Page 1

SCUBAPRO

Repair Guide

R390 - R380

Second Stages

USE THIS GUIDE AS A REFERENCE WHEN SERVICING THE R390 AND

R380 SECOND STAGES

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

Page 2

SCUBAPRO R 390 - R 380 Second Stages

P

/

N

4

3

0

4

0

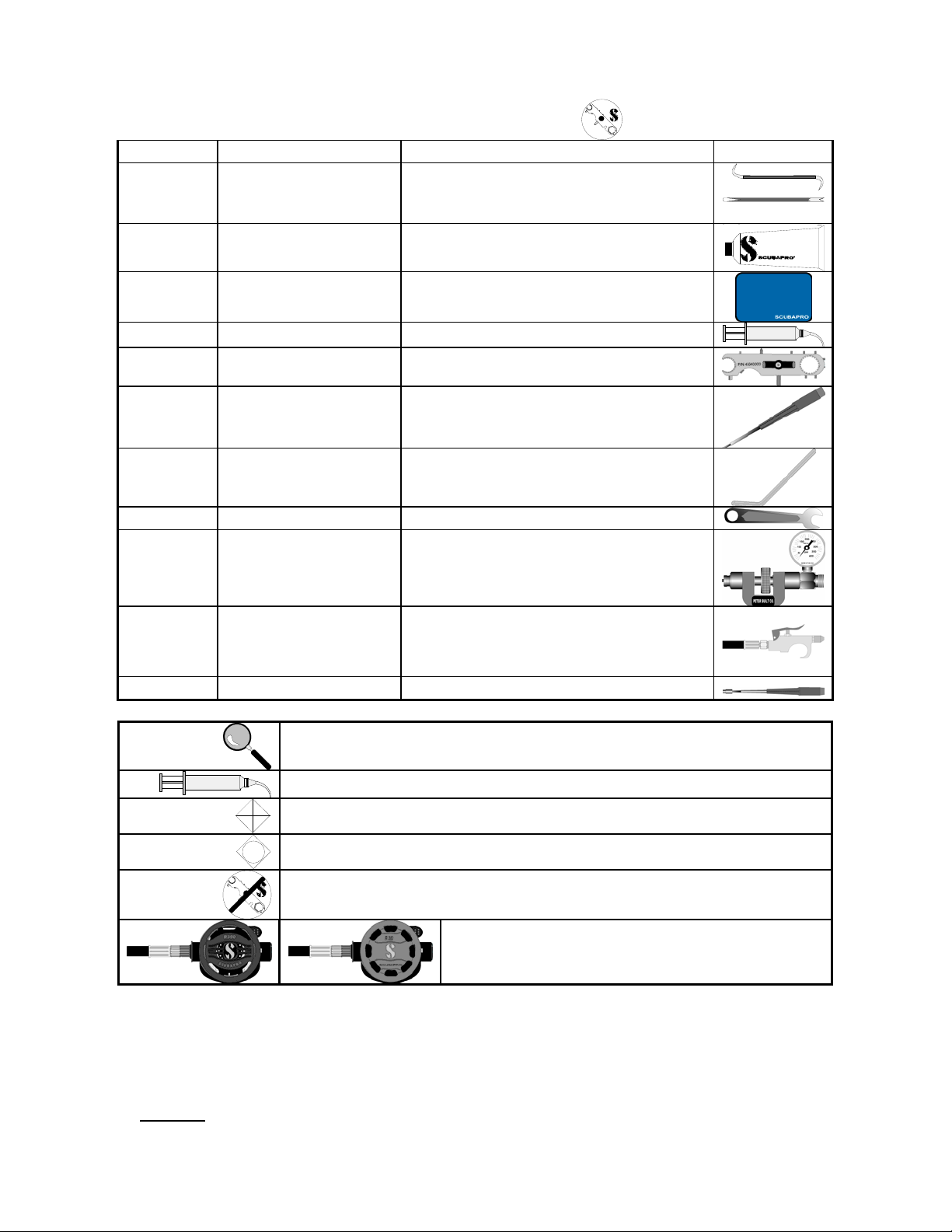

TOOLS NEEDED FOR REPAIR OF R390-R380

TOOLS

NEEDED

0

0

0

Quantity Part Number Description

1 set 10.102.100

(Peter Built)

