S

M

D

eLa

e

r

S

e

w

ePW

a

l

P

p

1

PW-Se

odel:

ies Str

-98

tch Pal

1HP, S

et Wra

-981

per

LP

istribut

V

rsion 1.0

st Updated:

d By:

10/10/19

S

aler Sales |

ww.sealers

les.com | Tel

: 818-718-88

8 | E-mail: contact@sealersales.com

Sealer Sales Page 2

SPW-981 Pallet Wrapper Manual

IMPORTANT - PLEASE READ THIS CAREFULLY

The development of a good safety program, that is rigidly

enforced, is absolutely imperative when involved in the operation of

industrial equipment. Our machinery is well designed and includes

extremely important safety features. The part you the user play

through proper installation and maintenance procedures is of far

greater significance than our designs. Only properly trained

individuals following rigidly enforced safety rules, as recommended

by A.N.S.I. and O.S.H.A., should be allowed to operate these

machines.

Sealer Sales Page 3

SPW-981 Pallet Wrapper Manual

TABLE OF CONTENTS

___________________________________________________________

Preface

Warranty Notice 5

Warranty 6-7

Warranty Exceptions 8

Warnings 9-11

General Safety Regulations 12

Unpacking 13-14

Pallet Wrapper Section

Description 15

Specifications 16

Technical Data 17

Installation and basic set up 18-19

Plugging Machine In 20

Installation of film roll 21

Installation of Optional Loading Ramp 22

Leveling turntable base 23

Front control panel 24

Turning on machine 25

Set machine parameter 26-27

Set bottom count 28

Set top count 29

Set wrap height 30

Setting program memory 31

Setting height in CM or inches 31-32

How to enter different program settings 33-35

Setting special function calibration for height setting 36-38

How to operate in automatic mode 39

How to operate in manual mode 39-40

Getting started 41-43

Sealer Sales Page 4

SPW-981 Pallet Wrapper Manual

Adjustments

Mechanical Brake Stretch 44

Film Roll Carriage Down Stroke Limit 45

Troubleshooting

Machine does not start 46-48

Machine in Emergency Stop Mode 49

Turntable will not turn 50

Film Carriage will not rise 51

Film is not Stretching 52

Maintenance

General Maintenance Requirements 53

Checking turntable chain tension 54-56

Replacing turntable drive chain 57

Replacing the turntable support rollers 58-59

Replacing the film carriage lift belt 60-61

Exploded view drawings with parts listings 62-69

Spare Parts List 70

Electrical Schematic 71

Sealer Sales Page 5

SPW-981 Pallet Wrapper Manual

IMPORTANT WARRANTY NOTICES

OPERATING AND MAINTENANCE MANUAL

The operating and maintenance manual has been

carefully prepared to provide the user with all the information needed

to properly install, operate, and maintain your Sealer Sales

equipment.

Please read this manual carefully and refer to it

for information on the care and use of your Sealer Sales equipment.

It is recommended that additional copies be ordered for use

by production, maintenance, and supervisory personnel. Although

the design of this equipment incorporates safeguards to

protect personnel, care should be used in operating, adjusting, and

servicing.

Attention is directed to the warranty which

accompanies all your Sealer Sales equipment. The terms and

conditions of this warranty apply only to unmodified units. Any

unauthorized modifications to the equipment automatically voids this

warranty.

Sealer Sales Page 6

SPW-981 Pallet Wrapper Manual

Sealer Sales

WARRANTY

Sealer Sales, Inc. warrants each new product

manufactured to be free from defects in material and

workmanship for a period of 1 year from date of shipment by Sealer

Sales.

Not covered by this warranty is normal wear of

components such as, but not limited to; belts, chains, fuses, bulbs,

rollers etc. or misuse or abuse of the machine or any components

thereof. As well, parts returned without the prescribed

paperwork will not be covered by this warranty. Labor to remove

or repair any component is also not covered by this warranty.

Damage in transport is the responsibility of the carrier and is not

covered under our warranty. This warranty is not transferable with

any subsequent resale.

Defective parts under warranty must be returned to Sealer

Sales freight prepaid. Sealer Sales’s sole obligation and

purchaser’s sole remedy in the event of a warranty dispute shall

be, at Sealer Sales’s option , to repair or replace the part in

question. Labor incurred in removing or installing the defective

part is not covered by this warranty. Prior to returning any parts

for any reason, contact Sealer Sales for a Return Authorization

Number. This number must accompany all returns.

This warranty shall not apply if equipment has been tampered

with, misused, improperly installed, altered, or has received damage

due to abuse, carelessness, accident or failure to follow

recommended regular maintenance procedures or has been serviced

by someone other than a duly authorized factory

representative without the express written consent of Sealer Sales,

Inc.

Sealer Sales Page 7

SPW-981 Pallet Wrapper Manual

This warranty is in lieu of all other warranties, expressed or

implied, including but not limited to warranties of merchantability and

fitness for a particular purpose, non-infringement or any other

matter.

Sealer Sales shall have no liability to any person for direct,

indirect, incidental or consequential damages or delay resulting from

any defect negligence, or tort and customer hereby waives for itself

any and all claims for punitive damages and all claims of negligence

of strict liability or both. In no event shall our liability exceed the

purchase price of the product which was actually paid.

Sealer Sales reserves the right to make changes,

additions, or improvements to our products with no obligation to

make such changes in any previously shipped product covered by this

warranty.

Sealer Sales shall not be held liable for any damages

arising out of or in connection with the operation of the equipment

should customer or its agent fail to maintain equipment in safe

operating condition. This warranty shall become unenforceable if and

to the extent the customer or its agents remove, disconnect, or

otherwise render useless any safety device and or parts designed or

affixed by us or fails to maintain and service equipment in a manner

as advised.

Sealer Sales provides a 2 year warranty on parts,

excluding shipping or freight costs for replacement parts. All

warranty parts are shipped F.O.B. Rancho Cucamonga,

California.

Sealer Sales Page 8

SPW-981 Pallet Wrapper Manual

WARRANTY EXCEPTIONS

The following parts are an exception to the general

warranty list on page 9. Each part listed below shall carry a 30-day

warranty unless designated otherwise.

SPW-981

1. Fuses

Sealer Sales Page 9

SPW-981 Pallet Wrapper Manual

WARNINGS

Every effort has been taken to ensure your safety while

operating this machine; however, there still remain certain risks. Do

not allow this machine to be operated before informing all personnel

of the following warnings.

