Page 1

OWNER'S MANUAL

STANDARD CABINET

Page 2

TABLE OF CONTENTS

BEFORE USING THE PRODUCT, BE SURE TO READ THE FOLLOWING:

TABLE OF CONTENTS

INTRODUCTION

1 HANDLING PRECAUTIONS .........................................................................1

2 PRECAUTIONS REGARDING INSTALLATION LOCATION .....................................3

2-1 LIMITATIONS OF USAGE ................................................................................................3

2-2 OPERATION AREA ..........................................................................................................4

3 PRECAUTIONS REGARDING PRODUCT OPERATION .............................5

3-1 BEFORE OPERATION .....................................................................................................5

3-2 DURING OPERATION (PAYING ATTENTION TO CUSTOMERS) ..................................6

4 PART DESCRIPTIONS ..................................................................................8

5 ACCESSORIES .............................................................................................9

TABLE OF CONTENTS

6 ASSEMBLY AND INSTALLATION ..............................................................10

7 PRECAUTIONS WHEN MOVING THE MACHINE ......................................19

7-1 MOVING THE MACHINE ................................................................................................19

8 GAME DESCRIPTION .................................................................................21

9 EXPLANATION OF TEST AND DATA DISPLAY.........................................33

9-1 SWITCH UNIT AND COIN METER ................................................................................34

9-2 SYSTEM TEST MODE ...................................................................................................35

9-3 GAME TEST MODE .......................................................................................................36

a. INPUT TEST ....................................................................................................................37

b. OUTPUT TEST ................................................................................................................38

c. GAME ASSIGNMENTS ...................................................................................................40

d. NETWORK SETTING ......................................................................................................41

e. CALIBRATION .................................................................................................................43

f. BOOKKEEPING ..............................................................................................................49

g. BACKUP DATA CLEAR ..................................................................................................52

10 MONITOR ....................................................................................................53

10-1 CAUTIONS/WARNINGS REGARDING SAFETY FOR HANDLING THE MONITOR ..53

10-2 CLEANING THE CRT SURFACES ..............................................................................55

10-3 ADJUSTMENT PROCEDURE ......................................................................................56

i

Page 3

11 CONTROL STICK ........................................................................................57

11-1 HOW TO REMOVE CONTROL STICK .........................................................................58

11-2 GREASING ...................................................................................................................59

11-3 VOLUME REPLACEMENT ...........................................................................................60

TABLE OF CONTENTS

11-4 MICROSWITCH REPLACEMENT ................................................................................64

11-5 GUIDE PLATE REPLACEMENT ..................................................................................65

12 THROTTLE LEVER .....................................................................................66

12-1 GREASING ...................................................................................................................67

12-2 VOLUME ADJUSTMENT OR REPLACEMENT ...........................................................69

13 PERIODIC INSPECTION .............................................................................73

14 TROUBLESHOOTING .................................................................................75

14-1 ERROR MESSAGES ....................................................................................................76

14-2 TROUBLESHOOTING TABLE .....................................................................................77

15 GAME BOARD ............................................................................................79

16 DESIGN RELATED PARTS .........................................................................80

17 NETWORK PLAY .........................................................................................81

17-1 NETWORK CABLE CONNECTIONS ...........................................................................81

17-2 NETWORK PLAY LINK SETTING ...............................................................................82

17-3 PRECAUTIONS IN NETWORK PLAY ..........................................................................84

18 OPTIONAL ITEMS .......................................................................................85

18-1 DOLLAR BILL VALIDATOR KIT ..................................................................................85

18-2 SECURITY BAR KIT ....................................................................................................85

19 PARTS LIST .................................................................................................86

20 WIRE COLOR CODE TABLE ......................................................................94

21 CABINET WIRING DIAGRAM ..........................................................2 PAGES

ii

Page 4

INTRODUCTION

This manual is intended to provide detailed descriptions together with all the necessary information covering the

general operation of electronic assemblies, electro-mechanicals, servicing control, spare parts, etc. for the product,

“AFTER BURNER CLIMAX.”

This manual is intended for the owners, personnel and managers in charge of operation of the product.

Operate the product after carefully reading and suffi ciently understanding the instructions.

In the unlikely event that the product does not function correctly, DO NOT allow anyone other than a technician

to touch the internal system. Turn off the power to the machine, making sure to unplug the electrical cord from the

outlet, and contact the offi ce listed below or the point-of-purchase for this product.

Use of this product is unlikely to cause physical injuries or damage to property. However, points that require special

attention are indicated by bold text, the word “IMPORTANT” and the symbol below.

Indicates important information that, if ignored, may result in the mishandling of

the product and cause faulty operation or damage to the product.

INTRODUCTION

Sega Amusements U.S.A., Inc.

800 Arthur Avenue, Elk Grove Village, IL 60007-5215, U.S.A.

TEL: 1-847-364-9787

TOLL FREE: 1-888-877-2669

FAX: 1-847-427-1065

SPECIFICATIONS

Installation space: 1,225 mm (48.2 in.) [Width] x 1,810 mm (71.3 in.) [Depth]

Height: 83”

Weight: 564 lbs

Power, maximum current: 5 A (AC 120 V, 60 Hz Area)

Monitor: 29 Type Color Monitor

NOTE: The contents herein described are subject to change without notice.

iii

Page 5

Use of GPL/LGPL software

This product can use GPL/LGPL software, which is open source software. This means that customers who purchase this

product can freely obtain, alter and pass-on the source code for this software (hereafter referred to as “the source code”).

INTRODUCTION

Downloaded this software is an indication of the customer’s agreement to the GPL/LGPL contract of use and thus the

download and all subsequent use of the source code is the full responsibility of the customer.

Furthermore this source code and the download service are provided totally as-is, with no guarantees of effectiveness,

completeness, usefulness or reliability, and our company offers no support concerning this source code.

Customers using this product who wish to obtain this source code should enter the following password on the website

below to download it.

URL: http: //amproduct-softlicense.sega.jp/

ID: amsoftwebdl

Password: segaamhd1

GPL/LGPL Contract Site

URL: http: //www.fsf.org/licenses/gpl.html

URL: http: //www.fsf.org/licenses/lgpl.html

iv

Page 6

Defi nition of ‘Site Maintenance Personnel or Other Qualifi ed Individuals’

Procedures not described in this manual or marked as 'to be carried out by site

maintenance personnel or other qualified professionals' should not be carried

out by personnel without the necessary skill or technology. Work carried out by

unqualifi ed persons may cause serious accidents, including electrocution.

Parts replacement, maintenance inspections and troubleshooting should be carried out by site maintenance personnel

or other qualifi ed professionals. This manual includes directions for potentially dangerous procedures which should

only be carried out by professionals with the appropriate specialized knowledge.

The site maintenance personnel or other qualifi ed professionals mentioned in this manual are defi ned as follows:

Site maintenance personnel:

Individuals with experience in maintaining amusement equipment, vending machines, etc., working under the

supervision of the owner/operator of this product to maintain machines within amusement facilities or similar

premises by carrying out everyday procedures such as assembly, maintenance inspections, and replacement of units/

expendable parts.

Activities to be carried out by site maintenance personnel:

Amusement equipment/vending machine assembly, maintenance inspection and replacement of units/expendable

parts.

INTRODUCTION

Other qualifi ed professionals:

Persons employed by amusement equipment manufacturers, or involved in design, production, testing or

maintenance of amusement equipment. The individual should have either graduated from technical school or hold

similar qualifi cations in electrical/electronics/mechanical engineering.

Activities to be carried out by other qualifi ed professionals:

Amusement equipment/vending machine assembly, repair/adjustment of electrical/electronic/mechanical parts.

v

Page 7

HANDLING PRECAUTIONS

1

When installing or inspecting the machine, be very careful of the following points and pay attention to ensure that the

player can enjoy the game safely.

Non-compliance with the following points or inappropriate handling running counter to the cautionary matters herein

stated can cause personal injury or damage to the machine.

• Before performing work, be sure to turn the power off. Performing the work without

turning the power off can cause an electric shock or short circuit. In the case work

should be performed in the status of power on, this manual always states to that

effect.

• To avoid an electric shock or short circuit, do not plug in or unplug quickly.

• To avoid an electric shock, do not plug in or unplug with a wet hand.

• Do not expose power cords or ground wires on the surface, (fl oor, passage, etc.). If

exposed, the power cords and ground wires are susceptible to damage. Damaged

cords and wires can cause an electric shock or short circuit.

• To avoid causing a fi re or an electric shock, do not put things on or damage the

power cords.

1

HANDLING PRECAUTIONS

• When, or after installing the product, do not unnecessarily pull the power cord. If

damaged, the power cord can cause a fi re or an electric shock.

• In case the power cord is damaged, ask for a replacement through where the

product was purchased from or the office herein stated. Using the cord as is

damaged can cause fi re, an electric shock or leakage.

• Be sure to perform grounding appropriately. Inappropriate grounding can cause

an electric shock.

• Be sure to use fuses meeting the specified rating. Using fuses exceeding the

specifi ed rating can cause a fi re or an electric shock.

• Be sure that connections such as IC BD are made properly. Insufficient insertion

can cause an electric shock.

• Specification changes, removal of equipment, conversion and/or addition, not

designated by SEGA are not permitted.

- Failure to observe this may cause a fire or an electric shock. Non-compliance

with this instruction can have a bad influence upon physical conditions of the

players or the onlookers, or result in injury during play.

- SEGA shall not be held responsible for damage, compensation for damage to a

third party, caused by specifi cation changes not designated by SEGA.

• Be sure to perform periodic maintenance inspections herein stated.

Page 8

• For the IC board circuit inspections, only the logic tester is allowed. The use of a

multiple-purpose tester is not permitted, so be careful in this regard.

1

HANDLING PRECAUTIONS

such as thinner, benzine, etc.

• Static electricity from your body may damage some electronics devices on the IC

board. Before handling the IC board, touch a grounded metallic surface so that the

static electricity can be discharged.

• Some parts are not designed and manufactured specifically for this game

machine. The manufacturers may discontinue, or change the specifi cations of such

general-purpose parts. If this is the case, SEGA cannot repair or replace a failed

game machine whether or not a warranty period has expired.

CONCERNING THE STICKER DISPLAY

This SEGA product has stickers attached describing the product manufacture No. (Serial No.) and Electrical

Specifi cations. It also has a Sticker describing where to contact for repair and for purchasing parts.

When inquiring about or asking for repairs, mention the Serial No. and Name of Machine indicated on the Sticker. The

Serial Number indicates the product register. Identical machines could have different parts depending on the date of

production. Also, improvements and modifi cations might have been made after the publication of this manual. In order

to ensure you order the correct parts, mention the Serial No. when contacting the applicable places.

• When cleaning the CRT surfaces, use a soft and dry cloth. Do not apply chemicals

CONCERNING WARNING DISPLAYS

This SEGA product has warning displays on stickers, labels and/or printed instructions adhered/attached to or

incorporated in the places where a potentially hazardous situation could arise. The warning displays are intended for

accident prevention for customers and for avoiding hazardous situations relating to maintenance and servicing work.

