Page 1

S E R VIC E MANUAL

C ODE : S M-A R C 240P -1

DIG IT A L C OL OR L E D P R INT E R

MODE L

C ONT E N T S

[1] C ONF IG UR AT IONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

[2] P AR T S R E PL AC E ME NT . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . 17

[3] ADJ US TME NT S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

[4] R E G UL AR MAINT E NANC E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

[5] T R OUB LE S HO OT ING P R OC E DUR E S . . . . . .. . . . . . . . . . . . . . . . 111

[6] C ONNE C T IO N DIAG R AM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

[7] AP P E NDIX A INT E R F AC E S P E C IF IC AT IONS . .. . . . . . . . . . . . . 156

[8] AP PE NDIX B 2ND/3R D T R AY MAINT E NANC E . . . . . . . . . . . . . . . 160

AR -C 240P

[9] AP PE NDIX C E R R O R ME S S AG E S . . . . . . . . . . . . . . . . . . . . . . . . 165

[10] P AR T S G UIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

P arts marke d with “ ” a re important for ma intaining the s afety of the s et. B e s ure to re place thes e pa rts with

specified ones for maintaining the s afety a nd performa nc e of the s et.

This docume nt has been publishe d to be us ed

S HA R P C OR P O R A T ION

for a fter s ales s ervice only.

The contents are s ubject to cha nge without notice.

Page 2

Page 3

CONTENTS

1. CONFIGURATIONS ......................................................................................... 6

1.1 System Configuration....................................................................................................... 6

1.2 Printer Configuration ........................................................................................................7

1.3 Supplies and Consumables.............................................................................................. 8

1.4 Specifications ................................................................................................................... 9

2. PARTS REPLACEMENT................................................................................ 17

2.1 Precautions in Replacing Parts ...................................................................................... 17

2.2 Parts layout .................................................................................................................... 19

2.3 Replacing Parts..............................................................................................................25

2.3.1 Top Cover......................................................................................................... 27

2.3.2 LED Head / LED Spring / Post-Guide............................................................... 28

2.3.3 Top Cover Unit ................................................................................................. 29

2.3.4 Control Panel Assy/ Control Panel Bezel/ LED Control PWB/ Toner Sensors/

Stacker Full Sensor/ Control Panel/ Control Panel Tape Harness/

Eject Rollers ..................................................................................................... 30

2.3.5 Top Cover Handle/ Top Cover Latch/ Top Cover Latch Spring........................ 31

2.3.6 Eject Guide Assy .............................................................................................. 32

2.3.7 Cassette Assy/ Front Cover Assy/ Front Cover Inner Baffle ........................... 33

2.3.8 Retard Pad Assy/ Retard Pad Assy Spring ...................................................... 34

2.3.9 Feed Roller and Nudger Roller......................................................................... 35

2.3.10 Rear Cover ....................................................................................................... 36

2.3.11 Face-Up Tray.................................................................................................... 37

2.3.12 Left Side Cover................................................................................................. 38

2.3.13 Right Side Cover .............................................................................................. 39

2.3.14 Multipurpose Tray Assy/ Multipurpose Tray Cover Assy/ Links/

Multipurpose Tray Top Cover/ Multipurpose Tray Drive Gear.......................... 40

2.3.15 Drum Contact Assys......................................................................................... 41

2.3.16 Media Thickness Sensor Assy......................................................................... 42

2.3.17 Registration Roller Assy (A)/ Registration Drive Gear (A) ................................ 43

2.3.18 Registration Roller Assy (B) ............................................................................. 44

2.3.19 Registration Clutch and Registration Motor Assy ............................................. 45

2.3.20 Main Cooling Fan ............................................................................................. 46

2.3.21 Color Registration Sensor Assy........................................................................ 47

2.3.22 Duplex Guide Assy ........................................................................................... 48

2.3.23 Electrical Chassis Cooling Fan......................................................................... 49

2.3.24 Printer Engine Controller PWB ......................................................................... 50

2.3.25 Printer Unit Chassis.......................................................................................... 51

2.3.26 Entrance Cassette Sensor Actuator ................................................................. 52

2.3.27 Entrance Sensor PWB...................................................................................... 53

2.3.28 Entrance MT Sensor Actuator / Entrance Belt Sensor Actuator /

Entrance Waste Chassis Sensor Actuator ...................................................... 54

2.3.29 Fuser Exit Roller ............................................................................................... 55

2.3.30 Exit Sensor Assy .............................................................................................. 56

2.3.31 Fuser Latching Handle (L) ................................................................................ 57

2.3.32 Belt Motor Assy ................................................................................................ 58

2.3.33 Fuser Latching Handle (R) ............................................................................... 59

2.3.34 Main Motor Assy............................................................................................... 60

2.3.35 Main Feeder Drive Motor.................................................................................. 61

2.3.36 Contact Assy/ Left Plate Assy .......................................................................... 62

2.3.37 Low Voltage Power Supply............................................................................... 63

2.3.38 High voltage power supply ............................................................................... 64

2.3.39 Main Feed Assy................................................................................................ 65

2.3.40 Cassette/ Left Guide Assy ................................................................................ 66

2.3.41 Cassette/ Right Guide Assy.............................................................................. 67

2.3.42 Fuser Unit ......................................................................................................... 68

3 /

Page 4

2.3.43 Belt Unit ............................................................................................................ 69

2.3.44 Duplex Unit ....................................................................................................... 70

2.3.45 Guide Rails (L) and (R)..................................................................................... 71

2.3.46 Duplex Transport Assembly ............................................................................. 72

2.3.47 CU Assy............................................................................................................ 74

3. Adjustment .................................................................................................... 76

3.0 System Maintenance MENU .......................................................................................... 76

3.0.1 ID Check Pattern Printing ( " TEST PRINT MENU " item )............................... 77

3.1 Maintenance Mode and Functions ................................................................................. 77

3.1.1 Maintenance menu ........................................................................................... 77

3.1.2 Engine maintenance mode............................................................................... 79

3.1.2.1 Operator panel .................................................................................. 79

3.1.2.2 Normal self-diagnostic mode (Level 1).............................................. 79

3.1.2.2.1 Entering self-diagnostic mode (Level 1) ............................ 80

3.1.2.2.2 Exiting the self-diagnostic mode ....................................... 80

3.1.2.3 Switch scan test ................................................................................ 80

3.1.2.4 Motor clutch test ................................................................................ 84

3.1.2.5 Test print ........................................................................................... 86

3.1.2.6 Initializing NVM ................................................................................. 90

3.1.2.7 Displaying the consumables counter ................................................ 91

3.1.2.8 Displaying the consumables continuation counter ............................ 91

3.1.2.9 Panel display details ......................................................................... 92

3.1.3 Various print jobs with single printer unit attached with a controller ................. 97

3.2 Adjustment After Replacing Parts .................................................................................. 98

3.2.1 Precautions in replacing the engine control board ........................................... 98

3.2.2 Precautions in replacing EEPROM................................................................... 98

3.2.3 Replacing EEPROM after replacing the TIG board .......................................... 99

3.2.4 Destination Setting (Checking Metod: Printing Demo Page)............................ 99

3.2.5 Recovery Flash ROM data on TIG board ....................................................... 100

3.3 Adjusting the Density ....................................................................................................100

3.4 Paper Thickness Detection Sensitivity Adjustment and Media Thickness Detection

Value Check..................................................................................................................101

3.4.1 Applicable Operating Systems and Interfaces, and File Required ................. 101

3.4.2 Setting ............................................................................................................ 102

3.4.2.1 Menu Setting ....................................................................................102

3.4.2.2 Media Setting ...................................................................................104

3.4.2.3 Sensitivity Adjustment ..................................................................... 105

3.4.2.4 Actions for NG Sensitivity Adjustment............................................. 106

3.4.3 Inputting the density of the calibration chip for density detection ................... 107

3.4.3.1 Density Adjustment Menu Setting ................................................... 107

3.4.4 Electronic Serial Number Input....................................................................... 109

4. regular maintenance ................................................................................... 110

4.1 Parts Replaced Regularly ............................................................................................ 110

4.2 Cleaning ....................................................................................................................... 110

4.3 Cleaning the LED Lens Array ...................................................................................... 110

4.4 Cleaning the Pick-up Roller ......................................................................................... 110

5. Troubleshooting Procedures ..................................................................... 111

5.1 Precautions before troubleshooting ............................................................................. 111

5.2 Precautions before handling an abnormal image ........................................................ 111

5.3 Precautions upon handling an abnormal image........................................................... 111

5.4 Preparing for Troubleshooting ..................................................................................... 112

5.5 Troubleshooting Procedure.......................................................................................... 112

5.5.1 LCD message list ........................................................................................... 113

5.5.2 Preparing for troubleshooting ......................................................................... 119

5.5.3 Troubleshooting for abnormal images ............................................................ 130

5.6 Fuse check................................................................................................................... 145

4/

Page 5

PARTS GUIDE.................................................................................................................180

6. CONNECTION DIAGRAM ............................................................................ 146

6.1 Resistance Checks ...................................................................................................... 146

6.2 Program/Font ROM Layouts ........................................................................................ 150

APPENDIX A INTERFACE SPECIFICATIONS ................................................. 156

1. Parallel Interface Specifications ................................................................................... 156

1.1 Parallel Interface..............................................................................................156

1.2 Parallel Interface Connector and Cable.......................................................... 156

1.3 Parallel Interface Level ................................................................................... 156

1.4 Timing Charts ................................................................................................. 157

1.5 Parallel I/F Signals.......................................................................................... 158

2. Universal Serial Bus (USB) Interface Specifications.................................................... 159

2.1 USB Interface ................................................................................................. 159

2.2 USB Interface Connector and Cable .............................................................. 159

2.3 USB Interface Signals .................................................................................... 159

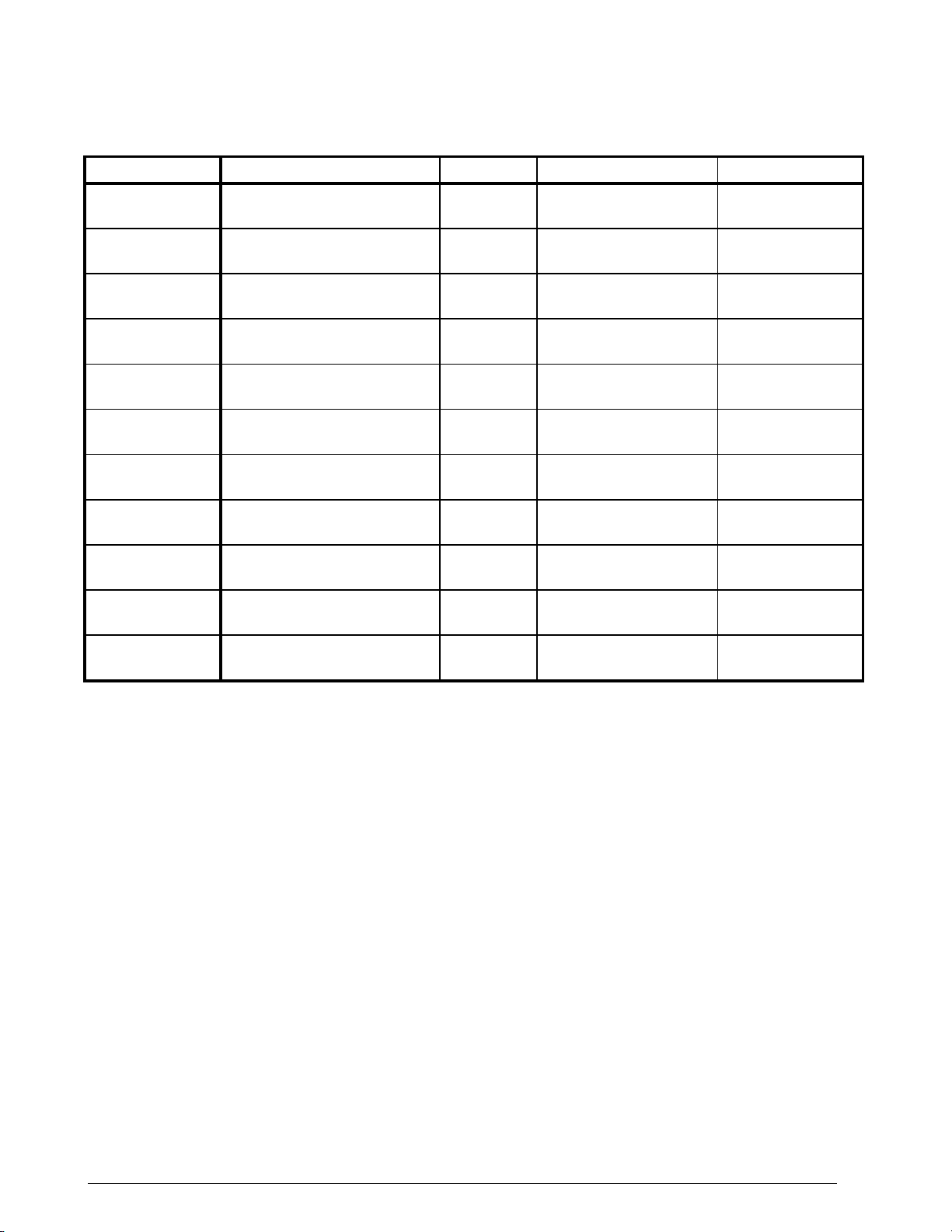

APPENDIX B 2ND/3RD TRAY MAINTENANCE .............................................. 160

1. Parts Replacement ...................................................................................................... 160

1.1 Cover Idle Roller Assy .................................................................................... 160

1.2 PCB ................................................................................................................ 161

1.3 Feeder Drive Assy .......................................................................................... 162

2. 2nd/3rd Tray PARTS LIST ............................................................................ 163

APPENDIX C ERROR MESSAGES ................................................................. 165

1. Error messages ........................................................................................................... 165

2. Error messages : Color, Media Detect ......................................................................... 172

3. Warning messages : usage, media .............................................................................. 175

4. Warning messages : Job Account ................................................................................ 176

5. Other Warning .............................................................................................................. 177

5/

Page 6

1. CONFIGURATIONS

1.1 System Configuration

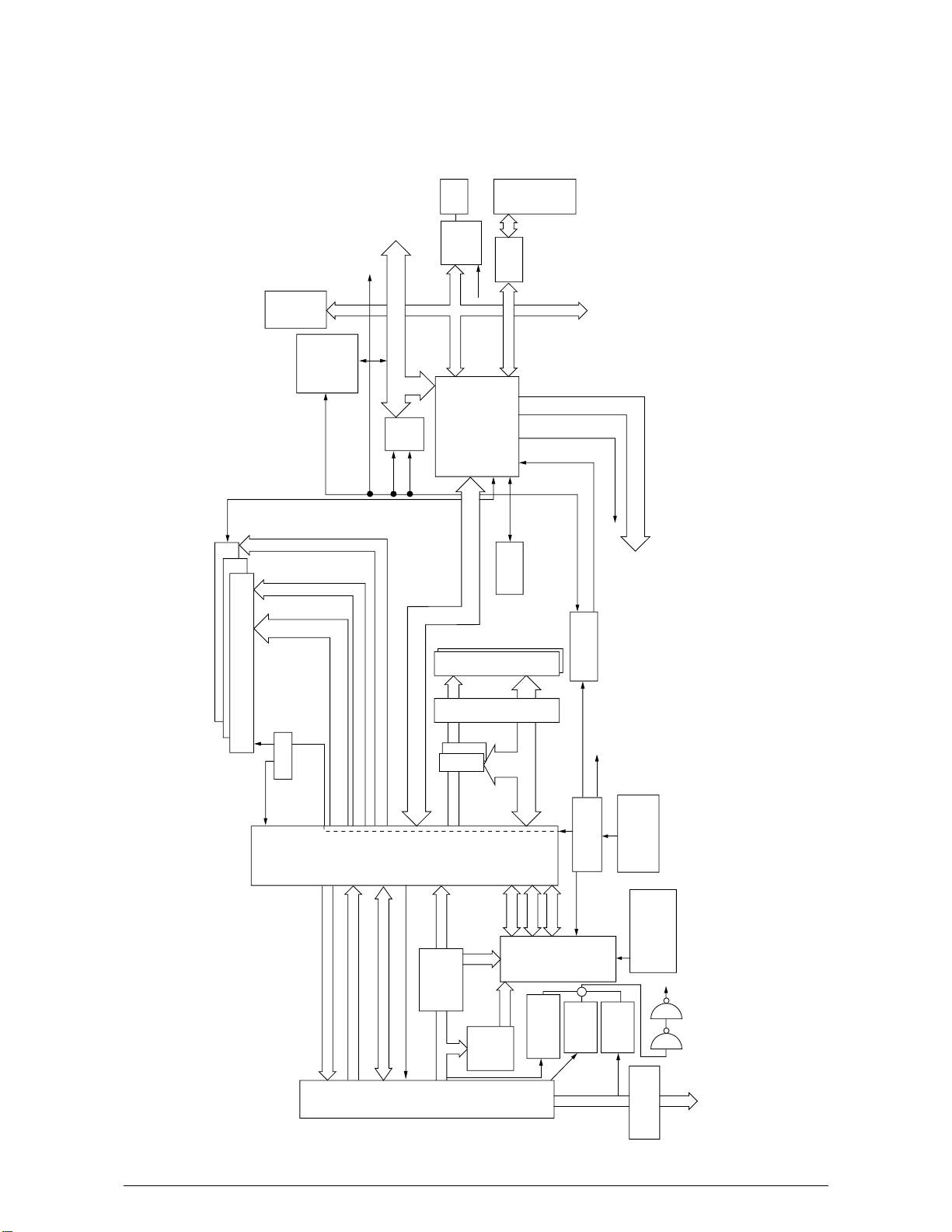

Figure 1-1 shows the system configuration of the ARC200P.

