Page 1

Date: Nov. 15, 1995

DIGITAL COPIER : AR-5040

No. : ARE-006

CHANGES AND ADDITIONS OF PARTS

1.Model name: AR-5040.

2.General: Changes and additions of parts have been carri ed on the machine listed above, and are

hereby reported.

3.Description: (1) The metal pattern of the DSD collar (P/G -52) used in the DV box unit is

interchangeable with that of models SF-9400/8870/8800, and the parts code for models

SF-9400/8870/8800 is printed on the side face. This is confusing however, and to

alleviate the potential of problems due to confusion, the printing has been discontinued

and the DSD collar for model AR-5040 is now marked with black to distinguish it.

(As is listed in the parts guide, the parts code for model AR-5040 is different from the

parts code for models SF-9400/8870/8800.)

(2) The black electro deposition used for the surface finishing of the CCD cover of the

scanner unit has been changed to black galvanization in order to decrease the noise

from the power supply.

In addition to the changes described above, the lower face of the cover in the 200V line

has been extended to prevent noise from being emitted from the lower face. This new

CCD cover is to be used in the machines of the 200V line.

From the start of 1994 Oct ober production.

17

200 V series

Lengthened

SHARP CORPORATION Reprography Division

1/7

Green

C

Page 2

(3) An ICB and capacitor has been added to the ICU PWB accommodate the special

photographic mode. The following parts codes of the ICU PWB have also been

changed in accordance with these changes.

Added parts VCKYTVIEF104Z (capacitor)added location C105 . C106

VHI74F00SJ/-1 (IC) added location IC70

VHI74F74SJ/-1 (IC) added location IC71

From the start of 1994 December production.

(Temporary measures have been carried out since the start of mass production.).

(4) A ferrite core has been added to the CL lead wire as a measure to improve noise

(only for models of the 200 V series).

Ferrite core

(RCORF0012FCZZ)

CL Lead wire

(DHAI-2344FCZZ)

Section wound with tape

From the start of 1994 Oct ober production.

(5) There was a danger of the rear end of the copy paper getting caught on the upper

ST sheet in the staple unit of the 100 V series. To alleviate this problem, the ST sheet

has been changed to the one used in the 200 V series.

From the start of 1994 December production.

(6) There was a mistake in the parts code listed in the parts guide for the AC cord

holder. Correction of the error as described below is requested (only for machines

bound for SEEG, UK and Australia ).

2/7

LFIX-0084FCZZ → LFIX-0016FCZZ.

(Mistaken) (Corrected)

Page 3

(7) An ground wire has been added in the operation panel (LCD PWB FG) as a measure

to improve noise. (This measure has been carried out only on the 200 V line.)

LCD PWB FG

Main SW

LCD PWB FG

Lower LCD case surface

OPE

Fixing plate

From the start of 1994 Oct ober production.

