Page 1

Introduction

SLE300

To the owner or user: This service manual is

intended to provide you, and the maintenance or

service tec hnician, with the information ne eded to

install, start up, cle an, main ta in and rep air this

product .

The SLE300 is an ice machine that produces

cubed ice on 4 vertical cu be free zing surfaces.

When harvested, the cubes fa ll individ ua lly int o the

ice storage bin. The S LE300 automatically

maintains the level of ice by tu rnin g on when the

ice level falls, and switch es of f whe n the bin is full.

The refrigeration system uses R-404A as the

refrigerant.

Table of Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Installation

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

SLD dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

RS or IS dispenser . . . . . . . . . . . . . . . . . . . . . . . . page 7

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Initial Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Electrical S equence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p age 13

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Water/ Refrigeration Schematic . . . . . . . . . . . . . . . . . . . . . . . . . page 16

Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p age 19

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

Parts lists and wiring diagrams are loca te d in the center of this manual, printed on yellow paper.

Note the warning symbo l where it appears in

this manual. It is an alert for impo rta nt safet y

informatio n on a hazard that might cause

serious injury.

Keep this manual for future reference.

This manual was printe d on recyc led paper.

January 1995

Page 1

Page 2

Drain

SLE30 0

Specifications

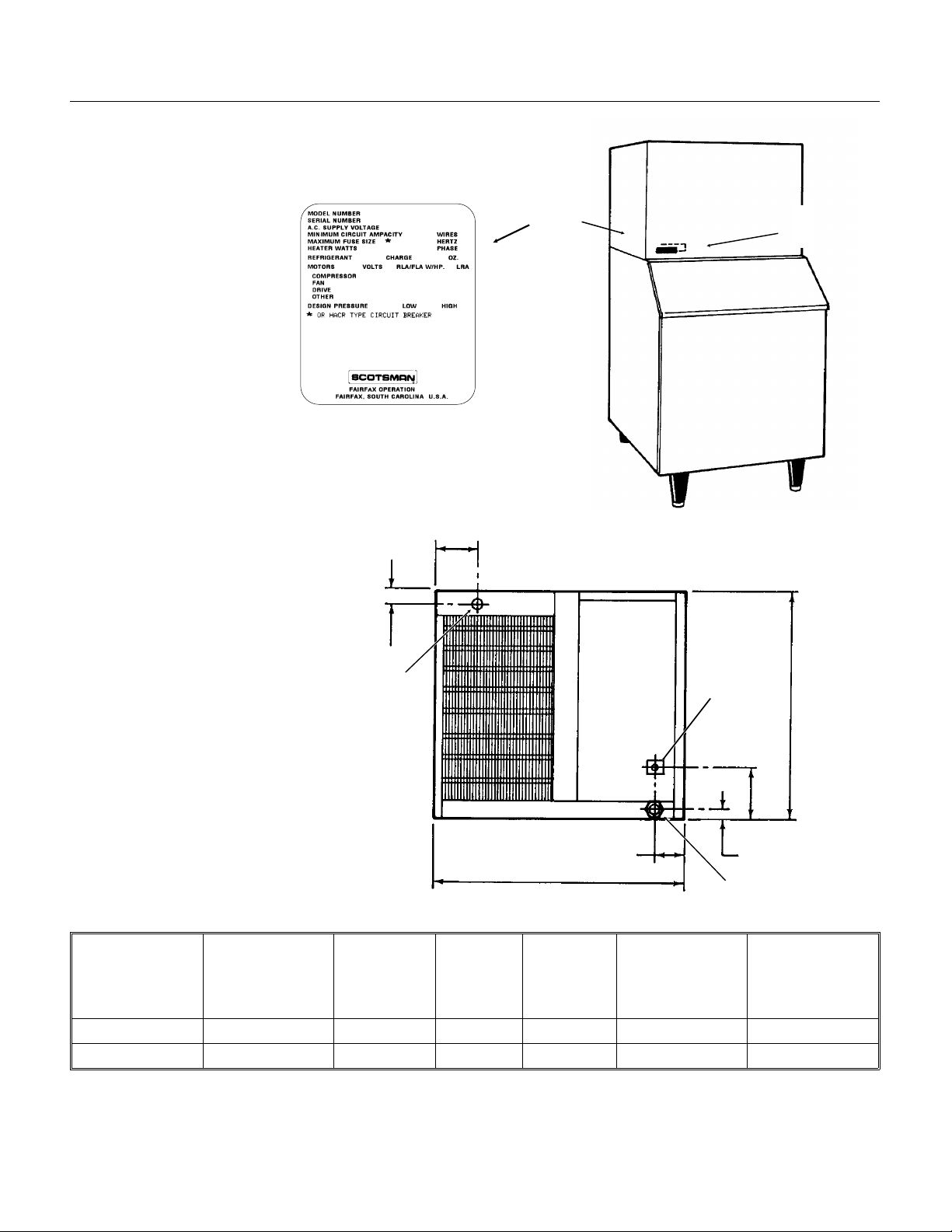

Information regardin g Model Numb er, Serial

Number, Ampacity and Maximum Fuse Size are

located on the nameplate of the ice ma chine. The

model numbe r, serial number an d refrigerant

charge are also list ed on

the serial number plate

just behind th e fr ont

panel.

If recharging, always

use the charge listed on

the ice machine.

Nameplate

SLE300 Cabinet

Serial Number

Plate

3

⁄8"

1

Electrical

Inl et

3 3⁄4"

SLE300 Back View

(Air Cooled Model Show n)

Wate r

Inlet

1

4

20"

⁄4"

Specifi cations:

The SLE300 will stack onto a

variety of ice storage bins, see

sales literat ure for pro per ic e

22"

7

⁄8"

storage bin.

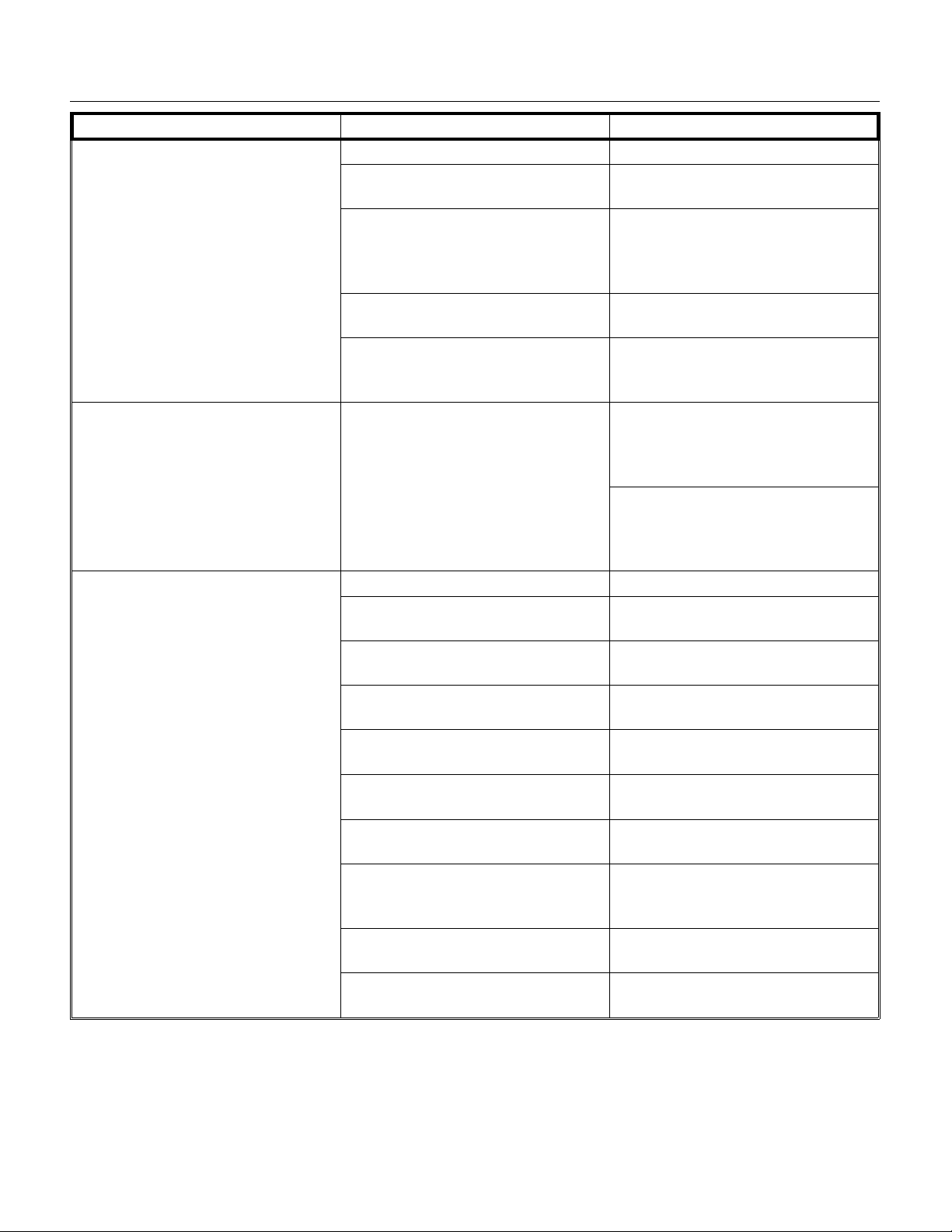

Model Number Dimensions

W" x D" x H "

Condenser

Type

Basic

Electrical

Minimum

Circuit

Ampacity*

Maximum

Fuse Size (or

HACR circuit

Refrigerant

Charge.

R-404A

breakers)

SLE300AS-1A 22 x 23 x 20 Air 115/60/1 17.3 20 15 ounces

SLE300WS-1A 22 x 23 x 20 Water 115/60/1 15.8 20 15 ounces

* Minimum Circuit Ampac ity is used to determin e

wire size and type per the Nationa l Elect ric Code.

January 1995

Page 2

Page 3

For The Installer: Environmental Limitations

The ice machine must be inst alle d ind oors in a

controlled environ ment.

Minimum Maximum

Air Temp 55

Water Temp 40

Water Pressure 20 PSI 60 PSI

Voltage 103.5 126.5

Operatin g the ice machine outside of the above

limitations, or outd oors, is pote ntially damag ing to

the machine, and it is misuse of the machine. This

may void the warranty.

