Page 1

MODEL

AR-BC320

DIGITAL FULL COLOR MULTIFUNCTIONAL

SYSTEM

OPERATION MANUAL

(for general information and copier operation)

• BEFORE USING

THE PRODUCT

•

MANAGING THE MACHINE

• PERIPHERAL DEVICES

• BEFORE MAKING

COPIES

• BASIC PROCEDURE

FOR MAKING COPIES

• CONVENIENT COPY

FUNCTIONS

•

MACHINE MAINTENANCE

(FOR COPYING)

• SPECIFICATIONS

Page

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

(Option)

Duplex bypass / inverter unit and

Stand / 3 x 500 sheet paper drawer

Be sure to become thoroughly familiar with this manual to

gain the maximum benefit from the product.

Before installing this product, be sure to read the

installation requirements and cautions sections.

Be sure to keep all operation manuals handy for reference

including this manual, the "Operation manual (for general

information and copier operation)" and operation manuals

for any optional equipment which has been installed.

Page 2

The power switch positions are marked " I " to indicate power "ON" and " " to indicate stand-by.

In the stand-by position, power is being supplied to a drying heater within the optical system of the copier.

Caution:

For complete electrical disconnection, pull out the main plug.

The socket-outlet shall be installed near the equipment and shall be easily accessible.

FOR YOUR RECORDS ...

To protect against loss or theft, record and retain for reference the machine’s serial number located on the back

of the unit.

Model Number AR-BC320

Serial Number

Date of Purchase

Place of Purchase

Authorized Sharp Copier/Printer

Service Department Number

Warranty

While every effort has been made to make this document as accurate and helpful as possible, SHARP Corporation

makes no warranty of any kind with regard to its content. All information included herein is subject to change without

notice. SHARP is not responsible for any loss or damages, direct or indirect, arising from or related to the use of this

operation manual.

Copyright SHARP Corporation 2004. All rights reserved. Reproduction, adaptation or translation without prior

©

written permission is prohibited, except as allowed under copyright laws.

This operation manual is also used for the AR-BC320 J.

Page 3

Part 1: General Information

Page 4

Page 5

NOTES

● Considerable care has been taken in preparing this manual. If you have any comments or concerns about the

manual, please contact your nearest SHARP Service Department.

● This product has undergone strict quality control and inspection procedures. In the unlikely event that a defect

or other problem is discovered, please contact your dealer or nearest SHARP Service Department.

● Aside from instances provided for by law, SHARP is not responsible for failures occurring during use of the

product or its options, or failures due to incorrect operation of the product and its options, or other failures, or for

any damage that occurs due to use of the product.

The display screens, messages, and key names shown in the manual may differ from those on the actual machine

due to product improvements and modifications.

OPERATION MANUALS

The following operation manuals are provided for the machine. Please read the appropriate manuals as needed for

the features you wish to learn about.

●●●●

Operation manual (for general information and copier operation) (this manual):

The first half of this manual provides general information about the machine, including safety information, loading

paper, removing misfeeds, and regular maintenance.

The second half of the manual explains how to use the copy functions.

●●●●

Key operator's guide:

This primarily explains key operator programs for machine management and copier related functions. Key

operator programs for the printer, the facsimile and network scanner functions are explained in separate

manuals.

Key operator programs are used by key operators to configure function settings to meet the needs of the

customer.

●●●●

Operation manual (for facsimile):

This manual explains the procedures for using the machine as a facsimile. To use the fax function, the facsimile

expansion kit must be installed.

●●●●

Installation guide (for printer):

This explains how to connect the machine to your computer, install the printer driver for Windows, and configure

the printer driver settings.

●●●●

Operation manual (for printer)*:

This manual explains the procedures for using the machine as a printer.

●●●●

Operation manual (for network scanner)*:

This manual explains the procedures for using the machine as a network scanner when connected to a computer.

* The Operation manual (for printer) and the Operation manual (for network scanner) are provided as PDF files

on the supplied CD-ROM.

These manuals are not provided as printed manuals.

Some options may not be available in some countries and regions. This manual assumes that the optional

facsimile expansion kit has been installed, however, the basic operations of the machine are the same regardless

of the peripheral devices that are installed. For the peripheral devices that can be installed, see "Part names and

functions of peripheral devices" (1-6).

0-1

Page 6

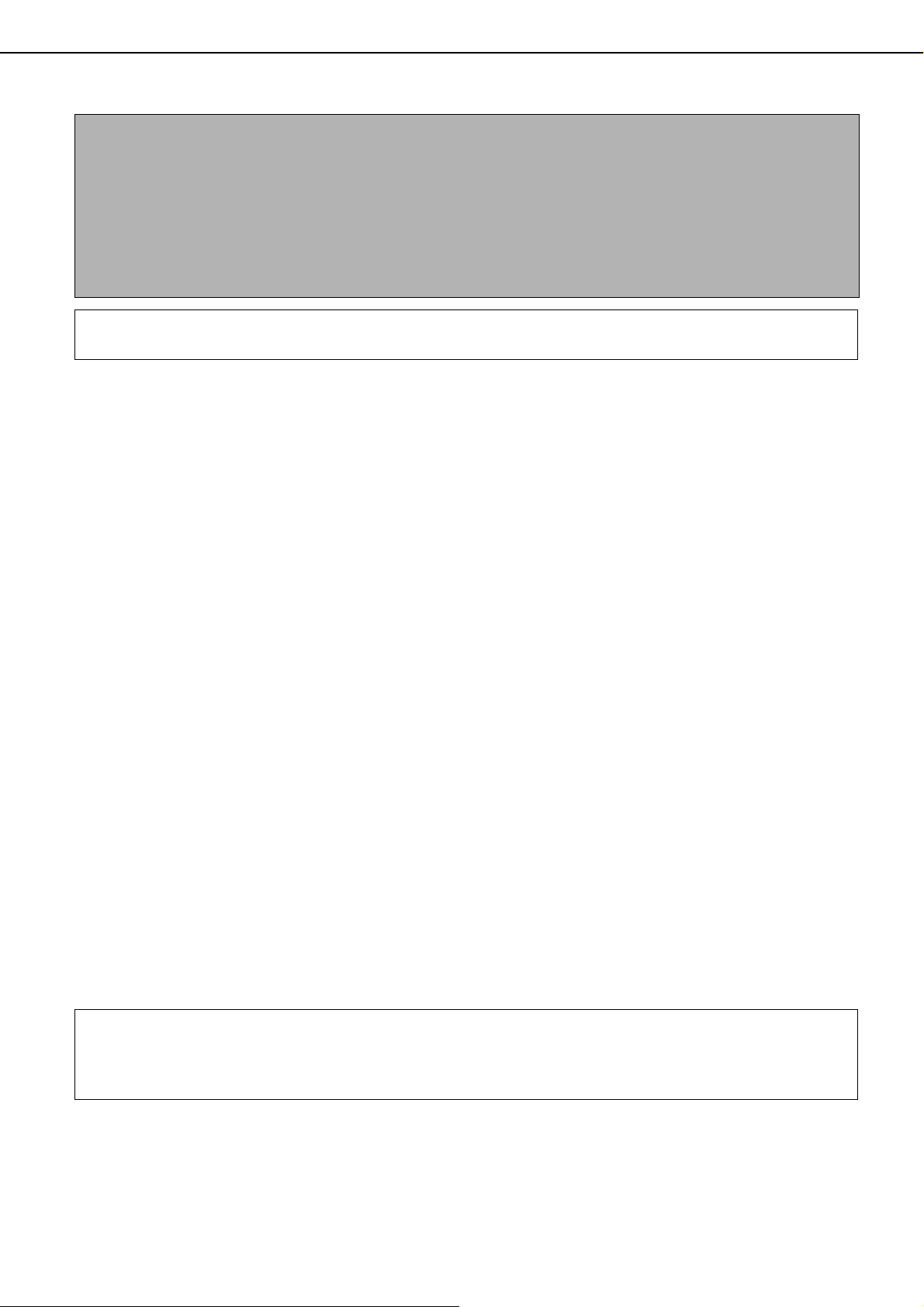

INSTALLATION REQUIREMENTS

Improper installation may damage this product. Please note the following during initial installation and whenever the

machine is moved.

1. The machine should be installed near an accessible

power outlet for easy connection.

2. Be sure to connect the power cord only to a power

outlet that meets the specified voltage and current

requirements. Also make certain the outlet is

properly grounded.

● For the power supply requirements, see the

name plate on the main unit.

3. Do not install your machine in areas that are:

● damp, humid, or very dusty

● exposed to direct sunlight

● poorly ventilated

● subject to extreme temperature or humidity

changes, e.g., near an air conditioner or heater.

4. Be sure to allow the required space around the

machine for servicing and proper ventilation.

31-1/2"

(80cm)

11-13/16"

(30cm)

23-5/8"

(60cm)

23-5/8"

(60cm)

A small amount of ozone is produced within the copier during operation. The emission level is insufficient to cause

any health hazard.

NOTE:

3

The present recommended long term exposure limit for ozone is 0.1 ppm (0.2 mg/m

weighted average concentration.

However, since the small amount that is emitted may have an objectionable odor, it is advisable to place the copier

in a ventilated area.

) calculated as an 8 hr. time-

0-2

Page 7

INSTALLATION REQUIREMENTS

Moving this machine

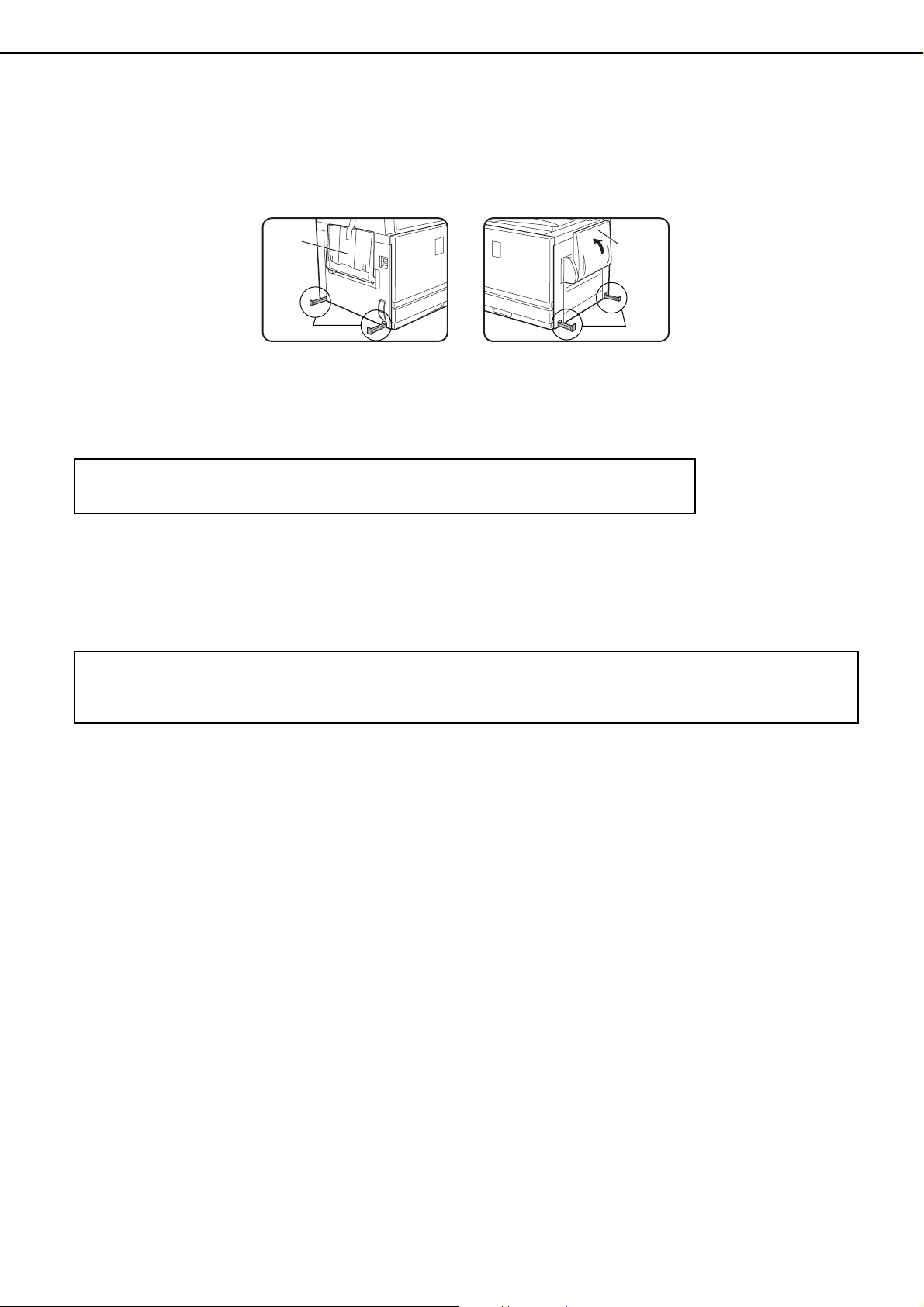

Pull out the four handles as shown below, grasp them firmly, and keep the machine horizontal while moving it.

Left side Right side

Exit

tray

Handles

Before lifting the machine,

fold up the exit tray and

tape it securely to the

machine.

Caution

Two people are required to lift and carry this machine.

If the machine has been placed on a stand/paper drawer:

The stand/paper drawer is on casters for moving. Unlock the casters and the adjusters of the stand/paper drawer and

gently move the machine taking care to steady it to prevent it from toppling.

For locking and unlocking the casters and the adjusters, see page 0-4.

If the machine is to be left unused for a long time

If the machine is to be left unused for a month or longer, follow the procedure on pages 2-6 and 2-7 to release

the pressure on the fusing roller.

Before lifting the machine,

fold up the bypass tray

and tape it securely to the

machine.

Bypass

tray

Handles

0-3

Page 8

CAUTIONS

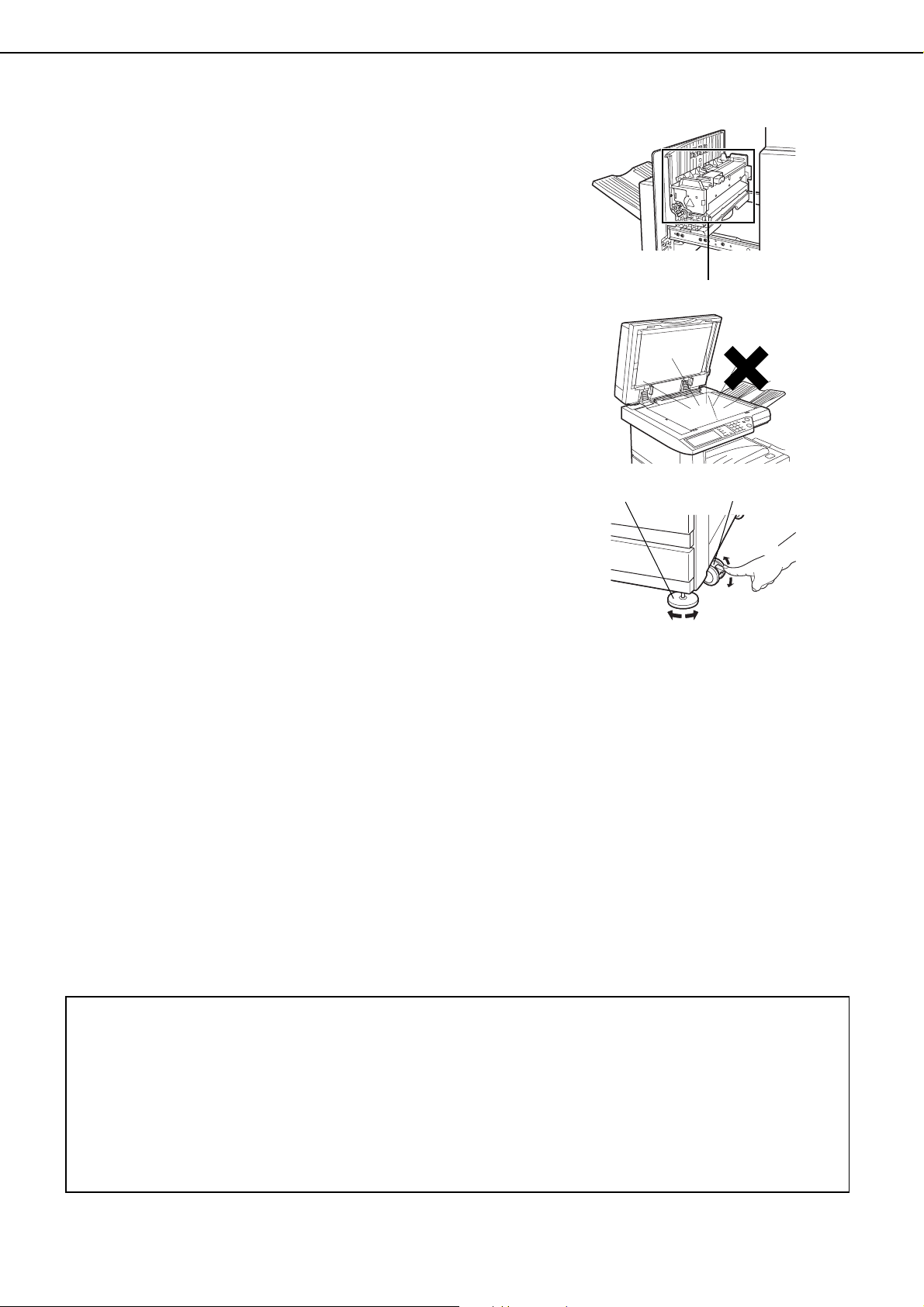

1. Do not touch the photoconductive drum. Scratches

or smudges on the drum will cause dirty prints.

