Page 1

SERVICE MANUAL

CODE: 00ZARDE2//A1E

DIGITAL COPIER

OPTIONS

AR-DD1

AR-DE1

AR-DD1

AR-CS1

MODEL AR-CS1

CONTENTS

[ 1 ] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 3 ] UNPACKING AND INSTALLATI ON . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 4 ] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . 4-1

AR-DE1

Desk

1-step paper

feed desk

Paper feed

module

[ 5 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . 5-1

[ 6 ] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[ 9 ] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Parts marked with "!" is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CAUTION FOR BATTERY REPLACEMENT

(Danish) ADVARSEL !

Lithiumbatteri – Eksplosionsfare ved fejlagtig håndtering.

(English) Caution !

Danger of explosion if battery is incorrectly replaced.

Dispose of used batteries according to manufacturer’s instructions.

(Finnish) VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä käytetty paristo valmistajan ohjeiden

(French) ATTENTION

Il y a danger d’explosion s’ il y a remplacement incorrect

de la batterie. Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé par

Mettre au rebut les batteries usagées conformément aux

(Swedish) VARNING

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandoren.

Replace only with the same or equivalent type

recommended by the manufacturer.

mukaisesti.

le constructeur.

instructions du fabricant.

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

Page 3

[1] PRODUCT OUTLINE

The AR-DD1 is the exclusive-use desk for a copier body, which

stores copy paper.

The AR-DD1 (1-step paper feed desk) serve as the paper feed unit

which also serves as a desk for a copier.

The AR-DE1 is composed of the paper feed/transport section, the

lift-up section, and the paper feed tray section. By installing the ARDE1 to a copier, the additional paper feed tray is available as shown

below;

Installation of the paper feed module (AR-CS1) to the AR-DE1 adds

one more paper feed tray.

Copier body

[1-step paper feed desk]

AR-DE1

550-sheet tray

(Slot for AR-CS1)

AR-CS1

Paper feed module

AR-CS1 (Option)

550-sheet tray

11. Tray falling/rising time (AR-DE1):

Within 8 sec (at min. number of set paper)

12. Power:

5V and 24V supplied from the copier.

13. Weight:

AR-DE1 25kg (excluding paper)

14. Drive form:

Drive motor (The DC brushless motor and the control PWB

are included in the desk.)

15. Operation control system:

Controlled by the communication command from the copier.

16. Paper transport path:

Paper entry from the lower section of the copier.

17. Dehumidifying heater:

Provided (power consumption 14W

18. External dimensions:

600(W) x 604(D) × 403(H)mm

19. Power consumption:

24W (MAX) 4.5W (Ready condition)

[2] SPECIFICATIONS

1. Model:

AR-DD1 Desk

AR-DE1 Desk-type paper feed unit

2. No. of steps of paper feed:

AR-DE1 1-step (2-step with the AR-CS1 installed)

3. Paper size:

A3/B4/A4R/B5R/A4/B5

(11" × 17"/8.5" × 13"/8.5" × 11"/8.5" × 11R)

4. Paper weight:

56 ∼ 105g/m

5. Paper capacity:

Each tray 500 sheets (Paper weight 80g/m2)

6. Paper set:

Center reference, tray size when shipping A3

7. Paper supply system:

Front loading system. Supplied at the top.

8. Paper feed system:

Paper pickup system by the takeup roller, torque limiter

separation system

9. Paper transport speed:

170mm/s ∼ 306mm/s (The spee d depends on the

communication command from the copier body.)

10. Paper feed speed:

33 sheets/min

2

[3] UNPACKING AND

INSTALLATION

1. UNPACKING

For unpacking, refer to the figure below.