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance . They me et or exce ed the

standards of UL, NSF, and CSA.

Scotsman assu mes no liability or res po nsib ility of

any kind for pro duct s ma nufa ct ured by Scotsman

that have be en alte red in any way, including the

use of any part and/or other components not

specifically approved by Scotsman.

0

F. 1000F.

0

F. 900F.

SLE300

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and design are subject to change

without notice.

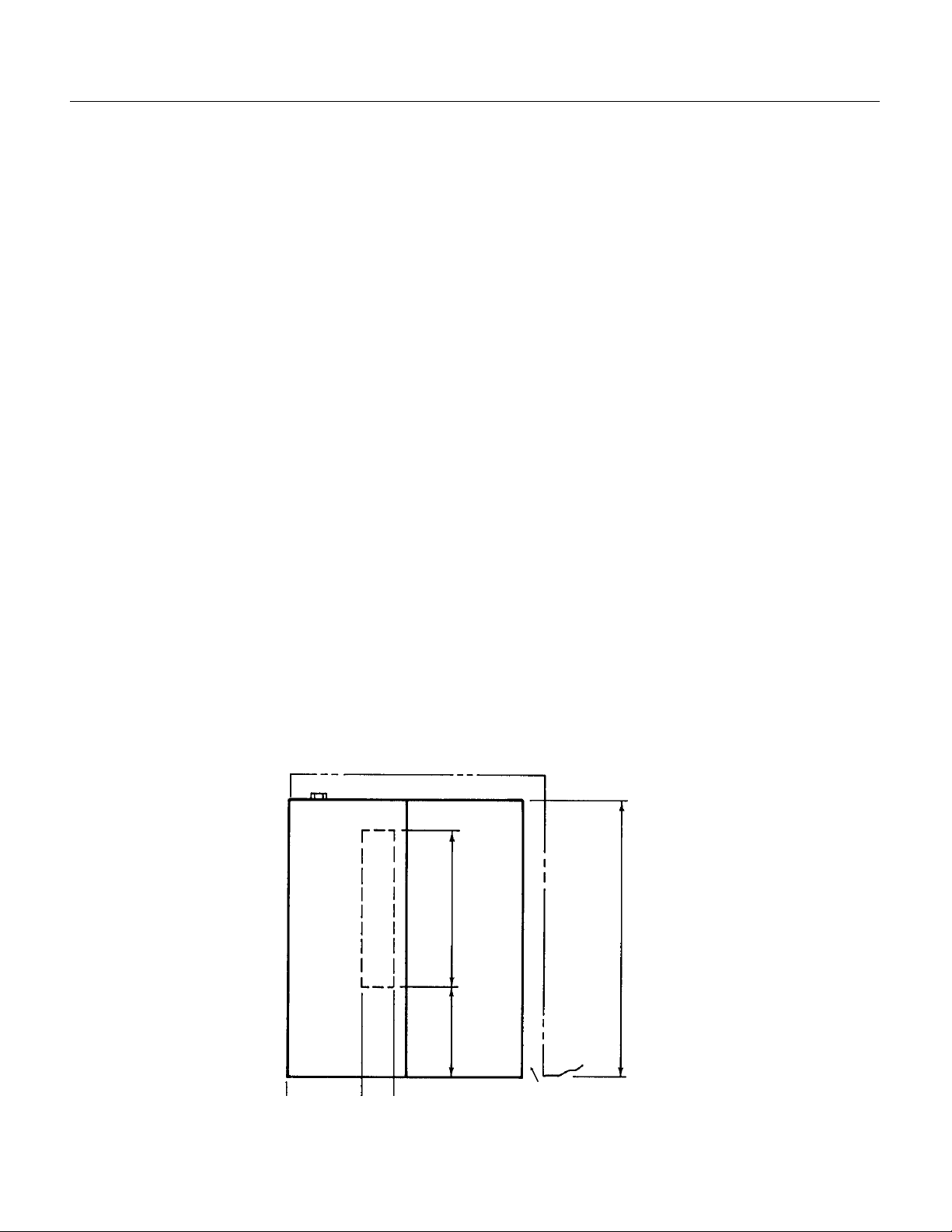

Airflow on air coo led models is :

••Intake thro ug h the right side grill.

••Ex ha u st throug h the back.

Dashed Lines Sho w

Outline of Ice Drop

Area.

Bin Control Mounts to

Right of Ice Drop Area.

7"

3"

6

12"

1

⁄2"

SLE300

Top View

23"

Do not install where this air flo w is obst ruc te d.

6" Space Required for

Air Flow (Air Cooled

Only) and Util it y

Connections

January 1995

Page 3

Page 4

SLE300

Installation

Water

The water supply for this ice machine has been in

contact with man y mat eria ls s ince it fell fro m the

sky as rain. All rain is slightly acidic , and tends to

dissolve the mat eria ls it come s in con tact with .

During water’s journ ey to the ice machine, it has

flowed ove r and thro ugh th e gro und, been pick ed

up by a municipal or priva te pump, fo rced thro ug h

a series of pipes of diffe ring construction and may

have been treated by the municipality providing

the wat e r.

The water supplied to this ice machin e will then

contain a variety of substances th at will likely show

up as solids during the ice making process. These

solids are similar to those found when water is

boiled out of a saucepan. Only the water boils

away, and t he minerals th at were in th e w ater

solidif y in the pan. Durin g ice making only the

water is frozen into ice, the minerals stay behind in

the reservoi r. This machine drain s ou t some of the

the water in the reservo ir eve ry cycle to minimize

the amount of minera ls in th e water syst em, but

after time the minerals will appear and have to be

dissolved by ice machine cleaner, the n flu shed

away during the clean ing proc ess .

Location

This ice machine may be installed in the open or

under a counter. Clearance may be req uire d at the

sides or top beyo nd what ’s nee ded to place the

cabinet into posit ion. Air co oled mod els take air in

the right side and exhaust out the back. Sp ace is

required for utilit y con nections at the back.

The ice machine is NOT designed for outdoor

use. It must be installed indoors, in a

controlled environment. The air and water

temperatures must not exceed rated limit s.

Pre-installation:

1. Inspect the place where the ice machine is to be

installed . Check fo r:

••space for the cabinet,

••water supply,

••drain av aila bilit y

••and electrical power su pply.

No extension co rds are allowe d. The buildin g dra in

inlet must be lower than the drain outlet of the ice

bin. The wate r sup ply mus t have a ha nd shu t of f

valve accessible when the unit is installed.

An ice machine is a food manuf act urin g pla nt ; it

takes a raw material, in this case water, and

transforms it into a food produ ct , ice. The purity of

the water is very import an t in obta inin g pure ice

and in maximizing product life .

The water to the ice machin e sh ould be filte red .

Water filters vary greatly in ability and functio n.

Install one that filte rs out suspende d solids to a

dimension of 5 microns or less . The fine r the filte r

the better , but finer filters may plug-up sooner than

course on es. It may be necessary to add a course

filter ahead of the fine filte r to prolong filter life.

Polyphosphat e feed ers are usually ef fect ive in

many water conditions.

Have the water teste d. Acid ic wate r or alka line

water will both cause corro sion . Disso lve d solid s

cannot be filtered out. Softened water is not

recommended . Neve r use de-ionized water.

Reverse-os mosis wate r must be treate d with

bufferin g agen ts befo re us e in the ice mac hin e.

Check with a water treatment specialist regarding

testing , tre atment and filters.

January 1995

Page 4

Page 5

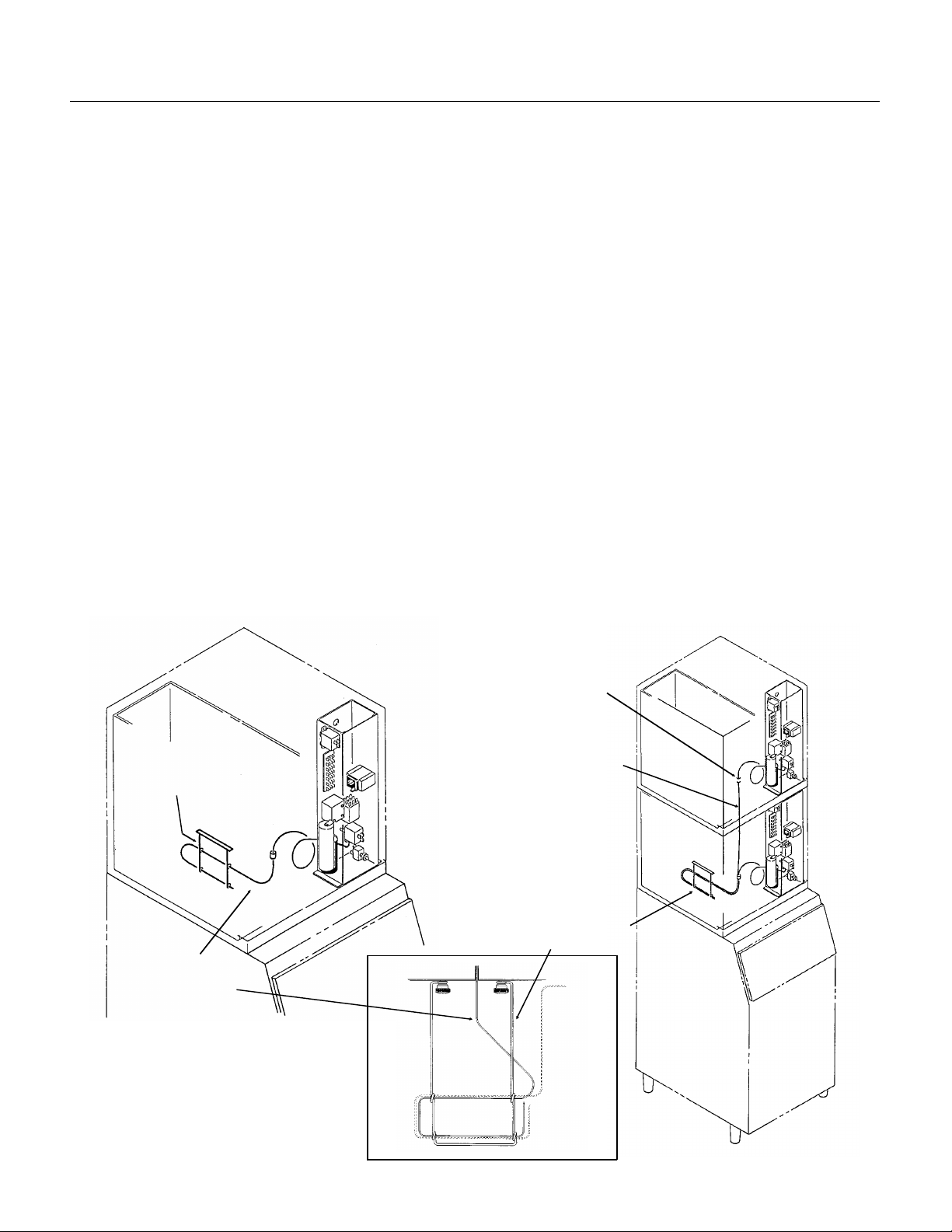

Stacking

Installation: Ic e Storage Bin

Thermostat

Capillary Tube

SLE300

Assembly:

1. Attach the legs, or optional casters, onto the ice

storage bin. Units th at are st ack ed shou ld only use

legs, not casters.