Some portions of the cabinet contain high voltage and may cause accidents if touched. When performing maintenance,

be very careful of the warning displays. It is especially important that any complex repair and replacement work not

mentioned herein should be performed by those technical personnel who have knowledge of electricity and technical

expertise.

In order to prevent accidents, caution any customer ignoring the warnings to cease and desist immediately.

2

2

Page 9

PRECAUTIONS REGARDING INSTALLATION LOCATION

2

This product is an indoor game machine. Do not install it outside. Even indoors,

avoid installing in places mentioned below so as not to cause a fi re, electric shock,

injury and/or malfunction.

- Places subject to rain or water leakage, or places subject to high humidity in the

proximity of an indoor swimming pool and/or shower, etc.

- Places subject to direct sunlight, or places subject to high temperatures in the

proximity of heating units, etc.

- Places filled with inflammable gas or vicinity of highly inflammable/volatile

chemicals or hazardous matter.

- Dusty places.

- Sloped surfaces.

- Places subject to any type of violent impact.

- Vicinity of anti-disaster facilities such as fi re exits and fi re extinguishers.

- The operating (ambient) temperature range is not from 5 to 30 degrees.

2-1 LIMITATIONS OF USAGE

2

PRECAUTIONS REGARDING INSTALLATION LOCATION

• Be sure to check the Electrical Specifications. Ensure that this product

is compatible with the location's power supply, voltage, and frequency

requirements. A plate describing Electrical Specifications is attached to the

product. Non-compliance with the Electrical Specifi cations can cause a fi re and

electric shock.

• This product requires a breaker and earth mechanism as part of the location

facilities. Using the product without these can cause a fi re and electric shock.

• Ensure that the indoor wiring for the power supply is rated at 15A or higher (AC

single phase 100V ~ 120V area), and 7A or higher (AC 220V ~ 240V area). Noncompliance with the Electrical Specifications can cause a fire and electric

shock.

• Be sure to use an independent power supply equipped with an earth leakage

breaker. Using a power supply without an earth leakage breaker can cause an

outbreak of fi re if a power surge occurs.

• Putting many loads on one electrical outlet can cause generation of heat and a

fi re resulting from overload.

• When using an extension cord, ensure that the cord is rated at 15A or higher (AC

100V ~ 120V area) and 7A or higher (AC 220V ~ 240V area). Using a cord rated

lower than the specifi ed rating can cause a fi re and electric shock.

Electricity Consumption:

MAX. 5 A (AC 120 V, 60 Hz)

3

Page 10

2

PRECAUTIONS REGARDING INSTALLATION LOCATION

2-2 OPERATION AREA

• Be sure to provide suffi cient space specifi ed in this manual. Do not allow objects to

block the ventilation ports. It can cause generation of heat and a fi re.

• SEGA shall not be held responsible for damage or compensation for damage to a

third party, resulting from the failure to observe this instruction.

• If the machine does not fit through the entryway to the installation location, do

not disassemble it without first consulting the instructions. The machine should

only be disassembled in accordance with the instructions listed in this manual;

do not attempt to disassemble it in any other way. Specifi c tools and adjustment

procedures are required to assemble and disassemble the mechanical parts.

Attempting to assemble or disassemble the machine without consulting the

instructions may result in accidents during assembly/disassembly and electric

shock, short circuits, and/or personal injury during operation. If the machine still

does not fit through the entryway after following the procedures in this manual,

contact your retailer or the offi ce listed in this manual.

• If the machine is still too large to fit through the entryway after following the

procedures listed in this manual, do not tip the machine on its side. Attempting to

transport the machine while it is tipped on its side may cause accidents. It may

also damage or warp parts of the machine, resulting in accidents during operation.

4

4

Page 11

PRECAUTIONS REGARDING PRODUCT OPERATION

3

To avoid injury and trouble, be sure to pay attention to the behavior of visitors and players.

3-1 BEFORE OPERATION

In order to avoid accidents, check the following before starting the operation:

• To ensure maximum safety for the players and the customers, ensure that where

the product is operated has sufficient lighting to allow any warnings to be read.

Operation under insufficient lighting can cause bodily contact with each other,

hitting accident, and/or trouble between customers.

• Be sure to perform appropriate adjustment of the monitor (projector). For operation

of this machine, do not leave monitor's flickering or deviation as is. Failure to

observe this can have a bad infl uence upon the players' or the customers' physical

conditions.

• It is suggested to ensure a space allowing the players who feel sick while playing

the game to take a rest.

• Check if all of the adjusters are in contact with the surface. If they are not, the

Cabinet can move and cause an accident.

3

PRECAUTIONS REGARDING PRODUCT OPERATION

• Do not put any heavy item on this product. Placing any heavy item on the product

can cause a falling down accident or parts damage.

• To avoid injury, be sure to provide suffi cient space by considering the potentially

crowded situation at the installation location. Insufficient installation space can

cause making bodily contact with each other, hitting accidents, and/or trouble

between customers.

• Check the control devices to make sure that there are no scratches or cracks on

parts touched by players, as such defects can cause injury to hands and fi ngers.

• Do not climb on the product. Climbing on the product can cause falling down

accidents. To check the top portion of the product, use a step ladder.

• To avoid electric shock, check to see if door & cover parts are damaged or

omitted.

• To avoid electric shock, short circuit and/or parts damage, do not put the following

items on or in the periphery of the product.

Flower vases, flowerpots, cups, water tanks, cosmetics, and receptacles/

containers/vessels containing chemicals and water.

5

Page 12

3-2 DURING OPERATION (PAYING ATTENTION TO CUSTOMERS)

To avoid injury and trouble, be sure to pay attention to the behavior of visitors and players.

3

PRECAUTIONS REGARDING PRODUCT OPERATION

• For safety reasons, do not allow any of the following people to play the game.

- Those who have high blood pressure or a heart problem.

- Those who have experienced muscle convulsion or loss of consciousness when

playing video games, etc.

- Those who have neck or spinal cord problems.

- Those who are intoxicated or under the infl uence of drugs.

- Pregnant women.

- Those who are not in good health.

- Those who do not follow the attendant’s instructions.

- Those who cannot grasp the Control Unit securely because of immobility in

fi ngers, hands or arms.

- Persons who disregard the product's warning displays.

The game cannot be played while sitting in a wheelchair.

• Even players who have never been adversely affected by light stimulus might

experience dizziness or headache depending on their physical condition when

playing the game.

• Instruct those who feel sick during play to have a medical examination.

• To avoid injury from falls and electric shocks due to spilled drinks, instruct the

player not to place heavy items or drinks on the product.

• To avoid electric shocks and short circuits, do not allow customers to put hands

and fi ngers or extraneous matter in the openings of the product or small openings

in or around the doors.

• To avoid falls and resulting injury, immediately stop the customer from leaning

against or climbing on the product, etc.

• To avoid electric shock and short circuit, do not allow customers to unplug the

power plug without a justifi able reason.

6

Page 13

• Prevent customers from sitting two at a time in the seat. This game is for one player

only. If two or more customers attempt to sit in the seat and play at the same time,

they may hit their heads, hands, or elbows, possibly resulting in serious injury.

• Customers should be warned not to place children on their laps while they play the

game. Doing so may cause the child to become trapped between the player and

the control panel and/or cause the machine to tip over.

• Immediately stop such violent acts as hitting and kicking the product. Such violent

acts can cause parts damage or falling down, resulting in injury due to fragments

and falling down.

• When entering or exiting the machine, players may trip over the base. Be sure to

warn players who do not appear to be exercising proper caution.

• Persons other than the player should not be allowed to touch the controls during

play. They may brush against or collide with the controls or the player, possibly

resulting in accidents.

3

PRECAUTIONS REGARDING PRODUCT OPERATION

• Players should be warned not to place personal effects or other objects on the

base of the machine. If the safety sensor fails to detect these items, the motion of

the machine may cause them to fl y out and strike other customers.

7

Page 14

PART DESCRIPTIONS

4

29" MONITOR

FRONT SPEAKERS

(Left & Right)

4

PART DESCRIPTIONS

CONTROL STICK

COIN CHUTE DOOR

CASH BOX DOOR

REAR SPEAKER

(Left & Right)

MAIN POWER SWITCH

FIG. 4 Overall View

Dimensions

(Width x Length x Height) (Weight)

Standard Cabinet 31” x 67” x 83” 564 lbs

SEAT

THROTTLE LEVER

LEG STEP

8

Page 15

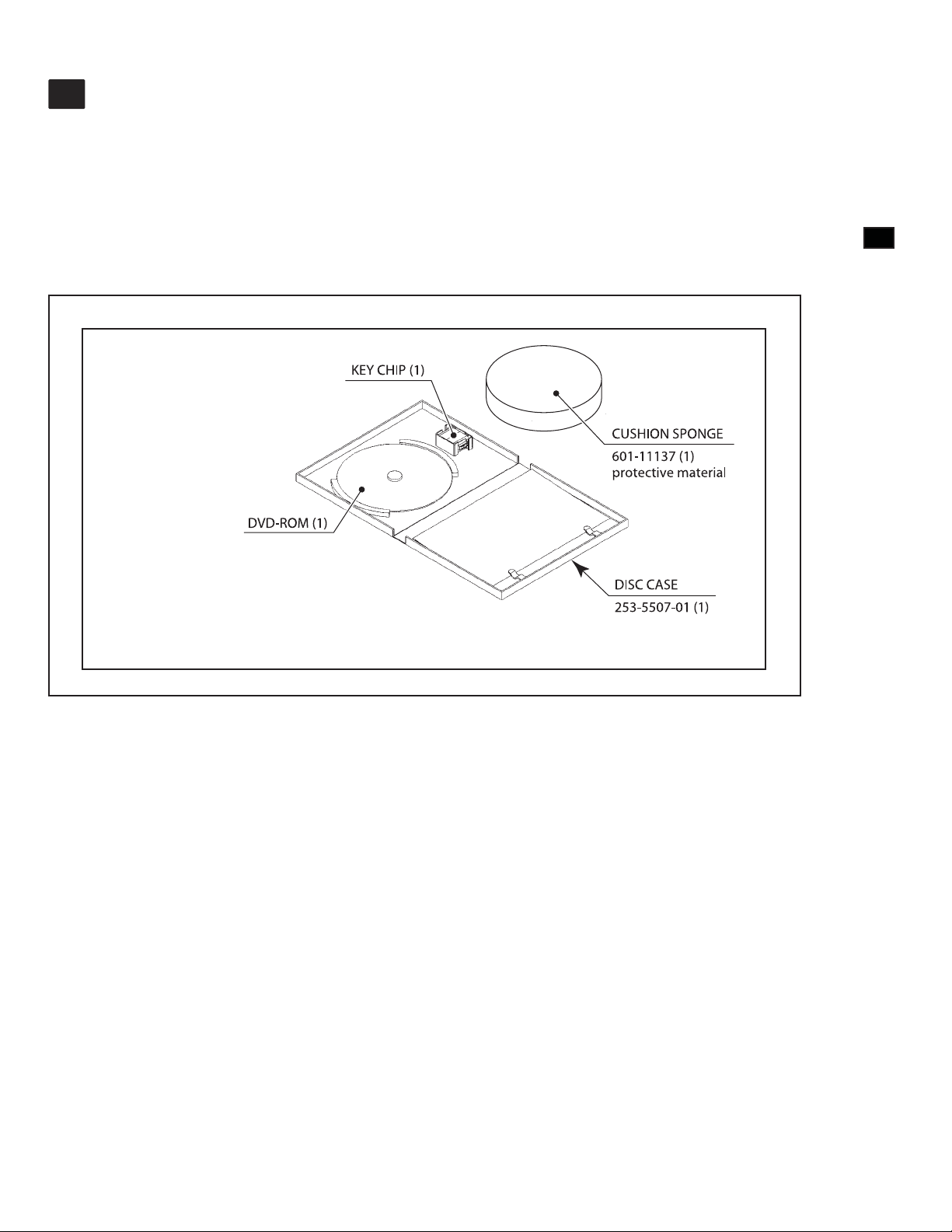

ACCESSORIES

5

MANUAL, ABX STD (1)

Part#: 525-30-300

DVD-SOFT KIT ABX (1)

Part#: 610-0727-0009

DVD KIT (1)

Software media, see 6-3.

