Page 1

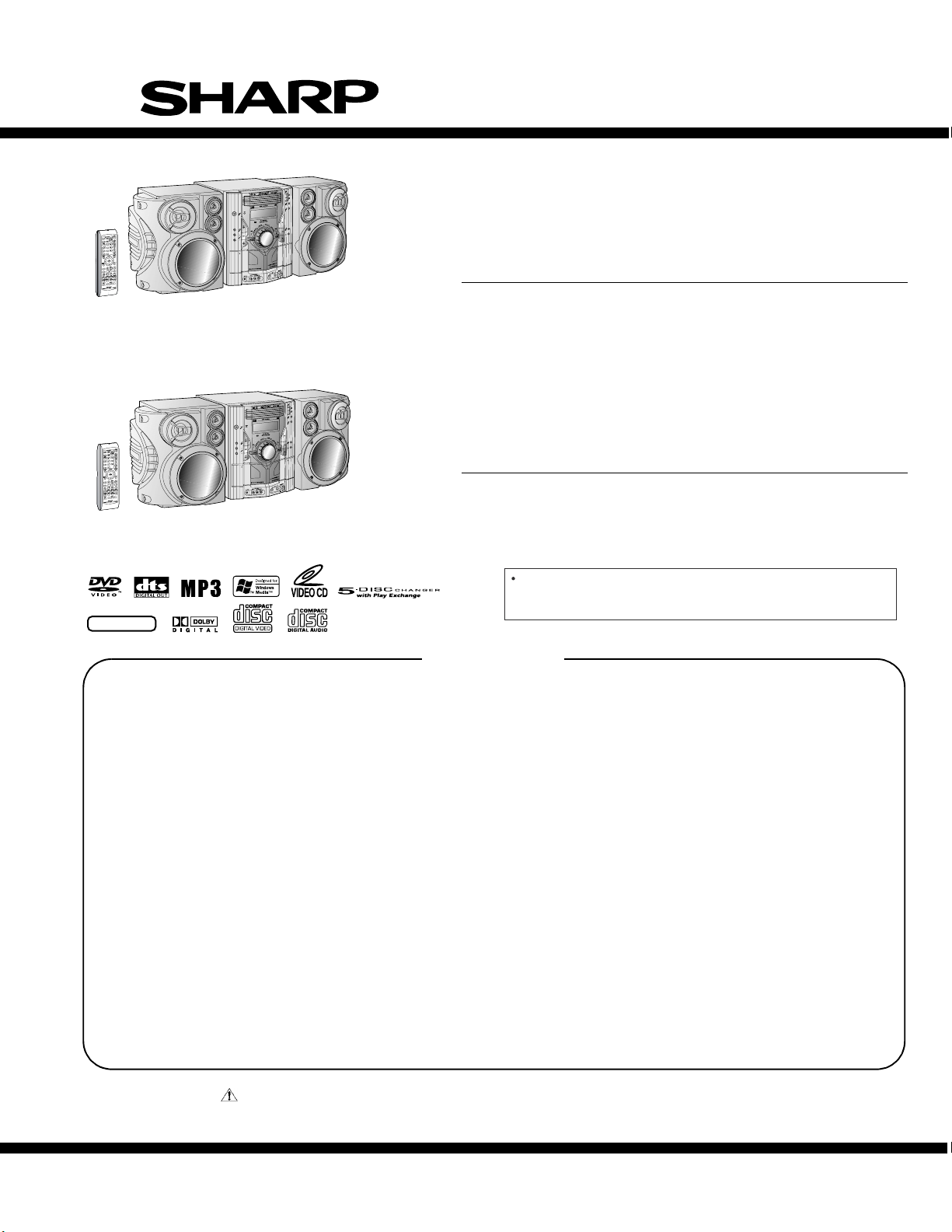

CD-DV999W

SERVICE MANUAL

No. S6447CDDV777W

Illustration: CD-DV777W

Illustration: CD-DV999W

NTSC/PAL

MINI COMPONENT SYSTEM

MODEL

CD-DV777W DVD Mini System consisting of CD-DV777W

and CP-DV777 (speaker system).

DVD MINI SYSTEM

CD-DV777W

DVD MINI SYSTEM

MODEL

CD-DV999W DVD Mini System consisting of CD-DV999W

and CP-DV999 (speaker system).

In the interests of user-safety the set should be restored to its

original condition and only parts identical to those specified be

used.

CONTENTS

CD-DV999W

(main unit)

(main unit)

CHAPTER 1. GENERAL DESCRIPTION

[1] Specifications ................................................. 1-1

[2] Names of parts............................................... 1-2

CHAPTER 2. ADJUSTMENTS

[1] Mechanism section ........................................ 2-1

[2] Tuner section ................................................. 2-1

[3] DVD/CD section ............................................. 2-2

[4] TEST Mode .................................................... 2-2

[5] CD Changer mechanism section ................. 2-10

CHAPTER 3. MECHANISM BLOCKS

[1] Caution on diassembly................................... 3-1

[2] Removing and reinstalling the main parts ........ 3-4

CHAPTER 4. DIAGRAMS

[1] Block diagrams............................................... 4-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for

maintaining the safety and performance of the set.

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Notes on schematic diagram .........................5-1

[2] Types of transistor and LED ..........................5-1

[3] Waveforms of DVD circuit..............................5-2

[4] Voltage...........................................................5-3

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] Schematic diagram ........................................6-1

[2] Wiring side of PWB......................................6-16

CHAPTER 7. FLOWCHART

[1] Troubleshooting .............................................7-1

CHAPTER 8. OTHERS

[1] Function table of IC .......................................8-1

[2] FL Display....................................................8-16

Parts Guide

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

CD-DV999W

SAFETY PRECAUTION FOR SERVICE MANUAL

WARNINGS

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1 BUT THE LASER

COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR CLASS 1. THEREFORE IT IS

IMPORTANT THAT THE FOLLOWING PRECAUTIONS ARE OBSERVED DURING SERVICINGTO PROTECT YOUR EYES

AGAINST EXPOSURE TO THE LASER BEAM.

1-WHEN THE CABINET ISREMOVED, THE POWER ISTURNED ON WITHOUT ACOMPACT DISC IN POSITION ANDTHE

PICKUP IS ON THE OUTER EDGE THE LASER WILL LIGHT FOR SEVERAL SECONDS TO DETECT A DISC. DO NOT

LOOK INTO THE PICKUP LENS.

2-THE LASER POWER OUTPUT OF THE PICKUP UNIT AND REPLACEMENT SERVICE PARTS ARE ALL FACTORY

PRESET BEFORE SHIPMENT.

DO NOT ATTEMPT TO READJUST THE LASER PICKUP UNIT DURING REPLACEMENT OR SERVICING.

3-UNDER NO CIRCUMSTANCES STARE INTO THE PICKUP LENS AT ANY TIME.

4-CAUTION-USE OF CONTROLS OR ADJUSTMENTS, OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

VOLTAGE SELECTION

Before operating the unit on mains, check the preset voltage. If the voltage is different from your local voltage, adjust the voltage

as follows.

Turn the selector with a screwdriver until the appropriate voltage number appears in the window (110 V, 127 V, 220 V or 230 V - 240 V AC).

QACCE0015AW00

AC POWER SUPPLY CORD AND AC PLUG ADAPTOR

– i –

Page 3

AudioCD-DV999W/CD-DV777WService ManualCD-DV999W/CD-DV777WMarketE

CHAPTER 1. GENERAL DESCRIPTION

[1] Specifications

CD-DV999W/CD-DV777W

General

Power source AC 110/127/220/230-240 V , 50/60 Hz

Power consumption 170 W

Dimensions Width: 260 mm (10-1/4")

Weight 10.5 kg (23.1 lbs.)

Height: 330 mm (13")

Depth: 326 mm (12-7/8")

Amplifier

Output power MPO: 740 W (370 W + 370 W) (10 % T.H.D.)

Output terminals Speakers: 6 ohms

Input terminals

RMS: 400 W (200 W + 200 W) (10 % T.H.D.)

RMS: 290 W (145 W + 145 W) (0.9 % T.H.D.)

Headphones: 16 - 50 ohms (recommended:

32 ohms)

Video output: 1 Vp-p (75 ohms)

Game/Auxiliary (audio signal): 500 mV/ 47 k ohms

Game/Video: 1 Vp-p

Microphone 1/2: 1 mV/600 ohms

Cassette deck

Frequency response 50 - 14,000 Hz (normal tape)

Signal/noise ratio 55 dB (TAPE 1, playback)

Wow and flutter 0.3 % (WRMS)

50 dB (TAPE 2, recording/playback)

Tuner

Frequency range FM: 88.0 - 108.0 MHz

AM: 531 - 1,602 kHz

DVD/VCD/CD player

Signal system NTSC/PAL

Supported disc types DVD, audio CD, CD-R, CD-RW, VCD, MP3/

Video output Output socket: Pin socket x 1

S-video output Y output level: 1 Vp-p (75 ohms)

Video signal Horizontal resolution: 500 lines

Audio signal Frequency characteristics:

CP-DV999

Type 3-way type speaker system

Maximum input power

Rated input power 200 W

Impedance 6 ohms

Dimensions Width: 277 mm (10-7/8")

Weight 4.8 kg (10.6 lbs.)/each

WMA

Output level: 1 Vp-p (75 ohms)

C output level: 0.628 Vp-p (75 ohms)

Output socket: S-video connector x 1

S/N ratio: 60 dB

Linear PCM DVD:

4 Hz to 22 kHz (48 kHz sampling)

4 Hz to 44 kHz (96 kHz sampling)

CD: 4 Hz to 20 kHz

S/N ratio: 96 dB, 1 kHz (CD)

Dynamic range:

96 dB (Linear PCM DVD)

96 dB (CD)

Total harmonic distortion ratio:

0.006 % maximum

with passive radiator

Super tweeter x 2

5 cm (2") tweeter x 1

16 cm (6-1/2") woofer x 1

10 cm (4") passive radiator

400 W

Height: 330 mm (13")

Depth: 279 mm (11")

General

Power source AC 110/127/220/230-240 V , 50/60 Hz

Power consumption 140 W

Dimensions Width: 260 mm (10-1/4")

Weight 8.9 kg (19.6 lbs.)

Height: 330 mm (13")

Depth: 326 mm (12-7/8")

Amplifier

Output power MPO: 600 W (300 W + 300 W) (10 % T.H.D.)

Output terminals Speakers: 6 ohms

Input terminals

RMS: 300 W (150 W + 150 W) (10 % T.H.D.)

RMS: 150 W (75 W + 75 W) (0.9 % T.H.D.)

Headphones: 16 - 50 ohms (recommended:

32 ohms)

Video output: 1 Vp-p (75 ohms)

Game/Auxiliary (audio signal): 500 mV/ 47 k ohms

Game/Video: 1 Vp-p/75 ohms

Microphone 1/2: 1 mV/600 ohms

Cassette deck

Frequency response 50 - 14,000 Hz (normal tape)

Signal/noise ratio 55 dB (TAPE 1, playback)

Wow and flutter 0.3 % (WRMS)

50 dB (TAPE 2, recording/playback)

DVD/VCD/CD player

Signal system NTSC/PAL

Supported disc types DVD, audio CD, CD-R, CD-RW, VCD, MP3/

Video output Output socket: Pin socket x 1

S-video output Y output level: 1 Vp-p (75 ohms)

Video signal Horizontal resolution: 500 lines

Audio signal Frequency characteristics:

WMA

Output level: 1 Vp-p (75 ohms)

C output level: 0.628 Vp-p (75 ohms)

Output socket: S-video connector x 1

S/N ratio: 60 dB

Linear PCM DVD:

4 Hz to 22 kHz (48 kHz sampling)

4 Hz to 44 kHz (96 kHz sampling)

CD:4Hzto20kHz

S/N ratio: 96 dB, 1 kHz (CD)

Dynamic range:

96 dB (Linear PCM DVD)

96 dB (CD)

Total harmonic distortion ratio:

0.006 % maximum

Tuner

Frequency range FM: 88.0 - 108.0 MHz

CP-DV777

Typ e 3-way type speaker system

Maximum input power

Rated input power 150 W

Impedance 6 ohms

Dimensions Width: 277 mm (10-7/8")

Weight 3.9 kg (8.6 lbs.)/each

AM: 531 - 1,602 kHz

with passive radiator

Super tweeter x 2

5 cm (2") tweeter x 1

16 cm (6-1/2") woofer x 1

10 cm (4") passive radiator

300 W

Height: 330 mm (13")

Depth: 279 mm (11")

Specifications for this model are subject to change without

prior notice.

1 – 1

Page 4

CD-DV999W/CD-DV777W

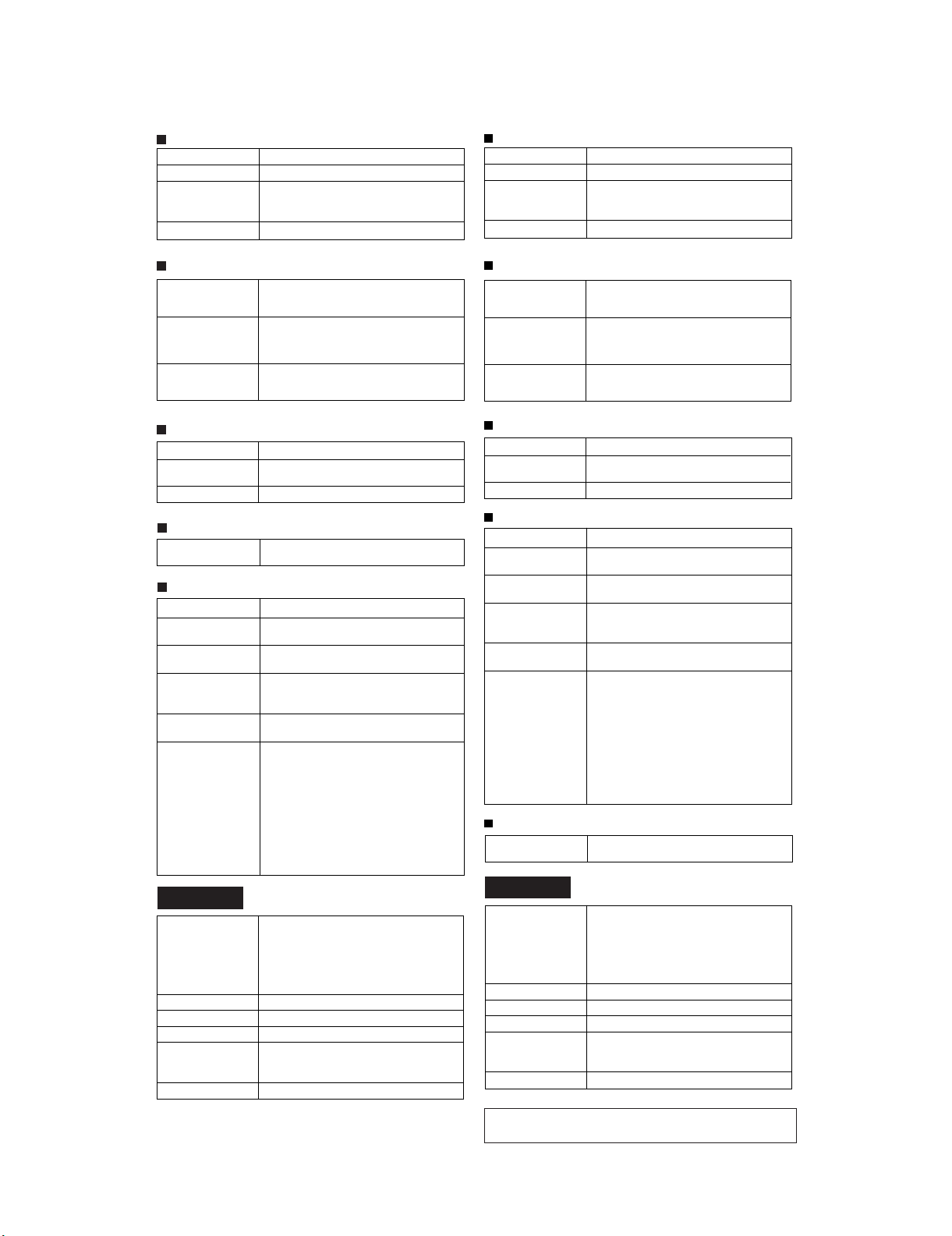

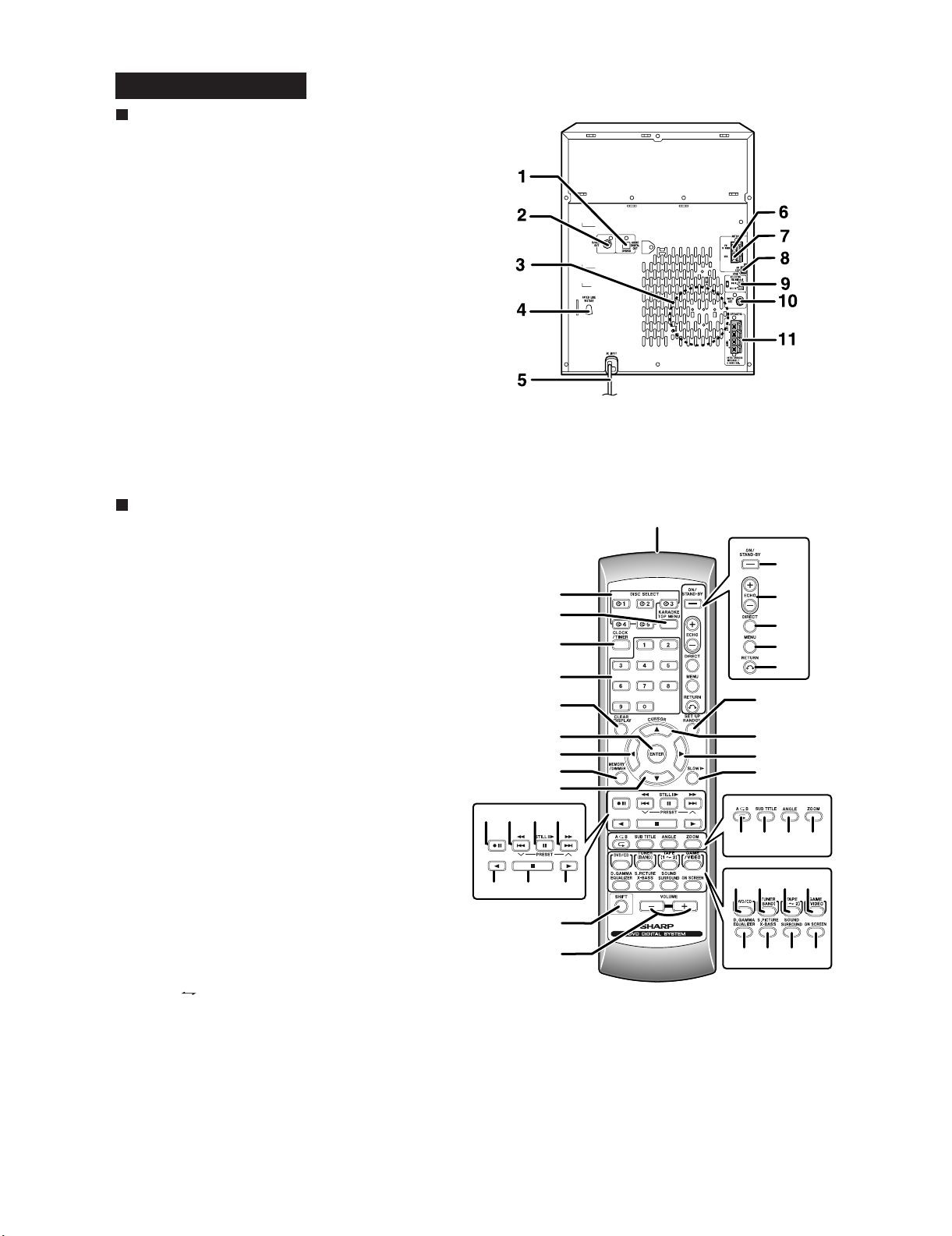

[2] Names of parts

CD-DV999W/CD-DV777W

Front panel

1. Disc Trays

2. Timer Set Indicator

3. On/Stand-by Button

4. DVD/Video CD/CD/MP3/WMA Track Up or Fast Forward, Tape 2

Fast Wind, Tuner Preset Up, Time Up Button

5. Clock/Timer Button

6. Tuning Up Button

7. Tuning Down Button

8. Tape 2 Reverse Mode Select Button

9. DVD/Video CD/CD/MP3/WMA Track Down or Fast Reverse, Tape 2

Fast Wind, Tuner Preset Down, Time Down Button

10. Equalizer Mode Select Button

11.

Tape 1 Cassette Compartment

12.

Game/Video Input Sockets

13. Headphone Socket

14. Disc Number Select Buttons

15. DVD/Video CD/CD/MP3/WMA Direct Play Button

16. Disc Tray Open/Close Button

DVD/Video CD/CD/MP3/WMA Play, Tape 1 Play,

17.

Tape 2 Forward Play Button

18. Memory/Set Button

19. Tape 2 Record Pause Button

20. Tape 2 Reverse Play Button

21. DVD/Video CD/CD/MP3/WMA or Tape Stop Button

22. Extra Bass/Demo Mode Button

23. Volume Control

Tape 2 Cassette Compartment

24.

25. Tuner (Band) Button

26. DVD/Video CD/CD/MP3/WMA Button

27. Tape (1

28. Game/Video Button

Mic 1

29.

30.

Mic 2

Mic Level

31.

