SHARP AR651, AR810 Service Manual

FIELD SERVICE HANDBOOK

CODE: 00ZAR810//H1E

DIGITAL COPIER

AR-651

MODEL

CONTENTS

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES . . . 1-1

2. ERROR CODE AND SELF- DIAGNOSIS . . . . . . . . . . . . . . . . . . . . 2-1

3. ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4. PREVENTIVE MAINTENANCE (PM) . . . . . . . . . . . . . . . . . . . . . . . 4-1

5. TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6. UPDATING THE FIRMWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

7. POWER SUPPLY UNIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

8. WIRE HARNESS CONNECTION DIAGRAMS . . . . . . . . . . . . . . . . 8-1

AR-810

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

GENERAL PRECAUTIONS REGARDING THE INSTALLATION

AND SERVICE FOR THE COPIER AR-651/810

The installation and service should be done by a qualified service technician.

1. Transportation/Installation

• When transporting/installing the copier, move it by the casters while lifting the stoppers.

The copier is quite heavy and weighs approximately 200 kg (441 lb), therefore pay full attention

when handling it.

• Be sure to use a dedicated outlet with AC 115V or 120V/20A (220V, 230V, 240V/10A) or more for

its power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

• Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for the copying operation, keep a minimum clearance of

80 cm (32”) on the left, 80 cm (32”) on the right and 10 cm (4”) in the rear.

• The socket-outlet shall be installed near the copier and shall be easily accessible.

2. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high-temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltage sections such as the chargers, high-voltage transformer, exposure lamp control inverter, inverter for the LCD backlight and power supply unit. Especially, the

board of these components should not be touched since the electirc charge may remain in the

condensers, etc. on them even after the power is turned OFF.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys, fan, etc.

• Be careful when removing the covers since there might be the parts with very sharp edges underneath.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

and rotating/operating sections. Avoid exposure to laser radiation.

• Use suitable measuring instruments and tools.

• Avoid exposure to laser radiation during servicing.

- Avoid direct exposure to the beam.

- Do not insert tools, parts, etc. that are reflective into the path of the laser beam.

- Remove all watches, rings, bracelets, etc. that are reflective.

3. Main Service Parts for Safety

• The breaker, door switch, fuse, thermostat, thermofuse, thermistor, etc. are particularly important

for safety. Be sure to handle/install them properly. If these parts are shorted circuit and/or made

their functions out, they may burn down, for instance, and may result in fatal accidents. Do not

allow a short circuit to occur. Do not use the parts not recommended by Sharp Corporation.

4. Cautionary Labels

• During servicing, be sure to check the rating plate and the cautionary labels such as “Unplug the

power cord during service”, “Hot area”, “Laser warning label” etc. to see if there is any dirt on their

surface and whether they are properly stuck to the copier.

5. Disposition of Consumable Parts, Packing Materials, Used batteries and RAM-ICs

• Regarding the recovery and disposal of the copier, supplies, consumable parts, packing materials, used batteries and RAM-ICs including litium batteries, it is recommended to follow the relevant local regulations or rules.

6. When parts are disassembled, reassembly is basically the reverse of disassembly unless

otherwise noted in this manual or other related documents. Be careful not to reassemble

small parts such as screws, washers, pins, E-rings, star washers in the wrong places.

7. Basically, the machine should not be operated with any parts removed or disassembled.

8. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may become damaged due to static electricity.

Caution: Before using the wristband, pull out the power cord plug of the copier and make

sure that there are no uninsulated charged objects in the vicinity.

Caution : Dispose of used batteries and RAM-ICs including lithium batteries

according to this manual.

Attention : Se débarrasser de batteries et RAM-ICs usés y compris les batteries en

lithium selon ce manuel.

Vorsicht : Entsorgung des gebrauchten Batterien und RAM-ICs (inklusive

der Lithium-Batterie) nach diesem Handbuch.

1. SPECIFICATIONS /

ACCESSORIES / OPTIONS /

SUPPLIES

2. ERROR CODE AND SELFDIAGNOSIS

3. ADJUSTMENT

4. PREVENTIVE MAINTENANCE

(PM)

5. TROUBLESHOOTING

6. FIRMWARE UPDATING

7. POWER SUPPLY UNIT

8. WIRE HARNESS

CONNECTION DIAGRAMS

CONTENTS

1. SPECIFICATIONS / ACCESSORIES / OPTIONS / SUPPLIES.................................................. 1-1

1. 1. Specifications ........................................................................................................................ 1-1

1. 2. Accessories ........................................................................................................................... 1-13

1. 3. Options .................................................................................................................................. 1-13

1. 4. Supplies ................................................................................................................................. 1-14

1. 5. System List ........................................................................................................................... 1-16

2. ERROR CODES AND SELF-DIAGNOSIS................................................................................... 2-1

2. 1. Error Codes ............................................................................................................................ 2-1

2. 2. Self-diagnosis Modes............................................................................................................. 2-8

2. 2. 1. Input check (test mode 03) ....................................................................................... 2-10

2. 2. 2. Output check (test mode 03) .................................................................................... 2-16

2. 2. 3. Test print mode (04) .................................................................................................. 2-19

2. 2. 4. Adjustment mode (05)............................................................................................... 2-20

2. 2. 5. Setting mode (08) ..................................................................................................... 2-31

3. ADJUSTMENT ............................................................................................................................ 3-1

3. 1. Hard Disk Formatting ............................................................................................................. 3-1

3. 2. Adjustment of Auto-toner Sensor ........................................................................................... 3-2

3. 3. Dimensional Adjustment of Copied Image .............................................................................. 3-4

3. 3. 1. Overview .................................................................................................................. 3-4

3. 3. 2. Paper alignment ........................................................................................................ 3-6

3. 3. 3. Printer related adjustment ......................................................................................... 3-7

3. 3. 4. Scanner related adjustment ...................................................................................... 3-12

3. 4. Image Quality Adjustment...................................................................................................... 3-19

3. 4. 1. Image density for copier ........................................................................................... 3-19

3. 4. 2. Sharpness adjustment for copier .............................................................................. 3-20

3. 4. 3. Gamma slope adjustment for copier ......................................................................... 3-20

3. 4. 4. Setting for range correction for copier ....................................................................... 3-21

3. 4. 5. Adjustment of background peak for range correction for copier ................................. 3-21

3. 4. 6. Adjustment of blurred/thin spotted text ..................................................................... 3-22

3. 4. 7. Adjustment of image density for printer ..................................................................... 3-22

3. 5. High-voltage Adjustment ........................................................................................................ 3-23

3. 6. Adjustment of Scanning Section ............................................................................................ 3-25

3. 6. 1. Carriages .................................................................................................................. 3-25

3. 6. 2. Lens unit ................................................................................................................... 3-29

3. 7. Adjustment of Paper Feeding System .................................................................................... 3-32

3. 7. 1. Sheet sideways deviation caused by paper feeding .................................................. 3-32

3. 8. Adjustment of Developer Unit ................................................................................................ 3-34

3. 9. Adjustment of Fuser Unit ....................................................................................................... 3-35

3. 9. 1. Adjustment of fuser roller pressure ........................................................................... 3-35

AR-651/810 CONTENTS

I

3. 9. 2. Setting of fuser roller temperature ............................................................................. 3-36

3. 9. 3. Adjustment of fuser inlet guide ................................................................................. 3-36

3. 9. 4. High-fusing mode ...................................................................................................... 3-37

3. 10 Adjustment of Exit/Reversal Unit ...........................................................................................3-38

3. 10. 1. Adjustment of sideways deviation at reverse discharging ......................................... 3-38

3. 11. Adjustmet of Reversing Automatic Document Feeder ............................................................ 3-39

3. 11. 1. Installing of the RADF unit........................................................................................ 3-39

3. 11. 2. Skew adjustment ...................................................................................................... 3-40

3. 11. 3. Adjustment of solenoid ............................................................................................. 3-41

3. 11. 4. Adjustment of RADF open/close switch.................................................................... 3-42

3. 11. 5. Adjustment of RADF height ...................................................................................... 3-42

4. PREVENTIVE MAINTENANCE (PM) ......................................................................................... 4-1

4. 1. PM Support Mode .................................................................................................................. 4-1

4. 1. 1. General description ................................................................................................... 4-1

4. 1. 2. Operational flow and operational screen .................................................................... 4-1

4. 2. General Descriptions for PM procedure .................................................................................. 4-5

4. 3. Operational Items in Overhauling ........................................................................................... 4-5

4. 4. Preventive Maintenance Checklist ......................................................................................... 4-5

4. 5. PM Kit ................................................................................................................................... 4-19

4. 6. Jig List ................................................................................................................................... 4-20

4. 7. Precautions for Storing and Handling Supplies ....................................................................... 4-21

4. 7. 1. Precautions for storing supplies ................................................................................ 4-21

4. 7. 2. Checking and cleaning of OPC drum ........................................................................ 4-21

4. 7. 3. Checking and cleaning of drum cleaning blade and transfer belt cleaning blade ............. 4-22

4. 7. 4. Handling of drum cleaning brush and transfer belt cleaning brush ............................. 4-23

4. 7. 5. Handling of transfer belt ............................................................................................ 4-23

4. 7. 6. Checking and cleaning of fuser roller and pressure roller ........................................... 4-23

4. 7. 7. Checking and replacing of cleaning web and cleaning rollers (felt, metal) .................. 4-24

4. 8. Replacement of maintenance parts ........................................................................................ 4-25

4. 8. 1. DRUM UNIT.............................................................................................................. 4-25

4. 8. 2. DEVELOPER UNIT .................................................................................................. 4-30

4. 8. 3. FUSER UNIT ............................................................................................................ 4-34

5. TROUBLESHOOTING ................................................................................................................ 5-1

5.1 Diagnosis and Prescription for Each Error Code and Phenomenum ....................................... 5-1

5.1.1 Paper transport jam .................................................................................................. 5-1

5.1.2 Paper misfeeding ...................................................................................................... 5-14

5.1.3 Cover open jam ........................................................................................................ 5-21

5.1.4 Jams at eit/reverse section and other transport jams ............................................... 5-24

5.1.5 Original jam in RADF ................................................................................................ 5-33

5.1.6 Paper jam in finisher ................................................................................................. 5-37

II AR-651/810 CONTENTS

5.1.7 Paper feeding system related service call ................................................................. 5-53

5.1.8 Process system related service call ......................................................................... 5-58

5.1.9 Scanning system related service call........................................................................ 5-60

5.1.10 Fuser unit related service call ................................................................................... 5-62

5.1.11 Communication related service call .......................................................................... 5-68

5.1.12 ADF related service call ............................................................................................ 5-71

5.1.13 Laser optical unit related service call ........................................................................ 5-76

5.1.14 Finisher related service call ...................................................................................... 5-79

5.1.15 Service call for others ..............................................................................................5-101

5.1.16 Troubleshooting for image quality control ................................................................. 5-102

5.1.17 Troubleshooting for surface potential control ............................................................5-105

5.2 Troubleshooting for the Image ............................................................................................... 5-107

6. FIRMWARE UPDATING .............................................................................................................. 6-1

6. 1. Software Installing for Firmware Updating .............................................................................. 6-2

6. 1. 1. Outline ...................................................................................................................... 6-2

6. 1. 2. Requirements ........................................................................................................... 6-2

6. 1. 3. Dial-up network function ............................................................................................ 6-4

6. 1. 4. Installing of dial-up network ....................................................................................... 6-8

6. 1. 5. Setting of dial-up network ......................................................................................... 6-10

6. 1. 6. Software installing for FTP server ............................................................................. 6-14

6. 2. Operation Procedure in [3][9] Mode ........................................................................................ 6-18

6. 2. 1. Outline ...................................................................................................................... 6-18

6. 2. 2. Preparation ............................................................................................................... 6-18

6. 2. 3. Updating procedure ................................................................................................... 6-20

6. 2. 4. Display ..................................................................................................................... 6-28

6. 3. Firmware Updating with Download Jig .................................................................................... 6-32

6. 3. 1. System firmware....................................................................................................... 6-33

6. 3. 2. Engine firmware ........................................................................................................ 6-39

7. POWER SUPPLY UNIT ........................................................................................................7-1

7. 1. Output Channel ...................................................................................................................... 7-1

7. 2. Fuse ...................................................................................................................................... 7-5

8. WIRE HARNESS CONNECTION DIAGRAMS ........................................................................8-1

8. 1. AC Wire Harness ................................................................................................................... 8-2

8. 2. DC Wire Harness ................................................................................................... 8-4, Appendix