A. AR-DD1

1 – 1

Page 4

B. AR-DE1

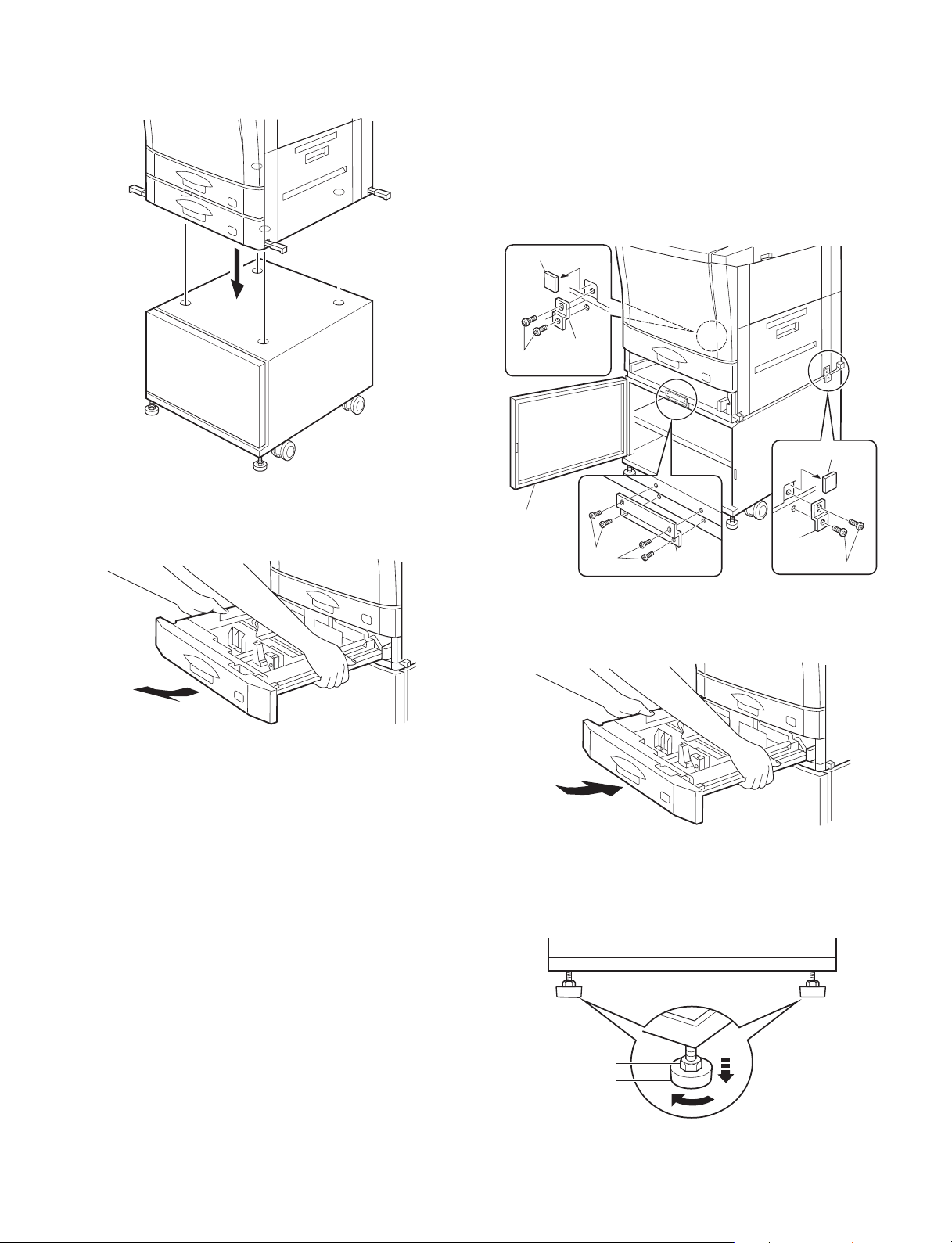

2. Installing procedure

A. AR-DD1

C. AR-CS1

Caster

(4 pcs.)

Adjuster / with cover

(3 pcs.)

Spring washer

(4 pcs.)

Connection plate

fixing screw

(8 pcs.)

Connection

plate small

(2 pcs.)

Connection

plate large

(1 pc.)

Caster fixing wrench

(1 pc.)

1. Install the caster and the adjuster.

Put the desk as shown below, and install the casters (4 pcs.) and

adjusters (4 pcs.).

When installing the casters, use the caster fixing wrench packed

together.

Caster fixing wrench

Caster

Spring washer

Adjuster / with cover

3 – 1

Page 5

2. Put the copier on the desk.

Hold the four knobs of the copier, fit the four tabs of the copier with

the four holes of the desk, and place the copier on the desk.

4. Connect the copier and the desk.

Open the desk front cover.

