Page 1

SERVICE MANUAL

CODE: 00ZARRB1//A1E

DIGITAL FULL COLOR COPIER/PRINTER/

MULTIFUNCTIONAL SYSTEM OPTION

DUPLEX BYPASS/INVERTER UNIT

MODEL

AR-RB1

CONTENTS

[1] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[3] INTERIOR CONSTRUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] DESCRIPTION OF OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] DISASSEMBLY, ASSEMBLY AND MAINTENANCE . . . . . . . . . . . 5-1

[6] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

PARTS GUIDE

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-RB1 SPECIFICATIONS 1 - 1

[1] SPECIFICATIONS

1. Type

2. System

3. Paper size

4. Paper weight

5. Paper capacity

6. Paper feed transport speed

7. Paper feed speed

8. Power supply

9. Weight

10. Drive pattern

11. Outer dimensions

12. Power consumption

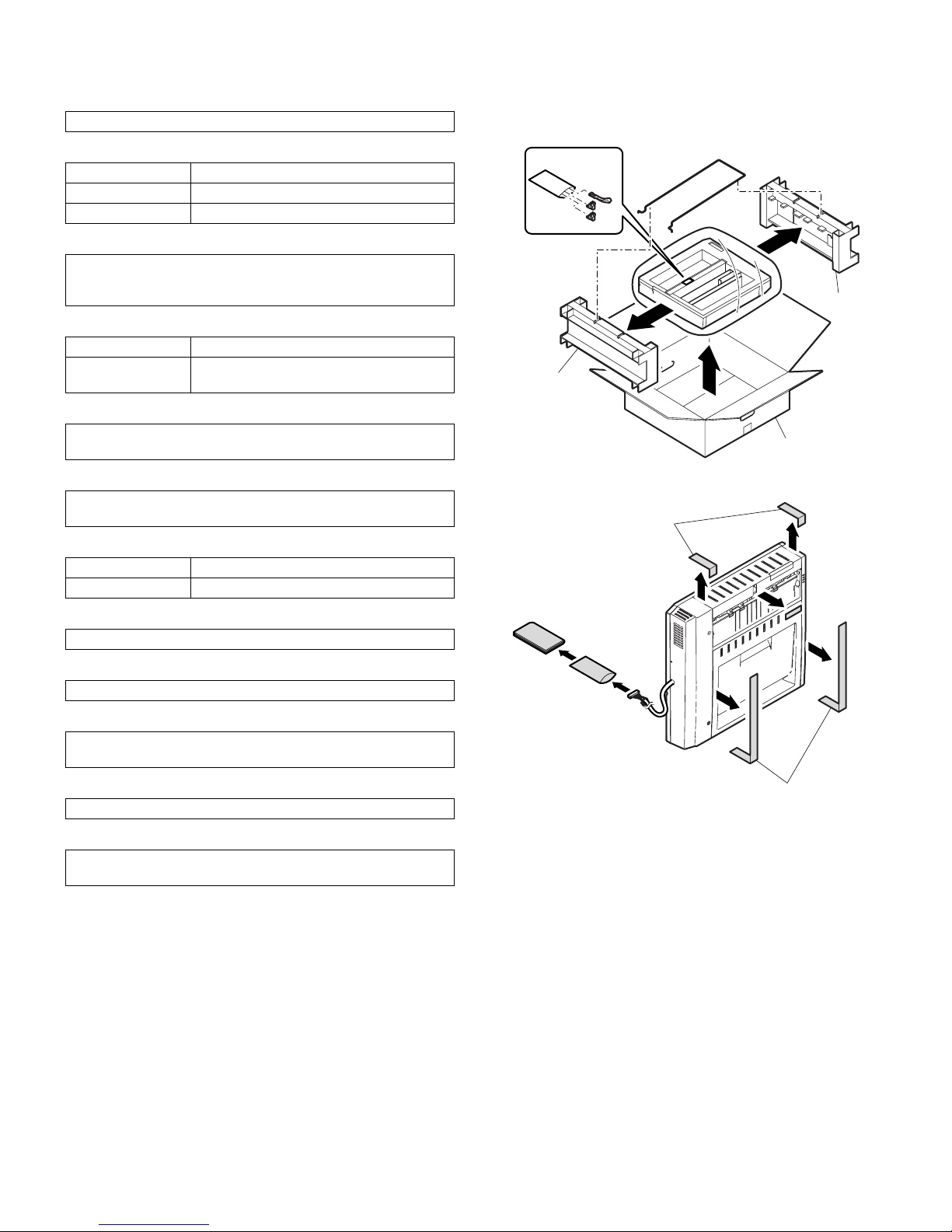

[2] UNPACKING AND

INSTALLATION

1. UNPACKING

Note: Never put the reverse bypass module down by the dotted sec-

tion on the floor. (The full actuator may be damaged.)

2. Installation

Before installation

• Start installation after checking that the DATA indicator on the operation panel is neither lit nor blinking.

• For installation of AR-RB1, an optional stand (AR-D17/AR-D18/ARD19) must have been installed.

• Ensure that the connecting plate located on the front side of the

optional stand and the connecting plates on the sides (one on the

right side and left side respectively) are securely attached.

Duplex bypass with paper delivery reverse

Straight path Face-up paper delivery

Reverse path Face-down delivery

Duplex bypass Reverse direction and delivery to duplex unit

A3W/A3/B4/A4/A4R/B5/B5R/A5/A6R/Custom

(12

×

18/11 × 17/8.5 × 14/8.5 × 13/8.5 × 11/8.5 × 11R/7.25 × 10.5R/

8.5

× 5.5/EXERA)

Face-up delivery 64 – 105g/m

2

, 106 – 300g/m

2

Face-down delivery/

ADU delivery

64 – 105g/m2, 106 – 200g/m

2

250 sheets

(conditions: A4/letter size recommended, face-down delivery)

58.5mm/s – 550mm/s

(speed based on signal commands from the copier)

Full color 26 sheets/min. (A4 landscape feed)

Monochrome 33 sheets/min. (A4 landscape feed)

5V, 24V supplied by the desk control PWB

6.5 kg

Paper feed, upper and lower turnover motors (stepping motors) and

drive PWB built-in

442.6 (W)

×

126.2 (D) × 431.8 (H) mm

24V: 1A/24W

5V: 0.1A/0.5W

Packing case

Spacer

Spacer

Accessories

Restraining tape

(remove)

Restraining tape (remove)

Page 3

AR-RB1 UNPACKING AND INSTALLATION 2 - 2

Parts included

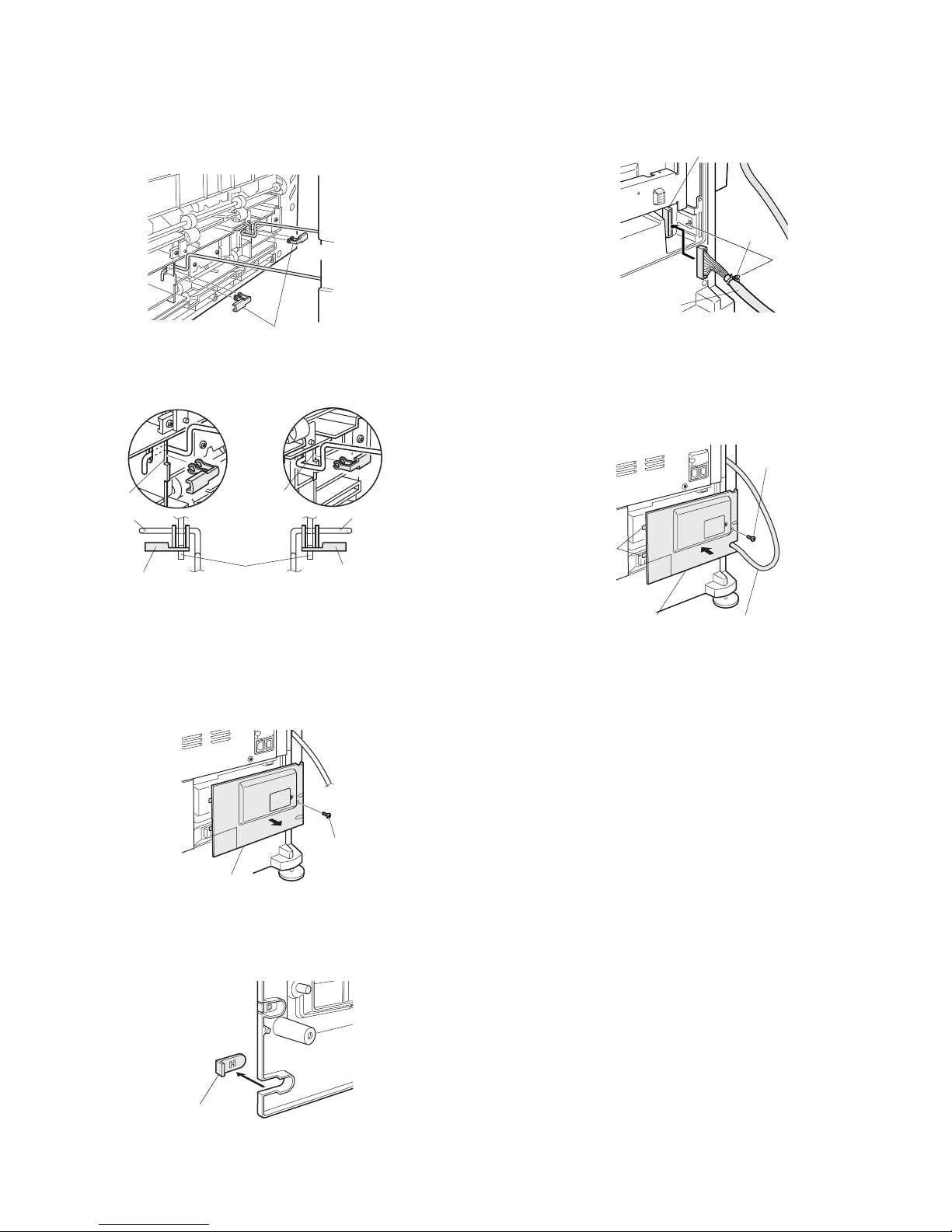

1. Turn off the main switch of the main unit.

1) Turn the main switch located on the left side of the main unit to the

"OFF" position.

2) Then remove the power plug of the main unit from the outlet.

2. Remove the actuator.

1) If the exit tray is installed to the main unit, remove it.

2) While holding the base of the exit actuator of the main unit with one

hand, pull the end of the actuator with the other hand to remove

the actuator.

3. Remove the paper output section covers.

1) Pull the centers of the two paper output section covers on the left

side of the main unit to remove them.

In the case of AR-D17/D18:

1) Pull the lock release lever on the left side of the main unit to pull

out the left cover until it stops.

2) Pull the upper part of the paper input section cover on the left side

of the optional stand to remove the paper input section cover.

Transport guide holder: 2 pcs.

Actuator: 1 pc.

Transport guide: 1 pc.

"OFF"

