1st PRINTING NOV 01

www.seuservice.com

OWNER’S MANUAL

SEGA ENTERPRISES, INC. USA

MANUAL NO. 999-1375

VISIT OUR WEBSITE!

BEFORE USING THE PRODUCT, BE SURE TO READ THE FOLLOWING:

To maintain the safety:

To ensure the safe usage of the product, be sure to read the following before using the product. The following

instructions are intended for the users, operators and the personnel in charge of the operation of the product.

After carefully reading and sufficiently understanding the warning displays and cautions, handle the product

appropriately. Be sure to keep this manual nearby the product or elsewhere convenient for referring to it

when necessary.

Herein, explanations which require special attention are enclosed with dual lines. Depending on the potentially hazardous degrees, the terms of WARNING, CAUTION, etc. are used. Be sure to understand the

contents of the displays before reading the text.

Indicates that mishandling the

product by disregarding this

warning will cause a potentially

hazardous situation which can

result in death or serious injury.

For the sage usage of the product, the following pictographs are used:

Indicates “HANDLE WITH CARE.” In order to protect the human body an equipment, this

display is attached to places where the Owner’s Manual and or Service Manual should be referred

to.

Perform work in accordance with the instructions herein stated.

Instructions for work are explained by paying attention to the aspect of accident prevention. Failing to

perform work as per the instructions can cause accidents. In the case where only those who have technical expertise should perform the work to avoid hazardous situation, the instructions herein state that the

serviceman should perform such work.

Be sure to turn off power before working on the machine.

To prevent electric shock, be sure to turn off power before starting the work in which the worker touches

the interior of the product. If the work is to be performed in the power-on status, the Instruction Manual

herein always states to that effect.

Indicates that mishandling the product

by disregarding this caution will cause

a slight hazardous situation which can

result in personal injury and or material

damage.

Be sure to ground the Earth Terminal (this, however, is not required in the case where a power cord

with earth is used).

This product is equipped with the Earth Terminal. When installing the product, Connect the Earth Terminal to the “accurately grounded indoor earth terminal” by using an earth wire. Unless the product is

grounded appropriately, the user can be subject to electric shock. After performing repair, etc. for the

Control equipment, ensure that the Earth Wire is firmly connected to the Control equipment.

Ensure that the Power Supply used is equipped with an Earth Leakage Breaker.

This product does not incorporate the Earth Leakage Breaker. Using a power supply which is not

equipped with the Earth Leakage Breaker can cause a fire when earth leakage occurs.

Be sure to use fuses which meet the specified rating. (only for the machines which use fuses).

Using fuses exceeding the specified rating can cause a fire and electric shock.

Specification changes (removal of equipment, conversion and addition) not designated by SEGA

are not allowed.

The parts of the product include warning labels for safety, covers for personal protection, etc. It is very

hazardous to operate the product by removing parts and or modifying the circuits. Should doors, lids

and protective parts be damaged or lost, refrain from operating the product, and contact where the

product was purchased from or the office herein stated. SEGA shall not be held responsible for any

accidents, compensation for damage to a third party, resulting from the specifications not designated by

SEGA.

Ensure that the product meets the requirements of appropriate Electrical Specifications.

Before installing the product, check for Electrical Specifications. SEGA products have a nameplate on

which Electrical Specifications are described. Ensure that the product is compatible with the power

supply voltage and frequency requirements of the location. Using any Electrical Specifications different

from the designated Specifications can cause a fire and electric shock.

Install and operate the product in places where appropriate lighting is available, allowing warning

labels to be clearly read.

To ensure safety for the customers, labels and printed instructions describing potentially hazardous

situation are applied to places where accidents can be caused. Ensure that where the product is operated

has sufficient lighting allowing the warnings to be read. If any label is peeled off, apply it again immediately. Please place an order with where the product was purchased from or the office herein stated.

When handling the Monitor, be very careful. (Applies only to the product w/monitor.)

Some of the monitor (TV) parts are subject to high tension voltage. Even after running off power, some

portions are still subject to high tension voltage sometimes. Monitor repair and replacement should be

performed only be those technical personnel who have knowledge of electricity and technical expertise.

Be sure to adjust the monitor (projector) properly. (Applies only to the product w/monitor.)

Do not operate the product leaving on-screen flickering or blurring as it is. Using the product with the

monitor not properly adjusted may cause dizziness or a headache to an operator, a player, or the customers.

When transporting or reselling this product, be sure to attach this manual to the product.

In the case where commercially available monitors and printers are used in this product, only the

contents relating to this product are explained herein. Some commercially available equipment has

functions and reactions not stated in this manual. Read this manual together with the specific Instruction Manual of such equipment.

•

Descriptions herein contained may be subject to improvement changes without notice.

•

The contents described herein are fully prepared with due care. However, should any question arise or

errors be found, please contact SEGA.

INSPECTIONS IMMEDIATELY AFTER TRANSPORTING THE PRODUCT TO THE LOCATION.

Normally, at the time of shipment, SEGA products are in a status allowing for usage immediately after

transporting to the location. Nevertheless, an irregular situation may occur during transportation. Before

turning on power, check the following points to ensure that the product has been transported in a satisfactory status.

Are there any dented portions or defects (cuts, etc.) on the external surfaces of the cabinet?

Are Casters and Adjusters, damaged?

Do the power supply voltage and frequency requirements meet with those of the location?

Are all wiring connectors correctly and securely connected? Unless connected in the correct direction,

connector connections can not be made accurately. Do not insert connectors forcibly.

Do power cords have cuts and dents?

Do the fuses used meet specified rating? Is the Circuit Protector in an energized status?

Are all accessories available?

Can all Doors and Lids be opened with the Accessory keys? Can Doors and Lids be firmly closed?

TABLE OF CONTENTS

BEFORE USING THE PRODUCT, BE SURE TO READ THE FOLLOWING:

TABLE OF CONTENTS

INTRODUCTION OF THE OWNER'S MANUAL

1. HANDLING PRECAUTIONS ......................................................................................1

2. PRECAUTIONS CONCERNING INSTALLATION LOCATION ..............................3

3. OPERATION .................................................................................................................5

4. NAME OF PARTS .......................................................................................................10

5. ACCESSORIES ...........................................................................................................11

6. ASSEMBLING AND INSTALLATION ..................................................................... 16

7. PRECAUTIONS TO BE HEEDED WHEN MOVING THE MACHINE .................. 29

8. CONTENTS OF GAME .............................................................................................. 31

9. EXPLANATION OF TEST AND DATA DISPLAY..................................................38

9 - 1 SWITCH UNIT AND COIN METER ................................................................39

9 - 2 SYSTEM TEST MODE ...................................................................................... 41

9 - 3 GAME TEST MODE .......................................................................................... 40

10. AIR DRIVE ..................................................................................................................57

10 - 1 OVERVIEW OF AIR DRIVE SYSTEM ...........................................................58

10 - 2 DEWATERING FROM THE AIR FILTER .......................................................59

10 - 3 DEWATERING FROM THE AIR TANK .........................................................60

10 - 4 REGULATOR.....................................................................................................61

10 - 5 AIR CLEANER ..................................................................................................62

11. MAINTENANCE OF MECHANISM UNIT ............................................................... 63

11 - 1 REMOVE THE LID & THE BELLOWS

BEFORE SARTING MAINTENANCE WORK ................................................64

11 - 2 GREASING AND RETIGHTENING THE BOLTS ..........................................69

11 - 3 ADJUSTMENT AND REPLACEMENT OF PITCH VOLUME ......................71

11 - 4 REMOVE THE INCLINATION SENSOR ........................................................72

12. HANDLE MECHANISM ............................................................................................ 74

12 - 1 ADJUSTING AND REPLACING THE THROTTLE V.R. ............................... 74

12 - 2 ADJUSTING OR REPLACING THE HANDLE V.R. ......................................77

12 - 3 GREASING.........................................................................................................79

13. COIN SELECTOR .......................................................................................................80

14. PROJECTOR ................................................................................................................ 84

14 - 1 CLEANING THE SCREEN ............................................................................... 84

14 - 2 ADJUSTMENT OF TOSHIBA PROJECTOR ................................................... 85

15. REPLACEMENT OF FLUORESCENT LAMP..........................................................95

16. PERIODIC INSPECTION TABLE .............................................................................96

17. TROUBLESHOOTING ............................................................................................... 97

17 - 1 TROUBLESHOOTING ......................................................................................97

17 - 2 ERROR MESSAGE .......................................................................................... 101

18. GAME BOARD ......................................................................................................... 103

18 - 1 REMOVING THE GAME BOARD ................................................................. 103

18 - 2 COMPOSITION OF GAME BOARD..............................................................105

19. DESIGN RELATED PARTS ..................................................................................... 106

20. COMMUNICATION PLAY ......................................................................................109

20 - 1 INSTALLATION PRECAUTIONS ................................................................109

20 - 2 CONNECTING THE COMMUNICATION CABLE .....................................110

20 - 3 SETTING FOR COMMUNICATION PLAY .................................................114

20 - 4 CAUTIONS TO BE HEEDED DURING COMMUNICATION PLAY ........ 115

21. PARTS LIST .............................................................................................................. 116

22. WIRE COLOR CODE TABLE..................................................................................171

23. WIRING DIAGRAM ................................................................................................. XX

24. PIPING DIAGRAM ................................................................................................... XX

SPECIFICATIONS

Installation space : 56in [1,435 mm] (W) X 123in[3120 mm] (D)

Height : 87.4 in. [2,220 mm]

Weight : 1,194 lbs. [543 kg.]

