Page 1

CONTENTS

Parts marked with “ ” are important for maintaining the safety of the machine. Be sure to replace these parts

with the replacement parts specified to maintain the safety and performance of the machine.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

INSTALLATION MANUAL

CODE : 00ZAR700//I1E

DIGITAL LASER COPIER/PRINTER

DIGITAL MULTIFUNCTIONAL SYSTEM

AR-M550N/M550U

AR-M620N/M620U

MODEL

AR-M700N/M700U

[ 1 ] AR-M550/M620 UNPACKING AND INSTALLATION . . . . . . . . . . 1 - 1

[ 2 ] AR-LC6 UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . 2 - 1

[ 3 ] AR-CF2 UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . 3 - 1

[ 4 ] AR-F15/F16 UNPACKING AND INSTALLATION . . . . . . . . . . . . . 4 - 1

[ 5 ] AR-PN4 UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . 5 - 1

[ 6 ] AR-P19 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[ 7 ] AR-FR11 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[ 8 ] AR-PK5 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

[ 9 ] AR-NS3 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] AR-FX8/AR-MM9 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

[11] MECHANICAL COUNTER INSTALLATION . . . . . . . . . . . . . . . . . 11-1

[12] DRY HEATER INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

1

1

1

1

2

2

Page 2

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 1

[1] AR-M550/M620/M700

UNPACKING AND INSTALLATION

1. Installing (use) conditions

Before installing the machine, check that the following installing (use)

conditions are satisfied.

If the installing (use) conditions are not satisfied, the machine may not

display full performances, resulting in troubles. It may also cause

safety problems. Therefore, be sure to arrange the installing (use) conditions before setting up the machine.

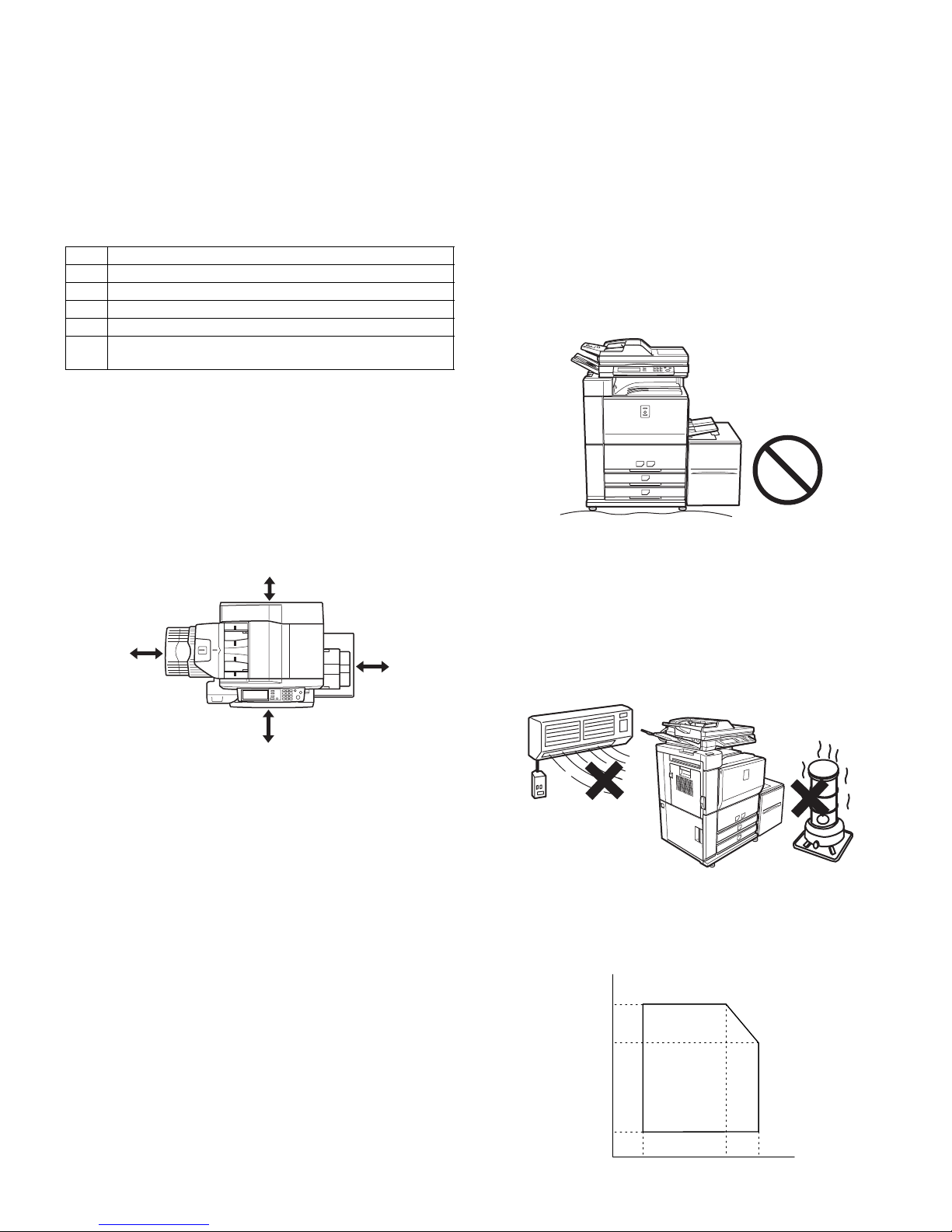

A. Bringing space

For installation of a large size machine, be sure to check that the door

size is great enough before bringing in.

B. Installing space

The following space must be provided around the machine in order to

assure machine performances and proper operations.

If any option is installed, provide the additional space for installing it.

Especially the space at the rear of the machine must be provided suffi-

ciently. If not, the machine cannot exhibit functions against heat and

dust, causing some troubles.

C. Power source

(Capacity, voltage, frequency, safety, plug)

If the power specifications are not satisfied, the machine cannot exhibit

full performances and may cause safety trouble.

Strictly observe the following specifications.

(1) Power capacity

Check that the following power capacity is satisfied. If not, additionally

provide a power source.

Current capacity

Japan: 20A or more

100V: 20A or more

200V: 10A or more

(2) Power voltage

Measure the voltage during copying to check that the voltage is in the

range of the specified voltage ±10%.

If the voltage is outside the specified range, use thicker lead wires to

reduce impedance.

(An electrical work is required.)

Use of a step-up transformer is also available. In this case, the capac-

ity must be great enough for the max. power consumption of the

machine.

(3) Power frequency, waveform

The frequency must be within the range of the specified frequency

±2%. If power waveform is deformed, a trouble may occur.

(4) Safety

Be sure to properly ground the machine.

(5) Power plug

Check the form of the power plug. If the shape does not match, do not

use it.

D. Floor strength and level

This machine is considerably heavy and becomes heavier with an

option installed.

The floor must be strong enough for assuring safety, and the machine

must be installed horizontally.

If not, toner concentration control is not properly performed, resulting in

degraded copy quality and distorted images.

E. Direct rays of the sun, dust, temperature,

humidity, gasses, chemicals, vibration

(1) Temperature and humidity

This machine is designed to perform properly under the specified temperature and humidity. If the temperature and humidity exceeds the

specified range, the machine may not operate properly and or cause

equipment failure.

Especially when the humidity is too high, paper absorbs humidity to

cause a paper jam or dirty copy.

(Do not install the machine near a stove, a humidifier, or an air conditioner.)

Do not install the machine near a heater, a cooler, or a humidifier.

Dew may be formed inside the machine to cause a trouble. Use

enough care for ventilation.

No. Content

1 Bringing space

2 Installing space

3 Power source (Capacity, fluctuation, safety)

4 Floor strength

5 Direct rays of the sun, dust, temperature, humidity, gases,

chemicals

31.5"

(80cm)

23.6"

(60cm)

23.6"

(60cm)

11.8"

(30cm)

Humidity (RH)

85%

60%

20%

10˚C 30˚C 35˚C Temperature

Page 3

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 2

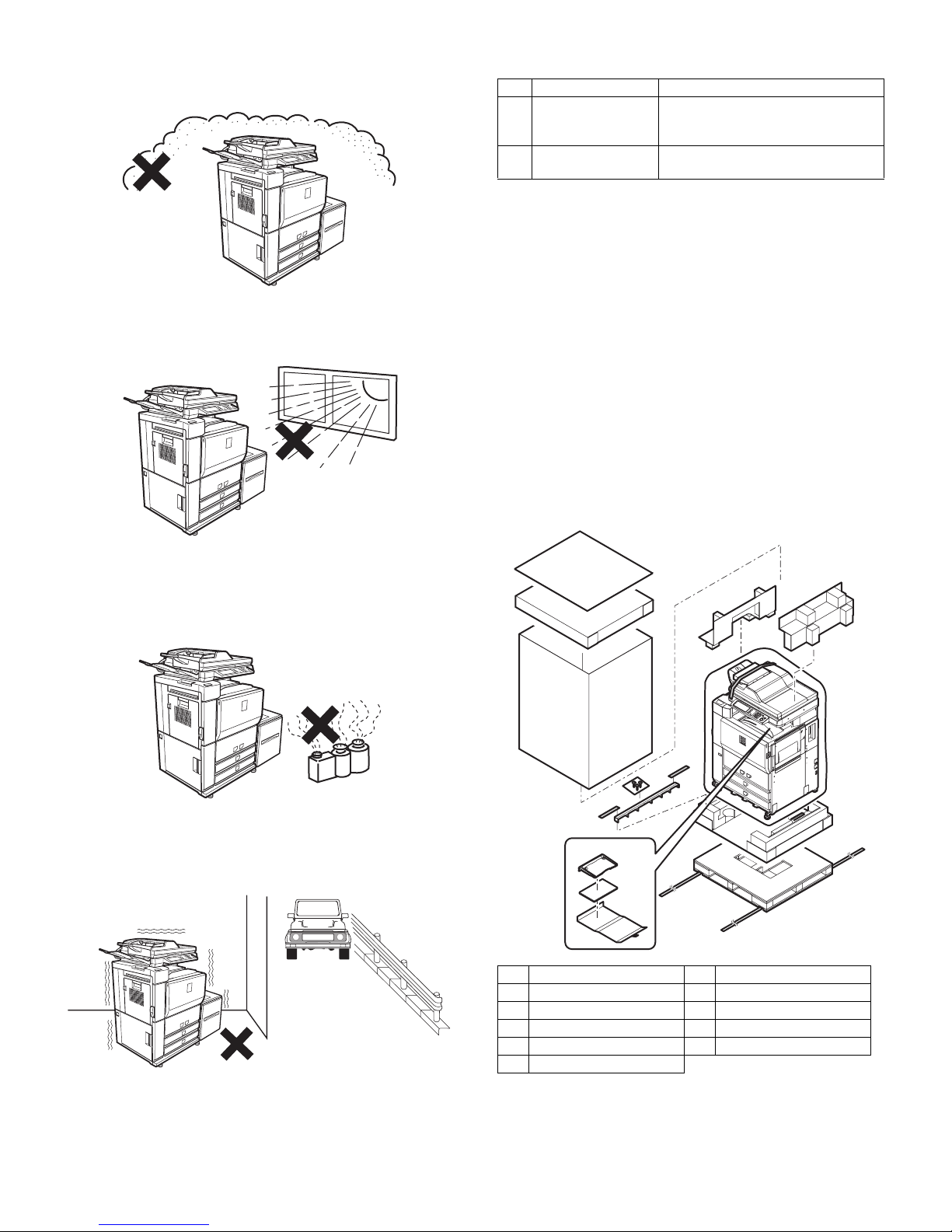

(2) Dust

If dust enters the machine, it may cause dirty copy and a paper jam,

resulting in a shortened lifetime.

(3) Direct rays of the sun

If the machine is installed under the rays of the sun, the exterior of the

machine may be discolored and abnormal copies may be produced.

(4) Gases and chemicals

Do not install the machine at a place where there are gases and chemicals. Especially be careful to avoid installation near a diazo-type

copier, which produces ammonium gas.

Copy quality may be adversely affected and a trouble may be caused.

(5) Vibration

Avoid installation near a machine which produces vibrations.

If vibrations are applied to the copier machine, copy images may be

deflected and a trouble may be caused.

2. Transit and delivery

A. Implements, facility, and manpower

It is recommendable to use a forklift for bringing in the machine for

safety.

If no forklift is available, manpower of four or more persons is required.

The machine is considerably heavy, and requires safety precautions

for delivery and installation.

Transit of the machine must be made in packed condition to the installing place.

B. Delivery

Remove the packing materials prior to installation in the ofice environment.

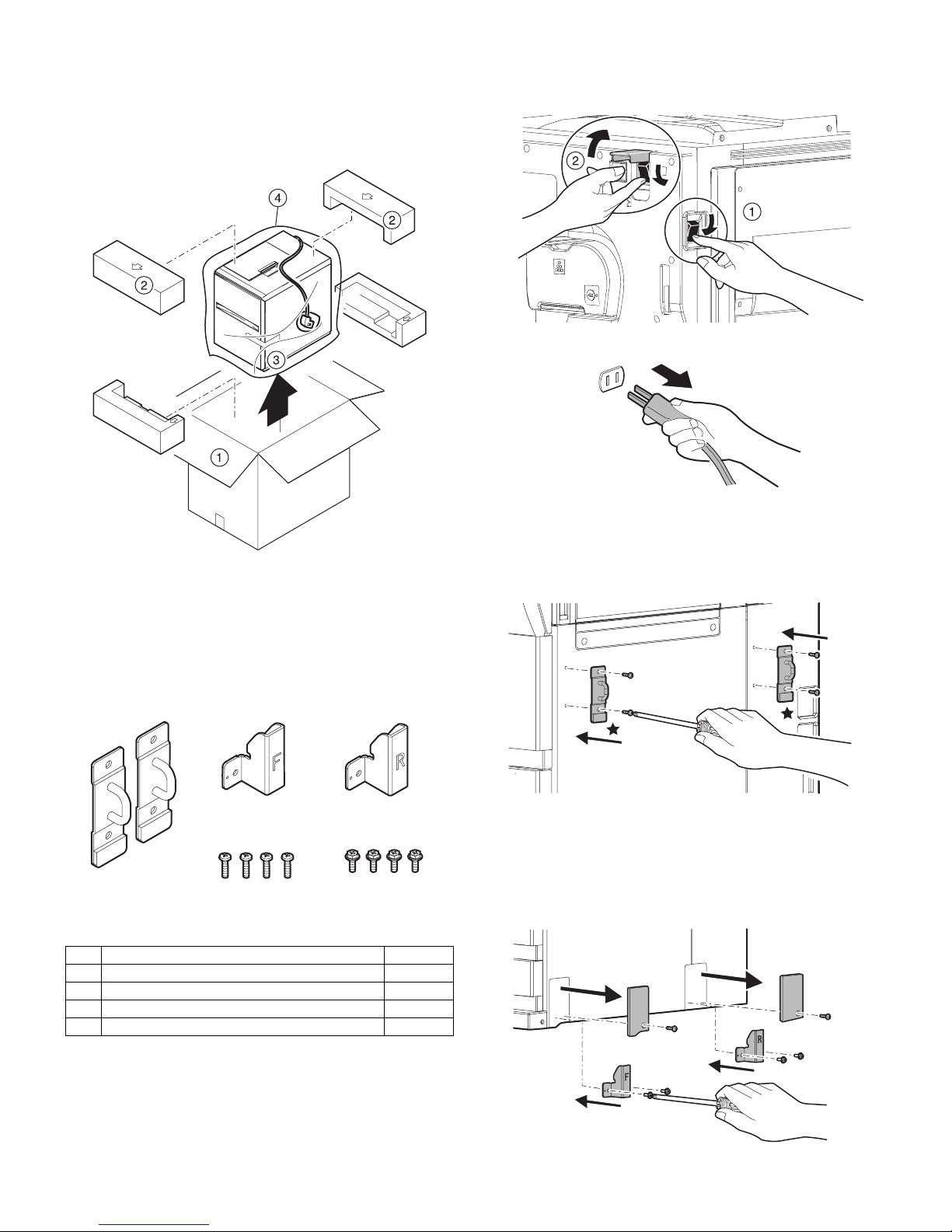

3. Unpacking

A. Unpacking procedure

1) Remove the PP band.

