Page 1

SLD150

Introduction

To the owner or user: This pro du ct ma nu al is a

source of information about the installation, start

up, cleaning , main tena nce and repai r of the

product.

The SLD150 is a Slim Line® brand hotel/mote l ice

dispense r. It is designed to us e a Scots man Slim

Line SLE300 or SLE40 0 ice mac hin e as the

source for ice.

Ice from the cuber falls int o the insu lat ed hopper,

where it is stored until needed. Whe n a user

push es th e d ispense but to n a r otating wheel

scoops the ice up to the to p front of the hopp er

where there is an out let to the ice ch ut e.

Table of Contents

Specifications/Limitation s . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Final Check List/Initial Start Up/Electrical Sequence . . . . . . . . . . . . . . . . . page 7

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Parts lists and wiring diagrams are located in the

center of this manua l, print ed on yellow paper.

Note the warning symbo l where it ap pe ars in thi s

manual. It is an alert for impo rtan t safe ty

informatio n on a hazard that might cause serio us

injury.

Keep this manual for future reference.

This manual was printe d on recycled pape r.

October 1996

Page 1

Page 2

SLD150

Specifications:

Limitations:

••Must meet the same limitat ions as th e cuber

installed on top of it:

550F. air minimum,

1000F. air maximum.

••Must be installed indoors.

•• Must allow space to the right for air int ak e when

using air cooled ice machine.

•• Compatible only with Scots man SLE300 or

SLE400 Slim Line® brand models.

••Must allow space for utility connec tio ns at the

back.

••Must have a drain.

Optional Kits (for SLD150-1B) Inc lud e:

