Page 1

SERVICE MANUAL

DIGITAL COPIER OPTION

FINISHER

MODEL AR-FN2

CONTENTS

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 3 ] UNPACKING AND INSTALLATION. . . . . . . . . . . . . . . . . . . . . . 1-1

[ 4 ] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . 4-1

[ 5 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] TEST MODE AND SETTING DIP SWITCHES . . . . . . . . . . . . . 6-1

[ 7 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] CIRCUIT DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

PARTS GUIDE

Parts marked with "! " is important for maintaining the safety of the set. Be sure to replace these parts with specified ones

for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

le constructeur.

instructions du fabricant.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

Page 3

[1] PRODUCT OUTLINE

6. Weight

This machine allows separate paper exit to different trays, and stapling of sorted copied sheets. The first-step tray holds 250 sheets,

and the second-step tray holds 750 sheets.

[2] SPECIFICATIONS

1. Type

Installation to copier body (Separate installation allowed)

2. Tray section specifications

Upper tray Lower tray

Tray type Normal tray Lift tray

Capacity 250 sheets (A4/Letter,

Storing system Face up Face up/Face

Paper exit size A3

Paper weight 52

Paper full detection None Yes

2

)

80g/m

~ A6R

´ 17" ~

11"

´ 8 1/2", 12" ´ 18"

5 1/2"

~ 128g/m

200g/m

above, A4/Letter size or

smaller)

2

, 176g/m2,

2

(For 105g/m2 or

750 sheets

(A4/Letter, 80g/m2)

down

A4, B5

´ 11"

8 1/2"

~ 128g/m

56

2

22Kg

7. Power

Supplied from the copier body.

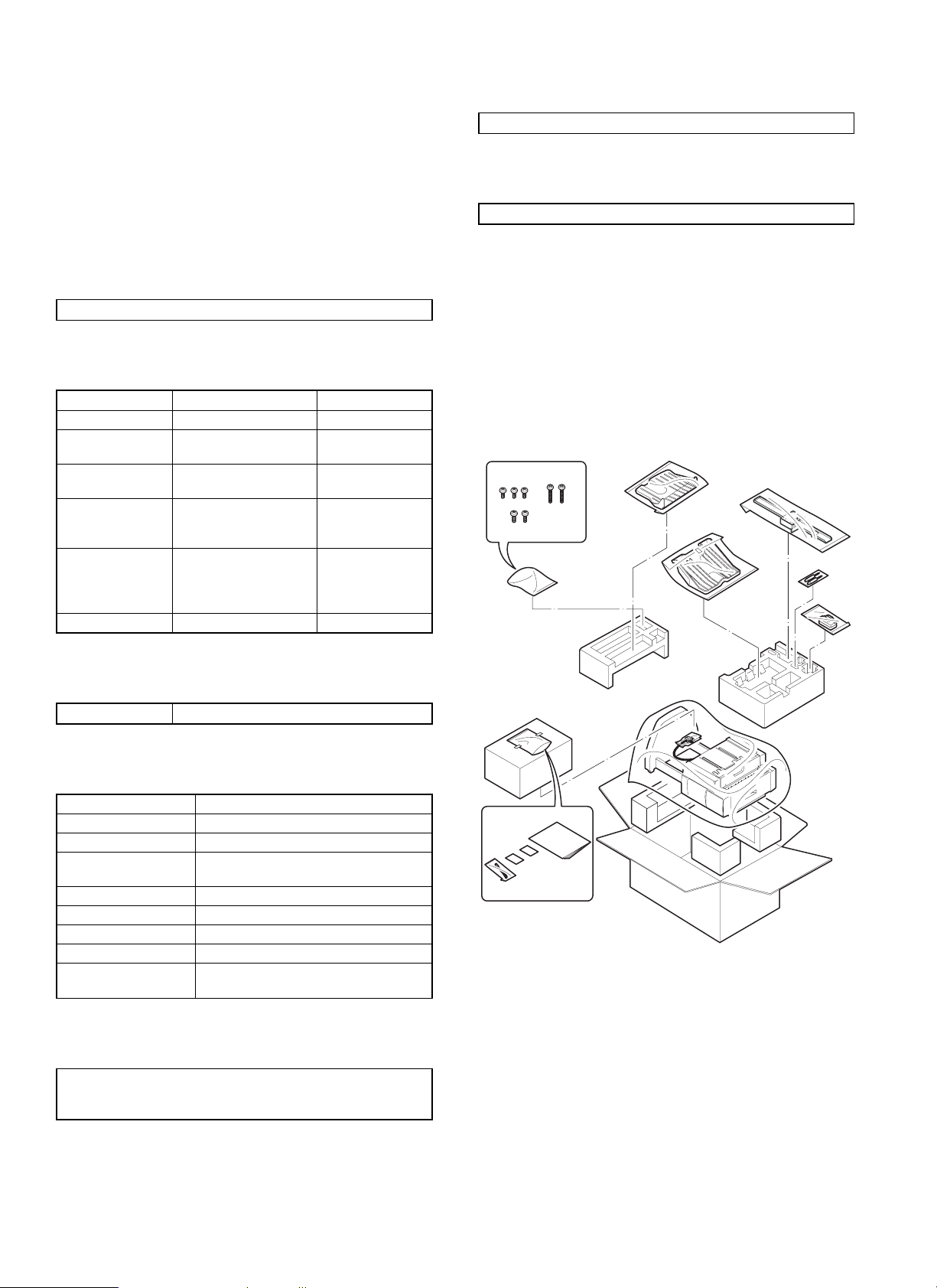

[3] UNPACKING AND

INSTALLATION

1. Unpacking

For unpacking, refer to the figure below.

3. Lift tray section

Offset amount 15mm, A4 35mm: B5 24mm: 8.5 ´ 11

4. Staple section

Storing system Face up

Stapling system Flat clinch

Stapling capacity 30 sheets (80g/m

Applicable size AB series: A4, B5

Inch series: 8 1/2

Alignment Max. shift width: 1mm

Stapling reference One position (front)

Staple supply system Cartridge system (5000 pcs.)

Staple Common with AR-SS1, SF-S54

Detection Detection of no staple/no cartridge/no

stapler

2

)

´ 11

5. External dimensions

457mm (W) ´ 518mm (D) ´ 820mm (H)

552mm (W)

extended)

´ 518mm (D) ´ 866mm (H)(with the upper tray

1 – 1

Page 4

2. Installation

Before installation, check that the following parts are included in the

package.

Parts included

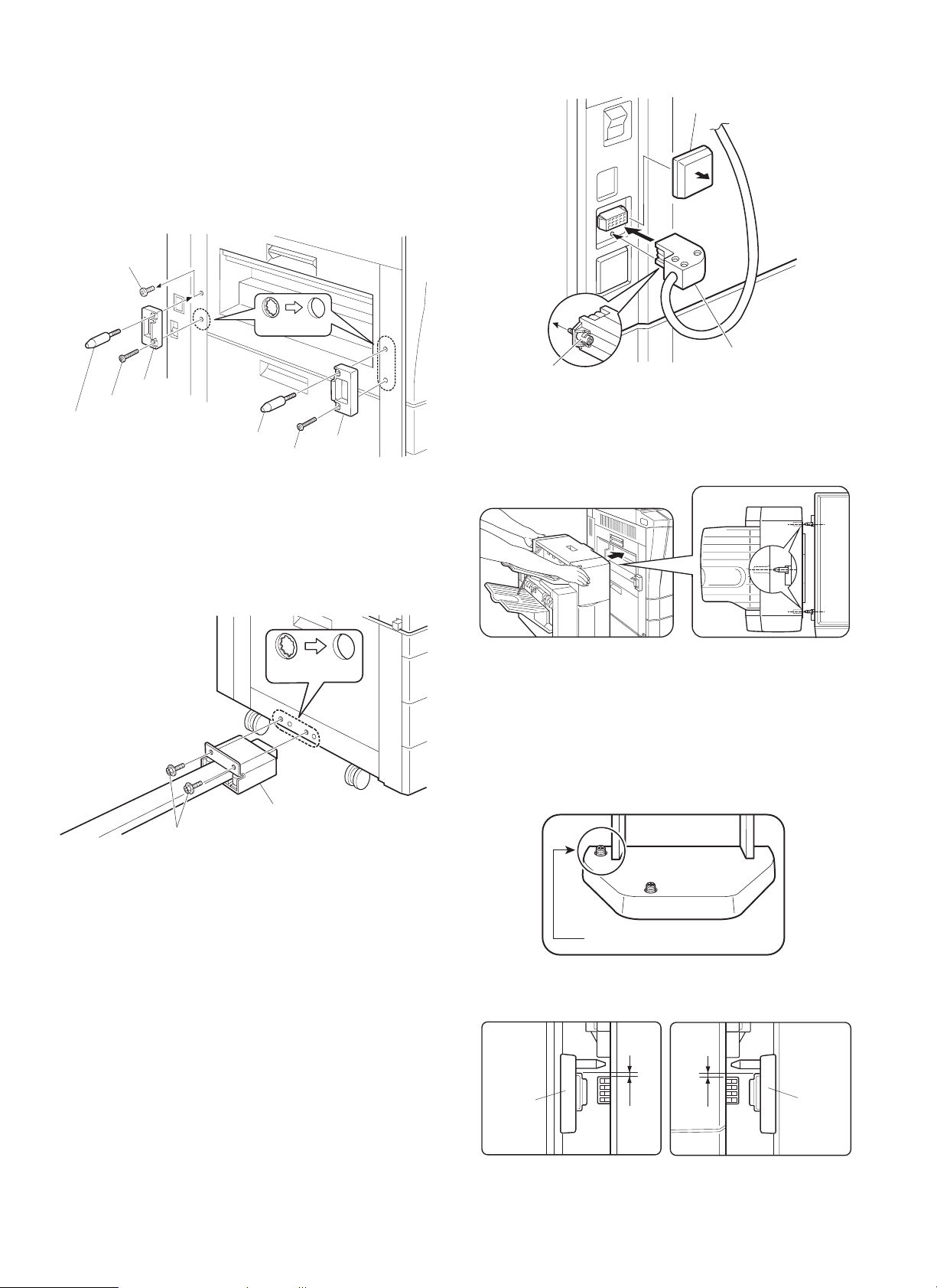

1. Attach the connecting plate to the finisher.

Insert the connecting plate into the lower part of the finisher and

secure it using two screws A.

Tray 2: 1

Connecting plate: 1

Lock plates: 2

Positioning screws: 2

Screws A: 3

Screws B: 2

Exit tray: 1

Paper holder lever: 1

Stapling position label A: 1

Stapling position label B: 1

Screws C: 2

Unplug the copier’s power cord before carrying out

the following procedure.

Carry out the following steps before installing the

AR-FN2.

1. Pull out the exit unit of the copier until it stops.

2. Remove the two exit area cover fixing screws and remove the exit

area cover.

3. Remove the two transport springs that are attached to the exit

paper guide.

4. Store the two removed transport springs by hanging on the exit

unit front frame (position in Fig. 1).

5. Reattach the exit area cover to its original position and secure it

using two fixing screws.

6. Insert the exit unit into the copier.

Exit unit

Exit area cover

Fixing screw

Fixing screw

Screws A

Connecting plate

2. Attach the paper holder lever.

Attach the paper holder lever by inserting it into the mounting location

of the finisher as shown in the figure.

Paper holder lever

3. Attach the exit tray and tray 2.

Insert tray 2 securely into the tray mounting stand and secure it using

one screw A. Then attach the exit tray to the finisher by inserting boss

at (1) first.

Screw A

Exit tray

Tray 2

(2)

(1)

[Fig. 1]

Transport spring

1 – 2

Page 5

4. Attach the lock plates.

Cut out the three lock plate mounting holes on the copier using a

Phillips screwdriver or the like and remove the burrs using a flat-blade

screwdriver or the like.

Then remove the screw from the left cabinet of the copier and secure

the lock plates to the copier as shown in the figure using screws B

(one for each plate) and positioning screws (one for each plate). (Be

careful about the orientation of the lock plates.)

Screw

Mounting holes

Lock plate

Screw B

Positioning screw

Positioning screw

Screw B

Lock plate

5. Connect the finisher with the copier.

Cut out the two mounting holes at the lower part of the desk (leftmost

hole and third hole from the left) using a Phillips screwdriver or the

like and remove the burrs using a flat-blade screwdriver or the like.

Secure the mounting plate that is attached to the finisher connecting

plate to the lower part of the desk using two screws C.