Power, maximum current : 1,250 W 11.5 A (AC 120V 60 Hz AREA)

1,150 W 6.4 A (AC 220V 50 Hz AREA)

1,240 W 7.0 A (AC 220V 60 Hz AREA)

1,150 W 5.8 A (AC 230V 50 Hz AREA)

1,140 W 5.6 A (AC 240V 50 Hz AREA)

For TAIWAN

Power, current : 1,250 W 12.5 A (MAX.)

750 W 7.0 A (MIN.)

MONITOR : 50 TYPE PROJECTION DISPLAY

INTRODUCTION OF THE OWNER'S MANUAL

This Owner's Manual is intended to provide detailed descriptions together with all the

necessary information covering the general operation of electronic assemblies,

electromechanicals, servicing control, spare parts, etc. as regards the product,

WAVERUNNER GP.

This manual is intended for the owners, personnel and managers in charge of operation

of the product. Operate the product after carefully reading and sufficiently

understanding the instructions. If the product fails to function satisfactorily, nontechnical personnel should under no circumstances touch the internal system. Should

any malfunctioning occur, turn the power off and unplug the Power Cord (AC Cable),

and contact where the product was purchased from.

Use of this product is unlikely to cause physical injuries or damages to property. However,

where special attention is required this is indicated by a thick line, the word "IMPORTANT"

and its sign in this manual.

Indicates that mishandling the product by disregarding this display can cause the

product's intrinsic performance not to be obtained, resulting in malfunctioning.

SEGA ENTERPRISES, INC. (U.S.A.)/CUSTOMER SERVICE

45133 Industrial Drive, Fremont, California 94538, U.S.A.

Phone: (415) 701-6580

Facsimile: (415) 701-6594

DEFINITION OF LOCATION'S MAINTENANCE MAN AND SERVICEMAN

Non-technical personnel who do not have technical knowledge and expertise

should refrain from performing such work that this manual requires the location's

maintenance man or a serviceman to carry out, or work which is not explained in

this manual. Failing to comply with this instruction can cause a severe accident

such as electric shock.

Ensure that parts replacement, servicing & inspections, and troubleshooting are performed by the

location's maintenance man or the serviceman. It is instructed herein that particularly hazardous

work should be performed by the serviceman who has technical expertise and knowledge.

The location's maintenance man and serviceman are herein defined as follows:

"Location's Maintenance Man" :

Those who have experience in the maintenance of amusement equipment and vending machines,

etc., and also participate in the servicing and control of the equipment through such routine work

as equipment assembly and installation, servicing and inspections, replacement of units and

consumables, etc. within the Amusement Facilities and or locations under the management of the

Owner and Owner's Operators of the product.

Activities of Location's Maintenance Man :

Assembly & installation, servicing & inspections, and replacement of units & consumables as

regards amusement equipment, vending machines, etc.

Serviceman :

Those who participate in the designing, manufacturing, inspections and maintenance service of

the equipment at an amusement equipment manufacturer.

Those who have technical expertise equivalent to that of technical high school graduates as regards electricity, electronics and or mechanical engineering, and daily take part in the servicing &

control and repair of amusement equipment.

Serviceman's Activities :

Assembly & installation and repair & adjustments of electrical, electronic and mechanical parts of

amusement equipment and vending machines.

General Precautions

Follow Instructions: All operating and use instructions should be followed.

Attachments: Do not use attachments not recommended by the product manufacturer as they may cause hazards.

Accessories: Do not place this product on an unstable cart, stand, tripod, bracket, or table. The product may fall,

causing serious injury to a child or adult, and serious damage to the product. Use only with a cart, stand, tripod, bracket, or

table recommended by the manufacturer, or sold with the product. Any mounting of the product should follow the

manufacturer’s instructions, and should use only mounting accessories recommended by the manufacturer.

Moving the Product: This product should be moved with care. Quick stops, excessive force, and uneven surfaces

may cause the product to overturn.

Ventilation: Slots and openings in the cabinet are provided for ventilation, to ensure reliable operation of the product

and to protect it from overheating; these openings must not be blocked or covered. The openings should never be blocked

by placing the product in a built-in installation such as a bookcase or rack unless proper ventilation is provided or the

manufacturer’s instructions have been adhered to.

Power Sources: This product should be operated only from the type of power source indicated on the marking label.

If you are not sure of the type of power supply to your location, consult your local power company. For products intended

to operate from battery power or other sources, refer to the operating instructions.

Grounding or Polarization: This product is equipped with a three-wire grounding-type plug, a plug having a third

(grounding) pin. This plug will only fit into a grounding-type power outlet. This is a safety feature. If you are unable to

insert the plug into the outlet, contact your electrician to replace your obsolete outlet. Do not defeat the safety purpose of the

grounding-type plug.

Power Cord Protection: Power-supply cords should be routed so that they are not likely to be walked on or pinched

by items placed upon or against them, paying particular attention to cords at plugs, convenience receptacles, and the point

where they exit from the product.

Overloading: Do not overload wall outlets, extension cords, or integral convenience receptacles as this can result in

a risk of fire or electric shock.

Object and Liquid Entry: Never push objects of any kind into this product through openings as they may touch

dangerous voltage points or short-out parts that could result in a fire or electric shock. Never spill liquid of any kind on the

product.

Servicing: Do not attempt to service this product yourself as opening or removing covers may expose you to danger-

ous voltage or other hazards. Refer all servicing to qualified service personnel.

Damage Requiring Service: Unplug this product from the wall outlet and refer servicing to qualified service person-

nel under the following conditions:

a) If the power cord or plug is damaged;

b) If liquid has been spilled, or objects have fallen into the product;

c) If the product has been exposed to rain or water;

d) If the product does not operate normally when following the operating instructions. Adjust only those controls that

are explained in the operating instructions. An improper adjustment of other controls may result in damage and will

often require extensive work by a qualified technician to restore the product to its normal operation;

e) If the product has been dropped or damaged in any way;

f) When the product exhibits a distinct change in performance; this indicates a need for service.

Replacement Parts: When replacement parts are required, be sure the service technician has used replacements parts

specified by the manufacturer or that have the same characteristics as the original part. Unauthorized substitutions may

result in fire, electric shock, or other hazards.

Safety Check: Upon completion of any service or repairs to this product, ask the service technician to perform safety

checks to determine that the product is in proper operating condition.

Heat: The product should be situated away from heat sources such as radiators, heat registers, stoves, or other prod-

ucts (including amplifiers) that produce heat.

Lithium Battery- Dispose of batteries only in accordance with the battery manufacturer’s recommendations.

Do not dispose in an open flame condition, since the battery may explode.

Cleaning: When cleaning the monitor glass, use water or glass cleaner and a soft cloth. Do not apply chemicals such

as benzine, thinner, etc.

Location: This an indoor game machine, DO NOT install it outside. To ensure proper usage, avoid installing indoors

in the places mentioned below:

• Places subject to rain/water leakage, or condensation due to humidity;

• In close proximity to a potential wet area;

• Locations receiving direct sunlight;

• Places close to heating units or hot air;

•In the vicinity of highly inflammable/volatile chemicals or hazardous matter;

• On sloped surfaces;

• In the vicinity of emergency response facilities such as fire exits and fire extinguishers;

• Places subject to any type of violent impact;

• Dusty places.

I

NSTALLATION PRECAUTIONS

• Verify the amperage of the branch circuit outlet before plugging in the power plug. Do not over-

load the circuit.

• Avoid using an extension cord. If one is required, use an extension cord of type SJT, 16/3 AWG

rated min. 120 VAC, 7A.

• Moving this unit requires a minimum clearance (of doors, etc.) of 32” (W) by 77” (H).

• For the operation of this machine, secure a minimum area of 64” (W) by 97”(D).

REGULATORY APPROVALS

This game has been tested and found to comply with the Federal Communications Commission Rules.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including interference

that may cause undesired operation.

This game has been tested and listed by Underwriters Laboratories, Inc., to ANSI/UL22.

LISTED

U

®

L

5K92

AMUSEMENT MACHINE

1. HANDLING PRECAUTIONS

When installing or inspecting the machine, be very careful of the following points and pay

attention to ensure that the player can enjoy the game safely.

Non-compliance with the following points or inappropriate handling running counter to the

cautionary matters herein stated can cause personal injury or damage to the machine.

Before performing work, be sure to turn power off. Performing the work

without turning power off can cause an electric shock or short circuit. In the

case work should be performed in the status of power on, this manual always

states to that effect.

To avoid electric shock or short circuit, do not plug in or unplug quickly.

To avoid electric shock, do not plug in or unplug with a wet hand.

Do not expose Power Cords and Earth Wires on the surface, (floor, passage,

etc.). If exposed, the Power Cords and Earth Wires are susceptible to damage.

Damaged cords and wires can cause electric shock or short circuit.

To avoid causing a fire or electric shock, do not put things on or damage

Power Cords.

When or after installing the product, do not unnecessarily pull the power cord.

If damaged, the power cord can cause a fire or electric shock.

In case the power cord is damaged, ask for replacement through where the

product was purchased from or the office herein stated. Using the cord as is

damaged can cause fire, electric shock or leakage.

Be sure to perform grounding appropriately. Inappropriate grounding can

cause an electric shock.

Be sure to use fuses meeting specified rating. Using fuses exceeding the

specified rating can cause a fire or electric shock.

Completely make connector connections for IC BD and others. Insufficient

insertion can cause an electric shock.

Specification changes, removal of equipment, conversion and/or addition, not

designated by SEGA are not permitted.

• Failure to observe this may cause a fire or an electric shock. Non-compliance

with this instruction can have a bad influence upon physical conditions of the

players or the lookers-on, or result in injury during play.

• SEGA shall not be held responsible for damage, compensation for damage to

a third party, caused by specification changes not designated by SEGA.

Be sure to perform periodic maintenance inspections herein stated.

