Page 1

SERVICE MANUAL

3-TRAY FINISHER

MODEL AR-FN1

CONTENTS

[ 1 ] BASIC SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] UNPACKING AND INSTALLATION. . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] PICTORIAL NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] OUTLINE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] DISASSEMBLY AND REINSTALLATION . . . . . . . . . . . . . . . . . 5-1

[ 6 ] ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] DESCRIPTION OF CIRCUITS. . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] CIRCUT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts marked with "! " is important for maintaining the safety of the set. Be sure to replace these parts with specified ones

for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

le constructeur.

instructions du fabricant.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

Page 3

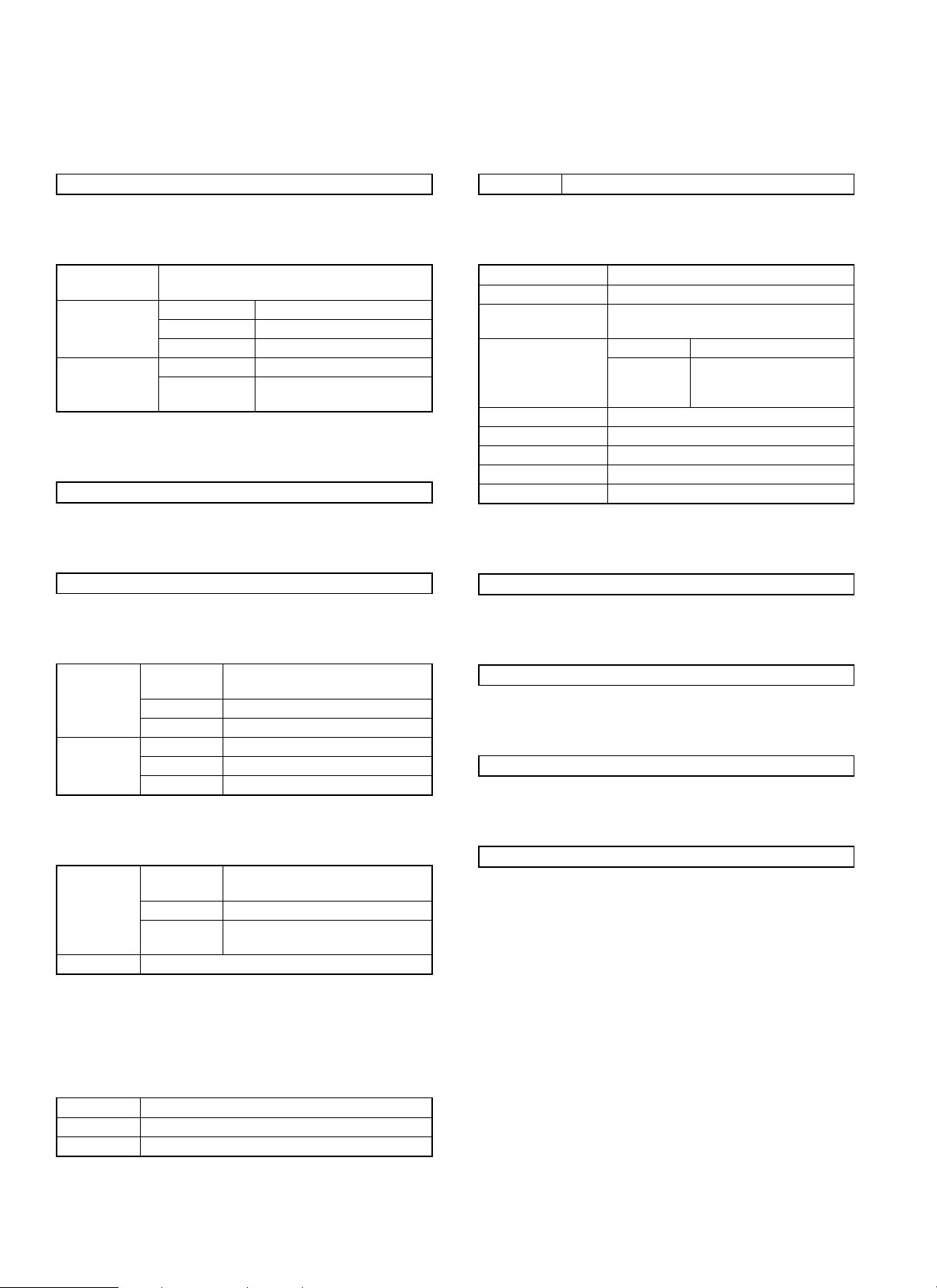

[1] BASIC SPECIFICATIONS

1. Type

Copier-fitted type (detachable)

2. Tray

1 Number of

trays

2 Type Top (tray 1) Normal tray

3 Number of

sheets

loadable

3

Middle (tray 2) Normal tray

Bottom (tray 3) Lift tray

Normal tray 500 (80 g/m

Lift tray 1500 (A4/11"

(A3/11"

3. Paper transfer

Center reference

4. Storage

Face-up/face-down

2

)

´ 8.5") 750

´ 17") (80 g/m

8. Lift tray

Off-set 30 mm

9. Staple unit

Paper discharge tray Lift tray

Storage Face-up

Number of sheets

that can be stapled

Paper size AB series A3, B4, A4, A4R, B5

2

)

Stapling reference 1 point (front)/ 1 point (far end)/ 2 points

Needle feed system Cartridge (5000 needles)

Detection No needle/no cartridge/stapler rotation

Service life more than 100 K

Manual mode None

50 sheets (80 g/m

25 sheets when the size is over A4/LT.

Inch series 11"

2

)

´ 17"/8.5" ´ 14"/

´ 13"/8.5" ´ 11"/

8.5"

8.5"

´ 11"R

10. Power supply

Supplied from copier (DC 24V, DC 5V)

5. Discharge size

Face-up Top A3 ~ A6R/11 ´ 17 ~ 8.5 ´ 5.5,

special paper

Middle A3

Bottom A3

Face-down Top A3

Middle A3

Bottom A3

~ A5/11 ´ 17 ~ 8.5 ´ 5.5

~ B5R/11 ´ 17 ~ 8.5 ´ 11R

~ B5/11 ´ 17 ~ 8.5 ´ 11R

~ B5/11 ´ 17 ~ 8.5 ´ 11R

~ B5R/ 11 ´ 17 ~ 8.5 ´ 11R

6. Paper weight

Face-up Top 52 ~ 128 g/m

Middle 56

Bottom 52 ~ 128 g/m

Face-down 56

* 1: Paper of 200g/m

For paper weight exceeding 105g/m

the paper size of A4/8.5"

~ 105 g/m

2

~ 176m2, can be used.

~ 105 g/m

2

, exceeded.

´ 11" or smaller can be used.

2

2

2

2

in the face up mode, only

7. Paper full detection

11. Power consumption

MAX 60W

12. Dimensions

590 (W) ´ 560 (D) ´ 998 (H)

13. Weight

About 50 kg

*

1

*

1

Top Provided

Middle Provided

Bottom Provided

1 – 1

Page 4

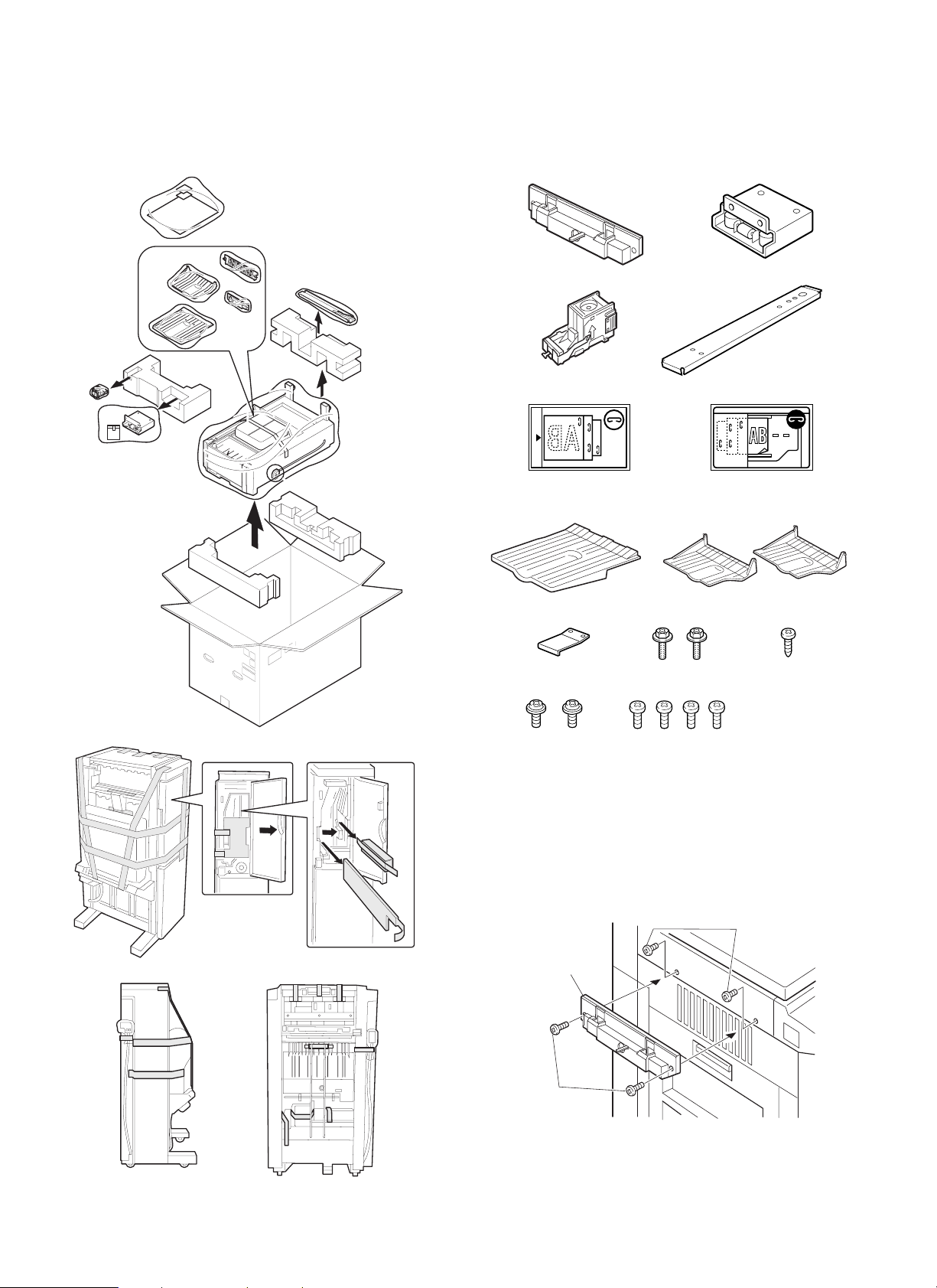

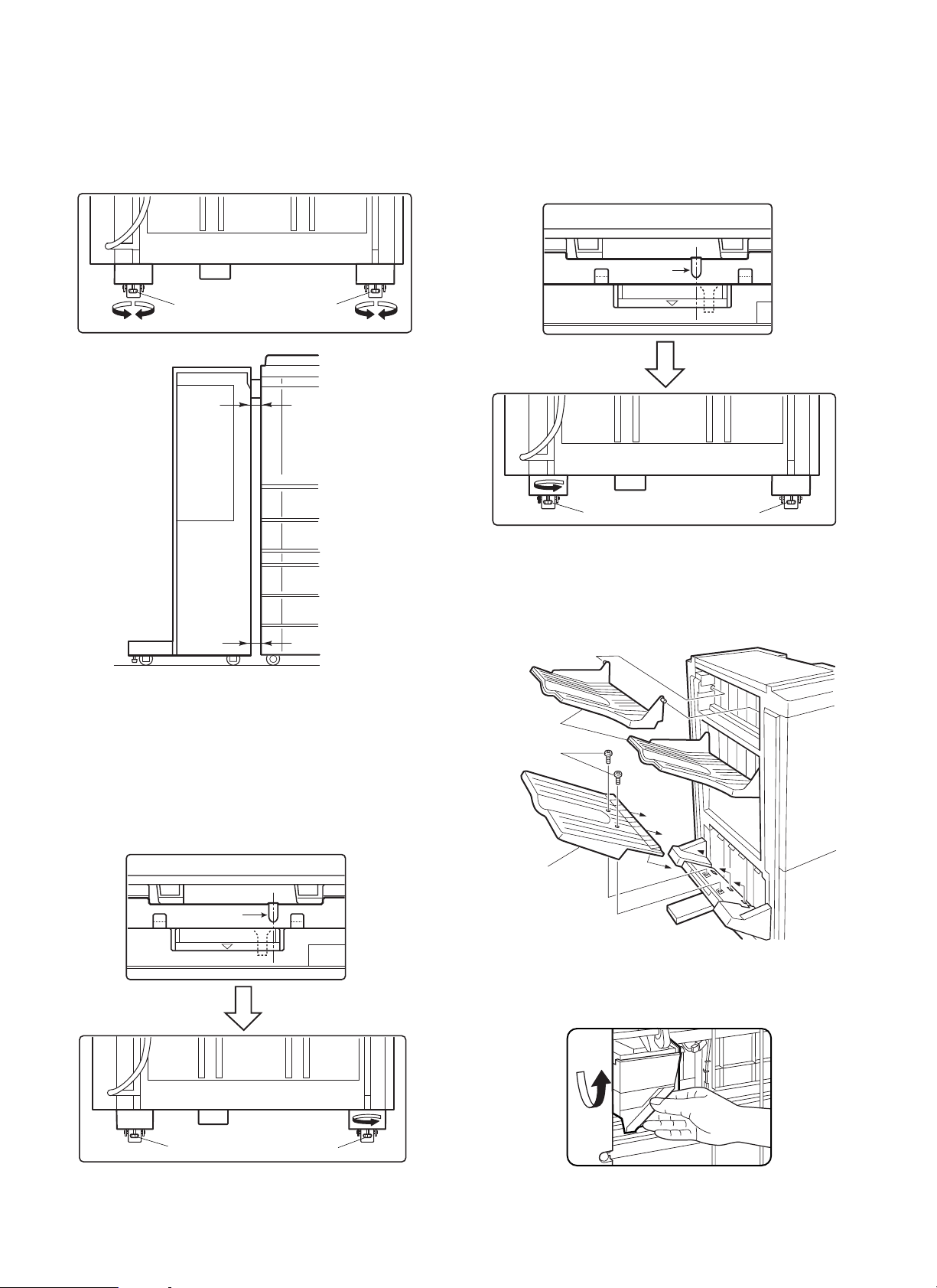

[2] UNPACKING AND INSTALLATION

1. Unpacking

Refer to the sketch below for unpacking.

2. Installation

Lock plate: 1

Staple cartridge: 1

Stapling position

label A: 1

Mounting plate: 1

Connecting plate: 1

Stapling position

label B: 1

Tray 3: 1 Exit trays: 2

Securing plate: 1 Screws A: 2 Screw B: 1

Screws C: 2

Screws D: 4

Unplug the copier’s power cord before carrying out

the following procedure.

1. Attach the lock plate and mounting plate.

Remove the two screws from the upper left cabinet of the copier and

attach the lock plate to the upper left cabinet using two screws D.

Screws for upper

left cabinet

Lock plate

2 – 1

Screws D

Page 5

· If the clearance is narrow at the upper part:

Turn knob A and knob B clockwise so that the clearances at the

upper part and lower part are uniform.

· If the clearance is wide at the upper part:

Turn knob A and knob B counterclockwise so that the clearances

at the upper part and lower part are uniform.

Knob BKnob A

Clearance

· If the connecting hole is displaced toward the front side:

Turn knob A counterclockwise so that the connecting hole matches

the guide pin.

Then, push the finisher into the copier.

If the clearance between the finisher and copier is not proper,

adjust the clearances at the upper part and lower part using procedure <1>.

(Top view)

Guide pin

Clearance

<2> If the guide pi n of the lock plate does not match the con-

necting hole of the finisher:

Turn the knobs at the lower part of the finisher to adjust the height.

· If the connecting hole is displaced toward the rear side:

Turn knob B counterclockwise so that the connecting hole matches

the guide pin.

Then, push the finisher into the copier.

If the clearance between the finisher and copier is not proper,

adjust the clearances at the upper part and lower part using procedure <1>.

(Top view)

Guide pin

Knob A

Knob B

7. Attach the exit tray and tray 3.

Insert the three pawls at the rear side of tray 3 into the holes of the

tray mounting platform and secure the tray using two screws.

Attach the two exit trays to the finisher from the boss at <1>.

