Page 1

CODE: 00ZARC160/F1E

DIGITAL FULL

COLOR COPIER

AR-C150

AR-C250

MODEL

CONTENTS

[ 1 ] CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[ 3 ] CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 5 ] EXTERNAL VIEW AND INTERNAL STRUCTURE. . . . . . . . . 5-4A

[ 6 ] MACHINE OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] SETTING AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[10] SELF DIAG MESSAGE AND TROUBLESHOOTING . . . . . . 10-2A

[11] MAINTENANCE AND DISASSEMBLY/ASSEMBLY . . . . . . . . 11-1

[12] BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ACTUAL WIRING CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

AR-C160

[14] OTHERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-8A

This Service Manual describes only the different points from the

AR-C150/C250. For servicing of the AR-C160, therefore, use this

Service Manual together with that of the AR-C150/C250.

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

Cautions on laser

Wave length 785 nm

Pulse times

North America: (4.374 µs ±4.4 ns)/7 mm

Europe: (5.732 µs ±5.7 ns)/7 mm

+10 nm

-15 nm

Output power 0.25 - 0.45 mW

Caution

This product contains a low power laser device. To ensure

continued safety do not remove any cover or attempt to

gain access to the inside of the product. Refer all

servicing to qualified personnel.

For North America:

SAFETY PRECAUTIONS

This Digital Copier is rated Class 1 and complies with 21 CFR 1040.10 and 1040.11 of the CDRH standards.

This means that the copier does not produce hazardous laser radiation. For your safety, observe the

precautions below.

●

Do not remove the cabinet, operation panel or any other covers.

●

The copier’s exterior covers contain several safety interlock switches. Do not bypass any safety interlock by

inserting wedges or other items into switch slots.

For Europe:

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

INVISIBLE LASER RADIATION

CAUTION

WHEN OPEN AND INTERLOCKS

DEFEATED. AVOID EXPOSURE

TO BEAM.

VORSICHT

UNSICHTBARE

LASERSTRAHLUNG WENN

ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM

STRAHL AUSSETZEN.

ADVARSEL

USYNLIG LASERSTRÅLNING VED

ÅBNING, NÅR

SIKKERHEDSBRYDERE ER UDE

AF FUNKTION. UNDGÅ

UDSAETTELSE FOR STRÅLNING.

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA MAINITULLA

TAVALLA SAATTAA ALTISTAA

KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

VAROITUS!

VARNING

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

CAUTION

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

VORSICHT

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGÅ UDSAETTELSE FOR STRÅLNING.

ADVARSEL

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

ADVERSEL

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

Laserstrahl

VARNING

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VAR O!

CLASS 1

LASER PRODUCT

LASER KLASSE 1

(Caution on power source)

Before servicing, be sure to disconnect the power plug from the power outlet.

Page 3

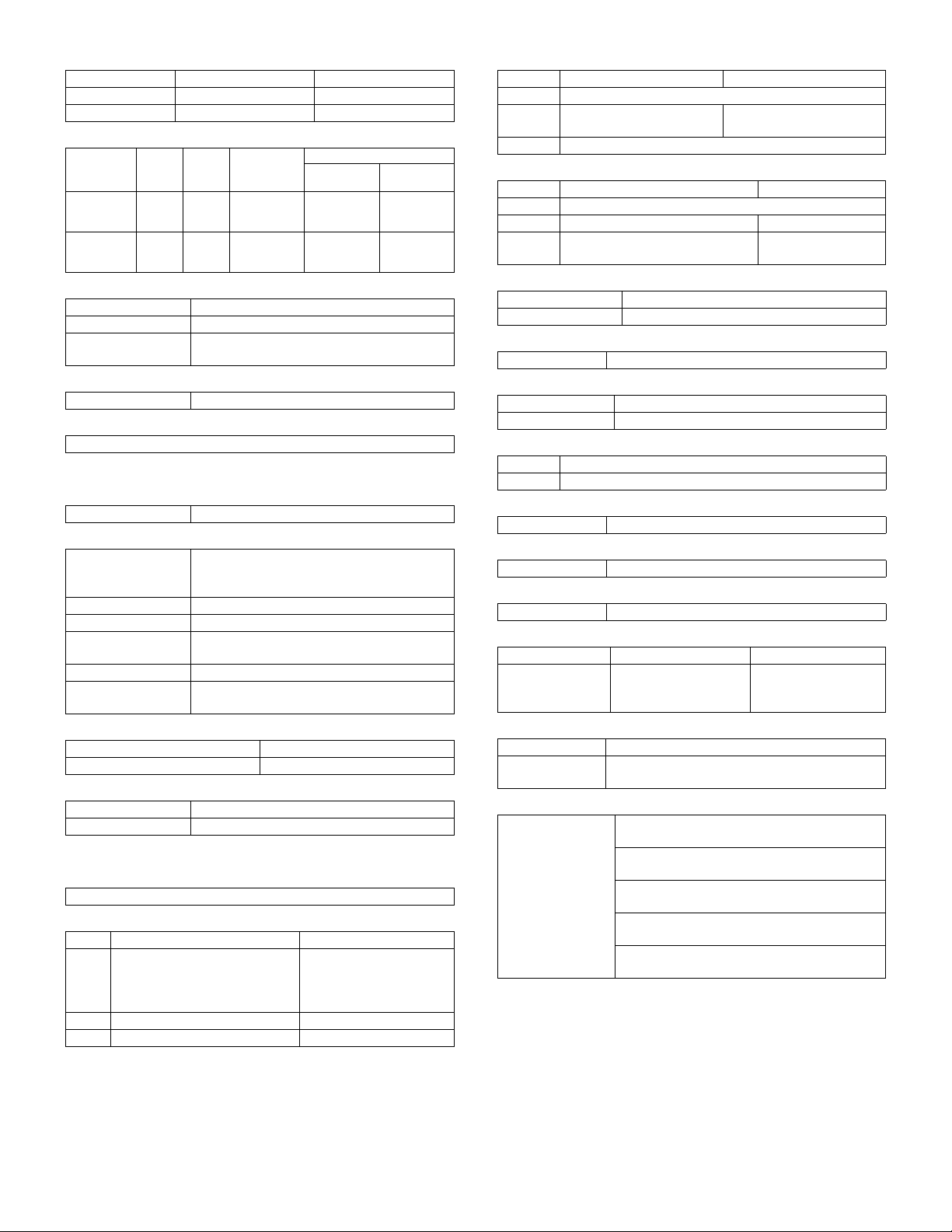

(Relationship between this Service Manual and

previous Service Manuals and how to utilize them)

There are following three kinds of Service Manuals for the AR-C100/

C150/C160/C250.

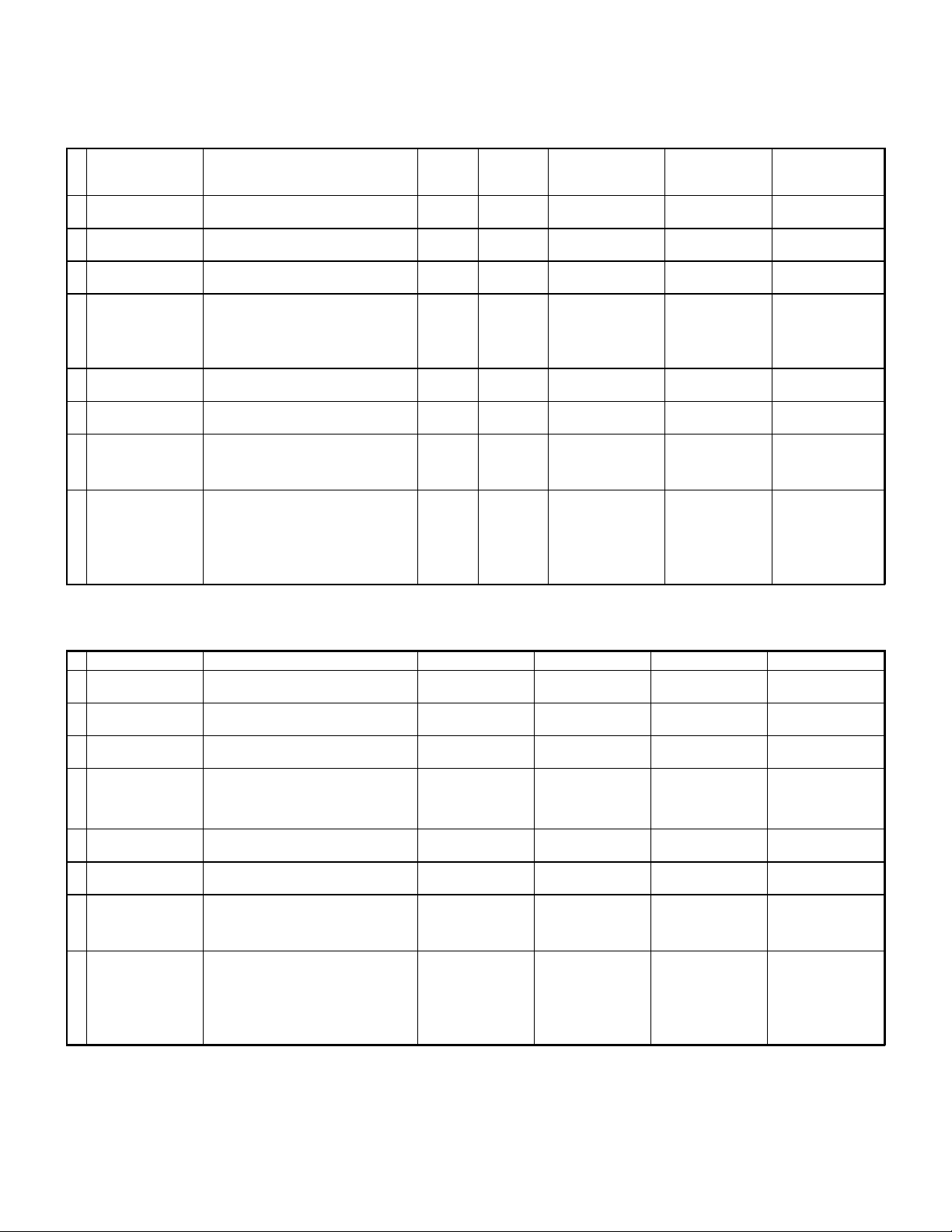

Document name Document code

AR-C100/C150 00ZARC150/F1E

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/C250 00ZARC160/F1E

The above list is made in the sequence of issuing. The later Service

Manual includes changes occurred before issuing of it.

(Service Manual required for servicing of each model)

Servicing of each model requires the following service manual.

Service Manual required for servicing

MODEL Document name Document code

AR-C100 AR-C100/C150 00ZARC150/F1E

AR-C150 AR-C100/C150 00ZARC150/F1E

AR-C160 AR-C100/C150 00ZARC150/F1E

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/C250 00ZARC160/F1E

AR-C250 AR-C100/C150 00ZARC150/F1E

AR-C100/C150/C250 00ZARC250/F2E

"List of Service Manuals and the contents" below indicates the relationship between each model and the contents of its Service Manual.

Refer to it to utilize the Service Manuals.

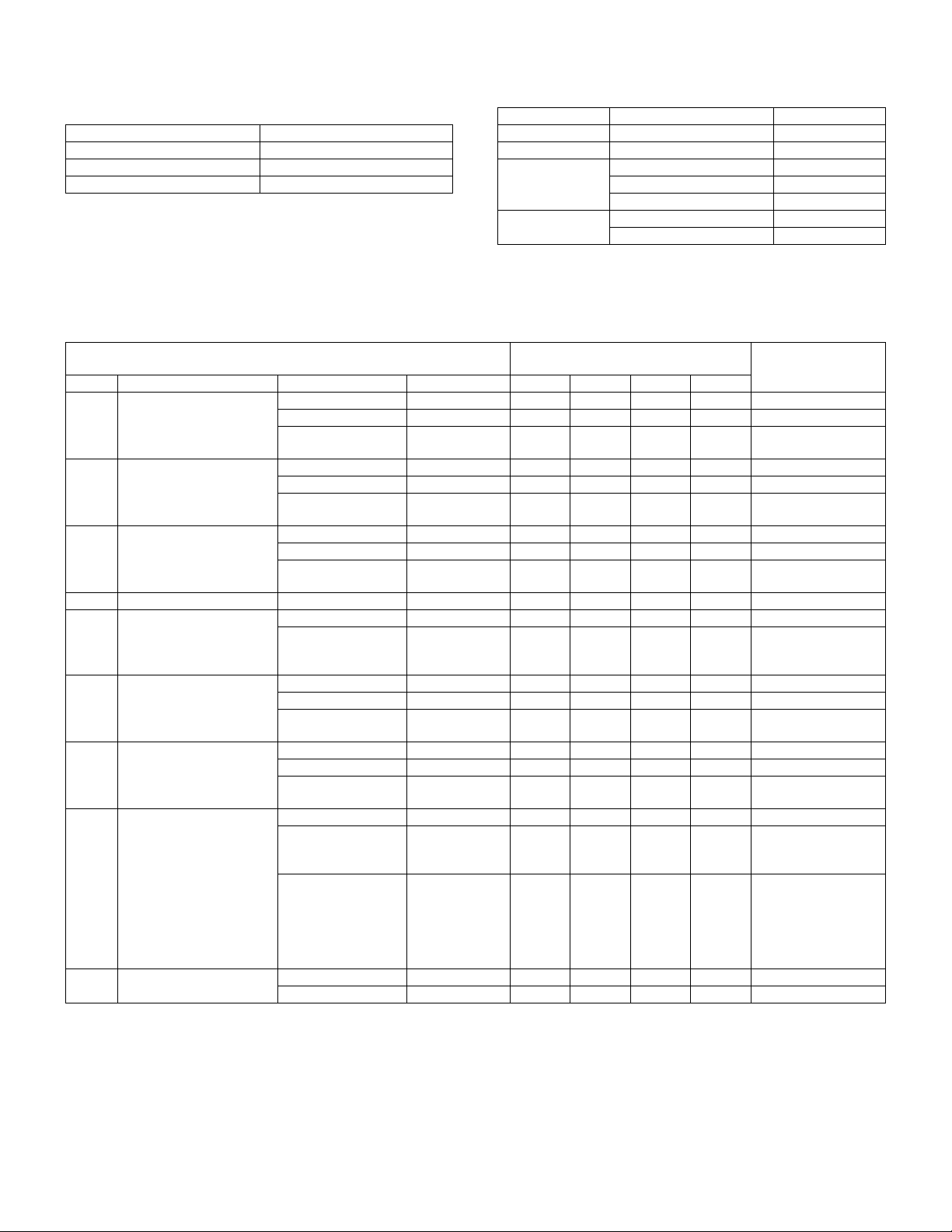

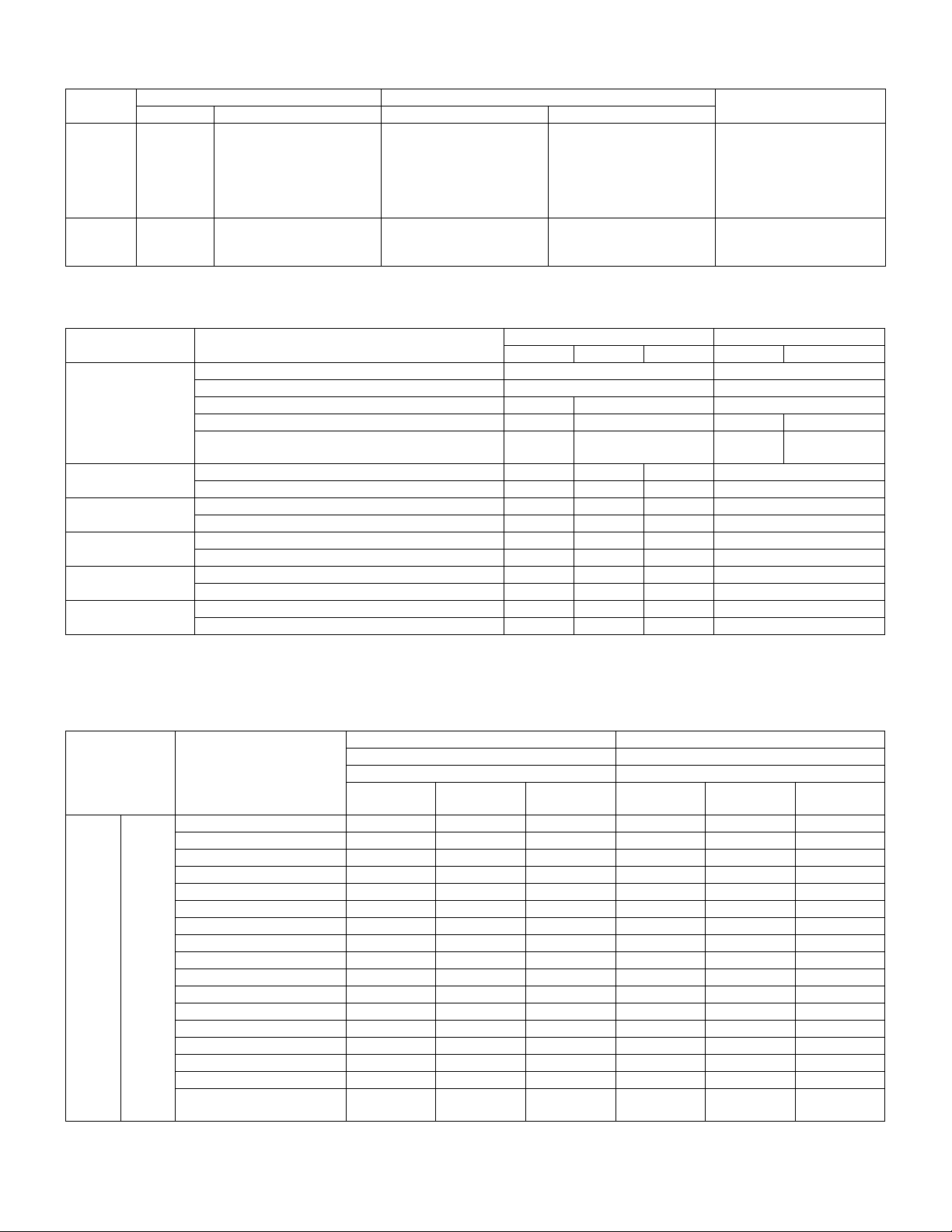

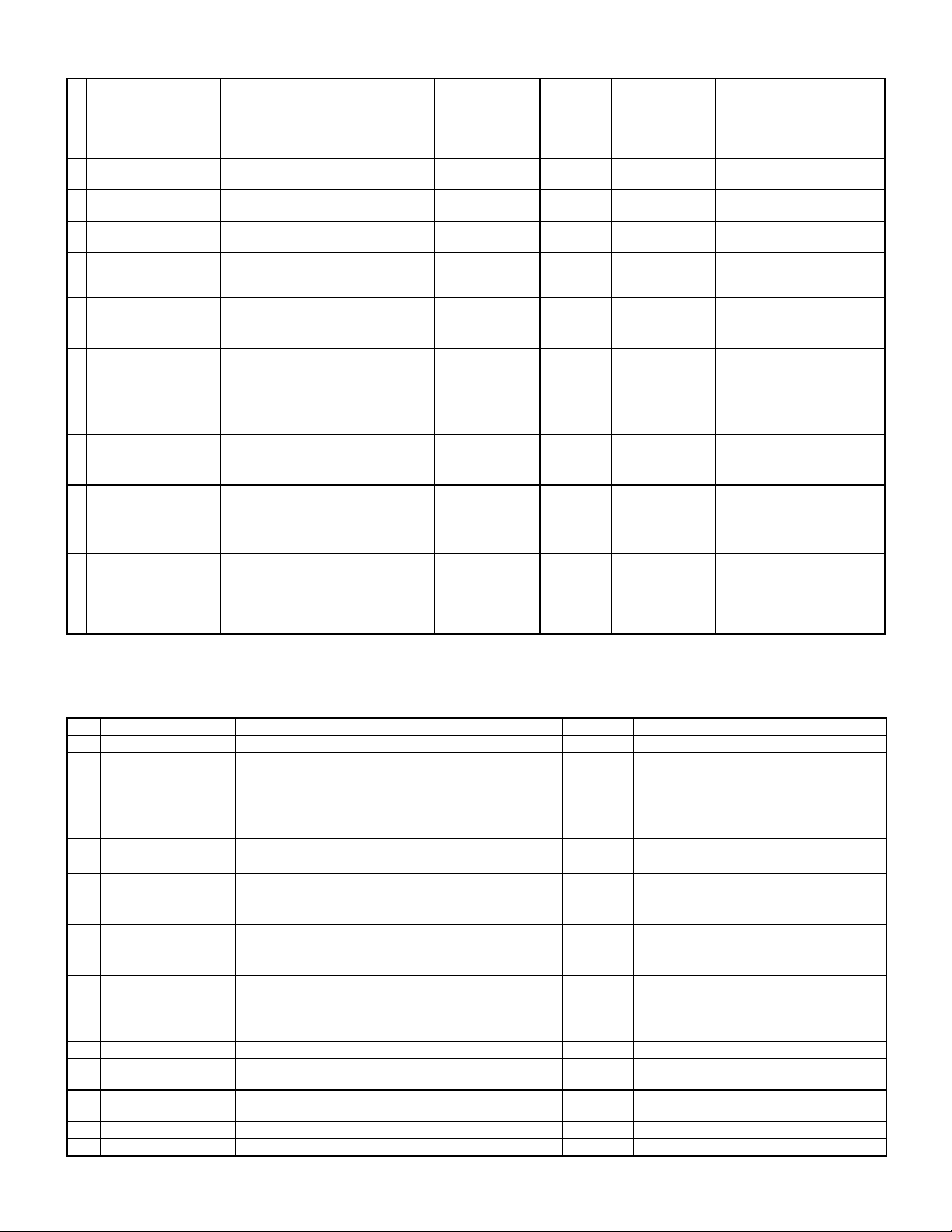

List of Service Manuals and the contents

Documents marked with ❍ includes the latest contents and the different points. Utilize them.

