Page 1

SELECTABLE ICE

SV/SVi-200/250 SCI

INSTALLATION & SERVICE GUIDE

Part Number 020001172

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

August 10, 2007 REV2

Page 2

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator, service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician should perform installation and startup of this equipment, consult the

If you cannot correct the service problem, call your MBE Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

Troubleshooting Guide

within this manual for service assistance.

UNPACKING AND INSPECTION

Note: The unit was thoroughly inspected before leaving the factory. Any damage or irregularities should

be noted at the time of delivery.

WARRANTY INFORMATION

Consult your local MBE Distributor for terms and conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general adjustments, cleaning, accessories and related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory.

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Materials

Authorization (RMA). Equipment returned without an RMA will be refused at MBE’s dock and returned to

the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

Page 3

TABLE OF CONTENTS

FOREWORD ........................................................................................................ 2

UNPACKING AND INSPECTION ......................................................................... 2

WARRANTY INFORMATION ............................................................................... 2

SAFETY ............................................................................................................... 4

IMPORTANT SAFETY INSTRUCTIONS ........................................................................... 4

CARBON DIOXIDE WARNING ......................................................................................... 4

QUALIFIED SERVICE PERSONNEL ................................................................................ 4

SHIPPING, STORAGE, AND RELOCATION ..................................................................... 4

ADDITIONAL WARNINGS ................................................................................................ 4

GROUNDING INSTRUCTIONS ........................................................................................ 5

SELECTABLE ICE MODULE ............................................................................................ 6

INSTALLATION .................................................................................................... 6

OPERATION ........................................................................................................ 7

SELECTABLE ICE DISPENSING ..................................................................................... 7

RECOMMENDED ICE TYPES .......................................................................................... 7

SELECTABLE ICE CONTROL BOARD ............................................................................ 8

USER MAINTENANCE ........................................................................................ 9

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE .................................... 9

SELECTABLE ICE MODULE REMOVAL ......................................................................... 9

SELECTABLE ICE CRUSHER DISASSEMBLY................................................................ 9

HOW TO REASSEMBLE THE ICE CRUSHER ASSEMBLY ........................................... 10

CLEANING INSTRUCTIONS .......................................................................................... 12

TROUBLESHOOTING .................................................................................................... 13

EXPLODED VIEWS, PARTS & DIAGRAMS ..................................................... 14

SELECTABLE ICE 115V WIRING ................................................................................... 14

SELECTABLE ICE EXPLODED VIEW ............................................................................ 15

SELECTABLE ICE MODULE EXPLODED VIEW ............................................................ 16

SELECTABLE ICE MOTOR EXPLODED VIEW .............................................................. 17

REMOTE BOX ASSEMBLY ............................................................................................ 18

FLAVOR MAGIC/SELECTABLE ICE MODULE .............................................................. 19

INDEX................................................................................................................. 23

