Page 1

AR-SP3

AR-SP3

AR-FX3

AR-DE9

CODE: 00ZAR15OPTA1E

DIGITAL COPIER OPTIONS

AR-SP3 (SPF)

AR-FX3 (FAX)

AR-DE9 (1 TRAY UNIT)

MODEL AR-PG1 (GDI + USB Kit)

∗ For the specifications, operational descriptions, circuit

diagrams, and Parts Guide of the AR-FX3, refer to the AR-F151

Service Manual and Parts Guide.

AR-PG1

CONTENTS

[ 1 ] GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . 2 - 1

[ 3 ] AR-SP3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

[ 4 ] AR-DE9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[ 5 ] AR-PG1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

● PARTS GUIDE

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

AR-SP3

[1] GENERAL

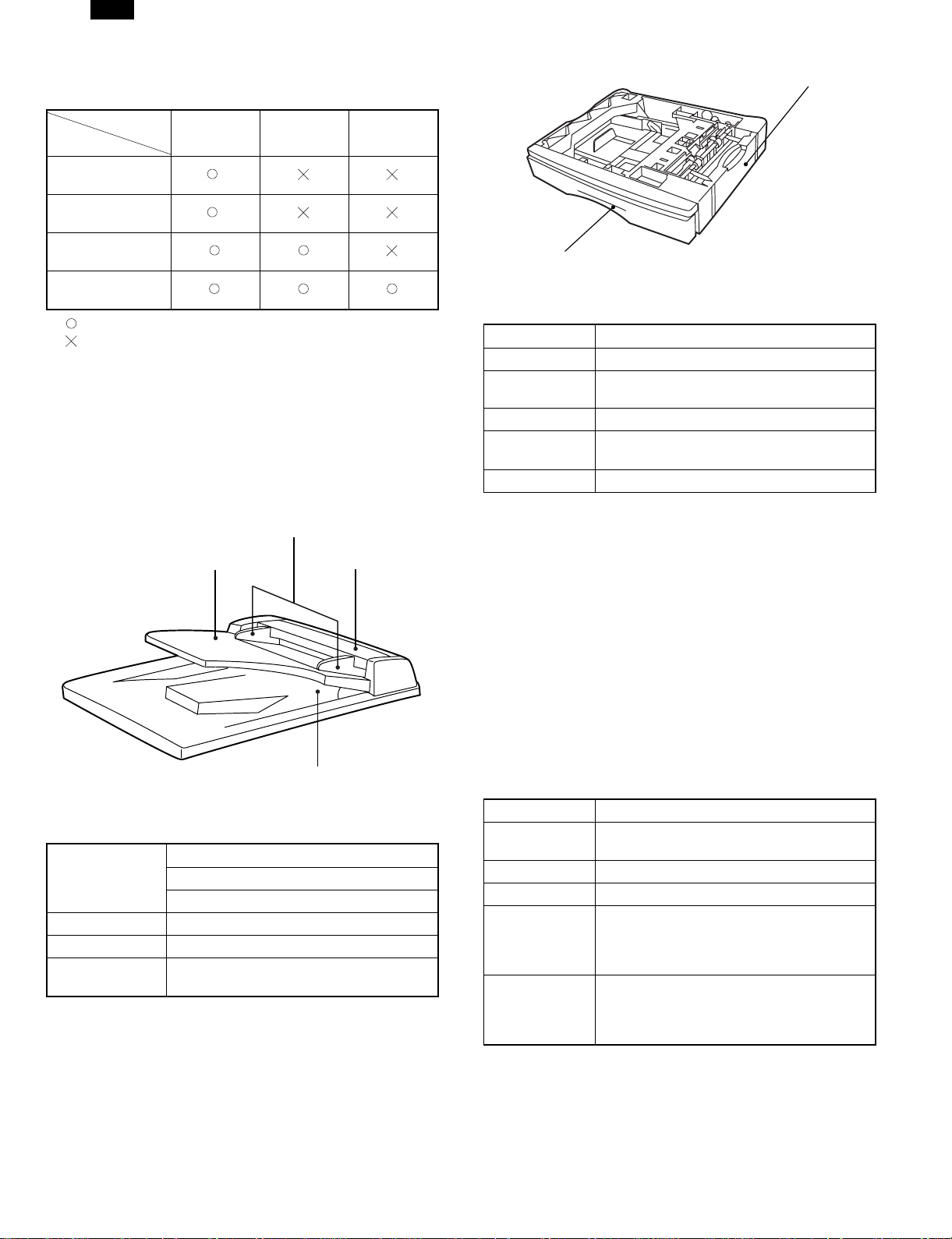

1. List of available options

Model

Option

AR-SP3

(SPF)

AR-FX3

(FAX)

AR-DE9

(1 TRAY UNIT)

AR-PG1

(GDI + USB Kit)

Option available

:

Option not available

:

∗1: The option setup is provided in the models for Europe.

FAX and SPF are incompatible.

2. Outline and specifications of each option

A. AR-SP3 (Single Pass Feeder)

The single pass feeder (SPF) holds up to 30 originals for automatic

feeding.

Part names

Document feeder tray

AR-150 AR-155 AR-F151

∗1

∗1

∗1

Original guides

Feeding roller cover

SPF exit area

Part names

Side cover

Tray

Specifications

Copy paper size 5-1/2″ × 8-1/2″ to 8-1/2″ × 14″

Paper weight 15 lbs. to 21 lbs.

Paper capacity

Weight Approx. 6.6 lbs. (3 kg)

Dimensions

Power supply Drawn from the copier

One paper tray with capacity for 250 sheets

of 21 lb. bond paper

19.6″ (W) × 15.6″ (D) × 3.5″ (H)

(498 mm (W) × 395 mm (D) × 88 mm (H))

C. AR-PG1 (GDI + USB Expansion Kit)

(1) MAIN FEATURES

a. Printing from Windows 3.1x, Windows 95, Windows 98*, and

Windows NT 4.0 applications

∗ USB is supported on Windows 98 pre-installed only.

●

High-speed and high-quality printing can be performed from Windows 3.1x, Windows 95, Windows 98, and Windows NT 4.0 applications through the SHARP GDI (Graphics Device Interface)

system.

●

Since print data is processed in the computer, waiting time

during printing is short.

b. High-speed printing at 8 pages/min.

●

First print time is approximately 9.6 seconds.

(Excluding the communication time with PC)

●

Print speed is 8 pages/min., when printing multiple pages.

(2) SPECIFICATIONS

Specifications

Acceptable

originals

Power supply Drawn from the copier

Weight Approx.6.6 lbs.(3kg)

Dimensions

Weight: 14 to 23 lbs.

Size: 5-1/2″ × 8-1/2″ to 8-1/2″ × 14″

Capacity: Up to 30 sheets

19.6″ (W) × 15″ (D) × 4.3″ (H)

(498 mm (W) × 380 mm (D) × 110 mm (H))

B AR-DE9 (250 - Sheet Paper Feed Unit)

The paper feed unit provides the convenience of increased paper

capacity for the copier and a greater choice of paper sizes readily available for copying.

Resolution 600 or 300 can be selected.

Page description

language

Page orientation Portrait or landscape

First print time Approx. 9.6 seconds*

Print speed

(multiple pages)

Interface port

∗ First print time may differ depending on operating conditions,

such as power-supply voltage and room temperature.

Also the time may differ depending on data quantity to be printed

and applications.

SHARP GDI (Parallel)

SHARP GDI, USB (USB)

Approx. 8 pages per minute (letter or A4)

(Parallel)

Approx. 6 pages per minute (letter or A4)

(USB)

Bi-directional parallel interface

(IEEE 1284 compliant) 2 m (6 feet) Max.

USB (B-type) interface (twisted pair cable)

2 m (6 feet) Max.

D. AR-FX3 (Facsimile Expansion Kit)

Refer to the AR-F151 Service Manual.

1 – 1

Page 3

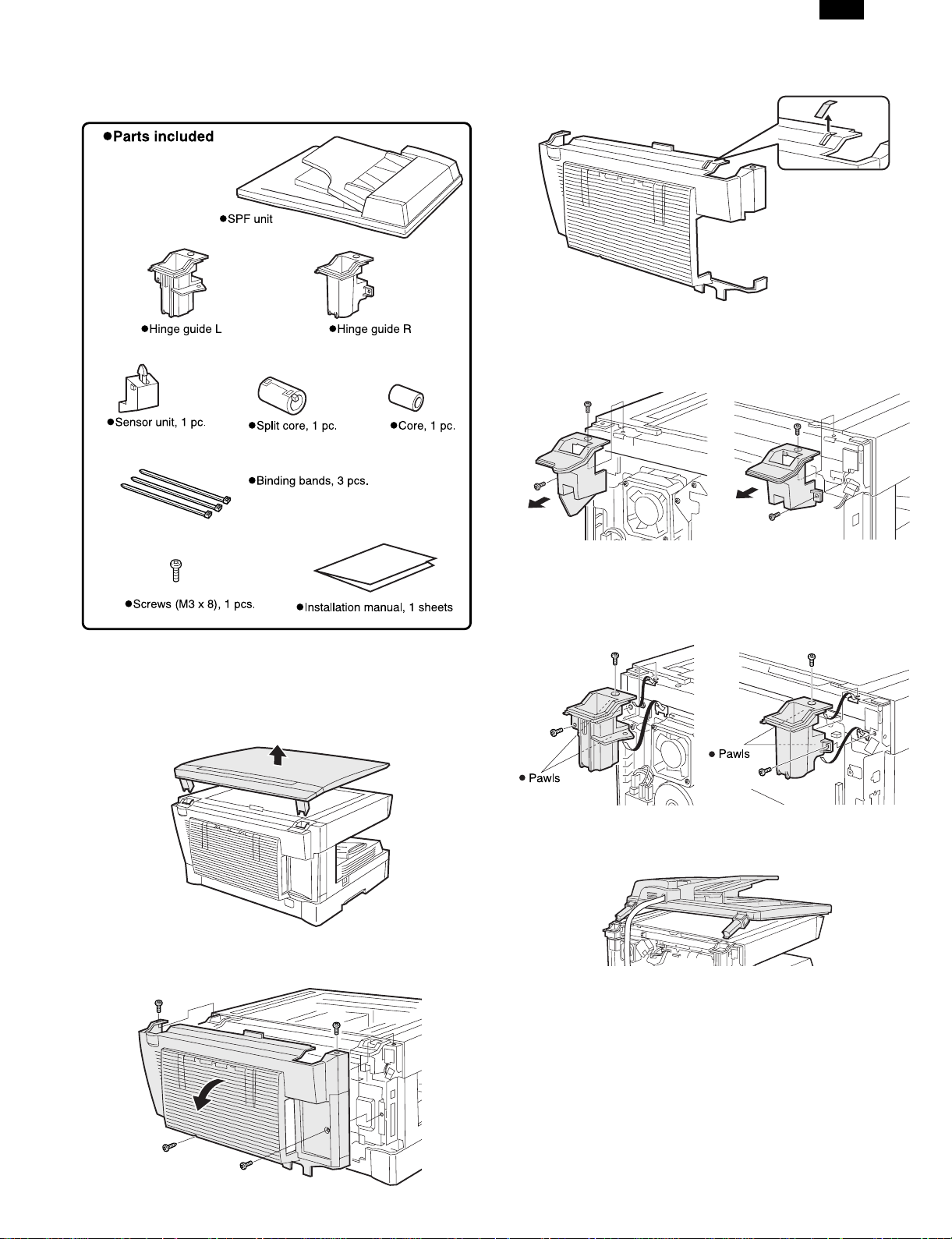

AR-SP3

[2] UNPACKING AND INSTALLATION

1. AR-SP3 Instalation Manual

3) Remove the Mylar sheet from the rear cabinet.

●

Remove the Mylar sheet that covers the hole for the actuator of

sensor unit.

4) Remove the hinge guides L and R.

●

Remove the screws (two for each) and then remove the hinge

guides L and R.

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

1) Remove the document cover.

●

Remove the document cover from the copier.

2) Remove the rear cabinet.

●

Remove the four screws and then remove the rear cabinet.

5) Attach the hinge guides L and R.

●

Attach the hinge guides L and R by fitting the pawls (two for

each) into the frame of the copier and secure them with the two

screws (M3 × 8) for each that have been removed in step 3.

6) Place the SPF on the copier.

2 – 1

Page 4

AR-SP3

7) Connect the SPF with the copier using the relay harness.

<1> Fit the snap band to the position shown in the illustration.

<2> Attach the core to the relay harness. At this time, take care on

the core position and twist the harness two or three times.

<3> Secure the relay harness with the harness clamp.

<4> Connect the connector.

(Connect the connectors by aligning the black lines.)

8) Attach the core to the ground wire and secure it.