Service Manual

Chapter Contents of Service Manual Document name Document code AR-C100 AR-C150 AR-C160 AR-C250

1 Configuration AR-C100/C150 00ZARC150/F1E

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/

C250

2 Specifications AR-C100/C150 00ZARC150/F1E

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/

C250

3 Consumable parts AR-C100/C150 00ZARC150/F1E

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/

C250

4 Setup AR-C100/C150 00ZARC150/F1E ❍❍❍❍

5 External view and internal

structure

6 Machine operations AR-C100/C150 00ZARC150/F1E

7 Setup and adjustment AR-C100/C150 00ZARC150/F1E

8 Simulation AR-C100/C150 00ZARC150/F1E

9 User program AR-C100/C150 00ZARC150/F1E

AR-C100/C150 00ZARC150/F1E ❍❍❍❍

AR-C100/C150/C160/

C250

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/

C250

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/

C250

AR-C100/C150/C250 00ZARC250/F2E ❍❍❍❍Includes the contents

AR-C100/C150/C160/

C250

AR-C100/C150/C250 00ZARC250/F2E ❍❍❍❍

00ZARC160/F1E ❍❍❍❍Includes the contents

00ZARC160/F1E ❍❍❍❍Includes the contents

00ZARC160/F1E ❍❍❍❍Includes the contents

00ZARC160/F1E ❍ Includes the contents

00ZARC160/F1E ❍❍❍

00ZARC160/F1E ❍❍❍❍Includes the contents

00ZARC160/F1E ❍ Includes only the

Service target model/Service document

reference page

NOTE

of all the models.

of all the models.

of all the models.

of AR-C100/C150/

C250.

of all the models.

of AR-C100/C150/

C250.

differences from the

AR-C100/C150/C250.

(However, the list

includes the contents

of all the models.)

Page 4

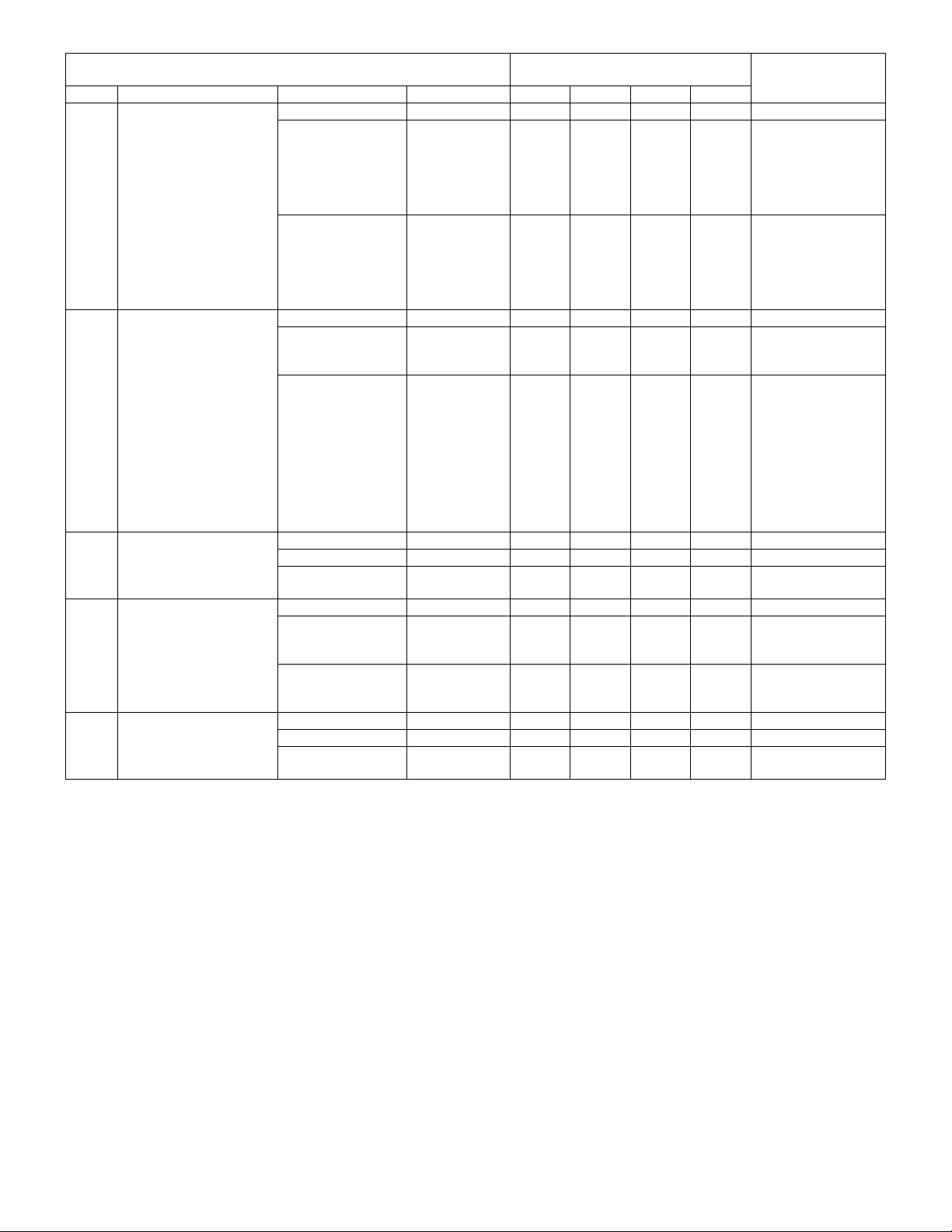

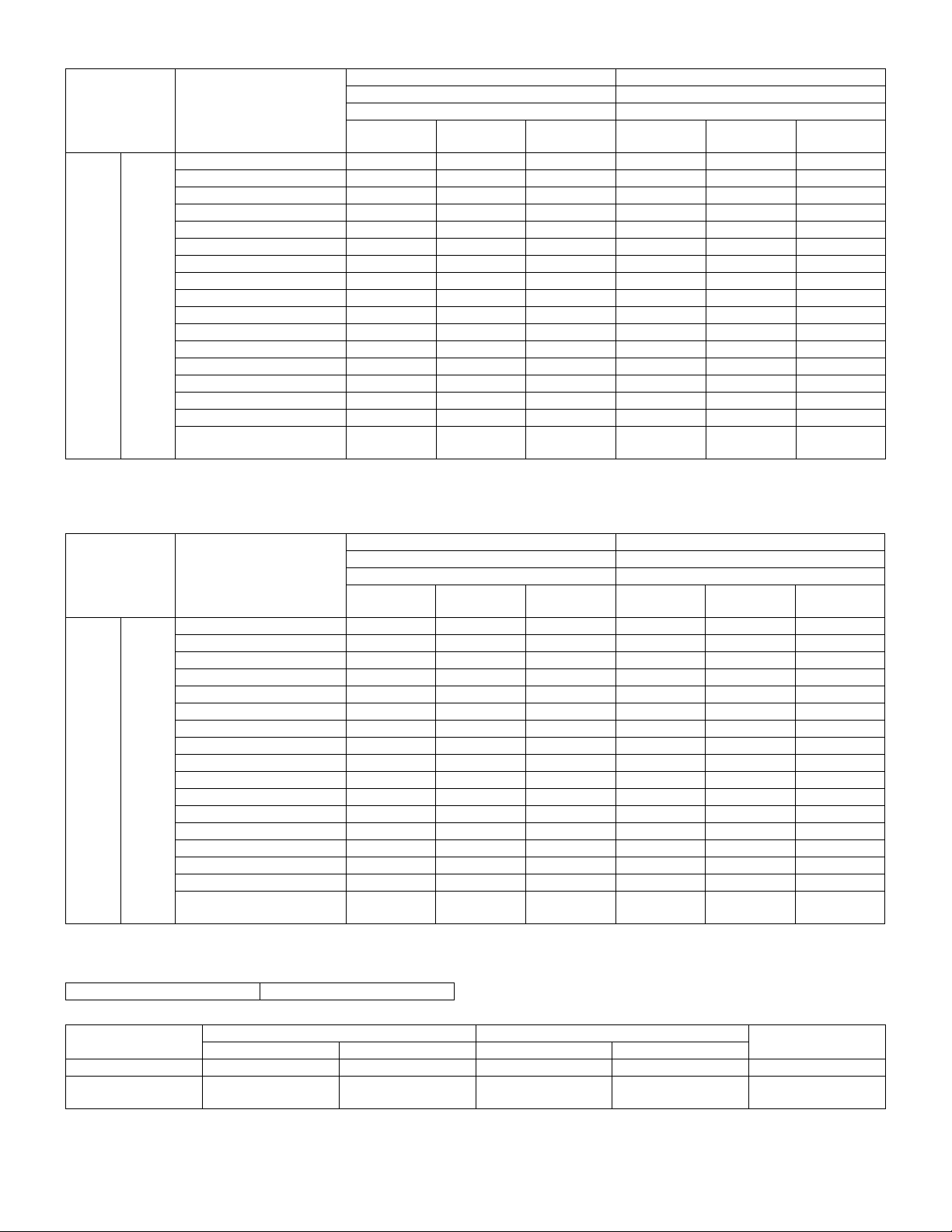

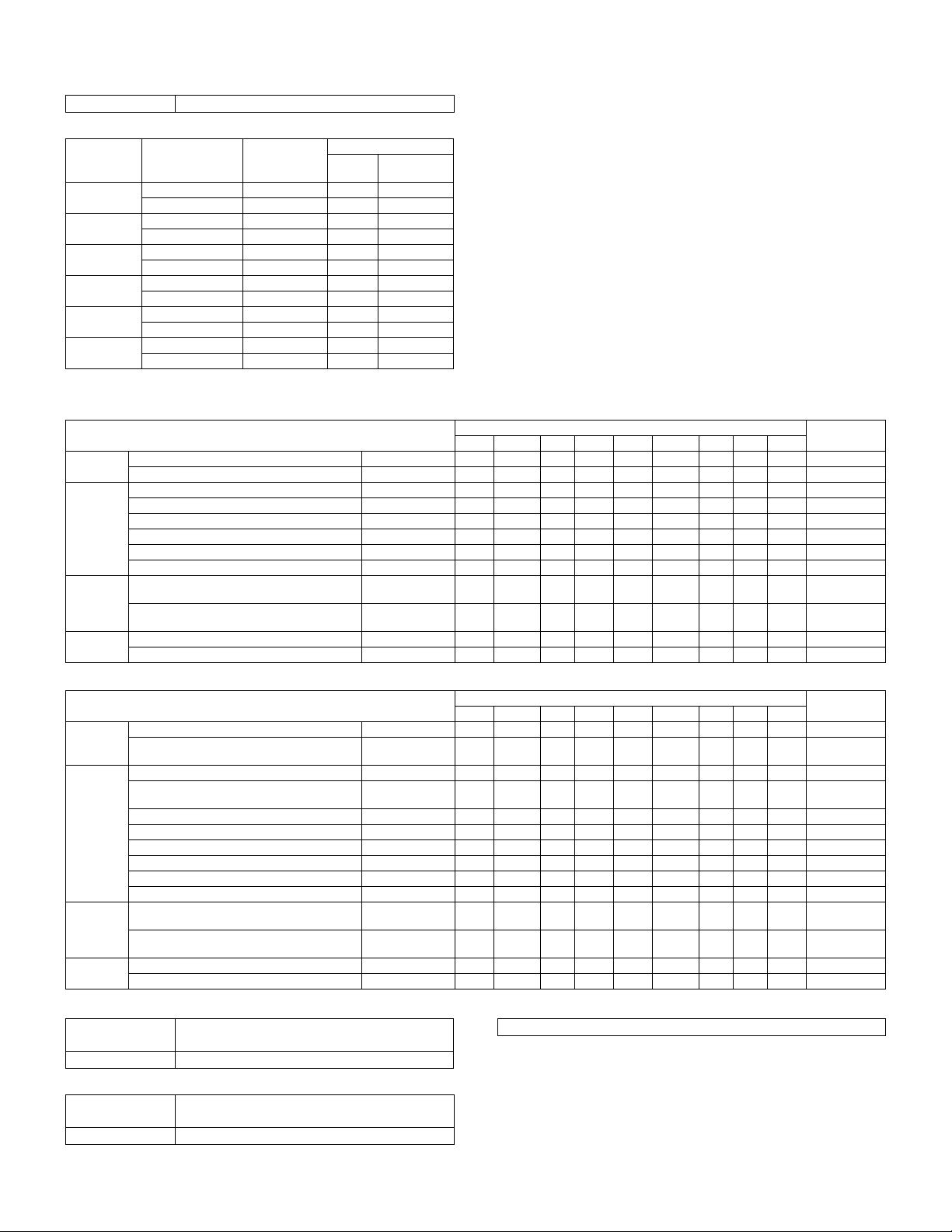

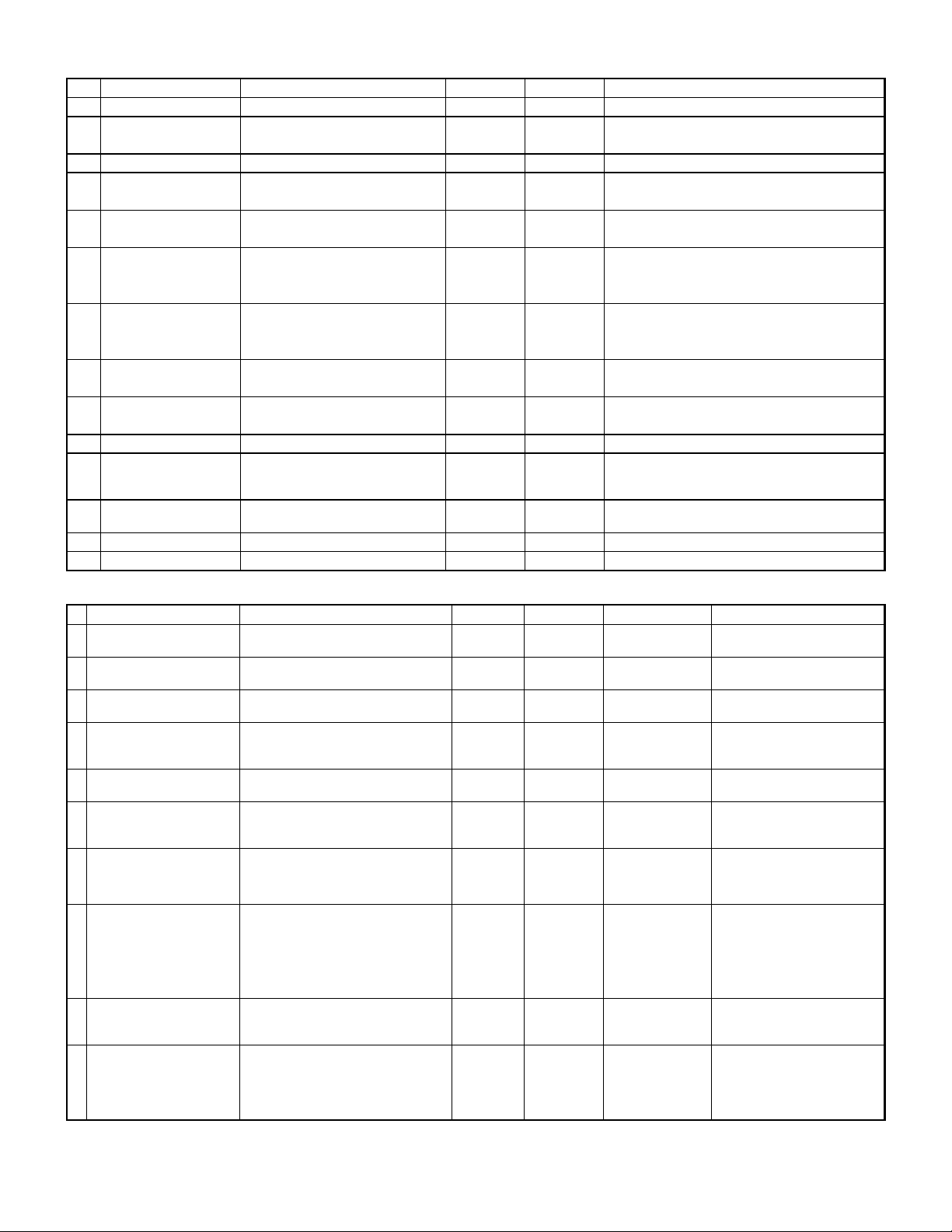

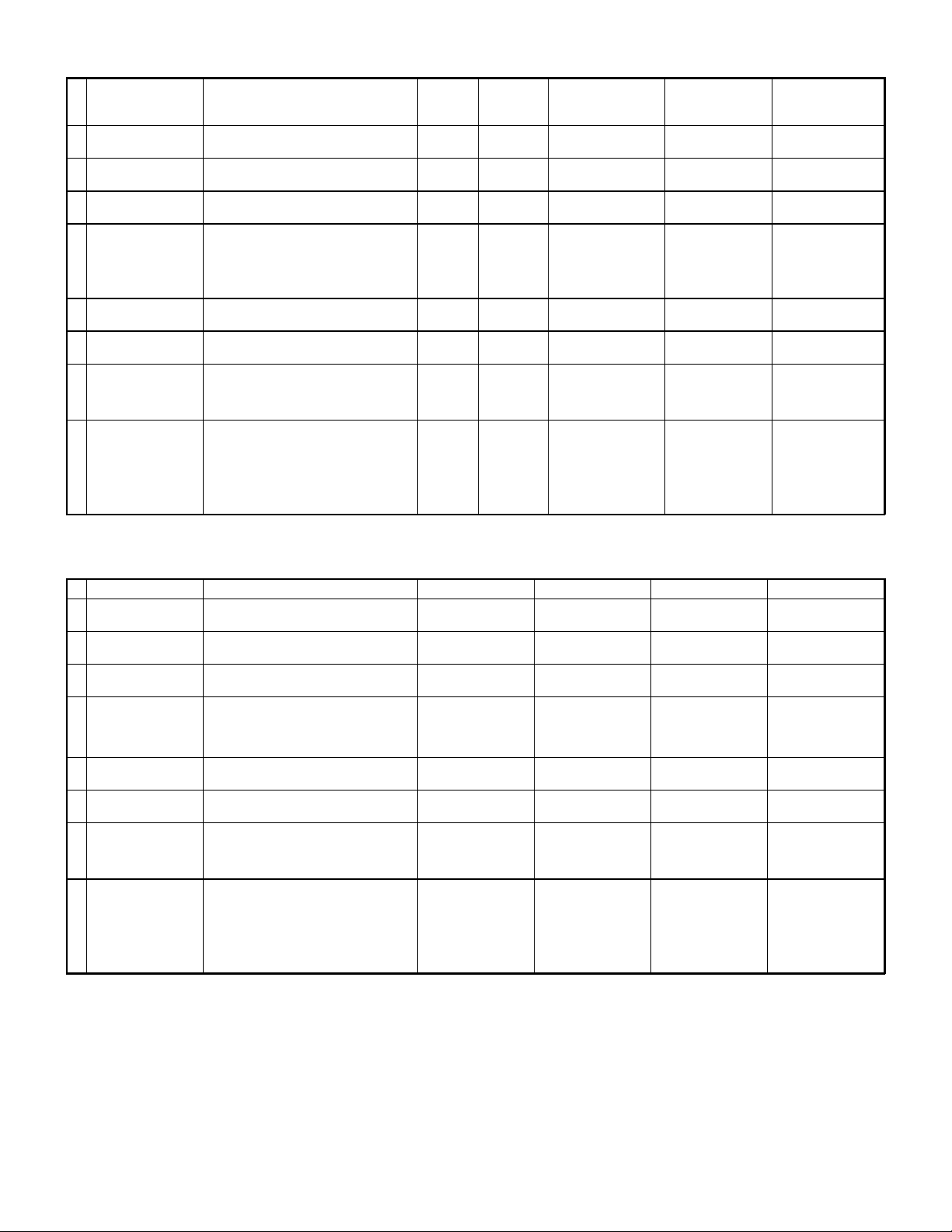

Service Manual

Service target model/Service document

reference page

Chapter Contents of Service Manual Document name Document code AR-C100 AR-C150 AR-C160 AR-C250

10 Self diag message and

troubleshooting

AR-C100/C150 00ZARC150/F1E ❍❍❍❍

AR-C100/C150/C250 00ZARC250/F2E ❍❍❍❍The list includes the

AR-C100/C150/C160/

00ZARC160/F1E ❍ Includes only the

C250

11 Disassembly/assembly and

maintenance

AR-C100/C150 00ZARC150/F1E ❍❍❍❍

AR-C100/C150/C250 00ZARC250/F2E ❍ Include only the

AR-C100/C150/C160/

00ZARC160/F1E ❍❍❍❍Includes only the

C250

12 Block diagram AR-C100/C150 00ZARC150/F1E ❍❍

AR-C100/C150/C250 00ZARC250/F2E ❍

AR-C100/C150/C160/

00ZARC160/F1E ❍

C250

13 Actual wiring diagram AR-C100/C150 00ZARC150/F1E ❍❍ ❍

AR-C100/C150/C250 00ZARC250/F2E ❍ Includes only the

AR-C100/C150/C160/

00ZARC160/F1E ❍ Includes all the

C250

14 Others AR-C100/C150 00ZARC150/F1E

AR-C100/C150/C250 00ZARC250/F2E

AR-C100/C150/C160/

00ZARC160/F1E ❍❍❍❍Includes the contents

C250

NOTE

contents of the ARC100/C150/C250. (The

details are only of the

differences from the

AR-C100/C150/C250.)

differences from the

AR-C100/C150/C250.

