SGS Thomson Microelectronics M28R400C Datasheet

1/50March 2003

M28R400CT

M28R400CB

4 Mbit (256Kb x16, Boot Block)

1.8V Supply Flash Memory

FEATURES SUMMARY

■ SUPPLY VOLTAGE

–V

DD

= 1.65V to 2.2V Core Power Supply

–V

DDQ

= 1.65V to 2.2V for Input/Output

–V

PP

= 12V for fast Program (optional)

■ ACCESS TIMES: 90ns, 120ns

■ PROGRAMMING TIME

– 10µs typic al

– Double Word Programming Option

■ COMMON FLASH INTERFACE

– 64 bit Security Code

■ MEMORY BLOCKS

– Parameter Blo cks (Top or Bottom location)

– Main Blocks

■ BLOCK LOCKING

– All blocks locked at Power Up

– Any combination of blocks can be locked

–WP

for Block Lock-Down

■ SECURITY

– 64 bit user Programmable OTP cells

– 64 bit unique device identifier

– One Parameter Block Permanently Lockable

■ AUTOMATIC STAND-BY MODE

■ PROGRAM and ERASE SUSPEND

■ 100,000 PROGRAM/ER ASE CYCL ES per

BLOCK

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Top Device Code, M28R400CT: 882Ah

– Bottom Device Code, M28R400CB: 882Bh

Figure 1. Packages

FBGA

TFBGA46 (ZB)

