Page 1

SERVICE MANUAL

CODE: 00ZARC172MA1E

DIGITAL FULL COLOR

MULTIFUNCTIONAL SYSTEM

MODEL

CONTENTS

[1] OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . 6-1

[7] DESCRIPTIONS OF EACH SECTION. . . . . . . . . . . . . . . . . . . . . . 7-1

[8] SETTING AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

AR-C172M

[11] TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ROM VERSION UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] PRINTER CONTROLLER SECTION . . . . . . . . . . . . . . . . . . . . . . 14-1

[15] OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

CONTENTS

[1] OUTLINE

1. Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Newly employed technology . . . . . . . . . . . . . . . . . . . . 1-1

[2] CONFIGURATION

1. Product Line and options. . . . . . . . . . . . . . . . . . . . . . . 2-1

A. Line of machines . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

B. Line of options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

C. Machine configuration list. . . . . . . . . . . . . . . . . . . . 2-2

D. Combination of options list. . . . . . . . . . . . . . . . . . . 2-3

2. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

[3] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

A. Base engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

B. Paper feed unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

C. Paper exit unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

D. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

2. Functional specifications . . . . . . . . . . . . . . . . . . . . . . . 3-4

A. Specifications of copy functions. . . . . . . . . . . . . . . 3-4

B. Scanner functon (Option) . . . . . . . . . . . . . . . . . . . . 3-6

C. Reversing single pass feeder. . . . . . . . . . . . . . . . . 3-9

3. Environment conditions . . . . . . . . . . . . . . . . . . . . . . . . 3-9

A. Operating environment conditions . . . . . . . . . . . . . 3-9

B. Transit environment conditions . . . . . . . . . . . . . . . 3-9

C. Supply storage environment conditions . . . . . . . . . 3-9

D. Standard temperature and humidity. . . . . . . . . . . . 3-9

[4] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

A. European Subsidiary . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Consumables (kit, unit) . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3. Photoconductor cartridge, toner cartridge . . . . . . . . . . 4-2

A. Lot number identification and the term of

validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

[5] UNPACKING AND INSTALLATION

1. Installing (use) conditions . . . . . . . . . . . . . . . . . . . . . . 5-1

A. Bringing space . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

B. Installing space . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

C. Power source

(Capacity, voltage, frequency, safety, plug) . . . . . . 5-1

D. Floor strength and level . . . . . . . . . . . . . . . . . . . . . 5-1

E. Direct rays of the sun, dust, temperature,

humidity, gasses, chemicals, vibration. . . . . . . . . . 5-1

2. Transit and delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

A. Implements, facility, and manpower. . . . . . . . . . . . 5-2

B. Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

3. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

A. Unpacking procedure . . . . . . . . . . . . . . . . . . . . . . . 5-2

4. Lock release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

A. Scanner (2/3 mirror unit) lock release . . . . . . . . . . 5-3

B. Main body cassette lock release . . . . . . . . . . . . . . 5-3

C. Transfer unit pressure release . . . . . . . . . . . . . . . . 5-3

5. Fusing heat roller pressing (F/R) . . . . . . . . . . . . . . . . . 5-4

6. Black drum cartridge insertion . . . . . . . . . . . . . . . . . . . 5-5

7. Paper exit tray installation (Optional). . . . . . . . . . . . . . 5-5

8. Toner cartridges installation. . . . . . . . . . . . . . . . . . . . . 5-5

9. AC cord connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

10. Machine power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

11. Specifications setup. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

12. Image quality check. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

13. Function and operation check . . . . . . . . . . . . . . . . . . . 5-7

14. Setup and adjustment data recording . . . . . . . . . . . . . 5-7

15. Necessary works before moving the machine. . . . . . . 5-7

[6] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. Name and function of each section . . . . . . . . . . . . . . . 6-1

A. External view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

B. Internal structure . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

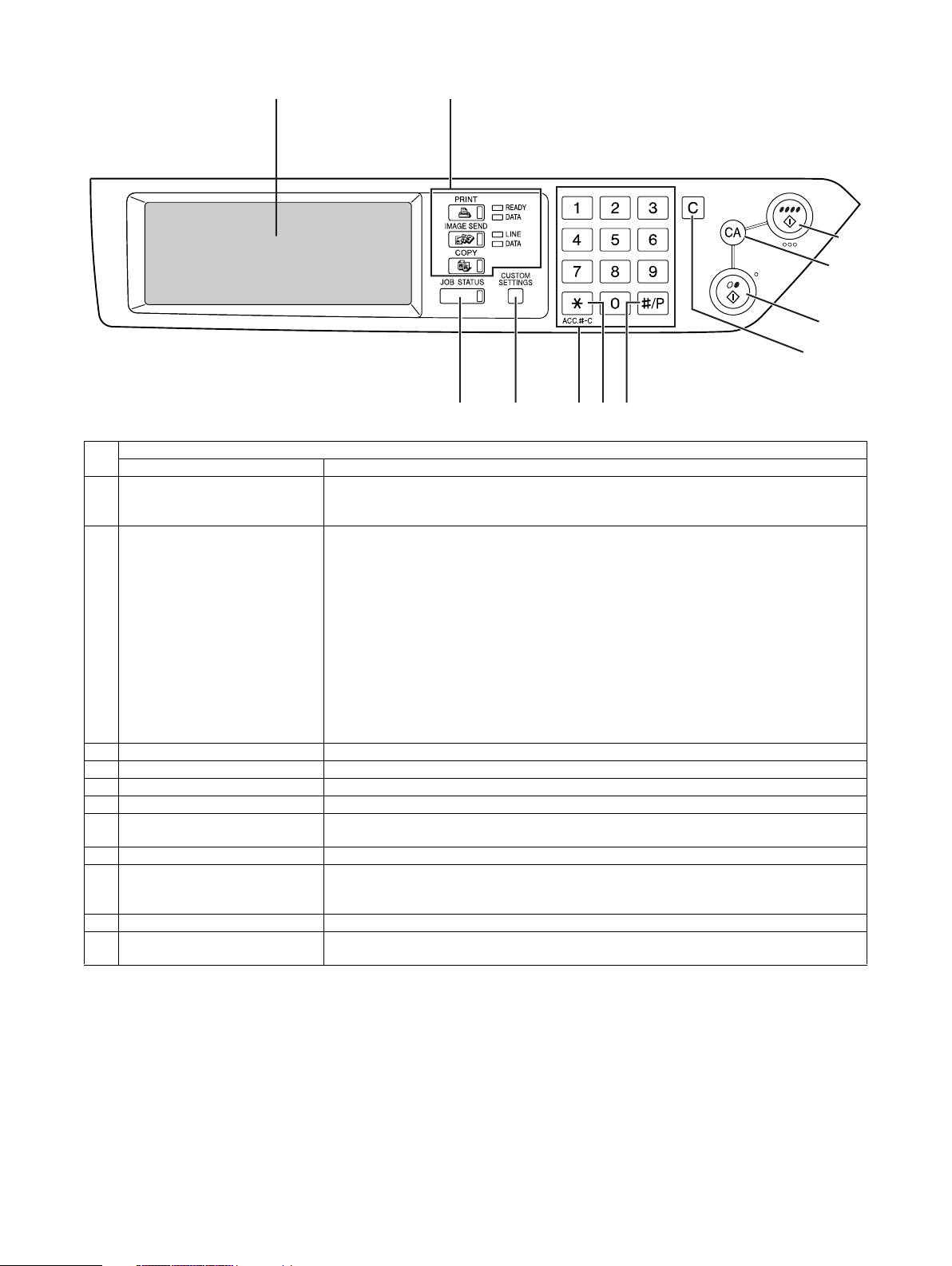

C. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

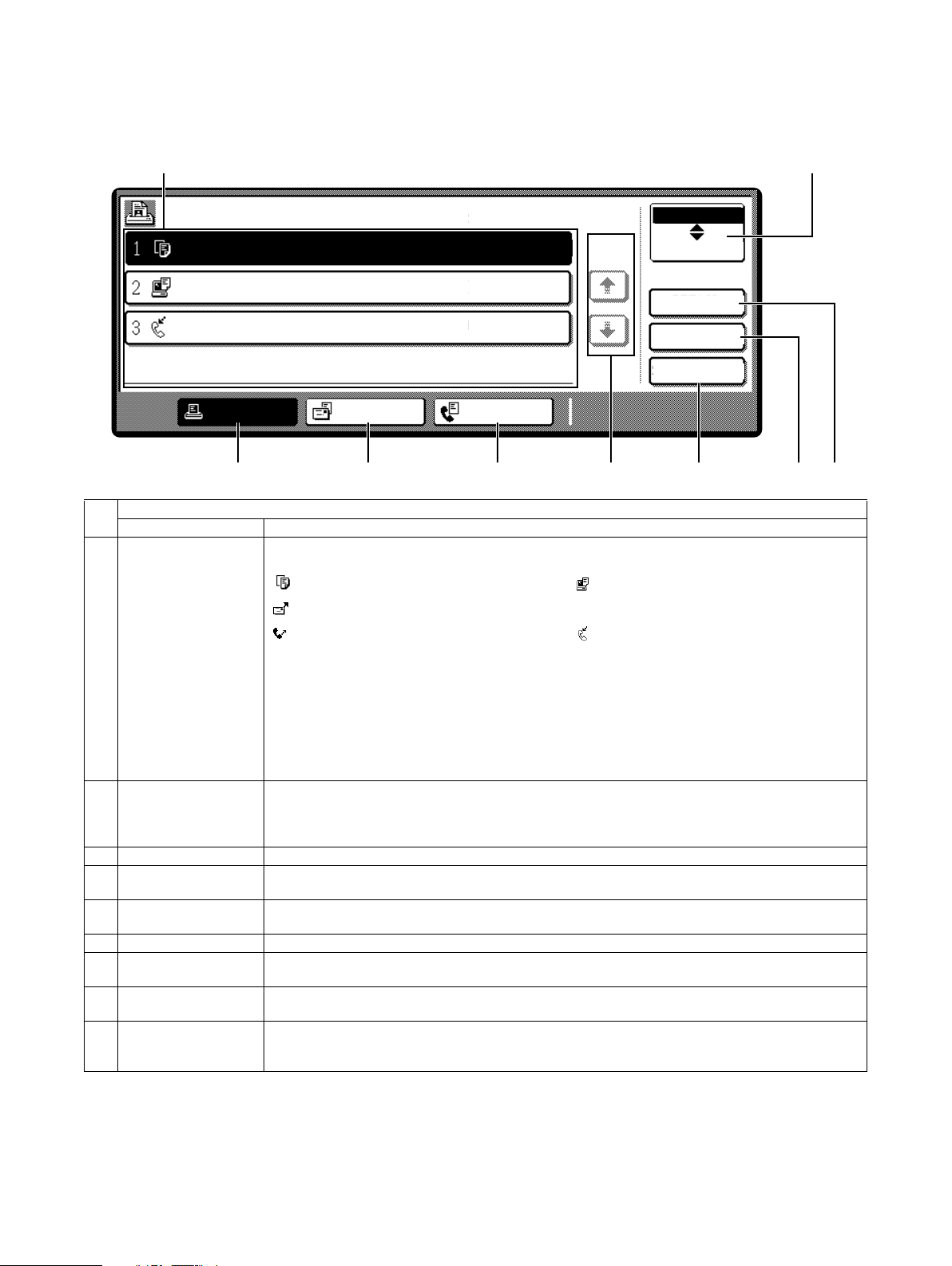

D. Job status screen (common to print, copy,

network scan and fax) . . . . . . . . . . . . . . . . . . . . . . 6-4

E. Cross section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

F. Motors, clutches, solenoids, fans . . . . . . . . . . . . . . 6-7

G. Sensors, switches and heaters . . . . . . . . . . . . . . . 6-8

H. PWB 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

H. PWB 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

[7] DESCRIPTIONS OF EACH SECTION

1. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

A. Operational descriptions . . . . . . . . . . . . . . . . . . . . 7-1

B. Disassembly/Assembly/Maintenance. . . . . . . . . . . 7-3

2. Transfer section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

A. Operational descriptions . . . . . . . . . . . . . . . . . . . . 7-7

B. Disassembly/assembly/maintenance. . . . . . . . . . 7-10

3. Process (image forming) section . . . . . . . . . . . . . . . . 7-15

A. Operational descriptions . . . . . . . . . . . . . . . . . . . 7-15

B. Disassembly/assembly/maintenance. . . . . . . . . . 7-19

4. Optical section (Scanner section) . . . . . . . . . . . . . . . 7-22

A. Operational descriptions . . . . . . . . . . . . . . . . . . . 7-22

B. Disassembly/assembly/maintenance. . . . . . . . . . 7-25

5. Paper feed, paper transport, and paper exit

sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

A. Operational descriptions . . . . . . . . . . . . . . . . . . . 7-27

B. Disassembly/assembly/maintenance. . . . . . . . . . 7-33

6. RSPF section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

A. Operational descriptions . . . . . . . . . . . . . . . . . . . 7-41

B. Disassembly/assembly/maintenance. . . . . . . . . . 7-43

7. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

A. Operational descriptions . . . . . . . . . . . . . . . . . . . 7-49

B. Disassembly/assembly/maintenance. . . . . . . . . . 7-50

8. External fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

A. Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

9. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

A. Disassembly/assembly/maintenance. . . . . . . . . . 7-53

[8] SETTING AND ADJUSTMENTS

[ADJ 1] High voltage adjustment . . . . . . . . . . . . . . . . . 8-2

[ADJ 2] Image density sensor adjustment . . . . . . . . . . 8-4

[ADJ 3] Image focus, image skew adjustment

(LED (writing) unit) . . . . . . . . . . . . . . . . . . . . . . 8-6

[ADJ 4] Image registration adjustment . . . . . . . . . . . . . 8-8

[ADJ 5] Image position/print area adjustment

(Print engine section). . . . . . . . . . . . . . . . . . . 8-14

[ADJ 6] Copy image distortion adjustment . . . . . . . . . 8-15

[ADJ 7] Copy image focus (main scanning direction

copy magnification ratio) adjustment

(CCD unit position adjustment) . . . . . . . . . . . 8-18

Page 3

[ADJ 8] Sub scanning direction copy magnification

ratio adjustment . . . . . . . . . . . . . . . . . . . . . . . 8-19

[ADJ 9] Main scanning direction copy image position

adjustment (Scanner (reading) section). . . . . 8-19

[ADJ 10] Copy image position/image loss/void area

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

[ADJ 11] Copy color balance/density adjustment . . . . . 8-21

[ADJ 12] Fusing pressure adjustment. . . . . . . . . . . . . . 8-35

[ADJ 13] Fusing paper guide position adjustment . . . . 8-36

[ADJ 14] Document size sensor adjustment. . . . . . . . . 8-36

[ADJ 15] Manual paper feed tray paper size sensor

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

[ADJ 16] Touch panel coordinates setting . . . . . . . . . . 8-37

[ADJ 17] Power voltage adjustment . . . . . . . . . . . . . . . 8-37

[ADJ 18] FAX/scanner mode image loss

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

[ADJ 19] RSPF scanning position automatic

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

[ADJ 20] RSPF lead edge skew adjustment. . . . . . . . . 8-39

[ADJ 21] Collective adjustment of image position and

magnification ratio . . . . . . . . . . . . . . . . . . . . . 8-40

[ADJ 22] Printer color balance adjustment . . . . . . . . . . 8-41

[9] SIMULATION

1. Outline and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Code-type simulation . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

A. Operating procedures and operations . . . . . . . . . . 9-1

B. Simulation list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

C. Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

[10] MAINTENANCE LIST

1. Maintenance system table . . . . . . . . . . . . . . . . . . . . . 10-1

2. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

A. Drum peripheral section . . . . . . . . . . . . . . . . . . . . 10-3

B. Developing section . . . . . . . . . . . . . . . . . . . . . . . . 10-3

C. Transfer section . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

D. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

E. Optical section (Scanner section). . . . . . . . . . . . . 10-6

F. Paper feed section, transport section. . . . . . . . . . 10-7

G. LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

H. RSPF section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

I. Filters, drive section, others . . . . . . . . . . . . . . . . . 10-9

3. Relationship of maintenance timing,

consumable part life, display message, and

machine operations . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

A. Relationship of maintenance counter, display

message, and machine operations . . . . . . . . . . 10-10

B. Relationship of transfer unit system counter,

display message, and machine operations . . . . 10-10

C. Relationship of fusing unit counter, display

message, and machine operations . . . . . . . . . . 10-11

D. Relationship of drum cartridge system counters,

messages, and machine operations. . . . . . . . . . 10-11

E. Relationship of toner cartridge system counters,

display messages, and machine operations . . . 10-12

[11] TROUBLESHOOTING

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. Functions and purposes . . . . . . . . . . . . . . . . . . . . . . 11-1

3. Kinds of self diagnostic messages. . . . . . . . . . . . . . . 11-1

4. Self diagnostic operation . . . . . . . . . . . . . . . . . . . . . . 11-1

A. Self diagnostic operation and work flow. . . . . . . . 11-1

5. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

6. Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

[12] ROM VERSION UP

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

A. Target ROM for version up. . . . . . . . . . . . . . . . . . 12-1

B. When version up of ROM is required . . . . . . . . . . 12-1

C. Flash ROM version up method . . . . . . . . . . . . . . 12-2

2. Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

A. Relationship between each ROM and

version up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

3. Necessary items for version up (copy) of

Flash ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-5

4. Flash ROM version up procedure . . . . . . . . . . . . . . . 12-6

A. By using a computer and the ICU PWB, the

program data of Flash ROM is written from the

computer to the Flash ROM of the ICU PWB. . . . 12-6

B. Method using two Flash ROM sockets on

the ICU MAIN PWB to copy between

Flash ROM’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-9

[13] ELECTRIC DIAGRAM

1. System block diagram. . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. Actual wiring chart. . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