M

Hopping

M

MT/

Registration

M

M

<Sensors, Switches and Thermistors>

Pulse Motor

M

Paper size sensor (4 bits)

Paper empty sensor

Paper near empty sensor

MT paper empty sensor

FF home switch

Loading sensor 1

Loading sensor 2

Media Thickness Detection

Density Detection

< advanced Sensors,>

Color Misalignment Detectin

LED Head

C ID M ID Y ID K IDBelt Heat

M M

M

Junction Board

Engine Control

Power Unit

Low Voltage

2nd/3rd Tray

Power Unit

High Voltage

Fuser

Unit

Unit

Duplex

Unit

K-ID

Unit

C-ID

Unit

M-ID

Unit

Y-ID

Belt

Unit

Figure 1-1

Operator Panel

IDE

DIMMs

3 ⋅ ROM

Centronics I/F

6 /

DIMM

4 ⋅ RAM

USB I/F

I/F(HDD)

Note

2 ⋅ Option Slots

DC Fan

LAN Card made by JCI

Note Option Slot:

Page 7

1.2 Printer Configuration

The inside of the printers is composed of the followings:

• Electrophotographic Processor

• Paper Paths

• Controller Block (CU and PU)

• Operator Panel

• Power Units (High Voltage Unit and Low Voltage Unit)

Figure 1-2 shows the printer configuration.

B

A

A

B

B

A

A

Figure 1-2

7 /

Page 8

1.3 Supplies and Consumables

8 /

Product Code Description Quantity Estimated Yield Comments

AR-C20TBU Black Toner Cartridge

AR-C20TCU Cyan Toner Cartridge

AR-C20TMU Magenta Toner Cartridge 1

AR-C20TYU Yellow Toner Cartridge 1

AR-C20BDR Black Image Drum

AR-C20CDR Cyan Image Drum

AR-C20MDR Magenta Image Drum

AR-C20YDR Yellow Image Drum

AR-C20TB1 Transfer Belt 1 60,000 Images/Belt

AR-C20FU1 Fuser Unit 1 60,000 Images/Belt

Deluxe Printer Cabinet

AR-C20ABD

(with Door)

1

1

1 30,000 Images/Unit

1 30,000 Image/Unit

1 30,000 Images/Unit

1 30,000 Images/Unit

10,000

Images/Cartridge

10,000

Images/Cartridge

10,000

Images/Cartridge

10,000

Images/Cartridge

@ 5% Image

Area

@ 5% Image

Area

@ 5% Image

Area

@ 5% Image

Area

(Customer

replaceable)

(Customer

replaceable)

(Customer

replaceable)

(Customer

replaceable)

(Customer

replaceable)

(Customer

replaceable)

Page 9

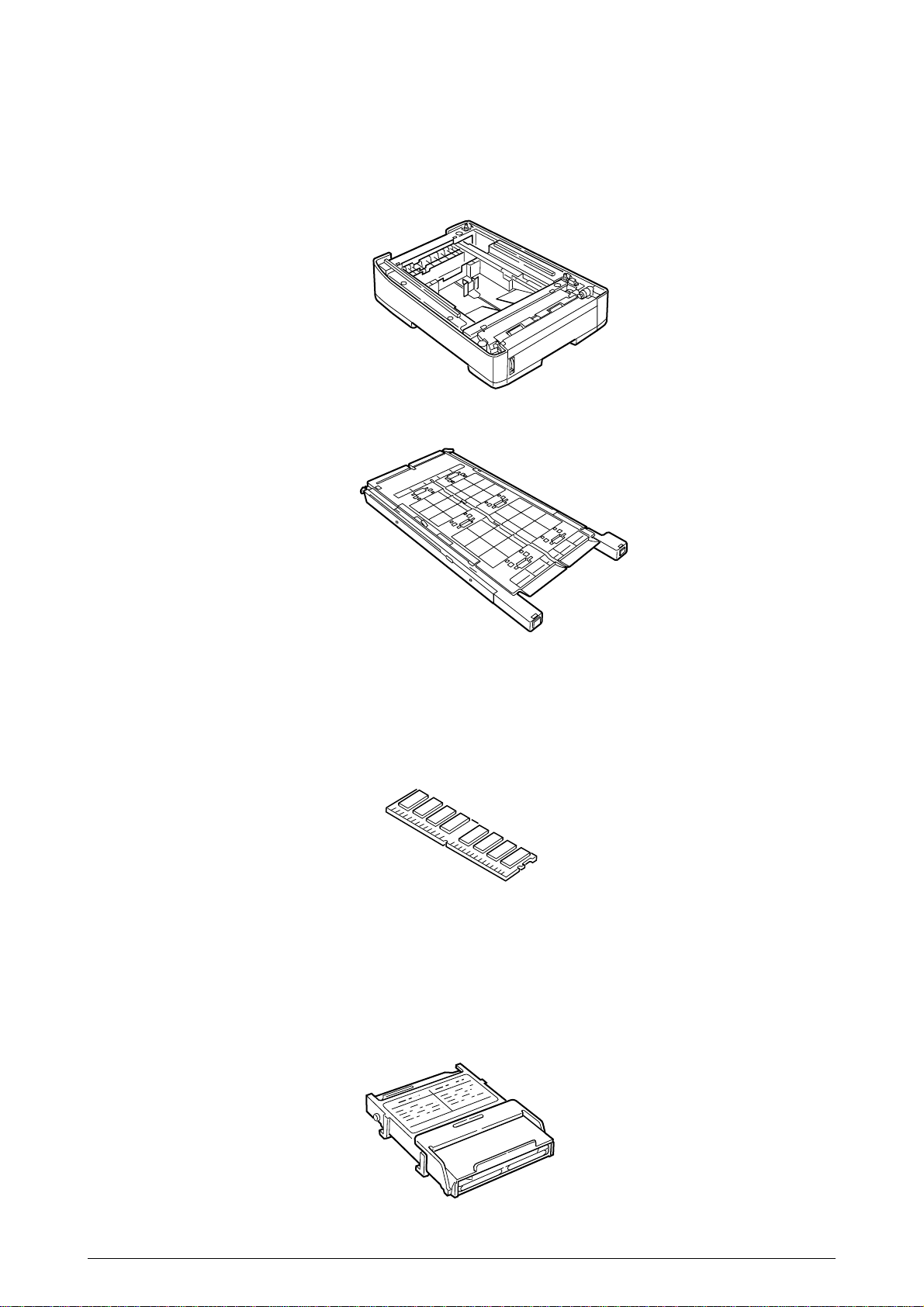

Option Configuration

(4) Internal Hark Disk (AR-C20HD)

SHP16x64S133C3 (128MB)

SHP32x64S133C3-B (256MB)

SHP64x64S133C3 (512MB)

The followings are available as options on the ARC200P.

(1) 2nd Tray/ 3rd Tray (AR-C20PFU)

(2) Duplex Unit (AR-C20ADU)

(3) Expansion Memory

9 /

Page 10

1.4 Specifications

(1) External Dimensions Height: 430mm Width: 430mm Length: 620mm

(2) Weight 42 kg

(3) Papers Type: Ordinary paper, Transparencies (Recommended: MLOHP01)

(4) Print Speed Color: 20 pages per minute (Transparency: 8 pages per minute)

(5) Resolution 600 ⋅ 600 dots per inch

Size: Postal card, Legal 13" or 14", Executive, A4, A5, B5, A6 (Only

the 1st tray and the front feeder support A6 and postal-card

sizes.)

2

Weight: 1st tray55 kg to 151 kg (64 to 176g/m

Front feeder 55 kg to 172 kg (64 to 203g/ m

)

2

)

Monochrome: 24 pages per minute (Transparency: 12 pages per minute)

Postal Card, Label, Thick Paper: 12 pages per minute

(6) Power Input 115 - 127 V , 220 - 240 V

(7) Power Consumption Peak: 1500W Normal Operation: 500W (5% duty)

Idle: 150W Power Saving Mode: 45W or less

(8) Frequency 50Hz or 60Hz ±2Hz

(9) Noise Operation: 56 dB (Without second tray)

Standby: 45 dB

Power Saving: 43 dB

(10) Consumable Life Toner Cartridge: 5,000 pages (5% duty) (each of Y, M, C and K)

Large-Capacity Toner Cartridge: 10,000 pages (5% duty)

(each of Y, M, C and K)

Image Drum: 30,000 pages (5% duty, Continuous printing)

(each of Y, M, C and K)

(11) Parts Replaced Periodically Fuser Unit Assy: Every 60,000 pages

Belt Cassette Assy: Equivalent of 60,000 pages (3 pages/job)

10 /

Page 11

(12) Temperatures and Relative Humidities

Temperature

Temperature Condition

Temperature( F) Temperature( C) Remark

Operation 50 to 89.6 10 to 32 17 to 27 C

(Temperatures to assure full

color print quality)

Non-Operation 32 to 109.4 0 to 43 Power-off

Storage (Max. One Year) -14 to 109.4 -10 to 43 With drum and toner

Transport (Max. One Month) -20 to 122 -29 to 50 With drum and without toner

Transport (Max. One Month) -20 to 122 -29 to 50 With drum and toner

Humidity

Humidity Condition

Relative Humidity Max. Wet-Bulb Remark

(%) Temperature( C)

Operation 20 to 80 25 50 to 70% (Humidities to assure full

color print quality)

Non-Operation 10 to 90 26.8 Power-off

Storage 10 to 90 35

Transport 10 to 90 40

(13) Printer Life 600,000 pages (on a A4-size basis) or five years

11 /

Page 12

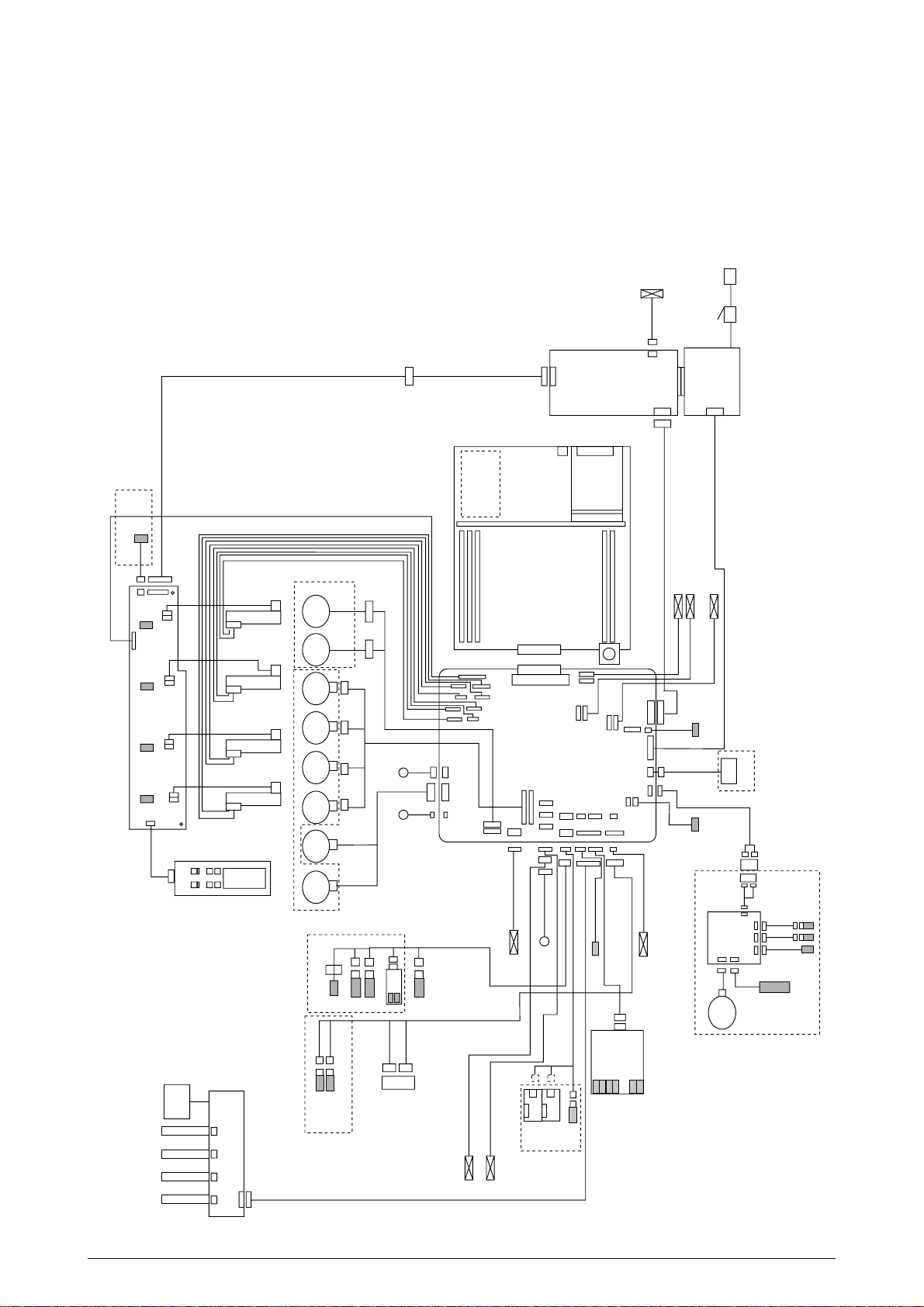

2. OPERATION DESCRIPTION

The C7500/C7300 of printers, tandem color electrophotographic page printers, adopt technologies

such as an LED array, OPC, dry single-component non-magnetic developing, roller transfer and

heat-compression fusing. A black-writing printing method by shedding light on print areas is used.

Figure 2-1-1(600dpi) provides the block diagram of the printer.

AC

FAN0

Sns.

STUCKFULL

14P

3P

POWER

STUCK

TNRC

3P

CPOW2

16P

OPTN

TNRM

MPOW2

3P3P3P

TNRY

YPOW2

TNRK

Toner Sensor (Y73-board)

KPOW2

PANEL

6P

6P

Belt

Fuse

C Fuse

M Fuse

Y Fuse

K Fuse

N71 Board

14P

JODEN

C LED HEAD

M LED HEAD

Y LED HEAD

K LED HEAD

Control Panel

X7N board

Heat

Motor

Belt

Motor

Motor

C IDU

Motor

M IDU

Motor

Y IDU

Main Motor Assy Belt Motor Assy

Motor

K IDU

Motor

FF/Regist

Motor

Hopping

2

Up/Down

Manual Bypass Feeder (MBF)

WHITE

BLUE

3P

3P

Paper Tray 1 Paper Empty

Paper Tray 2 Near Empty

WHITE YELLOW

46

Exit solenoid

BLACK YELLOW RED BLUE

4P 4P 4P 4P

shutter clutch

Cord 7

RED WHITE

4P 4P

4P

green

HUM

TEMP

OHP Sen.

