Page 1

SERVICE MANUAL

DIGITAL COPIER

Option: Paper Feed Unit

AR-D11

MODEL

[ 1 ] GENERAL........... .......................... .......................... .......................... ........1

[ 2 ] SPECIFICATIONS ....................................................................................1

[ 3 ] UNPACKING AND INSTALLATION..........................................................1

[ 4 ] EXTERNAL VIEW AND INTERNAL STRUCTURE...................................6

[ 5 ] OPERATIONAL DESCRIPTI ONS..................................... ........................7

[ 6 ] DISASSEMBLY AND ASSENBLY.............................................................7

AR-D12

CONTENTS

[ 7 ] MAINTENANCE............................................ .......................... ..................9

[ 8 ] ELECTRICAL SECTION .........................................................................10

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] GENERAL

The AR-D11 (1-stage paper feed unit) and the AR-D12 (2-stage paper

feed unit) are optional paper feed units added to the digital copier, and

their cassettes are common with those of the main machine.

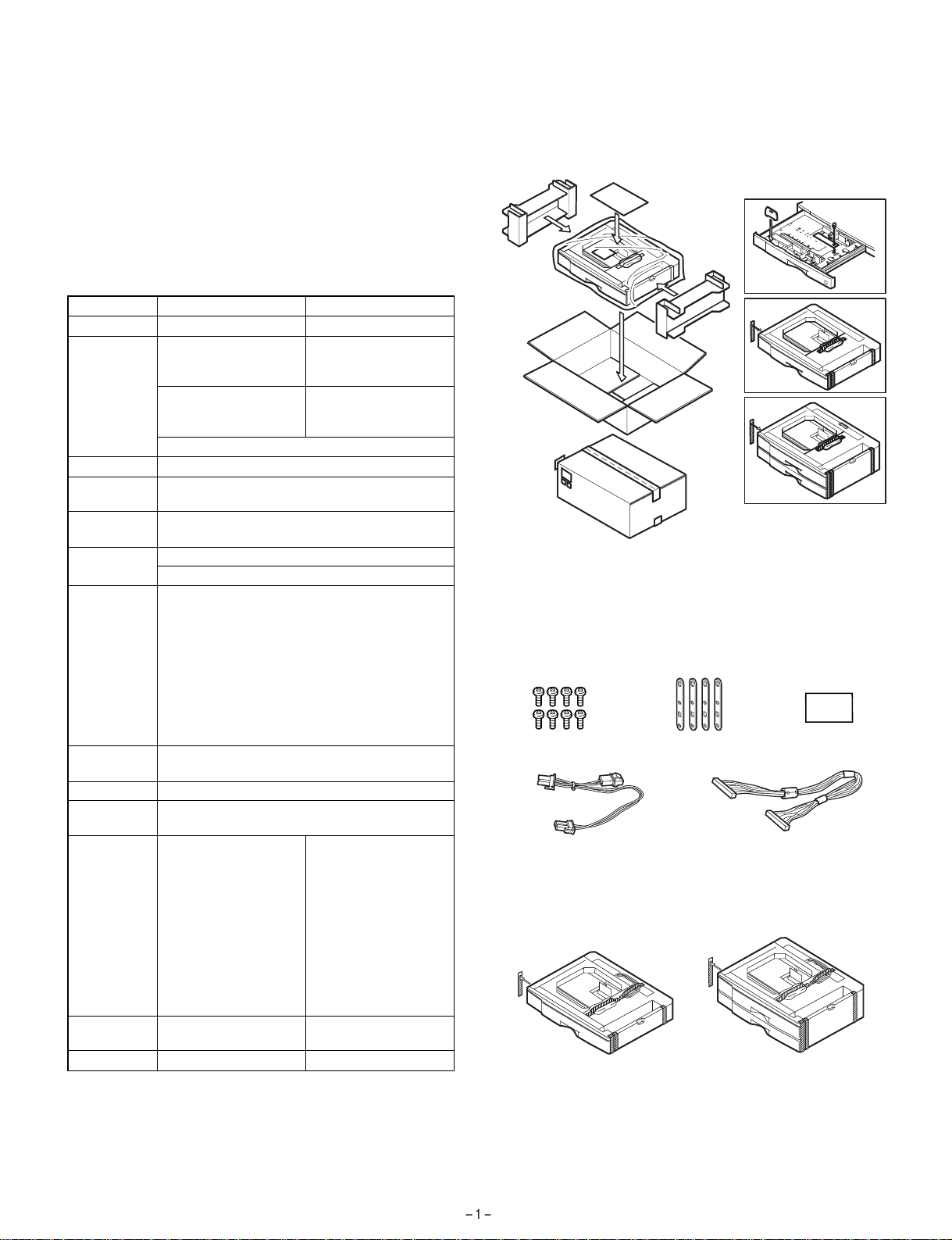

[2] SPECIFICATIONS

1. Paper feed unit (AR-D11/AR-D12)

[3] UNPACKING AND INSTALLATION

1. Unpacking

AR-D11 AR-D12

No. of stage 1-stage 2-stage

Capacity 550 pages x 1 stage

Size detection No (The paper size is set with the user program.)

Paper empty

detection

Paper feed

size

Size when

shipping

Size selection User selection (Set by the user program.)

Cassette

installation

Heater Provided only for Japan.

Power source Supplied from the copier. DC24V, power

Drive supply

(Japan)

500 pages x 1 stage

(EX Japan)

(Note) Japan: 64g/m

Provided

A3, B4, A4, A4R, B5, B5R, 16k, 16kR, 8k,

11 x 17, 8.5 x 14, 8.5 x 13, 8.5 x 11, 8.5 x 11R

AB series: A4

Inch series: 8.5 x 11

Japan: A3, B4, A4, A4R, B5, B5R, 8.5 x 11,

8.5 x 11R, 8.5 x 14, 11 x 17

Inch series: 11 x 17, 8.5 x 14, 8.5 x 11,

8.5 x 11R, A4, A3

Inch series foolscap: 11 x 17, 8.5 x 14, 8.5 x 13,

8.5 x 11, 8.5 x 11R, A4, A3

EX AB series foolscap: A3, B4, A4, A4R,

8.5 x 13, 8.5 x 14, 8.5 x 11, 11 x 17

Installed by the user.

consumption 5.6W

· When installed as the

2-stage cassette for

the 2-stage cassette

standard model:

Supplied via gears

from the copier.

550 pages x 2 stages

(Total 1, 100 pages)

(Japan)

500 pages x 2 stages

(Total 1, 000 pages)

(EX Japan)

2

, EX: 80g/m

Supplied by the

individual motor.

2

· When installed as the

optional 2-stage or 3stage cassette:

Supplied by the

individual motor.

