Page 1

CODE: 00ZAR507//A1E

Digital Copier

(AR-250)

(AR-280/281) (AR-285/286/335/336)

AR-250

AR-280/281

AR-285/286/287

(AR-287/337)

(AR-405)

(AR-407)

AR-335/336/337

AR-405/407

MODEL AR-501/505/507

(AR-501/505)

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[ 2 ] SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

(AR-507)

CONTENTS

[ 3 ] CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[ 4 ] INSTALLATION AND SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[ 5 ] EXTERNAL VIEW AND INTERNAL STRUCTURE. . . . . . . . . . 5-1

[ 6 ] SETTING AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . . . . . 6-1

[ 7 ] SIMULATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[ 8 ] DISASSEMBLY, ASSEMBLY, MAINTENANCE . . . . . . . . . . . . 8-1

[ 9 ] TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] OPERATIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] SPECIAL FUNCTIONS (AR-287/337/407/507). . . . . . . . . . . . 11-1

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

[1] GENERAL

1. Features of copying functions. . . . . . . . . . . . . . . . . . . . . 1-1

2. System outline (Options). . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3. Installation requirements. . . . . . . . . . . . . . . . . . . . . . . . 1-10

[2] SPECIFICATIONS

1. Machine type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Copy speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. 3. OC/DF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

4. Paper feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

5. Multi copy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

6. Warm up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

7. Copy magnification ratio . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

8. Exposure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

9. Print area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

10. Paper exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

11. Duplex module

(AR-285/286/287/335/336/337/405/407/501/505/507) . . 2-4

12. Shipping form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

13. Additional functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

14. Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

15. Other specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

16. Outlook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

17. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

18. Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

19. Environmental measures . . . . . . . . . . . . . . . . . . . . . . . . 2-5

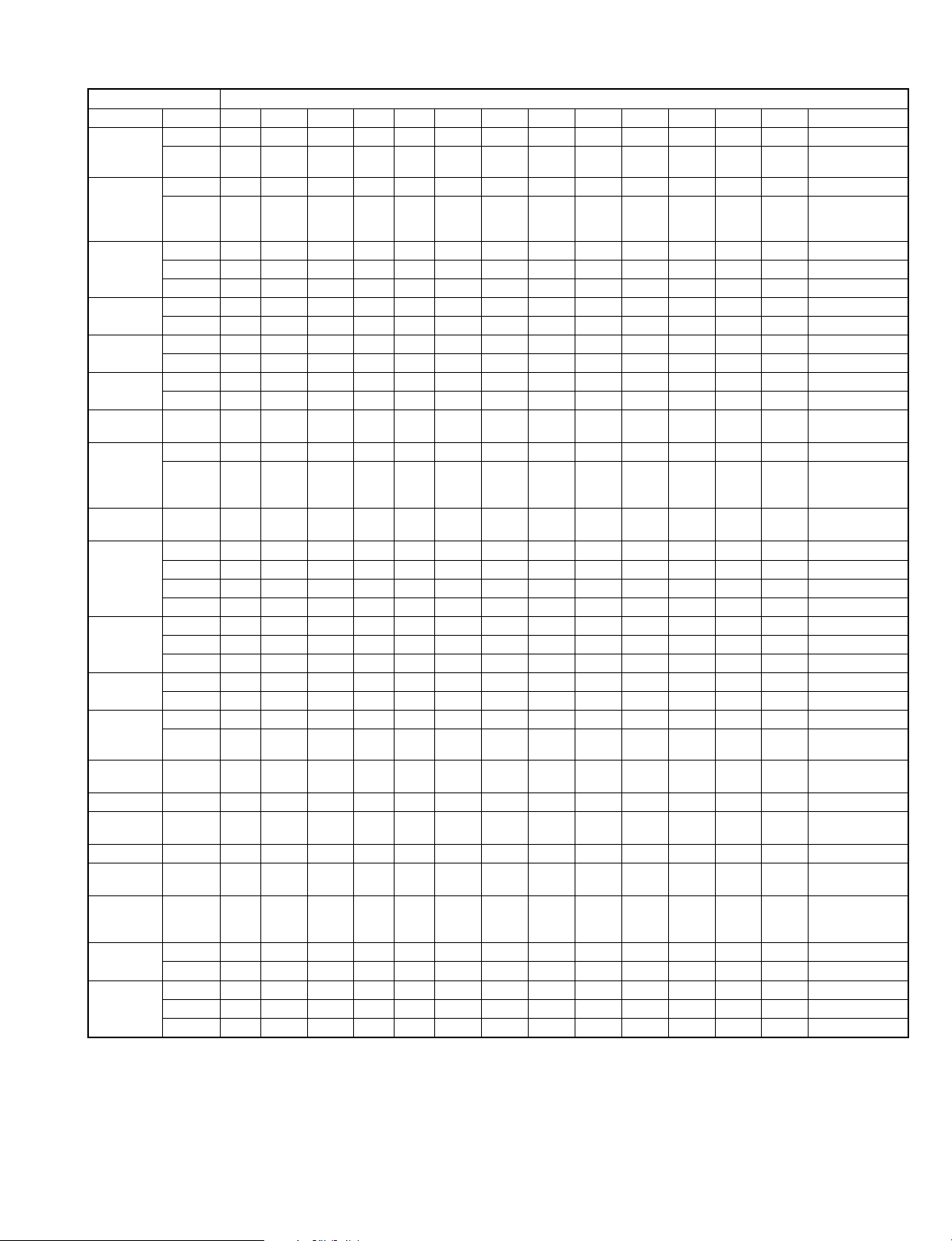

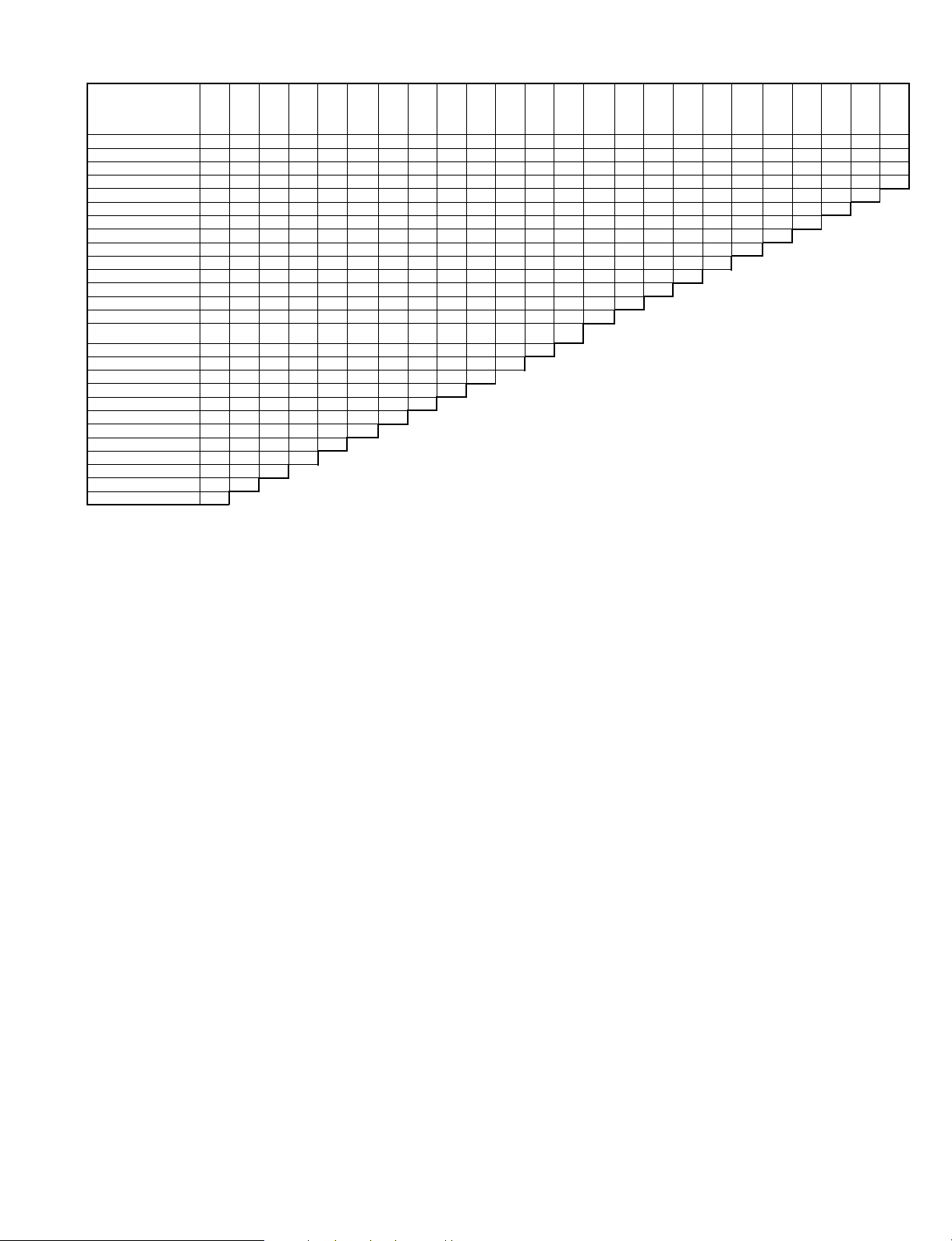

20. Combination of functions . . . . . . . . . . . . . . . . . . . . . . . . 2-6

[3] CONSUMABLE PARTS

1. Consumable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Copy paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3. Environment conditions. . . . . . . . . . . . . . . . . . . . . . . . . 3-11

4. Production number identification. . . . . . . . . . . . . . . . . . 3-11

[4] INSTALLATION AND SETUP

(Copier installation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1. Unpacking procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Installing procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

[5] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. Common section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

A. Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

B. Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

C. Operation Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

2. Copier body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

A. Major parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

B. PWB location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

C. Sensor location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

D. Motor location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

E. Clutch solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

F. 2-tray paper exit unit . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

G. SPF (AR-280/281 only) . . . . . . . . . . . . . . . . . . . . . . . 5-7

H. RADF

(AR-285/286/287/335/336/337/405/407 only) . . . . . . 5-8

I. RSPF (AR-501/505/507 only) . . . . . . . . . . . . . . . . . . 5-9

J. ADU (AR-285/335/505/507 only). . . . . . . . . . . . . . . 5-10

[6] SETTING AND ADJUSTMENTS

1. List of adjustment items . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Copier adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A. Process section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

CONTENTS

B. Laser scanner section . . . . . . . . . . . . . . . . . . . . . . . . 6-7

C. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

D. Image density adjustment . . . . . . . . . . . . . . . . . . . . 6-16

E. Paper feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

F. Paper transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

F. Resist amount adjustment. . . . . . . . . . . . . . . . . . . . 6-19

G. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

H. SPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

I. RADF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

J. RADF (AR-RF2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

[7] SIMULATION

1. Outline and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Code system simulation . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

A. Operating procedures and operations. . . . . . . . . . . . 7-1

B. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

C. Details of simulations. . . . . . . . . . . . . . . . . . . . . . . . . 7-6

[8] DISASSEMBLY, ASSEMBLY, MAINTENANCE

1 Maintenance table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. List of disassembly and assembly . . . . . . . . . . . . . . . . . 8-4

3. Counter clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

A. Developing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

B. Drum unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

C. Discharge lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

D. Scanner unit (Optical system) . . . . . . . . . . . . . . . . . 8-10

E. ICU peripheral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

F. Laser unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

G. Manual paper feed tray unit. . . . . . . . . . . . . . . . . . . 8-16

H. 500 tray paper unit. . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

I. Paper transport section . . . . . . . . . . . . . . . . . . . . . . 8-18

J. Suction unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

K. Fusing unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

L. Two-tray paper exit unit. . . . . . . . . . . . . . . . . . . . . . 8-23

M. One-tray paper unit . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

N. PCU/AC power/High voltage power/Main motor . . . 8-25

O. Major drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

P. Lift-up unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Q. RSPF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

[9] TROUBLE CODE LIST

1. Trouble code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

2. Self diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

3. Jam Cause Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

[10] OPERATIONAL DESCRIPTION

1. Outline and purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Image forming section correction operation

(Process correction operation) . . . . . . . . . . . . . . . . . . . 10-1

3. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

4. RSPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

[11] SPECIAL FUNCTIONS (AR-287/337/407/507)

1. Tandem function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. Confidential print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

3. Large volume document mode . . . . . . . . . . . . . . . . . . . 11-3

4. Security function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

5. Network Scanning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

6. E-mail Status/E-mail Alerts. . . . . . . . . . . . . . . . . . . . . . 11-5

Page 3

[1] GENERAL

1. Features of copying functions

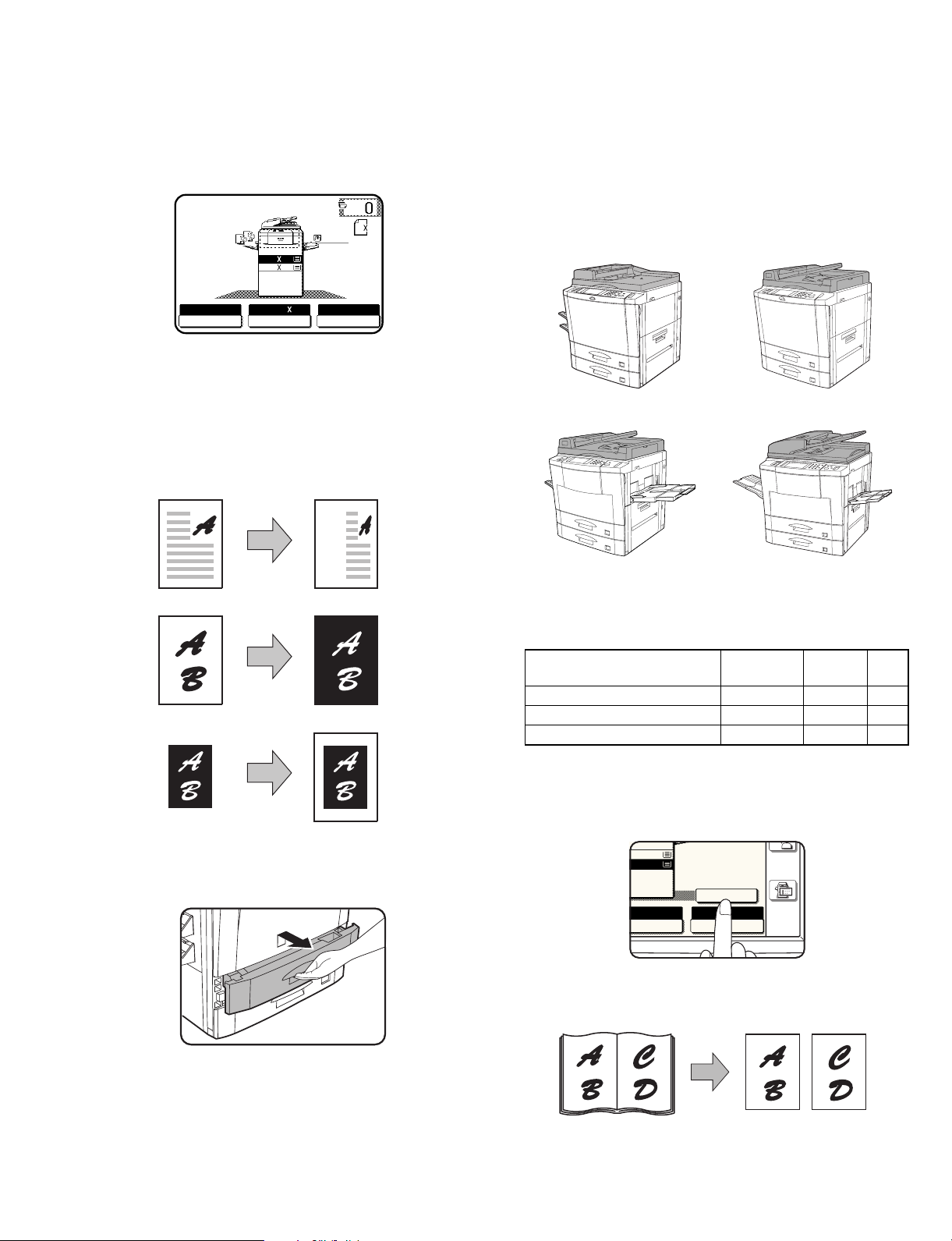

A. Touch panel

The touch panel with the back-lighted LCD simplifies various operations. It also shows operation descriptions and paper jam treatment.

READY TO COPY. (DOCUMENT FEEDER MODE)

1

8/ 11

ORIGINAL

2

1

1.8/ 11

2

2.11 17

AUTO

EXPOSURE PAPER SELECT

B. Various functions of digital system

Different from the conventional analog copiers, this machine employs

the digital system where the image data of a document scanned by

the CCD sensor (which converts photo signals into electrical signals)

are converted into digital signals. This digital system allows the independent zooming copy, black-white reversing copy, and centering

copy.

Independent zooming copy

1

AUTO 8/ 11

2

100%

COPY RATIO

D. Automatic document feeder as standard

provision

Without opening the document table cover, documents can be automatically fed and copied.

The automatic document feeder provided in the AR-280/285/286/287/

335/336/337/405/407/501/505/507 allows automatic reversion of

documents for duplex copying as well as simplex copying.

(The automatic document feeder of the AR-280/281 allows only simplex copying.)

AR-280/285/335 AR-286/287/336/337

Black-white reversing copy

Centering copy

C. Front loading paper tray

The paper trays including the two-step paper feed desk employ a

front loading system to facilitate paper loading.

AR-405/407 AR-501/505/507

E. Step zooming

The zooming function allows selection of the magnification ratio as

follows.

Magnification

ratio

Increment Steps

AR-280/281 25% to 200% 1% 176

AR-250/285/286/287/335/336/337 25% to 800% 1% 776

AR-405/407/501/505/507 25% to 400% 1% 376

F. Paper/magnification ratio auto selection

When the desired magnification ratio is specified, the suitable paper

size is automatically selected by the original size detection function. If

the copy paper size is specified, then the suitable magnification ratio

is automatically selected.

