2nd PRINTING AUG

www.seuservice.com

Deluxe Version

OWNER’S MANUAL

SEGA ENTERPRISES, INC. USA

MANUAL NO. 4201-6507-01

VISIT OUR WEBSITE!

BEFORE USING THE PRODUCT, BE SURE TO READ THE FOLLOWING:

To maintain the safety:

To ensure the safe usage of the product, be sure to read the following before using the product. The following

instructions are intended for the users, operators and the personnel in charge of the operation of the product.

After carefully reading and sufficiently understanding the warning displays and cautions, handle the product

appropriately. Be sure to keep this manual nearby the product or elsewhere convenient for referring to it

when necessary.

Herein, explanations which require special attention are enclosed with dual lines. Depending on the potentially hazardous degrees, the terms of WARNING, CAUTION, etc. are used. Be sure to understand the

contents of the displays before reading the text.

Indicates that mishandling the

product by disregarding this

warning will cause a potentially

hazardous situation which can

result in death or serious injury.

For the sage usage of the product, the following pictographs are used:

Indicates “HANDLE WITH CARE.” In order to protect the human body an equipment, this

display is attached to places where the Owner’s Manual and or Service Manual should be referred

to.

Perform work in accordance with the instructions herein stated.

Instructions for work are explained by paying attention to the aspect of accident prevention. Failing to

perform work as per the instructions can cause accidents. In the case where only those who have technical expertise should perform the work to avoid hazardous situation, the instructions herein state that the

serviceman should perform such work.

Be sure to turn off power before working on the machine.

To prevent electric shock, be sure to turn off power before starting the work in which the worker touches

the interior of the product. If the work is to be performed in the power-on status, the Instruction Manual

herein always states to that effect.

Indicates that mishandling the product

by disregarding this caution will cause

a slight hazardous situation which can

result in personal injury and or material

damage.

Be sure to ground the Earth Terminal (this, however, is not required in the case where a power cord

with earth is used).

This product is equipped with the Earth Terminal. When installing the product, Connect the Earth Terminal to the “accurately grounded indoor earth terminal” by using an earth wire. Unless the product is

grounded appropriately, the user can be subject to electric shock. After performing repair, etc. for the

Control equipment, ensure that the Earth Wire is firmly connected to the Control equipment.

Ensure that the Power Supply used is equipped with an Earth Leakage Breaker.

This product does not incorporate the Earth Leakage Breaker. Using a power supply which is not

equipped with the Earth Leakage Breaker can cause a fire when earth leakage occurs.

Be sure to use fuses which meet the specified rating. (only for the machines which use fuses).

Using fuses exceeding the specified rating can cause a fire and electric shock.

Specification changes (removal of equipment, conversion and addition) not designated by SEGA

are not allowed.

The parts of the product include warning labels for safety, covers for personal protection, etc. It is very

hazardous to operate the product by removing parts and or modifying the circuits. Should doors, lids

and protective parts be damaged or lost, refrain from operating the product, and contact where the

product was purchased from or the office herein stated. SEGA shall not be held responsible for any

accidents, compensation for damage to a third party, resulting from the specifications not designated by

SEGA.

Ensure that the product meets the requirements of appropriate Electrical Specifications.

Before installing the product, check for Electrical Specifications. SEGA products have a nameplate on

which Electrical Specifications are described. Ensure that the product is compatible with the power

supply voltage and frequency requirements of the location. Using any Electrical Specifications different

from the designated Specifications can cause a fire and electric shock.

Install and operate the product in places where appropriate lighting is available, allowing warning

labels to be clearly read.

To ensure safety for the customers, labels and printed instructions describing potentially hazardous

situation are applied to places where accidents can be caused. Ensure that where the product is operated

has sufficient lighting allowing the warnings to be read. If any label is peeled off, apply it again immediately. Please place an order with where the product was purchased from or the office herein stated.

When handling the Monitor, be very careful. (Applies only to the product w/monitor.)

Some of the monitor (TV) parts are subject to high tension voltage. Even after running off power, some

portions are still subject to high tension voltage sometimes. Monitor repair and replacement should be

performed only be those technical personnel who have knowledge of electricity and technical expertise.

Be sure to adjust the monitor (projector) properly. (Applies only to the product w/monitor.)

Do not operate the product leaving on-screen flickering or blurring as it is. Using the product with the

monitor not properly adjusted may cause dizziness or a headache to an operator, a player, or the customers.

When transporting or reselling this product, be sure to attach this manual to the product.

In the case where commercially available monitors and printers are used in this product, only the

contents relating to this product are explained herein. Some commercially available equipment has

functions and reactions not stated in this manual. Read this manual together with the specific Instruction Manual of such equipment.

•

Descriptions herein contained may be subject to improvement changes without notice.

•

The contents described herein are fully prepared with due care. However, should any question arise or

errors be found, please contact SEGA.

INSPECTIONS IMMEDIATELY AFTER TRANSPORTING THE PRODUCT TO THE LOCATION.

Normally, at the time of shipment, SEGA products are in a status allowing for usage immediately after

transporting to the location. Nevertheless, an irregular situation may occur during transportation. Before

turning on power, check the following points to ensure that the product has been transported in a satisfactory status.

Are there any dented portions or defects (cuts, etc.) on the external surfaces of the cabinet?

Are Casters and Adjusters, damaged?

Do the power supply voltage and frequency requirements meet with those of the location?

Are all wiring connectors correctly and securely connected? Unless connected in the correct direction,

connector connections can not be made accurately. Do not insert connectors forcibly.

Do power cords have cuts and dents?

Do the fuses used meet specified rating? Is the Circuit Protector in an energized status?

Are all accessories available?

Can all Doors and Lids be opened with the Accessory keys? Can Doors and Lids be firmly closed?

TABLE OF CONTENTS

BEFORE USING THE PRODUCT, BE SURE TO READ THE FOLLOWING:

TABLE OF CONTENTS

INTRODUCTION OF THE OWNER’S MANUAL

1. HANDLING PRECAUTIONS ................................................................................................

2. PRECAUTIONS CONCERNING INSTALLATION LOCATION ........................................

3. OPERATION ...........................................................................................................................

4. NAME OF PARTS ...................................................................................................................

5. ACCESSORIES ......................................................................................................................

6. ASSEMBLING AND INSTALLATION .................................................................................

7. PRINTER (OPTIONAL)..........................................................................................................

7 - 1 OPERATION WITH THE PRINTER ATTACHED..............................................

7 - 2 SETTING THE ROLL PAPER..............................................................................

7 - 3 CLEANING OF THE PRINTER HEAD...............................................................

7 - 4 COUNTERMEASURES AGAINST PAPER JAM...............................................

8. PRECAUTIONS TO BE HEEDED WHEN MOVING THE MACHINE ..............................

9. HANDLE MECHA........ .........................................................................................................

9 - 1 ADJUSTING OR REPLACING THE V.R. ..........................................................

9 - 2 GREASING...........................................................................................................

9 - 3 REPLACING PADDLE (WING) SHIFT SWITCH...........................................

10. 6-SPEED SHIFT........................................................ .............................................................

10- 1 REMOVING THE SHIFT LEVER......................................................................

10- 2 REPLACING THE SWITCH...............................................................................

11. ACCELERATOR & BRAKE.................................................................................................

11- 1 ADJUSTING AND REPLACING THE V.R. .....................................................

11- 2 GREASING...........................................................................................................

12. CLUTCH PEDAL....... ..........................................................................................................

12- 1 REMOVING THE CLUTCH PEDAL.................................................................

12- 2 VOLUME ADJUSTMENT/REPLACEMENT.....................................................

12- 3 GREASING..........................................................................................................

13. COIN SELECTOR..................................................................................................................

14. MONITOR...............................................................................................................................

14- 1 CAUTIONS AND WARNINGS CONCERNING THE SAFETY FOR

HANDLING THE MONITORS...........................................................................

14- 2 CAUTIONS TO BE HEEDED WHEN CLEANING THE CRT

SURFACES...........................................................................................................

14- 3 ADJUSTMENT METHOD...................................................................................

14- 4 CLEANING THE MONITOR GLASS................................................................

15. REPLACING THE FLOURESCENT LAMP, AND LAMPS.................................................

16. PERIODIC INSPECTION TABLE.........................................................................................

17. TROUBLESHOOTING..........................................................................................................

18. GAME BOARD......................................................................................................................

18 - 1 TAKING OUT THE BOARD..............................................................................

18 - 2 COMPOSITION OF GAME BOARD.................................................................

19. DESIGN RELATED PARTS...................................................................................................

20. PARTS LIST............................................................................................................................

21. WIRE COLOR CODE TABE..................................................................................................

22. WIRING DIAGRAM..............................................................................................................

1

2 - 3

4 - 5

6

7 - 9

10 - 19

20

20 - 21

21 - 24

25

26

27 - 29

30

30 - 33

33

34 - 35

36

36 - 37

38

39

39 - 40

40

41

41 - 42

43

44

45 - 48

49

49 - 51

51

52 - 53

54 - 56

57 - 65

66 - 67

68 - 70

71

71 - 72

72

73

74 - 143

144

145-149

SPECIFICATIONS

Installation Space : 1,310 mm (W) X 2,830 mm (D)

(51.6 in. X 111.4 in.)

Height : 2,660 mm (104.7 in.)

Weight : 370 kg. (815.7 lbs.)

Power, maximum current : 600 W 6.7 A (AC 110V 50 Hz AREA)

600 W 6.7 A (AC 110V 60 Hz AREA)

580 W 6.0 A (AC 120V 60 Hz AREA)

590 W 3.5 A (AC 220V 50 Hz AREA)

580 W 3.4 A (AC 220V 60 Hz AREA)

600 W 3.4 A (AC 230V 50 Hz AREA)

580 W 3.2 A (AC 230V 60 Hz AREA)

600 W 3.2 A (AC 240V 50 Hz AREA)

590 W 3.2 A (AC 240V 60 Hz AREA)

For TAIWAN

Power, current : 600 W 6.7 A (MAX.)

340 W 4.0 A (MIN.)

MONITOR : 50 TYPE COLOR MONITOR

INTRODUCTION OF THE OWNERS MANUAL

This Owner's Manual is intended to provide detailed descriptions together with all

the necessary information covering the general operation of electronic assemblies,

electromechanicals, servicing control, spare parts, etc. as regards the product,

F355 CHALLENGE DX TYPE.

This manual is intended for the owners, personnel and managers in charge of

operation of the product. Operate the product after carefully reading and sufficiently

understanding the instructions. If the product fails to function satisfactorily, nontechnical personnel should under no circumstances touch the internal system. Please

contact where the product was purchased from.

Use of this product is unlikely to cause physical injuries or damages to property. However,

where special attention is required this is indicated by a thick line, the word "IMPORTANT"

and its sign in this manual.

STOP

Indicates that mishandling the product by disregarding this display can cause the

product's intrinsic performance not to be obtained, resulting in malfunctioning.

IMPORTANT

SEGA ENTERPRISES, INC. (U.S.A.)/CUSTOMER SERVICE

45133 Industrial Drive, Fremont, California 94538, U.S.A.

Phone : (415) 701-6580

Fax : (415) 701-6594

DEFINITION OF LOCATION MAINTENANCE MAN AND SERVICEMAN

Non-technical personnel who do not have technical knowledge and expertise should

refrain from performing such work that this manual requires the location's

maintenance man or a serviceman to carry out, or work which is not explained in

this manual. Failing to comply with this instruction can cause a severe accident

such as electric shock.

Ensure that parts replacement, servicing & inspections, and troubleshooting are performed by the

location's maintenance man or the serviceman. It is instructed herein that particularly hazardous

work should be performed by the serviceman who has technical expertise and knowledge.

The location's maintenance man and serviceman are herein defined as follows:

"Location's Maintenance Man" :

Those who have experience in the maintenance of amusement equipment and vending machines,

etc., and also participate in the servicing and control of the equipment through such routine work

as equipment assembly and installation, servicing and inspections, replacement of units and

consumables, etc. within the Amusement Facilities and or locations under the management of the

Owner and Owner's Operators of the product.

Activities of Location's Maintenance Man :

Assembly & installation, servicing & inspections, and replacement of units & consumables as

regards amusement equipment, vending machines, etc.

Serviceman :

Those who participate in the designing, manufacturing, inspections and maintenance service of

the equipment at an amusement equipment manufacturer.

Those who have technical expertise equivalent to that of technical high school graduates as regards electricity, electronics and or mechanical engineering, and daily take part in the servicing &

control and repair of amusement equipment.

Serviceman's Activities :

Assembly & installation and repair & adjustments of electrical, electronic and mechanical parts of

amusement equipment and vending machines.

LISTED

U

®

L

5K92

AMUSEMENT MACHINE

1. HANDLING PRECAUTIONS

When installing or inspecting the machine, be very careful of the following points and pay

attention to ensure that the player can enjoy the game safely.

Non-compliance with the following points or inappropriate handling running counter to the

cautionary matters herein stated can cause personal injury or damage to the machine.

Before performing work, be sure to turn power off. Performing the work

without turning power off can cause an electric shock or short circuit. In the

case work should be performed in the status of power on, this manual always

states to that effect.

To avoid electric shock or short circuit, do not plug in or unplug quickly.

To avoid electric shock, do not plug in or unplug with a wet hand.

Do not expose Power Cords and Earth Wires on the surface, (floor, passage,

etc.). If exposed, the Power Cords and Earth Wires are susceptible to damage.

Damaged cords and wires can cause electric shock or short circuit.

To avoid causing a fire or electric shock, do not put things on or damage

Power Cords.

When or after installing the product, do not unnecessarily pull the power cord.

If damaged, the power cord can cause a fire or electric shock.

In case the power cord is damaged, ask for replacement through where the

product was purchased from or the office herein stated. Using the cord as is

damaged can cause fire, electric shock or leakage.

Be sure to perform grounding appropriately. Inappropriate grounding can

cause an electric shock.

Be sure to use fuses meeting specified rating. Using fuses exceeding the

specified rating can cause a fire or electric shock.

Completely make connector connections for IC BD and others. Insufficient

insertion can cause an electric shock.

To avoid causing a fire or electric shock, do not make Specification changes

by removing, converting and making additions unless otherwise designated by

SEGA.

Be sure to perform periodic maintenance inspections herein stated.

STOP

For the IC board circuit inspections, only the logic tester is allowed. The use

When cleaning the CRT surfaces, use a soft, dry cloth. Do not apply

IMPORTANT!

The electronic parts on the IC Board could be damaged due to human body's

of a multiple-purpose tester is not permitted, so be careful in this regard.

chemicals such as thinner, benzine, etc.

static electricity. Before performing IC Board related work, be sure to

discharge physically accumulated statics by touching grounded metallic

surfaces, etc.

1 www.seuservice.com

2. PRECAUTIONS CONCERNING INSTALLATION

LOCATION

This product is an indoor game machine. Do not install it outside. Even indoors,

avoid installing in places mentioned below so as not to cause a fire, electric shock,

injury and or malfunctioning.

Places subject to rain or water leakage, or places subject to high humidity in

the proximity of an indoor swimming pool and or shower, etc.

Places subject to direct sunlight, or places subject to high temperatures in the

proximity of heating units, etc.

Places filled with inflammable gas or vicinity of highly inflammable/volatile

chemicals or hazardous matter.

Dusty places.

Sloped surfaces.

Places subject to any type of violent impact.

Vicinity of anti-disaster facilities such as fire exits and fire extinguishers.

The operating (ambient) temperature range is from 5˚C to 40˚C.

Only in the case a projector is employed, the temperature range is from 5˚C to

30˚C.

LIMITATIONS OF USAGE REQUIREMENTS

Be sure to check the Electrical Specifications.

Ensure that this product is compatible with the location's power supply,

voltage and frequency requirements.

A plate describing Electrical Specifications is attached to the product.

Non-compliance with the Electric Specifications can cause a fire and electric

shock.

This product requires the Breaker and Earth Mechanisms as part of the

location facilities. Using them in a manner not independent can cause a fire

and electric shock.

Ensure that the indoor wiring for the power supply is rated at 15A or higher

(AC single phase 100 ~ 120V area), and 7A or higher (AC 220 ~ 240V area).

Non-compliance with the Electrical Specifications can cause a fire and

electric shock.

Be sure to independently use the power supply equipped with the Earth

Leakage Breaker. Using a power supply without the Earth Leakage Breaker

can cause an outbreak of fire when earth leakage occurs.

Putting many loads on one electrical outlet can cause generation of heat and a

fire resulting from overload.

When using an extension cord, ensure that the cord is rated at 15A or higher

(AC 100 ~ 120V area) and 7A or higher (AC 220 ~ 240V area). Using a cord

rated lower than the specified rating can cause a fire and electric shock.

2www.seuservice.com

Electric current consumption

MAX. 8.70 A (AC 110V 50 Hz)

MAX. 8.30 A (AC 110V 60 Hz)

MAX. 7.70 A (AC 120V 60 Hz)

MAX. 4.50 A (AC 220V 50 Hz)

MAX. 4.30 A (AC 220V 60 Hz)

MAX. 4.20 A (AC 230V 50 Hz)

MAX. 4.00 A (AC 230V 60 Hz)

MAX. 4.10 A (AC 240V 50 Hz)

MAX. 3.90 A (AC 240V 60 Hz)

MAX. 8.30 A (For TAIWAN)

STOP

For transporting the machine into the location's building, the minimum

IMPORTANT!

For the operation of this machine, secure a minimum area of 2.49m (W) X

necessary dimensions of the opening (of doors, etc.) are 1.2m(W) and

1.7m(H).

3.16m (D). For ventilation, provide an approximately 20cm. space between

the rear part of the cabinet and the wall.

FIG. 2

3 www.seuservice.com

3. OPERATION

2

2

2

2

2

PRECAUTIONS TO BE HEEDED BEFORE STARTING THE OPERATION

To avoid injury and trouble, be sure to constantly give careful attention to the behavior and

manner of the visitors and players.

In order to avoid accidents, check the following before starting the operation:

Check if all of the adjusters are in contact with the surface. If they are not, the

Cabinet can move and cause an accident.