2

1

Exit trays

Screws D

Pawl

Pawl

Tray 3

Pawl

Knob A

8. Attach the staple cartridge to the staple unit.

1 Turn the staple unit to face the front.

1

Knob B

2 – 3

Page 6

2 Insert the staple cartridge into the staple unit until it clicks in

place.

2

3 Return the staple unit to face down.

3

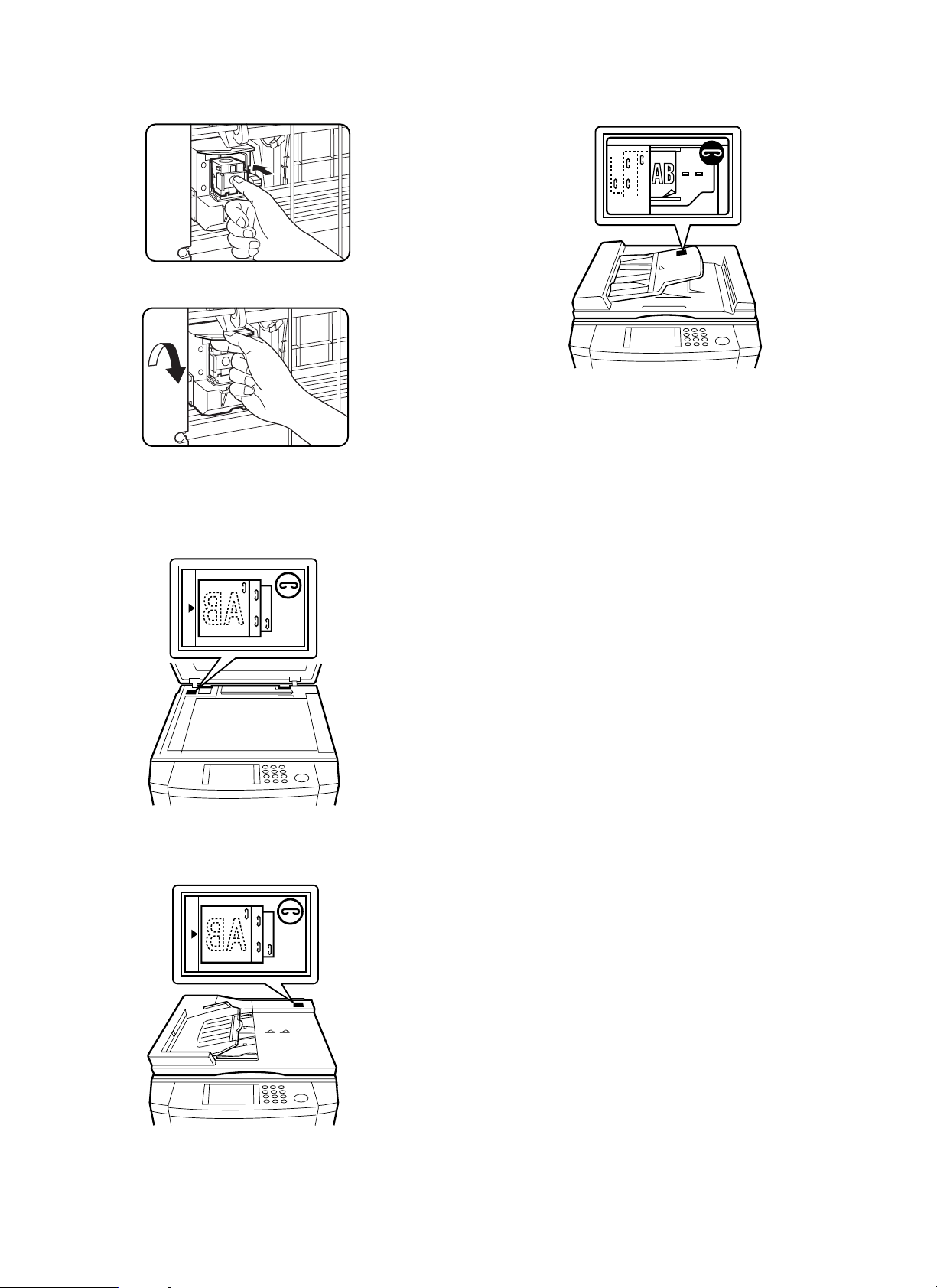

9. Paste the stapling position labels.

For document cover:

Stapling position label A

For ADF/RADF:

Stapling position label B

Connect the power cord, turn the main switch ON,

and perform the following procedure.

10. Check the finisher operation.

· Check the operation in the STAPLE SORT mode.

Make 10 sheets of copies in the STAPLE SORT mode.

Check to see if the copies are stapled properly.

For SPF:

Stapling position label A

11. Remove the tension spring of exit roller.

1) Pull out the exit unit of the copier until it stops.

2) Remove the 2 exit area cover securing screws and remove the

exit area cover.

3) Remove the 2 transport springs which are attached to the exit

area paper guide.

4) Store the 2 removed transport springs by hanging them on the exit

unit front frame (shown in Fig. 1).

5) Attach the exit area cover to its original position and secure it

using the 2 securing screws.

6) Insert the exit unit to the copier.

2 – 4

Page 7

Paper exit unit

Fixing screw

Paper exit cover

3)