WARNING........

Do not tamper with the electrical wiring. Only use a

licensed electrician for maintenance. Always disconnect the electrical

power before attempting any maintenance to all electrical and/or

moving parts.

WARNING........

In order to prevent injury to personnel and/or machinery

DO NOT INCREASE SETTINGS OR RATINGS ON EITHER ELECTRICAL

OR MECHANICAL OVERLOAD SAFETY DEVICES.

WARNING........

KEEP HANDS AWAY FROM MOVING CONVEYORS AND

ASSEMBLIES. Conveyor belts that have become worn or frayed are

capable of being hazardous. They should be replaced promptly.

WARNING........

NEVER OPERATE THIS OR ANY MOVING EQUIPMENT

WITHOUT ALL COVERS AND GUARDS IN PLACE. The internal

mechanism of most packaging machinery contains numerous shear,

pinch, and inrunning nip points, many of which are capable of

causing severe injury and/or permanent disfigurement.

Sealer Sales Page 10

SPW-981 Pallet Wrapper Manual

WARNING........

To minimize the potential for personnel injury, always be

sure that machine operators and others working on the machinery

are properly trained in the correct usage of the equipment and

properly instructed regarding the safety procedures for operation.

WARNING........

Heat sealing arms and sealing jaws on packaging

machinery can become very warm after a period of use. KEEP

HANDS AWAY WHILE IN OPERATION AND USE CAUTION IF THE

MACHINE HAS BEEN RUNNING RECENTLY.

WARNING........

ANY MODIFICATIONS TO EITHER THE ELECTRICAL

CIRCUITRY OR THE MECHANICAL ASSEMBLIES OF THE MACHINERY

WILL VOID ANY WARRANTIES ASSOCIATED WITH THIS

EQUIPMENT. Such modifications may introduce hazards that

would not otherwise be associated with this machinery. Sealer

Sales will not be responsible for any consequences resulting

from such unauthorized modifications.

WARNING........

The use of certain types of plastic films in sealing and/or

shrinking equipment may result in the release of HAZARDOUS FUMES

due to the degradation of the film at high temperatures. Before

using any plastic film in this equipment, the manufacturer or supplier

of the film should be contacted for specific information concerning

the potential release of hazardous fumes. ADEQUATE VENTILATION

MUST BE PROVIDED AT ALL TIMES.

Sealer Sales Page 11

SPW-981 Pallet Wrapper Manual

WARNING........

It is important that the machine operator turn off the Main

Power Switch when he/she has finished operating the unit.

Sealer Sales Page 12

SPW-981 Pallet Wrapper Manual

General Safety Regulations

Before using the machine or carrying out maintenance operations

read the following instructions very carefully:

Before

1. Read the instructions about how to set up the machine

2. Check all the safety guards on the machine and immediately

replace any worn or broken parts with original spares.

3. Make sure that no tools or other objects have been left lying

on the machine and that the machine itself is perfectly

clean.

4. Read the maintenance and spare parts very carefully.

5. Read all the labels and plates applied to the machine.

During

1. Do not wear clothing that could get tangled up in the

moving parts of the machine.

2. Do not put the hands or any kind of object inside the field of

operation of the machine

3. Do not load the machine with boxes heavier than those

recommended by the manufacturer.

After

1. Always stop the electric motor by pressing the red button on

the switch

2. Switch off the electric power.

Sealer Sales Page 13

SPW-981 Pallet Wrapper Manual

UNPACKING

THOROUGHLY INSPECT EQUIPMENT UPON ARRIVAL.

If goods are received short or in a damaged condition, it

is important that you notify the carrier’s driver before he leaves

your company and insist on a notation of the loss or damage

across the face of the freight bill. Unless this is done, no claim can

be enforced against the transportation company.

If concealed loss or damage is discovered, notify

the carrier at once and insist on an inspection. This is

absolutely necessary! A concealed damage report must be

made no later than ten (10) days from the date the shipment

was delivered. Unless you do this, the carrier will not

consider any claim for loss or damage. The carrier’s agent will

then make an inspection and grant a concealed damage notation. If

you give the transportation company a clear receipt for the goods

that have been damaged or lost in transit, you do so at your own risk

and expense.

All claims must be filed within 10 Days of delivery date or

carrier will not accept them.

Sealer Sales is willing to assist in every possible

manner to collect claims for loss or damage; however, this does

not hold Sealer Sales responsible for collection on claims or

replacement of material.