6.39 x 6.37mm

M28R400CT, M28R400CB

2/50

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

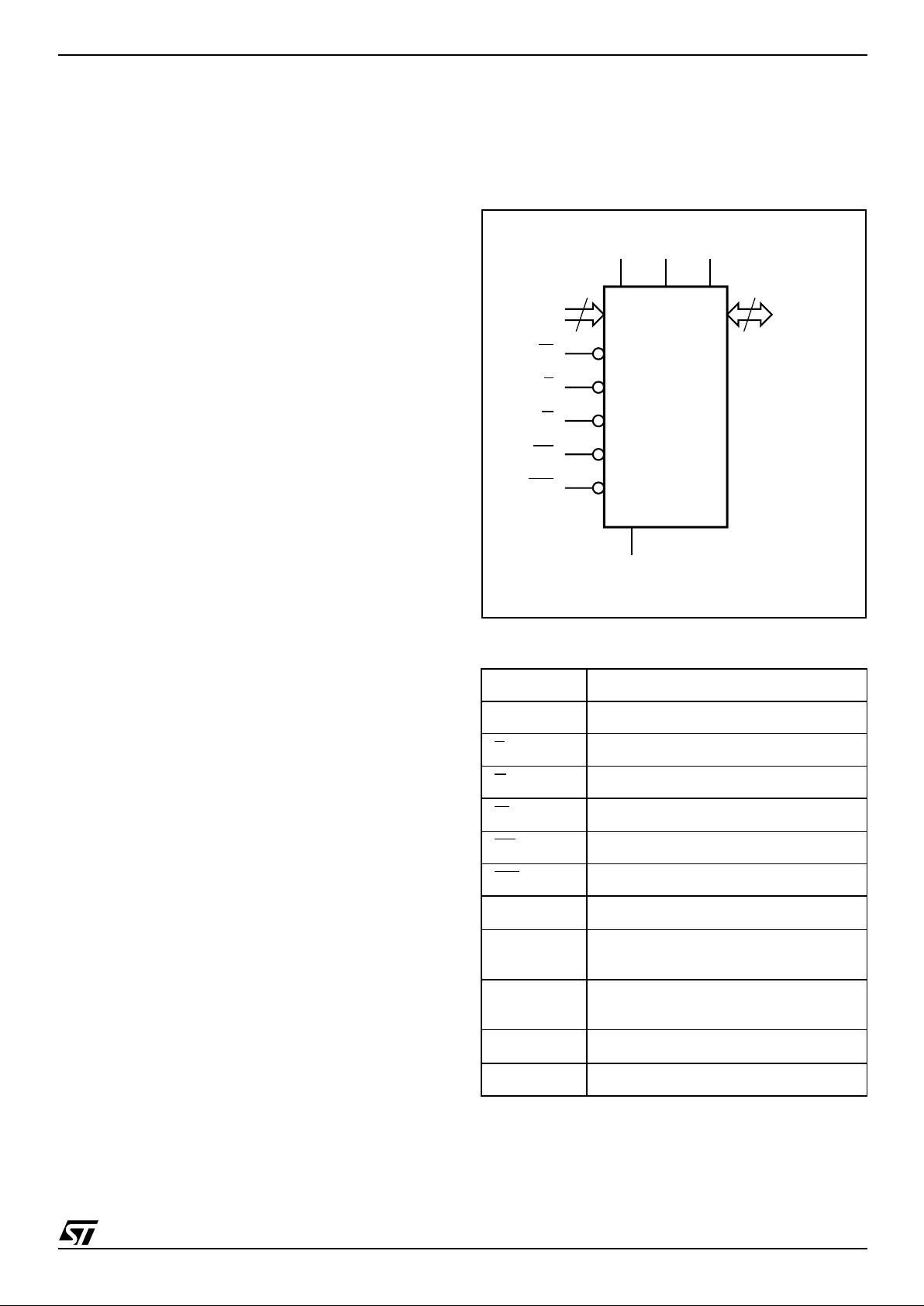

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

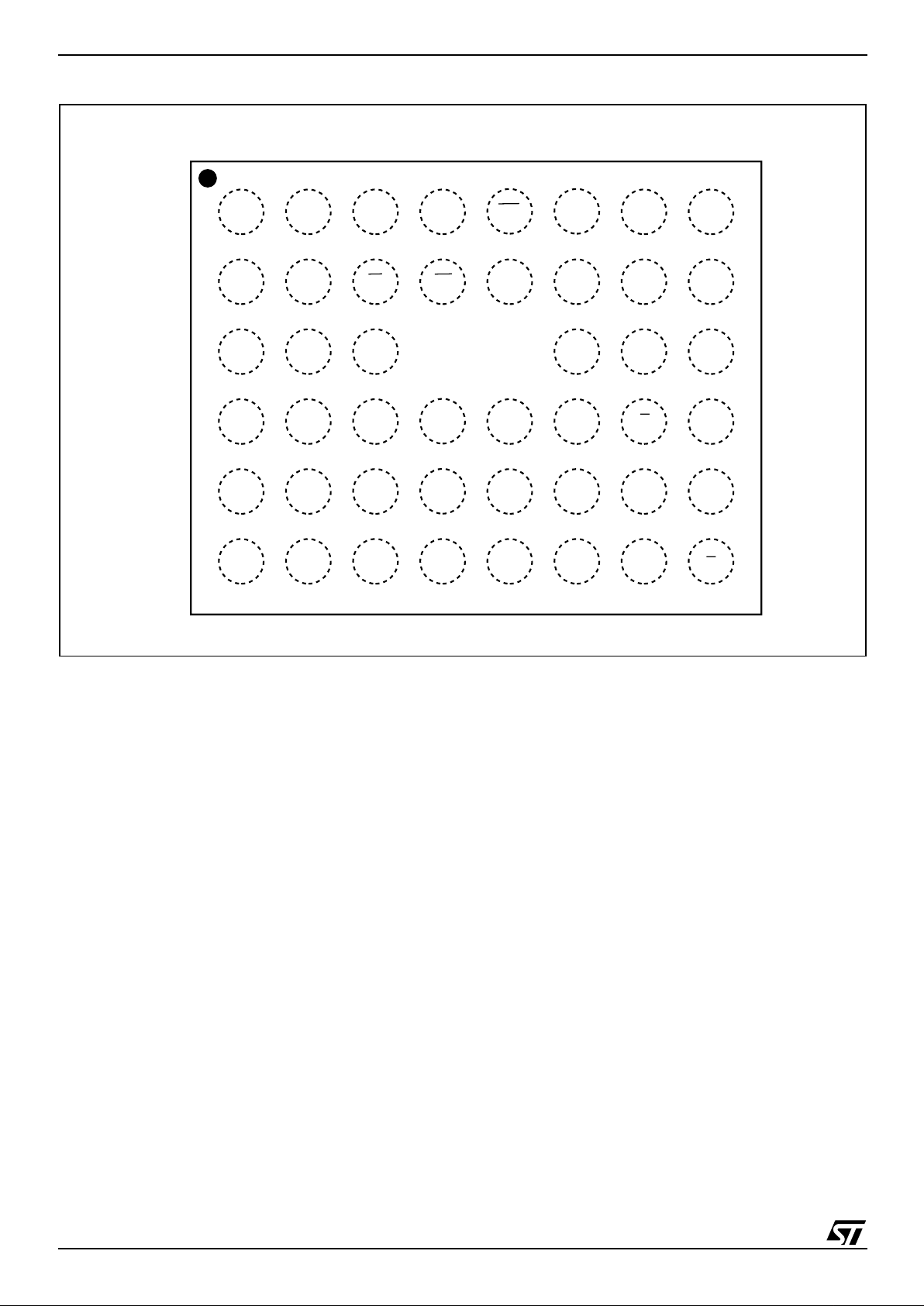

Figure 3. TFBGA Connections (Top view through package). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. Block Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5. Security Block Memory Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Address Inputs (A0-A17). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Input/Output (DQ0-DQ15). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output Enable (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Write Enable (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Write Protect (WP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Reset (RP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

DD

Supply Voltage (1.65V to 2.2V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

V

DDQ

Supply Voltage (1.65V to 2.2V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

PP

Program Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

SS

Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Read.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Write.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Automatic Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Read Electronic Signature Comma nd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

COMMAND INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Read Memory Array Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Read Status Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Read Electronic Signature Comma nd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Read CFI Query Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Block Erase Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chip Erase Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Double Word Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Clear Status Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Program/Erase Suspend Comm and . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Program/Erase Resume Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Protection Register Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Block Lock-Down Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3/50

