SGS Thomson Microelectronics M27512-F6, M27512-F1, M27512-3F6, M27512-3F1, M27512-2F1 Datasheet

...

1/11

NOT FOR NEW DESIGN

November 2000

This is information on a product still in production but not recommended for new designs.

M27512

NMOS 512 K bit (6 4Kb x 8) UV EPROM

■ FAST ACCESS TIME: 200ns

■ EXTENDED TEMPERATURE RANGE

■ SINGLE 5V SUPPLY VOLTAGE

■ LOW STANDBY CURRENT: 40mA max

■ TTL COMPATIBLE DURING READ and

PROGRAM

■ FAST PROGRAMMING ALGORITHM

■ ELECTRONIC SIGNATURE

■ PROGRAMMING VOLTAGE: 12V

DESCRIPTION

The M27512 is a 524,288 bit UV erasable and

electrically programmable memory EPRO M. It is

organized as 65,536 words by 8 bits.

The M27512 is housed in a 28 Pin Window Ceramic Frit-Seal Dual-in-Line package. The transparent lid allows the user to expose the chip to

ultraviolet light to erase the bit pattern. A new pattern can then be written to the device by following

the programming procedure.

Figure 1. Logic Diagram

AI00765B

16

Q0-Q7

V

CC

M27512

GV

PP

V

SS

8

A0-A15

E

1

28

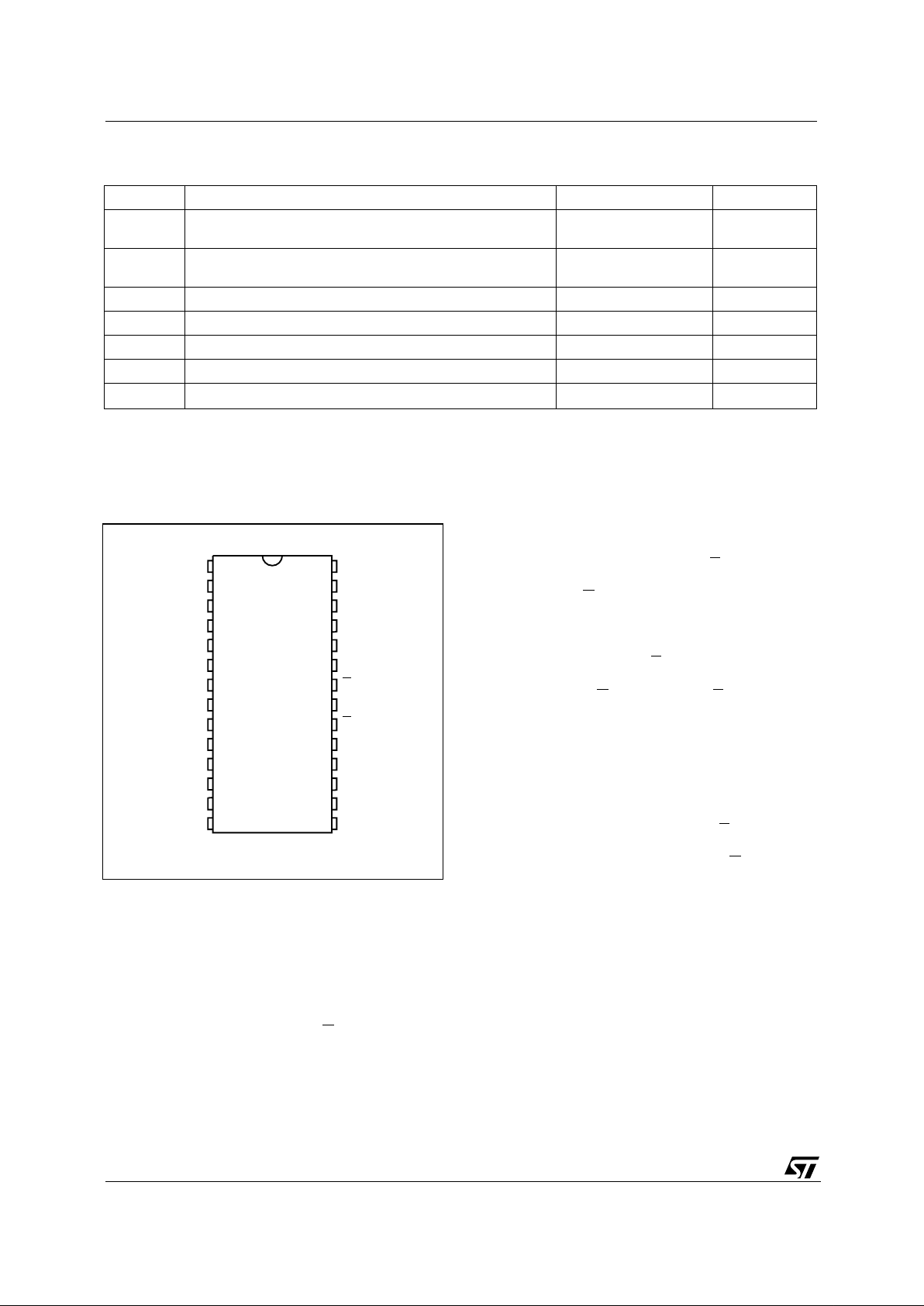

FDIP28W (F)

A1

A0

Q0

A7

A4

A3

A2

A6

A5

A13

A10

A8

A9

Q7

A14

A11

GV

PP

E

Q5Q1

Q2

Q3V

SS

Q4

Q6

A12

A15 V

CC

AI00766

M27512

8

1

2

3

4

5

6

7

9

10

11

12

13

14

16

15

28

27

26

25

24

23

22

21

20

19

18

17

Figure 2. DIP Pin Co n nect ion s

Symbol Parameter Value Unit

T

A

Ambient Operating T empera ture

Grade 1

Grade 6

0 to 70

–40 to 85

°C

T

BIAS

Temperature Under Bias

Grade 1

Grade 6

–10 to 80

–50 to 95

°C

T

STG

Storage Temperature –65 to 125 °C

V

IO

Input or Output Voltages –0.6 to 6.5 V

V

CC

Supply Voltage –0.6 to 6.5 V

V

A9

A9 Voltage –0.6 to 13.5 V

V

PP

Program Supply –0.6 to 14 V

Note: Except for the rating "Operating Temperature Range", st resses above t hose listed in t he Ta ble "Absolute Max imum R atings" may c ause