External

dimensions

Weight About 5kg About 10kg

596(W) x 471(D) x

97(H) mm

596(W) x 471(D) x

194(H) mm

AR-D11

AR-D12

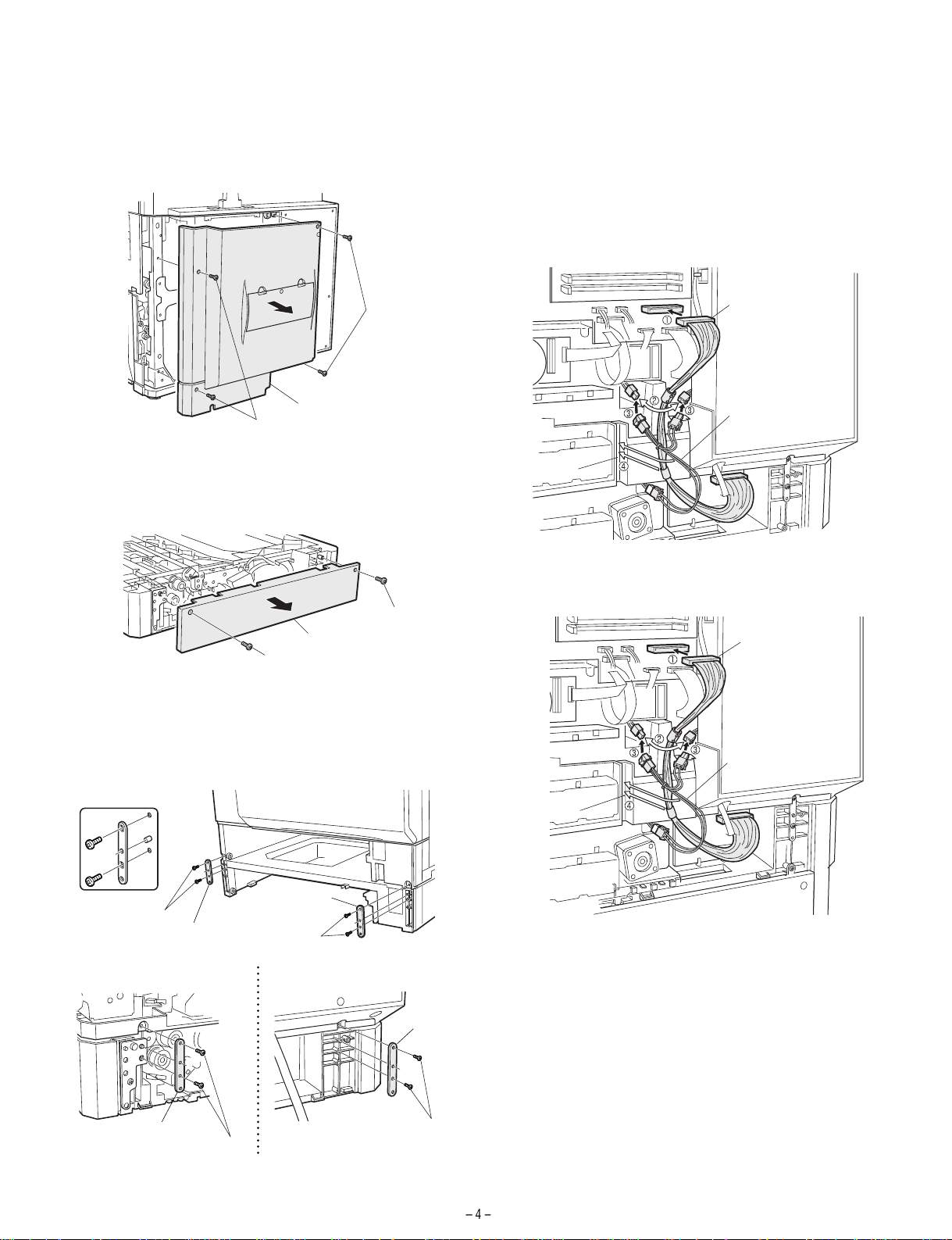

2. Installation

Parts included

Screws (M4 x 12): 8 pcs.

Relay harness

for dehumidifying heater

Remove all pieces of fixing tape and fixing mat erials from the paper

feed unit.

Fixing plates: 4 pcs.

Cassette relay harness

(contained in the optional paper feed unit)

Paper size label

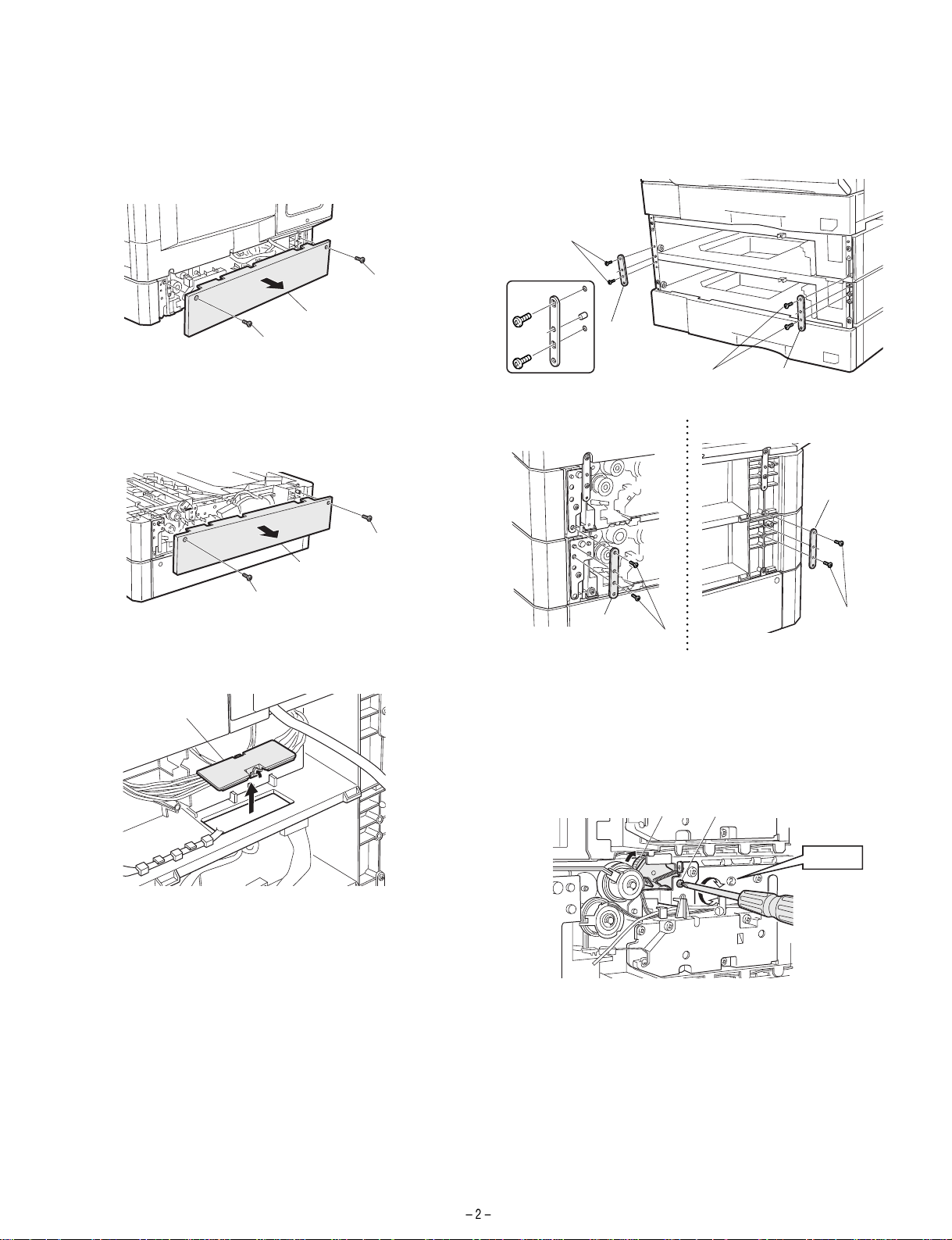

Page 3

For copier models with two paper trays.

