Page 1

SERVICE MANUAL

DIGITAL COPIER

MODEL AR-5015

CONTENTS

[ 1 ] GENERAL.......................................................................Refer to AR-163

[ 2 ] SPECIFICATIONS ................. .................... .. .................... .. .........AR-5015

[ 3 ] CONSUMABLE PARTS..... .. .................... .. .................... .. ...........AR-5015

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES..... ...........AR-5015

[ 5 ] UNPACKING AND INSTALLATION................................Refer to AR-163

[ 6 ] ADJUSTMENTS..............................................................Refer to AR-163

[ 7 ] SIMULATIONS................................................. ...........................AR-5015

[ 8 ] USER PROGRAMS ........................................................Refer to AR-163

[ 9 ] TROUBLE CODE LIST ...................................................Refer to AR-163

[10] MAINTENANCE................... .................... .. .................... .. ...........AR-5015

[11] DISASSEMBLY AND ASSEMBLY..............................................AR-5015

[12] FLASH ROM VERSION UP PROCEDURE. .. ................ .Refer to AR-163

[13] ELECTRICAL SECTION.............................................................AR-5015

PARTS GUIDE

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

Note for this Service Manual

This Service Manual describes only the items related to the AR-5015. For the other items common with t he AR-163, please refer to the AR-162/ 163

Service Manual (Document code: 00ZAR162//A1E). The table below shows which document(s) should be referred to for each section. (Refer to the

document marked with

[ 1 ] NOTE FOR SERVICING

[ 2 ] SPECIFICATIONS Some specifications and option setup

[ 3 ] COSUMABLE PARTS

[ 4 ] EXTERNAL VIEW AND INTERNAL

STRUCTURE

[ 5 ] UNPACKING AND INSTALLATION

[ 6 ] ADJUSTMENTS The AR-5015 does not support installation of an option unit. (Note 1)

[ 7 ] SIMULATION

[ 8 ] USER PROGRAM

[ 9 ] TROUBLE CODE LIST

[10] MAINTENANCE

[11] DISASSEMBLLY AND ASSEMBLY

[12] FLASH ROM VERSION UP PROCE DURE

[13] ELECTRICAL CIRCUIT The AR-5015 does not support installation of an option unit. (Note 1)

.)

Section AR-163 AR-5015 Changed item

Operation panel

The AR-5015 does not support installation of an option unit. (Note 1)

The AR-5015 does not support installation of an option unit. (Note 1)

The AR-5015 does not support installation of an option unit. (Note 1)

The AR-5015 does not support installation of an option unit. (Note 1)

Note 1: The AR-5015 does not support installation of an option unit such as SPF, paper feed unit, job separator, electronic sort unit, printer

expansion unit, and FAX expansion unit. Therefore, the descriptions on option units in each sect ion of t he reference document (AR-162/ 163

S/M) should be disregarded.

[ 2 ] SPECIFICATIONS

The table below shows the specifications of this model and the contents of changes from the AR-163.

Item AR-163 AR-5015

Copy speed 16 PPM 15 PPM

Multi-purpose tray 100 sheets 100 sheets

Standard tray 1 cassette (250 sheets) 1 cassette (250 sheets)

SOPM Yes (Depends on the destination) No

Option tray 1 tray Option No

2 tray Option No

Original detection No No

Original cover Yes Yes

SPF Option No

Electronic sort Option No

Job separator Option No

FAX expansion unit Option No

Printer expansion unit Option No

FAX expansion memory Option No

LCD panel Option No

Dust cover No No

APS Yes No

Page 3

>>>>> USE FONT <<<<<

Helvetica/ Helvetica-Condensed/ Century-Schoolbook/ Symbol & OriginalFonts: (RingWorld2/RingFont2/Pa

Symbol/PartsCod)

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

[ 3 ] CONSUMABLE PARTS

1. SUPPLY SYSTEM TABLE

A. Latin America

NO Name Content Life Model name Remark

1 Toner cartridge (Black)

<With IC>

2 Developer Developer

3 Drum kit Drum

For USA goverrnment

Toner

(Toner: Net Weight 475g)

Bag

(Developer: Net Weight 400g)

Drum fixing plate

B. Middle East/Africa

NO Name Content Life Model name Remark

1 Toner cartridge (Black)

<With IC>

2 Developer Developer

3 Drum kit Drum

Toner

(Toner: Net Weight 475g)

Bag

(Developer: Net Weight 400g)

Drum fixing plate

10

180K AR-015LT Life setting by A4 (8.5"x11") 6%

10

10 500K AR-015CD

1

50k AR-015DR

1

10

180K AR-015ET Life setting by A4 6% coverage

10

10 500K AR-015CD

1

50k AR-015DR

1

coverage

C. Europe

NO Name Content Life Model name Remark

10

1 Toner cartridge (Black)

<With IC>

2 Developer Developer

3 Drum kit Drum

Toner

(Toner: Net Weight 475g)

Bag

(Developer: Net Weight 400g)

Drum fixing plate

180K AR-015LT Life setting by A4 (8.5"x11") 6%

10

10 500K AR-015CD

1

50k AR-015DR

1

coverage

D. Asia

NO Name Content Life Model name Remark

1 Toner cartridge (Black)

<With IC>

2 Developer Developer

3 Drum kit Drum

Toner

(Toner: Net Weight 475g)

Bag

(Developer: Net Weight 400g)