2. The fusing unit is extremely hot. Exercise care in

this area.

3. Do not look directly at the light source. Doing so may

damage your eyes.

4. Four adjusters are provided on all optional stand/

paper drawer units. These adjusters should be

lowered until they contact the floor.

When moving the machine with the optional stand/

paper drawer, be sure to raise the adjusters. Also,

unlock the two casters at the front of the optional

stand/paper drawer. After moving the machine,

lower the four adjusters until they reach the floor and

lock the two casters.

Fusing unit

5. Do not make any modifications to this machine.

Doing so may result in personal injury or damage to

the machine.

6. Since this machine is heavy, it is recommended that

it be moved by more than one person to prevent

injury.

7. When connecting this machine to a computer, be

sure to first turn both the computer and the machine

off.

8. Do not make copies of anything which is prohibited

from copying by law. The following items are

normally prohibited from printing by national law.

Other items may be prohibited by local law.

●

Money ● Stamps ● Bonds ● Stocks

●

Bank drafts ● Checks ● Passports

●

Driver's licenses

Adjuster

Lock

Caster

Release

Lock

Release

"BATTERY DISPOSAL"

THIS PRODUCT CONTAINS A LITHIUM PRIMARY MEMORY BACK-UP BATTERY THAT MUST BE

DISPOSED OF PROPERLY. PLEASE CONTACT YOUR LOCAL SHARP DEALER OR AUTHORIZED SERVICE

REPRESENTATIVE FOR ASSISTANCE IN DISPOSING OF THIS BATTERY.

This product utilizes tin-lead solder, and a fluorescent lamp containing a small amount of mercury.

Disposal of these materials may be regulated due to environmental considerations.

For disposal or recycling information, please contact your local authorities or the Electronics Industries Alliance:

www.eia.org

0-4

Page 9

CONTENTS

OPERATION MANUALS.................................................0-1

INSTALLATION REQUIREMENTS.................................0-2

● Moving this machine..................................................0-3

CAUTIONS......................................................................0-4

CHAPTER 1

BEFORE USING THE PRODUCT

INTRODUCTION.............................................................1-2

MAIN FEATURES ...........................................................1-2

PART NAMES AND FUNCTIONS ..................................1-4

● Exterior......................................................................1-4

● Interior .......................................................................1-5

● Part names and functions of peripheral devices........1-6

● Operation panel.........................................................1-8

● Touch panel...............................................................1-9

AUDITING MODE .........................................................1-11

● Using the machine when the auditing mode is

enabled ...................................................................1-11

CHAPTER 2

MANAGING THE MACHINE

LOADING PAPER...........................................................2-2

● Loading paper in paper tray 1....................................2-2

● Changing the paper size in paper tray 1....................2-2

● Loading paper in the bypass tray ..............................2-4

● Loading paper in the stand/1 x 500 sheet paper drawer/

stand/3 x 500 sheet paper drawer.............................2-7

● Specifications (stand/1 x 500 sheet paper drawer/

stand/3 x 500 sheet paper drawer)............................2-7

● Loading paper in the duplex module/2 x 500 sheet

paper drawer .............................................................2-8

● Specifications (duplex module/2 x 500 sheet paper

drawer) ......................................................................2-8

● Specifications of paper trays .....................................2-9

● Setting the paper type (except the bypass tray)......2-11

● Setting the paper size when an extra size is loaded2-11

● Setting the paper type and paper size in the bypass

tray...........................................................................2-12

CUSTOM SETTINGS....................................................2-13

● Operation procedure common to all custom settings

.................................................................................2-13

● About the settings....................................................2-14

REPLACING THE TONER CARTRIDGES ...................2-15

STORAGE OF SUPPLIES ............................................2-17

MISFEED REMOVAL....................................................2-18

● Misfeed removal guidance.......................................2-18

● Misfeed in the paper feed area................................2-19

● Misfeed in the transport area, fusing area, and exit

area .........................................................................2-20

● Misfeed in the stand/1 x 500 sheet paper drawer....2-21

● Misfeed in the stand/3 x 500 sheet paper drawer....2-21

● Misfeed in the duplex bypass/inverter unit and duplex

module/2 x 500 sheet paper drawer........................2-22

TROUBLESHOOTING..................................................2-24

CHAPTER 3

PERIPHERAL DEVICES

SADDLE STITCH FINISHER ......................................... 3-2

● Part names and functions ......................................... 3-2

● Specifications............................................................ 3-2

● Saddle stitch finisher functions ................................. 3-4

● Using the saddle stitch finisher................................. 3-6

●

Staple cartridge replacement and staple jam removal

● Misfeed in the saddle stitch finisher........................ 3-10

● Troubleshooting saddle stitch finisher problems..... 3-12

● Stapling position quick reference guide for duplex

output...................................................................... 3-13

● Relation between print image and saddle stitch ..... 3-14

LARGE CAPACITY TRAY............................................ 3-15

● Part name ............................................................... 3-15

● Specifications.......................................................... 3-15

● Loading paper in the large capacity tray................. 3-16

● Misfeed in the large capacity tray ........................... 3-17

.. 3-7

0-5

Page 10

CONTENTS

CHAPTER 4

BEFORE MAKING COPIES

PART NAMES AND FUNCTIONS (The Reversing Automatic

Document Feeder)

● Exterior ..................................................................... 4-2

● Operation Panel........................................................ 4-3

● Touch Panel (main screen of copy mode) ................ 4-4

REVERSING AUTOMATIC DOCUMENT FEEDER....... 4-5

● Acceptable originals.................................................. 4-5

SETTING ORIGINALS ................................................... 4-6

SELECTING THE ORIGINAL SIZE................................ 4-8

STORING, DELETING, AND USING ORIGINAL SIZES

........................................................... 4-2

........ 4-9

CHAPTER 5

BASIC PROCEDURE FOR MAKING

COPIES

NORMAL COPYING....................................................... 5-2

● Copying from the reversing automatic document feeder

.................................................................................. 5-2

● Automatic two-sided copying from the reversing

automatic document feeder ...................................... 5-6

● Copying from the document glass ............................ 5-7

● Automatic two-sided copying from the document glass

.................................................................................. 5-9

EXPOSURE ADJUSTMENTS...................................... 5-10

REDUCTION/ENLARGEMENT/ZOOM ........................ 5-12

● Automatic selection (auto image) ........................... 5-12

● Manual selection..................................................... 5-13

● XY ZOOM ............................................................... 5-15

SPECIAL PAPERS....................................................... 5-17

IMAGE EDIT MENU ..................................................... 6-16

● Single color .............................................................6-17

● Mirror image ............................................................ 6-17

● Photo Repeat ..........................................................6-18

● Multi shot................................................................. 6-19

● 11" x 17" (A3) Full-bleed ......................................... 6-21

● Multi-page enlargement .......................................... 6-22

● Pamphlet copy ........................................................ 6-24

JOB PROGRAM MEMORY.......................................... 6-25

● Storing a job program.............................................. 6-25

● Recalling a job program .......................................... 6-26

● Deleting a stored job program................................. 6-26

INTERRUPTING A COPY RUN ................................... 6-27

CHAPTER 7

MACHINE MAINTENANCE (FOR

COPYING)

REMOVING AN ORIGINAL MISFEED........................... 7-2

● Removing a misfed original from the reversing automatic

document feeder ....................................................... 7-2

USER MAINTENANCE (For copying) ............................ 7-3

TROUBLESHOOTING.................................................... 7-4

CHAPTER 8

SPECIFICATIONS

SPECIFICATIONS.......................................................... 8-2

● Copier and Main unit................................................. 8-2

● Reversing automatic document feeder ..................... 8-4

● Duplex bypass/inverter unit (optional)....................... 8-4

INDEX............................................................................. 8-5

CHAPTER 6

CONVENIENT COPY FUNCTIONS

SPECIAL MODES .......................................................... 6-2

● Common operation procedure for using the special

functions ................................................................... 6-3

● Margin shift ............................................................... 6-4

● Erase ........................................................................ 6-5

● Dual page copy......................................................... 6-6

● Centering .................................................................. 6-7

● Transparency film with insert sheets ........................ 6-8

● Covers ...................................................................... 6-9

● B/W reverse ............................................................ 6-10

COLOR ADJUSTMENTS MENU.................................. 6-11

● RGB adjust ............................................................. 6-12

● Sharpness............................................................... 6-13

● Suppress background............................................. 6-13

● Color balance.......................................................... 6-14

● Brightness............................................................... 6-15

● Intensity .................................................................. 6-15

0-6

Page 11

CHAPTER 1

BEFORE USING THE

PRODUCT

This chapter contains basic information that should be read before using

the product.

Page

INTRODUCTION ...........................................................................................1-2

MAIN FEATURES..........................................................................................1-2

PART NAMES AND FUNCTIONS .................................................................1-4

●

Exterior...................................................................................................1-4

●

Interior....................................................................................................1-5

●

Part names and functions of peripheral devices ....................................1-6

●

Operation panel......................................................................................1-8

●

Touch panel ...........................................................................................1-9

AUDITING MODE ........................................................................................1-11

●

Using the machine when the auditing mode is enabled.......................1-11

1-1

Page 12

INTRODUCTION

To gain the maximum benefits in using this product, it is recommended that the user read this manual to become

familiar with all the features and functions of the basic product and the precautionary information contained in the

manual.

This product is a high speed Digital full color copier / printer that can be expanded to become multifunctional through

the installation of optional peripheral devices. The product can be extended to include printer, network scanning or

network printing capabilities. This manual describes the basic use of the product as a copier and does not contain

information on using any of the optional peripheral devices. Separate operation manuals are included with each of

the optional peripheral devices. Refer to these manuals for their operation.

Original and paper sizes

This machine allows use of standard sizes in both the inch and AB systems.

These are shown in the tables below.

Sizes in the inch system

11" x 17" (LEDGER)

8-1/2" x 14" (LEGAL)

8-1/2" x 13" (FOOLSCAP)

8-1/2" x 11" (LETTER)

7-1/4" x 10-1/2" (EXECUTIVE)

5-1/2" x 8-1/2" (INVOICE)

Sizes in the AB system

A3

B4

A4

B5

A5

The meaning of "R" in original and paper size indications

Some original and paper sizes can be placed in either the portrait or landscape orientations. To differentiate between

landscape and portrait, the landscape orientation size indication will contain an "R". These are indicated as 8-1/2" x

11"R, 5-1/2" x 8-1/2"R, A4R, B5R, etc. Sizes that can be placed only in the landscape orientation (11" x 17", 8-1/2"

x 14", 8-1/2" x 13", A3, B4) do not contain the "R" in their size indication.

Size indication with "R"

Landscape orientation

Size indication without "R"

Portrait orientation

MAIN FEATURES

Full-color copies with vivid colors based on digital technology

1

Photos, color text, and other originals are scanned by full-color CCD sensors, and the acquired image

information is output in vivid full color at a resolution of 600 dpi using digital image processing technology.

The machine can also be used as a full-color network printer, and network scanner.

A range of optional units to enhance productivity

2

A range of optional equipment is available to enhance productivity, such as duplex units for producing two-sided

output, additional paper feed units to increase the number of available paper sizes and paper capacity, and

paper output units that are capable of stapling and saddle stitch binding.

1-2

Page 13

MAIN FEATURES

Advanced image processing features based on digital technology

3

The scanned image data is converted to digital data, enabling the following advanced image processing features:

●●●● Photo Repeat :

Up to 24 full-size copies of a photo image can be made on a single sheet of paper (page 6-18).

●●●● Multi shot :

Up to four original pages can be copied onto a single sheet (page 6-19).

●●●● Pamphlet copy* :

Copies of original pages are arranged in proper order for copying so that the copies can be center-stapled and

folded into a pamphlet (page 6-24).

* Pamphlet copy requires the Duplex module/2 x 500 sheet paper drawer and Duplex bypass/inverter unit

options. If a saddle stitch finisher is installed, copies can be stapled in two positions along the center of copies

and folded at the center.

Image processing manual exposure adjustment for optimal copying

4

Image processing is optimized for the type of original being copied (text, photo, mixed text and photo or map). This

along with the ability to manually adjust exposure makes it possible to obtain copies that are faithful to the original.

Standard offset function makes it easy to distinguish between sets of copies

5

As sets of copies are delivered to the center tray, each set is offset from the previous set for easy separation.

1

PostScript compatible

6

Installation of an optional PS expansion kit (AR-PK4) gives PostScript compatibility (PostScript 3).

®

As an ENERGY STAR

®

ENERGY STAR

guidelines for energy efficiency.

Partner, SHARP has determined that this product meets the

Energy saving features

This product has the following two power reducing modes to help conserve natural resources and reduce

environmental pollution.

Preheat mode

Preheat mode automatically reduces the temperature of the fusing unit after the time set in the key operator

programs elapses when the machine is on standby. This allows the machine to use less power while on

standby. The machine automatically returns to normal operation when a key is pressed on the operation

panel, or when an original is placed to make a copy or send a fax.

Auto power shut-off mode

Auto power shut-off mode automatically shuts off power to the fusing unit after the time set in the key

operator programs elapses when the machine is on standby. This minimizes the power used by the

machine while on standby. When this mode activates, the touch panel screen turns off.

To return the machine to normal operation, press the mode select key (the indicator of this key will be lit).

Auto power shut-off mode can be configured in the key operator programs. The mode is initially set (factory

default setting) to activate after 60 seconds elapses. (See page 9 of the key operator's guide.)

If a print job or fax is received while auto power shut-off mode or preheat mode is activated, the machine

automatically returns to normal operation.

The Environmental Choice Program guidelines are applied to the products only in Canada. The

products that meet the Environmental Choice Program guidelines carry the logo shown above.

The products without the logo may not meet the Environmental Choice Program guidelines.