<1> Attach the core with two binding bands as shown in the il-

lustration by taking care that the core is in the specified position.

<2> Secure the ground wire to the hinge guides with the binding

bands.

<3> Secure the ground terminal to the frame of the copier with a

screw (M3 × 10) and handle the wiring so that the core is

under the hinge guides.

10) Attach the sensor unit.

●

While pushing up the sensor unit fully, secure it to the PWB

holder with a screw (M3 × 8).

M3X8

11) Attach the rear cabinet.

●

Remove the rib from the rear cabinet.

<1> Hang the four pawls shown in the illustration below on the

plate.

<2> Push down the actuator of the sensor unit.

<3> Position the cabinet to the upper screw positions.

<4> Ensure that the actuator is inserted into the square hole of the

cabinet.

Note: While pushing down the actuator of the sensor unit, attach

the rear cabinet so that the actuator is inserted into the hole

of the rear cabinet.

9) Remove the securing tape of the relay harness and connect the

harness to the sensor unit.

●

Remove the tape that secures the harness.

Then connect the connector of the relay harness to the supplied

sensorunit.

12) Attach the cover to the rear cabinet.

<1> Align the arrow marks as shown in the illustration.

<2> Then slide the cover to the left.

<3> Secure the cover with a screw.

2 – 2

Page 5

13) Attach the SPF to the copier.

●

Attach the SPF by inserting the hinge guide sections of the SP3

into the hinge guides L and R.

1

AR-SP3

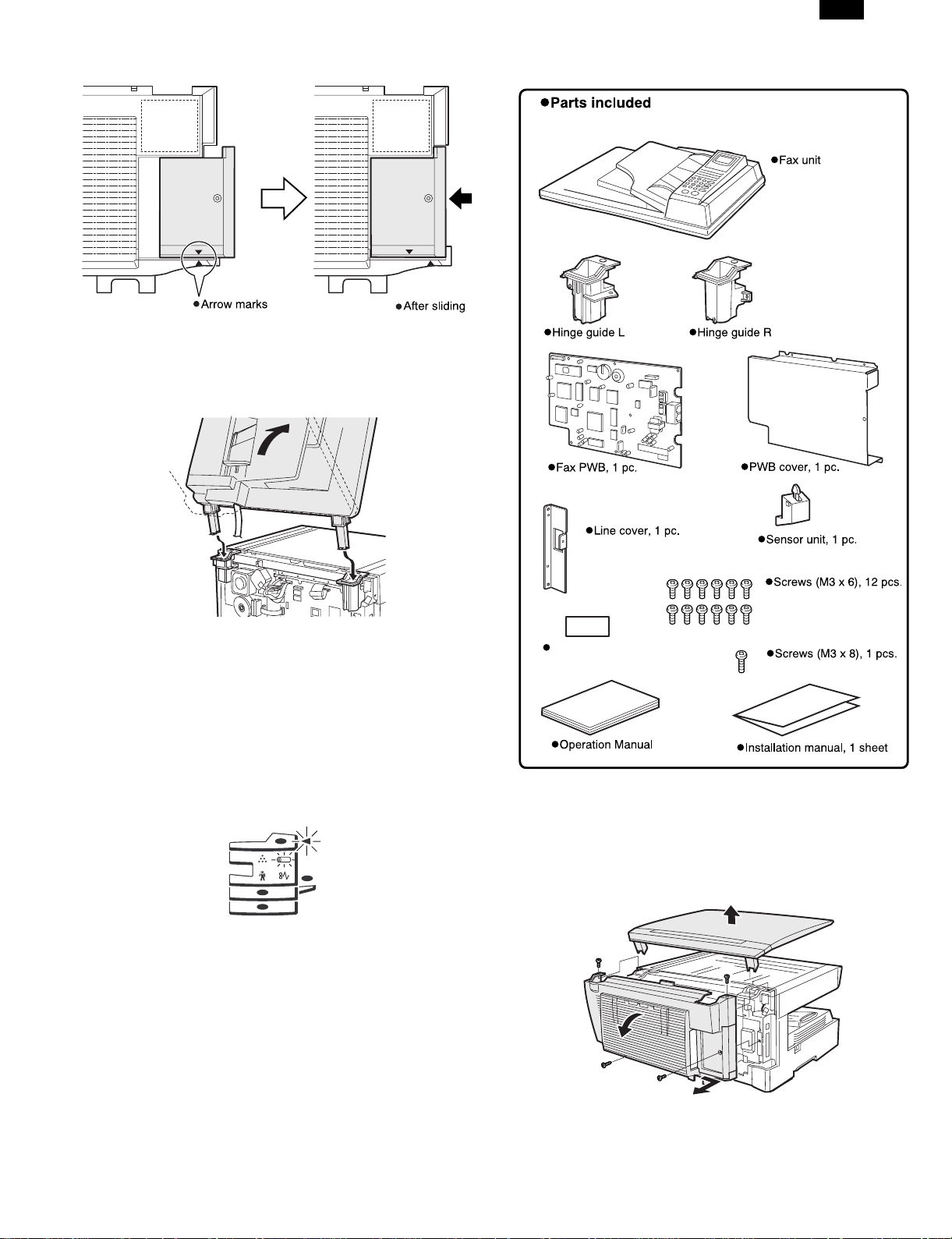

2. AR-FX3 Installation Manual

2

2

14) Insert the power plug into the outlet and turn the main switch of

the copier to the “ON” position.

15) Perform SIM setting.

●

Execute simulation [2] of [26] and enter [1].

16) Check the ON/OFF operation of the open detection sensor and

book detection sensor.

●

Execute simulation [2] of [2] and check that the indicator on the

operation panel lights up and goes out by opening and closing

the SPF. When the book detection sensor is turned ON/OFF, the

drum replacement lamp is turned ON/OFF accordingly.

17) Check the copy ratio, and then check the center displacement and

leading edge image void.

●

Place an original on the document glass and make a copy.

Then, place an original in the document feeder tray and make a

copy.

If the center of the copy from the document glass is displaced

from the copyfrom the document feeder, adjust the center referring to the service manual.

Circuit standard label, 1 sheet

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

1) Remove the document cover and the rear cabinet.

●

After removing the document cover, remove the four screws and

then remove the rear cabinet.

2 – 3

Page 6

AR-SP3

2) Remove the Mylar sheet from the rear cabinet.

●

Remove the Mylar sheet that covers the hole for the actuator of

sensor unit.

3) Remove the hinge guides L and R.

●

Remove the screws (two for each) and then remove the hinge

guides L and R.

6) Attach the sensor unit.

●

While pushing up the sensor unit fully, secure it to the PWB

holder with a screw (M3 × 8).

M3X8

7) Replace the line cover.

●

Remove the two screws, replace the line cover that has been attached at shipping with the supplied line cover, and secure it with

the two screws.

4) Attach the hinge guides L and R.

●

Attach the hinge guides L and R by fitting the pawls (two for

each) into the frame of the copier and secure them with the two

screws (M3 × 8) for each that have been removed in step 2.

5) Remove the securing tape of the relay harness and connect the

harness to the sensor unit.

●

Remove the tape that secures the harness.

Then connect the connector of the relay harness to the supplied

sensor unit.

8) Place the SPF on the copier.

9) Connect the SPF to the copier with the SPF relay harness.

<1> Fit the snap band to the position shown in the illustration.

<2> Remove the screw that secures the PWB holder and tighten

the ground wire together with the PWB holder.

<3> Secure the relay harness with the harness clamp.

<4> Connect the connector.(Connect the connectors by aligning

the black lines.)

2 – 4

Page 7

AR-SP3

10) Attach the fax PWB.

●

While ensuring that the connector of the fax PWB is securely

connected to that of the copier, attach the fax PWB to the PWB

cover with seven screws (M3 × 6) and connect the relay harness

connector.

Connect the relay harness to the connector of the fax PWB.

(Connect the connectors by aligning the black lines.)

11) Attach the PWB cover.

●

Attach the supplied PWB cover with five screws (M3 × 6).

13) Attach the cover to the rear cabinet.

<1> Align the arrow marks as shown in the illustration.

<2> Then slide the cover to the left.

<3> Secure the cover with a screw.

M3X6

M3X6

M3X6

M3X6

12) Attach the rear cabinet.

<1> Hang the four pawls shown in the illustration below on the

plate.

<2> Push down the actuator of the sensor unit.

<3> Position the cabinet to the upper screw positions.

<4> Ensure that the actuator is inserted into the square hole of the

cabinet.

Note: While pushing down the actuator of the sensor unit, attach

the rear cabinet so that the actuator is inserted into the hole

of the rear cabinet.

14) Attach the SPF to the copier.

●

Attach the SPF by inserting the hinge guide sections of the FX3

into the hinge guides L and R.

1

2

2

15) Stick the label to the rear cabinet.

●

After installing the FAX expansion kit in the machine, please put

the registration label, packed with the kit, on the prescribed location.

2 – 5

∗ For the details,refer to the AR-FX3 Installation Manual.

Page 8

AR-SP3

16) Insert the power plug into the outlet and turn the main switch of

the copier to the “ON” position.

17) Perform SIM setting.

Execute simulation [2] of [26] and enter [1].

18) Check the ON/OFF operation of the open detection sensor and

book detection sensor.

●

Execute simulation [2] of [2] and check that the indicator on the

operation panel lights up and goes out by opening and closing

the FAX-SPF. When the book detection sensor is turned

ON/OFF, the drum replacement lamp is turned ON/OFF accordingly.

19) Check the copy ratio, and then check the center displacement and

leading edge image void.

●

Place an original on the document glass and make a copy. Then,

place an original in the document feeder tray and make a copy.

If the center of the copy from the document glass is displaced

from the copy from the document feeder, adjust the center referring to the service manual.

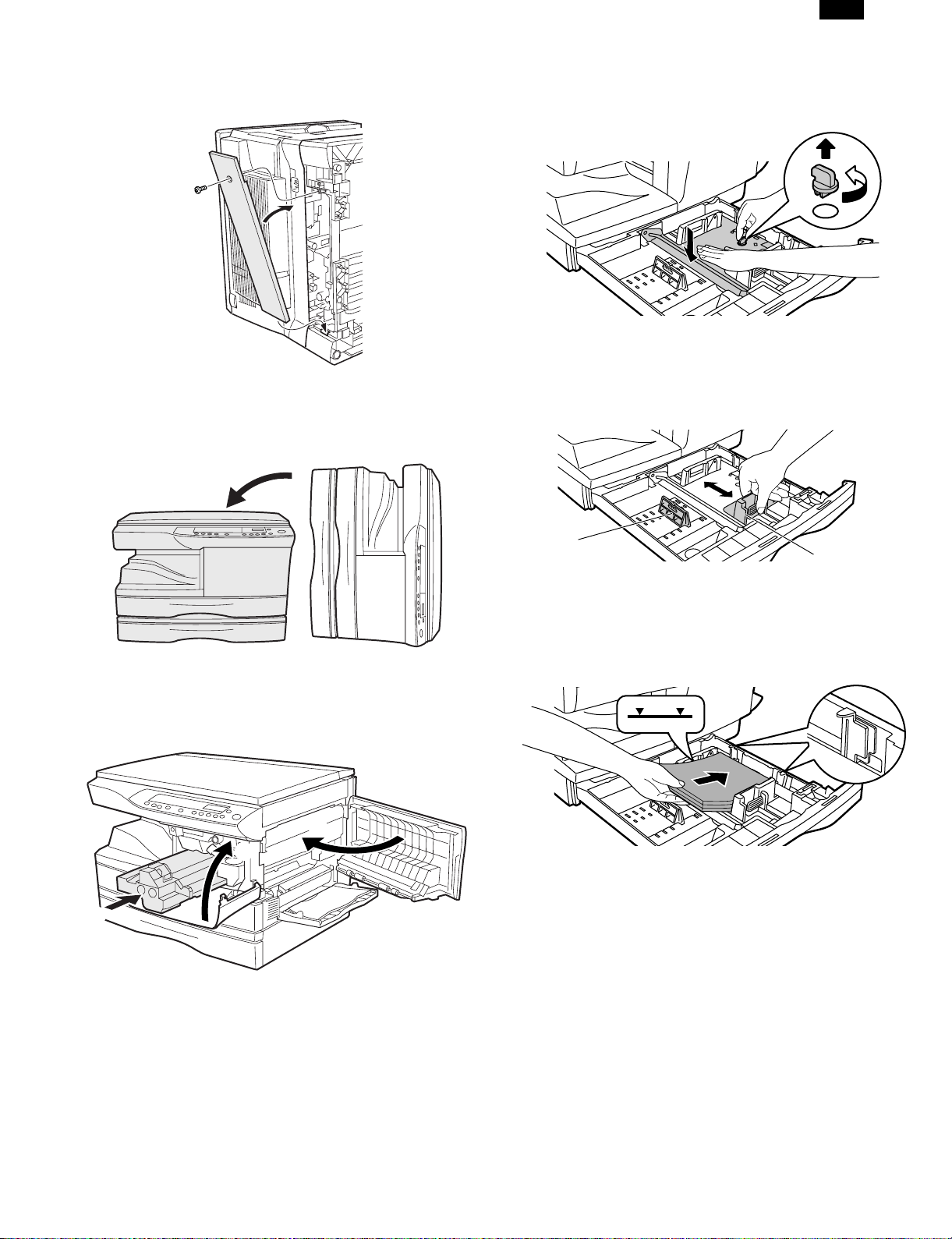

3. AR-DE9 Installation Manual

3) Remove the OP gear cover and rubber feet from the bottom of the

copier.