3. Signal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-18

[14] PRINTER CONTROLLER SECTION

1. System configuration. . . . . . . . . . . . . . . . . . . . . . . . . 14-1

A. Main unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

B. Basic composition . . . . . . . . . . . . . . . . . . . . . . . . 14-1

C. Accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

D. Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

E. Software, firmware diagram. . . . . . . . . . . . . . . . . 14-2

2. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

3. Configuration report (Test page) . . . . . . . . . . . . . . . . 14-6

4. Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

A. Major device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

B. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

C. Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-8

5. Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-9

A. Key operator program . . . . . . . . . . . . . . . . . . . . . 14-9

B. Jumper Setting. . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

6. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-11

A. Printer driver setting and operation . . . . . . . . . . 14-11

7. Firmware version up . . . . . . . . . . . . . . . . . . . . . . . . 14-13

A. Necessary items. . . . . . . . . . . . . . . . . . . . . . . . . 14-13

B. Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-13

8. AR-NS2 installing procedure . . . . . . . . . . . . . . . . . . 14-13

9. AR-PK4 installing procedures . . . . . . . . . . . . . . . . . 14-14

A. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-14

B. Check items . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-14

C. PS firmware ROM installation . . . . . . . . . . . . . . 14-14

D. PS printer utility software installation . . . . . . . . . 14-14

[15] OTHERS

1. Key operator program . . . . . . . . . . . . . . . . . . . . . . . . 15-1

A. Key operator program menu . . . . . . . . . . . . . . . . 15-1

2. Special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-2

Page 4

[1] OUTLINE

1. Product features

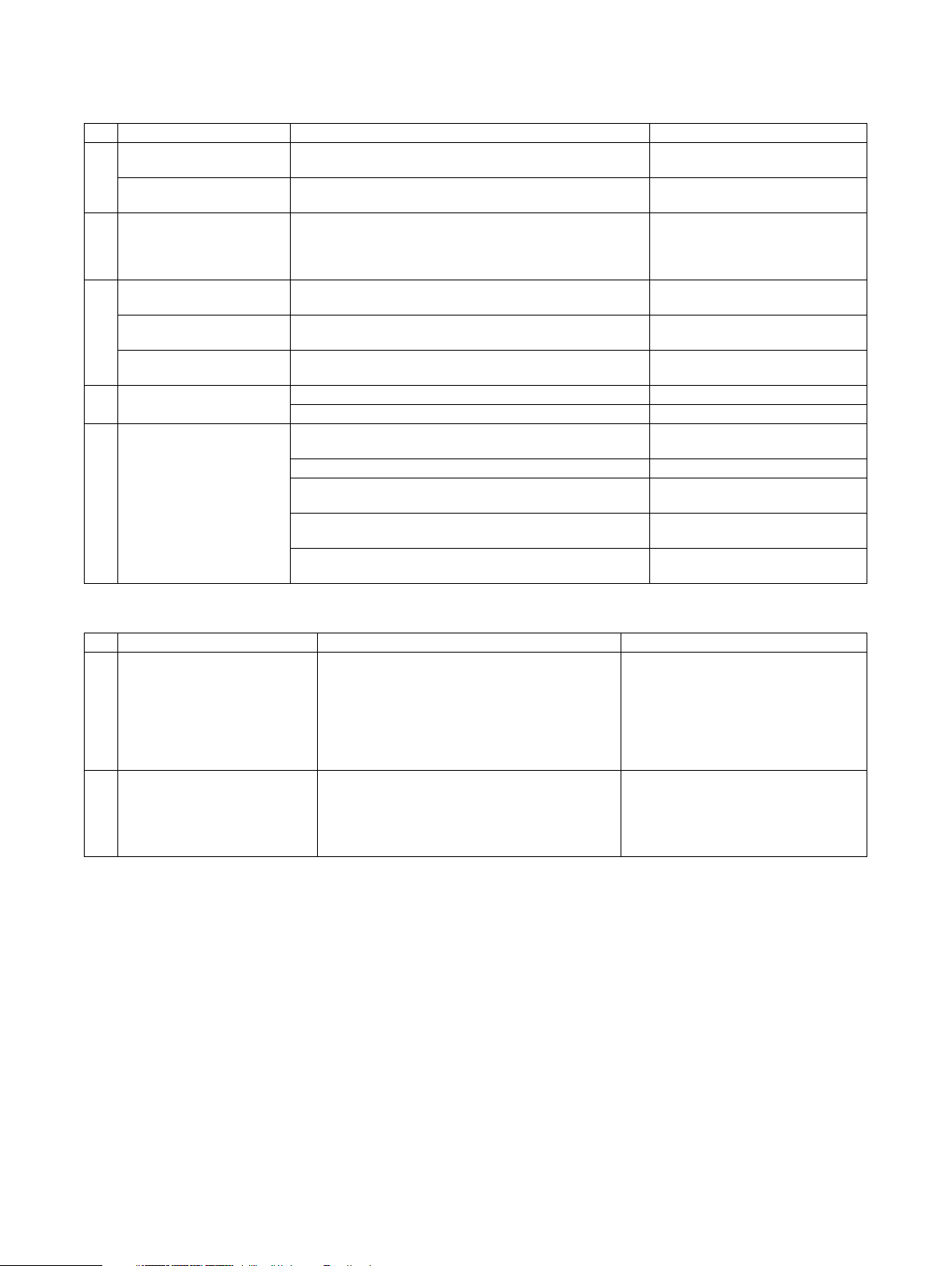

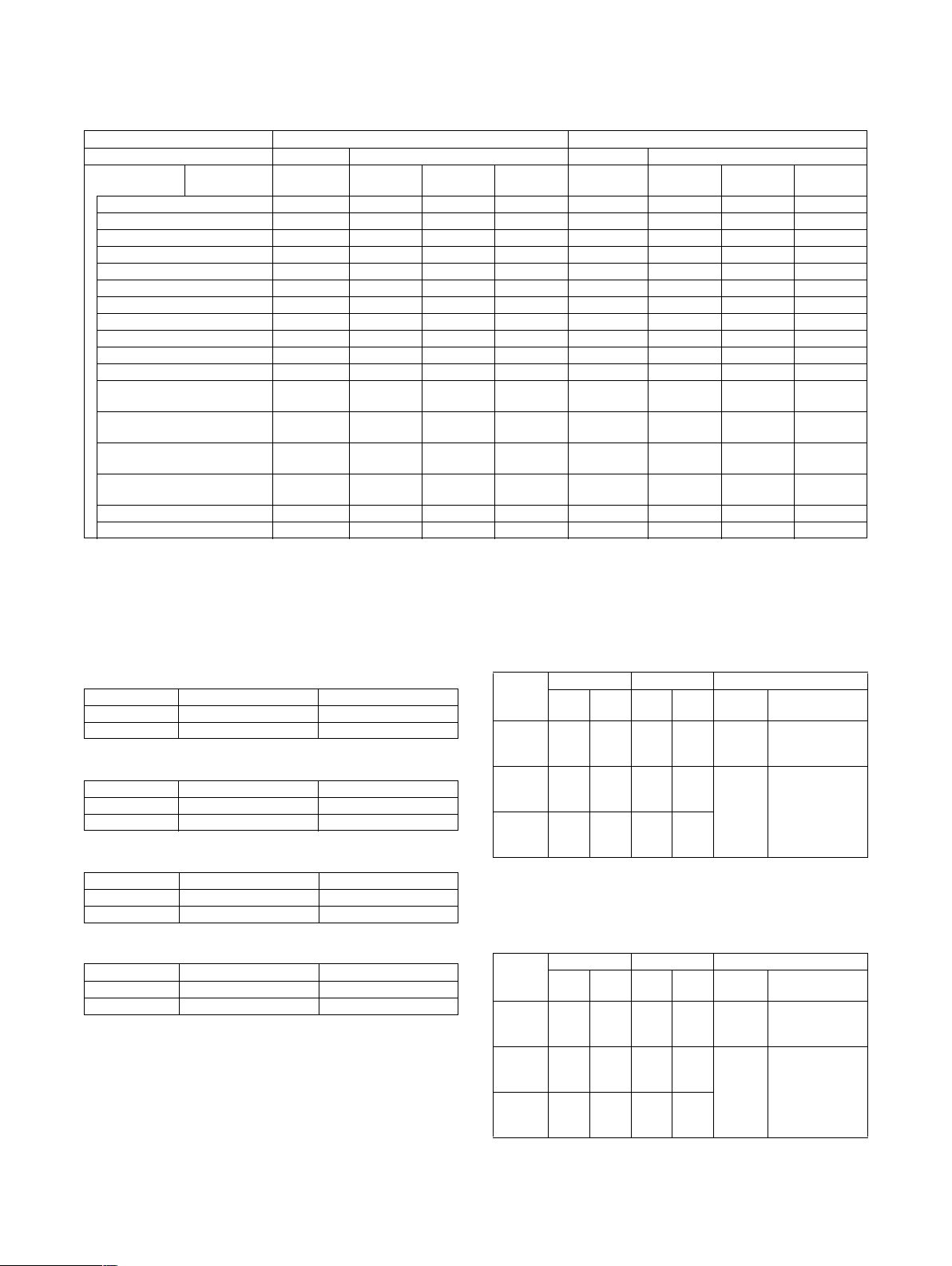

No. Feature Content Employed technology

1 Compact, lightweight, A3

tandem engine

High speed output Color: 17 PPM (A4/LT)

2 High-speed, first color copy Color: Within 11.7 sec

3 Manual paper feed capacity 300 sheets 64g/m

Heavy paper support 64 to 300g/m

Heavy paper duplex feed

support

4 Improved user maintenance Paper jam process: 2 positions of open/close (sides) Paper jam control technology

5 Improved service

maintenance

670 x 676 x 787mm (26.4 x 26.6 x 31 inch)

85.5kg (185.5 lbs.) (Copier body + photoconductor + toner)

B/W: 26 PPM (A4/LT)

B/W: Within 8.0 sec

A4, without pre-scan, RSPF not used, side paper exit, tray 1

used

64 to 200g/m

Toner supply: Cartridge replacement Mono-component wax-free toner

Developing section: Mono-component development

eliminates the need for developer replacement.

Drum section: Cartridge replacement Designed for easy maintenance

Fusing section: Simplified structure by wax-free. The unit can

be disassembled simply by releasing the lock with the knob.

Transfer section: One-touch extraction. Designed for easy

belt replacement.

Color resist automatic adjustment:

Visual judgment by paper exit is automatically performed.

2

(17 lbs.) Development of a large capacity

2

(17 to 80 lbs.) (Manual paper feed tray) Oil-less fusing unit, paper feed/

2

(17 to 54 lbs.) (Face up paper exit)

Mono-component wax-free toner,

LED printhead

Same document continusly on A4

(LT) plain paper in non offset mode.

LED printhead

manual feed tray

paper transport technology

Mono-component wax-free toner

Mono-component wax-free toner.

Designed for easy maintenance

Designed for easy maintenance

Process control technology, which

allows user adjustment.

2. Newly employed technology

Item Content Remark

1 LED printhead employed • Employment of the 4bit LED provides

16-gradation expressions for each of YMCK.

• Free from mechanical noises which are produced

from the unit such as an LSU. Printing is started

immediately without waiting for stabilization of the

polygon motor speed.

• Lower power consumption than an LSU

2 Oil-less fusing system employed • Development of a new wax-free toner

• The wax-free fusing system provides a simplified

structure and improved paper feed capability.

• Notes and remarks can be put on a copy image

similar to normal page.

Resolution: 600dpi (Total dots: 7,424

dots)

AR-C172M OUTLINE 1 - 1

Page 5

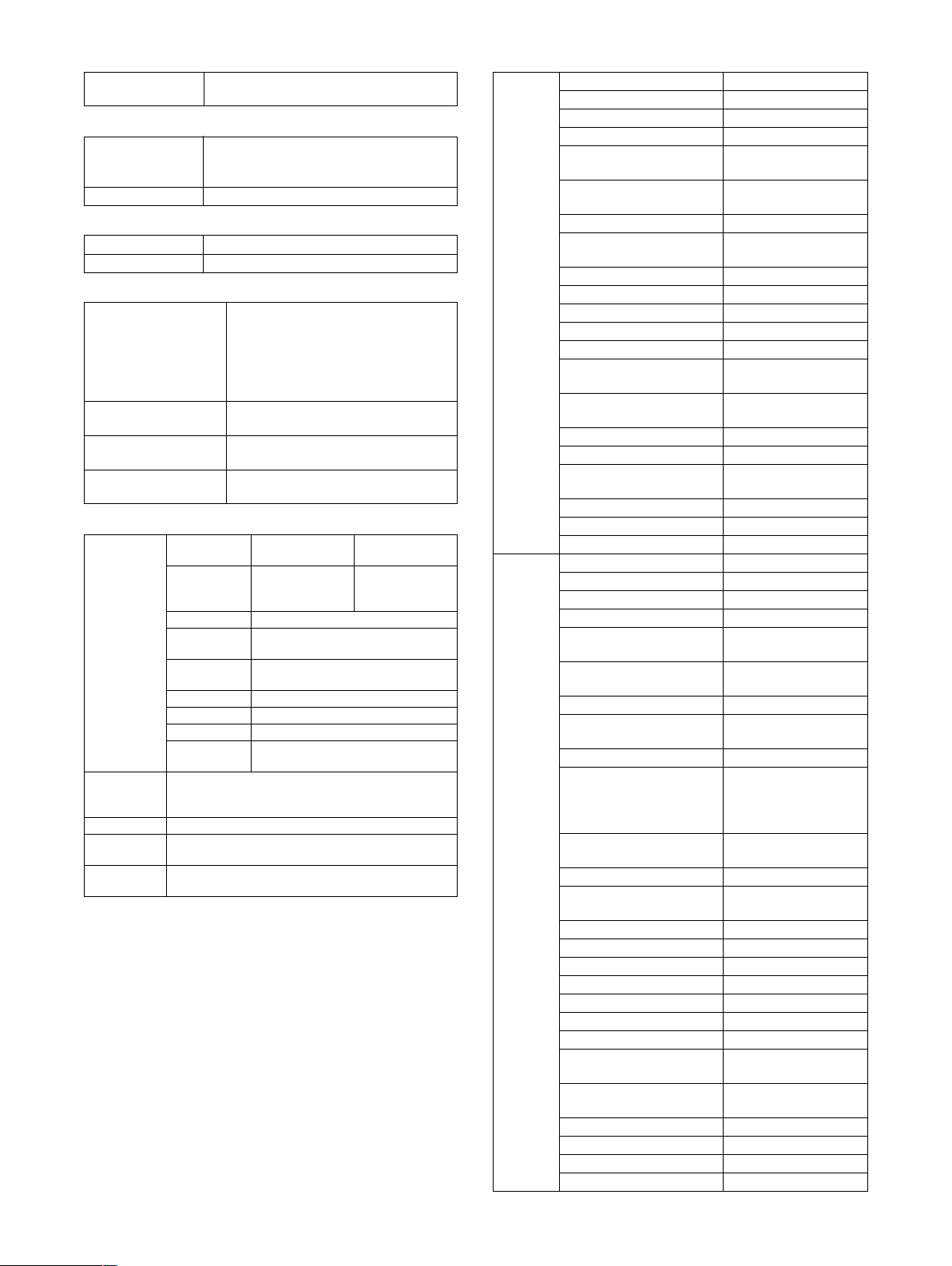

[2] CONFIGURATION

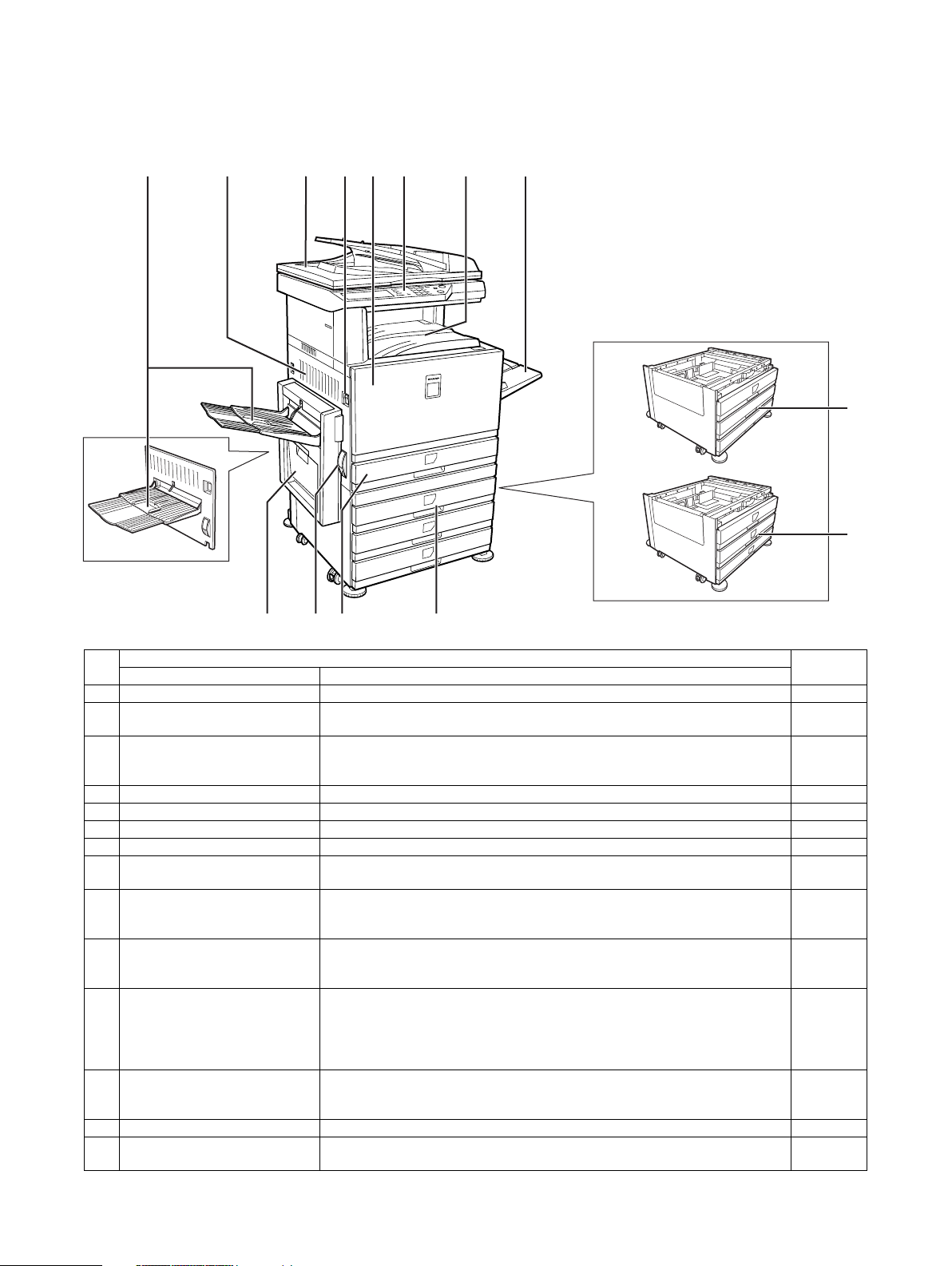

1. Product Line and options

A. Line of machines

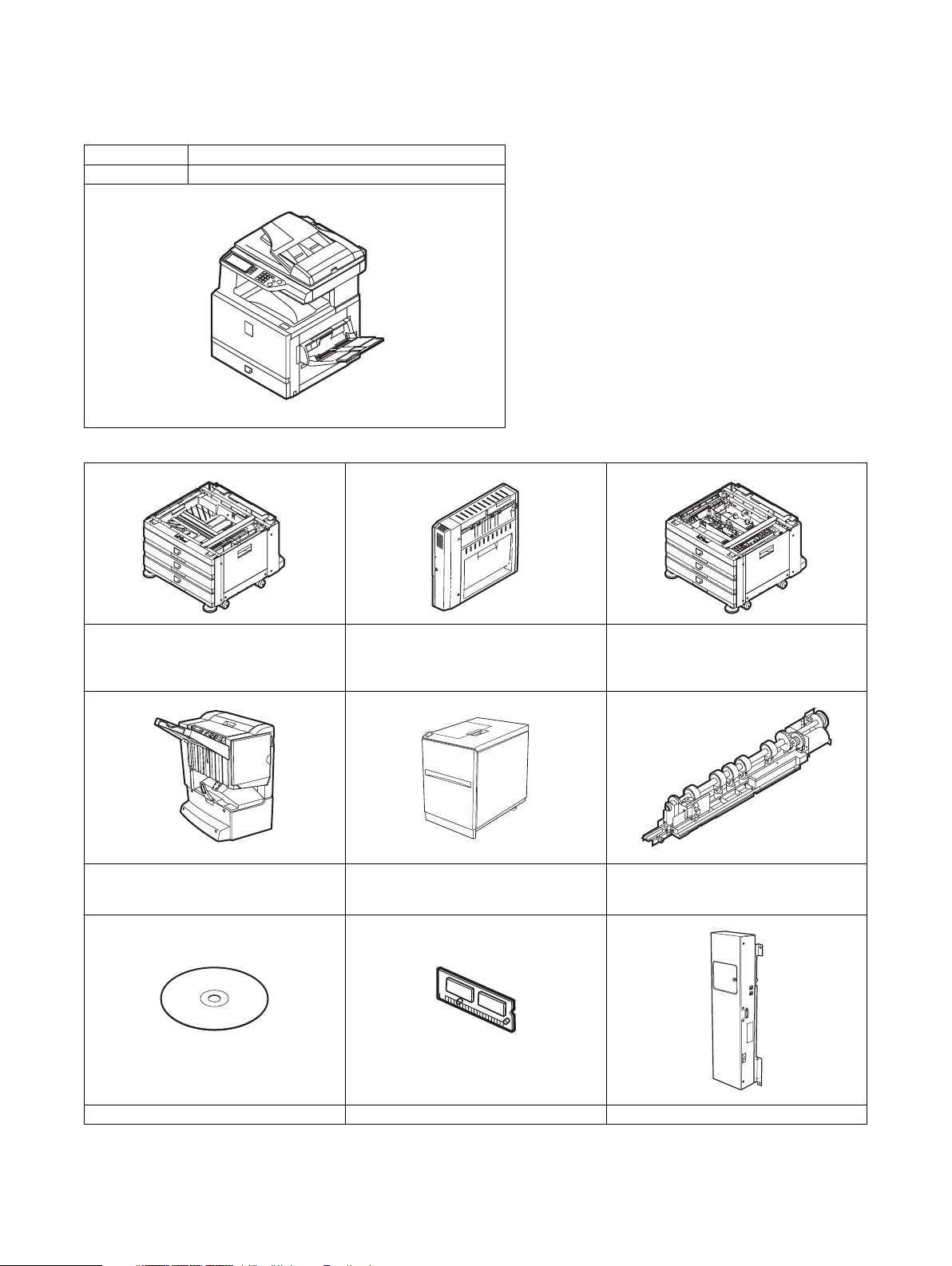

Model name Composition

AR-C172M Copier/Printer model

B. Line of options

AR-D18N/Paper feed module

(3-stage paper feed desk)

AR-D17N/Paper feed module

(1-stage paper feed desk)

AR-F13/Saddle finisher

(Requires Duplex bypass/Inverter unit

(AR-RB1).)

AR-RB1/Duplex bypass/Inverter unit

(Requires Desk.)

AR-LC8/Large capacity tray

AR-D19N/Duplex module + Paper feed

module (2-stage)

(Requires Duplex bypass/Inverter unit

(AR-RB1).)

AR-PN1A, AR-PN1B, AR-PN1C, AR-PN1D/

Punch unit

(for saddle stitch finisher (AR-F13))

AR-U11M, AR-U15M/Sharpdesk license kit AR-PK4/PS3 expansion kit AR-FX10/Facsimile expansion kit

AR-C172M CONFIGURATION 2 - 1

Page 6

AR-MM9/FAX memory (8MB) AR-FR23U/Data security kit

AR-TE3/Exit tray AR-SC2/Staple cartridge AR-NS2/Network scanner expansion kit

128/256MB expansion memory

(Local arrangement)

C. Machine configuration list

STD or ❍ (Yes) : Included in the set. (Included in the base engine.)

