Page 1

Introduction

SLC300

To the owner or user: This service manual is

intended to provide you, and the maintenance or

service technician, with the information needed to

install, start up, clean, maintain and repair this

product.

The SLC300 is an ice machine that produces

cubed ice on 4 vertical cube freezing surfaces.

When harvested, the cubes fall individually into the

ice storage bin. The SLC300 automatically

maintains the level of ice by turning on when the

ice level falls, and switches off when the bin is full.

The refrigeration system uses R-502 as the

refrigerant.

Table of Contents

Specifications page 2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Installation

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

SLD dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

RS or IS dispenser . . . . . . . . . . . . . . . . . . . . . . . . page 7

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Initial Start Up page 12

Electrical Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

Water/ Refrigeration Schematic . . . . . . . . . . . . . . . . . . . . . . . . . page 16

Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

Parts lists and wiring diagrams are located in the center of this manual, printed on yellow paper.

Note the warning symbol where it appears in this

manual. It is an alert for important safety

information on a hazard that might cause serious

injury.

Keep this manual for future reference.

This manual was printed on recycled paper.

November 1994

Page 1

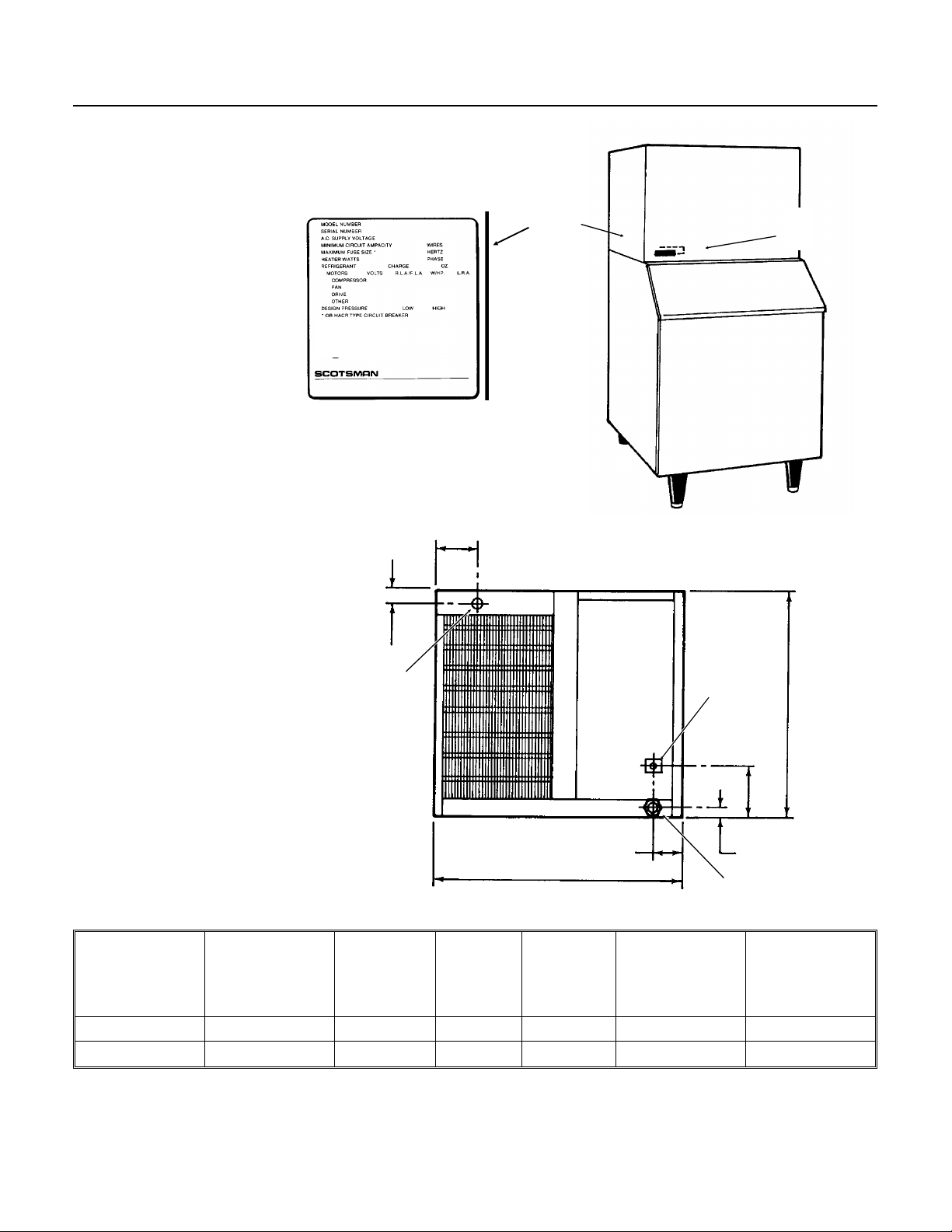

Page 2

Water

Inlet

Serial Number

Plate

SLC300

Specifications

Information regarding Model Number, Serial

Number, Ampacity and Maximum Fuse Size are

located on the nameplate of the ice machine. The

model number, serial number and refrigerant

charge are also listed on

the serial number plate

just behind the front

panel.

If recharging, always

use the charge listed on

the ice machine.

Nameplate

SLC300 Cabinet

3

1

⁄8"

Electrical

Inlet

3 3⁄4"

SLC300 Back View

(Air Cooled Model Shown)

20"

Specifications:

The SLC300 will stack onto a

1

4

⁄4"

variety of ice storage bins, see

sales literature for proper ice

storage bin.

7

There is an optional stainless

steel panel kit, SPKSLC, for this

22"

⁄8"

Drain

machine.

Model Number Dimensions

W" x D" x H"

Condenser

Type

Basic

Electrical

Minimum

Circuit

Ampacity*

Maximum

Fuse Size (or

HACR circuit

Refrigerant

Charge. R-502

breakers)

SLC300AE-1E 22 x 23 x 20 Air 115/60/1 19.7 20 15 ounces

SLC300WE-1E 22 x 23 x 20 Water 115/60/1 18.2 20 16 ounces

* Minimum Circuit Ampacity is used to determine

wire size and type per the National Electric Code.

