Sealer Sales HL-M810, HL-M810II User Manual

Continuous Band Sealer Instruction Manual

Distributed By:

Version 3.1

Last Updated: 9/11/19

Copyright © 2013 by Stephanie Hwang

All rights reserved. No part of this publication may be reproduced, distributed, or transmitted in any form or by any means, including photocopying, recording, or other electronic or mechanical methods, without the prior written permission of the publisher, except in the case of brief quotations embodied in critical reviews and certain other noncommercial uses permitted by copyright law. For permission requests, write to the publisher, addressed “Attention:

Permissions Coordinator,” at the address below.

Sealer Sales, Inc. 8820 Baird Avenue Northridge, Ca 91324 www.sealersales.com

Printed in the United States of America

General Information

Thank you for purchasing our HL-M810 band sealer.

This owner’s manual contains information relating to your band sealer machine. The manual will provide you with basic information concerning both operation and maintenance of your new machine. Please read it carefully as failure to do so may result in bodily injury and/or damage to the equipment.

Please fill in the information below. You will find the information on the machine identification plate. You will need this information when ordering replacement parts or making technical inquiries.

No part of this manual may be duplicated, reproduced, stored in a retrieval system, translated, transcribed, or transmitted in any form without the express prior written permission of Sealer Sales, Inc.

H L - M 8 1 0 E Q U I P M E N T I N F O R M A T I O N

Model #

Serial #

Purchase Date:

Reference # (found on packing slip)

Owner:

ii

Table of Contents |

|

Safety Instructions ........................................................................................... |

1 |

Introduction...................................................................................................... |

3 |

Operation .......................................................................................................... |

9 |

Maintenance.................................................................................................... |

18 |

Parts Diagram ................................................................................................. |

21 |

Troubleshooting............................................................................................. |

31 |

Spare Parts List............................................................................................... |

34 |

Quality Control Testing................................................................................. |

35 |

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

Safety Instructions

WARNING! Below are general safety precautions and warnings that should be understood prior to setting up or operating your equipment. Read and fully understand all instructions and warnings prior to using this unit. Your safety is most important! Failure to comply with procedures may result in serious injury or property damage. Remember: Your personal safety is your responsibility.

WARNING! Below are general safety precautions and warnings that should be understood prior to setting up or operating your equipment. Read and fully understand all instructions and warnings prior to using this unit. Your safety is most important! Failure to comply with procedures may result in serious injury or property damage. Remember: Your personal safety is your responsibility.

Unsafe practices or unauthorized modifications could result in accidents or property damage. Failure to follow these safety rules and take necessary precautions can result in serious injury as well as damage to equipment.

Never operate or service your band sealer until you have read this manual completely and understand it fully.

Plug the band sealer into a standard 120 Volt, 60Hz wall outlet or surge protector. We highly suggest using a surge protector. Some special order units are 220 Volt, 50Hz. Make adjustments as necessary.

Do not use the band sealer if the power cord, plug or any other parts are damaged. Be sure not to allow the power cord to drape into your work area. Check that all parts are operating properly and perform the intended functions. Check for all other conditions that may affect the operation.

Reduce risk of unintentional starting. Make sure the power switch is in the "OFF" position before plugging in to the power source.

Always disconnect sealer from power source before servicing, changing accessories or cleaning the unit.

To provide protection against the risk of electrical shock, the power connection must be properly grounded at all times.

Do not leave the sealer unattended when in use. Disconnect the sealer from the power source before leaving the work area.

Band sealer is used solely for sealing thermoplastic materials. Using the machine for any other purpose can cause damage to the machine and operator.

Always operate machine on a flat stable surface.

While operating machinery, wear close-fitting clothing and tie back long hair to prevent any external items from getting caught in the machine. Do not wear jewelry when operating the band sealer.

1

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

While machine is in operation do not touch the heating and/or cooling blocks. Blocks will be extremely hot and may burn your hands.

While machine is operating, do not place fingers, tools, or other foreign objects on or into the machine. Do not touch any moving parts while machine is operating. Fingers may get caught in between the gears / pinch points and cause significant injury.

While machine is operating, do not place fingers, tools, or other foreign objects on or into the machine. Do not touch any moving parts while machine is operating. Fingers may get caught in between the gears / pinch points and cause significant injury.

Thermoplastic bags and material are hand fed into the machine. Place bag on the guide and carefully feed the bag through the band sealer. Fingers may be placed on the guide but do not allow fingers to touch any of the moving parts on the band sealer.

Use emergency stop to turn off machine should material/bags get jammed into the machine. Carefully pull material out of the band sealer. Do NOT use fingers to touch any part of the machine.

The band sealer is not water resistant or water proof. Spraying down the machine will damage machine or cause electrical shock. Do not submerge the band sealer into water or liquid.

Do not operate band sealer in a corrosive or humid environment.

Always keep the machine clean, lubricated and in good working condition. Follow any maintenance and lubrication procedures outlined in this manual. Make sure unit is disconnected from power source before cleaning.

NEVER use any accessories or parts from other manufacturers. Machine should not be altered or modified using parts that are not genuine authorized parts. Doing so will VOID YOUR WARRANTY.