permanent damage to the device. These are stress ratings only and operation of the device at these or any other conditions above those

indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum Ratin g conditions for extended periods

may affect device reliability. Refer also to the STMicroelectronics SURE Program and other relevant quality document.

Table 2. Absol ute Maxim u m Ratin g s

DEVICE OPERATION

The six modes of operations of the M27512 are

listed in the Operating Modes table. A single 5V

power supply is required in the read mode. All

inputs are TTL levels except for

GVPP and 12V on

A9 for Electronic Signature.

Read Mode

The M27512 has two control functions, both of

which must be logically active in order to obtain

data at the outputs. Chip Enable (

E) is the power

control and should be used for device selection.

Output Enable (

G) is the output control and should

be used to gate data to the output pins, independent of device selection. Assuming that the

addresses are s table, address access time (t

AVQV

)

is equal to the delay from

E to output (t

ELQV

). Data

is available at the out puts after d elay of t

GLQV

from

the falling edge of

G, assuming that E has been low

and the addresses have been stable for at least

t

AVQ V-tGLQV

.

Stand by Mod e

The M27512 has a standby mode which reduces

the maximum active power current f rom 125m A to

40mA. The M27512 is placed in the standby mod e

by applying a TTL high signal to the

E input. Wh en

in the standby mode, the outputs are in a high

impedance state, independent of the

GVPP input.

Two Line Output Control

Because EPROM s are usually used in larger memory arrays, the product features a 2 line control

function which accommodates the use of multiple

memory connection. The two line control function

allows :

a. the lowest possible memory power dissipation,

b. complete assurance that output bus c ontent io n

will not occur.