January 1993

Page 2

Page 3

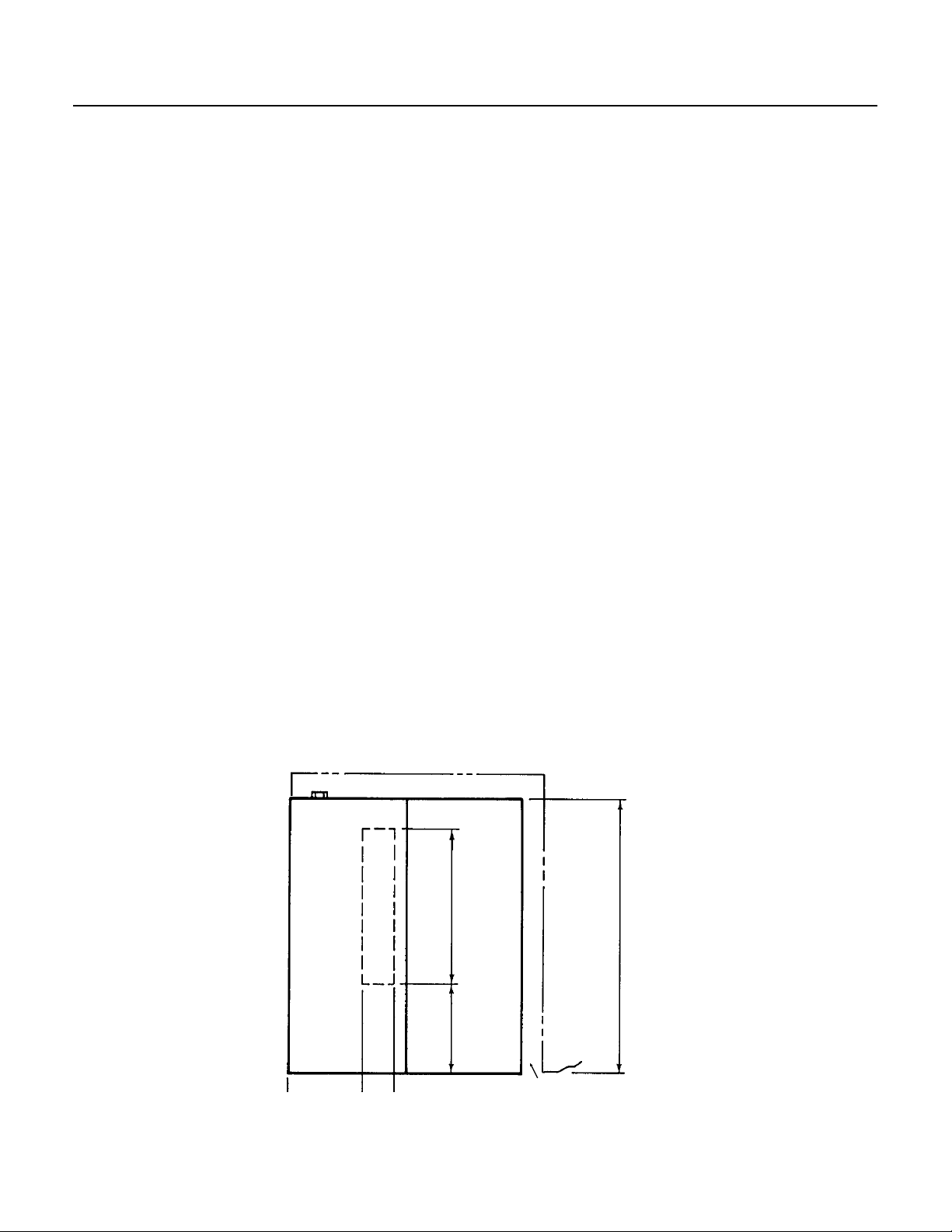

For The Installer: Environmental Limitations

23"

The ice machine must be installed indoors in a

controlled environment.

Minimum Maximum

0

Air Temp 55

Water Temp 40

Water Pressure 20 PSI 60 PSI

Voltage 103.5 126.5

Operating the ice machine outside of the above

limitations, or outdoors, is potentially damaging to

the machine, and it is misuse of the machine. This

may void the warranty.

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of UL, NSF, and CSA.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any part and/or other components not

specifically approved by Scotsman.

F. 1000F.

0

F. 900F.

SLC300

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and design are subject to change

without notice.

Airflow on air cooled models is:

••Intake through the right side grill.

••Exhaust through the back.

Dashed Lines Show

Outline of Ice Drop

Area.

Bin Control Mounts to

Right of Ice Drop Area.

7"

3"

6

12"

1

⁄2"

SLC300

Top View

Do not install where this air flow is obstructed.

6" Space Required for

Air Flow (Air Cooled

Only) and Utility

Connections

November 1994

Page 3

Page 4

SLC300

Installation

Water

The water supply for this ice machine has been in

contact with many materials since it fell from the

sky as rain. All rain is slightly acidic, and tends to

dissolve the materials it comes in contact with.

During water’s journey to the ice machine, it has

flowed over and through the ground, been picked

up by a municipal or private pump, forced through

a series of pipes of differing construction and may

have been treated by the municipality providing

the water.

The water supplied to this ice machine will then

contain a variety of substances that will likely show

up as solids during the ice making process. These

solids are similar to those found when water is

boiled out of a saucepan. Only the water boils

away, and the minerals that were in the water

solidify in the pan. During ice making only the

water is frozen into ice, the minerals stay behind in

the reservoir. This machine drains out some of the

the water in the reservoir every cycle to minimize

the amount of minerals in the water system, but

after time the minerals will appear and have to be

dissolved by ice machine cleaner, then flushed

away during the cleaning process.

Location

This ice machine may be installed in the open or

under a counter. Clearance may be required at the

sides or top beyond what’s needed to place the

cabinet into position. Air cooled models take air in

the right side and exhaust out the back. Space is

required for utility connections at the back.

The ice machine is NOT designed for outdoor

use. It must be installed indoors, in a

controlled environment. The air and water

temperatures must not exceed rated limits.

Pre-installation:

1. Inspect the place where the ice machine is to be

installed. Check for:

••space for the cabinet,

••water supply,

••drain availability

••and electrical power supply.

No extension cords are allowed. The building drain

inlet must be lower than the drain outlet of the ice

bin. The water supply must have a hand shut off

valve accessible when the unit is installed.

An ice machine is a food manufacturing plant; it

takes a raw material, in this case water, and

transforms it into a food product, ice. The purity of

the water is very important in obtaining pure ice

and in maximizing product life.

The water to the ice machine should be filtered.

Water filters vary greatly in ability and function.

Install one that filters out suspended solids to a

dimension of 5 microns or less. The finer the filter

the better, but finer filters may plug-up sooner than

course ones. It may be necessary to add a course

filter ahead of the fine filter to prolong filter life.

Polyphosphate feeders are usually effective in

many water conditions.

Have the water tested. Acidic water or alkaline

water will both cause corrosion. Dissolved solids

cannot be filtered out. Softened water is not

recommended. Never use de-ionized water.

Reverse-osmosis water must be treated with

buffering agents before use in the ice machine.

Check with a water treatment specialist regarding

testing, treatment and filters.

January 1993

Page 4

Page 5

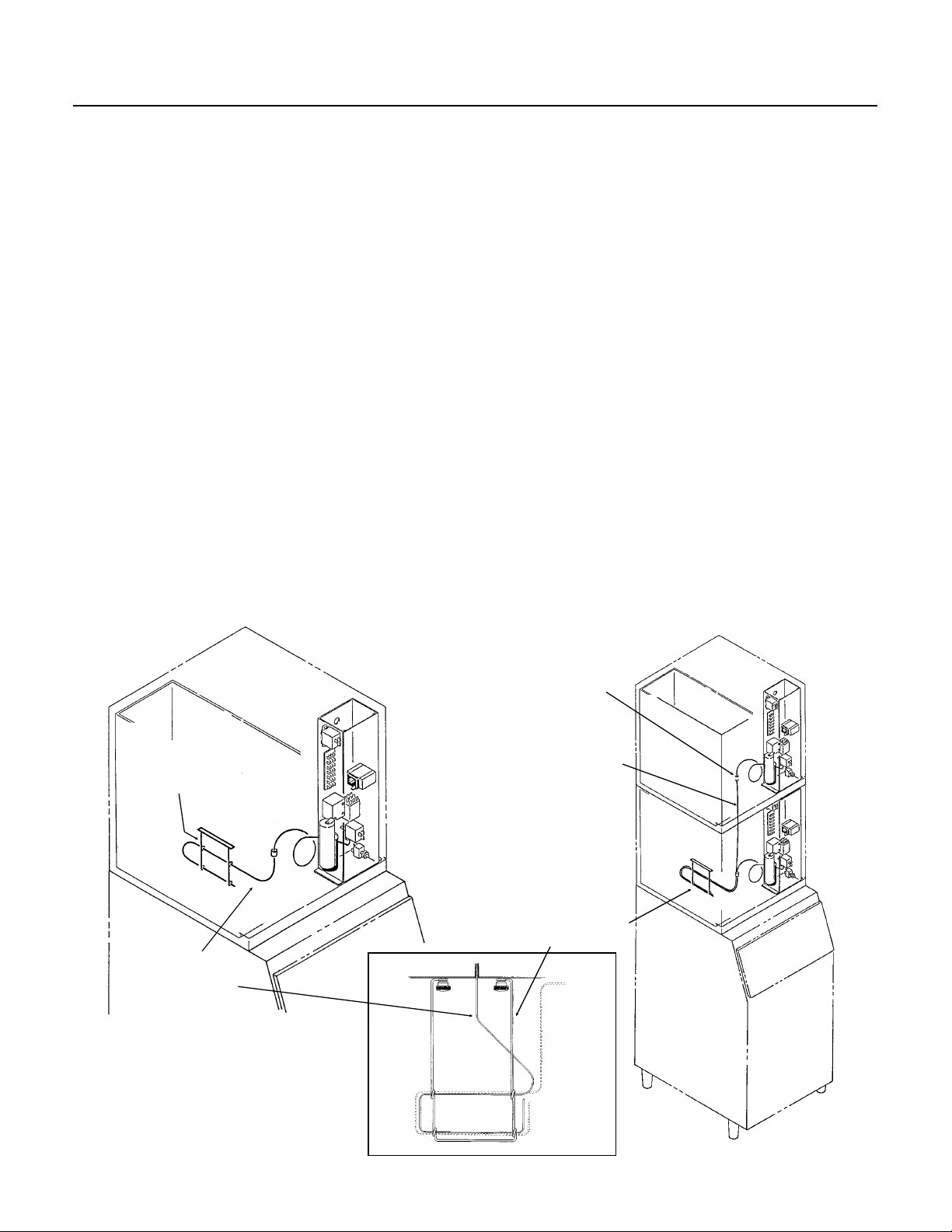

Installation: Ice Storage Bin

SLC300

Assembly:

1. Attach the legs, or optional casters, onto the ice

storage bin. Units that are stacked should only use

legs, not casters.

