Page 1

CODE : 00ZARD13//A1E

AR-D13

AR-DC1

AR-MU1

LASER PRINTER OPTIONS

P APER FEED UNIT

AR-D14

OPTIONAL POWER SUPPL Y UNIT

AR-D13

AR-D14

AR-MU1

MODEL AR-DC1

CONTENTS

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[2] CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[3] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[4] UNPACKING AND INSTALLATION. . . . . . . . . . . . . . . . . . . . . . 4 - 1

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES. . . . . . . 5 - 1

[6] ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE. . . . . . . . . 7 - 1

[8] BLOCK DIAGRAM, WIRING DIAGRAM. . . . . . . . . . . . . . . . . . 8 - 1

[9] OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Parts marked with “ “ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

[1] PRODUCT OUTLINE

This unit is installed to one of the following machines to ser ve as a duplex module.

When installing the unit to one of the following machines, one of the multi-purpose tray (AR-MU1), the large capacity paper feed desk (AR-D13), and

the 3-stage paper feed desk (AR-D14) must be installed in advance. For the AR-D13 and the AR-D14, the option power unit (AR-DC1) must be

installed together.

Applicable models AR-P350 / P450, AR-M350 / M450

DM-3500 / 3501 / 4500 / 4501, DM-3551 / 4551

[2] CONFIGURATION

1. For the AR-D13 and the AR-D14, the option power unit (AR-DC1) must be installed together.

2. When the AR-MU1 and the male bin stacker (AR-MS1) or the finisher (AR-FN5) are installed, the optional power unit (AR-DC1) must be installed

together.

3. The AR-MU1 cannot be installed together with the saddle finisher (AR-FN)/Scanner unit (AR-EF1/EF2).

AR-EF1/AR-EF2

AR-FN7

AR-D14

AR-FN6

AR-MS1

AR-MU1

AR-D13

AR-DC1

Related to paper feed unit

Multi purpose drawer

Stand/3 x 500 sheet paper drawer

Stand/MPD & 2000 sheet paper drawer

AR-D13/D14/MU1/DC1 PRODUCT OUTLINE, CONFIGURATION-1

AR-MU1

AR-D14

AR-D13

B/W scanner module/DSPF

Scanner rack

Multi purpose drawer

Stand/3 x 500 sheet paper drawer

Stand/MPD & 2000 sheet

Duplex module/bypass tray

Duplex module

Saddle stitch finisher

Finisher

Mail-bin stacker

Exit tray

Punch unit

Upper exit tray extension

Multi-function controller board

PS3 expansion kit

Print server card

Fax memory (8 MB)

Network scanner expansion kit

Facsimile expansion kit

Hard disk drive

Power supply unit

Page 3

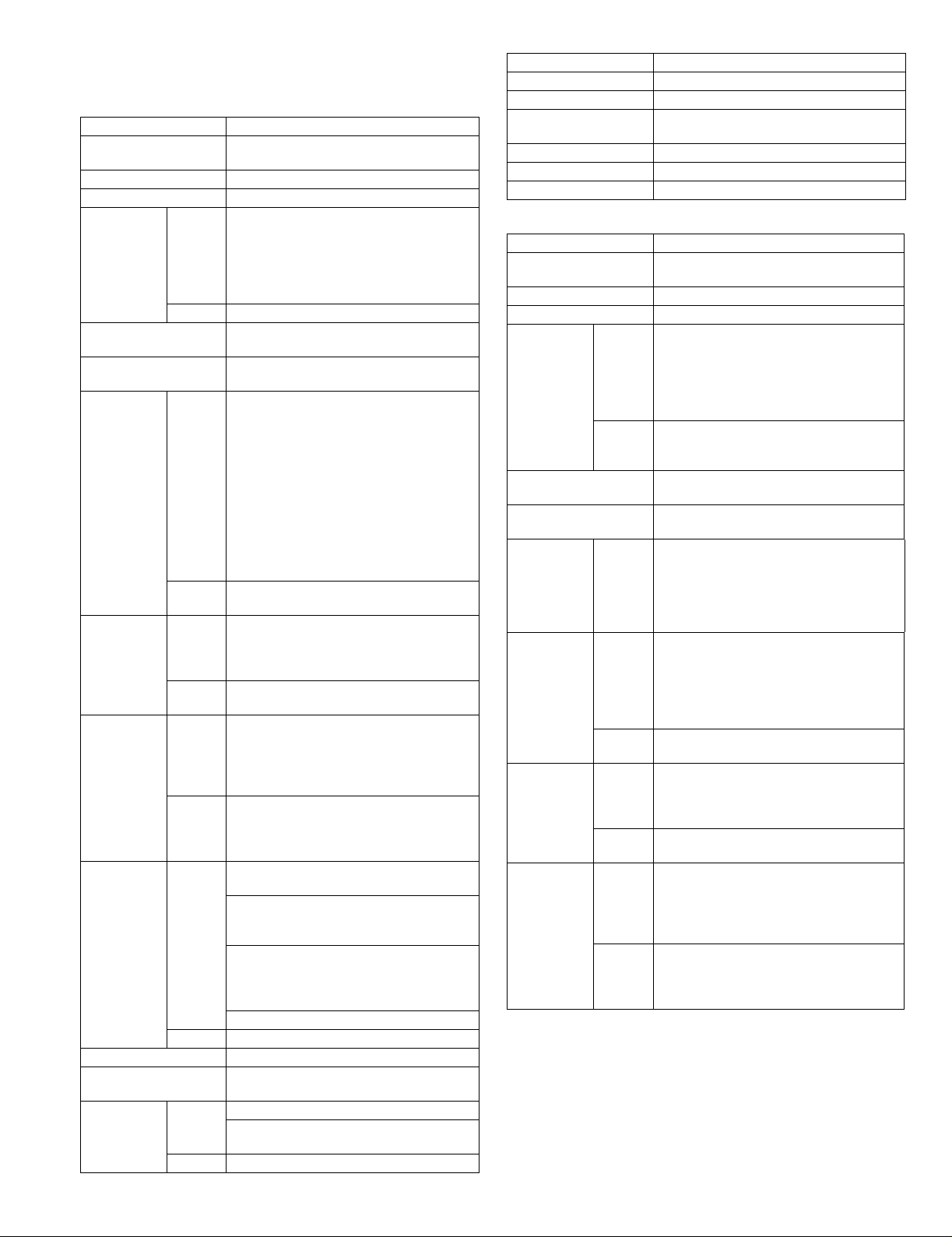

[3] SPECIFICATIONS

1. AR-D13

AR-D13

Type Stand MPD&2000 Sheet Paper Drawer

Transport speed To support 35-45 sheet/minute

Transport alignment Center alignment

Paper size 1 Tray A3, B4, A4, A4R, B5, B5R, A5R

2 Tray A4, 8.5"x11"

How to change the paper

size

Factory default paper

size setting

Media

available for

paper feeding

Paper

capacity

Paper type 1 Tray Plain, recycled, pre-printed, pre-punched,

Sizes to be

detected

Paper balance detection Provided (paper empty and 6 steps)

Paper loading system To be loaded from the upper side with front

Tray ascent/

descent time

1 Tray Plain paper:60-128g/m² / 16-34lbs

2 Tray Size guide plate comes with LCC unit.

1 Tray Standard:500sheets(80g/m²)

2 Tray 880+1,320sheets(64g/m²) /

2 Tray Plain, recycled, pre-printed, pre-punched,

1 Tray AutomaticAuto-AB:

2 Tray Size setting by the serviceman

Ascent Within 12 seconds

Descent Own weight descent

(large capacity tray + multi purpose drawer)

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R, 5.5"x8.5"R

Executive, Japanese p/c, Monarch(envelope)

Com-10(envelope), DL(envelope),

C5(envelope), ISO B5(envelope)

Guide adjustment by user / Software setting

by user

8.5"x11"

Index paper:176g/m² / 47lbs

Cover paper:200-205g/m² / 54-55lbs

Envelope:75-90g/m², 20-24lbs

Transparency film:(TBD)

* Media heavier than 105g/m² should be

A4/8.5x11" or smaller. Media heavier than

120g/m² should be fed from shorter edge.

* Only single paper feed is enabled for

overlay copy or copy on back-side of printed

paper.

Plain 60-105g/m² / 16-28lbs

Post card:40sheets

Envelope:40sheets

Transparency film:40sheets

800+1,200sheets(80g/m²)

color, letter head, labels, heavy,

transparency, Japanese p/c, envelope

(User can set bi-type for each of the above

paper type.)

color, letter head

(User can set bi-type for each of the above

paper type.)

A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R

AutomaticAuto-Inch:

11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R,

7.25"x10.5"R, 5.5" x 8.5R

Manual (input detection):

postal card, Monarch(envelope),

Com-10(envelope), DL(envelope),

C5(envelope), ISO B5(envelope)

Ignore detection selectable:

loading system

At paper empty , required ti me from tra y insert

to the empty detection

AR-D13

Dehumidification heater Not provided

Power consumption 32.2W or lower

Power source Supplied from main unit

(DC24V 1.3A / DC5V 0.2A)

External dimensions 585x530x404 (mm)

Occupied dimensions

Weight Approx. 35kg

2. AR-D14

AR-D14

Type Stand /3x500 Sheet Paper Drawer

Transport speed To suppor t 35-45 sheet/minute

Transport alignment Center alignment

Paper size 1 Tray A3, B4, A4, A4R, B5, B5R, A5R

2 or 3

Tray

How to change the paper

size

Factory default paper

size sett ing

Media

available for

paper feeding

Media

available for

paper feeding

Paper

capacity

Paper type 1 Tray Plain, recycled, pre-printed, pre-punched,

1 Tray Plain paper:60-128g/m² / 16-34lbs

1 Tray * Media heavier than 105g/m² should be

2 or 3

Tray

1 Tray Standard:500sheets(80g/m²)

2 or 3

Tray

2 or 3

Tray

(2 paper trays + 1 multi purpose drawer)

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R, 5.5"x8.5"R

Executive, Japanese p/c,Monarch(envelope)

Com-10(envelope), DL(envel ope),

C5(envelope), ISO B5(env elope)

A3, B4, A4, A4R, B5, B5R

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R, 7.25"x10.5"R

Unit is delivered with paper guide set at max.

position in width. (Both of two cassettes.)

To be set to maximum paper guide width at

factory default status (for both trays)

Index paper:176g/m² / 47lbs

Cover paper:200-205g/m² / 54-55lbs

Envelope:75-90g/m², 20-24lbs

Transparency film:(TBD)

A4/8.5x11" or smaller. Media heavier than

120g/m² should be fed from shorter edge.

* Only single paper feed is enabled for

overlay copy or copy on back-side of printed

paper.

Plain 60-105g/m² / 16-28lbs

Post card:40sheets

Envelope:40sheets

Transparency film:40sheets

Standard

paper:500sheets X 2(64g/m²)

color, letter head, labels, heavy,

transparency, Japanese p/c, envelope

(User can set bi-type for each of the above

paper type.)

Plain, recycled, pre-printed, pre-punched,

color, letter head

(User can set bi-type for each of the above

paper type.)

AR-D13/D14/MU1/DC1 SPECIFICATIONS-1

Page 4

AR-D14

Sizes to be

detected

Paper balance detection Provided (paper empty and 3 steps)

Paper loading system To be loaded from the upper side with front

Tray ascent/

descent time

Dehumidification heater Included in the service kit.

Power consumption 32.2W or lower

Power source Supplied from main unit

External dimensions 585x530x404 (mm)

Occupied dimensions

Weight Approx. 32kg

1 Tray AutomaticAuto-AB:

A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R

AutomaticAuto-Inch:

11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R,

7.25"x10.5"R, 5.5" x 8.5R

Manual (input detection):

postal card, Monarch(envelope),

Com-10(envelope), DL(envelope),

C5(envelope), ISO B5(envelope)

Ignore detection selectable:

2 or 3

Tray

Ascent Within 7 seconds

Descent Own weight descent

Automatic detection-AB

(200V system):A3, B4, A4, A4R, B5, B5R,

8.5"x13"

Automatic detection-inch

(100V system): 11"x17", 8.5"x14", 8.5"x13",

8.5"x11", 8.5"x11"R, 7.25"x10.5"R

loading system

At paper empty, required time from tray

insert to the empty detection

(DC24V 1.3A / DC5V 0.2A)