Connector cover

Screw

Connector

7. Check and adjust the height of the finisher.

Move the finisher toward the copier, and check and adjust the height

so that the guide pin of the copier is inserted smoothly into the

positioning hole of the finisher.

Mounting holes

Mounting plate

Screws C

6. Connect the finisher connector.

Cut the connector cover for connection of the finisher relay harness

connector on the copier using nippers.

Then connect the finisher relay harness connector to the connector

on the copier and secure the connector by tightening the screw on

the connector.

· Since adjustment has been made at shipping, this adjustment

is basically not needed. If the guide pin should not be inserted

smoothly, adjust the height using the following procedure.

<1> Push the finisher into the copier.

Then, rotate the adjusting screw on the rear side of the finisher

lower part (Fig. 1) so that length b of the lock plate and lock

pawl on the rear side is within

the lock plate and lock pawl on the front side.

Adjusting screw

Lock plate

± 0.5 mm in relation to length a of

[Fig. 1]

b

a

Lock plate

1 – 3

Page 6

<2> Push the finisher into the copier.

At this time, check to see if the clearance between the lower

part of the finisher and the copier is approximately 1 mm (small

clearance).

Approximately 1 mm

If the finisher touches the copier or the clearance is too large:

Adjust the clearance by rotating the adjusting screw that is attached

to the paper exit side of the lower part of the finisher (Fig. 2).

· If the finisher touches the copier or the finisher is not locked:

Rotate the adjusting screw clockwise so that the clearance between the lower part of the finisher and the copier is approximately

1 mm.

· If the clearance is too large:

Rotate the adjusting screw counter-clockwise so that the clearance

between the lower part of the finisher and the copier is approximately 1 mm.

8. Stick a stapling position label.

For document cover

Stapling position label A

For SPF

Stapling position label A

For ADF/RADF

Stapling position label B

Adjusting screw

[Fig. 2]

1 – 4

Page 7

Insert the power plug of the copier to an outlet, turn

the power switch to the "ON" position and then

perform the following procedure.

Finisher operation check

· Check the operation in the staple mode.

Make 10 copies in the staple mode and check that the copies are

stapled properly.

If the copies are not stapled at this time, use the following procedure to feed staples to the tip.

1. Open the stapler cover of the finisher.

2. Remove the staple cartridge.

Raise the staple cartridge release lever of the stapler unit to remove the staple cartridge.

5. Set the staple cartridge.

Open the stapler cover of the finisher and set the staple cartridge

in the stapler unit.

Insert the cartridge securely until it clicks.

Close the stapler cover.

Installation of the finishe r is now com plete.

3. Close the stapler cover of the finisher and remove the copies.

After removing the staple cartridge, close the stapler cover of the

finisher.

Then remove the copies from the finisher.

4. Check the staple cartridge.

Check that the first staple is at the STAPLE TEAR line of the

cartridge before setting the cartridge.

· If the first staple does not reach the STAPLE TEAR line, pull it

to the line.

· If the first staple protrudes past the STAPLE TEAR line, tear

the staples and align the first staple with the line.

(2)

(1)

