

DV-L88U

10-9. OPERATE CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

12345678910

48

Page 37

10-10. LCD SW CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

DV-L88U

F

E

D

C

B

A

12345678910

49

Page 38

DV-L88U DV-L88U

10-11. RF&MOTOR CIRCUIT SCHEMATIC DIAGRAM

J

I

H

G

F

E

D

C

B

A

1234567891011 12 13 14 15 16 17 18 19 20

50~51

Page 39

DV-L88U

J

11. PRINTED WIRING BOARD ASSEMBLIES 11-1. MAIN PWB

Component Side SIDE A

I

R4012

Q4012

D4011

R4015 R4014

D4012

R4018 R4013

R4017

R614

C628

R4011

Q4011

R4016

H

TP4009

G

TP4008

C629

C632

C631

L602

C601

C603

C627

C626

X601

R612

R613

R623

C630

C633

R615

R616

R617

R618

R619

R620

C634

R621

C635

C602

TP608

TP607

TP606

TP605

C604

F

R765

R762

R763

R764

TP4007

R4004 R4005 R4006

S4002 S4003 S4004 S4005

RMC4001

S4001

TP4006

TP4005

C4001

D4001

R4003

R4002

IC4001

C4003

C4002 R4001

CN703

L701

C707

C714

E

D

R761

C750

C747

C745

R756

R752

R753

C743

R750

R749

R748

C741

R747

R746

R745

C711

R743

R744

C740

R741

R742

C739

C710

R739

C738

R740

R737

C737

R738

R721

R722

R707

C718 R723

C715 L702

S801

C

S5501

Q4013

R4019

R602

C753

R724

C720

R713 C719

C709

R822

Q202

Q203

R605

R604

R606 R823

R607 R225

R608 C204

R609

FB604

IC601

C606C605

C735

C730

R726

C713

C705

R708

Q701

TP320

TP318

TP317

TP319

TP339

TP321

TP323

S802

TP322

TP346

TP344

TP345

TP343

R7702

L603

C201

Q205

C205

C624

TP302

TP301

L601

C619

C620 FB601

C613

C615 C616

C610 C611 C612 R601 C614

TP7723

TP7722

TP7721

TP7720

TP7719

TP7718

TP7717

TP7716

TP7715

TP7714

C749

R758

R759 C751

C748

R760

C746

C744

R751

FL701

R755

C742 R754

C733

TP701

R718

C723 R732

C724 R733

C725 R734

C726 R735

C727 R736

R716 R725

R719 R720

R768 C732

R780

R3306

R301

C301

C646

C617 C618

FB603

IC602

R534

R543

R540

R537

R532

R535

R589

R571

R525

R528

C3306

R524

C506

FL501

R522

C507

R520

R519

R597

IC507

R518

R517

R516

R556

R514

R590

R515

Q502

R523

R3317

R3315

R3316

IC3302

R3314

R757

C3301

R3305

R3302

C3302

R3303

R3304

C3305

R3301

R3309

R3310

IC3301

C3303

R3308

C519

C3304

R3307

R3311

C3307 C3308

R3313

R3312

IC502

C516

D510

TP502

TP503

C641 C640

TP501

R594

Q503

C504

R595

R570

C505 R592

R544

R521

R573

R512

R513

C510

D511

IC504

R507

R505

R506

R511

R530

C508

R508

R509

C511

C515

TP838

TP849

R580

D512

R588

R579

D505

R567

R568R569

R502

R587

R585

R582

R593

R510

R574

R561

Q501

C503

R541

R581

R539

R542

R538

R533

R584

R564 R565 R566

R562 R563

R503

R596

R504

C501

Z1

C625 R226

R603 C203

R611

R610 R227

C622

C623

C621

C608

C607

C609

TP704

C758

C759

C757

C756

C781

TP702

C706 R709

R710 C716

C728 R711

C731 C734

TP315

TP316

TP314

TP342

TP340

TP338

TP341

TP337

TP313

TP326

TP703

IC701

C780

R717

C729 R727

C717 R728

C712 C708

R714 R729

C721 R730

C722 R731

R767

TP303

TP311

TP308

TP305

TP310

C302

C304

TP309

TP306

TP304

TP312

TP330

TP335

TP332

TP327

TP324

TP331

TP336

TP334

TP328

TP325

C305

C303

CN301

TP329

TP307

TP333

B

A

12345678910

52

Page 40

Wiring Side SIDE A

J

I

H

G

DV-L88U

F

E

D

C

B

A

12345678910

53

Page 41

DV-L88U

J

I

H

G

F

Component Side SIDE B

FB201

TP847

C231

TP846

TP845

C216

C220C226

TP844

TP839

C222

TP840

C221

CN802

C219C225

