Securitron EL-DSB-CL, EL-DSB-BK, DSB-BK, DSB-BKI, DSB-CL User Manual

...

ASSA ABLOY, the global leader in

door opening solutions

SERIES DSB DUAL SENSE BAR

INSTALLATION and OPERATION

INSTRUCTIONS

Securitron Magnalock Corp. www.securitron.com

Tel 800.624.5625 techsupport@securitron.com

© Copyright, 2011, all rights reserved PN# 500-22700

Rev. F, 03/11

Securitron Magnalock Corp. www.securitron.com ASSA ABLOY, the global leader

1X 4X

Tel 800.624.5625 techsupport@securitron.com

in door opening solutions

SECURITRON SERIES DSB DUAL SENSE BAR

INSTALLATION AND OPERATION INSTRUCTIONS

1. INTRODUCTION

The Securitron Dual Sense Bar (Model DSB) is an exit device intended for use on magnetically

locked, non-fire rated doors only. The bar will operate via mechanical movement (push) to

provide a primary egress function that does not require human touch in addition to function by

touch sense. The mechanical function has been included to simplify use and ease exit for

personnel with prosthetics or those who may otherwise have their hands occupied (e.g. carrying

boxes, manipulating carts, maneuvering wheelchairs, etc.). The assembly consists of an

aluminum bar available in lengths to fit standard U.S. door openings: (36", 42", and 48"). The

end mounts provide the mounting platform for the bar and house the electronic PC boards and

mechanical switching mechanisms within the bar.

2. SPECIFICATIONS

MECHANICAL ELECTRICAL

Physical Size:

Height: 3” [76mm]

Depth: 3” [76mm] (from mounting surface)

Overall Length:

36” Door = 34-3/16” [868mm]

42” Door = 40-3/16” [1021mm]

48” Door = 46-3/16” [1173mm]

Operating Force (Maximum): 15 Lbs. [66.7N]

Environmental (Recommended):

Temperature Range: 32ºF [0ºC] to

120ºF [49ºC]