Exit actuator

Paper output

section covers

Lock release lever

Left cover

Paper input section cover

Page 4

AR-RB1 UNPACKING AND INSTALLATION 2 - 3

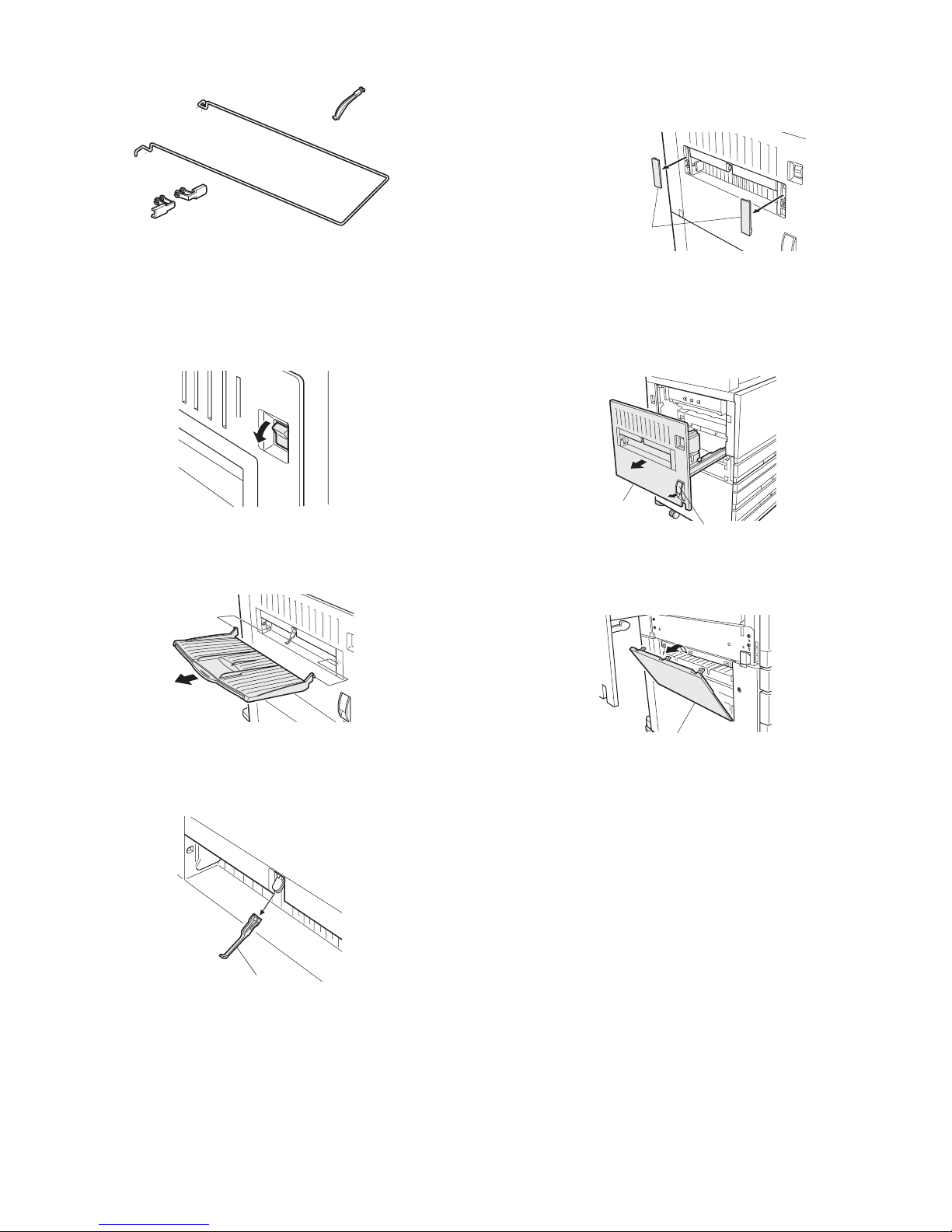

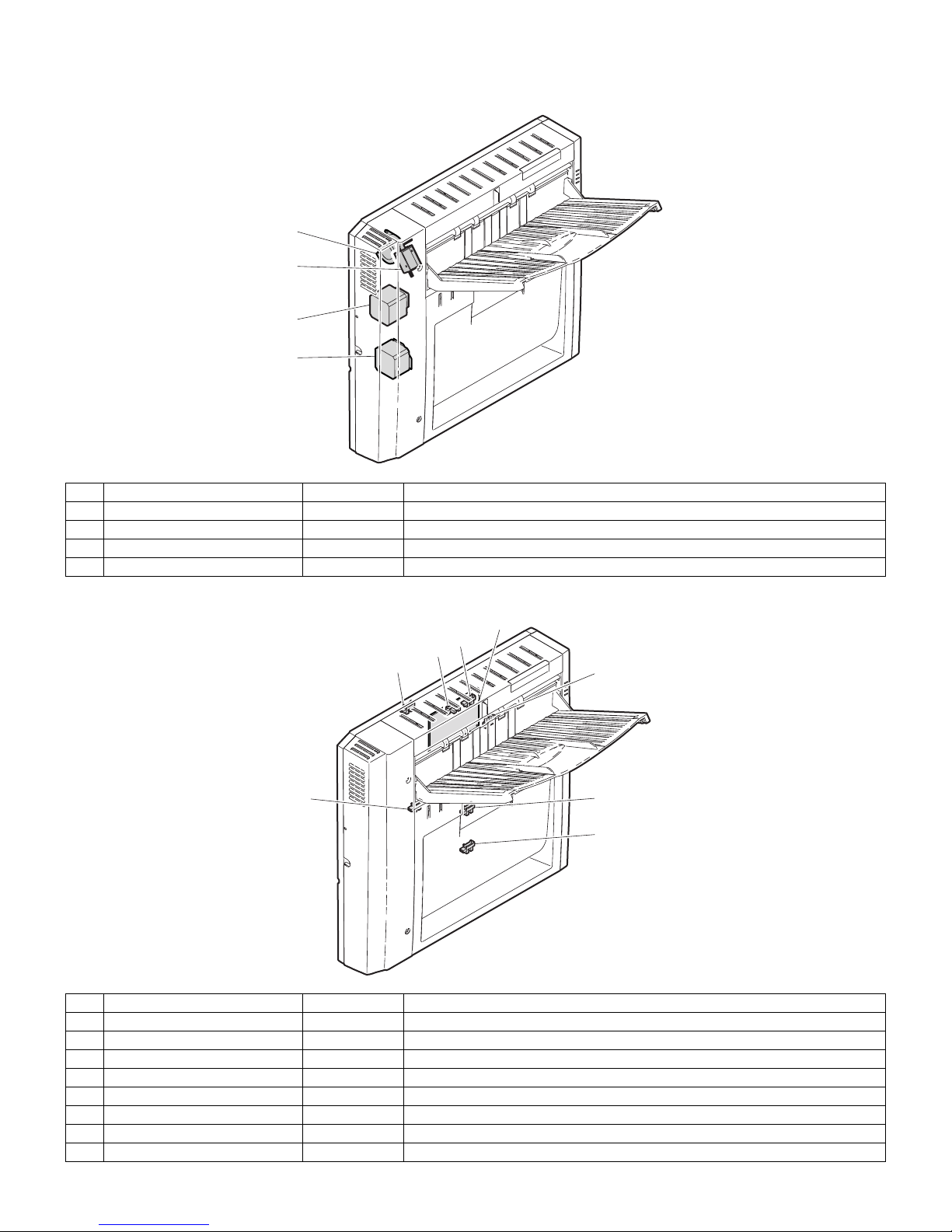

4. Attach the duplex bypass/inverter unit to the main

unit.

1) Close the left cover.

2) Hold the duplex bypass/inverter unit as shown in the illustration

and hang the two positioning bosses at the upper part in the two

positioning holes on the left cover of the main unit.

At this time, check that the two positioning bosses are hung

securely in the two positioning holes of the main unit.

3) Ensure that there is no clearance between the main unit and the

duplex bypass.

5. Secure the duplex bypass/inverter unit.

1) Close the cover of the duplex bypass/inverter unit and tighten the

two built-in screws to secure the duplex bypass to the main unit.

At this time, take care not to damage the transport surface with the

tip of a screwdriver.

2) Close the cover of the duplex bypass/inverter unit and reattach the

exit tray that has been removed in step 2<1> in the raised position

as shown in the illustration.

3) Insert the supplied actuator into the duplex bypass.

6. Attach the transport guide.

1) Pull the lock release lever to pull out the left cover.

2) Insert the transport guide into the paper input section (upper

groove) of the stand.

Positioning bosses

Positioning holes

Transport surface

Actuator

Lock release lever

Transport guide

Page 5

AR-RB1 UNPACKING AND INSTALLATION 2 - 4

3) Attach the transport guide to the duplex bypass/inverter unit and

insert the two transport guide holders into the two transport guides

respectively. At this time, ensure that the transport guide holders

are secured at the notch positions.

4) After checking that the transport guide is aligned with the guide of

the stand, close the left cover of the main unit securely.

7. Connect the harness of the duplex bypass/

inverter unit.

1) Remove the screw from the power supply cover on the rear side of

the optional stand and then remove the power supply cover.

2) Cut out the portion (indicated with H) of the removed power supply

cover shown in the illustration.

3) Connect the relay harness of the duplex bypass/inverter unit to the

connector of the optional stand.

Then, insert the snap band into the mounting hole shown in the

illustration to secure the relay harness.

4) Pass the relay harness through the cut out hole, hang the two

pawls of the power supply cover on the rear cabinet, and attach the

cover with the screw.

Installation of AR-RB1 is now complete.