8½X11

11 X 11

TO 8½X11

ER SELECT

AUTO IMAGE

100%

COPY RATIO

REVEW

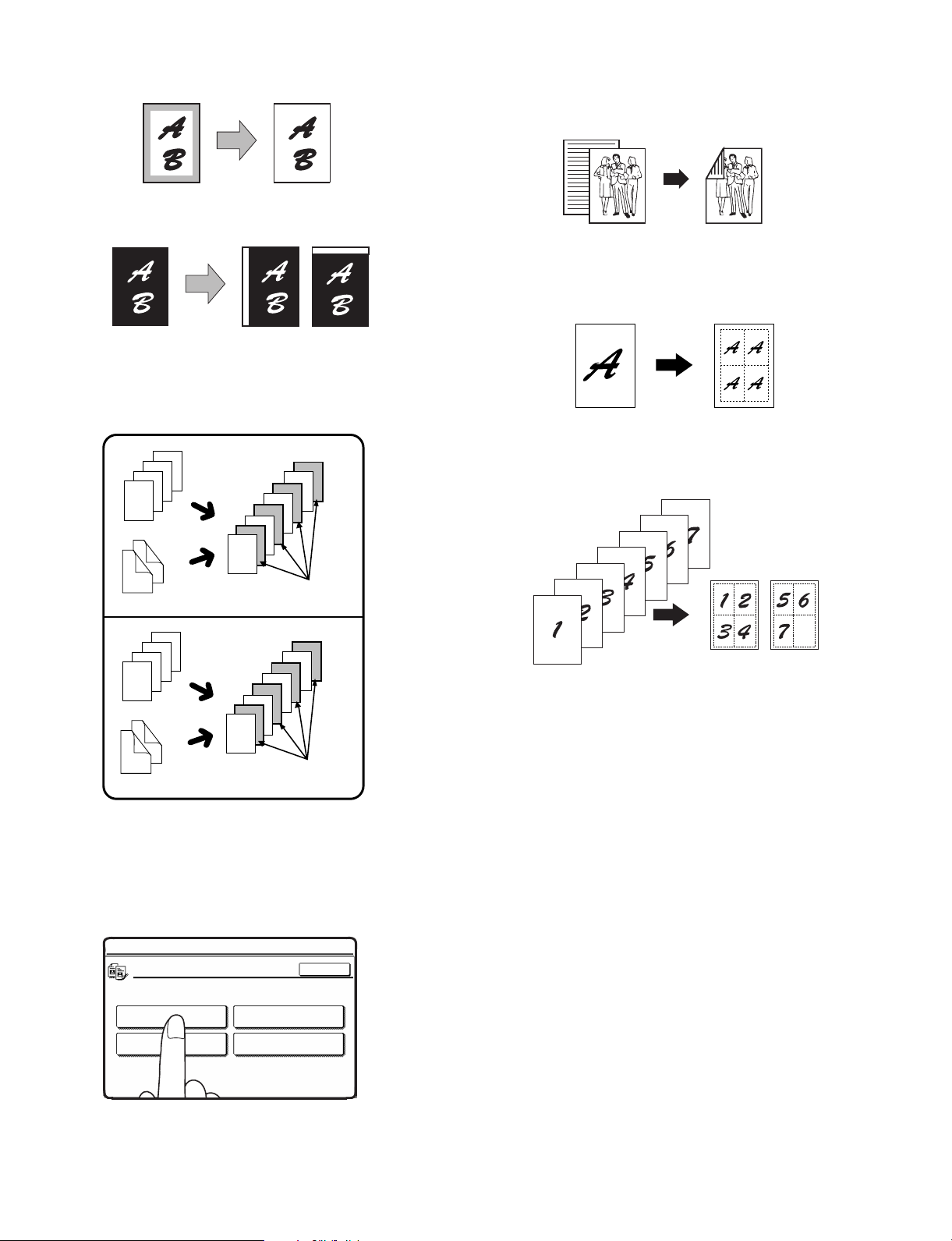

G. 1-set 2-copy

The right and the left pages of a book, etc. can be copied onto two

sheets of paper continuously.

1 – 1 7/13/2000

Page 4

H. Edge erase copying

Shade at the copy edge can be automatically erased.

I. Binding margin copying

Copying with binding margin can be made.

J. Transparency film with insert sheets

When copying onto transparency film, insert sheets can be placed

following each transparent sheet. The insert sheets can be processed

blank or can be copied with the same image as the transparent

sheets.

4

3

2

1

2

1

3

1

4

2

1

4

4

3

3

2

INSERTS WITH

PRINTING

M. Auto duplex copy

(AR-250/280/281 requires the option)

Duplex copy is made automatically.

Original Copy

N. REPEAT COPY

The REPEAT COPY is used to produce repeated images from an

original on to a single sheet of paper. Border lines can be drawn to

separate repeated images.

O. MULTI SHOT

The MULTI SHOT function is used to copy several originals, collectively in a specified order, onto one sheet.

4

3

2

1

3

1

4

2

1

4

3

2

INSERTS WITHOUT

PRINTING

K. Copy conditions registration/recall

Nine sets of complicated copying procedures can be stored and recalled when necessary.

L. Key operator program

The key operator program is used by the key operator to set and

cancel the customer functions.

KEY OPERATOR PROGRAMS

COPIER MODE

OTHER FUNCTION

SETTINGS

ENABLE/DISABLE

SETTINGS

TIMER SETTINGS

ACCOUNT CONTROL

OK

P. Hi-Fi copy (AR-280/285/335 only)

This function produces high image quality copies.

Q. DATE SIGN

The DATE SIGN function adds the current date to the copies. The

date will be printed at the upper right of the copies.

R. WATERMARK

The WATERMARK function adds a selected watermark such as

“CONFIDENTIAL” and “URGENT” to the copies. The watermark will

be printed in gray tone at the center of copies.

S. SELECT STAMP

The SELECT STAMP function adds a selected string such as “CONFIDENTIAL” and “URGENT” to the copies. The string will be printed in

white on a shaded background.

T. PAGE NUMBER

The PAGE NUMBER function adds page numbers to the copies.

7/13/2000 1 – 2

Page 5

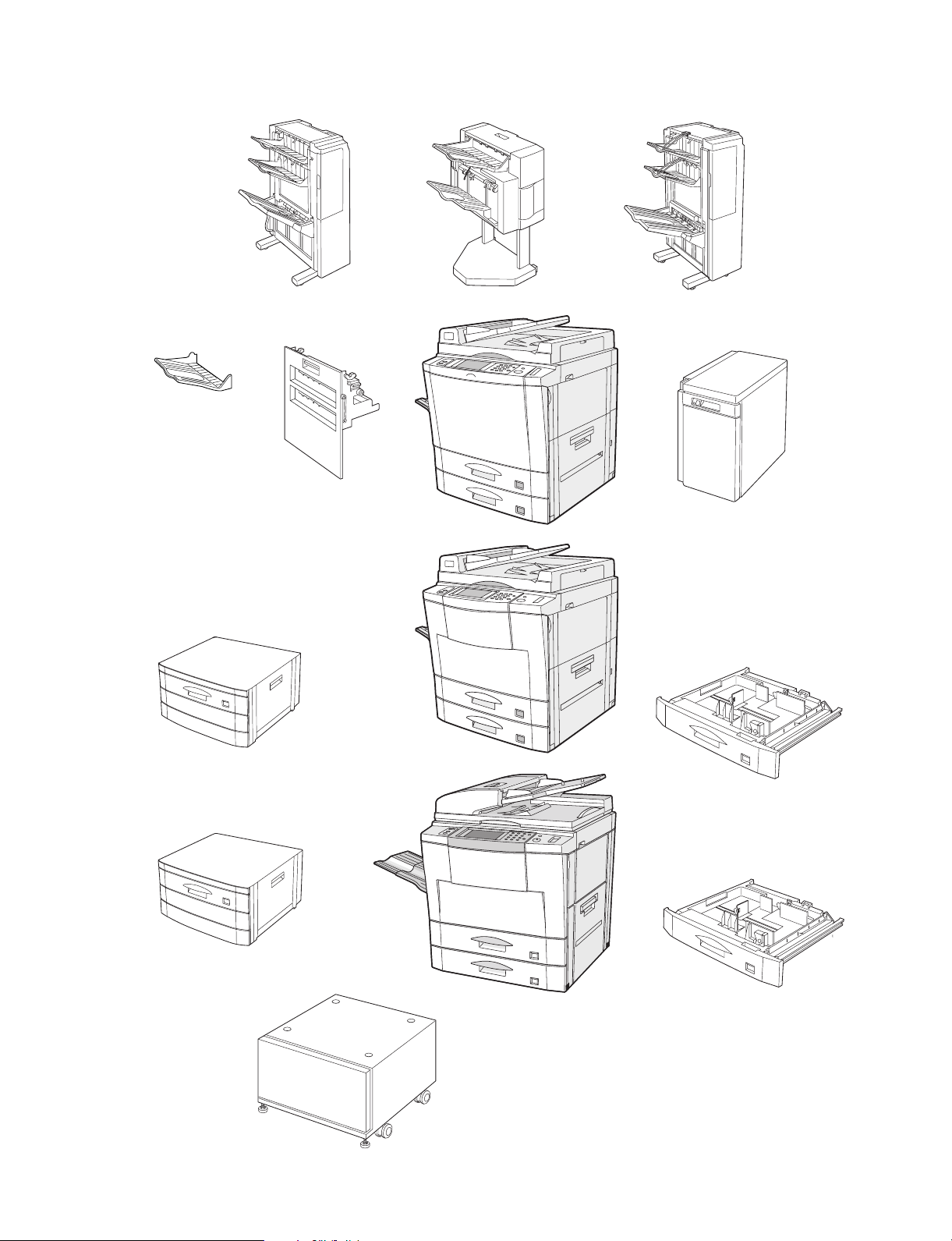

2. System outline (Options)

Copier model

Name Model AR-250 AR-280 AR-281 AR-285 AR-286 AR-287 AR-335 AR-336 AR-337 AR-405 AR-407 AR-501 AR-505 AR-507

Automatic

document

feeder

Reversing

automatic

document

feeder

Stand/500

sheet paper

drawer

Large

capacity tray

500-sheet

paper drawer

Desk AR-DD1 ❍❍❍❍❍❍❍❍❍— ❍❍❍ ❍

2-tray paper

exit unit

Exit tray AR-TE1 ❍ — ❍❍❍❍❍❍❍— ❍❍❍❍ (SEC/SECL)

Dual tray

output unit

Finisher AR-FN1 ❍❍ ❍❍❍— ❍❍————— —

Printer board AR-PB2 ❍❍ ❍❍❍— ❍❍— ❍ ——❍ —

NIC card (10

base T/2)

NIC card (10

base T/100

base TX)

AXIS fixing

angle

1GB-HDD AR-HD1 ❍ ———————————— —

Network

scanner kit

Mounting kit AR-XB3 — — ❍ — ❍❍ — ❍❍❍❍—— ❍

Document

cover

Tandem

connection

cable

Sharpdesk 5

license kit

Security ROM AR-FR1 — — — — — ❍ ——❍ ———— —

AR-SP1 ❍ Standard Standard — — ———————— —

RSPF———————————Standard Standard Standard

AR-RF1 ❍ ——❍❍Standard Standard Standard Standard ———— —

AR-RF2—————————Standard Standard — — —

AR-DE1 ❍❍ ❍❍❍— ❍❍————— —

AR-DE1N ❍❍❍❍❍❍❍❍❍❍❍—— —

AR-DE7———————————❍❍ ❍

AR-LC1 ❍❍ ❍❍❍— ❍❍— ❍ ——— —

AR-LC1N — ❍❍❍❍❍❍❍❍❍❍❍— ❍

AR-CS1 ❍❍❍❍❍❍❍❍❍❍❍—— —

AR-CS3———————————❍❍ ❍

AR-DD1N—————————❍ ——— —

AR-DU1 ❍❍ ❍— ❍ Standard — ❍ Standard — Standard — — Standard

AR-TE2———————————❍❍

AR-TR1 ❍ — ❍ — ❍❍ — ❍❍❍❍—— —

AR-FN1N ❍❍❍❍❍❍❍❍❍❍❍—— —

AR-FN2 ❍❍❍❍❍❍❍❍❍❍❍—— —

AR-FN3———————————❍❍ ❍

AR-PB2A — — — — — ❍ ——❍ — ❍ —— ❍

AR-SM1 — — — — — ❍ ——❍ — ❍ — ❍❍

JX96NCE8 ❍❍ ❍❍❍— ❍❍— ❍ ——❍ —

AR-NC1D ❍❍❍❍❍❍❍❍❍— ❍ — ❍❍

AR-NC3D ❍❍❍❍❍❍❍❍❍❍❍— ❍❍

AR-NC4D————————————— —

(AXIS

scanner)

AR-NS1 — — — — — ❍ ——❍ — ❍ —— ❍

AR-VR2 ❍ ———————————— —

AR-CA1 — — — — — — — — ❍ — ❍ — ❍❍

AR-U11M — — — — — ❍ ——❍ — ❍ —— ❍

AR-U15M — — — — — ❍ ——❍ — ❍ —— ❍

AR-FR2——————————❍ —— —

AR-FR3————————————— ❍

❍ — ❍ — ❍ ——❍ — ❍ ——❍ —

❍ (EX destinations

other than

SEC/SECL)

1 – 3 7/13/2000

Page 6

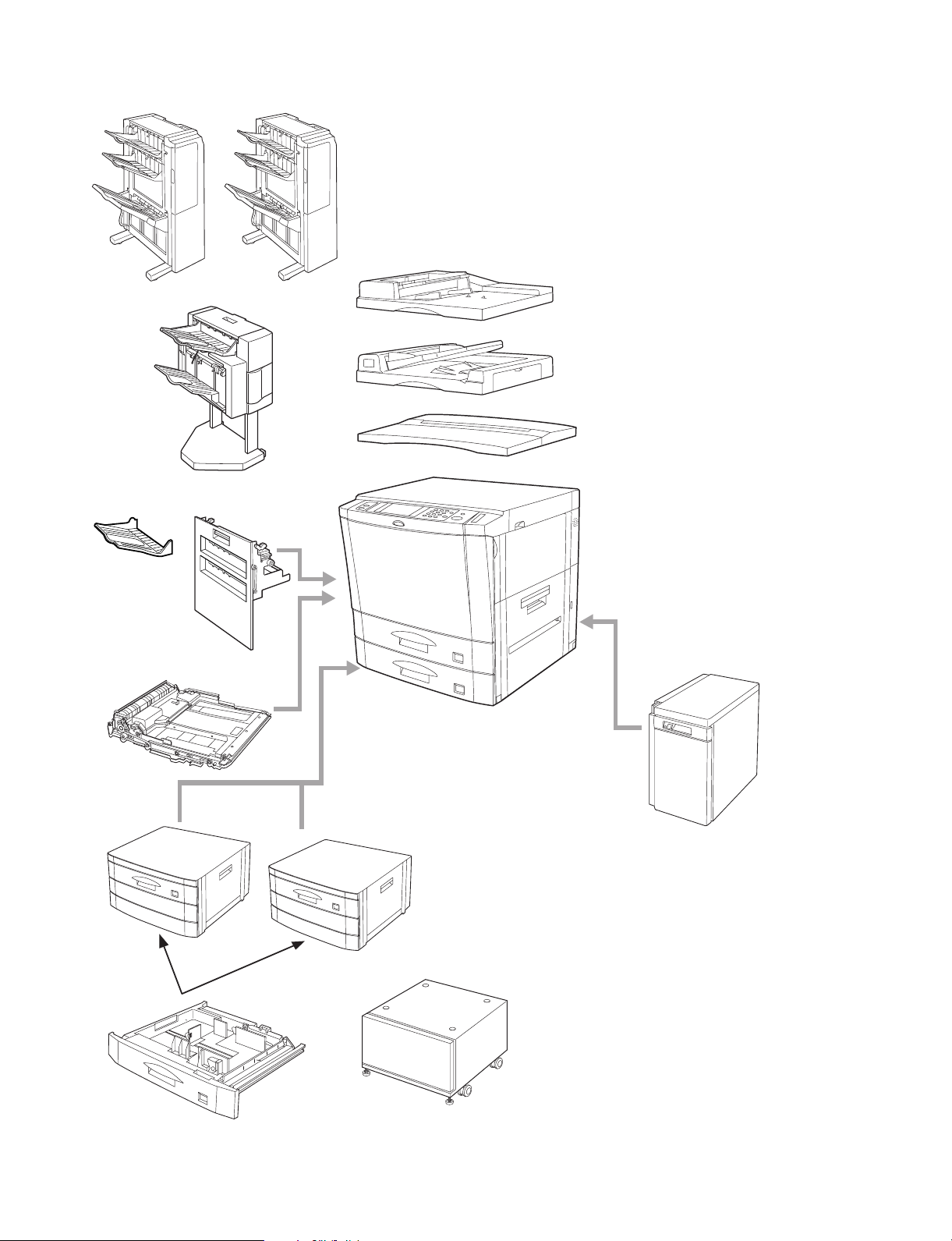

AR-250

Finisher

(AR-FN1)

Finisher

(AR-FN1N)

Exit tray

(AR-TE1)

Finisher

(AR-FN2)

Dual tray output unit

(AR-TR1)

Duplex module

(AR-DU1)

Automatic document feeder

(AR-SP1)

Reversing automatic document feeder

(AR-RF1)

Document cover

(AR-VR2)

Large capacity tray

(AR-LC1)

Stand/500 sheet

paper drawer

(AR-DE1)

500-sheet paper drawer

(AR-CS1)

7/13/2000 1 – 4

Stand/500 sheet

paper drawer

(AR-DE1N)

Desk (AR-DD1)

Printer expansion kit

·

(AR-PB2)

NIC card (10 base T/2) (Provided by Europe)

·

(JX96NCE8)

NIC card (10 base T/2) (Provided by local distributors)

·

(AR-NC1D)

NIC card (10 base T / 100 base TX)

·

(AR-NC3D)

AXIS fixing angle

·

(AXIS scanner)

Mounting kit

·

(AR-XB3)

1 GB HDD

·

(AR-HD1)

