1

9-5170-07

APOLLO ULTRASONIC OIL LEVEL MONITOR

THE RIGHT CHOICE

The Apollo Ultrasonic Oil Level

Monitor measures the level of usable oil in your tank in 10

graduations of the tank height.

We give a full 1 year warranty subject to normal conditions.

Supplied with long life lithium battery (3V-CR2430). The

warranty becomes invalid if the sealed unit is opened.

Suitable for use in tanks for the storage of diesel fuel,

kerosene, gas oil types A2, C1, C2, and D as defined by BS

2869. Check with the manufacturer and/or supplier before

using with any other fluids.

The Apollo Ultrasonic will fit easily to most standard oil storage

tanks (plastic or steel) that has a 20 mm, 32 mm or 38mm

(1½”) gauge hole.

TOOLS REQUIRED

Star/Philips head screwdriver.

INSTALLATION INSTRUCTIONS

1 SETTING RECEIVER

Accurately measure the height of your tank. Using the tank

height chart on page 2, read across to the relevant multi switch

settings. The multi switches are located in a recess at the back

of the receiver above the pins.

Using screwdriver or tip of ball point

pen, flip the relevant switch (es)

upwards (= ON). As an example, if the

tank is 850 mm high, set switches ON

(Up) Number 4 & 8.

Set switch 1 on/up to enable the low

level audible warning.

Your Apollo Ultrasonic receiver is now programmed to your

tank height.

2

MATCHING RECEIVER AND TRANSMITTER

You should match the receiver with the transmitter so that the

system code is unique to your tank.

You only need to do this once.

Plug receiver into a suitable and

convenient electrical socket and switch

on. The display screen on the front of

the receiver will show a flashing top bar

as shown in diagram. This indicates

that the receiver is awaiting a unique

code. The flashing top bar will last for 2

minutes during which time you can

match the transmitter to the receiver.

Hold the transmitter against the receiver

right hand side, as shown, so that the

black dots are touching each other

(important!) for about 20 seconds to

allow unique code to be transferred.

Bars will increase up the display screen.

During the matching process you will

hear an audible beep to indicate matching is in progress. A

change in tone will indicate completion of the matching

process. When all 10 bars are shown they will flash to

indicate that the unique code is transferred.

2

FITTING TRANSMITTER

The procedure is the same for fitting to

both old and new tanks.

For tanks with pre-drilled 20 mm or

32 mm hole

Remove cap from hole and insert

transmitter, ensuring the weather seal is

securely in place.

Ensure the transmitter is vertical on top of the tank.

Tighten on to the tank using the 2 stainless steel self-tapping

screws supplied. Do not over tighten. Do not use longer

screws.

For tanks with 1½” (38 mm) BSP gauge socket

An optional adapter is available

Unscrew cap from hole and fit the adapter provided by

screwing into gauge socket.

Fit the transmitter to the adaptor on the tank as described

above.

The Apollo Ultrasonic Oil Level Monitor is now fully installed

and signals should be received every hour. If the transmitter is

installed within 10 minutes of matching, the current level will be

displayed otherwise, it may take one hour for the correct oil

level indication to be displayed on screen.

NOTE:

Please ensure the receiver is plugged into an electrical socket

at all times. Do not unplug to reset.

In the event of a power failure or if the receiver is switched off

or moved to a new socket: When power returns again or unit is

switched on, the receiver display screen will show the top bar

flashing. There is no need to repeat the matching

instruction. The top bar will continue to flash for 2 minutes,

after which time the display screen will be blank, whilst the

unique signal is located. This may take up to one hour.

APOLLO ULTRASONIC ON SCREEN DISPLAYS

NORMAL MESSAGES (images for illustration purposes)

Full

OTHER MESSAGES:

Blank screen or top bar only after installation or following a

Early Warning

power failure

Receiver waiting for signal

- Do Nothing! Signal should be received within one hour.

Flashing triangle, no bars

No radio signal received from transmitter

(after waiting for 4 hours)

- Check for correct matching procedure

- location of receiver to transmitter (try

repositioning receiver)

- Check the transmitter seal is undamaged.

Fixed Triangle only

- Low battery warning, unit will continue to give a reading until the

battery is exhausted.

- Replace Lithium CR2430 battery in transmitter

- Please see over for further information on removing battery

Flashing triangle, middle bar only

No ultrasonic echo

- check the transmitter sensor cone is clean

- check that the transmitter is vertical

- check that the transmitter seal is undamaged

- If the message persists, check the transmitter

is vertical on the tank.

- Note: If the oil level is within 8 inches of the transmitter this

message along with other messages may occur. Wait until

the oil level drops below 8 inches for accurate reading.