1

www.seuservice.com

STOP

For the IC board circuit inspections, only the logic tester is allowed. The use

The Projector is employed for this machine. The Projector's screen is

IMPORTANT

Some parts are the ones designed and manufactured not specifically for this

of a multiple-purpose tester is not permitted, so be careful in this regard.

susceptible to damage, therefore, be very careful when cleaning the screen.

For details, refer to PROJECTOR.

game machine. The manufacturers may discontinue, or change the

specifications of, such general-purpose parts. If this is the case, Sega cannot

repair or replace a failed game machine whether or not a warranty period has

expired.

www.seuservice.com

2

2. PRECAUTIONS CONCERNING INSTALLATION

LOCATION

This product is an indoor game machine. Do not install it outside. Even indoors,

avoid installing in places mentioned below so as not to cause a fire, electric shock,

injury and or malfunctioning.

Places subject to rain or water leakage, or places subject to high humidity in

the proximity of an indoor swimming pool and or shower, etc.

Places subject to direct sunlight, or places subject to high temperatures in the

proximity of heating units, etc.

Places filled with inflammable gas or vicinity of highly inflammable/volatile

chemicals or hazardous matter.

Dusty places.

Sloped surfaces.

Places subject to any type of violent impact.

Vicinity of anti-disaster facilities such as fire exits and fire extinguishers.

The operating (ambient) temperature range is from 5˚ to 30˚.

LIMITATIONS OF USAGE REQUIREMENTS

Be sure to check the Electrical Specifications.

Ensure that this product is compatible with the location's power supply,

voltage and frequency requirements.

A plate describing Electrical Specifications is attached to the product.

Non-compliance with the Electrical Specifications can cause a fire and

electric shock.

This product requires the Breaker and Earth Mechanisms as part of the

location facilities. Using them in a manner not independent can cause a fire

and electric shock.

Ensure that the indoor wiring for the power supply is rated at 15A or higher

(AC single phase 100 ~ 120V area), and 8A or higher (AC 220 ~ 240V area).

Non-compliance with the Electrical Specifications can cause a fire and

electric shock.

Be sure to independently use the power supply equipped with the Earth

Leakage Breaker. Using a power supply without the Earth Leakage Breaker

can cause an outbreak of fire when earth leakage occurs.

Putting many loads on one electrical outlet can cause generation of heat and a

fire resulting from overload.

When using an extension cord, ensure that the cord is rated at 15A or higher

(AC 100 ~ 120V area) and 8A or higher (AC 220 ~ 240V area). Using a cord

rated lower than the specified rating can cause a fire and electric shock.

3

www.seuservice.com

OPERATION AREA

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

For the operation of this machine, secure a minimum area of 1.6m (W) X

3.1m (D). In order to prevent injury resulting from the falling down accident

during game play, be sure to secure the minimum area for operation.

Be sure to provide sufficient space so as to allow this product's ventilation fan

to function efficiently. To avoid machine malfunctioning and a fire, do not

place any obstacles near the ventilation opening.

SEGA shall not be held responsible for damage, compensation for damage to

a third party, resulting from the failure to observe this instruction.

For transporting the machine into the location's building, the minimum necessary

dimensions of the opening (of doors, etc.) are 1.45m(W) and 1.68m(H).

2345678901234567890123456789012123

Electric current consumption

MAX. 11.5 A (AC 120V 60 Hz)

MAX. 6.4 A (AC 220V 50 Hz)

MAX. 7.0 A (AC 220V 60 Hz)

MAX. 5.8 A (AC 230V 50 Hz)

MAX. 5.6 A (AC 240V 50 Hz)

MAX. 12.5 A (For TAIWAN)

www.seuservice.com

2345678901234567890123456789012123

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

23

15cm

6 inches

1.6m

63 inches

FIG. 2

4

3.55m

140 inches

3. OPERATION

PRECAUTIONS TO BE HEEDED BEFORE STARTING THE OPERATION

To avoid injury and trouble, be sure to constantly give careful attention to the behavior and

manner of the visitors and players.

In order to avoid accidents, check the following before starting the operation:

To ensure maximum safety for the players and the customers, ensure that

where the product is operated has sufficient lighting to allow any warnings to

be read. Operation under insufficient lighting can cause bodily contact with

each other, hitting accident, and or trouble between customers.

Be sure to perform appropriate adjustment of the monitor (projector). For

operation of this machine, do not leave monitor's flickering or deviation as is.

Failure to observe this can have a bad influence upon the players' or the

customers' physical conditions.

It is suggested to ensure a space allowing the players who feel sick while

playing the game to take a rest.

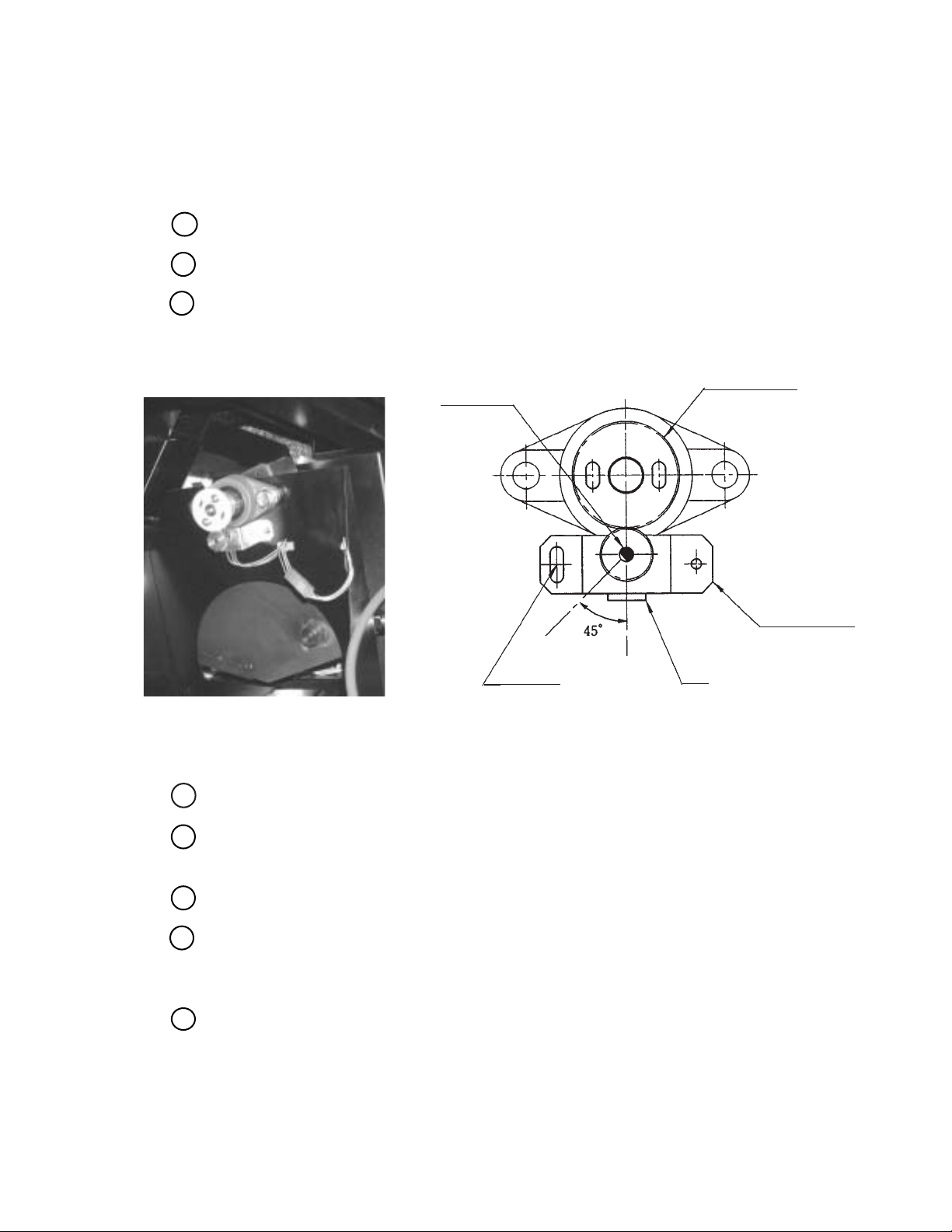

Check if all of the adjusters are in contact with the

surface. If they are not, the Cabinet can move and

cause an accident.

Check to see if the bottom bellows are damaged or

omitted. Bellows are important hazard-prevention

parts. Irregular bellows can cause injury.

Check bellows.

Ensure that all of the Adjusters are in contact with the floor.

Before commencing operation,

execute test run to check if the

Safety Sensor and the Motion

Stop Switch are satisfactorily

functioning to stop the

machine movements during

game. The Safety Sensor and

the Motion Stop Switch are

important hazard-prevention

parts. Irregular important

parts can cause injury.

Check for the Safety Sensor's

function to stop movements.

Safety Sensor

Motion Stop Switch

5

www.seuservice.com

Do not put any heavy item on this product. Placing any heavy item on the

product can cause a falling down accident or parts damage.

Do not climb on the product. Climbing on the product can cause falling down

accidents. To check the top portion of the product, use a step.

To avoid electric shock, check to see if door & cover parts are damaged or

omitted.

To avoid electric shock, short circuit and or parts damage, do not put the

following items on or in the periphery of the product.

Flower vases, flowerpots, cups, water tanks, cosmetics, and receptacles/

containers/vessels containing chemicals and water.

To avoid injury, be sure to provide sufficient space by considering the potentially

crowded situation at the installation location. Insufficient installation space can

cause making bodily contact with each other, hitting accidents, and or trouble

between customers.

Be sure to periodically dewater the Air Drive and dispose of the drain water.

