Page 1

Securitron Magnalock Corp. www.securitron.com ASSA ABLOY, the global leader

Tel 800.624.5625 techsupport@securitron.com

in door opening solutions

SECURITRON SERIES TSB TOUCH SENSE BAR

INSTALLATION AND OPERATION INSTRUCTIONS

1. DESCRIPTION

Securitron's Model TSB is an exit device for doors secured by magnetic locks. The assembly consists of an

aluminum bar available in lengths to fit on standard U.S. door openings: (36", 42", and 48"),

Polycarbonate end pieces to mount the bar on the door, and an electronic touch sensor mounted within

the bar. Fasteners for metal doors are included. For through door mounting please call factory for a nocharge TSB-TDM kit. Note that US type or metric fasteners are supplied depending of the version of

the bar which has been ordered. The metric version part numbers include the suffix: “M”. When the bar

is touched, a relay in the sensor is tripped, releasin g the lock. The bar's sensitivity is adjustable. In the

unlikely event of sensor failure, a push sw itch is mounted on the back side of the bar. Depressing the

switch has the same effect as activating the sensor by touch and therefore represents built in safety

redundancy. The TSB cannot be used outside in rain conditions.

As the TSB is normally used to allow egress on an electrically secured door, make sure that you

are complying with applicable building codes for your area. Check with your local building

department and/or fire prevention department.

2. PHYSICAL INSTALLATION

2.1 MOUNTING HOLE MARKING

The first step is to plan and mark the mounting hole positions. Be sure that you have the correct length

bar for the door and begin by removing the screws that secure the end caps on both ends of the bar. If it

appears that the bar is longer than it should be for the door, see Section 2.6 for cutting instructions.

Note which end has the sensor (circuit board) in it. This is the end that should be mounted on the

hinge side for easiest wire exit from the door.

For mounting hole drilling, we supply a template located at the end of t his instruction manual, alth ough it

is generally preferable to hold the bar in position and use it as a “self-template.” The templates are

particularly valuable if door preparation is to be done in advance. In setting your mounting holes, there

are three concerns:

They must be level or the bar will be tilted.

They must be the correct distance apart.

They must be correctly placed “left/right” on the door.

Leveling is best done by use of a carpenter's leve l. If one is not available, measure from the mounting

hole positions on each edge of the door to the door bottom. This is not as effective as it assumes that the

door is level which is not always true. N ote that in general, US building codes require the height of the

bar above the door bottom to be between 30 and 44 inches.

If the bar is used as its own template, you w ill automatically get correct separation between the mounting

holes. If you use the templates, note that there is a line drawn on each template which must line up with

the outer edge of the plastic end pieces on the bar. After you've mounted the templates, hold up the bar

to make sure the end piece lines up to get the correct distance.

Left/right placement on the door is an important point. In most installations, the bar should be centered

on the door. This produces the most attractive result. However, if the door has a vertical door stop on

the edge that swings open, you may need to shift the bar somewhat towards the hinge side to avoid

scraping the stop when the door opens. You should always experi mentally posi tion the bar on t he

door and open the door to see that there is no interference. Finally, if the installation is on an

aluminum frame glass door, make sure you don't position the bar so that the mounting screws go into the

glass. On standard doors, keeping the mounting holes at least 3/4" (19 mm) from the inner edge of the

aluminum will be safe.

2.2 MOUNTING HOLE DRILLING

There are three different procedures depending on the door type. Hollow metal doors employ supplied

machine screws and “blind nut” fasteners. This method leaves the outside of the door unaffected. Longer

machine screws and sex bolts may be used on hollow or solid wood doors, solid metal doors , or chalk filled

fire doors, the TSB-TDM kit for this type of mounting can be ordered from the factory at no-charge. With

this method, the sex bolt heads do show from the outside of the door. Note that the Touch Sense Bar

may not be used on a fire rated door that requires a fire rated latch (the TSB has no latch), but

sometimes fire doors are used on openings where a fire rated barrier is not required, because the

customer has selected this door type for other reasons (such as solidity). The third method is to use wood

screws (not supplied) on a solid wood door. By “solid wood”, we mean hardwood interior rather than

© Copyright 2012, all rights reserved PN# 500-16410

Page 1 Rev. E, 02/12

Page 2

pressed wood as the wood needs enough structural integrity to hold w ood screws. This method is strong

and simple and has the advantage of not showing sex bolts heads from the outside of the door.