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

Ensure that all of the

Adjusters are in contact

with the floor.

Do not put any heavy item on this product. Placing any heavy item on the

product can cause a falling down accident or parts damage.

Do not climb on the product. Climbing on the product can cause falling down

accidents. To check the top portion of the product, use a step.

To avoid electric shock, check to see if door & cover parts are damaged or

omitted.

To avoid electric shock, short circuit and or parts damage, do not put the

following items on or in the periphery of the product.

Flower vases, flowerpots, cups, water tanks, cosmetics, and receptacles/

containers/vessels containing chemicals and water.

To avoid injury, be sure to provide sufficient space by considering the potentially

crowded situation at the installation location. Insufficient installation space can

cause the customers to come into contact with or hit the others and result in injury

or trouble.

4www.seuservice.com

PRECAUTIONS TO BE HEEDED DURING OPERATION (PAYING ATTENTION TO CUSTOMERS)

To avoid injury and trouble, be sure to constantly give careful attention to the behavior and

manner of the visitors and players.

To avoid injury and accidents, those who fall under the following categories

are not allowed to play the game.

• Those who need assistance such as the use of an apparatus when walking.

• Those who have high blood pressure or a heart problem.

• Those who have experienced muscle convulsion or loss of consciousness

when playing video game, etc.

• Those who have a trouble in the neck and or spinal cord.

• Intoxicated persons.

• Pregnant women or those who are in the likelihood of pregnancy.

• Persons susceptible to motion sickness.

• Persons whose act runs counter to the product's warning displays.

To avoid injury resulting from falling down, and electric shock due to spilled

drinks, instruct the player not to place heavy items or drinks on the product.

To avoid electric shock and short circuit, do not allow customers to put hands

and fingers or extraneous matter in the openings of the product or small

openings in or around the doors.

To avoid falling down and injury resulting from falling down, immediately

stop the customer's leaning against or climbing on the product, etc.

To avoid electric shock and short circuit, do not allow the customers to

unplug the power plug without a justifiable reason.

To avoid a fire due to a cigarette stub, caution the customers so as not to put

dust on the Seat rear.

Caution the customers so as not to put dust on the outlet for driving records.

Failure to observe this may cause a fire due to cigarette stubs.

This product is intended for 1 Player only. Playing the game by 2 or more

Players riding on the seat together can cause falling down and collision

accidents by striking head, hand, or elbow.

Immediately stop such violent acts as hitting and kicking the product. Such

violent acts can cause parts damage or falling down, resulting in injury due to

fragments and falling down.

To avoid collision or falling down accident, caution the customers so as not to

come in to the Seat rear.

Instruct the Player to take firm hold of the Steering Wheel when in play. The

Steering Wheel is equipped with reaction mechanism. Holding the Steering

Wheel lightly while playing the game can cause a contingent accident.

Instruct the customer, other than the Player, not to touch the operation device

when in play. Touching the operation device during play can cause accidents

and trouble between customers.

Instruct the Player to adjust the seat before playing the game. Playing the

game in a forcible posture can cause a contingent accident.

This product is designed for players taller than 130cm and shorter than

210cm. To avoid accidents, instruct the customers who do not meet the

height requirements to refrain from playing the game.

5 www.seuservice.com

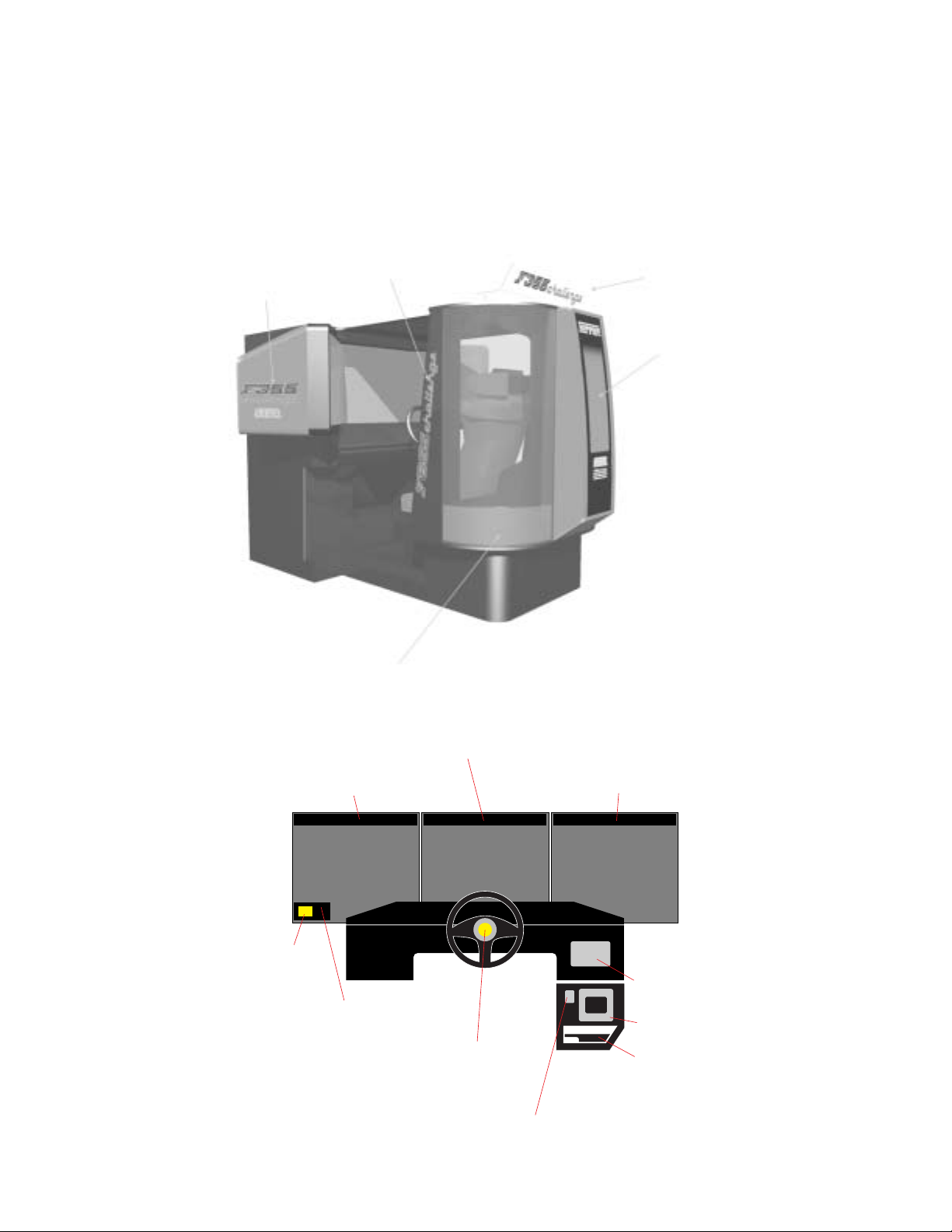

4. NAME OF PARTS

29 inch monitor

Accel.& Brake Pedal

Clutch Pedal

Coin chute door

FRONT CABINET

Steering Wheel

Billboard

Cashbox door

REAR CABINET

FIG. 4 a OVERVIEW

6-speed shift

Effect switch

AC unit

FIG. 4 c REAR VIEW

FIG. 4 b

TABLE 4

Width X Length X Height Weight

FRONT CABINET 2,080 mm X 780 mm X 1,649 mm 401 kg

REAR CABINET 1,190 mm X 1,480 mm X 1,649 mm 187 kg

When assembled 2,080 mm X 2,260 mm X 1,833 mm 598 kg

6www.seuservice.com

5. ACCESSORIES

When transporting the machine, make sure that the following parts are supplied.

The printer is available in this product as an optional. The printer prints Player's game results

on the paper exclusively used for this product. Contact where you purchased the product from

and mention the following Kit No. for an order. Detailed installation method is explained in the

Kit Manual contained in the Kit.

KIT NO. : XKT-0440-EX1 DESCRIPTION: PRINTER KIT FOR FRI DX EXP

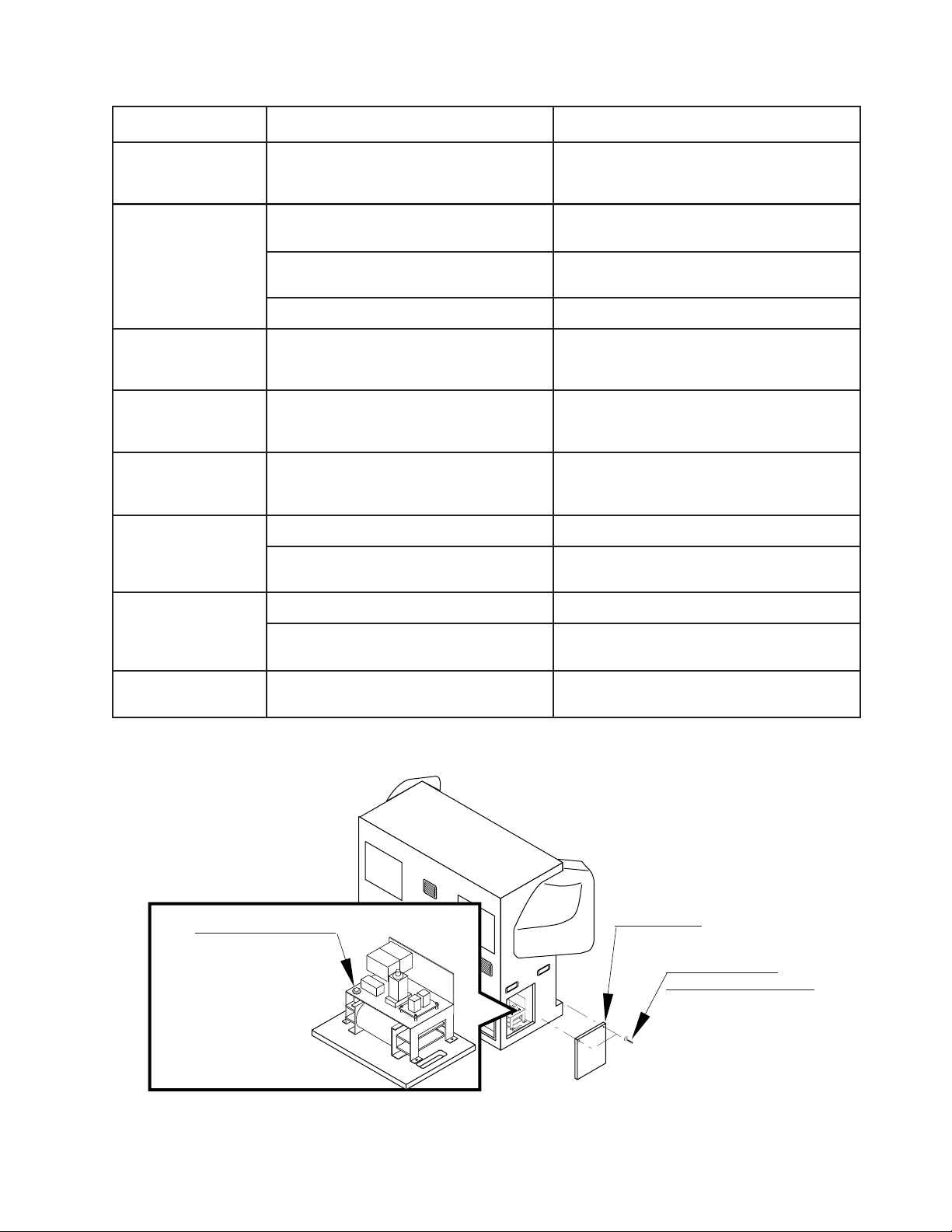

TABLE 5 ACCESSORIES

DESCRIPTION OWNERS MANUAL

Part No.( Qty. )

420-6507-01( 1 )

Note

Figures

If Part No. has no description, the Number has not been

registered or can not be registered. Such a part may not

be obtainable even if the customer desires to purchase it.

Therefore, ensure that the part is in safekeeping with you.

AC Cable (Power Cord)

600-6729 (1) AC 110V AREA

600-6695 (1) AC 120V AREA

600-6618 (1) AC 220 ~ 240V AREA

Used for installation, see 4 of Section 6.

SERVICE MANUAL

420-6508-01( 1 )

KEY MASTER

220-5576 ( 2 )

For opening/closing

the doors

TAMPERPROOF†WRENCH

M8 540-0009-01 (1)

TOOL

KEY

( 2 )

For the CASHBOX DOOR

CORD CLAMP

280-5009-01 (1)

Used for securing the

power cord.

see 4 of Section 6.

7 www.seuservice.com

VOL CONT B-5K OHM

220-5484

220-5373

Spare,

see Section 9, 11, 12.

(1)

SW MICRO TYPE

509-5387 (2)

Spare, see Section 9.

SW MICRO TYPE

509-5636 (2)

Spare, see Section 10.

FUSE 6.3A 250W

514-5086-6300 (1)

Spare, see Section 17.

CARTON BOX

601-10577 (1)

Used for transporting the

Game Board.

Refer to Next Page.

TAMPERPROOF†SCREW

008-B00830-0B (2)

Used for installing

BILLBOARD.

see 2 of Section 6.

8www.seuservice.com

HOW TO USE THE CARTON BOX

STOP

When requesting for the replacement/repair of this product's Game Board

(NAOMI BOARD), follow the instructions below. Transporting the Game Board

in an undesignated status is unacceptable. An erroneous handling can cause parts

IMPORTANT!

damage.

• Put the Game Board in the Carton Box together with the Shield Case. Do not

• By paying careful attention to the direction shown by the following Figure,

unnecessarily disassemble nor remove parts.

put the Shield Case in the Carton Box.

GRIP

FILTER BD side.

Ensure that the direction in which

the Shield Case is packed is correct.

GRIP

Remove the Brackets (the shape differs

FILTER BOARD

Enfold the Shield Case with the packing material shown, and put it in the carton box.

Positioning the Shield Case upside down or packing in the manner different from what is shown

in this Figure can cause the Game Board and other parts to be damaged.

depending on the specific type of machine).

9 www.seuservice.com

6. ASSEMBLING AND INSTALLATION

Perform assembly work by following the procedure herein stated. Failing to

comply with the instructions can cause electric shock hazard.

Perform assembling as per this manual. Since this is a complex machine,

erroneous assembling can cause an electric shock, machine damage and or not

functioning as per specified performance.

When assembling, be sure to use plural persons. Depending on the assembly

work, there are some cases in which working by one person alone can cause

personal injury or parts damage.

Ensure that connectors are accurately connected. Incomplete connections can

cause electric shock hazard.

Be careful so as not to damage wirings. Damaged wiring can cause electric

shock and short circuit hazards.

In the case the cabinet is separated into the front and rear portions, do not

push the upper rear part of the front cabinet. Failure to observe this causes the

front cabinet to fall down towards the monitor side and result in accidents and

injury to persons. When moving the front cabinet in the above case, be sure to

push it from side directions and move it by 2 or more persons for safety.

This work should be performed by the Location's Maintenance Man or

Serviceman. Performing work by non-technical personnel can cause a severe

accident such as electric shock. Failing to comply with this instruction can

cause a severe accident such as electric shock to the player during operation.

Provide sufficient space so that assembling can be performed. Performing

work in places with narrow space or low ceiling may cause an accident and

assembly work to be difficult.

When handling plastic parts, use care. Do not give a shock or apply excessive

load to the fluorescent lamps and plastic parts. Failure to observe this can cause

parts damage, resulting in injury due to fragments, cracks and broken pieces.

10www.seuservice.com

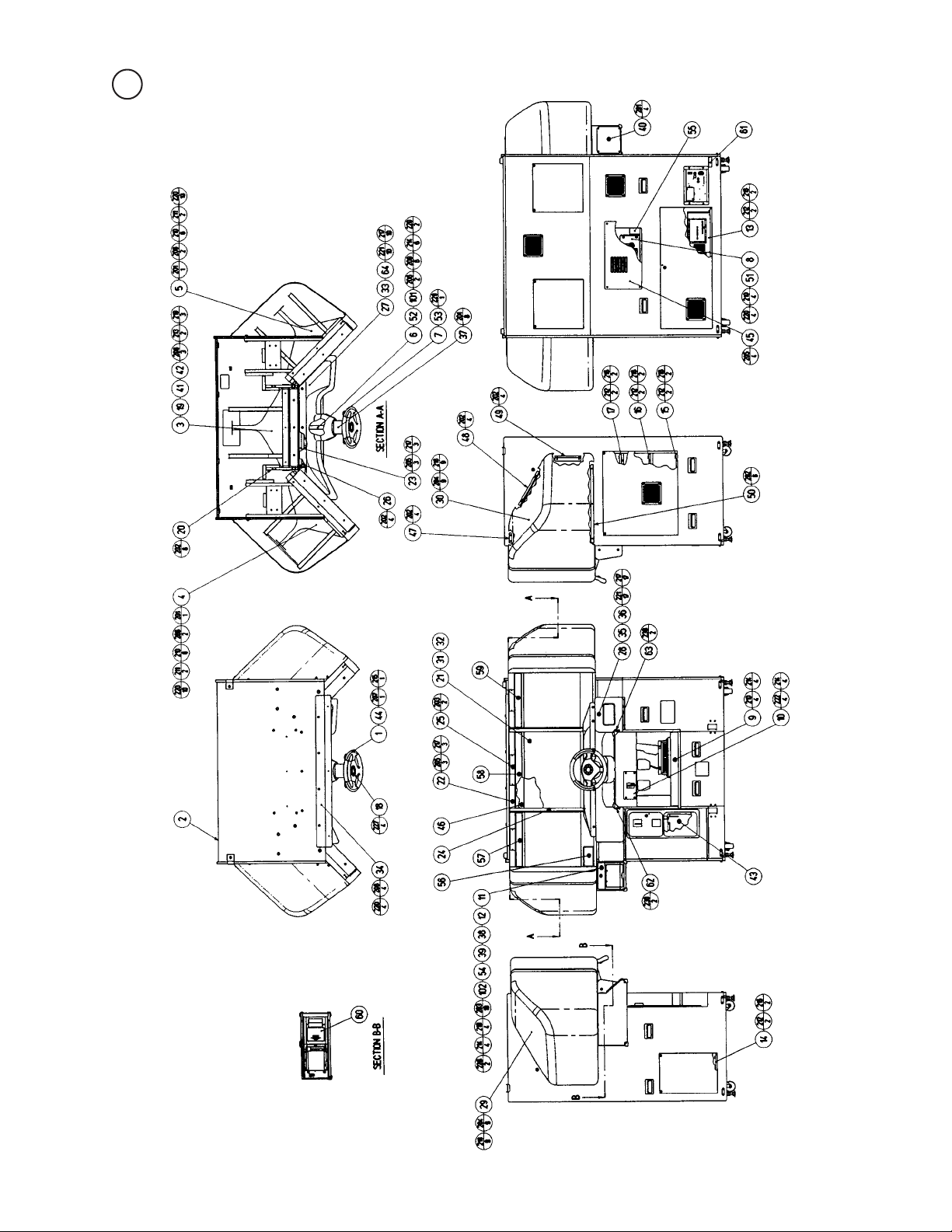

When carrying out the assembling and installation, follow the following 6-item sequence.