2. Be sure that the top edge of the bin has a good

gasket on it.

3. Place the ice machin e onto the stora ge bin.

4. Line up the ice machin e, check th at there is a

good seal betwee n the ice mac hin e and th e

storage bin.

5. If on a Scotsma n bin , at ta ch the ice mach ine to

the bin using the stra ps and bolt s ship pe d with the

ice machine. Drill two 1/8" holes in the back of the

bin and secure with sheet metal screws provided.

If on another brand bin, fo llow th e direct ion s

included with that bin.

Bin Thermostat Installation:

1. Remove thermo sta t bra cke t fro m pac kage.

2. Attach the bin thermostat bracket to the bottom

of the ice machine usin g the thumb sc rews

provided. The re are pre-d rilled and tapped holes

located just to the right of the cube drop area.

Stacking:

This machine will stack onto any SLE300 or

SLC400. Note : Do not us e cas ters wh en sta ckin g.

1. Remove and discard the left top panel from the

lower unit.

2. Rem ove knock ou t plug from t op right panel.

3. Place gaske t mat eria l around the top of the

bottom uni t’ s cabinet & evapora to r compartment.

4. Carefully lif t the uncrat ed top unit onto the

bottom unit. Use of a mechanical lift is

recommended for this step.

5. Align the two ice maker cabinets.

6. Secure the top unit to the bott om one with the

hardware and st rap s ship pe d with the upper

machine.

7. Locate and uncoil all of the bin thermo st at

capillary tube .

8. Route the bin thermostat capillary tube from the

upper unit, through the hole in the base, through

the lower unit and into the bin thermostat bracket.

Discard upper unit brac ket .

Bin Thermostat

Bracket

3. Locate and uncoil a portion of the

bin thermostat capillary tube. Route

the end of the capillary tube into the

plastic tube in the base of the ice

machine (next to the comp ress or) and

through the bin thermostat bracket.

Note: SLB150: Use thermostat

bracket packed with that bin.

Bin Thermostat

Installation

Routing Hole

Capillary Tube

Fasten Cabinets

Together At Back

With Straps &

Screws.

Bin Thermostat

Bracket

January 1995

Page 5

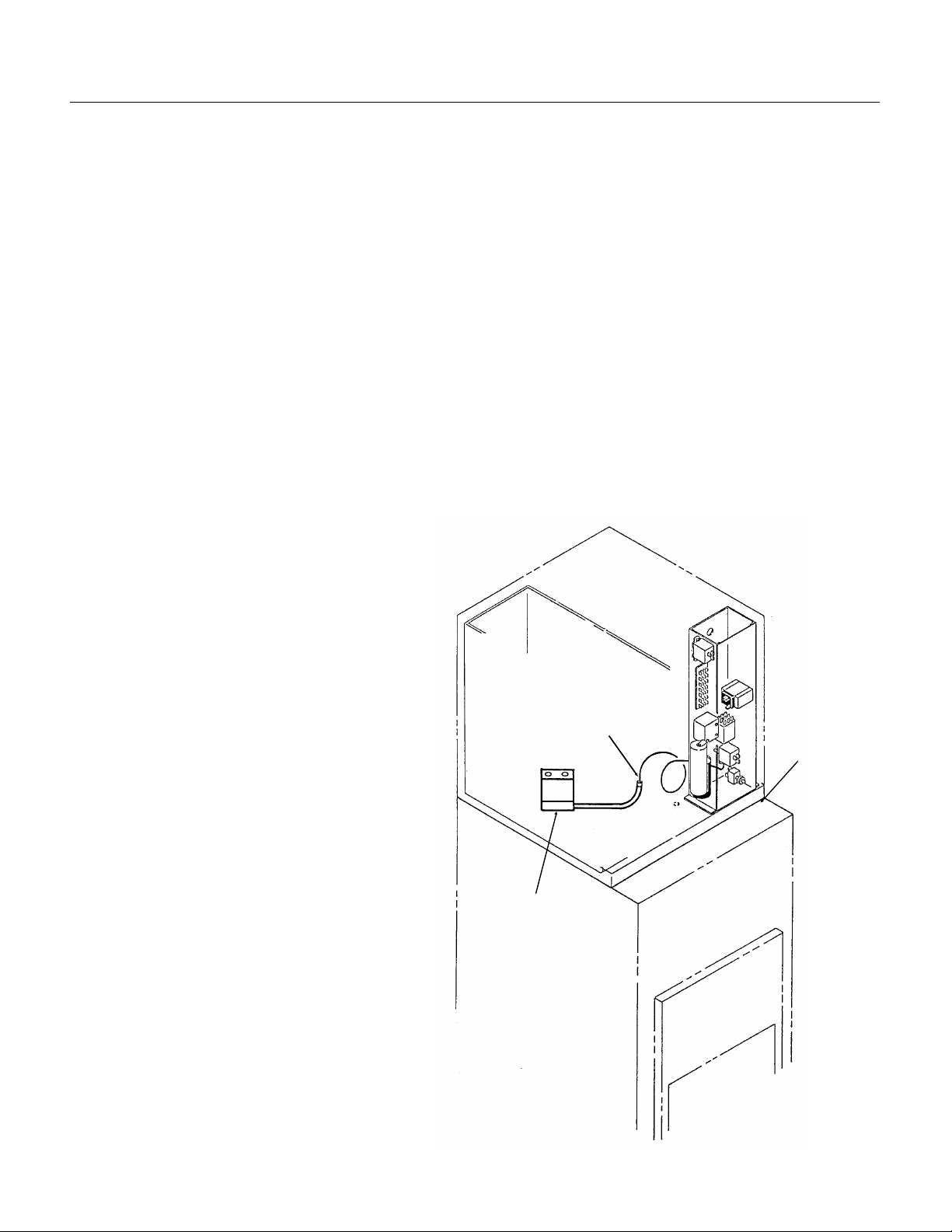

Page 6

Bin Thermostat Capillary

Tube Installation

SLE30 0

Installation: SLD150 Hotel Dispenser

Assembly

The ice machine must be pla ced ont o the top of

the dispenser, an d the bin thermostat capillary

tube routed into the bracket in the dispenser.

1. Check that the dispenser has a gasket all

around the perimeter of the top, 22" wide by 23"

deep.

2. Locate the inlet hole of the thermost at bracket ,

and make sure that it is open.

3. Place a corner post from the ice mac hin e cart on

at the front of left and right sides of the hotel

dispenser top.

4. Use a mechanica l lif t and pla ce th e ice ma chin e

onto the dispenser. The cardboard corner posts

should kee p the fro nt edg e of the ice mach ine up.

5. Remove the front panel of the ice machine.

6. Locate the bin thermostat capillary tube and

unc oi l about 18" of tub ing.

7. Locate plastic tube in base of ice

machine, next to compressor and

push the end of the capillary tu be thru

the tube, watch the capilla ry as it

comes out of the base, line it up with

the inlet hole of the thermosta t

bracket an d push it into the hole.

Move the cab ine t of the ice mach ine

until the capillary tube is going

straight down into the inlet hole.

8. Carefully remove the corner posts.

9. Push the capillary tube into the

thermostat bracket tube until abou t

14" of capillary tube is in the tube.

9 Remove the hardware package

from the mach ine , remove brackets.

10. At the back of the dispenser,

fasten brack ets to the ice machin e.

1 1. Using bracke ts for te mpla tes, drill

1/8" holes into the back of the

dispenser.

Route Capillary Tube

Through Plastic

Tube In Base

Bin Thermostat

Bracket Mounted In

Dispenser

Temporarily

Support Machin e

With Corner Posts

To Observe Cap

Tube Installat ion

12. Secure bra ckets to the dispenser

with sheet metal screws from the

hardware packa ge.

13. Follow other ins tallat ion

instructio ns from the SLD150.