For a hollow metal door, drill four 3/8" (9.5 mm) diameter holes only deep enough to get through the

inner side of the door- not completely through the door.

For through bolt mounting on various door types, drill four 1/4" (6 mm) holes completely throu gh the

door. For this type of installation (which may also be elected for a solid wood door) you will be using

screws and finishing sex bolts suitable for a 1 3/4" (44 mm) thick door supplied in the TSB-TDM kit.

Nearly all North American commercial doors are this thickness. If the doors you are working on are

different, you will have to purchase different len gth screws or apply some spacing techniques (described

later).

For a solid wood door, you may elect to mount the bar with wood screws (not furnished). We

recommend 2 3/4" (70 mm) #14 wood screws with a hex, pan, oval or round head. Drill four 3/16" (5

mm) diameter holes to a depth of 1 1/4" (30 mm).

2.3 WIREWAY HOLE DRILLING

The TSB connects to its power source and to the devices it controls via a six-conductor cable with push-on

connector (supplied). There are several different methods of getting this cable from the TSB to external

connection points. The first issue is whether the cable needs to enter the door (in which case a

wireway hole must be drilled in the door), or not. For most installations, it is preferred that the cable

enter the door. Exit from the door may be via the supplied door cord which may be mounted at the top of

the door where it is out of the way, or via any of many commercially available transfer hinges or pivots

(such as Securitron’s model EPT Electric Power Transfer or ELH Electric Hinge) which serve to route the

wiring off the door in a concealed manner. A wireway hole is th en drilled into the door in the position

shown on the template. It should be 3/8" (9.5 mm) in diameter. The cable is then pu lled into the door.

An alternate technique exists which does not route the cable into the door but which takes it directly

from the end piece to the frame via the door cord. This technique is preferred when the door type is

difficult to pull a wire through (such as any solid door). It is also a good technique when the frame is not

hollow as the door cord can route the cable directly from the end piece to a surface box mounted opposite

the end piece.

For the best security and appearance, you will not use the plastic door cord terminator when you route the

cord into the end piece. You will drill a hole in the plastic end piece. The hole should be dri lled through

the bottom flat of the end piece on the hinge side. The ideal hole size is 23/64" (9.1 mm) but as this drill

size is unusual, 3/8" (9.5 mm) also works. On the next page, a drawing appears to the right which shows

you hole location in the end piece. Note that this drawing shows the end piece you would select if the

hinge side of the door was on the left. If it's on the right, u se the other end piece but still locate the hole

at the inner, rear corner. With this method, the door cord is used to route the cable directly from the end

piece to the frame.