R261

FB819

FB818

R819

TP827

TP829

TP826

TP828

R820

R812

TP811

TP813

TP815

TP817

TP812

TP814

TP816

FB820

R813

IC508

C233

C215C232

C644C643

IC509

IC603

R818

TP831

TP830

TP818

D513

R622

TP819

TP832

TP820

TP836

TP833

TP834

TP835

TP837

CN801

TP821

TP823

TP825

C253

TP822

TP824

FB816

FB817

R804

C262

C256

L703

C261

C260

TP512

TP511

C251 C263

TP514

TP513

C254

C255

IC251

R252

R255

C259

TP517

TP515

TP518

TP516

R257

C6805

C6804

C6806

C6803

R827

Q802

Q801

R559

R558

R554

C252R557

R253

C257

C258

R258

R256

IC6801

R260

R259

R6825

C6802

R6826

IC6802

C6801

C6807

R6824

IC702

TP843

C217

C218

TP848

E

L501

C502

D

C

TP841

C224

C223

TP842

C331

C509

FB301

R304

C306

Q301

R310

R323R322

Q304

R303

R550

Q504

D514

C523

C522

R572

R575

R552

L301

C329

C330

R317

C324Z5C325Z4C326

TP348

TP347

IC301

R262

L302

C315

C317

C311

Q307

C333

C332

R316

TP349

CN302

IC501

C517R555

C321

C322

C327

C310

C328

C323

C320

C309

C318

C316

C308

C314

C313

C319

R311

R320

Q303

R319

R318

R7703

C307

C7706

R7723

R315

R7722

Q302

R7729

C7705

D301

R314

C312

C7704

Z3

Z2

IC7702

C7707

R7715

C7701

C7703

R7728

R7727

IC7701

R7726

R7725

R7721

R7714

R7717

R7713

R7718

C7702

C752

L7701

C7708

IC705

C7709

R7707

R7708

R7711

R7710

R7705

R7704

B

A

12345678910

54

Page 42

Wiring Side SIDE B

J

I

H

G

DV-L88U

F

E

D

C

B

A

12345678910

55

Page 43

DV-L88U

J

11-2. POWER PWB

Component Side SIDE A

FB9014

D9005

R2201

D2204

TP6601

FB9013

FB9012

FB9011

T9001

L9006

D9008

C9050

FB9035

FB9034

TP9019

Z15

Z14

CN9901

Z1

Z3

Z2

FB9026

FB9027

TP9021

TP9020

R9043

TP9005

C5502

R5572

R5575

R5584

R5585

R5504

R5505

Z26

C5504

R5514

C5505

R5515

C5506

R5516

Q5505

R5506

R5517

R5507

R5518

C5507

C5540 R5565

C6623

D9004

C9040

L9009

C9043

TP9009

Q9003

D9002

C9028

C9032

R9044

C2215

C2216

R2204

Q2204

D2205

Q2207

TP6625

TP5002TP6621

C6620

TP6624

C6611

I

J2001

H

FB6001

R2222

R2224

TP2009

C2217

IC2202

R2226

C2219

G

C2212

J2002

F

E

J6001

C2211

C2213

FB9040

R9045

FB9038

R9046

FB9041

C6603

C6001

C6621

CN6601

D

TP6627

C6646

C6645

R6650

R9050

C

R6649

C6640

C6637

R6658

IC6610

C6644

Q6604

C6643

C6629

R6637 C6631

R6635 R6639

C6627

R6642

R5590

C6639

R5591

B

R9048

R9049

FB9039

R2218

R2225

FB9046

R2227 C2220

C2210

R2229

Q2210

R2230

C2214

R2228

R2207

R6640

R2231

IC2201

C2201

C2205

C2204

R2206

Q2201

R2203

R2202

R2205 C2207

C2202

Q2202

C2206

TP6619

Q6601

C6614

R6624

D6602

TP6615

TP6614

TP6613

TP6612

TP6611

TP6610

TP6609

TP6608

TP6607

TP6606

TP6605

TP6604

TP6603

TP6602

TP6616

C6622

C6610

C6634

C6635

C6636

C6633

R6657

R6634

C6642

C6632

R6643

Q6603

R6647

C6630

R6641

R6636

C6626

C6628

R6638

C9029

L9004

Q9001

Q9002

C9027

Q9004

L9007

D9003

C9030

C9033

D9006

TP9022

TP9006

FB9031

FB9030

FB9029

TP9016

Q9907

C5520

FB9021

D5503

TH5501

R5522

R5521

X5501

R9913

R9914

R9910

R9909

TP9017

Q9903

Z21

R9906 R9905

FB9045

FB5503

R5529

C5516

FB5501

R5526

C5512

C5549

C5548

IC5502

C5514

R5525

C5511 R5523

C5515 R5524

Z10

Z11

Z9

TP9013

Z8

Z7

Z6

FB9022

FB9023

TP9018

R9042

C5510

C5542

R5573

R5594

R5574

R5595

C5543

C5539 R5511

X5502

C9049

C5513

R5527

TP1872

Z29

C9047

D9001

C9031

L9015

TP1881