Coin Mechanism, kit number KSLDC2

Key Mechanism, kit numb er KSLDK 2

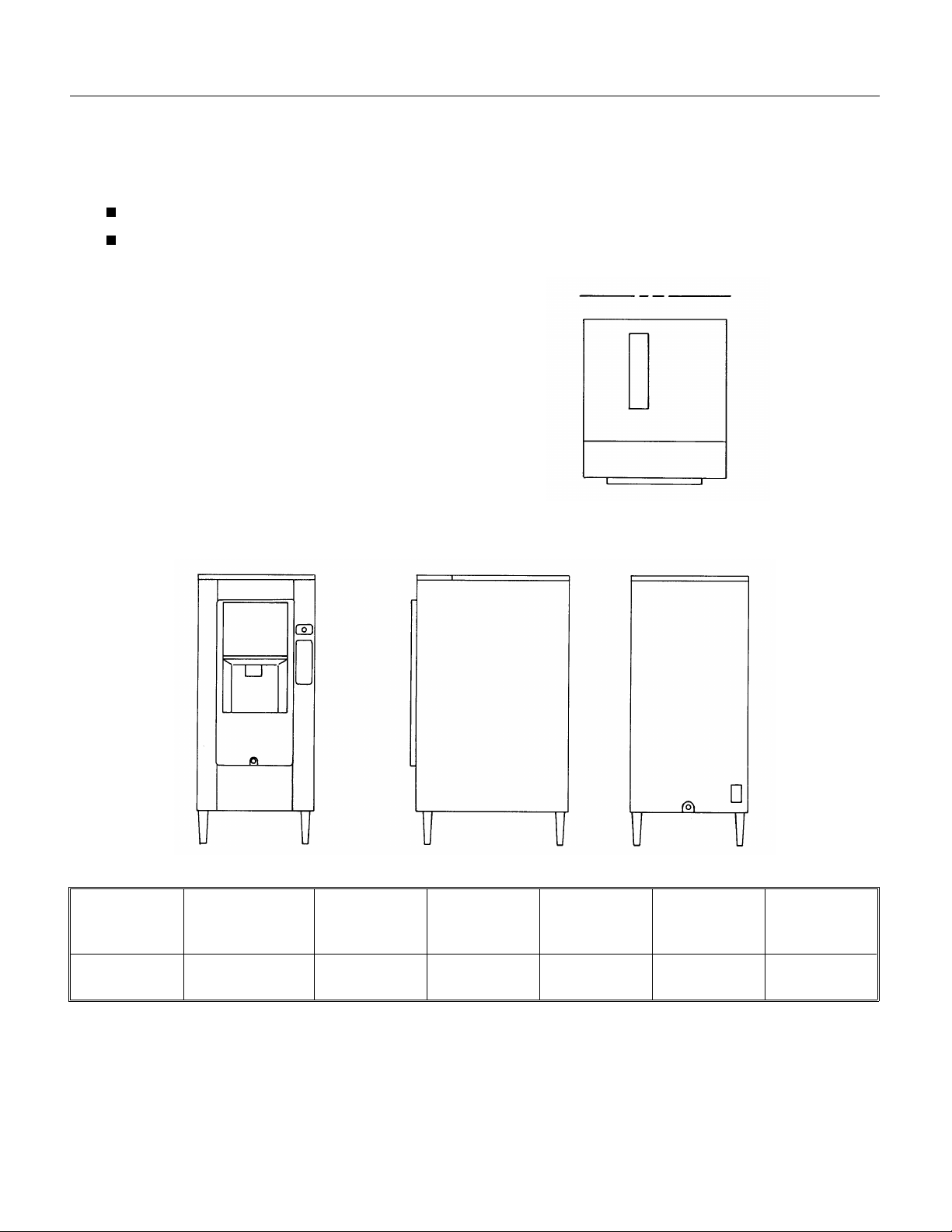

Top View of SLD150

All kits are field inst alle d.

Model Dimension s

(with legs) W

x D x H

SLD150S-1B 22" x 32" x 50" 115/60/1 Stainless

Basic

Electrical

Finish Ice Storage

Steel

Max Fuse

Capacity

90 lb. 15 2.9

Size

Min Circuit

Ampacity

October 1996

Page 2

Page 3

Installation: General

After the carton has been removed from the

dispenser, the legs may be installed.

Place flat portio ns of the carton on the floor beh ind

the dispenser and lay the dispen ser down on its

back.

Thread the legs into the base of the dispenser. Be

sure that the leg s are scre wed in all the way. Tu rn

the leg levelers in all the way.

Move the dispense r to an upright positio n and set

it in the location where it will be ins talled . Not e

where drain lines and elect rical conn ection s will be

made.