1-3

Page 14

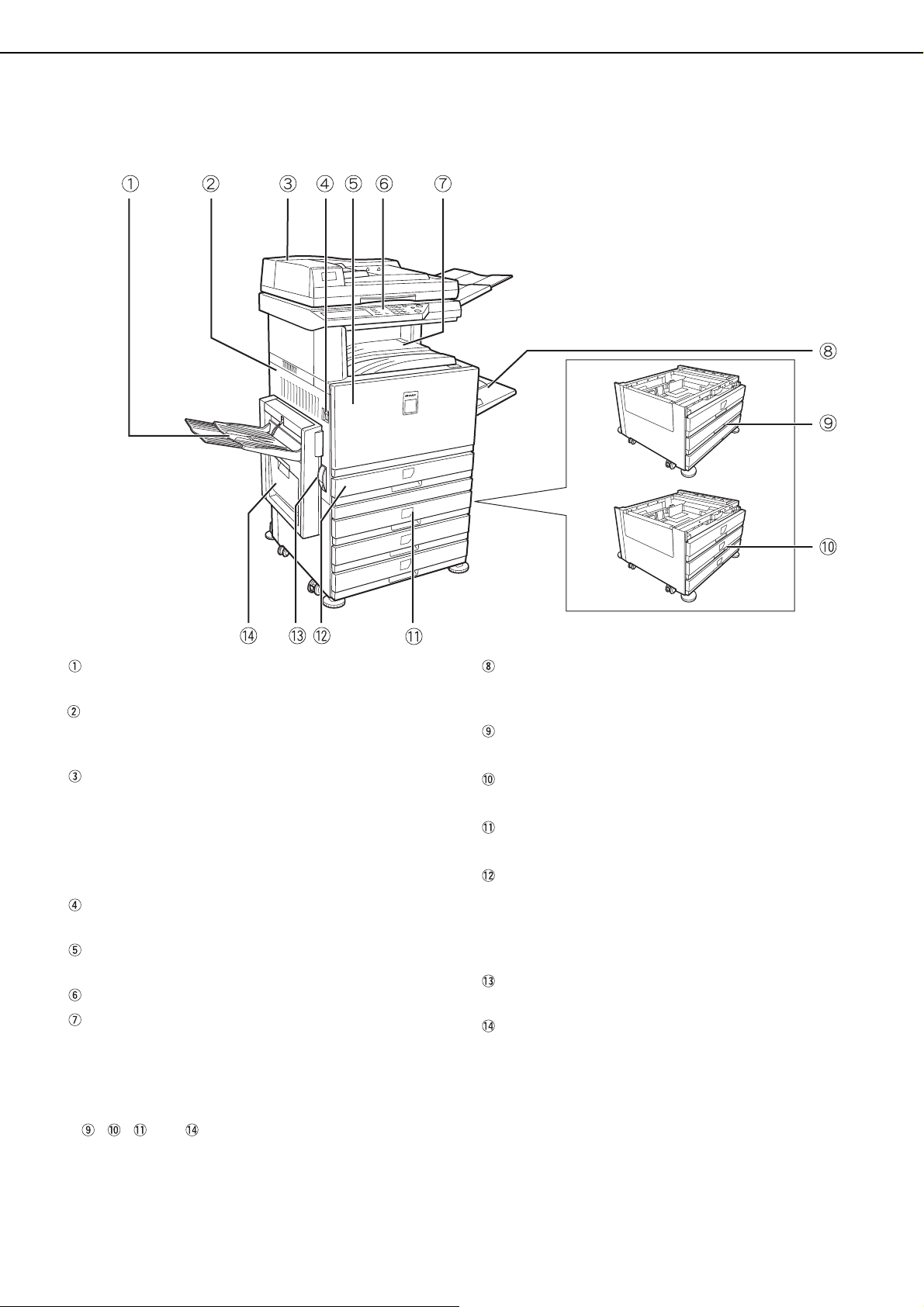

PART NAMES AND FUNCTIONS

Exterior

Left tray (See page 5-5)

Finished sheets are deposited here.

Left side cover

Open this cover when a paper misfeed occurs in

the fusing unit or the transfer unit.

Reversing automatic document feeder

(See page 4-2)

This automatically feeds originals to be scanned.

The feeder can turn the original over and scan the

back side as well as the front side for support of

two-sided originals.

Power switch

Press to turn power on and off.

Front cover

Open to replace toner cartridge.

Operation panel

Center tray (See page 5-5)

Finished sheets are deposited here.

Bypass tray

Special papers (including transparency film) and

copy paper can be fed from the bypass tray.

Stand/1 x 500 sheet paper drawer*

(See page 2-7)

Stand/3 x 500 sheet paper drawer*

(See page 2-7)

Duplex module/2 x 500 sheet paper drawer*

(See page 2-8)

Paper tray

Each tray can hold approximately 500 sheets of the

recommended paper for color (21 lbs. or 80 g/m

or approximately 500 sheets of SHARP standard

paper (21 lbs. or 80 g/m

Left side cover release

Push this release up to open the left side cover.

Duplex bypass/inverter unit and exit tray* (See

page 1-6)

2

).

2

),

* , , and are peripheral devices. For a description of these devices, see page 1-6.

1-4

Page 15

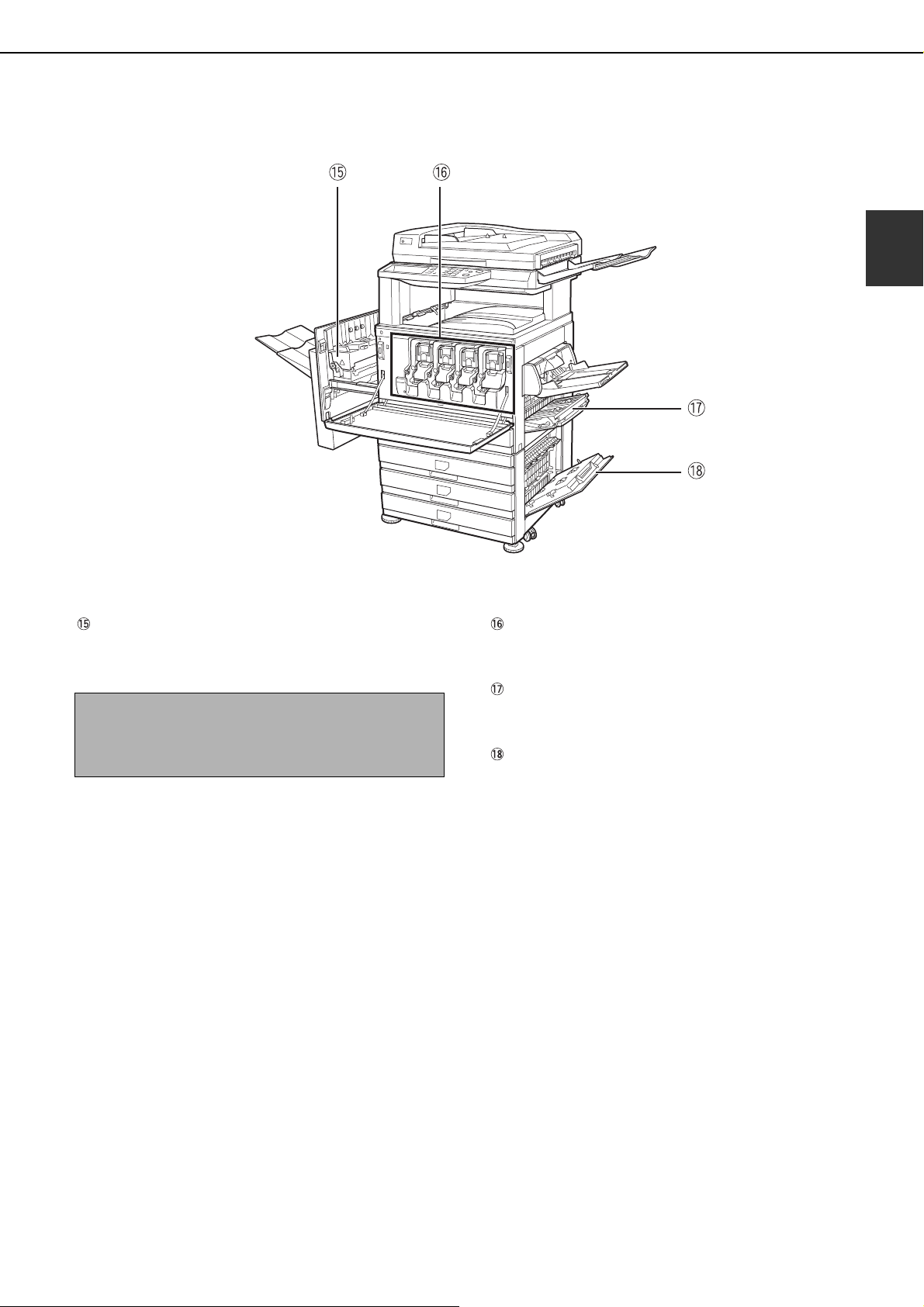

Interior

PART NAMES AND FUNCTIONS

1

Fusing unit

Toner images are fused here.

CAUTION

The fusing unit is hot. Take care in removing misfed

paper.

Toner cartridge

The toner cartridge must be replaced when

indicated on the operation panel. (See page 2-15)

Right side cover

Open when a misfeed has occurred in the paper

feed area.

Right cover of paper drawer

Open this cover to remove paper misfed in the

paper drawer.

1-5

Page 16

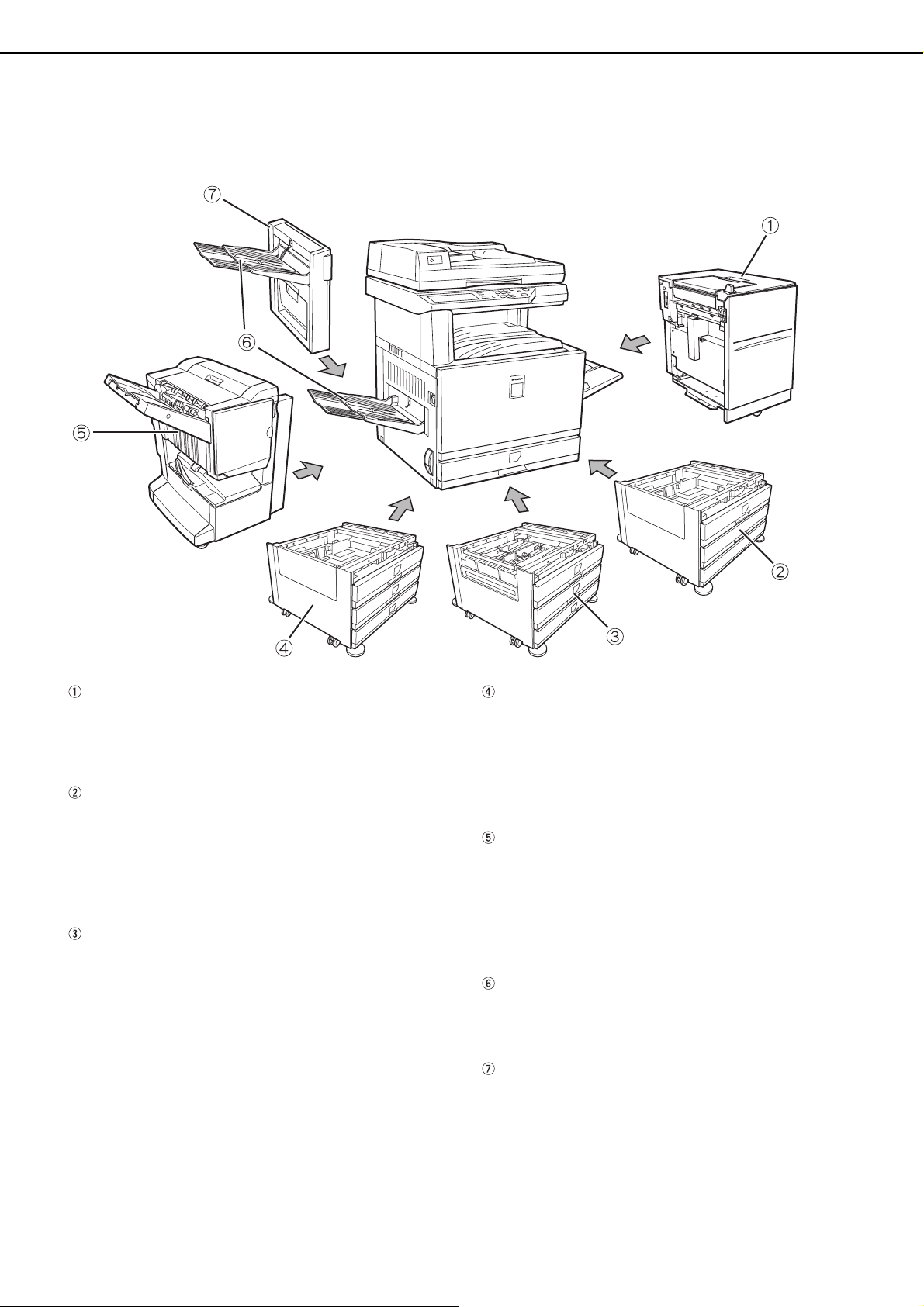

PART NAMES AND FUNCTIONS

Part names and functions of peripheral devices

Large Capacity tray (AR-LC8)

The large capacity tray provides the added

convenience of having 3,500 sheets of 8-1/2" x 11"

or A4 paper (21 lbs. or 80 g/m

2

) available.

Stand/1 x 500 sheet paper drawer (AR-D17N)

This stand has one paper tray. It can hold

approximately 500 sheets of the recommended

paper for color (21 lbs. or 80 g/m

2

), or

approximately 500 sheets of SHARP standard

2

paper (21 lbs. or 80 g/m

).

Duplex module/2 x 500 sheet paper drawer (AR-D19N)

This stand includes a module for automatic twosided printing and two paper trays. The two trays

can hold approximately 500 sheets of the

recommended paper for color (21 lbs. or 80 g/m

2

or approximately 500 sheets of SHARP standard

2

paper (21 lbs. or 80 g/m

). To perform two-sided

printing, a duplex bypass/inverter unit (AR-RB1) is

required.

Stand/3 x 500 sheet paper drawer (AR-D18N)

This stand has three paper trays. Each tray can

hold approximately 500 sheets of the

2

recommended paper for color (21 lbs. or 80 g/m

),

or approximately 500 sheets of SHARP standard

2

paper (21 lbs. or 80 g/m

).

Saddle stitch finisher (AR-F13)

The finisher can deliver sets saddle stitched and

folded at the paper centerline to form a pamphlet,

edge stapled in three different modes or unstapled.

For two-hole or three-hole output, a hole punch

module must be installed.

Exit tray (AR-TE3)

),

The exit tray is installed on the output outlet of the

machine or the duplex tray / inverter unit.

Duplex bypass/inverter unit (AR-RB1)

This module is required to automatically turn paper

over within the machine for automatic two-sided

printing.

1-6

Page 17

■■■■ Other optional equipment

PART NAMES AND FUNCTIONS

●●●●PS3 expansion kit (AR-PK4)

This kit provides compatibility of PostScript level 3

to the printer.

●●●●Facsimile expansion kit (AR-FX10)

This kit must be installed to use the fax function.

●●●●Fax memory (8 MB) (AR-MM9)

This adds memory for use by the fax function.

●●●●256 MB optional memory (AR-SM5)

This adds memory that is used for the copy

function, printer function, and scanner function.

■■■■ Face-up and face-down output

After printing, the paper is delivered to the exit tray. This product has two exit trays (center tray and left tray). The

paper specifications (page 8-3) and output conditions differ for each tray; however, if the paper and output

conditions are such that the paper can be delivered to either tray, you can select the tray to which the paper will

go.

● Paper exits to the center tray face-down only.

● Paper exits to the left tray face-up only. However, if a duplex bypass/inverter unit has been installed, face-

down output is also possible. In this case, face-up or face-down output is automatically selected according to

the paper and output conditions (it is not possible to manually select face-up or face-down.)