OP : Option

N/A or ✕ (No) : No support or no setup

Basic composition Copier/Printer/Scanner Remark

Supply system SRU

AR drum cartridge × 4 ❍

AR toner cartridge × 4OP

Printer controller board (Base memory: 128 MB) ❍

HDD ❍

Soft NIC ❍

ICU memory 256MB

Fax-Box (Facsimile expansion kit) OP

JOB SHIFTER ❍

LCC connection module ❍

RSPF ❍

Dehumidifier (Engine) For service kit

Network scanner expansion kit OP

AR-C172M CONFIGURATION 2 - 2

Page 7

D. Combination of options list

STD or ❍ (Yes) : Included in the set. (Included in the base engine.)

OP : Option

N/A or ✕ (No) : No support or no setup

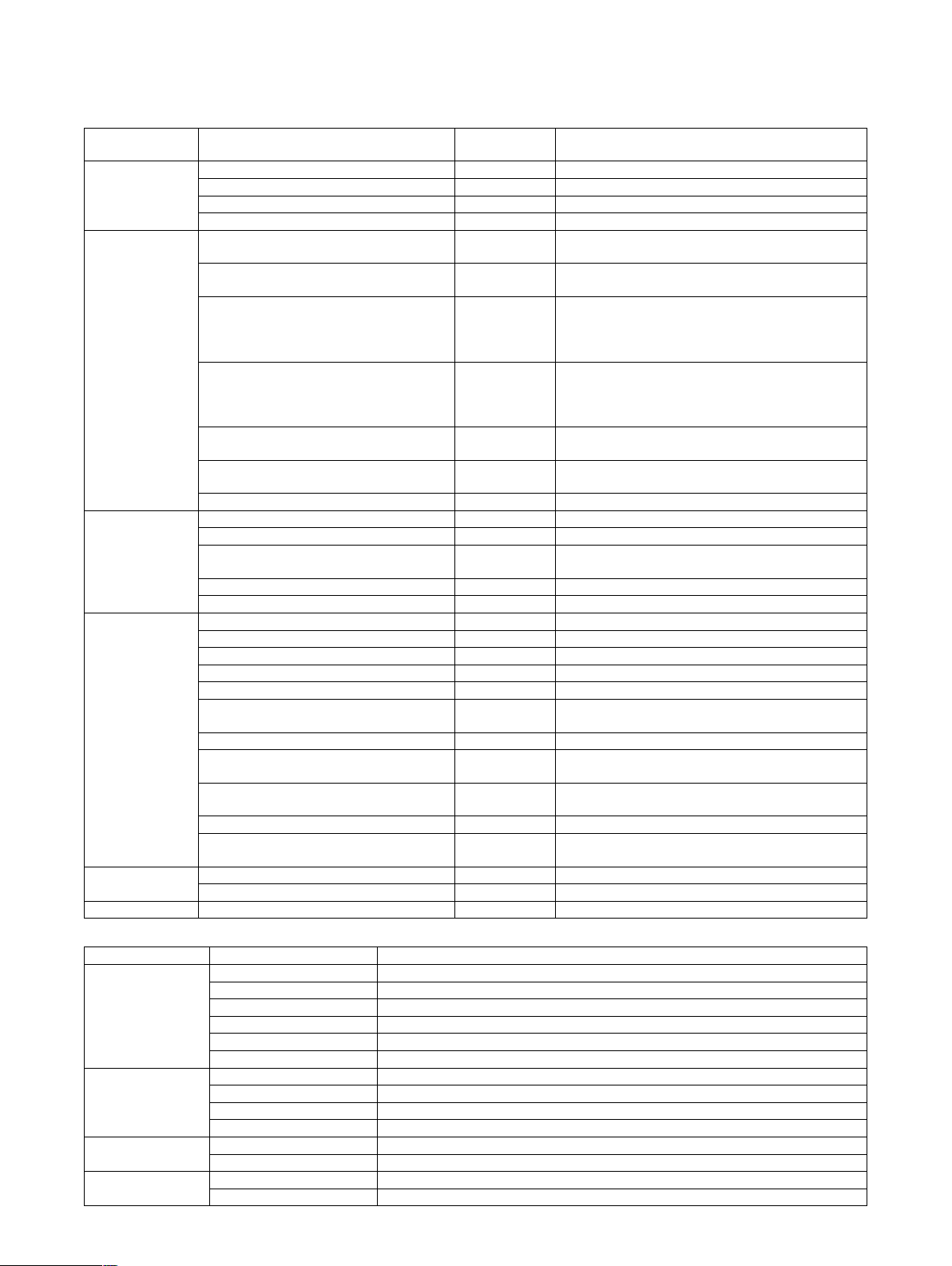

Section Item

Automatic

document feeder

and scanning

Integrated scanner unit STD

OC ✕

RSPF STD

Copier/Printer/

Scanner

Trial network scanner function STD

Paper feed

system/Duplex

One-stage tray

(Standard provision of the machine)

Manual paper feed tray

(Standard provision of the machine)

1-stage paper feed desk (AR-D17N)

STD

STD

OP

500 × 1 (80g/m

550 × 1 (64g/m

250 sheets (80g/m

300 sheets (64g/m

500 × 1 (80g/m

550 × 1 (64g/m

A 2-stage paper feed desk with duplex cannot be

∗

used.

3-stage paper feed desk (AR-D18N)

OP

500 × 3 (80g/m2) (21 lbs.)

550 × 3 (64g/m

A 2-stage paper feed desk with duplex cannot be

∗

used.

2-stage duplex paper feed desk (AR-D19N)

Reverse bypass module (AR-RB1)

OP

OP

Requires a duplex bypass/inverter unit. /

3-stage paper feed desk cannot be used.

Requires desk (3-stage/2-stage duplex paper feed

desk)

Large capacity tray (AR-LC8) OP Requires 2-stage duplex paper feed desk

Paper exit system Paper exit tray (AR-TE3) OP

Job shifter STD

Saddle finisher (AR-F13)

OP

Requires a desk (3-stage/2-stage paper feed desk

with duplex) and a duplex bypass/inverter unit.

Punch unit (AR-PN1A/PN1B/PN1C/PN1D) OP For saddle finisher

Staple cartridge (AR-SC2) OP For saddle finisher

Electrical system Printer controller STD 7410: 400 MHz type

Scanner interface board STD

Installed memory 128MB For printer board

Soft NIC STD

HDD (3.5 inch) STD 40GB

PS3 expansion kit (AR-PK4)

OP

Requires 512MB memory.

Product Key

128MB expansion memory ∗1 Local arrangement: For ICU or printer controller

256MB expansion memory ∗1 Local arrangement or AR-SM5: For ICU or printer

controller

Network scanner expansion kit (AR-NS2)

OP

Product Key

Requires memory expansion of 256MB or more.

Sharpdesk license kit (AR-U11M/U15M) OP

Various connection cables Not supported. Unavailable as an option (Use a commercially

available part.)

FAX system Fax controller (AR-FX10) OP

Fax memory (8 MB) (AR-MM9) OP

Other Data security kit (AR-FR23U) OP

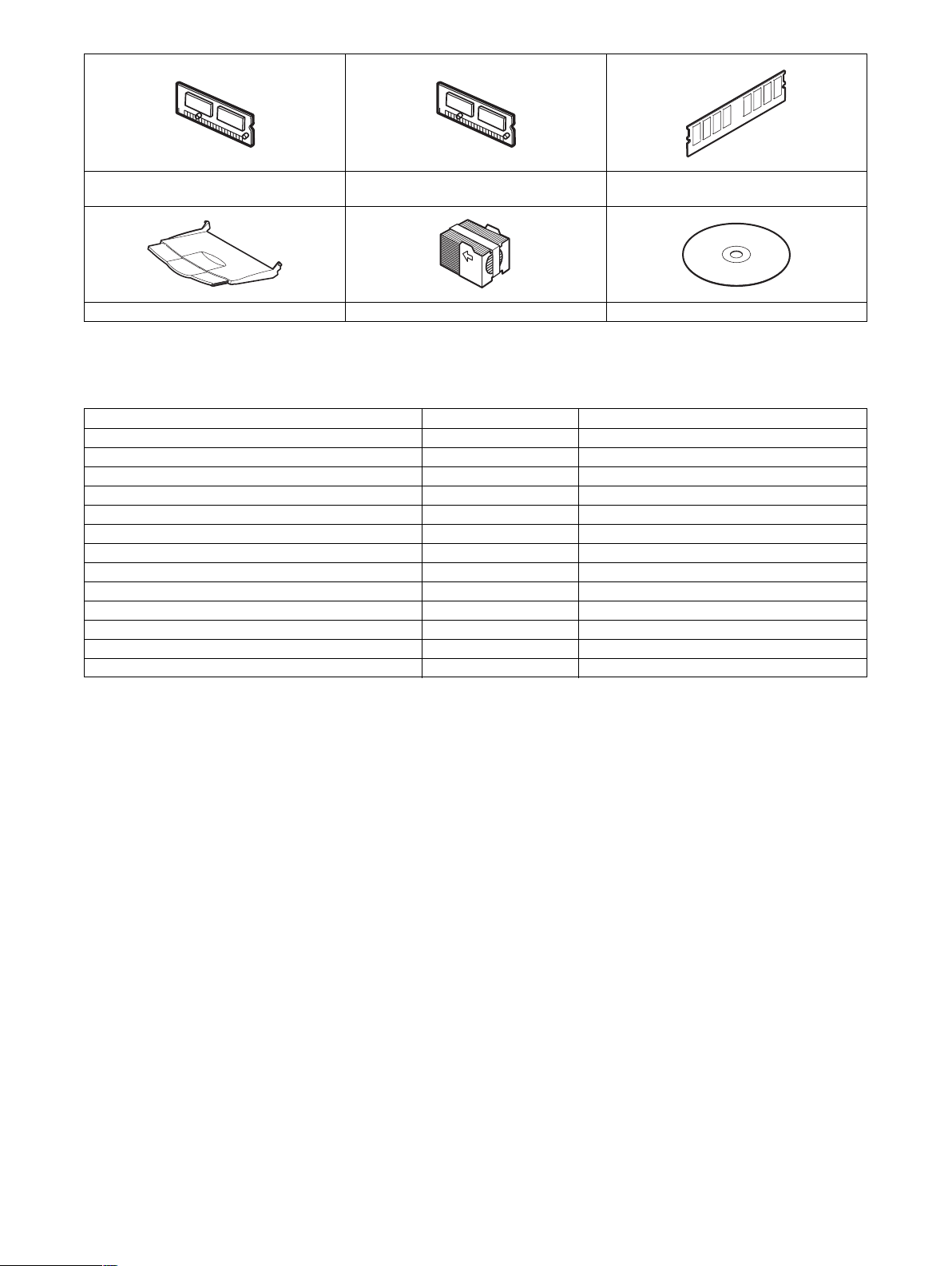

∗1: The AR-SM5 (256MB) can be used. For the other memories, choose among commercially available ones (table below) and set.

Manufacture P/N Description

Kingston SHP32X64S133C3-B 256MB, PC133, DIMM

SHP16X64S133C3 128MB, PC133, SODIMM

SHP16X64S133C3-B 128MB, PC133, DIMM

SHP32X64S133C3 256MB, PC133, DIMM

D1664A30 128MB, 168 PIN

D3264A30 256MB, 168 PIN

Memory Experts MXAR2372128B 128MB, PC100 OR PC133, 168 PIN

MXAR2371256 256MB, PC100 OR PC133, 168 PIN

MXAR2371128 128MB, PC100 OR PC133, 168 PIN

MXARSM5 256MB, PC100 OR PC133, 168 PIN

RAM components MIMD1289A63N1621E16E 128MB, 168 PIN PC133

MIMD1289A63N3221H16E 256MB, 168 PIN PC133

IO DATA LP-S100-128M

LP-S100-256M

2

) (21 lbs.)

2

) (17 lbs.)

2

) (21 lbs.)

2

) (17 lbs.)

2

) (21 lbs.)

2

) (17 lbs.)

2

) (17 lbs.)

Remark

AR-C172M CONFIGURATION 2 - 3

Page 8

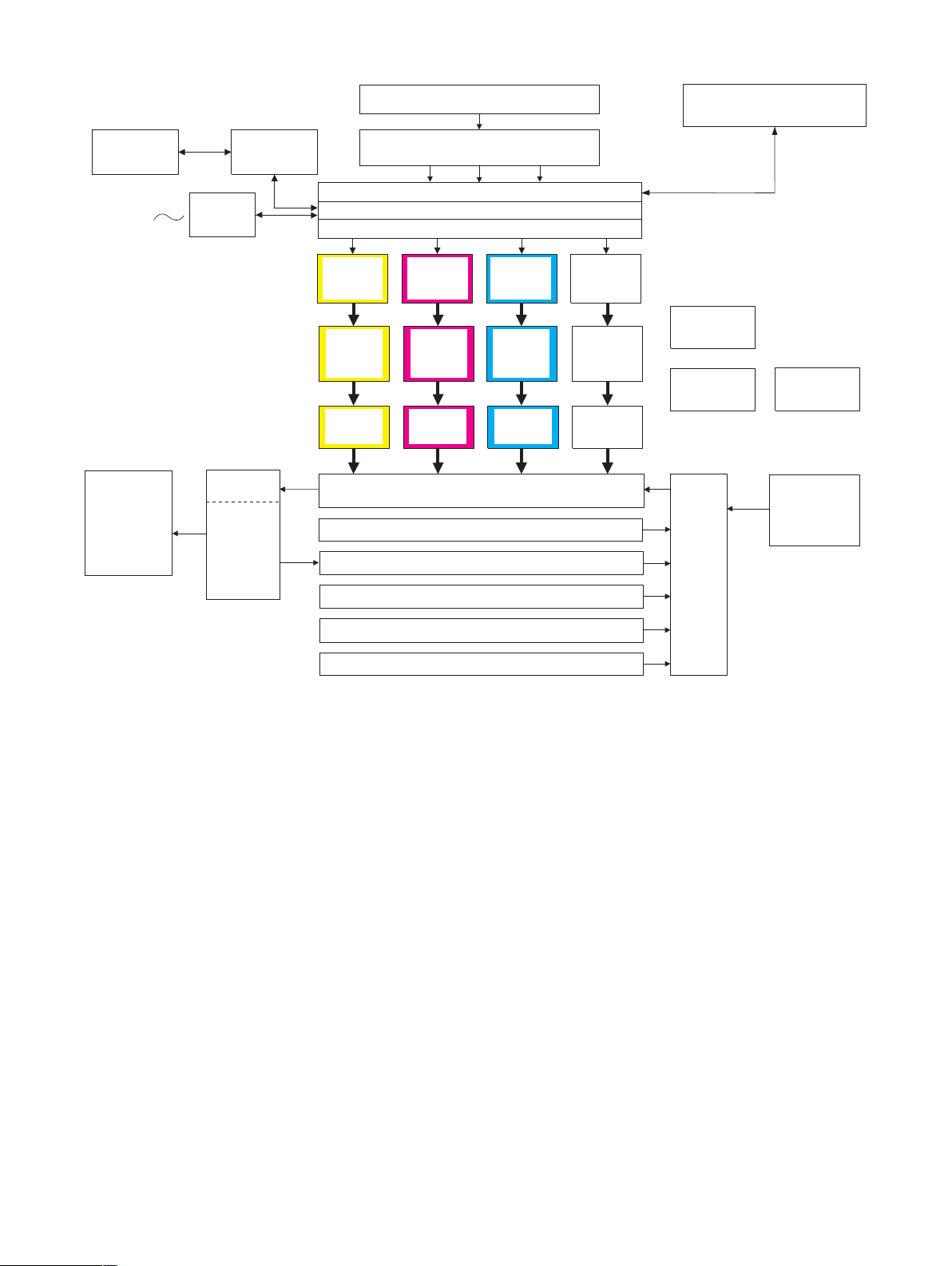

2. Block diagram

PC

Line

Finisher

(Option)

FAX

controller

(Option)

Fusing/paper

exit section

Duplex

bypass/

Inverter

(Option)

controller

unit

Printer

LED head

(writing)

section

(Y)

Photo-

conductor

section

(Y)

Developing

section

(Y)

RSPF unit

Image scanning (writing) section

(CCD PWB)

Image process section (MFP PWB)

Image process section 2 (ICU PWB)

Page memory

LED head

(writing)

section

(M)

Photo-

conductor

section

(M)

Developing

section

(M)

LED head

(writing)

section

(C)

Photo-

conductor

section

(C)

Developing

section

(C)

Transfer section

Paper feed tray section 1

Duplex section (Option)

Paper feed tray section 1 (Option)

LED head

(writing)

section

(K)

Photo-

conductor

section

(K)

Developing

section

(K)

Operation section

PCU PWB

DC power unit

Paper

transport

section

AC power unit

Large capacity

paper feed tray

unit (Option)

Paper feed tray section 2 (Option)

Paper feed tray section 3 (Option)