Brass o’ring picks

1 tube 41.047.000 Christo-Lube

1 47.010.000 Counter Mat

Christo-Lube

OXYGEN COMPATIBLE LUBRICANT

P/N 41-047-000

1 41.496.101 Lubricant syringe

1 43.040.000 Universal Tool

1 11.153.500

Ball-end Allen Wrench

(Peter Built)

1 43.300.225 VIVA Flow Vane Removal Tool

1 13mm low torque wrench

1 20.500.200

Pneumatic Adjusting tool

(Peter Built)

1 18.300.500 Blow Gun/Air Nozzle

1 ¼” Nut Driver

ICON LEGEND

Inspect carefully, replace if needed

Monoject

Lubricate properly

Replace annually

Dynamic o’ring, replace annually and lubricate properly

N

4

3

0

4

0

0

0

0

No tools needed for this step

TOOLS

NEEDED

P

/

Indicates the regulators affected by this step

Monoject

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

2

Page 3

SCUBAPRO R 390 - R 380 Second Stages

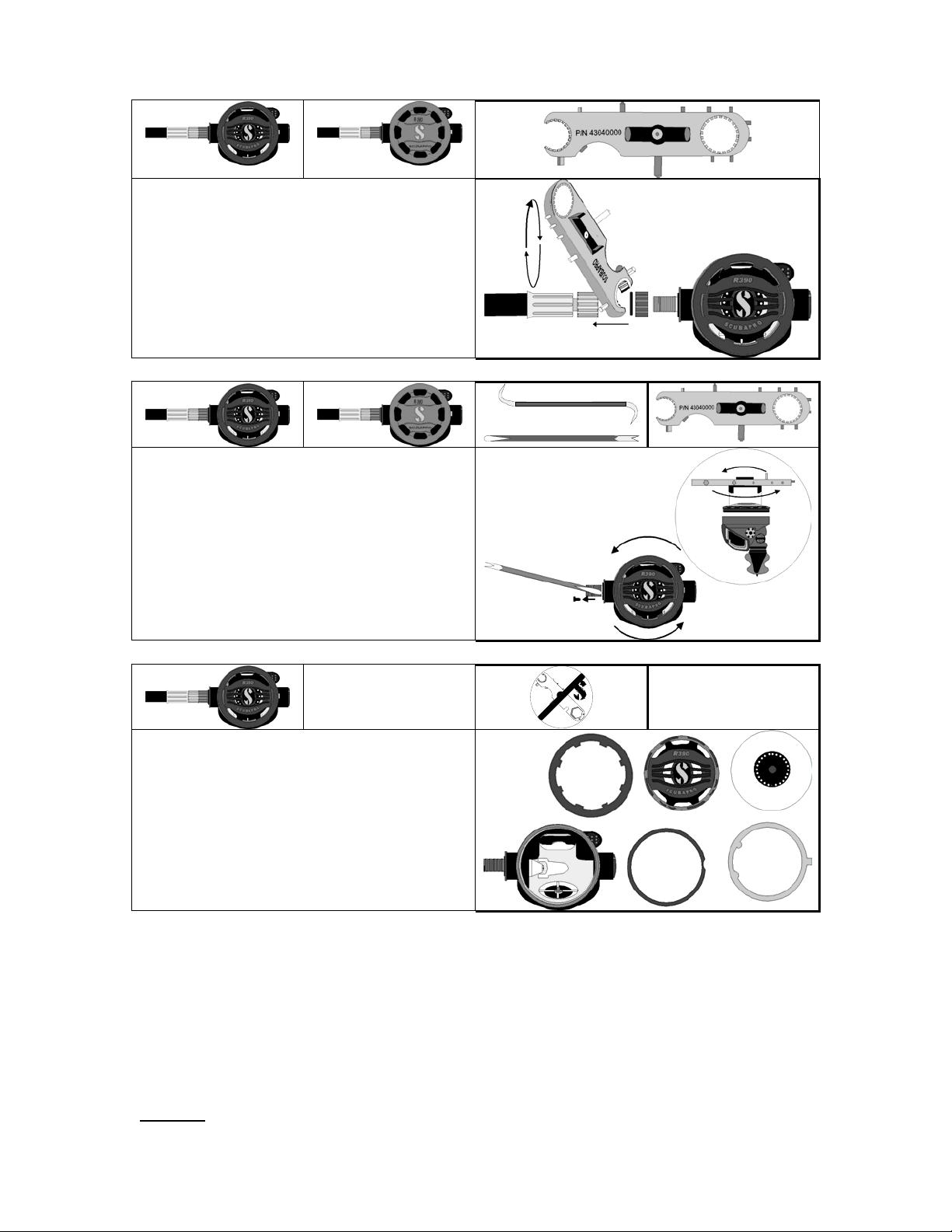

Remove hose and jam nut from the

second stage.

Remove the housing pin using the

brass pick or similar tool.

Use the universal tool as shown to

loosen the two-piece cover of the

R390.

P

/

N

4

3

0

4

0

TOOLS

NEEDED

0

0

0

No tools needed

this step

Remove the two-piece cover, friction

washers and diaphragm from the

second stage housing.

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

3

Page 4

SCUBAPRO R 390 - R 380 Second Stages

P

/

N

4

3

0

4

0

0

0

0

TOOLS

NEEDED

No tools needed

this step

Remove the two-piece cover, friction

washers and diaphragm from the

second stage housing.

Remove the washer from the air inlet.

