Page 1

G426601E REV1.2

INSTALLATION & USER MANUAL

z

To use this machine safely and correctly, read this manual carefully.

z

After reading this manual, be sure to keep it available nearby the product or

somewhere convenient so that it can be referred to whenever necessary.

z

When transporting or reselling this product, be sure to attach this manual to

the product.

© 2003, Simuline. Inc

Page 2

BEFORE USING THIS PRODUCT

Thank you for purchasing our arcade use simulator equipment “CYCRAFT” game

machine.

Safety notes:

To ensure the safe usage of the product, be sure to read the following before using this

product. The following instructions are intended for the users, operators and the

personnel in charge of the operation of the product.

After carefully reading and sufficiently understanding the warning displays and cautions,

handle the product appropriately. Be sure to keep this manual available nearby the

product or somewhere convenient so that it can be referred to whenever necessary.

In this manual, explanations, which require special attention, are enclosed with dual lines.

Depending on the degree of potential hazards, the terms of DANGER, WARNING,

CAUTION, etc. are used.

Be sure to understand the contents of the displays before reading the text.

Indicates that mishandling the

product by disregarding the

instructions can cause severe

injury

.

Indicates that mishandling the

product by disregarding the

instructions can cause a

potentially hazardous situation

that can result in serious

injury.

Indicates that mishandling the

product by disregarding the

instructions can cause a slightly

hazardous situation that can result

in light personal injury and or

material damage.

For the safe usage of the product, the following pictographs are used:

Indicates, “HANDLE WITH CARE”. In order to protect personnel and equipment,

this display is attached to places where the Owner’s manual and or Service

Manual should be referred.

Indicates a “Protective Earth Terminal”. Before operating the equipment, be sure

to connect it to the Earth line.

Page 2

Page 3

Perform work in accordance with the instruction herein stated.

Follow instructions carefully paying special attention from the standpoint of accident

prevention. Failure to follow instructions can cause accidents. Instructions will point out

those jobs requiring trained technicians or servicemen.

Before installing the product, check for the electrical specification sticker.

SIMULINE products have a sticker on which the electrical specifications are detailed.

Ensure that the product is compatible with the power supply voltage and frequency

requirements of the location in which the machine is to be installed.

Install and operate the product only in places where appropriate and sufficient

lighting is available such that warning stickers can be clearly read.

Be sure to turn off power before working on the machine.

To prevent electric shock, be sure to turn off power before starting any work in which the

worker is exposed to the interior of the product.

Exercise great care when handling the monitor.

Some of the monitor parts are subjected to high-tension voltage. Even after turning the

power off, some components retain high-tension voltage. Only qualified service engineers

should perform monitor repair and replacement.

Be sure to adjust the monitor properly.

Do not operate the product with on-screen flickering or blurring unadjusted. Using the

product with the monitor not properly adjusted may cause dizziness or a headache to an

operator, a player, or the customers.

Specification changes, removal of equipment, conversion and or additions not

designated by SIMULINE is not allowed.

Do not make any engineering changes by alterations, unauthorized parts replacements or

other modifications under any circumstances. Should doors, lids and protective parts be

damaged or lost, refrain from operating the product, and contact the office where the

product was purchased from or the office of Simuline given in this manual.

SIMULINE shall not be held responsible for any accidents, compensation for damage to a

third party, resulting from unauthorized changes and modifications to the product.

When transporting or reselling this product, be sure to attach this manual to the

product.

*Description herein contained may be subjected to improvements and changes without notice

Page 3

Page 4

**The contents described herein are fully prepared with due care. However, should any question arise or errors be found,

please contact SIMULINE.

Page 4

Page 5

INTRODUCTION OF THIS INSTALLATION & SERVICE MANUAL

This manual is intended to provide detailed descriptions together with all the necessary

information covering the general operation of electronic assemblies, electro mechanicals,

servicing control, spare parts, etc. for the product, CYCRAFT.

This manual is intended for the owners, personnel and managers in charge of operation

of the product. Operate the product after carefully reading and sufficiently understanding

the instructions. If the product fails to function satisfactorily, non-technical personnel

should under no circumstances touch the internal system. Please contact office where the

product was purchased.

Use of this product is unlikely to cause physical injuries or damages to property. However,

where special attention is required “IMPORTANT” symbol and message is given in the

manual as follows:

Indicates that mishandling the product by disregarding this message can cause

performance degradation or malfunctions.

DEFINITION OF PERSONNEL IN THIS MANUAL:

Non-technical personnel who do not have technical knowledge and expertise

should refrain from performing such work that this manual requires the arcade

maintenance personnel or a serviceman to carry out, or work, which is not

explained in this manual. Failing to comply with this instruction can cause severe

accidents such as electric shock.

Ensure that the arcade maintenance personnel or a serviceman performs parts

replacement, servicing & inspections, and troubleshooting. It is instructed herein that the

serviceman who has technical expertise and professional knowledge in the field should

perform particularly hazardous work.

The following definitions for personnel are used in this manual:

z Arcade maintenance personnel

Those who have experience in the maintenance of amusement equipment and

vending machines, etc. and also participate in the servicing and control of the

equipment through such routine work as equipment assembly and installation,

inspections, and replacement of parts and consumables, etc. within the amusement

facilities and or locations under the management of the owner and owner’s operators

of the product.

Page 5

Page 6

z Service Person

Those who carry out inspections and maintenance services of the CYCRAFT

should be under the authorization of Simuline Inc or Sega

It is mandatory that the Service Person must have technical expertise

equivalent to that of technical high school graduates in the fields of electricity,

electronics and or mechanics.

z Player

Persons who play games at facilities and shops where arcade amusement game

machines are installed.

z Gallery

Persons who are onlookers near the games at facilities and shops where arcade

amusement game machines are installed.

REVISION RECORDS:

Language: English

Rev: 1.2

Modified Date: December 2003 (gb / sk / esk)

O/S Version: 1.64

(Japan / Europe / USA)

Game Version: BGD0

PLACE TO BE CONTACTED:

For necessary repairs and parts, contact the Distributor whom you purchased your Cycraft.

SIMULINE, INC / CUSTOMER SERVICE

461-28

Jeon-Min-Dong

Yu-Sung-Gu

Deajeon

Korea

305-811

Phone: +82-42-610-1010

Fax: +82-42-862-0795

E-mail: sales@simuline.com

Web-Site: www.simuline.com

Page 6

Page 7

TABLE OF CONTENTS

BEFORE USING THE PRODUCT.