January 1995

Page 6

Page 7

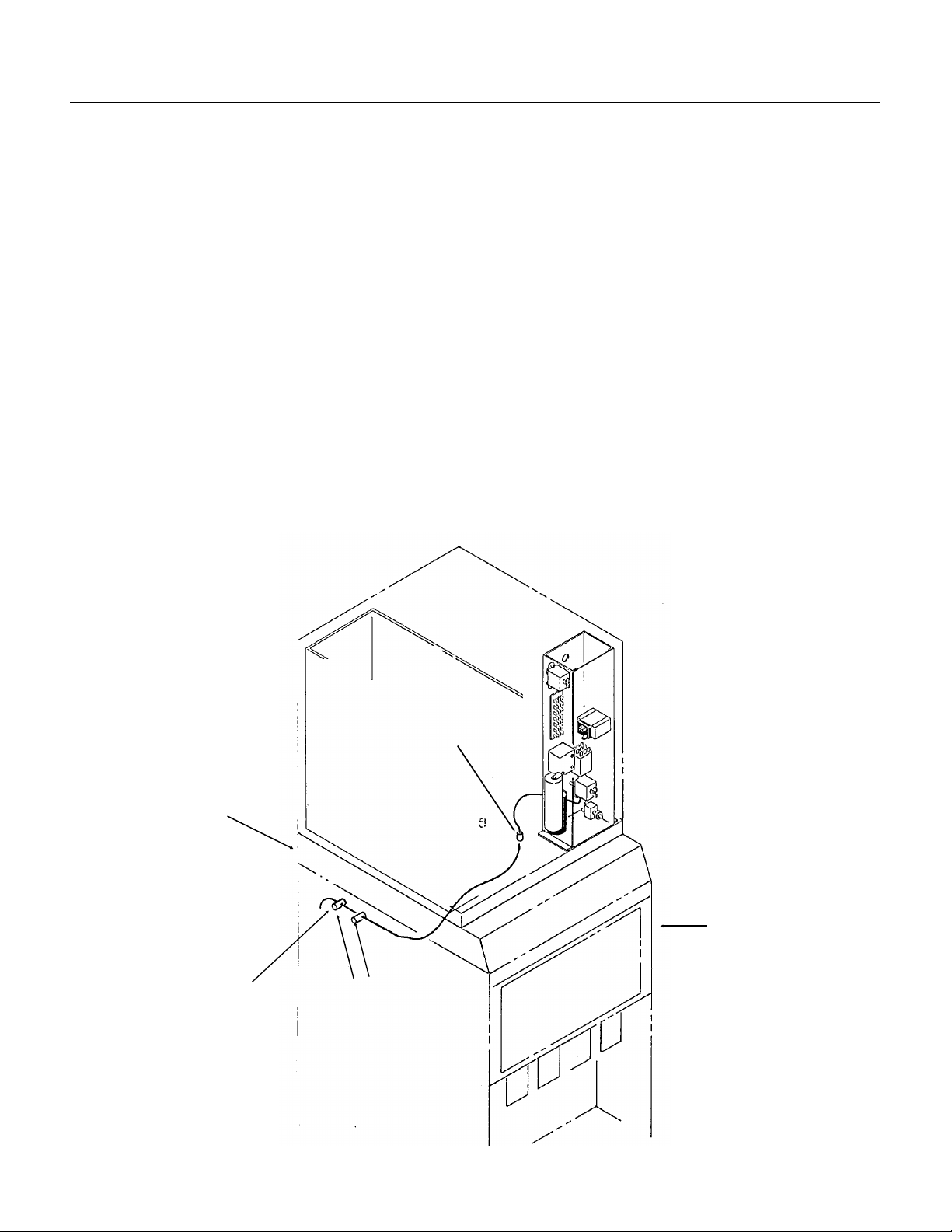

Installation: Sc ot sman IS or RS Dispens e r

RS or IS

Dispense r

SLE300

Assembly:

The assembly of the ice machin e onto the

dispenser requires two addit ion al parts: an adapte r

kit and a thermostat stand off kit.

1. Mark two spots on the inside left liner of the

dispenser: 2" down fro m the top, 4" from the back,

and 4" apart.

2. At the two marked spots , drill two 1/4 " holes thru

the plastic liner only.

3. From the stand off kit, locate the stand offs and

plastic anchors. Thread the stand offs partially into

the plastic anchors.

4. Push the anchors/stand offs into the holes.

5. Screw the stand of fs all th e way into the

anchors. Be sure th at the hole s in the stand offs

are horizontal.

6. Place a bead of silastic (from the kit) aro und the

stand off s.

7. From the adapter kit , pla ce th e st ain less stee l

adapter onto the top of the dispenser. Follow all

directions included with the kit.

8. After the ice machine has been placed on the

dispenser, remove the front panel and uncoil all of

the bin thermostat capillary tube.

9. Route the capillary t ube thru th e front hole in the

base of the ice mac hine, to the left side if the

dispenser towards the stand offs.

10. Route the end of the capillary tube thru th e

stand offs, bend the tube around the stand offs so

that it does not fall off.

1 1. Check that th e routing of the capilla ry tube is

away from the ice chute and up high near the base

of the ice machine.

Installation of Bin Thermostat

Capillary Tube

K1 Kit Adapter

Stand Offs From Kit K6

Drill 2 Holes For

Stand-Offs:

2" From Top Of

Dispenser &

4" From Back &

4" Apart

Route Capillary

Tube Through Front

Plastic Tube

Route Capillary

Tube Through

Stand Offs

January 1995

Page 7

Page 8

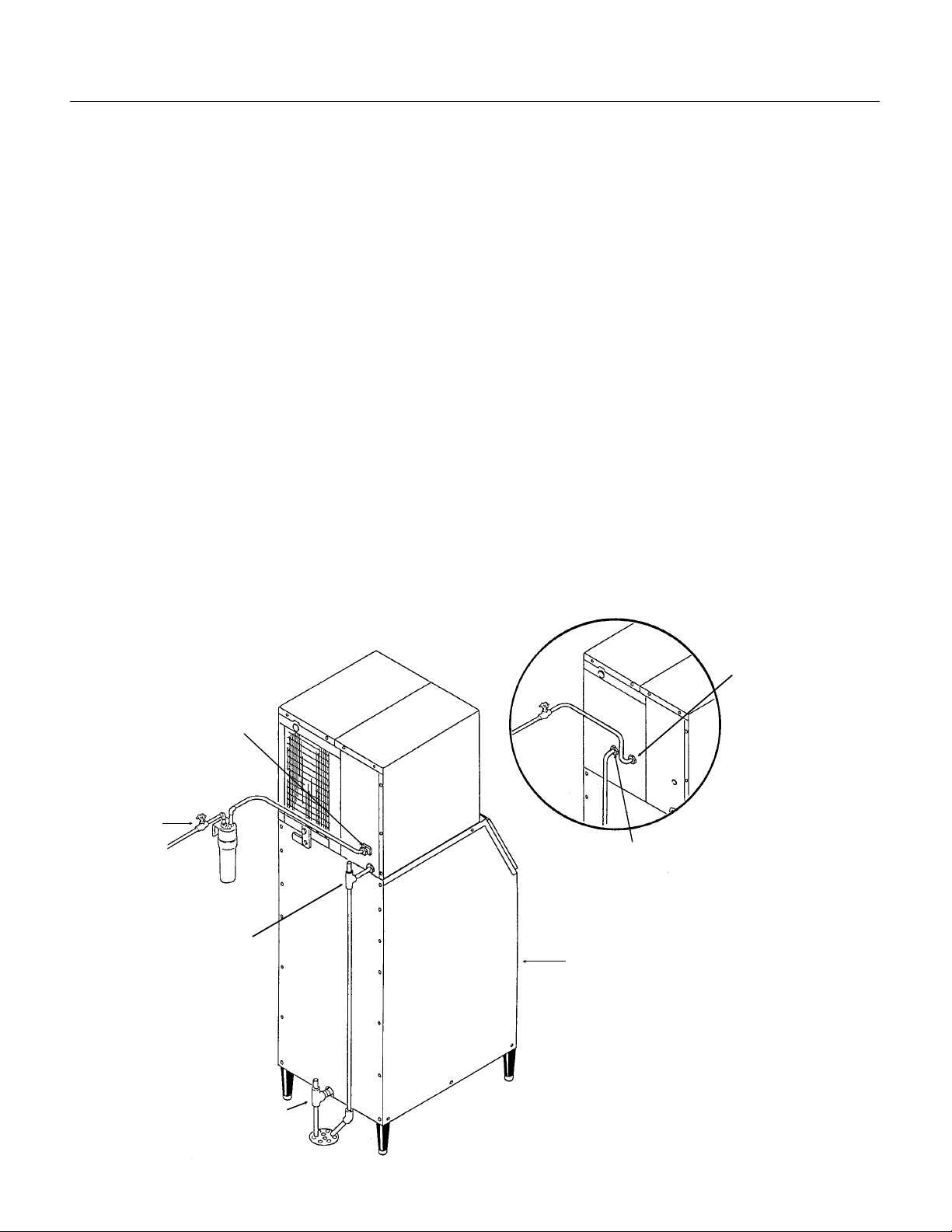

SLE300

Installation

For The Plumber

Supply:

Screw the 3/8" male fla re (fit tin g sh ipped in

package insid e cabinet) into the 1/4" FPT fitting at

the ba c k of the cabi net (thread tape

recommend ed). Con ne ct co ld pota ble wate r to th e

water inlet. A hand shut of f va lve fo r inlet wate r

should be insta lled near t he mach ine . A wat er filt er

is recommended. Flush the water line prio r to

connect ing to the ice machine.

If water cooled , con nect a separate water inlet line

to the water cooled condenser inlet fitting. It should

also have a hand shu t off valve.

Drains:

Connect a drain tube to the reserv oir dra in fit tin g at

the back of the cabinet. The drain tube from the

fitting mus t be run separa te ly fro m any ot her drain

tube. The reservoir drain is a 3/4" F.P.T. bra ss

fitting.

Drain tube material must be rigid and meet local

code.

Traps in the bin drain line without vents ahead of

them will cause poor draining.

The bin drain mus t be vented if the re is a lon g

horizontal run (5’ or more). The reservoir drain

mus t be vented and not connected to th e bin

drain. All drains are gravity, and must have a

minimum fall of 1/4" per foot of horizon tal ru n.

Wate r Coole d: The wat er cooled condenser drain

is not vented, and is routed separately.

Maintain th e air gap req uire d by local co de

between the end of the drain tubes and the

building drain rec epta cle.

Note: Drain tu bin g sh ou ld be insulated to prevent

condensation from forming on the tubing.

CONFORM TO ALL LOCAL CODES

3/8 Male Flare

Water Inlet

Water Shut

Off Valve

Reservoir Drain

3/4" FPT, Must Be Vented.

Bin Drain. May Be Routed F rom

The Bottom On Some Model

Bins. Fittin g May Be Plastic.

DO NOT OVERHEAT.