2. Be sure that the top edge of the bin has a good

gasket on it.

3. Place the ice machine onto the storage bin.

4. Line up the ice machine, check that there is a

good seal between the ice machine and the

storage bin.

5. If on a Scotsman bin, attach the ice machine to

the bin using the straps and bolts shipped with the

ice machine. Drill two 1/8" holes in the back of the

bin and secure with sheet metal screws provided.

If on another brand bin, follow the directions

included with that bin.

Bin Thermostat Installation:

1. Remove thermostat bracket from package.

2. Attach the bin thermostat bracket to the bottom

of the ice machine using the thumb screws

provided. There are pre-drilled and tapped holes

located just to the right of the cube drop area.

Stacking:

This machine will stack onto any SLC300 or

SLC400. Note: Do not use casters when stacking.

1. Remove and discard the left top panel from the

lower unit.

2. Remove knock out plug from top right panel.

3. Place gasket material around the top of the

bottom unit’s cabinet & evaporator compartment.

4. Carefully lift the uncrated top unit onto the

bottom unit. Use of a mechanical lift is

recommended for this step.

5. Align the two ice maker cabinets.

6. Secure the top unit to the bottom one with the

hardware and straps shipped with the upper

machine.

7. Locate and uncoil all of the bin thermostat

capillary tube.

8. Route the bin thermostat capillary tube from the

upper unit, through the hole in the base, through

the lower unit and into the bin thermostat bracket.

Discard upper unit bracket.

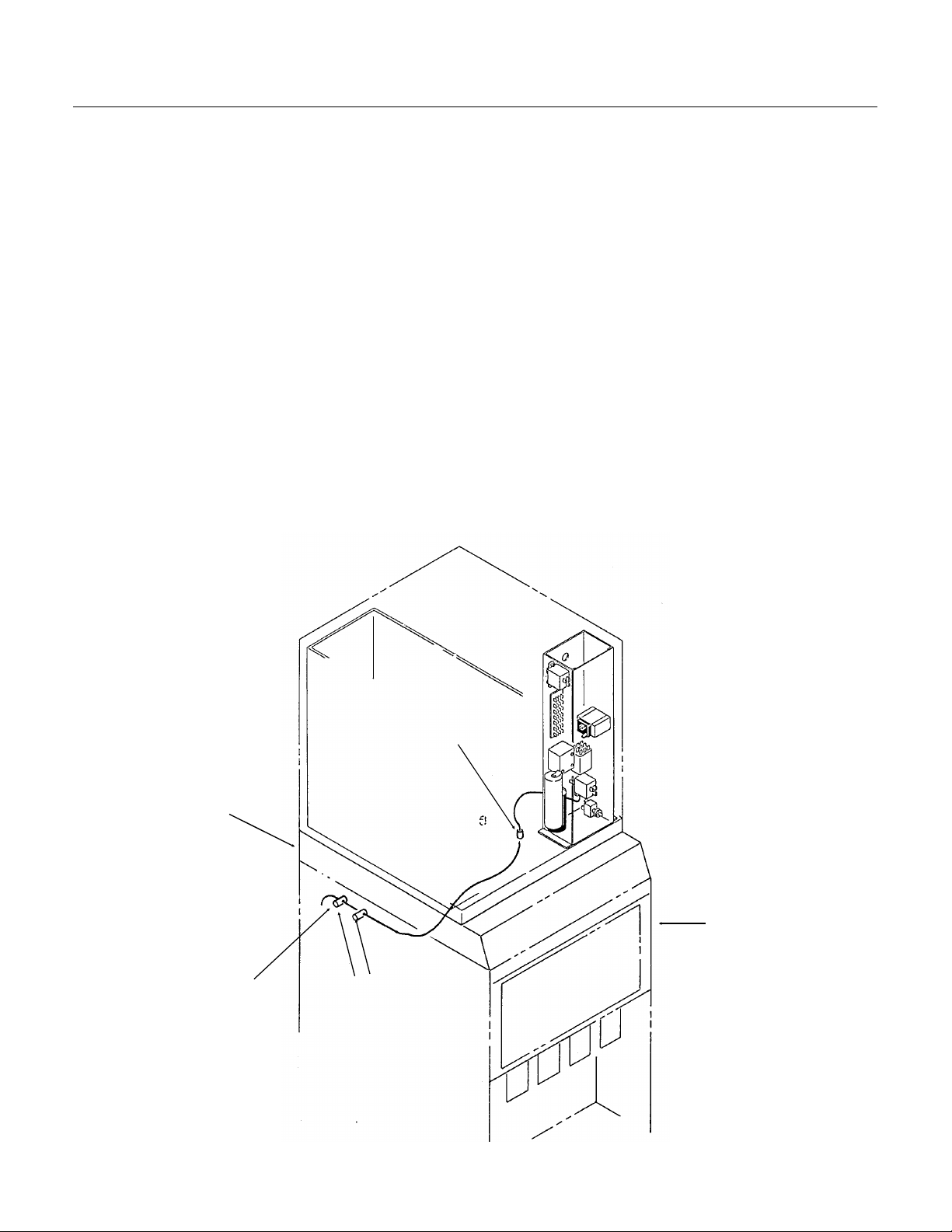

Bin Thermostat

Installation

Bin Thermostat

Bracket

Thermostat

Capillary Tube

3. Locate and uncoil a portion of the

bin thermostat capillary tube. Route

the end of the capillary tube into the

plastic tube in the base of the ice

machine (next to the compressor) and

through the bin thermostat bracket.

Note: SLB150: Use thermostat

bracket packed with that bin.

Stacking

Routing Hole

Capillary Tube

Fasten Cabinets

Together At Back

With Straps &

Screws.

Bin Thermostat

Bracket

November 1994

Page 5

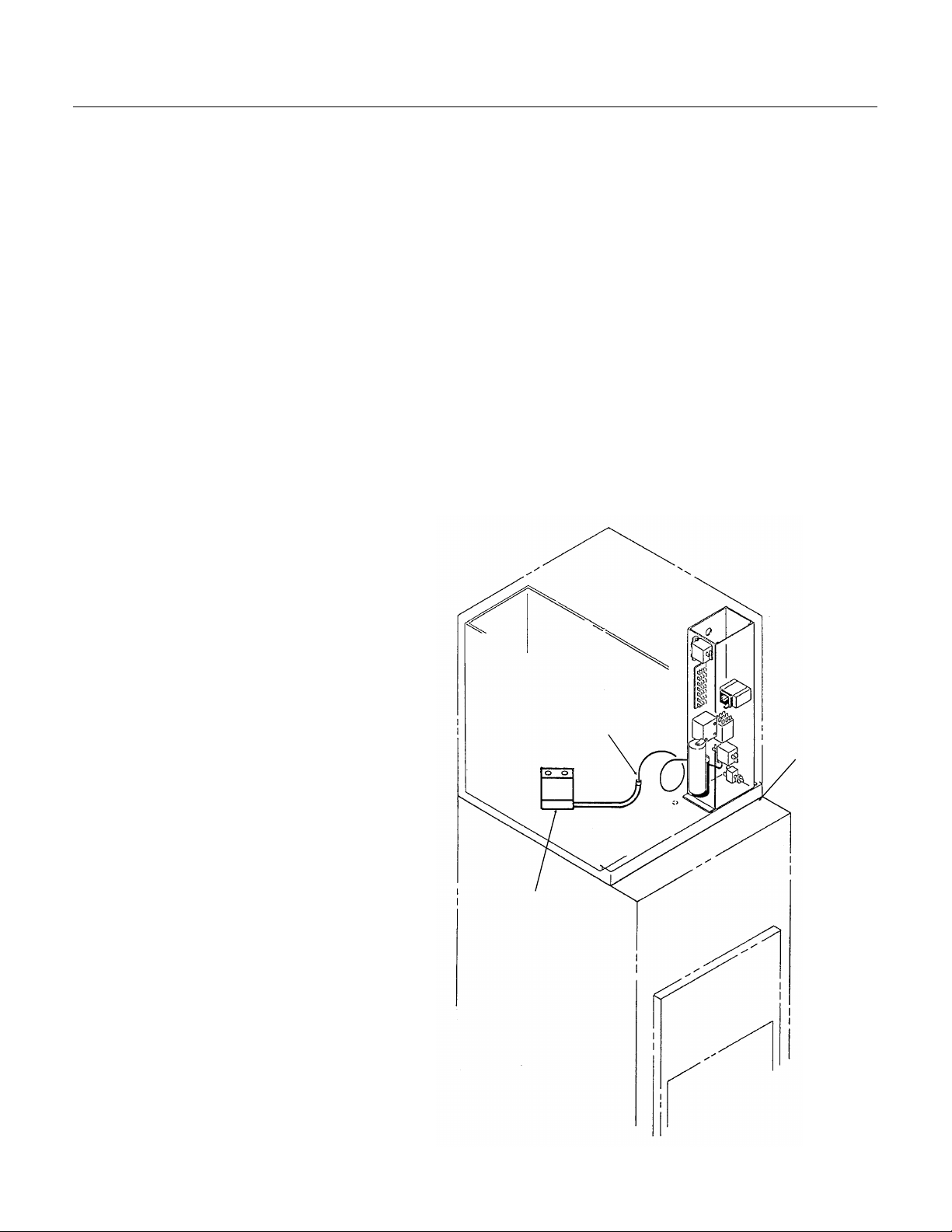

Page 6

Bin Thermostat Capillary

Tube Installation

SLC300

Installation: SLD150 Hotel Dispenser

Assembly

The ice machine must be placed onto the top of

the dispenser, and the bin thermostat capillary

tube routed into the bracket in the dispenser.