Install the connecting plate large to the connecting plate installing

position with the four connecting plate fixing screws to fix the copier

and the desk.

Then cut off the notch sections (at right and left of the copier) in the

connecting plate installing section.

Install the connecting plate small to the position shown in the figure

below with the connecting plate fixing screws (2 pcs. for each) to fix

the copier and the desk.

Notch

Connecting

Fixing

plate small

screw

Notch

3. Remove the lower tray of the copier.

Remove the lower tray of the copier as shown.

Front cover

Connecting

Fixing

screw

Connecting

plate large

plate small

Fixing screw

5. Install the lower tray of the copier.

Install the lower tray of the copier as shown.

6. Fix the desk to the floor.

Turn the nut of the adjuster which is in the lower section of the desk

with a wrench or nippers in the direction of arrow, and adjust and fix

the desk on the floor.

3 – 2

Nut

Adjuster

Page 6

B. AR-DE1

Packed items

Connecting plate (2 pcs.) Connecting plate cover (2 pcs.)

Connecting screw (6 pcs.)

2. Remove the tray from the copier.

Pull the lower tray out until it stops.

Then hold and lift the tray to remove.

Remove the power plug of the copier from the power

outlet, then perform the following procedures.

1. Put the copier on the desk.

Hold the knobs of the copier and fit the desk precisely with the desk

and put the copier on the desk.

Be sure to check that the positioning pins (2 pcs.) of the desk (top

front) are securely in the positioning holes.

Be careful that the copier and the bottom are not in contact with the

desk paper guide.

3. Connect the copier and the desk.

• Front connection

Put the connecting plate of the desk as shown, and fix the copier

and the desk with the connecting screws (2 pcs.).

Front

Connecting plates

Connecting

screws

Portioning pins

Paper guide

3 – 3

Page 7

• Side connection

Attach the connecting plates to the copier and the desk with the

round hole upside. Insert the connecting screws into the round

holes and fix.

Insert the connecting plate cover into the external fitting of the

copier and fix the copier and the desk with the connecting screw.

(1 pc. for each)

★ The connecting screw serves not only as the fixing screw but also

as an electrical grounding for the copier and the desk. Be sure to

fix the connecting screw.

Install the tray which was removed in procedure 2.

Right side

Connecting plate

Connecting screw

Connecting plate cover

5. Connect the desk connector.

Remove the connector cover fixing screw for connecting the desk

interface harness connector on the copier side, and remove the connector cover.

Connect the desk interface harness connector with the copier connector, and tighten the screw of the connector to fix the connector.

Connector cover

Fixing screw

Desk side connector

Connecting screw

Left side

Connecting plate

Connecting plate cover

Connecting screw

Connecting plate

Left side

4. Remove the package fixture of the tray.

Hold the knob of the tray and pull out the tray from the desk until it

stops.

Turn the package fixture which is fixing the paper falling/rising plate in

the tray in the arrow direction.

When shipping it is set to A3 size.

When selecting the paper size, perform paper selection.

The procedures are the same as those of the copier.

Fixture

Screw

6. Move the copier to the installing position.

7. Lock the caster.

Set the lock lever of the caster which is on the front lower side of the

desk in the arrow direction and lock the caster.

Lock lever

Lock lever

8. Fix the desk to the floor.

Loosen the lock nut of the adjuster with a wrench or nippers.

Turn the adjuster in the arrow direction until it reaches the floor. Fix all

the adjusters (4 pcs.) to the floor.

After fixing the adjusters, turn the lock nut fully upward.

Lock nut

Adjuster

Lock nut

Adjuster

Insert the power plug of the copier into the power outlet, and turn on

the power and perform the following procedures.

3 – 4

Page 8

C. AR-CS1

Packed items

3. Install the rear cabinet of the desk.

Install the rear cabinet which was removed in procedure 1 to the

original position, and fix it with fixing screws (6 pcs.).

Fixing screw (6 pcs.)

Tray rail left

(1 pc.)

Tray rail right cover

(1 pc.)

Paper fed unit

(1 pc.)

Stopper left

(1 pc.)

Fixing screw A

(M4 x 10) (7 pcs.)

Lift up unit

(1 pc.)

Stopper right

(1 pc.)

Fixing screw B

(M4 x 16) (1 (pc.)