Turn off the main switch of the copier and then remove the power plug

of the copier from the outlet.

1. Remove the rear cover from the copier.

Remove the two screws and then remove the rear cover from the

copier.

4. Attach the copier

Place the copier on the optional paper feed unit and remove the

second and third paper trays.

Connect the copier to the paper feed unit using four fixing plates and

two screws (M4 x 12) for each plate.

Front side

Screws (M4 x 12)

Screw

Rear cover

Screw

2. Remove the rear cover from the optional pap er feed

unit.

Remove the two screws and then remove the rear cover from the

optional paper feed unit.

Screw

Rear cover

Screw

3. Remove the connector cover.

Remove the cover from the connector.

Connector cover

Detailed view

Fixing plate

Left of rear side

Fixing plate

Screws (M4 x 12)

Screws

(M4 x 12)

Fixing plate

Right of rear side

Fixing plate

Screws

(M4 x 12)

5. Unlock the connection gear.

<1> Loosen the screw of the connection gear and ensure that the

connection gear has moved to the optional paper feed unit.

<2> Tighten the connection gear fixing screw again.

Connection gear

Connection gear fixing screw

CAUTION

6. Connect the harness.

<1> Connect the cassette relay harness contained in the optional

paper feed unit to the paper feed unit relay PWB.

<2> Remove the relay harness for dehumidifying heater connected to

the second paper tray.

<3> Connect the relay harness for dehumidification heater contained

in the optional paper tray to the optional paper tray.

