Page 1

SERVICE MANUAL

COLOR LED PRINTER

MODEL AR-C360P

SHARP CORPORATION

11.

01.2005

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

Document Revision History

Ver. Date

No.

Revision

In-Charge

Page Changes

Rev. 1 2 /

Page 3

Preface

This manual describes the procedures of the maintenance of the AR-C360P printer.

The document is produced for maintenance personnel use.

Note!

• The descriptions in this manual are subject to change without prior notice.

• In preparing the document, efforts have been made to ensure that the information in it is accurate.

• The parts used for the printers are sensitive and, if handled improperly, may be damaged. It is

strongly recommended that the products are maintained by maintenance men registered with

Sharp Electronics Corporation.

• Errors may be crept into the document. Sharp assumes no responsibility for any damage

resulting from, or claimed to be the results of, those repairs, adjustments or modifications to the

printers which are made by users using the manual.

Rev. 1 3 /

Page 4

In order to use the product with safety

In order to use the product with safety, make sure to read the user's manual (this manual) before using

the product.

General Caution

Do not touch the safety switch of the internal parts of the printer. Electric shock may

occur due to the occurrence of high pressure. The rotation of the gear may also cause

injury.

Do not use an extremely flammable spray around the printer. Fire may occur because of

parts with high temperature.

Please let our staff in Customer Center know after unplugging mains connector when

the cover gets extremely hot, is smoking, emits questionable odor, or is making strange

noise. Fire may occur.

Please let our staffs in Customer Center know after unplugging mains connector when

liquid such as water goes into the printer. Fire may occur.

Please take a foreign object away after unplugging when you drop foreign objects such

as clips into the printer. That situation may case electric shock, fire, and/or injury.

Do not conduct an operation or an analysis other than specified in user's manual. That

situation may case electric shock, fire, and/or injury.

Please let our staffs in Customer Center know after unplugging mains connector when

the printer has fallen down or damaged. That situation may case electric shock, fire, and

injury.

Do not connect the power cord, the printer cable, or the ground wire other than instructed in user's manual. Fire can be induced if misused.

Do not insert objects at the vent hole. Do not operate the printer with the rear cover

opened. Electric shock, fire, and/or injuries may occur.

Do not place a cup with liquid on the printer. Electric shock, fire, and/or injuries may

occur.

Risk of explosion if battery is replaced by an incorrect type.

Battery of the printer need not to be replaced. Do not touch the battery.

Replace the whole board to replace the CU main board.

In the case of replacing batteries at board repairs, replace with the specified type ones.

stallation of another type batteries may result in explosion.

Caution for used batteries are as follows; do not recharge, force open, heat or dispose

of in fire.

When open the printer cover, do not touch the fuser unit. You may get burned.

In-

Do not throw toner cartridges, or image drum cartridges into fire. You may get burned by

dust explosion.

Rev. 1 4 /

Page 5

Do not go near an ejection area while the power is on and in printing. You may get

injured.

Rev. 1 5 /

Page 6

Table of contents

1. Configuration .................................................................................................10

1.1 System Configuration ................................................................................................... 10

1.2 Printer Composition ...................................................................................................... 11

1.3 Optional Composition ................................................................................................... 12

1.4 Specifications ...............................................................................................................14

2. Descriptions of Operations..........................................................................16

2.1 Main Control PCB ........................................................................................................ 17

2.2 Engine Control PCB (S2V PWB) ................................................................................ 20

2.3 Power Unit .................................................................................................................... 21

2.4 Mechanical process ..................................................................................................... 22

2.4.1 Electrophotographic Processing Mechanism .................................................. 23

2.4.2 Paper Processing Mechanism ......................................................................... 27

2.5 Sensor .......................................................................................................................... 36

2.5.1 Paper-Related Sensor ..................................................................................... 36

2.5.2 Other Sensors ................................................................................................. 37

2.6 Color Drift Correction ................................................................................................... 38

2.7 Image Transfer Control According to Environmental Change (Room Temperature and

Relative Humidity) ........................................................................................................ 38

2.8 Paper Jam Detector ......................................................................................................39

2.9 Cover Open .................................................................................................................. 41

2.10 Toner Low Detection ................................................................................................... 41

2.11 Paper Size Detection ................................................................................................... 44

2.12 Power ON Process ...................................................................................................... 45

2.12.1 Self-Diagnostic Test ......................................................................................... 45

2.13 Color Drift Detection .................................................................................................... 46

2.14 Reading Version of Routine Replacement Units ........................................................ 47

2.15 Life Counter of Replaceable Units .............................................................................. 47

2.16 Toner Usage Level Detection ...................................................................................... 47

3. General Handling Operations ...................................................................... 48

Details undecided. ................................................................................................................... 48

4. Parts Replacement ........................................................................................49

4.1 Precautions When Replacing Parts .............................................................................49

4.2 Parts Layout .................................................................................................................51

4.3 Parts Replacement Method ......................................................................................... 67

4.3.1 Cover-Rear, Cover-Side (R), and Cover-Side (R) Rear ...................................... 68

4.3.2 Cover-Side (L) and Cover Assy-Front ..............................................................69

4.3.3 Stacker Assy-FU.............................................................................................. 70

4.3.4 Cover Assy-OP Panel, Cover-Guard (R), Cover-Guard (Front) and

Cover-Guard (L) .............................................................................................. 71

4.3.5 OP PCB ........................................................................................................... 72

4.3.6 Cover Assy-Top ............................................................................................... 73

4.3.7 FAN-PCB-Assy, CU-Board-Assy and S2V-PU-Board ..................................... 74

4.3.8 Job-Offset-Assy 723 and Basket-Assy ............................................................ 75

4.3.9 Plate Top Assy ................................................................................................. 76

Rev. 1 6 /

Page 7

4.3.10 Eject-Assy ....................................................................................................... 77

4.3.11 Motor-Pulse-Belt and Sensor-Resist-Assy ...................................................... 78

4.3.12 FDR Unit-MPT ..................................................................................................79

4.3.13 FDR Unit-Resist .............................................................................................. 80

4.3.14 Duct Assy ........................................................................................................ 81

4.3.15 HV-Assy ........................................................................................................... 82

4.3.16 Power Unit ......................................................................................................... 83

4.3.17 Low Voltage Power Source Assy and Motor-FAN ........................................... 84

4.3.18 Belt-Assy ......................................................................................................... 85

4.3.19 Fuser Unit-LBT ................................................................................................ 86

4.3.20 Unit-Duplex ...................................................................................................... 87

4.3.21 Paper Feed Roller ........................................................................................... 88

5. Adjustment .....................................................................................................90

5.0 System Maintenance Menu ......................................................................................... 90

5.0.1 ID Check Pattern Print (“TEST PRINT MENU” Item) ...................................... 92

5.1 Maintenance Menu and Its Function .......................................................................... 92

5.1.1 Maintenance Menu .......................................................................................... 92

5.1.2 Engine Maintenance Mode .............................................................................. 94

5.1.2.1 Operation Panel .............................................................................. 94

5.1.2.2 Regular Self-Diagnosis Mode (Level 1) .......................................... 95

5.1.2.2.1 How to Enter Self-Diagnosis Mode (Level 1) ............... 95

5.1.2.2.2 Escape from Self-Diagnosis Mode .............................. 95

5.1.2.3 Switch Scan Test ............................................................................. 96

5.1.2.4 Motor/Clutch Test .......................................................................... 100

5.1.2.5 Test Print ....................................................................................... 104

5.1.2.6 Initialize NVM ................................................................................ 108

5.1.2.7 Consummable Parts Counter Display ........................................... 109

5.1.2.8 Consumable Continual Counter Display ....................................... 109

5.1.2.9 Panel Display Details .....................................................................110

5.1.3 Various Printing Methods with a Stand-Alone Printer Coming with a Controller 115

5.2 Adjustment After Replacing Parts ............................................................................. 116

5.2.1 Precautions when Replacing the Engine Control PCB................................... 116

5.2.2 Precautions Upon EEPROM Replacement ....................................................116

5.2.7 Replacement of the CU Board and Onboard Devices for the 1200-dpi System 119

5.2.8 Precautions When Replacing the KeyChip (1200dpi Model) ......................... 119

5.2.9 Precautions When Replacing the HDD (1200dpi Model) ............................... 119

5.2.10 How to Set Clock (1200dpi Model) ................................................................. 119

5.3 Density Correction ...................................................................................................... 120

6.

Routine Replacement ................................................................................. 121

6.1

6.2

6.3

6.4

Rev. 1 7 /

Routine Replacement of Consumable Parts ............................................................ 121

Cleaning...................................................................................................................... 121

LED Lens Array Cleaning .......................................................................................... 121

Pickup Roller Cleaning .............................................................................................. 121

Page 8

7. Malfunction Repair Procedure ..................................................................122

7.1 Precautions Before Repairs ....................................................................................... 122

7.2 Items to Check Before Remedying Abnormal Image .............................................. 122

7.3 Precautions Before Remedying Abnormal Image .................................................... 122

7.4 Troubleshooting Preparations .................................................................................... 122

7.5 Troubleshooting .......................................................................................................... 122

7.5.1 LCD Message List ......................................................................................... 123

7.5.2 Preparing for Troubleshooting ....................................................................... 133

7.5.3 Troubleshooting With Abnormal Image ......................................................... 146

7.6 Check Fuse ................................................................................................................ 162

8. Connection Diagram ...................................................................................163

8.1 Check Resistance Value............................................................................................ 163

8.2 Diagram of Part Layout of Various PCB .................................................................. 169

9. Interface Specifications ..............................................................................175

9.1 Parallel Interface Specifications ................................................................................ 175

9.1.1 Parallel Interface Overview ........................................................................... 175

9.1.2 Parallel Interface Connector and Cable ........................................................ 175

9.1.3 Parallel Interface Level .................................................................................. 175

9.1.4 Timing Chart .................................................................................................. 180

9.1.5 Parallel Interface Signal ................................................................................ 181

9.2 USB Interface Specifications ..................................................................................... 182