To order the DVD-ROM by itself, use the following part number: 610-0726-0009: DVD SOFT ABX

5

ACCESSORIES

KEY CHIP (1)

CUSHION SPONGE

601-11137 (1)

protective material

DVD-ROM (1)

DISC CASE

253-5507-01 (1)

9

Page 16

6

ASSEMBL Y AND INST ALLATION

ASSEMBLY AND INST ALLATION

6

• Perform assembly work by following the procedure herein stated. Failure to comply

with the instructions can cause electric shock.

• Perform assembling as per this manual. Since this is a complex machine, incorrect

assembling can cause an electric shock, machine damage and/or improper

functioning as per specifi ed performance.

• When assembling, more than one person is required. Depending on the assembly

work, there are some cases in which working by one person alone can cause

personal injury or parts damage.

• Ensure that connectors are properly connected. Improper connections can cause

electric shock.

• Be careful not to damage the wires. Damaged wires may cause electric shock or

short circuit or present a risk of fi re.

• This work should be carried out by site maintenance personnel or other qualifi ed

professionals. Work performed by non-technical personnel can cause a severe

accident such as electric shock. Failing to comply with this instruction can cause

a severe accident such as electric shock to the player during operation. If no one

with proper technological expertise is available, request service from the office

indicated in this document or the point of purchase so as to ensure safety.

• Provide sufficient space so that assembling can be performed. Performing work

in places with narrow space or low ceiling may cause an accident and assembly

work to be diffi cult.

• To perform work safely and avoid serious accident such as the cabinet falling

down, do not perform work in places where step-like grade differences, a ditch, or

slope exist.

• If the machine is placed so that people will be passing through the vicinity, leave

at least 28” of space around the machine. If this space is too narrow, persons other

than the player may brush against or collide with the machine, possibly resulting in

accidents.

• Do not leave power cords, ground wires, or network cables exposed in areas

of heavy foot traffic. Doing so may cause them to become damaged, possibly

resulting in electric shock and/or short circuits. When laying wiring across the fl oor,

always use safety covers to protect the wires. (Wiring diameter: power cable approx. Ø 8; network cable - approx. Ø 5)

• Have a fl ashlight or another supplementary lighting unit available while working.

With indoor lighting alone, the cabinet interior may be too dark. Working without

proper lighting can lead to accidents. It also hinders proper work performance.

10

Page 17

• The cabinet has ventilation ports. Be sure not to block them. If they are blocked,

heat can build up, leading to fi re. This can also accelerate wearing of parts and

malfunctions.

• Secure ample ventilation space around the cabinet. If heat builds up, there could

be accidents associated with heat or smoke generation.

• If two cabinets are installed in alignment, make sure that there is ample distance

between them so that players or other customers will not come in contact or

collide with each other. If the distance is too narrow, there could be contacts or

collisions. If someone should fall down, head injury or other serious accident could

occur. Trouble between customers could also arise.

• Handle molded parts with care. Excessive weight or pressure may cause them to

break and the broken pieces may cause injury.

• When attaching or removing doors or lids, be careful that your hand or fi nger does

not get caught in anything.

6

ASSEMBL Y AND INST ALLATION

Be careful not to damage parts surfaces. In some cases, if such surfaces are

damaged, the part must be replaced; it cannot be reinforced or repaired.

Installation and assembly of this product should take place in the following sequence.

1 FIXATION TO INSTALLATION SITE

2 CONNECTION OF POWER AND GROUND

3 ENGAGEMENT OF POWER SUPPLY AND SOFTWARE INSTALLATION

4 ENGAGEMENT OF POWER SUPPLY AFTER INSTALLING SOFTWARE

5 CONFIRMATION OF ASSEMBLY

11

Page 18

6

ASSEMBL Y AND INST ALLATION

1 FIXATION TO INSTALLATION SITE

Make sure that all the adjusters contact the fl oor. Otherwise the cabinet could move,

causing an accident.

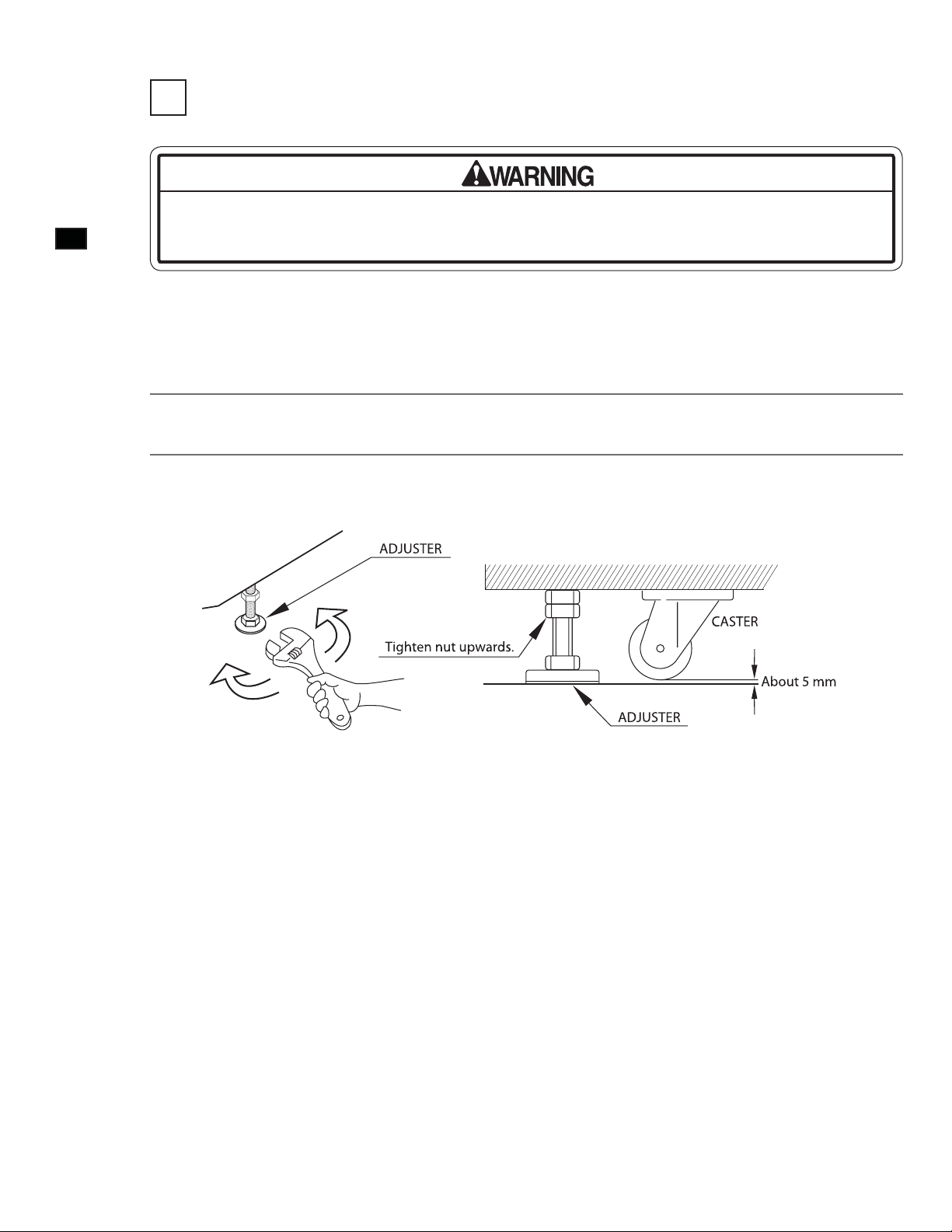

The product comes with casters attached at 4 locations and adjusters at 4 locations. When the installation site has been

determined, have the adjusters come in direct contact with the fl oor. Establish a gap of about 5 mm between the fl oor and

the casters and adjust the unit so that it will remain level.

Move the product to the installation site. If the product is to be installed near a wall, secure enough passageway

1

2

space for players to access the seat.

Use a wrench to set adjuster heights so that the unit will stay level. After setting, turn adjuster nuts upwards to

tighten them and secure adjuster heights.

12

FIG. 6-1a Illustration of Adjuster Setting

Ventilation Space

When installing the product next to a wall or other game unit, where customers will not be able to pass, secure 10”

(250 mm) of ventilation space between the product and the wall or game unit, as viewed from the left side facing

the monitor.

Page 19

2 CONNECTION OF POWER AND GROUND

• Use the power supply equipped with an earth leakage breaker. Use of power

supply without such a breaker could result in fi re if there is a current leakage.

• Have available a securely grounded indoor ground terminal. Without proper

grounding, customers could be electrocuted and product operations might not

always be stable.

• Do not expose the power cord. If these are exposed, customers could stumble

over them, for instance, and easily damage them. Additionally, if these lines are

damaged, there could be a risk of electrical shock or short circuit. Set these lines

at locations where they will not interfere with customer traffi c, or attach covers to

them.

• After laying out the power cord on the floor, be sure to always protect it. If the

power cord is left exposed, it can easily be damaged, resulting in electrical shock.