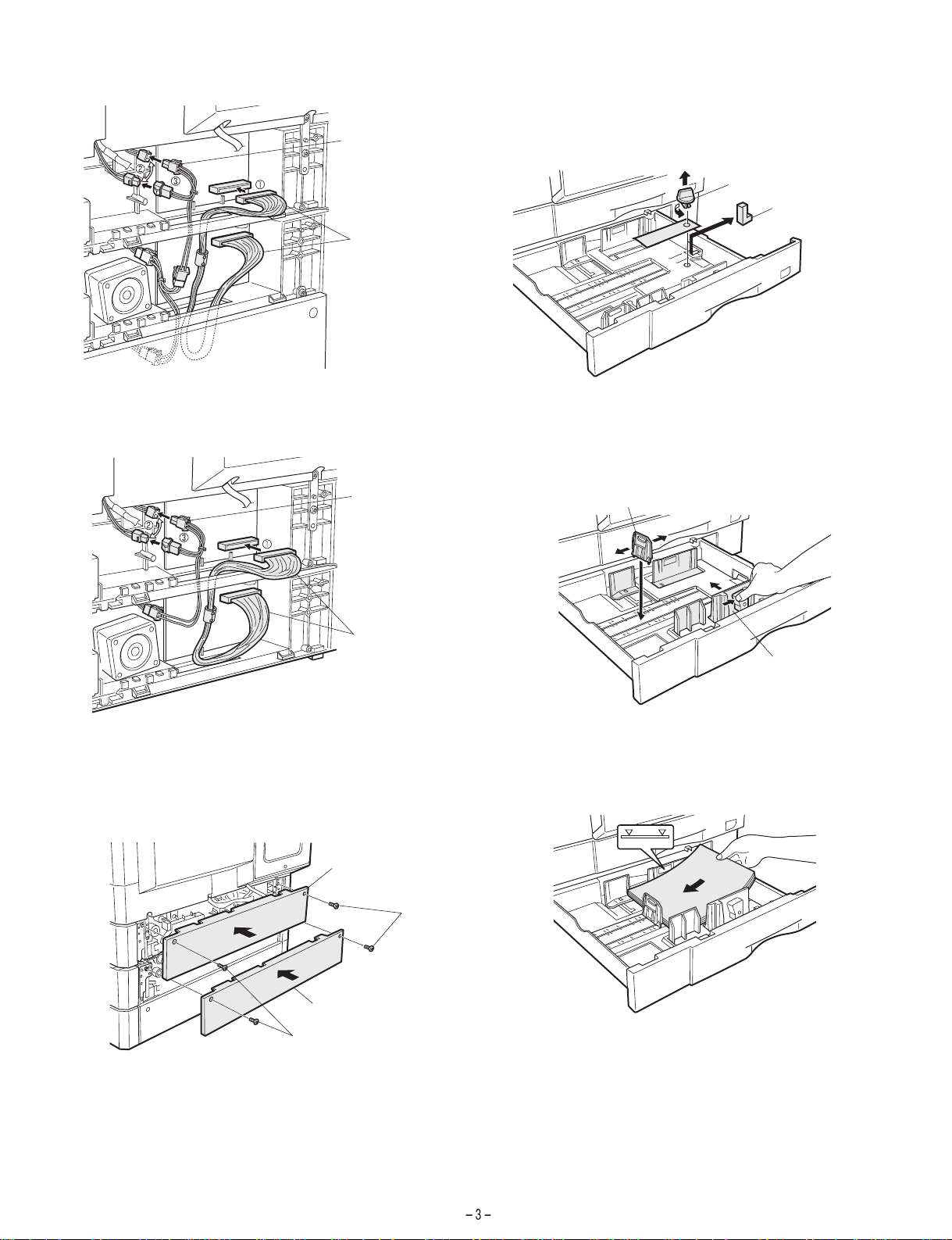

Page 4

· For two tray typ e

Relay harness for

dehumidification heater

Cassette relay harness

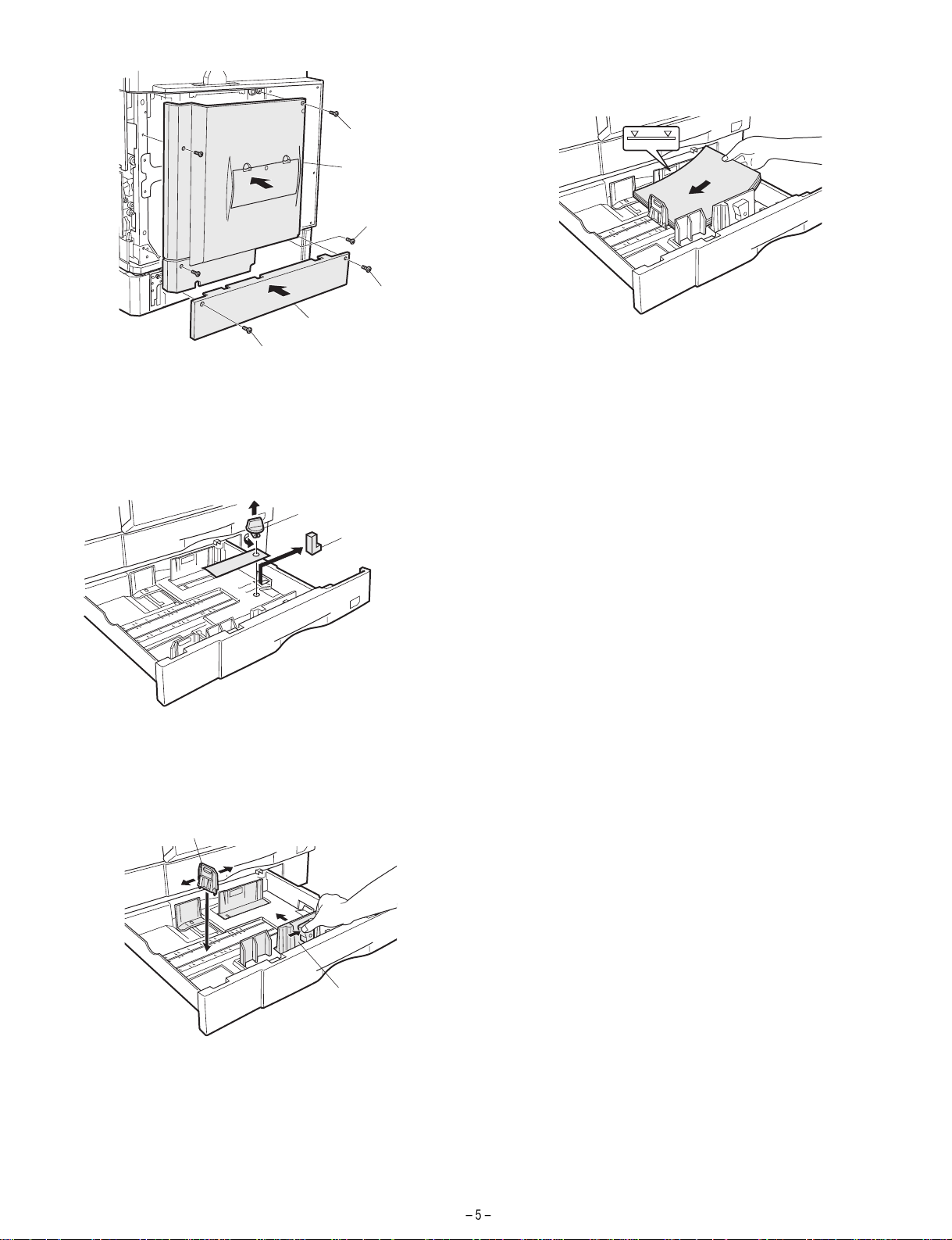

8. Remove the securing fixture for packing the paper

feed unit and remove the packing material.

Remove the securing fixture for packing that fixes the paper pressure

plate of the tray by rotating it in the direction of the arrow and remove

the packing material.

Securing fixture for packing

Packing material

[Caution]

Be sure to remove the

securing fixture before

turning on the power.

· For one tray type

Relay harness for

dehumidification heater

Cassette relay harness

7. Attach the rear covers of the copier and the optional

paper feed unit.

Attach the rear covers of the copier and the optional paper feed unit

using two screws respectively.

9. Change the paper size in the tray.

Hold the grip and slide the cassette side plate to adjust it to the paper

to be used.

Then, fit the rear end plate to the specified size position.

Rear plate

Side plate

Insert the power plug of the copier to the out let and turn on the main

switch of the copier. Then, carry out the following procedure.

10. Load paper into the paper tray.

Do not exceed the maximum height line.

Rear cover

Screws

Rear cover

Screws

11. Check for center displacement.

· Set an original on the document glass and copy it using the paper

tray in the copier.

Then, copy an original using the attached optional paper feed unit.

· If the center of the copy image from the tray in the copier is differ-

ent from that of the copy image from the optional paper feed unit,

carry out adjustment referring to the service manual.

Installation of Paper feed unit is now complete.

Page 5

For copier models w ith one paper tray

Turn off the main switch of the copier and then remove the power plug

of the copier from the outlet.

1. Remove the right rear cover from the copier.

Remove the four screws and then remove the right rear cover from

the copier.

4. Connect the harness.

<1> Connect the cassette relay harness contained in the paper feed

unit to the MCU PWB of the copier.

<2> Remove the relay harness for dehumidifying heater connected to

the paper tray in the main unit.

<3> Connect the relay harness for dehumidification heater contained

in the optional paper tray to the optional paper tray.

<4> Store the harness in the harness holder.

· For one tray type

Screws

Right rear cover

Screws

2. Remove the rear cover from the optional pap er feed

unit.

Remove the two screws and then remove the rear cover from the

optional paper feed unit.

Screw

Rear cover

Screw

3. Attach the copier

Place the copier on the optional paper feed unit and remove the first

and second paper trays.

Connect the copier to the paper feed unit using four fixing plates and

two screws (M4 x 12) for each plate.

Harness holder

· For two tray type

Cassette relay harness

Relay harness for

dehumidification heater

Cassette relay harness

Relay harness for

dehumidification heater

Detailed view

Screws (M4 x 12)

Left of rear side

Fixing plates

Fixing plates

Screws (M4 x 12)

Fixing plates

Screws (M4 x 12)

Right of rear side

Fixing plates

Screws (M4 x 12)

Harness holder

5. Attach the right rear cabinet of the copier an d the rear

cover(s) of the optional pap er fee d un it.

Attach the right rear cabinet of the copier using four screws, and

attach the rear cover(s) of the optional paper feed unit using two

screws respectively.

Page 6

Screw

Right rear cabinet

Screw

Screw

Rear cover

Screw

6. Remove the securing fixture for pac ki ng the pa pe r

feed unit and remove the packing material.

Remove the securing fixture for packing that fixes the paper pressure

plate of the tray by rotating it in the directi on of the arrow and remove

the packing material.

Securing fixture for packing

Packing material

8. Load paper into the paper tray.

Do not exceed the maximum height line.

9. Check for center displacement.

· Set an original on the document glass and copy it using the paper

tray in the copier.

Then, copy an original using the attached optional paper feed unit.

· If the center of the copy image from the tray in the copier is differ-

ent from that of the copy image from the optional paper feed unit,

carry out adjustment referring to the service manual.

Installation of Paper feed unit is now complete.

[Caution]

Be sure to remove the

securing fixture before

turning on the power.

7. Change the paper size in the tray.

Hold the grip and slide the cassette side plate to adjust it to the paper

to be used.

Then, fit the rear end plate to the specified size position.

Rear end plate

Side plate

Insert the power plug of the copier to the outlet and turn on the main

switch of the copier. Then, carry out the following procedure.

Page 7

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. External view

1

AR-D12 AR-D11

No. Name No. Name

1 Paper feed tray 2 Paper feed right cover

2. Internal structure

12

15

16

17

14

1

2

2

1

2

3

4

5

6

13

4

7

8

9

18

10

11

Motors, sensors, solenoids, etc.