1

2

3

4

5

6

The master key (accessories) in addition to the tools such as a Phillips type screwdriver, wrench

for M16 hexagon bolt, socket wrench, Ratchet Handle for M6, M8 hexagon bolt,

Tamperproof†wrench (accessories) are required for the assembly work.

ASSEMBLING THE CABINET

INSTALLING THE CENTER ROOF AND THE BILLBOARD

SECURING IN PLACE (ADJUSTER ADJUSTMENT)

POWER SUPPLY CONNECTION

TURNING POWER ON

ASSEMBLING CHECK

Phillips type screwdriver

24mm

SOCKET WRENCH,(for M6,M8 hexagon bolt)

RATCHET HANDLE

WRENCH (for M16 hexagon bolt)

TAMPERPROOF†WRENCH

KEY MASTER

11 www.seuservice.com

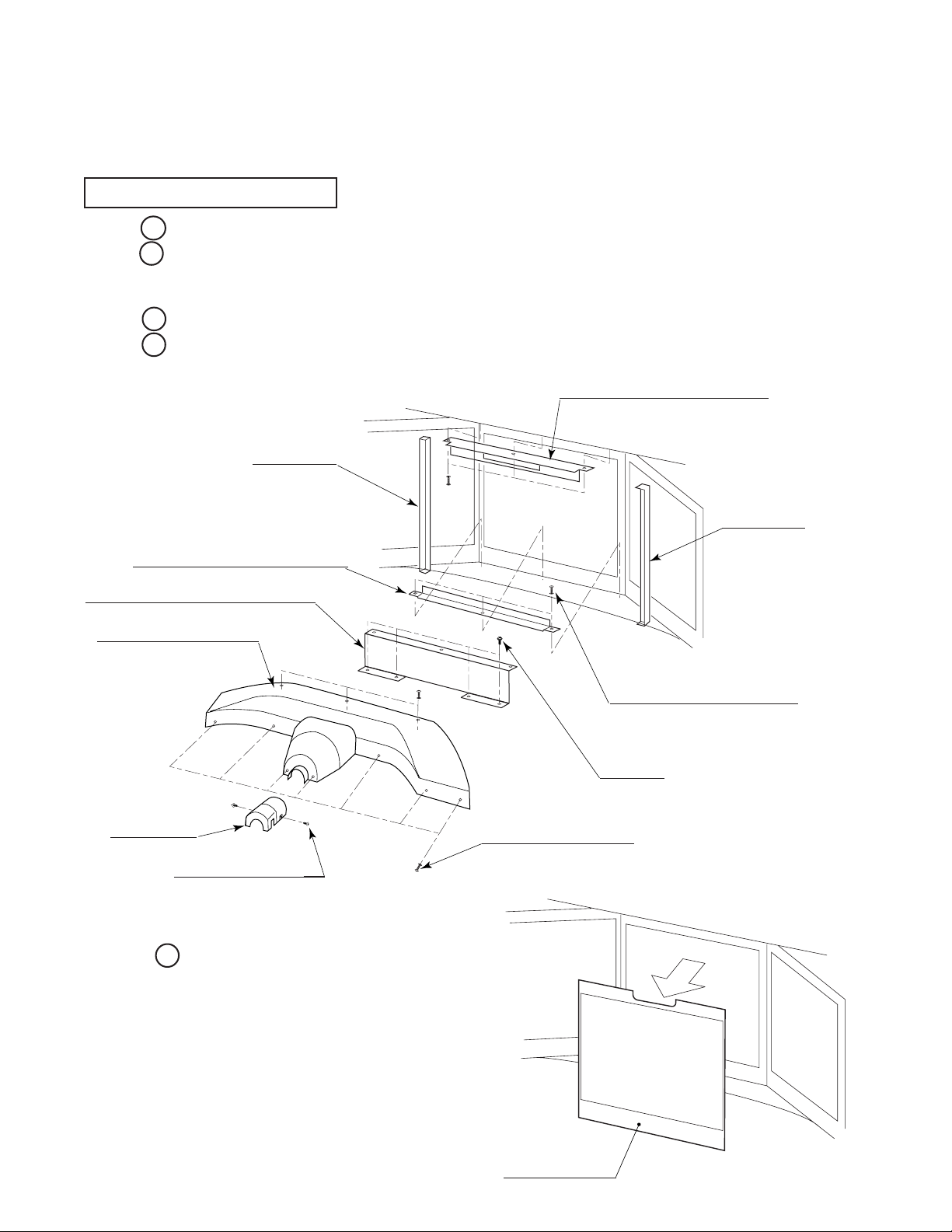

1

ASSEMBLING THE CABINET

1

Install the Joint Bracket L and 2 Joint Bracket R to the both sides of Front Cabinet, and 2 Joint

Pipes to the inside. At this time, temporarily install the Joint Brackets L and R.

JOINT BRACKET R

JOINT PIPE

Hexagon Bolt(2 each)

M8 X 30,w/spring washer,

flat washer used.

JOINT BRACKET L

FIG. 6. 1 a

Connect the wiring from the Front

2

Cabinet to the Rear Cabinet.

REAR CABINET side

Hexagon Bolt(4 each)

M8 X 20,w/spring washer,

flat washer used.

Hexagon Bolt(2) M8 X 30,w/spring washer, flat washer used.

Connect the Earth.

SCREW (1)

M4 X 8,w/flat & spring washers

Connect the Connectors.

FRONT CABINET side

FIG. 6. 1 b

12www.seuservice.com

Insert the Front Cabinet's Joint pipes into the Rear Cabinet's square holes to fit both cabinets

3

tight. Be sure to perform this work by 2 or more workers. Also, be careful so as not to pinch

the wiring.

Secure the joint portion of the

4

Cabinets with 6 Hexagon Bolts.

Firmly secure the Joint Brackets

L&R, respectively.

By using Joint Plate Center, secure

5

the joint portion of the Cabinets

with 4 Truss screws and Hexagon

Bolts.

HEXAGON BOLT (2)

M8 X 30,w/spring washer

JOINT BRACKET R

HEXAGON BOLT (2 each)

M8 X 20,w/spring washer,

flat washer used.

JOINT PLATE CENTER

TRUSS SCREW (4)

M4 X 16

HEXAGON BOLT (2 each)

M8 X 30,spring washer,

flat washer used.

JOINT BRACKET L

FIG. 6. 1 c

13 www.seuservice.com

INSTALLING THE CENTER ROOF AND THE BILLBOARD

2

1

Put the Center Roof on its installation position.

2

Put each of Roof Nut Plates F & R on to the fixed portion of the Center Roof front and rear and

secure with 3 Truss screws for each.

3

Remove the Shipping Bracket Rear from the Rear Cabinet's ceiling. Remove the 2 pairs of

Tamperproof screws and Hexagon Bolts.

4

Secure the Billboard with the 2 Tamperproof screws (separately packed) and the 2 flat washers

which previously secured the Shipping Bracket Rear.

ROOF NUT PLATE F

CENTER ROOF

ROOF NUT PLATE R

TRUSS SCREW (3 each)

M6 X 30,flat washer used.

BILLBOARD

TAMPERPROOF SCREW (2)

M8 X 30

SHIPPING

BRACKET REAR

HEXAGON NUT

M8,flat washer used.

TAMPERPROOF SCREW (2)

M8 X 30,flat washer used.

FIG. 6. 2

14www.seuservice.com

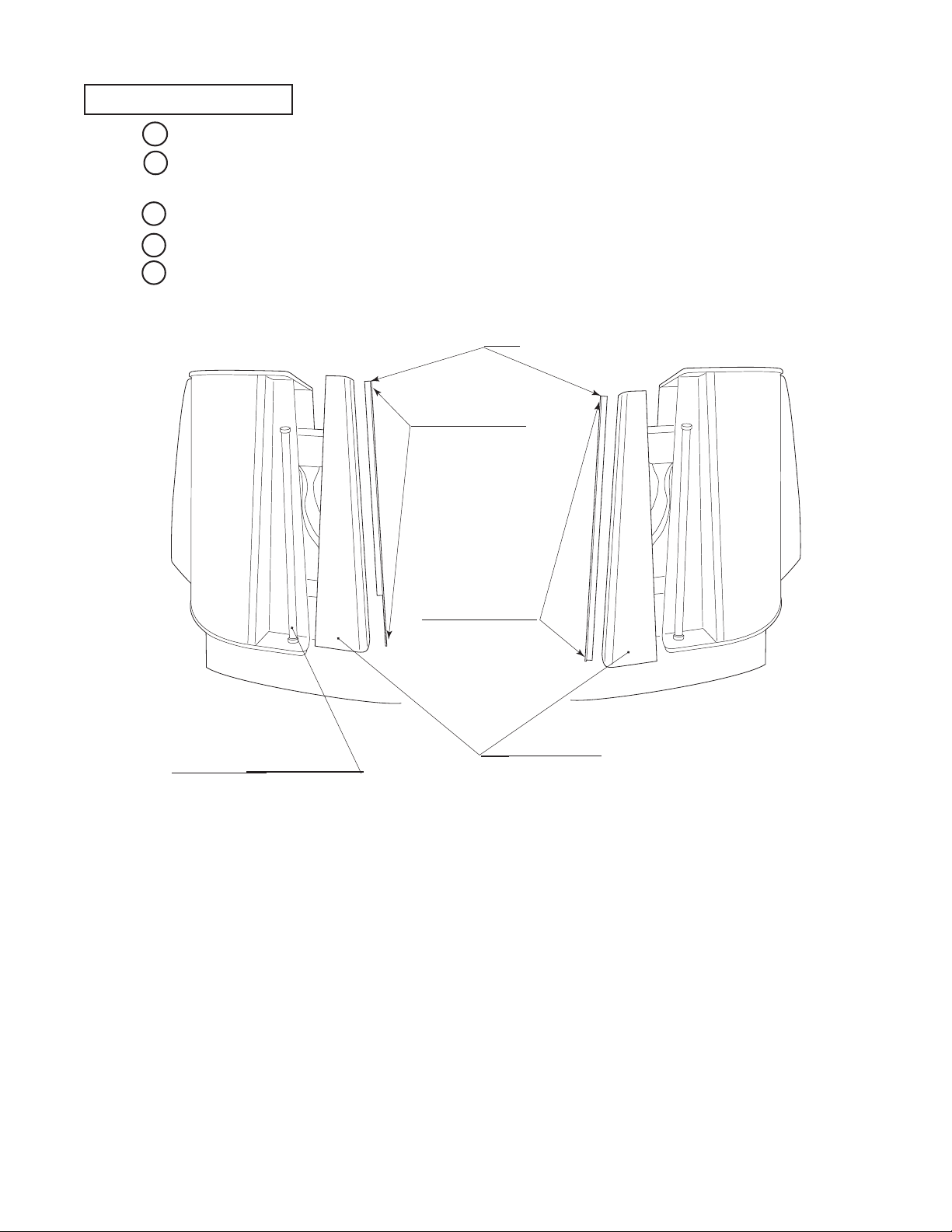

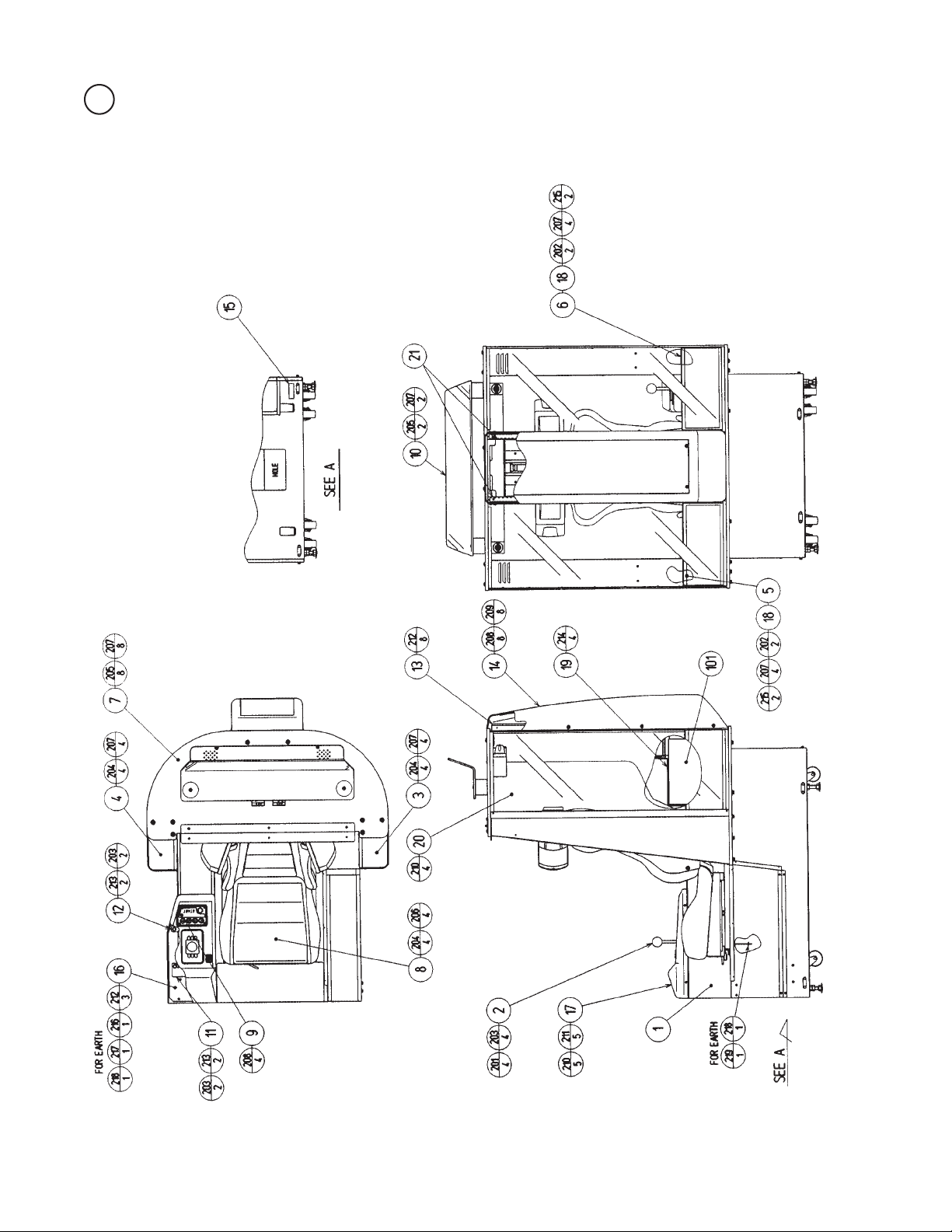

SECURING IN PLACE (ADJUSTER ADJUSTMENT)

3

2

2

2

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

Make sure that all of the adjusters are in contact with the floor. If they are not, the

cabinet can move and cause an accident.

This product has 8 casters (4 for Front Cabinet, 4 for Rear Cabinet) and 8 Adjusters (4 for Front

Cabinet, 4 for Rear Cabinet). (FIG. 6. 3a) When the installation position is determined, cause

the adjusters to come into contact with the floor directly, make adjustments in a manner so that

the casters will be raised approximately 5mm. from the floor and make sure that the machine

position is level.

1

Transport the product to the

installation position. Be sure to

provide adequate space allowing

the player to get on and off.

2

Have all of the Adjusters make

contact with the floor. Adjust the

Adjuster's height by using a

wrench so that the machine

position is kept level.

CASTER

3

After making adjustment, fasten

the Adjuster Nut upward and

secure the height of Adjuster

(FIG. 6. 3 b).

ADJUSTER

FIG. 6. 3 c

Refer to this Fig. (Scale:1/100)

for the layout of the place of

installation.

FASTEN UPWARD.

FIG. 6. 3 b ADJUSTER

15 www.seuservice.com

ADJUSTER

FIG. 6. 3 a BOTTOM VIEW

ADJUSTER

200mm

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234567890123456789012345678901212345678901

234

234567890123456789012345678901212345678901

234

234567890123456789012345678901212345678901

234

FIG. 6. 3 d

Be sure to provide space as shown between

the Air Vent and the wall surface.

CASTER

Approx.5mm

POWER SUPPLY, AND EARTH CONNECTION

4

Be sure to independently use the power supply socket outlet equipped with an

Earth Leakage Breaker. Using a power supply without an Earth Leakage

Breaker can cause a fire when electric leakage occurs.

Ensure that the "accurately grounded indoor earth terminal" and the earth wire

cable are available (except in the case where a power cord plug with earth is

used). This product is equipped with the earth terminal. Connect the earth

terminal and the indoor earth terminal with the prepared cable. If the

grounding work is not performed appropriately, customers can be subjected to

an electric shock, and the product's functioning may not be stable.

Ensure that the power cord and earth wire are not exposed on the surface

(passage, etc.). If exposed, they can be caught and are susceptible to damage.