AR-C172M CONFIGURATION 2 - 4

Page 9

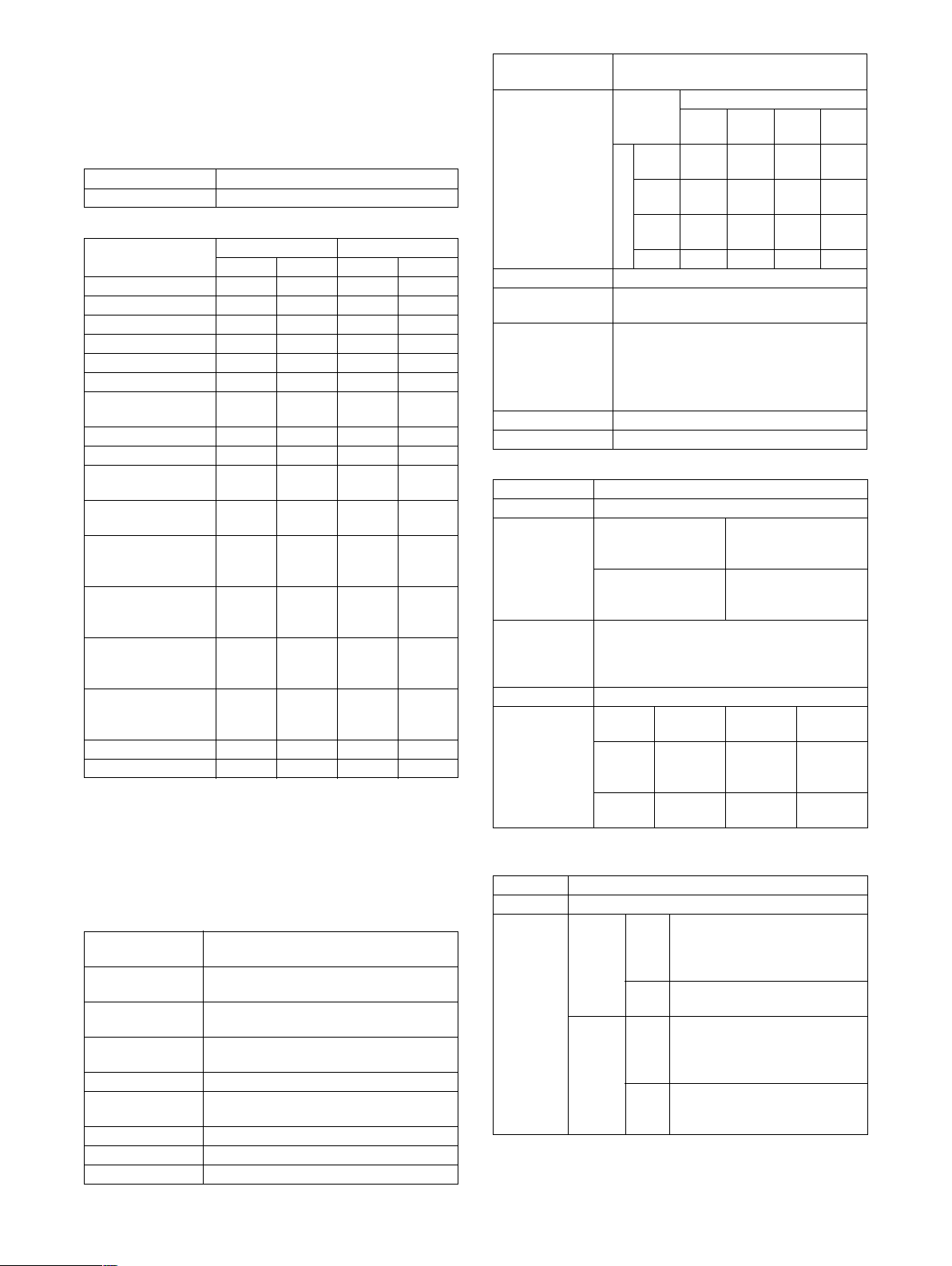

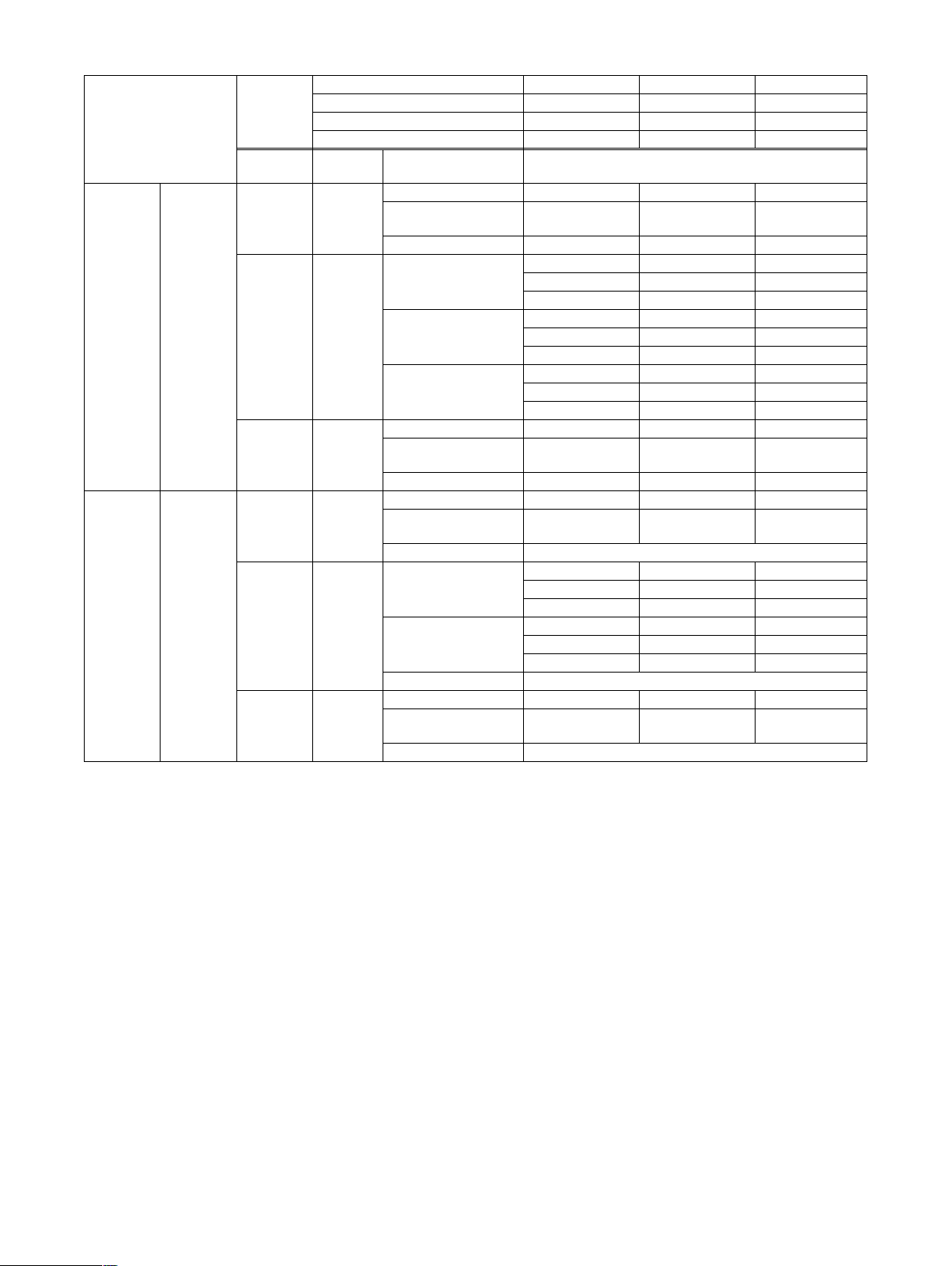

[3] SPECIFICATIONS

1. Basic specifications

A. Base engine

(1) Type

Type Desk-top

Color support Full color

(2) Engine speed

Paper size

A3W (12 x18) 5 ppm 5 cpm 7 ppm 7 cpm

A3, 11 x17, 8K 8 ppm 8 cpm 13 ppm 13 cpm

B4, 8.5 x14, 8.5 x13 10 ppm 10 cpm 15 ppm 15 cpm

8.5 x11,A4 17 ppm 17 cpm 26 ppm 26 cpm

A4R, 8.5 x 11R 12 ppm 12 cpm 19 ppm 19 cpm

B5,16K 17 ppm 17 cpm 26 ppm 26 cpm

B5R, 7.25 x 10.5R,

16KR

A5, 8.5 x 5.5 17 ppm 17 cpm 26 ppm 26 cpm

A6R (Normal paper) 13 ppm 13 cpm 13 ppm 13 cpm

Transparency

(Speed *

2

)

Transparency (Image

quality)

3

Heavy paper 1 *

(B5, A4, 8.5 x 11,

16K , A5, 8.5 x 5.5)

Heavy paper 1 *

3

(Except Envelope &

above size)

3

Heavy paper 2 *

(B5,

A4, 8.5 x11, 16K ,

A5, 8.5 x 5.5)

Heavy paper 2 *

3

(Except Envelope &

above size)

Envelope *

1

(all size) 5 ppm 5 cpm 6 ppm 6 cpm

EXTRA size 5 ppm 5 cpm 7 ppm 7 cpm

∗ The “cpm” (ppm) is copy speed. The speed is measured with

SOPM operation (same document continuously) and with the

offset off.

* 1: Type of envelopes: COM-10, Monarch, DL, C5

* 2: The fastest speed

* 3: Heavy paper 1: 106 to 200g/m

Heavy paper 2 : 201 to 300g/m

(3) Engine composition

Photoconductor

kind

Copying method Electrostatic copying system employing the

LED available print

area

Developing system Contact, non-magnetic 1-component

Charging system Saw teeth scorotron corona charging

Transfer system Transfer belt structure direct transfer

Cleaning system Counter blade cleaning system

Fusing system Pressure roller fusing system

Fusing unit life 2 years or 100K

OPC (Drum diameter: φ30mm x 4)

LED writing head

301 mm

development

system

Color B/W

Print Copy Print Copy

12 ppm 12 cpm 19 ppm 19 cpm

17 ppm 17 cpm 17 ppm 17 cpm

13 ppm 13 cpm 13 ppm 13 cpm

13 ppm 13 cpm 13 ppm 13 cpm

6 ppm 6 cpm 6 ppm 6 cpm

13 ppm 13 cpm 13 ppm 13 cpm

6 ppm 6 cpm 6 ppm 6 cpm

2

(28 lbs to 54 lbs).

2

(54 lbs to 80 lbs).

Fusing unit

replacement

Mode switching

speed (A → B)

Replaceable 30min after turning off the

power

B

Normal

Normal

Heavy

Heavy

paper

paper 1

paper 2

– 30 sec 40 sec 40 sec

OHP

paper

Heavy

30 sec – 40sec 40 sec

Heavy

40 sec 10 sec – 50 sec

A

paper 1

paper 2

OHP

45 sec 10 sec 20 sec –

Oil supply Oil-less system

Waste toner

process

Multi print speed

(at Max.)

Self collection of each toner cartridge

Waste toner box collection for transfer belt

B/W: 26 ppm (A4/Letter)

Color: 17 ppm (A4/Letter)

[In the case of manual paper feed]

B/W: 26 ppm (A4/Letter)

Color: 17 ppm (A4/Letter)

Shifter Standard (Default setting: Offset OFF)

Dehumidifier Service kit

(4) Shifter

Type Shifter

Paper weight 64 to 200g/m

Paper size

(64 to 200g/m

Non offset mode

2

)

(Simple load)

Offset mode A3 to A6R,

Productivity Non offset mode: Color 17 sheets,

Offset mode: Color 16 sheets,

Offset width 30mm

Alignment *

1

Non

offset

mode

Offset

mode

∗1: When A4/Letter recommended paper is used.

2

(17 to 54 lbs)

A3W to A6R,

12" x 18" to 8.5" x 5.5",

8K, 16K, 16KR

11" x 17" to 8.5" x 5.5",

8K, 16K, 16KR

B/W 26 sheets

B/W 24 sheets

Extending FR shift

Must not

fall from

——

the tray.

Within

50mm

Within

± 10mm

Between

jobs

10mm or

more

(5) Engine resolution

Resolution Writing: 600dpi x 600dpi

Smoothing None

Gradation When

copying

When

printing

∗1: Dither matrix allows printing in 1-pixel, 256-gradation (8bit).

∗2: For 4bit mode, an expansion memory of 128MB or more is

required in the printer controller.

Color Writing: 1 pixel 16 gradations for

each color (4 bit) *

1

E-sort mode:

1 pixel 2 gradations (1bit)

B/W Writing: 1 pixel 2 gradations

(1bit)

Color Writing:

1 pixel 2 gradations (1 bit)

16 gradations for each color

1 *2

(4 bit) *

B/W Writing:

1 pixel 2 gradations (1bit)

16 gradations (4 bit) *

1

AR-C172M SPECIFICATIONS 3 - 1

Page 10

(6) Warm-up

Warm-up time 99sec or less

Pre-heat function Yes

(7) Jam recovery time

With the left cover and front

cabinet open

With the right cover open About 8 sec

About 60 sec Left for 60sec

Normal condition

(8) Image chip (Printable area)

Full size Total circumference 4mm ± 2mm

∗ In A3/11" x 17" full image copy, there is no image chip in A3/

WLT image.

∗ When outputting cut position marks, printing can be made in the

range of image chip specification.

∗ When using RSPF, however, A3 full image copy cannot be

made.

Only when A3 full image is outputted, 6mm or less in

total.

(9) Printer controller

Type Built-in

CPU Power PC 7410-400 MHz

Memory 128MB (std.) max. 640MB

Add. memory slot 2 slot

Font 80 fonts (PCL5-c), 136fonts (PS3: option)

NIC Software NIC is standard

(10) Power source

Voltage 100 – 127 V

Frequency 50/60 Hz

Power cord Inlet type

• For optional stand (for AC power supply

/ Fax Box)

∗ Nighttime mode should be supported.

(11) Power consumption

Max. power consumption 1.5 kW

Sleep mode 80 W or less

(12) Noise/Ozone

Noise Operating B/W 63 dB or less (First)

Color 63 dB or less (First)

Stand-by 55 dB or less

Sleep 40 dB or less

3

Ozone 0.02 g/m

or less

(13) External dimensions

External dimensions 670 x 676 x 787 mm

(26.4 x 26.6 x 31 inch)

(14) Weight

Weight

Copier body: 75.5 kg (166.4 lbs.)

Copier body + photoconductor: 78.5 kg (173.1 lbs.)

Copier body + photoconductor + toner: 85.5 kg (188.5 lbs.)

(15) Machine occupying dimensions

Machine occupying dimensions:

(With manual feed tray/paper exit tray

extended)

1349 x 676 mm

(53.1 x 26.6 inch)

B. Paper feed unit

(1) Machine paper feed tray

Paper feed system 1-stage tray

Paper feed size AB series: A3, B4, A4, A4R, B5, A5,

Paper feed capacity *

Weight of paper

suitable for paper feed

Paper kind Normal paper (including recommended

Paper size detection Slide lever detection

Paper size selection User selection

Dehumidifier Service kit

Remaining quantity

detection

Initial size when

shipping

Tray attach/detach Possible

Universal support Universal tray (free size)

*1: 1g/m2 = 0.265625 lbs (applied to the flowing subjects)

(2) Manual feed tray (Bypass tray)

Transport reference Center reference

Paper feed capacity 250 sheets (80 g/m

Paper size A3W to A6R

Paper weight 64 to 300 g/m

Paper kind Normal paper (including recommended

Paper size detection Inch series: 12" x 18", 11" x 17",

Manual feed size

setup

∗ Detection of 8.5" x 14" can be changed to detection of 8.5" x 13"

(216 mm x 330 mm) by the diag setting.

8.5" x 11", EXTRA

Inch series: 11" x 17", 8.5" x 14",

8.5" x 13", 8.5" x 11", 8.5" x 11"R,

8.5" x 5.5", A4, EXTRA

(EXTRA setting)

AB tab setting section:

A3, B4, A4, A4R, B5, B5R, A5, EXTRA

Inch tab setting section:

11" x 17", 8.5" x 14", 8.5" x 13",

8.5" x 11", 8.5" x 11"R, 8.5" x 5.5",

7.25” x 10.5”R, EXTRA

1

550 sheets (64 g/m2 (17 lbs.) paper)

500 sheets (80 g/m

2

(21 lbs.) paper,

recommended paper for color)

2

64 to 105 g/m

(17 to 28 lbs)

paper for color), recycled paper,

printed paper, punched paper, color

paper, letter head

Yes (0, 25%, 50%, 75%, Full, 5 steps)

A3 (11" x 17")

2

2

), 100 sheets (Postcard)

(64 g/m

), 300 sheets

2

/ 17 to 80 lbs specified

paper for color

paper for color), OHP1, OHP2. heavy

paper 1 (106 to 200 g/m

heavy paper 2 (201 to 300 g/m

2

(28 to 53 lbs.)),

2

(54 to 80

lbs.)), envelope, specified size paper

By type setting should be available.

8.5" x 14", 8.5" x 11", 8.5" x 11"R,

7.25" x 10.5"R, 8.5" x 5.5", A3, B4, A4,

B5, A6R

AB series: A3W, A3, B4, A4, A4R, B5,

A5, A6R, 11" x 17", 8.5" x 14",

8.5" x 11", 7.25" x 10.5"R

Yes (Ignoring automatic setup)

Selected with key operation.

AR-C172M SPECIFICATIONS 3 - 2

Page 11

C. Paper exit unit

(1) Face down paper exit tray (Top section)

Paper exit position/system Machine top face down paper exit

Paper exit capacity 500 sheets (A4/LT recommended

paper for color)

Paper size A6R (Postcard), 8.5" x 5.5" to A3W

Paper weight 64 to 200g/m

Paper kind Normal paper (including

Remaining quantity

detection

Discharged paper full

detection

(2) Face up paper exit tray (sides)

Paper exit position/system Machine side face up paper exit

Paper exit capacity 250 sheets (A4/LT recommended

Paper size All sizes which are fed

Paper weight 64 to 300 g/m

Paper kind All sizes which are fed (except for

Remaining quantity

detection

Discharged paper full

detection

(3) Face down paper exit tray (side)

(With the reverse unit installed)

Paper exit position/system Machine side face down paper exit

Paper exit capacity 250 sheets (A4/LT recommended

Paper size A3W, A3, B4, A4, A4R, B5, B5R,

Paper weight 64 to 200 g/m

Paper kind Normal paper*

Remaining quantity

detection

Discharged paper full

detection

*1: Recommendable color paper, standard paper, recycled paper,

printed paper, perforated paper, color paper, letterhead

∗ A3W: Can not used shifter

2

(17 to 54 lbs.)

recommended paper for color),

heavy paper 1 (106 to 200 g/m

2

(28 to 54 lbs.))

No

Yes

paper for color)

2

(17 to 80 lbs.)

OHP sheets)

No

Yes

paper for color)

A5, 12" x 18", 11" x 17", 8.5" x 14",

8.5" x 13", 8.5" x 11", 8.5" x 11"R,

Executive-R, 8.5" x 5.5"

2

(17 to 54 lbs.)

1

No

Yes

(4) Face up paper exit tray (side)

(With the reverse unit installed)

Paper exit position/

system

Paper exit capacity 250 sheets (A4/LT recommended paper

Paper size A3W to A6R, 12" x 18" to 8.5" x 5.5",

Paper weight 64 to 300g/m

Paper kind Normal paper ∗

Remaining quantity

detection

Discharged paper full

detection

*1: Recommendable color paper, standard paper, recycled paper,

printed paper, perforated paper, color paper, letterhead

Machine side face up paper exit

for color)

DL, C5, COM-10, Monarch

2

(17 to 80 lbs.)

1

, OHP, heavy paper

2

(106 to 300 g/m

(28 to 80 lbs.)), all

other paper which is supported by the

machine.

No

Yes

D. Scanner section

(1) Resolution, gradation

Scan resolution (dpi) 600 x 600dpi

600 x 300dpi (B/W mode only, used

RSPF and 100% copy ratio)

Scan speed (opm)

(Copy mode)

Scan gradation 256 gradations for each color

Exposure lamp Xenon lamp without electrode tube

Output gradation 8bit for each color

(2) Document table

Scan range 297 x 432 mm or more (A3/WLT full image

Document

reference position

Detection Yes

Detection size Automatic detection

(600 x 600dpi mode)

Color 8 opm, B/W 21 opm: A4/LT size

(600 x 300dpi mode)

B/W 26 opm: A4/LT size

2 gradations for scanner B/W mode

only

1bit for Scanner B/W mode only

scan)

Center reference

Inch

series

<INCH-1: Default>

11" x 17", 8.5" x 14", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5"

<INCH-2>

11" x 17", 8.5" x 13", 8.5" x 11",

8.5" x 11"R, 5.5" x 8.5"

AB

series

<AB-1: Default>

A3, B4, A4, A4R, B5, B5R, A5

<AB-2>

A3, 8.5" x 13" (216 x 330), A4,

A4R, B5, B5R, A5

Manual

Yes

doc size

selection

AR-C172M SPECIFICATIONS 3 - 3

Page 12

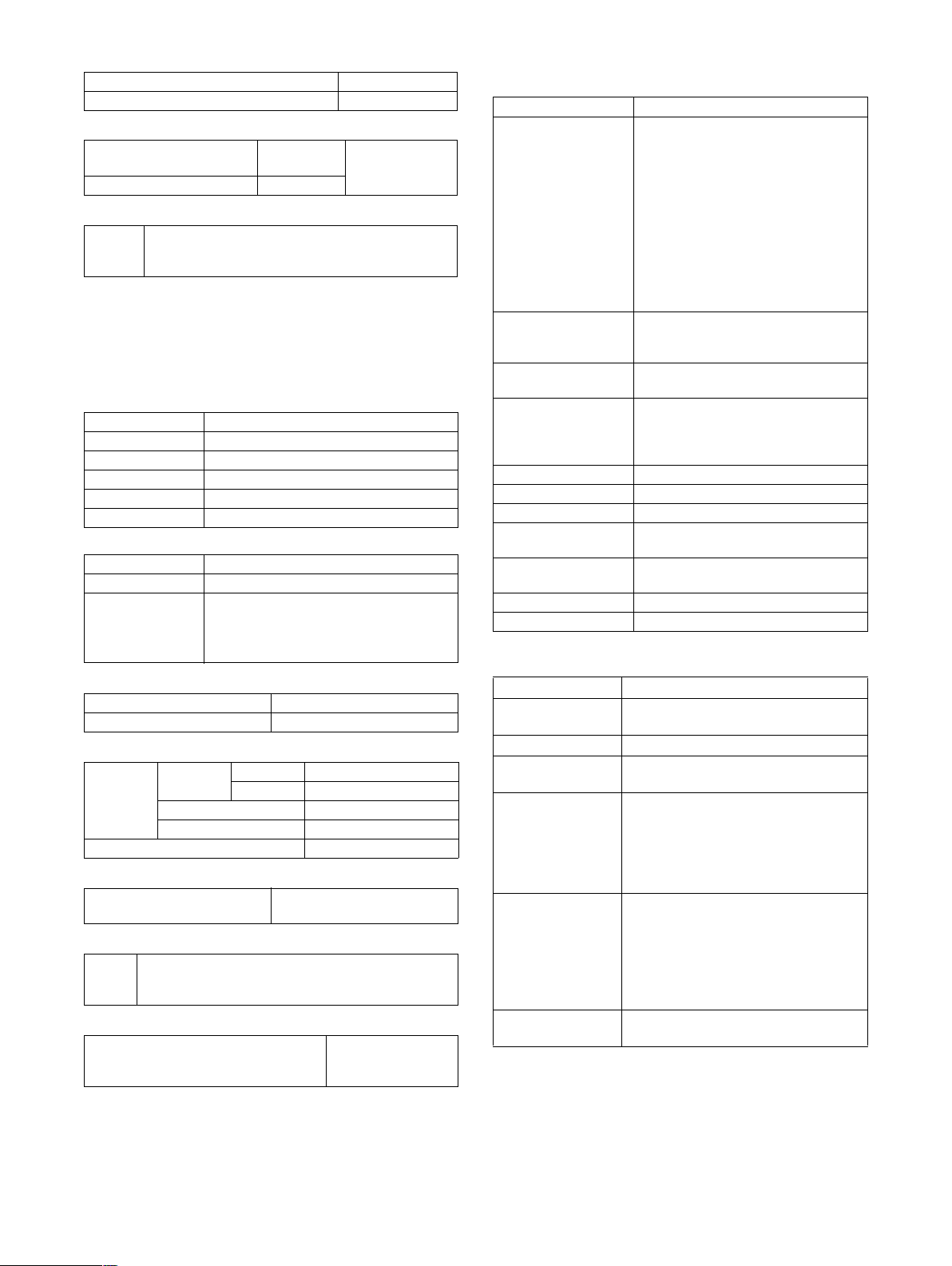

2. Functional specifications

A. Specifications of copy functions

(1) Copy speed (Continuous copy speed)

Color / B/W Color B/W

Print/Copy Print Copy Print Copy

Paper size

A3W (12

"

A3 (11" x 17") 8ppm 8 cpm 8 cpm 8 cpm 13 ppm 13ppm 13 ppm 13ppm

B4 (8.5

"

x 14" / 8.5" x 13") 10 ppm 10 cpm 10 cpm 10 cpm 15 ppm 15 ppm 15 ppm 15ppm

" (A4)

8.5" x 11

A4R (8.5

"