Page 7

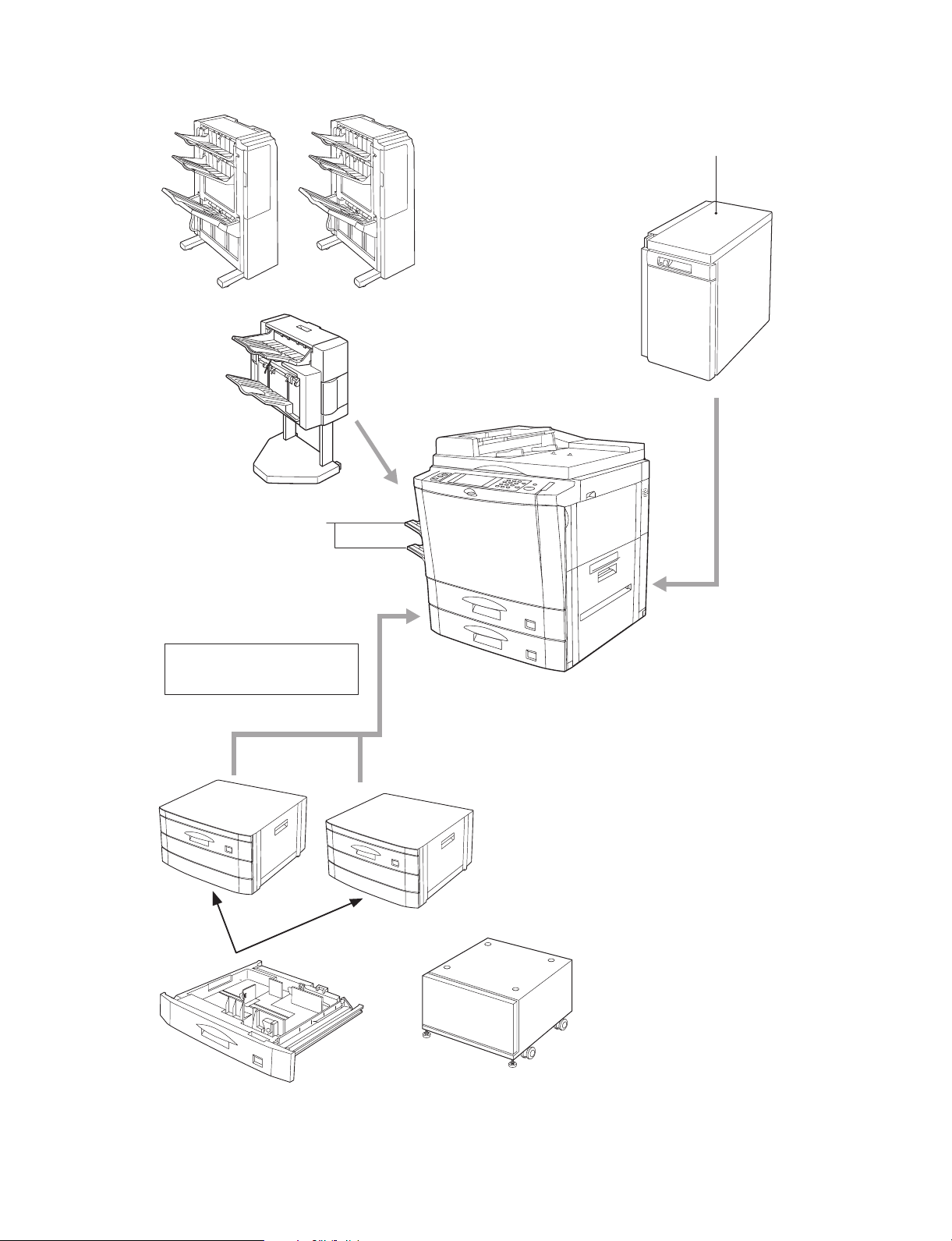

AR-280/285/335

Finisher

(AR-FN1)

Finisher

(AR-FN1N)

Large capacity (AR-LC1)

(AR-LC1N)

Finisher

(AR-FN2)

EXIT trays

(AR-TE1)

The duplex module (AR-DU1) is

provided as an optional component.

(AR-280)

Stand/500 sheet

paper drawer

(AR-DE1)

500-sheet paper drawer

(AR-CS1)

Stand/500 sheet

paper drawer

(AR-DE1N)

Desk (AR-DD1)

Printer expansion kit

·

(AR-PB2)

NIC card (10 base T/2) (Provided by Europe)

·

(JX96NCE8)

NIC card (10 base T/2) (Provided by local distributors)

·

(AR-NC1D)

NIC card (10 base T / 100 base TX)

·

(AR-NC3D)

1 – 5 7/13/2000

Page 8

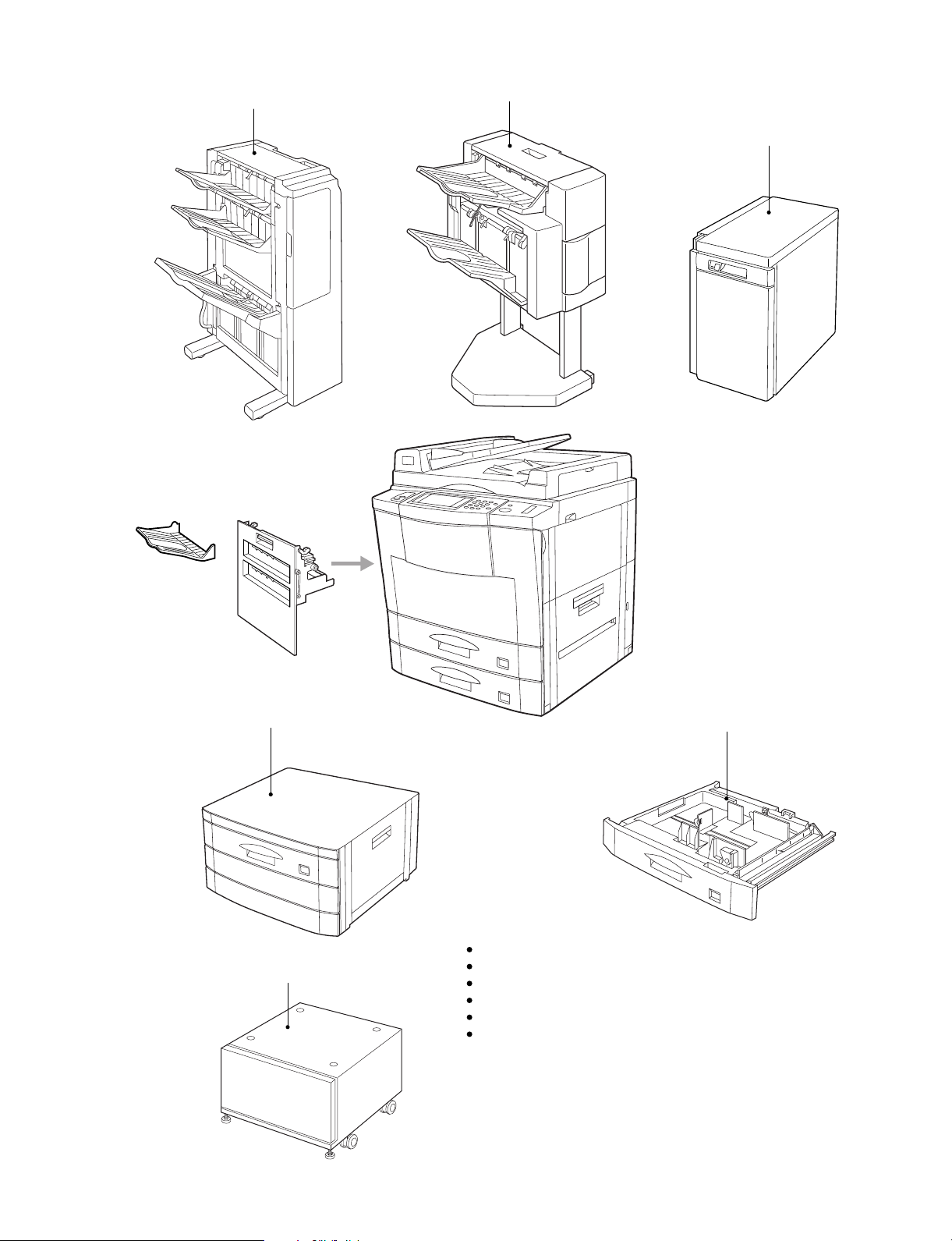

AR-281/286/336

Exit tray

(AR-TE1)

Finisher

(AR-FN1)

Dual tray output unit

(AR-TR1)

Finisher

(AR-FN1N)

Finisher

(AR-FN2)

AR-281

AR-286/336

2-tray paper exit unit (AR-281 only)

(AR-DU1)

Stand/500 sheet

paper drawer

(AR-DE1)

500-sheet paper drawer

(AR-CS1)

Stand/500 sheet

paper drawer

(AR-DE1N)

Desk (AR-DD1)

Large capacity

(AR-LC1)

(AR-LC1N)

Printer expansion kit

·

(AR-PB2)

NIC card (10 base T/2) (Provided by Europe)

·

(JX96NCE8)

NIC card (10 base T/2) (Provided by local distributors)

·

(AR-NC1D)

NIC card (10 base T / 100 base TX)

·

(AR-NC3D)

AXIS fixing angle

·

(AXIS scanner)

Mounting kit

·

(AR-XB3)

7/13/2000 1 – 6

Page 9

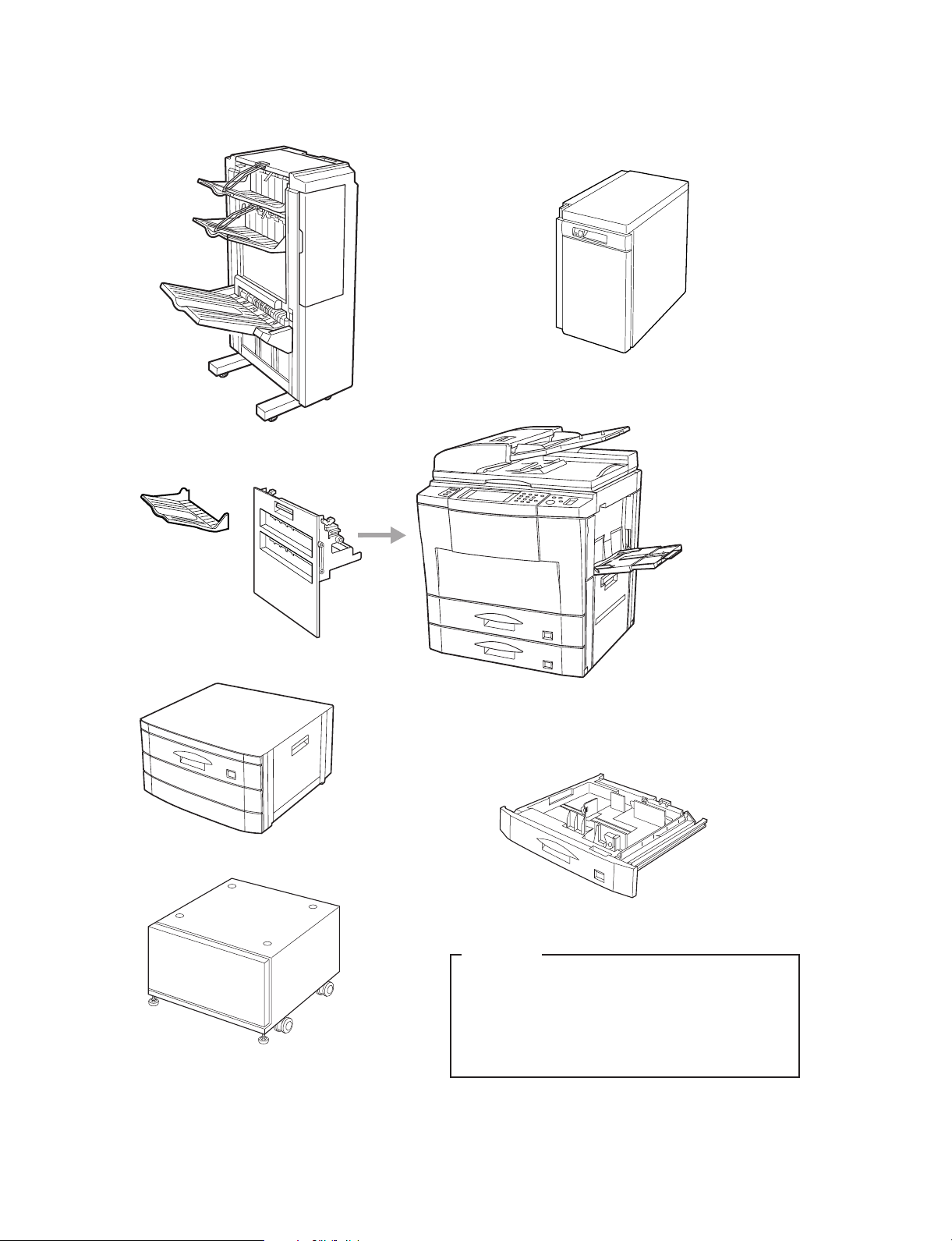

AR-405

Finisher (AR-FN1N)

Finisher (AR-FN2)

Large capacity tray (AR-LC1)

(AR-LC1N)

Exit tray

(AR-TE1)

Dual tray output unit

(AR-TR1)

Stand/500-sheet paper drawer (AR-DE1N)

500-sheet paper drawer (AR-CS1)

Desk (AR-DD1)

Printer board (AR-PB2)

NIC card(10baseT/2) (Provided by Europe) (JX96NCE8)

NIC card (10baseT/2) (Provided by Europe) (AR-NC1D)

NIC card (10baseT/100baseTX) (AR-NC3D)

AXIS fixing angle (AXIS scanner)

Mounting kit (AR-XB3)

1 – 7 7/13/2000

Page 10

AR-501/505

Exit tray

(AR-TE1)

(AR-TE2)

Finisher (AR-FN3)

Large capacity tray (AR-LC1N)

Dual tray output unit

(AR-TR1)

Stand/500-sheet paper drawer (AR-DE7)

Desk (AR-DD1)

500-sheet paper drawer (AR-CS3)

AR-505 only

Printer board (AR-PB2)

·

NIC card (10baseT/2) (Provided by Europe) (JX96NCE8)

·

NIC card (10baseT/2) (Provided by Europe) (AR-NC1D)

·

NIC card (10baseT/100baseTX) (AR-NC3D)

·

Printer board (Expansion memory 16MB x2 SIM) (AR-SM1)

·

AXIS fixing angle (AXIS scanner)

·

Tandem connection cable (AR-CA1)

·

7/13/2000 1 – 8

Page 11

AR-287/337/407/507

Finisher:

AR-FN1N (AR-287/337/407)

Finisher:

AR-FN2 (AR-287/337/407)

Finisher:

AR-FN3 (AR-507)

Exit tray:

AR-TE1 (AR-287/337/407/507 (SEC/SECL))

AR-TE2 (AR-507 (Other than SEC/SECL))

Dual tray output unit:

AR-TR1

Stand/500 sheet

paper drawer:

AR-DE1N (AR-287/337/407)

AR-287/337

AR-407

Large capacity:

AR-LC1N (AR-287/337/407/507)

500-sheet paper drawer:

AR-CS1 (AR-287/337/407)

Stand/500-sheet

paper drawer:

AR-DE7 (AR-507)

Desk: AR-DD1

AR-507

500-sheet paper drawer:

AR-CS3 (AR-507)

Printer board: AR-PB2A

·

NIC card (10baseT/2)

·

AR-NC1D

NIC card (10 base T/100 base TX): AR-NC3D

·

Printer board (Expansion memory 16MB x2 SIM):

·

AR-SM1 (AR-507)

Network scanner kit: AR-NS1

·

Tandem connection cable AR-CA1

·

Mounting kit: AR-XB3 (AR-287/337/407)

·

Sharpdesk 5 license kit: AR-U11M/U15M

·

Security ROM: AR-FR1 (AR-287/337)

·

1 – 9 7/13/2000

(Provided by local distributors):

AR-FR2 (AR-407)

AR-FR3 (AR-507)

Page 12

3. Installation requirements

To ensure safety and proper machine performance, please note the

following before initial installation and whenever the machine is to be

relocated.

1) The copier should be installed near an accessible power outlet for

easy connection.

2) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Also make certain the outlet is properly grounded.

3) Do not install the machine where it is:

· damp or humid,

· exposed to direct sunlight,

· extremely dusty,

· poorly ventilated,

· subject to extreme temperature or humidity changes (e.g., near

an air conditioner or heater).

A small amount of ozone is produced within the copier during operation. The emission level is insufficient to cause any health hazard.

NOTE: The present recommended long term exposure limit for

ozone is 0.1 ppm (0.2 mg/m

weighted average concentration.

However, since the small amount that is emitted may have

an objectionable odor, it is advisable to place the copier in a

ventilated area.

3

) calculated as an 8 hr. time-

Cautions

1) Do not touch the photoconductive drum. Scratches or smudges on

the drum will cause dirty copies.

2) The fusing unit is extremely hot. Exercise care in this area.

3) Since a hard disk drive is built into the copier, be sure to turn the

power switch to the "OFF" position when moving the copier. Take

care not to subject the copier to any vibration or shock.

Fusing unit

Photoconductive

drum

4) Do not look directly at the light source. Doing so may damage

your eyes.

4) Since a hard disk drive is built into this copier, place the copier on

a firm, level surface. Choose an area which is not subject to any

vibration.

5) Be sure to allow the required space around the machine for servicing and proper ventilation.

11-13/16"

(30cm)

23-5/8"

(60cm)

23-5/8"

(60cm)

11-13/16"

(30cm)

5) Installation adjusters are provided on the optional stand/500-sheet

paper drawer.When moving the machine with the optional

stand/500-sheet paper drawer, be sure to raise the installation

adjusters. After moving the machine, lower the installation adjusters until they reach the floor to lock the machine in place. (If the

casters are not locked securely, the machine will gradually move

and the cables of the RADF and the SPF are rubbed against the

wall, causing internal disconnection.)

Caster

Release

Lock Release

Lock

Adjuster

6) When copying is interrupted (for example, because the INTERRUPT function has been used, paper or toner has run out, a

misfeed has occurred, etc.), this copier will store the image data of

the originals read prior to the interruption. If copying of secret

documents is interrupted due to the above reasons, be sure to

either resume the interrupted copying by pressing the START key,

or clear the image data by pressing the clear all key after the

interrupt copying is completed or the trouble is cleared, because

the stored data may be printed by other operators.

