Page 1

Introduction

SCE275

To the owner or user: This service manual is

intended to provide you, and the maintenance or

service technician, with the information needed to

install, start up, clean, maintain and repair this

product.

The SCE275 is an ice machine that produces

cubed ice on a vertical freezing surface. The cubes

fall into the ice storage bin where they break up

into individual cubes.

Table of Contents

Specifications ···········································2

For The Installer: Environmental Limitations ···························3

Installation ·············································4

Installation ·············································5

For The Plumber··········································6

Installation ·············································7

Removal of the Cabinet ······································8

Component Location ·······································9

Component Description ······································10

AutoIQ Controller ·········································11

Initial Start Up ···········································12

Notes On Operation ········································13

Adjustments ············································14

How To Operate The AutoIQ Controller ······························15

How The Electronic Cuber Works ·································16

Water System ···········································17

Technicians Only: Freeze Cycle Operational Sequence ·····················18

Technicians Only: Harvest Cycle Operational Sequence ·····················19

Sanitizing and Water System Cleaning ······························20

Sanitizing and Cleaning ······································21

Additional Maintenance ······································22

Additional Maintenance ······································23

Additional Maintenance: Bin Controls ·······························24

Technical Characteristics ·····································25

Service Diagnosis ·········································26

Service Diagnosis ·········································27

Service Diagnosis ·········································28

PTCR ···············································29

Removal and Replacement: AutoIQ Controller ··························30

Removal and Replacement: Water Pump, Water Level Sensor ··················31

Removal and Replacement: Inlet Valve & Water Trough ·····················32

Removal and Replacement: Bin Control Set ···························33

Removal and Replacement: Thermistors ·····························34

Water Distributors ·········································35

Refrigeration System Service: R-404A ······························36

This manual was printed on recycled paper.

January 2003

The SCE275 automatically maintains the level of

ice by turning on when the ice level falls, and

switches off when the bin is full.

This unit is serviceable in place; the ice storage bin

and hood may be removed from the chassis to

allow service access without removing the ice

machine from its installed position. The

refrigeration system uses R-404A as the

refrigerant.

Parts lists and wiring diagrams are located in

the center of this manual.

Page 1

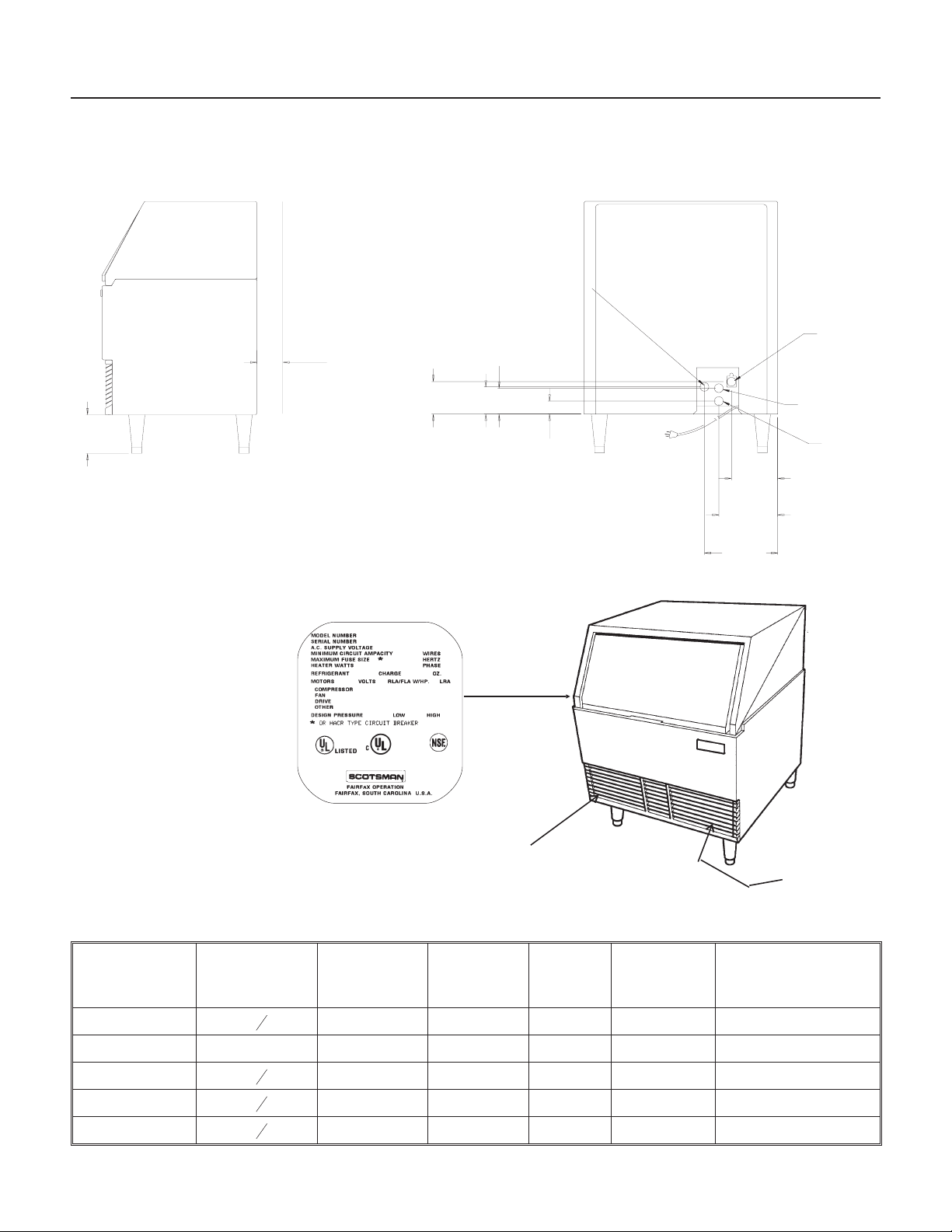

Page 2

SCE275

Specifications

4.00 IN.

10.16 CM.

MINIMUM UTILI TY

CLEARANCE

6.00 IN

15.2 CM.

The unit is equipped with an electrical power cord,

but should only be plugged into a circuit dedicated

to the ice machine.