Page 4

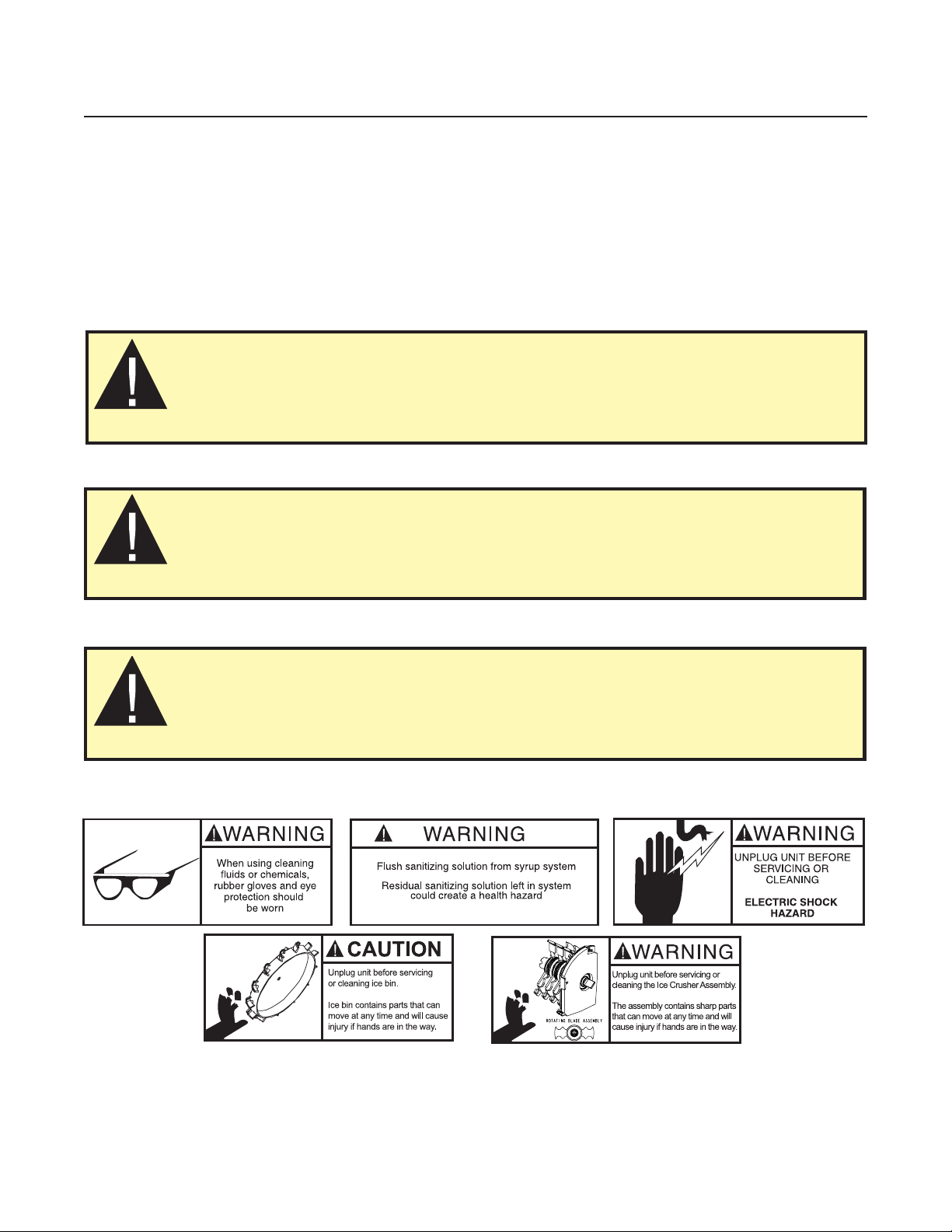

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual. Learn how to operate the Selectable Ice unit

properly. Do not allow anyone to operate the unit without proper training and keep it in proper

working condition. Unauthorized modifications to the Selectable Ice may impair function and/or

safety and affect the life of the unit.

CARBON DIOXIDE WARNING

DANGER: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas

causes tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO2 gas leak

is suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO

lines and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience stores with glass door self serve coolers. If you

suspect CO2 may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

WARNING: Only trained and certified electrical and plumbing technicians should service this unit.

All wiring and plumbing must conform to national and local codes.

2

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting

in damage to internal components.

ADDITIONAL WARNINGS

Installation and start-up of this equipment should be done by a qualified service technician. Operation,

maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

Save these instructions.

Page 5

Installation and Service Manual

SAFETY

GROUNDING INSTRUCTIONS

WARNING: Risk of electrical shock. Connect to a properly grounded outlet only.

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment grounding conductor. If repair or replacement of the cord or plug

is necessary, do not connect the equipment-grounding conductor to a live terminal. Check with a

qualified electrician or serviceman if the grounding instructions are not completely understood, or

if in doubt as to whether the appliance is properly grounded. Do not modify the plug provided with

the appliance – if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING – When using electric appliances, basic precautions should always be followed, including the following:

a)Read all the instructions before using the appliance.

b)To reduce the risk of injury, close supervision is necessary when an appliance is used

near children.

c) Do not contact moving parts.

d)Only use attachments recommended or sold by the manufacturer.

e)Do not use outdoors.

f) For a cord-connected appliance, the following shall be included:

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use and before servicing or cleaning.

• Do not operate any appliance with a damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any manner. Return appliance to the

nearest authorized service facility for examination, repair, or electrical or mechanical

adjustment.

g)For a permanently connected appliance – Turn the power switch to the off position when

the appliance is not in use and before servicing or cleaning.

h)For an appliance with a replaceable lamp – always unplug before replacing the lamp.

Replace the bulb with the same type.

i) For a grounded appliance – Connect to a properly grounded outlet only. See Grounding

Instructions.

SAVE THESE INSTRUCTIONS

5

Page 6

Installation and Service Manual

INSTALLATION

Please read installation section of the SV

Series Installation & Service Manual

to become familiar with the requirements to install an SV dispenser. The Selectable Ice dispensing system is mated to SV-200 and SV-250 model ice

and beverage Dispensers only.