●

Remove the screw and remove the OP gear cover.

Then, take off and remove the rubber feet.

4) Install the second cassette unit to the copier.

●

If the second cassette unit is aligned to the copier, it can be positioned automatically.

Hold the copier lightly to prevent it from toppling down and

secure the second cassette unit with four screws (M4 × 16).

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

1) Remove the DV cartridge from the copier.

●

Open the bypass tray, side cover, and front cover, and then

remove the DV cartridge.

1

3

2

2) Make the copier upright.

●

Close the front cover, side cover, and bypass tray, and then

make the copier upright in the orientation shown in the illustration.

5) Remove the rear cover and connect the connector.

●

Remove the screw and remove the rear cover.

Then, connect the connector of the second cassette unit to that

of the copier.

2 – 6

Page 9

AR-SP3

6) Attach the rear cover.

●

Attach the rear cover to its original position and secure it with the

screw (M4 × 12).

7) Return the copier to the normal orientation.

●

When returning the copier to the normal orientation, gently return

it without giving a shock.

9) Remove the paper tray lock for packing.

●

Remove the paper tray lock for packing that secures the turning

plate in the paper tray by rotating it in the direction of the arrow

and store it in the specified position.

10) Set the paper tray side guide.

●

Squeeze the lever of the paper tray side guide to slide the guide

to the position for the paper size to be used.

8) Insert the DV cartridge into the copier.

●

Open the bypass tray, side cover, and front cover, and insert the

DV cartridge. Then, close the front cover, side cover, and bypass

tray.

3

2

1

Paper guide (B)

Paper guide (A)

11) Load paper into the paper tray.

●

When loading paper, do not exceed the maximum height line.

12) Remove the optical locking screw and fusing unit packing lever so

that the copier is ready.

13) Insert the power plug into the outlet and turn the main switch to

the “ON” position. Then, perform the following procedure.

14) Perform SIM setting.

●

Execute simulation [3] of [26] and enter [1].

15) Check the center displacement.

●

Place an original on the document glass and make a copy using

the tray in the copier.

Then, make a copy using the tray in the installed optional paper

feed unit.

If the center of the copy from the optional paper feed unit is displaced from the copy from the tray in the copier, adjust the center referring to the service manual.

2 – 7

Page 10

AR-SP3

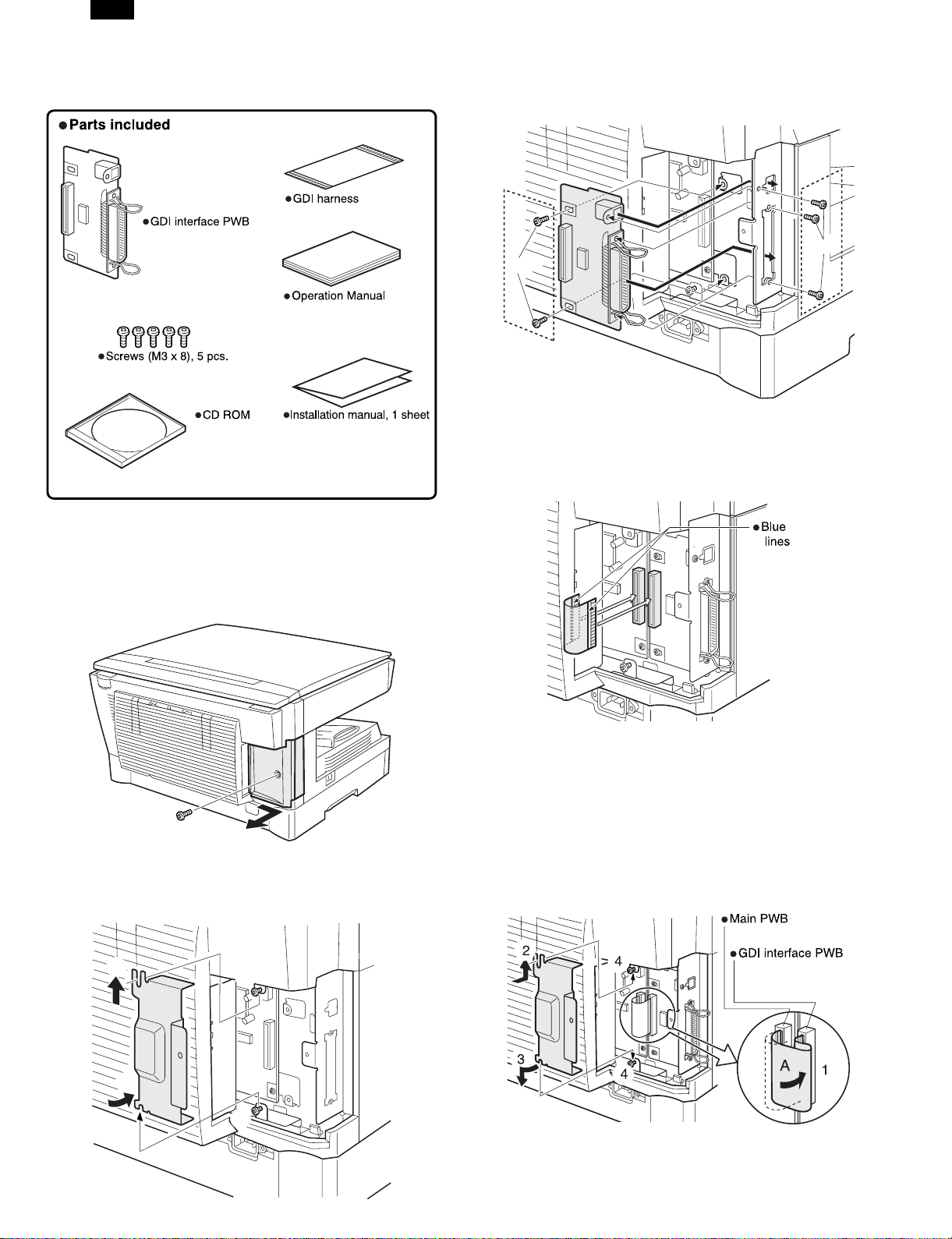

4. AR-PG1

A. Installation Manual

3) Attach the GDI interface PWB.

●

Fit the connector of the GDI PWB into the mounting position of

the copier, secure the side A with three screws, and then secure

the front B with two screws.

B

M3X8

4) Attach the GDI harness.

●

Attach the GDI harness so that the blue lines face forward and

also face toward the GDI interface side.

Note: Be careful about the direction of the blue lines.

A

M3X8

Turn the main switch to the “OFF” position and remove the power plug

from the outlet.

1) Remove the cover of the rear cabinet.

●

Remove the screw, slide the cover in the direction indicated by

the arrow, and remove the cover of the rear cabinet.

2) Remove the PWB cover.

<1> Loosen the screws that secure the PWB cover.

<2> Push up the PWB cover and

<3> Rotate it counterclockwise to remove it.

2

1

5) Attach the PWB cover.

<1> Before attaching the PWB cover, hold down the GDI harness

in the direction A in the illustration below.

<2> Fit the upper part of the PWB cover to the upper screw that

has been loosened in step 2 above.

<3> While rotating the lower part of the PWB cover clockwise, fit

it to the lower screw.

<4> Tighten the upper and lower screws to secure the cover.

3

1

2 – 8

Page 11

AR-SP3

6) Attach the rear cover.

●

Align the arrow marks as shown in the illustration and then slide

the cover to the left. Then, secure the cover with a screw.

Arrow marks

After sliding

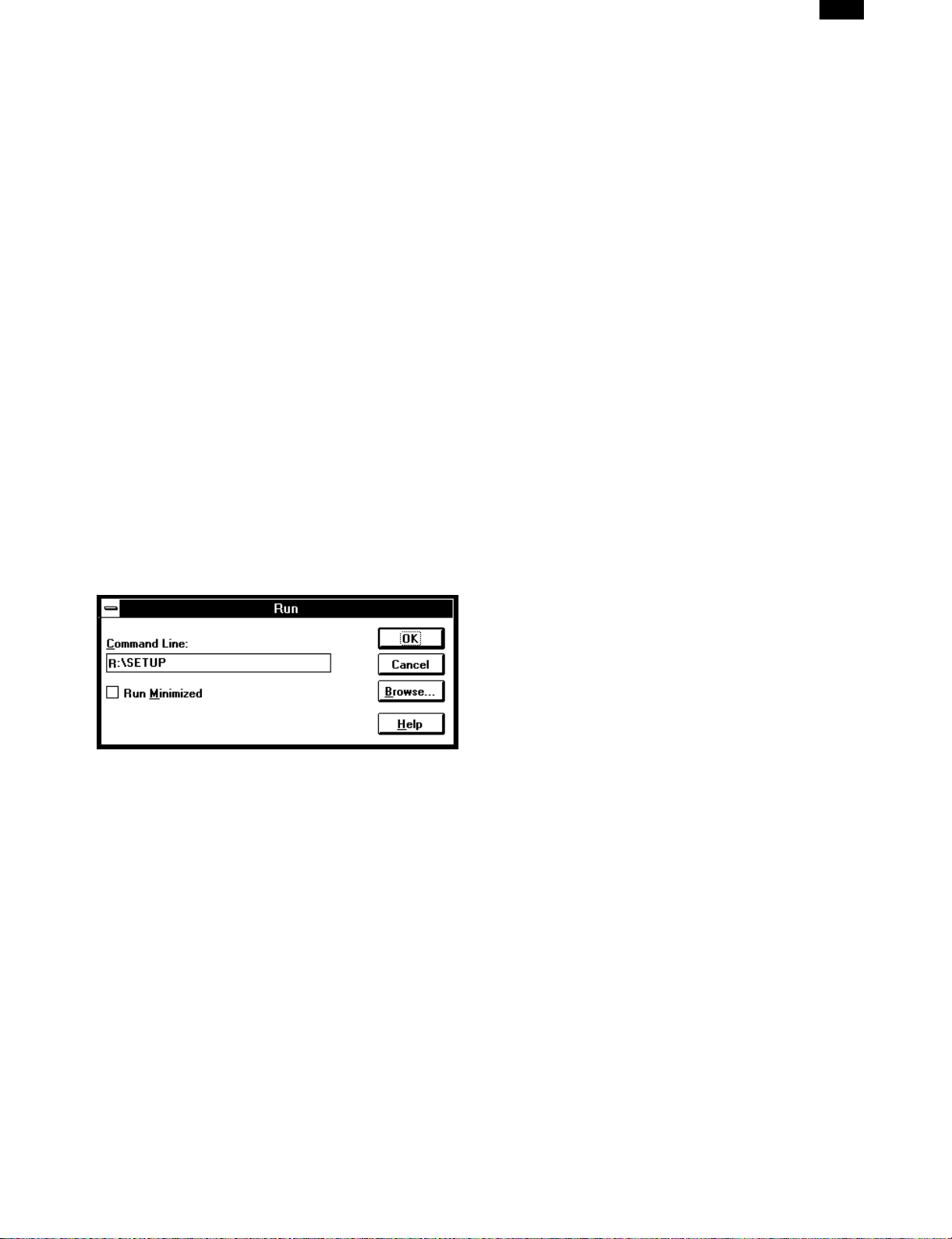

(3) Installing the printer driver

The software for your printer is provided on CD-ROM.

Before installing the printer driver, be sure to check the following items.

●

Is the printer connected properly to the computer?

●

Does the printer have paper?

●

Is there another GDI printer driver or Windows Printing System

printer driver already installed? If installed, change the printer

port setting. To change the printer port settings.

In this description, the following drive configuration is presumed.

Specify proper drives depending on the configuration of your computer.

Drive R: CD-ROM drive (installation source). If necessary,

Drive C: Hard disk drive (installation destination). If necessary,

a. Windows 95/Windows NT 4.0 Installation Instructions:

With both the computer and the printer turned off, connect the printer

to the computer with a parallel interface cable.

1) Load paper into the paper tray of the printer. For instructions on

loading paper, see the section LOADING COPY PAPER in the

copier operation manual.

2) Turn on the printer.