Socket

Socket

2) Button

Display

1. Disc Number Indicators

2. DVD/Video CD/CD/MP3/WMA Play Indicator

3. DVD/Video CD/CD/MP3/WMA Pause Indicator

4. DVD/Video CD/CD/MP3/WMA Repeat Indicator

5. DVD Indicator

6. VCD Indicator

7. CD Indicator

8. MP3 Indicator

9. Extra Bass Indicator

10. Memory Indicator

11. DVD Angle Indicator

12. DVD Chapter Indicator

13. DVD Title Indicator

14. WMA Indicator

15. Virtual Surround Indicator

16. Tape 2 Record Indicator

17. Timer Recording Indicator

18. Timer Play Indicator

19. Sleep Indicator

20. Tape 2 Reverse Play Indicator

21. Tape 1 Play or Tape 2 Forward Play Indicator

22. Tape Reverse Mode Indicator

23. FM Stereo Mode Indicator

24. FM Stereo Receiving Indicator

25. Daily Timer Indicator

26. Tuner Receiving Frequency Indicators

27. Karaoke Mode Indicator

1 – 2

Page 5

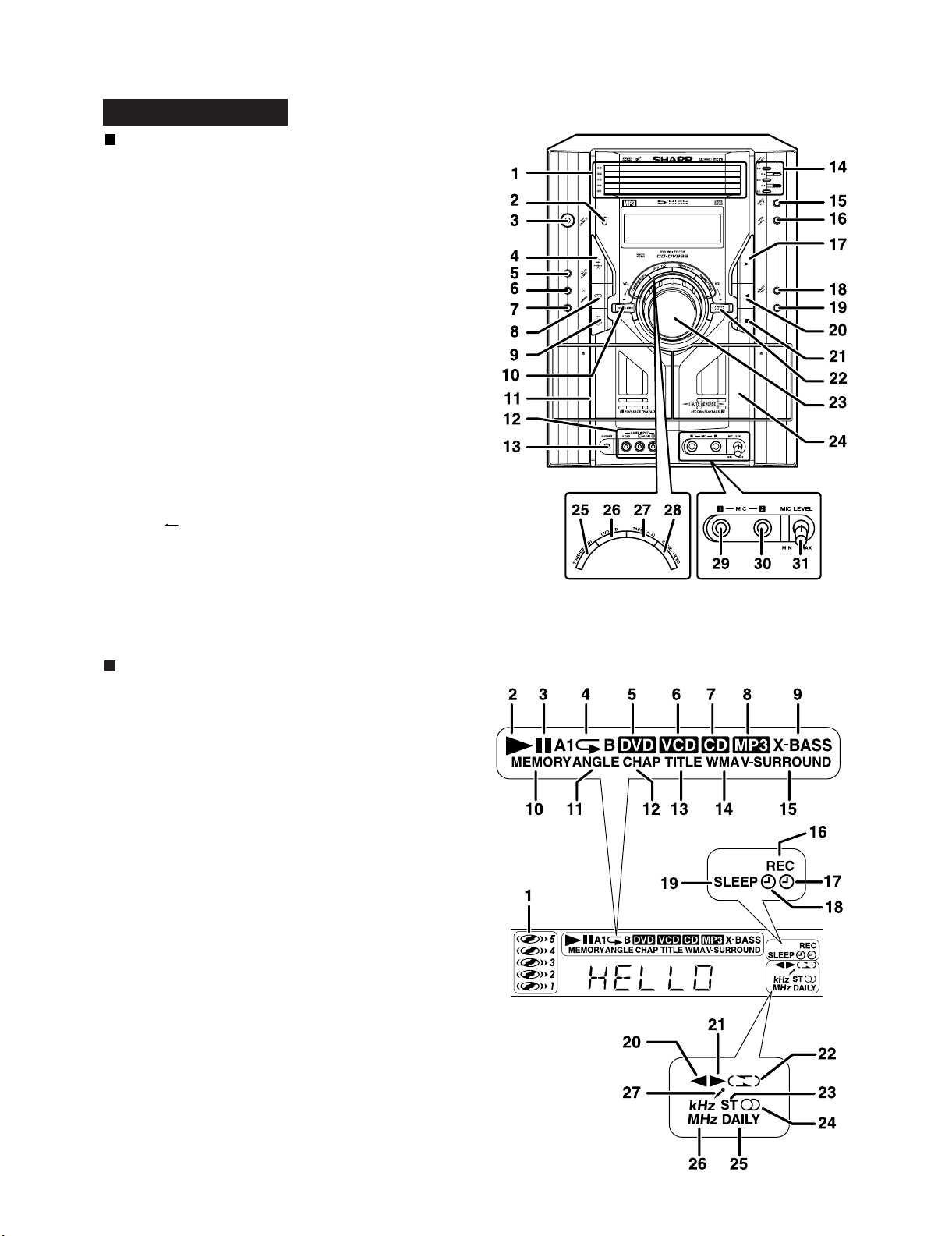

CD-DV999W/CD-DV777W

Rear panel

1. Audio Digital Output Socket

2. S-Video Output Socket

3. Cooling Fan

4. AC Voltage Selector

5. AC Power Lead

6. FM 75 Ohm Aerial Terminal

7. FM Aerial Earth Terminal

8. AM Loop Aerial Socket

9. Span Selector Switch

10. Video Output Socket

11. Speaker Terminals

CD-DV999W/CD-DV777W

Remote control

1. Remote Control Transmitter

2. Disc Number Select Buttons

3. DVD Top Menu Button

4. Clock/Timer Button

5. Direct Search Buttons

6. Clear/Display Button

7. Enter Button

8. Cursor Left Button

9. Memory/Dimmer Button

10. Cursor Down Button

11. Tape 2 Record Pause Button

12.

DVD Chapter Skip, DVD/Video CD/CD/MP3/WMA Fast Reverse,

Video CD/CD/MP3/WMA Track Down, Tape 2 Fast Wind and

Tuner Preset Down, Time Down Button

13. DVD/Video CD/CD/MP3/WMA Pause Button

14.

DVD Chapter Skip, DVD/Video CD/CD/MP3/WMA Fast Forward,

Video CD/

Tuner Preset Up, Time Up Button

15. Tape 2 Reverse Play Button

16. DVD/Video CD/CD/MP3/WMA/Tape Stop Button

17. DVD/Video CD/CD/MP3/WMA/Tape 1 Play,

Tape 2 Forward Play Button

18. Shift Button

19. Volume Up/Down Buttons

20. On/Stand-by Button

21. Echo Level Up/Down Buttons

22. DVD Direct Button

23. DVD Menu Button

24. Return Button

25. CD Random Button

26. Cursor Up Button

27. Cursor Right Button

28. DVD/Video CD Slow Button

29. DVD/Video CD/CD/MP3/WMA Repeat Button

30. DVD Subtitle Button

31. DVD Angle Button

32. DVD Zoom Button

33. DVD/Video CD/CD/MP3/WMA Button

34. Tuner (Band) Button

35. Tape (1

36. Game/Video Button

37. Equalizer Mode Select Button

38. Extra Bass Button

39. DVD 3-D Virtual Surround Button

40. DVD On Screen Button

CD/MP3/WMA Track Up, Tape 2 Fast Wind and

2) Button

2

3

4

5

6

7

8

9

10

11

12 13 14

15 16 17

18

19

1

20

21

22

23

24

25

26

27

28

29 30 31 32

33 34

35 36

37 38 39 40

1 – 3

Page 6

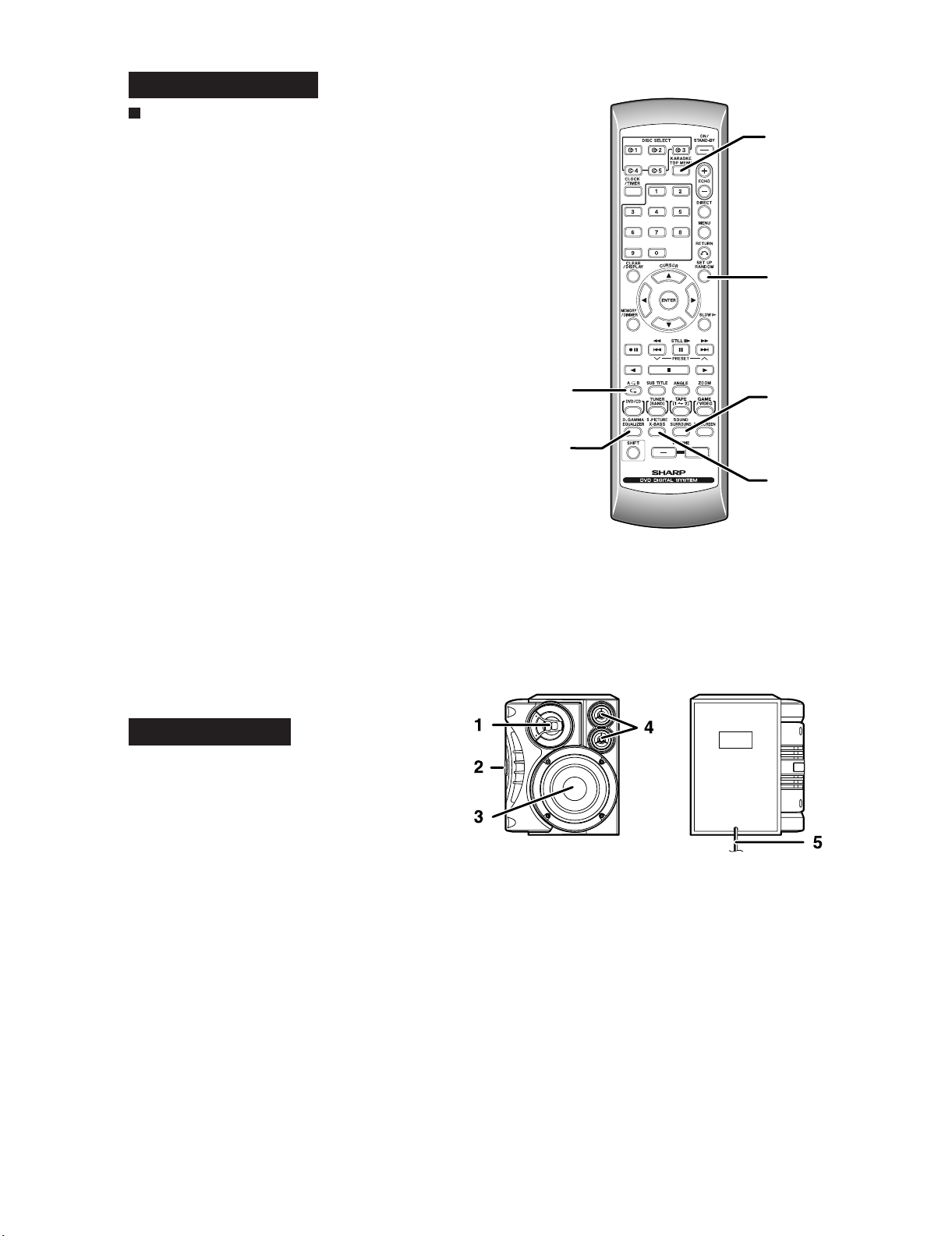

CD-DV999W/CD-DV777W

CD-DV999W/CD-DV777W

Remote control with shift button

1. Karaoke/Audio Mode Button

2. DVD Setup Button

3. DVD Sound Button

4. DVD Super Picture Button

5. DVD/Video CD/CD A-B Repeat Button

6. DVD Digital Gamma Button

1

2

CP-DV999/CP-DV777

1. Tweeter

2. Passive Radiator

3. Woofer

4. Super Tweeters

5. Speaker Wire

5

3

6

4

1 – 4

Page 7

AM IF

FM RF

TP301

TP302

FM IF

T301

T302

R356

R381

T303

T306

IC301

L312

T351

CNP301

AM/FM LOOP ANTENNA

FM BAND

COVERAGE fL

AM BAND

COVERAGE fL

AM TRACKING

fL

MAIN PWB

1

AudioCD-DV999W/CD-DV777WService ManualCD-DV999W/CD-DV777WMarketE

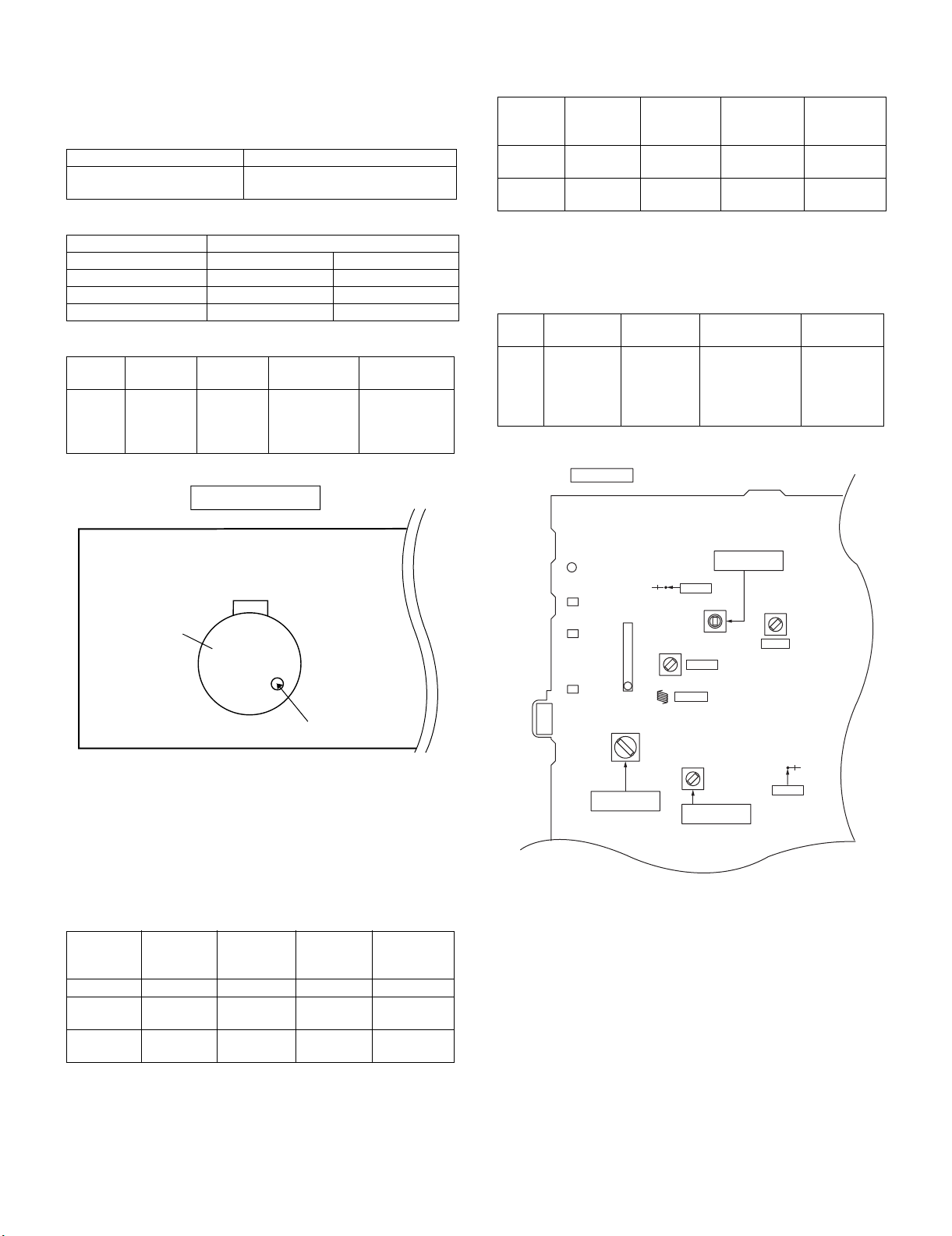

CHAPTER 2. ADJUSTMENTS

[1] Mechanism section

• Driving Force Check

Torque Meter Specified Value

Play: TW-2111 Tape 1: Over 80 g

• Torque Check

Torque Meter Specified Value

Play: TW-2111 30 to 80 g.cm 30 to 80 g.cm

Fast forward: TW-2231 — 70 to 180 g.cm

• Tape Speed

Test Tape Adjust-

Normal

MTT-111 Variable

speed

Tape 2: Over 80 g

Tape 1 Tape 2

— 70 to 180 g.cm

ing Point

Resistor in

motor.

Specified

Value

3,000 ± 30 Hz

Speaker

Instrument

Connection

Speaker Terminal (Load

resistance: 6

ohms)

CD-DV999W/CD-DV777W

•FM RF

Signal generator: 1 kHz, 40 kHz dev., FM modulated

Test

Stage

FM Band

Coverage

FM RF 98.00 MHz

*1. Input: Antenna Output: TP301

*2. Input: Antenna Output: Speaker terminal

•FM IF

Signal generator: 10.7 MHz, FM modulated

Test

Stage

IF 10.7 MHz 98 MHz T302 (Turn the

Frequency Frequency

Display

— 87.50 MHz T301 (fL):

1.3 V ± 0.1 V

98.00 MHz L312 *2

(10-30 dB)

Frequency Frequency

Display

Setting/Adjust-

ing Point

core of transformer T302

fully counter

clockwise)

Setting/

Adjusting

Point

Instrument

Connection

*1

Instrument

Connection

*1

TAPE MECHANISM

Tape

Motor

Variable Resistor in motor

Figure 1

[2] Tuner section

fL: Low-range frequency

fH: High-range frequency

• AM IF/RF

Signal generator: 400 Hz, 30%, AM modulated

Test Stage Frequency Frequency

AM IF 450 kHz 1,602 kHz T351 *1

AM Band

Coverage

AM

Tracking

*1. Input: Antenna Output: TP302

— 531 kHz (fL): T306

990 kHz 990 kHz (fL): T303 *1

*2. Input: Antenna Output: TP301

Display

Setting/

Adjusting

Parts

1.1 ± 0.1 V

Figure 2 Adjustment Points

Instrument

Connection

*2

2 – 1

Page 8

CD-DV999W/CD-DV777W

[3] DVD/CD section

1. DVD SECTION

• Adjustment

Since this DVD system incorporates the following automatic adjustment functions, readjustment is not needed when replacing the

pickup. Therefore, different PWBs and pickups can be combined

freely.

Each time a disc is changed, these adjustments are performed

automatically. Therefore, playback of each disc can be performed

under optimum conditions.

Items adjusted automatically

1) Offset adjustment (The offset voltage between the head amplifier

output and the VREF reference voltage is compensated inside the

IC.)

* Focus offset adjustment

* Tracking offset adjustment

2) Tracking balance adjustment

3) Gain adjustment (The gain is compensated inside the IC so that the

loop gain at the gain crossover frequency will be 0 dB.)

* Focus gain adjustment

* Tracking gain adjustment

DVD/CD Error code description

Error Explanation

10* CAM error. Can't detect CAM switch when CAM is moving.

11* When it detect cam operation error during initialize pro-

cess.

20* TRAY error. Can't detect TRAY switch when TRAY is mov-

ing.

21* When it detect TRAY operation error during initialize pro-

cess.

30 When it change to DVD/CD function, DVD cannot read ini-

tial data.

*'CHECKING'

If Error is detected, 'CHECKING' will be displayed instead of 'ERCD**'. 'ER-CD**' display will only be displayed when error had been

detected for the 5th times.

[4] TEST Mode

1. TEST Mode Functions

1.1. Entering the TEST Mode

While holding down both the button and the X-BUSS button of the

main unit from the power-off state, press the POWER button to enter

the Test Menu Mode.

1.4. Canceling TEST Mode

1. Press the POWER button in each TEST Mode to display

“CLEARAL” except SHIPPING TEST. Then reset and start.(Clear

RAM.)

2. It is necessary to play-off the A/C cord after “FINISHED” is displayed on the FL for SHIPPING TEST

2. Shipping TEST Mode

2.1. Outline

• ID command for initialization is sent to the DVD unit and E2PROM

in the unit is initialized.

• System Microcomputer and DVD changer initializerd

2.2. TEST Mode Operation

When entering the Shipping TEST Mode:

1. “WAIT” is displayed on the FL display.

2. “FINISHED” shall be kept displaying after Initiation is completed.

Manually play off the A/C cord to get out of the TEST Mode.

When lnitialization is failed, “INIT ERR” remains to be shown on the

FL display until play off the A/C cord.

2.3. Supplementary Note

1. When entering this TEST Mode, it is prohibited to press any key

until the above processing is completed.

3. DVD TEST Mode

3.1. Outline

• To send key codes of the TEST Mode 1 to the DVD unit to start the

TEST Mode.

• Thereafter the system’s microcomputer only sends key codes to

the DVD unit.

• The main unit operation is started in the same way as the normal

startup of the DVD/CD Function.

• Only monitor (video) output is normally controlled. “MUTE ON”

remained.

• During this TEST Mode, “DVD TEST” is shown on the FL display

and change to “DVD ****” (****: DVD version).

(Display is shown by OSD. Main unit display not available.)

3.2. TEST Mode Operation

1. The TEST Mode is started in the same way as the normal startup of

the DVD/CD Function. Then the DVD unit is normally started. During the TEST Mode, “DVD****” is continuously displayed.

1.2. Test mode processing

• When entering the TEST Mode, the ROM version are displayed as

follows.

Version on the FL display: UD***** (****: Version No.)

1.3. TEST Mode button

• Press direct designation button during the version display to enter

the specified TEST Mode as shown below.