SELECTABLE ICE MODULE

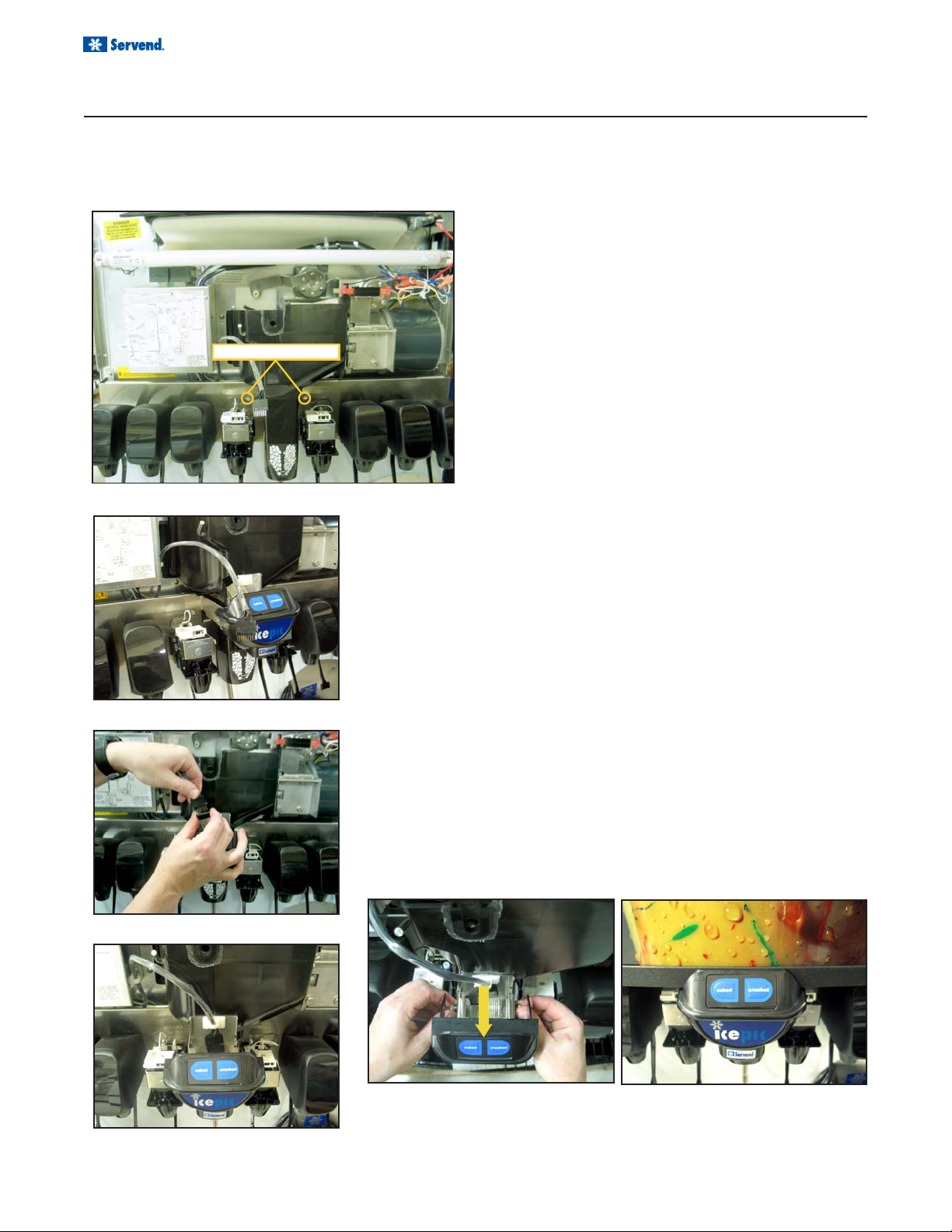

The Selectable Ice Module will not be installed on the

dispenser when unit is unboxed.

1. Locate the Selectable Ice Module box in the dispenser

bin and remove the module from the box.

2. Remove merchandiser from dispenser by taking out

the two screws located at the top of the merchandiser.

Once the screws are removed rotate the top of the

SLOTTED SCREWS

Figure 1

Figure 2

merchandiser towards you and then lift the merchandiser up to remove from unit.

3. Remove the valve covers from the two valves next to

the rocking chute. (See Figure 1)

4. Loosen the two slotted knurl screws located on the

valve mount cap. (See Figure 1)

5. Hang the Selectable Ice Module bracket over the valve

mount cap, and secure to the valve mount cap by tightening the knurl screws. (See Figure 2)

6. Connect the wiring harness to the Selectable Ice Module (Figure 3) and locate the wire harness in the plastic

clip as seen in figure 4.

7. Loosen the bracket adjustment screws and pull the

module toward you. This will allow for reinstallation of

the merchandiser. (See Figure 5)

8. Install merchandiser and adjust the Selectable Ice Module so that it is flush with the front of the merchandiser.

Tighten the adjustment screws. (See Figure 6)

If the equipment being installed has the Flavor Magic

option, follow the instructions on pages 7, 10, and 11 in

Flavor Magic manual 020001309 for installation of the

front module and the remote box. Also use manual

020001309 for programming and trouble shooting the

Flavor Magic portion of this equipment.