Never leave the band sealer unattended. Be safe, disconnect the band sealer from power source before leaving work area.

Close supervision is necessary when any machine is near children or persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge . This sealer is NOT to be used by children or by persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge.

Do NOT use the band sealer outdoors.

Do NOT use the band sealer while under the influence of drugs, medications or alcohol.

SAVE THESE INSTRUCTIONS - REFER TO THEM OFTEN AND USE THEM TO INSTRUCT OTHERS.

2

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

Introduction

HL-M810 is equipped with an electronic temperature controller and variable speed conveyor to seal all types of thermoplastic materials (PP, PE, stand up pouches, gusseted bags, moisture barrier bags, etc.). Seals are created using PTFE bands which maintain high seal quality and produce consistently strong, clean seals on all heat sealable bags. Because bags are placed on a conveyor system, the width of the bag does not matter. These versatile machines offer several adjustments which allow them to be used for a wide range of applications. These machines are used extensively in the food, medical, chemical, cosmetic, and electronic industries.

The HL-M810 band sealer adopts dry ink coding designed to print date and lot codes at the seal line. Ink dries instantly upon contact with packaging materials and produces clear and legible characters. Standard font size is 18PT which allows for two-line printing. An optional 10.5PT font size which allows for three-line printing can be purchased separately. Please ask your distributor for more information.

There are two configurations for the HL-M810 band sealer. The horizontal configuration (HL-M810I) is primarily used for sealing dry materials and when you can lay flat your pouch. The vertical configuration (HL-M810II) typically seals small solid products (ex: powders, grains, coffee) and liquids. In addition, sealing using the vertical configuration also works best with stand up pouches.

Features of the HL-M810 Band Sealer

Your band sealer is equipped with a wide range of standard features and capabilities.

Simple to use – minimal operator training

Fast warm up time

Unit feeds left to right

Rust inhibiting stainless steel construction

Equipped with bag entry guide for easy bag feeding and straight seals

Control panel includes industrial grade safety emergency stop switch

10amp protection power surge breaker

Equipped with photo sensor for optimal printing precision

Dry ink coder for printing characters at the seal line

Wide seal (8mm) to assure airtight seal / 15mm wide seal band sealer available via special order

PTFE sealing belts

Extended forced-air cooling system with extra wide cooling bars and 6 heat transfer orifices

One pair of brass sealing bars

Sealing method – constant heat

Adjustable 2-way pulley system for optimal stability and embossing clarity

Knurled pressure rolls with variable pressure adjustment

PID digital temperature controller 0-300˚C (572˚F) with dual alphanumeric displays (target & current temp)

Motorized rubber conveyor with speed control

3

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

Capable of speeds up to 472 inches/minute

How Does the HL-M810 Work?

HL-M810 is comprised of a stainless steel frame, speed adjusting mechanism, sealing temperature control system and transmission system. Turning on the heat for the band sealer will cause a rapid rise in the temperature of the heating blocks. Required temperature and speed can be adjusted via the temperature controller and speed adjusting device. Plastic material to be sealed is placed on the guide and

conveyor. Conveyor will then take the material between the two heating blocks to fuse the material together. Material will then pass through the cooling blocks to allow the material to congeal. Finally, a photoelectric sensor will direct the dry ink coder to print a clear and legible print at the seal line.

The motor drives the sealing belts, drive belts and conveyor simultaneously.