THE NAMEPLATE IS LOCATED

ON THE BACK PANEL

A Serial Number Plate is Located

on the Front Edge of the Base,

Behind the Right Front Grill

4.59 IN.

11. 66 CM .

WATER REGULATOR

3/8-18 NPT

(W/C ONLY)

3.68 IN.

9.35 CM.

4.06 IN.

10.31 CM.

1.68 IN.

4.27 CM.

BACK VIEW

ELECTRICAL CORD

7.17 IN.

18.21 CM.

9.12 IN.

23.16 CM.

11. 35 IN .

28.83 CM.

POTABLE

WATER INLET

3/8 FLARE

3/4 FPT

DRAIN

COND DRAIN

1/2-13 NPT

(W/C ONLY)

AutoIQ Controller

Controller Location in G

Model Number Dimensions

(w/o) legs

H"xW"xD"

SCE275A-1G 33 x 30

1

x 30 115/60/1 Air 15 18 ounces

4

Series and Higher

Basic

Electrical

Condenser

Type

Total

Load

Amps

Total Unit

Wattage

Refrigerant R-404A

(HP62)

Grill in A thru F

SCE275A-32G 33 x 30¼ x 30 208-230/60/1 Air 8.4 18 ounces

SCE275W-1G 33 x 30

SCE275A-6G 33 x 30

SCE275W-6G 33 x 30

1

x 30 115/60/1 Water 15 12 ounces

4

1

x 30 230/50/1 Air 7.5 1725 18 ounces

4

1

x 30 230/50/1 Water 7.5 1725 12 ounces

4

January 2003

Page 2

(Behind Right

Series)

Page 3

For The Installer: Environmental Limitations

The ice machine must be installed indoors in a

controlled environment.

Min Max

0

Air Temp 50

Water Temp 40

Water Pressure 20 PSI 80 PSI

Voltage (60 Hz) 103.5 126.5

Voltage (50 Hz) 207 253

F. 1000F.

0

F. 1000F.

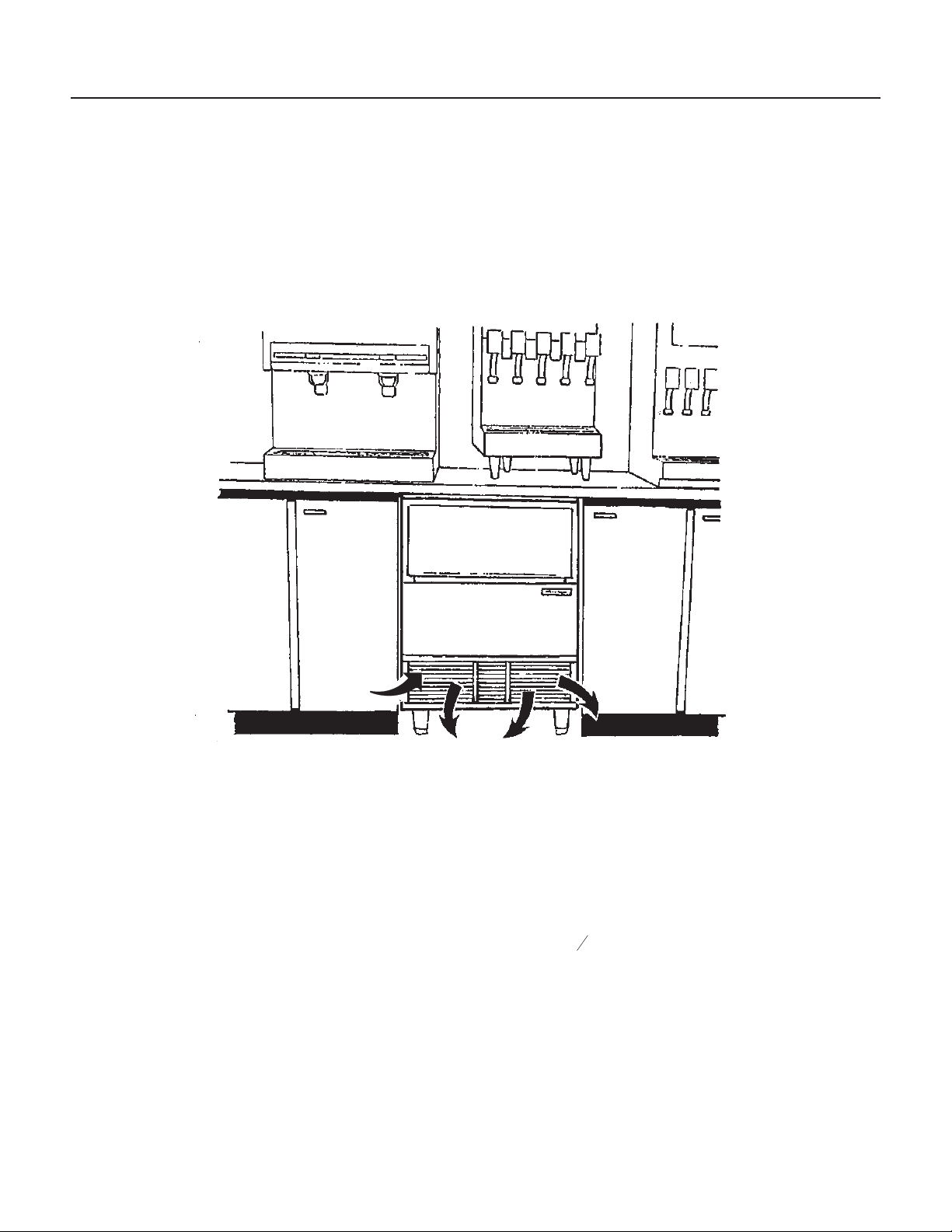

SCE275

Air In

Operating the ice machine outside of the above

limitations, or outdoors, is potentially damaging to

the machine, and it is misuse of the machine. This

may void the warranty.

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of UL, NSF, and CUL

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any part and/or other components not

specifically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and design are subject to change

without notice.