IIIAR-651/810 CONTENTS

1. SPECIFICATIONS

1.1. Specifications

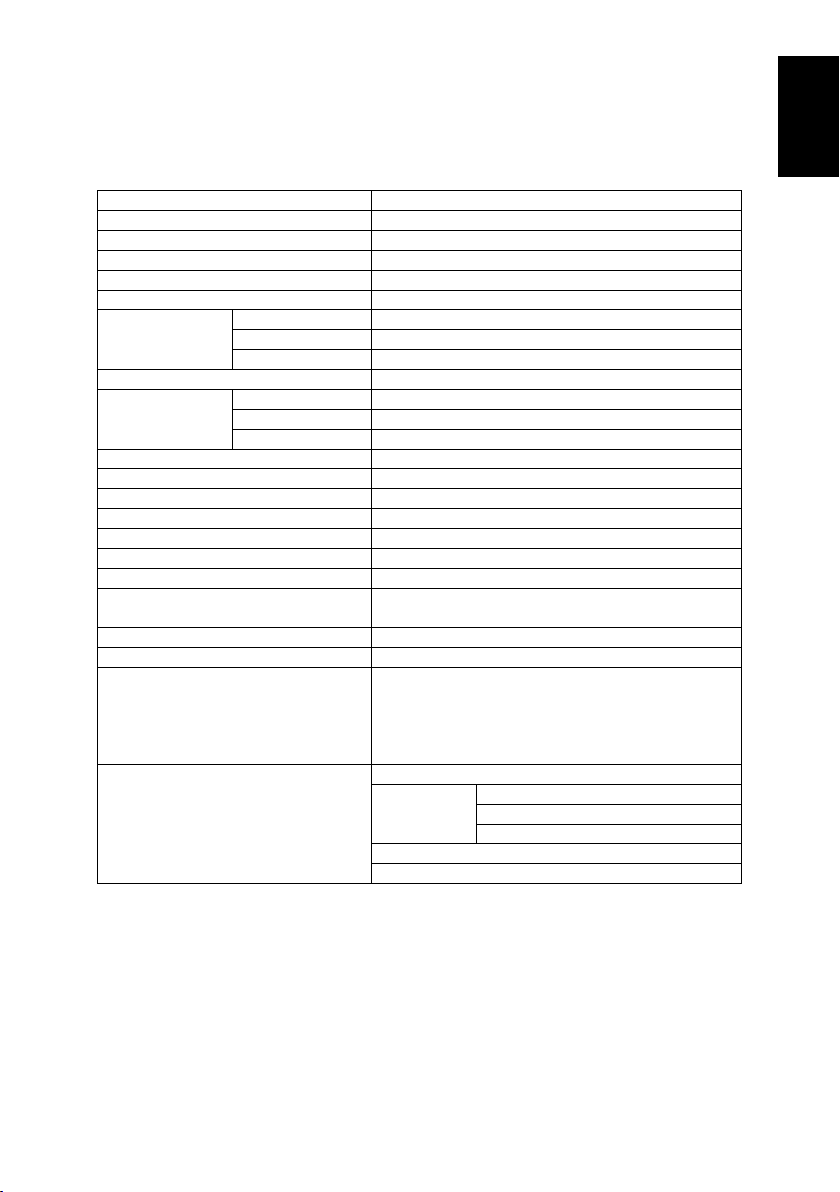

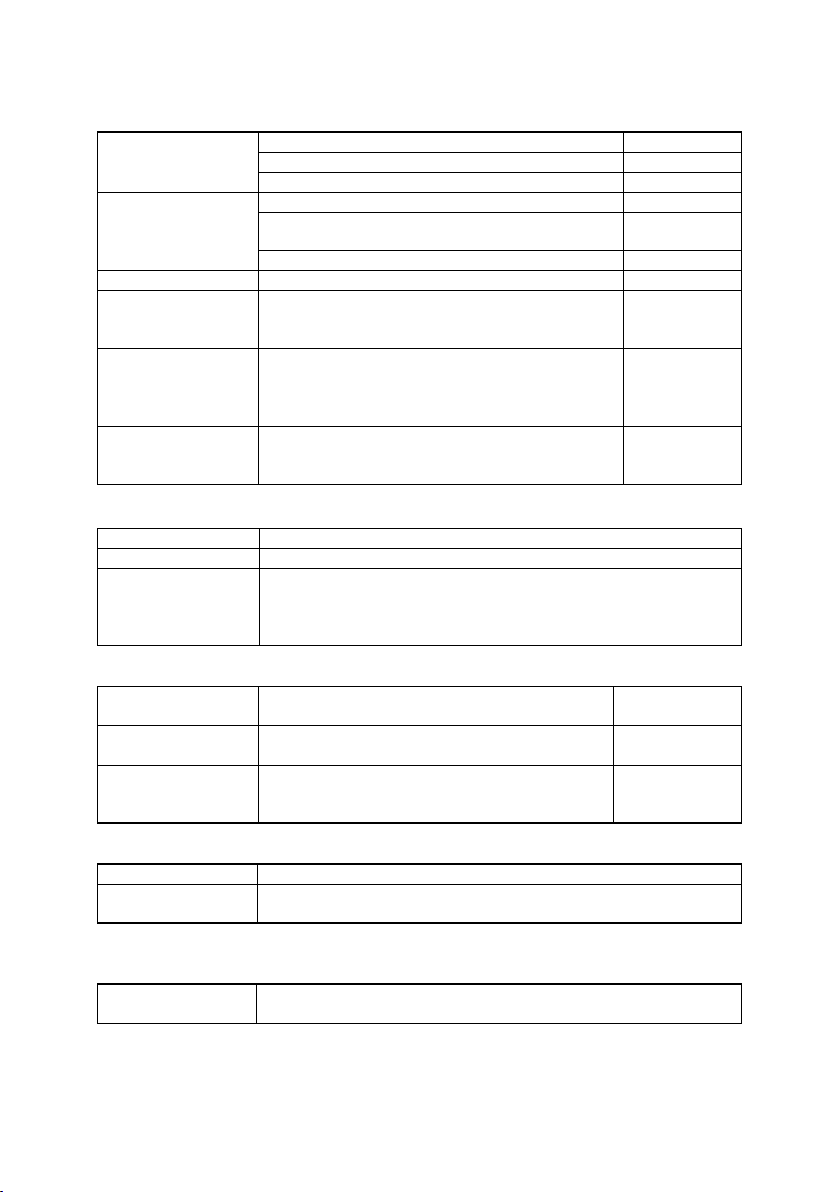

1.1.1. System

Copy system Indirect electronic photo system (Dry type)

Body type Console type

Original table type Fixed type (Left rear reference)

Original cover RADF standard provision

Frame structure Fixed frame type

Photoconductor OPC drum (φ100)

Original scan system Scan sensor CCD line sensor (7500 pixel)

Scan data output system 1 scan multi copy system

Exposure system Exposure light source Semiconductor laser

Developing system 2-component magnetic brush development system

Discharging system Photo discharge by red LED

Charging system Negative corona system (Scorotron)

Transfer system Transfer belt system

Separation system Transfer belt system

Transfer belt cleaning system Fur brush system + blade system

Drum cleaning system Blade system + Fur brush system

Toner supply system Front side toner cartridge supply

Toner concentration adjustment system Magnetic auto toner system

Toner recycle Yes

Toner empty detection system Electric detection system (Auto toner sensor)

Fusing system Heat roller system

Scan resolution 600 x 600 dpi

Scan light source Xenon lamp

Exposure resolution 600 dpi

Scan system Use of Polygon mirror

Note: Toner supply inhibited during printing

Note: When toner empty is detected, the toner supply symbol

flashes and the message is displayed.

Copying is inhibited until the toner concentration is

recovered.

Induced heating

system

Roller diameter (Upper) φ60

Roller diameter (Lower) φ60

700 to 1450 W (100V)

6000 to 1500 W (115V)

700 to 1500 W (230V)

1 - 1 AR-651/810 SPECIFICATIONS

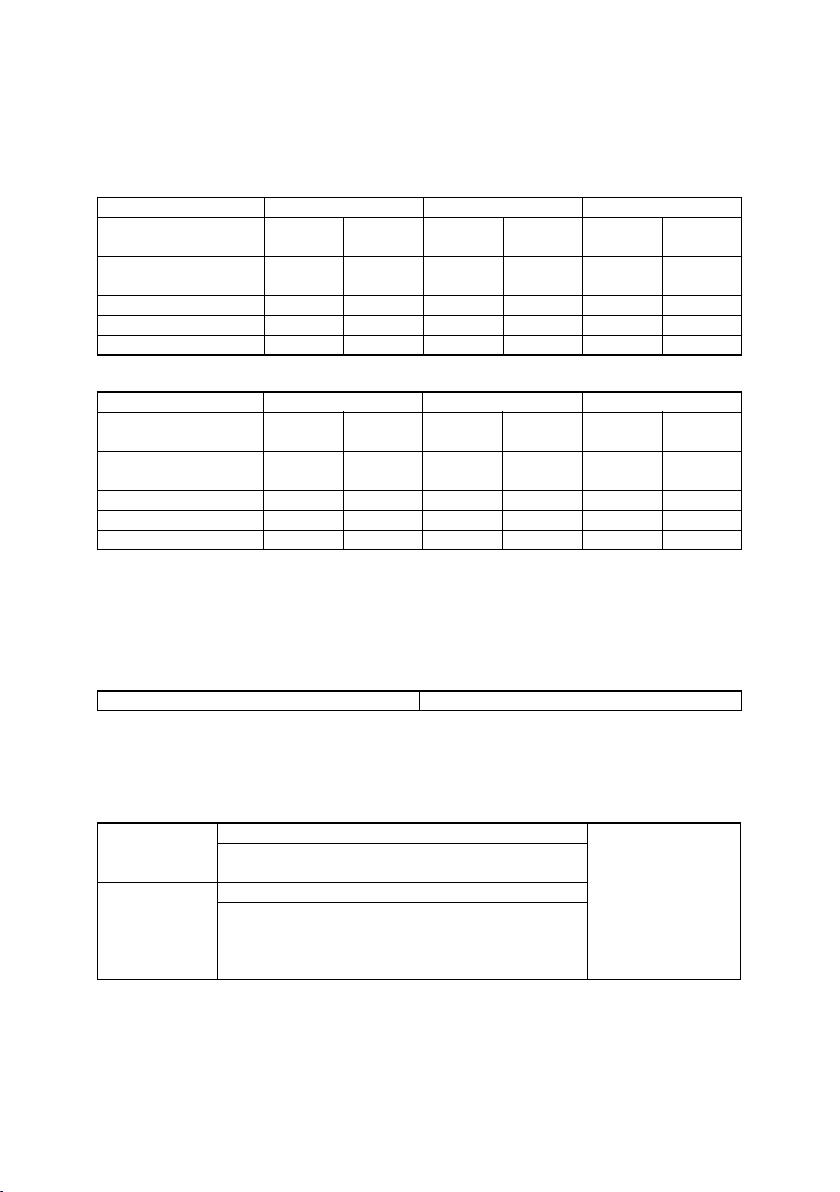

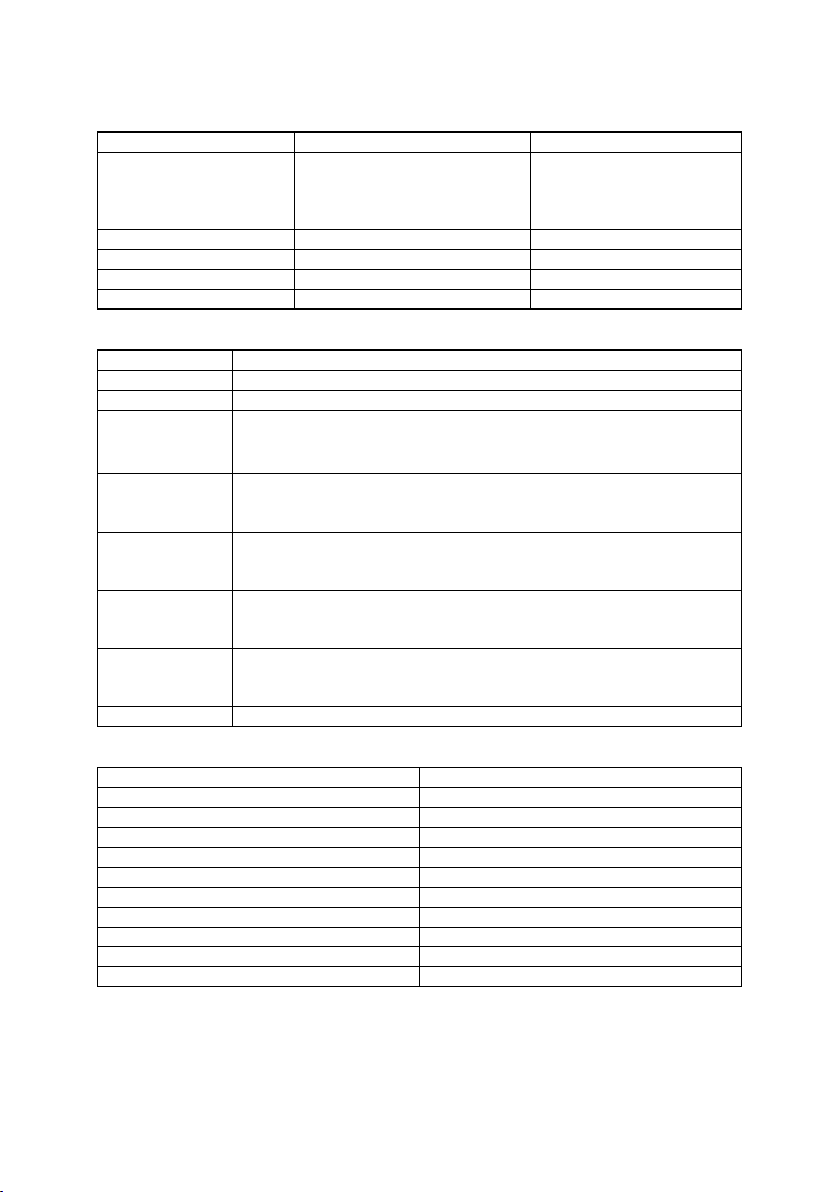

1.1.2. Basic specifications

A. Copy speed

(1) Continuous copy

AR-651 (cpm)

Paper feed system Cassette LCF (Note 3) Manual feed (Note 4)

Paper size Face up

A4, B5, A5-R, LT, ST-R

A4-R, B5-R, LT-R 50 48 — — 42 42

B4, FOLIO, LG, COMP 43 40 — — 37 37

A3, LD 37 34 — — 33 33

AR-810 (cpm)

Paper feed means PFP LCF (Note 3) Manual feed (Note 4)

Paper size Face up

A4, B5, A5-R, LT, ST-R

A4-R, B5-R, LT-R 61 56 — — 44 44

B4, FOLIO, LG, COMP 52 45 — — 39 39

A3, LD 43 37 — — 34 34

Note 1: Specification for manual set document, single copy, non-sort continuous copy

Note 2: State not entering the toner supply mode

Note 3: LCF is a tandem LCF (standard provision).