1. Check that the dispenser has a gasket all

around the perimeter of the top, 22" wide by 23"

deep.

2. Locate the inlet hole of the thermostat bracket,

and make sure that it is open.

3. Place a corner post from the ice machine carton

at the front of left and right sides of the hotel

dispenser top.

4. Use a mechanical lift and place the ice machine

onto the dispenser. The cardboard corner posts

should keep the front edge of the ice machine up.

5. Remove the front panel of the ice machine.

6. Locate the bin thermostat capillary tube and

uncoil about 18" of tubing.

7. Locate plastic tube in base of ice

machine, next to compressor and

push the end of the capillary tube thru

the tube, watch the capillary as it

comes out of the base, line it up with

the inlet hole of the thermostat

bracket and push it into the hole.

Move the cabinet of the ice machine

until the capillary tube is going

straight down into the inlet hole.

8. Carefully remove the corner posts.

9. Push the capillary tube into the

thermostat bracket tube until about

14" of capillary tube is in the tube.

9 Remove the hardware package

from the machine, remove brackets.

10. At the back of the dispenser,

fasten brackets to the ice machine.

11. Using brackets for templates, drill

1/8" holes into the back of the

dispenser.

Route Capillary Tube

Through Plastic

Tube In Base

Bin Thermostat

Bracket Mounted In

Dispenser

Temporarily

Support Machine

With Corner Posts

To Observe Cap

Tube Installation

12. Secure brackets to the dispenser

with sheet metal screws from the

hardware package.

13. Follow other installation

instructions from the SLD150.

January 1993

Page 6

Page 7

Installation: Scotsman IS or RS Dispenser

SLC300

Assembly:

The assembly of the ice machine onto the

dispenser requires two additional parts: an adapter

kit and a thermostat stand off kit.

1. Mark two spots on the inside left liner of the

dispenser: 2" down from the top, 4" from the back,

and 4" apart.

2. At the two marked spots, drill two 1/4" holes thru

the plastic liner only.

3. From the stand off kit, locate the stand offs and

plastic anchors. Thread the stand offs partially into

the plastic anchors.

4. Push the anchors/stand offs into the holes.

5. Screw the stand offs all the way into the

anchors. Be sure that the holes in the stand offs

are horizontal.

6. Place a bead of silastic (from the kit) around the

stand offs.

7. From the adapter kit, place the stainless steel

adapter onto the top of the dispenser. Follow all

directions included with the kit.

8. After the ice machine has been placed on the

dispenser, remove the front panel and uncoil all of

the bin thermostat capillary tube.

9. Route the capillary tube thru the front hole in the

base of the ice machine, to the left side if the

dispenser towards the stand offs.

10. Route the end of the capillary tube thru the

stand offs, bend the tube around the stand offs so

that it does not fall off.

11. Check that the routing of the capillary tube is

away from the ice chute and up high near the base

of the ice machine.

Installation of Bin Thermostat

Capillary Tube

K1 Kit Adapter

Stand Offs From Kit K6

Drill 2 Holes For

Stand-Offs:

2" From Top Of

Dispenser &

4" From Back &

4" Apart

Route Capillary

Tube Through Front

Plastic Tube

RS or IS

Dispenser

Route Capillary

Tube Through

Stand Offs

November 1994

Page 7

Page 8

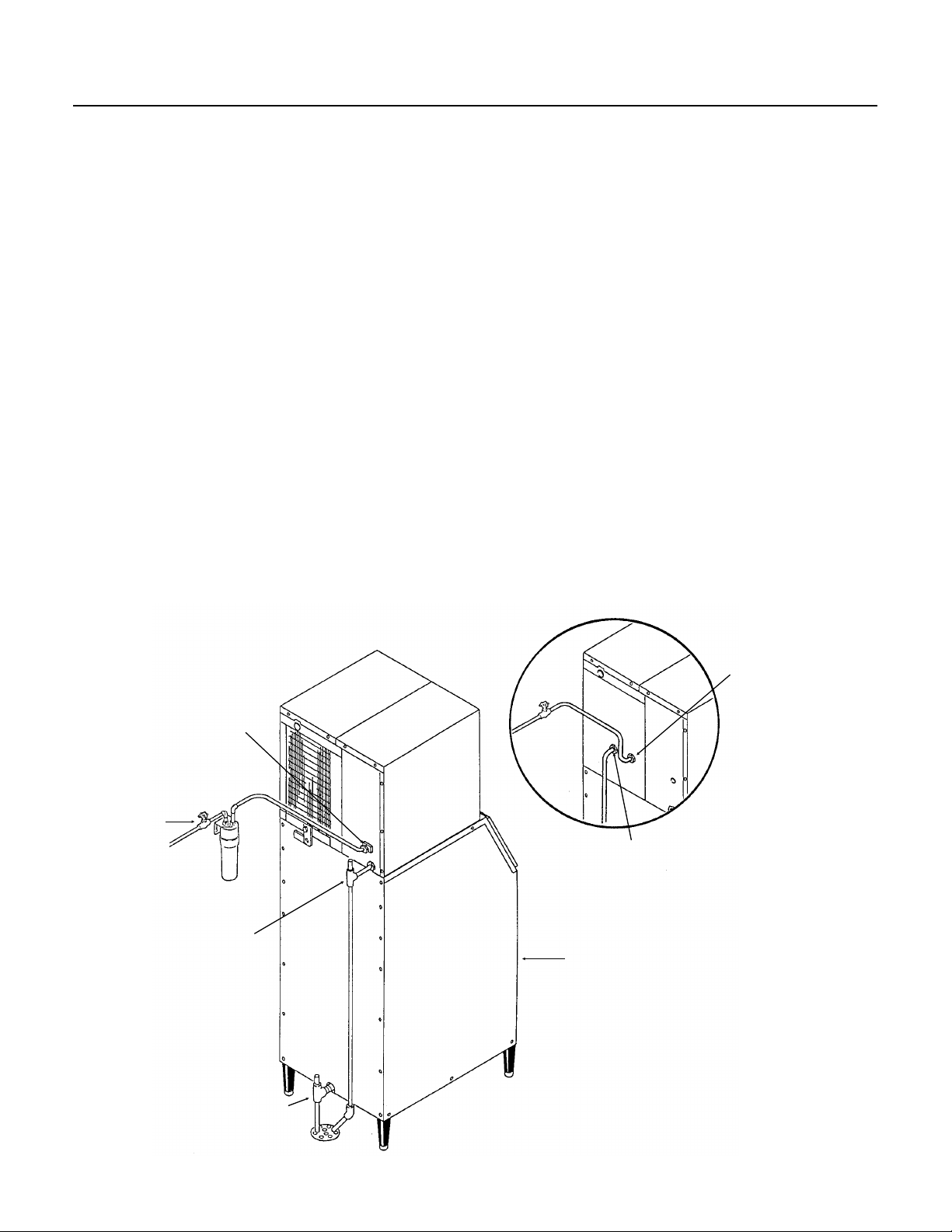

3/8" FPT Inlet

Water Cooled

Condenser Plumbing

Connections

SLC300

Installation

For The Plumber

Supply:

Screw the 3/8" male flare (fitting shipped in

package inside cabinet) into the 1/4" FPT fitting at

the back of the cabinet (thread tape

recommended). Connect cold potable water to the

water inlet. A hand shut off valve for inlet water

should be installed near the machine. A water filter

is recommended. Flush the water line prior to

connecting to the ice machine.