Remove the power plug of the copier from the power

outlet and perform the following procedure.

1. Remove the rear cabinet of the desk.

Remove the fixing screws (6 pcs.) of the rear cabinet of the desk, and

remove the rear cabinet.

Fixing screw (6 pcs.)

Rear cabinet

Rear cabinet

4. Remove the desk tray.

Pull out the tray (which is above the tray to be installed) until it stops.

Hold the both sides of the tray and lift it to remove.

5. Remove the cover.

Remove the fixing screws (2 pcs.) of the cover of the tray to be

installed, and remove the cover.

2. Install the lift up unit.

Remove the fixing screw (section ★) of the desk PWB mounting

plate, and open the desk PWB mounting plate.

Attach the lift up unit to the rear frame of the desk and slide it to the

left.

Fix the lift up unit with the fixing screws A (3 pcs.) and connect the

desk PWB connector to the lift up unit connector.

Return the desk PWB mounting plate to the original position, and fix it

with the fixing screw (section ★).

Desk PWB mounting

plate

Desk mounting

plate fixing screw

Fixing screw A

Desk PWB connector

Fixing screw A

Lift up unit

Fixing screw

Cover

Fixing screw

3 – 5

Page 9

6. Install the tray rail left.

Insert the tray rail left into the positioning section of the frame on the

left side of the desk. Put the tray rail onto the frame and fix it with

fixing screw A (1 pc.).

Positioning section

Positioning

section

Fixing screw A

9. Set the tray.

Lift the both sides of the rear of the tray, fit the tray guide with the tray

rail, and push it along the tray rail into the desk.

Check that the tray moves smoothly.

Tray rail left

7. Install the paper feed unit.

Put the paper feed unit on the guide rail and push it until it stops.

Engage the front side of the paper feed unit with the positioning boss

(2 positions) of the desk frame, and fix it with the fixing screw (1 pc.).

Paper feed unit

Positioning boss

Fixing screw A

Guide rail

8. Install the tray rail right cover.

Insert the positioning bosses (2 positions) of the tray rail right cover

into the positioning holes of the front frame on the right side of the

desk, and fix with the fixing screws A (2 pcs.).

10. Set the tray which was removed in procedure 4.

Lift the both sides of the rear of the tray, fit the tray guide with the tray

rail, and push it along the tray rail into the desk.

Check that the tray moves smoothly.

11. Install the stopper.

Pull out the upper tray.

Fix the stopper left to the left tray rail with the fixing screw B (1 pc.).

Fix the stopper right tot he tray rail right cover.

Left side Right side

Stopper left

Fixing screw B

Stopper right

Positioning boss

Tray rail right cover

Fixing screws A

Positioning boss

Select the paper size according to the paper to be used.

The selecting procedure is the same as that of the main body.

Fixing screw

Insert the power plug of the copier into the power outlet and turn on

the power. Perform the following procedure.

3 – 6

Page 10

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

1

2

3

No. Name Remark

1 Side cover

2 Tray Similar with AC-CS1.

3 Preliminary paper feed section For option (AR-CS1)

2. Internal structure

1) PWB

2

3

1

No. Unit name Function Remark

1 Desk main PWB unit Control the desk unit

2 Paper detector PWB Paper detection in the middle and the lower stage, and right

3 Lift up PWB Lift up PWB for the top stage (Included in the lift up unit.)

door open detection.

4 – 1

Page 11

2) Sensors and detectors

9.DCSPD1

2.DLUD2

1.DLUD1

3.DPED1

5.DPOD1

6.DPOD2

8.DDOPSW

7.DPOD3

4.DPED2

No. Code Name Kind Function Remark

1 DLUD1 Desk lift up detector 1 Photo sensor Top tray lift up detection (LOW

when lift up.)

2 DLUD2 Desk lift up detector 2 Photo sensor Middle tray lift up detection

(LOW when lift up.)

