Page 1

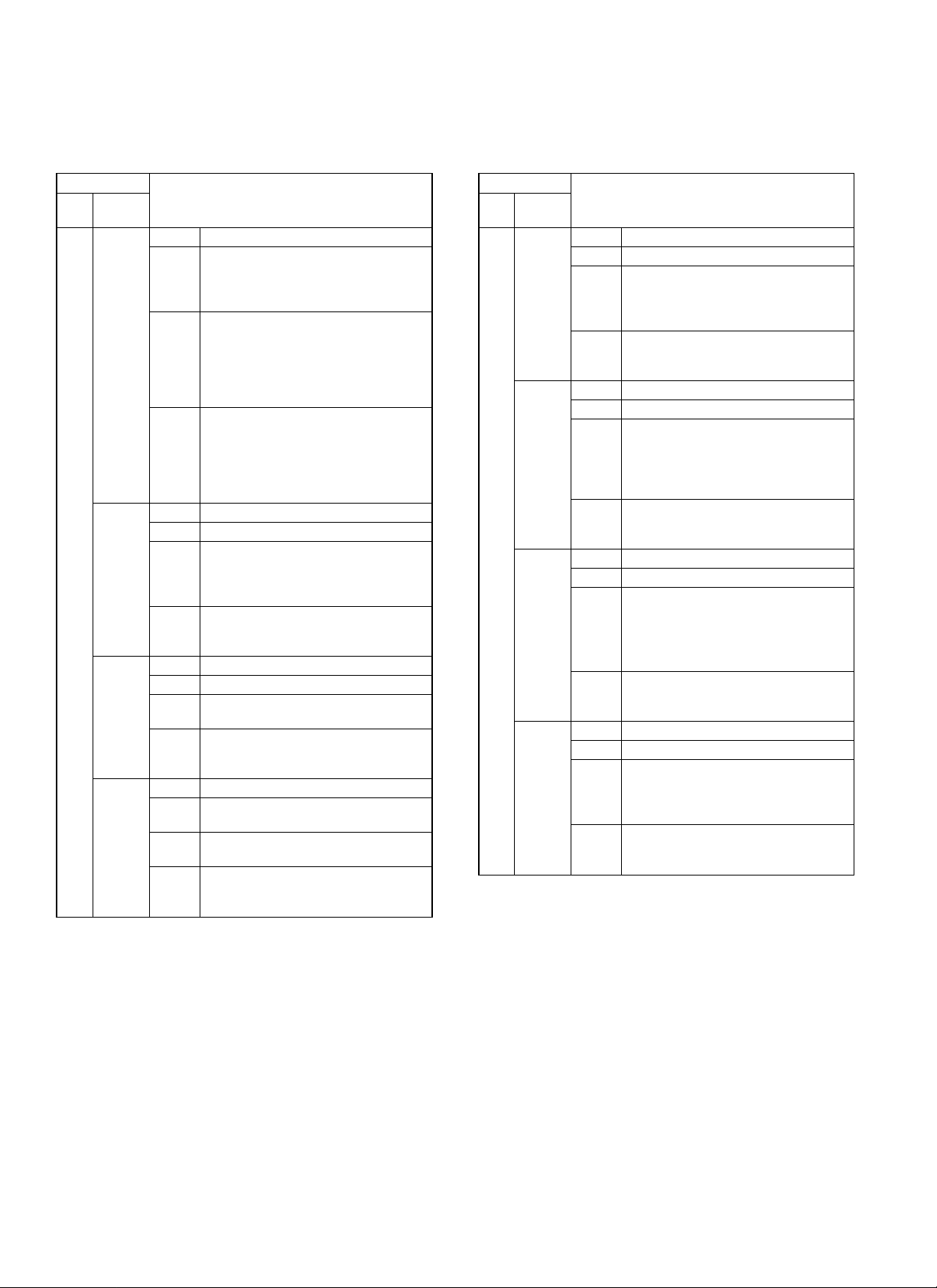

[10] TROUBLESHOOTING

1. T rouble code

Trouble code

Main

code

Sub

code

F1 00 Content Finisher communication trouble

Detail Communication line test error occurs

when power is turned on or after the exit

of a simulation mode.

Improper communication with sorter

Cause Improper connection or broken wire of

Check

and

remedy

01 Content Finisher 2 alignment section trouble

Detail Alignment plate shift trouble

Cause Motor lock

Check

and

remedy

04 Content Finisher elevater lower limit detected

Detail Elevater has exceeded lower limit.

Cause Sensor defective

Check

and

remedy

05 Content Stack tray sensor abnormality

Detail Stack tray sensor turns on in abnormal

Cause Sensor defective

Check

and

remedy

connector or harness between copier

and Finisher

Finisher control PWB defective

Control PWB (PCU) defective

Malfunction due to noise

Clear by turning the power supply

OFF/ON.

Check communication line connector and

harness.

Replace Finisher control PWB or PCU

PWB.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the jogger motor operation with

SIM 3-3.

Finisher control PWB defective

Check sensor with SIM3-2.

combination.

Finisher control PWB defective

Check sensor with SIM3-2.

Description

Trouble code

Main

code

Sub

code

F1 10 Content Staple unit operation trouble

Detail Staple operation trouble

Cause Motor lock

Check

and

remedy

11 Content Boomerang rotation

Detail Boomerang solenoid

Cause Boomerang solenoid operation trouble

Check

and

remedy

14 Content Stack tray abnormality

Detail Stack tray control sensor abnormality

Cause a) The paper level sensor or the full stack

Check

and

remedy

15 Content Stack tray motor lock

Detail Elevator motor trouble

Cause Motor lock

Check

and

remedy

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the staple motor operation with

SIM 3-3.