2.4 WIRE ROUTING

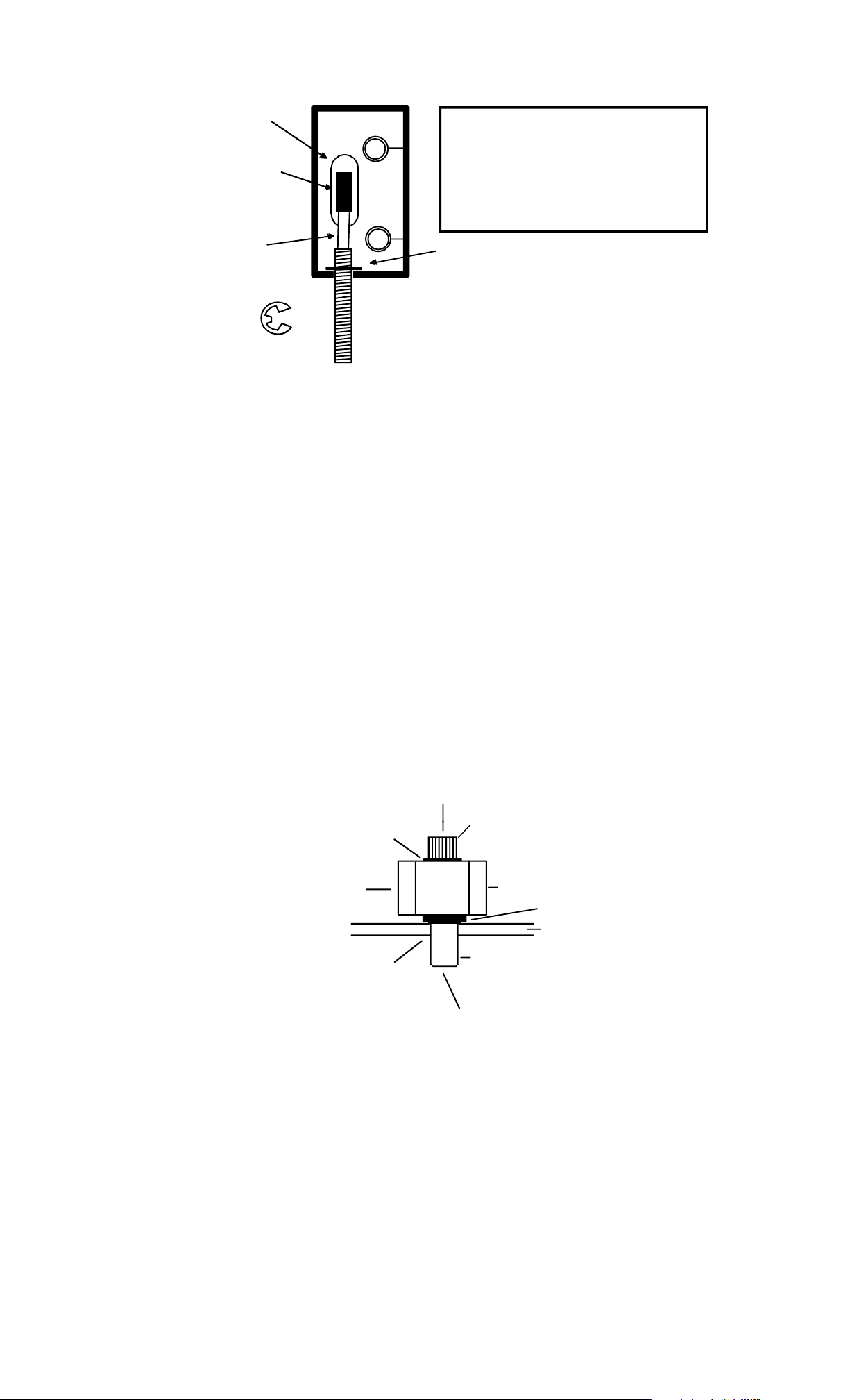

If you elect the method of wire routing which uses a hole in the end piece (see drawing below), you must

route your cable through the end piece prior to mounting the end piece to the door. This is

because the flat cable connector will not pass through the hole you h ave drilled in t he end piece. Begin by

threading the cable end without the connector down through the elongated slot in the end piece (the

slot is directly under the circuit board). From there, route it through the drilled hole in

the end piece. Begin by threading the cable end without the

connector down through the elongated slot in the end piece (the slot

is directly under the circuit board). From there, route it through the

drilled hole in the end piece so th at it exits the end piece. Next pass

the stainless door cord over the cable and slide it until you can push it

into the hole you have drilled in the end piece. Secure the stainless

cord inside the end piece with the supplied ”E” clamp. See Figure 1.

It shows this assembly for the end piece you would use for a door with

hinges to the left. If the hinges are on the right, use the opposite end

piece. The drawing will be “reversed” but the concept is unchanged.

Note that if you are mounting to a surface box, a second “E” clamp has

been supplied so that you can simply drill a hole in the box and secu re

the stainless cord from the inside with the second “E” clamp. If the

frame is hollow, you would employ the plastic door cord terminator

BOTTON VIEW OF

HINGE SIDE END

PIECE. DRILL 23/6

OR 3/8" HOLE AS

SHOWN, ABOUT

3/16" IN FROM

EACH EDGE.

when you mount the other end of the door cord to the frame. You are

now ready to mount the bar to the door.