1. PRODUCT SPECIFICATION

1.1 GENERAL SPECIFICATION

1.2 MOTION SYSTEM DESCRIPTION

1.3 SAFETY SYSTEM DESCRIPTION

2. INITIAL INSPECTION

3. NAMES OF MAJOR PARTS

4. TRANSPORTING AND MOVING

4.1 EQUIPMENT REQUIRED FOR UNLOADING AND TRANSPORT

4.2 UNLOADING AND OPENING THE CRATE

4.3 UNPACKING AND INSTALLING REAR CASTER WHEELS

4.4 MOVING THE MACHINE

5. INSTALLATION INSTRUCTION.

5.1 LOCA TION REQUIREMENTS

5.1.1 ENVIRONMENT REQUIREMENTS

5.1.2 ELECTRICAL REQUIREMENTS

5.2 EQUIPMENT REQUIRED FOR INSTALLATION

5.3 STEPS FOR INSTALLATION

5.4 SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)

5.5 CONNECTING THE HEAVE ACTUATOR

5.6 CONNECTING THE SAFETY LINK

5.7 ASSEMBLING THE FLOOR SENSOR PLATES

5.8 SETTING THE PHOTO SENSORS

5.9 COIN MECHANISM INST ALLATION

5.10 CONNECTING THE ELECTRIC POWER SOURCE

5.11 POST INSTALLATION TESTING AND INSPECTION

5.11.1 TESTING AND ALIGNING THE PHOTO SENSORS

5.11.2 TESTING AND ADJUSTING THE FLOOR PRESSURE SENSOR

5.12 ASSEMBLING THE FENCE

5.13 FIGURE OF CYCRAFT AFTER FINISHING THE INSTALLATION WORK

Page 7

Page 8

6. OPERATION & ADJUSTMENT INSTRUCTION

6.1 DESCRIPTION OF INDICATORS AND SWITCHES ON THE OPERATION

PANEL

6.2 TURNING THE POWER ON AND OFF

6.3 ADJUSTMENT OF THE SPEAKER VOLUMES

6.4 SETTING VIDEO MONITOR PARAMETERS

6.5 USING THE LCD PANEL TO SET CONFIGURATIONS

6.5.1 SETTING THE SAFETY SENSOR PARAMETERS

6.5.2 SETTING TCP/IP CONFIGURATION

6.5.3 VIEWING THE TOTAL COIN COUNT (STATISTICS)

6.6 SETTING THE COIN AND CREDIT CONFIGURATION

6.7 GAME PLAY OPERATION

7. MAINTENANCE & INSPECTION INSTRUCTION

7.1 ROUTINE MAINTENANCE

7.2 INSPECTION OF CRITICAL BOLTS AND CONNECTIONS

7.3 VERIFICATION OF SNAP RINGS

7.4 CHECKING WELD CONDITION

7.5 CHECKING THE ACT UATOR DRIVE BELT

7.6 CLEANING THE MSCU AIR FILTERS AND FAN

7.7 LUBRICA TING THE ACTUATORS

7.8 LUBRICA TING THE JOINTS

8. SERVICE & REPLACEMENT INSTRUCTION

8.1 EXCHANGING THE COMPACT FLASH CARD

8.2 REPLACEMENT OF SERVO CONTROLLER BOARD

9. TROUBLE SHOOTING

9.1 TROUBLESHOOTING TABLE

9.2 CONTROLLER ERROR MESSAGE TABLE

10. ELECTRIC SCHEMATICS

10.1 SCU SCHEMATIC

10.2 CABIN SCHEMATIC

10.3 MCU SCHEMATIC

Page 8

Page 9

1. PRODUCT SPECIFICATIONS

1.1 GENERAL SPECIFICATIONS

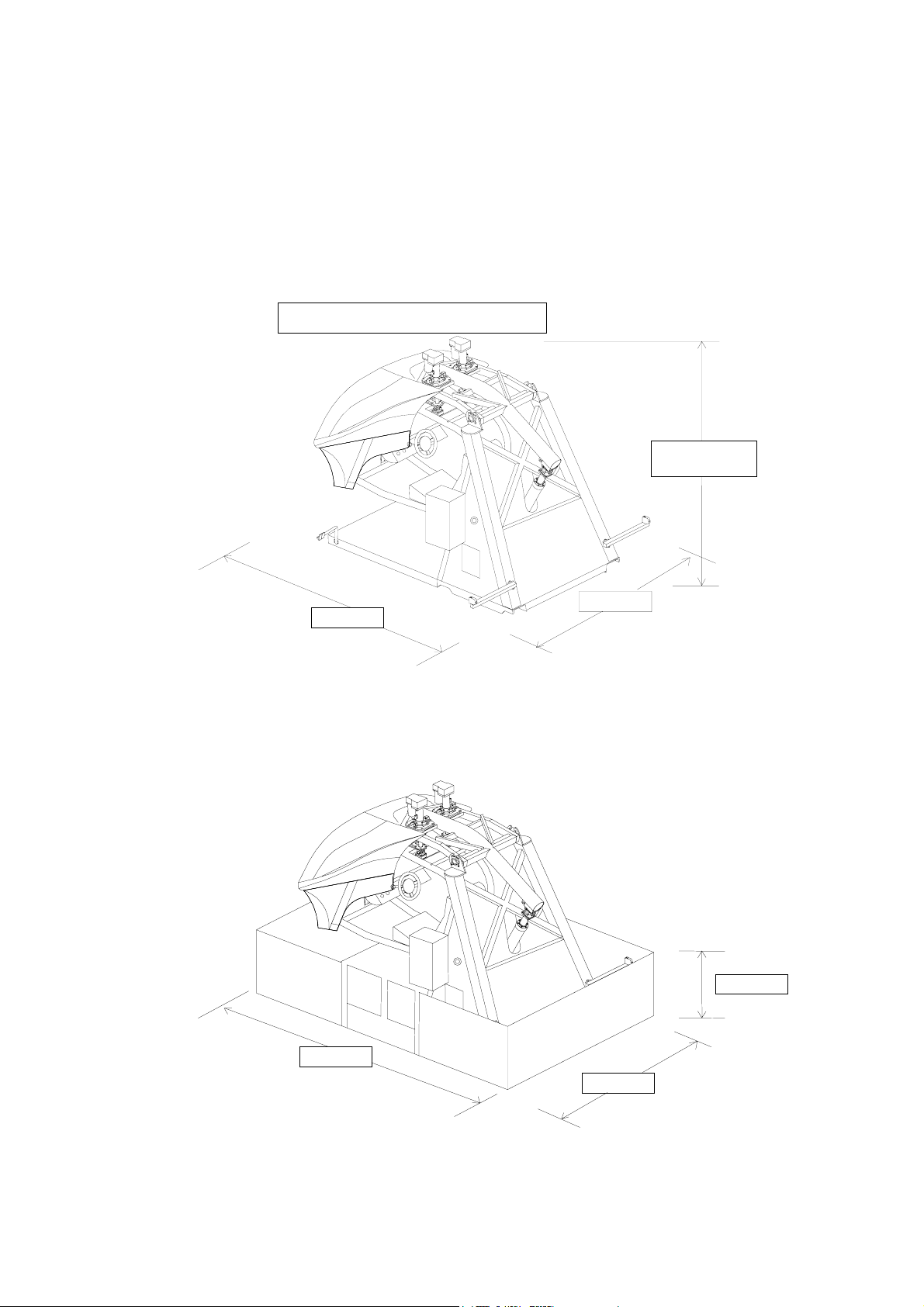

When the c abin is at the power- on position

2870 mm

Approximately

2200 mm

2150 mm

1000 mm

4050 mm

2900 mm

Page 9

Page 10

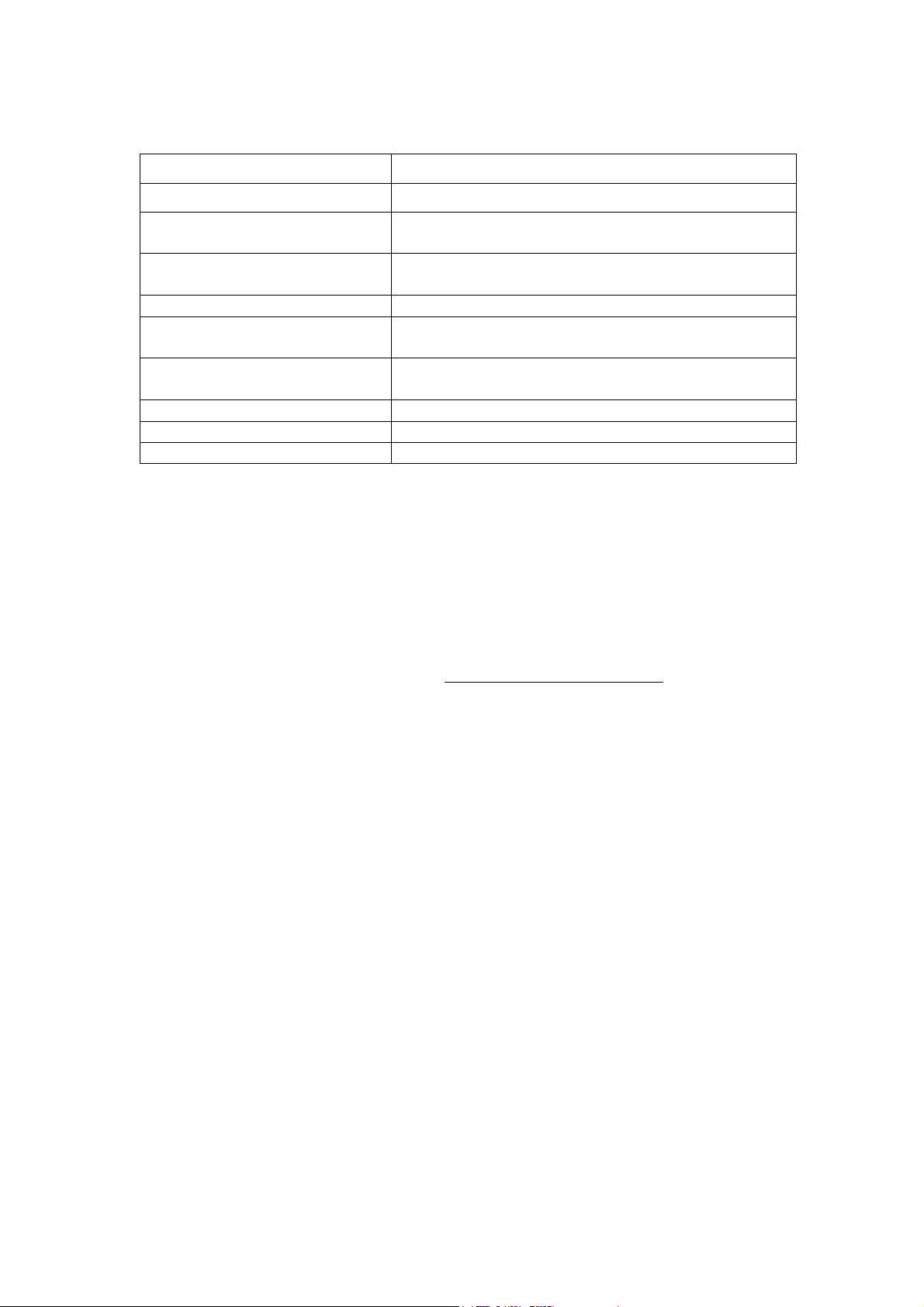

Category Coin-op interactive motion simulator

Play type Arcade game

Main Machine Dimensions

2870 mm (L) × 2150 mm (W) × ~ 2200 mm (H)

(At the power-on position.)

Main Machine Dimensions

2890 mm (L) × 1540 mm (W) × 2020 mm (H)

(Transport dimensions)

Fence Dimensions 4050 mm (L) × 2900 mm (W) × 1000 mm (H)

Weight Main Machine: (Approximately) 900 kg

Fence: (Approximately) 110 kg

Electric Power Single phase AC 200/208/220/230/240 V,

50/60 Hz, (Max) 10A

No. Of Passenger Single Player

Passenger Weight Limit 120 Kg

Compartment Semi-enclosed with seat belt

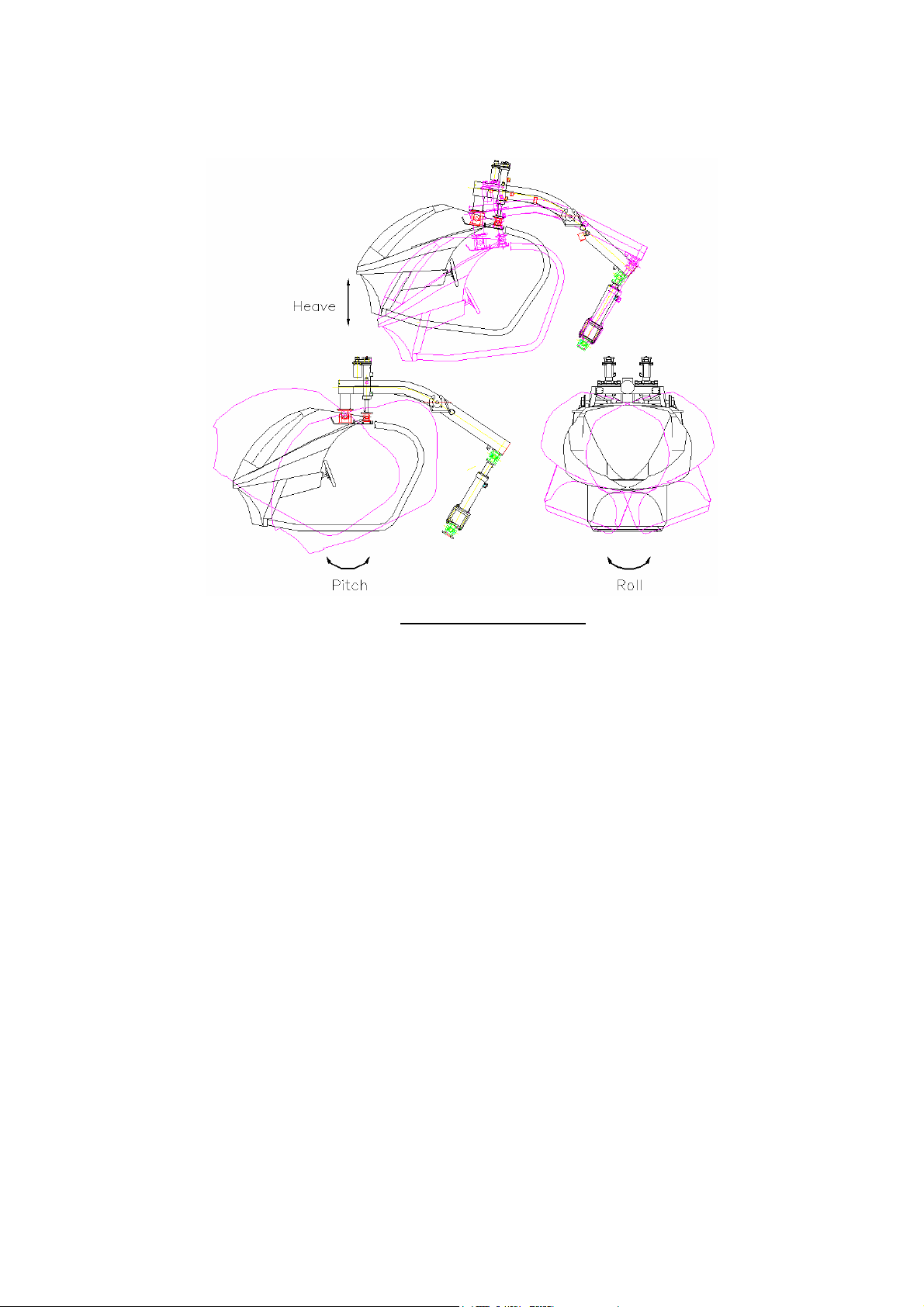

1.2 MOTION SYSTEM DESCRIPTION

The motion actuation system used in Cycraft is a very unique, high tech system that

distinguishes Cycraft from other simulator products. The motion system has the

following special features:

z Fully electric motion system: The

actuators are fully Electrical (no hydraulics),

making it superior in terms of maintainability and transportability.

z Patented “inverted” configuration (virtual 5 DOF system): The motion

actuators are configured such that pitch and roll rotational motions have their center of

rotations above the passenger. This patented technology enables the simulator to

produce the effects of a 5 X DOF (degrees of freedom) motion system although it has

only 3 DOF mechanically. Therefore, fast and accurate motion cueing is made

possible without increasing costs.

Page 10

Page 11

3 DOF Motion Systems

The heave actuator produces up/down heave motion by rocking the rocker arm, which

holds the passenger cabin. The two suspended actuators on the rocker arm

assembly produce the relative pitch and roll motions

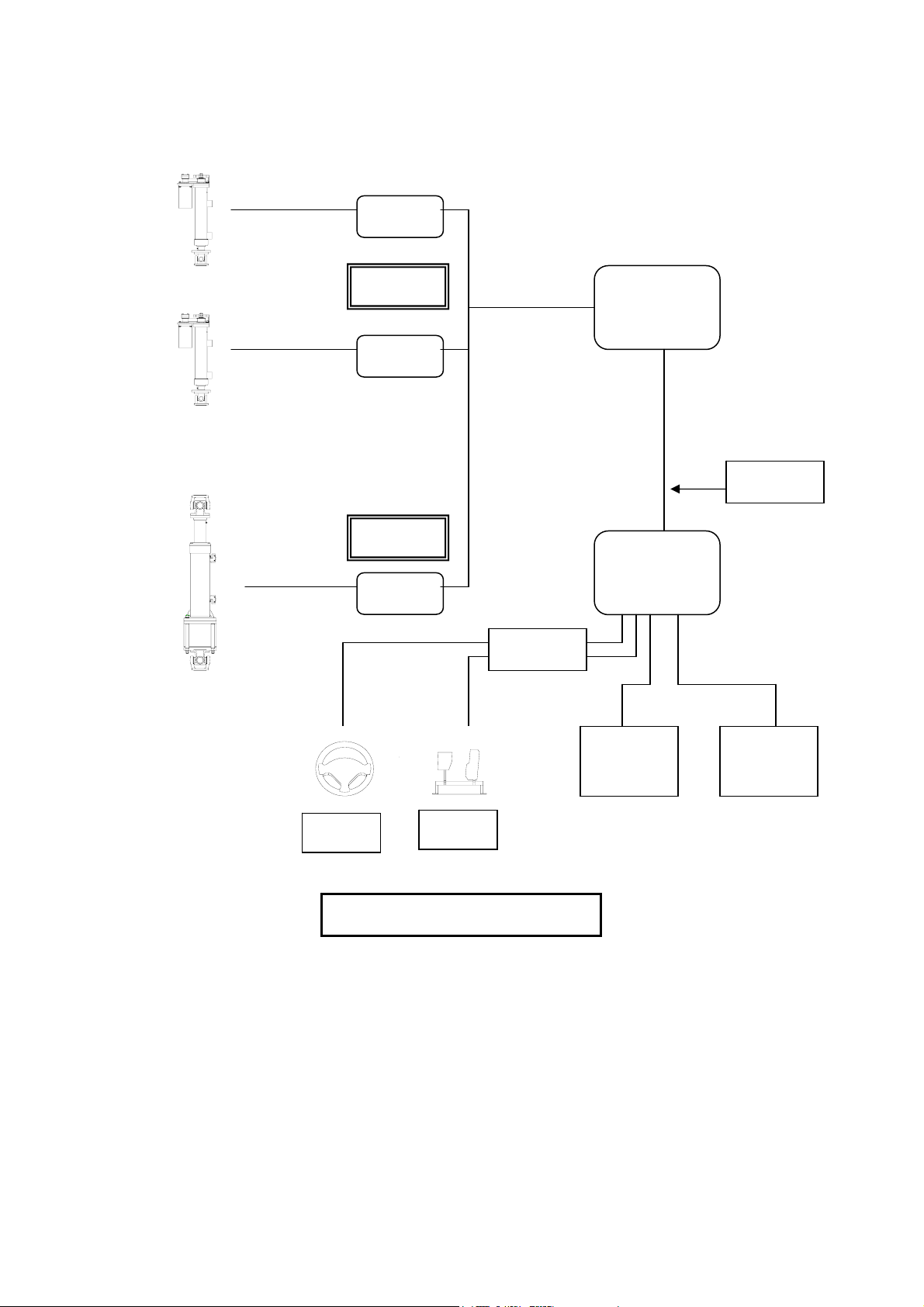

Separate controllers inside the MSCU control each of the linear actuators. The

controllers are in turn connected to the motion controller board, which generates the

commands for each actuator via high-speed industrial Control Area Network (CAN)

cable.