MBF Paper Empty

BLUE

OPTION

7P

MBF Stage

Figure 2-1-1 600dpi

3P

AC Switch

CN5

10

HDD

RAM

10P

TIG board

CN2

USB

CENTRO

LAN

ROM

Low-voltage

power supply

26P

CN3

CN2

FAN(LEFT)

FAN

High -voltage

power supply

16P

FAN

CN1 CN1

FAN

OPTN

C1200

M1200

MPOW

K1200

KPOW

2P

DCL

red

red

8P

yellow

yellow

HOPFF

2P

SHUTTER

4P

yellow

Paper

thickness

YELLOW

7P

CPOW

CUIF

Y1200

YPOW

PCB-K7N

ID

16P

8P

FAN8

red

BEL THET

red

3P3P

3P

2P

Regist

Gray

FAN2

FAN1

red

RCL

yellow

red

yellow

clutch

14P

Blue

16P

FAN7

RSNS

REG

blue

blue

PARTTEMP

10P

14P

red

black

FAN4

2P

3P

yellow

yellow

FAN5

FSENS

JODEN

9P

22P

Exit sensor

9P

HOP(INSNS1)

PAPIN(INSNS2)

PSWR(WRSNS)

TNRFUL

FCOVER

FEED

TR10P

4P

R71 board

yellow

COVOPN

PSIZE

cable40

POWER

HVOLT

DUPLEX

3P

16P

6P

16P

26P

3P

Duplex Unit

Upper Cover

Open Microswitch

Open

Front Cover

V71 Board

Motor

DUP

Microswitch

Main

Clutch

7P

7P

BLUE

Paper Size

PXC-Board

BLUE

WHITE

7P

7P

14P

RSENS

FSENS

INSENS

Sensor

WHITE

5P

Z7L

Z7R

Plate Senosr

Density

FAN1 (Pr)

FAN2 (Pow)

12 /

Page 13

2.1 Main Board (TIG PWB)

Figure 2-2 provides the block diagram of the main control board (TIG PWB).

USB

t

r

o

n

e

C

[1]

[2]

[0]

SPD

3

2

1

3

×

12

×

3.3V 100MHz

SDRAM DIMM

SDRAMCLK

C2516

3.3V

DRCLK

100MHz

IDE

HDD

FPGA

for IDE

33MHz

RAMCLK

From 702

L60851

33MHz

[15:0][7:0]

PCI

Reset

CENT

[15:0]

Local

48MHz

LVC

161284

PCI BUS [31:0]

PCI

Slot

C2 LSI

MHM2031-002

33MHz

SUB Bus

EEPROM

×

2

D [63:0]

b Line Address. Cont

a Line Address. Cont

×

2

Flash

SUB Bus A/D [31:0], Cont

A,Cont

D

[15:0]

Mask 32bit

D [63:0] D [63:0]

4

×

33MHz 3.3V

33MHz 3.3V

5

×

ROM DIMM

PLL102-5

33MHz

33MHz

2.5V

100MHz

CA1CLK

to PU Panel I/F

to PU PU-CU Command I/F

48MHz

to USB

Crystal

MHM

CA1 LSI

Video Data K, Y, M, C

11N7)

(uPD856

2030-003

Video I/F From PU

Panel I/F From C2 LSI

PU-CU I/F To C2 LSI

Core:2.5V

200

PU-CU

I/O:3.3V

CPU I/O:2.5V

2.5V

2.5V

2.5V

Regulator

3.3V

pin

D [63:0]

A [31:0]

I/O 2.5V

1.8V

Reset IC

1.8V

Regulator

Cont

PPC

750cx

Core:1.8V

+

(PU3V)

PST596

M62733ML

12V

5V

PLL702-01

2.5V

MPUCLK

I/O:2.5V

(PU12V)

Resonator

14.31818MHz

100MHz

internal

CPU CLK

(+5V)

PST596

3.3V

Regulator

setting Resister

to each LSI

74LVC04

3.3V

Figure 2-2

13 /

Page 14

(1) CPU

The CPU is PowerPC750CXe, a 64-bit bus RISC processor, which inputs an 100-MHz CLK

(= BUS CLK), and operates at 450MHz that is 4.5 times the input.

(2) Cache

PPC750Cxe has its cache only inside of it.

Speed: Same as CPU Core CLK speed

Capacity:

Primary Cache: 32 K bytes in D-cache capacity, 32 K bytes in I-cache capacity

Secondary Cache: 256 K bytes

(3) ROM

ROM is to be inserted into the two 168 pin DIMM slots. The slot A is for program ROM and

the slot B is for Japanese kanji fonts. The slot C is not assigned.

(4) RAM

RAM is to be inserted into the three 168 pin DIMM slots. The DIMMs must be fitted in

descending labeled type No. order into the slots 1, 3, 2 and 4.

SDRAM DIMM Specifications:

Speed: PC133 or more

Capacity: 64/128/256/512 MB

Configuration: Without parity. Without ECC. SPD information is required.

(5) EEPROM

EEPROM, an 8-pin DIP package, is to be inserted into the IC socket. The EEPROM is of 16

Kbits for 3.3V power supply, and settings for controlling the controller block are stored in it.

(6) Flash ROM

A 4Mbyte flash ROM is surface-mounted on the TIG board. The flash ROM is composed of

four 2048k-by-16bit chips, and fonts and macros can be stored in it.

(7) Memory Control LSI (CAI)

A 696-pin BGA package ASIC made by NEC. The chip mainly controls a CPU I/F, memory,

video data compression and decompression, and a PU-video I/F.

(8) Interface Control LSI (C2)

A BGA package ASIC made by Toshiba, which controls a PU command I/F, operator panel

I/F, IDE I/F, Centronics I/F, USB I/F, PCI I/F, EEPROM and a SPD (SDRAM DIMM) I/F.

(9) IDE HDD

An IDE connector is surface-mounted on the board to which an IDE HDD assembled using

exclusive molds will be connected. The IDE HDD is used for storing font data, spooling edited

video data and registering form data.

(10) PCI Bus Option

Two PCI I/F slots are provided for option board use. The bus, which uses an Oki Data original

connector, can accept an Ethernet board.

(11) Host Interface

Standard: Centronics two-way parallel I/F (IEEE-1284-compliant)

USB (USB1.1-compliant)

Additional Board: (connected to PCI BUS) Ethernet Board

14/

Page 15

2.2 Engine Controller Board (K7N PWB)

28MHz

OPTION TRAY

PAPER THICKNESS

SENSOR

COROR REGISTRATION

SENSOR

HEAT ROLLER TEMP

OHP

TEMPATURE

HUMIDITY

HEAD TEMP

DENSITY

COVER OPEN

(UPPER, STACKER, RIGHT SIDE)

1ST TRAY SENSORS

(PAPER END, PAPER NEAR END)

PAPER FEED SYSTEM SENSORS

(PAPER FEED, PAPER

REGISTRATION, EJECT)

MT SENSORS

(STAGE POSITION, PAPER END)

DUPLEX

DISPOSAL TONER SENSOR

ANALOG

SW

CPU

MSM66Q577

PAPER SIZE

STACKER FULL

CU

INT

CLK

RESET

FLASH

SRAM

MCON

LSI

EEPROM

CONTROL

PANEL

MOTOR

DRIVER

MOTOR

DRIVER

PULSE

MOTOR *9

GEARED

MOTOR

CLUTCH

PU FAN

FUSER FAN

ID, BELT,

FUSER

CHECKS

HIGH VOLTAGE POWER

SUPPLY SERIAL INTERFACE

32MHz

CLOCK

GENERATOR

LED HEAD (K)

LED HEAD (Y)

LED HEAD (M)

LED HEAD (C)

SDRAM

SDRAM

DCON

LSI

Figure 2-3

The engine control block (PU) is controlled by the engine controller board (K71 PWB) which

consists of a CPU (MSM66Q577), general LSI chip, flash ROM, EEPROM, pulse motor drivers and

a video memory (see Figure 2-3).

(1) CPU

This, a 16-bit CPU with an AD converter (OKI MSM66Q577), controls the entire system.

(2) General LSI

This LSI (UPD65454GD-241-LML, UPD65946GD-137-LML), which is contained in the

printer engine control block, incorporates 4 megabits of video memory and has functions

such as engine-controller interfacing, LED interfacing, motor control, sensor input, video

memory control, main scan color misalignment correction, skew correction and high-voltage

power supply control.

15/

Page 16

(3) MCON LSI

This LSI is used for inport of SENSORs and the cntrols of Pulse Motors,Cluches,FANs and

High Voltage Power Suply.

(4) Flash ROM

The flash ROM (29F800-70) is of 8-Mbits, and PU programs are stored in it.

(5) EEPROM

The EEPROM (NM93C66N-NW) is of 4-Kbits, and mounted on the board with an IC socket.

Correction values are stored in it.

(6) Pulse Motor Driver

The pulse motor driver (A2919SLBTR, A3955SLBTR,MTD2005) drives the eight pulse

motors to revolve the ID and transport media.

(7) SRAM

This SRAM (628100LG-55L) is used as working memory of the CPU.

(8) SDRAM

This SRAM (56V16160T) is used as data memory of the DCON LSI.

2.3 Power Units

There are a low voltage power unit consists of an AC filter circuit, low voltage power circuit and

heater driver circuit, and a high voltage power unit organizes a high voltage power circuit.

(1) Low Voltage Power Unit

This circuit generates the following voltages:

Output Voltage Use for

+5 V LED head

+5 V Logic circuit power supply, PU CPU

+34 V Motor, drive voltage and power supply voltage for high voltage power supply

+12 V High voltage power supply, Media Thickness Sensor power supply

(2) High Voltage Power Unit

This circuit generates the following voltages of not less than +34V, which are required for

electrophotographic process, according to control sequences from the controller board.

Output Voltage Use for Remark

CH -1000V to 1.4KV+/-50V Voltage to charging roller

DB -50 to -300V/ +300V Voltage to developing roller

SB -300V to -450V/ 0V Voltage to toner supplying roller

TR C: 0KV to 7KV Voltage to transfer roller Variable

K,Y,M: 0KV to 6KV

16/

Page 17

2. PARTS REPLACEMENT

This section describes the procedure for replacing the parts, assemblies and units in the field. The

replacing procedure is given for detachment. To attach, use the reverse procedure.

2.1 Precautions in Replacing Parts

(1) Before replacing the parts, be sure to remove the AC cable and the interface cable.

(a) To remove the AC cable, always use the following procedure.

i) Flip the power switch of the printer off (to “O”).

ii) Pull the AC inlet plug of the AC cable out of the AC receptable.

iii) Remove the AC cable and the interface cable from the printer.

(b) To connect the printer again, always use the following procedure.

i) Connect the AC cable and the interface cable to the printer.

ii) Insert the AC inlet plug into the AC receptacle.

iii) Flip the power switch of the printer on (to “I”).

Disconnect

(2) Do not disassemble the printer so long as it operates properly.

(3) Minimize the disassembly. Do not detach parts other than those shown in the replacing procedure.

(4) For maintenance, use designated tools.

(5) Follow the order instructed to disassemble the printer. Incorrect order may damage the parts.

(6) Small parts such as screws and collars tend to get lost, so temporarily place and fix them in

(7) When handling ICs and circuit boards such as microprocessors, ROMs and RAMs, do not use

Connect

their original positions.

gloves that likely to have static.

(8) Do not place the printed circuit boards directly on the printer or the floor.

17 /

Page 18

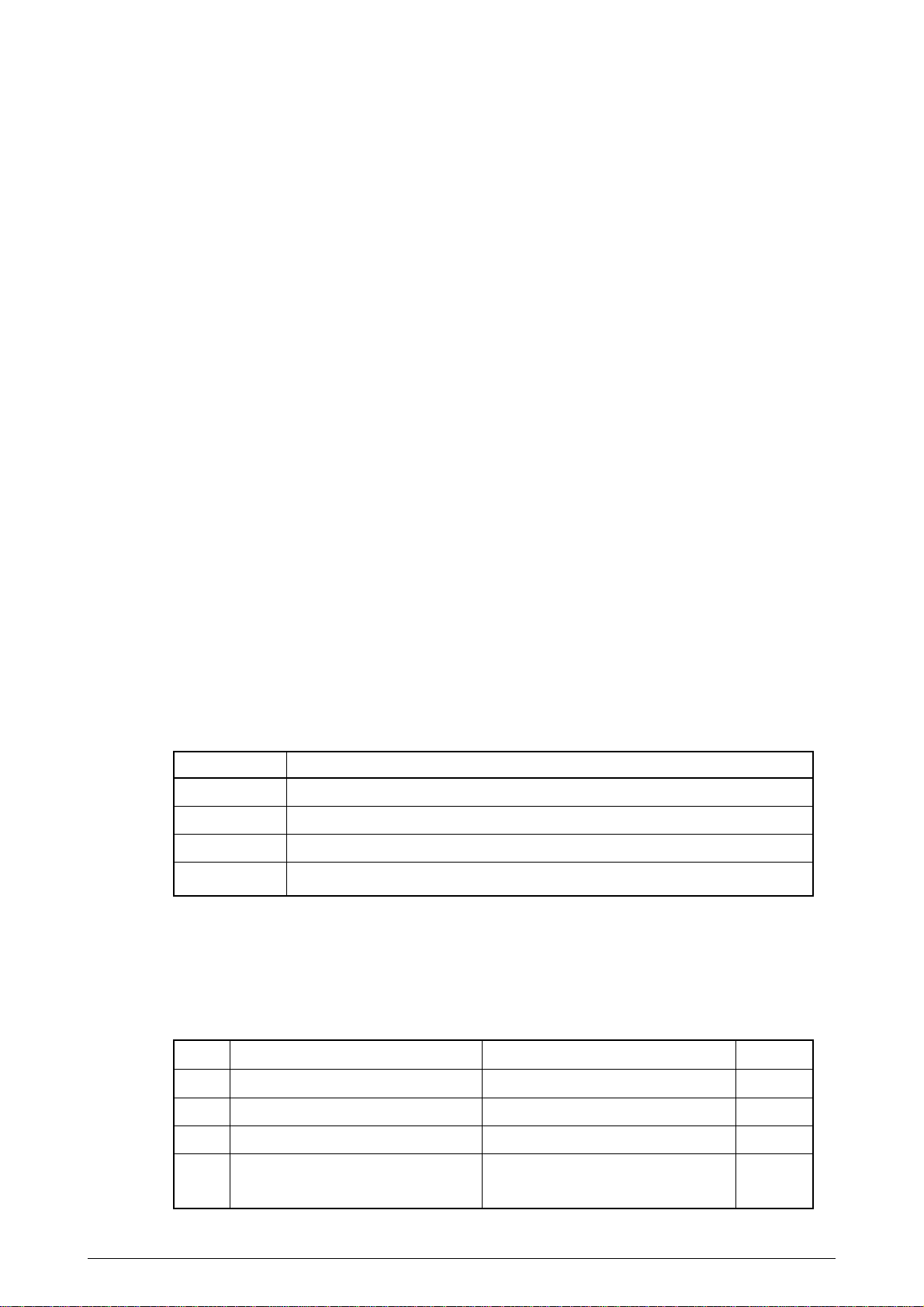

[Maintenance Tools]

Table 2-1 lists tools necessary to replace the printed circuit boards and the units.

Table 2-1 Maintenance Tools

No.