If water cooled, connect a separate water inlet line

to the water cooled condenser inlet fitting. It should

also have a hand shut off valve.

Drains:

Connect a drain tube to the reservoir drain fitting at

the back of the cabinet. The drain tube from the

fitting must be run separately from any other drain

tube. The reservoir drain is a 3/4" F.P.T. brass

fitting.

Drain tube material must be rigid and meet local

code.

Traps in the bin drain line without vents ahead of

them will cause poor draining.

The bin drain must be vented if there is a long

horizontal run (5’ or more). The reservoir drain

must be vented and not connected to the bin

drain. All drains are gravity, and must have a

minimum fall of 1/4" per foot of horizontal run.

Water Cooled: The water cooled condenser drain

is not vented, and is routed separately.

Maintain the air gap required by local code

between the end of the drain tubes and the

building drain receptacle.

Note: Drain tubing should be insulated to prevent

condensation from forming on the tubing.

CONFORM TO ALL LOCAL CODES

3/8 Male Flare

Water Inlet

Water Shut

Off Valve

Reservoir Drain

3/4" FPT, Must Be Vented.

Bin Drain. May Be Routed From

The Bottom On Some Model

Bins. Fitting May Be Plastic.

DO NOT OVERHEAT.

1/2" FPT

Outlet

Ice Storage Bin

(Typical)

Water Supply and Drain Connections

January 1993

Page 8

Page 9

Installation

SLC300

For The Electrician

This unit must be on a separate 115 volt AC 60

cycle single phase power supply. The maximum

fuse size for this circuit is listed on the nameplate,

and per the nameplate use fuses, or HACR circuit

breakers.

To make the electrical connections:

1. Remove the right top panel.

2. Remove the junction box cover.

3. Make the electrical connections to the wires in

the junction box. A ground screw is provided in the

junction box.

Hand Disconnect Switch

Junction Box

Follow All Local Codes - This Unit Must Be

Grounded. Usually a licensed electrician will be

required to connect the electrical service.

November 1994

Page 9

Page 10

SLC300

After Utility Connections

1. Level the cabinet, use the leg levelers on the

end of the legs to adjust the cabinet height. (Legs

should have been installed when the bin was

unpacked).

2. Wash out the bin. If desired, the interior of the

bin could be sanitized.

Final Check List

1. Is the ice maker cabinet in a room where

ambient temperatures are within the minimum and

maximum temperatures specified?

2. Has the water supply been connected?

3. Is the water pressure adequate?

4. Have the water connections been checked for

water leaks?

5. Have the drain connections been made?

6. Have the drain connections been checked for

leaks?

7. Is the cabinet level?

8. Is the ice machine connected to a 115 volt

electrical power supply and is the ice machine the

only load on that circuit?

9. Has all of the shipping material been removed

from the inside of the cabinet?

10. Has the bin and cabinet been wiped clean and

sanitized?

11. Has the Customer Evaluation & Warranty

Registration form been properly filled out? Check

for correct model and serial numbers from the

nameplate, then mail the completed form to

Scotsman.

12. Has the owner/user been given the name and

telephone number of the authorized Scotsman

Service Agency serving that location?

January 1993

Page 10

Page 11

Component Location

ICE/OFF/WASH Switch

Bin

Thermostat

Ice/Off/Wash

Switch

Many components are serviceable from the front

without removing the side panels.

Behind the front panel:

•• Water pump

•• Inlet water valve

•• Reservoir

•• Evaporators

•• Water distributor pan

•• Ice size control adjustment

••

ICE/OFF/WASH switch

•• Control box

Ice Size

Thermostat

Compressor

Relay

SLC300

Control Box Detail

High

Pressure

Cut Out

Harvest

Relay

Water Distributor

Pan

Bin Thermostat

Bracket

Ice Thickness Control

Control Box

Bin Thermostat

Water Inlet Valve

& Strainer

Component Location

Water Pump

Drain Elbow

November 1994

Page 11

Page 12

Correct Size &

Shape

Cube Size Diagram

Set

Screws

SLC300

Initial Start Up

After the final check list has been gone through,

the ice machine may be started up.

1. Open the water shut off valve; the inlet water

valve will open, and water will flow into the

reservoir..

Ice Thickness

Probe Adjustment

2. Switch on the electrical power.

3. Remove the front panel.

3. Locate the ICE/OFF/WASH switch, switch

Up for LARGER

Down for SMALLER

it to WASH.

4. The water pump will begin to pump water over

the evaporators.

5. Allow the reservoir to refill. Normal water level is

1/8" below the high point of the lower curve of the

siphon u-tube.

6. Switch the ICE/OFF/WASH switch to OFF.

7. Check the action of the siphon. The water level

in the reservoir should drop to the bottom curve of

the U-bend (normal water level) in about 2

minutes. If not, check for proper drain tube

connections.

Ice Size Adjustment

Plate:

Cubes Too

Thick

8. Switch the ICE/OFF/WASH switch to ON.

9. On air cooled models the fan motor will begin to

turn, and warm air will be discharged from the

back of the ice machine.

On water cooled models warm water will begin to

flow from the condenser drain.

10. The water temperature in the reservoir will

soon be 32

0

F., and ice should begin to form on the

evaporators.

11. Allow the ice machine to operate for about

15-20 minutes. The ice should be fully formed and

should be harvested within a few minutes.

12. After harvest, check the ice cube size.

Compare a fresh cube to the diagram on the

back of the front panel. If needed, adjust the

cube size by loosening the two set screws and

moving the ice thickness probe plate.

Move the plate down for smaller cubes and up

for larger. Re-tighten set screws.

For proper operation, the ice thickness should be

set to the 1

11

⁄16" diameter.

The machine is designed to harvest cubes of

only the correct thickness.

1 11⁄16"

Cubes Too

Thin

January 1993

Page 12

Page 13

Initial Start Up

SLC300

Note: If the first batch of cubes are not all uniform

discs, some ice machine cleaner should be added

to the reservoir.

1. After ice has been harvested, but before new

cubes begin to form, switch the ICE/OFF/WASH

switch to WASH.

2. Add 4 oz. of ice machine cleaner to the

reservoir. Allow unit to operate that way for 10

minutes.

3. Switch ICE/OFF/WASH switch to OFF

4. Shut the water supply off.

5. Remove the splash guard, and drain the

reservoir by removing the drain elbow.

7. Replace all parts, turn on the water and move

ICE/OFF/WASH switch to ICE. The next batch of

ice should be uniform.

13. Check harvest. The machine will have to

harvest all of the cubes before it goes back into the

freeze cycle.

14. Check operation of the bin control circuit by

holding ice on the bin control tube in the bin.

If the ice maker does not stop within 1 minute,

while keeping ice on the thermostat, rotate the bin

thermostat shaft counter clockwise until the ice

maker does stop. Remove the ice from the

capillary tube; the ice maker should restart within 2

minutes. If it does not, rotate the adjusting shaft

clockwise until the machines starts.

15. Replace all the panels. The ice machine is now

ready for automatic operation.

Siphon Tube Schematic

U-Tube Adjusted

Here = No Purge

Siphon Breaker Hole

U-Tube Here =

Maximum Purge

Water Level

At Harvest

Water Level With

Pump ON

Water Inlet

1/8 - 1/4

Electrical Sequence:

This describes the sequence through a complete

cycle.

Freeze Cycle:

During the first part of the freeze cycle, the ice

machine compressor, fan motor if air cooled, and

water pump are operating.

Assume the bin thermostat is closed.

The ice size thermostat contact 2-3 are closed,

connecting power to:

••The fan motor (thru relay)

••The pump motor (thru relay and ice/off/wash

switch.

The Harvest Termination Thermostat is closed, but

there is no power thru it.

The ice size thermostat heater is on.

Harvest:

In the harvest cycle, the compressor is operating,

and the hot gas valve is energized. The water

pump is off, and air cooled models switch the fan

off.

The bin thermostat is still closed.

When the ice near the ice size thermostat sensing

tube grows large enough to force water over the

sensing tube, that tube looses heat, and at 38

contacts 2-3 open and 2-1 close.

This removes power from the water pump and fan

and connects power to the relay coil. When the

relay coil has power, it connects power to the:

o

••Hot gas valve coil

The harvest termination switch is closed, and

power flows thru it to the relay coil. This keeps the

relay energized, even when the ice size thermostat

switches contact position as a result of ice falling

away from the sensing tube.

The ice size thermostat heater is on.