M28R400CT, M28R400CB

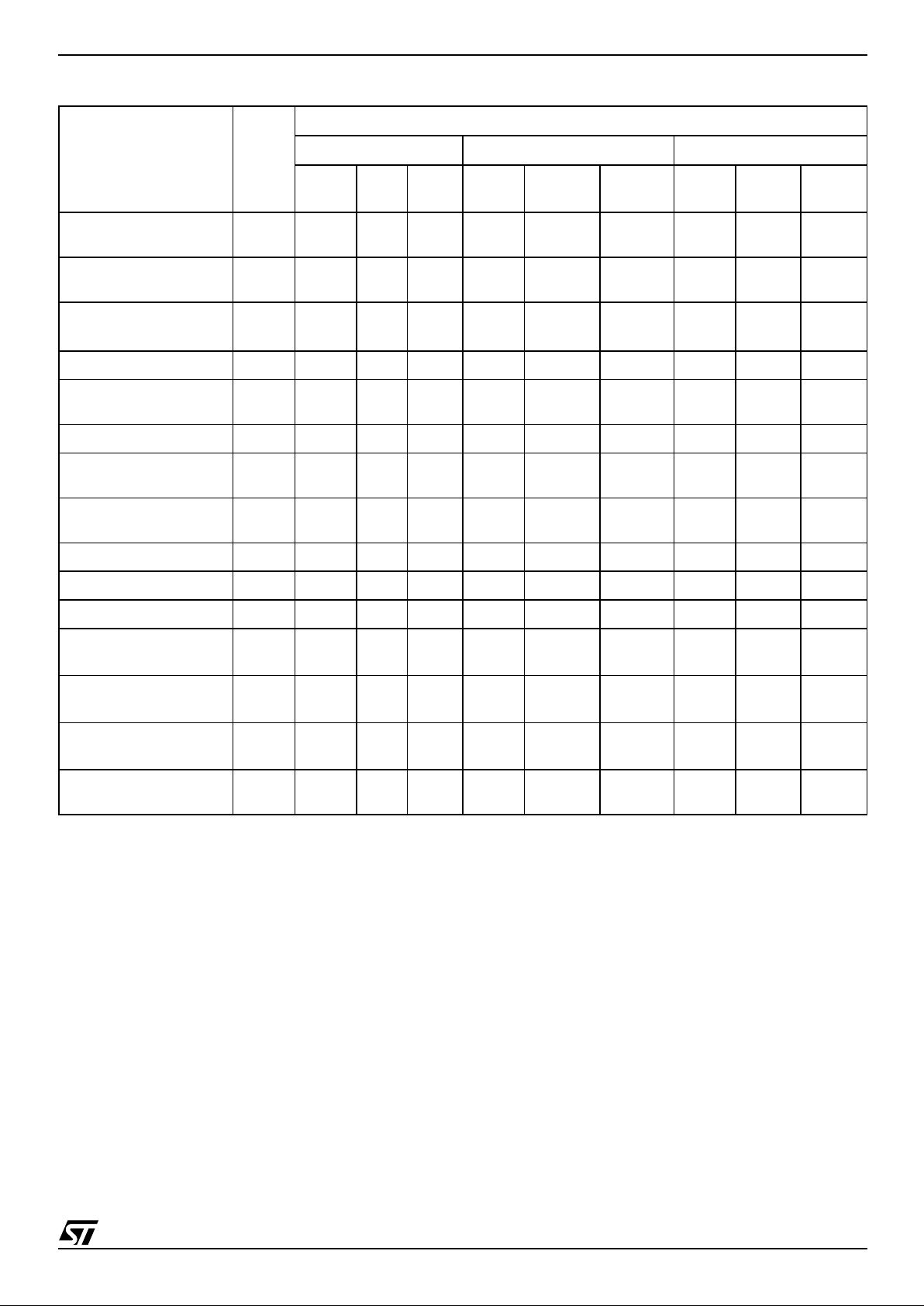

Table 3. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 4. Read Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5. Read Block Lock Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 6. Read Protection Register and Lock Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 7. Program, Erase Times and Program/Erase Endu rance Cycles . . . . . . . . . . . . . . . . . . . . 15

BLOCK LOCKING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reading a Block’s Lock Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Locked State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unlocked State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Lock-Down State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Locking Operations During Erase Suspend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. Block Lock Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 9. Protection Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

STATUS REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Program/Erase Controller Sta tus (Bit 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Erase Suspend Status (Bit 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Erase Status (Bit 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Program Status (Bit 4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

V

PP

Status (Bit 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Program Suspend Status (Bit 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Block Protection Status (Bit 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Reserved (Bit 0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 9

Table 10. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 11. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 12. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 6. AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 7. AC Measurement Load Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 13. Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 14. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 8. Re ad AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 15. Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9. Write AC Waveforms, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 16. Write AC Characteristics, Write Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 10. Write AC Waveforms, Ch ip Enable Controlled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 17. Write AC Characteristics, Ch ip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 11. Power-Up and Reset AC Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 18. Power-Up and Reset AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

M28R400CT, M28R400CB

4/50

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 12. TFBGA46 6.39x6.37mm - 8x6 ball array, 0.75 mm pitch, Bottom View Package Outline29

Table 19. TFBGA46 6.39x6.37mm - 8x6 ball array, 0.75 mm pitch, Package Mechanical Data. . . 29

Figure 13. TFBGA46 Daisy Chain - Package Connections (Top view through package) . . . . . . . . 30

Figure 14. TFBGA46 Daisy Chain - PCB Connections proposal (Top view through package). . . . 30

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 20. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 21. Daisy Chain Ordering Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

APPENDIX A. BLOCK ADDRESS T ABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 22. Top Boot Block Addresses, M28R400CT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 23. Bottom Boot Block Addresses, M28R400CB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

APPENDIX B. COMMON FLASH INTERFACE (CFI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 24. Query Structure Overvie w . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 25. CFI Query Identification String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 26. CFI Query System Interface Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 27. Device Geometry Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 28. Primary Algorithm-Specific Extended Query Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 29. Security Code Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

APPENDIX C. FLOWCHARTS AND PSEUDO CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 15. Program Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 16. Double Word Program Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 17. Program Suspend & Resume Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . 40

Figure 18. Block Erase Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 19. Erase Suspend & Resume Flowchart and Pseudo Code. . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 20. Locking Operations Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 21. Protection Register Program Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . 44

APPENDIX D. COMMAND INTERFACE AND PROGRAM/ERASE CONTROLLER STATE . . . . . . . 45

Table 30. Write State Machine Current/Next, sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 31. Write State Machine Current/Next, sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 32. Document Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

5/50

M28R400CT, M28R400CB

SUMMARY DESCRIPTION

The M28R400C is a 4 Mbit (256Kbit x 16) non-volatile Flash memory that can be erased electrically

at the block level and programmed in-system on a

Word-by-Word basis. These operations can be

performed using a single low voltage (1.65 to

2.2V) supply. V

DDQ

allows to drive the I/O pin

down to 1.65V. An optional 12V V

PP

power supply

is provided to speed up customer programming.

The device features an asymmetrical blocked ar-

chitecture. The M28R400C has an array of 15

blocks: 8 Parameter Blocks of 4 KWord and 7

Main Blocks of 32 KWord. M28R400CT has the

Parameter Blocks at the top of the memory address space while the M28R400CB locates the

Parameter Blocks starting from the bottom. The

memory maps are s hown in Figure 4, Block Addresses.

The M28R400C features an instant, individual

block locking scheme that allo ws any block to be

locked or unlocked with no latency, enabling instant code and data protection. All blocks have

three levels of protection. They can be locked and

locked-down individually preventing any accidental programming or erasure. There is an additional

hardware protection against program and block

erase. When V

PP

≤ V

PPLK

all blocks are p rotected

against program or block erase. All blocks are

locked at power-up.

Each block can be erased separately. Erase can

be suspended in order to perform either read or

program in any other block and then resumed.

Program can be suspended to read data in any

other block and then resumed. Each block can be

programmed and erased over 100,000 cycles.

The device includes a 128 b it Protection Regi ster

and a Security Block to increase the protection of

a system design. The Protection Register is divided into two 64 bit segments, the first one contains

a unique device number writte n by ST, while the

second one is one-time-programm able by the user. The user programmable segm ent can be permanently protected. The Security Block,

parameter block 0, can be perman ently protected

by the user. Figure 5, shows the Security Block

Memory Ma p.

Program and Erase c ommands are written to the

Command Interface of the memory. An on-chip

Program/Erase Controller takes care of the timings necessary for program and erase operations.

The end of a program or erase operation can be

detected and any error conditions identified. The

command set required to control the memory is

consistent with JEDEC standards.

The memory is offered in a TFBGA46 (0.75mm

pitch) package and is supplied with all the bits

erased (set to ’1’).

Figure 2. Logic Diagram

Table 1. Signal Names

A0-A17 Address Inputs

DQ0-DQ15 Data Input/Output

E

Chip Enable

G

Output Enable

W

Write Enable

RP

Reset

WP

Write Protect

V

DD

Core Power Supply

V

DDQ

Power Supply for

Input/Output

V

PP

Optional Supply Voltage for

Fast Program & Erase

V

SS

Ground

NC Not Connected Internally

AI04392

18

A0-A17

W

DQ0-DQ15

V

DD

M28R400CT

M28R400CB

E

V

SS

16

G

RP

WP

V

DDQVPP

M28R400CT, M28R400CB

6/50

Figure 3. TFBGA Connections (Top view through package)

AI04142

C

B

A

87654321

E

D

F

A4

A7V

PP

A8A11

A13

A0EDQ8DQ5DQ14A16

V

SS

DQ0DQ9DQ3DQ6

DQ15

V

DDQ

DQ1DQ10V

DD

DQ7V

SS

DQ2

A2

A5A17WA10

A14

A1A3A6A9A12A15

RP NC

DQ4

DQ13

G

DQ12

DQ11

WP NC

7/50

M28R400CT, M28R400CB

Figure 4. Block Addresses

Note: Also see Appe ndi x A, Tables 22 and 23 for a f ul l l isting of the B l ock Addresses.