1

1-7

Page 18

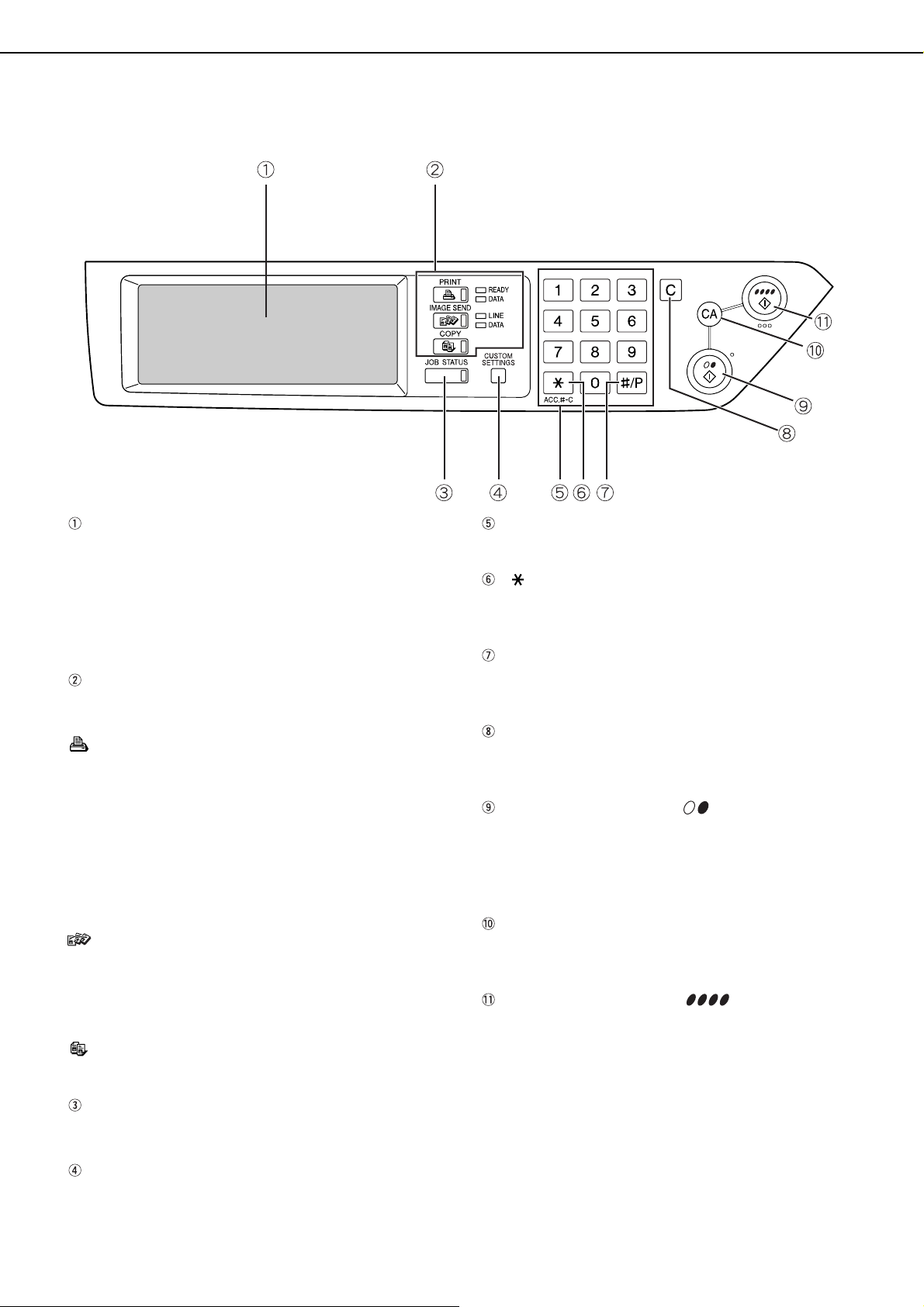

PART NAMES AND FUNCTIONS

Operation panel

Touch panel

The machine status, messages and touch keys are

displayed on the panel. When using the touch

panel, first change the display to the mode that you

wish to use: printer mode, copy mode, network

scanner mode, or fax mode*. For details see the

next page.

Mode select keys and indicators

Use to change modes and the corresponding

display on the touch panel.

[PRINT] key/READY indicator/DATA indicator

Press to enter the printer mode.

READY indicator

Print data can be received when this indicator is

lit.

DATA indicator

Lights up or blinks when print data is being

received. Also lights up or blinks when printing is

being performed.

[IMAGE SEND] key/LINE indicator/DATA

indicator

Press this key to switch the display between

network scanner mode and fax mode*. (See the

operation manuals for network scanner and fax.)

[COPY] key

Press to select the copy mode.

Numeric keys

Use to enter number values for various settings.

[ ] key ([ACC.#-C] key)

This is used when the copy, network scan, and fax*

functions are used.

[#/P] key

This is used as a program key when using the copy

function, and to dial when using the fax function*.

[C] key

This key is used in copy mode, network scanner

mode, and fax mode*.

[BLACK COPY START ( )] key

This is used to make black and white copies and to

scan a black and white original when the network

scan function is used. This is also used to scan an

original to be faxed using the fax function*.

[CA] key

This key is used in copy mode, network scanner

mode, and fax mode*.

[COLOR COPY START ( )] key

This is used to make full-color or single-color

copies and to scan a color original when the

network scanner function is used.

[JOB STATUS] key

Press to display the current job status. (See page

1-10.)

[CUSTOM SETTINGS] key

Use to adjust the contrast of the touch panel or to

set key operator programs. (See page 2-13.)

1-8

* When the fax option is installed.

Page 19

Touch panel

JOB QUEUE

COPY

Suzuki

0666211221

003 / 00

003 / 00

010 / 00

SETS / PRO

1/13

COMPLETE

CANCEL OK

RIGHT

BINDING

LEFT

BINDING

TRANSPARENCY

INSERTS

DUAL PAGE

COPY

SPECIAL MODES

2-SIDED COPY

OUTPUT

READY TO COPY.

B4

P

OR

A3

A4

DUPLEX

PART NAMES AND FUNCTIONS

Using the touch panel

[Example 1]

Items on the touch panel

are easily selectable by

touching the key

associated with the item

with a finger. Selection

of an item will be

Beep

tone

[Example 2]

The confirmation beeps can be disabled by a key

operator program. (See page 10 of the key

operator's guide.)

accompanied with a

beep tone to confirm the

item was selected. Also,

the key area for the item

will be highlighted for

visual confirmation.

Keys which are grayed

out on any screen are

not selectable. If a

grayed out key is

touched, a double beep

will be sounded.

Selection of function

[Example 1]

[Example 2]

Copier feature

● Dual page copy

● Centering

● Transparency inserts

● Mirror image

● 11"x17" (A3) Full-bleed

● B/W Reverse

Items which are

highlighted at the time a

screen appears are

already selected and will

be registered to function if

the [OK] key is touched.

When the machine is

used in the copy mode,

the functions shown in

the table below can only

be set or canceled on

the special feature

screen by alternate

touches of the function

keys on the panel.

1

The touch panel screens shown in this manual are

printed images, and may appear different from the

actual screens.

[Example 3]

When the machine is

used in the copy mode

and a special feature is

selected, a

corresponding icon

representing the feature

will appear on the touch

key and on the main

screen of the mode

selected. If this icon is

touched, the setting

screen of the function (or

a menu screen) will

appear, allowing the

settings to be checked

or adjusted and the

function to be canceled

easily.

1-9

Page 20

PART NAMES AND FUNCTIONS

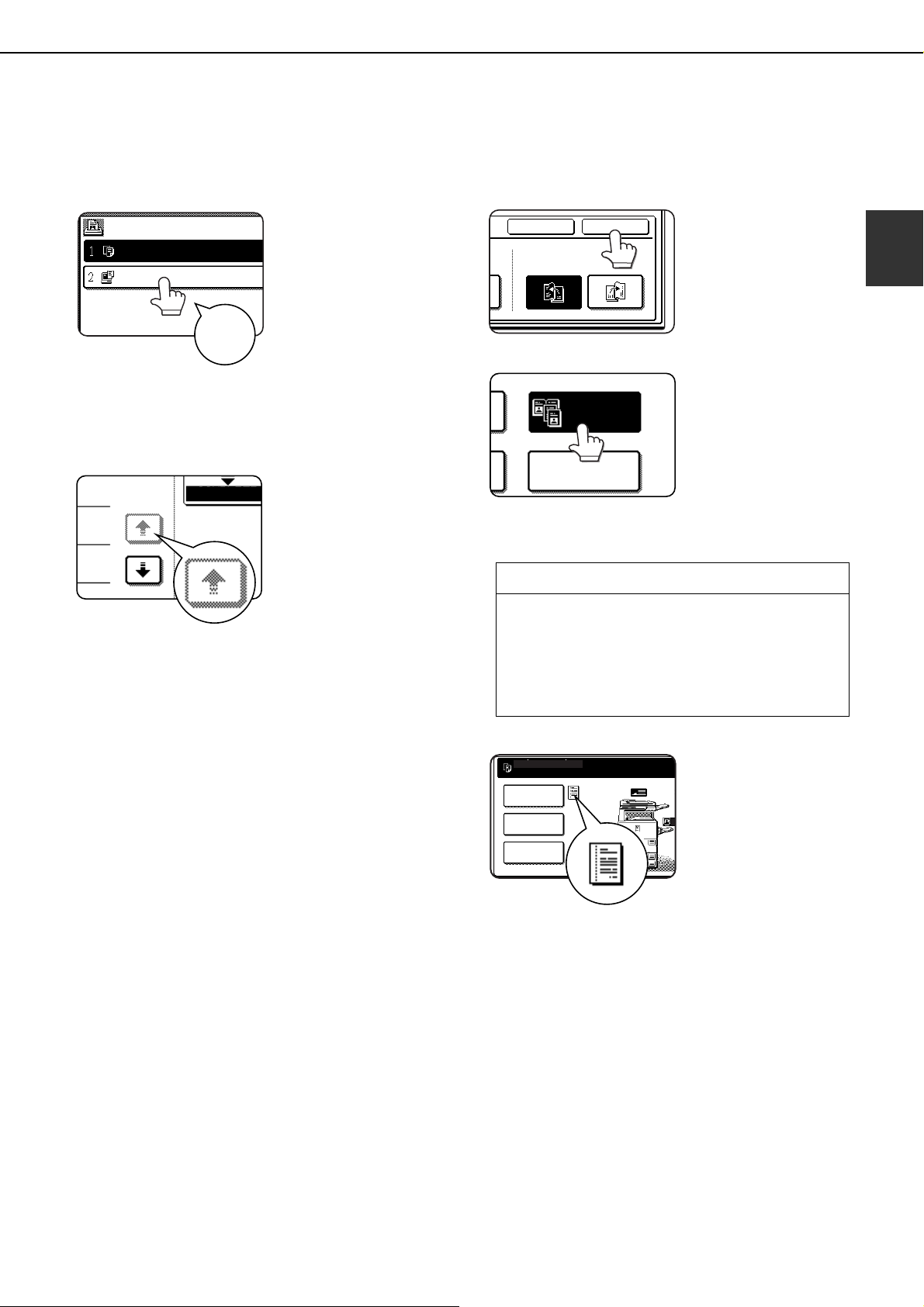

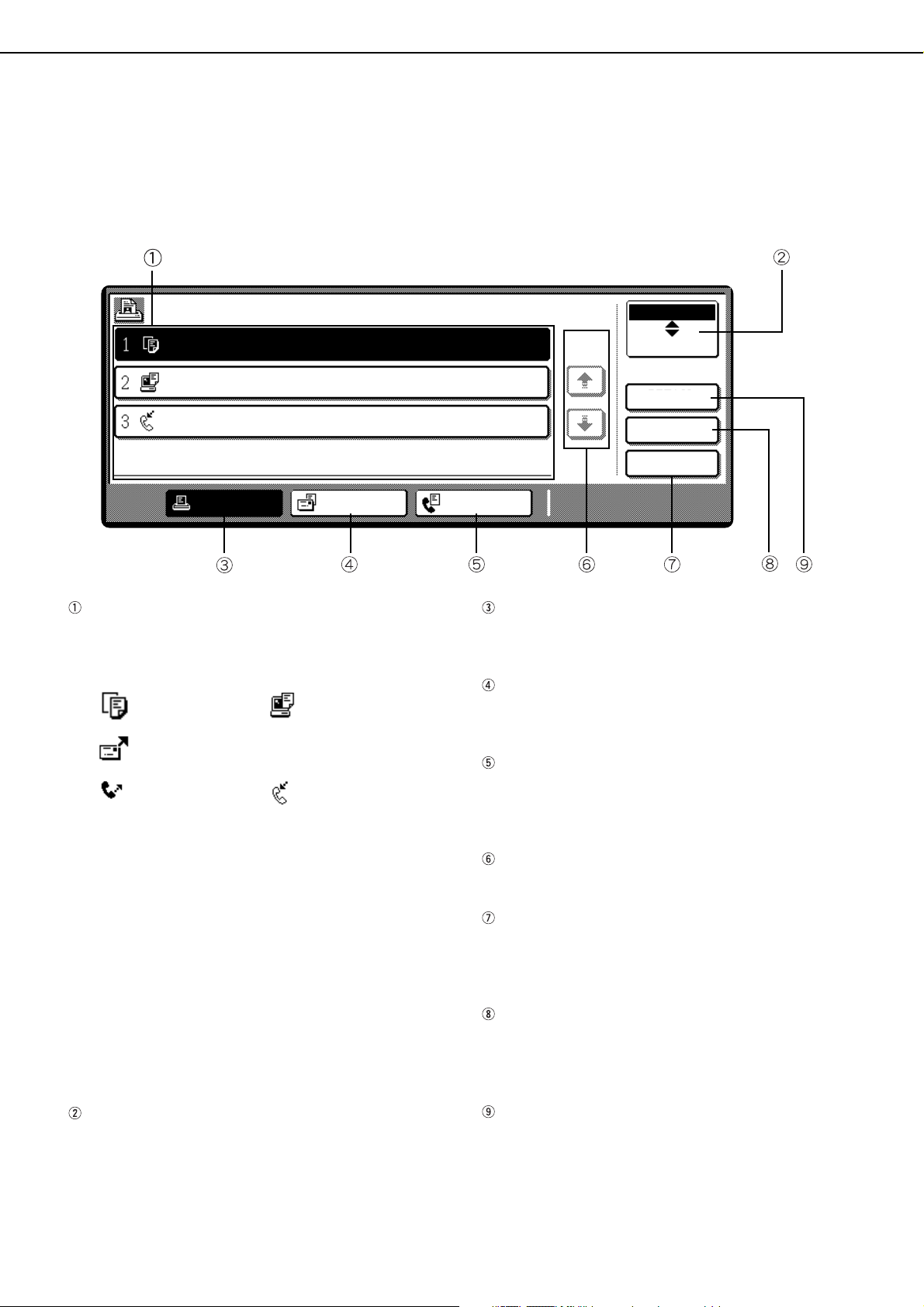

Job status screen (common to print, copy, network scan and fax)

This screen is displayed when the [JOB STATUS] key on the operation panel is pressed.

A job list showing the current job at the top of the job queue or a list showing completed jobs can be displayed.

The contents of jobs can be viewed or jobs can be deleted from the queue. (The screen below is an example and

differs from actual screens.)

JOB QUEUE

COPY

Suzuki

066211221

PRINT JOB SCANNER JOB

Job list

This shows the current job and the jobs waiting to

be run. The icons to the left of the jobs in the queue

show the job mode.

Copy mode Printer mode

Network scanner mode

Fax send job Fax reception job

The displayed jobs in the job list are themselves

operation keys. To cancel printing or to give a job

the highest print priority, touch the relevant job key

to select the job and execute the desired operation

using the keys described in 5 and 6.

* "PAPER EMPTY" in the job status display

When a job status display indicates "PAPER

EMPTY", the specified paper size for the job is not

loaded in any of the trays.

When the [DETAIL] key appears, the key of a job in

the job queue can be touched followed by the

[DETAIL] key to change the paper size selection to

a different paper size (only in printer mode).

SETS / PROGRESS

003 / 000

003 / 000

001 / 000

STATUS

PAPER EMPTY

WAITING

WAITING

FAX JOB

[PRINT JOB] key

Use to display the print job list for printer, copy and

fax mode.

[SCANNER JOB] key

This displays a list of jobs that only used the

network scanner function.

[FAX JOB] key

This displays the transmission/reception status

and finished jobs of fax mode when the fax option

is installed.

Display switching keys

Use to switch the page of the displayed job list.

[STOP/DELETE] key

Use to cancel or delete the current job or delete the

selected reserved job. Note that a fax print job

cannot be canceled or deleted.

[PRIORITY] key

This only appears in the job status screen of fax

mode. Touch this key to give priority to a job that

has been selected in the job queue.

JOB QUEUE

1/1

*

COMPLETE

DETAIL

PRIORITY

STOP/DELETE

Mode select key

This only appears in the job status screen of fax

mode. The key is used to switch the job list display

between "JOB QUEUE" and "COMPLETE".

"JOB QUEUE": Shows stored jobs and the job in

progress.

"COMPLETE" : Shows finished jobs.

1-10

[DETAIL] key

The key is only effective for computer print jobs and

only appears in the job status screen of the printer

mode. It is used to display detailed information of a

selected print job and to change the paper size for

the print job.