1

2

3

4

5

6

7 1

8

No. 1-100 Philips

screwdriver

No. 2-200 Philips

screwdriver, Magnetized

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

Handy cleaner

LED Head cleaner

Q' ty Place of use RemarksService Tools

1

2~2.5 mm screws

1

3~5 mm screws

1

1

1

1

1

9 1

10

Label

11

12

High voltage probe

Transparency sheet

( thickness premeasured)

0ZZ42404301//

Stage height adjustment jig

0ZZ42423701//

-

Microdriver

2.0mm

1

Adjustment for Media

Thickness sensor

1

Adjustment for Media

Thickness sensor

1

Adjustment for Lever

adjust

(Media Thickness)

18 /

Page 19

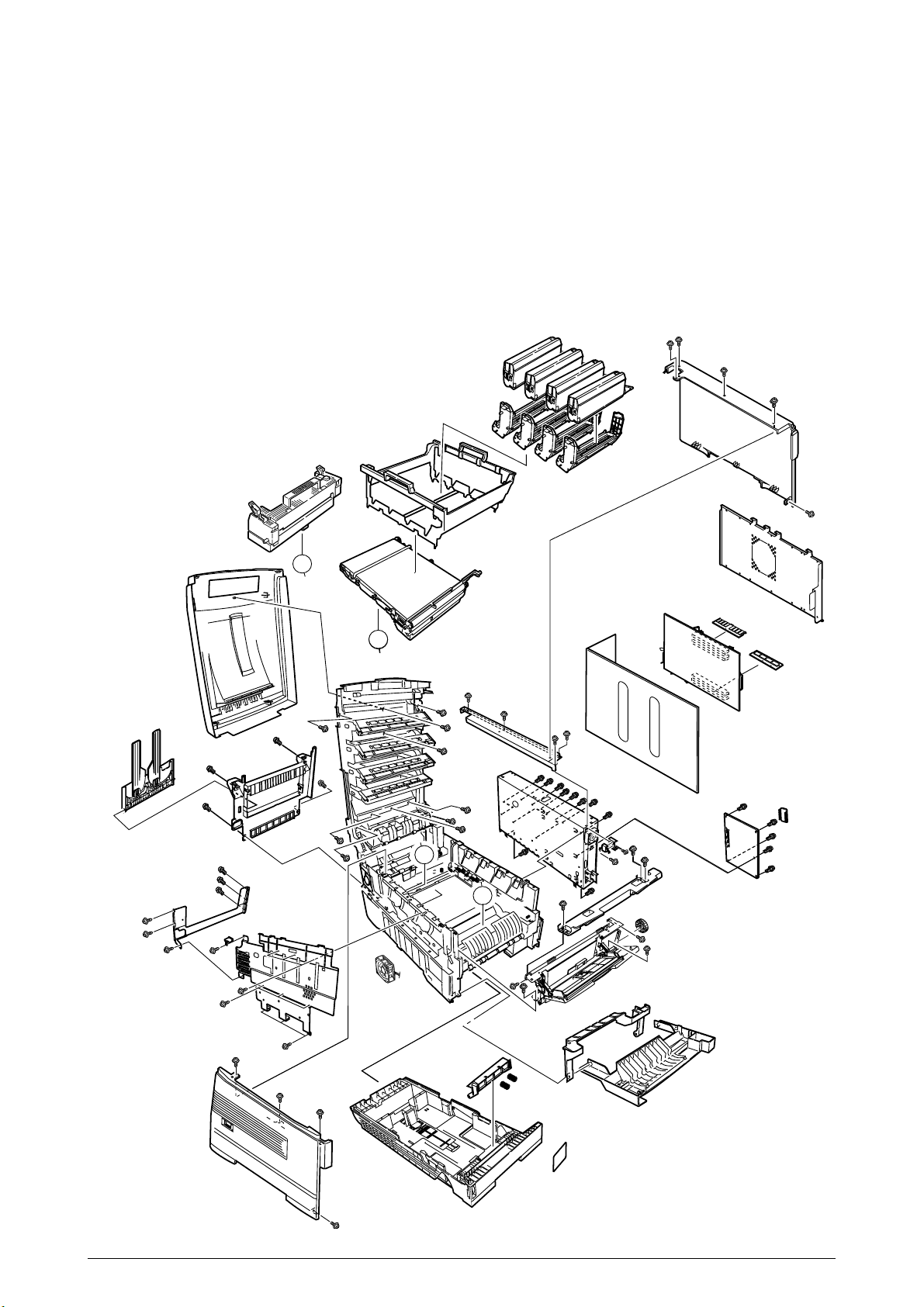

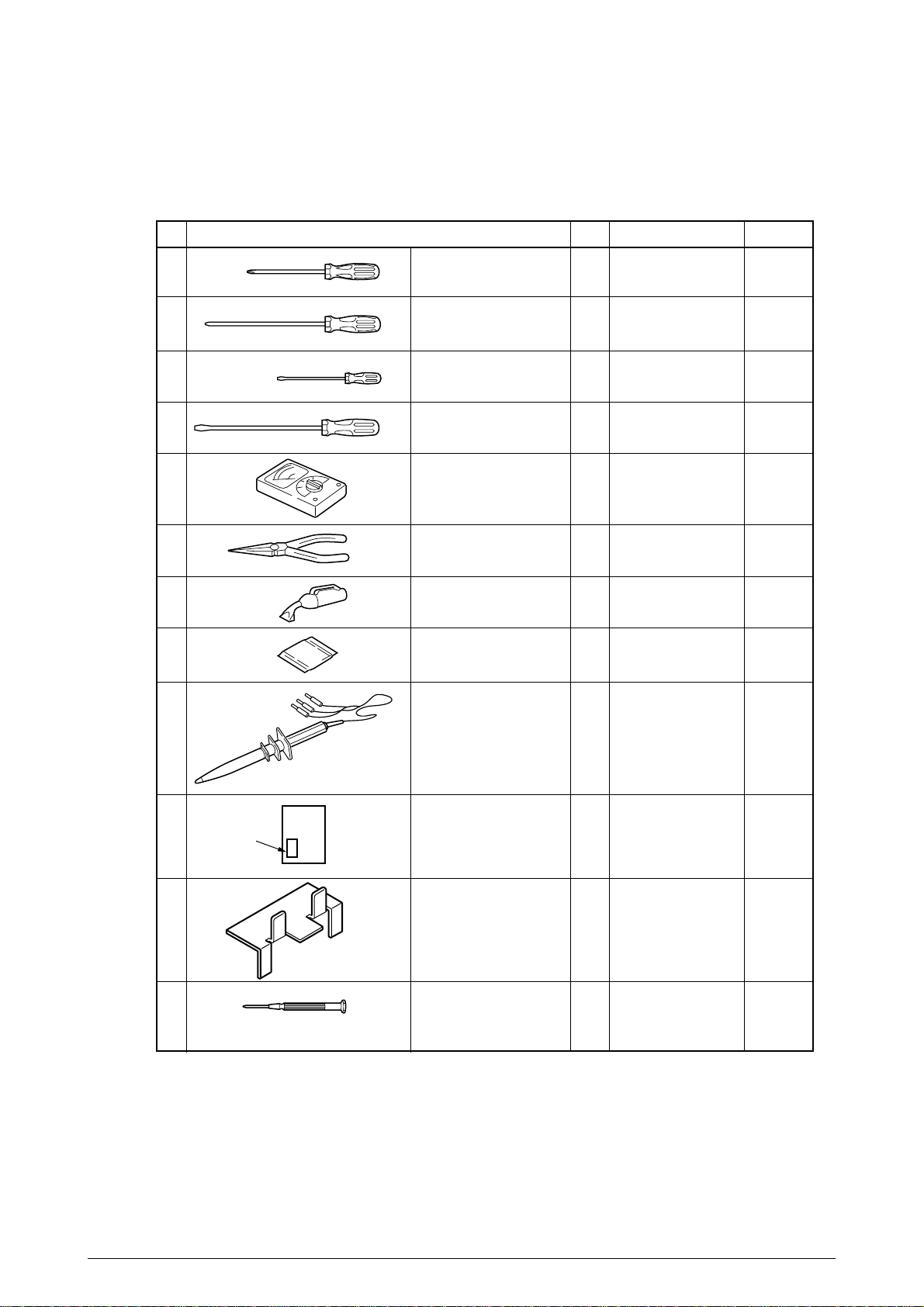

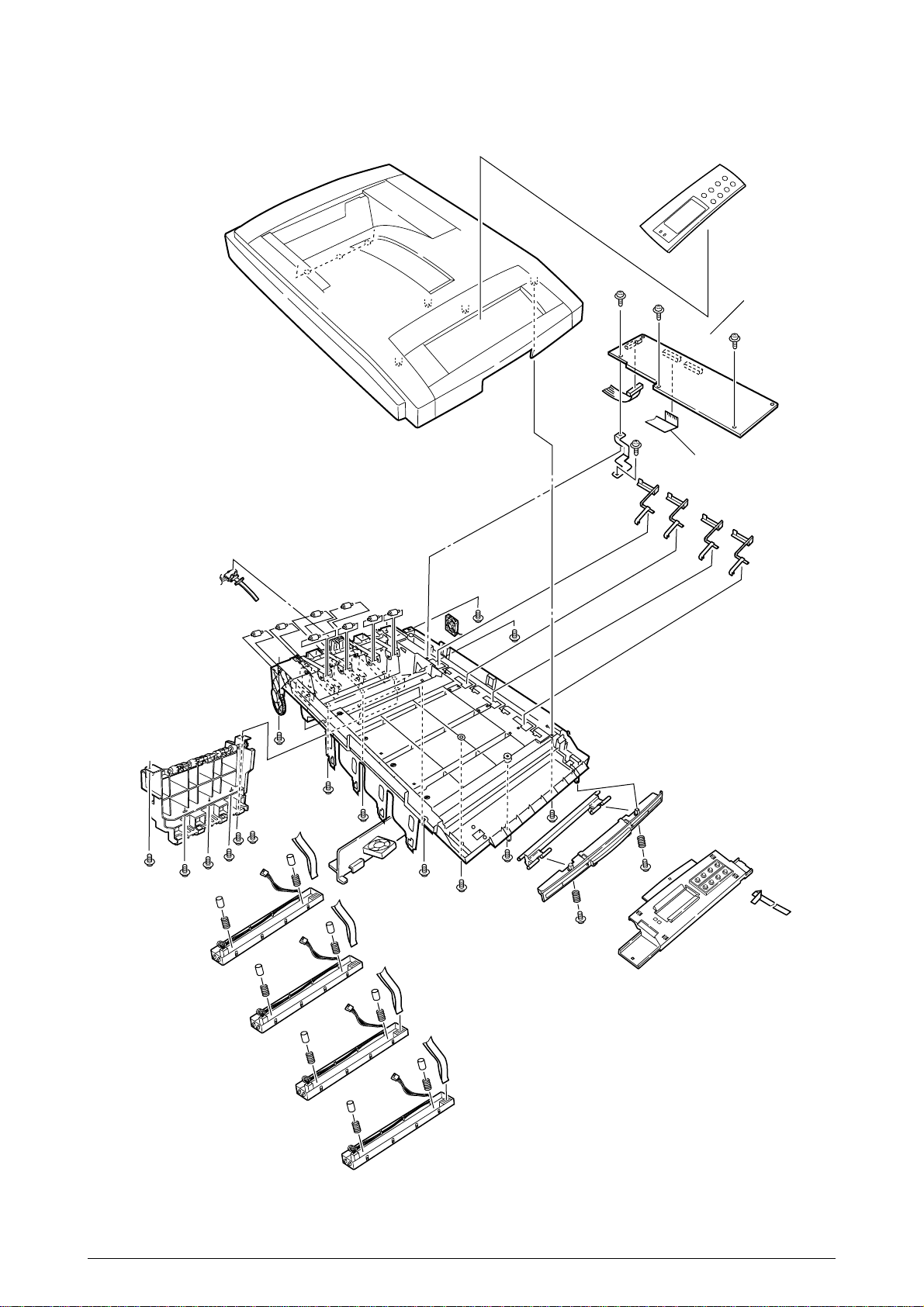

2.2 Parts layout

B

A

A

B

B

A

A

Figure 2-1

19 /

Page 20

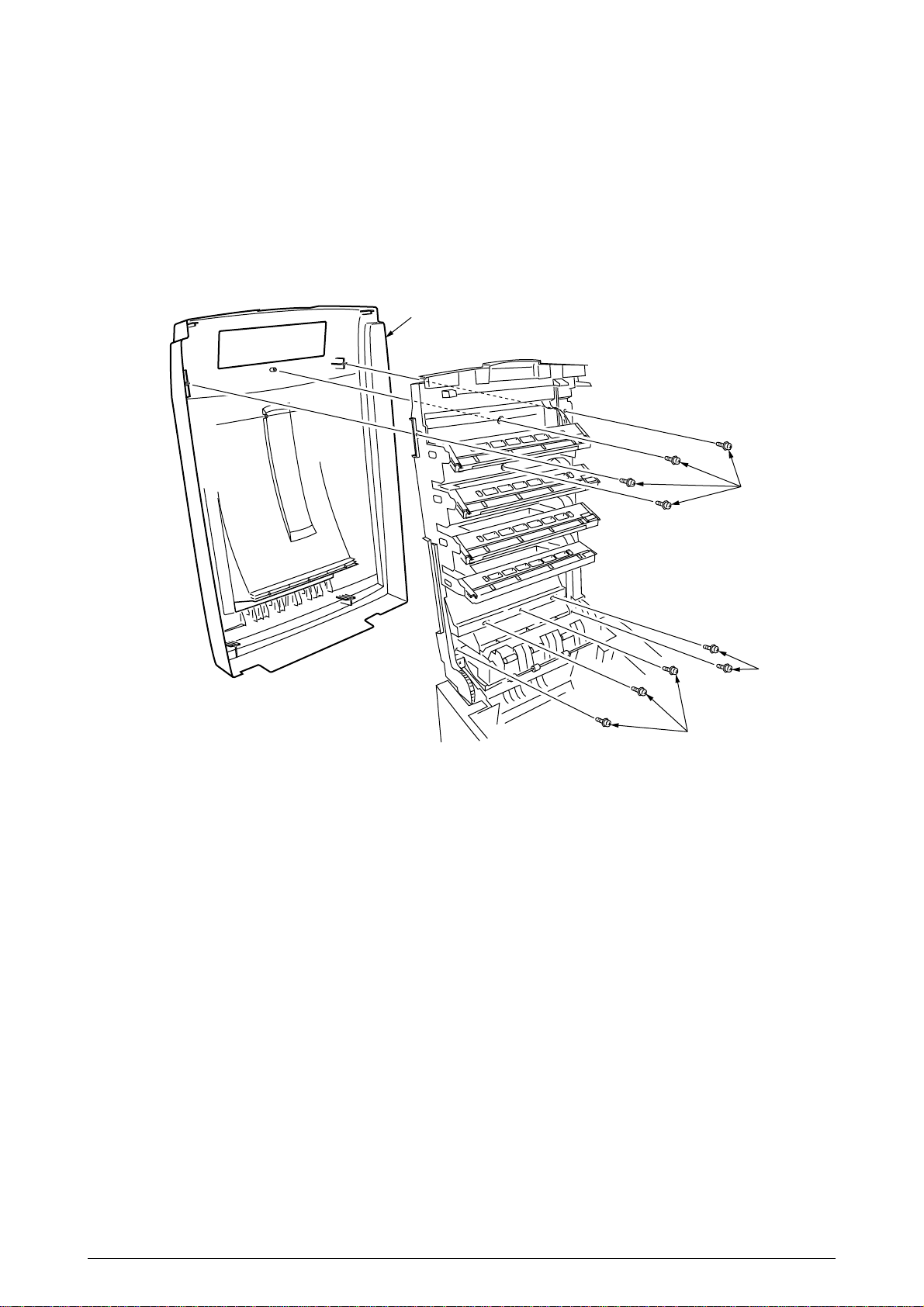

[Top Cover Assy]

