Page 1

q

SERVICE MANUAL

Digital copier

MODEL

CONTENTS

CODE : 00Z

ARSP6//A1E

Reverse Single

Pass Feeder (RSPF)

Single Pass Feeder (SPF)

AR-RP6

AR-SP6

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

[3] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . 4

[5] OPEREATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . 5

[6] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

[7] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 8

[8] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

[9] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts marked with "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales servic e only.

The contents are subject to change without notice.

Page 2

[1] PRODUCT OUTLINE

This machine is a duplex document auto feeder attached to a digital

copier.

It feeds originals automatically to allow continuous copying.

[2] SPECIFICATIONS

AR-RP6 AR-SP6

Document set direction Face up

Document set position Right/Center reference

Document transport

system

Document feed sequence Top take-up feed

Document size AB series: A3 ~ A5

Document weight 56 ~ 90g/m

Document set quantity Max. 40 sheets (Stack range: within 4mm)

Dimensions 583mm (W) x 435mm (D) x 133mm (H)

Weight About 5.4 kg About 5.0 kg

Power source S up p l i ed f r o m th e

Power consumption 26.4W 21W

Document size detection On the document feed tray

Detection size Japan: A3, B4, A4, A4R, B5, B5R,

Mixture of different

document sizes

Document reverse Allowed

Display section (LED) None

Document exchange

speed

Sheet through type

Inch series: 11 x 17 ~ 8.5 x 5.5

2

, 15 ~ 24lbs

2

: Set capacity = 30 sheets)

(90g/m

copier. (DC 24V)

Inch series: 11 x 17, 8.5 x 14, 8.5 x 11,

EX AB series: A3, B4, A4, A 4R, A 5 , B5,

Mixture paper feed: Not available

Random paper feed: Not available

(without 8.5 x 5.5)

S 3 S, 16 sheets/min (AR-160M)

S 3 S, 20 sheets/min (AR-200M)

Supplied from the

copier. (DC 24V, 5V)

A5

8.5 x 11R, 8.5 x 5.5

B5R, A5R

Not allowed

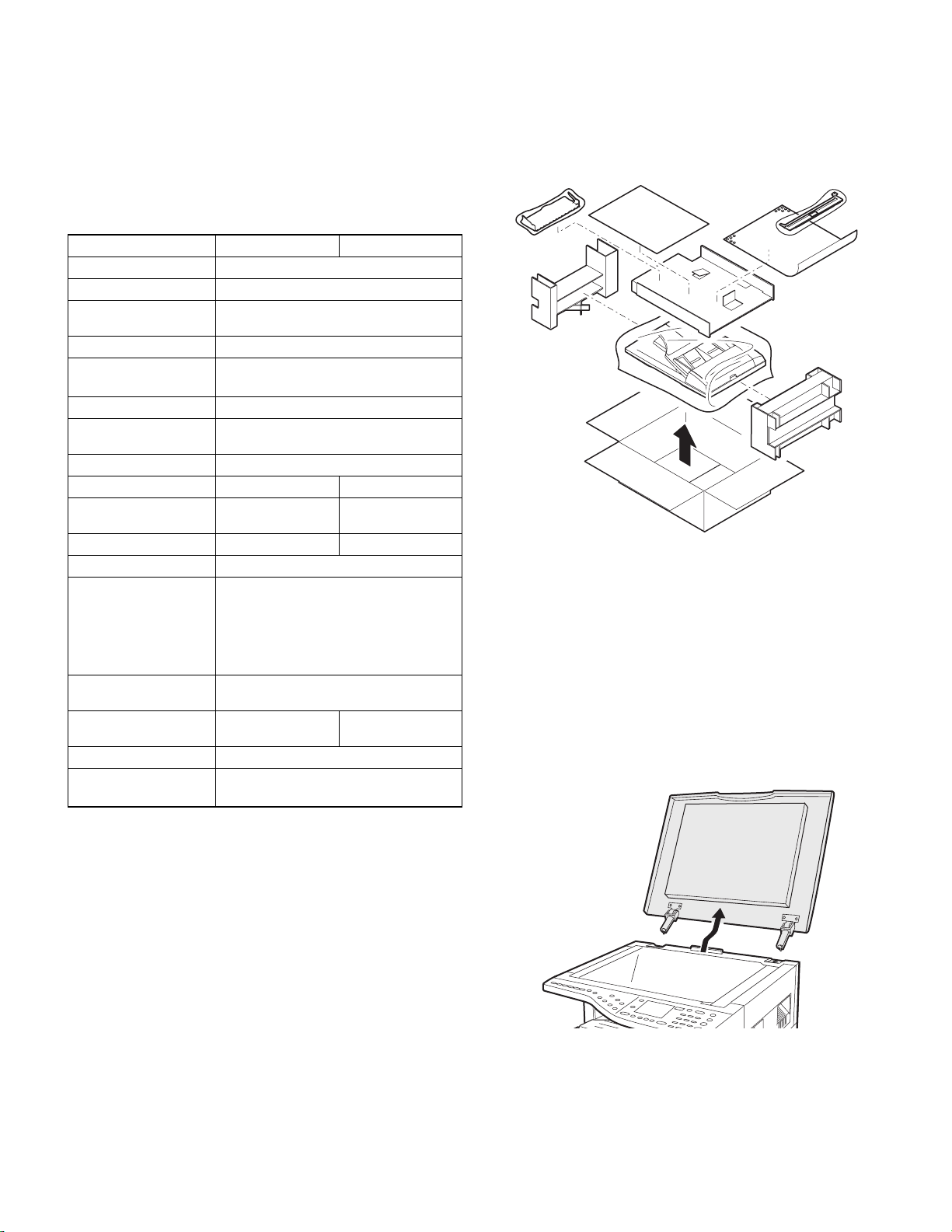

[3] UNPACKING AND INSTALLATION

1. Unpacking

For unpacking, refer to the figure below.

2. Installation

Turn the main switch of the copier to the “OFF” position and then

remove the power plug of the copier from the outlet.

1. Remove th e document cover.

Lift the document cover from the copier and tilt it to the rear side to

remove it.