PN# 500-16410

Page 2 Rev. E, 02/12

Page 3

FIG. 1: REAR VIEW OF END PIECE SHOWING CABLE ROUTING THROUGH END PIECE

ELONGATED SLOT

RECOMMENDED TOOLS

MEDIUM, SMALL PHILLIPS DRIVERS

CABLE CONNECTOR

WHICH ATTACHES

TO CIRCUIT BOARD

DRILL MOTOR

1/4", 3/8, 1/8" DRILL BITS

WIRE CUTTER/STRIPPER

VOLT/OHM METER

CRIMP CONNECTORS AND PLIERS

6 CONDUCTOR

JACKETED CABLE

"E" CLAMP

STAINLESS DOOR CORD INSERTS

"E" CLAMP INSTALLED TO

SECURE STAINLESS CORD

INTO HOLE DRILLED IN BOTT OM

OF END PIECE. SECURES WITH

"E" CLAMP

If you are using the preferred method of pulling the cable through the door, the cable must be inserted

into the 3/8" wireway hole you have drilled in the door. Th e connector will be left protruding from this

hole. The connector will pass through the elongated slot in the end piece, so the cable should be pulled

first and then the bar may be mounted. If you are using the door cord rather than a transfer hinge or

pivot to bring the cable from the door into the frame, remember that you must pass the cable through the

cord before fishing it into the frame.

Note that if, for any special reason, y ou find it desirable to pull the cable through the bar, this must not

be done. The cable must always exit the bar at the end piece which includes the circuit board.

If it goes through the bar, it creates electronic interference w ith the touch sensing function which voids

the performance of the bar.

2.5 BAR MOUNTING

The holes you have drilled for bar mounting (Section 2.2) were different depending on the type of door.

Similarly the final mounting procedure depends on the door type.

In the case of a hollow metal door, identify the four supplied blind nuts. The nuts are used as follows.

Insert the nuts with the knurl engaging the edge of each hole. Then utilize the supplied col lapsing tool to

collapse the nuts. Use of the tool is shown in Figure 2. Next, use the shorter (2 1/4" or 54 mm)) supplied

machine screws. Place a tooth washer under the head of each screw and mount the bar. Do not over

torque.

FIG. 2: COLLAPSING THE BLIND NUTS (METAL DOOR)

WHILE TURNING WITH ALLE N

WRENCH, PRESS IN TO KEEP

NUT SEATED IN DOOR

CAP SCREW

FLAT WASHER

HOLD WITH WRENCH OR

VISE GRIP WHILE TURNING

CAP SCREW

DRILL 3/8" (9.5MM) HOLE

PRESS IN BLIND

NUT AS SHOWN

TOOL

KNURL

DOOR

BLIND NUT

COLLAPSES WHEN CAP SCREW

TURNED WITH A LLEN WRENCH

WHILE TOOL HELD FAST

WITH BOX WRENCH

For through bolt + sex bolt mounting, you will be using longer 3 1/2" (90 mm) machine screws with

the sex bolts supplied in the TSB-TDM kit. You should have already drilled 1/4" (6 mm) holes th rough the

door. The next step is to install the sex bolts. From the outside of the door, enlarge the holes to 3/8"

(9.5 mm) diameter, 1" (25 mm) deep. Push in the sex bolts. Then place a tooth washer under the head

of each screw and mount the bar. Note that the screw length is suitable for a 1 3/4" (44 mm) thick door.

Nearly all North American commercial doors are this thickness. If you have a door of different thickness,

a number of techniques can be applied. Screws of different lengths can be purchased or the supplied

screws may be cut (if the door is thinner). Since the sex bolts are short, however, some final adjustments

may be necessary. Spacing washers may be added under the screw heads but if you raise the heads too

high they will interfere with removal of the circuit board (if this ever becomes necessary). The board can

still be removed but the mounting screws will have to come out first and this is inconvenient. Another

PN# 500-16410

Page 3 Rev. E, 02/12

Page 4

technique that is possible on solid doors is to recess the sex bolts into the door by using a 1/2" (12.5 mm)

counter bore.

In the case of a solid wood door, if you have elected to use wood screws (not furnished), place a tooth

washer under the head of each screw and mount the bar. Figure 3 provides a visual reference for these

three methods.