2) Remove the top case.

3) Remove the internal packing pads and the items packed together

with the machine.

No. Content Method

1 Implements, facility,

and manpower

Use a forklift. (If no forklift is available,

manpower of four or more persons is

required.)

2 Delivery Transit must be made in packed

condition.

1 PP band 7 Polyethylene bag

2 Top case 8 Bottom case unit

3 Pack case 9 Accessory unit

4 Skid pad 10 Paper exit tray AS

5 Top pad R 11 Operation manual

6 Top pad L

Page 4

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 3

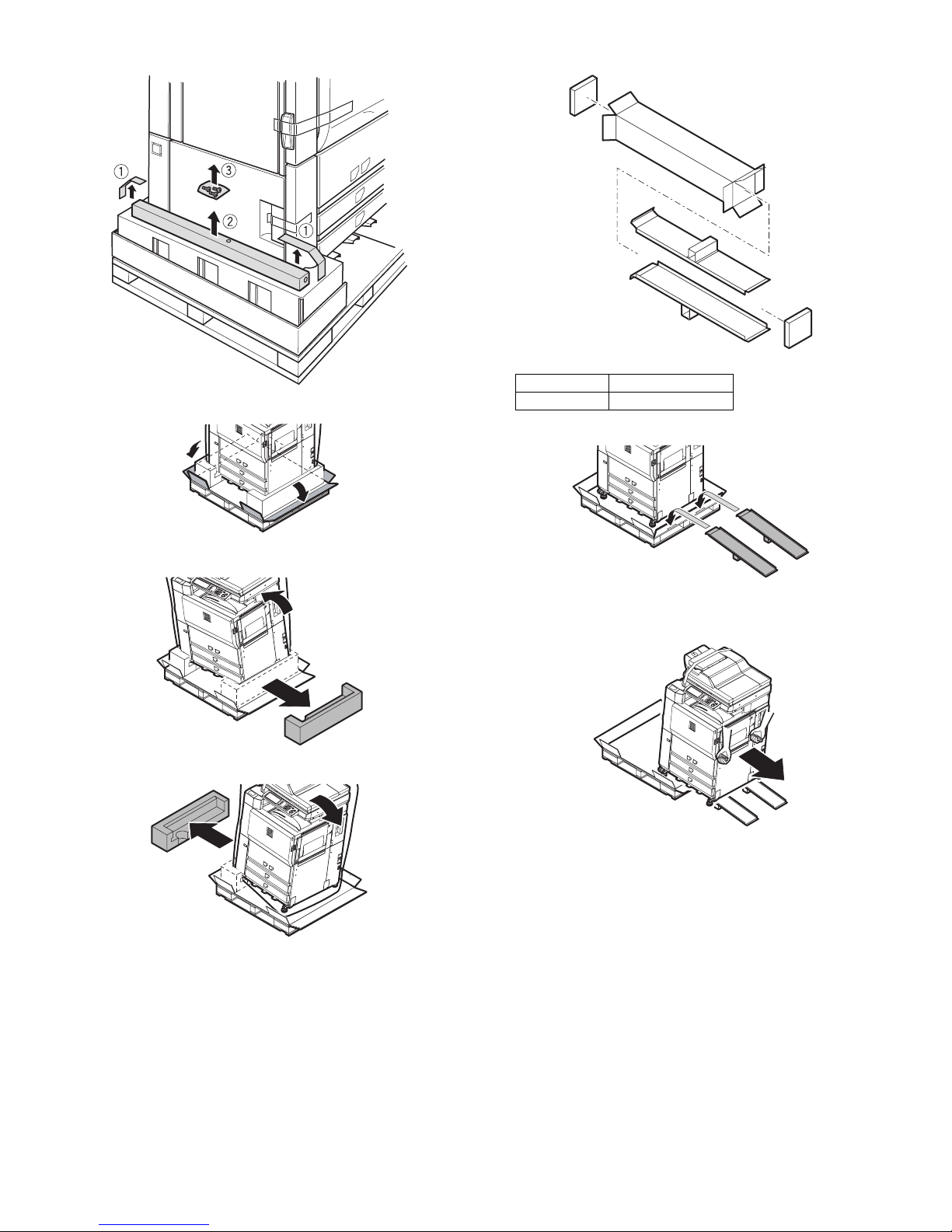

4) Remove the adjuster cover and the screw (in the bag).

5) Cut the four corners of the bottom case.

6) Lift the machine slightly, and remove the bottom pad L.

7) Lift the machine slightly, and remove the bottom pad R.

8) Remove the slope.

∗ Slope: Parts

9) Attach the slope to the concave section of the skid.

10) Hold the machine grips and push them down in the arrow direc-

tion.

Part name Part code

Skid slope DKiT-0367FCZZ

Page 5

: Feb. 9 2004

2

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 4

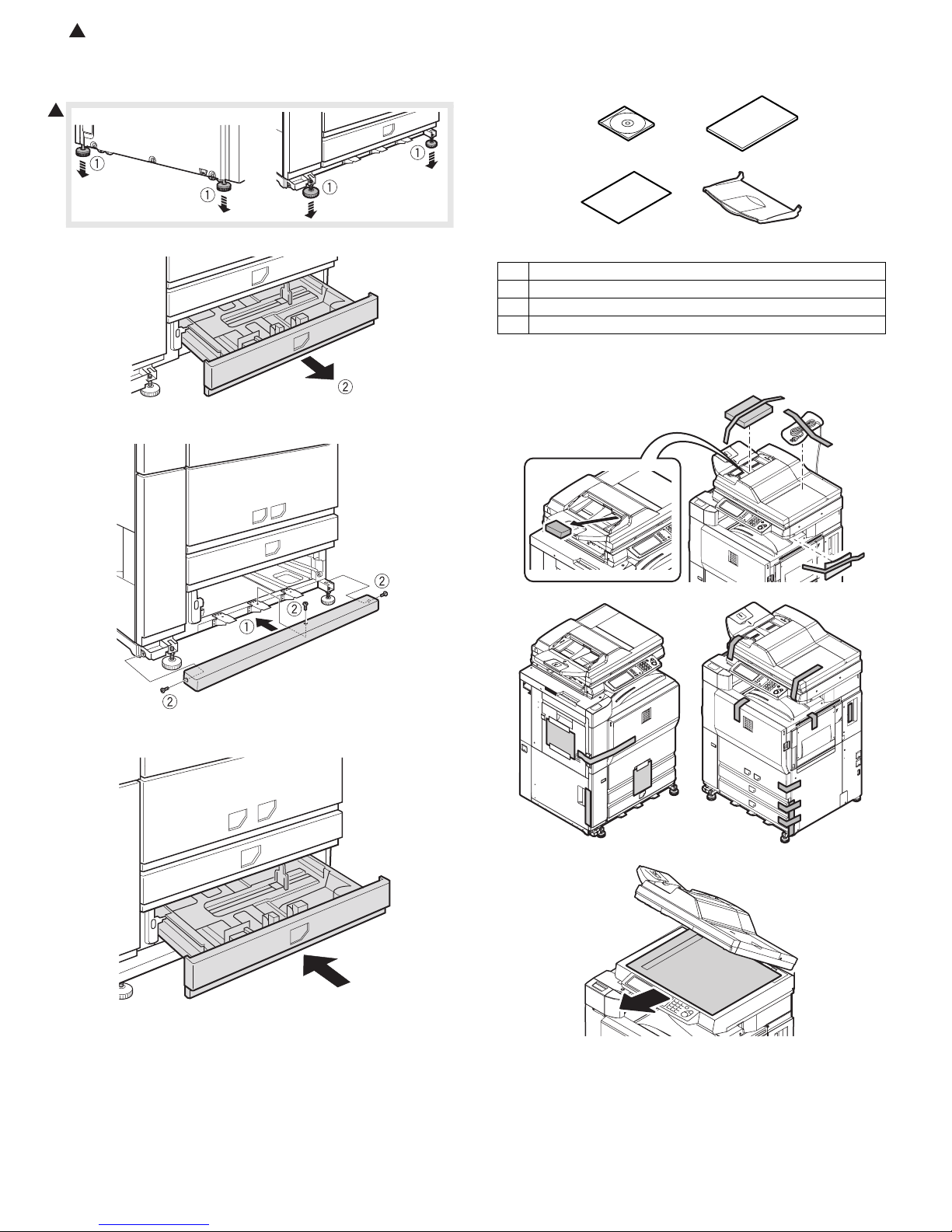

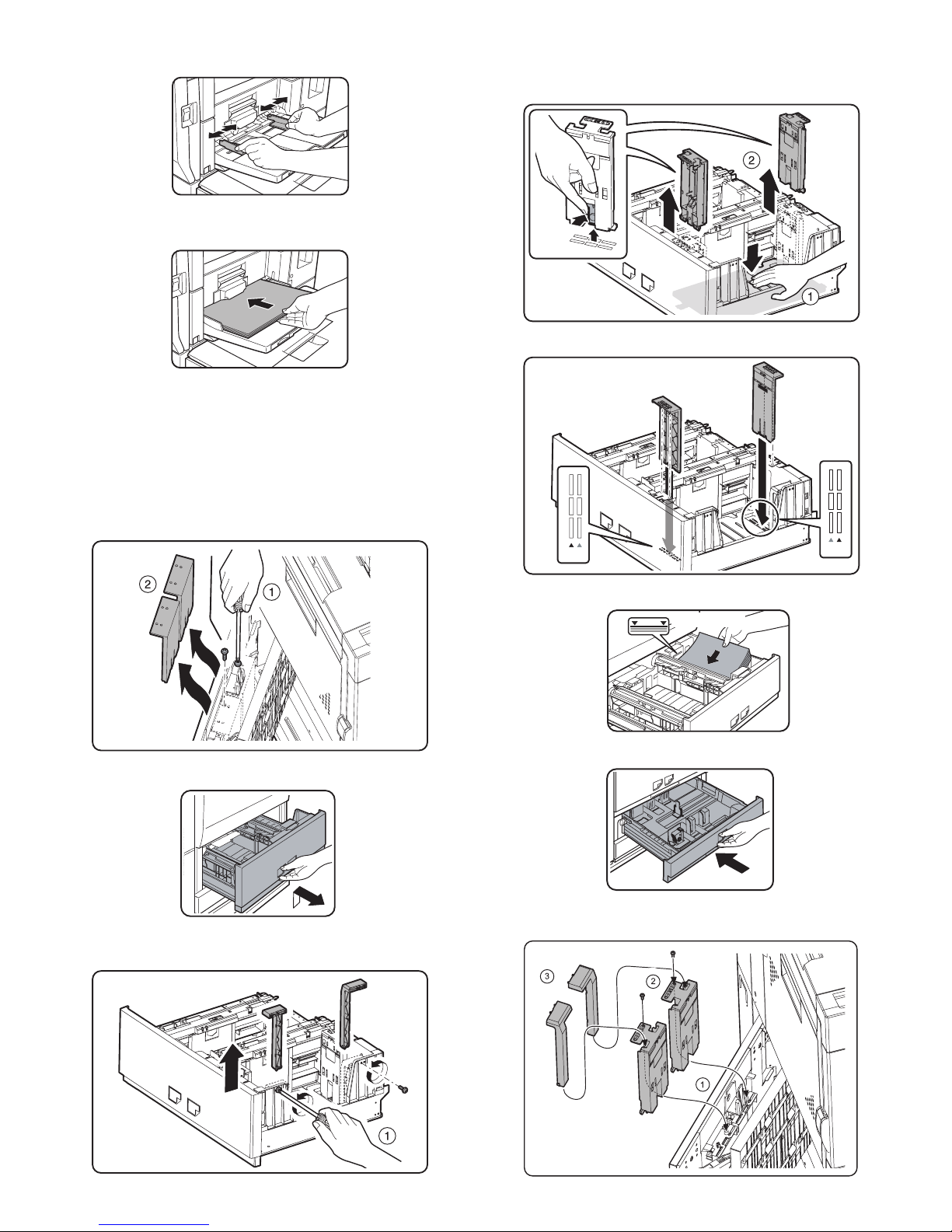

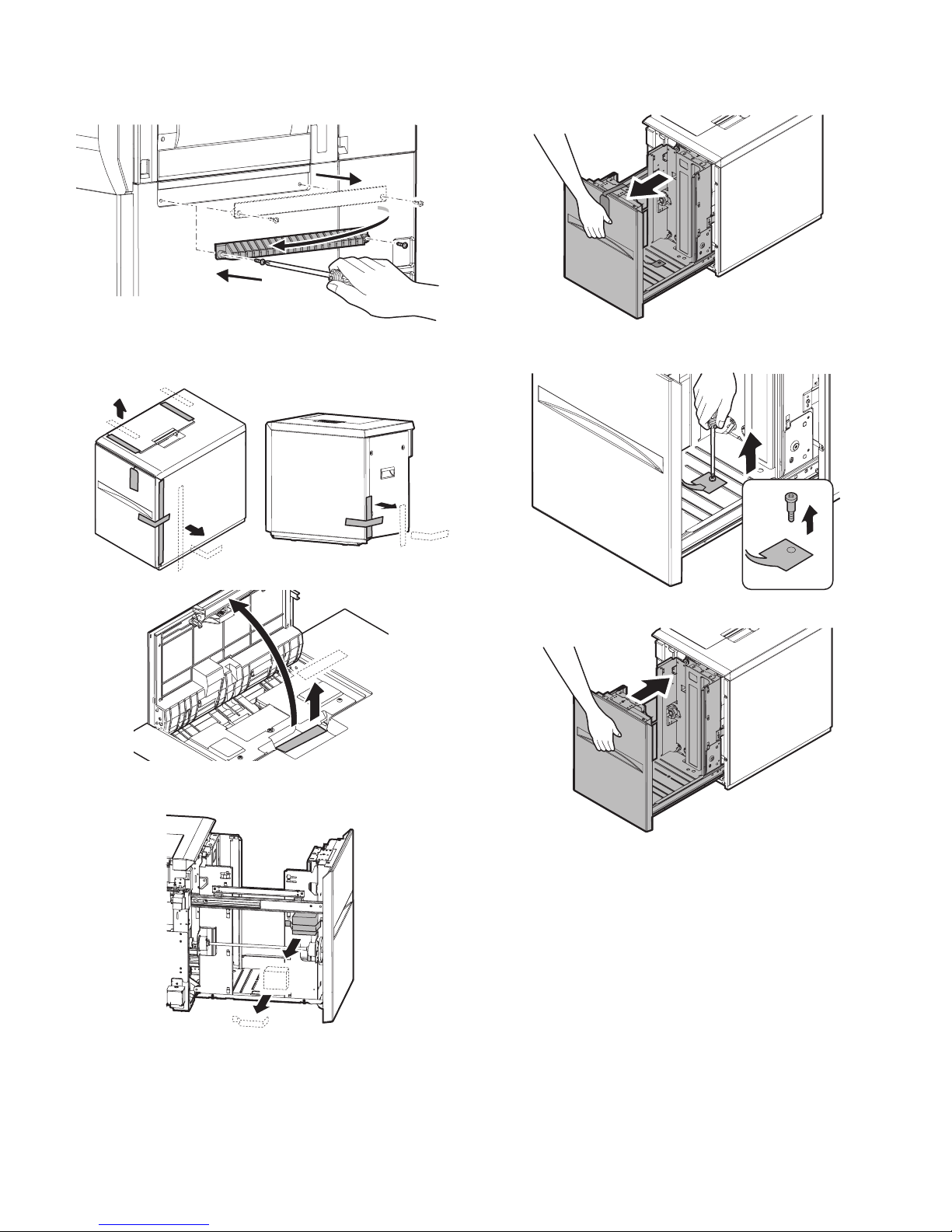

B. Adjuster cover installation

1) Move the main unit to the installing position, and turn the adjuster to

fix the main unit.