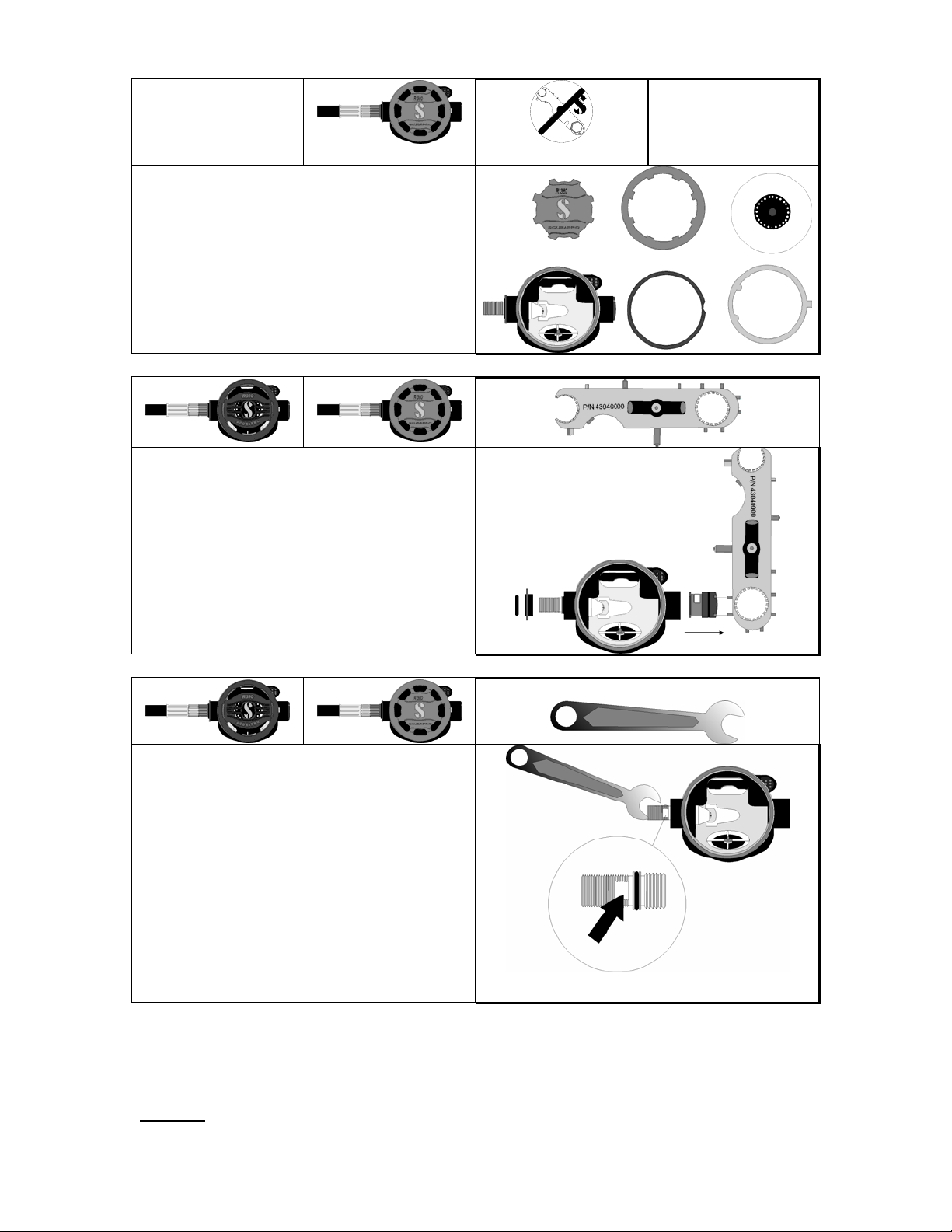

Using the universal tool remove the

housing plug by turning and then

pushing from the inside of the housing.

Use a 13mm or ½” low torque (thin)

wrench to loosen and remove the valve

body. The wrench should rest on the

“flat” sides of the valve body, which are

designed to permit gripping by a

wrench.

Caution: Do not score the threads on

the valve body when applying the

wrench. Scoring the threads will result

in damage and require replacement of

the valve body.

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

4

Page 5

SCUBAPRO R 390 - R 380 Second Stages

No tools needed this

P

/

N

4

3

0

4

0

0

0

0

TOOLS

NEEDED

step

Push the valve housing to the inside of

the case to remove. Take care not to

lose the housing plug.

Note: There are two aspirator holes in

the housing. The housing plug should

be in the aspirator hole AWAY from the

mouthpiece if the regulator is set up as

a right hand second stage.

Remove the nyloc nut from the poppet

assembly using the ¼” Nut Driver.

Remove the poppet assembly from the

housing.

Use the universal tool to remove the

adjustable orifice from the valve body.

This Step Is Only Performed As Needed

When it is necessary to remove the

VIVA flow vane, use the flow vane

removal tool (p/n 43.300.225).

Note: This step is seldom needed,

unless the VIVA flow vane o’ring is

worn or damaged.