Drum fixing plate

10

180K AR-015CT Life setting by A4 6% coverage

10

10 500K AR-015CD

1

50k AR-015DR

1

Page 4

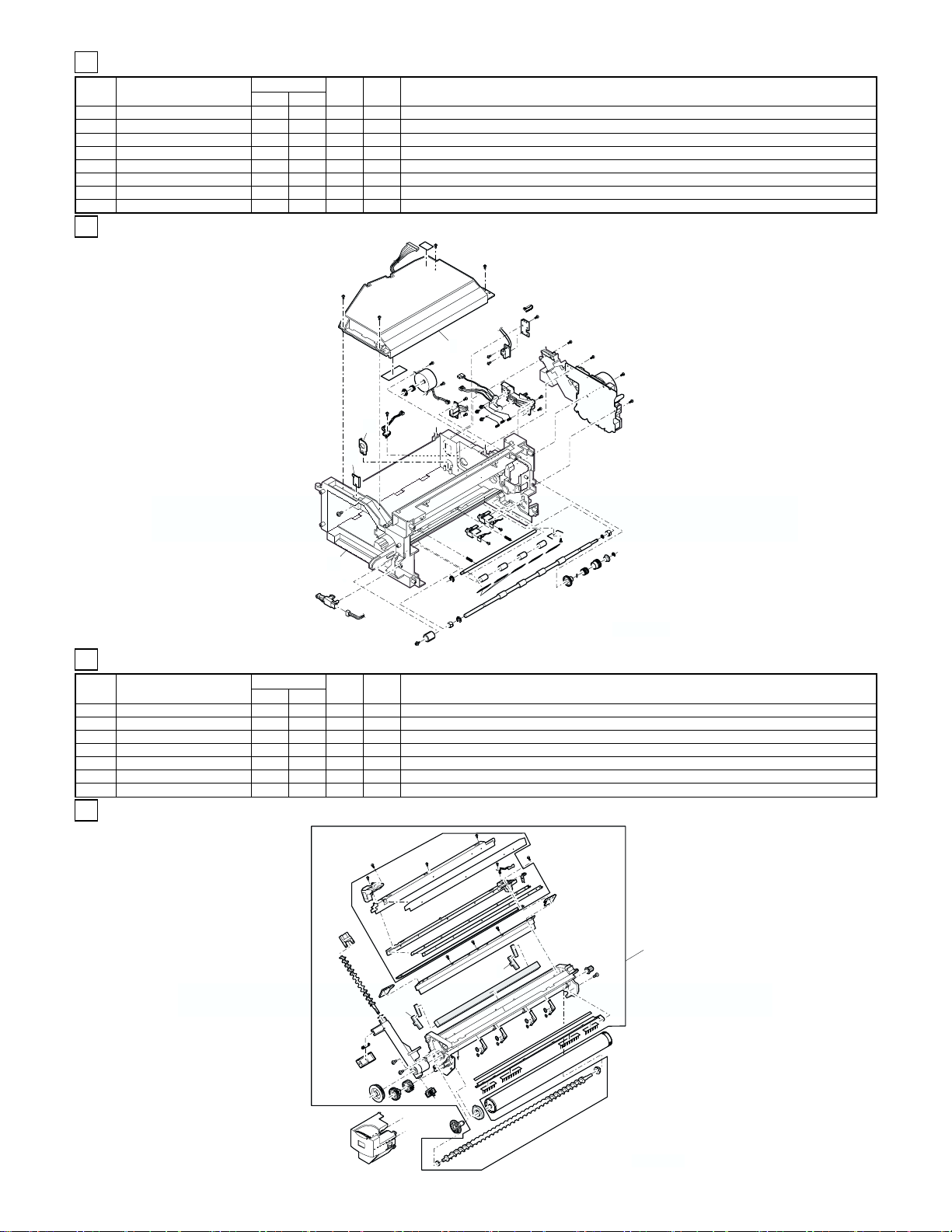

[ 4 ] EXTERNAL VIEWS AND INTERNAL STRUCTURES

3. OPERATION SECTION

1110987654321

1312

Inch system

8

21

14 15 1716

Not used

1 INTERRUPT key and indicator 2 Copy quantity display 3 ZOOM indicator

4 Copy ratio display key 5 Zoom keys 6 PAPER SIZE ENTER key

7 AUDIT CLEAR key 8 PAPER SIZE indicators 9 Alarm indicators

10 POWER SAVE indicator 11 Output tray full indicator 12 B/W REVERSE key and indicator

13 XY-ZOOM key and indicator 14 AUTO/MANUAL/PHOTO key and indicators 15 Light and dark keys and indicators

16 Numeric keys 17 Zero key 18 CLEAR key

19 START key and indicator 20 CLEAR ALL key 21 PRESET RATIO selector keys and indicators

22 ORIGINAL SIZE ENTER key and

indicators

25 Paper feed location/misfeed location

indicators

18 19

2120

23 TRAY SELECT key 24 AUTO IMAGE key and indicator

26 DUAL PAGE COPY key and indicator

242322

25

26

22

Page 5

[ 7 ] SIMULATIONS

The table below shows the changed points in simulations. (Items marked with* are changed.)

Main

code

Sub

code

21 1 Maintenance cycle

Contents Details of operation I nit ial value Set range

setting

Used to display the currently set maintenance cycle at the numbers

shown at right. When the set value is entered and the start key is

pressed, the set value is stored.

Key operation/Display

0: 2500 sheets 4: 150000 sheets

1: 5000 sheets 5: FREE (999999 sheets)

2: 25000 sheets* 6: 10000 sheets

3: 50000 sheets* 7: 7500 sheets

2* 0~7*

21 2 Mini maintenance

cycle setting

26 6 Destination setting Used to display the current destination setting with the numbers at right.

Used to display the currently set mini maintenance cycle at the numbers

shown at right. When the set value is entered and the start key is

pressed, the set value is stored.

Key operation/Display

0: 2500 sheets 4: 50000 sheets

1: 5000 sheets

2: 10000 sheets

3: FREE (999999 sheets)

After entering the set value, press the start key, and the set value is

stored.

Key operation/Display

0: Japan 8: EX AB series

1: USA (Inch series) 9: EX inch series (FC conformity)

2: Canada (Inch series) 10: EX AB series (FC conformity)

3: Germany 1 (AB series) (Australia, Newzealand)

4: UK (AB series) 11: China (AB series)

5: Not used 12: Taiwan (AB series)

6: France (AB series) 13: Germany 2 (AB series)

7: EX inch series

4 0~4*

70~13

26 10 Model name input* Used to display and register the model name. 1 0~1

Key operation/Display

0: ARS140 1: AR5015

30 1 Machine sensor

operation check

Used to check the sensor in the machine transport system with LED on

the operation panel.