Figure 2-2

20 /

Page 21

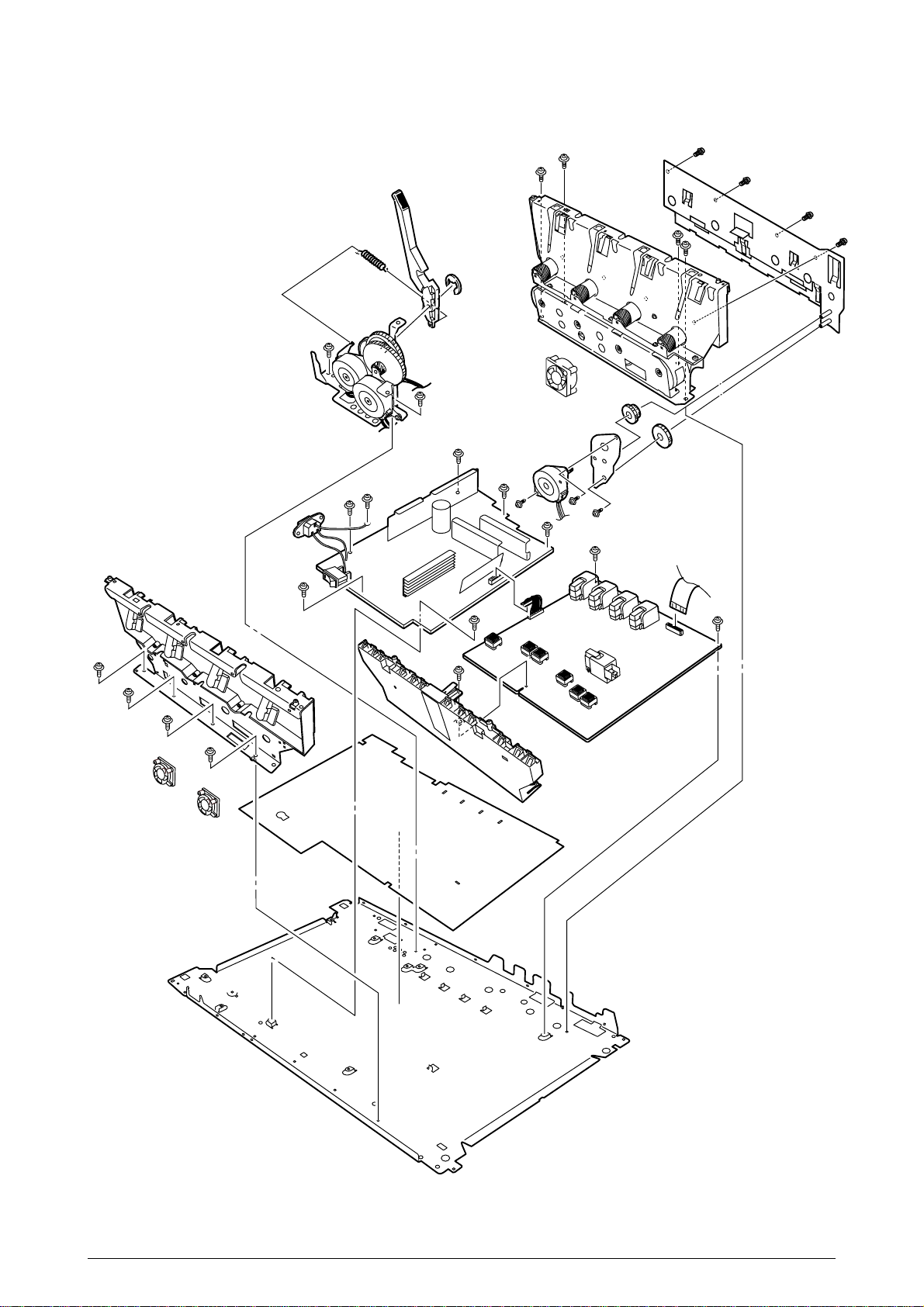

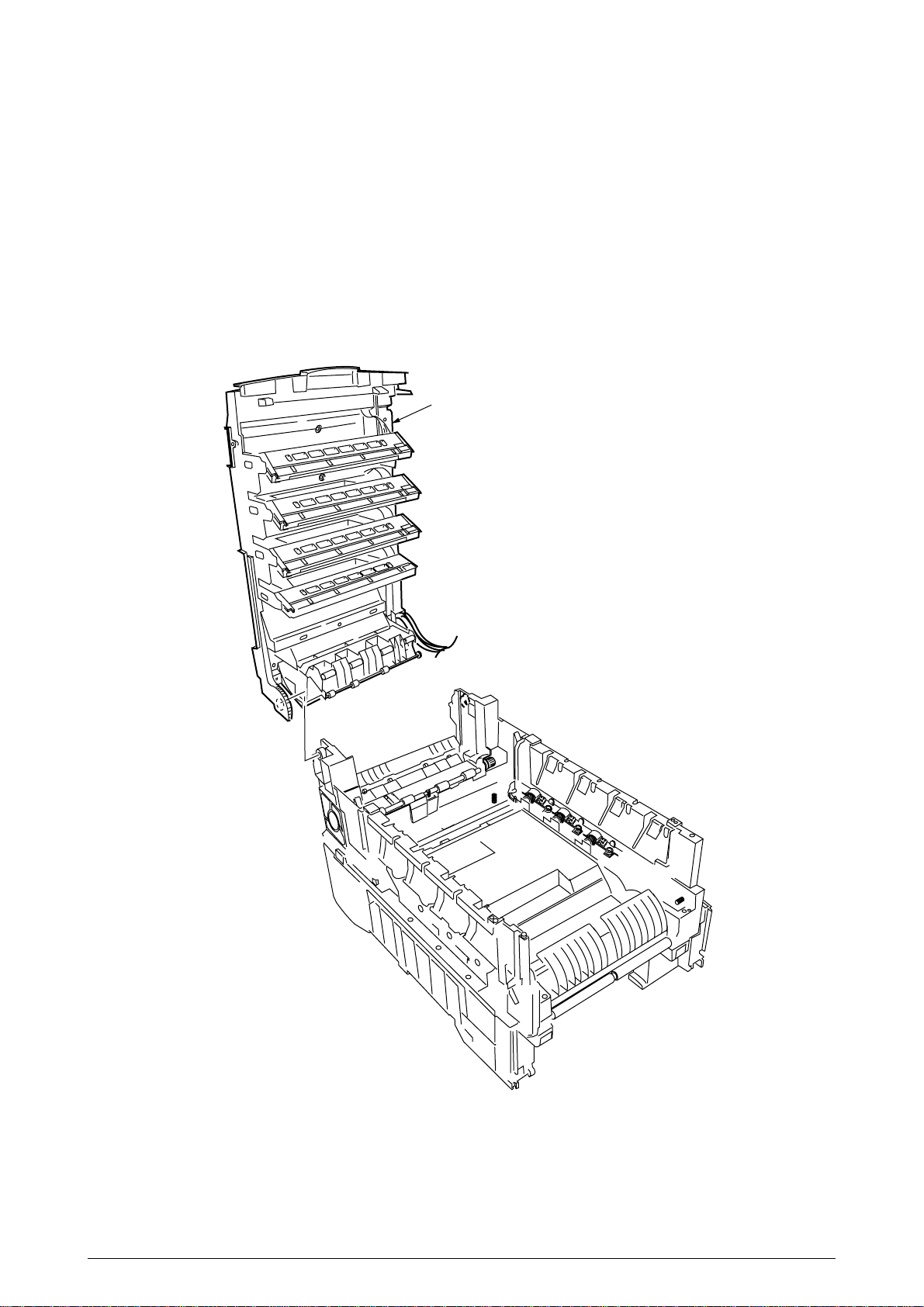

[Printer Unit-1/2]

Figure 2-3

A

A

21 /

Page 22

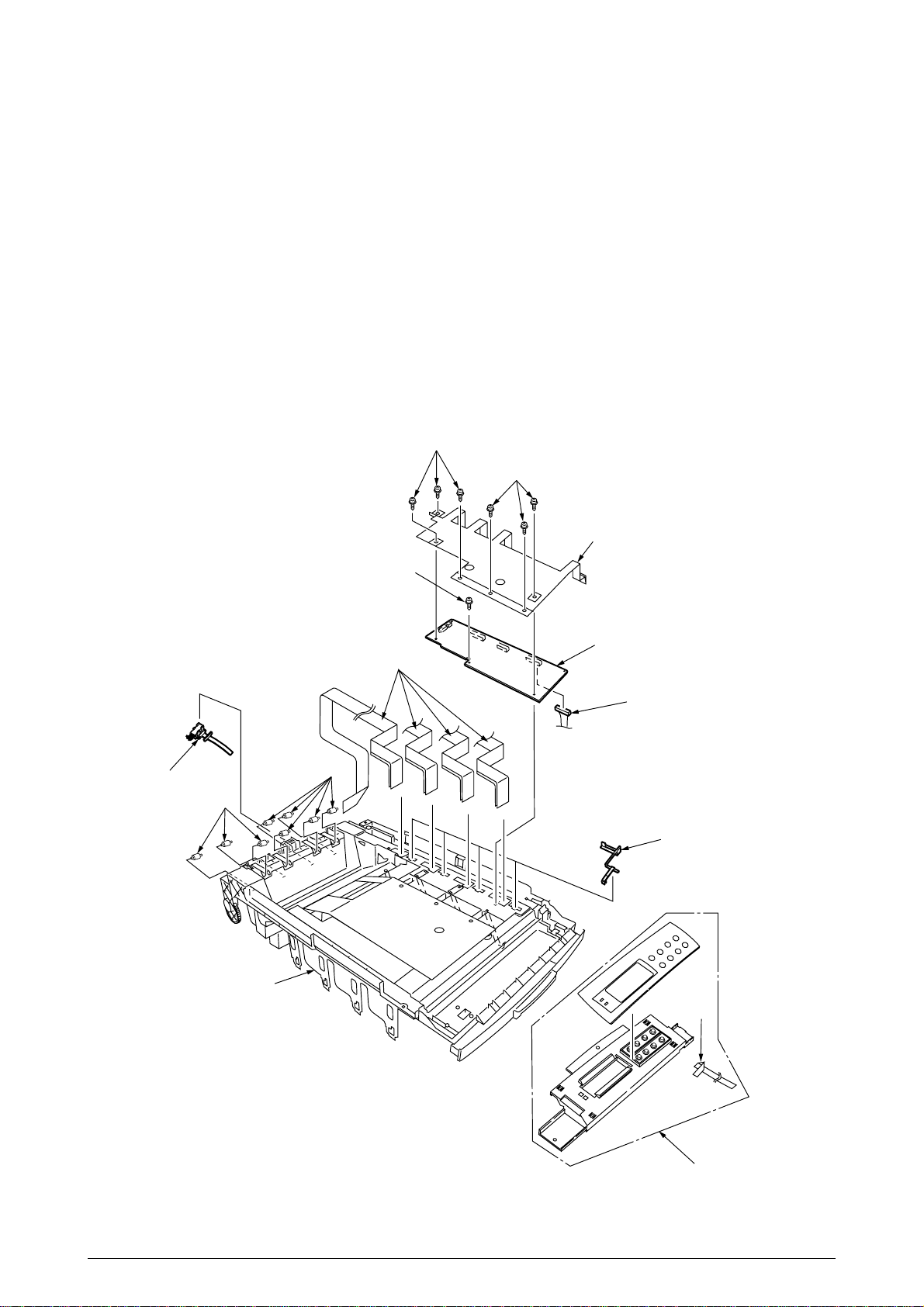

[Printer Unit-2/2]

Figure 2-4

22 /

Page 23

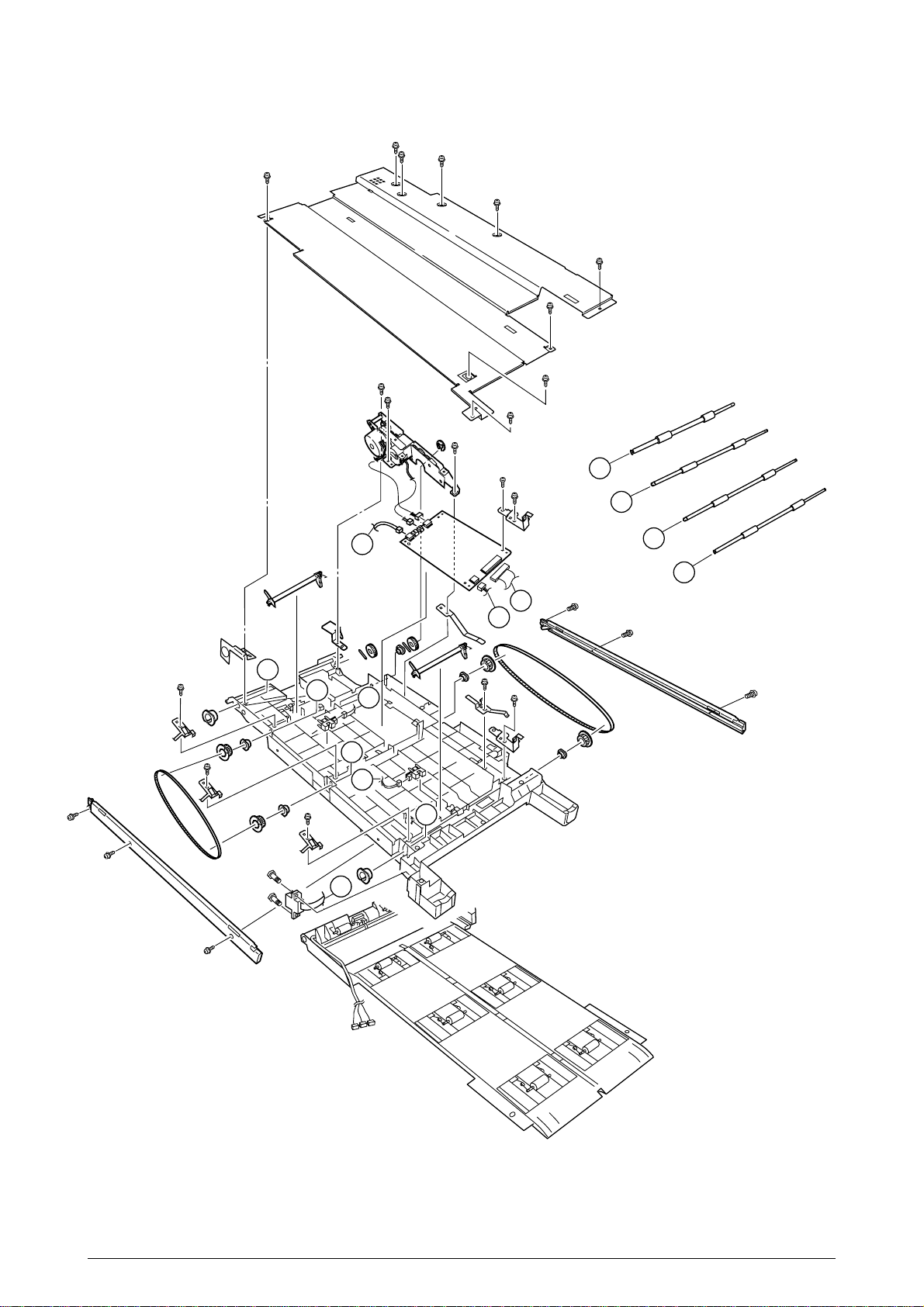

[Cassette Guide Assy (L),(R)]

B

A

C

C’

A

B

C

C’

Figure 2-5

23 /

Page 24

[Duplex Unit]