3 DPED1 Desk paper empty detector 1 Photo sensor Top tray paper

(presence/empty) detection

(LOW at paper presence)

4 DPED2 Desk paper empty detector 2 Photo sensor Middle tray paper

(presence/empty) detection

(LOW at paper presence)

5 DPOD1 Desk paper exit detector 1 Photo sensor Top stage paper exit detection

6 DPOD2 Desk paper exit detector 2 Photo sensor Middle stage paper exit

detection

7 DPOD3 Desk paper exit detector 3 Photo sensor Low stage paper exit detection For AR-DE2 only (Included in

8 DDOPSW Desk right door open/close

detector

9 DCSPD1 Desk remaining paper quantity

detector 1 (Top stage)

10 DCSPD2 Desk remaining paper quantity

detector 2 (Middle stage)

Photo sensor Right door open/close detection (Included in the paper exit

Photo sensor Remaining paper quantity

detection (For top stage)

Photo sensor Remaining paper quantity

detection (For middle stage)

4 – 2

(Included in the paper feed

unit.)

For AR-DE2 only (included in

the paper feed unit.)

(Included in the paper feed

unit.)

For AR-DE2 only (Included in

the paper feed unit.) (Similar

with AR-CS1.)

(Included in the paper exit

PWB.)

the paper feed unit.)

PWB.)

(Included in the lift up PWB.)

For AR-DE2 only (Included in

the lift up PWB.) (Similar with

AR-CS1.)

Page 12

3) Clutches, motors, and solenoids

5.DPFS1

2.DLUM1

7.DPFC1

1.DM

4.DTRC

8.DPFC2

3.DLUM2

6.DPFS2

No. Code Name Kind Function Remark

1 DM Desk motor Brushless motor Desk transport mechanism

drive

2 DLUM1 Desk lift up motor 1 Synchronous motor Top tray lift/fall plate drive

3 DLUM2 Desk lift up motor 2 Synchronous motor Middle tray lift/fall plate drive

4 DTRC Desk vertical transport roller

clutch

5 DPFS1 Desk paper feed solenoid 1 Solenoid Top tray paper takeup roller

6 DPFS2 Desk paper feed solenoid 2 Solenoid Middle tray paper takeup roller

7 DPFC1 Desk paper feed clutch 1 Magnetic clutch Top tray paper transport roller

8 DPFC2 Desk paper feed clutch 2 Magnetic clutch Middle tray paper transport

Magnetic clutch Vertical transport mechanism

drive and transmission

drive

For AR-DE2 only

drive

drive

For AR-DE2 only

roller drive

4 – 3

Page 13

[5] DISASSEMBLY AND ASSEMBLY

1. Paper feed unit

2)

1) 3)

2)

A. Paper feed, Pic up, Resist roller

1)

3)

3)

6)

5)

1)

* 1. When attaching the clutch, be sure to fit the clutch notch into

the B portion as shown in the figure above.

* 2. When inserting the shaft into the roller, attention shall be paid

so that the pin C on the shaft faces down.

4)

2)

B

7)

8)

C

5 – 1

Page 14

2. Paper transfer

B. Paper transfer roller

3)

2)

A. Paper transfer cover

1)

2)

1)

2)

3)

2)

1)

1)

4)

4)

1)

5)

6)

6)

4)

4)

6)

1)

3)

1)

2)

6)

5)

3)

2)

2)

5 – 2

5)

3)

2)

1)

1)

1)

1)

Page 15

C. Paper transfer idle roller

1)

1)

1)

1)

1)

2)

6)

2)

2)

2)

4)

4)

5)

6)

2)

5)

2)

6)

4)

2)

4)

4)

4)

D. Transport paper guide

Attach the transport paper guide fully to the rear frame side (in the

arrow direction).

3. Desk control PWB, Paper transfer motor

2)

1)

1)

1)

3)

1)

5 – 3

Page 16

5. Lift up unit

6)

7)

4. Drive unit

2)

1)

2)

6)

1)

5)

3)

3)

4)

2)

1)

5)

3)

3)

4)

3)

5 – 4

Page 17

[6] ADJUSTMENTS

1. Adjust the cabinet surface position.

Loosen the fixing screws (4 pcs.) which are fixing the front cabinet,

and shift the front cabinet in the arrow direction to adjust the position.

