Page 1

AR-FN7

CODE : 00ZARFN7//A1E

LASER PRINTER OPTIONS

FINISHER

PUNCH UNIT

AR-FN7

MODEL

CONTENTS

[1] INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[2] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[3] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[4] DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[5] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

[6] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[7] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[8] SIMULATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

AR-PN1

[9] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

• CIRCUIT DIAGRAM

Parts marked with “ “ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used for

SHARP CORPORATION

after sales service only.

The contents are subject to change without notice.

Page 2

[1] INTRODUCTION

1. Product outline

This unit is installed to the following machines to perform the after-process of output paper from a printer, a copier, or a fax machine.

A. Features

1) Employment of the through-type stapler

Employment of the through-type stapler allows to make saddle stitch by one stapler.

2) 3 kinds of auto staple functions

There are 3 staple positions available. (One position in the front, one position at the back, 2 positions at the center)

3) Saddle stitch function

Up to 10 sheets of paper can be stapled at the center and folded into two and discharged.

4) Punch function (Option)

By installation of a puncher unit, paper can be punched to make holes for a binder. (Applicable for 64 - 128g/m². OHP films cannot be used.)

Applicable models AR-P350 / P450, AR-M350 / M450

DM-3500 / 3501 / 4500 / 4501, DM-3551 / 4551

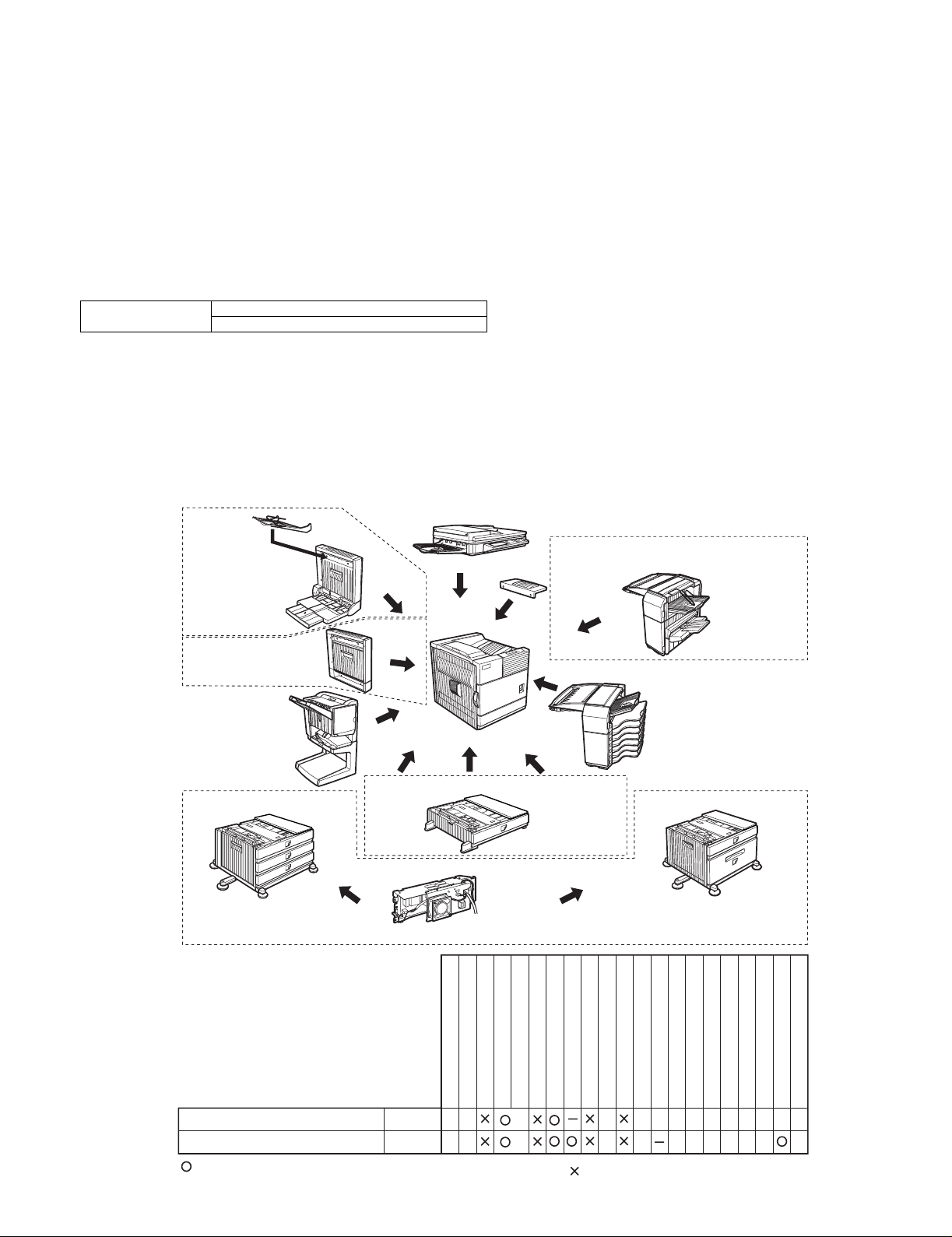

2. Configuration

1. Before installation of this unit, the large-capacity tray (AR-DU3 or AR-DU4) must be installed in advance.

(When installing the AR-DU3/DU4, the option power unit (AR-DC1) is required.)

2. When installing this unit, the duplex module (AR-DU3) must be installed together.

3. This unit cannot be installed with the following units:

•Duplex module (AR-DU4) with the manual paper feed tray

•Paper exit tray (AR-TE4)

•Multi-purpose tray (AR-MU1)

•Finisher (AR-FN6)

Simultaneous

installation

not allowed

AR-DU3

Simultaneous

installation is required

AR-FN7

AR-D14

AR-TE4

Simultaneous installation not allowed

AR-DU4

Simultaneous installation not allowed

AR-MU1

AR-DC1

Simultaneous installation is required

AR-FN6

AR-D13

Output units

Saddle stitch finisher

Punch unit

*1

=Any of the units must be installed together.

B/W scanner module/DSPF

Scanner rack

Multi purpose drawer

Stand/3 x 500 sheet paper drawer

Stand/MPD & 2000 sheet

Duplex module/bypass tray

AR-FN7

AR-PN1

AR-FN7/PN1 INTRODUCTION-1

*1

*1

Duplex module

Saddle stitch finisher

Finisher

Mail-bin stacker

Exit tray

Multi-function controller board

Punch unit

Upper exit tray extension

PS3 expansion kit

Print server card

Network scanner expansion kit

Fax memory (8 MB)

Facsimile expansion kit

Power supply unit

Hard disk drive

Page 3

3. Specifications

A. AR-FN7

(1) Basic specifications

Type Console type finisher

Transport speed 35/45 ppm

Transport reference Center reference

Tray type

(Number of trays)

Paper exit direction Face down

Paper exit paper size A3, B4, A4, A4R, B5, B5R, A5R,

Power consumption 50W or below

Power source Supplied from the option power

External dimensions (W x D x H) 532 x 600 x 467mm

Occupying dimensions (W x D)

Weight About 39kg

(2) Finishing section

Capacity of

paper exit and

load

Offset function Provided

Paper size which

can be stapled

Kinds and

weights of paper

to be discharged

Quantity of paper

to be stapled

(Max.)

Stapling 3 kinds

Staple supply Staple cartridge replacement

Staple detection Staple empty detection

(3) Saddle stitch section

Stapling type Center stapling: Center folding

Stapling position 1200mm pitch from the paper center

Weight of paper applicable f or

saddle stitch

Paper size 64 - 80g/m²

Book tray stacking type Fixed

Quantity of paper to be stapled 10 sets (6 - 10 pages)

Upper tray Lift-up/down offset tray

Lower tray Book tray for saddle stitch

11" x 17", 8.5" x 14", 8.5" x 13",

8.5" x 11", 8.5" x 11"R,

5.5" x 8.5"R

Executive

(DC24V, ???A)

Non-staple 1,000 sheets (Small size)

500 sheets (Large size)

Staple sort 30 sheets

Max 1,000 sheets (Small size)

500 sheets: (Large size)

Large size A3, B4

11" x 17", 8.5" x 14", 8.5" x 13"

Small size A4R, B5, B5R, A5R,

8.5" x 11", 8.5" x 11"R, 5.5" x 8.5"R

Executive

A3, B4, A4, A4R, B5, B5R

11" x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11", .5" x 11"R

Normal paper 60 - 12g/m² (16 - 34lbs)

Index paper 176g/m² (47lbs)

Cover paper 200 - 205g/m², 54 - 55lbs

OHP

50 sheets

(Small size, 128g/m² x 2 + 80g/m² x 48)

25 sheets (Large size, 80g/m² x 25)

Large size A3, B4,

11" x 17", 8.5" x 14", 8.5" x 13"

Small size A4, A4R,

8.5" x 11", 8.5" x 11"R, B5

(One in the front, one at the back: two positions)

2-position stapling: Front stapling, A3, B4, 11" x 17",

8.5" x 14", 8.5" x 13", A4, 8.5" x 11", B5 only

Cartridge empty detection

Staple jam detection

A3, A4R, B4,

11" x 17", 8.5" x 11"R

(Cover: 64 - 128g/m²)

20 sets (1 - 5 pages)

B. AR-PN1

Type Punch unit

No. of punch holes/Hole diameter 2 holes / 6.5mm

Intervals between punch holes 80±1mm

Size of paper applicable for punching Max. A3, Min. B5R

Quantity of paper applicable for punching

AR-FN7/PN1 INTRODUCTION-2

Page 4

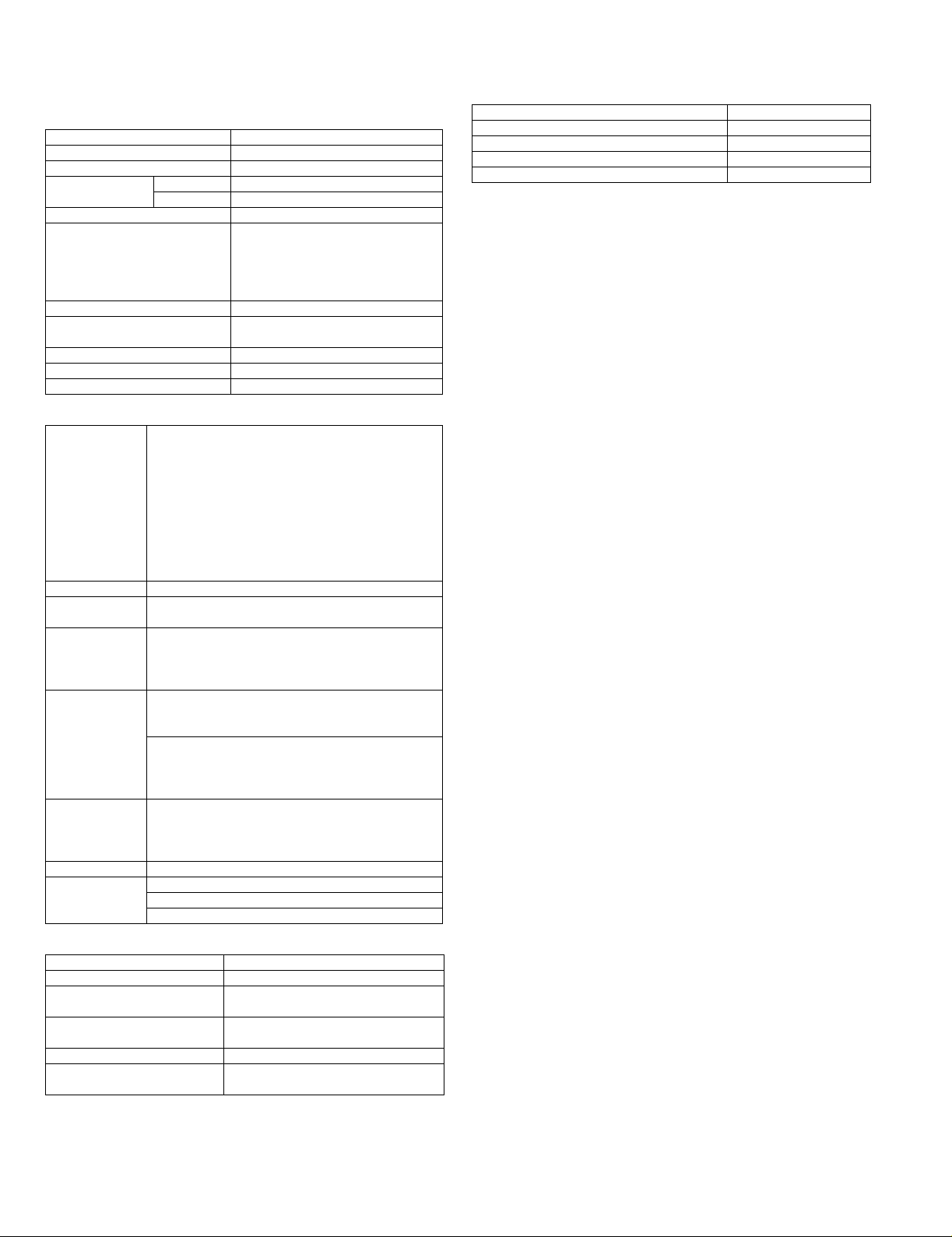

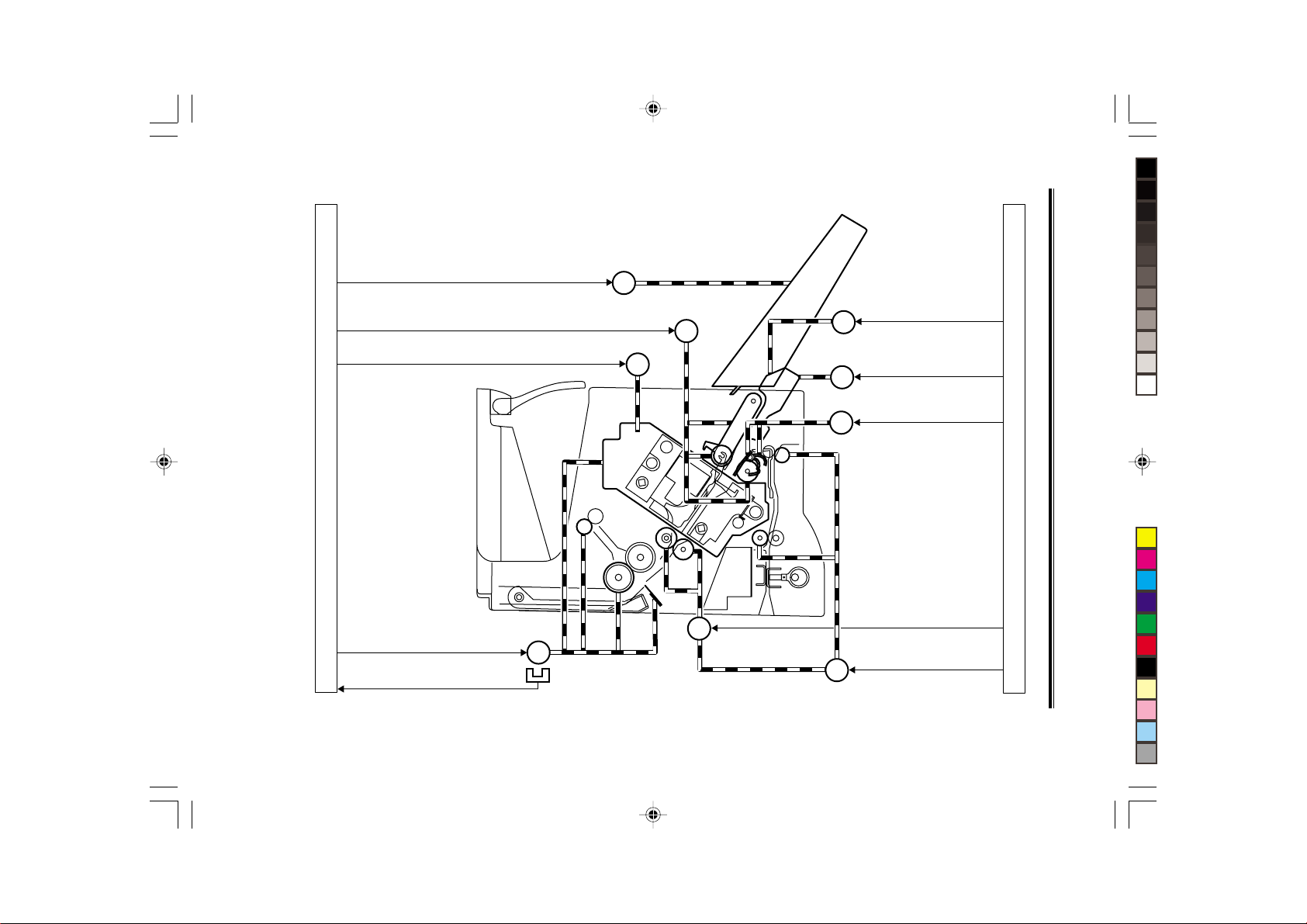

4. Identification of each section

[5]

[3]

[4][2]

[6]

[1]

A. Cross section

(1) Finisher section

[1]

[2]

[3] [7][5][4] [6]

[9]

[8]

[10]

[11]

(2) Saddle section

Fig. F01-301-02

[1] Book making stopper

[2] Book making tray

[3] Bundle transport roller

[4] Book making exit roller

[5] Paper folding roller

[6] Paper pushing plate

(3) Puncher section (Option)

[3][1]

[2]

[4]

Fig. F01-301-01

[1] Paper exit tray

[2] Alignment plate (Front, back)

[3] Paddle

[4] Paper exit roller

[5] Process tray stopper

[6] Transport roller

[7] Puncher section (Option)