If damaged, the cord and wire can cause electric shock and short circuit

accidents. Ensure that the wiring position is not in the customer's passage

way or the wiring has protective covering.

After wiring power cord on the floor, be sure to protect the power cord.

Exposed power cord is susceptible to damage and causes an electric shock

accident.

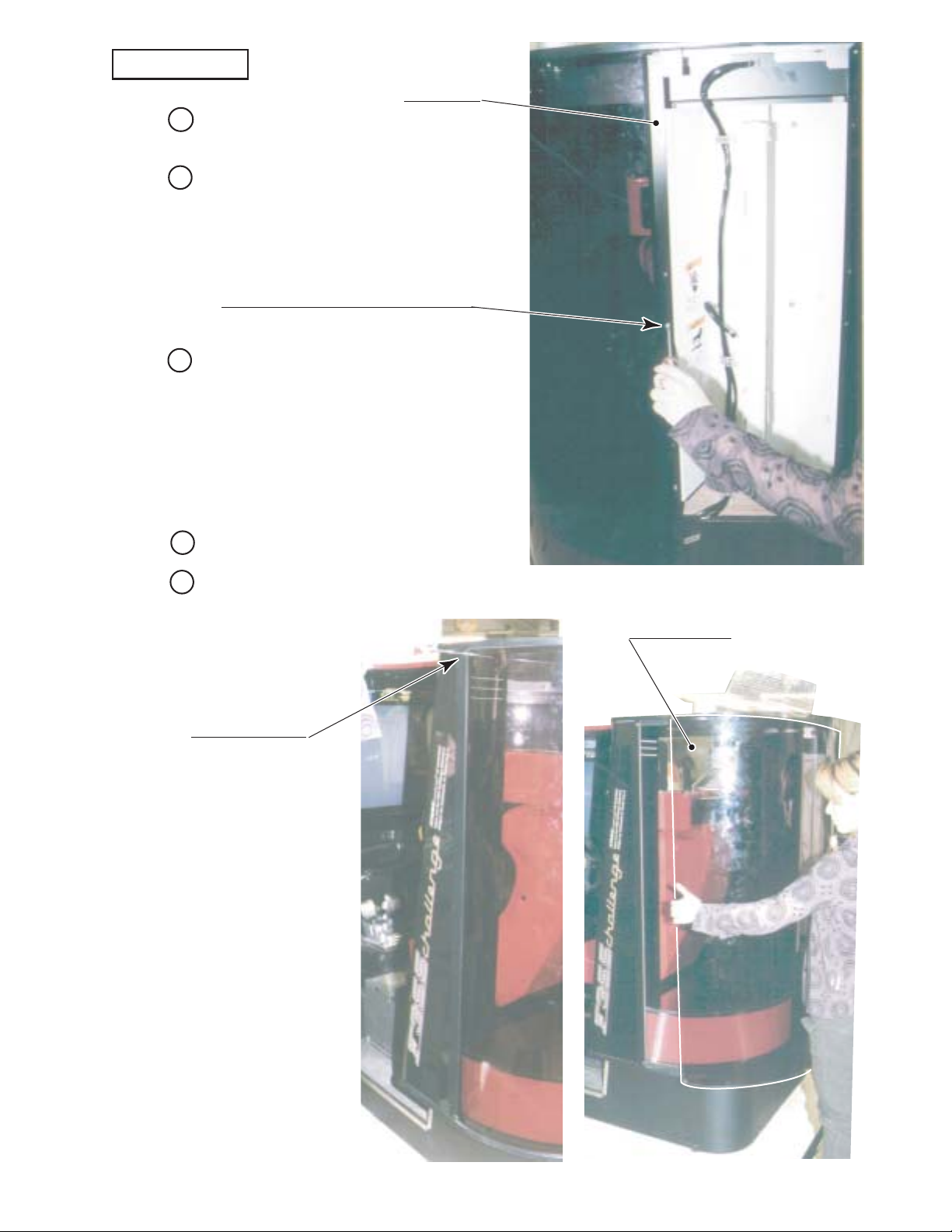

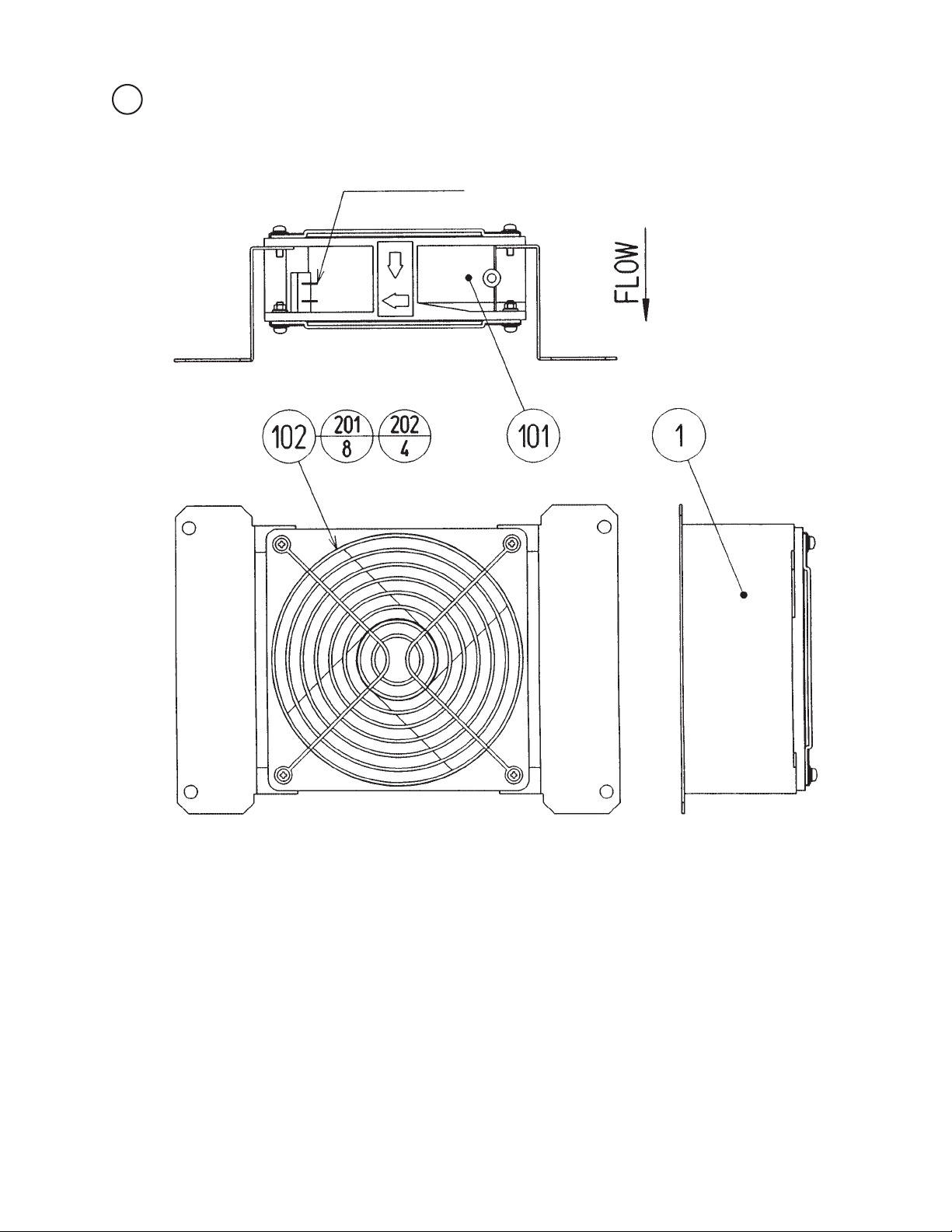

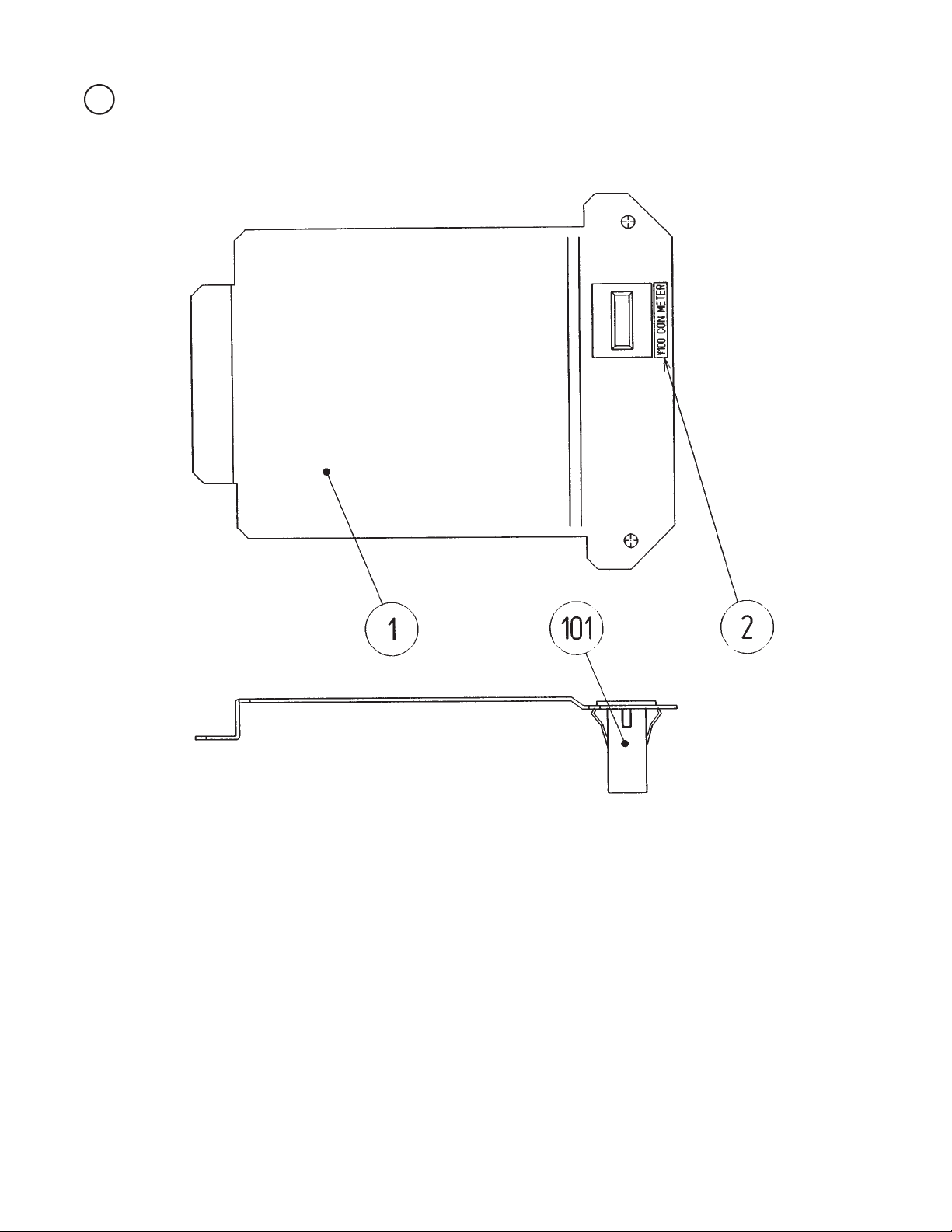

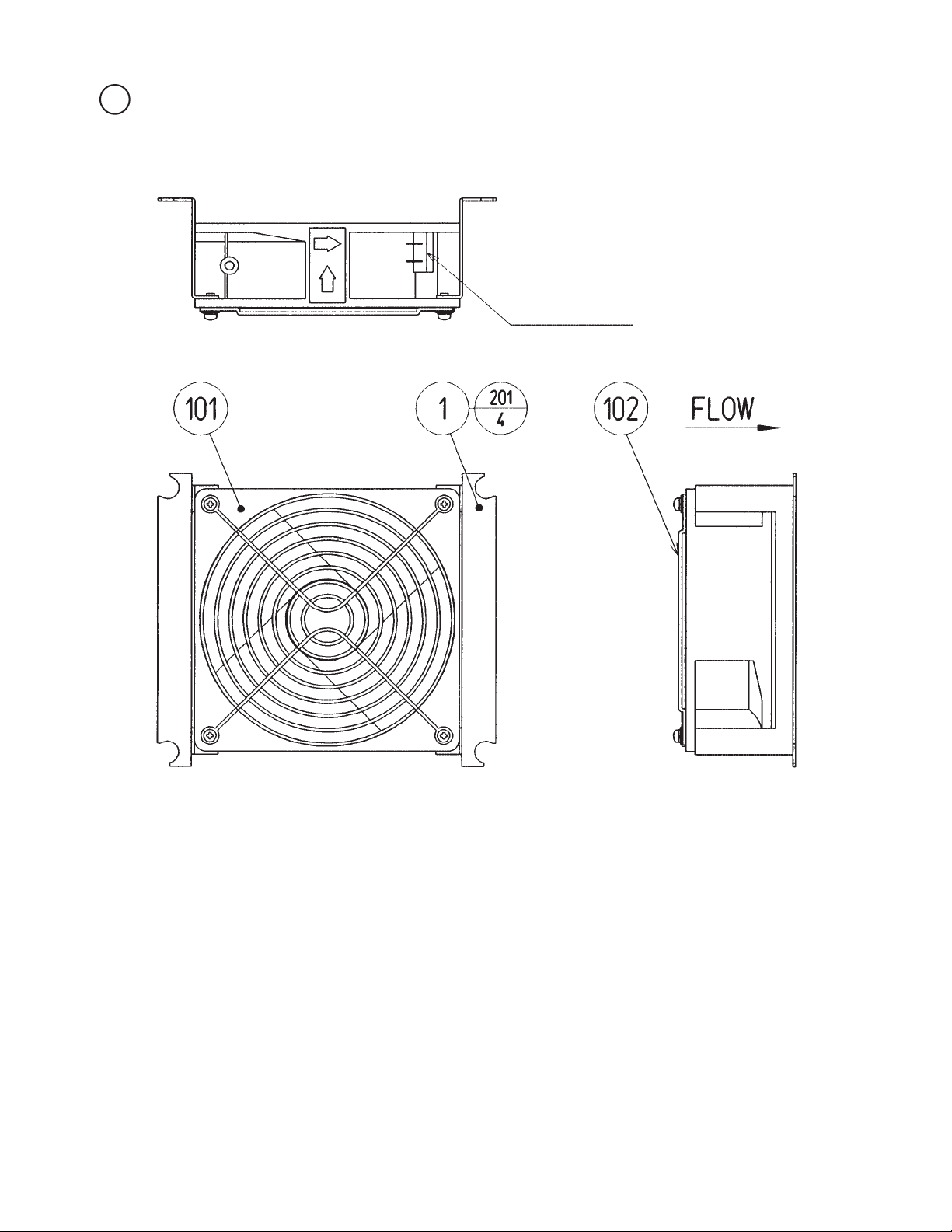

The AC Unit is mounted on the rear of the machine. The AC Unit has Main SW,

Circuit Protector and the Inlet which connects the Power Cord.

1

Ensure that the Main SW is OFF.

EARTH TERMINAL

Connect with the indoor earth terminal.

MAIN SW

Main SW off

CIRCUIT PROTECTOR

AC Cable (Power Cord)

FIG. 6. 4 a AC unit

INLET

16www.seuservice.com

Connect one end of the earth wire to the AC Unit

2

earth terminal, and the other end to the indoor earth

Connect the Earth Wire

to the Earth Terminal.

terminal. The AC Unit earth terminal has a Bolt

and Nut combination. Take off the Nut, pass the

end of earth wire through the Bolt, and fasten the

Nut.

Note that the Earth Wire is incorporated in the

Power Cord for the Areas of AC 120V (USA) and

AC 220Å`240V, and therefore, this procedure is

not necessary.

FIG. 6. 4 b Earth Wire Connection

3

Firmly insert the power plug into the socket outlet.

Insert the opposite side of Power Cord plug to the

AC Unit's connector ("INLET").

4

Perform wiring for the Power Cord and Earth Wire. Install protective covering for the Power

Cord and Earth Wire.

FIG. 6. 4 c Connecting Power Cord and Earth Wire

HOW TO USE THE CORD CLAMP

Wiring Cover

In case the Power Plug is apt to come out of place, secure the

Power Cord to the periphery of the AC Unit with the Cord

Clamp (an accessory).

17 www.seuservice.com

5

TURNING POWER ON

Turn the Main SW of AC Unit ON to turn power on. When the power is turned on, the

fluorescent lamps of the left & right of Seat in the Rear cabinet, the back, and the inside the

Billboard light up. The screen displays the starting of Naomi System and then proceeds to

ADVERTISE mode. During this time, the machine automatically performs Power On check.

Do not touch the machine until Power On check is finished and ADVERTISE mode is displayed

on the screen. In the Power On check, the steering wheel turns left and right, then returns to the

centering position and stops. In this check, the values of V.R. inside the control panel are

corrected. Until the check is finished (the steering wheel stops automatically), do not touch the

steering wheel or play the game. If you do, the steering wheel reaction during the game

(reaction at the time of a course-out or crashing) can not be obtained correctly. In case of an

abnormal reaction during the game, turn the power on again from the beginning and complete

the power-on check. In this product, once the power is turned off, the data of inserted coins less

than one credit and BONUS ADDER is cleared. As the exclusively used paper is not supplied

to the Printer at the time of shipment, the message "Printer unavailable" is displayed on the

Advertise screen and the 2 red Lamps of the Rear Cabinet back side light up.

FIG. 6. 5

18www.seuservice.com

6

ASSEMBLING CHECK

In the TEST mode, ascertain that the assembly has been made correctly, IC BD. is satisfactory,

and the screen adjustment is appropriate. For details, refer to the SERVICE MANUAL. In the

test mode, perform the following test:

• MEMORY TEST

The on-board memory is tested automatically.

• CRT TEST

The screen on which the monitor is adjusted is displayed.

• INPUT TEST

Each switch and V.R. are tested.

• OUTPUT TEST

The lamp, motor, etc. are tested.