Sealer Sales Page 14

SPW-981 Pallet Wrapper Manual

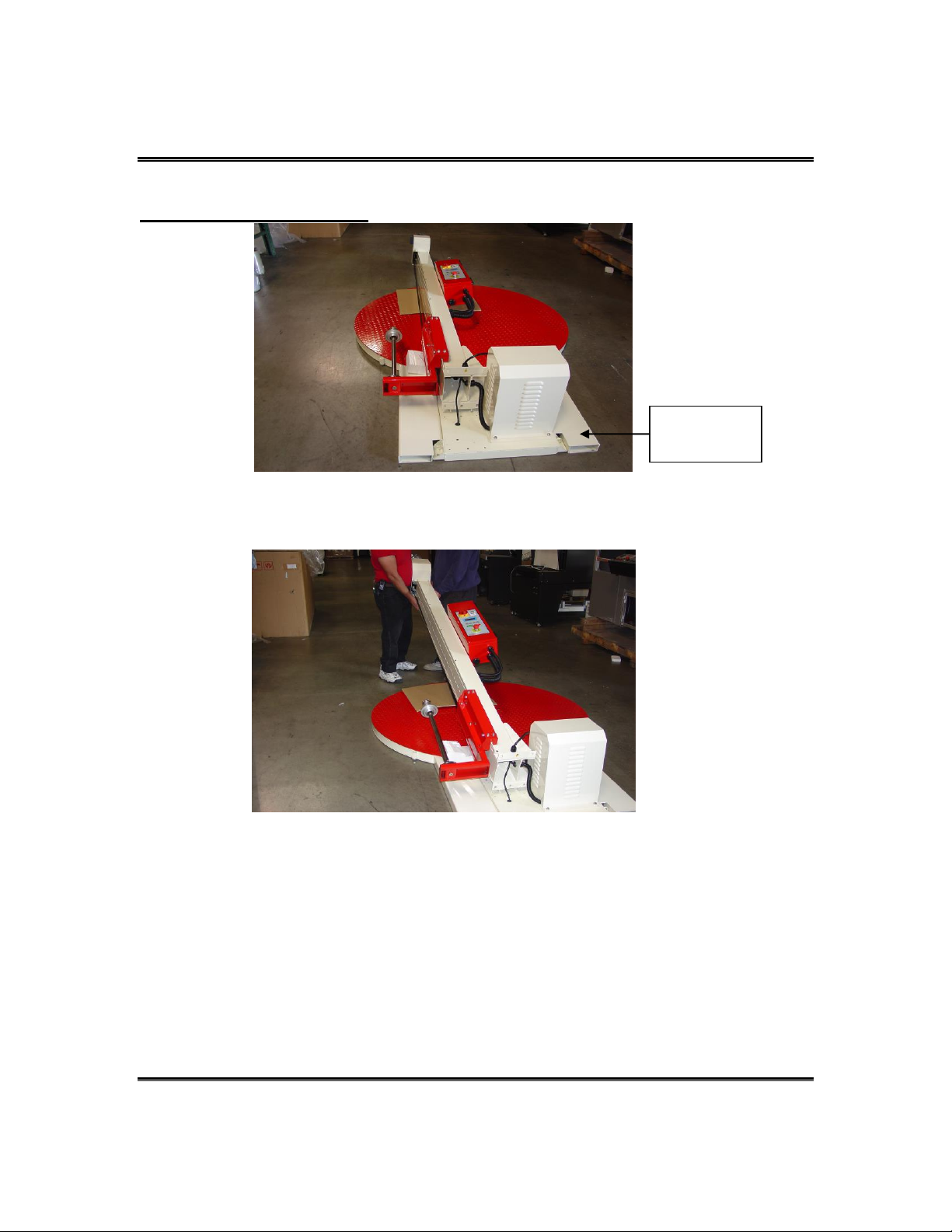

Unpacking

* Picture shown with

optional ramp

Your model SPW-981 is enclosed in a wooden crate for

protection. If you machine does not arrive in good condition, write on

shipping paperwork that concealed damage may have occurred.

You must write on bill of lading that concealed damage may have

occurred. If you do not – The Freight companies will not pay any

damage claims filed due to clear signed bill of lading.

Remove stretch film protective wrap and remove pallet wrapper from

crate.

* Pallet Wrapper is fork lift portable and has fork channel at base of

frame. You may use these channels to remove the Pallet Wrapper

with fork lift.

Sealer Sales Page 15

SPW-981 Pallet Wrapper Manual

Description

The model SPW-981 is a versatile, reliable and economical

pallet stretch wrapping machine designed to accommodate a large

variety of pallet sizes. Using modern technology the model SPW-981

will apply stretch film to a pallet load. This inexpensive system

offers a high degree of protection for any pallet load.

Operation

The operation of the model SPW-981 pallet wrapper

comprises 4 easy steps

1. Operator places pallet load on revolving turntable by

means of forklift or pallet jack (if optional ramp is used)

2. Operator attaches stretch film to turntable base

3. Press “start” cycle for automatic operation

4. Cut film from pallet load at completion of work cycle.

Sealer Sales Page 16

SPW-981 Pallet Wrapper Manual

Specifications

Roll Dimensions

The machine is capable of using different types of stretch film with

the following dimensions:

A: Internal diameter of roll 3” (76.2mm)

B: External diameter of roll 12” (300mm)

C: Height of roll: 20”

D: Thickness of film: STD 80gauge

*Other film thickness may be used

E: Weight of roll: 40lbs max

In order to obtain the best results while using your machine we

recommend using a good quality stretch film.

Pallet Dimensions

The model SPW-981 can generally wrap pallets with the overall

dimensions listed below

Maximum Length: 48” (1,200mm)

Maximum Width: 48” (1,200mm)

Maximum Height: 85” (2,150mm)

Pallet Weight

Maximum recommended pallet weight load is 3,000lbs (1,400kg)

Sealer Sales Page 17

Machine Weight

1,000lbs (4.75kg)

Shipping Weight-Approximate

1,400lbs (640kg)

Crated Dimensions

129”L x 63” W x 29” H

(3,277mm) x (1,600mm) x (737mm)

Power Requirements

110volt/15amp

Recommended Operating Temperatures

Min 40 f / Max 104 f

+5 / +40 c

Turntable Rotation Speed

10RPM

SPW-981 Pallet Wrapper Manual

Technical Data

Sealer Sales Page 18

Fork lift

channels

SPW-981 Pallet Wrapper Manual

Installation & Set Up

Use the two fork channels mounted on each side of base to

remove Pallet Wrapper from crate and place on floor in desired

position near electrical outlet.

The mast is heavy- Take precaution when lifting mast.

Sealer Sales Page 19

SPW-981 Pallet Wrapper Manual

Take care when raising mast so you do not pinch cables when

lowering mast.

Clear all cables before lowering mast.

Once mast is raised, use the 10mm bolts provided and mount the

mast to base. Mounting hardware is provided 3 bolts at back of mast

and 3 bolts in front.

