Page 1

GL-1 Gate Lock

Installation Instructions and

Operating Manual

1

500-22090, Rev A

Page 2

Table of Contents

Table of Contents..............................................................................................2

Specifications.....................................................................................................3

Physical.......................................................................................................... 3

Electrical.........................................................................................................3

Product Overview..............................................................................................3

Product Features:.....................................................................................3

Product Components........................................................................................4

Recommended Tools........................................................................................4

Installing the GL1 Electromechanical Gate Lock..........................................5

Perform a Pre-Installation Survey..............................................................5

Perform the Cylinder Lock/Cover Hole Plug Installation.........................8

Mount the GL1 and Connect the Electrical.............................................10

Complete the GL1 Installation...................................................................13

Operating Instructions....................................................................................13

Troubleshooting............................................................................................... 14

®

MagnaCare

Lifetime Replacement Warranty............................................15

2

500-22090, Rev A

Page 3

Specifications

Physical

Holding Force 2,000 lbs [907 kg]

Preload Up to 100 lbs (Fail Locked only)

Dimensions 2 ¾” L X 7 ¼” H X 3 ¼” D

[70 mm L X 184 mm H X 83 mm D]

Electrical

12 VDC Current Requirement Initial (Peak): 870 mA (~ 1 sec)

Reduced: 290 mA

Power Consumption: 3.5 Watts

24 VDC Current Requirement Initial (Peak): 720 mA (~ 1 sec)

Reduced: 170 mA

Power Consumption: 4.1 Watts

Operating Temperature –58 to +167°F [–50 to +75°C]

Product Overview

The GL1 Electromechanical Gate Lock is designed to secure a wide

variety of vehicle and pedestrian gate applications where security and

weather resistance are required. The GL1 functions equally well in both

electrically and manually operated gate installations and can be used for

swing gates, sliding gates, stock cage gates or other applications.

Product Features:

• 2000 lbs holding force

• Operates under preload up to 100 lbs.

• Automatic dual voltage—no field adjustment required

• Manual key override (right or left hand)—Fail Locked only

3

500-22090, Rev A

Page 4

• Self-aligning receiver (up to +/- 1/2" horizontally or vertically)

helps compensate for gate misalignment and sag

• Tamper proof cast housing

• Latch status monitor switch (SPDT)