2 – 5

Page 8

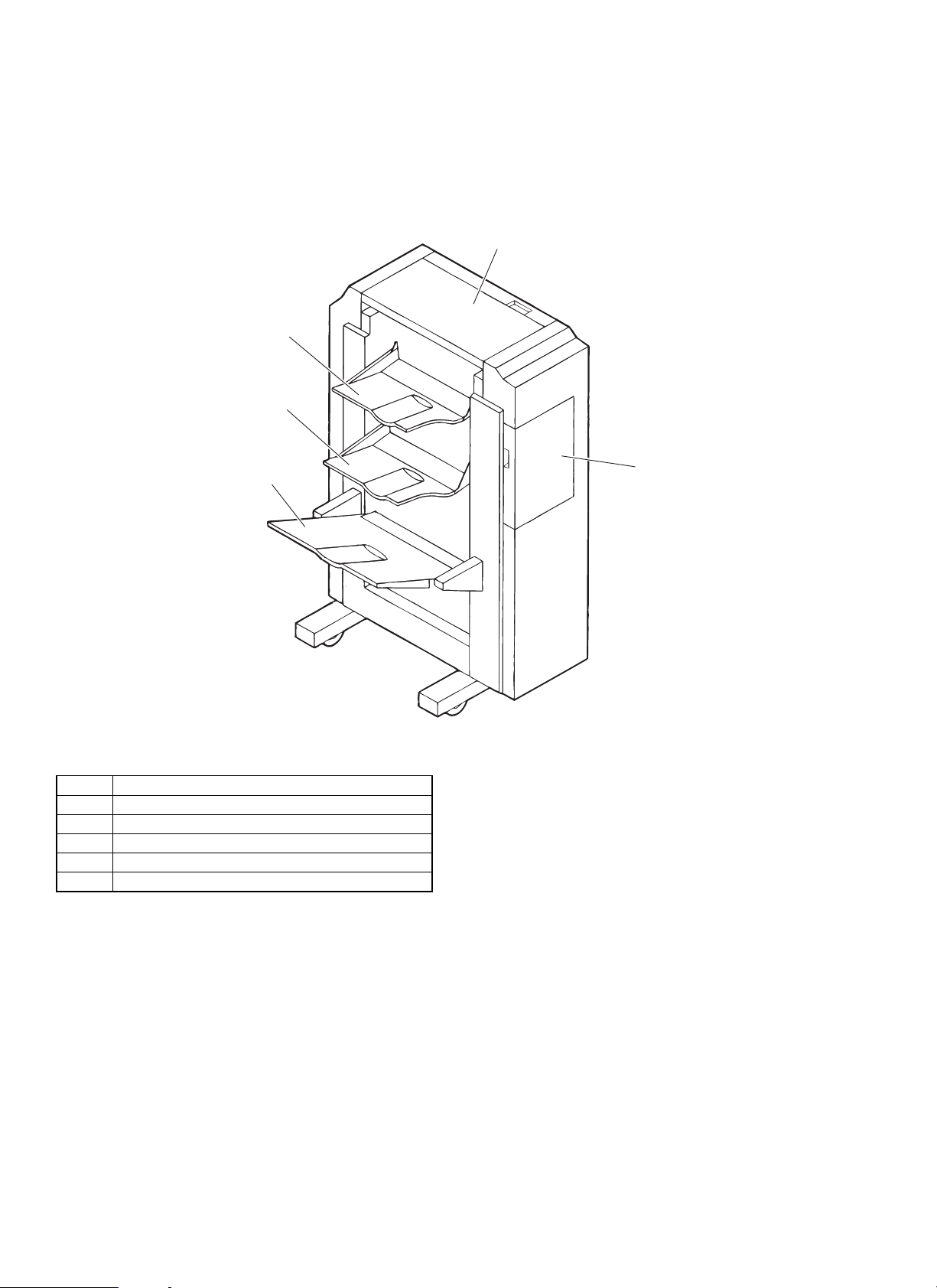

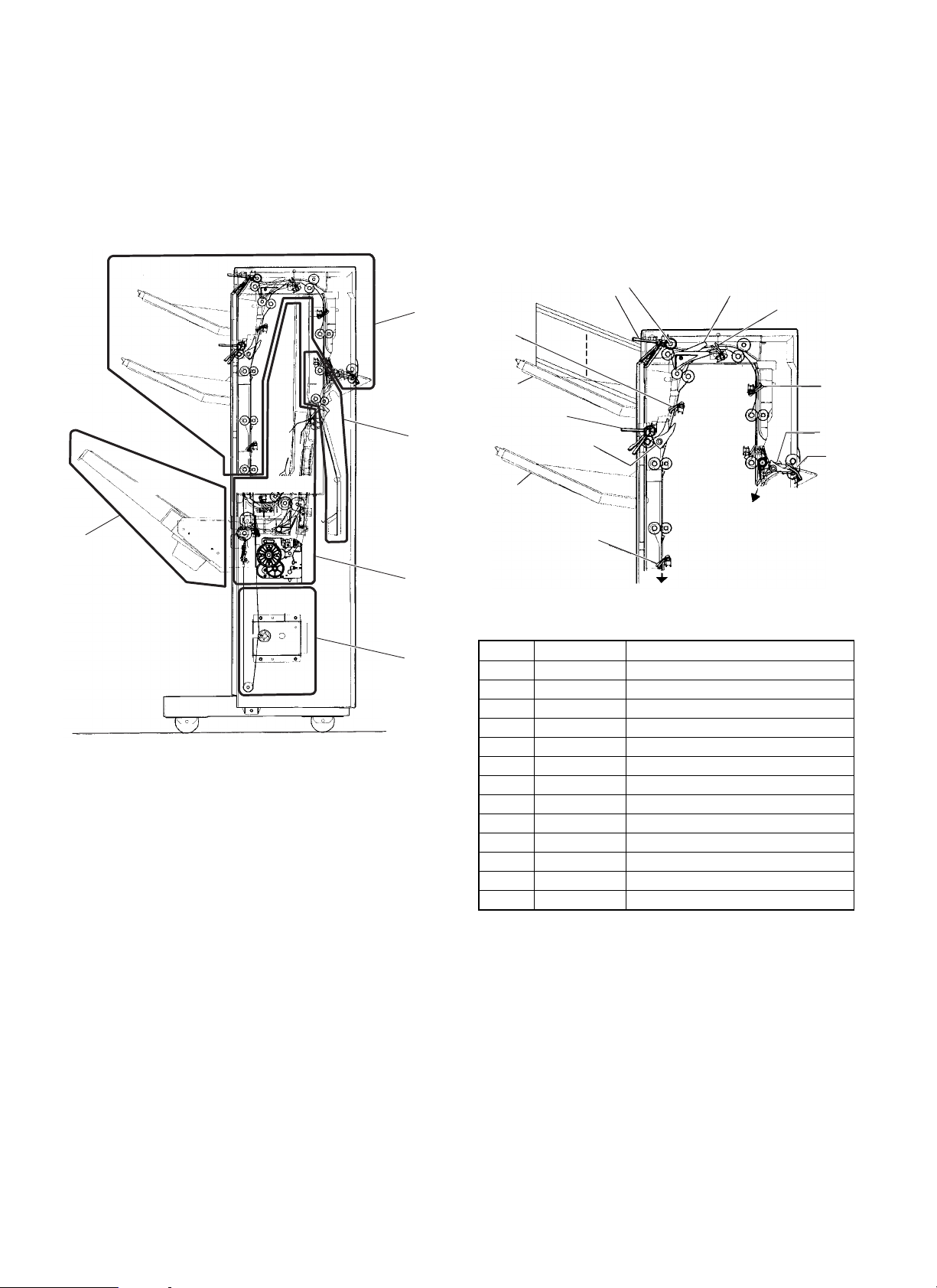

[3] PICTORIAL NOMENCLATURE

1. External view

3

4

1

5

No. Part name

1 Upper door

2 Front door

3 Tray 1

4 Tray 2

5 Tray 3

2

3 – 1

Page 9

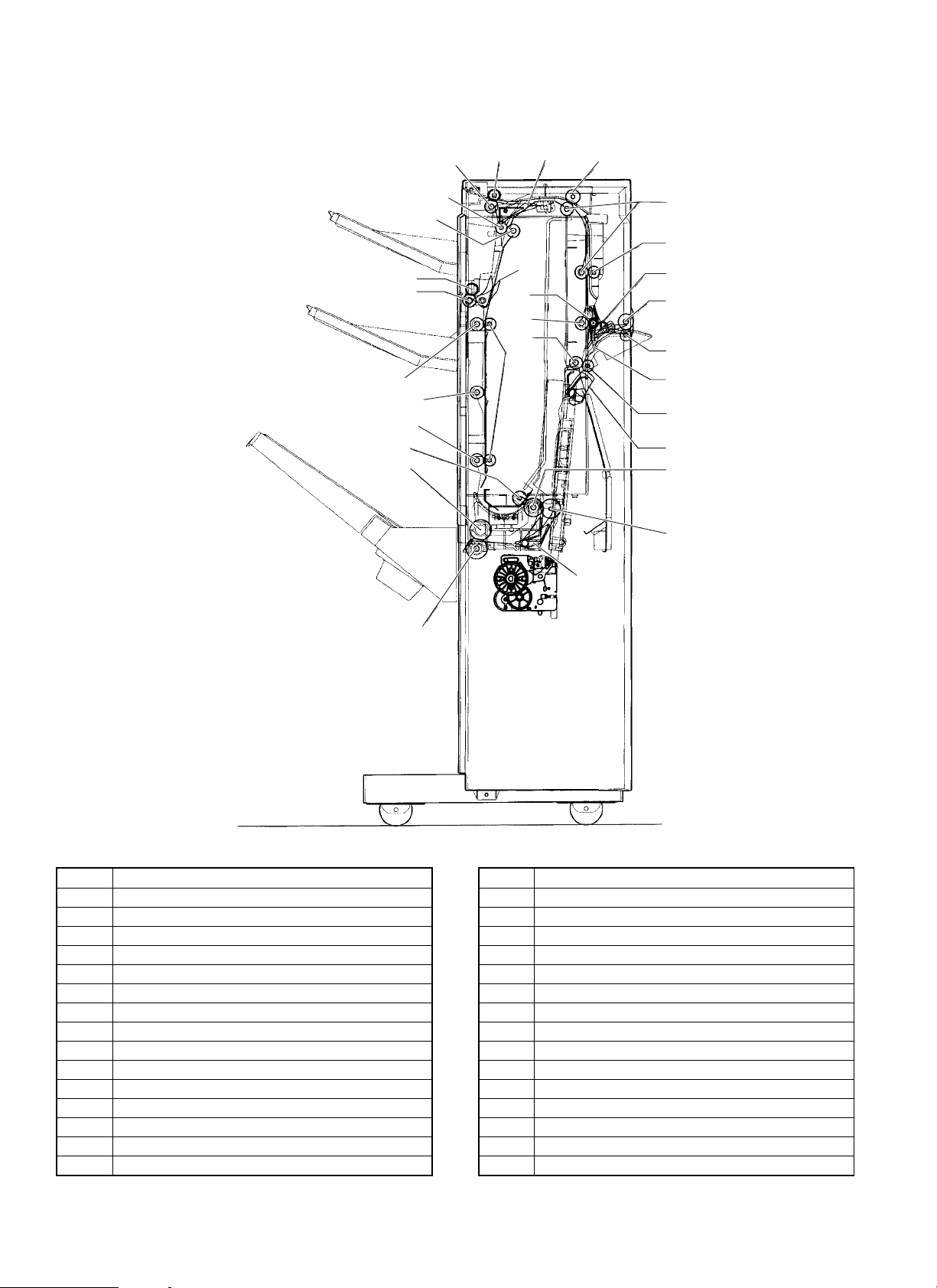

2. Internal view

20

19

18

23

22

30

29

25

26

27

28

21

11

24

6

7

1

2

3

4

5

8

9

10

12

13

14

15

16

No. Part name

1 Paper discharge gate 1

2 Transfer follow-up roller 2

3 Vertical transfer roller 1

4 Transfer follow-up roller 1

5 Paper entry gate

6 Reversion paper discharge follow-up roller

7 Reversion paper discharge roller

8 Paper entry Shaft

9 Paper entry De-curler

10 Reversion gate

11 Reversion roller

12 Reversion pressure release roller

13 Short cut gate

14 S tray paper entry roller

15 Paper delivery pressure release roller

17

No. Part name

16 Paper discharge gate 3

17 Paper discharge roller 4

18 Paper discharge roller 3

19 S tray paper entry follow-up roller

20 Vertical transfer roller 3

21 Transfer follow-up roller 1

22 Paper discharge roller 2

23 Follower roller FIN

24 Paper discharge gate 2

25 Vertical transfer roller 2

26 Transfer follow-up roller 1

27 Paper discharge roller 1

28 Follower roller FIN

29 De-curler roller

30 Vertical transport roller 3 lower

3 – 2

Page 10

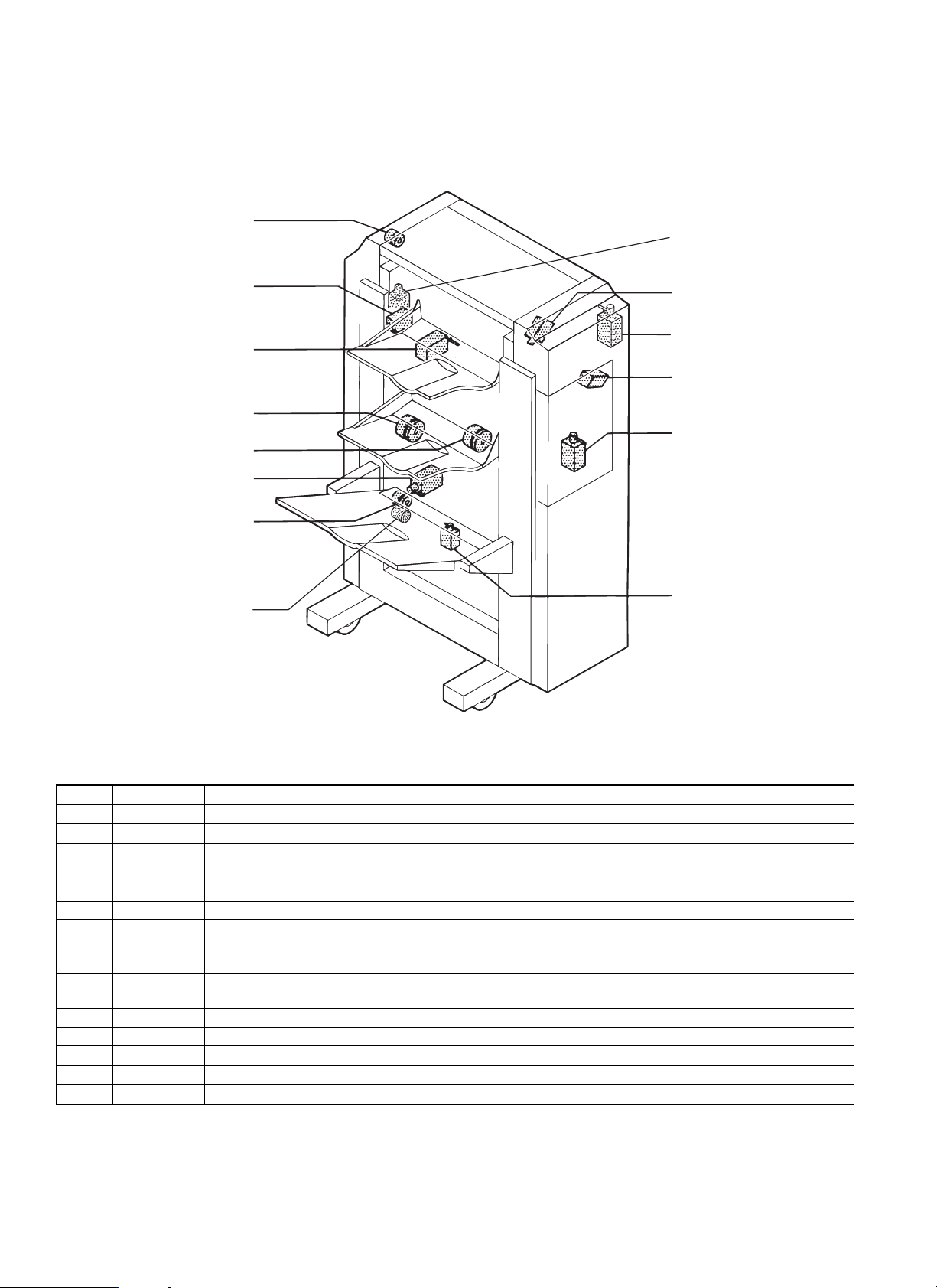

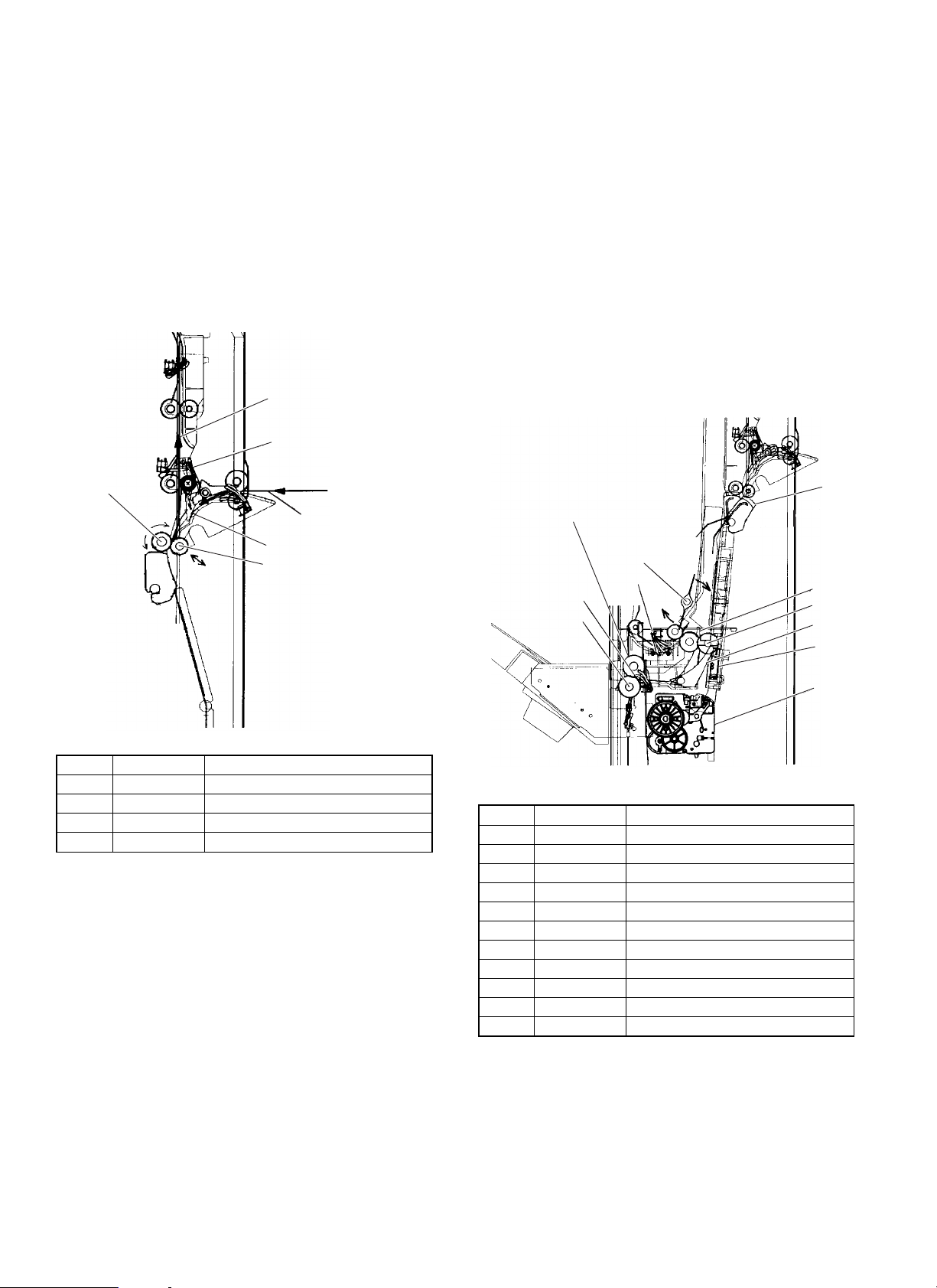

3. Clutch, solenoid

9. T12CL

13. PPSL

4. OG2SL

2. RRSL

10. PDCL

11. STORCL

5. OG3SL

12. T3ORSL

7. T3SLCL

3. OG1SL

14. STSL

1. INGSL

6. SPSL

8. T3UPSL

No. Signal name Name Function and Operation

1 INGSL Paper entry gate solenoid Switching between reversion/short cut path and outside turn path

2 RRSL Reversion roller pressure release solenoid Pressing reverse roller

3 OG1SL Paper discharge gate solenoid 1 Switching tray 1 paper delivery gate

4 OG2SL Paper discharge gate solenoid 2 Switching tray 2 paper delivery gate

5 OG3SL Paper discharge gate solenoid 3 Switching tray 3 paper delivery gate

6 SPSL Short path switching solenoid Switching short path gate

T3SLCL Tray 3 deceleration clutch Changing the speed of tray 3 paper speed change roller (Low

7

8 T3UPSL Tray 3 upper limit solenoid Pulling in tray 3 upper limit detection actuator

9 T12CL Tray 1 and 2 deceleration clutch

10 PDCL Puddler clutch Puddling in staple tray

11 STORCL ST paper delivery roller pressure release clutch Pressing staple paper delivery roller

12 T3ORSL Tray 3 paper exit roller clutch Changing the speed of tray 3 paper discharge roller (Low speed)

13 PPSL Paper holding solenoid Alignment of paper when stapling.

14 STSL Staple tray solenoid Holding the rear edge of paper in the staple tray.

speed)

Changing the speed of tray 1 and 2 paper delivery roller

(Low speed)