Sealer Sales Page 20

SPW-981 Pallet Wrapper Manual

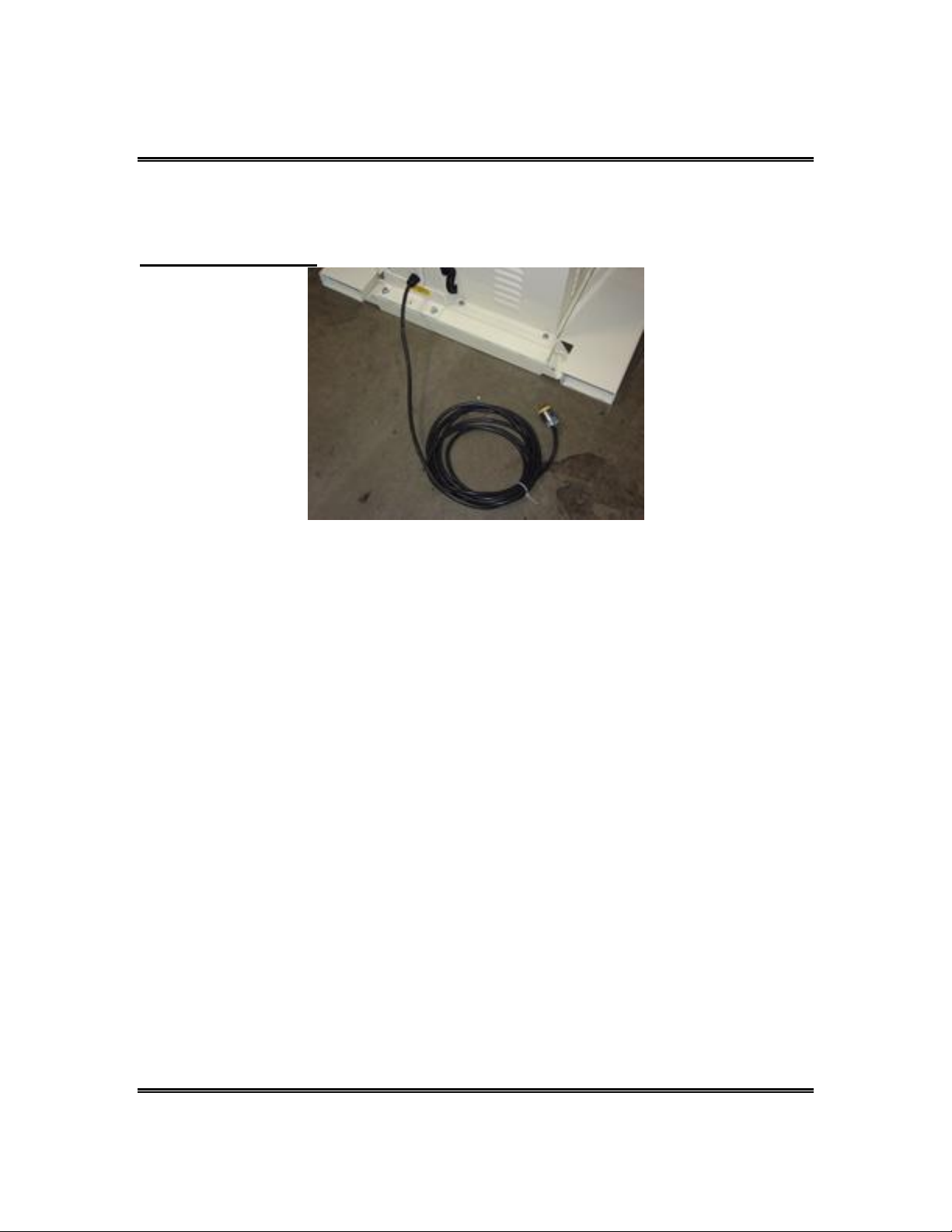

Plug Machine In

Machine comes complete with power cord and 110volt plug.

*Make sure to use a dedicated line- Do not run any other

equipment on same power line.

Before plugging in machine make sure main power switch is in off

position.

Plug into regular 110volt power outlet.

Make sure the voltage supplied to the machine is 110 volt.

Sealer Sales Page 21

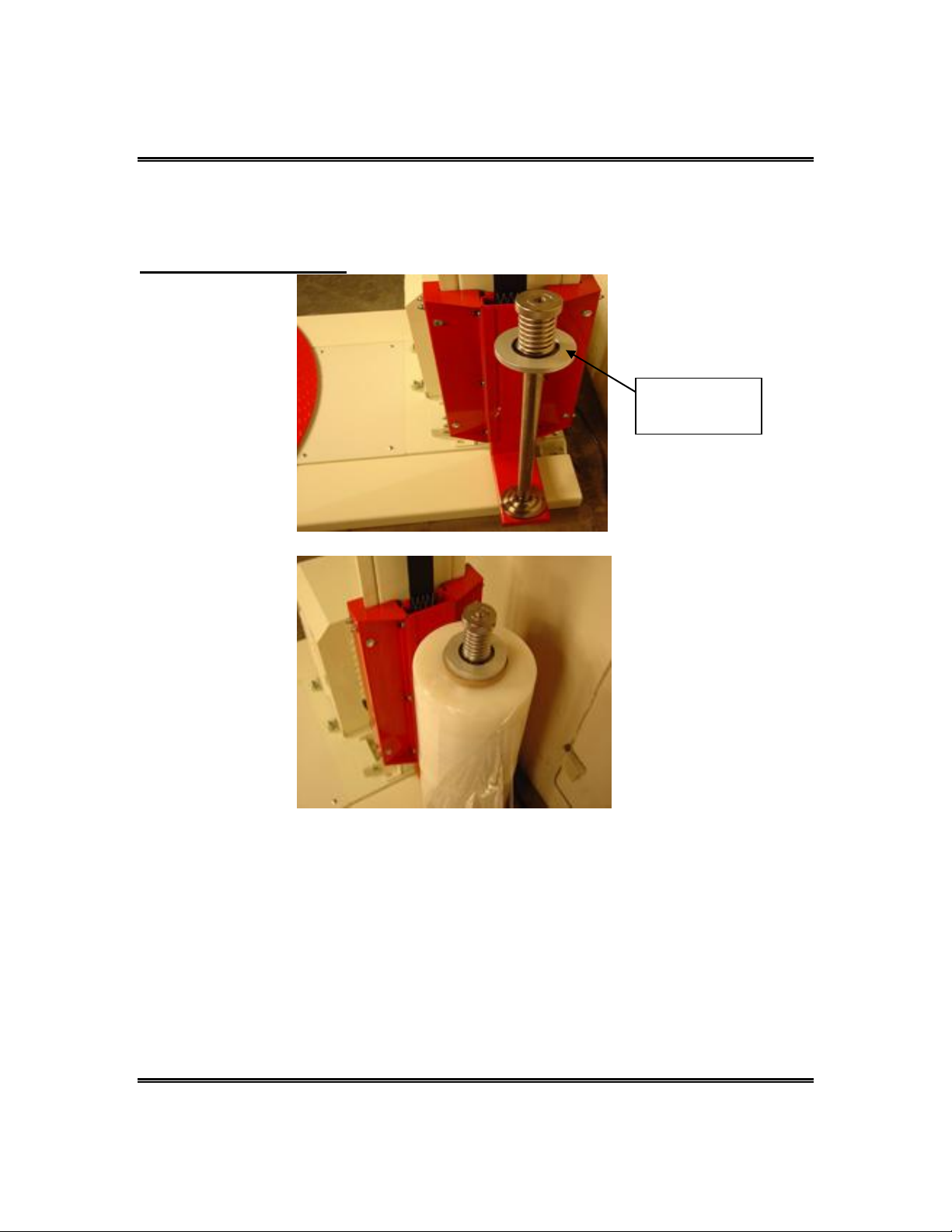

Tension spring

assembly

SPW-981 Pallet Wrapper Manual

Installing Film Roll

Remove film tension spring assembly by turning counter clock wise.