AR-SP6/RP6 PRODUCT OUTLINE

– 1 –

Page 3

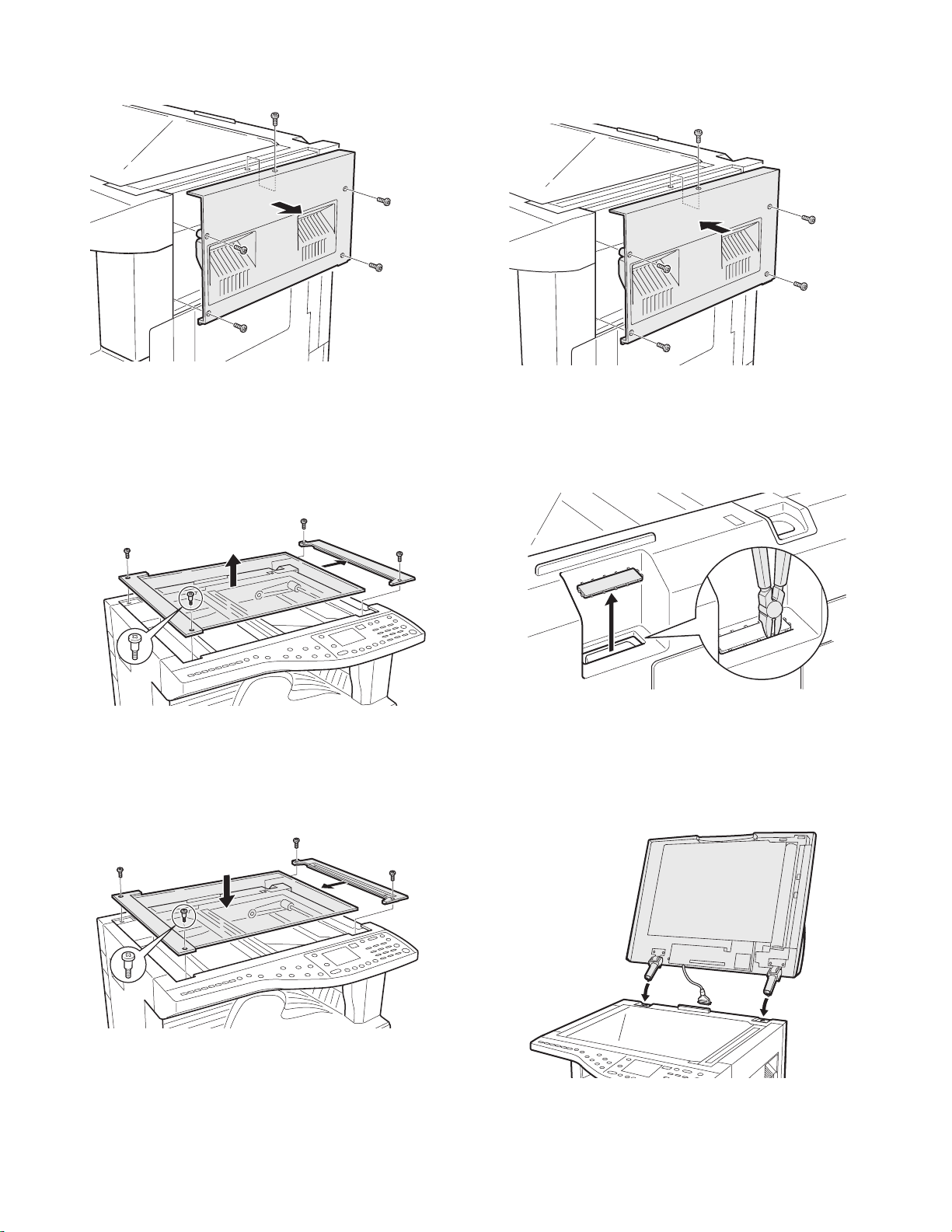

2. Remove the right cabinet.

Remove the screws and remove the right cabinet.

5. Attach the right cabinet.

Reattach the right cabinet to its original position and fix it with the

screws.

3. Remove the document glass and the right document

glass holder.

Remove the screws, remove the document glass from the copier, and

then remove the right document glass holder.

4. Attach the SPF glass holder.

Fit the SPF glass holder to the document glass.

Attach the document glass to the copier and fix it with the screws.

6. Cut out the cut-out portion.

Cut out the cut-out portion of the rear cabinet with nippers or the like.

At this time, be careful about the orientation of the nippers so that the

cut plane of the rear cabinet is flat.

7. Attach the automatic document feeder.

Insert the hinge portions of the document feeder into the mounting portions of the copier by holding the feeder at an angle toward the rear

side.

AR-SP6/RP6 UNPACKING AND INSTALLATION

– 2 –

Page 4

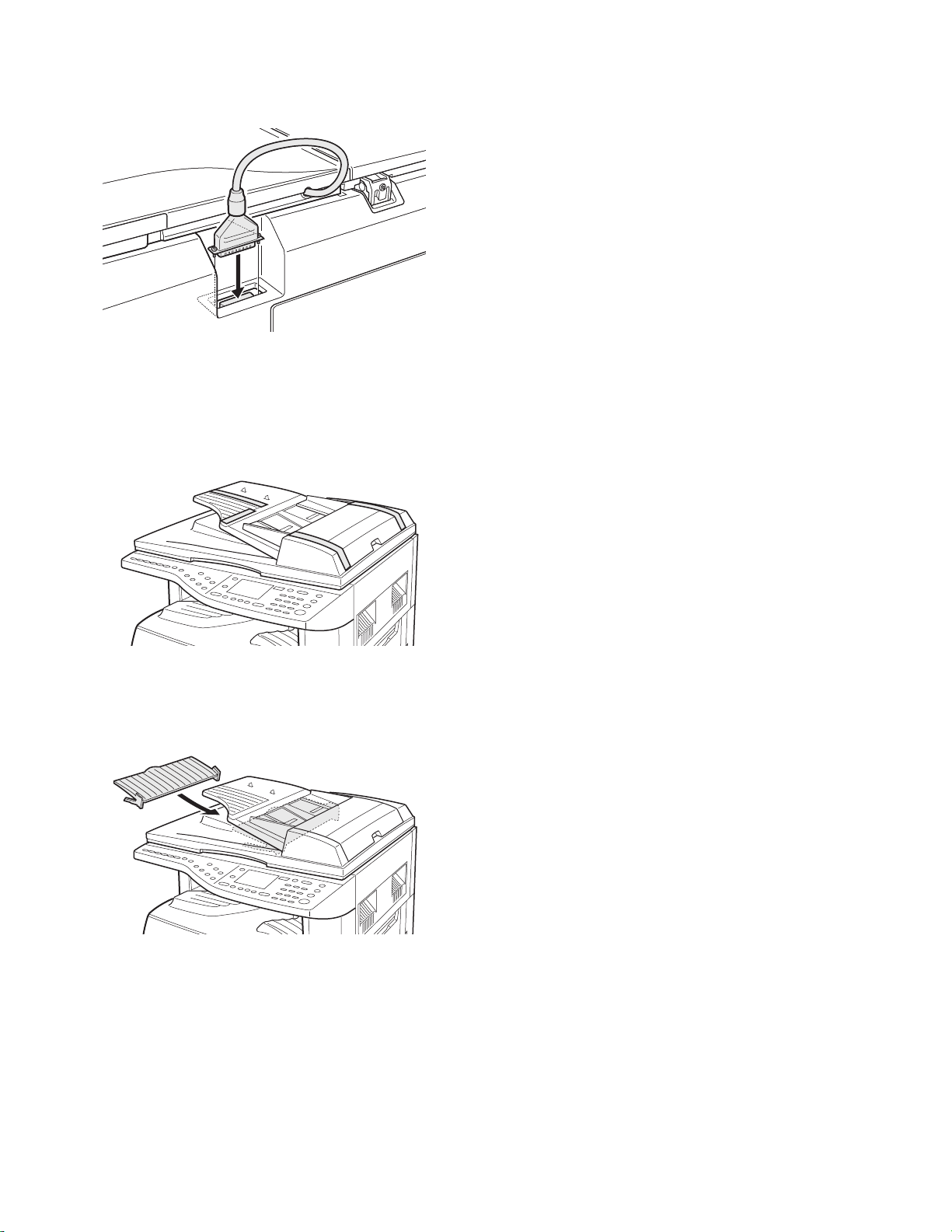

8. Connect the relay connector.

Connect the harness of the automatic document feeder to the connector of the copier and tighten the screws on the connector.

9. Remove the filament tape.

Remove the filament tape located in the positions shown in the illustration.

Insert the power plug of the copier to the outl et and turn on

the main switch of the copier.

11. Adjust the white compensation pixels.

• Open the automatic document feeder, execute simulation 63-7 referring to the service manual, and adjust the automatic white compensation pixels of the document feeder.

12. Check the copy magnification ratio.

• Set an original on the document glass and copy it.

Then, set an original in the document feeder tray and copy it.

• If the magnification ratio of the copy from the document feeder is different from that of the copy from the document glass, execute simulation 48-5 to carry out adjustment referring to the service manual.

13. Check the center displacement.

• Set an original on the document glass and copy it.

Then, set an original in the document feeder tray and copy it.

• If the center of the copy image from the document feeder is different

from that of the copy image from the document glass, execute simulation 50-12 to carry out adjustment referring to the service manual.

14. Check the top end position.

• Set an original on the document glass and copy it.

Then, set an original in the document feeder tray and copy it.

• If the top end position of the copy image from the document feeder is

different from that of the copy image from the document glass, execute simulation 50-06 to carry out adjustment referring to the service

manual.

10. Attach the intermediate tray. (AR-RP6 only)

Insert the intermediate tray all the way into the document feeder.