3 – 3

Page 11

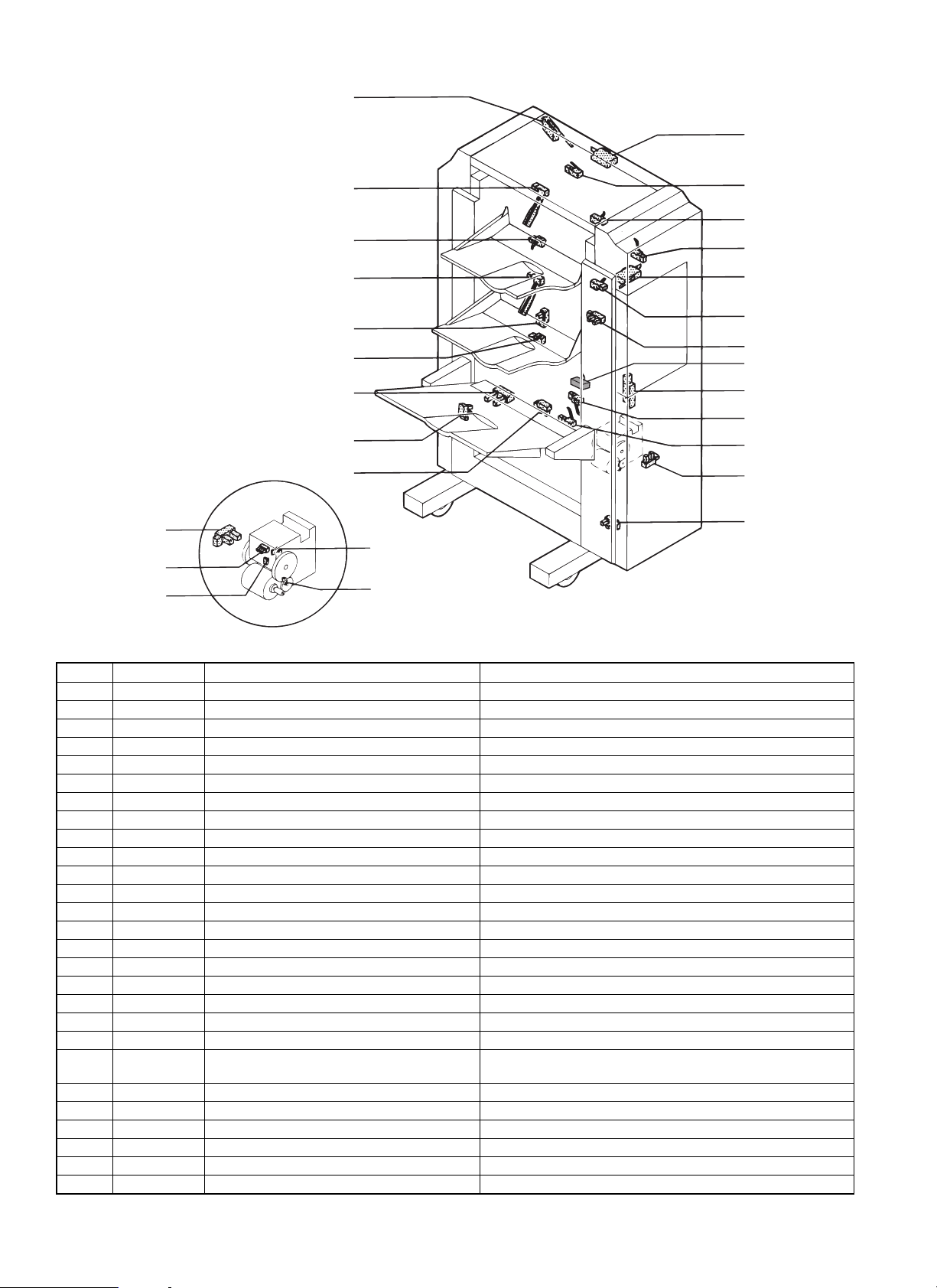

4. Sensor

2. DSW2

1. DSW1

23. STND

27. READY

25. LSTS

13. T1PF

9. PFD3

14. T2PF

20. JGHP

10. PFD4

18. EVRE

19. OFHP

16. T3UP

8. PFD2

7. PFD1

5. INPD

3. DSW3

6. RVPD

21. PSHP

28. STID2

12. STPD

11. STID

15. T3OD

22. STUHP

17. T3DN

24. STHP

26. NCTS

Stapler unit

No. Signal name Name Function and Operation

1 DSW1 Copier connection switch Detecting the finisher attached to the copier

2 DSW2 Top door opening switch Detecting top door opening

3 DSW3 Front door opening switch Detecting front door opening

5 INPD Paper entry sensor Detecting paper entry

6 RVPD Reversion paper discharge sensor Detecting paper discharge

7 PFD1 Transfer detecting sensor 1 Detecting transfer 1

8 PFD2 Transfer detecting sensor 2 Detecting transfer 2

9 PFD3 Transfer detecting sensor 3 Detecting transfer 3

10 PFD4 Transfer detecting sensor 4 Detecting transfer 4

11 STID Staple tray paper entry sensor Detecting staple tray paper entry

12 STPD Staple tray paper sensor Detecting the presence of paper in staple tray

13 T1PF Tray 1 full sensor Detecting tray 1 filled with paper

14 T2PF Tray 2 full sensor Detecting tray 2 filled with paper

15 T3OD Tray 3 paper delivery sensor Detecting tray 3 paper delivery

16 T3UP Tray 3 upper limit sensor Detecting tray 3 upper limit

17 T3DN Tray 3 lower limit sensor Detecting tray 3 lower limit

18 EVRE Elevator motor encoder Elevator motor encoder

19 OFHP Offset motor home position detecting sensor Detecting offset motor home position

20 JGHP Jogger motor home position detecting sensor Detecting jogger motor home position

21 PSHP Pusher motor home position detecting sensor Detecting pusher motor home position

22 STUHP Staple UN movement motor home position

detecting sensor

23 STND Staple needle replacement sensor Detecting stapler rotation for the replacement of needles

24 STHP Stapler home position detecting sensor Detecting stapler home position

25 LSTS Staple detecting sensor Detecting the presence of needles in stapler

26 NCTS Stapler cartridge sensor Detecting the presence of stapler cartridge in stapler

27 READY Stapler self priming sensor Detecting needles in stapling position

28 STID2 Staple tray paper entry sensor 2 Detecting staple tray paper entry 2

Detecting staple UN movement motor home position

3 – 4

Page 12

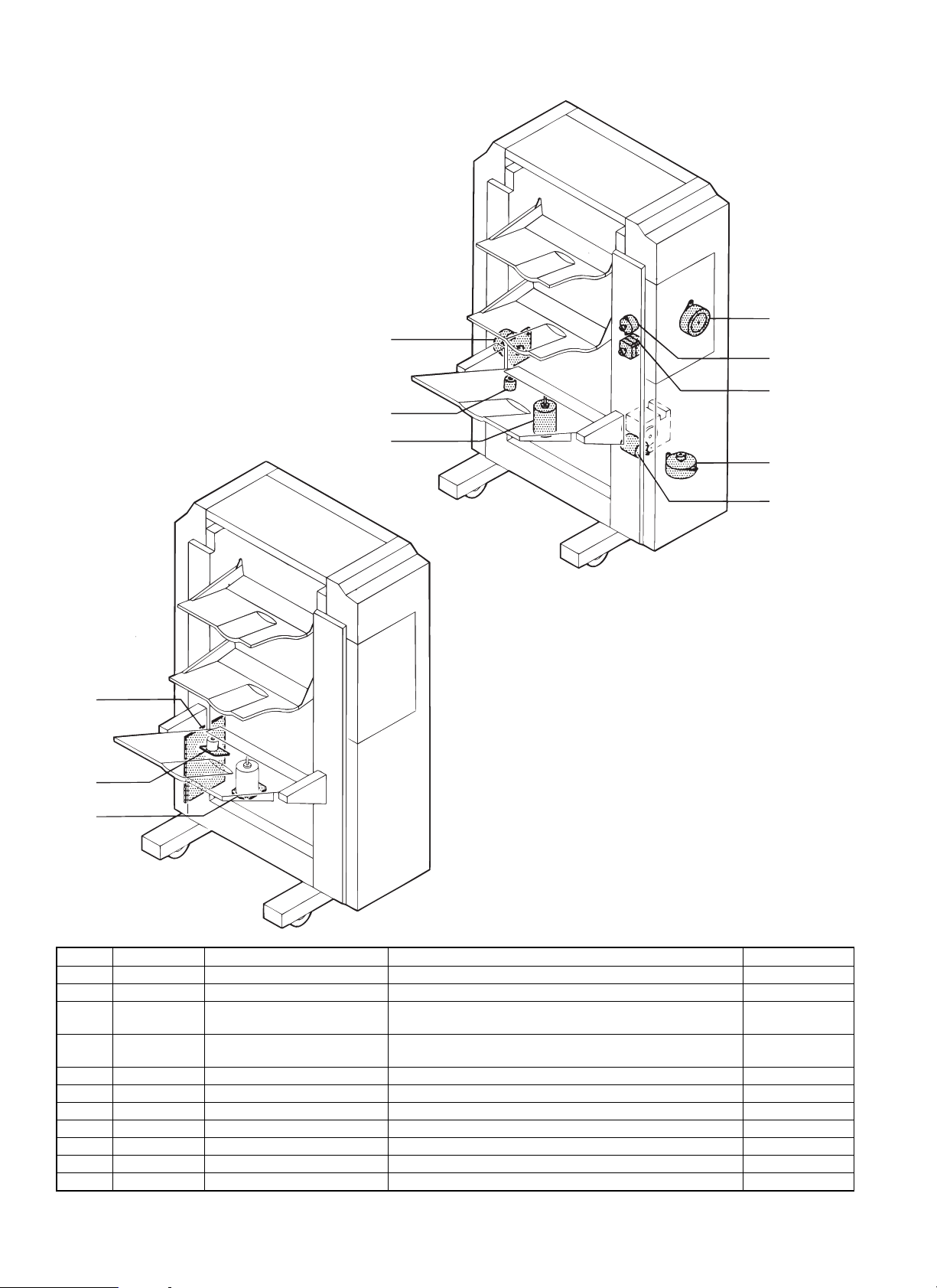

5. Motor and PWB unit

2. RVM

1. FM

3. JGM

4. PSM

7. OFM

6. EVM

5. STUM

8. STM

9

10

11

No. Signal name Name Function and Operation Type

1 FM Main drive motor Transferring paper inside finisher DC brushless

2 RVM Reversion motor Reversing the paper DC stepping

3 JGM Jogger motor Positioning jogger to suit paper size and aligning paper in

staple tray

4 PSM Pusher motor Lowering the paper in staple tray to stapling position and lifting

the paper to delivery position

5 STUM Staple unit movement motor Moving staple unit to stapling position DC stepping

6 EVM Elevator motor Raising and lowing tray 3 DC brush

7 OFM Offset motor Shifting tray 3 back and forth to sort the paper in tray 3 DC brush

8 STM Staple motor Driving staple unit DC brush

9 Finisher main PWB 100/200 100/200V, Finisher control —

10 Filter PWB Common, Eliminating brush motor noise —

11 Filter PWB Common, Eliminating brush motor noise —

DC stepping

DC stepping

3 – 5

Page 13

[4] OUTLINE OF OPERATION

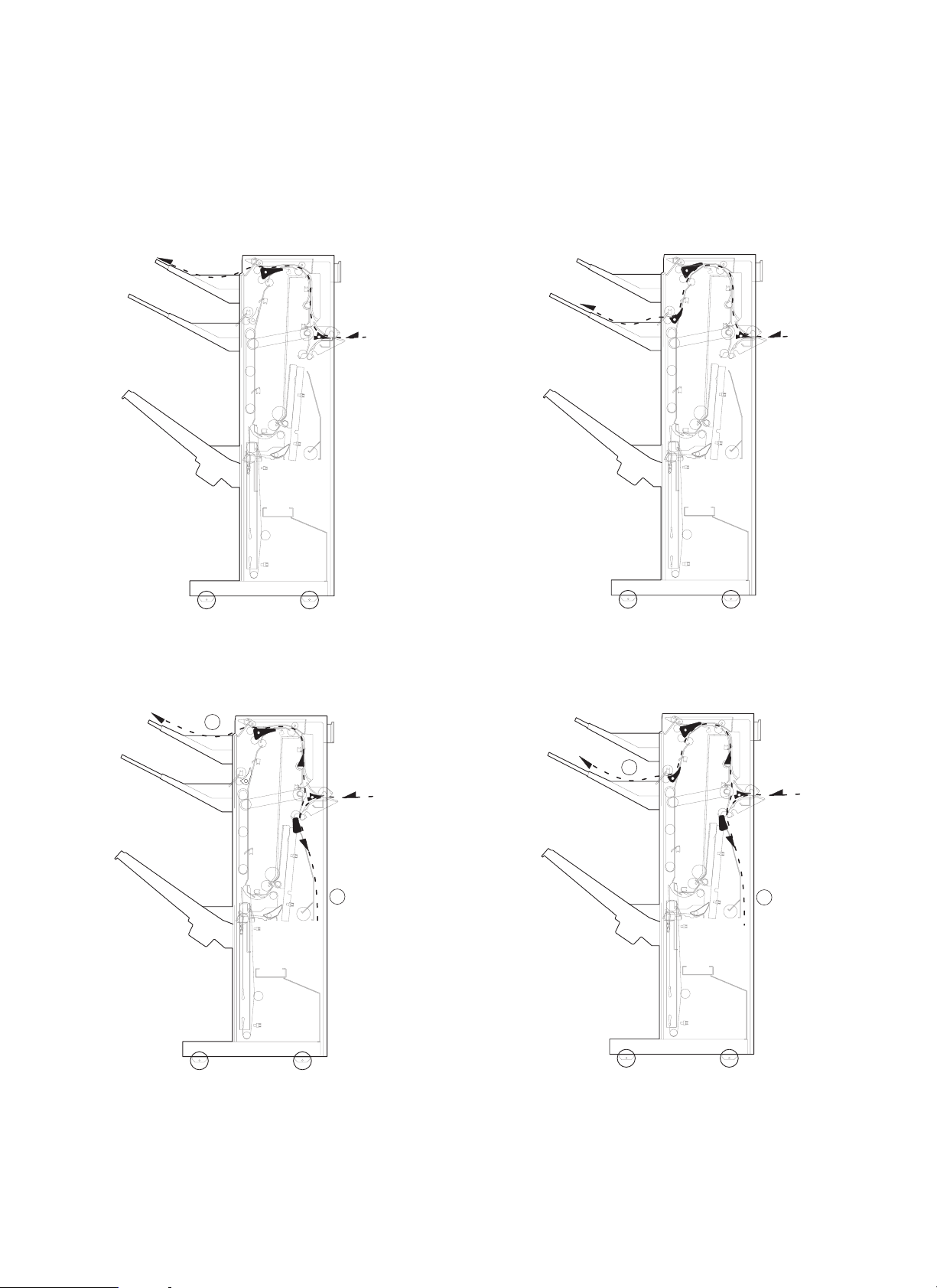

1. Transfer route

The 3-tray finisher’s transfer routes are as follows.

a. Tray 1 face-up paper discharge

c. Tray 2 face-up paper discharge

b. Tray 1 face-down paper discharge

2

d. Tray 2 face-down paper discharge

2

1

1

4 – 1

Page 14

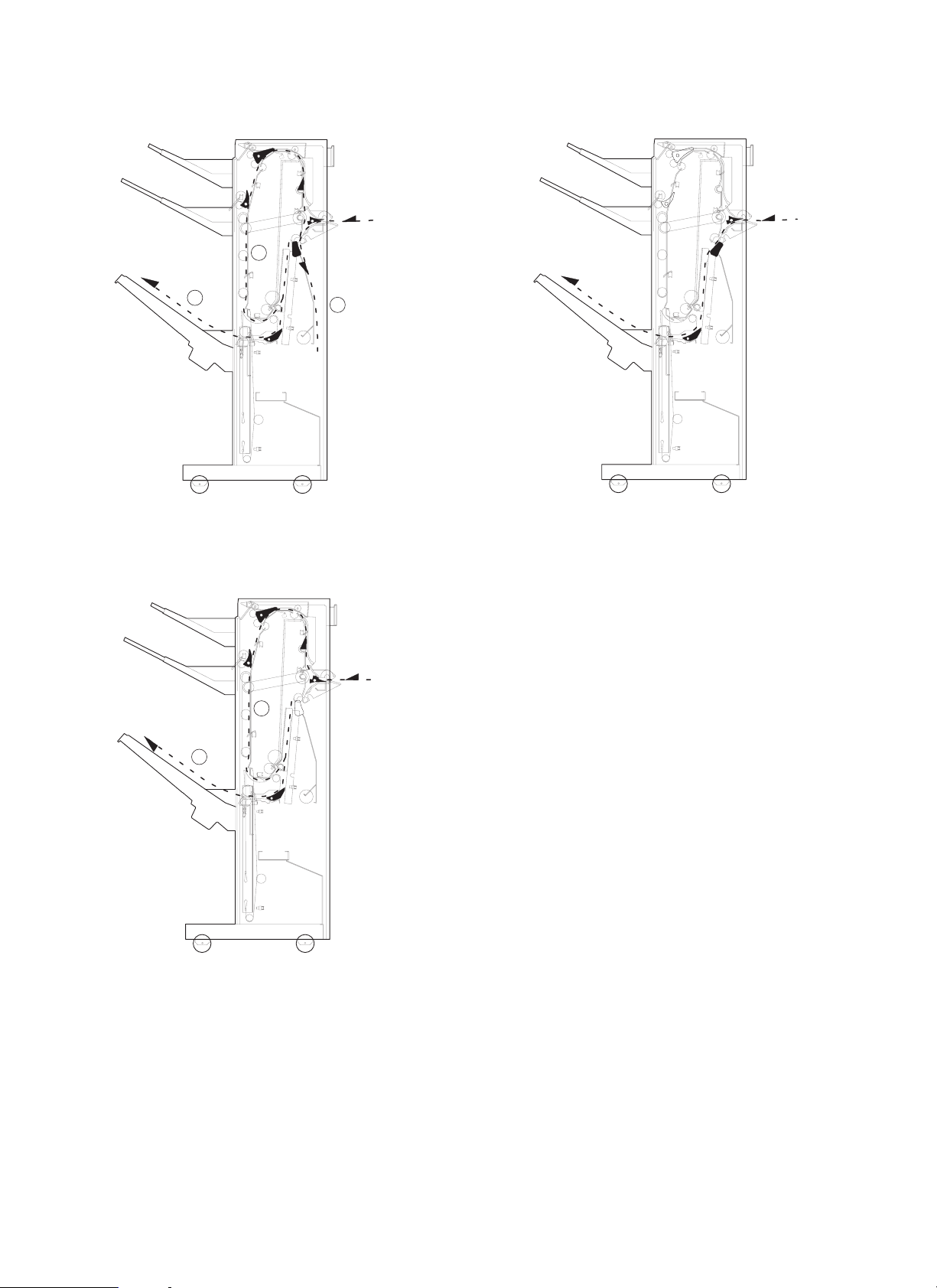

e. Tray 3 outside turn face-up paper discharge

2

g. Tray 3 chart-cut face-up paper discharge

3

f. Tray 3 outside turn face-down paper discharge

1

1

2

4 – 2

Page 15

2. Explanation of each section

The 3-tray finisher consists of (1)an upper paper transfer section, (2)a

reversion section, (3)a staple tray, (4)an offset tray, and (5)an elevator section.

It has the following functions: Paper discharge to a selected tray,

paper reversion, stapling for paper delivered to the offset tray (3

positions), offset, and elevation. Each function is performed according

to the mode instructed by the copier.

5) Trays 1 (10) and 2 (7) paper discharge operation

When paper is delivered to the trays 1 (10) and 2 (7) at a high-speed

in the 3 tray finisher, the trays 1 and 2 deceleration clutch (13) is

operated at paper delivery timing to decelerate the paper discharge

rollers 1 and 2 in order to align the paper to the trays 1 (10) and 2 (7)

with high accuracy.

6) Trays 1 (10) and 2 (7) paper full detection

Whether the trays 1 (10) and 2 (7) are filled with paper is detected by

the tray 1 and 2 paper full sensor.

1)

2)

4)

3)

5)

A. Upper paper transfer section

1) Paper transfer

By rotating the main driving motor (FM), the transfer rollers in the

finisher are driven.

The transfer speed is switched over between the copier speed mode

and the high-speed mode according to the paper discharge mode

and paper size.

2) Paper entry gate (4)

The paper entry gate (4) is operated by the paper entry solenoid(INGSL) to select the upper transfer (outside route) and reversion/short path according to the mode.

3) Paper discharge gate 1 (1)

The paper discharge gate 1 (1) is operated by the paper discharge

gate 1 solenoid (OG1SL), to select between the routes for paper

discharge to the tray 1 (10) and transport to the tray 2 (7)/staple tray.

4) Paper discharge gate 2 (8)

The paper discharge gate 2 (8) is operated by the paper discharge

gate 2 solenoid (OG2SL) to select between the routes for paper

discharge to the tray 2 (7) and transport to the staple tray.

(13)

(12)

(1)

(11)

(10)

(9)

(8)

(7)

Document reversion and

short-cut path

(6)

To stapler tray

No. Signal name Name

(1) — Paper discharge gate

(2) PFD2 Transfer detecting sensor 2

(3) PFD1 Transfer detecting sensor 1

(4) — Paper entry gate

(5) INPD Paper entry sensor

(6) PFD4 Transfer detecting sensor 4

(7) — Tray 2

(8) — Paper discharge gate 2

(9) T2PF Tray 2 paper full detecting sensor

(10) — Tray 1

(11) PFD3 Transfer detecting sensor 3

(12) T1PF Tray paper full sensor

(13) TI2CL Trays 1 and 2 deceleration clutch

(2)

(3)

(4)

(5)

4 – 3

Page 16

B. Reversion unit

1) Reversion motor (RVM)

The reversion motor is connected to the reversion roller (4).

The paper is pulled into the reversion path by the reversion motor

rotating in forward, and fed into the upper transfer route by the motor

rotating in reverse. When the paper is discharged through the shortpath, its transfer is performed by the reversion roller (4) until the

paper enters the staple tray.

2) Reversion pressure release roller

The reversion pressure release roller (3) is pressure released or pressurized through ON/OFF control of the reversion roller pressure release solenoid, to achieve the reversion of the paper at a high speed

without reducing JOB efficiency.

(1st sheet is reversed

and discharged.)

(1)

5) Short path switching gate (1)

The short path switching gate (1) is operated by the short path

switching solenoid (SPSL), to select the short path to feed paper to

the reversion path and stable tray.