• ½”-14 NPSM inside pipe thread

• Surface Mount

• Black finish

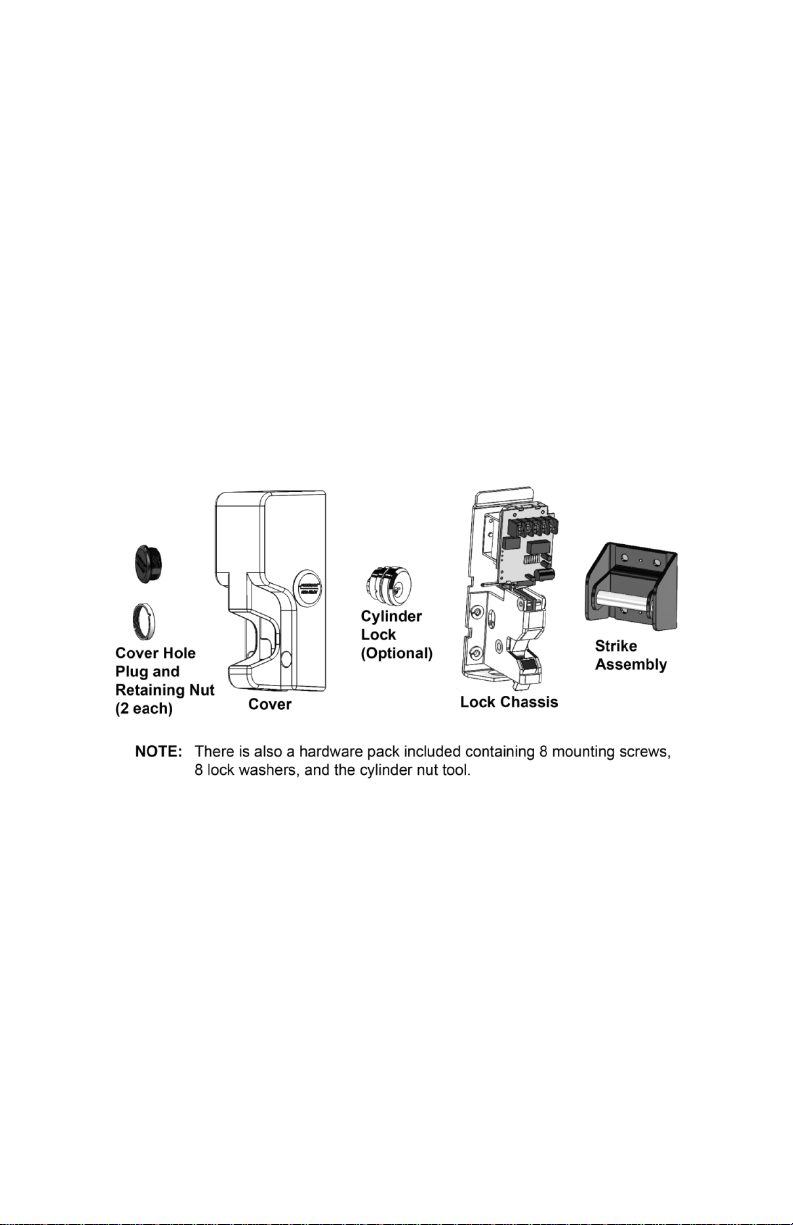

Product Components

Upon unpacking this product, an inventory should be made to

ensure that all the required components and hardware have been

included. Along with these instructions and the installation

template, the lock assembly should include the following items:

Recommended Tools

Hammer Screwdriver, #2 Phillips

Center Punch Hex (Allen) wrench, 3/16” [5 mm]

Drill Bits: 5/16”, 3/8”, ½” Tap, ¼”-20 UNC [M6-1.0]

4

500-22090, Rev A

Page 5

Installing the GL1 Electromechanical

Gate Lock

Installation Concerns

CAUTION: It is vital that all welding be completed prior to

making any electrical connections to the mounted

GL1. Welding in or around an electrically-connected

lock assembly can cause damage to the electronic

components.

• Installation should be performed by a qualified service person, who

conforms to all local codes and complies with The National Electrical

Code (or equivalent).

• The FMK-SL (Sliding Gate) and the FMK-SW (Swing Gate) mounting

bracket kits are recommended for installing the GL1.

• The GL1 must be mounted in the upright vertical position with the

conduit opening on the bottom.

• The GL1 should not be used for dual swing gates.

Perform a Pre-Installation Survey

Due to the variety of mounting configurations available with this product,

it is strongly recommended that an initial physical survey and

assessment be made of the actual area where the lock will be installed to

determine the optimal method of mounting prior to installation. The

following should be considered:

• Physical strength of mounting areas

structural integrity of mounting surfaces be strong enough to meet or

exceed the holding force of the lock.

• Protection of the lock from external attack

must be protected to a reasonable degree from potential damage

due to intruders or vandals.

• Convenience and accessibility of area to be protected

: It is recommended that the

: The lock and the wiring

: The lock

5

500-22090, Rev A

Page 6

assembly should be installed in a location that will not hinder or

create a potential safety hazard to authorized personnel routinely

accessing the protected area.

Because of the diversity in gate construction and installation

configurations, optimum mounting platforms may be achieved by welding

adequate size metal plates, channels or tubing to the fence frame and

the gate. Formed angle and brackets along with appropriately sized

fasteners may also be utilized to mechanically secure mounting

platforms for the lock and strike.

Figure 1, “Swinging Gate Mount,” Figure 2, “Sliding Gate Mount,” Figure

3, “Installation Spacing Dimensions,” and Figure 4, “Chassis Welding,”

show some basic mounting configurations on a chain-link style fence

frame and gate.

Figure 1. Swinging Gate Mount

Figure 2. Sliding Gate Mount

6

500-22090, Rev A

Page 7

Figure 3. Installation Spacing Dimensions

Figure 4. Chassis Welding

7

500-22090, Rev A

Page 8

Perform the Cylinder Lock/Cover Hole Plug

Installation

NOTE 1: The GL1 provides for the additional function of an optional key-

operated cylinder lock. The cylinder lock can be installed to

either side of the lock cover, because the GL-1 lock latching

mechanism features an actuator lever that will engage the

cylinder lock from either side.

