Page 1

AR-DE7

AR-CS3

CODE: 00ZARDE7//A1E

DIGITAL COPIER

OPTIONS

AR-DE7

MODEL AR-CS3

1-step paper

feed desk

Paper feed

module

AR-DE7

CONTENTS

[Note]

This Service Manual describes only the differences from 00ZARDE2//A1E.

The items which are not described in this Manual are common with the

00ZARDE2//A1E.

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 3 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . 1-1

[ 4 ] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . 4-1

[ 5 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

PARTS GUIDE

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-DE7

List of different points between the AR-DE7/CS3 and the AR-DD1/DE1/CS1

No.

Page Item Content Change Remark

AR-DD1/DE1/CS1 AR-DE7/CS3

1 1-1 [2]-9 Paper transport speed:

170mm/s – 306mm/s Changed to 432mm/s

2 1-1 [2]-10 Paper feed speed:

33 sheets/min Changed to 50 sheets/min

3 1-1 [2]-19 Power consumption:

24W (MAX) Changed to 36W (MAX)

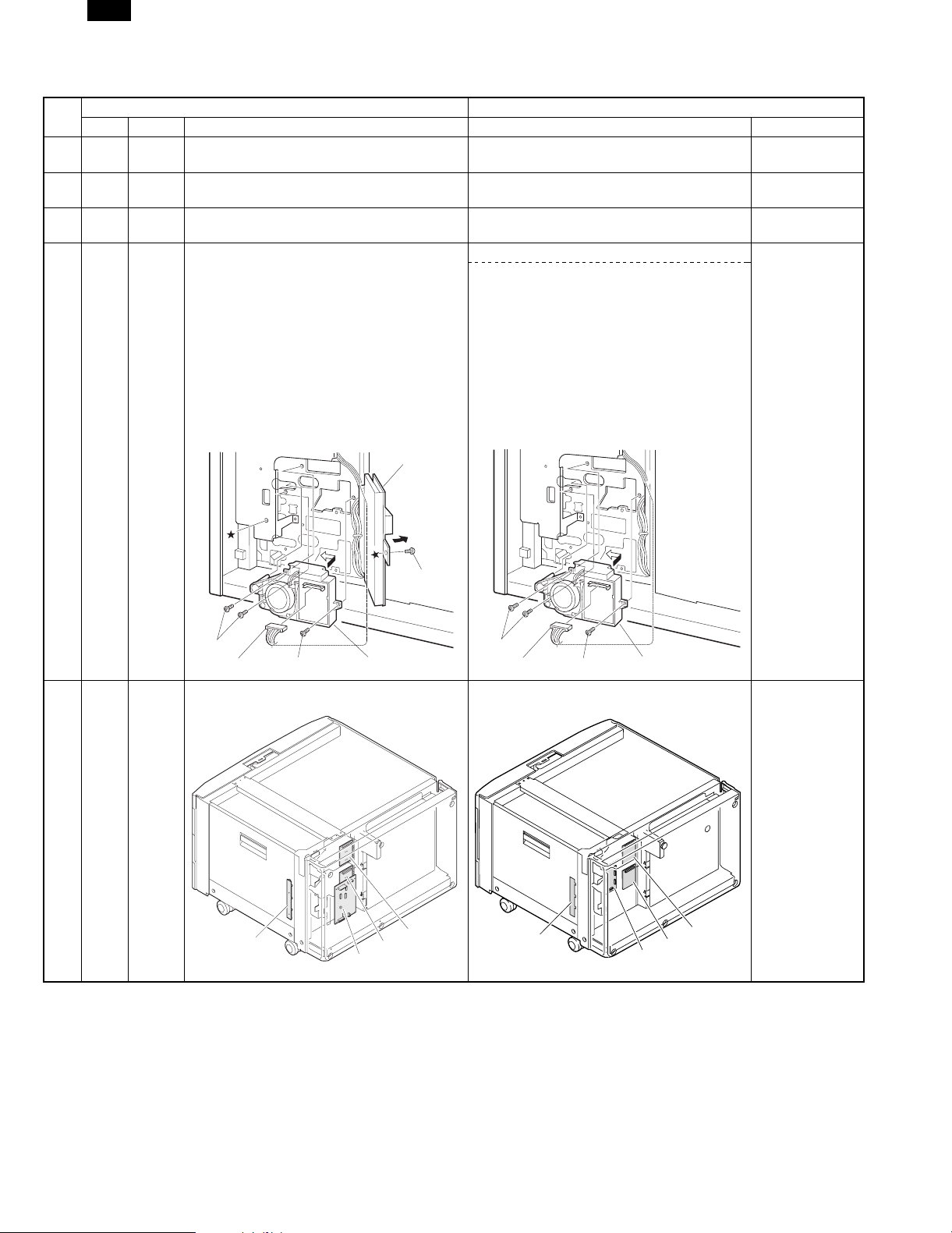

4 3-5 [3]-2-C 2. Install the lift up unit.

Remove the fixing screw (section ★) of the desk

PWB mounting plate, and open the desk PWB

mounting plate.

Attach the lift up unit to the rear frame of the

desk and slide it to the left.

Fix the lift up unit with the fixing screws A (3

pcs.) and connect the desk PWB connector to

Change Desk PWB

2. Install the lift up unit.

Attach the lift up unit to the rear frame of the

desk and slide it to the left.

Fix the lift up unit with the fixing screws A (3

pcs.) and connect the desk PWB connector to

the lift up unit connector.

the lift up unit connector.

Return the desk PWB mounting plate to the

original position, and fix it with the fixing screw

(section ★).

Desk PWB mounting

plate

mounting plate

abolished.

(Changed to the

duplex PWB.)

Desk mounting

plate fixing screw

Fixing screw A

Desk PWB connector Fixing screw A Lift up unit

Fixing screw A

Desk PWB connector Fixing screw A Lift up unit

5 4-1 [4]-2 1) PWB Illustration changed Desk main PWB

installing position

changed.

(Changed to the

duplex PWB)

2

1

3

4

2

1

3

4

8/6/1999 – 1 –

Page 3

AR-DE7

No.