TEST MODE

No. TEST Mode Direct Designation Button

1 SHIPPING TEST open/close

2 DVD TEST DVD/CD

3 DVD DISPLAY TEST disc 2

2 – 2

Page 9

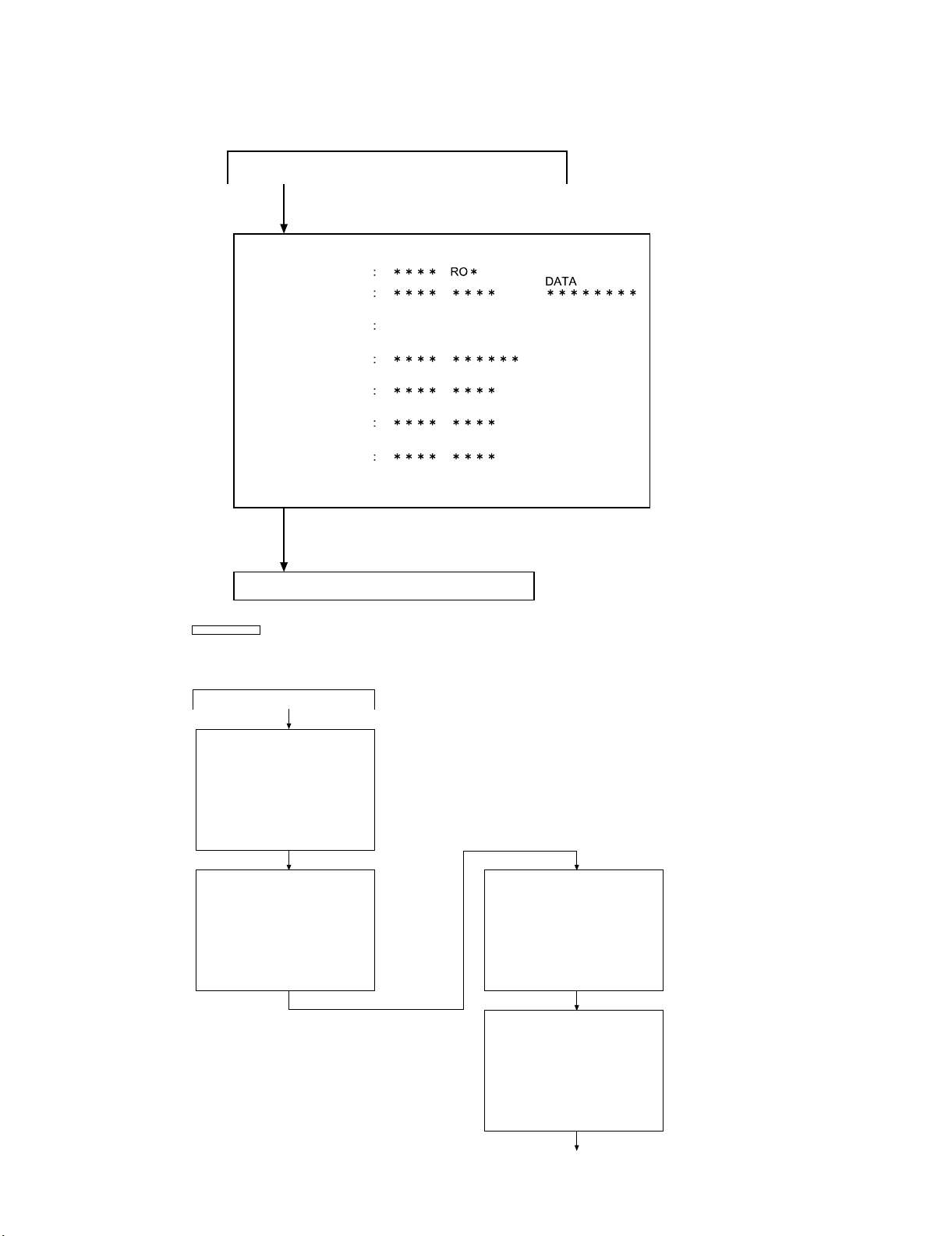

2. DVD TEST Mode

1. Press the DVD/CD button on the main unit from the TEST mode

initial condition to enter "DVD TEST".

CD-DV999W/CD-DV777W

F0000000 00000000

(Press the "1" key of the remote control.)

TEST MODE

Model name (MODEL)

Program version/

Creation date

CPRM key code

(CPRM)

CPRM Serial No.

(S/N)

Microcode

version (UCODE)

Servo program version

(SODCV)

Source code

version (CSTMV)

FFFF FFFF

RO*: Region No.

Press the "PLAY" key of the remote control 8 times.

TEST Mode initial screen returns.

(TEST Mode initial screen)

LASER TEST Mode

1. Press the DVD/CD button on the main unit from the TEST mode

initial condition to enter "DVD TEST".

F0000000 00000000

Press the (3) key.

DYNAMIC TEST

1 : LASER TEST

2 : STEP TEST

3 : PLAY TEST

3 : PLAY TEST NO TRAY

MENU:SPIN OFFSET ADJUST

Press the (1) key. Press the (1) key.

LASER TEST

DVD LD ON

(TEST MODE initial screen)

The screen display as shown on the left.

the tray opens and DVD

laser lights on.

The spin rotates

approx. 1 sec.

The pick slightly moves

in the circumference

direction.

Press the (1) key.

LASER TEST

CD LD ON

LASER TEST

LD OFF

DVD laser lights off and

CD laser lights on.

The spin rotates approx.

1 sec.

The pick slightly moves in

the circumference direction.

Laser lights off.

The spin rotates approx.

1 sec.

The pick slightly moves in

the circumference direction.

Press the (1) key to shift to "DVD LD ON".

Press the "STOP" key to return to the "DYNAMIC TEST" screen.

2 – 3

Page 10

CD-DV999W/CD-DV777W

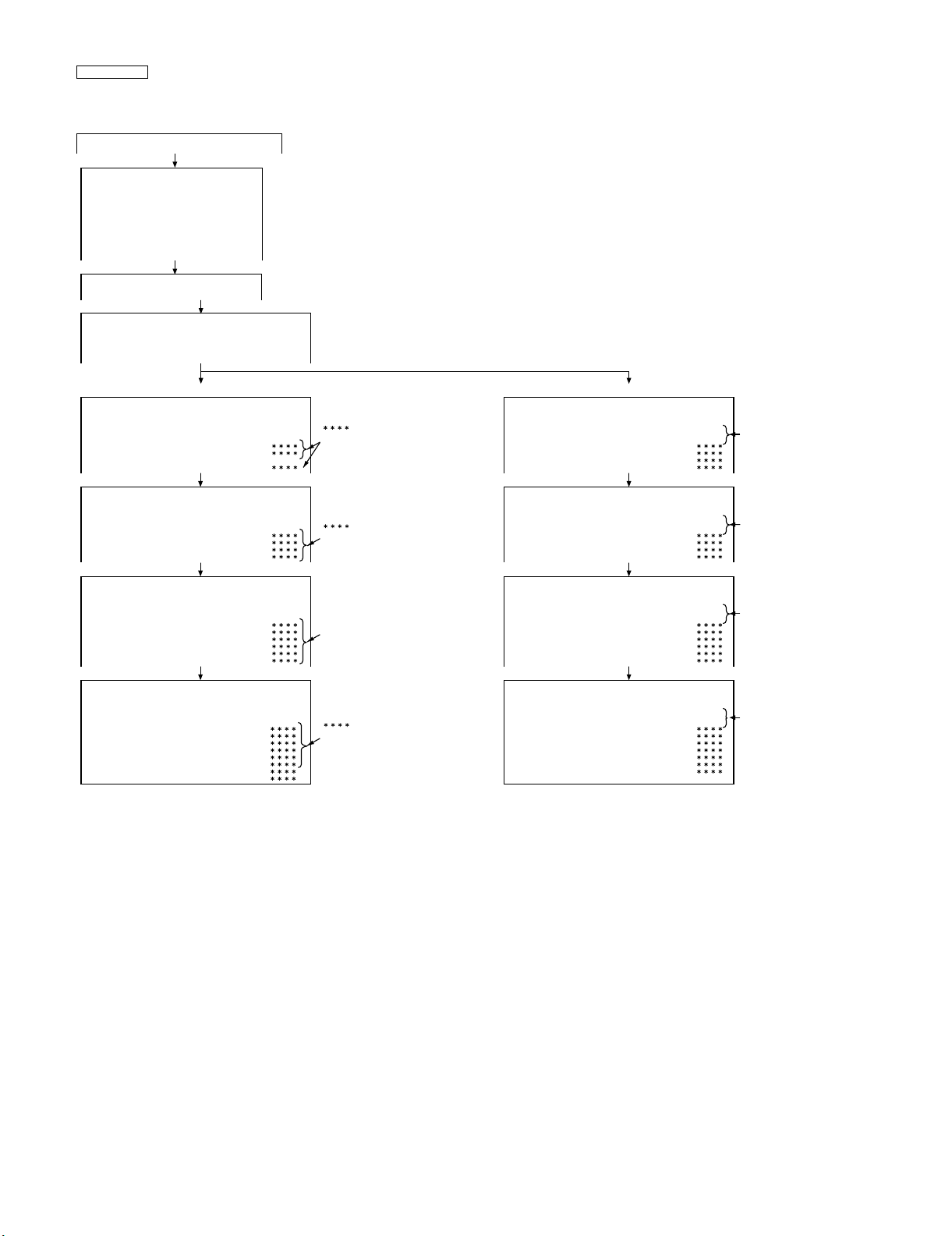

Step Execute Mode

1. Press the DVD/CD button on the main unit from the TEST mode

initial condition to enter "DVD TEST".

F0000000 00000000

Press the (3) key.

DYNAMIC TEST

1:LASER TEST

2:STEP TEST

3:PLAY TEST

9:PLAY TEST NO TRAY

MENU : SPIN OFFSET ADJUST

Press the (2) key.

STEP TEST

TRAY OPEN

Press the "PLAY" key.

STEP TEST

FOCUS ON

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

Press the "PLAY" key.

STEP TEST

TRACK ING ON

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

ASAGC

4-digit alphanumeric

TEAGC

4-digit alphanumeric

FBAL0

0000

TBAL0

Press the "PLAY" key.

Press the "PLAY" key.

Press the "PLAY" key.

Press the "STOP" key to return to the DYNAMIC TEST screen.

Turn the power from off to on to clear the Step Execute Mode.

4-digit alphanumeric

STEP TEST

FBAL STUDY

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

4-digit alphanumeric

ASAGC

4-digit alphanumeric

TEAGC

4-digit alphanumeric

FBAL0

4-digit alphanumeric

TBAL0

STEP TEST

GAIN STUDY

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

4-digit alphanumeric

ASAGC

4-digit alphanumeric

TEAGC

4-digit alphanumeric

FBAL0

4-digit alphanumeric

TBAL0

4-digit alphanumeric

FCGA0

4-digit alphanumeric

TKGA0

STEP TEST

D V D I D 8-digit numeric

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

4-digit alphanumeric

ASAGC

4-digit alphanumeric

TEAGC

4-digit alphanumeric

FBAL0

4-digit alphanumeric

TBAL0

4-digit alphanumeric

FCGA0

4-digit alphanumeric

TKGA0

4-digit alphanumeric

FCBT0

4-digit alphanumeric

OFTR0

4-digit alphanumeric

4-digit alphanumeric

DVD CD

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

FCGA1

TKGA1

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

FCGA1

TKGA1

FCBT1

OFTR1

(TEST MODE initial screen).

The screen display as shown on the left.

The tray opens. Put the disc on the tray.

Focus On.

0000

0000

Tracking On.

0000

0000

0000

0000

0000

0000

0000

0000

0000

" ": 4-digit alphanumeric also

displayed for DVD double deck disc.

Focus balance adjustment values displayed.

" ": 4-digit alphanumeric also displayed for

DVD double deck disc.

Focus tracking gain adjustment values displayed.

4-digit alphanumeric also displayed for "****"

in the case of DVD double deck disc.

Equalizer adjustment values and Off-track Level

adjustment values displayed. 8-digit numeric of

DVD ID grows.

" ": 4-digit alphanumeric also displayed

for DVD double deck disc.

Press the "PLAY" key.

STEP TEST

TRACK ING ON

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

4-digit alphanumeric

ASAGC

4-digit alphanumeric

TEAGC

0000

FBAL0

4-digit alphanumeric

TBAL0

Press the "PLAY" key.

STEP TEST

FBAL STUDY

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

4-digit alphanumeric

ASAGC

4-digit alphanumeric

TEAGC

4-digit alphanumeric

FBAL0

4-digit alphanumeric

TBAL0

Press the "PLAY" key.

STEP TEST

GAIN STUDY

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

4-digit alphanumeric

ASAGC

4-digit alphanumeric

TEAGC

4-digit alphanumeric

FBAL0

4-digit alphanumeric

TBAL0

4-digit alphanumeric

FCGA0

4-digit alphanumeric

TKGA0

Press the "PLAY" key.

STEP TEST

C D N O 2-digit numeric T I M E 6-digit numeric

4-digit alphanumeric

ASMAX

4-digit alphanumeric

FEPP

4-digit alphanumeric

ASAGC

4-digit alphanumeric

TEAGC

4-digit alphanumeric

FBAL0

4-digit alphanumeric

TBAL0

4-digit alphanumeric

FCGA0

4-digit alphanumeric

TKGA0

4-digit alphanumeric

FCBT0

4-digit alphanumeric

TEOFS

Press the "STOP" key to return to the DYNAMIC TEST screen.

Turn power from off to on to clear the Step Execute Mode.

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

FCGA1

TKGA1

4-digit alphanumeric

4-digit alphanumeric

ASAGC

TEAGC

FBAL1

TBAL1

FCGA1

TKGA1

FCBT1

4-digit alphanumeric

TEOFS

Tracking On.

0000

"0000": 4-digit alphanumeric

0000

also displayed for CD-RW.

Focus balance adjustment

values displayed.

0000

"0000": 4-digit alphanumeric

0000

also displayed for CD-RW.

Focus tracking gain adjustment

values displayed.

0000

"0000": 4-digit alphanumeric

0000

also displayed for CD-RW.

Equalizer adjustment value and

TES signal offset displayed.

6-digit numeric of the TIME counter grows.

0000

"0000": 4-digit alphanumeric

0000

also displayed for CD-RW.

2 – 4

Page 11

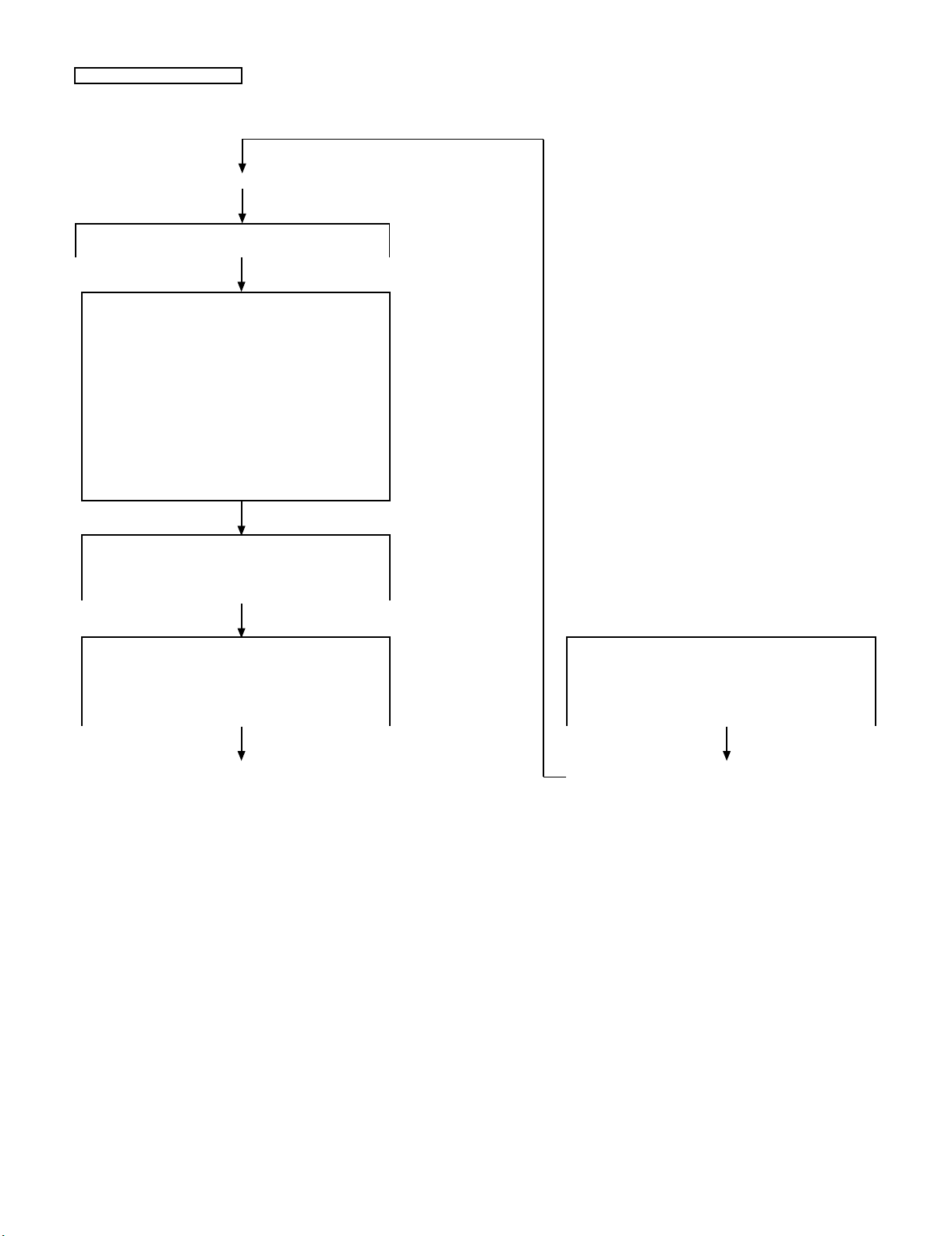

Spin Offset Adjustment Mode

Note 1: After replacing the DVD main PWB unit and the DVD mechanism chassis unit,

be sure to adjust spin offset.

Start from "NO DISC" (the tray closed).

CD-DV999W/CD-DV777W

F0000000 00000000

Press the "3" key.

DYNAMIC TEST

1:LASER TEST

2:STEP TEST

3:PLAY TEST

3:PLAY TEST NO TRAY

M E N U:SPIN OFFSET ADJUST

Press the "MENU" key.

SPIN OFFSET ADJUST

SPIN AD OFFSET

SPIN OFFSET TEST

ADJUST COMPLETE

SPIN 4-digit alphanumeric

The screen display as

shown on the left

The screen display as

shown on the left

Tray opens.

Adjustment started

4-digit alphanumeric

displayed

Failure

SPIN OFFSET TEST

ADJUST FAILED

2 – 5

Turn off the power and clear the Spin Offset Adjustment

Mode to try again from the start.

Page 12

CD-DV999W/CD-DV777W

3.3. DVD Display Test

To display servo adjustment values, error rates, laser current, etc. during DVD playback.

1. Press the DISC 2 button on the main unit from the TEST Mode initial condition.

2. DVD starts up with “DVD” blinking on the FL display.

3. Press the Tuner/Band button to display DVD adjustment values, etc. Press it again and the display disappears and the normal screen returns.

The error rates displayed are for reference; they are not the judging criteria.

4. Press the “Power” button to cancel this mode.

DVD

FG0 TG0 TG1FG1 FBL0 TBL0 TBL1FBL1

Average error rate

Audio buffer space Video buffer space Number of error occurrence

TitleNo ChapNo

CD

Audio buffer space Video buffer space Number of error occurrence

TrNo TIME

When the Spin Offset Mode is never executed

DVD

FG0

Average error rate

Maximum error rate Laser output

Sector ID

Maximum error rat Laser output

TG0 TG1FG1 FBL0 TBL0 TBL1FBL1

SPIN READ NG

Audio buffer space Video buffer space Number of error occurrence

TitleNo ChapNo Sector ID

CD

Audio buffer space Video buffer space Number of error occurrence

TrNo TIME

2 – 6

Page 13

3.4. ROM Rewrite Mode

Description of version name

Example: VER: VXW0223A

From the left:

V : Video model

X : CD-DV***W

W : Southeast Asia

0223A:Version

* The format may be changed.

ex)VXW0223A

2 Destination

1 Model

V: Video model/A: Audio/Model for SACD

X : CD-DV***W

1 Model

J : Japan

H : Europe

U : USA

K : Korea/Philippines

W : Southeast Asia

A : Australia

Z : Middle East

C : China

M : Mexico

2 Destination

1. Creating version upgrade disc

• Write the following three files on CD-R/CD-RW.

• !$#%&’().@{}

• D-combo3.cdr

• ********.bin

(********: Names differ according to versions)

• Write the files at lowest possible speed.

• Do not mix other data.

2. During normal power-on, insert the version upgrade disc.

3. After the version upgrade disc is normally determined, the message, “VERSION UP DISC IS DETECTED” and the version are displayed on OSD. Then ROM data read is started.

OSD display (Example)

VERSION UP DISC

IS DETECTED

0905

CD-DV999W/CD-DV777W

7. Confirming the version

• A few moments after entering the DVD TEST Mode, “DVD ****”

is displayed on the main unit.

(****: 4-digit numeric version code)

• To confirm the detailed version information, press the “1” key of

the remote control.

The system information is displayed on the OSD display.

(“********”: Version name) Check that the version name conforms to the write data.

4. When the data read is completed, “NOW FLASH WRITE START…”

is displayed on OSD. Then the Flash Rom rewrite is entered.

OSD display (Example)

NOW FLASH WRITE START...

5. When rewrite is normally completed, “FL W: END” is displayed on

the main unit. Eject the disc automatically coming out from the tray.