2.6 CUTTING THE BAR

If the bar needs to be shortened to install properly, it can be easily cut in t he field. It must be cut from

the end which does not mount the sensor. Remove the end piece completely by unscrewing the two

self tapping screws that hold it to the bar. It is better to remove both end pieces so as to avoid damaging

the sensor circuit board by metal filings. Note that when you remove the second end piece which carries

the sensor, the sensor will slide out easily with the end piece. There is, however, a ring terminal which

circles one of the end piece-to-bar mounting screws. This ring terminal is connected by a wire to the

circuit board. This connection is how the sensor “sees” the bar. When you reinstall the end piece, be sure

to reinstall the ring terminal.

FIG. 3: END VIEW SHOWING USE OF DIFFERENT FASTENING METHODS

THREE MOUNTING METHODS DEPENDING ON DOOR TYPE

SOLID WO OD DOOR

WITH WOOD SCREWS

SELECTED

2 1/4" (57MM)

MACHINE

SCREW

METAL DOOR

THROUGH BOLT

+ SEX BOLT MOUNTING

BLIND NUT

3 1/2" (90MM)

MACHINE

SCREW

NOTE: ALWAYS PUT TOOTH

WASHER UNDER SCREW HEAD

SEX

BOLT

2 3/4" (70MM)

WOOD SCREW

Cutting is ideally performed by a band or cut-off saw to produce a neat result. However, with care, a

hacksaw can be used. The cut need not be perfect because the bar “pockets” into the end cap. This hides

a poor cut from viewing from the front. The rear of the bar is not pocketed, however, and if the bar is

being mounted on an aluminum frame glass door, a sloppy cut will be apparen t from the outside and will

worsen the appearance of the installation.

3. ELECTRICAL CONNECTIONS

3.1 SPECIFICATIONS

Power Supply:

Voltage – 12/24VDC

Current – 50 milliamps at rest (not being touched) and 12 milliamps while operating (being touched)

Relay Contacts:

Maximum 2 amps @ 30VDC

3.2 SENSOR WIRING

The TSB has 6 colored wires which are for sensor power and DPST relay output:

Red – “+” DC Power

Black – “-” DC Power

White - Relay Common, Pole 1

Green - Relay Normally Closed, Pole 1

Blue - Relay Common, Pole 2

Orange - Relay Normally Open, Pole 2

The cable connector is plugged into the male connector on the circuit board so that the cable routes

directly back into the end piece. When the bar is touched, the relay changes state. For additional safety,

the operation of the TSB is fail safe, itself. When the TSB receives power, its control relay

automatically energizes. It de-energizes when the unit is touched. For releasing a magnetic lock, the

PN# 500-16410

Page 4 Rev. E, 02/12

Page 5

_

_

T

following drawing (Figure 4) shows typical connections of sensor, power supply and fail safe (released

when powered) lock. Fail secure electric locks are normally not permitted for use with the TSB on

required exit applications. NO contacts, however, are available from the sensor for special signaling

applications and for integration with the Request to E xit (REX) f unct ion of an access con trol in stallat ion, as

will be explained. Note installation of th e MOV in para llel with th e elect ric lock. The M OV is su pplied lo ose

with the TSB. It is a black or blue disk-like component with two bare wires for connection. The MOV acts

to suppress the lock’s inductive kickback which will greatly shorten the life of the relay contacts if not

suppressed. To work properly it should be spliced in as close to the electric lock as possible. It has no

polarity. If, however, Securitron's Magnalock is used in the installation, the MOV is not

necessary as the Magnalock is internally suppressed.

FIG. 4: TSB WIRING FOR MAGNETIC LOCK

CABLE

CABLE

RED (+ POWER)

BLACK (- POWER)

WHITE (RELAY COM1)

GREEN (RELAY N.C.1)

TSB WIRING FOR ONE MAGNETIC LOCK

RED (+ POWER)

BLACK (- POWER)

WHITE (RELAY COM1)

GREEN (RELAY N.C.1)

MOV

MOV

+

_

MAGNETIC

LOCK

+

+

_

MAGNETIC

LOCK

+

POWER SUPPLY

12-24 VO LTS

POWER SUPPLY

12-24 VO LTS

CABLE

RED (+ POWER)

BLACK (- POWER)

WHITE (RELAY COM1)

GREEN (RELAY N.C.1)

SB WIRING FOR MULTIPLE MAGNETIC LOCKS

MOV

_

MAGNETIC

LOCK

+

NOTE 1: MOV NOT NEEDED IF SECURITRON MAGNALOCK USED

NOTE 2: POWER SUPPLY MUST ALWAYS CONNECT DIRECTLY TO SENSOR

NOTE 3: IN POWER HOOK UP, POLARITY MUST BE OBSERVED

When connecting power, polarity must be observed. As an additional safety feature, the TSB

includes a low voltage sensing circuit. The unit will keep working normally if input voltage declines

until it reaches roughly 9 volts. At that point, the T SB will automatically act as if all power was remov ed.