During the game, the game computer regularly sends the attitude data and other

dynamic properties data in real time to the motion control computer. The motion

board then calculates in real time, the motion necessary to give the passenger the

best feeling of reality and converts this motion to commands for the motion controllers

and actuators.

Page 11

Page 12

Servo Control

,

Board #3

Mitsubishi

Servo Control

Board #2

Toshiba

Servo Control

Board #1

CAN NETWORK

I / O Board

Motion Computer

Flash Rom Fitted

Sega Game System

NAOMI 2 or Triforce,

Dimm Bd, GD Rom

Drive

3 x Boards

TCPIP

I/O Bd, PSU.

LAN cable

Handle

Game

Monitor

Pedal

Audio

System

SYSTEM DIAGRAM OF CYCRAFT

Page 12

Page 13

1.3 SAFETY SYSTEM FEATURES

Operators of Cycraft should familiarize themselves with the safety features of Cycraft

to ensure that they are functioning properly for safe and proper operation. Cycraft

incorporates a number of safety features to ensure that accidents and injury will not be

caused to passengers and on-lookers due to the motion of the simulator. Following

is a description of each safety feature.

z Fence: A sturdy metal fence with an entrance door is provided with Cycraft. It will

ensure that on-lookers and waiting players will be kept a safe distance from the moving

cabin. The fence will also prevent on-lookers from approaching too closely and

unnecessarily tripping the photo sensors during play. Warning signs and regulation

signs are attached to the fence and door to inform customers and on-lookers.

z Side Photo Sensor: Two photo sensors attached on either side of the outer frame

of Cycraft cause the motion to stop if any obstacle obstructs the line between the

sensor and the reflective plate during play. Therefore, even if people enter the fence

and approach Cycraft when it is moving, safety is ensured since the photo sensor will

be tripped and motion stopped. Motion resumes 3 seconds after the obstacle is

removed.

z Floor Sensor: The floor plate beneath the cabin (seat) is a pressure sensor, which

activates when stepped on. It is guaranteed to detect pressures above 20 kg.

Activation of the floor sensor will stop the Cycraft motion as with the photo sensors

described above. Motion will re-activate 3 seconds after the pressure is removed.

The floor sensor guarantees safety even in the case when people somehow approach

Cycraft without tripping the photo sensor and also in the case when the passenger falls

from the cabin during play for any reason.

z Seat Belt Sensor: The seat belt buckle in Cycraft is equipped with a sensor that

detects when the seat belt is fastened or not. Cycraft will not start the game unless

the seat belt is fastened properly. Also, if the seat belt is unfastened during the game,

the motion will stop until it is re-fastened.

z Game Stop Button: This button, located inside the cabin allows the player to stop

the game anytime during play. Pressing this button will terminate the game and lower

the cabin to the initial position.

z Motion Stop Switch: The motion stop button located behind the coin chute case

stops the motion when pressed. Motion restarts 3 seconds after the button is

released. This button can be pressed by outside on-lookers or by the operator in

Page 13

Page 14

case the photo or floor sensors cannot be activated or the motion must be stopped for

safety reasons.

z Power Cutoff Switch: This button located inside the operator panel but accessible

through a sliding door on the operator panel cover shuts off the main power to the

system. Pressing this switch will stop the ongoing motion of the system but will not

stop and hold the position of the cabin as with the other buttons and safety features.

Instead, the cabin will slowly pitch forward (nose down) and glide down to its lowest

position due to its own weight. Therefore, this switch should NOT be pressed

when the motion needs to be stopped. This switch should only be used in the rare

emergency case when power must be cut off such as when a fire is ignited.

NEVER press the power cutoff switch when there is a person or obstacle

UNDER the cabin. The cabin will glide down after the switch is pressed and

can cause serious injury to anybody under the cabin.

z Safety Link (page 29) and Safety Oriented Mechanical Design: The safety link

located on the rear part of the rocker arm functions to prevent a free fall of the cabin in

case the heave actuator is broken off from the rocker arm. The two rocker arm

bearings and center shaft of the rocker arm is designed such that even if one of the

bearings comes loose, the shaft will be held up by the frame to prevent a fall. The

cabin is suspended by three universal joints (central joint and two joints connecting to

the actuators). Therefore, even if one of the joints fail, the other two will support the

cabin to prevent a complete free fall.

z Other Safety Features: Cycraft is equipped with

Brake Boards to supply step down

voltages to critical motor controller circuits, in case of power outages so that the cabin

(seat) does not fall abruptly. At power outages (and also when the power cutoff switch

is pressed) the motor control circuits with brake boards will make sure that the

simulator will shutdown and rest softly.

z Safe Inherent Design: The basic configuration of the inverted motion system allows

for the cabin to be suspended much lower from the ground than conventional motion

simulators. Also, it is dynamically much more stable by making it very difficult to tip

the cabin over to it’s side. Thus, the Cycraft structural design is inherently much safer

than conventional motion simulators.

Page 14

Page 15

INITIAL INSPECTION

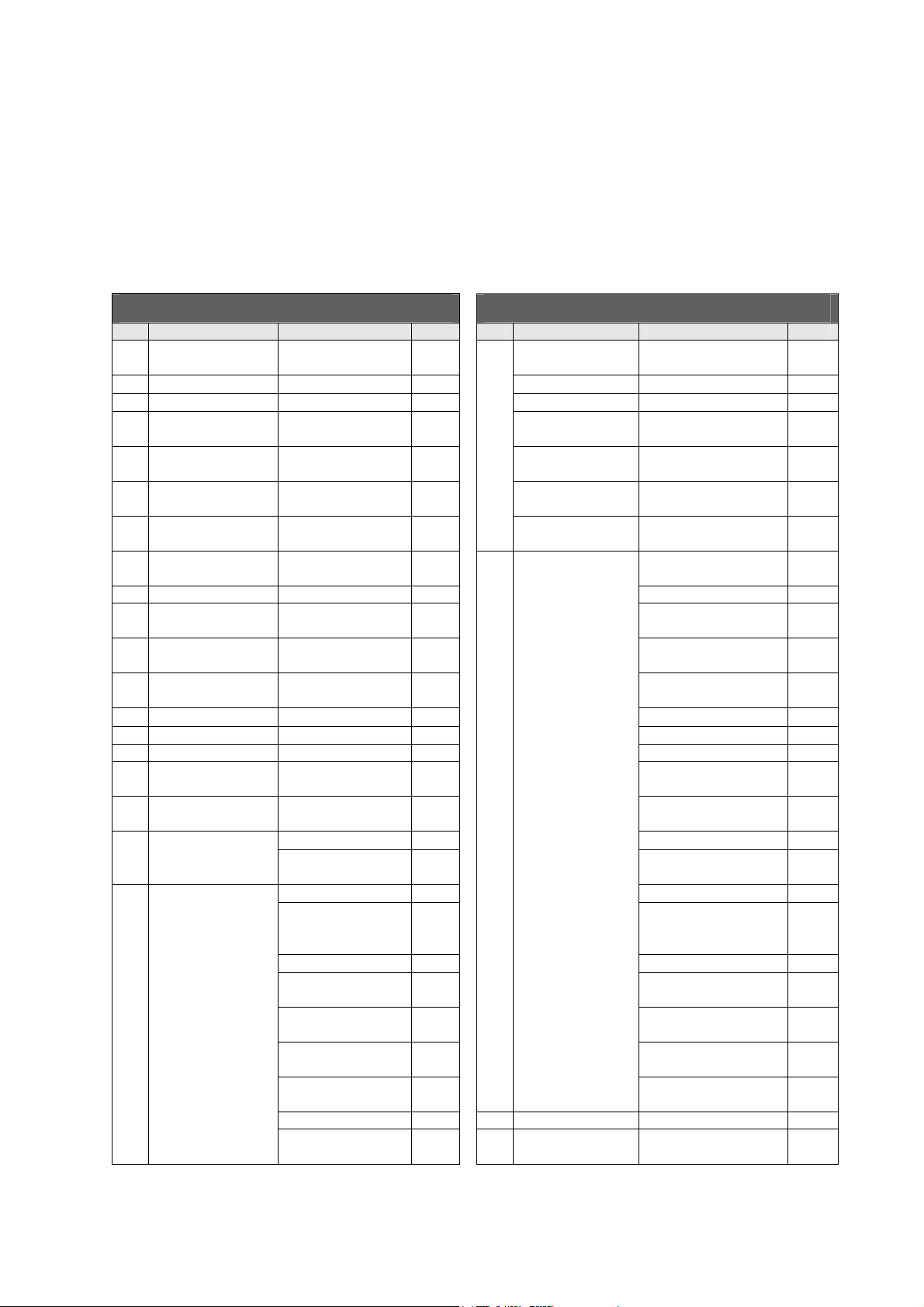

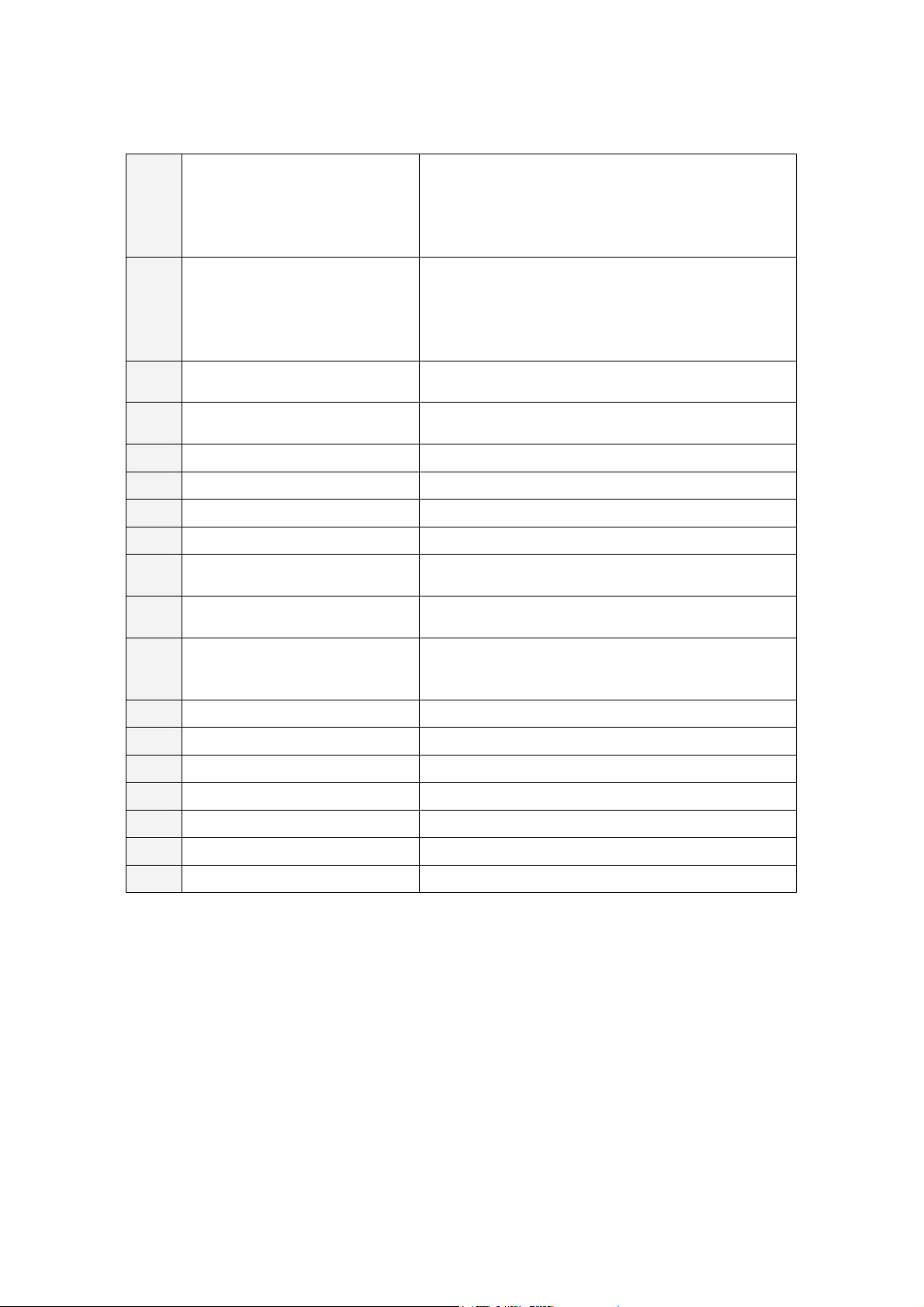

2.1 PACKING LIST

CYCRAFT PACKING LIST (1/2) CYCRAFT PACKING LIST (2/2)