3) Turn on your computer and start Windows.

4) When using Windows 95 on a personal computer with plug & play*,

the “Update Device Driver Wizard” window will appear. Insert the installation CD-ROM into the CD-ROM drive. Click the Next button

and follow the on-screen instructions. Proceed to step 7. If the

“Copying Files” window appears during this operation, enter R:\ (if

the CD-ROM is designated as drive R) and click the OK button.

replace R with the letter of your CD-ROM drive.

replace C with the letter of your hard disk drive.

B. Installing the printer driver software

(1) Description of the printer driver

The printer driver is the software program which runs the printer. It converts the data in your file into information that the printer can understand. It also controls communication between the printer and

computer as the data is printed.

(2) Checking the hardware and software requirements

You will need the following hardware and software in order to install the

printer driver.

Computer type IBM PC/AT or compatible computer

equipped with a bi-directional parallel or

USB interface, and CD-ROM drive

Windows type Windows 3.1x, Windows 95, Windows 98*,

Windows NT 4.0

∗ USB is supported on Windows 98

preinstalled only.

CPU 486DX 66 MHz or better

Physical RAM Windows 95, Windows 3.1x: 8MB (16MB or

more is recommended.)

Windows NT4.0: 12MB (16MB or more is

recommended.)

Windows 98: 16MB (32MB or more is

recommended.)

Display 640 × 480 dots (VGA) or better

Hard disk free space 10 MB or more

Caution: The printer driver included in this product cannot be used

under Windows NT3.5x, OS/2, pure MS-DOS and other

operating systems which are not described above.

●

If you use Windows 95 and the “New Hardware Found” window

will appear, click the Driver from Disk Provided by Hardware

Manufacturer button and then click OK. Proceed to step 6.

●

If you use Windows 95 and the screen shown above or the “New

Hardware Found” window does not appear, proceed to step 5.

●

If you use Windows NT 4.0, proceed to step 5.

∗ Plug & play

This feature is effective if both the computer and peripheral equipment are equipped with IEEE 1284 compliant parallel interface.

5) Insert the installation CD-ROM into the CD-ROM drive.

Click the Start button and select Run. When the screen shown

below appears, type R:\SETUP (if the CD-ROM is designated as

drive R) and click the OK button. Proceed to step 7.

2 – 9

Page 12

AR-SP3

6) “Install from Disk” window will appear. Insert the installation CD-

ROM into the CD-ROM drive. Type R:\ (if the CD-ROM is designated as drive R) and click the OK button. Proceed to step 7.

7) The installation program will start. To install the printer driver to

the default folder, click the Next button. To select a different folder,

select Browse or type in the new path and folder name. Click OK

and say YES to create the folder, select the Next button to continue.

8) On the display, you will see “printer port to be used”. Normally, this

is LPT1 and it is selected automatically.

Ensure that Yes is checked to use the printer as the default

printer.

Finally click the Next button.

9) A “Confirm installation” window will be displayed. To continue in-

stallation, click the Yes button.

10) When the installation is complete, you will be asked whether or not

to print a test page. If you wish to do so, click the Yes button. At

this time, ensure that paper is loaded in the paper tray.

11) If the test print completes successfully, click the Finish button.

“The installation of the SHARP AR-150 Series Software is complete.” window will be displayed. Click the OK button.

b. Windows 98:

With both the computer and the printer turned off, connect the printer

to the computer with either a parallel or a USB interface cable.

1) Load paper into the paper tray of the printer. For instructions on

loading paper, see the section LOADING COPY PAPER found in

the copier operation manual.

2) Turn on the printer.

3) Turn on your computer and start Windows.

4) When using Windows 98 on a personal computer with plug & play*,

the “Add New Hardware Wizard” window will appear. Click the Next

button and follow the on-screen instructions.

●

If the “Add New Hardware Wizard” window does not appear,

proceed to step 8.

∗ Plug &play: For plug & play information

5) Select Search for the best driver for your device and click the Next

button.

6) Insert the installation CD-ROM into the CD-ROM drive. (If you are

using the USB interface, confirm that the installation CD-ROM is in

the CD-ROM drive.) Select the CD-ROM drive and click the Next

button.

When using the USB interface:

●

Connect your personal computer and the printer using a USB interface cable if you have not already done so.

●

When the “Add New Hardware Wizard” window appears, insert

the installation CD-ROM, click the Next button, follow the onscreen instructions, and finally click the Finish button.

7) Windows driver file search will find the device “SHARP AR-150

Series”. Click the Next button. Proceed to step 9.

8) Insert the installation CD-ROM into the CD-ROM drive. (If you are

using the USB interface, confirm that the installation CD-ROM is in

the CD-ROM drive.) Click the Start button and select Run. When

the window shown below appears, type R:\SETUP (if the CD-ROM

is designated as drive R) and click the OK button. Proceed to step

9.

2 – 10

Page 13

AR-SP3

9) The installation program will start. To select a different folder, select

Browse and type in the path and folder name where the printer

driver will be installed. Click OK and say YES to create the folder,

select the Next button to continue. To install the printer driver to the

default folder, click the Next button.

10) On the display you will see “printer port to be used”. The printer

port is selected automatically. If you are using the parallel interface, this is LPT1. If you are using the USB interface, this is

LPT/USB1. Ensure that Yes is checked to use the printer as the

default printer. Finally click the Next button.

11) A “Confirm installation” window will be displayed. To continue in-

stallation, click the Yes button.

12) When the installation is complete, you will be asked whether or not

to print a test page. If you wish to do so, click the Yes button. At

this time, ensure that paper is loaded in the paper tray.

13) If the test print completes successfully, click the Finish button.

“The installation of the SHARP AR-150 Series Software is complete.” window will be displayed. Click the OK button.

c. Windows 3.1x:

With both the computer and the printer turned off, connect the printer

to the computer with a parallel interface cable.

1) Load paper into the paper tray of the printer. For instructions on

loading paper, see the section LOADING COPY PAPER in the

copier operation manual.

2) Turn on the printer and then start Windows on your computer.

3) Insert the installation CD-ROM into a CD-ROM drive.

4) Choose File from the Menu bar in Program Manager, and then

choose the Run... command.

5) Type R:\SETUP (if the CD-ROM is designated as drive R) in the

command line box and then click the OK button.

a. Uninstall AR-150 Series

The printer driver can be uninstalled. If the driver is uninstalled, printing

can no longer be performed on the printer.

For proper uninstallation, be sure to use the SHARP uninstall program

of the printer driver group.

Readme

The latest information on the printer driver is included in this document.

Read the Readme first.

Advanced Settings

See help for Advanced Settings.

Status Monitor

The Status Monitor window provides visual information about the

printer state and current job.

DOS Emulation Setup

Status Monitor HELP

Assistance and information for Status Monitor.

DOS Emulation HELP

Assistance and information for DOS Emulation support.

Advanced Settings HELP

Assistance and information for Advanced Settings.

6) Select a directory to which the printer driver will be installed and

click the Next button. To install it to the default directory, click the

Next button.

7) A “printer port to be used” window will be displayed. Normally, LPT1

is automatically set.

Then ensure that Yes is checked to use this printer as the default

printer.

8) A “Confirm installation” window will be displayed. To continue installation, click Yes.

9) When the installation is complete, restart Windows.

(4) AR-150 Series printer driver group

When the printer driver is installed, the SHARP AR-150 Series printer

driver group will be created. This group of software programs provides

the following functions:

2 – 11

Page 14

AR-SP3

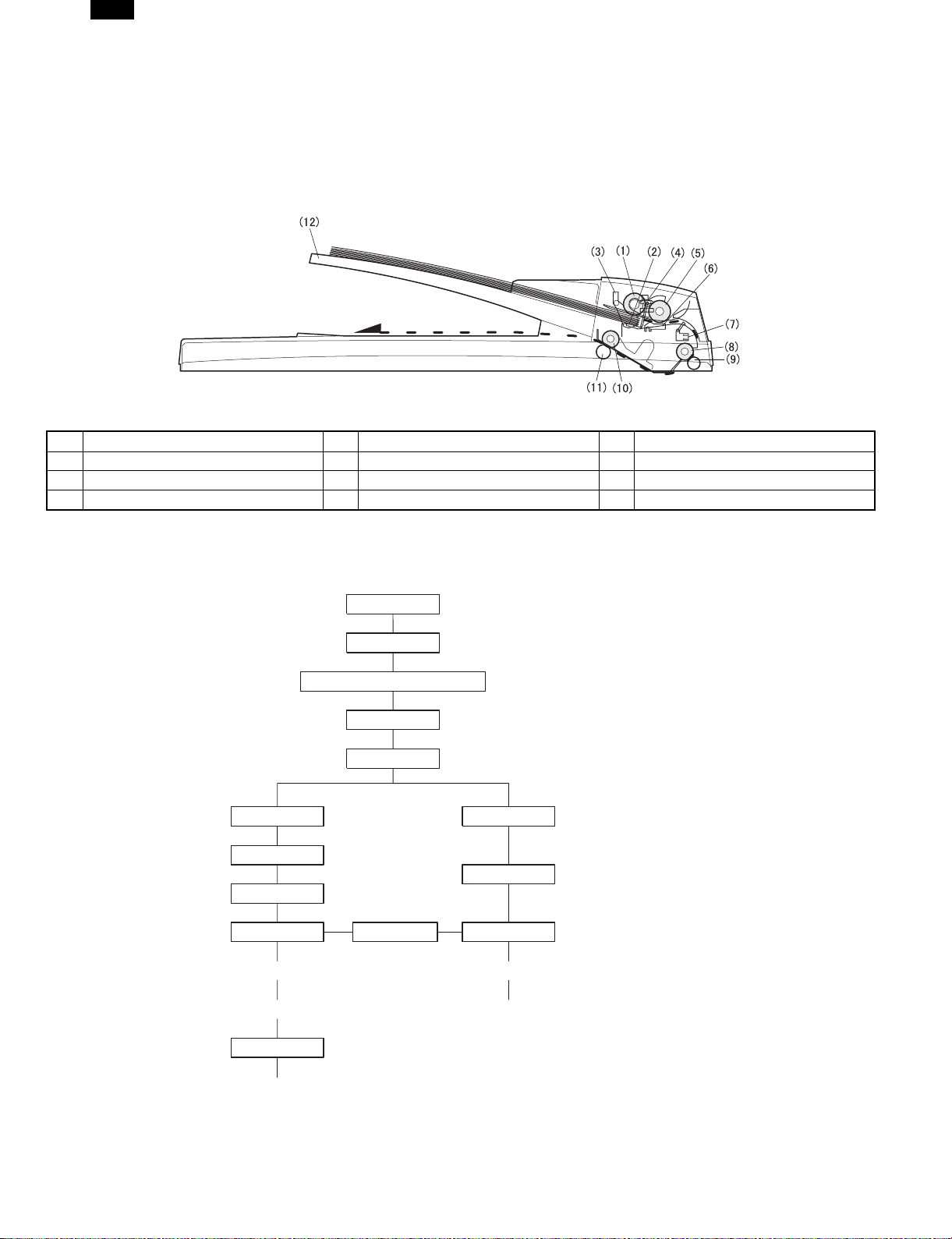

[3] AR-SP3

1. Operational descriptions

A. Outline

The SPF (Single Path Feeder) is installed to the AL-1000/1200 as a standard provision, and it automatically copies up to 30 sheets of documents

of a same size. (Only one set of copies)