M27512

2/11

For the most efficient us e of these two control lines,

E should be decoded and used as the primary

device selecting function, while

GVPP should be

made a common connection to all devices in the

array and connected to the

READ line from the

system control bus. This ensures that all deselected memory devices are in their low power

standby mode and that the output pins are only

active when data is r equired from a particular memory device.

System Considerati on s

The power switching characteristics of fast

EPROMs require careful decoupling of the devices.

The supply current, I

CC

, has three segments that

are of interes t to the s ystem designer : the s tandby

current level, the active c urrent level, and t ransient

current peaks that are produced by the falling and

rising edges of

E. The magnitude of the transient

current peaks is dependent on the capacitive and

inductive loading of the device at the output. The

associated transient voltage peaks can be suppressed by complying with the two line output

control and by properly selected decoupling capacitors. It is recommenced that a 1µF ceramic

capacitor be used on every device between V

CC

and VSS. This should be a high frequency capacitor

of low inherent inductance and should be placed

as close to the device as possible. In addition, a

4.7µF bulk electrolytic capacitor should be used

between V

CC

and VSS for every eight devices. Th e

bulk capacitor should be located near the power

supply connection point. The purpose of the bulk

capacitor is to overcome the voltage drop caused

by the inductive effects of PC B trac es.

Programming

When delivered, and after each erasure, all bits of

the M27512 are in the “1" stat e. Data is intr oduce d

by selectively programming ”0s" into the desired bit

locations. Although only “0s” will be programmed,

both “1s” and “0s” can be present in the dat a word.

The only way to change a “0" to a ”1" is by ultraviolet

light erasure. The M27512 is in the programming

mode when

GVPP input is at 12.5V and E is at

TTL-low. The data to be programmed is applied 8

bits in parallel to the data output pins. The levels

required for the address and data inputs are TTL.

The M27512 can us e PRESTO P rogramming Algorithm that drastically reduces the programming

time (typically less than 50 seconds). Never theless

to achieve compatibility with all programming

equipment, the standard Fast Programming Algorithm may also be used.

Fast Prog rammi ng Alg or ithm

Fast Programming Algorithm rapidly programs

M27512 EPROMs using an efficient and reliable

method suited to the production programming environment. Programming reliability is also ens ured

as the incremental program margin of each byte is

continually monitored to determine when it has

been successfully program med. A flowc hart of the

M27512 Fast Programming Algorithm is shown in

Figure 8.

Mode E GV

PP

A9 Q0 - Q7

Read V

IL

V

IL

X Data Out

Output Disable V

IL

V

IH

X Hi-Z

Program V

IL

Pulse V

PP

X Data In

Verify V

IH

V

IL

X Data Out

Program Inhibit V

IH

V

PP

X Hi-Z

Standby V

IH

X X Hi-Z

Electronic Signature V

IL

V

IL

V

ID

Codes

Note: X = VIH or VIL, VID = 12V ± 0.5%.

Table 3. Operating Modes

Identifier A0 Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 Hex Data

Manufacturer’s Code V

IL

00100000 20h

Device Code V

IH

00001101 0Dh

T a b le 4. Electro ni c Sig n atu r e

DEVICE OPERATION (cont’d)