Load film roll and tighten spring tension assembly. Whenever it is

necessary to wrap the film more tightly around the pallet, thus saving

material, the film roll unwinding can be varied by turning the hand

wheel which by means of the clutch below it, brakes the film and

stretches it more tightly.

*Special care should be taken when using rolls of stretch film with

single sided cling. Make sure the roll is facing the right direction, so

that the cling or sticky side of the film is in contact with the pallet

load.

Sealer Sales Page 22

SPW-981 Pallet Wrapper Manual

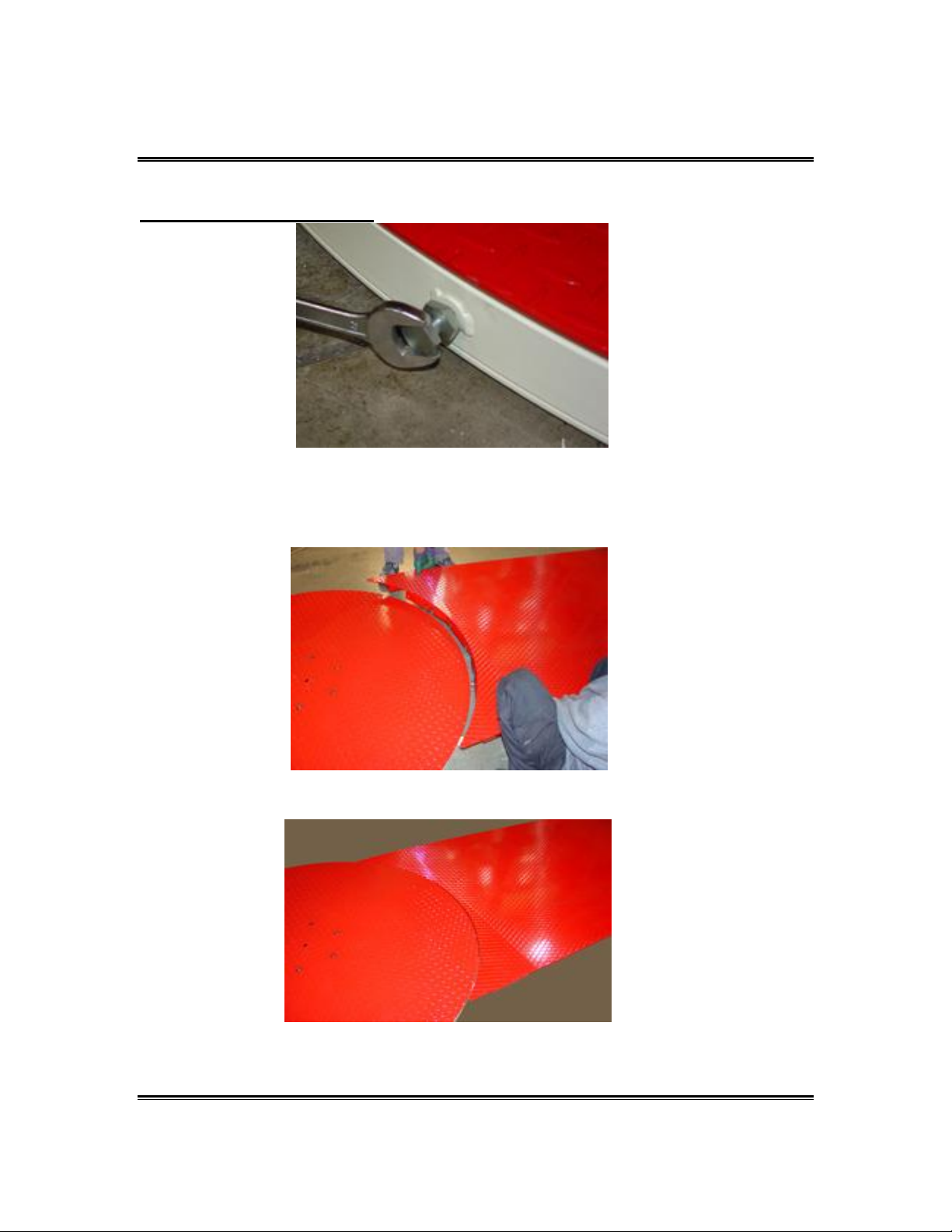

Install Loading Ramp

Install custom bolt to base frame in threaded holes provided in

frame. Ramp can be mounted from three sides. Bolt holes are

provided on all three sides. Ramp requires on two bolts to secure

ramp.

Ramp is very heavy, use two people to lower ramp over bolts.

Align slots in ramp with slot in bolt. Lower ramp into position.

Ramp should fit evenly and snug against frame.

Sealer Sales Page 23

SPW-981 Pallet Wrapper Manual

Leveling Turntable Base

Adjust the 4 leveling bolts on base frame so turntable base sits

evenly on floor.