STAPLE

TEAR line

1 – 5

Page 8

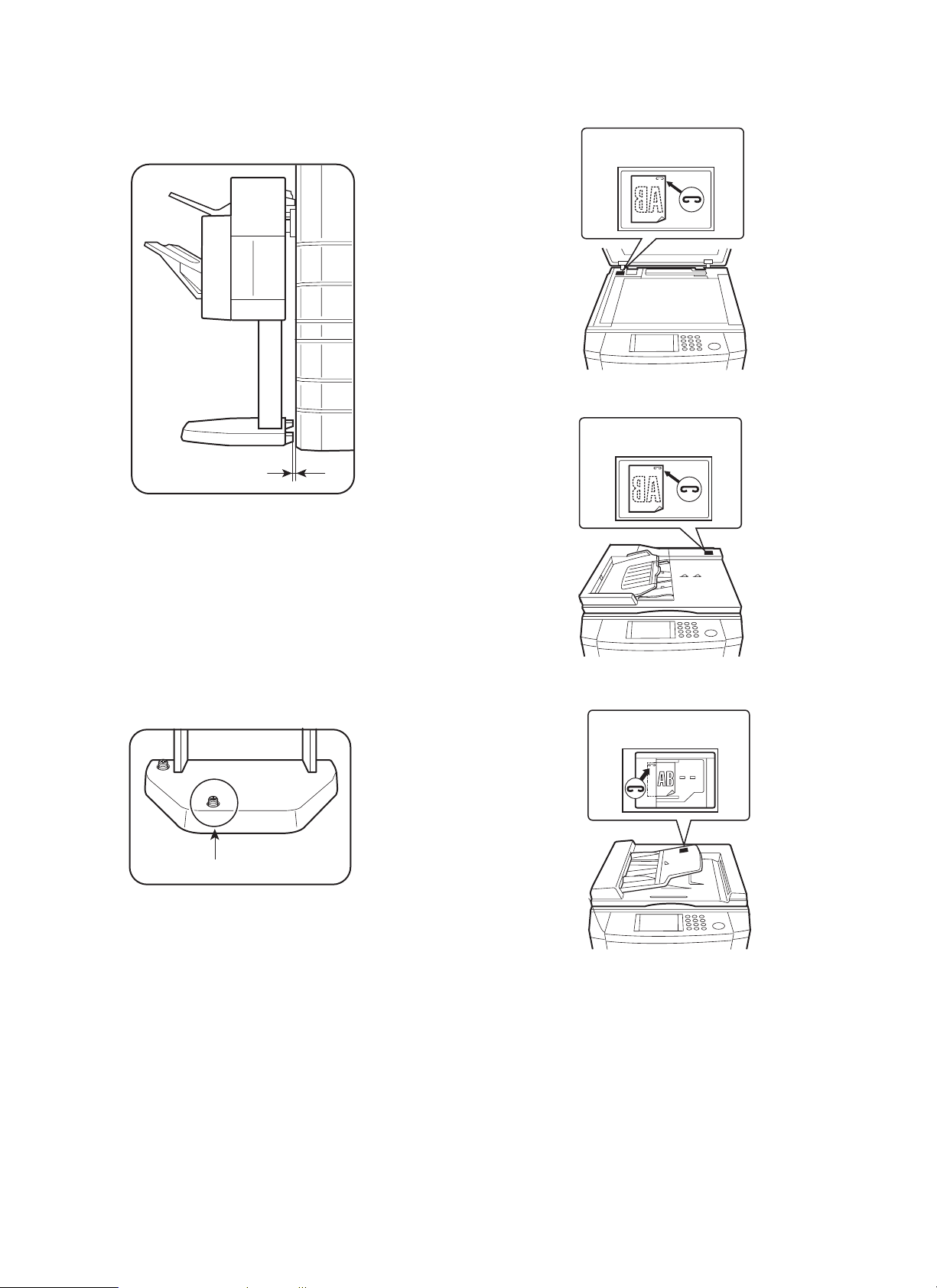

[4] EXTERNAL VIEW AND INTERNAL

STRUCTURE

1. External parts

1

2

2. Rollers, flapper, etc.

1234

15

4

5

3

6

7

5

8

9

14

13

12

11

10

No. Part name

1 Top cover

2 Rear cover

3 Front cover

4 Tray

5 Lift tray

No. Part name

1 Paper in sensor lever

2 Flapper

3 Paper exit/reverse follower roller

4 Paper exit/reverse roller

5 Bundle roller

6 Push roller

7 Paper exit sensor lever

8 Alignment tray sensor lever

9 Alignment lever

10 Intermediate tray paper exit follower roller

11 Intermediate tray paper exit roller

12 Paper transport follower roller

13 Paper transport roller

14 Finisher inlet roller

15 Finisher inlet follower roller

4 – 1

Page 9

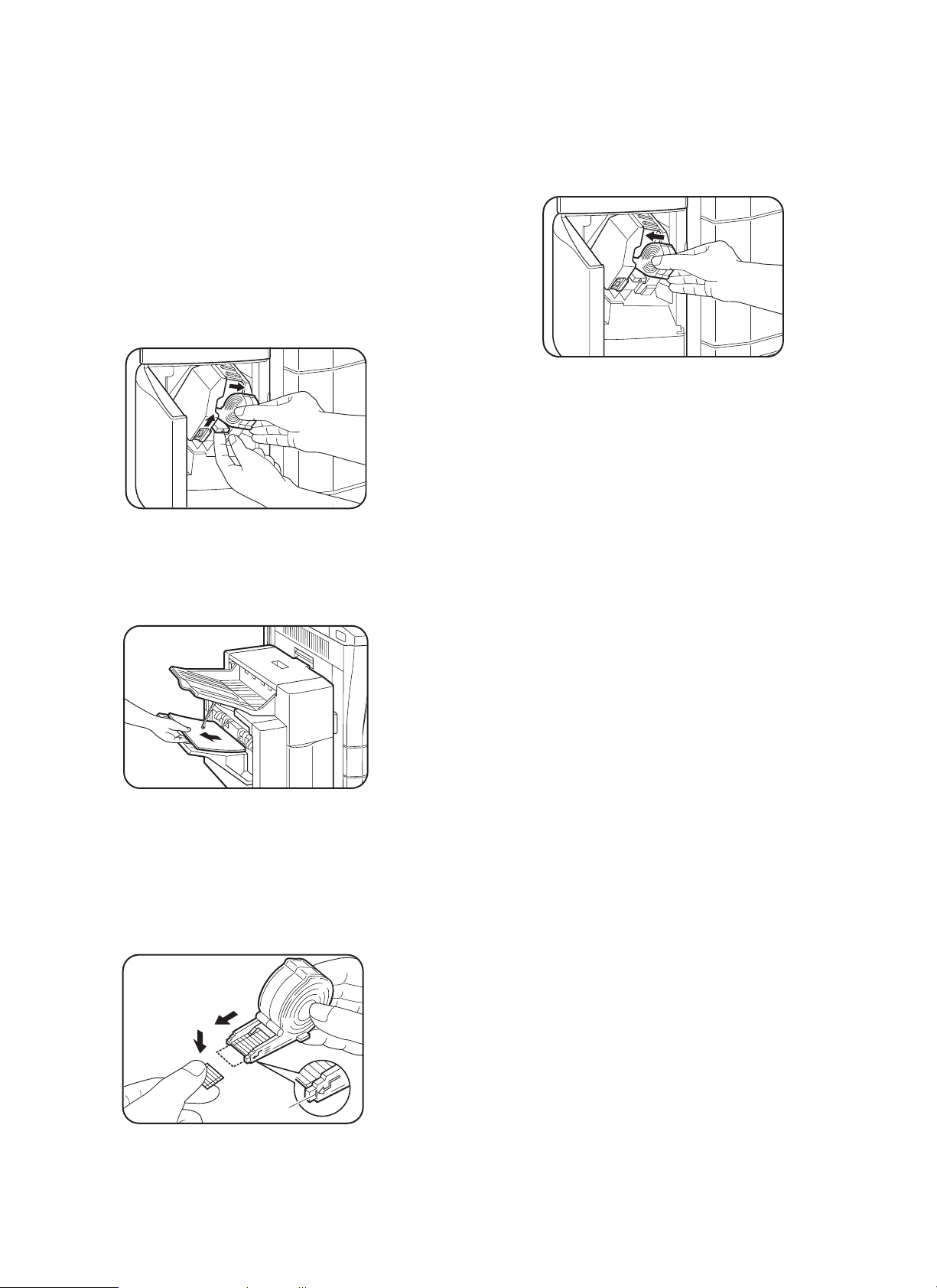

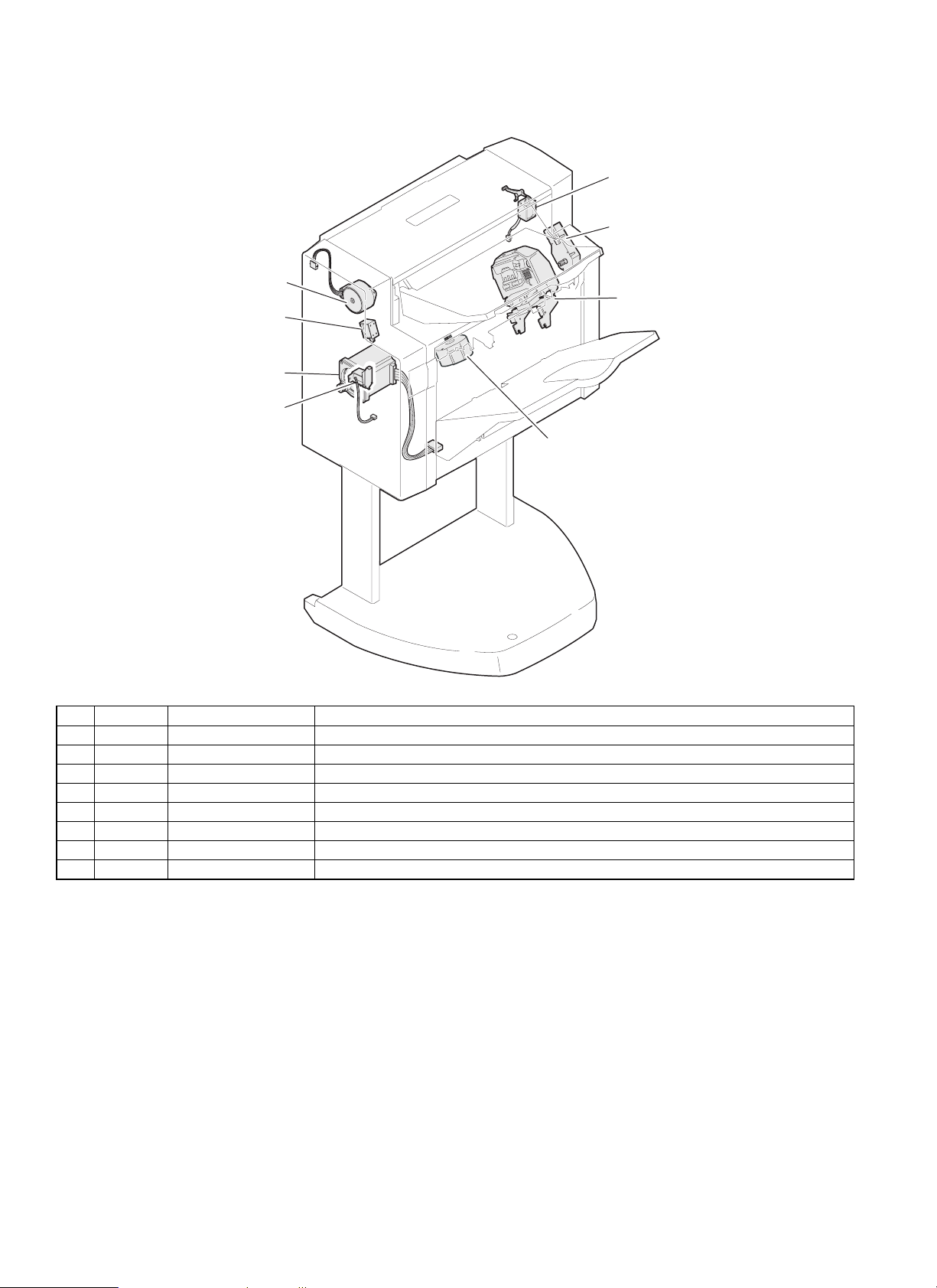

3. Motors, solenoids

2. DRM

6. PRSL

3. TMM

5. SU

8. BS

1. DTM

7. PDS

4. DSM

No. Code Name Function

1 DTM Transport motor Drives paper through the transport path.

2 DRM Reverse motor Discharges paper to the upper tray or reverses paper and sends to the lower transport path.

3 TMM Bin shift motor Moves the accumulation tray up and down.

4 DSM Alignment motor Drives the alignment plate in alignment operation.

5 SU Stapler Staples a paper bundle.

6 PRSL Reverse solenoid Sends paper directly to the lower transport path when turned on.

7 PDS Paddle solenoid Rotates the paddle when turned on.

8 BS Boomerang solenoid Rotates the boomerang when turned on.

4 – 2

Page 10

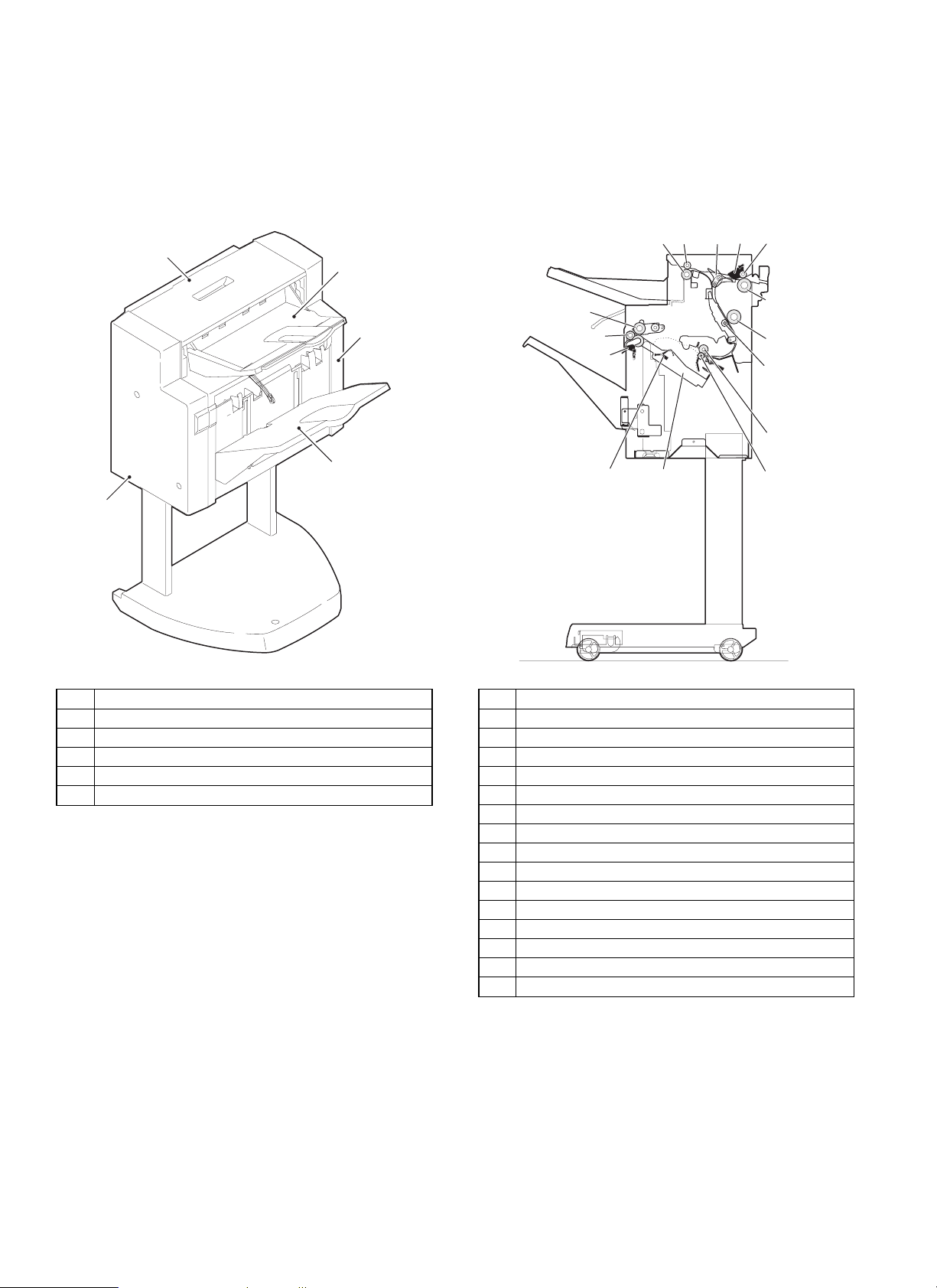

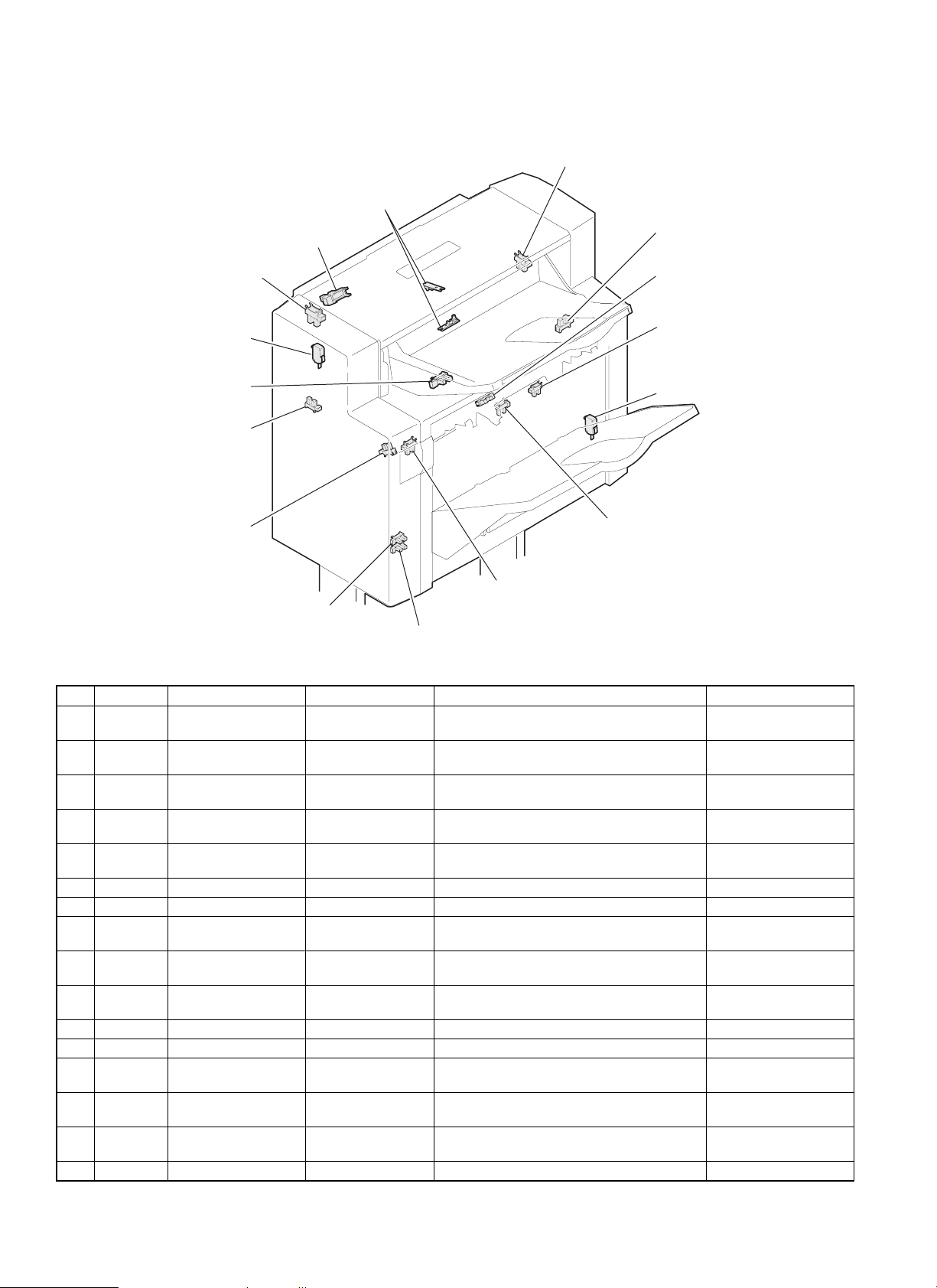

4. Sensors, switches

12. ULS2

14. PRS

10. UCS

15. SSW

1. JTES

11. ULS1

5. SBHPS

3. PIS

6. FSS

7. TMMRS

4. BES

8. PLS

16. CSW

9. AS

2. BRS

13. TLS

No. Code Name Type Function, operation Contact, output

1 JTES Process tray paper

exit sensor

2 BRS Boomerang rotation

sensor

3 PIS Transport inlet sensor Photo interrupter HIGH when the paper lead edge is sent to the

4 BES Bundle exit sensor Photo interrupter Detection of paper on the process tray HIGH when paper is

5 SBHPS Paper alignment plate

home position sensor

6 FSS Full stack sensor Photo interrupter Accumulation tray full detection HIGH when paper is full.

7 TMMRS Tray rotation sensor Photo interrupter Tray lift motor rotation detection Pulse output

8 PLS Paper level sensor Photo interrupter Paper level detection in the accumulation tray HIGH when paper is

9 AS Accumulation tray

sensor

10 UCS Upper cover sensor Photo interrupter Upper transport path cover open/close

11 ULS1 Unit lock sensor 1 Photo interrupter Lock detection with the copier (Rear side) LOW when locked.

12 ULS2 Unit lock sensor 2 Photo interrupter Lock detection with the copier (Front side) LOW when locked.

13 TLS Tray limit sensor Photo interrupter Accumulation tray lower limit detection HIGH when the lower

14 PRS Paper reverse sensor Transmission sensor HIGH when paper is fed in front of the fixed

15 SSW Set switch Micro switch Lower transport path cover open/close

16 CSW Cover switch Micro switch Stapler cover open/close detection LOW when closed.

Photo interrupter HIGH when the paper lead edge is transported

to the process tray tip.