6) Staple tray paper discharge

When the paper delivery roller pressure release clutch (STORCL) is

turned ON, the paper delivery pressure release roller (4) is pressurized through the cam to discharge the paper from the stable tray.

7) Paper discharge gate 3 (5)

The paper discharge gate 3 (5) is operated by the paper discharge

gate 3 solenoid (OG3SL) to switch over the routes of paper inside the

staple tray between the paper discharge side and the staple side of

the off-set tray.

8) Tray 3 deceleration clutch (8)

Tray 3 paper exit roller clutch (2)

The paper discharge rollers 3 and 4 are speed changed to improve

the stackability of stapled paper being discharged to the off-set tray.

(4)

Entry

Discharged

Pressure

release

No. Signal name Part name

(1) RVPD Reversion paper delivery sensor

(2) — Reversion gate

(3) — Reversion pressure release roller

(4) — Reversion roller

(2nd sheet is reversed

and entered.)

(2)

(3)

C. Staple tray

1) Jogger motor (JGM)

The jogger motor is driven when the paper is fed into the staple tray,

to operate the jog plates F and R so as to align the sidewise edge of

the paper.

2) Puddler (11)

The puddler clutch (PDCL) is turned ON when the paper is fed into

the staple tray, to give the puddler a full turn so as to drop the paper

downward (pusher), thus achieving alignment in the vertical direction.

3) Pusher motor (PSM)

With the pusher motor rotating, the paper stored inside the staple tray

is lowered from the home position (discharge position) to the stapling

position; after stapling, the paper inside the staple tray is elevated

from the stapling position to the home position.

4) Staple unit movement motor (STUM)

The staple unit is moved to the stapling positions (front, far end, 2

centers) by the staple unit motor.

(2)

(11)

(10)

(9)

(8)

No. Signal name Part name

(1) — Short path switching gate

(2) T3SLCL Tray 3 speed reduction clutch

(3) — Tray 3 speed reduction clutch

(4) — Paper delivery pressure release roller

(5) — Paper discharge gate 3

(6) STPD Staple tray paper detection sensor

(7) — Staple unit

(8) T3ORSL Tray 3 paper exit clutch

(9) T3OD Tray 3 paper delivery sensor

(10) STID Staple tray paper entry sensor

(11) — Puddler

(1)

(3)

(4)

(5)

(6)

(7)

4 – 4

Page 17

(Operation of stapling)

1) 2) 2) 1)

Jog plate

R

Pusher

Paper size

Jog plate

F

Jogging in lateral direction

1) The jog plates are moved to the stand-by position before the

paper is fed to the staple tray.

2) Immediately after the paper is fed into the staple tray, the jog plate

is moved to the paper size position to ensure the alignment of the

paper.

Staple unit

Home

position

Staple unit moving

motor

Pusher

2) 4)

3)

1)

5)

Paper discharge

position

Staple position

ST rail

Staple unit movement at the time of stapling (1-point

stapling)

1) The stapler unit is moved to the stapling position.

– The number of sheets to be stapled is fed to the staple tray –

2) The pusher (the sheets to be stapled) is lowered the stapling

position.

3) The paper is stapled ... (in the case of 2-point stapling, the action

that is described on the following page is added.)

4) The pusher (the sheets stapled) is elevated to the paper discharge position.

5) After the job, the stapler unit is returned to the home position.

Pusher

Staple unit

moving range

Staple position

ST rail

Staple unit moving

motor

1)

3)

4)

5)

2)

Stapler unit movement at the time of stapling

(2-point stapling action is added.)

1) The pusher is elevated to the position which makes it possible for

the staple unit to move.

2) The staple unit is moved to the staple position where the 2nd

staple is driven.

3) The pusher (sheets to be stapled) is lowered to the stapling position.

4) Sheets are stapled.

5) The staple unit is returned to the 1st staple position.

(After the job is finished, the staple unit is returned to the home

position.)

D. Off-set tray

1) Off-set motor (3)

When the off-set motor (3) is driven, the tray is shifted sidewise

against the direction in which the sheets are delivered, so that the

sheets discharged into the off-set tray (1) are sorted by the specified

number of sheets. The rotation is unidirectional and controlled by the

crank. The motor is braked to a stop by the off-set home position

sensor (2) turning ON.

(3)

(2)

Moving range

(30 mm)

(1)

4 – 5

No. Signal name Part name

(1) — Tray 3 (Off-set tray)

(2) OFHP OFHP Off-set home position sensor

(3) OFM Off-set mo tor

Page 18

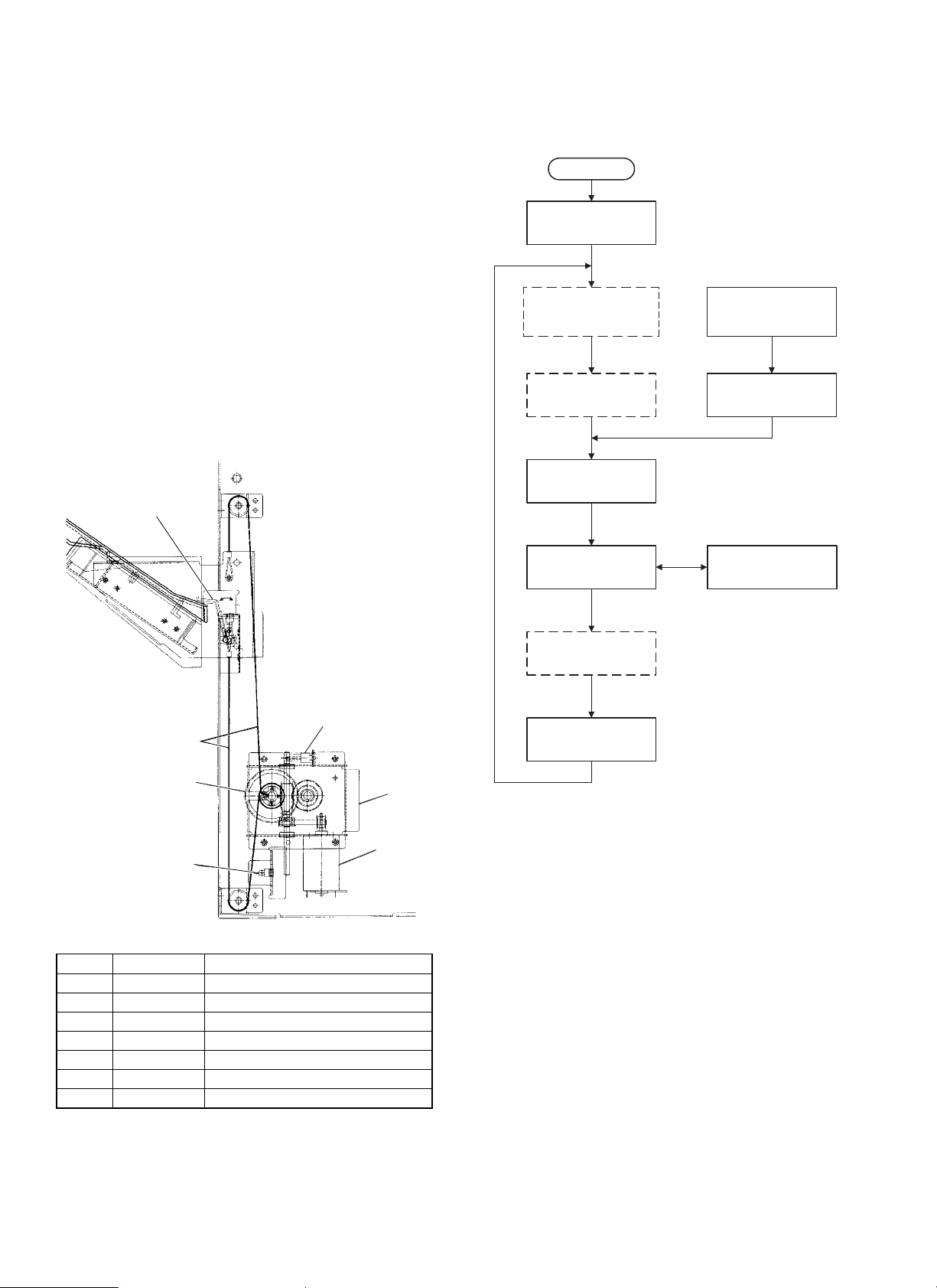

E. Elevator

1) Elevator motor (3)

When the elevator motor (3) is driven, the winding pulley (5) is rotated

in both forward and reverse to wind up the wire (6) stretching vertically so that the tray 3 (off-set tray) is moved up and down. This

allows the discharge of paper at a fixed position according to the

number of sheets to be loaded on the off-set tray.

2) Off-set tray full and load detection

When the power is turned ON, the off-set tray lowers to the lower limit

sensor (4) position. Then it elevates until the upper limit sensor (7)

turns ON, while counting the encoder pulses of the elevator motor (3).

The volume of paper loaded on the off-set tray is calculated (0 100%) by counting the number of pulses from the elevator encoder

(1).

The off-set tray is judged to be full when both the lower and upper

limit sensors (4, 7) are turned ON.

3) Upper limit sensor solenoid (T3UPSL)

When the paper is discharged from the off-set tray, the upper limit

sensor solenoid is turned on to pull in the actuator so that the sheet

discharged does not ride on the actuator of the upper limit sensor (7).

(7)

3. Basic operation

A. Basic operation flowchart

Power ON

Initialization when

powered on

Independent movement

of staple unit

(Staple position)

Independent shifting

(Offset tray)

JOB_START

Operation when

JAM error occurs

Operation when

door is closed

(1)

(6)

(5)

(4)

No. Signal name Part name

(1) — Elevator motor encoder

(2) — Elevator drive unit

(3) EVM Elevator motor

(4) T3DN Tray 3 lower limit sensor

(5) — Winding pulley

(6) — Wire

(7) T3UP Tray 3 upper limit sensor

(3)

(2)

Transfer

Off-set trail paper

discharge

JOB_END

Fig. 1 Basic operation flowchart

Stapling

1) Initialization

The finisher is initialized (home positioning of each motor) at the

following timing.

· When the power is turned on.

· The finisher leaves the copier and when either of the top or bottom

door is opened.

· When the copier start key is pressed (JOB_START):

· Recovery action is performed.