9.2.1 USB Interface Overview ................................................................................ 182

9.2.2 USB Interface Connector and Cable ............................................................. 182

9.2.3 USB Interface Signal ..................................................................................... 182

10. Error message list ......................................................................................183

Rev. 1 8 /

Page 9

Rev. 1 9 /

Page 10

1. CONFIGURATION

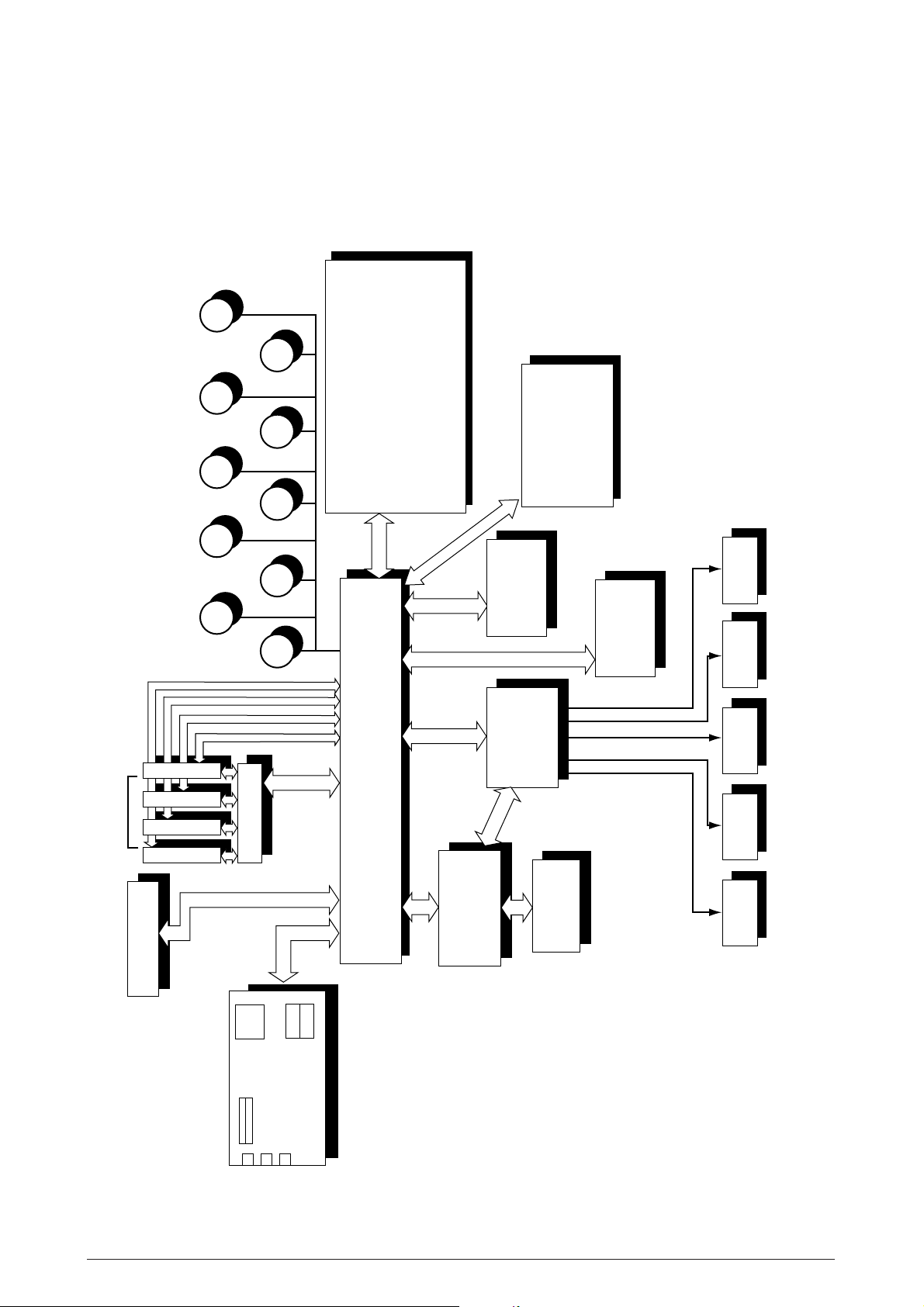

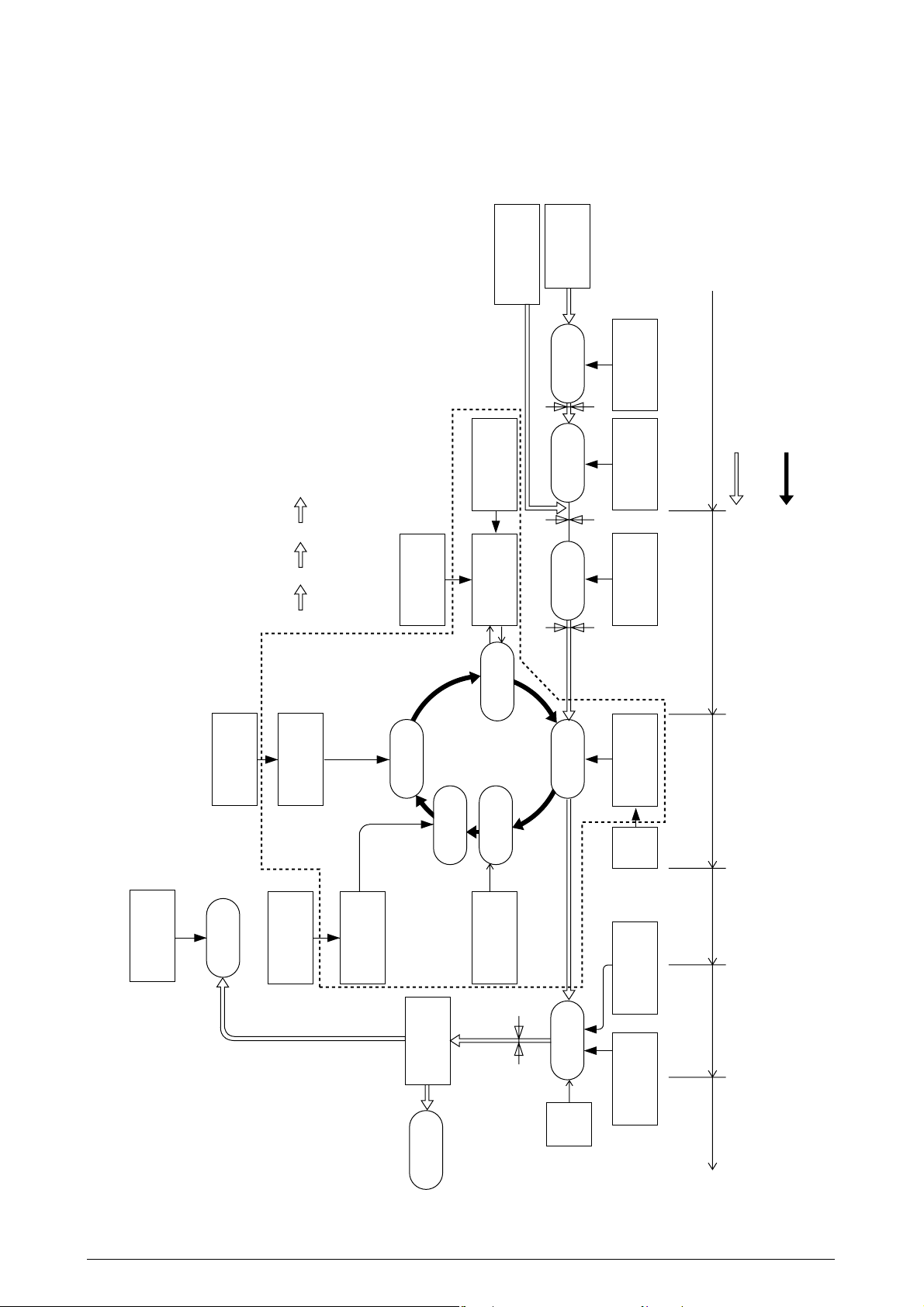

1.1 System Configuration

Figure 1-1 illustrates the System Configuration of this printer.

Motor

Geared

DC motor

M

Hopping

M

MT/

Resist

M

K ID

M

Pulse Motor

Y ID

C ID

Paper Conveyor Sensor

Paper Size Detector

Fuser Temperature Detector

Ambient Temperature/Humidity Detector

Remaining Toner Level Detector

M

<Sensor, Switch and Thermistor>

ID, Belt, Fuser Check

Heavy Paper Sensor

Density Sensor

Color Drift Sensor

<High Performance Sensor>

LED Head

Operation Panel

Belt

Fuser M ID

M M

Connection PCB

IDE

HDD

Job

M

Offset

Paper Tray

2nd/3rd Tray

Large-Volume

Printer Unit

Double-Side

C-ID UnitM-ID UnitY-ID Unit K-ID Unit

Power Unit

High Voltage

Figure 1-1

Engine Controller

Power Unit

Low Voltage

DC FAN

DC FAN

Fuser Unit

Belt Unit

Area

Control

SDRAM DIMM 2

1200dpi PCB (ASP)

USB

Centro

Ethernet

Rev. 1 10 /

Page 11

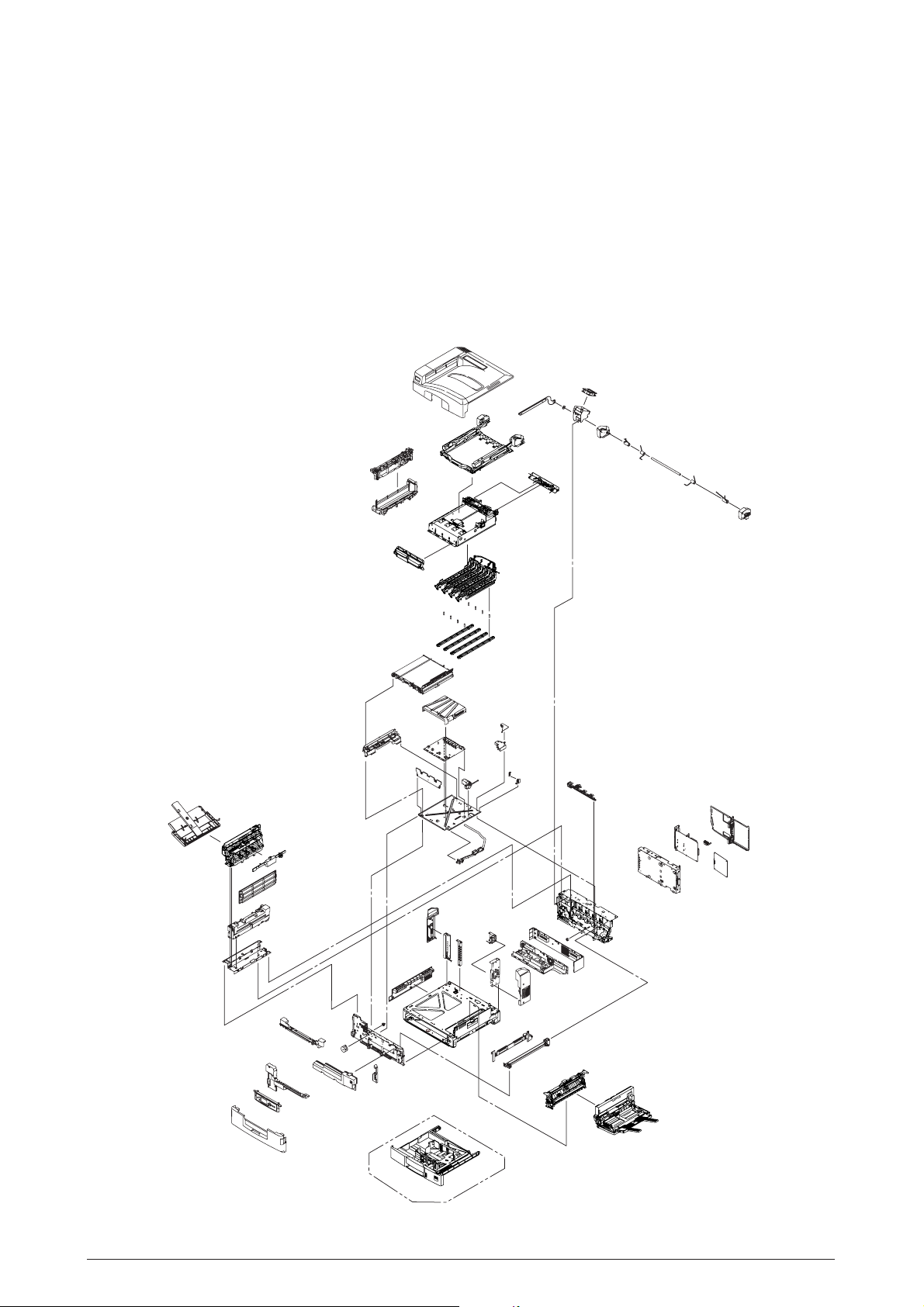

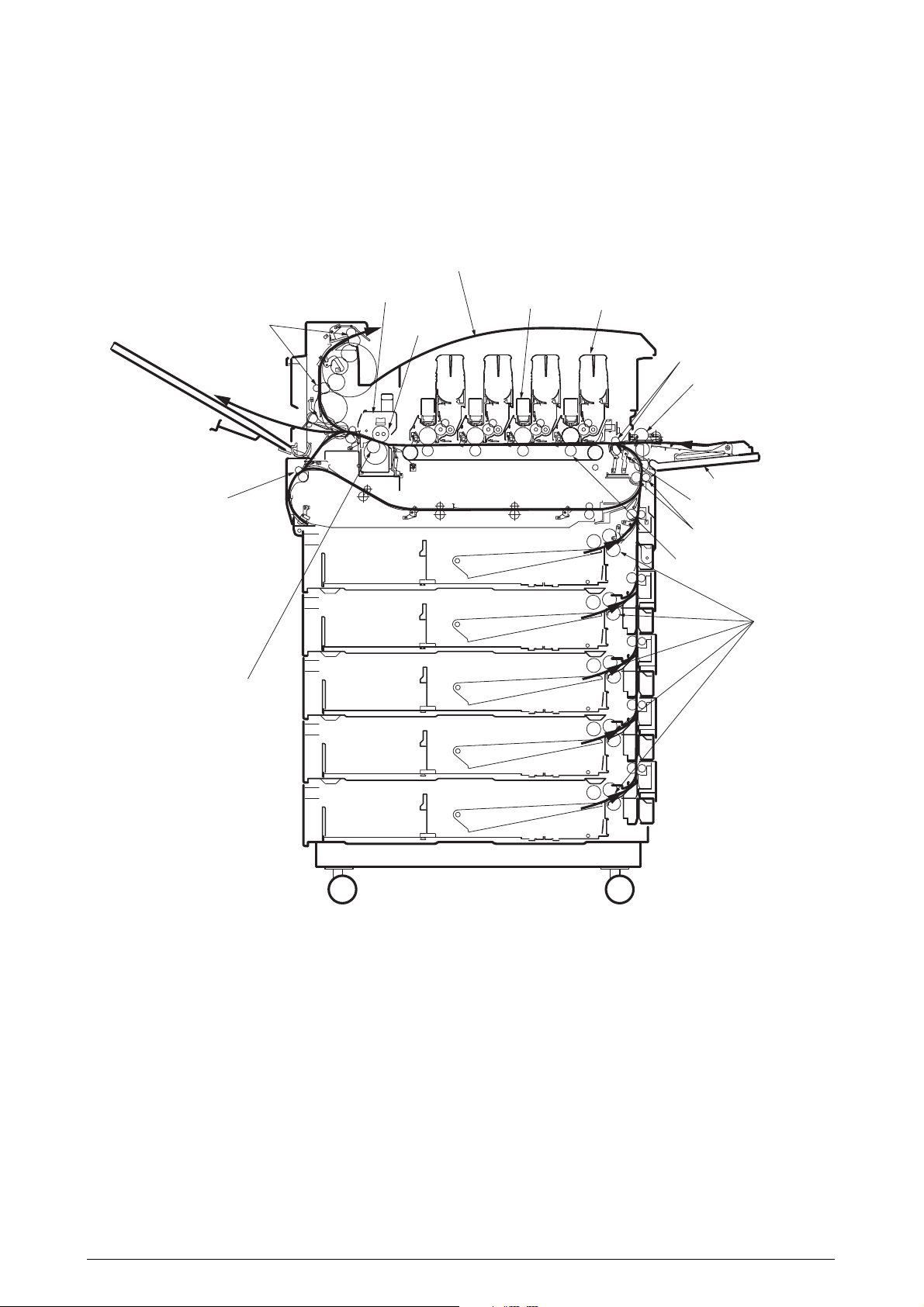

1.2 Printer Composition

The internal part of the printer consists of the following parts.

• Digital Photo Processor

• Paper Travel Path

• Control Unit (CU and PU)

• Operation Panel

• Power Source (High Voltage Area/Low Voltage Area)

Figure 1-2 illustrates the printer composition.

Figure 1-2

Rev. 1 11 /

Page 12

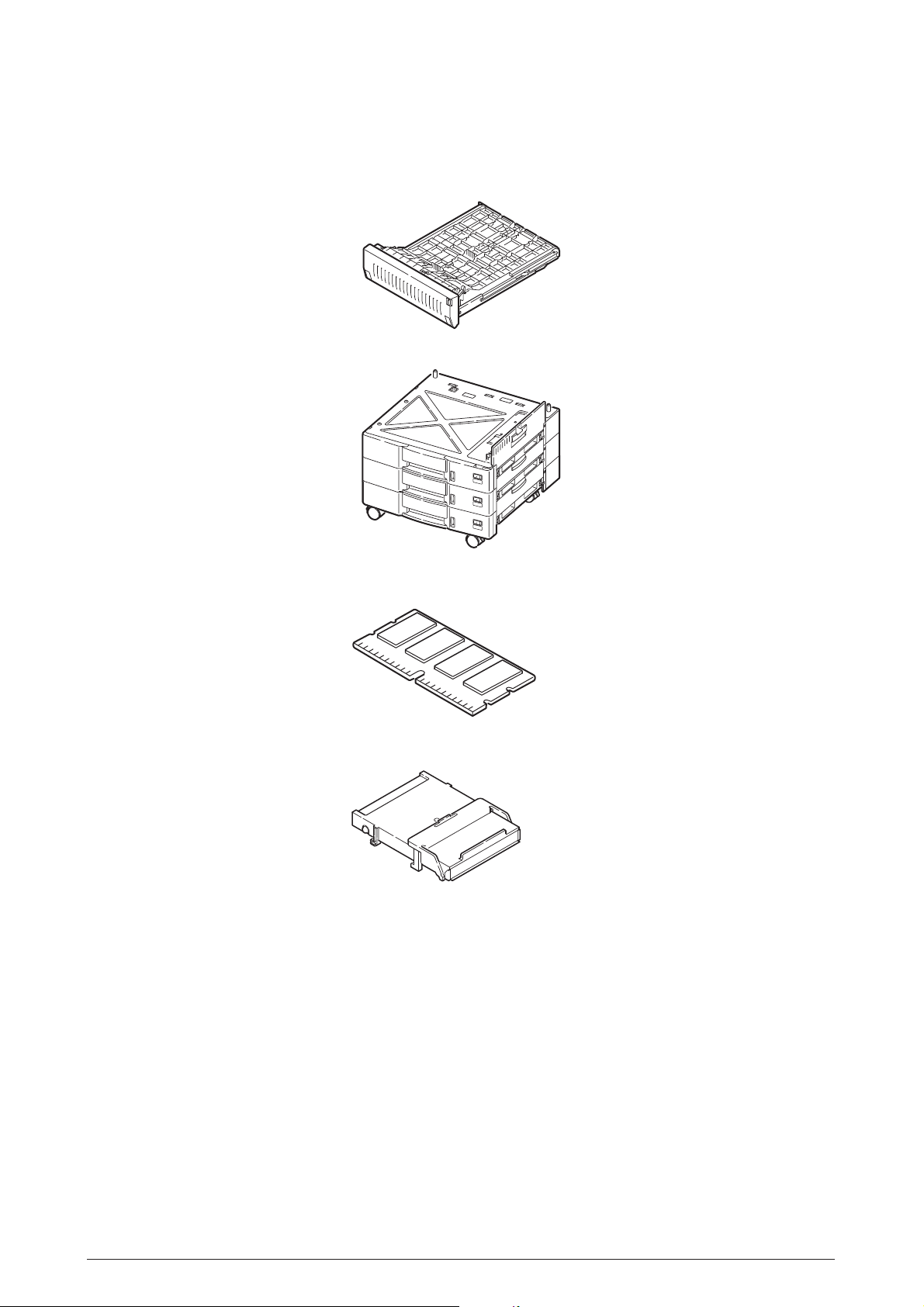

1.3 Composition

This printer comes standard with the following options.