Transport guide holders

Front side

Rear side

Transport guide holder

Transport guide holder

Transport guide

Transport guide

Front side

Rear side

Notch

Notch

Notches

Power supply cover

Screw

Cut-out portion

Snap band

Relay harness

Connector

Power supply cover

Pawls

Screw

Relay harness

Page 6

AR-RB1 INTERIOR CONSTRUCTION 3 - 1

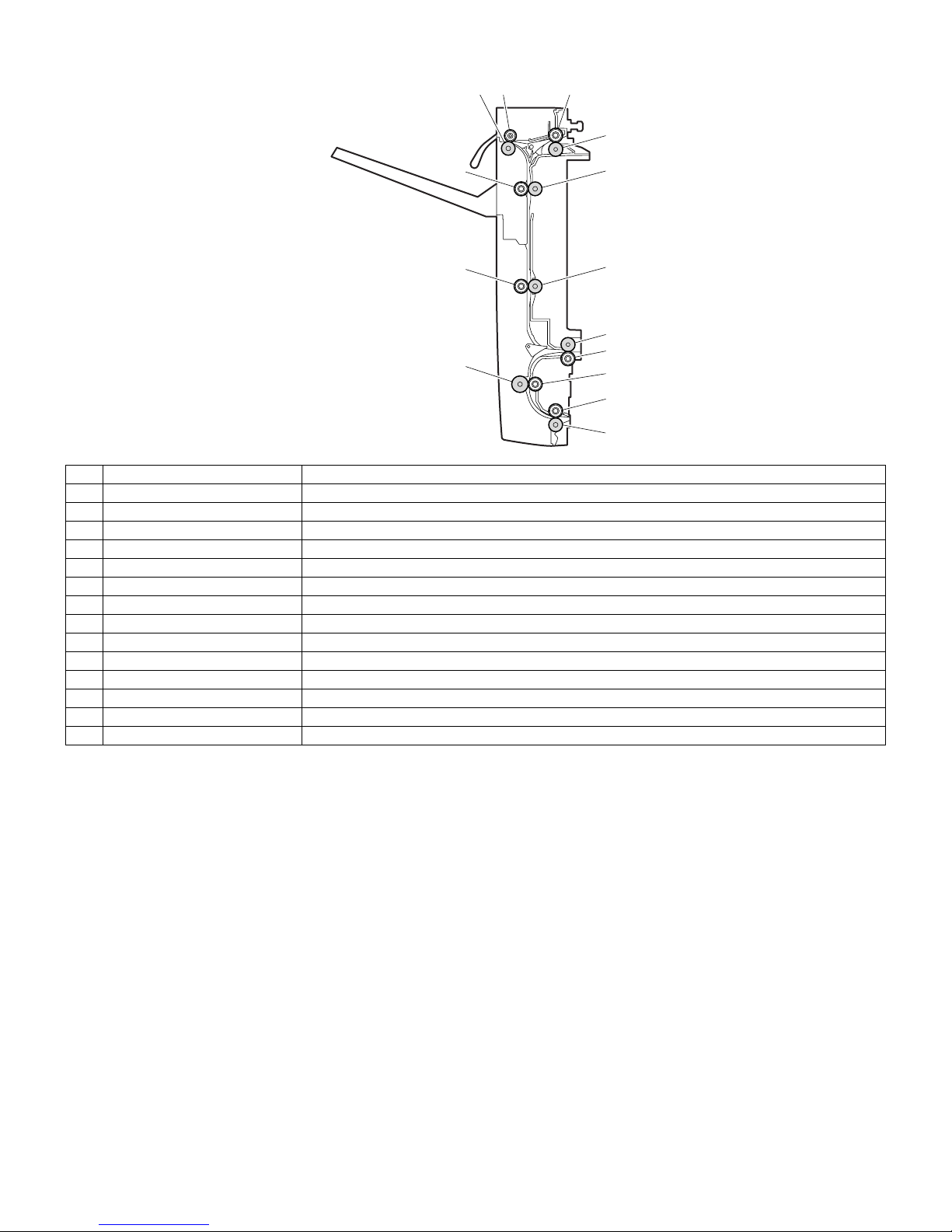

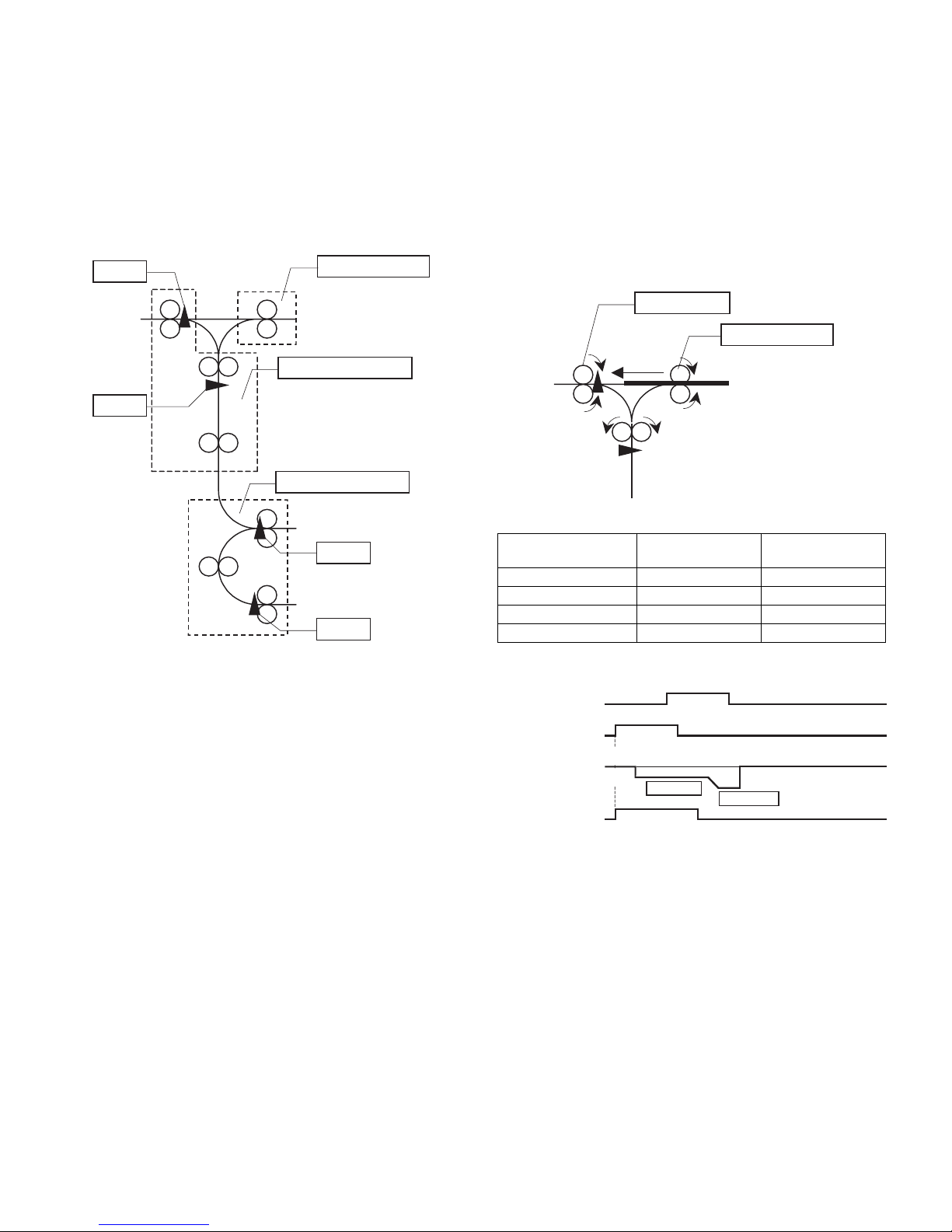

[3] INTERIOR CONSTRUCTION

Motors and solenoid

PWB and sensors

No. Name Abbreviation Function/operation

1 Paper feed motor BIM Transports paper to the paper feed section

2 Gate solenoid BGSOL Switches the gate for straight delivery and reverse delivery

3 Upper turnover motor BRM Paper transport in upper section

4 Lower turnover motor BTM Paper transport in lower section

No. Name Abbreviation Function/operation

1 Door open/closed detector 1 BDD1 Detects open/closed status of upper door

2 Paper delivery sensor BPOD Detects discharged paper

3 Full capacity detection sensor BPFD Detects full capacity status in paper tray

4 BY drive PWB BY drive PWB INVERTER drive and controller

5 Transport sensor 1 BPPD1 Detects transport of paper

6 Reverse section detection sensor BPRD Detects presence of paper in the reverse section

7 Transport sensor 1 BPPD2 Detects transport of paper

8 Door open/closed detector 2 BDD2 Detects open/closed status of lower door

1

2

3

4

1

2

3

4

6

5

7

8

Page 7

AR-RB1 INTERIOR CONSTRUCTION 3 - 2

Cross-section diagram

No. Name Function/operation

1 Delivery roller Discharges paper to the tray, or transports paper to the finisher.

2 Idle roller Applies a pressure to the delivery roller to transport and discharge paper.

3 Idle roller Applies a pressure to the paper feed roller to transport paper.

4 Paper feed roller Transports paper being transported from the main unit to the paper-out and reverse bypass direction.

5 Upper reverse roller Transports paper to the paper-out and reverse bypass direction.

6 Upper transport roller Transports paper to the paper-out and reverse bypass direction.

7 Lower reverse roller Reverses paper and transports it to ADU.

8 Idle roller Applies a pressure to the lower reverse roller to transport paper.

9 Idle roller Applies a pressure to the lower transport roller to transport paper.

10 Idle roller Applies a pressure to the paper exit roller to transport paper.

11 Paper exit roller Transports paper to ADU.

12 Lower transport roller Transports paper to ADU.

13 Idle roller Applies a pressure to the upper transport roller to transport paper.

14 Idle roller Applies a pressure to the upper reverse roller to transport paper.

1

2

3

4

5

14

13

12

6

7

8

9

10

11

Page 8

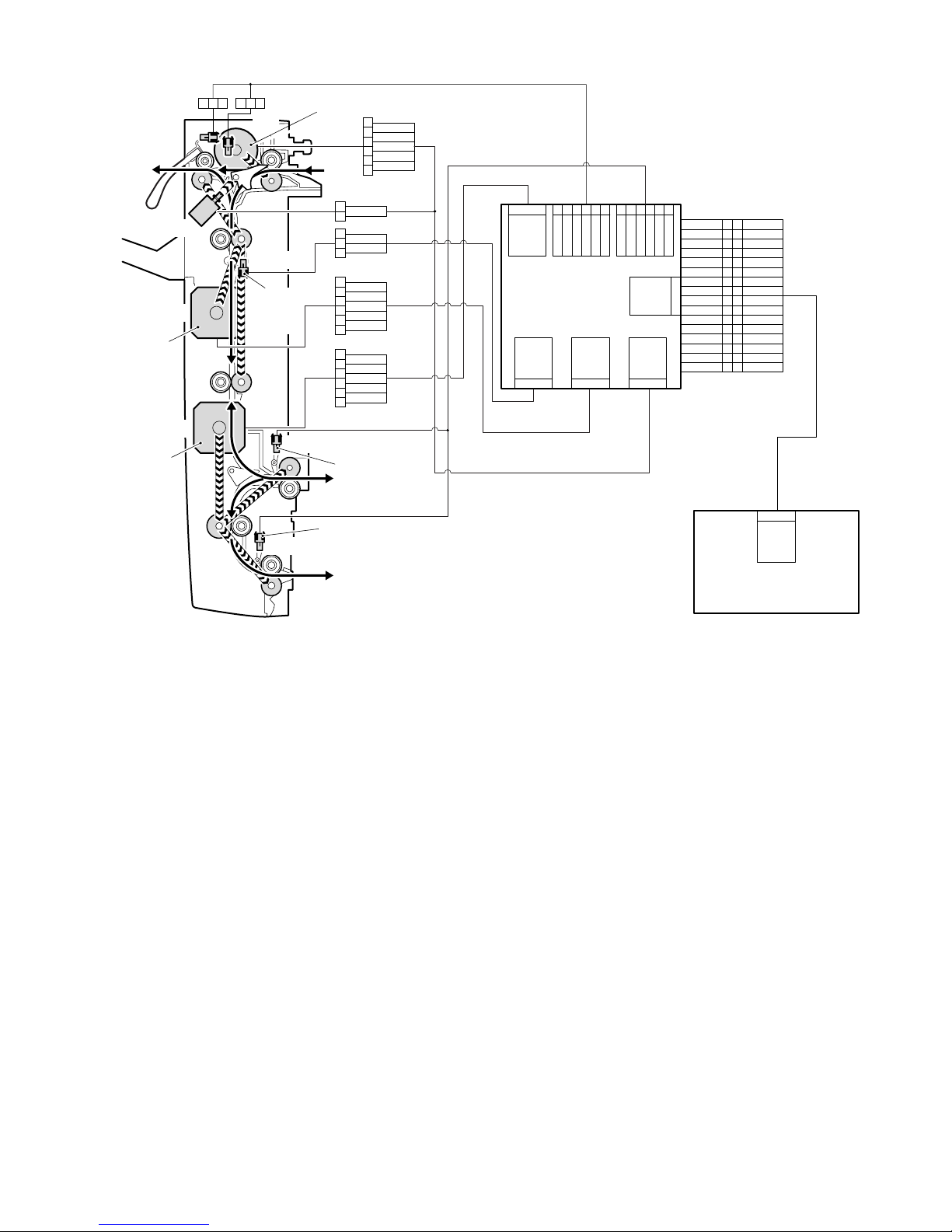

AR-RB1 DESCRIPTION OF OPERATION 4 - 1

[4] DESCRIPTION OF OPERATION

[Outline of operation]

• The operations include straight delivery, reverse tray delivery, reverse finisher delivery, and ADU delivery (when AR-D19 is installed) operations.

[Sensor and solenoid operation]

BIM (paper in-motor) changes the transport path of the fed paper when BGSOL (gate solenoid) straight delivery is ON and all other operations are

OFF.

• In the case of straight delivery, BPOD (paper discharge detect) detects the passing paper.

• In the case of reverse tray delivery operation, the paper-in motor and the upper reverse motor operates, the paper is fed, and BPPD1 is detected.

Afterward, the upper reverse motor stops, and the paper transport stops.

Next, the upper reverse motor rotates in reverse to transport paper to the direction of paper exit tray.

After BPOD (paper discharge detect) detects the passing paper, it turns off the upper reverse motor.

• In the case of reverse finisher delivery operation, the same as reverse tray delivery operation.

• In the case of ADU operation, the lower reverse motor operates, and the paper being transported to the reverse roller is detected by BPRD.

After being detected, the lower reverse motor stops, then it rotates in reverse, and the paper is transported to ADU.

After BPPD2 detects the passing paper, it turns off the motor.

27

29

+24V

+5V

31

GND

17

19

BRM/A

BRM/B

21

23

BPOWD

BTMA

25

BTMB

7

9

/BDD2

BFM

11

13

BIMA

BIMB

15

Vref1

1

3

/BPOD

/BPPD1

5

/BPRD

28

30

+24V

GND

32

/BYSET

18

20

BRMA

BRMB

22

24

BTM/A

BTM/B

26

+24V

8

10

BGSOL

BIM/A

12

14

BIM/B

BPOWD2

16

Vref2

2

4

/BPFD

/BPPD2

6

/BDD1

9

GND87/BPOD

+5V65GND

/BPFD4+5V6GND54/BPRD

+5V32GND

/BPPD21+5V

CN-H (6pin)

CN-E (3pin) CN-D (6pin) CN-C (8pin)

CN-G (9pin) CN-F (10pin)

CN-A (32pin)

BY drive PWB

Desk control PWB

CN-G (32pin)

1

2

5

3

4

6

BTM/B

+24V

+24V

BTMB

BTMA

BTM/A

1

2

5

3

4

6

BIM/B

+24V

+24V

BIMB

BIMA

BIM/A

1

2

5

3

4

6

BRM/B

+24V

+24V

BRMB

BRMA

BRM/A

1

2

3

+5V

/BPPD1

GND

1

23123

1

2

+24V

/BGSOL

ADU

BRM

BPPD2

BPPD1

BGSOL

BPRD

BTM

BIM

BPODBPFD

Paper feed motor

Upper turnover

motor

Transport of

paper

detected

Lower turnover

motor

Presence of

paper in reverse

section detected

Transport of

paper detected

Page 9

AR-RB1 DESCRIPTION OF OPERATION 4 - 2

(1) Initial operation

When the power to the copier is turned on, in order to confirm whether

or not there is paper in the transport path, the paper input motor, upper

turnover motor and lower turnover motor revolve for a predetermined

time.

Even after the predetermined time has passed, if all the transport sensors are OFF and it is determined that there is no paper in the transport path, if within a given period of time at least one transport sensor

turned ON, it is interpreted as paper being present in the transport path

(paper jam).

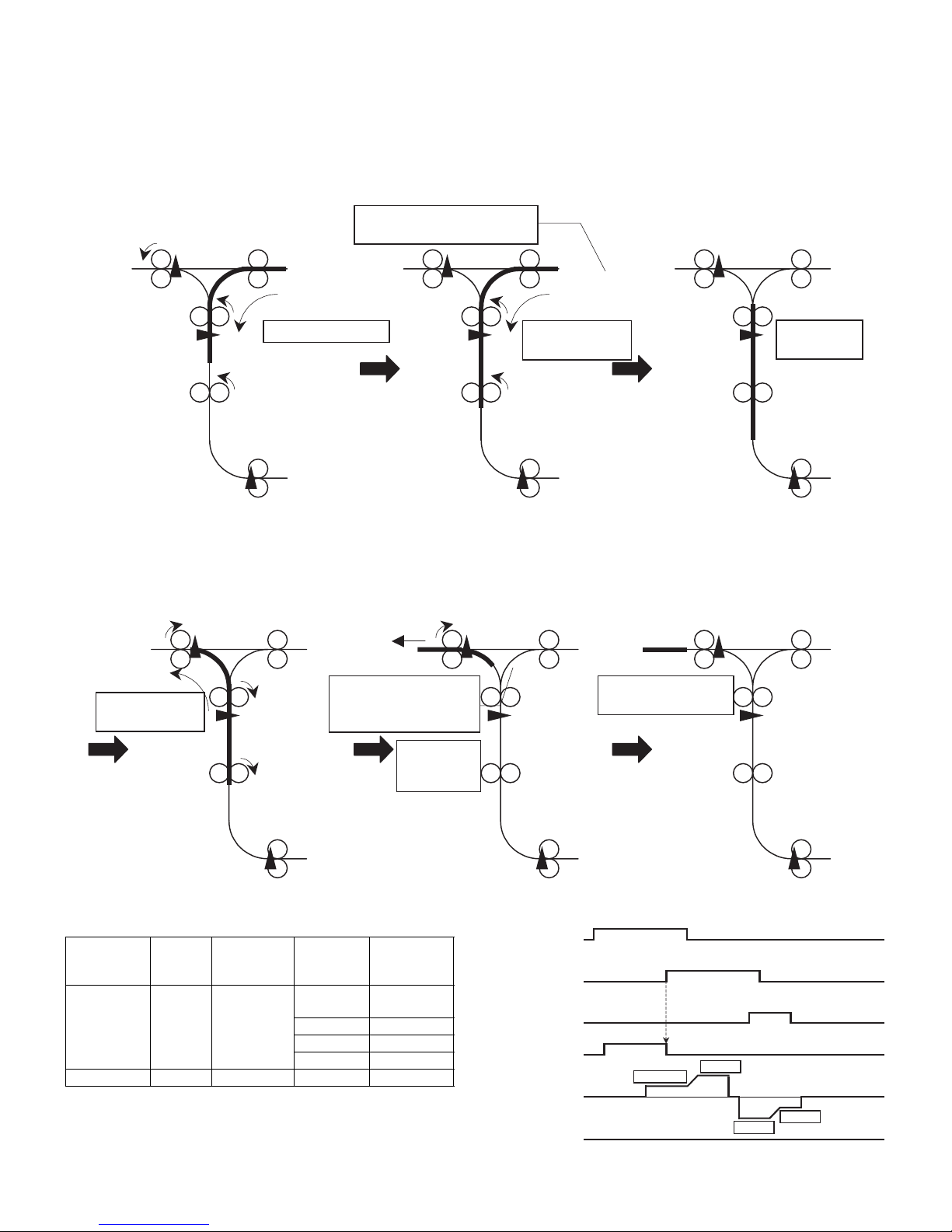

(2) Straight delivery operation

In this operation, the paper discharged from the copier is sent directly

to the paper exit tray or transported to the finisher.