(However, the list

includes the contents

of all the models.)

differences from the

AR-C10/C150.

differences from the

AR-C100/C150/C250.

(However, for the

contents of necessary

work items of

maintenance and

servicing of all the

models, refer to this

Manual.)

differences from the

AR-C100/C150/C250.

contents of the ARC160.

of all the models.

Page 5

[ 1 ] CONFIGURATION

1. Main unit and option lineup. . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

[ 2 ] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Operating specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

A. Common operations . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

B. Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

A. Operation (display/operation) section . . . . . . . . . . . . . 2-8

B. Paper feeding, paper conveyance,

and discharge section . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

C. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

D. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

E. Image processing section . . . . . . . . . . . . . . . . . . . . . 2-10

F. Fuser section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

G. Drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

H. Engine controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

I. Image processing controller . . . . . . . . . . . . . . . . . . . 2-12

J. Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

K. Power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

4. Safety and environmental protection standards . . . . . . . 2-13

A. Safety standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

B. Environmental standards. . . . . . . . . . . . . . . . . . . . . . 2-13

5. Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

A. Space required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

B. Operating ambient conditions . . . . . . . . . . . . . . . . . . 2-13

C. Ambient storage conditions. . . . . . . . . . . . . . . . . . . . 2-13

D. Ambient conditions for transporting. . . . . . . . . . . . . . 2-13

E. Standard temperature and humidity . . . . . . . . . . . . . 2-13

[ 3 ] CONSUMABLE PARTS

1. Consumable parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Compatibility of Supplies for AR-C150/250/160

(Overseas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

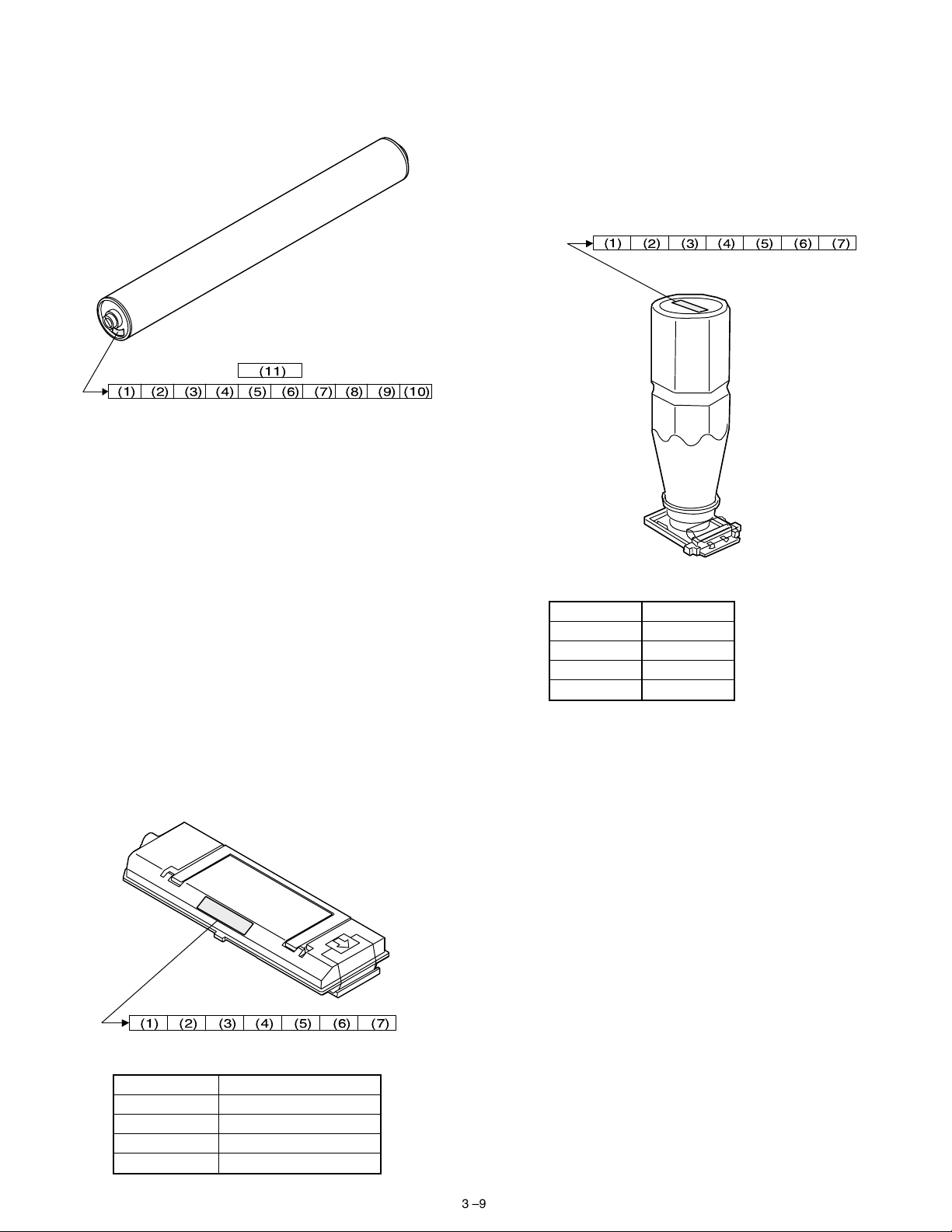

3. Photoconductor, developer, toner. . . . . . . . . . . . . . . . . . . 3-9

A. Serial number identification, effective life . . . . . . . . . . 3-9

4. Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

5. Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . . 3-10

[ 5 ] EXTERNAL VIEW AND INTERNAL STRUCTURE

B. Internal parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4A

[ 6 ] MACHINE OPERATIONS

1. Operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Operation menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

3. Pre-heat mode and sleep mode operations . . . . . . . . . . . 6-5

A. Operation timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

B. Pre-heat mode and sleep mode operations . . . . . . . . 6-5

4. Consumable parts life and machine operation . . . . . . . . . 6-8

[ 7 ] SETTING AND ADJUSTMENTS

1. Adjustment/setup items list . . . . . . . . . . . . . . . . . . . . . . . . 7-1

ADJ M1 DV doctor gap adjustment . . . . . . . . . . . . . . . . . 7-2

ADJ M2 DV roller main pole position adjustment . . . . . . 7-2

ADJ M3 Toner concentration control reference level

setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

ADJ M4 High voltage adjustment . . . . . . . . . . . . . . . . . . 7-3

ADJ M5 Paper skew adjustment . . . . . . . . . . . . . . . . . . . 7-5

ADJ M6 Image density sensor adjustment . . . . . . . . . . . 7-5

ADJ M7 Image skew adjustment (Scanner (Writing)

unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

ADJ M8 Photoconductor phase adjustment . . . . . . . . . . 7-8

ADJ M9A Image resist adjustment (Auto adjustment)

(AR-C250/C160) (New version of AR-C150) . . 7-10

CONTENTS

ADJ M9 Main scanning direction copy magnification

ratio adjustment (Manual adjustment)

(Scanner (Writing) unit)

Main scanning direction image registration

adjustment (Manual adjustment)

(Scanner (Writing) unit) . . . . . . . . . . . . . . . . . . 7-12

ADJ M10 Sub scanning direction color image resist

adjustment (Manual adjustment)

(Scanner (Writing) unit) (Color) . . . . . . . . . . . . 7-14

ADJ M11 Image distortion adjustment. . . . . . . . . . . . . . . 7-18

ADJ M12 Image focus (main scanning direction copy

magnification ratio) adjustment (CCD position

adjustment) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

ADJ M13 Sub scanning direction copy magnification ratio

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

ADJ M14 Image position adjustment (Main scanning

direction) (Print engine) . . . . . . . . . . . . . . . . . . 7-21

ADJ M15 Image position adjustment (Main scanning

direction) (Scanner (Writing)). . . . . . . . . . . . . . 7-22

ADJ M16 "Image position, image loss, void area

adjustment" . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

ADJ M17 Copy color balance and density adjustment . . 7-24

ADJ M18 Document size sensor adjustment. . . . . . . . . . 7-38

ADJ M19 Waste toner full detection level adjustment . . . 7-38

ADJ M20 Touch panel coordinates setting . . . . . . . . . . . 7-38

ADJ M21 Transfer belt level adjustment

(Transfer belt traveling adjustment). . . . . . . . . 7-39

ADJ M22 Fusing pressure adjustment . . . . . . . . . . . . . . 7-39

ADJ M23 Power voltage adjustment

(AR-C100/C150/C250) . . . . . . . . . . . . . . . . . . 7-40

ADJ M24 Manual paper feed size detection level

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

ADJ M25 OHP sensor adjustment. . . . . . . . . . . . . . . . . . 7-40

[ 8 ] SIMULATION

1. Outline and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Code system simulation . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

A. Operating procedures and operations. . . . . . . . . . . . . 8-1

B. Simulation list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

C. Details of simulation . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

[10] SELF DIAG MESSAGE AND TROUBLESHOOTING

5. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2A

6. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6A

[11] MAINTENANCE AND DISASSEMBLY/ASSEMBLY

1. Necessary procedure for maintenance and servicing. . . 11-1

2. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

3. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

S06 Image process section. . . . . . . . . . . . . . . . . . . 11-9

S07 Fusing/paper exit section. . . . . . . . . . . . . . . . . 11-9

S10 PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

[12] BLOCK DIAGRAM

1. Overall block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ACTUAL WIRING CHART . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] OTHERS

1. List of adjustment/setup values . . . . . . . . . . . . . . . . . . 14-8A

Page 6

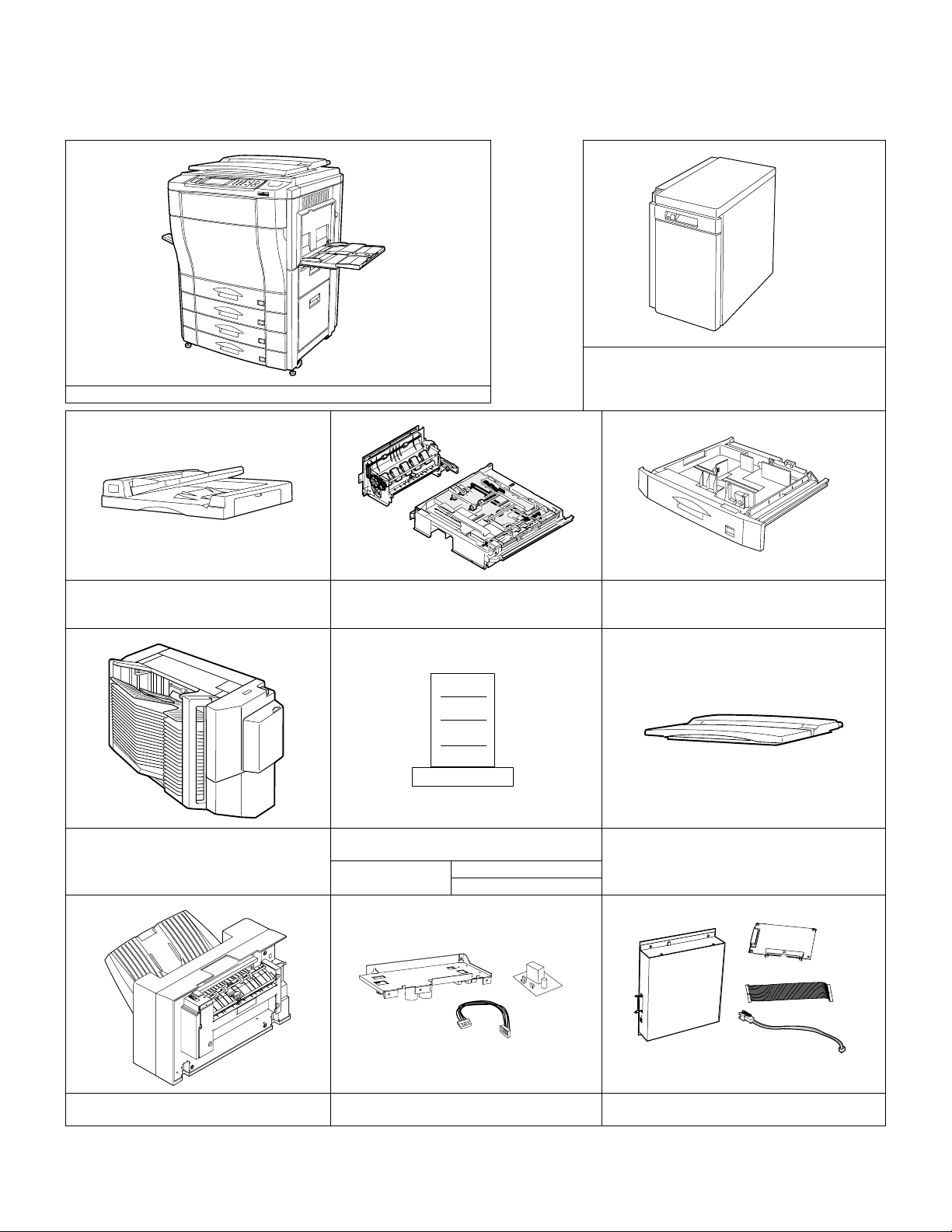

[1] CONFIGURATION

1. Main unit and option lineup

(1) Main unit lineup (2) Option lineup

AR-LC2 (AR-C150/C250)/Large capacity tray

(excluding Japan)

AR-C150/C250/C160

AR-LC2N (AR-C160/C250/C150)/ Large capacity tray

(excluding Japan)

AR-RF1/Reversing automatic document feeder

AR-SS2/20 bin staple sorter

AR-DU2 (AR-C150/C250)/Duplex module

AR-DU2N (AR-C160/C250/C150)/Duplex

module

AR-PE1 (AR-C150/C250) / Fiery Printer

Printer engine I/F kit

(AR-C150/C250)

controller

(AR-PX1)

(AR-PX2) (North America)

AR-CS2 (AR-C150/C250)/500 sheet paper drawer

AR-CS2N (AR-C160/C250/C150)/500 sheet paper

drawer

AR-VR2/Original cover (excluding Japan)

AR-FN4 Finisher (Use for AR-C250/C160) AR-PX3/PX4 (AR-C160)/Printer power unit

1 – 1

CD ROM

Operation Manual

AR-PE2 (AR-C160)/Built-in type printer controller

(with I/F PWB)

Page 7

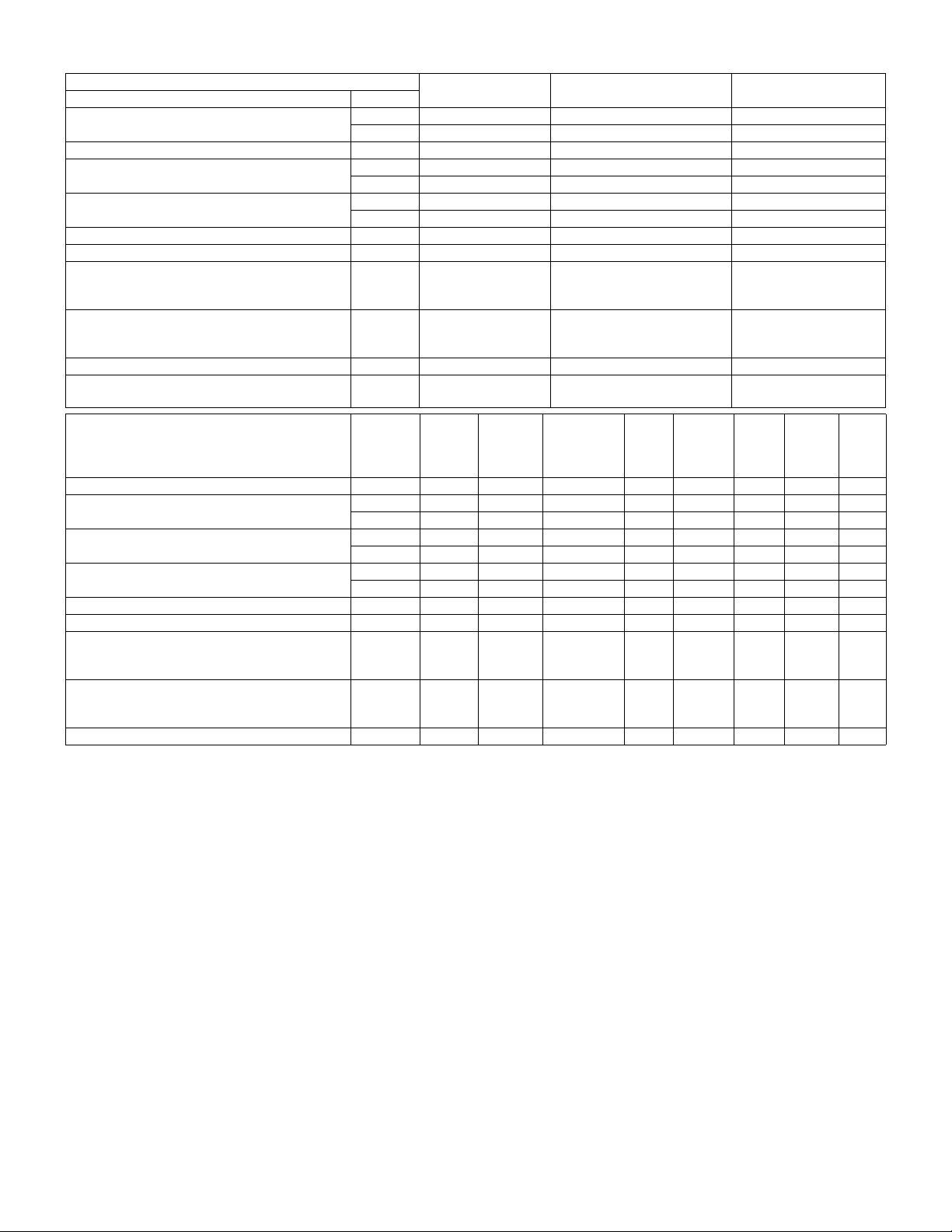

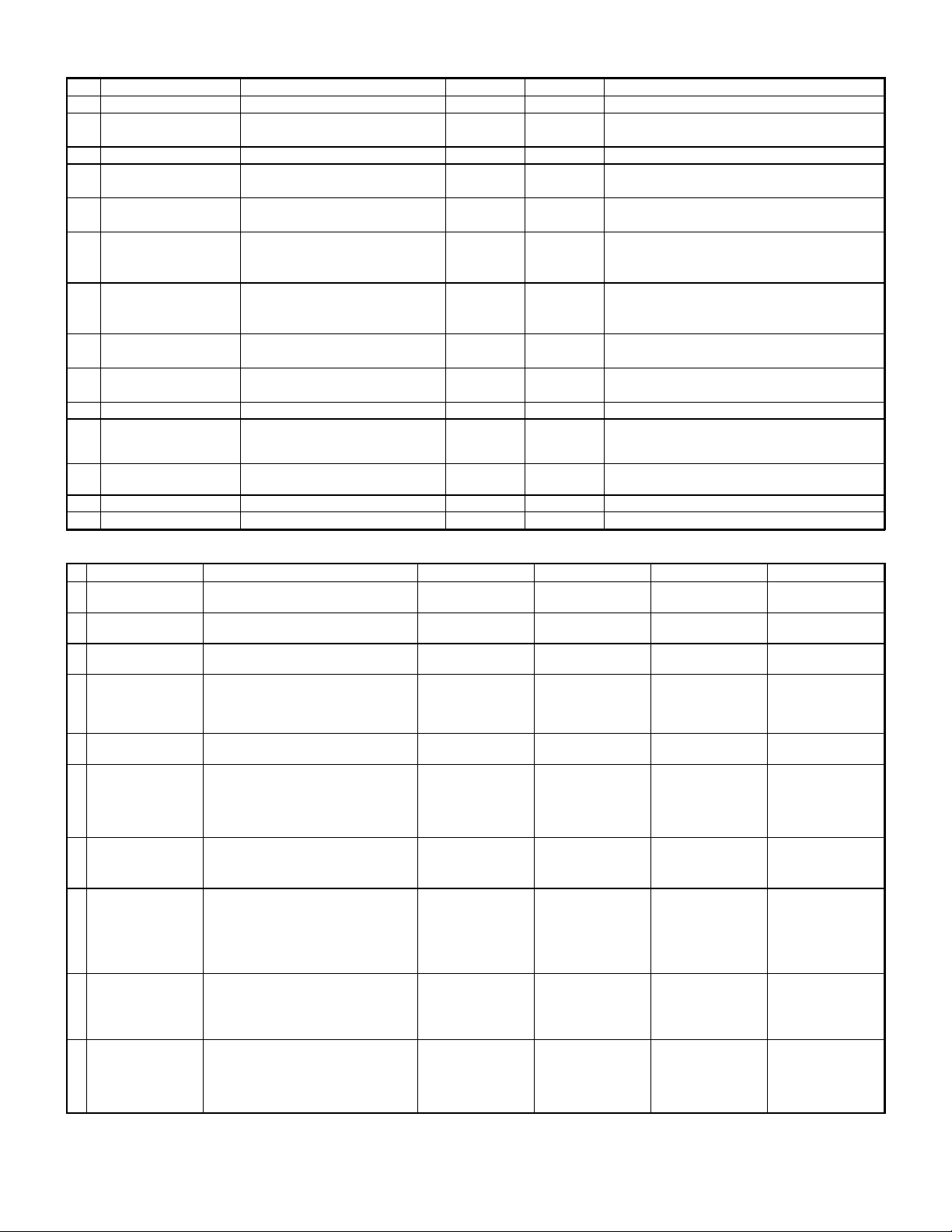

(3) Option combinations

Option

Item Model

Large capacity tray

Reversing automatic document feeder AR-RF1 AR-C150/C250/C160 Supplied from the copier body.