If a lock is being controlled, it will release. Input voltage could decline if the unit was being operated on

batteries and the batteries were discharging or because of a fault in the power supply.

3.3 DOUBLE BREAK WIRING

Many installations include a controlled access device such as a digital keypad or card reader. Such devices

typically have a REX (request to exit) input. When dry contacts close on this input, the entry device will

open the lock for the same amount of time that is programmed for entry. Use of the REX input for exit

has two benefits: you pick up timed exiting and also in the case of most entry controls, the REX input

must be used for exiting to avoid an alarm condition at the door.

If the REX input alone is used for exiting a safety/reliability problem will exist. If the entry

device malfunctions, exit will not be possible and people may be trapped. We therefore always

recommend double break wiring which is supported by the TSB because of its two pole relay. The TSB's

NC contacts are used to break power to the fail safe electric lock while its NO contacts trip the RE X input

PN# 500-16410

Page 5 Rev. E, 02/12

Page 6

of the controlled entry device. This releases the lock a second time, hence the term, “double break”. If

the controlled entry device fails for any reason, direct exit is still possible.

3.4 ALL SECURITRON EQUIPMENT INSTALLATION

Figures 4 and 5 show “generic” use of the Touch Bar with any type magnetic lock and power supply.

Often, Securitron supplies all of these products and the installer expects an interconnection drawing for all

Securitron products. We provide such drawings in many of our manuals. In this case, the replacement of

the generic products shown above with Securitron products is so simple as not to require separate

drawings. Just note that for any Securitron Magnalock, the red wire denotes the “+” input and the black

wire denotes the negative. Remember that you don't need to install the MOV with any Securitron

Magnalock. Securitron offers a wide range of different power supplies, so it is necessary to consult the

individual power supply manual to identify the DC output terminals. Then connect the power supply

outputs to the rest of the system as shown above.

FIG. 5: TSB DOUBLE BREAK WIRING

POWER SUPPLY

CABLE

RED (+ POWER)

BLACK (- POWER)

WHITE (RELAY COM1)

GREEN (REL AY N. C.1 )

BLUE (RELAY COM2)

ORANGE (RELAY N.O.2)

NC

NC

ACCESS CONTROL

LOCK CONTROL

MOV

MAGNETIC

12-24 VOLTS

+

LOCK

NC CONTACTS

ACCESS CONTROL

REX INPUT

3.5 ADJUSTING SENSITIVITY

With wiring completed, sensor adjustment should be set. Note that the sensor board has a potentiometer

on it accessible when the bar's end cap is removed (see Figure 6). The potentiometer has a small red LED

light installed in front of it that will aid y ou in adjusting the sensitivity. The potent iometer on the sensor

will increase sensitivity when turned clockwise and decrease it when turned counterclockwise. Turn the

pot clockwise without touching the bar with a small flat blade screwdriver until you see the red LED

light turn on; you should also hear the relay click off. In this condition , sensitivity is so high that the bar

is “sensing” all of the time. Slowly rotate the pot counter-clockwise until you see the red LED light turn off

(you should hear the relay click on) and then another 15 degrees counter-clockwise. This is generally a

good setting. Before replacing the end cap, experiment by touching the bar and observe that the lock

releases. Experiment with gloves if you expect that they will be used. You may want to increase the

sensitivity somewhat, but if you leav e it just below the point where it is cont inuously released, you risk a

condition where the unit will fail by being released all the time.