4 – 6

Page 19

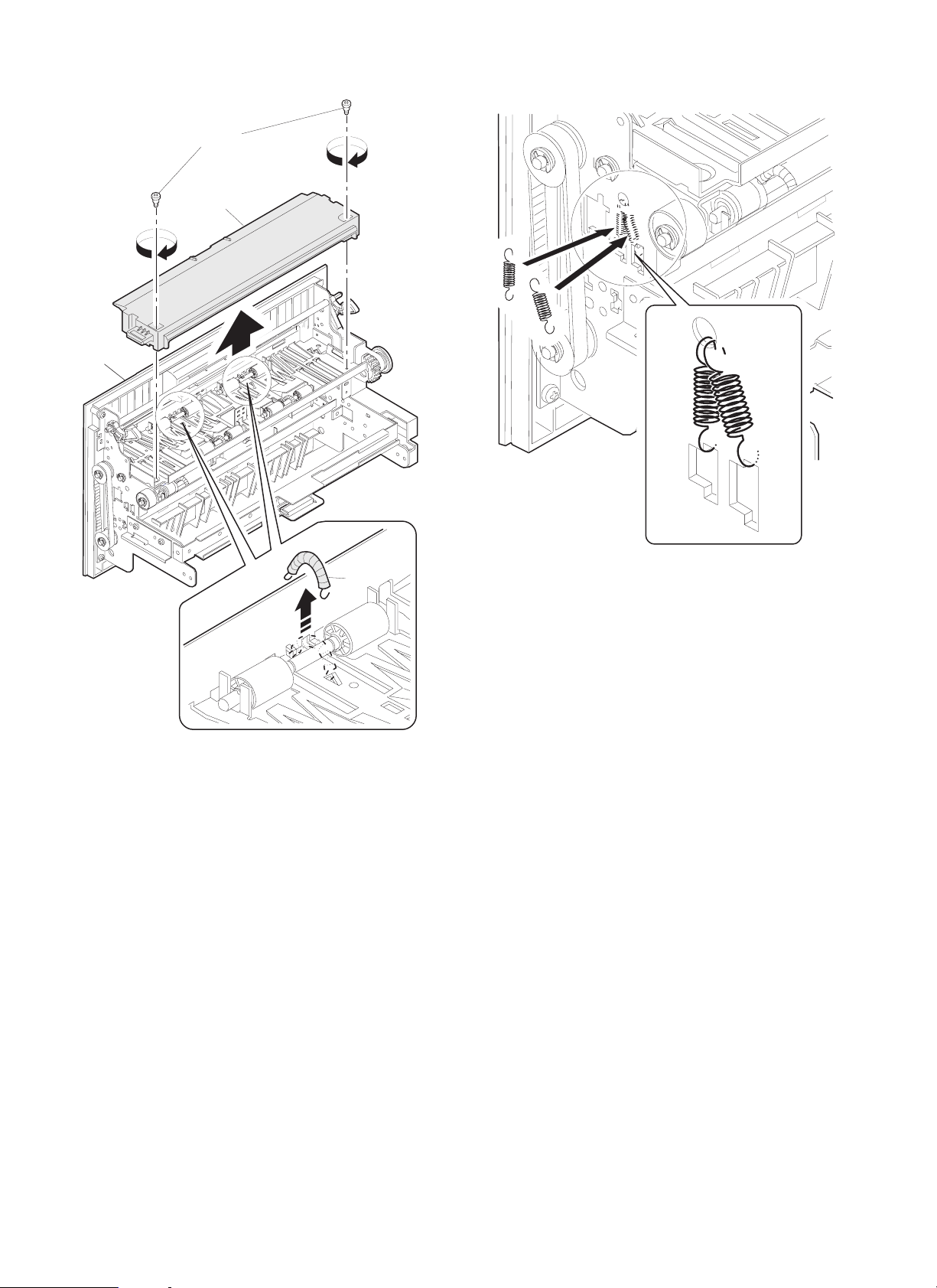

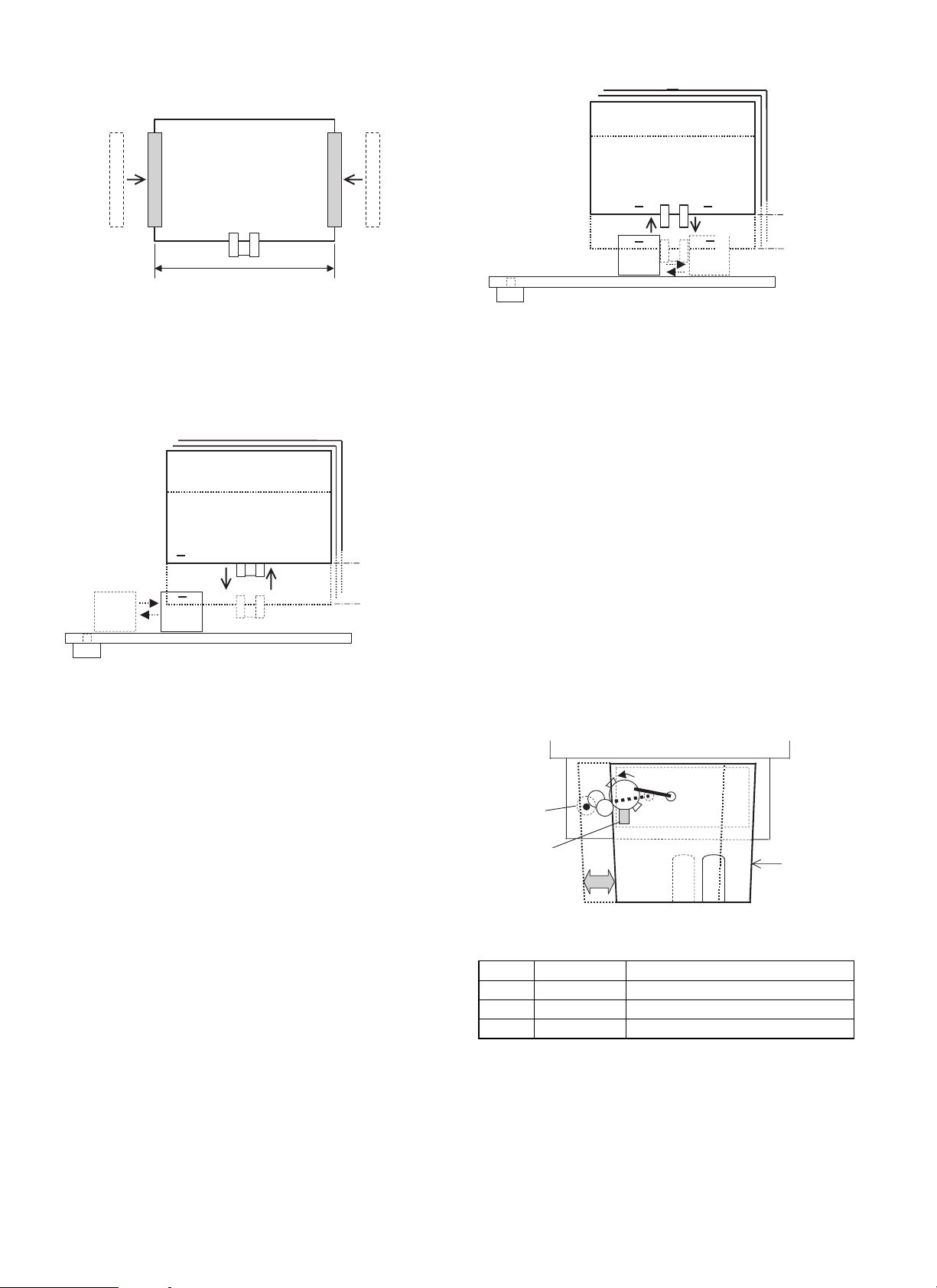

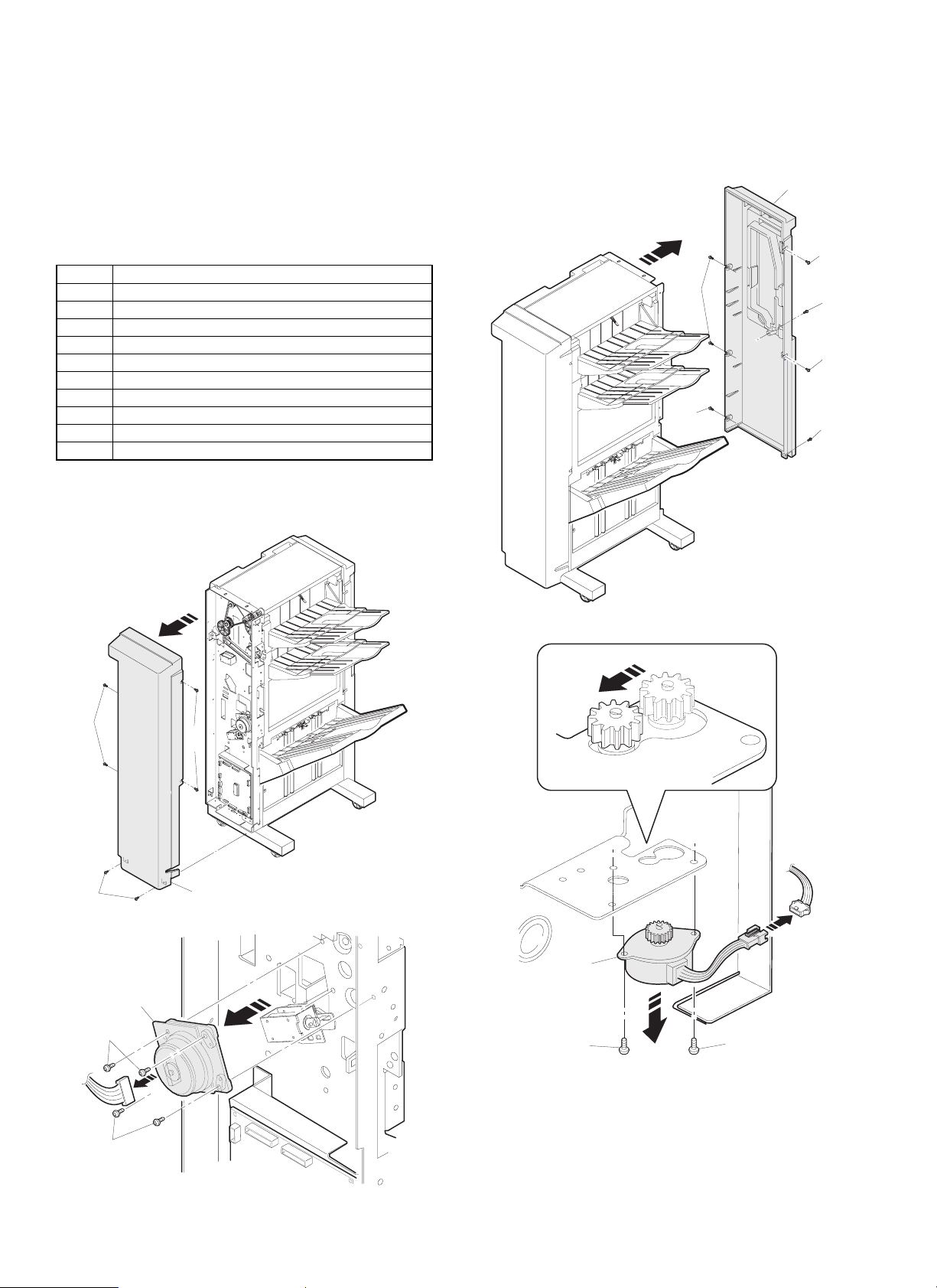

[5] DISASSEMBLY AND REINSTALLATION

[Note]

· This section explains the procedure for disassembling and rein-

stalling the unit. Reinstall the unit in the reverse order of disassembly.

· Disassemble the unit in numerical order in each sketch.

· This section covers the procedure for disassembling the following

major parts. For the other parts, refer to the Parts Guide.

No. Part name

1 Main drive motor

2 Staple unit movement motor

3 Reversing motor

4 Elevator motor

5 Off-set motor

6 Stapler

7 Jogger motor

8 Pusher motor

9 Elevator wires, top and bottom

10 Paper discharge roller 3

1. Main drive motor

2. Staple unit movement motor

1)

1)

3)

2)

1)

2)

1)

2)

3)

5)

5)

6)

1)

4)

5)

4)

4)

5 – 1

Page 20

3. Reversion motor 4. Elevator motor

3)

2)

1)

1)

4)

1)

1)

2)

2)

3)

(A)

1)

4)

5)

6)

5)

5)

4)

5)

5)

5)

[Note] Before trying to remove the frame stay 6), make sure the tray

3 is at the upper limit position.

If the tray 3 is not at the upper limit position, turn the knurled

part on the shaft A in the sketch and move the tray 3 to the

upper limit.

7)

7)

7)

5 – 2

7)

7)

Page 21

9)

11)

12)

13)

5. Off-set motor

1)

2)

8)

10)

8)

14)

8)

13)

6)

4)

3)

5)

8)

A

9)

B

15)

7)

6)

[Note] When the setting the tray 3 cover (bottom), use caution not to

get the wire caught in the harness B.

When setting the off-set motor 9), pay attention to the filter

PWB A. For the direction, see the sketch given above.

16)

A

[Note] When setting the elevator motor 16, pay attention to the direc-

tion of the filter PWB A. For the direction, see the sketch

given above.

5 – 3

Page 22

6. Stapler

6)

5)

5)

10)

2)

9)

3)

1)

7. Jogger motor

1)

8)

7)

2)

5 – 4

Page 23

4)

4)

3)

3)

6)

3)

5)

3)

3)

3)

6)

3)

3)

3)

3)

5)

[Note] When installing the jogger motor 6), pay attention to the har-

ness pulling-out direction. See the sketch given above.

8. Pusher motor

1)

2)

8)

5)

7)

7)

5 – 5

Page 24

9. Elevator wires, top and bottom

6)

11)

4)

2)

2)

3)

(A)

1)

1)

7)

5)

5)

7)

8)

7)

4)

5)

5)

10)

12)

13)

10)

10)

13)

12)

7)

7)

[Note] If the tray 3 is not at the upper limit position, turn the knurled

part on the shaft A in the sketch and move the tray 3 to the

upper limit position.

8)

8)

9)

8)

8)

8)

[Note] Remove the two screws 13) and:

1) Move the off-set tray to the lower limit position.

2) Turn the knurled part on the elevator worm gear shaft under the

elevator drive box so that the D-cut surface on the winding pulley

points upward.

C

14)

17)

15)

A

18)

16)

B

[Note] Remove the elevator wires (top, bottom) at the rear frame

5 – 6

side in the same manner.

Page 25

[Reinstalling elevator wires (top, bottom) at the front

frame side]

1) Insert both the top elevator wire 15) and bottom elevator wire 16)

into the elevator pulley drive shaft A. Secure the winding pulley

18) with the screw 17).

2) Hook the bottom elevator wire 16) on the lower wire roller B from

the left side of the winding pulley 18), without giving extra winding.

With the wire extended upward, hook the wire mounting spring 14)

on the wire hook.

3) Wind the top elevator wire 15) onto the winding pulley 18) 3 and

3/4 turns in the clockwise direction, and hook on the upper wire

roller C. Hold it stretched downward.

4) When setting the top and bottom elevator wires at the rear frame

side (see the sketch below), observe the following conditions:

[Note] Observe the following conditions when setting elevator-wires

(top and bottom) at the rear frame side. See the sketch below.

· The bottom elevator wire 16) should be hooked onto the

bottom wire roller B from the right side of the winding pulley

18) without giving extra winding.

· The top elevator wire 15) should be wound onto the winding

pulley 18) 3 and 3/4 turns in the counterclockwise direction.

10. Paper discharge roller 3

10-1. Paper discharge roller 3 (top)

5)

3)

1)

5)

2)

1)

6)

4)

5)

4)

5)

15)

16)

14)

18)

C

17)

2)

8)

7)

7)

A

9)

B

10)

9)

5 – 7

Page 26

A

11)

7)

12)

7)

A

[Note] After removing the E-ring 11), slide the bearing A in the direc-

tion A to remove the paper discharge roller 3 12).

11) 12)

10-2. Paper discharge roller 3 (bottom)

1)

2)

4)

5)

3)

9)

D

A

B

8)

D

3)

6)

6)

B

[Note] After removing the E-ring 8), slide the bearing A in the direc-

tion A to remove the paper discharge roller 4 9).

[Caution to be taken wh en rein stalling ]

When reinstalling the paper discharge roller 4, make sure that the

lock screw C settles in the U-shape notch D in the clutch B.

5 – 8

A

8)

9)

Page 27

[6] ADJUSTMENT

The following table shows the main parts requiring adjustment at the

time of replacement

Item Part name

1 Jogger F/R

2 Paper entry gate solenoid

3 Reversion roller pressure release solenoid

4 Paper discharge gate solenoid 1

5 Paper discharge gate solenoid 2

6 Paper discharge gate solenoid 3

7 Short path switching solenoid

8 Tray 3 upper limit solenoid

9 Paper holding solenoid

10 Paddler clutch

11 Vertical transport roller 3 intermediate unit

12 Paper entry port de-curler unit

Note: Remove or install parts in numerical order shown in the follow-

ing figures.

1. Jogger F/R

A. Let the unit staple 5 sheets of A4 or letter paper and check the

bundle of the sheets for deviation in directions A).

Condition Adjusting procedure

1 When the deviation in the

direction A) exceeds 1 mm.

Note: The width between joggers can be visually checked by observ-

ing the label inside the staple tray.

Jogger

Decrease the simulation value.

(Decreasing the simulation by

1 narrows the width between

the joggers by 0.63 mm.)

Increase the simulation value.

(Increasing the simulation value

by 1 widens the width between

the joggers by 0.63 mm)

Label

A)

Pin

B. When the deviation in directions A) is are within 1 mm, there is no

need to adjust the jogger F/R.

C. When the deviation exceeds 1 mm, adjust the jogger F/R accord-

ing to the simulation 3-6: Adjusting Finisher Jogger Position.

Letter position

A

Jogger

A4 position

The spacing between

labels is 0.5 mm.

Sim. 3-6: Adjusting Finisher Jogger Position

The screen above is displayed after the sub number of the simulation

is entered.

1) Adjust the value with the numeric keypad.

2) The joggers in the finisher are operated by pressing the [EXECUTE] key. The [EXECUTE] key is displayed in reverse video

during loading operation. When the [EXECUTE] key in this state

is pressed, loading operation can be canceled.

6 – 1

Page 28

2. Paper entry gate solenoid

[Adjustment and precaution in setting]

2)

2)

3)

1)

2)

1)

2)

Positioning mark

8)

P

Q

View looking from P

B

A

View looking from Q

1) Insert the paper entry gate solenoid pin A into the hole B on the

paper feed gate arm and secure with the screw 4). In this step,

align the F flame edge with the position aligning stamp as shown

in the enlargement above.

2) When setting the paper entry gate solenoid spring 8), ensure that

the direction of the spring hook is as shown in the figure.

5)

6)

4)

7)

3. Reversion roller pressure release

solenoid

2)

1)

2)

3)

6 – 2

Page 29

4. Paper discharge gate solenoid 1

3)

1)

6)

7)

5)

4)

[Precaution in setting]

1) Insert the solenoid pin B through the slot A in the paper feed lever,

insert the shaft C through the D-cut hole in the paper feed lever,

and secure the solenoid with the screw 4). In this step, align the

edge of the gate solenoid installation plate with the position aligning stamp as shown in the enlargement below.

C

2)

2)

2)

1)

2)

A

B

5)

4)

Positioning marks

6)

7)

4)

6 – 3

Page 30

[Adjustment and precaution in setting]

1) Insert the solenoid pin A through the longer slot in the valve

moving arm B shown in the figure below and secure with the

screw 4). In this step, align the edge of the solenoid installation

plate 6) with the position aligning stamp as shown in the enlargement.

2) Hook one end of the paper discharge solenoid spring C in the

smaller slot in the valve moving arm B and the other end in the

hole in the F flame.

B

A

6)

5)

6)

C

Positioning lines

Match the right-most with the

middle of the second.

5. Paper discharge gate solenoid 2

4)

4)

[Adjustment and precaution in setting]

1) Insert the solenoid pin A through the longer slot in the paper

discharge gate 2 B and secure with the screw 4). In this step, the

solenoid installation plate 6) is positioned as shown in the enlargement below.

7)

B

A

4)

2)

2)

Positioning mark

1)

3)

6 – 4

Page 31

6. Paper discharge gate solenoid 3

7. Short path switching solenoid

2)

2)

7)

1)

6)

3)

5)

4)

1)

2)

3)

4)

[Adjustment and precaution in setting]

1) Insert the solenoid pin B through the notch in the manual stopper

rotation arm A and secure with the screw 4). In this step, align the

edge of the solenoid installation plate 6) with the positioning line at

the center.

A

B

4)

11)

3)

3)

3)

3)

10)

6 – 5

Page 32

8. Tray 3 upper limit solenoid

[Adjustment and precautions in setting]

1) Adjust the distance from the end A of the installation plate 6) to

the actuator B for 8 mm, with the solenoid fully pulled. Secure the

solenoid with the screw 4).

8mm

AB

C

P

Slide the upper limit sensor unit 2) in the direction indicated by the

arrow and remove it.

1)

2)

D

As a rough guide, screw so

that the edges of solenoid

mounting plate 6) are

matched.

Line

2) Use caution to align the notch C of the upper limit sensor unit 2

with the notch D of the rear edge reinforcement plate when securing the upper limit sensor unit 2 with the screw 1). (See the figure

below.)

4)

6)

4)

3)

6)

5)

6 – 6

Page 33

9. Paper holding solenoid

10. Paddler clutch

2)

2)

1)

3)

2)

2)

1)

3)

[Adjustment and note for setting]

Adjust the guide solenoid fixing plate so that the staple tray guide is in

contact with the solenoid fulcrum arm.

Staple

movable

PG

[Adjustment and note for setting]

Adjust the paddler adjustment plate so that the paddler tip enters the

clearance of the staple tray guide.

6 – 7

Paddler

Page 34

11. Vertical transport roller 3 intermediate

unit

Insert the jig between the de-curler roller and the de-curler follower

shaft of the vertical transport roller 3 intermediate unit, and install it.

Set values

Without paper entry

port de-curler unit

Nip amount 1.3

Shaft dimension 20.8 21.6

Jig

± 0.1 0.5 ± 0.1

De-curler jig R 1.3 De-curler jig R 0.5

De-curler jig F 1.3 De-curler jig F 0.5

[Process]

1) Temporarily install the vertical transport roller 3 intermediate unit

and the de-curler follower shaft to the machine.

2) Insert de-curler jigs F and R between the de-curler roller and the

de-curler follower shaft. While gently pressing the jigs downward,

tighten the fixing screw to fix the jigs.

3) Check that the de-curler jig R enters between the front side and

the rear side of the shaft.

4) If the jig R does not enter smoothly, repeat the above procedures

and check again.