• SOUND TEST

The sound related BD and wiring connections are tested. Be sure to check if the sound is

satisfactorily emitted from each speaker and the sound volume is appropriate.

Perform the above inspections also at the time of monthly inspection.

19 www.seuservice.com

7. PRINTER (OPTIONAL)

Refer to this section only when the Printer (optional) is attached.

Be sure to turn off power unless otherwise specified before performing work.

Performing work on the energized machine can cause hands or fingers to be

pinched in or in jured due to the machine's sudden move.

Do not touch undesignated places. Failure to observe this may cause a burn

due to the Head's high temperature when printing.

When performing work that uses the cutter, be very careful so as not to cut

hands or fingers.

STOP

Be sure to use the exclusively used paper and a Cleaning Pen. Using

Be sure to use the new roll paper unwrapped immediately before the use.

IMPORTANT!

When setting the paper with the power on, if the paper volume is small, the

When the Printer is malfunctioning, the 2 Error

Lamps attached to the Rear Cabinet back side flash or

light up. The Lamps flash when the paper is

exhausted and light up when the trouble is other than

the running out of paper.

When placing an order, contact where you purchased

the product or the Printer Kit from in stating the

following part number and the description.

The following set (Part Number: 601-10735-01) consists of 4 rolls of exclusively used paper

and a Cleaning Pen.

PART NUMBER: 601-10735-01 DESCRIPTION: PAPER FOR F355 ENG

unspecified parts can cause malfunctioning and/or a damage to parts.

Using the roll paper previously unwrapped and left for a while can cause

malfunctioning due to deterioration resulted from humidity.

Printer might not accept the set roll paper. In that case, follow the "SETTING

THE PAPER WITH THE POWER OFF" procedures to set the paper.

ERROR LAMP

FIG. 7

7 - 1 OPERATION WITH THE PRINTER ATTACHED

The Printer which prints Player's Driving Data and the GAME BOARD do not keep the data to

be printed. When "PRINTING CAN NOT BE DONE" is displayed or the PRINTER is set to

OFF in the Test mode, printing can not be done as the product does not have such system as

printing out the data at a later operation. Therefore, as for the printing, instruct the Player to pay

attention to the following.

Although YES is selected to the "PRINT OUT?" question displayed on the monitor, printing

can not be done if a credit worth coin is not inserted within the time limit. Such credit (coin)

as inserted after the time limit is regarded as a game play credit.

If the Printer malfunctions such as a paper jam occurred during printing, the printing for the

Driving Data can not be done as neither the Printer nor the ROMs on the GAME BOARD

keeps the data.

When "PRINTING CAN NOT BE DONE" is displayed or the PRINTER is set to OFF in the

Test mode, printing can not be done as the product does not have such system as printing out

the data at a later execution.

20www.seuservice.com

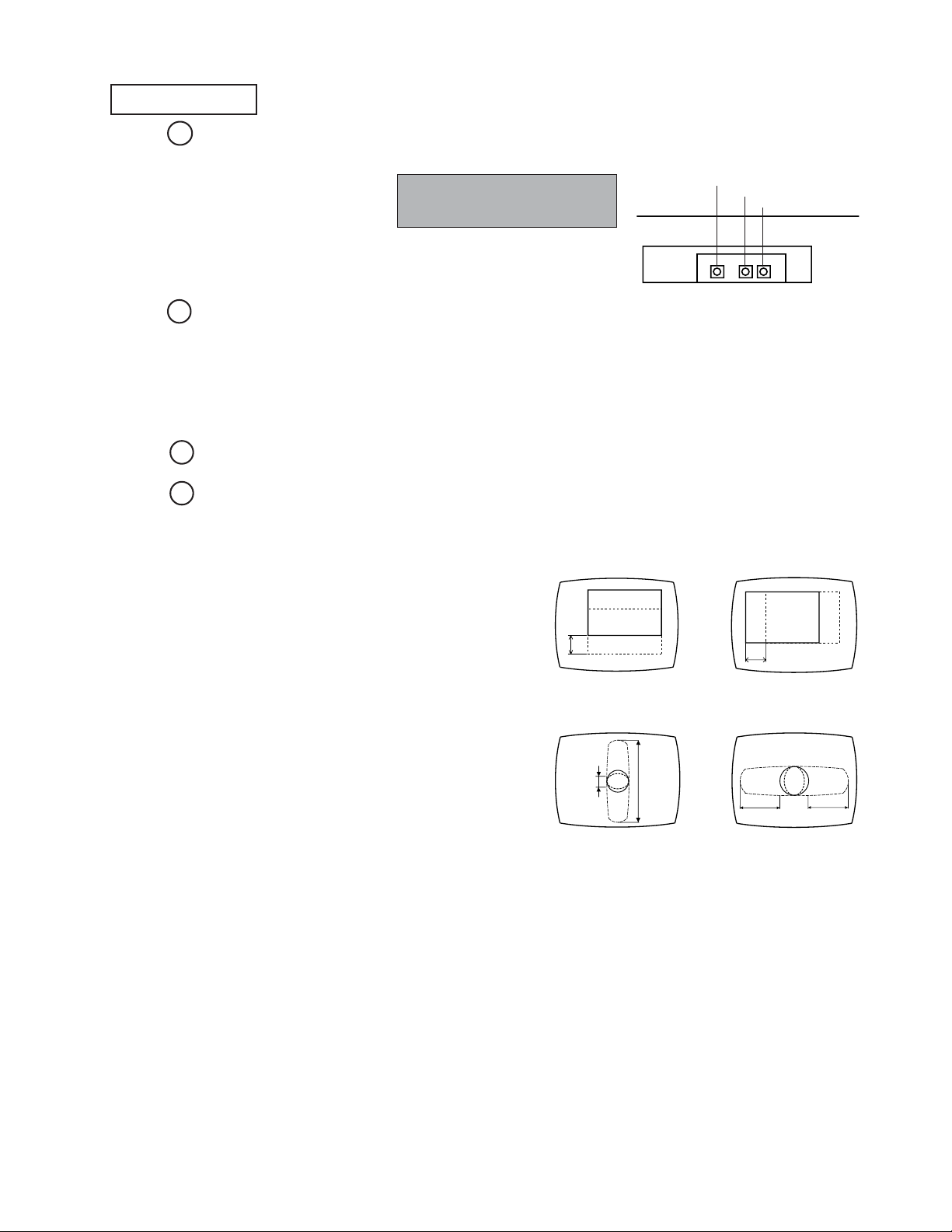

DIP SW SETTING

The Printer has 2 DIP Switches. To avoid

malfunctioning, use the Switches as adjusted

at the time of shipment.

7 -2 SETTING THE ROLL PAPER

The 2 red Lamps at the Rear Cabinet back side flash indicating the PAPER END Error under

normal operation. Prepare the new Roll Paper exclusively used for the product and the Master

Key. To set the Roll Paper, perform Printer's initialization to remove the cause of the error.

Turn off power or enter into the Test Mode to perform the initialization. Explanations for

setting the Roll Paper in cases of power on and off are given as follows. Further, when the Roll

Paper is set after the Printer Kit is installed, performing work with the power off is necessary as

the power is turned off when installing the Kit. The Roll Paper has Marks indicating position in

order to print and cut properly. The Mark indicating the end of paper appears at the end of Roll

Paper. The Printer's Sensor detects the Mark and interprets it as the end of Roll Paper. At the

beginning of Cabinet's installation, the red Lamps light up as the Mark indicating the end of

Paper is not detected.

SW1 SW 2

Setting at the time of shipment

DIP SW

FIG. 7. 1

SETTING THE PAPER WITH THE POWER ON

1

Enter into the TEST Mode and have PRINTER TEST

screen displayed on the monitor. "ERROR!!" next to the

MESSAGE and "PAPER END" next to the WARNING

are displayed on the monitor.

PRINTER TEST

MESSAGE : ERROR !!

ERROR :

WARNING : PAPER END

STATUS :

COUNTER :

INIT

F-FEED

2

Unlock with the Master Key and

remove the Printer Door.

Printer Door

FIG. 7. 2 a

ASSY Printer

Draw the ASSY Printer toward you.

3

FIG. 7. 2 b

21 www.seuservice.com

Pull up the Head Up Lever.

4

Take out the roll shaft from the Printer.

5

6

Pass the shaft through the core of the new Roll Paper.

7

Install the roll shaft in which the paper is inserted into the unit. Make sure to put the Roll Paper

on to the correct position.

Roll shaft

New Roll Paper

Head Up Lever

FIG. 7. 2 c

8

Insert the paper tip in to the roll paper insertion

slot. Feed the Roll Paper tip through the exit

slot straight by hand. At this time, if the Paper

tip comes out in excess of the exit slot, Printer

performs automatic feeding and cuts the Paper

after feeding about one page long.

9

Push down the Head Up Lever.

FIG. 7. 2 d

Push down the Head Up Lever.

The feeding point of the Roll

Paper tip.

FIG. 7. 2 e

22www.seuservice.com

Select and execute the INIT in the

10

PRINTER TEST. The "PRINTER

INIT!!" message flashes next to

"MESSAGE" on the monitor and

then goes off. The Printer's

initialization is finished.

11

Select and execute the "POSITION

SET." "NOW PRINTING"

message is displayed next to the

"MESSAGE" on the monitor and

then goes off. The Printer starts

automatic feeding of the paper

(AUTO LOADING) and then cuts

the paper automatically. If the

Paper tip position is appropriate,

the automatic feeding's movement

is slight and the paper cutting may

not be done. Before executing the

POSITION SET, the paper

position can be adjusted by

executing F-FEED or B-FEED in

the PRINTER TEST mode.

12

Exit from the TEST Mode.

13

Push the ASSY PRINTER up to

the point the PRINTER reaches the

Securing Part in the innermost of

the unit.

PRINTER TEST

MESSAGE : PRINTER INIT!

ERROR :

WARNING :

STATUS :

COUNTER :

-> INIT

F-FEED

B-FEED

POSITION SET

PRINTER TEST

MESSAGE : NOW PRINTING

ERROR :

WARNING :

STATUS :

COUNTER :

INIT

F-FEED

B-FEED

-> POSITION SET

In case that the paper tip

comes out in excess of the

exit slot, Paper is cut after

Printer feeds Paper one page

long.

14

Lock the Printer Door to secure.

SETTING THE PAPER WITH THE POWER OFF

Turn off power.

1

Unlock with the Master Key and remove the

2

Printer Door.

Draw the ASSY Printer toward you.

3

Pull up the Head Up Lever.

4

Take out the roll shaft from the Printer.

5

Pass the shaft through the core of the new Roll

6

Paper.

7

Install the roll shaft in which the paper is inserted

into the unit. Make sure to put the Roll Paper on to

the correct position.

FIG. 7. 2 f

Printer Door

FIG. 7. 2 g

23 www.seuservice.com

Note that this Roll Paper

holder will not be seen

when setting the new

Paper for the first time.

Roll shaft

New Roll Paper

Head Up Lever

8

Insert the paper tip in to the Roll Paper insertion slot. Feed the Roll Paper tip through the exit

FIG. 7. 2 h

slot straight by hand. At this time, if the Paper tip is in excess of the feeding point, the

automatic feeding of Paper is performed and the Paper is cut after feeding about one page long.

9

Push down the Head Up Lever.

The feeding point of the Roll

Paper tip.

Push down the Head Up Lever.

10

Turn on power. The Printer starts automatic feeding of the paper (AUTO LOADING) and then

FIG. 7. 2 i

cuts the paper automatically. If the Paper tip position is appropriate as per previous procedure,

the automatic feeding's movement is slight and the paper cutting may not be done.

11

Push the ASSY PRINTER into the point the PRINTER reaches the securing part in the

innermost of the unit.

12

Lock the Printer Door to secure.

24www.seuservice.com

7 - 3 CLEANING OF THE PRINTER HEAD

Each time the Roll Paper is supplied, clean the Printer Head. Prepare the cleaning pen which is

included in the Print Paper Set exclusively used for this product and a Master Key.

1

Turn off power.

Unlock with the Master Key and

2

remove the Printer Door.

3

Draw the ASSY Printer toward you.

4

Push up the Head Up Lever.

5

Remove the Roll Paper.

6

Push down the Cutter Lever and open

the Auto Cutter.

7

By using the cleaning pen, clean the printer head.

Roll Paper

Head Up Lever

Auto Cutter

Cutter Lever

FIG. 7. 3 a

Use the exclusively used

Cleaning Pen.

FIG.7. 3 b

8

Lift the Auto Cutter and lock.

Set the Roll Paper.

9

10

Push down the Head Up Lever and turn on power. The Printer performs automatic feeding and

cutting of the paper.

FIG. 7. 3 c

11

Put the ASSY Printer and lock the printer door to secure.

25 www.seuservice.com

7 - 4 COUNTERMEASURES AGAINST PAPER JAM

Prepare a Master Key and scissors or a knife for eliminating the warped, wrinkled paper due to

paper jam. To perform the following work, turning off power is necessary for 2 reasons. One is

that performing work on the energized Cabinet may cause hands and fingers to be injured due to

unexpected move of the cutter or the motor. To avoid such an unforeseen accident, be sure to

turn off power before performing work. The other reason is that in order to remove the cause of

error from the Printer, turning power off is necessary. Be sure to remove the cause of error to

make the Printer function properly.

1

Turn off power.

2

Unlock with the Master Key and

remove the Printer Door.

3

Draw the ASSY Printer toward

you.

4

Pull up the Head Up Lever.

5

Push down the Cutter Lever and

open the Auto Cutter.

6

Remove the jammed paper.

7

Eliminate the warped, wrinkled

paper due to the paper jam. At this

time, after eliminating the paper,

any portion can come to the tip as

the Printer automatically adjusts

the Paper position by feeding and

cutting the Paper.

Head Up Lever

Auto Cutter

Cutter Lever

FIG. 7. 4 a

FIG. 7. 4 b

8

Lift the Auto Cutter and lock.

Insert the paper tip in to the roll paper insertion slot. Feed the Roll Paper tip through the exit

9

slot straight by hand until the paper tip can be seen from the exit slot.

Pull up the Head Up Lever.

10

11

Turn on power. The Printer performs automatic feeding (AUTO LOADING) and cutting of the

paper.

12

Put the ASSY Printer and lock the printer door to secure.

26www.seuservice.com

8.

PRECAUTIONS TO BE HEEDED WHEN MOVING THE MACHINE

When moving the machine, be sure to unplug the power plug. Moving the

machine with the plug as is inserted can damage the power cord and cause fire

and electric shock hazards.

When moving the machine on the floor, retract the Adjusters and ensure that

Casters make contact with the floor. During transportation, pay careful

attention so that Casters do not tread power cords and earth wires. Damaging

the power cords can cause electric shock and short circuit hazards.

When lifting the cabinet, be sure to hold the grip portions or bottom part.

Lifting the cabinet by holding other portions can damage parts and installation

portions due to the empty weight of the cabinet, and cause personal injury.

In the case the cabinet is separated into the front and rear portions, do not

push the upper rear part of the front cabinet. Failure to observe this causes the

front cabinet to fall down towards the monitor side and result in accidents and

injury to persons. When moving the front cabinet in the above case, be sure to

push it from side directions and move it by 2 or more persons for safety.

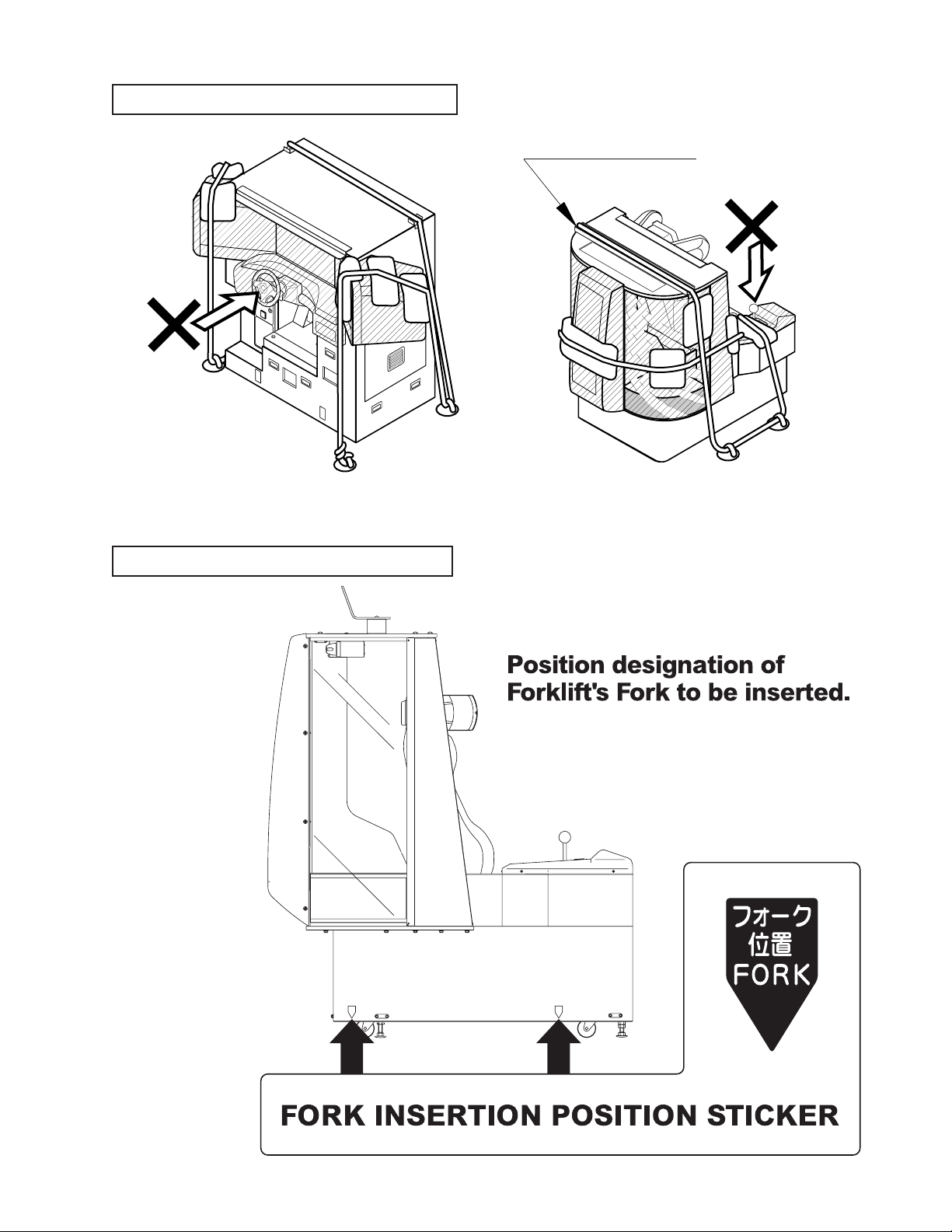

Do not insert the fork to places other than designated when using a Forklift to

transport the machine.