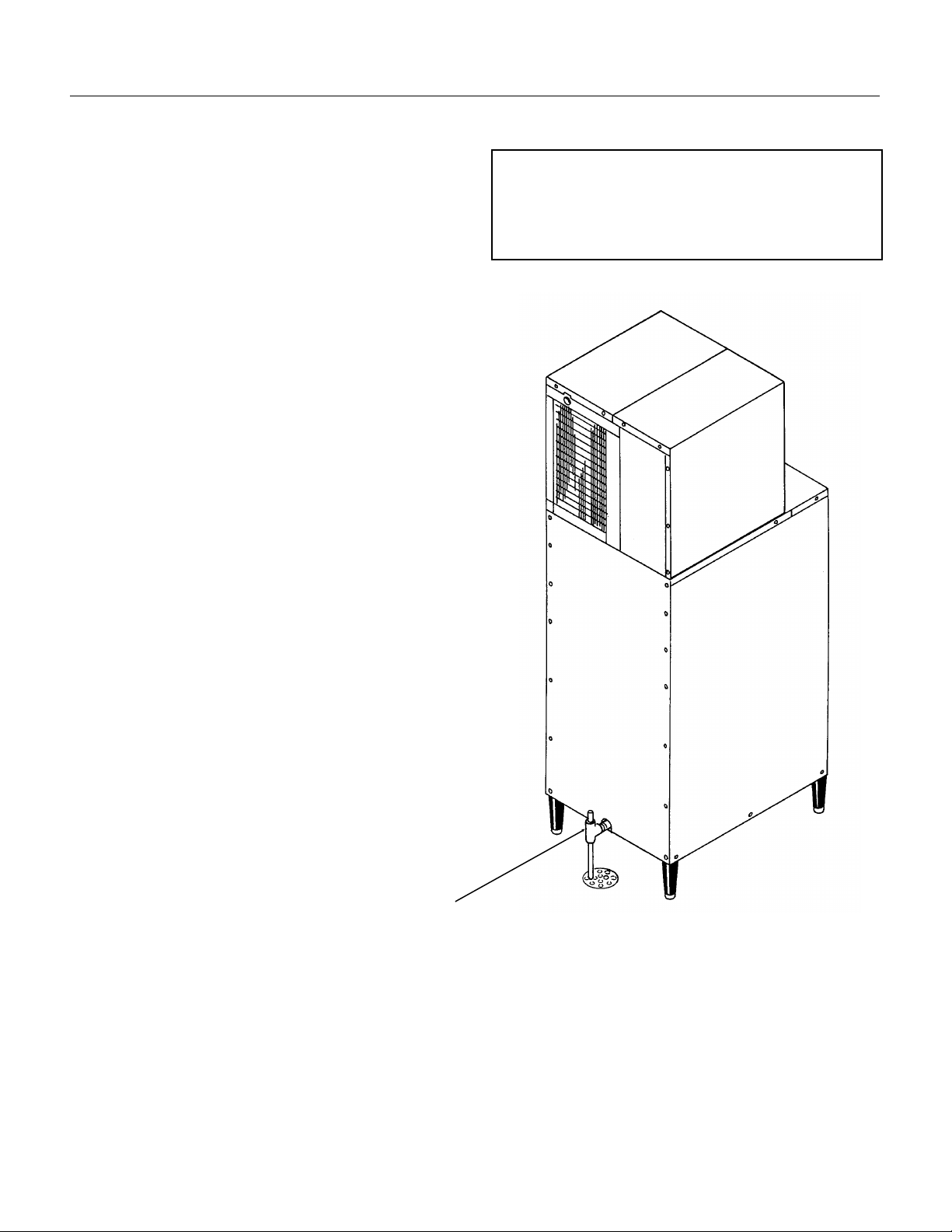

Drain:

The dispenser has a 3/4" FPT drain fitting at the

bottom cent er of the back pane l. Con nect 3/4" rigid

tubing to this connection, a vent is recommended

for most installations. Route the drain tu bing to the

building drain. Follow all applicable plumbin g

codes.

SLD150

Note

Remove any packing material from inside the

storage bin. Retain keys for later use.

Check that gasket tape is on the top outside edge of

the dispense r where the ice machine will rest.

Because the drain tubing will be very cold,

insulatio n is recommenc ed.

Electrical:

There is an electrical jun ction box on the lower

back panel

Make the electrical connectio ns there. Follow all

applicable electrica l codes. Use a licensed

electri c ian.

The dispenser must be insta lled so th at it is a

separate piece of equipment from the ice machine.

The drains and ele ctrica l supply mus t be separat e.