January 2003

Air Out

Airflow on air cooled models is:

Intake through the left front grill.

Exhaust through the right front grill.

Do not install where this air flow is obstructed.

The SCE275 has a removable cabinet. When

installed, the machine should have some extra

1

clearance (

") on the left and right sides so that the

8

cabinet may be easily removed when the machine

is in place.

Page 3

Page 4

SCE275

Installation

Water

The water supply for this ice machine has been in

contact with many materials since it fell from the

sky as rain. All rain is slightly acidic, and tends to

dissolve the materials it comes in contact with.

During water’s journey to the ice machine, it has

flowed over and through the ground, been picked

up by a municipal or private pump, forced through

a series of pipes of differing construction and may

have been treated by the municipality providing the

water.

This means that there is no such thing as “pure”

water. All water contains some level of impurity.

There are two ways water carries the impurities:

suspended and dissolved. Water filters can remove

the suspended solids, but cannot remove the

dissolved portion.

Cube ice machines use more water than is made

into ice, the excess amount is used to dilute the

concentration of minerals and “rinse” out the water

system to keep the water scale from clogging up

the machine. That water rinse, combined with

water filters, prolongs the times between needed

water system cleanings.

The water to the ice machine should be filtered.

Water filters vary greatly in ability and function.

Install one that filters out suspended solids to a

dimension of 5 microns or less. The finer the filter

the better, but finer filters may plug-up sooner than

course ones. It may be necessary to add a course

filter ahead of the fine filter to prolong filter life.

Electrical power is supplied through a cord

connected to the unit. All local codes must be

followed.

Pre-installation:

1. Inspect the place where the ice machine is to be

installed. Check for:

space for the cabinet,

water supply,

drain availability

and electrical power supply.

No extension cords are allowed. The building drain

inlet must be lower than the drain outlet(s) at the

back of the ice machine. The water supply must

have a hand shut off valve accessible when the

unit is installed.

2. Determine the method of installation, is the

machine to be installed under the counter? Is the

drain in the floor under the machine? Is the water

inlet valve accessible?

Unpack and Assemble

1. Remove legs and scoop from storage bin.

2. Remove shipping materials from ice making

area.

The SCE275 is factory set for a water purge that

will work in most water conditions. While the

amount of purge is adjustable, only change it if

necessary.

Note: Water use adjustments are customer

convenience adjustments; they are not factory

defects and are NOT covered by warranty.

This ice machine may be installed in the open or

under a counter. No clearance is required at the

sides or top beyond what’s needed to place the

cabinet into position. Air cooled models blow air in

and out through the grills at the front. Space is

required for utility connections at the back.

The ice machine is not designed for outdoor

use. It must be installed indoors, in a controlled

environment. The air and water temperatures

must not exceed rated limits.

January 2003

Remove Material Located Between

Cube Deflector and Troughs

3. Place corner posts from the shipping carton on

the floor behind the ice machine. Tip the ice

machine on its back and remove the shipping skid.

4. Screw the legs into the threaded holes in the

base of the ice machine.

5. Tip the ice machine back to an upright position.

Page 4

Page 5

Installation

SCE275

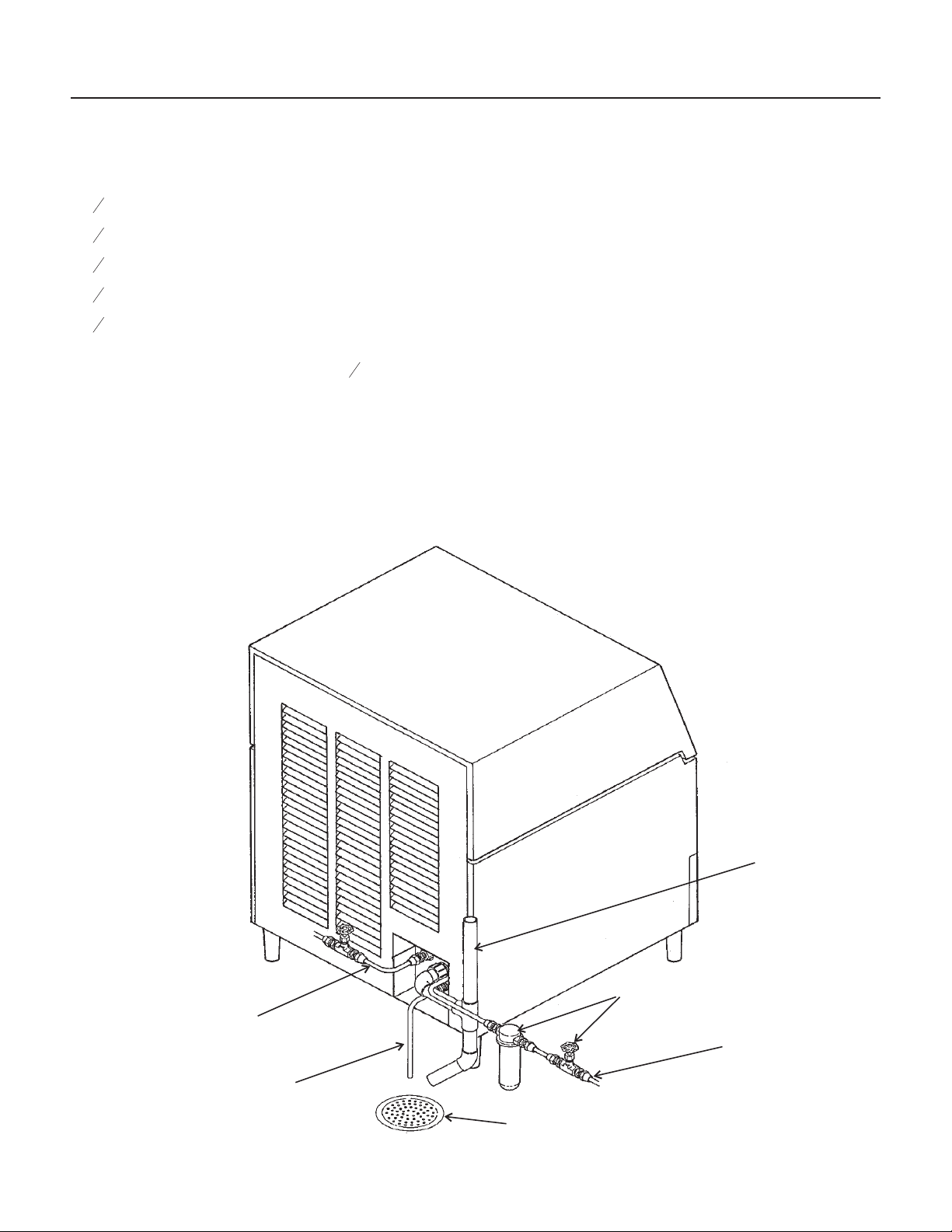

For The Plumber

Begin by planning the installation and obtaining the

needed supplies:

3

" soft copper tubing

8

3

" rigid drain tubing

4

3

" FPT fitting for bin/reservoir drain connection

4

1

" FPT fitting for condenser drain connection

2

3

" FPT fitting for water cooled condenser inlet

8

connection

1. Connect cold potable water to the

3

" male flare

8

at the back of the cabinet. A water filter and hand

shut off valve is recommended. Flush the water

line prior to connecting to the ice machine.

If water cooled, connect a separate water inlet line

to the water cooled condenser inlet fitting. It should

also have a hand shut off valve.

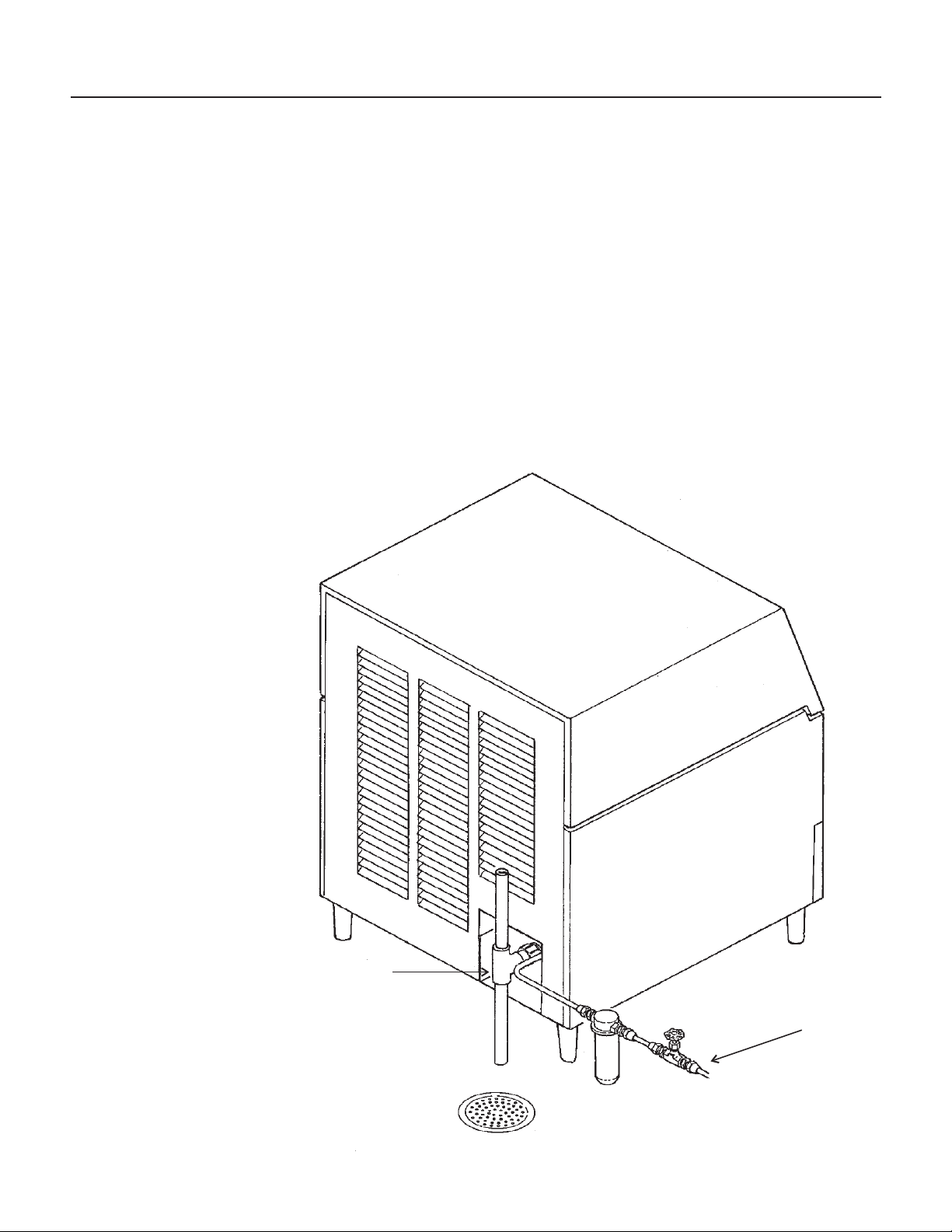

Plumbing Connections,

Water Cooled Shown

A loop of copper tubing may be used between the

ice machine and the water supply. This will allow

the ice machine to be pulled out from its installed

location without disconnecting the water line. No

back-flow preventer should be needed in the inlet

potable water line because provision for that is

incorporated in this N.S.F. listed product (the water

valve outlet is above the reservoir wall and cannot

siphon).

2. Connect a drain tube to each drain connection

(water cooled drain must be separate).

3. Route the drain tubes to the building drain

receptacle.

CONFORM TO ALL LOCAL CODES

Water Cooled Inlet

Water Cooled Drain

Reservoir & Bin

Drain

Field Supplied Filter

and Hand Valve

Potable Water Inlet

Drain Receptacle

January 2003

Page 5

Page 6

SCE275

For The Plumber

Drain Configuration:

Water cooled models must use a separate drain

tube from the reservoir/bin drain.