Excessively gathered water can cause the Air Drive Mechanism to malfunction

and get out of order.

www.seuservice.com

FILTER

DRAIN TUBE

WATER TANK

6

PRECAUTIONS TO BE HEEDED DURING OPERATION (PAYING ATTENTION TO CUSTOMERS)

To avoid injury and trouble, be sure to constantly give careful attention to the behavior and

manner of the visitors and players.

To avoid injury and accidents, those who fall under the following categories

are not allowed to play the game.

• Those who need assistance such as the use of an apparatus when walking.

• Those who have high blood pressure or a heart problem.

• Those who have experienced muscle convulsion or loss of consciousness when

playing video game, etc.

• Those who have a trouble in the neck and or spinal cord.

•Intoxicated persons.

•Pregnant women or those who are in the likelihood of pregnancy.

• Persons susceptible to motion sickness.

• Persons whose act runs counter to the product's warning displays.

A player who has never been adversely affected by light stimulus might

experience dizziness or headache depending on his physical condition when

playing the game. Especially, small children can be subject to those

conditions. Caution guardians of small children to keep watch on their

children during play.

Instruct those who feel sick during play to have a medical examination.

To avoid electric shock and short circuit, do not allow customers to put hands

and fingers or extraneous matter in the openings of the product or small

openings in or around the doors.

To avoid falling down and injury resulting from falling down, immediately

stop the customer's leaning against or climbing on the product, etc.

To avoid electric shock and short circuit, do not allow the customers to

unplug the power plug without a justifiable reason.

The player whose feet can not be

placed on the base could fall

down and cause injury. To avoid

injury, instruct persons of short

stature to refrain from playing the

game.

7

www.seuservice.com

To avoid injury and parts

damage, instruct players that only

up to two persons are allowed to

ride.

To avoid injury resulting from

falling down, and electric shock

due to spilled drinks, instruct the

player not to place heavy items or

drinks on the product.

Instruct the player to take a firm

grip of the handle Bars during

play. This machine reacts as per

the contents of the game. To

avoid injury, instruct the players

to refrain from single-handed

taking grip of the handle Bar

(which is very likely to cause

potentially hazardous situation,

should he attempt to do so).

To avoid injury and trouble

resulting from coming into

contact with each other, instruct

persons other than the players to

keep away from the mechanism

base. The Safety Sensor

functions to stop only the

machine movement from the

Compressor. The ride can be

moved by the player.

Do not place drinks

on the base!

www.seuservice.com

8

Immediately stop such violent acts as hitting and kicking the product. Such

violent acts can cause parts damage or falling down, resulting in injury due to

fragments and falling down.

When riding in tandem,

firmly hold on to the front

player. To avoid injury, do

not stand driving the ride.

9

www.seuservice.com

4. NAME OF PARTS

BILLBOARD

PTV 50 TYPE PROJECTOR

FRONT CABINET

RIDE

FIG. 4 a

COMPRESSOR BOX

ASSY WIRE TUBE

TABLE 4 Dimensions and Weights

COIN

CHUTE

DOOR

CASHBOX DOOR

AC UNIT

FIG. 4 b

REAR CABINET

Items Width X Depth X Height Weight

PTV 44.9in

[1,140mm](W) X 9.98in[253.5mm](D) X 65.75in[1,670mm] (H) 242-lbs[110kg]

BILLBOARD 45.4in[1,152mm](W) X 17.9in[454mm] (D) X 11.7in[297mm] (H) 33-lbs[15kg]

FRONT CABINET 45.3in[1,150mm] (W) X 35.3in[896mm] (D) X 39.6in[1,005mm] (H) 215.6-lbs[98kg]

REAR CABINET 56.5in[1,435mm](W) X 65.6in[1,665mm](D) X 42.5in[1,080mm] (H) 545.6-lbs[248kg]

COMPRESSOR BOX 43.9in[1,115mm](W) X 20.3in[514mm] (D) X 30.5in[775mm] (H) 156-lbs[71kg]

www.seuservice.com

10

5. ACCESSORIES

When transporting the machine, make sure that the following parts are supplied.

TABLE 5 a ACCESSORIES

DESCRIPTION OWNERS MANUAL

Part No. (Qty.)

420-6659-01 (1)

Note

Figures

If Part No. has no description, the Number has not been

registered or can not be registered. Such a part may not be

obtainable even if the customer desires to purchase it.

Therefore, ensure that the part is in safekeeping with you.

SERVICE MANUAL NAOMI ENG

420-6455-01 (1)

INSTRUCTION MANUAL FOR THE

GAME BOARD

SEAL TAPE

090-0037 (1)

Used for the maintenance of Air Drive,

for air leakage prevention.

KEY MASTER

220-5576 (2)

For opening/closing the doors

KEY (2)

For the CASHBOX DOOR

The Keys are inside the Coin

Chute Door at the time of shipment

from the factory.

VOL CONT B-5K OHM

220-5373

220-5484

(2)

Spare, see Section 12.

AIR CLEANER

601-8188 (2)

For spare, re

fer to Section 10.

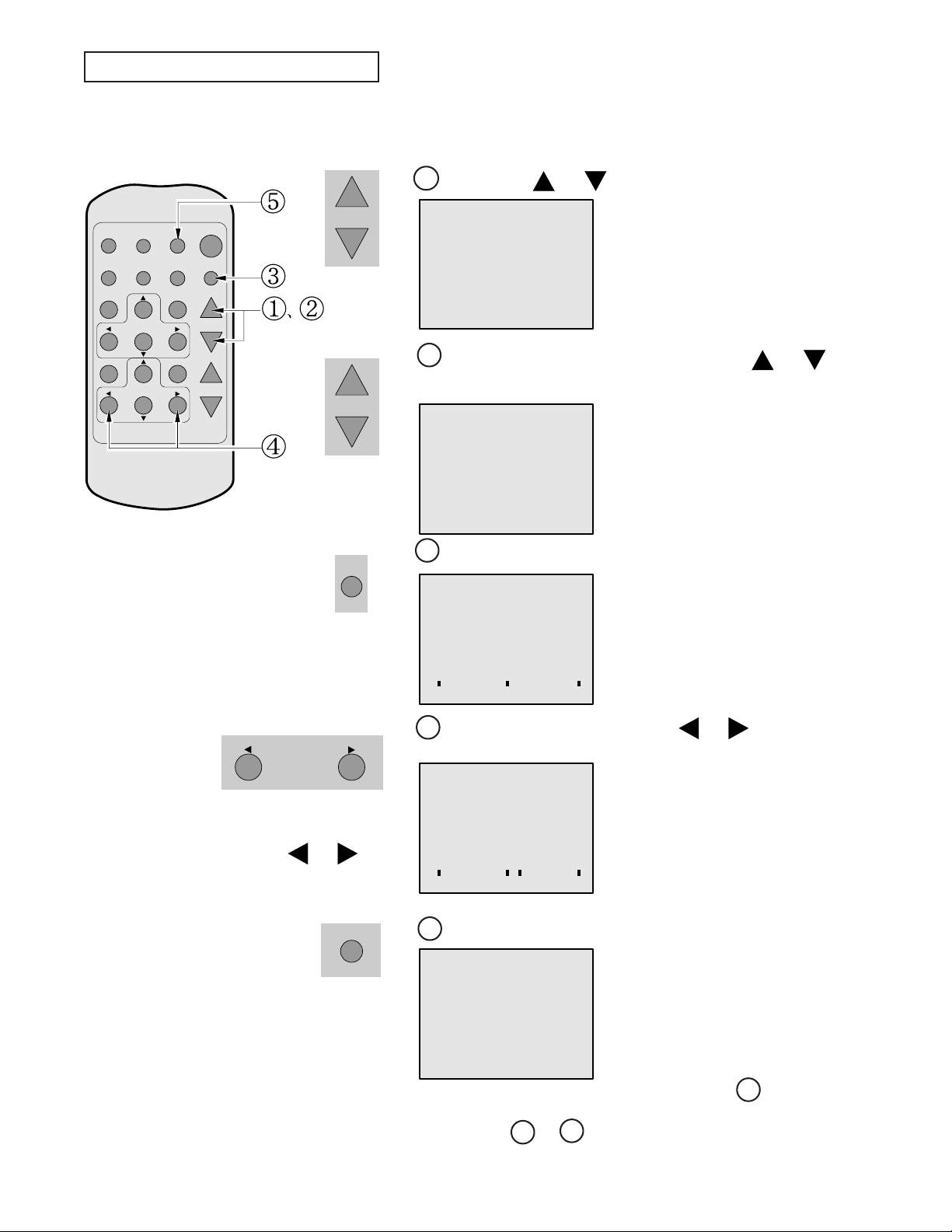

Remote Controller used for

adjustment of the projector.

See Section 14.

200-5536(1)

The Remote Controller is attached to

the Projector at the time of shipment.

TEST MODE WRITING

RBG

POSITION

ADJUST

P

SET

PIC-ADJ

RESET

SELECT

11

www.seuservice.com

FUSE 7A

514-5036-7000 (1)

Spare, see Section 17.

CARTON BOX

601-10532 (1)

Used for transporting the GameBoard.

See FIG 5.

www.seuservice.com

12

HOW TO USE THE CARTON BOX

When requesting for the replacement/repair of this product's Game Board

(NAOMI BOARD), follow the instructions below. Transporting the Game Board

in an undesignated status is unacceptable. An erroneous handling can cause parts

damage.

• Put the Game Board in the Carton Box together with the Shield Case. Do not

unnecessarily disassemble nor remove parts.

• By paying careful attention to the following Figure and the direction shown

by on-Carton-Box printing, put the Shield Case in the Carton Box.

• When putting the Shield Case in the Carton Box, do not remove Leg Brackets.