Duplex module

500 sheet paper drawer

20 bin staple sorter AR-SS2 AR-C150/C250/C160 Supplied from the copier body.

Department supervision card reader (Japan only) AR-EC1 AR-C150/C250/C160 Supplied from the copier body. Japan only

Fiery Printer controller/Printer engine I/F kit

Fiery printer controller (built-in type, with printer

connection kit)/DC power unit

Original cover AR-VR2 AR-C150/C250/C160 Outside of Japan only

Finisher AR-FN4 AR-C250/C160 Supplied from the copier body

Item Model Finisher

RADF AR-RF1 ❍❍ ❍ ❍❍❍❍—

Duplex module

Paper feed tray

LCC (Outside of Japan only)

20 bin staple sorter AR-SS2 ✕❍ ❍ — — — — —

Department supervision card reader (Japan only) AR-EC1 ❍▲ — — — — — —

Fiery Printer controller/Printer I/F kit

Fiery printer controller (built-in type, with printer

connection kit)/DC power unit

Finisher AR-FN4 — — — — — — — —

❍: Possible ✕: Not possible ▲: Possible; however, only operational in copy mode (does not operation in printer mode)

AR-LC2 AR-C150/C250 Supplied from the copier body. Outside of Japan only

AR-LC2N AR-C150/C250/C160 Supplied from the copier body. Outside of Japan only

AR-DU2 AR-C150/C250 Supplied from the copier body.

AR-DU2N AR-C150/C250/C160 Supplied from the copier body.

AR-CS2 AR-C150/C250 Supplied from the copier body.

AR-CS2N AR-C150/C250/C160 Supplied from the copier body.

AR-PE1/

AR-PX1/

AR-PX2

AR-PE2/

AR-PX3/

AR-PX4

AR-DU2 ❍❍ ❍ ❍❍✕— —

AR-DU2N ❍❍ ❍ ❍❍✕— —

AR-CS2 ❍❍ ❍ ❍❍— — —

AR-CS2N ❍❍ ❍ ❍❍— — —

AR-LC2 ❍❍ ❍ ❍— — — —

AR-LC2N ❍❍ ❍ ❍— — — —

AR-PE1/

AR-PX1/

AR-PX2

AR-PE2/

AR-PX3/

AR-PX4

Model Power source Note

AR-C150/C250

AR-C160

Fiery

Printer

controller

❍ — — — — — — —

❍ — — — — — — —

Supplied from the copier body.

(AR-PX1)

Supplied from the exclusive

DC power unit.

Department

supervision

card reader

(Japan only)

20 bin

staple

sorter

LCC

(Outside

of Japan

only)

Sorting is disabled in the

copy mode.

500

sheet

paper

drawer

Duplex

module

RADF

1 – 2

Page 8

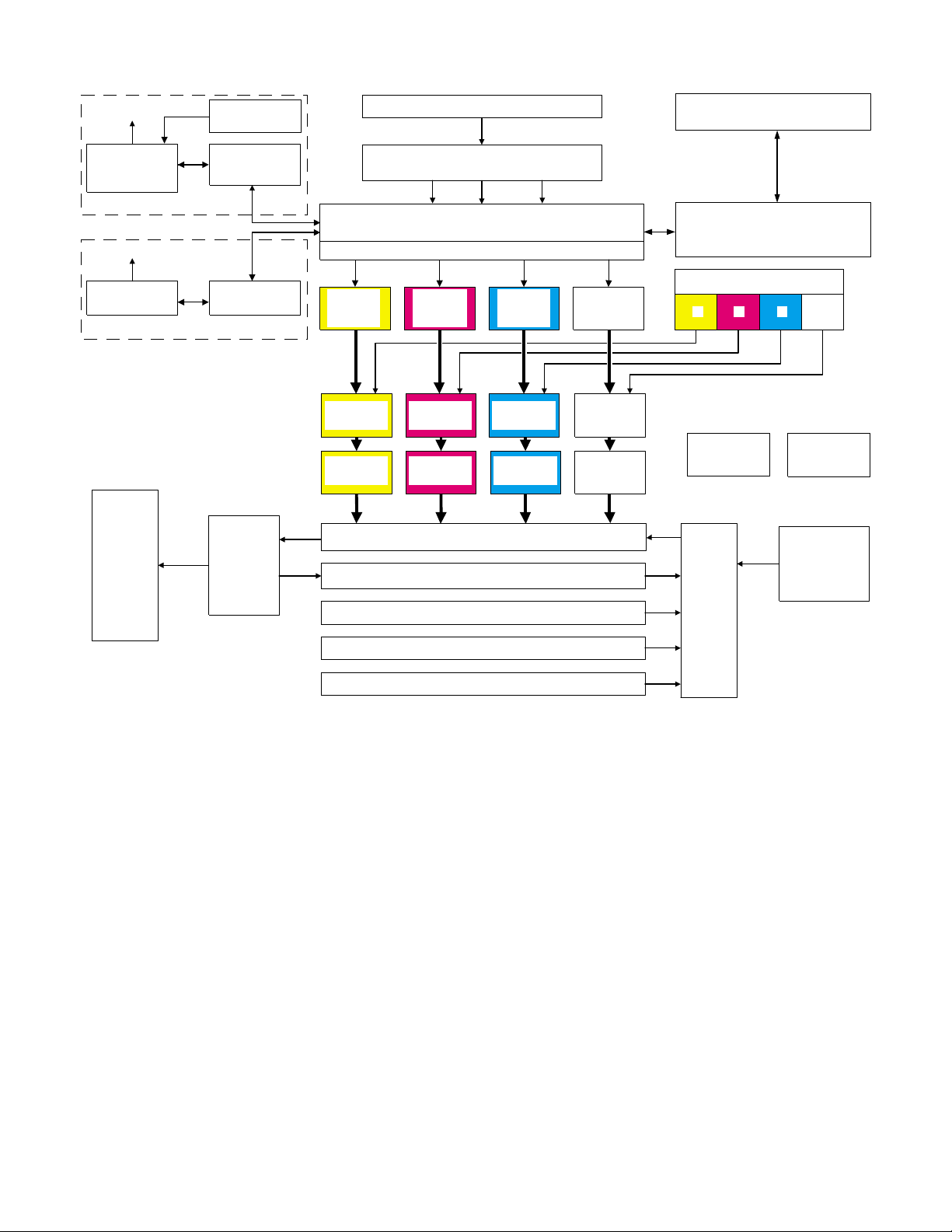

2. Block diagram

Network

Built-in type

printer controller

(option)

AR-C160

Network

Printer controller

(option)

AR-C150/C250

Finisher/

Sorter unit

(Option)

DC power unit

(option)

Printer I/F PWB

(option)

Printer I/F PWB

(option)

Fusing/

paper exit

section

RADF unit (Option)

Image scanning (reading) section

Image forming section

(SCAN ICU PWB / IMAGE ICU PWB / MAIN ICU PWB)

Page memory

Scanner

(writing)

section (Y)

OPC section

(Y)

Developing

section (Y)

Scanner

(writing)

section (M)

OPC section

(M)

Developing

section (M)

Scanner

(writing)

section (C)

OPC section

(C)

Developing

section (C)

Scanner

(writing)

section (K)

OPC section

(K)

Developing

section (K)

Transfer section

Duplex section (Option) / Paper feed tray section 4 (Option)

Paper feed tray section 1

Paper feed tray section 2

Operation section

Engine control section

(MAIN PCU PWB / SUB PCU PWB)

Toner hopper section

MKCY

DC power unit

AC power unit

Large capacity

paper feed tray

(Option)

Paper

transport

section

Paper feed tray section 3

1 – 3

Page 9

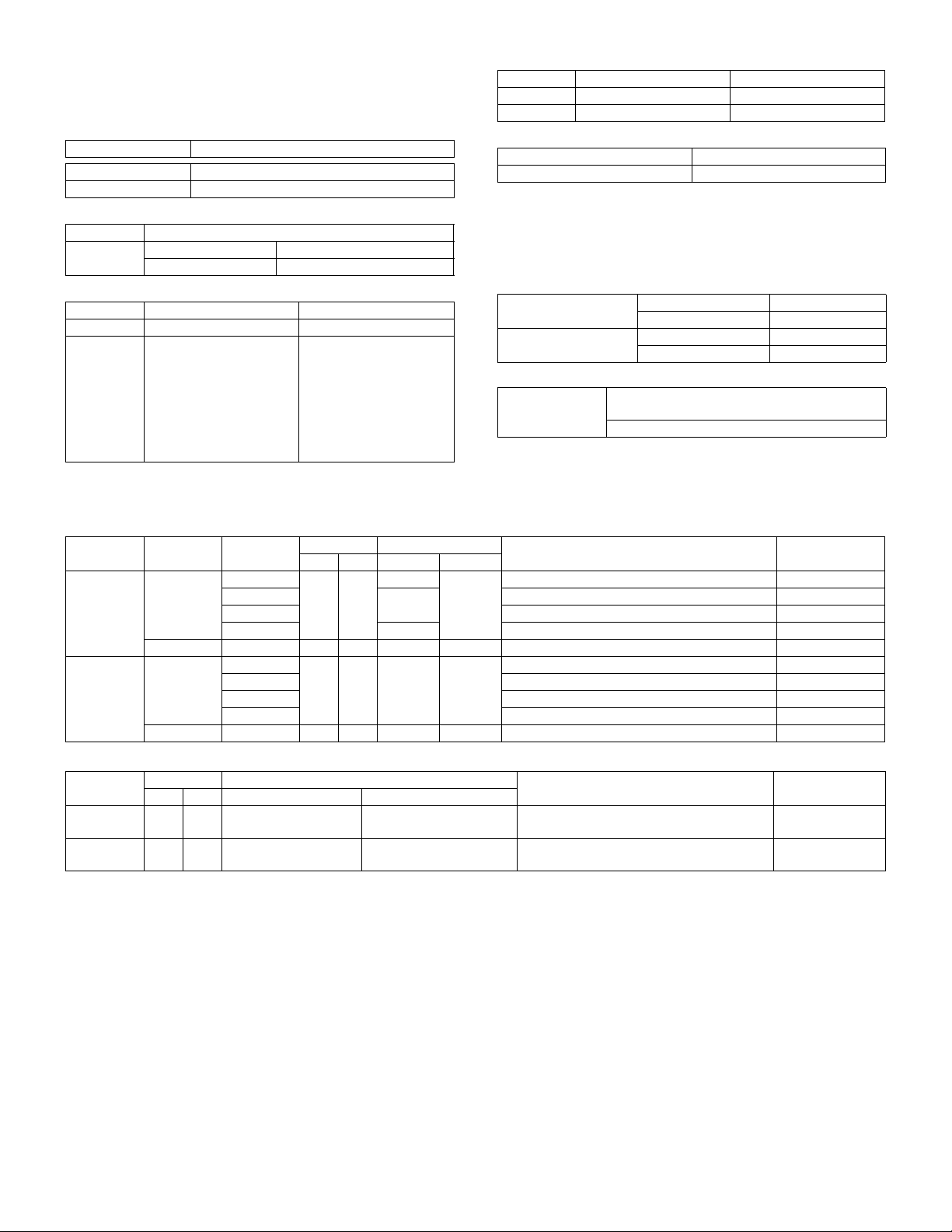

[2] SPECIFICATIONS

1. Basic specifications

(1) Type

Type Console

Operation mode Format

Copy mode Full-color digital (electronic photographic)

(2) Target users

Mode Volume of usage

Copy mode Scope 5,000 to 20,000 sheets/month

Average copy volume 8,000 to 12,000 sheets/month

(3) External dimensions

AR-C150/C250/C160 AR-C100

Packaged — —

Main unit 750 × 695 × 1010mm

(29.5 × 27.4 × 39.8)

(height: floor to glass

surface)

750 × 695 × 1060mm

(29.5 × 27.4 × 41.7)

(height: floor to OC top

surface)

725 × 695 × 1010mm

(28.5 × 27.4 × 39.8)

(height: floor to glass

surface)

725 × 695 × 1060mm

(28.5 × 27.4 × 41.7)

(height: floor to OC top

surface)

(4) Weight

AR-C150/C250/C160 AR-C100

Packaged About 164.6Kg (363 lbs) About 167.6Kg (370 lbs)

Main unit 152Kg (335 lbs) 155Kg (342 lbs)

(5) Machine life

Total (copy and print) volume 800,000 sheets

Lifetime 5 years

2. Operating specifications

A. Common operations

(1) Warm-up time/Jam recovery time

a. Warm-up time (ambient temp. of 20°C)

After turned on AR-C100/C150 Max. 200 seconds

AR-C250/C160 Max. 330 seconds

Recovery from warm-up

mode

b. Jam recovery time

Jam recovery time Under 30 seconds (conditions: door open/fusing

AR-C100 130 seconds

AR-C150/C250/C160 30 seconds

unit drawn)

Under 8 seconds (conditions: door open)

B. Copy mode

(1) Document size

Scan mode Paper type Location

Original

stand mode

RADF mode AB Series Japan A5 A3 A3, B4, A4, A4R, B5, B5R, A5

AB Series Japan B5 A3 A3, B4, A4, A4R, B5, B5R

Australia A5 A3, A4, A4R, A5, 216 × 330mm

Other A A3, B4, A4, A4R, A5

Other B B5 A3, B4, A4, A4R, B5, B5R

Inch Series 8.5 × 5.5 11 × 17 11 × 17, 8.5 × 14, 8.5 × 11, 8.5 × 11R, 8.5 × 5.5

Australia A3, A4, A4R, A5, 216 × 330mm, B4

Other A A3, B4, A4, A4R, A5

Other B A3, B4, A4, A4R, B5, B5R, A5

Inch Series 8.5 × 5.5 11 × 17 11 × 17, 8.5 × 14, 8.5 × 11, 8.5 × 11R, 8.5 × 5.5

(2) Paper size

Paper type

AB Series

Inch Series

Dimensions Paper size

Min. Max. Min. Max.

——

——

A6 (A6R) Postcard A3 wide (305 × 457 mm) A3 wide (305 × 457 mm)

Dimensions Paper size

Min. Max. Min. Max.

A3, B4, A4, A4R, B5, B5R, A5

8.5 × 5.5 12 × 18 12 × 18, 11 × 17, 8.5 × 14, 8.5 × 11,

8.5 × 11R, 8.5 × 5.5

Paper sizes Note

Paper sizes Note

2 – 1

Page 10

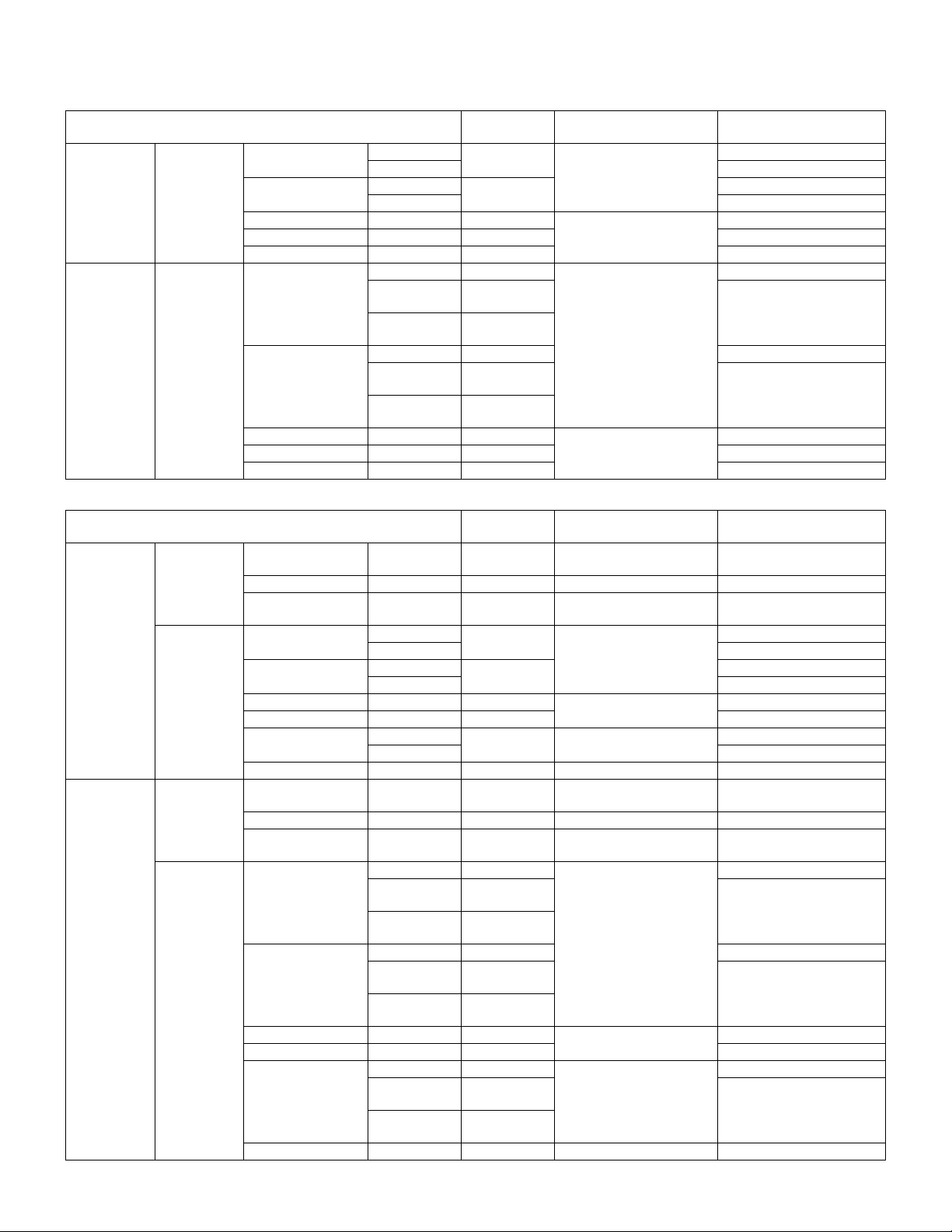

(3) Exposure

a. Exposure mode

(AR-C100/C150)

Copy mode Model

Color Text/Photo mode Manual AR-C100/C150 Area separation, filter

Auto Color blance, density fixed

Text mode Manual AR-C150

Auto Color blance, density fixed

Printed Photo mode Manual AR-C150 Filter process, dither pattern

Photo mode Manual AR-C100/C150

Map mode Manual AR-C150

Monochrome Text/Photo mode Manual AR-C150 Area separation, filter

(AR-C250)

Color Copy

document

mode

Normal mode Text mode Manual AR-C250 Area separation, filter

Monochrome Copy

document

mode

Normal mode Text mode Manual AR-C250 Area separation, filter

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Text mode Manual AR-C150

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Printed Photo mode Manual AR-C150 Filter process, dither pattern

Photo mode Manual AR-C100/C150

Map mode Manual AR-C100/C150

Copy mode Model

Text/Printed Photo

mode

Printed Photo mode Manual AR-C250 Filter process, dither pattern Pre-scan operation allowed

Text mode Manual AR-C250 Area separation, filter

Text/Printed Photo

mode

Printed Photo mode Manual AR-C250 Filter process, dither pattern

Photo mode Manual AR-C250

Text/Photo mode Manual AR-C250 Area separation, filter

Map mode Manual AR-C250 Filter process, dither pattern

Text/Printed Photo

mode

Printed Photo mode Manual AR-C250 Filter process, dither pattern

Text mode Manual AR-C250 Area separation, filter

Text/Printed Photo

mode

Printed Photo mode Manual AR-C250 Filter process, dither pattern

Photo mode Manual AR-C250

Text/Photo mode Manual AR-C250 Area separation, filter

Map mode Manual AR-C250 Filter process, dither pattern

Manual AR-C250 Area separation, filter

Auto Color balance, density fixed.

Manual AR-C250

Auto Color balance, density fixed.

Auto Color balance, density fixed.

Manual AR-C250 Area separation, filter

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Manual AR-C250

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

AR-C150 Pre-scan can be inhibited

AR-C150

AR-C150 Pre-scan can be inhibited

AR-C150

AR-C250 Pre-scan oepration can be

AR-C250

AR-C250 Pre-scan oepration can be

AR-C250

AR-C250 Pre-scan oepration can be

AR-C250

Image process,

gradation control

process, dither pattern

process, dither pattern

Image process,

gradation control

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

Note

with the user program.

with the user program.

Note

Pre-scan operation allowed

Pre-scan operation allowed

inhibited with the user

program.

inhibited with the user

program.

inhibited with the user

program.

2 – 2

Page 11

(AR-C160)

Color Copy

document

mode

Normal mode Text mode Manual AR-C160 Area separation, filter

Color

enhancement

mode

Monochrome Copy

document

mode

Normal mode Text mode Manual AR-C160 Area separation, filter

Copy mode Model

Text/Printed Photo

mode

Printed Photo mode Manual AR-C160 Filter process, dither pattern Pre-scan operation allowed

Text mode Manual AR-C160 Area separation, filter

Text/Printed Photo

mode

Printed Photo mode Manual AR-C160 Filter process, dither pattern

Photo mode Manual AR-C160

Text/Photo mode Manual AR-C160 Area separation, filter

Map mode Manual AR-C160 Filter process, dither pattern

Text mode Manual AR-C160 Area separation, filter

Text/Printed Photo

mode

Printed Photo mode Manual AR-C160 Filter process, dither pattern Pre-scan operation allowed

Photo mode Manual AR-C160 Pre-scan operation allowed

Text/Photo mode Manual AR-C160 Area separation, filter

Map mode Manual AR-C160 Filter process, dither pattern Pre-scan operation allowed

Text/Printed Photo

mode

Printed Photo mode Manual AR-C160 Filter process, dither pattern

Text mode Manual AR-C160 Area separation, filter

Text/Printed Photo

mode

Printed Photo mode Manual AR-C160 Filter process, dither pattern

Photo mode Manual AR-C160

Text/Photo mode Manual AR-C160 Area separation, filter

Map mode Manual AR-C160 Filter process, dither pattern

Manual AR-C160 Area separation, filter

Auto Color balance, density fixed.