Photo interrupter HIGH when the boomerang is rotating in the

accumulation tray exit section.

finisher.

Photo interrupter Detection of the home position of the alignment

plate on the process tray

Photo interrupter Paper presence detection i the accumulation

tray

detection

tray.

detection

HIGH when paper is

detected.

HIGH when the

boomerang is rotating.

HIGH when paper is

detected.

detected.

HIGH when stopping at

the home position.

detected.

LOW when paper is

detected.

LOW when closed.

limit is detected.

LOW when paper is

detected.

LOW when closed.

4 – 3

Page 11

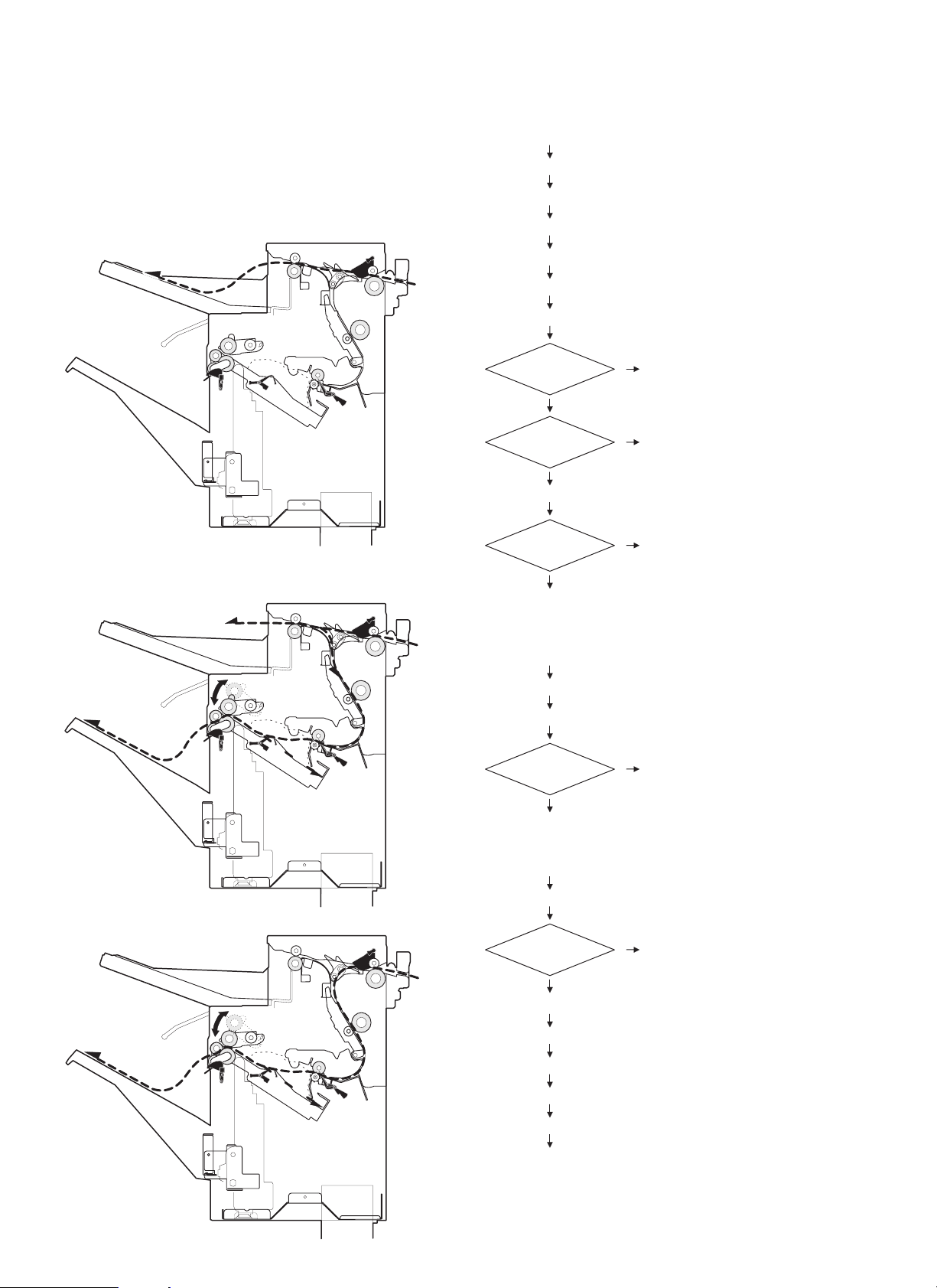

[5] OPERATIONAL DESCRIPTIONS

1. Paper transport path

The paper transport path is shown in the figure below.

(The dotted line ( - - - - - ) shows the paper transport path.)

<Non-job mode: Discharged to the top tray.>

2. Operation process

START

STEP 01 Copier print start ON

STEP 02 Operation mode command received

STEP 03 JOB_START command received

STEP 04 Transport motor start

STEP 05 Paper exit operation specify command 2 received

STEP 06 Copier paper exit information command received

<Long job/Staple mode: Discharged to the job tray.>

1 Reversing paper

Paper exit tray

Paper exit to the offset tray

Reversing

NO

STEP 07 Reverse solenoid ON

Paper exit mode

Staple mode

Go to (3)

Paper exit to the top tray

Go to (1)

YES

Go to (2)

Normal mode

Go to (4)

(1)

STEP 08 Finisher inlet sensor ON

STEP 09 Finisher inlet sensor OFF

YES

Next paper

Go to STEP 05

2 Without reversing

5 – 1

NO

Go to STEP 57

(2)

STEP 10 Finisher inlet sensor ON

Reversing

YES

STEP 11 Reverse motor forward rotation ON

STEP 12 Reverse sensor ON

STEP 13 Inlet sensor OFF

STEP 14 Reverse sensor OFF

STEP 15 Reverse motor forward rotation OFF

Go to STEP 16

NO

Go to STEP 20

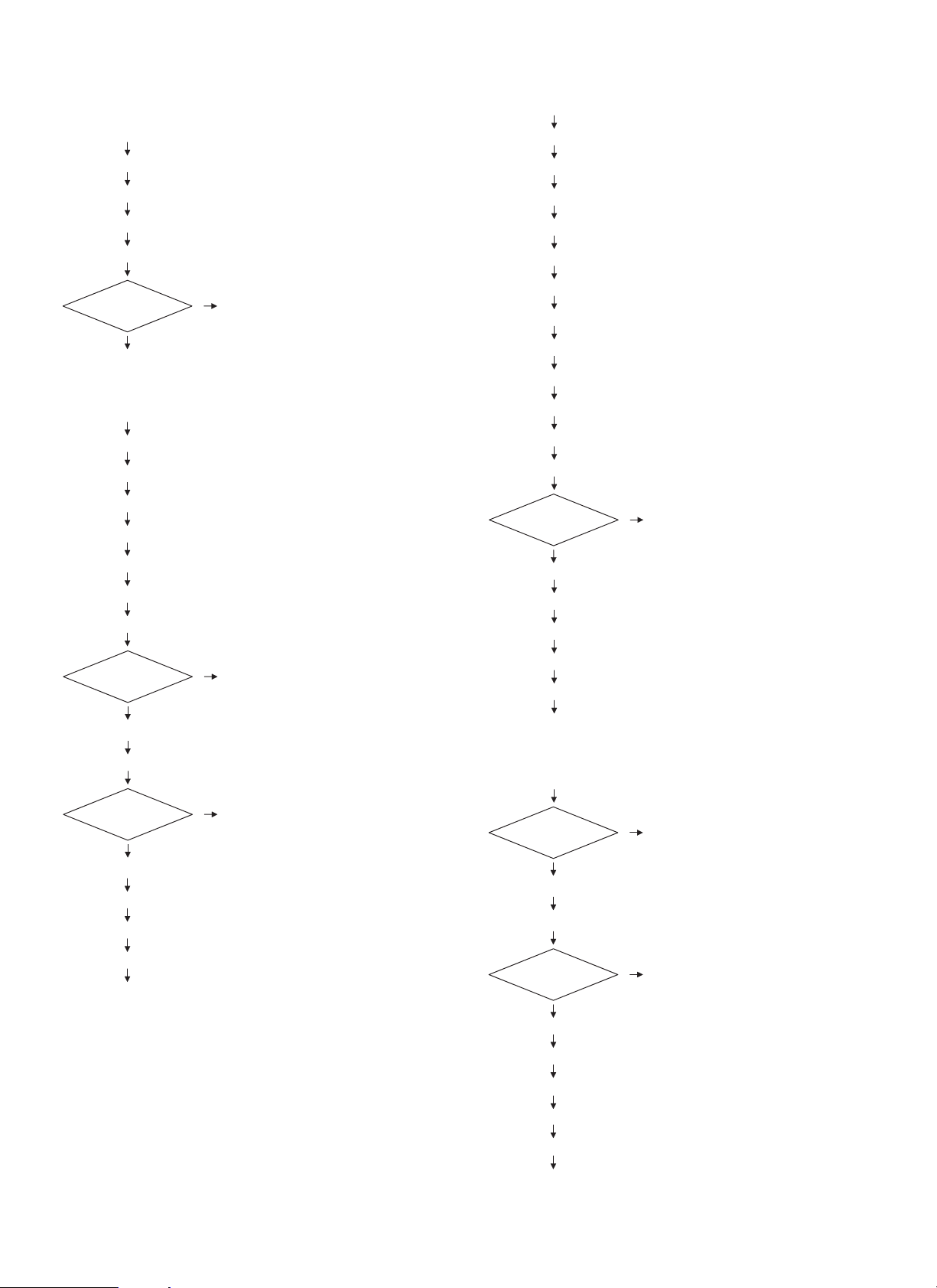

Page 12

(3)

STEP 16 Reverse motor reverse rotation ON

STEP 17 Reverse sensor ON

STEP 18 Reverse sensor OFF

STEP 19 Reverse motor reverse rotation OFF

STEP 20 Process tray paper exit sensor ON

Offset

With offset

Go to (4)

Without offset

Go to STEP 24

(4)

STEP 21 Process tray paper exit sensor OFF

STEP 22 Alignment motor ON

STEP 23 Alignment motor OFF

STEP 24 Boomerang solenoid ON

STEP 25 Boomerang solenoid OFF

STEP 26 Boomerang rotation sensor OFF

STEP 27 Boomerang rotation sensor ON

STEP 34 Inlet sensor ON

STEP 35 Inlet sensor OFF

STEP 36 Process tray paper exit sensor ON

STEP 37 Paddle solenoid ON

STEP 38 Paddle solenoid OFF

STEP 39 Process tray paper exit sensor OFF

STEP 40 Alignment motor ON

STEP 41 Alignment motor OFF

STEP 42 Paddle solenoid ON (One turn)

STEP 43 Paddle solenoid OFF

STEP 44 Paddle solenoid ON (Two turns)

STEP 45 Paddle solenoid OFF

NO

Staple treatment

YES

STEP 46 Staple process

STEP 47 Boomerang solenoid ON

STEP 48 Boomerang solenoid OFF

Go to STEP 05

Paper level

sensor

ON

STEP 28 Bin shift motor ON

STEP 29 Bin shift motor OFF when paper level sensor OFF

Next paper

NO

STEP 30 Boomerang solenoid ON

STEP 31 Boomerang solenoid OFF

STEP 32 Boomerang rotation sensor OFF

STEP 33 Boomerang rotation sensor ON

Go to STEP 57

OFF

Go to STEP 29

YES

Go to STEP 05

STEP 49 Boomerang rotation sensor OFF

STEP 50 Boomerang rotation sensor ON

Go to (5)

(5)