B5 17ppm 17 cpm 17 cpm 17 cpm 26 ppm 26 cpm 26 cpm 26 cpm

B5R (7.25

A5 (8.5" x 5.5") 17ppm 17 cpm 17 cpm 17 cpm 26 ppm 26 cpm 26 cpm 26 cpm

A6R (Normal paper) 13ppm 13 cpm 13 cpm 13 cpm 13 ppm 13 ppm 13 ppm 13ppm

OHP (Speed *

OHP (Image quality) 13 ppm 13 cpm 13 cpm 13 cpm 13 ppm 13 cpm 13 cpm 13 cpm

Heavy paper 1 *

8.5" x 11", A5, 5.5" x 5.5")

Heavy paper 1 *

other sizes than the above)

Heavy paper 2 *

11", A5, 8.5" x 5.5")

Heavy paper 2

other sizes than the above)

Envelope

Special size 5 ppm 5 ppm 5 ppm 5 ppm 7ppm 7 cpm 7 cpm 7 cpm

Magnification

ratio

x 18") 5 ppm 5 cpm 5 cpm 5 cpm 7 ppm 7 cpm 7 cpm 7 cpm

x 11"R) 12 ppm 12ppm 12 ppm 12 ppm 19 ppm 19 ppm 19 ppm 19ppm

"

x 10.5"R) 12 ppm 12 ppm 12 ppm 12 ppm 19 ppm 19 ppm 19 ppm 19ppm

1

) 17ppm 17 cpm 17 cpm 17 cpm 17 ppm 17 cpm 17 cpm 17 cpm

2

(B5, A4,

2

(Envelope*3and

2

(B5, A4, 8.5" x

*2

(Envelope*3 and

*3

(All kinds) 5ppm 5ppm 5ppm 5ppm 6ppm 6 cpm 6 cpm 6 cpm

ppm (print per minute): print per minute when printing two or more pages of a single document.

cpm (copy per minute): copy per minute when scan multi copying of a single document. When offset function OFF

*1: Max. speed *2: Heavy paper 1: 106 to 200g/m

*3: Kind of envelopes: COM10, Monarch, DL, C5

Normal

(100%)

17ppm 17 cpm 17 cpm 17 cpm 26 ppm 26 cpm 26 cpm 26 cpm

13ppm 13 cpm 13 cpm 13 cpm 13 ppm 13 cpm 13 cpm 13 cpm

6 ppm 6 cpm 6 cpm 6 cpm 6ppm 6 cpm 6 cpm 6 cpm

13ppm 13 cpm 13 cpm 13 cpm 13 ppm 13 cpm 13 cpm 13 cpm

6 ppm 6 cpm 6 cpm 6 cpm 6ppm 6 cpm 6 cpm 6 cpm

Reduction

(25%)

2

Normal

(100%)

Enlargement

(400%)

Normal

(100%)

Reduction

(25%)

(28 lbs to 54lbs), heavy paper 2: 201 to 300g/m2 (54 lbs to 80lbs)

Normal

(100%)

Enlargement

(400%)

(2) First copy time

a. To side tray of main unit face up, with APS off and group

mode on

Platen/ RSPF B/W Color

Platen Within 8.0 sec. (A4/LT) Within 11.7 sec. (A4/LT)

RSPF Within 10.5 sec. (A4/LT) Within 14.0 sec. (A4/LT)

b. To top of main unit face down, with APS off and group mode

on

Platen/ RSPF B/W Color

Platen Within 10.2 sec. (A4/LT) Within 15.0 sec. (A4/LT)

RSPF Within 13.0 sec. (A4/LT) Within 17.0 sec. (A4/LT)

c. With rotation copying. To side tray of main unit face up, with

A4R original and A4 paper

Platen/ RSPF B/W Color

Platen Within 12.0 sec. (A4/LT) Within 17.0 sec. (A4/LT)

RSPF Within 14.0 sec. (A4/LT) Within 19.0 sec. (A4/LT)

d. With rotation copying. To top of main unit face down, with

A4R original and A4 paper

Platen/ RSPF B/W Color

Platens Within 14.5 sec. (A4/LT) Within 19.5 sec (A4/LT)

RSPF Within 16.0 sec. (A4/LT) Within 22.0 sec. (A4/LT)

Condition: The transfer belt positions are B/W positions.

(3) Job speed

a. For Group mode

Mode

S to S

(10pages

X 1set)

S to D

(10pages

X 5sets)

D to D

(5pages

X 5sets)

General copy condition:

Original size = A4 or (8.5" x 11"), Output to side tray by group

mode, Transfer belt position = B/W position, Paper feeding from

Tray 1, Not using APS, using RSPF, copy ratio: 100%

b. For E-sort mode ON

Mode

S to S

(10pages

X 1set)

S to D

(10pages

X 5sets)

D to D

(5pages

X 5sets)

General copy condition:

Original size = A4 or (8.5" x 11"), Output to side tray by E-sort

mode, Transfer belt position = B/W position, Paper feeding from

Tray 1, Not using APS, using RSPF, copy ratio: 100%

B/W (1-bit) Color Condition by mode

600 x

600 x

1-bit or

600 x

600dpi

300dpi

20.5

cpm

20.0

cpm

20.0

cpm

B/W (1-bit) Color Condition by mode

600 x

600dpi

300dpi

20.0

cpm

20.0

cpm

18.0

cpm

26.0

cpm

20.0

cpm

20.0

cpm

600 x

25.5

cpm

20.0

cpm

19.0

cpm

4-bit

4-bit

4-bit

4-bit

1-bit or

4-bit

1-bit

1-bit

1-bit

1st copy Config

600dpi

12.0

Exclusive

cpm

14.0

cpm

Inclusive

14.0

cpm

600 x

1st copy Config

600dpi

12.0

Exclusive

cpm

13.5

cpm

Inclusive

13.0

cpm

RSPF+bypass

module with

inverter unit

RSPF+Paper deck

(2trays +ADU)

+bypass module

with inverter unit

+512MB memory

RSPF+bypass

module with

inverter unit

RSPF+Paper deck

(2trays +ADU)

+bypass module

with inverter unit

+512MB memory

AR-C172M SPECIFICATIONS 3 - 4

Page 13

(4) Continuous copy

Multi max. number 999 sheets

(Adjustable with key operator pogram)

(5) Resolution

Scan resolution 600 x 600 dpi

Writing resolution 600 x 600 dpi

600 x 300dpi (B/W copy only, used RSPF

and 100%copy ratio)

(6) Copy document

Document size Max. A3 (11” x 17”)

Document kind Sheet/book document

(7) Copy magnification ratio

Copy magnification

ratio

Custom magnification

ratio registration

Zoom 50 to 200% (increment of 1% for 50 to

Independent zoom Yes (OC: 25, 400%, 50 to 200%,

AB series: 25%, 50%, 70%, 81%,

86%, 100%, 115%, 122%, 141%,

200%, 400%

Inch series: 25%, 50%, 64%, 77%,

100%, 121%, 129%, 200%, 400%

(400% only in OC mode)

AB series/Inch series: 4 keys (2E/2R)

200%)

RSPF: 50 to 200%, increment of 1%)

(8) Density, copy image process

Exposure

mode

Color

enhancement

(OC only)

Manual steps 9 steps

Smoothing

process

Toner save

mode

Display Color

Auto Text/Printed Photo

Text Text

Text/Printed

Photo

Text

/Photograph

Printed Photo Printed Photo

Photograph Photograph

Map Map

Copy document Copy document (Effective for Text, Text/

Yes (Effective for Text, Text/Printed, Text/Photograph,

Printed, Photograph, Map)

No

Yes (for B/W)

(Hexadecimal)

Default ME3

Pre-scan: No

Text/Printed Photo

Text/Photograph

Printed, Printed)

B/W (binary)

auto:

Text

Pre-scan: No

AE

(9) Copy functions

Functions APS Yes

AMS Yes

ACS (Auto Color Selection) No

Paper type select Yes

Free size input Document: Yes

Coy Protection Technology

(CPT)

Auto tray switching Yes

Rotation copy Yes (A4/8.5 x 11/B5

Rotation sort No

Electronic sort (E-RDH) Yes (Color / B/W)

Copy reservation No

Program call/registration Yes (Max. 10 items)

Proof copy No

Pre-heat Yes (Conditions are set

Auto power shut off Yes (Conditions are set

Department management Yes (200 departments)

Key operator program Yes

Communication support

(RIC)

Process control Yes

Card counter support No

Coin vendor support Yes

Special

functions

Binding margin Yes

Edge erase/Center erase Yes

1 set 2 copy Yes (OC mode only)

Cover insertion Yes

OHP insert paper Yes (White paper

Insert paper insertion

(Index)

Centering Yes

Multi shot (N in 1) Yes (Ruled line ON/

Center binding Yes (Option)

Duplex copy direction

switch

Negative/Positive

conversion

B/W inversion Yes (B/W only)

Photo repeat Yes (2/4/8/12/16/24)

RGB adjustment Yes

Color balance Yes

Color Gamma adjustment Yes (OC only)

Brightness adjustment Yes

Contrast adjustment No

Sharpness adjustment Yes

Mirror image Yes

Single color 6 colors (R, G, B, C, M,

Enlargement continuous

copy

Background erase Yes

A3 wide copy Yes (OC only)

Auto color calibration Yes

Auto registration Yes

Paper: Yes

Yes

paper size only)

by the key operation.)

by the key operation.)

Yes

insertion only)

No

OFF allowed)

Option

∗ Requires Duplex

desk, Duplex pass/

Inverter.

No

10 is for visiting cards.

Y)

Yes (OC only)

AR-C172M SPECIFICATIONS 3 - 5

Page 14

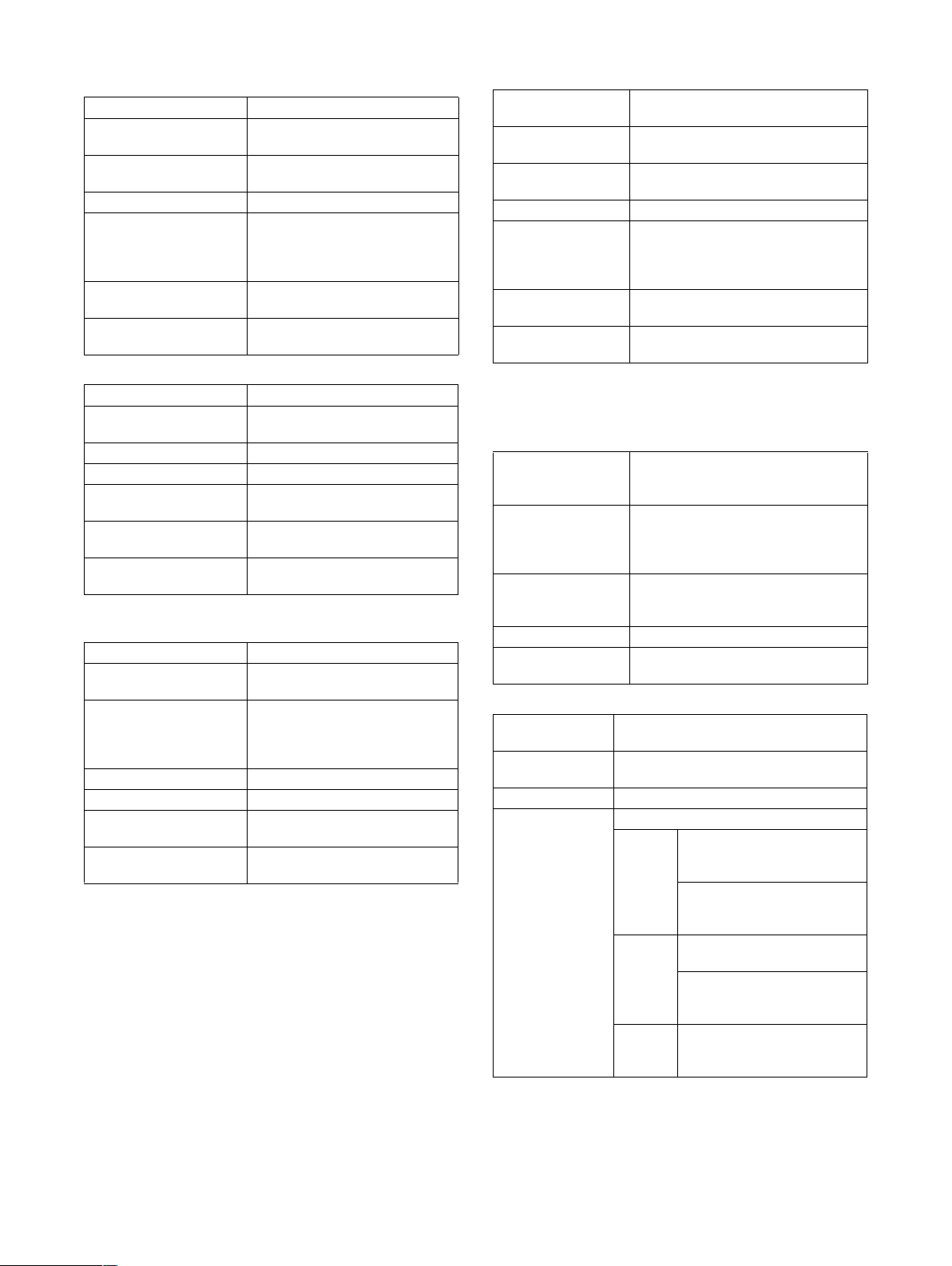

(10) Memory limitation matrix

Combination Standard Expansion 1 Expansion 2

ICU PWB

Copier specifications

Mode

Electronic

Copy Single Color

(4 bit)

Color

(1 bit)

B/W Yes to A4 (8.5" x 11") 400 surfaces 400 surfaces 680 surfaces

Copy Duplex Color

(4 bit)

Color

(1 bit)

B/W Yes to A4 (8.5" x 11") 400 surfaces 400 surfaces 680 surfaces

B/W (Electronic sort): Equivalent to "TEST SHEET B." SOPM: Scan Once Print (Copy) Many

Color (Electronic sort): [JBIG], [A3: 2 sheets], *1: Equal to “What’s color”, *2: Equal to “Fruits- Map”, *3: Equal to “Photo chart”

Note: 1) Interrupt copy is available in Electronic sort mode, only 1 set.

(Duplex copy, staple, Multi shot (N in 1) and Multi-enlargement are not available.)

2) Color E-sort as Interrupt copy is not available.

Standard (Slot 1) 256MB 256MB 256MB

Expansion memory (Slot 2) — 128MB 256MB

Total memory capacity 256MB 384MB 512MB

sort

Document size

Upper limit of document scan quantity

(number of surfaces)

No to A4 (8.5" x 11") SOPM SOPM SOPM

B4, A3

SOPM SOPM SOPM

(8.5" x 14", 11" x 17")

A3W (12" x 18") SOPM SOPM SOPM

Yes to A4 (8.5" x 11") 100 surfaces*

37 surfaces*

21 surfaces*

B4, A3

(8.5" x 14", 11" x 17")

50 surfaces*

18 surfaces*

10 surfaces*

A3W (12" x 18") 41 surfaces*

15 surfaces*

8 surfaces*

B4, A3

200 surfaces 200 surfaces 340 surfaces

1

2

3

1

2

3

1

2

3

100 surfaces*

37 surfaces*

21 surfaces*

50 surfaces*

18 surfaces*

10 surfaces*

41 surfaces*

15 surfaces*

8 surfaces*

1

2

3

1

2

3

1

2

3

180 surfaces*

64 surfaces*

37 surfaces*

90 surfaces*

32 surfaces*

18 surfaces*

74 surfaces*

26 surfaces*

15 surfaces*

(8.5" x 14", 11" x 17")

A3W (12" x 18") 165 surfaces 165 surfaces 280 surfaces

No to A4 (8.5" x 11") SOPM SOPM SOPM

B4, A3

No SOPM SOPM

(8.5" x 14", 11" x 17")

A3W (12" x 18") No paper pass allowed

Yes to A4 (8.5" x 11") 100 surfaces*

37 surfaces*

21 surfaces*

B4, A3

(8.5" x 14", 11" x 17")

50 surfaces*

18 surfaces*

10 surfaces*

1

2

3

1

2

3

100 surfaces*

37 surfaces*

21 surfaces*

50 surfaces*

18 surfaces*

10 surfaces*

1

2

3

1

2

3

180 surfaces*

64 surfaces*

37 surfaces*

90 surfaces*

32 surfaces*

18 surfaces*

A3W (12" x 18") No paper pass allowed

B4, A3

200 surfaces 200 surfaces 340 surfaces

(8.5" x 14", 11" x 17")

A3W (12" x 18") No paper pass allowed

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

B. Scanner functon (Option)

The scanner function is enabled by canceling the product key.

This function requires installation of an expansion memory of

256MB and a scanner expansion board.

(1) PUSH SCAN

PUSH SCAN is used to send scan data to PC or a file server by

the operation on the machine operation panel.

PUSH SCAN has the following three modes:

• SCAN TO E-MAIL (SMTP)

Scan data area attached to an E-mail.

• SCAN TO FILE SERVER (FTP)

Scan data are sent to a file server by FTP.

The URL can be e-mailed simultaneously.

• SCAN TO DESKTOP (FTP)

Scan data are sent to the desktop user. (Sharpdesk and the net-

work scanner tool are required.)

AR-C172M SPECIFICATIONS 3 - 6

a. Operation flow (PUSH SCAN)

1. Push [IMAGE SEND] button on the operation panel to switch

to the main menu of the image send mode.

2. Press [ADDRESS DIRECTORY] or [E-MAIL ADDRESS] button to set a destination. (The local address book cannot be

retrieved.)

3. According to the necessity, set the sender with [SENDER

LIST] button.

4. According to necessity, select the scanning conditions with

[EXPOSURE], [RESOLUTION], [FILE FORMAT] and [ORIGINAL] buttons.

5. Press the color start key or the black-and-white start key to

start scanning. When the color start key is pressed, scanning

is made in color. When the black-and-white start key is

pressed, scanning is made in black and white.

Engine operates according to the setting made, such as: LED

of the color start key is turned on or LED of mono start key is

turned on.

Page 15

b. Basic operations (PUSH SCAN)

Network protocol TCP/IP, SMTP, FTP, (HTTP)

Trial mode required Supported by the service diag.

The upper limit is 500 scans (surfaces). Without canceling the product key, scanning functions are enabled.

500 counts in total of color and black-and-white scans.

There is no counter for trial. Resolution level: [lowest] or [lower] key only.

Destination registration 500 items of scan to E-mail from Embedded Web Server + group, and 100itmes of Scan to FTP + Desktop

(Max. 600 items can be registered.)

Scan to E-mail and group can be registered from the operation panel.

A destination name can be set with max. 18 characters in two bytes (or 36 characters in one byte).

An E-mail address can beg set with max. 50 characters in one byte.

Address book The static address book stored in MFP is supported.

Destination select Selected from the operation panel.

Selection of two or more destinations is allowed. (Only Scan to E-mail)

Sending to temporary users can be made.

CC: / BCC: Send enable

Sender select Select from the list of senders (20) on the operation panel.

If it is not set, the default which is set by Web is used.

Setting can be made from the key operator program.

Image setup Image quality setup Color (RGB, each 8bit), Monochrome binary (1bit)

Binary system Error diffusion

Text/photo area separation Automatic

Moire reduction mode Yes

Color enhancement mode N/A

Density Automatic (Monochrome only. For color, same as density 3 manual.)

Manual (9 steps: 1 to 5, 0.5 increment)

Default: 3

Resolution Color Monochrome

Low 2 100 dpi x 100 dpi 150 dpi x 150 dpi

Low 1 150 dpi x 150 dpi 200 dpi x 200 dpi (Default)

Normal 200 dpi x 200 dpi 300 dpi x 300 dpi

High 1 300 dpi x 300 dpi 400 dpi x 400 dpi

High 2 600 dpi x 600 dpi 600 dpi x 600 dpi

The above resolutions are displayed on the panel. There is no optional setting of

resolution.

Document Document arrangement Single surface document

Duplex document (side bind)

Duplex document (top bind)

Image rotation 0°

90° (A document is rotated 90 degrees to be set. Used mainly for portrait image

scan of Legal, B4, A3. etc.)

Note: 600 x 600dpi A3 size full color scan: 90-degree image rotate every time.

Document detection size Automatic detection (The automatic detection allowable size can be set by the

key operation.)

Manual setup (Automatic detection cancel: Fixed sizes)

Manual setup (Automatic detection cancel: Other than fixed sizes)

AB series: mm setting, inch series: inch setting

Document type/ Image

quality type

Text

Text/Printed Photo

Text/Photograph

Printed Photo ∗

Photograph ∗

∗: Only in manual density adjustment

Map ∗

(The default: Text mode / Automatic)

AR-C172M SPECIFICATIONS 3 - 7

Page 16

File format B/W (1bit) TIFF-Non compression (Multi page allowed)

Color (RGB x 8bits) PDF High compression (Multi page allowed)

Filed by each page ON / OFF

Process when the specified value is exceeded The specified size can be set with the key operator program. When the size

OC multi scan Documents of two or more pages can be set as one file from the platen. (Except

Job history The job history is not recorded.