Double-Side Printer Unit

Large-Volume Paper Tray

Additional Memory: 512MB

Internal Harddisk

Rev. 1 12 /

Page 13

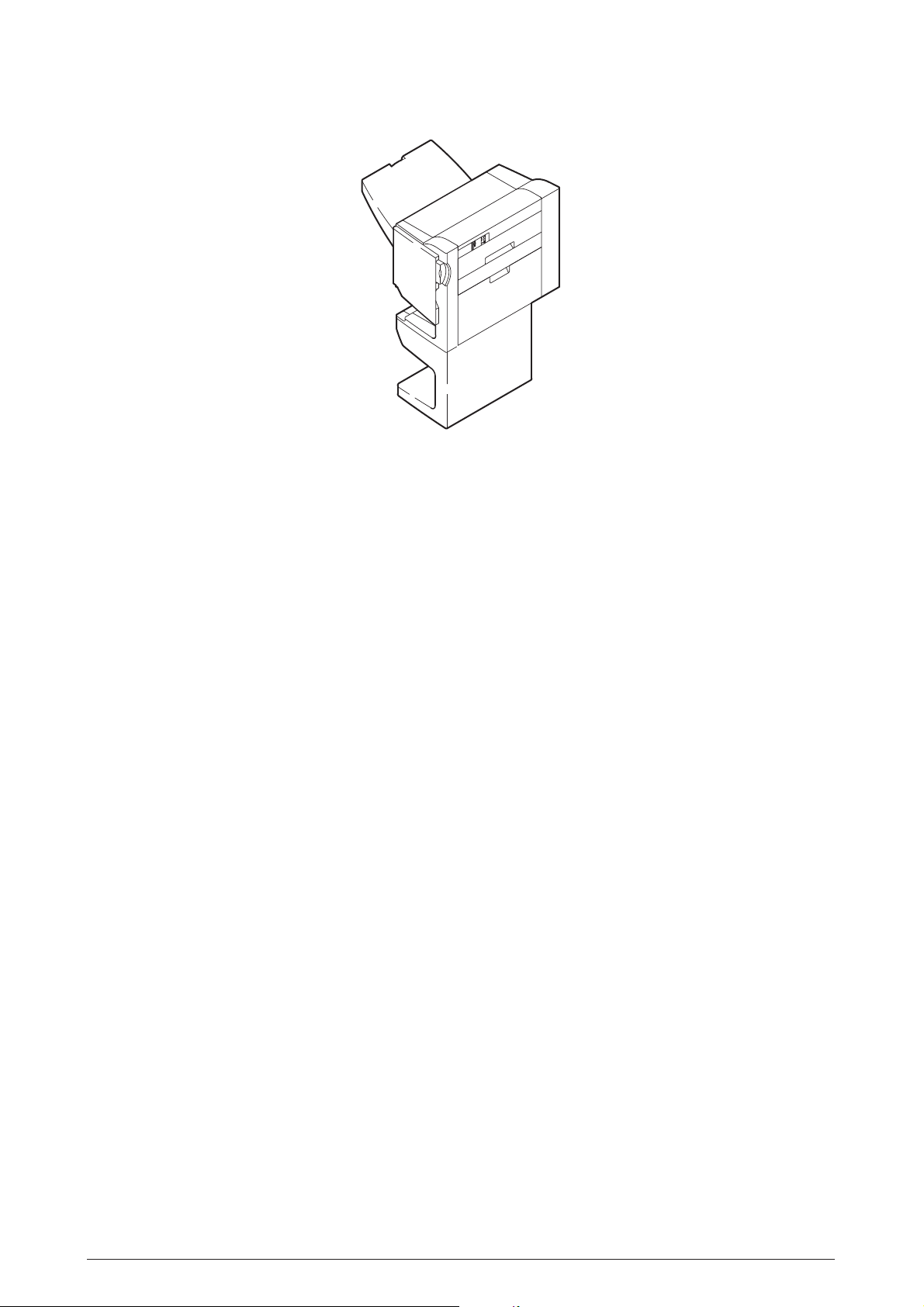

Finisher Unit (AR-C36TF)

2/3 Hole Punch Unit (AR-C36HP)

(No Image)

Rev. 1 13 /

Page 14

1.4 Specifications

(1) Dimensions (H × W × D): 462 mm × 640 mm × 615 mm

(2) Weight: 65 kg

(3) Paper

Paper Type: Regular paper and transparency

Paper Size: Post Card, Legal 13”or 14”, Executive, A4, A5, B5, A6,

Continuous Paper Feed: 1st Tray : 55 kg to 172 kg (64 to 203g/m

(4) Print Speed

Color: 36 ppm (OHP: 10 ppm)

Monochrome: 40 ppm (OHP: 15 ppm)

(Recommended: ML OHP01)

A3, A3 Nobi, B4

(However, A6 and Post Card:1stTray and

Front Feeder only)

Front Feeder : 55 kg to 172 kg (64 to 203g/m

2

)

2

)

Post Card, Label, Heavy Paper:

15 ppm

(5) Resolution: 1200 × 600/4bit gray scale

(6) Input Power: 100VAC ±10%

(7) Power Consumption Peak : 1500W

Normal : 750W average (Reference value)

Idle : 200W (Reference value)

Power Save Mode : 55W

(8) Frequency: 50/60Hz ±2Hz

(9) Noise

During Operations: 55dB (when second tray is not attached)

Standby Time: 45 dB

Power Save: 43 dB

(10) Life of Consumables

Toner Cartridge: 7,500 pages (5% Duty)

Large-Volume Toner Cartridge: 15,000 pages (5% Duty) (Y, M, C, K each)

Imaging Drum: 42,000 page (5% Duty, Continuous Printing)

or 30,00 pages (for 3P/J)

(11) Routine Replacement of Consumable Parts

Fuser Unit Assy: 100,000 pages

Transfer Belt: 100,000 pages

Waste Toner Box: 30,000 pages

Rev. 1 14 /

Page 15

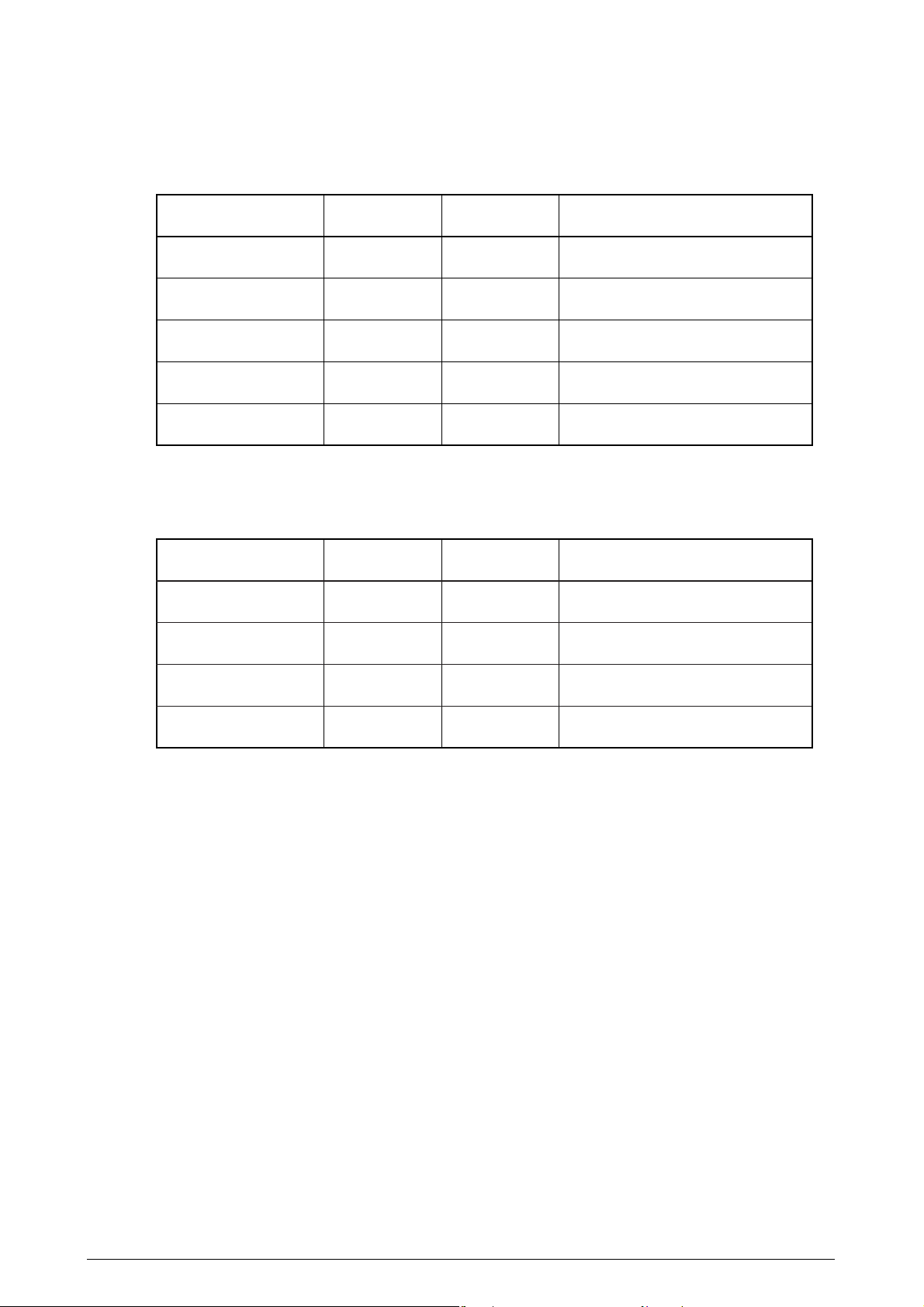

(12) Temperature and Relative Humidity

Temperature

Temperature Conditions

Operating

Not Operating

Storage (1 Year Max)

Transport (1 month Max)

Transport (1 month Max)

Relative Humidity

Operating

Not Operating

Temperature

(°F)

50 to 89.6

32 to 109.4

-14 to 109.4

-20 to 122

-20 to 122

Temperature

(°C)

10 to 32

0 to 43

-10 to 43

-29 to 50

-29 to 50

Relative Humidity Conditions

Relative Humidity

(%)

Maximum Web Bulb

Temperature (°C)

20 to 80

10 to 90

26.8

25

Remarks

17 to 27 °C (Temperature

guaranteeing full-color print quality)

Power OFF

Drum and Toner: Yes

Drum: Yes/Toner: No

Drum and Toner: Yes

Remarks

50-70% (Temperature guaranteeing

full-color print quality)

Power OFF

Storage

Transport

10 to 90

10 to 90

35

40

Rev. 1 15 /

Page 16

Rev. 1 16 /

Page 17

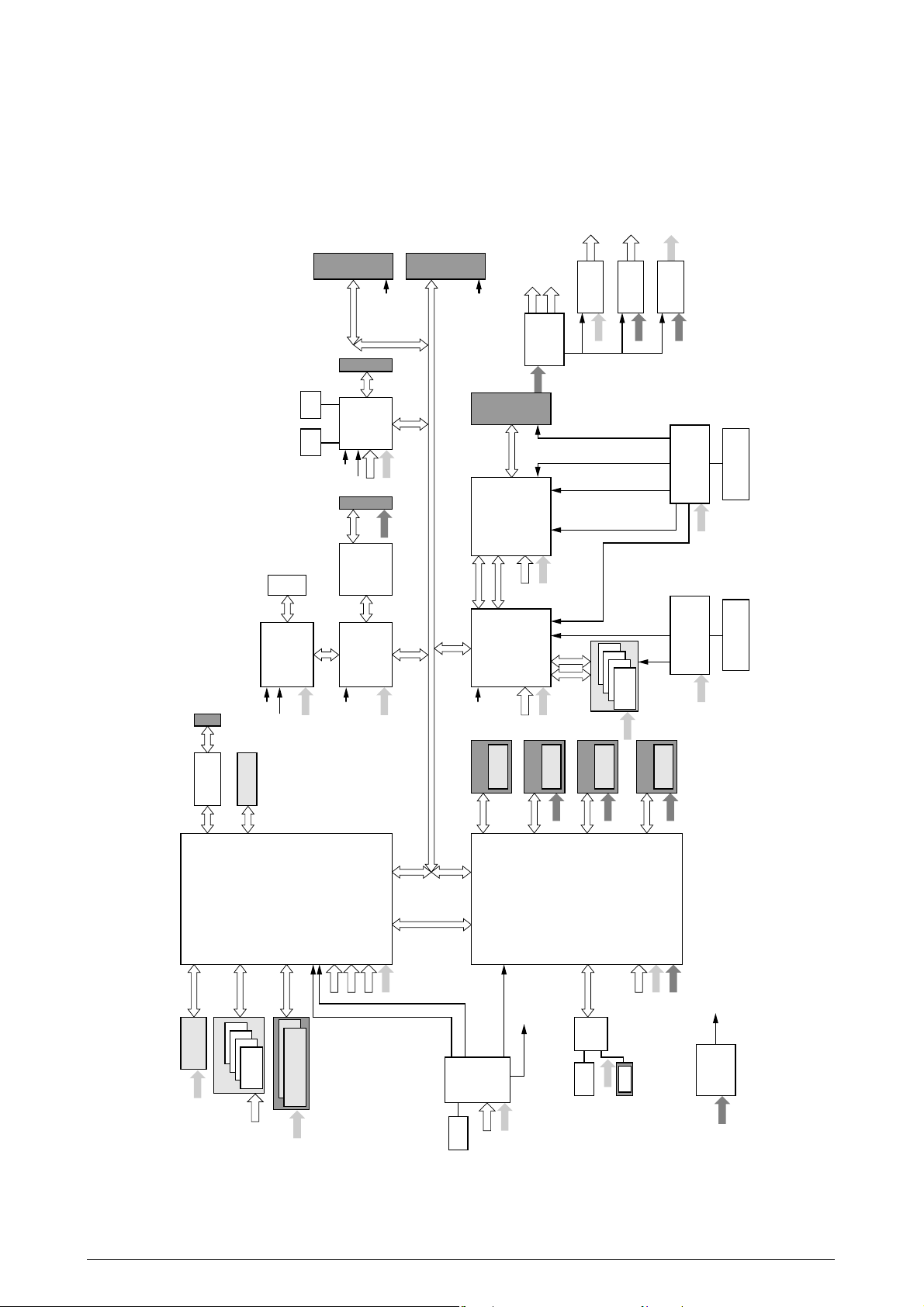

2.1 Main Control PCB

Main Control PCB (ASP-PWB) (1200dpi)

Figure 2-2-1 illustrates the block diagram of the Main Control PCB (ASP PWB).