B. Document transport path and basic composition

(1) Pickup roller (2) Sheet of document for paper feed (3) Set detection ACT

(4) Paper stopper (5) Document feed roller (6) Separation sheet

(7) Paper entry sensor (8) PS roller D (9) Transport follower roller

(10) Paper exit roller (11) Paper exit follower roller (12) Document tray

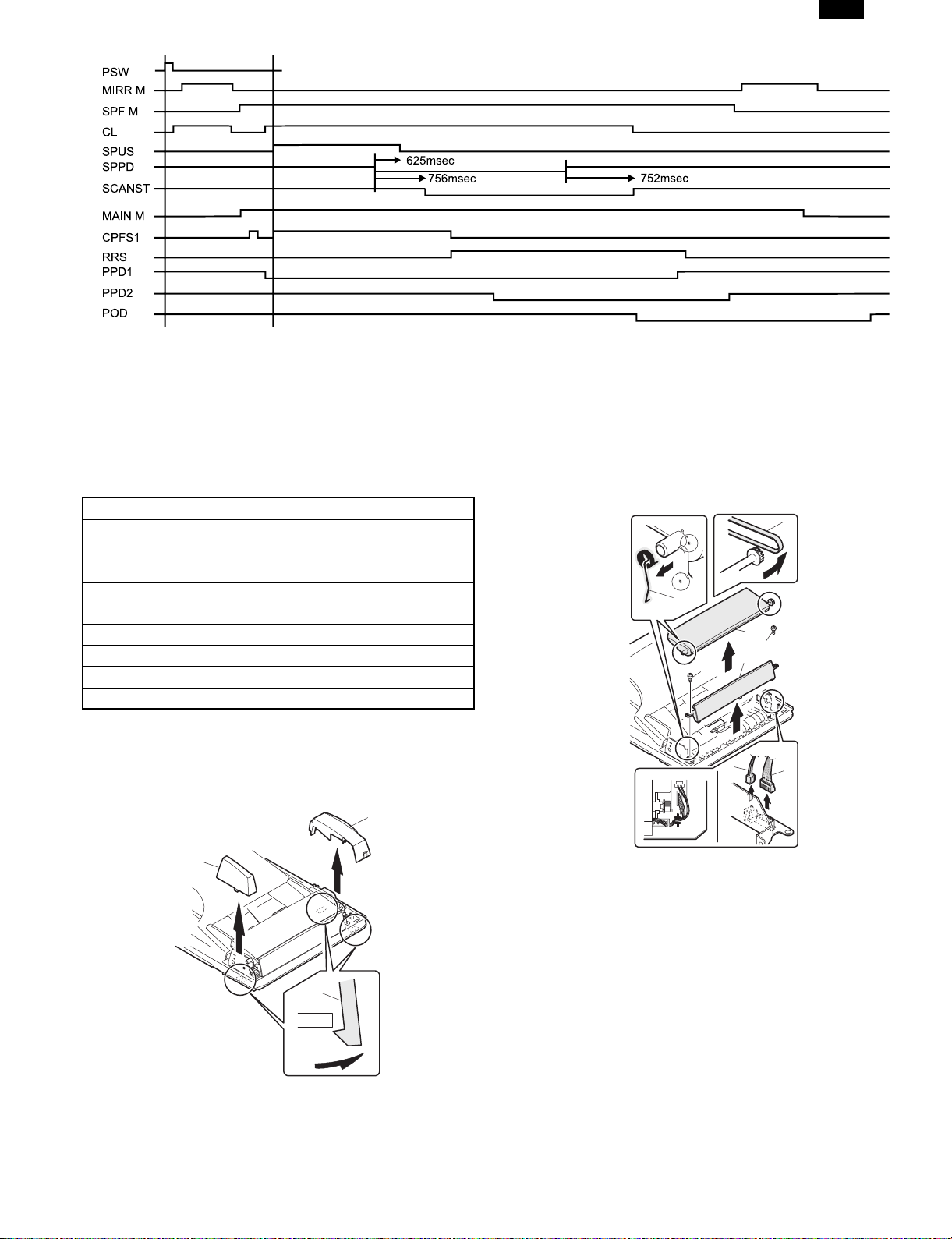

C. Operational descriptions

(Copier side)

MM rotation

CPFS ON

PPD ON

RRC ON

(Transfer)

Time chart (Tray feed)

Document set

SPID ON

Document feed unit lamp ON

PSW ON

MIRM rotation

Main motor rotation

Paper feed

Synchronization

Paper transport

Document set sensor

Copy start

The scanner is shifted

to the exposure position.

(SPF side)

SPFM rotation

SPUS ON

SPPD ON

(Exposure)

SPF motor rotation

Document feed

Document transport sensor

Document transport

(Fusing)

POD ON

(Paper exit)

In the zooming mode, the magnification ratio in the sub

scanning direction (paper transport direction) is adjusted

by changing the document transport speed.

(Document exit)

3 – 1

Page 15

D. Cases where a document jam is caused

a. When SPPD is ON (document remaining) when the power is turned on.

b. When SPPD is not turned ON within about 1.5 sec (at 100% copy) after starting the document feed operation.

c. When SPPD is not turned on within about 4.7 sec (at 100% copy) after turning on SPPD.

d. When the SPF document jam release door or the OC cover is opened during document transport (SPF motor rotating).

AR-SP3

2. Disassembly and assembly

No. Part name Ref.

A Sensor PWB

B Pickup solenoid

C Clutch

D Manual paper feed roller, pickup roller

E Belt

F SPF motor

G Paper entry sensor

H PS roller

I Paper exit roller

Pickup unit removal

1) Remove three fixing pawls from the bottom of the machine.

2) Remove the front cover and the rear cover.

2

2

1) Remove the belt, the paper feed frame SP, and two harnesses.

2) Remove the pickup unit.

1

1

2

3

4

3

1

*

When installing the parts, be careful of the hole position of the paper

1

frame SP.

1

3 – 2

Page 16

AR-SP3

A. Sensor PWB

1) Remove two screws from the bottom of the pickup unit.

2) Remove the upper cover.

2

1

1

1) Remove two screws.

2) Remove the sensor PWB.

3) Remove the harness.

1

2

1

3

C. Clutch

1) Remove the E-ring.

2) Remove the pulley and bush.

3) Slide the bush in the arrow direction.

4) Lift the clutch, and 5) remove the clutch.

2

5

3

1) Remove the E-ring.

2) Remove the parts.

1

4

1

B. Pickup solenoid

1) Remove two screws.

2) Remove the pickup solenoid

2

*

When installing, hang iron core A on the solenoid arm.

1

A

2

D. Manual paper feed roller, pickup roller

1) Lift the paper stopper.

2) Slide the takeup roller unit.

3) Slide the bush in the arrow direction.

4) Remove the takeup roller unit.

A

1

2

4

3

3 – 3

Page 17

*

When installing the takeup roller, hang the projection of the takeup

roller unit on the solenoid arm.

1) Remove the parts.

2) Remove the manual paper feed roller.

3) Remove the pickup roller.

4) Remove the parts.

4

3

1

1

F. SPF motor

1) Remove the harness.

2) Remove four screws.

3) Remove the drive unit.

4) Remove the belt.

5) Remove two screws.

6) Remove the SPF motor.

5

AR-SP3

6

2

1

1

Transport unit removal

1) Remove two screws.

2) Remove the document tray unit.

3) Remove five screws.

4) Remove the transport unit.

3

3

1

5

2

2

3

4

2

3

1

3

G. Paper entry sensor

1) Loosen the screw.

2) Open the paper exit PG.

3) Remove the paper entry sensor.

4) Remove the harness.

4

E. Belt

1) Remove the belt.

4

3

1

2

1

3 – 4

Page 18

AR-SP3

H. PS roller

1) Remove the parts.

2) Remove the PS roller.

1

I. Paper exit roller

1) Remove the parts.

2) Remove the paper exit roller.

1

1

1) Open the right cabinet.

2) Remove three screws.

3) Remove one connector.

4) While tilting down the 2nd connection arm A, pull and remove the

paper feed unit toward you.

C

D

1

2

*

When installing, securely insert two bosses C on the machine side

and two bosses D on the paper feed unit side. Be sure to fix the

earth B.

*

Insert the 2nd page feed.

D

4

1

A

3

B

2

A. Paper sensor

1) Remove the pawl.

2) Remove the paper sensor.

3) Remove the harness.

2

2

[4] AR-DE9

1. Disassembly and assembly

No. Part name Ref.

A Paper sensor

B Cassette detection SW

C Paper feed solenoid

D Transport roller

E Paper feed clutch

F 2nd paper feed roller

Paper feed unit removal

1) Remove the screw.

2) Remove the rear cover.

*

When installing, engage the pawl and install the unit.

3

1

B. Cassette detection SW

1) Remove the pawl.

2) Remove the cassette detection SW.

3) Remove the harness.

1

3

2

A

2

1

4 – 1

Page 19

AR-SP3

C. Paper feed solenoid

1) Remove the screw.

2) Remove the connector.

3) Remove the paper feed solenoid.

3

D. Transport roller

1) Remove two E-rings.

2) Remove the transport roller.

E. Paper feed clutch

1) Remove the E-ring.

2) Remove the paper feed clutch.

3) Remove the parts.

2

A

2

1

1

3

4

1

A

B

3

2

*

Install so that the earth spring A is brought into contact over bearing

B.

*

When installing, fit the cut surface A.

F. 2nd paper feed roller

1) Remove the E-ring and the parts.

2) Remove the 2nd paper feed roller.

1

B

2

C

D

A

1

4 – 2

*

When installing, hang the 2nd connection arm on the 2nd connection

arm SP B. Be sure to install so that the earth spring C is in contact

under the bearing D.

Page 20

E

AR-SP3

[5] AR-PG1

1. Electrical section

A. GDI/USB PWB

Personal

Personal

Computer

IEEE1284

DATA+

IC504

244

7SH08F

IC501

IC113 74HC14

7

PDATA0

74LS

245

IC601

GDI/USB PWB

7

/1284_EN

PDATA0

ASIC

IC10

MCU PWB

/STB,/AUTOFD,/SLCTIN,/INIT

74LS

244A

74LS

IC602

REV

/STB,/AUTOFD,

/SLCTIN,/INIT

/USB_EN

/ACK,BUSY,PE,/FAULT,SLCT

244B

74LS

IC603

/ACK,BUSY,PE,

/FAULT,SLCT

The GDI/USB PWB has two circuits; one for transmitting and receiving

IEEE1284 signals and the other for transmitting and receiving USB signals and converting USB signals into IEEE1284 signals.

IC601, 602 and 603 are connected between IEEE1284 an ASIC to convert signals.

IC501 transmits and receives USB signals and converts USB signals

into IEEE1284 signals.

IC502 stores various setup data necessary for USB operation of IC501.

IC503 informs the CPU of connection of USB. It is connected with PC

via a USB cable. When 5V is inputted from PC to the IC’s input pin,

the output pin (signal name: USB-IN) is driven to HIGH to inform the

CPU of connection of USB.

IC504 detects connection with PC via a USB cable, supplies power to

the USB port signal line (signal name: DATA+) to enable USB communication.

When USB is connected, the CPU enables USB and disables

IEEE1284.

(When USB is enabled, IE1284 is disabled.)

Computer

USB

DATA -

GND

DATA +

5V

USS-725

RESET/DISABL

IC9

IC503

5V

7SH08F

USB-IN

CPU

EEPR

OM

IC502

2. Interface

A. PARALLEL INTERFACE

This printer uses a bi-directional parallel interface. Use the supplied interface cable.

Connector

36-pin DDK 57LE-40360-730B (D29) female connector or equivalent

connector

Cable

Shielded type bi-directional parallel interface

For best results,, use a printer interface cable which is IEEE1284 compliant.

Pin configuration

The pin numbers and signal names are listed in the following table.

18

36 19

Pin

No.

Signal name

1 STB 19 GND (STB RET)

2 DATA1 20 GND (DATA1 RET)

3 DATA2 21 GND (DATA2 RET)

4 DATA3 22 GND (DATA3 RET)

5 DATA4 23 GND (DATA4 RET)

6 DATA5 24 GND (DATA5 RET)

7 DATA6 25 GND (DATA6 RET)

8 DATA7 26 GND (DATA7 RET)

9 DATA8 27 GND (DATA8 RET)

10 ACKNLG 28

11 BUSY 29 GND (BUSY RET)

12 PE (Paper End) 30 GND (PE RET)

13 SLTC 31 INPRM

14 AUTO LF 32 FAULT

15 (NC) 33 (NC)

16 GND (0 V) 34 (NC)

17 FG 35 +5 V

18 +5 V 36 SLTC IN

Pin

No.

1

Signal name

GND

(ACKNLG RET)

5 – 1

Page 21

B. USB INTERFACE

Connector

4-pin DDK DUSB-BRA42-T11

Type-B connector

Cable

Shielded twisted pair cable

(2 m (6 feet) Max.: high-speed transmission equivalent)

Pin configuration

The pin numbers and signal names are listed in the following table.

Pin No. Signal name

1 +5V

2 – DATA

3 +DATA

4 GND

3. Print Area

The print area of this printer is shown below.