An exploded view and parts list for the Flavor Magic/

Selectable Ice module and Remote box are included in

the EXPLODED VIEWS, PARTS, AND DIAGRAMS

section of this manual.

Figure 3

Figure 5

Figure 4

Figure 6

6

Page 7

Installation and Service Manual

OPERATION

SELECTABLE ICE DISPENSING

The first step of selectable ice dispensing is selecting the type ice to be dispensed (Cubed or Crushed). To select the

type ice to be dispensed, press the Cubed or Crushed selection on the key pad located on the front of the dispenser.

Once a type of ice is selected the dispenser will default to that type ice until the other type ice is selected.

Crushed Ice Sequence of Operation:

The customer presses the decorative ice chute and the

microswitch initiates the crushed ice dispensing process.

When activated, the microswitch energizes a solenoid

that opens the ice crusher housing door. The micro switch

also starts the gear motor and ice crusher motor. The

gear motor turns the paddle wheel and U-bar agitator.

The paddle wheel carries ice to the crusher assembly.

Once the ice reaches the crusher housing, four stationary blades and three rotating blades crush the ice and

push it through the opening in the ice crusher housing.

The crushed ice then falls through the opening into the

decorative ice chute, and into the customer’s cup.

Cubed Ice Sequence of Operation:

The customer presses the decorative ice chute and the

microswitch initiates the cube ice dispensing process.

When activated, the microswitch energizes a solenoid

that opens the cube ice dispense door, and the agitator

motor starts. The agitator motor turns the paddle wheel

and U-bar agitator. The paddle wheel carries ice to the

cubed ice dispense point. The ice then falls through the

opening into the decorative ice chute, and into the

customer’s cup.