No. Code Name Type Function/Operation Remark

1 PWB Interface PWB –

2 Drive motor Hybrid Drives gears.

3 LUM1AD Lift-up motor (No. 1 tray)

4 /PCLIA Paper feed clutch Electromagnetic clutch Rotates the paper feed roller.

5 TRCLA Transport clutch Electromagnetic clutch Rotates the transport roller.

6 CSS1 Cassette detection SW Contact Detects cassette empty.

7 CSS2 Cassette detection SW Contact Detects cassette empty. AR-D12 only

8 LUM2B Lift-up motor (No. 2 tray)

9 /PCS1B Paper feed solenoid DC solenoid Feeds paper.

10 DRS1 Door open/close detection SW Contact Detects door open/close.

11 DRS2 Door open/close detection SW Contact Detects door open/close. AR-D12 only

12 PAP1 Paper empty sensor Photo transmission Detects paper empty in the cassette.

13 LUD1 Upper limit sensor Photo transmission Detects the upper limit for paper pickup.

14 PPD1 Paper entry sensor Photo transmission Detects paper transport.

15 PAP2 Paper empty sensor Photo transmission Detects paper empty in the cassette. AR-D12 only

16 LUD2 Upper limit sensor Photo transmission Detects the upper limit for paper pickup. AR-D12 only

17 PPD2 Paper empty sensor Photo transmission Detects paper transport. AR-D12 only

18 /PCS2 Paper feed solenoid DC solenoid Feeds paper. AR-D12 only

Page 8

[5] OPERATIONAL DESCRIPTIONS

1. Paper transport path

[6] DISASSEMBLY AND ASSENBLY

For disassembly, follow instructions of illustrations 1, 2, 3, ... in this

sequence. For assembly, reverse the disassembly procedures.

For replacement of parts described in this manual, refer to the Parts

Guide.

1. Paper feed solenoid

1-1

2. Operational descriptions

The operations of this unit is controlled by the copier, and the pickup

roller, the paper feed roller, etc. are driven by the drive motor.

Paper picked up by the pickup roller is transported by the paper feed

roller, detected by the paper entry sensor, and fed to the resist roller.

6

5

4

3

2

1

5

4

3

2

1

1-2

1-3

1)

1)

2)

2)

No. Part name Operation

1 Pickup roller Picks up paper.

2 Paper feed roller Transports paper.

3 Separation sheet Press paper to the paper feed

roller.

4 Paper entry detection ACT Detects transport of paper.

5 Paper entry sensor Detects transport of paper.

6 Resist roller Synchronizes the paper lead

edge and the image lead edge.

1)

3)

Page 9

2. Paper feed rollers

Reference : Illust (1-1)

2-1

3-A-2

1)

3)

4)

4)

3. Motors, clutches, belts

3-1

2)

1)

B. Lift-up motor

3-B-1

2)

3-5

1)

3)

2)

2)

2)

1)

3)

2)

2)

2)

A. Drive motor

3-A-1

1)

1)

1)

3)

2)

C. Paper feed clutch / Transport clutch

3-C-1

1)

1)

1)

3)

3)

2)

3)

2)

1)

2)

3)

Page 10

D. Belt

Reference : Illust (1-1)

3-D-1

3)

2)

1)

3-D-2

3)

6)

5)

4)

3)

2)

[7] MAINTENANCE

No. Name Work item When service call

1 Pickup roller Cleaning

2 Paper feed roller Cleaning

1)

Page 11

[8] ELECTRICAL SECTION

1. Block diagrams

Copier

(MCU PWB)

CSSEL(A,B,C)

Y2

2

(PCL,PCS,LUM)

AI,BI,/AI,/BI

OPCASSEL

Y1B

1B

(PCL,PCS,

TRCL,LUM)

Y1A

1A(PCL,PCS,

TRCL,LUM)

DATA

SELECTOR

5V

DATA

SELECTOR

TRANSISTOR

ARRAY

24V

MOTOR

DRIVER

CASSETTE INTERFACE PWB

DATA

SELECTOR

PPD1B

PAP1B

LUD1B

DRS1B

CSS1B

24V

/PCL1B

/PCS1B

/TRCLB

LUM1BD

MOTOR

(A,/A,B,/B)

24V

PPD1B

PAP1B

LUD1B

5V

5V

PPD2

PAP2

LUD2

DRS2

CSS2

/PCL2

/PCS2

LUM2D

24V

5V

:MULTI CASSETTE LOWER

5V

DRS1B

CSS1B

DATA

SELECTOR

/PCL1B

TRANSISTOR

ARRAY

/PCS1B

/TRCLB

24V

LUM1BD

MOTOR

DRIVER

CASSETTE INTERFACE PWB

:OPTION 2nd CASSETTE or MULTI CASSETTE

24V

MOTOR

(A,/A,B,/B)

24V

5V

PPD2

PAP2

LUD2

DRS2

CSS2

/PCL2

/PCS2

LUM2D

24V

Page 12

D

C

B

A

12345678

1

2

179228-2(AMP)

PHR-3

PL

GL

123

MULTI CASSETTE (UPPER)

CASSETTE INTERFACE PWB

FG

SRA-01T-3.2

SRA-21T-4

PULSE

MOTOR

PHR-5

3BI

2/AI

524V1

4/BI

1AI

CN6(B5B-PH-K-S)

+24V

+24V

PGND

1A

2A

20B

CN9(53314-1015)

GL

GL

RD

RD

Sensor PWB

SGND

1

B6B-PH-K-S

GLORPKLBBR

PHR-6

PHR-8

GLBRORPKLB

1

CN8(B8B-PH-K-S)

SGND

PGND

SGND

18B

19B

GL

GL

DRS

HPIN

SGND

B3B-PH-K-S

PPD1H:Paper entry sensor

LUD1H:Lift-up upper

limit sensor

HDRS:Door sensor

PAP1H:

PPD

LUD

PAP

+5V

DRS1

26543

BR

BR

BR

RD

7

4

LUD1

/PCS1B

PAP13PPD1 26SGND5+5V

DRS1

+3.3V

SGND

+5V3A+5V4A+3.3V

SGND

5A

6A

16B

17B

15B

BL

BL

GL

GL

GL

OR

OR

8+24V

PGND

7A

LUM2#

14B

PK

Paper feed

clutch

Paper feed

solenoid

BR

BR

1

2

SMR-02V-N(RD)(JST)

1

2

BR

RD

SMP-02V-NC(RD)(JST)

PHR-3

PLPLLB

3

1

N.C. 2

/PCL1A

+24V

CN3(B3B-PH-K-S)

PCL2#

LUM1B#

TRCLB#

Y2

CSSELA#

Y1B

Y1A

PCS2#

8A

11A

10B

12B9A10A

13B

11B

PL

LB

LB

PL

PK

PK

BR

BR

BR

HPR-3(BK)

1

TRCLA

CN2(B3B-PH-K-K(BK))

CSSELC#

PCS1B#

9B

12A

PL

LB

N.C. 2

CSSELB#

13A

LB

PK

3

+24V

CN1(B3B-PH-K-R(RD))