Failure to observe this could cause falling down and injury resulting from

falling down.

Do not push glass-made or plastic parts. Failure to observe this may damage parts

and cause injury due to fragments resulting from damage.

STOP

IMPORTANT!

When transporting the product in places with steps, disassemble into each unit

To protect surface, do not directly apply a rope to the surfaces of product.

before transporting. Inclining the product in an as is assembled condition or

placing the cabinet in places with steps can damage the unit's joining portions.

Use protective materials to the places the rope is applied to.

In the case the cabinet is

separated into the front and

rear portions, do not push the

upper rear part of the front

cabinet.

FIG. 8 a

27 www.seuservice.com

When transporting the product in places with steps or step-like

5

5

5

5

differences in grade, disassemble into each unit before

transporting.

GRIP

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234

2345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234

FIG. 8 b

Have casters make contact with the floor.

Do not push glass-made or plastic parts.

FIG. 8 c

28www.seuservice.com

Precautions concerning applying a rope.

FIG. 8 d

• Do not apply a rope to Handle or Lever.

•Use protective materials to the places the rope is applied to.

SHIPPING BRACKET REAR

Caution when transporting the machine

FIG. 8 e

29 www.seuservice.com

9. HANDLE MECHA

Before starting to work, ensure that the Power SW is OFF. Failure to observe

this can cause electric shock or short circuit.

Use care so as not to damage wirings. Damaged wiring can cause electric

shock or short circuit.

Do not touch undesignated places. Touching places not designated can cause

electric shock or short circuit.

This work should be performed by the Location's Maintenance Man or

Serviceman. Performing work by non-technical personnel can cause electric

shock hazard.

Do not insert hand into the mechanism so as not to cause hand and fingers

pinched in. Failure to observe this can cause a serious injury such as a

fracture.

When performing work such as parts replacement other than those specified in

this manual, be sure to contact where you purchased the product from and

confirm the work procedures and obtain precautions prior to performing work.

Inappropriate parts replacement and/or installing with erroneous adjustment

can cause an overload or the parts to come into contact, resulting in an electric

shock, a short circuit, and a fire.

STOP

When adjusting the Volume, be sure to use 2 workers.

IMPORTANT!

9 - 1 ADJUSTING OR REPLACING THE V.R.

In cases the Steering operability is poor and the adjustment of VOLUME SETTING in the

TEST mode is ineffective, the causes may be the Volume Gear's mesh failure and or Volume

malfunctioning. By using the following procedure, adjust Volume gear mesh, or replace the

Volume. In this product, when the Steering Wheel is moved fully left/right, if the Volume shaft

is rotating within the movable range, the Volume is not feared to be damaged. Secure the

Volume in the manner the Volume shaft is oriented as shown and the gears are appropriately

engaged when the steering wheel is in the centering position allowing the car to go straight

forward.

ADJUSTING THE VOLUME

Be sure to use 2 workers in adjusting the Volume, one is for operating the Steering Wheel and the

other one for performing the

adjustment.

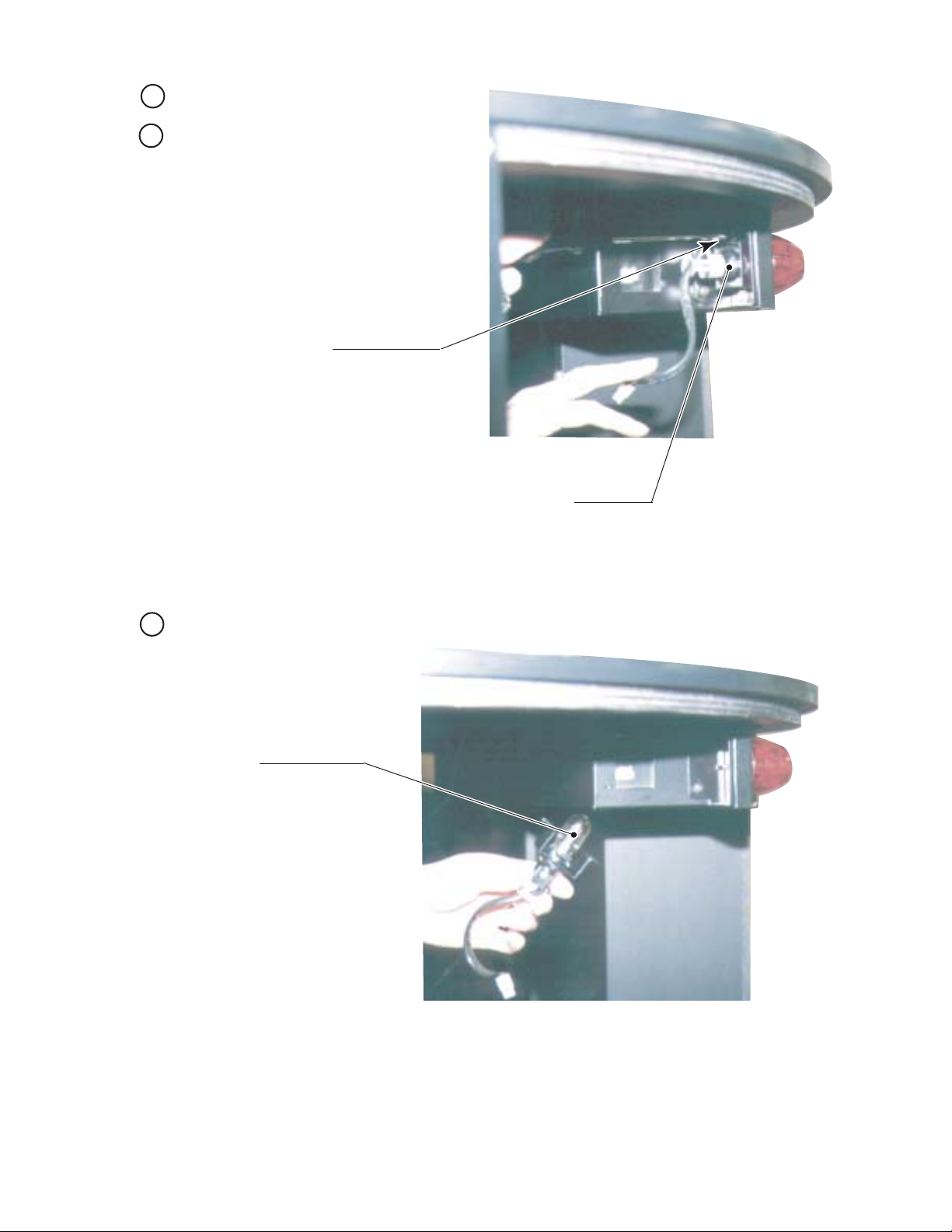

REAR LID

1

Turn off power.

2

Take out 4 Truss screws to remove

the Rear Lid from the back of

Front Cabinet. At this time,

carefully support the Rear Lid as

taking out the 4 Truss screws can

cause the Rear Lid to drop.

PHOTO 9. 1 a

TRUSS SCREW (4)

M4 X 16

30www.seuservice.com

Perform the adjustment while another person is securing the Steering Wheel in the centering

3

position.

The V.R. is on the VR BASE (a white, plastic made part). Loosen the 2 screws which secure

4

the VR BASE and adjust the angle and appropriateness of gear mesh by moving the VR BASE.

5

Adjust to an appropriate mesh by securing the Steering Wheel in the direction allowing the car

to advance straight forward and ensuring the "D" CUT FACE of the Volume shaft is oriented as

shown.

6

Tighten the 2 screws to secure the VR BASE.

VR BASE

SCREW (2)

M4 X 12,w/flat & spring washers

"D" CUT FACE

FIG. 9. 1 a

7

Turn on power.

Set the Center Value of the Volume in the TEST mode.

8

In the TEST mode, check to see if the Volume Value varies smoothly in accordance with the

9

steering wheel operation.

31 www.seuservice.com

REPLACING THE VOLUME

Disconnect the connector from the

1

Volume.

2

Take out 2 screws to remove the

Volume together with VR BASE

from the HANDLE MECHA.

SCREW (2)

M4 X 12,w/flat & spring washers

3

Take out 2 screws from the VR

BASE reverse side to remove the

Volume together with VR Bracket

from the VR BASE.

4

Remove the Volume from VR

Bracket and replace.

TRUSS SCREW (2)

M4 X 12

VR BASE

PHOTO 9. 1 b

PHOTO 9. 1 c

32www.seuservice.com

After replacing the Volume, engage the gears at the angular position shown and fix the VR

5

Bracket.

VR BASE

SCREW(2)

M4 X 12,w/flat & spring washers

FIG. 9. 1 b

V.R.

220-5484

Turn on power.

6

7

Set the Center Value of the Volume in the TEST mode.

220-5373

8

In the TEST mode, check to see if the Volume Value varies smoothly in accordance with the

steering wheel operation.

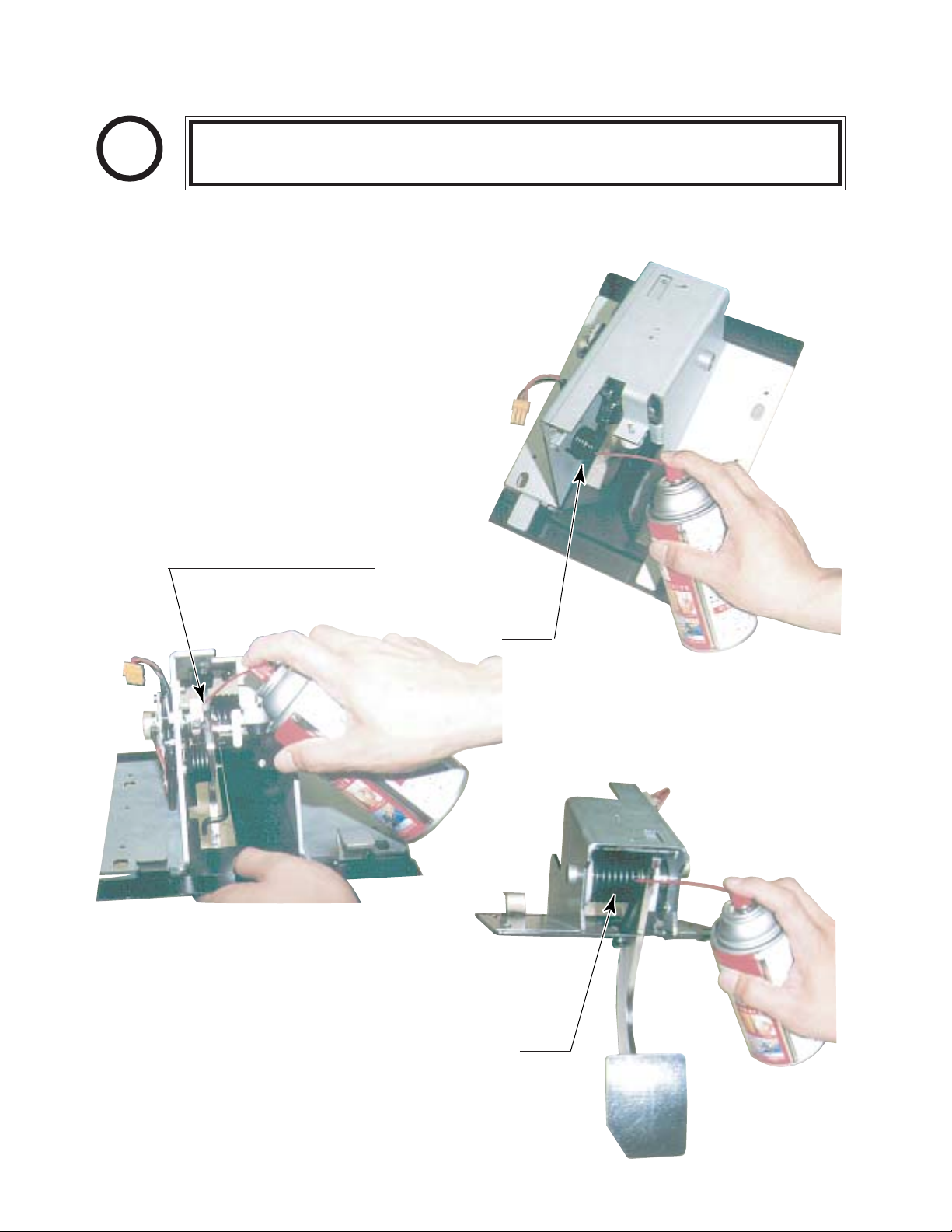

9 - 2 GREASING

STOP

Be sure to use the designated grease. Using undesignated grease can cause

Do not apply greasing to undesignated places. Failure to observe this can cause

IMPORTANT!

Apply greasing to gear

mesh portions once every

3 months.

Use GREASE MATE

(SEGA PART NO.

090-0066).

parts damage.

malfunctioning or quality deterioration of parts.

VOLUME GEAR MESH PORTION

PHOTO 9. 2

33 www.seuservice.com

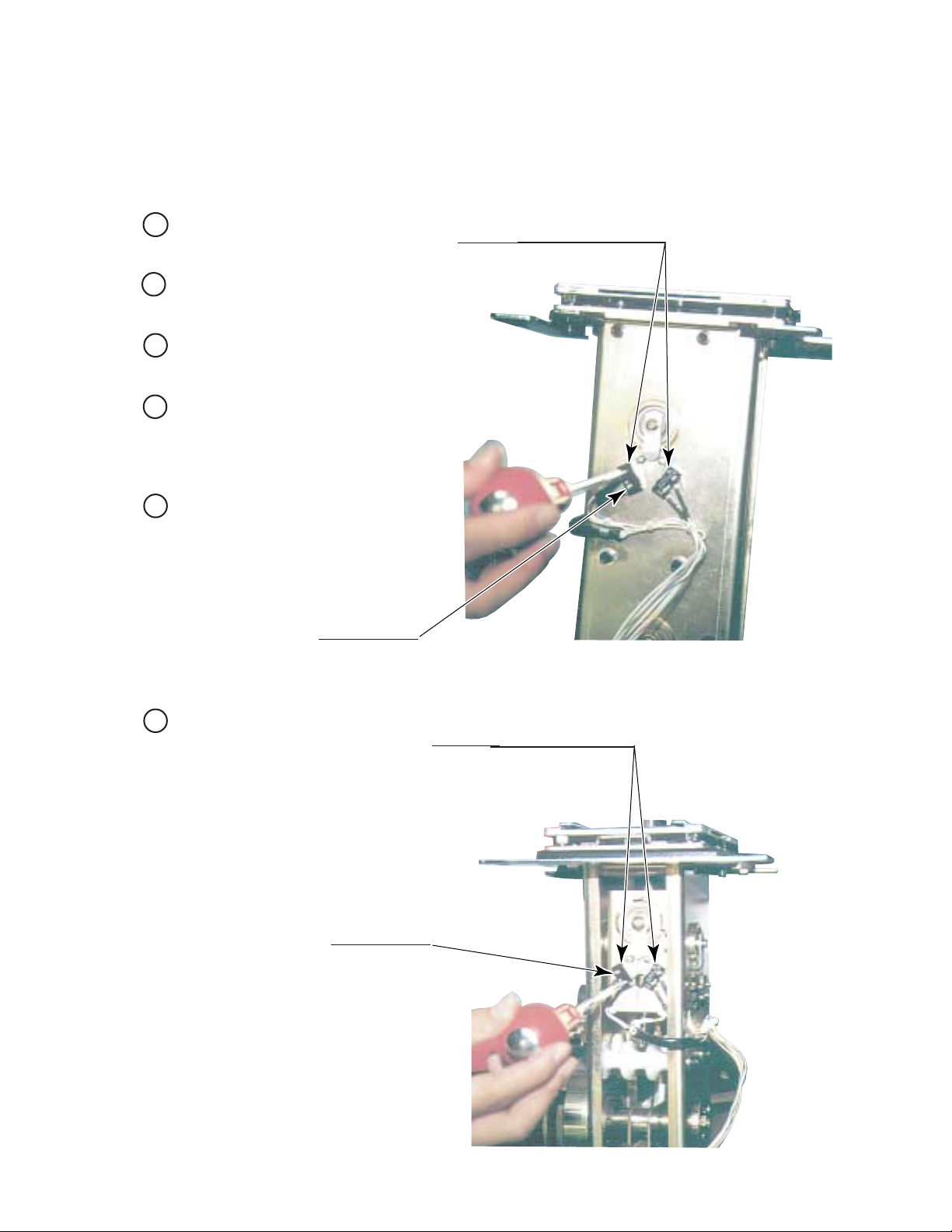

9 - 3 REPLACING PADDLE (WING) SHIFT SWITCH

In case the Paddle Shift operability is poor, malfunctioning of or a damage to the Microswitch

inside the Paddle Shift can be considered.

1

Turn off power.

2

Take out 2 Truss screws for

each to remove Boss Cover

Upper and Lower.

3

Disconnect the wiring

connected to the Microswitch.

TRUSS SCREW (2 each)

M4 X 8

BOSS COVER

PADDLE SHIFT

PHOTO 9. 3 a

BOSS COVER

34www.seuservice.com

Take out 2 screws to replace

4

the Microswitch.

Adjust Microswitch's

5

actuator to an angular

position so as not to touch

the Switch when operating

the Shift Lever.