7/13/2000 1 – 10

Page 13

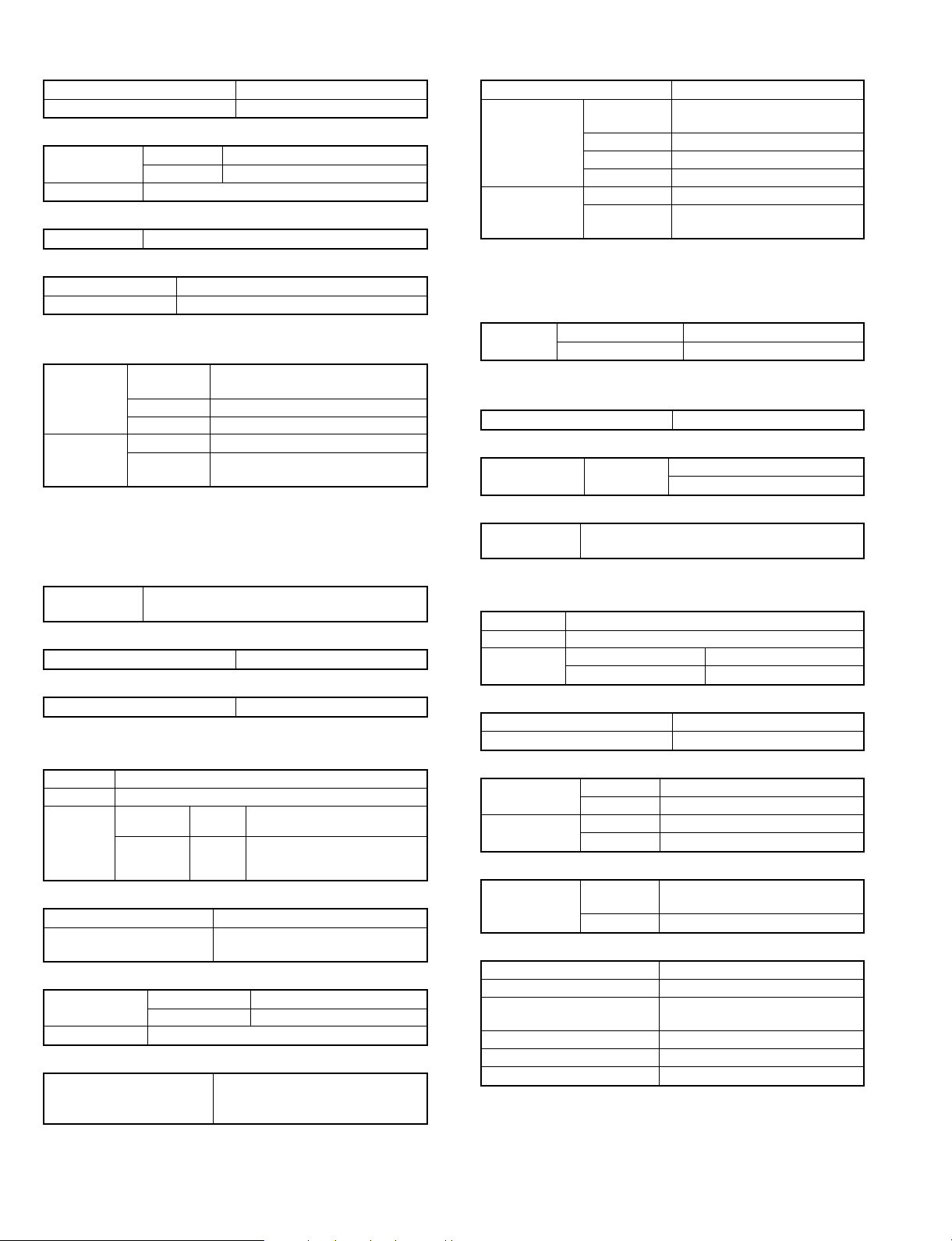

[2] SPECIFICATIONS

1. Machine type

Product

CPM Type

Name

AR-250 25 Simplex Desk top – 1 tray 48 MB –

AR-280 28 Simplex Desk top SPF 2 tray 16 MB 1 GB

AR-281 28 Simplex Desk top SPF 1 tray 16 MB 2 GB

AR-285 28 Duplex Desk top RADF 2 tray 16 MB 1 GB

AR-286 28 Duplex Desk top RADF 1 tray 16 MB 2 GB

AR-287 28 Duplex Desk top RADF 1 tray 32 MB 4.3 GB

AR-335 33 Duplex Desk top RADF 2 tray 16 MB 1 GB

AR-336 33 Duplex Desk top RADF 1 tray 16 MB 2 GB

AR-337 33 Duplex Desk top RADF 1 tray 32 MB 4.3 GB

AR-405 40 Duplex Desk top RADF 1 tray 16 MB 2 GB

AR-407 40 Duplex Desk top RADF 1 tray 32 MB 4.3 GB

AR-501 50 Duplex Desk top RSPF 1 tray 48 MB 2 GB

AR-505 50 Duplex Desk top RSPF 1 tray 48 MB 2 GB

AR-507 50 Duplex Desk top RSPF 1 tray 48 MB 4.3 GB

* Memory capacity is of the main body only, excluding optional

expansion memory.

* Standard’s spec.

2. Copy speed

A. Basic Speed

per 1 scan AR-250

Single 25 cpm 28 cpm 28 cpm 28 cpm 34 cpm 47 cpm

Multiple 25 cpm 28 cpm 28 cpm 33 cpm 40 cpm 50 cpm

* Speeds from all the paper feed ports including the normal copy

and the manual feed copy.

B. Normal copy (100%)

A4/8.5 ´ 11 25 28 28 33 40 50

A3/11 ´ 17 13 14 14 17 19 25

B4/8.5 ´ 14/

8.5 ´ 13

B5/A5/

8.5 ´ 5.5

A4R/B5R/

8.5 ´ 11

C. Enlargement copy

A4/8.5 ´ 11 25 28 28 33 40 50

A3/11 ´ 17 13 14 14 17 19 25

B4/8.5 ´ 14/

8.5 ´ 13

B5/A5/

8.5 ´ 5.5

A4R/B5R/

8.5 ´ 11

D. Reduction copy (25%)

A4/8.5 ´ 11 25 28 28 33 40 50

A3/11 ´ 17 13 14 14 17 17 25

B4/8.5 ´ 14/

8.5 ´ 13

B5/A5/

8.5 ´ 5.5

A4R/B5R/

8.5 ´ 11

AR-280

AR-281

AR-250

AR-250

AR-250

AR-280

AR-281

15 17 17 21 24 29

25 28 28 33 40 50

18 20 20 24 27 35

AR-280

AR-281

(800%)

15 17 17 21 24 29

25 28 28 33 40 50

18 20 20 24 27 35

AR-280

AR-281

15 17 17 21 24 29

25 28 28 33 40 50

18 20 20 24 27 35

Document

AR-285

AR-286

AR-287

AR-285

AR-286

AR-287

AR-285

AR-286

AR-287

(800%)

AR-285

AR-286

AR-287

Feeder

AR-335

AR-336

AR-337

AR-335

AR-336

AR-337

AR-335

AR-336

AR-337

(800%)

AR-335

AR-336

AR-337

Paper

Exit

RAM HD

AR-405

AR-407

AR-405

AR-407

AR-405

AR-407

(400%)

AR-405

AR-407

Memory

AR-501

AR-505

AR-507

AR-501

AR-505

AR-507

AR-501

AR-505

AR-507

(400%)

AR-501

AR-505

AR-507

E. First Copy time

(1) Basic Speed

Model AR-250

Speed (sec.) 5.2 5.2 5.2 5.2 4.5 4.3

AR-280

AR-281

AR-285

AR-286

AR-287

When the paper is fed from the Upper tray on the base unit.

Machines are measured when paper is fed from the upper tray of 2-

tray exit unit.

AR-335

AR-336

AR-337

AR-405

AR-407

AR-501

AR-505

AR-507

(2) Detail

AR-250

Upper cassette

(sec.)

Lower cassette

(sec.)

Multi-Baypass

Tray (sec.)

Stand/Upper paper drawer (sec.)

Stand/Medium

paper drawer

(sec.)

LCC (sec.) 5.9 5.9 5.9 5.9 5.2 4.7

AR-280

AR-281

5.2 5.2 5.2 5.2 4.5 4.3

5.7 5.7 5.7 5.7 5.0 4.5

5.3 5.3 5.3 5.3 4.6 4.3

6.6 6.6 6.6 6.6 5.9 5.2

6.9 6.9 6.9 6.9 6.2 5.5

AR-285

AR-286

AR-287

Refer to each specification for the first copy time when paper is fed

from the document feeder or the optional paper feed tray.

AR-335

AR-336

AR-337

AR-405

AR-407

AR-501

AR-505

AR-507

(3) First copy time from the document feeder

AR-250

Model

When the SPF is used

(sec.)

When the RADF is

used (sec.)

When the RSPF is

used (sec.)

AR-281

AR-286

AR-287

AR-280

7.87.8———

8.8 — 8.8 7.6 —

————7.0

When the paper is fed from the Upper tray on the base unit.

AR-285

AR-335

AR-336

AR-337

AR-405

AR-407

AR-501

AR-505

AR-507

3. OC/DF

A. Document table

Max. document size A3/11 ´ 17

Document reference position Center left

Document detection Yes

Inch Series

Detection size

AB Series A3, B4, A4, A4R, A5

Australia A3, 216 ´ 330, A4, A4R, A5 (Note 1)

B5 areas A3, B4, A4, A4R, B5, B5R

OR guide display

Inch Series 11, 8.5, 5.5

AB Series

(Note 1) For areas other than Australia, "B4/8.5 ´ 11" can be

changed to "8.5 ´ 13" by the simulation.

(Note 2) The display of 8.5" for AB series is of the line display only.

There is no size display.

B. SPF (AR-280/281)

(1) Document set

Set direction Face down

Set position Center reference

Set quantity

A4/8.5 ´ 11 30 sheets 30 sheets of 80g/m

Greater than

the above.

11 ´ 17, 8.5 ´ 14, 8.5 ´ 11,

8.5 ´ 11R, 8.5 ´ 5.5

A3/A4, B4/B5, A4R/A5, B5R,

11, 8.5 (Note 2)

15 sheets

For 80 ~ 128g/m

4.7mm thick can se set.

2

must be set.

2

, paper of max.

2 – 1 7/13/2000

Page 14

(2) Document transport

Document transport system Sheet through type

Document feed sequence Top take-up feed

(3) Document Size

Document Size

Paper Weight 50 ~ 128g/m

AB Series A3 ~ A5

Inch Series 11 ´ 17 ~ 8.5 ´ 5.5

2

(14 ~ 34 lbs.)

(4) Multi quantity

Multi quantity In the high fidelity mode, multi copy is inhibited.

(5) Document mix feed

Mix paper feed Allowed.

Random paper feed Not allowed.

No linkage with AMS is made.

(6) Document detection

Detection

size

Inch Series

AB Series A3, B4, A4, A4R, A5

Australia A3, A4, A4R, A5, 216 ´ 330 (Note 1)

Document

guide display

Inch Series 11, 8.5, 5.5

AB Series

(Note 1) For areas other than Australia, "B4/8.5 ´ 11" can be

changed to "8.5 ´ 13" by the simulation.

(Note 2) The display of 8.5" for AB series is of the line display only.

There is no size display.

11 ´ 17, 8.5 ´ 14, 8.5 ´ 11,

8.5 ´ 11R, 8.5 ´ 5.5

A3/A4, B4/B5, A4R/A5, B5R, 8.5

(Note 2)

(7) Stream mode

Stream mode

The stream mode can be selected by the key

operation program. (Only group mode)

(8) Document reverse

Document reverse No

(9) Display section

Display section No

C. RADF (AR-285/286/287/335/336/337/405/407)

(1) Document set

Set direction

Set position

Set quantity A4/8.5 ´ 11 50 sheets 35 ~ 80g/m2:

(2) Document transport system

Document transport system Belt system

Document fed sequence

(3) Document size

Document size

Weight 35 ~ 128g/m

(4) Document stop system

Document stop system

Face up

Center reference

Thickness Less than 6.5 mm

Greater than

the above

30 sheets 80 ~ 128g/m

Thickness Less than 5 mm

(50 sheets of 80g/m

Lower take-up paper feed

(Face up paper feed)

AB Series A3 ~ A5

Inch Series 11 ´ 17 ~ 8.5 ´ 5.5

2

(10 ~ 34 lbs.)

Stopper system

(Position control for single copy )

(Duplex copy)

2

:

2

)

(5) Document detection on the tray

Document detection on the tray Yes

Inch Series 11 ´ 17, 8.5 ´ 14, 8.5 ´ 11,

8.5 ´ 11R, 8.5 ´ 5.5, 8.5 ´ 13

Detection size

AB Series A3, B4, A4, A4R, A5, 8.5 ´ 13

B5 area A3, B4, A4, A4R, B5, B5R, A5

Australia A3, B4, A4, A4R, A5, 216 ´ 330

Document

guide display

Inch Series 11, 8.5, 5.5

AB Series A3/A4, B4/B5, A4R/A5, B5R,

8.5 (Note)

(Note) AB series 8.5" display is of line display only. Size display is

not made.

When setting Sim, "8.5 ´ 14" and "8.5 ´ 13" are separately detected.

(7) Document mix feed

Document

mix feed

No linkage with AMS is made.

Mix paper feed Possible (Same width size)

Random paper feed Possible

(8) Document reversion

Document reversion Yes

(9) Display

Display section LED display

Document feed display section

Document remaining display

(10) Stream mode

Stream mode

The stream mode can be selected by the key

operation program. (Only group mode)

D. RSPF (AR-501/505/507)

(1) Document set

Set direction Face up

Set position Center reference

Set quantity

Less than 80g/m

Greater than the above Thickness Less than 6 mm

(2) Document transport

Document transport system Sheet through type

Document feed sequence Top take-up feed

(3) Document size

Document Size

Paper Weight

AB Series A3 ~ A5

Inch Series 11 ´ 17 ~ 8.5 ´ 5.5

Simplex 50 ~ 128g/m

Duplex 50 ~ 110g/m

(4) Document detection

Detection size

Inch Series

AB Series A3, B4, A4, A4R, A5, B5, B5R

(5) Others

Dimensions (W x D x H) 576 x 505 x 142 mm

Weight About 13.5 kg

Super supply

Zooming ratio 100 to 400%

Document exchange speed Max. 50 sheets/minute

Power consumption DC24V: 48W, DC5V: 2W

2

50 sheets

2

(14 ~ 34 lbs.)

2

(14 ~ 29 lbs.)

11 ´ 17, 8.5 ´ 14, 8.5 ´ 11,

8.5 ´ 11R, 8.5 ´ 5.5

DC 24V, DC 5V

(Supplied from main body)

7/13/2000 2 – 2

Page 15

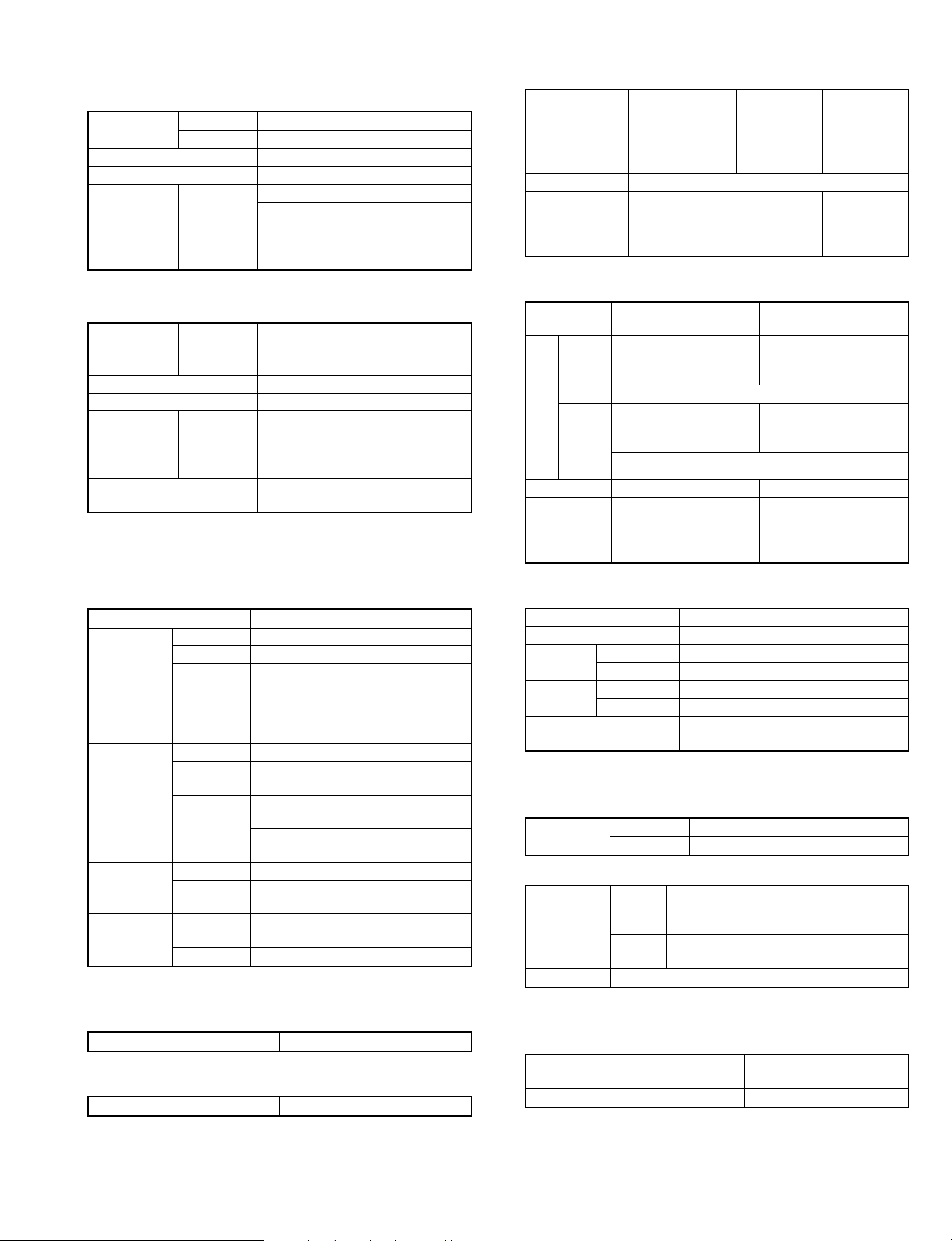

4. Paper feed

6. Warm up

A. Outline of paper feed

Copy size

(Max. ~ Min.)

Paper feed system 2 Tray + Manual Feed Tray

Paper feed capacity 500 ´ 2 + 50 (80g/m

Remaining

detection

AB Series A3 ~ A6R, Postcard

Inch Series 11 ´ 17 ~ 8.5 ´ 5.5

Paper feed

tray section

Manual

Feed Tray

Level detection available

0~ 25%, 25%~ 50%, 50%~ 85%,

85%~

Empty detection only available

2

)

B. Details of paper feed section

(1) Paper feed tray

Paper feed

size

Paper weight 56 ~ 105g/m

Paper size selection User operation (slide switch system)

Slide switch

Cassette

attachment/detachment

When the slide switch is set to "Special", the operation is made on the

set size of the key operator program.