+1.8V

LT1764EQ

3.3V to 1.8V

+3.3V

1

ENG_CLK

0

ENG_CLK

CLK

VCLK2 SERIAL-

+2.5V

Regulator

5V to 2.5V

LTC3412EFE

+5.0V

nomount

X’tal

30.000

EEPROM

MHz

PCI

PCICLK

Slot

100pin

USB

USB2.0

NET2280

HW_

RESET-N

PCICLK3

Connector

120pinTQFP

+2.5V

+3.3V

Connector

IEEE1284

+5.0V

PCI

Slot

68pin

Regulator

PLLVDD

CVDD

PCICLK2

COREGOOD

PLVDD

MAX1718

5V to CVDD

StepDownCont

+5.0V

I/F

Engine

WDATA0/1/2/3

256pinBGA

Xilinx FPGA

XC2S200E-6FT256C

+3.3V

LM2636

Regulator

5V to 3.3V

+5.0V

Clock Generator

CY27EE16FZEC

14.318MHz

Crystal oscillator

CN

W83783S

FAN Control

S_A[12:0]

8Mbit Flash

Resident 256MByte

+3.3V

Microwire

2kbit EEPROM

S_DQ[63:0]

4

3

2

1

DDR

512Mbit

PCICLK6

SDRAM

+2.5V

LED

XC9572XL

Xilinx FPGA

100pinTQFP

+3.3V

HW_RESET-N

CPU

TM5800

474pinCBGA

C_A[12:0]

C_DQ[63:0]

2

1

SDRAM DIMM

+3.3V

Parallel

74LVX161284

ASIC1

144pinPQFP

PCICLK1

+3.3V, 2.5V, CVDD, PLLVDD

+2.5V

CVDD

PLLVDD

+3.3V

+3.3V

CPU Sideband PCI_AD[31:0]

VIDEO_0/1/2/3

PCICLK5

PCI_CLK_CPU 33MHz

CPU_CLK 66MHz

Clock Gen

X’tal

14.318MHz

LPC BUS

ASIC2

256Kbit

I2CROM

PCI_CLK_SB=33MHz

CLK14MCLK48M

0.75%

Center-spread

+3.3V

+2.5V

+1.8V

+3.3V

544pinPBAG

+1.8V

+3.3V

2Mbit

Boot Flash

+5.0V

XD[7:0]

SA[19:0]

PCI_CLK[6:0]

4MByte

Resident

BRDATA0[31:0]

BRDATA1[31:0]

BRDATA2[31:0]

BRDATA3[31:0]

Primary IDE

CompactFlash

P_DA[2:0]

P_DD[15:0]

M1535+

353pinBGA

SouthBridge

XD[7:0]

RTC

X’tal

32.768MHz

VCLK0/1

4

3

64MB

+5.0V

+3.3V

2

1

8Mbit

PIPELINED

Battery

SRAM

+3.3V

HDD 2.5inch

S_DA[2:0]

S_DD[15:0]

+2.5V

ICLK_VXP

MCLK_VXP

Clock Generator

0/1/2/3

MCLK_SRAM

20GB

Secondary IDE

+5.0V

+3.3V

+5.0V

14.318MHz

Crystal oscillator

CY27EE16FZEC

+3.3V +3.3V

HW_RESET-N

LEUS-T

MAX811

Reset IC

+5.0V

Figure 2-2-1

Rev. 1 17 /

Page 18

The Main Control PCB of the 1200dpi printer consists of a CPU, RAM, HDD, CompactFlash, SouthBridge

LSI, EEPROM, KeyChip, PCI Bus Option and Advanced Interface.

(1) CPU

1GHz Transmeta TM5800 CPU.

(2) RAM

There are 3 types of RAMs. SDRAM DIMM is the only user option RAM. The DDR and

video RAM configuration is fixed and cannot be modified. Only the total memory of the

DDR and SDRAM DIMM is recognized as a usable RAM within the system configuration.

DDR : This is 256MB and 266MHz in speed, and directly soldered on the ASP PCB.

SDRAM DIMM : 128, 256, and 512MB; 133MHz speed, 144p DIMM mounted in DIMM slot.

Video RAM : RAM that is directly soldered on ASP PCB for the video LSI.

(3) HDD/CompactFlash

The 1200-dpi program is stored in a storage medium. Depending on the model, the system

is equipped with HDD or CompactFlash. However, HDD may be added as an option to

a model with CompactFlash. HDD is a mold assembly similar to the one for the 600-dpi

system.

(4) SouthBridge LSI

This is a ALI-make BGA package LSI. It mainly controls the USB I/F, Centro I/F, image

processing LSI, Ethernet board, and MFP extension board via the PCI bus.

(5) Image Processing LSI

This is an EFI-make BGA package LSI. It is mainly for image processing.

(6) EEPROM

This is a 3.3V/256kbit EEPROM with an 8-pin DIP package mounted on the IC socket.

It stores various settings that the control unit manages.

(7) KeyChip

The KeyChip is an 8-pin DIP package mounted on the IC socket. It is purchased from

EFI and stores EFI management information.

(8) PCI Bus

100-pin: An MFP extension board is available as optional equipment.

68-pin: A LAN card is provided as standard equipment.

(9) Advanced Interface

Standard :Centronic Parallel I/F (IEEE-1284)

USB (USB2.0) I/F

Ethernet Board

Additional PCB : MFP Extension Board (PCI BUS Connection)

Rev. 1 18 /

Page 19

Rev. 1 19 /

Page 20

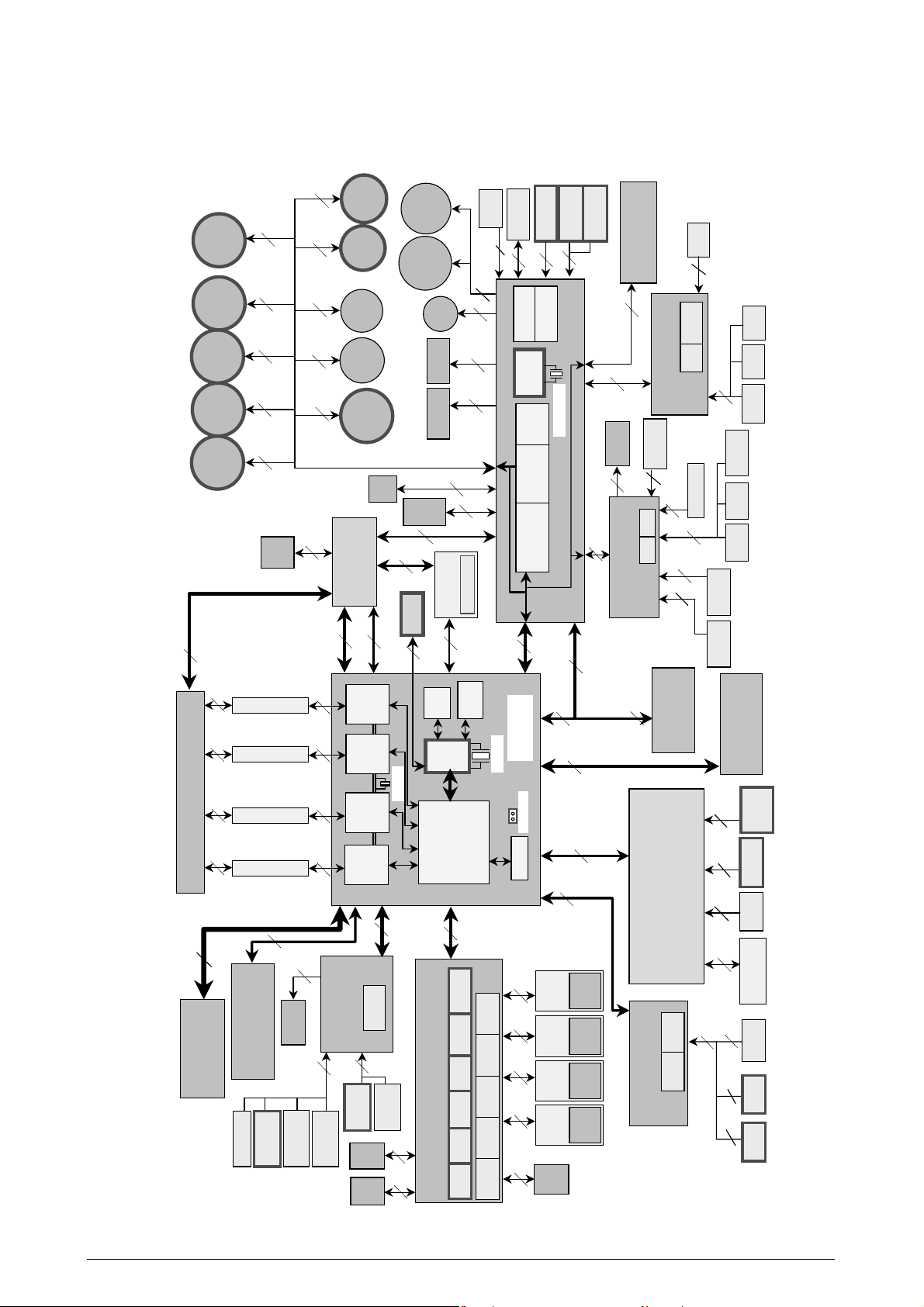

2.2 Engine Control PCB (S2V PWB)

Figure 2-3 illustrates the block diagram of the Engine Control PCB (S2V PWB).

4

Toner

Supply

Motor MC

Fuser

C-ID

M-ID

Y-ID

K-ID

9

Motor

Motor

9

Motor

999

Motor

Toner

44

49

Supply

BELT

Motor

Job

Offset

Toner

Disposal

Motor KY

Motor

Motor

Motor

FAN

FAN

3

Power

UNIT

LV-POWER

11

4

2

BELT

FAN

4

RFID

9

Regist

Tray1

/MPT

PU-

2

Motor

Motor

Geared

1st Regist

Registration

Board

Cover

8

Motor

2

2

Clutch

2

Shutter

3

3

(fuse)

Thermister*4

FUSER UNIT

12

MPT

1st Paper

Size SW

Waste toner

Hole IC

Waste toner

Box Hole IC

Belt

Hole IC

2

5

3

Driver

Tray1/MPT

Motor driver

Regist Motor

SUB

CPU

6

DUPLEX UNIT

13

10

BELT

Motor

Driver

19.66MHz

BOARD-MOTOR-DRIVER (S2M)

KY

TonerSupply

Motor Driver

JobOffset/

Motor Driver

TonerSupplyMC

2nd Regist

Clutch

ENV Sensor

4

2

WR IN2

20

BOARD-

FRONT-SENSOR

(S2S)

70

4

BOARD-

Hum/Temp

END

PAPER

3

1st Paper

Near END

1st

Lifter

(S2C)

Media weight

9

MPT

MPT

Paper End

Hopping

TRAY-SENSOR

3

9

OHP

Sensor

3

3

MPT Paper

END

MPT Home

Position

1st

Cover

IN1

1st

Hopping

C LED HEAD

M LED HEAD

(S2H)

Y LED HEAD

K LED HEAD

44 44

BOARD-LED-HEAD-POWER-RELAY

100

6

10 10 10 10

COCOA

ASIC

COCOA

ASIC

COCOA

ASIC

COCOA

2

(S2R)

SENSOR

Job offset

BOARD-REAR-

6

Cover

Left

ID

FAN

Position

FAN

Fuser

Unit

Contoroller

(X7G)

Solenoid

BOARD-

EXIT

Facedown

OPERATION PANEL

Stacker

Full faceUP

12

Stacker Full

faceDown

Job offset

ASIC

19MHz

13

paper end

Cover

Face UP

(top)

33

32kbit

SRAM

Flash

8Mbit

10

PU-BOARD

CPU

ASIC

MCON

28MHz

EEPROM

(S2V)

9

Short Plug

16

14

24

PCB

C-ID

UNIT

(fuse)

M-ID

Y-ID

K-ID

FAN

UNIT

UNIT

UNIT

ID

(fuse)

(fuse)

(fuse)

(front)

Eraser

PCB

Eraser

PCB

Eraser

PCB

Eraser

Toner

Supply

ID

UpDown

Toner

Supply

Toner-C

Sensor

Toner-M

Sensor

Toner-Y

Sensor

Toner-K

Sensor

3 3 3

33

C-Drum

Phase

(SGG)

M-Drum

Phase

Y-Drum

Phase

BOARD-CARTRIDGE-SENSOR

K-Drum

Phase

(S2J)

(S2J)

(S2J)

(S2J)

14

OPTIONAL

TRAY UNIT

UNIT

HV-POWER

Aligment

Right

Aligment

Left

BOARD-

REGIST-SENSOR

(S2Z)

23 3

2

11

FINISHER/

Disposal

COVER

5

3

3

INVERTER UNIT

Disposal

Toner Full

Hole IC

Toner Box

Upper

(fuse)

BELT UNIT

Density

Sensor

Slack

Paper

Fuser

release

Figure 2-3

Rev. 1 20 /

Page 21

2.3 Power Unit

This is a high voltage power unit consisting of high voltage power source circuit and a low voltage

power unit composed of a power unit consists of an AC filter circuit, low voltage power source circuit

and heater drive circuit.

(1) Low Voltage Power Unit

This circuit generates the following voltage.

Output Voltage

+5V (1)

+5V (2)

+5V (3)

+24V

PU, Logic Circuit Power Source

LED Head

CU

For Monitor Drive

Purpose

(2) High Voltage Power Unit

This circuit generates the following voltage that is more powerful than +24V necessary for

the electrophotographic process, according to the control sequence from the control PCB.