Display

<Lighting at sensor ON>

Paper entry sensor : Machine position JAM LED

Duplex sensor : Manual feed tray position LED

Paper exit sensor : JAM LED

Page 6

[10] MAINTENANCE

1. MAINTENANCE TABLE

: Check (Clean, adjust, or replace when required.) : Clean ▲ : Replace : Adjust ✩ : Lubricate

Unit name Part name When calling 25K 50K 75K 100K 125K 150K

Drum peripheral OPC drum – –

Cleaning blade – – – –

Side seal

MC unit

(MC charging electrode) – ( )()()()()()

(MC grid) – (

(MC case) – (

Transfer wire

Transfer paper guide

Developing section Developer – – – –

DV seal

DV side seal

Side Mylar – –––––

Optical section Lamp unit Reflector

Mirror

No. 2/3 mirror unit Mirror

Pulley

CCD peripheral Lens

Glass Table glass

White Plate

Other Drive wire

Rail

Document cover

Document size sensor

LSU Dust-proof glass

Paper feed section Multi paper feed

section

Paper transport section PS roller

Fusing section Upper heat roller

Drive section Gears

Paper exit section Ozone filter *1

Takeup roller

Paper feed roller

Spring clutch

Transport (paper exit) rollers

Spring clutch

Pressure roller

Pressure roller bearing

Upper separation pawl

Lower separation pawl

Belts

–

–

✩ ✩ ✩ ✩

✩ ✩ ✩ ✩

✩ ✩ ✩ ✩

✩ ✩ ✩ ✩

)()()()()()

)()()()()()

– –

– –

✩

*1 : Recommendable replacement time: 50K (Letter, 5% print)

Page 7

2. MAINTENANCE DISPLAY SYSTEM

According to the change in toner and developer life, the LED ON timing is changed.

Toner Life 18K

Remaining quantity check

Remaining quantity NEAR EMPTY

LED ON Flash

Machine Operation allowed Stop

Developer Life 50K

LED ON at 50K of the developer count.

Machine Selection is available between Not Stop and Stop by Service Simulation (SIM 26-37) Setup.

Maintenance LED Selection is available among 50K, 25K, 10K, 7.5K, 5K, and free (no lighting) with SIM 21-1.

Machine Not stop.

1 a. Press and hold the density adjustment LIGHT key for more than 5 sec, and the machine

will enter the user program mode.

b. Press and hold the "%"key for more than 5 sec, and the remaining quantity will be

displayed on the copy quantity display in one of the following levels: (Remaining quantity

display levels: 100%, 75%, 50%, 25%, 10%, LO)

c. Press the density adjustment LIGHT key to cancel.

EMPTY

About 10%

(If Stop is selected, the LED will flash and stop at 50K)

Default: Not Stop

Clear: SIM 42-1

Default: 25K

Clear: SIM 20-1

1 : Installation of a new toner cartridge allows to display the remaining quantity.

Page 8

[11] DISASSEMBLY AND ASSEMBLY

11. DEV ELOPING SECTION

A. Developing box

a) Side mylar attachment reference

The side mylar attachment reference is shonw in the figure below.

C

0.5

0

A

Side mylar

DV side sheet

0

0

D

0.5

0.5

0

B

0.5

Side mylar

DV side sheet

2. Remove the Screen grid

3. Push the elect rode cleaner onto the electrode tip so that the electrode tip comes into the electrode cleaner to clean. (repeat two or

three times. )

Electrode cleaner

12. PROCESS SECTION

B. Charger cleaning

1. Remove the MC holder unit

(2)

(1)

Electrode section

(1)

Note: Do not move the electrode cleaner with the electrode tip in it.

When cleaning, clean all the electrodes evenly.

D. Moquette F/R of process frame unit

To improve reliability of the drum unit, the AR-5015 must use the

following parts.

• Process frame unit : CFRM-0021QS67

• Moquette F : PSEL-0129QSZZ

• Moquette R : PSEL-0130QSZZ

Page 9

[13] ELECTRICAL SECTION

1. BLOCK DIAGRAM

BD-PWB

APC-PWB

Polygon-Motor

LSU-PWB

CN4

PS-FAN

PS-SW

Down-Load-CON

CCD-PWB

Mirror-Motor

SCANNER

SCANNERHPSENSOR

Copy-Lamp

COVER

SWITCH

CN20 CN35 CN2 CN1

CN29 CN17

MCU-PWB

CN6 CN5

CN38

CN27

CN28

CN32 CN33

CN14 CN22

HVU

CRUM

UNIT

Power Supply

SIDE

COVER

SWITCH

DEV

SENSOR

Toner-Motor MAIN-Motor

PAPERINSENSOR

CASETTE

PAPER

EMPTY

SENSOR

HAND

PAPER

EMPTY

SENSOR

SWITCH

CASETTE

FUSER COOLING FAN

CN23 CN24

CN26

PAPER OUT

SENSOR

CN18 CN36 CN13 CN12

CN15 CN19

PS

ROLLER

CASETTE

PICK UP

HAND

PICK UP

THERMISTER

Fuser-Lamp

SOL

SOL

SOL

ERDH-OP-PWBCOPY-OP-PWB

OPERATION PANEL

Page 10

2. ACTUAL WIRING DIAGRAM

ACTUAL WIRING DIAGRAM 1/2

Page 11

ACTUAL WIRING DIAGRAM 2/2

Page 12

1 Exteriors

2 Operation panel section

3 Side door unit

4 2nd,3rd mirror unit

5 Optical unit

PARTS GUIDE

MODEL AR-5015

CONTENTS

6 Middle frame unit

7 Process unit

8 DV cartridge unit

9 Fusing unit

G Base plate unit 1

H Base plate unit 2

I Manual paper feeding multi unit

J Delivery frame unit

L 250 sheets tray unit

M Packing material & Accessories

P MCU PWB

] ERDH OP PWB

■ Index

The AR-5015 Parts Guide describes only changed from AR-163 Parts Guide.