AR-SP6/RP6 UNPACKING AND INSTALLATION

– 3 –

Page 5

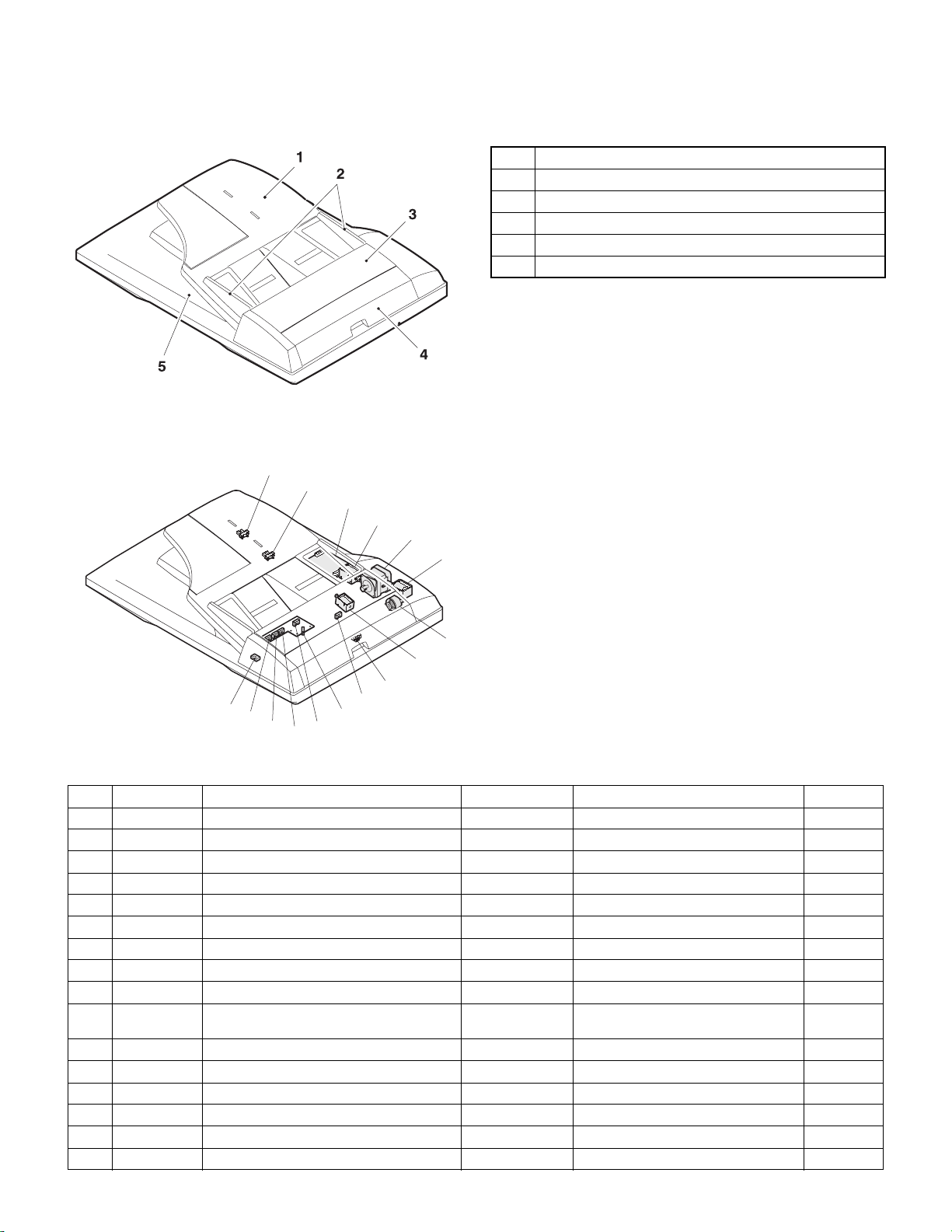

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

No. Name

1 Document set tray

2 Document guide

3 Document feed section cover

4 Document transport section cover

5 Document exit section

2. Internal structure

14

13

12

11

10

8

9

6

7

15

5

4

3

16

2

1

Sensor, detector, etc.

No. Code Name Type Function/Operation Note

1 W0 Document set sensor Photo transmission Detects presence of documents.

2 COVER Open/close sensor Photo transmission Detects open/close of the paper feed unit.

3 W1 Document width sensor (A4R, LTR, A5) Photo transmission Detects the document width on the tray.

4 W2 Document width sensor (B4, B5) Photo transmission Detects the document width on the tray.

5 W3 Document width sensor (WL, TR, A5R, A4, LT) Photo transmission Detects the document width on the tray.

6 PSOL Pickup solenoid — —

7 PAPER Paper entry sensor Photo transmission Detects presence of documents.

8 RSOL Pressure release solenoid — — AR-RP6 only

9 CLH Transport clutch — —

10 MOT SPF (RSPF) motor Stepping motor Drives document feed on the tray, trans-

11 GSOL Gate solenoid — — AR-RP6 only

12 — Interface PWB — —

13 L1 Document length detection SW (Short) Photo transmission Detects the document length on the tray.

14 L2 Document length detection SW (Long) Photo transmission Detects the document length on the tray.

15 COVER OPEN Book sensor Photo transmission Detects the SPF (RSPF) float.

16 PO Paper exit sensor Photo transmission Detects presence of documents.

port, and paper exit roller.

AR-SP6/RP6 EXTERNAL VIEW AND INTERNAL STRUCTURE

– 4 –

Page 6

[5] OPEREATIONAL DESCRIPTIONS

1. Major parts of the paper feed section 2. Out line of operations

1 2 3,4 5 6 7 8

12

No. Part name Operation Note

1 Document length

sensor (L2)

2 Document length

sensor (L1)

3 Document set

sensor (W0)

4 Document width

sensor (W1, W2, W3)

5 Pickup roller Picks up documents.

6 Paper feed roller Feeds and transports docu-

7 Paper entry sensor

(PAPER)

8 PS roller Makes synchronization

9 PS follower roller Makes synchronization

10 Transport roller Transports documents.

11 Transport follower

roller

12 Paper exit sensor

(PO)

13 Paper exit follower

roller

14 Paper exit roller Discharges documents.

15 Reverse gate Opens/closes the document

16 Paper exit gate Separate document exit to the

17 Intermediate tray Discharges documents to the

Detects the document length

on the tray.

Detects the document length

on the tray.

Detects presence of documents.

Detects the document width.

ments.

Detects transport of docu-

ments.

between the document lead

edge and the image lead edge.

between the document lead

edge and the image lead edge.

Transports documents.

Detects transport of documents.

Discharges documents.

reverse path.

intermediate or the paper exit

tray.

intermediate tray during document reverse.

AR-RP6

only

AR-RP6

only

910111314 151617

■AR-RP6 (RSPF)

[Duplex documents]

1) Document set (Document set sensor ON)

4

2) Document size detection (Document width sensors W1, W2, W3

detect the document width, and document length sensors L1, L2 detect the

document length.)

4

3) Copier COPY key ON

4

4) RSPF motor ON

4

5) Pickup solenoid ON

4

6) Pickup roller and paper feed roller rotation

4

7) Paper entry sensor detects the document presence.

4

8) PS roller rotation

4

9) Copying (Front surface of document)

4

10) Transport roller rotation

4

11) Paper exit roller rotation

4

12) Paper exit gate falls down.

(Documents are discharged to the intermediate tray.)

4

13) Reverse gate falls down.

4

14) Paper exit roller reverse rotation

(Documents are fed to the reverse path.)

4

15) Paper entry sensor detects document presence.

4

16) PS roller rotation

4

17) Copying (Back surface of document)

4

18) Transport roller rotation

4

19) Paper exit roller rotation

4

20) Paper exit gate falls down

(Documents are discharged to the intermediate tray.)

4

21) Reverse gate falls down.

4

22) Paper exit roller reverse rotation

(Documents are fed to the reverse path.)

4

23) Paper entry sensor detects document presence.

4

24) PS roller rotation

4

25) Paper exit roller rotation

4

26) Paper exit gate lifts up.

4

27) Documents are fed to the paper exit tray.

4

28) Next document 3 (YES) 3 Go to 4).

4 (NO)

29) RSPF motor OFF

AR-SP6/RP6 OPEREATIONAL DESCRIPTIONS

– 5 –

Page 7

■AR-SP6 (SPF)

3. Document size detection

1) Document set (Document set sensor ON)

4

2) Document size detection (Document width sensors W1,

W2, W3 detect the document

width, and document length sensors L1, L2 detect the document

length.)