Paper level

sensor

ON

STEP 51 Bin shift motor ON

STEP 52 Bin shift motor OFF when paper level sensor OFF

Next paper

NO

STEP 53 Boomerang solenoid ON

STEP 54 Boomerang solenoid OFF

STEP 55 Boomerang rotation sensor OFF

OFF

Go to STEP 52

YES

Go to STEP 05

5 – 2

STEP 56 Boomerang rotation sensor ON

STEP 57 Transport motor stop

END

Page 13

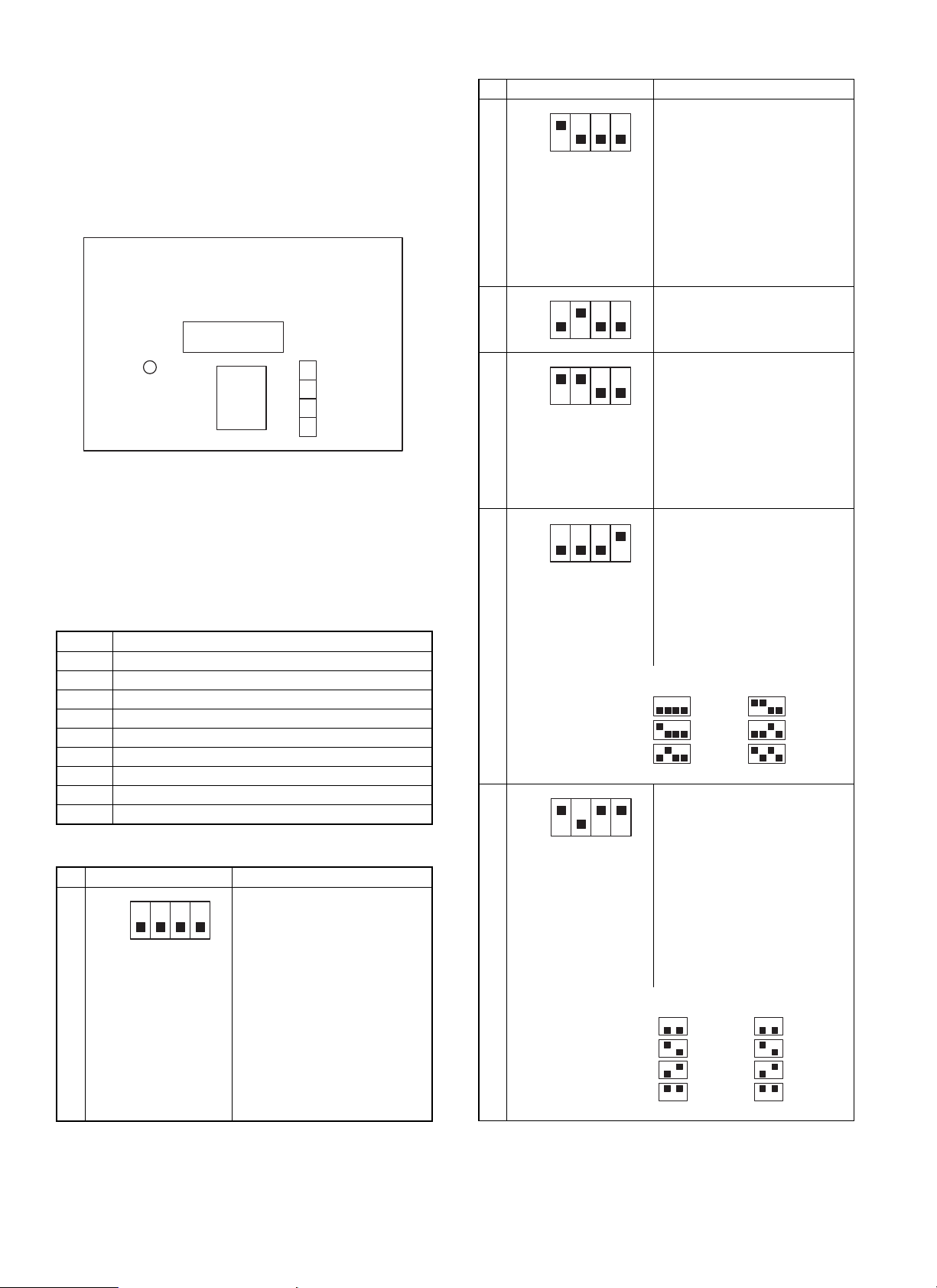

[6] TEST MODE AND SETTING DIP

SWITCHES

1. Position of dip switches

The dip switches are located on the main PWB as shown in the figure

below.

ROM

LED

CPU

2. Setting dip switches

(1) Selecting test modes

Select the test mode type using the dip switches. Holding down the

push switch, turn on the power to get in the selected test mode. After

that, change over the dip switches and press the push switch as

necessary.

1 Load individual operation check mode 1

2 Load individual operation check mode 2

3 Staple operation check mode

4 Alignment plate stop position check mode

5 Non-job tray exit mode

6 No-reverse offset exit mode

7 Reverse offset exit mode

8 Staple exit mode

9 Reverse offset aging mode

10 Staple aging mode

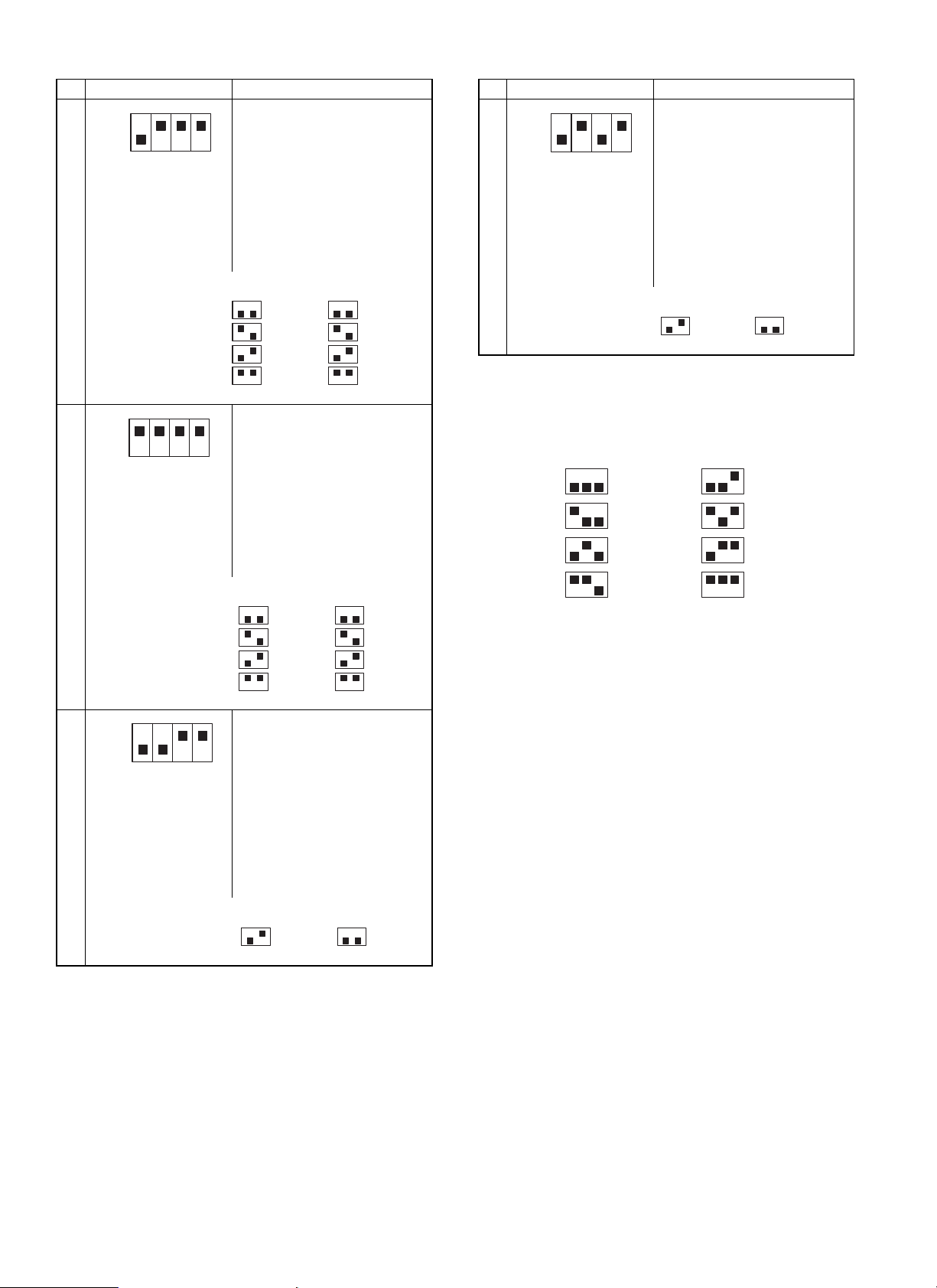

(2) S e ttin g te s t mode

1 2 3 4 Description

Loaded test mode 1

ON

OFF

1

In this test mode, each actuator is

activated and deactivated every

time the push switch is pressed.

The following operations is

repeated:

Reverse SOL

Puddle SOL

Discharge SOL

Transfer motor

Stack tray motor

DIPSW

¯

¯

¯

¯

1 2 3 4 Description

Loaded test mode 2

ON

OFF

In this mode, each actuator is

activated and deactivated every

time the push switch is pressed.

The following operations are

2

repeated:

Reverse motor

(forward rotation)

¯

Reverse motor

(reverse rotation)

Matching plate

Stapler operation check mode

ON

3

OFF

In this mode, the stapler operates

once every time the push switch is

pressed.

Matching plate stop position

ON

OFF

check mode

In this mode, the matching plate

stops at the paper matching

4

position and returns to its home

position every time the push

switch is pressed.

Staple discharge JOG discharge

® Letter ® B5 ® A4 ® Letter

A4

® B5

Non-job tray discharge mode

ON

OFF

After turning on the machine in a

test mode, set to this mode with

the dip switches. Pressing the

push switch sets paper size and

performs initial operation. After

the completion of the initial

operation, it becomes possible to

5

pass paper. The settings of the

dip switches are as follows:

1

ON

OFF

234

A3_T

A4_Y

A4_T

ON

OFF

1

234

LETTER_Y

LETTER_T

EXE_Y

No-reversion offset discharge

ON

OFF

mode

After turning on the machine in a

test mode, set to this mode with

the dip switches. Pressing the

push switch sets paper size and

the number of sheets to be

processed and performs initial

operation. After the completion of

the initial operation, it becomes

6

possible to pass paper. The

settings of the dip switches are as

follows:

ON

OFF

12

A4

LETTER

B4

EXE

ON

OFF

34

2pls

5pls

10pls

30pls

6 – 1

Page 14

1 2 3 4 Description

Reversion offset discharge mode

ON

OFF

After turning on the machine in a

test mode, set to this mode with

the dip switches. Pressing the

push switch sets paper size, the

number of sheets to be processed

and performs initial operation.

After the completion of the initial

operation, it becomes possible to

7

pass paper. The settings of the

dip switches are as follows:

10

1 2 3 4 Description

Staple aging mode

ON

OFF

After turning on the machine in a

test mode, set to this mode with

the dip switches. Pressing the

push switch sets paper size to

Letter and the number of sheets

to be processed to 2, and

performs initial operation. After

the completion of the initial

operation, aging operation starts.

The settings of the dip switches

are as follows:

ON

OFF

12

A4

LETTER

B4

EXE

ON

OFF

34

2pls

5pls

10pls

30pls

ON

OFF

12

LETTER_Y

34

2pls

(3) When DIP SW4 is turned on, offset exit paper is

reversely discharged. (Used to check the

Staple discharge mode

ON

OFF

After turning on the machine in a

test mode, set to this mode with

the dip switches. Pressing the

push switch sets paper size, the

number of sheets to be processed

and performs initial operation.

After the completion of the initial

operation, it becomes possible to

8

pass paper. The settings of the

dip switches are as follows:

ON

OFF

12

A4

LETTER

B4

EXE

ON

OFF

34

2pls

5pls

10pls

30pls

reversing operation in the printer mode.)

1

ON

OFF

23

2pls

4pls

6pls

8pls

ON

OFF

1

23

10pls

12pls

14pls

16pls

(4) All the dip switches are factory set to OFF.

Reversion offset aging mode

ON

OFF

After turning on the machine in a

test mode, set to this mode with

the dip switches. Pressing the

push switch sets paper size to

Letter and the number of sheets

to be pressed to 2, and performs

9

initial operation. After the

completion of the initial operation,

aging operation starts. The

settings of the dip switches are as

follows:

ON

OFF

12

LETTER_Y

34

2pls

6 – 2

Page 15

[7] DISASSEMBLY AND ASSEMBLY

(Note)

· This chapter describes mainly the disassembly procedures. For

assembly procedures, reverse the disassembly procedures.

· For disassembly, remove the parts in the sequence of numbering

in the figure.

1. Upper cover ass’y

1)

2)

3)

11)

9)

7)

8)

12)

10)

10)

13)

4)

6)

5)

7 – 1

Page 16

2. Tray cover ass’y

Remove the front and the rear covers.