For the common parts, please refer to the AR-163 Parts Guide (Code: 00ZAR162//P1/)

MODEL REFER MODEL

AR-5015 AR-163

Page 13

補修部品のランク付

市場における補修部品の在庫管理が、適正に運営出来る手助けとなることを、目的とします。

Aランク : 取替頻度が比較的多く、在庫を必要とするパーツ。

Bランク : 取替頻度は比較的少ないが、在庫を必要とするパーツ。

Cランク : 取替頻度はほとんどないと思われるパーツ。

Dランク : 取替頻度はほとんどないが新品再生に必要なパーツ。

Eランク : ユニットパーツ。サービス効率アップの為、在庫する事を推奨するパーツ。

Sランク : 消耗品

但し、複写機のパーツについては、同一パーツ名であっても、下記パーツは、使用箇所の相違により、A・Bランク分けします。

パーツ名 : 金属製のギャー、スプロケット、ベアリング、ゴム製のベルト、スプリングクラッチ機構

Aランク : 常に回転しているか、付加がかかっている箇所に使用され、回転回数が増える事により、変形又は磨耗が生じその性能が発揮でき

なくなるパーツ。

Bランク : 回転部分に使用されているが、磨耗度が比較的少ないパーツ。

DEFINITION

The definition of each Rank is as follows and also noted in the list

A : Parts necessary to be stocked as High usage parts.

B : Parts necessary to be stocked as Standard usage parts.

C : Low usage parts.

D : Parts necessary for refurbish.

E : Unit parts recommended to be stocked for efficient after sales service.

Please note that the lead time for the said parts may be longer than normal parts.

S : Consumable parts.

Please note that the following parts used in Copier under the same description are classified into A or B Rank depending upon the place

used.

Example : Gear made of Metal, Sprocket, Bearing, Belt made of Rubber, Spring clutch mechanism.

A Rank : The parts which may be with the revolution or loading.

B Rank : Parts similar to A Rank parts, but are not included in Rank A.

安全性・信頼性確保のため部品は、必ず正規のものをご使用下さい。

!

印の商品は、安全上重要な部品です。交換をする時は、安全および性能維持のため必ず指定の部品をご使用下さい。

Because parts marked with “!” is indispensable for the machine safety maintenance and operation, it must be replaced with the parts

specific to the product specification.

当モデルのサービス資料には、この資料以外にサービスマニュアル(回路図含む)があります。合わせて御利用下さい。

F

Other than this Parts Guide, please refer to documents Service Manual (including Circuit Diagram) of this model.

F

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature. Do not order from parts department.

外装

1

(Exteriors)

NO. PARTS CODE

GCOVH0010QSZ3

1

PSHEZ0058QSZ1

2

CCAB-0012QS0V

10

CCAB-0012QS0W

GFTA-0001QSZ1

11

TLABZ0058QSZZ

49

CCOVH0010QS51

501

操作部

2

(Operation panel section)

NO. PARTS CODE

HPNLH0021QSZZ

HPNLH0021QSZ2

HPNLH0021QSZ3

3

HPNLH0021QSZ4

HPNLH0021QSZ1

HPNLH0022QSZZ

4

HPNLH0022QSZ1

JBTN-0018QSZZ

6

JBTN-0029QSZZ

7

JBTN-0026QSZZ

13

JBTN-0030QSZZ

14

JBTN-0027QSZZ

15

CPWBF0025QSE3

17

CPWBF0024QSE1

19

CPWBF0024QSE2

XEPSD30P08X00

46

PRICE RANK

Ex. Ja.

BC GJ N D

AU FG N D

BA FX N D

BA FX N D

AT EZ D

AD DJ C

BM HV E

PRICE RANK

Ex. Ja.

AT EZ N D

AT EZ N D

AT EZ N D

AT EZ N D

AT EZ N D

AK EB N D

AK EB N D

AE DJ C

AE DS C

AE DJ C

AD DJ C

AD DJ C

AH DX N E

BL HL N E

BL HL N E

AA DD C

NEW

MARK

NEW

MARK

PART

RANK

OC cover OC

OC sheet OC

Front exterior (Japan)

Front exterior (Except Japan)

Front cabinet cover

Class 1 label (200V Series)

OC cover unit OC

PART

RANK

ZEB Main Deco.panel (Japan) ZEB

ZEB Main Deco.panel (LAG2,LAG4) ZEB

ZEB Main Deco.panel (Philippines) ZEB

ZEB Main Deco.panel (Europe) ZEB

ZEB Main Deco.panel (Other countries) ZEB

ZEB Special Deco.panel (Japan) ZEB

ZEB Special Deco.panel (Except Japan) ZEB

Function key

Select key

Interrupt key

Mode select key

Density select key

ERDH operation PWB ERDH

COPY operation PWB (Japan Other countries) COPY

COPY operation PWB (LAG2,LAG4) COPY

Screw (3×8X)

DESCRIPTION

DESCRIPTION

カバー

マット

前キャビネット

前キャビネット

前キャビ蓋

クラス1ラベル

カバーユニット

メインデコパネル

メインデコパネル

メインデコパネル

メインデコパネル

メインデコパネル

特殊デコパネル

特殊デコパネル

部門キー

選択キー

割込みキー

画質キー

濃度キー

操作基板

操作基板

操作基板

ビス

– 1 –

Page 14

外装

1

(Exteriors)

501

1

2

49

2

操作部

11

(Operation panel section)

15

13

14

19

10

PRP00641

3

4

6

7

17

46

PRP00642

– 2 –

Page 15

サイドドアーユニット

3

NO. PARTS CODE

LFRM-0016QSZ2

10

サイドドアーユニット

3

(Side door unit)

PRICE RANK

Ex. Ja.