Page Item Content Change Remark

AR-DD1/DE1/CS1 AR-DE7/CS3

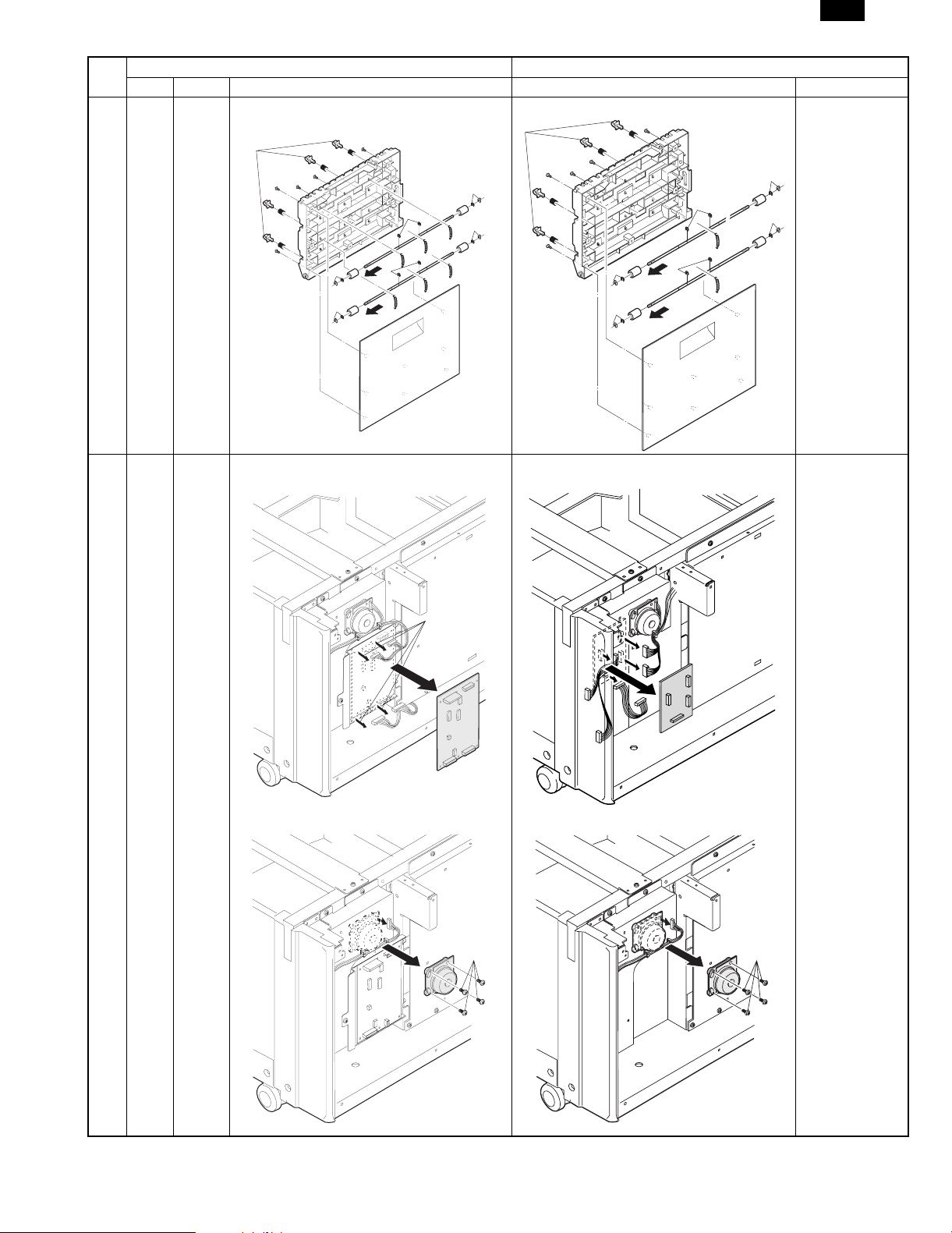

6 5-3 [5]-2-C Paper transfer idle roller Illustration changed

1)

1)

1)

1)

1)

1)

2)

2)

2)

5)

6)

2)

2)

6)

4)

2)

5)

4)

6)

2)

4)

4)

4)

4)

1)

1)

1)

1)

2)

2)

2)

5)

6)

2)

2)

2)

5)

6)

6)

2)

4)

4)

7 5-3 [5]-3 Desk control PWB, Paper transfer motor Illustration changed Changed to the

duplex PWB.

2)

1)

1)

1)

3)

1)

Desk main PWB

abolished.

2)

1)

2)

1)

– 2 – 8/6/1999

Page 4

AR-DE7

No.

Page Item Content Change Remark

AR-DD1/DE1/CS1 AR-DE7/CS3

8 5-4 [5]-4 Drive unit Illustration changed Desk main PWB

added.

2)

5)

4)

1)

5)

3)

3)

3)

4)

3)

3)

3)

9 5-4 [5]-5 Lift up unit Illustration changed Desk main PWB

added.