No Item Description Qty No Item Description Qty

CYCRAFT Main

1

Body

2 Rear Caster (R) 1 ea Hex Nut M8 7 ea

3 Rear Caster (L) 1 ea Clamping Filter 1 ea

Floor Sensor Plate

4

(A)

Floor Sensor Plate

5

(B)

Floor Sensor Plate

6

(C)

Floor Sensor Plate

7

(D)

8 Boarding Step 1 ea 20 Spare Parts Box

9 Coin Chute Tower 1 ea Monitor BD Fuse 1 ea

Fence Holding

10

Bracket (A)

Fence Holding

11

Bracket (B)

Fence Holding

12

Bracket (C)

13 Gate Door (R) 1 ea Grease 400g

14 Gate Door (L) 1 ea Paint (Red)

15 Fence Pole (A) A Type 4 ea Fence U Bracket 2 ea

16 Fence Pole (B) B Type 2 ea

17 Fence Pole (C) C Type 3 ea

18 Wire Mesh 1200 mm 6 ea SUS Nut M6 2 ea

1800 mm 2 ea

19 Installation Kit Box Safety Link 1 ea Hex Bolt M12 x 35L 2 ea

Fence U Bracket 32 ea Hex Bolt M8x20L 2 ea

SUS Nut M6 32 ea

Hex Bolt M12 x 35L 10 ea 21 NAOMI2 Carton 1 ea

1 ea 19 Hex Bolt M8x20L 10 ea

A Type 1 ea Fence Sign Plate 4 ea

B Type 1 ea

C Type 1 ea

D Type 1 ea

1030 mm 1 ea Cable Tie 5 ea

690 mm 1 ea Pushbutton Lamp 2 ea

550 mm 1 ea Grease Gun 1 ea

Boarding Step

Joint Bracket

SUS Wrench Bolt

M6x10L

SUS Wrench Bolt

M6x25L

Counter Sink Head

Bolt

Hex Bolt M8x30L

DU Bush10*15

2 ea

32 ea Hex Nut M8 2 ea

32 ea Truss Bolt M4 x12L 5 ea

4 ea

8 ea 22 GD-ROM Carton 1 ea

Fence Sign Ring

Clip

Play Instruction

Sticker

Installation & User

Manual

8 ea

1 set

1 ea

Floor Sensor

Micro switch

SUS Wrench Bolt

M6x10L

SUS Wrench Bolt

M6x25L

Count Sink Head Bolt

M6x 10L

Hex Bolt M8x30L

DU Bush10*15

Rubber Washer

Round Head Bolt

M5x10L

Harness for coin

mechanism

2 ea

200ml

2 ea

2 ea

2 ea

2 ea

4 ea

1 set

Page 15

Page 16

Rubber Washer

2.2 GENERAL RECEIVING INSPECTION

Only QUALIFIED SERVICE PERSONNEL should carry out inspection.

All Simuline products are manufactured so that operation is possible immediately after the

proper installation. However, it can be possible that an irregular situation occurs during

transport and delivery to prevent this. To verify that transport and delivery has be carried

out without irregularity, a proper general receiving inspection should be made as follows:

z Are then any dented parts or defects (cuts, etc.) on the external surfaces of the

product?

z Are castors and leg adjusters present and undamaged?

z Do the power supply voltage and frequency requirements match with the local supply?

z Are all wiring connectors correctly and securely connected? Unless connected in the

correct direction, connector connections cannot be made successfully. Do not insert

connectors forcibly.

z Are all IC’s of each IC board firmly inserted?

z Does the power cord have any cuts or dents?

z Do fuses meet the specified rating?

z Are such units such as monitors, control equipment, IC boards, etc. firmly secured?

z Are all earth wires connected?

z Are all accessories available?

z Can all doors and lids be opened with the accessory keys and/or tools?

Page 16

Page 17

3. NAMES OF MAJOR PARTS

18

17

28

12

15

16

13

14

11

Page 17

Page 18

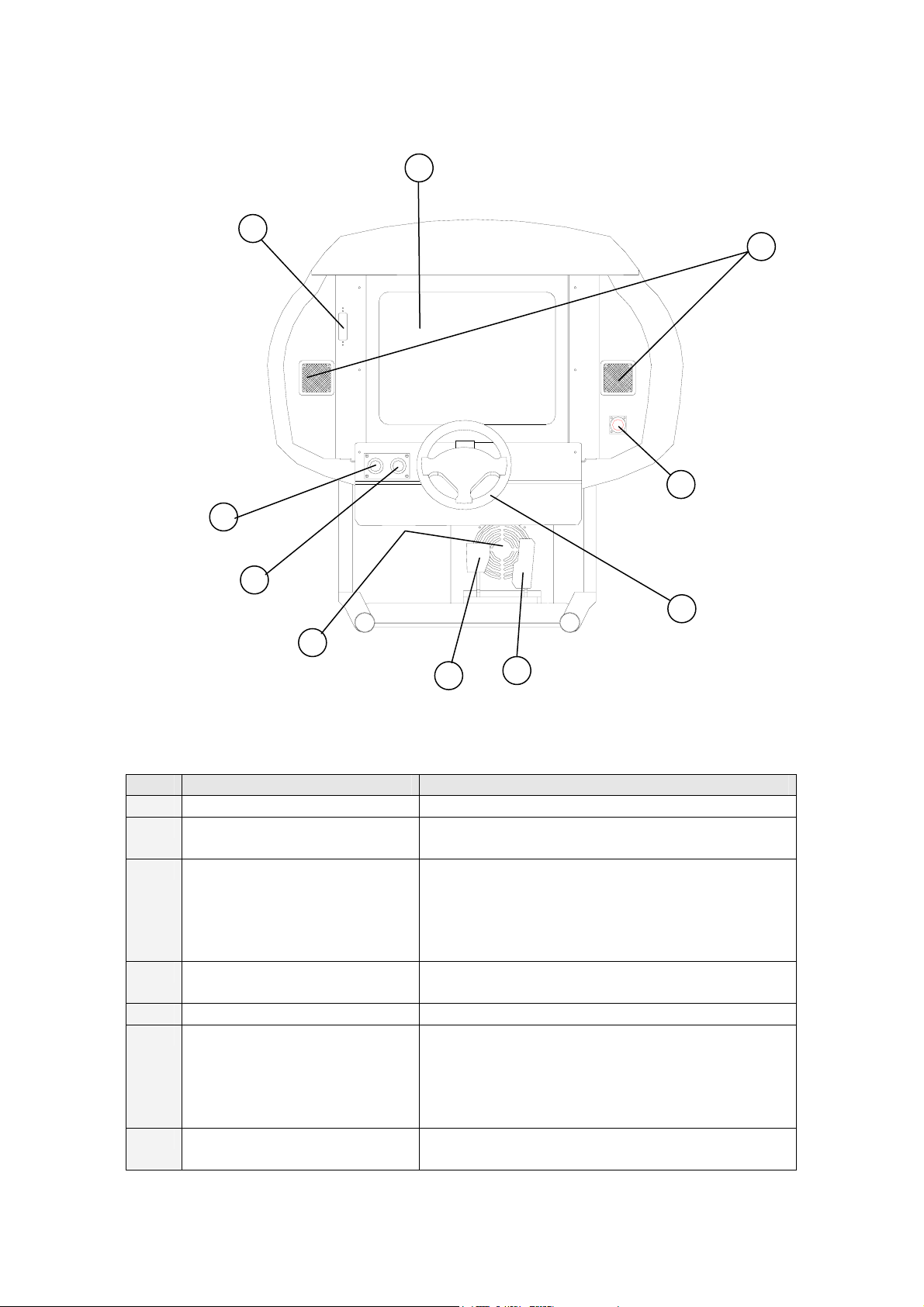

19

26

22

27

21

20

23

29

25

24

No. Item Description

1 Cabin (Seat + Monitor) Carries the player and moves during operation.

2 Main Frame Holds the cabin, actuator system and

electronics.

3 Actuators Three electric linear actuators that move the

cabin in 3 DOF (degrees of freedom). The two

actuators on top of the cabin creates pitch and

roll motions. The actuator behind the cabin

creates heave motion.

4 Motion System Cabinet

Unit (MSCU)

Houses all the control electronics and electrical

components.

5 Coin Chute Tower Carries the coin chute mechanism.

6 Motion Stop Switch Pressing this button will stop the simulator

motion but game play will continue. Motion

resumes 3 seconds after the switch is released.

This button can be used in case of emergency

when motion must be stopped.

7 Operator Panel Houses indicators and switches to set and

control Cycraft. Refer to Chapter 2 for details.

Page 18

Page 19

8,9 Safety Photo Sensors &

Reflectors

There are 2 photo sensors on each side of the

outer frame. If any of the sensor lines are

obstructed, the simulator will stop in its current

orientation until 3 seconds after the removal of

the obstruction.

10 Safety Floor Sensor The metal floor plate underneath the cabin is a

pressure sensor that stops the simulators

motion when stepped on. The simulator will

begin to move again 3 seconds after the

removal of the pressure.

11~

Safety Floor Sensor Plates 11 = A type, 12 = B type, 13 = C type,

14

15 Floor Sensor Indicator

Lamp

14 = D type

Lamp (Green) goes off when the floor sensor is

activated.

16 Safety Link Safety link connected to the rocker arm.

17 Heave Actuator Joint

18 Rocker Arm Tilts up and down to create heave motion.

19 Start Button Begins the game after coin is inserted.

20 View Button Changes the driver’s view perspective during

play.

21 Game Stop Button Terminates the game and lowers the cabin to

the initial position.

22 Video Control Buttons Removing this cover exposes the control

buttons to adjust video screen parameters.

Refer to Chapter 2 for details.

23 Steering Wheel Produces steering input for the game.

24 Accelerator Pedal Produces accelerator input for the game.

25 Brake Pedal Produces braking input for the game.

26 Monitor Displays game graphics.

27 Front Speakers Produces audio effects.

28 Rear Speakers Produces audio effects.

29 Subwoofer Produces audio effects with low frequency

Page 19

Page 20

4. TRANSPORTING AND MOVING

4.1 EQUIPMENT REQUIRED FOR UNLOADING AND TRANSPORT

No Equipment Description Qty Purpose

1 Fork Lift Capacity over 1500 kg

Boom attached fork

2 Wood block 10 cm x 10 cm x 100 cm

3 Rear caster

(Supplied)

4 Socket wrench &

Extension bar

(Over 200 mm)

1 Lift and transport out of

packing crate.

4 Set under the base

frame so that fork can

be inserted and

removed easily.

2 Used together with front

casters (already

installed) to roll the

machine to destination

location.

1 Attaching the rear

casters.