3/8" FPT Inlet

Water Cooled

Condenser Plumbing

Connections

1/2" FPT

Outlet

Ice Storage Bin

(Typical)

Water Supply and Drain Con necti on s

January 1995

Page 8

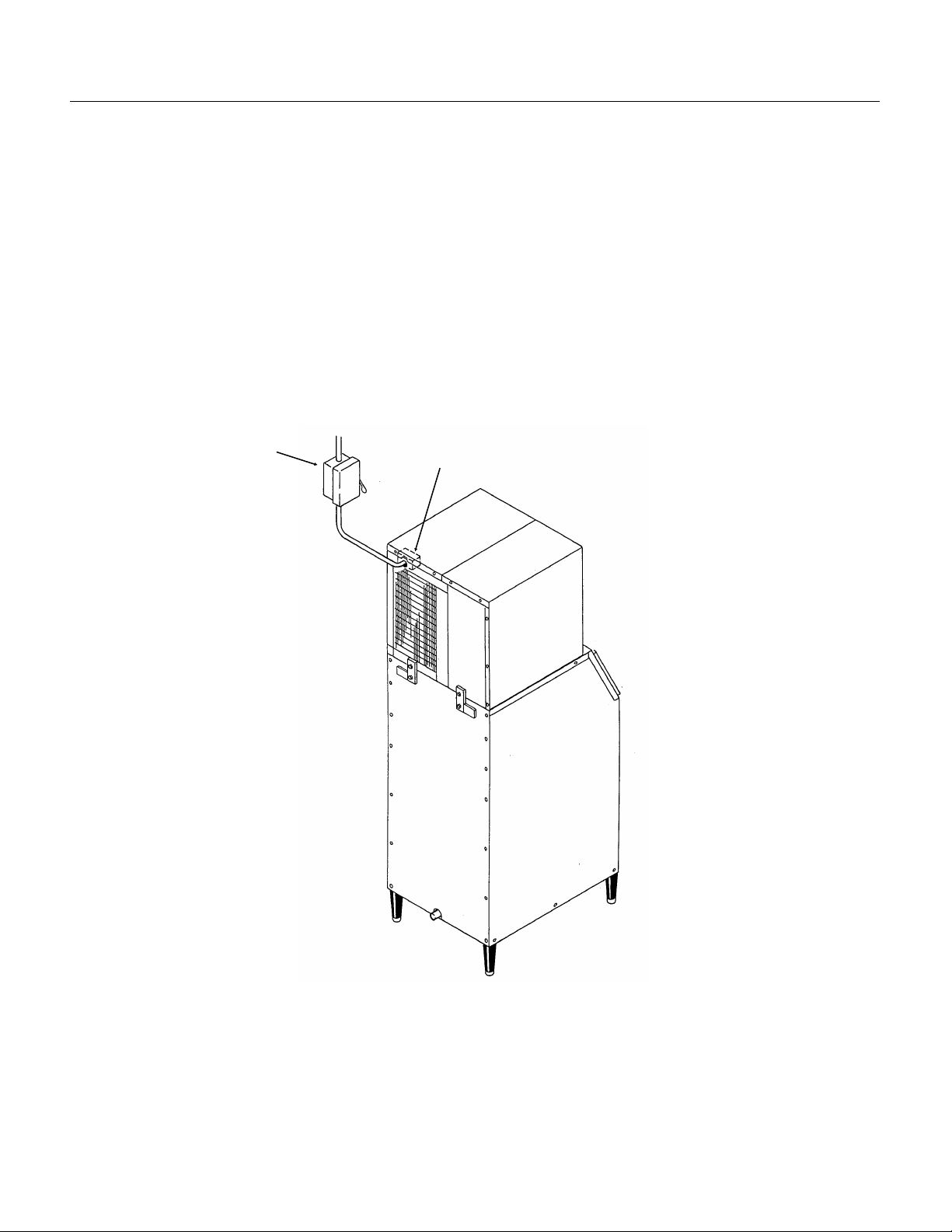

Page 9

Installation

SLE300

For The Electr ic ia n

This unit must be on a separat e 115 volt AC 60

cycle single phas e power sup ply. The maximum

fuse size for this circuit is listed on the name plate ,

and per th e nameplate use fuses, or HACR circuit

breakers.

To make the electrical connections:

1. Remove the right top panel.

2. Remove the junction box cover .

3. Make the electrical connections to the wires in

the junction box. A ground screw is provide d in the

junction box.

Hand Disconnect Switch

Junction Box

Follow All Local Codes - This Unit Must Be

Grounded. Usually a licensed electrician will be

required to connect th e elect rical se rvice .

January 1995

Page 9

Page 10

SLE300

After Utility Connections

1. Level the cabine t, use the leg leve lers on the

end of the legs to adjust the ca binet height. (Legs

should have be en installed when the bin was

unpacked) .

2. Wash out the bin. If desired, the interior of the

bin could be sanitized.

Final Che ck List

1. Is the ice maker cabinet in a roo m where

ambient temperature s are within the minimum and

maximum temperat ure s specified?

2. Has the water supply been connected?

3. Is the wa ter pressure adequate?

4. Have the water connections b een checked for

water leaks?

5. Have the drain con nections been made?

6. Have the drain connections been checked for

leaks?

7. Is the cabinet level?

8. Is the ice machine connect ed to a 1 1 5 volt

electrical power supply and is the ice machine the

only load on that circuit?

9. Has all of the shipping material been remov ed

from the inside of the cabinet?

10. H as the bin and cabinet been wiped clean and

sanitized ?

11. Has the Customer Evaluation & Warranty

Registration form been properly fille d out? Check

for correct mod el and se rial numbe rs f rom the

nameplate, then mail the comple te d form to

Scotsman .

12. Has the owner/u ser been give n the name and

telephone number of the au thorized Scotsman

Service Agency serving that location?

January 1995

Page 10

Page 11

Component Location

ICE/OFF/WASH Switch

Bin Thermostat

Control Box

Many components are serv icea ble from th e front

without removin g the side panels .

SLE300

Behind the front panel:

•• Water pump

•• Inlet water va lve

•• Reservoir

•• Evaporators

•• Water distributor pan

•• Ice size control adjustment

•• ICE/OFF/WASH switch

•• Control box

Ice Size

Thermostat

Compressor

Relay

Ice Thickness Contro l

Control Bo x Detail

High

Pressure

Cut Out

Harvest

Relay

Bin

Thermostat

Ice/Off/Wash

Switch

Water Distributor

Pan

Bin Thermostat

Bracket

Water Inlet Valve

& Strainer

Water Pump

Drain Elbow

Componen t Locati o n

January 1995

Page 11

Page 12

Correct Size &

Shape

Cube Size Diagram

Set

Screws

SLE300

Initial Start Up

After the final check list has been gone through,

the ice machine may be started up.

1. Open the water sh ut of f va lve; the inlet wate r

valve will open, and water will flow into the

reservoi r..

Ice Thickness

Probe Adjustment

2. Switch on the electrical power.

3. Remove the front panel.

3. Locate the I CE/OFF/WASH switch, switch

Up for LARGER

Down for SMALLER

it to WASH.

4. The water pump will begin to pump water ove r

the ev aporator s .

5. Allow the reservoir to refill. Norma l water leve l is

1/8" below the high point of the lowe r curve of the

sip hon u-tub e.

6. Switch the ICE/OFF/WASH switch to OFF.

7. Check the action of the siphon. The water level

in the reservoir sho uld drop to the bottom curv e of

the U-bend (normal water level) in about 2

minutes. If not, check for proper drain tube

connections.

Ice Size Adjustment

Plate:

Cubes Too

Thick

8. Switch the ICE/OFF/WASH switch to ON.

9. On air cooled models the fa n motor will beg in to

turn, and warm air will be discharged from t he

back of the ice machine .

On water cooled models warm water will begin to

flow from the conden ser dra in.

10. The water temperatu re in the res ervo ir will

soon b e 32

0

F., and ice should begin to form on the

evaporato rs.

1 1. Allow the ice mac hine to operat e for abo ut

15-20 minutes . The ice sho uld be fully f orme d and

should be harvested within a few minutes.

12. After harv est , ch eck the ice cub e size .

Compare a fresh cube to the diagram on the

back of the front panel. If needed, adjust the

cube size by loosening the two set screws and

moving the ice thickness probe plate.

Move the plate down for smaller cubes and up

for larger . Re-tighten set screws.

For proper operat ion , th e ice thick ness sho uld be

11

set to the 1

⁄16" diameter.

The machine is designed to harvest cubes of

only the correct thickness.

1 11⁄16"

Cubes Too

Thin

January 1995

Page 12

Page 13

Initial Start Up

SLE300

Note: If the fi rs t ba tch of cu be s are not all un ifo r m

discs, some ice machin e cle an er sho uld be added

to the reservoir.

1. After ice ha s been harvested, but be fore new

cubes begin to form, switch the ICE/OFF/WASH

switch to WASH.

2. Add 4 oz. of ice machine cleaner to the

reservoi r. Allow unit to operate that way fo r 10

minutes.

3. Switch ICE/OFF/WASH switch to OFF

4. Shu t the water supply of f.

5. Remove the splash guard, and drain the

reservoir by removing the drain elbow.

7. Replace all parts, turn on the water and move

ICE/OFF/WASH switch to ICE. The next batch

of ice should be uniform.

13. Check harvest. The machin e will have to

harvest all of the cub es befo re it go es back into the

freeze cycle.

14. Check operation of the bin co ntrol circu it by

holding ice on the bin control tu be in the bin.

If the ice maker does no t sto p with in 1 minute ,

while keeping ice on the th ermostat, rotate the bin

thermostat shaft counter clockwise until the ice

maker does stop. Remo ve the ice from th e

capillary tube; the ice make r sho uld resta rt with in 2

minutes. If it do es not, rotate the adjust ing shaf t

clockwise until the machines starts.

15. Replace all the panels. The ice machine is now

ready for automatic operation.

Siphon Tube Schematic

U-Tube Adjusted

Here = No Purge

Siphon Breaker Hole

U-Tube Here =

Maximum Purge

Water Level

At Harvest

Water Level With

Pump ON

Water Inlet

1/8 - 1/4

Drain Outlet

Elbow

Bottom of

Reservoir

January 1995

Electrical Sequence:

Freeze Cycle:

During the first part of the free ze cyc le, the ice

machine comp res sor, fan motor if air coole d, and

water pump are operat ing.

Assume the bin thermo stat is open (low ice), relay

K1 will NOT have power thru its coil and K1

contacts 6-2 will be closed, connec tin g power to

the ice size thermosta t.

The ice size thermostat con tact 2-3 are clo sed,

connecting power to the fan and pump motors.

The Harvest Termin ation Thermo st at is closed to

NC, but there is no power thru it.

The ice size thermostat heater is on, and the

compressor contactor coil is energized.

Harvest:

In the harvest cycle , th e compressor is operating,

and the hot gas valve is energized . The wate r

pump is off, and air cooled mod els swit ch the fan

off.The bin thermo stat is still open .

When the ice near the ice size thermo sta t se nsin g

tube grows large enough to force water over the

sensing tu be , th at tub e loo se s hea t, and at 38

contact s 2-3 ope n and 2-1 close.