Utility Sharpdesk V3.0 or later

LDAP Yes

JOB restriction The scanner mode is disabled during printing. After completion of a print job, it is

User Authentication Yes

POP before SMTP Yes

Address Book Non Anonymous for NST Yes

TIFF-G3-1dim (Multi page allowed)

TIFF-G4 (Multi page allowed)

PDF-Non compression (Multi page allowed)

PDF-G3-1dim (Multi page allowed)

PDF-G4 (Multi page allowed)

PDF Medium compression (Multi page allowed)

PDF Low compression (Multi page allowed)

JPEG High compression (Multi page inhibited)

JPEG Medium compression (Multi page inhibited)

JPEG Low compression (Multi page inhibited)

Multi page inhibited: Means images on two or more pages cannot be sent as one

file. They can sent or saved as two or more attached files.

(In JPEG, fixed to ON.)

exceeds the specified level, scan is cancelled.

for JPEG)

enabled. (Print controller restriction)

(2) Scanner function memory restriction matrix

Combination Standard Expansion-1 Expansion-2

ICU PWB

Network scan

specifications

Printer

controller

PWB

Trial

mode

PUSH scan

Normal

mode

(Option)

∗: Expansion memory must be installed to both of the Copier ICU and the Printer board.

Standard (Slot 1) 256 MB 256 MB 256 MB

Expansion memory (Slot 2) — 128 MB 256 MB

Total memory capacity 256 MB 384 MB 512 MB

Combination Standard Expansion-1 Expansion-2 Expansion-3 Expansion-4

Standard (Onboard) 128 MB 128 MB 128 MB 128 MB 128 MB

Expansion memory (Slot 1) — 128 MB 256 MB 256MB 256 MB

Expansion memory (Slot 2) —— — 128MB 256 MB

Total memory capacity 128 MB 256 MB 384 MB 512 MB 640 MB

Color

Monochrome

Color ✕✕

Monochrome ✕✕

❍

150dpi or less

❍

200dpi or less

❍

300dpi or less

❍ (∗)

600dpi or less

❍

600dpi or less

AR-C172M SPECIFICATIONS 3 - 8

Page 17

C. Reversing single pass feeder

Type RSPF (Reversing single pass feeder)

Document set

direction

Document

reference

position

Document paper

feed reference

Document

transport system

Kinds of out-ofspecification

documents

Document load

capacity

Document

detection Yes/No

Detection size AB-1/

Document

inversion

Document weight 56 to 90g/m

Stream feeding

mode

Mixed-load

documents

Document tray

guide display

Power supply From main unit (26.4 W)

Dimensions (W x D x H) 583 x 435 x 133 mm

Weight Approx. 5.4 kg

Face up reference

Center reference

Upper take-up reference (1 to N paper feed

reference)

Sheet through system

OHP, perforated documents, photograph,

catalogue

40 sheets (Thickness 4mm or less.

For 90g/m

Yes (Size detection on the document tray,

traveling detection)

AB-3

AB-2 A3, 216 x 330, A4, A4R, B5, B5R,

Inch-1 11" x 17", 8.5" x 14", 8.5" x 11",

Inch-2 11" x 17", 8.5" x 13", 8.5" x 11",

Selection between 8.5" x 13" and 8.5" x 14"

can be made by the user setting.

Yes (However, 8.5" x 5.5" is inhibited.)

Yes (Standby 5 sec)

Mixed-load paper feed: Inhibited

Random paper feed: Inhibited

A3/A4, 11, B4/B5, 8.5, A4R/A5, B5R, A5R,

5.5

2

, 30 sheets can be set.)

A3, B4, A4, A4R, B5, B5R, A5

A5

8.5" x 11"R, 8.5" x 5.5"

8.5" x 11"R, 8.5" x 5.5"

2

(15 to 24 lbs.)

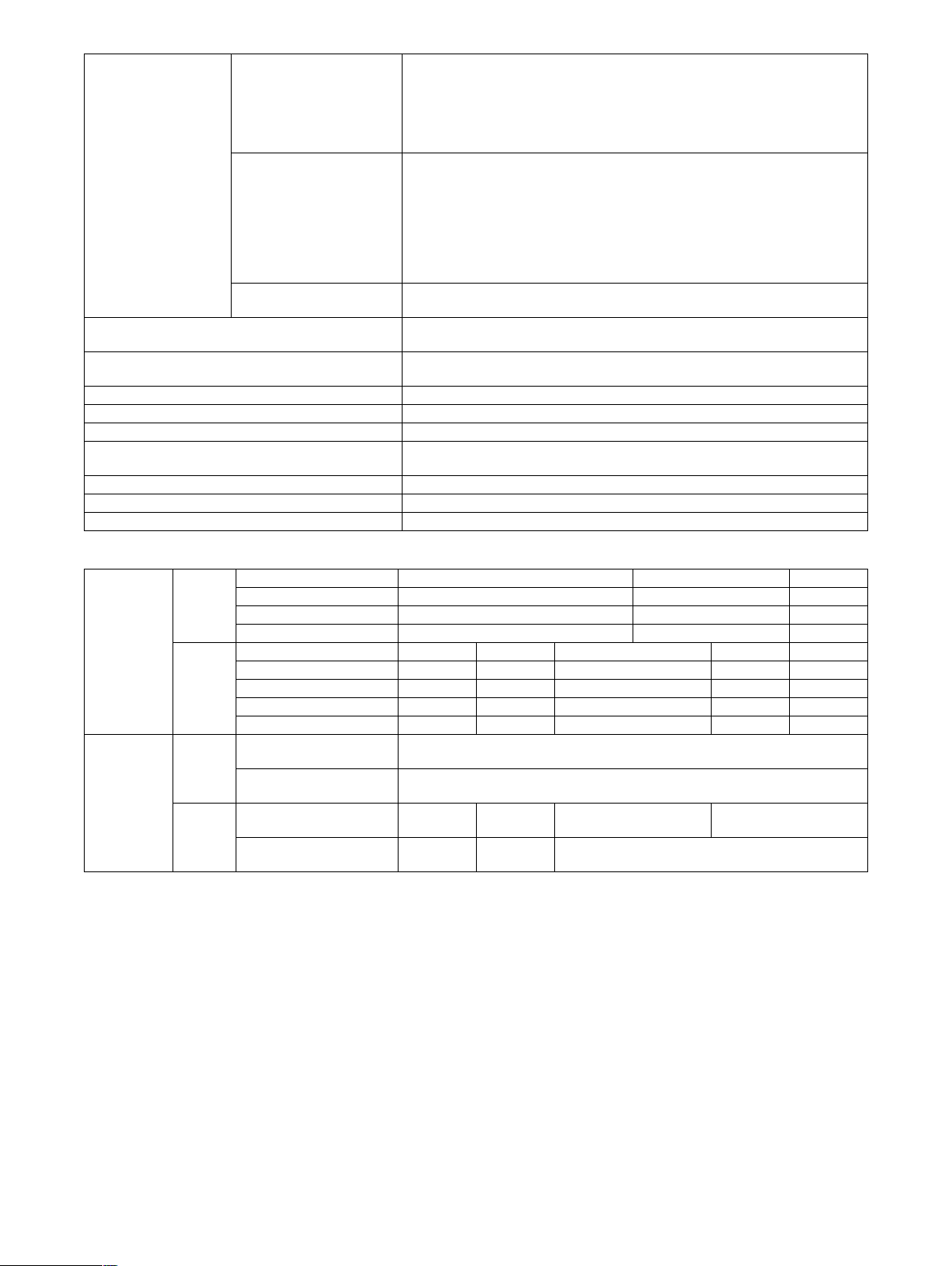

3. Environment conditions

A. Operating environment conditions

Humidity

RH

˚

˚

˚ ˚

Temperature

B. Transit environment conditions

Humidity

RH

˚

˚

˚ ˚

Temperature

C. Supply storage environment conditions

Humidity

RH

D. Standard temperature and humidity

Temperature 20 to 25°C (68 to 77°F)

Humidity 65 ±5%

AR-C172M SPECIFICATIONS 3 - 9

–5˚ ˚

Temperature

Page 18

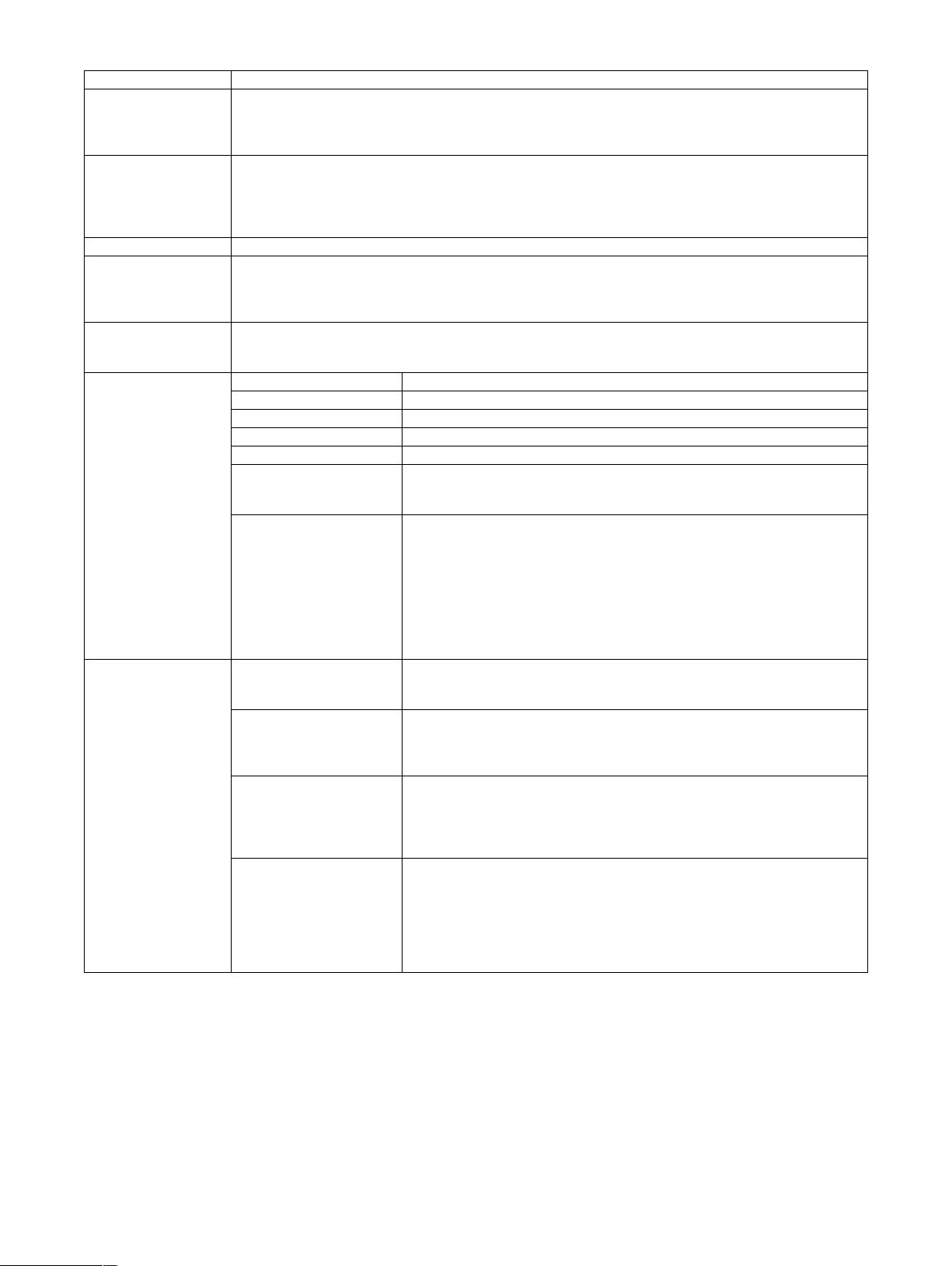

[4] CONSUMABLE PARTS

1. Supply system table

A. European Subsidiary

No. Item Model Name Content Life

1 Toner Cartridge

(Black)

2 Toner Cartridge

(Cyan)

3 Toner Cartridge

(Magenta)

4 Toner Cartridge

(Yellow)

5 Drum Cartridge AR-C26DUN Drum Cartridge

6 Drum AR-C26DMN OPC Drum x 1 50k Common

7 Main Charger Kit AR-C26MKE Charger Unit x 1 50k Common

AR-C26TBN Toner Cartridge (Black) with IC Chip

(Toner ; Net 525g)

AR-C26TCE Toner Cartridge (Cyan) with IC Chip

(Toner ; Net 315g)

AR-C26TME Toner Cartridge (Magenta) with IC Chip

(Toner ; Net 315g)

AR-C26TYE Toner Cartridge (Yellow) with IC Chip

(Toner ; Net 315g)

(Drum/Unit Parts included)

Color identification seal (C/M/Y/Bk) x 1 each

Cleaning Blade x 1

Toner Receiving Seal x 1

x 1 16.7k Common

x 1 11k Common

x 1 11k Common

x 1 11k Common

x 1 50k Common

Commonality with

other host machines

(AR-C170)

(AR-C262)

(AR-C260)

(AR-C170)

(AR-C262)

(AR-C260)

(AR-C170)

(AR-C262)

(AR-C260)

(AR-C170)

(AR-C262)

(AR-C170)

(AR-C262)

(AR-C170)

(AR-C262)

(AR-C260)

(AR-C170)

(AR-C262)

Remarks

* Life : A4 size

at Area

Coverage 6%

* Life : A4 size

at Area

Coverage 5%

* Life : A4 size

at Area

Coverage 5%

* Life : A4 size

at Area

Coverage 5%

2. Consumables (kit, unit)

Part name Model name Content Life

1 Upper heat roller kit AR-C26UH Upper heat roller x 1 100K *1

Heat roller 60T gear x 1

Upper heat roller bearing x 2

Thermistor x 1

Upper heat roller stopper x 2

2 Lower heat roller kit AR-C26LH Lower heat roller x 1 100K *1

Lower heat roller bearing x 2

Thermistor x 1

Lower heat roller stopper x 2

Fusing separation pawl lower x 2

3 Transfer belt kit AR-C26TT Transfer belt x 1 100K *1

4 Transfer roller kit AR-C26TX Transfer roller x 4 100K

5 Transfer waste toner tank unit AR-C26HB Transfer waste toner tank unit x 1 100K

6 Filter kit AR-C26FL Ozone filter A x 1 50K

Ozone filter B x 1

7 Saddle staple cartridge AR-SC2 —

5 Fusing unit AR-C26FU (230V heater lamp)

AR-C26FU1 (120V heater lamp)

AR-C26FU2 (100V heater lamp)

6 Transfer belt unit AR-C26TU Transfer unit for servicing 100K *1

Fusing unit for servicing

(including upper/lower heater lamps)

*1: Replace at 100K or within 2 years

*1

AR-C172M CONSUMABLE PARTS 4 - 1

Page 19

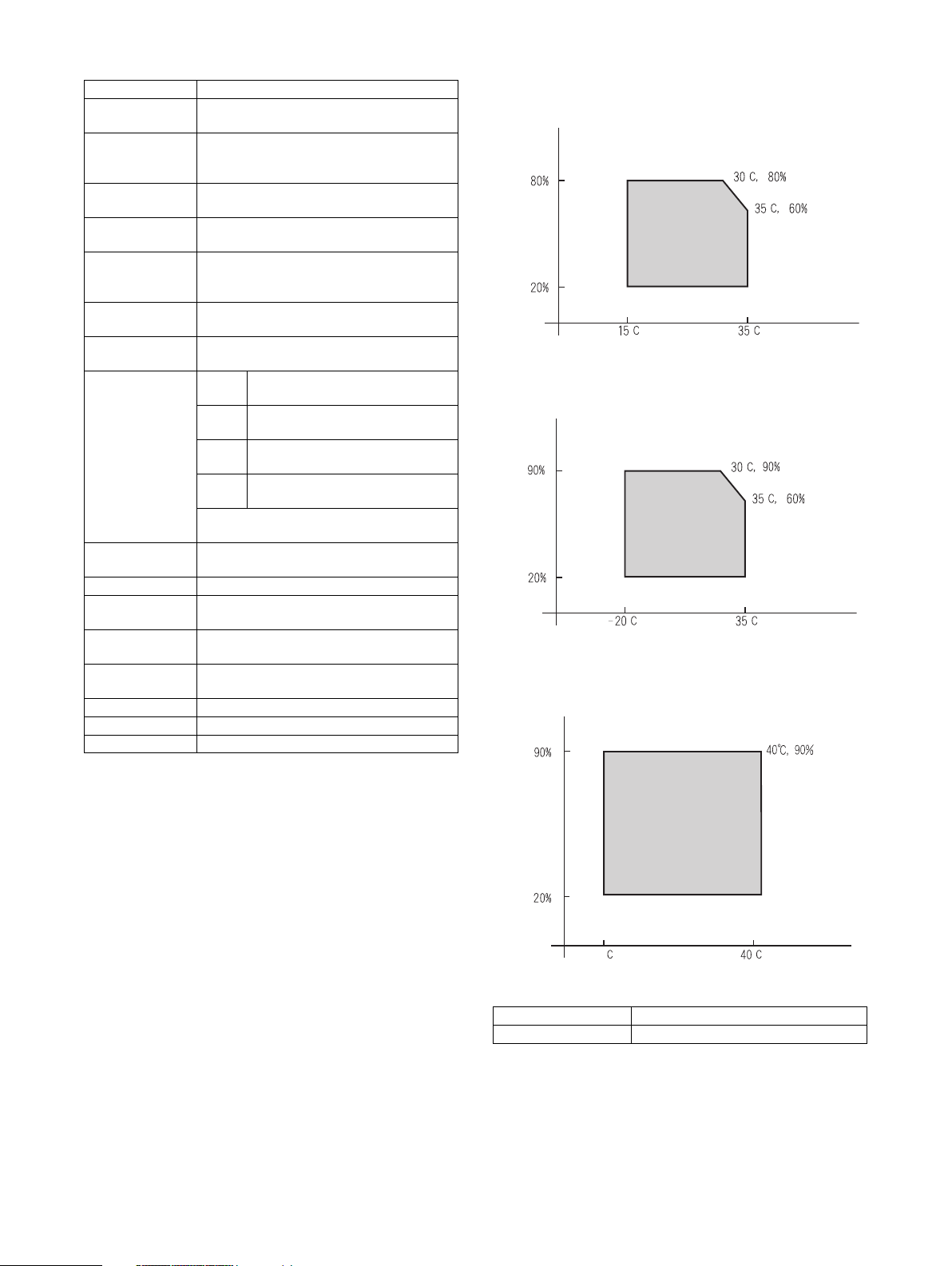

3. Photoconductor cartridge, toner cartridge

A. Lot number identification and the term of validity

(1) Photoconductor

(1) Alphabet

(2) Figure

(3) Figure or X, Y, Z

(4) (5) Figure

(6) Alphabet

(1) (2) (3) (4) (5) (6)

The term of validity: 36 months from the production day (month).

(2) Photoconductor cartridge

(1) Figure

(2) Figure

(3) Alphabet

(4) Alphabet

(5) (6) Figure

(7) Figure or X, Y, Z

Indicates the model support code.

Indicates the end digit of the packing year.

Indicates the packing month. (X= October, Y= November,

Z= December)

Indicates the packing day.

Indicates the production division.

Version No.

The end digit of the year.

Production code (B for SOCC)

Destination code

Production day

Indicates the production month. (X= October, Y= November,

Z= December)

(1) (2) (3) (4) (5) (6) (7)

The term of validity: 36 months from the production day (month).

(3) Toner cartridge

(1)

(4) (5) (6) (7)

The term of validity: 24 months from the production day (month).

(2) (3)

(1) Alphabet or figure

Unit code

(2) Alphabet

Destination code

(3) Alphabet

Skating

(4) Alphabet

Production site code

(5) Figure

Serial number (5 digits)

(6) Figure

Production year, month, day (6 digits)

(7) Alphabet

Version No. (A ~ sequentially revised)

AR-C172M CONSUMABLE PARTS 4 - 2

Page 20

[5] UNPACKING AND INSTALLATION

1. Installing (use) conditions

Before installing the machine, check that the following installing

(use) conditions are satisfied.

If the installing (use) conditions are not satisfied, the machine may

not display full performances, resulting in troubles. It may also

cause safety problems. Therefore, be sure to arrange the installing

(use) conditions before setting up the machine.