2) Remove the bottom tray from the main unit.

3) Install the adjuster cover to the main unit.

4) Insert the bottom tray into the main unit.

Note: This machine includes a hard disk drive, which must be pro-

tected against vibrations and shocks.

Never move the machine with the power ON.

Packed items

C. Remove the fixing tape and the reinforcing

material

2

1 Driver (CD-ROM) x 1

2 Operation manual x 1

3 Delivery and installation report x 1

4 Paper exit tray x 1

12

34

Page 6

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 5

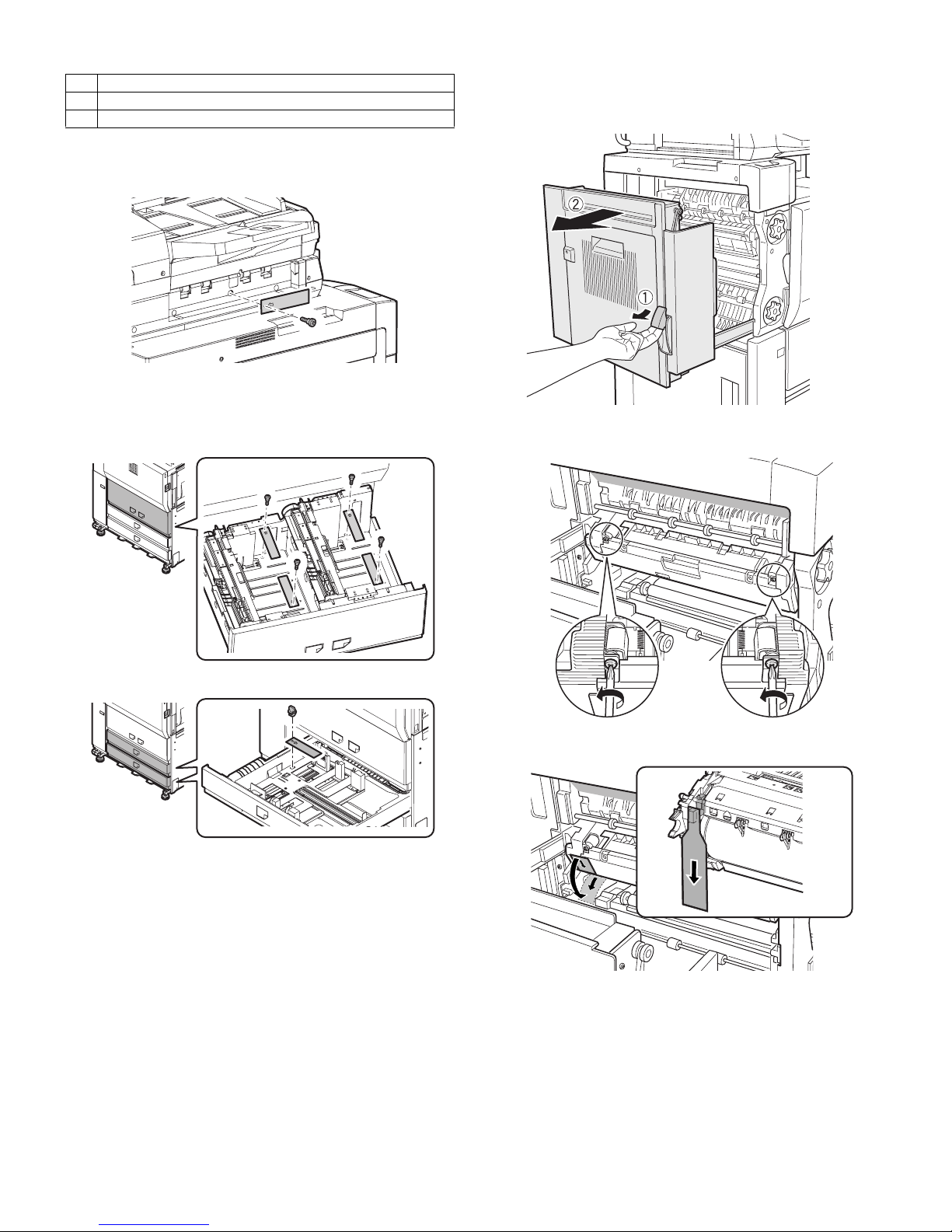

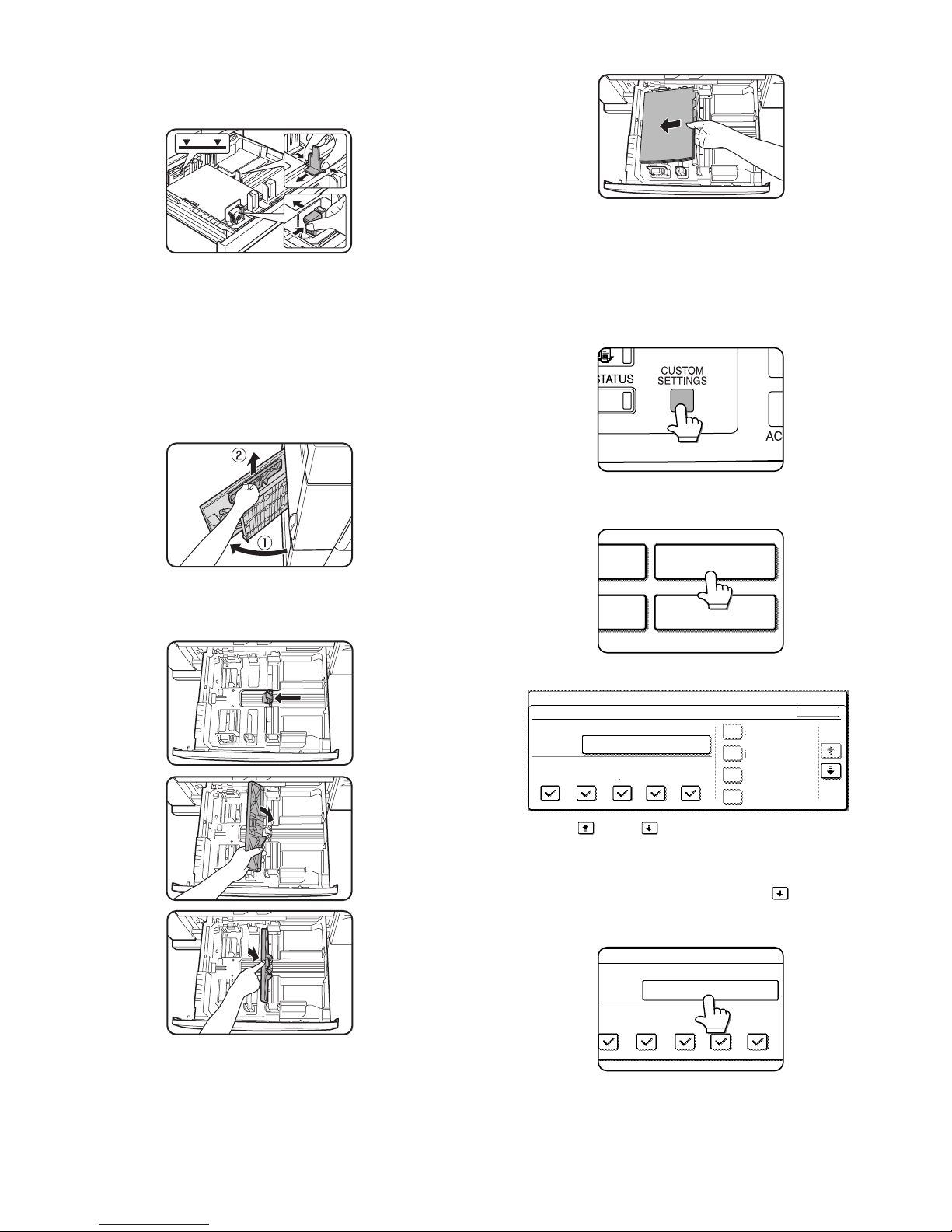

D. Lock release

(1) No. 2/3 mirror base lock release

Remove the No. 2/3 mirror base fixing screw and the label of note for

unpacking on the left side.

(2) Tray rotation release plate lock release

Remove the paper feed tray rotation plate fixing screw and the label of

note for tray.

[Tray 1, Tray 2]

[Tray 3, Tray 4]

E. Press the fusing section (upper and lower heat

rollers) and remove the process separation pawl

fixing block.

1) Pull the knob on the left door to pull out the left door.

2) Turn the pressing screw in the fusing section as shown in the figure

below (fully loosen it) to press the heat roller.

3) Remove the separation pawl fixing block from the process unit.

4) Replace the left door.

Lock position

1 No. 2/3 mirror base lock screw

2 Tray rotation plate fixing material

2

Page 7

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 6

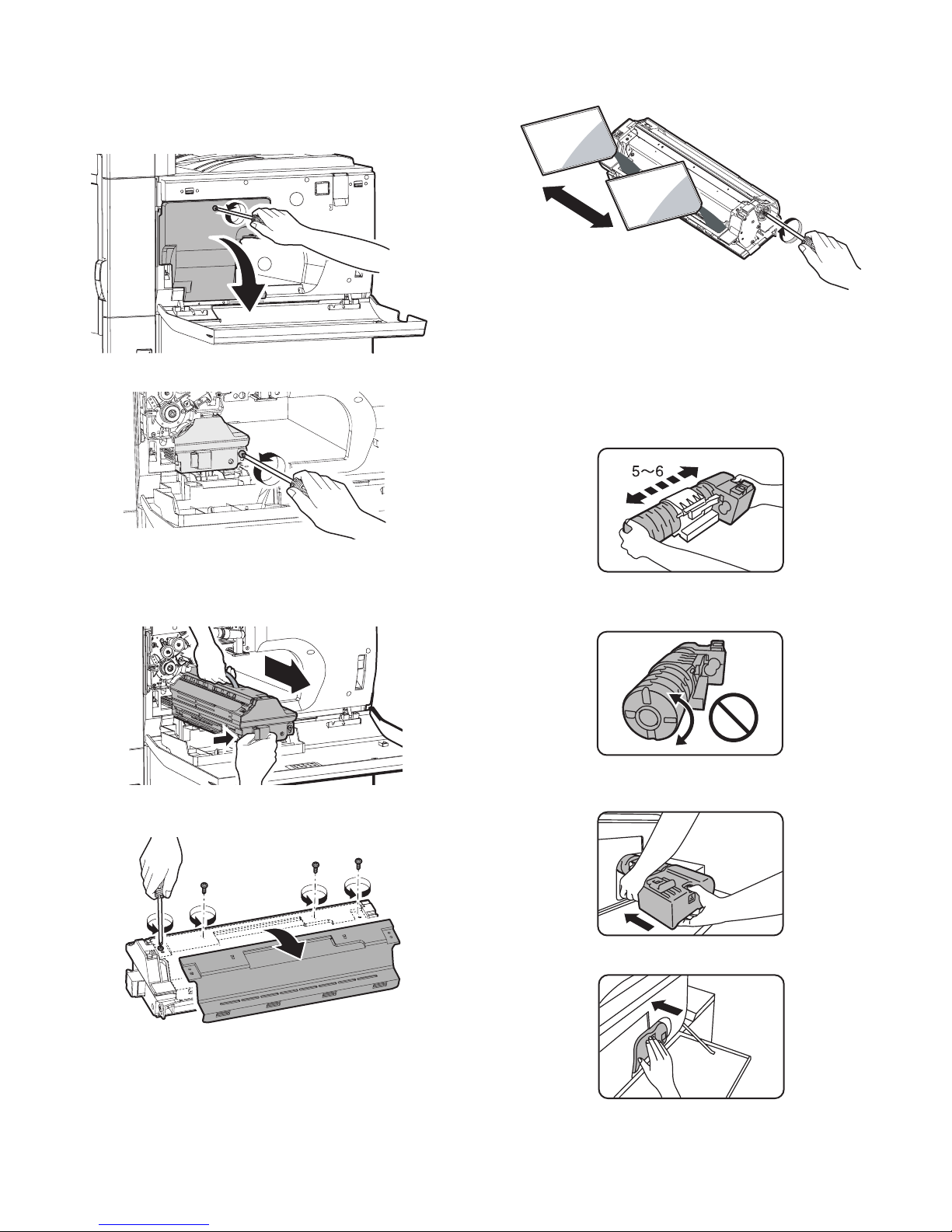

F. Set developer

(1) Supply developer

1) Open the front cabinet.

2) Loosen the blue screw of the process cover, and tilt down the process cover toward you.

3) Loosen the blue screw which is fixing the developing unit.

4) While pressing the developing unit lock lever, pull out the developing unit.

Hold the strap of the developing unit and remove the developing

unit.

5) Remove the four fixing screws of toner hopper in the developing

unit.

6) While supplying developer from the developer supply port of the

developing unit, turn the MG gear clockwise with a plus screwdriver

to supply all developer to the developing unit.

7) Install the toner hopper to the developing unit.

8) Insert the developing unit to the main unit and fix it with the blue

screw.

9) Close the process cover and fix it with the blue screw.

(2) Toner set

1) Remove the toner cartridge from the box, and shake it several

times horizontally.

Note: Be sure to shake the toner cartridge horizontally.

Be careful not rotate as shown in the figure below.

2) Insert the toner cartridge into the main unit insertion port as shown

below. In this case, do not turn the cartridge.

3) Insert the toner cartridge until it is locked.