Fasten 2 screws to secure

6

the Microswitch.

7

Check to ensure that the

Switch goes ON and OFF in

consistency with the

operation.

SCREW (2)

M3 X 16

PHOTO 9. 3 b

MICROSWITCH

509-5387

35 www.seuservice.com

10. 6-SPEED SHIFT

Before starting to work, ensure that the Power SW is OFF. Failure to observe

this can cause electric shock or short circuit.

Use care so as not to damage wirings. Damaged wiring can cause electric

shock or short circuit.

Do not touch undesignated places. Touching places not designated can cause

electric shock or short circuit.

This work should be performed by the Location's Maintenance Man or

Serviceman. Performing work by non-technical personnel can cause electric

shock hazard.

When performing work such as parts replacement other than those specified

in this manual, be sure to contact where you purchased the product from.

Confirm the work procedures and obtain precautions from where you

purchased the product from prior to performing work. Inappropriate parts

replacement and/or installation with erroneous adjustment can cause an

overload or the parts to come into contact, resulting in an electric shock, a

short circuit, and a fire.

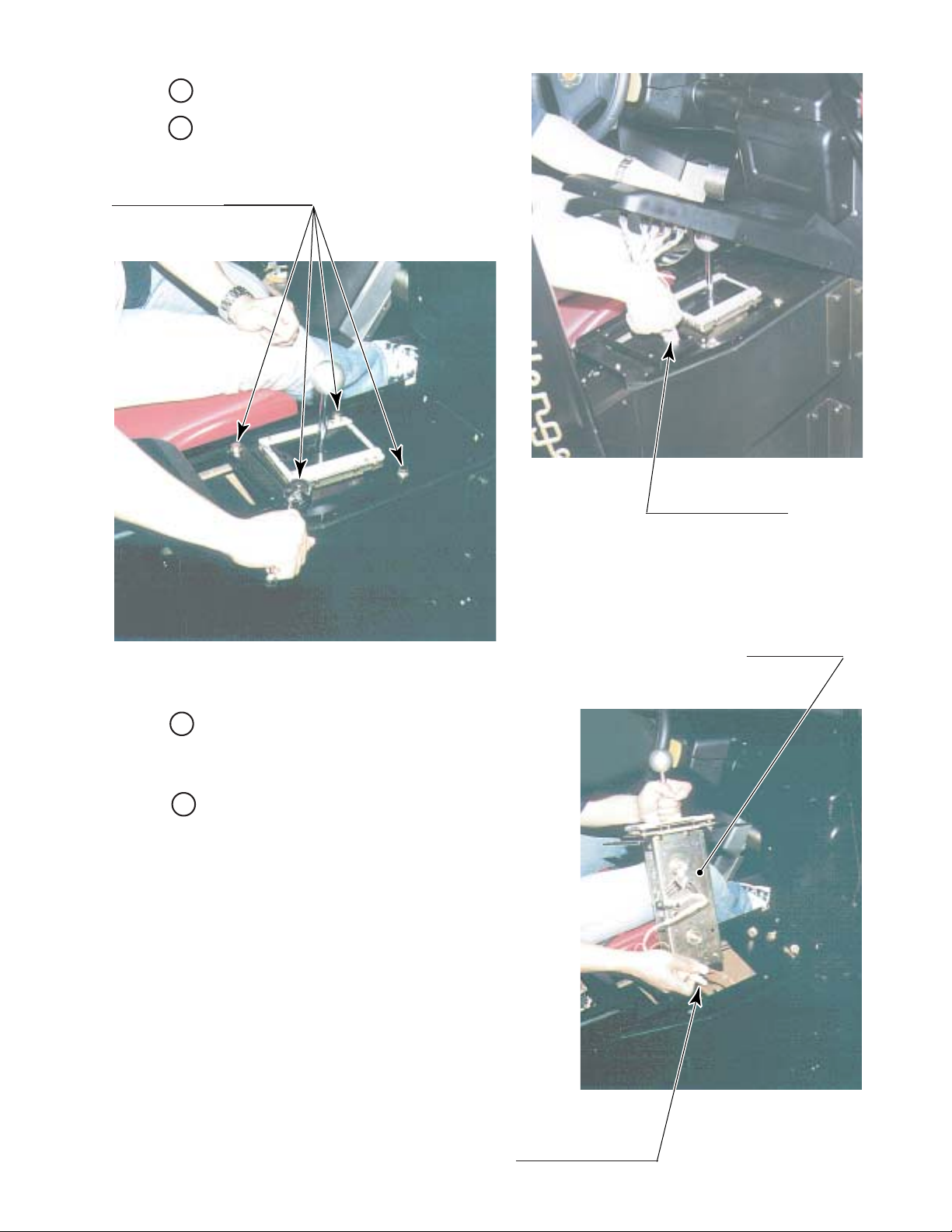

10 - 1 REMOVING THE SHIFT LEVER

Turn off power.

1

Take out 4 screws securing the EFFECT Switch.

2

3

Take out 5 Truss screws which secure the Console Cover.

EFFECT SWITCH

TRUSS SCREW (4)

M4 X 12

CONSOLE COVER

TRUSS SCREW (5)

M4 X 12,large washers used

PHOTO 10. 1 a

36www.seuservice.com

Disconnect a connector.

4

5

Take out 4 Hexagon Bolts.

HEXAGON BOLT (4)

M8 X 40,w/flat & spring washers

Disconnect the connector

PHOTO 10. 1 c

Lift the 6-speed Shift vertically. At this time,

6

use care so as not to hang the wiring or hit the

other parts.

Disconnect 2 connectors to remove the 6-speed

7

Shift.

PHOTO 10. 1 b

6-SPEED SHIFT

PHOTO 10. 1 d

Disconnect the connector

37 www.seuservice.com

10 - 2 REPLACING THE SWITCH

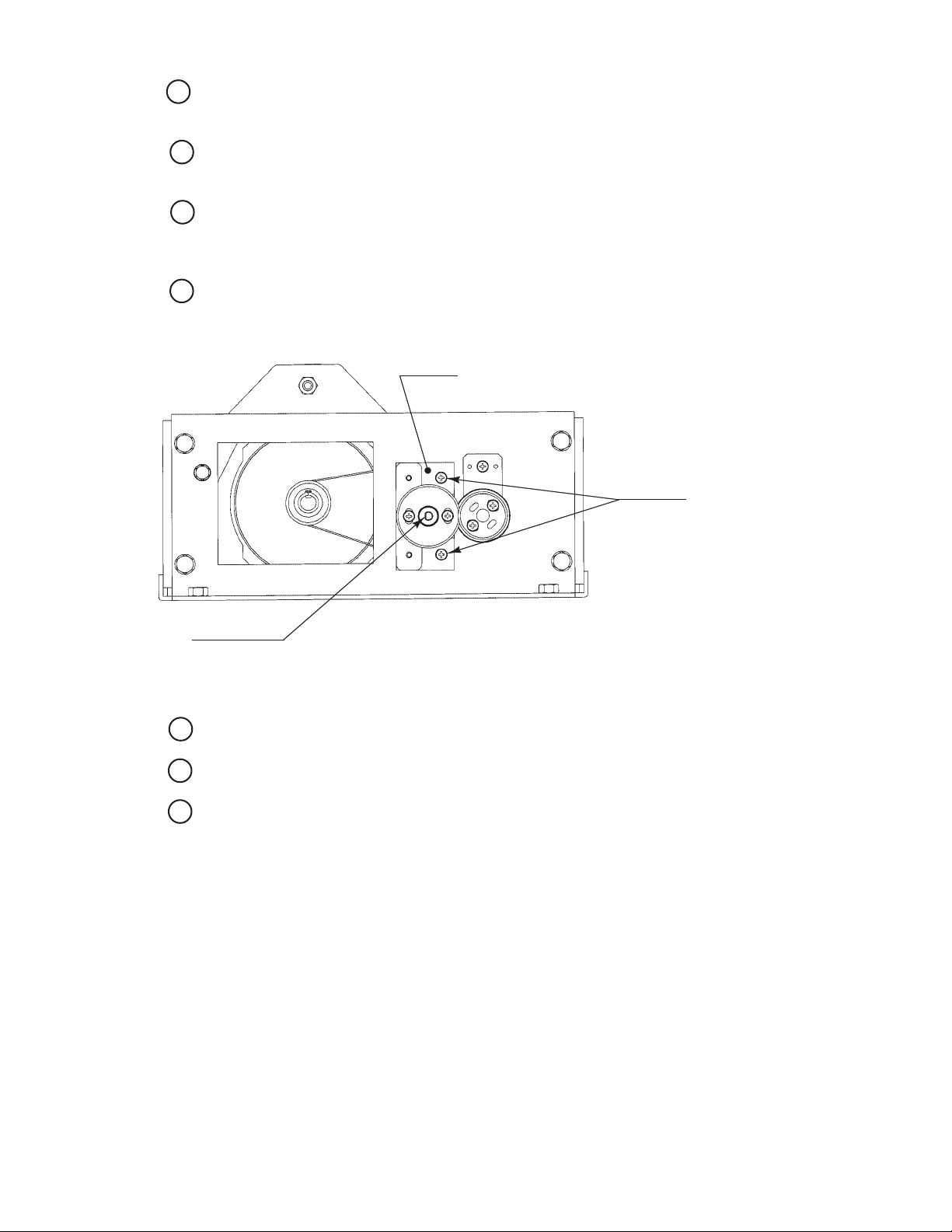

In case 6-speed Shift operability is poor, malfunction of or damage to the Microswitch of

Mechanism can be considered. The 6-speed Shift has 4 Microswitches. Be sure to check which

Switch malfunctions prior to performing work.

1

Remove 6-speed Shift as per

procedure 10-1.

2

Disconnect the wiring connected to

the Microswitch.

Take out 2 screws to replace the

3

Microswitch.

Adjust Microswitch's actuator to

4

an angular position so as not to

touch the Switch when operating

the Shift Lever.

5

Fasten 2 screws to secure the

Microswitch.

SCREW (2)

M2.3 X 10,w/flat & spring washers

MICROSWITCH

509-5636

6

Check to ensure that the Switch

goes ON and OFF in consistency

with the operation.

MICROSWITCH

509-5636

PHOTO 10. 2 a

SCREW (2)

M2.3 X 10,w/flat & spring washers

PHOTO 10. 2 b

38www.seuservice.com

11. ACCELERATOR & BRAKE

Before starting to work, ensure that the Power SW is OFF. Failure to observe

this can cause electric shock or short circuit.

Use care so as not to damage wirings. Damaged wiring can cause electric

shock or short circuit.

Do not touch undesignated places. Touching places not designated can cause

electric shock or short circuit.

This work should be performed by the Location's Maintenance Man or

Serviceman. Performing work by non-technical personnel can cause electric

shock hazard.

When performing work such as parts replacement other than those specified

in this manual, be sure to contact where you purchased the product from.

Confirm the work procedures and obtain precautions from where you

purchased the product from prior to performing work. Inappropriate parts

replacement and/or installation with erroneous adjustment can cause an

overload or the parts to come into contact, resulting in an electric shock, a

short circuit, and a fire.

If Accel. and Brake operation is not satisfactory, adjustment of Volume installation position or

Volume replacement is needed. Also, be sure to apply greasing to the gear mesh portion once

every 3 months.

11 - 1 ADJUSTING AND REPLACING THE V.R.

The appropriate value for both ACCEL. Volume and Brake Volume is under 30H when released

and over C0H when stepped on. Check Volume values in the TEST mode. Since work is

performed inside the energized cabinet, be very careful so as not to touch undesignated places.

Touching places not specified can cause electric shock or short circuit.

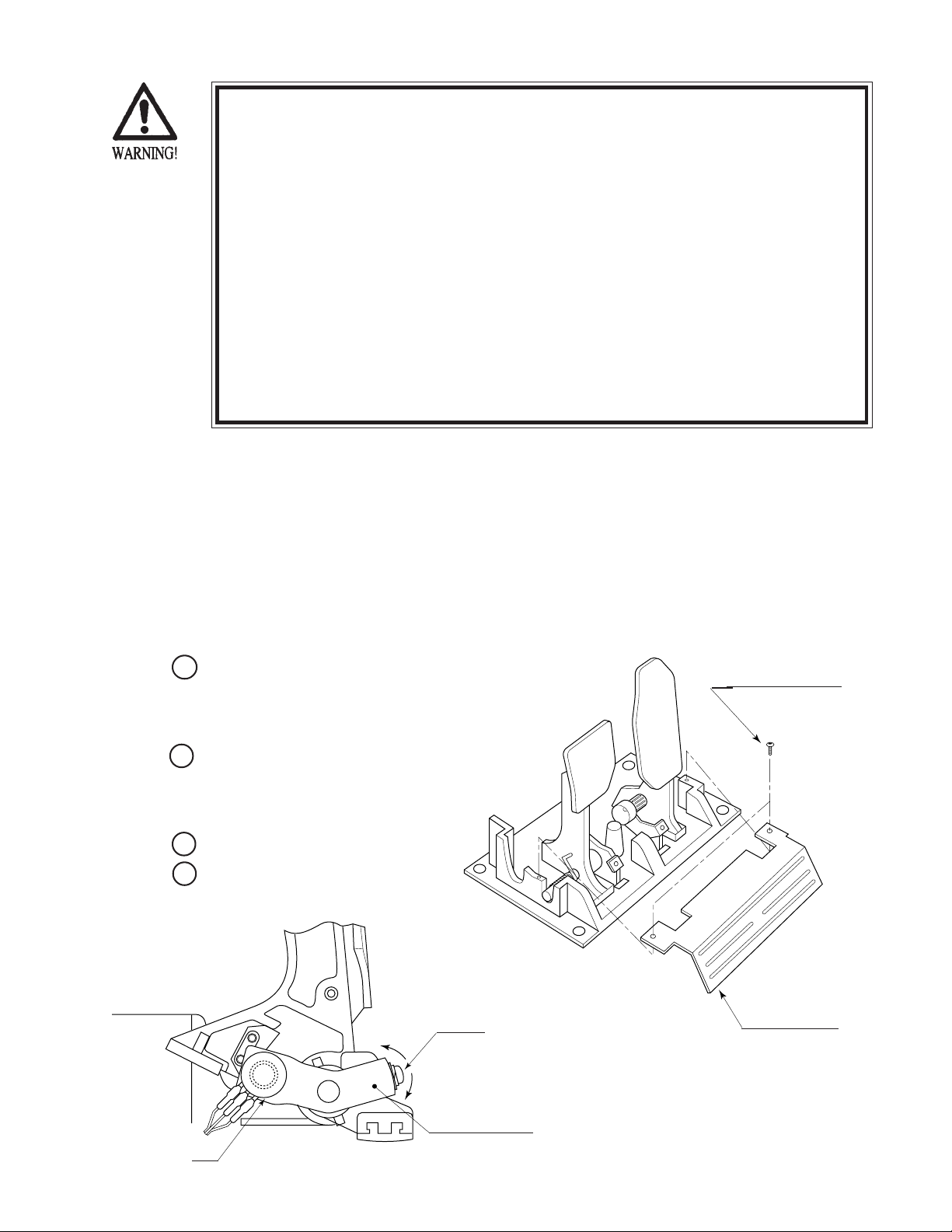

1

Take out the 2 truss screws and

remove the Front Cover from the

Accel. & Brake Unit

(FIG. 11. 1 a).

2

Loosen the screw which secure the

Potentiobase, and adjust the

Volume value by moving the Base.

(FIG. 11. 1 b)

3

Secure the Potentiobase.

4

Perform Volume setting in the

Volume setting mode.

TRUSS SCREW (2)

M4 X 8, chrome

V.R.

220-5484

220-5373

FIG. 11. 1 b

SCREW

M5 X 12,

w/flat & spring washers

POTENTIOBASE

39 www.seuservice.com

FIG. 11. 1 a

FRONT COVER

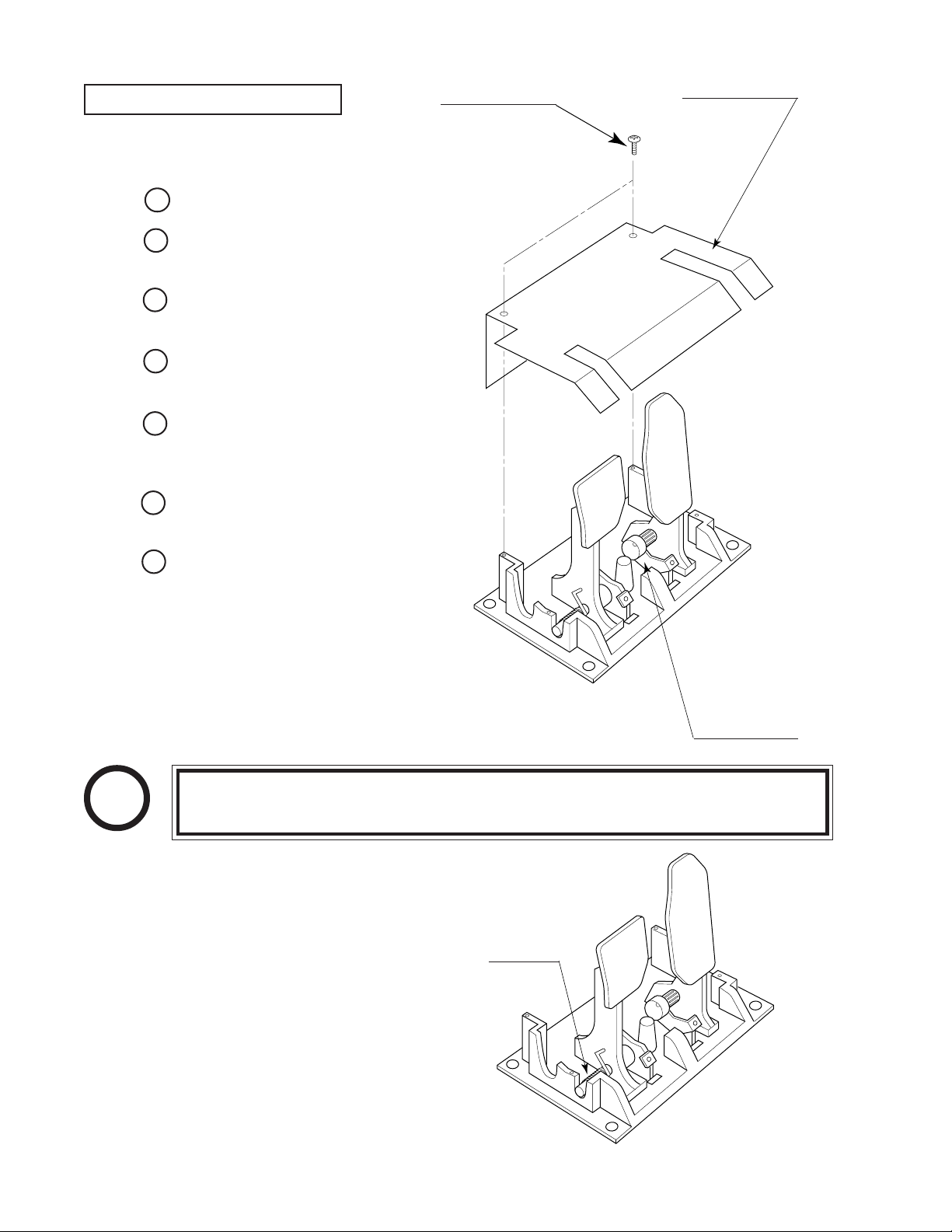

REPLACING THE VOLUME

1

Turn the power off.