Drain

October 1996

Page 3

Page 4

SLD150

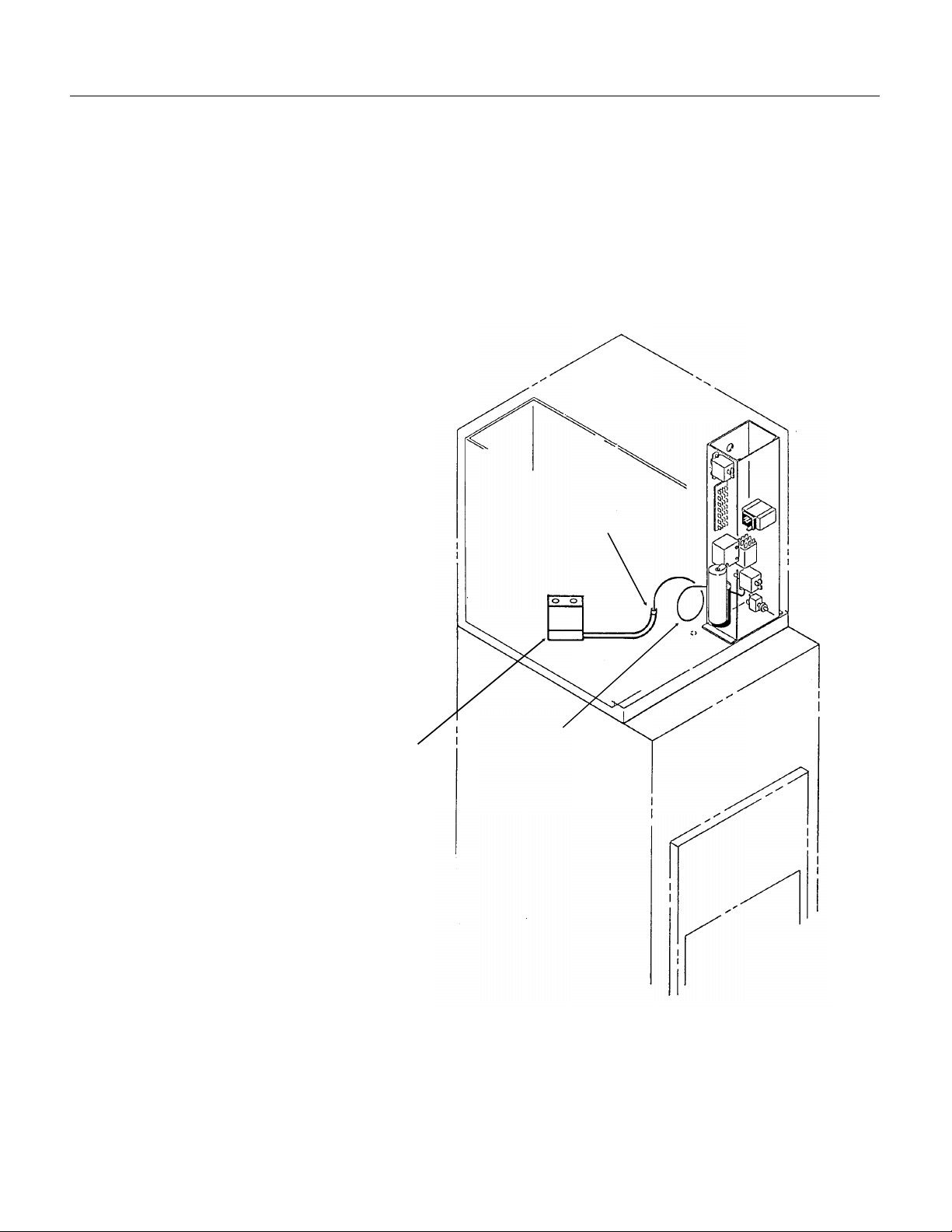

Installati on: Ic e Machine

Check that gas ket tape ha s be en place d at the

outside edge of the dispenser top.

Place corne r post s from th e cart on on top of the

dispenser, at the left and right front corners.

Locate bin thermos ta t brac ket ent ran ce hole, it s

found at the right side of the hole in the top of the

dispenser. Make sure the hole is open.

Place the ice machine onto the dispenser. The ice

machine is heavy, use of a mechanical hoist is

recommended.

The ice machine should be tilted up

slightly. Uncoil about 18" of bin

thermostat capilla ry tube.

Push the end of the capillary tube

thru the plastic tube loca te d to the

left of the compressor.

Observe the tube as it pushes

down o ut of the base. Adjust the

position of the ice machine so that

the capillary tube enters the hole

for the dispenser’s bin thermostat

bracket.

Plastic Tube

Carefully remove cardboard

supports and allow ice machine to

rest on dispenser gasket.

Caution: Bin th ermo stat ca pilla ry

tube must not be kinked or broken

during installation.

Follow all instruct ions fo r

installat ion of the ice mac hin e.