• The projected portions of the packing material is intended for cushioning.

Therefore, do not bend the projected portions.

"CHECK SIDE" Display

FILTER BOARD

Bend the packing material in numerical order, and wrap the Shield Case with the packing

material and put it in the Carton Box as shown. Putting it upside down or packing otherwise in

the manner not shown can damage the Game Board and the parts.

@

A

Serial No. Display

B

Serial No. Display

Projected portions of

the packing material.

FIG. 5

13

www.seuservice.com

TABLE 5 b

The following Table 5b lists the parts that had been separately packed when the product was

shipped from the factory but are necessary when you use the product. These parts will be

mounted on the product when installing and assembling it.

AC Cable (Power Cord)

600-6729

600-7228

600-6695 (1) <For USA>

600-6619 (1) <AC 220V HONG KONG>

600-6618 (1) <AC 220 ~ 240V AREA>

Used for installation,

see 5 of Section 6.

(1) <For TAIWAN>

123

The following Table 5c lists the parts that are necessary when setting for the communication

play. Flex Tube, Connector 29 and Fiber Plate had been assembled when the product was

shipped from the factory. (See Section 20.)

TABLE 5 c

WIRE HARN EARTH W/LUG

M6

600-6664-02 (1)

<For TAIWAN>

Used for installation,

see 5 of Section 6.

CORD CLAMP

280-5009-01 (1)

Used for installation,

see 5 of Section 6.

FIBER PLATE

WRG-0502 (2)

FLEX TUBE

310-5285-290100 (1)

Assembled Flex Tube

CONN 29

310-5286-29 (2)

www.seuservice.com

14

ASSY FIBER CABLE

600-6275-0700 (2)

NUMBER STICKER

WRG-0003 (1)

1 set of every two sheet sticker, the number 2, 3 and 4.

15

www.seuservice.com

6. ASSEMBLING AND INSTALLATION

Perform assembly work by following the procedure herein stated. Failing to

comply with the instructions can cause electric shock hazard.

Perform assembling as per this manual. Since this is a complex machine,

erroneous assembling can cause an electric shock, machine damage and or not

functioning as per specified performance.

When assembling, be sure to use plural persons. Depending on the assembly

work, there are some cases in which working by one person alone can cause

personal injury or parts damage.

Ensure that connectors are accurately connected. Incomplete connections can

cause electric shock hazard.

Be careful so as not to damage wirings. Damaged wiring can cause electric

shock and short circuit hazards.

Do not carelessly push the PTV. Pushing the PTV carelessly can cause the

PTV to fall down.

This work should be performed by the Location's Maintenance Man or

Serviceman. Performing work by non-technical personnel can cause a severe

accident such as electric shock. Failing to comply with this instruction can

cause a severe accident such as electric shock to the player during operation.

Provide sufficient space so that assembling can be performed. Performing

work in places with narrow space or low ceiling may cause an accident and

assembly work to be difficult.

To perform work safely and avoid serious accident such as the cabinet's

falling down, do not perform work in places where step-like grade

differences, a ditch, or slope exist.

To perform work safely and securely, be sure to prepare a step which is in a

secure and stable condition. Performing work without using the step can cause

violent falling down accidents.

When carrying out the assembling and installation, follow the following 7-item sequence.

ASSEMBLING THE PTV

1

WIRING CONNECTIONS BETWEEN THE CABINETS

2

SECURING IN PLACE (ADJUSTER ADJUSTMENT)

3

4

REMOVING THE SHIPPING BRACKET

5

POWER SUPPLY, AND EARTH CONNECTION

6

TURNING POWER ON

7

ASSEMBLY CHECK

www.seuservice.com

16

Tools required for the work

1

Phillips type screwdriver (for M4, M5 screw)

24mm

WRENCH (for M16 hexagon bolt)

Box nut screwdriver (for M4 hexagon nut) or WRENCH

KEY MASTER

ASSEMBLING THE PTV

1

Fix the two mask holders onto the PTV top panel each with the 2 countersunk-head screws.

Insert the TV mask from the underside as illustrated below, and secure with a total of 6 screws.

2

Fix two PTV holders onto the PTV front side each with the 2 screws.

3

MASK

SCREW (4)

M5 X 20,

w/flat & spring washers

PTV

COUNTERSUNK-HEAD SCREW (2 each)

M4 X 12

MASK HOLDER

TRUSS SCREW (2)

M5 X 25,flat washer used.

FIG. 6. 1 a

PTV HOLDER

SCREW (2 each)

M5 X 16,w/flat & spring washers

17

www.seuservice.com

4

Mount the PTV onto the Front Cabinet.

When performing this work, be sure to

use 4 or more persons.

FIG. 6. 1 b

5

Fix between the PTV and the Front Cabinet on the Cabinet's both sides with 2 screws for each.

6

While supporting the Billboard by 2 persons, another person using a step is to connect the

Billboard wire connector into the terminal board of the PTV top panel.

FIG. 6. 1 d

SCREW (2)

M5 X 16,w/flat & spring washers

BILLBOARD

Connect the Connector.

TRUSS SCREW (2 each)

M5 X 30,flat washer used.

www.seuservice.com

When performing this work, be sure to use 2 or

more persons and be sure to use a step.

18

FIG. 6. 1 c

Insert the Billboard into the holder

7

bracket, fix to PTV with the 2

screws.

Remove the 2 truss screws;

8

dismount the lower lid form the

Front Cabinet's face side.

TRUSS SCREW (black)

M4 X 25

LOWER LID

PHOTO 6. 1 a

9

Connect two wire-connectors inside the Front Cabinet into the PTV connector panel. The

connection angle is fixed. Easy to fix them arranging the angle and the orientation of each

connector. Be sure of the correct connection in order to prevent the damage of the connector or

the terminal portion. There are fixed screws both sides of the Video signal (D-sub) connector.

Fasten them securely.

Connect the Connector.

19

PHOTO 6. 1 b

www.seuservice.com

2

WIRING CONNECTIONS BETWEEN THE CABINETS

Perform the cabinet-to-cabinet wiring. With the ASSY Wire Tube, which installed to the Rear

Cabinet at the time of shipment, connect between the Front Cabinet and the Rear Cabinet.

1

Remove the fixed 4 truss screws

and remove the front cabinet side

Tube Bracket of the ASSY Wire

Tube from the Rear Cabinet.

2

Reinstall the removed 4 truss

screws into the Rear Cabinet.

TRUSS SCREW (4),black

M4 X 12

PHOTO 6. 2 a

3

There are one earth wire and a total of seven wire connectors in the front cabinet side of the

ASSY Wire Tube. Connect the earth wire to the earth terminal stud on the Connector Panel of

the Front Cabinet. Fasten with the hexagon nut in the order of the round earth terminal, the flat

washer and the spring washer.

4

Connect the seven wire connectors to each terminal on the Connector Panel of the Front

Cabinet.

www.seuservice.com

HEXAGON NUT

M4,flat & spring washers used.

PHOTO 6. 2 b

20

Install the Tube Bracket to the Front Cabinet, and fix it with the 4 truss screws by using care so

5

as not to damage the wiring.

TRUSS SCREW (4),black

M5 X 20

PHOTO 6. 2 c

21

www.seuservice.com

3

SECURING IN PLACE (ADJUSTER ADJUSTMENT)

Make sure that all of the adjusters are in contact with the floor. If they are not, the

cabinet can move and cause an accident.

This product has 8 casters (4 for FRONT CABINET, 4 for REAR CABINET) and 8 Adjusters

(4 for FRONT CABINET, 4 for REAR CABINET). (FIG. 6. 3a) When the installation position

is determined, cause the adjusters to come into contact with the floor directly, make adjustments

in a manner so that the casters will be raised approximately 5mm from the floor and make sure

that the machine position is level.

1

Transport the product to the

installation position. Be sure to

provide adequate space allowing

the player to get on and off.

Have all of the Adjusters make

2

contact with the floor. Adjust the

Adjuster's height by using a

wrench so that the machine

position is kept level.

CASTER

After making adjustment, fasten

3

the Adjuster Nut upward and

secure the height of Adjuster

(FIG. 6. 3 b).

ADJUSTER

FIG. 6. 3 a BOTTOM VIEW

ADJUSTER

CASTER

FASTEN UPWARD.

Approx.5mm

ADJUSTER

FIG. 6. 3 b ADJUSTER

FIG. 6. 3 c

Refer to this Fig. (Scale:1/100) for

the layout of the place of installation.

www.seuservice.com

10cm

FIG. 6. 3 d

Be sure to provide space as shown between the Air

Vent and the wall surface.

22

15cm

4

REMOVING THE SHIPPING BRACKET

Before turning the power on, be sure to remove the Sipping Brackets. Turning

power on without removing the Sipping Brackets may cause the parts

damage.

Keep the Sipping Brackets carefully. Removing the product without the

Sipping Brackets can cause parts damage.

At the time of shipment, the Shipping Brackets are secured to rear both sides of the Ride. By

taking out 2 screws from each bracket, remove the Shipping Brackets. Reinstall the removing

screws as before.

SHIPPING BRACKET L (OPPOSITE SIDE: R)

TRUSS SCREW (1)

M4 X 8

TRUSS SCREW (1)

M4 X 12

PHOTO 6. 4

23

www.seuservice.com

5

POWER SUPPLY, AND EARTH CONNECTION

Be sure to independently use the power supply socket outlet equipped with an

Earth Leakage Breaker. Using a power supply without an Earth Leakage

Breaker can cause a fire when electric leakage occurs.

Ensure that the "accurately grounded indoor earth terminal" and the earth wire

cable are available (except in the case where a power cord plug with earth is

used). This product is equipped with the earth terminal. Connect the earth

terminal and the indoor earth terminal with the prepared cable. If the

grounding work is not performed appropriately, customers can be subjected to

an electric shock, and the product's functioning may not be stable.