AT EZ C

NEW

MARK

(Side door unit)

10

PART

RANK

Right door inner N

DESCRIPTION

右ドアインナー

N

第

4

2.3

ミラーユニット

NO. PARTS CODE

NPLYZ0017QSZZ

4

CPLTM0156QS02

9

CPLTM0155QS02

13

ユニット

CMIR-0008QS32

901

第

4

2.3

(Unit)

ミラーユニット

(2nd,3rd mirror unit)

PRICE RANK

Ex. Ja.

AE DS C

AH DX C

AH DX C

BB GD E

NEW

MARK

PART

RANK

(2nd,3rd mirror unit)

4

PRP00643

DESCRIPTION

W pulley W

Pulley fixing plate R

Pulley fixing plate F

2nd,3rd mirror unit

4

9

プーリー

プーリー取付板

プーリー取付板

第

ミラーユニット

2.3

R

F

13

PRP00644

– 3 –

Page 16

光学ユニット

5

(Optical unit)

NO. PARTS CODE

CMIR-0008QS32

2

CLNS-0003RS53

8

NPLYZ0016QSZZ

18

DHAI-0200QSZZ

81

XEBSD30P06000

93

LPLTM4715FCZ1

96

TCAUH0933FCZZ

97

! CREFL0004QS33

501

光学ユニット

5

(Optical unit)

PRICE RANK

Ex. Ja.

BB GD E

BR LX E

AF DS C

AS EZ C

AA DD C

AF DS C

AB DD C

BL HG E

NEW

MARK

PART

RANK

2nd,3rd mirror unit

Lens unit

Pulley

CL harness CL

Screw (3×6)

Wire fixing plate F

55FE2 high temperature label 55FE2

Copy lamp unit

DESCRIPTION

第

ミラーユニット

2.3

レンズユニット

テイプーリー

ハーネス

ビス

ワイヤー取り付け板

高温注意ラベル

コピーランプユニット

F

501

2

18

18

96

8

93

97

96

93

81

– 4 –

PRP00645

Page 17

中間フレームユニット

6

NO. PARTS CODE

DUNTK0041RS14

7

LFRM-0024QSZ3

46

LPINS0301FCZZ

47

LANGT0003QSZ1

51

中間フレームユニット

6

(Middle frame unit)

PRICE RANK

Ex. Ja.

BG GX E

BC GJ C

AD DJ C

AC DJ C

NEW

MARK

PART

RANK

(Middle frame unit)

47

51

DESCRIPTION

LSU unit LSU

Middle frame

DV guide pin DV

SRU fixing angle SRU

7

中間フレーム

ユニット

ガイドピン

取付けアングル

プロセスユニット

7

(Process unit)

NO. PARTS CODE

PSEL-0130QSZZ

5

PSEL-0129QSZZ

6

CFRM-0021QS67

501

プロセスユニット

7

(Process unit)

46

PRICE RANK

Ex. Ja.

AF DS N C

AF DS N C

BK HG N E

NEW

MARK

PRP00646

PART

RANK

Seal R PAN (Except Japan)

Seal F PAN (Except Japan)

Process frame unit (Except Japan)

DESCRIPTION

501

5

6

モケット

R PAN

モケット

F PAN

プロセスフレームユニット

– 5 –

PRP00647

Page 18

現像カートリッジユニット

8

NO. PARTS CODE

PSEL-0067QSZ3

7

PCOVP0072QS12

11

RDTCM0001YSZZ

31

PSEL-0105QSZZ

45

PSHEP0262QSZZ

46

PSEL-0114QSZZ

47

PSEL-0115QSZZ

48

PSHEP0324QSZZ

49

現像カートリッジユニット

8

(DV cartridge unit)

PRICE RANK

Ex. Ja.

AG DX C

AH DX N C

AZ FQ B

AA DJ C

AC DJ C

AC DJ C

AD DJ C

AC DJ C

NEW

MARK

PART

RANK

(DV cartridge unit)

DESCRIPTION

TG seal LDAR TG

DV cover DV

ATC sensor ATC

TN-SEL-FR TN-SEL-FR

DV-UND-Sheet DV-UND

DV-MKT-F DV-MKT-F

DV-MKT-F2 DV-MKT-F2

DVB-SHE-FBR (Except Japan) DVB-SHE-FBR

シール

カバー

センサー

LDAR

シート

定着ユニット

9

(Fusing unit)

NO. PARTS CODE

PCOVP0029QSZ2

5

MSPRT0089QSZ2

32

PRICE RANK

Ex. Ja.

AT EZ C

AC DJ C

NEW

MARK

45

48

PART

RANK

Fusing cover

Pressure spring B

7

47

49

A

31

A

11

46

A

49

PRP00648

DESCRIPTION

定着カバー

加圧バネ

B

定着ユニット

9

(Fusing unit)

B

5

A

B

32

A

32

PRP00649

– 6 –

Page 19

台板ユニット

11

1(Base plate unit 1)

NO. PARTS CODE

DHAI-0091QSZ2

2

CPWBF0023QSE1

9

GFTA-0005QSZZ

56

XEBSD40P12000

57

PCLR-0010QSZZ

58

台板ユニット

12

2(Base plate unit 2)

NO. PARTS CODE

DUNTK0049RS18

9

! RDEN-0004QSZZ

! DHAI-0142QSZ1

! DHAI-0143QSZ1

! DUNTK0050RS29

! DUNTK0050RS30

! DUNTK0050RS31

! DUNTK0050RS32

DUNTK0049RS19

11

18

TCAUS0009QSZZ

CPLTM0071QS02

30

CPWBX0096QSF5

37

CPWBX0096QSF6

CPWBF0033QSE1

43

DHAI-0123QSZ1

45

RCILZ0013QSZZ

98

LPFTF0001QSZZ

120

DHAI-0261QSZZ

121

501

PRICE RANK

Ex. Ja.