Note 4: Copy speed for manual feed is a speed with the size specified. If the size is not specified, the copy speed

is same as that of A3/LD.

(2) First copy

First copy time 3.2 sec or less

Note 1: The above specification is for manual set document, normal ratio, A4/LT size, 1st stage cassette paper

feed, and face-up exit.

Note 2: When APS is not used.

Face down

exit

65 65

Face down

exit

81 81

exit

exit

Face up

(A4, LT)65(A4, LT)

Face up

(A4, LT)81(A4, LT)

exit

65

exit

81

Face down

exit

Face down

exit

Face up

exit

48 48

Face up

exit

50 50

Face down

exit

Face down

exit

B. Warm-up time

Normal About 160sec (160sec + 20% or less) Evaluation conditions

Note 1: State not entering the toner supply mode

Note 2: When there is no preceding entry

Pre-heating About 45sec

Note 1: When the heater is at 155°C in preheating (AR-651)

When the heater is at 70°C in preheating (AR-810)

Note 2: State not entering the toner supply mode

Note 3: When there is no preceding entry

AR-651/810 SPECIFICATIONS 1 - 2

1. Room temperature

20°C or above

2. Rated power

C. Original

Max. size A3 or LD

Kind Sheet, cubic material, book

Original size detection Glass surface: Yes

Allowable original size for

auto detection

Note 1: Fixed detection system with the RADF open

RADF: Yes

Note 1: Document width and length are detected in RADF paper feed.

Note 2: Only the first paper is detected except when mixed sizes of sheets are

loaded.

Fixed size AB series: A3, A4, A4-R, A5-R, B4, B5, B5-R

LT series: LD, LG, LT, LT-R, ST-R

D. Paper

(1) Size

Fixed size Cassette AB series: A3, A4, A4-R, A5-R, B4, B5, B5-R, FOLIO

Tandem LCF AB series: A4

Manual feed AB series: A3, A4, A4-R, A5-R, B4, B5, B5-R, FOLIO

Note 1: Postcards can be used. (Reverse copy and duplex copy are inhibited.)

Note 2: Name cards cannot be used.

Note 3: Same surface copy cannot be used.

Note 4: Envelopes cannot be used.

Note 5: Fixed-size paper width is detected with the manual feed tray guide width.

Note 6: Manual feed of mixed-size sheets cannot be made.

(2) Kind

Cassette

Manual feed

• PPC paper

Note 1: Tracing paper, OHP films, label paper, postcards, and other special paper

Note 2: Tab paper can be used only in the second stage cassette.

• PPC paper

• Tracing paper: Out of warranty for reliability

• OHP film: Out of warranty for reliability

• Tab paper: Out of warranty for reliability

LT series: LD, LG, LT, LT-R, ST-R, COM

LT series: LT

LT series: LD, LG, LT, LT-R, ST-R, COM

cannot be used.

(3) Max. weight

Cassette/Manual feed 64 to 209 g/m²

Note 1: 80 to 209 g/m² or less available in the Heavy paper mode.

17 lbs to 110 lbs-index

1 - 3 AR-651/810 SPECIFICATIONS

E. Paper feed

Paper feed means Cassette, 2 steps

Capacity Cassette: 500 sheets (Loading height: 55mm or less)

Manual feed start START key start

Priority paper feed means Yes

Manual feed size

specification

Paper size change The paper guide in the cassette is shifted to the fixed size

Tandem LCF

Manual feed

Tandem LCF: 1250 x 2 sheets (Loading height: 137mm or

less)

Manual feed: 100 sheets (Loading height: 11mm or less)

Note 1: Priority can be switched to the other paper feed

means by date input in the adjustment mode.

Can be specified by pressing the paper size key after loading

paper.

Note 1: Size specification allows binding margin, duplex edge

erase, and continuous paper copy.

position, and the paper size is changed by the setup code or

the setup of the special menu.

F. Continuous copy

Number of copies 1 to 9999 sheets (Max. number of copies), in increment of 1

Input system Input by 10 key

Counting system Reduction system

Note 1: "1" is displayed in auto clear or during warm-up.

Note 2: Count-down display on the print status display for every print job

Note 3: For a cop job, the status is also displayed on the copy display.

G. Density adjustment

Automatic density

adjustment

Manual density

adjustment

Priority mode Automatic density adjustment

Yes

11-step adjustment (Operated by keys on the control panel

LCD)

Note 1: Selection of automatic/manual is available by data

input in the adjustment mode.

Tandem LCF

Factory setup: Auto

H. Picture quality mode

Image process mode Standard mode/Photo mode/Text mode

Priority mode Standard mode

Note 1: Selectable by data input in the adjustment mode.

I. Magnification ratio

(1) Reduction, enlargement

Reduction, enlargement Automatic setup by selection of the document size and the paper size

AR-651/810 SPECIFICATIONS 1 - 4

Note 1: Any fixed size (including different series) can be set to Japan A5, OTHER.

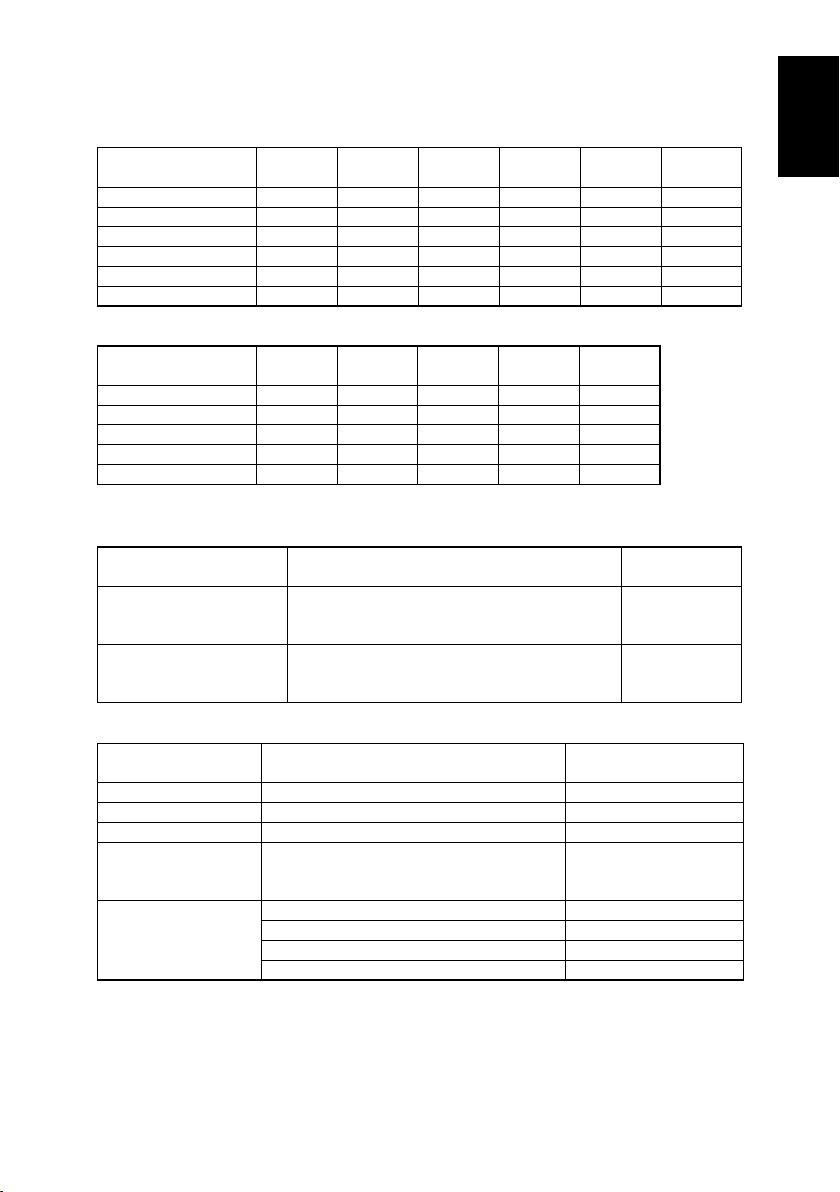

(2) Selected magnification ratio

a. AB series

Document

Paper

A3 100 86 71 71 61 50

B4 115 100 82 82 71 57

FOLIO 127 110 100 90 78 63

A4 141 122 100 100 86 71

B5 163 141 115 115 100 82

A5 200 173 141 141 122 100

b. LT Series

Paper

Document

LD 10082786550

COMP 108 100 84 78 54

LG 121 100 100 78 60

LT 129 119 100 100 65

ST 200 165 154 129 100

Note: Figures indicate the selected magnification ratios (%).

(3) Others

Zoom 25 to 400%, in increment of 1%

Copy range display No

Automatic paper select(APS)/

Automatic magnification ratio

select (AMS)

A3 B4 FOLIO A4 B5 A5

LD COMP LG LT ST

25 to 200%, in increment of 1% (when the RADF is used)

Note 1: The center position is displayed in continuous

paper copy and book copy.

Yes Priority on APS

when shipping

J. Counter display

Total counter Mechanical, 7 digits

A3/LD double count mode Yes (Electronic counter) Factory setup: ON

PM counter Yes (Electronic counter) Factory setup: 460K, 500K

Resettable counter No

Document counter Yes (Electronic counter) Factory setup

JOB counter Copy counter

Displayed on the control panel.

Europe: Yes

Others: No

Print counter

Copy scan counter

File/network scan counter

1 - 5 AR-651/810 SPECIFICATIONS

K. Charger wire cleaning

Charger wire cleaning Automatic cleaning system

Note: The charger wire is cleaned.

L. Special functions

Interruption Yes

Pre-heating Yes Key input can be

Sleep Yes (when the controller is connected) Excluding the options and

Auto off Yes (When the controller is not connected)

Auto clear Yes

Self diag Yes

Error code history Yes

Department

management (pass

code function)

Dew prevention Yes (Option depending on the destination)

Message Yes

All clear Yes

Mode memory Yes (4 modes) Inhibited in interruption

Cover mode Yes (following 4 modes)

Note 1: Automatic pre-heat function can be set in the

adjustment mode.

Note 2: Time can be set in the adjustment mode.

(Setup: 15, 20, 30, 45, 60 min)

Note 3: The fusing unit temperature in pre-heating can be

changed in the adjustment mode.

Note: The power consumption in the sleep mode is max.

20W.

Note 1: Time up to off can be set in the adjustment mode or

on the adjustment menu. (Max. 240 min.)

Note 2: Use/Non-use can be selected by setup on the

adjustment mode.

Note 3: Selection of user setup allow/inhibit on time setup

can be set.

Note: Setup can be changed in the adjustment mode or on

the adjustment menu. (15 to 150sec (in increment of

15 sec))

Yes (The number of copies and the number of prints are

managed for each department.)

Note 1: Entry of the pass code in 5 digits is required when

supplying the power or in auto clear for copying.

Note 2: Common use with the key counter is inhibited.

Note 3: Max. 150 kinds can be set.

Note 1: Graphic LCD, back-light provided

(1) White cover mode

(2) Copy cover mode

(3) White cover/white back cover mode

(4) Copy cover/white back cover mode

accepted during warm-up

or ready state.