[8] Paper exit belt

[9] Bundle exit roller

[10] Stapler

[11] Saddle section

Fig. F01-301-03

[1] Dice

[2] Cam

[3] Punch

[4] Punch dust bo x

AR-FN7/PN1 INTRODUCTION-3

Page 5

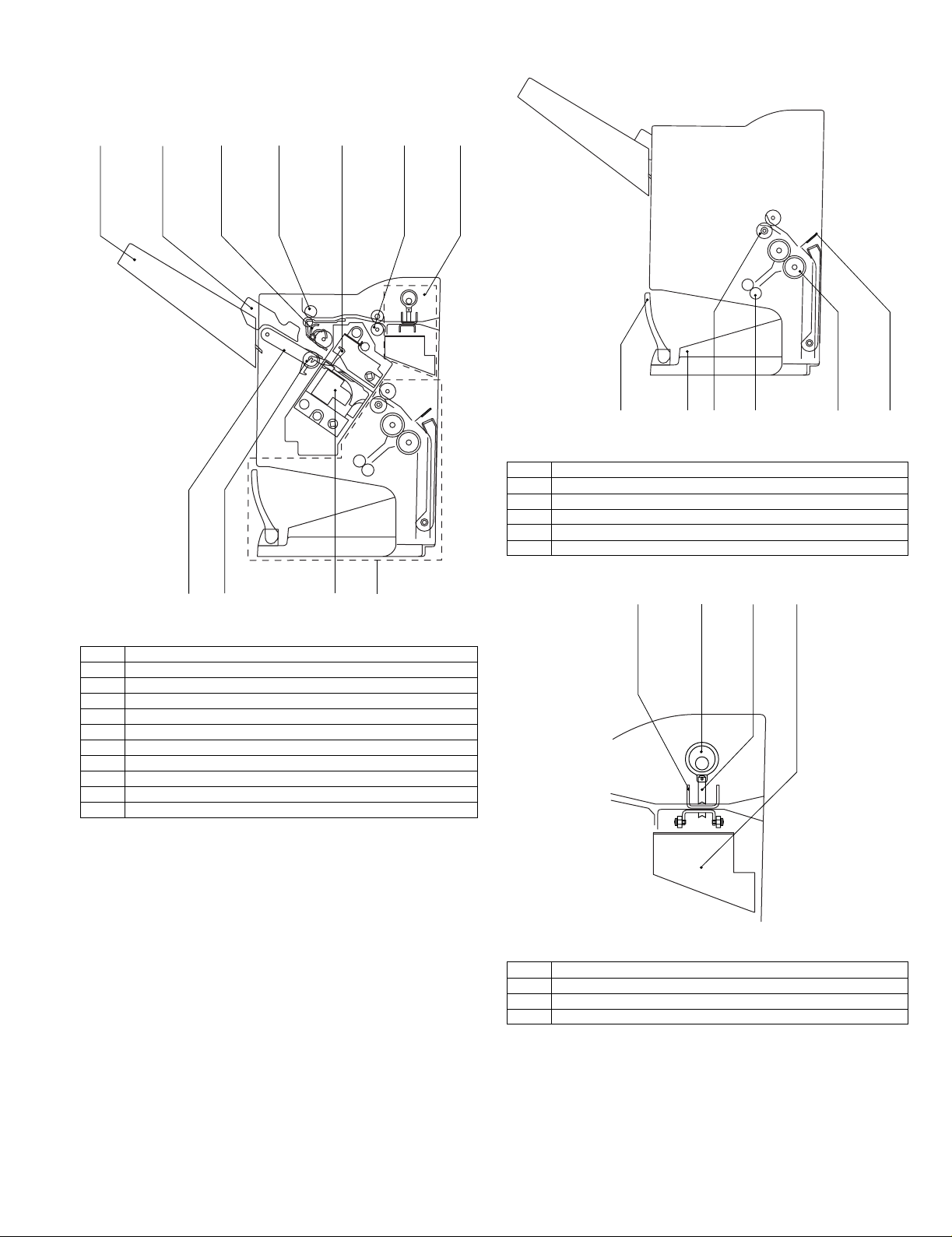

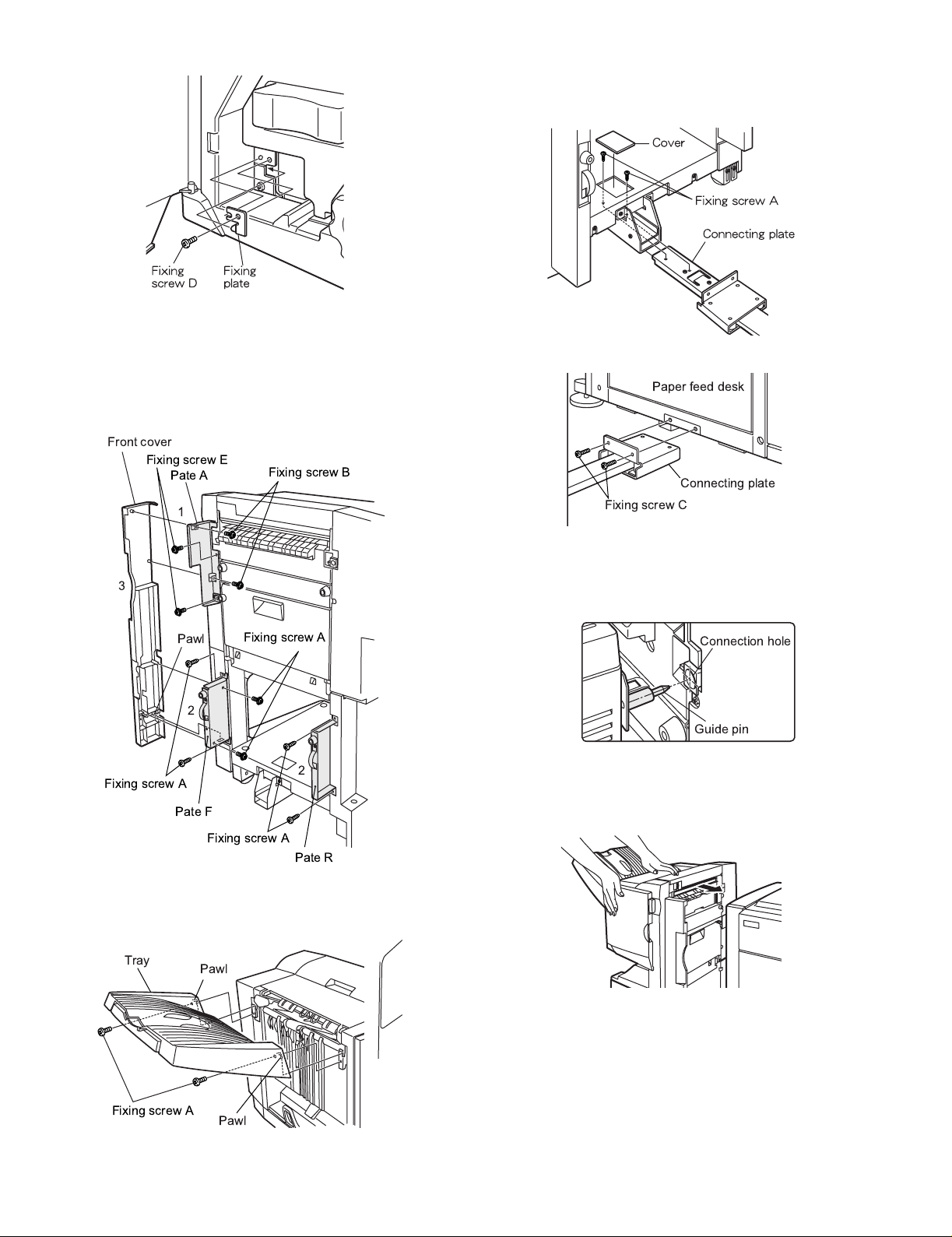

[2] UNPACKING AND INSTALLATION

1. AR-FN7

<Before installation>

•For installation of the AR-FN7, the option desk (the AR-D13, a largecapacity paper feed desk, or the AR-D14, a 3-stage paper feed desk)

and the duplex module (AR-DU3) must be installed in advance.

In addition, the power unit (AR-DC1) is also required.

<Items packed together>

Plate A:

1pc.

Plate F:

1pc.

Plate R:

1pc.

Staple unit:1pc.

3) Process the paper feed desk.

<1>Release lock of the left adjuster at the left lower side of the paper

feed desk, and remove the left adjuster.

<2>Use a screwdriver to make 4 holes through 4 installing holes of the

paper feed desk, and remove burs from the holes with a screwdriver

(-).

Mounting

hole

Mounting

hole

Locking plate:

1pc.

"OFF"

Grounding

plate R:

1pc.

Screw B:

4pcs.

Connecting

plate:

Screw D:

1pc.

1pc.

Screw E:

2pcs.

Screw C:

8pcs.

Fixing plate:

1pc.

Front cover:

1pc.

Tray:

1pc.

1) Turn off the main switch of the printer.

<1>Turn off the main switch on the front panel of the printer.

<2>Disconnect the power plug of the printer from the power outlet.

2) Attach the locking plate to the duplex module.

<1>Remove the fixing screw which is on the rear side of the duplex

module.

<2>Use a screwdriver (+) to make a hole through the installing hole in

the front side of the duplex module. Remove burrs with a screwdriv er

(-) from the hole.

<3>Install the locking plate to the duplex module with two fixing screws.

Grounding

plate F:

1pc.

Screw A:

6pcs.

Left adjuster

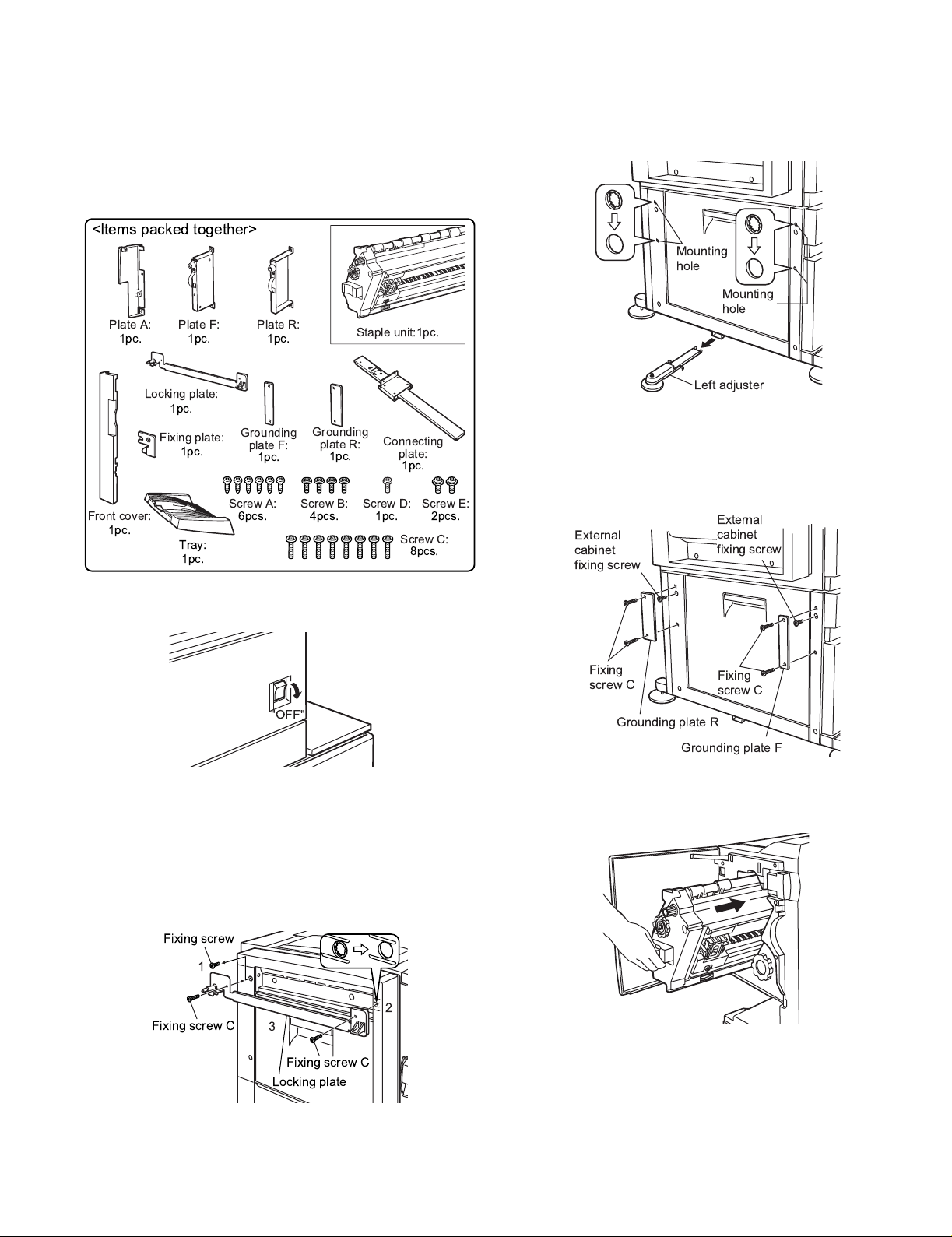

4) Attach a grounding plate to the paper feed desk.

<1>Remove two screws which are fixing the external cabinet of the

paper feed desk.

<2>Install the grounding plate F and the grounding plate R to the paper

feed desk with fixing screws (2pcs. for each).

External

External

cabinet

cabinet

fixing screw

fixing screw

Fixing

screw C

Fixing

screw C

Grounding plate R

Grounding plate F

5) Install the staple unit to the finisher.

<1>Open the front cabinet of the finisher, and insert the staple unit into

the finisher.

Fixing screw

1

Fixing screw C

2

3

Fixing screw C

Locking plate

AR-FN7/PN1 UNPACKING AND INSTALLATION-1

Page 6

<2>Install the fixing plate with the fixing screw.

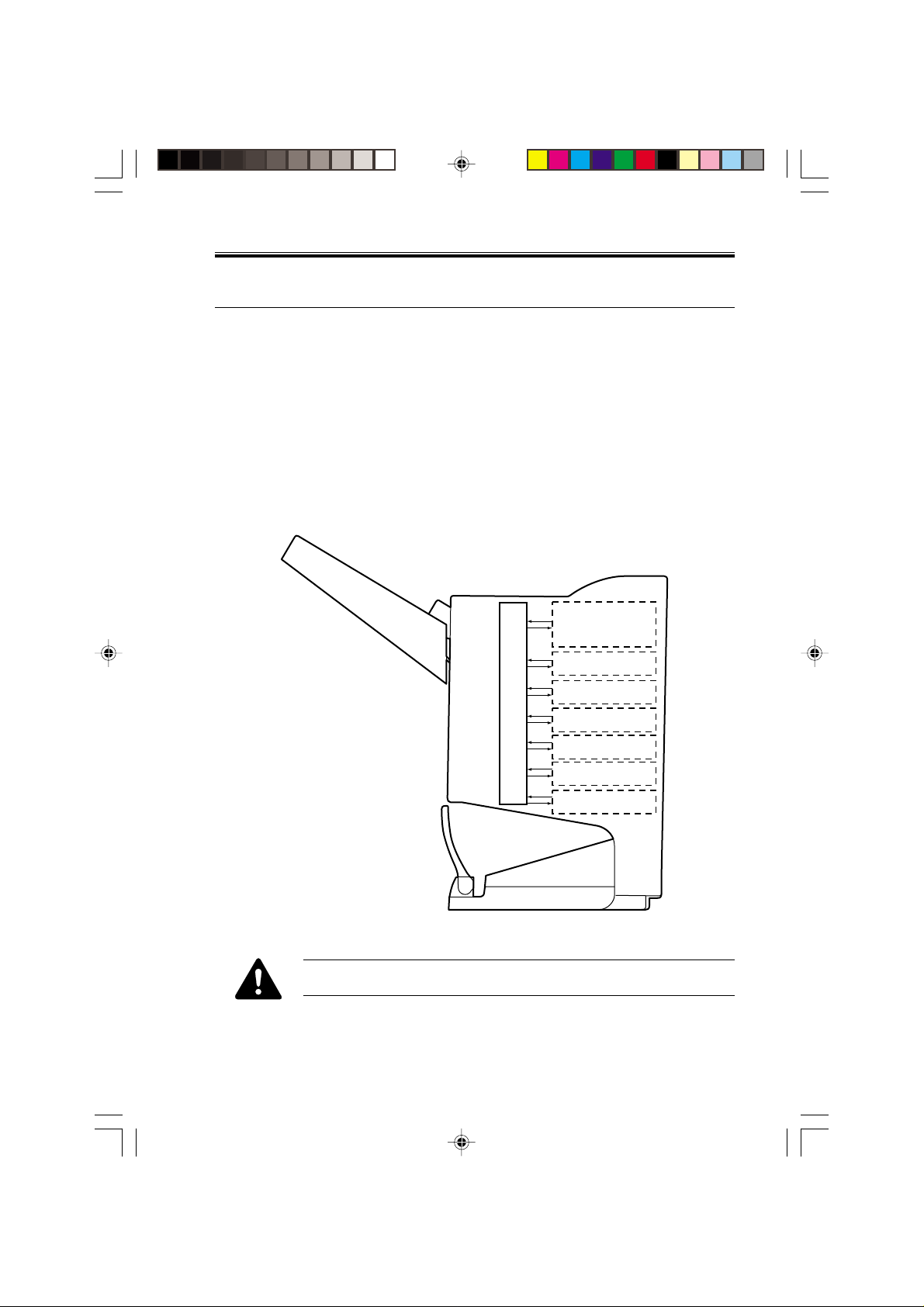

6) Install the cover to the finisher.

<1>Install plate A to the position shown in the figure below, and fix it with

two fixing screws.

<2>Install plate F and plate r to their position shown in the figure below

and fix them with fixing screws (2 pcs. for each).

<3>Inser t the pawl of the lower side of the front cover into the mounting

hole of plate F, and fix it with four fixing screws.

Front cover

Fixing screw E

Pate A

Fixing screw B

1

8) Connect the finisher to the paper feed desk.

<1>Remove the cover from the finisher stand.

<2>Install the connecting plate to the finisher with two fixing screws A.

<3>Install the cover to the original position.

<4>Install the finisher to the paper feed desk with two fixing screws C.

Paper feed desk

Connecting plate

Fixing screw C

3

Pawl

Fixing screw A

2

2

Fixing screw A

Pate F

Fixing screw A

Pate R

7) Install the tray.

<1>Hang two pawls of the tray on the installing section of the machine,

and fix them with two fixing screws A.

Tray

Pawl

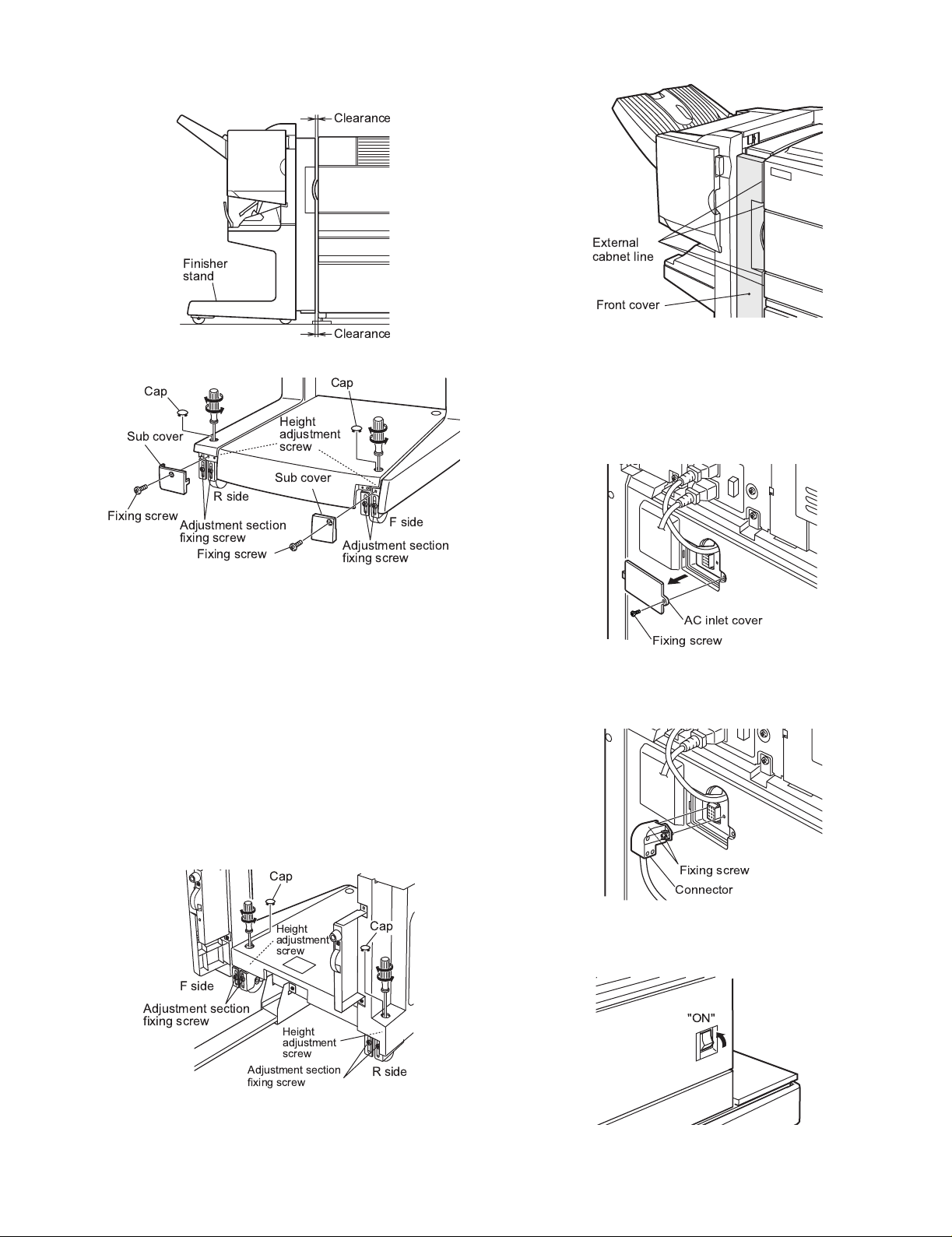

9) Check and adjust the height of the finisher.

* Move the finisher toward the printer, and check to insure that the

guide pin of the locking plate in inserted into the connection hole of

the finisher smoothly. If not, adjust as follows.

Connection hole

Guide pin

a. When the guide pin of the locking plate is aligned with the

connection hole of the finisher:

<1>Push the finisher into the machine.

Fixing screw A

Pawl

<2>If the upper and lower clearances between the printer and the

finisher are not even, remove the cap on the front/rear side of the

finisher stand with a screwdriver, remove the fixing screw (1pc for

each) of the sub cover in the front/rear side, and remove the sub

cover.

<3>Loosen the fixing screws (4 pcs.) in the adjustment section of the

finisher shown in the figure, and adjust the height adjustment screws

the front and at the back so that the clearances are even.