M27512

3/11

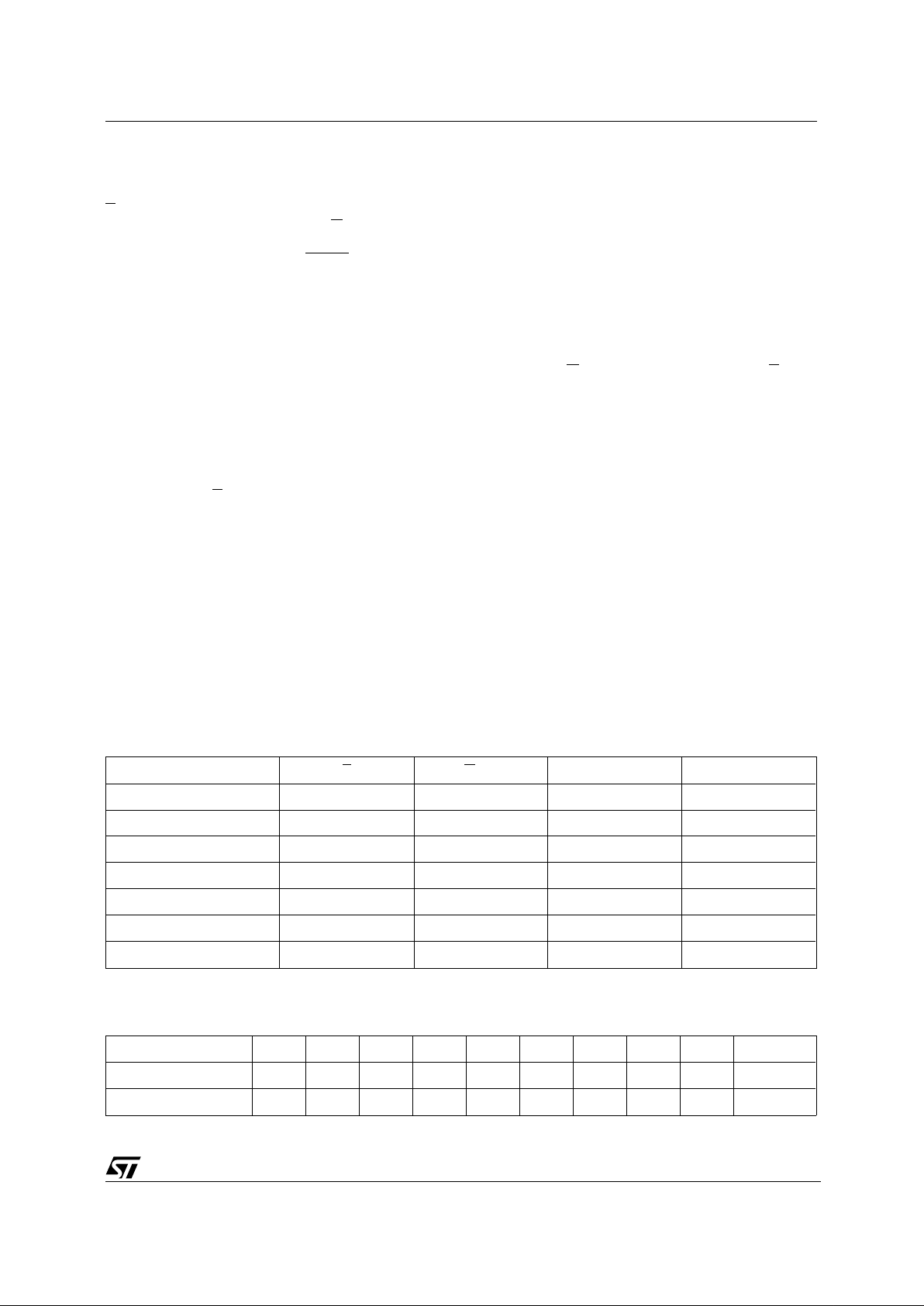

AI00827

2.4V

0.45V

2.0V

0.8V

Figure 3. AC T est ing Input Ou tput Waveform s

Input Rise and Fall Times ≤ 20ns

Input Pulse Voltages 0.45V to 2.4V

Input and Output Timing Ref. Voltages 0.8V to 2.0V

AC MEASUREMENT CONDITIONS

AI00828

1.3V

OUT

CL = 100pF

CL includes JIG capacitance

3.3kΩ

1N914

DEVICE

UNDER

TEST

Figure 4. AC Testing L oad Circui t

Note that Output Hi-Z is defined as the point where data

is no longer driven.

Symbol Parameter Test Condition Min Max Unit

C

IN

Input Capacitance VIN = 0V 6 pF

C

OUT

Output Capacitance V

OUT

= 0V 12 pF

Note: 1. Sampled only, not 100% tested.