Factory setup (Note 2):

15 min

the dump heater.

Factory setup (Note 1):

90 min

Factory setup (Note 2):

Yes

Factory setup (Note 3)

Japan, North America,

Australia: Allow

Europe: Inhibit

Factory setup: 45sec

Factory setup: OFF

Entry of OOOO is

rejected. (Note 1)

copy

AR-651/810 SPECIFICATIONS 1 - 6

Sheet insertion mode Yes (following 2 modes)

(1) White sheet insertion mode

(2) Copy paper insertion mode

Weekly timer Yes

Pre-heat start Yes

Pre-heat copy Yes

Max. 6 jobs.

Note 1: The next copy job mode setup can be made when

document scan is completed. When the START key

is pressed, preceding entry of document is started.

Note 2: In the 6th job, the machine is in the scan reservation

state. After completion of copy 1 job, scan is

automatically started.

Automatic duplex

Yes Factory setup: OFF

automatic selection

Time display Yes

Copy riser support No

Automatic sort Yes Factory setup: ON

Automatic cassette

Yes

selection

Network printer Network printer board can be connected. (Option)

DSS No

Language selection Yes (Japanese, English, German, French, Spanish, Italian:

Factory setup)

Note: Language data depends on the HDD.

FROM update Yes (following 2 methods)

Serviceman support

(1) Downloading from PC

(2) Downloading from a jig PC board.

Adjustment code

Yes (05, 08 code) Serviceman support

output

Mixed-size document

Yes (when the RADF is installed)

mode

Heavy paper mode Yes

Note 1: One of the following two modes must be selected

according to the kind of Heavy paper.

• Heavy paper mode 1: For paper of 80 g/m² to 163

g/m²

• Heavy paper mode 2: For paper of 163 g/m² - 209

g/m²

Note 2: The copy speed standard for using Heavy paper is

as shown below:

• Cassette, LCF (Tandem) paper feed, A4/LT size

AR-651 AR-810

Normal paper 65 81

Heavy paper mode 1 65 81

Heavy paper mode 2 65 65

Paper used for evaluation

North America: Wausau

Exact/Index

Europe: Noisydra Color

Copy

Note 3: The duplex function is available.

1 - 7 AR-651/810 SPECIFICATIONS

M. Edit functions

Continuous paper copy Yes

Edge erase Yes

Note: The edge erase priority mode

can be selected by the

adjustment mode.

Binding margin (Image shift) Yes

Trimming, masking Yes

2 in 1 Yes

4 in 1 Yes Normal position for document set

Factory setup: No priority

N. Tab paper

Paper feed means Supported only for manual paper feed and the second stage cassette.

Paper feed direction The tab side must be on the rear side when feeding.

Kind of tab paper A4/LT size

Tab width

Print on the tab

section

Duplex print No

Staple Yes

Punch Yes

Insert Yes

• Manual paper feed: 10 to 20 mm

• Cassette 2: 12 to 17mm

Note 1: Initial value of tab width: 13mm

Yes

Note 1: The overall input image is shifted to ward the tab side (rear edge).

Note 2: The copy speed is reduced similarly to the heavy paper mode.

Note 1: Selection inhibited between Single ⇒ Duplex and Duplex ⇒ Duplex

Note 2: In duplex print with tab paper inserted, single print is made only in the tab paper.

Note: There is a limitation on the number of stapled sheets according to the heavy

paper specifications.

Note: When tab paper is inserted, tab paper is not punched. However, punching on tab

paper can be set in the setup mode.

O. Digital edit function

Independent zoom Yes

Mirror image Yes

Black-white reversion Yes

Electronic sort Yes

Magazine sort Yes

Page numbering Yes

Rotation copy Yes

Image overlay Yes

Document storage Yes

Date/time writing Yes

Image direction Yes

AR-651/810 SPECIFICATIONS 1 - 8

P. Operation panel

Operation keys Hard key

Status display Displayed with the message display and LED

Message display Graphic LCD with touch panel (with back-light)

Print status key Yes

Note 1: The number of keys is 19 as follows:

ENERGY SAVER

INTERRUPT

CLEAR ALL (CA)

CLEAR

STOP

START

PRINTER/NETWORK

COPY

0 to 9 (10 keys)

JOB STATUS

HELP

Note 1: There are following 9 LEDs.

ENERGY SAVER

TIMER

INTERRUPT

CLEAR ALL

PRINTER/NETWORK

DATA

ERROR

COPY

JOB STASUS

Note 1: Detail of LCD

Number of display dots: 320 x 240 (1/4 VGA)

Display area: 115.17mm x 86.37mm

Display mode: Blue mode

The display when the print status key is pressed is composed of the job list, the print status,

and the cassette tab.

• Job list: The print jobs are listed. The job sequence can be changed and any job can be

deleted.

• Print status: Indicates which paper feed stage is used. In case of paper empty, the paper

feed stage blinks.

• Cassette: The cassette size and the attribute (cover paper, sheet, special) can be set.

Q. Environmental conditions

Normal use 10 to 30°C, 20 to 85% RH, without dew Recommended paper

Special use (1) –5 to 10°C, 20 to 85% RH, without dew

Transit and storage with

consumable parts packed together

Transit and storage with

consumable parts packed together

Transit and storage of consumable

parts

(2) 30 to 35°C, 20 to 85% RH, without dew

–10 to 35°C, 85% RH or less, without dew

–40 to 50°C, 85% RH or less, without dew

–10 to 35°C, 85% RH or less, without dew

1 - 9 AR-651/810 SPECIFICATIONS

immediately after

unpacking must be used.

R. Noises

When ready 45dB (A) or less

When continuous copying 65dB (A) or less

S. Complying standards

Safety standards 1) Electric appliances safety regulation

Interruption wave

standards

2) S mark

3) UL

4) CSA (C-UL)

5) CDRH

6) TUV

7) CE mark

1) VCCI

2) FCC (IC)

3) CE mark

4) C-TICK (Australia)

5) Radio wave regulations

6) Domestic harmonic wave

T. Power source

Power voltage, frequency 100V-50/60Hz, 115V-50/60Hz, 220 to 240V-50/60Hz

Power consumption 2.0 kW or less

Power cord 2m

Note: Including options.

Note: Detachable for the 200 series.

U. External view

External dimensions (1) Machine: W698 x D777 x H1213 mm

Weight Machine only: 214 kg (including developer and the OPC drum)

Occupying area (1) Machine only: W1401 x D777 mm

Note 1: Excluding the manual paper feed tray and the paper exit tray.

(2) Machine + finisher: W1416 x D777 x H1213 mm

Note 1: Excluding the manual paper feed tray.

Note: Including the manual feed tray and the paper exit tray.

(2) Machine + finisher: W1742 x D777 mm

Note: Including the manual feed tray and the finisher tray.

V. Packing

External dimensions W764 x D867 x H1305 mm (including the pallet)

Weight 240 kg

Items packed together Operation Manual

AR-651/810 SPECIFICATIONS 1 - 10

OPC drum

Drum cover

Operation Manual pocket

Spacer for the document tray

Rear edge guide for tab paper

Maintenance management table (CCASZ0067FC02)

Delivery and installation report (TCADZ1510FCZZ) (Australia)

MSDS card (TCADZ) (North America, Europe)

Warranty paper for Australia (TGANE1001QCZB) (Australia)

cover-screws, 3 pcs.

W. Maintenance

(1) Periodic inspection

Execution interval 460,000 sheets 500,000 sheets

AR-651 AR810

X. Automatic document feeder

Automatic document feeder Standard provision

(1)Functions

Functions Automatic separation and feed of loaded documents

Allowed documents Fixed size AB series: A3, A4, A4-R, A5-R, B4, B5, B5-R

Document capacity 100 sheets or loading height 16 mm or less

Process speed Corresponding to 65 sheets/min

Document process method Loading: The last document at the bottom, face up

Document position Center reference

Power source Supplied from the machine

Use frequency Print quantity: RADF = 5 : 1 (Single document : Duplex document = 20 : 1)

a) Automatic magnification ratio/paper selection

b) Duplex documents supported

c) SADF/ADF

LT series: LD, LG, LT, LT-R, ST-R

Kind: Quality paper

Max. weight Single copy documents: 50 g/m² to 127 g/m² (13 to 34 Lbs)

Duplex documents: 50 g/m² to 104 g/m² (13 to 28 Lbs)

Note: All size 80 g/m² or 20lbs paper

Note 1: A4/LT size, single → Single mode, normal ratio

Paper feed method: From the top, fed one by one to the copy section.

Paper exit method: From the top, face down, accumulated sequentially

Y. Automatic duplex unit

Automatic duplex unit Standard provision

Kind Stackless, switchback duplex unit

Allowable paper Fixed size AB series: A3, A4, A4-R, A5-R, B4, B5, B5-R, FOLIO

Kind PPC paper

Paper weight Weight: 64 to 209 g/m² (17 lbs to 110 lbs-index)

Curl level 5 mm or less (Paper feed section)

Transport reference Center reference

LT series: LD, LG, LT, LT-R, ST-R, COM

1 - 11 AR-651/810 SPECIFICATIONS

Z. Tandem LCF

Standard provision

Kind Single paper feed (Right), single shift (Left) type large

Paper supply system Front loading type No separation of right

Max. loading capacity Loading height: 137mm or less x 2 stages

Allowable paper size AB series: A4

Paper kind PPC paper

Paper weight 64 to 209 g/m²

Transport reference Center reference

Curl level 5 mm or less

capacity paper feed unit

and left (Overall pull-out)

(1250 x 2 sheets, paper thickness 0.106mm, 80 g/m² /

20 lbs paper)

LT series: LT

(OHP films, gum labels, and special paper cannot be

used.)

17 lbs-bond to 110 lbs-index

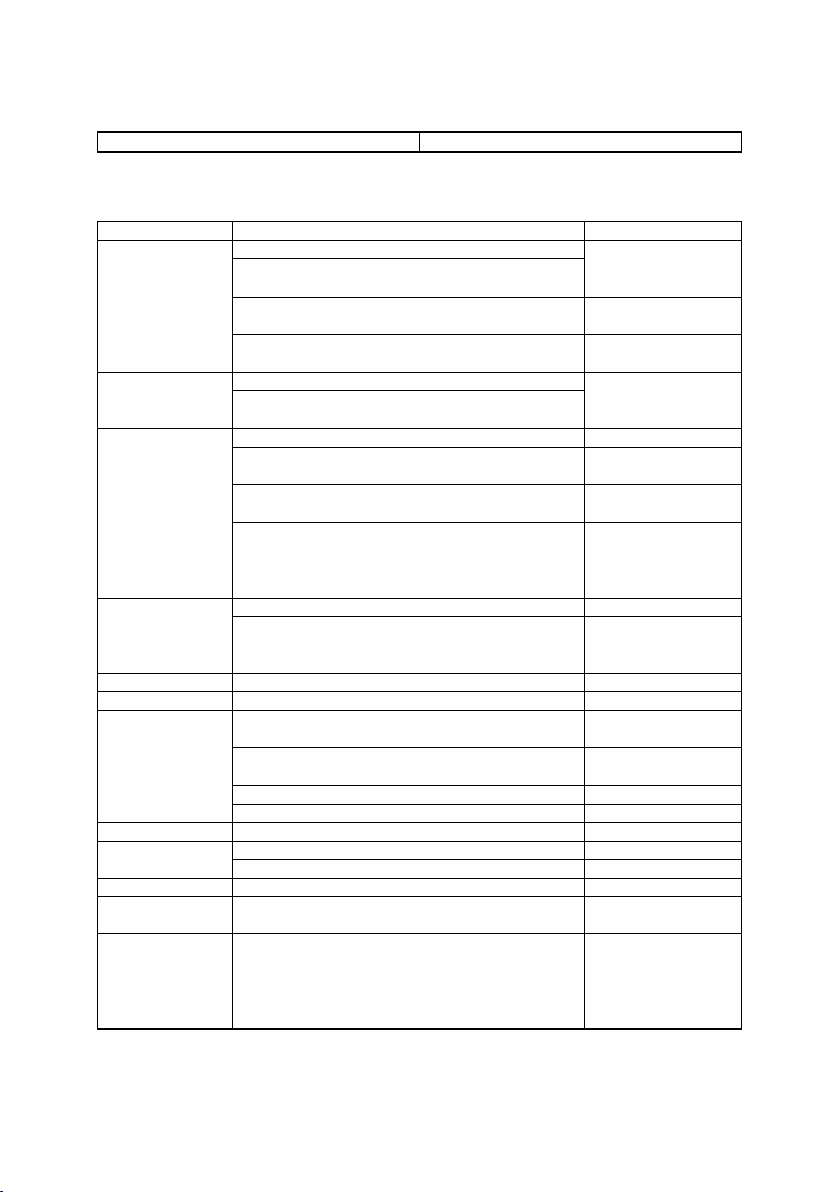

1.1.3. Image, image specifications

A. Image quality

Image density 1.0 or above Original density: 1.0

Background copy 3.0% or less Difference in reflection ratio with

Resolution Normal ratio 100%: Vertical 4.0 mm or above/

Horizontal 3.6 mm or above

Enlargement 200%: Vertical 4.5mm or above/

Horizontal 4.0 mm or above

Reduction 50%: Vertical 2.0 mm or above/

Horizontal 1.7mm or above

Gradation Standard: 5 steps or more Evaluated in the gradation

Text: 4 steps or more

Photo: 6 steps or more

Distortion ±1.0%

Magnification ratio error Normal ratio: ±1.0%

Enlargement 200% / Reduction 50%: ±1.5%

Lead edge position shift Machine 0±2 mm

System 0±4.0 mm

Horizontal shift Machine 0±3.0 mm

System 0±4.0 mm

Slant Machine 1.0 mm or less

System 3.0 mm or less/200 mm

non-transferred paper

evaluation step. Measured with

the background as 1 step.