Top View

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

5

Page 6

If the VIVA flow vane is removed, it may be

necessary to replace the entire VIVA

assembly, including the o’ring.

SCUBAPRO R 390 - R 380 Second Stages

No tools needed

P

/

N

4

3

0

4

0

0

0

0

TOOLS

NEEDED

this step

This Step Is Only Performed As Needed

Carefully inspect and lubricate the o’ring.

The venturi vane is reversible.

Maximum VIVA

:

Place the new knob and vane assembly

back into the housing with the crescentshaped notch facing forward toward the

back of the diaphragm for maximum VIVA.

Minimal VIVA:

Place the new knob and vane assembly

back into the housing with the crescentshaped notch facing forward toward the

mouthpiece opening for minimal VIVA (ie:

for rental equipment).

Push the vane inward until it is locked in

place.

This Step Is Only Performed As Needed

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

6

Page 7

SCUBAPRO R 390 - R 380 Second Stages

If removal of the exhaust valve is

necessary, use the ball-end allen wrench

to push out the exhaust tee pin. Remove

the center section of the exhaust tee.

To remove the exhaust valve, grasp with

fingers and pull firmly out.

The exhaust valve will seldom need to be

replaced. Careful inspection is usually all

that is necessary. If the valve is removed

during service, it may be damaged during

the process, requiring

replacement.