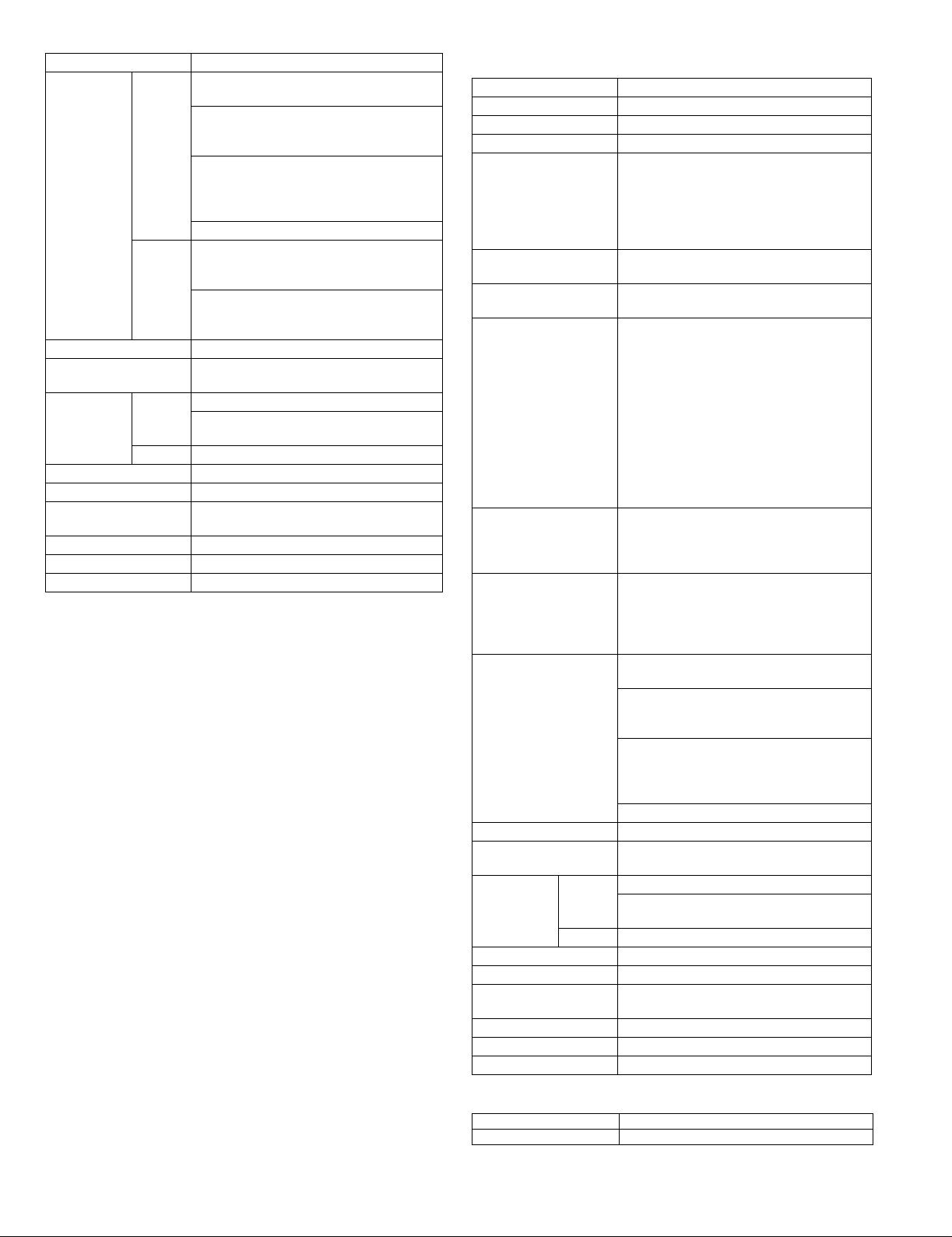

3. AR-MU1

AR-MU1

Type Multi purpose drawer for add-on use

Transport speed To suppor t 35-55 sheets/minute

Transport alignment Center alignment

Paper size A3, B4, A4, A4R, B5, B5R, A5R

How to change the paper

size

Factory default paper

size sett ing

Media available f or paper

feeding

Paper capacity Standard:500sheets(80g/m²)

Paper type Plain, recycled, pre-printed, pre-punched,

Sizes to be detected AutomaticAuto-AB:

Paper balance detection Provided (paper empty and 3 steps)

Paper loading system To be loaded from the upper side with front

Tray ascent/

descent time

Dehumidification heater Included in the ser vice kit.

Power consumption 24.5W or lower

Power source Supplied from main unit

External dimensions 585x530x114 (mm)

Occupied dimensions

Weight Approx. 11kg

Ascent Within 7 seconds

Descent Own weight descent

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R, 5.5"x8.5"R

Executive , Japanese p/c, Monarch(envelope)

Com-10(envelope), DL(envel ope),

C5(envelope), ISO B5(env elope)

Guide adjustment by user / Software setting

by user

To be set to maximum paper guide width at

factory default status.

Plain paper:60-128g/m² / 16-34lbs

Index paper:176g/m² / 47lbs

Cover paper:200-205g/m² / 54-55lbs

Envelope:75-90g/m², 20-24lbs

Transparency film:(TBD)

* Media heavier than 105g/m² should be

A4/8.5x11" or smaller. Media heavier than

120g/m² should be fed from shorter edge.

* Only single paper feed is enabled for

overlay copy or copy on back-side of printed

paper.

Post card:40sheets

Envelope:40sheets

Transparency film:40sheets

color, letter head, labels, heavy,

transparency, Japanese p/c, envelope

(User can set bi-type for each of the above

paper type.)

A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R

AutomaticAuto-Inch:

11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R,

7.25"x10.5"R, 5.5" x 8.5R

Manual (input detection):

postal card, Monarch(envelope),

Com-10(envelope), DL(envel ope),

C5(envelope), ISO B5(env elope)

Ignore detection selectable:

loading system

At paper empty , required time from tra y insert

to the empty detection

(DC24V 1A / DC5V 0.1A)

4. AR-DC1

Input AC 100-127V / 220-240V (Two kinds)

Output DC 24V

AR-D13/D14/MU1/DC1 SPECIFICATIONS-2

Page 5

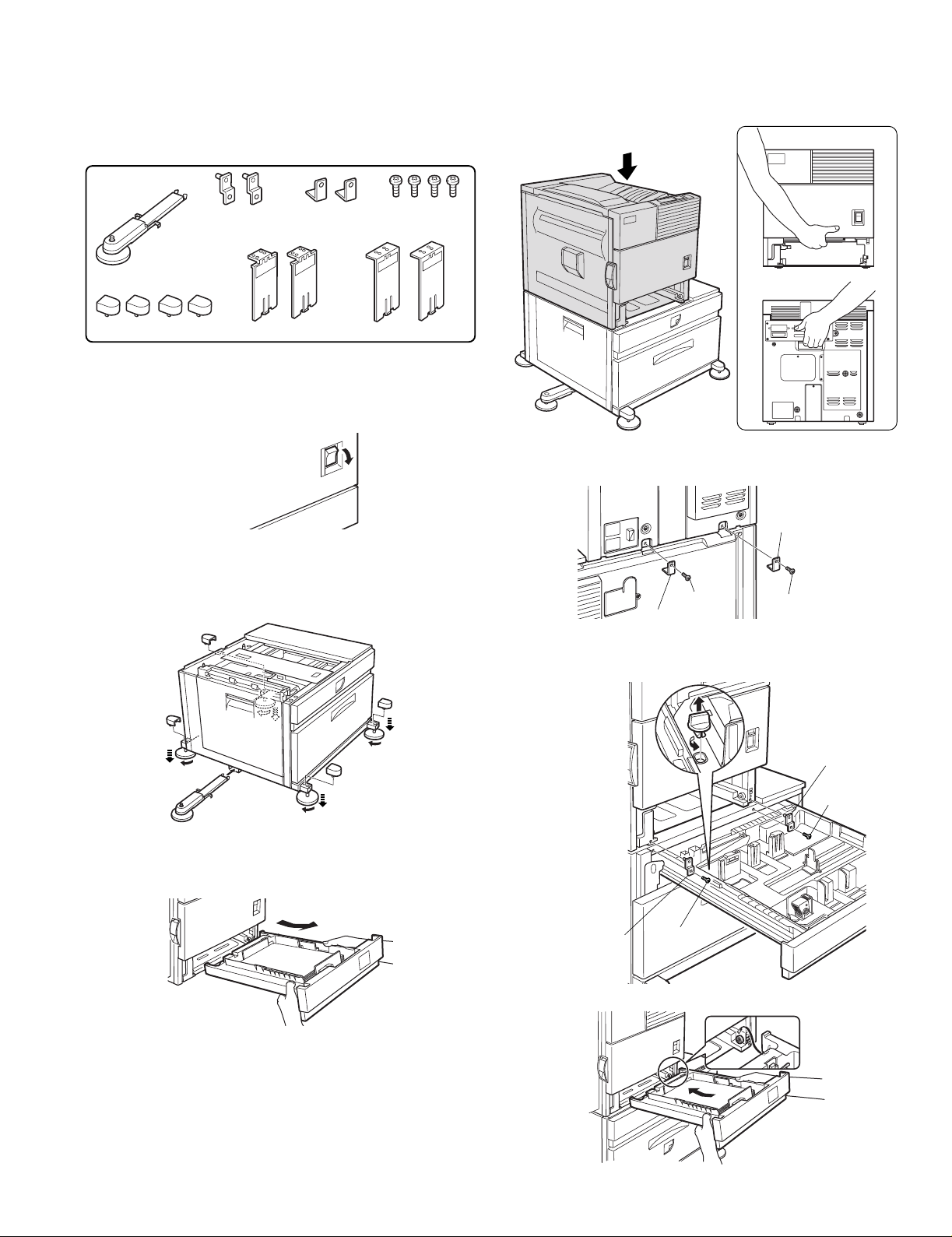

[4] UNPACKING AND INSTALLATION

Screw

Screw

Front

mounting plate

Front mounting

plate

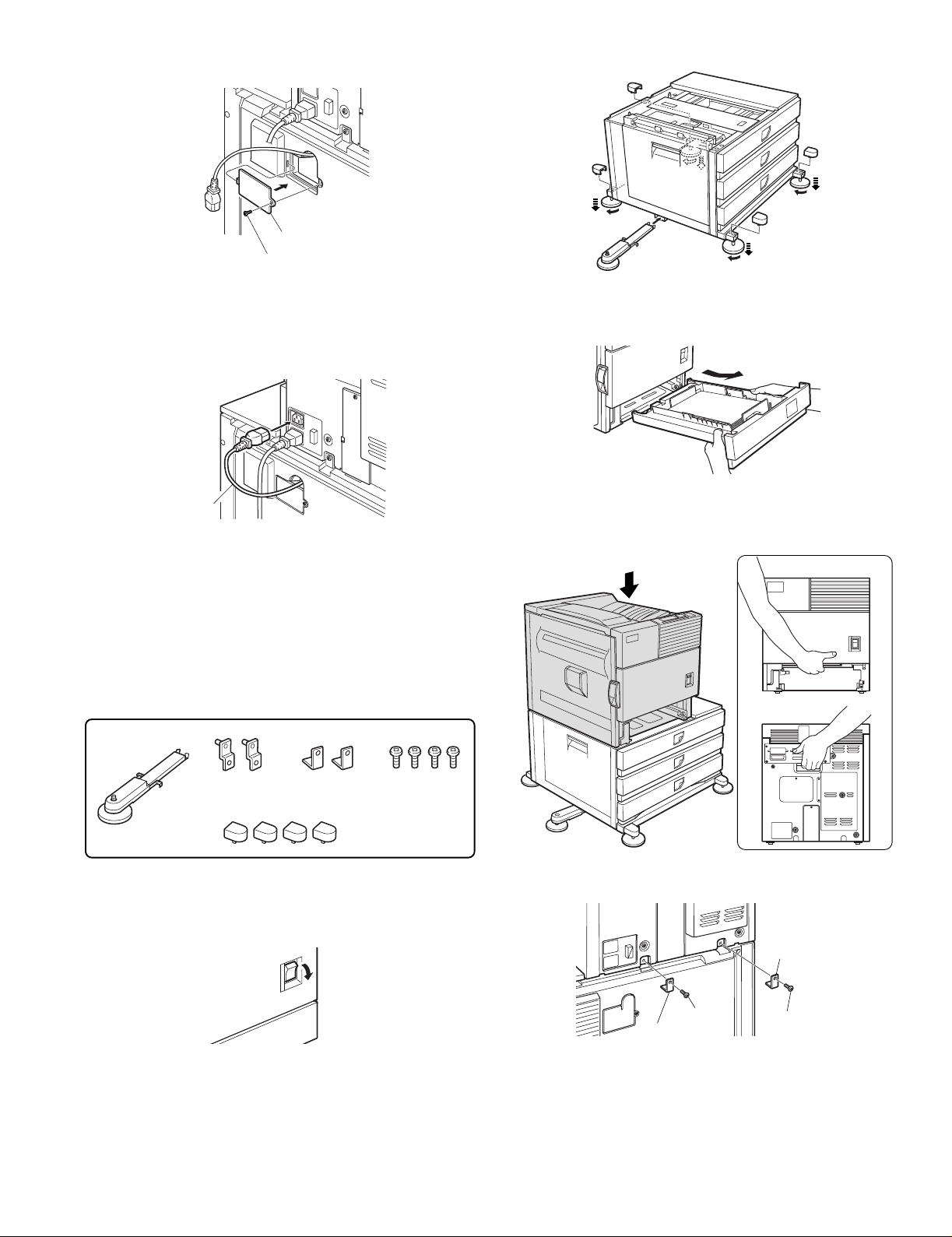

1.AR-D13

<Before installation>

•For installation, a power supply unit (AR-DC1) is needed.

<Parts included>

<2>Hold the main unit of the printer at the positions shown in the

illustration and put the main unit on the stand/paper drawer so that

the front side and the left side of the main unit are al igned to those of

the stand/paper drawer.

Front side

Left adjuster: 1 pc.

Adjuster covers: 4 pcs.

Front mounting

plates: 2 pcs.

Left paper guides: 2 pcs. Right paper guides: 2 pcs.

Rear mounting

plates: 2 pcs.

Screws: 4 pcs.

1) Turn off the main switch of the main unit of the printer.

Tur n the main switch located on the front side of the printer to the

"OFF" position.