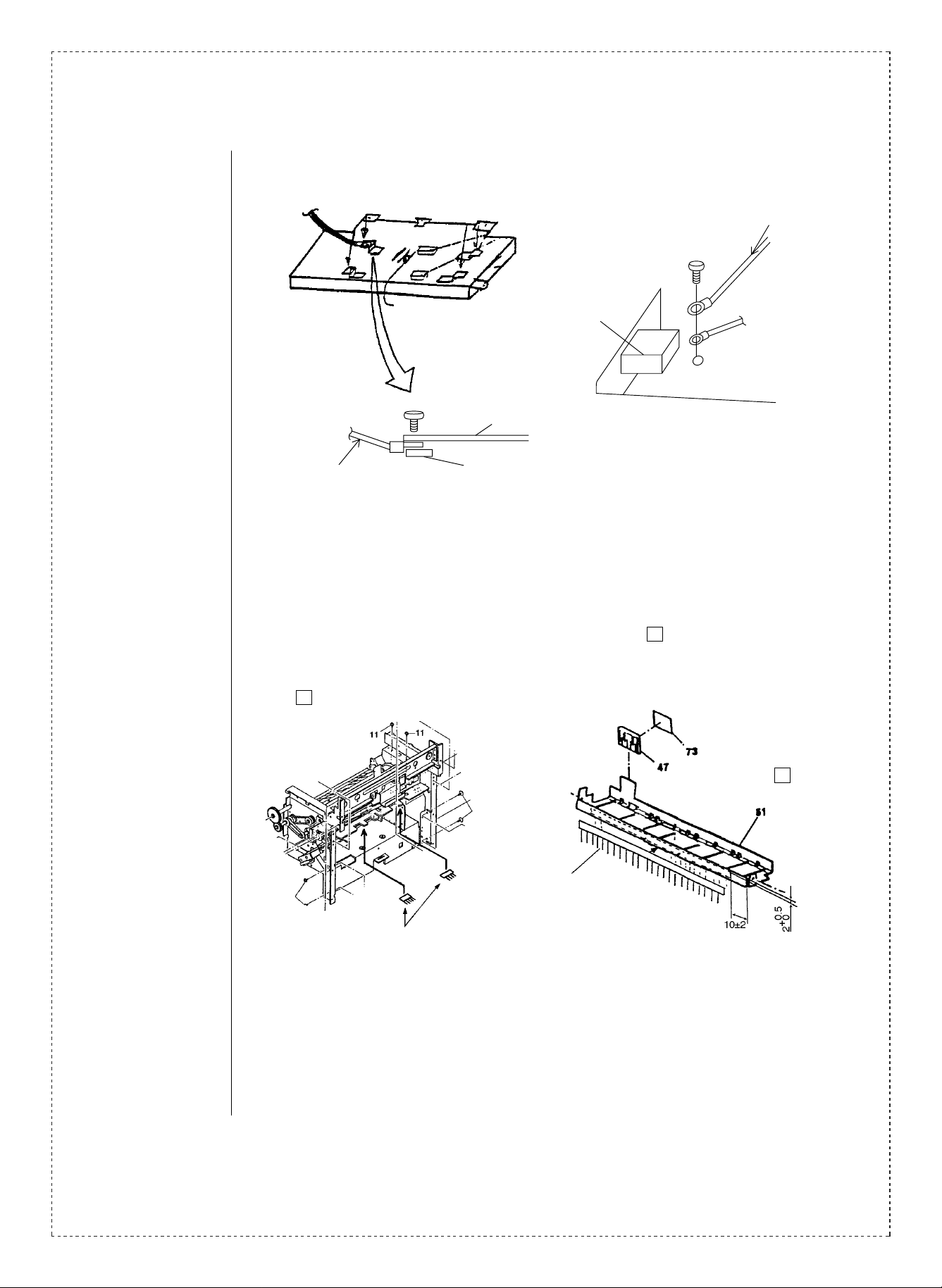

(8) The parts additions and discontinuances listed below have been carried out since

the start of mass production after the parts guide was compiled, and are hereby

reported.

51

P/G

Discontinued part FIN drop sheets (Qty: 2) P/G -131

47

Added discharge brush.

PBRSR0083FCZZ

Added discharge brush.

PBRSR0141FCZZ

Sub PG upper unit

51

-51

From the start of mass production.

3/7

Page 4

(9) The fixing screws used to attach the mai n drive unit and the DR drive unit to the

frame have been changed to improve operationability.

9

P/G -9 M4 x 12 → M4 x 14

From the start of 1994 Oct ober production.

(10) The parts listed below have been added as a measure to reduce noise.

(This change has been carried out only on the 200 V series.)

Front side

Mesh wire

(QCNW-0138FCZZ)

Standard

Standard

P/G No. gasket added

to the FIN joint plate

51

Gasket

Finished tray

View from the

paper side

P/G No. mesh wire added to the

finished shift unit

Shift unit

From the start of 1994 Oct ober production.

(11) Sheets have been added to the gate section to improve stacking performance.

Added FIN paper

discharge sheet

4/7

From the start of mass production.

Page 5

(12) A ferrite core has been added to the finisher main PWB fixing plate unit in order to

comply with the CE mark standards. (This change has been carried out on the 200 V

series only.)

P/G No.

Added ferrite core

55

From the start of 1995 April production.

(13) A laser warning label has been added to the front cabinet and to the finisher

section. This change has been carried out only on machines bound for SUK.