NOTE 2: IF the cylinder lock is not

(provided) must be installed on both sides of the cover.

1. SELECT the side of the lock cover that will be the most convenient

for the key access after installation if installing the optional manual

override.

2. INSTALL the optional cylinder lock.

NOTE: The following step is critical to the proper operation of the

mechanical override. The cam of the cylinder (“MS” type)

must come into contact with the actuator lever pin to

operate the release trigger of the lock mechanism when

the cover is assembled to the lock chassis.

a. ASSEMBLE the cam, as necessary, so that the key rotation

moves the cam to point toward the rear (opening) of the cover.

b. INSERT the cylinder lock with applicable spacer (i.e., Sargent

Number 90) into the applicable cover hole (see table below and

Figure 5, “Cylinder Lock Installation”).

Size of Cylinder Lock Spacer Required

1” ¼”

1 1/8” 3/8”

used, THEN a cover hole plug

8

500-22090, Rev A

Page 9

Figure 5. Cylinder Lock Installation

c. SLIP the spacer over the cylinder lock and INSERT the cylinder

lock into the applicable side hole on the lock cover.

d. SLIP the lock mounting nut over the cylinder lock inside the

cover and THREAD the nut onto the lock body by hand.

e. TIGHTEN to secure the nut in place using the provided cylinder

nut tool.

f. INSTALL a cover hole plug in the opposite side of the cover, and

SECURE its retaining nut using the provided retaining nut tool.

NOTE: The following steps are performed if the cylinder lock is not

used.

3. INSTALL the two cover hole plugs (provided) through both sides of

the cover (see Figure 6, Cover Hole Plug and Retaining Nut”).

4. SECURE the cover hole plugs in place using the retaining nuts and

provided cylinder nut tool (see Figure 6, “Cover Hole Plug and

Retaining Nut”).

9

500-22090, Rev A

Page 10

Figure 6. Cover Hole Plug and Retaining Nut

Mount the GL1 and Connect the Electrical

NOTE: The FMK-SL (Sliding Gate) and the FMK-SW (Swing Gate)

mounting bracket kits are recommended for installing the GL1.

1. IF not using one of the recommended mounting bracket kits,

THEN USE the included template to locate and install mounting

hardware.

2. INSTALL the lock chassis using the top two lock chassis mounting

positions.

NOTE: The following chart shows wire gauge sizing versus voltage

versus distance:

Distance Gauge 12V Gauge 24V Distance Gauge 12V Gauge 24V

100 FT 20 GA 22 GA 800 FT 12 GA 14 GA

200 FT 18 GA 20 GA 1500 FT 10 GA 10 GA

400 FT 14 GA 16 GA 2000 FT 8 GA 8 GA

10

500-22090, Rev A

Page 11

3. ROUTE all electrical wiring through either the provided wire conduit

coupling in the bottom of the lock chassis or through the ½” [12.7

mm] hole in the rear of the lock mounting chassis (see Figure 7,

“Wire Routing”).

4. FEED wires through the hole in the side of the lock chassis opposite

to the cylinder lock, if installed.

5. IF there is no cylinder lock installed,

THEN FEED wires through either side of the lock chassis (see

Figure 7).

Figure 7. Wire Routing

6. CONNECT wires to the terminal block on the PC board (see

Figure 8, “PC Board Terminal Block,” and Figure 9, “System

Connections”).

11

500-22090, Rev A

Page 12

Figure 8. PC Board Terminal Block

Figure 9. System Connections

7. PERFORM a functional test of the GL1.

12

500-22090, Rev A

Page 13

Complete the GL1 Installation

CAUTION: Lock cover must be installed straight on to avoid

possible damage to the PC Board.

1. INSTALL the lock cover over the lock mounting chassis by placing

the cover straight on and then sliding to engage.

2. SECURE the cover to the mounting surface using two (2) socket

head cap screws and two (2) split lock washers.

3. PLUG conduit fitting if not used, welding the plug for maximum

security.