Sealer Sales Page 24

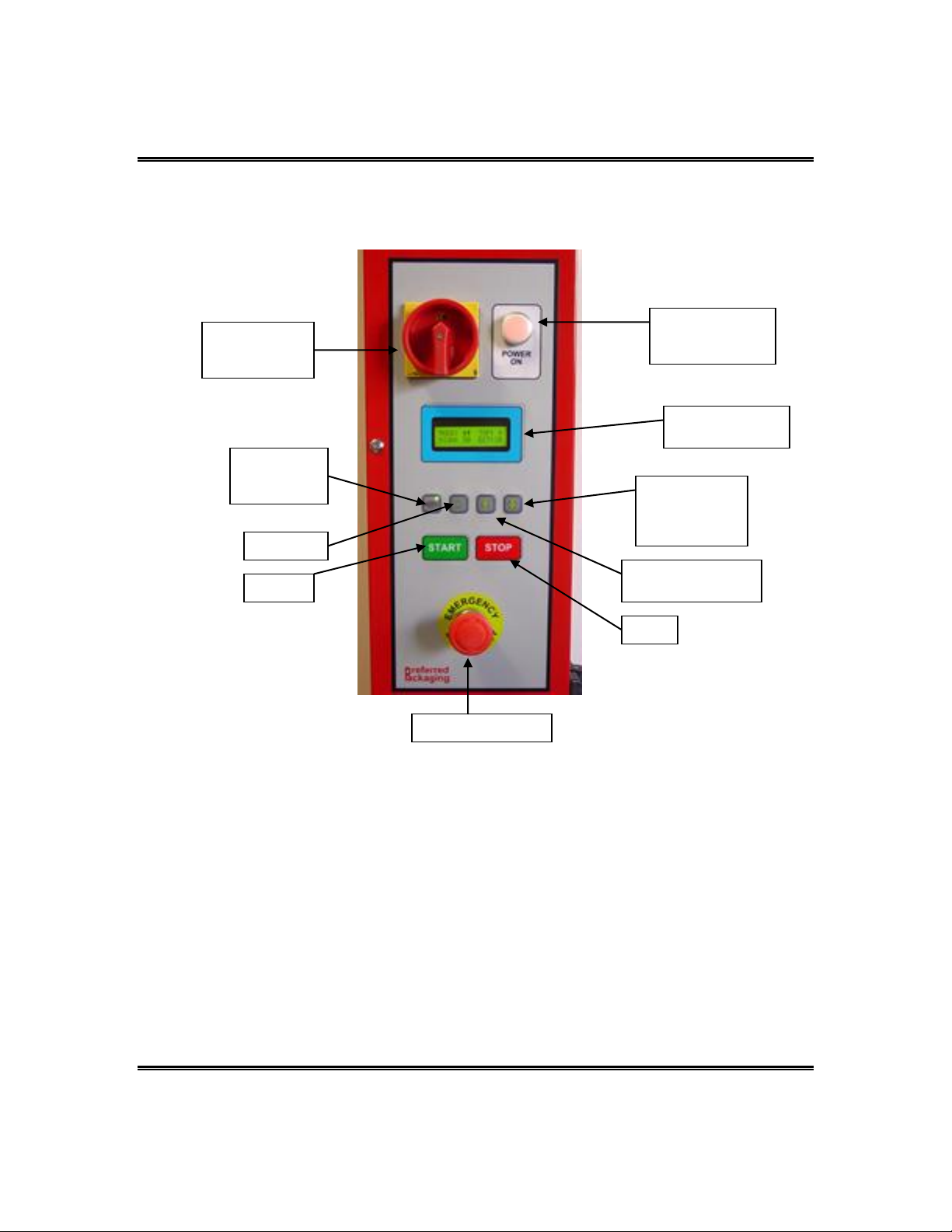

Power indicator

light

LED Control

Up arrow key

increase

value

Down arrow key

decrease value

Stop

Emergency Stop

Start

Set Mode

Automatic

Mode

Main power

switch

SPW-981 Pallet Wrapper Manual

Screen

Front Control Panel

Sealer Sales Page 25

SPW-981 Pallet Wrapper Manual

Turning on Machine

Turn power switch to on position

Sealer Sales Page 26

Mode-up and

down cycle

Pallet height

setting 84”

Indicates top

wrap count

Indicates

bottom wrap

count (4)

Set Key

SPW-981 Pallet Wrapper Manual

Set Machine Parameters

When you turn on your machine the model number will

temporarily be displayed.

The front control LED will now display what the current

machine parameters are set at.

Press set key once and display will show “set machine

parameters”.

Sealer Sales Page 27

Set

SPW-981 Pallet Wrapper Manual

Set Machine Parameters

Press and select mode will appear mode indicates

pallet wrapper will start at bottom of cycle raise to selected height

setting then return to bottom of cycle.

Sealer Sales Page 28

Set

SPW-981 Pallet Wrapper Manual

Set Bottom Count

Press and “set bottom count” will appear. The number

on the display tells you how many times the turntable will cycle

before it starts upward.

To change wrap count simply press arrow key up to increase

bottom wrap count or down arrow key to decrease wrap count.

Sealer Sales Page 29

Set

SPW-981 Pallet Wrapper Manual

Set Top Count

Press top wrap count will appear.

To change top wrap count simply press arrow key up to increase

or down to decrease top wrap count.

Sealer Sales Page 30

Set

84 inch

SPW-981 Pallet Wrapper Manual

Set Wrap Height

Press and wrap height will appear use arrow keys up or

down to increase or decrease wrap height. Display indicates

what height film carriage will rise to.

*Note: If you are wrapping different height pallet loads you will

need to adjust the height setting to fit the pallet load.

Press up or down arrow keys to increase or decrease film

carriage height.

*The film carriage travels at a fixed speed and is not

adjustable.

Sealer Sales Page 31

Set

SPW-981 Pallet Wrapper Manual

Setting Program Memory

Your model SPW-981 is equipped with a 10 program memory

function which will allow you to pre-set up to 10 different

program settings for different pallet requirements.

Setting Unit of Measure=or inches

From main display menu press Press key display will

auto key until light goes out. Show “set” machine parameters”.

Press arrow key to advance to From “select memory” 1-10

next screen “select memory” screen press up arrow key to

1-10. reach next screen.

Sealer Sales Page 32

Set

SPW-981 Pallet Wrapper Manual

From “set memory parameters” Allows you to set the

Press up arrow key to set unit of measurements in cm or inches.

Measure.

Use the up or down keys to set unit of measure form cm to inches

when finished press will take you back to the main menu.

Sealer Sales Page 33

Set

SPW-981 Pallet Wrapper Manual

Entering Different Program Settings

Press auto until light goes out-you Press key to advance to

are now in manual mode. next screen.

Press arrow key up to advance to Press arrow key up to advance to

next screen. next screen.

Sealer Sales Page 34

Set

Set

SPW-981 Pallet Wrapper Manual

Press key to access Choose operated mode up and

Machine parameters. down cycle or up only/ down only.

Press when complete.

Use arrow key to set# of bottom Use arrow key to choose # of top

wrap counts. wrap counts.

Sealer Sales Page 35

SPW-981 Pallet Wrapper Manual

Select wrap height for this “Set memory” will appear this

program. screen allows you to choose which

program you would like the information

stored in. You can choose from 1-10.

report this process to program other

parameters for different pallet wrapping

requirements.

Press auto key again and light will go on-machine is now in automatic

mode. Simply press start to activate machine.

Sealer Sales Page 36

Set

SPW-981 Pallet Wrapper Manual

Setting Special Function Calibration-For Height Setting

1. Special function calibration is factory set

2. This function should only be used if you are using 50hz power

supply (or).