The unit stays in the harvest cycle until the

thermodisc on the suction line warms up to 55

At that time the harvest cycle is terminated, and

the unit will go back into the freeze cycle.

Whenever there is ice on the bin thermostat, it

opens and stops the ice making process.

o

F.

F.,

Drain Outlet

Elbow

Bottom of

Reservoir

November 1994

Page 13

Page 14

SLC300

Maintenance, Cleaning and Sanitizing

Cleaning Schedule:

••Scrub the outside of the cabinet once a week

with soap and water.

••Sanitize the bin interior once a month.

••Clean the water system and air cooled

condenser a minimum of twice per year. If in an

area of high mineral concentration in the water

supply, clean water system 4 times a year.

Inlet Water Valve Screens

If a restriction of incoming water is suspected, the

screen on the inlet side of the water valve should

be inspected & cleaned. There is a strainer in the

water line; the strainer screen should also be

inspected for restricting minerals.

Air Cooled condenser (air cooled only):

Remove the right side panel.

The air flow thru the condenser is from front to

back, so dust will build up on the fan side of the

condenser fins.

The fan motor, bracket and part of the shroud may

be removed as an assembly:

1. Unplug the fan motor.

2. Remove 3 screws at the right edge of the fan

shroud.

3. Pull the assembly out the right side. The

condenser fins are then visible for cleaning.

The fins of the condenser will become fouled with

dirt, and must be cleaned. A vacuum cleaner with a

soft brush attachment will extract most loose dust

stuck to the surface of the condenser fins..

Water cooled units:

The water cooled condenser may, over time and

under certain water conditions, become internally

restricted by minerals. These will have to be

dissolved by acid or the condenser replaced. Only

a qualified service agent should attempt this type

of service.

Ice Storage Bin

The interior liner of the bin is in contact with a food

product: ice. The storage bin must be cleaned

regularly to maintain a sanitary environment.

Once a week cleaning with soap and water, a hot

water rinse and an air dry is a basic procedure.

Every 30 days, the liner should be sanitized with a

commercial ice machine sanitizer, according to the

directions of the sanitizer, or with a solution of

household bleach and water:

1. Mix the bleach and water using the ratio of two

ounces of bleach to two gallons of water.

2. Wipe all interior surfaces of the ice storage bin

with the bleach and water.

3. Allow to air dry.

To Remove Scale:

1. Mix a cleaning solution of 4 ounces of Scotsman

Ice Machine Cleaner to 4 pints of warm

0

(95

F.-1100F.) water.

2. Using rubber gloves, dip a nylon scouring pad

into the cleaning solution and scrub the scale off

the liner.

3. After the scale has been removed, rinse all

surfaces inside the bin with clean, potable water.

Stainless Steel Bin Liner

The stainless steel liner of the bin will require

periodic cleaning. Chemicals in the water supply,

such as chlorine, cause brown stains to appear on

the surface of the stainless steel parts.

1. General Cleaning - staining is usually removed

by washing the parts with ordinary cleaning

powder such as Bon-Ami or Copper-Glo and

water. After cleaning, rinse with clear water.

2. Water treatment. The chlorine enters the

machine from the municipal water supply. It can be

removed from the water supply by using a

charcoal or activated carbon water filter to treat the

water to the ice machine. If staining is severe,

filters of this type are recommended.

Exterior Cabinet Cleaning:

The exterior cabinet may be cleaned by scrubbing

with soap and water. Do not use cleaners

containing petroleum products.

A nylon type brush may be used to scrub stubborn

deposits.

January 1993

Page 14

Page 15

Cleaning: Ice Machine Water System

SLC300

Dissolve and Remove Minerals:

1. Remove front panel.

2. Move the ICE/OFF/WASH switch to OFF.

3. Remove the splash guard.

4. Shut the water supply off by pushing the water

valve button in.

5. Drain the water from the sump by removing the

drain elbow.

6. Disconnect hose from the water distributor pan,

and remove the water distributor pan.

7. Mix a solution of 5 oz. ice machine cleaner and

1 gallon of warm (95

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of water or

milk. Call Physician

immediately. In case of

external contact, flush

with water.

KEEP OUT OF THE

REACH OF CHILDREN.

8. Wash the splash guard, drain elbow and water

distributor pan with the ice machine cleaner/water

solution.

9. With the solution of ice machine cleaner and

water, wash the refrigeration tubing, liner,

evaporators, support brackets and the water pump

assembly. Use the brush and/or a clean cloth.

10. Replace the drain elbow.

11. Open the water supply by pushing the water

valve button in to the original position and allow

the sump to refill.

12. Add 5 oz. ice machine cleaner to the sump

area.

13. Replace the water distributor pan and splash

guard. Be certain the hose to water distributor pan

is connected to pan.

o

F. - 115oF.) water.

15. Shut the water supply off by pushing the water

valve button in.

16. Drain the water from the sump by removing the

drain elbow.

Sanitize:

17. Remove the water distributor pan.

18. Mix a sanitizer solution of 1 ounce of

household bleach to 2 gallons of warm (95

o

115

F.) water

19. Wash the splash guard and the water

distributor pan with the solution of sanitizer. Allow

to air dry.

20. With the sanitizer solution, wash the

refrigeration tubing, liner, evaporators, support

brackets and water pump assembly; use the brush

and/or a clean cloth.

21. Replace the water distributor pan and splash

guard. Be certain that the hose to the water

distributor pan is tightly connected to the pan, and

that the flow washer in the hose is not in sideways.

22. Replace the drain elbow.

23. Add ice machine sanitizer solution to the sump

area until it is full.

24. Move the ICE/OFF/WASH switch to WASH

add more sanitizer solution to the sump area until

it is full again.

25. After 5 minutes, move the ICE/OFF/WASH

switch to OFF.

26. Remove the splash guard.

27. Drain the water from the sump by removing the

drain elbow.

28. Replace the drain elbow and splash guard

29. Open the water supply by pushing the water

valve button in (to the original position) and allow

the sump to refill.

30. Move the ICE/OFF/WASH switch to ICE.

31. Replace the front panel.

32. Discard first batch of ice and all other batches

until all traces of cleaner and sanitizer disappear.

o

F. -

14. Move the ICE/OFF/WASH switch to wash and

allow the solution to circulate for 15 minutes, then

move the ICE/OFF/WASH switch to OFF.

17. Remove the splash guard.

November 1994

Page 15

Page 16

Discharge Line

Fan Motor

(On)

SLC300

Refrigeration Schematic:

Freeze Cycle:

From the compressor, hot discharge gas is

pumped to the condenser, either air or water

cooled.

At the condenser, heat from the refrigerant flows

into the cooling medium, either air or water, and

the refrigerant condenses into a liquid. From the

condenser the liquid refrigerant flows through the

liquid line to the metering device - a thermostatic

expansion valve.

At the expansion valve, the liquid refrigerant

passes from a high pressure zone to one of

relatively low pressure, and in the low pressure

zone it evaporates. The low pressure zone where

the refrigerant evaporates is the evaporator. When

the refrigerant evaporates, it absorbs heat from the

metal parts of the evaporator and the water flowing

over it.

From the evaporator, the refrigerant flows back to

the compressor through the suction line.

Water Schematic:

Water flows into the ice machine from its inlet

connection at the back of the cabinet, through the

inlet water valve and into the reservoir. The water

in the reservoir is pumped up and through the

water distributor tube at the top of the evaporators.

From there, the water flows over both sides of the

evaporators and back into the reservoir.

Melted ice and water spills into the bin flow

through a drain in the base of the bin to the

exterior drain connection at the back of the cabinet.

Evaporators

Inlet Water

Valve &

Strainer

Float

Valve

Water Distribution

System

Water

Pump

(On)

Thermostatic

Expansion Valve

Suction Line

Hot Gas Valve (Closed)

Condenser

Compressor

Dryer

Water Reservoir

Siphon

Tube

Refrigeration Schematic

January 1993

Page 16

Page 17

Harvest Cycle:

Discharge Line

Fan Motor

(Off)

SLC300

The ice maker continures to freeze the water into

ice unitl the ice next to the ice size thermostat

probe has become thick enough to force water

over the probe. After the cold water has reduced

the temperature of the probe to 38

o

F., the ice size

thermotstat will switch the machine into the harvest

cycle.

During the harvest cycle, the refrigerant flows from

the condenser, through the discharge line to a

branch in the line containing the Hot Gas Valve.

This valve is Open during the harvest cycle,

allowing the hot discharge gas to bypass the

condenser and enter the evaporator at its inlet.