6

ASSEMBL Y AND INST ALLATION

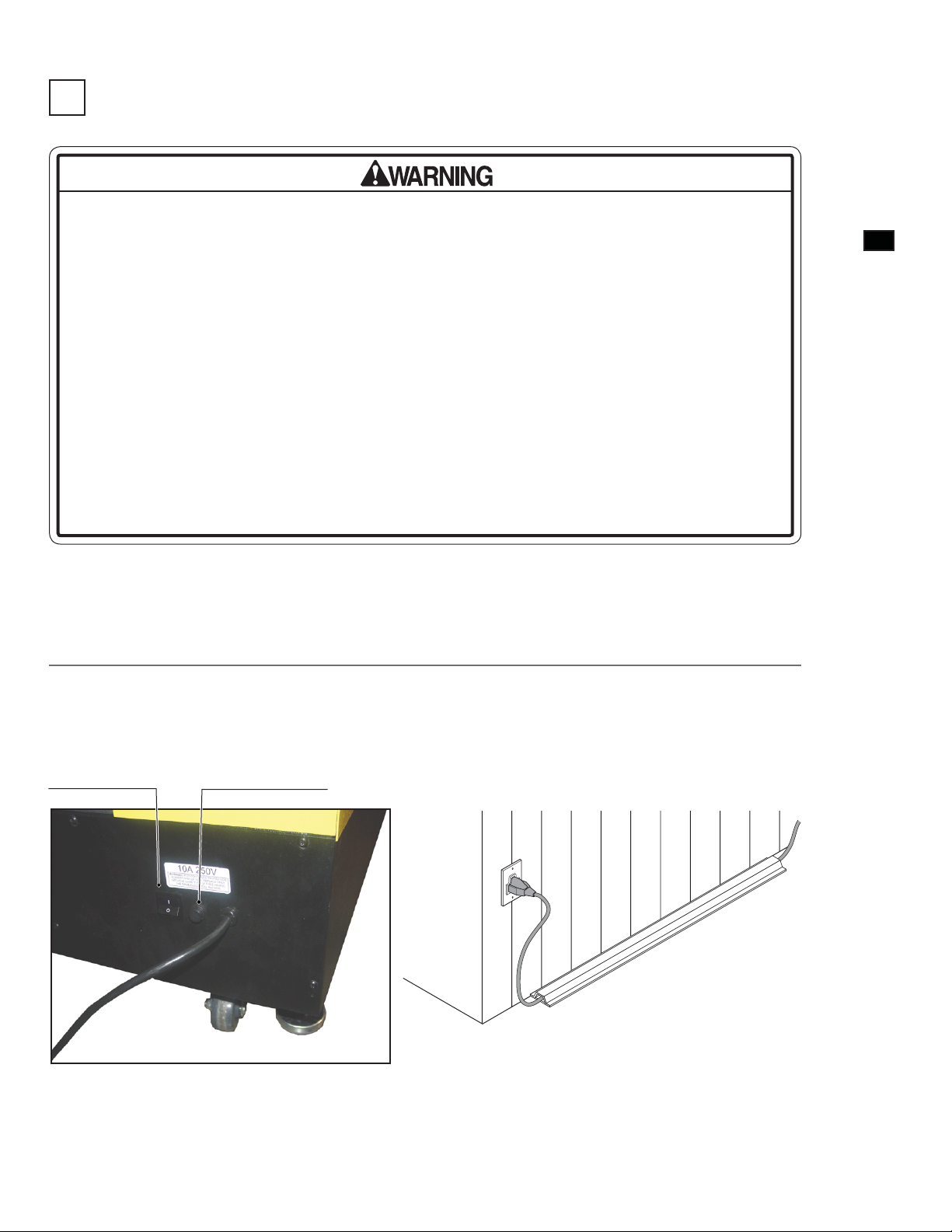

Insert the power cord plug into a “power outlet with ground terminal.” If there is no “power outlet with ground

terminal,” be sure to establish ground by some other means; for example, by connecting the AC unit ground terminal to a

ground wire with a ground mechanism prepared separately. If you use a conversion adapter sold on the market to supply

power, connect the ground wire terminal of the adapter to a “securely grounded ground terminal.”

Confi rm that the main switch is at OFF. Fully insert the power cord connector on the side opposite the power

1

Main power switch

plug into the AC unit inlet. Fully insert the power cord plug into the outlet. The power cord is laid out indoors.

Protect the power cord by attaching wire cover to it.

Main Fuse, (10A, 250V)

FIG. 6-2a View, Front bottom cabinet

FIG. 6-2b

13

Page 20

6

ASSEMBL Y AND INST ALLATION

3 ENGAGEMENT OF POWER SUPPLY AND SOFTWARE INSTALLATION

• Be careful not to damage the DVD wire by getting it caught between objects, etc.

Doing so may cause a short circuit or fi re.

• The following explanation assumes that the product has been assembled properly

as explained above. If there is an error or if the product operates in a manner other

than as indicated below, cut off the power supply immediately. Failure to do so

may result in a fi re or electrical shock.

• If you look directly at the laser beam in the DVD DRIVE, you could suffer vision

impairment. Do not look inside the DVD DRIVE.

• The software is not installed on the game board (LINDBERGH) when the power

supply is engaged, so the “Error 22” message is not a malfunction. However, if there

is another error display, or if there is no video output at all, there might have been

an error in product assembly, wiring connections might be faulty, or the LINDBERGH

might not be functioning properly.

• After the power supply is engaged, wait for “Error 22” message to be displayed. If

the product is indiscriminately operated in any way beforehand, there could be

unexpected problems or malfunctions, as well as damage to parts.

• Once “Error 22” is displayed, set the DVD-ROM in the DVD DRIVE and re-engage

the power supply. Installation takes place.

• After the power supply is engaged, the DVD DRIVE tray will not come out for about

30 seconds even if you press the switch. This is due to DVD DRIVE initialization.

• The DVD DRIVE tray can come out or return only while the power supply is

engaged. The tray cannot be opened or closed while the power is off.

• Even after the software has been installed, store the DVD software kit, DVD DRIVE

and DVD wire in a secure location.

• If for any reason installation cannot be completed, an error is displayed. Refer to

the service manual and take corrective action.

14

Page 21

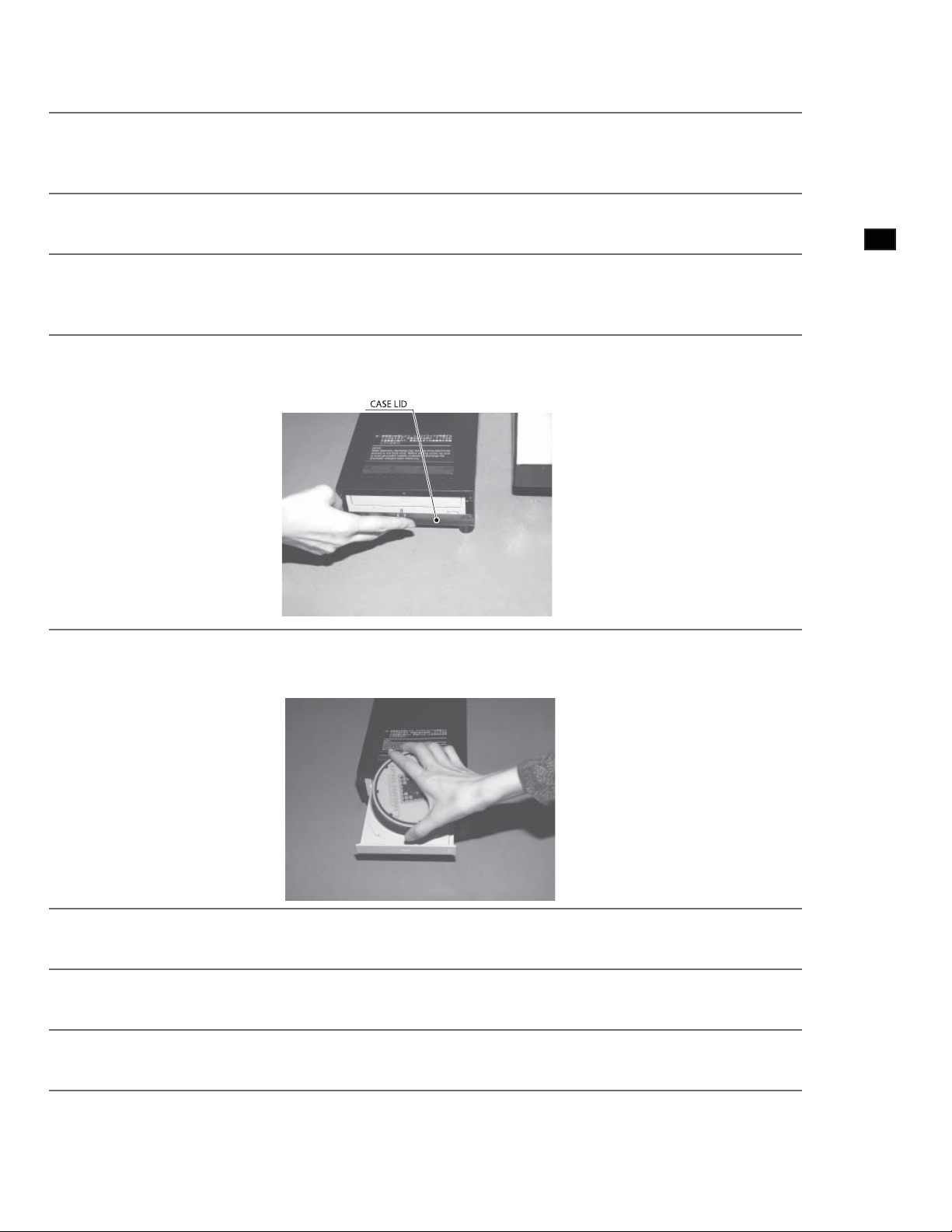

Use 2 Keys and 2 scrws off to open bottom seat then view DVD Drive inside of Base cabinet.

Before engaging the power supply, be sure that no one is on the base and that there are no tools, etc., on the seat.

1

When the product is shipped from the factory, the software has not yet been installed. But when the software is

installed and the power supply is engaged, the seat will move left and right.

Turn the main switch of the AC unit to ON and engage the power supply.

2

The LINDBERGH start-up screen appears. Wait for at least one minute. The error state is established. Check

3

to be sure it is “Error 22.” If it is “Error 22,” proceed to the next operation. If it is not “Error 22,” refer to the

LINDBERGH service manual and take corrective action.

Take out 1 urea (plastic head) screw and remove the DVD DRIVE case lid.

4

6

ASSEMBL Y AND INST ALLATION

5

6

7

8

FIG. 6-3a

Press the DVD DRIVE switch and the DVD DRIVE tray will come out. Set the DVD from the DVD kit into the

tray. Always have the labeled side facing upward.

FIG. 6-3b

Press the DVD DRIVE switch. The tray goes back into the drive. Re-engage the power. Turn the main switch to

OFF once, wait for at least one minute, then turn the switch back to ON.

Software is installed automatically from the DVD to the LINDBERGH. In some cases, it may take about 5

minutes to install software to the LINDBERGH.

Screen will shows Attract Mode screen appears.

9

Press the DVD DRIVE switch so that the tray comes out. Remove the DVD. Press the DVD DRIVE switch so

that the tray goes back into the unit. If the power is cut off, the tray will not move.

15

Page 22

6

ASSEMBL Y AND INST ALLATION

4 ENGAGEMENT OF POWER SUPPLY AFTER INSTALLING SOFTWARE

Only engage the power supply after checking the surroundings. Initialization takes

place automatically when engaging the power supply after software installation. At

this time the seat will move, and if anyone is near the product, they may collide with

the product, fall down, or get their hand or fi nger caught somewhere.

It takes about 2 minutes and 30 seconds for initialization to complete after the

power has been engaged. Do not touch the product or press any buttons until after

initialization is completed. If an anomaly is detected during initialization, there is an

error display. Unless the cause of the error is removed and initialization is allowed to

complete normally, the product will not operate properly.

Set the main switch of the AC unit to ON and engage the power. When the power is engaged, 1 fl uorescent lamp in the

billboard and 2 fl uorescent lamps on the seat rear surface will light up.