Figure 5. Security Block Memory Map

AI04393

4 KWords

3FFFF

3F000

32 KWords

0FFFF

08000

32 KWords

07FFF

00000

M28R400CT

Top Boot Block Addresses

4 KWords

38FFF

38000

32 KWords

30000

37FFF

Total of 8

4 KWord Blocks

Total of 7

32 KWord Blocks

4 KWords

3FFFF

38000

32 KWords

32 KWords

00FFF

00000

M28R400CB

Bottom Boot Block Addresses

4 KWords

37FFF

0FFFF

32 KWords

30000

08000

Total of 7

32 KWord Blocks

Total of 8

4 KWord Blocks

07FFF

07000

AI03523

Parameter Block # 0

User Programmable OTP

Unique device number

Protection Register Lock 2 1 0

88h

85h

84h

81h

80h

M28R400CT, M28R400CB

8/50

SIGNAL DESCRIPTIONS

See Figure 2 Logic Diagram and Table 1,Signal

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A17). The Address Inputs

select the cell s in the memory arra y to access during Bus Read operations. During Bus Write operations they control the commands sent to the

Command Interface of the internal state machine.

Data Input/Output (DQ0-DQ15). The Data I/O

outputs the data stored at the selected address

during a Bus Read operation or inputs a command

or the data to be programmed durin g a Write Bus

operation.

Chip Enable (E

). The Chip Enable input acti-

vates the memory control logic, input buffers, decoders and sense amplifiers. When Chip Enable is

at V

IL

and Reset is at VIH the device is in active

mode. When Chi p E nable is at V

IH

the memory is

deselected, the outputs are high im pedance and

the power consumption is reduced to the stand-by

level.

Output Enable (G

). The Output Enable controls

data outputs during the Bus Read operation of the

memory.

Write Enable (W

). The Write Enable controls the

Bus Write operation of the memory’s Command

Interface. The data and address inputs are latched

on the rising edge of Chip Enable, E, or Write Enable, W

, whichever occurs first.

Write Protect (WP

). Write Protect is an input

that gives an additional hardware protection for

each block. When Write Protect is at V

IL

, the Loc kDown is enabled and the protection status of the

block cannot be changed. When Write Protect is at

V

IH

, the Lock-Down is disabled and the block can

be locked or unlocked. (refer to Table 6, Read Protection Register and Protection Register Lock).

Reset (RP

). The Reset input provides a hard-

ware reset of the mem ory. When Reset is at V

IL

,

the memory is in reset mode: the outputs are high

impedance and the current consumption is minimized. After Reset all blocks are in the Locked

state. When Reset is at V

IH

, the device is in normal

operation. Exiting reset mode the device enters

read array mode, but a negative transition of Chip

Enable or a c hange of the address is require d to

ensure valid data outputs.

V

DD

Supply Vol tag e (1 . 65 V to 2.2V) . V

DD

provides the power supply to the i nternal core of

the memory device. It is the main power supply for

all operations (Read, Program and Erase).

V

DDQ

Supply Voltage (1.65V to 2.2 V). V

DDQ

provides the power supply to the I/O pins and enables all Outputs to be powered independently

from V

DD

. V

DDQ

can be tied to VDD or can use a

separate supply.

V

PP

Program Supply Voltage. VPP is both a

control input and a power supply pin. The two

functions are selected by the voltage range applied to the pin. The Supply Voltage V

DD

and the

Program Supply Voltage V

PP

can be applied in

any order.

If V

PP

is kept in a low voltage range (0V to 3.6V)

V

PP

is seen as a control input. In this case a volt-

age lower than V

PPLK

gives protection against pro-

gram or block erase, while V

PP

> V

PP1

enables

these functions (see Table 14, DC Characteristics

for the relevant values). V

PP

is only sampled at the

beginning of a program or bloc k erase; a change

in its value after the operation has started does not

have any effect and program or erase operations

continue.

If V

PP

is in the range 11.4V to 12.6V it acts as a

power supply pin. In this condition V

PP

must be

stable until the Program/Erase al gorithm is completed (see Table 16 and 17).

V

SS

Ground. VSS is the ref erence for all voltage

measurements.

Note: Each device in a system should have

V

DD, VDDQ

and VPP decoupled with a 0.1µF ca-

pacitor close to the pin. See Figure 7, AC Measurement Load Circu it. The PCB trace widths

should be sufficient to carry the required V

PP

program and erase currents.

9/50

M28R400CT, M28R400CB

BUS OPERATIONS

There are six standard bus operations that control

the device. These are B us Read, Bus Wri te, Output Disable, Standby, Automatic Standby and Reset. See Table 2, Bus Operations, for a summary.

Typically glitches of less than 5ns on Chip Enable

or Write Enable are ignored by the memory and do

not affect bus operations.

Read. Read Bus operations are used to ou tput

the contents of the Memory Array, the Electr onic

Signature, the Status Register and the Common

Flash Interface. Both Chip Enable and Output Enable must be at V

IL

in order to perform a read operation. The Chip Enable in put should b e used to

enable the device. Out put E nable s houl d be us ed

to gate data onto the output. The data read depends on the previous command written to the

memory (see Command Interface section). See

Figure 8, Read Mode AC Wa veforms, and Table

15, Read AC Characteristics, for details of when

the output becomes valid.

Read mode is the default state of the device when

exiting Reset or after power-up.

Write. Bus Write operations write Comm ands to

the memory or latch Input Data to be programmed.

A write operation is initiated when Chip Enable

and Write Enable are at V

IL

with Output Enable at

V

IH

. Commands, Input Data and Addresses are

latched on the rising edge of Write Enable or Chip

Enable, whichever occurs first.

See Figures 9 and 10, Write A C Wav eforms, and

Tables 16 and 17, Write AC Characteristics, for

details of the timing requirements.

Output Disable. The data outputs are high impedance when the Output Enable is at V

IH

.