4

3) Copier COPY key ON

4

4) SPF motor ON

4

5) Pickup solenoid ON

4

6) Pickup roller and paper feed roller rotation

4

7) Paper entry sensor detects the document presence.

4

8) PS roller rotation

4

9) Copying (Front surface of document)

4

10) Transport roller rotation

4

11) Paper exit roller rotation

4

12) Documents are fed to the paper exit tray.

4

13) Next document 3 (YES) 3 Go to 4).

4 (NO)

14) SPF motor OFF

1) Document size detection with the document set tray

When documents are set on the document set tray in the auto selection

mode of paper/copy magnification ratio, the document size is detected

and paper and the copy magnification ratio are automatically selected.

When different sizes of documents are set, the max. size is detected.

The document width is detected by the document width sensors (W1,

W2, W3), and the document length is detected by the document length

sensors (L1, L2) to identify the document size. Judgement of the document size is made in a certain timing after detecting the document w ith

the document set sensor (W0).

Document

length sensor

AB series

Inch

series

Document set

size and set

direction

A5 onnnn

B5 oonnn

A5R nnnnn

A4 ooonn

B5R nnnon

A4R onnon

8.5” x 13” onnoo

B4 onnoo

A3 ooooo

8.5” x 5.5” onnnn

8.5” x 5.5”R nnnnn

11” x 8.5” ooonn

11” x 8.5”R onnon

8.5” x 13” onnoo

8.5” x 14” onnoo

11” x 17” ooooo

Document width sensor

W1 W2 W3 L1 L2

Note: Detection sensor ON: o, OFF: n

AR-SP6/RP6 OPEREATIONAL DESCRIPTIONS

– 6 –

Page 8

[6] ADJUSTMENTS

(1) Auto white correction pixel adjustment

[Function]

The white correction start pixel position is automatically adjusted.

This adjustment is performed after the lens unit is replaced.

[Operation]

Open the SPF (RSPF) unit and press the [OK] key.

7-segment indicates the order number of the pixel of the white sheet for SPF (RSPF)

exposure correction in the SPF (RSPF) position.

It will display on 7-segment, if values are 93-299, and data are written into the EEPROM.

It will display on 7-segment, it values are 0-92 or 230-999, and data are not written into

the EEPROM.

It will display "--" on 7-segment, it values is 1000 or larger, and data are not written into

the EEPROM..

[CA] key: Cancels the test command.

[Interruption] key: Shifts to the sub code entry menu.

The SPF white correction start pixel = Displayed pixel position - 34

Interruption is inhibited during execution.

If the simulation is executed with the SPF unit closed, an error is resulted.

During execution,"EXEC" is highlighted

(2) Magnification ratio adjustment

Note: • When performing this adjustment, check that the CCD unit is

properly installed.

• When performing this adjustment, check that the OC mode

adjustment in copying is completed.

1) Place a scale on the document table as shown be low, and make a

normal copy to make a test chart.

(3) Document off center adjustment

Note: When performing this adjustment, check that the paper off-cen-

ter is properly adjusted.

1) Set the center position adjustment test chart (made by yourself) on

the SPF (RSPF).

<Adjustment specifications>

Draw a line in the center of paper. (In the scanning direction)

2) Make a normal copy from the manual feed tray, and co mpare the

copy and the test chart.

If an adjustment is required, perform the following procedures.

3) Execute SIM 50-12.

4) The current off-center adjustment value is displayed on the display

section in two digits.

5) Enter the set value and press the START key.

The entered correction value is started and a copy is made.

<Adjustment specifications>

Mode Specification SIM Set value

Document

off-center

(AR-RP6)

Document

off-center

(AR-SP6)

Simplex:

Center

Duplex:

Center

m

m

3.0mm

3.5mm

SIM 50-12

TEXT:

SPF surface

PHOTO:

SPF back

AE: Surface

TEXT: Back

Add 1:

0.1mm shifted to

R side.

Reduce 1:

0.1mm shifted to

L side.

Set

range

1 ~ 99

(4) Image lead edge position adjustme nt

1) Set a scale on the OC table as shown below.

Note: Since the printed paper is used as the test chart,

place the scale in parallel to both sides.

2) Set the test chart to the SPF (RSPF) and make a normal copy.

3) Compare the copy and the test chart.

If an adjustment is needed, perform the following procedures.

4) Execute SIM 48-5.

5) The current correction value is displayed on the display section in

two digits.

6) Enter the set value, and press the START key.

The entered correction value is stored and a copy is made.

7) Change the TEXT mode.

The TEXT lamp lights up, and the current correction value of the

back surface sub scanning direction magnification ratio is displayed

on the display section in two digits.

8) Enter the set value, and press the START key.

The entered correction value is stored and a copy is made.

<Adjustment specifications>

Mode Spec SIM Set value

Magnification

ratio adjustment

Normal:

m 1.0%

SIM 48-5

AE: Surface

TEXT: Back

Add 1:

Reduce 1:

0.1% increase

0.1% decrease

Set

range

1 ~ 99

Note: Since the printed paper is used as the test chart,

place the scale in parallel to both sides.

2) Make a copy, and use the copied paper as the document and make

a copy from SPF (RSPF) again.

3) Check the copied paper. If an adjustment is required, perform the

following procedures.

4) Execute SIM 50-6.

5) Set the SPF/RSPF lead edge position set value so that the image

similar to the adjusted image at the OC image lead edge position

described previously is printed.

<Adjustment specifications>

Adjustment

mode

Image

lead edge

position

SIM Set value Specification

SIM 50-6 1step: 0.1mm shift Lead edge void:

1 ~ 4mm

Image loss:

Set

range

1 ~ 99

3mm or less

AR-SP6/RP6 ADJUSTMENTS

– 7 –

Page 9

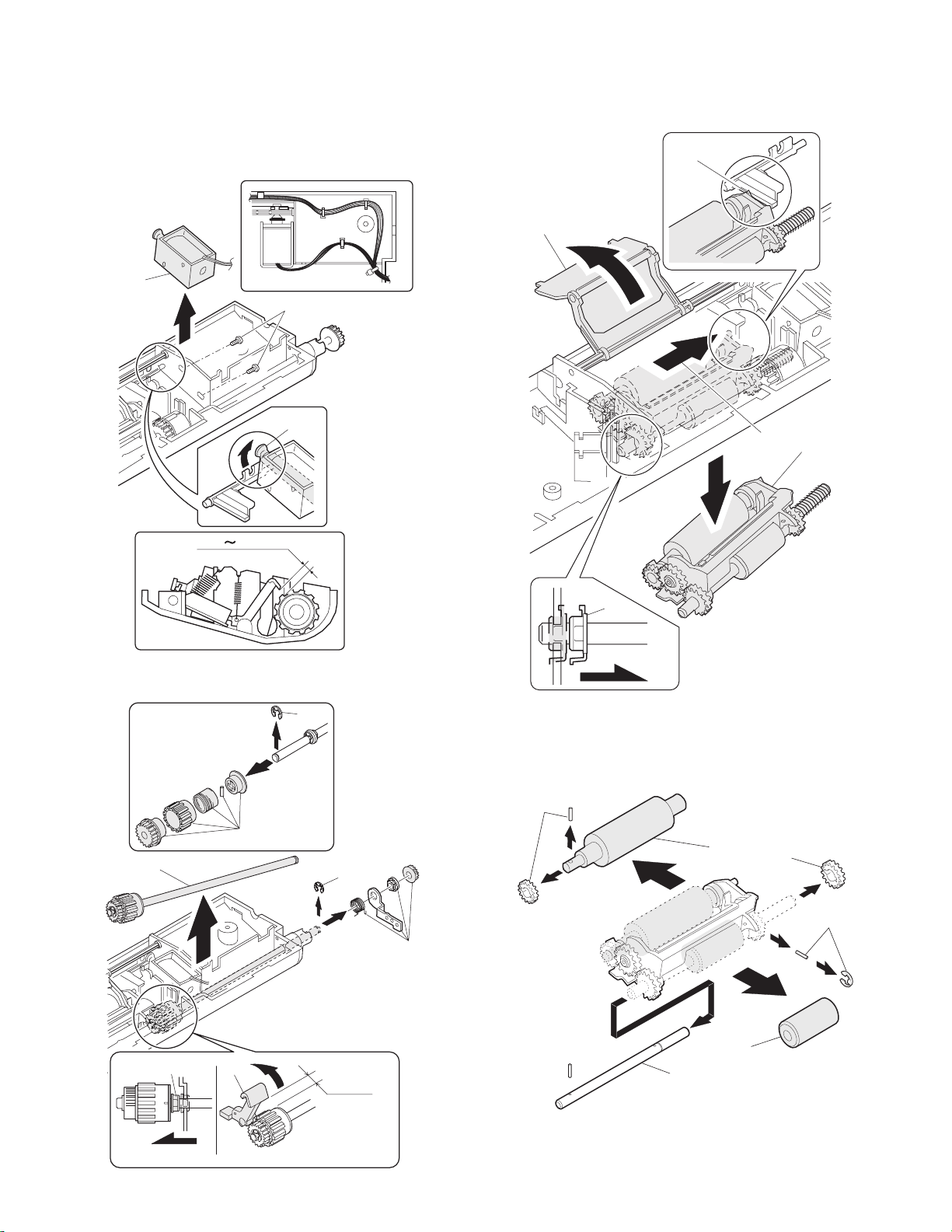

[7] DISASSEMBLY AND ASSEMBLY

1. External fitting section

Note: Turn the paw in the arrow direction.

3

2) Document feed section cover

2

2

1

1

1

2

3) Sensor PWB

1

2. Paper feed unit section

1) Paper feed unit

3

4

2

2

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 8 –

Page 10

4) Pickup solenoid

Note: Remove section A of the pickup solenoid from the solenoid arm

groove.

When assembling, adjust the spacing between the clutch latch

and sleeve with the pick-up solenoid pulled. The size should be

the distance from the tip of the clutch latch and the root of the

clutch sleeve latch.

2

1

A

6) Pickup roller ass’y

Note: When assembling the pickup roller ass’y 4, check that rib A is on

the rib of the solenoid arm.

A

1

2

4

2.5 4.5mm

5) Clutch gear ass’y

5

3

6

7) Pick up roller, paper feed roller

4

6

1

2

3

1

1

3

4

From Edge pawl

2.5~4.0

1

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 9 –

2

Page 11

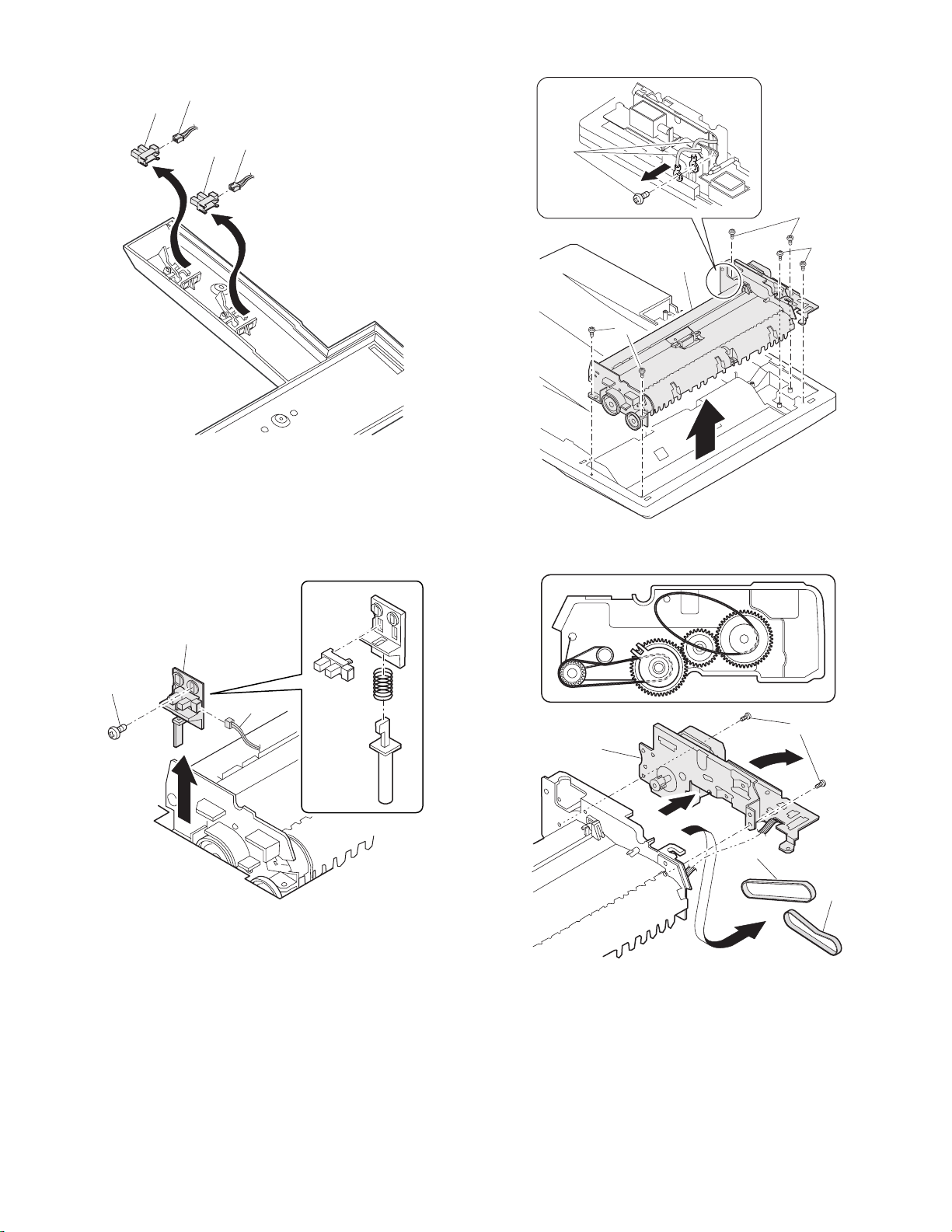

3. Interface PWB

5. Document tray section

1

1) Document tray

1

2

A

2

3

1

B

1

B

1

A

2) Rack cover

■■■■AR-RP6

1

1

1

4. Gate solenoid

■■■■AR-RP6 only

2

1

Bearing

■■■■AR-SP6

1

1

1

2

Note: When assembling, check that the paper exit gate hook is set in

the solenoid groove.

When assembling, the bearing D-cut surface shuold be faced

down.