The water cooled condenser drain should not be

vented.

Drain tube material must be rigid and meet local

code.

Traps in the bin drain line without vents ahead of

them will cause poor draining.

The bin drain must be vented if there is a long

horizontal run (5’ or more).

All drains are gravity, and must have a minimum

fall of ¼" per foot of horizontal run.

Maintain the air gap required by local code

between the end of the drain tubes and the

building drain

receptacle.

Note: Drain tubing

should be insulated

to prevent

condensation from

forming on the

tubing.

Vented Drain

Air Cooled Plumbing

Connections

Potable Water

Supply

January 2003

Page 6

Page 7

Installation

For The Electrician

The 115 volt, 60 Hz model is a cord-connected

unit, and must be on a separate 115 volt AC 60

cycle single phase power supply. The maximum

fuse size for this circuit should be 15 amps. Per the

nameplate use fuses, or HACR circuit breakers.

Connect 50 Hz models to the correct voltage and

fuses.

Follow All Local Codes - This Unit Must Be

Grounded. Do not use extension cords and do not

disable or by-pass ground prong on electrical plug.

After Utility Connections:

1. Level the cabinet, use the leg levelers on the

end of the legs to adjust the cabinet height. (Legs

should have been installed when the unit was

unpacked). Check for levelness at the reservoir.

SCE275

2. Wash out the bin and hood. If desired, the

interior of the bin could be sanitized.

3. Locate the scoop, wash it and have it available

for use when needed.

Final Check List

1. Is the ice maker cabinet in a room where

ambient temperatures are within the minimum and

maximum temperatures specified?

2. Has the water supply been connected?

3. Is the water pressure adequate?

4. Have the water connections been checked for

water leaks?

5. Have the drain connections been made?

6. Have the drain connections been checked for

leaks?

7. Is the cabinet level?

8. Is the ice machine plugged into an electrical

power supply of the proper voltage and is the ice

machine the only load on that circuit?

10. Has the bin and cabinet been wiped clean and

sanitized?

11. Has the Customer Evaluation & Warranty

Registration form been filled out? Check for correct

model and serial numbers from the nameplate,

then mail the completed form to Scotsman.

12. Has the owner/user been given the name and

telephone number of the authorized Scotsman

Service Agency serving that location?

13. To start up machine, follow the directions on

page 12. For more information on the unit, turn to

the next page.

9. Has all of the shipping material been removed

from the inside of the cabinet? Check for

materials between the cube deflector and the

water troughs (see page 4). Be sure the cube

deflector is in place.

January 2003

Page 7

Page 8

SCE275

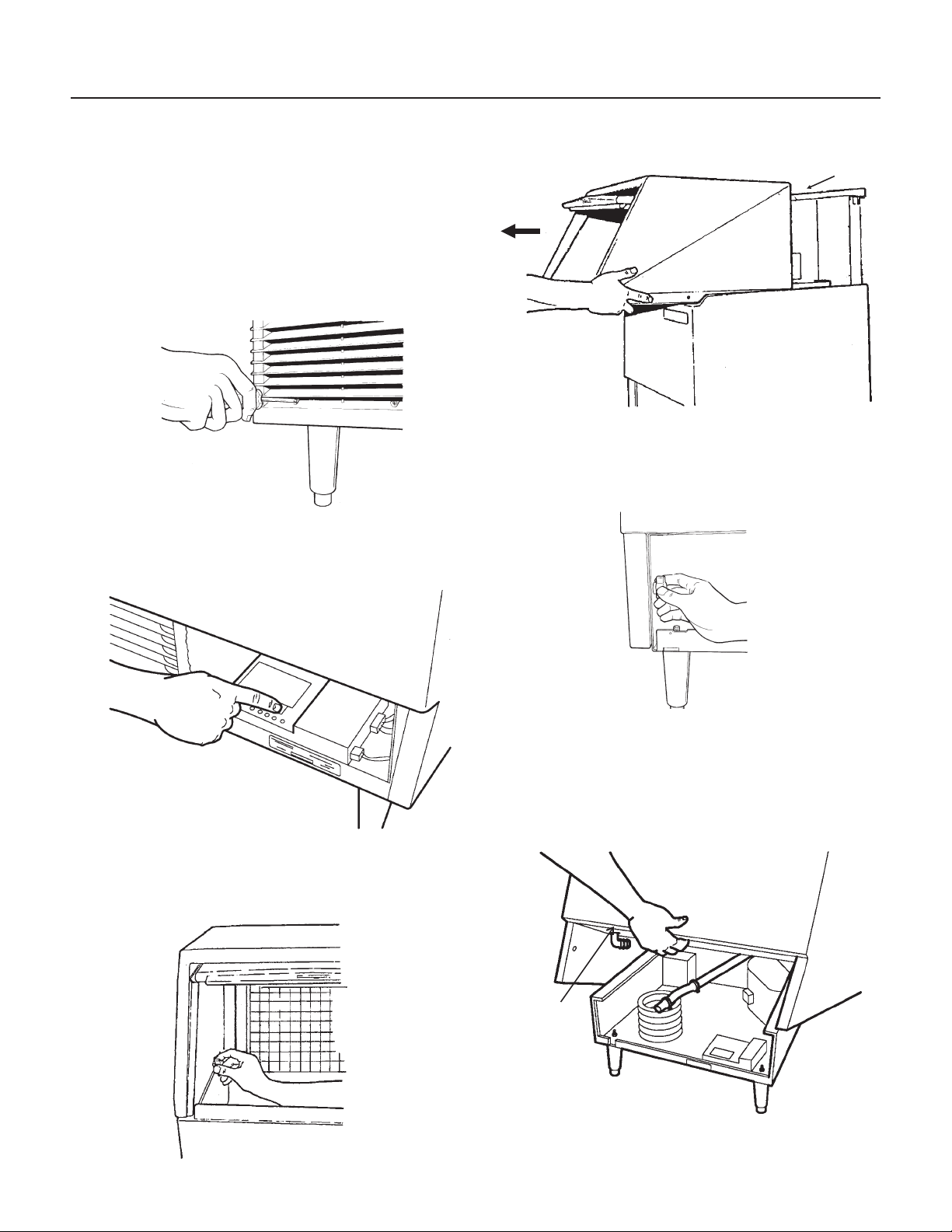

Removal of the Cabinet

One of the most useful features of this ice machine

is the ability to remove the cabinet from the ice

machine without removing the ice machine from its

installed position.