When the paper input motor and upper turnover motor revolve, the

paper input roller and delivery roller rotate in the directions as shown in

the figure below to discharge the paper.

If the paper is delivered to the finisher, it is transported at the same

speed at which it is discharged from the copier.

As the paper is discharged to the paper exit tray, when the trailing

edge reaches a point 50mm from the delivery roller on the copier side,

the speed of the delivery roller increases, and the paper is discharged

to the tray.

Unit: mm/s

Sensor input, motor output, solenoid output timing is as below.

Paper input motor

BPOD

BPPD1

BPRD

BPPD2

Upper turnover motor

Lower turnover motor

Paper kind

Copier process

speed

RB1 tray delivery

speed

Thick paper 2 58.5 58.5

Envelope 117 117

OHP (priority: quality) 58.5 120

OHP (priority: speed) 117 160

Paper input roller

Delivery roller

BPOD

(Paper exit sensor)

BIM

(Paper-in motor)

BRM

(Upper reverse motor)

Process speed

BGSOL

(Gate solenoid)

Delivery speed

(Direction of

paper-in)

(Direction of

paper-out)

Page 10

AR-RB1 DESCRIPTION OF OPERATION 4 - 3

(3) Reverse tray delivery operation

A. When paper length is 249mm or less (letter size or less)

(Both the paper input motor and upper turnover motor operate)

The relation between the process speed and the transport speed in

RB1 is as follow.

Unit: mm/s

Sensor input, motor output, solenoid output timing is as below.

Processing speed

The paper input motor and

upper turnover motor are

caused to turn in time with the

copier processing speed, thus

transporting the paper.

When the trailing edge of the paper

reaches a point 13mm from the copier

POD off, the transport speed in RB1

is accelerated.

Trailing edge of paper reaches

point 13mm from POD off

Transport speed

(high speed)

Transport speed

(high speed)

Transport

speed

(low speed)

When the trailing edge of

the paper reaches the upper

reverse stop point, the

motor stops.

Motor stop

(paper stop)

Motor stop

(discharge complete)

The upper turnover motor is

caused to revolve in the paper

delivery direction, and the paper

is discharged.

When the trailing edge of the paper

reaches a point 50mm before the

delivery roller, the transport speed

decreases.

Trailing edge of paper

reaches point 50mm

before delivery roller

After the trailing edge of the paper

passes the delivery roller, the

upper turnover motor stops.

Paper kind

Copier

process

speed

RB1 transport

speed

(high speed)

Paper size

RB1 transport

speed

(low speed)

Normal paper 117/140 550 A3/A3W

/EXTRA

450

A4R 430

A4/B5/B5R 400

B4/A5 320

Thick paper 1 58.5 195 All size 195

POD

(Paper exit sensor)

BPPD1

(Transport sensor 1)

BPOD

(Paper-out sensor)

BIM

(Paper-in motor)

BRM

(Upper reverse motor)

BGSOL

(Gate solenoid)

(Direction of paper-out)

(Direction of paper-in)

Process speed

High speed

High speed

Low speed

Page 11

AR-RB1 DESCRIPTION OF OPERATION 4 - 4

B. When the paper length is 250mm or more (B5R or more)

(The paper input motor, upper turnover motor and lower turnover motor all operate.)

As for the relation between the process speed and the transport speed

in RB1, refer to the table (3)-A.

Sensor input, motor output, solenoid output timing is as below.

Processing speed

The paper input motor and

upper turnover motor are

caused to turn in time with the

copier processing speed, thus

transporting the paper.

When the trailing edge of the paper

reaches a point 13mm from the copier

POD off, the transport speed in RB1

is accelerated.

Trailing edge of paper reaches

point 13mm from POD off

Transport speed

(high speed)

Transport speed

(high speed)

When the trailing edge of the

paper reaches the upper reverse

stop point, the upper turnover

motor and the lower turnover

motor stop.

Motor stop

(paper stop)

The upper turnover motor and the

lower turnover motor are caused to

revolve in the paper delivery direction,

and the paper is discharged.

The lower reverse motor stops at

BPPD1 off, when the trailing edge of the

paper reaches a point 50mm before the

delivery roller, the transport speed

decreases.

Trailing edge of paper

reaches point 50mm

before delivery roller

After the trailing edge of the paper

passes the delivery roller, the

upper turnover motor stops.

Transport

speed

(low speed)

Lower

turnover

motor stop

Motor stop

(discharge complete)

POD

(Paper exit

sensor)

BPPD1

(Transport

sensor 1)

BPRD

(Reverse section

detection sensor)

BPOD

(Paper-out sensor)

BIM

(Paper-in motor)

BRM

(Upper reverse

motor)

(Direction of paper-in)

(Direction of paper-out)

(Direction of paper-in)

(Direction of paper-out)

BTM

(Lower reverse

motor)

BGSOL

(Gate solenoid)

Process speed

Process speed

High speed

High speed

High speed

High speed

Low speed

Page 12

AR-RB1 DESCRIPTION OF OPERATION 4 - 5

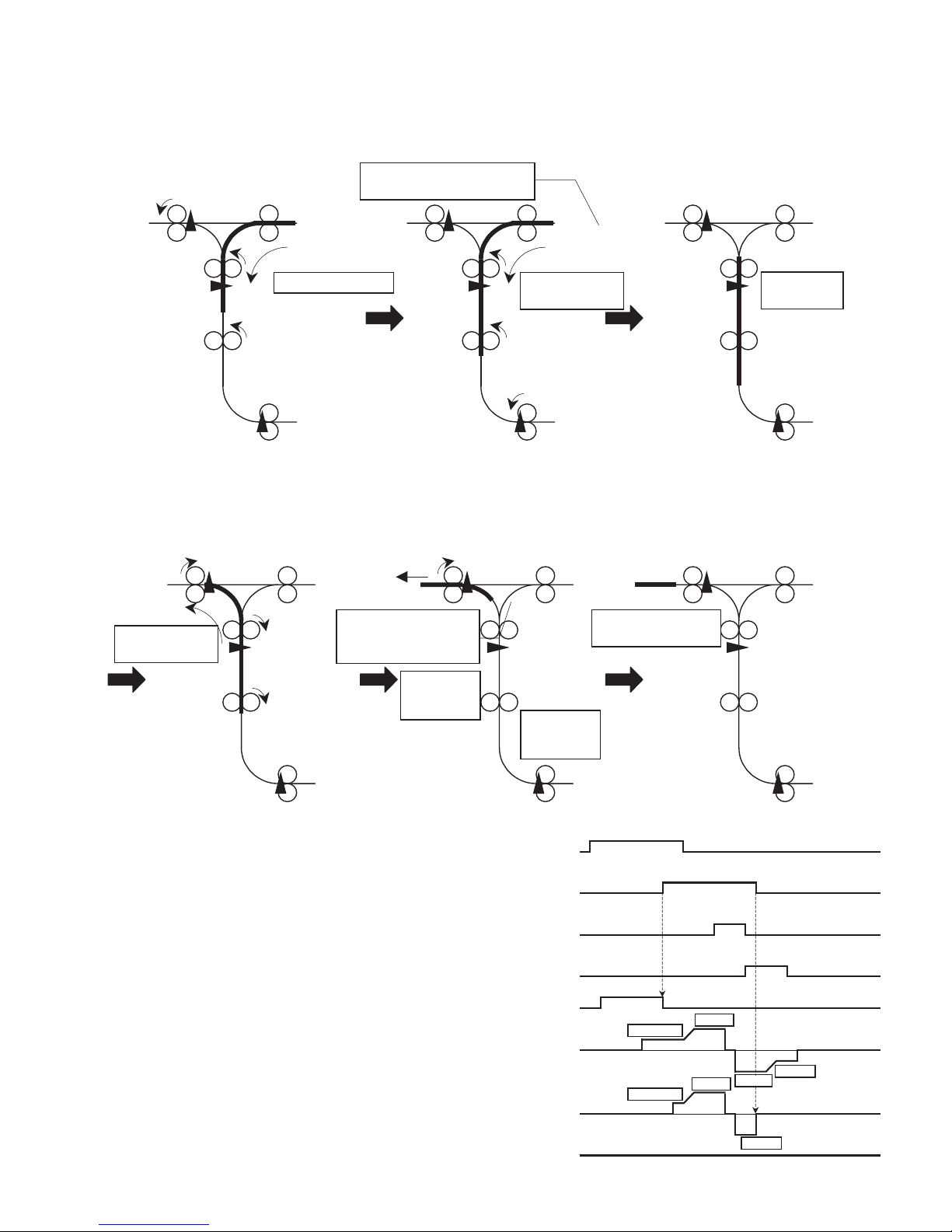

(4) Reverse finisher delivery operation

A. When paper length is 249mm or less (letter size or less)

(Both the paper input motor and upper turnover motor operate)

Table showing relation between the processing speed and the transport speed in RB1

Unit: mm/s

Sensor input, motor output, solenoid output timing is as below.

B. When the paper length is 250mm or more

(B5R or more)

(The paper input motor, upper turnover motor and lower turnover motor

all operate.)

Other than this, it is controlled by the same conditions as for letter-size

or less.

The paper input motor and

upper turnover motor are

caused to turn in time with the

copier processing speed, thus

transporting the paper.

Processing speed

When the trailing edge of the paper

reaches a point 13mm from the copier

POD off, the transport speed in RB1

is accelerated.

Trailing edge of paper reaches

point 13mm from POD off

When the trailing edge of

the paper reaches the upper

reverse stop point, the

motor stops.

Transport speed

(high speed)

Motor stop

(paper stop)

The upper turnover motor is

caused to revolve in the paper

delivery direction, and the paper

is discharged.

Just before the leading edge of the

paper reaches the first roller of the

finisher, the transport speed decreases.

After the trailing edge of the paper

passes the delivery roller, the

upper turnover motor stops.

Transport speed

(high speed)

Motor stop

(discharge

complete)

Finisher

No. 1 roller

Transport

speed

(low speed)

Copier processing

speed

RB1 transport speed

(high)

RB1 transport speed

(Finisher speed)

58.5 195 195

117 550 450

140 550 550

POD

(Paper exit sensor)

BPPD1

(Transport sensor 1)

BPOD

(Paper-out sensor)

BIM

(Paper-in motor)

BRM

(Upper reverse

motor)

(Direction of paper-in)

(Direction of paper-out)

BGSOL

(Gate solenoid)

Process speed

Finisher speed

High speed

High speed

Page 13

AR-RB1 DESCRIPTION OF OPERATION 4 - 6

(5) ADU delivery operation (AR-D19 the installed)

Table showing relation between the processing speed and the transport speed in RB1

Unit: mm/s

Sensor input, motor output, solenoid output timing is as below.

Processing speed

The paper input motor and

upper turnover motor are

caused to turn in time with the

copier processing speed, thus

transporting the paper.

When the trailing edge of the paper

reaches a point 13mm from the copier

POD off, the transport speed in RB1

is accelerated.

Trailing edge of paper reaches

point 13mm from POD off

Transport speed

(high speed)

Transport speed

(high speed)

Transport speed

(high speed)

Lower reverse

stop point

When the trailing edge of the

paper reaches the lower reverse

stop point, the motor stops.

The lower turnover motor is caused to

revolve in the direction of the ADU,

discharging the paper.

When the trailing edge of the paper

passes the delivery roller, the

motor stops.

Copier processing speed RB1 transport speed (high)

58.5 195

117 550

140 550

POD

(Paper exit sensor)

BPPD1

(Transport sensor 1)

BPRD

(Reverse section

detection sensor)

BPPD2

(Transport sensor 2)

BIM

(Paper-in motor)

(Direction of paper-in)

(Direction of paper-out)

(Direction of paper-in)

(Direction of paper-out)

BRM

(Upper reverse

motor)

BTM

(Lower reverse

motor)

BGSOL

(Gate solenoid)

Process speed

High speed

High speed

High speed

Page 14

AR-RB1 DISASSEMBLY, ASSEMBLY AND MAINTENANCE 5 - 1

[5] DISASSEMBLY, ASSEMBLY AND MAINTENANCE

1. Maintenance system table

✕ : Check (for cleaning, replacement or adjustment as necessary) ❍ : Clean ▲ : Replace ∆

: Adjust ✩ : Lubricate ❏ : Relocate

Unit name No. Part name

When

requested

50K 100K 150K 200K 250K 300K 350K 400K Remarks

Transport

section

1 Transport rollers ❍ ❍❍❍❍❍❍❍❍

2Rollers ❍ ❍❍❍❍❍❍❍❍

3 Transport paper guides ❍ ❍❍❍❍❍❍❍❍

Drive unit 4 Gears ✕ ✕✕✕✕(designated spots)

5Belts ✕✕

Others 6 Sensors ✕ ✕✕✕✕

7 Discharge brushes ✕ ✕✕✕✕

NOTE: When to replace: Check the counter value on the respective paper feed entrances.

Paper feed rollers/torque limiter parts: 100K or 2 years.