This removes power from the water pump and fan

and connects power to the defrost relay coil. Whe n

the relay coil has power, it connects power to the:

••Hot gas valve coil

The harvest termination switch is closed, an d

power flows thru it to the defrost relay coil. This

keeps the relay energized, even when the ice size

thermostat switch es cont act pos itio n as a result of

ice falling away from th e sensin g tube .

The unit stays in the harves t cycle until the

thermodisc on the suctio n line warms up to 55

at that time the defrost thermodisk switches to NO

and the harvest cycle is termin at ed. If the bin

thermostat is still open, relay K1 will st ill not have

power and the unit will go back into the freeze

cycle. If rela y K1 has power, it shuts off th e ice

machine by cutt ing power to the ice size

thermostat and contactor coil.

The ice size thermostat heater is on.

Whenever there is ice on the bin thermostat, it

closes a circuit to the coil of relay K1 and stops the

ice making process at the end of a harvest cycle.

Page 13

o

F.

o

F.,

Page 14

SLE30 0

Maintenance, Cleaning and Sanit izing

Cleaning Schedule:

••Scrub the outside of the cabinet once a week

wit h soa p and water.

••Sanitize the bin interior once a month.

•• Clean the water system and air cooled

condenser a minimum of twice per y ear. If in an

area of high mineral con ce nt rat ion in the wate r

supply, clean wate r syst em 4 times a year.

Air Cooled condenser (air cooled only):

Remove th e right side pan el.

The air flow thru the cond enser is fro m f ron t to

back, so dust will build up on the fan side of the

condenser fin s.

The fan motor, bracket and part of the shroud may

be removed as an assembly:

1. Unplug the fan motor.

2. Remove 3 screws at the righ t edge of the fan

shroud.

3. Pull the assembly out th e right side . The

condenser fins are then visible for cleaning.

The fins of the condenser will become fo ule d with

dirt, and must be cleaned. A vacuum cleaner with

a soft brush attac hme nt will extrac t most loose

dust stuck to the surface of the condenser fins..

Water cooled un its:

The water cooled condenser may, over time and

under certain water conditions, become internally

restricted by minerals. Thes e will have to be

dissolved by acid or the condenser replaced. Only

a qualified service agent should att emp t th is type

of service.

Ice Storage Bin

The interior liner of the bin is in contac t with a food

product : ic e. The storage bin must be cleaned

regularly to maintain a sanitary environment.

Once a week cleaning with soap and water, a hot

water rinse and an air dry is a basic procedure.

Every 30 days, the liner should be sanitiz ed with a

commercial ice machine san itize r, according to the

direction s of the sanitizer, or with a solu tio n of

household bleach a nd water:

1. Mix the bleach and water using the ratio of two

ounces of blea ch to two gallons of water.

2. Wipe all interior surfa ces of th e ice storage bin

with the bleach and water.

3. Allow t o air dry.

T o Re move Scale:

1. Mix a cleaning solution of 4 ounces of Scotsman

Ice Machine Cleaner to 4 pints of warm

0

F.-1100F.) water.

(95

2. Using rubber gloves, dip a nylon scouring pad

into the clean ing solut ion and scrub the scale off

the liner .

3. After the scale ha s been remove d, rinse all

surfaces inside the bin with clean, potable water.

Stainless Steel Bin Liner

The stainless ste el line r of th e bin will require

periodic cleaning. Chemicals in the water suppl y,

such as chlorine, cause bro wn stains to appear on

the surface of the sta inle ss ste el pa rts .

1. General Cleaning - staining is usually remov ed

by washing the parts with ordinary cleanin g

powder such as Bon-Ami or Copper-Glo and

water. After cleanin g, rin se with clea r wate r.

2. Water tre atment. The chlorine enters the

machine fro m the municip al water supply . It can be

removed from the wate r supply by us ing a

charcoal or ac tiva te d carbo n wat er filt er to trea t th e

water to the ice machine. If staining is severe,

filters of this type are recommended.

Exterior Cabinet Cleaning:

The exterior cabinet may be cleaned by scrubbing

with soap and water. Do not use cleane rs

containing petroleum products.

A nylon type brus h may be used to scrub stubbo rn

deposits.

January 1995

Page 14

Page 15

Cleaning: Ice Machine Water System

Dissolve and Remove Minerals:

SLE300

1. Remove front panel.

2. Move the ICE/OFF/WASH switch to OFF.

3. Remove the splash guard.

4. Shu t the water supply of f.

5. Drain the water from the sump by removing the

drain elbow.

6. Disconnect hose from the wat er dis trib ut or pan,

and remove the water distrib utor pa n.

7. Mix a solution of 5 oz . ice mac hin e clea ne r and

1 gallon of warm (95

Scotsman Ice Machine

Cleaner contai ns acids.

These co mp ou nd s may

cause bur ns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of water or

milk. Call Physician

immediately. In case of

external contact, flush

with water.

KEEP OUT OF THE

REACH OF CH ILDR E N.

8. Wash the splash guard, drain elbow and water

distributor pan with the ice machine cleaner/water

solution.

9. With the solutio n of ice mach ine cleaner and

water, wash the refrigerat ion tub ing , line r,

evaporato rs, su pport brack et s and the water p ump

assembly. Use the brush an d/ or a cle an cloth .

10. Replace th e dr a i n e lbow .

1 1. Open the wat er sup ply and allow the sump to

refill.

12. Add 5 oz. ice mac hin e clea ner t o the su mp

area.

13. Replace th e water distributor pan and splash

guard. Be cert ain the hose to water dis trib ut or pa n

is connected to pan.

14. M ove the ICE/OFF/WAS H swit ch to wash and

allow the solutio n to circula te for 15 minut es, then

mov e the ICE/O FF/WA S H swit ch to OFF.

o

F. - 115oF.) water.

17. Remove the splash guard.

15. Shut the water supply off.

16. Drain the water from the sump by remo vin g the

drain elbow.

Sanitize:

17. Remove the water distrib ut or pan.

18. Mix a sanitizer solutio n of 1 ounce of

household bleach to 2 gallons of warm (95

o

F.) water

115

19. Wa sh th e sp lash gua rd and th e wat er

distributor pa n with the solut ion of sanit izer. Allow

to air dry.

20. With the sanitizer solution, wash the

refrigeration tubing, liner, evaporators, support

brackets and water pump assembly; use the brush

and/or a clean cloth.

21. Replace th e water distributor pan and splash

guard. Be certain that the hose to the water

distributor pa n is tightly connec ted to the pan, and

that the flow washer in the hose is not in sideways.

22. Replace th e dr a i n e lbow .

23. Add ice machin e sanit izer so lution to the sump

area until it is full.

24. M ove the ICE/OFF/WAS H swit ch to W ASH

add more sanitizer solu tio n to the sump area until

it is full again.

25. After 5 minutes, move the ICE/OFF/ WASH

switch to OFF.

26. Remove the splash guard.

27. Drain the water from the sump by remo vin g the

drain elbow.

28. Replac e the dra in elbow and splash guard

29. Open the water supply an d allow the sump to

refill.

30. M ove the ICE/OFF/WAS H swit ch to ICE.

31. Replace the front panel.

32. Discard first batch of ice and all other batch es

until all traces of cle aner and sanitiz er disappear.

o

F. -

January 1995

Page 15

Page 16

Fan Motor

(On)

SLE300

Refrigeration Schem atic :

Freeze Cycle:

From the compresso r, hot discharge gas is

pumped to the conde nse r, either air or water

cooled.

At the cond enser, he at from the refrigerant flows

into the cooling med ium, eith er air or wat er, and

the refrigeran t co nden ses into a liquid . From the

condenser the liqu id ref rige ran t flo ws th rou gh the

liquid line to the metering device - a thermostatic

expansio n va lve.

At the expansion valve , th e liqu id ref rige ran t

passes fro m a high press ure zone to one of

relatively low pressure, and in the low pressure

zone it evapora tes. The low pressure zone where

the refrigerant evaporates is the evapora to r. When

the refrigeran t ev apora te s, it abso rbs he at from th e

metal parts of the evapo rat or an d the water flowing

over it.

From the evaporator, the refrigerant flows back to

the compresso r through the suction line.

Water Schematic:

Wate r flows int o the ice machin e fro m its inle t

connection at the back of the cabinet, through the

inlet water va lve and int o the res ervo i r. The water

in the reservoi r is pump ed up and th rou gh the

water distrib ut or tube at the top of the evapora to rs.

From there, the water flo ws over bot h sides of the

evaporators and back into the reservoir.

Melted ice and water spills into the bin flow

through a drain in the base of the bin to the

exterior drain connection at the back of the cabinet .

Evaporators

Inlet Water

Valve

Float

Valve

Water Distribution

System

Water

Pump

(On)

Thermostatic

Expansion Valve

Suction Line

Hot Gas Valve (Closed)

Discharge Li ne

Condenser

Compressor

Dryer

Water Reservoir

Siphon

Tube

Refrigeration Schematic

January 1995

Page 16

Page 17

Harvest Cycle:

Condenser

Compressor

Refrigeration Schematic

Fan Motor

(Off)

SLE300

The ice maker con tin ure s to fre ez e the wat er int o

ice unitl the ice next to the ice size thermostat

probe has become thick enough to force wate r

over the pro be. After the cold water has red uced

the temperature of the probe to 38

o

F., the ice size

thermotsta t will switch the machin e into the harve st

cycle.

During the harvest cyc le, the refrig era nt flows from

the condenser, through the discharg e line to a

branch in the line cont ain ing the Hot Gas Va lve .

This valve is Open during the harve st cyc le,

allowing the hot discharge gas to bypass the

condenser and enter the evapo rat or at its inlet .

The hot discharge gase s warm up the ev apora to r

enough to allow the surf ace of the ice froze n to the

evaporator to melt. The remain ing ice will then fall

off into the bin .

Water Distribution

System

During the Harvest Cycle, the water level rise s,

filling the reservoir ove r the siphon tube and

siphoning some of the res ervo ir wate r out to the

drain.

The harvest cycle continues until the suction line

warms up e nough to cause th e harvest termination

thermost at to switc h the machine bac k into the

freeze cycle.