Machine: Fixed document,

single-side, normal ratio

Machine: Fixed document,

single-side, normal ratio, sort

mode

Machine: Fixed document,

single-side, normal ratio

AR-651/810 SPECIFICATIONS 1 - 12

1.2. Accessories

Operation manual

Drum

Drum cover

Operation Manual pocket

Spacer for original tray

Rear edge guide for tab paper

Maintenance management table (CCASZ0067FC02)

Delivery and installation report (TCADZ1510FCZZ) (Australia)

MSDS card (TCADZ) (North America, Europe)

Warranty paper for Australia (TGANE1001QCZB) (Australia)

cover-screws, 3 pcs.

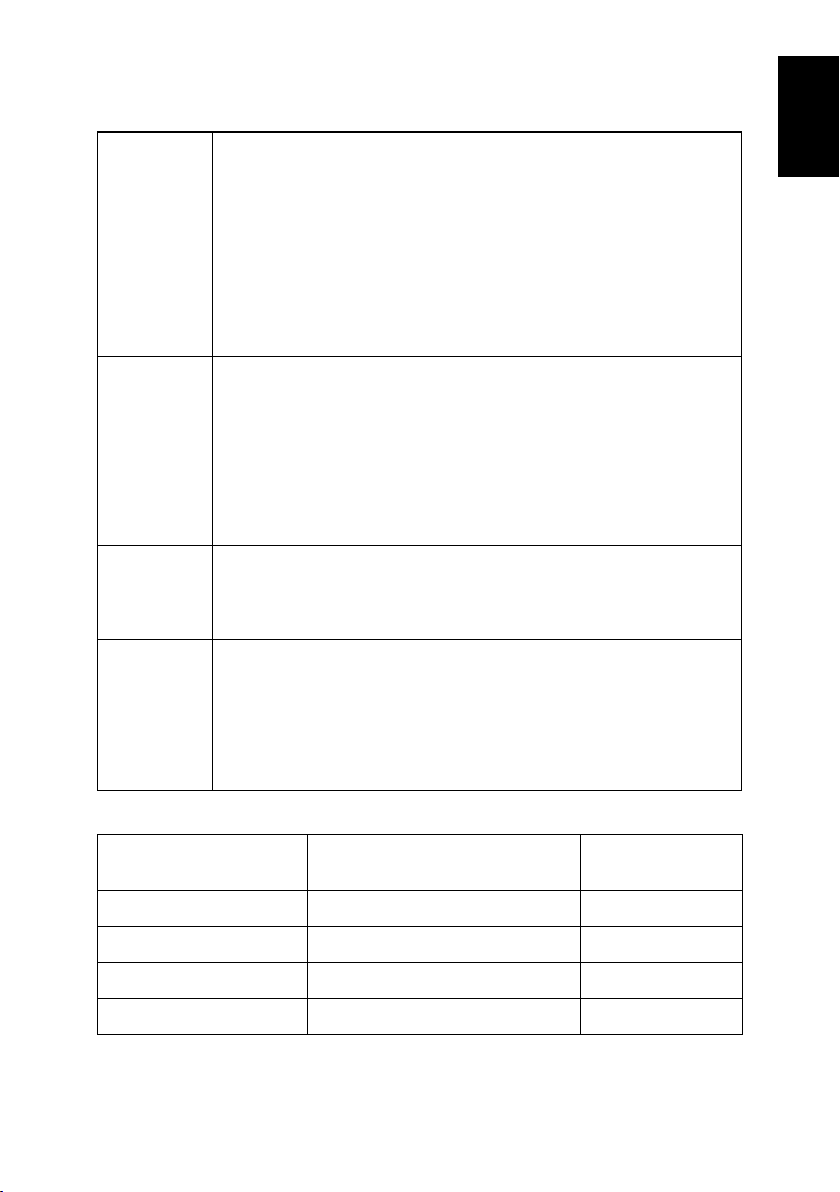

1.3. Options

Large capacity paper feed tray AR-LC4

Finisher AR-F11

Punch unit AR-PN3A 2 holes (φ6.5) Europe

Inserter AR-CF1

Printer kit AR-P15

ITEM MODEL NOTE

AR-F12 Saddle stitch finisher

AR-PN3B 2 holes/3 holes automatic selection(φ8.0) North America

AR-PN3C 4 holes (φ6.5) (80mm pitch) France

AR-PN3D 4 holes (φ6.5) (70, 21mm pitch) Sweden

AR-PK2

AR-PK3

1 - 13 AR-651/810 SPECIFICATIONS

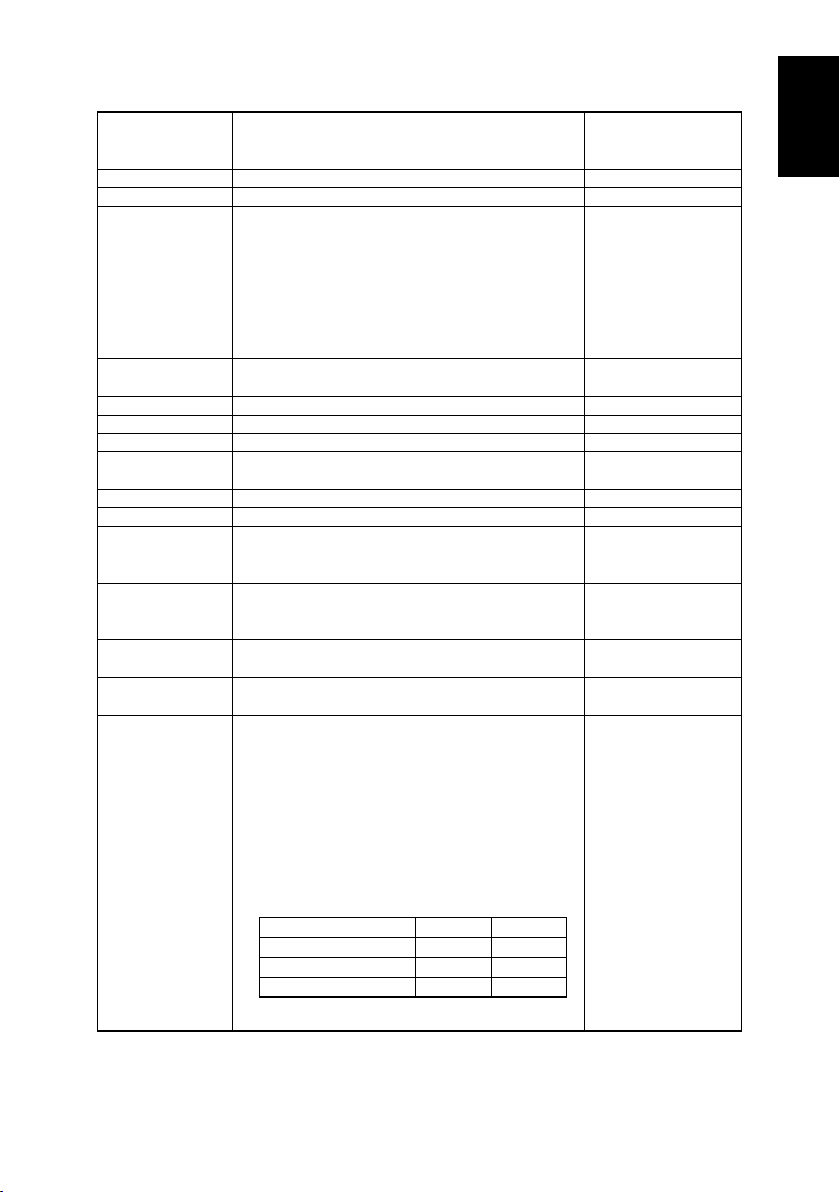

MT=NT x 4

AR-810DR 10

AR-810ND 4

AR-810MT 1 * Life: A4 size at 6% AC

MT=NT x 4

AR-810LT 1 * Life: A4 size at 6% AC

AR-810DV 4

AR-810DM 10

(60K x 4)

x 4 240k

(Toner; Net Weight 1350g)

1 Toner CA (Black) Toner

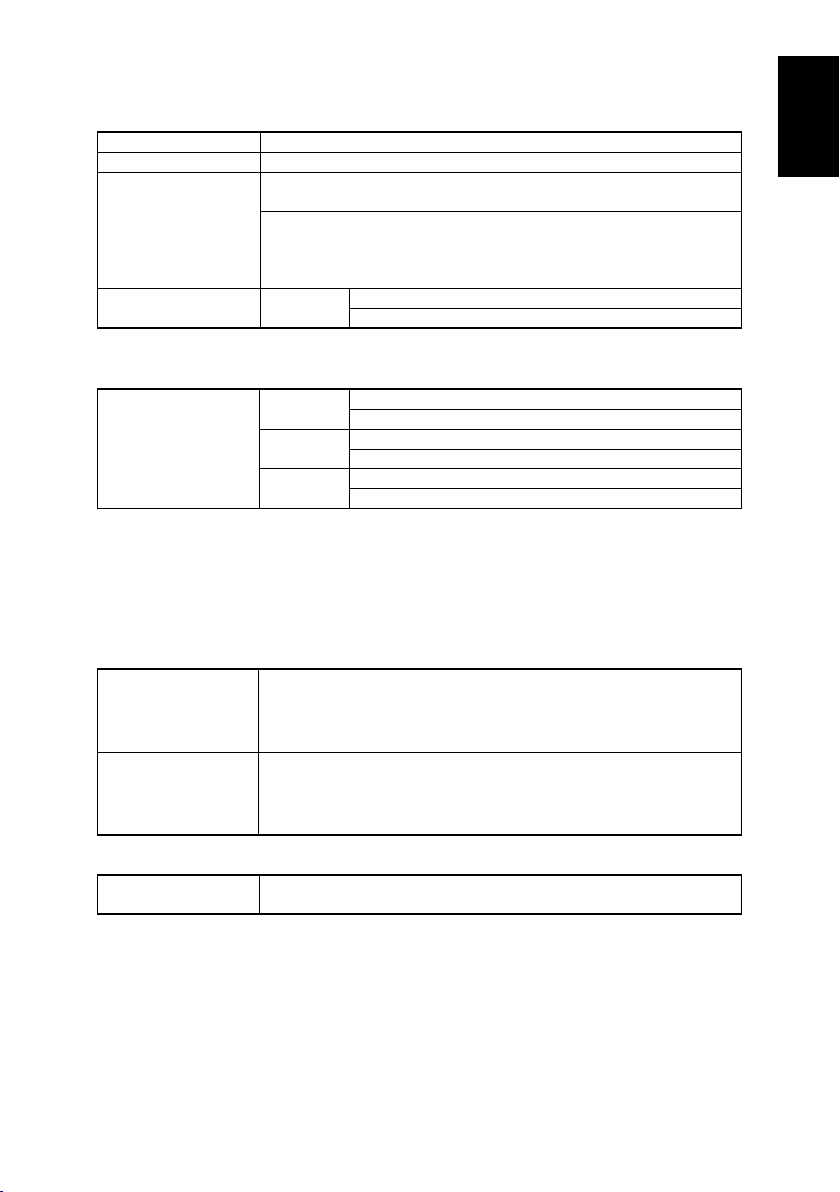

No. Item Content Life Model Name Packing Unit Remarks

1.4. Supplies

SEC/SECL/(LAG)

AR-651/810 SPECIFICATIONS 1 - 14

x 1 460K (AR-651)

2 Developer Developer

500K (AR-810)

(Developer; Net Weight 1500g)

3 Drum Drum x 1 460K (AR-651)

500K (AR-810)

Note 1) Master/individual cartons are printed in 2 languages (English/French).