Standby. S tandby disables m ost of the internal

circuitry allowing a substantial reduction of the current consumption. The memory is in stand-by

when Chip Enable is at V

IH

and the devic e is in

read mode. The power consumption is reduced to

the stand-by level and t he outputs are set to high

impedance, independently from the Output Enable

or Write Enable inputs. If Chip En able switches to

V

IH

during a program or erase operat ion, the de-

vice enters Standby mode when finished.

Automatic Standby. Automatic Standby pro-

vides a low power consumption state during Read

mode. Following a read operation, the device enters Automatic Standby after 150ns of bus inactivity even if Chip Enable is Low, V

IL

, and the supply

current is reduced to I

DD1

. The data Inputs/Outputs will still output data if a bus Read operation is

in progress.

Reset. During Reset mode when Output Enable

is Low, V

IL

, the memory is deselected and the outputs are high impedance. The memory is in Reset

mode when Reset is at V

IL

. The power consumption is reduced to the Standby level, independently

from the Chip Enable, Output Enable or Write Enable inputs. If Reset is pulled to V

SS

during a Program or Erase, this operation is aborted and the

memory content is no longer valid.

Table 2. Bus Operations

Note: X = VIL or VIH, V

PPH

= 12V ± 5%.

Operation E G W RP WP

V

PP

DQ0-DQ15

Bus Read

V

IL

V

IL

V

IH

V

IH

X Don’t Care Data Output

Bus Write

V

IL

V

IH

V

IL

V

IH

X

V

DD

or V

PPH

Data Input

Output Disable

V

IL

V

IH

V

IH

V

IH

X Don’t Care Hi-Z

Standby

V

IH

XX

V

IH

X Don’t Care Hi-Z

Reset X X X

V

IL

X Don’t Care Hi-Z

M28R400CT, M28R400CB

10/50

COMMAND INTERFACE

All Bus Write operations to the memory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. An internal Program/Erase Controller handles all timings and verifies the correct execution

of the Program and Erase commands. The Program/Erase Controller provides a S tatus Register

whose output may be read at any time during, to

monitor the progress of the operation, or t he Program/Erase states. See Appendix D, Table 30,

Write State Machine Current/Next, for a summary

of the Command Interface.

The Command Interface is reset to Read mode

when power is first applied, when exiting from Reset or whenever V

DD

is lower than V

LKO

. Command sequences must be followed exactly. Any

invalid combination of commands will reset the device to Read mode. Refer to Table 3, Commands,

in conjunction with the text descriptions below.

Read Memory Array Command

The Read command returns the memory to its

Read mode. One Bus Write cycle is required to issue the Read Memory Array command and return

the memory to Read mode . Subsequent read operations will read the addressed loc ation and output the data. When a device Reset occurs, the

memory defaults to Read mode.

Read Status Register Command

The Status Register indicates when a program or

erase operation is complete and the success or

failure of the operation itself. Issue a Read Status

Register command to rea d the Status Register’s

contents. Subsequent Bus Read operations read

the Status Register at any address , until another

command is issued. See Table 10, Status Register

Bits, for details on the definitions of the bits.

The Read Status Register command may be issued at any time, even during a Program/Erase

operation. Any Read attempt during a Program/

Erase operation will automatically outp ut the content of the Status Register.

Read Electronic Signature Command

The Read Electronic Signature command reads

the Manufacturer and Device Codes and the Block

Locking Status, or the Protection Register.

The Read Electronic Signature command consists

of one write cycle, a subsequent read will output

the Manufacturer Code, the Device Code, the

Block Lock and Lock-Down Status, or the Protection and Lock Register. See Tables 4, 5 and 6 for

the valid address.

Read CFI Query Command

The Read Query Command is used t o read data

from the Common Flash Interface (CFI ) Memory

Area, allowing programming equipment or appli-

cations to automatically match their interface to

the characteristics of the device. One Bus Write

cycle is required to issue the Read Query Command. Once the command is issued subsequent

Bus Read operations read from the Common

Flash Interface Memory Area. See Appendix B,

Common Flash Inte rface, Tables 2 4, 25, 26, 27,

28 and 29 for details on the information contained

in the Common Flash Interface memory area.

Block Erase Command

The Block Erase c ommand can be used to erase

a block. It sets all the bits within the selected block

to ’1’. A ll previous data in t he block is lost. If t he

block is protected then the Erase operation will

abort, the data in the block will not be changed and

the Status Register will output the error.

Two Bus Write cycles are required to issue the

command.

■ The first bus cycle sets up the Erase command.

■ The second latches the block address in the

internal state machine and starts the Program/

Erase Controller.

If the second bus cycle is not Write Erase Confirm

(D0h), Status Register bits b4 and b5 are s et and

the command aborts.

Erase aborts if Reset turns to V

IL

. As data integrity

cannot be guaranteed when the Erase operation is

aborted, the block must be erased again.

During Erase operations the memory will accept

the Read Status Register com mand and th e Program/Erase Suspend command, all other commands will be ignored. Typical Erase times are

given in Table 7, Program, Erase Times and Program/Erase Endurance Cycles.

See Appendix C, Figure 18, Block Erase Flowchart and Pseudo Code, for a suggested flowchart

for using the Block Erase command.

Chip Erase Command

The Chip Erase command can be used to erase

the entire chip. It sets all of the bits in unprotected

blocks of the memory to ’1’. All previous data is

lost. Two Bus Write operations are requ ired to issue the Chip Erase Command.

■ The first bus cycle sets up the Chip Erase

command.

■ The second confirms the Chip Erase command

and starts the Program/Erase Controller.

The command can be issued to any address. If

any blocks are protec ted then these are ignored

and all the other blocks are erased. If all of the

blocks are protected the Chip Erase op erat i on appears to start but wi ll terminate, leaving the data

unchanged. No error condition is gi ven when protected blocks are ignored.

11/50

M28R400CT, M28R400CB

During the erase o peration th e memory w ill only

accept the Read Status Register command. All

other commands will be ignored, including the

Erase Suspend com mand. It is no t possible to issue any command to abort the operation.

Chip Erase commands should be limited to a maximum of 100 Program/Erase cycles. After 100 Program/Erase cycles the internal algorithm will still

operate properly but some degradation in performance may oc c ur.

Typical chip erase times are given in Table 7.

Program Command

The memory array can be programmed word-byword. Two bus write cycles are required to issue

the Program Command.

■ The first bus cycle sets up the Program

command.

■ The second latches the Address and the Data to

be written and starts the Program/Erase

Controller.