After the LINDBERGH start-up screen has appeared, the “initialization in progress” screen appears and initialization

begins.

The Attract Mode demo appears on the monitor and sound is output from the speakers to the left and right of the monitor

and to the left and right of the seat backrest. The LEDs at the upper right and left of the monitor also light up.

If the unit is set for no sound during Attract Mode, there is no sound output.

If there are enough credits to enable play, the start button on the control panel fl ashes. It goes out if there are no credits

during Attract Mode.

If the setting is for network play, the screen for “checking network” message appears on the monitor after completion of

initialization.

If there are no problems with the connections or settings for network play, the Attract Mode screen appears.

If there are any anomalies or faults in the connections or settings for network play, the confirmation screen or error

message is displayed. Inspect the connections and settings of the cable for network play.

Upon completion of initialization, if the seat inclines and stops, for instance, re-engage the power source and execute

initialization once again.

Even when the power source has been cut off, credit count and ranking data are kept stored in the product. However,

fractional coin counts (inserted coins that do not amount to one credit) and bonus counts are not kept.

16

Page 23

5 CONFIRMATION OF ASSEMBLY

Use test mode to confirm that assembly is proper, and that the LINDBERGH, connecting boards, and input/output

devices are normal.

Perform the following tests in test mode.

For tests (1) to (4), refer to the LINDBERGH service manual. For tests (5) to (7), see [9-3 Game Test Mode].

The items displayed on the test screen for tests (5) and (6) vary depending on the setting for cabinet type in the game

setting screen.

(1) Information Display Screen

When “SYSTEM INFORMATION,” “STORAGE INFORMATION,” or “JVS TEST” has been selected on the system

test mode menu, system information, game information and information on JVS I/O board connected to LINDBERGH

are displayed.

If each category of information is displayed without anomalies, the LINDBERGH is normal.

(2) JVS Input Test Screen

When “INPUT TEST” has been selected on the JVS test screen, data input to the JVS I/O board is displayed. On the

product, this is the screen for the testing coin switch.

Insert a coin. If the display to the side of the switch changes the switch and wiring connections are normal.

(3) Monitor Test Screen

When “MONITOR TEST” has been selected on the system test mode menu, the screen for checking monitor adjustment

status appears.

Monitor adjustment is completed when the product is shipped from the factory, but you should observe the test screen to

determine whether further adjustment is necessary. Refer to Chapter 10 and adjust the monitor if necessary.

6

ASSEMBL Y AND INST ALLATION

(4) Speaker Test Screen

When “SPEAKER TEST” has been selected on the system test mode menu, the screen for checking speaker sound

output appears.

To confi rm that audio output is normal, have test sound output from the game unit’s speaker.

(5) Input Test

When “INPUT TEST” has been selected on the game test mode menu, the screen for testing input device appears. Test

operate the input device by pressing each switch. If the display on the side of each input device changes to “ON” and

numerical values change smoothly in accordance with each operation, the input device and its wiring connections are

normal.

FIG. 6-5a Input Test Screen

17

Page 24

6

ASSEMBL Y AND INST ALLATION

(6) Output Test

When “OUTPUT TEST” has been selected on the game test mode menu, the screen for testing lamps and other output

devices appears.

If each output device operates properly, the output device and its wiring connections are normal.

FIG. 6-5b Output Test Screen

(7) Calibration

Confi rm that the operability of input devices and seat motions during game play do not present any hindrances to play.

Calibration is adjusted when the product is shipped from the factory but it might need to be adjusted again because of

vibrations during transport, etc.

If such things as operability are not satisfactory, select “CALIBRATION” on the game test mode menu and check and

adjust settings.

18

FIG. 6-5c Calibration Menu

Conduct the aforesaid tests when performing routine tests each month.

Page 25

PRECAUTIONS WHEN MOVING THE MACHINE

7

• Always disconnect the power cable before moving the product. If it is moved

with the power cable connected, the cable could be damaged, causing fi re or

electric shock.

• To move the unit over the fl oor, pull in the adjustors and have the casters contact

the fl oor. While moving the unit, be careful that the casters do not roll over the

power cord or the ground wire. If cord or wire is damaged, there could be

electrical shocks and/or short circuits.

• To lift up the cabinet, hold it at the bottom. If you hold it anywhere else, the

weight of the cabinet could cause damage to parts or attachments, resulting in

injury.

Do not hold or press the plastic parts as indicated by the figure. Failure to observe

this instruction may break the parts, and eventually the broken pieces may cause a

personal injury.

7

PRECAUTIONS WHEN MOVING THE MACHINE AND

7-1 MOVING THE MACHINE

• Observe the following precautions when moving the machine. Failure to observe

these precautions may result in damage to the casters and/or the fl ooring.

- The machine should be moved along a level fl oor.

- Ramps should be used to climb/descend steps 0.400” or greater in height.

- The machine should not be moved any faster than walking speed (about 1.243

MPH).

- The machine should not be tilted too far to one side or loaded excessively on

one side only.

19

Page 26

7

PRECAUTIONS WHEN MOVING THE MACHINE AND

Precautions in Moving Loads

• This product weighs over 550 lbs. It cannot be lifted by human strength alone.

Trying to do so could cause accidents. Use a crane or other powered hauling unit

to move the product.

• When moving a load, insert buffer material between the base and the platform

wall and attach the product securely to the platform with rope or other means. If

exterior parts are damaged or deformed, there could be electrical shocks and/or

short circuits.

• A minimum of 2 or 3 persons is needed to load this machine onto a forklift truck.

The procedure cannot be carried out safely with fewer than this number.

• The forklift should have a platform of at least 60” in length. The procedure cannot

be carried out safely with a platform shorter than this.

• When using a crane to move this machine, ensure that the person operating the

crane is properly qualified. Do not attempt to carry out this procedure without

properly qualifi ed personnel.

• Do not push or support the monitor, control stick, throttle lever or plastic

components while moving or loading the product. Otherwise these components

could be damaged, resulting in injuries from fragments, cracks, etc.

• When transporting the unit by truck, etc., do not secure it with rope, etc., in any

position other than as illustrated. Otherwise components could be damaged,

resulting in injuries from fragments, cracks, etc. Also protect amply with cloth, etc.,

those areas contacted by rope, etc.

• When placing the machine onto a platform or onto the ground, lower it slowly in an

upright, level position. If the machine is lowered at an angle, the weight may be

distributed unevenly and damage to casters/adjusters may result.

20

• Do not have adjustors contact the fl oor on the platform. Otherwise they could be

damaged or deformed by tilts or vibrations during transport.

• Make sure that the product will not undergo violent oscillations. Lay out a vibrationproof mat, for instance, and place the product on top of it.

Page 27

GAME DESCRIPTION

8

The following explanations apply when the product is functioning satisfactorily. Should there be any actions different

from the following contents, some sort of faults may have occurred. Immediately look into the cause of the fault and

eliminate the cause thereof to ensure satisfactory operation.

Normally, when the power is on, the fl uorescent lamp in the billboard on the monitor and the two fl uorescent lamps on

the seat rear surface are lit up. In Attract Mode, such things as game content and rankings are shown on the Attract Mode

Demonstration screen on the monitor.

The colors emitted by the LEDs on the billboard right and left vary depending on the screen content.

Audio output comes from the speakers at the left and right of the monitor and the left and right of the seat backrest.

Presence or absence of audio output in the Attract Mode can be selected by means of the settings in the test mode.

The START button on the control panel is an illuminated button. In Attract Mode, this button is not lit up.

If there are enough credits to enable play, the START button fl ashes. When it is pressed and the game is started, the

START button light goes out.

After the game is over, if there are enough credits to enable play, the START button fl ashes.

The colors emitted by the LEDs on the billboard right and left vary depending on conditions.

LED

BILLBOARD FLUORESCENT LAMP

MONITOR, 29"SANWA

SPEAKERS (At left and right of monitor)

8

GAME DESCRIPTION

CONTROL STICK

FIG. 8a

21

Page 28

8

GAME DESCRIPTION

REAR SPEAKER

(Left & Right)

SEAT

THROTTLE LEVER

FIG. 8b

22

GUN TRIGGER

MISSILE TRIGGER

START BUTTON

FIG. 8c

Page 29

Game Outline

- AFTER BURNER CLIMAX is a fl ight shooting game that features exhilarating gameplay.

- The player takes on the role of the leader of the “Brave Fangs”, a special air-force unit whose mission is to prevent

the outbreak of all-out nuclear war.

- Fighting the enemy, you proceed through the game’s stages. Attack targets include jet fi ghters, bombers, helicopters,

missile launch sites and facilities.

- Using CLIMAX Mode, a special form of attack style, it is possible to take down large groups of enemies at once.

Attract Mode

The Attract Mode cycles through the following screens.

1. Logo Display

2. Title Screen

3. Movie

4. Title Screen

5. Ranking

6. Title Screen

7. Controls

8. Title Screen

9. Demonstration

10. Return to 1

8

GAME DESCRIPTION

Insert a coin and press the START button during the Attract Mode and the game will start.

However, during FREE PLAY no coins need to be inserted.

Pull the trigger during the Attract Mode and it will skip to the next screen. (The Logo Display cannot be skipped).