AR-FN7/PN1 UNPACKING AND INSTALLATION-2

Page 7

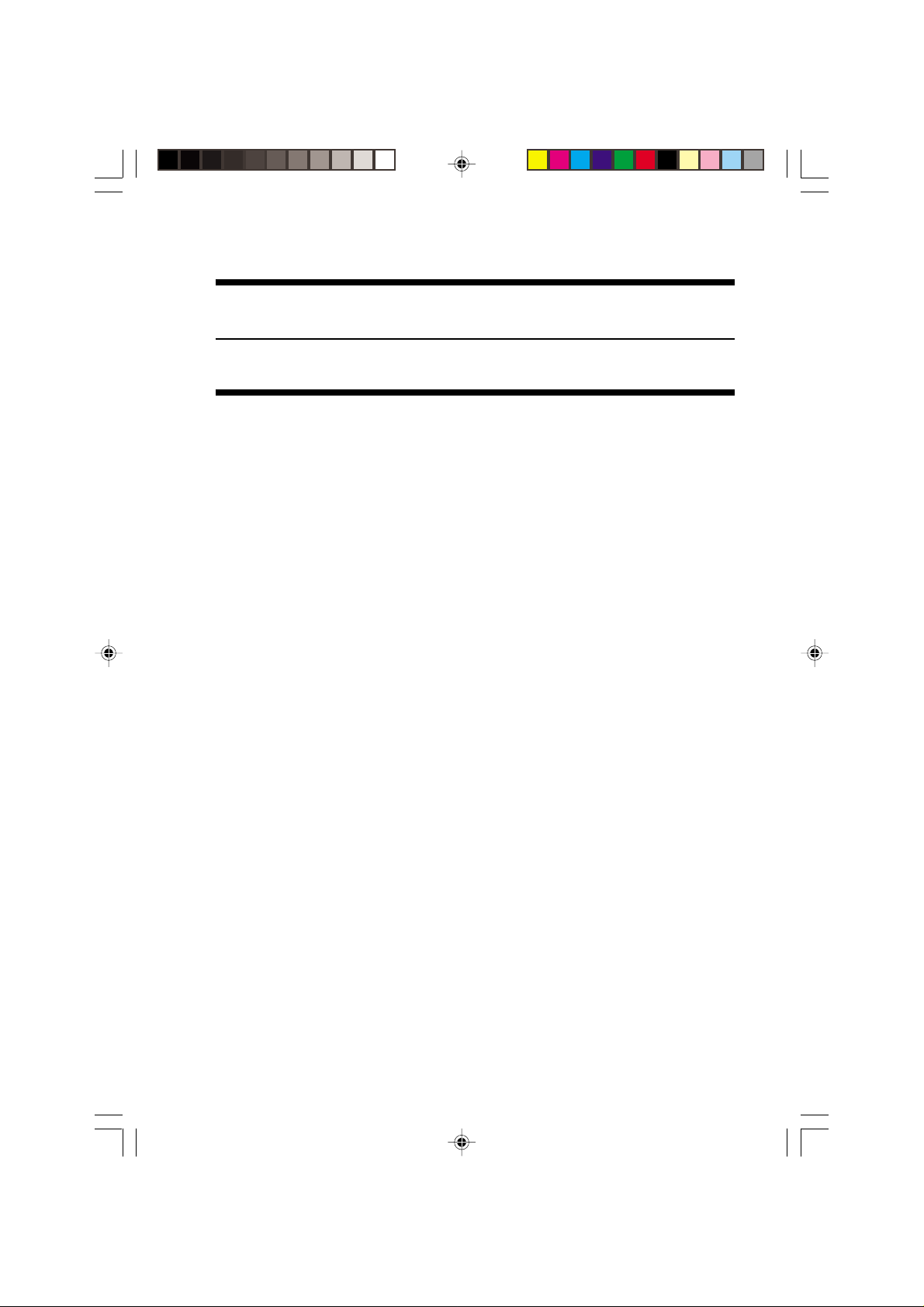

<4>When the clearances are adjusted to be even, tighten the fixing

e

e

Fixing screw

Connector

screws (4 pcs.) in the adjustment section, and install the cap and the

sub cover.

Clearanc

Finisher

stand

External

cabnet line

Front cover

Clearanc

Cap

Cap

Height

Sub cover

adjustment

screw

Sub cover

R side

Fixing screw

Adjustment section

fixing screw

Fixing screw

Adjustment section

fixing screw

F side

b. When the guide pin of the locking plate is not aligned with the

connection hole of the finisher:

<1>For the rear side, loosen the two fixing screws of the adjustment

section at the rear as shown in the figure.

<2>Turn the height adjustment screw to adjust so that the guide pin of

the locking plate is aligned with the connection hole of the finisher.

<3>For the front side, remove the cap from the front side of the finisher

stand with a screwdriver (-). Loosen the fixing screw of the

adjustment section on the front side similarly to the rear side. Tu rn

the height adjustment screw to adjust so that the external line of the

finisher front cover is aligned with the external line of the machine as

shown in the figure.

<4>Check that the guide pin is inserted into the hole smoothly, and

tighten the fixing screws of the adjustment section on the front side

and the rear side.

<5>Perform the clearance adjustment between the finisher and the

printer with procedures of a.

10) Remove the AC inlet cover from the rear cabinet of the paper feed

desk.

<1>Remove the fixing screw of the AC inlet cover, and remove the AC

inlet cover.

AC inlet cover

Fixing screw

11) Connect the connector of the finisher.

<1>Connect the connector of the finisher to the paper feed desk.

<2>Tighten the fixing screw of the connector.

F side

Adjustment section

fixing screw

Cap

Height

adjustment

screw

Height

adjustment

screw

Adjustment section

fixing screw

Cap

12) Turn on the main switch of the printer.

<1>Insert the power plug of the printer into the power outlet.

<2>Turn on the main switch of the printer.

R side

AR-FN7/PN1 UNPACKING AND INSTALLATION-3

"ON"

Page 8

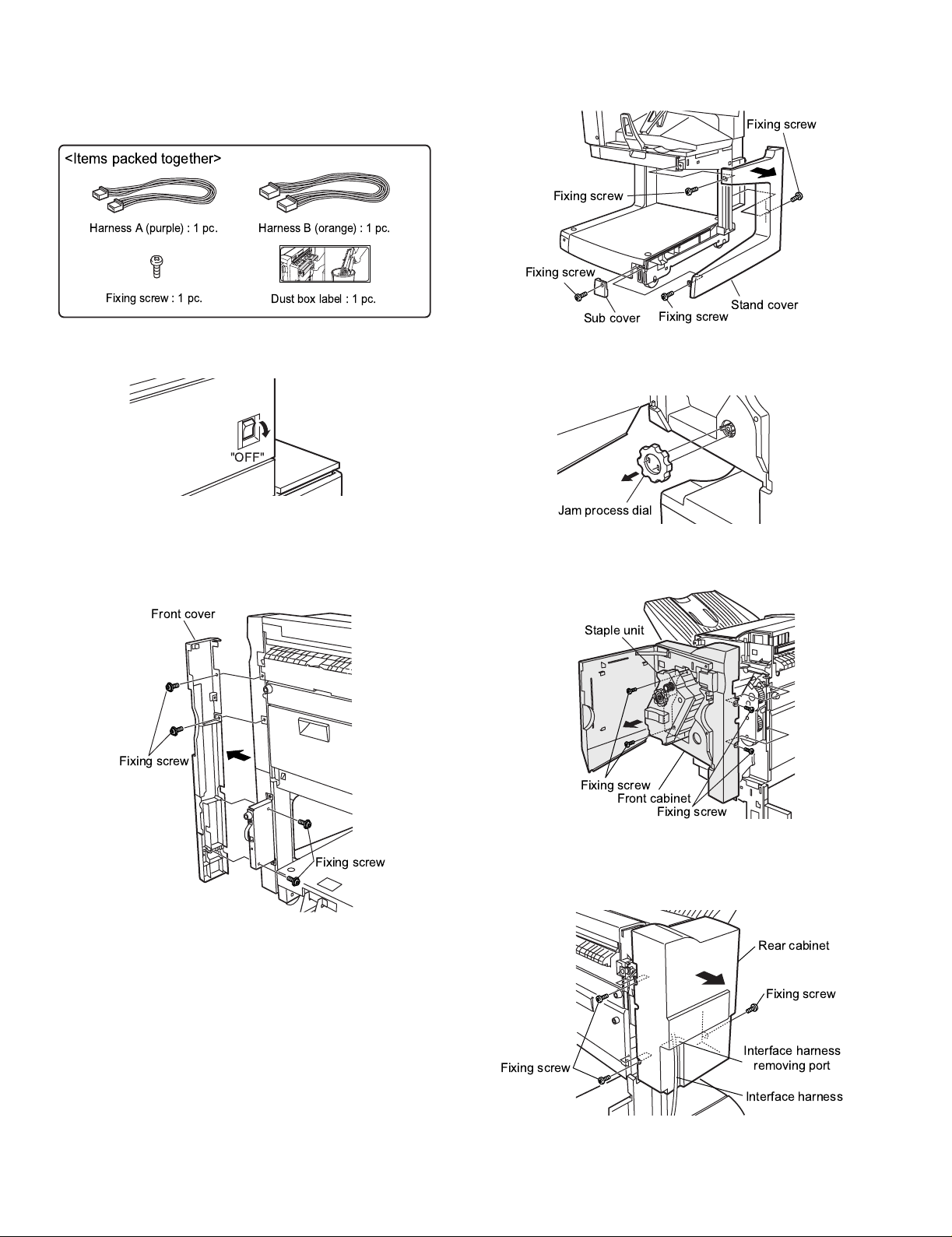

2. AR-PN1

<Before installation>

* For installation of the AR-PN1, the saddle finisher (AR-FN7) must be

installed in advance.

<Items packed together>

<2>Remove the fixing screw of the sub cover, and remove the sub cover.

<3>Remove three fixing screws of the stand cover, and remove the stand

cover.

Fixing screw

Fixing screw

Harness A (purple):1pc.

Fixing screw:1pc.

1) Turn off the main switch of the printer.

<1>T urn off the main swit ch of the printer.

<2>Disconnect the power plug of the printer from the power outlet.

2) Remove the right front cover of the finisher.

<1>Remove four fixing screws of the front cover, and remove the front

cover.

Front cover

Harness B (orange):1pc.

Dust box label:1pc.

"OFF"

Fixing screw

Sub cover

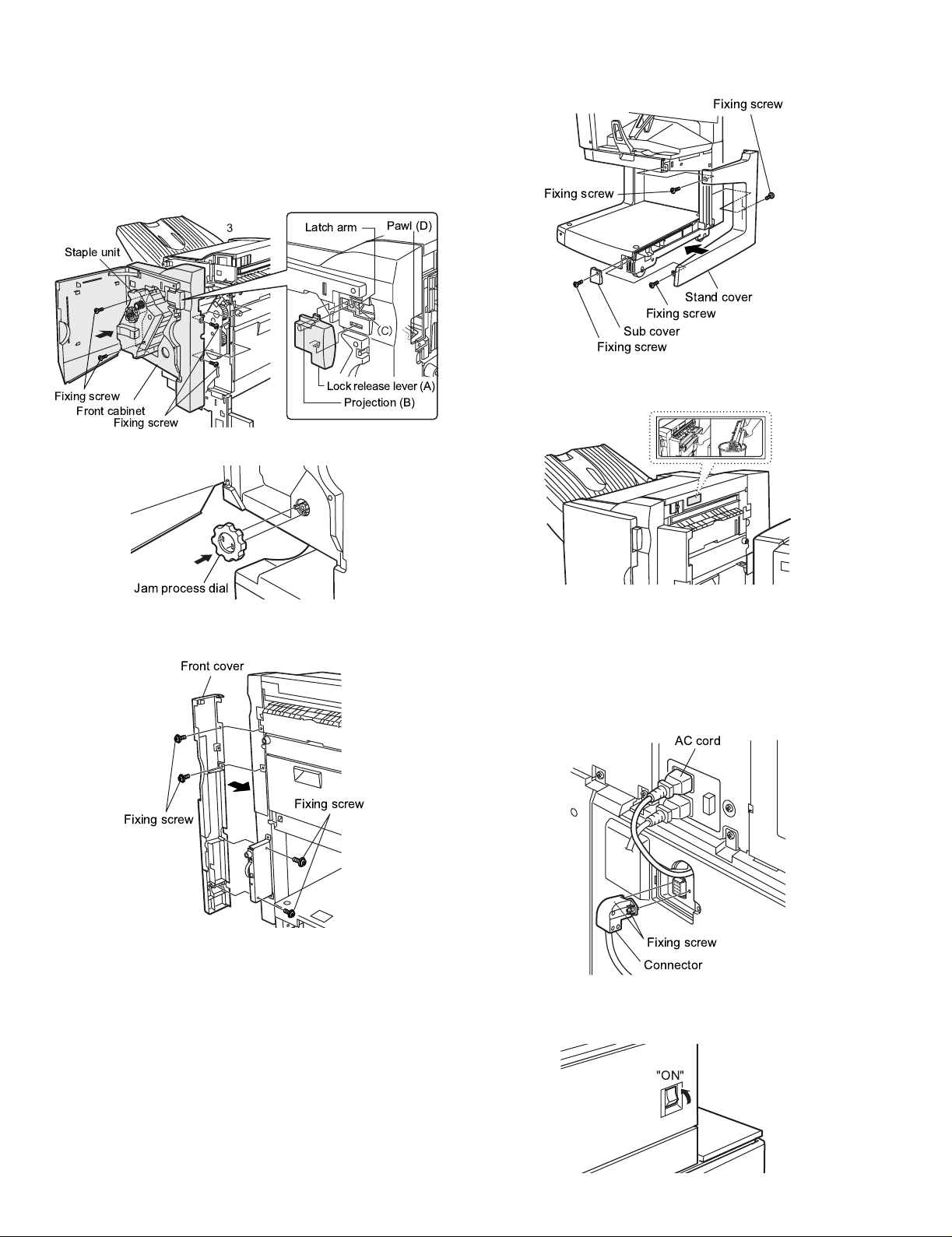

3) Remove the front cabinet and the rear cabinet of the finisher.

<1>Open the front cover of the finisher , and remove the jam process dial.

Jam process dial

<2>Remove four fixing screws of the front cabinet, and pull out the stapl e

unit until it stops, and remove the front cabinet.

Staple unit

Fixing screw

Stand cover

Fixing screw

Fixing screw

<3>Remove three fixing screws of the rear cabinet, and remove the rear

Fixing screw

AR-FN7/PN1 UNPACKING AND INSTALLATION-4

cabinet.

* At that time, remove the interface harness from the rear cabinet

removing port.

Fixing screw

Front cabinet

Fixing screw

Rear cabinet

Fixing screw

Interface harness

removing port

Interface harness

Page 9

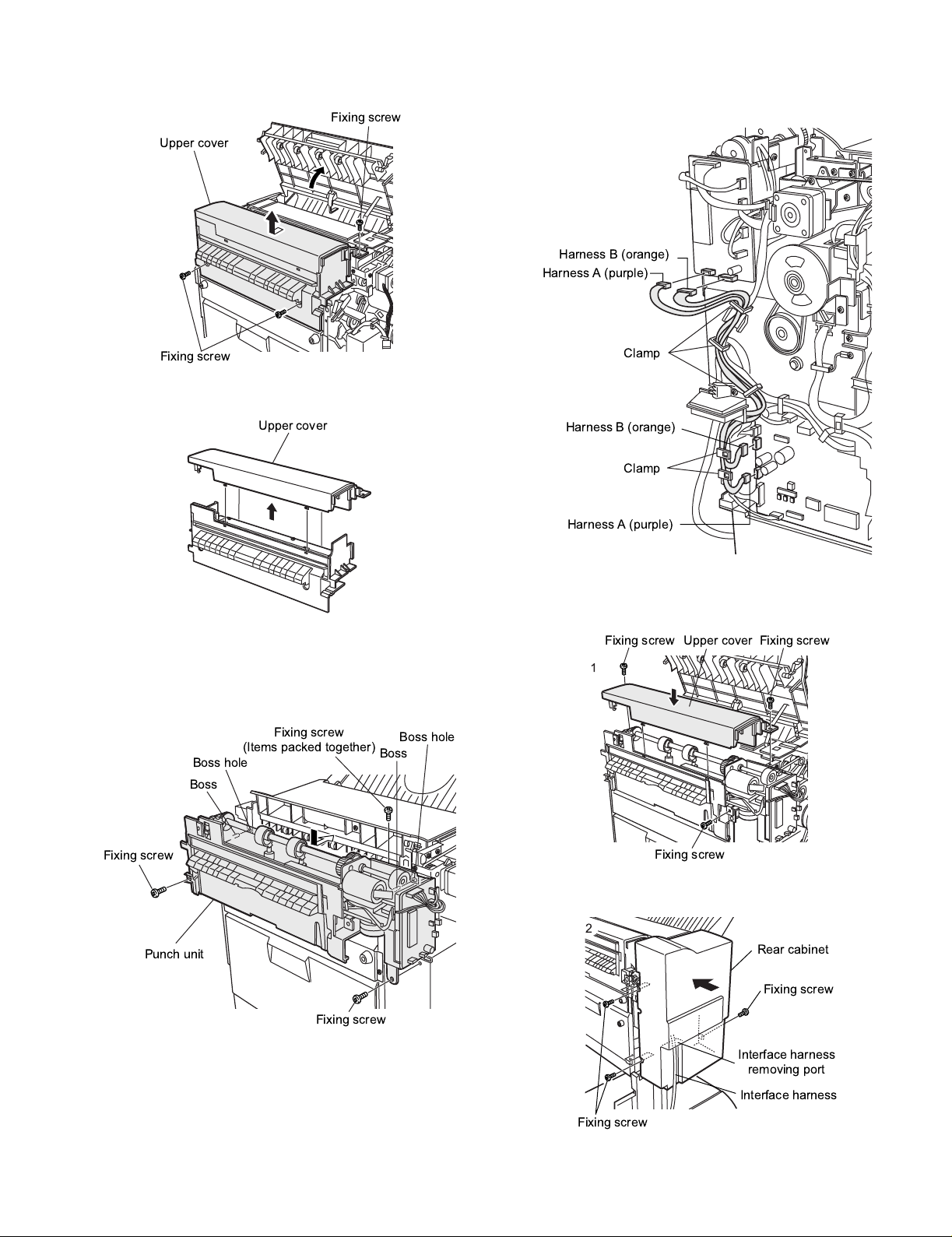

4) Remove the upper cover.

Harness A (purple)

Harness A (purple)

Harness B (orange)

Harness B (orange)

Clamp

Clamp

<1>Remove three fixing screws of the upper cover, and remove the

upper cover.

Fixing screw

Upper cover

Fixing screw

<2>Disengage four pawls of the removed upper cover, and separate it

into upper and lower portions, and reuse the upper portion.

Upper cover

6) Connect the punch unit harness to the finisher PWB.

<1>Remove the clamp which is fixing the harness. Wire the harness A

(purple) and harness B (orange) as shown in the figure, and fix them

with the clamp.