7)

5)

2)

5)

6)

5)

1)

3. Cover top

3)

1) Remove the outer cover.

3)

4)

(2)

(3)

7 – 2

(1)

(1)

(4)

Page 17

4. Flapper and reverse motor

1) Remove the outer cover.

2) Remove the cover top assembly (with main cover).

Match the prsjection with the

groove

(A)

A

(5)

(2)

(A)

(3)

(1)

5. Cover guide assembly

1) Remove the outer cover.

2) Remove the cover top assembly (with main cover).

(6)

(4)

(7)

(2)

(1)

(3)

(5)

(4)

7 – 3

Page 18

6. Matching tray unit

1) Remove the outer cover.

2) Remove the cover top assembly (with main cover).

5)

4)

3)

4)

3)

7)

6)

1)

3)

2)

7. Guide paddle

8)

1) Remove the outer cover.

2) Remove the front and rear cover masks and flapper.

3) Remove the paper reversion/discharge guide bracket.

(3)

(4)

(5)

(6)

(5)

(7)

(2)

(1)

7 – 4

Page 19

8. Control PWB and large gear

1) Remove the outer cover.

2) Remove the connector from the control PWB.

(6)

(4)

(3)

(5)

(8)

(7)

(1)

(1)

(1)

(2)

(1)

(13)

9. Bundle discharge roller

1) Remove the outer cover.

2) Remove the large gear.

3) Remove the tray’s side cover.

(2)

(1)

(7)

(8)

(9)

(10)

(11)

7 – 5

(12)

(14)

(6)

(5)

(14)

(4)

(3)

(1)

Page 20

[8] ADJUSTMENTS

1. De-curler roller gap adjustment

Adjustment procedures

1) Remove the paper entry guide 1) and paper entry guide lever 2).

2) Push the adjustment plate 3) fully to the end of the adjustment

margin in the arrow direction, and fix it with screw 4).

There are two adjustment positions for adjustment plate 3). Adjust

in the same manner. As a result, decolor roller 5) and roller shaft

6) are bent in 2.0mm.

(6)

(5)

(3)

(1)

(2)

(4)

Roller pushing amount: 0mm Roller pushing amount: 1mm Roller pushing amount: 2mm

(Note) When replacing de-curler roller 5) and roller shaft 6), be sure

to perform the above adjustment in advance.

8 – 1

Page 21

[9] MAINTENANCE

Note: Before performing maintenance, be sure to disconnect the power plug from the power outlet.

Maintena n c e lis t

(Content) ★: Lubricate | : Clean ü: Adjust ▲: Replace ✕: Check (Clean, replace, adjust according to necessity.)

Part name 80K 160K 240K 320K 400K 480K Same cycle hereinafter

A Reverse sensor (Transmission type)

1 Finisher inlet roller

2 Paper reverse/exit roller ||||||

B

3 Paper transport roller ||||||

4 Intermediate tray exit roller ||||||

5 Bundle exit roller ||||||

C Timing belt ✕✕✕✕✕ü

1 Torque limiter

2 Torque limiter ★★★★★▲

D

3 Torque limiter ★★★★★▲

4 Torque limiter ★★★★★▲

1 Discharge brush (Upper tray paper exit section)

E

2 Discharge brush (Intermediate tray section) ✕✕✕✕✕▲

F Staple unit Replace after operations of 100 thousand times.

||||||

||||||

★★★★★▲

✕✕✕✕✕▲

A. Reverse sensor

(1)

(1)

9 – 1

(1)

Page 22

B. Rollers

(1)

(3)

(4)

(2)

(5)

(2)

(4)

(5)

(1)

(3)

(5)

(5)

(5)

9 – 2

Page 23

C. Timing belt

D. Torque lim ite r

(4)

(2)

(1)

(3)

9 – 3

Page 24

E. Discharge brush

(1)

F. Staple unit

(2)

(1)

(2)

9 – 4

Page 25

[10] TROUBLESHOOTING

1. Trouble code

Trouble code

Main

code

Sub

code

F1 00 Content Finisher communication trouble

Detail Communication line test error occurs

when power is turned on or after the exit

of a simulation mode.

Improper communication with sorter

Cause Improper connection or broken wire of

Check

and

remedy

01 Content Finisher 2 alignment section trouble

Detail Alignment plate shift trouble

Cause Motor lock

Check

and

remedy

04 Content Finisher elevater lower limit detected

Detail Elevater has exceeded lower limit.

Cause Sensor defective

Check

and

remedy

05 Content Stack tray sensor abnormality

Detail Stack tray sensor turns on in abnormal

Cause Sensor defective

Check

and

remedy

connector or harness between copier

and Finisher

Finisher control PWB defective

Control PWB (PCU) defective

Malfunction due to noise

Clear by turning the power supply

OFF/ON.

Check communication line connector and

harness.

Replace Finisher control PWB or PCU

PWB.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the jogger motor operation with

SIM 3-3.

Finisher control PWB defective

Check sensor with SIM3-2.

combination.

Finisher control PWB defective

Check sensor with SIM3-2.

Description

Trouble code

Main

code

Sub

code

F1 10 Content Staple unit operation trouble

Detail Staple operation trouble

Cause Motor lock

Check

and

remedy

11 Content Boomerang rotation

Detail Boomerang solenoid

Cause Boomerang solenoid operation trouble

Check

and

remedy

14 Content Stack tray abnormality

Detail Stack tray control sensor abnormality

Cause a) The paper level sensor or the full stack

Check

and

remedy

15 Content Stack tray motor lock

Detail Elevator motor trouble

Cause Motor lock

Check

and

remedy

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the staple motor operation with

SIM 3-3.

Boomerang rotation sensor abnormality

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the with SIM 3-2.

b) When the tray is lifted, the stack tray is

Check the sensors with SIM 3-2.

Check the elevator motor operation with

SIM 3-3.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the elevator motor operation with

SIM 3-3.

Description

sensor are not turned on in a certain

time after starting the tray.

locked.

10 – 1

Page 26

2. Troubleshooting

Trouble Cause Troubleshooting and treatment

(1) When the main switch of

the copier is turned on,

it does not work at all.

(2) The transport motor

does not operate.

(3) The reverse motor does

not operate.

(4) The alignment motor

does not operate.

(5) The accumulation tray

motor does not operate.

(6) The boomerang

solenoid does not

operate.

(7) The reverse solenoid

does not operate.

(8) The paddle solenoid

does not operate.

(9) The copier display

shows "Finisher paper

jam."

(10) The copier display

shows "Finisher not

connected."

(11) The copier display

shows Finisher cover

open.

(12) Paper is stopped

during exit operation

1. Contact trouble with the copier Check contact of each connector.

2. Contact trouble of the connector

pin of the connection wire with the

copier

3. Stapler section cover switch, lower

transport path set switch trouble

4. Control PWB trouble If DC24V and DC5V are inputted from the copier and LED on the control

1. Motor connector pin contact trouble

Make a conduction test between connectors and replace, if not

conducting.

Make a conduction test between switches, and replace if necessary.

PWB does not blink and 24V is ont supplied to CN8-1, replace the control

PWB.

· Check contact of the connector, and repair if necessary.

· Make a conduction test of connector pins and replace if not conducting.

2. Motor coil disconnection Make a conduction test between coils and replace the motor if ont

conducting.

3. Control PWB trouble If the motor does not operate in the load operation mode, replace the

control PWB.

1. Solenoid connector pin contact

trouble

2. Solenoid coil disconnection Make a conduction test between coils, and replace the solenoid if not

3. Control PWB trouble If the solenoid does not operate in the load operation mode, replace the

1. Paper jam Visually inspect and remove the jam.

2. Transport entry port sensor trouble Measure the voltage at TP41 on the control PWB. If it is not 0V at sensor

3. Treatment tray exit sensor trouble Measure the voltage at TP56 on the control PWB. If it is not 0V at sensor

4. Bundle exit sensor trouble Measure the voltage at TP58 on the control PWB. If it is not 0V at sensor

5. Paper reverse sensor trouble Measure the voltage at TP22 on the control PWB. If it is not 0V at sensor

6. Sensor connector pin contact

trouble

7. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

1. Finisher not connected Connect the finisher.

2. Unit lock sensor 1 trouble Measure the voltage at TP20 on the control PWB. If it is not 0V at when

3. Unit lock sensor 2 trouble Measure the voltage at TP46 on the control PWB. If it is not 0V when

6. Sensor connector pin contact

trouble

7. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

1. Upper cover open Visually inspect and remove the cover.

2. Upper cover sensor trouble Measure the voltage at TP17 on the control PWB. If it is not 0V at sensor

3. Sensor connector pin contact

trouble

4. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

1. Boomerang rotation sensor trouble Measure the voltage at TP59 on the control PWB. If it is not 0V at sensor

2. Paper alignment home position

sensor trouble

3. Sensor connector pin contact

trouble

4. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

· Check contact of the connector, and repair if necessary.

· Make a conduction test of connector pins, and replace if not

conducting.

conducting.

control PWB.

OFF and 5V at ON, replace the transport path entry port sensor.

OFF and 5V at ON, replace the treatment tray exit sensor.

OFF and 5V at ON, replace the bundle exit sensor.

OFF and 5V at ON, replace the paper reverse sensor.

Make a conduction test of connector pins, and replace the pin if not

conducting.

phenomenon is not changed, replace the control PWB.

coupling and 5V when not coupling, replace the unit lock sensor 1.

coupling and 5V when not coupling, replace the unit lock sensor 2.

Make a conduction test of connector pins, and replace the pin if not

conducting.

phenomenon is not changed, replace the control PWB.

OFF and 5V at ON, replace the transport path entry port sensor.

Make a conduction test of connector pins, and replace pins if not

conducting.

phenomenon is not changed, replace the control PWB.

OFF and 5V at sensor ON, replace the transport path entry port sensor.

Measure the voltage at TP23 on the control PWB. If it is not 0V at sensor

oFF and 5V at ON, replace the transport path entry sensor.

Make a conduction test of connector pins, and replace the pins if not

conducting.

phenomenon is not changed, replace the control PWB.

10 – 2

Page 27

Trouble Cause Troubleshooting and treatment

(13) The accumulation tray

does not stop at the

proper position.

1. Tray rotation sensor trouble Measure the voltage at TP5 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry sensor.

2. Full stack sensor trouble Measure the voltage at TP16 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry port sensor.

3. Tray limit sensor trouble Measure the voltage at Tp18 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry port sensor.

4. Paper surface sensor trouble Measure the voltage at TP47 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry port sensor.

5. Accumulation tray sensor trouble Measure the voltage at TP19 on the control PWB. If it is not 5V at sensor

OFF and 0V at ON, replace the transport path entry port sensor.

6. Sensor connector pin contact

trouble

Make a conduction test of connector pins, and replace pins if not

conducting.

7. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

phenomenon is not changed, replace the control PWB.

10 – 3

Page 28

[11] CIRCUIT DESCRIPTIONS

1. Outline

This circuit controls document transport, reverse, alignment, stapling and discharge.

It is composed of a circuit which controls sensors, switches,and copier signals input, and a circuit which drives the motors and the solenoids, and

CPU, G/C and it peripheral circuits

2. Block diagram

Paper transport

Communication

circuit

Paper reverse

sensor input

circuit

Transport path

entry sensor input

circuit

Address bus

motor drive

circuit

Paper alignment

motor drive

circuit

Paper reverse

motor drive

circuit

Process tray paper

exit sensor input

circuit

Bundle exit sensor

inpout circuit

Accumulation tray

sensor input

circuit

Boomerang

rotation sensor

input circuit

Unit lock sensor 1

input circuit

Unit lock sensor 2

input circuit

Upper cover

sensor input

circuit

Paper alignment

home position

sensor input circuit

Paper level

sensor input

circuit

Data bus

DIP switch push

switch

rush current

limit circuit

+24V

Open/close

switch input

circuit

Power ON

reset circuit

Oscillation

circuit

11MHz

Bin shift motor

drive circuit

Boomerang solenoid

drive circuit

Reverse solenoid

drive circuit

Paddle solenoid

drive circuit

Staple motor

drive circuit

Current limit

circuit

Stapler home

position sensor

input circuit

Staple near end

sensor input circuit

Staple presence

sensor input circuit

Tray rotation

sensor input

ircuit

Tray limit sensor

input circuit

Full stack sensor

input circuit

Power circuit

11 – 1

Page 29

3. Operations

A. Sensor input circuit

[a] Transport path entry sensor (PIS)

PIS is a photo interrupter which integrates a light emitting diode and photo transistor. A document from the copier is detected by the lever-system

actuator. The light path is interrupted when document presence.