1

1

2

2

2

1

1

3

3

4

4

5

2

2

2

6

7

6

6

5

Page 15

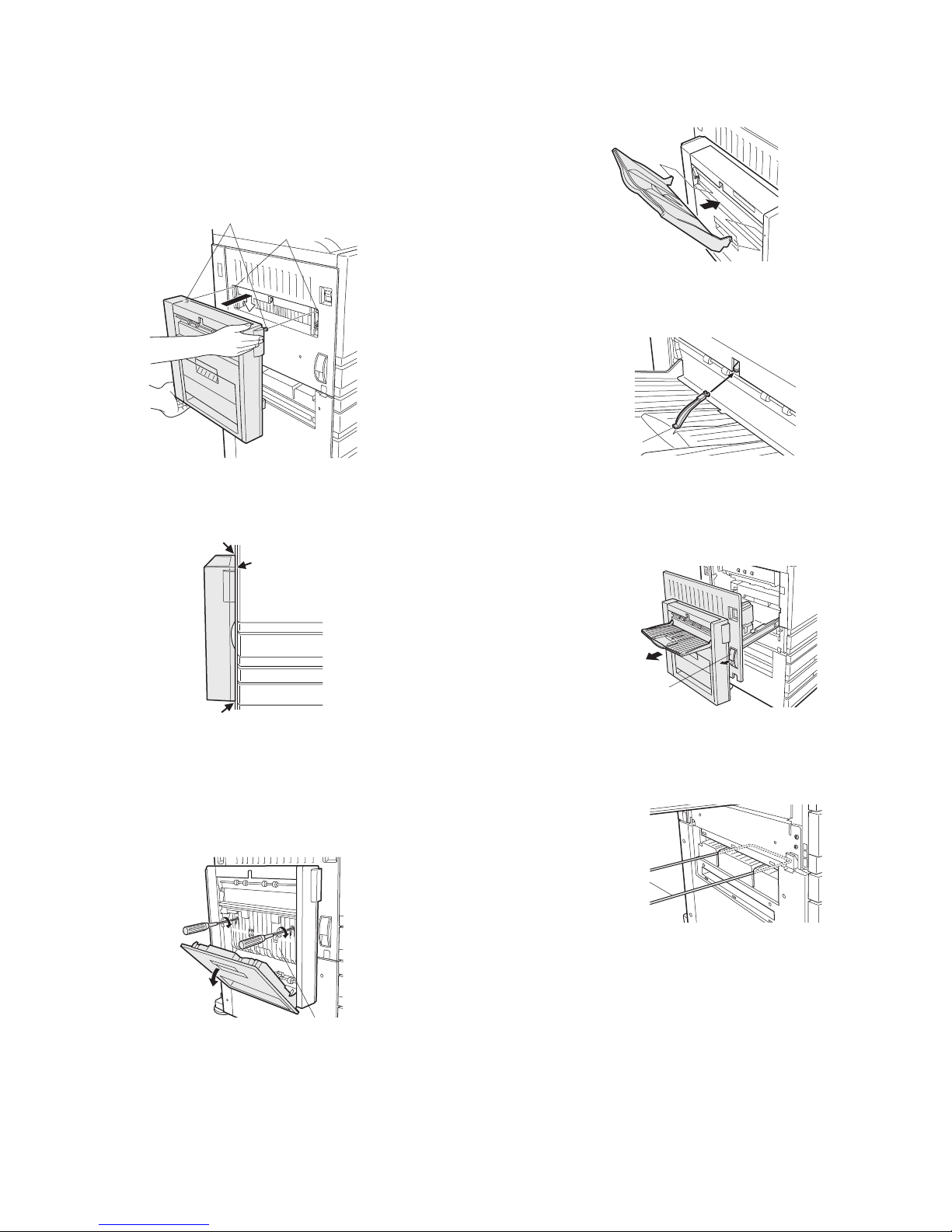

AR-RB1 DISASSEMBLY, ASSEMBLY AND MAINTENANCE 5 - 2

2. Maintenance

A. Transport section

✕ : Check (for cleaning, replacement or adjustment as necessary) ❍ : Clean ▲ : Replace ∆

: Adjust ✩ : Lubricate ❏ : Relocate

(1) All transport rollers

a. Copier

1) Detach the connector and remove the screws. Remove (A) the

bypass drive PWB.

<1> Delivery roller

1) Open (A) the left door.

2) Open (B) the upper open/close unit.

3) Remove the screws, and remove (C) the rear casing.

4) Remove the screws, and remove (D) the front casing.

5) Remove the E-rings, gears and bearings, and take out (E) the

delivery roller.

<2> Paper input roller

1) Remove the rear and front casings.

2) Detach the connector, remove the screws, and take out (A) the

paper input motor unit.

3) Remove the E-rings, gears and bearings, and take out (B) the

paper input roller.

Unit name No. Part name

When

requested

50K 100K 150K 200K 250K 300K 350K 400K Remarks

Transport

section

1 Transport rollers

❍ ❍❍❍❍❍❍❍❍

2Rollers

❍ ❍❍❍❍❍❍❍❍

3 Transport paper guides

❍ ❍❍❍❍❍❍❍❍

A

A

B

D

C

E

A

B

Page 16

AR-RB1 DISASSEMBLY, ASSEMBLY AND MAINTENANCE 5 - 3

<3> Upper turnover roller

1) Remove the rear and front casings.

2) Remove the bypass drive PWB.

3) Remove the E-ring, Mylar, belt, pulley, gears, pins and bearings,

and take out (B) the upper turnover roller.

<4>Lower turnover roller

1) Remove the rear and front casings.

2) Remove (A) the E-ring, and slide the bearing over.

3) Remove the belt, and take out the lower turnover roller unit.

4) Remove the E-rings, pulley, pin, Mylar and bearings from (B) the

lower turnover roller.

<5> Upper transport roller

1) Remove the rear and front casings.

2) Remove the E-rings, belt, pulley, pin and bearings.

3) Remove (A) the upper transport roller.

<6> Lower transport roller

1) Remove the rear and front casings.

2) Remove (A) the E-ring, belt and pulley.

3) Remove (B) the E-rings, slide the bearing over, and take out the

lower transport roller unit.

4) Remove the pin and bearing from (C) the lower transport roller.

<7> Delivery roller

1) Remove the rear and front casings.

2) Remove the screws, remove (A), and take out (B) the left door unit.

3) Remove the E-rings, belt, pulley, pin and bearings. Take out (C)

the delivery roller.

B

A

A

B

A

A

B

B

C

A

B

C

Page 17

AR-RB1 DISASSEMBLY, ASSEMBLY AND MAINTENANCE 5 - 4

(2) Rollers

a. Paper delivery cabinet

1) Remove the delivery roller.

2) Remove (A) the screw, remove (B) the ADU open/closed sensor

mounting plate, and detach the connector.

3) Remove the screws, and take out (C) the paper delivery cabinet

unit.

(3) Transport paper guides

B. Drive section

✕ : Check (for cleaning, replacement or adjustment as necessary) ❍ : Clean ▲ : Replace ∆ : Adjust ✩ : Lubricate ❏ : Relocate

(1) Gears

a. Copier

1) Remove the rear casing. 2) Remove the front gears.

A

B

C

Unit name No. Part name

When

requested

50K 100K 150K 200K 250K 300K 350K 400K Remarks

Drive unit 1 Gears ✕ ✕✕✕✕(designated spots)

2Belts ✕✕

Page 18

AR-RB1 DISASSEMBLY, ASSEMBLY AND MAINTENANCE 5 - 5

(2) Belts

a. Copier

1) Remove the rear casing.

C. Others

✕ : Check (for cleaning, replacement or adjustment as necessary) ❍ : Clean ▲ : Replace∆ : Adjust ✩ : Lubricate ❏ : Relocate

(1) Sensors

a. Copier

1) Remove the screw, and remove the sensor holder.

2) Remove the screws, and remove the sensor covers.

b. Upper open/closed unit

1) Open the upper open/closed unit, remove the E-ring and bearing,

and take out (A) the gate unit.

2) Remove the screw, and remove (B) the upper cabinet.

Unit name No. Part name

When

requested

50K 100K 150K 200K 250K 300K 350K 400K Remarks

Others 1 Sensors ✕ ✕✕✕✕

2 Discharge brushes ✕ ✕✕✕✕

A

B

Page 19

AR-RB1 DISASSEMBLY, ASSEMBLY AND MAINTENANCE 5 - 6

c. Paper delivery cabinet unit

1) Remove the rear casing.

2) Open the left door unit, remove the screw, and remove (A) the

ADU open/closed sensor mounting plate.

(2) Discharge brushes

D. Principal parts

(1) Paper input motor

1) Remove the rear casing.

2) Detach the connector, remove the screws, and remove (A) the

paper input motor.

(2) Upper reverse transport motor/Lower reverse

transport motor

1) Remove the rear casing.

2) Detach the harness from the clamp.

3) Remove the connector, remove the screws, and take out the upper

reverse transport motor unit/the lower reverse transport motor unit.

4) Remove the screws, and remove (A) the upper reverse transport

motor/(B) the lower reverse transport motor.

(3) SF pressure release solenoid

1) Remove the rear and front casings.

2) Remove the delivery roller, and take out the paper delivery cabinet

unit.

3) Remove the paper input motor unit.

4) Detach the connector, remove the screws and spring, and remove

(A) the SF pressure release solenoid.

(4) Bypass drive PWB

1) Detach the connector, remove the screws, and take out (A) the

bypass drive PWB.

A

B

C

A

A

B

A

A

Page 20

AR-RB1 ELECTRICAL SECTION 6 - 1

BIMB

/BDD1

N.C.

/BPPD2

BRM/A

Vref1

BIM/A

/BPRD

BFM

/BPPD1

BRMA

/BDD2

/BPOD

BIM/B

BIMA

Vref2

/BPFD

BPOWD2

N.C.

BGSOL

10

17

18

12

7

1

16914

19

20

3

11

8

5152134

6

XADRP-40V

32

39

21

GND

252926

BRMB31BPOWD

33

30

BTMA

40

38

35

27

BTM/B

36

BTM/A34+24V2824BTMB

23

BRM/B

22

37

12

19

1

596

111310

20

18

15716

14

8

432

17

36

233127

24

38

322930

3437333935

264028

25

22

21

+24V

+24V

+5V

GND

/BYSET

F.G.

F.G.

BIM/A

/BFM

BIMB

BRMA

/BPOD

BIMA

/BPFD

/BPPD2

/BPRD

/BPPD1

/BDD2

BIM/B

/BDD1

/BGSOL

BRM/A

BRM/B

BRMB

8

5

2

10

426

4

2

3

2

371

8

4

6

1

+24V 1

CN-B

+24V 2

+24V 5

+24V 7

CN-C

+24V 2

+24V 5

+5V 1

3GND

CN-E

1+5V35

GND

+5V

6

8

GND

+5V 9

GND

CN-F

+5V 1

3GND

+5V 4

6GND

+5V 7

9GND

CN-G

CN-D

CN-H

/BFM2

+24V1

BFM

4

+24V

BIM

+24V

BIM/A

352

BIMB

BIM/B

BIMA

1

6

45136

2

2 /BGSOL

+24V1

BGSOL

BRM

312 /BPPD1

+5V

GND

BPPD1

132 /BPPD2

+5V

GND

BPPD2

132 /BPRD

+5V

GND

BPRD

/BDD2

1 GND

3 +5V

2 BDD2

BDD1

+5V

GND1

3

2 /BDD1

BPFD

1

3 +5V

2 /BPFD

GND

BPOD

1

3 +5V

2 /BPOD

GND

AR-RB1

B2B-PH-K-S

B8B-PH-K-S

B6B-PH-K-R

B3B-PH-K-S

B10B-PH-K-S

B9B-PH-K-S

B6B-PH-K-S

BY DRIVE PWB

4

1BTM/B

BTMB

+24V

2

3

BTM/A

+24V6BTMA

5

BTM

29

15

4

BIMA

Vref2

Vref1

+24V

BRM/A

25

14

7

BPOWD222BRMA

GND

28

16

+5V

20

173219

8

12

2

5

BIM/A10

26

BTMB

30

/BPPD1

11

23

CN-A

BGSOL

BTM/B

/BDD2

+24V

18

BRMB

/BPPD2

BPOWD

/BPRD

/BPOD

/BDD1

+24V

BFM

/BPFD

13

1

24

GND31

6

BIM/B

BTMA

BIMB

BTM/A

27

S32B-PHDSS213

BRM/B

9

GND(/BYSET)

N.C.

EXIN1

EXIN2

GND

GND

SMP-06V-BC SMR-06V-B

AR-D17/18/19

[6] ELECTRICAL SECTION

(1) Actual wiring chart

Page 21

AR-RB1 ELECTRICAL SECTION 6 - 2

(2) Signal list

(3) Block diagram

SIGNAL NAME NAME Function/Operation

BDD Door open detection 1 Detects upper door open.

BDD2 Door open detection 2 Detects left door open.

BGSOL Gate solenoid Switches straight or reverse paper exit.

BIM Paper entry motor Transports paper in the paper entry section.

BPFD Full sensor Detects paper full on the tray.

BPOD Paper exit sensor Detects paper exit.

BPPD1 Transport sensor 1 Detects paper transport.

BPPD2 Transport sensor 2 Detects paper transport.

BPRD Reverse section sensor Detects paper presence in the reverse section.

BRM Upper reverse motor Transports paper in the upper section.

BTM Lower reverse motor Transports paper in the lower section.