PCL1B#

BI#

8B

14A

BR

123

LB

PHR-3

PHR-3(RD)

LB

1

LUM1AD

AI#

7B

PL

Lift-up motor

Cassette

detection

1

2

179228-2(AMP)

GL

PL

GL

PHR-3(BL)

GL

PL

GL

3

3

1

N.C. 2

CSS1

SGND

N.C. 2

PGND

CN7(B3B-PH-K-B(BL))

OPCASSEL#

/BI#

/AI#

LUM1A#5B

+24V17A

TRCLA#4B

+24V18A

PCS1A#3B

PGND19A

PCL1A#2B

PGND20A

6B

15A

16A

LB

PL

LB

PK

BR

RD

SGND1B

PK

GL

GL

GL

BR

RD

1

2

179228-2(AMP)

PHR-3

LB

GL

123

DRS

HPIN

SGND

B3B-PH-K-S

Sensor PWB

PAP1H:

LUD1H:Lift-up upper

limit sensor

PPD1H:Paper entry sensor

DRS:Door sensor

PPD

LUD

HPIN

PAP

+5V

SGND

1

26543

B6B-PH-K-S

GLORPKLBBR

BR

PHR-6

PHDR-14VS

GLORPKLBBRBRRDPLRD

PL

GL

3+5V

2PPD2

6

5DRS2

7

4PAP2

1SGND

PGND

LUD2

CSS2

CN4(B14B-PHDSS-B)

CN5(53314-1015)

9108

+24V

/PCL2

Cassette

detection

1

2

Paper feed

clutch

179228-2(AMP)

PL

GL

Lift-up motor

Paper feed

solenoid

321

GL

LB

PHR-3

BR

BR

PL

PL

1

2

1

2

SMR-02V-N(RD)(JST)

11

+24V

BR

12

/PCS2

SMR-02V-B(JST)

1

2

1

2

RD

BR

RD

PL

SMP-02V-BC(JST)

SMP-02V-NC(RD)(JST)

GL

LB

14

13PGND

LUM2D

MULTI CASSETTE (LOWER)

2 1

3

MULTI CASSETTTE

1

2

179228-2(AMP)

SENSOR PWB

SGND

B6B-PH-K-S

1

GLORPKLBBR

PHR-8 PHR-6

GLBRORPKLBBRBR

1

CN8(B8B-PH-K-S)

SGND

SGND

SGND

17B

18B

GL

GL

GL

GL

GL

GL

SGND

SGND

SGND

17B

18B

PPD1H:Paper entry sensor

PPD

26543

BR

5A

OR

OR

ORORBL

5A

B3B-PH-K-S

PAP1H:

PAP

+5V

4

PAP13PPD1 26SGND5+5V

+5V3A+5V4A+3.3V

6A

16B

BL

+5V3A+5V4A+3.3V

6A

16B

PHR-3

PL

BL

BL

123

DRS

DRS:Door sensor

DRS1

DRS1

+3.3V

15B

GL

GL

+3.3V

15B

GL

HPIN

SGND

LUD1H:Lift-up upper

limit sensor

LUD

RD

7

LUD1

/PCS1A

LUM2#

PGND

7A

14B

PK

BR

PK

BR

LUM2#

PGND

7A

14B

8+24V

Y1A

8A

PL

PL

Y1A

8A

2nd CASSETTE

FG

SRA-01T-3.2

OPTION 2nd CASSETTE ONLY

SRA-21T-4

PLUSE

MOTOR

PHR-5

3BI

2/AI

524V1

4/BI

1AI

CN6(B5B-PH-K-S)

+24V

+24V

PGND

PGND

CASSETTE INTERFACE PWB

1A

2A

20B

19B

CN9(53314-1015)

GL

GL

GL

RD

RD

51089-4005

GLRDRD

GL

GL

+24V

+24V

PGND

PGND

1A

2A

20B

19B

SGND

SGND

MCU PWB

2. Actual wiring diagram

PCS2#

13B

LB

LB

PCS2#

13B

Lift-up motor

Cassette

detection

123

1

1

N.C. 2

LUM1AD

OPCASSEL#

/AI#

6B

16A

BR

/AI#

OPCASSEL#

6B

16A

GL

GL

3

PGND

LUM1A#5B

PL

RD

PLRDBRGLLB

LUM1A#5B

+24V17A

+24V17A

PL

PHR-3(BL)

PL

CN7(B3B-PH-K-B(BL))

TRCLA#4B

LB

RD

TRCLA#4B

2

179228-2(AMP)

GL

GL

3

1

N.C. 2

CSS1

SGND

+24V18A

PCS1A#3B

PGND19A

PK

GL

PKBRRDGLGL

+24V18A

PCS1A#3B

PGND19A

51089-4005

GLRDRD

ORORBL

GL

GL

GL

GL

GL

5A

2A

1A

20B

19B

+24V

+24V

PGND

PGND

CN5(53314-1015)

SGND1B

PCL1A#2B

PGND20A

GL

GL

BR

SGND1B

PCL1A#2B

PGND20A

6A

16B

17B

18B

SGND

+5V3A+5V4A+3.3V

SGND

SGND

SGND

PK

PK

BL

GL

BR

LB

PL

8A

7A

15B

14B

13B

12B9A10A

PCS2#

+3.3V

LUM2#

PGND

Y1B

PCL2#

Y2

N.C.

PK

PL

LB

11A

11B

N.C.

CSSELA#

PKBRBR

CN4(B14B-PHDSS-B)

10B

N.C.

PL

9B

12A

N.C.

CSSELC#

1SGND

2 PPD2

8B

13A

N.C.

CSSELB#

3+5V

4 PAP2

PLLBBR

PK

LB

7B

15A

14A

/BI#

BI#

AI#

PGND

LUD2

6

5DRS2

7

6B

/AI#

CSS2

16A

OPCASSEL#

PLRDBRGLLB

+24V

9108

LUM1B# 5B

/PCL2

+24V 17A

+24V

11

TRCLB# 4B

/PCS2

12

+24V 18A

13 PGND

PKBRRDGLGL

PCS1B# 3B

PGND 19A

PCL1B# 2B

PGND 20A

LUM2D

14

SGND 1B

2nd CASSETTTE

Paper feed

clutch

Paper feed

solenoid

SMR-02V-N(RD)(JST)

BR

BR

1

2

1

2

BR

RD

SMP-02V-NC(RD)(JST)

PHR-3

PL

1

N.C. 2

/PCL1A

CN3(B3B-PH-K-S)

PCL2#

LUM1B#

TRCLB#

Y2

CSSELA#

CSSELC#

Y1B

12B9A10A

11A

10B

12A

11B

PL

LB

PK

PK

BR

BR

PK

PL

PKBRBR

LB

Y1B

PCL2#

LUM1B#

TRCLB#

Y2

CSSELA#

CSSELC#

12B9A10A

11A

10B

12A

11B

PL

3

+24V

PCS1B#

9B

PL

PL

PCS1B#

9B

HPR-3(BK)

LB

1

TRCLA

CN2(B3B-PH-K-K(BK))