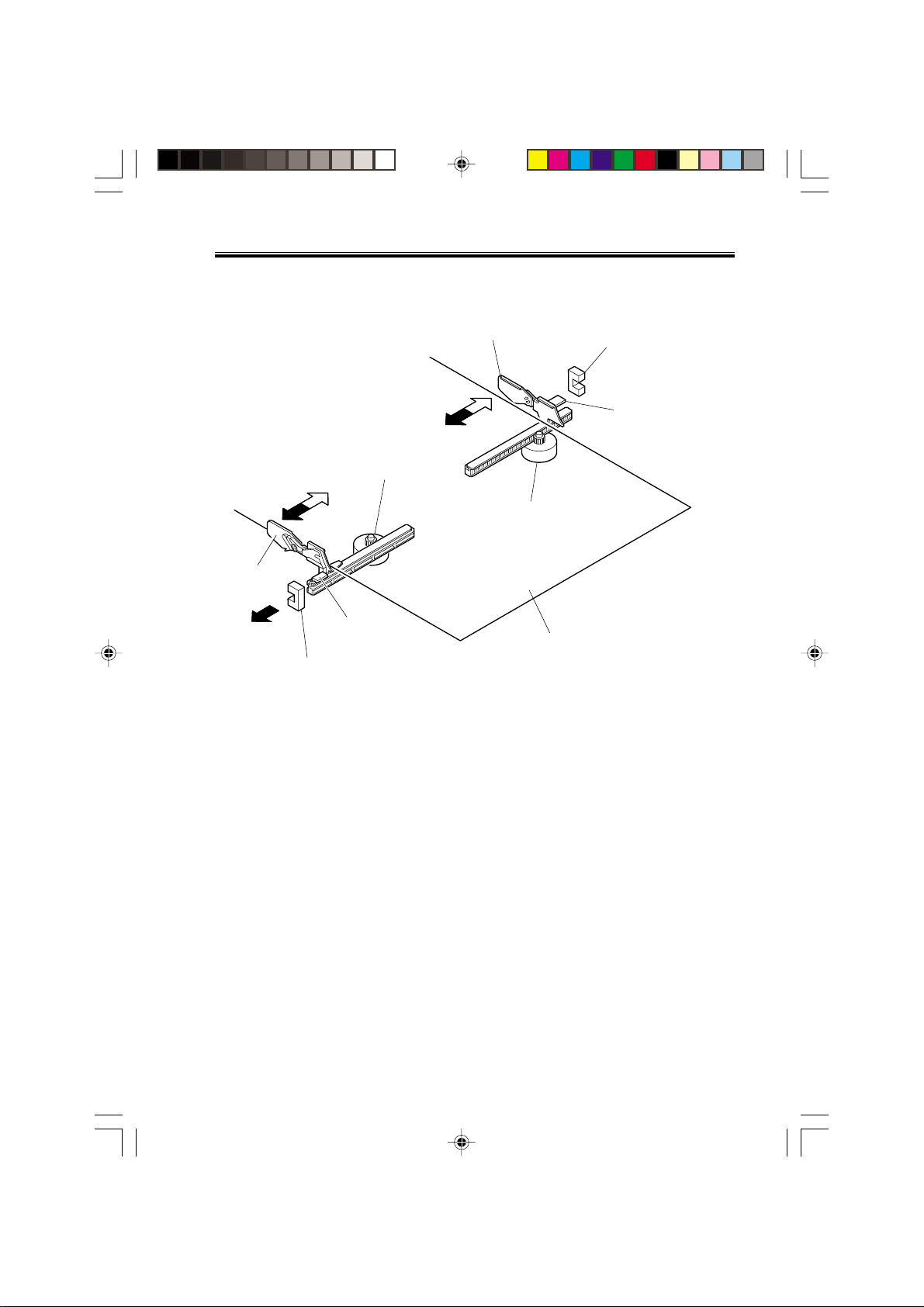

5) Install the punch unit.

<1>Insert two bosses of the punch unit into the boss holes of the fini sher,

Note:Use one fixing screw which is packed together and two fixing

and fix the unit with three fixing screws.

screws which were removed in procedure 4).

Fixing screw

(Items packed together)

Boss hole

Boss

Fixing screw

Punch unit

Fixing screw

Boss hole

Boss

7) Install the covers which were removed.

<1>Hang two pawls of the upper cover on the unit and fix it with three

fixing screws.

Upper cover

1

Fixing screwFixing screw

Fixing screw

<2>Pass the interface harness of the rear cabinet, and fix with three

screws.

2

Rear cabinet

Fixing screw

Interface harness

removing port

Interface harness

Fixing screw

AR-FN7/PN1 UNPACKING AND INSTALLATION-5

Page 10

<3>Install the front cabinet to the original position, push the staple unit

into the machine, and fix it with four fixing screws.

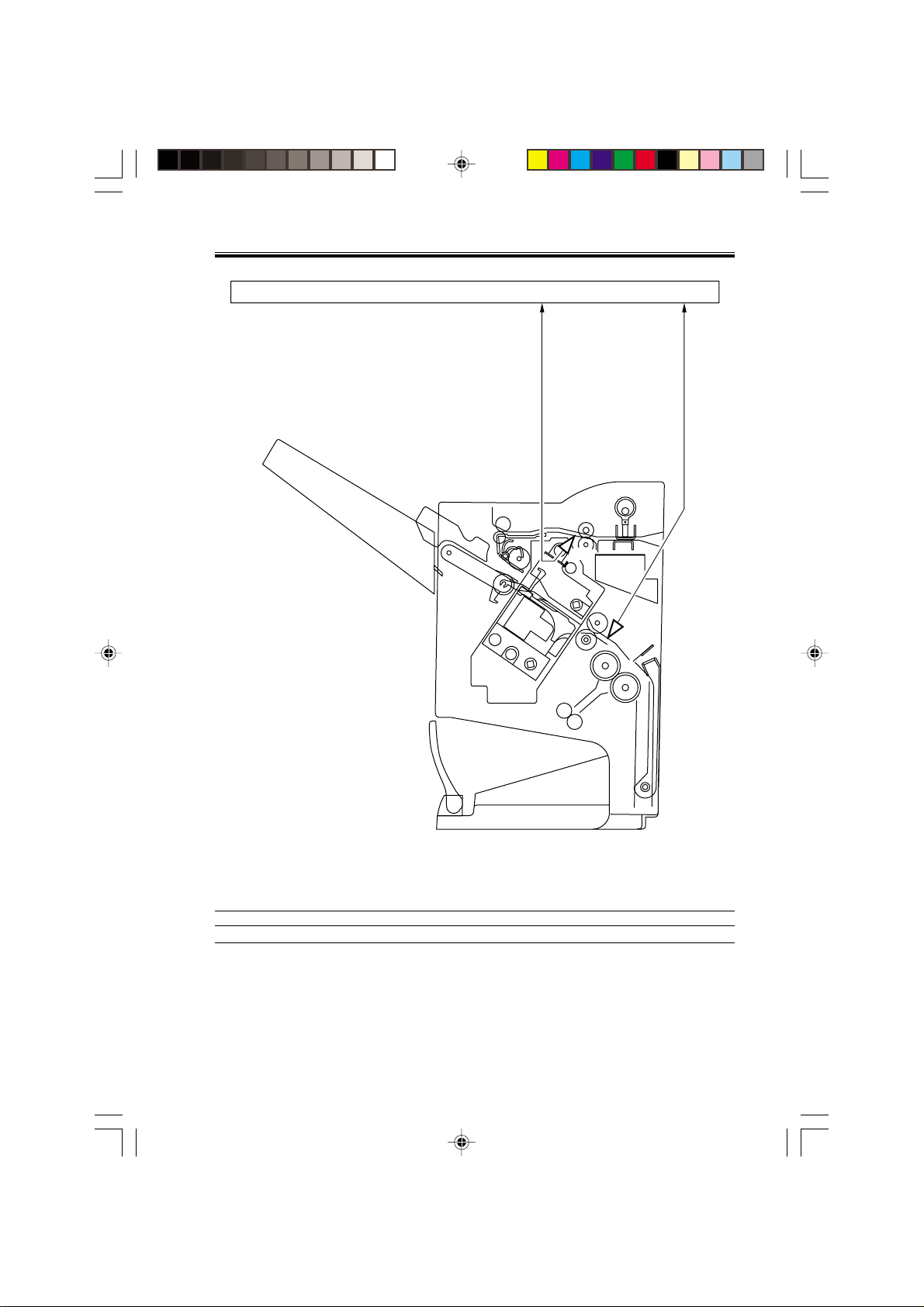

* When installing, insert the projection (B) of the lock release lever into

the latch arm hole (C).

* After installation, release the latch and move the lever to check that it

slides smoothly.

* If it does not move smoothly, disengage the pawl on the lower side of

the release lever with a screwdriver (-) and remove the lever. Then

insert is again.

<2>Install the stand cover with three fixing screws, and install the sub

cover with one fixing screw.

Fixing screw

Fixing screw

Latch arm

Lock release lever (A)

Projection (B)

Staple unit

Fixing screw

Front cabinet

3

Fixing screw

<4>Install the jam process dial, and close the front cover.

Jam process dial

8) Install the right front cover of the finisher.

<1>Install the front cover with four fixing screws.

Front cover

Pawl (D)

Stand cover

Fixing screw

Sub cover

Fixing screw

9) Attach the dust box label to the upper cover.

<1>Attach the dust box cover to the position shown in the figure below.

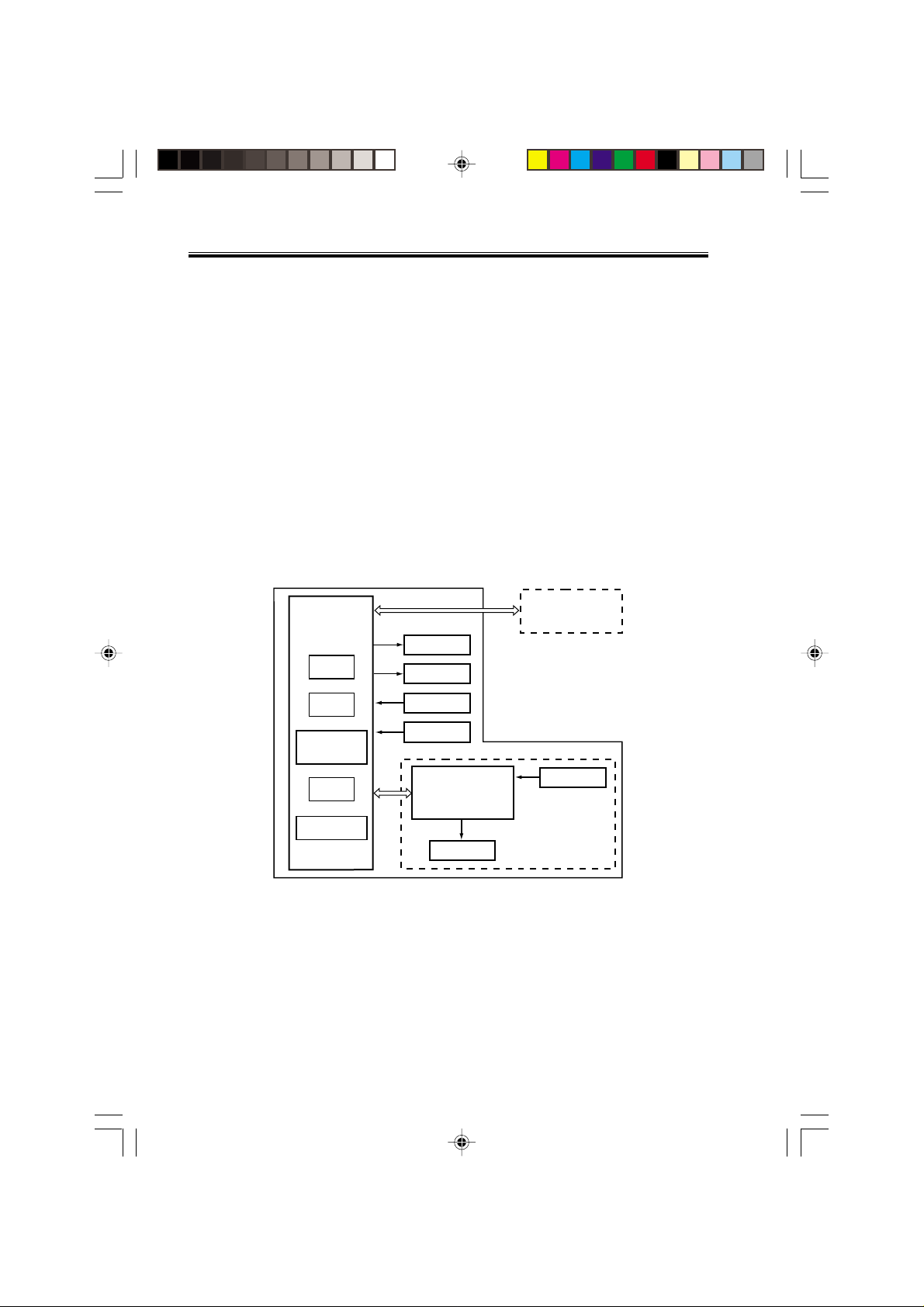

10) Connect the connector to the paper feed desk, and connect the AC

cord of the power unit to the printer.

<1>Connect the connector of the interface harness of the finisher to the

paper feed desk, and tighten the connector fixing screw.

<2>Connect the AC cord of the power unit to the inlet connector of the

printer as shown in the figure.

AC cord

Fixing screw

Fixing screw

Fixing screw

Connector

11) Turn on the main switch of the printer.

<1>Inser t the power plug of the printer to the power outlet.

<2>Turn on the main switch of the printer.

"ON"

AR-FN7/PN1 UNPACKING AND INSTALLATION-6

Page 11

CHAPTER 2

OUTLINE OF OPERATION

COPYRIGHT

#ChapterCover.p65 3/28/01, 12:05 PM2

©

2001 CANON INC. 2001 2001 2001 2001 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 12

CHAPTER 2 OUTLINE OF OPERATION

1 Basic Operations

1.1 Specifications

The finisher serves to deliver sheets coming from its host machine. The mode of delivery

may be non-sort stack, job offset*, or staple delivery.

The saddle unit built into the finisher is used to fold a stack of sheets coming from the fin-

isher unit in half for delivery.

All these operations are controlled by various commands sent by the host machine in ad-

dition to the commands from the finisher controller PCB.

The puncher unit (option) is designed for installation to the pickup assembly of the fin-

isher, and is used to punch holes in sheets coming from the host machine.

The above operations are controlled with various commands from the finisher controller

PCB as well as the commands from the punch controller PCB.

Puncher unit drive

system (puncher unit;

option)

Alignment drive system

Stapler drive system

The position of delivery is shifted to the front/rear for each stack to assist

sorting.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM1

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-101-01

Delivery drive system

Control system

Feed drive system

Tray drive system

Saddle unit

drive system

2-1

Page 13

CHAPTER 2 OUTLINE OF OPERATION

1.2 Outline of the Electrical Circuitry

The sequence of finisher operations is controlled by the finisher controller PCB. The finisher controller PCB is a 16-bit microprocessor (CPU), and is also used for combination

with the host machine (serial).

The finisher controller PCB drive motors and other loads in response to the various commands from the host machine. It also communicates such data as on the states of various

sensors and switches to the host machine by way of the serial communication line.

The ICs mounted to the finisher controller PCB have the following functions:

• IC13 (CPU)

Controls sequence of operations.

• IC12 (EEP-ROM)

Backs up adjustment settings.

• IC6 (EP-ROM)

Stores sequence programs.

F02-102-01 shows the flow of signals between finisher and options controller:

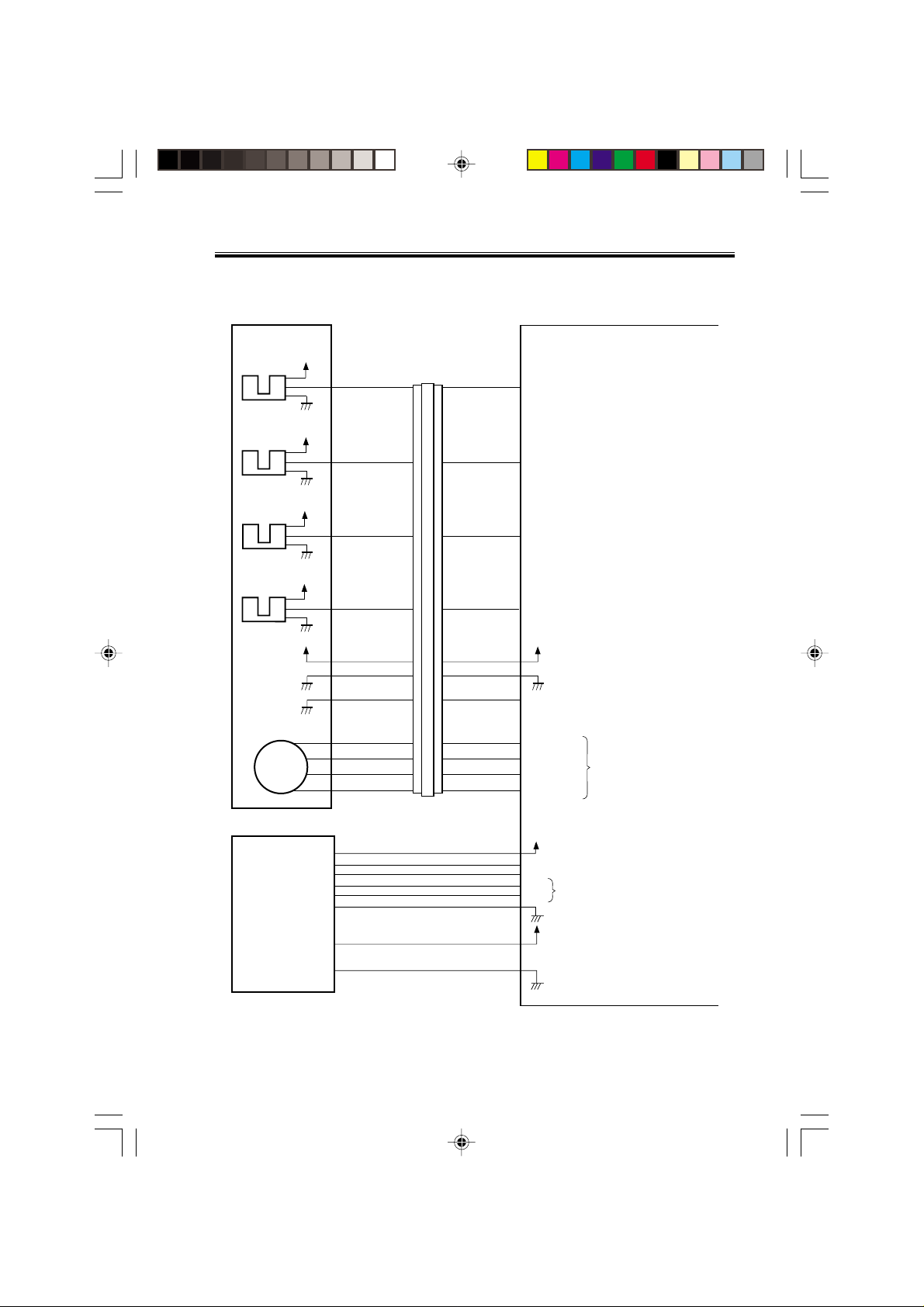

Finisher unit

Finisher

controller

PCB

IC13

CPU

IC12

EEP-ROM

IC11

Communica-

tion IC

IC6

EP-ROM

IC1

Regulator IC

• IC11 (communication IC)

Communicates with the host machine.

• IC1 (regulator IC)

Generates 5 V.

Host machine DC

controller PCB

CPU

Motor

Clutch

Switch

Sensor

Puncher unit (option)

Punch controller

PCB

Motor

Sensor

2-2

Chap02.p65 3/28/01, 12:07 PM2

COPYRIGHT

©

F02-102-01

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 14

CHAPTER 2 OUTLINE OF OPERATION

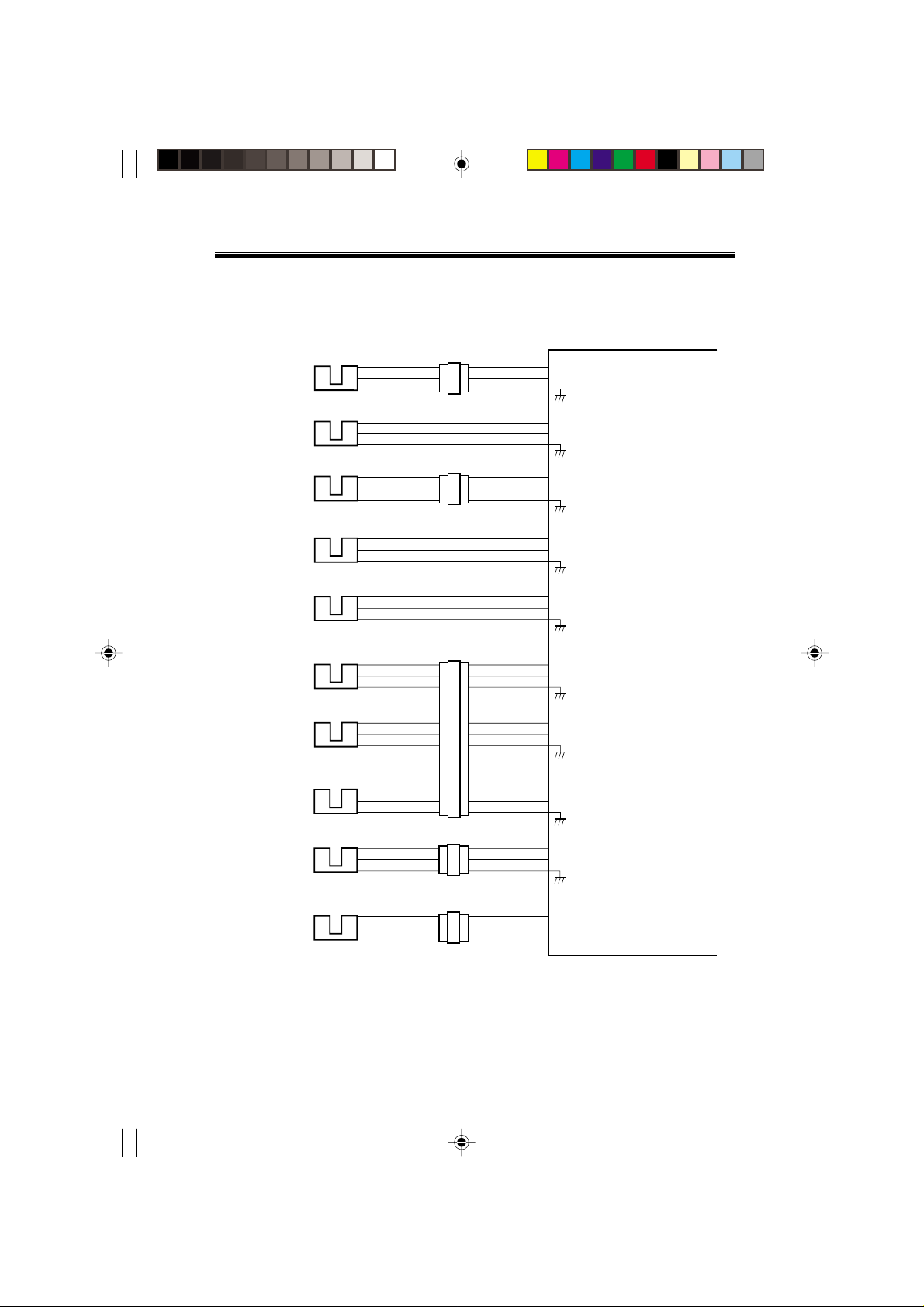

1.3 Inputs to and Outputs from the Finisher Controller PCB

1.3.1 Inputs to the Finisher Controller PCB (1/2)

Finisher controller PCB

Inlet sensor

Paddle home

position sensor

PI1

PI2

CN44-3

CN51-1

CN43-1

-1

-2

-3

-2

CN42-3

-3

-2

-1

-2

CN16-10

-12

-11

CN9-1

-3

-2

+5 V

ENT_S

+5 V

PDL_HP

When the sensor

detects paper, ‘1’ .