(Sizes of 13" in AB series and B5 are set with the key operator program.)

AB Series A3/B4/A4/A4R/B5/B5R/A5

Inch Series

AB Series

Inch Series

11 ´ 17/8.5 ´ 14/8.5 ´ 13/

8.5 ´ 11/8.5 ´ 11R/5.5 ´ 8.5

A5/A4/A4R/B4/A3/B5/8.5 ´ 11/

EXTRA

11 ´ 17/8.5 ´ 14/8.5 ´ 13/8.5 ´ 11/

8.5 ´ 11R/5.5 ´ 8.5/A4/EXTRA

Only the lower cassette possible

2

(15 ~ 28 lbs.)

(2) Manual Feed Tray

Manual feed tray type Folding, complete attachment

AB Series A3 ~ A6R

Inch Series 11 ´ 17 ~ 8.5 ´ 5.5

Paper size

Paper kind

Detection

size

Manual feed

tray guide

display

(Note 1) For 11" ´ 8.5" of AB series, only the line is displayed and

Paper

Weight

Multi feed Standard paper, special paper

Single feed

Special

paper

AB Series A3/B4/A4/A4R/B5/B5R/A5/A6R

Inch Series

AB Series

Inch Series 11, 8.5, 5.5

the size is not displayed.

52 ~ 128g/m

(index paper), 200g/m2 (cover paper)

(For greater than 105g/m

size is A4 or smaller. For greater than

128g/m

Standard paper, special paper, No. 2

original paper

OHP, label paper, reproduction

paper, index paper, cover paper

For multi and back surface copy, only

the single paper feed is allowed.

11 ´ 17/8.5 ´ 14/8.5 ´ 11/

8.5 ´ 11R/5.5 ´ 8.5/7.25 x 10.5

A3/A4, B4/B5, A4R/A5, A5R, B5R,

11, 8.5 (NOTE 1)

2

(14 ~ 34 lbs.), 176g/m

2

, 28lbs, the

2

(34 lbs) portrait feed only.

2

(3) Dehumidifying heater

Yes/No No

5. Multi copy

Multi max. quantity 999

AR-250/280/

281/285/286/287/

335/336/337

Warm up time Less than 65 sec

Pre-heat yes/no Yes

Jam recovery

time

About 10sec (Leaving the

machine for 60 sec after

opening the door, standard

condition, polygon stop.)

AR-405/407

Less than

75 sec

AR-501/

505/507

About

150 sec

About

30 sec

7. Copy magnification ratio

AR-250/280/281/285/

286/287/335/336/337

25, 50, 70, 81, 86, 100,

AB

Series

Inch

Series

Fixed magnification ratio

Zoom width 25 ~ 800% 25 ~ 400%

Independent

magnification width

115, 122, 141, 200, 400,

800%

5R + 6E

25, 50, 64, 77, 95, 100,

121, 129, 141, 200, 400,

800%

5R + 6E

25 ~ 800% for

horizontal/vertical

(25 ~ 800%

(high fidelity copy))

AR-405/407/

501/505/507

25, 50, 70, 81, 86, 100,

115, 122, 141, 200,

400%

25, 50, 64, 77, 95, 100,

121, 129, 141, 200,

400%

25 ~ 400% for

horizontal/vertical

8. Exposure

Exposure mode Auto, character, character/photo, photo

Manual steps 9 steps

Resolution

Gradation

Toner save mode

Read 400 dpi

Write 600 dpi

Read 256 gradations

Write 2 gradations (Default)

Set with the key operator program.

(In U.K., it is treated by a serviceman.)

9. Print area

A. Max. print area

Max. area

AB Series 416 ´ 293 mm

Inch Series 428 ´ 275 mm

B. Loss width

AR-501

AR-505

Void area

Image Loss Less than 5 mm

AR-507

Other

models

Lead edge 4 mm or less, rear edge 4 mm

or less, FR total 5 mm or less

Lead edge 3 mm or less, rear edge 4 mm

or less, FR total 5 mm or less

10. Paper exit

A. Paper exit form

AR-280/285/335

Paper exit form 2-tray paper exit 1-tray paper exit

AR-250/281/286/287/336/

337/405/407/501/505/507

2 – 3 7/13/2000

Page 16

B. Paper exit section

AR-250/281/

286/287/336/

337/405/407

AR-501/

505/507

Face up &

Face down

Paper exit tray

capacity

Paper exit

surface

(Face up/Face

down)

AR-280/

285/335

Upper Tray 250 sheets

Lower Tray 100 sheets —

Upper Tray Face up

Lower Tray Face up —

C. Paper size

Upper

Tray

Lower

Tray

AB Series A3 ~ A6R

Inch Series 11 ´ 17 ~ 8.5 ´ 5.5

AB Series A3 ~ A5

Inch Series 11 ´ 17 ~ 8.5 ´ 5.5

Duplex pass section : 56 ~ 105g/m

Size Paper Weight

50 ~ 128g/m

176g/m

50 ~ 105g/m

2

2

2

, 200g/m

2

,

11. Duplex module (AR-285/286/287/335/

336/337/405/407/501/505/507)

A. Auto duplex unit

AR-285/286/287/335/336/

337/405/407/501/505/507

Standard

Auto Duplex Unit

AR-250/280/281

Option

(AR-DU1)

B. Paper size

AB Series A3, B4, A4, A4R, B5, B5R, A5

Paper size

Paper Weight

Inch Series

11 ´ 17, 8.5 ´ 14, 8.5 ´ 13, 8.5 ´ 11,

8.5 ´ 11R, 7.25 ´ 10.5R

56 ~ 105g/m

2

(Same as the paper feed

section of the main body)

C. Capacity

Capacity 1 Sheet (Single Pass Method)

12. Shipping form

A. Packing form

Body Body/accessories

B. Paper size

First Tray

Second Tray

AB Series A3

Inch Series 11 ´ 17

AB Series A3

Inch Series 11 ´ 17

13. Additional functions

A. Main body functions

APS

AMS AMS by flow scan with DF is not allowed.

Auto tray switching

1 scan multi copy

Rotation copy

Pre-heat Conditions are set with the key operation.

Auto shut off Conditions are set with the key operation.

Message display

Key operator program

Communication

Process control

Coin vendor Only the connector is provided on the PWB.

E-mail Status/E-mail Alerts

(AR-287/337/407/507)

B. Copy function

AR-250/280/281/285/286/335/336/405/501/505

AR-250/280/281/

285/286/335/336

Job call/

registration

Dept. control

Binding margin

Edge erase AB series: 10mm, Inch series: 1/2" with adjustment

Center erase

1-set, 2-copy

2

Independent

zooming

White/black

reversion

Cover paper Cover/back cover/cover and back cover

OHP insert paper

Centering

Multi shot (Nin1) Paper feed size is up to A4.

Repeat copy

Date print Time setting by the key operation.

Stamp function

Middle binding HD is required for AR-250.

Page print HD is required for AR-250.

Max. 50 dept. Max. 500 dept.

Shift width AB series: 10mm, Inch series: 1/2" with

adjustment (Binding direction selectable)

25 ~ 800% for

vertical/horizontal

All surface only (only in the manual mode)

Insert paper copy Yes/No

selectable

AR-287/337/407/507

AR-287/337 AR-407 AR-507

Job call/ registration 9

Dept. control

Binding margin

Edge erase AB series: 10mm, Inch series: 1/2" with adjustment

Center erase

1-set, 2-copy

Independent zooming

White/black reversion All surface only (only in the manual mode)

Cover paper Cover/back cover/cover and back cover

OHP insert paper

Centering

Multi shot (Nin1)

Repeat copy Combination with AMS allowed

Date print Time setting by the key operation.

Stamp function

Middle binding

Page print

Confidential print

Security function Security ROM is installed. (AR-FR1/FR2/FR3)

Tandem print

(copy/print)

Network scanner When the scanner expansion kit is installed

Large quantity

document mode

*1: 60 sheets for sizes greater than A4 with print data

Shift width AB series: 10mm, Inch series: 1/2" with

25 to 800% for

vertical/horizontal

Insert paper copy Yes/No

When the tandem connection cable is connected

AR-405 AR-501/505

9

(Only the copy function is controlled.)

25 ~ 400% for vertical/horizontal

Only 1 face-up paper exit is

possible

Max. 50 dept. Max. 500 dept.

(Copy/Print/Tandem)

adjustment (Binding direction selectable)

25 to 400% for vertical/horizontal

selectable

(AR-287 invalid)

Documents of 120 sheets *1

Only 1 face-up paper

exit is possible

7/13/2000 2 – 4

Page 17

14. Options

Document

feeder

Paper

feed

Duplex

module

Finishing

AR-285

AR-250 AR-280

SPF Option Standard — — —

RADF Option — Standard Standard —

RSPF ————Standard

1 tray desk

(AR-DE1)

Large capacity

tray (AR-LC1)

Tray module

(AR-CS1)

Desk (AR-DD1) Option Option Option Option Option

Auto duplex

module

(AR-DU1)

Dual tray

output unit

(AR-TR1)

Finisher

(AR-FN1)

Finisher

(AR-FN2)

FN3 Option — — — Option

Option Option Option Option

Option Option Option Option

Option Option Option Option Option

Option Option Standard Standard Standard

Option Standard Standard Option —

Option Option Option Option —

Option — — Option —

AR-286

AR-287

AR-335

AR-336

AR-337

AR-405

AR-407

AR-501

AR-505

AR-507

Option

(AR-DE7)

Option

(AR-LC1N)

15. Other specifications

Photoconductor kind OPC drum

Photoconductor dia. 65 f

Process cleaning Blade

Exposure lamp No-electrode xenon lamp

Developing system Dry, 2-component magnetic brush

development

Charging system DC negative scorotron (saw tooth electrode)

Transfer system DC positive control

Separation system AC corotron/DC bias separation pawl

Fusing system Heat roller

Fusing cleaning Yes (AR-501/505/507 only)

(AR-287/337/407 only)

AC corotron/DC bias separation pawl/

Separation lamp (AR-501/505 only)

Photo discharge/AC corotron/

DC bias separation pawl (AR-507 only)

16. Outlook

W x D x H (mm)

AR-250 600 ´ 695 ´ 658 1292 ´ 630 About 81 kg

AR-280 600 ´ 695 ´ 698 1292 ´ 695 About 89 kg

AR-281 600 ´ 695 ´ 735 1292 ´ 695 About 87 kg

AR-285/335 600 ´ 695 ´ 750 1292 ´ 695 About 98 kg

AR-286/336 600 ´ 695 ´ 718 1292 ´ 695 About 101 kg

AR-287/337 600 ´ 695 ´ 750 1292 ´ 695 Approx 98 kg

AR-405 600 ´ 700 ´ 750 1292 ´ 700 About 98 kg

AR-407 600 ´ 700 ´ 750 1292 ´ 700 Approx 98 kg

AR-501/505 600 ´ 700 ´ 773 1292 ´ 700 About 102 kg

AR-507 600 ´ 700 ´ 773 1292 ´ 700 Approx 102 kg

Machine

occupying

dimensions

Weight

17. Power supply

Voltage 100 V, 110 V, 120 V, 127 V, 220-230 V, 240 V

Frequency 50/60 Hz Common

18. Power consumption

Max. power

consumption

AR-280/

285/335

Less than

1440 W

AR-250/281/

286/287/336/

337/405/407

Less than

1440 W

AR-501/

505/507

Less than

1590 W

19. Environmental measures

A. EnergyStar

AR-250 AR-280/285

Low power mode (Pre-heat mode)

Recovery time Less than 30 sec

Power

Sleep mode

(Power save mode)

consumption

Shift time Max. 240 min (Default 60 min)

Less than

101.25 W

Less than

15 W

Less than

112.8 W

Less than

15 W

AR-281/

286/287

Less than

112.8 W

AR-335 AR-336/337 AR-405/407

Less than

132.05 W

Less than

132.05 W

Less than

159 W

AR-501/

505/507

Less than

197.5 W

Less than

1 min

Less than

15 W

Less than

15 W

Less than

15 W

Less than

15 W

Less than

20 W

Max. 240 min

(Default

90 min)

2 – 5 7/13/2000

Page 18

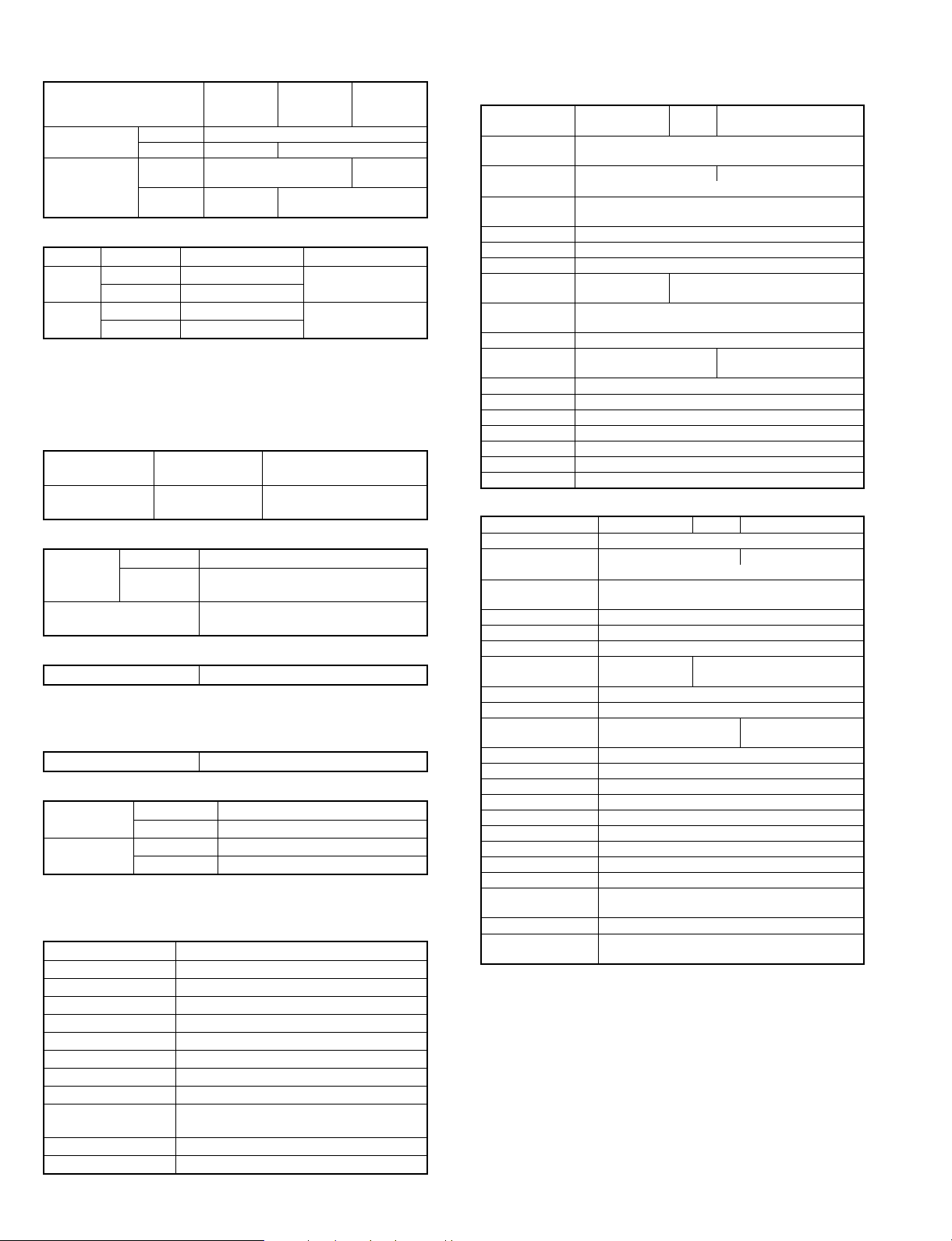

20. Combination of functions

AR-280/285/335

Inde-

AMS Water

pendent

zooming

S ® S

S (Even number) ® D

S (Odd number) ® D (DF only)

S ® D (Auto)

D ® D (DF only)

D ® S (DF only)

Staple sort

Sort

Group

Offset

Duplex copy direction switch

Hi-Fi copy (*)

Cover insertion (DF only)

OHP insert paper

Multi shot (DF only)

Repeat

Middle binding

1-set 2-copy (Document table only)

Binding margin

Edge erase

Centering

Black-white reversion

Date print

Page print

Stamp

Water mark

AMS

❍❍❍❍❍❍❍❍❍❍❍▲❍❍❍❍❍✕❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍▲❍❍✕❍✕❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍✕▲❍❍✕❍✕❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍▲❍❍✕❍✕❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍✕▲❍❍✕❍✕ ✕❍❍❍❍

❍❍❍❍❍❍❍❍❍❍✕▲❍❍❍❍❍✕❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍✕❍❍✕❍✕❍❍✕ ✕

❍❍❍❍❍❍❍❍❍❍❍❍❍❍D ❍ D ❍❍✕

❍❍❍❍❍❍❍❍❍❍❍❍❍❍D ❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍✕❍✕✕✕❍✕

❍❍✕✕✕✕✕✕❍❍❍✕✕✕❍❍

❍❍❍❍❍❍✕❍❍❍✕✕✕✕✕

❍❍❍❍❍❍✕❍❍❍❍✕✕✕

✕✕❍❍❍❍✕❍❍❍✕✕✕

❍✕❍❍❍❍❍❍❍❍✕✕

✕❍❍❍❍❍✕❍❍❍✕

❍❍❍❍❍❍✕❍❍❍

❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍

❍❍✕❍❍❍

❍❍❍❍❍

❍❍❍❍

❍❍✕

❍❍

❍

▲ Follows the setting on the middle binding display.

D Only one set of copies available.

* Combination with SPF mode is inhibited.