A. 600 dpi

2

34

1

B. 300 dpi

AR-SP3

Paper

size

Letter 5100 4900 6600 6400 100 100 100

Legal 5100 4900 8400 8200 100 100 100

Invoice 3300 3100 5100 4900 100 100 100

A4 4960 4760 7014 6814 100 100 100

A5 3508 3308 4960 4760 100 100 100

B5 4298 4098 6070 5870 100 100 100

Folio 5100 4900 7800 7600 100 100 100

Foolscap 5100 4900 7440 7240 100 100 100

ABCDEFG

E

Dots

Portrait

E

D C

F

Paper

size

Letter 2550 2450 3300 3200 50 50 50

Legal 2550 2450 4200 4100 50 50 50

Invoice 1650 1550 2550 2450 50 50 50

A4 2480 2380 3507 3407 50 50 50

A5 1754 1654 2480 2380 50 50 50

B5 2149 2049 3035 2935 50 50 50

Folio 2550 2450 3900 3800 50 50 50

Foolscap 2550 2450 3720 3620 50 50 50

E

ABCDEFG

Landscape

E

G

F

Dots

B A

D

G

B

A

5 – 2

C

Paper size

Print area

Page 22

IEEE1284 CON

47u 16V

100J 1/2W

S GND

F GND

S GND

DATA 8

DATA 7

DATA 6

DATA 5

DATA 4

DATA 3

DATA 2

DATA 1

AR-SP3

4. Circuit diagram

(2-A3)

(2-A3)

PARAAD7

PARAAD6

(2-A3)

(2-A3)

PARAAD4

PARAAD5

(2-A2)

(2-A2)

PARAAD2

PARAAD3

11

(2-A2)

PARAAD1

(2-A2)

PARAAD0

E

D

C

B

44

36

35

34

33

32

31

30

VCC

(NC)

GND29GND28GND27GND26GND25GND24GND23GND22GND21GND20GND19GND

S GND

/FAULT

/SLCTIN

/INPRIM

E

D

C

B

IEEE1284 CON

DATA 8

DATA 7

DATA 6

DATA 5

DATA 4

DATA 3

DATA 2

DATA 1

/DSTB

CN501

5V1

(2-B4)

5V1

5V1

22000p

C613

47u 16V

C501

SBO-02SAN

L501

9

8

7

6

5

4

3

2

1

1.2kJ

R625

1.2kJ

R624

1.2kJ

R623

1.2kJ

R622

1.2kJ

R621

1.2kJ

R620

1.2kJ

R619

1.2kJ

R618

R601

5V1

A1

IC601

B1

2

1

2

1

2

1

2

1

22J

22J

22J

22J

22J

22J

22J

R606

R604

R603

R602

R608

R607

R605

100p

C608

100p

C607

100p

C606

100p

C605

100p

C604

100p

C603

100p

C602

100p

C601

1

19G9A88A77A66A55A44A33A22

C619

DIR

74LS245

11B812B713B614B515B416B317B218

D604

D603

D602

D601

0.1u

(NC)14/AUTOLF13SLCT12PE11BUSY10/ACK

15

3

DAP202K

3

DAP202K

3

DAP202K

3

DAP202K

22J

SHIELD

VCC17F GND

S GND

18

16

R629

R628

R627

R626

5V1

33

3.3kJ

R630

5V1

5V1

F.G

100J 1/2W

R501

1.2kJ

1.2kJ

1.2kJ

1.2kJ

2

3

1

D606

DAP202K

2

3

1

D605

DAP202K

22J

22J

22J

22J

R610

R609

R612

R611

C612

560p

33p

C611

33p

C610

1000p

C609

0.1u

5V1

IC602

C621

(2-A2)

(2-A2)

(2-A3)

(2-A2)

/INIT

/AUTOFD

/STB

/SLCTIN

2A4152A3132A2112A181A461A341A221A1

2Y452Y372Y292Y1

1Y4141Y3161Y2181Y1

3

12

(2-D3)

/USB-EN

192G11G17

74LS244

22J

22J

R614

R613

IC603

1A461A341A221A1

8

5V1

5V1

22

2

3

1

D609

2

DAP202K

3

1

D608

2

DAP202K

3

1

DAP202K

D607

22J

22J

22J

R615

R617

R616

(2-A2)

(2-A2)

(2-A2)

(2-A2)

100p

C618

100p

100p

C617

100p

C616

C615

100p

C614

3

2Y452Y372Y292Y1121Y4141Y3161Y2181Y1

1G

2A4152A3132A2112A1

1

17

C620

(2-A2)

PE

BUSY

/ACK

SLCT

/FAULT

2G

74LS244

19

0.1u

A

GDI PWB(GDI SECTION)

CN502

PARAAD1

PARAAD0

PARAAD3

PARAAD2

PARAAD5

PARAAD4

987654321

PARAAD7

PARAAD6

10

A

(2-E3)

(2-B3)

(2-B1)

USB-ON

USB-IN

3.3V

USB-ON

/USB-EN

/1284-EN

USB-IN

/GDI-IN

SLCT

/FAULTPEBUSY

/ACK

/STB

/AUTOFD

/SLCTIN

/INIT

/REV

313029282726252423222120191817161514131211

31FE-BT-VK-N

5 – 3

Page 23

AR-SP3

R511TC7SH08FU

C520

3

11

E

D

C

10kJ

0.1u

B

44

(1-A4)

USB-ON

E

1

5

3.3V

IC504A

D

4

3A22A11

A0

GND

0.1u

Vcc7/WC6SCK5SDA

IC502

C512

8

5V25V2

5V2

1kJ

R503

1kJ

SBO-02SAN

R502

C509

C508

5V2 3.3V

3.3V

0.1u

C622

1.5u 16V

C502

L503

SBO-02SAN

3.3V

(1-A4)

0.1u

C504

1.5u 16V

C503

C

5V2

L502

5V1

(1-B4)

B

33

(2-D3)

5V-USB

10kJ

R510

10kJ

R509

R508

0.1u

C519 24J

2

3

4

TC7SH08FU

1.5kJ

R507

(1-A4)

/USB-EN

3.3V

3.3V

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

IC501

48

DISABLE_1284

RESET

SELF_PWRD

SDA0

SCL

PDATA17

PCONTROL4

PCONTROL3

GND

VDD

PDATA7

VDD5

PDATA16

PCONTROL2

PCONTROL1

PDATA6

PDATA15

PCONTROL0

1

5V2

47

TEST046TEST1

PERROR

2

45

VDD

PDATA55GND

VDD5

3

4

C505

C513

44

43

GND

SIXTEEN_BIT

PDATA14

6

0.1u

24C16

0.1u

0.1u

3.3V

SHIELD

CN503

5V-USB

(2-E3,C1)

24J

R506

R505

C515

0.1u

41

40

42

39

DPLS

DMNS

PLL_VSS

PLL_VDD

PDATA416PDATA3

nFAULT

VDD

nSELECTIN

9

8

7

10

0.1u

C506

GND3D+2D-15V

4

24J

38

VDD

PDATA13

11

5V2

C518

0.1u

37

CLK_HI

GND

12

C507

USB-B CONNECTOR

0.1u

35

36

GND

CLK_LO

SCAN_EN

PDATA0

PDATA10

PDATA1

PDATA11

PDATA2

nAUTOFD

PDATA12

nSTROBE

VDD5

14

13

0.1u

C517

X501

C516

34

SUSPEND

PLH

HLH

nACK

nINIT

VDD

GND

VDD5

BUSY

SELECT

15

15p

12MHz

15p

3.3V

C514

33

nUSB_RESET

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

F.G

USS-725

22

0.1u

5V2

(2-D3)

3.3V5V2

0.1u

C511

0.1u

C510

5V2

2

1

5

IC503A

4

USB-IN 5V-USB

(1-A4)

A

GDI PWB (USB SECTION)

PARAAD6

PARAAD7

(1-C1)

(1-C1)

PE

(1-C2)

PARAAD5

(1-C1)

/SLCTIN

(1-B3)

PARAAD4

/FAULT

(1-C2)

(1-C1)

5 – 4

/STB

(1-B3)

SLCT

(1-C2)

PARAAD3

(1-C1)

/AUTOFD

BUSY

(1-C2)

(1-B3)

/INIT

PARAAD2

(1-B3)

(1-C1)

/ACK

(1-C2)

PARAAD0

PARAAD1

(1-C1)

(1-C1)

A

Page 24

PARTS GUIDE

CODE:00ZAR150PT/P1

AR-SP3

AR-FX3

AR-DE9

MODEL AR-PG1

AR-150P

1 AR-SP3-1(Exterors)

2 AR-SP3-2(Pick up unit)

3 AR-SP3-3(Transport unit)

4 AR-FX3-1(Base tray unit)

5 AR-FX3-2(Fax panel pick up unit)

6 AR-FX3-3(Fax transport unit)

7 AR-DE9(2nd frame unit)

8 AR-DE9(2nd paper feeding unit)

CONTENTS

9 AR-SP3(Packing material & Accessories)

F AR-FX3(Packing material & Accessories)

G AR-DE9(Packing material & Accessories)

H AR-PG1(Packing material & Accessories)

I AR-FX3(Fax panel PWB)

J AR-FX3(Fax PWB)

K AR-PG1(GDI/USB PWB)

■ Index

SHARP CORPORATION

This document has been published to be

used for after sales service only.

The contents are subject to change without

notice.

Page 25

AR-150P

DEFINITION

The definition of each Rank is as follows and also noted in the lis t

A : Parts necessary to be stocked as High usage parts.

B : Parts necessary to be stocked as Standard usage parts.

C : Low usage parts.

D : Parts necessary for refurbish.

E : Unit parts recommended to be stocked for efficient after sales service.

Please note that the lead time for the said parts may be longer than normal parts.

S : Consumable parts.

Please note that the following parts used in Copier under the same description are classi fied into A or B Rank depending

upon the place used.

Example : Gear made of Metal, Sprocket, Beari ng, Belt made of Rubber, Spring clutch mechanism.

A Rank : The parts which may be with the revol ution or loading.

B Rank : Parts similar to A Rank parts, but are not incl uded in Rank A.

Because parts marked with "!" is indispensable for the machine safety maintenance and operati on, it must be replaced with

the parts specific to the product specification.

F Other than this Parts Guide, please refer to documents Service Manual (including Circuit Diagram) of this model.

F Please use the 13 digit code described in the right hand corner of front cover of the document, when you place an order.

F For U.S. only-Use order codes provided in advertising literature.

Do not order from parts department.

1 AR-SP3-1(Exterors)

NO. PARTS CODE

LSOU-0004QSZZ AX

1

LPLTP0011QSZZ AH

2

LPLTP0012QSZZ AH

3

NGERR0377FCZZ AD

4

XEPSD30P08X00 AA

5

NGERH0193FCZZ AB

6

MSPRP0059QSZZ AD

7

PCOVP0036QSZZ AK

8

CFRM-0011QS51 BE

11

XEBSD40P10000 AA

13

CFRM-0013QS51 BS

14

LBNDJ0013FCZ1 AA

15

PSHEP0038QSZZ AE

16

PSHEP0063QSZZ AC

17

MSPRP0113QSZ1 AD

18

PSHEP0037QSZ1 AE

19

XEBSD30P08000 AA

20

MHNG-0003QSZZ AX

21

XEBSE40P14000 AA

22

NROLP0011QSZZ AD

23

PSPO-0001QSZZ AB

24

NSFTZ0010QSZZ AE

25

MSPRT0061QSZZ AC

26

MSPRP0060QSZZ AD

27

NROLP0010QSZZ AD

28

NSFTZ0009QSZZ AE

29

LPLTM0096QSZZ AF

30

LX-BZ0016QSZZ AC

31

MHNG-0004QSZZ AX

32

LSOU-0005QSZ3 BB

33

PCUSS0010QSZ1 AV

34

PSHEZ0102QSZZ AD

35

PSHEZ0112QSZZ AE

36

MSPRC0149QSZZ AC

37

CSOU-0004QS51 BC

501

PRICE

RANK

NEW

MARK

PART

RANK

D Original tray

C Control plate F

C Control plate R

C Manual feeding rack gear

CScrew (3´8X)

C Manual feeding gear

C Control plate spring

D Rack cover

E SPF pick up unit

CScrew (4´10)

E SPF transport unit

C Wire band

C Base tray sheet

C Transport sheet

C Earth spring

C OC mat sheet

CScrew (3´8)

C SPF hinge L

CScrew (4´14)

C Delivery roller

C Sponge

C Delivery shaft

C Delivery spring

C Transport spring

C Transport roller

C Transport shaft

C Base tray reinforce plate

CScrew (3´8)

C SPF hinge R

D Base tray

C OC sheet

C Motor pressure sheet

C Delivery earth sheet SPF

C PS earth spring SPF

E SPF original tray unit

DESCRIPTION

– 1 –

Page 26

1 AR-SP3-1(Exterors)

2

AR-150P

11

1

3

14

13

13

15

13

22

13

501

19

21

22

23

31

25

24

20

28

17

20

26

31

17

28

27

24

31

30

16

20

23

27

37

35

36

29

22

31

FCP03950

18

19

31

32

4

4

5

7

8

5

5

6

5

33

22

34

– 2 –

Page 27

AR-150P

2 AR-SP3-2(Pick up unit)

NO. PARTS CODE

GCAB-0008QSZZ AM

1

PSPO-0002QSZZ AC

2

MARMP0003QSZ1 AD

4

LSTPP0001QSZZ AD

5

XEBSD30P08000 AA

6

CPWBF0009QS51 AG

7

DHAI-0055QSZZ AK

8

MLEVP0009QSZZ AD

9

MLEVP0010QSZZ AE

10

RPLU-0004QSZ1 AQ

11

XBPSD30P06KS0 AA

12

MARMP0002QSZZ AD

13

MSPRT0067QSZ1 AB

14

XRESP40-06000 AA

15

NGERH0073QSZZ AE

16

PPIPP0008QSZZ AD

17

MSPRC1316FCZ1 AE

18

LBOSZ1508FCZZ AG

19

LBSHZ0303FCZZ AC

20

NSFTZ0012QSZZ AG

21

NPLYZ0010QSZZ AE

23

XRESP30-06000 AA

24

MSPRT0066QSZ1 AC

25

PTME-0019QSZZ AD

26

NROLP0024QSZZ AL

27

NGERH0990FCZZ AB

28

XPSSP20-07000 AA

29

NGERH0992FCZZ AB

30

NROLR0922FCZZ AR

31

NSFTZ0011QSZZ AG

32

MSPRC0115QSZZ AB

33

MARMP0004QSZZ AF

34

LFRM-0011QSZ1 AL

35

MSPRD0114QSZ1 AD

36

(Unit)