Packaged for the machine: DR 460K/DV UN/Process UN

European Subsidiary

(60K x 4)

x 4 240k

(Toner; Net Weight 1350g)

1 Toner CA (Black) Toner

No. Item Content Life Model Name Packing Unit Remarks

x 1 460K (AR-651)

2 Developer Developer

500K (AR-810)

(Developer; Net Weight 1500g)

3 Drum Drum x 1 460K (AR-651)

500K (AR-810)

Packaged for the machine: DR 460K/DV UN/Process UN

Note 1) Master/individual cartons are printed in 4 languages (English/French/Spanish/Germany).

200K: Tray

Common with FN9

Common with S55,S55N,FN8/9

350K: Tandem LCC

AR-810KA 1 common between AR651 and AR810

500K

Drum cleaning blade x1 460K

Drum separation claw x2

Drum cleaning roller x1

Charger wire (Main) x1

Charger wire cleaning pad x1

Charger grid x1

Maintenance Kit 1

1

No. Item Content Life Model Name Packing Unit Remarks

AR-810LC 1 common between AR651 and AR810

AR-810FU 1 common between AR651 and AR810

500K

500K

Transfer belt x1

Transfer belt brush roller x1

Transfer belt cleaning blade x1

Air filter (toner filter) x1

Hear roller lower x1

Upper separation claw x6

Cleaning web x1

Web press roller x1

Heat roller cleaning roller (Upper) x1

Heat roller cleaning roller (Lower) x1

2 Maintenance Kit 2 Ozone filter x1 460K

3 Fusing Kit Heat roller upper x1 460K

1 - 15 AR-651/810 SPECIFICATIONS

4 DF Kit Pick-up roller (ADF) x1 500K AR-810DF 1 common between AR651 and AR810

AR-810RT 1 common between AR651 and AR810

350K

Feed roller (ADF) x1

Separation Roller (ADF) x1

Feed roller (Main) x1

Separation roller (Main) x1

Staple cartridge x3 5000 x 3 SF-SC11 20 Cartridge for AR-F11/12

Staple cartridge x3 2000 x 3 AR-SC3 40 For AR-F12 (Saddle Stitch Finisher)

5000 staples

Stitch 2000 staples

5 Roller Kit Pick-up roller (Main) x1 200K

6 Waste toner bottle Waste toner bottle x4 AR-810HB 1 common between AR651 and AR810

7 Stapler for Finisher

8 Stapler for Saddle

Note 1: NO.1 to 3 item --- AR651 (460K), AR810 (500K)

Note 2: Maintenance parts other than above items must be ordered through the parts department using the proper part number.