7)

2)

5)

4)

6)

6)

1)

3)

3)

4)

10 7-2 [7]-2 Paper transport secttion Illustration changed

2

7)

6)

6)

5)

3)

3)

2

2

2

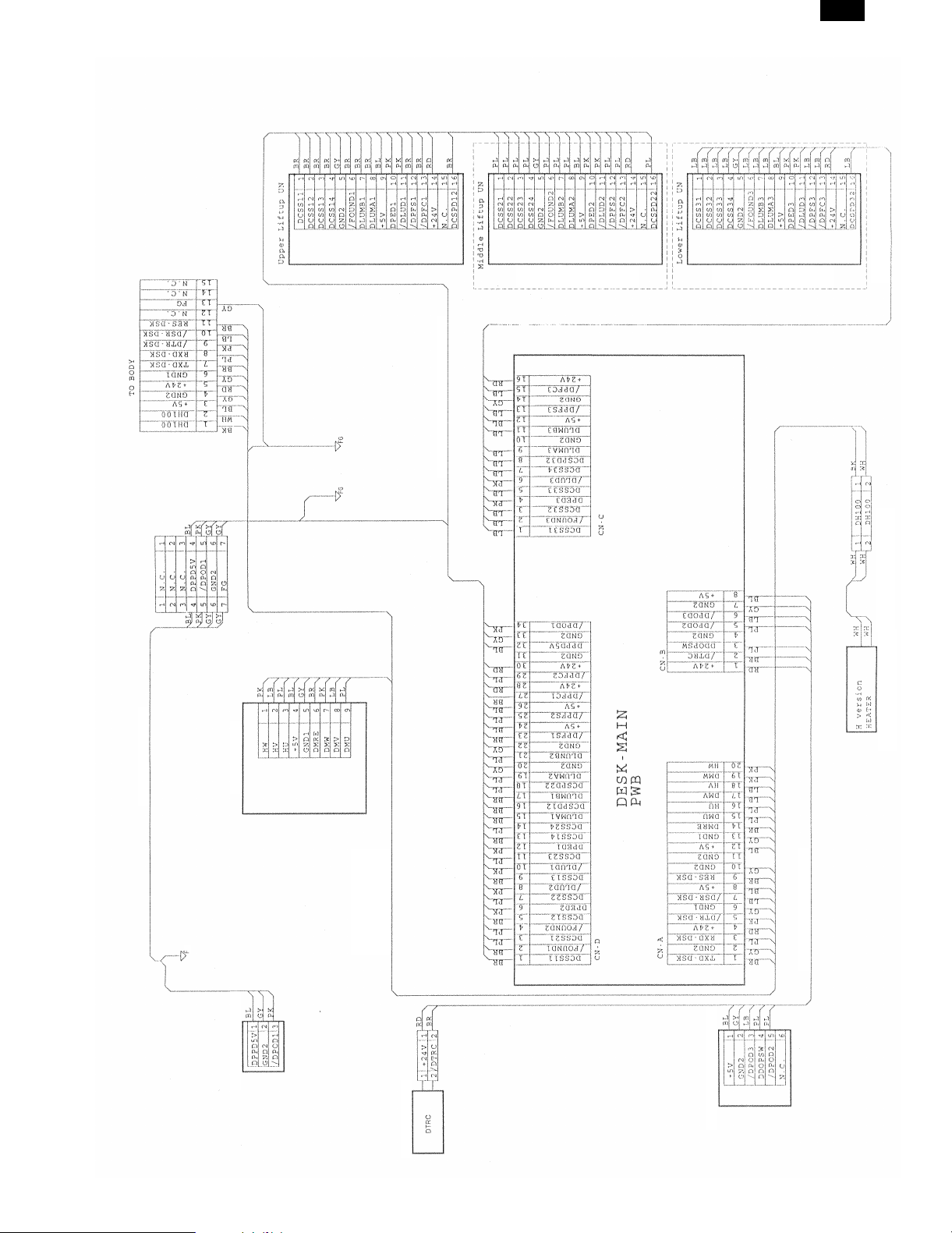

11 9-1 [9]-1 Actual wiring diagram Change Refer to the

attached page.

12 9-3 [9]-3 Main PWB block diagram Change Refer to the

attached page.

13 9-4 [9]-4 Parts arrangement Changed to the duplex PWB. Refer to the

attached page.