23

Page 30

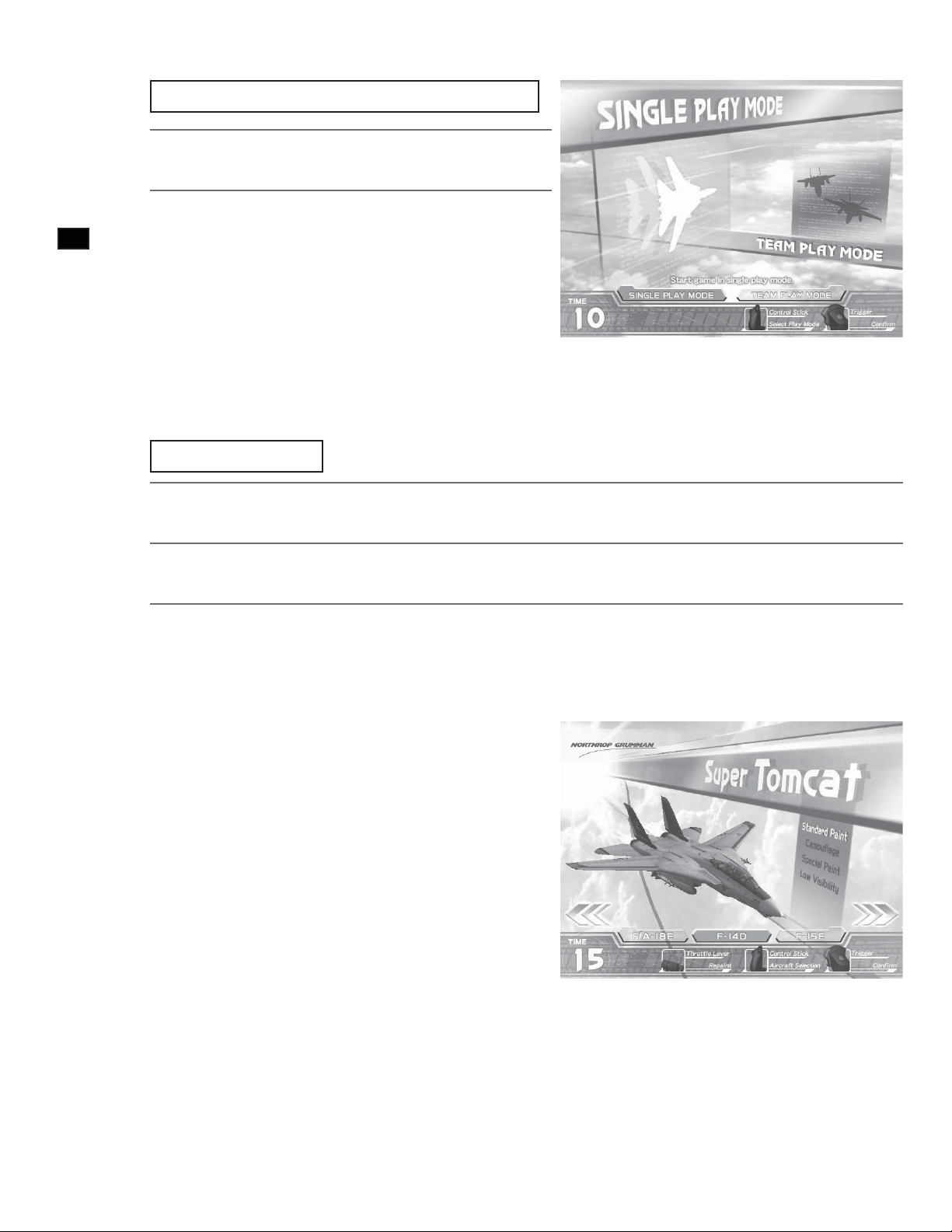

Game Mode Select (Network Play only)

Move the control stick left/right to select a game mode.

1

Pull the trigger or press the START button to confi rm

8

2

GAME DESCRIPTION

ONE-PLAYER Mode:

Play for one player.

selection.

TWO-PLAYER Mode:

Two players play at the same time. Co-operate or compete to clear all stages. At each stage, scores are compared and the

winner/loser is displayed.

Aircraft Select

Move the control stick left/right to select an aircraft.

FIG. 8e MODE SELECT Screen

1

Push the throttle lever forward or back to change the aircraft paint pattern.

2

Pull the trigger or press the START button to confi rm selection.

3

The three following aircraft can be selected.

- F-14D Super Tomcat

- F-15E Strike Eagle

- F/A-18E Super Hornet

The four following paint patterns can also be selected.

- Standard Paint

- Camoufl age

- Special Paint

- Low Visibility

24

FIG. 8f AIRCRAFT SELECT Screen

Page 31

Stage Composition

FIG. 8g Stage Composition

8

GAME DESCRIPTION

There are a total of 21 stages.

- There are 17 basic stages (shown in squares on the above diagram)

- There are 2 secret stages (stages 06S and 10S on the above diagram)

- There are 2 extra stages (stages 14 and 15 on the above diagram)

Some stages simply have a number, like “01”, and some also have a letter included, like “04A”.

- The numbers on the above diagram denote stage number.

- Where the route splits, an “A” or “B” follows the stage number.

- Secret stages have an “S” following the number.

There are a number of routes that can be taken to the end of the game.

- In some cases the player can choose their route, and in some cases their play will automatically decide which route is

taken.

- The dotted lines on the above diagram denote a route that is automatically determined by play.

- The “No. of Stars earned” effects progress to secret stages.

- The “No. of Critical Commands completed” effects progress to the extra stages.

There are 3 endings.

- There is ENDING A, ENDING B and ENDING C, with ENDING A being the best.

- There are 15 stages to reach ENDING A and ENDING B.

- There are 13 stages to reach ENDING C.

25

Page 32

Controls

8

GAME DESCRIPTION

FIG. 8h Throttle Lever FIG. 8i Control Stick

The player aircraft is controlled by the “Throttle Lever” and “Control Stick”.

<Throttle Lever>

Used to change the speed of the player aircraft.

Pull the lever towards you to decrease speed. Push the lever away from you to increase speed.

Push the lever all the way away from you to activate CLIMAX Mode. CLIMAX Mode requires a full Climax

Gauge to activate.

<Control Stick>

Alters the movement direction of the player aircraft.

Move right to move to the right. Move left to move to the left.

Pull towards you to ascend. Push away from you to descend.

The gun trigger fi res guns, and the missile trigger fi res missiles.

Game Explanation

26

FIG. 8j GAME SCREEN Explanation

Page 33

<Game Rules>

Either clearing all the stages, or all the player aircraft being lost results in Game Over.

All the player aircraft have been lost when there are no remaining player aircraft and the armor gauge falls to 0%.

When an aircraft’s armor gauge falls to 0%, that aircraft is lost, and the remaining player aircraft are reduced by one.

During game play, there are no increases in the number of aircraft and no restoration of the armor gauge.

The number of aircraft at the start of the game is set in test mode.

<Screen Explanation>

- SCORE: Current score.

- COMBO: Current combo. Defeating enemies in quick succession results in a combo.

- MISSILE:

- CLIMAX GAUGE: Once this gauge is fi lled, CLIMAX Mode can be activated.

- SPEED GAUGE: The speed of the player aircraft.

- STAGE: Current stage number.

- STAR:

- LOCK-ON CURSOR: Align this cursor with an enemy to lock-on.

- PLAYER’S AIRCRAFT:

- ARMOR: When the gauge falls to 0% a player aircraft is lost.

- CRITICAL COMMAND: Displays a Critical Command in progress.

<Lock-On>

Remaining number of missiles. Required to fire missiles. They are gradually

replenished.

Current number of stars. Defeating many enemies without taking any damage

earns stars.

When there are no remaining aircraft and the armor gauge falls to 0% it is Game

Over.

8

GAME DESCRIPTION

FIG. 8k Locking On

27

Page 34

Using missiles is the most basic method of attack. A missile may still miss a locked on enemy if your timing is off.

Align the lock-on cursor with an enemy to lock-on to them.

1

Fire a missile while locked on and it will home in on the enemy.

2

8

GAME DESCRIPTION

<After Burners>

When the throttle lever is moved to FAST (far away from you), the after burners ignite and maximum acceleration can

be realized.

The after burners can only be used for a limited period of time.

You must then return your speed to normal for a while before the after burners can be fi red again.

Moving the throttle from SLOW to FAST will allow the after burners to be fi red again more quickly than normal.

<Rolling>

Rolling is a technique for avoiding missiles. Normally, missiles can be avoided by other actions. Rolling is performed as

follows.

Move the control stick left or right for a short time. Move it momentarily all the way to the other side and the

1

<CLIMAX Mode>

aircraft will roll

28

FIG. 8l Activating CLIMAX Mode

FIG. 8m CLIMAX MODE ACTIVATION Screen

Page 35

Using CLIMAX Mode allows a larger number of enemies to be locked on to and taken out at once.

During CLIMAX Mode the lock-on cursor expands, providing more opportunities to attack. You can now quickly lock

onto multiple enemies. During CLIMAX Mode, the number of remaining missile shots is unlimited.

In CLIMAX Mode, motion can begin by pushing the throttle lever all the way to CLIMAX position, the farthest point

away from you.

The Climax Gauge must also be full before CLIMAX Mode will activate. Keeping the throttle lever pushed all the way

from you will keep CLIMAX Mode active.

CLIMAX Mode ends under the following circumstances.

- If the throttle lever is moved out of the CLIMAX position.

- If the Climax Gauge becomes totally empty.

- If damage can be taken during CLIMAX Mode.

[CLIMAX Mode Hints]

* Defeating enemies quickly is vital. The less you use the gauge up, the more often CLIMAX Mode can be used.

* An infi nite number of missiles can be used during CLIMAX Mode, presenting an opportunity to attack even if the

number of remaining missiles are low.

* A Combo increases simply by locking on and fi ring a missile.

<TWO-PLAYER Mode>

8

GAME DESCRIPTION

FIG. 8n TWO-PLAYER Mode GAME Screen

<Game Rules>

Two players compete at the same time to get the higher score. It is also possible to co-operate to clear the stages.

The conditions for Game Over are the same as for the one-player game.

<Evaluation>

Results (WIN/LOSE/DRAW) are determined by comparing the score earned in each stage.

MID-GAME RESULT and TOTAL RESULT display the total score comparison up until that point.

29

Page 36

<Screen Explanation>

- RIVAL: Position and direction of your rival.

- RIVAL’S STATUS: An icon that displays your rival’s current status.

- DOWNED: Displayed when either player is shot down.

8

GAME DESCRIPTION

- PLAYER NUMBER: Player number.

Route Select

Displayed on the right on the Player 01 screen and the left on the Player 02 screen.

(Icons are: CLIMAX Mode, Down, Game Over)

(In red: Player 01 downed; In blue: Player 02 downed)

FIG. 8o ROUTE SELECT Screen

Move the control stick left/right to move the cursor.

1

Pull the gun trigger to select the route.

2

Select the route you wish to take on the ROUTE SELECT screen. The countdown appears in the middle of the screen. If

the time runs out then the route that the cursor is currently highlighting shall be selected.

30

Page 37

CONTINUE Screen

FIG. 8p CONTINUE Screen

On the CONTINUE screen, select whether to continue the game or quit. The countdown appears in the middle of the

screen. If the time runs out, NO will be automatically selected.

8

GAME DESCRIPTION

To continue the game, perform the following before the countdown reaches 0.

<Credit Remains>

If enough credits remain to continue the game, the CONTINUE screen appears and the START button flashes. The

START button is used to select YES when there are enough credits to continue. It is also used to select YES when FREE

PLAY has been set. At any other time the START button has no effect.

Move the control stick left/right to move the cursor.

1

Pull the gun trigger or press the START button to select.

2

<No Credit>

Insert coins. When a coin is inserted the count down resets to 9. When enough coins have been inserted to

1

continue, the START button fl ashes.

Tilt the control stick left/right and move the cursor to YES.

2

3

Pull the gun trigger or press the START button to select.

31

Page 38

Name Entry

If stage 13A, 13B or stage 15 are cleared, and the score is in the top 20 then you can enter your name.

8

GAME DESCRIPTION

A maximum of three characters can be entered.

Name entry ends when END is selected or when time runs out.

Move the control stick left/right to move the cursor. Pull the trigger to select the letter the cursor is aligned to.

1

FIG. 8q NAME ENTRY Screen

Pull the throttle lever towards you to move the cursor to the DEL position. Press the START button to confi rm

2

If name entry ends without anything being input, the name will appear as “???”

If prohibited characters are included in the name, it will automatically be changed to “- - -”

the entered name.

Other Notes

<Change BGM>

On the “PLEASE WAIT” screen displayed after selecting an aircraft, leave the throttle in SLOW and pull the missile

trigger to change the music to the After Burner II BGM.

<Aircraft licenses>

The rights to use all of the aircraft that appear in the game have been obtained from the appropriate licensers.

© SEGA Corporation, 2006

32

Produced under license from Boeing Management Company. Boeing, McDonnell Douglas, McDonnell,

Douglas, North American Aviation, their distinctive airplane liveries, logos and product markings are among the

trademarks owned by Boeing.