2

1

Page 8

: Feb. 9 2004

2

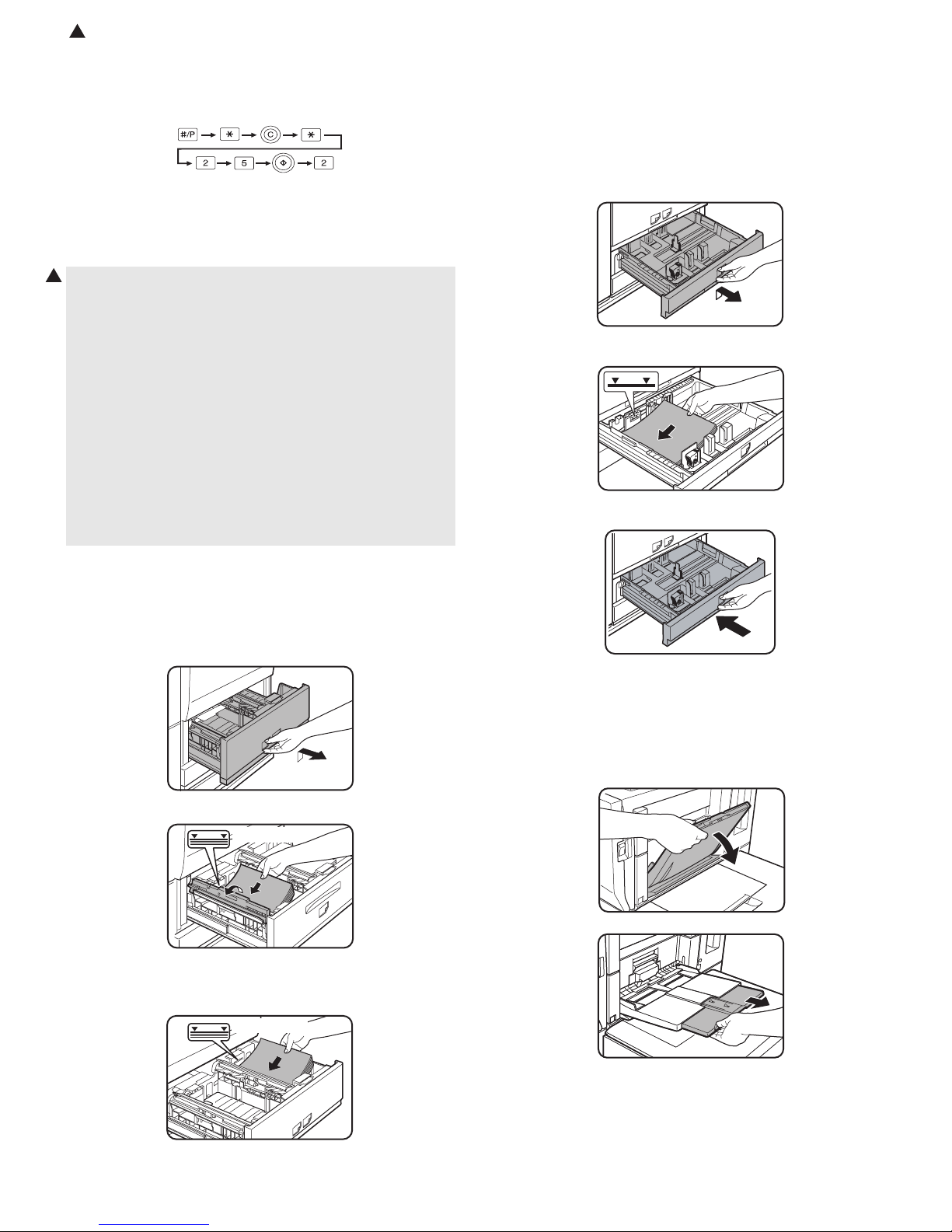

(3) Set the toner density reference control level

Insert the power plug into the power outlet, and turn on the power

switch of the main unit.

1) With the front cabinet open, enter the SIM 25-2 mode.

2) Close the front cabinet.

3) Press START key to execute the simulation. Toner is stirred for 3

minutes, and sampling of the toner density control sensor value is

repeated 16 times. The average level of the sensor detection level

is set (stored) as the reference toner density control value.

Note: The 70-sheet machine (AR-M700N/U) performs resetting after

2

normal completion of toner concentration control level setting

operation (3 min) by SIM25-2, and supplies toner during warming up when the fuser heater lamp is turned ON in order to

increase the toner concentration level by 0.5%.

When there is some toner in the intermediate hopper, the above

toner supply operation is completed in about 90 sec.

Since the warming-up time of fusing is within 2 min, the machine

goes to the print ready state in 1 min 30 sec or 2 min.

When, however, there is no toner in the intermediate hopper (on

installation, etc.), toner is supplied from the toner bottle to the

developing unit and it takes more time than the above to reach

the specified toner concentration level, that is, it takes about 200

sec for the machine to go to the print ready state.

Toner supply operation to increase the toner concentration level

by 0.5% after completion of SIM25-2 is performed only in the 70sheet machine, and not performed in the 55/62-sheet machines.

4) Slowly insert the tray 1 and the tray 2.

(2) Supply paper to the tray 3 and the tray 4

The tray 3 is for 11" x 17" to 5-1/2" x 8-1/2"R size (A3 size to A5R) and

special paper, and the tray 4 is for 11" x 17" to 5-1/2" x 8-1/2"R size

(A3 size to A5R) paper.

(For the kinds of paper and special paper, refer to the specifications of

this manual.)

1) Pull out the tray 3 and the tray 4 until they stop.

2) Supply paper so that the specified line is not exceeded.

3) Slowly insert the tray 3 or the tray 4.

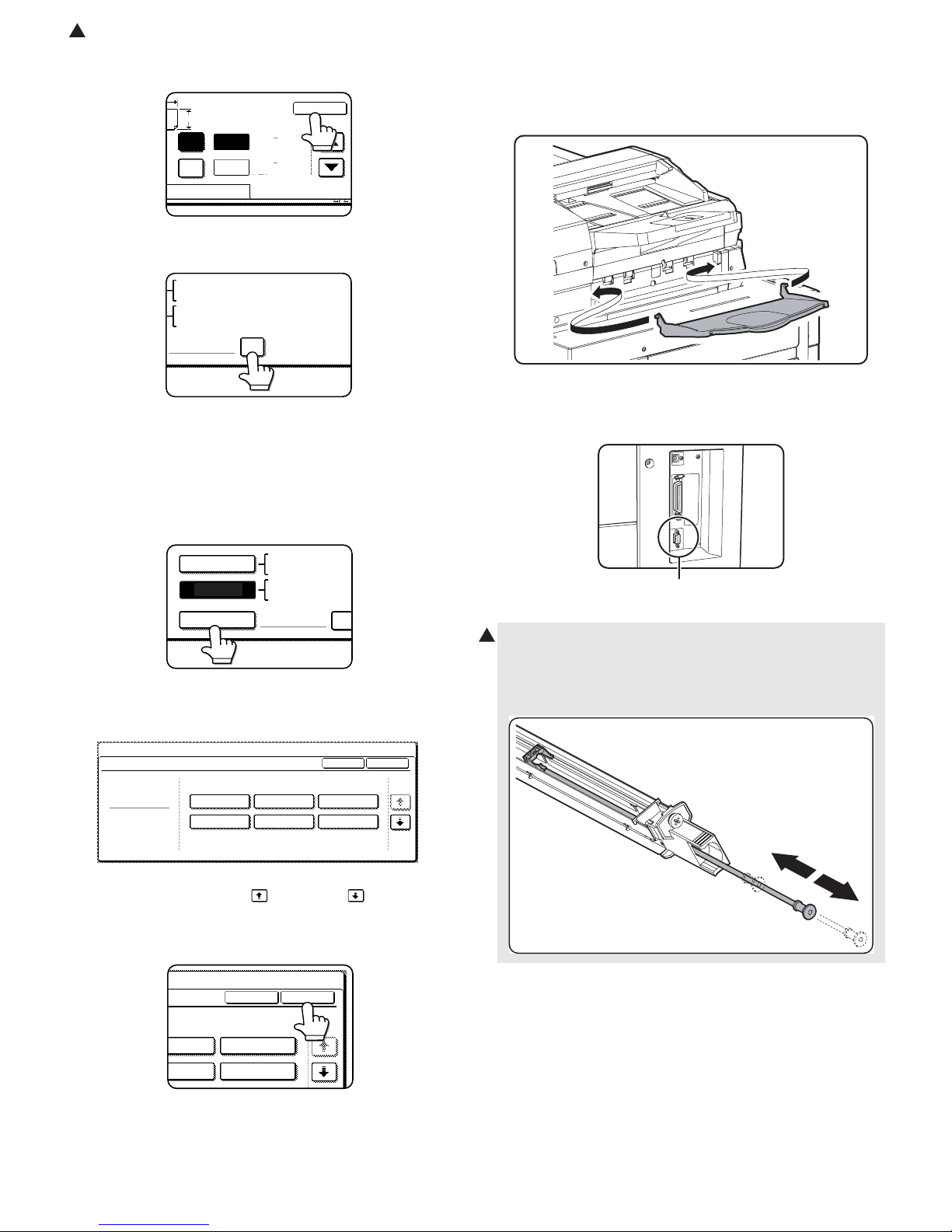

G. Paper supply

(1) Supply to tray 1 and tray 2

The tray 1 is for A4 or 8-1/2" x 11" paper, and the tray 2 is for A4 or B5

or 8-1/2" x 11" paper. (The factory setting of the tray 2 is B5.)

1) Pull out the tray 1 and the tray 2 until they stop.

2) Lift the paper guide, and supply paper to the tray 1.

Specified line

After supplying paper, be sure to return the paper guide to the original position.

3) Supply paper to the tray 2 similarly.

(3) Supply paper to the manual paper feed tray.

The manual paper feed tray is for 11" x 17" to 8-1/2" x 11"R size (A3

size to A5R) and special paper.

(For the kinds of paper and special paper, refer to the specifications of

this manual.)

1) Open the manual paper feed tray.

Specified line

Note: Supply paper so that the paper quantity level does not exceed

the specified line.

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 7

Note: When setting 11" x 17", 8-1/2" x 14", 8-1/2" x 13", or 8-1/2" x

11"R (A3, B4, or A4R) paper, be sure to pull out the auxiliary

tray.

If it is not pulled out completely, the size of paper set on the

manual paper feed tray is not displayed properly.

Page 9

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 8

2) Set the manual paper feed guide to the set paper size.

3) Set the paper with print face up and insert until it makes contact

with the manual paper feed guide.

Note: If there is any gap between paper and the manual paper feed

guide, skew feed or wrinkles may be caused. Be sure to set

paper so that there is no gap between paper and the guide.

(4) Tray 2 paper size change

When changing the paper size of the tray 2 from B5 to A4, replace the

guide plate with the A4-exclusive regulation plate.

1) Remove the A4-exclusive regulation plate from the storage position

left inside of the machine. (It is fixed with a fixing screw under the

tab paper guide.)

2) Pull out the tray 1 and the tray 2.

3) Remove the B5 size regulation plate and the rear edge regulation

plates F and R from the tray 2.

When removing the B5 size regulation plate, slightly press the

paper feed base plate downward and press the hook under the regulation plate to remove.

4) Install the A4 size regulation plate.

5) Supply paper to the tray 2.

6) Push the tray 1 and the tray 2.

Note: Store the B5 size regulation plate and the rear edge regulation

plates F and R for future use.

A4

LT

A4

LT

Specified line

Page 10

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 9

(5) Tray 3 or tray 4 paper size change

1) Pull out the tray 3 or the tray 4.

2) Hold and slide the fixing knob (slide system) of the partition plates A

and B to fit with the size of paper to be supplied.

3) Supply paper into the tray.

4) Push the tray.

Note: Note that a certain special paper cannot be used for the tray 4.

To use the special paper, use the tray 3.

(6) Tab paper setting

To use tab paper, install the exclusive-use guide to the tray 3.

Note that the tray 4 cannot be used.

1) Remove the exclusive-use guide from the storage position left

inside of the machine.

2) Pull out the tray 3.

3) Slide the partition plate to tab paper as shown in the figure below

and install it so that it covers the partition plate.

4) Supply tab paper with the print face up into the tray 3.

5) Push the tray 3.

(7) Setting the paper type and paper size

Follow these steps to change the paper type setting when the paper

type has been changed in a paper tray. For the paper types that can be

used in each tray.

1) Press the [CUSTOM SETTINGS] key.

The custom setting menu screen will appear.

2) Touch the [TRAY SETTINGS] key.

The paper tray selection screen will appear.

3) Display the setting screen of the desired paper tray.

Touch the key or key to display the setting screen of the

desired paper tray.

Note: To automatically switch to a tray with the same size and type of

paper (if there is one) in the event that the paper tray runs out of

paper, display the last screen with the key and select

[AUTO TRAY SWITCHING].

4) Touch the [TYPE / SIZE] key.

TRAY SETTINGS

TA

PRINTER

CONDITION

1/8

PLAIN / 8 x11

OK

PRINT

TRAY SETTINGS

TYPE / SIZE

CUSTOM SETTINGS

TRAY1

FAX

I-FAX

COPY

DOC.

FILING

FIXED PAPER

DISABLE DUPLEX

DISABLE STAPLE

DISABLE PUNCH

1

/

2

TYPE / SIZE

TRAY3

PRINT

COPY

I-FAX

DOC.

FILING

FAX

PLAIN / 8 x11

1

/

2

Page 11

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 10

5) Select the type of paper that was loaded in the tray.

Example: The paper type of tray 3 is selected.

Touch the desired paper type to select it. The paper size setting

screen will appear.

Notes:

• Tabbed paper can only be used in tray 3 and the bypass tray.

• Label sheet, OHP: Tray 1, 2, 4, and 5 cannot be used.

• Heavy paper: Tray 1, 2, and 5 cannot be used.

6) Select the size of paper that was loaded in the tray.

Touch the appropriate keys (checkboxes).

Note: Sizes that can be selected vary depending on the selected

paper type.

7) Touch the [OK] key in the size setting screen.

You will return to the tray setting screen of step 3.

8) Select output functions that can be used with the selected tray.

Touch the checkboxes under the desired items to select them.

Note: When the inserter (option) is selected, printing of faxes and

Internet faxes is not possible.

User type

Select a "User type" when the name of the paper type does not appear

in the selections or when you wish to select the tray attributes yourself.

Touch the key in step 5 on the previous page to display the user

type selection screen and then select a user type.

9) Set the attributes of the paper tray only if you have selected a user

type. (Touch the checkboxes to the left of the items to select them.)

Notes:

• Paper tray attributes cannot be set when a user type is not selected.

• Tray attributes depend on the selected paper.

• "FIXED PAPER SIDE" and "DISABLE DUPLEX" cannot be simulta-

neously enabled.

10) Configure paper settings for each tray and then touch the [OK] key

to exit.

Note: The size and type of paper loaded in the bypass tray can also

be set from the paper setting screen. Touch the [PAPER

SELECT] key in the main screen to display the paper selection

screen, and then touch the [PAPER SELECT] key of the bypass

tray and go to step 5.

(8) Setting the paper size when a special size is loaded

Note: Special sizes of paper cannot be loaded in trays 1, 2, 4 and 5.