Humidity: 10% to 90% RH

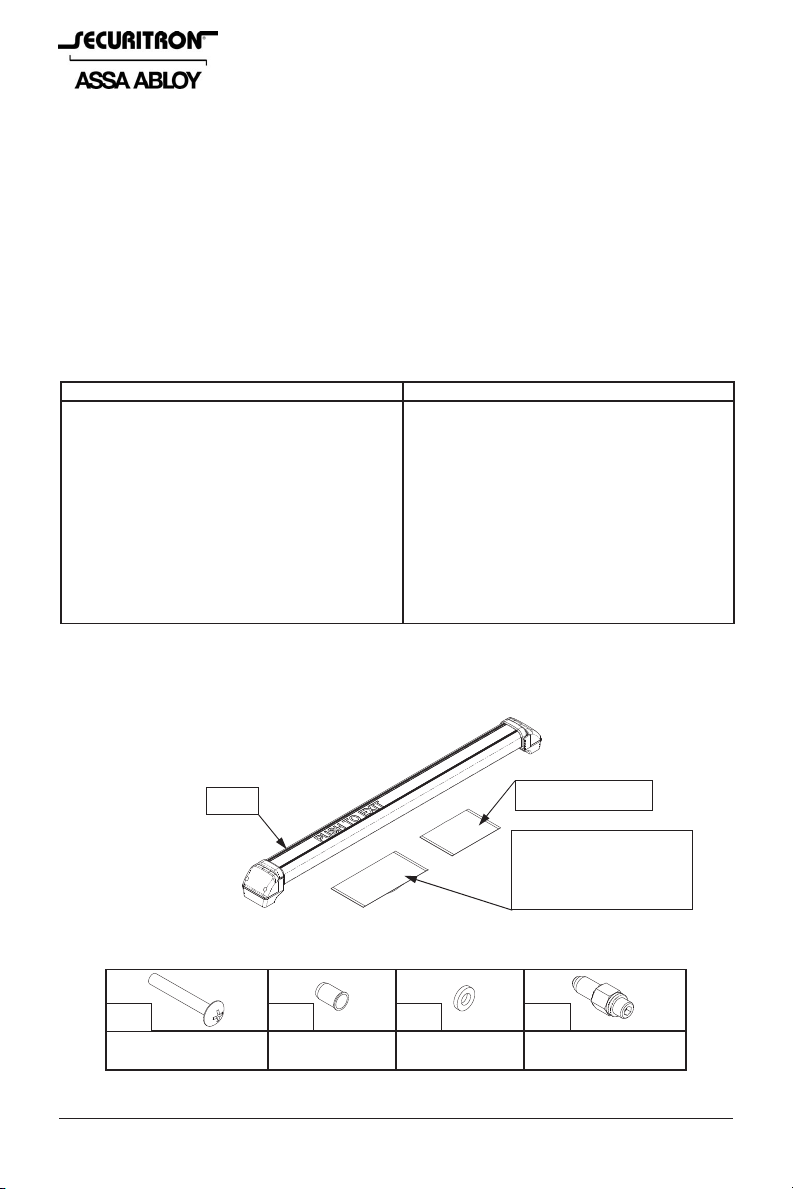

3. PRODUCT OVERVIEW

Upon unpacking this product, an inventory should be made to ensure that all the required

components and hardware have been included. Along with these instructions, the DSB product

should include the following items:

Voltage Input: 12 or 24 Volts DC

Current Draw (Base - At Rest): 24mA

(DPST) Contact Rating: 1 Amp @ both 12

and 24VDC

Illuminated Sign (Option): 20mA Maximum

(additional)

DSB Connection: 16-Foot [4.88 Meter] Wire

Cable with Traditional Connector

ELDSB Connection: Wiring Harness with

ElectroLynx Connector

DSB

Hardware Pack

Traditional Power

Cable (w/ TSB-C)

OR

ElectroLynx Harness

Figure 1

4. HARDWARE (U.S. STANDARD)

4X

Phillips Truss Head

Screw, 1-3/4” Long

4X

Blind Nut

Plastic Flat

Washer

Blind Nut Collapsing

Tool

© Copyright, 2011, all rights reserved PN# 500-22700

Page 1 Rev. F, 03/11

Fasteners for metal doors (aluminum frame and hollow steel) are included. For through door

mounting please call Securitron for a no-charge DSB-TDM kit. Note that US standard or metric

fasteners are supplied depending on the version of the bar which was ordered. (The metric

version part number for a DSB series bar will include the suffix “M”).

5. RECOMMENDED TOOLS

Bubble Level Power Drill

Hammer Pliers, Vise-grip

Center Punch

Wrenches:

1/2” Box-end (or Adjustable Wrench)

Drill Bits:

3/8” [9.5mm], 11/16” [17.5mm]

Screwdrivers:

#1 and #2 Phillips, 1/8” [3mm] Flat

Standard DSB Hex Wrench: 3/16”

Metric DSB Hex Wrench: 5mm

6. INSTALLATION INSTRUCTIONS

AS THE DSB IS NORMALLY USED TO ALLOW EGRESS ON AN ELECTRICALLY SECURED

DOOR, ENSURE THAT ALL APPLICABLE BUILDING AND FIRE CODES ARE BEING

FOLLOWED. VERIFY INSTALLATION WITH LOCAL BUILDING AND/OR FIRE

PREVENTION CODES AND REGULATIONS.

THE DUAL SENSE BAR MAY NOT BE USED ON A FIRE RATED DOOR THAT REQUIRES A

FIRE RATED LATCH! THE DSB HAS NO LATCH. IN SOME INSTANCES HOWEVER, FIRE

DOORS ARE ALLOWED ON OPENINGS WHERE A FIRE RATED BARRIER IS NOT

REQUIRED. USE OF THE DSB SHOULD ALWAYS BE VERIFIED AND APPROVED

THROUGH LOCAL BUILDING CODE AND/OR FIRE PREVENTION DEPARTMENTS.

6.1. BAR POSITIONING AND MOUNTING HOLE MARKING

Using a #1 Phillips screwdriver, remove the screws and the end caps from both ends of the bar.

Verify that the bar is the correct length for the door. If it appears that the bar is longer than it

should be for the door, see Section 6.6 for cutting instructions. Take note of which end has the

main (touch sense) PC board in it, this end has a ring terminal connecting the PCB to the bar

profile. This is the end that should be mounted on the hinge side for the most convenient wire

exit from the door.