Page 21

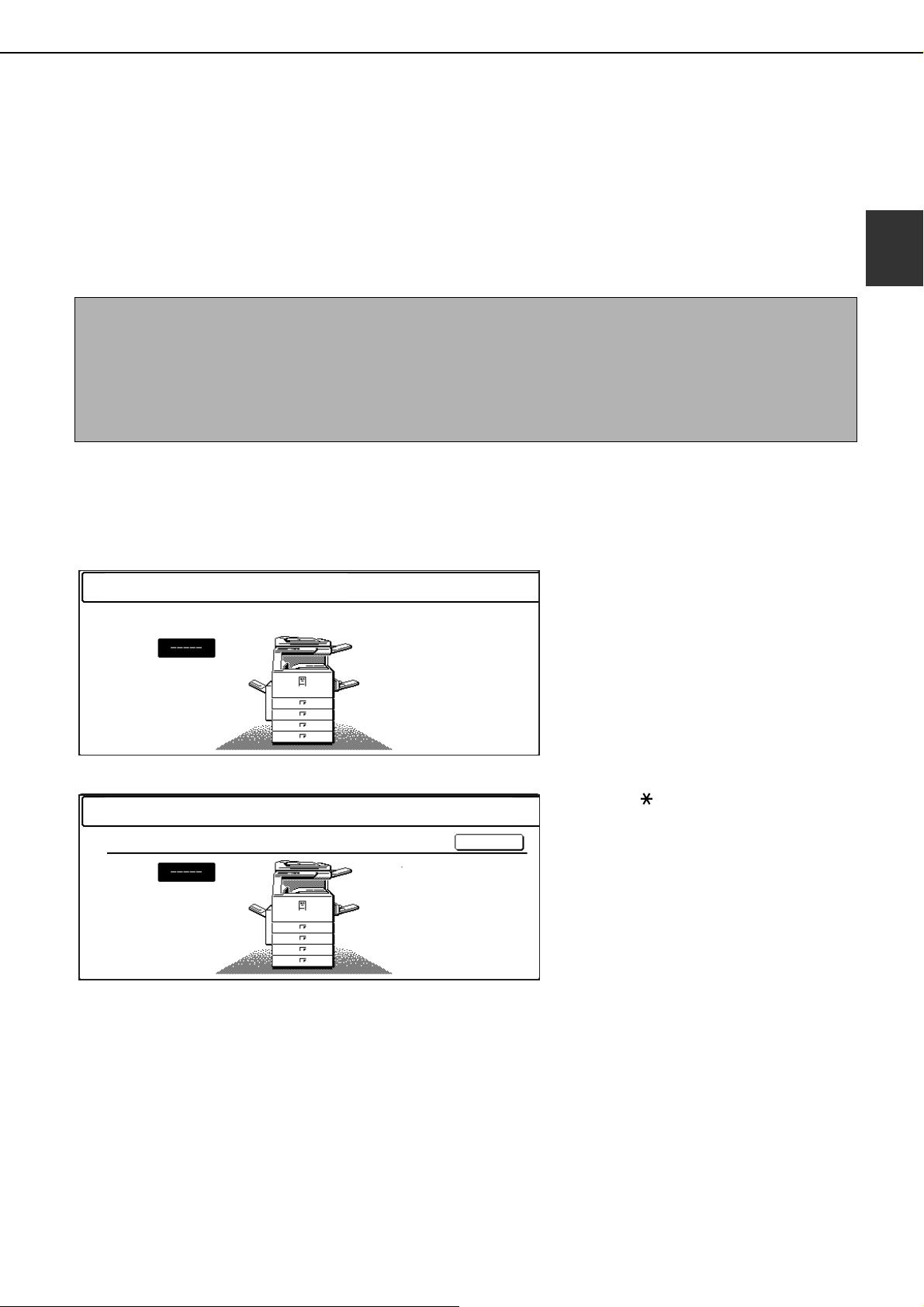

AUDITING MODE

ENTER YOUR ACCOUNT NUMBER.

ENTER YOUR ACCOUNT NUMBER FOR THE COLOR MODE.

PRESS [CANCEL] TO CHANGE TO B/W MODE.

CANCEL

When the account counter function is turned on, a count is kept of the number of copy sheets used by each account

(maximum of 200 accounts). The counts can be displayed and totaled as needed.

The key operator programs can be used to enable auditing mode separately for copy mode, fax mode, network

scanner mode and printer mode. (Page 6 of key operator's guide)

Using the machine when the auditing mode is enabled

The procedure for using the machine for copying functions when the Auditing Mode has been enabled for the copier

functions is explained below.

NOTES

● When the account counter is turned on for fax or network scanner functions, a message will appear prompting

you to enter your account number each time the touch panel is changed to the main screen of the function. Enter

your account number as explained below and then proceed with the job.

● When the account counter is turned on for the printer function, you must enter your account number in the setting

screen of the printer driver on your computer in order to print.

When the account counter is turned on, the following messages appear on the touch panel. There are two types of

prompts, depending on whether the account counter was turned on for both the color copy and the black and white

copy modes, or only for color copy mode.

●Account counter enabled for both the color copy and the black and white copy modes

1

●The account counter is enabled only for the color copy mode

AUDITING MODE FOR COLOR

In this case, enter your 5-digit account number as explained on the next page to gain access to the copier functions.

When the [ ] key ([ACC.#-C] key) or the

[COLOR COPY START] key is pressed, the

message at left appears.

1-11

Page 22

AUDITING MODE

Enter your account number (5 digits) with

1

the numeric keys.

As you enter your

account number, the

hyphens ( ) change to

asterisks ( ). If you

enter an incorrect digit,

press the key and reenter the correct digit.

When a correct account

number is entered, the

following message will

appear.

ACCOUNT STATUS:COPIES MADE/REMAINING

B/W

S.COLOR

F.COLOR

This does not appear if the account counter

has only been set for color copy mode.

If a limit has been set by key operator program

for the number of copies that can be made by

the account, the remaining number that can be

made is displayed.

This message appears for several seconds and

then changes to the following message.

Follow the appropriate steps to perform

2

the copy job.

When copying is begun, the following message

will appear.

READY TO COPY.

PRESS [ACC.#] WHEN FINISHED.

In the case of interrupt copying (page 6-27), the

following message will appear.

READY TO COPY. WHEN INTERRUPT COPYING

IS FINISHED PRESS [CANCEL].

When the copy job is finished, press the

3

[ ] key ([ACC.#-C] key)

READY TO COPY.

NOTE

If "Account number security" is turned on in the key

operator programs, the following message will

appear in the event that an incorrect account number

is entered three times in a row. (Page 8 of the key

operator's guide)

PLEASE SEE YOUR KEY OPERATOR FOR

ASSISTANCE.

While this message appears (for about one minute),

no other operations can be performed.

1-12

Page 23

CHAPTER 2

MANAGING THE MACHINE

This chapter explains how to load paper, replace the toner cartridge,

and remove paper misfeeds. It also contains information about supplies.

Page

LOADING PAPER..........................................................................................2-2

●

Loading paper in paper tray 1 ................................................................2-2

●

Changing the paper size in paper tray 1 ................................................2-2

●

Loading paper in the bypass tray...........................................................2-4

●

Loading paper in the stand/1 x 500 sheet paper drawer/stand/3 x 500

sheet paper drawer..................................................................................... 2-7

●

Specifications (stand/1 x 500 sheet paper drawer/stand/3 x 500

sheet paper drawer)...............................................................................2-7

●

Loading paper in the duplex module/2 x 500 sheet paper drawer .........2-8

●

Specifications (duplex module/2 x 500 sheet paper drawer) .................2-8

●

Specifications of paper trays ..................................................................2-9

●

Setting the paper type (except the bypass tray)...................................2-11

●

Setting the paper size when an extra size is loaded ............................2-11

●

Setting the paper type and paper size in the bypass tray ....................2-12

CUSTOM SETTINGS ..................................................................................2-13

●

Operation procedure common to all custom settings...........................2-13

●

About the settings ................................................................................2-14

REPLACING THE TONER CARTRIDGES..................................................2-15

STORAGE OF SUPPLIES...........................................................................2-17

MISFEED REMOVAL ..................................................................................2-18

●

Misfeed removal guidance ...................................................................2-18

●

Misfeed in the paper feed area ............................................................2-19

●

Misfeed in the transport area, fusing area, and exit area.....................2-20

●

Misfeed in the stand/1 x 500 sheet paper drawer................................2-21

●

Misfeed in the stand/3 x 500 sheet paper drawer................................2-21

●

Misfeed in the duplex bypass/inverter unit and duplex module/2 x 500

sheet paper drawer ..............................................................................2-22

TROUBLESHOOTING.................................................................................2-24

2-1

Page 24

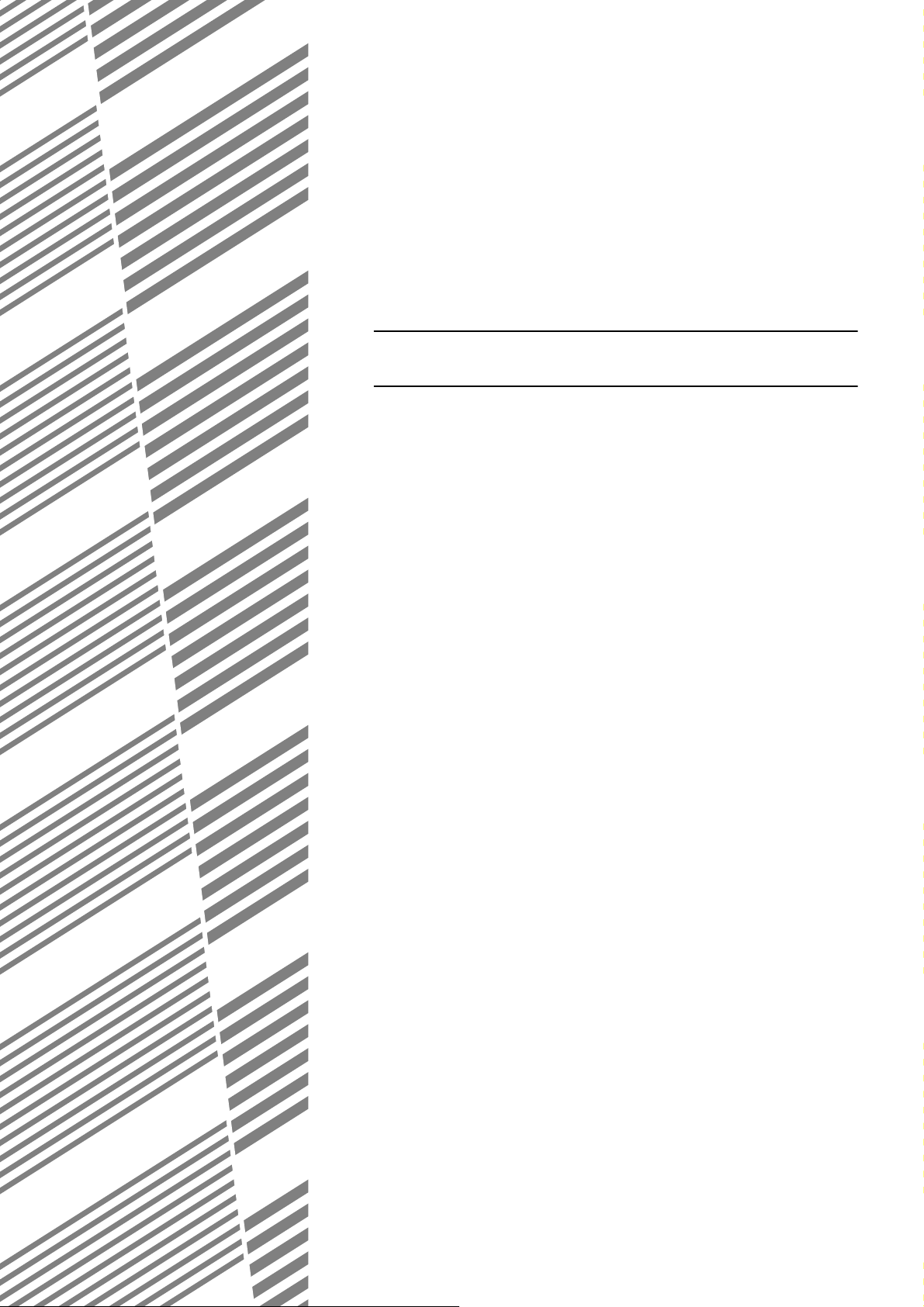

LOADING PAPER

The message "ADD PAPER" or "OPEN TRAY AND ADD PAPER" will appear when paper runs out during operation.

Follow the procedure below to load paper.

NOTES

● Do not use curled or folded paper. Doing so may cause a misfeed.

● For best results use paper supplied by SHARP. (See pages 2-9, 2-17.)

● When you change the paper type and size in paper tray 1, you must change the paper type and size settings as

explained in "Setting the paper type" (page 2-11).

● Do not place heavy objects or press hard on any tray which is pulled out.

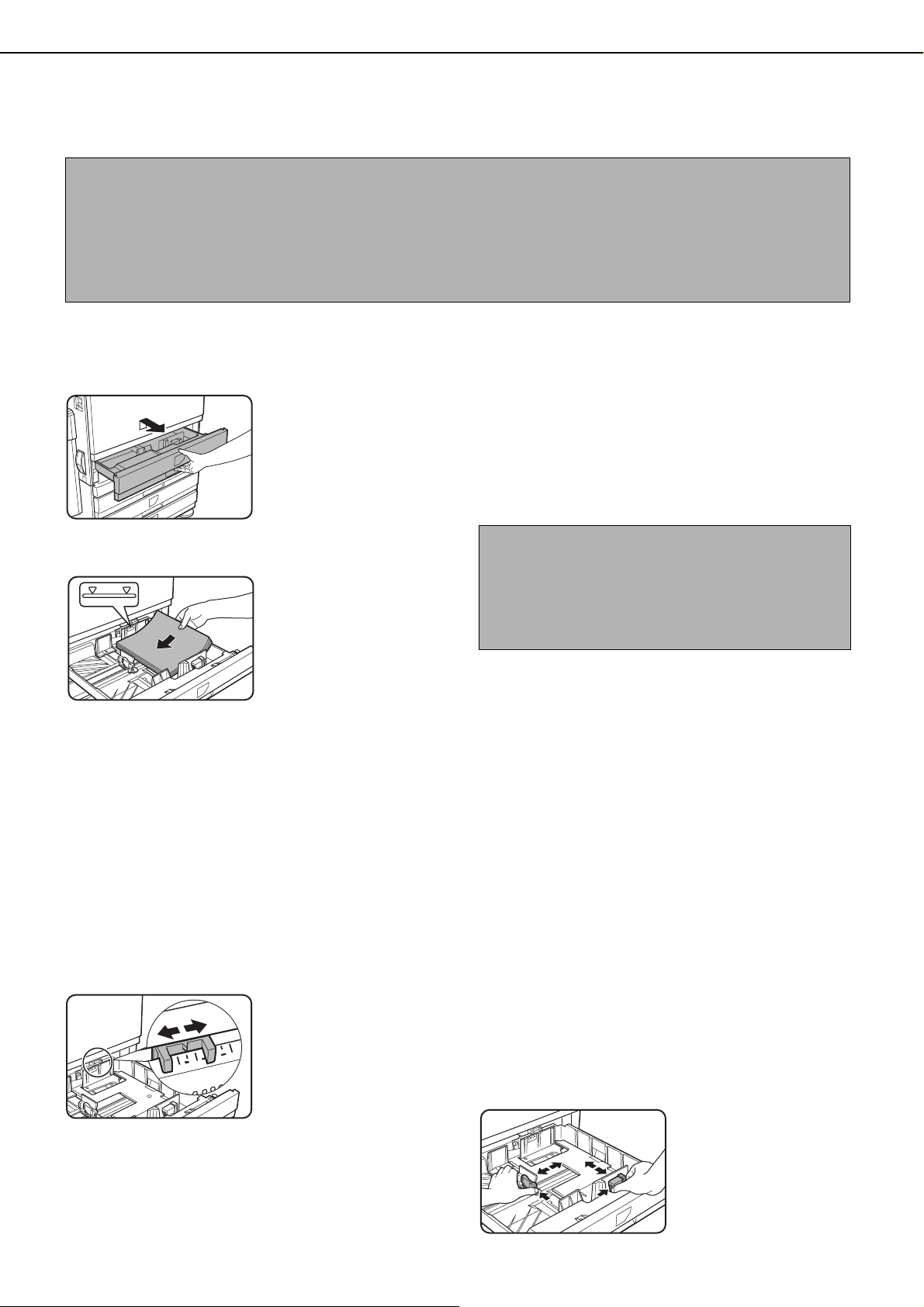

Loading paper in paper tray 1

Pull out paper tray 1.