a

Direction A

bba

Direction B

6 – 1

Page 18

[7] MAINTENANCE

1. Paper feed section

1

1

1

2

3

No. Name Work item Cycle Model Remark

1 Rollers Check 80 K AR-DE1 Reference: paper feed port counter

2 Brake spring Lubricate 160 K AR-DE1

3 Torque limiter Check 80 K AR-DE1

Replace 120 K or 2 years AR-DE1 Reference: Paper feed port counter

7 – 1

Page 19

2. Paper transport section

1

2

1

2

1

2

No. Name Work item Cycle Model Remark

1 Transport rollers Clean 80 K AR-DE1

2 Rollers Clean 80 K AR-DE1

2

2

2

7 – 2

Page 20

3. Drive section, others

2

1

3

No. Name Work item Cycle Model Remark

1 Gears Lubricate 80 K AR-DE1

2 Belts Check 240 K AR-DE1

3 Sensors Check 80 K AR-DE1

3

7 – 3

Page 21

[8] TROUBLESHOOTING

1. T ro ubl e code li st

Trouble

code

U6 00 Desk communication trouble Desk

01 Desk 1 CS lift up trouble Desk

02 Desk 2 CS lift up trouble Desk

03 Desk 3 CS lift up trouble Desk

08 Desk 24V power abnormality Desk

10 Desk transport motor trouble Desk

Trouble content Remark

2. Details

Trouble

code

U6 00 Content Desk communication trouble

Detail Communication error with the desk.

Cause Improper connection or disconnection of

Check

and

remedy

01

Content Desk 1, 2, 3 tray lift up trouble

∼

Detail Desk 1, 2, 3 tray lift up trouble

03

Cause Sensor trouble

Check

and

remedy

08 Content Desk 24V power trouble

Detail DC24 V is not supplied to the desk.

Cause Improper connection or disconnection of

Check

and

remedy

10 Content Desk transport motor trouble

Detail Desk transport motor operation trouble

Cause Motor lock

Check

and

remedy

Error during the communication line test

after turning on the power or after exiting

the simulation mode.

the connector and the harness.

Desk control PWB trouble

Control PWB (PCU) trouble

Malfunction due to noises

Canceled by turning off/on the power.

Check the connector and the harness of

the communication line.

Desk control PWB trouble

Gear breakage

Lift up motor trouble

Check the lift up sensor operation with

SIM 4-2.

Check the lift up motor operation with SIm

4-3.

the connector and the harness.

Desk control PWB trouble

Power unit trouble

Check the connector and the harness of

the power line.

Check 24V supply with the power unit and

the desk control PWB.

Motor RPM abnormality

Overcurrent to the motor

Desk control PWB trouble

Check the transport motor operation with

SIM 4-3.

Details of trouble

Trouble

detection

8 – 1

Page 22

[9] ELECTRICAL SECTION

1. Actual wiring diagram

Top stage paper exit sensor

BL

1

Transport roller clutch

DTRC

DPPD5V

GND2

/DPOD1

1

+24V

/DTRC

2

GY

2

PK

3

RD

1

BR

2

PPD interface harness

Desk main motor

DMHW

DMHV

DMHU

+5V

GND1

DMRE

DMW

DMV

DMU

1

2

3

4

5

6

7

8

9

PK

LB

PL

BL

GY

BR

PK

LB

PL

Drive system harness

N.C.

1

N.C.

2

N.C.

3

DPPD5V

44

PK

/DPOD1

5

GY

GND2

6

GY

FG

7

1

2

3

5

GY

6

GY

7

(Japan spec.)

Copier interface harness

(EX spec.)

Copier interface harness H

To copier

RXD-DSK

TXD-DSK

RES-DSK

/DTR-DSK

/DSR-DSK

/TRC-DSK

N.C.

FG

N.C.

1011121413

BR

PK

LB

PL

15

GY

BR

PK

GND2

GND1

+24V

DH100

DH100

+5V

1

2

56789

3

4

GYRDGY

WH

BK

BL

Top stage lift up UN

DCSS11

DCSS12

DCSS13

DCSS14

GND2

/FOUND1

DLUMB1

DLUMA1

+5V

DPED1

/DLUD1

/DPFS1

/DPFC1

+24V

N.C.

DCSPD12

BR

1

BR

2

BR

3

BR

4

GY

5

BR

6

BR

7

BR

8

BL

9

PK

10

PK

11

BR

12

BR

13

RD

14

15

BR

16

9 – 1

PFD PWB UN

+5V

GND2

/DPOD3

DPOPSW

/DPOD2

.N.C.