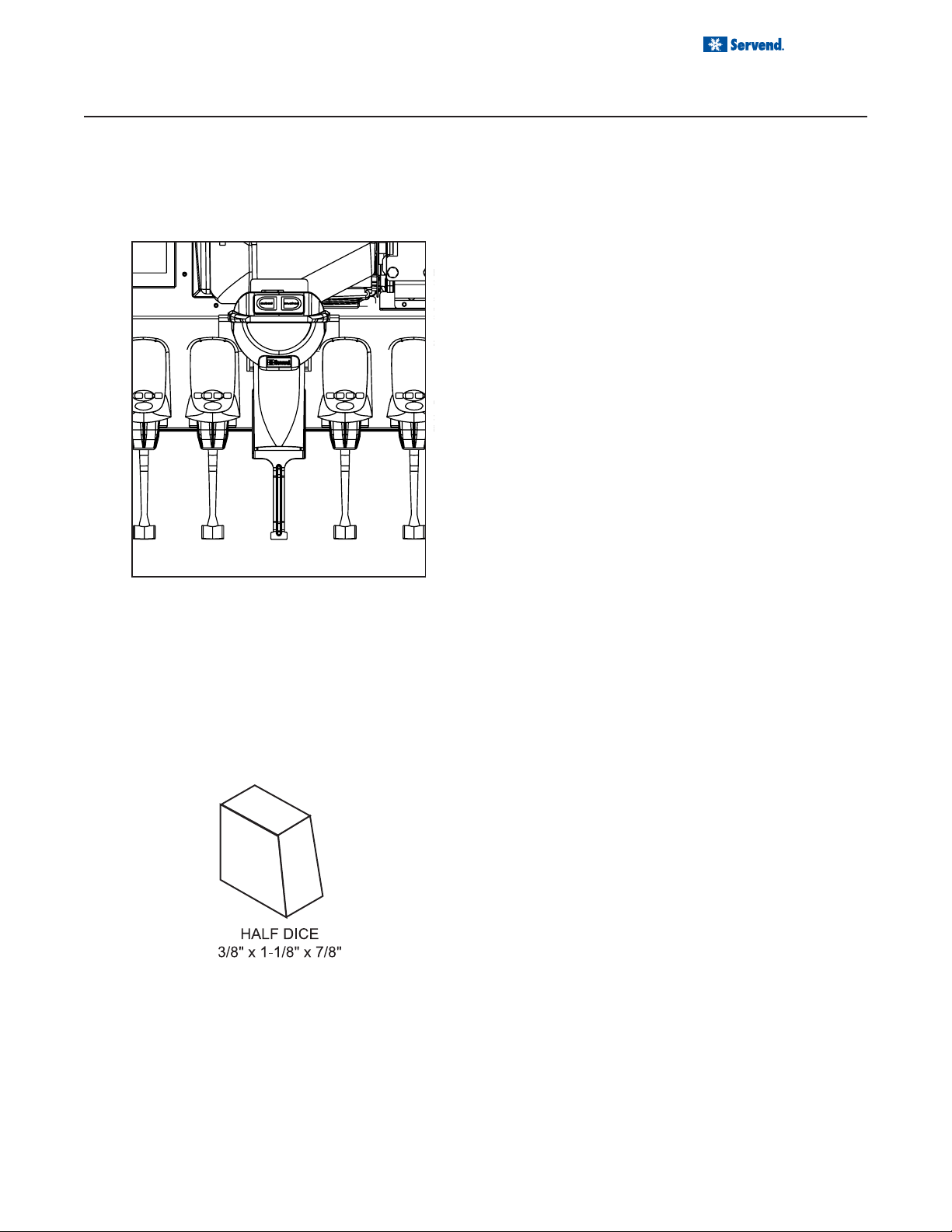

RECOMMENDED ICE TYPES

Manitowoc Half Dice Ice has been shown to give the

best performance in this dispenser. Hoshizaki America,

Inc., ice machines with crescent-style shape cubes are

not compatible with this dispenser.

Super-cooled ice is ice that has been stored below 32o F

(0o C). Super-cooled ice should be allowed to warm at

room temperature for 25 to 30 minutes before emptying

into the dispenser. Failure to do so may result in severe

damage to the dispenser.

7

Page 8

Installation and Service Manual

OPERATION

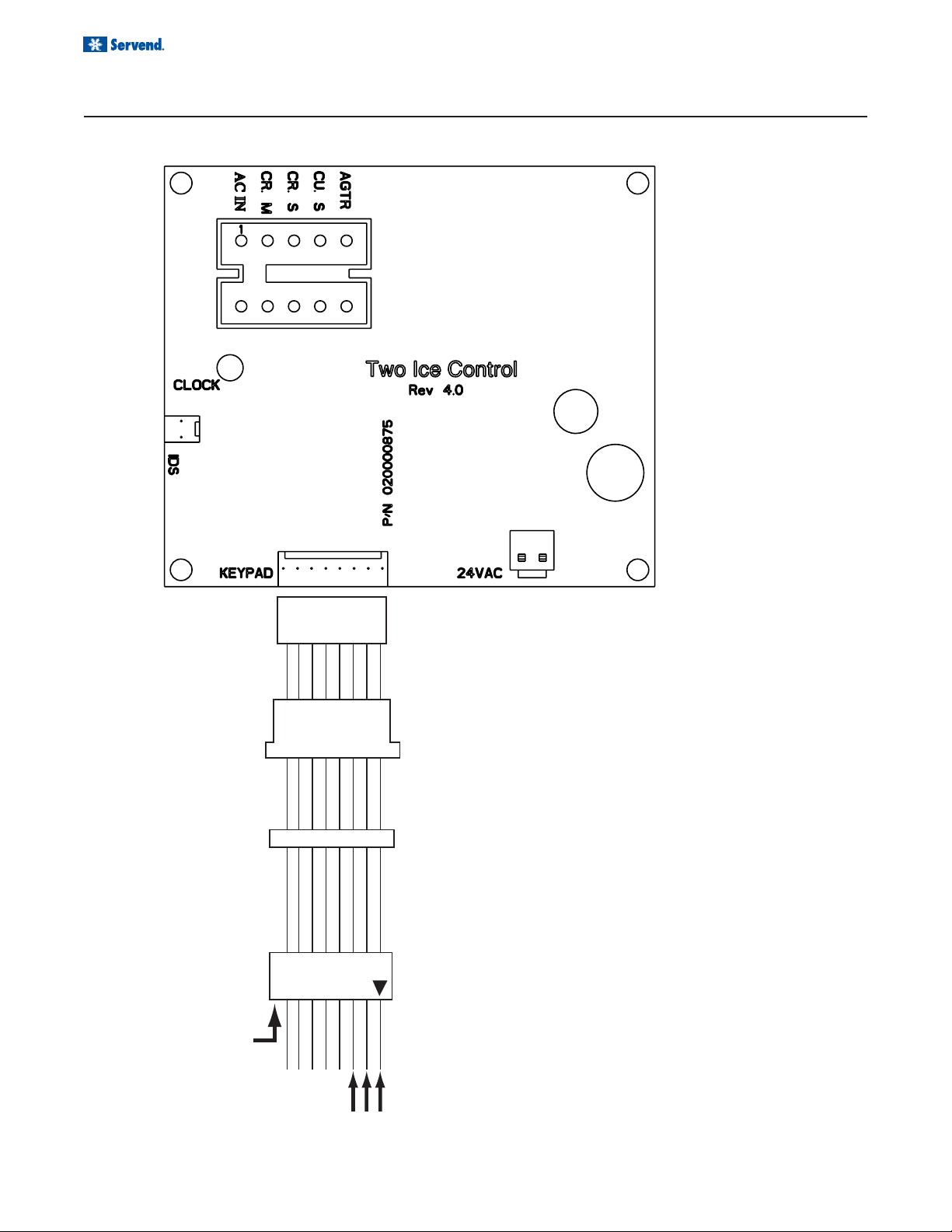

SELECTABLE ICE CONTROL BOARD

No Pin

Triangle on the harness indicates pin 1 location, pin 9

location is blank.