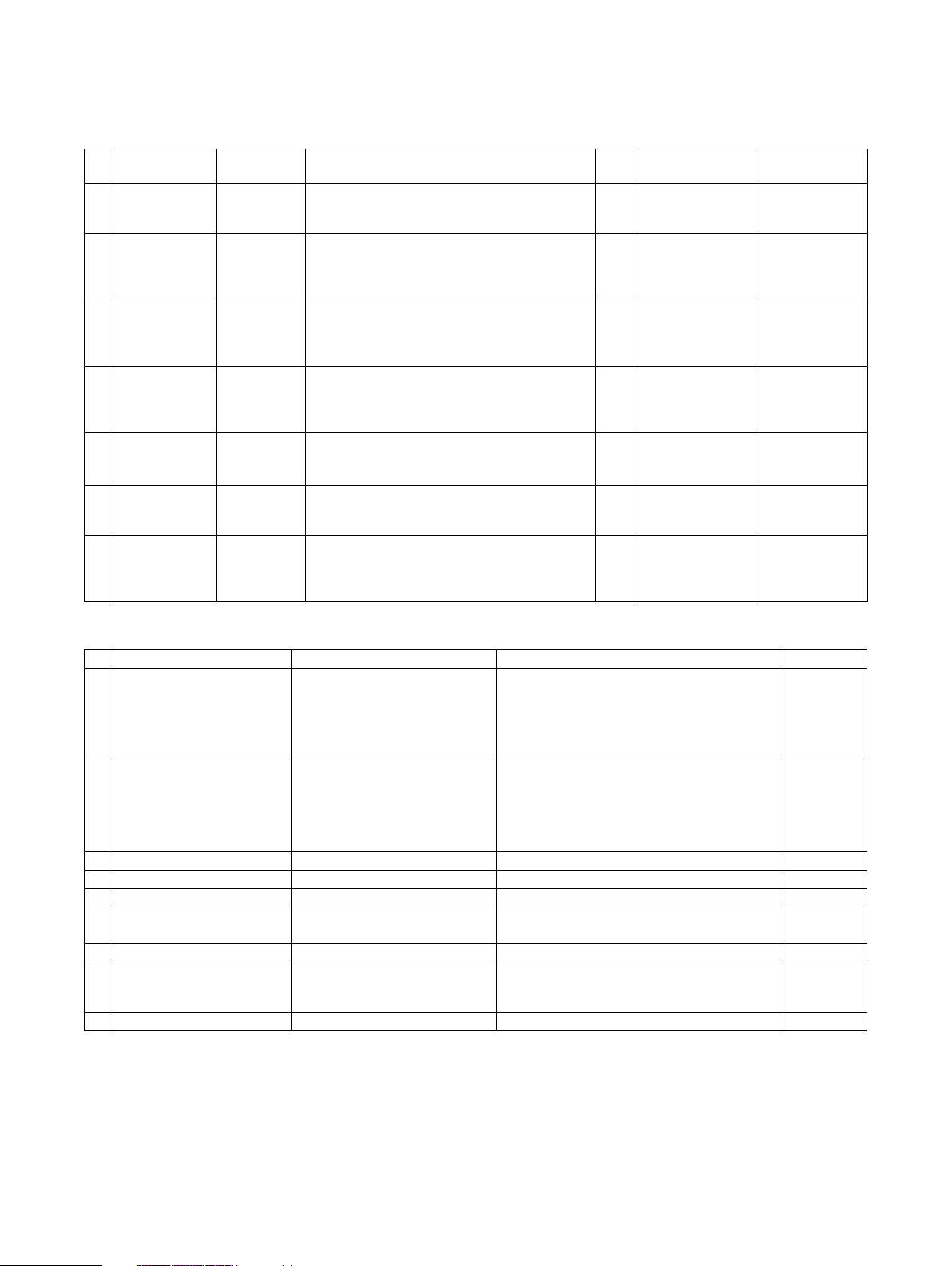

No. Content

1 Bringing space

2 Installing space

3 Power source (Capacity, fluctuation, safety)

4 Floor strength

5 Direct rays of the sun, dust, temperature, humidity,

gases, chemicals

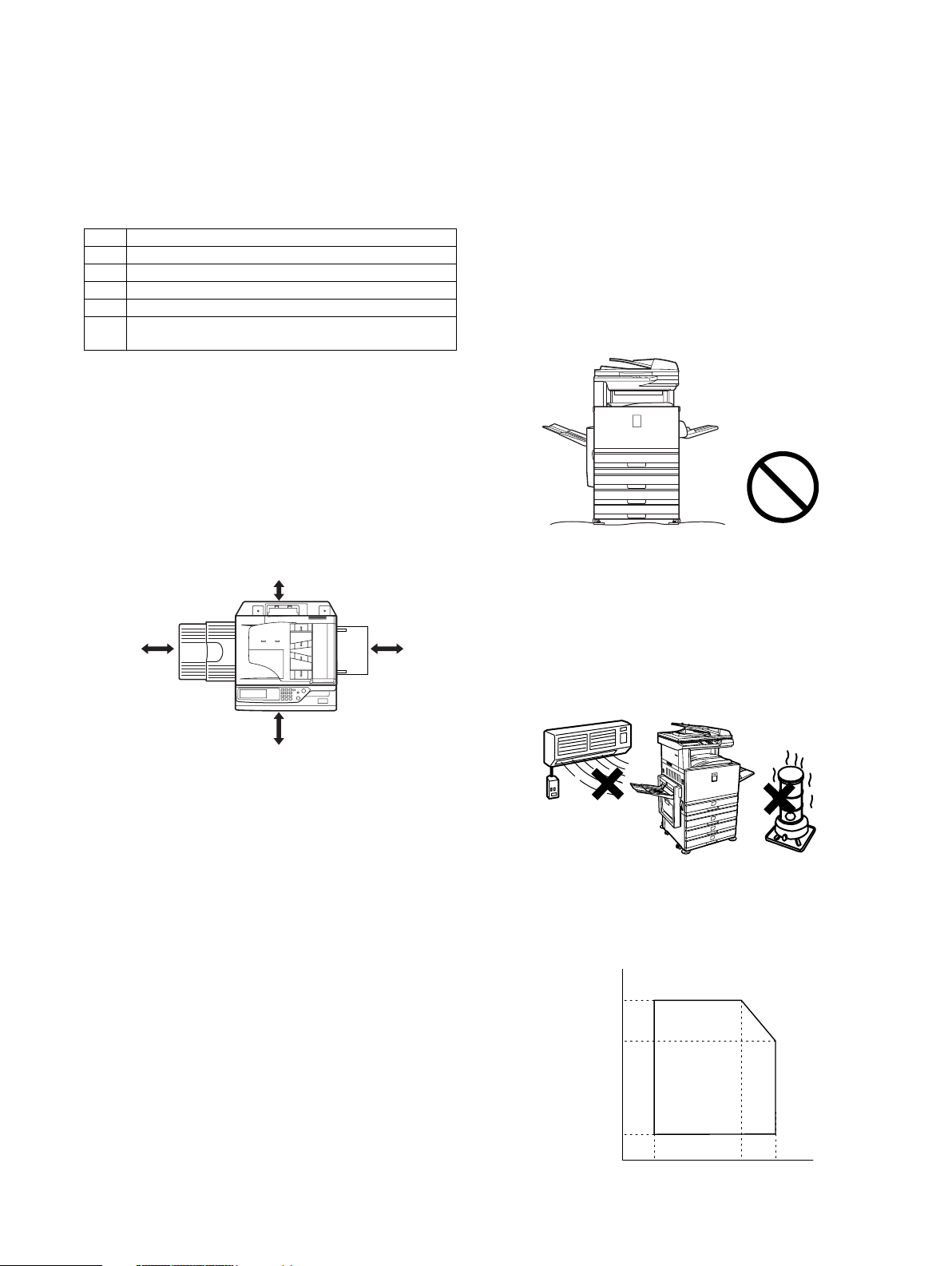

A. Bringing space

For installation of a large size machine, be sure to check that the

door size is great enough before bringing in.

B. Installing space

The following space must be provided around the machine in

order to assure machine performances and proper operations.

If any option is installed, provide the additional space for installing

it.

Especially the space at the rear of the machine must be provided

sufficiently. If not, the machine cannot exhibit functions against

heat and dust, causing some troubles.

30cm

(11.8")

80 cm

(31.5")

60cm

(23.6")

60cm

(23.6")

(3) Power frequency, waveform

The frequency must be within the range of the specified frequency

±2%. If power waveform is deformed, a trouble may occur.

(4) Safety

Be sure to properly ground the machine.

(5) Power plug

Check the form of the power plug. If the shape does not match, do

not use it.

D. Floor strength and level

This machine is considerably heavy and becomes heavier with an

option installed.

The floor must be strong enough for assuring safety.

If not, color shift or image distortion may occur.

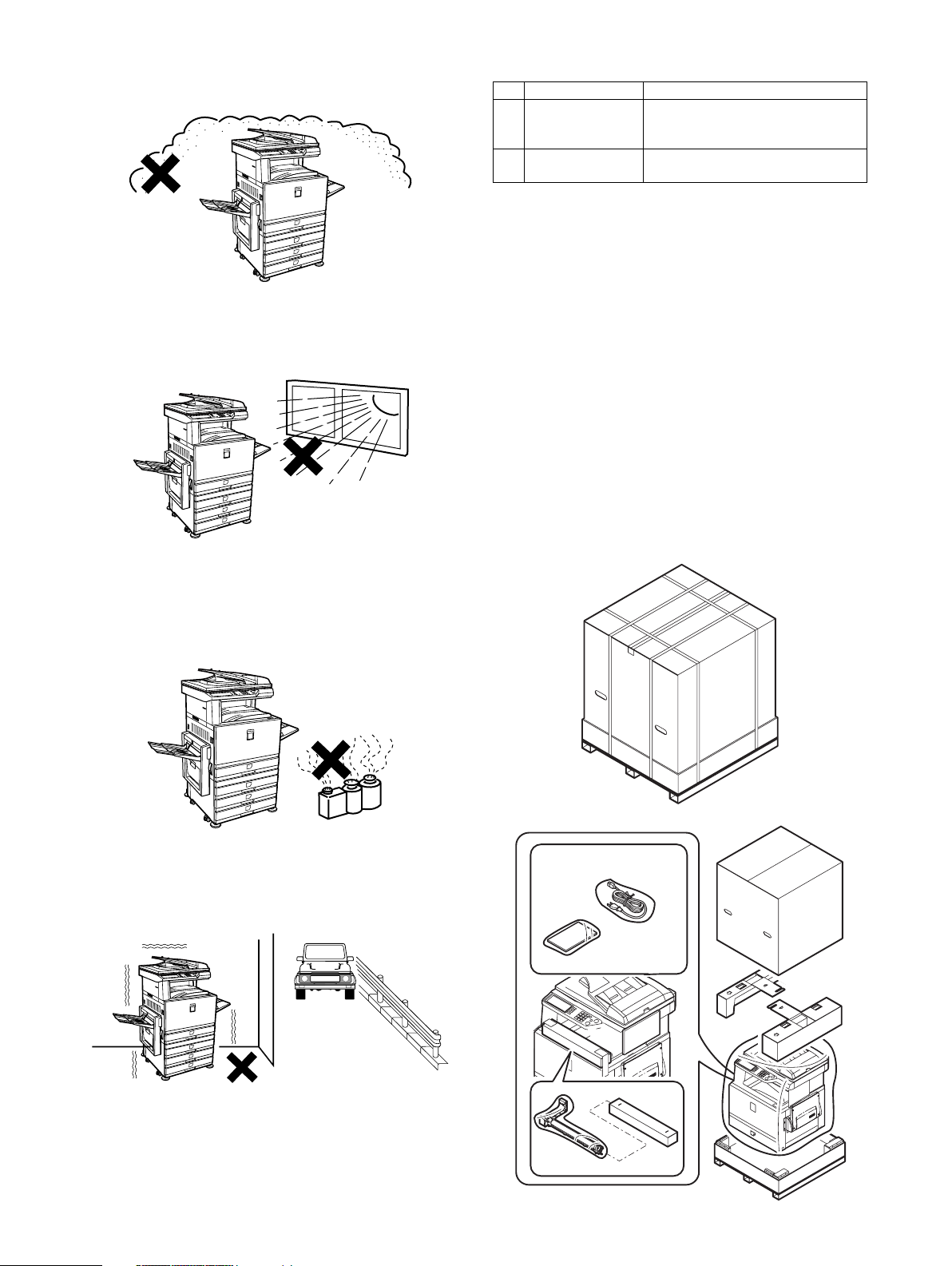

E. Direct rays of the sun, dust, temperature,

humidity, gasses, chemicals, vibration

(1) Temperature and humidity

This machine is designed to perform properly under the specified

temperature and humidity. If the temperature and humidity

exceeds the specified range, the machine may not operate properly and or cause equipment failure.

Especially when the humidity is too high, paper absorbs humidity

to cause a paper jam or dirty copy.

C. Power source

(Capacity, voltage, frequency, safety, plug)

If the power specifications are not satisfied, the machine cannot

exhibit full performances and may cause safety trouble.

Strictly observe the following specifications.

(1) Power capacity

Check that the following power capacity is satisfied. If not, additionally provide a power source.

Current capacity

100V: 15A or more

200V: 10A or more

(2) Power voltage

Measure the voltage during copying to check that the voltage is in

the range of the specified voltage ±10%.

If the voltage is outside the specified range, use thicker lead wires

to reduce impedance.

(An electrical work is required.)

Use of a step-up transformer is also available. In this case, the

capacity must be great enough for the max. power consumption of

the machine.

AR-C172M UNPACKING AND INSTALLATION 5 - 1

(Do not install the machine near a stove, a humidifier, or an air

conditioner.)

Do not install the machine near a heater, a cooler, or a humidifier.

Dew may be formed inside the machine to cause a trouble. Use

enough care for ventilation.

Humidity (RH)

80%

60%

20%

15˚C30˚C35˚C

Temperature

Page 21

(2) Dust

If dust enters the machine, it may cause dirty copy and a paper

jam, resulting in a shortened lifetime.

(3) Direct rays of the sun

If the machine is installed under the rays of the sun, the exterior of

the machine may be discolored and abnormal copies may be produced.

(4) Gases and chemicals

Do not install the machine at a place where there are gases and

chemicals. Especially be careful to avoid installation near a diazotype copier, which produces ammonium gas.

Copy quality may be adversely affected and a trouble may be

caused.

2. Transit and delivery

No. Content Method

1 Implements, facility,

and man power

2 Delivery Transit must be made in packed

Use a forklift. (If no forklift is available,

manpower of four persons is

required.)

condition.

A. Implements, facility, and manpower

It is recommendable to use a forklift for bringing in the machine for

safety.

If no forklift is available, man-power of four persons is required.

The machine is considerably heavy, and requires safety precautions for delivery and installation.

Transit of the machine must be made in packed condition to the

installing place.

B. Delivery

Remove the packing materials prior to installation in the ofice environment.

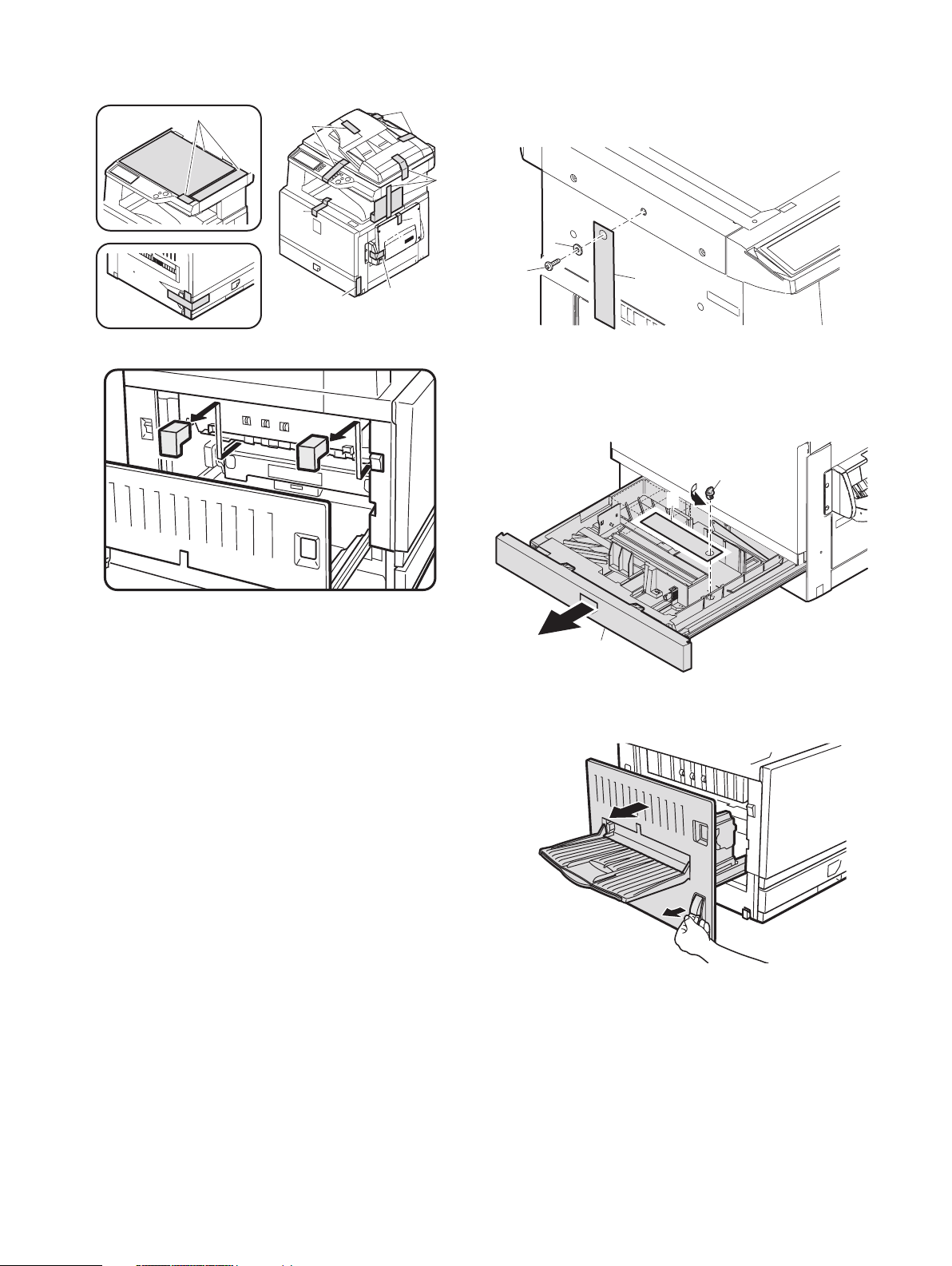

3. Unpacking

A. Unpacking procedure

1) Remove the PP band.

2) Remove the top case.

3) Remove the internal packing pads and the items packed

together with the machine.

4) Remove the machine from the package.

(5) Vibration

Avoid installation near a machine which produces vibrations.

If vibrations are applied to the copier machine, copy images may

be deflected and a trouble may be caused.

AR-C172M UNPACKING AND INSTALLATION 5 - 2

Page 22

Fixing tape and protection pads removal

1) Remove the fixing tape and protection pads from the machine.

2

1

1

1

4. Lock release

A. Scanner (2/3 mirror unit) lock release

1) Remove the scanner fixing screw, and remove the caution

label.

1

1

1

2) Open the left door, and remove the transfer fixing pads.

1

1

2

1

3

B. Main body cassette lock release

1) Pull out the main body cassette.

2) Remove the rotation plate fixing pad and remove the caution

label.