3. If the height setting on the control panel is set at a specific

height say for example (48”) and the film carriage will only rise

(40”) the machine is out of calibration and should be reset using

the following instructions.

Press auto key until light goes Press key and hold for 2-3

Out-you may now operate seconds and display will show

Machine in manual mode. “special function calibration”.

Sealer Sales Page 37

SPW-981 Pallet Wrapper Manual

Press the start key. The film Display will show special function

Carriage will rise to the top of the running until film carriage reaches

Mast and stop. top of mast.

Film carriage at top of mast.

Sealer Sales Page 38

SPW-981 Pallet Wrapper Manual

Once film carriage reaches top display will start at home. Press down

arrow key to return film carriage to bottom of mast.

*This calibration feature set the time required for the film carriage to

reach the top of the mast. This time it will then be calibrated to the

settings on the control panel for the required height setting.

Sealer Sales Page 39

Auto

Auto

Start

SPW-981 Pallet Wrapper Manual

Operated in Automatic Mode

With machine in mode press start and machine will

automatically wrap at preset parameters.

Operate in Manual Mode

To run machine in manual mode press key until light goes out.

Press to run turntable in manual mode. Turntable will run as

Long as start key is depressed. Once released the turntable will stop

turning.

Sealer Sales Page 40

SPW-981 Pallet Wrapper Manual

To operate film carriage in manual mode make sure auto light

is not on and press arrow keys up or down to raise or lower film

carriage.

Sealer Sales Page 41

SPW-981 Pallet Wrapper Manual

Getting Started

Turn power switch to “on” position.

Place pallet load into turntable and try to center pallet load

evenly on turntable base.

Pull several feet of film off the roll enough to attach to turntable.

Tighten tension knob to establish pre-stretch tension in film.

Sealer Sales Page 42

SPW-981 Pallet Wrapper Manual

With tension knob fully tightened threads will be exposed 1 to 1.5” a

fully tightened knob will provide approximately 100 to 150% film prestretch. We recommend starting at 50% depending on the quality of

stretch film used.

Attach film tale to metal tab on turntable base.

Sealer Sales Page 43

SPW-981 Pallet Wrapper Manual

Press the auto mode button.

Press the start button. The machine stops automatically at the end

of the cycle.

Cut the stretch film by hand and press excess film against pallet load

to attach.

Remove the pallet load via fork lift or pallet jack if ramp is used. The

cycle can be interrupted at any time by pressing the emergency push

button stop switch located at the bottom of the front control panel.

The machine is now ready to repeat the wrap cycle as per the

pre-set values. The number of top or bottom wrap counts or

carriage height can be changed at any time.

Sealer Sales Page 44

SPW-981 Pallet Wrapper Manual

Adjustments-Mechanical Brake Stretch

When tension control spring is loose the pallet wrap will apply

film loosely to the load.

By turning the tension spring clockwise to tighten film roll the film will

be stretched and applied tightly to the pallet load. At maximum

tension you will stretch film approximately 125 to 150%.

Sealer Sales Page 45

SPW-981 Pallet Wrapper Manual

Adjustment of Film Carriage Down Stroke Limit

The down stock limit switch should be set as low as possible

without hitting the machine frame. This will insure the stretch film

will grab pallet load and wooden pallet together to secure load.

Sealer Sales Page 46

Emergency

stop switch

Power switch

on

SPW-981 Pallet Wrapper Manual

Troubleshooting

Machine will not start

1. Check to make sure the machine is plugged into 110volt power

Source. Check for voltage present in line.

A. Make sure main power switch is in “on” position.

B. Make sure emergency stop switch is not depressed

and activated. Turn counter clockwise to disengage.

Sealer Sales Page 47

Auto

Start

SPW-981 Pallet Wrapper Manual

Make sure you have put machine in mode. Light will be on.

Make sure to press button to activate machine.

Sealer Sales Page 48

SPW-981 Pallet Wrapper Manual

Remove the 3 screws holding front control panel closed.

Test fuse F-1 and F-2 for continuity. Replace if required.

Sealer Sales Page 49

Emergency Stop

SPW-981 Pallet Wrapper Manual

Machine in Emergency Stop Mode

Turn emergency stop switch counter clock wise to disengage.

Sealer Sales Page 50

SPW-981 Pallet Wrapper Manual

Turntable will not turn

1. Check electrical connections

2. Check contactor and replace if necessary.

3. Check connections to turntable drive motor. Test motor –

Replace if necessary.

Sealer Sales Page 51

SPW-981 Pallet Wrapper Manual

Film Carriage will not rise

Remove turntable top plate.

Check micro switch- make sure switch is hitting activation plate

mounted to sprocket. If switch is not hitting plate it will not count

the resolutions. Adjust switch outward until it is activated by plate.

Sealer Sales Page 52

SPW-981 Pallet Wrapper Manual

Film will not stretch

Tighten spring tension control

Clutch disk wear occurred – Replace if necessary.

Sealer Sales Page 53

SPW-981 Pallet Wrapper Manual

Maintenance

1. No special preventative maintenance operations are required,

but it is a good habit to check regularly the condition of the

main machine parts, carriage belt, turntable drive chain, etc.

2. Always replace worn out parts with original spare parts to

prevent inefficiency and potential damage to machine.

3. All maintenance operations should be carried out by personnel

in charge of mechanical maintenance.

Sealer Sales Page 54

Chain

guard cover

SPW-981 Pallet Wrapper Manual

Maintenance

A. Check drive chain tension-replace drive chain

1. Remove the 4 screws that hold the chain guard in place.

2. Remove the 6 screws holding turntable top in place and

Slide top plate off base.

3. Turntable chain is now fully accessible.

Sealer Sales Page 55

Drive motor

cover

SPW-981 Pallet Wrapper Manual

Loosen bolts and remove turntable drive motor cover.

Loosen motor adjustment plate bolts.

Sealer Sales Page 56

SPW-981 Pallet Wrapper Manual

6. Tighten chain tension adjustment bolts.

7. Adjust chain tension so chain just touches nylon support.

Sealer Sales Page 57

SPW-981 Pallet Wrapper Manual

Replace Drive Chain

1. To remove chain first follow steps 1-4 in previous section to

loosen motor mounting bolts.

2. Loosen adjustment bolts completely and slide chain from

sprocket.