Continuity between pin 1&2 = cubed ice

Continuity between pin 1&3 = crushed ice

9

Pin Locations

8

321

Page 9

Installation and Service Manual

USER MAINTENANCE

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE

See cleaning section of the SV

COTTER PIN

Series User, Installation & Service Manual

bin and other components of the SV unit.

Before servicing or cleaning any part of the Selectable

Ice unit be sure to unplug it from its power source. In order to access the module and crusher you must first remove the merchandiser by taking out the two screws located at the top of the merchandiser. Once the screws

are removed, rotate the top of the merchandiser towards

you and then lift the merchandiser up to remove from unit.

Selectable Ice Module Removal

1. Loosen knurled screws.

2. Disconnect housing bracket

Selectable Ice Crusher Disassembly

1. Unplug unit before cleaning or servicing the Crusher

Assembly.

2. Remove the merchandiser by taking out the two

screws located at the top of the merchandiser. Once

the screws are removed rotate the top of the merchandiser towards you and then lift the merchandiser

up to remove from unit.

for cleaning procedures involving the

SOLENOID

ARM

HOUSING

DOOR

DRIP PAN

CHUTE ROD

DECORATIVE

CHUTE

Note: When the Merchandiser is removed an elec-

trical safety switch disconnects power to the

Ice Crusher assembly.

3. Remove the Ice Chute by pulling the cotter pin out

on the right side of the chute rod and pulling the

chute rod toward the left side of the dispenser.

4. Remove the crushed ice and cube ice doors from

the dispenser by lifting the solenoid arms up and

pushing the doors back to disengage the door from

the solenoid arms.

5. Remove the Crusher Drip Pan by pulling it forward.

MOTOR MOUNT

HOUSING MOUNT

9

Page 10

Installation and Service Manual

HOW TO DISASSEMBLE FOR CLEANING OR MAINTENANCE

CRUSHER HOUSING

LOCKING TAB

HUB/BLADE

ASSEMBLY

CRUSHER HOUSING

USER MAINTENANCE

6. See the following steps to remove the ice crusher

blade assembly from the crusher housing.

A. Unlock the Crusher Hub/Blade assembly from

the Crusher Housing by pushing locking tab in,

and rotating the Hub/Blade assembly clockwise.

B. Pull the Hub/Blade assembly out of the hous-

ing approx. ½” to disengage the Crusher Axle

from the motor shaft.

C. Rotate the knob on the Crusher Axle so it is in a

vertical position. (This will assure the rotating

blades will not interfere with pulling the Hub/Blade

assembly from the housing.)

D. Now the Hub/Blade assembly will be free from

the housing and you will be able to completely

remove the Hub/Blade assembly from unit.

HUB/BLADE

ASSEMBLY

AXLE KNOB

HOW TO REASSEMBLE THE ICE CRUSHER ASSEMBLY

STATIONARY BLADES

AXLE KNOB

CRUSHER HOUSING

1. Insert the Hub/Blade assembly into the Ice Crusher

Housing. When inserting the Hub/Blade assembly you

must align the Stationary blades with the locating slots

in the Ice Crusher Housing.

2. When inserting the Hub/Blade assembly into the Ice

Crusher Housing you must also make sure the Axle

Knob is in a vertical position. This will align the rotating

blades with the Housing to assure a quick and easy

installation.

10

HUB/BLADE ASSEMBLY

Page 11

LOCKING TAB

HUB/BLADE

ASSEMBLY

Installation and Service Manual

USER MAINTENANCE

HOW TO REASSEMBLE THE ICE CRUSHER ASSEMBLY

3. Once all blades are in the Crusher Housing you will need

to align the Crusher Axle with the motor shaft. You can

do this by turning the Axle Knob and pushing the blade

assembly toward the motor until the Hub/Blade assembly is flush with the end of the Crusher Housing.

4. To lock the Hub/Blade assembly into the housing, rotate the Crusher Hub/Blade assembly counter clockwise until the locking tab snaps into place and the

Crusher Hub/Blade assembly is secure.

5. Replace the Crusher Drip Pan.

6. Reattach the Decorative Ice Chute by inserting the chute

rod through the Decorative Chute, Housing Mount, and

Motor Mount. Secure the Chute Rod by inserting the

cotter pin through the rod on the right side of the chute.

7. Ensure the extension at the top of the Decorative

Chute is behind the arm of the Activation Switch.