Manual AR-C160

Auto Color balance, density fixed.

Auto Color balance, density fixed.

Auto Pre-scan operation allowed

Manual AR-C160 Pre-scan operation allowed

Auto Pre-scan operation allowed

Auto Pre-scan operation allowed

Manual AR-C160 Area separation, filter

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Manual AR-C160

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

AR-C160 Pre-scan oepration can be

AR-C160

AR-C160 Pre-scan oepration can be

AR-C160

AR-C160 Pre-scan oepration can be

AR-C160

Image process,

gradation control

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

process, dither pattern

Note

Pre-scan operation allowed

Pre-scan operation allowed

Pre-scan operation allowed

Pre-scan operation allowed

inhibited with the user

program.

inhibited with the user

program.

inhibited with the user

program.

2 – 3

Page 12

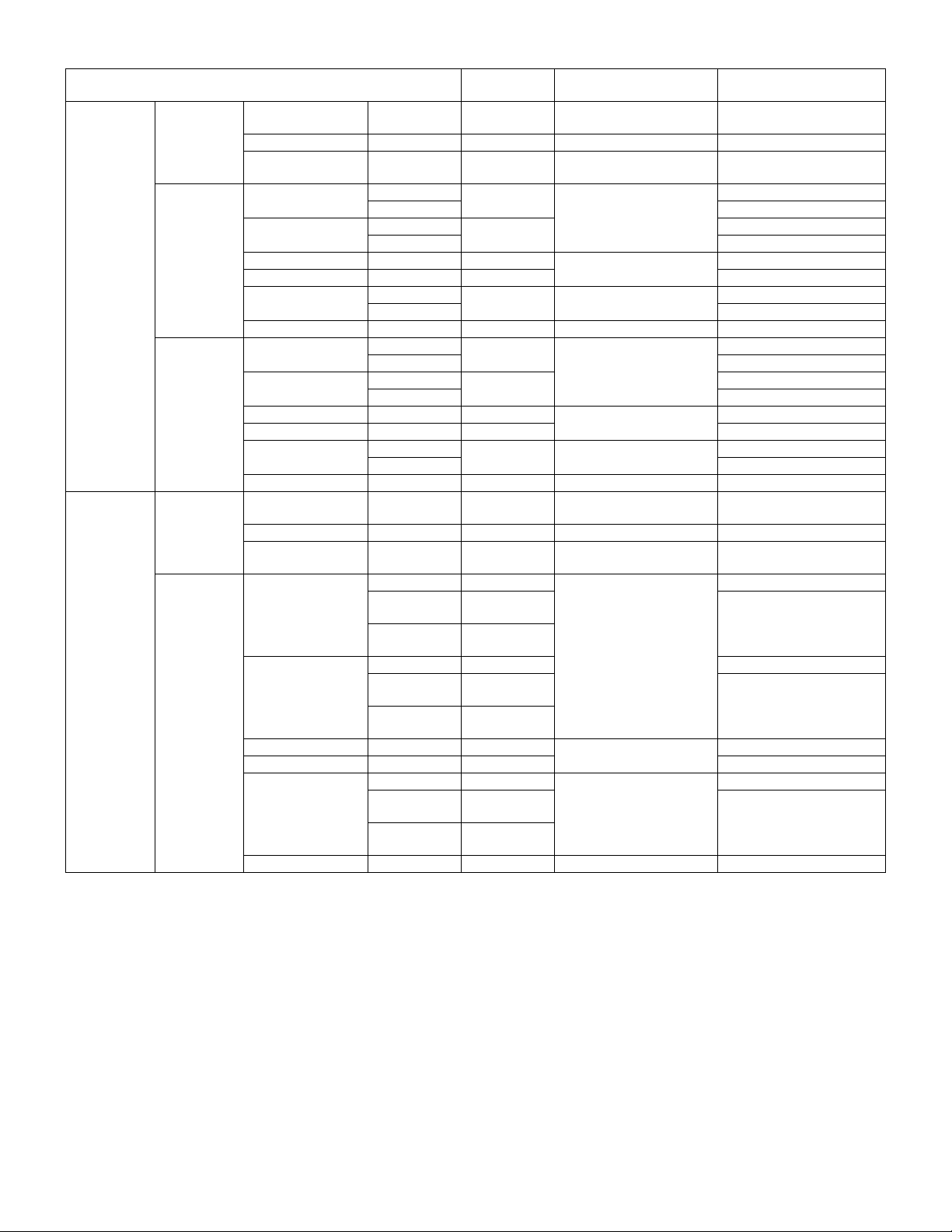

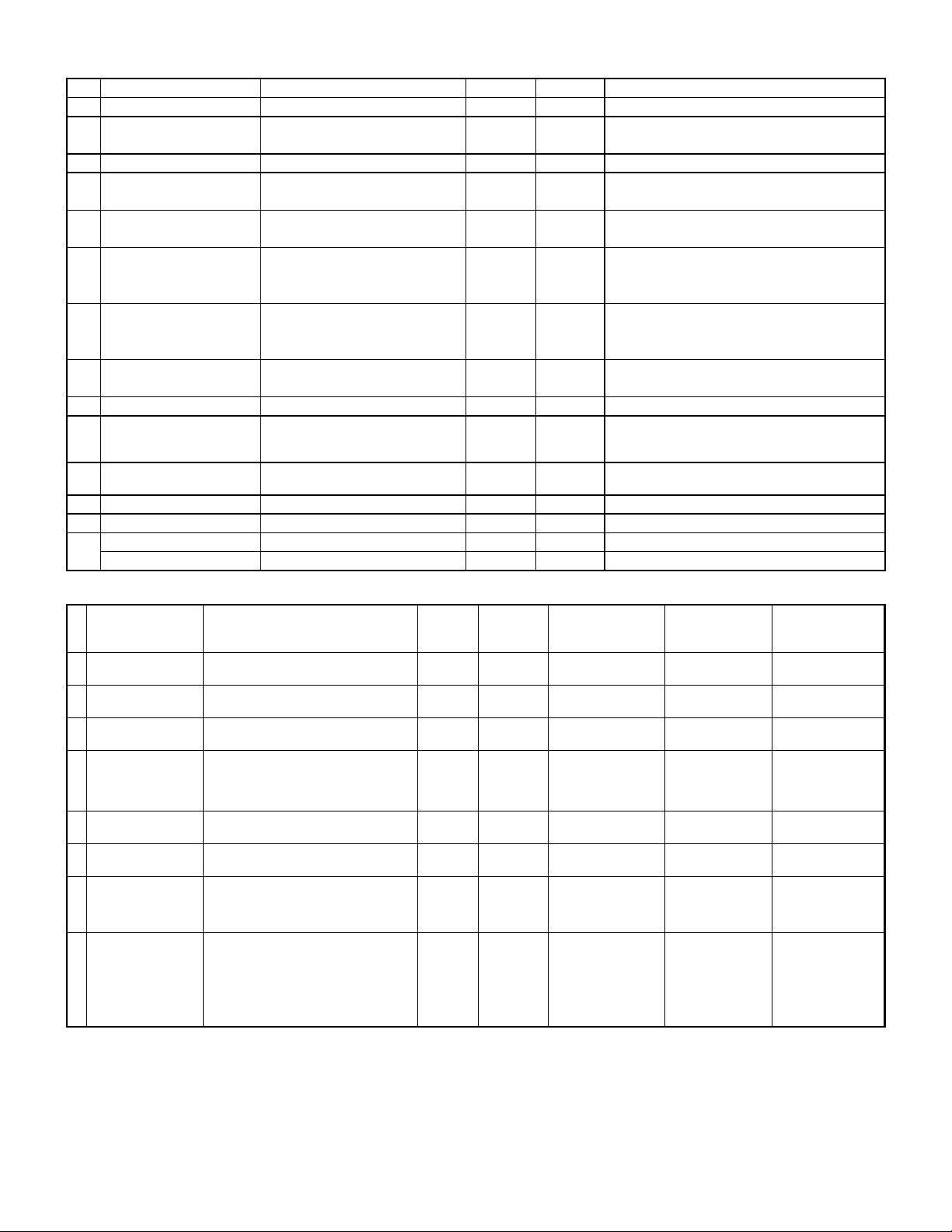

Models and copy mode

Models and the copy mode are shown below. The copy mode differs depending on the model.

The copy mode (Note *1) is substantially same as the copy mode (Note *2), and they differ in display.

Since the descriptions on the copy mode of the AR-C250/C160 is the most accurate, refer to it.

Copy mode

Color Copy

document

mode

Normal mode Manual TEXT MODE TEXT MODE TEXT MODE — Area separation, filter

Color

enhancement

mode

Monochrome Copy

document

mode

Normal mode Manual TEXT MODE TEXT MODE TEXT MODE — Area separation, filter

Manual TEXT/

Manual PRINTED

Manual TEXT MODE TEXT MODE — — Area separation, filter

Auto Color balance, density

Manual TEXT/

Auto Color balance, density

Manual PRINTED

Manual PHOTO MODE PHOTO MODE PHOTO MODE PHOTO MODE

Manual TEXT/PHOTO

Auto Color balance, density

Manual MAP MODE MAP MODE MAP MODE — Filter process, dither

Manual — TEXT MODE — — Area separation, filter

Auto Pre-scan operation allowed

Manual — TEXT/

Auto Pre-scan operation allowed

Manual — PRINTED

Manual — PHOTO MODE — — Pre-scan operation allowed

Manual — TEXT/PHOTO

Auto Pre-scan operation allowed

Manual — MAP MODE — — Filter process, dither

Manual TEXT/

Manual PRINTED

Manual TEXT MODE TEXT MODE — — Area separation, filter

Auto (Non prescan mode)

Auto (Pre-scan

mode)

Manual TEXT/

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Manual PRINTED

Manual PHOTO MODE PHOTO MODE PHOTO MODE PHOTO MODE

Manual TEXT/PHOTO

Auto (Non pre-

scan mode)

Auto (Pre-scan

mode)

Manual MAP MODE MAP MODE MAP MODE MAP MODE Filter process, dither

AR-C250 AR-C160 AR-C150 AR-C100

PRINTED

PHOTO MODE

PHOTO MODE

PRINTED

PHOTO MODE

(*1)

PHOTO MODE

MODE

PRINTED

PHOTO MODE

PHOTO MODE

PRINTED

PHOTO MODE

(*1)

PHOTO MODE

MODE

TEXT/

PRINTED

PHOTO MODE

PRINTED

PHOTO MODE

TEXT/

PRINTED

PHOTO MODE

(*1)

PRINTED

PHOTO MODE

TEXT/PHOTO

MODE

PRINTED

PHOTO MODE

(*1)

PHOTO MODE

MODE

TEXT/

PRINTED

PHOTO MODE

PRINTED

PHOTO MODE

TEXT/

PRINTED

PHOTO MODE

(*1)

PRINTED

PHOTO MODE

TEXT/PHOTO

MODE

— — Area separation, filter

— — Filter process, dither

TEXT/PHOTO

MODE (*2)

PRINTED

PHOTO MODE

— — Area separation, filter

— — Pre-scan operation allowed

— — Filter process, dither

— — Area separation, filter

— — Area separation, filter

— — Filter process, dither

TEXT/PHOTO

MODE (*2)

PRINTED

PHOTO MODE

— — Area separation, filter

TEXT/PHOTO

MODE (*2)

— Filter process, dither

—

— Filter process, dither

Image process,

gradation control

process, dither pattern

pattern

process, dither pattern

process, dither pattern

pattern

process, dither pattern

pattern

process, dither pattern

pattern

process, dither pattern

pattern

process, dither pattern

pattern

process, dither pattern

process, dither pattern

pattern

process, dither pattern

pattern

NOTE

Pre-scan operation allowed

Pre-scan operation allowed

Pre-scan operation allowed

fixed.

fixed.

fixed.

Pre-scan operation allowed

Pre-scan operation allowed

Pre-scan operation allowed

Pre-scan operation allowed

Pre-scan oepration can be

inhibited with the user

program.

Pre-scan oepration can be

inhibited with the user

program.

Pre-scan oepration can be

inhibited with the user

program.

2 – 4

Page 13

b. Relationship between pre-scan operations and the copy mode

Color Copy B/W Copy

Copy mode

COPY OF COPY mode ONCOPY OF COPY

mode OFF

AUTO TEXT/

PRTD.PHOTONO(Switch to Manual mode)

TEXT/PHOTO NO

TEXT NO

MANUAL TEXT/

PRTD.PHOTO

TEXT/PHOTO

PRINTED

PHOTO

PHOTO

(Switch to Manual mode)

(Switch to Manual mode)

YES YES YES YES YES

NO

Key is not displayed

YES YES YES YES YES

NO

Key is not displayed

YES YES

YES YES

YES YES

YES

[COPY OF COPY]

key is not displayed

YES

[COPY OF COPY]

key is not displayed

TEXT YES YES YES YES YES

MAP

NO

Key is not displayed

YES

[COPY OF COPY]

key is not displayed

c. Resolution

• Read

Main scanning direction Sub scanning direction

Basic resolution Basic resolution

600dpi 600dpi

•Write

Main scanning direction Sub scanning direction

Basic resolution Basic resolution

600dpi 600dpi

d. Gradation/image processing

Scanning Printing

256 gradations (8bit) 256 gradations (8bit)

e. Distortion

Print horizontal line

D

1m

| D |

203mm

Print

vertical line

60 m

f. Toner save mode

Toner save

percentage

Approx 15%

∗

Can only be set for monochrome mode

(set by key operator) (Set by simulation in Japan and the U.K.)

Color enhancement

mode (AR-C160 only)

YES

YES

YES

COPY OF COPY mode ONCOPY OF COPY

mode OFF

NO

(Switch to Manual mode)

NO

(Switch to Manual mode)

NO

(Switch to Manual mode)

NO

Key is not displayed

NO

Key is not displayed

NO

Key is not displayed

YES

YES

YES

YES

[COPY OF COPY]

key is not displayed

YES

[COPY OF COPY]

key is not displayed

YES

[COPY OF COPY]

key is not displayed

(4) Copy magnification

a. Copy magnification (independent magnification by direction is

possible)

Main scanning direction Sub scanning direction

Magnification

Mode

range/fixed

Mode

magnification

Zoom mode 25/50 to 400%

Fixed

magnification

mode

25, 50, 70, 81, 86,

100, 115, 122,

141, 200, 400%

(AB Series)

Fixed

magnification

mode

25, 50, 64, 77, 95,

100, 121, 129,

141, 200, 400%

(Inch Series)

∗

The minimum copy magnification for the AR-C100 is 50%.

∗ Zoom mode 25/50 to 400%

Fixed

magnification

mode

(AB Series)

Fixed

magnification

mode

(Inch Series)

b. Copy magnification precision

Main scanning direction Sub scanning direction

Copy

magnification

Magnification

precision

Copy

magnification

Normal copy 100% ± 0.8% Normal copy 100% ± 0.8%

Enlargement

copy

Reduction

copy

Set magnification

± 1.0%

Set magnification

± 1.0%

Enlargement

copy

Reduction

copy

c. Zoom method

Main scanning direction Performed through image processing

Sub scanning direction Performed by changing image processing

and scanning speed

Magnification

range/fixed

magnification

25, 50, 70, 81, 86,

100, 115, 122,

141, 200, 400%

25, 50, 64, 77, 95,

100, 121, 129,

141, 200, 400%

Magnification

precision

Set magnification

± 1.0%

Set magnification

± 1.0%

2 – 5

Page 14

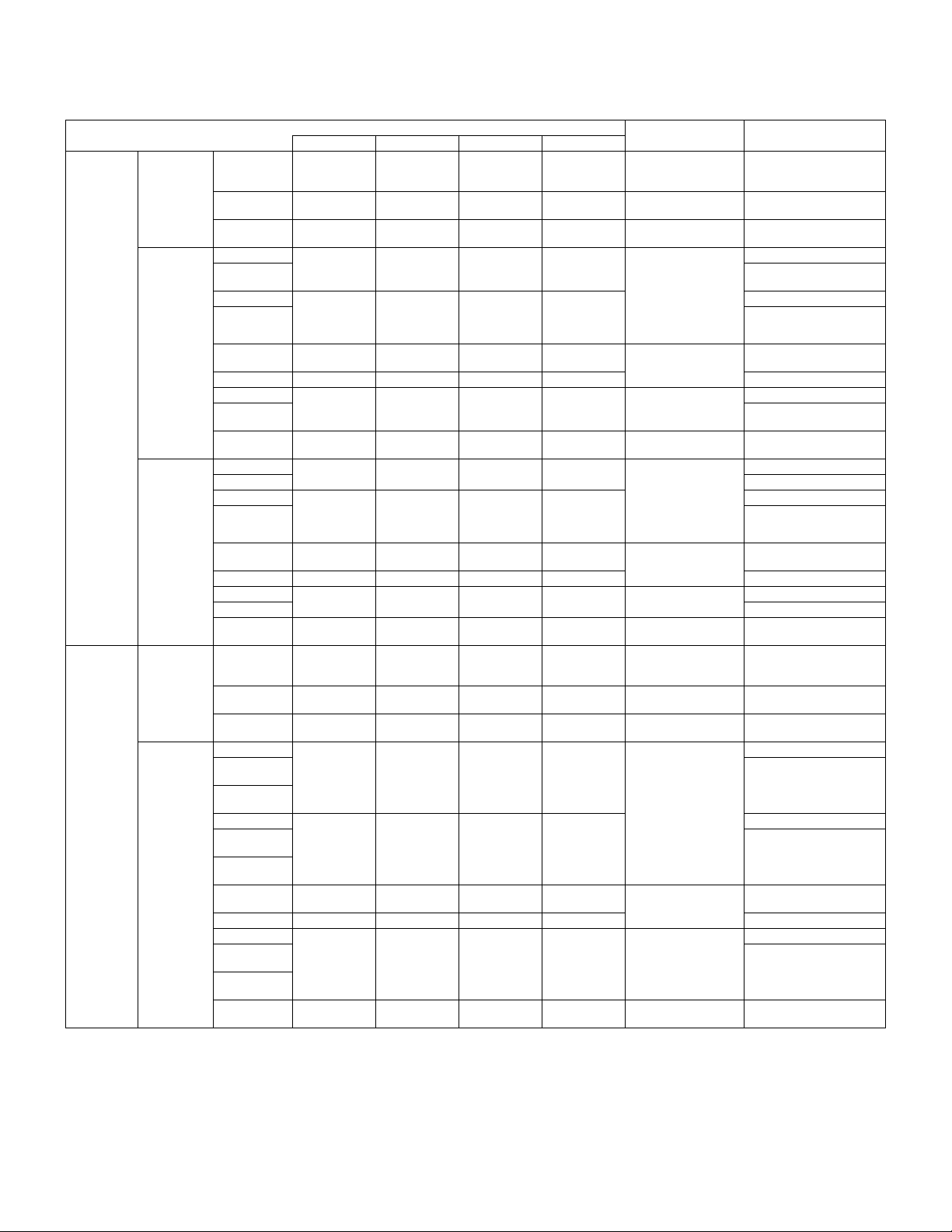

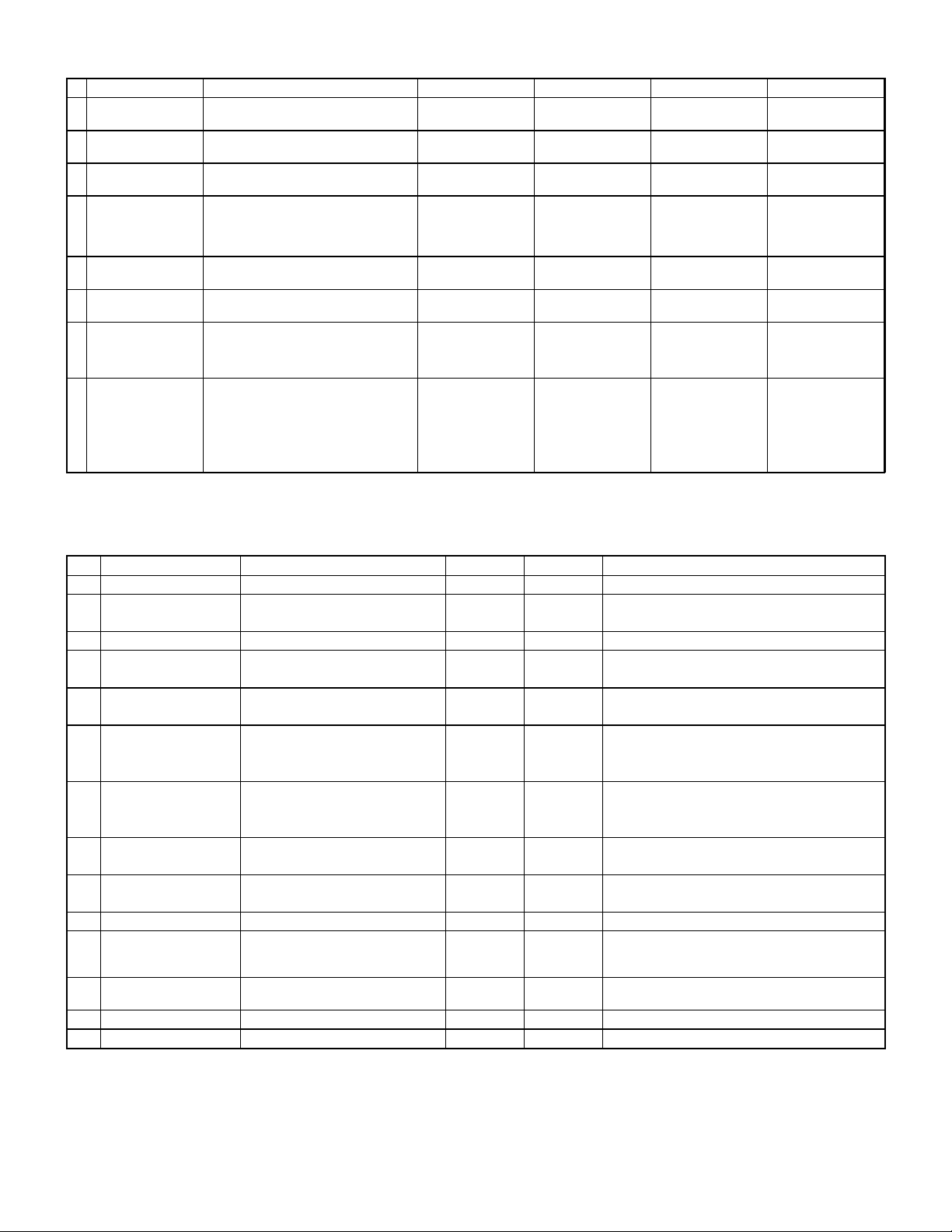

(5) Job speed

Copy method for each copy mode

Black-and-white copy Color copy

Up to A4/LT B4/RG to A3/WLT Up to A4/LT B4/RG to A3/WLT

Single-side

copy

Duplex

copy

1 scan/

multi-copy

1 scan/

multi-copy

1 scan/multi-copy

Multi scan/copy * (AR-C150/

C160)

1 scan/multi copy (AR-C250)

Multi scan/copy

(AR-C150/C160)

1 scan/multi copy (AR-C250)

Multi scan/copy *

(AR-C150/C160)

1 scan/multi copy (AR-C250)

Multi scan/copy

(AR-C150/C160)

1 scan/multi copy (AR-C250)

Multi scan/copy * —

* No multi-copy mode, only single copy

a. First copy time

• Original stand mode (non SPF/ADF/RADF mode) (Unit: sec.)