The hot discharge gases warm up the evaporator

enough to allow the surface of the ice frozen to the

evaporator to melt. The remaining ice will then fall

off into the bin.

Water Distribution

System

During the Harvest Cycle, the water level rises,

filling the reservoir over the siphon tube and

siphoning some of the reservoir water out to the

drain.

The harvest cycle continues until the suction line

warms up enough to cause the harvest termination

thermostat to switch the machine back into the

freeze cycle.

Evaporators

Inlet

Water

Valve

Water Reservoir

Water

Pump

(Off)

Siphon

Tube

(Draining)

Thermostatic

Expansion Valve

Suction Line

Hot Gas Valve (Open)

Condenser

Compressor

Dryer

Refrigeration Schematic

November 1994

Page 17

Page 18

SLC300

Technical Characteristics

Typical Cycle Time

••16 minutes @ 90

Typical Harvest Ice Weight

••2.4 pounds .

Typical Low Side Pressure

••18-20 PSIG just before harvest

Typical Freeze Cycle Discharge Pressure

••190 - 240 PSIG @ 70

••250 - 290 PSIG @ 90

••250 for water cooled

Refrigerant Charge:

Air cooled = 15 ounces R-502; Water cooled = 16 ounces R-502

••

Harvest Time

••Normally 1

o

F. air and 70oF. water; 13 minutes @ 70oF. air and 50oF. water

o

F. air and 50oF. water

o

F. air and 70oF. water

1

⁄2 to 2 minutes. Depends upon time required to warm suction line to 55oF.

Typical Suction Pressure, In Harvest:

••105 -120 PSIG (@75

Typical Discharge Pressure, In Harvest:

o

F. air temp., will be lower in cooler ambients)

••120 - 150 PSIG

Water Cooled High Pressure Cut Out

••Cuts out at 380 PSIG, resets at 315 PSIG

Typical Compressor Amp Draw:

••6-7 during freeze cycle; 9-10 during harvest cycle

Compressor:

••Tecumseh AK9466J

Thermostatic Expansion Valve

••Superheat is 3

Bin Thermostat

••Cut out at 35

Ice Size Thermostat:

o

- 6oF.

o

F., cut in at 39oF.. Adjustable warmer.

•• Switches to harvest cycle with temperature fall to 38

oF.

Resets at 43oF.

Ice Size Heater

••

Adds heat to ice size thermostat to prevent premature harvest. 6,000 ohms resistance.

Harvest Termination Thermostat

•• Opens to switch to freeze cycle with temperature rise to 55

January 1993

Page 18

o

F. Resets at 40oF.

Page 19

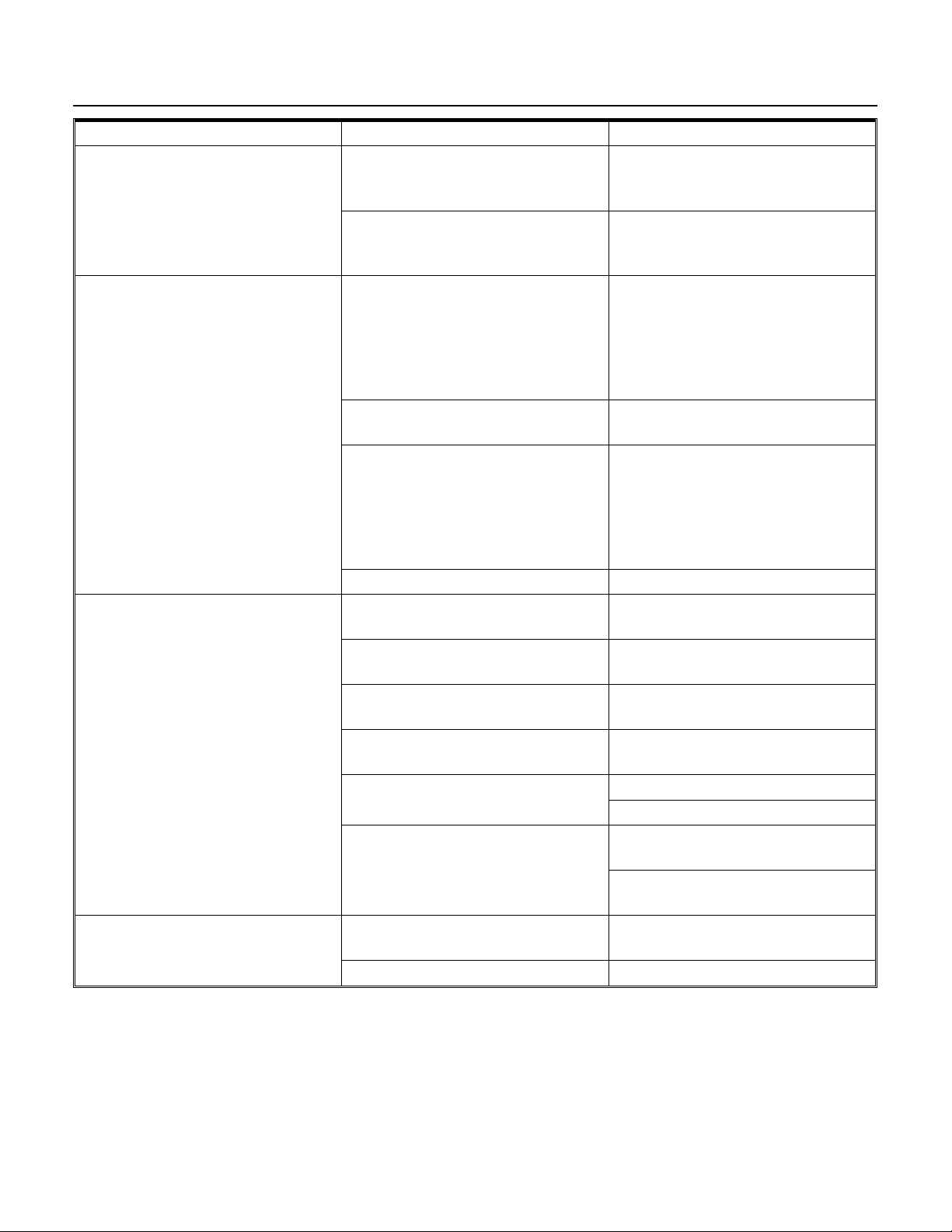

Service Diagnosis:

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

No ice is made, nothing operates Unit off, due to no power Restore power

Unit off, due to ICE/OFF/WASH

switch in OFF position

Unit off, due to bin thermostat

open

Water cooled unit off, due to high

pressure cut out open

No ice, compressor off No cooling due to compressor not

operating

No ice is made, compressor is

operating

No water due to water turned off. Reconnect water supply

No water due to water filter

plugged.

No water due to strainer screen

plugged

No water due to inlet water valve

will not open

Water in reservoir, but no water

over evaporators

No cooling at evaporator due to

hot gas valve leaking thru

No cooling at evaporator due to

fan not turning

Fan and pump do not have

power; hot gas valve opens and

closes.

No cooling at evaporator due to

dirty condenser

No cooling due to compressor not

pumping

Switch ICE/OFF/WASH switch to

ICE

Check temperature at bin

thermostat bracket, if warmer than

o

40

F., thermostat should be

closed. Adjust/replace thermostat.

Lack of water to condenser,

check water supply and water

regulating valve.

Check compressor for voltage,

continuity, and operation. Check

starting components. Replace if

found to be faulty.

Check temperature of

compressor, if hot may be lack of

refrigerant, defective TXV or

compressor

Replace water filter

Clean out inlet screen

Replace valve

Water pump does not work,

replace pump

Replace hot gas valve

Check & replace fan motor.

Coil or relay open, replace relay.

Clean condenser

Check system pressures, replace

compressor if not pumping

SLC300

November 1994

Page 19

Page 20

SLC300

Service Diagnosis:

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

No ice compressor is operating No cooling due to low refrigerant

charge

Ice is made, but not harvested. Ice size thermostat contacts do

not switch position

Ice will not slide down ice rack

due to minerals on rack.

Ice will not slide down ice rack

due to ice rack out of position

Ice will not slide down ice rack

due to bent ice rack

Lack of heat during harvest cycle

due to unit in air temp. less than

0

55

F.

Lack of heat during harvest due to

water flowing thru water cooled

condenser

Lack of heat during harvest due to

lack of refrigerant

Lack of heat during harvest due to

hot gas valve not opening fully.

Ice does not slide down face of

evaporator due to minerals on

evaporator surface

Harvest cycle too short due to

harvest termination thermostat

opens at too low a temperature.