When the paddle is at

home position, ‘1’.

Swing guide

home position

sensor

Aligning plate

home position

sensor (front)

Aligning plate

home position

sensor (rear)

Processing

tray sensor

Delivery belt

home position

sensor

Tray paper sensor

Paper surface

sensor

Folding position

sensor

PI3

PI4

PI5

PI6

PI7

PI8

PI9

PI10

CN55-3

CN23-3

CN36-3

CN30-3

CN31-3

CN32-3

CN35-3

CN39-3

CN54-1

-1

-2

-1

-2

-1

-2

CN29-1

-1

-2

-1

-2

-1

-2

CN34-1

-1

-2

CN38-1

-2

-1

CN53-3

-3

-2

CN28-9

-3

-2

-4

-6

-5

-7

-9

-8

CN33-3

-3

-2

CN37-9

-2

-3

CN9-7

CN4

CN5-13

-15

-14

CN5-1

CN5-10

-12

-11

CN16-1

+5 V

-9

BDL_ROL_HP

-8

+5 V

-3

F JOG_HP

-2

+5 V

R JOG_HP

+5 V

-3

ADJ_TRAY_S

-2

-4

+5 V

-6

EJCT_BLT_HP

-5

-7

+5 V

-9

TRY_EMPS

-8

+5 V

LVL_S

+5 V

-2

BIND_P

-3

BIND_L

-1

-2

-7

-8

-6

-4

-5

-3

-1

-2

-1

-2

-8

-7

When the swing guide

is at home position, ‘1’.

When the aligning

plate (front) is at

home position, ‘1’.

When the aligning

plate (rear) is at

home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the delivery belt

is at home position, ‘1’.

When paper is present

on the tray, ‘1’.

When the paper

surface is detected,

‘1’.

When paper is

detected, ‘0’.

When LED is lit, ‘1’.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM3

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-103-01

2-3

Page 15

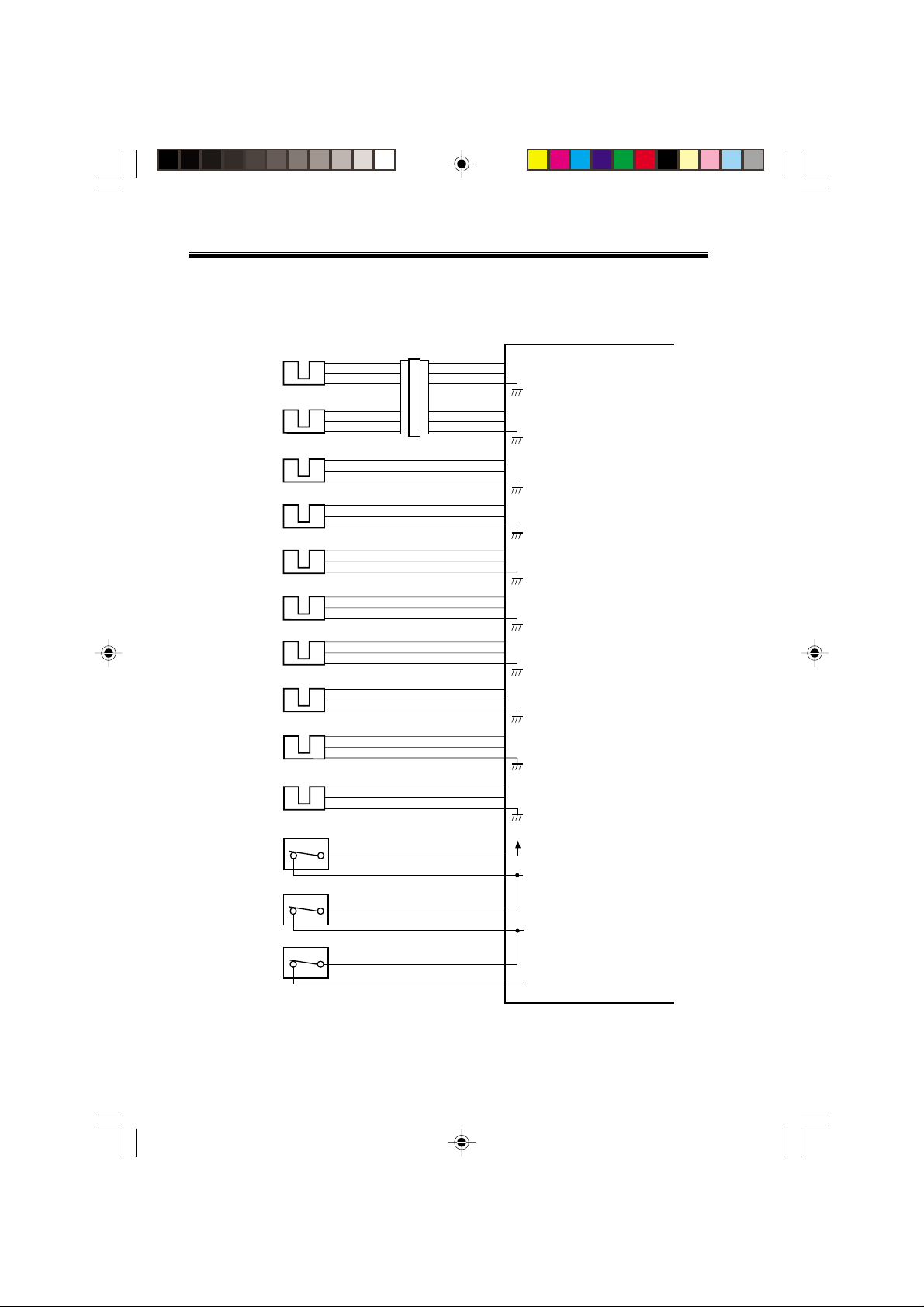

CHAPTER 2 OUTLINE OF OPERATION

1.3.2 Inputs to the Finisher Controller PCB (2/2)

Folding home

position sensor

Stack feed roller

(upper) home

position sensor

Bind tray sensor

Staple/fold motor

clock sensor

Shift upper limit

sensor

Shift lower limit

sensor

Shift motor clock

sensor

Front door sensor

Upper cover sensor

PI11

PI12

PI13

PI14

PI15

PI16

PI17

PI22

PI23

CN40-3

CN41-3

CN47-3

CN52-1

CN50-3

CN49-3

CN48-3

CN25-3

CN24-3

-1

-2

-1

-2

-1

-2

-2

-3

-1

-2

-1

-2

-1

-2

-1

-2

-1

-2

CN38-4

CN37-6

-6

-5

-7

-9

-8

-4

-5

-3

-1

-2

CN15-10

CN16-4

CN15-1

CN9-6

-12

-11

CN15-7

CN15-4

CN4-7

CN4-4

-6

-5

-7

-9

-8

-3

-2

-5

-4

-9

-8

-6

-5

-9

-8

-6

-5

Finisher controller PCB

+5 V

BIND_HP

+5 V

BIND_ROL_HP

+5 V

BIND_EMPS

+5 V

BIND_CLK

+5 V

SIFT_UPLMT

+5 V

SIFT_DNLMT

+5 V

SIFT_CLK

+5 V

FDOOR_S

+5 V

TOPCOV_S

When at folding home position, ‘0’.

When the stack feed roller

(upper) is at home position, ‘1’.

When the sensor

detects paper, ‘1’.

When the staple/fold motor is

rotating, alternates between

‘1’ and ‘0’.

When the tray is at the

upper limit, ‘1’.

When the tray is at the

lower limit, ‘1’.

While the shift motor

is rotating, alternates

between ‘1’ and ‘0’.

When the front door

is open, ‘1’.

When the upper cover

is open, ‘1’.

PI24

Full stack sensor

Joint switch

Front door switch

Stapler safety

switch

2-4

Chap02.p65 3/28/01, 12:07 PM4

CN73-3

MS2

N. O.

CN69-2

MS1

N. O.

CN68-2

MS3

N. O.

CN66-2

COPYRIGHT

©

CN19-1

+5 V

CN8-6

CN8-4

CN8-2

-3

-2

-5

-3

-1

PAPER_F

+24 VP

JOINT SW

FRONT SW

STPLSAFE SW

-1

-2

-1

-1

-1

When the paper is

full, ‘1’.

When connected to

the host machine, ‘1’.

When the front

door is closed, ‘1’.

When the swing

guide is closed, ‘1’.

F02-103-02

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 16

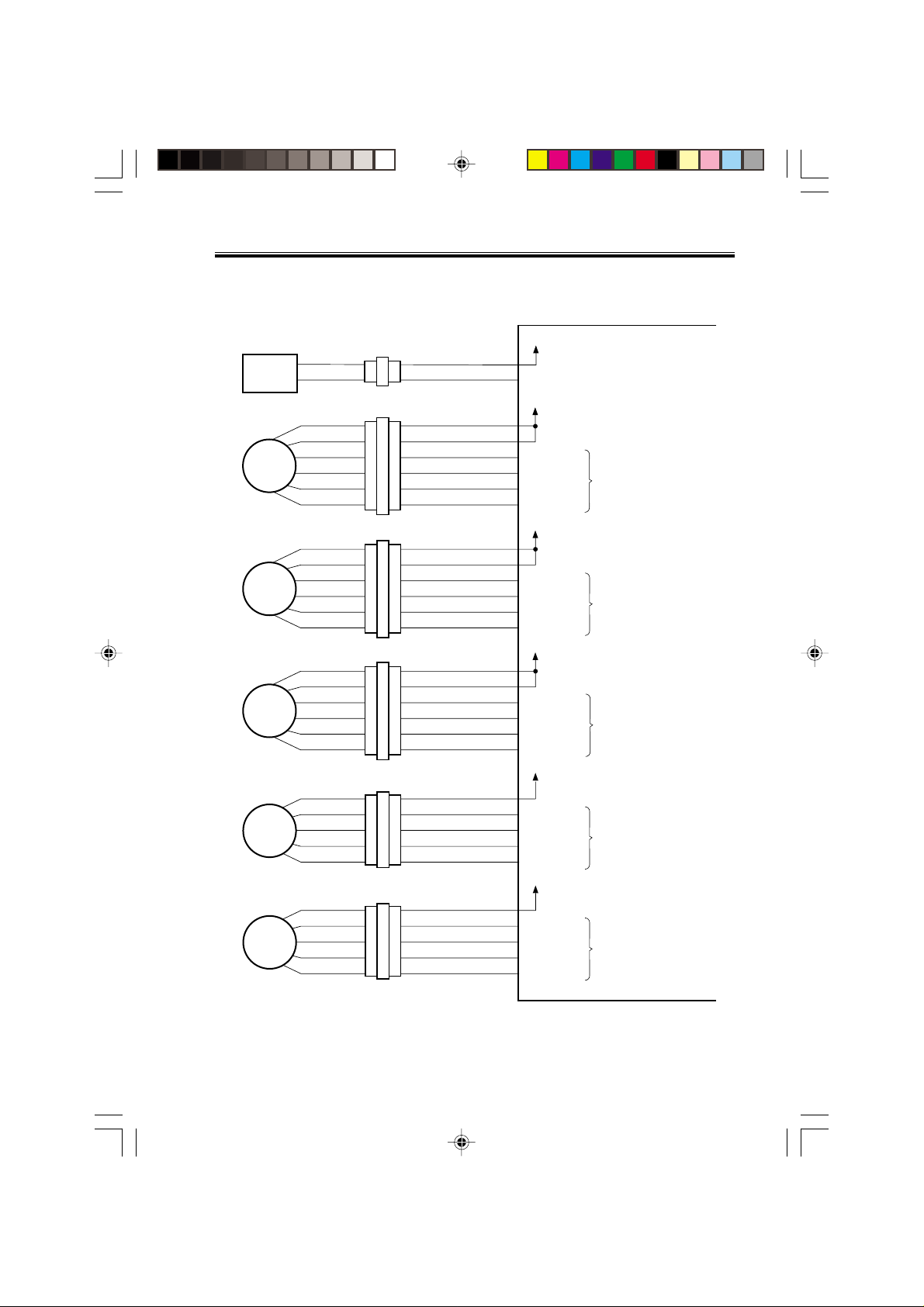

CHAPTER 2 OUTLINE OF OPERATION

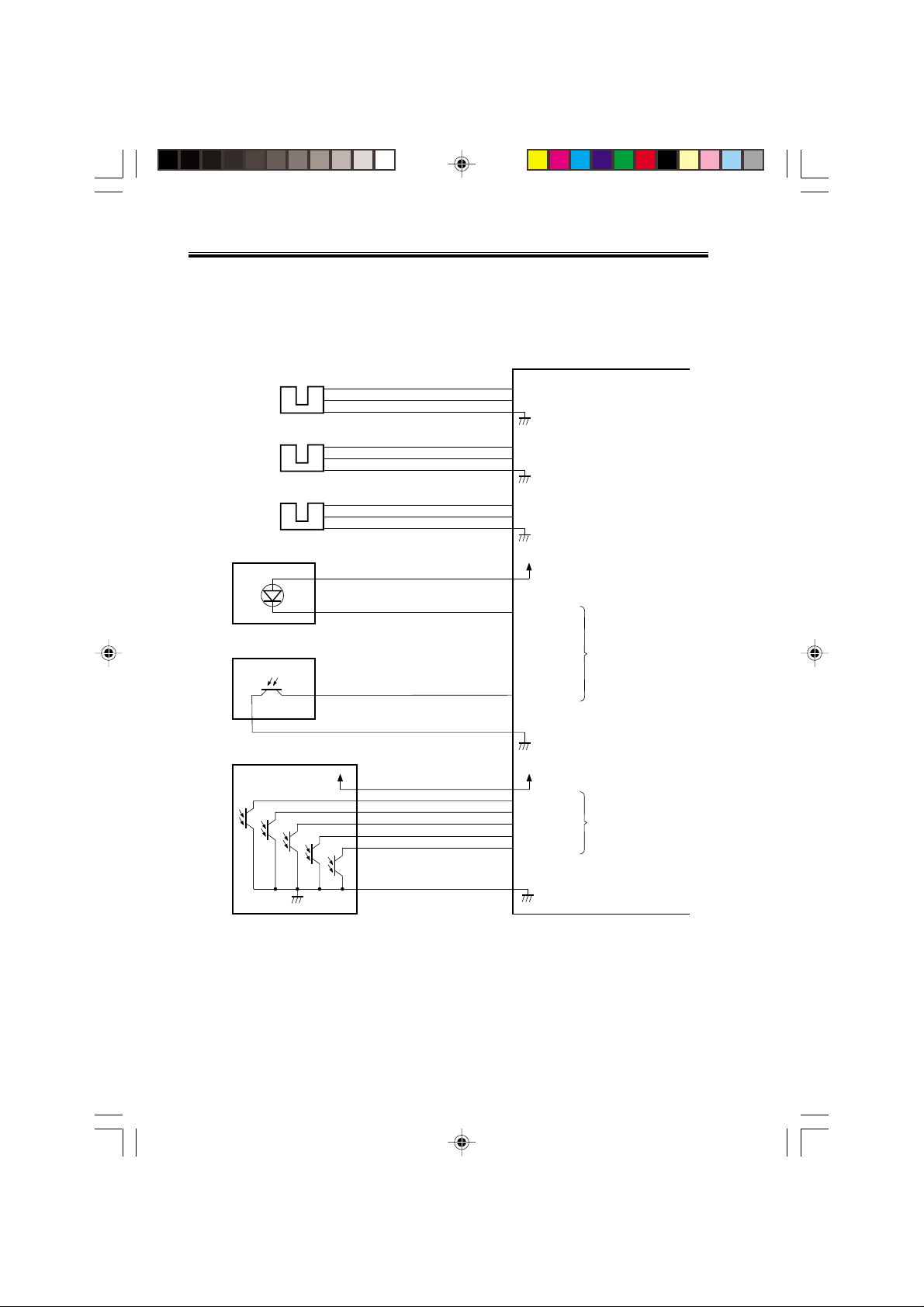

1.3.3 Outputs from the Finisher Controller PCB (1/2)

Finisher controller PCB

Binding clutch

CL1

Feed motor

M1

Paddle motor

M2

Delivery motor

M3

Alignment motor

(front)

M4

Alignment motor

(rear)

M5

CN63-1

CN65-1

-1

-2

-6

-5

-4

-3

-2

-1

-6

-5

-4

-3

-2

-1

-6

-5

-4

-3

-2

-1

-2

-3

-4

-5

-2

-3

-4

-5

CN72

CN56

CN57

CN59

-2

-1

-1

-2

-3

-4

-5

-6

-1

-2

-3

-4

-5

-6

-1

-2

-3

-4

-5

-6

CN62-5

CN64-5

CN18-1

CN10-1

CN10-7

CN13-1

CN3-1

-4

-3

-2

-1

CN3-6

-4

-3

-2

-1

-2

B_CLU

-2

-3

FEEDMTR_A

-4

FEEDMTR_*A

-5

FEEDMTR_B

-6

FEEDMTR_*B

-8

-9

PDLMTR_A

-10

PDLMTR_*A

-11

PDLMTR_B

-12

PDLMTR_*B

-2

-3

EJCTMTR_A

-4

EJCTMTR_*A

-5

EJCTMTR_B

-6

EJCTMTR_*B

-2

FJOGMTR_A

-3

FJOGMTR_*A

-4

FJOGMTR_B

-5

FJOGMTR_*B

-7

RJOGMTR_A

-8

RJOGMTR_*A

-9

RJOGMTR_B

-10

RJOGMTR_*B

+24 V

When the drive is transmitted,

‘1’.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

+24 V

Switches between ‘1’ and

‘0’ according to the

direction of motor rotation.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM5