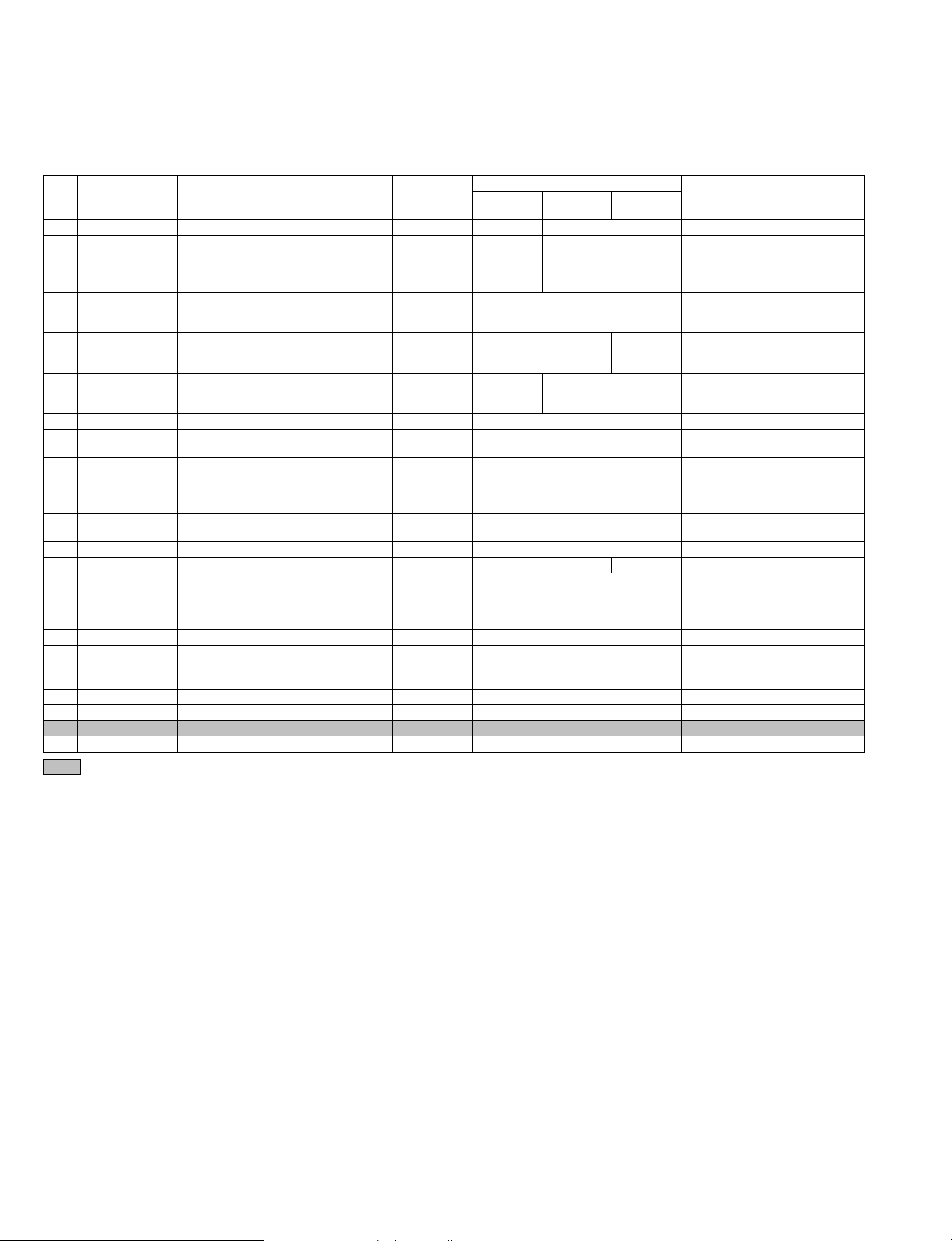

AR-250/281/286/287/336/337/405/407

AMS Water

Independent

zooming

S ® S

S ® D (Auto)

D ® D (DF only)

D ® S (DF only)

Staple sort

Sort

Group

Offset

Duplex copy direction switch

Cover insertion (DF only)

OHP insert paper

Multi shot (DF only)

Repeat

Middle binding

1-set 2-copy (Document table only)

Binding margin

Edge erase

Centering

Black-white reversion

Date print

Page print

Stamp

Water mark

AMS

▲ Follows the setting on the middle binding display.

D Only one set of copies available.

❍❍❍❍❍❍❍❍❍❍❍▲❍❍❍❍✕❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍▲❍❍✕❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍✕▲❍❍✕❍✕❍❍❍❍

❍❍❍❍❍❍❍❍❍❍✕▲❍❍❍❍✕❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍✕❍❍✕❍❍❍✕✕

❍❍❍❍❍❍❍❍❍❍❍❍❍❍D ❍❍❍✕

❍❍❍❍❍❍❍❍❍❍❍❍❍❍D ❍❍❍

❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍✕❍✕✕✕❍

❍❍❍❍❍❍✕❍❍❍✕✕✕✕✕

❍❍❍❍❍❍✕❍❍❍❍✕✕✕

✕✕❍❍❍❍✕❍❍❍✕ ✕✕

❍✕❍❍❍❍❍❍❍❍✕✕

✕❍❍❍❍❍✕❍❍❍✕

❍❍❍❍❍❍✕❍❍❍

❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍

❍❍ ✕❍❍ ❍

❍❍❍❍❍

❍❍❍❍

❍❍ ✕

❍❍

❍

mark

mark

Stamp Page

print

Stamp Page

print

Date

print

Date

print

Blackwhite

reversion

Blackwhite

reversion

Centering

Centering

Edge

erase

Edge

erase

Binding

margin

Binding

margin

1-set

2copy

(Docu

-ment

table

only)

1-set 2copy

(Document

table

only)

Middle

binding

Middle

binding

Repeat

Repeat

Multi

shot

(DF

only)

Multi

shot

OHP

insert

paper

OHP

insert

paper

Cover

insertion

(DF

only)

Hi-Fi

copy

Cover

insertion

(DF

only)

Du-

Offset Group Sort Staple

plex

copy

direction

switch

Offset Group Sort Staple

Duplex

copy

direction

switch

sort

sort

7/13/2000 2 – 6

Page 19

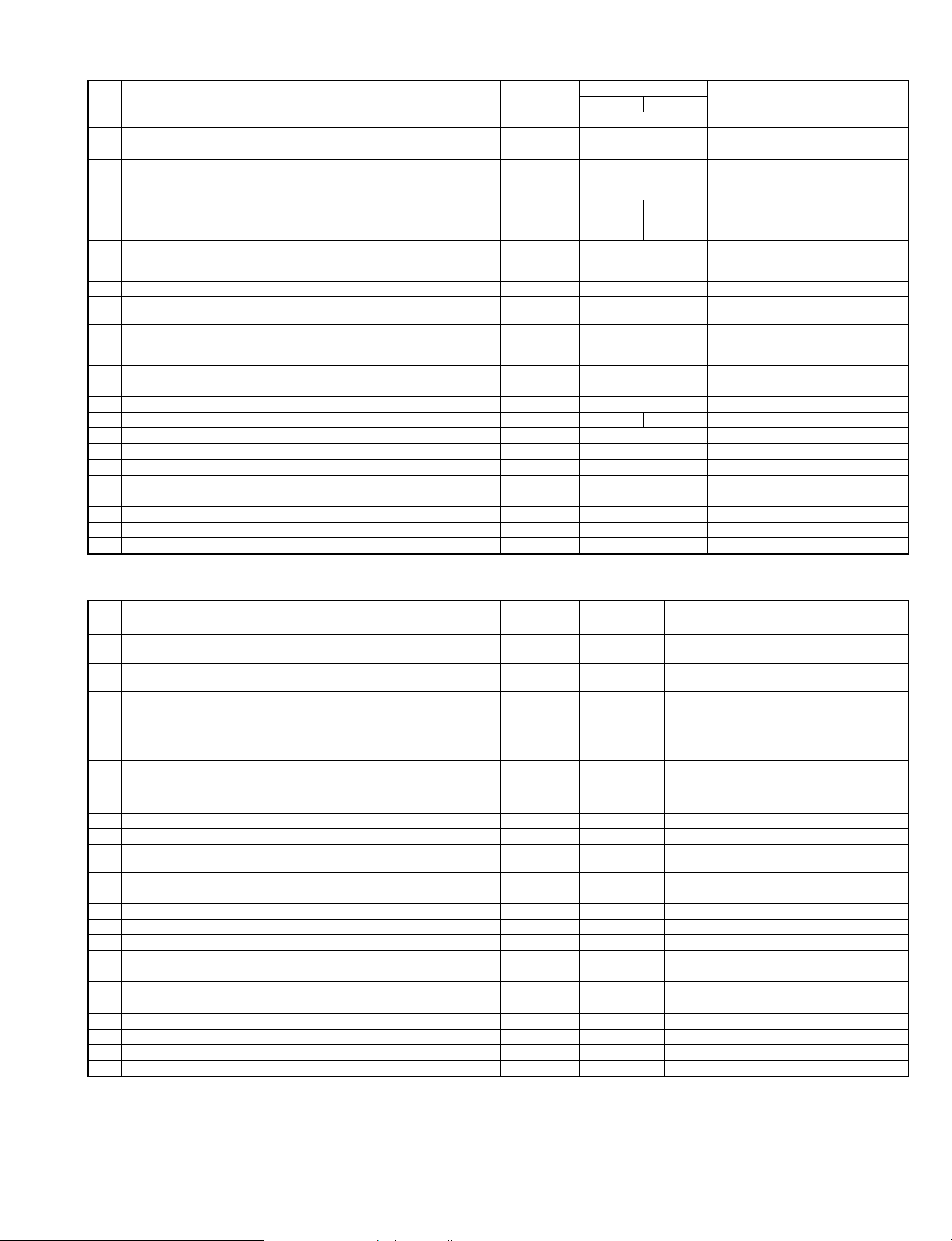

AR-501/505/507

Inter-

Tan-

Inde-

S ® S

S ® D

D ® D (DF only)

D ® S (DF only)

Staple sort

Sort

Group

Offset

Duplex copy direction switch

Cover insertion (DF only)

OHP insert paper

Multi shot

Repeat

Middle binding

1-set 2-copy (Document table

only)

Binding margin

Edge erase

Center erase

Centering

Black-white reversion

Date print

Page print

Stamp

Water mark

AMS

Independent zooming

Tandem copy

ruption

dem

copy

*

AMS Water

pendent

*

zooming

❍❍❍❍❍❍❍❍❍❍❍❍❍❍▲❍❍❍❍ ✕❍❍❍❍

✕❍❍❍❍❍❍❍❍❍❍❍❍❍▲❍❍✕ ❍❍❍❍❍❍

✕❍❍❍❍❍❍❍❍❍❍❍❍✕▲❍❍✕ ❍✕❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍❍❍✕ ▲❍❍❍❍✕❍❍❍❍

✕❍❍❍❍❍❍❍❍❍❍❍❍❍ ✕❍❍✕ ❍❍✕✕✕

❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍D ❍❍❍✕

❍✕❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍D ❍❍❍

❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍❍✕ ❍❍

✕❍❍❍❍❍❍❍❍❍❍❍❍✕❍✕✕ ✕ ❍

✕❍❍❍❍❍❍❍✕❍❍❍❍ ✕✕✕✕✕

❍✕❍❍❍❍❍❍✕❍❍❍❍❍✕✕✕

✕❍✕❍❍❍❍❍✕✕❍❍❍✕✕✕

❍❍❍✕❍❍❍❍❍✕❍❍❍✕ ✕

❍❍✕❍❍❍❍❍✕✕❍❍❍✕

❍❍❍❍❍❍❍❍✕❍✕❍❍

❍❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍❍

❍❍❍❍❍❍❍❍❍❍

❍❍❍✕❍❍❍❍❍

❍❍❍❍✕❍❍❍

❍❍❍❍❍❍❍

❍❍❍❍❍❍

❍❍❍❍✕

❍❍❍❍

❍❍❍

❍❍

✕

mark

Stamp Page

print

Date

print

Blackwhite

reversion

▲ Follows the setting on the middle binding display.

D Only one set of copies available.

When making an interruption, the number of documents is limited.

Single copy: Max. 20 sheets (A3/B4 document: 10sheets)

Duplex copy: Max. 10 sheets (A3/B4 document: 5 sheets)

* This function is valid in the AR-505 only.

Centering

Center

erase

Edge

erase

Binding

margin

1-set

2-copy

(Document

table

only)

Middle

binding

Repeat

Multi

shot

OHP

insert

paper

Cover

insertion

(DF

only)

Du-

Offset Group Sort Stapplex

copy

direction

switch

le sort

2 – 7 7/13/2000

Page 20

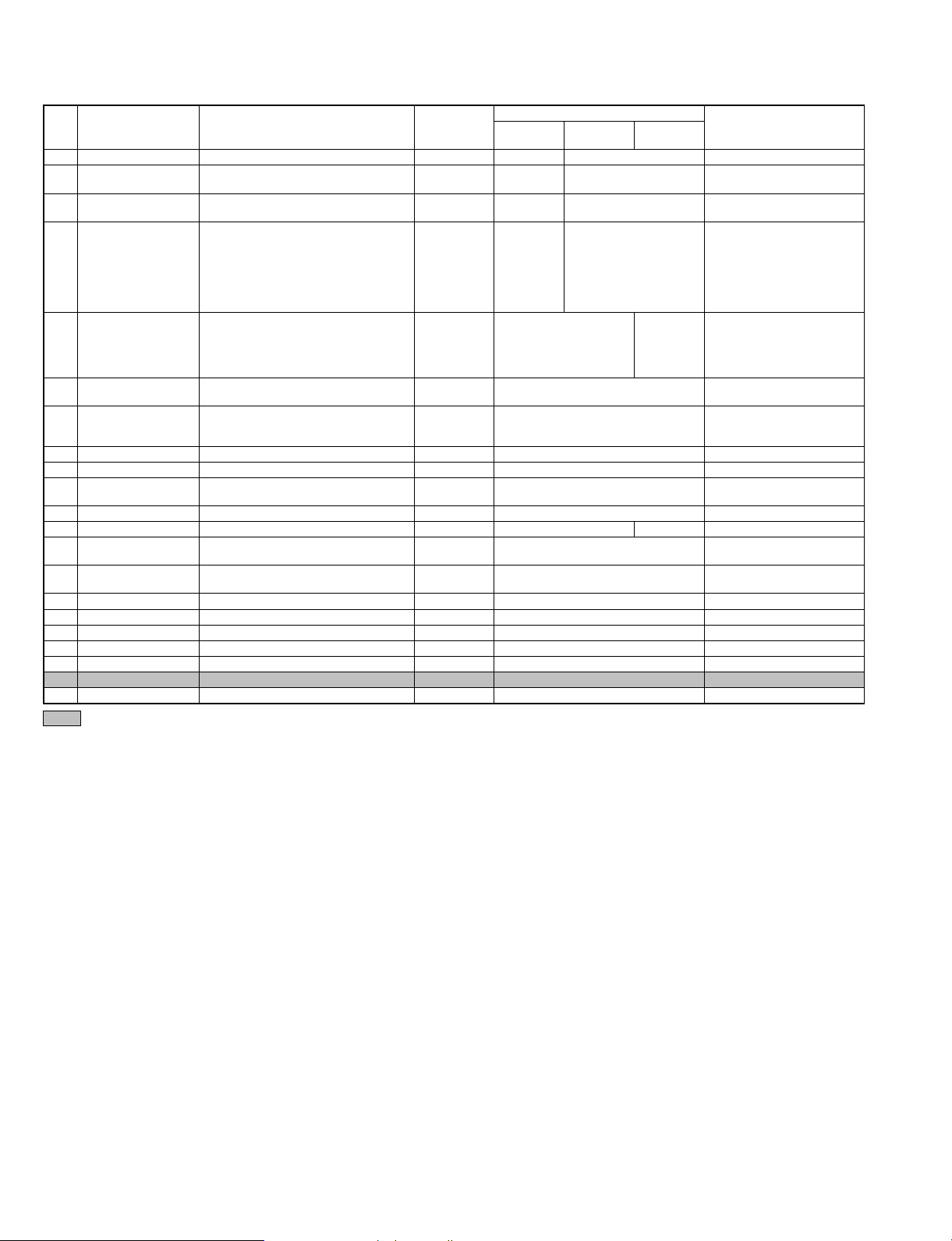

[3] CONSUMABLE PARTS

1. Consumable Parts List

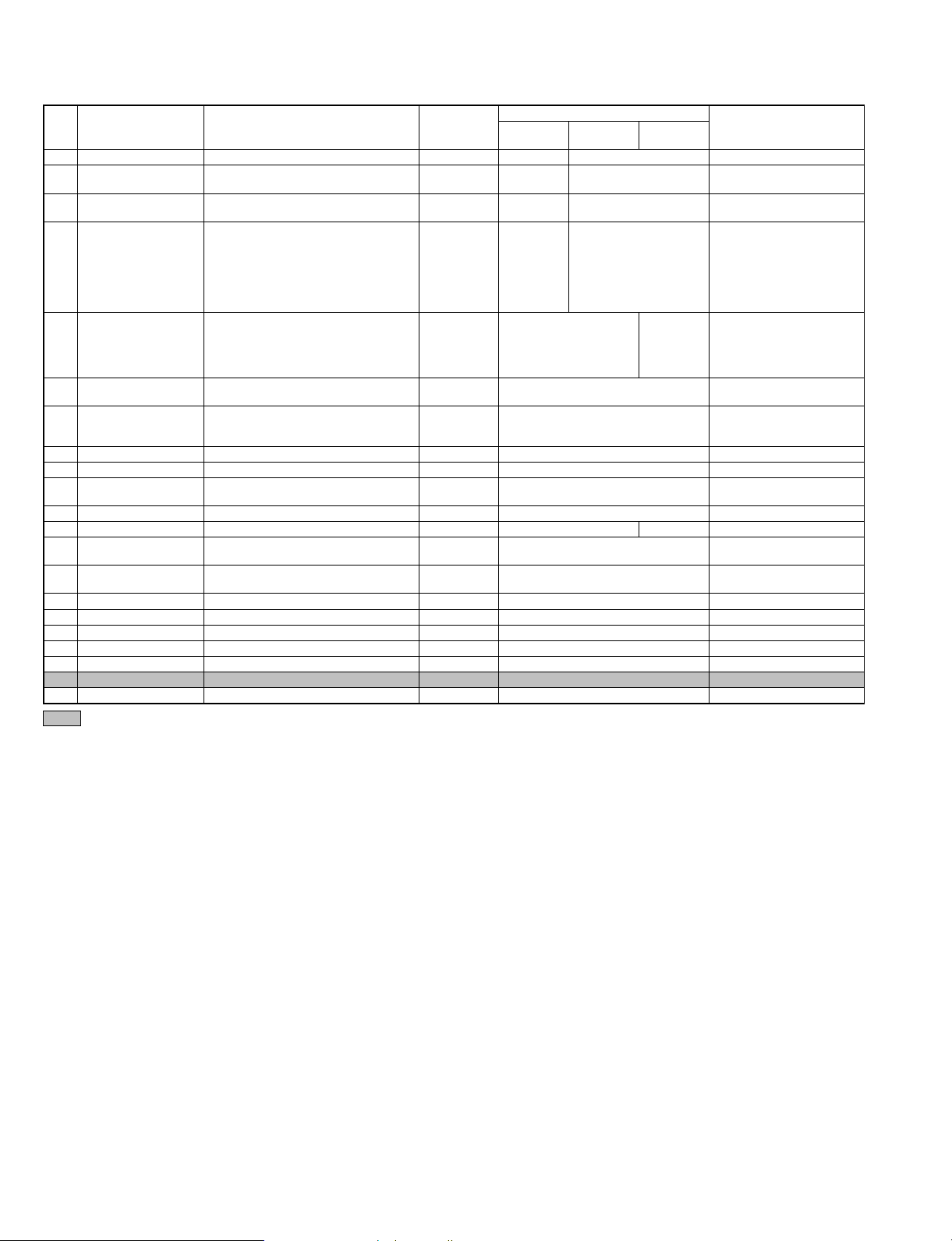

A. USA

AR-250/280/281/285/286/287/335/336/337

No. ITEM CONTENTS LIFE

1 Drum OPC Drum ´1 160K AR-330DR AR-336DR

2 Developer (Black) Developer (800g) ´10 80K (´10)

3 Toner (Black) Toner Cartridge (700g) ´10 17.5K (´10)

Upper Heat Roller

4

Kit

Lower Heat Roller

5

Kit

80K Maintenance

6

Kit

7 Cleaner Blade Cleaner Blade ´10 80K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

8 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

9 Staple Cartridge Staple Cartridge (SF-SC12) ´3 5K staples ´3 SF-LS12

9 Upper Heat Roller Upper Heat Roller ´1 160K AR-330HU

Fusing Separation

10

Pawl (upper)