[Trays 3 and the bypass tray]

1) Perform steps 1 through 5 of "Setting the paper type and paper

size".

2) Touch the [SIZE INPUT] key and then touch the [INCH] tab.

(The size entry palette appears.)

3) Touch the key or the key to enter the X (width) and Y

(length) dimensions of the paper.

X (width) is initially selected. To enter Y (length), touch the [Y] key

and then enter the length.

[AUTO-INCH] key: Select when you have loaded an inch-based

size of paper.

[AUTO-AB] key: Select when you have loaded an AB size of

paper.

[SIZE INPUT] key: Select to directly enter a paper size.

[NON STANDARD

SIZE] checkbox:

Select when you have loaded a non-standard

size of paper.

CANCEL

1/2

PLAIN

RECYCLED

PRE-PRINTED PRE-PUNCHED

LETTER HEAD

COLOR

HEAVY PAPER

TAB PAPER

LABELS

TRANSPARENCY

TRAY 3 TYPE/SIZE SETTING

SELECT THE PAPER TYPE.

CUSTOM SETTINGS

1/2

11X17,8 X14,8 X11

8 X11R,7 X10 ,5 X8 R

1

/

2

1

/

2

1

/

2

1

/

2

1

/

4

1

/

2

1

/

2

A3,A4,A4R,A5R,B4,B5

B5R,216X330(8 X13)

1

/

2

TYPE

OK

PLAIN

TRAY3 TYPE/SIZE SETTING

CUSTOM SETTINGS

TYPE

AUTO-INCH

SIZE INPUT

AUTO-AB

SIZE

X Y

NON STANDARD

SIZE

2/2

PRINT

COPY

FAX

I-FAX

DOC.

FILING

CUSTOM SETTINGS

TRAY 3 TYPE/SIZE SETTING

2/2

USER TYPE 1

CANCEL

SELECT THE PAPER TYPE

USER TYPE 5

USER TYPE 2

USER TYPE 6

USER TYPE 3

USER TYPE 7

USER TYPE 4

1/2

"FIXED

PAPER SIDE":

Select when paper is to be loaded print side down

in the tray.

Make sure a checkmark does not appear when

paper is to be loaded print side up.

• If the two-sided function is prohibited in

"DISABLING OF DUPLEX" in the key operator

programs, do not use this setting.

"DISABLE

DUPLEX":

Prohibits two-sided printing.

Enable when the back side of the paper cannot be

printed on.

"DISABLE

STAPLE":

Prohibits stapling. Enable when using special

papers such as transparency film and label sheets.

"DISABLE

PUNCH":

Prohibits punching. Enable when using special

papers such as transparency film and label sheets.

FIXED PAPER SIDE

DOC.

FILING

DISABLE DUPLEX

DISABLE STAPLE

DISABLE PUNCH

AB

Y

11

17

X

(5 1/2 17)

inch

INCH

OK

(5 1/2 11 5/8)

inch

Y

X

AB

Y

11

17

Y

X

INCH

OK

(5 1/2 17)

inch

(5 1/2 11 5/8)

inch

Page 12

: Feb. 9 2004

2

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 11

4) Touch the [OK] key. (You will return to the size setting screen of

step 2.)

5) If the paper is a non-standard size, select the [NON STANDARD

SIZE] checkbox.

6) Perform steps 7 through 10 of "Setting the paper type and paper

size".

[Inserter (option)]

1) Perform steps 1 through 5 of "Setting the paper type and paper

size".

2) Touch the [SIZE SELECT] key. (The size selection screen

appears.)

Note: When tabbed paper is selected, the [NON STANDARD SIZE]

checkbox of the [SIZE SELECT] key cannot be selected.

3) Select the desired paper size.

There are separate screens for inch-based paper selection and AB

paper selection. Touch the key or the key to switch

between the screens.

4) Touch the [OK] key. (You will return to the size setting screen of

step 2.)

5) Perform steps 7 through 10 of "Setting the paper type and paper

size".

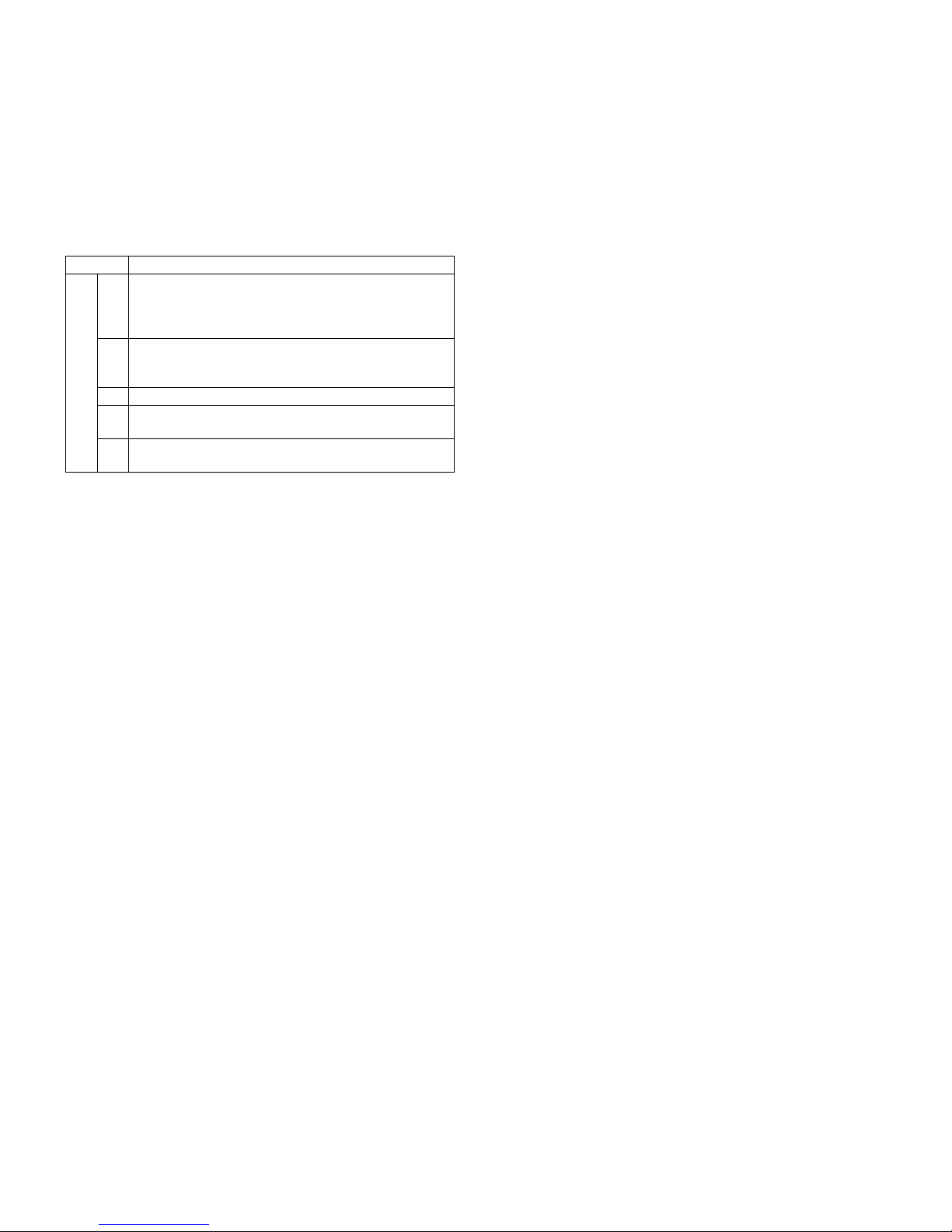

H. The other parts setting

(1) Document exit tray installation

Install the document exit tray to the scanner unit as shown in the figure

below.

(2) Other notes

Check to insure that the cable connected to the service terminal (A in

the figure below) is 3m or less.

X

AB

Y

11

17

Y

X

INCH

OK

(5 1/2 17)

inch

(5 1/2 11 5/8)

inch

NON STANDARD

SIZE

11X17,8 X14,8 X11

1

/

2

1

/

2

8 X11R,7 X10 ,5 X8 R

1

/

2

1

/

4

1

/

2

1

/

2

1

/

2

A3,A4,A4R,A5R,B4,B5

B5R,216x330(8 x13)

X17 Y11

5

/

8

1

/

2

SIZE SELECT

11X17,8 X14,8

X

1

/

2

1

/

2

8 X11R,7 X10 ,5

1

/

2

1

/

4

1

/

2

A3,A4,A4R,A5R,B

AUTO-INCH

AUTO-AB

B5R

1/2

PLAIN

11X17

OK

TYPE

INSERTER TYPE/SIZE SETTING

TYPE

CUSTOM SETTINGS

8 X14

1

/

2

8 X11

1

/

2

8 X11R

1

/

2

7 X10

1

/

4

1

/

2

5 X8 R

1

/

2

1

/

2

SIZE

1

/

2

X10

/

4

1

/

2

1/2

TYPE

8 X11

1

/

2

5 X8 R

1

/

2

1

/

2

SIZE

OK

4. Cleaning

A. Main charger

1) Reciprocate the MC cleaner shaft back and forth to clean the electrode tip.

(A)

2

Page 13

AR-M550/M620/M700 INSTALLATION MANUAL (AR-M550/M620/M700) 1 - 12

5. Image quality check

Check the following contents. For adjustment and check procedures,

refer to the chapter of adjustments.

A. Focus (Resolution)

B. Copy image off-center

C. Image loss, void area

6. Specifications setting

Use SIM 26 to set the customer's desired specifications.

7. Recording of setting and adjustment

data

Use SIM 22-6 to print and keep the various setting and adjustment

data (list).

When a memory trouble occurs, or when the PCU PWB or the ICU

PWB is replaced, if the above information is not available, all the

adjustment must be performed from the beginning again.

If the above information is available, however, directly enter the setting

and adjustment values for efficient servicing.

8. Preparation for transit

When moving the copier, turn off the power and perform the following

works.

1) Remove the paper from the paper tray.

2) Remove the developing unit from the main unit.

3) Lock the position which was released at installation (see the page

1-5).

4) Remove the adjuster cover, and raise the adjuster (see the page 1-

5).

Note: Since the main unit includes the hard disk drive, be careful not

to apply vibrations and shocks during transit.

Sim No. Content

26 2 Used to set the paper size of the tray 2 and the large

capacity tray. (When the paper size is changed, this

simulation must be used to change the paper size by

software.)

5 A3 paper 1 count/2 count setting

Used to set the count mode of the total counter, the

developer counter, and the maintenance counter.

6 Specifications depending on the destination

18 Used to set YES/NO of toner save operation. (This

function is valid only in Japan and UK versions.)

35 Used to set whether the trouble history is displayed as

one time trouble or the number of times of trouble.

Page 14

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 1

[2] AR-LC6 UNPACKING AND

INSTALLATION

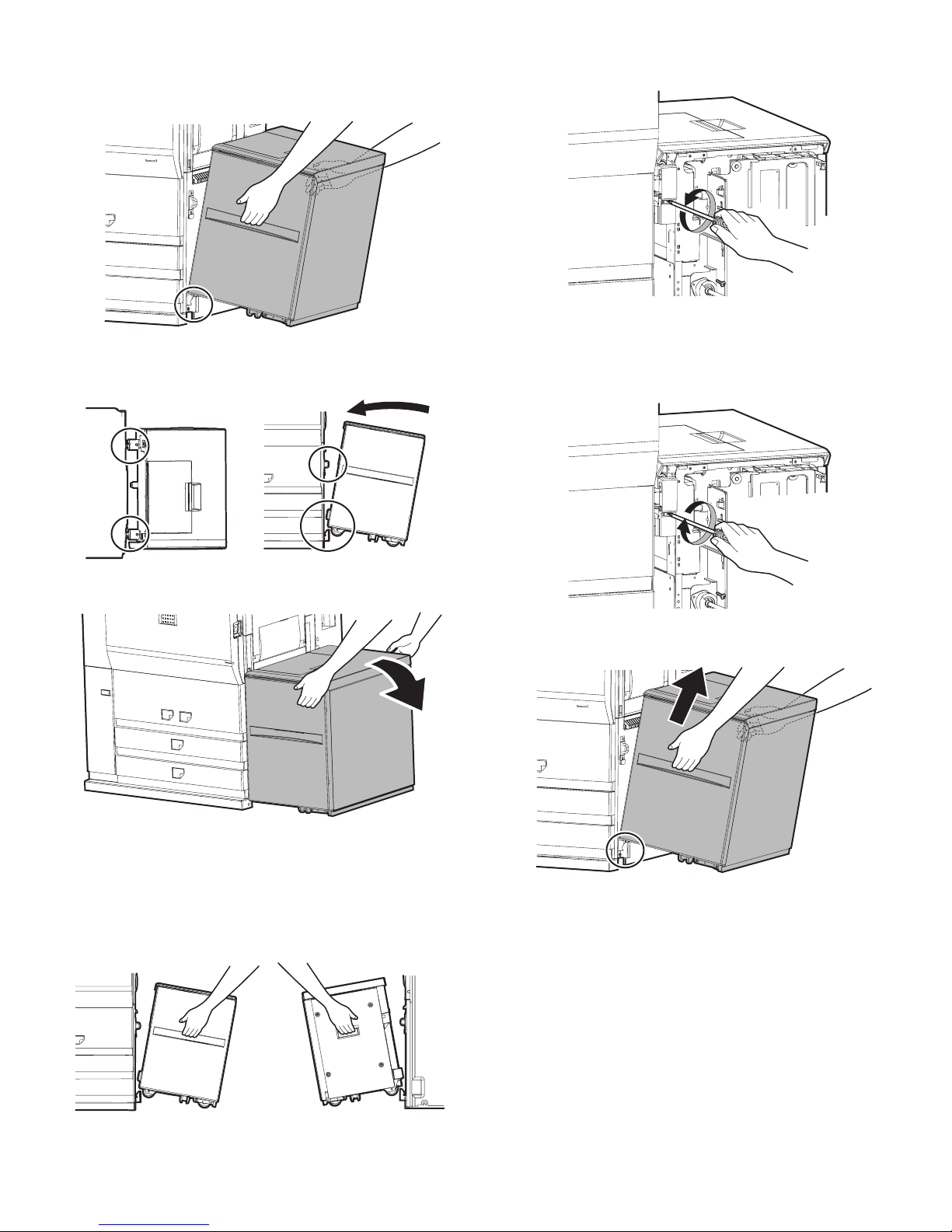

1. Unpacking

(Removal of the main unit)

2. Installation

<Before installation>

• Packaged parts check

Check to insure that all the following parts are packaged.

• Check that the printer is in stand-by state.

Check that the DATA indicator on the operation panel is neither lit

nor blinking.

Parts included

A. Turn off the power of the main unit.

1) Turn OFF the power switch on the right side of the main unit.

2) Open the front cabinet, and turn OFF the main power switch.

3) Disconnect the power plug from the power outlet.

B. Attach the upper mounting plates and the lower

front/rear connecting plates.

1) Attach the two upper mounting plates with the rubber portion (★)

down to the right side of the main unit using screws A (two for

each).