Then remove the power plug from the outlet.

"OFF"

2) Attach the adjusters and adjust them.

<1>Inser t the left adjusters to the stand/paper drawer.

<2>T urn the five adjusters to lower them until they touch the floor.

<3>Attach the four adjuster covers.

3

3

3

2

Rear side

4) Connect the main unit to the stand/paper drawer.

<1>Attach the rear mounting plates with two supplied screws.

Rear

mounting plate

Screw

Rear mounting plate

Screw

<2>Pull out the upper paper tray of the stand/paper drawer until it stops

and attach the front mounting plates with two supplied screws.

Then, remove the lock of the paper tra y and close the tray.

2

2

1

3) Put the main unit of the printer on the stand/paper drawer.

<1>Pull out the paper tray of the main unit until it stops and then remove

it by lifting both ends of the tray.

3

2

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-1

<3>Reattach the paper tray of the main unit.

Page 6

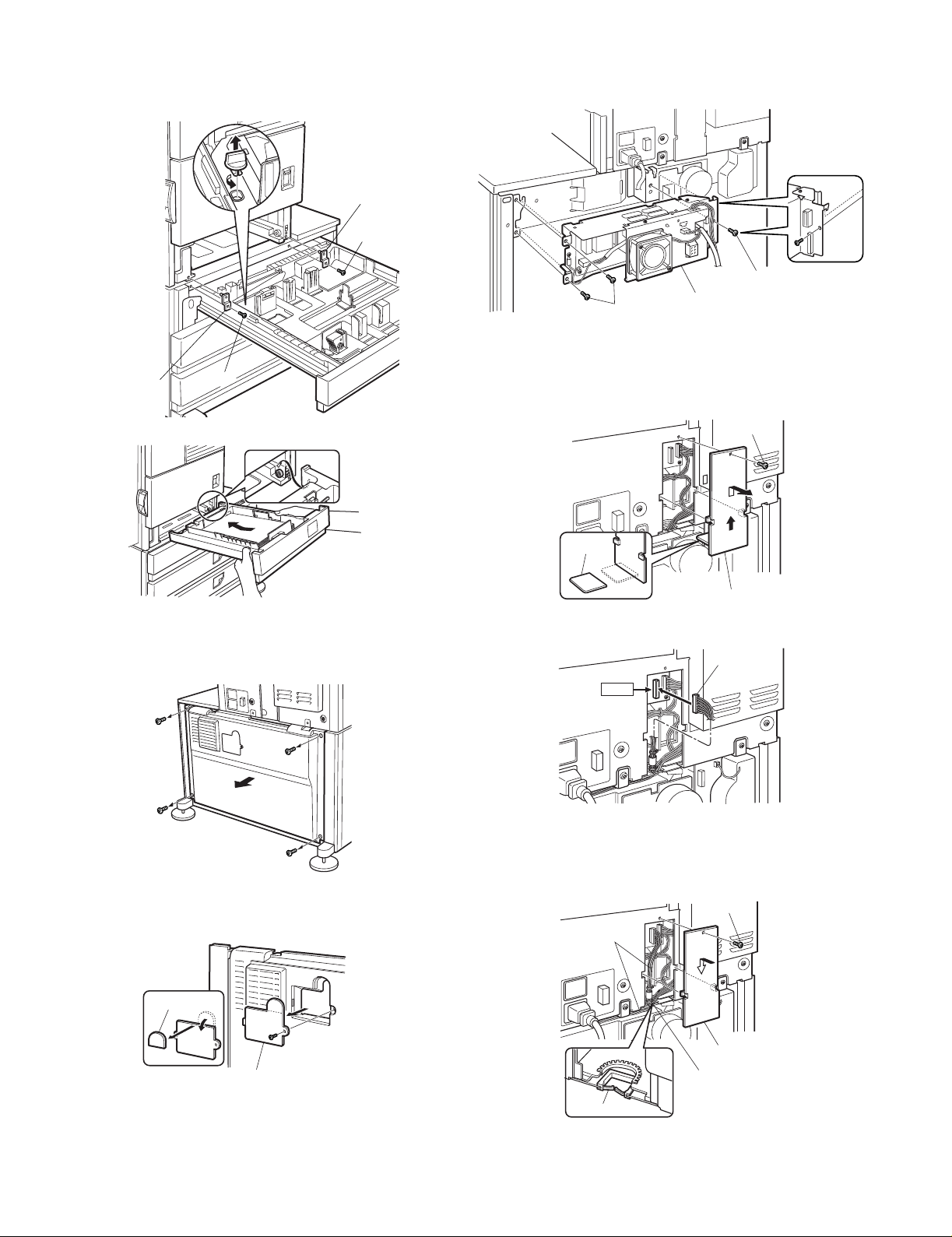

5) Remove the rear cabinet of the stand/paper drawer and remove the

AC inlet cover.

<1>Remove the four screws that fix the rear cabinet and then remov e the

rear cabinet.

Rear cabinet

<2>Remove the screw that fixes the AC inlet cover and then remove the

AC inlet cover.

<3>Process the AC inlet cover as shown in the illustration.

Cut out.

AC inlet cover

<2>Connect the optional power supply harness connector to CN11 (red

connector) of the PCU PWB of the main unit of the printer.

Connector

CN11

<3>Reattach the harness cover to its original position and fix it with the

removed screw.

At this time, ensure that the optional power supply harness are

arranged as shown in the illustration.

•Fix the harness securely to the wire saddle.

Screw

Optional power

supply harness

2/ Screw

Harness cover

Wire saddle

6) Attach the power supply unit.

Attach the power supply unit to the positioning portion of the multi

purpose drawer and then fix it with three supplied screws.

Screws

Screws

Power supply unit

7) Connect the power supply unit harness to the PCU PWB of the main

unit of the printer.

<1>Remove the screw that fixes the harness cover of the main unit of the

printer and slide the harness cover up to remove it.

Process the harness cover as shown in the illustration.

Screw

Wire saddle

8) Connect the relay harness of the stand/paper drawer to the power

supply unit.

Connect the relay harness of the stand/paper drawer to the

connector of the power supply unit.

Connector of the power supply connector

Relay harness of the

stand/paper drawer

9) Attach the rear cabinet of the stand/paper drawer.

<1>Pass the cord of the power supply unit through the hole of the rear

cabinet and attach the rear cabinet to the stand/paper drawer.

Cut out.

Harness cover

Rear cabinet

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-2

Page 7

<2>Attach the AC inlet cover to the rear cabinet of the stand/paper

Front side

Rear side

drawer and fix it with the removed screw.

<3>Attach the four adjuster covers.

3

AC inlet cover

Screw

10) Connect the AC cord of the power supply unit to the main unit of the

printer.

Connect the AC cord of the power supply unit to the inlet connector

of the main unit of the printer at the location shown in the illustration.

AC cord

11) Attach the paper guides to the lower tra y (large capacity tra y) and set

the size.

Refer to "Setting and adjustment" described later.

12) Adjust the position of the paper guides of the upper paper tray of the

stand/paper drawer.

Refer to "Setting and adjustment" described later.

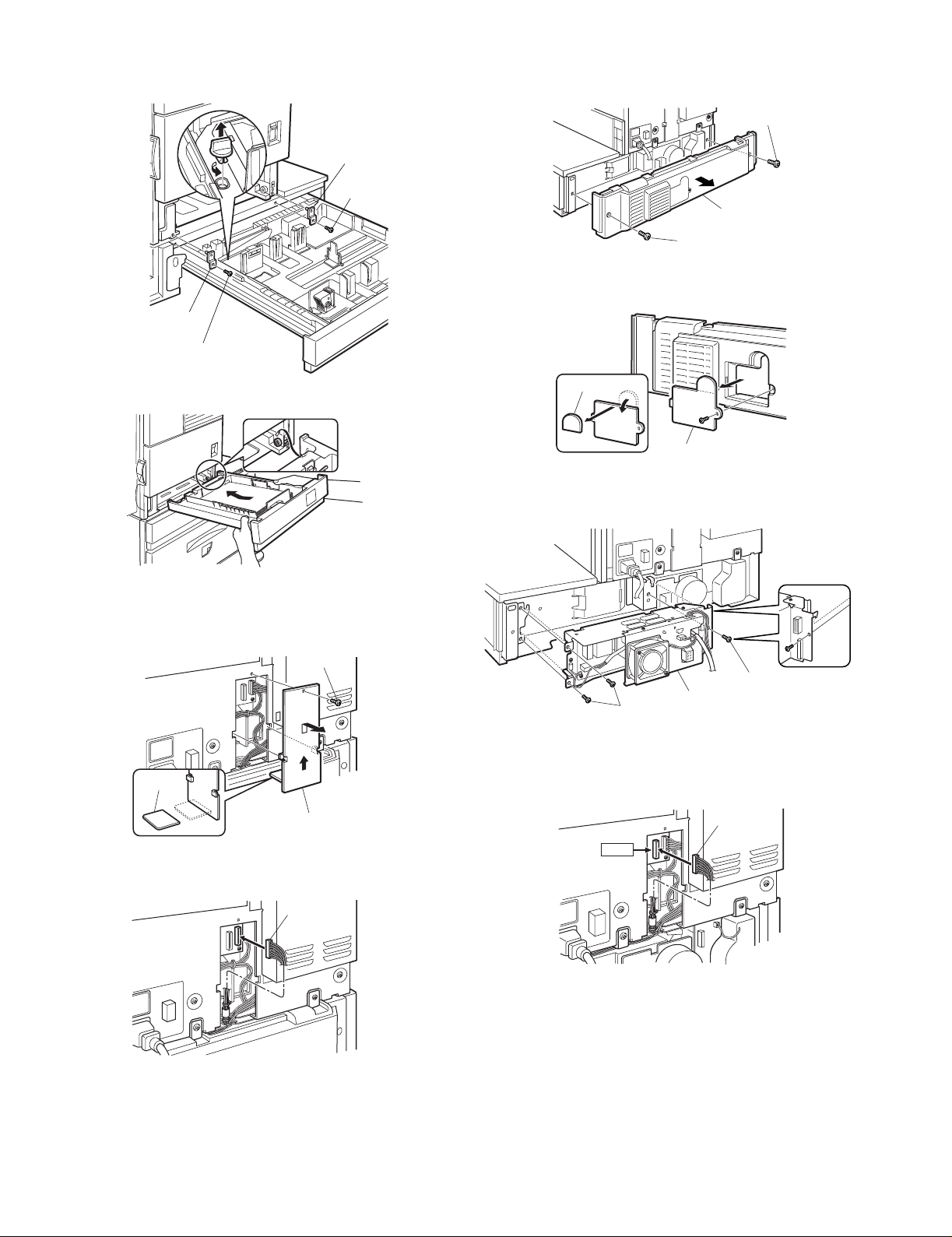

2.AR-D14

<Before installation>

•For installation, a power supply unit (AR-DC1) is needed.

3

3

2

2

2

1

3) Put the main unit of the printer on the stand/paper drawer.

<1>Pull out the paper tray of the main unit until it stops and then remove

it by lifting both ends of the tray.

<2>Hold the main unit of the printer at the positions shown in the

illustration and put the main unit on the stand/paper drawer so that

the front side and the left side of the main unit are al igned to those of

the stand/paper drawer.

3

2

<Parts included>

Screws: 4 pcs.

Left adjuster: 1 pc.

Front mounting

plates: 2 pcs.

Rear mounting

plates: 2 pcs.

Adjuster covers: 4 pcs.

1) Turn off the main switch of the main unit of the printer.

Tur n the main switch located on the front side of the printer to the

"OFF" position.

Then remove the power plug from the outlet.

"OFF"

2) Attach the adjusters and adjust them.

<1>Inser t the left adjusters to the stand/paper drawer.

<2>T urn the five adjusters to lower them until they touch the floor.

4) Connect the main unit to the stand/paper drawer.

<1>Attach the rear mounting plates with two supplied screws.

Rear

mounting plate

Screw

Rear mounting plate

Screw

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-3

Page 8

<2>Pull out the upper paper tray of the stand/paper drawer until it stops

and attach the front mounting plates with two supplied screws.

Then, remove the lock of the paper tray and close the tray.

Remove the locks of the middle tray and the lower tray similarly.

Front

mounting plate

Screw

Front mounting

plate

Screw

<3>Reattach the paper tray of the main unit.

6) Attach the power supply unit.

Attach the power supply unit to the positioning portion of the multi

purpose drawer and then fix it with three supplied screws.

Screws

Screws

Power supply unit

7) Connect the power supply unit harness to the PCU PWB of the main

unit of the printer.

<1>Remove the screw that fixes the harness cover of the main unit of the

printer and slide the harness cover up to remove it.

Process the harness cover as shown in the illustration.

Screw

5) Remove the rear cabinet of the stand/paper drawer and remove the

AC inlet cover.

<1>Remove the four screws that fix the rear cabinet and then remov e the

rear cabinet.

Rear cabinet

<2>Remove the screw that fixes the AC inlet cover and then remove the

AC inlet cover.

<3>Process the AC inlet cover as shown in the illustration.

Cut out.

Harness cover

<2>Connect the optional power supply harness connector to CN11 (red

connector) of the PCU PWB of the main unit of the printer.

Connector

CN11

<3>Reattach the harness cover to its original position and fix it with the

removed screw.

At this time, ensure that the optional power supply unit harness is

arranged as shown in the illustration.