Output

CH

DB

SB

BB

TR

-0.8 to -1.4kV

-100 to -450V/250V

-300 to -700V

Drop from SB Output with Zener

0 to 7kV

Voltage

Purpose

Power to Electrification Roller

Power to Development Roller

Power to Toner Supply Roller

Power to Development Blade

Power to Transfer Roller

Remarks

Rev. 1 21 /

Page 22

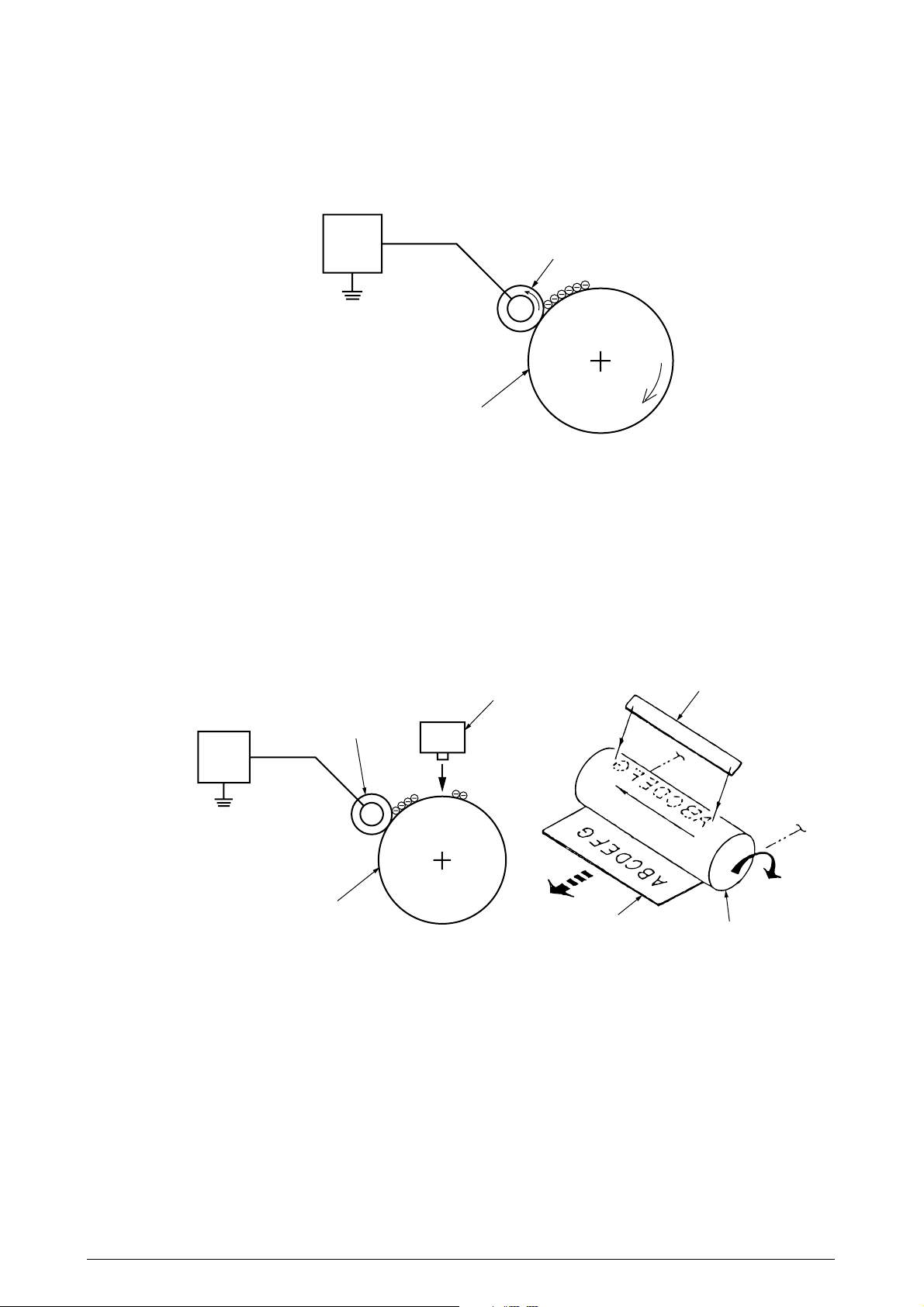

2.4 Mechanical process

Figure 2-4 illustrates the mechanical process of the AR-C360P.

tray

Multi purpose

Paper

cassette

Feeding

(MT, 1ST, 2ND)

Hopping roller

YMC

× 4

K

Control signal

LED head

Power supply

Exposure

Electrification

Toner

Paper feed sensor 1

container

roller

Development

Paper feed sensor 2

Development

Cleaning

regist

Paper

regist

Paper

Transfer

Regist roller 1Regist roller 2

Light sensor

Transfer roller

Power

supply

A motion of a paper

OPC drum rotation

roller

Discharge

Discharge

(Face down)

Power supply

roller

Electrification

Cleaning blade

Backup roller

selection

Paper path

Fixing

Heat roller

roller

Discharge

Discharge Fixing Cleaning Transfer Paper conveyance Paper advance

(Face up)

Discharge

Discharge sensor

Figure 2-4

Rev. 1 22 /

Page 23

2.4.1 Electrophotographic Processing Mechanism

(1) Electrophotographic process

The overview of the electrophotographic process is described below.

1 Electrification

DC power is applied to the CH roller to evenly negatively electrify the surface of the

OPC drum.

2 Exposure

The LED head irradiates light on the surface of the OPC drum that is charged with

a negative electrical load. The negative electrical load attenuates according to the

intensity of light, for the irradiation area of the OPC drum surface. Further, the

electrostatic latent image is created on the OPC drum surface according to the

electrical potential.

3 Development

The negatively charged toner comes in contact with the OPC drum to fuse the

electrostatic latent image by electrostatic force, to create a significant image on the

surface of the OPC drum.

4 Transfer

Paper is pressed against the surface of the OPC drum, then conveyed by the transfer

roller from behind. The toner and positive electrical load of a reverse electrode is

applied, then the toner image is transferred to the paper.

5 Cleaning

The cleaning blade removes residual toner on the OPC drum after the toner is

transferred to the paper.

6 Fuser

Heat and pressure is applied to the toner image on the paper to fuse the image on

the paper.

Rev. 1 23 /

Page 24

(2) Electrification

A negative DC power is applied to the electrification roller to evenly negatively electrify

the surface of the OPC drum.

Power

supply

unit

Electrification roller

OPC drum

(3) Exposure

The LED head irradiates light on the surface of the OPC drum that is charged with a

negative electrical load. The negative electrical load attenuates according to the intensity

of light, for the irradiation area of the OPC drum surface. Further, the electrostatic latent

image is created on the OPC drum surface according to the electrical potential.

Power

supply

unit

Electrification roller

OPC drum

LED head

Paper

LED head

OPC drum

Rev. 1 24 /

Page 25

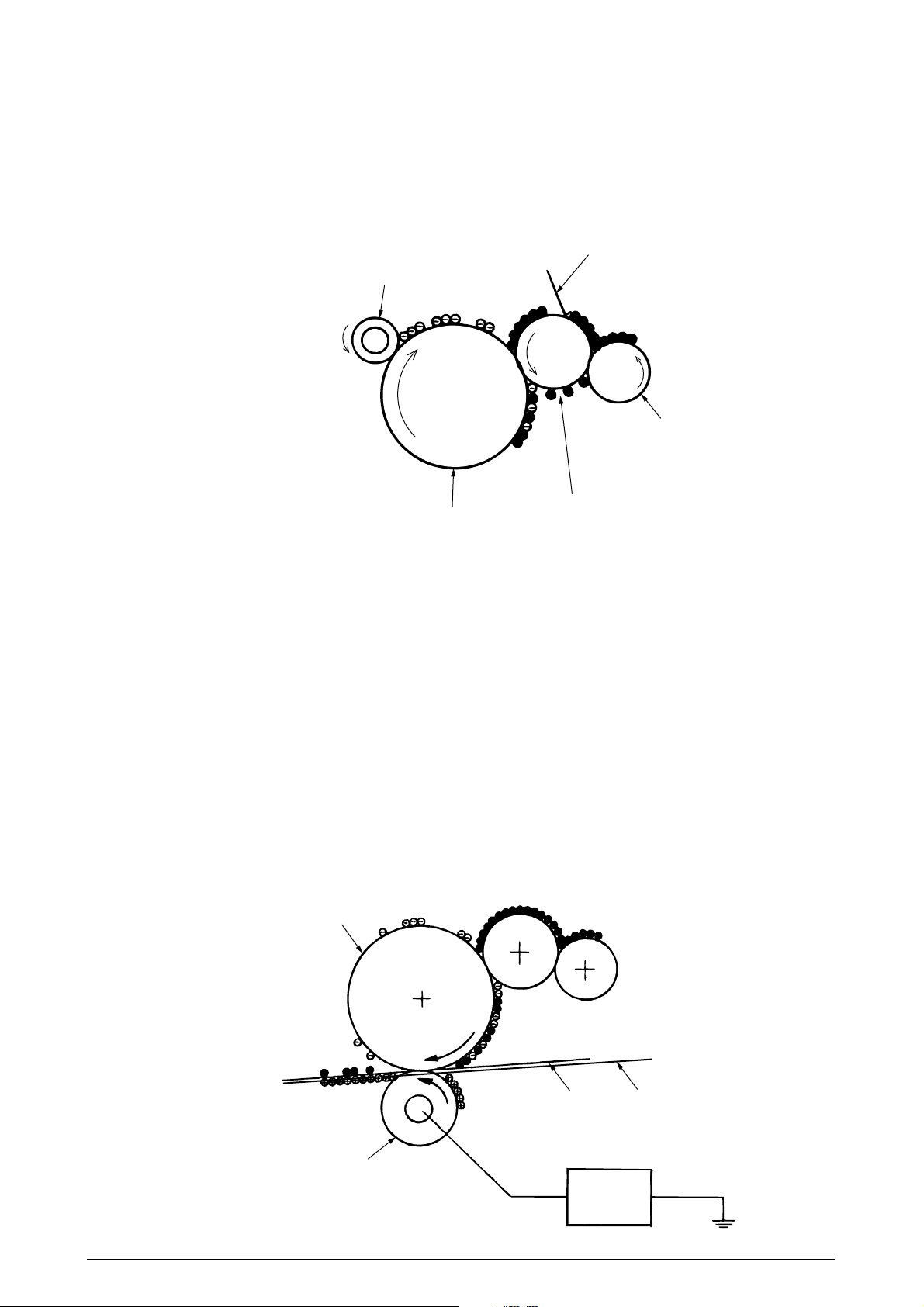

(4) Development

The negatively charged toner comes in contact with the OPC drum to fuse the electrostatic

latent image by electrostatic force, to create a significant image on the surface of the OPC

drum.

1 The sponge roller precipitates toner on the development roller. The toner is then

negatively electrified.

Electrification roller

Development blade

Sponge roller

OPC drum

Development roller

2 The development blade removes excess toner from the development roller, then a

thin toner layer is created on the development roller.

3 The toner is sucked into the electrostatic latent image where the OPC drum and

development roller comes in contact.

(5) Transfer

The transfer roller is made of a conductive sponge. Paper is pressed against the OPC

drum surface, then the paper and OPC drum surface is adhered.

Paper is pressed against the surface of the OPC drum, then conveyed by the transfer roller

from behind. The toner and positive electrical load (that is reverse with the toner) is applied,

then the toner image is transferred to the paper.

When the power source applies powerful positive power on the transfer roller, the positive

electrical load induced by the transfer roller is transferred to the paper surface at the

contact point between the transfer roller and paper. The negative electrical load toner is

then sucked from the OPC drum surface on to the paper surface.

OPC drum

Paper

Transfer roller

Rev. 1 25 /

Conveyance belt

Power

supply

unit

Page 26

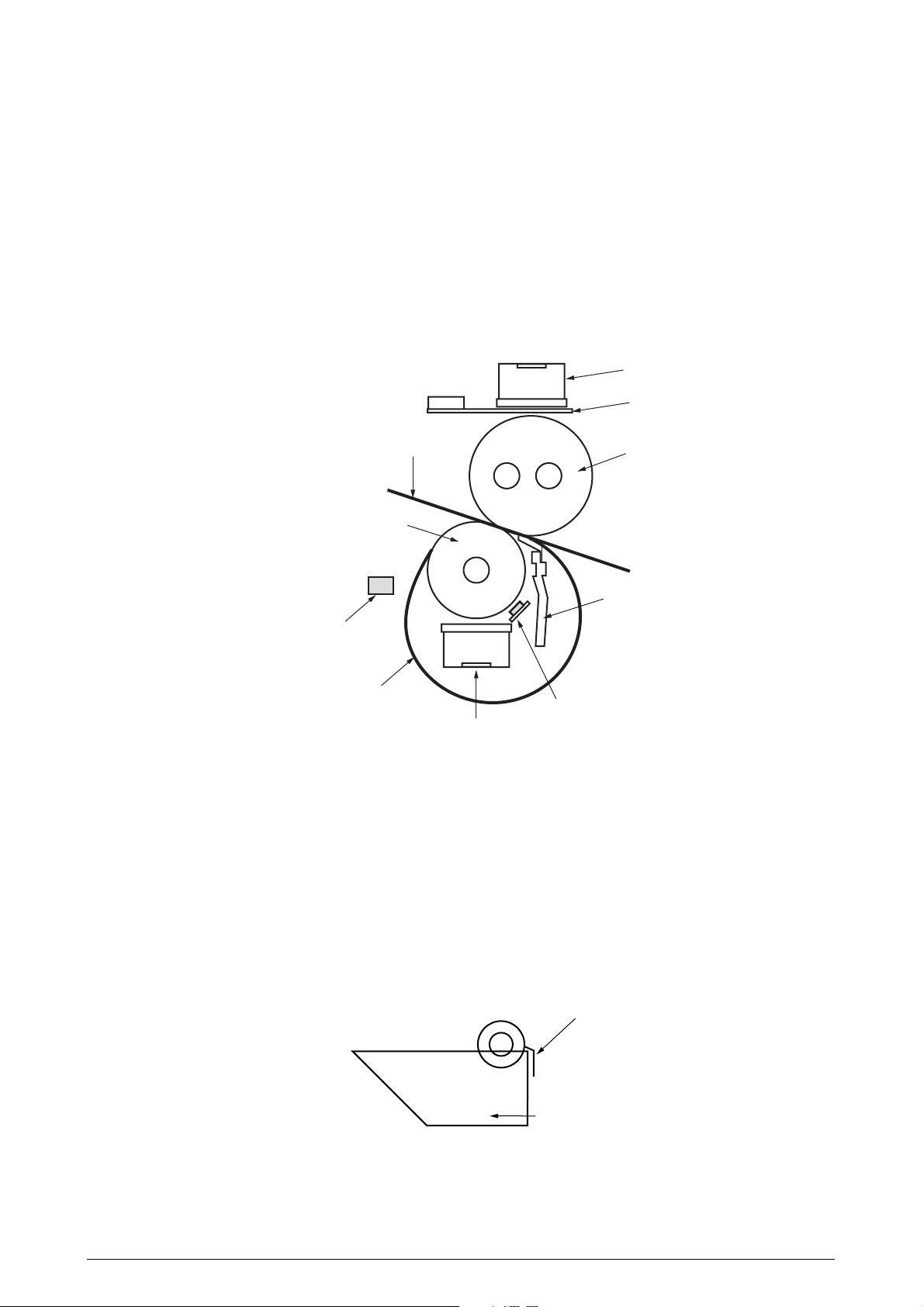

(6) Fuser

The toner image transferred on the paper is fused on the paper by heat and pressure when

the paper passes through the heat roller and backup roller.

The Teflon coated heat roller is heated by a 800W or 350W internal halogen lamp, and

backup roller is heated by a 50W internal halogen lamp. The fuser temperature is controlled

according to the sum of the temperature that is not contacted with the thermistor ground

against the heat roller surface and the temperature that is detected with the thermistor

ground on the backup roller surface. There is also a thermostat for safety purposes. When

the heat roller temperature rises above a certain temperature, the thermostat opens and

shuts down the power supplied to the heater. The backup roller unit is pressed against the

heater with a press spring on both sides.

Thermostat

Thermistor

Paper

Backup roller

Backup roller unit

Fuser belt

Thermistor

Thermostat

Heat roller

Pat

(7) Cleaning

The cleaning blade scrapes off residual toner on the OPC drum after the toner is transferred to the paper, then the disposal toner of the disposal toner box is collected at the

rear.

(8) Cleaning

The cleaning blade scrapes off residual toner on the transfer belt then collects is in the

disposal toner box of the transfer belt unit.