PN# 500-16410

Page 6 Rev. E, 02/12

Page 7

FIG. 6: END VIEW OF SENSOR/CIRCUIT BOARD

3.6 USE OF REDUNDANT (BACKUP) SWITCH AND LABELS

A red push switch is mounted on the rear of the bar. The purpose of this switch is to provide backup in

case of any malfunction or misadjustment of the sensor. Pushing the button breaks the connection

between the white (COM1) and green (NC1) wires just the same way as if the bar was touched. It

therefore provides a “hard” backup circuit break which will release the controlled fail safe lock. It does not

however affect the COM2 and NO2 circuit (blue and orange). If these NO contacts are being used, for

example, to provide REX input to an access control system, pushing the backup button will not achieve

this, but egress safety is maintained as with the switch mounted, there are two independent controls

which can release the door. In the event that the sensor fails, the butt on will still work.

A label is supplied which should be affixed to the bar (see drawing to

the right) to draw attention to the backup switch. Application of the label

is particularly important where people encounter the bar whom are not

familiar with it such as in a public occupancy. The label includes two

arrows owing to the uncertainty of which end of the bar it will be

mounted on.

A second label stating “PUSH TO EXIT” is also shipped with the bar. If

desired, this label can be affixed to the front center of the bar itself in

order to prompt users that the bar (rather than the door) must be pushed

EMERGENCY

RELEASE

BUTTON

to gain egress.

4. ELECTRIC LOCK SELECTION

Electric lock selection is important to obtain best results from the TSB. The product allows silent and

immediate egress without the mechanical action of traditional exit devices which require periodic

maintenance and replacement. Having no moving parts, the TSB possesses an extended operating life.

The product was designed for use with Securitron's Magnalock. The Magnalock secures the door

with magnetic force only and therefore has no possibility of jamming and thereby denying egress. The

Magnalock also has internal electronics which allow it to release very rapidly. When used with the TSB,

which is also a fast device, exit is immediate and th e impression a person exiting gets is that the door is

not locked at all. Other magnetic locks generally operate significan tly more slowly than the Magnalock.

This makes egress less convenient as a person must pause somewhat after touching the bar until the door

releases.

5. OPERATIONAL SECURITY CONSIDERATIONS

Typical use of the Touch Sense Bar provides free egress from the interior protected area. The electric lock

secures against unauthorized entry. It is of important concern that persons on the outside cannot activate

the bar from the outside. This is a common problem with other interior release devices. For instance, if a

panic bar with switch is used, it is possible to trip it from the outside if the intruder can introduce a coat

hanger in between the door and frame. Aluminum frame glass doors tend to allow this more than other

types. Similarly, microwave detectors used on the inside can sometimes be activated from the outside if

the door is vibrated strongly.

The Touch Sense Bar is more secure with respect to the outside. To assure this, however, the user must

be made aware of certain operational characteristics. The sensor functions by setting up an oscillating

electric field which conforms along any metal surface that contacts the sensor's antenna wire. In the

Touch Sense Bar it is the bar itself that carries the field. The electric field is disturbed by the near

proximity of ionized fluids within the body, which form a conductive mass. It is this mass that the bar

detects. As a proximity device the bar is sensitive to the closeness of the mass. For example, if a person

wearing gloves touches the bar with his finger tip, the door will generally not release. When the gloved

hand is wrapped around the bar in normal use, the door will release because the conductive mass of the

hand is in much closer contact with the bar.

PN# 500-16410

Page 7 Rev. E, 02/12

Page 8

The main security concern regarding outside entry is if a person could introduce a metal wire from the

outside and make metal to metal contact with the bar. The field could then propagate along the wire and

be activated by the intruder's hand. In practice, this is unlikely. The bar is anodized and therefore

insulated so it will not make contact with the wire. The intruder would have to scratch away the

anodization which requires both effort and knowledge. Also the field propagates weakly along a thin wire.

If, however, high security from the outside is critica l in the application, two steps should be tak en. First,

the sensitivity of the bar should be set as low as satisfies the exit performance requirements. Second, the

insulation on the bar should be increased by painting it. This significantly increases resistance to

scratching. Electrostatic (powder coat) paint is recommended for greatest toughness.

6. SENSOR REPLACEMENT

A: Remove the end cap on the sensor side. Remove the cable connector from the circuit board.

B. Remove the two screws that connect the end piece to the aluminum bar. Note that this will free the

ring terminal that is soldered int o the board on the pad marked, “bar”. This ring terminal is the way the

sensor makes contact with the bar. Slide the complete end piece out of the bar.