D

C

G

B

A

E

F

D

C

G

B

F

A

E

Figure 2-6

24 /

Page 25

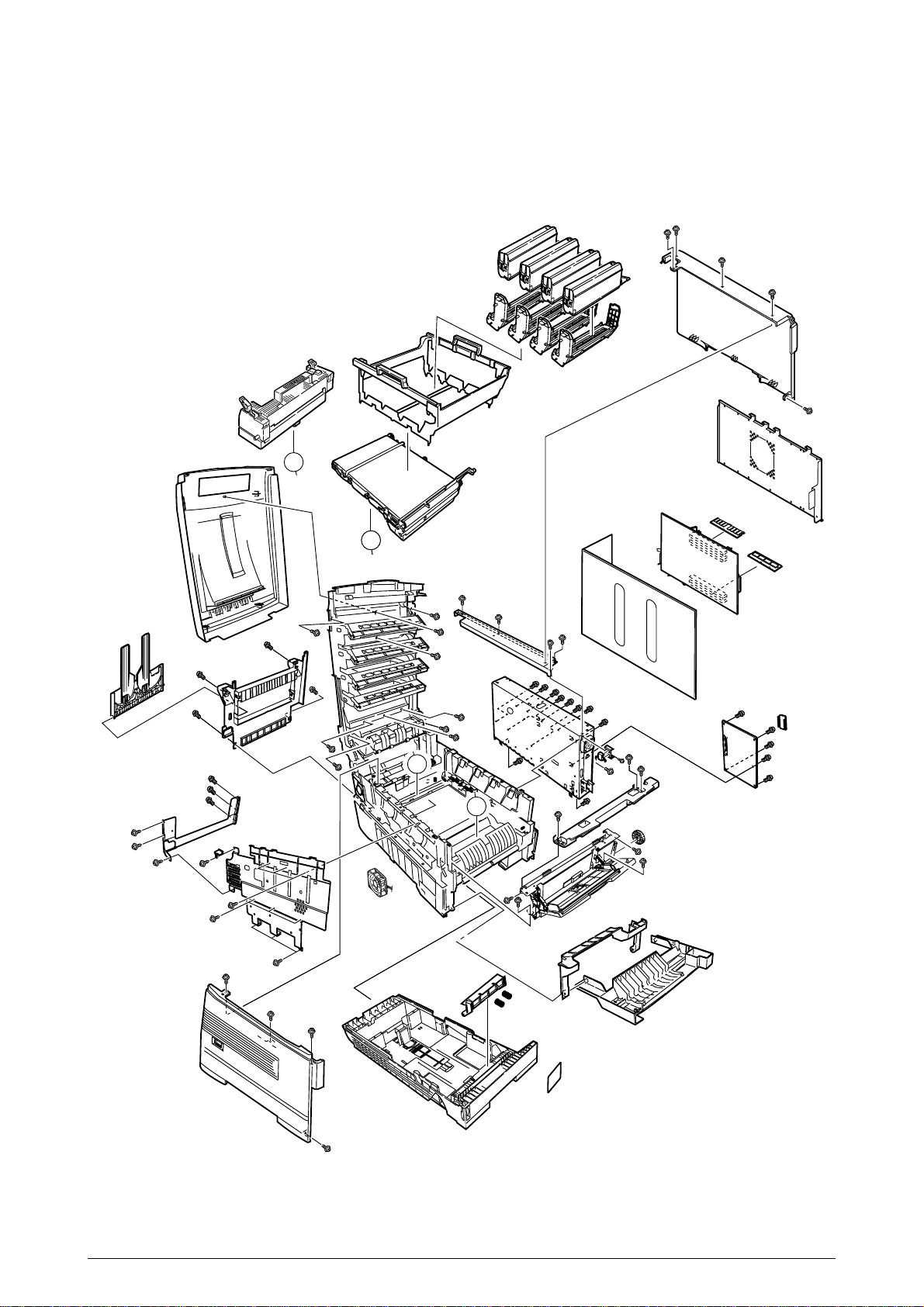

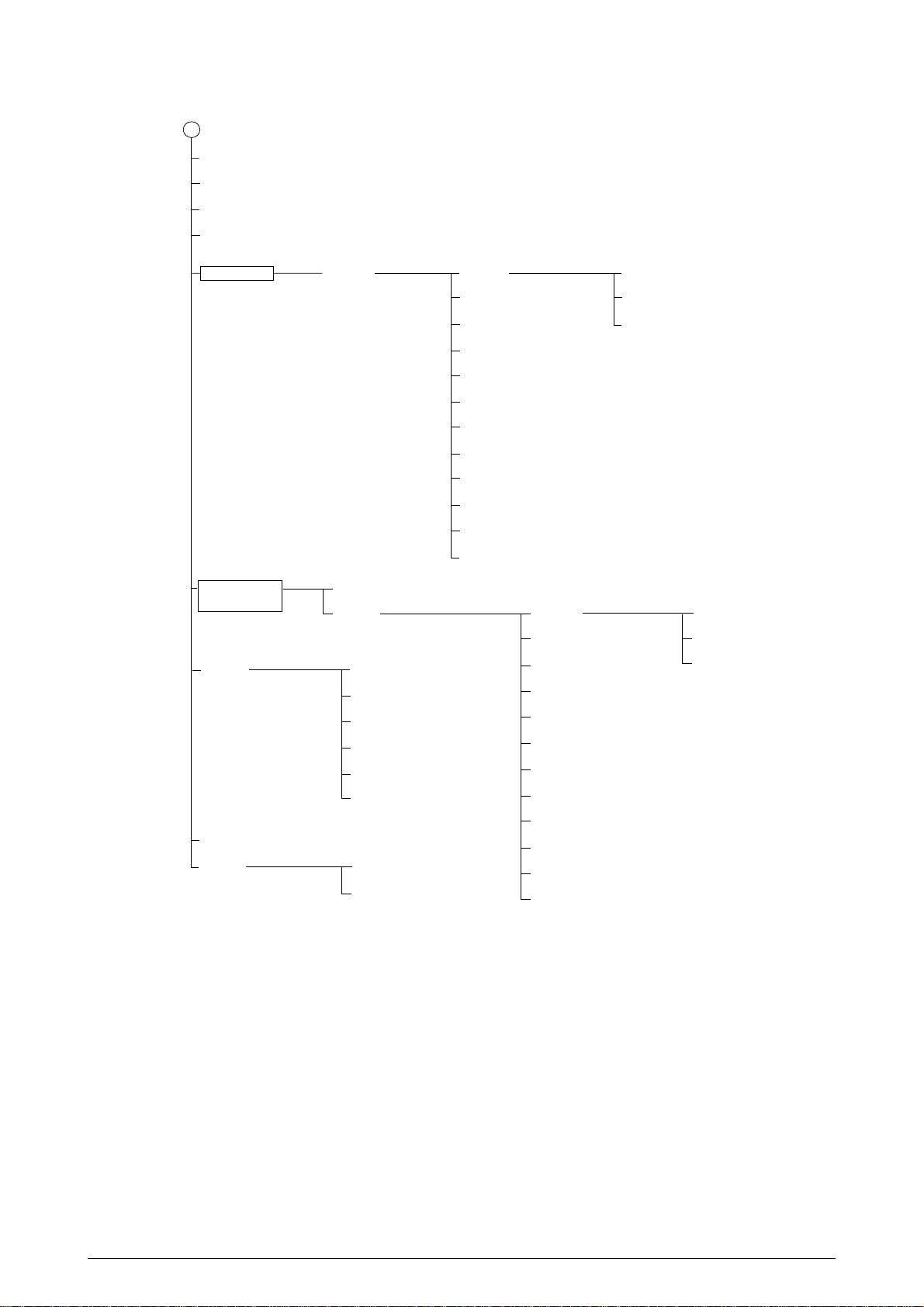

2.3 Replacing Parts

This section describes how to replace the parts and assemblies shown in the following disassembling system diagram.

AR-C200P

Print Engine Controller PWB (2.3.23)

x 4

LED Assy (2.3.2)

Low Voltage Power Supply (2.3.36)

High Voltage Power Supply (2.3.37)

0ZZ41940001//

Printer NIP

-

0ZZ40839001//

Left Cassette Guide Assy (2.3.40)

0ZZ40839406//

Right Cassette Guide Assy (2.3.41)

0ZZ40839801//

Main Feed Assy (2.3.39)

0ZZ40844306//

Regist Roller Assy (A) (2.3.17)

0ZZ41940201//

Printer Unit

0ZZ41128101//

Insurator

0ZZ42153101//

Main Cooling Fan Assy (2.3.20)

2381023P0003

HV Tape Harness

40847306

Main Motor Assy (2.3.34)

40848801

Transport (Transfer) Belt Motor Assy (2.3.32)

0ZZ40850201//

Contact Assy (2.3.36)

0ZZ41303606//

Left Plate Assy (2.3.36)

0ZZ40864301//

Rear Cover (2.3.10)

0ZZ40864411//

Left Side Cover (2.3.12)

0ZZ40864503//

Right Side Cover (2.3.13)

0ZZ40864601//

Front Cover Assy (2.3.7)

41042501

Front Cover Inner Baffle (2.3.7)

0ZZ41374902//

Face Up Tray (2.3.11)

0ZZ40864901//

Frame Assy - Release

A

0ZZ40371302//

Feed Roller (2.3.9)

0ZZ40325401//

Main Feeder Drive Gear (2.3.39)

0ZZ40313202//

Nudger Roller (2.3.9)

0ZZ41940301//

Printer Chassis (2.3.17)

0ZZ40844307//

Regist Roller Assy (B) (2.3.18)

0ZZ40845801//

Registration Motor Assy (2.3.19)

0ZZ41187102//

Registration Clutch (2.3.19)

0ZZ40859201//

Duplex Guide Assy (2.3.22)

0ZZ40848501//

Main Feeder Drive Gear A (2.3.35)

0ZZ40848601//

Main Feeder Drive Gear B (2.3.35)

0ZZ40846001//

Main Feeder Motor (2.3.35)

0ZZ40841401//

Fuser Latching Handle (R) (2.3.33)

0ZZ40841501//

Fuser Latching Handle Spring (2.3.33)

Plastic Slide (2.3.41)

0ZZ40349101//

Cassette Guide Pivot (L) (2.3.41)

0ZZ40349701//

Plastic Roller (2.3.41)

0ZZ40928101//

Cassette Spring (2.3.41)

Cassette Lock (2.3.41)

Cassette Lock Spring (2.3.41)

Foot (2.3.41)

0ZZ40368304//

Paper Size Sensing PWB PXC (2.3.41)

0ZZ50928901//

Paper Size Actuator (2.3.41)

0ZZ41143701//

Duplex Assy Ground contact (2.3.41)

0ZZ41309106//

2nd Tray Connector (2.3.41)

0ZZ41285701//

Plate Assy-SW(Front) (2.3.41)

Plastic Slide (2.3.40)

0ZZ40349102//

Cassette Guide Pivot (R) (2.3.40)

0ZZ40349701//

Plastic Roller (2.3.40)

0ZZ40928101//

Cassette Spring (2.3.40)

Cassette Lock (2.3.40)

Cassette Lock Spring (2.3.40)

Foot (2.3.40)

0ZZ41275901//

Microswitch-Assy (2.3.41)

0ZZ40841301//

Fuser Latching Handle (L) (2.3.31)

0ZZ40841501//

Fuser Latching Handle Spring (2.3.31)

0ZZ40841601//

Entrance Sensor Actuator #1 (2.3.26)

0ZZ40841701//

Entrance Sensor Actuator #2 (2.3.28)

0ZZ40841801//

Entrance Senspr Actuator #3 (2.3.28)

0ZZ42199601//

Waste Toner Sensor Actuator (2.3.28)

0ZZ41253601//

Duplex Gate solenoid Assy (2.3.29)

0ZZ41968701//

Registration Shutter Solenoid Assy

0ZZ41944201//

Registration Shutter

0ZZ41968501//

Registration Shutter Spring

0ZZ42170801//

Fuser Drive Gear-C (2.3.29)

0ZZ40323902//

Fuser Exit Roller (2.3.29)

0ZZ40316301//

Fuser Drive Gear-B (2.3.29)

Fuser Exit Roller Bushing (L) (2.3.29)

Fuser Exit Roller Bushing (R) (2.3.29)

0ZZ41189701// x 4

Drum Contact Assy (2.3.15)

0ZZ41258301//

Entrance Sensor PWB (2.3.27)

0ZZ41312801//

Left Top Cover Spring Assy (2.3.25)

0ZZ41312901//

Right Top Cover Spring Assy (2.3.25)

0ZZ41944001//

Color Registration Sensor Assy (2.3.21)

0ZZ41073601//

Exit Sensor Assy (2.3.30)

25 /

Page 26

A

0ZZ41911201//

Thickness Plate Assy

0ZZ41928801//

Stage-Pickup

0ZZ41888701//

Cover-Seal-Sensor

0ZZ41911101//

Thickness Sensor Assy

CU Board Assy

0ZZ41940701//

Cover Assy Stacker

0ZZ40862006//

Multipurpose Feeder Assy (2.3.14)

0ZZ40952701//

Multipurpose Tray Top Cover (2.3.14)

0ZZ40866701//

Cassette Assy (2.3.8)

Board Assy-CU

0ZZ40859702//

Top Cover (2.3.1)

0ZZ41988101//

Cover-Assy-Inner (2.3.3)

0ZZ40325101//

Multipurpose Feeder Drive Gear (2.3.14)

0ZZ41045801//

Link (2.3.14)

4YB4120-1137P001

MT Paper Empty Sensor (2.3.14)

0ZZ41849401//

MT OHP Sensor (2.3.14)

0ZZ41276001//

MT Position Sensor (2.3.14)

0ZZ40866301//

Multipurpose Tray Cover Assy (2.3.14)

0ZZ41438401//

Retard Pad Assy (2.3.8)

0ZZ41439401//

Retard Pad Assy Spring (2.3.8)

⋅

2

⋅

2

Board_TIG

0ZZ41964009//

Board Assy.-CU(711)

0ZZ41278601//

Guide_Rail (A)

0ZZ41278701//

Guide_Rail (B)

0ZZ41410201//

Motor-Fan 60x60x15

0ZZ41723901//

Screw

PB4013-3100P006 x9

Cup Screw (S Tight M3)

P3-6G

Screw (Round Head)

Tapping Screw

Screw(Round Head, SW+2W)

0ZZ41467401//

Plate FG (Centronics)

0ZZ41254601//

Plate Blank

⋅

2

⋅

4

⋅

2

0ZZ41316501//

Top Cover Inner Frame Assy (2.3.4)

0ZZ42216201//

LED Assy Spring (2.3.2)

0ZZ41960901//

LED Control PWB (Y71) (2.3.4)

0ZZ40365404//

Stack Full Sensor (2.3.4)

0ZZ40860601//

Toner Sensor

0ZZ40866102//

Control Panel Assy (2.3.4)

2381003P0014

Control Panel Tape Harness (2.3.4)

0ZZ41409601//

LED Harness K (2.3.4)

0ZZ41309602//

LED Harness Y (2.3.4)

0ZZ41309603//

LED Harness M (2.3.4)

0ZZ41309604//

LED Harness C (2.3.4)

0ZZ40861501//

Eject Guide Assy (2.3.6)

PCB Assy_TIG

Board Memory 64MB

Board CRF

⋅

8

⋅

4

0ZZ40861201//

Top Cover Handle (2.3.5)

0ZZ40861301//

Top Cover Latch (2.3.5)

0ZZ40861401//

Top Cover Latch Spring (2.3.5)

⋅

2

26 /

Page 27

2.3.1 Top Cover

(1) Open the Top Cover assy.

(2) Remove the nine screws 1 to detach the top cover 2.

2

1

Figure 2-3-1 Top Cover

1

1

27/

Page 28

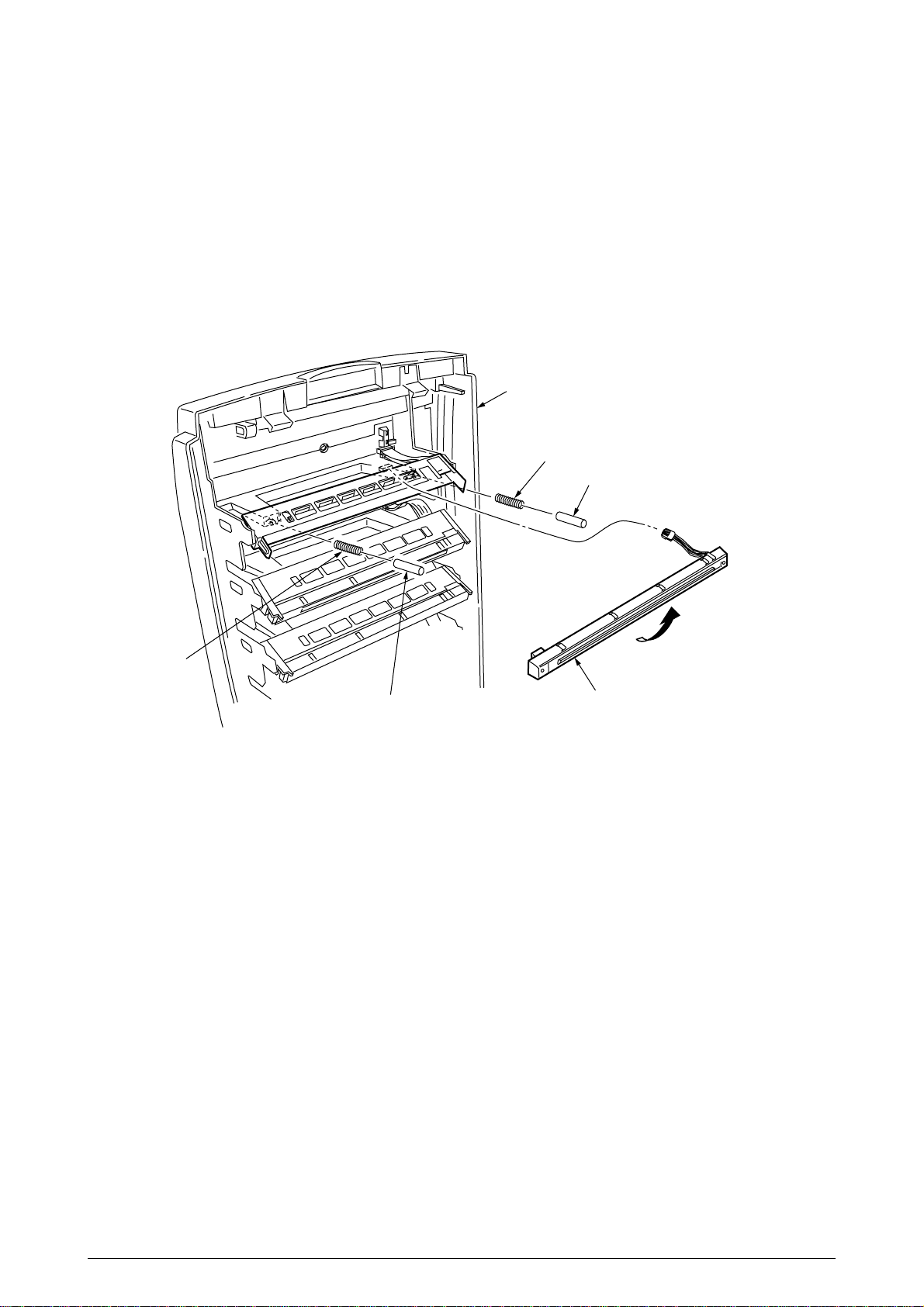

2.3.2 LED Head / LED Spring / Post-Guide

(1) Open the top cover 1.