During Program operations the memory will accept the Read Status Register command and the

Program/Erase Suspend command. Typical Program times are given in Tab le 7, P rogram, Erase

Times and Program/Erase Endurance Cycles.

Programming aborts if Res et goes to V

IL

. As data

integrity cannot be guaranteed when the program

operation is aborted, the block containing the

memory location must be erased and reprogrammed.

See Appendix C, Figure 15, Program Flowchart

and Pseudo Code, for t he flowchart for using t he

Program command.

Double Word Program Command

This feature is offered to improve the programming

throughput, writing a page of two adjacent words

in parallel.The two words m ust differ only for the

address A0. Program m ing s hould not be attempted when V

PP

is not at V

PPH

. The command can be

executed if V

PP

is below V

PPH

but the result is not

guaranteed.

Three bus write cycles are necessary to issue the

Double Word Program command.

■ The first bus cycle sets up the Double Word

Program Command.

■ The second bus cycle latches the Address and

the Data of the first word to be written.

■ The third bus cycle latches the Address and the

Data of the second word to be written and starts

the Program/Erase Controller.

Read operations output the Status Register content after the programming has started. Programming aborts if Reset goe s to V

IL

. As data integrity

cannot be guaranteed when the program opera-

tion is aborted, the block containin g the memory

location must be erased and reprogrammed.

See Appendix C, Figure 16, Double Word Program Flowchart and Pseudo Code, for the flowchart for using the Double Word Program

command.

Clear Status Register Command

The Clear Status Register com m and can be used

to reset bits 1, 3, 4 and 5 in the Status Register to

‘0’. One bus write cycle is required to issue the

Clear Status Register command.

The bits in the Status Register do not automatically return to ‘0’ when a new Program or Erase command is issued. The error bits in the Status

Register should be cleared before attempting a

new Program or Erase command.

Program/Erase Suspend Command

The Program/Erase Suspend command is used to

pause a Program or Erase operation. One bus

write cycle is required to issue the Program/Erase

command and pause the Program/Erase controller.

During Program/Erase Suspend the Command Interface will accept the Program/Erase Resume,

Read Array, Read Status Register, Read Electronic Signature and Read CFI Query commands. Additionally, if the suspend operation was Erase then

the Program, Block Lock, Block Lock-Down or

Protection Program commands will also be accepted. The block being erased may be protected

by issuing the Block Protect, Block Lock or Protection Program commands. When the Program/

Erase Resume com mand is issued the operation

will complete. Only the blocks not being erased

may be read or programmed correctly.

During a Program/Erase Suspend, the device can

be placed in a pseudo-standby mode by taking

Chip Ena ble to V

IH

. Program/Erase is aborted if

Reset turns to V

IL

.

See Appendix C, Figure 17 , Program Suspend &

Resume Flowchart and Pseudo Code, and Figure

19, Erase Suspend & Resume Flowchart and

Pseudo Code for flowcharts for using the Program/

Erase Suspend command.

Program/Er ase Resu me Command

The Program/Erase Resume command can be

used to restart the Program/Erase Controller after

a Program/Erase Suspend operation has paused

it. One Bus Write cycle is required to issue the

command. Once the command is issued subsequent Bus Read operations read the Status Register.

See Appendix C, Figure 17 , Program Suspend &

Resume Flowchart and Pseudo Code, and Figure

19, Erase Suspend & Resume Flowchart and

M28R400CT, M28R400CB

12/50

Pseudo Code for flowcharts for using the Program/

Erase Resume command.

Prot ection Register Program Command

The Protection Register Program command is

used to Program the 64 bit user One-Time-Programmable (OTP) segment of the Protection Register. The segment is programmed 16 bits at a

time. When shipped all bits in the segment are set

to ‘1’. The user can only program the bits to ‘0’.

Two write cycles are required to issue the Pro tec-

tion Register Program command.

■ The first bus cycle sets up the Protection

Register Program command.

■ The second latches the Address and the Data to

be written to the Protection Register and starts

the Program/Erase Controller.

Read operations output the Status Register content after the programming has started.

The segment can be protected by programming bit

1 of the Protection Lock Register. Bit 1 of the Protection Lock Register protects bit 2 of the Protection Lock Register. Programming bit 2 of the

Protection Lock Register will result in a permanent

protection of the Security Block (see Figure 5, Security Block Memory Map). Attempting to program

a previously protected Protection Register will result in a Status Register error. The protection of

the Protection Register a nd/or the Security Block

is not reversible.

The Protection Register Program cannot be suspended. See Appendix C, Figure 21, Protection

Register Program Flowchart and Pseudo Code,

for the flowchart for using th e Protection Regi ster

Program command.

Block Lock Command

The Block Lock command is used to lock a block

and prevent Program or Erase operations from

changing the data in it. All blocks are locked at

power-up or reset.

Two Bus Write cycles are required to issue the

Block Lock command.

■ The first bus cycle sets up the Block Lock

command.

■ The second Bus Write cycle latches the block

address.

The lock status c an be monitored for eac h block

using the Read Electronic Signature command.

Table. 9 shows the protection status after issuing

a Block Lock command.

The Block Lock bit s are volatile, once set they remain set until a hardware reset or power-down/

power-up. They are cleared by a Blocks Unlock

command. Refer to the section, Block Locking, for

a detailed explanation.

Block Unlock Command

The Blocks Unlock comm and is used to unlock a

block, allowing the block to be programmed or

erased. Two Bus Write cy cles are required to issue the Blocks Unlock command.

■ The first bus cycle sets up the Block Unlock

command.

■ The second Bus Write cycle latches the block

address.

The lock status c an be monitored for eac h block

using the Read Electronic Signature command.

Table. 9 shows the protection status after issuing

a Block Unlock command. Refer to the section,

Block Locking, for a detailed explanation.

Block Lock-Down Command

A locked block cannot be Programmed or Erased,

or have its protection status changed wh en WP

is

low, V

IL

. When WP is high, V

IH,

the Lock-Down

function is disabled and the locked bloc ks can be

individually unlocked by the Block Unlock command.

Two Bus Write cycles are required to issue the

Block Lock-Down command.

■ The first bus cycle sets up the Block Lock

command.

■ The second Bus Write cycle latches the block

address.

The lock status c an be monitored for eac h block

using the Read Electronic Signature command.

Locked-Down blocks revert to the locked (and not

locked-down) state when the device is reset on

power-down. Table. 9 shows the protection status

after issuing a Block Lock-Down co mmand. Refer

to the section, Block Locking, for a detailed explanation.