Ensure that the power cord and earth wire are not exposed on the surface

(passage, etc.). If exposed, they can be caught and are susceptible to damage.

If damaged, the cord and wire can cause electric shock and short circuit

accidents. Ensure that the wiring position is not in the customer's passage

way or the wiring has protective covering.

After wiring power cord on the floor, be sure to protect the power cord.

Exposed power cord is susceptible to damage and causes an electric shock

accident.

The AC Unit is mounted on the right side of the machine. The AC Unit has Main SW, Circuit

Protector, Earth Terminal and the Inlet which connects the Power Cord.

1

Ensure that the Main SW is OFF.

MAIN SW

CIRCUIT PROTECTOR

Main SW off

INLET

EARTH TERMINAL

Connect with the

indoor earth terminal.

AC Cable (Power Cord)

FIG. 6. 5 a AC UNIT

www.seuservice.com

24

2

Connect one end of the earth wire to the AC Unit

earth terminal, and the other end to the indoor earth

terminal. The AC Unit earth terminal has a Bolt and

Nut combination. Take off the Nut, pass the end of

earth wire through the Bolt, and fasten the Nut.

3

Note that the Earth Wire is incorporated in the Power

Cord for the Areas of AC 120V (USA) and AC 220 ~

240V, and therefore, this procedure is not necessary.

4

Firmly insert the power plug into the

socket outlet.

Insert the opposite side of Power Cord

plug to the AC Unit's connector

("INLET").

5

Perform wiring for the Power Cord

and Earth Wire. Install protective

covering for the Power Cord and

Earth Wire.

Connect the Earth Wire

to the Earth Terminal.

FIG. 6. 5 b Earth Wire Connection

HOW TO USE THE CORD CLAMP

Wiring Cover

FIG. 6. 5 c Connecting Power Cord and Earth Wire

In case the Power Plug is apt to come out of place, secure the

Power Cord to the periphery of the AC Unit with the Cord

Clamp (an accessory).

25

www.seuservice.com

6

TURNING POWER ON

When the power is turned on, the ride portion moves. To prevent injury, first

check for safety in the periphery of the ride and then turn power on.

If ERROR is displayed in the ADVERTISE mode, do not operate the

machine. Operating the machine when ERROR is displayed can cause

serious hazard.

During initialization settings, do not touch the ride portion. Wait until the

initialization settings are automatically finished. Touching the ride portion during

setting can cause inaccurate settings and unsatisfactory functioning during game

play.

Turn the AC Unit Main SW ON to turn on the machine's power supply. At the same time the

power is turned on for the power supply, the machine starts the initialization setting movements

and displays the screen on which the setting is being made. Do not touch the Ride until the

initialization setting movements are automatically finished.

1

Approximately 5 seconds after the power is turned on, the compressor starts to operate. If the

pressure inside the tank is insufficient, it takes several minutes to attain the preset pressure. At

the time of installation assembly, it takes approximately 3 minutes. When operation is being

continued, it takes approximately one and half minutes due to the prestress.

2

The ride portion secures the left/right inclination to the center.

3

The front of the ride portion

lowers.

4

The front of the ride portion is

raised.

5

The front of the ride portion

moves to the intermediate

position in the up/down

movement.

6

The front of the ride portion

lowers.

7

The compressor stops.

FIG. 6. 6

After finishing the initialization

setting movements, the ADVERTISE mode returns. During the setting movements, if any

irregularity, malfunctioning, etc. of the moving mechanism are found, ERROR display is shown

on the lower part of the ADVERTISE mode screen. In this case, the machine will not operate

satisfactorily. Please contact the Distributor, etc. where this product was purchased from.

In the case where several machines are connected, network check is performed after

initialization settings are finished, and the screen displays to the effect that the check is being

conducted. After checking, the ADVERTISE mode returns. Normally the network checking

takes 1 ~ 3 minutes. If there is any irregularity in the communication connection, check screen

display will continue.

www.seuservice.com

26

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

7

ASSEMBLY CHECK

In the TEST MODE, ascertain that the assembly has been made correctly and IC BD is

satisfactory (refer to Section 9).

In the test mode, perform the following test:

( 1 ) MEMORY TEST

RAM TEST

IC29 GOOD

IC35 GOOD

IC09 GOOD IC10 GOOD

IC11 GOOD IC12 GOOD

IC16 GOOD IC18 GOOD

IC20 GOOD IC22 GOOD

IC17 GOOD IC19 GOOD

IC21 GOOD IC23 GOOD

PRESS TEST BUTTON TO EXIT

( 2 ) C.R.T. TEST

C.R.T. TEST 1/2

1 32

RED

GREEN

BLUE

WHITE

PRESS TEST BUTTON TO CONTINUE

Selecting the RAM TEST in the test mode

menu causes the on-board memory to be tested

automatically. The game board is satisfactory if

the display beside each IC No. shows GOOD.

In the test mode menu, selecting C.R.T. TEST allows the

screen (on which the projector is tested) to be displayed.

Although the projector adjustments have been made at the

time of shipment from the factory, color deviation, etc., may

occur due to the effect caused by geomagnetism, the location

building's steel frames and other game machines in the

periphery. By watching the test mode screen, make

judgment as to whether an adjustment is needed. If it is

necessary, adjust the projector by referring to Section 14.

234567890123456789012

C.R.T. TEST 2/2

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

234567890123456789012

PRESS TEST BUTTON TO EXIT

27

www.seuservice.com

( 3 ) SOUND TEST

SOUND TEST

RIGHT SPEAKER OFF

LEFT SPEAKER OFF

-> EXIT

SELECT WITH SERVICE BUTTON

AND

PRESS TEST BUTTON

( 4 ) INPUT TEST

In the test mode, selecting SOUND TEST

causes the screen (on which sound related BD

and wiring connections are tested) to be

displayed.

Be sure to check if the sound is satisfactorily

emitted from each speaker and the sound

volume is appropriate.

INPUT TEST

HANDLE BAR 0H

ROLL 0H

THROTTLE LEVER FFH

PITCH 0H

START OFF

VIEW OFF

SAFETY SENSOR OFF

SERVICE OFF

TEST OFF

PRESS TEST AND SERVICE BUTTON TO EXIT

( 5 ) OUTPUT TEST

OUTPUT TEST

> START LAMP OFF

VIEW LAMP OFF

EXIT

Selecting the INPUT TEST on the test mode

menu screen causes the screen (on which each

switch and V. R. are tested) to be displayed.

Press each switch. If the display beside each

switch indicates "ON," the switch and wiring

connections are satisfactory.

Check the display of each V.R. value. If the V.

R. is malfunctioning, refer to Sections 11 & 12.

In the output test mode, carry out lamp test to

ascertain that each lamp lights up satisfactorily.

SELECT WITH SERVICE BUTTON

AND PRESS TEST BUTTON

Perform the above inspections also at the time of monthly inspection.

www.seuservice.com

28

7.

PRECAUTIONS TO BE HEEDED WHEN MOVING THE MACHINE

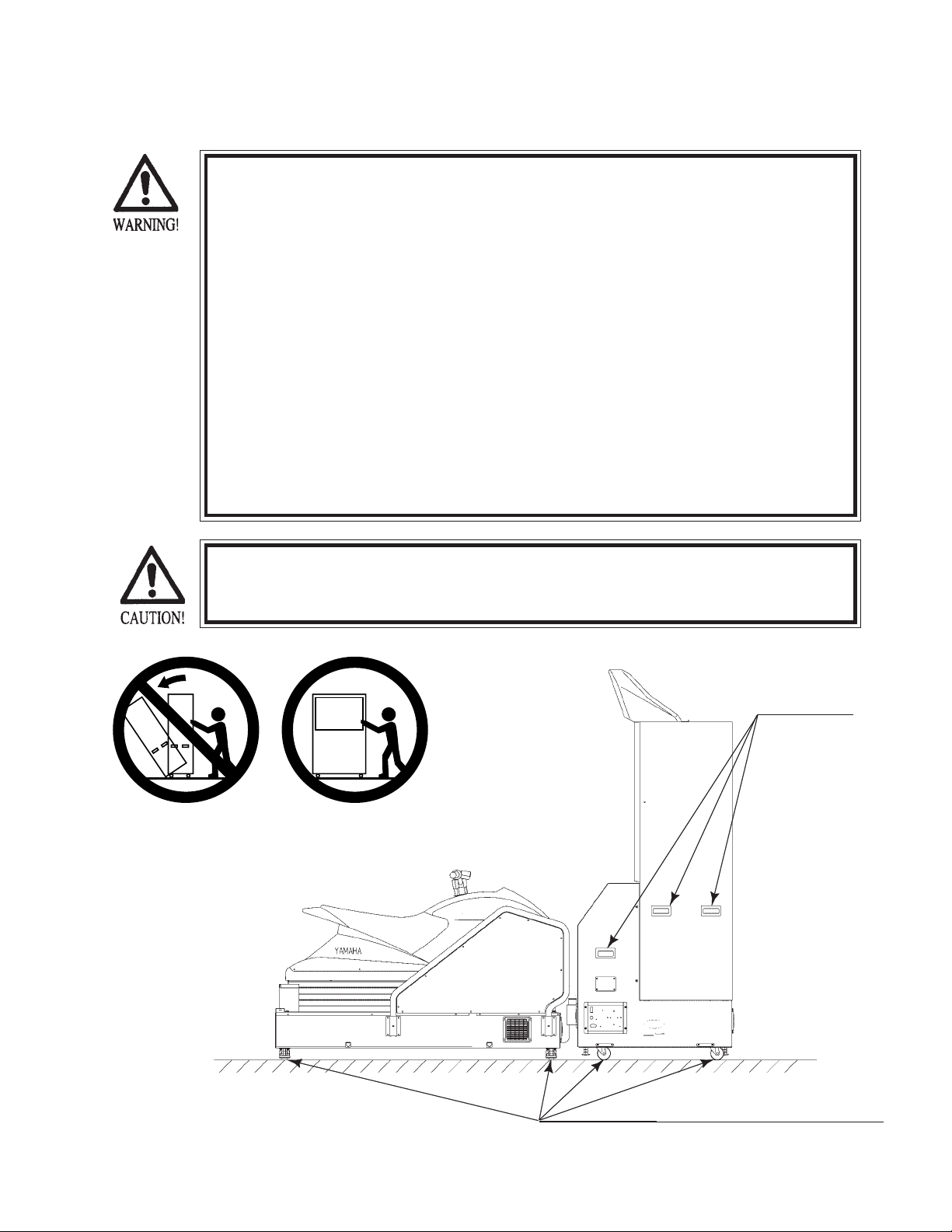

When moving the machine, be sure to pull out the plug from the power

supply. Moving the machine with the plug as is inserted can cause the power

cord to be damaged, resulting in a fire and or electric shock.