5 Wrench

6 Philips type

screwdriver

7 Bolt Hex head M12 x 35 L 6 Attaching the casters

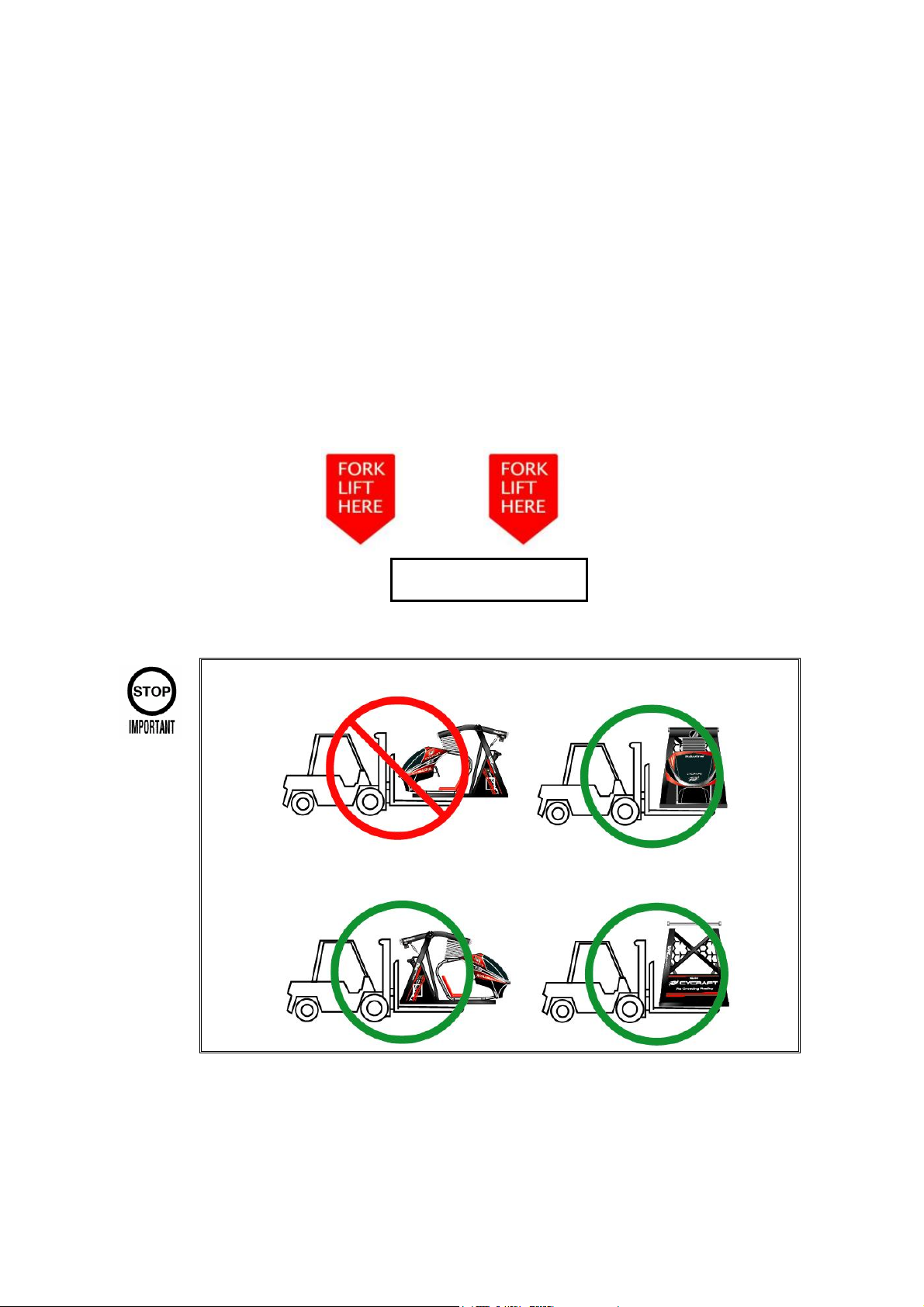

4.2 UNLOADING AND OPENING THE CRATE

1) When unloading the crate from the container or truck, it is recommended to insert

the forklift from the heavier rear side of the crate.

2) The crate should not be opened from the front. Open the rear and/or one of the

sides when opening the crate.

1 Adjusting the level of

casters.

1 Loosening and

securing

truss bolts

Page 20

Page 21

4.3 UNPACKING AND INSTALLING REAR CASTER WHEELS

1) After the crate is opened, unpack the separate accessories and components so

that the main simulator body is accessible.

2) Insert forklift from the rear of Cycraft or from the side. DO NOT INSERT FORKS

FROM THE FRONT SIDE. When inserting forks from the side, make sure the

forks are positioned to enter the cutoff sections in order to ensure Cycraft does not

tip over. Insert forks fully until the tips are visible on the other side.

Fork Lift Insert Mark

DO NOT INSERT FORKS FROM THE FRONT SIDE

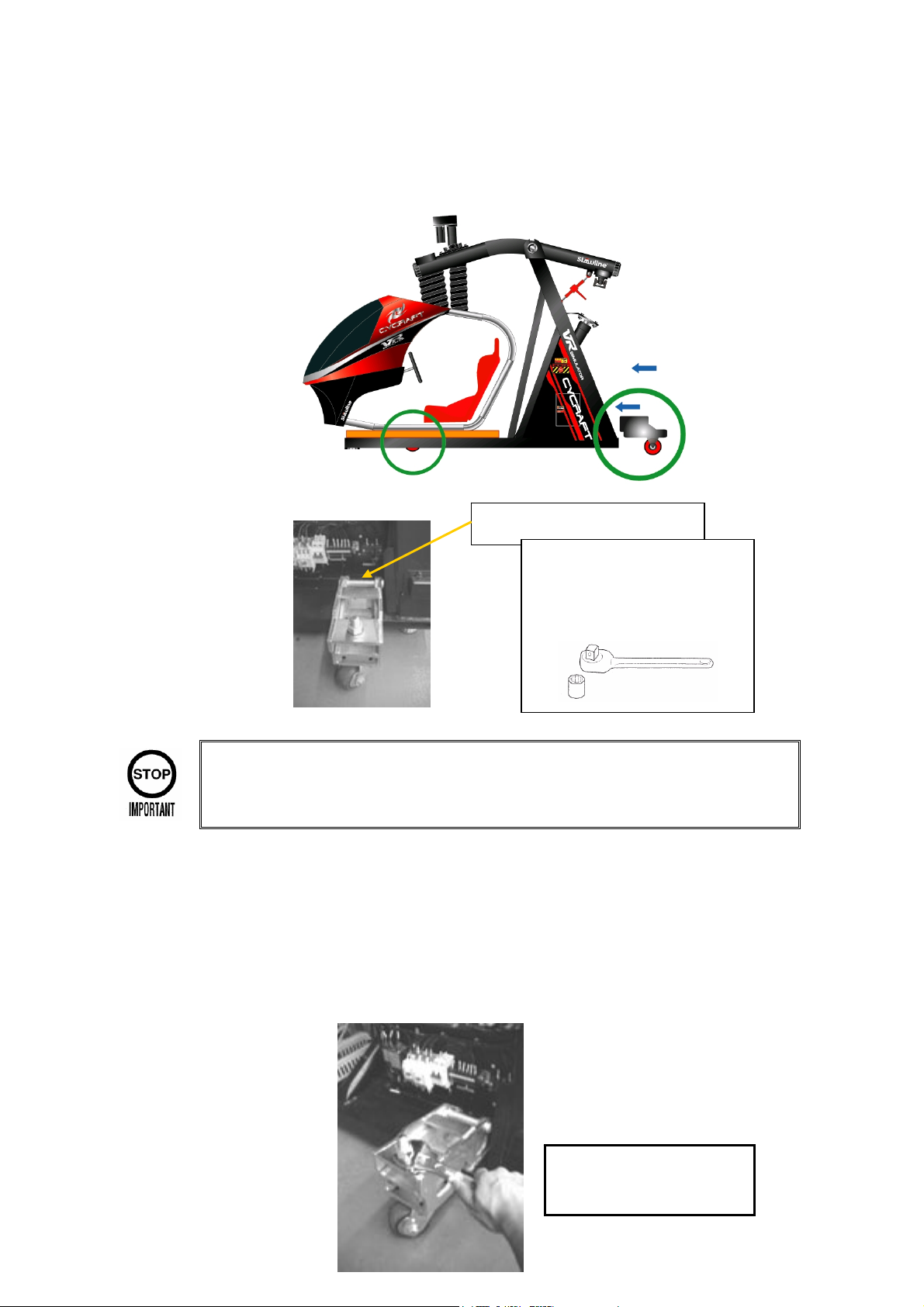

3) After CAREFULLY taking Cycraft out of the crate, install the rear two wheels by

Page 21

Page 22

first removing the MSCU cover as shown in the figure below. Note that the front

two wheels are already installed.

3 x Hex head Bolt M12 x 35L

Socket wrench (19mm) &

Extension bar

(Over 200 mm)

Be careful not to step on and damage the floor pressure sensor springs and

switches installed on the frame beneath the cabin

4) Adjust the heights of the wheels by rotating the nut on top of each wheel using

wrench until Cycraft is raised sufficiently for transport. Then, carefully roll Cycraft

to its destination location. After Cycraft is positioned in it’s installation location,

lower Cycraft by turning the wheel height adjustment nuts counterclockwise and

disassemble each of the wheel assembly.

To lift up the base frame,

turn the nut clockwise

Page 22

Page 23

4.4 MOVING THE MACHINE

Only QUALIFIED SERVICE PERSONNEL should carry out this operation.

Cycraft simulator is a complex & delicate machine. Special care must always be taken

when handling Cycraft.

When moving Cycraft within a facility, it is recommended to utilize the casters provided

with the product. It is not necessary to disassemble the heave actuator and/or the safety

link. Only the fence and boarding step with coin chute need to be disassembled.

When Cycraft must be moved long distances by truck, it is recommended that the heave

actuator and safety link be disassembled

such that the cabin is set securely on the base

of the outer frame. Trucking Cycraft without the heave actuator disassembled can cause

mechanical damage to the actuator due to shock and vibration during transport. Be sure

to lay the wooden plate between the cabin and the base frame as when Cycraft was

delivered. This plate protects the floor sensors and switches during transport.

z When moving the machine, be sure to remove the power cord and plug

from the power supply. Moving the machine with the power cord inserted can

cause the power cord to be damaged, resulting in a fire or electric shock when

installed in a new location.

z When moving the machine, with the heave actuator in the assembled

state, make sure that the machine is not exposed to high vibrations and shock.

Mechanical and structural damage can result.

Page 23

Page 24

5. INSTALLATION INSTRUCTION

5.1 LOCATION REQUIREMENTS

5.1.1 ENVIRONMENT REQUIREMENTS

Cycraft is designed for indoor use and should never be installed outdoors.

Environment and facility requirements are as follows:

Installation location Indoor use only

Ambient temperature 5 to 40 C

Humidity 10 to 70 % (no condensing)

Min. Entrance

1540 mm (W) x 2100 mm (H)

dimensions

Min. Ceiling Height 2400 mm (H)

Min. Footprint

4050 mm (L) x 2900 mm (W)

(incl. Fence)

Min. Floor Loading 310 kg/m

2

Cleanliness Free of dust and debris

z Never install the game machine outdoors

Also avoid the following locations even though they are indoors.

z Near a leaky roof, close to any kind of dripping water, or any place with high

humidity that can condense

z Close to an indoor pool or showers

z Exposed to direct sunlight

z Exposed to direct heat, such as close to a heater vent, or in a highly heated

room

z Close to flammable or volatile chemicals, or dangerous materials

z Avoid floors that slope(any slope more than 2 de grees)

z Avoid strong vibrations

z Avoid dusty locations

z Avoid any location that does not allow enough space around the machine

Page 24

Page 25

5.1.2 ELECTRICAL REQUIREMENTS

The facility should provide the following electrical power outputs for Cycraft:

Input Voltage Single Phase

AC 200V, 208V, 220V, 230V, 240V

Frequency 50 / 60 Hz

Rated Current (Max) 8.5 Amp

Peak Current (Max) 10 Amp

Building Circuit Breaker

13 Amp

(Recommended)

Note: The average power requirement is measured power consumption during

normal operation. Peak power requirement is theoretical short-term peak power

possible for short times during special driving conditions.

Therefore, it is

recommended that facility power to be based on peak power requirements for the

best results.

5.2 EQUIPMENT REQUIRED FOR INSTALLATION

No Tools Description Q’ty Purpose

1 Philips type

screwdriver

2 Wrench

(19 mm ~ 27 mm)

3 Hex Key

1 Loosening and securing

truss bolts

1 Adjusting the levers.

1 Boarding step,

( 6mm)

4 Hex Key

Coin Chute Tower

1 Fence

( 5mm )

5 Hex Key

(2.5 mm)

1 Photo sensor, mirror

6 Spanner (22 mm) 2 Turnbuckle

Safety Link

Page 25

Page 26

7 Spanner (19 mm)

8 Spanner (13 mm)

2 Heave actuator (M12)

2 Floor sensor plate (M8)

9 Spanner (10 mm)

10 Mini Socket Wrench

(5/16 inch)

5.3 STEPS FOR INSTALLATION

Installation should be carried out according to the following steps.