T able 5. Capacitance

(1)

(TA = 25 °C, f = 1 MHz )

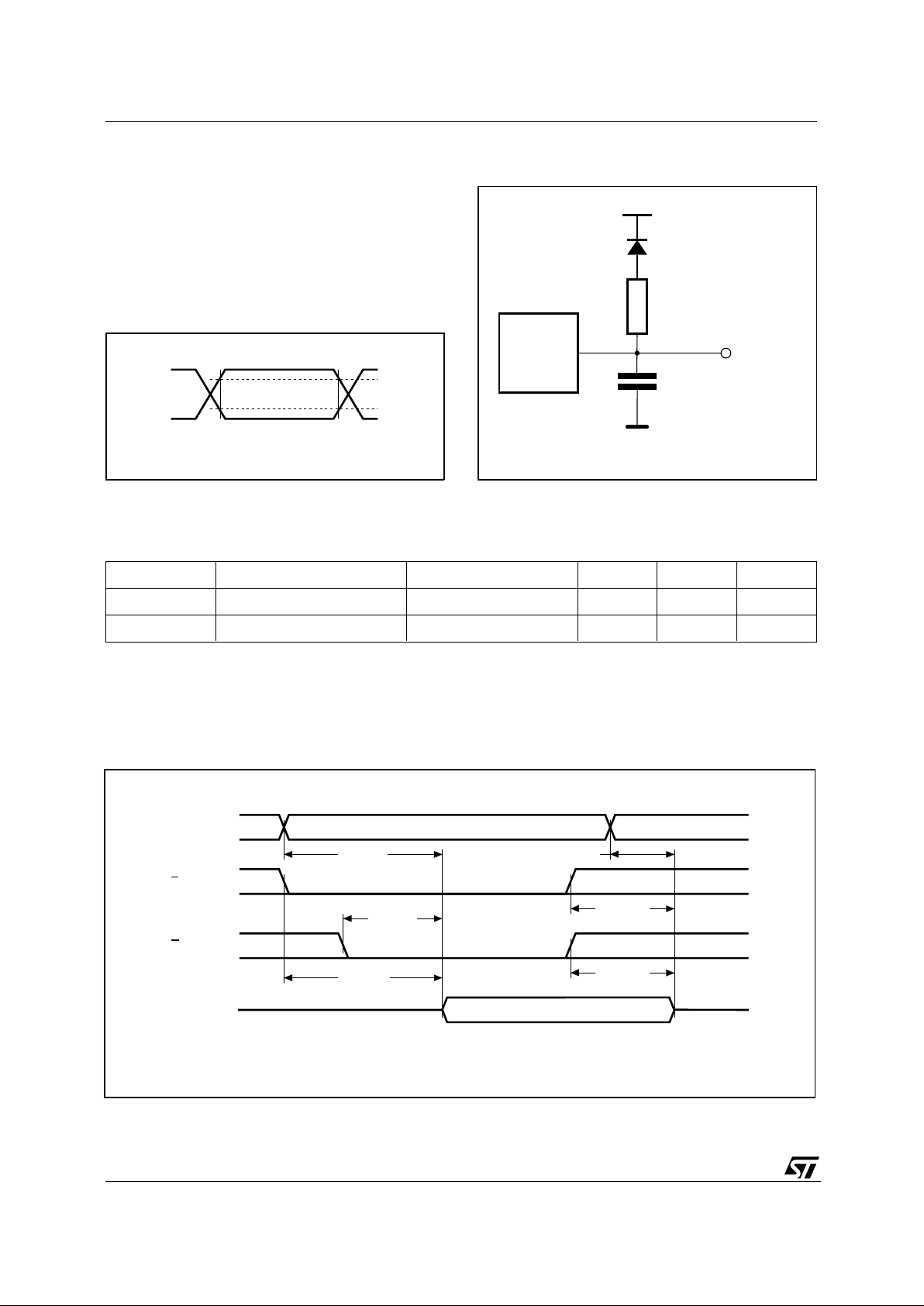

AI00735

tAXQX

tEHQZ

DATA OUT

A0-A15

E

G

Q0-Q7

tAVQV

tGHQZ

tGLQV

tELQV

VALID

Hi-Z

Figure 5. Read Mode AC Wav efo rm s

M27512

4/11

Loading...

Loading...