When moving the machine on the floor, retract the Adjusters and ensure that

Casters make contact with the floor. During transportation, pay careful

attention so that Casters do not tread power cords and earth wires. Damaging

the power cords can cause an electric shock and or short circuit.

In places where step-like grade differences exist, be sure to separate the PTV,

PTV Base, and the Cabinet. Inclining the PTV as is mounted on the PTV

Base can cause the PTV to fall off from the Base and result in injury.

When lifting the cabinet, be sure to hold the catch portions or bottom part.

Lifting the cabinet by holding other portions can damage parts and installation

portions due to the empty weight of the cabinet, and cause personal injury.

When moving the PTV, do not push it from the rear side. Push it from

sideways. Pushing the PTV from the rear side can have the PTV fall down,

causing personal injury etc. In case the floor has slanted surfaces or step-like

differences, be sure to move the machine by 2 or more persons.

Keep the Sipping Brackets carefully. Removing the product without the Sipping

Brackets can cause parts damage.

Do not push PTV from the back. Pushing the PTV

from the back can cause the PTV to fall down. Push

it from the side.

GRIP PORTION

FIG. 7 a

29

On level surfaces,move the machine by causing

the Casters to make contact with the surfaces.

www.seuservice.com

When transporting the product in places with steps

or step-like differences in grade, disassemble into

each unit before transporting.

FIG. 7 b

www.seuservice.com

30

8. CONTENTS OF GAME

The following explanations apply to the case the product is functioning satisfactory. Should

there be any moves different from the following contents, some sort of faults may have

occurred. Immediately look into the cause of the fault and eliminate the cause therefore to

ensure satisfactory operation.

System Behavior in Advertising (Plying-for-Hire) Mode

While the power is connected to the system, the fluorescent light on the billboard is kept on. In

an advertising mode, the system opens an operation explanation screen or a ranking data screen.

The view button flashes when the screen explains how to operate the view button.

Located on the left and right ends of the cabinet, the speakers output audio information. You

may set the ADVERTISE SOUND item to OFF on the GAME ASSIGNMENTS screen so that

this audio output function is disabled in an advertising mode.

The start button flashes when the screen displays the PRESS START BUTTON message. This

PRESS START BUTTON message appears in two cases; when the credit reaches a gamestartable level in an advertising mode and shortly after opening the operation explanation

screen.

Coin Inlet

Fluorescent lamps are lit.

Image output on the monitor.

Emits sounds.

Throttle Lever

Start Button

Ride

Handlebars

View Button (Change the viewpoint)

FIG. 8 a External View of the Cabinet

31

www.seuservice.com

Features of the WaveRunner GP

It provides several marine scenes where a cruising course appearance varies from play to play.

The WaveRunner GP game features:

•Effects of Stern Wave

A stern wave is the wave produced on the wake of a boat. If your boat runs on the stern

waves produced by another boat, it may jump unexpectedly, reduce its speed, or meet any

other navigating difficulty. You must prevent your boat from running on the stern waves and

navigate it with attention to where and how other boats are moving.

• Water-Level-Depending Jumps

A large jump (or a group of small jumps) may appear on the course when a water level is

lower (or higher). The jump that was submerged on your first round cruise may be above the

water on your second round cruise. Therefore, you must navigate your boat differently and/

or change a cruising path, from cruise to cruise, so that you can use an approaching jump.

How to Play

•Insert the coin(s).

• Make sure that the screen shows the PRESS START BUTTON message and that the start

button flashes, and then climb onto the seat.

•Press the start button, and make sure that the operation explanation screen appears. (See the

note 1 below.)

• Wait until the time is counted down to 0 (zero) on the operation explanation screen or

alternately press the start button to exit the screen. In either case the COURSE SELECT

screen appears.

Highlights a selected

course.

Illustrates a course

layout.

Shows an image of the

selected course.

Indicates how to operate

the handlebars and the

throttle lever.

Indicates a limit

time for a course

selection.

FIG. 8 b

www.seuservice.com

32

• The system provides three courses: NOVICE, INTERMEDIATE, and EXPERT. These are

displayed on the upper part of the screen. The selected course is highlighted. To migrate

from one course to another, turn the handlebars leftwards or rightwards. To decide a course,

squeeze the throttle lever. (See the note 2 below.)

MOTION STOP SWITCH

Turn the handlebars left/right

to choose the course.

Grip the throttle lever to

decide a course.

•Wait until the time is counted down to 0 (zero) on the screen, and then the game starts. (See

the note 3 below.)

• Make sure that the boat starts to move at this moment.

• The screen shows some information; your ranking position among the players (on its upper

right part), a limit time (upper middle), your lap time, best lap time record, and best total

time record (upper left), a tachometer and a speed meter (bottom right), and a speed-down

gauge (bottom left). The speed-down gauge indicates a reduction of the cruising speed as a

result of your boat running on the stern waves. It is dimmed when your boat is not running

on the stern waves.

Player's Lap Time

Best Lap Time Record

Best Total Time Record

View button

FIG. 8 c

Start button

Limit Time

Player's Ranking

Position

Speed-Down Gauge

(It is dimmed when your boat

is not running on the stern

waves.)

FIG. 8 d

33

Tachometer and

Speed Meter

www.seuservice.com

• When your boat runs on the stern waves, the speed-down gauge is undimmed and its triangle

becomes filled with shade. If you keep your boat running on the stern waves, the triangle is

shaded more and more.

When the triangle is fully shaded, a warning message "Get out of the wake!" appears on the

screen. If you make your boat off the stern waves at this moment, the speed-down gauge is

again dimmed. If not, it is initialized to 0 (zero) and becomes filled with shade again.

Initially the gauge is dimmed. When the boat runs on the stern

waves, the gauge is undimmed

and becomes filled with shade.

FIG 8 e

• When the game starts, the system starts counting down the limit time. If you successfully pass

a checkpoint on the course within the limit time, the bonus time is added to the remaining time.

If not, the game is over. (See the note 4 below.)

• For any course of NOVICE, INTERMEDIATE, or EXPERT. When you have successfully

cruised around it two times, you reach the goal and the game is over. (See the note 5 below.)

• To navigate the boat while playing the game, use the throttle lever and the handlebars, and tilt

up the boat by shifting your body. To increase a cruising speed, squeeze the throttle lever while

to decrease un-squeeze. To turn the boat leftwards and rightwards, turn the handlebars

leftwards and rightwards respectively. To quickly turn the boat, turn the handlebars and then

tilt up the boat to a turning direction of the handlebars. Note that just tilting up the boat without

turning the handlebars does not enable to turn the boat. Press the view button to toggle a viewpoint between a navigator's point and a rearward point.

• When reaching the goal, you can register your name if your lap time is good. Your registered

name will be on a screen's ranking list in an advertising mode.

When the gauge is fully

shaded, a warning message

appears.

NOTES:

1) For an interactive communication play. Insert the one-play worth of coin(s) on the operation

explanation screen and press the start button to enter the race. The system opens the entry

screen where you wait until an opposition will enter the race by also inserting the one-play

worth of coin(s) and pressing the start button. The entry screen closes and the operation

explanation screen opens automatically, when a limit time is counted down to 0 (zero).

2) For an interactive communication play. When every player, after entering the race, has

finished selecting a course, the racing course is decided by majority. In case of a tie, the

course with a lower difficulty level is chosen.

3) Alternately, you can press the start button to decide a course.

4) For an interactive communication play. The bonus time is added to the remaining time when

a leading player passes a checkpoint. The place of a player is indicated as 'place/the number

of players' (e.g. 2/4 for a 4-player race, 1/2 for 2-player race). A player number, as 1P and

2P, is shown above the head of a playing character on the screen.

5) You cannot change the number of rounding cruises.

www.seuservice.com

34

Outline of the Courses

Three cruising courses are provided as below. Note that they are different from each other not

only in the difficulty level but also in the appearance and device.

• Novice Course

This course gives the image of a tropical island against a blue sky where the hot sun grills

white beaches. Generally, this novice course curves very gently.

There are three checkpoints including a starting point.

When your boat approaches a palm tree, the coconuts will fall down on your cruising path.

Three dolphins may appear on the way and accompany your boat.

The key part for reaching the goal is located at the end of the course that is sharply curved

and enclosed with the cliffs.

•Intermediate Course

This course gives the image of a thick rainforest with mysterious remains. Generally, this

intermediate course is a very narrow river with rather many curves.

There are four checkpoints including a starting point.

The highlight of this course is a jump from the 50-meter giant waterfall.