Locate leak, recover remaining

refrigerant, replace dryer,

evacuate and weigh in nameplate

charge.

Ice not made near thermostat

probe due to water distributor

holes restricted. Clean water

distributor pan.

Thermostat defective, replace it

Clean machine with ice machine

cleaner.

Reposition ice rack

Replace ice rack

Warm up air or move machine.

Replace water regulating valve

Check low side pressure during

harvest. If low either the charge is

low or the hot gas valve does not

open fully. If charge is the

problem, locate leak, recover

remaining refrigerant, repair leak,

replace drier, evacuate and weigh

in nameplate charge.

Check low side pressure during

harvest. If low either the charge is

low or the hot gas valve does not

open fully.

Clean water system with ice

machine cleaner

Replace harvest termination

thermostat

January 1993

Page 20

Page 21

SLC300

Service Diagnosis:

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

Ice is made, but will not harvest Will not harvest due to hot gas

valve not opening.

Slow/incomplete harvest due to

hot gas valve not fully open.

Makes ice, but very little High discharge pressure, due to

dirty condenser; faulty fan motor;

not enough water thru water

cooled condenser, high water

temperatures, water reg. valve set

too high.

Inlet water temperatures and

room ambient very high

Long freeze cycle due to hot gas

valve leaking thru.

Compressor inefficient Check/replace compressor

Cubes are wrong size/shape Ice size thermostat not adjusted

properly

Freeze cycle too short due to

heater open

Water system is restricted with

minerals

Ice thickness probe tube covered

with minerals

Not enough water Check water supply pressure

Too much superheat Check superheat, replace TXV if

Ice fused together in bin Ice in bin too long Advise user to pour water on ice

Too many minerals in water Suggest water treatment to user.

Check for voltage to coil in

harvest, if there is voltage

replace hot gas valve

Check low side pressure in

harvest, replace hot gas valve if

too low with correct ref. charge.

Check for causes of high

discharge pressure and correct.

Advise user, suggest additional

room cooling.

Check temperature of tubes to

and from hot gas valve; there

should be a temperature drop

across the valve in the freeze

cycle. Replace valve if temps are

nearly equal.

Adjust ice size thermostat; use

gauge shipped with machine

Check/replace heater on ice size

thermostat probe tube.

Clean water system with

Scotsman Ice Machine Cleaner

Clean tube with ice machine

cleaner

Check water supply for restrictions

too high.

Check hot gas valve for leak-thru;

replace if leaks thru.

to ease removal

November 1994

Page 21

Page 22

Replacement of Ice Size Thermostat

Probe Tube

& Bracket

SLC300

Removal and Replacement

Ice Size Thermostat:

Before replacing the ice size thermostat, it should

be positively determined that it is at fault.

1. Disconnect electrical power.

Electrical shock hazard.

Electrical shock can

cause personal injury.

Disconnect power before

beginning to service

components.

2. Remove the front panel.

3. Remove the control box cover.

4. Locate the ice size thermostat.

5. Remove the two screws holding the control to

the control box, and lift the control out.

Primary Resistor (Heater)

1. Disconnect electrical power.

2. Disconnect the primary resistors yellow wire

from terminal #4 and the white wire from terminal

#1. Pull the two wires out of the control box and

thru the insulated wall.

3. Mark location of adjustment bracket.

4. Remove two screws and the ice size thermostat

probe tube bracket.

5. Remove the evaporator side plastic sleeve and

heater from the tube.

6. Reverse the prior steps to replace. Probe tube

must be inserted into plastic guide attached to

evaporator.

7. Place adjustment bracket in its original position.

Check ice size.

Evaporator

Heater

6. Pull the three wires off the posts of the ice size

thermostat.

7. Locate bulb on suction line.

8. Follow the capillary tube of the ice size

thermostat: the end of the ice size thermostat is

inserted in a tube. Pull it out of the tube.

9. Pull the capillary tube of the ice size thermostat

thru the grommet in the side of the control box.

10. Remove the ice size thermostat from the

control box.

11. Replace the ice size thermostat with the proper

part number, following the above steps from 10-1.

Capillary

Tube

January 1993

Page 22

Page 23

Removal and Replacement

SLC300

Water Pump

The pump provides the force to move the water

from the reservoir to the freezing surface. The

pump does not need oil, but if it becomes noisy,

overheats, or will not pump it should be replaced.

Be certain to confirm electrical faults with a

voltmeter or ohmmeter before replacing the pump.

The pump should be operating whenever the

machine is in the freeze cycle.

1. Unplug or disconnect the electrical power.

Electrical shock hazard.

Electrical shock can

cause personal injury.

Disconnect power before

beginning to service

components.

Inlet Water Valve

The valve may plug-up from minerals in the water,

and may be cleaned rather than replaced.

1. Shut off the water supply.

2. Unscrew the fitting at the top of the valve, and

pull the water inlet tube out of the valve body.

3. Remove the screws holding the valve bracket to

the liner.

4. Remove the valve from the ice machine.

5. Reverse the above steps to reassemble.

2. Unplug the pump from its connection.

5. Loosen the two fasteners holding the cover to

the wall.

6. Remove pump cover from the machine.

7. Pull discharge hose from pump discharge port.

8. Remove pump from ice machine.

9. Reverse above steps to replace.

Shut Off Valve

Inlet Water Valve &

Strainer

Float Valve

Siphon "U" Tube

Pump Cover

Thumb

Screws

Replacement of Water

Pump

November 1994

Page 23

Page 24

SLC300

Removal and Replacement: Refrigeration System

General:

••Scotsman recommends that any work on the

refrigeration system only be done when it is

certain that the system needs repair.

••Refrigerant should not be added except as a

way to determine the proper operation of the

product. If the system was low on refrigerant,

there is a leak, and it must be found and

repaired.

••Refrigerant must not be vented to the

atmosphere.

••This system has a critical charge, it must be

recharged with the correct amount of refrigerant

as listed on the nameplate of the ice machine,

or performance will suffer.

••Anytime the refrigeration system has been

opened, the dryer should be replaced.

••When brazing the tubing connections to the hot

gas or thermostatic expansion valve, the

component must be protected by heat sink

material.

Specifically:

Recover, reclaim or recycle refrigerant. The

method chosen is up to the service company.

There are various mechanical devices that may be

used to recycle refrigerant at the field level,

however, Scotsman requires that any refrigerant

placed into a Scotsman ice machine meet ARI

spec 700. Reclaim programs are available through

most refrigerant wholesalers.

Use conservation minded service procedures:

••Refrain from checking refrigeration

pressures without reason.

ways to determine the proper operation of a

Scotsman ice machine without using refrigerant

gauges. Visual inspection of the water system,

observation of the ice formation, amp draw,

voltage, and other techniques will lead to proper

diagnosis. Scotsman also recommends that, at

the time of initial start up, gauges not be used.

There are many

••If gauges must be used, do not always

check the high side pressure.

condenser is clean and seems to be operating

correctly, it most likely is. The low side pressure

is much more important on an ice machine than

is the high side.

If the

••If gauges must be used, use very short hoses.

Minimal refrigerant discharged into the hoses

equals minimal refrigerant discharged into the

air.

••If hi side pressure must be checked, use a

quick connect at the end of the discharge

to minimize the release of refrigerant, J/B

hose

Industries part number A33000 works well.

••If using recycled refrigerant, it must meet ARI

spec 700 or have been cleaned by a machine

capable of attaining ARI spec 700.

If the refrigeration system must be serviced, the

quality of service must insure that there will

not be a repeat failure, as repeat failures will

cause refrigerant to be discharged into the air by

the failure or when the failure is corrected:

••If there has been a compressor burn out, check

for acid in the oil. If acid is indicated, extra steps

must be taken to clean up the system.

••Never use refrigerant, such as R-11, to clean

up or flush out a refrigeration system. When

system clean-up is required, the use of suction

line filter-dryers and liquid line filter-dryers are

recommended.

••Always replace the dryer when repairing a leak

or replacing a refrigeration component.

••Evacuate the system with a good vacuum

pump to 500 microns or less. If the triple

evacuation method is used, the vacuum should

be broken each time with dry nitrogen, not

refrigerant. Evacuation must be from both sides

of the system.

••Weigh in or measure in the nameplate charge.

Recharge into the high side.

••Check for leaks with a high quality, electronic

leak detector. Halide torches will not locate the

very small leaks.

If an ice machine is to be discarded and still

contains refrigerant, Scotsman recommends that

the refrigerant be recovered, reclaimed, or

recycled so that it is not discharged into the air.

January 1993

Page 24

Loading...

Loading...