Cleaning braid

Disposal Toner Box

Rev. 1 26 /

Page 27

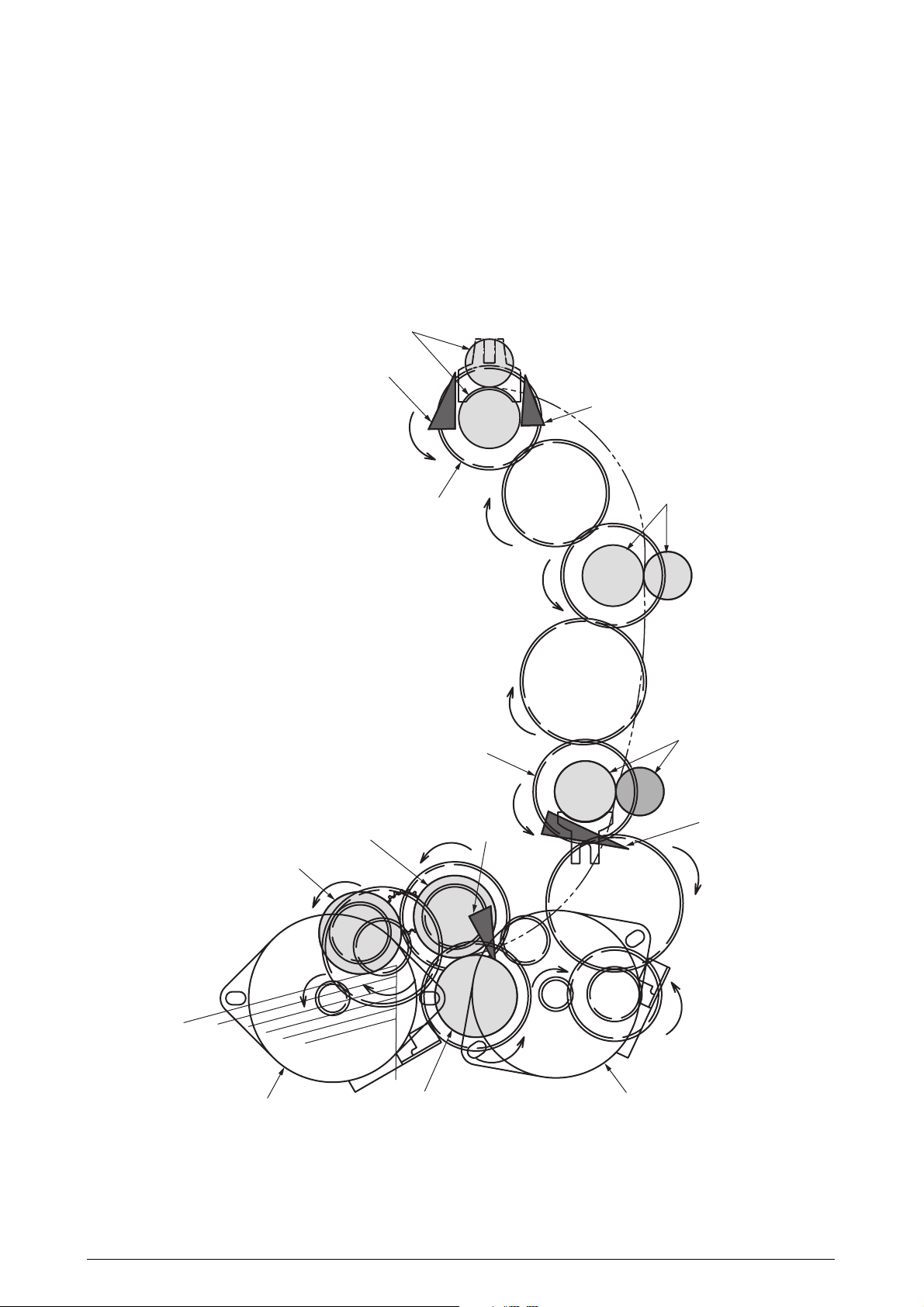

2.4.2 Paper Processing Mechanism

Figure 2-5 illustrates how the paper transfers through the AR-C360P.

Face down stacker

Discharge roller

Discharge roller

Backup roller

Fuser assembly

Heat roller

Cassette 1

Cassette 2

Cassette 3

Low-pressure

power supply

Belt unit

Head x4

High-pressure

power supply

Unit x4

Regist roller Assy (B)

Hopping roller

Multipurpose tray

Cleaning blade

Regist roller Assy (A)

Transfer roller

Feed roller

Cassette 4

Cassette 5

Figure 2-5 Paper Path

Rev. 1 27 /

Page 28

(1) Paper Supplied from the 1st Tray

1. Paper proceeds when the paper supply motor turns (CCW) and the paper supply

clutch is connected, until the IN1 sensor turns ON.

2. When the IN1 sensor is turned ON, a certain volume of paper is further transported

until it is against the 1st resist roller. (this corrects paper skew)

3. The paper is transported to the transport belt when the electromagnetic clutch which

delivers power that the register strike motor is turning (CW) and the thrust reliance

of a paper is completed to the 1st register strike roller is connected.

2nd regist roller

Write sensor

IN2 sensor

Middle transport roller

The clutch of

electromagnetism

Pickup roller

Feed motor

Feed roller

Paper

The clutch of

electromagnetism

Feed sensor

Retard roller

Figure 2-6

1st regist roller

IN1 sensor

Regist motor

Rev. 1 28 /

Page 29

(2) Paper Supplied from the Option Tray

1. Paper proceeds when the paper supply motor turns (CCW) and the paper supply

clutch is connected, until the IN sensor of the top tray to supply the paper, turns ON.

2. When the IN sensor is turned ON, a certain volume of paper is further transported

against the regist roller. (this corrects paper skew)

3. The paper is conveyed to the AR-C360P when the electromagnetic clutch which delivers

power that the register strike motor is turning (CW) and the thrust reliance of a paper

is completed to the 1st register strike roller is connected.

electromagnetism

Regist motor

The clutch of

electromagnetism

The clutch of

1st Regist roller

IN1 sensor

Regist roller

Upper tray

Option paper tray

IN sensor

Pickup roller

Feed motor

Feed roller

Retard roller

Feed sensor

Regist motor

Figure 2-7

Rev. 1 29 /

Page 30

(3) Paper Supplied from MPT

1. In the usual case, sheet receiving is depressed by the arm for rise and fall at a home

position.

2. When a regist motor rotates in the direction of (b), the arm for rise and fall drives

and sheet receiving is rotated. The paper on sheet receiving goes up to the position

where a lift rise sensor is turned on, and feeding is attained because the arm for rise

and fall goes up.

3. The hopping motor is shared with the tray and MPT feeding uses the inversion of

tray feeding.

If a hopping motor reverse-rotates, a pickup roller and a feed roller will drive and a

paper will be sent out.

4. After an entrance sensor (2) is turned on by the paper tip, a paper is sent by

specification length. A paper will stop, if the tip reaches the 2nd register strike roller

Assy.

5. A regist motor rotates in the direction of (a) simultaneously, and a paper is conveyed

with the 2nd regist roller Assy. A hopping motor is rotated until a paper arrives at

the position of the image drum cartridge (black).

6. A hopping motor is rebooted, in order to make paper feed to the following paper, when

an after the end escapes from the hopping sensor.

7. When operation of 4 to 6 is repeated and a lift rise sensor turns off, a regist motor

is rotated in the direction of (b), and the arm for rise and fall is driven, and it goes

up until a lift rise sensor turns on the paper on sheet receipt.

8. After the completion of paper sending operation, when a lift rise sensor detects off,

a regist motor is rotated in the direction of (b), and sheet receiving is returned to a

home position by dropping the arm for rise and fall.

Rev. 1 30 /

Page 31

Feed roller

Entrance sensor (2)

Write sensor

2nd Regist roller Assy (B)

The clutch gear of

electromagnetism (2)

Hopping sensor

Retard roller

Pickup roller

Lift up sensor

Paper existence sensor

Paper

Paper existence sensor

Middle transport roller

Hopping motor drive

a

Regist motor drive

b

Figure 2-8

Rev. 1 31 /

Page 32

(4) Conveyor Belt

1. The conveyor belt motor drives the conveyor belt when turning in the direction of the

arrow (a). The belt unit consists of one conveyor roller that is directly under the drum

for each color, with the conveyor belt in between the drum.

When a specified voltage is applied, the conveyor belt and conveyor roller transfers

the toner image on the drum for each color, then feeds the paper on the conveyor

belt to the fuser unit.

Drum

Conveyor belt

KY MC

Transfer roller

Transfer belt motor

Figure 2-9

Rev. 1 32 /

Page 33

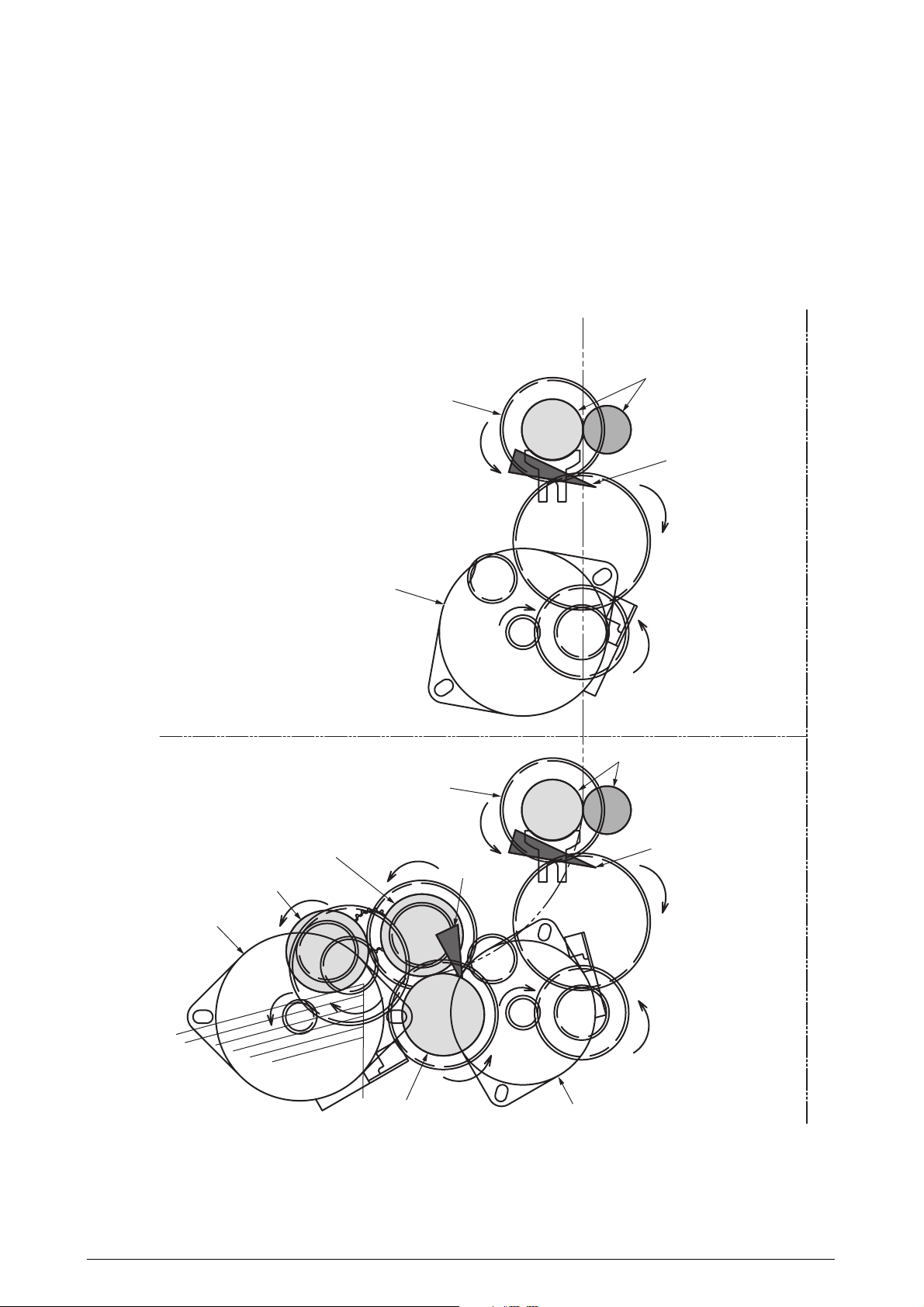

(5) ID Unit Up/Down Operations

1. The C-ID motor drives the ID unit up and down.

2. Figure 2-10-a indicates ID unit operations during color printing. When the C-ID motor

rotates (CCW), the lift uplink slides to the left, and as indicated in Figure 2-10-a, each

ID unit moves DOWN. The printer is now ready for color printing.

3. Figure 2-10-b indicates the ID unit operations during monochrome printing. When the

C-ID motor rotates (CW), the lift uplink slides to the right, and as indicated in Figure

2-10-b, all units other than the K-ID moves UP. The printer is now ready for blackand-white printing.

ID Unit Operations During Color Printing

C-ID Unit down

M-ID Unit down

Y-ID Unit down

K-ID Unit down

Lift uplink

C-ID Unit M-ID Unit

C-ID Motor

(CCW)

Figure 2-10-a

ID Unit Operations During Monochrome Printing

C-ID Unit lift up

M-ID Unit lift up

Y-ID Unit lift up

K-ID Unit down

C-ID Unit M-ID Unit

Y-ID Unit

Y-ID Unit

K-ID Unit

K-ID Unit

Lift uplink

C-ID Motor

(CW)

Figure 2-10-b

Rev. 1 33 /

Page 34

(6) Fuser Unit and Paper Output

1. The fuser unit and discharge roller is driven by a single DC motor. The heater roller

turns when the fuser motor turns in the direction of the arrow (a). This roller fuses

the toner image on the paper with heat and pressure.

2. At the same time, the four discharge rollers are activated to discharge paper.

3. The discharge path to the face-up or face-down stacker is automatically switched by

the paper separator solenoid.

Discharge roller

Face-down stacker

Face-up stacker

Fuser unit

Heat roller

Paper separator

a

Fuser motor

Figure 2-11

Rev. 1 34 /

Page 35

(7) Double-Side Printer Unit

1. When the double-side Printer Unit receives double-side print instructions, the separator is opened by the solenoid after one side of the paper fed from the tray is

completely printed, then the path is switched to the double-side printer unit.

At this time, roller (1) turns in the direction of arrow (a), therefore, the paper is

retracted to the undersurface of a double-side printer unit.

2. Further, when the tip of the paper passes through the double-side printer entrance

sensor after a certain period of time, the roller starts a reverse rotation. Roller (1)

turns in the direction of arrow (b), then sends the paper inside the double-side printer

unit. After that, it passes through roller (2), (3), (4) and (5), prints the other side of

the paper, then discharges the paper, and re-feeds it back to the unit.

Separator

Solenoid

Double-sided

entrance sensor

Roller (1)

a

b

Motor A

Motor B

Roller (2)

Roller (3)

Figure 2-12

Roller (4)

Roller (5)

Rev. 1 35 /

Page 36

2.5 Sensor

2.5.1 Paper-Related Sensor

Stacker Full FD sensor

Stacker Full

FU sensor

Dup-in sensor

Dup-in2 sensor

Job-off sensor

Drive roller

Exit sensor

Looseness sensor

Sensor

Entrance MT Sensor

Entrance Cassette Sensor

Entrance Belt Sensor

Paper Discharge Sensor

Double-Side Print

Entrance Sensor

Double-Side Print Rear

Sensor

Double-Side Print Front

Sensor

Stack Full Sensor

Face-Down Paper

Discharge Sensor

Face-Down Route Sensor

Conveyance Sensor

C drum K drumY drumM drum

Drive roller

WR sensor

MPT home sensor

Density / color gap sensor

Dup R sensor

Conveyor belt

Dup F sensor

Function

This detects the top of the paper entering and

then determines the timing to switch from the

hopping to the conveyor.