De-curler follower shaft

De-curler roller

With paper entry

port de-curler unit

Fixing screw

Fixing jig R

Rear side Front side

R1.3

De-curler jig R1.3 De-curler jig F1.3

F1.3

Fixing screw

Fixing jig F

R0.5

De-curler jig R0.5

De-curler jig F0.5

6 – 8

Page 35

12. Paper entry port de-curler unit

· Nip amount adjustment

For the paper entry de-curler unit, adjust the nip amount of the

de-curler roller according to the destination as shown below.

Nip amount 0.5 ± 0.1 0.8 ± 0.1 1.2 ± 0.1 1.6 ± 0.1

(Reference) Shaft

dimension

Inch series F/R

EX AB series F R

Japan F/R

· Adjustment procedure

The nip amount adjustment is made with the paper entry de-curler

jig.

1) Insert the jig to fit the inscribed mark of each nip amount as

shown in he figure below.

2) Press the de-curler adjustment plate F (arrow section) until the

shaft is in contact with the jig.

3) Tighten the screw.

Perform the same procedure to the front side and the rear side.

21.6 21.3 20.9 20.5

Front side insertion position

De-curler adjustment plate F (R)

Paper entry de-curler

follower shaft

3

Screw tightening (M4x8, 3 pcs.)

Hold th section.

2

Paper entry de-curler

Insert

Rear side insertion position

Paper entry de-curler

1

jig

6 – 9

Page 36

[7] MAINTENANCE

If reception is performed during maintenance work, it is very dangerous. Therefore, be sure to disconnect the power cable from the machine.

1. Maintenance system table

| : Cleaning ★:

Lubrication

Name Work

Rollers Clean Maintenance service 80K or 2 years

Paper guides Clean Maintenance service 80K or 2 years

Gears Lubricate Grease Maintenance service 80K or 2 years

Belts Check Maintenance service 120K or 2 years

Sensors Check Maintenance service 80K or 2 years

Staple unit Replace Maintenance service 100K

✕: Check (Clean, replace, or adjust according to necessity.)

Execution conditions

Execution timing Cycle

Note

7 – 1

Page 37

(Rollers/Paper guides)

C

C

D

E

F

B

A

A

B

E

D

F

7 – 2

Page 38

K

K

G

H

J

L

G

I

H

I

L

J

7 – 3

Page 39

(Gears)

Others (Sensors) (Belts)

7 – 4

Page 40

[8] TROUBLESHOOTING

1. Trouble code

Trouble code

Main

code

Sub

code

F1 00 Content Finisher communication trouble

Detail Communication line test error occurs

when power is turned on or after the exit

of a simulation mode.

Improper communication with sorter

Cause Improper connection or broken wire of

Check

and

remedy

01 Content Finisher jogger shift trouble

Detail Jogger shift trouble

Cause Motor lock

Check

and

remedy

02 Content Finisher transport motor error

Detail Transport motor drive trouble

Cause Motor lock

Check

and

remedy

04 Content Finisher indexer lower limit detected

Detail Indexer has exceeded lower limit.

Cause Sensor defective

Check

and

remedy

05 Content Finisher elevator motor trouble

Detail Indexer has exceeded upper limit

Cause Sensor defective

Check

and

remedy

06 Content Finisher shift motor error

Detail Finisher shift motor trouble

Cause Motor lock

Check

and

remedy

connector or harness between copier

and Finisher

Finisher control PWB defective

Control PWB (PCU) defective

Malfunction due to noise

Clear by turning the power supply

OFF/ON.

Check communication line connector and

harness.

Replace Finisher control PWB or PCU

PWB.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the jogger motor operation with

SIM 3-3.

Check transport motor operation with

SIM3-3.

Finisher control PWB defective

Check sensor with SIM3-2.

Finisher control PWB defective

Check sensor with SIM3-2.

Improper motor speed

Overcurrent to motor

Finisher control PWB defective

Check shift motor operation with SIM3-3.

Description

Trouble code

Main

code

Sub

code

F1 08 Content Finisher staple shift motor trouble

Detail Staple motor drive trouble

Cause Motor lock

Check

and

remedy

10 Content Staple unit operation trouble

Detail Staple operation trouble

Cause Motor lock

Check

and

remedy

11 Content Pusher motor trouble

Detail Pusher motor trouble

Cause Motor lock

Check

and

remedy

15 Content Finisher elevator motor trouble

Detail Elevator motor trouble

Cause Motor lock

Check

and

remedy

80 Content Finisher power trouble

Detail 24V power is not supplied to the finisher

Cause Connector harness improper connection

Check

and

remedy

Motor RPM abnormality

Motor overcurrent

Finisher control PWB trouble

Check the staple motor operation with

SIM 3-3.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the staple motor operation with

SIM 3-3.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the pusher motor operation with

SIM 3-3.

Motor rpm abnormality

Motor overcurrent

Finisher control PWB trouble

Check the elevator motor operation with

SIM 3-3.

PWB.

or disconnection

Finisher control PWB trouble

Power unit trouble

Check the sensor operation with SIM 3-2.

Description

8 – 1

Page 41

(1) Finisher does not operate. (excluding JAM

state)

1

2

Is connection

cable properly

connected?

Is load on motor

shaft normal?

CNA-6 and CNA-5 of

Is motor winding

(between U, V, and W)

CNA-1 and CNA-3 of

connected normally?

signals of main PWB

Motor rotates

even slightly?

YES

YES

+5V between

main PWB?

YES

shorted?

NO

+24V between

main PWB?

Is harness

YES

YES

Are

DSW1, 2, 3

OK?

YES

NO

Connect connection

cable to body properly.

Check mechanical load

NO

and driving system.

Remove foreign matter.

NO

Check or replace harness

or check supply voltage.

YES

NO

NO

Replace motor.

NO

Check or replace harness

or check supply voltage.

Connect harness

Check connections.

Check harnesses at

upper and lower surfaces

NO

and harness leading to

upper transfer switch for

Is voltage

connections, and replace

applied to motor

connector?

properly.

if necessary.

NO

Staple unit

moving motor rotates

normally?

YES

Pusher motor rotates

normally?

YES

Jogger motor rotates

normally?

YES

Check main PWB and

replace if necessary.

NO

NO

NO

4

4

4

YES

Transfer motor

rotates normally?

YES

Is motor

encoder output

normal?

Elevator motor

YES

rotates normally?

YES

Check main PWB and

replace if necessary.

Off-set motor

rotates normally?

YES

NO

2

NO

Check motor and

replace if necessary.

NO

3

NO

3

YES

8 – 2

Page 42

(2) Transfer motor error (3) Elevator and off-set moter error

2

Is load on motor

shaft normal?

YES

Is motor winding

(between U, V, and W)

shorted?

NO

Is harness

connected normally?

YES

Check mechanical load

NO

and driving system.

Remove foreign matter.

YES

NO

Replace motor.

Connect harness

properly.

3

Is fuse blown out?

YES

Is load on motor

shaft normal?

YES

Is motor winding

shorted?

NO

NO

NO

YES

Replace fuse.

Check mechanical load

and driving system.

Remove foreign matter.

Replace motor.

Motor rotates

even slightly?

YES

Is motor

encoder output

normal?

YES

Check main PWB and

replace if necessary.

NO

NO

replace if necessary.

Is voltage

applied to motor

connector?

YES

Check motor and

NO

Is harness

connected normally?

YES

Motor rotates

even slightly?

YES

Is motor

encoder sensor output

normal?

YES

NO

NO

NO

Connect harness

applied on motor

Check motor and

replace if necessary.

Replace sensor

mounting and replace

Check harness and

replace if necessary.

properly.

Is voltage

connector?

YES

if necessary.

NO

8 – 3

Check main PWB and

replace if necessary.

Page 43

(4) Stepping moter error

(6) Clutch and solenoid error

4

Is load on motor

shaft normal?

YES

Is motor winding

shorted?

NO

Is harness connected

normally?

YES

Check mechanical

NO

load and driving system.

Remove foreign matter.

YES

NO

Replace motor.

Connect harness

properly.

6

Is each

load properly

mounted?

YES

Conduction

between coils of each

load?

YES

Conduction

between connectors and

terminals?

YES

NO

Check mounting and

replace if necessary.

NO

NO

Replace clutch or

Check harness and

replace if necessary.

solenoid.

Check main PWB and

replace if necessary.

(5) Sensor error

5

Is sensor

mounted properly?

Is harness connected

properly?

Replace main PWB.

YES

Check sensor mounting

NO

and harness and replace

if necessary.

Replace main PWB.

8 – 4

Page 44

[9] DESCRIPTION OF CIRCUITS

1. Outline

The finisher main circuit transmits and receives data to and from the copier main PWB. According to instructions from the copier, it controls loads,

sensors and the input of switching information.

The finisher main circuit consists of a circuit which receives signals from sensors and switches, a circuit which drives solenoids and clutches, CPU,

ROM, expansion I/O and other peripheral circuits.

2. Block diagram

The finisher block diagram is shown in Fig. 1.

Copier

Jogger motor HP sensor

Stapler self-priming sensor

Pusher motor HP sensor

Staple unit HP sensor

Tray 2 paper full sensor

Stapler needle

replacement sensor

Elevator motor encoder

Off-set HP sensor

Staple HP sensor

Transfer motor encoder

Paper entry sensor

Reversion paper discharge sensor

Transfer detection sensor 1

Transfer detection sensor 2

Transfer detection sensor 3

Transfer detection sensor 4

Tray 3 paper discharge sensor

Staple tray paper entry sensor

Staple paper detection sensor

Tray 1 paper full sensor

Staple tray paper entry sensor 2

Tray 3 upper limit sensor

Tray 3 lower limit sensor

Staple needle detection sensor

Staple cartridge sensor

Copier connection

switch

Upper door switch

Front door switch

BUFF

IC14

+5V

GND1

GND2

10V generating

circuit

ZD1,7,Q5

JGHP

READY

PSHP

STUHP

T2PF

STND

EVRE

OFHP

STHP

FMRE

INPD

RVPD

PFD1

PFD2

PFD3

PFD4

T3OD

STID

STPD

T1PF

STID2

T3UP

T3DN

LSTS

NCTS

+24VIN

Level

conversion

circuit

ZD3,4,5,6

F-RES

X1

[Mode 1]

+24VIN

IC19

+24V

F-TXD

F-RXD

F-DTR

F-DSR

F-RES

8MHz

"1"

"0"

"0"

PWD

DSW1

DSW2

DSW3

+10V

RXD0

TXD0

P95

P94

/RES

XTAL

EXTAL

MD0

MD1

MD2

P70

P71

P72

P74

P75

P77

P80

P81

PA0

PA6

EXPA0

EXPA1

EXPA3

EXPA4

EXPA5

EXPA6

EXPA7

EXPB0

EXPB1

EXPB2

EXPB3

EXPB4

EXPB5

EXPB6

EXPB7

EXPG0

‚d‚w‚o‚f‚O

EXPG1

EXPG2

EXPG3

RES

CPU(H8/3040)

IC2

EXP(M66500F)

IC3

PA4

PA7

P44

P 45

PB0~3

P40~43

PB4~7

P60

P46 PPSL

P47 STSL

A0~16

D0~7

CS0

RD

WR

CS2

CS

WR

RD

D0~7

A0~2

EXPE4

EXPE5

EXPE0

EXPE1

ECPC0~3

EXPF0

EXPF1

EXPF2

EXPF3

EXPF4

EXPF5

EXPF6

EXPF7

EXPC4

EXPC5

EXPC6

EXPC7

+10V

FMPWM

FMDIR

OFMA

OFMB

: A,B,A/,B/

*

RM*

STUM*

PM*

PMPD

A0~16

D0~7

ROMCS

RD

WR

EXPCS

EXPCS

WR

RD

D0~7

A0~2

STMA

STMB

EMA

EMB

JM*

INGSL

T3UPSL

OG1SL

OG3SL

RRSL

T30RCL1

PDCL

STORCL

SPSL

T12CL

OG2SL

T3SLCL

PPSL

STSL

2-phase brushless

motor driving circuit

DC brush motor

4

2-phase stepping

motor constant-current

2-phase stepping

4

motor constant current

4

2-phase stepping

motor constant current

17

8

DC brush motor

driving circuit(H driver)

DC brush motor

driving circuit(H driver)

4

2-phase stepping

motor constant current

driving circuit IC8

Solenoid/

Solenoid/

IC10,16,20

driving circuit

IC1

driving circuit

IC4

driving circuit

IC7

driving circuit

IC11

ROM(1M)

A0~16

D0~7

CS

OE

IC6

IC9,Q1,2,3,4

IC12,13

clutch

driving

circuit

IC17,18

clutch

driving

circuit

IC5

HU,HV,HW

Main driving motor

M

(FM)

[Brushless motor]

Off-set motor

M

(OFM)

[Brush motor]

Reversion motor

M

(RVM)

[Stepping motor]

Staple unit moving

M

motor (STUM)

[PM stepping motor]

Pusher motor

M

(PSM)

[HYB stepping motor]

Staple motor

M

(STM)

[Brush motor]

Elevator motor

M

(EVM)

[Brush motor]

Jogger motor

M

(JGM)

[PM stepping motor]

-

Paper entry gate solenoid

Tray 3 upper limit solenoid

Paper discharge gate solenoid

Paper discharge gate 3 solenoid

Reversion roller pressure release SL

Tray 3 paper exit roller clutch

Puddler clutch

ST paper discharge roller

pressure release clutch

Short path switching SL

Tray 1 / 2 speed change clutch

Paper discharge gate 2 solenoid

Tray 3 low speed clutch

Paper holding solenoid

Staple tray solenoid

Stapler

Fig. 1 3 tray finisher block diagram

9 – 1

Main PWB

Page 45

3. CPU (HB/3040)

A. Outline

The CPU (IC2) controls finisher loads and the system synchronously,

transmitting and receiving data to and from the copier main PWB

through the serial communication line.

B. Features

The HB/3040 is a high-performance single chip microprocessor using

the 32-bit H8/300H CPU as a core, integrating peripheral functions

necessary for system configuration.

The HB/300H CPU has an internal 32-bit configuration and is

equipped with 16-bit

optimized instruction set for high-speed operation. It can handle 16M

byte linear address space.

As peripheral functions, it contains ROM, RAM, 16-bit integrated

timer unit (ITU), programmable timing patter controller (TPC), watchdog timer (WDT), serial communication interface (SCI), A/D converter, D/A converter, I/O port, DMA controller (DMAC), and refresh

controller.

C. Terminal connection diagram

´ 16 general-purpose registers and a simple,

A Vcc

Vref

P70/AN0

P71/AN1

P72/AN2

P73/AN3

P74/AN4

P75/AN5

P76/AN6/DA0

P77/AN7/DA1

A Vss

P80/RFSH/IRQ0

P81/CS3/RAS/IRQ1

P82/CS2/IRQ2

P83/CS1/IRQ3

P84/CS0

PA0/TP0/TEND0/TCLKA

PA1/TP1/TEND1/TCLKB

PA2/TP2/TIOCA0/TCLKC

PA3/TP3/TIOCB0/TCLKD

PA4/TP4/TIOCA1/A23

PA5/TP5/TIOCB1/A22

PA6/TP6/TIOCA2/A21

PA7/TP7/TIOCB2/A20

Vss

P63/AS

Vcc

XTAL

EXTAL

Vss

NMI

RES

STBY

Φ

P62/BACK

P61/BREQ

P60/WAIT

Vss

P53/A19

IRQ5/SCK1/P95

P52/A18

D0/P40

D1/P41

D2/P42

D3/P43

MD2

MD1

MD0

P66/LWR

P65/HWR

P64/RD

75747372717069686766656463626160595857565554535251

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

12345678910111213141516171819202122232425

Vcc

TIOCA3/TP8/PB0

TIOCB3/TP9/PB1

TIOCA4/TP10/PB2

TIOCB4/TP11/PB3

TOCXA4/TP12/PB4

H8/3040

Vss

RES0

TXD0/P90

TXD1/P91

DREQ0/TP14/PB6

TOCXB4/TP13/PB5

RXD0/P92

RXD1/P93

IRQ4/SCK0/P94

P51/A17

P50/A16

P27/A15

Vss

D4/P44

P26/A14

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

D5/P45

D6/P46

A13/P25

A12/P24

A11/P23

A10/P22

A9/P21

A8/P20

Vss

A7/P17

A6/P16

A5/P15

A4/P14

A3/P13

A2/P12

A1/P11

A0/P10

35 Vcc

D15/P37

D14/P36

D13/P35

D12/P34

D11/P33

D10/P32

D9/P31

D8/P30

D7/P47

ADTRG/DREQ1/TP15/PB7

9 – 2

Page 46

D. CPU: H8/3040 (IC2) terminal signals

Pin

No.