Produced under a license from Northrop Grumman Systems Corporation. F-14D Super Tomcat, F-5E Tiger II,

A-10A Thunderbolt II, B-2A Spirit, and CVN-65 Enterprise are trademarks of Northrop Grumman Systems

Corp. and are used under a license to Sega Corporation.

Page 39

EXPLANATION OF TEST AND DATA DISPLAY

9

• Do not touch any parts that are not specified in these directions. Touching

unspecifi ed locations may lead to electric shock or cause short circuits.

• Because of the position of the switch unit, you must assume an unnatural posture to

operate in test mode, which can cause pain in the shoulder, waist, etc. You could

also get caught by parts in the coin chute door, for instance, and suffer abrasions.

Have a fl ashlight on hand and operate in test mode very carefully. The door interior

is dark and narrow and you could easily make mistakes in operation.

• Be careful that a finger or hand does not get caught when opening/closing the

coin chute door.

9

EXPLANATION OF TEST AND DATA DISPLAY

• When you enter the Test Mode, fractional coin and bonus adder data is erased.

• Adjust the sound to the optimum volume, taking into consideration the

environmental requirements of the installation location.

• Removing the Coin Meter circuitry renders the game inoperable.

33

Page 40

9-1 SWITCH UNIT AND COIN METER

Switch Unit

In test mode, the switch unit in the coin chute door is operated.

9

EXPLANATION OF TEST AND DATA DISPLAY

Unlock and open the coin chute door. Inside is a switch unit. There is a monitor adjustment panel at the bottom.

(See Chapter 10.)

COIN METER 2 (OPTION)

TEST SW

COIN METER 1

FIG. 9-1a Coin Meter

TEST Switch (TEST)

Establishes test mode. Becomes the button to confi rm selections in test mode.

REAR SPEAKERS VOLUME

SERVICE SW

FRONT SPEAKERS VOLUME

34

SERVICE Switch (SERVICE)

Makes it possible to enter credits for service without increasing the coin meter. Becomes the button to select items in

test mode.

Front Speaker Volume (FRONT SP.VOL)

This is the volume knob for speakers at the left and right of the monitor. Turn the knob to the right to increase speaker

volume.

Rear Speaker Volume (REAR SP.VOL)

This is the volume knob for speakers at the left and right of the seat backrest. Turn the knob to the right to increase

speaker volume.

Coin Meter

After using a Coin Door key to unlock it, the coin meter can be found inside. (Coin Meter 2 which located in Left is

option.)

Page 41

9-2 SYSTEM TEST MODE

• The details of changes to test mode settings are saved when you exit from test

mode by selecting EXIT from the system test mode menu. Be careful because if the

power is turned off before that point, changes to the settings will be lost.

• Use with the specified settings. If settings other than those specified are used,

inappropriate operations or malfunction may occur.

In the system test mode, the main activities include checking LINDBERGH information and actions and the setting of

coin/credit. Also, a screen appears for checking screen adjustments. For details, see the LINDBERGH service manual,

which is provided separately.

Use the following settings with this product. If the settings are not as specified, error messages might appear and

operations might not be normal.

COIN ASSIGNMENTS

COIN CHUTE TYPE: COMMON

SERVICE TYPE: COMMON

NETWORK SETTING

NETWORK TYPE: MAIN

MAIN NETWORK: SETTING NOT REQUIRED

9

EXPLANATION OF TEST AND DATA DISPLAY

1

2

3

4

When the TEST Button is pressed, the system test mode menu screen (SYSTEM TEST MENU) appears.

Use the SERVICE Button to move the cursor to the desired test item.

Press the TEST Button to confi rm selection of the item.

When testing and checking are completed, select EXIT and press the TEST Button. The SYSTEM TEST MENU

screen reappears.

When all tests are completed, select EXIT and press the TEST Button. The game screen reappears.

SYSTEM TEST MENU

SYSTEM INFORMATION

STORAGE INFORMATION

JVS TEST

MONITOR TEST

SPEAKER TEST

COIN ASSIGNMENTS

CLOCK SETTING

NETWORK SETTING

GAME TEST MODE

-> EXIT

SELECT WITH SERVICE AND PRESS TEST

FIG. 9-2 SYSTEM TEST MENU Screen

35

Page 42

9-3 GAME TEST MODE

9

EXPLANATION OF TEST AND DATA DISPLAY

To change settings in the game test mode, simply making changes on the setting

screen will not be effective. Complete the test mode in normal fashion.

Highlight GAME TEST Mode on the system test mode menu, and press the TEST Button to enter the game test mode.

Once you enter the game test mode, the game test menu will be displayed.

The items displayed on each test screen vary depending on the setting of CABINET TYPE on the game setting screen in

game test mode.

36

FIG. 9-3 GAME TEST MENU Screen

Page 43

1

2

Press the SERVICE Button to highlight the desired menu item with the cursor.

Press the TEST Button to perform the selected item. To learn how to proceed after executing the selected item,

read the item’s explanation. You can also use the control stick and gun trigger to make selections in game test

mode.

When test or setting is completed, take steps to have the game test mode menu screen reappear. The steps

3

4

<Item Explanation>

involved vary with the item.

Select EXIT and press the TEST Button. The system test mode menu screen reappears.

On the system test mode menu screen, select EXIT and press the TEST Button. The game screen reappears

a. INPUT TEST: Perform an input test.

b. OUTPUT TEST: Perform an output test.

c. GAME ASSIGNMENTS: Set up game settings.

d. NETWORK SETTING: Set up network settings.

e. CALIBRATION: Perform calibration.

f. BOOKKEEPING: View bookkeeping records.

g. BACKUP DATA CLEAR: Clear data.

h. EXIT: Return to system test mode menu.

9

EXPLANATION OF TEST AND DATA DISPLAY

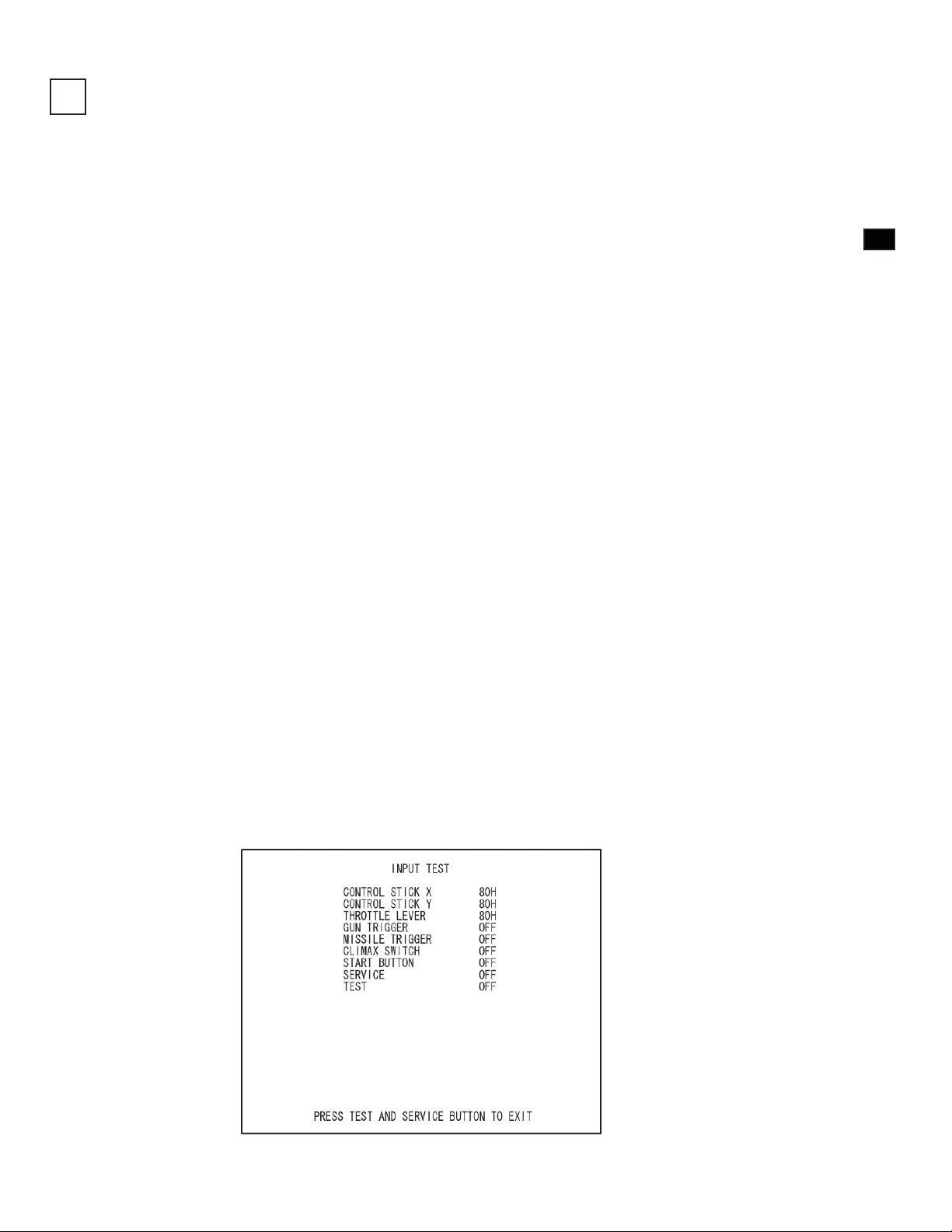

a. INPUT TEST

FIG. 9-3a INPUT TEST Screen (CABINET TYPE: STANDARD)

37

Page 44

The condition of each input device can be checked. Periodically check the condition of each input device on this screen.

The number of items displayed varies depending on the setting of CABINET TYPE.

<Operation>

Manipulate the control stick or throttle lever and confirm that the input value on the right side of the item

1

changes smoothly in response to manipulation.

9

EXPLANATION OF TEST AND DATA DISPLAY

2

3

<Menu Explanation>

CONTROL STICK X: Control stick left/right input value

CONTROL STICK Y: Control stick up/down input value

THROTTLE LEVER: Throttle lever front/back input value

GUN TRIGGER: Gun trigger

Manipulate the triggers and buttons and check the display on the right side of the item. The display is normal if

it shows ON when trigger or button is pressed and OFF when trigger or button is released.

When the SERVICE Button and TEST Button are pressed simultaneously, the game test mode menu screen

reappears.