Sealer Sales Page 58

SPW-981 Pallet Wrapper Manual

Replace Turntable Support Rollers

Remove the 6 turntable screws holding the top in place.

These are 14 sets of rollers – replace as needed.

Place screw driver under roller and gently pry roller upward.

Sealer Sales Page 59

SPW-981 Pallet Wrapper Manual

Remove complete roller assembly and replace.

Sealer Sales Page 60

SPW-981 Pallet Wrapper Manual

Replace Film Carriage Belt

Remove 6 bolts holding roll shaft. This will allow access to lower belt

attachment. Remove clip pins holding shaft in place then remove

belt.

Remove top belt cover.

Sealer Sales Page 61

SPW-981 Pallet Wrapper Manual

To unwind belt at top, place block under film carriage to lift up so it

does not touch bottom switch. In manual mode activate film carriage

down. This should unwind belt enough to access the screws holding

the upper belt in place.

Sealer Sales Page 62

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 63

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 64

Pos.

Part #

Qty

Description

1

B10049

1

Tower cover

2

B10050

1

Tower base

3

S01-08120

1

Hexagon bolt, M8x120

4

S15-0802

5

Plain washer, M8

5

S12-0808

1

Hexagon nut, M8

6

S01-0820

4

Hexagon bolt, M8x20

7

S16-0800

4

Spring washer, M8

8

B10051

2

Plastic knob screw

9

B10052

2

Control box bracket

10

B10053

1

Control box

11

B10054

2

Door hinge

12

S02-0612

8

Hex socket bolt, M6x12

13

B10055

1

Wire pipe, large

14

B10056

1

Wire pipe, small

15

B10057

1

Control box base

16

S15-0601

4

Plain washer, M6

17

S16-0600

4

Spring washer, M6

18

S12-0605

4

Hexagon nut, M6

19

E33400

2

Fuse box

20

E11000

1

Magnet contactor

21

E11100

2

Magnet contactor

22

E15000

2

Overload contactor

23

E30800

13

Terminal block

24

E24500

1

Power switch

25

E26500

1

Pilot lamp

26

E23100

1

Emergency stop switch

27

E05100

1

Control board, 110V

28

E05200

1

LCD display board

29

B10058

1

Control panel sticker

30

B10059

1

Control box front door

31

S08-0630

3

Truss head machine screw, M6x30

32

B10060

2

Limiter switch bracket

33

E29000

2

Limiter switch

34

S04-0612

4

Flat socket head screw, M6x12

35

E41100

2

Fuse

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 65

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 66

Pos.

Part #

Qty

Description

1

E63000

1

Up-down gear motor, 110V/ 60Hz

2

S02-0820

4

Hex socket bolt, M8x20

3

S16-0800

4

Spring washer, M8

4

B10002

1

Tapered gear

5

S09-0610

4

Hex socket set screw, M6x10

6

B10003

1

Tapered gear

7

B10004

2

Guide plate

8

B10005

1

Belt pulley

9

B10006

1

Belt pulley shaft

10

S24-1000

2

External circlip, S10

11

B10007

1

Belt shaft

12

B10008

1

Belt

13

S21-060622

1

Round end key, 6x6x22

14

S21-060690

1

Round end key, 6x6x90

15

B10009

1

Top cover

16

S08-0610

6

Truss head machine screw, M6x10

17

B10010

1

Motor cover

18

B10011

1

Motor base

19

B10012

1

Knurled knob

20

B10013

1

Spring

21

B10014

1

Spacer

22

S23-3200

1

Internal circlip, S32

23

S56006

1

Ball bearing 6006zz

24

B10015

1

Shaft

25

B10016

1

Upper core holder

26

B10017

1

Core shaft

27

B10018

1

Lower core holder

28

B10019

1

Brake plate

29

S24-2500

1

External circlip, S25

30

B10030

1

Film carriage

31

S24-1000

1

Cone washer, M10

32

S04-1020

1

Flat socket head screw, M10x20

33

B10032

1

Spring

34

B10033

1

Shaft

35

B10034

1

Safety latch

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 67

Pos.

Part #

Qty

Description

36

S01-0650

8

Hexagon bolt, M6x50

37

B10001

30

Plastic wheel

38

B10035

8

Spacer

39

S16-0600

6

Spring washer, M6

40

B10036

2

Film carriage side cover

41

S02-0612

6

Hex socket bolt, M6x12

42

S01-0670

4

Hexagon bolt, M6x70

43

S12-0605

12

Hexagon nut, M6

44

B10071

1

Shaft

45

S56900

2

Ball bearing 6900

46

B10072

1

Roller

47

E28500

1

Limiter switch

48

B10074

1

Spring

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 68

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 69

Pos.

Part #

Qty

Description

1

B10037

1

Turntable

2

S04-1020

6

Flat socket head screw, M10x20

3

B10038

1

Turntable Sprocket

4

B10039

1

Washer

5

S56211

1

Ball bearing 6211zz

6

B10040

1

Turntable base

7

B10041

14

Shaft

8

B10042

28

Collar, short

9

B10043

28

Support roller

10

B10044

14

Collar, long

11

S02-0612

2

Hex socket bolt, M6x12

12

B10045

1

Plastic board

13

S01-1030

2

Hexagon bolt, M10x30

14

S12-1008

2

Hexagon nut, M10

15

B10046

1

Chain, 3/4”

16

S09-0810

2

Hex socket set screw, M8x10

17

B10047

1

Sprocket

18

S04-0820

4

Flat socket head screw, M8x20

19

S15-0802

4

Plain washer, M8

20

S16-0800

4

Spring washer, M8

21

S01-0820

4

Hexagon bolt, M8x20

22

S12-0806

4

Hexagon nut, M8

23

E63100

1

Turntable motor, 110V/ 60Hz

24

B10048

1

Load ramp (Option)

SPW-981 Pallet Wrapper Manual

Sealer Sales Page 70

Item #

Part #

Description

Qty.

Sug. Retail

1710-28

Chain Lube

1

39.95

33

E29000

Limit Switch

1

38.50

35

E41100

Fuse 8A 2 5.00

9

B10043

Turntable support rollers

2

76.00

20

B100113

Spring 1 18.00

47

E28500

Limiter switch-turntable

1

38.50

Total Cost

$215.95

SPW-981 Pallet Wrapper Manual

Spare Parts List

Sealer Sales Page 71

SPW-981 Pallet Wrapper Manual

Loading...

Loading...