The signal is passed to the CPU (IC9-61 pin) through the noise filter of R13 and C17.

Logic of the signal inputted to the CPU: Document presence

R45 is the current limiting resistor of LED. R67 is the sensor load resistor.

Transport entry port

sensor

(PIS)

[b] Treatment tray exit sensor (JTES)

JTES is the sensor same as the transport entry port sensor (PIS). The document discharged to the treatment tray is detected by the lever-system

actuator. The light path is interrupted when document presence.

The signal is passed to the CPU (IC9-59 pin) through the noise filter of R14 and C18.

Logic of the signal inputted to the CPU: Document presence

R46 is the current limiting resistor of LED. R68 is the sensor load resistor.

® H, Document empty ® L

Transport entry port sensor input circuit

® H, Document empty ® L

Process tray paper

exit sensor

(JTES)

Process tray paper exit sensor input circuit

[c] Bundle exit sensor (BES)

BES is the sensor same as the transport entry port sensor (PIS).

The document on the treatment tray is detected by the lever-system actuator. The light path is interrupted when document is present.

The signal is passed to the CPU (IC9-56 pin) through the noise filter of R17 and C20.

Logic of the signal inputted to the CPU: Document present

R47 is the current limiting resistor of LED. R69 is the sensor load resistor.

Bundle exit sensor

(BES)

® H, Document empty ® L

Bundle exit sensor input circuit

11 – 2

Page 30

[d] Full stack sensor (FSS)

FSS is the sensor same as the transport entry port sensor (PIS).

The document full state on the treatment tray is detected by the douser liked with the tray movement. The light path is interrupted when document

full.

The signal is passed to the G/A (IC5-39 pin) through the noise filter of R1 and C3.

Logic of the signal inputted to the G/A: Document tray full detected

R39 is the current limiting resistor of LED. R52 is the sensor load resistor.

Full stack sensor

(FSS)

® H, Document tray full not detected ® L

Full stack sensor input circuit

[e] Tray limit sensor (TLS)

TLS is the sensor same as the transport entry port sensor (PIS).

The tray bottom (limit) is detected by the douser liked with the tray movement. The light path is interrupted when "Limit." The signal is passed to the

G/A (IC5-41 pin) through the noise filter of R4 and C6.

Logic of the signal inputted to the G/A: Limit detected

R40 is the current limiting resistor of LED. R53 is the sensor load resistor.

® H, Limit not detected ® L

Tray Limit sensor

(TLS)

Limit sensor input circuit

[f] Paper level sensor (PLS)

PLS is the sensor same as the transport entry port sensor (PIS).

The paper level on the tray is detected by the lever-system actuator. The light path is interrupted when "Paper level detected." The signal is passed

to the CPU (IC9-75 pin) through the noise filter of R10 and C15.

Logic of the signal inputted to the CPU: Paper level detected

R44 is the current limiting resistor of LED. R66 is the sensor load resistor.

Paper surface sensor

(PLS)

® H, Paper level not detected ® L

paper surface sensor input circuit

11 – 3

Page 31

[g] Accumulation tray sensor (AS)

AS is the sensor same as the transport entry port sensor (PIS).

The document presence on the tray is detected by the lever-system actuator. The light path is interrupted when paper presence.

The signal is passed to the CPU (IC9-18 pin) through the noise filter of R5 and C7.

Logic of the signal inputted to the CPU: Paper presence

R38 is the current limiting resistor of LED. R49 is the sensor load resistor.

Accumulation tray

sensor

(AS)

® H, Paper empty ® L

Accumulation tray sensor input circuit

[h] Boomerang rotation sensor (BRS)

BRS is the sensor same as the transport entry port sensor (PIS).

The boomerang rotation and home position are detected by the slit plate. The light path is interrupted when in the home position.

The signal is passed to the CPU (IC9-60 pin) through the noise filter of R16 and C19.

Logic of the signal inputted to the CPU: Home position

R48 is the current limiting resistor of LED. R70 is the sensor load resistor.

® H, Rotating ® L

Boomerang rotation

sensor

(BRS)

Boomerang rotation sensor input circuit

[i] Tray rotation sensor (TMMRS)

TMMRS is the sensor same as the transport entry port sensor (PIS).

The rotation of the motor which lifts up and down the tray is detected. Since the encoder is used as the slit plate, pulses are detected during

rotation.

The signal is passed to the G/A (IC5-40 pin) through the noise filter of R2 and C4.

Logic of the signal inputted to the G/A: Light path interrupted

R37 is the current limiting resistor of LED. R50 is the sensor load resistor.

Tray rotation sensor

(TMMRS)

® H, Light path not interrupted ® L

Tray rotation sensor input circuit

11 – 4

Page 32

[j] Unit lock sensor 1 (ULS1)

ULS1 is the sensor same as the transport entry port sensor (PIS).

The rear side connection with the copier is detected.

The light path is interrupted when connected.

The signal is passed to the CPU (IC9-58 pin) through the noise filter of R6 and C8.

Logic of the signal inputted to the CPU: Not connected

R41 is the current limiting resistor of LED. R51 is the sensor load resistor.

® H, Connected ® L

Unit lock sensor 1

(ULS1)

Unit lock sensor 1 input circuit

[k] Unit lock sensor 2 (ULS2)

ULS2 is the sensor same as the transport entry port sensor (PIS).

The front side connection with the copier is detected.

The light path is interrupted when connected.

The signal is passed to the CPU (IC9-73 pin) through the noise filter of R30 and C29.

Logic of the signal inputted to the CPU: Not connected

R106 is the current limiting resistor of LED. R29 is the sensor load resistor.

® H, Connected ® L

Unit lock sensor 2

(ULS2)

Unit lock sensor 2 input circuit

[l] Upper cover sensor (UCS)

UCS is the sensor same as the transport entry port sensor (PIS).

The open/close of the upper cover of the transport path is detected.

The light path is interrupted when cover closed.

The signal is passed to the CPU (IC9-57 pin) through the noise filter of R3 and C5.

Logic of the signal inputted to the CPU: Cover open

R42 is the current limiting resistor of LED. R54 is the sensor load resistor.

Upper cover sensor

(UCS)

® H, Cover closed ® L

Upper cover sensor input circuit

11 – 5

Page 33

[m] Paper alignment plate home position sensor (SBHPS)

SBHPS is the sensor same as the transport entry port sensor (PIS).

The alignment plate home position is detected.

The light path is interrupted when in the home position.

The signal is passed to the CPU (IC9-72 pin) through the noise filter of R9 and C13.

Logic of the signal inputted to the CPU: Home position not detected

R43 is the current limiting resistor of LED. R61 is the sensor load resistor.

® H, Home position detected ® L

Paper alignment plate

home position

sensor

(SBHPS)

Paper alignment plate home position sensor input circuit

SB

[n] Paper reverse sensor (PRS)

PRS is the transmission type sensor where the LED and the photo transistor are separated.

The document presence in the reverse section is detected.

The light path is interrupted when document detected.

The light emitting side is illuminated by the output of the CPU (IC 9-50 pin) through Q9.

IC 9-50 pin logic: Light emitting

R91 is the current limiting resistor of the light emitted diode.

On the other hand, the signal is inputted to the CPU (IC-9-74 pin) through the noise filter of R8 and C12 and the comparator (IC 4-1).

The reference voltage of the comparator is determined by division of the power voltage (+5V) with R85 and R86.

R88 is used to provide hysteresis to the reference voltage.

R60 is the pull-up resistor of the comparator output.

C11 in the signal line is used to absorb noises. R90 is the load resistor of the photo transistor.

Logic of signal inputted to the CPU: Document presence

® H, Not emitting ® L

® H, DOcument empty ® L

PRL

Paper reverse sensor

(PRS)

Paper reverse sensor input circuit

11 – 6

Page 34

[o] Set switch (SSW)

SSW is the micro switch for release a paper jam in the paper transport path.

This switch is connected with +24V. By opening the open/close section, the contact is opened and this switch actuates as a safety switch. It is

connected in series to CSW.

When the switch is ON, +24V is applied to the cathode of ZD1 and the base current is supplied to Q5 to turn on Q5, inputting the open/close signal

to the CPU (IC 9-17 pin).

C2 and C9 are used to absorb noises. R57 is the pull-up resistor. Logic of signals inputted to the CPU: Cover open

® H, Cover close ® L

[p] Cover switch (CSW)

CSW is the switch of the cover which is opened and closed when replacing staplers.

This switch is connected with –24V. When the open/close section is opened, the contact is opened and this switch actuates as a safety switch. It is

connected in series to SSW.

When the switch is ON, +24V is applied to the cathode of ZD2 and the base current is supplied to Q4 to turn on Q4, inputting the open/close signal

to the CPU (IC 9-16 pin).

C1 is used to absorb noises. R58 is the pull-up resistor.

Logic of signals inputted to the CPU: Cover open

Set switch

(SSW)

® H, Cover close ® L

Set switch input circuit

Cover switch

(CSW)

Cover switch input circuit

11 – 7

Page 35

[q] Stapler home position sensor (SHPS)

SHPS is the micro switch used to detect the staple stand-by position. It is ON when in the home position.

The signal is inputted to the CPU (IC 9-76 pin) through the noise filter of R12 and C16 and the schmidt trigger (IC 1-2).

Logic of signals inputted to the CPU: Home position not detected

Staple home position

sensor

(SHPS)

® H, Home position detected ® L

Staple home position sensor input circuit

[r] Staple near end sensor (NNES)

NNES is the reflection-type sensor which detects staple near end. It integrates the LED and the photo transistor.

No reflection at near end.

The signal is inputted to CPU (IC 9-63 pin) through the noise filter of R18 and C52. DA1 is the protection diode which protects the +5V line voltage

from deflection.

Since this signal is analog, staple empty is detected by the threshold value of 2.75V.

Logic of the signal inputted to the CPU: Staple presence

® 2.75V or less, Staple empty ® 2.75V or above

Staple near end sensor

(NNES)

Stapler near end sensor input circuit

[s] Stapler presence sensor (STP)

STP is used to detect the connection of the stapler unit.

When the connecter is connected, the signal is connected to GND and detected.

The signal is inputted to CPU (IC 9-19 pin) through the noise filter of R7 and C10. R59 is the pull-up resistor.

Stapler presence sensor

(STP)

Stapler presence sensor input circuit

11 – 8

Page 36

B. Solenoid drive circuit

[a] Boomerang solenoid (BS)

BS is the open-frame type solenoid.

By the operation of this solenoid, the large gear is rotated in linkage with the transport motor. In addition, the boomerang in the paper exit section is

rotated in linkage with the large gear. The drive signal from G/A (IC 5-32 pin) is inputted to the gate of FET (Q12).

D1 is used to absorb surging when turning off the solenoid.

R20 is for protection of G/A, and C114 is for absorbing noises. R113 is the pull-down resistor.

Boomerang solenoid

(BS)

Boomerang solenoid input circuit

[b] Reverse solenoid (PRSL)

PRSL is the open-frame type solenoid.

By the operation of this solenoid, the flapper is switched to change the document transport path.

Solenoid ON: Not reversed, Solenoid OFF: reversed

The drive signal from G/A (IC 5-34 pin) is inputted to the gate of FET (Q14).

The drive signal (ON at H) controls PWM, and the ON duty is variable in the range of 0

D3 is for absorbing serge when the solenoid is OFF.

D1 is used to absorb surging when the solenoid is turned off.

R22 is for protection of G/A. C117 is for absorbing noises. R105 is the pull-down resistor.

~ 100% (255 steps).

Reveerse solenoid

(PRSL)

Reverse solenoid drive circuit

[c] Paddle solenoid (PDS)

PDS is the flapper-type solenoid.

By the operation of this solenoid, paddle is rotated in linkage with the transport motor.

The drive signal from G/A (IC 5-33 pin) is inputted to the gate of FET (Q13).

The drive signal (ON at H) controls PWM, and the ON DUTY is variable in the range of 0

D3 is for absorbing serge when the solenoid is OFF.

D2 is used to absorb surging when the solenoid is turned off. R21 is for protection of G/A. C116 is for absorbing noises. R104 is the pull-down

resistor.

~ 100% (255 steps).

Paddle solenoid

(PDS)

Paddle solenoid drive circuit

11 – 9

Page 37

C. Motor drive circuit

[a] Document transport motor (D TM )

This circuit controls rotation, stop, and rotating direction of DTM and the motor current. It is composed of the G/A (IC5), the constant-current

chopper system driver IC (IC11), etc.