To Remove:

To remove the cabinet base the hood must be

removed first.

1. Remove 5 screws and the three grills at the front

of the base.

STEP 1

2. Push and hold the Off button the AutoIQ

Controller until the machine has switched OFF. Be

certain the ice machine has been switched off.

4. Pull the hood and door assembly straight out

until it can be lifted up.

STEP 4

5. In the area behind the grills (removed in step 1)

are two knobs similar to those removed in step 3.

STEP 5

Hood

STEP 2

Note: Controller on left

side of cabinet on G

series and higher.

3. Open the bin door and unscrew the knobs at the

left and right inside of the ice storage bin. Unscrew

the knobs all the way out.

STEP 3

Unscrew and remove the two knobs.

6. Locate the bin drain. Loosen the hose clamp

holding the drain tube to its fitting and pull the drain

tube off of the fitting.

7. Lift up the front of the base and rotate the base

up and off of the ice machine.

Bin Drain

The machine is now exposed for service.

January 2003

Page 8

Page 9

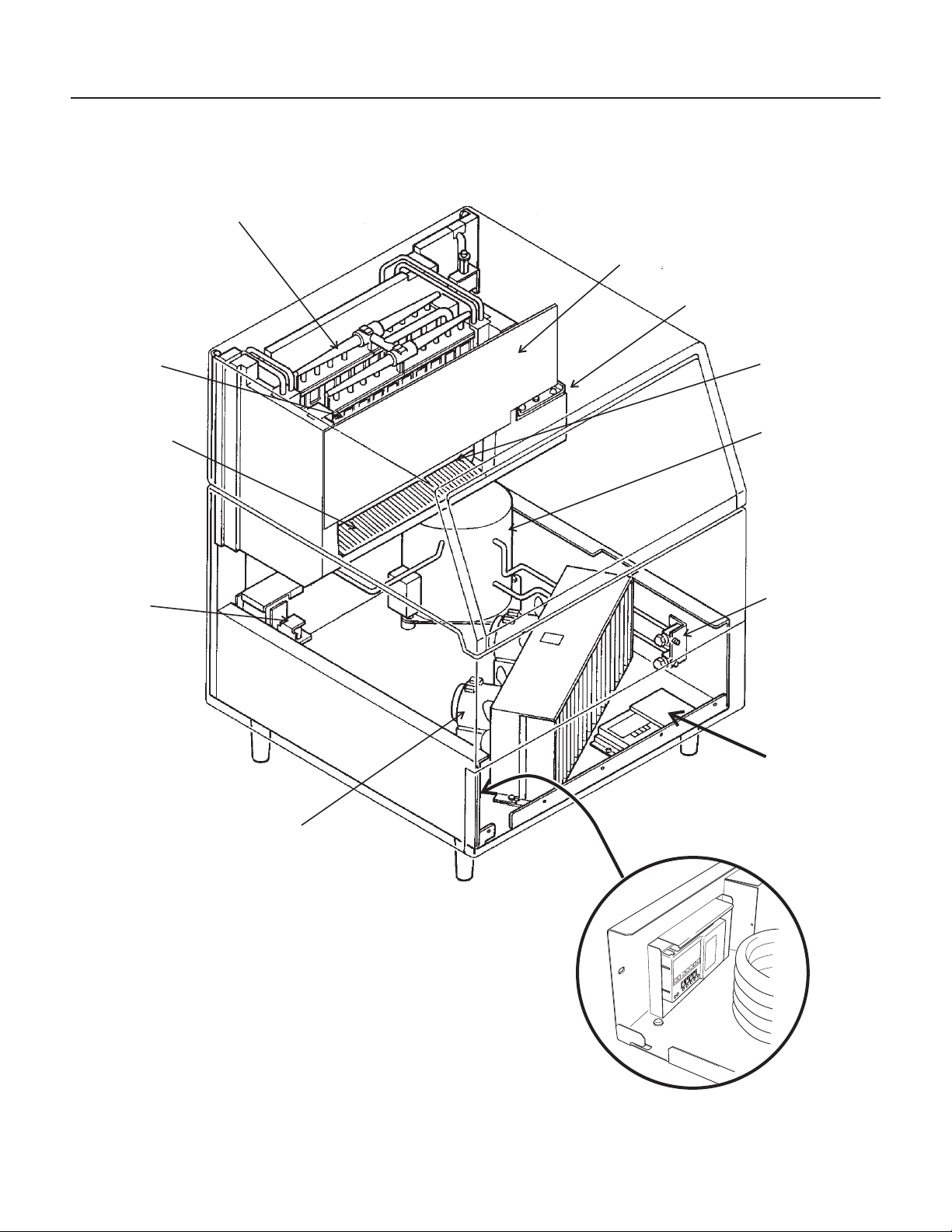

Component Location

SCE275

The ice machine is designed for front service.

Many components are serviceable from the front

without removing the cabinet. With the cabinet

removed, nearly all components are serviceable.

Water Distributors

Evaporators

Cube Deflector

When the bin is removed, the condensing unit is

visible.

Evaporator Cover

Reservoir

Water Trough

Compressor

Water Inlet

Valve

Fan Motors

Component Location

These parts are located inside the bin:

Evaporators

Water Reservoir

Water Pump

Refrigeration

Access Valves

AutoIQ

Controller,

location shown

for A thru F

series

Cube Deflector

Water Troughs

Water Distributors

Water Level Sensor

Controller Location, G series

and higher

January 2003

Page 9

Page 10

SCE275

Component Description

High Pressure Cut Out - Water Cooled Only

This is a switch that opens to stop the ice machine

when the internal refrigeration pressures become

too high (over 450 PSIG). It is an automatic reset.