8/6/1999 – 3 –

Page 5

AR-DE7

AR-DE7 option

Paper feed system harness 1 2-cassette W

AR-DE7 no provision

AR-DE7 no provision

(Japan spec. only)

PPD interface harness

1. Actual wiring diagram

[9] ELECTRICAL SECTION

Desk main motor

Top stage paper exit sensor

Copier interface harness H W

(Japan spec.)

Copier interface harness 100

W (EX spec.)

Dehumidifying heater

Transport sensor harness W

PFD PWB UN

Transport roller clutch

9 – 1 8/6/1999

Page 6

AR-DE7

+24V

+10V

(24vm)

24V monitor

P36

P63

(DLUM3)

Lift up motor

IC05

driver

P34,P35

P62

(DLUM2)

Lift up motor

Output

section

IC04

driver

Output

P32,P33

section (1)

P64

(DLUM1)

Lift up motor

(2)

IC03

driver

P30,P31

IC08

(DPFC)

paper feed

Paper feed clutch

C P U

TXD,P52

(DTRC)

Transport clutch

solenoid (DPFS)

IC01

P10~P15,P17

driver

X1,X2

Output

section

Paper empty sensor

(DLUD)

(DPED)

Top cassette

remaining paper

Upper limit sensor

(1)

P40~P42,

P70,P72

(DPCD)

(DCSPD)

Door open/close

Paper exit sensor

quantity detection

P21~P27

sensor (DDCPSW)

(2)

Input

section

IC06

driver

IC02

RES,RXD,P46

IC09

X1

(8.00MHz)

Input

section

IC11, IC12

8-CHANNEL

(1)

MULTI

PLEXER

section

Communication

(DCSS)

Tray size detection

stage tray paper

remaining quantity

Middle stage, lower

sensor (DCSPD2, 3)

+5V

IC07

driver

+5V

driver

IC10

amplifier

operation

PWB

Copier main

Transport

motor (DM)

3. Main PWB blook diagram

8/6/1999 9 – 2

Motor drive section

Page 7

4. Parts arrangement

AR-DE7

CN-C

B16B-PHDSS-B

DCSS31

1

/FOUND3

2

DCSS32

3

DPED3

4

5

DCSS33

/DLUD3

6

DCSS34

7

DCSPD32

8

DLUMA3

9

GND2

10

DLUMB3

11

12

+5V

/DPFS3

13

GND2

14

/DPFC3

15

+24V

16

0EUPWB0406J31,41,51only

CN-D

B34B-PHDSS-B

1

DCSS11

2

/FOUND1

DCSS21

3

4

/FOUND2

DCSS12

5

6

DPED2

DCSS22

7

8

/DLUD2

DCSS13

9

10

/DLUD1

11

DCSS23

12

DPED1

DCSS14

13

14

DCSS24

DLUMA1

15

DCSPD12

16

DLUMB1

17

18 DCSPD22

DLUMA2

19

20

GND2

DLUMB2

21

22

GND2

23

/DPFS1

24

+5V

25

/DPFS2

26

+5V

27

/DPFC1

28

+24V

29 /DPFC2

30

+24V

31

GND2

32 DPPD5V

GND233

/DPOD1

34

CN-B

1

2

3

4

5

6

7

8

CN-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

B8B-PH-K-S

+24V

/DTRC

DDOPSW

GND2

/DPOD2

/DPOD3

GND2

+5V

B20B-PHDSS-B

TXD-DSK

GND2

RXD-DSK

+24V

/DTR-DSK

GND1

/DSR-DSK

+5V

RES-DSK

GND2

GND2

+5V

GND1

DMRE

DMU

HU

DMV

HV

DMW

HW

9 – 3 8/6/1999

Page 8

AR-DE7

Page 9

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

le constructeur.

Mettre au rebut les batteries usagées conformément aux

instructions du fabricant.

(Swedish) VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

AR-DE7

Page 10

AR-DE7

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted,

in any form or by any means,

electronic; mechanical; photocopying; recording or otherwise

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1999 August Printed in Japan

Loading...

Loading...