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-103-03

2-5

Page 17

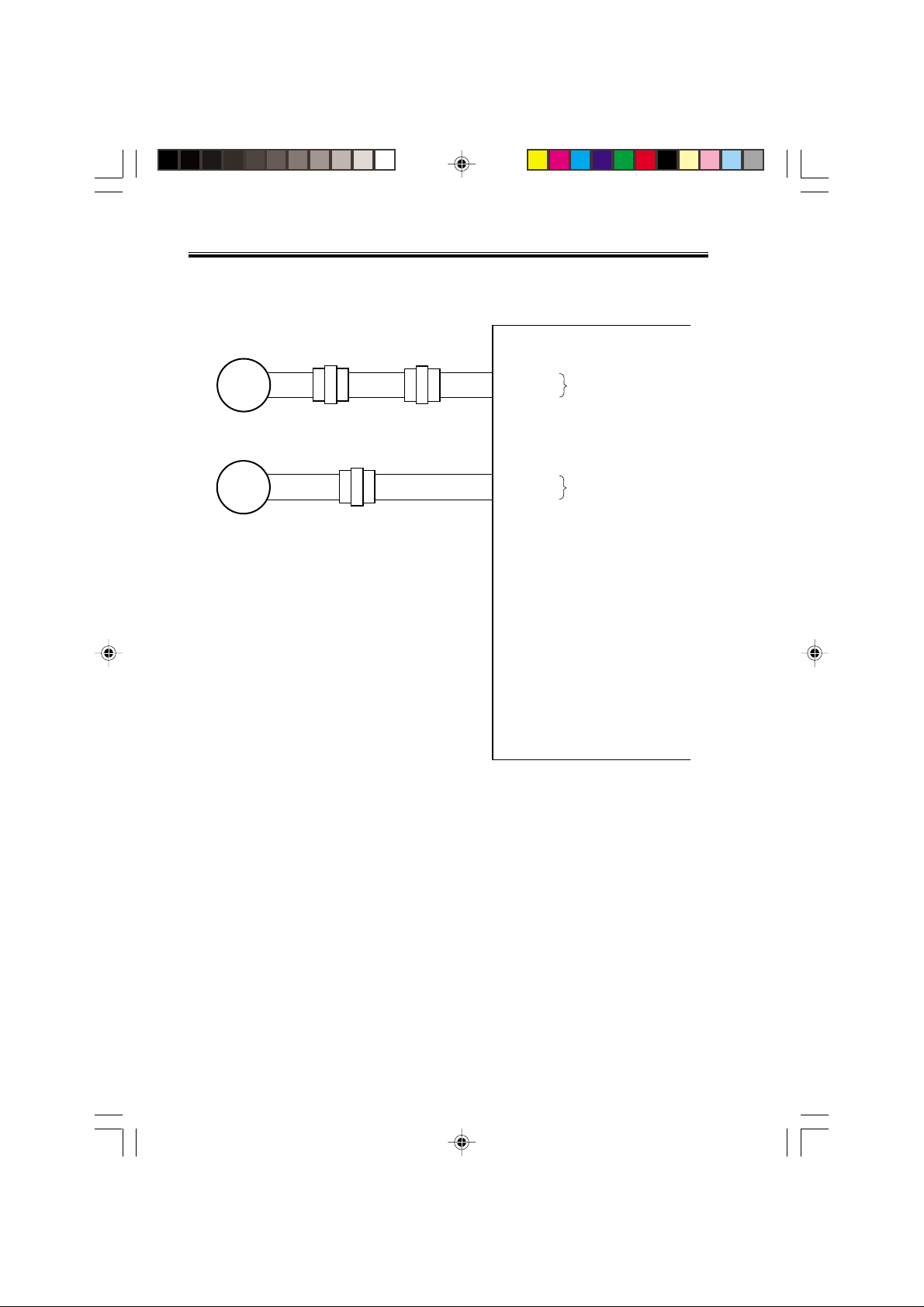

CHAPTER 2 OUTLINE OF OPERATION

1.3.4 Outputs from the Finisher Controller PCB (2/2)

Shift motor

M6

Staple/fold motor

M7

-2

-1

-2

-1

CN70

-2

-1

CN71

-2

-1

-2

-1

CN70

CN6-1

-2

-1

CN6-3

SIFTMTR_1

-2

SIFTMTR_0

BINDMTR_1

-4

BINDMTR_0

Finisher controller PCB

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

Switches between ‘+’ and

‘–’ according to the

direction of motor rotation.

2-6

Chap02.p65 3/28/01, 12:07 PM6

COPYRIGHT

©

F02-103-04

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 18

CHAPTER 2 OUTLINE OF OPERATION

1.3.5 Inputs to and Outputs from the Finisher Controller

Stapler unit

Slide home

position sensor

PI18

Staple home

position sensor

PI19

Staple empty

sensor

PI20

Staple top

position sensor

PI21

Slide motor

M8

+5 V

+5 V

+5 V

+5 V

+5 V

CN72-5

CN72-4

CN72-3

CN72-2

CN72-6

CN72-1

CN72-7

CN72-10

CN72-11

CN72-12

CN72-13

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN72A-5

CN72A-4

CN72A-3

CN72A-2

CN72A-6

CN72A-1

CN72A-7

CN72B-5

CN72B-4

CN72B-3

CN72B-2

CN11-3

CN11-4

CN11-5

CN11-6

CN11-2

CN11-7

CN11-1

CN7-3

CN7-4

CN7-5

CN7-6

Finisher controller PCB

SLID_HP

STPL_HP

HOOK_S

SELF_P

+5 V

STPL_CNCT

SLIDMTR_A

SLIDMTR_*A

SLIDMTR_B

SLIDMTR_*B

When the stapler is at home

position, ‘1’.

When the stapler is at

stapling home position, ‘0’.

When the cartridge has

staples, ‘0’.

When the staple is at top

the stapler, ‘0’.

When the stapler is

connected, ‘0’.

Switches between ‘1’ and

‘0’ according to the direction

of motor rotation.

Host

machine

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM7

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

CN2-1

CN1-1

F02-103-05

+24 V

-3

GND

-4

GND

-5

TXD

-7

-6

-2

Communication line

RXD

+24 V

2-7

Page 19

CHAPTER 2 OUTLINE OF OPERATION

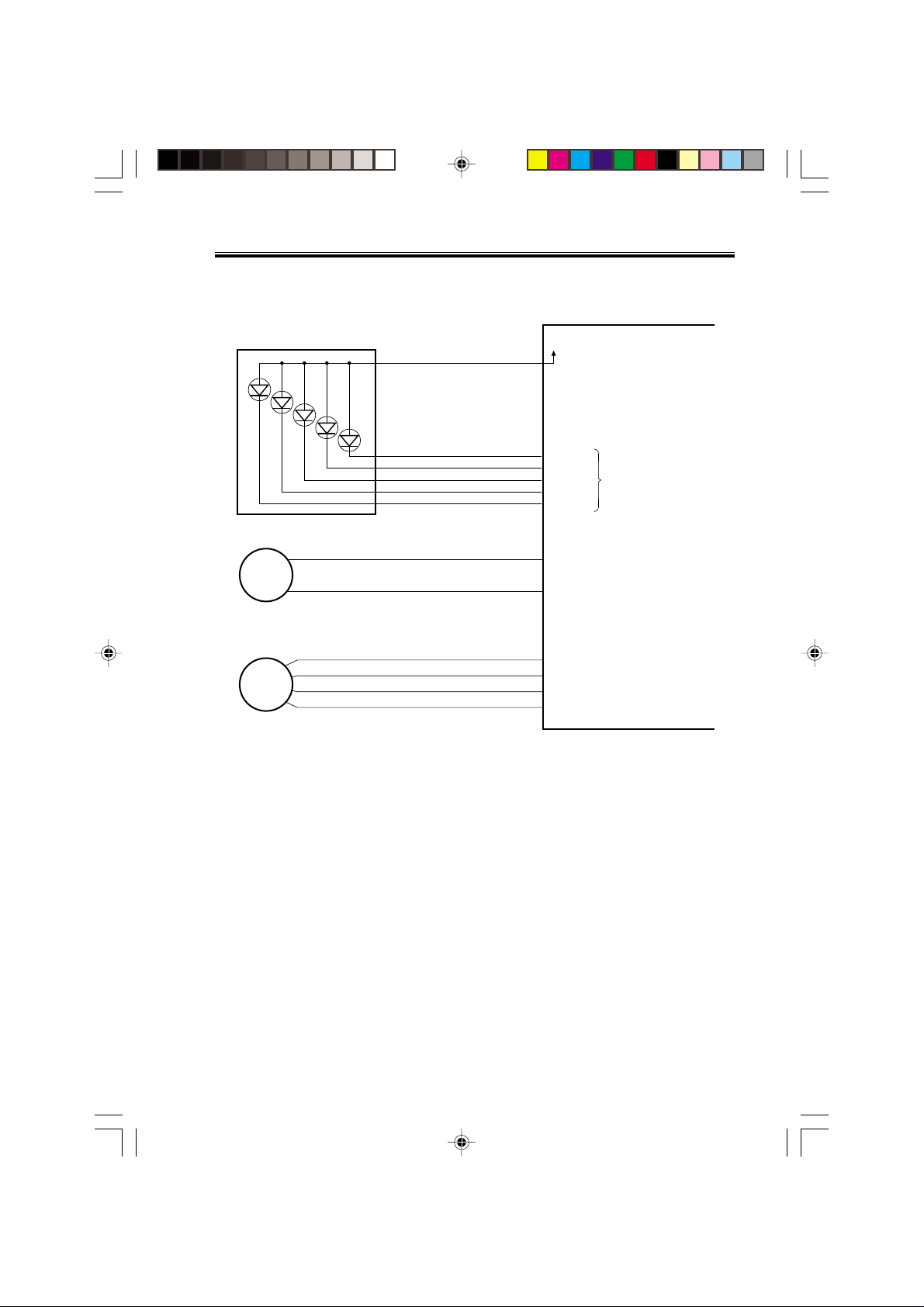

1.4 Inputs to and Outputs from the Punch Controller PCB

(option)

1.4.1 Inputs to and Outputs from the Punch Controller PCB

Punch controller PCB

PI1P

Punch home

position sensor

J2008-3

-1

-2

J1006-4

-6

-5

+5 V

PUNCH

When the hole puncher is

at home position, ‘0’.

Horizontal

registration

home position

sensor

Punch motor

clock sensor

Waste full LED PCB

LED121

Waste full photosensor PCB

PT131

PT1

PI2P

PI3P

Photosensor PCB

PT2

PT3

PT4

J2007-3

J2009-3

+5 V

PT5

J1006-1

J1006-7

J1005-1

J1005-3

-11

-10

-13

-3

-2

-9

-8

-2

4

-9

-8

-7

+5 V

SLIDE

+5 V

CLOCK

+5V

DUSTLED

DUSTPTR

+5 V

SREG1*

SREG2*

SREG3*

SREG4*

PAEND*

-1

-2

-1

-2

J1007-12

When the punch slide

unit is at home position,

‘1’.

While the punch motor

is rotating, alternates

between ‘0’ and ‘1’.

When the light is

blocked, ‘0’.

When paper is

detected, ‘0’.

2-8

Chap02.p65 3/28/01, 12:07 PM8

COPYRIGHT

©

F02-104-01

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 20

CHAPTER 2 OUTLINE OF OPERATION

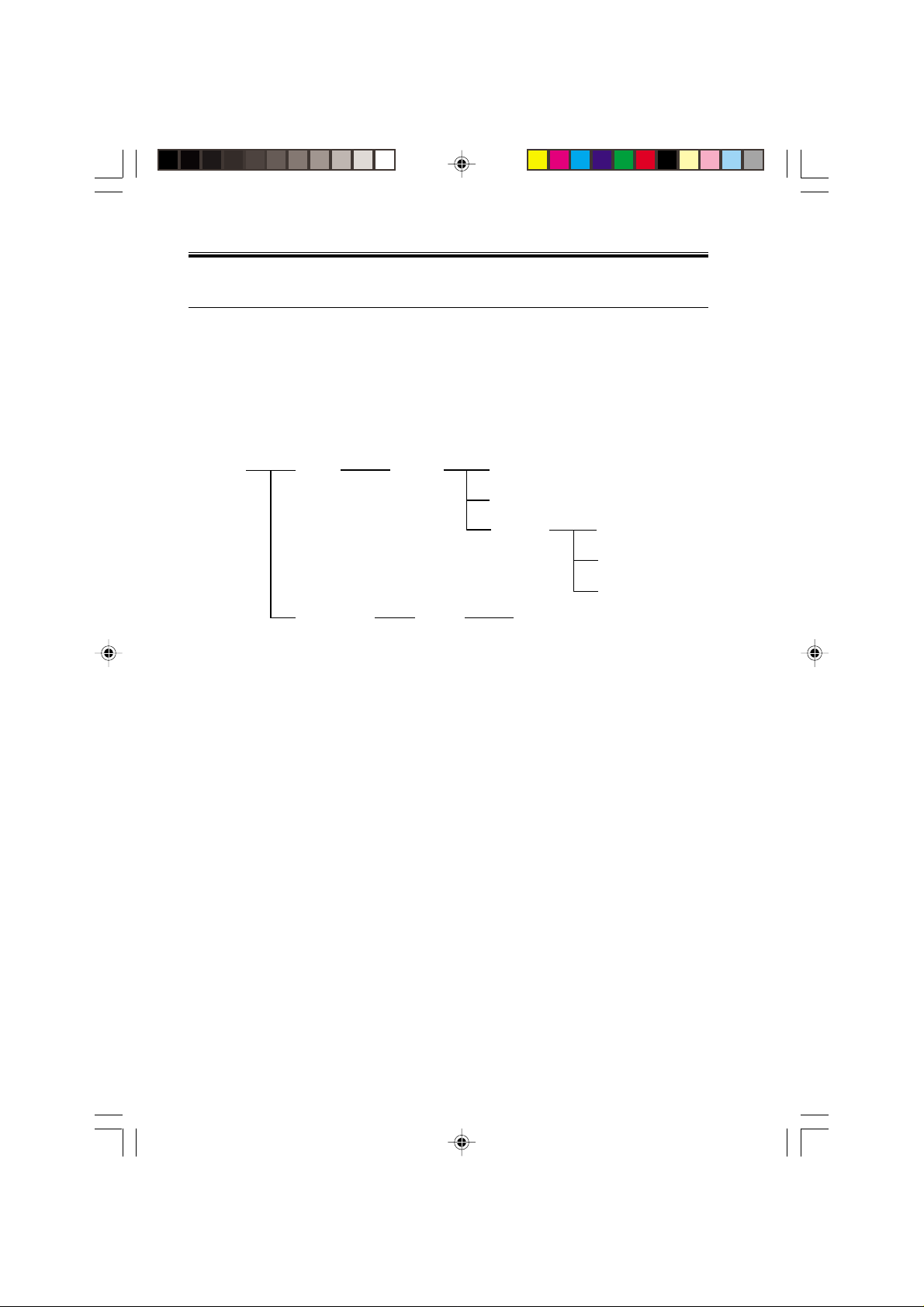

1.4.2 Outputs from the Punch Controller PCB

LED PCB

LED5

Punch motor

M1P

Horizontal

registration

motor

M2P

LED4

LED3

LED2

LED1

J1007-6

J1002-1

J1001-1

-1

-5

-4

-3

-2

-2

-2

-3

-4

+5V

LEDON5

LEDON4

LEDON3

LEDON2

LEDON1

A

B

A*

B*

Punch controller PCB

When ‘1’, LED goes ON.

Switches between ‘+’

and ‘–’ according to

the direction of motor

rotation.

Switches the pulse

signals according to

the rotation of the motor.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM9

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-104-02

2-9

Page 21

CHAPTER 2 OUTLINE OF OPERATION

2 Feed/Drive System

2.1 Outline

The machine performs the following in response to the commands coming from its host

machine on the sheets arriving from the host machine for delivery: simple stacking, job offset, and stapling or folding (in two).

If a punch unit (option) is installed, the sheets are pouched and delivered to the delivery

tray.

Sheets may be delivered in either of five ways (including one for the puncher unit):

Delivery

method

delivery

PunchingNormal

StitchingSaddle delivery

F02-201-01

Simple stacking

Job offset

Stapling Front 1-point stapling

Rear 1-point stapling

Middle 2-point stapling

Middle 2-point stapling

2-10

Chap02.p65 3/28/01, 12:07 PM10

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 22

CHAPTER 2 OUTLINE OF OPERATION

2.1.1 Normal Delivery

a. Simple Stacking

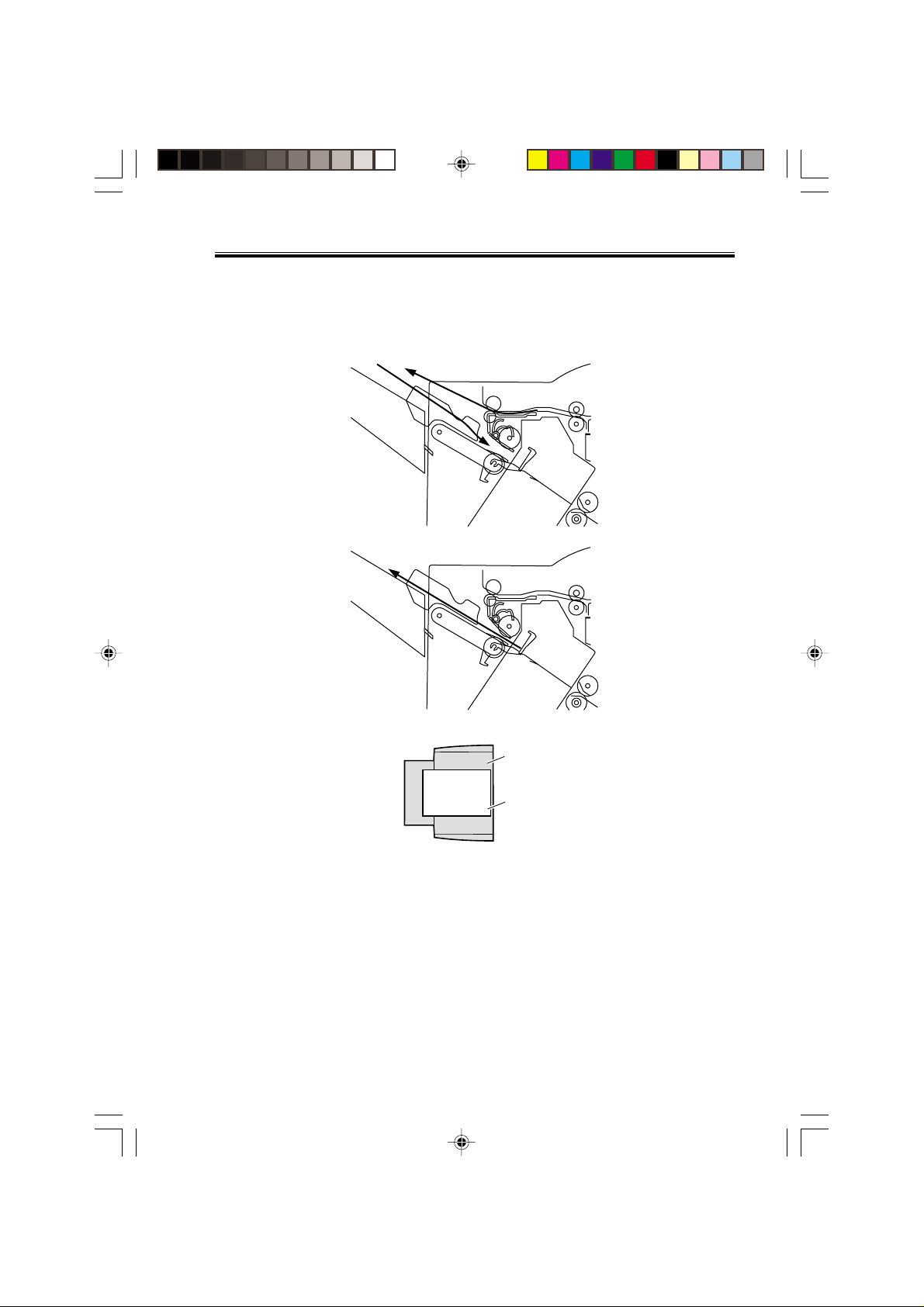

The machine pulls in the sheet once to the processing tray and then delivers it to the deliv-