Paper supply mode Paper size

AR-C150 AR-C160 AR-C250 AR-C150 AR-C160/C250

Color Monochrome

Manual paper feed 8.5 × 11, A4 (Normal paper) 9.8 19.5

A4, 11 × 8.5 (OHP) 84.8 94.5

B5, A4, 11 × 8.5 (thick paper) 69.8 — 79.5

B5, A4, 11 × 8.5 (thick paper) (Mode 1) (106 – 130g/m

B5, A4, 11 × 8.5 (thick paper) (Mode 2) (131 – 200g/m

(131 – 280g/m

2

: AR-C160)

2

) — 69.8 — 79.5

2

)

— 119.8 — 129.5

1st paper feed tray A4 10.5 9.8 10.2 19.5

8.5 × 11 10.5 9.8 10.2 19.5

2nd paper feed tray A4 11.3 10.4 11.1 20.3

8.5 × 11 11.3 10.4 11.1 20.3

3rd paper feed tray A4 12.2 11.0 12.0 21.2

8.5 × 11 12.2 11.0 12.0 21.2

4th paper feed tray A4 13.1 11.6 12.9 22.1

8.5 × 11 13.1 11.6 12.9 22.1

LCC A4 10.2 9.8 10.2 19.5

8.5 × 11 10.2 9.8 10.2 19.5

∗

1st paper feed tray is installed for optional slot.

b. Multi-copy speed

(Conditions) Scanner speed: 15 cpm, using A4/letter standard paper, and no prescan

(Conditions) S

→ S color: One copy of A4 (L1) original (10 sheets), no optional settings other than RADF, and not including fast copy

(AR-C150)

Color Monochrome

1 scan: 1 copy 1 scan: Multiple copy

Copy mode Paper size

Original

stand

mode

S

→ S

(1 – 3

paper

feed

tray)

A3 7 7 6 13 13 13

A3 wide (12 × 18) (

B4 9 9 8 15 15 15

A4 15 15 12 25 (24) 25 (24) 25 (24)

A4R 111110191919

Reduction

copy (25%)

∗1) 776777

Copy magnification Copy magnification

Normal copy

(100%)

Enlargement

copy (400%)

Reduction

copy (25%)

Normal copy

A5 15 15 12 25 25 25

B5 15 15 12 25 25 25

B5R 111110191919

11 × 17 7 7 6 13 13 13

8.5 × 14 9 9 8 15 15 15

8.5 × 11 15 15 12 25 25 25

8.5 × 11R 11 11 10 19 19 19

8.5 × 5.5 15 15 12 25 (24) 25 (24) 25 (24)

8.5 × 13/F.S 9 9 8 15 15 15

A4, 11 × 8.5 (OHP) 101010101010

B5, A4, 11 × 8.5 (thick paper) 10 10 10 10 10 10

Other than B5, A4, 11 × 8.5

555555

(thick paper)

The numbers in the parenthesis are the copy speeds when the 4th paper cassette is used.

A3 wide copy

1 scan/multi copy

(B&W) (AR-C250)

Multi scan/copy

(color) (AR-C250)

Multi scan/copy

(color/B&W) (AR-C150/C160)

Enlargement

(100%)

copy (400%)

2 – 6

Page 15

(AR-C250)

Color Monochrome

1 scan: Multiple copy (1 scan: 1 copy) 1 scan: Multiple copy

Copy mode Paper size

Original

stand

mode

S

→

(1 – 3

paper

feed

tray)

S

A3 13 13 13 13 13 13

A3 wide (12 × 18) (

B4 15 15 15 15 15 15

A4 25 (24) 25 (24) 25 (24) 25 (24) 25 (24) 25 (24)

A4R 191919191919

A5 25 (

B5 25 (

Reduction

copy (25%)

∗1) 777777

Copy magnification Copy magnification

Normal copy

(100%)

26) 25 (∗26) 25 (∗26) 25 (∗26) 25 (∗26) 25 (∗26)

∗

26) 25 (∗26) 25 (∗26) 25 (∗26) 25 (∗26) 25 (∗26)

∗

Enlargement

copy (400%)

Reduction

copy (25%)

Normal copy

(100%)

Enlargement

copy (400%)

B5R 191919191919

11 × 17 13 13 13 13 13 13

8.5 × 14 15 15 15 15 15 15

8.5 × 11 25 (24) 25 (24) 25 (24) 25 (24) 25 (24) 25 (24)

8.5 × 11R 19 19 19 19 19 19

26) 25 (∗26) 25 (∗26) 25 (∗26) 25 (∗26) 25 (∗26)

8.5 × 5.5 25 (

∗

8.5 × 13/F.S 15 15 15 15 15 15

A4, 11 × 8.5 (OHP) 10 10 10 10 10 10

B5, A4, 11 × 8.5 (thick paper) 10 10 10 10 10 10

Other than B5, A4, 11 × 8.5

555555

(thick paper)

The numbers in the parenthesis are the copy speeds when the 4th paper cassette is used.

(

1): 1 scan: 1 copy

∗

: Only for Taiwan version

∗

(AR-C160)

Color Monochrome

1 scan:1 copy 1 scan:Multiple copy

Copy mode Paper size

Original

stand

mode

S

→ S

(1 – 3

paper

feed

tray)

A3 7 7 6 15 15 15

A3 wide (12 × 18) (

B4 9 9 8 17 17 17

A4 16 16 12 32 (31) 32 (31) 32 (31)

A4R 111110222222

A5 16 16 12 32 (

B5 16 16 12 32 (

Reduction

copy (25%)

∗1) 776777

Copy magnification Copy magnification

Normal copy

(100%)

Enlargement

copy (400%)

Reduction

copy (25%)

33) 32 (∗33) 32 (∗33)

∗

∗33) 32 (∗33) 32 (∗33)

Normal copy

(100%)

Enlargement

copy (400%)

B5R 111110222222

11 × 17 7 7 6 15 15 15

8.5 × 14 9 9 8 17 17 17

8.5 × 11 16 16 12 32 (31) 32 (31) 32 (31)

8.5 × 11R 11 11 10 22 22 22

8.5 × 5.5 16 16 12 32 (

∗33) 32 (∗33) 32 (∗33)

8.5 × 13/F.S 9 9 8 17 17 17

A4, 11 × 8.5 (OHP) 101010101010

B5, A4, 11 × 8.5 (thick paper) 10 10 10 10 10 10

Other than B5, A4, 11 × 8.5

555555

(thick paper)

The numbers in the parenthesis are the copy speeds when the 4th paper cassette is used.

∗: Only for Taiwan version

c. Maximum no. of copies

Multi max. quantity 999 sheets

• Maximum number of copies that can be set for each copy mode

Black-and-white copy Color copy

Up to A4/LT B4/RG to A3/WLT Up to A4/LT B4/RG to A3/WLT

A3 wide copy

Single-side copy 999 999 999 999 999

Duplex copy

999

1 (AR-C150/C160)

999 (AR-C250)

1 (AR-C150/C160)

999 (AR-C250)

1—

2 – 7

Page 16

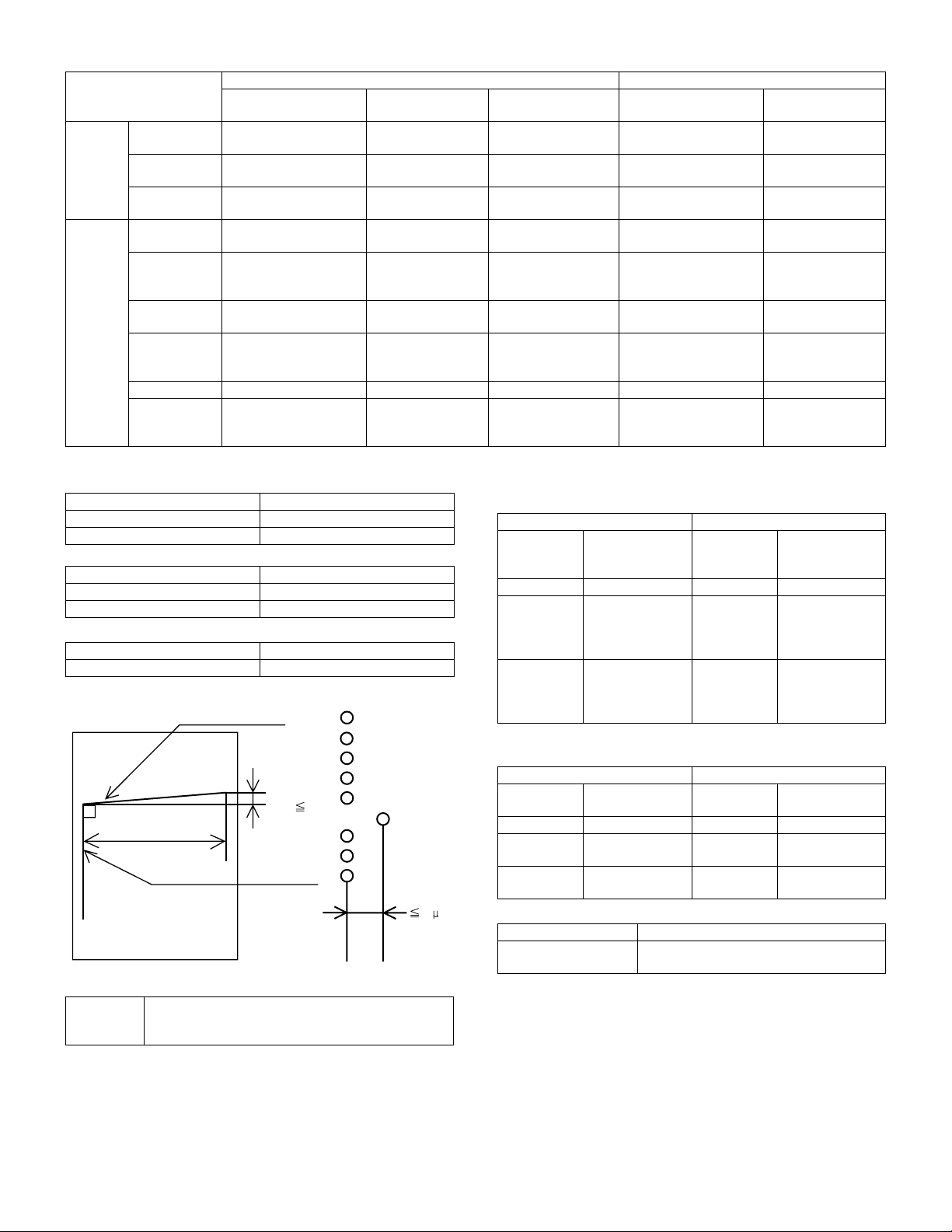

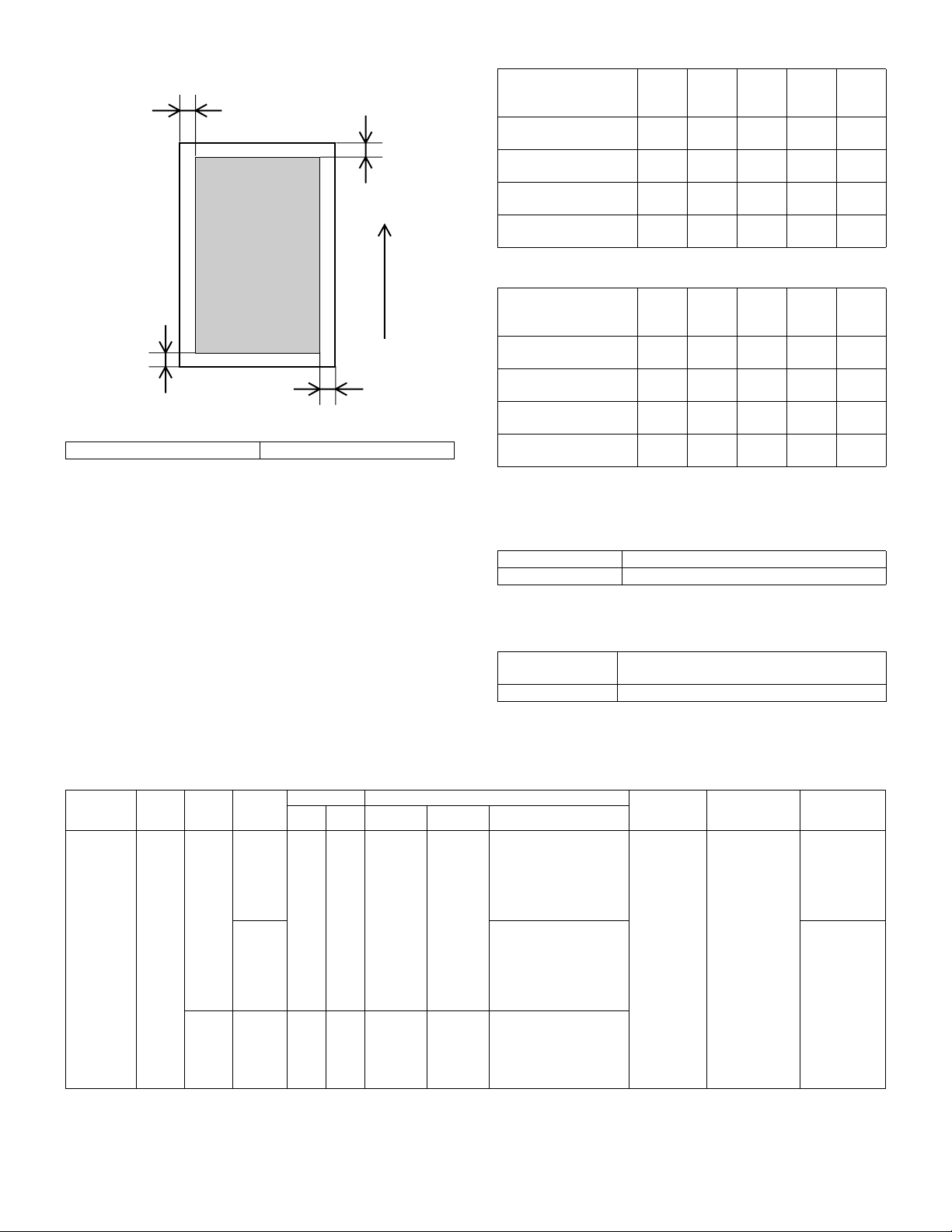

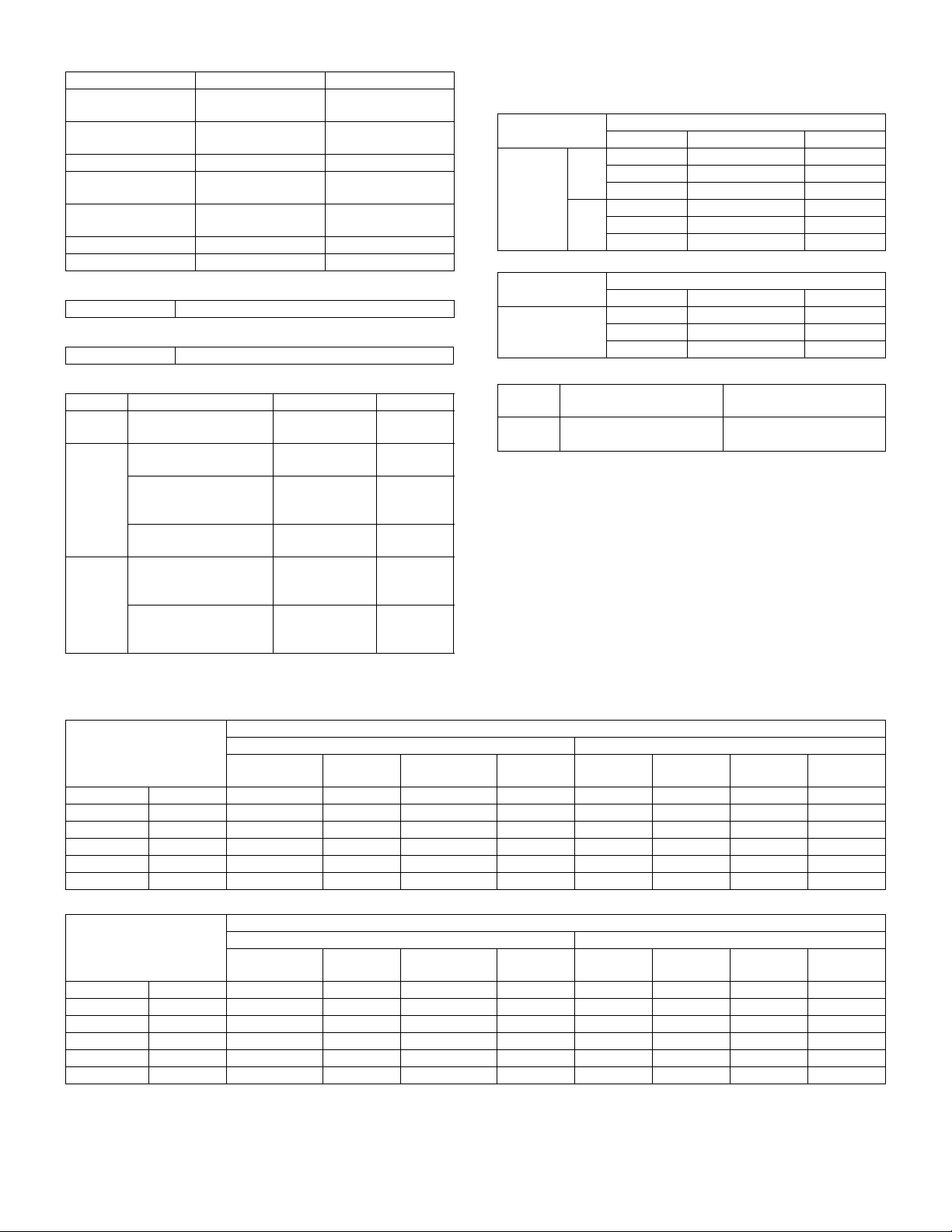

(6) Copy area

C

(Front edge)

Printed image

(image area)

B

(Rear edge)

Dimensions show void area

Copy area 297 × 432mm

• Image loss

Front

edge

One side copy

A

(excluding A3 (11 × 17))

One side copy for A3

(11 × 17)

Max.

5mm

Max.

5mm

Duplex copying Max.

5mm

OHP copying Max.

10mm

∗

0mm image loss for A3 originals and A3 wide copying.

Feeding

direction

• Void area

Front

edge

One side copy

(excluding A3 (11 × 17))

One side copy for A3

(11 × 17)

D

Duplex copying Max.

Max.

5mm

Max.

5mm

5mm

OHP copying Max.

10mm

(A)

(A)

Rear

edge

(B)

Max.

5mm

Max.

7mm

Max.

7mm

Max.

10mm

Rear

edge

(B)

Max.

5mm

Max.

7mm

Max.

7mm

Max.

10mm

Total

(C + D)

Max.

6mm

Max.

6mm

Max.

6mm

Max.

6mm

Total

(C + D)

Max.

6mm

Max.

6mm

Max.

6mm

Max.

6mm

Left

edge

(C)

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

Left

edge

(C)

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

Right

edge

(D)

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

Right

edge

(D)

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

Max.