Middle stage lift up UN

GY

BR

BL

BLLBPL

PLLBPL

1

2

56789

3

4

HU

HV

/DPOD2

+5V

/DPOD3

DMRE

+5V(DM)

CN-D CN-C

GYPLRD

PK

101112131415161718

DDOPSW

DMU

HW

GND1(DM)

N.C.

GND2

+24V

BR

PK

LB

DMV

N.C.

DMW

/DTRC

BR

1

TXD-DSK

GYPLRDPKGY

2

56789

3

4

GND2

+24V

/DTR-DSK

/RXD-DSK

GND1

GY

BR

PK

LB

BL

101112

HV

N.C.

GND2

+5V

/DSR-DSK

/TRC-DSK

AR-DE2 standard provision

AR-DE1 option (AR-CS1)

DESK-MAIN

PWB

CN-A CN-B

AR-DE2 paper feed system harness 3-cassette

N.C.

GND2

/DPFS1

/DPFS2

/DPFS3

+24V

/DPFC1

+5V

/DPFC2

+5V

/DPFC3

+5V

DLUMA3

DPPD5V

+24V

+24V

BL

1

GY

2

LB

3

PL

4

PL

5

6

4

1

2

56789

3

BRRDPLRDLBRDBRPLBL

10111213141516171819202122232425262728

BL

DLUMB3

LB

BL

LBBLLBPLGYPLGYBRGYBRGY

GND2

DLUMA2

DLUMB2

GND2

DLUMA1

DLUMB1

N.C.

GND2

/DPOD1

DCSS11

/FOUND1

1

2

BRBRPLPLLBLBBRPKPLPKLB

PK

H version heater

Dehumidifying heater

DCSS21

/FOUND2

4

3

WH

WH

DCSS31

56789

N.C.

N.C.

/FOUND3

DCSS12

DPED2

DCSS22

/DLUD2

101112131415161718192021222324252627282930

N.C.

DCSS32

/DLUD1

DPED1

PKPKBRPKPLPKLBBRPL

WH

1

DH100

WH

DH100

2

DCSS13

DPED3

DCSS23

/DLUD3

DCSS33

BK

1

WH

2

(Japan spec. only)

N.C.

DCSPD12

DCSPD22

N.C.

DCSPD32

LB

DCSS14

DCSS24

N.C.

BRPLLB

DCSS34

N.C.

N.C.

AR-DE1 paper feed system harness 2-cassette

AR-DE2 option

DCSS21

DCSS22

DCSS23

DCSS24

GND2

/FOUND2

DLUMB2

DLUMA2

+5V

DPED2

/DLUD2

/DPFS2

/DPFC2

+24V

N.C.

DCSPD22

Lower stage lift up UN

DCSS31

DCSS32

DCSS33

DCSS34

GND2

/FOUND3

DLUMB3

DLUMA3

+5V

DPED3

/DLUD3

/DPFS3

/DPFC3

+24V

N.C.

DCSPD32

PL

1

PL

2

PL

3

PL

4

GY

5

PL

6

PL

7

PL

8

BL

9

PK

10

PK

11

PL

12

PL

13

RD

14

15

PL

16

LB

1

LB

2

LB

3

LB

4

GY

5

LB

6

LB

7

LB

8

BL

9

PK

10

PK

11

LB

12

LB

13

RD

14

15

LB

16

Page 23

2. System blook diagram

9 – 2

Desk main motor

Hall element

DMHW

DMHV

2

DMHU

Encoder

DMRE

2

Motor

DMW

DMV

DMU

Top stage paper exit sensor

/DPOD1

4

Transport roller clutch

1

/DTRC

24

1

24V

5V

220

Desk main PWB

DPPD5V

Copier body

DC power

/DSR-DSK

/DTR-DSK

RXD-DSK

TXD-DSK

RES-DSK

supply circuit

/TRC-DSK

DH100

Top tray

24V

Remaining paper

quantity detection

DCSPD12

Interface PWB

2

DLU B1

DLUMA1

Lift up motor

Lift up unit

5V

Remaining paper

quantity detection

DCSPD22

2

DLUMB1

DLUMA1

Lift up motor

Lift up unit

Paper feed

unit detection

/FOUND

DCSS11

DCSS12

DCSS13

DCSS14

Tray size detection

Paper feed

unit detection

/FOUND2

Interface PWB

DCSS11

DCSS12

DCSS13

DCSS14

Tray size detection

paper detection

DPED1

Upper limit detection

/DLUD1

Paper feed SOL

/DPFS1

paper feed SL

/DPFC1

Paper feed unit

Middle tray

paper detection

DPED2

Upper limit detection

/DLUD2

Paper feed SOL

/DPFS2

paper feed SL

/DPFC2

Paper feed unit

AR-DE2 standard provision

AR-DE1 option (AR-CS1)