•Fix the harness securely to the wire saddle.

Screw

Optional power

supply harness

Cut out.

AC inlet cover

Harness cover

Wire saddle

Wire saddle

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-4

Page 9

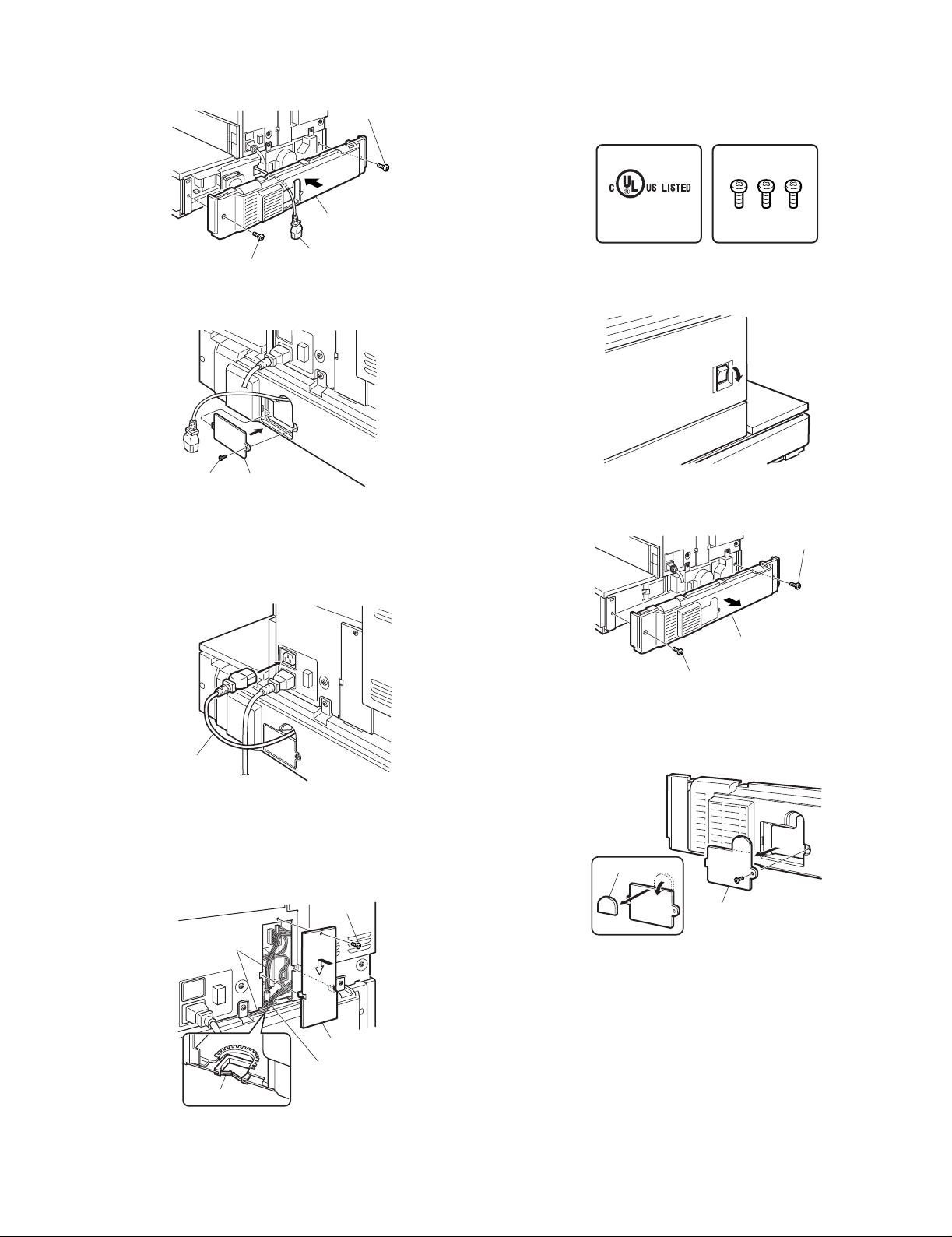

8) Connect the relay harness of the stand/paper drawer to the power

supply unit.

Connect the relay harness of the stand/paper drawer to the

connector of the power supply unit.

Connector of the power supply connector

3.AR-MU1

<Before installation>

•When installing AR-MS1, if you install a finisher or mail-bin stacker

together, a power supply unit (AR-DC1) is needed.

<Parts included>

Relay harness of the

stand/paper drawer

9) Attach the rear cabinet of the stand/paper drawer.

<1>Pass the cord of the power supply unit through the hole of the rear

cabinet and attach the rear cabinet to the stand/paper drawer.

Rear cabinet

<2>Attach the AC inlet cover to the rear cabinet of the stand/paper

drawer and fix it with the removed screw.

Front mounting plates: 2 pcs.

Rear mounting plates: 2 pcs.

Screws: 4 pcs.

1) Turn off the main switch of the main unit of the printer.

Turn the main switch located on the front side of the main unit to the

"OFF" position.

Then, remove the power plug of the main unit from the outlet.

2) Put the main unit of the printer on the multi purpose drawer.

<1>Pull out the paper tray of the main unit until it stops and then remove

it by lifting both ends of the tray.

<2>Hold the main unit of the printer at the positions shown in the

illustration and put the main unit on the multi purpose drawer so that

the front side and the left side of the main unit are al igned to those of

the multi purpose drawer.

Front side

AC inlet cover

Screw

10) Connect the AC cord of the power supply unit to the main unit of the

printer.

Connect the AC cord of the power supply unit to the inlet connector

of the main unit of the printer at the location shown in the illustration.

AC cord

11) Adjust the position of the paper guides of the upper paper tray of the

stand/paper drawer.

Refer to "Setting and adjustment" described later.

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-5

Rear side

3) Connect the main unit of the printer to the multi purpose drawer.

<1>Attach the rear mounting plates with two supplied screws.

Rear mounting

plate

Screw

Rear mounting plate

Screw

Page 10

<2>Pull out the paper tray of the multi purpose drawer until it stops and

attach the front mounting plates with two supplied screws.

Then, remove the lock of the paper tray and close the tray.

Front

mounting plate

Screw

Front mounting plate

Screw

5) Remove the rear cabinet of the multi purpose drawer.

<1>Remove the two screws that fix the rear cabinet of the multi purpose

drawer and then remove the rear cabinet.

Screw

Rear cabinet

Screw

<2>Remove the screw that fixes the AC inlet cover and then remove the

AC inlet cover.

Process the AC inlet cover as shown in the illustration.

<3>Reattach the paper tray of the main unit of the printer.

4) Connect the harness to the main unit of the printer.

<1>Remove the screw that fixes the harness cover of the main unit of the

printer and then slide the harness cover up to remove it.

Process the harness cover as shown in the illustration.

Screw

Cut out.

Harness cover

Cut out.

AC inlet cover

6) Attach the power supply unit.

Attach the power supply unit to the positioning portion of the multi

purpose drawer and then fix it with three supplied screws.

Screws

Screws

Optional power supply unit

7) Connect the power supply unit harness to the PCU PWB of the main

unit of the printer.

Connect the power supply harness connector to CN11 (red

connector) of the PCU PWB of the main unit of the printer.

Connector

<2>Connect the connector of the relay harness of the multi purpose

drawer to the connector of the PCU PWB of the main unit of the

printer.

Connector

If you do not install a finisher, saddle stitch finisher or mail-bin stacker,

the steps below are not needed. Proceed to step 10).

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-6

CN11

Page 11

8) Attach the rear cabinet of the paper tray.

<1>Pass the AC cord of the power supply unit as shown in the illustration

and attach the rear cabinet with two screws.

Screw

Rear cabinet

4.AR-DC1

<Before installation>

•Start installation after checking that the DATA indicator on the operation

panel is not lit or blinking.

Parts included

I.T.E.

ACCESSORY

9K11

Screws (3)

Screw

AC cord

<2>Attach the AC inlet cover to the paper tray and fix it with the remov ed

screw.

Screw

AC inlet cover

9) Connect the AC cord of the power supply unit to the main unit of the

printer.

Connect the AC cord of the power supply unit to the inlet connector

of the main unit of the printer at the location shown in the illustration.

Then, proceed to step 11).

1) Turn the main switch of the printer to "OFF".

Turn the main switch located on the front of the printer to "OFF".

Then, remove the power plug of the printer from the outlet.

"OFF"

2) Remove the multi rear cabinet.

Remove the two screws that secure the multi rear cabinet and

remove the multi rear cabinet.

Screw

Multi rear cabinet

Screw

AC cord

10) Attach the harness cover.

Reattach the harness cover to its original position and fix it with the

removed screw.

At this time, ensure that the power supply unit harness is arranged

as shown in the illustration.

•Fix the harness securely to the wire saddle.

Screw

Optional power

supply harnesses

Harness cover

Wire saddle

Wire saddle

11) Adjust the position of the paper guides of the paper tray.

Refer to "Setting and adjustment" described later.

3) Remov e the AC inlet cover from the multi rear cabinet.

Remove the screw that secures the AC inlet cover and remove the

AC inlet cover.

Work the AC inlet cover as shown in the illustration.

Cut-out

AC inlet cover

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-7

Page 12

4) Attach an optional power supply unit to the multi-purpose section.

Attach an optional power supply unit to the positioning portion of the

multi-purpose section and secure it with the three screws included in

this product.

6) Attach the multi rear cabinet.

<1>Pass the AC cord of the optional power supply unit as shown in the

illustration and secure the multi rear cabinet with the two screws.

Screw

Multi rear cabinet

Screws

Screw

Optional power supply unit

5) Connect the optional power supply harness to the PCU PWB of the

printer.

<1>Remove the screw that secures the harness cover of the printer and

slide the harness cover upward to remove it.

Work the harness cover as shown in the illustration.

Screw

Cut-out

Harness cover

<2>Connect the connector of the optional power supply harness to

CN11 of the PCU PWB of the printer.

Connector

CN11

Screw

AC cord

<2>Attach the AC inlet cover to the multi rear cabinet and secure it with

the removed screw.

Screw

AC inlet cover

7) Connect the AC cord of the optional power supply unit to the printer.

Connect the AC cord of the optional power supply unit to the positi on

of the inlet connector of the printer shown in the illustration.

AC cord

<3>Reattach the harness cover to its original position and secure it with

the removed screw.

At this time, check that wiring of the optional power supply harness

has been handled as shown in the illustration.

Screw

Optional power

supply harness

Harness cover

Harness cover

8) Turn the power switch of the printer to "ON".

Insert the power plug of the printer to the outlet.

Then, turn the main switch located on the front of the printer to "ON".

"ON"