2

Take out the 2 screws and remove the

Potentiocover (FIG. 11. 1 c).

3

Disconnect the connector of the

Volume to be replaced.

4

Remove the screw which secures the

Potentiobase (FIG. 11. 1 b).

Remove the Potentiobase together

5

with the Volume as is attached.

(FIG. 11. 1 c)

6

Remove the Base and Gear to replace

the Volume.

TRUSS SCREW (2)

M4 X 8

POTENTIOCOVER

7

Adjust the Volume as per the previous

page after replacing.

11 - 2 GREASING

STOP

Be sure to use the designated grease. Using undesignated grease can cause parts

damage.

IMPORTANT!

Once every 3 months, apply greasing

to the Spring and Gear mesh portion.

For spray greasing, use GREASE

MATE (PART No. 090-0066).

FIG. 11. 1 c

GREASING

POTENTIOBASE

FIG. 11. 2

40www.seuservice.com

12. CLUTCH PEDAL

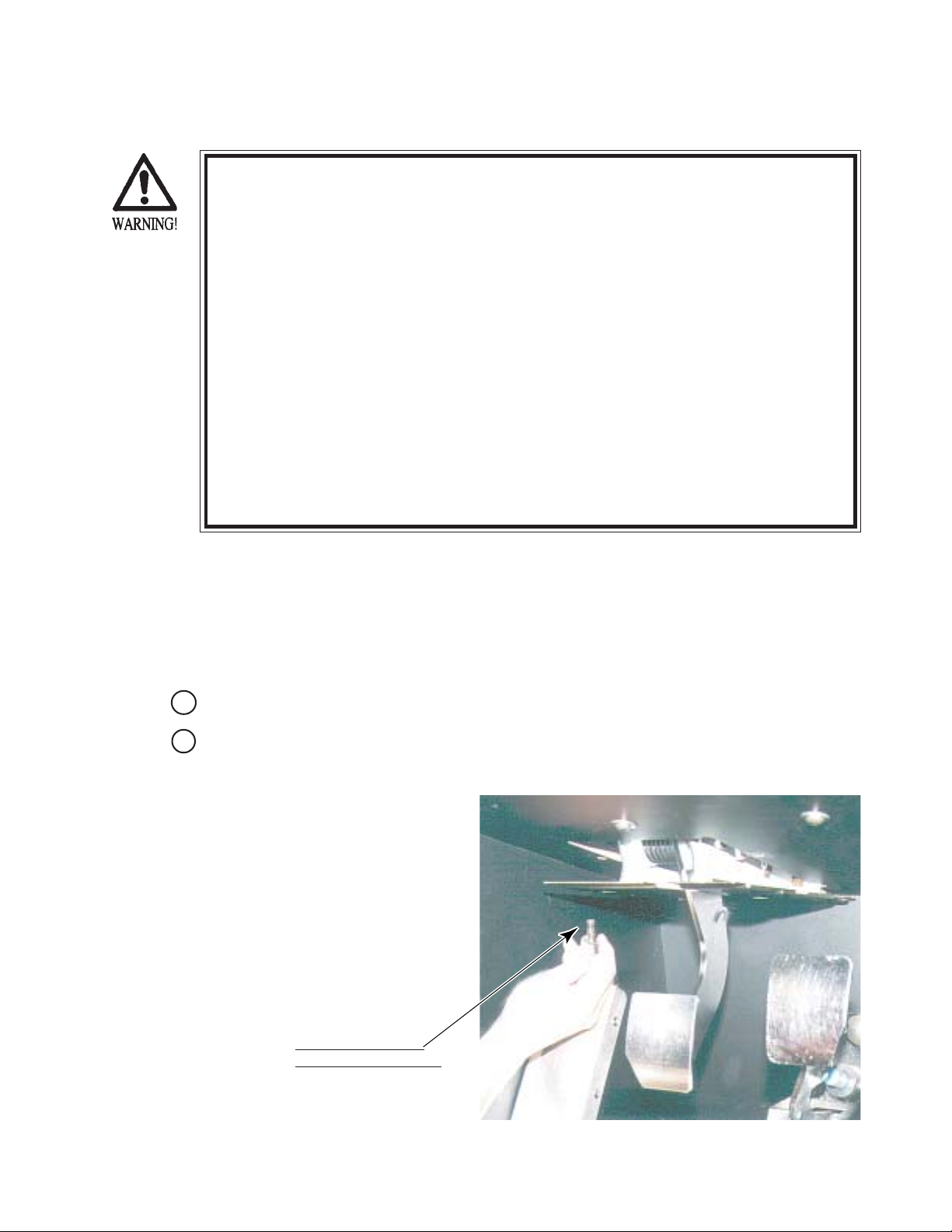

Before starting to work, ensure that the Power SW is OFF. Failure to observe

this can cause electric shock or short circuit.

Use care so as not to damage wirings. Damaged wiring can cause electric

shock or short circuit.

Do not touch undesignated places. Touching places not designated can cause

electric shock or short circuit.

This work should be performed by the Location's Maintenance Man or

Serviceman. Performing work by non-technical personnel can cause electric

shock hazard.

When performing work such as parts replacement other than those specified

in this manual, be sure to contact where you purchased the product from.

Confirm the work procedures and obtain precautions from where you

purchased the product from prior to performing work. Inappropriate parts

replacement and/or installation with erroneous adjustment can cause an

overload or the parts to come into contact, resulting in an electric shock, a

short circuit, and a fire.

If the Clutch Pedal's operation is not satisfactory, the V.R. installation position adjustments or

V.R. replacement is needed. Also, be sure to apply greasing to the V.R. Gear mesh portion and

the 2 Springs once every 3 months.

12 - 1 REMOVING THE CRUTCH PEDAL

1

Turn off power.

2

Take out 4 Hexagon Bolts. At this time, support the Clutch Pedal as taking out the bolts can

cause the Clutch Pedal to fall.

PHOTO 12. 1 a

HEXAGON BOLT (4)

M8 X 30,w/spring washer

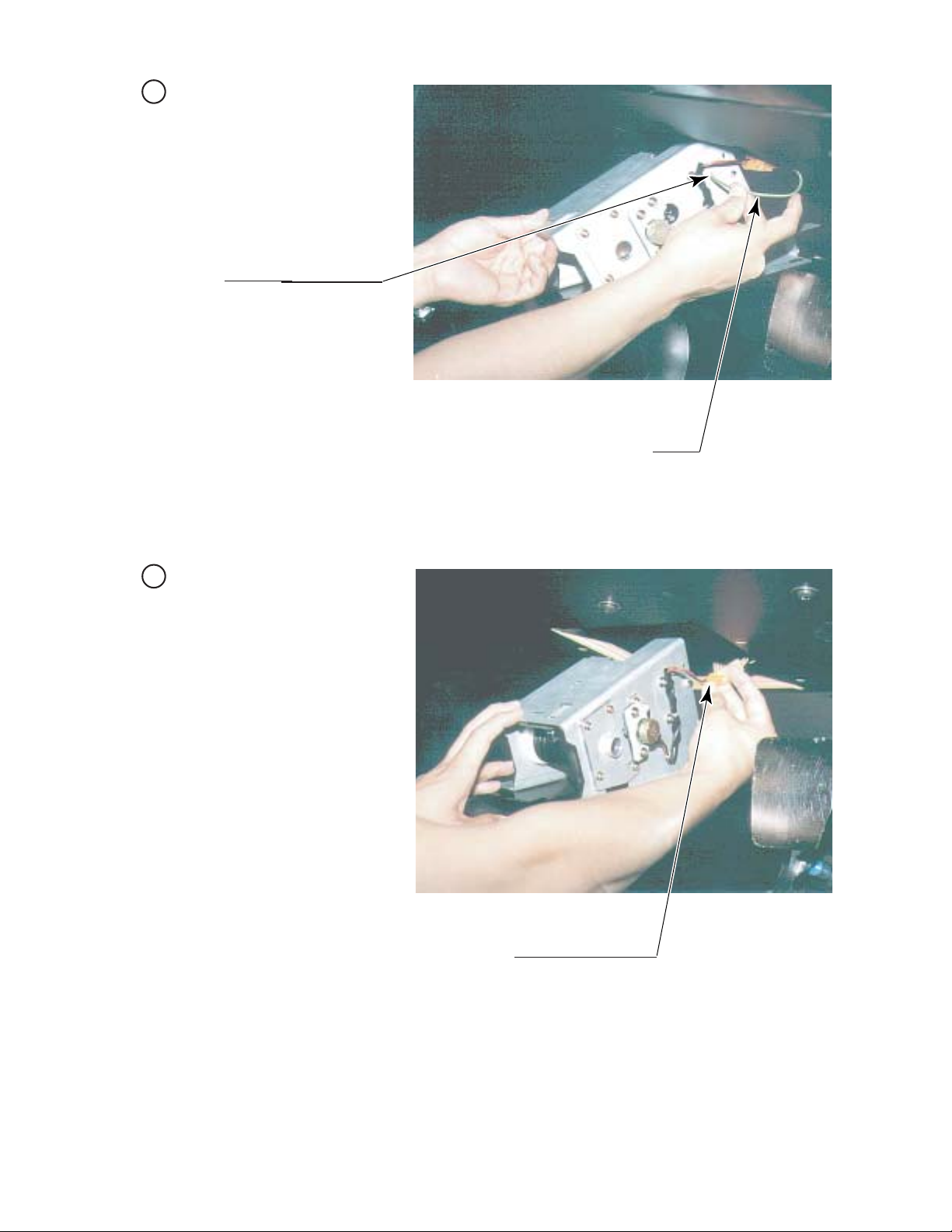

41 www.seuservice.com

Take out a screw to remove

3

the earth wire which is

connected to the Clutch

Pedal Mechanism side.

SCREW (1)

M4 X 8,w/flat & spring washers

EARTH

PHOTO 12. 1 b

Disconnect the connector to

4

remove the Clutch Pedal.

Disconnect the connector

PHOTO 12. 1 c

42www.seuservice.com

12 - 2 VOLUME ADJUSTMENT/REPLACEMENT

The appropriate value of Crutch Volume is under 30H when released and over C0H when

stepped on. Check Volume values in the TEST mode. Since work is performed inside the

energized cabinet, be very careful so as not to touch undesignated places. Touching places not

specified can cause electric shock or short circuit.

ADJUSTING THE VOLUME

Loosen 2 screws which secure the Volume Bracket to adjust the gear mesh.

1

2

Tighten the 2 screws.

3

In the TEST mode, check to ensure that the Volume Values are within the appropriate range and

vary smoothly in consistency with the Pedal operation.

VR BRACKET

SCREW (2)

M4 X 8,w/flat &

spring washers

PHOTO 12. 2

V.R.220-5484

220-5373

REPLACING THE VOLUME

1

Disconnect the connector from the Volume.

Take out 2 screws to remove the Volume together with the VR Bracket from the Crutch Pedal

2

Mechanism.

3

Remove the Volume from the VR Bracket to replace.

After replacing the Volume, engage the gears and fix the VR Bracket.

4

In the TEST mode, check to ensure that the Volume Values are within the appropriate range and

5

vary smoothly in consistency with the Pedal operation.

43 www.seuservice.com

12 - 3 GREASING

STOP

Be sure to use the designated grease. Using undesignated grease can cause parts

damage.

IMPORTANT!

Once every 3 months, apply greasing to the Spring and Gear mesh portion. For spray greasing,

use GREASE MATE (PART No. 090-0066).

VOLUME GEAR MESH PORTION

SPRING

SPRING

PHOTO 12. 3

44www.seuservice.com

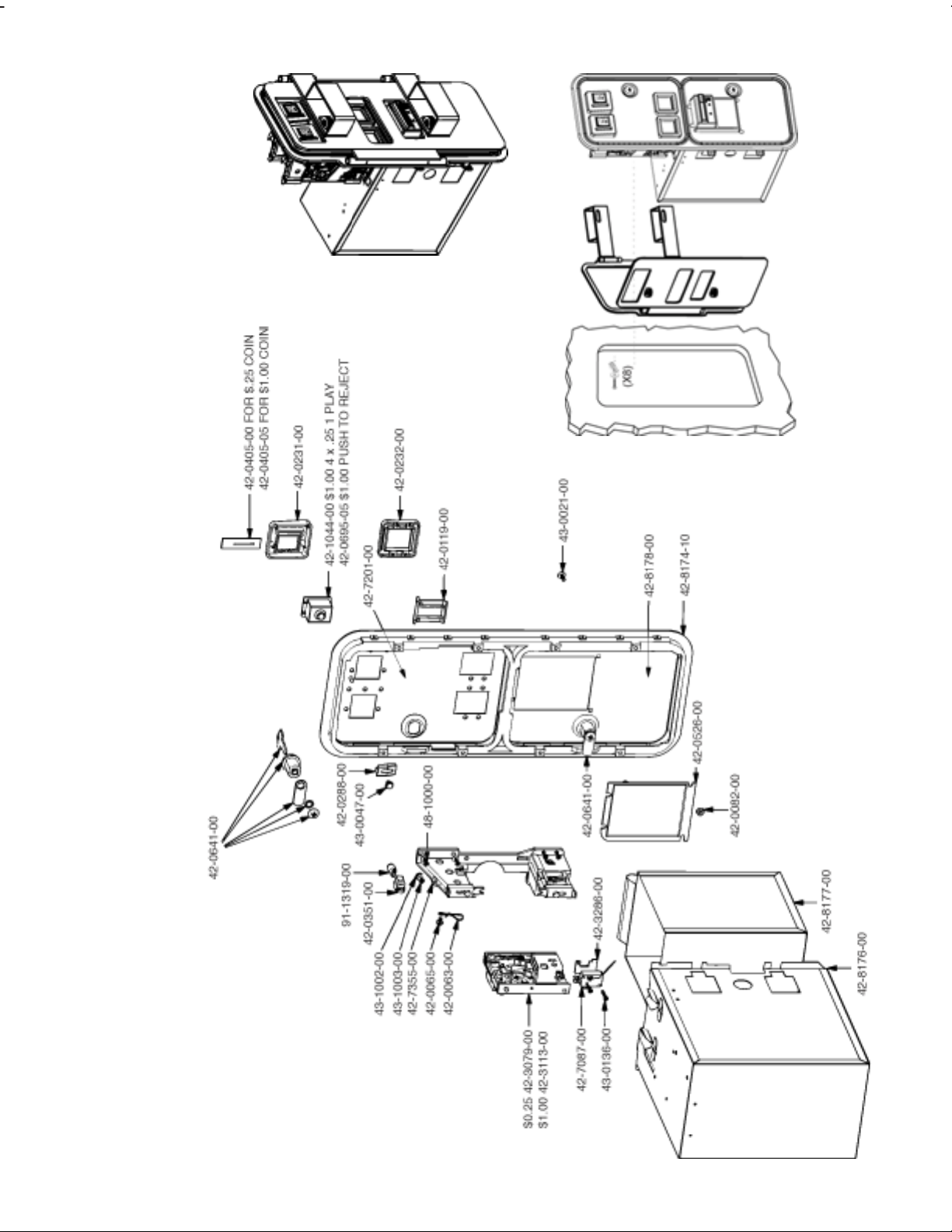

13. COIN SELECTOR

HANDLING THE COIN JAM

If the coin is not rejected when the REJECT button is pressed, open the coin chute door and

open the selector gate. After removing the jammed coin, put a normal coin in and check to see

that the selector correctly functions.

CLEANING THE COIN SELECTOR

STOP

IMPORTANT!

Remove and clean smears by using a

soft cloth dipped in water or diluted

chemical detergent and then

squeezed dry.

Never apply machine oil, etc. to the

Coin Selector.

After cleaning the Coin Selector,

insert a regular coin in the normal

working status and ensure that the

Selector correctly functions.

GATE

FIG. 13 a

The coin selector should be cleaned once every

1

3 months. When cleaning, follow the procedure

below:

2

Turn the power for the machine OFF. Open the

coin chute door.

Open the gate and dust off by using a soft brush

(made of wool, etc.).

3

Remove and clean smears by using a soft cloth

dipped in water or diluted chemical detergent

and then squeezed dry.

4

Remove the CRADLE.

When removing the retaining ring

(E ring), be very careful so as not to bend the

rotary shaft.

Remove stain from the rotary shaft and shaft

5

receiving portions by wiping off with a soft

cloth, etc.

After wiping off as per above, further apply

6

a dry cloth, etc. to cause the coin selector to dry

completely.

COIN INSERTION TEST

Once every month, when performing the Coin

SW Test, simultaneously check the following:

Does the Coin Meter count satisfactorily?