C: With the end piece now loose in your hand, push the circuit board farther into the end piece. The

direction is as if you were pushing it into the bar. There will be some resistance from the wires that

connect the backup switch to the circuit board. Push it only far enough to completely reveal the

rectangular body of the backup switch.

D: Unscrew the cap that holds the backup switch to the end piece. Push up the freed backup switch. Now

the complete sensor + backup switch can be slid away from the end piece by continuing to slide the board

in the same direction.

E: To install the new sensor assembly, reverse the procedure detailed above. But note that the wires that

connect the backup push button to the circuit board must be folded over in the center of the board- inside

of the potentiometer. If the wires are allowed to fold outside t he potentiometer, they will block access to

it and the board will not be able to slide fully forward.

PN# 500-16410

Page 8 Rev. E, 02/12

Page 9

APPENDIX A

TROUBLESHOOTING

PROBLEM- The door will not release when the bar is touched.

To monitor operation of the bar, it is quite easy to see the red L ED light indicator and hear the relay click

when the bar is touched. If the red LED does not turn on and you don't hear a click, try the backup

switch. If the door does not release from the backup switch, it is almost certain that the overall wiring of

the installation is at fault. If the door re leases from the backup switch, the general wiring is correct but

the sensor is not reading your touch. Make sure you understand section 3.5 on how to adjust sensitivity

of the bar. It may be set too low. Another fault could be that the sensor itself is not receiving 12-24 DC

power on the red and black wires. Check the power supply and, be sure the input polarity is correct.

Also, even if power is being applied on the red and black wires, it's possible that it's not getting into the

sensor. Check the connector block that plugs into the sensor card for loose wires. Finally, it is possible

that the ring terminal that connects the sensor to the bar itself has come loose. See Figure 6.

If the red LED does turn on and you can hear this click and the door does not release, try the

backup switch. If the door still doesn't release, the problem must be in the installation wiring as it is

nearly impossible to have a failed sensor relay and backup switch at the same time. Review your wiring

to make sure the sensor is correctly applied in the circuit. If you see the red LED turn on and you hear

the click but only the backup switch releases t he door, call the factory as the defect appears to be in the

relay contacts and the sensor will have to be replaced.

PROBLEM- The door remains released constantly

If you see the red LED turn on and hear a click when you touch the bar but the lock remains

released, the problem is probably in the wiring which should be reviewed to be sure the sensor is correctly

applied in the circuit. If you see red LED on and don't hear a click, the sensor is probably adjusted

too high (review section 3.5). Rotate the adjustment pot counter-clockwise while not touching the bar.

If this doesn't lock the door, some effect is probably keeping the relay de-energized all the time

(remember; the relay is energized when the lock is secure to maintain f a il safe operation).

The most likely cause for the relay to remain energized is that the sensor “sees” an overwhelmingly large

signal as if someone was continually touching the bar. This will happen if the bar is not properly isolated

from a metal door. Because of the plastic end pieces, the intrinsic isolation of the bar from t he door is

many times greater than it needs to be. Make sure that there is no “foreign object” creating a conductive

path from the bar to the door. An example would be metal blinds.

The same effect will occur if the bar is used o utside in the rain or if wa ter is flo wing down the in side of t he

door. This overcomes the electrical isolation needed between the bar and door.

Certain large electronic noise sources can “swamp” the sensor although this is rare. Examples would

include large radio or radar transmitters in the building or a high voltage neon sign mounted within a few

feet of the door. Call the factory if you suspect noise induced problems.

Finally, in very rare instances, the sensor can “hang up” in a condition that continuously releases the door.

De-power the unit and turn the adjustment pot all the way counterclockwise. Then, re-power the unit and

note that the door locks. Then, readjust the sensor potentiometer normally .

IF YOUR PROBLEM PERSISTS, CALL SECURITRON: 1-800-MAG-LOCK

MAGNACARE

LIMITED LIFETIME WARRANTY

Warranty information visit: www.securitron.com/en/site/securitron/About/MagnaCare-Warranty

PN# 500-16410

Page 9 Rev. E, 02/12

Page 10

TSB TEMPLATE

S

E

N

I

L

D

E

T

T

O

D

Do not photocopy

G

N

O

L

A

T

U

C

PN# 500-16410

Page 10 Rev. E, 02/12

Loading...

Loading...