Evaporator s

Inlet

Water

Valve

Water Reservoir

Water

Pump

(Off)

Sipho n

Tube

(Draining)

Thermostatic

Expansion Valve

Suction Line

Hot Gas Valve (Open)

Discharge Li ne

Dryer

January 1995

Page 17

Page 18

SLE300

Technical Charact eris ti cs

Typical Cycle Time

••18 minutes @ 90

Typical Harvest Ice Weight

••2.8 - 3.2 pounds

Typical Low Side Pressure, 8 minutes into freeze

••20 PSIG @ 70

••26 PSIG @ 90

••42 PSIG @ 100

••22 - 27 PSIG for water cooled

Typical Freeze Cycle Discharge Pressure

••196 PSIG @ 70

••262 PSIG @ 90

••350 PSIG @ 100

••270 for water cooled

o

F. air and 70oF. water; 15 minute s @ 70oF. air and 50oF. water

o

F. Air

o

F. Air

o

F. Air

o

F. Air

o

F. Air

o

F. Air

Refrigerant Charge:

••15 ounces R-404A

Harvest Time

••Normally 1

Typical Suction Pressure, In Harvest:

1

⁄2 to 2 minutes. Depends upon time required to warm suc tio n line to 55oF.

••

Typical Discharge Pressure, In Harvest:

••

High Pressure Cut Out

••Cuts out at 380 PSIG, reset s at 315 PSIG

Thermostatic Expansion Valve

••Superheat is 3

Bin Thermostat

••Cut In to shut OFF machine at 35

Ice Size Thermostat:

o

- 6oF.

o

F.; Cut Out to Start ma chin e at 39oF. Adjustable warme r.

•• Switches to harve st cyc le with temp eratu re fa ll to 38

oF.

Resets at 43oF.

Ice Size Heater

••Adds heat to ice size th ermo st at to preven t pre mat ure harv est. 6, 000 ohms resis ta nce .

Harvest Termination Thermostat

•• Switc hes from cont acts C-NC to contacts C-NO at a temperature rise to 55

Resets at 40

o

F.

January 1995

Page 18

o

F. (return to freeze or OFF).

Page 19

Service Diagnosis:

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

No ice is made, nothin g opera te s Unit off, due to no power Restore po wer

Unit off, due to ICE/OFF/WASH

switch in OFF position

Unit off, due to bin thermo st at

closed

Unit off, due to relay K1 coil open. Check relay coil, if open repla ce

Water cooled unit off, due to high

pressure cu t ou t op en

No ice, compress or of f No cooling due to compressor not

operatin g

No ice is made, compressor is

operatin g

No water due to water turned off. Reconnect water supply

No water due to water f ilte r

plu gged.

No water due to strainer screen

plugged

No water due to inlet wate r valve

will not open

Water in reservo ir, bu t no water

over evaporators

No cooling at evaporator due to

hot gas valve lea king thru

No cooling at evaporator due to

fan not turning

Fan and pump do not have

power; hot gas valve opens and

closes.

No cooling at evaporator due to

dirty condenser

No cooling due to compre sso r n ot

pumping

Switch ICE/OFF/WASH switch to

ICE

Check temperature at bin

thermostat bracket, if warmer than

o

F., thermostat should be

40

closed. Adjust/replace thermostat.

relay.

Lack of water to condenser,

check water sup ply and wat er

regulating valve.

Check compressor for voltage,

continuity, and operation. Check

starting components. Replace if

found to be faulty.

Check temperature of

compresso r, if hot may be lack of

refrigera nt, defe ctiv e TXV or

compresso r

Replace wat er fi lt er

Clean out inlet screen

Replace valve

Water pump does not work,

replace pu mp

Replace ho t gas valv e

Check & replace fan motor.

Coil or relay open, rep lac e rela y.

Clean condenser

Check system pressures, replace

compressor if not pumping

SLE300

January 1995

Page 19

Page 20

SLE30 0

Service Diagnosis:

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

No ice compresso r is operating No cooling due to low refrig era nt

charge

Ice is made, but not harvested. Ice size thermostat contacts do

not switch position

Ice will not slide down ice rack

due to minerals on rack.

Ice will not slide down ice rack

due to ice rack out of position

Ice will not slide down ice rack

due to bent ice ra c k

Lack of heat during harv est cycle

due to unit in air temp. less than

0

F.

55

Lack of heat during harvest due to

water flowing thru wate r coo led

condenser

Lack of heat during harvest due to

lack of refrigerant

Lack of heat during harvest due to

hot gas valve not opening fully.

Ice does not slide down face of

evaporato r due to mine rals on

evaporator surface

Harvest cycle too short du e to

harvest termina tio n thermo stat

opens at too low a temperature.

Locate leak, recover remaining

refrigera nt , rep lace drye r ,

evacuate and weigh in nameplate

charge.

Ice not made near thermo st at

probe due to water distribut or

holes restricted. Clean water

distributor pan.

Thermosta t de fective, replace it

Clean machine with ice mach ine

cleaner.

Reposition ice rack

Replace ice rack

Warm up air or move machine.

Replace water regulating va lve

Check low side pre ssu re du ring

harvest . If low eith er th e cha rge is

low or the hot gas valve does not

open fully. If charge is the

problem, locate leak, recover

remaining refrig era nt , rep air leak,

replace drie r, ev acu at e and weig h

in nameplate charge.

Check low side pre ssu re du ring

harvest . If low eith er th e cha rge is

low or the hot gas valve does not

open fully.

Clean water system with ice

machine cle aner

Replace harve st termination

thermostat

January 1995

Page 20

Page 21

SLE300

Service Diagnosis:

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

Ice is made, but will not harvest Will not harvest due to hot gas

valve not opening.

Slow/incomplete harvest due to

hot gas valve not fully open.

Makes ice, but very litt le High discharg e pressu re, due to

dirty condens er; faulty fa n motor;

not enough water thru water

cooled condenser, high water

temperatures, water reg. valve set

too high.

Inlet water temperatures and

room ambient very high

Long freeze cycle due to hot gas

valve leakin g thru.

Compressor ine ff icie nt Check/re pla ce compressor

Cubes are wrong size/sh ape Ice size thermostat not adjust ed

properl y

Freeze cycle too sh ort due to

heat e r open

Water system is rest rict ed with

minerals

Ice thickness probe tube covered

with minerals

Not enough water Check water supply pressure

Too much superheat Check superheat, replace TXV if

Ice fused togethe r in bin Ice in bin too long Advise user to pour water on ice

Too many minerals in water Suggest water treatment to user.

Check for volt ag e to coil in

harvest , if th ere is voltage

replace ho t gas valv e

Check low side pressure in

harvest, replace hot gas valve if

too low with correct ref. charge.

Check for causes of high

discharg e pre ssu re and corre ct .

Advise user, sugg est additio na l

room cooling.

Check temp erature of tubes to

and from hot gas valve; th ere

should be a temp erature drop

across the valve in the freeze

cycle. Replace valve if temps are

nearly equal.

Adjust ice size thermostat; use

gauge shipped with machine

Check/re pla ce he at er on ic e size

thermostat probe tube.

Clean water system with

Scotsman Ice Machine Cleaner

Clean tube with ice machine

cleaner

Check water supply for restrictions

too hi g h.

Check hot gas valve for leak-thru;

replace if lea ks th ru.

to ease remova l

January 1995

Page 21

Page 22

SLE30 0

Removal and Replacem ent

Ice Size Thermostat:

Before replac ing the ice size thermostat , it should

be positively determine d that it is at fault.

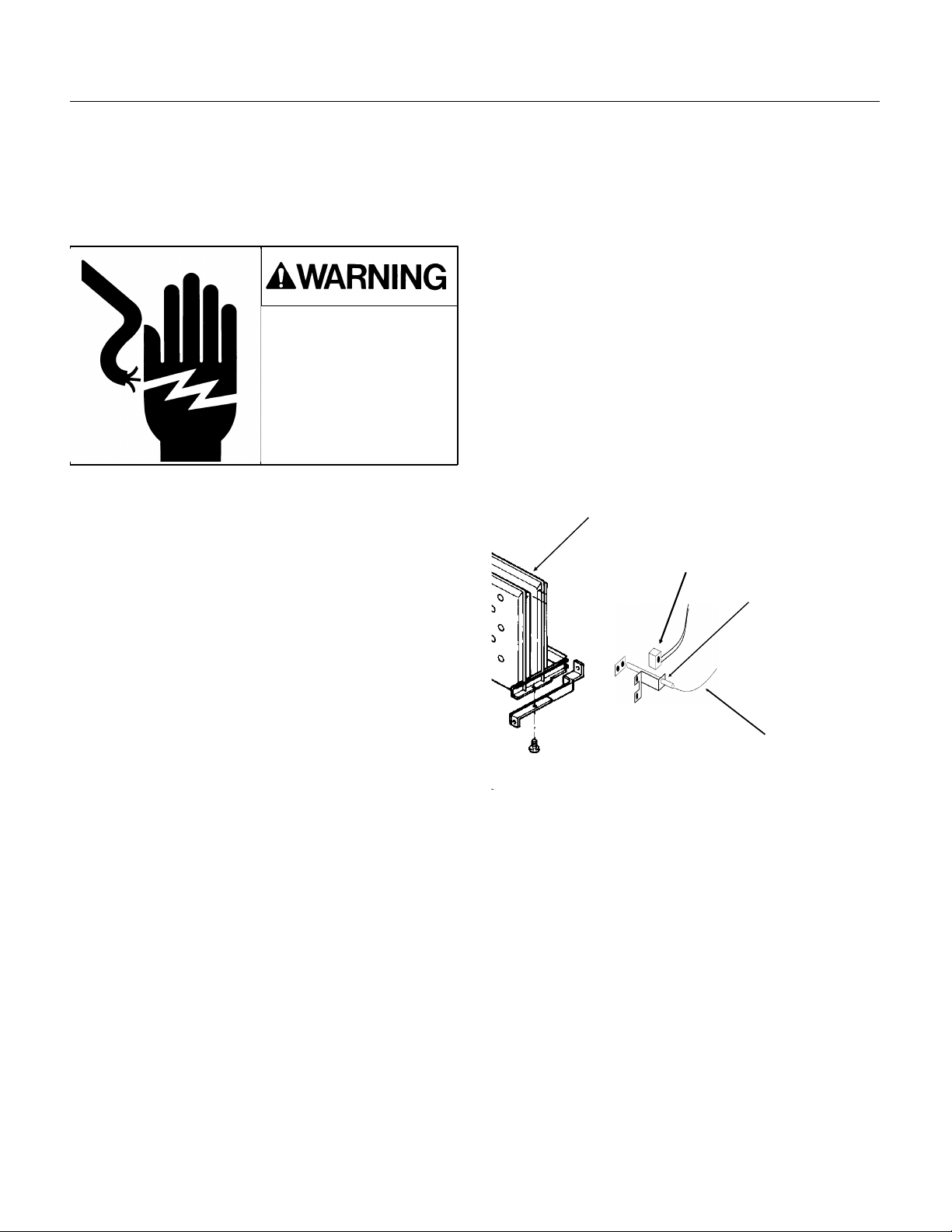

1. Disconnect electrical power.

Electrical sho ck hazar d.