DRIP PAN

MOTOR MOUNT

HOUSING MOUNT

COTTER PIN

CHUTE ROD

DECORATIVE

CHUTE

11

Page 12

Installation and Service Manual

USER MAINTENANCE

CLEANING INSTRUCTIONS

Clean and sanitize unit according to the directions in the cleaning section of the

Manual

CRUSHER HOUSING

HUB/BLADE

ASSEMBLY

. Clean and sanitize the Selectable Ice components according to the following instructions.

1. Mix a solution of mild detergent to clean the Select-

HOUSING DOOR

DRIP PAN

DECORATIVE CHUTE

SANITARY LEVER

able Ice components. Using the detergent solution

and a soft bristle brush or clean cloth, clean the following components:

• Decorative Chute

• Housing

• Housing Door

• Sanitary Lever

• Hub/Blade Assembly

• Drip Pan

2. Rinse all parts in clean running water.

3. Mix a sanitizing solution of ¼ oz liquid, unscented

bleach (5.25% CL NaO concentration) for each gallon

of water. Mixture should provide 100 ppm available

chlorine.

4. Using the sanitizing solution, soft bristle brushes, or a

clean cloth, sanitize the components listed in step 1.

The ice storage chamber should be sanitized with a

soft bristle brush to adequately clean the metering

wheel slot and drainage area.

5. Reverse the procedure to reassemble the Selectable

Ice mechanism.

6. Reconnect power to unit.

7. Check for proper operation.

SV Installation & Service

12

Page 13

Installation and Service Manual

USER MAINTENANCE

TROUBLESHOOTING

This section is for troubleshooting the Selectable Ice dispensing system. Any problems with the base SV unit

should be diagnosed with Troublshooting section of the

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

SV Series User, Installation & Service Manual

.

Dispenser does not

dispense crushed ice.

1) Nothing is heard.

2) Crusher motor hums but

does not turn.

3) Crusher dispense door

does not open.

4) Gear box on motor a. Gear box on motor faulty.

5) Crusher Motor turns but Gear

Motor for Paddlewheel/Agitator

Bar does not turn.

a. No power to dispenser

b. Loose wiring

c. Dispense switch faulty

d. Crusher Moto r Faulty.

e. Dispenser Safety Switch Open.

a. Blades obstructed.

b. Motor faulty

c. Faulty start relay/capacitor

a. Door sole noi d faulty

b. Loose wiring to solenoid

b. Crusher Axle broken

a. Agitator Gear Motor faulty.

b. Loose wiring.

a. Check power source and power cord.

b. Check wiring

c. Replace switch

d. Replace Motor/Gear Box

e. Assure Merchandiser is installed correctly

with the safety switch in the closed position.

a. Check for obstructions in ice crusher

housing.

b. Replace Motor

c. Check relay/capacitor and replace if bad.

a. Replace Solenoid

b. Check wiring

a. Replace Ice Crusher Motor Assembly

b. Replace Crusher Axle

a. Replace Agitator Gear Motor.

b. Check wiring

Nothing on dispenser

works.

Difficulty inserting

Blade/Hub Assembly into

Crusher housing

Crushed Ice dispenses

continuously, or by itself.

No flashing lights on

keypad, Fluorescent light

was on, crusher and

whole ice dispenser will

not function, transformer

breaker blown.

c. Obstruction in Ice bin stopping motor

a. No power to dispenser Check power source

b. Dispenser Safety Switch opens. Assure Merchandiser is installed correctly with

c. Loose wiring Check wiring.

a. Stationary Blades not aligned with

locating slots at top and bottom of

crushe r ho usi ng

b. Rotating Blades not in vertical

position.

c. Check for ice in Crusher Housing.

Ice Dispense Switch Faulty Replace the Ice dispense switch.

Water shorted out wiring harness on

valves only.

c. Check for obstruction.

the safety switch in the closed position.

See "How to Disassemble for Maintenance"

section in this manual.

Clean up water and reset transformer.

13

Page 14

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

SELECTABLE ICE 115V WIRING

Below are instructions for testing the timed agitation on the SI unit:

14

Page 15

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

SELECTABLE ICE EXPLODED VIEW

NO. Part# Description

1 00212539 STANDOFF 7/16 HIGH

2 1001005 STARTER LEV FS2

3 1001006 STARTER BASE

4 5008229 TRANSFORMER 75VA 120V W/BREAKER

5 5008644 BALLAST 115/60

6 5012374 CLIP HITCH PIN

7 5031408 BLADE / HUB

8 5031515 CAPACITOR CRUSHER

9 5031516 BRACKET CAPACITOR MTR ED-8110-1

10 5031518 RELAY MOTOR ED-8110-1

11 020000201 CAP CAPACITOR MOTOR

12 020000592 MERCH BOTTOM W/ LENS

13 020000867 PADDLE WHEEL AREA

14 020000874 DOOR WHOLE ICE

15 020000875 CONTROL BOARD 120V

16 020000879 DOOR CRUSHED ICE

17 020000914 CHUTE DECORATIVE

18 020000951 SOLENOID ASSY

19 020000952 ROD SELECTABLE ICE

NO. Part# Description

20 020000993 CHANNEL MOTOR MOUNT

21 020001001 LEVER RC NARROW SHORT

22 020001025 LABEL WIRING 115/60

23 020001026 HOUSING

24 020001046 BOX ELECTRICAL

25 020001047 COVER BOX ELECTRICAL

26 020001072 MODULE SELECTABLE ICE

27 020001140 MICROSWITCH SAFETY

28 020001141 MOTOR SCI

29 020001285 WIRE WRAP

30 020001361 DRIPPAN

— 020000335 HARNESS ACTIVATION SWITCH

— 020000336 HARNESS KEYPAD

— 020000337 HARNESS TRANSFORMER

— 020000338 HARNESS CONTROL BOARD

15

Page 16

EXPLODED VIEWS, PARTS & DIAGRAMS

SELECTABLE ICE MODULE EXPLODED VIEW

Page 17

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

SELECTABLE ICE MOTOR EXPLODED VIEW

NO. Part# Description

1 00850705 NUT 10-32 HEX W/LOCK

2 0900901 SCR 6-32 X 1" SS PH RHMS

3 0901904 WASHER LOCK 1/4IN SS

4 0901915 WASHER STAR #8 SS

5 0902304 SCR 6-32 ESNA SS

6 1000703 MICROSWITCH

7 5007377 BOLT 1/4-20 ESNA SS

8 5012081 SCR 8-32 x 1/4" PH PS

9 5031264 MOUNT MOTOR

10 5031267 GASKET MOTOR

11 5031281 MOUNT HOUSING

12 5031369 MOTOR ED-8110-1

13 5031370 SOLENOID ROTARY

14 5031615 ARM SOLENOID ROTARY

15 5031835 BRACKET MICROSWITCH EXT

17

Page 18

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

REMOTE BOX ASSEMBLY

NO. Part# Description

1 202-FN-D22 VLV ELEC PL BLK

2 00212539 STANDOFF 7/16 HIGH

3 5011940 SCREW 8-32 X 1/2

4 5030437 BOARD CTRL 4 FLAVOR FM

5 5030441 HARNESS 2VLV FM

6 020000500 CVR FM ELEC BOX

7 020000501 HOUSING FM ELEC BOX

8 020000512 MNT FM CIRCUIT BOARD

9 020000586 HARNESS CTRL BRD POL FM INT

10 020000589 HARNESS POWER 24V FM

11 020001297 CORD GRIP

12 020001303 Tubing 1/4 x 12FT

18

Page 19

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

FLAVOR MAGIC/SELECTABLE ICE MODULE

NO. Part# Description

1 501-25 NOZZLE SOFTPOUR BLK

2 850350 FLAT WASHER .219ID X .500OD .502

3 905403 CLIP PLASTIC WIRE & CORD

4 5012790 SCR 10-32X1/2 KNURL UNSLT

5 5029806 RIVNUT 10-32

6 5030446 TUBING 1/4 X 4 FT

7 5031193 KEYPAD 4 BUTTON FM

8 5031453 RETAINER QUAD TUBE FM

9 O20000473 COVER FRONT FM ICEPIC

10 O20000493 COVER REAR FM ICEPIC

11 O20000846 BRACKET MOUNTING CENTER

12 O20000876 KEYPAD SELECTABLE ICE

13 O20001034 LABEL LOGO SERVEND HORZ

14 O20001153 BRACKET WELDED FM

19

Page 20

Page 21

Page 22

Page 23

INDEX

B

brixing ....................................... 2

C

Carbon Dioxide ......................... 4

Cleaning .................................... 2

CO2 ........................................... 5

CO2 monitors ............................ 5

D

damage ..................................... 2

delivery ...................................... 2

distributor .................................. 2

F

FOREWORD ............................ 2

I

INSPECTION ............................ 2

INSTALLATION ......................... 6

Installation Date ........................ 2

irregularities .............................. 2

M

MBE .......................................... 2

Model Number .......................... 2

modifications ............................. 4

O

Operation .................................. 4

Q

Qualified Service Personnel ..... 4

R

Relocation ................................. 4

return procedures ..................... 2

S

SAFETY ............................... 4, 5

sanitizing ................................... 5

Serial Number ........................... 2

service assistance .................... 2

Service Personnel ..................... 4

Shipping .................................... 4

Shipping, Storage, Relocation .. 4

start-up ...................................... 4

Storage ..................................... 4

U

UNPACKING ............................. 2

W

Warning ..................................... 4

WARRANTY INFORMATION ... 2

water-to-syrup ratio.

See

brixing

Page 24

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

020001172 August 10, 2007 REV2

Loading...

Loading...