PCL1B#

CSSELB#

8B

13A

LB

PK

PK

PCL1B#

CSSELB#

8B

13A

LB

PHR-3

PHR-3(RD)

LB

LB

3

N.C. 2

+24V

CN1(B3B-PH-K-R(RD))

/BI#

BI#

AI#

7B

15A

14A

PL

LB

PK

BR

PK

PLLBBR

LB

/BI#

BI#

AI#

7B

14A

15A

8 7 6 5 4

D

C

B

A

Page 13

D

C

CSS1

PPD1

DRS1

PAP1

LUD1

B

PPD2

PAP2

CSS2

DRS2

LUD2

A

12345678

Multi Cassette Only

2200pF/50Vx5

10Kx7

R37

3.3V

R41 R40R42R43

R39 R38

C35

C38 C37C39C40

JP2 JP1

JP1 MOTOR L MOTOR

JP2 1, 2 Cassette L 1 Step

10Kx5

3.3V

R15R13 R12

R14 R16

C9C12

C13

C11

C10

(QS53)

2200pF/50Vx6

2 1

Option Cassette Only

(QS52,QS53)

(2-1A)

AIBI24V1

/BI

/AI

F2

ICP-N38

47uF/35V

C1

+

0.047uF/50V

C18

24V

R23

7.5K

C22

2200pF/

7.5K

R31

C31

2200pF/50V

0.047uF/50V

C19

10

18

1

Vmm

OUT A

OUT B

CrA2CrB26VsA4RsA9VrefA3VrefB25RsB19VsB24In /A5In A6In /B23In B

IC2

R20

1K

50V

C20

3300pF/50V

C33

0.1uF/25V

R3 1.5(1W)

R33 2.4k

R32

1.5kF

8

OUT /A

20

OUT /B

R36 2.4k

NC17NC16NC15NC14NC12NC

R22

1K

C34

R4 1.5(1W)

11

27

PG7PG13PG21LG

MTD1361

22

C21

3300pF/50V

0.1uF/25V

R34

430F

AI#

BI#

/AI#

/BI#

C36

0.1uF/25V

IC5

16

PCL1A#

R29 1.5K

R30 1.5K

I11I22I33I44I55I66I7

IC1

COM

O116O215O314O413O512O611O7

9

24V

D04D13D22D31D415D514D613D7

VCC

W6Y

5

Y1A

PCL2#

LUM1A#

TRCLA#

PCS1A#

PCS2#

R25 1.5K

R27 1.5K

R28 1.5K

R26 1.5K

12

7

G

74HC151AF

GND

A11B10C

8

9

1Kx3

R17

R18

R19

CSSELB#

CSSELA#

CSSELC#

LUM2#

R24 1.5K

7

8

GND

TD62001

10

C7

0.047uF/50V

C8

0.047uF/

UDZS3.9B

ZD2

UDZS3.9B

ZD3

UDZS3.9B

ZD1

50V

C26

0.1uF/25V

IC4

16

D04D13D22D31D415D514D613D7

VCC

W6Y

5

Y2

12

7

G

74HC151AF

GND

A11B10C

8

9

C24

C25 C23

3

1000pF/50Vx3

C32

0.1uF/25V

R35

2.4KF

1

VOUT

IC3

KIA78S05P

VIN

3

R5

3. Interface PWB circuit diagram (1/2)

24V

C5

10uF/16V

GND

2

C6

10uF/35V

R6

3.6K 1/4W

3.6K 1/4W

D

Q5

DTC143ZKA

47k

4.7k

OPCASSEL#

C

R11

10k

R2

24V

/PCL2

/PCS2

/PCL1A

/TRCLA

/PCS1A

1.5k(1/2W)

F3

ICP-N38

5

6

3

Q4

IMZ4

LUM1AD

Q3

2

DTC114EKA

1 3

R10

1.5k

2

R21

47

4 1

Multi Cassette Only

24V

(QS53)

B

R7

10k

R1

1.5k(1/2W)