/BPOD1

/BPFD1

/BPPD1

/BPPD2

/BPRD

/BDD1

/BDD2

/BYPSET

+5V

+24V

BPFD

Paper delivery sensor

Transport sensor 1

Full capacity detection sensor

BDD2

BPOD

+5V

+5V

BPPD2

Door open/closed detection sensor 1

+5V

+5V

Door open/closed detection sensor 2

Transport motor

BPPD1

BDD1

+5V

Reverse section detection sensor+5V

BPRD

+5V

Transport sensor 2

BGSOL

Gate solenoid

+24V

(MTD1361)

Turnover motor

Paper input motor

Chopping circuit

+24V

BIM

BRM

AR-RB1

6

4

GND

+24V

+24V

BFM

Cool down fan motor

(MTD1361)

Chopping circuit

Transistor

Transistor

BTM +24V

(MTD1361)

Chopping circuit

GND

6

4

4

AR-D17/18/19

Page 22

AR-RB1 ELECTRICAL SECTION 6 - 3

CNA-30

GND

CNA-28

+24V

C2

473Z/16V

Q102

RT1N141C

C24

223Z/50V

C23

47uF/35V

+

D102

R19

6.8KJ

R1 6.8KJ

C8 222K/50V

C4

332K/50V

CNB-1

+24V

C26

47uF/35V

+

C3

332K/50V

R9

1KJ

C5

473Z/16V

R10

1KJ

CNA-17

BRM/A

Q101

RT1N141C

R30

1kJ

CNA-15

Vref1

TR1

2SD1264P

ZD1

HZ27-3

C25

473Z/16V

CNA-16

Vref2

R32

2.4kJ

CNA-29

+5V

CNA-27

+24V

CNA-31

GND

CNA-32

/BYSET

BRMA

CNH-4

BRM/A

CNH-6

BRMB

CNH-3

BRM/B

CNH-1

CNC-2

+24V

CNC-5

+24V

CNC-7

+24V

CND-2

+24V

CND-5

+24V

CNE-1

+5V

CNF-1

+5V

CNF-4

+5V

CNF-7

+5V

CNG-1

+5V

CNG-4

+5V

CNG-7

+5V

CNE-3

GND

CNF-3

GND

CNF-6

GND

CNF-9

GND

CNG-3

GND

CNG-9

GND

CNB-2

/BFM

CNC-8

/BGSOL

CNA-8

BGSOL

CNA-1

/BPOD

CNA-2

/BPFD

CNA-3

/BPPD1

CNA-4

/BPPD2

CNA-5

/BPRD

CNA-6

/BDD1

CNA-7

/BDD2

CNG-8

/BPOD

CNG-5

/BPFD

CNE-2

/BPPD1

CNF-2

/BPPD2

CNF-5

/BPRD

CNG-2

/BDD1

CNF-8

/BDD2

C22

223Z/50V

C1 222K/50V

CNA-26

+24V

CNG-6

GND

CNA-14

BPOWD2

Q103

RT1N141C

R2

430J

R28

360J

R3

6.8KJ

C17

223Z/50V

R40

6.8KJ

C19

473Z/16V

R47

360J

BTMA

CND-4

D105

R50

0.47J(1W)

R42

0.47J(1W)

C18

332K/50V

R44

1KJ

R49

6.8KJ

R27 6.8KJ

C14 222K/50V

C21 222K/50V

CNA-21

BPOWD

CNA-22

BTM/A

CNA-23

BTMA

CNA-25

BTMB

CNA-24

BTM/B

BTM/A

CND-6

BTMB

CND-3

BTM/B

CND-1

Q104

RT1N141C

R46

2.4kJ

R35

CNA-20

BRMB

CNA-18

BRMA

CNA-19

BRM/B

R34R38

R48

R39

R51

R45

4.7KJ

R41

4.7KJ

R43

4.7KJ

R37

4.7KJ

R12 R8R7R11

R14

0.47J(1W)

R6

0.47J(1W)

R36

1KJ

C15

332K/50V

CNH-2

+24V

CNH-5

+24V

BIMB

CNC-3

BIM/A

CNC-6

BIMA

CNC-4

R21 6.8KJ

R22

6.8KJ

C10 222K/50V

C11 222K/50V

C7

332K/50V

R16

1KJ

R5

0.47J(1W)

C6

332K/50V

BIM/B

CNC-1

R4

0.47J(1W)

D110

R13

1KJ

R25R23R26R24

CNA-10

BIM/A

CNA-11

BIMA

CNA-12

BIM/B

C16

223Z/50V

CNA-13

BIMB

R31

360J

R15

430J

R17

6.8KJ

R29

1kJ

R33

2.4kJ

CNA-9

BFM

CP3

CP2

CP1

IC101

MTD1361F

IC3

TD62003AP

D104

D107

D109D112D111

D106

D101

C20

47uF/35V

+

IC2

MTD1361

C13

47uF/35V

+

D103

R18

300J

IC1

MTD1361

C12

47uF/35V

+

D108

R20

6.8KJ

C9

473Z/16V

+5V

+24V

+24V

+24V

+5V

+24V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+5V

+24V

+5V

+5V

B

1

E2C

3

B

1

E2C

3

B

1

E2C

3

B

1

E2C

3

NC2NC5Rs A3Vs A25Vs B18Rs B12Vref A24Vref B

19

NC6NC

7

Vmm

22PG15NC8NC9NC10

CR A

23NC13NC21

PG

28

IN /A26IN A27IN /B17IN B

16

CR B

20

OUT A

4

OUT /A

1

OUT B

11

OUT /B

14

COM

9

I11I22I33I44I55I66I77GND

8

O116O215O314O413O512O611O7

10

NC11NC12Rs A9Vs A4Vs B24Rs B19Vref A3Vref B

25

NC14NC

15

Vmm

1PG7PG21LG27NC16

CR A

2NC17PG13

IN /A5IN A6IN /B23IN B

22

CR B

26

OUT A

10

OUT /A

8

OUT B

18

OUT /B

20

NC11NC12Rs A9Vs A4Vs B24Rs B19Vref A3Vref B

25

NC14NC

15

Vmm

1PG7PG21LG27NC16

CR A

2NC17PG13

IN /A5IN A6IN /B23IN B

22

CR B

26

OUT A

10

OUT /A

8

OUT B

18

OUT /B

20

+5V

GND

12345

6

(JST:B10B-PH-K-S)

BIM/A

16

22

19

/BPFD

9

/BPRD

26

3

BRMA

BPOWD2

BRM/A

21

/BDD1

CN-A

17811

BPOWD

5

10BFM

25

2

24

18

Vref2

BGSOL

BIMA

/BPPD2

15

/BPOD

7

20 BRMB

4/BPPD1

+24V

1

23

27 28

29 30

BRM/B /BPOD

DESK

BODY

6

12

13 14BIMB

8

BPFD

Vref1

+5V

7

/BFM

(JST:B2B-PH-K-S)

+24V

CN-B

1

BFM

2

/BDD2

+24V

+5V

5

BIM/B1

GND

CN-C

6

3

/BGSOL

BDD2

(JST:B8B-PH-K-S)

4

2

(JST:B6B-PH-K-S)

CN-D

+24V

GND

+24V

+24V

BTMA

BTM/B5BTM/A

1

BTMB

6

3

+24V

BTM

4

2

M1FL20U × 4

NOTE 1: Assumed 1/16 W for a resistance that does not register a rated loss.

Upper turnover motor

100% : I=0.63A

70% : I=0.45A

40% : I=0.30A

POWD100%:I=0.54A

POWD70%:I=0.40A

POWD40%:I=0.28A

/BYSETGND

DESK

BODY

/BDD2

CN-F

+5V

GND

/BPFD

9

+5V

/BDD1

GND

BIMB

+24V

+24V7BIMA

BIM

8

BIM/A

BGSOL

/BPRD

+5V

5

1

GND

6

3

BPRD

(JST:B9B-PH-K-S)

428

7

+5V

GND

CN-A

CN-G

CN-C CN-B

CN-F

CN-D

BPOD

BDD1

BPPD2

4.7k X 2

CN-E

BPPD1

GND

/BPPD1

(JST:S3B-PH-K-S)

+5V

/BPPD2

CN-E

312

9

Lower turnover motor

I=0.53A

M1FL20U × 4

POWD : I=0.47A

4.7k X 4

4.7k X 4

(JST:S32B-PHDSS)

31 32

BTM/A

BTMA BTM/B

BTMB

CN-G

(JST:B6B-PH-K-R)

CN-H

+24V

BRMA

BRM/B5BRM/A

1

BRMB

6

3

+24V

BRM

4

2

BIM/B

CN-H

4.7k X 4

Paper input motor

I=0.45A

10 N.C

M1FL20U × 4

Not

installed

A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A A

B

C

D

87654

3

21

12345678

D

C

B

A

(4) Circuit diagram

Page 23

AR-RB1 ELECTRICAL SECTION 6 - 4

A. Parts side B. Solder side

(5) Layout of parts

Page 24

Memo

Page 25

q

PARTS GUIDE

反転付きバイパスモジュール

DUPLEX BYPASS/INVERTER UNIT

MODEL

このパーツガイドに掲載されている表示価格ランクは消費税抜きです。

CONTENTS

1

外装部及び左ドアユニット (Exteriors & Left door unit)

2

上開閉ユニット (Upper Open/Shut unit)

3

排紙ユニット及び上搬送部 (Delivery paper unit & Upper transport section)

4

下搬送部及びフレームセクション (Lower transport section & Frame section)

5

反転ベース部 (Reverse base section)

6

配線部 (Wiring section)

7

梱包&付属品 (Packing material & Accessories)

■

索引 (Index)

AR-RB1

SHARP CORPORATION

Page 26

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : メンテナンスパーツ、メンテナンスパーツには入っていないがメンテナンスパーツに近い消耗パーツ。

Bランク : 性能・機能パーツ ( センサー、クラッチ等の電気パーツ )、消耗パーツ。

Eランク : 基板含むユニットパーツ。

Dランク : 整備パーツ ( 外装、パッキング、同梱パーツ )。

Cランク : 上記ランク以外のパーツ ( 基板の子部品を除いたもの )。

DEFINITION

The definition of each Rank is as follows and also noted in the list

A: Maintenance parts, and consumable parts which are not included in but closely related to maintenance parts.

B: Performance/function parts (sensors, clutches, and other electrical parts), consumable parts.

E: Unit parts including PWB.

D: Preparation parts (External fitting, packing, parts packed together).

C: Parts other than the above (excluding sub components of PWB).

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

! 印の商品は、安全上重要な部品です。交換をする時は、安全及び性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with "!" is indispensable for the machine safety maintenance and operation, it must be replaced with

the parts specific to the product specification.

F

当モデルのサービス資料には、この資料以外にサービスマニュアル ( 回路図含む ) があります。合わせてご利用下さい。

F Other than this Parts Guide, please refer to documents Service Manual(including Circuit Diagram)of this model.

Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

1

外装部及び左ドアユニット (Exteriors & Left door unit)

NO. PARTS CODE

1 XEBSE40P10000 AA DD C

2 XEBSE30P10000 AA DD C

3 LHLDZ1540FCZZ AG DS N C

4 XHBSD40P08000 AA DD C

5 LHLDZ1469FCZZ AE DJ C

7 GCAB-1012FCZZ BC GD N D

8 GCAB-1011FCZZ BC GD N D

9 XHBSE40P10000 AA DD C

10 MARMP0263FCZZ AF DS C

11 XEBSD40P10000 AA DD C

12 PGIDM2008FCZZ AX FG N C

13 MSPRD3132FCZZ AG DX N C

14 0EULEV0402JW2 AU EZ N C

15 XRESP50-06000 AA DD C

16 NSFTZ2722FCZZ AU FG N C

17 NROLP1356FCZZ AG DX C

18 MSPRC3140FCZZ AD DJ N C

19 GDOR-0037FCZZ BT NE N D

20 PGIDM2001FCZZ AY FQ N C

21 PGIDM1999FCZZ AU EZ N C

22 MSPRT3167FCZZ AE DS N B

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Screw(4×10) ビス

Screw(3×10) ビス

Fulcrum holder 支点ホルダー

Screw(4×8) ビス

Upper transport fulcrum holder 上搬送支点ホルダー

R cabinet R キャビ

F cabinet F キャビ

Screw(4×10) ビス

Open/Shut door arm 開閉ドアアーム

Screw(4×10) ビス

Knob cover PG 取手カバー PG

Knob return spring 取手復帰スプリング

GID lock release lever GID ロック解除レバー

E-ring(E5) E- リング

Transport sub shaft 搬送従動軸

Sub roller D 従動ローラー D

Transport sub spring 搬送従動スプリング

Left door 左ドア

Left door middle PG 左ドア中 PG

Lower gate 下ゲート

Lower gate return spring 下ゲート復帰スプリング

DESCRIPTION

2

上開閉ユニット (Upper Open/Shut unit)