1

Load paper into the tray.

2

Gently pull the tray out

until it stops.

Load a stack of paper no

higher than the indicator

line (about 500 sheets of

the recommended paper

for color (21 lbs. or 80 g/

2

m

), or approximately

500 sheets of SHARP

standard paper (21 lbs.

or 80 g/m

2

)).

Gently push tray 1 into the machine.

3

Push the tray firmly all the way into the machine.

Set the paper type.

4

If you change the paper type, be sure to set the

paper type refer to "Setting the paper type" (page

2-11).

NOTE

If you load a different size of the same type of paper,

you only need to change the position of the size slide

(see step 2 below); you do not need to change the

paper type.

Loading paper in paper tray 1 is now

5

complete.

Changing the paper size in paper tray 1

The following paper size settings are available for paper tray1: 11" x 17" to 8-1/2" x 5-1/2" (A3 to A5), and "EXTRA"*1.

Use the following procedure to change the size as needed.

1

This is limited to square or rectangular paper, 11" x 17" to 8-1/2" x 5-1/2" (A3 to A5) size.

*

Pull out paper tray 1.

1

If paper remains in the tray, remove it.

Adjust the paper size slide to the paper

2

size.

Move the paper size

slide right or left to

indicate the paper size

being loaded.

If a special size paper is

loaded in the paper tray,

set the size slide to

"EXTRA" to inform the machine that a special size

paper has been loaded. (When AB-based size

paper is loaded, move the size slide to "EXTRA".)

2-2

Note that setting the size slide to "EXTRA" only

informs the machine that a special size of paper

has been loaded; it does not inform the machine of

the specific size. If you wish to inform the machine

of the specific size, follow the steps in "Setting the

paper size when an extra size is loaded" (page 2-

11). (If you do not set a size, part or all of the image

may not print.)

Adjust the guide plates A and B by

3

squeezing their lock levers and sliding

them to the paper size to be loaded.

The guide plates A and

B are slidable. Adjust

them to the paper size to

be loaded while

squeezing their lock

levers.

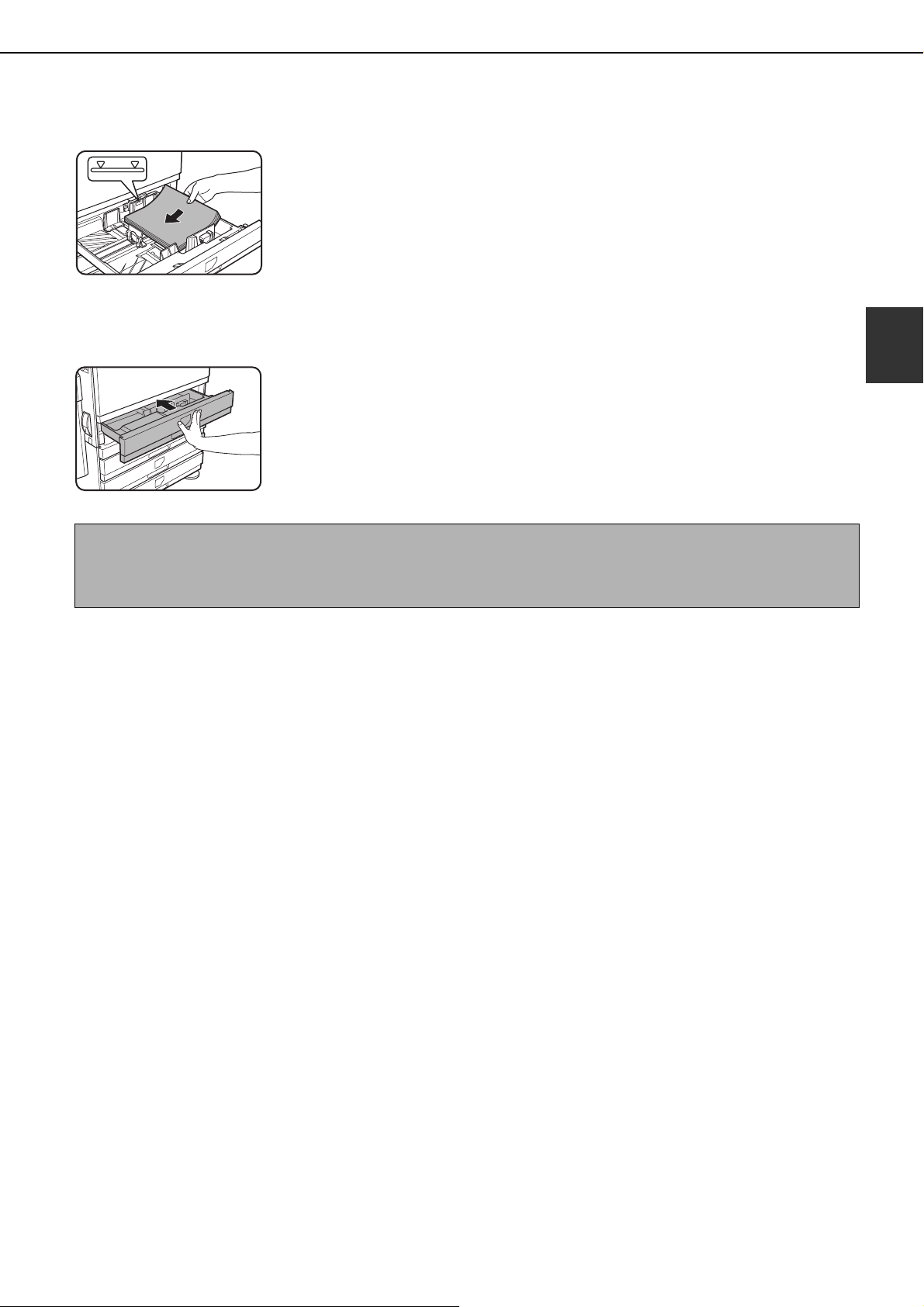

Page 25

LOADING PAPER

Load paper into the tray.

4

Gently push tray 1 into the machine.

5

Push the tray firmly all

the way into the

machine.

NOTE

If the size slide position (step 2 of page 2-2) is not set correctly after changing the paper size, or if the paper type

(page 2-11) is not set correctly, incorrect paper selection or paper misfeeding may occur.

Set the paper type of the paper that was

6

loaded in the 1st tray.

If you loaded a different type of paper from the

previous paper, be sure to set the new paper type

as explained in "Setting the paper type" (page 2-

11).

Changing paper size in paper tray 1 is now

7

complete.

2

2-3

Page 26

LOADING PAPER

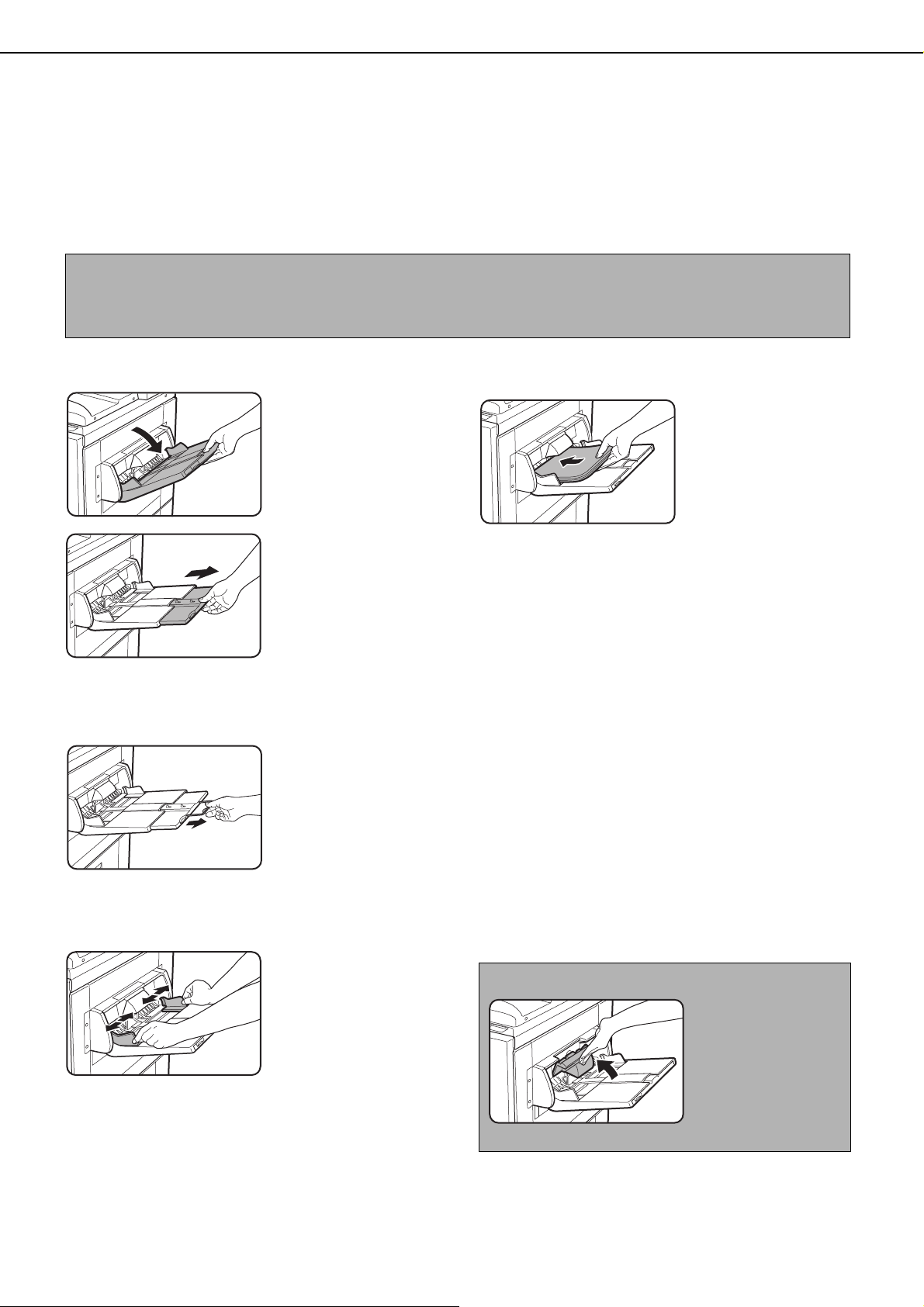

Loading paper in the bypass tray

The bypass tray can be used to feed the same paper specified for paper tray 1 or for special papers. For paper types

that can be used in the bypass tray, see the specifications for the bypass tray in the paper tray specifications (page

2-9).

Up to 250 sheets of SHARP standard paper or up to 100 postcards can be set in the bypass tray.

NOTES

● After loading the paper in the bypass tray, be sure to set the paper type and size (step 4) if these were changed.

● Do not use inkjet paper. This may cause misfeeds in the fusing unit.

Open the bypass tray.

1

When loading paper that

will extend past the end

of the tray, pull out the

tray extension to support

the paper and to allow the

paper sensors to properly

sense the paper size.

Be sure to pull the tray extension all the way out. If

the tray extension is not pulled all the way out, the

size of the paper loaded in the bypass tray may not

display correctly.

To support papers that

extend past the tray

extension, pull out the

wire extension.

Insert the copy paper all the way into the

3

bypass tray. (Do not force the paper in.)

Place the copy paper

face up. If the bypass

tray guides are set

wider than the copy

paper, the inside of the

machine may become

soiled, resulting in

smudges on succeeding copies. Special purpose

papers other than SHARP recommended

transparency film must be fed individually. Multiple

sheets of SHARP recommended transparency

film can be loaded in the bypass tray.

Set the type and size of the paper loaded in

4

the bypass tray.

If you loaded a different type of paper from the

previous paper, be sure to set the new paper type

as explained in "Setting the paper type and paper

size in the bypass tray" (page 2-12). If you loaded

a special size of paper in the bypass tray, set the

paper size as explained in "Setting the paper type

and paper size in the bypass tray" (page 2-12).

(If you do not set a size, part or all of the image

may not print.)

Set the bypass tray guides to the width of

2

the copy paper.

2-4

This completes the procedure for loading

5

paper in the bypass tray.

NOTE

When loading paper in

the bypass tray or

closing the tray, close

the paper cover as

shown.

Page 27

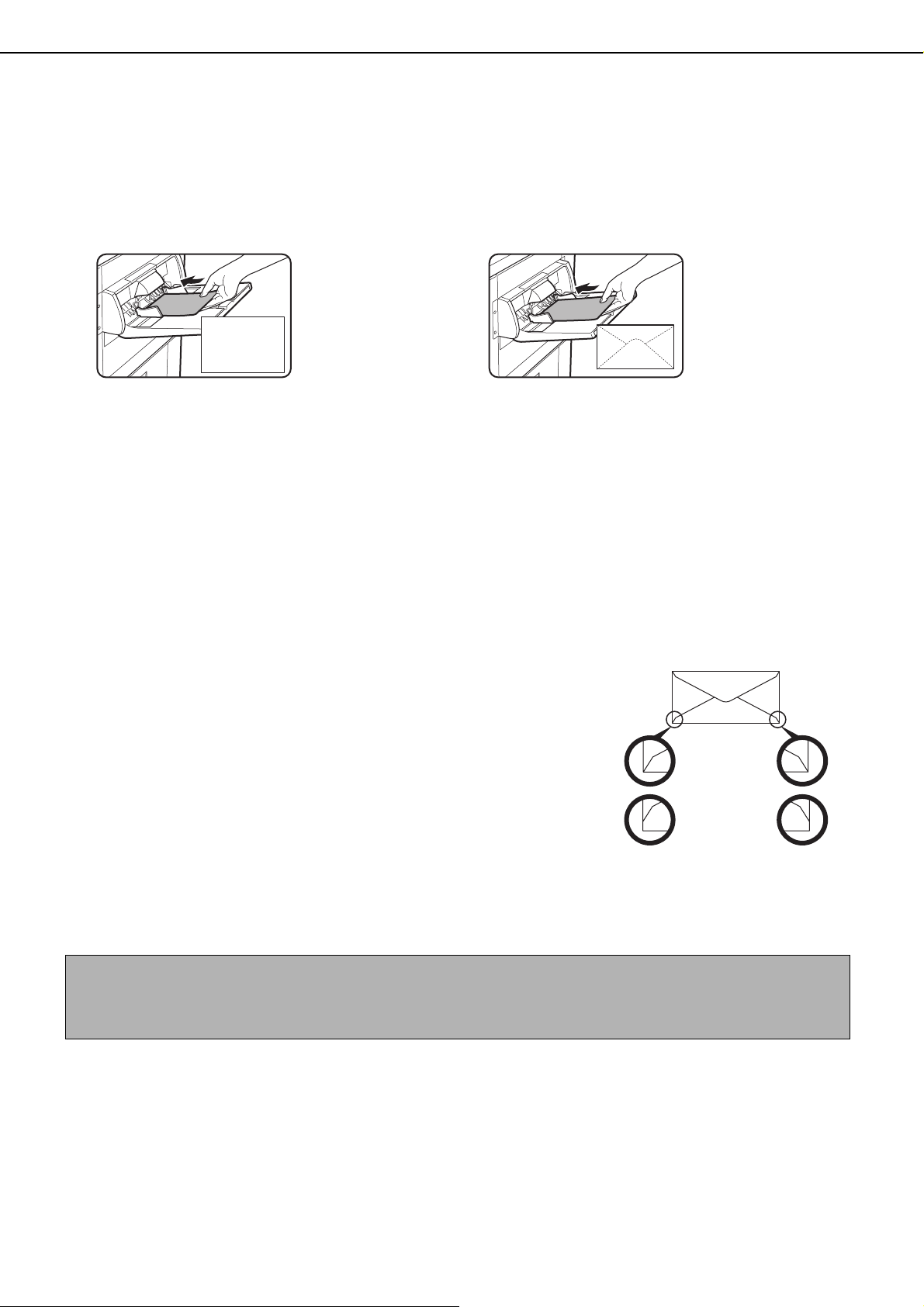

NOTES

● Be sure to load 5-1/2" x 8-1/2" paper, A6 paper, A5

paper, and postcards as shown in the diagram

below.