AR-D13/D14/MU1/DC1 UNPACKING AND INSTALLATION-8

Page 13

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES

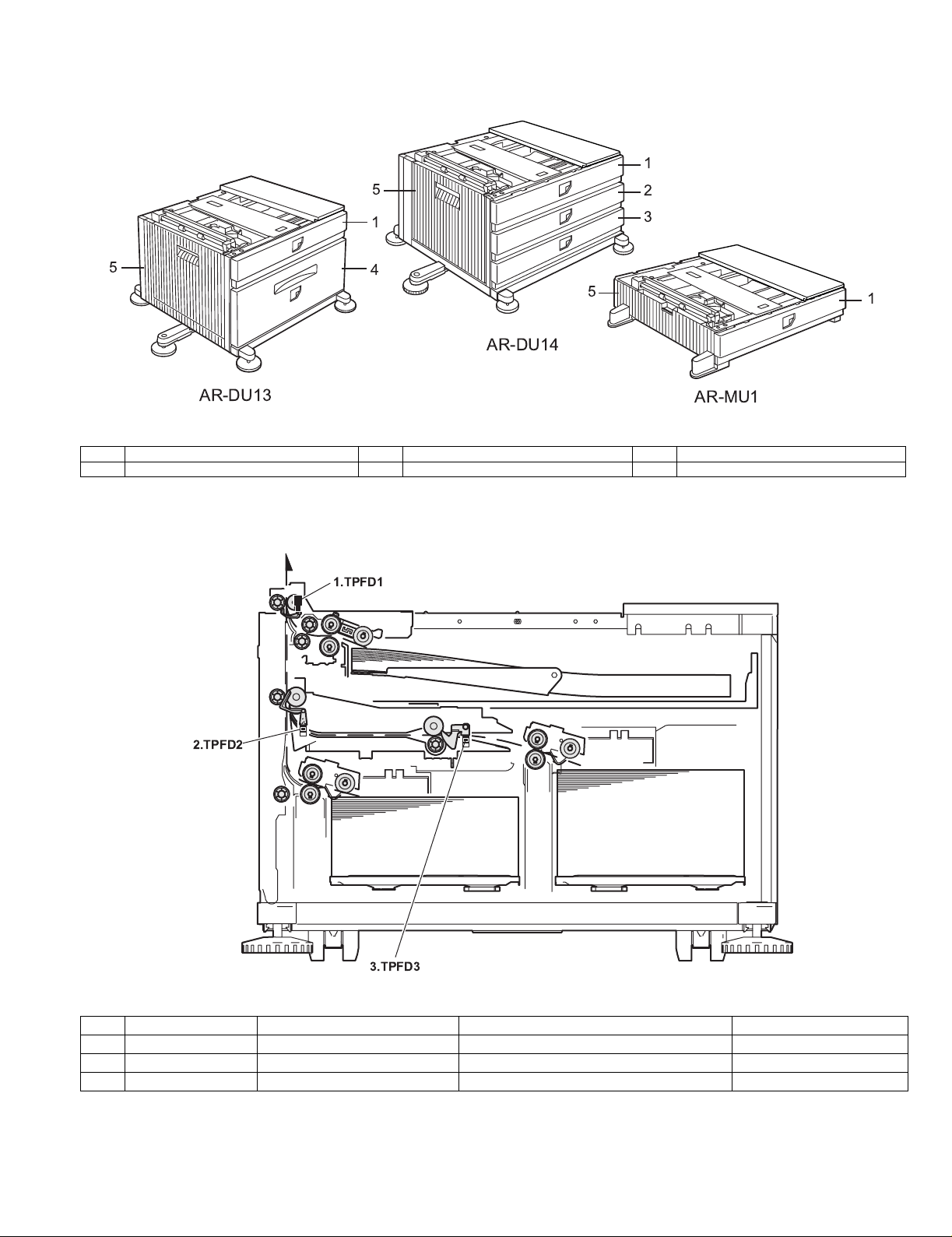

A. External view

5

1

1

2

3

5

4

5

AR-DU14

AR-DU13

1 Multi-purpose tray (No. 2 tray) 2 No. 3 tray 3 No. 4 tray

4 Large capacity tray 5 Desk left door

B. Internal structure

(1) AR-D13

1.TPFD1

1

AR-MU1

1TPFD1

2TPFD2

3TPFD3

2.TPFD2

3.TPFD3

Code Name Function Remark

AR-D13/D14/MU1/DC1 EXTERNAL VIEWS AND INTERNAL STRUCTURES-1

Page 14

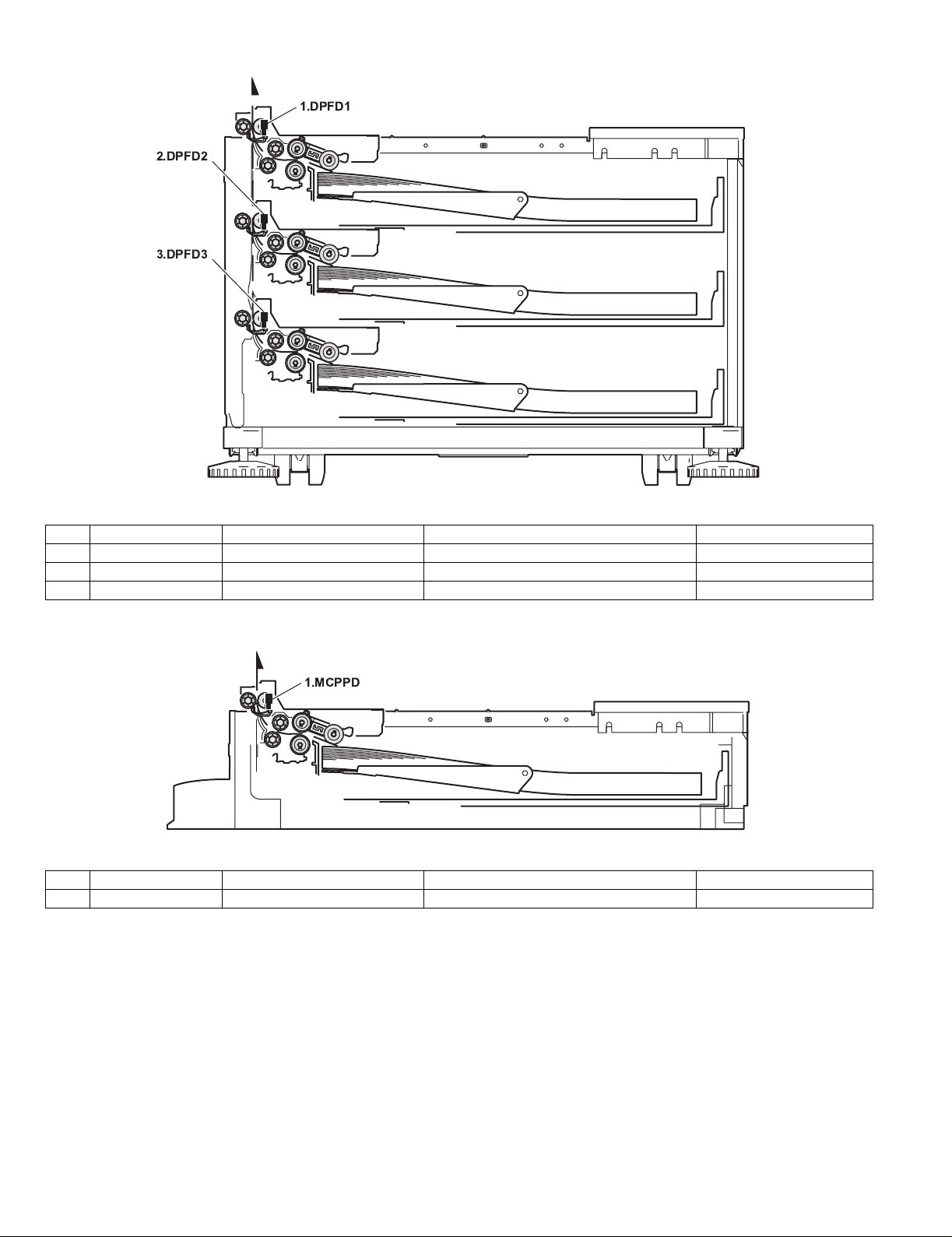

(2) AR-D14

1.DPFD1

2.DPFD2

3.DPFD3

1DPFD1

2DPFD2

3DPFD3

(3) AR-MU1

1MCPPD

Code Name Function Remark

1.MCPPD

Code Name Function Remark

AR-D13/D14/MU1/DC1 EXTERNAL VIEWS AND INTERNAL STRUCTURES-2

Page 15

C. Motor, clutch

(1) AR-D13

3.TPFCL

2.TPCL1

1.TLUM1

4.MCLUM

5.MCPCL

6.TMM

7.TPCL2

8.TLUM2

Code Name Function Remark

1 TLUM1 Tandem tray 1 lift-up motor Tandem tray 1 lift-up

2 TPCL1 Tandem tray 1 paper feed clutch Clutch for paper feed from tandem tray 1

3 TPFCL LCC transport clutch Clutch for transport from LCC desk

4 MCLUM Multi-purpose tray lift-up motor Multi-purpose tray lift-up

5 MCPCL Multi-purpose paper feed clutch Clutch for paper feed from Multi-purpose tray

6 TMM LCC transport motor LCC desk paper transport

7 TPCL2 T andem tray 2 paper feed clutch Clutch for paper feed from tandem tray 2

8 TLUM2 Tandem tray 2 lift-up motor Tandem tray 2 lift-up

AR-D13/D14/MU1/DC1 EXTERNAL VIEWS AND INTERNAL STRUCTURES-3

Page 16

(2) AR-D14

5.MCPCL

4.MCLUM

3.DPFCL

2.DLUM1

1.DLUM2

Code Name Function Remark

1 DLUM2 No. 4 tray lift-up motor Gate switch between duplex and paper exit

2 DLUM1 No. 3 tray lift-up motor Cooling the machine and inside of ADU

3 DPFCL Desk transport clutch Clutch for transport from LCC desk

4 MCLUM Multi-purpose tray lift-up motor Multi-purpose tray lift-up

5 MCPCL Multi-purpose paper feed clutch Clutch for paper feed from Multi-purpose tray

6 DMM No. 3 tray desk transport motor No. 3 tray desk paper transport

7 DPCL2 No. 4 tray paper feed clutch Clutch for paper feed from tandem tray 2

8 DPCL1 No. 3 tray paper feed clutch Clutch for paper feed from tandem tray 1

6.DMM

8.DPCL1

7.DPCL2

(3) AR-MU1

4.MCM

3.MCPCL

2.MCLUM

1.MCFCL

Code Name Function Remark

1 MCFCL Multi-purpose tray transport clutch Multi-purpose tray transport clutch

2 MCLUM Multi-purpose tray lift-up motor Multi-purpose tray lift-up

3 MCPCL Multi-purpose paper feed clutch Clutch for paper feed from Multi-purpose tray

4 MCM Multi-purpose tray transport motor Multi-purpose tray paper transport

AR-D13/D14/MU1/DC1 EXTERNAL VIEWS AND INTERNAL STRUCTURES-4

Page 17

D. PWB, sensor

(1) AR-D13

2.TSPD1

3.TDRS

5.TPFD3

4.MCSPD

6.MCLUD

21.MP tray rear edge size PWB

7.MCSS1

9.MCSS3

8.MCSS2

10.MCSS4

1.TPFD2

19.TLUD1

20.TPED1

18.

17.MCPWS

14.TSPD2

15.MCPED

16.TPFD1

11.TTSD

12.TLUD2

13.TPED2

Code Name Function Active condition Remark

1 TPFD2 Tandem tray paper transport sensor 2 Tandem tray paper transport detection L : Paper detected

2 TSPD1 Tandem 1 tray

remaining paper quantity sensor

Tandem 1 tray

remaining paper quantity detection

3 TDRS Side door open/close sensor Side door open/close detection H : Door closed

4 MCSPD MP tray remaining paper quantity sensor MP tray remaining paper quantity detection

5 TPFD3 Tandem tray paper transport sensor 3 Tandem tray paper transport detection L : Paper detected

6 MCLUD MP tray upper limit sensor MP tray upper limit detection H : Upper limit

detected

7 MCSS1 MP tray rear edge sensor 1 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

8 MCSS2 MP tray rear edge sensor 2 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

9 MCSS3 MP tray rear edge sensor 3 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

10 MCSS4 MP tray rear edge sensor 4 MP tray rear edge size detection L : When pressed In MP tray rear

edge size PWB

11 TTSD Tandem tray open/close sensor Tandem tray open/close detection H : Tray closed

12 TLLD2 Tandem 2 tray upper limit sensor Tandem tray 2 upper limit detection L : Upper limit

detected

13 TPED2 Tandem 2 tray paper empty sensor Tandem tray 2 paper empty detection H : Paper loaded

14 TSPD2 Tandem 2 tray

remaining paper quantity sensor

Tandem 2 tray

remaining paper quantity detection

15 MCPED MP tray paper empty sensor MP tray paper empty detection L : Paper loaded

16 TPFD1 Tandem tray paper transport sensor 1 Tandem tray paper transport detection L : Paper detected

17 MCPWS MP tray width sensor MP tray paper width detection Slide volume

18 Control PWB Control PWB Communication with the machine,

machine operation control

19 TLLD1 Tandem 1 tray upper limit sensor Tandem tray 1 upper limit detection L : Upper limit

detected

20 TPED1 Tandem 1 tray paper empty sensor Tandem tray 1 paper empty detection H : Paper loaded

21 MP tray rear

MP tray rear edge size PWB Multi-purpose tray rear edge size detection

edge size PWB

AR-D13/D14/MU1/DC1 EXTERNAL VIEWS AND INTERNAL STRUCTURES-5

Page 18

(2) AR-D14

1.DDRS

2.MCSPD

3.

4.MCLUD

5.MCPED

28.MP tray rear edge size PWB

6.MCSS1

8.MCSS3

29.No. 3 tray rear edge size PWB

7.MCSS2

9.MCSS4

27.DSPD1

26.DLUD1

25.DSPD2

24.MCPWS

23.DLUD2

22.DPED2

21.DPFD3

19.DPED1

20.DPFD2

10.DCSS11

12.DCSS13

30.No. 4 tray rear edge size PWB

14.DCSS21

18.DPFD1

16.DCSS23

11.DCSS12

13.DCSS14

15.DCSS22

17.DCSS24

Code Name Function Active condition Remark

1 DDRS Side door open/close sensor Side door open/close detection H : Door closed

2 MCSPD MP tray

remaining paper quantity sensor

MP tray

remaining paper quantity detection

3 Control PWB Control PWB Communication with the machine,

machine operation control

4 MCLUD MP tray upper limit sensor MP tray upper limit detection H : Upper limit

detected

5 MCPED MP tray paper empty sensor MP tray paper empty detection L : Paper loaded

6 MDSS1 MP tray rear edge sensor 1 MP tray rear edge size detection L : When pressed In MP tray rear edge size PWB

7 MCSS2 MP tray rear edge sensor 2 MP tray rear edge size detection L : When pressed In MP tray rear edge size PWB

8 MCSS3 MP tray rear edge sensor 3 MP tray rear edge size detection L : When pressed In MP tray rear edge size PWB

9 MCSS4 MP tray rear edge sensor 4 MP tray rear edge size detection L : When pressed In MP tray rear edge size PWB

10 DCSS11 No. 3 tray rear edge sensor 1 No. 3 tray rear edge size detection L : When pressed In No. 3 tray rear edge size PWB

11 DCSS12 No. 3 tray rear edge sensor 2 No. 3 tray rear edge size detection L : When pressed In No. 3 tray rear edge size PWB

12 DCSS13 No. 3 tray rear edge sensor 3 No. 3 tray rear edge size detection L : When pressed In No. 3 tray rear edge size PWB

13 DCSS14 No. 3 tray rear edge sensor 4 No. 3 tray rear edge size detection L : When pressed In No. 3 tray rear edge size PWB

14 DCSS21 No. 4 tray rear edge sensor 1 No. 4 tray rear edge size detection L : When pressed In No. 4 tray rear edge size PWB