2

3

1

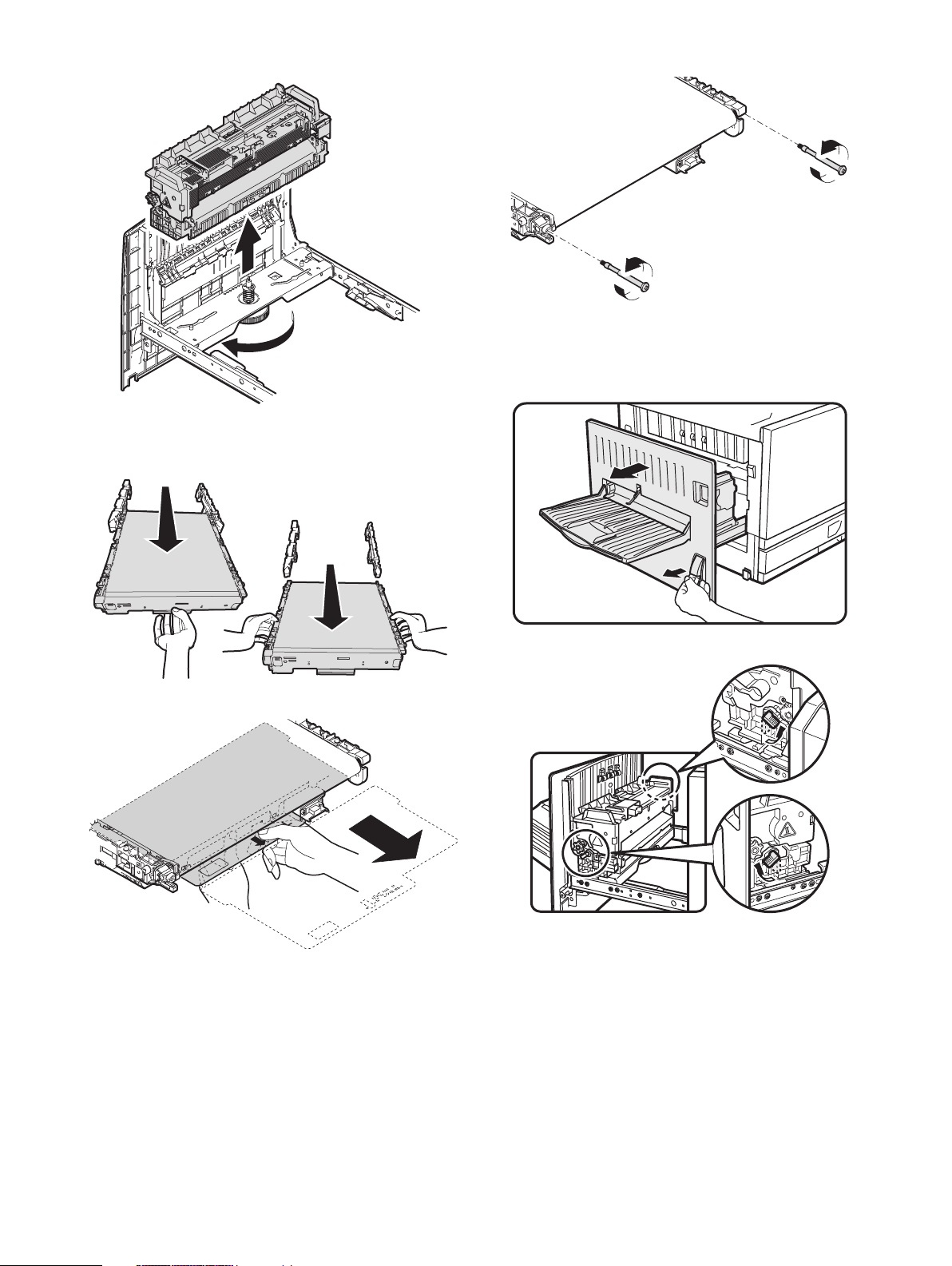

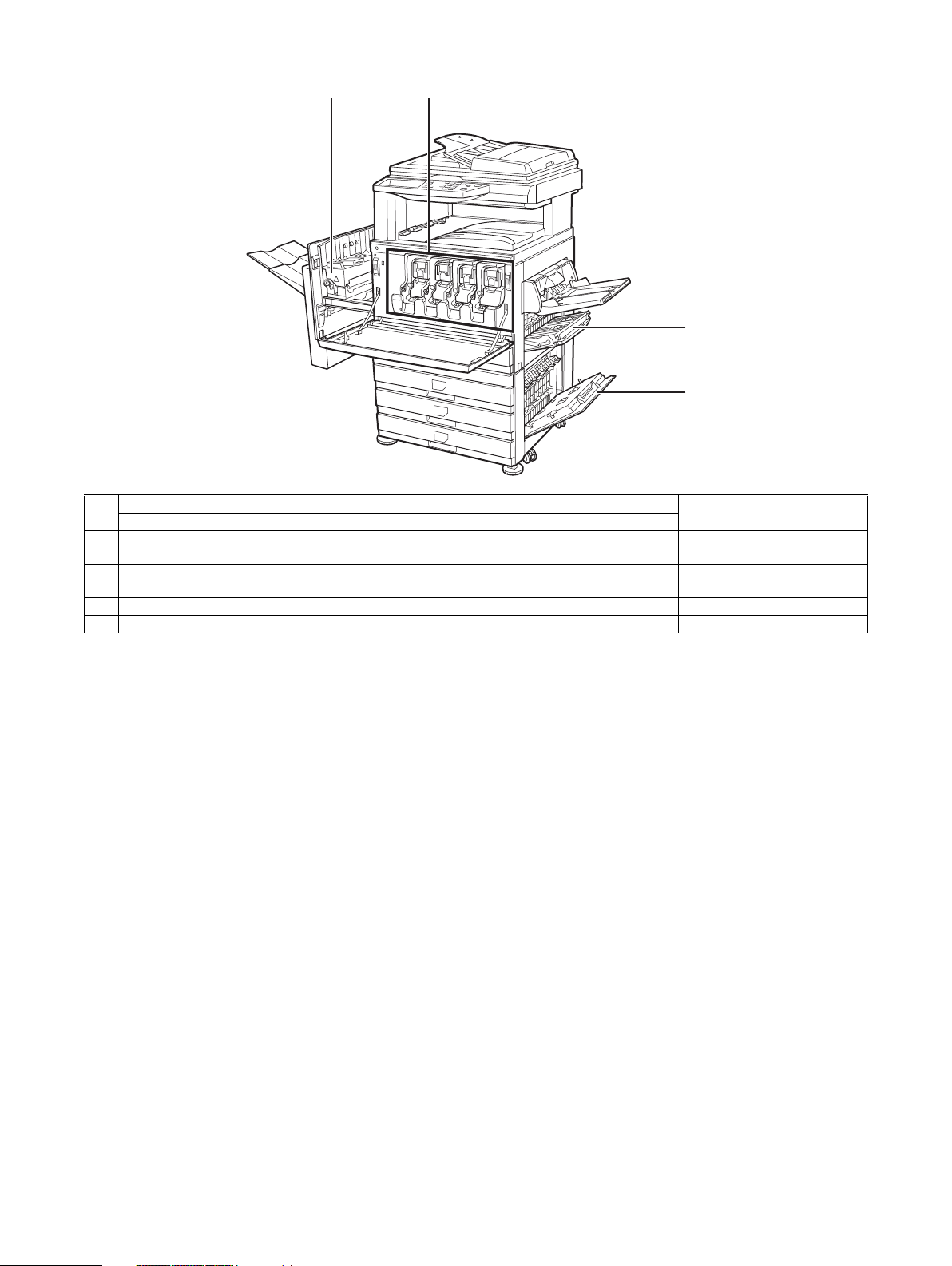

C. Transfer unit pressure release

1) Pull the knob and open the left door.

AR-C172M UNPACKING AND INSTALLATION 5 - 3

Page 23

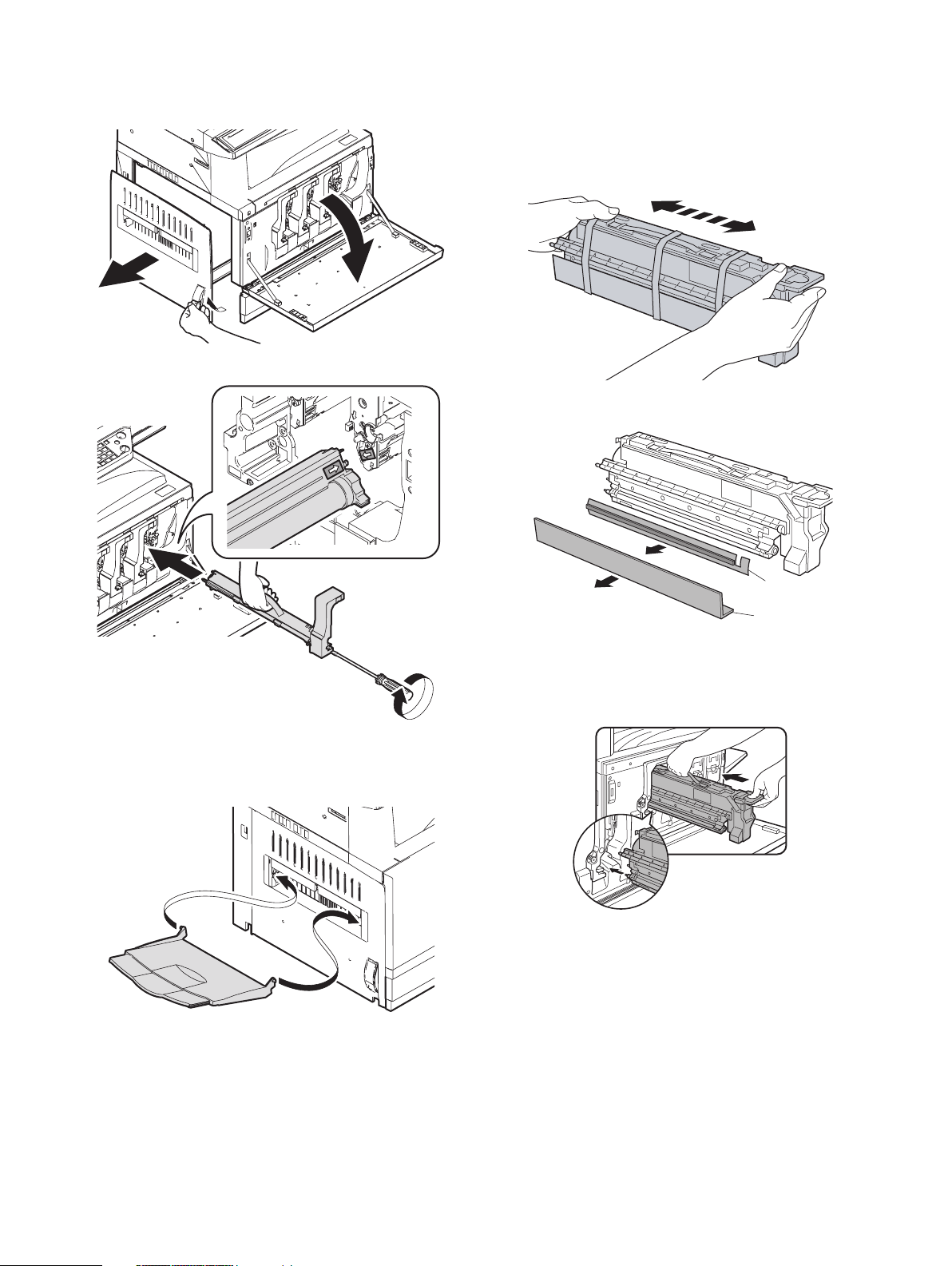

2) Loosen the roller knob (A), and remove the fusing unit (B).

B

6) Remove the screw and apply a tension to the transfer belt.

A

3) Hold section A of the transfer unit and pull it out so that the

both sides of the transfer unit can be held.

4) Hold sections B and remove the transfer unit.

B

A

5) Remove the transfer belt protect sheet.

7) Install the transfer unit to the machine.

5. Fusing heat roller pressing (F/R)

1) Pull the knob and open the left door.

2) Turn the pressure release lever to press.

Note: If the machine is left for one month or more, the heat roller

rubber may be deformed. In such a case, therefore, release

the pressure.

AR-C172M UNPACKING AND INSTALLATION 5 - 4

Page 24

6. Black drum cartridge insertion

1) Pull the knob and open the left door.

2) Open the front cover.

8. Toner cartridges installation

* The life of each toner cartridge packed together with the

machine is as follows:

Black toner CA: 8.3K (6%) equivalent

Color toner CA: 5.5K (5%) equivalent

1) Shake the toner cartridge horizontally several times.

2

3

1

3) Insert the black drum cartridge, and fix it with a screw.

2) Remove the tape, and remove the protection pad.

2

1

3) Open the front cover.

4) Insert the toner cartridge.

∗ As shown below, fit the cartridge with the insertion port and

push it in.

7. Paper exit tray installation (Optional)

1) Install the paper exit tray to the left door.

Note: Be sure to install the color cartridges to their proper posi-

tions. Avoid instillation to a different color position.

AR-C172M UNPACKING AND INSTALLATION 5 - 5

Page 25

[Color toner cartridge positions]

Yellow

Magenta

Cyan

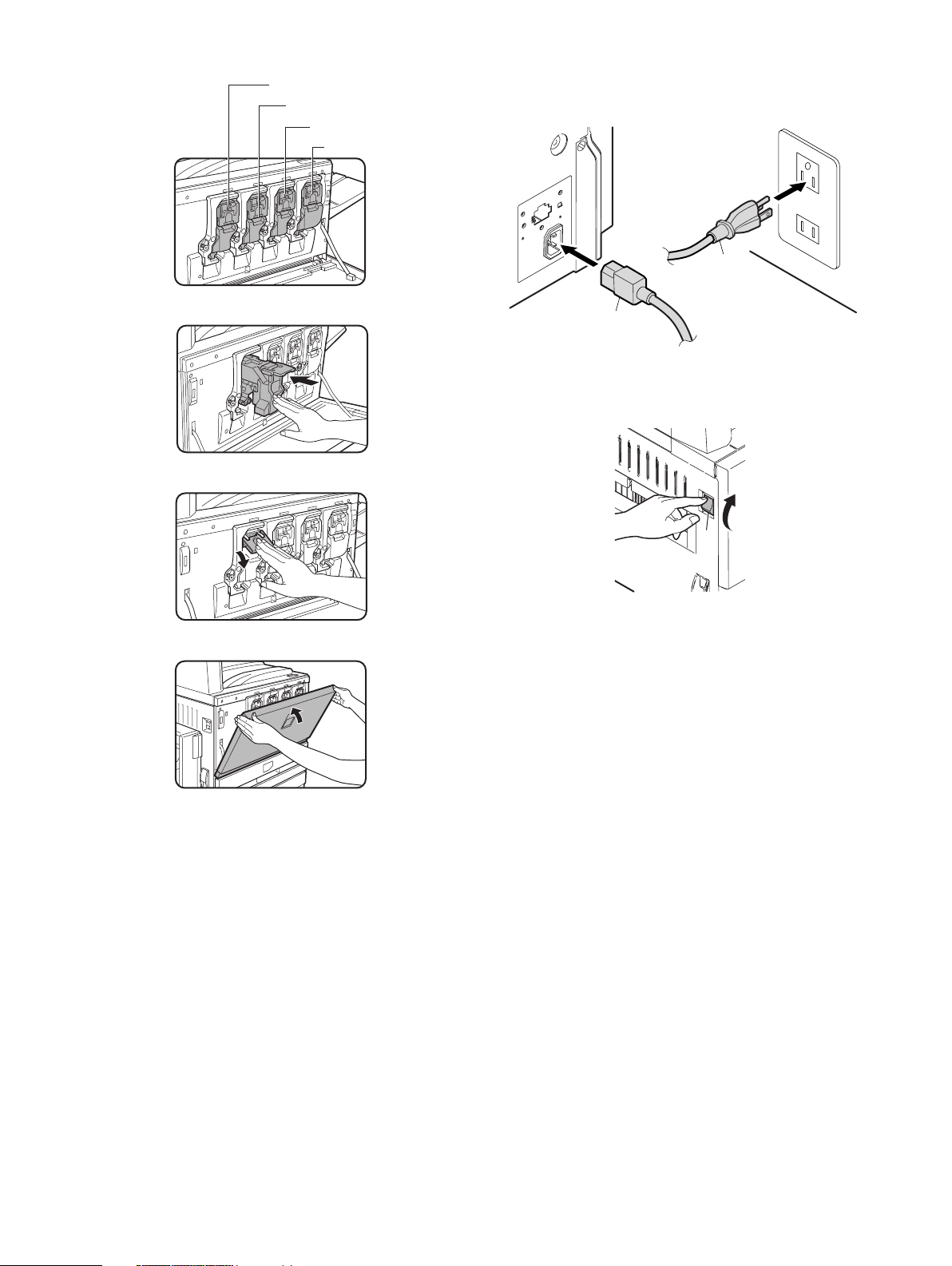

9. AC cord connection

1) Insert the AC power plug into the connector at the rear of the

machine, and connect the other end to the power outlet.

Black

2

5) Insert the cartridge securely until it locks.

6) Return the cartridge lever to the original position.

7) Close the front cover.

1

10. Machine power ON

1) Turn on the power switch on the left side of the machine.

1

AR-C172M UNPACKING AND INSTALLATION 5 - 6

Page 26

11. Specifications setup

Used to set the specifications with SIM26 according to the customer's request.

SIM No Content

26 6 Used to set the destination.

To customize the following items after completion of the destination setup, change the set values.

SIM No Content

26 2 Used to set the large capacity paper feed tray paper

size.

Used to set the detection paper size and display

when using 8.5 x 13 size paper and document.

Used to set the paper kind and the display form in the

manual paper feed mode.

3 Used to set the auditor specification mode.

5 Used to set the count mode of the total counter and

the maintenance counter.

18 Used to set YES/NO of the toner save mode (Only in

UK and Japan versions) For other destination

versions, this setup is made by the user program.

52 Used to set YES/NO of counting when non-print

paper is passed through each counter.

53 Used to set YES/NO of user calibration permission.

65 Used to set the limit number of sheets for stapling.

On completion of the installation of the AR-F13 finisher, please

change the default output tray of the machine to the top tray of the

finisher.

12. Image quality check

Check the following items related to image quality. For details of

the adjustment and checking procedures, refer to the chapter of

adjustments.

1) Image focus, image skew (Refer to ADJ 3.)

2) Image registration (Refer to ADJ 4.)

3) Image loss, void area (Refer to ADJ 10.)

4) Copy color balance, density (Refer to ADJ 11.)

Check that the above items are normal. If not, make the adjust-

ment.

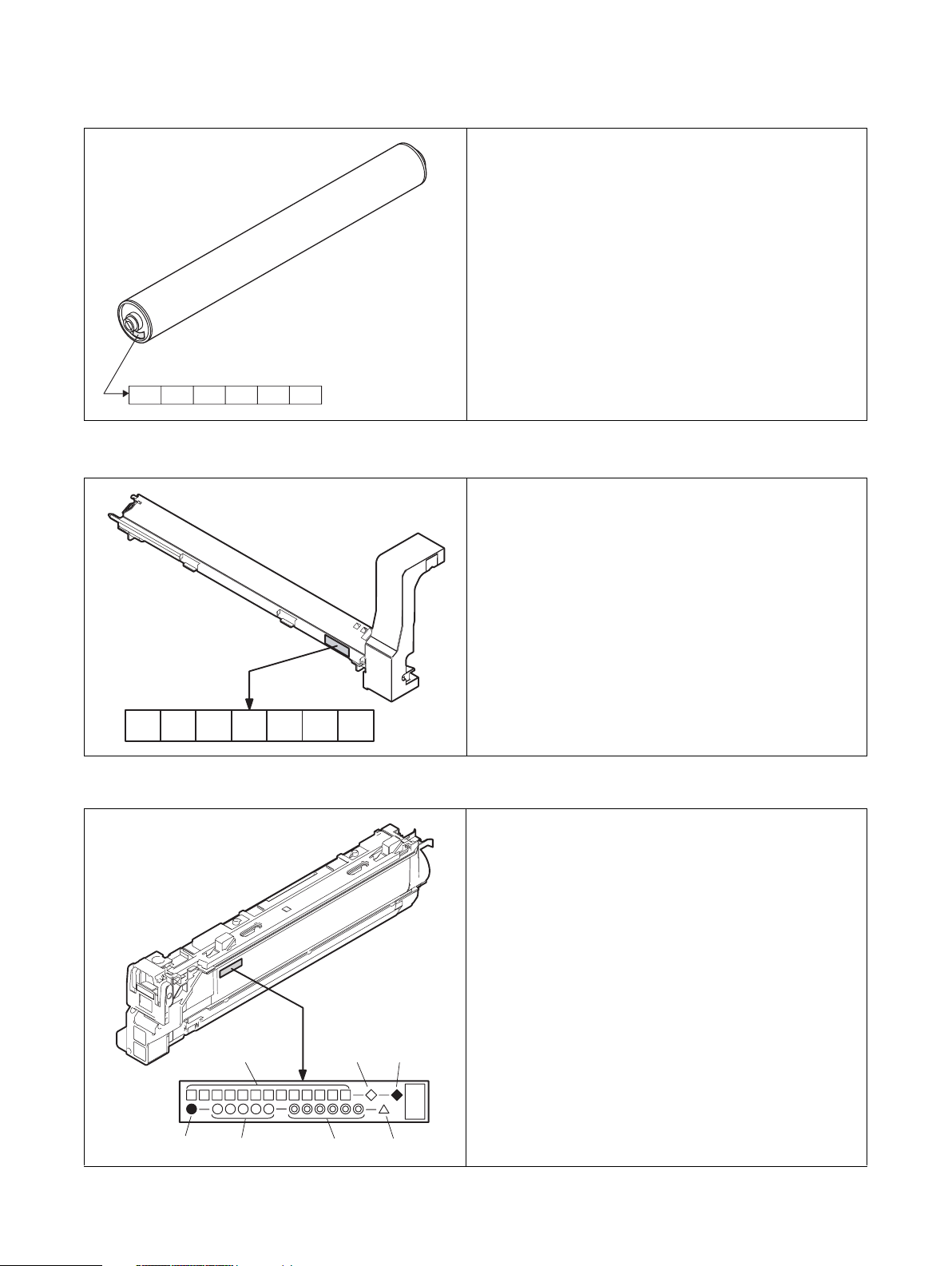

13. Function and operation check

Check that the following operations are normal.

Check item Installation

Key input operation (Operation

panel)

Display (Operation panel)

Paper feed

operation

Paper size detection operation

Document size

detection

operation

RSPF

operation/

Duplex copy

operation

Bookbinding operation When the finisher is installed.

Stapling operation When the finisher is installed.

Grouping operation When the finisher is installed.

Sorting operation When the finisher is installed.

Manual paper

feed

Machine paper

tray

Desk unit paper

feed tray

Document table

mode

RSPF mode

S-S mode

D-S mode

S-D mode When the desk unit with the

D-D mode When the desk unit with the

When the desk unit is installed.

duplex unit is installed.

duplex unit is installed.

14. Setup and adjustment data recording

Print the various setup data and the adjustment data (list) with

SIM22-6 and keep the data.