ery tray.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM11

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Tray

Paper

F02-201-02

2-11

Page 23

CHAPTER 2 OUTLINE OF OPERATION

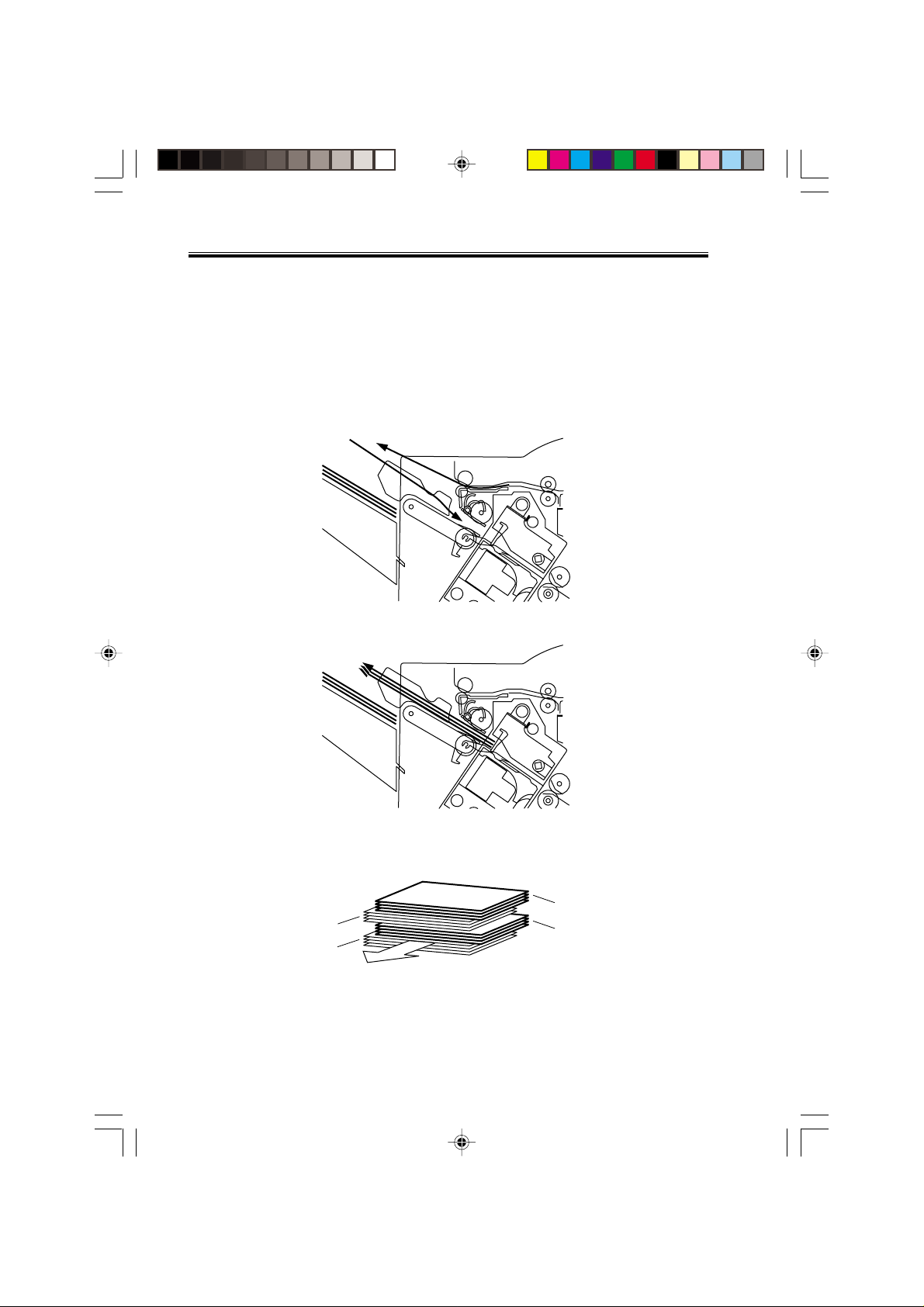

b. Job Offset

The machine pulls the sheet once to the processing tray. It then moves the sheet to the

front or the rear using the aligning plate. When it has deposited a specific number of sheets,

it delivers them in the form of a aligning plane. When the number of sheets stacked on the

processing tray reaches a specified value, the sheets are delivered in a form of a stack. Even

if the specified value is not reached, stacked sheets are temporarily delivered when 10 sheets

of large-size paper (300 mm or longer) or 30 sheets of small-size paper (299 mm or shorter)

have been stacked. (5- and STMT-sizes: 10 sheets)

Results of offset delivery (4 jobs)

3rd set

1st set

(direction of delivery)

2-12

Chap02.p65 3/28/01, 12:07 PM12

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

4th set

2nd set

F02-201-03

Page 24

CHAPTER 2 OUTLINE OF OPERATION

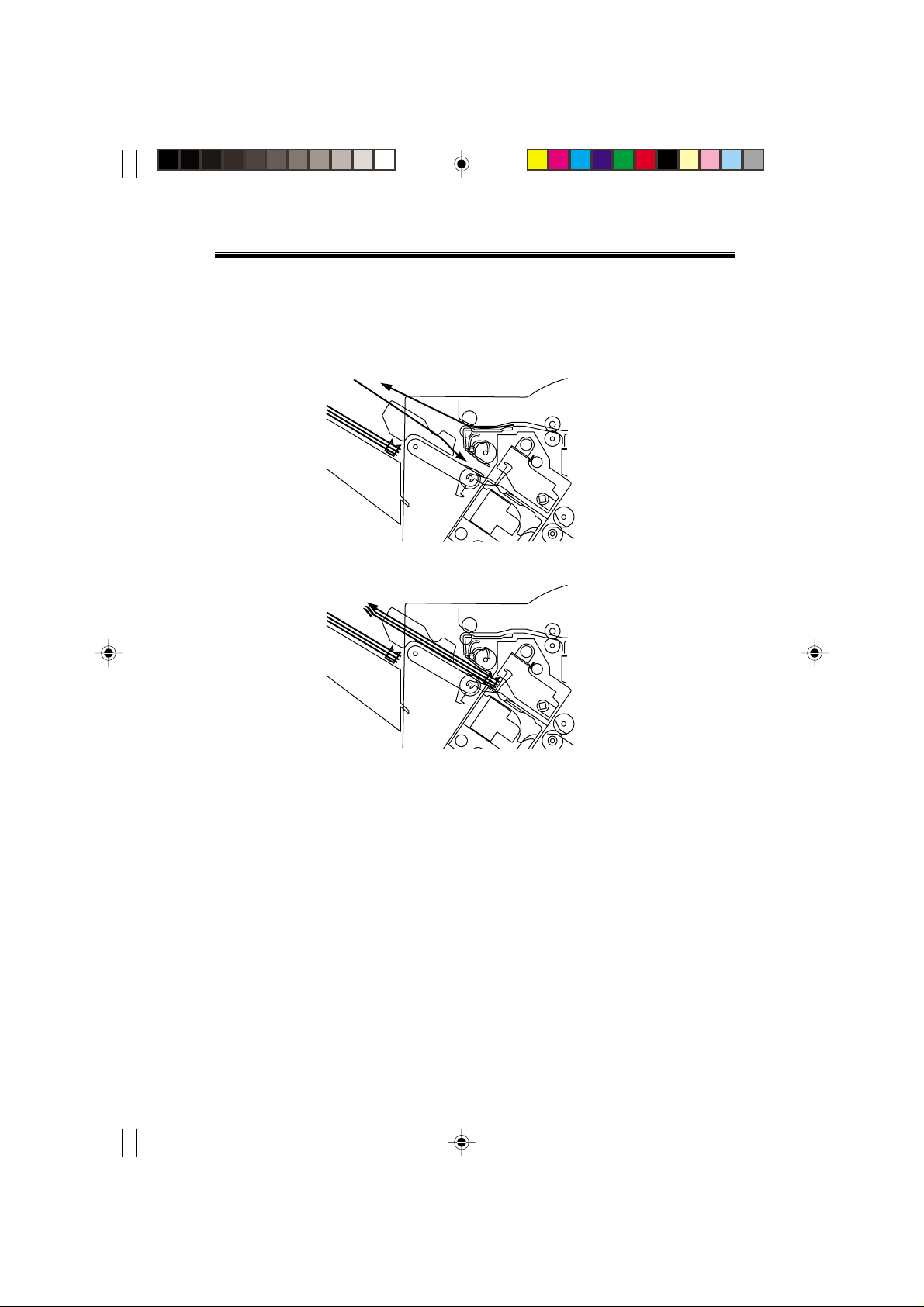

c. Stapling

The machine stacks sheets coming from its host machine on the processing tray. When

the number of sheets stacked on the processing tray reaches a specified value, the finisher

staples them delivers the stapled stack to the delivery tray.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM13

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-201-04

2-13

Page 25

CHAPTER 2 OUTLINE OF OPERATION

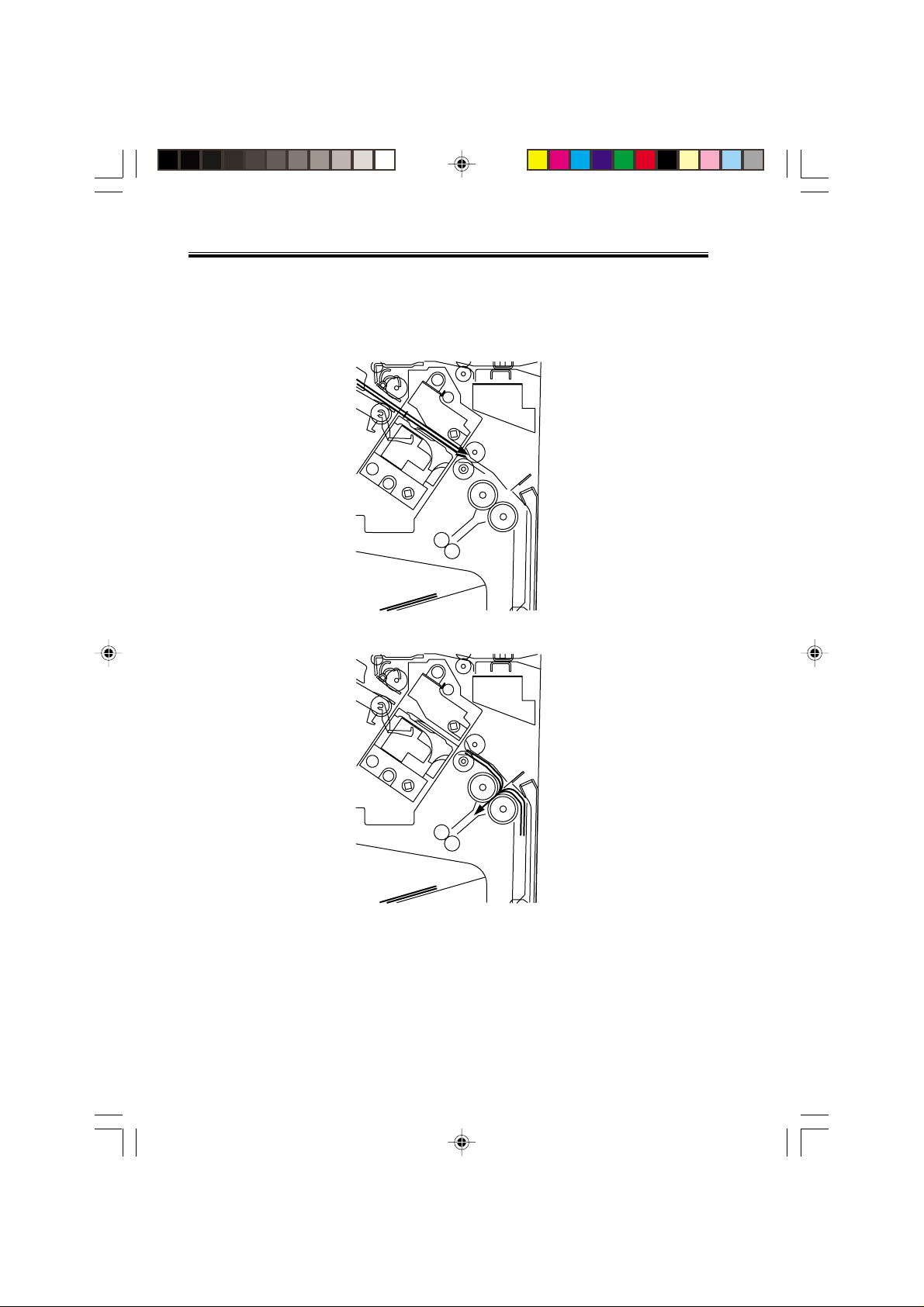

d. Saddle Deliver y

The machine deposits a stack of sheets on the processing tray, staples it (middle 2-point),

and then moves it to the saddle unit. The saddle unit folds the stack in two, and delivers it to

the bind tray.

2-14

Chap02.p65 3/28/01, 12:07 PM14

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-201-05

Page 26

CHAPTER 2 OUTLINE OF OPERATION

2.2 Feed/Delivery

2.2.1 Outline

The machine forwards the sheets coming from its host machine to the delivery tray, processing tray, or saddle unit according to the type of delivery used. The sheets forwarded to

the processing tray or the saddle unit are offset, stapled, or folded.

F02-202-01 shows the motors that are associated with moving and aligning sheets. These

motors are controlled (rotated clockwise or counterclockwise) by the microprocessor (CPU)

on the finisher controller PCB.

The paper path is equipped with the sensors shown in T02-202-02 used to monitor the arrival or passage of sheets.

If a sheet fails to arrive at or move past a specific sensor within a specific period of time,

the finisher controller will assume a jam, and stops the ongoing operation and, at the same

time, communicates the presence of a jam to the host machine.

Connector on finisher

Notation

M1

M2

M3

M4

M5

M7

Name

Feed motor

Paddle motor

Delivery motor

Alignment plate motor

(front)

Alignment plate motor

(rear)

Staple/fold motor

Description

Stepping motor

Stepping motor

Stepping motor

Stepping motor

Stepping motor

Brush DC motor

controller PCB

CN10

CN10

CN13

CN3

CN3

CN6

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM15

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

T02-202-01

2-15

Page 27

Chap02.p65 3/28/01, 12:07 PM16

2-16

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Shift motor drive signal SIFTMTR

Delivery motor drive signal EJCTMTR

Slide motor drive signal SLIDMTR

Finisher controller PCB (2/2)

F02-202-01

Staple/fold motor drive signal BINDMTR

Staple/fold motor clock detect signal

BIND_CLK

M7

PI14

M6

M8

M3

CL

Alignment plate motor

(front) drive signal FJOGMTR

M4

Alignment plate motor

(rear) drive signal RJOGMTR

M5

Paddle motor

M2

M1

drive signal PDLMTR

Bind clutch drive signal B_CLU

Feed motor

drive signal FEEDMTR

CHAPTER 2 OUTLINE OF OPERATION

Finisher controller PCB (1/2)

Page 28

CHAPTER 2 OUTLINE OF OPERATION

Finisher controller PCB

Inlet paper detect signal ENT_P

Fold position paper detect signal BIND_P

PI1

PI10

Notation

PI1

PI10

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM17

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Name

Inlet sensor

Fold position sensor

F02-202-02

Description

Photointerrupter

Photointerrupter

T02-202-02

Connector on finisher

controller PCB

CN16

CN16

2-17

Page 29

CHAPTER 2 OUTLINE OF OPERATION

2.3 Job Offset

2.3.1 Outline

"Job offset" refers to the operation by which the machine delivers a set of sheets with

them pulled forward or backward for sorting.

Switching between the forward and backward directions is made using an aligning plate

(front) and an aligning plate (rear).

The sheet coming between the delivery rollers is fed onto the processing tray and then fed

toward the stopper by the paddle.

A swing guide is at the up position while a sheet is being pulled onto the processing tray

or during alignment. It is at the down position during stack feeding, stack delivery, or stapling.

At power-on, the finisher controller PCB drives the aligning plate (front) motor (M4) and

the aligning plate (rear) motor (M5) to return the two aligning plates to their home positions.

Sensor

Aligning plate (front)

home position sensor

Aligning plate (rear)

home position sensor

Swing guide home position sensor

Paddle home position

sensor

Symbol

PI4

PI5

PI3

PI2

Connector

CN4-3

CN5-15

CN9-9

CN9-3

T02-203-01

Function

Drives the aligning

plate (front)

Drives the aligning

plate (rear)

Drives the swing

guide drive.

Drives the paddle

(feeds paper).

Motor

Aligning plate

(front) motor

Aligning plate

(rear) motor

Paddle motor

Paddle motor

Simbol

M4

M5

M2

M2

2-18

Chap02.p65 3/28/01, 12:07 PM18

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 30

CHAPTER 2 OUTLINE OF OPERATION

Alignment plate (front)

motor (M4)

Aligning plate

(front)

(Front)

Aligning plate (front) home position sensor (PI4)

Light-shielding plate

Aligning plate (rear)

Alignment plate (rear)

motor (M5)

F02-203-01

Aligning plate (rear)

home position sensor (PI5)

Light-shielding plate

Paper

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM19

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-19

Page 31

CHAPTER 2 OUTLINE OF OPERATION

2.3.2 Processing Tray Paper Stacking Operation

A sheet coming between the delivery rollers is fed onto the processing tray. Then, the

paddle taps on the sheet surface twice (once for the second and subsequent sheets) to locate

the sheet against the processing tray stopper.

Paper

Aligning plate

Delivery belt

T02-203-02

Paddle

Stack delivery roller (upper)

Swing guide

Processing tray stopper

Stack delivery roller (lower)

2-20

Chap02.p65 3/28/01, 12:07 PM20

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 32

CHAPTER 2 OUTLINE OF OPERATION

2.3.3 Offset Operation

Each sheet is pulled forward or backward using the aligning plate (front) and the aligning

plate (rear).

The offset operation is performed each time a sheet is pulled onto the processing tray.

Aligning plate (rear)

Sheet to be offset

Tray

Aligning plate (front)

F02-203-03 Offsetting in the forward direction

Aligning plate (rear)

Sheet to be offset

Tray

Aligning plate (front)

F02-203-04 Offsetting in the backward direction

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM21

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-21

Page 33

CHAPTER 2 OUTLINE OF OPERATION

2.3.4 Stack Delivery Operation

Stack delivery takes place when 10 sheets of large-size paper or 30 sheets of small-size

paper (A5- and STMT-sizes: 10 sheets) have been stacked on the processing tray with them

offset in either direction.

The paddle motor rotates and the swing guide descends to hold the paper stack between

the upper and lower stack delivery rollers. The delivery motor rotates in the forward direction to rotate the delivery rollers, feeding the paper stack in the delivery direction. The delivery belt home position sensor is turned OFF. The delivery motor is driven a specified number of pulses, causing the swing guide to ascend. Next, the paper delivery motor is driven.

Next, the delivery motor is driven to deliver the paper stack with the nails of the delivery

belt that rotates in sync with the stack delivery rollers.

Swing guide

F02-203-05

Job offset sequence

Inlet sensor (PI1)

Processing tray sensor

(PI6)

Feed motor (M1)

Delivery motor (M3)

Delivery belt home

position sensor (PI7)

Paddle motor (M2)

Paddle home position

sensor (PI2)

Swing guide home

position sensor (PI3)

Stapler safety switch

(MS3)

Alignment motor (front)

(M4)

Aligning plate home position

sensor (front) (PI4)

Alignment motor (rear)

(M5)

Aligning plate home position

sensor (rear) (PI5)

2-22

Chap02.p65 3/28/01, 12:18 PM22

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Start signal

Host machine delivery signal

360msec

F02-203-06

360msec 360msec

60msec

360msec

30msec

220msec

CW rotation CCW rotation

Page 34

CHAPTER 2 OUTLINE OF OPERATION

3. Stapling Operation

3.1 Outline

Staple operation is performed to staple a specified sheets of paper using a stapler unit.

The stapling position depends on the staple mode and paper size.

When the machine starts immediately after power-on, the finisher controller PCB drives

the slide motor (M8) to return the stapler unit to the home position. The stapler unit starts

moving toward the front of the stapler frame. It stops when the slide home position sensor

(PI18) on the slide PCB located under the stapler unit. Next, the slide motor is driven a

specified number of pulses. The stapler unit moves to rear standby position at the back of

the machine, entering the standby state.

Sensor

Slide home position

sensor

Staple home position

sensor

Staple empty sensor

Staple top position

sensor

Simbol

PI18

PI19

PI20

PI21

Connector

CN11-3

CN11-4

CN11-5

CN11-6

Detects the home position for the

stapler moving back and forth.

Detects the home position for the

stapling operation

Detects presence or absence of

staples in the cartridge.

Detects the staple top position.

Function

Function Motor Symbol Remarks

Moves the stapler. Slide motor M8 –

Performs stapling operation. Staple/fold motor M7 –

T02-301-01

Remarks

–

In the stapler

In the stapler

In the stapler

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM23

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-23

Page 35

CHAPTER 2 OUTLINE OF OPERATION

Stapler

Slide motor

(M8)

Paper stack

(Deliver direction)

Light-shielding plate

Slide home position sensor (PI18)

F02-301-01

2-24

Chap02.p65 3/28/01, 12:07 PM24

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 36

CHAPTER 2 OUTLINE OF OPERATION

3.2 Stapling Operation

When stacking and alignment of paper on the processing tray are complete, the finisher

controller PCB drives the paddle motor (M2) in the reverse direction and lowers the swing

guide. When the swing guide descends, the paper stack is sandwiched between the upper

and lower stack delivery rollers.