3.0mm

(7) Languages supported

Japanese, English (USA/UK), German, French, Spanish, Italian,

Dutch, Swedish, Norwegian, Finnish, Danish

(8) Internal auditor

Format Key operation/card operation (optional)

No. of departments 400 (200 with card type)

B. Paper feeding, paper conveyance, and discharge section

(1) Paper feeding performance

a. Paper feed ability

Paper feed

mode

(section)

Manual feed

section

(Multi paper

feed)

Feed

method

— AB

Paper

type

Series

Inch

Series

Location

Japan — — A6 (A6R)

Others A3 wide, A3, B4, A4, A4R,

Dimensions Paper size

Min. Max. Min. Max. Paper sizes

Postcard

— — 8.5 × 5.5 12 × 18 12 × 18, 11 × 17, 8.5 × 14,

A3 wide

(12 × 18)

A3 wide, A3, B4, A4, A4R,

B5, B5R, A5, Postcard,

11 × 17, 8.5 × 14, 8.5 × 11

(Paper guide display: 11,

8.5, A3 wide, A3, B4, A4,

A4R, B5, B5R, A5, A5R,

B6R, A6R, Postcard)

B5, A5, A6R, 11 × 17,

8.5 × 14, 8.5 × 11,

7.25 × 10.5R

(Paper guide display: 11,

8.5, A3 wide, A3, B4, B5,

A4R, A5, B5R, A5R)

8.5 × 11, 8.5 × 11R,

8.5 × 5.5, 7.25 × 10.5R, A3,

B4, A4, B5, A6R

(Paper guide display: 12,

11, 8.5, 5.5, A3, B4, A4, B5)

3. Engine specifications

A. Operation (display/operation) section

Display Large mono-color LCD display (AR-C150/C160)

Large color LCD display (AR-C250)

Operating procedure Touch-panel input

Paper weight Capacity Note

60 to 200g/m

(16 to 55lbs.)

(AR-C150/

C250)

60 to 280g/m

(16 to 75 lbs)

(AR-C160)

2

50 sheets (6mm)

(max. 80g/m

paper)

2

Special paper

2

(OHP film),

(recommended

product),

Postcard and

thick paper

Special paper

(OHP film) and

thick paper

2 – 8

Page 17

Paper feed

mode

(section)

Manual feed

section

(Single

paper feed)

1st to 4th

cassette

feeding unit

Feed

method

— AB

— AB

Paper

type

Series

Inch

Series

Series

Inch

Series

Location

Japan — — A6 (A6R)

Others A3 wide, A3, B4, A4, A4R,

Japan — — A5 A3 A3, B4, A4, A4R, B5, B5R,

Others A3, B4, A4, A4R, B5, A5,

Dimensions Paper size

Min. Max. Min. Max. Paper sizes

Postcard

— — 8.5 × 5.5 12 × 18 12 × 18, 11 × 17, 8.5 × 14,

— — 8.5 × 5.5 11 × 17 11 × 17, 8.5 × 14, 8.5 × 13,

A3 wide

(12 × 18)

A3 wide, A3, B4, A4, A4R,

B5, B5R, A5, Postcard,

11 × 17, 8.5 × 14, 8.5 × 11

(Paper guide display: 11,

8.5, A3 wide, A3, B4, A4,

A4R, B5, B5R, A5, A5R,

B6R, A6R, Postcard)

B5, A5, A6R, 11 × 17,

8.5 × 14, 8.5 × 11,

7.25 × 10.5R

(Paper guide display:)

8.5 × 11, 8.5 × 11R,

8.5 × 5.5, 7.25 × 10.5R, A3,

B4, A4, B5, A6R

(Paper guide display: 12,

11, 8.5, 5.5, A3, B4, A4, B5)

A5, EXTRA

8.5 × 11

8.5 × 11, 8.5 × 11R,

8.5 × 5.5, A4, EXTRA

60 to 200g/m

(16 to 55lbs.)

(AR-C150/

C250)

60 to 280g/m

(16 to 75lbs.)

(AR-C160)

60 to 105g/m

(16 to 28lbs.)

b. Document detection

Paper feed

mode (section)

Manual feed

section

Paper

type

AB

Series

Inch

Series

Location of

use

Detection size

Japan A3 wide, A3, B4, A4, A4R, B5, B5R, A5,

Postcard, 11 × 17, 8.5 × 14, 8.5 × 11

Others A3 wide, A3, B4, A4, A4R, B5, A5, A6R,

11 × 17, 8.5 × 14, 8.5 × 11, 7.25 × 10.5R

12 × 18, 11 × 17, 8.5 × 14, 8.5 × 11,

8.5 × 11R, 8.5 × 5.5, A3, B4, A4, B5, A6R,

Paper detection size and

detection method

Electrical resistance

changes according to

position of paper width

guide (volume sensor)

7.25 × 10.5R

1st to 4th

cassette

feeding unit

∗

When setting the paper size switch to EXTRA, it is necessary to set the paper size by key operation.

∗

For A and B sizes (excluding Japan), it is necessary to set the paper size switch to EXTRA for 13" and B5R.

(2) Finishing performance

AB

Series

Inch

Series

Japan A3, B4, A4, A4R, B5, B5R, A5, EXTRA Detection method by

Others A3, B4, A4, A4R, B5, A5, 8.5 × 11, EXTRA

11 × 17, 8.5 × 14, 8.5 × 13, 8.5 × 11,

8.5 × 11R, 8.5 × 5.5, A4, EXTRA

switch signal combination

(switches paper detection

block position)

c. Scanning area

Facing mode Paper size Paper weight Capacity Note

Face up All paper

sizes

All paper sizes

that can be fed

250 sheets

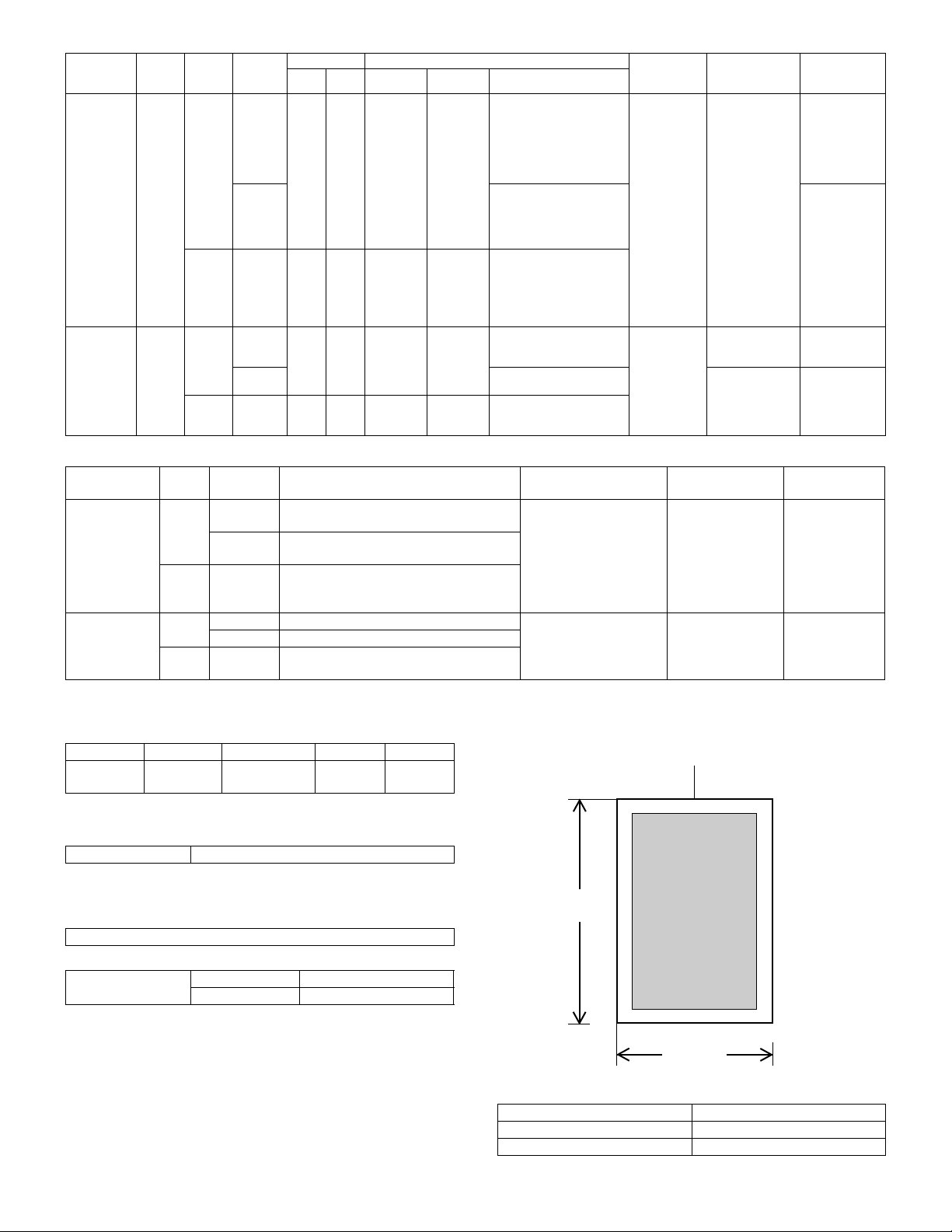

C. Scanner section

(1) Type

Scanning method By 3-color (RGB) CCD image sensor

(2) Original standard position, scanning size, and

scanning area

a. Original standard position

Left-center

b. Scanning size

Max. original size AB Series A3

Inch Series 11 × 17

432 mm

Paper weight Capacity Note

2

50 sheets (6mm)

(max. 80g/m

paper)

2

2

500 sheets × 3 (4)

(max. 80g/m2

paper)

500 sheets × 3 (4)

(max. 80g/m

paper)

Size switching

method

2

2

Special paper

(OHP film),

Postcard and

thick paper

Special paper

(OHP film) and

thick paper

Note

Aligns with paper

width guide (sliding

type)

Aligns universal

guide (sliding type)

Remaining

amount detector

Center

(3) Resolution

2 – 9

297 mm

Main scanning direction Sub scanning direction

Basic resolution Basic resolution

600dpi 600dpi

Page 18

(4) Gradation

Input Output

Monochrome 256 gradations (8bit) 256 gradations (8bit)

Color 256 gradations (8bit) 256 gradations (8bit)

(5) Scanning speed

Scan mode Scan Return

Color 117

Monochrome 117

mm/sec

mm/sec

468

mm/sec

468

mm/sec

Scans per

minute

15 sheets/min

16 sheets/min

(AR-C160)

15 sheets/min

16 sheets/min

(AR-C160)

Original size

A4

(11" × 8.5")A3(11" × 17")

15 sheets/min

16 sheets/min

(AR-C160)

15 sheets/min

16 sheets/min

(AR-C160)

7 sheets/min

7 sheets/min

(6) Light source

Type Halogen lamp

Drive voltage 70V

Power consumption 130W (AR-C150)

170W (AR-C250/C160)

(7) Scanning sensor

Type 3-line color CCD

(8) Color separation method

Color separation by 3-color (RGB) CCD image sensor

D. Scanner section

(1) Type

Type Laser scanning

(2) Laser unit specifications

Speed of rotation 27,600rpm (AR-C150/C250)

Color mode 27,600rpm (AR-C160)

Monochrome mode 33,000rpm (AR-C160)

Mirror surfaces 6 surfaces

Laser power 5mW

Laser beam size 65

Laser wavelength 785

Scan width

× 85µm (AR-C150/C250)

70µm (AR-C160)

×

60

µm

AB Series: 420mm Inch Series: 432mm

(sub scan direction)

(3) Resolution

Main scanning direction Sub scanning direction

600dpi 600dpi

(4) Gradation

Monochrome 256 gradations (8bit)

Color 256 gradations (8bit)

E. Image processing section

(1) Imaging speed

117 mm/sec

(2) Photosensitive drum

Black (AR-C160 only)

Type OPC

Life 40,000 sheets 80,000 sheets

Form Cartridge Cartridge

φ40mm (3 pieces) (C, M, Y)

(AR-C160)

OPC

φ40mm (4 pieces) (C, M, Y,

K) (AR-C150/C250)

φ40mm (1 pieces) (K)

OPC

(3) Toner

Black Color (C, M, Y)

Type —

Capacity 600g (AR-C150/C250)

650g (AR-C160/C250)

267g each (AR-C150)

300g each (AR-C250/C160)

Form Cartridge

(4) Developer

Black Color (C, M, Y)

Type Ferrite type

Capacity 650g 650g each

Life 40,000 sheets (AR-C150/C250)

40,000 sheets each

80,000 sheets (AR-C160)

(5) Charging system

Charging system DC negative scorotron (saw tooth electrode)

Voltage – 320V to – 830V

(6) Exposure

Method Exposure from laser diode

(7) Developing system

Developing system Dry, 2-component magnetic brush development

Voltage – 120V to – 600V

(8) Transfer

Method DC positive static electricity transfer (transfer belt method)

Voltage 1.75 to 5KV

(9) Paper separation system

Method Curvature release + Separation pawl

(10) Discharging

Method Discharging lamp method

(11) Cleaning

Method Blade method

(12) Toner compartment capacity

Black Color (C, M, Y)

Capacity 600g (AR-C150/C250)

650g (AR-C160)

267g (AR-C150)

300g (AR-C250/

C150/C160)

(13) Waste toner collector capacity

Capacity —

Printed sheets 40K (Conditions of each color 5% coverage, total

20% coverage)

(14) Correction functions

Correction functions Toner density correction (toner density control

level correction)

Drum sensitivity correction (laser power control

level correction)

Transfer-ability correction (transfer voltage

control level correction)

Developing-ability correction (developing bias

voltage control level correction)

Halftone correction (laser power duty control

level correction)

2 – 10

Page 19

F. Fuser section

(1) Type

Fusing system Heat roller system (oil usage)

(2) Lamp

Main unit

voltage

ratings

100V Main heater lamp Halogen lamp 100V 1000W

110V Main heater lamp Halogen lamp — —

120V Main heater lamp Halogen lamp 120V 1200W

127V Main heater lamp Halogen lamp — —

220 to 230V Main heater lamp Halogen lamp 230V 1300W

240V Main heater lamp Halogen lamp 230V 1300W

Lamp Type

Sub heater lamp Halogen lamp 100V 700W

Sub heater lamp Halogen lamp — —

Sub heater lamp Halogen lamp 120V 700W

Sub heater lamp Halogen lamp — —

Sub heater lamp Halogen lamp 230V 700W

Sub heater lamp Halogen lamp 230V 700W

(3) Fuser temperature

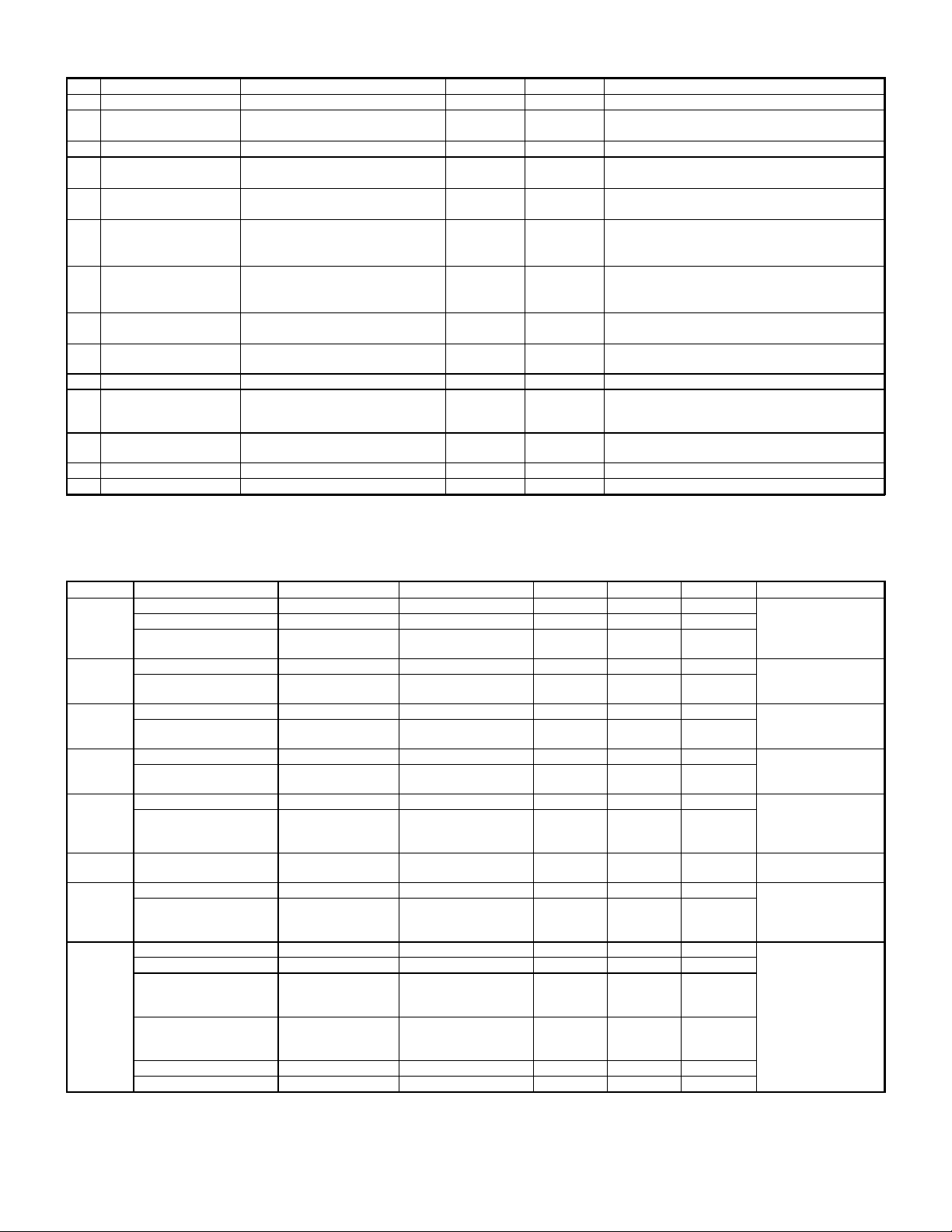

(AR-C100/C150)

Mode

Ready

condition

Copy/Print

mode

Pre-heat

mode

Sleep

mode

Ready condition control temperature (HL1) Upper heat roller 187 187 187 177 177 187 187 187 187

Ready condition control temperature (HL2) Lower heat roller 142 142 142 132 132 142 142 142 142

Normal mode control temperature (HL1) Upper heat roller 180 180 180 170 170 180 180 180 180

Normal mode control temperature (HL2) Lower heat roller 135 135 135 125 125 135 135 135 135

Thick paper mode control temperature (HL1) Upper heat roller 200 200 200 200 200 200 200 200 200 AR-C150 only

Thick paper mode control temperature (HL2) Lower heat roller 155 155 155 155 155 155 155 155 155 AR-C150 only

OHP mode control temperature (HL1) Upper heat roller 180 180 180 180 180 180 180 180 180 AR-C150 only

OHP mode control temperature (HL2) Lower heat roller 175 175 175 175 175 175 175 175 175 AR-C150 only

Energy saving mode control temperature (HL1) Upper heat roller

Control temperature when resetting from preheat to B/W (HL1)

HL1 Upper heat roller OFF OFF OFF OFF OFF OFF OFF OFF OFF

HL2 Lower heat roller OFF OFF OFF OFF OFF OFF OFF OFF OFF

(AR-C250/C160)

Mode

Ready

condition

Copy/Print

mode

Pre-heat

mode

Sleep

mode

Ready condition control temperature (HL1) Upper heat roller 177 177 177 177 177 177 177 177 177

Ready condition control temperature (HL2) Lower heat roller

Normal mode control temperature (HL1) Upper heat roller 170 170 170 170 170 170 170 170 170

Normal mode control temperature (HL2) Lower heat roller

Thick paper mode 1 control temperature (HL1) Upper heat roller 185 185 185 185 185 185 185 185 185

Thick paper mode 1 control temperature (HL2) Lower heat roller 155 155 155 155 155 155 155 155 155

Thick paper mode 2 control temperature (HL1) Upper heat roller 200 200 200 200 200 200 200 200 200

Thick paper mode 2 control temperature (HL2) Lower heat roller 155 155 155 155 155 155 155 155 155

OHP mode control temperature (HL1) Upper heat roller 180 180 180 180 180 180 180 180 180

OHP mode control temperature (HL2) Lower heat roller 175 175 175 175 175 175 175 175 175

Energy saving mode control temperature (HL1) Upper heat roller 136

Control temperature when resetting from preheat to B/W (HL1)

HL1 Upper heat roller OFF OFF OFF OFF OFF OFF OFF OFF OFF

HL2 Lower heat roller OFF OFF OFF OFF OFF OFF OFF OFF OFF

(4) Heat roller

Type Silicone rubber roller φ40mm (AR-C150)

Life 40K

φ50mm (AR-C250/C160)

(5) Pressure roller

Type Silicone rubber roller

Life 40K

φ40mm (AR-C150)

φ50mm (AR-C250/C160)

Lamp rating

Vol tag e

Power

consumption

Upper heat roller

Upper heat roller 148

U.S.A Canada Inch Japan AB_B Europe U.K Aus. AB_A

140 140 140

155 155 155

U.S.A Canada Inch Japan AB_B Europe U.K Aus. AB_A

132 132 132

125 125 125

(146)

(158)

136

(146)

148

(158)

Control temperature

140

(137)

155

(152)

Control temperature

140

(132)

140

(125)

136

136

(146)

(146)

148

148

(158)

(158)

140 140 140 140 140

155 155 155 155 155

140

132 132 132 132

(132)

140

125 125 125 125

(125)

136

136

136

136

(146)

148

(158)

(146)

148

(158)

(146)

148

(158)

(146)

148

(158)

136

(146)

148

(158)

(6) Release method

Forced release by releasing tabs

NOTE

( ) AR-C100

( ) AR-C100

NOTE

( ) AR-C160

( ) AR-C160

( ) AR-C160

( ) AR-C160

2 – 11

Page 20

G. Drive section

Drive section Motor name Motor type

Toner hopper

(C, M, Y, K)

Photosensitive drum

(C, M, Y, K)

Image scanner Scanner motor Stepping motor

Developing

(C, M, Y, K)

Paper feed and

conveyance

Transfer belt Transfer belt motor Stepping motor

Fusing Fusing motor DC brush-less motor

Toner motor

(Y, M, C, K)

Drum motor

(Y, M, C, K)

Developing motor

(Y, M, C, K)

Paper feed motor DC brush-less motor

Synchronous motor

Stepping motor

DC brush-less motor

H. Engine controller

Processor M68334

I. Image processing controller

Processor MCF5202

J. Memory

Type Capacity Memory contents Location

DRAM 128MB (AR-C150/C160)

Flash

ROM

EEPROM 64Kbit (AR-C100)

256MB (AR-C250)

32Mbit Program data ICU MAIN

16Mbit (AR-C150/C250/

C160)

8Mbit (AR-C100)

16Mbit (AR-C150/C160)

16Mbit × 2 (AR-C250)

256Kbit (AR-C150/C160/

C250)

64Kbit Setting,

Image data ICU MAIN

Program data PCU PWB

Program data Operation

Setting,

adjustment,

counter data, etc.

adjustment,

counter data, etc.