Bin

Thermostat

Bracket In

SLD150

Capillary

Tube

Installatio n of Bin Thermostat

October 1996

Page 4

Page 5

Kits: Coin Mechanism (KSLDC2)

SLD150

A kit is availab le to inst all a coin mech anism, an d

another kit is available to install a room key

mechanism. Bot h come with detaile d inst ruct ion s,

summarized here:

Coin Mechanism, ins ta ll after ice mach ine has

been operating:

1. Disconnect electrical power.

Electrical Shock Hazard.

Disconnect electrical

power before beginning

procedures.

2. Locate key, unlock and remove sink. The n

remove the top front brace and control bo x cover.

4. Remove all the wires from the push butto n

switch.

5. Remove the nuts that secure the push button

cover to the dispenser and remove the cover.

6. Remove the screws that hold the push butt on

switch to the dispenser and remove the push

button switch.

7. Install the small cover plat e from the kit.

8. Remove cover plate on right side of front panel,

below push button switch; use 5/16" nut driver.

9. Install the mountin g pla te fron the kit using the

nuts from the kit.

10. Secu re the coin mechani s m to th e mounting

plate from the inside of the dispenser. Use the

screws, flat was hers and lockwashe rs from the kit.

mechanism and hold in the safe ty int erlo ck switc h.

Push the slide in and release it. The dispen ser

should dispense ice into the container.

17. Check if the pro per amo un t of ice was

dispensed.

If more ice is needed:

••Increase the time by tu rnin g the time r

adjustment dial clockwise.

If less ice is needed:

••Decrease the time by turning the timer

adjustment dial counter clockwise.

The initial set tin g sh ould be 4 on the dial, or 8

seconds . Each se gment equals 2 secon ds .

Important : Disco nne ct the powe r sup ply when

adjusting the timer.

18. Place new sch ematic over the old one.

19. Install th e coin box .

19. Reconnect power to dispe ns er.

20. Repla c e con t ro l box cover.

21. Replace sink .

22. Check operation of coin box and key lo ck. After

everythin g is ope rat ing , give key to use r.

Control Box Layout

Control Relay

Adjustment

Coin Mech

Timer

Coin Mech

Relay

1 1 . Remo ve the cover from th e contro l box.

12. Remove the timer mechanism from the kit and

install it in the control box.

13. Remove wires numbered 8 and 9 from the

control box , they will be rep lace d by new wires

from the kit marked 8 and 9.

14. Install the new wires, followin g the wiring

diagram from the kit.

15. Reconnect th e ele ct ric al po wer supply to the

machine.

16. Place a cont ain er in th e drop zone of the

dispenser. Place a quarter in the slide of the coin

October 1996

Agitation Timer

Electrical Sequence

1. Coin switch closes, connecting power to timer .

2. Tim e r clo se s internal contact s, co nn ec ting

power to gearmotor (and door sole no id if -1B )

3. Gearmotor rotate s dispen se wheel until int ern al

timer contacts (AND cam swit ch cont acts if -1)

open. The time of rota tio n (an d amoun t of ice

dispensed) is determin ed by the timer.

Page 5

Page 6

SLD150

Key Kit Installation: (KSLDK2 )

1. Disconnect electrical power

Electrical Shock Hazard.

Disconnect electrical

power before beginning

procedures.

2. Remove sink and drain pan.

3. Remove cover.

4. Remove control box cover

5. From kit, locate brass fittin g. Obt ain typic al door

lock cylinder from the mot el/ hote l.

6. Insert cylinder into brass fitting (most cylinders

will fit). Mark place where cylinder sticks out past

brass fittin g. Cut off excess cylin de r.

7. Insert cylinde r into hole on plate in kit. Pla ce

switch mounting bracket behind cover plate and

over fitting, with the switch bel ow the fitting. Using

the locknut pro vide d, fas ten th e fittin g in pla ce with

the flats vertica l.

8. Place the cylinder in the brass fit tin g, and

secure to the fittin g with the set scre w.

9. Push hotel/mote l key int o the cylinde r and

adjust lever of micro switch so the switch clo ses

when the key is pushed all the way in.

10. Install plate and switch asse mbly int o

dispenser. Secure with nuts removed from origin al

plate.