Then turn the power off.

6. If “FL W: ERR” or “CANT READ” is displayed on the main unit or

“FL W: END” is not displayed after 10 minutes, turn the power off to

try again from the start.

ROM DATA READING

956

VERSION UP DISC

IS DETECTED

0905

READ COMPLETE

8. Press the POWER button to display “CLEARAL”

• Reset and start the system microcomputer to control the TEST

MODE.

2 – 7

Page 14

CD-DV999W/CD-DV777W

3.5. List of Keys Used for DVD TEST Mode and Transmit Key Codes to the Unit

Button for System

Communication

C-PLAY Play 26h

C-PAUSE/STILL

(Remote Control)

C-STOP (Remote control) Stop 27h

C-STOP (Main Unit) Stop 27h

SKIP-UP/CUE Skip+ 2Ch In this TEST Mode Skip+/Next button code (2Ch) is constantly transferred.

SKIP-DWN/REV Skip- 2Bh In this TEST Mode Skip-/Prev button code (2Bh) is constantly transferred.

SKIP-UP

(Remote Control)

SKIP-DWN

(Remote Control)

REPEAT (Remote Control) Repeat 32h

A-B repeat

(Remote Control)

PROGRAM

(Remote Control)

“1” key (Remote Control) 1 01h

“2” key (Remote Control) 2 02h

“3” key (Remote Control) 3 03h

“4” key (Remote Control) 4 04h

“5” key (Remote Control) 5 05h

“6” key (Remote Control) 6 06h

“7” key (Remote Control) 7 07h

“8” key (Remote Control) 8 08h

“9” key (Remote Control) 9 09h

“0” key (Remote Control) 0 0Ah

ENTER (Remote Control) Enter 70h

MENU (Remote Control) MENU 68h

SLOW> (Remote Control) SLOW> 72h

Button Code Button Code

HEX Value

Pause/still 29h

Skip+ 2Ch

Skip- 2Bh

A-B Repeat 49h

Program 1Fh

Remarks

Buttons used for the TEST Mode are shown above. When pressing the following DVD-related buttons, corresponding button codes are transmitted.

ON SCREEN, SURROUND, CUE, REVIEW, Curser ↑, ↓, ←, →, RETURN, ZOOM, TOP-MENU, CLEAR, RANDOM subtitle, angle, sound, DVD

MENU, Gamma, S-picture, DIRECT, DISPLAY, SET-UP.

3.6. Supplementary Note

1. Do not press buttons other than the DVD-related buttons, except for the Power button. Do not switch functions; do not control volumes.

For the electronic volume IC and the monitor output control, constantly fix the setting to DVD/CD function.

2 – 8

Page 15

4. CD-ROM Write Mode

F

z

4.1. Outline

DVD-ROM can be upgraded from CD-ROM. The write mode is

entered from the normal mode.

1. When any CD-ROM for version upgrade DVD is detected, the status informs that the version upgrade ROM is being read.

When DVD microcomputer is changed to System microcomputer

and byte 24 status data detects 0Fh:

• The TEST Mode is entered by the status reception. (Required to

be internally recognized.)

• The Power button /Function switching is prohibited.

(Power supply is necessary until write is completed.)

• It is prohibited to accept any button input until write is com-

pleted.

• Change the display as follows:

TOC READ

Standard Specification of Stereo System Error Message Display Contents

Error Contents Display Notes

CD CD Changer Mechanism Error. 'ER-CD**' (*) 10: CAM SW Detection NG during normal operation

DVD Communication Error. 'ER-CD30' DVD COMMUNICATION ERROR.

Focus Not Match/IL Time Over. 'NO DISC'

TUNER PLL Unlock. PLL Unlock.

M 87.50 MH

11: CAM SW Detection NG during initialize process

20:TRAY SW Detection NG during normal operation

21:TRAY SW Detection NG during initialize process

2. To expand into RAM, DVD performs read-operation.

3. When reading ends, transmission stops for writing.

(Ignore stoppage of transmission during write.)

When transmission stops, the transmission port receives write

states, which are displayed according to port states.

DVD DATA DVD CLK State Unit display

1 L H During read FLASH WR

2 H L During write FL W : S T R

3 H H Write ended FL W : E N D

4 L L Write error FL W : E R R

4. The DVD/CD tray will automatically open when end of rewrite is

detected.

(The DVD status is not relevant since there is no communication.)

5. To close the DVD/CD door, cancel the TEST Mode and reset when

the Power button is pressed.

6. To initialze the E2PROM, do the shipping TEST mode.

CD-DV999W/CD-DV777W

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**'. 'ER-CD**' display will only be display when

error had been detected for the 5 th times.

Speaker abnormal detection and +B PROTECTION display

In case speaker abnormal detection or +B PROTECTION had

occurred, it can be check by pressing 'POWER', ' ' and 'X-BASS'

button. MicroComputer version number will displayed as "UD".

Press ‘GAME/VIDEO’ button during version number display and then

press ‘POWER’, ‘MEMORY/SET’ and ‘GAME/VIDEO’ button. Display

will show "S** B**". S is referring to speaker abnormal detection and B

is referring to +B PROTECTION. ** is in hex valve.

+B PROTECTION is condition when irregular process occur on power

supply line.

BEFORE TRANSPORTING THE UNIT

The following process need to be taken after set tapering/parts

replacement.

7. Press the ON/STAND-BY button to enter stand-by mode.

8. While pressing down the button and the X-BASS/DEMO button, press the ON/STAND-BY button. The Micro Computer version

number will be displayed as "UD".

9. Press OPEN/CLOSE button until "WAIT"→ "FINISHED" appears.

10.Unplug the AC cord and the unit is ready for transporting.

2 – 9

Page 16

CD-DV999W/CD-DV777W

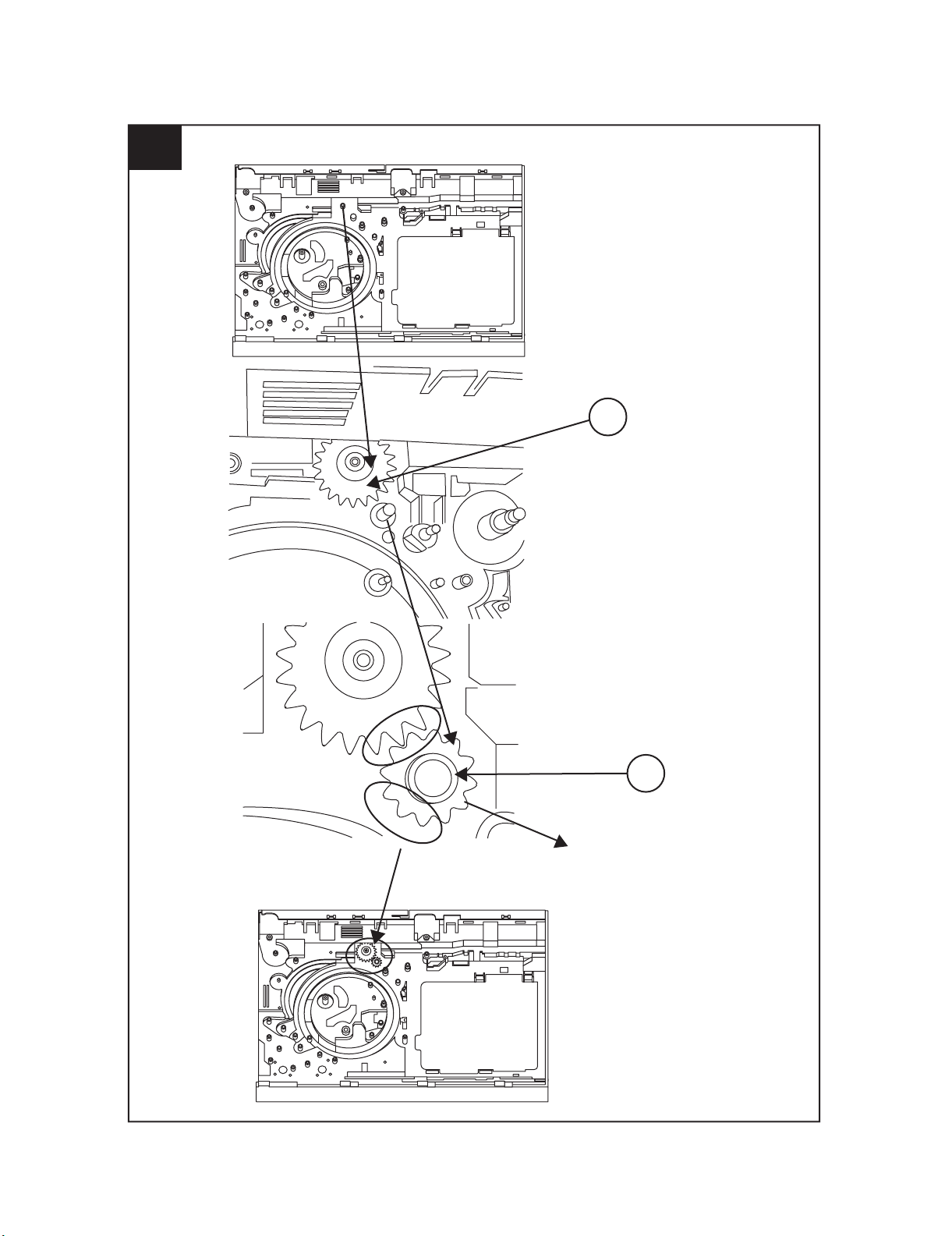

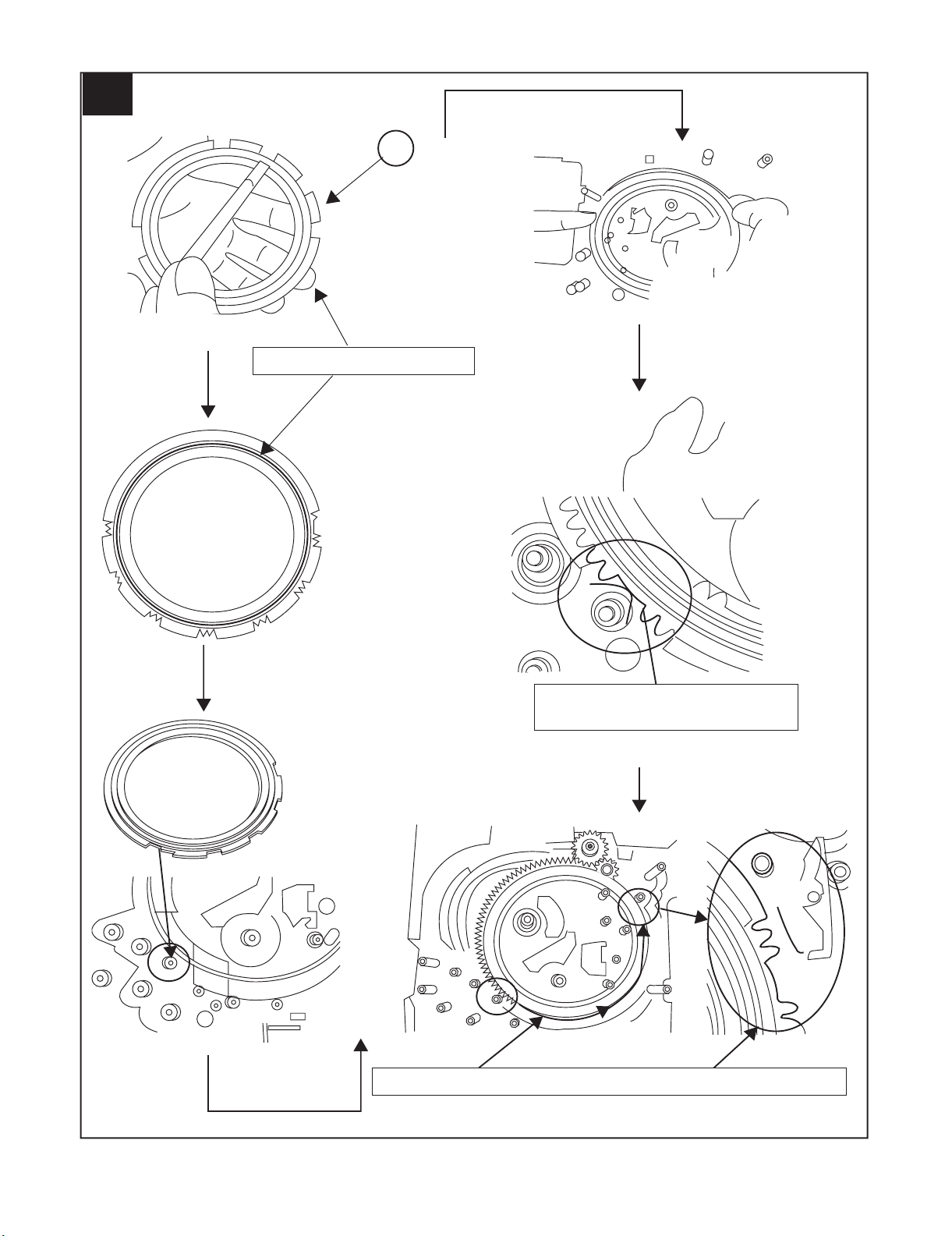

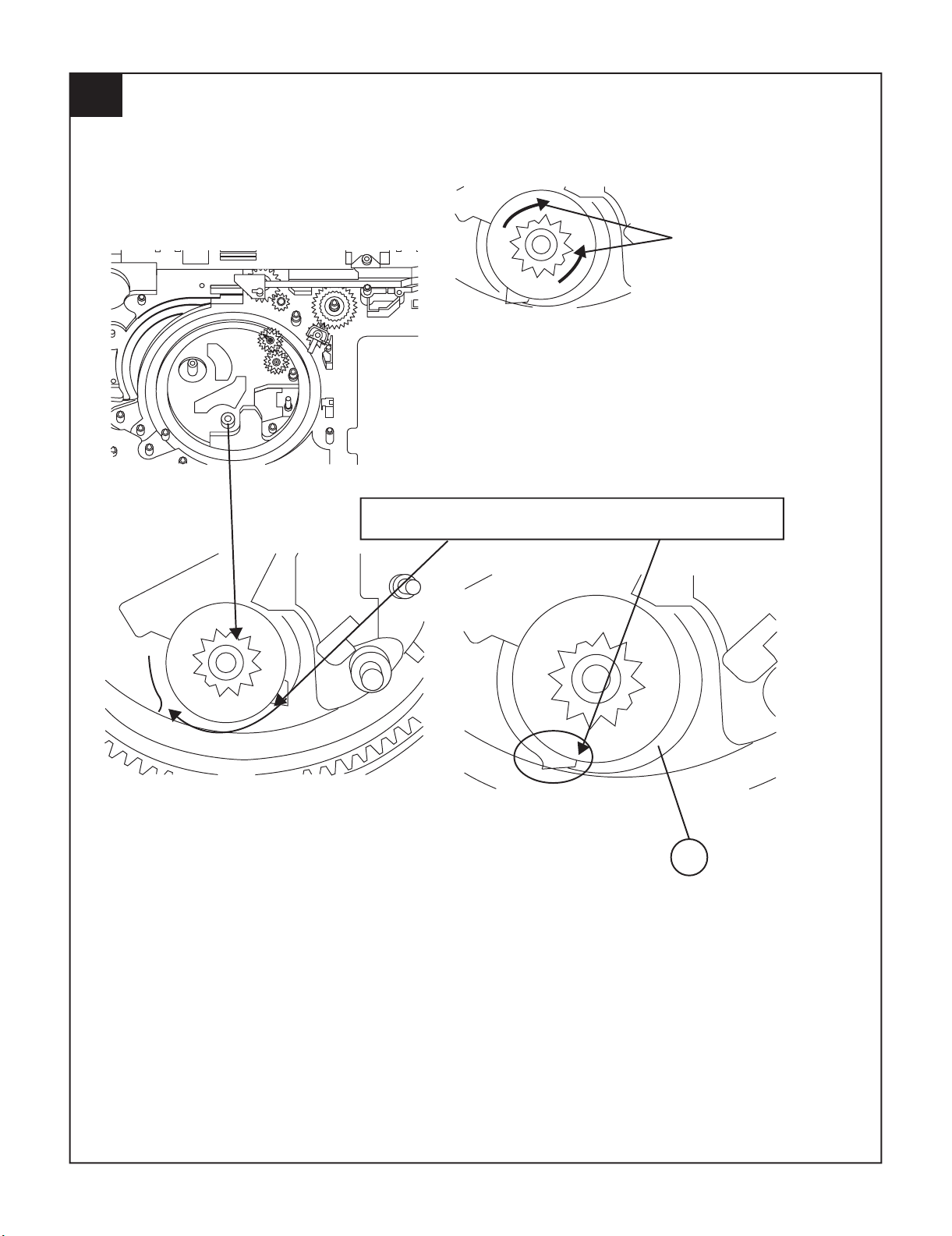

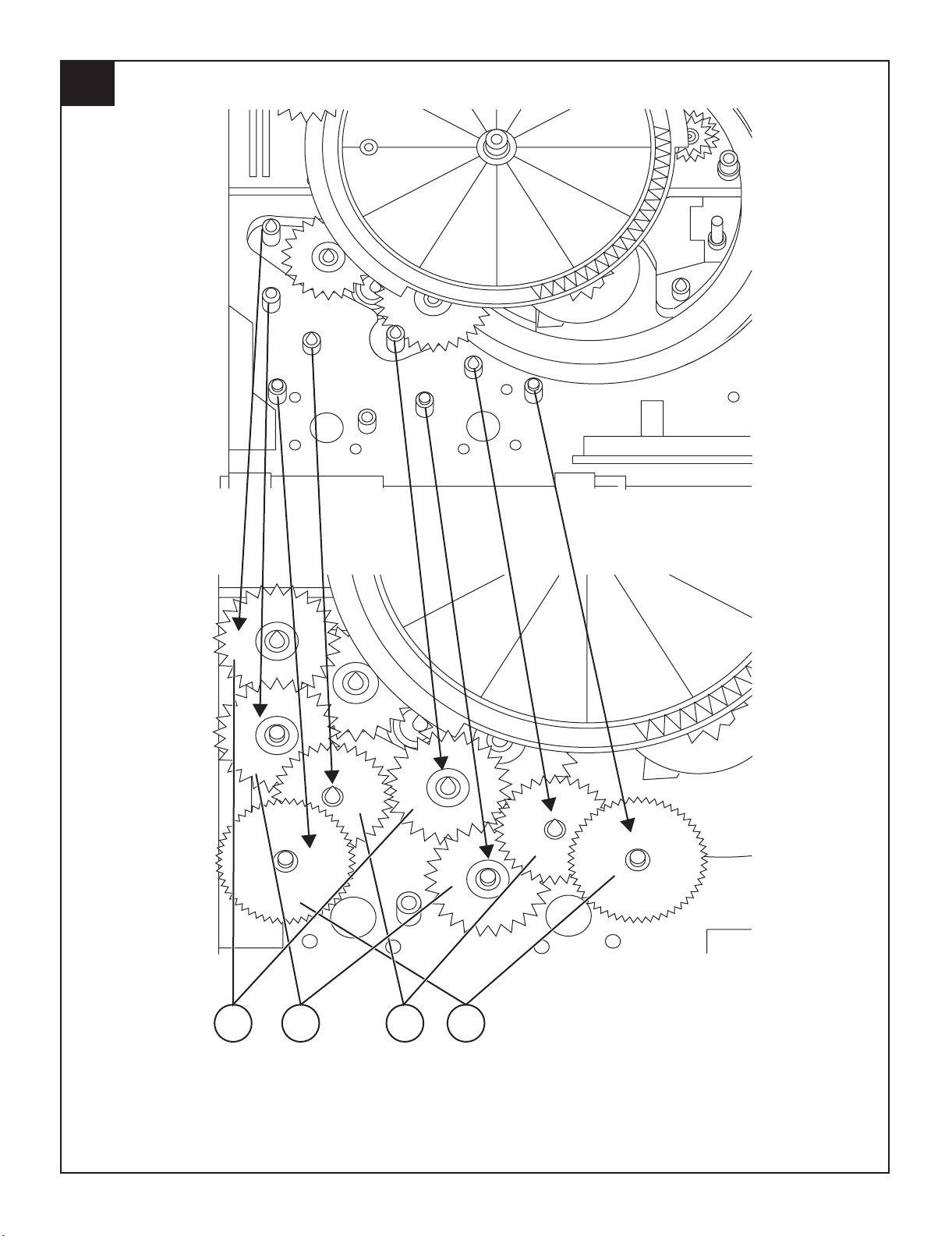

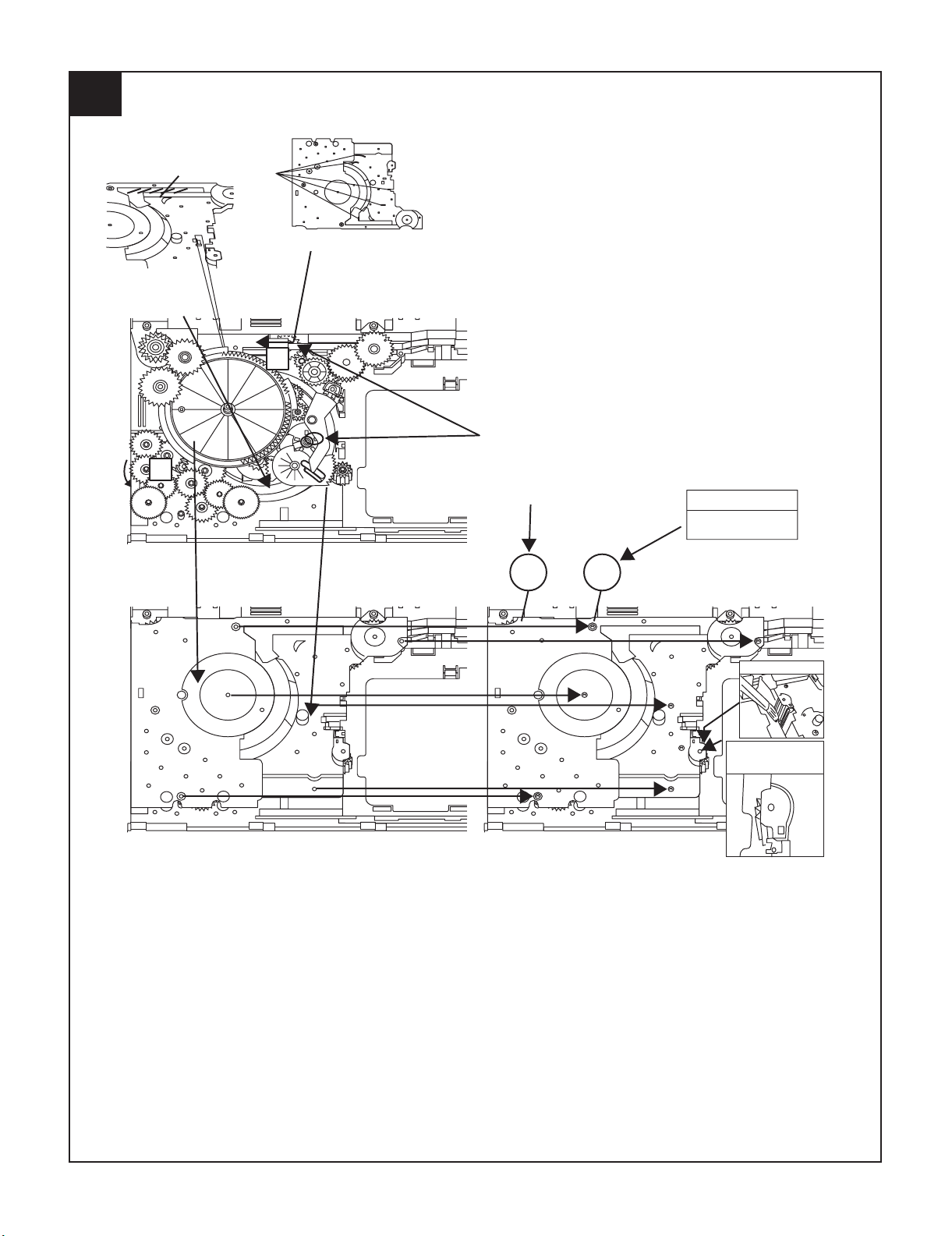

[5] CD Changer mechanism section

• A number in the drawing sheet is the number of the parts guide

(CHANGER MECHANISM PARTS).