CFRM-0011QS51 BE

901

PRICE

RANK

NEW

PART

MARK

RANK

D Open and shut exterior

C Stopper sponge

C Stopper arm

C Paper stopper

CScrew (3´8)

E SPF sensor PWB

C Sensor harness

C Set detect lever ACT

C Open and shut detect lever ACT

B PU solenoid

CScrew (3´6KS)

C Solenoid arm

C Solenoid arm spring

C E type ring

C Clutch gear (20T)

C SPF clutch sleeve

C MF clutch spring B

C Cam boss A2

C M bushing C

C Clutch shaft

C 20MXL pulley

C E type ring

C Clutch pawl spring

B Clutch pawl

C Pick up roller

C Gear (16T)

C Spring pin (f2-7)

C Gear (20T)

C Manual feeding roller

C PF shaft

C Paper feeding spring

C Pick up arm

N C Paper feedind frame

C PF frame spring

E SPF pick up unit

DESCRIPTION

2 AR-SP3-2(Pick up unit)

1

4

5

6

7

8

36

9

6

6

13

10

35

14

11

2

15

19

18

16

17

21

15

20

12

23

24

20

20

12

25

26

30

15

33

27

28

30

29

6

20

30

29

29

34

32

31

FCP03951

– 3 –

Page 28

3 AR-SP3-3(Transport unit)

NO. PARTS CODE

PGIDM0042QSZZ AL

1

XEBSD30P12000 AA

2

LX-BZ0012QSZZ AC

3

NGERH0972FCZZ AB

4

MARMP0001QSZZ AF

5

XBPSD30P05K00 AA

6

RMOTP0013QSZZ BB

7

DHAI-0084QSZ1 AT

8

DHAI-0054QSZZ AR

9

LBNDJ0013FCZ1 AA

10

MSPRT0064QSZ1 AC

11

LFRM-0013QSZZ AG

12

XRESP50-06000 AA

13

PSHEP3029FCZZ AA

14

NBLTT0006QSZZ AG

15

NGERH0047QSZZ AF

16

XPSSP20-09000 AA

17

NBRGC0098FCZZ AC

18

NBRGM5006BCZZ AB

19

LFRM-0012QSZZ AD

20

PSHEZ0039QSZZ AG

21

LPLTP0013QSZZ AD

22

MSPRC0062QSZZ AC

23

MSPRP0065QSZZ AD

24

PSHEZ2174FCZZ AB

25

NPLYZ0146FCZZ AB

26

NBLTT0003QSZZ AG

27

JKNBZ0004QSZZ AD

28

MSPRC0063QSZZ AB

29

PGIDM0024QSZZ AQ

30

RDTCT0004QSZZ AL

31

NROLM0023QSZZ AP

32

PBRSR0003QSZZ AL

33

PGIDH0029QSZZ AL

34

PSHEP0044QSZZ AF

35

NROLM0022QSZZ AP

36

PCOVP0037QSZZ AH

37

PCOVP0038QSZZ AL

38

XEBSD30P08000 AA

39

RCORF1023LCZZ AL

40

(Unit)

CFRM-0013QS51 BS

901

PRICE

RANK

NEW

MARK

PART

RANK

C U-turn paper guide

CScrew (3´12)

CScrew

C Gear (27T)

C Drive arm

CScrew (3´5K)

B SPF motor

C Grand wire

C SPF interface harness

C Wire band

C Drive arm spring

C Drive frame

C E type ring

C Flange sheet DUP2

B Belt (83MXL4.8)

C Gear (48T/15T)

C Spring pin (f2-9)

C Bearing

C Bearing

CFrame R

C Sheet

CPlate

C Pressure spring

C Open and shut lock spring

C Paper feeding sheet

C 22MXL pulley

B Belt (91MXL4.8)

C JAM release knob

C Delivery paper guide spring

C Transport paper guide

B Inlet detect sensor

C Delivery roller

B Discharge brush

C Delivery paper guide

C White sheet

C PS roller

D Front cover

D Rear cover

CScrew (3´8)

C Core

E SPF transport unit

AR-150P

DESCRIPTION

3 AR-SP3-3(Transport unit)

2

13

26

39

37

17

13

33

19

28

24

17

27

25

29

19

32

22

23

30

31

21

38

2

1

15

5

3

4

18

17

16

14

13

2

40

9

8

10

7

39

11

39

12

6

13

36

20

19

35

24

29

34

FCP03952

– 4 –

Page 29

AR-150P

4 AR-FX3-1(Base tray unit)

NO. PARTS CODE

LANGT0005QSZZ AD

1

XEBSD30P10000 AA

2

XEBSD40P10000 AA

3

PGIDM0024QSZ2 AQ

4

LBNDJ0013FCZ1 AA

6

LANGT0004QSZZ AC

8

XEBSD30P12000 AA

9

PSHEP0038QSZZ AE

12

PSHEP0063QSZZ AC

13

PSHEZ0102QSZZ AD

14

MSPRP0113QSZ1 AD

15

PSHEP0037QSZ1 AE

16

NROLP0011QSZZ AD

18

PSPO-0001QSZZ AB

19

NSFTZ0010QSZZ AE

20

NSFTZ0009QSZZ AE

21

PSHEZ0112QSZZ AE

22

NROLP0010QSZZ AD

23

MSPRT0061QSZZ AC

24

XEBSD30P08000 AA

25

MSPRP0060QSZZ AD

26

MSPRC0149QSZZ AC

27

MHNG-0004QSZZ AX

28

XEBSE40P14000 AA

29

LPLTM0096QSZZ AF

30

LX-BZ0016QSZZ AC

31

MHNG-0003QSYZ AX

32

PCUSS0010QSZ1 AV

33

LSOU-0005QSZ3 BB

34

PCOVP0036QSZZ AK

35

NGERH0193FCZZ AB

36

MSPRP0059QSZZ AD

37

XEPSD30P08X00 AA

39

NGERR0377FCZZ AD

41

LPLTP0140QSZZ AF

42

LSOU-0020QSZZ AT

43

LPLTP0139QSZZ AF

44

PRICE

RANK

NEW

MARK

PART

RANK

C Shaft holding angle R

CScrew (3´10)

CScrew (4´10)

C Transport PG

C Wire band

C Shaft holding angle F

CScrew (3´12)

C Base tray sheet

C Transport sheet

C Motor pressure sheet

C Earth spring

C OC mat sheet

C Delivery roller

C Sponge

C Delivery shaft

C Transport shaft

C Delivery earth sheet SPF

C Transport roller

C Delivery spring

CScrew (3´8)

C Transport spring

C SPF earth spring

C SPF hinge R

CScrew (4´14)

C Base tray reinforce plate

CScrew (3´8)

C SPF hinge L

C OC sheet

D Base tray XC

D Rack cover

C UC manual feed gear

C Control plate spring

CScrew (3´8X)

C Manual feed gear

C Reguration plate R- XC

C Document tray XC

C Reguration plate F- XC

DESCRIPTION

– 5 –

Page 30

4 AR-FX3-1(Base tray unit)

AR-150P

42

43

37

39

36

38

35

39

33

41

32

29

44

34

3

6

5

9

4

3

3

2

1

29

8

3

16

18

31

19

12

20

24

25

26

25

23

19

18

22

13

26

14

15

16

31

21

27

29

28

– 6 –

30

31

FCP03953

Page 31

AR-150P

5 AR-FX3-2(Fax panel pick up unit)

PRICE

NEW

NO. PARTS CODE

PFILW0009QSZZ AL

1

CCAB-0027QS01 AS

2

JBTN-0039QSZZ AE

3

JBTN-0038QSZZ AF

4

CBTN-0041QS01 AH

5

CBTN-0040QS01 AH

6

JBTN-0036QSZZ AF

7

CBTN-0037QS01 AK

8

CPWBF0046QS51 BH

9

XEBSD26P06000 AA

10

PSPO-0006QSZ1 AB

11

NSFTZ0012QSZZ AG

12

XRESP40-06000 AA

13

LBOSZ1508FCZZ AG

14

MSPRC1316FCZ1 AE

15

PPIPP0008QSZZ AD

16

NGERH0073QSZZ AE

17

LBSHZ0303FCZZ AC

18

MARMP0003QSZ1 AD

19

LSTPP0008QSZZ AD

20

RPLU-0017QSZZ AQ

21

MLEVP0009QSZZ AD

22

MLEVP0010QSZZ AE

23

MSPRT0067QSZ1 AB

24

MARMP0002QSZZ AD

25

LPLTP0150QSZZ AG

26

MLEVP0011QSZ1 AE

27

LFRM-0033QSZZ AP

28

PTME-0019QSZZ AD

29

MSPRT0066QSZ1 AC

30

XBPSD30P06KS0 AA

31

NPLYZ0010QSZZ AE

32

DHAI-0160QSZZ AH

37

DHAI-0159QSZ1 AN

39

CPWBF0009QS52 AU

40

XEBSD30P08000 AA

41

MARMP0004QSZZ AF

42

MSPRC0115QSZZ AB

44

NGERH0992FCZZ AB

45

NROLR0922FCZZ AR

46

XPSSP20-07000 AA

47

NSFTZ0011QSZZ AG

48

NROLP0024QSZZ AL

49

XRESP30-06000 AA

50

NGERH0990FCZZ AB

51

RANK

MARK

PART

RANK

C FAX filter XC

C Operation exterior FAX XC

C Enter key XC

C Function key XC

C Stop key XC

C Start key XC

C One touch key XC

C Ten key XC

E FAX panel PWB

C Screw (2.6´6)

C Stopper sponge

C Clutch shaft

C E type ring

C Cam boss A2

C MF clutch spring B

C SPF clutch sleeve

C Clutch gear (20T)

C M bushing C

C Stopper arm

C Paper stopper F

B PU sorenoid FAX

C Set detect lever ACT

C Open and shut detect lever ACT

C Solenoid arm spring

C Solenoid arm

C FAX filter base

C B4 actuator FAX

C Paper feeding frame XC

B Clutch pawl N

C Clutch pawl spring

CScrew (3´6KS)

C 20MXL pulley

C SPF sensor FAX

C FAX opration harness

E FAX sensor PWB

CScrew (3´8)

C Pick up arm

C Paper feeding spring

C Gear (20T)

C Manual paper feed roller

C Spring pin (f2-7)

C Paper feeding shaft

C Pick up roller

C E type ring

C Gear (16T)

DESCRIPTION

– 7 –

Page 32

5 AR-FX3-2(Fax panel pick up unit)

AR-150P

1

26

2

39

3

14

5

17

13

6

4

15

16

18

13

21

12

19

7

8

20

23

24

25

31

13

22

9

27

30

31

10

10

41

32

18

28

29

10

11

40

40

37

– 8 –

47

51

18

46

45

45

42

31

47

49

45

44

50

18

48

FCP03954

Page 33

AR-150P

6 AR-FX3-3(Fax transport unit)

PRICE

NO. PARTS CODE

LPLTM0146QSZZ AD

1

XEBSD30P08000 AA

2

PGIDM0058QSZZ AK

3

XEBSD30P12000 AA

4

VSP50PB518P// AL

5

XEPSD30P08X00 AA

6

PCOVP0043QSZZ AL

7

PCOVP0042QSZZ AH

8

RMOTP0013QSZZ BB

9

LFRM-0013QSZZ AG

10

MARMP0001QSZZ AF

11

NGERH0972FCZZ AB

12

LX-BZ0012QSZZ AC

13

LBNDJ0013FCZ1 AA

14

MSPRT0064QSZ1 AC

15

XEBSD30P08000 AA

16

XBPSD30P05K00 AA

17

NBLTT0006QSZZ AG

18

XRESP50-06000 AA

19

PSHEP3029FCZZ AA

20

NGERH0047QSZZ AF

21

XPSSP20-09000 AA

22

NBRGC0098FCZZ AC

23

XEBSD30P08000 AA

24

NBRGM5006BCZZ AB

25

LFRM-0012QSZZ AD

26

PGIDM0024QSZ2 AQ

27

MSPRC0063QSZZ AB

28

NROLM0023QSZZ AP

29

NROLM0022QSZZ AP

30

PSHEZ0164QSZZ AF

31

PGIDH0029QSZZ AL

32

PBRSR0003QSZZ AL

33

DHAI-0161QSZ2 BA

34

JKNBZ0004QSZZ AD

35

NBLTT0003QSZZ AG

37

NPLYZ0146FCZZ AB

38

MSPRP0065QSZZ AD

41

PSHEZ2174FCZZ AB

42

LPLTP0013QSZZ AD

43

PSHEZ0039QSZZ AG

44

MSPRC0062QSZZ AC

45

RDTCT0004QSZZ AL

46

DHAI-0162QSZZ AE

47

PTUBP0119FCZZ AB

50

RANK

NEW

MARK

6 AR-FX3-3(Fax transport unit)

PART

RANK

C PG reinforce plate

CScrew (3´8)