Note 3: No.1 to 6 items are UNCOMPATIBLE with existing machine

Inserter

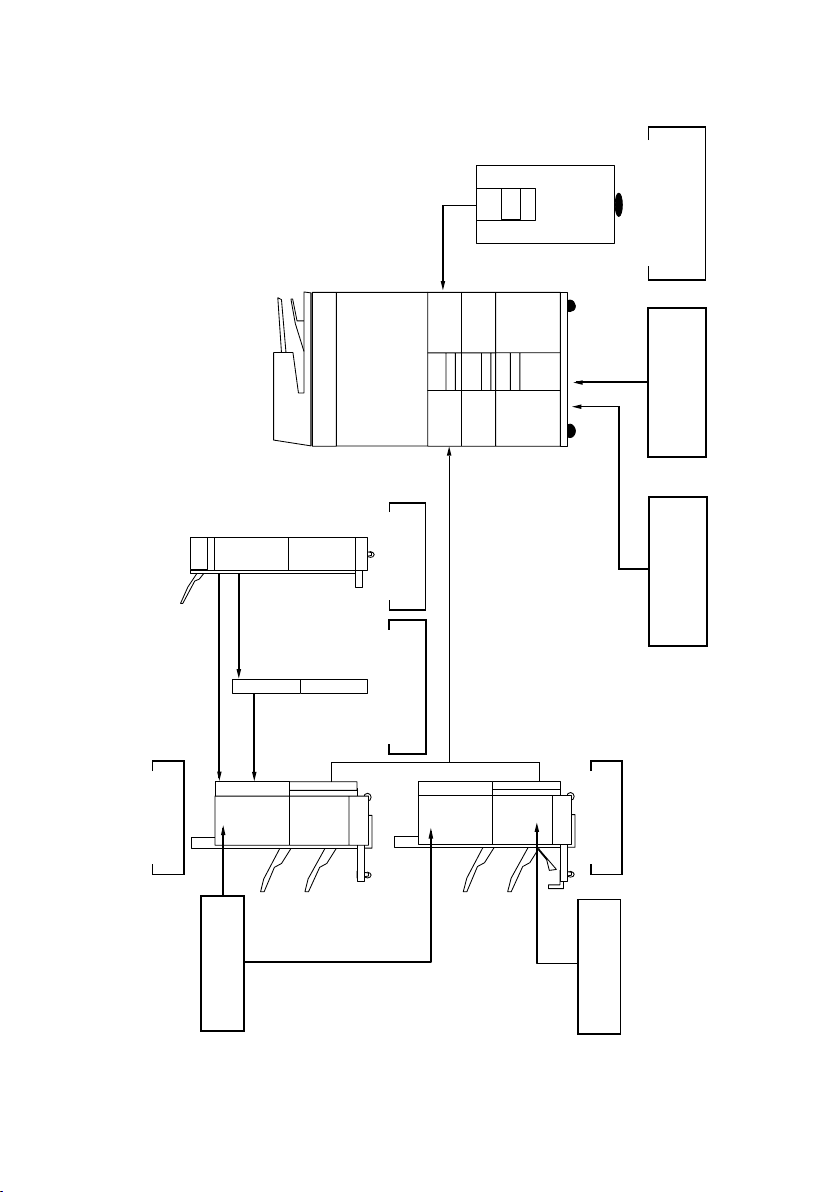

AR-CF1

AR-PN3

Hole punch unit

LCF

AR-LC4

AR-P15

Printer board

AR-PK2

AR-PK3

Printer controller

AR-F11

Finisher

AR-SC3

Staple cartridge

1.5. System List

AR-651/810 SPECIFICATIONS 1 - 16

AR-F12

Finisher

SF-SC11

Staple catridge

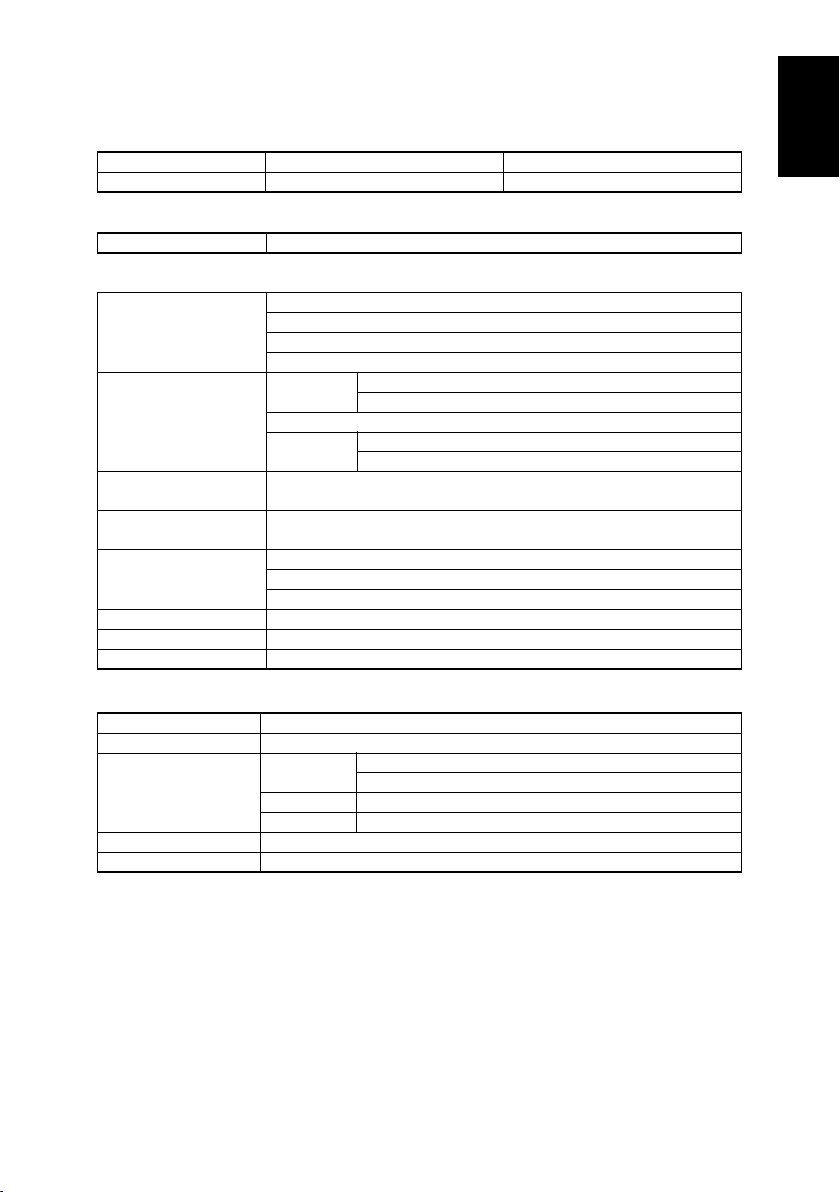

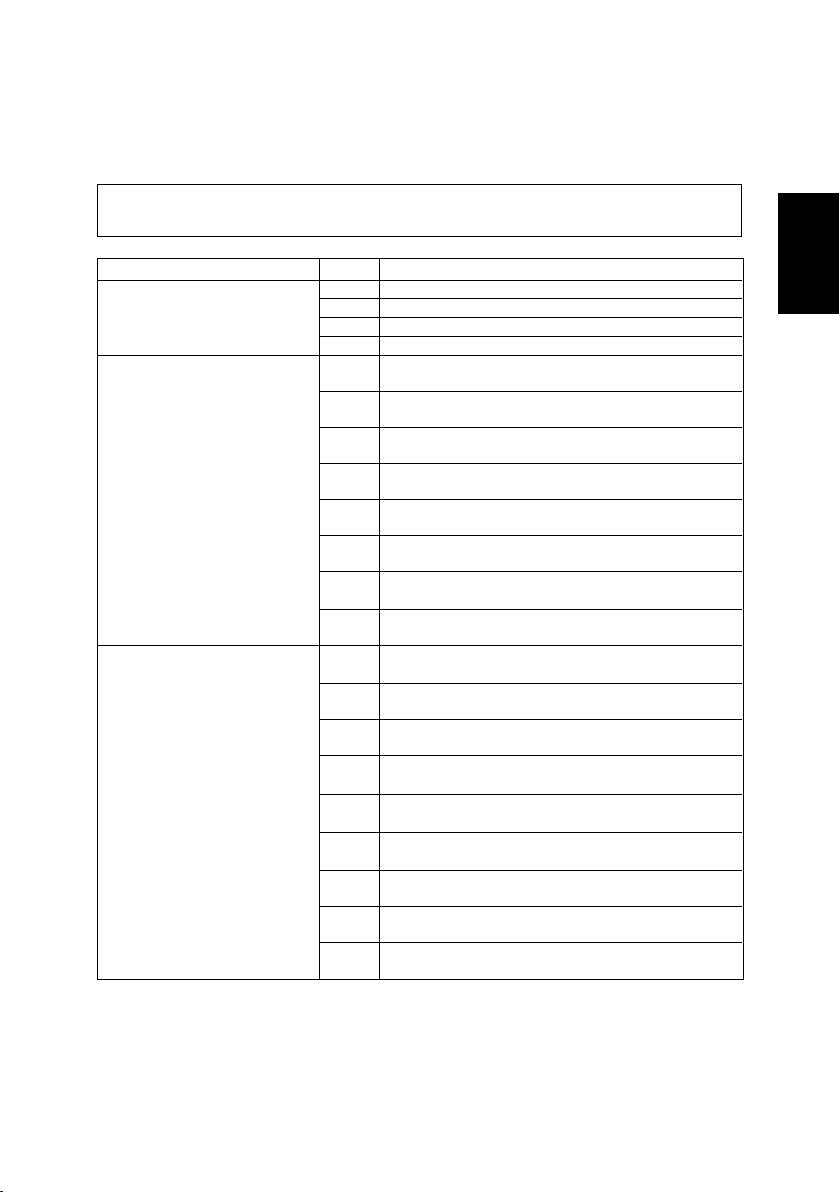

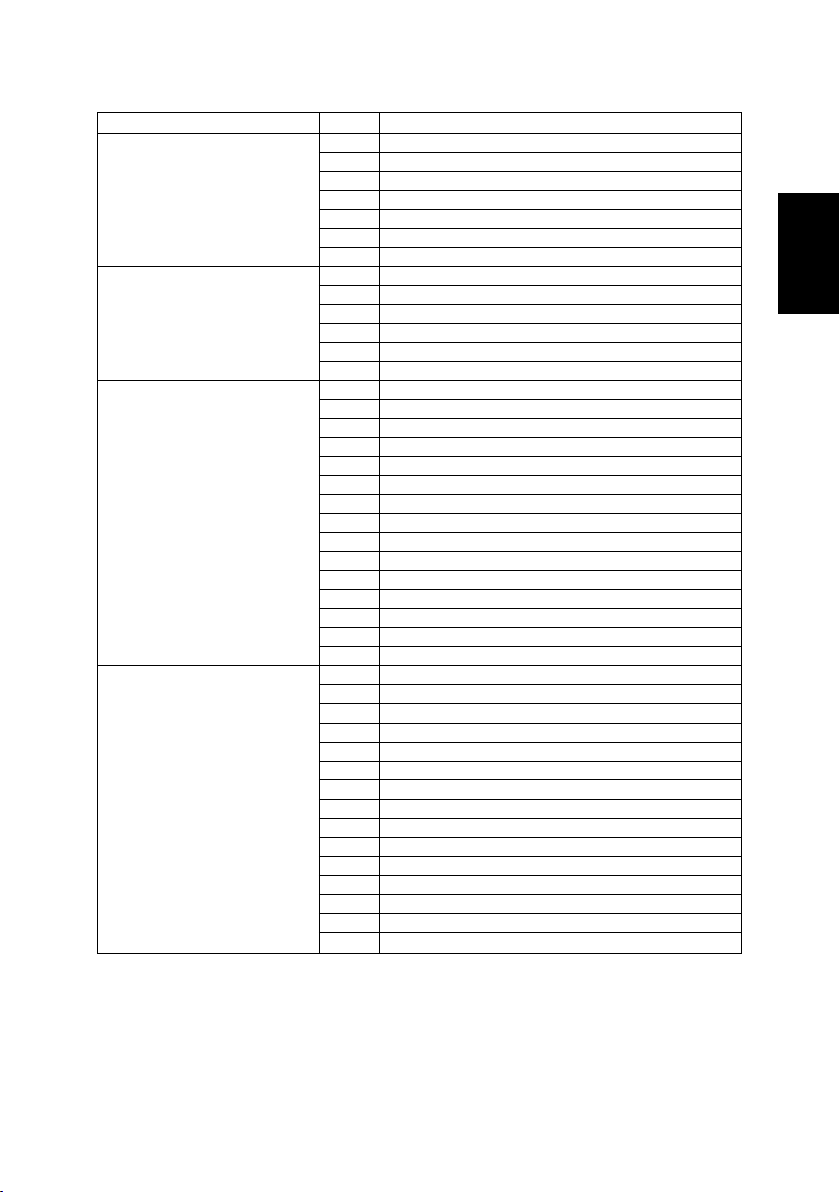

2. ERROR CODES AND SELF-DIAGNOSIS

2. 1. Error Codes

Instead of the set number, one of the following error codes is displayed with pressing the [CLEAR] key and

the digital key “8” simultaneously when the “CLEAR PAPER” or “CALL SERVICE” symbol is flashing.

Paper transport jam inside the E01 Leading edge of paper not reaching the fuser exit sensor

Group

copier (1) E02 Trailing edge of paper not passing the fuser exit sensor

Paper misfeeding E11 Misfeeding during duplex printing

Paper transport jam inside the copier (2) E20 Paper fed from the 1st cassette

Error Code

E03 Paper remaining inside the copier at power ON

E09 Jam caused by an abnormal HDD

(paper not reaching the registration sensor)

E12 Bypass misfeeding

(paper not reaching the registration sensor)

E13 1st cassette misfeeding

(paper not reaching the 1st cassette feed sensor)

E14 2nd cassette misfeeding

(paper not reaching the 2nd cassette feed sensor)

E15 3rd cassette misfeeding

(paper not reaching the 3rd cassette feed sensor)

E16 4th cassette misfeeding

(paper not reaching the 4th cassette feed sensor)

E18 Tandem LCF misfeeding

(paper not reaching the tandem LCF feed sensor)

E19 External LCF misfeeding

(paper not reaching the external LCF feed sensor)

(not reaching the registration sensor)

E21 Paper fed from the 1st cassette

(not reaching the 1st cassette transport sensor)

E22 Paper fed from the 2nd cassette

(not reaching the registration sensor)

E23 Paper fed from the 2nd cassette

(not reaching the 1st cassette transport sensor)

E24 Paper fed from the 2nd cassette

(not reaching the 2nd cassette transport sensor)

E25 Paper fed from the external LCF

(not reaching the registration sensor)

E30 Paper fed from the 3rd cassette

(not reaching the registration sensor)

E31 Paper fed from the 3rd cassette

(not reaching the 1st cassette transport sensor)

E32 Paper fed from the 3rd cassette

(not reaching the 2nd cassette transport sensor)

Machine Status

2 - 1 AR-651/810 ERROR CODES AND SELF-DIAGNOSIS

Group

Error Code

Machine Status

Paper transport jam inside the copier (2) E33 Paper fed from the 3rd cassette

(not reaching the 3rd cassette transport sensor)

E34 Paper fed from the 4th cassette

(not reaching the registration sensor)

E35 Paper fed from the 4th cassette

(not reaching the 1st cassette transport sensor)

E36 Paper fed from the 4th cassette

(not reaching the 2nd cassette transport sensor)

E37 Paper fed from the 4th cassette

(not reaching the 3rd cassette transport sensor)

E38 Paper fed from the 4th cassette

(not reaching the 4th cassette transport sensor)

E3C Paper fed from the tandem LCF

(not reaching the registration sensor)

E3D Paper fed from the tandem LCF

(not reaching the 1st cassette feed sensor)

E3E Paper fed from the tandem LCF

(not reaching the 2nd cassette feed sensor)

E3F Paper fed from the tandem LCF

(not reaching the tandem LCF transport sensor)

Cover open jam E41 Front cover opened during printing

E44 Feed cover opened during printing

E45 LCF side cover opened during printing

E46 Bypass feed unit cover opened during printing

E47 Exit cover opened during printing

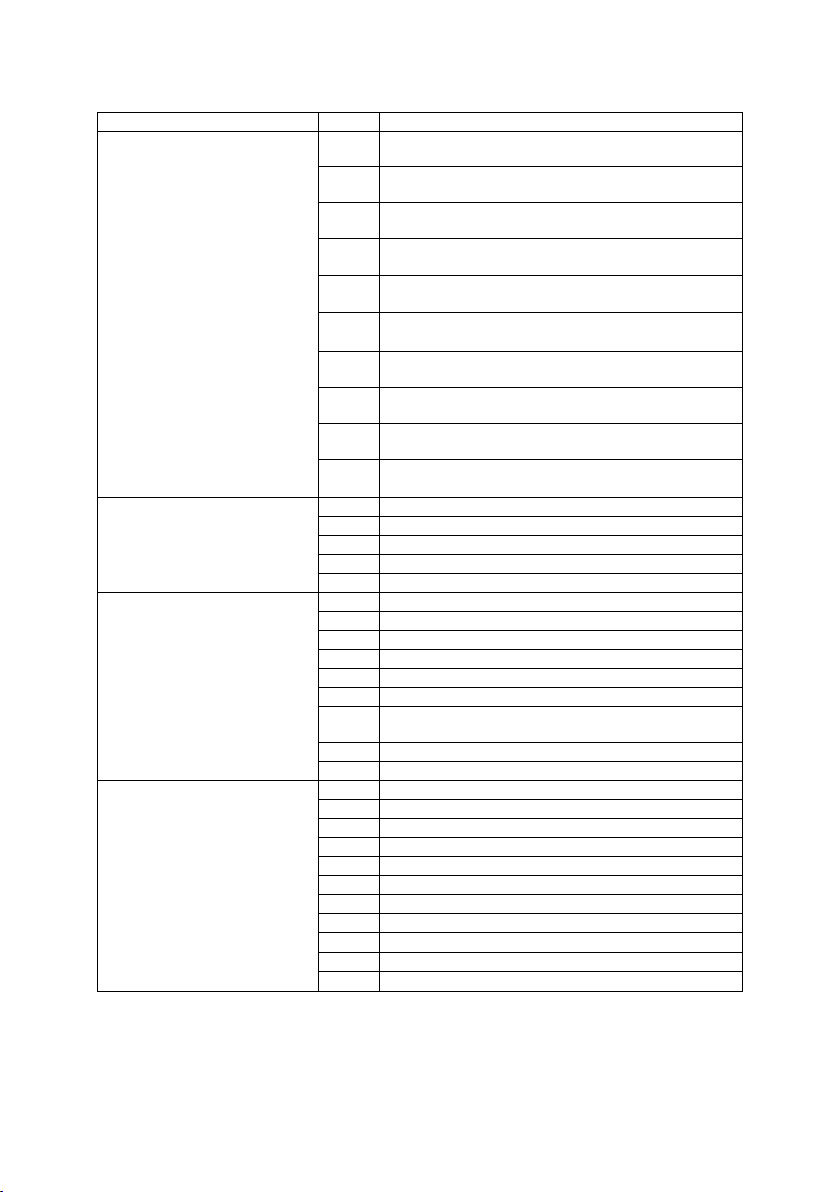

Transport jam (exit/reversing section E50 Leading edge of paper not reaching the reverse sensor 2