Specifications

|

|

HL-M810I (Horizontal) |

|

|

HL-M810II (Vertical) |

|

|

|

|

|

|

||

Power |

|

110V/60Hz |

|

|||

Motor Power |

|

50W |

|

|

||

Sealing Speed |

|

0-472 inches/minutes |

|

|||

Sealing Width |

|

8mm (Optional 15mm width available) |

|

|||

Temperature Range |

|

0-300˚C (572˚F) |

|

|||

Conveyor Size |

|

37” x 6” |

|

|||

Max Conveyor Load |

|

6.6lbs |

|

|

||

Min/Max Height of Bag (Vertical Only) |

|

N/A |

|

7 7/8” / 12” |

|

|

Printing Heating Power |

|

40 x 2 (W) |

|

|||

Character Size |

|

3x5x7mm / 18PT – 2 lines |

|

|||

|

|

2x3x7mm / 10.5PT – 3 lines (additional option available) |

|

|||

Printing Colors |

|

Black, Blue, Green, Red, White, Yellow |

|

|||

Dimensions |

|

37” x 16” x 14” |

|

37” x 16” x 26” |

|

|

Weight |

|

85lbs |

|

95lbs |

|

|

4

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

Getting to Know your Band Sealer

5

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

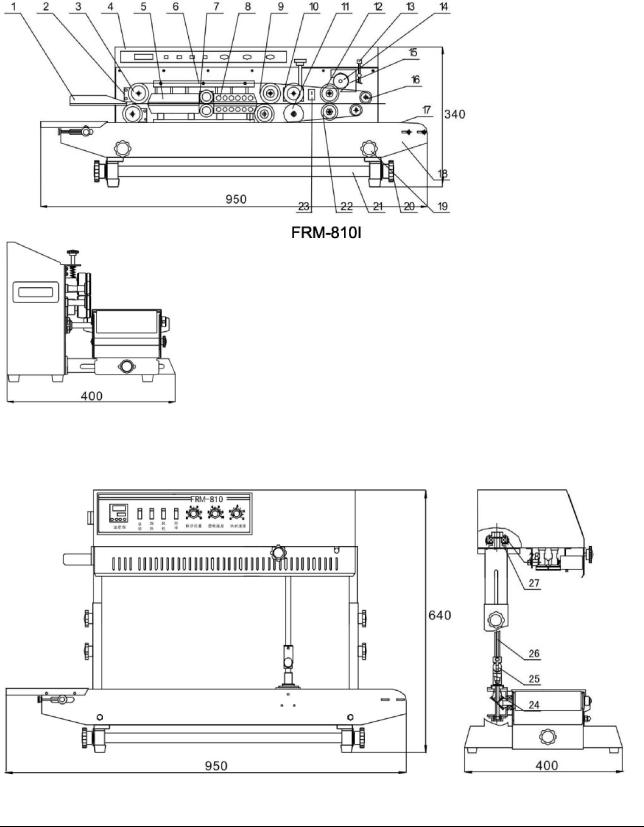

HL-M810 Diagram

Figure 1. Horizontal Band Sealer (1) Guide, (2) Driven Wheel Seat (Adjusting Block), (3) Driven Wheel, (4) Control Panel, (5) Heating Block, (6) Sealing Belt,

(7) Pinch Roller, (8) Cooling Block, (9) Driving Wheel, (10) Embossing Roller, (11) Silicone Wheel, (12) Printing Wheel, (13) Ink Wheel Adjusting Device, (14) Ink Roller, (15) Ink Roller Heating Block, (16) Guide Wheel (Small), (17) Conveyor Belt, (18) Conveyor Table, (19) Fastening Knob for Elevating Table, (20) Transverse Tightening Knob for Conveyor Table, (21) Ledge, (22) Silicone Wheel, (23) Photoelectric Sensor

Figure 2. Vertical Band Sealer (24-26) Umbrella Gear w/ Long Shaft

6

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

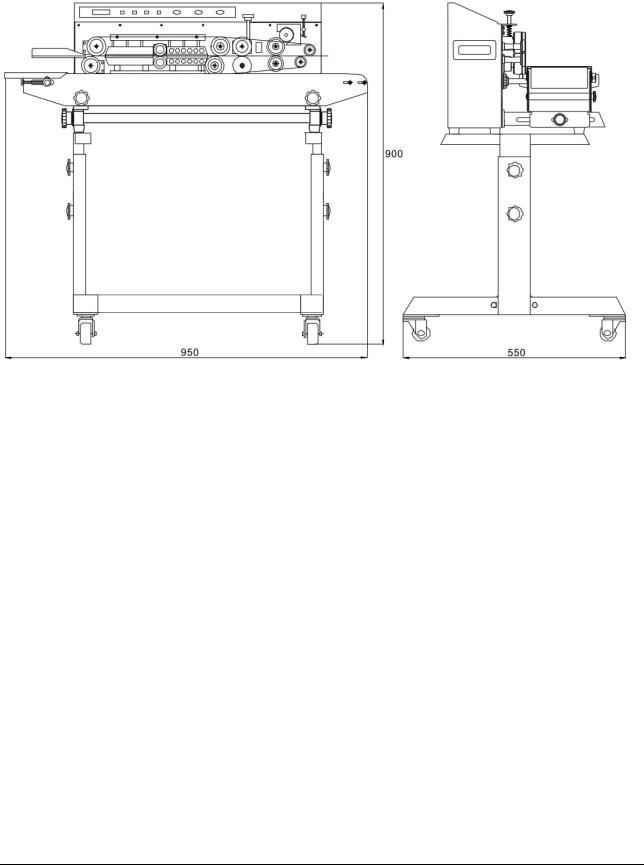

Figure 3. Horizontal Band Sealer with Stand. Optional stand available for HL-M810. Please ask your distributor.

7

H L - M 8 1 0 I N S T R U C T I O N M A N U A L

Electrical Circuit Diagram

Figure 4. Electrical Circuit Diagram. (QF1) High Rupture Switch, (SB1) Emergency Stop Switch, (K1) Power Switch, (K2) Switch/Heat Sealing, (K3) Switch/Fan, (K4) Switch/Print, (K5) Switch/Aerate.Vacuum, (W1) Speed-Regulating Potentiometer; (W2) Coding Position-Regulating Potentiometer; (W3) Temperature-Regulating Potentiometer for Ink Roller; (HE1) Heating Element for Sealing, (R3/R4) Heating Element of Ink Roller; (MD), Speed Adjusting Motor; (M) Aerate/Vacuum, (FAN) Fan, (TC1) Transformer, (YC1) Electromagnetic Clutch, (YC2) Electromagnetic Brake, (SQ1) Photoelectric Sensor; (SQ2) Groove Sensor; (THC1) Sealing Temperature Controller; (ST1) Thermocouple

8

Loading...

Loading...