2) Remove the fixing screw of the front/rear cover on the lower right

side of the main unit. Attach the lower front side (engraved mark F)

of the connecting plate to the lower front side of the main unit with

two fixing screws B.

Attach the lower rear side (engraved mark R) of the connecting

plate to the lower rear side of the main unit with two fixing screws

B.

1 Upper mounting plate 2pcs.

2 Lower front connecting plate 1pc.

3 Lower rear connecting plate 1pc.

4 Fixing screw A (M4 x 16 small screw bind uniqlo) 4pcs.

5 Fixing screw B (Hex washer S tight M4 x 12) 4pcs.

1

23

45

Page 15

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 2

3) Remove the fixing screws (2 pcs.) of the machine entry port, and

remove the entry port cover.

4) Attach the entry port cover reversely to the machine and fix it with

the two fixing screws which was removed in procedure 3).

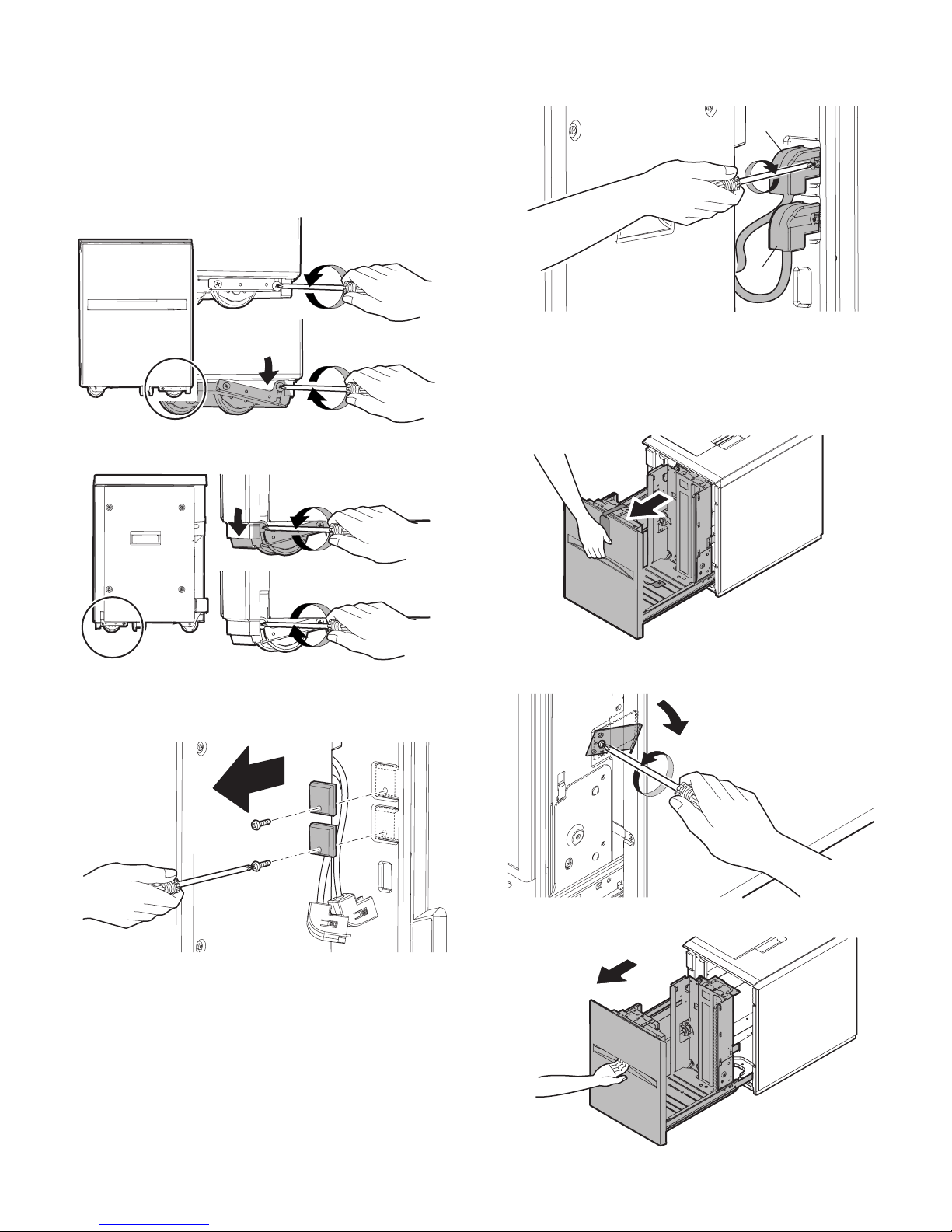

C. Fixing material and packaged part removal

1) Remove the fixing material from the large capacity paper feed tray.

2) Remove the fixing material from the packaged part, and remove

the packaged part.

D. Remove the paper feed base screw of the large

capacity tray.

1) Slowly pull out the paper feed base tray until it stops.

2) Remove the paper feed base fixing screw (1 pc.) of the large

capacity tray.

3) Push the large capacity tray slowly into the original position.

Page 16

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 3

E. Attach the large capacity tray to the main unit.

1) Hold the grips of the front and the rear cabinets with both hands,

and lift the left side.

2) Hang the metal fixture of the large capacity tray on the lower front/

rear side of the connecting plate on the main unit side.

Push the large capacity tray onto the main unit and attach it.

At that time, check that the large capacity tray is locked to the main

unit.

∗ If lock is incomplete, when the power switch is turned on, the mes-

sage, “Check installation of tray 5” is displayed on the operation

panel.

∗ Push the large capacity tray onto the machine, and lock it securely.

[Note]

Note 1): When lifting the LCC, insert fingers into the grip sections of

the front and rear cabinets and install slowly.

Note 2): Turn the lock release screw of the front cover counterclock-

wise to loosen and check that the screw is free.

∗ If the screw is tight at that time, installation will be incom-

plete.

<<How to separate the large capacity tray from the main unit>>

1) Turn the lock release screw of the front cover clockwise and

tighten the screw securely to release lock.

2) Then hold the grips of the front and the rear cabinets with both

hands, and lift the left side. The large capacity tray will come off.

F side R side

Page 17

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 4

F. Adjust the caster

1) After installing the large capacity tray to the main unit, loosen the

screws (one in the front and one in the rear) of the adjustment

caster mounting plate attached to the lower side of the large

capacity tray.

At that time, the casters of the adjustment caster mounting plate

are brought into contact with the floor by the spring force.

2) Tighten the screws of the caster mounting plate which were loosened in procedure 1).

G. Connect the connector of the large capacity tray.

1) Remove the screw (one for each) from the connector cover on the

main unit and then remove the two connector covers.

2)

Connect the large capacity tray interface harness connector and

the heating heater interface harness connector to the main unit

connector, and tighten the connector screw to fix the connector.

H. Select the paper size.

(1) Change A4 size to LT size

The factory setting of the paper size is A4. To select another size, perform the following procedures.

1) Pull out the large capacity tray until it stops.

2) Loosen the stopper fixing screw (1 pc.) on the lower right side of

the paper feed tray to disable the stopper function.

3) Then pull out the paper feed tray again until it stops.

F side

R side

a

b

Page 18

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 5

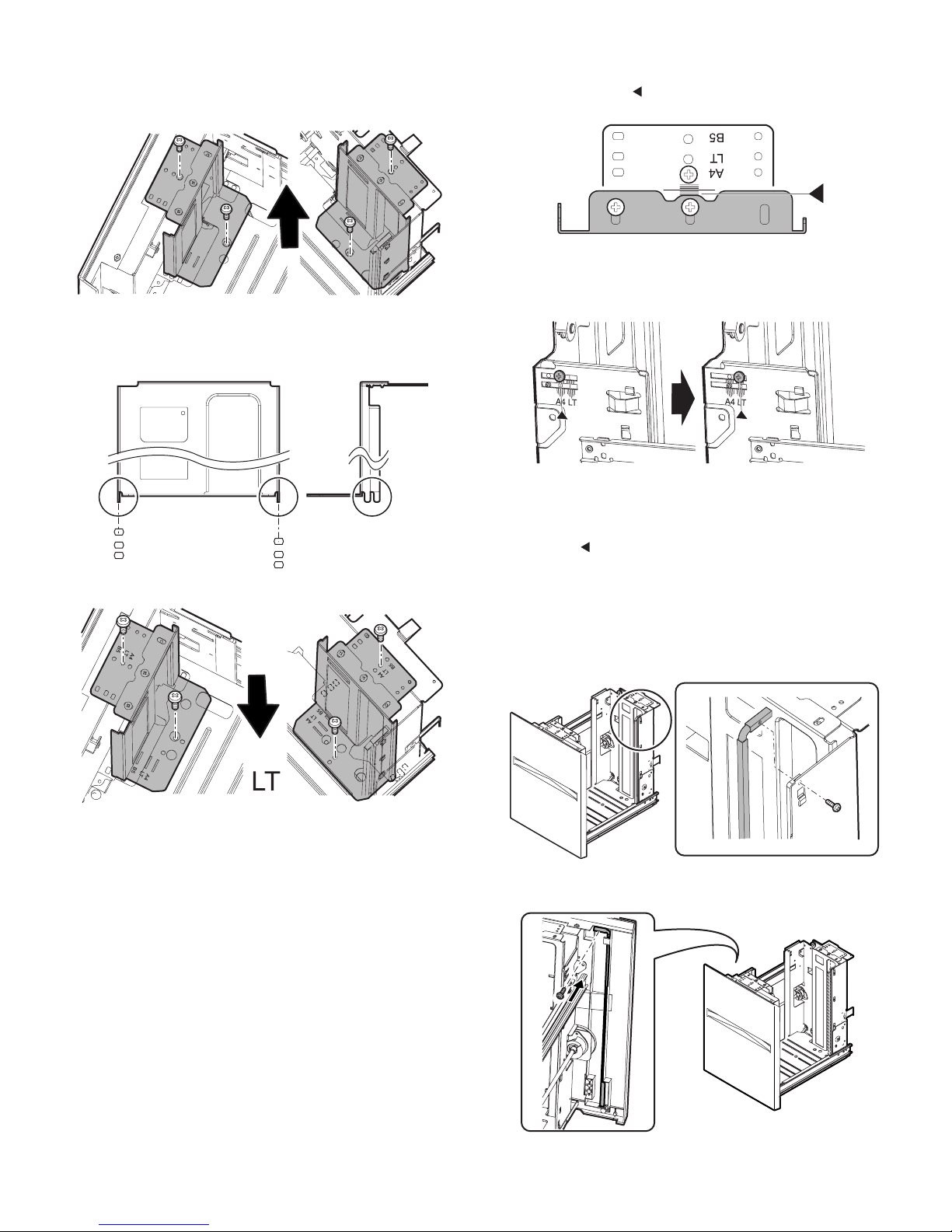

a. Side plate size change-over

1) Remove the four fixing screws (blue) which are fixing the upper

and the lower sections of the side plate F and the side plate R.

2) Then fit the paper feed tray on the lower side of the side plate F

and the side plate R with the engraved marks of the side plates

according to the size, and insert it. Also fit the upper side to the

size and fix it with the four fixing screws (blue).

b. Auxiliary guide size change-over

1) When changing the size of the side plate R, check to confirm the

mark positions of " " on the side plate R and the size guide

adjustment plate.

2) Loosen the auxiliary guide fixing screw (Flat screw 1pc).

3) Change the mark position (▲) of the auxiliary guide and the cassette R from A4 to LT, and fix them with the fixing screw (flat

screw, 1pc).

At that time, adjust so that the mark positions (▲) on the auxiliary

guide and the cassette R are at the same positions of the mark

positions ( ) of the side plate R and the size guide adjustment

plate checked in the procedure 1). (If the scale of the size guide

adjustment plate is at the center, set the position at the center. If is

it at 1mm toward the front side, set the position at 1mm toward the

front side.)

c. Rear edge shaft change-over

1) Remove the rear edge shaft fixing screw (blue) on the right side of

the paper feed tray, and remove the rear edge shaft.

2) Tighten the removed rear edge shaft with the fixing screw (blue

screw) and store it in the storage space inside the front cabinet.

F side R side

F side R side

A4 LT

[When LT size]

Page 19

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 6

3) Push the paper feed tray slightly, and return the disabled stopper

to the original position, and tighten the fixing screw.

At that time, check that the stopper pawl is engaged with the stopper receiver of the large capacity tray.

4) Push the large capacity tray slowly into the original position.

I. Turn the main power switch on the main unit to

the ON position.

1) Insert the power plug of the main unit to the outlet.

2) Turn the main power switch to the ON position.

Then close the front cabinet cover.

3) Turn ON the power switch on the right side of the main unit.

J. Set the size.

Execute SIM 26-2 (Size setting) by the key operations of the main unit.

1) The size selection menu of the large capacity tray is displayed on

the operation panel message display.

2) Select the size number from the message menu and enter the

number with the 10-key.

Page 20

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 7

K. Carry out the print off center adjustment

(1) Adjustments with simulations

Since the off-center adjustment has been made at shipping, there is

normally no need to adjust. If, however, the center is shifted, carry out

the following steps to adjust.

1) Set a test chart (document) on the document table properly.

2) Execute SIM 50-5 (Print off center) by the key operation of the

main unit.

3) In SIM 50-5, the display is shown as follows to allow setting of the

print off center adjustment value for each paper feed tray.

[When shifted to the front side]

When the print line is shifted from the center of paper in the direction A:

Increase the value.

Then make a copy to check that the center is not shifted.

[When shifted to the rear side]

When the print line is shifted from the center of paper in the direction B:

Decrease the value.

Then make a copy again to check that the center is not shifted. Repeat

this procedure as required.

∗ For details of the adjustment and check procedures, refer to the

chapter of adjustments in the Service Manual of the main unit.

(2) Mechanical adjustment

Since the off-center adjustment has been made at shipping, there is

normally no need to adjust. If the center is shifted, however, adjust with

the simulation. If the shift is not recovered, perform the following steps

to adjust.

1) Pull out the large capacity tray until it stops.

2) Loosen the stopper fixing screw (1 pc.) on the lower right side of

the paper feed tray to disable the stopper function.

Adjustment position Set value

Display

item

Item description Default

Set

range

TRAY1 TRAY1

(LCC left

side)

Print off center

adjustment position

TRAY2 TRAY2

(LCC right

side)

Print off center

adjustment position

TRAY3 TRAY3 Print off center

adjustment position

TRAY4 TRAY4 Print off center

adjustment position

BPT Manual

paper feed

Print off center

adjustment position

LCC Large

capacity tray

Print off center

adjustment position

50 0 to 99Shift by

0.1mm for

set value 1

ADU Duplex Print off center

adjustment position

(ADU)

2

SIMULATION 50-5

LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START.

0.TRAY SELECT 1 1.PRINT START

(ADJUSTMENT DATA)

LEAD EDGE: 2.RRCB 50 20.SIDE2 ADJ. 50

RESIST: 3.T1 50 4.T2 50 5.T3 50 6.T4 50

7.BPT 50 8.LCC 50 9.ADU 50

OFF CENTER: 10.T1 50 11.T2 50 12.T3 50 13.T4 50

14.BPT 50 15.LCC 50 16.ADU 50

(VOID SETTING) 17.LEAD_EDGE(DENA) 35

18.TRAIL_EDGE(DENB) 35 19. FRONT/REAR 35

R side

F side

Direction A

Center line of image (first image)

(Fig. 1)

R side

F side

Direction B

Center line of image (first image)

(Fig. 2)

Page 21

AR-M550/M620/M700 INSTALLATION MANUAL (AR-LC6) 2 - 8

3) Then pull out the paper feed tray again until it stops.