AE DS C

AW FG E

AC DJ C

AA DD C

AC DJ C

PRICE RANK

Ex. Ja.

BH GX N E

BH GX N E

BY TF N E

AQ EQ N B

AS EQ N B

AF DS C

AL EB C

BZ TR N E

CB TX N E

AP EQ E

AU EZ C

BA FX N B

AC DJ C

AF DS N C

CC UB N E

CC UB N E

CC UB N E

CC UB N E

NEW

MARK

NEW

MARK

PART

RANK

Tray SW harness

Dry heater PWB (Japan)

2nd cover (Except Japan) 2nd

Screw (4×12) (Except Japan)

Color

PART

RANK

AC switch unit (100V series) AC

AC switch unit (200V series) AC

Composite power supply unit (200V series)

AC cord (230V) (Lebanon,Iran,Nigeria,West Africa,Algeria,

AC cord (230V) (Soudi Arabia,

LAG plug caushion lagel (LAG4) LAG

Drive joint plate

MCU PWB (Japan) MCU

MCU PWB (Except Japan) MCU

RCU PWB

PS low voltage harness PS

Reactle (200V series)

Pully flange

Reactle interface harness (200V Series)

Power supply unit (100V)

Power supply unit (120V)

Power supply unit (230V)

Power supply unit (127V)

Egypt,Jordan,Syria,Tunisia,Morocco,STCL) AC

Yemen,Oman,Qatar,Bahrain,Kuwait,UAE) AC

DESCRIPTION

DESCRIPTION

トレイ検知SWハーネス

除湿ヒーター基板

蓋

ビス

カラー

PAN

スイッチユニット

スイッチユニット

複合電源ユニット

コード

コード

プラグコーションラベル

駆動連結板

基板

基板

リモートシステム中継基板

低電圧ハーネス

リアクトル

プーリーフランジ

リアクトル中継ハーネス

電源ユニット

電源ユニット

電源ユニット

電源ユニット

11

台板ユニット

1(Base plate unit 1)

9

2

58

56

57

PRP00650

– 7 –

Page 20

12

台板ユニット

2(Base plate unit 2)

43

501

A

121

37

45

D

C

9

C

D

120

11

18

30

200V series

A

18

98

PRP00651

– 8 –

Page 21

手差しマルチユニット

13

NO. PARTS CODE

LPLTP0056QSZ3

3

NROLR0922FCZZ

13

CSOU-0009QS31

502

CSOU-0009QS32

手差しマルチユニット

13

13

(Manual paper feeding multi unit)

PRICE RANK

Ex. Ja.

AD DJ N C

AR EZ C

BC GJ E

AZ FQ N E

NEW

MARK

PART

RANK

Stopper plate

Manual paper feed roller B9

Manual feeding tray unit (Japan)

Manual paper tray unit (Except Japan)

(Manual paper feeding multi unit)

3

DESCRIPTION

ストッパー板

手差しローラー

手差しトレイユニット

手差しトレイユニット

B9

排紙フレームユニット

14

NO. PARTS CODE

LFRM-0027QSZ1

39

排紙フレームユニット

14

(Delivery frame unit)

PRICE RANK

Ex. Ja.

AV FG N C

NEW

MARK

PART

RANK

(Delivery frame unit)

Delivery frame

502

PRP00652

DESCRIPTION

排紙フレ-ム

39

– 9 –

PRP00653

Page 22

16 250

枚トレイユニット

NO. PARTS CODE

PSPAZ0022QSZZ

20

(250 sheets tray unit)

PRICE RANK

Ex. Ja.

AC DJ C

NEW

MARK

PART

RANK

Rotation plate S spacer

DESCRIPTION

回転板Sスペーサー

16 250

17

枚トレイユニット

梱包材&付属品

NO. PARTS CODE

SPAKC0395RSZZ

SPAKC0396RS11

1

SPAKC0396RSZZ

SPAKA0083RSZZ

4

CCLEZ0005RS51

12

SPAKA0150RSZZ

17

TINSJ0646QSZZ

TINSE0647QSZZ

TINSE0653QSZZ

20

TINSF0648QSZZ

TINSS0650QSZZ

TINSA0649QSZZ

TCADZ0164QSZZ

24

SPAKA0133QSZZ

101

SPAKA3914FCZZ

102

(250 sheets tray unit)

20

(Packing material & Accessories)

PRICE RANK

Ex. Ja.

BP LP N D

BR LX N D

BR LX N D

AD DJ N D

AQ EQ E

AA DJ N D

AV ZZ N D

AV FG N D

AV FG N D

AU FG N D

AV FG N D

AU FG N D

AG DX N D

AG DS D

AC DJ D

NEW

MARK

PART

RANK

Packing case (Japan)

Packing case (SRS,SRSSC,STCL)

Packing case (Other countries)

Top packing cushion (Except Japan)

Charger cleaner unit

Accessories protect packing cushion

Operation manual (COPY)(Japanese)

Operation manual (COPY)(English)

Operation manual (COPY)(English)(SRH)

Operation manual (COPY)(French)

Operation manual (COPY)(Spanish)

Operation manual (COPY)(Arabic)

Inst. manual card (Japan)

Spacer A (Japan)

DV sleeve (Japan) DV

PRP00654

DESCRIPTION

パッキングケース

パッキングケース

パッキングケース

天アド

チャージャークリーナユニット

付属保護材

取扱説明書

取扱説明書

取扱説明書

取扱説明書

取扱説明書

取扱説明書

設置手順書

スペーサー

A

スリーブ

梱包材&付属品

17

(Packing material & Accessories)

2

3

4

15

– 10 –

1

24

20

17

12

PRP00655

Page 23

20 MCU

基板

(MCU PWB)

NO. PARTS CODE

VHI29F04014QS

1

VHI29F04015QS

QCNCW7191RC1B

18

QSOCZ0002QSZZ

40

VCCUCY1AJ105Z

53

VCEAGU1VW476M

60

VCKYCY1HB102K

VCKYCY1HB102K

63

VCKYCY1HB102K

VHEUDZS5.6B-1

69

VHIMC7805CT-1

73

VHINJM2103M-1

75

VHVICPN38//-1

130

ユニット

CPWBX0096QSF5

901

CPWBX0096QSF6

(Unit)

PRICE RANK

Ex. Ja.