F1

ICP-N38

5

6

Q2

IMZ4

LUM2D

2

Q1

DTC114EKA

1 3

R8

1.5k

2

R9

47

4 1

3

8 7 6 5 4

A

Page 14

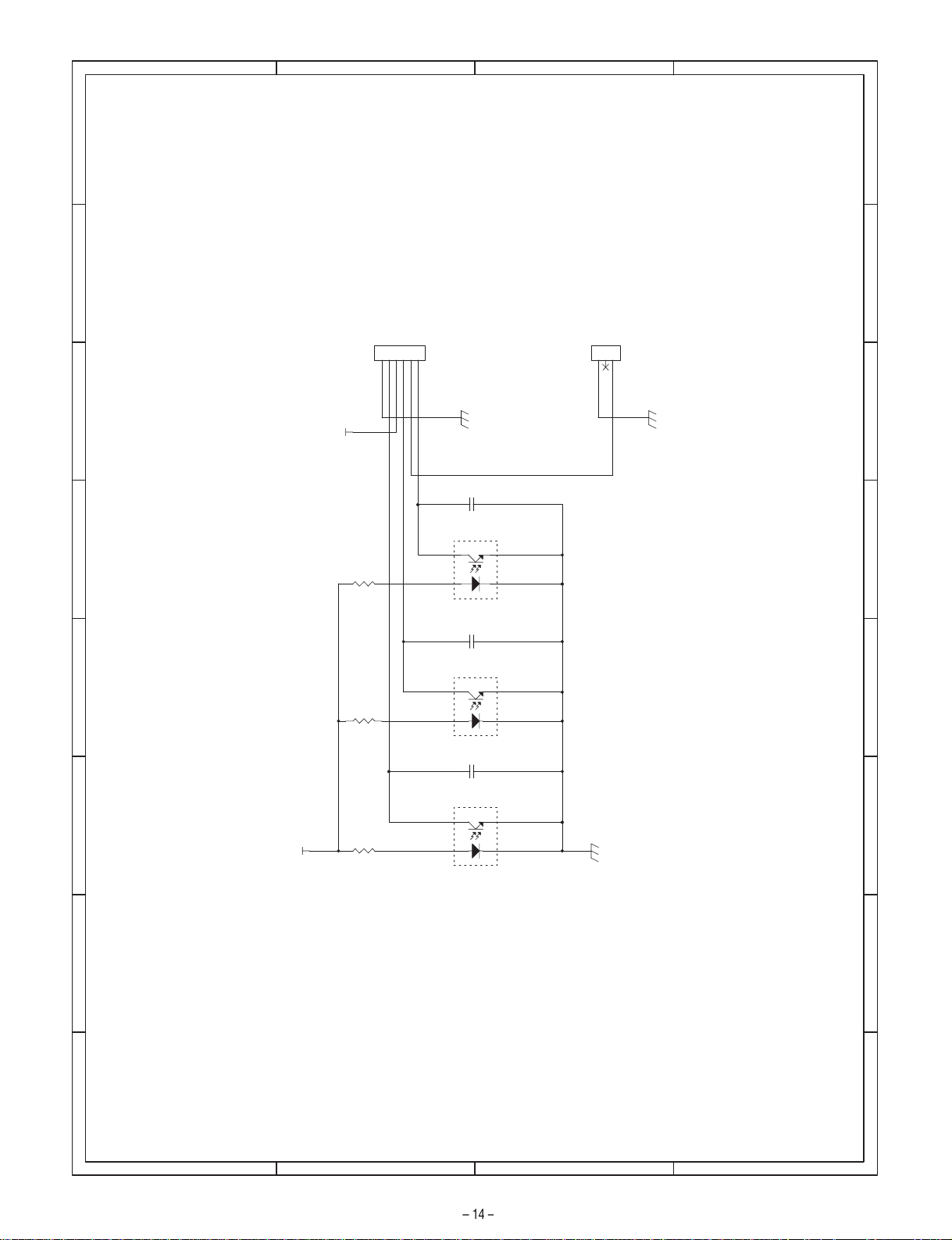

D

C

LUM2#

B

PCS2#

PCL2#

LUM1B#

PCS1B#

PCL1B#

AI#

/AI#

TRCLB#

A

12345678

Option Cassette Only

CN7

123

123

CN1

B3B-PH-K-E(BL)

LUM1AD/TRCLA

B3B-PH-K-R(RD)

3.3V

5V

246

8

101214161820222426283032363438

CN5

1357911131517192123252729

4

•¢

3133353739

C17

C16

40

B40B-PADKS-1

7

3

•¢

•¢

0.1uF/25V

0.1uF/25V

(QS51,QS52)

NOTE

QS51:STANDARD 2ND CASSETTE

QS52:OPTION 2ND CASSETTE

QS53:OPTION MULTI CASSETTE

2 1

3

5V 3.3V

123

CN3

24V

/PCL1A CSS1

246

8

CN9

1357911131517192123252729

123

B3B-PH-K-S

LUM2#

PCS2#

PCL2#

101214161820222426283032363438

CN2

LUM1B#

TRCLB#

PCS1B#

PCL1B#

AI#

/AI#

B3B-PH-K-K(BK)

TRCLA#

PCS1A#

3133353739

PCL1A#

C15

0.047uF/50V

24V

C14

Y2

BI#

LUD2

/BI#

CSSELA#

CSSELB#

CSSELC#

OPCASSEL#

CSS2

/PCL2

/PCS2

LUM2D

8

101214

B14B-PHDSS-B

0.047uF/50V

Option Cassette Only

(QS52,QS53)

CN8

5V

12345

CN6

AI

BI

/AI

1234567

B5B-PH-K-S

/BI

24V1

8

B8B-PH-K-S

Y1B

C30

0.1uF/25V

+

C3

10uF/16V

C29

0.1uF/25V

+

C4

10uF/16V

Multi Cassette Only

40

B40B-PADSS-1

7

•¢3•¢

(QS53)

5V

PPD2

PAP2

246

135791113

CN4

C2

47uF/35V

+

F4

ICP-N50

24V

BI#

3. Interface PWB circuit diagram (2/2)

Y1AY2Y1B

/BI#

CSSELB#

CSSELA#

CSSELC#

OPCASSEL# LUM1A#

D

C28

0.047uF/50V

C27

0.047uF/50V

C

24V

DRS2

24V

PAP1

LUD1

PPD1

DRS1

/PCS1A

B

A

8 7 6 5 4

Page 15

D

C

B

A

12345678

2 1

12345

PPD

6

S6B-PH-K-S

PAP

LUD

DRS

CN1

123

CN2

S3B-PH-K-S

DRS

3

5V

C3

102pF

PT3

GP1S58V

R3

220J/ 1/4W

Upper limit

C2

102pF

PT2

GP1S58V

R2

220J/ 1/4W

C1

102pF

PT1

GP1S58V

R1

5V

220J/ 1/4W

4. Sensor PWB circuit diagram

D

8 7 6 5 4

C

B

A

Page 16

5. Parts layout

1) Cassette interface PWB

a. Parts surface

CN3 (B3B-PH-K-S)

3 +24V

2 N.C.

1 /PCL1A

CN4 (B14B-PHDSS-B)

13 PGND

11 +24V

9 +24V

7 PGND

5 DRS2

3 +5V

1 SGND

14 LUM2D

12 /PCS2

10 /PCL2

8 CSS2

6 LUD2

4 PAP2

2 PPD2

CN2 (B3B-PH-K BL)

3 +24V

2 N.C.

1 TRCLA

CN1 (B3B-PH-K-R RD)

3 PGND

2 N.C.

1 LUM1AD

CN6 (B5B-PH-K-S)

5 24V1

4 /B1

3 B1

2 /A1

1 A1

CN7 (B3B-PH-K BL)

3 SGND

2 N.C.

1 CSS1

CN8 (B8B-PH-K-S)

8 +24V

7 /PCS1B

6 LUD1

5 DRS1

4 PAP1

3 +5V

2 PPD1

1 SGND

CN5 (53314-1015) CN9 (53314-1015)

2 +24V

4 PGND

6 SGND

8 SGND

10 +5V

12 +3.3V

14 LUM2#

16 PCS2#

18 PCL#

20 N.C.

22 N.C.

24 N.C.

26 N.C.

28 A1#

30 /A1#

32 LUM1B#

34 TRCLB#

36 PCS1B#

38 PCL1B#

40 SGND

1 +24V

3 PGND

5 SGND

7 SGND

9 +5V

11 +3.3V

13 PGND

15 Y1B

17 N.C.

19 Y2

21 CSSELA#

23 CSSELC#

25 CSSELB#

27 B1#

29 /B1#

31 OPCASSEL#

33 +24V

35 +24V

37 PGND

39 PGND

2 +24V

4 PGND

6 SGND

8 SGND

10 +5V

12 +3.3V

14 LUM2#

16 PCS2#

18 PCL2#

20 LUM1B#

22 TRCLB#

24 PCS1B#

26 PCL1B#

28 A1#

30 /A1#

32 LUM1A#

34 TRCAL#

36 PCS1A#

38 PCL1A#

40 SGND

1 +24V

3 PGND

5 SGND

7 SGND

9 +5V

11 +3.3V

13 PGND

15 Y1A

17 Y1B

19 Y2

21 CSSELA#

23 CSSELC#

25 CSSELB#

27 B1#

29 /B1#

31 OPCASSEL#

33 +24V

35 +24V

37 PGND

39 PGND

Page 17

b. Solder surface

2) Cassette sensor PWB

a. Parts surface b. Solder surface

CN1 (S6B-PH-K-S)

6 LUD

5 DRS

4 PAP

3 5V

2 PPD

1 SGND

3 DRS

2 N.C.

1 SGND

Page 18

(For USA,CANADA)

CAUTION FOR BATTERY DISPOSAL

Contains lithium-ion battery. Must be disposed of properly.

Remove the battery from the product and contact

agencies for information on recycling and disposal options.

federal or state environmental

Page 19

Symbol/PartsCod)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

COPYRIGHT ã 2001 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this public ation may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means ,

electronic, mechanical, photocop ying, recording, or oth erwise,

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

2001 April Printed in Japan

Loading...

Loading...