11 Heat Roller Gear Heat Roller Gear ´10 160K (´10) SF-216HG SF216HG= (SF216JG) ´10

12 Lower Heat Roller Lower Heat Roller ´1 160K AR-330HR AR-505HR

Fusing Separation

13

Pawl (lower)

Drum Separation

14

Pawl

15 Screen Grid Screen Grid ´10 80K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

16 Charging Plate Charging Plate ´10 80K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

Waste Toner

17

Bottle

18 Busing Busing ´2 ´10 160K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

19 Ozone Filter Ozone Filter ´10 80K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

20 Copy Lamp Copy Lamp ´10 AR-330CL AR-330CL= (AR-330DL) ´10

21 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

Upper Heat Roller

Fusing Separation Pawl (upper)

Heat Roller Gear

Lower Heat Roller

Fusing Separation Pawl (lower)

Cleaner Blade

Charging Plate Unit

Drum Separation Unit

Fusing Separation Pawl (upper) ´4 ´10 80K (´10) SF-216UP

Fusing Separation Pawl (lower) ´2 ´10 80K (´10) SF-240LP

Drum Separation Pawl ´2 ´10 80K (´10) SF-240DP

Waste Toner Bottle ´1 AR-330TB

´1

´4

´1

´1

´2

´1

´1

´1

160K AR-330UH

160K AR-330LH AR-505LH

80K AR-330KA1 AR-400KA

AR-280/285/

AR-330MD

(AR330ND)

AR-330MT

(AR-330NT)

: AR-280/285/335 only

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

335

MODEL NAME

AR-250/281/

286/336

AR-336MD

(AR-336ND)

AR-400MT

(AR-400NT)

AR-287/337

REMARKS

AR-330MD = (AR-330ND) ´ 10

AR-336MD = (AR-336ND) ´ 10

AR-330MT = (AR-330NT) ´ 10

AR-400MT = (AR-400NT) ´ 10

Replacement of fusing separation

pawl for every 90 K should be done

using those supplied separately.

Replacement of fusing separation

pawl for every 90 K should be done

using those supplied separately.

Cartridge for AR-FN1

Common with S55,S55 N

Cartridge for AR-FN2

Common with S54

SF-LS12= (SF-SC12) ´3

SF216UP=SF-216TP

(incl.4 pawls) ´10

SF240LP=SF-240MP

(incl.2 pawls) ´10

SF240DP=SF-240EP

(incl.2 pawls) ´10

7/13/2000 3 – 1

Page 21

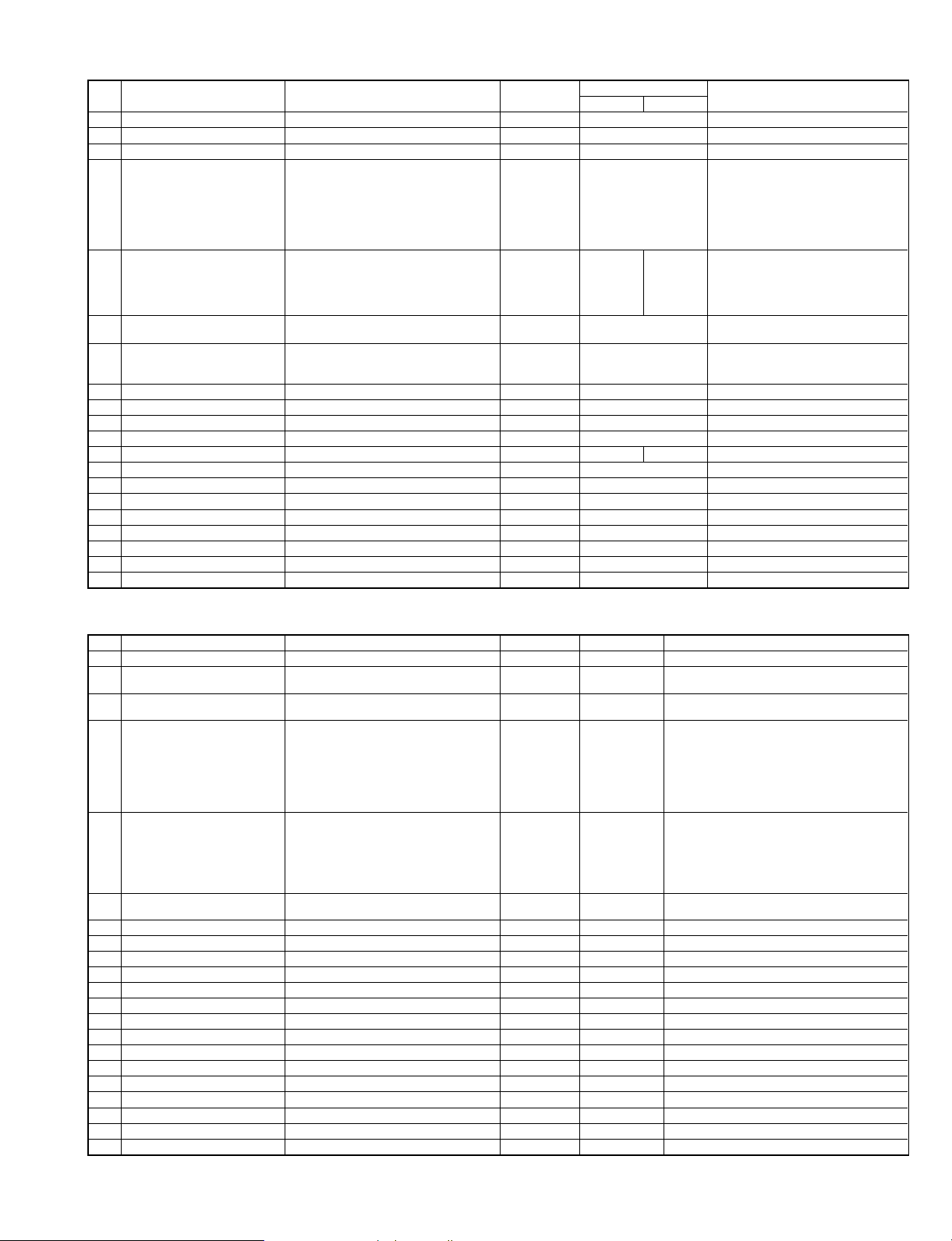

AR-405/407

No. ITEM CONTENTS LIFE

1 Drum OPC Drum ´1 180K AR-400DR

2 Developer (Black) Developer (800g) ´10 90K (´10) AR-400MD AR-400MD = (AR-400ND) ´ 10

3 Toner (Black) Toner Cartridge (700g) ´10 22K (´1) AR-400MT AR-400MT = (AR-400NT) ´ 10

4 Upper Heat Roller Kit

5 Lower Heat Roller Kit

6 90K Maintenance Kit

7 Cleaner Blade Cleaner Blade ´10 90K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

8 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

9 Staple Cartridge Staple Cartridge (SF-SC12) ´3 5K staples ´3 SF-LS12

9 Upper Heat Roller Upper Heat Roller ´1 180K AR-330HU

10 Fusing Separation Pawl (upper) Fusing Separation Pawl (upper) ´4 ´10 90K (´10) SF-216UP SF216UP=SF-216TP (incl.4 pawls) ´10

11 Heat Roller Gear Heat Roller Gear ´10 180K (´10) SF-216HG SF216HG= (SF216JG) ´10

12 Lower Heat Roller Lower Heat Roller ´1 180K AR-330HR AR-505HR

13 Fusing Separation Pawl (lower) Fusing Separation Pawl (lower) ´2 ´10 90K (´10) SF-240LP SF240LP=SF-240MP (incl.2 pawls) ´10

14 Drum Separation Pawl Drum Separation Pawl ´2 ´10 90K (´10) SF-240DP SF240DP=SF-240EP (incl.2 pawls) ´10

15 Screen Grid Screen Grid ´10 90K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

16 Charging Plate Charging Plate ´10 90K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

17 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

18 Busing Busing ´2 ´10 180K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

19 Ozone Filter Ozone Filter ´10 90K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

20 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

Upper Heat Roller

Fusing Separation Pawl (upper)

Heat Roller Gear

Lower Heat Roller

Fusing Separation Pawl (lower)

Cleaner Blade

Charging Plate Unit

Drum Separation Unit

´1

´4

´1

´1

´2

´1

´1

´1

180K AR-330UH

180K AR-330LH AR-505LH

90K AR-400KA1

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

MODEL NAME

AR-405 AR-407

REMARKS

Replacement of fusing separation pawl

for every 90 K should be done using

those supplied separately.

Replacement of fusing separation pawl

for every 90 K should be done using

those supplied separately.

Cartridge for AR-FN1

Common with S55,S55 N

Cartridge for AR-FN2

Common with S54

SF-LS12= (SF-SC12) ´3

AR-501/505/507

No. ITEM CONTENTS LIFE MODEL NAME REMARKS

1 Drum OPC Drum ´1 250K AR-500DR

2 Developer (Black) Developer (800g) ´10 250K (´10)

3 Toner (Black) Toner Cartridge (700g) ´10 25K (´10)

4 Upper Heat Roller Kit

5 Lower Heat Roller Kit

6 125K Maintenance Kit

7 Cleaner Blade Cleaner Blade ´10 125K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

8 Curl Adjustment Roller Curl Adjustment Roller ´10 250K (´10) AR-505KR AR-505KR= (AR-505JR) ´10

9 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

10 Upper Heat Roller Upper Heat Roller ´1 250K AR-505HU

11 Fusing Separation Pawl (upper) Fusing Separation Pawl (upper) ´4 ´10 125K (´10) AR-505UP AR-505UP=AR-505TP (incl.4 pawls) ´10

12 Heat Roller Gear Heat Roller Gear ´10 250K (´10) SF-216HG SF216HG= (SF216JG) ´10

13 Lower Heat Roller Lower Heat Roller ´1 250K AR-505HR

14 Fusing Separation Pawl (lower) Fusing Separation Pawl (lower) ´2 ´10 125K (´10) SF-240LP SF240LP=SF-240MP (incl.2 pawls) ´10

15 Drum Separation Pawl Drum Separation Pawl ´2 ´10 125K (´10) AR-505DP AR-505DP=AR-505EP (incl.2 pawls) ´10

16 Screen Grid Screen Grid ´10 125K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

17 Charging Plate Charging Plate ´10 125K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

18 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

19 Busing Busing ´2 ´10 250K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

20 Ozone Filter Ozone Filter ´10 125K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

21 Ozone Filter 50 Ozone Filter 50 ´10 125K (´10) AR-505FL AR-505FL= (AR-505JL) ´10

22 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

Upper Heat Roller

Fusing Separation Pawl (upper)

Heat Roller Gear

Lower Heat Roller

Fusing Separation Pawl (lower)

Cleaner Blade

Charging Plate Unit

Drum Separation Unit

Upper CL Roller Unit

´1

´4

´1

´1

´2

´1

´1

´1

´1

250K AR-505UH

250K AR-505LH

125K AR-505KA1

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

AR-500MD

(AR500ND)

AR-500MT

(AR-500NT)

(AR-500ND) ´10 = AR-500MD

(AR-500NT) ´10 = AR-500MT

Cartridge for AR-FN1/FN1N/FN3

Common with S55,S55 N

3 – 2 7/13/2000

Page 22

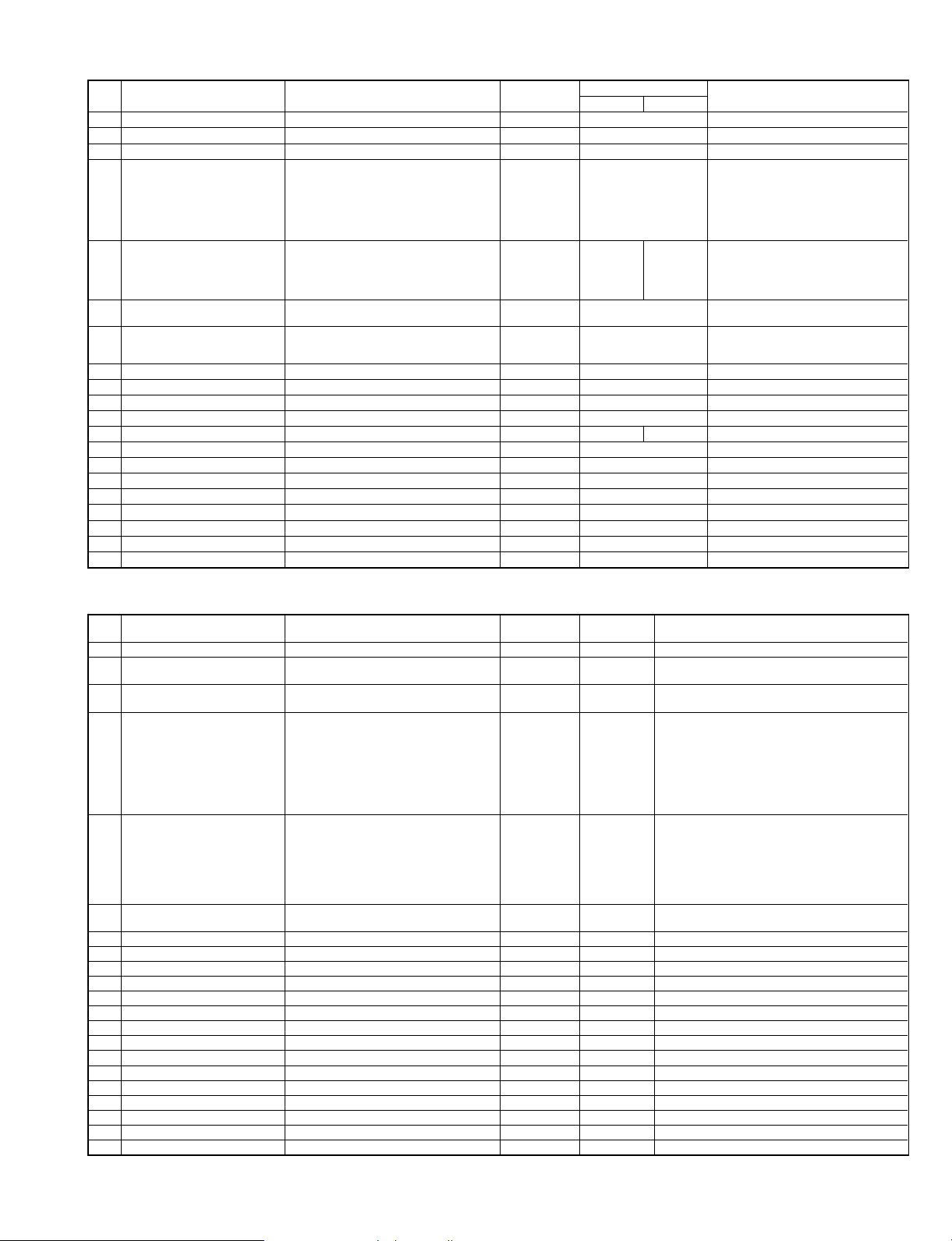

B. Canada

AR-250/280/281/285/286/287/335/336/337

No. ITEM CONTENTS LIFE

1 Drum OPC Drum ´1 160K AR-330DR AR-336DR

2 Developer (Black) Developer (800g) ´10 80K (´10)

3 Toner (Black) Toner Cartridge (700g) ´10 17.5K (´10)

Cleaner Blade

Charging Plate Unit

4 80K PM Kit

5 160K PM Kit

6 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

7 Staple Cartridge Staple Cartridge (SF-SC12) ´3 5K staples ´3 SF-LS12

8 Cleaner Blade Cleaner Blade ´10 80K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

9 Upper Heat Roller Upper Heat Roller ´1 160K AR-330HU

Fusing Separation

10

Pawl (upper)

11 Heat Roller Gear Heat Roller Gear ´10 160K (´10) SF-216HG SF216HG= (SF216JG) ´10

12 Lower Heat Roller Lower Heat Roller ´1 160K AR-330HR AR-505HR

Fusing Separation

13

Pawl (lower)

14 Drum Separation Pawl Drum Separation Pawl ´2 ´10 80K (´10) SF-240DP

15 Screen Grid Screen Grid ´10 80K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

16 Charging Plate Charging Plate ´10 80K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

17 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

18 Busing Busing ´2 ´10 160K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

19 Ozone Filter Ozone Filter ´10 80K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

20 Copy Lamp Copy Lamp ´10 AR-330CL AR-330CL= (AR-330DL) ´10

21 MC Unit MC Uni t ´10 AR-330MC AR-330MC= (AR-330NC) ´10

Waste Toner Bottle

Fusing Separation Pawl (upper)