1

141

2 – 10

140

HALF GEAR

MUST ARRANGE AS SHOWN

Page 17

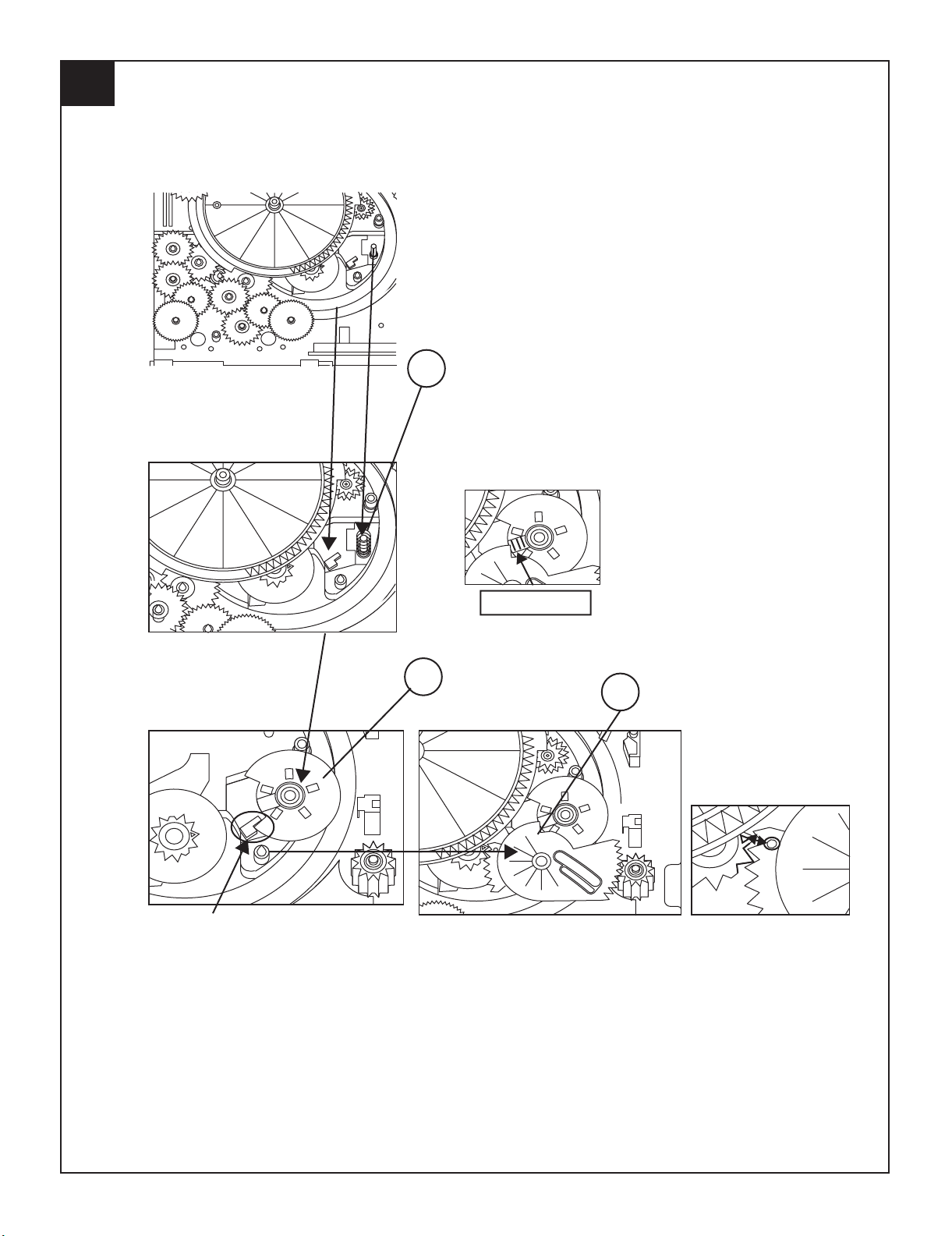

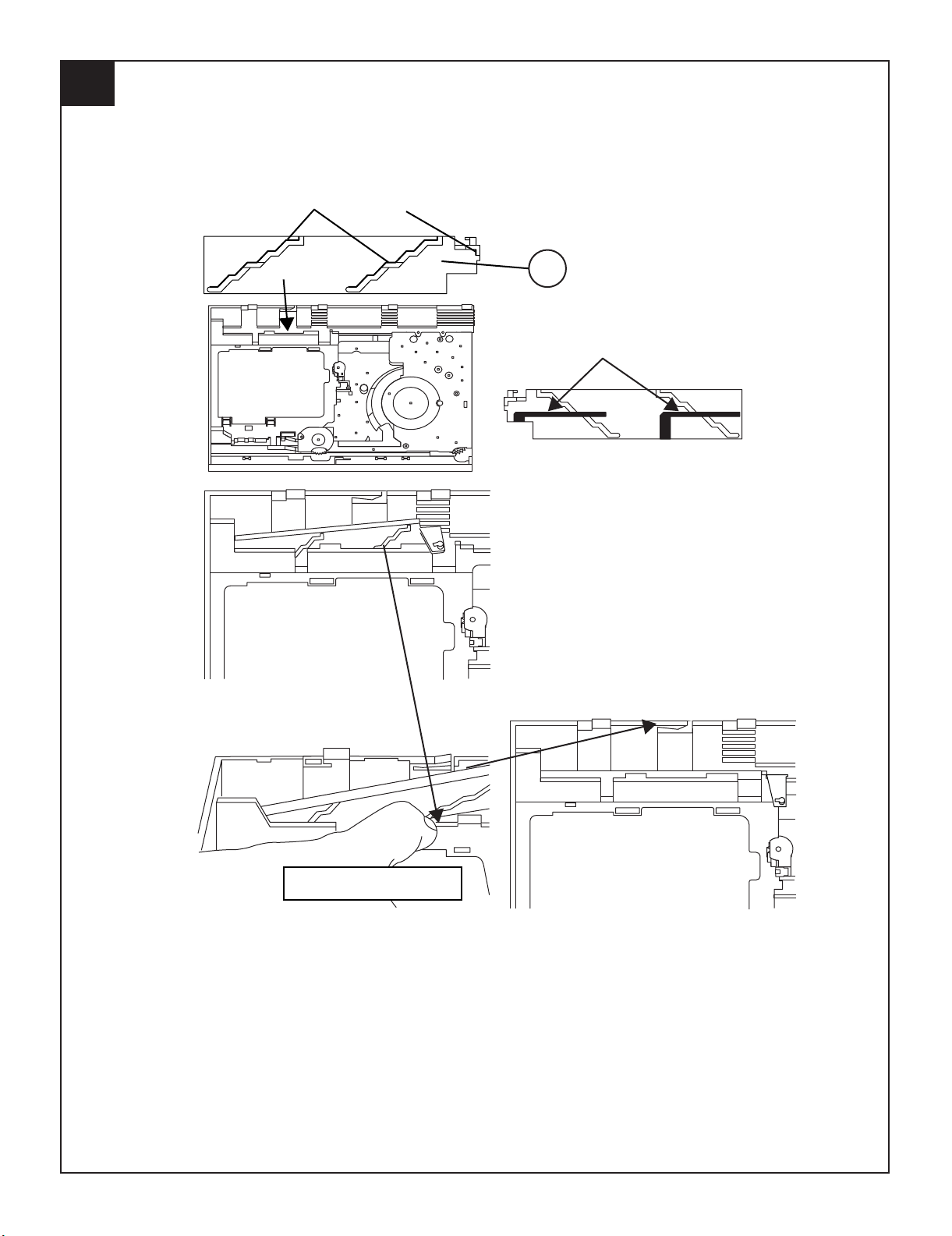

2

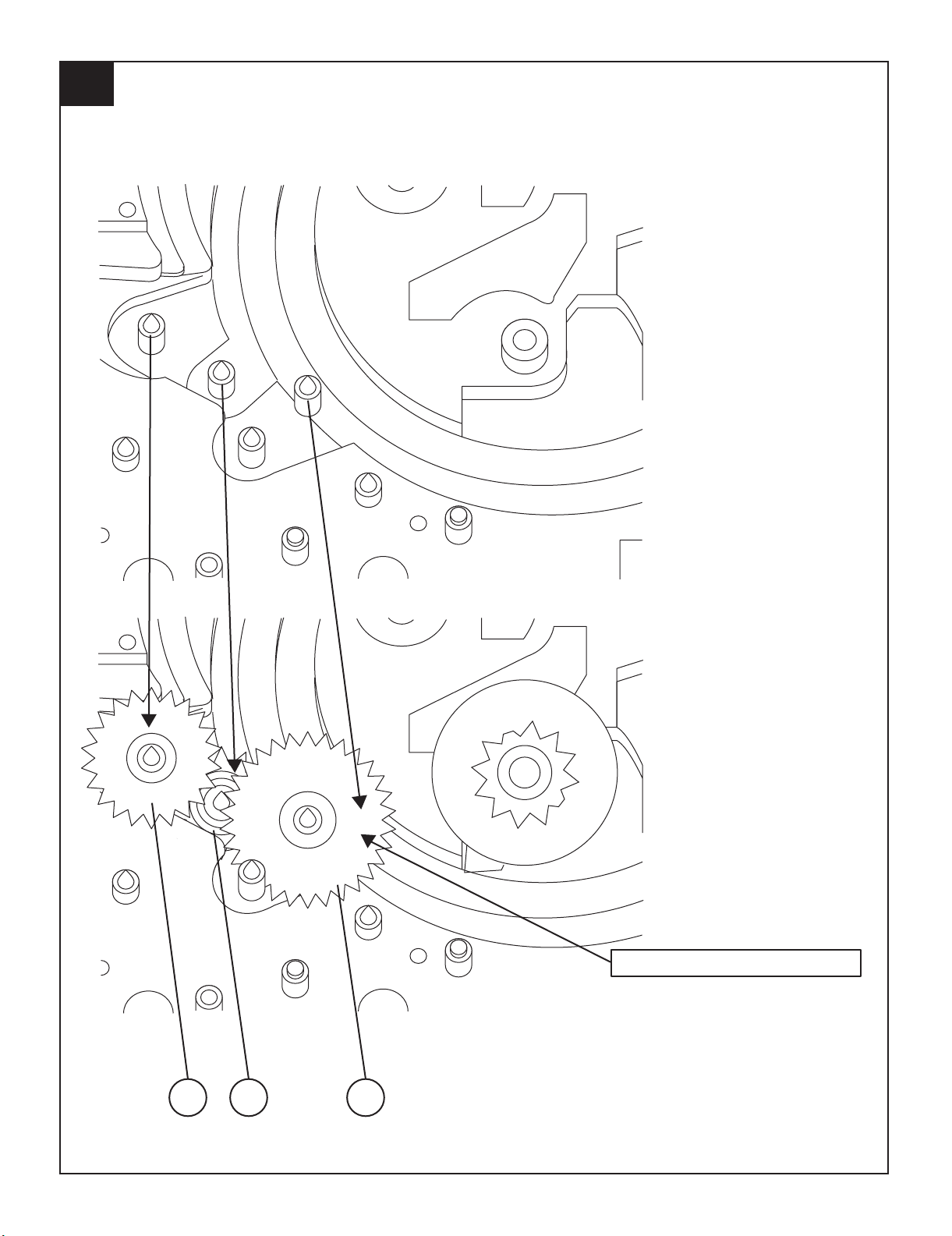

CD-DV999W/CD-DV777W

139

APPLY SANKOL BEFORE FIX

FIX ITEM 1 ACCORDING TO THE

SHOWN PICTURE ABOVE

ROTATE MODE BIG GEAR UNTIL REACH AS SHOWN IN PICTURE

2 – 11

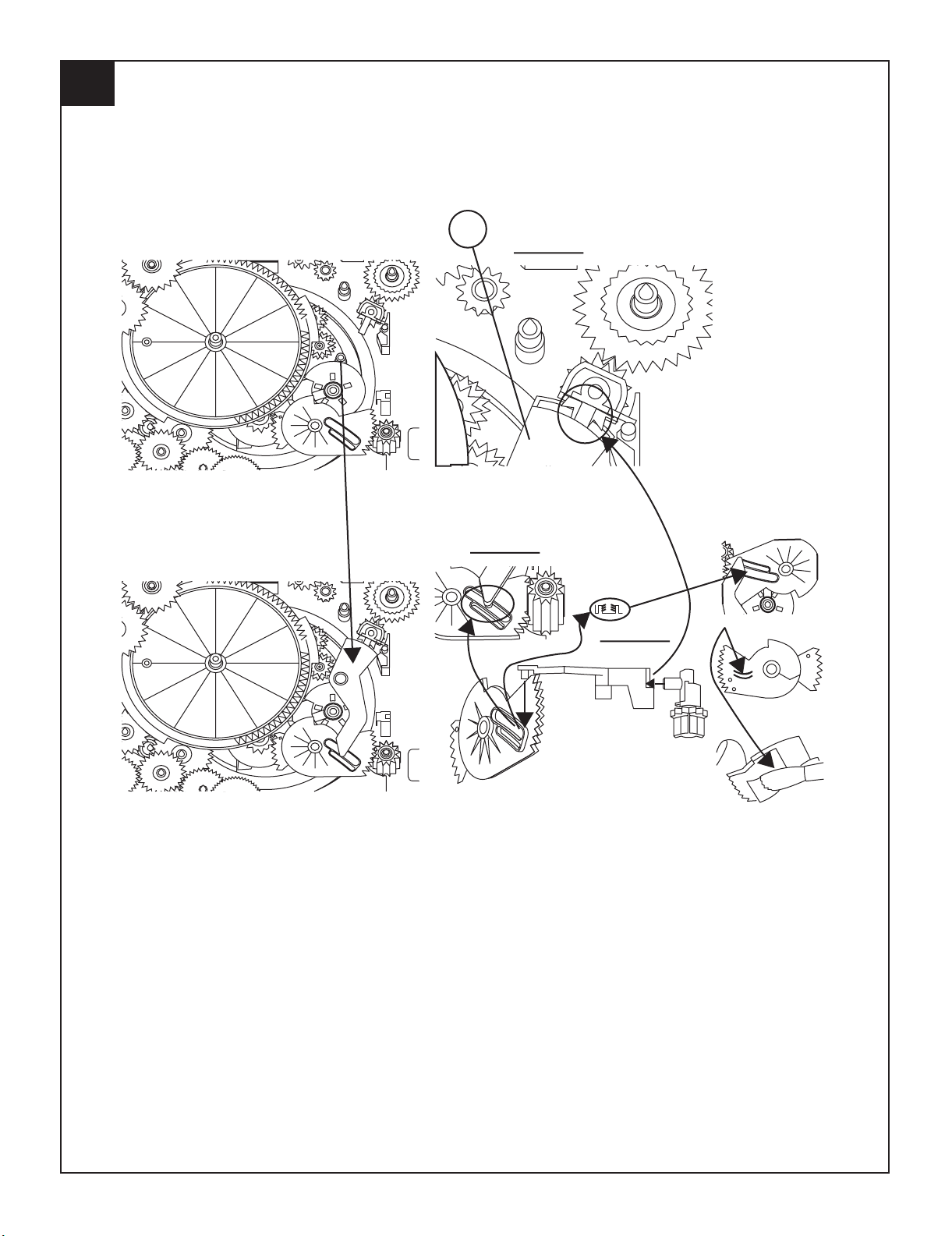

Page 18

CD-DV999W/CD-DV777W

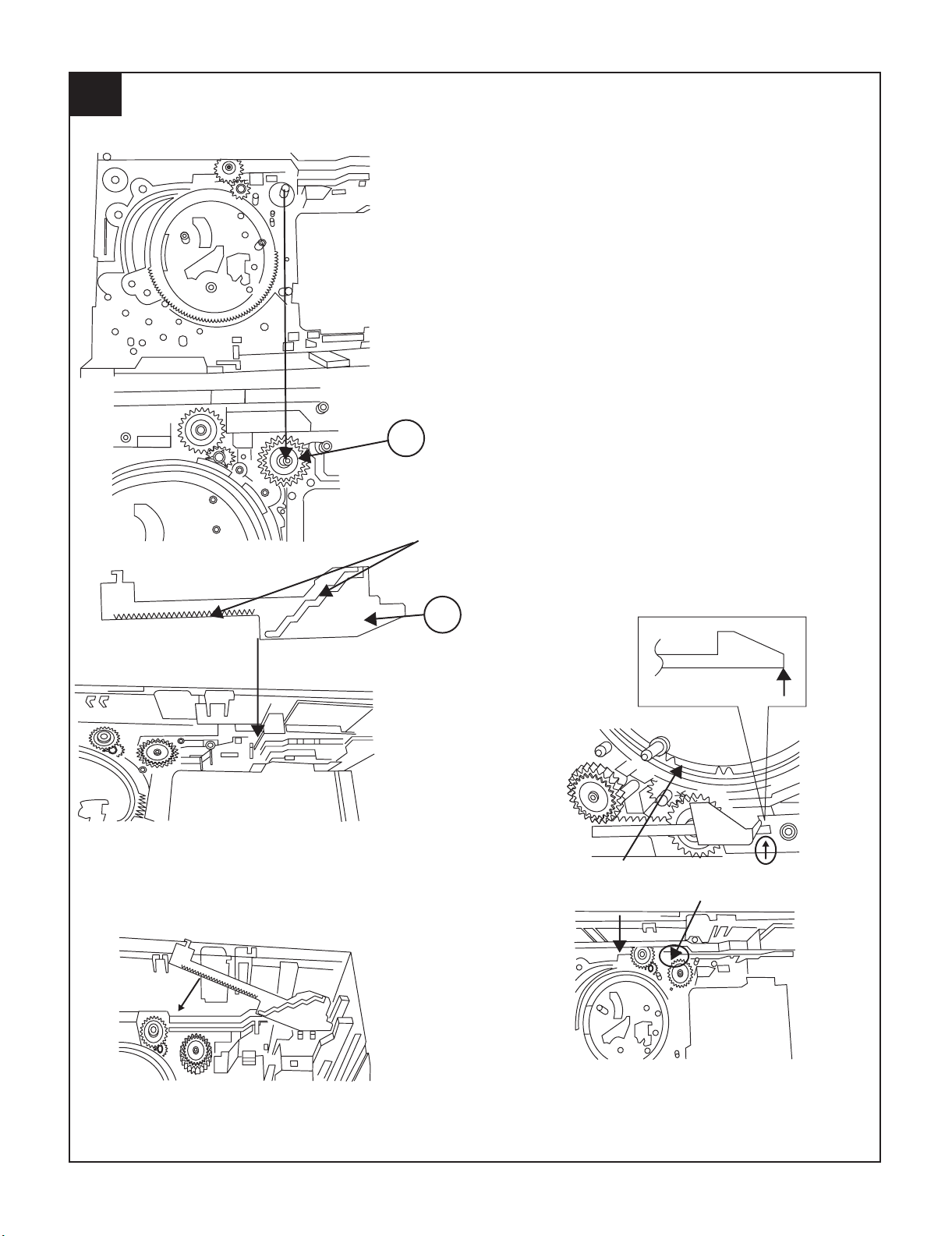

3

143

APPLY GREASE

112

PULL THE LEVER UNITIL

REACH THE ARROW MARK

2 – 12

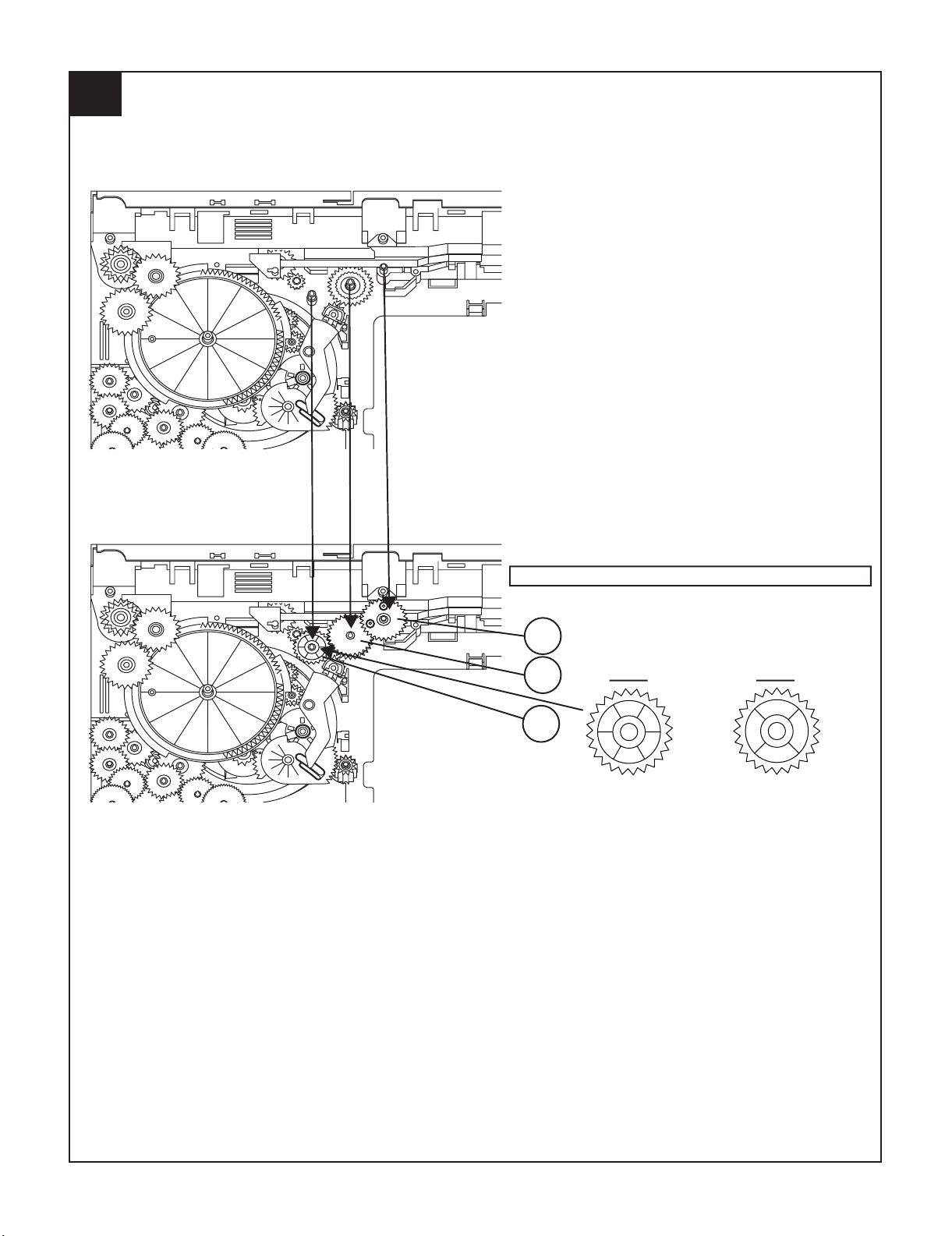

Page 19

4

CD-DV999W/CD-DV777W

FIGURE 2

FIGURE 1

152

142

APPLY GREASE

118

SLOT CLAMP SW ARM INSIDE BASE SLOT

2 – 13

Page 20

CD-DV999W/CD-DV777W

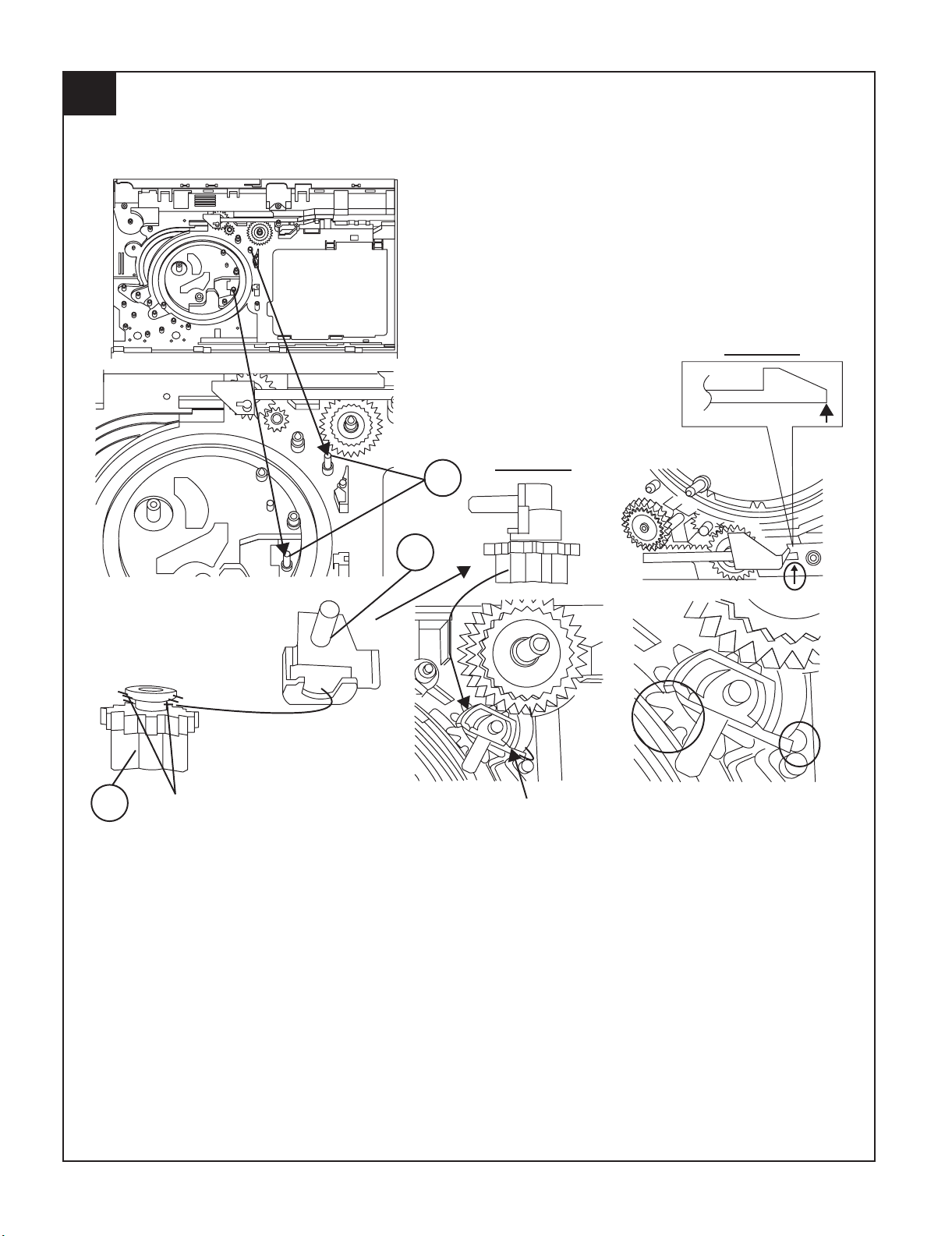

5

APPLY GREASE AT BOTTOM SIDE

OF GEAR FOLLOW MARKING

NO NEED APPLY GREASE AT BOTTOM

SIDE

FIGURE 1

APPLY GREASE AT

TOP SIDE OF GEAR

FOLLOW MARKING

127

OTHER THAN FIGURE 1 DIRECTION ALL N.G

O.K

128

N.G

BLACK MARK

2 – 14

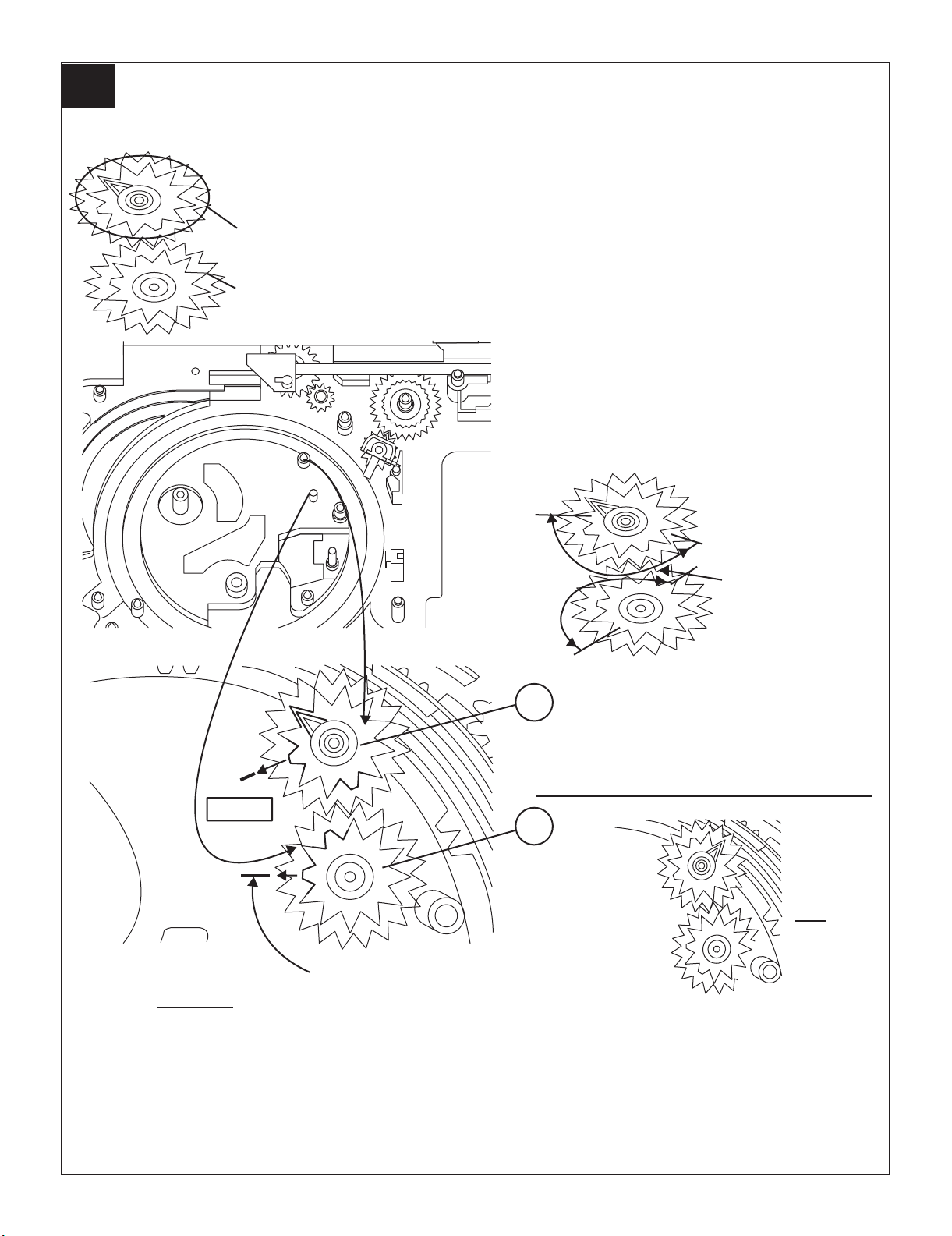

Page 21

6

CD-DV999W/CD-DV777W

APPLY GREASE AT

HALF GEAR AREA

ROTATE CLOCKWISE UNTIL REACH HERE (MAXIMUM)

129

2 – 15

Page 22

CD-DV999W/CD-DV777W

7

CHANGE COLOR TO BLACK

150151148

2 – 16

Page 23

8

CD-DV999W/CD-DV777W

TRAY BIG GEAR

CHANGE COLOR

TO BLACK

MUST FREE FROM GREASE THE SHOWN AREA

O.K

GREASE APPLICATION LENGTH

GREASE APPLICATION PORTION

N.G

124

TRAY BIG GEAR

CHANGE COLOR

TO BLACK

SHOWN HOLE MUST FACING ARROW DIRECTION

131

2 – 17

Page 24

CD-DV999W/CD-DV777W

9

138 126 125

APPLY GREASE AT

BOTTOM SIDE ONLY

TR-RE JOINT GEAR C

APPLY GREASE ONLY AT TOP SIDE GEAR

MUST FIX ACCORDING TO THE HOLE'S

2 – 18

Page 25

10

CD-DV999W/CD-DV777W

148 147 146 145

2 – 19

Page 26

CD-DV999W/CD-DV777W

11

121

144

WH EN FIXING ITEM 2 MUST FOLLOW AS SHOWN

APPLY GREASE

130

2 – 20

Page 27

12

CD-DV999W/CD-DV777W

117

FIGURE 2

FIGURE 1

APPLY GREASE

FIGURE 3

APPLY GREASE SC141

2 – 21

Page 28

CD-DV999W/CD-DV777W

13

ITEM 2 , 3 MUST APPLY GREASE ON TOP SIDE GEAR ONLY

134

GEAR 112 GEAR 112

133

132

O.K

TOP VIEW AFTER

ASSY

N.G

FIX REVERSE N.G

2 – 22

Page 29

14

APPLY GREASE BEFORE FIX

A

MOVE 112 UNTIL TOUCH THE WALL

B

DURING GEAR A ROTATE

MUST PRESS SHOWN AREA

AND LEVER B WILL MOVE

ARROW DIRECTION THEN

FIX PART 108

CD-DV999W/CD-DV777W

SCREW TORQUE

+0.5

2 kgf-cm

-0

108 803 x6

APPLY GREASE

CONFIRM WHETHER

FIXED

PROPELY OR NOT

2 – 23

Page 30

CD-DV999W/CD-DV777W

15

APPLY GREASE

115

BEHIND THE LEVER NEED TO APPLY GREASE

PULL IT THEN LEVER WILL

MOVE IN

2 – 24

Page 31

16

CD-DV999W/CD-DV777W

123

115

APPLY GREASE

APPLY GREASE BEFORE FIX

APPLY GREASE

AT BOSS

SPRING MUST ARRANGE UNDER THE HOOK

BOARD R

BOARD R

O.K LR JOINT LEV

LR JOINT LEV

N.G

2 – 25

Page 32

CD-DV999W/CD-DV777W

17

ASSY REVERSELY N.G

103 137 136

APPLY GREASE

BIG SLOT MUST FACING OUT

WH EN FIX & AFTER FIX TO BASE CHASSIS

AFTER ASSY CONFIRM THE FREE DROP

GEAR POSITION DURING FIXING

2 – 26

Page 33

18

CD-DV999W/CD-DV777W

ASSY REVERSELY N.G

APPLY GREASE

114

135

136

BIG SLOT MUST FACING OUT

WH EN FIX & AFTER FIX TO BASE CHASSIS

AFTER ASSY CONFIRM THE FREE DROP

GEAR POSITION DURING FIXING

CONFIRM BOTH GEAR SIT PROPELY & LOCKED

2 – 27

Page 34

CD-DV999W/CD-DV777W

19

AFTER FIX OUTER UP/DOWN LEVER HOLD SHOWN PORTION AND

MOVE UP/DOWN THEN CONFIRM LEVER GO INSIDE THE HOLE OR NOT

120

BIGGER SLOT FACING OUT

IF GO INSIDE HOLE

IS O.K

IF NO GO INSIDE HOLE IS N.G

119

BIGGER SLOT FACING OUT

2 – 28