13/50

M28R400CT, M28R400CB

Table 3. Commands

Note: 1. X = Don’t Care.

2. The signature addresses ar e l i st ed in Tables 4, 5 and 6.

3. Addr 1 and Addr 2 must be consecu tive Addres ses differ i ng only for A0.

Commands

No. of

Cycles

Bus Write Operations

1st Cycle 2nd Cycle 3nd Cycle

Bus

Op.

Addr Data

Bus

Op.

Addr Data

Bus

Op.

Addr Data

Read Memory Array 1+ Write X FFh

Read

Read

Addr

Data

Read Status Register 1+ Write X 70h

Read

X

Status

Register

Read Electronic Signature 1+ Write X 90h

Read

Signature

Addr

(2)

Signature

Read CFI Query 1+ Write 55h 98h Read CFI Addr Query

Block Erase 2 Write X 20h Write

Block

Addr

D0h

Chip Erase 2 Write X 80h Write X D0h

Program 2 Write X

40h or

10h

Write Addr

Data

Input

Double Word Pr ogram

(3)

3 Write X 30h Write Addr 1

Data

Input

Write Addr 2

Data

Input

Clear Status Register 1 Write X 50h

Program/E rase Suspend 1 W rite X B 0h

Program/Erase Resume 1 Wr ite X D0h

Block Lock 2 Write X 60h Write

Block

Address

01h

Block Unlock 2 Write X 60h Write

Block

Address

D0h

Block Lock-Down 2 Write X 60h Write

Block

Address

2Fh

Protection Register

Program

2 Write X C0h Write

Address

Data

Input

M28R400CT, M28R400CB

14/50

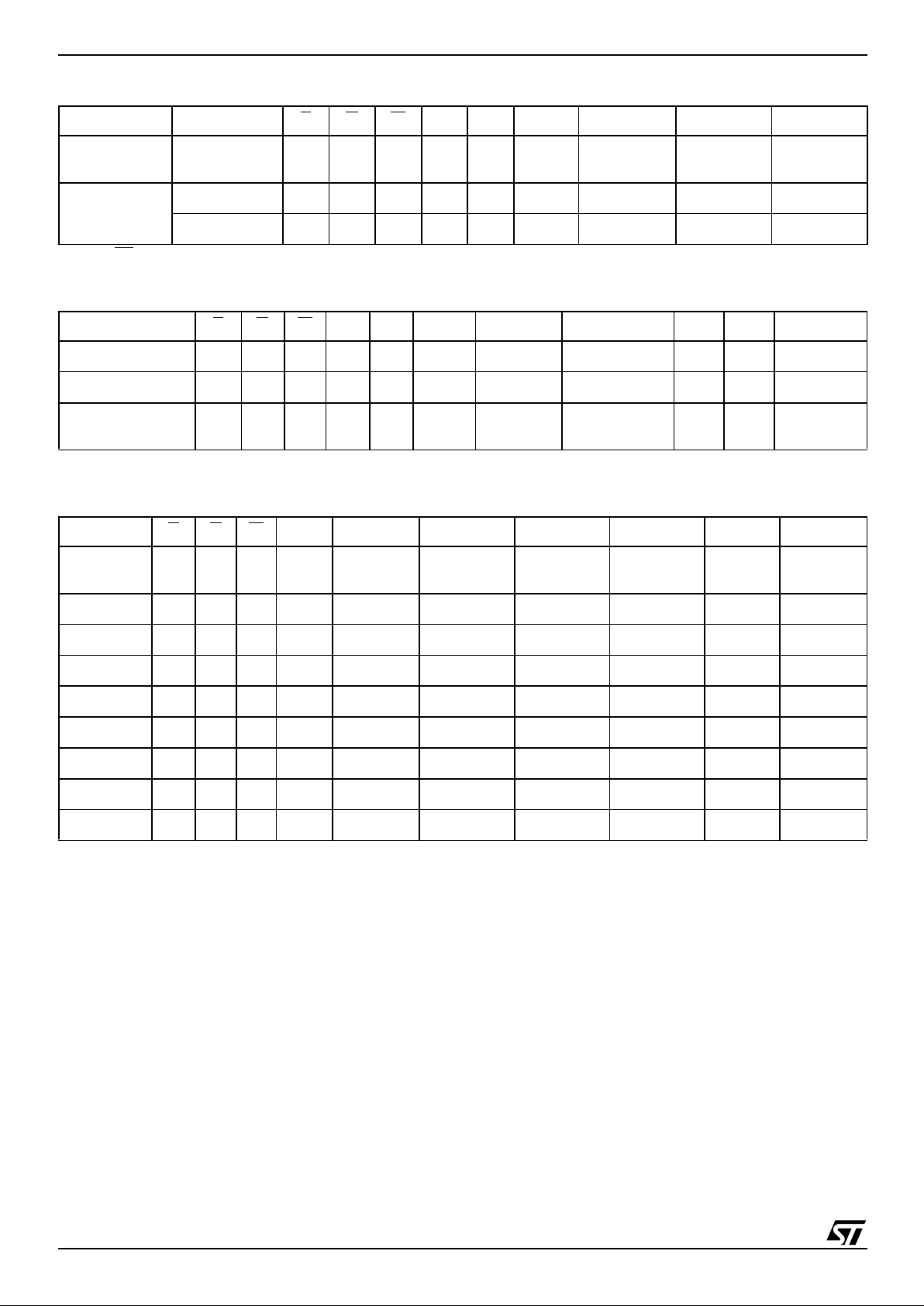

Table 4. Read Electronic Signature

Note: RP = VIH.

Table 5. Read Block Lock Signature

Note: 1. A Lo ck ed-Down Block can be locked "DQ0 = 1" or unlock ed "DQ0 = 0"; see Block Lock i ng section.

Table 6. Read Protection Register and Lock Register

Code Device E G W A0 A1 A2-A7 A8-A17 D Q0-DQ7 DQ8-DQ15

Manufacture.