Almost empty

No Signal

No Echo

2

9-5170-07

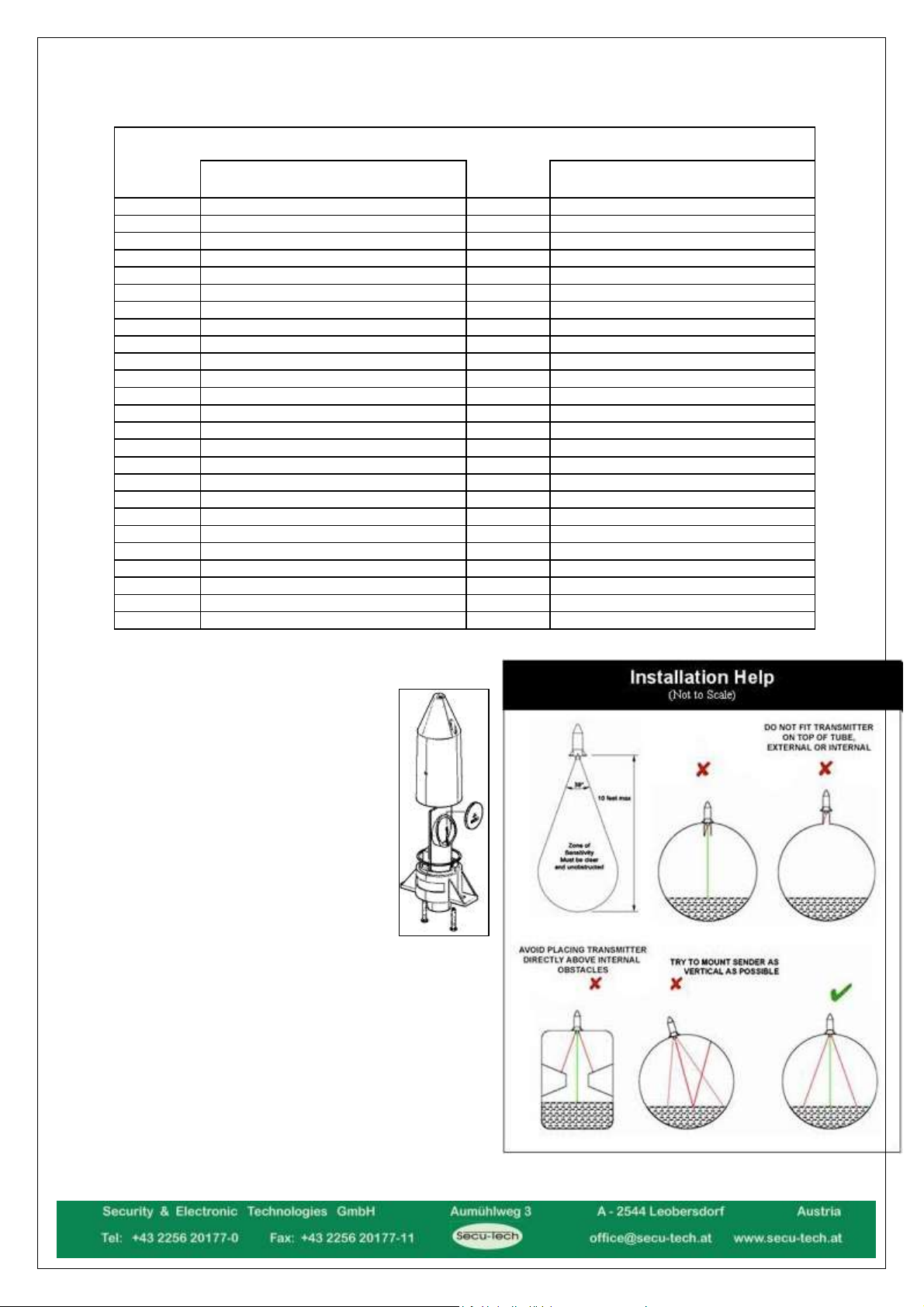

APOLLO ULTRASONIC RECEIVER MULTI SWITCH SETTING CHART

Measure the vertical height of the tank from the transmitter position on top of the tank to the bottom of the tank.

Read to the nearest measurement on the chart. Switch 1 on/up and enable the low level audible warning

Height of

tank in mm.

Set

Switch

es On

Height of

tank in mm.

Set

Switch

es On

500

1

1750

1,3,4,5,6,7

550

1,7

1800

1,2,8

600

1,6,8

1850

1,2,7,8

650

1,6,7,8

1900

1,2,6,7

700

1,5,7

1950

1,2,5

750

1,5,6

2000

1,2,5,7,8

800

1,5,6,7,8

2050

1,2,5,6,8

850

1,4,8

2100

1,2,4

900

1,4,6

2150

1,2,4,7

950

1,4,6,7

2200

1,2,4,6,8

1000

1,4,5,8

2250

1,2,4,6,7,8

1050

1,4,5,7,8

2300

1,2,4,5,7

1100

1,4,5,6,7

2350

1,2,4,5,6

1150

1,3

2400

1,2,4,5,6,7,8

1200

1,3,7,8

2450

1,2,3,8

1250

1,3,6,8

2500

1,2,3,6

1300

1,3,5

2550

1,2,3,6,7

1350

1,3,5,7

2600

1,2,3,5,8

1400

1,3,5,6,8

2650

1,2,3,5,7,8

1450

1,3,5,6,7,8

2700

1,2,3,5,6,7

1500

1,3,4,7

2750

1,2,3,4

1550

1,3,4,6

2800

1,2,3,4,7,8

1600

1,3,4,6,7,8

2850

1,2,3,4,6,8

1650

1,3,4,5,8

2900

1,2,3,4,5

1700

1,3,4,5,6

3000

1,2,3,4,5,6,8

Battery removal

Remove the transmitter unit from the tank and

take it to a safe location.

The battery can be accessed by removing 2

self-tapping screws from the base of the unit.

See sketch.

Remove the old battery noting the orientation

(‘+’ mark facing outwards), and replace with a

new battery. 3V-CR2430.

Re-assemble, ensuring the O-Ring is

undamaged and secured in position.

Re-locate the transmitter on the tank.

No Need to Rematch

Specifications

Tank Depth measurement:

Minimum depth: 0.1 m, Maximum depth: 3 m

Max communication distance:

200m in normal ‘line of sight’ conditions

Power Supply:

Receiver: 150-250V, 50-60Hz, Meets EN60335

Transmitter: 3-volt lithium cell

Battery life:

10 years (estimated life)

Wireless communications:

433 mHz.FM transmission, EN 300-220

Max and Min Operation Temp (Transmitter):

Operating temperature range -10° - +60°C.

Not Suitable for pressurised containers. Use on tanks vented to

Atmosphere.

Rights for Austria, Germany Switzerland by Secu-Tech.

Loading...

Loading...