Evaporators

Where the ice is formed. There are two vertical

evaporator plates that form vertical strips of cubes.

The strips break up into individual cubes as they

fall.

Thermostatic Expansion Valve

The thermostatic expansion valve is used to meter

liquid refrigerant into the evaporator, adjusting the

flow of refrigerant as required to make ice.

Reservoir:

Contains the water used for ice.

Water Inlet Valve:

Opens to allow water into the reservoir.

Water Level Sensor:

Controls the size of the ice cube by measuring how

much water is used in a cycle. It consists of a float,

stem and electric eye. The stem will move slightly

when the pump is on, this is normal. As the

machine makes ice the reservoir water level will fall

and the visible portion of the stem will slide down

thru the slot in the sensor body.

AutoIQ Controller:

Controls the operation of the ice machine. Turns it

on and off; switches it between cycles; shows

information via indicator lights; and shuts the

machine down if there is a problem.

Evaporators/Freezing Compartment:

Location of the 2 evaporators. Ice forms on the

evaporators and is released when warmed up

during the harvest cycle.

Cube Deflector:

The slots in the inclined deflector let the water

falling from the evaporators back into the reservoir,

but when ice falls during harvest, the ice slides off

into the bin.

Water Trough

Diverts water from the evaporators to the right and

left to keep water off the ice.

Refrigeration Service Access Valves:

Only to be used by a certified technician. Allows

access to the refrigeration system for diagnostic

information.

Water Pump:

Forces the water from the reservoir to the top of

the evaporators. The motor is separated from the

reservoir water to minimize contact with the water.

Compressor:

The refrigerant vapor pump, it forces the refrigerant

to flow thru the refrigeration system tubing.

Hot Gas Valve:

Closed during freeze, it opens during harvest to

divert hot discharge refrigerant gas into the inlet of

the evaporators.

Condenser:

Either air or water cooled, discharges the heat

produced in ice making.

January 2003

Page 10

Page 11

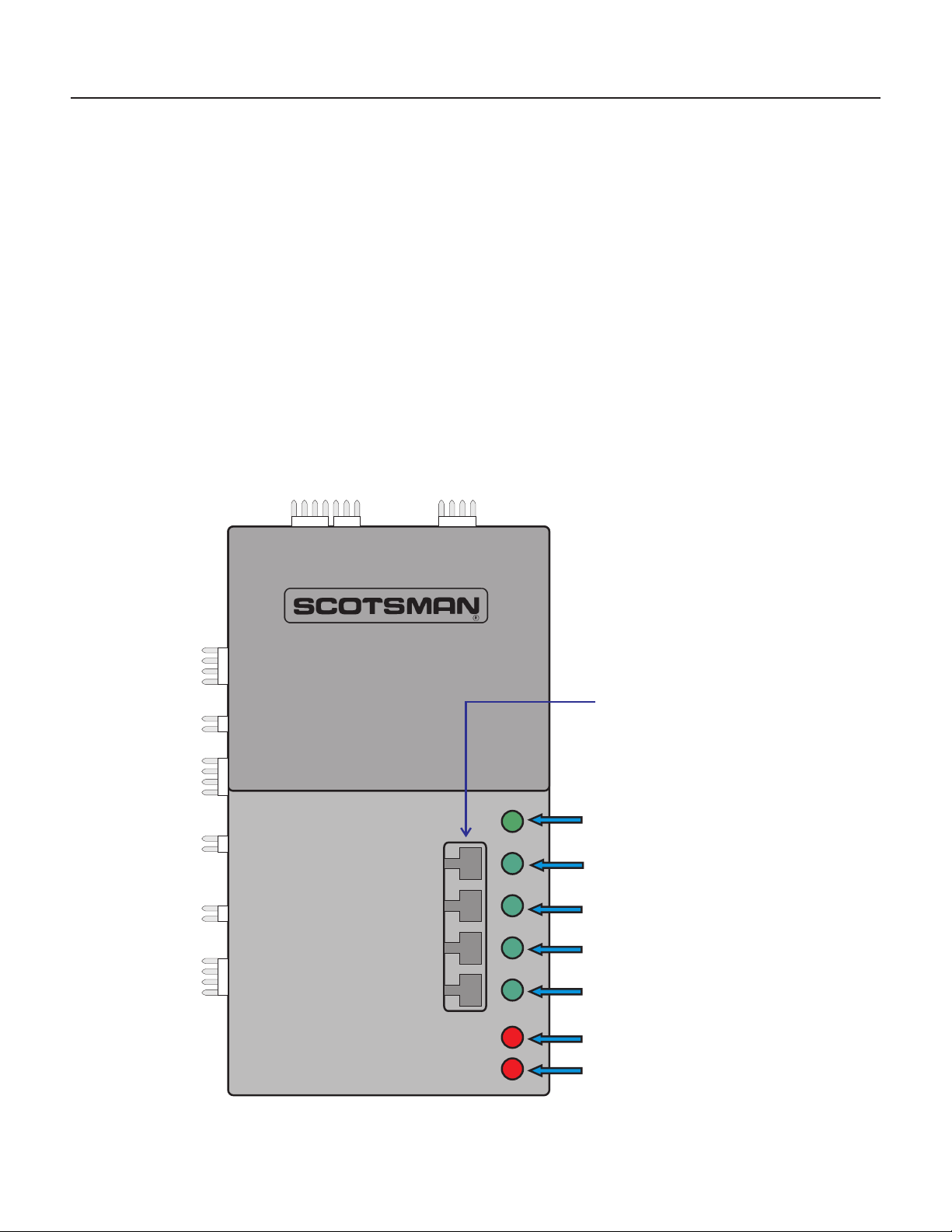

AutoIQ Controller

SCE275

Indicator Lights:

Bin Full: On when bin is full, goes on and off as

ice falls during a harvest cycle.

Freeze: On when the unit is in the Freeze cycle,

blinks when a freeze mode is pending.

Harvest: On when the unit is in the Harvest

cycle.

Clean: On when the unit is in the Clean cycle,

blinks when preparing for a clean mode.