In the mangrove woodlands, tall mangroves block your boat. You must be careful not to let it

hit against them.

Big snakes and giant fishes produce an atmosphere of rainforest.

The key parts for reaching the goal are the curves located short of the giant waterfall, in the

mangrove woodlands, and in the cave at the end of the course. You must navigate your boat

with careful attention to these curved spots.

• Expert Course

This course gives the image of a waterfront where the surrounding skyscrapers are blazing in

the evening darkness. This expert course features several combinations of a straight path and

a sharp curve.

There are four checkpoints including a starting point.

All the scenes (the likes of the Brooklyn Bridge, the Statue of Liberty, and the Broadway

with loud neon signs and large illumination bulletin boards) produce an atmosphere of big

city.

The key part for reaching the goal is the sharp curves located immediately after the straight

paths.

35

www.seuservice.com

9. EXPLANATION OF TEST AND DATA DISPLAY

By operating the switch unit, periodically perform the tests and data check. When installing the

machine initially or collecting cash, or when the machine does not function correctly, perform

checking in accordance with the explanations given in this section.

The following shows tests and modes that should be utilized as applicable.

NAOMI GAME BOARD is used for the product. The system of this game board allows another game to be played by replacing the ROM Board Case mounted on the NAOMI CASE. As

such, the Test Mode of this system consists of the System Test Mode for the system to execute

SELF-TEST, COIN ASSIGNMENTS, etc. used in common for the machines employing the

NAOMI BOARD, and the Game Test Mode for the specific product to execute Input/Output

test for the operation equipment, difficulty setting, etc.

When the 2 or more machines are linked for communication play, be careful to

enter the TEST mode. If one of the machines linked enters the TEST mode, all

others display the NETWORK CHECK screen.

www.seuservice.com

36

TABLE 10 EXPLANATION OF TEST MODE

ITEMS DESCRIPTION

REFERENCE

SECTIONS

INSTALLATION

OF MACHINE

MEMORY

PERIODIC

SERVICING

CONTROL

SYSTEM

When the machine is installed, perform the following:

1. Check to see that each setting is as per standard setting made at

the time of shipment.

2. In the INPUT TEST mode, check such input devices as each

SW, V.R., etc.

3. In the OUTPUT TEST mode, check such output devices as

lamps, motors, etc.

4. In the self-test mode, check ICs on the IC Board.

Choose the board test item in the MENU mode to allow the selftest to be performed. In this test, PROGRAM RAMs, ROMs, and

ICs on the IC Board are checked.

Periodically perform the following:

1. Self-Test

2. Ascertain each setting.

3. In the INPUT TEST mode, test the control device.

4. In the OUTPUT TEST mode, check such output devices as

lamps, motors, etc.

1. In the INPUT TEST mode, check such input devices as each

SW, V.R., etc.

2. Adjust or replace each SW and VR.

3. If the problem can not be solved yet, check the control's moves.

SERVICE MANUAL

9-3d

9-3b

9-3c

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUAL

9-3d, e

9-3b

9-3c

SERVICE MANUAL

9-3e

11,12

MONITOR

IC BOARD

DATA CHECK

In the MONITOR ADJUSTMENT mode, check to see if the

PROJECTOR adjustment is appropriately made.

1. Self-Test

2. In the SOUND TEST mode, check the sound related ROMs.

Check such data as game play time and histogram to adjust the

difficulty level, etc.

SERVICE MANUAL

14

SERVICE MANUAL

SERVICE MANUAL

SERVICE MANUAL

9-3h

37

www.seuservice.com

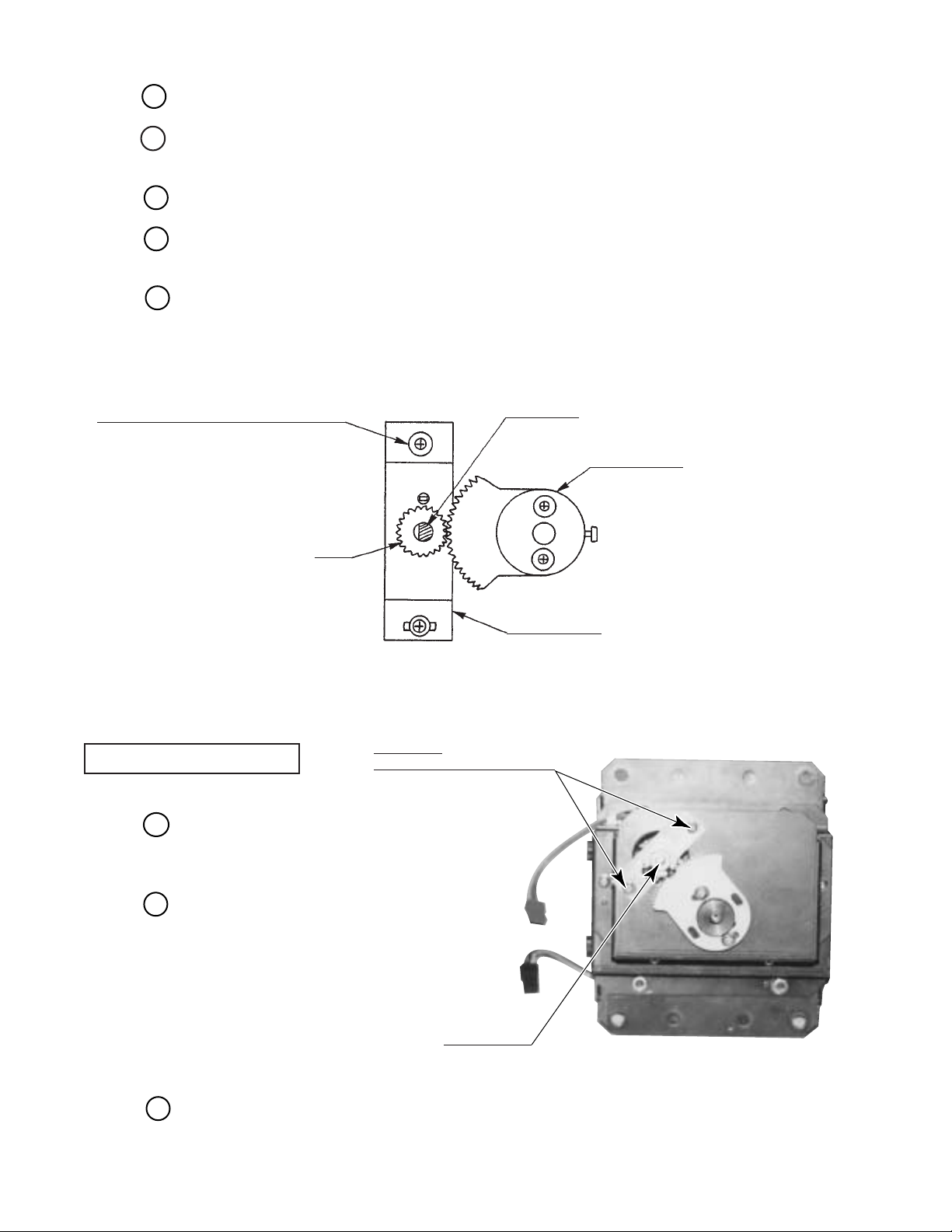

9 - 1 SWITCH UNIT AND COIN METER

Do not touch places other than those specified. Touching places not specified can

cause an electric shock or short circuit accident.

Adjust to the optimum sound volume by considering the environmental

requirements of the installation location.

If the COIN METER and the game board are electrically disconnected, game

play is not possible.

SWITCH UNIT

Open the coin chute door, and the switch unit

shown will appear. The functioning of each

SW is as follows:

FIG. 9. 1 a SWITCH UNIT

TEST BUTTON : For the handling of the test button, refer to the following pages.

(TEST)

SERVICE BUTTON : Gives credits without registering on the coin meter.

(SERVICE)

SOUND VOLUME : Adjust the Speaker Volume.

(SOUND VOLUME)

COIN METER

SOUND VOLUME

TEST BUTTON

SERVICE BUTTON

Open the Cashbox Door with the exclusively used key

and the COIN METER will appear underneath the

Cashbox.

FIG. 9. 1 b COIN METER

www.seuservice.com

COIN METER

38

9 - 2 SYSTEM TEST MODE

The contents of settings changed in the TEST mode are stored when the test

mode is finished from EXIT in the menu mode. If the power is turned off

before the TEST mode is finished, the contents of setting change become

ineffective.

Executing "BACKUP DATA CLEAR" in the SYSTEM TEST MODE does

not clear the BOOKKEEPING data in the GAME TEST mode.

Entering the TEST mode clears fractional number of coins less than one credit

and BONUS ADDER data.

Perform setting as per specified in this manual for operation. If setting not

specified is performed for operation, proper function of this product may not

be obtained.

In the SYSTEM TEST MODE, IC BD functioning can be checked, the monitor adjusted, and

the coin setting performed.

Refer to NAOMI SERIVCE MANUAL for the details. Note that the setting of the following

items need to be performed in accordance with the instruction given.

• CABINET TYPE: 1PLAYER(S)

• MONITOR TYPE: HORIZONTAL

• SERVICE TYPE: COMMON

• COIN CHUTE TYPE: COMMON

The SEQUENCE SETTING items of COIN ASSIGNMENTS are as follows.

• SEQUENCE SETTING

SEQUENCE 1: Number of credits required for starting the game.

SEQUENCE 2: Number of credits required for continuing the play.

SEQUENCE 3 ~ 8: NOT USED

39

www.seuservice.com

9 - 3 GAME TEST MODE

As soon as it enters the Game Test mode, the Ride starts moving. Before entering

the Game Test Mode, be sure to keep away a person(s) from the Ride. Since the