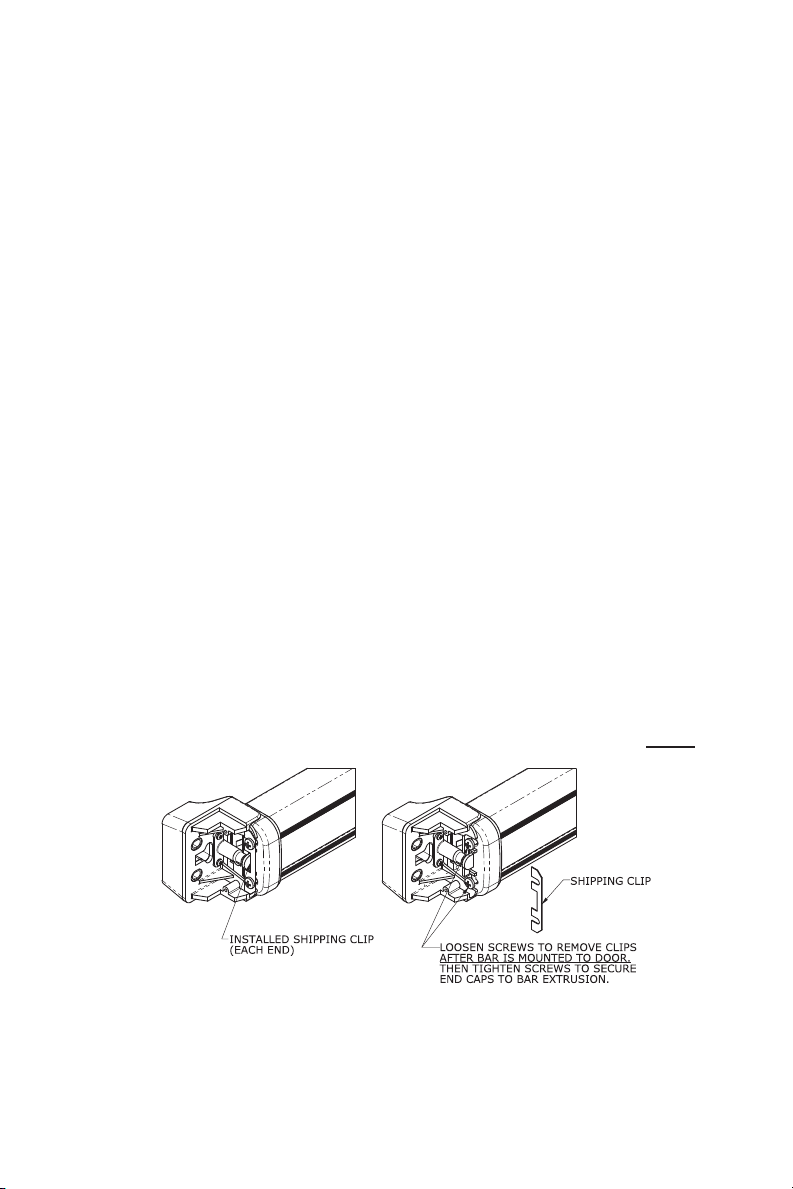

The DSB, as shipped from the factory, is assembled with shipping clips at each end that

temporarily hold the bar together while positioning and mounting the bar to the door (see

Figure 2).

FOR EASE OF INSTALLATION, DO NOT REMOVE THE SHIPPING CLIPS UNTIL AFTER

THE

BAR HAS BEEN MOUNTED.