15 DCSS22 No. 4 tray rear edge sensor 2 No. 4 tray rear edge size detection L : When pressed In No. 4 tray rear edge size PWB

16 DCSS23 No. 4 tray rear edge sensor 3 No. 4 tray rear edge size detection L : When pressed In No. 4 tray rear edge size PWB

17 DCSS24 No. 4 tray rear edge sensor 4 No. 4 tray rear edge size detection L : When pressed In No. 4 tray rear edge size PWB

18 DPFD1 Desk paper transport sensor 1 Desk paper transport detection L : Paper detected

19 DPED1 N. 3 tray paper empty sensor N. 3 tray paper empty detection L : Paper loaded

20 DPFD2 Desk paper transport sensor 2 Desk paper transport detection L : Paper detected

21 DPFD3 Desk paper transport sensor 3 Desk paper transport detection L : Paper detected

22 DPED2 No. 4 tray paper empty sensor No. 4 tray paper empty detection L : Paper loaded

23 DLUD2 No. 4 tray upper limit sensor No. 4 tray upper limit detection H : Upper limit

detected

24 MCPWS MP tray width sensor MP tray paper width detection Analog voltage Slide volume

25 DSPD2 No. 4 tray

remaining paper quantity sensor

No. 4 tray

remaining paper quantity detection

26 DLUD1 No. 3 tray upper limit sensor No. 3 tray upper limit detection H : Upper limit

detected

27 DSPD1 No. 3 tray

remaining paper quantity sensor

28 MP tray rear

MP tray rear edge size PWB MP tray rear edge size detection

No. 3 tray

remaining paper quantity detection

edge size PWB

29 No. 3 tra y rear

No. 3 tray rear edge size PWB No. 3 tray rear edge size detection

edge size PWB

30 No. 4 tra y rear

No. 4 tray rear edge size PWB No. 4 tray rear edge size detection

edge size PWB

AR-D13/D14/MU1/DC1 EXTERNAL VIEWS AND INTERNAL STRUCTURES-6

Page 19

(3) AR-MU1

12.MP tray rear edge size PWB

6.MCSS2

8.MCSS4

1.MCDRS

2.

3.MCSPD

11.MCPWS

4.MCLUD

5.MCSS1

7.MCSS3

9.MCPED

10.MCPPD

Code Name Function Active condition Remark

1 MCDRS MP door open / close sensor M P left door open / close detection H : Door closed

2 Control PWB Control PWB Communication with the machine,

machine operation control

3 MCSPD MP tray remaining paper

quantity sensor

MP tray remaining paper quantity detection L : When

pressed

4 MCLUD MP tray upper limit sensor MP tray upper limit detection H : Upper limit

detected

5 MDSS1 MP tray rear edge sensor 1 MP tray rear edge size detection L : When

In MP tray rear edge size PWB

pressed

6 MCSS2 MP tray rear edge sensor 2 MP tray rear edge size detection L : When

In MP tray rear edge size PWB

pressed

7 MCSS3 MP tray rear edge sensor 3 MP tray rear edge size detection L : When

In MP tray rear edge size PWB

pressed

8 MCSS4 MP tray rear edge sensor 4 MP tray rear edge size detection L : When

In MP tray rear edge size PWB

pressed

9 MCPED MP tray paper empty sensor MP tray paper empty detection L : Paper loaded

10 MCPPD MP transport sensor Detection of paper on the path L : Paper

detected

11 MCPWS MP tray width sensor MP tray paper width detection Analog voltage Slide volume

12 MP tray rear

edge size PWB

MP tray rear

edge size PWB

MP tray rear edge size detection

AR-D13/D14/MU1/DC1 EXTERNAL VIEWS AND INTERNAL STRUCTURES-7

Page 20

[6] ADJUSTMENTS

TRAY SETTING

TRAY1

LETTER

PLAIN

CHANGE TRAY1

SETTING OK?

1. Paper guide position adjustment

(AR-D13/D14/MU1)

(AR-P350/P450,

DM-3500/3501, DM-4500/4501)

1) Turn the main switch on while pressing the [MENU] key and

the [OK] key of the operation panel of the main unit of the printer.

2) Press the [MENU] key several times to display

"SIZE ADJUSTMENT A" and press the [OK] key.

3) "MAXIMUM SIZE" is displayed.

Pull out the paper tray and extend t he paper guides to the maximum.

Then, return the paper tray into the main unit and press the [OK] key.

4) "MINIMUM SIZE" is displayed.

Pull out the paper tray again and narrow the paper guides to the

minimum. Then, return the paper tray into the main unit and press

the [OK] key.

5) Press the [BACK/CLEAR] key to exit the setting mode.

3. Setting the paper size and type

When the paper size or type is changed in a paper tray, set them

referring to the following procedure.

A. Setting the paper size and type from the operation

panel on the main printer

(AR-P350/P450, DM-3500/3501/4500/4501)

1) Press the [MENU] key repeatedly until "CUSTOM SETTINGS"

appear in the message display.

2) Press the [OK] key.

When the [OK] key is pressed, "TRAY SETTING" will appear in the

message display.

2. Large capacity tray size setup (AR-D13)

1) Insert the left paper guides and right paper guides to the front and

rear guide slots for the paper size to be used.

Left paper guides

Right paper guides

Paper guide

2) Turn the main switch on while pressing the [MENU] key and

the [OK] key of the operation panel of the main unit of the printer.

3) After pressing the [MENU] key several times to display

"TRAY 1 SIZE SETUP" in the message display, press the [ ] key to

display "LCC SIZE SETUP" and press the [OK] key.

4) Press the [ ] or [ ] key to change the size and press the [OK] k ey.

* The large capacity tray paper size is A4 or LTR only.

3) Press the [OK] key.

When the [OK] key is pressed,the message shown to be left will

appear in the message display.

4) Select the desired paper tray.

Press the [ ] or [ ] key repeatedly until the desired paper tray is

indicated in the display.

5) Press the [OK] key.

The paper size and paper type of the tray selected in step 4) will

appear.

•If TRAY 1 is selected in step 4), the message shown to the left will

appear in the display.

6) Press the [ ] key.

•If TRAY 1 is selected in step 4), the message shown to the left will

appear in the display.

AR-D13/D14/MU1/DC1 ADJUSTMENTS-1

Page 21

7) Press the [OK] key.

TOTAL COUNT

TRAY SETTINGS

TRAY 1

TRAY 2

TRAY 3

PLAIN / AUTO-INCH

RECYCLED / AUTO-INCH

TYPE / SIZE

PLAIN / 8 X11

1

/

2

SIZE

A4

OK

SIZE

A4

OK

To cancel the setting change, press the [BACK/C] key to return to

step 4).

NOTE:Special paper such as thick paper, transparency film, labels, and

postcards can be set for tray 2 and the bypass tray.

Envelopes can be set only for tray 2.

8) Select the paper type that has been set in the tray.

Press the [ ] or [ ] key repeatedly until the paper type that has

been set appears.

PLAIN

OK?

9) Press the [OK] key.

10) Ensure that the desired paper size is selected.

Press the [ ] or [ ] key repeatedly until the desired paper size

appears.

3) Select the paper tray for which the setting is to be made.

•If the desired tray is not on the display, use [ ] or [ ] key to scroll the

display until it appears.

4) Select the paper type and the paper size.

•If TRAY 1 has been selected in step 3:

LETTER

OK?

•Depending on the selected tray, a selection for "AUTO-AB" and

"AUTO-INCH" may appear.

"AUTO-AB": Select when you have set AB system paper.

"AUTO-INCH": Select when you have set inch system paper.

When the paper system is changed from the inch sy stem to the AB

system or vise versa, the paper type must be designated. Select the

paper type.

•If you have set paper of non-standard size, select "NON STANDARD".

This size can be selected when tray 2 or the bypass tray has been

selected in step 4).

11) Press the [OK] key to terminate the setting.

B. Setting the paper type

and size from the touch panel

(AR-M350/M450, DM-3551/4551)

1) Press the [CUSTOM SETTINGS] key.

The custom setting menu screen will appear.

The highlighted keys indicate the current selections. To change

either type or size or both, touch the desired keys to highlight the

selections.

Paper types

Special papers such as transparency film and labels can be set for tray 2

and the bypass tray.Envelopes can be set only for tray 2.

Paper sizes

•Depending on the selected tray, a selection for "AUTO-AB" and

"AUTO-INCH" may appear.

"AUTO-AB": Select when you have set AB system paper.

"AUTO-INCH": Select when you have set inch system paper.

When the paper system is changed from the inch system to the AB

system or vise versa, the paper type must be designated. Select the

paper type.

•If you have set paper of non-standard size, select

"NON STANDARD SIZE". This size key appears when tray 2 or the

bypass tray has been selected in step 3).

5) Touch the [OK] key to complete the setting.

2) Press the [TRAY SETTINGS] key.

The paper tray selection screen will appear.

AR-D13/D14/MU1/DC1 ADJUSTMENTS-2

Page 22

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE

1.Maintenance System Table

Check (Clean, replace, or adjust as necessary.) Clean Replace Adjust Lubricate Move position

A. When installed to a AR-series machine

Unit name Part name

Paper feed

separation section

Transport section Transport rollers

Drive section Gears (Specified position)

Other Sensors

Paper feed rollers ( ) *1

Torque limiter ( ) *1

Transport paper guides

Belts

B. When installed to a DM-series machine

Unit name Part name

Paper feed

separation section

Transport section Transport rollers

Drive section Gears (Specified position)

Other Sensors

Paper feed rollers ( ) *1:Replace the whole set.

Torque limiter ( )

Transport paper guides

Belts

When

calling

When

calling

50K 100K 150K 200K 250K 300K 350K 400K Remark

50K 100K 150K 200K 250K 300K 350K 400K Remark

*1: Replacement reference: Use the counter value of each paper feed port.

Paper feed roller/Separation pad/Torque limiter section: 80K or 2 years

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-1

Page 23

2. Maintenance

A. AR-D13

(1)Multi-purpose paper feed section

a. Paper feed unit disassembly

1) Remove the stopper, and pull out the multi-purpose tray.

1)

2) Remove the left door.

1)

2)

b. Roller/Torque limiter

No. Name Job item Cycle

1 Rollers Clean 40K

Check 80K

Replace 80K or 2 years

2 Torque limiter Check 240K

Replace 480K

1) Remove the stopper, and pull out the multi-purpose tray.

2) Remove the paper guide.

2)

3) Disengage the roller hook, and remove the roller.

a

1)

3) Remove the multi-purpose paper feed unit.

4)

3)

5)

3)

3)

* When installing the roller, check to insure that the hook is securely

engaged in the groove.

4) After removing the roller, remove the torque limiter.

b

* When installing the torque limiter, check to insure that the pin is fully

inserted into the torque limiter groove.

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-2

Page 24

c. Belt

No. Name Job item Cycle

1 Belts Che ck 240K

(2)Tandem tray paper feed section

a. Paper feed unit disassembly

1) Remove the stopper, and pull out the large capacity tray.

1)

2) Remove the left door.

1)

2)

d. Sensor

No. Name Job item Cycle

1 Sensors Check 80K

1)

1)

3)

1)

2)

1)

4)

a

4)

1)

3) Remove the tandem paper feed unit.

3)

4)

a

3)

a

8)

9)

8)

7)

6)

a

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-3

Page 25

b. Roller/Torque limiter

No. Name Job item Cycle

1 Rollers Clean 40K

Check 80K

Replace 80K or 2 years

2 Torque limiter Check 240K

Replace 480K

1) Remove the stopper, and pull out the large capacity tray.

2) Disengage the roller hook, and remove the roller and the torque

limiter.

•Tandem tray 1

2)

a

b

c. Belt

No. Name Job item Cycle

1 Gears Lubricate 40K

2 Belts Check 240K

•Tandem tray 1

•Tandem tray 2

a

•Tandem tray 2

2)

b

a

2)

* When installing the roller, check to insure that the hook is securely

engaged in the groove.

* When installing the torque limiter, check to insure that the pin is fully

inserted into the torque limiter groove.

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-4

Page 26

d. Sensor

No. Name Job item Cycle

1 Sensors Check 80K

a. Transport roller/Roller

No. Name Job item Cycle

1 Transport rollers Clean 40K

2 Rollers Clean 40K

1)

1)

3)

a

1)

2)

b

1)

4)

3)

4)

a

4)

3)

a

a

b

b

a

a

b

a

(3)Paper transport section

1) Remove the left door.

1)

2)

a

b

1)

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-5

Page 27

b. Belt

No. Name Job item Cycle

1 Gears Lubricate 40K

2 Belts Check 240K

b. Tandem tray drive section

1) Remove the tandem tray drive section.

(4)Drive section

1) Remove the rear cabinet.

1)

2)

1)

a. Multi-purpose tray drive section

1) Remove the multi-purpose tray drive section.

6)

6)

6)

7)

7)

6)

2) Gear/Belt

No. Name Job item Cycle

1 Gears Lubricate 40K

2 Belts Check 240K

7)

8)

4)

3)

2) Gear/Belt

No. Name Job item Cycle

1 Gears Lubricate 40K

2 Belts Check 240K

5)

4)

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-6

Page 28

(5)Others

1) Remove the rear cabinet.

1)

2)

B. AR-D14

(1)Paper feed section

a. Paper feed unit disassembly

1) Remove the stopper, and pull out the tray.