LOADING PAPER

A6 paper, post cards.

5-1/2" x 8-1/2" paper, A5 paper.

● When loading plain paper other than paper

recommended for color, SHARP standard paper,

special media other than postcards, SHARPrecommended transparency film, or paper to be

printed on the back, the paper must be loaded one

sheet at a time. Loading more than one sheet at a

time will cause misfeeds.

● Before loading heavy paper, straighten any curling

in the paper.

● When adding paper, remove any paper remaining

in the tray, combine it with the paper to be added,

and reload as a single stack.

● Do not use paper that has already been printed on

by a plain paper fax machine or a laser printer.

This may cause printed images to become dirty.

● When printing on transparency film, be sure to

remove each sheet as it exits the machine.

Allowing sheets to stack in the output tray may

cause curling.

● Use only SHARP-recommended transparency

film. Insert the film so that the rounded corner is on

the left for horizontal loading, or on the right for

vertical loading.

2

Horizontal

loading

● When loading multiple sheets of transparency film

in the bypass tray, fan the sheets several times

before loading.

Vertical

loading

2-5

Page 28

LOADING PAPER

■■■■ Setting envelopes or postcards

When setting envelopes or postcards in the bypass tray, set them in the orientation shown below.

Loading postcards

Insert the postcard with the side to be printed on

facing up. The postcard should be oriented as

shown in the diagram.

Loading envelopes

Only the front side of envelopes can be printed.

Insert the envelope with the front side facing up.

Printing onto envelopes or postcards

●Attempting to print onto both sides of envelopes or postcards may result in misfeeds or poor prints.

●Do not use pre-printed envelopes.

●Before inserting a postcard or envelope, straighten any curled edges. Curled edges may cause creases, color

deviations, misfeeds, and poor quality images.

Printing onto envelopes

●Attempting to print on envelopes that have metal clasps, plastic snaps, string closures, windows, linings, selfadhesive patches or synthetic materials may cause misfeeds, inadequate toner adherence or other trouble.

●Envelopes with embossed surfaces may cause the prints to become smudged.

●Use only envelopes which are flat and crisply folded. Curled or poorly formed envelopes may be poorly printed

or may cause misfeeds.

●Print quality is not guaranteed in the area 13/32" or 10 mm from the

edges of the envelope.

●Print quality is not guaranteed on parts of envelopes where there is a

large step-like change of thickness, such as on three-layer or four-layer

envelopes.

●Print quality is not guaranteed on envelopes having peel off flaps for

sealing the envelopes.

Can be used

Cannot be used

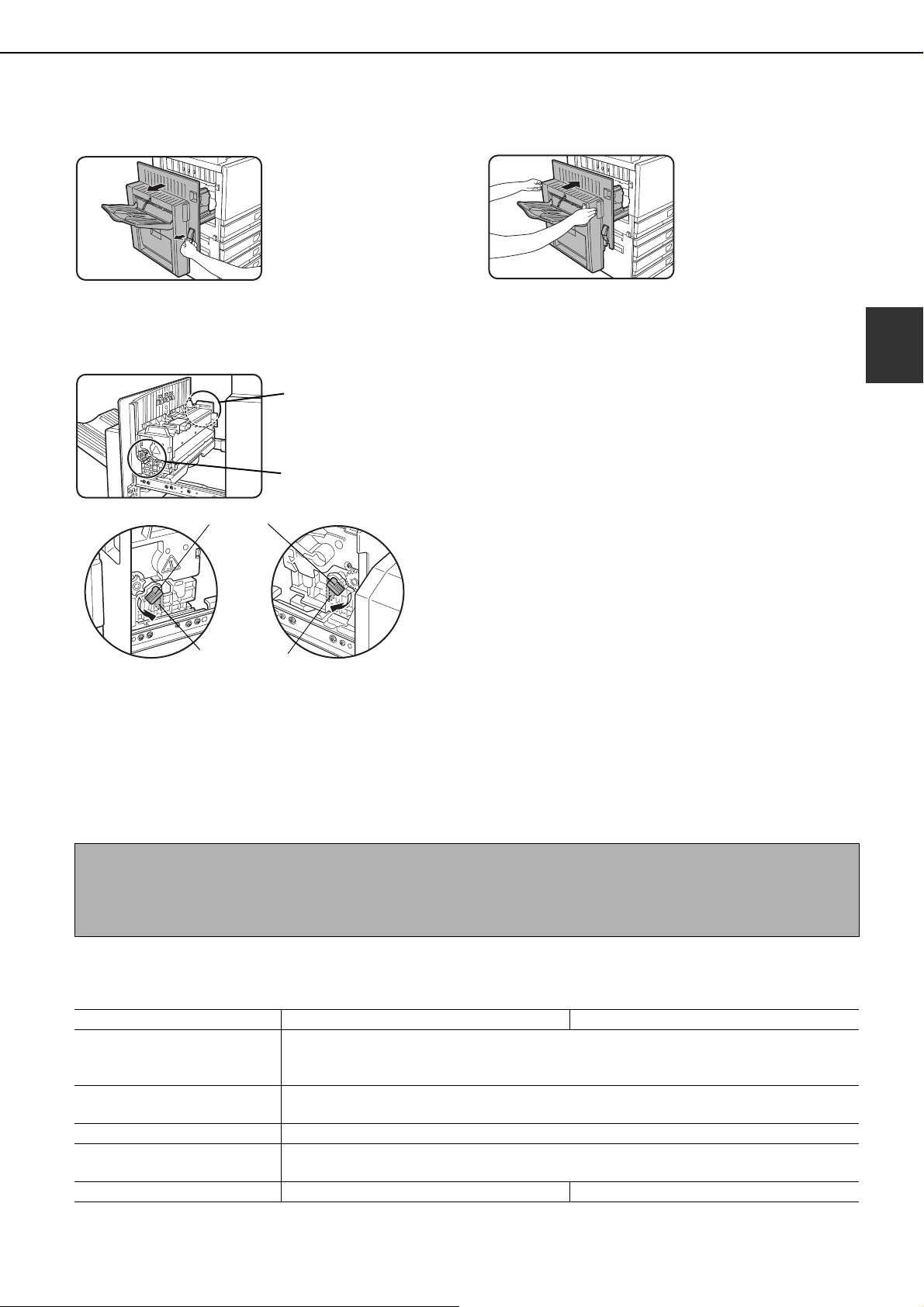

Fusing unit pressure adjusting levers

In some cases damage to the envelopes, color deviations, or smudging may occur even if envelopes within the

specifications are used. This problem may be reduced by shifting the fusing unit pressure adjusting levers from

their normal pressure position to the lower pressure position. Follow the procedure on the next page. (2-7)

NOTE

Be sure to return the lever to the normal position when you have finished feeding envelopes. If not, inadequate

toner adherence, paper misfeeds or other trouble may occur.

2-6

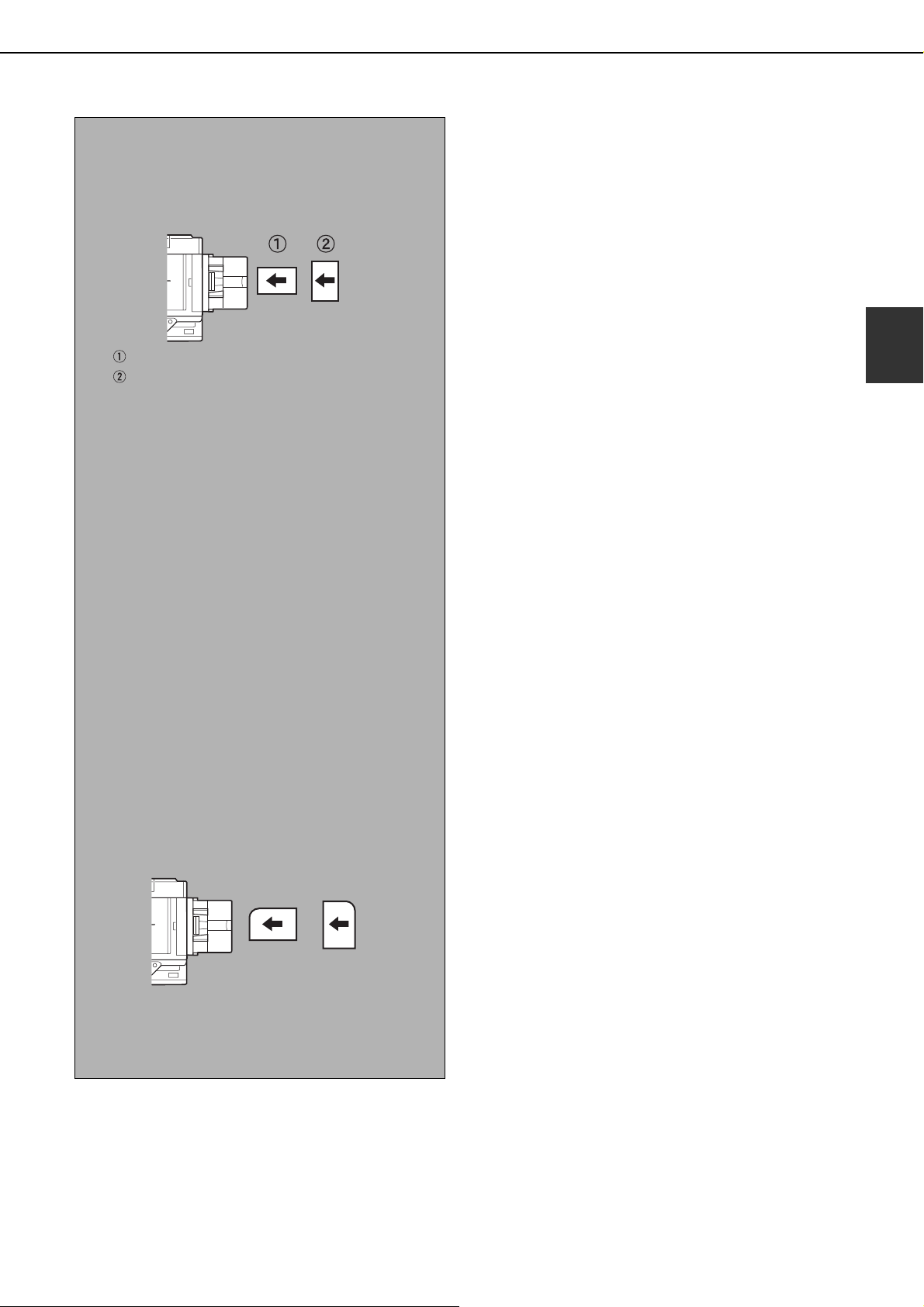

Page 29

LOADING PAPER

Unlatch the duplex bypass/inverter unit

1

and slide it to the left.

Unlatch the unit and

gently move it away from

the machine. If the

machine is not equipped

with a duplex bypass/

inverter unit, open the

side cover similarly.

Lower the two fusing unit pressure

2

adjusting levers marked A and B in the

illustration.

A

B

Normal

position

Gently close the duplex bypass/inverter

3

unit.

If the machine is not

equipped with a duplex

bypass/inverter unit,

close the side cover.

2

B:Front side of

fusing unit

Lower pressure

position

A:Rear side of

fusing unit

Loading paper in the stand/1 x 500 sheet paper drawer/ stand/3 x 500 sheet paper drawer

Upper tray / middle tray / lower tray*

Up to 500 sheets of paper recommended for color or SHARP recommended plain paper can be loaded in these trays.

The method of loading paper is the same as for paper tray 1 in the main unit (see the explanation on page 2-2).

* The stand/1 x 500 sheet paper drawer only has the upper tray.

NOTE

If the size of paper being loaded is different from the previous size, or is an extra size, or if the paper type is different

from the previous type, you must change the paper tray settings in the custom settings. Change the settings as

explained in "Setting the paper type" and "Setting the paper size when an extra size is loaded" on page 2-11.

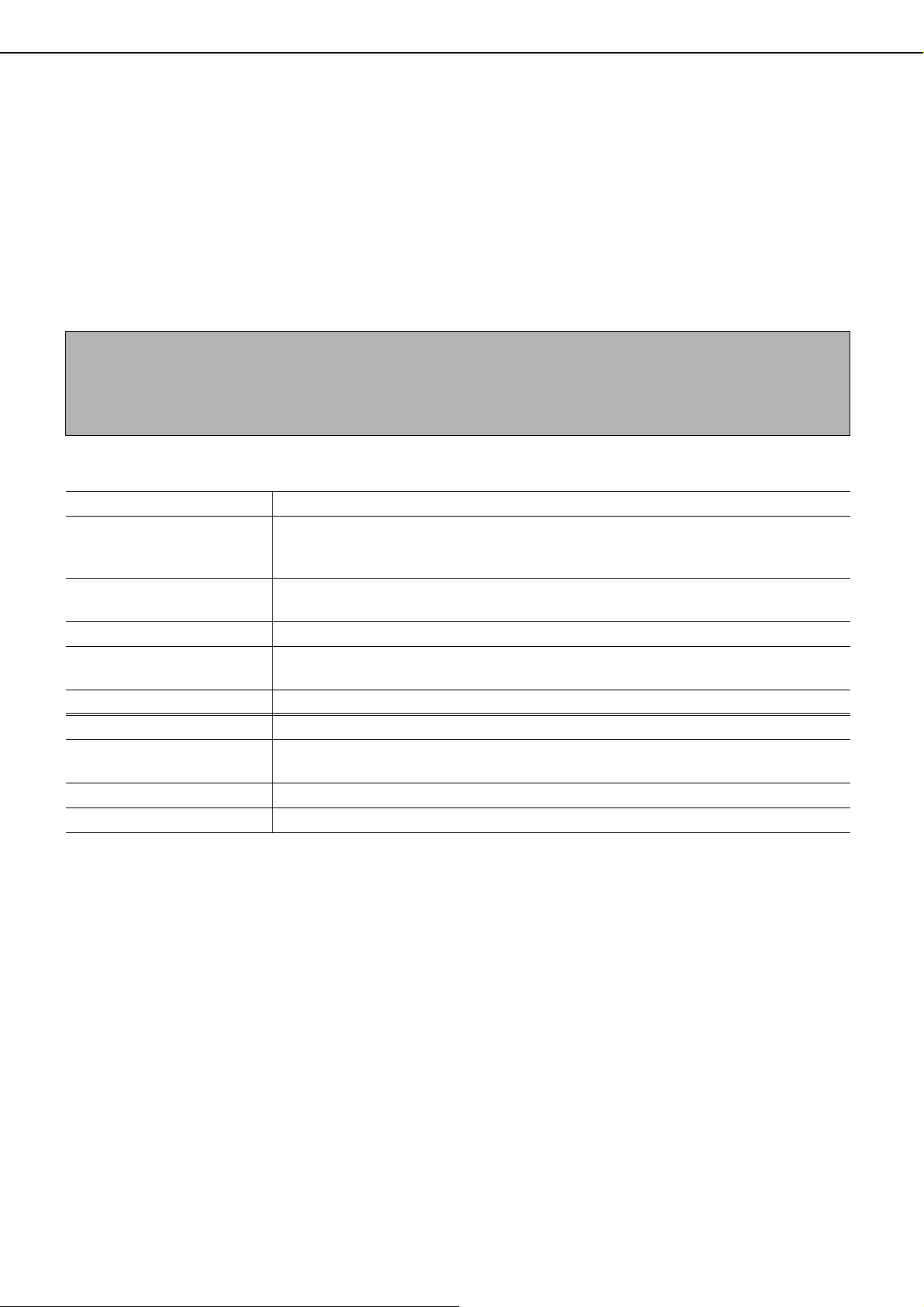

Specifications (stand/1 x 500 sheet paper drawer/stand/3 x 500 sheet paper drawer)

Name

Paper size/weight

Paper capacity

Power supply Supplied from the main unit

Dimensions

Weight Approximately 49.6 lbs. or 22.5 kg Approximately 65.0 lbs. or 29.5 kg

Specifications are subject to change for improvement without notice.