This detects the tip of the paper transferred,

then determines the length of the paper

according to the time it takes the tips of the

paper to reach the sensor.

This detects the tip and end of the paper, then

determines paper discharge.

This determines the tip of the paper entering

the double-side printer unit, then determines

the times it takes for the inverse roller to

inverse from CCW to CW.

This detects the tip of the paper after inversion

by the double-side printer unit.

After inversion by the double-side printer unit,

the end and tip of the paper is detected and

then paper discharge is determined.

This detects paper-full in the face-down

stacker.

This detects paper conveyance to the paper

discharge roller, then determines the timing to

offset job operations.

When the paper jams, this detects the paper

jam in the face-down conveyance rotor.

This detects the paper conveyed from the

option tray.

IN2 sensor

MPT Hopping sensor

Paper Hopping sensor

State of Sensor

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Stack Full

OFF

: Stack Empty

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Paper Available

OFF

: Paper Unavailable

ON

: Paper Available

OFF

: Paper Unavailable

MPT PE sensor

IN1 sensor

Rev. 1 36 /

Page 37

2.5.2 Other Sensors

1 Paper Empty Sensor

This sensor checks whether the paper cassette is empty or not.

2 Paper Near-End Sensor

This sensor checks whether the paper cassette will be empty soon or not.

3 MBF Paper Empty Sensor

This sensor checks whether there is paper in the front feeder.

4 MBF Hopping Switch

This micro-switch checks whether the front feeder table is in the UP position or DOWN

position.

5 Stack-Full Sensor

This sensor checks whether the stacker is full or not.

6 Paper Size Switch

This sensor detects the size of the paper in the paper cassette.

7 EP UP/DOWN Sensor (one sensor each for Y, M, C, K)

This sensor checks whether the I/D unit is in the UP position or DOWN position.

8 Toner K, Y, M and C Sensor

This sensor checks the toner residual quantity in an image drum, when a sensor lever

measures a time interval to open periodically.

9 RFID Sensor

The radio communications of this sensor are carried out to IC tip built in the toner cartridge,

and it checks the existence of a toner cartridge, and the toner residual quantity in a toner

cartridge.

0 Thermal Sensor

Refer to 2.7 “Image Transfer Control Due to Environmental Change”.

A Humidity Sensor

Refer to 2.7 “Image Transfer Control Due to Environmental Change”.

B Transparency Sensor

This sensor detects whether there is a transparency or not.

C Positioning Sensor

This sensor reads the printed position pattern on the left and right ends of the transfer

belt when color drift is corrected. (Refer to Section 2.13)

D Density Sensor

This sensor measures the pattern density to measure the density printed on the conveyor

belt.

E Media Thickness Sensor

This sensor detects the thickness of the media.

F Disposal Toner Sensor

This sensor checks whether the disposal toner in the disposal toner box is full or not.

G Looseness Sensor

This sensor detects looseness in paper transport and adjusts the speed.

Rev. 1 37 /

Page 38

2.6 Color Drift Correction

The AR-C360P comes with several ID units and LED heads, therefore, causes color drift. This mechanical

color drift can automatically be corrected with the following procedures.

(1) Automatically Corrected Color Drift

1 X Axis Color Drift (position off-alignment due to LED head)

2 Skew Color Drift (position off-alignment due to LED head)

3 Y Axis Color Drift (I/D unit and position off-alignment due to LED head)

(2) Correction Method

The color drift detection pattern set is printed on the belt. This is then read by the reflection

sensor to detect the color drift value of each color and therefore, determine the correction

level. The modification takes place by comparing the each colors’ (Cyan, Magenta and

Yellow) write timing with black, according to the correction value.

2.7 Image Transfer Control According to Environmental Change (Room Tempera-

ture and Relative Humidity)

The AR-C360P measures the room temperature with the room temperature sensor and measures the

relative humidity with the humidity sensor. It further computes the optimal transfer voltage under the

environmental conditions (temperature and RH) measured. Then printing is controlled in real-time at

this optimal voltage.

Environmental Detection Table

Sensor reading value

5† <10

10† <15

15† <20

Tempe-

rature

20† <25

(°C)

25† <30

30† <35

35† <40

Sensor reading value

5† <10

10† <15

15† <20

Tempe-

rature

20† <25

(°C)

25† <30

30† <35

35† <40

<5

40†

<5

40†

Sensor reading value

Register value

<59(H)

16B(H)† <19E(H)

19E(H)† <1D1(H)

1D1(H)† <204(H)

204(H)† <236(H)

236(H)† <265(H)

265(H)† <290(H)

290(H)† <2B9(H)

2B9(H)†

Sensor reading value

Register value

<59(H)

16B(H)† <19E(H)

19E(H)† <1D1(H)

1D1(H)† <204(H)

204(H)† <236(H)

236(H)† <265(H)

265(H)† <290(H)

290(H)† <2B9(H)

2B9(H)†

<15

<1E(H)

<15

<1E(H)

N/L1 N/L1 N/L2 N/N

N/L1

H/L

8

8

8

8

7

7

7

6

6

15† <25

1E(H)† <33(H)

8

8

8

7

7

6

6

6

5

15† <25

1E(H)† <33(H)

L/L

H/L

25† <35

33(H)† <47(H)

8

8

7

7

6

6

5

4

4

25† <35

33(H)† <47(H)

N/L2 N/N

35† <45

47(H)† <5C(H)

35† <45

47(H)† <5C(H)

7

7

7

6

5

4

4

2

2

Humidity (%)

45† <55

5C(H)† <70(H)

7

7

6

5

4

4

2

1

1

Humidity (%)

45† <55

5C(H)† <70(H)

H/H

55† <65

70(H)† <85(H)

7

6

5

4

4

3

1

H/H H/H

1

1

55† <65

70(H)† <85(H)

H/H H/H

65† <75

85(H)† <99(H)

7

6

5

4

3

H/H H/H

1

1

1

1

65† <75

85(H)† <99(H)

H/H H/H

75† <85

99(H)† <AE(H)

6

5

4

3

3

1

1

1

1

75† <85

99(H)† <AE(H)

85 †

AE(H)†

6

5

4

3

2

1

1

1

1

85 †

AE(H)†

Rev. 1 38 /

Page 39

2.8 Paper Jam Detector

The AR-C360P detects paper jam during printing after turning on the power source. If there is any paper

jam detected, the printing process is immediately canceled. In this case, open the cover, remove the

paper that is jammed, and close the cover to resume printing.

Error Code Displayed on LCD

400,401

372

Paper Size Error

Mis-feeding in Double-Side

Print Conveyance Assy

390

1-391

2-392

MT mis-feed.

Cassette 1, 2, 3, 4 or 5 mid-

feed.

3-393

4-394

5-395

370

Paper jam when printing on

the other side with Double-

Side Print.

383

Paper jam at the entrance

of the Double-Side Printer

Unit.

371

Paper jam at the input of the

Double-Side Printer Unit.

382

381

380

490

1-491

2-492

Paper discharge jam.

Paper conveyance jam

Paper output jam.

MT out of paper.

Cassette 1, 2, 3, 4 or 5 out

of paper

3-493

4-494

5-495

Error

State

After the Entrance Cassette Sensor turns ON, it

won t turn OFF for a certain period of time. It detects

several different types of paper sizes.

Failure to feed paper from the Double-Side Print

Conveyance Assy.

Paper feed from the MT failed. (If, after Hopping, the

Entrance MT Sensor does not turn ON within a

certain period of time)

Paper supply failed from Cassette 1, 2, 3, 4 and 5.

(If, after Hopping, the Entrance Cassette Sensor

does not turn ON within a certain period of time)

The double-side printer rear sensor does not turn

ON when printing the other side with the double-side

printer unit.

The double-side printer IN sensor does not turn ON

when supplying paper to the double-side printer unit.

The double-side printer front sensor does not turn

ON while the double-side printer unit is operating.

The paper discharge sensor senses the tip of the

paper but does not sense the end of the paper after

that within a certain period of time. The paper

discharge sensor turns ON, but does not turn OFF

after that.

The paper is conveyed on the belt, however, the

paper discharge sensor does not turn ON.

After hopping is completed, the paper does not

reach the entrance belt sensor or the MT sensor.

If printing is started when the MT is out of paper.

Cassette 1, 2, 3, 4 or 5 out of paper

Entrance belt sensor

Double-side print

entrance sensor

Double-side print rear sense

370

382

Discharge

Discharge sensor

Double-side

383

print entry

Double-side print

front sensor

Double-side print rear sense

381

Paper

conveyor

Double-side print input

371

Entrance MT sensor

Cassette 1

Cassette 2

Cassette 3

Cassette 4

Cassette 5

380

Paper feed

390

Entrance cassette sensor

372

391

392

393

394

395

Multipurpose tray part

(MT)

Mis-feed in MT

Mis-feed in double-sided printing

Mis-feed in a cassette 1

Mis-feed in a cassette 2

Mis-feed in a cassette 3

Mis-feed in a cassette 4

Mis-feed in a cassette 5

Rev. 1 39/

Page 40

Rev. 1 40 /

Page 41

2.10 Toner Low Detection

• Structure

This device consists of a constant speed rotating agitation gear and agitation bar.

Projection Agitation barAgitation gear

• Detection

The minimum height length of stay (OFF time) of a target board which attached the toner

low level state in the end of a churning bar is measured and detected by the sensor.

OFF time (minimum height) ON time (maximum height)

Sensor

Agitation bar

Target board

The light which emitted light by the

sensor reflects with a target board, and

received light by the sensor. Therefore,

the minimum height length of stay is

detectable.

The light which emitted light by the

sensor does not reflect with a target

board, and does not received light by

the sensor.

Rev. 1 41 /

Page 42

Toner High level State

• The agitation bar interlocks and turns with the

agitation gear.

• Since there is a toner even if a agitation bar

reaches the maximum height, the other side

of the bar is still inside the toner. Therefore,

the agitation bar turns by the force of the

agitation gear.

Toner Low Level State

Agitation bar

Target board

• When the agitation bar reaches the maximum height, the agitation bar falls in the

minimum height by prudence since there is

no resistance by the toner. At this time, the

minimum height length of stay of a target

board becomes long. This time is measured

and a toner low level state is detected.

Toner Supply Operation

• When continuation 3 cycle detection of the

toner low level state is carried out, a toner

supply roller and a toner cartridge agitation

spring will rotate, and the toner of a toner

cartridge will be supplied to the inside of an

image drum cartridge. Then, when one cycle

of toner high level is detected, toner supply

agitator and a toner cartridge agitation spring

will stop, and toner supply will stop.

Toner cartridge

agitation spring

Toner supply board

Agitation bar

Target board

Rotation direction of

toner supply agitator

Rev. 1 42 /

Page 43

Toner High Level State (at 37ppm*1)

ON

TNRSNS t1<0.85

OFF

t1

T=2.3

Toner Low Level State (at 37ppm

ON

TNRSNS

OFF

• After a toner supply start, when a toner low sate is detected 20 consecutive times, it is

recognized as the toner being low.

(After recognizing toner low, then toner low is displayed after printing an equivalent of 5%

of 200 A4 sheets.)

The toner in a toner cartridge is lost.

• If a toner full state is detected 10 consecutive times, the toner low state is canceled.

• If the toner sensor does not change over 3 cycles (2.3 sec. X 3), then the toner sensor

alarm is activated.

• The toner sensor does not detect anything when the drum motor is stopped.

*1

A 37ppm printout is at the warming up stage. T and t1 fluctuates in proportion to the

printing speed.

*1

)

t1

t1>0.85

T=2.3

Rev. 1 43 /

Page 44

2.11 Paper Size Detection

A cam is interlocked with the paper guide of the paper cassette, then four tab-pieces via this cam drives

the system according to the paper guide setting position.

When the paper cassette is attached to the printer, the micro-switch detects the state of the tab-piece

and then recognizes the size of the paper.

Cassette NONE

A3 Nobi

Tabloid

A3

B4

Legal 14"

Legal 13"

A4 Portrait

Letter Portrait

Executive

B5 Portrait

Letter Landscape

A4 Landscape

A5

B5 Landscape

A6

PSZSW1

0

0

1

1

0

0

0

1

1

1

1

1

0

0

1

0

PSZSW2

0

0

0

0

0

1

1

1

1

1

1

0

0

1

0

1

PSZSW3

0

1

1

0

0

0

0

1

1

0

0

1

1

1

0

1

PSZSW4

0

1

1

1

1

1

0

0

1

1

0

0

0

0

0

1

Rev. 1 44 /

Page 45

2.12 Power ON Process

2.12.1 Self-Diagnostic Test

(1) Initial Test

When the power is turned On, the following check automatically takes place.

(a) ROM Check

(b) RAM Check

(c) EEPROM Check

(d) Flash ROM Check

(e) Mechanical Check

(f ) Option Unit Check

(2) ROM Check

The ROM is checked by calculating the HASH value.

(3) RAM Check

(a) The type of RAM is checked for its specifications. Any RAM that falls out of the

specifications will result in an Error.

(b) The RAM in each slot is checked by read-after-write.

(4) EEPROM Check

The specific data stored in the fixed address of the EEPROM is checked.

(5) Flash ROM Check

The flash ROM format is checked. If it is unformatted, then read-after-write check takes

place and the flash ROM is formatted.

(6) Option Unit Check

Before entering the run mode, the unit is checked for the presence of an optional units

(HDD, NIC, Option Tray, Double-Side Printer Unit, Finisher, etc.).

Rev. 1 45 /

Page 46

2.13 Mis-Registration Detection

The Z71-PCB reflective optical sensor detects color drift. There is one each on the left and right side

in front of the cleaning blade behind the belt unit. A color drift detection pattern is printed on both ends

of the left and right side of the belt. Then the reflective optical sensor reads this detection pattern to

measure the drift level based on black as a standard. The correction value is then determined based

on this measurement. Then the main scanning, sub-scanning, and skewed color drift correction automatically takes place.

This detection takes place when the power is turned ON, cover is closed, the printer is left unused

for 2 hours or longer, and every time after printing 400 sheets.