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 10 –

Page 12

3) Document length sensor SW

2

1

2

1

2) Drive frame unit

1

1

1

2

1

6. Drive frame section

1) Book sensor

2

1

3) Drive frame ass’y and drive belt

3

1

2

3

4

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 11 –

Page 13

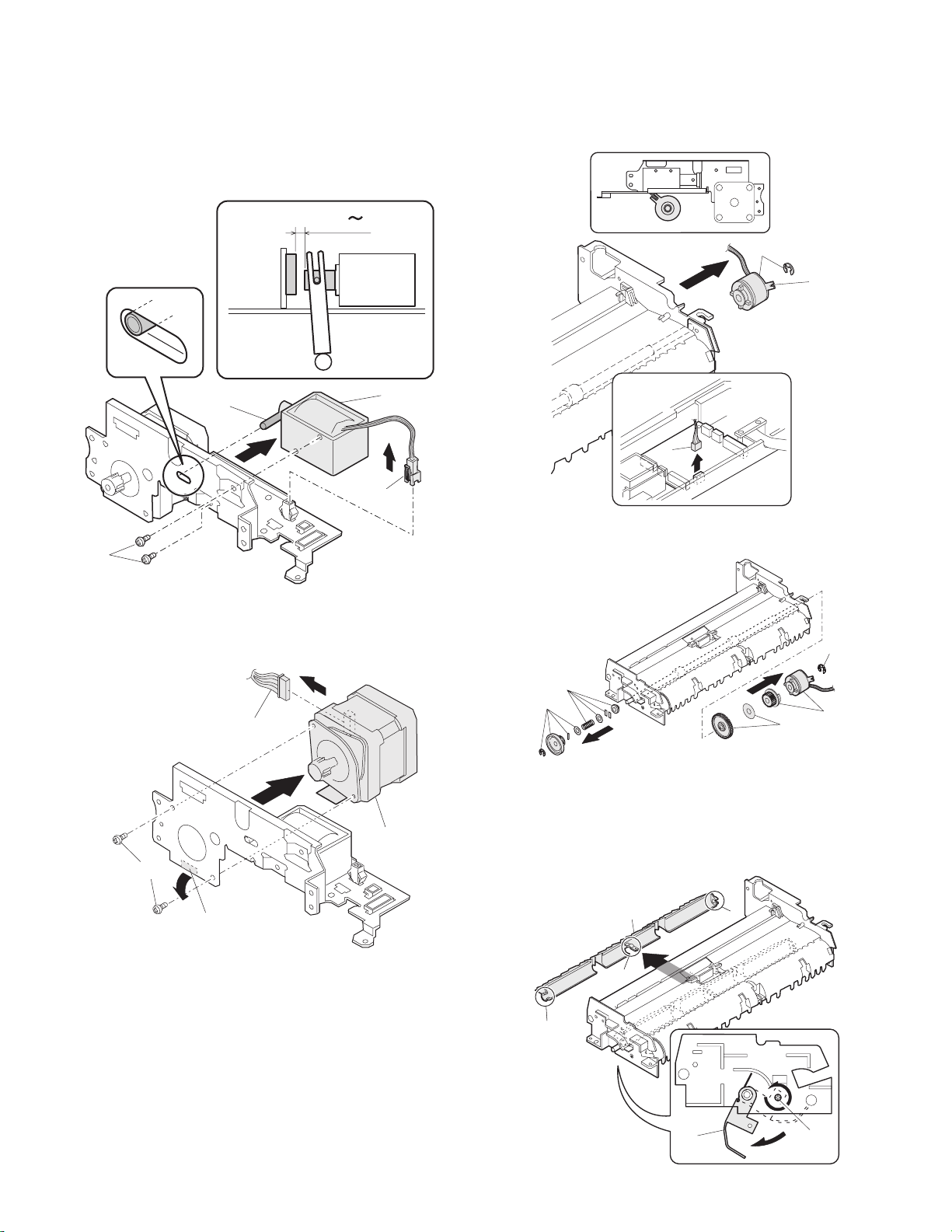

4) Pressure release solenoid

■■■■AR-RP6 only

Note: Make sure the spring pin A is inserted into the slot.

Make sure that the clearance between the position at which force

is applied and the sound deadening sponge is 0.5 ~ 2 mm when

the pressure release solenoid plunger is pulled toward the solenoid side.

0.5 2mm

7. Transport section

1) Clutch

Note: When assembling, check that the rib is in the clutch groove A

and fix it with E-ring.

2

A

A

2

5) RSPF motor / SPF motor

1

3

3

1

1

2) Transport roller gear

1

1

1

3) Reverse gate

■■■■AR-RP6 only

4

Note: When assembling the inversion gate, apply grease G-484 on the

area A.

1

1

2

A

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 12 –

3

A

A

2

1

Page 14

4) Transport roller

Note: Note that the spring will come off when removing.

■■■■AR-RP6

5) PS roller

1

1

1

■■■■AR-SP6

1

2

1

1

6) Paper feed paper guide lower

Note: When assembling, check that the paper feed paper guide lower

is securely set to rib A and boss B.

+

1mm

-

0 0.5mm

2

1

1

1

AR-SP6/RP6 DI SASSEMBLY AND ASSEMBLY

– 13 –

B

1

A

Page 15

7) Paper feed paper guide upper

[8] MAINTENANCE

1

8) Paper exit roller

2

1

1. Maintenance parts

No. Name Work item Service call Remark

1 Pickup roller Cleaning o

2-1 Separation unit Cleaning o Replace when

2-2 Front separation

sheet

3 Paper feed roller Cleaning o

4 PS roller Cleaning o

5 Transport roller Cleaning o

6 Paper exit roller Cleaning o

Cleaning o

1

worn down.

3

1

2

8. Hinge L

Note: When assembling the hinge L, reference is based on the mark of

base tray and the center line of the 5 lines of the hinge L

extended horizontally.

1

1

2

1

2-2

2-1

6

5

4

Note: When performing maintenance, refer to [7] DISASSEMBLY AND

ASSEMBLY.

AR-SP6/RP6 MAINTENANCE

– 14 –

Page 16

D

1

SENSOR

5V

C

B

SOL/CLU

A

RSPF ONLY

5V

5V

24V

24V

5V

24V

24V

24V

24V

24V

234

L2

L1

W0W1W2

SPF SENSOR PWB

W3

PAPER

/SPFOUT

SPFOPEN

/CLH

/PSOL

/RSOL

/GSOL

MOTOR

(A,B,/A,/B)

2 1

/SPFCOVER

3

5

DATA

SELECTOR

5V

TRANSISTOR

24V

ARRAY

MOTOR

DRIVER

5 4

SPF/RSPF INTERFACE PWB

678

7 6

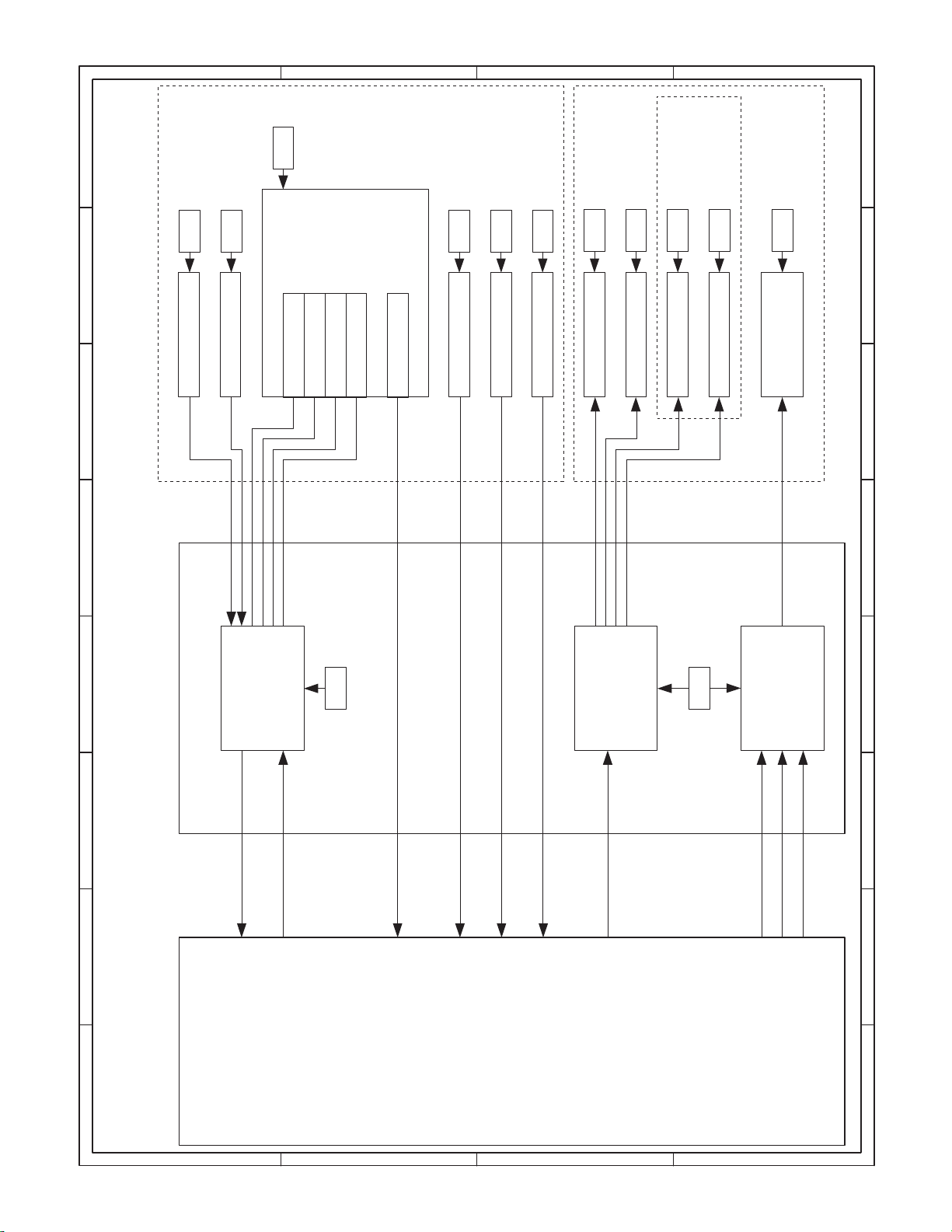

[9] ELECTRICAL SECTION

1. Block diagram

PEGASUS

(MCU PWB)