Page 35

20

CD-DV999W/CD-DV777W

BIG SLOT FACING OUT

110

2 – 29

Page 36

CD-DV999W/CD-DV777W

21

PUSH THE LEVER ACCORDING TO ARROW

DIRECTION THEN FIX

WH EN FIX MAIN BASE ASSY FOLLOW ACCORDING TO O.K PICTURE

MAKE SURE MECHA HOLDER SHAFT FIX PROPELY TO LEVER

O.K

N.G

N.G

2 – 30

Page 37

22

CD-DV999W/CD-DV777W

APPLY SANKOL

101

102

APPLY SANKOL AT TRAY SLIDING PORTION

APPLY SANKOL ON TOP

FIX TRAY NO 1 FIRST THAN

FOLLOW OTHER

APPLY SANKOL INSIDE THE SLOT

& OTHER SHOWN PORTION

RIB

RIB

COSMO GUIDE TRAY HAVE

MARKING AS SHOWN

2 – 31

Page 38

CD-DV999W/CD-DV777W

23

GEAR UP/DOWN BOARD

111

APPLY GREASE AT INNER & OUTER GEAR SLIDING PORTION

WH EN FIX GEAR UP/

DOWN BOARD THE

TWO LEVER MUST AT

PARALLEL LINE &

POSITION AT TOP

MAX SIDE

2 – 32

AFTER ASSY GEAR UP/DOWN BOARD

Page 39

24

CD-DV999W/CD-DV777W

SCREW TORQUE

+0.5

3 kgf-cm

-0

2 – 33

804

Page 40

CD-DV999W/CD-DV777W

25

AFTER ASSY TOP PLATE

FIX THE FFC

FFC4

AFTER PUSH MAKE SURE SNAP PROPELY

AFTER FIX PUSH FOLLOW ARROW DIRECTION

BEFORE LOCK

AFTER LOCK

BACK

PORTION

107

122

BEFORE LOCK

PRESS IN

SLOT IN

BEFORE LOCK

AFTER LOCK

AFTER LOCK

MUST CONFIRM

MUST CONFIRM

2 – 34

Page 41

26

CD-DV999W/CD-DV777W

O.K

N.G

CAUTION

1. MAKE SURE NO PWB CHIP INSIDE SET .( BEFORE

FIX MAKE SURE PWB NO DUST , GREASE & ETC )

803

2 – 35

Page 42

CD-DV999W/CD-DV777W

27

THE TWO SLOT

MUST FREE FROM GREASE

APPLY GREASE BELOW

THE MARKING FOR

BOTH PORTION

ASSEMBLY SEQUENCE

1. APPLY GREASE TO MAIN BASE

GREASE APPLICATION AREA

ALL BOSS

APPLY GREASE

APPLY GREASE

CAUTION

TRAY SLIDING

AREA MUST

FREE FROM

GREASE

APPLY GREASE

APPLY GREASE AT WALL

APPLY GREASE

APPLY GREASE

APPLY GREASE

AT BOTH SLOT

105

APPLY GREASE AT 3 HALF MOON

1 RIB ONLY

APPLY GREASE

APPLY GREASE

INSIDE SLOT

2 – 36

Page 43

28

REFERENCE ONLY

MOTOR GEAR HEIGHT FROM

MAIN BASE 12.2

+

0.1

-

CD-DV999W/CD-DV777W

0.1

-

+

12.2

MOTOR SCREWING HOLE

MUST HAVE GAP

M1,2

801

-0

13.8 + 0.2

SCREW TORQUE

1.5 + 0.5

-0

AFTER SCREW MOTOR,CONFIRM THE

ARRANGEMENT AS IN FIGURE 2

FIGURE 2

APPLY GREASE

2 – 37

Page 44

CD-DV999W/CD-DV777W

29

APPLY SANKOL

3.1 + 0.1

SHAFT X 3 DIM AFTER INSERTION

MUST CONFIRM EVERYDAY

SANKOL APPLICATION AREA

109-2

APPLY GREASE AT THE SLIDING PORTION

114

116

UP / DOWN

HOLDER CHANGE

TO NATURE

COLOR

APPLY GREASE

2 – 38

Page 45

30

CD-DV999W/CD-DV777W

BEFORE MELT IT

AFTER MELT IT ( MUST FLAT )

CHANGE COLOR

TO NATURE

WHEN FITTING STABILIZER PLATE TO STABILIZER,

ROTATE STABILIZER ANTI CLOCKWISE BY JIG

( BY HAND CANNOT X )

BELOW

AFTER ASSY TO HOLDER

STABILIZER NEED CLEAN

WITH ALCOHOL DISC

TOUCHING SURFACE

2 – 39

Page 46

CD-DV999W/CD-DV777W

31

104

APPLY GREASE

MUST MAKE SURE SNAP PROPELY BOTH SIDE

ALL SURFACE MUST TOUCH

O.K N.G

GAP

N.G

2 – 40

Page 47

32

CD-DV999W/CD-DV777W

NO GAP HAVE GAP

O.K N.G

2 – 41

Page 48

CD-DV999W/CD-DV777W

AudioCD-DV999W/CD-DV777WService ManualCD-DV999W/CD-DV777WMarketE

CHAPTER 3. MECHANISM BLOCKS

[1] Caution on diassembly

Caution on Disassembly

Follow the below-mentioned notes when disassembling the unit and reassembling it, to keep it safe and ensure excellent performance:

1. Take cassette tape, and compact disc out of the unit.

2. Be sure to remove the power supply plug from the wall outlet before starting to disassemble the unit.

3. Take off nylon bands or wire holders where they need to be removed when disassembling the unit. After servicing the unit, be sure to rearrange

the leads where they were before disassembling.