and others) E51 Leading edge of paper not reaching the transport sensor 1

E52 Leading edge of paper not reaching the transport sensor 2

E54 Leading edge of paper not reaching the transport sensor 3

E55 Paper remaining on the transport path when CRUN is OFF

E57 Leading edge of paper not reaching the reverse sensor 1

E58 Trailing edge of paper not passing the reverse sensor 1 or

reverse sensor 2

E59 Trailing edge of paper not passing the exit sensor

E5A Leading edge of paper not reaching the exit sensor

Transport jam (RADF) E71 Original feeding jam

E72 Original transport jam

E73 Original discharging jam

E74 Original reversing jam

E76 Small original discharging jam

E77 Scanning section transport jam

E7B RADF opened at the original transporting

E7C RADF opened at the large original discharging

E7D RADF opened at the small original reversing

E7E RADF opened at the small original discharging

E7F RADF opened at the original scanning section

AR-651/810 ERROR CODES AND SELF-DIAGNOSIS 2 - 2

Group

Error Code

Machine Status

Transport jam (RADF) E80 Jam access cover opened at the original feeding

E81 Jam access cover opened at the original transporting

E82 Jam access cover opened at the large original dischaging

E83 Jam access cover opened at the small original reversing

E84 Jam access cover opened at the small original discharging

E85 Jam access cover opened at the original scanning section

Paper jam in finisher E9F Punching jam

EA1 Finisher paper transport delay jam

EA2 Finisher paper transport stop jam

EA3 Paper remaining inside the finisher at power ON

EA4 Finisher front door opened during printing

EA5 Finisher stapling jam

EA6 Finisher early arrival jam

EA7 Stack transport jam before stapling

EA8 Saddle stitcher stapling jam

EA9 Saddle stitcher door opened during printing

EAA Paper remaining at the saddle stitcher at power ON

EAB Saddle stitcher paper transport stop jam

EAC Saddle stitcher paper transport delay jam

EAD Print end command time-out jam

EAE Receiving time time-out jam

EB3 Ready time time-out jam

EC0 Inserter feeding delay jam

EC1 Inserter feeding stop jam

EC2 Inserter reverse path delay jam 1

EC3 Inserter reverse path stop jam 1

EC4 Inserter reverse path delay jam 2

EC5 Inserter reverse path stop jam 2

EC6 Inserter transport delay jam 1

EC7 Inserter transport stop jam 1

EC8 Inserter transport delay jam 2

EC9 Inserter transport stop jam 2

ECA Paper remaining in the inserter when power is ON

ECB Wrong size of inserter

ECC Inserter feeding Jam

Paper transport jam inside the EB5 Paper left on the transport path

copier (3) EB6 Paper left on the transport path

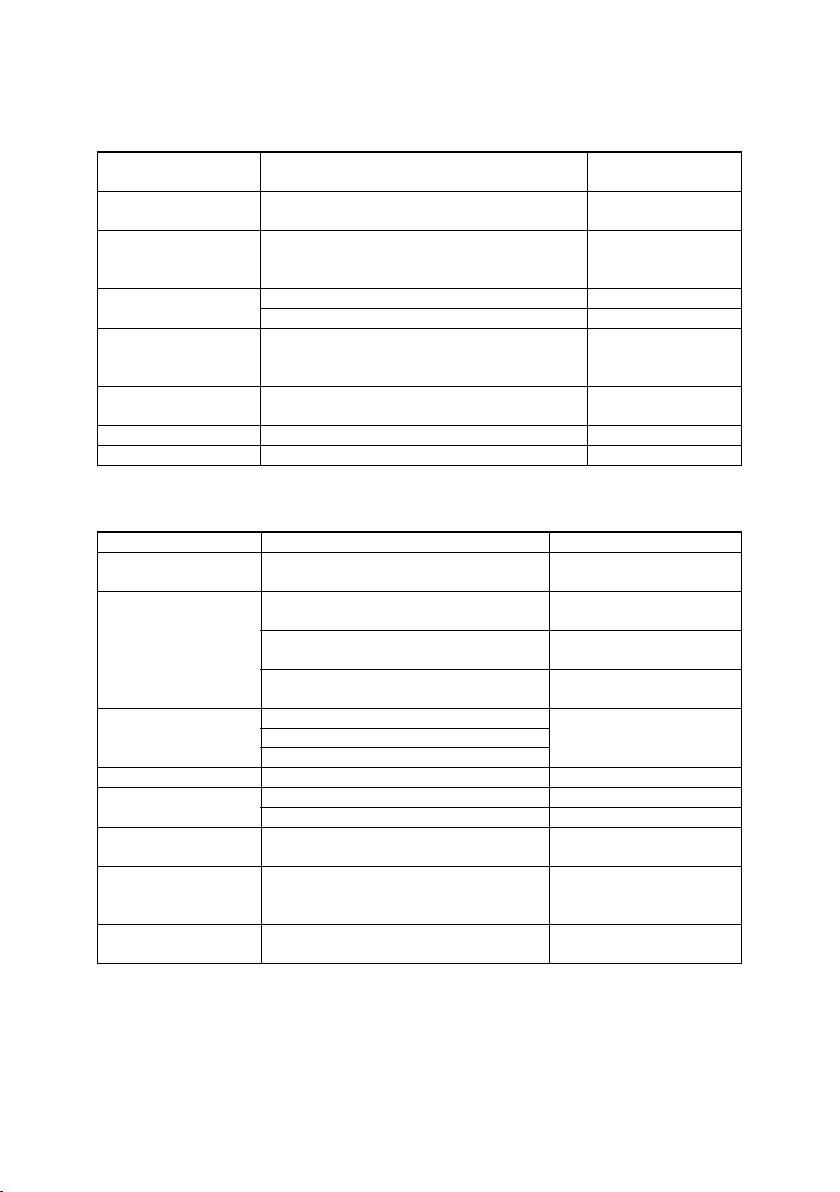

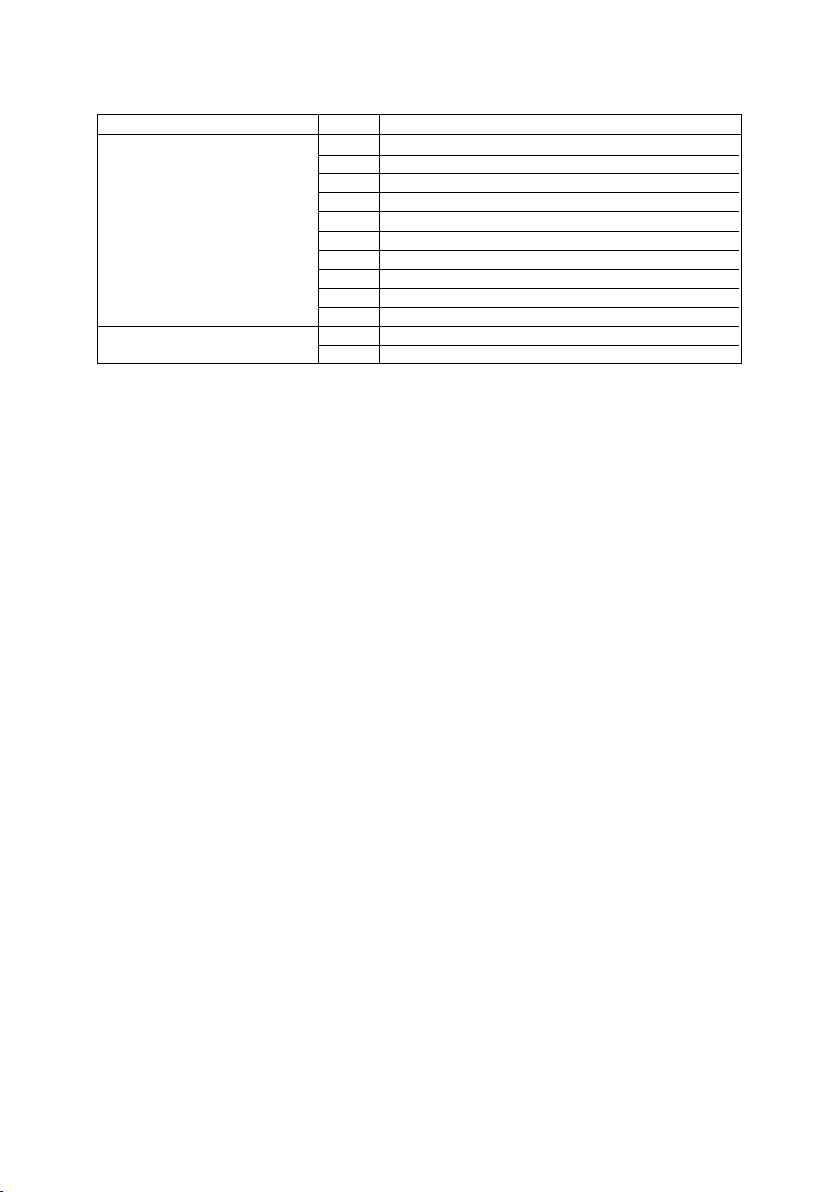

2 - 3 AR-651/810 ERROR CODES AND SELF-DIAGNOSIS

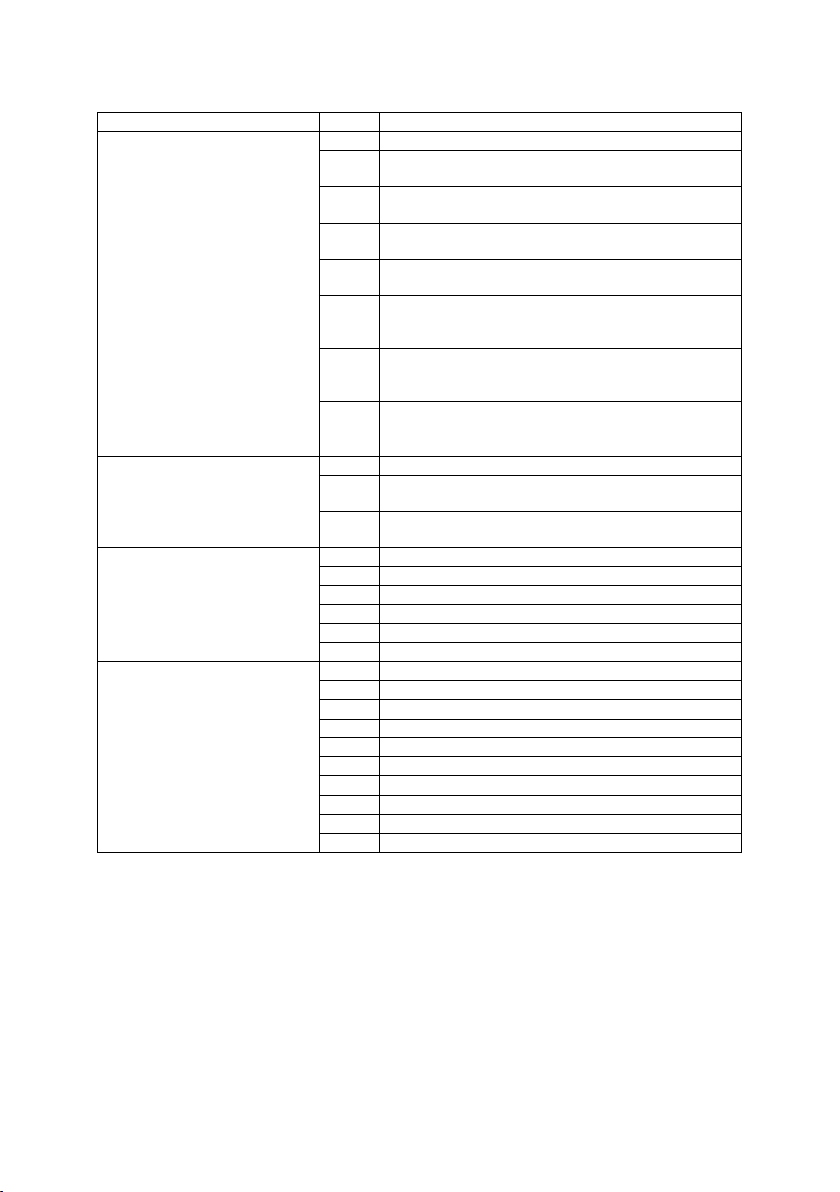

Group

Paper feeding system related service call

Error Code

C04 Abnormal feed motor

Machine Status

C13 Abnormal 1st cassette tray (Paper can be fed from cassettes

other than the 1st cassette.)

C14 Abnormal 2nd cassette tray (Paper can be fed from cassettes

other than the 2nd cassette.)

C15 Abnormal 3rd cassette tray (Paper can be fed from cassettes

other than the 3rd cassette.)

C16 Abnormal 4th cassette tray (Paper can be fed from cassettes

other than the 4th cassette.)

C18 Abnormal tandem LCF tray-up motor

(Paper can be fed from cassettes other than the tandem LCF

cassette.)

C1A Abnormal tandem LCF end fence motor

(Paper can be fed from cassettes other than the tandem LCF

cassette.)

C1C Abnormal external LCF tray-up motor

(Paper can be fed from cassettes other than the external

LCF)

Scanning system related service call C26 Peak detection error

C27 Carriage home position sensor not going OFF within a fixed

time

C28 Carriage home position sensor not going ON within a fixed

time

Processing system related service call C36 Abnormal main charger wire cleaner drive motor

C37 Abnormal transfer belt cam motor

CD1 Abnormal drum cleaning brush motor

CD2 Abnormal used toner transport motor

CD3 Abnormal recycle toner transport motor

CD4 Full toner bag

Fuser unit related service call C41 Abnormal thermistor or heater at the power ON

C43 Abnormal thermistor after abnormality judgment

C44 Abnormal fuser after abnormality judgment

C45 Abnormal side thermistor after the copier has become ready

C46 Abnormal pressure roller thermistor during a ready state

C47 Abnormal IH power voltage / IH initialization error

C48 IGBT high temperature

C49 Abnormal IH circuit or coil

C4A Cleaning web finished

CD5 Web motor signal path error

AR-651/810 ERROR CODES AND SELF-DIAGNOSIS 2 - 4

Group

Error Code

Machine Status

Communication related service call C55 RADF I/F error

C56 Communication error between main CPU and PFC

C57 Communication error between main CPU and IPC board

C58 Communication error between IPC board and finisher

C59 Communication error between main CPU and laser CPU

F07 Communication error between SYS board and LGC board

F11 Communication error between SYS board and SLG board

RADF related service call C73 EEPROM initialization error

C82 Read sensor adjustment error

C83 Original length sensor adjustment error

C84 Small original reverse sensor adjustment error

C85 Abnormal tray lift motor

C86 Large original exit sensor adjustment error

Laser optical unit related service call CA1 Abnormal polygonal motor

CA2 H-Sync detection error

CA3 Secondary scanning coarse adjustment error

CA5 Laser power adjustment error

CA6 Laser calibration error

CA9 Image data transmission error from SYS board

CAA Secondary scanning fine adjustment error

CAB Secondary scanning inter-page compensation error

CAC Primary scanning dot adjustment error

CD0 Laser initializing time out

CE0 Abnormal comparator

CE1 Beam sensor detection error

CE2 Sensor busy error

CE3 Primary scanning adjustment error

CE4 Abnormal window comparator

Finisher related service call CB1 Abnormal feed motor

CB2 Abnormal delivery motor

CB3 Abnormal tray lift motor

CB4 Abnormal alignment motor

CB5 Abnormal staple motor

CB6 Abnormal stapler shift motor

CB7 Abnormal height sensor

CB8 Abnormal backup RAM data

CB9 Abnormal saddle stitcher paper pushing plate motor

CBA Abnormal saddle stitcher stitch motor (front)

CBB Abnormal saddle stitcher stitch motor (rear)

CBC Abnormal saddle stitcher alignment motor

CBD Abnormal saddle stitcher guide motor

CBE Abnormal saddle stitcher paper folding motor

CBF Abnormal saddle stitcher paper positioning plate motor

2 - 5 AR-651/810 ERROR CODES AND SELF-DIAGNOSIS

Group

Finisher related service call CC0 Abnormal saddle stitcher sensor connector connection

Service call for others C94 Abnormal main CPU

Error Code

CC1 Abnormal saddle stitcher microswitch

CC2 Abnormal communication between finisher and saddle stitcher

CC4 Abnormal swing motor

CC5 Abnormal horizontal registration motor

CC6 Abnormal punch motor

CC7 Abnormal punch unit backup RAM data

CCC Communication error between inserter and finisher

CCD Abnormal inserter EEPROM

CCE Abnormal inserter fan

F10 HDD formatting error

Machine Status

AR-651/810 ERROR CODES AND SELF-DIAGNOSIS 2 - 6

Loading...

Loading...