Fusing Separation Pawl (lower)

Screen Grid

Drum Separation Unit

Upper Heat Roller

Lower Heat Roller

Toner Receiving Seal

DV Seal

Heat Roller Gear

Fusing Separation Pawl (upper) ´4 ´10 80K (´10) SF-216UP

Fusing Separation Pawl (lower) ´2 ´10 80K (´10) SF-240LP

´1

´1

´3

´4

´2

´1

´1

´1

´1

´1

´1

´1

80K AR-330KA AR-400KA

160K AR-330KB AR-337KB

AR-280/285/

AR-330MD

(AR330ND)

AR-330MT

(AR-330NT)

: AR-280/285/335 only

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

335

MODEL NAME

AR-250/281/

286/336

AR-336MD

(AR-336ND)

AR-400MT

(AR-400NT)

AR-287/337

REMARKS

AR-330MD = (AR-330ND) ´ 10

AR-336MD = (AR-336ND) ´ 10

AR-330MT = (AR-330NT) ´ 10

AR-400MT = (AR-400NT) ´ 10

Cartridge for AR-FN1

Common with S55,S55 N

Cartridge for AR-FN2

Common with S54

SF-LS12= (SF-SC12) ´3

SF216UP=SF-216TP

(incl.4 pawls) ´10

SF240LP=SF-240MP

(incl.2 pawls) ´10

SF240DP=SF-240EP

(incl.2 pawls) ´10

7/13/2000 3 – 3

Page 23

AR-405/407

No. ITEM CONTENTS LIFE

1 Drum OPC Drum ´1 180K AR-400DR

2 Developer (Black) Developer (800g) ´10 80K (´10) AR-400MD AR-400MD = (AR-400ND) ´ 10

3 Toner (Black) Toner Cartridge (700g) ´10 22K (´1) AR-400MT AR-400MT = (AR-400NT) ´ 10

4 90K PM Kit

5 180K PM Kit

6 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

7 Staple Cartridge Staple Cartridge (SF-SC12) ´3 5K staples ´3 SF-LS12

8 Cleaner Blade Cleaner Blade ´10 90K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

9 Upper Heat Roller Upper Heat Roller ´1 180K AR-330HU

10 Fusing Separation Pawl (upper) Fusing Separation Pawl (upper) ´4 ´10 90K (´10) SF-216UP

11 Heat Roller Gear Heat Roller Gear ´10 180K (´10) SF-216HG SF216HG= (SF216JG) ´10

12 Lower Heat Roller Lower Heat Roller ´1 180K AR-330HR AR-505HR

13 Fusing Separation Pawl (lower) Fusing Separation Pawl (lower) ´2 ´10 90K (´10) SF-240LP

14 Drum Separation Pawl Drum Separation Pawl ´2 ´10 90K (´10) SF-240DP

15 Screen Grid Screen Grid ´10 90K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

16 Charging Plate Charging Plate ´10 90K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

17 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

18 Busing Busing ´2 ´10 180K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

19 Ozone Filter Ozone Filter ´10 90K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

20 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

Cleaner Blade

Charging Plate Unit

Waste Toner Bottle

Fusing Separation Pawl (upper)

Fusing Separation Pawl (lower)

Screen Grid

Drum Separation Unit

Upper Heat Roller

Lower Heat Roller

Toner Receiving Seal

DV Seal

Heat Roller Gear

´1

´1

´3

´4

´2

´1

´1

´1

´1

´1

´1

´1

90K AR-400KA

180K AR-330KB AR-337KB

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

MODEL NAME

AR-405 AR-407

REMARKS

Cartridge for AR-FN1

Common with S55,S55 N

Cartridge for AR-FN2

Common with S54

SF-LS12= (SF-SC12) ´3

SF216UP=SF-216TP (incl.4

pawls) ´10

SF240LP=SF-240MP (incl.2

pawls) ´10

SF240DP=SF-240EP (incl.2

pawls) ´10

AR-505/507

No. ITEM CONTENTS LIFE

1 Drum OPC Drum ´1 250K AR-500DR

2 Developer (Black) Developer (800g) ´10 250K (´10)

3 Toner (Black) Toner Cartridge (700g) ´10 25K (´10)

Cleaner Blade

Charging Plate Unit

Waste Toner Bottle

4 125K PM Kit

5 250K PM Kit

6 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

7 Cleaner Blade Cleaner Blade ´10 125K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

8 Upper Heat Roller Upper Heat Roller ´1 250K AR-505HU

9 Fusing Separation Pawl (upper) Fusing Separation Pawl (upper) ´4 ´10 125K (´10) AR-505UP AR-505UP=AR-505TP (incl.4 pawls) ´10

10 Heat Roller Gear Heat Roller Gear ´10 250K (´10) SF-216HG SF216HG= (SF216JG) ´10

11 Lower Heat Roller Lower Heat Roller ´1 250K AR-505HR

12 Fusing Separation Pawl (lower) Fusing Separation Pawl (lower) ´2 ´10 125K (´10) SF-240LP SF240LP=SF-240MP (incl.2 pawls) ´10

13 Drum Separation Pawl Drum Separation Pawl ´2 ´10 125K (´10) AR-505DP AR-505DP=AR-505EP (incl.2 pawls) ´10

14 Screen Grid Screen Grid ´10 125K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

15 Charging Plate Charging Plate ´10 125K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

16 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

17 Busing Busing ´2 ´10 250K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

18 Ozone Filter Ozone Filter ´10 125K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

19 Ozone Filter 50 Ozone Filter 50 ´10 125K (´10) AR-505FL AR-505FL= (AR-505JL) ´10

20 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

21 Curl Adjustment Roller Curl Adjustment Roller ´10 250K (´10) AR-505KR AR-505KR= (AR-505JR) ´10

Fusing Separation Pawl (upper)

Fusing Separation Pawl (lower)

Screen Grid

Drum Separation Unit

Cleaning Roller

Upper CL Roller Unit

Upper Heat Roller

Lower Heat Roller

Toner Receiving Seal

DV Seal

Heat Roller Gear

Curl Adjustment Roller

´1

´1

´3

´4

´2

´1

´1

´1

´1

´1

´1

´1

´1

´1

´1

125K AR-505KA

250K AR-505KB

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

MODEL

NAME

AR-500MD

(AR500ND)

AR-500MT

(AR-500NT)

REMARKS

(AR-500ND) ´10 = AR-500MD

(AR-500NT) ´10 = AR-500MT

Cartridge for AR-FN1/FN1N/FN3

Common with S55,S55 N

3 – 4 7/13/2000

Page 24

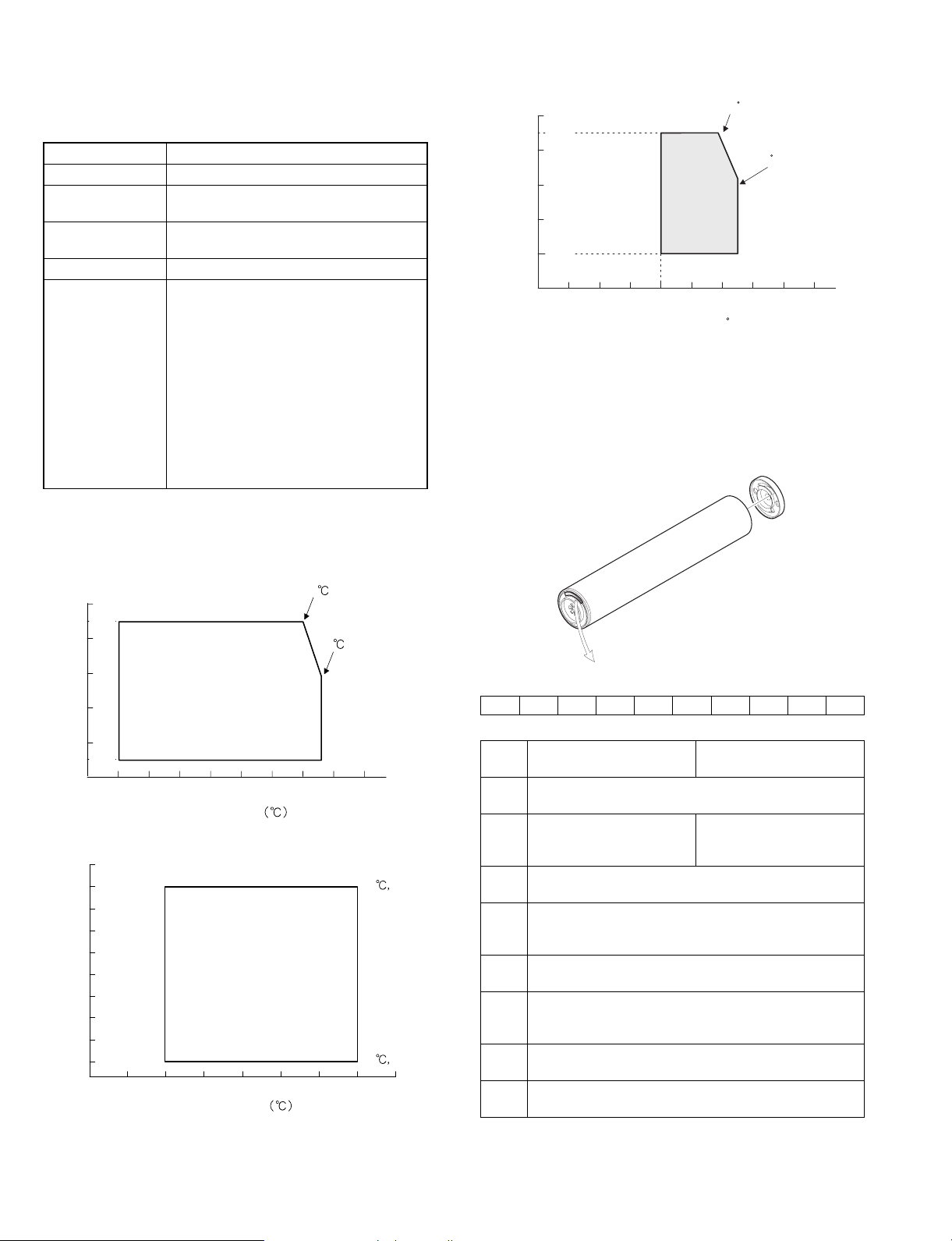

C. Europe / U.K. / Australia / New Zealand

AR-250/280/281/285/286/287/335/336/337

No. ITEM CONTENTS LIFE

1 Drum OPC Drum ´1 160K AR-330DM AR-331DM

2 Developer (Black) Developer (800g) ´10 80K (´10)

3 Toner (Black) Toner Cartridge (700g) ´10 17.5K (´10)

Cleaner Blade

Charging Plate Unit

4 80K PM Kit

5 160K PM Kit

6 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

7 Staple Cartridge Staple Cartridge (SF-SC12) ´3 5K staples ´3 SF-LS12

8 Cleaner Blade Cleaner Blade ´10 80K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

9 Upper Heat Roller Upper Heat Roller ´1 160K AR-330HU

Fusing Separation Pawl

10

(upper)

11 Heat Roller Gear Heat Roller Gear ´10 160K (´10) SF-216HG SF216HG= (SF216JG) ´10

12 Lower Heat Roller Lower Heat Roller ´1 160K AR-330HR AR-505HR

Fusing Separation Pawl

13

(upper)

14 Drum Separation Pawl Drum Separation Pawl ´2 ´10 80K (´10) SF-240DP

15 Screen Grid Screen Grid ´10 80K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

16 Charging Plate Charging Plate ´10 80K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

17 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

18 Busing Busing ´2 ´10 160K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

19 Ozone Filter Ozone Filter ´10 80K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

20 Copy Lamp Copy Lamp ´10 AR-330CL AR-330CL= (AR-330DL) ´10

21 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

Waste Toner Bottle

Fusing Separation Pawl (upper)

Fusing Separation Pawl (lower)

Screen Grid

Drum Separation Unit

Upper Heat Roller

Lower Heat Roller

Toner Receiving Seal

DV Seal

Heat Roller Gear

Fusing Separation Pawl (upper) ´4 ´10 80K (´10) SF-216UP

Fusing Separation Pawl (lower) ´2 ´10 80K (´10) SF-240LP

´1

´1

´3

´4

´2

´1

´1

´1

´1

´1

´1

´1

80K AR-330KA AR-400KA

160K AR-330KB AR-337KB

AR-280/285/

AR-330LD

(AR330DV)

AR-330LT

(AR-330T)

: AR-280/285/335 only

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

335

MODEL NAME

AR-250/281/

286/336

AR-336LD

(AR-336DV)

AR-400LT

(AR-400T)

AR-287/337

REMARKS

AR-330LD = (AR-330DV) ´ 10

AR-336LD = (AR-336DV) ´ 10

AR-330LT = (AR-330T) ´ 10

AR-400LT = (AR-400T) ´ 10

Cartridge for AR-FN1

Common with S55,S55 N

Cartridge for AR-FN2

Common with S54

SF-LS12= (SF-SC12) ´3

SF216UP=SF-216TP

(incl.4 pawls) ´10

SF240LP=SF-240MP

(incl.2 pawls) ´10

SF240DP=SF-240EP

(incl.2 pawls) ´10

7/13/2000 3 – 5

Page 25

AR-405/407

No. ITEM CONTENTS LIFE

1 Drum OPC Drum ´1 180K AR-400DM

2 Developer (Black) Developer (800g) ´10 90K (´10) AR-400LD AR-400LD = (AR-400DV) ´ 10

3 Toner (Black) Toner Cartridge (700g) ´10 22K (´1) AR-400LT AR-400LT = (AR-400T) ´ 10

Cleaner Blade

Charging Plate Unit

4 90K PM Kit

5 180K PM Kit

6 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

7 Staple Cartridge Staple Cartridge (SF-SC12) ´3 5K staples ´3 SF-LS12

8 Cleaner Blade Cleaner Blade ´10 90K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

9 Upper Heat Roller Upper Heat Roller ´1 180K AR-400HU

10 Fusing Separation Pawl (upper) Fusing Separation Pawl (upper) ´4 ´10 90K (´10) SF-216UP SF216UP=SF-216TP (incl.4 pawls) ´10

11 Heat Roller Gear Heat Roller Gear ´10 180K (´10) SF-216HG SF216HG= (SF216JG) ´10

12 Lower Heat Roller Lower Heat Roller ´1 180K AR-330HR AR-505HR

13 Fusing Separation Pawl (upper) Fusing Separation Pawl (lower) ´2 ´10 90K (´10) SF-240LP SF240LP=SF-240MP (incl.2 pawls) ´10

14 Drum Separation Pawl Drum Separation Pawl ´2 ´10 90K (´10) SF-240DP SF240DP=SF-240EP (incl.2 pawls) ´10

15 Screen Grid Screen Grid ´10 90K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

16 Charging Plate Charging Plate ´10 90K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

17 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

18 Busing Busing ´2 ´10 180K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

19 Ozone Filter Ozone Filter ´10 90K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

20 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

Waste Toner Bottle

Fusing Separation Pawl (upper)

Fusing Separation Pawl (lower)

Screen Grid

Drum Separation Unit

Upper Heat Roller

Lower Heat Roller

Toner Receiving Seal

DV Seal

Heat Roller Gear

´1

´1

´3

´4

´2

´1

´1

´1

´1

´1

´1

´1

90K AR-400KA

180K AR-400KB AR-407KB

Note: Maintenance parts other than mentioned above must be ordered through the parts department using the proper part number.

MODEL NAME

AR-405 AR-407

REMARKS

Cartridge for AR-FN1

Common with S55,S55 N

Cartridge for AR-FN2

Common with S54

SF-LS12= (SF-SC12) ´3

AR-505/507

No. ITEM CONTENTS LIFE MODEL NAME REMARKS

1 Drum OPC Drum ´1 250K AR-500DM

2 Developer (Black) Developer (800g) ´10 250K (´10)

3 Toner (Black) Toner Cartridge (700g) ´10 25K (´10)

Cleaner Blade

Charging Plate Unit

Waste Toner Bottle

4 125K PM Kit

5 250K PM Kit

6 Staple Cartridge Staple Cartridge (SF-SC11) ´3 5K staples ´3 SF-SC11

7 Cleaner Blade Cleaner Blade ´10 125K (´10) AR-330CB AR-330CB= (AR-330BL) ´10

8 Upper Heat Roller Upper Heat Roller ´1 250K AR-505HU

9 Fusing Separation Pawl (upper) Fusing Separation Pawl (upper) ´4 ´10 125K (´10) AR-505UP AR-505UP=AR-505TP (incl.4 pawls) ´10

10 Heat Roller Gear Heat Roller Gear ´10 250K (´10) SF-216HG SF216HG= (SF216JG) ´10

11 Lower Heat Roller Lower Heat Roller ´1 250K AR-505HR

12 Fusing Separation Pawl (lower) Fusing Separation Pawl (lower) ´2 ´10 125K (´10) SF-240LP SF240LP=SF-240MP (incl.2 pawls) ´10

13 Drum Separation Pawl Drum Separation Pawl ´2 ´10 125K (´10) AR-505DP AR-505DP=AR-505EP (incl.2 pawls) ´10

14 Screen Grid Screen Grid ´10 125K (´10) AR-330SU AR-330SU= (AR-330TU) ´10

15 Charging Plate Charging Plate ´10 125K (´10) AR-330PU AR-330PU= (AR-330NU) ´10

16 Waste Toner Bottle Waste Toner Bottle ´1 AR-330TB

17 Busing Busing ´2 ´10 250K (´10) SF-240BU SF-240BU= (SF-240DU) ´10

18 Ozone Filter Ozone Filter ´10 125K (´10) AR-330FL AR-330FL= (AR-330JL) ´10

19 Ozone Filter 50 Ozone Filter 50 ´10 125K (´10) AR-505FL AR-505FL= (AR-505JL) ´10

20 MC Unit MC Unit ´10 AR-330MC AR-330MC= (AR-330NC) ´10

21 Curl Adjustment Roller Curl Adjustment Roller ´10 250K (´10) AR-505KR AR-505KR= (AR-505JR) ´10

Fusing Separation Pawl (upper)

Fusing Separation Pawl (lower)

Screen Grid

Drum Separation Unit

Cleaning Roller

Upper Heat Roller

Lower Heat Roller

Toner Receiving Seal

DV Seal

Heat Roller Gear

Curl Adjustment Roller

Upper CL Roller Unit

´1

´1

´3

´4

´2

´1

´1

´1

´1

´1

´1

´1

´1

´1

´1

125K AR-505KA

250K AR-505KB