MISSILE TRIGGER: Missile trigger

CLIMAX SWITCH: ON when throttle lever is pressed to monitor side; OFF when lever is released

START BUTTON: START button

SERVICE: SERVICE Button

TEST: TEST Button

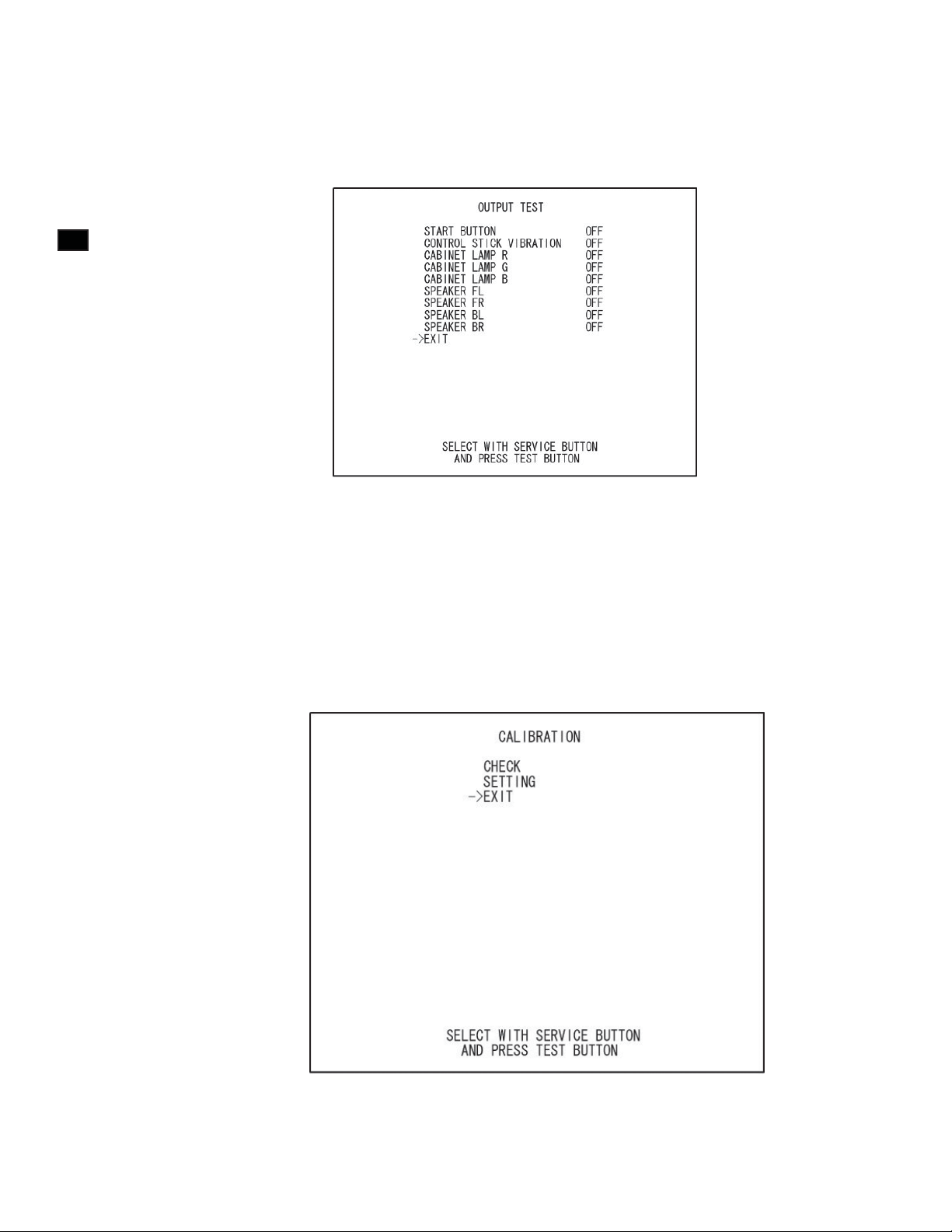

b. OUTPUT TEST

38

FIG. 9-3b OUTPUT TEST Screen (CABINET TYPE: STANDARD)

Page 45

The condition of each output device can be checked. Periodically check the condition of each output device on this

screen. Conditions are normal if each device operates and yields output as indicated below.

The number of items displayed varies depending on the setting of CABINET TYPE. For safety, in performing tests in

which the seat moves, manipulate the control stick and gun trigger without standing on the base.

<Operation>

Press the SERVICE Button and move the cursor to the item (output device) you want to test.

1

While the TEST Button is depressed, the display on the right side of the item goes from OFF to ON and the

2

selected output device operates. Confi rm that the device operates normally. If the speakers are operating, you

will hear a buzz-like noise.

Press the SERVICE Button and move the cursor to EXIT.

3

When the TEST Button is pressed, the game test mode menu screen reappears.

4

<Menu Explanation>

START BUTTON: START button lights up at ON; extinguishes at OFF.

CONTROL STICK VIBRATION: Control stick vibrates at ON; stops at OFF.

CABINET LAMP R: LED glows red at ON; extinguishes at OFF.

CABINET LAMP G: LED glows green at ON; extinguishes at OFF.

9

EXPLANATION OF TEST AND DATA DISPLAY

CABINET LAMP B: LED glows blue at ON; extinguishes at OFF.

SPEAKER FL: Monitor left side speaker produces sound at ON; no sound at OFF.

SPEAKER FR: Monitor right side speaker produces sound at ON; no sound at OFF.

SPEAKER BL: Backrest left speaker produces sound at ON; no sound at OFF.

SPEAKER BR: Backrest right speaker produces sound at ON; no sound at OFF.

EXIT: GAME TEST MENU screen reappears.

When AUDIO OUTPUT on the game setting screen is set to “2CH”, speaker-related items change as follows. At “2CH”,

sound is output only from the left and right monitor speakers.

SPEAKER FL: Monitor left speaker produces sound at ON; no sound at OFF.

SPEAKER FR: Monitor right speaker produces sound at ON; no sound at OFF.

39

Page 46

c. GAME ASSIGNMENTS

When the store is crowded inside and motions might be dangerous to customers

passing near the product, set the cabinet so it will not move, then operate the

9

EXPLANATION OF TEST AND DATA DISPLAY

product.

• Setting changes do not become effective until EXIT is selected on the setting

screen. After a setting has been changed, be sure to always exit the setting screen.

• Use this product with the CABINET TYPE set at STANDARD. Otherwise there could be

erroneous operations.

40

FIG. 9-3c GAME ASSIGNMENTS Screen (CABINET TYPE: STANDARD)

Page 47

The various game settings are established. The number of menu items differs depending on the CABINET TYPE setting

in game assignments.

<Operation>

Press the SERVICE Button, move the cursor to the item whose setting is to be changed and select the item.

1

When the TEST Button is pressed, the preset value of the selected item changes. When AUDIO OUTPUT is set

2

3

<Menu Explanation>

DIFFICULTY: Set the Game Difficulty (VERY EASY/EASY/NORMAL/HARD/VERY

PLAYERS AIRCRAFT: Set the number of player aircraft at the start of the game (1 - 9).

CABINET TYPE: Set the cabinet type (DELUXE/STANDARD).

CABINET MOVEMENT: Turn Cabinet Movement ON/OFF.

CONTROL STICK VIBRATION: Turn control stick vibration ON/OFF.

ADVERTISE SOUND: Turn sound during Attract Mode ON/OFF.

AUDIO OUTPUT: Set the speaker output (4CH/2CH).

EXIT: Return to the game test menu screen.

d. NETWORK SETTING

to “2CH”, sound is output only from the monitor right and left speakers.

Press the SERVICE Button and move the cursor to EXIT. When the TEST Button is pressed, the game setting

screen exits and the game test mode menu screen reappears.

HARD).

9

EXPLANATION OF TEST AND DATA DISPLAY

• Network play cannot be implemented without proper setting for network play.

Instead, an error message may be displayed.

• Setting changes do not become effective until EXIT is selected on the setting

screen. After a setting has been changed, be sure to always exit the setting screen.

FIG. 9-3d01 NETWORK SETTING Screen (LINK NUM: 1)

FIG. 9-3d02 NETWORK SETTING Screen (LINK NUM: 2)

41

Page 48

To setup network play with this product, connect two game machines with a network cable.

Change to the settings for network play by proceeding as follows. The number of menu items differs depending on the

LINK NUM setting.

<Operation>

9

EXPLANATION OF TEST AND DATA DISPLAY

1

2

Press the SERVICE button, move the cursor to LINK NUM and select it.

When the TEST button is pressed, the value set for LINK NUM changes. Set each of the two game machines to

“2”. LINK ID is displayed.

Press the SERVICE button, move the cursor to LINK ID and select it.

3

When the TEST button is pressed, the value set for LINK ID changes. Set this value to “1” for one machine and

4

to “2” for the other machine.

Press the SERVICE button and move the cursor to EXIT.

5

When the TEST button is pressed, the network play setting screen exits and the game test mode menu screen

6

<Menu Explanation>

LINK NUM: Set the number of cabinets to link (1 or 2).

LINK ID: Numbers for game machine network play (1/2).

NOTES:

EXIT: Return to the game test menu screen.

reappears.

- Make sure that the two cabinets being used are both given different numbers. If the same number if used

for both, then two-player play will not be possible.

- It is recommended that, facing the screens, the cabinet on the left is given number 1 and the cabinet on

the right is given number 2.

42

NOTE:

After Burner Climax games able 2 cabinets LINK PLAY.

You need 1 LINK (LAN) cable. You need create hole for LINK cable

bottom wood of both base cabinets then thru LINK CABLE there.

(Please refer Chapter 20)

NETWORK (LAN) CABLE (OPTION)

600-7269-0300 (1)

Page 49

e. CALIBRATION

• Change will not be effective simply by making a change on the calibration screen.

When a setting has been changed, be sure to always exit the test mode.

• Calibration is relevant to operability. Manipulate and adjust the input device with

appropriate force. Do not make adjustments with excessive force.

9

EXPLANATION OF TEST AND DATA DISPLAY

FIG. 9-3e01 CALIBRATION Screen

Adjust the volume input value of the input device. When the volume has been replaced, check and adjust it on this

screen.

<Operation>

Press the SERVICE Button and move the cursor to the item you want to select.

1

When the TEST Button is pressed, the selected item is executed.

2

Perform checks and adjustments.

3

The calibration screen reappears.

4

When an adjustment has been made, select CHECK and, on the calibration check screen, make sure that the

adjustment is appropriate.

Press the SERVICE Button and move the cursor to EXIT.

5

6

When the TEST Button is pressed, the calibration screen exits and the game test mode menu screen reappears.

43

Page 50

<Menu Explanation>

CHECK: Proceed to the calibration check screen.

SETTING: Proceed to the calibration screen.

EXIT: Return to the game test menu screen.

9

EXPLANATION OF TEST AND DATA DISPLAY

Calibration Check Screen

FIG. 9-3e02 CALIBRATION Check Screen

<Operation>

Operate the input device whose input value is to be checked.

1

When the TEST Button is pressed, the calibration screen reappears.

2

<Menu Explanation>

CONTROL STICK X: When minimum and maximum values have been input, MIN and MAX are displayed at

the <※1> position, depending on the input. If both MIN and MAX are not displayed

then the game cannot be played properly.

CONTROL STICK Y: When minimum and maximum values have been input, MIN and MAX are displayed at

the <※2> position, depending on the input. If both MIN and MAX are not displayed

then the game cannot be played properly.

44

THROTTLE LEVER: When minimum, maximum, and CLIMAX values have been input, MIN, MAX, and

CLIMAX are displayed at the <※3> position, depending on the input. If MIN, MAX

and CLIMAX are not displayed then the game cannot be played properly.

Page 51

Calibration Select Screen

Shown below is the recommended range in the value for the center position of each

volume. Attach volume so that its value is within this range. [Throttle lever: 80H ± 4H,