PWB

PWB

control PWB

PCU PWB

ICU MAIN

PWB

K. Power source

(1) DC power supply

(AR-C150/C250)

Type

DC power

supply

(AR-C160)

DC power supply 24V 15A

Main 24V 15A

Sub 26V 0.5A

Type

Voltage Capacity (current) Note

5.1V 7.5A

3.4V 5.5A

5V2 1.1A

5Vs 0.1A

Voltage Capacity (current) Note

5.1V 7.5A

3.4V 5.5A

(2) Dehumidifier functionality

Section Paper conveyor section

Method Surface heater Surface heater

(Japan only)

* With ON/OFF switch

Output

Output

Image scanner section

(optional outside of Japan)

(3) Operating voltage/power consumption

(AR-C150/C250)

Power consumption

Power supply voltage/

frequency

100V 50/60Hz Max. 101W — Max. 10W 1500W ——— 1500W

110V 50/60Hz Max. 101W — Max. 10W 1500W ——— 1500W

120V 50/60Hz Max. 101W — Max. 10W 1500W ——— 1500W

127V 50/60Hz Max. 101W — Max. 10W 1500W ——— 1500W

220 to 230V 50/60Hz Max. 101W — Max. 10W 1800W — 1175W — 1800W

240V 50/60Hz Max. 101W — Max. 10W 1800W — 1325W — 1800W

(AR-C160)

Power supply voltage/

frequency

100V 50/60Hz Max. 128.2wh — Max. 15W 1500W ——— 1500W

110V 50/60Hz Max. 128.2wh — Max. 15W 1500W ——— 1500W

120V 50/60Hz Max. 128.2wh — Max. 15W 1500W ——— 1500W

127V 50/60Hz Max. 128.2wh — Max. 15W 1500W ——— 1500W

220 to 230V 50/60Hz Max. 128.2wh — Max. 15W 1800W — 1175W — 1800W

240V 50/60Hz Max. 128.2wh — Max. 15W 1800W — 1325W — 1800W

Preheat

condition

Preheat

condition

Main unit With full options

Ready

condition

Ready

condition

Sleep mode

condition

Main unit With full options

Sleep mode

condition

Max.

Power consumption

Max.

Preheat

condition

Preheat

condition

Ready

condition

Ready

condition

Sleep mode

condition

Sleep mode

condition

Max.

Max.

2 – 12

Page 21

4. Safety and environmental protection

standards

A. Safety standards

Item Standard Country

Safety standards S mark (Electrical regulations) Japan

UL U.S.A

SEMKO Sweden

GS Mark Germany

Environmental standards FCC U.S.A

VCCI Japan

CE Europe

C-tick Australia

B. Environmental standards

(1) Power consumption and environmental standards

Item Standard Country

Power consumption Energy Star Japan, U.S.A, Europe

ECP, Nordic Canada

Environmental standards Swan, Nordic Sweden

(2) Ozone level

Max. 0.02mg/m

(3) Noise level

Noise mode

Noise power level Max. 66dB Max. 40dB —

Noise pressure level ———

3

Main unit

During

operation

Ready

condition

Sleep mode

condition

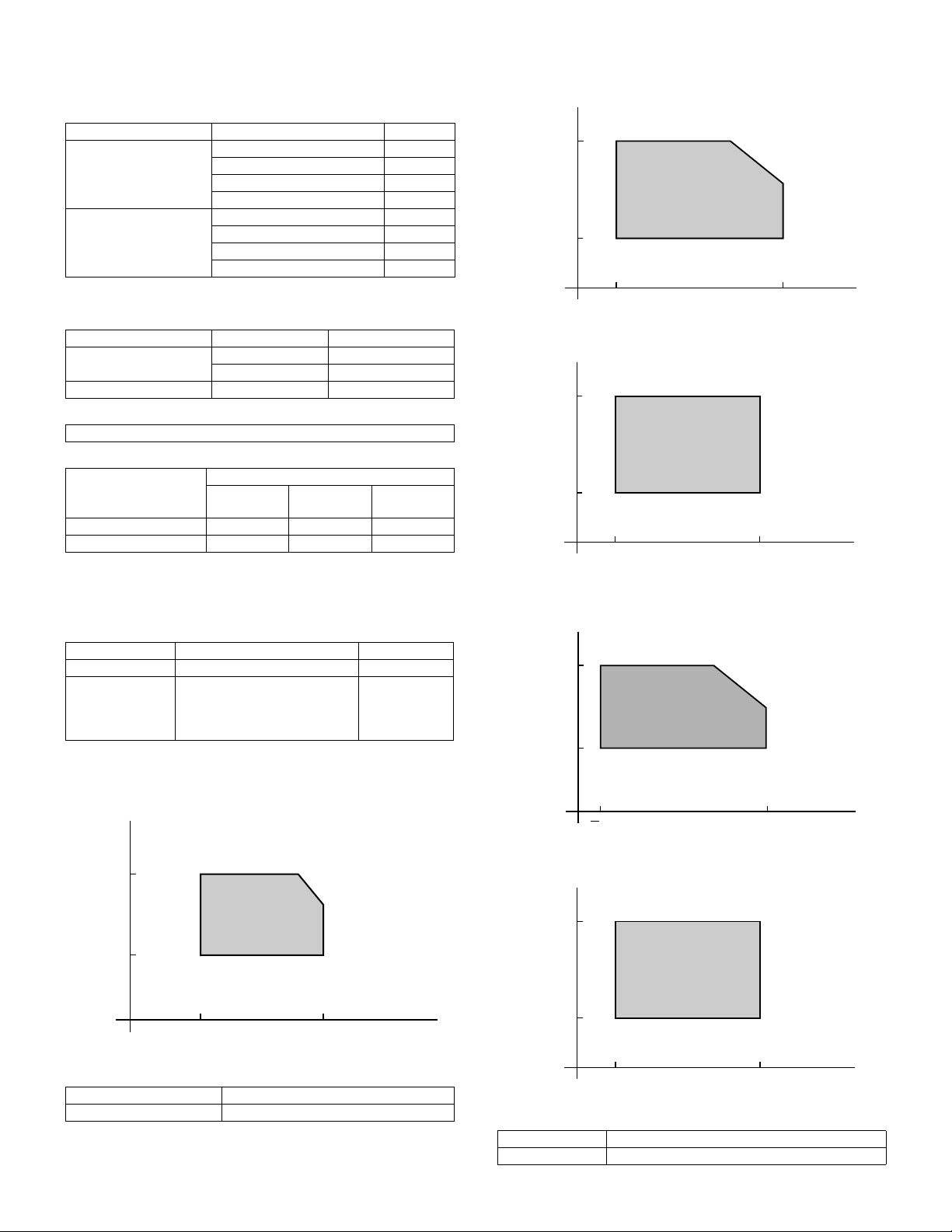

5. Ambient conditions

A. Space required

(1) Area required

AR-C150/C160/C250 AR-C100

Main unit 1412 × 695mm (55.6" × 27.4") 1220 × 695mm

With full options (With AR-SS2)

B. Operating ambient conditions

(1) Temperature/Humidity

1504 × 695mm (59.2" × 27.4")

(With AR-FN4)

1690 × 695mm (66.6" × 27.4")

—

C. Ambient storage conditions

Humidity

RH

90%

10%

Humidity

RH

90%

20%

–10˚C50˚C

Consumable items (unopened)

–5˚C40˚C

Main unit

40˚C, 90%

Temperature

40˚C, 90%

Temperature

D. Ambient conditions for transporting

Humidity

RH

90%

20%

Main unit

30˚C, 90%

50˚C, 60%

45˚C, 60%

Humidity

RH

80%

30˚C, 80%

20%

15˚C 35˚C

Temperature

(2) Power supply voltage and frequency

Power supply voltage Rated voltage ± 10%

Power supply frequency Rated frequency ± 2%

35˚C, 60%

20˚C45˚C

Humidity

RH

90%

10%

–5˚C40˚C

Temperature

Consumable items

Temperature

E. Standard temperature and humidity

Temperature 20 to 25°C

Humidity 65 ± 5%

2 – 13

40˚C, 90%

Page 22

[3] CONSUMABLE PARTS

1. Consumable parts list

AR-C150 Supply List (U.S.A./CANADA)

NAME CONTENT(S)

1 Color Toner (cyan) "Toner Cartridge (cyan) (267g),

Instruction Sheet"

2 Color Toner (magenta) "Toner Cartridge (magenta) (267g),

Instruction Sheet"

3 Color Toner (yellow) "Toner Cartridge (yellow) (267g),

Instruction Sheet"

4 Toner (black) "Toner Cartridge (black) (600g),

Instruction Sheet"

5 Color Developer kit [Developer (cyan × 1, magenta × 1,

yellow × 1) (650g each)

6 Black Developer kit [Developer (black) (650g) × 1 × 10 40K × 10 AR-C15MD1 204 × 391 × 290/9.10 (AR-C15ND1) × 10 =

7 Drum Unit Drum Unit × 1 40K AR-C15DU 402 × 568 × 198/6.73 Not applicable for

(Drum/Unit Parts included) × 1

Color Seal (C, M, Y, Bk each × 2)

8 Drum Kit Drum × 1 40K AR-C15DK 418 × 146 × 519/4.60 Not applicable for

Cleaning Blade × 1

Toner Receiving Seal × 1

Charger Unit × 1

Color Seal (C, M, Y, Bk each × 1)

LIFE

Note 1)

× 10 4K Note 1)

× 10

× 10 4K Note 1)

× 10

× 10 4K Note 1)

× 10

× 10 8K Note 1)

× 10

× 3 40K

each × 3

Model

AR-C15MT6 329 × 590 × 218/5.62 A (AR-C15NT6) × 10 =

AR-C15MT7 329 × 590 × 218/5.62 A (AR-C15NT7) × 10 =

AR-C15MT8 329 × 590 × 218/5.62 A (AR-C15NT8) × 10 =

AR-C15MT1 429 × 610 × 246/10.97 A (AR-C15NT1) × 10 =

AR-C15MD9 294 × 391 × 170/7.71 (AR-C15ND9) × 3 =

Note 1) A4 document with 10% coverage

Note 2) Inner carton printed in 2 languages including English and French

AR-C150/250 Supply List (U.S.A/Canada)

NAME CONTENT (S) LIFE MODEL INCOMPATIBILITY REMARK

1 Color Toner (cyan) Toner Cartridge (cyan) (300g),

Instruction Sheet

2 Color Toner (magenta) Toner Cartridge (magenta) (300g),

Instruction Sheet

3 Color Toner (yellow) Toner Cartridge (yellow) (300g),

Instruction Sheet

4 Toner (black) Toner Cartridge (black) (600g),

Instruction Sheet

5 Color Developer kit [Developer (cyan × 1, magenta × 1,

yellow × 1) (650g each) ]

6 Black Developer kit [Developer (black) (650g) × 1] × 10 40K × 10 AR-C15MD1 (AR-C15ND1) × 10 =

7 Drum Unit Drum Unit × 1 40K AR-C25DU Not applicable for

(Drum/Unit Parts included) × 1

Color Seal (C, M, Y, Bk each × 2)

8 Drum Kit Drum × 1 40K AR-C25DK Not applicable for

Cleaning Blade × 1

Toner Receiving Seal × 1

Charger Unit × 1

Color Seal (C, M, Y, Bk each × 1)

Note 1) A4 document with 10% coverage

Note 2) Inner carton printed in 2 languages including English and French

Note 3) A4 document with 6% coverage

× 10 4.85K × 10 Note 1) AR-C25MT6 A (AR-C25NT6) × 10 =

× 10 4.85K × 10 Note 1) AR-C25MT7 A (AR-C25NT7) × 10 =

× 10 4.85K × 10 Note 1) AR-C25MT8 A (AR-C25NT8) × 10 =

× 10 8.64K × 10 Note 1)

21.7K × 10 Note 3)

× 3 40K each color × 3 AR-C15MD9 (AR-C15ND9) × 3 =

DIMENSIONS

(W × D × H): mm

/WHIGHT: kg

AR-C25MT1 A (AR-C25NT1) × 10 =

INCOMPATIBILITY REMARK

AR-C15MT6

AR-C15MT7

AR-C15MT8

AR-C15MT1

The AR-C25MT1 or

AR-C16MT1 can be

used.

AR-C15MD9

AR-C15MD1

AR-C250, AR-C160

AR-C250, AR-C160

AR-C25MT6

AR-C25MT7

AR-C25MT8

AR-C25MT1

The AR-C16MT1 can

be used.

AR-C15MD9

AR-C15MD1

black in AR-C160.

black in AR-C160.

3 – 1

Page 23

AR-C150/C250 supply system (USA/Canada)

No. Name Content Life Model Remark

1 Developer unit kit Developer unit × 4— AR-DW1

2 Waste toner container kit Drum waste toner container (AS) × 1 40K AR-C15HB 5% coverage of each of C/M/Y/K, total 20% coverage

Transfer waste toner tank unit × 1

3 Fusing oil Fusing oil (800g) × 10 40K × 10 AR-C15LL AR-C15LL = AR-C15SL × 10

4 Upper heat roller kit Upper heat roller unit × 1 40K AR-C15UH

Upper cleaning roller × 1

5 Lower heat roller kit Lower heat roller unit × 1 40K AR-C15LH

Fusing separation pawl lower × 5

6 Fusing oil applying kit Oil applying unit × 1 40K AR-C15KH

Oil filter unit × 1

Applying unit mini oil bottle × 1

7 Filter kit Process ozone filter × 2 80K AR-C15FL

Toner duct ozone filter × 1

Toner filter × 1

8 Transfer belt kit Transfer belt × 1 160K AR-C15TT

Belt separation pawl × 2

9 Transfer roller kit Transfer blade × 1 80K AR-C15TX

Transfer roller × 4

10 Staple cartridge Staple cartridge (SF-SC11) × 3 5,000 × 3 SF-SC11 For AR-SS2. Common with FN1.

11 Fusing unit Fusing unit

(Except for motor, PWB,

upper/lower lamps)

12 Transfer unit Transfer unit

(Except for motor)

13 DV seal kit DV seal unit (assemble) × 3 80K AR-C15DS

14 Staple cartridge Staple cartridge 3,000 × 3 AR-SC1 For AR-FN4

× 1

× 1 AR-C15TU (For servicing)

AR-C25UH

AR-C25LH

AR-C25KH

AR-C15FU

AR-C25FU

For AR-C150

For AR-C250

For AR-C150

For AR-C250

For AR-C150

For AR-C250

(For servicing)

For AR-C150

For AR-C250

AR-C160 Supply List (U.S.A/Canada)

NAME CONTENT (S) LIFE MODEL INCOMPATIBILITY REMARK

1 Color Toner (cyan) Toner Cartridge (cyan) (300g),

Instruction Sheet

2 Color Toner (magenta) Toner Cartridge (magenta) (300g),

Instruction Sheet

3 Color Toner (yellow) Toner Cartridge (yellow) (300g),

Instruction Sheet

4 Toner (black) Toner Cartridge (black) (650g),

Instruction Sheet

5 Color Developer kit [Developer (cyan × 1, magenta × 1,

yellow × 1) (650g each) ]

6 Black Developer kit [Developer (black) (650g) × 1] × 10 80K × 10 AR-C16MD1 (AR-C16ND1) × 10 = AR-C16MD1

7 Drum Unit Drum Unit × 1 40K AR-C25DU Use for C, M, Y

(Drum/Unit Parts included) × 1

Color Seal (C, M, Y, each × 2)

8 Drum Kit Drum (Color) × 1 40K AR-C25DK Use for C, M, Y

Cleaning Blade × 1

Toner Receiving Seal × 1

Charger Unit × 1

Color Seal (C, M, Y, each × 1)

9 Drum Drum (Black) 80K AR-C16DR Use for Black

10 Main charger kit Main charger unit × 1 40K AR-16MK Use for Black

Cleaning blade × 1

Toner receving seal × 1

RS roller cleaner × 1

Note 1) A4 document with 10% coverage

Note 2) Inner carton printed in 2 languages including English and French

Note 3) A4 document with 6% coverage

× 10 4.85K × 10

Note 1)

× 10 4.85K × 10

Note 1)

× 10 4.85K × 10

Note 1)

× 10 21.7K × 10

Note 3)

× 3 40K each

color × 3

AR-C25MT6 A (AR-C25NT6) × 10 = AR-C25MT6

AR-C25MT7 A (AR-C25NT7) × 10 = AR-C25MT7

AR-C25MT8 A (AR-C25NT8) × 10 = AR-C25MT8

AR-C16MT1 A (AR-C16NT1) × 10 = AR-C16MT1

The AR-C25MT1 or AR-C16MT1

can be used.

AR-C15MD9 (AR-C15ND9) × 3 = AR-C15MD9

Not applicable for AR-C150 and

AR-C250.

Not applicable for AR-C150 and

AR-C250.

Not applicable for AR-C150 and

AR-C250.

3 – 2

Page 24

AR-C160 supply system (USA/Canada)

No. Name Content Life Model Remark

1 Developer unit kit Developer unit × 4— AR-DW1

2 Waste toner container kit Drum waste toner container (AS) × 1 40K AR-C15HB 5% coverage of each of C/M/Y/K, total 20% coverage

Transfer waste toner tank unit × 1

3 Fusing oil Fusing oil (800g) × 10 40K × 10 AR-C15LL AR-C15LL = AR-C15SL × 10

4 Upper heat roller kit Upper heat roller unit × 1 40K AR-C16UH For AR-C160

Upper cleaning roller × 1

5 Lower heat roller kit Lower heat roller unit × 1 40K AR-C16LH For AR-C160

Fusing separation pawl lower × 5

6 Fusing oil applying kit Oil applying unit × 1 40K AR-C15KH

Oil filter unit × 1

Applying unit mini oil bottle × 1

7 Filter kit Process ozone filter × 2 80K AR-C15FL

Toner duct ozone filter × 1

Toner filter × 1

8 Transfer belt kit Transfer belt × 1 160K AR-C16TT

Transfer roller kit Transfer roller × 4

9 Staple cartridge Staple cartridge (SF-SC11) × 3 5,000 × 3 SF-SC11 For AR-SS2. Common with FN1.

10 Fusing unit Fusing unit

(Except for motor, PWB,

upper/lower lamps)

11 Transfer unit Transfer unit

(Except for motor)

12 DV seal kit DV seal unit (assemble) × 3 80K AR-C15DS

13 Staple cartridge Staple cartridge 3,000 × 3 AR-SC1 For AR-FN4

14 Transfer belt cleaning blade kit Transfer belt cleaning blade × 1 80K AR-C16TG AR-C16TG = AR-C160G × 10 (for USA)

Transfer belt cleaning blade kit Transfer belt cleaning blade × 1 80K AR-C16TK AR-C16TK = AR-C160K × 10 (for Canada)

× 1 AR-C16FU (For servicing)

× 1 AR-C16TU (For servicing)

AR-C25KH

For AR-C150

For AR-C250

For AR-C160

AR-C150 Supply List (Europe/Australia/New Zealand)

NAME CONTENT(S)

1 Color Toner (cyan) "Toner Cartridge (cyan) (267g),

Instruction Sheet"

2 Color Toner (magenta) "Toner Cartridge (magenta) (267g),

Instruction Sheet"

3 Color Toner (yellow) "Toner Cartridge (yellow) (267g),

Instruction Sheet"

4 Toner (black) "Toner Cartridge (black) (600g),

Instruction Sheet"

5 Color Developer kit [Developer (cyan × 1, magenta × 1,

yellow × 1) (650g each)

6 Black Developer kit [Developer (black) (650g) × 1 × 10 40K AR-C15LD1 204 × 391 × 290/9.10 (AR-C15DV1) × 10 =

7 Drum Unit Drum Unit × 1 40K AR-C15DU 402 × 568 × 198/6.73 Not applicable for

(Drum/Unit Parts included) × 1

Color Seal (C, M, Y, Bk each × 2)

8 Drum Kit Drum × 1 40K AR-C15DK 418 × 146 × 519/4.60 Not applicable for

Cleaning Blade × 1

Toner Receiving Seal × 1

Charger Unit × 1