1 VCC VCC Power supply (

2 PB0 RMA OUT H Reversion motor drive signal A

3 PB1 RMA/ OUT H Reversion motor drive signal A/

4 PB2 RMB OUT H Reversion motor drive signal B

5 PB3 RMB/ OUT H Reversion motor drive signal B/

6 PB4 PMA OUT H Pusher motor drive signal A

7 PB5 PMA/ OUT H Pusher motor drive signal A/

8 PB6 PMB OUT H Pusher motor drive signal B

9 PB7 PMB/ OUT H Pusher motor drive signal B/

10 /RES0 RES0/ OUT L External device reset signal

11 VSS GND Power supply (GND)

12 P90 F-RXD OUT UART output

13 P91 N.C

14 P92 F-TXD IN UART input

15 P93 N.C

16 P94 F-DSR OUT H DSR signal output to copier (communication request at H)

17 P95 F-DTR IN H DTR signal input from copier (communication permission at H)

18 P40 STUMA OUT H Staple unit movement motor drive signal A

19 P41 STUMA/ OUT H Staple unit movement motor drive signal A/

20 P42 STUMB OUT H Staple unit movement motor drive signal B

21 P43 STUMB/ OUT H Staple unit movement motor drive signal B/

22 VSS GND Power supply (GND)

23 P44 OFMA OUT H Off-set motor CCW drive signal

24 P45 OFMB OUT H Off-set motor CW drive signal

25 P46 PPSL OUT H Paper holding solenoid drive signal

26 P47 STSL OUT H Staple tray solenoid drive signal

27 P30 D0 IN/OUT Data signal (D0)

28 P31 D1 IN/OUT Data signal (D1)

29 P32 D2 IN/OUT Data signal (D2)

30 P33 D3 IN/OUT Data signal (D3)

31 P34 D4 IN/OUT Data signal (D4)

32 P35 D5 IN/OUT Data signal (D5)

33 P36 D6 IN/OUT Data signal (D6)

34 P37 D7 IN/OUT Data signal (D7)

35 VCC VCC Power supply (

36 P10 A0 OUT Address signal (A0)

37 P11 A1 OUT Address signal (A1)

38 P12 A2 OUT Address signal (A2)

39 P13 A3 OUT Address signal (A3)

40 P14 A4 OUT Address signal (A4)

41 P15 A5 OUT Address signal (A5)

42 P16 A6 OUT Address signal (A6)

43 P17 A7 OUT Address signal (A7)

44 VSS GND Power supply (GND)

45 P20 A8 OUT Address signal (A8)

46 P21 A9 OUT Address signal (A9)

47 P22 A10 OUT Address signal (A10)

48 P23 A11 OUT Address signal (A11)

49 P24 A12 OUT Address signal (A12)

50 P25 A13 OUT Address signal (A13)

51 P26 A14 OUT Address signal (A14)

52 P27 A15 OUT Address signal (A15)

53 P50 A16 OUT Address signal (A16)

54 P51 A17 OUT Address signal (A17)

55 P52 A18 OUT Address signal (A18)

56 P53 A19 OUT Address signal (A19)

57 VSS GND Power supply (GND)

58 P60 PMPD OUT H Pusher motor power down signal (power down at H)

59 P61 N.C

60 P62 N.C

61 S-CLK S-CLK OUT System lock signal

62 /STBY STBY/ IN L Stand-by signal (fixed at H level)

63 /RES RES/ IN L Reset signal (reset at L)

64 NMI NMI IN H Non-maskable interruption (fixed at L level)

65 VSS GND Power supply (GND)

66 EXTAL EXTAL IN Clock (8MHz)

67 XTAL XTAL IN Clock (8MHz)

68 VCC VCC Power supply (

Port

Signal

name

IN/OUT ACTIVE Specification Remarks

+ 5V)

+ 5V)

+ 5V)

9 – 3

Page 47

Pin

No.

69 P63 AS/ OUT H Address strobe signal

70 P64 RD/ OUT L ROM, I/O read signal (read at L)

71 P65 HWR/ OUT L Upper write signal (write at L)

72 P66 LWR/ OUT L Lower write signal (write at L)

73 MD0 MD0 IN Mode setting signal 0 (fixed at H level)

74 MD1 MD1 IN Mode setting signal 1 (fixed at L level)

75 MD2 MD2 IN Mode setting signal 2 (fixed at L level)

76 AVCC AVCC A/D, D/A converter power supply

77 VREF VREF A/D, D/A converter reference voltage

78 P70 JGHP IN H Jogger motor home position signal (home position at H)

79 P71 READY/ IN L Stapler self-priming signal (ready at L)

80 P72 PSHP IN H Pusher motor home position signal (home position at H)

81 P73 N.C

82 P74 STUHP IN H Stapler unit home position signal (home position at H)

83 P75 T2PF/ IN L Tray 2 paper full sensor signal (full at L)

84 P76 N.C

85 P77 STND IN L Stapler needle replacement sensor (needle being replaced at L)

86 AVSS GND Power supply (GND)

87 P80 EVRE IN Elevator motor encoder

88 P81 OFHP IN H Off-set tray home position signal (home position at H)

89 P82 EXPCS/ OUT L Expansion I/O chip select signal (select at L)

90 P83 N.C

91 P84 ROMCS/ OUT L ROM chip select signal (select at L)

92 VSS GND Power supply (GND)

93 PA0 STHP/ IN L Stapler home position signal (home position at L)

94 PA1 N.C

95 PA2 N.C

96 PA3 N.C

97 PA4 FMPWM/ OUT L Transfer motor control signal (PWM output)

98 PA5 N.C

99 PA6 FMRE IN H Transfer motor encoder signal

100 PA7 FMDIR OUT L Transfer motor direction control signal (CW at L)

Port

Signal

name

IN/OUT ACTIVE Specification Remarks

4. Expansion I/O (M66500FP)

A. Outline

The expansion I/O converts data from the CPU into load control

signals and input signals from sensors and switches into data for the

CPU.

The expansion I/O uses the M66500FP.

B. Features

· I/Os are expandable up to 44 bits

(8-bit I/O port

´ 1)

port

· Directly connectable to 12 MHz CPU without weight

· Writable to output port in input mode

· Output terminal status can be read from CPU

· Possible to drive transistor array

· 24 mA high-dielectric output port (16 bits) is incorporated.

· TTL level terminal at CPU side

· I/O terminal is CMOS level schmitt trigger input

´ 3, 8-bit high-dielectric output port ´ 2, 4-bit input

C. Terminal connection diagram

64 PF5

63 PF4

62 PF3

61 PF2

60 PF1

56 PG2

59 PF0

58 GND2

57 PG3

55 PG1

PF6

PF7

Vcc

PE0

PE1

PE2

PE3

PE4

PE5

PE6

PE7

GND3

PB0

PB1

PB2

PB3

PB4

PB5

PB6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2021222324252627282930

M66500FP

54 PG0

53 PC3

52 PC2

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

31

32

PC1

PC0

PC4

PC5

PC6

PC7

D7

D6

D5

D4

D3

D2

D1

D0

A0

A1

A2

GND1

RESET

9 – 4

PB7

PA7

PA6

PA5

PA4

PA3

PA2

PA1

PA0

Vcc

RD

WR

CS

Page 48

D. Expansion I/O: M66500FP (IC3) terminal signals

Pin

No.

10 PE6 N.C

11 PE7 N.C

12 GND GND Power supply (GND)

13 PB0 STID/ IN L Staple tray paper entry sensor signal (On at L)

14 PB1 STPD/ IN L Staple tray paper sensor signal (On at L)

15 PB2 T1PF/ IN L Tray 1 paper full sensor signal (On at L)

16 PB3 STID IN L Staple tray paper entry sensor 2 signal (ON at L)

17 PB4 T3UP IN H Tray 3 upper limit sensor signal (On at H)

18 PB5 T3DN IN H Tray 3 lower limit sensor signal (On at H)

19 PB6 LSTS/ IN L Stapler needle sensor signal (presence of needle at L)

20 PB7 NCTS/ IN L Stapler cartridge sensor signal (presence of cartridge at L)

21 PA7 T3OD/ IN L Tray 3 paper discharge sensor signal (On at L)

22 PA6 PFD4/ IN L Transfer sensor signal 4 (On at L)

23 PA5 PFD3/ IN L Transfer sensor signal 3 (On at L)

24 PA4 PFD2/ IN L Transfer sensor signal 2 (On at L)

25 PA3 PFD1/ IN L Transfer sensor signal 1 (On at L)

26 PA2 N.C

27 PA1 RVPD/ IN L Reversion paper discharge sensor signal (On at L)

28 PA0 INPD/ IN L Paper entry sensor signal (On at L)

29 VCC VCC Power supply (

30 /RD RD/ IN L Data read signal (read at L)

31 /WR WR/ IN L Data write signal (write at L)

32 /CS CS/ IN L Chip select signal (select at L)

33 RESET RESET IN H Reset signal (reset at H)

34 GND GND Power supply (GND)

35 A2 A2 IN Address signal (A2)

36 A1 A1 IN Address signal (A1)

37 A0 A0 IN Address signal (A0)

38 D0 D0 IN/OUT Data signal (D0)

39 D1 D1 IN/OUT Data signal (D1)

40 D2 D2 IN/OUT Data signal (D2)

41 D3 D3 IN/OUT Data signal (D3)

42 D4 D4 IN/OUT Data signal (D4)

43 D5 D5 IN/OUT Data signal (D5)

44 D6 D6 IN/OUT Data signal (D6)

45 D7 D7 IN/OUT Data signal (D7)

46 PC7 T3SLCL OUT H Tray 3 low speed clutch drive signal (On at H)

47 PC6 OG2SL OUT H Paper discharge gate 2 solenoid (On at H)

48 PC5 T12CL OUT H Tray 1/2 low speed clutch drive signal (On at L)

49 PC4 SPSL OUT H Short path switching solenoid (On at H)

50 PC0 JMA OUT H Jogger motor drive signal A

51 PC1 JMA/ OUT H Jogger motor drive signal /A

52 PC2 JMB OUT H Jogger motor drive signal B

53 PC3 JMB/ OUT H Jogger motor drive signal /B

54 PG0 PWD IN H Power supply shut-off monitoring signal (power shut-off at H)

55 PG1 DSW1 IN H Connection to copier detection signal (disconnection at H)

56 PG2 DSW2 IN H Upper door opening and closing detection signal (door open at H)

57 PG3 DSW3 IN H Front door opening and closing detection signal (door open at H)

58 GND GND Power supply (GND)

59 PF0 INGSL/ OUT L Paper entry gate solenoid drive signal (On at L)

60 PF1 T3UPSL/ OUT L Tray 3 paper full defector drive solenoid signal (On at L)

61 PF2 OG1SL/ OUT L Paper discharge gate 1 solenoid drive signal (On at L)

62 PF3 OG3SL/ OUT L Paper discharge gate 3 solenoid drive signal (On at L)

63 PF4 RRSL OUT L Reversion roller pressure release solenoid drive signal (On at L)

64 PF5 T30RCL/ OUT L Tray 3 high speed clutch drive signal (On at L)

Port

1 PF6 PDCL/ OUT L Puddler clutch drive signal (On at L)

2 PF7 STORCL/ OUT L Paper discharge roller pressure release clutch (On at L)

3 VCC VCC Power supply (

4 PE0 EMA OUT H Elevator motor CW drive signal

5 PE1 EMB OUT H Elevator motor CCW drive signal

6 PE2 N.C

7 PE3 N.C

8 PE4 STMA OUT H Staple motor CW drive signal

9 PE5 STMB OUT H Staple motor CCW drive signal

Signal

name

IN/OUT ACTIVE Specifications Remarks

+ 5V)

+ 5V)

9 – 5

Page 49

5. Communication buffer and reset circuit

In the communication buffer circuit, the transmission signal (F-TXD)

and communication permit signal (F-DTR) from the copier is received

by the transistor array TD62504 (IC14), while the reception signal

(F-RXD) and communication request signal (F-DSR) transmitted from

the finisher to the copier is output from the IC14.

+5V

1SS133x5

D14 D18

D15 D17

F-TXD

F-RXD

F-DTR

F-DSR

F-RES

from Copier

D16

D10

1SS133x5

D12

D11

D9

D13

C171

0.1U

+5V

BR12-2

4.7K

+5V

BR14-6

4.7K

+5V

BR12-3

4.7K

+5V

BR14-5

4.7K

+5V

R199

1K

The reset signal from the copier is also received by the IC14 and

input to the CPU’s reset terminal (active at L). In addition, the reversion signal is input to the expansion I/O reset terminal (active at H).

For each signal, a protective diode is inserted between

GND.

+5V

IC14

C131

0.1U

BR14-2

4.7K

14

RXD0/P92

F-TXD

+5V

BR12-5

4.7K

+5V

BR14-3

4.7K

+5V

BR12-6

4.7K

+5V

R139

1K

+5V

BR14-7

4.7K

F-RXD

F-DTR

F-DSR

RES/

RES

12

17

16

63

33

TXD0/P90

P95

P94

RES

CPU

(IC02)

RESET

I/O

(IC03)

4

10

IC14

16

1

TD62504F

IC14

11

6

TD62504F TD62504F

2

TD62504F

IC14

12

TD62504F

IC14

3

TD62504F

IC14

15

5

14

BR14-4

4.7K

+5V

13

7

TD62504F

IC14

+ 5V and

Signal

name

Description Logic (connector level)

F-TXD Signal line from copier to finisher Start bit detection at H

Usual (marking state) at L

F-RXD Signal line from finisher to copier Start bit detection at L

Usual (marking state) at L

F-DTR Status display signal line for the signal showing communication permit

from finisher to copier

F-DSR Status display signal line for the signal showing communication request

from finisher to copier

Communication from finisher to copier is inhibited at H

Communication from finisher to copier is permitted at L

No communication request from finisher to copier at H

Communication request from finisher to copier at L

F-RES Hard rest signal from copier Reset at H

Reset is released at L

6. Sensor input circuit

The signal from each sensor is 10 kohm pull-up resistance, noise-removing 1000 pF capacitor, 10 kohm protective resistance, CPU, and

expansion I/O input port.

HP sensor

*1

AMP

*1:Rated Voltage Sircuit

The sensor signal for transfer system is input to the schmitt trigger

input port because the sensor input circuit is not provided with rectifier

circuit.

+5V

+5V

Ω

10K

Ω

10K

1000PF

P**

CPU

(IC02)

Transfer system sensor

240

+5V

+5V

Ω

10K

Ω

1000PF

10K

*2

Ω

PA or PB

I/O

(IC03)

*2 Schumit trigger input port

9 – 6

Page 50

7. Switch input circuit

This circuit checks whether the finisher is connected to the copier,

both the top and front doors are opened. It is connected to microswitches whose contacts are closed when the finisher is connected to the copier or the doors are closed.

Each switch is connected in series from

power supply switch for the drive. That is,

+ 24V so that it becomes a

+ 24V is not conducted to

the drive if all the 3 microswitches are closed.

When the finisher is connected to the copier, the microswitch turns

on, letting

+ 24V be applied to ZD4. This allows electric current to flow

to the base resistance of the transistor array TD62504 (IC19), thus

turning on the transistor to change the expansion I/O PG1 (DSW1

signal) to L level.

Power supply +24V

Upper

Copier connection sw

Upper door sw

Lower

Front door sw

Microswitch x 3

Normal: SW ON

Copier separated

or door open: SW OFF

+24VIN

+24V1

+24V1

+24V2

+24V2

+24V

ZD05

RD6.2EB2

ZD04

RD6.2EB2

ZD03

RD6.2EB2

ZD06

RD6.2EB2

+24V

to each motor and

solenoid clutch

PWD

DSW1

DSW2

DSW3

Finisher door monitoring circuit

When the finisher is disconnected from the copier, the transistor is

turned off to change the expansion I/O PG1 to H level. ZD4 (RD6.2E)

has a threshold level preset, to increase detection speed when the

supply of

+ 24V is cut off. The levels of PG2 and 3 (DSW2, 3 signals)

also change when the top and front door switch is opened and

closed.

In addition, when

+ 24V power supply from the copier is cut off, the

expansion I/O PG0 (PWD signal) level changes at the above circuit.

+5V

BR10

1

2

3

4

5

6

7

8

IC19

I1

I2

I3

I4

I5

I6

I7

GND

TD62504F

COM

234

16

O1

15

O2

14

O3

13

O4

12

O5

11

O6

10

O7

9

56

10Kx5

PWD 54

DSW1 55

DSW2 56

DSW3 57

PG0

PG1

PG2

PG3

I/O

(IC03)

Here are logic’s at the time of the power supply from the copier being