Electrical shock can

cause personal injury.

Disconnect power before

beginning to service

components.

2. Remove the front panel.

3. Remove the control box cover.

4. Locate the ice size thermostat.

5. Remove the two screws holdin g the cont rol to

the control box, and lift the con tro l out.

6. Pull the three wires off the posts of the ice size

thermost at.

Primary Resistor (Heater)

1. Disconnect electrical power.

2. Disconnect the primary resisto rs yello w wire

from terminal #4 and the white wire from te rmina l

#1. Pull the two wires out of the control box and

thru the insulated wall.

3. Mark locatio n of adju st ment bracket.

4. Remove two screws and the ice size thermo stat

probe tub e bra cke t.

5. Remove the evaporator side plastic sleeve and

heater from the tube.

6. Reverse the prio r ste ps to re pla ce . Pro be tub e

must be inserted into plas tic guide att ac hed to

evapora tor.

7. Place adjustmen t bra cke t in its origin al position.

Check ice size.

Evaporator

Heater

Probe Tube

& Bracket

7. Locate bulb on suction line.

8. Follow the capillary tube of the ice size

thermost at: th e end of the ice size thermostat is

inserted in a tube. Pull it out of the tube.

9. Pull the capillary tube of the ice size thermost at

thru the grommet in the side of th e contro l box .

10. Remove the ice size thermo st at from the

control box.

11. Replace the ice size thermo sta t with the prop er

part number, following the above steps fro m 1 0-1 .

Capillary

Tube

Replacement of Ice Size Thermostat

January 1995

Page 22

Page 23

Removal and Replacem ent

SLE300

Water Pump

The pump provides the force to move the water

from the rese rvoir to the free zin g surface. The

pump does not need oil, but if it becomes noisy,

overheats, or will not pump it should be replaced.

Be certain to confirm electrical faults with a

voltmeter or ohmmeter before replacing th e pump.

The pump should be opera ting whenever the

machine is in the free ze cy cle.

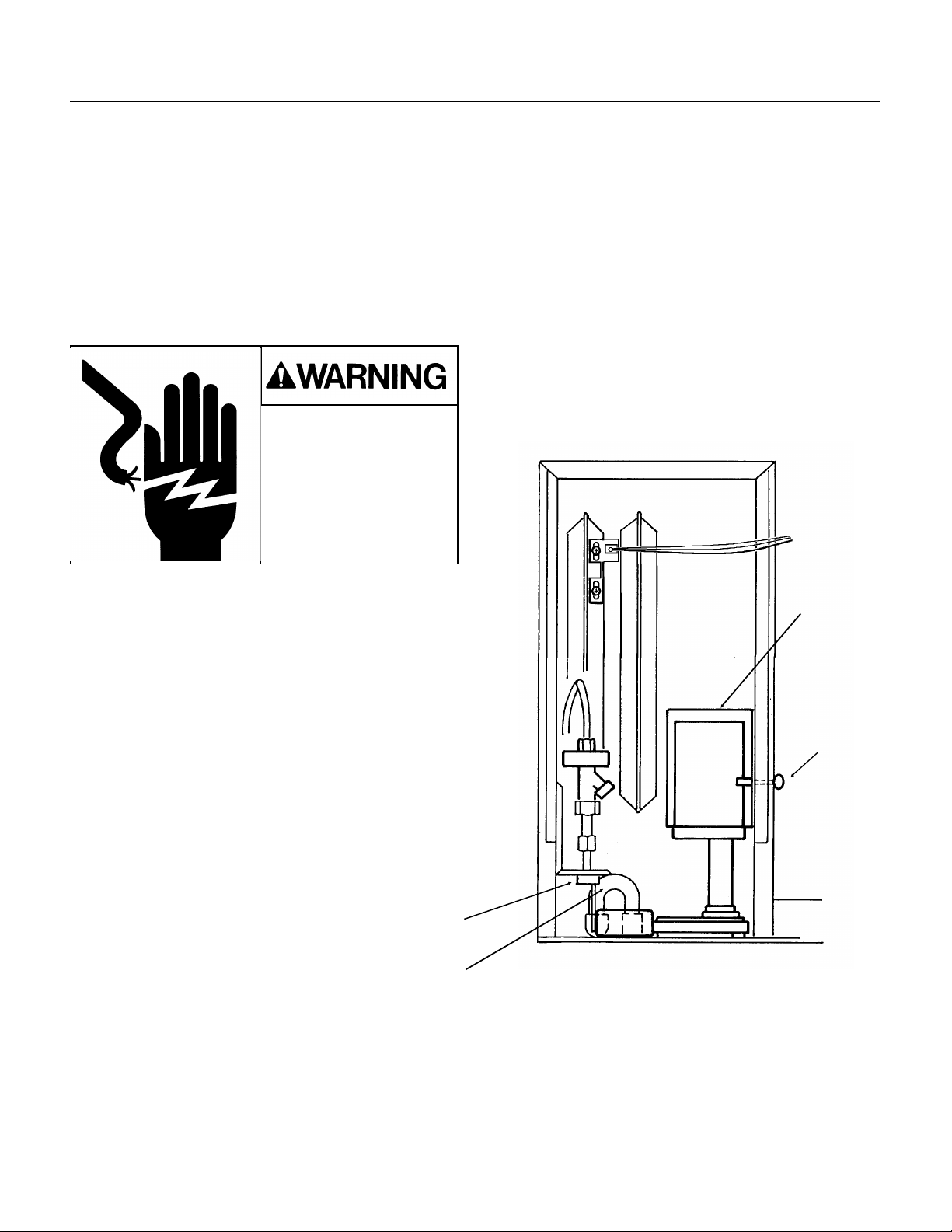

1. Unplug or disconne ct the elect rica l powe r.

Electrical sho ck hazar d.

Electrical shock can

cause personal injury.

Disconnect power before

beginning to service

components.

Inlet Water Valve

The valve may plu g-up from minerals in the water,

and may be cleaned rather tha n rep lac ed.

1. Shu t off the wat e r supply.

2. Unscrew the fitt ing at the to p of the valve, and

pull the water inlet tube out of the valve body.

3. Remove the screws h old ing the valve brac ket to

the liner .

4. Remove the valve fro m the ice mach ine.

5. Reverse the abov e ste ps to reassemble.

2. Unplug the pump from its connection.

5. Loosen the two fasteners holding the cover to

the wall.

6. Remove pump cov er fro m the machin e.

7. Pull discharge hose fro m pump disch arg e port.

8. Remove pump from ice machine.

9. Reverse abov e ste ps to rep lace .

Float Valve

Siphon "U" Tub e

Pump Cov er

Thumb

Screws

Replacement of Water

Pump

January 1995

Page 23

Page 24

VAPOR V APOR

TEMP. PRESS. TEMP. PRESS.

(DEG F) (PSIG) DEG F) (PSIG)

-20 17 70 146

-18 18 72 150

-16 20 74 155

-14 21 76 161

-12 23 78 166

-10 24 80 171

-8 26 82 177

-6 28 84 182

-4 29 86 188

-2 31 88 194

0 33 90 200

2 35 92 206

4 37 94 212

6 39 96 219

8 41 98 225

10 43 100 232

12 46 102 239

14 48 104 246

16 50 106 253

18 53 108 260

20 55 110 268

22 58 112 275

24 60 114 283

26 63 116 291

28 66 118 299

30 69 120 307

32 72 122 316

34 75 124 324

36 78 126 333

38 81 128 342

40 85 130 351

42 88 132 360

44 91 134 370

SLE300

Removal and Replacement: Refrigeration System

This ice machine uses R-404 A (HP6 2) ref rige ran t and polyole ster oil. Do

NOT use mineral oil in this refrig era tio n syste m.

••R-404A is a "Near Aze otrope" so liquid charging is require d:

••When the system is serv iced , a specia l liquid line drie r is requ ired . It is

included with replacement compressors.

••HP62 is not comp atible wit h mineral oil, so th ese ice mach ine s use

Polyoles ter oil. Po lyole st er oil ab sorb s wat er very easily . When one of

these refrige rat ion systems is opened for service, it must be re-seale d

as soon as possible (15 minutes maximum).

••Special leak detec tio n equip men t is required to locat e small refrige ran t

leaks. Usua lly a lea k det ec to r capa ble of de tecting a Halongenate d

refrigerant or HFC-134a will work. Check with the leak detect or

manufactu rer if in doub t.

LIQUID CHARGING Instructions for R-404A

In preparation for charging, the low side hose should ha ve a sight glas s,

and/or a restrictor device (such as a "Charge Faster") installed in it for

metering liqu id int o the low side of the syste m.

1. After a thorough evacuat ion to at leas t 200 microns, shut of f the

manifold valves and switch off the vacuum pump.

2. Place a drum of R-40 4A ont o an elect ron ic sca le.

3. Attach the chargin g hose to the drum.

4. Open the valve on the drum and purge the chargin g hose.

5. Zero out the scale.

6. Shut the low side access valve at the ice machine.

7. Open the discharge manifold valve full open .

8. Watch the sca le, when the correct charg e is shown, shut the manifold

valve.

Note: If all of the charge will not "go in" the discharge side:

A. Shut the discharge acce ss valv e at the ice mach ine .

B. Switch the machine on .

C. Open the low side acces s valve at the ice machine.

D. Open the low side manifo ld valve an d obse rve the sig ht glass to be

certain that only gas is flowin g int o the sys tem.

E. When the proper charge is indicated on the scale, shut of f the

manifold valve(s ).

9. Shut off the valve on the refrig erant drum.

10. Re-open the man ifo ld va lves unt il all liquid has flo wed out of the

hoses.

Pressure-T emperature Chart for HP62

11. Shut the low side access valve on the ice mach ine .

12. Remove hoses from ice machine and replace all ca ps.

January 1995

Page 24

Loading...

Loading...