Operating Instructions

The Gate Lock is a direct- latching fail safe/locked

electromechanical lock which incorporates

voltage system. The GL1 does not automatically

re-lock if the strike

always be pushed closed to mechanically re-latch in order for the GL1

to re-lock.

is not moved from the latch. The s trike mus t

Securitron’s unique dua l

Fail Locked Version (GL1-FL):

volts DC, observing polarity (See

energize and unlock the Gate Lock allowing the gate to be

opened. Removing the input voltage will de-energize the Gate

Lock and will allow it to

is closed.

Fail Safe Version (GL1-FS):

to keep the Gate Lock in a locked

voltage will de-energize and unlock the Gate Lock allowing the gate

be opened. Applying input voltage will energize and lock the Gate

Lock awaiting the gate to

Additionally, the Gate Lock may include an optional gate status

sensing feature. When the gate

the Gate Lock will report this closed condition by outputting a

circuit condition between the C and NO terminals. When the gate is

open, there is an open circuit between the C and NO terminals. This

dry Single Pole Double Throw (SPDT) output can carry

VDC maximum.

be closed.

Applying input voltage of 12 or 24

Wiring diagram below), will

mechanically latch securely when the gate

The input voltage must be maintained

mode. Removing the input

(strike assembly) is latched closed,

closed

1 Amp @ 30

13

500-22090, Rev A

to

Page 14

Troubleshooting

PROBLEM: The lock does not latch.

▪

CHECK lock-to-strike engagement distance—strike may be

mounted too far away from the

▪

CHECK wire routing to ensure wiring does not impede the

function of the lock mechanism

or behind lock catch.

▪

ENSURE that there is power supplied to the unit and that the

lock is

wired correctly.

PROBLEM: The lock output does not report secure

condition.

▪

CHECK wiring to ensure wires are connected to the appropriate

terminals.

▪

CHECK status of lock/strike to verify that lock and strike are

physically latched.

▪

CHECK for damage to monitor lever.

PROBLEM: The lock does not release.

lock.

manual override/actuator lever,

▪

CHECK for excessive pre-load to lock—the gate l ock latching

mechanism is not designed to

of 100 lbs (Fail-Secure only).

▪

CHECK incoming voltage at the lock.

o

For fail locked models, electrical power is required to energize

and release the lock—VERIFY that there is power to the lock

and that the voltage being delivered is within the operating

specifications.

o

For fail safe models, electrical power is removed to deenergize and release the locking

the power to the lock has been terminated.

▪

CHECK wire routing to ensure wiring does not impede the

function of the lock mechanism

release under pre-loads in excess

mechanism—VERIFY that

manual override/actuator lever.

14

500-22090, Rev A

Page 15

PROBLEM: Cover does not fit on the lock.

▪

CHECK welding—If the lock chassis was welded to the mounting

surface; verify that there are

edge of the chassis back plate.

▪

CHECK wire routing to ensure that the placement of the wires is

not inhibiting the proper fit of

▪

Cover must be straight on and slid into position (DO NOT TILT).

no welds that extend beyond the

the cover to the lock chassis.

PROBLEM: Manual override does not work.

▪

CHECK cover to verify that the lock cover is fully seated and

securely fastened in place.

▪

CHECK mortise lock installation.

▪

VERIFY that the compatible cylinder lock is correctly installed

and functions

CHECK rotation direction.

▪

Check wire routing to ensure that the placement of the wires does

not impede the rotation of

mechanism.

▪

CHECK that the GL1 is being used in Fail Locked mode—manual

override does not work in Fail Safe mode.

If any problem persists, call Technical Support at

properly— REVIEW i nstallation in structions and

the cam or movement of the latching

1-800-624-5625 (toll free).

MagnaCare® Lifetime Replacement

Warranty

MagnaCare is the industry’s best warranty, and covers every product

manufactured by Securitron. No registration is required. Product will be

replaced forever, for any reason, including but not limited to installation

error, vandalism, or act of God. Replacement product is shipped the

next day at Securitron’s expense if needed.

For more information, visit www.securitron.com

15

500-22090, Rev A

Page 16

Securitron

10027 S. 51st St. Ste 102

Phoenix, AZ 85044

Tel: 1-800-624-5625

Mon-Fri: 6:00am - 4:00pm PDT

Fax: 1-800-232-7329

s

e

c

uritr

o

n.c

o

m

16

© 2014, Hanchett Entry Systems, Inc., an ASSA ABLOY Group Company.

500-22090, Rev A

Loading...

Loading...