SEA COMPACT 400,COMPACT 800 Fitting & User Instructions

Sistemi elettronici

di Aperture Porte e Cancelli

FITTING AND CONNECTION INSTRUCTIONS

ENGLISH

The Compact 400/800 consists of a hydraulic pump and a

hydraulic jack, both of which coupled in a supporting box

treated with cataphoresis.

The pump unit casing, which is used as an oil tank, contains the

electric motor, fluid pump, distributor and hydraulic oil.

It is also provided with an adjustable slowing-down device in

the two stop phases of the leaf .

The wheeling unit is composed by a double piston connected to

a rack which engages with the pinion of the leaf dragging shaft.

Gates up to 2 meters long can be securely locked using the

operators internal hydraulic locking system, thus ensuring

perfect keeping in closing and in opening.

For gate in excess of stated value: A hydraulic non locking

operator should be used in conjunction with a separate electrical

locking device to ensure keeping in closing.

For rotation angles not included between 90°-100 and 130°140° respectively, slowing down is either in closing or in

opening.

In case of power failure: The operator's internal hydraulic locking

can be released using a special key and the gate used manually.

(versions with slow-down only)

1 Release Cover

2 Release Extention

3 Braking regulation screw

(where provided)

4 Exit hole for electric cables

5 By-pass regulation

Compact 400 Compact 800

230 V (±5%) 50/60 Hz

220 W

1,1 A

1400 rpm

45

50 bar

40 bar

-20°C +55°C

130°C

56 da Nm

12,5uF

13 Kg 13,8 Kg

IP55

400 Kg 800 Kg

Versions with slow-down

REV 02 - 09/2005

6 Filling oil Cap

7 Oil level indicator

8 Water draining hole

9 Draining screw

10 Screw for braking regulation stop

MAIN PARTS NOMENCLATURE

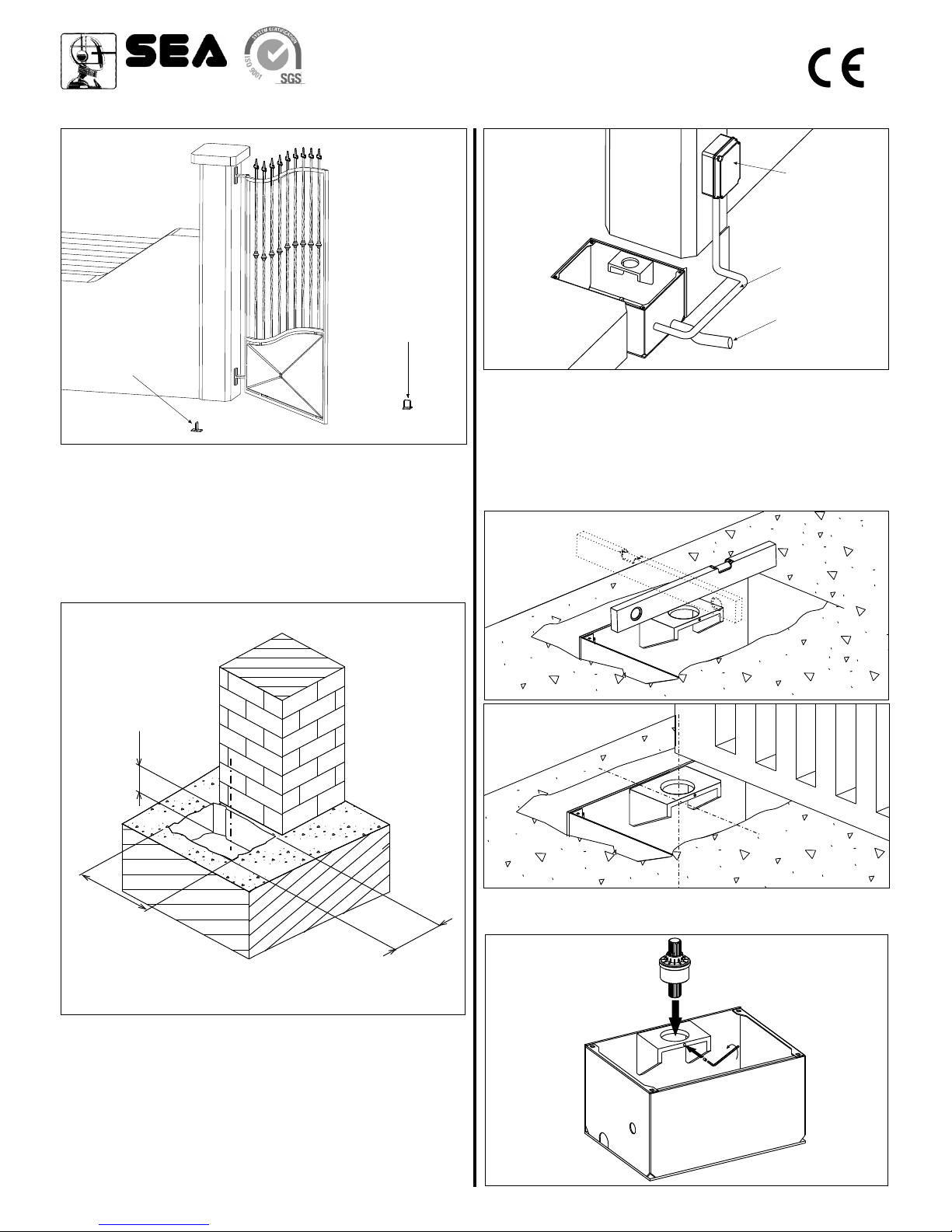

1. GATE ARRANGEMENT

You must do some checks on the gate to see if fitting a

COMPACT system is possible:

A. (Make sure that) the fixed and moving parts of the gate are

strong and non-deformable;

B. the weight of each gate leaf must not exceed 400 Kg

(Compact 400), 800 Kg (Compact 800) ;

C. the hinges and general structure must be in good condition

and the gate must move smoothly throughout its travel;

E. as the limit switches are not provided within the actuator, it is

necessary to install mechanical limit switches stops to be fixed to

the ground in closing and in opening (Fig. 3).

D. the upper hinge alone is sufficient to install the unit; those

which are unnecessary can be eliminated (the lower and that in

the middle if exists);

DIMENSIONS (mm)

cod. 67410085

TECHNICAL DATA

Power supply