CD-DV999W/CD-DV777W

STEP

REMOVAL PROCEDURE

1 Top/Side Cabinet 1. Screw .................... (A1) x11

2 Changer Unit/ 1. Screw ...................... (B1) x2

Rear Panel B 2. Hook ........................ (B2) x2

3

Rear Panel A/

S-Video/Audio Out

PWB with

Fan motor

4 Main PWB 1. Screw ...................... (D1) x2

5 Front Panel 1. Screw ...................... (E1) x2

6 Tape Mechanism 1. Screw .......................(F1) x6

7 Mic PWB 1. Knob .......................(G1) x1

8 Display PWB 1. Knob ........................ (H1) x1

3. Flat Cable................ (B3) x2

4. Socket ..................... (B4) x3

1. Screw ...................... (C1) x6

2. Socket ..................... (C2) x4

2. Flat Cable ............... (D2) x1

3. Socket ..................... (D3) x5

4. Flat Wire .................. (D4) x1

5. Screw ...................... (D5) x4

2. Flat Wire .................. (E2) x1

3. Hook ........................

(E3) x2

2. Flat Cable ................(F2) x1

2. Screw ..................... (G2) x1

2. Screw ....................(H2) x10

........................

3. Hook (H3) x5

9 Game Input PWB 1. Screw...................... (J1) x2

10 Sub PWB 1. Screw .......................(K1) x1

11 DVD Servo PWB 1. Screw ....................... (L1) x3

12 Changer 1. Screw ...................... (M1) x4

Mechanism Unit 2. Changer Chassis .... (M2) x1

13 DVD Mechanism 1. Screw .......................(N1) x4

(A1)x3

φ3x10mm

Rear Panel B

2. Flat Cable ................ (K2) x1

3. Hook ........................ (K3) x1

2. Flat Cable ................ (L2) x1

3. Socket ...................... (L3) x2

2. Bracket ..................... (N2) x1

Top/Side Cabinet

Front Panel

S-VIDEO/ AUDIO

OUT PWB

Rear

Panel B

(B1)x2

φ3x10mm

Rear

Panel A

(C1)x6

φ3x10mm

(C2)x3

(E3)x1

(B2)x1

Pull

Changer

Mechanism

Unit

Fan Motor

(D2)x1

(D3)x1

(D5)x4

φ3x6mm

SUB PWB

(B3)x1

(B4)x1

(B4)x1

(D1)x1

φ3x18mm

(D3)x1

(C2)x1

DVD SERVO

PWB

Main PWB

Lug Wire

Main PWB

(E2)x1

Front Panel

(B3)x1

(B4)x1

(B2)x1

Pull

(D1)x1

φ3x10mm

Front

Panel

Rear Panel A

(A1)x5

φ3x10mm

(A1)x3

φ3x10mm

3 – 1

(D4)x1

(D3)x1

Power PWB

(E1)x2

φ3x8mm

Main

PWB

(E3)x1

Page 49

CD-DV999W/CD-DV777W

Tape

Mechanism

Lug Wire

(F1)x6

φ3x10mm

(D3)x1

(H2)x10

φ2.6x10mm

(D3)x1

Mic PWB

Lug Wire

Front Panel

(F2)x1

Display PWB

Front Panel

(H3)x5

(M1)x4

φ3x10mm

(M2)x1

Changer

Mechanism

Unit

(L2)x1

Mic PWB

(G2)x1

φ3x10mm

(K2)x1

Pull

(K1)x1

φ3x10mm

Sub PWB

(L2)x1

(J1)x2

φ3x10mm

(K3)x1

(L1)x3

φ2.6x10mm

DVD Servo

PWB

(H1)x1

(G1)x1

Game Input

PWB

(L3)x2

Changer

Mechanism

Unit

(N1)x2

φ2.6x10mm

DVD Mechanism

Unit

(N1)x2

φ2x12mm

Changer

Mechanism

Unit

(N2)x1

Pull

DVD Servo

PWB

3 – 2

Page 50

CD-DV999W/CD-DV777W

CP-DV999/CP-DV777

STEP

REMOVAL PROCEDURE

1 Passive Radiator 1. Screw ...................... (A1) x4

2. Side Panel .............. (A2) x1

3. Screw ...................... (A3) x4

2 Woofer 1. Front Panel ............. (B1) x1

2. Screw ...................... (B2) x4

3 Tweeter 1. Screw ...................... (C1) x2

4 Super Tweeter 1. Screw ...................... (D1) x4

Front Panel

Speaker Box

(C1)x2

φ3x12mm

Super Tweeter

(D1)x2

φ3x12mm

Tweeter

(A3)x4

φ4x16mm

Passive Radiator

Screwdriver

Passive Radiator

(B1)x1

(A2)x1

(A1)x4

φ4x35mm

Super Tweeter

(D1)x2

φ3x12mm

(B2)x4

φ4x16mm

Speaker Box

Woofer

Driver should

be pried away

from Speaker Box.

Speaker Box

3 – 3

Page 51

[2] Removing and reinstalling the main parts

1. TAPE MECHANISM SECTION

Perform steps 1 to 5 and 6 of the disassembly method to remove the

tape mechanism.

1.1. How to remove the record/playback and erase heads

(TAPE 2) (See Fig. 1)

1. When you remove the screws (A1) x 2 pcs., the recording/playback head and three-dimensional head of the erasing head can be

removed.

TAPE 2

Clutch Ass'y

Record/Playback

Head

Erase Head

CD-DV999W/CD-DV777W

<B>

Pinch Roller

(C1)x1

TAPE 2

Pinch Roller

(C1)x1

Pinch

Roller

Pawl

<A>

Pull

Figure 3

1.4. How to remove the belt (TAPE 2) (See Fig. 4)

1. Remove the main belt (D1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (D2) x 1 pc.

1.5. How to remove the belt (TAPE 1) (See Fig. 4)

1. Remove the main belt (E1) x 1 pc., from the motor side.

2. Remove the FF/REW belt (E2) x 1 pc.

TAPE 1/TAPE 2

Pull

<B>

<A>

Pinch

Roller

Pawl

(A1)x2

¯2x6mm

Figure 1

1.2. How to remove the playback head (TAPE 1)(See Fig. 2)

1. When you remove the screws (B1) x 2 pcs., the playback head can

be removed.

(B1)x2

¯2x9mm

TAPE 1

Clutch Ass'y

Playback

Head

Tape

Motor

TAPE 2

Main Belt

(D1)x1

TAPE 1

Main Belt

(E1)x1

TAPE 1

FF/REW

Belt

(E2)x1

TAPE 2

Main Belt

(D1)x1

FF/REW

Belt

(D2)x1

Tape

Motor

Main Belt

(E1)x1

Figure 4

1.6. How to remove the motor (See Fig. 5)

1. Remove the screws (F1) x 2 pcs., to remove the motor.

Tape

Motor

Clutch Ass'y

Figure 2

1.3. How to remove the pinch roller (TAPE 1/2) (See Fig. 3)

1. Carefully bend the pinch roller pawl in the direction of the arrow

<A>, and remove the pinch roller (C1) x 1 pc., in the direction of the

arrow <B>.

Note:

When installing the pinch roller, pay attention to the spring mounting

position.

(F1)x2

¯2.6x5mm

Figure 5

3 – 4

Page 52

CD-DV999W/CD-DV777W

Mark 1

(DISC 1)

(DISC 2)

(DISC 3)

(DISC 4)

(DISC 5)

Gear up down board

Mark 3 Mark 5

Mark 2 Mark 4

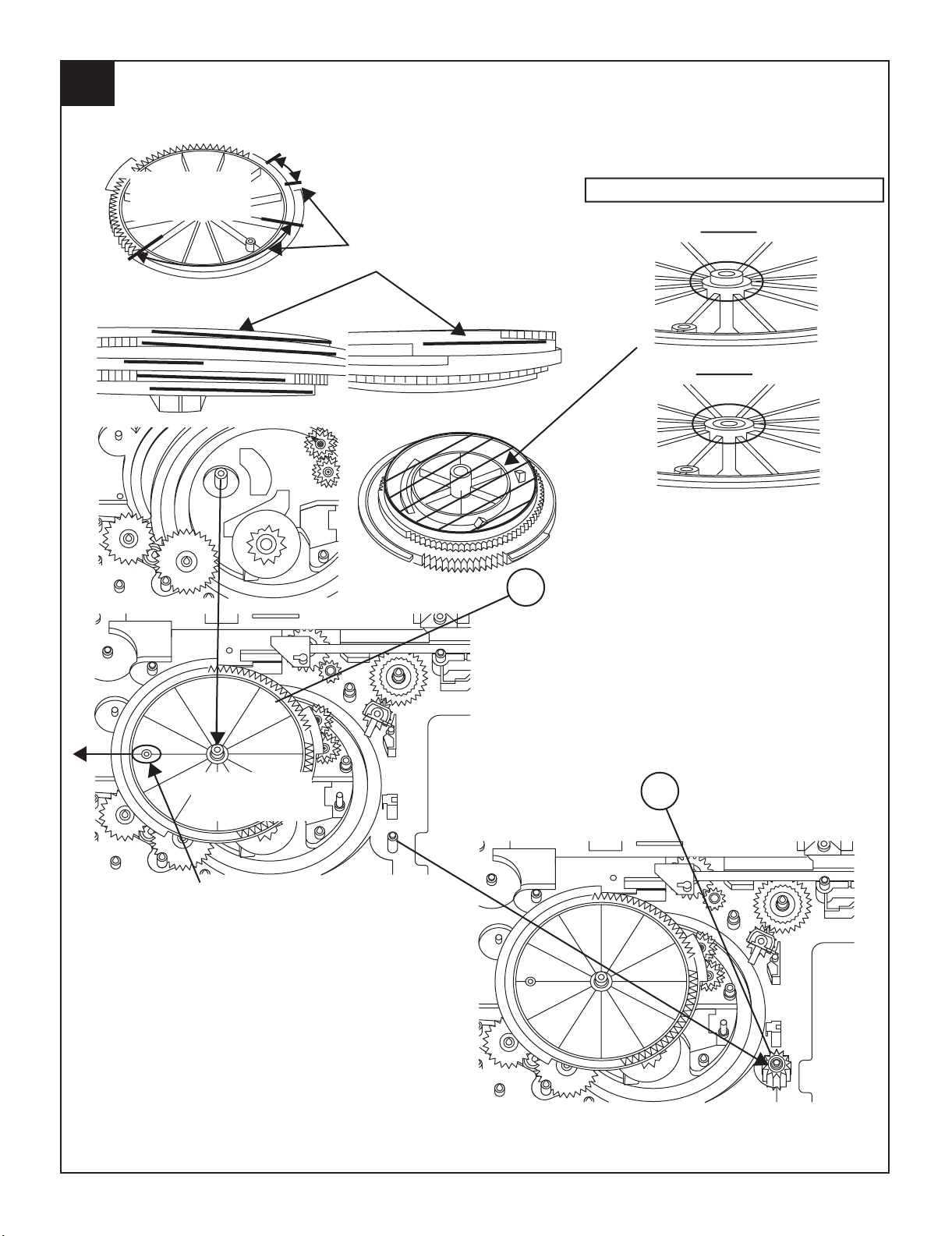

2. CD MECHANISM SECTION

Perform steps 1, 2, 11, 12 and 13 of the disassembly method to

remove the CD mechanism.

2.1. Remove the pickup. (See Fig. 1)

1. Remove the stop washer (A1) x 1 pc., to remove the gear (A2) x 1

pc.

2. Remove the screws (A3) x 2 pcs., to remove the shaft (A4) x 1 pc.

3. Remove the pickup.

Note

After removing the connector for the optical pickup from the connector

wrap the conductive aluminium foil around the front end of connector

so as to protect the optical pickup from electrostatic damage.

(A3)x2

φ2.6x6mm

CD Mechanism

Shaft

(A4)x1

Gear

(A2)x1

Reduction gear C

Front Rear

Figure 3

2. In another case, if CD mechanism is at tray No.1 play position and

to remove CD located in tray No.3, the procedure is as follows:

If the gear up down board is located at tray No.1 position, then

rotate gear clock-wise until it at stock position. Rotate reduction

gear D clockwise (Figure 4) to move the CD mechanism to tray

No.3 position.This is confirmed by checking the gear up down

board position by the marking as indicated on the main chassis as

shown in Figure 5.

Reduction gear D

Stop Washer

(A1)x1

Pickup Unit

Figure 1

3. CHANGER MECHANISM SECTION

Perform steps 1, 2, 11, 12 and 13 of the disassembly method to

remove the CD changer mechanism.

3.1. How to remove CD Disc (See Fig. 2~5)

1. When CD is at play position (Figure 2), rotate reduction gear C

clock-wise as shown in Figure 3 Until disc tray is at stock position,

then rotate further to eject the disc tray so that CD can be removed

from the tray.

CD Disc

Disc Tray

Guide Tray

CD At play position.

CD Disc

Up Down

Figure 4

Figure 5

Figure 2

CD At stalk position.

3 – 5

Page 53

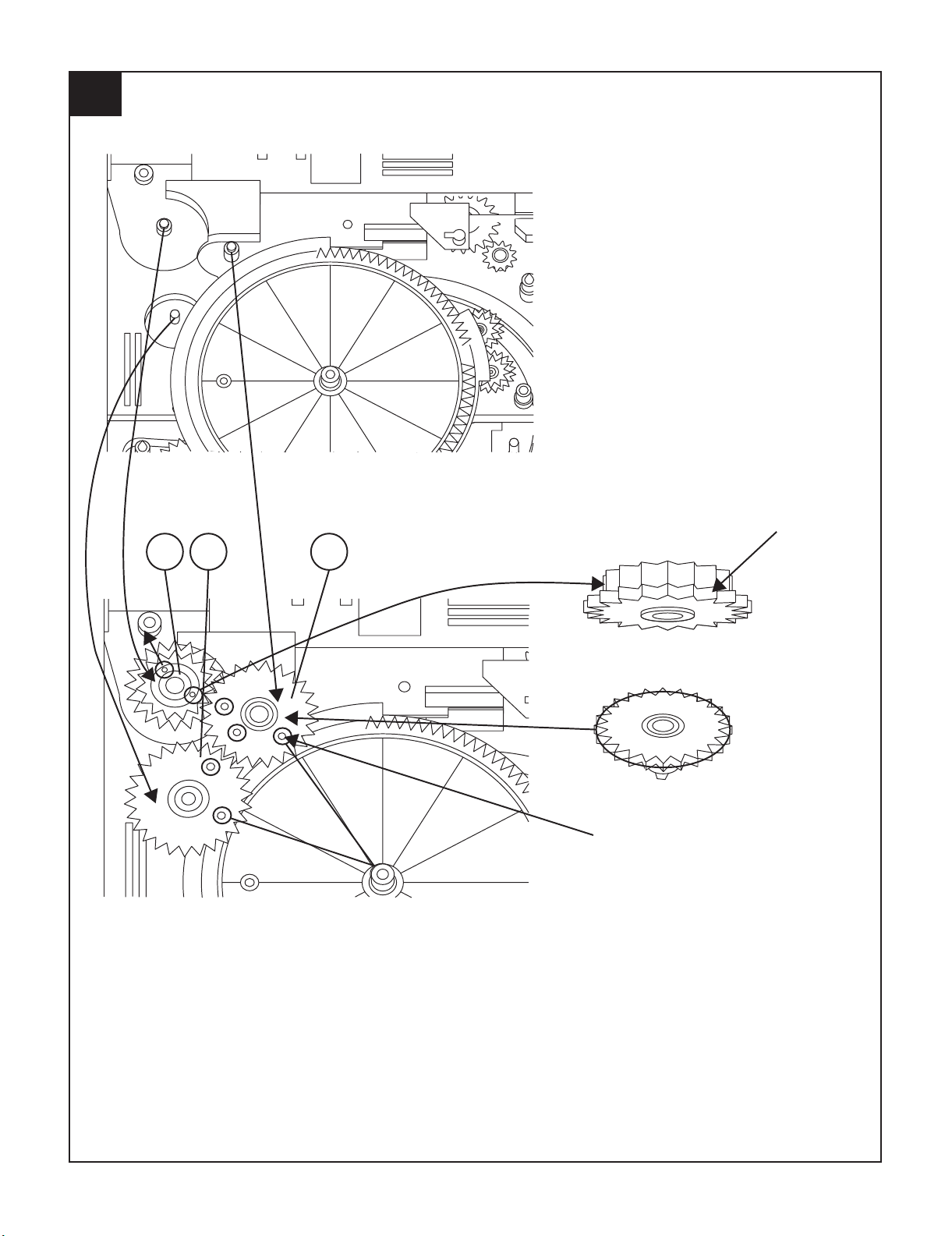

3.2. How to Remove the tray motor/main cam motor/5Changer Motor PWB (See Fig. 6)

1. Remove the screws (A1)x 2 pcs., to remove tray motor/main cam

motor/5-Changer Motor PWB.

Changer Mechanism Unit

CD-DV999W/CD-DV777W

Main Cam Motor

(A1)x2

φ2x10mm

Figure 6

NOTE: There are 2 more screws tighten the motors at the bottom of

main chassis. Before performing procedure 1 above, disc stop

spring, top plate sear up down board and trays must be

removed, then only the 2 screws can be untighten.

Tray Motor

5-Changer

Motor PWB

3 – 6

Page 54

CD-DV999W/CD-DV777W

b

R

I

4

C

AudioCD-DV999W/CD-DV777WService ManualCD-DV999W/CD-DV777WMarketE

CHAPTER 4. DIAGRAMS

[1] Block diagrams

D3.3V

A5V

IC501

3

2

1

AUDIO

DIGITAL

OUT

DVD/CD

SO7001

S-VIDEO

OUT

JK7002

VIDEO

OUT

M2

MAIN CAM

MOTOR

M

M

M1

TRAY

MOTOR

FROM MAIN PWB

FROM MAIN PWB

CN3203

14

13

12

11

10

CN3201

10

11

CN3003

10

11

12

13

CN3004

SPDIF

1

DGND

2

3

D3.3V

MUTE

TXD

DGND

RXD

PROGRESSIVE

9

ASPECT

VGND

8

Py_OUT

7

Pb_OUT

6

Pr_OUT

5

VGND

4

V_OUT

3

C_OUT

2

1

CAM-

1

CAM+

2

TR-

3

TR+

4

DVD_CS

5

DVD_CLK

6

SYS_DATA

7

DVD_DATA

8

DVD A_MUTE

9

RESET

RXD_CTL_IN

RÐCH

1

AUDIO_GND

2

LÐCH

3

M_GND

4

A_5V

5

D_GND

6

+8V

7

S_5V

8

S_5V

9

A_GND

D_1.5V

A3.3V

D3.3V

A_5V

+8V

S_5V

D1.5V

A3.3V

D3.3V

Q3100

Q3101

Q3102

IC3003

TC7WT126

BUFFER

D3.3V

D3.3V

IC3503,IC3504

20

TCLV573T

8 bit LATCH IC

5

6

DGNDAUDIO

94

Q3501

D3.3V

131412

14

15

16

13

D3.3V

D3.3V

1,7,8

IC3002

BD4825G

RESET

A0-A15

8

7

IC3801

PCM1748E

D/A CONVERTER

GND

IC3501

IXA173WJ

FLASH ROM

27,46

1,10

Figure 4-1 BLOCK DIAGRAM (1/4)

ADAC_DA

NEXOENEXCENEXWEFADT(0-20)

IECOUT

DAC1OUT

DAC4OUT

DAC5OUT

DVD_CS

S_CLK

S_DIN

S_DOUT

AMUTE

NRST

RXD_CLT_IN

P15(RXD_CLT)

D_3.3V

43,49,55,75,81

1,3,9,15,29,35,41

1,12D3.3V

10

ADAC_CK

ADAC_L

768FS

181

RXD

52

158

163

164

60

53

55

54

94

68

59

47

NRAS

NCSM

IC3401

IX0614AW

64M SD-RAM

D_GND

14

15

IC3601

BU2363FV

CLOCK

GENERATOR

2,11

D_GND

BA(0-1)

DQM(0-3)

MA(0-11)

MDQ(0-31)

MCK

NWE

NCAS

6,12,32,38,44,46,52

58,72,78,84,86

873

X3601

974817296

IC30

IXA46

DVD ED

49,92,170

D_3.3V

B

8

4K

4 – 1

Page 55

3

IC3001

IXA464AW

DVD EDCODER

49,92,170

V

BR24L04F

8

4K bit EEPROM

IC3602

1-4,7

104,118,145,149

153,157,165

A3.3V

6

5

63

P2(SDA)

P3(SCL)

FG

SPIN

66

146

106,119,138

151,155,159,167

4,11,16,24,30,43

58,69,80,93,99,169

177,183,194,198,206

211,215,221,224,230

236,241,245,248,254

1,7,14,23,29,42

56,79,91,171,182

189,195,202,209

218,226,233,240,250

15,67,98,186

213,222,244

62

121-131

134,136

VHALF

137

73,71,70

152,150

133,135

LPCO1

LPCO2

CD-DV999W/CD-DV777W

FG

7

5,6

VCC

S_5V

SPIN

31-34

VHALF

VCC

M_8V

A_GND

D_GND

D3.3V

D1.5V

74

Q3305

Q3306

Q3303

Q3304

D3301

A_GND

25

9,27,28

29

A_GND

14

IC3702

NJM12904

8

OPE.AMP.