Figure 2

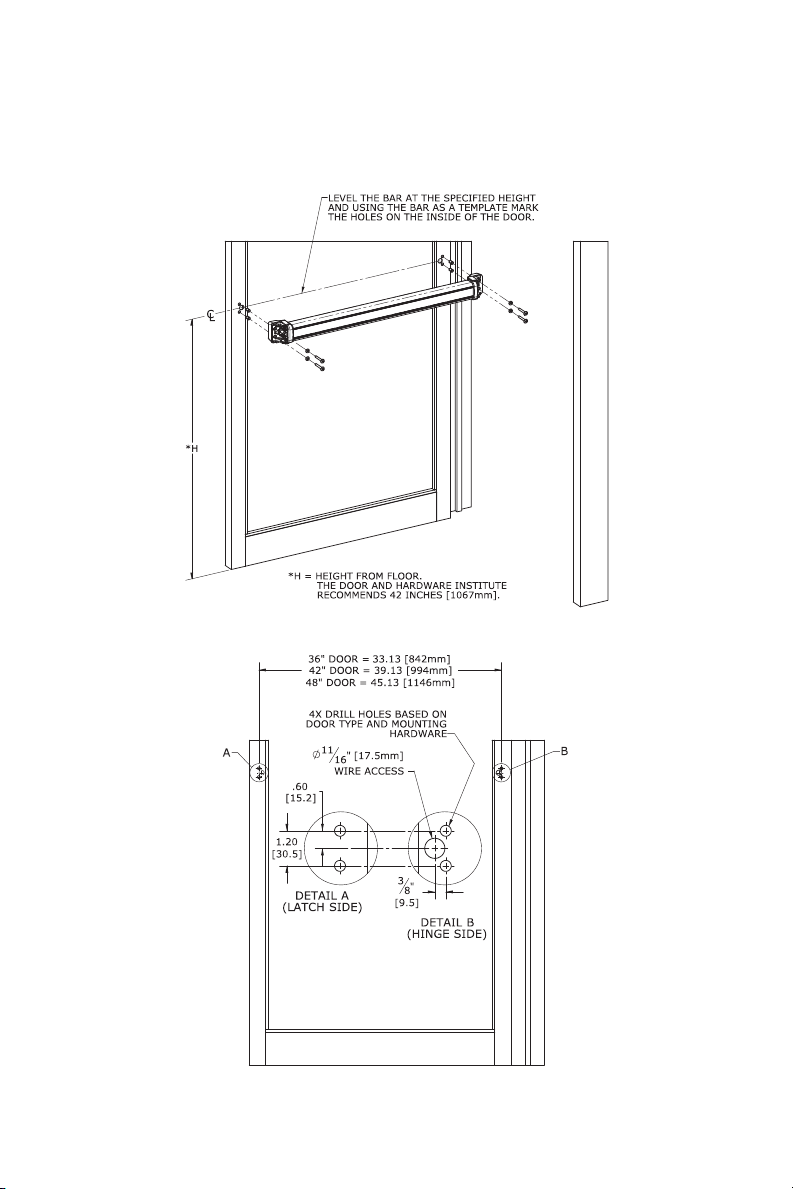

For best results, the assembled DSB itself may be used as a template to locate and mark the

mounting holes. When positioning the bar for marking the holes, ensure the following:

The bar is positioned at the correct height from the floor (see Figure 3).

Generally, US Building Codes require that the bar be located between 30 inches [762mm] and

44 inches [1118mm] from the bottom of the door.

PN# 500-22700

Page 2 Rev. F, 03/11

The bar is level.

The bar is centered on the door (left to right) between the door frame stops.

By using the assembled bar as a template, the correct separation between the mounting holes

will automatically be maintained. After marking the hole locations, verify that the centers of the

holes are at the required distance as shown in Figure 4.