LED head

CMYK

ID

CMYK

Transfer belt

The belt run direction

Color drift sensor L/R

Transfer belt

Color drift sensor R

The belt run direction

Color drift sensor L

(Figure seen from the bottom)

Cleaning blade

Cleaning blade

Rev. 1 46 /

Page 47

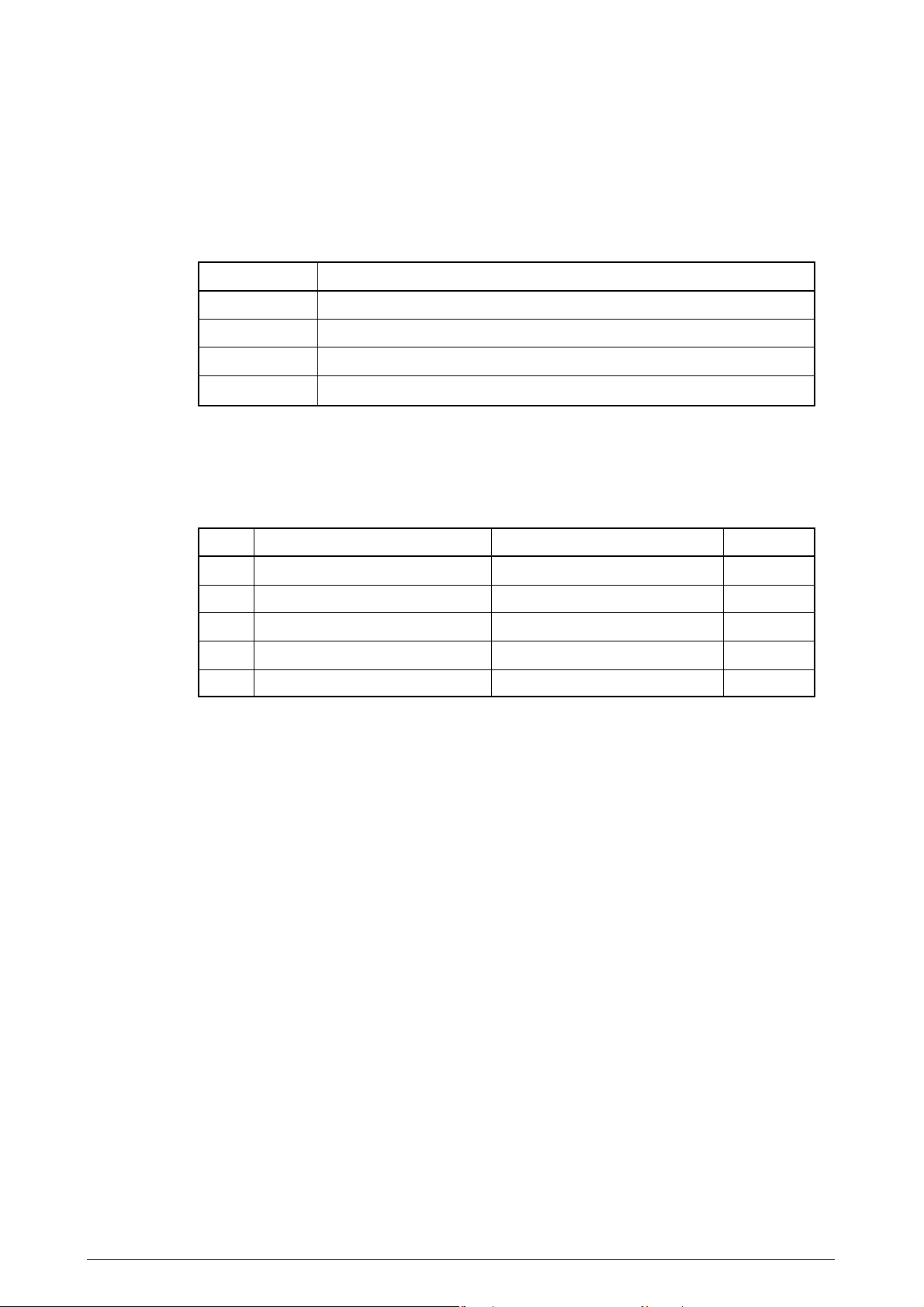

2.14 Reading Version of Routine Replacement Units

This determines whether the parts are new or old according to the I/D of the consumable parts that

are routinely replaced, the fuser unit, and the state of the fuse in the belt unit (good/dead). If the fuse

is in a conductive state, then it is considered a new unit. A NEW or OLD decision takes place when

the power is turned ON and when the cover is closed. When the part is NEW, the life counter of the

unit is reset, and the NEW/OLD decision-making fuse in each unit is cut.

2.15 Life Counter of Replaceable Units

The following Table lists the life counter of the I/D, fuser unit, and belt unit that are routinely replaced

consumable parts.

Unit

ID

Toner Cartridge

Belt Unit

Fuser Unit

State

Count the drum rotation in a unit of

[Letter Paper Length + Paper Interval

during continuous print].

Life: When printing a distance

equivalent to 26K sheets (3P/J).

Count the number of print dots.

Determine the usage level according to

the counter value.

(Refer to 2.16)

Convert the drum rotation into [Letter

Paper Length + Distance Between

Paper Upon Continuous Printing].

One sheet of paper passing through is

counted as one on the counter.

Life: (1)When the counter value reached

80K or, (2)When reaching a 2000

count after detecting a Belt

Disposal Toner Near-Full state.

One sheet of paper passing through is

counted as one on the counter.

Life: When counter value is 80K.

Life processing

Stop Printing

However, 500 sheets can be

printed by opening and

closing the cover.

Stop Printing

However, 20 sheets can be

printed by re-turning the

power back ON or

opening/closing the cover.

Stop Printing

However, 20 sheets can be

printed by re-turning the

power back ON or

opening/closing the cover.

Alarm (This unit can still be

used)

2.16 Toner Usage Level Detection

The toner usage level is detected by counting the number of dots printed. The counted number of

dots is written in in IC tip in a toner cartridge.

Once toner low is detected, the toner shall be considered empty after dot counting 1,050 A4 sheets

at 5%.

However, when the power is turned back ON, and the cover is opened and closed, the printer can

still print 20 more sheets.

Rev. 1 47 /

Page 48

Rev. 1 48 /

Page 49

4. PARTS REPLACEMENT

This section describes the parts in the field, assembly and the procedures to replace the parts, assembly

and unit. Note that only the disassembling procedures are described to replace parts. To assemble

parts, just follow the steps in reverse order of disassembling.

4.1 Precautions When Replacing Parts

(1) ALWAYS unplugging the AC cable and interface cables before replacing parts.

(a) ALWAYS perform the following procedures when unplugging the AC cable.

1 Turn OFF “Ο” the power of the printer.

2 Unplug the AC inlet plug of the AC cable from the AC receptacle.

3 Unplug the AC cable and disconnect the interface cables from the printer.

(b) ALWAYS perform the following procedures to reconnect the printer.

1 Connect the AC cable and interface cables to the printer.

2 Connect the AC inlet plug into the AC receptacle.

4 Turn ON “I” the power of the printer.

(2) NEVER disassemble the printer when it is operating normally.

(3) When disassembling the Assy, disassemble only the minimum necessary. NEVER remove

any parts other than those indicated in the Parts Replacement Procedures.

(4) Only use designated Maintenance Tools.

(5) Disassemble the parts according to the order instructed. Failure to do so may result in

damaging the parts.

(6) Temporarily screw back on the screw, collar and other small parts on it’s original location,

to prevent losing these parts.

(7) NEVER wear gloves when handling the micro processor, ROM, RAM and other IC parts

or the circuit PCB, since gloves may generate static electricity.

(8) NEVER place the printer PCB directly on the unit or floor.

Rev. 1 49 /

Page 50

[Maintenance Tools ]

The tools necessary to replace the printed circuit board (PCB) and unit are indicated in Table 4-1.

Table 4-1 Maintenance Tools

No.

1

2

3

4

5

6

7 1

8

Maintenance Tools

No. 1-100

+ Screw Driver

No. 2-200

+ Magnetic Screw Driver

No. 3-100 Screw Driver

No. 5-200 Screw Driver

Digital Multimeter

Pliers

Portable Vacuum Cleaner

LED Head Cleaner

P/N 4PB4083-2248P001

Quantity

Purpose Remarks

1

2-2.5 mm screw

1

3-5 mm screw

1

1

1

1

1

LED Head Cleaner

10

11

9

Label

High Voltage Probe

Cut-Sheet Film

(Maintenance)

42404301

- Micro-Driver

2.0mm

1

Paper Thickness

1

Sensor for

Adjustment

Transparency Sheet

Paper Thickness

1

for Adjustment

Rev. 1 50 /

Page 51

4.2 Parts Layout

Printer Unit - (120V)

Rev. 1 51 /

Page 52

Base-Assy (1/2)

A

A

Rev. 1 52 /

Page 53

Base-Assy (2/2)

Rev. 1`54 /

Page 54

Side-R-Assy

Rev. 1 55 /

Page 55

Side-F-Assy

Rev. 1 56 /

Page 56

Cover Assy-OP Panel

Rev. 1 56 /

Page 57

FDR Unit-Regist

B

A

B

A

Rev. 1 57 /

Page 58

FDR Unit-MPT

Rev. 1 58 /

Page 59

Sensor-Regist-Assy

Rev. 1 59 /

Page 60

Eject-Assy

2

Rev. 1 60 /

Page 61

Plate-Top-Assy

A

A

A

A

Rev. 1 61 /

Page 62

Job-Offset-Assy

Rev. 1 62 /

Page 63

Basket-Assy

Rev. 1 63 /

Page 64

Plate-Shield-Box-Assy

Rev. 1 64 /

Page 65

Unit-Duplex (1/2)

8

Rev. 1 65 /

Page 66

Unit-Duplex (2/2)

Rev. 1 66 /

Page 67

4.3 Parts Replacement Method

This section describes the procedures to replace the parts and assembly indicated in the disassembly

diagram.

Rev. 1 67 /

Page 68

4.3.1 Cover-Rear, Cover-Side (R), and Cover-Side (R) Rear

(1) Unscrew the 5 screws 1, then remove Cover-Rear 2.

(2) Unscrew the 2 screws 3, then remove Cover-Side (R) 4 with it warped.

(3) Unscrew the screws 3, then remove Cover-Side (R) Rear 6.

3

4

1

2

5

6

Rev. 1 68 /

Page 69

4.3.2 Cover-Side (L) and Cover Assy-Front

(1) Open Cover Assy-Top 1.

(2) Unscrew the 4 screws 2, then remove the Cover-Side (L) 3.

(3) Open the Cover Assy-Front 4 by 90°, unscrew the 2 screws 5, then slide the Assy to

the side and remove.

1

2

5

4

3

5

Rev. 1 69 /

Page 70

4.3.3 Stacker Assy-FU

(1) Open Cover Assy-Top 1.

(2) Open Stacker Assy-FU 2, then remove the 2 stoppers 3. Push these to one side, remove

the post, then remove the Stacker Assy-FU 2.

1

2

Rev. 1 70 /

Page 71

4.3.4 Cover Assy-OP Panel, Cover-Guard (R), Cover-Guard (Front) and Cover-Guard (L)

(1) Open Cover Assy-Top 1, then lift Basket-Assy 2.

(2) Remove Cover Assy-OP Panel 3 from its supporting point.

(3) Unscrew screw 4, remove the hinges, and then remove Cover-Guard (R) 5.

(4) Unscrew 2 screws 6, then remove Cover-Guard (Front) 7.

(5) Unscrew 2 screw 8, then remove the 2 hinges and remove the Cover-Guard (L) 9.

1

2

8

3

9

6

7

8

5

4

Rev. 1 71 /

Page 72

4.3.5 OP PCB

(1) Remove the Cover Assy-OP Panel. (Refer to Section 4.3.4)

(2) Remove Cover-OP Panel 2 from Frame-OP-Panel 1.

(3) Unscrew the 2 screws 3, then remove hinge (R) 4 and Cover Hinge (R) 5.

(4) Unscrew 2 screws 6, then remove the Hinge (L)7, Cover-Hinge (L)8 and Plate-Shield

(OP) 9.

(5) Remove Cover-LCD 0, Button-key A, and Lens-LED B, then remove the OP PCB C.

1

A

8

6

2

7

3

B

0

4

C

A

A

9

5

Rev. 1 72 /

Page 73

4.3.6 Cover Assy-Top

(1) Open Cover Assy-Top 1.

(2) Unscrew 8 screws 2, then remove the 3 hinges and the Cover Assy-Top 1.

1

2

× 8

Rev. 1 73 /

Page 74

4.3.7 FAN-PCB-Assy, CU-Board-Assy and S2V-PU-Board

(1) Open the Cover Assy-Top.

(2) Remove the covers concerned. (Refer to Section 4.3.2)

(3) Remove the connector, then Remove FAN-PCB-Assy 1.

(4) Unscrew the 2 screws, remove the Plate-Shield-Assy 3, then remove the connector.

(5) Unscrew 7 screws 4, then remove CU-Board-Assy 5.

(6) Disconnect all 17 Connectors, then unscrew 4 screws 6, and remove S2V-PU-Board 7.

(7) Unscrew 9 screws 8, remove the Plate-Shield-Box-Assy 9, then remove all the connec-

tors.

5

1

4 × 7

9

2

7

8 × 9

6 × 4

3

Rev. 1 74 /

Page 75

4.3.8 Job-Offset-Assy and Basket-Assy

(1) Open the Cover Assy-Top.

(2) Unscrew screw 1, remove Frame-Duct 2, then remove the connector (remove the

connector through the shaft)

(3) Remove the 2 hinges, then remove the Job-Offset-Assy 3, and disconnect the connector.

(4) Unscrew 2 screws 4, then remove the 2 hinges, and remove the Cover Assy-Top (Sub)

5.

(5) Remove the 3 E-rings 6, unscrew 2 screws 7, then remove the Plate-Support (Top) 8,

Colla 9, Shaft-Top (A) 0, Shaft-Top (B) A, Spring-Torsion-Top (L) B, Spring-Torsion-

Top (A) C, Spring-Torsion-Top (R) D and Spring-Torsion-Top (R) E.

(6) Unscrew 3 screws F, then remove the Gear-Assy-L G.

(7) Unscrew 3 screws H, then remove Gear-Assy-R I.

(8) Remove the high toner Assy tube J, then remove Basket-Assy K.

4

8

6

9

0

F

G

K

7

B

C

D

A

3

H

1

I

E

5

2

7

H

6

Rev. 1 75 /

Page 76

4.3.9 Plate Top Assy

(1) Remove Job-Offset-Assy 723/Basket-Assy. (Refer to Section 4.3.6)

(2) Lift back Plate-Top Assy 1, then unscrew 2 screws 2.

(3) Lift forward Plate-Top Assy 1, then unscrew 3 screws 3 and remove Plate-Dumper-Assy

(R)4.

(4) Remove E-ring 5, and unscrew screw 6. then remove Plate-Dumper-TCR-SUB 7 and

Dumper R 8.

(5) Unscrew 3 screws 9, then remove Plate-Dumper-Assy (L)0.

(6) Remove E-ring A, and unscrew screw B. Then remove Plate-Dumper-TCR-SUB C and

Dumper L D.

(7) Remove Shaft-Top E, Spring-Torsion-BAS (L) F, and Spring-Torsion-Top-R G, then

remove Plate-Top Assy 1.

B

A

D

1

9

F

E

2

1

G

C

9

3

0

8

5

4

6

7

Rev. 1 76 /

Page 77

4.3.10 Eject-Assy

(1) Remove the 7 hinges then remove Cover-Board 1.

(2) Remove the 13 connectors, and unscrew the 2 screws 2. Then remove the 3 hinges and

remove the Eject-Assy 3.

2

3

1

Rev. 1 77 /

Page 78

4.3.11 Motor-Pulse-Belt and Sensor-Resist-Assy

(1) Unscrew the 2 screws 1, then remove the 4-pin connector and remove the Motor-Pulse-

Belt 2.

(2) Unscrew 7 screws 3, then remove the 4 connectors (2-pin, 14-pin, 3-pin, 5-pin), and

remove the Sensor-Resist-Assy 4.

4

3

1

3

3

2

3