BB GD N B

BB GD N B

AG DX C

AD DJ C

AC DD C

AB DD C

AA DD C

AA DD C

AA DD C

AC DJ B

AD DJ B

AH DX B

AF DS B

BZ TR N E

CB TX N E

NEW

MARK

PART

RANK

FLASH ROM (29F04013QS) (Japan)[IC20]

FLASH ROM (29F04015QS) (Except Japan)[IC20]

Connector (12pin) [CN12]

IC socket (8pin) [IC4] IC

Capacitor (10WV 1µF) [C15,281]

Capacitor (35WV 47µF) [C72,75,76,96]

Capacitor (50WV 1000pF) [C4,5,18,21,23]

Capacitor (50WV 1000pF) [C77∼81,105∼112]

Capacitor (50WV 1000pF) [C115∼130]

Zener diode (UDZS5.6B) [ZD1∼16,18,19]

IC (MC7805CT-2) [IC15] IC

IC (NJM2103M) [IC2] IC

IC (NJM2103M) [F1,2,3,6,7] IC

MCU PWB (Japan) MCU

MCU PWB (Except Japan) MCU

DESCRIPTION

フラッシュ

ROM

フラッシュ

ROM

コネクター

ソケット

コンデンサー

コンデンサー

コンデンサー

コンデンサー

コンデンサー

ツェナーダイオード

基板

基板

33 ERDH

操作基板

NO. PARTS CODE

QSW-P0008QSZZ

3

VHP1LHLE-002A

4

ユニット

CPWBF0025QSE3

901

(Unit)

(ERDH OP PWB)

PRICE RANK

Ex. Ja.

AC DJ B

AC DJ B

AH DX N E

NEW

MARK

PART

RANK

DESCRIPTION

Switch (EVQ-23G-04K) [K1,2,3]

LED (Red) (1LHLE-002A) [D1,2,3] LED

ERDH operation PWB ERDH

スイッチ

操作基板

– 11 –

Page 24

■

索引 (Index)

PARTS CODE

[C]

CCAB-0012QS0V 578 107 0415

CCAB-0012QS0W 578 107 0416

CCLEZ0005RS51 578 704 0029

CCOVH0010QS51 572 110 1105

CFRM-0021QS67 578 213 0368

CLNS-0003RS53 578 372 0015

CMIR-0008QS32 578 374 0023

" 578 374 0023

CPLTM0071QS02 578 221 0646

CPLTM0155QS02 578 221 0679

CPLTM0156QS02 578 221 0680

CPWBF0023QSE1 578 684 0788

CPWBF0024QSE1 578 684 0890

CPWBF0024QSE2 578 684 0891

CPWBF0025QSE3 578 684 0880

" 578 684 0880

CPWBF0033QSE1 578 684 0792

CPWBX0096QSF5 578 684 0881

" 578 684 0881

CPWBX0096QSF6 578 684 0892

" 578 684 0892

CREFL0004QS33 578 432 0003

CSOU-0009QS31 578 226 0126

CSOU-0009QS32 578 226 0176

[D]

DHAI-0091QSZ2 578 542 0109

DHAI-0123QSZ1 572 542 1587

DHAI-0142QSZ1 578 542 0239

DHAI-0143QSZ1 578 542 0240

DHAI-0200QSZZ 578 542 0233

DHAI-0261QSZZ 578 542 0241

DUNTK0041RS14 578 685 0515

DUNTK0049RS18 578 685 0540

DUNTK0049RS19 578 685 0541

DUNTK0050RS29 578 685 0542

DUNTK0050RS30 578 685 0543

DUNTK0050RS31 578 685 0544

DUNTK0050RS32 578 685 0545

[G]

GCOVH0010QSZ3 578 110 0184

GFTA-0001QSZ1 578 117 0030

GFTA-0005QSZZ 572 117 0094

[H]

HPNLH0021QSZ1 578 158 0270

HPNLH0021QSZ2 578 158 0271

HPNLH0021QSZ3 578 158 0272

HPNLH0021QSZ4 578 158 0277

HPNLH0021QSZZ 578 158 0269

HPNLH0022QSZ1 578 158 0274

HPNLH0022QSZZ 578 158 0273

[J]

JBTN-0018QSZZ 572 170 0446

JBTN-0026QSZZ 572 170 0459

JBTN-0027QSZZ 572 170 0460

JBTN-0029QSZZ 572 170 0449

JBTN-0030QSZZ 572 170 0461

[L]

LANGT0003QSZ1 578 200 0200

LFRM-0016QSZ2 578 213 0356

LFRM-0024QSZ3 578 213 0343

LFRM-0027QSZ1 578 213 0365

LPFTF0001QSZZ 572 217 0088

LPINS0301FCZZ 572 218 0426

LPLTM4715FCZ1 572 221 5595

LPLTP0056QSZ3 578 221 0705

[M]

MSPRT0089QSZ2 578 258 0611

[N]

NPLYZ0016QSZZ 578 284 0068

NPLYZ0017QSZZ 578 284 0069

NROLR0922FCZZ 572 287 1120

[P]

PCLR-0010QSZZ 578 318 0039

PCOVP0029QSZ2 578 323 0247

PCOVP0072QS12 578 323 0252

PSEL-0067QSZ3 578 400 0221

PSEL-0105QSZZ 578 400 0235

PSEL-0114QSZZ 578 400 0233

JAPAN ONLY

ORDER CODE

PRICE R.

NO.

Ex.