Figure 3

Figure 4

PN# 500-22700

Page 3 Rev. F, 03/11

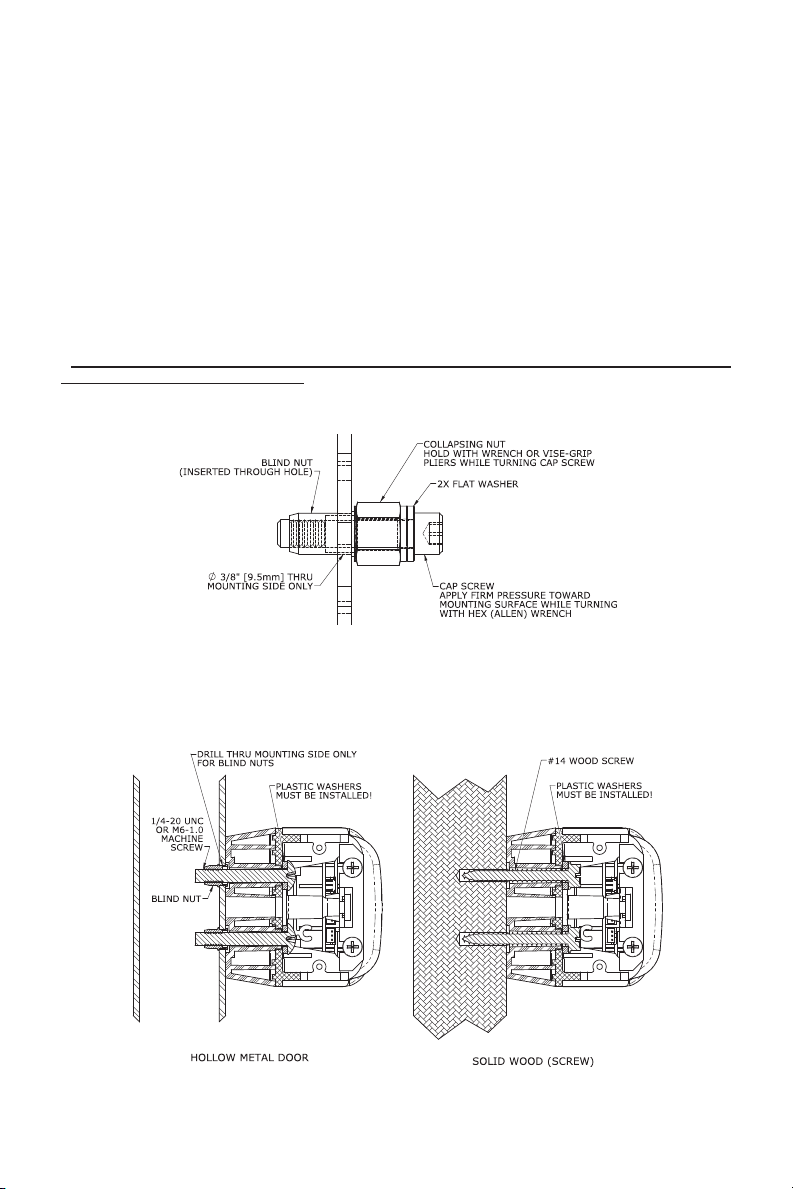

6.2. HOLLOW METAL DOOR PREPARATION

The bar should be mounted to the door using the blind nuts and screws provided as shown in

Figure 6. Use the following step-by-step instructions and Figure 5 for the installation of the

blind nuts:

a. Drill the four (4) 3/8” [9.5mm] diameter holes through the interior (mounting) surface of the

door at the previously marked hole locations. DO NOT drill completely through the door.

b. Insert one blind nut assembled to the installation tool into a mounting hole.

c. While holding the collapsing nut of the tool with a 1/2” box-end wrench, turn the socket head

cap screw using a 3/16” (or 5mm) hex wrench. Note: Maintain firm pressure toward the

mounting surface while collapsing the nut.

d. Once the blind nut is adequately collapsed, remove the tool from the installed nut by backing

the cap screw out of the blind nut.

e. Install all blind nuts by using the collapsing tool and repeating the previous steps.

f. After all blind nuts are installed, hold the bar in place over the blind nuts and secure into

place with the *plastic washers and mounting screws provided.

*THE PLASTIC WASHERS MUST BE INSTALLED UNDER THE SCREW HEADS FOR THE

DSB TO FUNCTION PROPERLY. ALSO ENSURE THAT THERE IS 1/32” CLEARANCE

BETWEEN EACH BAR END CAP AND THE INNER FLANGE OF THE BASE MOUNT BEFORE

FINAL TIGHTENING OF THE MOUNTING SCREWS.

Figure 5

6.3. SOLID WOOD DOOR PREPARATION:

The bar may be mounted using wood screws (not furnished). Four (4) #14 wood (or SMS)

screws with a hex head are recommended (see Figure 6).