(2) Remove the three cables, and unhook the LED Head 2 at two places to demount it (the two

springs 3, Post-Guide 4 become detached together with the LED Head 2).

1

3

4

3

4

Figure 2-3-2 LED Head / LED Spring / Post-Guide

2

28 /

Page 29

2.3.3 Top Cover Unit

(1) Remove the top cover (see section 2.3.1).

(2) Remove the rear cover (see section 2.3.10).

(3) Remove the left side cover (see section 2.3.12).

(4) Remove the right side cover (see section 2.3.13).

(5) Remove the shield plates A and B (see section 2.3.23), and unplug the connector to separate

the top cover.

(6) Disengage the top cover unit 1 at two places to detach it.

1

Figure 2-3-3 Top Cover Unit

29 /

Page 30

2.3.4 Control Panel Assy/ Control Panel Bezel/ LED Control PWB/ Toner Sensors/ Stacker Full Sensor/

Control Panel/ Control Panel Tape Harness/ Eject Rollers

(1) Remove the control panel Assy 1.

(2) Detach the control panel tape harness 2.

(3) Remove the top cover unit (see section 2.3.3).

(4) Unscrew the six screws 3 to remove the earth plate 4.

(5) Remove the two screws 5, unhook all the connectors 6 and demount the LED control PWB 7.

(6) Disengage the four claws to demount the toner sensor 8.

(7) Demount the stacker full sensor 9.

(8) Demount the exit rollers A.

(9) Detach the LED harnesses, K, Y, M and C B.

(10) Detach the top cover inner frame Assy C.

3

3

9

4

5

7

A

6

0

0

8

B

2

1

Figure 2-3-4 Control Panel Assy/ Control Panel Bezel/ LED Control PWB/ Toner Sensors/ Stacker

Full Sensor/ Control Panel/ Control Panel Tape Harness/ Eject Rollers

30 /

Page 31

2.3.5 Top Cover Handle/ Top Cover Latch/ Top Cover Latch Spring

(1) Remove the two screws 1 to detach the top cover handle 2 and disengage the top cover latch

3 (at the same time, the two top cover latch springs 4 become detached).

1

3

2

1

4

4

Figure 2-3-5 Top Cover Handle/ Tope Cover Latch/ Top Cover Latch Spring

31 /

Page 32

2.3.6 Eject Guide Assy

(1) Remove the five screws 1 to detach the eject guide Assy 2.

1

1

1

2

Figure 2-3-6 Eject Guide Assy

32 /

Page 33

2.3.7 Cassette Assy/ Front Cover Assy/ Front Cover Inner Baffle

(1) Detach the cassette Assy 1.

(2) Open the front cover 2, and disengage it at two places to detach it.

(3) Detach the front cover inner baffle 3.

3

1

Figure 2-3-7 Cassette Assy/ Front Cover Assy/ Front Cover Inner Baffle

2

33 /

Page 34

2.3.8 Retard Pad Assy/ Retard Pad Assy Spring

(1) Remove the cassette 1.

(2) Detach the retard pad Assy 2 (at the same time, the spring 3 becomes detached).

1

2

3

Figure 2-3-8 Retard Pad Assy/ Retard Pad Assy Spring

34 /

Page 35

2.3.9 Feed Roller and Nudger Roller

(1) Remove the cassette.

(2) Unlatch and demount the feed roller 1.

(3) Unlatch and demount the nudger roller 2.

2

1

Figure 2-3-9 Feed Roller and Nudger Roller

35 /

Page 36

2.3.10 Rear Cover

(1) Remove the left side cover (see section 2.3.12).

(2) Remove the four screws 1 to detach the rear cover 2.

Note!

When attaching the rear cover, take care not to allow the spring 3 to get caught in parts.

3

1

2

1

1

Figure 2-3-10 Rear Cover

36 /

Page 37

2.3.11 Face-Up Tray

(1) Open the face-up tray 1 in the arrow direction, and disengage it at two places to detach it.

Figure 2-3-11 Face-Up Tray

1

37 /

Page 38

2.3.12 Left Side Cover

(1) Open the top cover 1.

(2) Open the front cover 2 and undo the screw 3.

(3) Remove the four screws 4 to detach the left side cover 5.

4

1

4

4

5

Figure 2-3-12 Left Side Cover

3

2

38 /

Page 39

2.3.13 Right Side Cover

(1) Open the top cover 1.

(2) Open the front cover 2 and undo the screw 3.

(2) Remove the five screws 4 to detach the right side cover 5.

4

4

1

5

3

2

Figure 2-3-13 Right Side Cover

39 /

Page 40

2.3.14 Multipurpose Tray Assy/ Multipurpose Tray Cover Assy/ Links/ Multipurpose Tray Top Cover/

Multipurpose Tray Drive Gear

(1) Remove the left side cover (see section 2.3.12).

(2) Remove the right side cover (see section 2.3.13).

(3) Detach the Cover Seal Sensor and the Thickness Sensor Connector (see section 2.3.16).

(4) Remove the three screws 1 to detach the multipurpose tray top cover 2.

(5) Remove the three screws 3 (two of them are black) and the connector to detach the multipurpose

tray 4.

(6) Disengage A and B at both sides of the assembly to detach the multipurpose tray cover Assy

5 (at the same time, the links 6 become detached).

(7) Unhook and detach the multipurpose tray drive gear 7.

6

3

1

1

7

2

4

6

3

3

B

B

A

7

A

5

Figure 2-3-14 Multipurpose Tray Assy/ Multipurpose Tray Cover Assy/ Links/ Multipurpose Tray Top

Cover/ Multipurpose Tray Drive Gear

40 /

Page 41

2.3.15 Drum Contact Assys

(1) Insert a flatblade screwdriver between the printer case and the drum contact Assy 1 to demount

the drum contact Assy 1.

1

Figure 2-3-15 Drum Contact Assys

41 /

Page 42

2.3.16 Media Thickness Sensor Assy

(1) Detach the Cover Seal Sensor 1 and the Thickness Sensor Connector 2.

(2) Remove the two screws 3 to demount the Media Thickness Assy.

(3) Insert a microdriver(-) between the Thickness Plate Assy 4 and Thickness Sensor Assy 5 to

demount the Thickness Sensor Assy 5

Note!

When attaching the Media Thickness Assy, adjust [Spin lever adjust by microdriver(-)] the

position of lever (White).

The upper surface of the lever be in agreement with a datum level. (Adjustment range 0/-

0.5mm)

Lever(White)

0/-0.5mm

Adjustment

range

View A

Datum

level

1

Datum

level

Lever(White)

Microdriver

2

View A

3

5

3

Lever

adjust

4

Figure 2-3-16 Media Thickness Sensor Assy

42 /

Page 43

2.3.17 Registration Roller Assy (A)/ Registration Drive Gear (A)

(1) Remove the left side cover (see section 2.3.12).

(2) Remove the right side cover (see section 2.3.13).

(3) Remove the multipurpose tray (see section 2.3.14).

(4) Remove the Media Thickness Sensor Assy. (see section 2.3.16).

(5) Remove the screw 1 of the Pickup Stage 2.

(6) Remove the four screws 3 to demount the registration roller Assy (A) 4and the Pickup Stage

2.

(7) Remove the E ring 5 to detach the registration gear (A) 6.

Note!

Stage height adjustment jig

1

Top surface

Stage height adjustment jig

When attaching the pickup stage 2, place the stage height adjustment jig between the

pressure roller and the registration roller and, until the top surface of the pickup stage

reaches the jig, move the pickup stage toward the jig.(See Table 2-1 Maintenance Tools)

Top surface

3

1

2

4

3

6

5

Figure 2-3-17 Registration Roller Assy (A)/ Registration Driver Gear (A)

43 /

Page 44

2.3.18 Registration Roller Assy (B)

(1) Remove the cassette Assy.

(2) Open the front cover.

(3) Remove the right side cover (see section 2.3.13).

(4) Remove the left plate Assy (see section 2.3.23).

(5) Remove the registration clutch (see section 2.3.19).

(7) Unscrew the four screws 1, and pull out the registration Assy (B) 1 in the arrow direction.

2

1

1

1

Figure 2-3-18 Registration Roller Assy (B)

44 /

Page 45

2.3.19 Registration Clutch and Registration Motor Assy

(1) Remove the left side cover (see section 2.3.12).

(2) Remove the left plate Assy (see section 2.3.23).

(3) Remove the connector and the E ring 1, then remove the two screws 2, the earth 3 and the

registration clutch 4.

(4) Remove the connector to remove the two screws 5 and the registration motor Assy 6.

5

4

Figure 2-3-19 Registration Clutch and Registration Motor Assy

6

5

2

3

2

1

45 /

Page 46

2.3.20 Main Cooling Fan

(1) Unhook the connector 1, and remove the screw 2 and the cooling fan 3.

Note!

When attaching the cooling fan, observe its correct orientation.

Figure 2-3-20 Main Cooling Fan

Outlet

3

1

2

46 /

Page 47

2.3.21 Color Registration Sensor Assy

(1) Remove the two screws 1 and the two connectors to demount the color registration sensor

Assy 2.

(2) Remove the earth plate B 3.

1

1

2

3

Connectors

Figure 2-3-21 Color Registration Sensor Assy

47 /

Page 48

2.3.22 Duplex Guide Assy

(1) Unlatch and demount the duplex guide 1.

1

Main chassis (rear)

Figure 2-3-22 Duplex Guide Assy

48 /

Page 49

2.3.23 Electrical Chassis Cooling Fan

(1) Unscrew the four screws 1 to remove the plate A 2.

(2) Unscrew the thirty-four screws 3 to remove the shield plate B 4.

(3) Remove the printer engine controller PWB (see section 2.3.24).

(4) Unscrew the eleven screws 5 to remove the shield plate 6.

(5) Unscrew the two screws 7 to demount the electrical chassis cooling fan 8.

1

1

7

8

6

2

4

5

5

3

5

Outlet

5

3

Figure 2-3-23 Electrical Chassis Cooling Fan

49 /

Page 50

2.3.24 Printer Engine Controller PWB

(1) Remove the right side cover (see section 2.3.13).

(2) Remove the left plate Assy (see section 2.3.23).

(3) Remove the five screws 1 and all the connectors to demount the printer engine controller

PWB 2.

2

Figure 2-3-24 Printer Engine Controller PWB

1

1

50 /

Page 51

2.3.25 Printer Unit Chassis

(1) Unscrew the two screws 1 and remove the AC inlet 2.

(2) Unscrew the four black screws 3 and five screws 4 to detach the printer unit chassis 5.

(3) Unscrew the four black screws 6 and remove the left top cover spring Assy 7.

(4) Unscrew the four black screws 8 and remove the right top cover spring Assy 9.

6

6

3

7

4

4

3

4

9

3

5

8

8

4

3

2

1

Figure 2-3-25 Pinter Unit Chassis

51 /

Page 52

2.3.26 Entrance Cassette Sensor Actuator

(1) Remove the printer unit chassis (see section 2.3.25).

(2) Turn over the main chassis.

(3) Remove the two clamps with tweezers to demount the entrance cassette sensor actuator 1.

1

Main chassis

Figure 2-3-26 Entrance Cassette Sensor Actuator

52 /

Page 53

2.3.27 Entrance Sensor PWB

(1) Remove the registration roller Assy (B) (see section 2.3.18).

(2) Remove the two screws 1 to demount the entrance sensor PWB 2.

Figure 2-3-27 Entrance Sensor PWB

1

2

53 /

Page 54

2.3.28 Entrance MT Sensor Actuator / Entrance Belt Sensor Actuator / Entrance Waste Chassis Sensor

Actuator

(1) Remove the entrance sensor PWB (R71) (see section 2.3.27).

(2) Unlatch and detach the entrance MT sensor actuator 1.

(3) Unlatch and detach the entrance belt actuator 2.

(4) Release the latch and remove the Entrance Waste Chassis Sensor Actuator 3.

2

1

3

Figure 2-3-28 Entrance MT Sensor Actuator / Entrance Belt Sensor Actuator /

Entrance Waste Chassis Sensor Actuator

54 /

Page 55

2.3.29 Fuser Exit Roller

(1) Unscrew the two screws 1 to remove the duplex gate solenoid Assy 2.

(2) Unscrew the screw 3 to remove the fuser exit roller contact 4.

(3) Remove the fuser drive gear -A 5 and fuser drive gear -A 6.

(4) Unscrew the screw 7 to remove the fuser drive gear -C 8.

(5) Unlatch and detach the fuser drive gear -B 9 and fuser exit roller bush (R) 0.

(6) Unlatch and detach the fuser exit roller bush (L) A and fuser exit roller B.

B

A

1

7

8

0

9

6

5

3

4

2

Figure 2-3-29 Fuser Exit Roller

55 /

Page 56

2.3.30 Exit Sensor Assy

(1) Remove the fuser exit roller (see section 2.3.29).

(2) Remove the screw 1 and connector to demount the (red and blue) exit sensor Assy 2.

1

2

Figure 2-3-30 Exit Sensor Assy

56 /

Page 57

2.3.31 Fuser Latching Handle (L)

(1) Remove the latching handle spring 1.

(2) Unscrew the screw 2 to detach the fuser latching handle (L) 3.

3

1

2

Figure 2-3-31 Fuser Latching Handle (L)

57 /

Page 58

2.3.32 Belt Motor Assy

(1) Remove the fuser latching handle (R) (see section 2.3.33).

(2) Remove the two screws 1 to detach the two connectors 2.

(3) Demount the belt motor Assy 3.

1

3

1

2

Figure 2-3-32 Belt Motor Assy

58 /

Page 59

2.3.33 Fuser Latching Handle (R)

(1) Remove the printer unit chassis (see section 2.3.25).

(2) Remove the E ring 1.

(3) Remove the fuser latching handle spring 2 to detach the fuser latching handle (R) 3.

3

2

1

Figure 2-3-33 Fuser Latching Handle (R)

59 /

Page 60

2.3.34 Main Motor Assy

(1) Remove the belt motor Assy (see section 2.3.32).

(2) Remove all the connectors.

(3) Remove the four screws 1 to demount the main motor Assy 2.

1

2

1

1

Figure 2-3-34 Main Motor Assy

60 /

Page 61

2.3.35 Main Feeder Drive Motor

(1) Remove the two screws 1 to detach the main feeder drive motor 2.

(2) Unscrew the screw 3 to remove the main feeder drive motor bracket 4.