STEP 1 SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)

STEP 2 CONNECTING THE HEAVE ACTUATOR

STEP 3 CONNECTING THE SAFETY LINK

STEP 4 ASSE MBLING THE FLOOR SENSOR PLATE

STEP 5 SETTING THE PHOTO SENSORS

STEP 6 COIN MECHANISM INSTALLATIONS

STEP 7 CONNECTING THE POWER CORD

STEP 8 TESTING AND ALIGNING THE PHOTO SENSORS

STEP 9 TESTING AND ADJUSTING THE FLOOR SENSOR

STEP 10 FENCE ASSEMBLY

5.4 SECURING IN PLACE (LEG ADJUSTER ADJUSTMENT)

1 Fence mesh (M6)

1 Coin mechanism

After Cycraft is placed in location, the level pads must be adjusted correctly to prevent

Cycraft from moving about the floor due to its own motion. Cycraft has 3 stationary

rubber pads and 4 adjustable level pads as shown.

POSITION OF 3 PCS RUBBER

Front side of CYCRAFT

RUBBER

PAD

Page 26

PADS & 4 LEVERS (TOP VIEW)

LEG

LEVELER

Page 27

The processes to place Rubber Pads and adjust the Leg Levelers are as follows:

1) Make sure that all of the four adjustable Leg Levelers are not touching the ground.

If it is, raise it so that only the three rubber pads touch the ground. The center of

mass of Cycraft is very near the central rear rubber pad. Therefore, it is

advisable to have two people stand on top of the front two rubber pads to make

sure the three pads are touching the ground securely.

2) Lower the 4 adjustable Leg Levelers so that they touch the ground and evenly

hold the weight of Cycraft. Do not extend them so much that the central rubber

pad is raised from the floor.

To secure the machine,

turn the adjusting nut

clockwise.

Adjusting Nut

Level Pad

3) After you are satisfied that the pads are set correctly, you can proceed to

assemble Cycraft. However, after assembly, the pads should be observed during

the test runs and adjusted further if there seems to be excessive movement or

uneven loading and lifting of the pads.

5.5 CONNECTING THE HEAVE ACTUATOR

At no time during the installation and assembly process should personnel

place body parts or go beneath the cabin. Take note that there is always the

danger of the cabin falling.

1) Install the turnbuckle firmly between the frame and rocker arm as shown.

Page 27

Page 28

Turnbuckle

2) Turn-buckle works as a kind of ratchet mechanism. Lower the rear end of the

rocker arm by ratcheting up the turnbuckle clockwise as seen from the rear until

the turnbuckle almost go to its limit.

During this process the

cabin will be lifted up. As it lifts up it will simultaneously tip to

wards the front and slide backwards

D

3) isassemble the heave actuator holding bracket and free the heave actuator.

Make sure the actuator is supported so that it does not fall over to one side when

the holding bracket is disassembled.

4) Rotate the actuator piston counterclockwise as seen from the top to extend the

actuator. Match the 4 bolt holes of the flange and rocker arm mating part close

Page 28

Page 29

enough so that bolts can be inserted. It is not necessary to have the flange

mated exactly to the rocker arm at this stage.

5) Tighten the four bolts evenly one at a time. The heave actuator piston will extend

as the bolts are tightened. Tighten all four bolts to 1200 kgf

bolt and relative side of the flange as in the figure so that it can later be inspected

easily for looseness.

6) Rotate the turn-buckle clockwise to lower the cabin and extend the heave

actuator fully. When the bolts connecting the turnbuckle to the rocker arm feels

loose and the weight of the cabin is held fully by the actuator, disassemble the

turnbuckle completely from each end and remove it.

5.6 CONNECTING THE SAFETY LINK

1) Position the safety link as in the figure below with the longer link section above the

shorter link section. Tighten the bolt connecting the link to the rocker arm to 1200

kgf

zcm torque and mark the bolt position so that it can later be inspected for

looseness.

2

) Make sure that the link is bent such that the center-connecting joint protrudes

zcm torque. Mark the

forward and the link is bent in the “<” shape as in the figure.

Incorrect

Correct

If the link is installed incorrectly in the reverse “L” shape (see figure), the

link will hit the actuator and actuator joint when heave motion occurs and

the system will be damaged. Make sure it is installed correctly.

Page 29

Page 30

Longer Link

Section

.7 ASSEMBLING THE FLOOR SENSOR PLATE

5

NEVER go under the cabin to install or service the floor pressure sensor

system when the main power is O

malfunctions. Always place a structure to support the cabin in case it falls.

Turn the main power off when it is necessary to go under the cabin.

Be careful not to damage the springs and micro switches on the bottom

frame when assembling the floor sensor plates

1) Make s ower frame structure where

ure there are no objects or debris on top of the l

Figure of Cycraft after

assembling the heave

actuator and safety link

N. Serious injury can result if the system

the floor plates must be installed.

2) Two persons should lift each of the 4 sections of the floor plate and place them in

the specified position. Be careful not to damage the springs and micro switches.

3) ch of the floor plate sections as in the figure.

There are two guide holes in ea

Insert the provided spacer, washer, and bolt assembly into each of the guide holes

and tighten securely.

4) After assembly, make sure each floor plate section moves about 1/2 inches up and

down freely.

Page 30

Page 31

Hexa bolt M8 x 30L

Spring Washer

Flat Washer

Rubber Washer(11*20*3t)

DU Bush 10*15

Page 31

Page 32

5.8 ASSEMBLING THE BOARDING STEP AND COIN CHUTE TOWER

The boarding step and coin chute tower should be assembled at this stage so that

electrical connections to the coin mechanism can be made and functional testing of

Cycraft can be performed before final assembly of the fence. To assemble the

boarding step and coin chute tower, follow the next procedure.

1) Attach the coin chute tower on the boarding step.

Coin Chute Tower

Boarding Step

Flat Washer

Spring

Washer

2) Then attach two boarding step joint bracket to the boarding step.

Hex head Bolt M8

Spring Washer

Boarding Step Joint

Bracket

Flat Washer

Page 32

Page 33

3) Position the assembled boarding step and secure it to the base of Cycraft as

shown.

Hex head Bolt M8 x 30L

Spring Washer

Flat Washer

5.9 SETTING THE PHOTO SENSORS

There is a set of photo sensor and reflective plate on each side of Cycraft. Set the

photo sensor system as follows:

1) Loosen the setscrews of the reflective plate arms and rotate the arms so that the

reflective plates point backwards at 90-degree angles from the sides of Cycraft

and tighten the setscrews.

Tool : HEX KEY 2.5 mm

Page 33

Page 34

2) setscrews of the photo sensor arms and unfold them so that the arms

Loosen the

point outward and the photo sensor lens points toward the reflective plate.

Sensor Lens

Set Screw

3) Tighten the setscrews to secure the arms. Remove the clear protective plastic on

the photo sensor lens if it is still intact.

4) It may be necessary to adjust the photo sensor alignment later on. This process

is described in the Chapter 5.12.

5.9 COIN MECHANISM INSTALLATION

Only Qualified Service Personnel should carry out this operation.

ycraft uses the standard coin box faceplate provided by Happ Controls and Sega

C

Enterprise. The compatible model numbers are,

HAPPS: Frame 42-327

Lower Door 42-3245-16

Upper Door 42-7201-00

SEGA: ASAHI Standard. Also SR3, NRI & Alberici coin validators are

electronically compatible. Contact your distributor for coin loom specifications.

The coin chute door and coin mechanism to be used must physically match the above

2-00

coin chute frame. When fitting the coin mechanism to the door please refer to the

specific manufacturers installation instructions for that coin mechanism.

Page 34

Page 35

To mechanically assemble the coin chute frame and cash door,

1

) Loosen all of the bolts on the frame that secure the clips.

2) Turn all clips in towards the door.

3) Position the door into the aperture in the coin chute tower.

4) Turn the clips around so that they will hold the door in the machine.

5) Tighten all of the bolts.

5.9.1 WIRING CONNECTION

1) Route the bundle of cables into the coin chute tower.

Insert the cables through this

hole and secure

the end of bellows with truss

M4 bolts and nuts attached

in shipping. Please ensure

to use the Rubber Bellows

& cable ties supplied w

the Cycraft

ith

Page 35

Page 36

2) There are 4 electric connectors, the P1 (10 pins), P2 (4 pins), P3 (2 pins) and

P4 (2 pins) for Coin Validator / Bill Acceptor & Coin Me

ter interfacing to the

Sega I/O circuit. The pin assignments for each connector are:

P4 (2p)

P3 (2p)

P1 (10p)

P2 (4p)

P1 (10 pins White plug : for coin validator)

1 ---------- GND (wire colour GREEN)

2 ---------- +12V (wire colour YELLOW)

7 ----------- COIN SW1 in Sega I/O BD (wire colour BROWN)

8 ----------- COIN SW2 in Sega I/O BD (wire colour WHITE)

P2 (4 pins : for b

ill acceptor power & 12V lamp)

1------------ 110V AC(R)

2------------- 110V

AC(T)

3------------- +12V (wire colour BROWN)

4------------- GND (wire colour WHITE)

P3 (2 pins : for coin meter for chute #1)

{always AC

TIVE with Electronic

Mech}

1------------ COIN METER 1 for Sega I/O BD (wire c

olour BROWN)

2------------- +5V (wire colour WHITE)

P4 (2 pins : for coin meter for chute #2)

1------------ COIN METER 2 for Sega I/O BD (wire c

{SPARE meter conn

ection}

olour YELLOW)

2------------- +5V (wire colour GREEN)

3) Attach the coin chute door and coin selector. Then, perform the wiring referring to

the electric schematic #1 of the SCU provided in session 10.1 to determine the

correct connection method.

Page 36

Page 37

5.10 CO

NNECTING THE POWER CORD

Before supplying power to the power cord, make sure that the system is

properly configured inside the MSCU for your facility power supply voltage.

Improper configuration can damage your system permanently.

Cycraft is designed to accept the single phase 200V, 208V, 220V, 230V, and 240 VAC,

50/60 Hz power sources to support the different electric power systems in different

parts of the world. However, the system must be configured correctly for each power

supply voltage by connecting an electric line to one of three available terminals inside

the MSCU.

Spec (Recommended)

ification of the main AC power cord

Main AC Power Cord

Prep ith above specification description.

To c

1) Op

Isolation Tube

UL 16 AWG

UL 16 AWG

UL 16 AWG (Green Color)

are the main AC power cord compatible w

onnect and/or verify the power cord voltage setting,

en the MSCU cover in the rear of the simulator.

Before opening the MSCU cover, make sure the power line is NOT

connected to the building power source and that there is no electrical

2 sq. - 4 O

2 sq. - 4 O

300 mm

Isolation Tube

1.25 sq. - 4 O

power supplied to the system to prevent injury from electrical shock.

Page 37

Page 38

2) Locate the input voltage selection rminal block and the voltage selection wire te

shown in the picture below.

3) Connect the voltage selection wire to the terminal that matches your facility supply

voltage according to the input voltage selection terminal wiring instruction.

4) Locate the power cord connection terminal and connect the two power lines and

the earth line of the power cord as shown below. Make especially sure that the

earth line is properly connected for safe and proper operation.

R0

Positive (Brown) Negative (Blue)

Primary Earth Point.

(Green Wire)

T0

5) Verify all connections & connect power cord to the facility input voltage source.

Page 38

Page 39

6) Go to the Operator Panel (page 44) and verify that the red LED labeled “Main

Power” is lighted. Before proceeding to start the power up sequence of Cycraft,

operators should familiarize themselves with the switches and controls on the

Operator Panel.

5.11 TING AND INSPECTION

POST INSTALLATION TES

After the mechanical and electrical installation is complete, it is necessary to carry out

a fi arry out

nal checking procedure and make some adjustments if necessary. To c

the final tests and adjustments, you must power UP Cycraft.

Carry out the Power-UP sequence according the procedure outlined in section 6.2.

Before you power-up Cycraft, make sure of the following:

(a) The power cord is connected to the correct voltage outlet and the green main

power LED is lighted.

(b) The emergency power off switch and motion stop switch (behind the coin chute

box) are released.

Make sure there are no personnel or objects under or in the area of the cabin

before switching the power on. The power up sequence will move the cabin

and personnel can be injured.

Make sure there are no passengers in the cabin when power is turned on.

The extra weight of the passenger can cause a fault in the power ON

sequence.

After successful power UP, it is possible that a beeping sound is heard and the red

LED labeled “Safety Sensor” on the Operator Panel is lighted. This indicates that

adjustments on the safety sensors (floor sensor and/or photo sensors) are needed.

Even if the beeping sound is not made, read the following sections and verify that the

sensors are in the best operating conditions.