1)

1)

2) Remove the control PWB and the sensors.

No. Name Job item Cycle

1 Sensors Check 80K

1)

2)

1)

2) Remove the left door.

1)

2)

1)

3) Remove the paper feed unit.

5)

4)

3)

5)

a

3)

3)

5)

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-7

3)

3)

3)

Page 29

b. Roller/Torque limiter

No. Name Job item Cycle

1 Rollers Clean 40K

Check 80K

Replace 80K or 2 years

2 Torque limiter Check 240K

Replace 480K

1) Remove the stopper, and pull out the multi-purpose tray.

1)

2) Remove the paper guide.

2)

c. Belt

No. Name Job item Cycle

1 Belts Check 240K

3) Disengage the roller hook, and remove the roller.

a

3)

* When installing the roller, check to insure that the hook is securely

engaged in the groove.

4) After removing the roller, remove the torque limiter.

b

d. Sensor

No. Name Job item Cycle

1 Sensors Check 80K

1)

1)

3)

a

1)

2)

1)

4)

3)

4)

a

4)

3)

a

* When installing the torque limiter, check to insure that the pin is fully

inserted into the torque limiter groove.

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-8

a

Page 30

(2)Paper transport section

1) Remove the left door.

1)

2)

1)

a. Transpor t roller/Roller

No. Name Job item Cycle

1 Transport rollers Clean 40K

2 Rollers Clean 40K

(3)Drive section

1) Remove the rear cabinet.

1)

2)

1)

a. Multi-purpose tray drive section

1) Remove the multi-purpose tray drive section.

5)

b

a

a

b

a

a

b

4)

4)

3)

2) Gear/Belt

No. Name Job item Cycle

1 Gears Lubricate 40K

2 Belts Check 240K

b

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE-9

Page 31

b. Tandem tray drive section

1) Remove the tandem tray drive section.

(5)Others

1) Remove the rear cabinet.

9)

11)

10)

2) Gear/Belt

No. Name Job item Cycle

1 Gears Lubricate 40K

2 Belts Check 240K

10)

9)

9)

1)

2)

1)

2) Remove the control PWB.

a

3) Remove the sensors.

No. Name Job item Cycle

1 Sensors Check 80K

1)

1)

1)

2)

3)

a

4)

1)

3)

4)

a

4)

3)

a

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE -10

Page 32

C. AR-MU1

(1)Paper feed section

a. Paper feed unit disassembly

1) Remove the stopper, and pull out the tray.

***************************************TBD************************************

2) Remove the paper feed unit.

1)

4) After removing the roller, remove the torque limiter.

b

* When installing the torque limiter, check to insure that the pin is fully

inserted into the torque limiter groove.

c. Belt

No. Name Job item Cycle

1 Belts Check 240K

2)

b. Roller/Torque limiter

No. Name Job item Cycle

1 Rollers Clean 40K

2 Torque limiter Check 240K

1) Remove the stopper, and pull out the multi-purpose tray.

2) Remove the paper guide.

3)

1)

Check 80K

Replace 80K or 2 years

Replace 480K

2)

3) Disengage the roller hook, and remove the roller.

a

3)

* When installing the roller, check to insure that the hook is securely

engaged in the groove.

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE -11

Page 33

d. Sensor

No. Name Job item Cycle

1 Sensors Check 80K

(3)Drive section

1) Remove the rear cabinet.

1)

1)

3)

a

1)

2)

1)

4)

3)

4)

a

4)

3)

a

1)

2)

2) Remove the tray drive section.

1)

4)

3)

5)

4)

3) Gear/Belt

No. Name Job item Cycle

1 Gears Lubricate 40K

2 Belts Check 240K

a

(2)Paper transport section

a. Transpor t roller/Roller

No. Name Job item Cycle

1 Transport rollers Clean 40K

2 Rollers Clean 40K

a

b

b

b

a

(4)Others

1) Pull out the multi-purpose tray.

a

4)

5)

AR-D13/D14/MU1/DC1 DISASSEMBLY AND ASSEMBLY, MAINTENANCE -12

Page 34

[8] BLOCK DIAGRAM, WIRING DIAG RAM

1. BLOCK DIAGRAM

A. AR-D13

E

D

C

24V

TPCL1/

24V

TPCL2/

24V

MCPCL/

24V

TPFCL/

24V

TLUM1/

24V

TLUM2/

TRANSISTOR

ARRAY

24V

MCLUM/

TD62003

24V/P-GND

TMM

TMM/

TMMCLK/

DIGITAL

TRANSISTOR

DIGITAL

TMM-T

TRANSISTOR

5V/S-GND

5V/S-GND

TSPD1

TSPD2

5V/S-GND

5V/S-GND

TLUD1

TLUD2

5V/S-GND

5V/S-GND

TPED2

TPED1

5V/S-GND

5V/S-GND

TPFD1

TTSD

5V/S-GND

5V/S-GND

TPFD3

TPFD2

5V/S-GND

5V/S-GND

MCPED

TDRS

S-GND

5V/S-GND

MCSS1

MCLUD

S-GND

MCSS2

S-GND

MCSS3

S-GND

MCSS4

5V/S-GND

5V/S-GND

MCPWS

MCSPD

OPTION

DCPS

+24V

+5V

S-GND

P-GND

CPU

H8/3644

E

D

C

TANDEM DESK UNIT

DIGITAL

TRANSISTOR

DIGITAL

TRANSISTOR

DIGITAL

TRANSISTOR

DIGITAL

TRANSISTOR

B

DSR-DSK/

DTR-DSK/

RXD-DSK

TXD-DSK

A

PRINTER

Tandem Desk Block Diagram (AR-D13)

E E

D D

DIGITAL

RES-DSK

TRANSISTOR

TRC-DSK/

F-GND

AC N

AC L

Tandem Control PWB

DIGITAL

TRANSISTOR

DIGITAL

TRANSISTOR

DHRY2

AC N

24V

AC L

DH DESK

AC N

SCN UN

AC L

SCN UN

A A

DHRY1

DH PWB

AC L

AC N

OPTIONALY

DH MPF

C C

B B

B

A

AR-D13/D14/MU1/DC1 BLOCK DIAGRAM, WIRING DIAGRAM-1

Page 35

B. AR-D14

E

24V

24V

24V

24V

24V

24V

24V

24V/P-GND

5V/S-GND

5V/S-GND

5V/S-GND

5V/S-GND

DPED2

DPFD2

DPFD3

5V/S-GND

5V/S-GND

DPFD1

DDRS

5V/S-GND

5V/S-GND

MCPED

MCLUD

S-GND

MCSS1

S-GND

MCSS2

S-GND

MCSS3

S-GND

MCSS4

5V/S-GND

5V/S-GND

MCSPD

MCPWS

S-GND

DCSS11

S-GND

DCSS12

S-GND

DCSS13

S-GND

DCSS14

S-GND

DCSS21

S-GND

DCSS22

S-GND

DCSS23

S-GND

DCSS24

+5V

OPTION

DCPS

+24V

S-GND

DPCL1/

DPCL2/

MCPCL/

DPFCL/

DLUM1/

DLUM2/

MCLUM/

DMM/

DMM

DMMCLK/

DMM-T

5V/S-GND

5V/S-GND

DSPD1

DSPD2

5V/S-GND

5V/S-GND

DLUD2

DLUD1

DPED1

D

TD62003

DIGITAL

TRANSISTOR

DIGITAL

TRANSISTOR

ARRAY

TRANSISTOR

C

E

P-GND

D

C

H8/3644

CPU

2nd Control PWB

3TRAY DESK UNIT

DIGITAL

TRANSISTOR

DIGITAL

DHRY1

DH PWB

AC N

OPTIONALY

TRANSISTOR

DHRY2

AC L

AC N

AC L

AC N

SCN UN

B

24V

AC L

A

SCN UN

DIGITAL

TRANSISTOR

DIGITAL

DIGITAL

TRANSISTOR

DIGITAL

TRANSISTOR

DIGITAL

TRANSISTOR

TRANSISTOR

B

TXD-DSK

RXD-DSK

DTR-DSK/

DSR-DSK/

RES-DSK

TRC-DSK/

F-GND

AC N

AC L

A

PRINTER

3TRAY Block Diagram (AR-D14)

E E

D D

AR-D13/D14/MU1/DC1 BLOCK DIAGRAM, WIRING DIAGRAM-2

DH MPF

DH DESK

C C

B B

A A

Page 36

C. AR-MU1

E

VB

MCFCL/

MCPCL/

VB

MCLUM/

VD/S-GND

VD/S-GND

VD/S-GND

VD/S-GND

VD/S-GND

S-GND

S-GND

S-GND

MCSS2

MCSS3

S-GND

MCSS4

S-GND

MCSPD

MCPED

MCSS1

MCDRS

MCPPD

MCLUD

D

MCSET

VAREF

MCPWS

VB/P-GND

MCM

DH MPF

E

D

OPTIONALY

AC L

AC N

VB

MCLUD

MCSPD

MCPED

MCSS1

MCSS2

MCDRS

C

MCPPD

MCSET

MCSS3

MCSS4

MCPWS

MCFCL/

MCPCL/

DCPR/VBMCMCLK/

MCLUM/

MCM-T

MCM/

DH PWB

C

MALTI CS UNIT

B

+5V1(VD)

A

MPT Block Diagram (AR-MU1)

E E

Multi PWB

MCPPD

MCDRS

MCLUD

PRINTER

D D

MCPED

MCSPD

MCSET

MCSS1

MCSS2

MCSS3

MCSS4

GND1(S-GND)

C C

VAREF

MCPWS

MCPCL/

+24V2(VB)

MCFCL/

MCLUM/

GND2(P-GND)

DCPR/

B B

MCM-T

MCMCLK/

MCM/

AC N

B

AC L

A

A A

AR-D13/D14/MU1/DC1 BLOCK DIAGRAM, WIRING DIAGRAM-3

Page 37

2. WIRING DIAGRAM

A. AR-D13

E

TSPD2

VD(+5V)

TSPD2

S-GND

123

179228-3

D

TAN Sensor

PWB

S-GND

TPED2

TLUD2

1

2

3

VD(+5VR)

VD(+5V)

4

5

PHR-5

TSPD1

TSPD1

2

1 VD(+5V)

S-GND

3

179228-3

TLUM2

TLUM2

VB(+24V)

2

1

LIFT MOTOR UNIT

PHR-2

TPFD2

VD(+5V)

TPFD2

132

S-GND

179228-3

TTSD

VD(+5V)

TTSD

S-GND

321

179228-3

2

1

2

1

SMP-02V-BC SMR-02V-B

TPCL1

1

1

2

2

SMP-02V-NC SMR-02V-N

TPCL2

TPFD3

VD(+5V)

TPFD3

1

2

S-GND

3

179228-3

TAN Sensor

TPED1

TLUD1

1

2

PWB

S-GND1VD(+5VR)

VD(+5V)

4

3

5

PHR-5

TLUM1

TLUM1/

VB(+24V)

2

LIFT MOTOR UNIT

PHR-2

DH DESK (OPTIONALY)

DH MPF (OPTIONALY)

ELP-02

1211

22

2

1

ELR-02VF

3AC N12

2

B2P3-VH

N.C

AC L

AC L 1

N.C

CN-E

CN-D

CN-A

CN-B

AC L

VB(+24V)

DHRY1

DHRY2

213

PHR-331

123

ELP-02

ELR-02

B2P3-VH-R

AC N 3

N.C

AC N

CN-C

AC L

B2P3-VH

DH PWB

(OPTIONALY)

N.C

AC N

2

B2P3-VH

SCN UN

PRINTER UN

2

1

1

2

ELR-02VF ELP-02

E

D

2

1

2

3

4

5

6 N.C.

7

8

9

10

PHR-12

CN-B

S-GND1

TSPD1

VD(+5V)

TLUM2/

VB(TLUM2)

S-GND

TPFD2

VD(+5V)

S-GND

TTSD1211

VD(+5V)

CN-C

2

VB(+24V)

TPCL1/

PHR-2

(RED)

CN-G

VB(+24V) 1

PHR-2-R(RED)

TPCL2/

1234567

CN-I

TPFD3

S-GND

VD(+5V)

S-GND

TLUD1

VD(+5VR)

9

8

PHR-9

N.C

VD(+5V)

TPED1

CN-J

123

TLUM1/

45678910

N.C.

N.C.

VB(TLUM1)

N.C.

N.C.

N.C.

C

CN-A

TSPD2

VD(+5V)

S-GND

123456789

B

1

2

2

1

SMR-02V-N SMP-02V-NC

1

2

PHR-2

+24V

MCLUM/

LIFT MOTOR UNIT

MCLUM

MCPCL

A

11

11

2

2

TPFCL

10

9

10

1

SMP-02V-BCSMR-02V-B

1

789

5

6

678

5

TMMCLK/

45312

412

4

TMM-T

TMM

3

3

TMM/

2

GND1

1

+24V

SMR-11V-N SMP-11V-NC

PHR-5

1

+5V

MCSPD 2

MCSPD

3

GND2

179228-3

1N.C.