D

YSPF

/SPFCOVER

SEL(A#,B#,C#)

C

AR-SP6/RP6 ELECTRICAL SECTION

PAPER

– 15 –

/SPFOUT

SPFOPEN

SPF(CLH,PSOL,RSOL,GSOL)

B

/MODA,/MODB)

SPF(MODA,MODB,

A

PDOWNA

PDOWNB

8

Page 17

D

C

B

A

12345678

DSPF ONLY

ORIGINAL TRAY

Sensor PWB

PAPER FEED UNIT

W0

5v

1

2

BL

OR

W2

W1

4

3

PLBRLB

W3

5

SPFCOVER

SGND7

6

GY

PK

SPFPSOL

L1

321

ORLBGY

L2

321

ORGYBL

PAPER

(Paper Entry Sensor)

213

GYBRPL

SPFRSOL

SPFGSOL

A

3

1

BLLBPK

/B2/A

PLUSE MOTOR

4B

PLRDRD

24V1624V1

5

2 1

PHR-7

BLORPLBRLBGYPK

2

3

5V

W1

W0 17

BU7P-TR-P-H

6

5

BLORPLBRLBGYPK

PHDR-20

BLORPLBRLBGYPK

7

1

5

5VW0W1

CN6

B20B-PHDSS

PHR-3

DF3-3S-2C

ORLBGY

PHNR-7-HPHNR-7-H

SGND 71

SPFCOVER 62

W3 53

W2 44

1

2

SPFPSOL

24V1

BU2P-TR-P-H

2

1

BL

RD

PHNR-2-H

BU6P-TR-P-H

2

L1

5V 16

5

ORLBGY

3

SGND

4

ORGYBL

5V 43

ORGYBL

PHNR-2-H

BL

RD

9

20314

SGND

W2

W3

SPFCOVER

11

/PSOL 6

24V1

ORLBGY

2

15

L1

5V

16

SGND

ORGYBL

45V

DF3-3S-2C

PHNR-6-HPHNR-6-H

SGND 61

L2 52

1

SPFRSOL

1

LB

2

SMR-02V-N(JST)

24V1

2

RD

SMP-02V-BC(JST)

GYBRPL

17SGND

L2 13

18SGND

pull up 8

LB

19PAPER

PHR-2

RD

CN4

B2B-PH-K-S

2/GSOL

24V1 1

1224V1

/RSOL 10

PHR-6

PHR-7

BLLBPK

CN3

B7B-PH-K-S

3

PL

RD

RD

3/B

2/A

5N.C.

4B

1A

624V1

724V1

2. Actual wiring diagram

PAPER

1

CN5

B26B-PHDSS

25

PAPER

MCU PWB Interface PWB

/SPFCOVER

SELA#

3

2

20

16

/SPFCOVER

SELA#

D

SPFMODB

SELB#

5

4

17

SPFMODB

SELB#

/SPFMODB

SELC#

3 7 6

/SPFMODB

SELC#

N.C.6SGND

SGND7YSPF

9108

12

13-18

N.C.

SGND

SGND

11

15

YSPF

SPFOPEN

5V

12

13

24

SPFOPEN

5V

SPFGSOL

SPFMODA

15

16

22

5

SPFGSOL

SPFMODA

/SPFMODA

SPFRSOL

181719

4 921

/SPFMODA

SPFRSOL

SPFCLH

SPFCLH

PDOWNA

PDOWNA

/SPFOUT

14

19

/SPFOUT

C

AR-SP6/RP6 ELECTRICAL SECTION

PDOWNB

SPFPSOL

212220

1023 8

PDOWNB

SPFPSOL

– 16 –

PGND

23

11

PGND

PGND

24

14

PGND

SPF0PEN2

SGND

N.C.2

24V1

24V

24V

25

26

CN7

1

B3B-PH-K-S

/CLH

3

CN1

BL

FG

PHR-3

SRA-21T-4

SRA-21T-4SRA-21T-4

BL BL

BL

1

2

26

FG

24V

24V

SPFCLH

5V

3

1

B3B-PH-K-R(RD)

GY

OR

BRBR

PHR-3(RD)

DF3-3S-2C

GY

OR

123

/SPFOUT2

SGND

1

CN2

B3B-PH-K-K(BK)

GR

GY

PHR-3(BK)

DF3-3S-2C

GYORGR

123

5V

3

OR

EARTH PLATE(SPF ONLY)

8 7 6 5 4

SPFOPEN

(Book Sensor)

B

/SPFOUT

(Paper Exit Sensor)

A

Page 18

D

CN2-6 (B3)

CN6-3 (B2)

CN2-10 (B3)

CN3-3 (A2)

C

B

A

12345678

/CLH

/RSOL

/GSOL

/PSOL

24V1

C115

0.047u/50V

C114

0.047u/50V

5V

1C2C3C4C5C6C7C

1B2B3B4B5B6B7B

IC2

SPFCLH

SPFPSOL

(A4) CN1-21

(A4) CN1-19

IC101

COM

GND

TD62003AP

SPFRSOL

SPFGSOL

(A4) CN1-17

(A4) CN1-15

CN1-11 (A4)

YSPF

ZD102

UDZ5.6

C120

0.1u/25V

Y

W

VCC

D0D1D2D3D4D5D6D7ABC

GND

CN7-4 (B2)

CN7-3 (A2)

CN7-2 (B3)

CN7-1 (B3)

CN7-6,7 (B3)

BA/B

/A

2 1

Pattern width: 0.5mm or above

C1

47u/35V

3

C104

R107

R101

C107

0.047u/50V

24V1

7.5KJ

C113

7.5KJ

2200pF/50V

2200pF/

50V

C110

C103

3300pF/50V

0.047u/50V

IC1

R104

C108

0.1uF/25V

1KJ

Vmm

CrA

CrB

R102 2.4k

OUT A

VsA

R1 1.5(1W)

OUT B

RsA

OUT /A

VrefA

NCNCNCNCNCNCPG

OUT /B

VrefB

RsB

VsB

In /A

In A

R105

R2 1.5(1W)

R106 2.4k

In /B

1KJ

C112

LG

PG

PG

In B

0.1uF/25V

C111

MTD1361

3300pF/50V

/SPFMODB

/SPFMODA

SPFMODA

(C4) CN1-6

(C4) CN1-16

(C4) CN1-18

Pattern width: 1.0mm or above

SPFMODB

(C4) CN1-4

CN1-5 (A4)

CN1-7 (A4)

CN1-3 (A4)

SELA#

SELC#

SELB#

C118

1000p/50V

C117

1000p/50V

C119

1000p/50V

ZD103

UDZ5.6

ZD101

UDZ5.6

ZD104

UDZ5.6

G

74HC151

R111

R113

R112

R115

R114

R117

R116

10K

10K

10K

10K

10K

10K

10K

Document size senser

(A3) CN2-9

(A3) CN2-3

(A3) CN2-7

W0W2W3W1L2

L1

(A3) CN2-5

(A3) CN2-15

(A3) CN2-13

5V

3-1. Interface PWB (1/2)

3. Circuit Diagram

D

C122

C121

C124

C123

C126

C125

/SPFDTC

1000pF/50V*7

JP1

DSPF

Y

W3

W2

W1

W0

/SPFDTC (L)

L2

L1

SPF(H)/DSPF(L)