C U turn P/G XC

CScrew (3´12)

B Speaker

CScrew (3´8X)

C Rear cover XC

C Front cover XC

B SPF motor

C Drive frame

C Drive arm

C Gear (27T)

CScrew

C Wire band

C Drive arm spring

CScrew (3´8)

CScrew (3´5K)

B Belt (83MXL4.8)

C E type ring

C Flange sheet DUP2

C Gear (48T/15T)

C Spring pin (f2-9)

C Bearing R

CScrew (3´8)

C Metal D (B-F6-7)

CFrame R

C Transport PG

C Delivery PG spring

C Delivery roller

C PS roller

C White sheet R

C Delivery paper guide

B Discharge brush

C SPF intertface harness FAX

C JAM release knob

B Belt (91MXL4.8)

C Pulley (22MXL)

C Open and shut lock spring

C Paper feeding sheet

CPlate

C Plape

C Pressure spring

B Inlet detect sensor

C Speaker harness

C MC protect tube

DESCRIPTION

7

19

37

29

38

24

5

41

4

3

23

28

22

27

50

6

21

47

20

24

26

50

6

11

19

13

12

18

19

25

2

1

4

44

43

8

45

42

41

25

22

17

16

14

10

9

15

16

34

46

28

30

25

22

35

33

32

31

FCP03955

– 9 –

Page 34

7 AR-DE9(2nd frame unit)

NO. PARTS CODE

GCOVA0005QSZZ AM

1

XEBSE40P12000 AA

2

GCOVA0006QSZZ AN

3

PGIDM0016QSZZ AY

4

XEBSD40P12000 AA

5

LPLTM0036QSZZ AF

6

GLEGG0064FCZZ AC

7

PGIDM0015QSZZ AY

8

MSPRC2544FCZZ AC

9

GCOVA0007QSZZ AK

10

NROLP1060FCZZ AF

11

MSPRT0112QSZ1 AC

12

MARMP0012QSZZ AD

13

GCOVA0008QSZZ AK

14

XHBSD40P08000 AA

15

CFRM-0009QS53 BE

17

DHAI-0053QSZZ AM

18

PRICE

RANK

7 AR-DE9(2nd frame unit)

NEW

MARK

PART

RANK

D Front cover

CScrew (4´12)

D Rear cover

C Guide L

CScrew (4´12)

C 2ND joint plate R

D Rubber foot

C Guide R

C 2ND transport cover spring

D Transport cover

C U-turn roller

C Transport collar spring

C 2ND door arm

D Right cover

CScrew (4´8)

E 2nd paper feeding unit

C 2CS interface harness

AR-150P

DESCRIPTION

16

2

1

2

18

2

2

15

3

5

5

4

5

6

17

9

8

7

9

13

7

11

12

16

10

16

11

12

13

14

– 10 –

16

FCP03956

Page 35

AR-150P

8 AR-DE9(2nd paper feeding unit)

PRICE

NEW

NO. PARTS CODE

NROLP0019QSZ1 AP

1

NBRGZ1043HCZZ AD

2

XRESP40-06000 AA

3

NGERH0992FCZZ AB

5

XPSSP20-07000 AA

6

LBOSZ1031FCZZ AC

7

MSPRC0161QSZZ AF

8

PPIPP0007QSZZ AD

9

NGERH1132FCZZ AH

10

NGERH1207FCZZ AF

11

MARMP0229FCZZ AE

12

MSPRC2545FCZZ AB

13

DHAI-0158QSZZ AN

14

VHPGP1A71A1-1 AG

15

MLEVP0033QSZZ AF

16

MSPRD0058QSZZ AG

17

RPLU-0010QSZZ AN

18

XHBSD30P06000 AA

19

PTME-0008QSZZ AD

20

MSPRC2546FCZZ AB

21

NGERH0041QSZZ AF

22

NGERH0990FCZZ AB

23

QSW-B0003QSZZ AF

24

CROLP0015QS01 AU

25

LFRM-0009QSZ2 AQ

26

MLEVP0050QSZZ AD

27

MSPRD0159QSZZ AC

28

XWHSD30-08160 AA

29

XEBSD30P08000 AA

30

LBNDJ0013FCZ1 AA

31

(Unit)

CFRM-0009QS53 BE

901

RANK

MARK

PART

RANK

DESCRIPTION

C Transport roller

C Bearing (B-F5-13)

C E type ring

C Gear (20T)

C Spring pin (f2-7)

C Clutch boss

C Clutch spring

C Clutch pipe

C Clutch gear (29T)

C Joint gear (40T)

C Joint arm

C 2nd joint arm spring

C 2nd harness

B Photo sensor (GP1A71A1)

C PPDI actuator

C Earth spring

B PF solenoid

CScrew (3´6)

C PF clutch pawl

C 2nd clutch pawl spring

C 2nd gear ID (18T/26T)

C Gear (16T)

B Tray detect switch

C Paper feeding roller

D Paper feeding frame

C Actuator lever

C 2nd actuator spring

C Washer

CScrew (3´8)

C Wire band

E 2nd paper feeding unit

8 AR-DE9(2nd paper feeding unit)

24

14

15

27

28

29

30

1

16

14

26

2

18

6

5

3

17

13

11

12

8

9

2

10

3

3

7

20

22

21

3

23

23

31

19

24

14

3

25

FCP03957

– 11 –

Page 36

9 AR-SP3(Packing material & Accessories)

PRICE

NEW

NO. PARTS CODE

SSAKA0019SCZZ AA

1

TCADZ0075QSZZ AE

2

SPAKA0221QSZZ AE

3

SSAKH3012KCZZ AD

4

SPAKA0219QSZZ AP

5

SPAKA0220QSZZ AQ

6

SPAKC0222QSZZ AT

7

PCUSS0010QSZ1 AV

8

RCORF0022FCZZ AQ

9

LBNDJ0013FCZ1 AA

10

XBBSE30P08000 AA

11

SSAKA2011KCZZ AA

12

DUNT-0084QS11 AU

13

PGIDM0019QSZZ AH

14

PGIDM0020QSZZ AH

15

SSAKA3442QCZZ AB

16

RANK

PART

MARK

RANK

D Vinyl bag (120´180mm)

NDCard

N D Spacer

D Vinyl bag (790´740mm)

N D Packing add L

N D Packing add R

N D Packing case

COC mat

C Ferrite core

C Band

CScrew (3´8)

D Vinyl bag

E DSPF sensor unit

C Hinge guide L

C Hinge guide R

D Vinyl bag (340´450mm)

9 AR-SP3(Packing material & Accessories)

1

14

15

AR-150P

DESCRIPTION

2

8

5

3

16

11

12

10

13

9

4

12

6

– 12 –

7

FCP03958

Page 37

AR-150P

10 AR-FX3(Packing material & Accessories)

PRICE

NEW

NO. PARTS CODE

PCUSS0010QSZ1 AV

1

TCADZ0076QSZZ AE

3

SPAKA0227QSZZ AE

4

TINSE0258QSZZ AX

5

SPAKA0226QSZZ AE

6

SPAKA0224QSZZ AQ

7

SSAKH3012KCZZ AD

8

SPAKC0229QSZZ AT

9

XHBSE30P08000 AA

10

SSAKA2011KCZZ AA

12

SPAKA0225QSZZ AQ

13

SSAKA0019SCZZ AA

14

SPAKA399ACCZZ AB

15

SPAKA0228QSZZ AE

16

PCOVP0046QSZZ AF

17

PCOVP0045QSZZ AL

18

PGIDM0019QSZZ AH

19

PGIDM0020QSZZ AH

20

SSAKA3442QCZZ AB

21

DUNT-0084QS11 AU

22

QCNW-7197XCZZ AH

101

TLABH0152QSZZ AD

102

RANK

PART

MARK

RANK

COC mat

NDCard

N D Spacer B

N D Operation manual

N D Spacer A

N D Packing add L

D Vinyl bag (790´740mm)

N D Packing case

CScrew (3´8)

D Vinyl bag

N D Packing add R

D Vinyl bag (120´180mm)

D Vinyl bag

N D Protect sheet

D Line cover A

D PWB cover

C Hinge guide L

C Hinge guide R

D Vinyl bag (340´450mm)

E DSPF sensor unit

B Line cable

N C Label

10 AR-FX3(Packing material & Accessories)

DESCRIPTION

18

17

15

16

20

14

21

19

1

3

5

6

4

7

10

11

8

12

22

13

9

FCP3959

– 13 –

Page 38

11 AR-DE9(Packing material & Accessories)

PRICE

NEW

NO. PARTS CODE

TTAG-0002QSZZ AB

1

LHLDW1226FCZZ AB

2

TCADZ0077QSZZ AE

3

SPAKA5108FCZZ AF

4

SSAKH0021SCZZ AC

5

SPAKC0223QSZZ AQ

6

XEBSE40P12000 AA

7

XEBSE40P16000 AA

8

SSAKA2011KCZZ AA

9

RANK

PART

MARK

RANK

N C Tray rotation tag

C Holder

NDCard

D Packing add

D Vinyl bag

N D Packing case

CScrew (4´12)

CScrew (4´16)

D Vinyl bag

11 AR-DE9(Packing material & Accessories)

AR-150P

DESCRIPTION

3

4

6

12 AR-PG1(Packing material & Accessories)

PRICE

NEW

NO. PARTS CODE

SPAK-548ECCZZ AB

1

SPAKA5824FCZZ AF

2

DHAI-0173QSZZ AE

3

XBBSE30P08000 AA

4

SSAKA0019SCZZ AA

5

DUNT-0130QSZ1 AL

6

TCADZ0078QSZZ AH

7

SPAKC0231QSZZ AG

8

TINSE0305QSZZ AY

9

RANK

PART

MARK

RANK

D Vinyl bag (140´260mm)

N D Protect sheet

N C GDAI harness

CScrew (3´8)

D Vinyl bag (120´180mm)

N D CD-ROM

NDCard

D Packing case

N D Operation manual

7

9

8

5

1

2

FCP03960

DESCRIPTION

12 AR-PG1(Packing material & Accessories)

GDI PWB,GDI harness

4

6

5

7

8

9

1

GDI PWB

2

3

FCP3961

– 14 –

Page 39

AR-150P

13 AR-FX3(Fax panel PWB)

NO. PARTS CODE

PSPAF0013QSZZ AD

1

QCNCM0811FCZZ AC

2

QSW-P0005QSZZ AC

3

RCRMZ0002QSZZ AE

4

RVR-B1440QCZZ AF

5

VCCCTV1HH471J AA

6

VCEAJU1CW226M AB

7

VCKYTV1EB104K AA

8

VHDDAN202U/-1 AB

9

VHDDAP202U/-1 AB

10

VHIHD4074344/ AX

11

VHINJM431U/-1 AF

12

VHP1LHLE-002A AC

13

VRS-TP2BD000J AA

14

VRS-TS2AD101J AA

15

VRS-TS2AD102J AA

16

VRS-TS2AD103J AA

17

VRS-TS2AD105J AA

18

VRS-TS2AD202J AA

19

VRS-TS2AD203J AA

20

VRS-TS2AD242F AB

21

VRS-TS2AD272F AA

22

VRS-TS2AD391J AA

23

VRS-TX2HD511J AB

24

VSDTA143EK/-1 AB

25

VVLHLM3212-01 BA

26

(Unit)

CPWBF0046QS51 BH

901

PRICE

RANK

NEW

PART

MARK

RANK

C LCD spacer

C Connector (9pin) [CN701]

B Tact swtch (B3F-6102) [S701~747]

C Crystal [Y701]

B Volume (RK09J11TO) [VR701]

C Capacitor (50WV 470pF) [C705~707]

C Capacitor (16WV 22mF) [C702,703]