2

GND2

MCSS16MCSS23MCSS3 5

MPT LD PWB

4

PHR-6

MCSS4

S-GND

TLUD2

VD(+5VR)

N.C

TPED2

VD(+5V)

CN-D

PHR-9

VB(+24V)

+24V(MCLUM)

TPFCL/13MCLUM/

MCPCL/

GND1(P-GND)

VB(+24V)

VB(+24V)

23456789101112

1

PAPER FEEDING UNIT

TMM/

MCSPD

TMM-T

TMMCLK/

18

17

18

17

2

MCLUD1GND2 3

+5V

MCLUD

GND2(S-GND)

VD(+5V)

14151617181920

16

16

179228-3

MCSS1

MCSS3

MCSS2

GND2(S-GND)

14

15

15

14

+5V

TPFD1

TPFD1

MCSS4

F-GND

PHDR-20VS-1

13

13

312

179228-3

GND2

CN-E

VD(+5V)

MCLUD

VD(+5V)

23456789101112

1 GND2(S-GND)

SRA-21T-4

8

7

9

8

7

9

3

1

2

179228-3

GND2

+5V1TDRS

TDRS

MCPED

TDRS

GND2(S-GND)

GND2(S-GND)

VD(+5V)

4

5

6

5

4

6

SMR-18V-B SMP-18V-BC

3

2

179228-3

MCPED

+5V

GND2

MCPED

TPFD1

GND2(S-GND)

VD(+5V)

MCPWS2

131415

MCPWS

VD(+5V)

N.C.

16

PHDR-16VS-1

N.C.

N.C.

N.C.

CN-M

32132

1

1T3T2T

MCPWS

VAREF

MCPWS2

MPT VR UN

PHR-10

/RESMD/RXD

/TXD

318

2

SMP-03V-BCSMR-03V-B

1

2

CN-N

DHRY1

CLOCK OUT

+5V(VD)

FVpp

RES

659411

7

PHR-3

DHRY23VB(+24V)

TXD

S-GND

10

TEST

CN-F

PHR-11

CN-G

TXD-DSK

RXD-DSK/

DTR-DSK/

P-GND

GND2

DSR-DSK/

S-GND

+24V(VB)

+5V(VD)

1234567891011

4

3111

8

7

6

532

9

7

6

542111

9

8

6311

8

5210

7

419

+24V(VB)

+5V(VD)

DSR-DSK/

GND2

RXD-DSK/

S-GND

DTR-DSK/

TXD-DSK

P-GND

OPTION

DCPS

TAN Control PWB

RES-DSK

TRC-DSK/

12 N.C.

PHDR-12VS-1

SMR-11V-B

10

10

TRC-DSK/

RES-DSK

C

B

A

AR-D13 Wiring Diagram

E E

AR-D13/D14/MU1/DC1 BLOCK DIAGRAM, WIRING DIAGRAM-4

D D

C C

B B

A A

Page 38

B. AR-D14

E

PAPER FEEDING UNIT

D

C

DLUD2

VD(+5V)

DLUD2

S-GND

3

2

1

16

18

17

171316515

18

179228-3

DPED2

DPED2

VD(+5V)

1

2

15

14 14

S-GND

3

13

179228-3

DPFD3

DPFD3

VD(+5V)

2

1

6

5

6

179228-3

SMR-18V-N

4

4 S-GND3

SMP-18V-NC

1

DSPD2

DSPD21VD(+5V)

2

S-GND3

PHR-12

179228-3

CN-B

1

2

3

4

5

6

7

8

9

10

11

12

S-GND

DSPD2

VD(+5V)

DLUM2/

N.C.

VB(DLUM2)

N.C.

N.C.

N.C.

N.C

N.C

N.C

CN-A

1 S-GND

DLUM2

2

LIFT UP MOTOR UNIT

PHR-2

DLUD2

S-GND

VD(+5V)

VD(+5V)

DPFD32

4

3

596

7 S-GND

DPED2

VD(+5V)

8

PHR-9

CN-H

DPCL2

11

22

1

2DPCL2/

VB(+24V)

SMP-02V-BC SMR-02V-B

PHR-2

CN-G

DPCL1

11

22

2

1

DPCL1/

VB(+24V)

SMP-02V-NC SMR-02V-N

PHR-2-R(RED)

DLUD1

DPED1

VD(+5V)

DLUD1

S-GND

S-GND

DPED1

312

2

3

1 VD(+5V)

179228-3

179228-3

PAPER FEEDING UNIT

2

3

59714S-GND

S-GND

DPFD2

VD(+5V)

DLUD1

CN-I

CN-D

DPFCL/

VB(+24V)

VB(+24V)

MCPCL/

+24V(MCLUM)5

1

397

DPFD2

S-GND

DPFD2

2

3

1 VD(+5V)

179228-3

456131415161718

456131415161718

SMP-18V-NC SMR-18V-N

8

PHR-9-R(RED)

DPED1

S-GND

VD(+5V)

VD(+5V) 6

VB(+24V)

GND1(P-GND)4MCSS21720VD(+5V)

DMM-T

MCSPD

DMM/2GND2(S-GND)

DMMCLK/

12

11

8

6 MCLUM/

10

CN-J

13

14

DLUM1

1

1

2

N.C.

DLUM1/

GND2(S-GND)

MCSS1

16

15

DSPD1

DSPD12S-GND

VD(+5V)

LIFT UP MOTOR UNIT

1

2

3

179228-3

PHR-2

8

369

5

7N.C

4

10N.C.

DSPD1

N.C

VB(DLUM1)

VD(+5V)

S-GND

N.C

CN-E

F-GND

MCSS4

MCSS3

18

19

PHDR-20VS-1

PHR-10

CN-K

MCLUD

VD(+5V)4GND2(S-GND)1

3135

PLS-PWB1

N.C.

DCSS11

DCSS124

1

3

2 GND2

2

1

3

4

DCSS146DCSS13

DCSS15

MCPED

VD(+5V)

GND2(S-GND)

GND2(S-GND)

DCSS13

6 DCSS14

5

S-GND5DCSS12

DCSS11

DDRS

VD(+5V)

967

PHR-6

PHR-6

CN-L

DPFD1

MCPWS2

VD(+5V)

GND2(S-GND)

12

N.C.

1

DCSS24

DCSS25

VD(+5V)

MCPWS

151611141028

PLS-PWB2

GND2

DCSS235

DCSS21

DCSS22

246

3

5DCSS216342

DCSS23

DCSS221S-GND

N.C.

PHDR-16VS-1

DCSS24

PHR-6-R(RED)

PHR-6-R(RED)

CN-M

/RXD

MD

/RES

27813

DH MPF (OPTIONALY)

ELP-02

121

1

2

ELR-02VF

132

2

AC N1N.C3N.C

AC L

CN-E

CN-B

VB(+24V)

DHRY1

1

2

1

CN-N

VB(+24V)3DHRY2

DHRY1

RES

+5V(VD)

CLOCK OUT

/TXD

FVpp

TXD

DH DESK (OPTIONALY)

ELP-02

22

1

ELR-02

B2P3-VH

B2P3-VH-R

AC L

AC N

CN-D

CN-A

AC N3AC L2AC L

N.C

DHRY2

1

2

PHR-332

3

B2P3-VH

PHR-3

CN-F

TEST

S-GND

10

114956

PHR-11

DH PWB

CN-C

N.C

1

P-GND

+24V(VB)

AC N

VD(+5V)

(OPTIONALY)

B2P3-VH

TXD-DSK

DSR-DSK/

S-GND

RXD-DSK/1DTR-DSK/

GND2

543

792

6

PRINTER UN

22

SCN UN

2nd Control PWB

RES-DSK8TRC-DSK/

11

10

12 N.C.

PHDR-12VS-1

ELP-02

1

1

ELR-02VF

E

D

C

B

11

10

11

SMP-02V-NC

1

2

22

1

2

1

1

SMR-02V-N

1

2

PHR-2

+24V

A

MCLUM/

LIFT MOTOR UNIT

MCLUM

MCPCL/

DPFCL/

7

6

7

8

6

SMP-02V-BC

SMR-02V-B

5109

3

4

49385

DMM/

DMM-T

DMMCLK/

DMM

2

2

GND1

1

1

12345

+24V

SMP-11V-NC

SMR-11V-N

PHR-5

1

+5V

MCSPD 2

MCSPD

3

GND2

179228-3

1N.C.

2

MCSS16MCSS23MCSS3 5

GND2

MPT LD PWB

4

PHR-6

MCSS4

3TRAY Desk Wiring Diagram (AR-D14)

E E

D D

161718

161718

12331

PAPER FEEDING UNIT

179228-3

+5V

GND2

MCLUD

MCLUD

+5V

2

DPFD1

DPFD1

C C

131415

179228-3

GND2

9

12312

179228-3

DDRS

+5V

GND2

DDRS

+5V

45678

456789131415

3

GND2

MCPED

MCPED

SRA-21T-4

SMR-18V-B SMP-18V-BC

179228-3

SMR-11V-B

521

9

8143637

11

10

2

98765

4

11

10

6

9

7

8DTR-DSK/

RXD-DSK/

GND2 4

TXD-DSK5F-GND

S-GND

A A

10

11

RES-DSK

DSR-DSK/

TRC-DSK

12

B

A

1

3VD(+5V)

P-GND 2

+24V(VB)

OPTION

DCPS

SMP-03V-BC

11

3

3

22

SMR-03V-B

1T

3T

VAREF2TMCPWS

MCPWS2

MPT VR UN

B B

AR-D13/D14/MU1/DC1 BLOCK DIAGRAM, WIRING DIAGRAM-5

Page 39

C. AR-MU1

E

PAPER FEEDING UNIT

D

MCLUD

MCLUD

+5V3+5V

GND2

2

1

18

16

17

17

18

16

1

15

15

MCPPD

GND2

MCPPD

2

3

13

14

14

13

+5V

1

9

9

MCDRS

MCDRS

2

8

8

MCPED

GND23

GND23

MCPED

+5V

1

2

SMR-18V-BSMP-18V-BC

4

6

7

5

5

6

4

7

MCPWS

2T

321

MPT VR UN

VAREF

MCPWS2

3T

1T

231

SMP-03V-BC SMR-03V-B

MCSPD

MCSPD

+5V

123 GND2

E

D

MCSS3

52643

MCSS4

PHR-6

MCLUM

MCLUM/

24V

2

1

PHR-2

LIFT MOTOR UNIT

MCM

MCM/4GND1

MCM-T

+24V

MCMCLK/

3

1

5

2

PHR-5

MCFCL

22

MCPCL

SMR-02V-B

112211

SMP-02V-BC

SMR-02V-NSMP-02V-NC

SRA-21T-4

GND2

N.C.

1

MPT LD PWB

MCSS2

MCSS1

DH PWB

(OPTIONALY)

CN-A

AC N

AC L13N.C

B2P3-VH

2

ELP-02

22

11

ELR-02VF

C

B

A

C

3

1

254

678

GND1

+24V

20

19

MCLUM/

MCM-T

MCM/

MCM-T

MCMCLK/

N.C

MCM/

22

23

21

MCMCLK/

MCM/

e/?

+24V

+24V

MCFCL/

DCPR/

24

PHDR-24VS-1

PADP-24V-1-E

DCPR/

9

PHR-9

MCPCL/

CN-B

DH MPF(OPTIONALY)

DCPR/

N.C

2

1 +24V

PHR-3

3

ELP-02ELR-02VF

11

22

2N.C

B2P3-VH

AC L 1

AC N 3

CN-C

CN-B

DCPR/

+24V21N.C

3

PHR-3

125

647

3

9

10

11

12

2

PHR-2

24V1MCLUM/

MCSS3

MCSS4

MCSS28MCSS1

GND2

GND2

GND2

GND2

GND2

GND2

GND2

GND2

CN-E

+5V

1

2

+5V

3

+5V

4

+5V

5

+5V

6

VAREF

N.C.

7

8

MCPWS2

9

MCPWS

10

MCPPD

11

MCDRS

MCPED

12

MCLUD

13

14

MCSPD

PHDR-14VS-1

CN-F

MPT

PWB

PHDR-12VS-1

CN-A

GND15MCPED16MCSS310MCSET4MCM-T

MCDRS

VAREF

MCPPD2MCPWS

+5V

GND2

+24V

CN-C

6

8

7

1

MCSS417MCPCL/11MCMCLK/

MCSS23MCSPD14MCLUM/

MCSS1

12

13

15

9 MCLUD

CN-D

MCFCL/

18

B

3

8

5

2

7

4

1

GND1

+5V

GND2

VAREF

MCPPD

MCDRS

MCPED

+24V

MCLUD

11

10

MCPWS

MCSS1

MCSS2

14

13

MCSS3

MCSS4

MCSPD

16

MCSET

17

18192024232221

MCPCL/

MCFCL/

15

12

9

6

TO PRINTER BODY

A

MPT Wiring Diagram (AR-MU1)

E E

D D

AR-D13/D14/MU1/DC1 BLOCK DIAGRAM, WIRING DIAGRAM-6

PRINTER UN

C C

B B

A A

Page 40

3. CIRCUIT DIAGRAM

P

7

2

3

2

A. AR-D13 / AR-D14

A

3

D213

DAN202K

DSR-DSK/

CNF-9

DTR-DSK/

TXD-DSK

TXD

RES-DSK

RES

RXD-DSK/

TRC-DSK/

VD

R165

4.7kJ

D212

DAP202K

VD

R118

4.7kJ

VD

R116

4.7kJ

DAP202K

D201

1

3

2

1

3

2

DAP202K

D210

E

CNF-8

CNF-6

CNM-9

D

CNF-10

CNM-8

CNF-7

CNF-11

C

3

1

2

1

DTC114YKA