PFD PWB unit

Middle stage paper exit sensor

Lower stage paper exit sensor

/DPOD2

2

Right door open/close sensor

2

DDOPSW

/DPOD3

2

Japan spec. only

H version heater

Dehumidifying heater

Remaining paper

quantity detection

2

Lift up motor

Lift up unit

Paper feed

DCSPD32

unit detection

/FOUND3

Interface PWB

DLUNB3

DLUMA3

DCSS31

DCSS32

DCSS33

DCSS34

Tray size detection

AR-DE2 option (AR-CS1)

Lower tray

paper detection

DPED3

Upper limit detection

/DLUD3

Paper feed SOL

/DPFS3

paper feed SL

/DPFC3

Paper feed unit

Page 24

3. Main PWB blook diagram

Transport clutch

(DTRC)

IC07

Transport

motor (DM)

driver

IC02

driver

+24V

+10V

9 – 3

+5V

+5V

Motor drive section

Copier main

PWB

IC04

driver

IC12

operation

amplifier

Tray size detection

(DCSS)

Middle stage, lower

stage tray paper

remaining quantity

sensor (DCSPD2, 3)

Communication

section

Input

section

(1)

IC10

X1

(8.00MHz)

IC08,IC09

8-CHANNEL

MULTI

PLEXER

P17

P63

P62

P64

RES,RXD,P46,P47

TXD,P52

X1,X2

P70,P72

IC11

C P U

P36

P34,P35

P32,P33

Output

section (1)

P30,P31

P10~P17

P40~P42,

P21~P27

24V monitor

(24vm)

IC03

driver

IC05

driver

IC06

driver

IC01

driver

Output

section

(2)

Output

section

(1)

Input

section

(2)

Lift up motor

(DLUM1)

Lift up motor

(DLUM2)

Lift up motor

(DLUM3)

Paper feed clutch

(DPFC)

paper feed

solenoid (DPFS)

Transport clutch

(DTRC)

Paper empty sensor

(DPED)

Upper limit sensor

(DLUD)

Top cassette

remaining paper

quantity detection

(DCSPD)

Paper exit sensor

(DPCD)

Door open/close

sensor (DDCPSW)

Page 25

4. Parts arrangement

CN-C

TXD-DSK

GND2

/RXD-DSK

+24V

/DTR-DSK

/DSR-DSK

+5V

/RES-DSK

GND2

/TRC-DSK

N.C.

CN-D

+5V(DM)

+5V

DMRE

/DPOD2

HU

/DPOD3

HV

DDOPSW

HW

GND2

GND1(DM)

N.C.

DMU

+24V

DMV

N.C.

DMW

/DTRC

1

2

3

4

5

6GND1

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

CN-B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

CN-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

DCSS11

/FOUND1

DCSS21

/FOUND2

DCSS3

/FOUND3

DCSS12

DPED2

DCSS22

/DLUD2

DCSS32

N.C.

N.C.

/DLUD1

N.C.

DPED1

DCSS13

DPED3

DCSS23

/DLUD3

DCSS33

DCSPD12

DCSPD22

N.C.

DCSPD32

N.C.

DCSS14

N.C.

DCSS24

DCSS34

/DPFS1

+24V

/DPFS2

+24V

/DPFS3

+24V

/DPFC1

+5V

/DPFC2

+5V

/DPFC3

+5V

DLUMA3

DPPD5V

DLUMB3

N.C.

DLUMA2

GND

DLUMB2

GND

DLUMA1

GND2

DLUMB1

N.C.

N.C.

GND2

N.C.

/DPOD1

9 – 4

Page 26

q

COPYRIGHT 1998 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Printing Reprographic Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

1998 May Printed in Japan S

Loading...

Loading...