Motor Power

Absorbed current

Motor rotation speed

Cycles hour (with a 20°C temperature)

Max Pressure of the 0.50 lt pump in use

Max Pressure of the 0,75 lt pump in use

Operating temperature

Thermal protection intervention

Max torque

Starting capacitor

Weight

Protection class

Maximum weight of the gate

Braking regulation

11

22

33

44

55

66

77

88

99

1010

33

218

209

50

395

- 4

0

*

4

2 meters

COMPACT

400

AC

4 meters

800 Kg

400 Kg

Max leaf weight Max leaf width

Underground hydraulic operators

GRAPHIC FOR THE USE OF COMPACT 400

AND COMPACT 800 OPERATORS

COMPACT

400

AC

COMPACT 400 SB

(With electric lock)

COMPACT

400

SB (w.e.l.)

COMPACT

800 AC

COMPACT 800

AC

COMPACT 800 SB

(With electric lock)

COMPACT 800

SB

(With electric lock)

Fig. 1

* 180° version

Fig. 2

13/32

COMPACT 400 (with and without slowdown)

COMPACT 800 (with and without slowdown)

Sistemi elettronici

di Aperture Porte e Cancelli

Fig. 7

2.2. Inside the excavated pit you have to plan:

- rain water drainage;

- a water waste pipe in flexible plastic of about 40 mm of

diameter to put inside the provided hole of the box before it is

concreted (Fig. 5). It must be brought until the drain of the

sewer line;

- a sheath for the passage of electrical cables of about 20 mm

of diameter which must be brought to the proximity of the

electric connection box (Fig. 5).

Fig. 6

2. CARRYING BOX INSTALLATION

2.1. The hole which contains the carrying box must have the

approximate dimensions mentioned in Fig. 4.

For a correct placing, it is obbligatory to follow closely the quote

of 60 mm which corresponds to the minimum distance of the

rotation axis from the pillar.

Fig. 4

60

0 -

6

40*

450

220

* Compact 400 180°/Compact 800 180° box versions

dimensions (mm)

Fig. 3

Limit switch stop

in opening

Limit switch stop

in closing

2.3. Before concreting the carrying box, use a level to make it

perfectly horizontal to the ground (Fig. 6) and perpendicular to

the axis of the gate (Fig. 7).

The axis of the upper hinge of the gate must correspond exactly

to the axis of the carrying box shaft.

Follow the distance of 50 mm closely between the carrying box

cover and the base of the gate (Fig. 2) remembering that the Ushaped iron will be inserted on it (see the paragraph 3).

Fig. 5

Sheath for electric

cables passage

Flexible pipe

for water draining

Electric

connection box

2.4. Put the jointed splined shaft into the upper hole of the

carrying box and fix it with the provided screw (Fig. 8)

Fig. 8

REV 02 - 09/2005cod. 67410085

14/32

Loading...

Loading...