NO. PARTS CODE

1 XEBSD40P06000 AA DD C

2 LPLTM5932FCZZ AC DJ C

3 VHPGP1A71L3-1 AG DS B

4 GCAB-1009FCZZ BD GJ N D

5 MLEVP0872FCZZ AN EG N C

6 MSPRT3138FCZZ AE DS N C

7 MLEVP0808FCZZ AL EB C

8 MSPRD2966FCZZ AC DJ C

9 PSHEP5073FCZZ AC DJ N C

10 PGIDM2000FCZZ BC GJ N C

11 NSFTZ2729FCZZ AR EQ N C

12 NROLP1082FCZZ AD DJ C

13 MLOKZ0001QSZZ AC DJ C

14 MSPRC3166FCZZ AE DS N C

15 XEPSD30P08X00 AA DD C

16 PGIDM2011FCZZ AV FG N C

17 PGIDM1997FCZZ AS EZ N C

18 MSPRT3135FCZZ AF DS N B

19 PGIDM1998FCZZ BH GX N C

20 PSHEP5072FCZZ AC DJ N C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Screw(4×6) ビス

Tray2 sensor fixing plate トレイ 2 センサー取付板

Photo sensor(GP1A71L) フォトセンサー

Upper Open/Shut cabinet 上開閉キャビ

Full detect actuator 満杯検知アクチュエーター

Delivery sub spring 排紙従動スプリング

Delivery paper actuator 出紙アクチュエーター

Actuator spring T4 アクチュエータスプリング T4

Paper feed gate protect sheet R 入紙ゲート防振シート R

Upper Open/Shut PG 上開閉 PG

Delivery sub shaft 排紙従動軸

Transport sub roller J 搬送従動ローラー J

Transport PG lock PA 搬送 PG ロック PA

Upper Open/Shut lock spring 上開閉ロックスプリング

Screw(3×8X) ビス

Paper feed gate F 入紙ゲート F

Paper feed gate 入紙ゲート

Paper feed gate return spring 入紙ゲート復帰スプリング

Delivery gate 排紙ゲート

Paper feed gate protect sheet F 入紙ゲート防振シート F

DESCRIPTION

– 1 –

Page 27

上開閉ユニット (Upper Open/Shut unit)

2

21 XEBSE40P10000 AA DD C

22 PBRSS0221FCZZ AT EZ N B

24 XEBSE30P10000 AA DD C

25 LBSHZ0303FCZZ AC DJ C

26 XRESP40-06000 AA DD C

1

外装部及び左ドアユニット (Exteriors & Left door unit)

Screw(4×10) ビス

Discharge brush 除電ブラシ

Screw(3×10) ビス

M bush(C) M ブッシング (C)

E-ring(E4) E- リング

2

1

2

1

3

1

3

8

11

12

4

5

17

13

15

14

11

16

18

20

7

21

9

21

22

10

19

FCP06128

上開閉ユニット (Upper Open/Shut unit)

2

4

1

2

6

5

7

3

8

10

25

26

15

24

9

24

14

13

11

20

3

21

11

22

14

12

13

21

12

15

18

16

17

19

26

FCP06129

– 2 –

Page 28

3

排紙ユニット及び上搬送部 (Delivery paper unit & Upper transport section)

NO. PARTS CODE

1 XRESP50-06000 AA DD C

2 NGERH1521FCZZ AK DX N B

4 NGERH1520FCZZ AL EB N B

5 CPLTM6066FC01 AY FQ N C

6 LHLDW1490FCZZ AD DJ C

7 XHBSE40P10000 AA DD C

8 RMOTS0886FCZZ BD GN N B

9 XHBSE30P06000 AA DD C

10 NBRGC0691FCZZ AG DX B

13 NGERH1522FCZZ AV FG N B

14 MSPRT3155FCZZ AF DS N C

15 RPLU-0341FCZZ AW FG B

18 XEBSD30P06000 AA DD C

19 XEBSE40P10000 AA DD C

20 XBBSD30P04000 AA DD C

21 NROLR1412FCZZ AX FG N B

22 NROLR1413FCZZ AY FQ N B

23 LPLTM5912FCZZ AQ EQ C

24 0EUGER0423N01 AN EG B

25 NROLP1356FCZZ AG DX C

26 NSFTZ2722FCZZ AU FG N C

27 MSPRC3140FCZZ AD DJ N C

28 GCAB-1010FCZZ BG GT N D

29 VHPGP1A71L3-1 AG DS B

30 PSHEP5038FCZZ AC DJ N C

31 NBLTH0380FCZZ AL EB N C

32 NPLYZ0395FCZZ AG DS C

33 NBLTH0398FCZZ AP EQ N C

34 NPLYZ0413FCZZ AK DX N C

35 LX-BZ0930FCZZ AC DD C

36 LPLTM6067FCZZ AQ EQ N C

37 LHLDW1009ACZZ AA DD C

38 XBBSD30P06000 AA DD C

39 RMOTS0870FCZZ BA HG N B

40 LPINS0327FCZZ AC DJ C

41 NROLR1424FCZZ AY FQ N B

42 NROLR1414FCZZ AX FG N B

43 NGERH1471FCZ1 AL EB N C

44 NGERH0863FCZZ AB DD C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

E-ring(E5) E- リング

GEAR(20T/40T) ギヤ

Gear(16T/40T) ギヤ

Motor fixing plate upper unit モーター取付板上ユニット

Edge wire saddle エッジワイヤーサドル

Screw(4×10) ビス

Paper feed motor(φ42) 入紙モーター

Screw(3×6) ビス

Bearing(B-F6-63) 軸受

One way gear(22T) ワンウェイギヤ

Solenoid return spring ソレノイド復帰スプリング

SF release solenoid SF 圧解ソレノイド

Screw(3×6) ビス

Screw(4×10) ビス

Screw(3×4) ビス

Paper feed roller 入紙ローラー

Delivery roller 排紙ローラー

ADU Open/Shut sensor fixing plate ADU 開閉センサー取付板

One way gear(18T) ワンウェイギヤ

Sub roller D 従動ローラー D

Transport sub shaft 搬送従動軸

Transport sub spring 搬送従動スプリング

Delivery cabinet 排紙キャビ

Photo sensor(GP1A71L) フォトセンサー

Flange mylar RB1 フランジマイラー RB1

Belt(60S2M150) ベルト

Pulley(S2M40) プーリー

Belt(40S3M309) ベルト

Pulley 20P(S3M) プーリー 20P

Screw(4×6) ビス

Motor fixing plate lower モーター取付板下

Mini clamp ミニクランプ

Screw(3×6) ビス

ADU transport motor lower ADU 搬送モータ下

Spring pin(2×10) スプリングピン

Upper reverse roller 上反転ローラー

Transport roller 搬送ローラー

M transport gear(22T) M 搬送ギヤ

Pick up roller gear(18T) ピックアップローラーギヤ

DESCRIPTION

3

排紙ユニット及び上搬送部 (Delivery paper unit & Upper transport section)

1

2

10

1

1

43

1

1

4

1

7

8

9

5

6

21

20

22

14

10

1

1

33

15

10

34

10

1

35

18

19

13

1

32

31

30

1

40

40

23

41

42

25

9

26

1

27

38

37

39

36

34

1

10

1

35

43

18

29

1

10

10

19

1

1

24

1

44

10

1

28

FCP06130

– 3 –

Page 29

4

下搬送部及びフレーム部 (Lower transport section & Frame section)

NO. PARTS CODE

1 XHBSE40P10000 AA DD C

2 RMOTS0869FCZZ BH HC B

3 LX-BZ0930FCZZ AC DD C

4 LFRM-1089FCZZ AP EQ N D

5 XBBSD30P06000 AA DD C

6 NBRGC0136FCZZ AC DD C

7 XRESP50-06000 AA DD C

8 NROLR1415FCZZ AY FQ N B

9 0EUHLD0309G// AD DJ C

10 NBRGC0691FCZZ AG DX B

11 NROLR1423FCZZ BA FX N B

12 LPINS0261FCZZ AB DD C

13 XRESP70-08000 AA DD C

14 NBRGC0504FCZZ AC DJ C

15 PSHEP5038FCZZ AC DJ N C

16 LPINS0327FCZZ AC DJ C

17 NROLR1425FCZZ AX FG N B

18 NPLYZ0413FCZZ AK DX N C

19 NBLTH0396FCZZ AN EG N C

20 NPLYZ0395FCZZ AG DS C

21 NPLYZ0383FCZZ AF DS C

22 NBLTH0397FCZZ AN EQ N C

23 NBLTH0395FCZZ AP EQ N C

24 LSTYM0300FCZZ AT EZ N C

25 MSPRP3139FCZZ AN EG N C

26 LX-BZ0958FCZZ AL EB N C

27 LHLDZ1461FCZZ AF DS C

28 MSPRC2881FCZZ AB DJ C

29 XEBSE30P10000 AA DD C

30 NSFTZ2723FCZZ AW FG N C

31 NROLP0896FCZZ AC DD C

32 NROLP1356FCZZ AG DX C

33 NSFTZ2733FCZZ AX FG N C

34 XEBSE40P10000 AA DD C

35 MSPRC3140FCZZ AD DJ N C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Screw(4×10) ビス

ADU transport motor upper ADU 搬送モータ上

Screw(4×6) ビス

Reverse drive frame 反転駆動フレーム

Screw(3×6) ビス

Bearing(B-F-63) 軸受

E-ring(E5) E- リング

Lower reverse roller 下反転ローラー

Micro wire saddle マイクロワイヤーサドル

Bearing(B-F6-63) 軸受

Transport roller lower 搬送ローラー下

Spring pin(3×10) スプリングピン

E-ring(E7) E- リング

Bearing(B-F8-13) 軸受

Flange mylar RB1 フランジマイラー RB1

Spring pin スプリングピン

Delivery roller 出紙ローラー

Pulley 20P(S3M) プーリー 20P

Belt(60S2M186) ベルト

Pulley(S2M40) プーリー

Pulley(24P) プーリー

Belt(40S3M204) ベルト

Belt(40S3M225) ベルト

Joint stay 連結ステイ

Frame earth plate spring フレームアース板バネ

Reverse position screw 反転位置決メ段ビス

Sub roller holder 従動ローラーホルダー

Sub roller spring T1 従動ローラースプリング T1

Screw(3×10) ビス

Reverse sub shaft 反転従動軸

Transport sub roller 搬送従動ローラー

Sub roller D 従動ローラー D

Lower sub shaft 下従動軸

Screw(4×10) ビス

Transport sub spring 搬送従動スプリング

DESCRIPTION

4

下搬送部及びフレーム部 (Lower transport section & Frame section)

26

25

1

1

24

27

29

28

29

28

31

26

1

30

1

25

1

35

32

32

7

5

7

6

1

35

33

2

16

18

7

4

3

15

19

20

14

13

16

21

22

13

21

23

10

7

18

7

34

34

9

12

11

10

7

8

34

14

13

10

7

34

17

FCP06131

– 4 –

Page 30

5

反転ベース部 (Reverse base section)

NO. PARTS CODE

1 LX-BZ0955FCZZ AG DX N C

2 MSPRC3159FCZZ AE DJ N C

3 NBRGC0649FCZZ AF DS C

4 VHPGP1A71L3-1 AG DS B

6 LBNDJ0014FCZ1 AB DJ C

8 XEBSE30P14000 AA DD C

9 LPLTP5827FCZZ AF DS C

11 XEBSE30P10000 AA DD C

12 CPWBN1538FC31 BP LP N E

13 MLEVP0876FCZZ AH DX N C

14 MSPRD3150FCZZ AE DS N C

15 MLEVP0808FCZZ AL EB C

16 MSPRD2966FCZZ AC DJ C

17 PSHEP5011FCZZ AF DS N C

18 NSFTZ2723FCZZ AW FG N C

19 NROLP1356FCZZ AG DX C

20 MSPRC2881FCZZ AB DJ C

21 LHLDZ1461FCZZ AF DS C

5

反転ベース部 (Reverse base section)

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Reverse fixing screw 反転取付ビス

Screw return spring 段ビス復帰スプリング

Bearing 軸受

Photo sensor(GP1A71L) フォトセンサー

Wire band(BIG) 結束バンド大

Screw(3×14) ビス

Multi sensor fixing plate マルチセンサー取付板

Screw(3×10) ビス

BY drive PWB unit BY 駆動基板ユニット

Transport upper actuator 搬送上アクチェーター

Transport upper actuator spring 搬送上アクチェータースプリング

Delivery paper actuator 出紙アクチュエーター

Actuator spring T4 アクチュエータスプリング T4

Sensor cover sheet センサーカバーシート

Reverse sub shaft 反転従動軸

Sub roller D 従動ローラー D

Sub roller spring T1 従動ローラースプリング T1

Sub roller holder 従動ローラーホルダー

DESCRIPTION

8

9

11

6

4

12

1

4

13

14

17

11

4

1

2

4

15

16

3

2

3

8

8

19

18

17

21

11

11

16

15

11

20

21

21

20

19

18

11

FCP06132

6

配線部 (Wiring section)

NO. PARTS CODE

1 DHAI-3398FCZZ AE DS N C

2 DHAI-3383FCZZ AR EQ N C

3 DHAI-3379FCZZ BC GJ N C

4 DHAI-3382FCZZ AU EZ N C

5 DHAI-3381FCZZ AG DS N C

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

BY earth harness 2 BY アースハーネス 2

BY delivery sensor harness BY 排紙センサ - ハ - ネス

BY interface harness BY 中継ハ - ネス

BY reverse harness BY 反転ハ - ネス

BY transport sensor harness BY 搬送センサ - ハ - ネス

DESCRIPTION

– 5 –

Page 31

配線部 (Wiring section)

6

1

2

3

4

5

FCP06133

77

梱包&付属品 (Packing material & Accessories)

NO. PARTS CODE

1 MLEVP0879FCZZ AK DX N C

2 LHLDZ1543FCZZ AG DS N C

3 SSAKA0006UCZZ AA DD D

4 PGIDW2006FCZZ BD GN N C

5 SPAKA6352FCZZ AZ FQ N D

6 0EUSAK0615P// AF DS D

SPAKC6373FCZZ BB GD N D

7

SPAKC6351FCZZ BB GD N D

8 SPAK-545ECCZZ AA DD N D

9 SPAKA6196FCZZ AV FG N D

7

梱包&付属品 (Packing material & Accessories)

PRICE RANK

Ex. Ja.