1 1 . Remo ve wire #8 from normally open termina l

of the dispenser switch and reconnect it to the

normally open terminal of the room key

microswitch.

12. Disconnect wire #9 from the normally open

terminal of the dispense switch and connec t it to

the normally open terminal of the room key switch.

13. Use wire #6 from kit, and connect the normally

open post of the dispense switch and common of

the room key switch

Install control box cover.

Replace drain pan and sink.

Reconnect po wer and check ve nd ing . Pushing key

in and holding vend but ton do wn should start vend.

October 1996

Page 6

Page 7

Final Check List /Init ial Start Up

1. Check that ele ctrical power has been sup plie d.

2. Check that a drain, separate from the ice

machine, insula te d and mad e of rigid tu bin g, has

been connected to the dispenser.

3. Check that th e ice machin e has be en proper ly

installed per the ice mach ine s inst alla tion

directions .

4. Check that the ice machine/dispenser assembly

is level front to back and left to rig ht.

5. Check that optional kits, if any, have been

correctly installed.

6. Check that the sink ke y, and coin box key if

used, are av aila ble.

To Start:

1. Connect electrical power.

2. Go thru ice machin e sta rt up proce dure s. Let ice

machine make two harves ts.

SLD150

3. Push vend switch button in.

4. Rotor should rotate 1/4 turn and stop.

5. Ice will b e dispensed from ice chute.

6. Remove sink , and che ck dra in area for leaks. If

none, replace sink.

7. Fill out the warranty registration form and place

it in the mail.

8. Give th e operator the key(s) and instructions on

the operatio n and main te na nce of the pro duct.

Check that the operat or kno ws who to call fo r

service, and has the product/service manuals for

the machines.

Electrical Sequence

Pushing the vend button closes a contact to the

gear motor (and to the ice door sole no id of

SLD150-1B mod els).

SLD150-1 model: When the gearmotor begin s to

turn, the cam switch on the gearmo tor clo ses , so

that the vend switch may be released without

interruptin g th e vend ing , until th e cam has move d

1/4 turn. The cam switch then opens to terminate

the ve nd.

SLD150-1 B mod el: The gearmo to r and ice door

solenoid will have power and the dispenser will

continue to operate as long as the dispe nse switch

is pushed in. This mod el als o has a agita tio n cy cle

of 3 seconds every 2 hours. The solenoid does not

engage during agita tio n and no ice is dispe ns ed.

October 1996

Page 7

Page 8

Gear Mo tor

SLD150

Operational Schemat ic

Ice Machine

Bin Thermostat

Storage Bin

Drain

Ice Chute

Sink

Drain Pan

Condensate Pan

October 1996

Page 8

Page 9

Cleaning

SLD150

General Care and Cleanin g

Periodically ins pect and clean the ice dispenser to

keep it operating a t peak performanc e.

Wash the outside of the dispenser with warm

water and soap. Rinse off an d wipe dry.

Cleaning and Saniti zin g of the Ice Storage Bin:

The minerals, chlorin e and other impuritie s in the

water are rejecte d fro m the wate r during the freez e

cycle of the ice machine. These mine rals will

collect in the storage bin. The ice storage bin

should be cleaned and san itize d every 90 days.

1. Remove all of the ice stored ins ide the

dispenser bin and shut off the ice maker.

2. Disconnect electrical power

Electrical Shock Hazard.

Disconnect electrical

power before beginning

procedures.

Wash the entire bin area and the delivery area.

Use a clean brush or cloth.

9. Rinse all areas wash ed with clean, fresh water.

10. Using the ice machin e clea nin g so lut ion , clea n

the ice grill, sink, and water pan. Rinse these

parts with cle an, fresh water.

11. To sanitize: Use a lo cally ap pro ved sa nit izer. A

possible sanit izer: Mix a solut ion of ice machin e

sanitizer and wat er: 1 ounc e of hou sehold blea ch

to 2 gallons of (95

interior surf ac es and the wheel with the sanitize r

solution . Use a cle an cloth .