Figure 6

PN# 500-22700

Page 4 Rev. F, 03/11

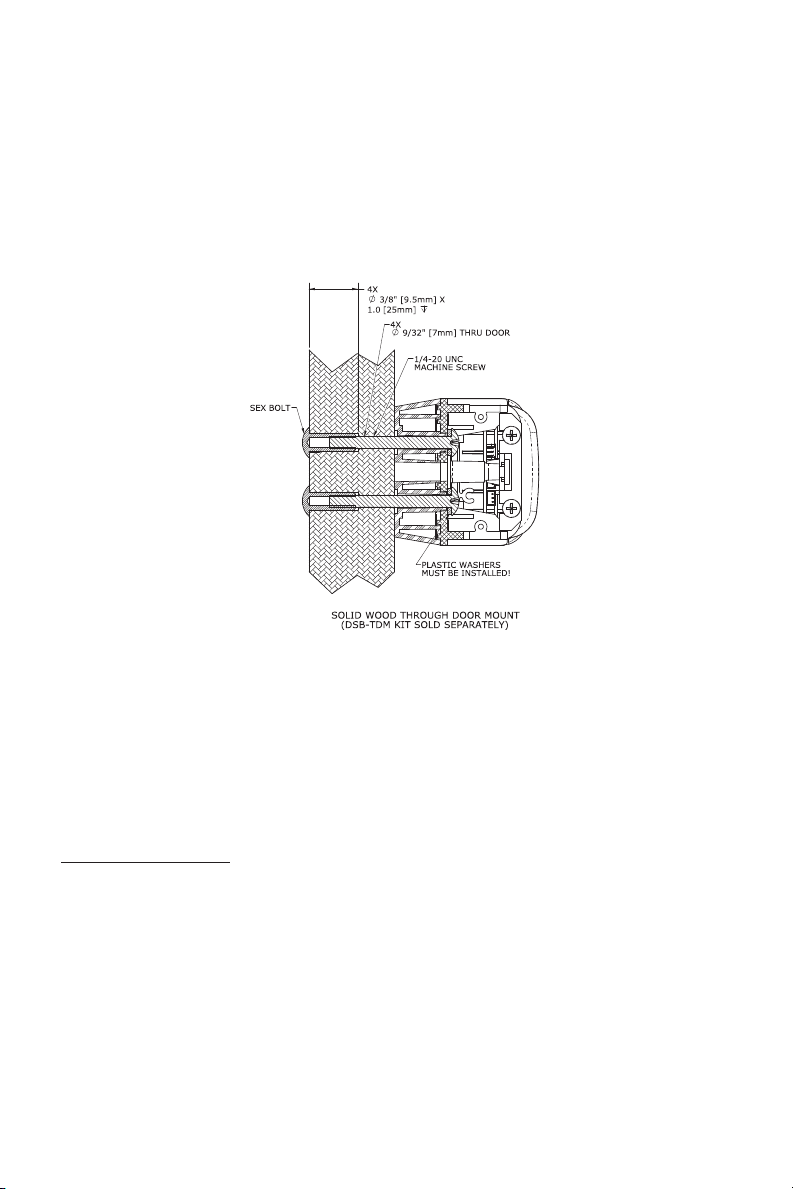

6.4. BOLT THROUGH DOOR PREPARATION:

For through-bolt mounting on various door types a DSB-TDM kit will be required (see Figure 7).

This product accessory is furnished separately and can be ordered from the factory at no charge.

This configuration may be used on solid wood doors, hollow or solid metal doors, or chalk filled

*fire doors. Please follow instructions included with the DSB-TDM kit for proper installation.

*THE DUAL SENSE BAR MAY NOT BE USED ON A FIRE RATED DOOR THAT REQUIRES A

FIRE RATED LATCH! THE DSB HAS NO LATCH. IN SOME INSTANCES HOWEVER, FIRE

DOORS ARE ALLOWED ON OPENINGS WHERE A FIRE RATED BARRIER IS NOT

REQUIRED. USE OF THE DSB SHOULD ALWAYS BE VERIFIED AND APPROVED

THROUGH LOCAL BUILDING CODE AND/OR FIRE PREVENTION DEPARTMENTS.

Figure 7

6.5. WIRE ACCESS HOLES

The DSB connects to a power source and access control systems via either a 16-foot 6conductor traditional wiring cable assembly (included with the standard DSB series), or an 8conductor ElectroLynx connector “pigtail” harness (included with the ELDSB series).

All DSB/ELDSB installations require that an 11/16” [17.5mm] diameter wire way hole be located

in the hinge side of the door at the position shown (see Figure 4). This hole allows either the

traditional cable with connector or the ElectroLynx wiring harness connectors to be pulled into

the door.

DSB – Traditional Wiring

:

Wire routing from a hollow door implementing the traditional wiring method may be achieved

using a door cord. The TSB-C (included with the standard DSB) may be mounted toward the top

of the door between the door and frame, or mounted directly between the bar end mount and

frame (see Appendix B). Other commercially available electrical transfer hinges or pivots (such

as Securitron’s EPT or EPTL Electric Power Transfer) may also be used to route the wiring from

the door to the frame in a concealed manner. The following step-by-step instructions may be

used for the installation of the armored door cord between the door and frame:

a. Drill a 3/8” [9.5mm] diameter hole in the door and frame (hinge side) as shown in Figure 8.

b. Insert one (1) door cord insert into each end of the flexible cord conduit.

c. Run electrical wiring as required through the flexible cord conduit (with inserts) and the holes

in the door and frame.

d. Position the door cord caps to completely cover each 3/8” [9.5mm] diameter hole and use

the cap mounting holes as a template to mark and then drill two (2) 1/8” [3.2mm] pilot holes

for mounting.

PN# 500-22700

Page 5 Rev. F, 03/11

Loading...

Loading...