Code

V

IL

V

IL

V

IH

V

IL

V

IL

0 Don’t Care 20h 00h

Device Code

M28R400CT

V

IL

V

IL

V

IH

V

IH

V

IL

0 Don’t Care 2Ah 88h

M28R400CB

V

IL

V

IL

V

IH

V

IH

V

IL

0 Don’t Care 2Bh 88h

Block Status E

G W A0 A1 A2-A7 A8-A11 A12-A17 DQ0 DQ1 DQ2-DQ15

Locked Block

V

IL

V

IL

V

IHVIL

V

IH

0 Don’t Care Block Address 1 0 00h

Unlocked Block

V

IL

V

IL

V

IHVIL

V

IH

0 Don’t Care Block Address 0 0 00h

Locked-Down

Block

V

IL

V

IL

V

IHVIL

V

IH

0 Don’t Care Block Address

X

(1)

1 00h

Word E

G W A0-A7 A8-A17 DQ0 DQ1 DQ2 DQ3-DQ7 DQ8-DQ15

Lock

V

IL

VILV

IH

80h Don’t Care 0

OTP Prot.

data

Security

prot. data

00h 00h

Unique ID 0

V

IL

VILV

IH

81h Don’t Care ID data ID data ID data ID data ID data

Unique ID 1

V

IL

VILV

IH

82h Don’t Care ID data ID data ID data ID data ID data

Unique ID 2

V

IL

VILV

IH

83h Don’t Care ID data ID data ID data ID data ID data

Unique ID 3

V

IL

VILV

IH

84h Don’t Care ID data ID data ID data ID data ID data

OTP 0

V

IL

VILV

IH

85h Don’t Care OTP data OTP data OTP data OTP data OTP data

OTP 1

V

IL

VILV

IH

86h Don’t Care OTP data OTP data OTP data OTP data OTP data

OTP 2

V

IL

VILV

IH

87h Don’t Care OTP data OTP data OTP data OTP data OTP data

OTP 3

V

IL

VILV

IH

88h Don’t Care OTP data OTP data OTP data OTP data OTP data

15/50

M28R400CT, M28R400CB

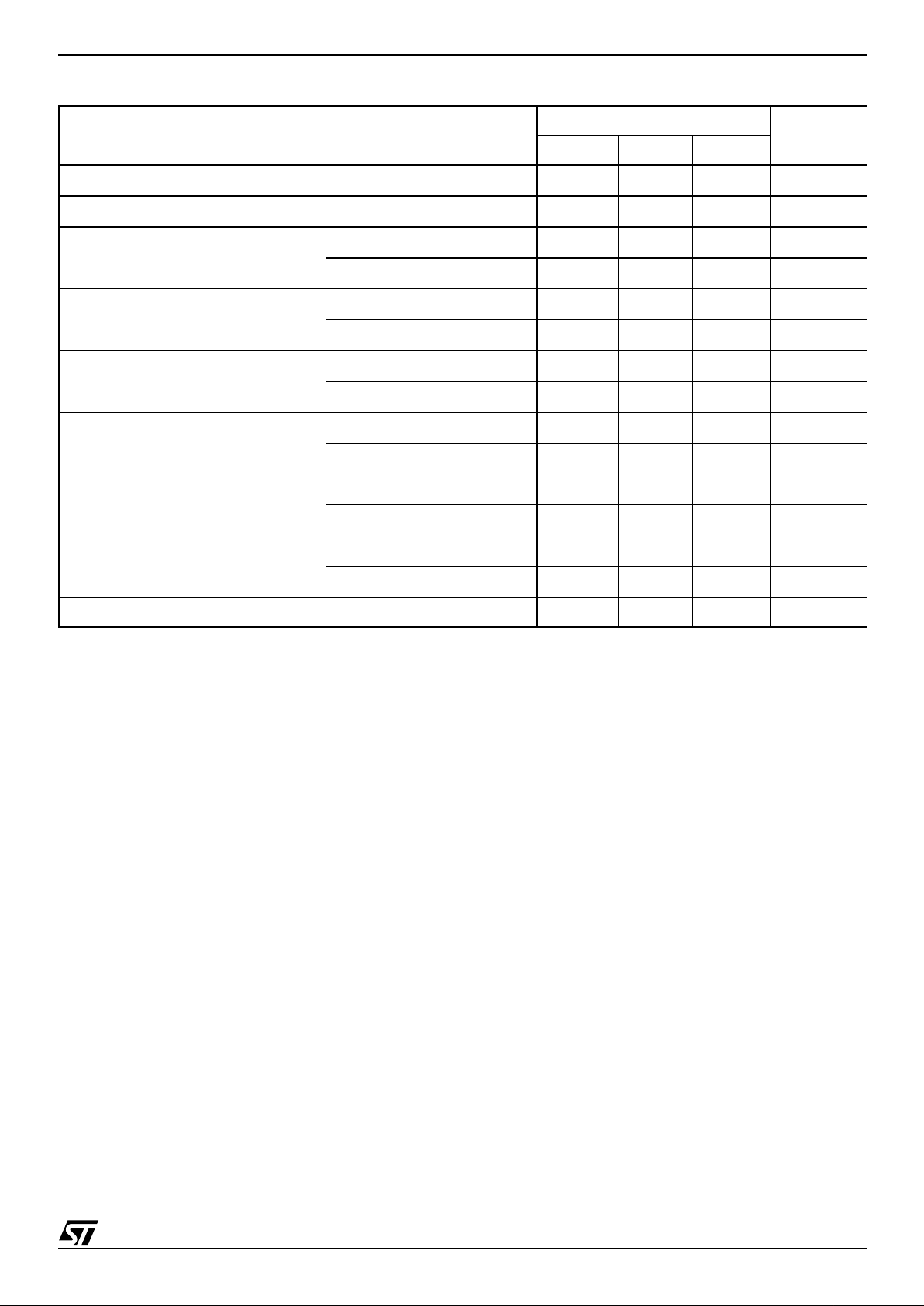

Table 7. Program, Erase Times and Program/Erase Endura nce Cycles

Parameter Test Conditions

M28R400C

Unit

Min Typ Max

Word Program

V

PP

= V

DD

10 200 µs

Double Word Program

V

PP

= 12V ±5%

10 200 µs

Main Block Program

V

PP

= 12V ±5%

0.16 5 s

V

PP

= V

DD

0.32 5 s

Parameter Block Program

V

PP

= 12V ±5%

0.02 4 s

V

PP

= V

DD

0.04 4 s

Main Block Erase

V

PP

= 12V ±5%

110 s

V

PP

= V

DD

110 s

Chip Erase (preprogrammed)

V

PP

= 12V ±5%

210 s

V

PP

= V

DD

210 s

Chip Program

V

PP

= 12V ±5%

1.25 s

V

PP

= V

DD

25 s

Parameter Block Erase

V

PP

= 12V ±5%

0.8 10 s

V

PP

= V

DD

0.8 10 s

Program/Erase Cycles (per Block) 100,000 cycles

Loading...

Loading...