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of water or

milk. Call Physician

immediately. In case of

external contact, flush

with water.

KEEP OUT OF THE

REACH OF CHILDREN.

o

F.-1150F.) water. Wash all

Moving parts in bin will

cause injury if hands

are in the way.

Disconnect electrical

power before beginning

procedures.

3. Locate key and remove sink.

4. Remove top fron t pane l (in front of ice machin e).

5. Remove the fron t top pane l (abo ve ice chute).

6. Reach int o the op en ing , loca te the large nut

securing the whe el to the driv e shaft . Remo ve the

nut.

7. Pull the wheel of f th e drive shaf t and lea ve it in

the dispenser.

8. Mix a solution of 5 ounc es of ice mach ine

cleaner to 1 gallon of warm (95

o

F.-1150F.) water.

12. Allow the parts t o air dr y.

13. Reassemble wheel and large nut onto drive

shaft.

14. Replace all pane ls.

15. Reconne ct po wer, be sure ice machine is

switched back on.

October 1996

Page 9

Page 10

SLD150

Service Diagnosis

PROBLEM POSSIBLE CAUSE PROBABLE FIX

Does not vend No ice Check ice mac hine

No power Check powe r su pp l y

Vend switch open Check/rep lac e vend swit ch

Sink interloc k switch open Check/rep lac e sink interlo ck

switch

Ice jams in chute Machine is not leve l

Front panel not on all the way Reinstall pane l

Gearmotor open Check/rep lac e gearmotor

Cam switch open (SLD150-1) Check/rep lac e cam swit ch

Adjust cam switch to clos e when

on high part of cam

Ice door does no t op en

(SLD150-1B )

Drive shaft broken Check/rep lac e drive shaft.

Coin Mechanis m Does not vend, no ice Check the above, plus coin switch

Leaks water Bin drain leaks Check bin drain connections and

Check for power to solenoid.

Check linkage from solenoid to

door

Check wiring

Check timer

fittings

Check for clogged bin drain tubing

October 1996

Page 10

Page 11

Removal and Replacement

Electrical Shock Hazard.

Disconnect electrical

power before beginning

procedures.

Gear Motor

1. Disconnect electrical power

2. Locate key and remove sink.

3. Disconnect wires at gearmotor

4. Mark position of cam switch brack et, and

remove bracke t with cam switch from gearmot or.

5. Remove 4 nuts securin g gearmot or base o

cabinet.

6. Pull gearmoto r down and out of cabinet.

7. Remove gearmotor from ba se.

Reverse to reassemble.

SLD150

Drive Shaft

1. Remove all of the ice stored ins ide the

dispenser bin and shut off the ice maker.

2. Disconnect electrical power

3. Locate key and remove sink.

4. Remove top fron t pane l (in front of ice machin e).

5. Remove the fron t top pane l (abo ve ice chute).

6. Reach int o the op en ing , loca te the large nut

securing the whe el to the driv e shaft . Remo ve the

nut.

7. Disconnect wires at gearmotor.

8. Mark po sition of cam switch bracket and remove

bracket with cam switch from ge armot or.

9. Remove 4 nuts securin g gearmotor to cabinet .

10. Pull ge armotor down and out of cabinet.

1 1 . Remo ve six cap screws holding drive shaft

housing to cabinet.

12. Pull drive shaft housin g fro m the bin.

13. Remove snap ring from end of drive shaft, and

tap shaft out of bearings with plastic headed or

dead blow hammer.

14. Reverse to reas semb le.

Dispense Wheel

1. Remove all of the ice stored ins ide the

dispenser bin and shut off the ice maker.

2. Disconnect electrical power.

3. Remove ice machin e from dis pense r.

4. Remove large disp enser to p panel.

5. Reach int o the op en ing , loca te the large nut

securing the whe el to the driv e shaft . Remo ve the

nut.

6. Pull the wheel of f th e drive shaf t and remo ve it

from the dispenser.

Reverse to reassemble.

October 1996

Page 11

Loading...

Loading...