The finisher controller PCB moves the stapler for stapling according to the specified stapling position (when rear 1-point stapling is specified, the stapler does not move but it

staples at the standby position). As the stapler moves forward, the processing tray stopper is

folded forward.

Paper stack

Swing guide

Stack delivery roller (upper)

Processing tray stopper

Delivery tray

Stack

delivery

roller

(lower)

Stapler

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM25

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-302-01

2-25

Page 37

CHAPTER 2 OUTLINE OF OPERATION

Paddle motor (M2)

Staple safety switch

(MS3)

Swing guide

Stack delivery roller

(upper)

Swing guide home

position sensor (PI3)

Light-shielding plate

Stack delivery roller

(lower)

2-26

Chap02.p65 3/28/01, 12:07 PM26

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-302-02

Page 38

CHAPTER 2 OUTLINE OF OPERATION

3.3 Delivery Operation after Stapling

When stapling is complete, the finisher controller PCB drives the deliver motor in the forward direction to feed the paper stack (sandwiched between the stack delivery rollers) in the

delivery direction. The delivery belt home position sensor is turned OFF. The delivery motor is driven a specified number of pulses, causing the swing guide to ascend. At the same

time, the slide motor is driven to return the stapler back to the standby position, followed by

driving of the delivery motor. Then, the paper stack is delivered with the nails of the delivery belt that rotates in sync with the stack delivery rollers.

Paper stack

Swing guide

Delivery tray

Delivery belt

Stack delivery

roller (lower)

F02-303-01

Stapler

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM27

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-27

Page 39

CHAPTER 2 OUTLINE OF OPERATION

Paddle motor (M2)

Staple safety

switch (MS3)

Swing guide

Swing guide

home position sensor (PI3)

Light-shielding plate

Stack delivery roller (lower)

2-28

Chap02.p65 3/28/01, 12:07 PM28

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Stack delivery roller (upper)

F02-303-02

Page 40

CHAPTER 2 OUTLINE OF OPERATION

3.4 Stapler Unit

The staple/fold motor (M7) is used to perform stapling operation. This motor rotates the

cam one turn for stapling. The home position of this cam is detected by the staple home position sensor (PI19).

The staple/fold motor is rotated in the forward or reverse direction under the control of

the macro computer (IC13) on the finisher controller PCB.

When the staple home position sensor is OFF, the finisher controller PCB rotates the

staple/fold motor in the forward direction until the sensor turns ON, allowing the staple cam

to the original position.

The staple empty sensor (PI20) is used to detect presence/absence of a staple cartridge in

the machine and presence/absence of staples in the cartridge.

The stale top position sensor (PI21) is used to determine whether staples are pushed up to

the top of the staple cartridge.

The finisher controller circuit does not drive the staple/fold motor (M7) unless the staple

safety switch (MS3) is ON (the swing guide is close). This assures safety in case where you

happen to put your finger in the stapler.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM29

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-29

Page 41

CHAPTER 2 OUTLINE OF OPERATION

F02-304-01

Staple home position detect signal

2-30

Chap02.p65 3/28/01, 12:07 PM30

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Staple top position detect signal

Staple empty detect signal

Finisher controller PCB

F02-304-02

M7

Staple/hold motor drive signal

Page 42

CHAPTER 2 OUTLINE OF OPERATION

3.4.1 Stapler Movement Controller

The stapler unit is moved by the slide motor (M8). Its home position is detected by the

slide home position sensor (PI18). The stapler waits at the back irrespective of the staple

mode and paper size. After paper has been stacked on the processing tray, the stapler is

moved to the specified stapling position in response to the stapling command from the host

machine.

F02-304-03 shows the standby position of the stapler and the stapling position depending

on the staple mode.

a. Front 1-point stapling

The stapler waits at the back. The stapler moves to and returns from the stapling position

for each stapling operation.

Standby position

Stapler

Feed direction

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM31

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Stopper

Stapling position

F02-304-03

2-31

Page 43

CHAPTER 2 OUTLINE OF OPERATION

b. Rear 1-point stapling

The stapler waits at the back. The stapling position is the same as the standby position.

Standby position

Stabling position

Stapler

Feed direction

Stopper

F02-304-04

c. Middle 2-point stapling

The stapler waits at the back. The stapler moves to and returns from the stapling position

for each stapling operation. The stapler first staples a paper stack at the rear stapling position and then staples it at the front stapling position.

Feed direction

2-32

Chap02.p65 3/28/01, 12:07 PM32

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Standby position

Stapler

Stapling position

Stopper

Stapling position

F02-304-05

Page 44

CHAPTER 2 OUTLINE OF OPERATION

d. Middle 2-point stapling (bind mode)

The stapler waits at the back. The stapler moves to and returns from the stapling position

for each stapling operation. The stapler first staples a paper stack at the rear stapling position and then staples it at the front stapling position.

Standby position

Stapler

Stapling position

Stopper

Feed direction

Stapling position

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM33

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-304-06

2-33

Page 45

CHAPTER 2 OUTLINE OF OPERATION

Stapling Operation Sequence

Rear 1-point Stapling of 2 Sheets

Start signal

Host machine delivery signal

Inlet sensor (PI1)

Processing tray sensor

(PI6)

Feed motor (M1)

Delivery motor (M3)

Delivery belt home

position sensor (PI7)

Paddle motor (M2)

Paddle home position

sensor (PI2)

Swing guide home

position sensor (PI3)

Stapler safety switch

(MS3)

Alignment motor (front)

(M4)

Aligning plate home position

sensor (front) (PI4)

Staple/fold motor

(M7)

Staple home position

sensor (PI19)

360msec

360msec

20msec

Staple

???

10msec

2-34

Chap02.p65 3/28/01, 12:18 PM34

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

CW rotation CCW rotation

F02-304-07

Page 46

CHAPTER 2 OUTLINE OF OPERATION

4 Delivery Tray Operation

4.1 Outline

The machine has a delivery tray in the finisher unit and a bind tray in the saddle unit.

The bind tray in the saddle unit is of the fixed type and all the folded paper stacks are delivered to this tray. This tray has a bind tray sensor (PI13) to detect presence/absence of paper.

The delivery tray in the finisher unit is moved up and down using a shift motor (M6).

The finisher has a tray paper sensor (PI8) to detect presence/absence of paper on the stack

tray.

The home position sensor of the delivery tray is detected by the paper surface sensor

(PI19). When paper has already been stacked on the delivery tray, the home position is on

the top surface of the stacked paper. When paper has not yet been stacked on the delivery

tray, the home position is at the position where the edge of the delivery tray is detected. At

power-on, the finisher controller PCB drives the shift motor (M6) to return the delivery tray

to the home position.

When the paper coming from the processing tray is stacked on the delivery tray, the shift

motor is driven a specified number of pulses, causing the delivery tray to descend. Clock

pulses are detected by the shift motor clock sensor (PI17). Then, the delivery tray returns to

the home position for the next stacking operation.

The upper limit of the delivery tray is detected by the shift upper limit sensor (PI15).

When the shift upper limit sensor (PI15) is turned ON, the finisher controller PCB stops the

shift motor (M6) that is ascending.

The lower limit of the delivery tray is detected by the shift lower limit sensor (PI16).

When the shift lower limit sensor (PI16) is turned ON, the finisher controller PCB stops the

shift motor (M6) that is descending.

The finisher unit has a full stack sensor (PI24) to detect overstacking of large-size or

mixed paper according to the stack height.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM35

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-35

Page 47

CHAPTER 2 OUTLINE OF OPERATION

Shift upper limit sensor

(PI15)

Shift lower limit sensor

(PI16)

Shift motor clock sensor

(PI17)

Tray paper sensor (PI8)

Paper surface sensor (PI9)

Edge

Delivery tray

Full stack sensor (PI24)

Shift motor (M6)

F02-401-01

2-36

Chap02.p65 3/28/01, 12:07 PM36

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 48

CHAPTER 2 OUTLINE OF OPERATION

5 Saddle Unit

5.1 Basic Operations

5.1.1 Outline

The machine stitches a stack of sheets (middle 2-point), then folds the stack in two in the

finisher. These operations are controlled by the finisher controller PCB.

The finisher controller PCB is controlled by the commands from the host machine.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM37

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-37

Page 49

CHAPTER 2 OUTLINE OF OPERATION

5.2 Feed/Drive System

5.2.1 Outline

This machine stitches the paper stack coming from the finisher, folds it, and delivers it to

the bind tray in the saddle unit in response to the commands from the host machine.

That is, the machine performs the following operations:

1) Paper feed-in

2) Stitching

3) Stack feed

4) Folding/delivery

1) Paper feed-in

2) Stitching

3) Stack feed

4) Folding/delivery

F02-502-01

2-38

Chap02.p65 3/28/01, 12:07 PM38

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 50

CHAPTER 2 OUTLINE OF OPERATION

a. Paper feed-in

After being aligned on the processing tray, a stack of sheets is sandwiched between the

stack delivery rollers. As the stack delivery rollers rotate, the stack is fed toward the saddle

unit.

Stack delivery roller (upper)

Paper stack

Stack delivery roller

(lower)

F02-502-02

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM39

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-39

Page 51

CHAPTER 2 OUTLINE OF OPERATION

b. Stitching

When the center of the paper stack (stitching position) reaches the stapler's staple posi-

tion, the stapler stitches the paper stack.

When only one sheet is fed from the host machine, the next step (stack feed) is performed

without performing the stitching operation.

Stapler (lower)

Staple

F02-502-03

Stapler (upper)

2-40

Chap02.p65 3/28/01, 12:07 PM40

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 52

CHAPTER 2 OUTLINE OF OPERATION

c. Stack feed

The stack feed rollers feed the paper stack to the stack folding/delivery position where the

center of the stack (stitched position) is level with the paper pushing plate and paper folding

roller's nip part.

Stack feed roller (upper)

Paper pushing plate

Stack feed roller (lower)

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM41

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Paper fold roller

F02-502-04

2-41

Page 53

CHAPTER 2 OUTLINE OF OPERATION

d. Folding/deliver y

The paper pushing plate pushes in the center of the paper stack to feed it toward the paper

fold rollers. Then, the paper fold rollers and bind delivery rollers deliver the paper stack to

the bind tray.

2-42

Chap02.p65 3/28/01, 12:07 PM42

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Bind delivery rollers

Paper fold rollers

F02-502-05

Page 54

CHAPTER 2 OUTLINE OF OPERATION

5.3 Paper Feed System

5.3.1 Outline

The paper feed system feeds a stack of sheets (coming from the finisher) to the position

where the center of the paper stack (stitching position) is aligned to the stapler's staple, allowing the next step (stitching and folding) to be performed.

When sheets of paper have been stacked and aligned on the processing tray, the paddle

motor (M2) rotates in the reverse direction, causing the swing guide to descend. As the

swing guide descends, the paper stack is sandwiched between the upper and lower stack delivery rollers. The delivery motor (M3) rotates in the reverse direction, feeding the paper

stack toward the saddle unit. When the leading edge of the paper stack reaches the folding

position sensor (PI10), the finisher controller PCB drives the delivery motor a specified

number of motor pulses to stop the center of the paper stack (stitching position) at the

stapler's staple position. Before the paper stack passes through the stack feed rollers, the

feed motor (M1) is driven to rotate the stack feed roller (lower) so that the leading edge of

the paper stack is not bent.

Stack delivery roller (upper)

Paper stack

Fold position sensor

Stack delivery roller

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM43

(lower)

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Stack feed roller (lower)

F02-503-01

2-43

Page 55

CHAPTER 2 OUTLINE OF OPERATION

5.4 Stack Feed System

5.4.1 Outline

The stack feed system feeds the stitched paper stack to the folding position.

When stitching is complete, the feed motor (M1) rotates, causing the stack feed roller (upper) to descend. The paper stack is sandwiched between the stack feed rollers. Then, the

bind clutch (CL1) is turned ON to rotate the feed motor (M1) in the forward direction, thus

feeding the paper stack to the folding position. The feed amount is equivalent to the number

of pulses used to drive the feed motor (M1) until the paper stack reaches the folding position.

Stack feed roller (upper)

Feed amount

Stack feed roller (lower)

2-44

Chap02.p65 3/28/01, 12:07 PM44

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

F02-504-01

Page 56

CHAPTER 2 OUTLINE OF OPERATION

5.5 Fold/Delivery System

5.5.1 Outline

The paper fold mechanism consists of a guide plate, paper fold rollers, and a paper push-

ing plate.

The guide plate, paper fold rollers, and paper pushing plate are driven by the staple/fold

motor (M7). The drive force is transferred with a combination of gears and cams. Motor

operation is monitored by the staple/fold motor lock sensor (PI14).

Until the paper stack reaches the folding position, the guide plate covers the paper fold

rollers to act as a paper path through which a paper stack is fed to the saddle unit and to prevent a paper stack from touching the rollers.

A folding home position sensor (PI11) is provided to detect the positions of the paper fold

rollers and paper pushing plate.

The paper stack folded in two by the paper fold rollers is delivered by bind delivery rollers.

The bind delivery rollers are also driven by the staple/fold motor (M7).

A bind tray sensor (PI13) is provided on the bind tray to detect presence/absence of a paper stack; however, it is not used to detect a jam.

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM45

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

2-45

Page 57

CHAPTER 2 OUTLINE OF OPERATION

5.5.2 Paper F olding

Paper is folded using paper fold rollers and a paper pushing plate.

Almost concurrently with the start of roller rotation, the paper pushing plate starts operating to push the paper stack into the gap between the paper fold rollers. When the paper

stack is fed about 10 mm with the rotation of the paper fold rollers, the paper pushing plate

returns to the home position. Then, the paper stack is delivered to the bind tray using the

paper fold rollers and bind delivery rollers.

Half the entire surface of each paper fold roller is uncovered excluding the central area

and the area at the left and right ends. The uncovered surface of the upper paper fold roller

comes in touch with the uncovered surface of the lower paper fold roller only at the center

and left and right ends, allowing a paper stack to be fed without causing creases. The other

half of the upper paper fold roller that is covered comes in touch with the other half of the

lower paper fold roller that is also covered, allowing a paper stack to be folded while being

fed.

Sensor flag

Folding home position sensor (PI11)

Came

Paper stack

Paper fold roller (upper)

Staple/fold

motor

2-46

M7

Paper fold roller (lower)

COPYRIGHT

Paper pushing plate

F02-505-01

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Chap02.p65 3/28/01, 12:07 PM46

Page 58

Paper fold roller (upper)

CHAPTER 2 OUTLINE OF OPERATION

Folding

home position sensor (PI11)

Paper pushing plate

Staple/fold

motor

Paper fold roller (lower)

M7

Paper stack

[Paper folding start position]

Outlet

F02-505-02

Paper stack

Inlet

Paper push plate

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM47

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Folds/feeds a paper stack.

Feeds a paper stack.

F02-505-03

2-47

Page 59

CHAPTER 2 OUTLINE OF OPERATION

Feed motor (M1)

Delivery motor (M3)

Paddle motor (M2)

Paddle home position

sensor (PI2)

Swing guide home

position sensor (PI3)

Stapler safety switch

(MS3)

Slide motor (M8)

Staple/fold motor (M7)

Staple home position

sensor (PI19)

Folding position sensor

(PI10)

Stack feed roller (upper)

home position sensor (PI12)

Binding cluch (CL1)

Folding home position

sensor (PI11)

Bind tray sensor (PI13)

Staply

?????

13571msec

50msec

2-48

Chap02.p65 3/28/01, 12:18 PM48

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

CW rotation CCW rotation

F02-505-04

Page 60

CHAPTER 2 OUTLINE OF OPERATION

6 Puncher Unit (option)

6.1 Basic Operations

6.1.1 Outline

The puncher unit is an option, and is designed for installation to the pickup assembly of

the finisher. The puncher unit is not equipped with a paper feeding mechanism, and the

sheets from the host machine move through the puncher unit and then the feed system of the

finisher.

When the trailing edge of a sheet from the host machine reaches the puncher unit, the

sheet is stopped once, and the punch shaft is rotated to punch a hole along the trailing edge.

These operations are controlled with various commands from the finisher controller PCB as

well as the commands from the punch controller PCB.

Punch drive system

Horizontal registration

drive system

Punch controller PCB

COPYRIGHT

Chap02.p65 3/28/01, 12:07 PM49

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Finisher unit control system

F02-601-01

2-49

Page 61

CHAPTER 2 OUTLINE OF OPERATION

6.2 Punching Operation

6.2.1 Outline

The puncher unit is located in the pickup assembly of the finisher, and is used to punch

holes in sheets that have been sent from the host machine and stopped inside it. When the

trailing edge of a sheet reaches the puncher unit, the inlet roller of the finisher assembly

stops the sheet to punch a hole along the trailing edge of the sheet.

The punch unit consists of a die and hole puncher (punch blade).

The hole puncher is driven by the punch motor (M1P). It is attached to the eccentric cam

of the punch shaft, and the rotation of the punch shaft is converted into reciprocating motion

for punching operation.

The punch motor (M1P) is a DC motor. The home position of the punch shaft is detected

by the punch home position sensor (PI1P). To make sure that the punch motor, which is a

DC motor, stops exactly at its home position, the punch motor is stopped in relation to the

count of the clock pulses kept by the punch motor clock sensor (PI3P).

A single punching operation is executed by rotating the punch shaft 180° from its home

position.

As many as five light-receiving transistors (photosensor PCB) are mounted over the inlet

paper path of the puncher unit; on the other hand, as many as five LEDs (LED PCB) are

mounted under the path, together serving as five sensors. The frontmost sensor (LED5, PT5)

is used to detect the training edge of sheets, and the remaining four (LED1 through LED4,

PT1 through PTR4) are used as horizontal registration sensors to detect the rear position of

sheets when punching holes.

The punch motor, punch unit, and sensors make up the punch slide unit, which moves to

the front/rear to suit the selected paper size. The movement to the front/rear is driven by the

horizontal registration motor (M2P). The home position of the punch slide unit is detected

by the horizontal registration home position sensor (PI2P), and the horizontal registration

motor (M2P) is a stepping motor.

The punch motor and horizontal registration motor are controlled with various commands

from the finisher controller PCB as well as the commands from the punch controller PCB.

The waste paper occurring as the result of punching is collected in the waste paper case.

The case is monitored by the LED121 on the waste full LED PCB and PT131 on the waste

full photosensor PCB.

2-50

Chap02.p65 3/28/01, 12:07 PM50

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 62

Chap02.p65 3/28/01, 12:07 PM51

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

LED121

2-51

Punch controller PCB (2/2)

F02-602-01

Punch motor clock (PI3P)

detection signal PUNCHCLK

Waste full detection signal

(LED121, PT131) DFULL

Horizontal registration home position

(PI2P) detection signal SREGHP

Punch home position (PI1P)

detection signal PUNCHHP

PT131

Trailing edge detection signal

(LED5, PT5) PAEND

Horizonal registration detection

signal (LED1~4, PT1~4) SREG1~4

5

5

4

4

3

3

2

2

PT1

LED1

Punch motor (M1P) drive signal

Punch controller PCB (1/2)

CHAPTER 2 OUTLINE OF OPERATION

Horizontal registration motor

(M2P) drive signal

Page 63

CHAPTER 2 OUTLINE OF OPERATION

6.2.2 Punching Operation

The hole puncher is driven by the punch motor (M1P). The home position for the hole

puncher is detected by the punch home position sensor (PI1P).

The punch unit comes in four types, selected to suit the country of installation: 2-hole

(Puncher Unit-J1), 2- and 3-hole (Puncher Unit-K1), or two types of 4-hole (Puncher UnitG1, Puncher Unit-H1).

The 2-hole and 4-hole types punch a hole when the punch shaft is rotated 180° from the

home position, causing the punch to make a single round trip. The 2-/3-hole type punches a

hole, but the circumference of the punch shaft is divided into two (half for 2-hole and the

other half for 3-hole).

2-52

Chap02.p65 3/28/01, 12:07 PM52

COPYRIGHT

©

2001 CANON INC. 2000 2000 2000 2000 CANON SADDLE FINISHER G1 REV.0 MAR. 2001

Page 64

CHAPTER 2 OUTLINE OF OPERATION

a. 2-Hole, 4-Hole Type