Page 39

Page 40

5.11.1 TESTING AND ALIGNING THE PHOTO SENSORS

Make sure that the Yellow LED on top of the photo sensor is lighted when there is

1)

no obstacle between the photo sensor and the reflective mirror.

Tap and slightly s

2) hake the photo sensor bar and the reflective mirror bar. Make

sure that small vibrations and motion of the photo sensor and the reflective plate

does not cause the Yellow LED to instantaneously turn off.

3) Make sure that the Yellow LED turns off when an ob

stacle is placed between the

sensor and reflective plate.

4) If any of the above tests fail, carry out the following to align the sensor and mirror:

A. Remove the steel cover of the photo sensor and expose the sensor holding

bracket and screws as shown below.

Bolts For Photo sensor

Position Adjustment

B. Loo

sen the screws as necessary to align the photo sensor correctly. Adjust

the

reflective plate alignment by loosening the setscrews shown below.

C. Align the reflective mirror and the photo sensor correctly by observing the

Yellow LED on top of the photo sensor. Tighten all setscrews when complete.

D. e tests described in steps 1), 2), and

Carry out th

3) above.

Page 40

Page 41

5.11.2 TESTING AND ADJUSTING THE FLOOR PRESSURE SENSOR

NEVER go under the cabin to install or service the floor pressure sensor

system when the main power is ON. Serious injury can result if the system

malfunctions. If it is necessary to work under the cabin,

and support the cabin by a strong structure if it is necessary to raise it.

turn the power off

Verify that the two green floor sensor LED’s on each side

1) of the MSCU front side

cover (see figure) is turned On when nothing is on top of the floor plates. If the

green LED is OFF, the floor

sensor system must be adjusted.

2) Verify that stepping on different parts of the floor sensor lightly turns the Green

LED off. If the LED does not turn off, the floor sensor system must be adjusted

te that a 20kg weight on any part of the

(no floor sensor must activate the sensor).

3) If any of the above tests do not pass, it is possible that the springs or sensors have

been damaged or slightly bent out of shape during transport and installation. To

adjust the floor sensor carry out the following steps on the floor plate section(s)

that do not operate properly:

A. Each floor plate has 4 sets of springs and switches under it. Lift the plate off

to expose them.

B. With the plate lifted, the Green floor sensor LED must be ON. If not, this

indicates a defective sensor switch or wiring. Refer to the service manual for

instructions on how to replace the floor sensor switch.

C. Press each sensor lightly and verify that it clicks when pressed within its stroke.

Verify operation of the Green LED.

Micro Switch

Arm

Spring

Micro Switch

D. The suspected switch’s sensitivity can be increased or decreased by slightly b

ending the sensor contact lever up or down (see figure below). Do not bend

more than 1 or 2 millimeters.

Page 41

Page 42

E. Note that making the sensor too sensitive (i.e. bending the lever

will

cause the sensor to activate due to the own weight of the floor plate or

ma

ke it so sensitive that slight motions or vibrations during play will trip the

sen

sor. Making the sensor too insensitive (i.e. bending the lever down too

u fully

ch) will cause the sensor to not activate even when the floor plate if

m

ressed down.

p

up too much)

F. You can find the micro switch’s number on the wiring diagram using the sensor

arrangement figure as shown below.

Page 42

Page 43

5.12

1)

Confirm that boarding step is fitting to the base frame of main machine with no gap

to t

ASSEMBLING THE FENCE

he ground and locate the 9 fence poles around Cycraft as shown.

Boarding Step

2) Assemble the pole and mesh from the pole no.1 to the pole no.9 in the order of

clockwise. It is needed to be aware that there are 3 kinds of poles. Type B (no 1,9)

are the gate door poles with lower the junction ring other than poles. Others are

Type A. You can identify the Type Bs with the position of O-ring which is lower than

that of Type As. Type C are when fitted to base plate bracket which are screwed

on to the machine. Only three positions are required (no 3,5,7) No7 is the short

base and no 3 is the longest base plate bracket

3) The fence U bracket assembling work is as shown below. Perform total 32

assembling of U bracket and 4 door gate bolt fixings.

Page 43

Page 44

Pole

U Bracket

Tool : Hexa Key 5 mm

Wire Mesh

5.14 FIGURE OF CYCRAFT AFTER FINISHING THE INSTALLATION WORK

6.

Figure of Power-ON position

Page 44

Page 45

6. OPE

RATING & ADJUSTMENT

6.1 DESCRIPTION OF INDICATORS AND SWITCHES ON THE OPERATION PANEL

14

6

5

8

13

UPS OFF

POWER CUTOFF

SWITCH

SOURCE

DRIVINGNORMAL BELTERROR SENSOR

L-VOL

R-VOL W-VOL

S P E A K E R

DISPLAY

CABINMSCUPOWER

4

SEATCONTROL SAFETY

MAINTENANCE

RUN

BUZZER

1

7

SYSTEM ON SERVICE

2

3

ESC

SYSTEM

SHUTDOWN

UPMENU/SET DOWN

TEST

Simuline

CABIN

ON

OFF

12

11

9

10

Page 45

Page 46

No Item Description

1

Power Cutoff

Switch

This push button switch cuts off the main power to the

Cycraft. It should be used in such emergenc

situations as when a fire breaks out in the system.

Note that pressing this switch will cause the cabin to

glide down to the un-powered rest position. Therefore,

the space under the cabin must be free from objects

and personnel to prevent damage and injury.

2

System ON Button

These buttons are used to power up the simulator norm

ally. Press the buttons for 2 seconds or longer to activa

te.

3

System Shutdown B

utton

These buttons are used to power down the simulator

normally. Press the buttons for 2 seconds or longer to

activate

4

Maintenance Switch

This switch is for use by trained maintenance personnel

only. The switch allows the computer systems to boot up

without starting the simulator operation for special

maintenance and troubleshooting purposes. This

switch should always be in the down position when the

simulator is being operated normally.

5

Supply Power LEDs

These LEDs light respectively, when the main power,

power to the actuator controllers, and the cabin power

are supplied.

6

Condition LEDs

These LEDs light according to the status of the simulator

as follows:

z NORMAL LED: Lights (Green) when in normal

operating condition.

z DRIVING LED: Lights (Green) when simulator is in

driving condition.

z CONTROL ERROR LED: Lights (Red) when an

error condition in the motion system is detected.

System will automatically power down.

z SAFETY SENSOR LED: Lights (Red) when either

the photo sensor or floor pressure sensor is

activated.

z SEAT BELT LED: Lights (Red) when the seat belt is

released during the game.

7

Menu, Set, Up &

Down, LCD Panel

These buttons and the LCD panel are used to configure

the simulator settings and show the current status of the

simulator. They are explained in a separate section

below in this manual.

9

Service Button

This button increments the credit. It has the same effec

t as inserting a coin in the coin selector. But there is n

o change of coin meter.

y

Page 46

Page 47

10

Test Button

This button i

s used to configure the game computer.

Refer to the game computer manual for further

information.

11

Cabin Power Switch

This switch turns on and off the power supply to the 29”

monitor and speaker amp. and other components inside

the Cabin. Power can be turned on only if the Main AC

power is on.

12

Buzzer

Activates when a system error occurs or when the

safety sensors are activated.

13

Sound Volume

Knobs

14

Motion

Stop Switch

Cabin interior speaker volume knobs for the front

speakers, back speakers and the subwoofer.

Pressing the Motion Stop Switch will stop the cabin

motion and hold it in its current position. Motion will

resume normally 3 seconds after the switch is released.

The game will continue without motion even when the

switch is pressed.

Page 47

Page 48

6.2 TURNING THE POWER ON

AND OFF

fo t,

Be re you power-up Cycraf make sure of the following:

1) The power cord is connected to the correct voltage outlet and the green main

power LE

2) The power cutoff switch a the coin chute tower) are

D is lighted.

nd motion stop switch (behind

released.

Make sure there are no personnel or objects near or under the cabin before

switching the po r on in order to prevent damage and injury.

we

Make sure there are no when power is turned on.

The extra weight of the passenger can cause a fault in the power ON

sequence.

t passengers in the cabin

To power ON Cycraft, switch the cabin power switch ON and press the green

“SYSTEM ON” button on the operator panel for about 3 seconds. The power up

sequence will proceed automatically according to the following sequence:

1) The main power contacts will close with a few clicking sounds and the MCU power

LED, cabin power LED, and the LCD panel will light up.

2) The monitor screen inside the cabin will show the start-up sequence of NAOMI2 or

Triforce game board.

3) The cabin will pitch UP fully and slowly put itself to the horizontal initial position.

Also, the steering wheel will rotate slowly to the right and left limits and then come

to rest in the neutral position. Make sure the steering wheel is not obstructed

during this process.

4) When the “SYSTEM ON” sequence is complete, the cabin monitor will show the

game’s graphics screen with the message “Insert Coin to Start”.

Upon successful SYSTEM ON, the Operator Panel LED’s and the LCD display will

indicate as follows:

Page 48

Page 49

INDICATOR Items (page 45) CONDITION REMARK

Power Pilot Lamps 5 All 4 lamps

Cycraft Sets OK

ON (Green)

Normal LED (Green) 6-1 ON (Green) Will turn off when

driving starts

D

riving LED (Green) 6-2 OFF Will turn on when

driving starts

Control Error LED (Red) 6-3 OFF ON @ Error

Safe ED (Red) 6-4 OFF/ON Will turn on if photo ty Sensor L

sensor or floor

sensor is activated.

Seat Belt LED (Red) 6-5 OFF/ON Will turn on if seat

belt is not locked.

LCD Display 7 See below CAN – TCP - NOR

CAN NOR

TCP CAN TCP NOR

1) 43 2) 43 3) 43

LCD Display After Power ON

1) 8043 2) 8043 3) 8043

LCD Display when GAME is ON

CAN = Control Area Network

= Telephony Connection Protocol or (LAN = Local A

TCP rea Network)

NOR = Normal Operation (All Systems OK)

The SYSTEM SHUT DOWN Sequence can be initiated at any time by pressing the

d “SYSTEM OFF” button for about 2 seconds. The cabin monitor will turn off and

re

e cabin will glide down to the nose down rest position. Then, the main powers to

th

the computers and other components will shut off automatically.

Before turning off the power, MAKE SURE THERE IS NO PERSON OR

OBSTACL

ower off and can cause serious damage or injury.

p

E NEAR OR UNDER THE CABIN. The cabin will glide dow n upon

Page 49

Page 50

6.3 HE SPEAKER OLUMES

ADJUSTMENT OF T V

Cycraft has 5 speaker the 2 front stereo peakers on each s

s installed in cabin – s ide of

the monitor, 2 rear stereo speakers in the chair shoulder area, and 1 woofer speaker

located behind the b celera als. Th

rake and ac tor ped ree knobs are provided on the

Operator Panel to set the front, rear, and woofer speaker volumes independently.

6.4 SETTING VIDEO MONITOR PARAMETERS

VIDEO CONTROLLER

LOCATION IN CABIN

VIDEO

CONTROLLER

.

VIDEO CONTROLLER BUTTO

N FUNCTIONS

BUTTON FUNCTION

MENU (SELECTION) In the beginning, start the VIDEO controls.

In a sub menu, moves the control to the higher level.

EXIT (DEGAUSSING) In the main menu, exits the VIDEO controls.

U

P In the beginning, proceeds to the contrast adjustment.

In the main menu, moves the control me

nu to the right.

In a sub menu, increase the adjustment.

DOWN In the main menu, moves the control menu to the left.

In a sub menu, decrease the adjustment

Page 50

Page 51

VIDEO Control Menu Set

The brightness, contrast, color, alignment, sharpness, and degaussing settings for the

cabin graphics monitor can be adjusted by using the monitor setting panel located in

the upper left had side of the front monitor panel. To access the panel, first remove

the two screws on the panel cover. Instructions for adjustment will display on the

monitor during the adjustment process.

6.5 USING THE LCD PANEL TO SET CONFIGURATIONS

The LCD display and the 4 buttons below it inside the Operator Panel can be used to

s

et different configurations. Operation method and functions of the LCD buttons are

as described in the table below.

BUTTON FUNCTION

ESC Returns the menu to the upper level

MENU/SET W isplay

hen pressed for 1 seconds the first time, it puts the d

in guration main

the setting mode and brings up the confi

m the

enu. Once inside the setting mode, it will set

h

ighlighted menu item.

UP Highlights the upper menu item.

DOWN Highlights the lower menu item.

Page 51

Page 52

[MAINTENANCE MODE ]

=>1. DIOTEST

2. MOTION TEST

3. SETUP TCP/IP

4. SENSOR USAGE

5. STATISTICS

6. MOTION LEVEL

7. F ALLING DETECT

8. EXIT

Configuration of LCD Main

Menu

All settings through the LCD panel can be made only when the system is powered up

in the “maintenance mode”. This mode is entered by first putting the Maintenance

Switch in the operation panel in the “Maintenance” position and powering up the

system. After the maintenance mode is entered, configuration and settings can be

made as described in the following sub-sections.