Boomerang rotation sensor abnormality

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the with SIM 3-2.

b) When the tray is lifted, the stack tray is

Check the sensors with SIM 3-2.

Check the elevator motor operation with

SIM 3-3.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the elevator motor operation with

SIM 3-3.

Description

sensor are not turned on in a certain

time after starting the tray.

locked.

10 – 1

Page 2

2. T roubleshooting

Trouble Cause Troubleshooting and treatment

(1) When the main switch of

the copier is turned on,

it does not work at all.

(2) The transport motor

does not operate.

(3) The reverse motor does

not operate.

(4) The alignment motor

does not operate.

(5) The accumulation tray

motor does not operate.

(6) The boomerang

solenoid does not

operate.

(7) The reverse solenoid

does not operate.

(8) The paddle solenoid

does not operate.

(9) The copier display

shows "Finisher paper

jam."

(10) The copier display

shows "Finisher not

connected."

(11) The copier display

shows Finisher cover

open.

(12) Paper is stopped

during exit operation

1. Contact trouble with the copier Check contact of each connector.

2. Contact trouble of the connector

pin of the connection wire with the

copier

3. Stapler section cover switch, lower

transport path set switch trouble

4. Control PWB trouble If DC24V and DC5V are inputted from the copier and LED on the control

1. Motor connector pin contact trouble

Make a conduction test between connectors and replace, if not

conducting.

Make a conduction test between switches, and replace if necessary.

PWB does not blink and 24V is ont supplied to CN8-1, replace the control

PWB.

· Check contact of the connector, and repair if necessary.

· Make a conduction test of connector pins and replace if not conducting.

2. Motor coil disconnection Make a conduction test between coils and replace the motor if ont

conducting.

3. Control PWB trouble If the motor does not operate in the load operation mode, replace the

control PWB.

1. Solenoid connector pin contact

trouble

2. Solenoid coil disconnection Make a conduction test between coils, and replace the solenoid if not

3. Control PWB trouble If the solenoid does not operate in the load operation mode, replace the

1. Paper jam Visually inspect and remove the jam.

2. Transport entry port sensor trouble Measure the voltage at TP41 on the control PWB. If it is not 0V at sensor

3. Treatment tray exit sensor trouble Measure the voltage at TP56 on the control PWB. If it is not 0V at sensor

4. Bundle exit sensor trouble Measure the voltage at TP58 on the control PWB. If it is not 0V at sensor

5. Paper reverse sensor trouble Measure the voltage at TP22 on the control PWB. If it is not 0V at sensor

6. Sensor connector pin contact

trouble

7. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

1. Finisher not connected Connect the finisher.

2. Unit lock sensor 1 trouble Measure the voltage at TP20 on the control PWB. If it is not 0V at when

3. Unit lock sensor 2 trouble Measure the voltage at TP46 on the control PWB. If it is not 0V when

6. Sensor connector pin contact

trouble

7. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

1. Upper cover open Visually inspect and remove the cover.

2. Upper cover sensor trouble Measure the voltage at TP17 on the control PWB. If it is not 0V at sensor

3. Sensor connector pin contact

trouble

4. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

1. Boomerang rotation sensor trouble Measure the voltage at TP59 on the control PWB. If it is not 0V at sensor

2. Paper alignment home position

sensor trouble

3. Sensor connector pin contact

trouble

4. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

· Check contact of the connector, and repair if necessary.

· Make a conduction test of connector pins, and replace if not

conducting.

conducting.

control PWB.

OFF and 5V at ON, replace the transport path entry port sensor.

OFF and 5V at ON, replace the treatment tray exit sensor.

OFF and 5V at ON, replace the bundle exit sensor.

OFF and 5V at ON, replace the paper reverse sensor.

Make a conduction test of connector pins, and replace the pin if not

conducting.

phenomenon is not changed, replace the control PWB.

coupling and 5V when not coupling, replace the unit lock sensor 1.

coupling and 5V when not coupling, replace the unit lock sensor 2.

Make a conduction test of connector pins, and replace the pin if not

conducting.

phenomenon is not changed, replace the control PWB.

OFF and 5V at ON, replace the transport path entry port sensor.

Make a conduction test of connector pins, and replace pins if not

conducting.

phenomenon is not changed, replace the control PWB.

OFF and 5V at sensor ON, replace the transport path entry port sensor.

Measure the voltage at TP23 on the control PWB. If it is not 0V at sensor

oFF and 5V at ON, replace the transport path entry sensor.

Make a conduction test of connector pins, and replace the pins if not

conducting.

phenomenon is not changed, replace the control PWB.

10 – 2

Page 3

Trouble Cause Troubleshooting and treatment

(13) The accumulation tray

does not stop at the

proper position.

1. Tray rotation sensor trouble Measure the voltage at TP5 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry sensor.

2. Full stack sensor trouble Measure the voltage at TP16 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry port sensor.

3. Tray limit sensor trouble Measure the voltage at Tp18 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry port sensor.

4. Paper surface sensor trouble Measure the voltage at TP47 on the control PWB. If it is not 0V at sensor

OFF and 5V at ON, replace the transport path entry port sensor.

5. Accumulation tray sensor trouble Measure the voltage at TP19 on the control PWB. If it is not 5V at sensor

OFF and 0V at ON, replace the transport path entry port sensor.

6. Sensor connector pin contact

trouble

Make a conduction test of connector pins, and replace pins if not

conducting.

7. Control PWB trouble When each sensor is turned on/off, the sensor level is changed but the

phenomenon is not changed, replace the control PWB.

10 – 3

Loading...

Loading...