Laser warning label

P/G No.

Sub paper guide upper

51

Laser warning label

P/G No. Front exterior left

48

Sub paper guide upper

Laser warning label

P/G No. Front exterior right

1

From the start of 1995 April production.

Laser

warning

label

5/7

Page 6

(14) An additional manual has been added to supplement the explanation contents of

the operation manual. This change has been carried out only on machines bound

for SUK.

From the start of 1995 February production.

(15) Parts in one of the sections of the shield box have been assembled and the

assembled unit is being offered as a service part. Furthermore, a carved

grounding mark has been added, and the former grounding mark label has

been discontinued.

P/G No. XBPSD40P08KSO.

P/G No. NSFTZ2116FCZZ.

P/G No. LBSHZ0251FCZZ. Assembled

P/G No. LPLTM4733FCZZ.

P/G No. PBOX-0100FCZZ.

P/G No. LHLDW2106SCZZ.

35 -3

35 -8

35 -9

35 -10

35 -11

35 -21

From the start of 1995 May production.

Ref.

Model

No.

(2)

(3) All

AR-5040

(4)

name

Version P/G No.

100V

series

200V

series

200V

series

12 -28 PCOVP1248FCZZ

68 -27

68

68 -59

35 -17

68 -901

12 — RCORF0012FCZZ AH Ferrite core

Current parts New parts

Parts code Parts code

PCOVP1321FCZZ BA

PCOVP1322FCZZ BB

VCKYTV1EF104Z

(Q’ty: 86) (Q’ty: 88)

— VHI74F00SJ/-1

VHI74F74SJ/-1

(Q’ty: 1) (Q’ty: 2)

CPWBN1031FC51 CPWBN1031FC52 EZ ICU PWB 1

Price

Parts name

rank

CCD cover

AA Capacitor

IC [ IC70 ]

AE

IC

CBOX-0100FC31

Effec-

Inter-

tive

change-

time

ability

1st lot

’94/10

1st lot

’94/12

1st lot

’94/10

Note

3

6

6

6/7

(5)

(6)

(7)

(8) All

100V

series

SEEG

U.K.

Australia

200V

series

49 -52

49 -53 PSHEP3620FCZZ PSHEP3735FCZZ AF Upper S T sheet B

35 -16 LFIX-0084FCZZ LFIX-0016FCZZ AD AC cord holder —

2

51 -131

51

47 PBRSR0141FCZZ AF Discharge brush Q’ty: 2

PSHEP3622FCZZ PSHEZ3734FCZZ AG ST cover sheet

— QCNW-0139FCZZ AN LCD PWB FG

PSHEP3618FCZZ

(Q’ty: 2)

—

(Discontinuance) — FIN drop sheets

PBRSR0083FCZZ AH Discharge brush

1st lot

’94/12

1st lot

’94/10

See

text

3

6

—

6

Page 7

Ref.

No.

(9)

(10)

Model

name

Version P/G No.

9-9

All

51

200V

series

50 QCNW-0138FCZZ AN Mesh wire

Current parts New parts

Parts code Parts code

XBBSD40P12000 XBBSD40P14000 AA Screw(M4X14)

PGSK-0006FCZZ AV Gasket

Price

Parts name

rank

Effec-

tive

time

1st lot

’94/10

Inter-

change-

ability

3 Q’ty: 6

Note

(11) All 54 PSHEP3852FCZZ AC

200V

(12)

AR-5040

(13)

(14) 74 TCADZ1216FCZZ AP

(15) All

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

s p eci fi e d on es fo r m ain ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

55 RCORF1013LCZZ AN Ferrite core

series

1

48

SUK

only

51

35 CBOX-0100FC31 BT Shield box unit

35 -12 TLAB-4681CCZZ (Discontinuance) —

!

—

TCAUS0003GCZZ AB

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

FIN paper

discharge sheets

Laser warning

label

operation

manual

Grounding mark

label

1st lot Q’ty: 2

1st lot

’95/4

1st lot

’95/4

1st lot

’95/2

1st lot

’95/5

6

Q’ty: 3

7/7

Loading...

Loading...