If the exhaust valve is removed, carefully

inspect and replace if necessary.

Replace the exhaust tee center section

and use the ball-end allen wrench to

replace the exhaust tee pin.

This Step Is Only Performed As Needed

This Step Is Only Performed As Needed

Inspect all washers and the lever.

Replace the poppet seat and nyloc nut.

Reassemble the valve housing. The nyloc

nut should be adjusted as follows:

a. Maximum of one poppet carrier

thread showing through if used for

a primary regulator.

b. Maximum of two poppet carrier

threads showing through if used for

an octopus regulator

c. Maximum of three poppet carrier

threads showing through under all

circumstances.

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

7

Page 8

Inspect and lubricate the two static

o’rings on the valve body and

adjustable orifice.

Insert the adjustable orifice into the

valve body and turn the adjustable

orifice inward one complete turn using

the universal tool.

Install the valve housing and valve

body into the case.

Hold the lever DOWN while assembling

these pieces. This will help prevent

engraving of the poppet seat during the

threading process.

SCUBAPRO R 390 - R 380 Second Stages

Monoject

No tools needed

P

/

N

4

3

0

4

0

0

0

0

TOOLS

NEEDED

this step

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

8

Page 9

SCUBAPRO R 390 - R 380 Second Stages

Use a 13mm or ½” low torque (thin)

wrench to tighten the valve body. The

wrench should rest on the “flat” sides of

the valve body, which are designed to

permit gripping by a wrench. Hold the

lever arm down as you tighten the

valve body to prevent engraving of the

poppet seat.

Caution: Do not score the threads on

the valve body when applying the

wrench. Scoring the threads will result

in damage and require replacement of

the valve body.

Inspect and lubricate the valve body

o’ring. Reinstall the washer and o’ring

on the outside of the valve body.

Inspect and lubricate the plug o’ring.

Reinstall the plug in the regulator case

using the universal tool. Turn the plug

¼ turn until it locks in place.

Monoject

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

9

Page 10

SCUBAPRO R 390 - R 380 Second Stages

Install the jam nut on the valve body

and tighten using the universal tool.

Inspect the diaphragm and install.

Install the anti-friction washer on top of

the diaphragm being careful to insert

the tab in the side of the case.

Install the washer on top of the antifriction washer.

No tools needed

P

/

N

4

TOOLS

NEEDED

3

0

4

0

0

0

0

this step

No tools needed

P

/

N

4

3

0

4

0

0

0

0

TOOLS

NEEDED

this step

Inspect the diaphragm and install.

Install the anti-friction washer on top of

the diaphragm being careful to insert

the tab in the side of the case.

Install the washer on top of the antifriction washer.

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

10

Page 11

SCUBAPRO R 390 - R 380 Second Stages

Install the two-piece front cover. Use

the universal tool as shown to tighten.

Insert the case pin.

Mount the pneumatic adjusting tool into

the second stage body, and thread on

the second stage low-pressure hose.

Use the pneumatic adjusting tool to

make the initial air-on adjustments to

the second stage, and to stop all free

flowing. Once free flow stops, de-tune

the second stage orifice from the

twelve o’clock position to the one

o’clock position.

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

11

Page 12

SCUBAPRO R 390 - R 380 Second Stages

Reinstall the low-pressure hose on the

second stage body.

Check the cracking effort of the

regulator.

R390 Inhalation effort range:

Primary Regulators: 1.2 to 1.8 inches

of water

Octopus/Alternate Air Source: 1.4 to

1.8 inches of water

R380 Inhalation effort range:

Primary Regulators: 1.2 to 1.8 inches

of water

Octopus/Alternate Air Source: 1.4 to

1.8 inches of water

2003 SCUBAPRO

Important note

technicians are required to attend an annual service training program to insure safe handling and servicing of SCUBAPRO products. All SCUBAPRO technicians

must be employed by an authorized SCUBAPRO facility.

: The following information is not designed to be a complete training guide for servicing the listed SCUBAPRO regulators. All SCUBAPRO

12

Loading...

Loading...