NEW

MARK

PART

RANK

Full the tip detect actuator 満杯先端アクチェーター

Wire PG holder ワイヤー PG ホルダー

Vinyl bag(40×60) ポリ袋

Wire PG ワイヤー PG

Spacer スペーサー

Vinyl bag(740×900) ポリ袋

Packing case (JAPAN only) パッキンケース

Packing case (Except JAPAN) パッキンケース

Vinyl bag(100×220) ポリ袋

Vinyl bag(100×400) ポリ袋

4

1

3

2

DESCRIPTION

5

9

8

6

5

7

FCP06134

– 6 –

Page 32

■

索引 (Index)

PARTS CODE

[C]

CPLTM6066FC01

CPWBN1538FC31

[D]

DHAI-3379FCZZ

DHAI-3381FCZZ

DHAI-3382FCZZ

DHAI-3383FCZZ

DHAI-3398FCZZ

[G]

GCAB-1009FCZZ

GCAB-1010FCZZ

GCAB-1011FCZZ

GCAB-1012FCZZ

GDOR-0037FCZZ

[L]

LBNDJ0014FCZ1

LBSHZ0303FCZZ

LFRM-1089FCZZ

LHLDW1009ACZZ

LHLDW1490FCZZ

LHLDZ1461FCZZ

LHLDZ1469FCZZ

LHLDZ1540FCZZ

LHLDZ1543FCZZ

LPINS0261FCZZ

LPINS0327FCZZ

LPLTM5912FCZZ

LPLTM5932FCZZ

LPLTM6067FCZZ

LPLTP5827FCZZ

LSTYM0300FCZZ

LX-BZ0930FCZZ

LX-BZ0955FCZZ

LX-BZ0958FCZZ

MARMP0263FCZZ

MLEVP0808FCZZ

MLEVP0872FCZZ

MLEVP0876FCZZ

MLEVP0879FCZZ

MLOKZ0001QSZZ

MSPRC2881FCZZ

MSPRC3140FCZZ

MSPRC3159FCZZ

MSPRC3166FCZZ

MSPRD2966FCZZ

MSPRD3132FCZZ

MSPRD3150FCZZ

MSPRP3139FCZZ

MSPRT3135FCZZ

MSPRT3138FCZZ

MSPRT3155FCZZ

MSPRT3167FCZZ

NBLTH0380FCZZ

NBLTH0395FCZZ

NBLTH0396FCZZ

NBLTH0397FCZZ

NBLTH0398FCZZ

NBRGC0136FCZZ

NBRGC0504FCZZ

NBRGC0649FCZZ

NBRGC0691FCZZ

NGERH0863FCZZ

NGERH1471FCZ1

NGERH1520FCZZ

NGERH1521FCZZ

NGERH1522FCZZ

NPLYZ0383FCZZ

"

"

"

[M]

"

"

"

"

"

[N]

"

JAPAN ONLY

ORDER CODE

572 221 8109 3- 5 AY FQ N C

572 684 3991 5- 12 BP LP N E

572 542 2239 6- 3 BC GJ N C

572 542 2240 6- 5 AG DS N C

572 542 2241 6- 4 AU EZ N C

572 542 2242 6- 2 AR EQ N C

572 542 2246 6- 1 AE DS N C

572 107 2132 2- 4 BD GJ N D

572 107 2133 3- 28 BG GT N D

572 107 2134 1- 8 BC GD N D

572 107 2135 1- 7 BC GD N D

572 113 0083 1- 19 BT NE N D

572 201 0163 5- 6 AB DJ C

572 204 0302 2- 25 AC DJ C

572 213 2219 4- 4 AP EQ N D

541 214 5023 3- 37 AA DD C

572 214 2191 3- 6 AD DJ C

572 214 2180 4- 27 AF DS C

572 214 2180 5- 21 AF DS C

572 214 2182 1- 5 AE DJ C

572 214 2322 1- 3 AG DS N C

572 214 2325 7- 2 AG DS N C

572 218 0339 4- 12 AB DD C

572 218 0605 3- 40 AC DJ C

572 218 0605 4- 16 AC DJ C

572 221 7814 3- 23 AQ EQ C

572 221 7867 2- 2 AC DJ C

572 221 8114 3- 36 AQ EQ N C

572 221 7850 5- 9 AF DS C

572 231 0587 4- 24 AT EZ N C

572 970 2327 3- 35 AC DD C

572 970 2327 4- 3 AC DD C

572 970 2556 5- 1 AG DX N C

572 970 2557 4- 26 AL EB N C

572 240 0423 1- 10 AF DS C

572 248 1334 2- 7 AL EB C

572 248 1334 5- 15 AL EB C

572 248 1458 2- 5 AN EG N C

572 248 1461 5- 13 AH DX N C

572 248 1462 7- 1 AK DX N C

572 252 0020 2- 13 AC DJ C

572 258 3817 4- 28 AB DJ C

572 258 3817 5- 20 AB DJ C

572 258 4098 1- 18 AD DJ N C

572 258 4098 3- 27 AD DJ N C

572 258 4098 4- 35 AD DJ N C

572 258 4101 5- 2 AE DJ N C

572 258 4102 2- 14 AE DS N C

572 258 3830 2- 8 AC DJ C

572 258 3830 5- 16 AC DJ C

572 258 4104 1- 13 AG DX N C

572 258 4108 5- 14 AE DS N C

572 258 4111 4- 25 AN EG N C

572 258 4113 2- 18 AF DS N B

572 258 4114 2- 6 AE DS N C

572 258 4118 3- 14 AF DS N C

572 258 4119 1- 22 AE DS N B

572 271 0836 3- 31 AL EB N C

572 271 0839 4- 23 AP EQ N C

572 271 0840 4- 19 AN EG N C

572 271 0841 4- 22 AN EQ N C

572 271 0842 3- 33 AP EQ N C

572 272 0096 4- 6 AC DD C

572 272 0467 4- 14 AC DJ C

572 272 0718 5- 3 AF DS C

572 272 0804 3- 10 AG DX B

572 272 0804 4- 10 AG DX B

572 281 0941 3- 44 AB DD C

572 281 2308 3- 43 AL EB N C

572 281 2309 3- 4 AL EB N B

572 281 2310 3- 2 AK DX N B

572 281 2311 3- 13 AV FG N B

572 284 0811 4- 21 AF DS C

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

NPLYZ0395FCZZ

"

NPLYZ0413FCZZ

"

NROLP0896FCZZ

NROLP1082FCZZ

NROLP1356FCZZ

"

"

"

NROLR1412FCZZ

NROLR1413FCZZ

NROLR1414FCZZ

NROLR1415FCZZ

NROLR1423FCZZ

NROLR1424FCZZ

NROLR1425FCZZ

NSFTZ2722FCZZ

"

NSFTZ2723FCZZ

"

NSFTZ2729FCZZ

NSFTZ2733FCZZ

[P]

PBRSS0221FCZZ

PGIDM1997FCZZ

PGIDM1998FCZZ

PGIDM1999FCZZ

PGIDM2000FCZZ

PGIDM2001FCZZ

PGIDM2008FCZZ

PGIDM2011FCZZ

PGIDW2006FCZZ

PSHEP5011FCZZ

PSHEP5038FCZZ

"

PSHEP5072FCZZ

PSHEP5073FCZZ

[R]

RMOTS0869FCZZ

RMOTS0870FCZZ

RMOTS0886FCZZ

RPLU-0341FCZZ

[S]

SPAK-545ECCZZ

SPAKA6196FCZZ

SPAKA6352FCZZ

SPAKC6351FCZZ

SPAKC6373FCZZ

SSAKA0006UCZZ

[V]

VHPGP1A71L3-1

"

"

[X]

XBBSD30P04000

XBBSD30P06000

"

XEBSD30P06000

XEBSD40P06000

XEBSD40P10000

XEBSE30P10000

"

"

"

XEBSE30P14000

XEBSE40P10000

"

"

"

XEPSD30P08X00

XHBSD40P08000

XHBSE30P06000

XHBSE40P10000

"

"

XRESP40-06000

XRESP50-06000

"

"

XRESP70-08000

JAPAN ONLY

ORDER CODE

572 284 0814 3- 32 AG DS C

572 284 0814 4- 20 AG DS C

572 284 0870 3- 34 AK DX N C

572 284 0870 4- 18 AK DX N C

572 287 1092 4- 31 AC DD C

572 287 1431 2- 12 AD DJ C

572 287 2212 1- 17 AG DX C

572 287 2212 3- 25 AG DX C

572 287 2212 4- 32 AG DX C

572 287 2212 5- 19 AG DX C

572 287 2354 3- 21 AX FG N B

572 287 2355 3- 22 AY FQ N B

572 287 2356 3- 42 AX FG N B

572 287 2357 4- 8 AY FQ N B

572 287 2362 4- 11 BA FX N B

572 287 2363 3- 41 AY FQ N B

572 287 2364 4- 17 AX FG N B

572 290 2885 1- 16 AU FG N C

572 290 2885 3- 26 AU FG N C

572 290 2886 4- 30 AW FG N C

572 290 2886 5- 18 AW FG N C

572 290 2890 2- 11 AR EQ N C

572 290 2893 4- 33 AX FG N C

572 310 0364 2- 22 AT EZ N B

572 345 3883 2- 17 AS EZ N C

572 345 3884 2- 19 BH GX N C

572 345 3885 1- 21 AU EZ N C

572 345 3886 2- 10 BC GJ N C

572 345 3887 1- 20 AY FQ N C

572 345 3892 1- 12 AX FG N C

572 345 3893 2- 16 AV FG N C

572 345 3894 7- 4 BD GN N C

572 403 5208 5- 17 AF DS N C

572 403 5209 3- 30 AC DJ N C

572 403 5209 4- 15 AC DJ N C

572 403 5226 2- 20 AC DJ N C

572 403 5227 2- 9 AC DJ N C

572 630 1061 4- 2 BH HC B

572 630 1062 3- 39 BA HG N B

572 630 1114 3- 8 BD GN N B

572 647 0379 3- 15 AW FG B

500 900 0006 7- 8 AA DD N D

572 902 1629 7- 9 AV FG N D

572 902 1697 7- 5 AZ FQ N D

572 901 1886 7- 7 BB GD N D

572 901 1890 7- 7 BB GD N D

541 906 1016 7- 3 AA DD D

572 568 0153 2- 3 AG DS B

572 568 0153 3- 29 AG DS B

572 568 0153 5- 4 AG DS B

541 970 5027 3- 20 AA DD C

541 970 5028 3- 38 AA DD C

541 970 5028 4- 5 AA DD C

578 970 0102 3- 18 AA DD C

572 970 1363 2- 1 AA DD C

572 970 0588 1- 11 AA DD C

595 970 0122 1- 2 AA DD C

595 970 0122 2- 24 AA DD C

595 970 0122 4- 29 AA DD C

595 970 0122 5- 11 AA DD C

578 970 0104 5- 8 AA DD C

572 970 0575 1- 1 AA DD C

572 970 0575 2- 21 AA DD C

572 970 0575 3- 19 AA DD C

572 970 0575 4- 34 AA DD C

595 970 0136 2- 15 AA DD C

578 970 0074 1- 4 AA DD C

578 970 0070 3- 9 AA DD C

595 970 0167 1- 9 AA DD C

595 970 0167 3- 7 AA DD C

595 970 0167 4- 1 AA DD C

509 399 5001 2- 26 AA DD C

572 399 0063 1- 15 AA DD C

572 399 0063 3- 1 AA DD C

572 399 0063 4- 7 AA DD C

571 399 0027 4- 13 AA DD C

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 7 –

Page 33

PARTS CODE

[0]

0EUGER0423N01

0EUHLD0309G//

0EULEV0402JW2

0EUSAK0615P//

JAPAN ONLY

ORDER CODE

572 281 1894 3- 24 AN EG B

572 214 1585 4- 9 AD DJ C

572 248 1464 1- 14 AU EZ N C

572 906 0124 7- 6 AF DS D

NO.

PRICE R.

Ex. Ja.

NEW P/R

PARTS CODE

JAPAN ONLY

ORDER CODE

NO.

PRICE R.

Ex. Ja.

NEW P/R

– 8 –

Page 34

Memo

Page 35

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

le constructeur.

Mettre au rebut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

(German) Achtung

Explosionsgefahr bei Verwendung inkorrekter Batterien.

Als Ersatzbatterien dürfen nur Batterien vom gleichen Typ oder

vom Hersteller empfohlene Batterien verwendet werden.

Entsorgung der gebrauchten Batterien nur nach den vom

Hersteller angegebenen Anweisungen.

CAUTION FOR BATTERY REPLACEMENT

(For USA, CANADA)

Contains lithium-ion battery. Must be disposed of properly.

Remove the battery from the product and contact

federal or state environmental

agencies for information on recycling and disposal options.

CAUTION FOR BATTERY DISPOSAL

Page 36

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

Trademark Acknowledgments

Microsoft Windows, MS-DOS, Windows NT, Windows 2000 are trademarks of Microsoft

Corporation in the U. S. A. and other countries.

Macintosh, Power Macintosh, Mac OS, LaserWriter, and AppleTalk are registered trademarks of

Apple Computer, Inc.

IBM, PC/ AT, and PowerPC are trademarks of International Business Machines Corporation.

Pentium is a registered trademark of Intel Corporation.

PCL is a trademark of the Hewlett- Packard Company.

PostScript is a registered trademark of Adobe Systems Incorporated.

NetWare is a registered trademark of Novell, Inc.

All other trademarks and copyrights are the property of their respective owners.

SHARP CORPORATION

Digital Document System Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2003 January Printed in Japan

Loading...

Loading...