Stand/1 x 500 sheet paper drawer (AR-D17N) Stand/3 x 500 sheet paper drawer (AR-D18N)

11" x 17", 8-1/2" x 14", 8-1/2" x 13", 8-1/2" x 11", 8-1/2" x 11"R, 7-1/4" x 10-1/2"R,

5-1/2" x 8-1/2", Extra. (A3, B4, A4, A4R, B5, B5R, A5)

/ 17 to 28 lbs. or 64 to 105 g/m

Paper recommended for color (21 lbs. or 80 g/m

SHARP standard paper (21 lbs. or 80 g/m

23-5/8" (W) x 25-9/32" (D) x 15-7/8" (H) (600 mm (W) x 642 mm (D) x 403 mm (H))

(not including the adjuster)

2

2

): 500 sheets;

2

): 500 sheets

2-7

Page 30

LOADING PAPER

Loading paper in the duplex module/2 x 500 sheet paper drawer

Upper tray:

The upper tray contains a duplex module that automatically turns print paper over for automatic two-sided printing.

Middle and lower paper trays:

The middle and lower trays are paper trays.

Up to 500 sheets of paper recommended for color or SHARP recommended plain paper can be loaded in these trays.

The method of loading paper is the same as for paper tray 1 in the main unit. See the explanation on page 2-2.

NOTE

If the size of paper being loaded is different from the previous size, or is an extra size, or if the paper type is different

from the previous type, you must change the paper tray settings in the custom settings. Change the settings as

explained in "Setting the paper type" and "Setting the paper size when an extra size is loaded" on page 2-11.

Specifications (duplex module/2 x 500 sheet paper drawer)

Name Duplex module/2 x 500 sheet paper drawer (AR-D19N)

11" x 17", 8-1/2" x 14", 8-1/2" x 13", 8-1/2" x 11", 8-1/2" x 11"R, 7-1/4" x 10-1/2"R,

Paper size/weight

Paper capacity

Power supply Supplied from the main unit

Dimensions

Weight Approximately 68.3 lbs. or 31 kg

Duplex module

Size of plain paper

Weight of plain paper 17 to 54 lbs. or 64 to 200 g/m

Number of sheets One sheet (single pass type)

Specifications are subject to change for improvement without notice.

5-1/2" x 8-1/2", Extra. (A3, B4, A4, A4R, B5, B5R, A5)

/ 17 to 28 lbs. or 64 to 105 g/m

Paper recommended for color (21 lbs. or 80 g/m

SHARP standard paper (21 lbs. or 80 g/m

23-5/8" (W) x 25-9/32" (D) x 15-7/8" (H) (600 mm (W) x 642 mm (D) x 403 mm (H))

11" x 17", 8-1/2" x 14", 8-1/2" x 13", 8-1/2" x 11", 8-1/2" x 11"R, 7-1/4" x 10-1/2R",

5-1/2" x 8-1/2", A3, B4, A4, A4R, B5, B5R, A5

2

2

): 500 sheets

(not including the adjuster)

2

2

): 500 sheets;

2-8

Page 31

LOADING PAPER

Specifications of paper trays

The specifications for the types and sizes of paper that can be loaded in the paper trays are shown below.

Tray No.

Paper tray type

A Paper tray 1 Tray 1

B Bypass tray

Stand/1 x 500

C

sheet paper drawer

Stand/3 x

500 sheet

D

paper

drawer

Duplex

module/2 x

E

500 sheet

paper

drawer

F

Large Capacity tray

Upper Tray 2

Middle Tray 3

Lower Tray 4

Upper Duplex

Middle Tray 2

Lower Tray 3

(tray

name)

Bypass

tray

Tray 2

Tray 4*1

or

Tray 5*

Applicable paper types Applicable paper sizes Remarks

11"x17", 8-1/2"x14",

8-1/2"x13", 8-1/2"x11",

Paper recommended for color

Plain paper

Same as paper types and sizes in row A

* Paper size 12" x 18" (A3W) and A6R can also be used in the bypass tray

Heavy

paper 1

Special

paper (Refer

to the next

page for

applicable

special

papers.)

Same as paper types and sizes in row A

Duplex module

(See page 2-8 for paper sizes and weights that can be used.)

Same as paper types and sizes in row A

Same as paper types in row A 8-1/2"x11" (A4)

2

Heavy

paper

Heavy

paper 2

Transparency film Transparency film

Envelopes

8-1/2"x11"R, 5-1/2"x8-1/2",

7-1/4"x10-1/2"R, Extra. (A3,

B4, A4, A4R, B5, B5R, A5)

11"x17", 8-1/2"x14",

8-1/2"x13", 8-1/2"x11",

8-1/2"x11"R, 5-1/2"x8-1/2",

7-1/4"x10-1/2"R, Extra. (A3,

B4, A4, A4R, B5, B5R, A5)

5-1/2"x8-1/2" - 12"x18" (A6R

- A3W), Special (paper

weight: 28 to 54 lbs. (106 to

200 g/m

5-1/2"x8-1/2" - 12"x18" (A6R

- A3W), Special (paper

weight: 54 to 80 lbs. (201 to

300 g/m

●Standard-size envelopes

2

)), Postcard

2

))

that can be used

:COM10,Monarch,DL,C5

See

"STORAGE

OF

SUPPLIES"

on page 2-17

See "More

information on

plain paper"

on the next

page

See "More

information on

special media

that can be

used" on the

next page

See the

specifications

in "LARGE

CAPACITY

TRAY" on

page 3-15, and

"More

information on

plain paper" on

the next page.

2

*1 When the Duplex module/2 x 500 sheet paper drawer is installed.

*2 When the Stand/3 x 500 sheet paper drawer is installed.

2-9

Page 32

LOADING PAPER

■■■■ More information on plain paper

The following restrictions apply to plain paper. Be sure to load the paper correctly. Incorrect loading may result

in skewed feeding or misfeeds.

Paper in inch system Paper in AB system

5-1/2"x8-1/2" - 12"x18"* A6R - A3W*

Plain

paper

SHARP standard

paper

Restrictions on paper

other than SHARP

21 lbs. 80g/m

17 to 28 lbs. or 64 to 105g/m

2

2

standard paper

Recycled, colored, pre-punched, pre-printed and letterhead papers must conform to the same conditions as

above.

* In the large capacity tray, only 8-1/2" x 11" size paper can be used when using inch sizes, and only A4 can be

used when using AB sizes.

■■■■ More information on special media that can be used

The following restrictions apply to special media. The use of incorrect media may result in fusing problems (weak

adhesion of toner to paper or toner smudging when rubbed), skewed feeding, misfeeds, or other failures.

Type Remarks

For paper sizes from 5-1/2" x 8-1/2" to 12" x 18" (A6R to A3W),

2

) can be used.

2

) can be used.

Special

paper

Heavy

paper

heavy paper 1

heavy paper 2

paper weights from 28 to 54 lbs. (106 to 200 g/m

● Postcards can be used.

Do not use folded postcards, picture postcards, or postcards with

a coated front. These may cause misfeeds or a dirty printed

image.

For paper sizes from 5-1/2" x 8-1/2" to 12" x 18" (A6R to A3W),

paper weights from 54 to 80 lbs. (201 to 300 g/m

Transparency film Use SHARP recommended transparencies.

Applicable standard envelopes: COM-10, Monarch, DL, C5

Envelopes

Envelopes can only be fed from the Bypass tray. Applicable paper

stock weight for envelopes is 20 to 23 lbs. or 75 to 90 g/m

2

● Special paper such as heavy paper 2, transparency film, and envelopes cannot be output to the center tray.

● Paper that cannot be output to the center tray is output face-up to the left tray.

■■■■ Paper that can be used for automatic two-sided printing

Paper used for automatic two-sided printing (paper that can be fed through the duplex module) must meet the

following conditions:

Paper type : Plain paper as specified on page above.

Paper size : Must be one of the following standard sizes: 11" x 17", 8-1/2" x 14", 8-1/2" x 13", 8-1/2" x 11",

8-1/2" x 11"R, 7-1/4" x 10-1/2" or 5-1/2" x 8-1/2" (A3, B4, A4, A4R, B5, B5R or A5)

Paper weight : 17 to 54 lbs. or 64 to 200 g/m

2

NOTES

● Special papers as described above cannot be used for automatic two-sided printing. Heavy paper up to 54 lbs.

2

(200 g/m

) can be used.

● The image quality and toner fusibility of special papers may change due to ambient conditions, operating

conditions, and paper characteristics, resulting in image quality inferior to that of SHARP standard paper.

● Various types of plain paper and special paper are sold. Some of these cannot be used in the machine. Please

consult your retailer or your dealer when buying paper.

2-10

Page 33

LOADING PAPER

TOT L COUNT

TRAY SETTINGS

KEYBOARD

SELECT

KEY

ADDRES

CONTRO

CONTRA

TRAY 1

TRAY 2 PLAIN /

TYPE / SIZE

PLAIN /

PLAIN

PRE-PRINTED

RECYCLED

LETTER HEAD

PRE-PUNCHED

COLOR

Setting the paper type (except the bypass tray)

Follow these steps to change the paper type setting

when the paper type has been changed in a paper tray.

For the paper types that can be used in each tray, see

page 2-9. To change the paper type setting for the

bypass tray, see page 2-12.

Press the [CUSTOM SETTINGS] key.

1

The custom setting

menu screen will

appear.

Touch the [TRAY SETTINGS] key.

2

The paper tray selection

screen will appear.

Setting the paper size when an extra size is loaded

When a paper tray is set to "extra", this informs the

machine that an extra size is being used. It does not

inform the specific size. To enter the specific size of the

paper loaded, follow the steps below.

For example, if A4 size paper is loaded in the tray (with

the size slide set to "extra"), you can use this procedure

to set the paper size recognized by the machine to A4

size. If you loaded an irregular size of paper, you can

enter the dimensions of the paper.

To set the paper size when an extra size of paper is

loaded in the bypass tray, see page 2-12.

Perform steps 1 through 4 of "Setting the

1

paper type" at left.

Touch the key to display the paper size

2

setting screen.

CUSTOM SETTINGS

TRAY 3 TYPE/SIZE SETTING

EXTRA SIZE

A3 B4

B5R

11X17

1

/

5 X8

2

A5

1

/

8 X14

2

1

1

/

7 X10 R

4

1

/

2

/

2

A4

8K

1

/

8 X13

2

EXTRA

A4R

16K

1

/

2

8 X11

8 X11R

B5

16KR

1

/

2

OK

2/3

2

Select the paper tray for which the setting

3

is to be made. (For the tray numbers, see

the tray specifications on page 2-9.)

If the desired tray is not

on the display, use or

key to scroll the

display until it appears.

Select the type of paper that was loaded in

4

the tray.

The currently selected

paper type will be

highlighted. To change

the setting, touch the

desired type.

NOTE

Special paper such as transparency film,

envelopes, and postcards can only be used in the

bypass tray.

When the loaded paper size appears in the

3

display (if you loaded an AB-based size

such as A4), touch the size key to highlight

it, and then touch the [OK] key to complete

the procedure.

If an irregular size of paper was loaded

4

after the [EXTRA] key was touched, touch

the key in the screen of step 2 to display

the following screen.

(5 1/2 17)

1

/

5

X

Y

When the screen opens the X key will be

highlighted. Use the

enter the X dimension. Next touch the Y key to

highlight it and enter the dimensions for Y.

The permitted range for the X dimension is 5-1/2 to

17 inches (139 to 432 mm), and the permitted

range for the Y dimension is 7-1/4 to 11-3/4 inches

(182 to 297 mm).

When both have been entered, touch the [OK] to

complete the operation.

2

1

7

4

/

inch

(7 1/4 11 3/4)

inch

and

touch keys to

Touch the [OK] key to complete the

5

setting.

2-11

Page 34

LOADING PAPER

PAPER SELECT

AUTO 8½x11

100%

PAPER SELECT

8½x11

PAPER SELECT

100%

COPY RATIO

PLAIN

HEAVY PAPER

TRANSPARENCY

ENVELOPE

UTO

EXPOSURE

PAPER SELECT

PLAIN

HEAVY PAPER

TRANSPARENCY

ENVELOPE

Setting the paper type and paper size in the bypass tray

Follow the steps below to set the type and size of the paper loaded in the bypass tray.

Touch the [PAPER SELECT] key.

1

(When copy mode is selected)

Touch the [PAPER

SELECT] key in the

main screen of the copy

mode.

(When printer mode is selected)

Touch the [PAPER

SELECT] key in the

main screen of printer

mode.

CONDITION

SETTINGS

Touch the key for the desired paper type.

2

(When copy mode is selected)

The key for the selected

paper type will be

highlighted.

Touch [HEAVY PAPER 1] or [HEAVY

3

PAPER 2], and go to step 6.

HEAVY PAPER1 28+lbs. 54 lbs.

HEAVY PAPER2 54+lbs. 80 lbs.

For the types of heavy paper that can be used, see

page 2-10.

Touch [SPEED MODE] or [QUALITY MODE]

4

for the transparency film, and go to step 7.

SPEED MODE

QUALITY MODE

● SPEED MODE is for fast printing.

● QUALITY MODE is for a high quality image.

Touch the type of envelope, and go to step 7.

5

COM-10

MONARCH

DL

YOKEI-2

OK

C5

CHOKEI3

YOKEI-4

(When printer mode is selected)

The steps that follow differ depending on the

paper type selected. Follow the steps for the

selected type.

● If you touched [PLAIN], go to step 6.

● If you touched [HEAVY PAPER], go to step 3

● If you touched [TRANSPARENCY], go to step 4.

● If you touched [ENVELOPE], go to step 5.

2-12

CONDITION

SETTINGS

If you inserted a non-standard size of paper

6

in the bypass tray, remove the checkmark

from "ENABLE AUTO SIZE DETECTION" and

then touch the [EXTRA SIZE] tab.

When the

screen opens, the X key will be highlighted.

Use the and

touch keys to enter the X

dimension. If you inserted a standard size of

paper in the bypass tray, make sure that a

checkmark appears in the [ENABLE AUTO

SIZE DETECTION] checkbox.

ENABLE AUTO SIZE DETECTION

EXTRA SIZE

OK

(5 1/2 17)

5 ½

X

Y

EXTRA SIZE

inch

(4 11 3/4)

4

inch

BASIC SETTING

range for the Y dimension is 4 to 11-3/4 inches

(100 to 297 mm).

Touch the [OK] key to complete the setting.

7

BASIC SETTING

Next touch the key to

highlight it and enter the

dimensions for Y.

The permitted range for

the X dimension is 5-1/2

to 17 inches (139 to 432

mm), and the permitted

Page 35

CUSTOM SETTINGS

The items that can be set with the custom settings are shown below.

● Total count ................................... The number of pages processed by the machine and optional equipment

can be displayed. (See page 2-14.)

● Display contrast ........................... Used to adjust the contrast of the operation panel display. (See page 2-14.)

● List print ....................................... Used to print a list of machine settings. (See page 2-14.)

● Clock adjust

● Tray settings ................................ The paper type, paper size and automatic tray switching can be set for each

For the detailed descriptions and use of the settings listed below, see the Operation manuals

for fax* and network scanner.

● Address control............................ Use this to store fax destinations (fax numbers). This is also used to store

● Receive mode.............................. Use this to configure fax reception settings (auto/manual).

● Fax data forward.......................... Faxes received to memory can be forwarded to another destination.

● Keyboard select........................... When using the fax function or network scanner function, you can switch

● Key operator program.................. These are programs that are used by the key operator (administrator of the

* These fax settings can be configured only if the fax function has been enabled.

....................................Used to set the date and time of the built-in clock of the machine. (See this page.)

tray. Automatic tray switching allows feeding to switch between trays

loaded with the same type and size of paper. If one tray runs out of paper

during printing, printing will continue from the other tray. (

See

page 2-14)

groups, memory boxes, and user indexes.

E-mail addresses, user indexes, and scanner senders can be stored for the

network scanner function.

the arrangement of the letter keys in the display keyboard used for storing

and editing destinations in the English character entry screen.

machine) to configure machine settings. A key appears for these settings in

the custom settings menu screen. For information on these settings, see

the key operator's guide.

2

Operation procedure common to all custom settings