[When shifted to the front side]

When shifting the print line from the paper center in the arrow direction

as shown below:

4) Loosen the red fixing screws (2 pcs. for each) of the front/back size

guide adjustment plate, and slide the side guide adjustment plate

in the direction A (R side) by the shift dimension. Tighten the red

fixing screws (2 pcs. for each). Slide the auxiliary guide in the

direction of A by the same dimension.

Then push the paper feed tray into the machine, and return the

stopper to the original position, and fix it with the fixing screw (1 pc.).

At that time, check that the stopper pawl is engaged with the stopper receiver of the large capacity tray.

5) Push the large capacity tray to the original position slowly.

Then make a copy again to check that the center is not shifted. Repeat

this procedure as required.

[When shifted to the rear side]

When shifting the print line from the paper center in the arrow direction

as shown below:

4) Loosen the red fixing screws (2 pcs. for each) of the front/back size

guide adjustment plate, and slide the side guide adjustment plate

in the direction B (F side) by the shift dimension. Tighten the red

fixing screws (2 pcs. for each), and push the paper feed tray into

the machine. Return the stopper to the original position, and fix it

with the fixing screw (1 pc.). Slide the auxiliary guide in the direction of B by the same dimension.

At that time, check that the stopper pawl is engaged with the stopper receiver of the large capacity tray.

5) Push the large capacity tray slowly into the original position.

Then make a copy again to check that the center is not shifted. Repeat

this procedure as required.

A

R side

F side

B

R side

F side

Page 22

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 1

[3] AR-CF2 UNPACKING AND

INSTALLATION

<Before installation>

Start installation after checking that the DATA indicator on the operation panel is neither lit nor blinking.

1. Unpacking

(Removal of the main unit)

(Removal of the parts included)

(Removal of the fixing member)

1) Remove the tape and open the upper door.

2) Remove the tape and remove the miramatte.

3) Remove the tape and remove the fixing member.

Page 23

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 2

4) Remove the tape and open the base cover.

5) Remove the connector cable fixing tape.

2. Installation

(Packaged parts check)

• Check to insure that all the following parts are packaged.

(1) Turn off the power of the main unit

1) Turn OFF the power switch on the right side of the main unit.

2) Open the front cabinet, and turn OFF the main power switch.

3) Disconnect the power plug from the power outlet.

<When the finisher (F15) or the saddle finisher (F16) is

installed>

(2) Removal of the connector between the main unit and

the finisher

1) Remove the screw from the finisher connector connected to the left

side of the main unit.

2) Disconnect the finisher connector.

Parts name Quantity

1 Positioning plate 1 pc.

2 Upper limit regulation wire 1 pc.

3 Button cover 1 pc.

4

Screw C (M4 x 12 small screw bind) 3 pcs.

5

Screw D (M3 x 8 tapping bind) 2 pcs.

6

Screw E (M4 x 7 small screw bind) 2 pcs.

7

Screw F (M4 x 14 tapping bind) 2 pcs.

1

3

7

5

6

4

2

1

1

1

1

∗ If it is not installed, perform procedure (4).

1

2

3

1

1

2

Page 24

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 3

(3) Removal of the rail, the connectting plate, and the

earth plate

1) Separate the finisher and the main unit.

2) Remove two screws which are fixing the connecting plate under the

finisher.

3) Remove the plate (fixed by one screw) from the rear lower section

of the finisher.

4) Go to procedure 5.

<When the finisher (F15) and the saddle finisher (F16) are

not installed to the main unit>

(4) Attach the positioning pin and the earth plate to the

main unit. (Use the packaged parts of the finisher.)

1) Remove the connector cover fixing screw for connection of the finisher joint harness connector, and remove the connector cover.

∗ Only when the finisher and the inserter are installed together, per-

form this procedure.

Note: For fixing screws H and I, use the packaged parts of the AR-

F15/F16.

3) Attach the earth plate with the fixing screws H (2 pcs.) to the left

lower section of the main unit.

In this case, attach so that the R mark on the earth plate faces up.

4) Pull out the lock release lever on the left side of the main unit, and

open the left door.

5) Remove the paper exit cover on the upper side of the left door.

6) Close the left door.

1

2

1

2

1

2

2) Attach the positioning pin with two fixing screws I to the left upper

section of the main unit. Be careful to the attachment direction of

the positioning pin.

1

F

R

2

1

Page 25

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 4

7) Attach the connecting plate to the with fixing screws I (2 pcs.) main

unit.

(5) Install the positioning plate and the button cover to the

finisher

1) Remove the step screw (1 pc) and the screws (2 pcs.) which are fixing the punch cover.

2) Fit the holds of the screws removed in step 1) with the screw holes

of the positioning plate, and fix it with the three fixing screws C.

(6) Install the upper limit regulation wire to the inserter

(7) Install the inserter to the finisher

1) Open the front door of the inserter, and loosen the lock fixing screw

until the screw is released.

2) Stand the tray.

3) Install the button cover with the lock button fixing screws D (2 pcs.)

to hide the lock button on the top of the punch cover.

Use positions

1

1) Open the front door of the inserter, and install the upper limit regulation wire with the two fixing screws E.

1

1

2

Page 26

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 5

3) Hold the lower section of the front cabinet and the grip of the rear

cabinet as shown in the figure, tilt the inserter a little so that the indication hole in the inserter support section is fit with the metal fixture

of the finisher connecting plate installing section, and install it.

∗ At that time, check that the finisher lock lever is engaged on the

inserter groove securely.

4) Tighten the fixing screw of the inserter lock to fix the inserter and

the finisher.

5) Check that the finisher lock lever is engaged on the inserter groove

securely.

[When the inserter cannot be installed to the finisher]

When the finisher and the inserter differ in the height, perform the following height adjustment, and insert the inserter.

1) Set all the finisher height adjustment screws (4 positions) to the

center positions.

2) Insert the inserter to the finisher. (Refer to the procedure (7) in this

section.)

(8) Fix the extension guide of the tray

1) Pull out the extension guide of the inserter paper feed tray until it

stops.

2) Tighten the fixing screws F (2 pcs.) on the back side of the paper

feed tray.

1

Page 27

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 6

(9) Install the connection plate. (Use the packaged parts of

the finisher.)

Remark: The plate and the connection plate are common to the fin-

isher. Please reuse rail and connector plate for inserter.

(10) Connect the connector

1) Connect the finisher relay harness connector to the inserter connector, and tighten the connector screw to fix it.

2) Fix the finisher relay harness to the rear side of the inserter with two

clamps.

3) Connect the inserter relay harness connector to the main unit connector, and tighten the connector screw to fix the connector.

(11) Install the inserter to the main unit

1) Bring the inserter closer to the main unit.

2) Check that the main unit positioning pin enters smoothly into the

center of the inserter positioning guide.

1) Install the connection plate to the inserter with the fixing screws G

(2 pieces.).

1

1

2

Page 28

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 7

A. When the positioning pin does not enter smoothly:

1) Loosen the adjustment section fixing screws (2 pcs.) on the rear

side.

2) Turn and adjust the rear side height adjustment bolt so that the center height of the positioning pin comes at the center of the positioning guide.

3) Tighten two fixing screws of the rear side adjustment section.

4) Loosen the front side adjustment section fixing screws (2 pcs.)

5) Turn and adjust the front side height adjustment bolt so that it is at

the same position with the rear side adjustment section fixing

screw.

6) Tighten two fixing screws of the front side adjustment section.

(12) Finisher and inserter height adjustment

1) Check the height of the inserter front cabinet and the finisher front

cabinet.

2) Check the height of the inserter rear cabinet and the finisher rear

cabinet.

<When the height is proper>

Go to procedure 13.

<When the height is not proper>

A. Adjust the height of the front side.

1) Open the finisher front door upper, remove the spanner stored in

the upper section of the front door, and close the front door upper.

2) Open the front door of the inserter, open the front door lower of the

finisher

F

R

Page 29

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 8

3) Loosen the fixing screws (2 pcs.) of the adjustment section of the

base.

4) Use the spanner removed in step 1) to adjust the height adjustment

bolt so that the upper cabinet is of the same height.

5) Tighten the adjustment section fixing screws (2 pcs.).

6) Close the finisher front door lower, and close the inserter front door.

B. Adjust the rear side height.

1) Remove two screws which are fixing the base cover attached to the

finisher rear side base section, and remove the base cover.

2) Loosen the adjustment section fixing screws (2 pcs.).

3) Use the spanner and adjust the height adjustment bolt so that the

height of the rear side cabinet top surface is of the same height.

4) Tighten the adjustment section fixing screws (2 pcs.).

5) Install the base cover.

(13) Check the clearance between the main unit and the

inserter

1) Push the inserter into the main unit.

2) Check the upper and the lower clearances between the main unit

and the inserter cabinet.

Page 30

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 9

• When the upper and the lower clearances differ:

1) Open the front upper door of the finisher, and remove the spanner

(fixed with a screw) from the inside of the door.

2) Remove the base cover (fixed with a screw in the front and a screw

at the back) fixed to the front and the rear of the finisher base section.

3) Loosen the front side and the rear side adjustment section fixing

screws (2 pcs. for each side).

4) Turn the front and the rear side adjustment bolts with the spanner

removed in step 1) so that the upper and the lower clearances are

the same.

5) Check that the upper and the lower clearances are even when

viewed from the front and the back.

6) Tighten the front and the rear side adjustment section fixing screws

(2 pcs. for each side).

7) Install the base cover (front and rear).

8) Return the spanner to the original position.

(14) Install the plate

∗ At that time, check to insure that the upper and lower positioning

tabs are in the plate holes.

Remark: The plate and the connection plate are common to the fin-

isher. Please reuse rail and connector plate for inserter.

1) Hang the plate on the rear lower side of the inserter as shown in the

figure, and fix it with the fixing screw G (1 pc).

1

Page 31

AR-M550/M620/M700 INSTALLATION MANUAL (AR-CF2) 3 - 10

(15) Turn ON the main power switch

1) Insert the power plug of the main unit to the outlet.

2) Open the front cabinet, and open the power cover.

3) Turn ON the main power switch, close the power cover, and close

the front cabinet.

4) Turn ON the power switch on the right side of the main unit.

Page 32

AR-M550/M620/M700 INSTALLATION MANUAL (AR-F15/F16) 4 - 1

[4] AR-F15/F16 UNPACKING AND

INSTALLATION

1. Unpacking

When removing or moving, be sure to perform by two persons not to

drop the unit.

A. Unpacking procedure

(1) Removal of the main unit

1) Remove the fixing member and remove the top case.

2) Remove the packaged parts from the add.

3) Check the packaged parts.

Packaged parts

4) Hold the upper section of the machine with two persons, and pull it

up and stand it straight.

(The machine is very heavy. Be careful.)

5) Remove the tape and the skid.

6) Remove the upper add.

1 Positioning pin 1 pc. 5 Staple label 2 pcs.

2 Earth plate 1 pc. 6 Screw G (M4 x 6) 3 pcs.

3 Earth mounting plate 1 pc. 7 Screw H (M4 x 10) 2 pcs.

4 Rail mounting plate 1 pc. 8 Screw I (M4 x 18) 4 pcs.

12

56

3

487

Page 33

AR-M550/M620/M700 INSTALLATION MANUAL (AR-F15/F16) 4 - 2

7) One person holds the machine so that it does not fall down. The

other person tilts the machine a little to remove packing material.

8) Bring the base of the unit into contact with the floor so that it does

not fall down.

(The base section is slippery. Be careful of that.)

9) Tilt the machine to the opposite side a little, and remove packing

material on the opposite side.

10) Slowly bring the base section of the machine on the opposite side

to contact with the floor.

11) Remove the vinyl cover.

(2) Fixing member removal

Remove the taping from the finisher.

Remove the shipment locking material with red sticky note.

1) Remove the tape.

2) Remove the tape and remove the protection board and the sheet.

3) Remove the tape and open the upper cover.

4) Remove the tape and remove the transit fixing member and the

sheet.

5) Remove the tape and remove the lower tray transit fixing member.

1

1

2

1

2

1

Page 34

AR-M550/M620/M700 INSTALLATION MANUAL (AR-F15/F16) 4 - 3

6) Remove the tape and the fixing member.

7) Remove the tape and remove the jam release door transit fixing

member.

8) Remove the tape and remove the jam release door handle section

transit fixing member.

9) Remove the power cable fixing tape.

10) Open the upper front door, and remove the staple transit fixing

member.

11) Open the lower door, and remove the each tape.

12) Pull out the stitcher remove the screw, and remove the stitcher

transmit fixing member.

13) Remove the screw, and remove the lower cover.

14) Remove the screw, and remove the transit fixing members F and

R.

15) Remove the screw, and remove lift tray rail section transit fixing

members (4 positions).

1

2

3

1

2

1

2

2

2

1

2

2

Page 35

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-F15/F16) 4 - 4

B. Note for packing

(1) Finisher transit fixing member installation

1) Remove the rear cabinet of the finisher.

2) Turn on the power of the main unit.

3) Raise the DIP switch 1, 2, 4, 5, and 6 on the rear of the finisher.

4) Press SW1 button (left side) of the PWB. (It is located over the DIP

switch.)

∗ The finisher tray moves to the screw fixing position.

5) Turn off the power of the main unit.

6) Reset the DIP switch to the original state.

7) Install the cabinet.

8) Install the lift tray rail section fixing members (4 positions) with four

screws.

2. Installation

A. Installation procedure

(1) Turn off the power of the main unit.

1) Turn OFF the power switch on the right side of the main unit.

2) Open the front cabinet, and turn OFF the main power switch.

3) Disconnect the power plug from the power outlet.

(2) Attach the positioning pin and the earth plate to the

main unit.

When unpacking Before packing (Shifted to

the screw fixing position.)

1) Attach the positioning pin with two fixing screws I to the left upper

section of the main unit. Be careful to the attachment direction of

the positioning pin.

1

Page 36

AR-M550/M620/M700 INSTALLATION MANUAL (AR-F15/F16) 4 - 5

2) Attach the earth plate with the fixing screws H (2 pcs.) to the left

lower section of the main unit.

In this case, attach so that the R mark on the earth plate faces up.

3) Pull out the lock release lever on the left side of the main unit, and

open the left door.

4) Remove the paper exit cover on the upper side of the left door.

5) Close the left door.

6) Install the connection plate to the main unit with the fixing screws I

(2 pcs.).

(3) Plate and connection plate installation

1) Install the plate to the finisher as shown in the figure, and fix it with

the fixing screw G (1 pc).

2) Install the rail and the finisher with two screws G (M4 x 6).

(4) Caster adjustment

A. Bring the finisher closer to the main unit and check that the

guide pin of the main unit enters into the connection hole in the

finisher smoothly.