1

2,3

35,36

1,2

L

H

3,4

7,26

M_GND

S_5V

PD_CD

IC3704

LA6261

FOCUS/TRACKING

SPIN/SLED DRIVER

18

12

16

S_5V

IC3301

7SB3157P

ANALOG

SWITCH

Q3307

DVD_H

4

A_GND

SPIN-

SPIN+

5,6

CN3301

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

A_3.3V

GND

LD_DVD

NC

VOSC

PDMON

LD(CD)

VR(DVD)

VR(CD)

NC

VE

VCC

Vref

G(PDIC)

VF

VB

VA

RF

CD/DVD

VD

VC

TR-

TR+

FO+

FO-

D_GND

DVD MECHANISM

UNIT ASS'Y

SPIN-

SPIN+

IN SW

SL-

SL+

AGND

FG

LED

M

SPINDLE

MOTOR

M

SENSOR

PWB

PICKUP

SLED

MOTOR

UNIT ASSY

Figure 4-2 BLOCK DIAGRAM (2/4)

4 – 2

Page 56

CD-DV999W/CD-DV777W

2

V

FM

ANTENNA

BF301

B.P.F

1

2

1

2

3

REC.

JK1

MIC

JK2

MIC

VRK1

MIC LEVEL

FROM DVD SECTION

TAPE 1

P.B. HEAD

TAPE 2

REC./P.B.

HEAD

AM LOOP

ANTENNA

40

LATCH

DATA

9

CLOCK

ROUT

LOUT

4

12

13

22

CN3004

L-CH

R-CH

L-CH

R-CH

SO302

FM ANTENNA

TERMINAL

CNP301

ICK1

M65856SP

MIC AMP.

42

41

35

36

32

RIN

31

LIN

VCC

23

P.B.

AC BIAS

ERASE

HEAD

IC301

TA7358AP

FM FRONT END

1

4

3

L312 T301

FM RF

AM TRACKING

T303 T306

ICK2

KIA4558P

OPE AMP.

6

5

2

3

BI601CNS601

+B4QK1

1

3

4

SWITCHING

Q101~

Q104

Q105

Q106

Q111

L103

BIAS

OSC

7

1

L(T1)

R(T1)

L(T2)

R(T2)

POP REDUCE

LREC

RREC

SWITCHING

+B4

5

7

FM

VIDEO OUT

1

24

2

23

6

T1/T2

REC

9

16

11

12

NOR/

15

HIGH

Q114

SWITCHING

Q112

SWITCHING

6

9

8

OSC

FM

OSC

OSC BUFF

Q302

AM BAND

COVERAGE

FM+B

JK691

VIDEO

P.B

H/N

T1/T2

19

Q113

SWITCHING

FM IF

T302

SWITCHING

GAME INPUT

13

L

4

21

R

7

18

+B4

JK690

L

R

+B4

PB

RECRL

VT

Q360

AUX

CF303

20

FM

TUNER

AM OSC OUT

X352

4.5 MHz

1

OSC

DVD

AM OSC IN

22 111615

7

TAPE

21

AM IF

AM MIX

AM RF IN

T351

IC101

AN7345K

PLAYBACK AND RECORD/

10

ALC

PLAYBACK AMP.

+B4

Q109

Q110

BIAS

+B7

+B7

MOTOR

DRIVER

Q706

Q711

Q712

Q707

Q708

Q714~

Q717

SOLENOID

DRIVER

10.7 MHz

450 kHz

CF352

7

STEREO

4

AM IF

CF351

985

GND

FM+B

FM/AM

OUT

1821 12162324

IC302

LC72131

PLL(TUNER)

CLK

DO

DI

CE

5436

MO/ST

FM/AM

9

10

17

8

L

9

16

R

L

10

15

R

L

11

14

AUDIO PROCESSOR

R

L

12

13

R

+B4

MECHANISM

17

21

23

IC601

LC75341

7

18

3

Q107

Q108

MUTING

LED

DRIVER

Q710

LED703

TAPE

ASS'Y

ZD351

5.1V

X351

456 kHz

13

17

FM

DET

VCO

14

L

MO/ST

R

15

FM/AM

MPXIN

+B4

+B4

1

DI

2

CE

24

CLK

R

21

4

L

58

MICROCOMPUTER

+B4

IC303

LA1832S

FM IF DET./

FM MPX./

AM IF

-20dB

ATT

Q601

Q602

REC/PLAY

IC602

7

NJM2533

VIDEO

SWITCH

3

JOG701

VOLUME

30

IC701

IXA023AW

SYSTEM

(2/2)

Q603

Q604

T1/T2

BIAS

SYSTEM

+B11

DVD1.7

+B10

DVD3.7

MUTE

VF1

Figure 4-3 BLOCK DIAGRAM (3/4)

4 – 3

Page 57

D

FL701

FL DISPLAY

812 45

27

26

~

CD-DV999W/CD-DV777W

47

~

5150

/

SYSTEM

2

S

+B11

DVD1.7V

+B10

DVD3.7V

MUTE

VF2

VF1

-VF

VOLTAGE

REGULATOR

IC856

2

LD1117V

VOLTAGE

REGULATOR

IC856

LD1117V33

SP DET.

D905~D907

IC901

STK41244

POWER AMP.

18

L

14

R

7

1

6

+B9

+B6

+B8

12

2

+B3

+B7

+B4

D870D871

5

-B1

-B2

+B2

A_+5V

SW5V

D+5V

1

+B1

LD+8V

M+13V

A+10V

SELECTOR

3850 27 28 26

58

~

78

79

VLOAD

MICROCOMPUTER

VDD

12345 67

L-OUT

R-OUT

CD-DV777W STK41242

CD-DV999W

11

8

80

~

97

99

100

+B5

MULTI REGULATOR

IC853

2

BD9701T

1-CH DC-DC

CONVERTER

SW601

SPAN

+B5

46

47

IC701

IXA004AW

SYSTEM

(1/2)

RESET

11 1210 16 21 24 20 17 18 19

+B5

XL701

4.19 MHz

RESET

Q709

+B5

Q901~

Q904

IC851

AN80T53

7

2

6

+5V

1

VOLTAGE REGULATOR

IC901

STK41244

KIA7808AP

SP RELAY

ON-OFF

D802

3

IC852

VDD

VDD

59

~

D801

40

25 13 27

AVDD

CLK

CEDIDO

Q905

F802

T5A L250V

F801

T5A L 250V

D803,

D804

Q801

3

39

+B5

34

33

~~

31

53

56

15

41

FAN MOTOR

DRIVER

RL914

F804

T2A L 250V

F803

T2A L250V

VOLTAGE

REGULATOR

UNSW_5.6V

+B5

TAPE

MECHANISM

ASS'Y

RX701

REMOTE

3

SENSOR

SW701-SW708

SW712-SW716

SW724-SW735

Q906

TRANSFORMER

2

KEY

TO CD

SECTION

+B8

M

SO902

SPEAKER

TERMINAL

+B7

JK701

HEADPHONES

PT801

POWER

IC854

311

AN78L05

1

+B5

M901

FAN

MOTOR

T.F.

F807

2.5A L250V

F806

T2.5A L 250V

1

VOLTAGE REGULATOR

230-240 V

220 V

127 V

110V

SW801

VOLTAGE

SELECTOR

F805

T5A L 250V

L841

LINE FILTER

AC POWER SUPPLY COR

AC 110/127/220/230-240 V,

50/60 Hz

1

1

2

2

Figure 4-4 BLOCK DIAGRAM (4/4)

4 – 4

Page 58

CD-DV999W/CD-DV777W

AudioCD-DV999W/CD-DV777WService ManualCD-DV999W/CD-DV777WMarketE

CHAPTER 5. CIRCUIT DESCRIPTION

[1] Notes on schematic diagram

•Resistor:

To differentiate the units of resistors, such symbol as K and M are

used: the symbol K means 1000 ohm and the symbol M means

1000 kohm and the resistor without any symbol is ohm-type resistor. Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is used: this symbol P

means pico-farad and the unit of the capacitor without such a symbol is microfarad. As to electrolytic capacitor, the expression

“capacitance/withstand voltage” is used.

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

• Schematic diagram and Wiring Side of P.W.Board for this model are

subject to change for improvement without prior notice.

• The indicated voltage in each section is the one measured by Digital Multimeter between such a section and the chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the main section, a tape is being played back.

3. In the deck section, a tape is being played back.

( ) indicates the record state.

4. In the power section, a tape is being played back.

5. In the CD section, the CD is stopped.

• Parts marked with “ “ ( ) are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the

set.

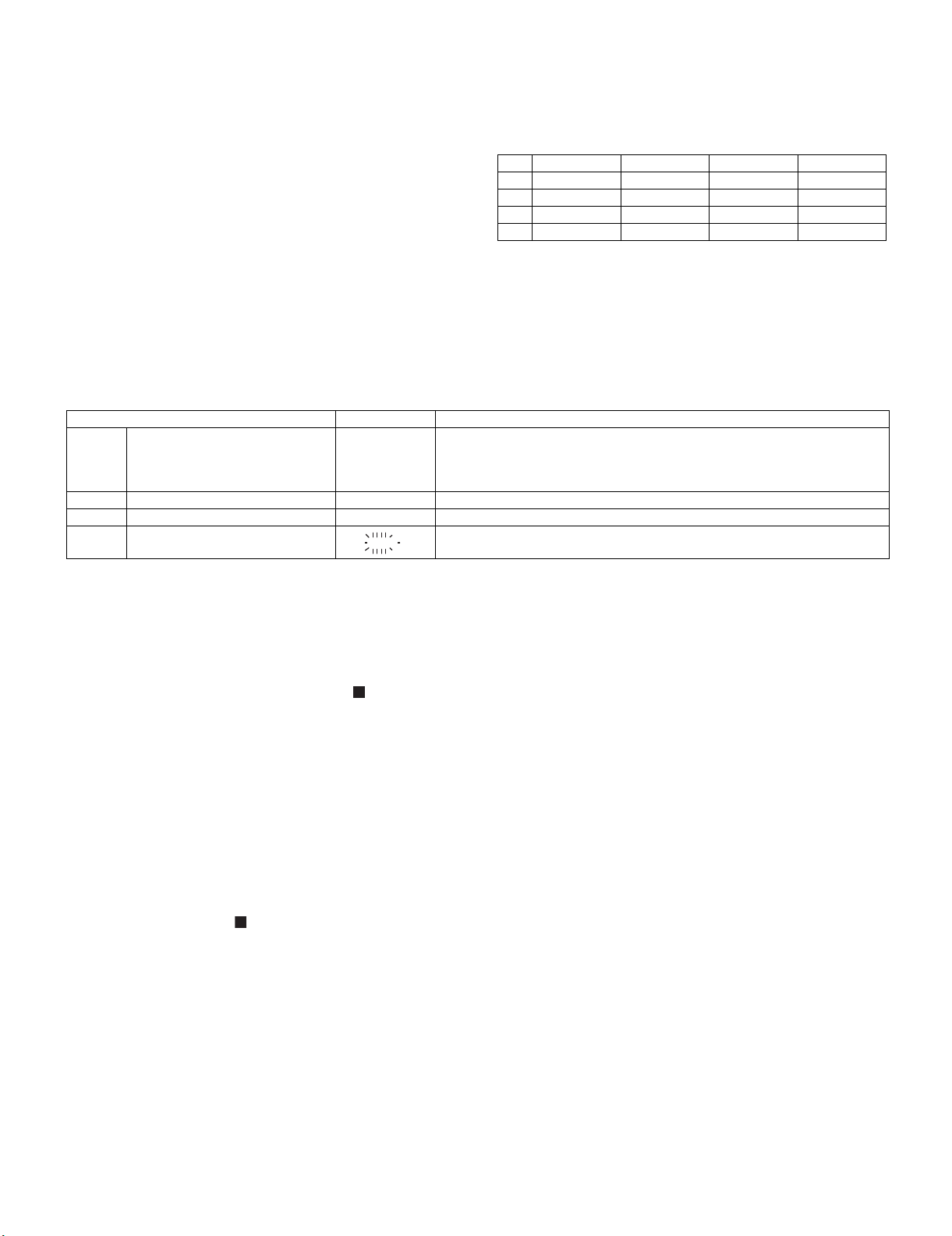

REF. NO DESCRIPTION POSITION

JOG701 VOLUME ON—OFF

NSW1 PICKUP IN ON—OFF

SW1 CLAMP ON—OFF

SW2 TRAY SW1 ON—OFF

SW3 TRAY SW2 ON—OFF

SW4 DISC ON—OFF

SW601 SPAN SELECTOR 100 kHz/

SW701 POWER ON/STAND-BY ON—OFF

SW702 CLOCK/TIMER ON—OFF

SW703 TUNING UP ON—OFF

SW704 TUNING DOWN ON—OFF

SW705 FAST REWIND/PRESET DOWN ON—OFF

SW706 EQUALIZER ON—OFF

SW707 FAST FORWARD/PRESET UP ON—OFF

SW708 REVERSE MODE ON—OFF

SW712 TUNER (BAND) ON—OFF

10 kHz

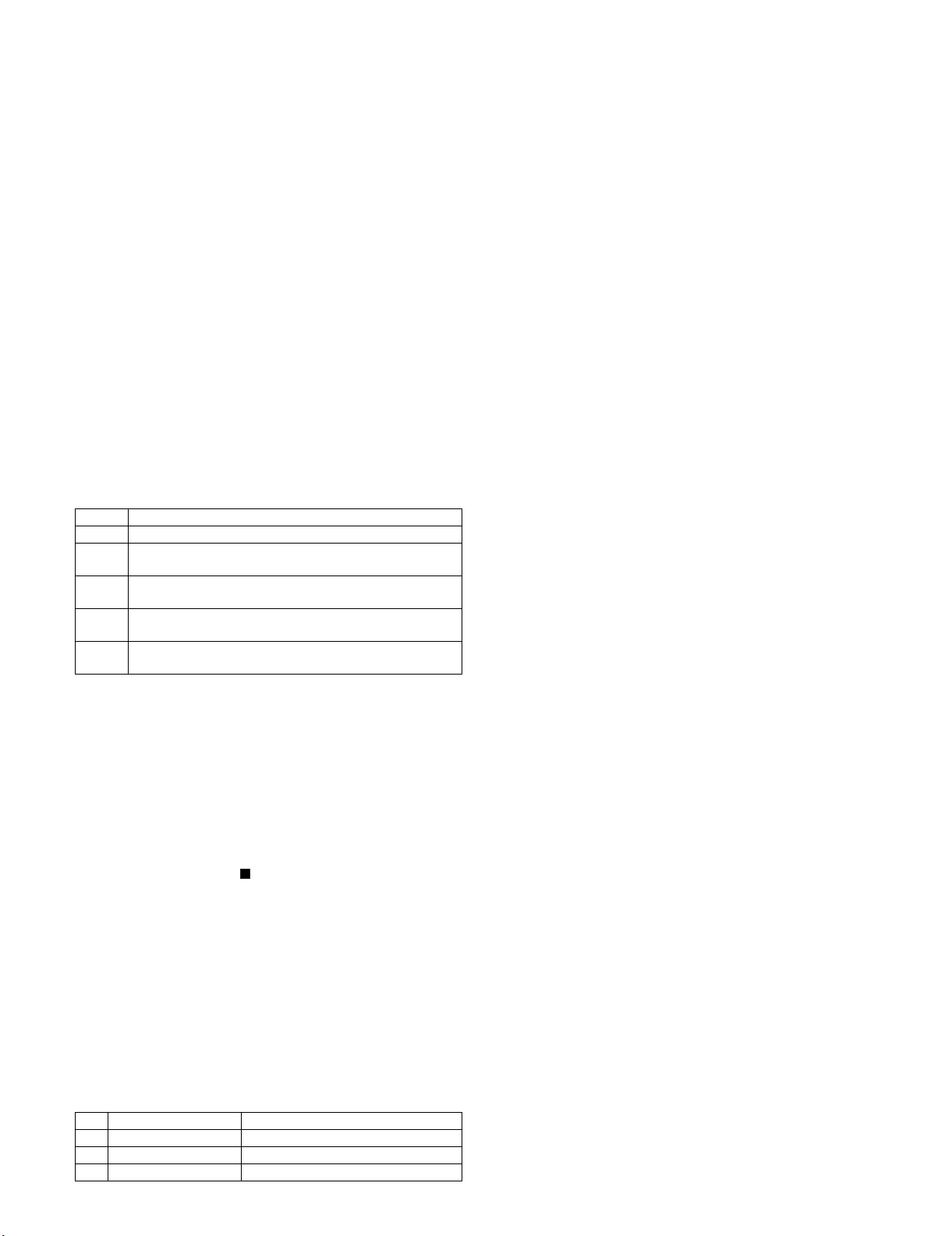

[2] Types of transistor and LED

FRONT

VIEW

ECB

(S)(G)(D)

(1)(2)(3)

KRC107 M

KTA1266 GR

KTC3265 Y

KTA1273 Y

KTA1274 Y

KTC3194 Y

KTC3199 GR

KTC3200 GR

KTC3203 Y

B

(3)

(1)

E

TOP

VIEW

KRA107 S

KRC102 S

KRC104 S

KTA1504 Y

KTA1298 Y

KTC3875 GR

2SB709 AR

2SD601 AR

(2)

REF. NO DESCRIPTION POSITION

SW713 CD ON—OFF

SW714 TAPE ON—OFF

SW715 GAME/VIDEO ON—OFF

SW716 X-BASS/DEMO ON—OFF

SW724 REVERSE PLAY ON—OFF

SW725 PLAY/REPEAT ON—OFF

SW726 STOP ON—OFF

SW727 REC/PAUSE ON—OFF

SW728 MEMORY/SET ON—OFF

SW729 OPEN/CLOSE ON—OFF

SW730 DIRECT PLAY ON—OFF

SW731 DISC2 ON—OFF

SW732 DISC4 ON—OFF

SW733 DISC5 ON—OFF

SW734 DISC3 ON—OFF

SW735 DISC1 ON—OFF

SW801 VOLTAGE SELECTOR 230-240 V

TOP VIEWTOP VIEW

C

FRONT

VIEW

DS1SS133

1N4004S

304VT2H3

SDPB50CD

FRONT

VIEW

5 – 1

AC AC

D10XB60F

Page 59

[3] Waveforms of DVD circuit

CD-DV999W/CD-DV777W

2003/10/16 13:19:45

Stopped

DVD_CS IN1

S_DIN2

Normal

20 MS/s 50 µs/div786

CH1 10:1

0.500 V/div

DC 10kHz

CH2 10:1

0.500 V/div

DC Full

CH3 10:1

0.500 V/div

DC Full

CH4 10:1

0.500 V/div

DC Full

S_DOUT3

Edge CH1

Auto

0.400 V

SCLK OUT4

SIMPLE

Level

1.000 V

5 – 2

Page 60

CD-DV999W/CD-DV777W

[4] Voltage

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

IC1

VOLTAGE

3.20 V

1.61V

1.61 V

1.60 V

1.61 V

3.08 V

1.65 V

1.65 V

1.65 V

1.65 V

1.48 V

0V

1.65 V

0V

1.65 V

1.47 V

1.48 V

0V

0V

0V

1.60 V

0V

1.61 V

1.61 V

0V

0V

3.20 V

0V

3.20 V

0V

0V

1.59 V

1.60 V

3.20 V

0V

0V

0V

0V

0V

0V

3.61 V

0V

0V

1.80 V

3.60 V

0V

1.45 V

1.49 V

3.19 V

3.79 V

0V

0V

0V

0V

0V

0V

0V

0V

0V

3.20 V

0V

0V

0.63 V

0V

5.16 V

5.18 V

4.68 V

0V

0V

0V

0V

0V

0V

4.86 V

4.86 V

3.01 V

0V

1.12 V

0V

3.20 V

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

IC2

VOLTAGE

2.10 V

2.20 V

2.10 V

2.20 V

2.10 V

2.20 V

0V

4.37 V

5.02 V

3.20 V

1.62 V

1.65 V

1.62 V

1.65 V

1.62 V

0V

1.62 V

1.64 V

4.71 V

4.71 V

3.92 V

3.11 V

3.10 V

2.50 V

1.65 V

0V

5.02 V

8.68 V

5.02 V

0.59 V

0.71 V

0V

0V

0V

2.11 V

2.20 V

IC101

VOLTAGE

0V

0V

0.57 V

2.03 V

0.44 V

0V

0V

0.58 V

3.45 V

3.35 V

0V

0V

6.97 V

4.16 V

0V

3.42 V

0.57 V

0V

0V

0.41 V

2.03 V

0.57 V

0V

0V

PIN

NO.

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

PIN

NO.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

IC301

VOLTAGE

0V

0V

0.29 V

0.20 V

0V

0.29 V

0.26 V

0.29 V

0.29 V

IC302

VOLTAGE

2.57 V

0V

0V

0V

0V

5.22 V

10.18 V

4.76 V

0V

0V

5.23 V

0V

5.23 V

0V

0V

2.59 V

5.24 V

0V

0V

10.18 V

0V

2.57 V

IC303

VOLTAGE

1.97 V

5.15 V

1.97 V

1.96 V

0V

0V

5.21 V

3.59 V

5.15 V

0V

2.01 V

1.25 V

2.27 V

1.13 V

1.10 V

1.96 V

0V