6.5

.1 SETTING THE SAFETY SENSOR PARAMETERS

1 nu by pressing the MENU/SET button for 2

) Bring up the configuration main me

seconds.

) Highlight the “4. Sensor Usage” item by using the UP and DOWN buttons. The

2

highlighted item is indicated by the “=>” sign.

) Press MENU/SET button to bring up the Sensor Usage sub-menu.

3

=> 1. Sa

fety sensor

2. Seat belt

3. Motion stop

4. Exit

Sensor Usage Sub-Menu

Each of the items in

disable the floor and

the above list can be enabled or disabled. For example, to

photo sensors, highlight item 1, press the MENU/SET button,

and use the UP and DOWN switches to toggle to the “OFF” setting.

4 fter setting the sen to the previous upper level

) A sor, press the ESC button to go

until the main m

menu enu is displayed.

5) Highlight “4. Exit” and press MENU/ESC for three seconds to fix the settings and

exit the menu.

Page 52

Page 53

T ways

he safety sensors, motion stop switch and seat belt sensor should al

be enabled (in the “ON” setting) during all normal situations. The featu

d ions, for

isable the safety settings should be used only in special situat

e under the

xample when an attendant is present near the machine, solely

discretion and responsibility of the operator. Simuline Inc. will not

for any accidents or damages resulting from operation of Cycraft with a

the safety features disabled.

be liable

6.5

.2 SETTING TCP/IP CONFIGURATION

This function allows the TCP/IP setting of the motion board to be set. The motion

computer and the game computer are connected

via TCP/IP. All settings are preset

in the factory but for future upgrades and maintenance, it may be necessary to adjust

settings.

1) Bring up the configuration main menu by pressing the MENU/SET button for 2

seconds.

re to

ny of

2) Highlight the “3. SETUP TCP/IP” item by using the UP and DOWN buttons. The

highlighted item is indicated by the “=>” sign.

3) Press MENU/SET button to bring up the TCP/IP setting sub-menu.

[SET TCP/IP]

=> 1. IP ADDRESS

2. SUBNET MASK

3. GATEWAY ADDR

4. EXIT

4) Highlight a desired parameter and use the UP and DOWN buttons to

c

hange the values.

nd select the

The

following are the factory pre-set values for the Club Kart game.

IP ADDRESS : 192.168.1.1

SUBNET MASK : 255.255.255.0

GA TEWAY ADD

R: 192.168.1.1

Page 53

Page 54

6.5.3 VIEWIN

G THE TOTAL GAME MOTIONS COUNT (STATISTICS)

The to l n

viewed by

ta

umber of games with motions accepted by Cycraft after production can be

selecting the “5. Statistics” item from the configuration main menu.

6.5.4 TESTIN

G THE DIGITAL INPUT/OUTPUT CHANNELS

The digital input/output (DIO) channels in Cycraft can be tested for functionality by

using the LCD panel on the Operator Panel. To carry out DIO test,

Bring up the configuration main menu by pressing the MENU/SET button for 2

1)

seconds.

2) Highlight the “1. DIO TEST” item by using the UP and DOWN buttons. The

highlighted item is indicated by the “=>” sign.

3) Press M

ENU/SET button. This will display the first DIO channel. Pressing the

UP and DOWN buttons will navigate through the different DIO items.

4) Press the MENU/SET button when the desired channel appears. If it is an input

channel, t

he state of the channel (either ON or OFF) will appear on the screen.

Proper operation can be checked by physically activating the channel and

verifying that the state shown changes accord

current output command will be indicated. Use the UP and DO

ingly. If it is an output channel, the

WN arrows to

change the command state and verify that the output is physically activated (i.e.

lamp turns on and off)

5) When finished, press t tedly until main screen appears.

6) There are 17 DIO Test item

Seatbelt Sensor

Game Stop SW

Safety Sensor

Motion Stop SW

Shutdown SW

Keypad 1

Keypad 2

Keypad 3

Keypad 4

.

he ESC switch repea

s.

Maintenance SW

Page 54

Page 55

LED Nor mal

LED Driving

LED Error

LED Safety

LED Seatbelt

Buzzer

.5.5 MOTION TEST

6

This menu item runs the motion system of Cycraft through a serie

low speed motion. It can be used to verify that the actuators are operating properly.

s

After finishing the test, you should press the shutdown SW to finalizing the test.

6.5

.6 MOTION LEVEL

This is only use for Simuline. Default factory set is 1. Do not change the value without

req

uest from Simuline.

6.5.7

FALLING DETECT

Thi

s is only use for Simuline. Default factory set is 2. Do not change the value without

req

uest from Simuline.

6.6 CONFIGURA TION

SETTING THE COIN AND CREDIT

s of pre-recorded

The coin an tion (i.e. cost per game) must be set directly on the game

d credit configura

computer (NAOMI2) by using the “Service” and “Test” buttons on the Operator Panel.

Refer to the NAOMI2 service manual for instruction on how to change the coin and

credit co

nfiguration.

Page 55

Page 56

6.7 GAME PLA N

Y OPERATIO

T must make sure that all the safety features are functioning

he operator

c accepting passengers. Manufacturer shall not be held

orrectly before

liable for damages and claims due to operation of Cycraft without all safety

features operating properly.

ake sure that all safety sensor functions are operating properly. To start the game,

M

player must first insert the correct amount of coins, enter the cabin and put on the seat

belt. The screen will then show the “Press Start Button” sign. Pressing the Start

button will raise the cabin to the neutral position and the game will start, beginning

from the car and course selection process.

uring play, the GAME STOP button can be pressed to stop the game at any time.

D

Players who feel nauseous from the motion or need to terminate the game for any

other reason can use th

is button to discontinue the game and exit the simulator.

The View button is used t

v

iew and tail following view. It is recommended that players use the driver’s seat

o toggle the graphics viewpoint between the driver’s seat

view for best virtual reality effects.

After the game is finished, the cabin will come down to the initial position and the

player may exit.

Page 56

Page 57

7. MAINTENANCE AND REPLA

7.1 ROUTINE

MAINTENANCE

M

aintenance and repair shall be performed only by qualified mechanical and

el

ectrical maintenance personnel in accordance with instructions provided in

th

e manuals.

Routine maintenance and inspection of Cycraft should be carried out to ensure safe

operation and longevity of the machine. Contact your distributor or the manufacturer

for any instructions beyond those given in the manuals and for any questions

regarding maintenance and repair procedures.

R

outine Maintenance and Frequency:

Frequency Maintenance Activity

Daily Verify that all the safety sensors (floor sensor, photo sensor, motio

Daily Check the system for abnormal noise and vibrations. There should

Weekly Verify that all the bolts connecting the outer frame, actuators and

Weekly Verify that the snap rings in each of the universal joints are lodged in

Monthly Check all weld areas of the frame and actuator described in the next

Monthly Check the actuator drive belt for indication of tears, cracks, or other

Monthly Clean the MSCU air filters and fan.

Every 6 Months Lubricate the actuators with grease provided by manufacturer or

Every 18

Months

CEMENT

n

stop switch) are working properly. If any malfunction is foun

d, repair

it before accepting players.

not be screeching, grinding, or rattling noises which can indica

loose bolts or abnormally rubbing of parts. If such suspected noise

are heard, ver

Inspect bolts and

ify the source and repair or replace as necessary.

connections and the integrity of the mechanical

te

s

system as described below.

cabin are not loose according to the procedure described in the next

section. Tighten if necessary.

their grooves correctly according to the procedure described in the

next section. The snap ring must be set securely in place.

section for cracks or other damage. None is acceptable.

damage. Exchange immediately if any damage is found.

equivalent.

Lubricate the joints with grease provided by manufacturer or

equivalent

Page 57

Page 58

All inspections described below must be performed with all electrical POWER

OFF. Attempting to carry out

serious injury to personnel due to abrupt motion and electrical shock.

7.2

INSPECTION OF CRITICAL BOLTS AND CONNECTIONS

The above figures indicate the location of critical bolts on Cycraft. These bolts hold

up the cabin and can cause the cabin to drop if they come

with a white line after assembly so that misaligned marking lines can identify loose

bolts easily.

the processes with the power ON can cause

loose. They are marked

E

D

C

F

A

B

Page 58

Page 59

Point

Part Picture How to check Inspection

A

B

C

Hexahead bolt M12 x 8 points

Lower joint of heave actuator is inside of

MSCU so in order to inspect the bolts, the

MSCU cover must be removed.

Hexahead bolt M12 x 8 points

Hexahead bolt M12 x 4 points

D

Hexahead bolt M10 x 8 points

E

Hexahead bolt M10 x 4 points (Lower)

Hexahead nut M10 x 4 points (Upper)

F

Page 59

Page 60

7.3 VERIFICATION OF SNAP RINGS

The universal bearings have two snap rings each which prevent the actual bearing

SNAP RING

from popping out of its cage. Verify that the snap rings ar

respective grooves. If any appear to be

screw driver or other sharp object and check da ot

repeat. If the problem persists, cont a

replacement part.

7.4 CHECKING WELD CONDITION

Visually check all the weld areas of the outer frame for signs of cracks or failure.

None is acceptable. If any problems are found, contact your distributor or the

manufacturer.

7.5 CHECKING THE ACTUATOR DRIVE BELT

The actuator drive belt can be accessed by removing the he

figure .

below

e lodged securely in their

loose, push them back in place using a

ily to make sure the problem does n

act your distributor or manufacturer for

belt cover as shown in t

Page 60

TOP ACTUATOR

DRIVER BELT

Page 61

Visually inspect both of the belts for wear or tear. If any damage to the belt is

discovered, the belt must be replaced. Check the tension of the belt. If the belt is

loose, it must be tightened. The n the belt is

described in the Installation and Service manual.

7.6 CLEANING THE MSCU AIR FIL

The MSCU air filters and fans are located as shown in the above figure. They should

be cleaned regularly to ensure proper ventilation and prevent excessive rise in electric

component temperatures. Pull out the filter cover to access the filter. Take the filter

out and clean with water. Ensure the filter is dry before replacing. Clean the

ventilation fan with

a damp cloth.

procedure to replace and tighte

TERS AND FAN

MSCU AIR FILTER

MSCU FAN

Make sure water does not drip into the open circuitry in the MSCU during

cleanin

g. Permanent electrical damage can occur.

Page 61

Page 62

7.7 LUBRICATING THE ACTUATORS

Thi

s maintenance work should be performed every 6 months.

1) Prepare grease gun with grease specified as below or equivalent:

KLUBER HIMONAX WS433

2) Take off the actuator bellows and bearing covers and identify the grease nipples

as shown in the figure below:

4

5

2

3

1

ACTUATOR GREASE

NIPPLE POSITIONS

3) Inject grease in the amounts given in the table below for each of the components:

Page 62

Page 63

No. Part Picture Amount of

Grease

1 Heave Actuator Cylinder 60 grams

2,4 Top Actuators Cylinder

30 grams

3,5 Top Actuators Bearing

10 grams

4) Wipe away any excessive grease.

5) Play the game for at least three games and wipe away all excessive

grease.

6) Replace all covers and bellows.

7.8 LUBRICATING THE JOINTS

This maintenance work should be performed every 18 months.

1) Prepare grease gun with grease specified as below or equivalent:

KLUBER HIMONAX WS433

2) Identify the grease nipples as shown in the figure below.

Page 63

Page 64

7

5

6

3

8

4 2

JOINT GREASE

NIPPLE POSITIONS

3) s

Inject grease in the amounts given in the table below for each of the component

1

:

No. Part Picture Amount

1 Heave Actuator

5 grams

of Grease

Universal joint

(Upper)

2 Heave Actuator

5 grams

Universal Joint

(Lower)

3,4 Rocker Arm Joint 5 grams

Page 64

Page 65

5,6 Top Actuator Gi

mbal Joint

5 grams

7,8 Top Actuator Uni

5 grams

versal Joint

9 l

5 grams Central Universa

Joint

e aw xcessive grease.

ay any e4) Wip

5) Play the game for at least three games and wipe away all excessive grease.

6) Replace all covers and bellows.

Page 65

Page 66

8. REPL M PARTS. ACE ENT OF SERVICE

On ervice Personnel must carry out maintenance. Ensure that the

ly Qualified S

main power is switched OFF and disconnected before attempting any work.

8.1 EXCHANGING THE COMPACT FLASH CARD

Cycraft’s motion board inside the MSCU is programmed to log any occurrence of

errors with relevant system st us data onto a compact flash card. In case of

unidentifiab be recommended that the flash card be