1- 10 BA FX N D

1- 10 BA FX N D

17- 12 AQ EQ E

1-501 BM HV E

7-501 BK HG N E

5- 8 BR LX E

4-901 BB GD E

5- 2 BB GD E

12- 30 AL EB C

4- 13 AH DX C

4- 9 AH DX C

11- 9 AW FG E

2- 19 BL HL N E

2- 19 BL HL N E

2- 17 AH DX N E

33-901 AH DX N E

12- 43 AP EQ E

12- 37 BZ TR N E

20-901 BZ TR N E

12- 37 CB TX N E

20-901 CB TX N E

5-501 BL HG E

13-502 BC GJ E

13-502 AZ FQ N E

11- 2 AE DS C

12- 45 AU EZ C

12- 18 AQ EQ N B

12- 18 AS EQ N B

5- 81 AS EZ C

12-121 AF DS N C

6- 7 BG GX E

12- 9 BH GX N E

12- 9 BH GX N E

12-501 CC UB N E

12-501 CC UB N E

12-501 CC UB N E

12-501 CC UB N E

1- 1 BC GJ N D

1- 11 AT EZ D

11- 56 AC DJ C

2- 3 AT EZ N D

2- 3 AT EZ N D

2- 3 AT EZ N D

2- 3 AT EZ N D

2- 3 AT EZ N D

2- 4 AK EB N D

2- 4 AK EB N D

2- 6 AE DJ C

2- 13 AE DJ C

2- 15 AD DJ C

2- 7 AE DS C

2- 14 AD DJ C

6- 51 AC DJ C

3- 10 AT EZ C

6- 46 BC GJ C

14- 39 AV FG N C

12-120 AC DJ C

6- 47 AD DJ C

5- 96 AF DS C

13- 3 AD DJ N C

9- 32 AC DJ C

5- 18 AF DS C

4- 4 AE DS C

13- 13 AR EZ C

11- 58 AC DJ C

9- 5 AT EZ C

8- 11 AH DX N C

8- 7 AG DX C

8- 45 AA DJ C

8- 47 AC DJ C

Ja.

NEW P/R

PARTS CODE

PSEL-0115QSZZ 578 400 0234

PSEL-0129QSZZ 578 400 0239

PSEL-0130QSZZ 578 400 0240

PSHEP0262QSZZ 578 403 0644

PSHEP0324QSZZ 578 403 0713

PSHEZ0058QSZ1 578 403 0720

PSPAZ0022QSZZ 578 413 0120

[Q]

QCNCW7191RC1B 572 510 1027

QSOCZ0002QSZZ 578 527 0027

QSW-P0008QSZZ 572 530 0679

[R]

RCILZ0013QSZZ 578 614 0093

RDEN-0004QSZZ 578 685 0537

RDTCM0001YSZZ 572 618 0136

[S]

SPAKA0083RSZZ 578 902 0315

SPAKA0133QSZZ 572 902 1473

SPAKA0150RSZZ 578 902 0316

SPAKA3914FCZZ 572 902 0485

SPAKC0395RSZZ 578 901 0559

SPAKC0396RS11 578 901 0561

SPAKC0396RSZZ 578 901 0560

[T]

TCADZ0164QSZZ 578 913 0197

TCAUH0933FCZZ 572 914 0129

TCAUS0009QSZZ 572 914 0679

TINSA0649QSZZ 578 916 0603

TINSE0647QSZZ 578 916 0604

TINSE0653QSZZ 578 916 0605

TINSF0648QSZZ 578 916 0606

TINSJ0646QSZZ 578 916 0595

TINSS0650QSZZ 578 916 0607

TLABZ0058QSZZ 572 917 3341

[V]

VCCUCY1AJ105Z 596 593 0899

VCEAGU1VW476M 579 594 0046

VCKYCY1HB102K 594 593 0044

VHEUDZS5.6B-1 594 571 0179

VHI29F04014QS 578 573 1232

VHI29F04015QS 578 573 1233

VHIMC7805CT-1 572 573 0076

VHINJM2103M-1 578 573 1129

VHP1LHLE-002A 578 574 0043

VHVICPN38//-1 585 577 0022

[X]

XEBSD30P06000 578 970 0102

XEBSD40P12000 578 970 0084

XEPSD30P08X00 595 970 0136

JAPAN ONLY

ORDER CODE

PRICE R.

NO.

8- 48 AD DJ C

7- 6 AF DS N C

7- 5 AF DS N C

8- 46 AC DJ C

8- 49 AC DJ C

1- 2 AU FG N D

16- 20 AC DJ C

20- 18 AG DX C

20- 40 AD DJ C

33- 3 AC DJ B

12- 98 BA FX N B

12- 11 BY TF N E

8- 31 AZ FQ B

17- 4 AD DJ N D

17-101 AG DS D

17- 17 AA DJ N D

17-102 AC DJ D

17- 1 BP LP N D

17- 1 BR LX N D

17- 1 BR LX N D

17- 24 AG DX N D

5- 97 AB DD C

12- 18 AF DS C

17- 20 AU FG N D

17- 20 AV FG N D

17- 20 AV FG N D

17- 20 AU FG N D

17- 20 AV ZZ N D

17- 20 AV FG N D

1- 49 AD DJ C

20- 53 AC DD C

20- 60 AB DD C

20- 63 AA DD C

20- 69 AC DJ B

20- 1 BB GD N B

20- 1 BB GD N B

20- 73 AD DJ B

20- 75 AH DX B

33- 4 AC DJ B

20-130 AF DS B

5- 93 AA DD C

11- 57 AA DD C

2- 46 AA DD C

Ex.

Ja.

NEW P/R

– 12 –

Page 25

COPYRIGHT 2001 BY SHARP CORPORATION

All rights reserved.

Printed in Ja pan.

No part of this public ation may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means ,

electronic, mechanical, photocop ying, recording, or oth erwise,

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Quality & Reliability Control Center

Yamatokoriyama, Nara 639-1186, Japan

2001 June Printed in Japan

Loading...

Loading...