LHLHLHL

SELA

L

SELB

LLL

SELC

Senser Mtorix

L

H

L

L

H

H

H

H

L

H

HHH

C

AR-SP6/RP6 ELECTRICAL SECTION

– 17 –

C2

$PIN0

C109

0.1u/25V

10k

PDOWNA

(C4) CN1-20

10u/16V

110F

R110

Q102

DTC114EK

10k

10k

Q101

DTC114EK

10k

PDOWNB

(C4) CN1-22

8 7 6 5 4

A

5V

R103

620F

TP103

$PIN0

R109

430F

$PIN0

TP102

R108

390F

1

TP101

B

Page 19

D

C

B

A

12345678

CN1-2 (C4)

(E4)

(D4)

/PSOL

/RSOL

8

1012141618

/SPFCOVER

20

R119

R118

470

470

246

5V

123

CN7

B3B-PH-K-S

24V1

/CLH

(E4)

2 1

1357911131517

CN6

5V

24V1

W3

(B3)

(B3)

CN4-2 (B2)

(C1)

CN2-20 (B3)

(B2) CN5-2

(C1)

/SPFOUT

SPFMODB

SPFOPEN

/SPFMODB

/SPFCOVERPAPER

W1W2W0

(B3)

(B3)

(C1)

(C1)

SPFMODA

/SPFMODA

L2

L1

(B3)

(B3)

(B1)

(B1)

PDOWNA

PDOWNB

19

PAPER

CN1-1 (A4)

24V1

F1

B20B-PHDSS

C127

0.1u/25V

ICP-N38

C105

0.047u

C106

0.047u

CN1-14 (C4)

C102

0.1u/25V

/SPFOUT

5V

123

CN2

B3B-PH-K-E(BL)

CN1-12 (C4)

C101

0.1u/25V

SPFOPEN

5V

123

CN1

B3B-PH-K-R(RD)

3

246

CN5

135791113151719212325

SELA#

CN2-19 (A3)

3-2. Interface PWB (2/2)

D

8

101214161820222426

SELB#

SELC#

YSPF

5V

(E3)

(E3)

(E3)

(E3)

SPFGSOL

SFPRSOL

SPFCLH

5V

(D4)

(D4)

(D4)

1

2

B26B-PHDSS

C116

0.1u/25V

+

C3

10u/16V

SPFPSOL

(D4)

C

CN4

B2B-PH-K-S

24V1

/GSOL

(E4)

CN3

24V1

1234567

B7B-PH-K-S

A/A/B

B

(E4)

(E4)

(E4)

(E4)

8 7 6 5 4

B

A

AR-SP6/RP6 ELECTRICAL SECTION

– 18 –

Page 20

D

C

B

A

12345678

2 1

3

3-3. Sensor PWB

D

C

AR-SP6/RP6 ELECTRICAL SECTION

– 19 –

8 7 6 5 4

B

A

Page 21

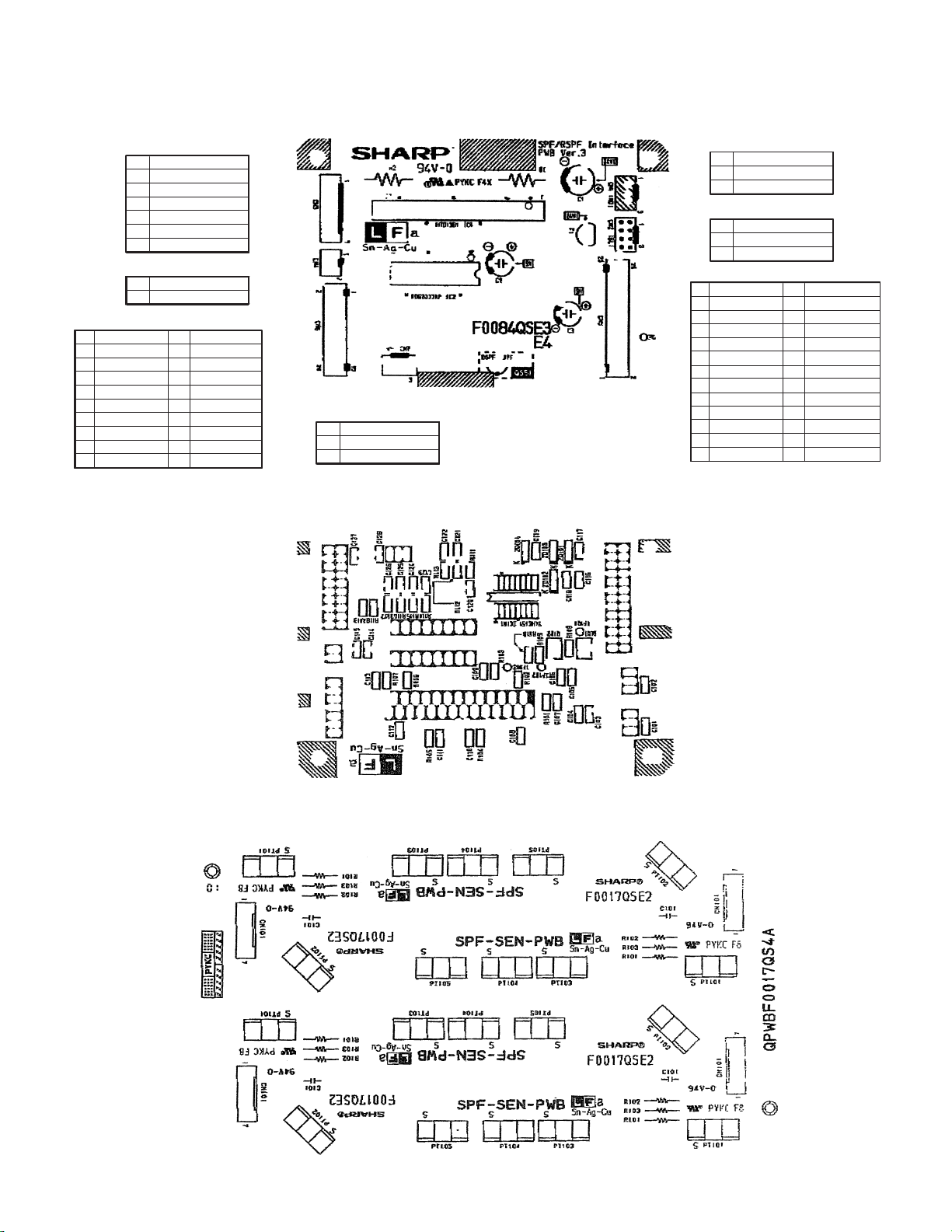

4. Parts arrangement

4-1. Interface PWB

a. Parts surface

CN3(B7B-PH-K-S)

1

2

3

4

5

6

7

CN4(B2B-PH-K-S)

1

2

CN6(B20B-PHDSS)

25V15V

45V3W3

6 /PSOL 5 W0

8 Pull up 7 W1

10 /RSOL 9 W2

12 24V1 11 24V1

14 SGND 13 L2

16 SGND 15 L1

18 SGND 17 SGND

20 SPFCOVER 19 PAPER

A

/A

/B

B

N.C.

24V1

24V1

24V1

/GSOL

CN7(B3B-PH-K-S)

1 24V1

2 N.C.

3 /CLH

CN1(B3B-PH-K-R RD)

1 SGND

2 SPFOPEN

35V

CN2(B3B-PH-K-E BK)

1 SGND

2 /SPFOUT

35V

CN5(B26B-PHDSS)

24V1

25

PGND

23

SPFPSOL

21

SPFCLH

19

SPFRSOL

17

SPFGSOL

15

13

11

5V

YSPF

SGND

9

SELC#

7

SELB#

5

SELA#

3

PAPER

1

24V1

26

PGND

24

PDOWNB

22

PDOWNA

20

/SPFMODA

18

SPFMODA

16

/SPFOUT

14

SPFOPEN

12

SGND

10

8

/SPFMODB

6

SPFMODB

4

/SPFCOVER

2

N.C.

b. Solder surface

4-2. Sensor PWB

AR-SP6/RP6 ELECTRICAL SECTION

– 20 –

Page 22

q

COPYRIGHT

No part of this publication may be reproduced,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

2003 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

stored in a retrieval system, or transmitted.

In any form or by any means,

SHARP CORPORATION

Digital Document Systems Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2003 June Printed in Japan t

Loading...

Loading...