(3) Remove the main feeder drive motor gears A 5 and B 6.

1

5

2

6

4

1

3

Figure 2-3-35 Main Feeder Drive Motor

61 /

Page 62

2.3.36 Contact Assy/ Left Plate Assy

(1) Remove the printer unit chassis (see section 2.3.25).

(2) Remove the four screws 1 to detach the left plate Assy 2.

(3) Remove the screw 3 to detach the contact Assy 4.

4

2

3

1

1

Figure 2-3-36 Contact Assy/ Left Plate Assy

62 /

Page 63

2.3.37 Low Voltage Power Supply

(1) Remove the printer unit chassis (see section 2.3.25).

(2) Unhook the connector 1.

(3) Unscrew the screw 2 to remove the earth cable 3.

(4) Unscrew the six screws 4 to demount the low voltage power supply 5.

1

4

2

4

3

5

4

Figure 2-3-37 Low Voltage Power Supply

63 /

Page 64

2.3.38 High voltage power supply

(1) Remove the contact Assy (see section 2.3.36).

(2) Unhook the connector of the high voltage power supply 1.

(3) Remove the two screws 2 to detach the high voltage power supply 1 and the tape harness 3.

2

3

1

2

Figure 2-3-38 High Voltage Power Supply

64 /

Page 65

2.3.39 Main Feed Assy

(1) Remove the printer unit chassis (see section 2.3.25).

(2) Remove the low voltage power supply and high voltage power supply (see sections 2.3.37 and

2.3.38).

(3) Unscrew the five screws 1 to remove the lower plate 2.

(4) Unscrew the four screws 3 to demount the main feed Assy 4.

(5) Unhook and remove the main feed drive gear 5.

1

1

2

1

3

1

3

5

4

Figure 2-3-39 Main Feed Assy

65 /

Page 66

2.3.40 Cassette/ Left Guide Assy

(1) Remove the printer unit chassis (see section 2.3.25).

(2) Remove the main feed Assy (see section 2.3.39).

(3) Remove the three screws 1 to detach the left cassette guide Assy 2. At the same time, the

earth plate 3 becomes detached.

(4) Remove the cassette lift spring 4, then remove the plastic slide 5, the cassette lift arm (L) 6

and the plastic roller 7.

(5) Remove the two feet 8.

(6) Remove the cassette lock spring 9, then remove the cassette lock 0.

2

8

9

0

3

5

8

4

7

6

1

1

Figure 2-3-40 Cassette/ Left Guide Assy

66 /

Page 67

2.3.41 Cassette/ Right Guide Assy

(1) Remove the printer unit chassis (see section 2.3.25).

(2) Remove the main feed Assy (see section 2.3.39).

(3) Remove the five screws 1 to detach the right cassette guide Assy 2. At the same time, the

earth plate 3 becomes detached.

(4) Remove the cassette lift spring 4, then detach the plastic slide 5, the cassette lift arm (L) 6

and the plastic roller 7.

(5) Unscrew the screw 8 to remove the paper size actuator 9.

(6) Unscrew the screw 0 to remove the paper size sensing PWB A in the downward direction.

(7) Remove the two feet B.

(8) Remove the cassette lock spring C, then remove the cassette lock D.

(9) Unscrew the two screws E to remove the 2nd tray connector F.

(10) Unscrew the screw G, then remove the duplex Assy ground contact H.

1

H

G

0

B

A

9

8

5

D

C

3

2

4

6

7

A

F

E

1

Figure 2-3-41 Printer Tray/ Right Guide Assy

67 /

Page 68

2.3.42 Fuser Unit

(1) Open the top cover 1.

(2) Push the right and left fuser levers (blue) 2 in the arrow direction to detach the fuser unit 3.

3

1

2

2

Figure 2-3-42 Fuser Unit

68 /

Page 69

2.3.43 Belt Unit

(1) Open the top cover 1.

(2) Remove the I/D unit.

(3) Push the lever (blue) 2 in the arrow direction, raise the handle (blue)3 and detach the belt unit

4.

3

4

1

2

Figure 2-3-43 Belt Unit

69 /

Page 70

2.3.44 Duplex Unit

(1) Remove the cassette Assy, the front cover Assy and the front cover inner baffle.

(2) Unlatch the rear at the right and left, and pull the duplex unit 1 toward the front.

Latch

Figure 2-3-44 Duplex Unit

Latch

1

70 /

Page 71

2.3.45 Guide Rails (L) and (R)

(1) Remove the duplex unit (see section 2.3.44).

(2) Remove the six screws 1 to detach the guide rails (L) 2 and (R) 3.

1

1

2

3

1

1

Figure 2-3-45 Guide Rail (L), (R)

71 /

Page 72

2.3.46 Duplex Transport Assembly

(1) Turn over the duplex transport Assy.

(2) Unscrew the three screws 1 and five screws 2 to detach the plate 3.

(3) Unplug the connector and detach the mold Assy 4.

(4) Detach the two actuators 5.

(5) Unscrew the screws 6 and 7 to remove the earth 8.

(6) Unhook the connector and disengage the two claws to detach PCB-MOP 9.

(7) Unplug the cable and, warping the claw, detach the transport sensor.

(8) Unscrew the two screws to detach the cord duplex connector Assy.

(9) Unscrew the screw 0 to remove the earth A.

(10) Unscrew the screw B to remove the earth C.

(11) Unscrew the screw D to remove the earth E.

(12) Detach the bush F, gear G and bush H, then detach the roller I.

(13) Unscrew the screw J to remove the earth K.

(14) Detach the gear L and bush M. At the same time, the mini pitch belt N becomes detached.

(15) Detach the gear O and bush P, then detach the roller Q. At the same time, the mini pitch belt

R becomes detached.

(16) Unscrew the screw S to remove the earth T.

(17) Remove the E ring U and three screws V to detach the motor Assy W. At the same time, the

earth X becomes detached.

(18) Detach the gear Y and bush Z.

(19) Detach the gear [, knock-pin \ and bush ], then detach the roller _.

(20) Detach the bush a, gear b, knock-pin c and bush d, then detach the roller e. At the same

time, the earths f and g become detached.

(21) Detach the idle roller shaft and the idle roller, then detach the idle roller springs (eight springs).

(22) Remove the cable of the duplex transport sensor Assy from the claw of the cover-upper.

Disengage the claw, then detach the sensor.

72 /

Page 73

2

1

3

2

T

S

J

f

a

K

Y

D

Z

5

M

g

C

W

G

cb

d

G

B

F

]

\

[

V

U

5

P

A

X

9

V

F

0

O

2

7

6

8

e

_

D

E

C

Q

I

B

A

B

R

C

G

H

D

A

E

L

N

Cord duplex

connector Assy

Duplex transfer Assy

73 /

F

E

Figure 2-3-46 Duplex Transport Assembly

Duplex transport sensor ⋅ 2

4

Idle roller spring

Idle roller ⋅ 8

Idle roller shaft ⋅ 8

Page 74

2.3.47 CU Assy

(1) Pulling out Controller Board

1. Undo the two screws 1.

2. Pull the controller board 2 out.

3. Place the controller board 2 on a flat table.

(2) Detaching Fan

1. Remove the connector 3.

2. Remove the two screws 4.

3. Detach the fan 5.

2

3

1

1

4

5

Figure 2-3-47 CU Assy (1/2)

74 /

Page 75

(3) Demounting TIG Board

1. Remove the three screws 6 and screw 7 to detach the fan bracket 8.

2. Remove the screw 9 and four screws 0 to detach the plate support A and the guide rail AB.

3. Remove the two screws C to detach the guide rail BD.

4. Remove the two screws E and two screws F and the plate-FG(Centro)G, then demount

the SWA board H.

6

8

7

9

0

A

H

0

D

C

A

F

F

G

B

0

B

C

E

0

6

Figure 2-3-47 CU Assy (2/2)

75 /

Page 76

3. ADJUSTMENT

This device is adjusted by key input from the operator panel.

Other than the general menu, this device supports a maintenance menu. Select the menu that

matches your objective.

3.0 System Maintenance MENU

The printer enters this mode when you turn on the power supply switch while holding down the

[Menu]+[Item]+[Value]+[Cancel] (0+1+6+7)switches.

Note:

This menu is not disclosed to end-users because changes can be made to brand/

destination, etc.

Category

USER

CONFIGURATION

MENU

ENG STATUS PRINT

Table 3-0 (1/2) Maintenance Menu display Table

Item(1st Line)

USER

ENGINE SPEED

HIGH RESOLUTION

ENG STATUS PRINT

Value(2nd Line)

ODA

OEL

APS

JP1

JPOEM1

OEMA

OEML

HIGH

LOW

ENABLE

DISABLE

EXECUTE

Functions

DF

*

Sets Brand

JPOEM1: Japan OEM

OEMA: Overseas OEM for A4 default

OEML: Overseas OEM for Letter default

Boots up automatically when the Menu is existed.

*

For swithing the engine speed between the

overseas 16/24PPM model and the 20/24PPM

model.

(Valid only for 600dpi Head)

HIGH: 20/24PPM model ARC200P

LOW : 16/24PPM model

Reboots automatically as the menu is exited.

note: This function is ignored.

Not used.

note: Don’t change the setting value.

*

Selecting by the Select switch, then

pressing the On-line switch will prompt

initialization and printing Engine information.

TEST PRINT MENU

PAGE CNT PRINT

PERSONALITY

TEST PRINT MENU

PAGE CNT PRINT

PCL

IBM PPR III XL

EPSON FX

Adobe Postscript

HP-GL/2

PCL XL

PDF

ENABLE

DISABLE

ENABLE

DISABLE

ENABLE

DISABLE

ENABLE

DISABLE

ENABLE

DISABLE

ENABLE

DISABLE

ENABLE

DISABLE

ENABLE

DISABLE

ENABLE

DISABLE

Switches ENABLE and DISABLE to display the

TEST PRINT MENU category in the User Menu.

*

( See "ID Check Pattern" section. )

Sets printing or not printing the total page count

in PRINT MENU MAP.

*

Cange the default PDL for each brand.

*

PDLs that are disabled in this Menu will not be

*

displayed on User Menu or Adomin Menu’s

PERSONALITY.

When print data in the PDL language set to

*

DISABLE is received, the printer will display

INVALID DATA and discard received data. (HPGL/2 is under development, and there is no plan

to implement as yet in the product. )

*

The PDF function requires Adobe Postscript;

thus, switching ON/OFF of PDF alone is

disabled.

*

(Setting Adobe Postscript on DISABLE will set

the PDF function to DISABLE as well. )

neither Adobe Postscript nor

PDF can be set to DISABLE. (They are to be

*

always set to ENABLE for use. Even if they are

set to DISABLE, the printer processes the data it

*

receives. This item is incorporated only in the

menu ahead of time for future extension. )

76 /

Page 77

Table 3-0 (2/2) Maintenance Menu display Table

Category

NETWORK

DIAGNOSTIC MODE

XX.XX.XX

Switch operations and LCD displays in Engine Self-diagnostic Mode depend on the instructions from the Engine F/W;

hence, they are different from the operation spec in the Controller F/W.

Engine Self-diagnostic Mode is excutable even if the Controller board is removed.

For details, see the Engine Unit spec as needed.

Item(1st Line)

Value(2nd Line)

Functions

DF

The details depend on Network.

( Not used )

Enters engine self-diagnostic mode.

The display in place of xx.xx varies among the

PU version.

(The disply within this category depends on the

Engine Maintenance specs.)

3.0.1 ID Check Pattern Printing ( " TEST PRINT MENU " item )

This pattern can be used for the cause investigation (specifying of color(C,M,Y,K) of the problem

item, the confirmation of the periodicity) of the following problem that it originated in ID, the LED

head. It is composed of CMYK color 20% duty each of the patterns (print 2 pages).

Operation: (Press switch)

Without HDD: "0" - "0" - "3" - "3"

With HDD : "0" - "0" - "0" - "3" - "3"

- Vertical Black/White Lines

- Vertical Black/White Bands

- Horizontal Black/White Lines

- Horizontal Black/White Bands

Print pattern: Page.1 Page.2

Y

M+Y M C K

3.1 Maintenance Mode and Functions

3.1.1 Maintenance menu

Y

M+Y

M

C

K

A maintenance menu category is located in the general menu category.

The following items are those that can be set with this menu.

77 /

Page 78

Maintenance Menu

Category

MAINTENANCE MENU

Item(1st Line)

EEPROM reset

SAVE MENU Save

menu setting

RESTORE MENU

Return to saved

menu setting

POWER SAVE

Power save

function

Normal paper black

setting

Value(2nd Line)

EXECUTE

EXECUTE

EXECUTE

Enabled

Disabled

0

+1

+2

-2

-1

DF

Resets EEPROM for CU.

*

Saves current menu setting. A

*

message asking Are you sure?

and a choice of YES/NO will

appear.

Changes setting to the stored menu

*

setting. (Displayed only when a

menu setting is stored.)

NOTE

attached). In HDD if HDD exists.

Enables or disables the power save

*

mode. The time to switch to Power

Save Enable can be changed with

the Power Save Delay Time Item in

the System Configuration Menu.

Normal Paper/Black Print

*

Used for fine adjustment when

scratches or dots are notable on

print results.

Decrement if the highly-dense print

portion seems dispersed or

scattered with white dust.

Increment if the print result seems

faint.

Functions

: Stored in CU Flash (directly

Normal paper color

setting

OHP paper black

setting

OHP paper color

setting

0

+1

+2

-2

-1

0

+1

+2

-2

-1

0

+1

+2

-2

-1

Normal Paper/Color Print

*

Used for fine adjustment when

scratches or dots are notable on

print results.

Decrement if the highly-dense print

portion seems dispersed or

scattered with white dust.

Increment if the print result seems

faint.

*

OHP/Black Print

Used for fine adjustment when

scratches or dots are notable on

print results.

Decrement if the highly-dense print

portion seems dispersed or

scattered with white dust.

Increment if the print result seems

faint.

*

OHP/Color Print

Used for fine adjustment when

scratches or dots are notable on

print results.

Decrement if the highly-dense print

portion seems dispersed or

scattered with white dust.

Increment if the print result seems

faint.

78 /

Page 79

3.1.2 Engine maintenance mode

SHARP

ARC200P

ARC200P

SHARP

Three modes from Level 1 to Level 3 are in the engine maintenance mode. Level 1 is a mode that

checks the media transport and basic movement of the print system. Level 2 checks the counter

for consumables and tests the correcting function of color displacement, and is a mode that does

not require special knowledge. Level 3, on the other hand, requires special knowledge for handling

the process parameter setting and is contained in the independent experimental element of PU.

Basically, levels other than Level 1 should not be used.

3.1.2.1 Operator panel

The description for operations related to self-diagnosis is made presuming the arrangement of the

operator panel shown below.

0123

3.1.2.2 Normal self-diagnostic mode (Level 1)

Items in the normal self-diagnostic mode menu are listed below.

• Switch scan test

• Motor & clutch test

• Executing test pattern

• NVM initialization

• Consumables counter display

• Consumables continuation counter display

4567

0123

4567

79 /

Page 80

3.1.2.2.1 Entering self-diagnostic mode (Level 1)

1. The system maintenance menu mode is entered by turning the power ON while pressing the

))

11

66

,

,

)

1

6

))

11

66

2. Press the

DIAGNOSTIC MODE

XX.XX.XX FACTORY/SHIPPING

3. The [XX.XX.XX] in [DISGNOSTIC MODE XX.XX.XX] that is displayed in the LCD display is the

ROM version. The set value for FACTORY WORKING MODE is displayed in the right side of

the bottom line. [SHIPPING] is normally set.

4. Proceed to each self-diagnosis step by pressing the

(The menu item rotates by pressing the

3.1.2.2.2 Exiting the self-diagnostic mode

1. Turn the power OFF, then turn it on after ten seconds.

77

, and

))

)

))

keys simultaneously.

7

77

key several times until [DIAGNOSTIC MODE] is displayed.

11

1,

11

55

5 key.)

55

11

1 or

11

55

5 key.

55

3.1.2.3 Switch scan test

This self-diagnosis is used for checking the input sensor and switch.

1. Press the

displayed on the top line.

(Key

2. Press the

following test listed in Table 3-1. (Key

3. The test starts by pressing the