B. At that time, check that the center of the guide pin is in the cen-

ter of the scale marked on the side of the connection hole, and

the pin direction coincides with the hole direction.

C. If the guide pin is not in the center, or if the guide pin does not

enter smoothly, adjust as follows:

F

R

2

1

Page 37

AR-M550/M620/M700 INSTALLATION MANUAL (AR-F15/F16) 4 - 6

1) Remove the fixing screw of base cover (2 positions) in the front and

the back of the finisher, and remove the base cover.

2) Remove the fixing screws (2 pcs.) of the rear cover on the rear of

the finisher, and remove the rear cover.

3) Only for the AR-F15, remove the front cabinet lower fixing screws

(2 pcs.).

4) Open the front cabinet lower, and loosen the fixing screws (2 pcs

for each) of four casters.

5) Remove the spanner stored inside of the front cabinet upper, and

close the front cabinet upper.

6) Turn the bolt with the removed spanner so that the guide pin is in

the specified range of the scale.

(At that time, lift the finisher a little, and the bolt can be turned manually.)

7) After completion of the adjustment, tighten the caster fixing screws

(8 pcs.) and close the front cabinet lower.

8) Check to insure that the intervals at the upper and the lower sides

of the main unit and the finisher are even.

9) Attach the foot covers in front and at the back of the finisher and the

rear cover on the rear side, and tighten all the fixing screws.

Page 38

AR-M550/M620/M700 INSTALLATION MANUAL (AR-F15/F16) 4 - 7

(5) Attach the staple position label.

Attach the staple position label as shown in the figure.

∗ The label attachment position shown above is based on the corner

of the cabinet.

(6) Connect the finisher connector.

A. Remove the connector cover fixing screw for connection of the fin-

isher joint harness connector, and remove the connector cover.

B. Connect the finisher relay harness connector to the main unit con-

nector, and tighten the screw on the connector to fix.

(7) Turn ON the main power switch.

1) Insert the power plug of the main unit to the outlet.

2) Open the front cabinet, and open the power cover.

3) Turn ON the main power switch, close the power cover, and close

the front cabinet.

4) Turn ON the power switch on the right side of the main unit.

0.5mm

40mm

2mm

2mm

1

2

3

Page 39

AR-M550/M620/M700 INSTALLATION MANUAL (AR-PN4) 5 - 1

[5] AR-PN4 UNPACKING AND INSTALLATION

1. Unpacking

(1) Removal of the main unit

(2) Removal of the fixing member

Packaged parts (accessories)

2. Installation

(1) Turn off the power of the main unit.

1) Turn OFF the power switch on the right side of the main unit.

2) Open the front cabinet, and turn OFF the main power switch.

3) Disconnect the power plug from the power outlet.

Punch position label 2 pcs.

Page 40

AR-M550/M620/M700 INSTALLATION MANUAL (AR-PN4) 5 - 2

(2) Punch cover disassembly

1) Remove the punch cover fixing screws (6 pcs.), and lift the punch

cover slightly to remove it from the finisher.

2) Remove the fixing screw (1 pc.) of the punch cover front door from

inside of the punch cover.

3) Remove the cabinet B fixing screws (2 pcs.) on the rear side of the

finisher, and remove the rear cabinet B.

(3) Paper guide disassembly

1) Remove the paper guide fixing screw (1 pc.) and remove the paper

guide from the finisher.

(4) Punch unit assembly

1) Hang the punch unit on the step screws (2 pcs.) of the finisher and

assemble it.

2) Fix the punch unit with the paper guide fixing screw (1 pc.) which

was removed in step (3).

(5) Connector connection

1) Connect the punch joint harness connectors (2 pcs.) of the punch

unit to the connectors (2 positions) of the finisher PWB.

Page 41

AR-M550/M620/M700 INSTALLATION MANUAL (AR-PN4) 5 - 3

(6) Punch cover assembly

1) Attach the rear cabinet B to the original position, and fit it with the

fixing screws (2 pcs.).

2) Open the front door of the punch cover, attach the punch cover to

the original position, and fix it with the fixing screws (6 pcs.).

In this case, use the fixing screws at their original positions.

Memo: Open the lower cover before hand. This makes assembly eas-

ier.

(7) Position label attachment

1) Attach the punch position label as shown in the figure.

∗ The label attachment position shown above is based on the corner

of the cabinet.

(8) Finisher connector connection

1) Remove the connector cover fixing screw for connection of the finisher joint harness connector, and remove the connector cover.

2) Connect the finisher joint harness connector to the main unit connector, and tighten the screw on the connector to fix.

(9) Turn ON the main power switch.

1) Insert the power plug into the power outlet.

0.5mm

40mm

40mm

2mm

2mm

Page 42

AR-M550/M620/M700 INSTALLATION MANUAL (AR-PN4) 5 - 4

2) Open the front cabinet, and open the power cover.

3) Turn ON the main power switch, close the power cover, and close

the front cabinet.

4) Turn ON the power switch on the right side of the main unit.

Page 43

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-P19) 6 - 1

[6] AR-P19 INSTALLATION

<Before installation>

To enable the printer expansion function, the product key must be

acquired.

(1) Turn off the switches of the main unit.

1) Turn the power switch located on the right side of the main unit to

the "OFF" position.

2) Open the front cabinet and turn the main power switch to the

"OFF" position.

3) Remove the power plug of the main unit from the outlet.

(2) Remove the control PWB.

1) Remove the two screws that secure the upper right cabinet and

remove the upper right cabinet.

∗ If cables are connected to the control PWB, remove all cables.

2) Remove the four screws that secure the control PWB unit to the

main unit.

3) Raise the two grips and hold them to pull out the control PWB unit

until the stopper is engaged.

4) Remove the two flat cable connectors.

5) While using your finger to release the stopper, pull the control PWB

unit out of the main unit.

(3) Mount the printer expansion ROMs and a print server

card to the control PWB.

1) Remove the ROMs (MAIN and BOOT ROMs) from the control

PWB and replace them with the two ROMs (MAIN and BOOT

ROMs) of the printer expansion kit.

The MAIN and BOOT ROMs are indicated with "MAIN" and

"BOOT" on the labels on the ROMs respectively.

When mounting the printer expansion kit ROMs, insert them to the

same positions in the same orientations as those before replacement until they click and ensure that the inserted ROMs are locked

with the sockets.

2) Remove the screws that secure the cover and remove the cover.

Then, insert the connector of the print server card to the connector

of the control PWB.

3) Secure the print server card using the screws that have been

removed.

Parts included

MAIN ROM: 1 pc.

·

Printer utility CD-ROM: 1 pc.

·

Network utility CD-ROM: 1 pc.

·

Product key sheet: 1 sheet

Print server card: 1 pc.

BOOT ROM: 1 pc.

Screws

Upper right cabinet

MAIN ROM

Notches

BOOT ROM

Screws

Cover

Print server card

Page 44

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-P19) 6 - 2

(4) Reattach the control PWB.

1) Reattach the control PWB unit to the main unit.

2) Reconnect the two flat cable connectors that have been removed

in step (2).

3) Secure the unit with the four screws.

4) Return the grips to their original positions.

5) Pull out the grip of the main unit, pass it through the hole shown in

the illustration, then reattach the upper right cabinet that has been

removed in step (2) to the main unit, and secure it with the two

screws.

∗ Reconnect the cables that have been removed to the control PWB

located on the side of the main unit.

If another peripheral device must be installed, carry out the following

steps at the end of the installation work.

(5) Turn on the main switches of the main unit.

1) Insert the power plug of the main unit to the outlet.

2) Turn on the main power switch and then close the front cabinet.

3) Turn the main switch located on the right side of the main unit to

the "ON" position.

(6) Enable the printer expansion function.

1) To enable the printer expansion function, use the keys on the operation panel to enter the product key.

For entry of the product key, see the section of key operator programs of the operation manual for the main unit.

After completing product key entry, turn off the power switch and

the main power switch of the main unit and then turn on the power

switch and the main power switch of the main unit again.

2) Carry out the network setting for the print server card.

Use the key operator programs to carry out the network setting for

this machine.

For this network setting, the customer's network environment must

be checked. Consult the network administrator to carry out the setting.

3) According to the customer's network environment, install the

printer driver software using the supplied CD-ROM.

Installation of the driver software to the computer server and its

setting must be performed by the customer or based on discussion

with the customer.

(7) Check the operation of the printer expansion function.

When installation of the printer driver is complete, carry out test page

printing to check to see if printing and output can be performed normally.

(When test printing is complete, use the list print of in custom settings

to print the network settings for this machine and keep the print carefully.)

Grip

Screws

Upper right cabinet

Page 45

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-FR11) 7 - 1

[7] AR-FR11 INSTALLATION

<Before installation>

• To enable the data security function, the product key must be

acquired.

• If unfinished data remains in the memory of the main unit (including

HDD), output or transmit all the data to clear the data remaining in

the main unit and then start installation.

(1) Turn off the switches of the main unit.

1) Turn the power switch located on the right side of the main unit to

the "OFF" position.

2) Open the front cabinet and turn the main power switch to the

"OFF" position.

3) Remove the power plug of the main unit from the outlet.

(2) Remove the control PWB.

1) Remove the two screws that secure the upper right cabinet and

remove the upper right cabinet.

∗ If cables are connected to the control PWB, remove all cables.

2) Remove the four screws that secure the control PWB unit.

3) Raise the two grips and hold them to pull out the control PWB unit

until the stopper is engaged.

4) Remove the two flat cable connectors.

5) While using your finger to release the stopper, pull the control PWB

unit out of the main unit.

(3) Mount the data security kit ROMs to the control PWB.

Remove the ROMs (MAIN and BOOT ROMs) from the control PWB

and replace them with the two ROMs (MAIN and BOOT ROMs) of the

data security kit.

The MAIN and BOOT ROMs are indicated with "MAIN" and "BOOT" on

the labels on the ROMs respectively.

When mounting the data security kit ROMs, insert them to the same

positions in the same orientations as those before replacement until

they click and ensure that the inserted ROMs are locked with the sockets.

Parts included

MAIN ROM: 1 pc.

BOOT ROM: 1 pc.

Screws

Upper right cabinet

MAIN ROM

Notches

BOOT ROM

Page 46

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-FR11) 7 - 2

(4) Reattach the control PWB.

1) Reattach the control PWB unit to the main unit.

2) Reconnect the two flat cable connectors that have been removed

in step (2).

3) Secure the unit with the four screws.

4) Return the grips to their original positions.

5) Pull out the grip of the main unit, pass it through the hole shown in

the illustration, then reattach the upper right cabinet that has been

removed in step (2) to the main unit, and secure it with the two

screws.

∗ Reconnect all the cables that have been removed in step (2)-1) to

the control PWB.

If another peripheral device must be installed, carry out the following

steps at the end of the installation work.

(5) Turn on the main switches of the main unit.

1) Insert the power plug of the main unit to the outlet.

2) Turn on the main power switch and then close the front cabinet.

3) Turn the main switch located on the right side of the main unit to

the "ON" position.

(6) Make preparations for enabling the data security

function.

To enable the data security function, use the keys on the operation

panel to enter the product key.

For entry of the product key, see the section of key operator programs

of the operation manual for the main unit.

After completing product key entry, turn off the power switch and the

main power switch of the main unit and then turn on the power switch

and the main power switch again.

(7) Make user settings of the data security function.

You can make operation settings of the data security function using a

key operator program.

If some files have been stored using the quick file function before

installation of AR-FR11, be sure to execute [CLEAR ALL MEMORY]

after installation to delete all the stored files.

Grip

Screws

Upper right cabinet

Page 47

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-PK5) 8 - 1

[8] AR-PK5 INSTALLATION

<Before installation>

• To enable the PS expansion function, the product key must be

acquired.

• For models on which the printer and network functions cannot be

used, a printer expansion ROM and a Print Server Card must be

installed in advance.

Parts included

• CD-ROM: 1 pc.

• Product key sheet: 1 sheet

(1) Enable the PS expansion function.

To enable the PS expansion function, use the keys on the operation

panel to enter the product key.

For entry of the product key, see the online manual included in the supplied CD-ROM or the section of key operator programs of the operation

manual for the main unit.

After completing product key entry, turn off the power switch and the

main power switch of the main unit and then turn on the power switch

and the main power switch of the main unit again.

(2) Check the operation of the PS expansion function.

1) Use the keys on the operation panel to execute test page printing

and print the PS FONT LIST as a test print.

2) Installation of the driver software to the computer server and its

setting must be performed by the customer or based on discussion

with the customer.

For installation of the driver software, see the installation guide.

3) Finally, execute printing from the computer server and check that

printing is performed normally.

Page 48

: Jan. 9 2004

1

AR-M550/M620/M700 INSTALLATION MANUAL (AR-NS3) 9 - 1

[9] AR-NS3 INSTALLATION

<Before installation>

• To enable the scanner function, the product key must be acquired.

• For models on which the printer and network functions cannot be

used, a printer expansion ROM and a Print Server Card must be

installed in advance.

Parts included

• CD-ROM: 1 pc.

• Product key sheet: 1 sheet

• Installation guide: 1 sheet

(1) Enable the scanner function.

To enable the scanner function, use the keys on the operation panel to

enter the product key.

For entry of the product key, see the section of key operator programs

of the operation manual for the main unit.

After completing product key entry, turn off the power switch and the

main power switch of the main unit and then turn on the power switch

and the main power switch of the main unit again.

(2) Check the operation of the scanner function.

1) Installation of the driver software to the computer server and its

setting must be performed by the customer or based on discussion

with the customer.

2) Finally, referring to the installation guide, set the destination profile.

Send image data and check that the image is properly received.

Page 49

AR-M550/M620/M700 INSTALLATION MANUAL (AR-FX8) 10 - 1

[10] AR-FX8/AR-MM9 INSTALLATION

<Before installation>

• For installation of AR-FX8, the MFP control PWB unit must have

been installed.

• Start installation after checking that the LINE indicator and the DATA

indicator below it on the operation panel are neither lit nor blinking.

1) Turn off the power switch of the main unit.

<1>Turn the power switch located on the right side of the main unit to

the "OFF" position.

<2>Open the front cabinet and turn the main power switch to the

"OFF" position.

<3>Remove the power plug of the main unit from the outlet.

2) Remove the MFP control PWB.

<1>Remove the two screws that secure the upper right cabinet and

remove the upper right cabinet.

<2>Remove the four screws that secure the MFP control PWB unit to

the main unit.

<3>Raise the two grips and hold them to pull out the MFP control PWB

unit until the stopper is engaged.

<4>Remove the two flat cable connectors.

<5>While using your finger to release the stopper, pull the MFP control

PWB unit out of the main unit.

<Step for mounting extended memory (AR-MM9)>

* If you need not mount an extended memory, proceed to step 4).

3) Mount an extended memory.

Mount an extended memory to the socket located on the back of

the FAX interface PWB unit.

4) Attach the FAX interface PWB unit.

Connect the FAX interface PWB unit to the FAX interface PWB

connector (100 pin) on the MFP control PWB unit and secure it

with two screws J.

5) Connect the FAX interface cable.

Connect the FAX interface cable to the MFP control PWB unit.

<Caution>

Ensure that both ends of the connector are securely locked and the

connector is not inserted at an angle.