The G/A (IC5-78

The PWM signal outputted from the G/A (IC 5-51 pin) is divided and integrated with R89, R15, and C62 to be converted into a constant voltage. The

converted voltage is inputted to IC11-9 pin and 11 pin to set the motor current value. The motor current value is controlled arbitrarily by varying the

ON DUTY of the PWM signal.

C89- 92 and C101 are for absorbing noises. C59 and C62 are for reducing sounds when the motor is held. C50 and C69 are for stabilizing the +5V

power. C66 is for stabilizing the ST +24V power.

~ 81 pin) outputs the stepping motor drive excitement pattern signal to control the motor rotating speed and the rotating direction.

paper transport motor

(DTM)

Paper transport motor drive circuit

[b] Document alignment m oto r (DSM )

This circuit controls rotation, stop, and rotating direction of DSM and the motor current. It is composed of the G/A (IC5), the constant-current

chopper system driver IC (IC7), etc.

The G/A (IC5-25

The PWM signal outputted from the G/A (IC 5-35 pin) is divided and integrated with R93, R94 and C64 to be converted into a constant voltage. The

converted voltage is inputted to IC7-9 pin and 11 pin to set the motor current value. The motor current value is controlled arbitrarily by varying the

ON DUTY of the PWM signal.

C93- 96 and C103 are for absorbing noises. C61 and C64 are for reducing sounds when the motor is held. C47 and C68 are for stabilizing the +5V

power. C65 is for stabilizing the ST +24V power.

~ 28 pin) outputs the stepping motor drive excitement pattern signal to control the motor rotating speed and the rotating direction.

Document alignment

motor (DSM)

Document alignment motor

11 – 10

Page 38

[c] Document reverse motor (DRM)

This circuit controls rotation, stop, and rotating direction of DRM and the motor current. It is composed of the G/A (IC5), the constant-current

chopper system driver IC (IC6), etc.

The G/A (IC5-57

The PWM signal outputted from the G/A (IC 5-50 pin) is divided and integrated with R92, R87, and C63 to be converted into a constant voltage. The

converted voltage is inputted to IC6-9 pin and 11 pin to set the motor current value. The motor current value is controlled arbitrarily by varying the

ON DUTY of the PWM signal.

C97-100 and C102 are for absorbing noises. C60 and C63 are for reducing sounds when the motor is held. C45 and C67 are for stabilizing the +5V

power. C65 of DSM is commonly used for stabilizing the ST +24V power.

~ 60 pin) outputs the stepping motor drive excitement pattern signal to control the motor rotating speed and the rotating direction.

Paper reverse motor

(DRM)

Paper reverse motor drive circuit

[d] Bin shift motor (TM M )

This circuit controls rotation, stop, and rotating direction of DTM and the motor current. It is composed of the G/A (IC5), the bridge circuit composed

of the FET (Q15

The motor rotation, stop, and rotating direction are controlled by the combinations of binary logic inputted from the CPU (IC9) to the G/A (IC5)

through the data bus. By this control, the control signal is outputted to the G/A (IC5-74

These signals are inputted to the bridge circuit.

C25, C26, and C104

Q7 and Q8 are used to turn on Q17 and Q18 respectively.

R75, R76, R81, and R82 are the dividing resistances used to obtain VGS of the FET.

In addition, the following hard limit is provided for the rotating direction of TMM.

CW direction (Bin UP): Document level sensor (PLS)

CCW direction (Bin DOWN): Tray limit sensor (TLS)

~ 18), etc.

~ 77 pin).

~ C107 are for absorbing noises.

Bin shift motor

(TMM)

Bin shift motor drive circuit

11 – 11

Page 39

[e] Stapler (SU)

The stapler unit includes the staple motor (STPM), the stapler home position sensor (SHPS), and the staple near end sensor (NNSE).

For SHPS and NNES, refer to A-[q] and [r].

STPM controls the rotation, stop and rotating direction. It is composed of the G/A (IC5) and the bridge circuit composed of the FET (Q2, Q3, Q19,

and Q20).

The motor rotation, stop, and rotating direction are controlled by the combinations of binary logic inputted from the CPU (IC9) to the G/A (IC5)

through the data bus. By this control, the control signal is outputted to the G/A (IC5-20

These signals are inputted to the bridge circuit.

C27, C28, and C108

Q10 and Q11 are used to turn on Q2 and Q3 respectively.

R78, R79, R81, R83, R84 are the dividing resistances used to obtain VGS of the FET.

~ C111 are for absorbing noises.

~ 23 pin).

Staple motor

(STPM)

Staple motor drive circuit

D. Other circuits

[a] Reset circuit

This circuit generates the rest signal of the CPU and the G/A. It is composed of IC8 and its peripheral circuits.

IC8 is provided with the power on reset function when supplying the power and the reset function in case of abnormal decrease of +5V. The reset

state is held until a certain time passes from the time when the power line reached about 4.3V after supplying the power. The reset holding time is

set with the capacity of C82.

This circuit is provided also with the watchdog timer function. The watchdog timer is built in the G/A (IC5), and it starts operation when the RESET

pin becomes HIGH. This monitors hung up or other abnormality of the CPU.

The monitoring method is: The initial value (data) is written from the CPU to the G/A. This data is counted down inside the G/A. Normally the data is

rewritten before returning to the initial value. In case of hung up of the CPU, however, the data is not returned to the initial value and the counter

becomes zero.

At that time, the G/A resets the CPU and retries until the CPU gets started again.

C48, C49, and C51 are for absorbing noises.

Reset circuit

11 – 12

Page 40

[b] Rush current limit circuit

This circuit limits a rush current which flows into the current regeneration capacitors (C65, C66) which are provided in the document transport motor

(DTM), document reverse motor (DRM), and the document alignment motor (DSM). It is composed of the posistor (PTH1) for limiting the current

and the FET (Q1) fort flowing the current in the normal state.

During the time from when the set switch (SSW) or the cover switch (CSW) is closed to when the ZD3 cathode voltage reaches 12V, the base

current of Q6 is not supplied and it is kept at OFF. Therefore, Q1 is OFF and a current flows through PTH1.

On the other hand, when the ZD3 cathode voltage exceeds 12V, the base current flows through Q6 to turn it on. Therefore Q1 is turned on and the

current flowing through PTH1 flows through Q1, canceling the current limit operation.

R72 and R108 are the discharge resistances for discharging charges accumulated in C65 and C66 when SSW or CSW is opened.

R73 and C58 form the integration circuit which sets the timing of flowing a current through PTH1 when SSW or CSW is closed. D5 is the shot key

diode which discharges the charges of C58. C24 is for absorbing noises. R74 and R80 are the dividing resistors to obtain VGS used to turn on Q1.

+24V

(Power supplied from the main body)

Rush current limit circuit

[c] Current limit circuit

This circuit is used to limit the starting current of the staple motor at a certain level. It is composed of the resistor for detection of the current value

and the voltage comparator.

The negative voltage side of the motor is connected with the pickup resistance of R99 and R100, and the current flowing through the drive circuit is

converted into a voltage value by this pickup resistor.

The converted voltage value is compared with the reference voltage by the comparator (IC3-1).

The reference voltage is obtained by dividing the zenor voltage generated by R77 and ZD4 with R97 and R98.

When the voltage exceeds this reference level, the output pin 1 of IC3-1 becomes LOW, and the voltage is inputted to the G/A 101 pin to stop

supplying the +24V power to the motor.

Therefore, the current value is not increased further.

When the converted voltage value falls below the reference level, the +24V power is supplied again to start conduction of the motor.

Since the operating current level of this circuit is considerably high, it operates only when the motor starts, and does not operates in the normal

state.

R11 and C30 are for absorbing the noises. R71 is the pull-up resistance.

Current limit circuit

11 – 13

Page 41

12345678

D

Bundle exit sensor

Process tray paper

exit sensor

Boomerang rotation

sensor

C

Trasnport entry

port sensor

[12] ELECTRICAL SECTION

1. Circuit diagram

Paper reverse sensor

1/2

D

Bin shift motor

Bin shift motor

Paper transport sensor

C

Paper reverse motor

Paper alignment

home position sensor

Unit lock sensor 2

Paper surface sensor

B

Stapler home position sensor

Stapler presence sensor

Staple near end sensor

Paper alignment motor

B

Staple motor

A

A

12345678

12 – 1 12 – 2

Page 42

12345678

2/2

D

Accumulation tray sensor

Tray rotation sensor

Test connector

Set switch

Cover switch

Boomerang solenoid

Paper alignment solenoid

C

Paddle solenoid

Full stack sensor

tray limit sensor

Reverse solenoid

D

C

B

Unit lick 1 sensor

Upper cover sensor

A

B

A

12345678

12 – 3 12 – 4

Page 43

2. Practical wiring diagram

12345678

Process tray paper exit sensor

D

Boomerang rotation sensor

Transport entry port sensor

Unit lock sensor 2 (Front)

Paper reverse sensor (LED)

Paper reverse sensor

Upper cover sensor

C

Unitb lock sensor 1 (Rear)

Bundle exit sensor

Paper alignment plate

home position sensor

Boomerang solenoid

Paddle solenoid

KH56LM2B006

Paper transport motor

TKP54FP8-719

Paper alignment motor

TKP54FP8-718

Paper reverse

D

C

B

A

Full stack sensor

Tray rotation sensor

Tray limit sensor

Paper surface sensor

Accumulation tray sensor

(Accumulation tray paper

presence)

Power interface

Socket Contact

Bin shift motor

B73600-0301

Reverse solenoid

Set switch (Transport path switch)

Cover switch

(Stapler front cover switch)

NU2016

Stapler

B

A

12 – 5 12 – 6

12345678

Page 44

CONTROL PWB SIGNAL ARRANFGEMENT (PARTS SURFACE)

+24V

SBHPS

SGND

+5V

BES

+24V

PDS

DTM_B

DTM_*A

+24V

DTM_*B

+24V

PASOL

BS

+24V

CN5-1 +5V

CN5-2

SGND

UCS

CN5-3

CN5-4

+5V

SGND

CN5-5

CN5-6

ULS1

CN5-7

SGND

CN4-4

PRS

CN4-3

+5V

PRL

CN4-2

+5V

CN4-1

CN3-1 +5V

CN3-2

SGND

JTES

CN3-3

CN3-4

+5V

SGND

CN3-5

CN3-6

BRS

CN3-7

+5V

SGND

CN3-8

CN3-9

PIS

+5V

CN3-10

CN3-11

SGND

CN3-12

ULS2

CN17-1

PSW2

CN17-2

SGND

+5V

CN17-3

BUZER

CN17-4

CN17-5

SGND

CN2-5

DSR

CN2-4

DTR

TXD

CN2-3

RES

CN2-2

CN2-1 RXD

CN6-6

CN6-4

CN6-5

CN6-3

CN6-2 SGND

CN6-1 +5V

CN7-2

CN7-1

CN8-5

CN8-6 DTM_A

CN8-4

CN8-2

CN8-3

CN8-1

CN9-4

CN9-3

CN9-1

CN9-2

CN10-13

CN10-12

CN10-11

CN10-10

CN10-9

CN10-8

CN10-7

CN10-6

CN10-5

CN10-4

CN10-3

CN10-2

CN10-1

CN11-9 TLS

CN11-8

CN11-7

CN11-6

CN11-5

CN11-4

CN11-3

CN11-2

CN11-1

PGND

DRM_*B

DRM_B

DRM_*A

DRM_A

+24V

+24V

DSM_*B

DSM_B

DSM_*A

DSM_A

+24V

+24V

SGND

+5V

TMMRS

SGND

+5V

FSS

SGND

+5V

CN1-4

CN1-3

CN1-2

CN1-1

SGND

+5V

PGND

+24V

SSW

DC+24V

CN15-1

CN15-2

SSW

+24V

CN15-4

CN15-3

+5V

SGND

CN14-1

CN14-2

PLS

+5V

CN14-3

CN14-4

SGND

AS

CN14-6

CN14-5

12 – 7

STP

+5V

CN13-1

CN13-2

SHPS

SGND

CN13-3

CN13-4

STPM0

STPM1

CN13-5

CN13-6

NHES

CN13-7

SGND

OTH

CN16-1

CN16-2

+5V

CN16-3

TMM0

TMM1

CN12-1

CN12-2

+24V

PRSL

CN12-4

CN12-3

Page 45

CONTROL PWB SIGNAL ARRANFGEMENT (SOLDER SURFACE)

12 – 8

Page 46

q

COPYRIGHT C 1998 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Printing & Reprographic Systems

Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1998 July Printed in Japan S

Loading...

Loading...