Off: On when the unit has been switched off,

blinks when the machine is preparing to shut off.

Water Error: On when the controller has

identified a problem with the water system.

Refrigeration Error: On when the controller

has identified a problem with the refrigeration

system.

89

Cycle Definitions:

Freeze: The refrigeration system is operating to

remove heat from the evaporators. The

compressor, fan motor (if air cooled) and water

pump are ON.

Harvest: The refrigeration and water systems

are operating to harvest the ice cubes. While

the compressor is on for the full cycle, the water

pump will be off at the beginning and inlet water

valve will switch off before the end.

Clean: The Inlet Water Valve opens to fill the

reservoir. The Water Pump starts. The Clean

indicator light is switched ON. A manually

initiated rinse flushes the system.

7

6

5

4

3

2

1

PUSH BUTTON

CONTROL SWITCHES

INDICATOR LIGHTS:

BIN FULL

FREEZE

HARVEST

CLEAN

OFF

ERROR LIGHTS:

WATER

REFRIGERATION

January 2003

Page 11

Page 12

SCE275

Initial Start Up

1. Remove two screws and the left grill (G series

and higher).

2. Locate the AutoIQ Controller - use a flashlight to

see the buttons and lights.

3. Plug the machine in or switch on the electrical

power. Note that the controller’s indicator lights all

flash on briefly when power is connected.

4. Open the water supply valve to the machine.

5. Push and release the Freeze cycle push button

(the Freeze indicator light will blink until the

compressor starts). The next several operations

are automatic.

Initial Start (30 seconds)

The Freeze light begins to blink.

The Hot Gas Solenoid valve will be open.

The inlet water valve opens to fill the reservoir

and shuts off when the reservoir is full. Note: If

the reservoir does not fill the next steps do not

happen.

The water pump starts. Note: if the pump does

not start the next steps do not happen.

The inlet water valve opens again to refill the

reservoir.

After 30 seconds, the hot gas valve closes and

the compressor starts.

Freeze Cycle:

The Freeze indicator light will come on. The

machine will stay in a Freeze cycle for many

minutes. Slush may appear in the reservoir, it is

temporary and normal.

Under certain conditions, the pump may stop for

a few seconds. After that the inlet water valve

will refill the reservoir.

The fan motors (of air cooled models) will begin

to turn and soon warm air will be forced out the

front of the cabinet. After 4 minutes the fan

motors may cycle on and off every 30 seconds

in cooler ambients.

As the freeze cycle progresses, the water level

will fall and the inlet water valve will open to refill

the reservoir. This will happen twice every cycle.

The freeze cycle will continue until the water

level in the reservoir has fallen again to its

factory set point, then the AutoIQ Controller may

switch the air cooled fans off. After a short time,

the Harvest Cycle will begin.

Harvest Cycle:

The Harvest indicator light will be ON,

The hot gas valve will open.

The water pump will stop. It will restart in less

than a minute.

The Inlet water valve will open. The machine will

fill the reservoir and overflow it for a specified

number of seconds then shut off. The harvest

cycle may still be in progress.

The Bin Full indicator light will go on and off as

ice falls from the evaporators.

6. Machines are shipped from the factory with the

purge level set to accommodate average water

conditions. To achieve optimal machine

performance, set the purge level to the minimum

setting.

Note: While the amount of water purge is

adjustable, only those installations with a water

supply known to be excellent (very low TDS or total

dissolved solids) should adjust to the minimum

setting. See page 14 for purge adjustment

instructions.

7. Observe ice harvest. Check that the ice slides

easily into the bin, and does not hang up on any

mis-positioned part.

8. After about 5 minutes the machine will return to

a freeze cycle.

Note: The first 1-2 harvest cycles will be very

long to establish a typical harvest time.

9. Fill out the Customer Evaluation and Warranty

Registration. Send it to Scotsman.

10. Replace the front grill.

11. Inform the user of the location and telephone

number of the local service company. Also inform

the user of the required maintenance of the

machine.

August 2000

Page 12

Page 13

Notes On Operation

SCE275

1. The electric eyes signal the ice machine to shut

off whenever the bin becomes full. After the eyes

sense that there is ice between them, the ice

machine will shut off at the end of the next harvest

cycle. This last harvest cycle will be longer than the

rest, and will be for the Maximum Harvest Time.

Note: Ice will normally fill up to the bottom of the

evaporators before the machine shuts off.

2. After the bin has filled the ice machine will not

be able to restart for 4 minutes. However, if

needed, the Freeze button may be pushed and the

unit will restart.

For example: If ice is removed from the bin

immediately after the machine has filled up and

shut off, the machine will not restart for 4 minutes.

3. If the bin controls sense a bin full signal before

any water is used (float stem up), the machine will

shut off on bin full.

If there was a problem during Initial Start Up:

If an error light came on, check the following.

1. Water error.

A water error could have been determined by the

AutoIQ Controller if the inlet water valve does not

fill the reservoir, or if the water pump does not start

and lower the water level.

2. Refrigeration error.

A refrigeration error could have been determined

by the AutoIQ Controller if the water temperature

did not drop during the freeze cycle. The controller

will next check the compressor discharge

temperature. If the discharge temperature is too

low, the refrigerant error light will be switched on,

and the machine will Shut Down.

Resets:

Note: The machine may be reset and restarted by

pushing and releasing the Off push button switch,

and then pushing and releasing the freeze push

button switch.

Water Cooled: If the water to the water cooled

condenser circuit is cut off during a freeze cycle,

the high pressure cut out will stop the operation of

the compressor. The control is an automatic reset,

but if the water interruption is prolonged, the

AutoIQ Controller will shut the machine down when

maximum freeze time has been exceeded.

January 2003

Page 13

Page 14

SCE275

Adjustments

How to adjust the water cooled discharge

pressure

Water cooled models use a water regulating valve

to control how much cooling water flows thru the

water cooled condenser. At the top of that valve,

located in the bottom rear of the ice machine, is an

adjustment stem.

To Adjust:

1. Attach a refrigeration manifold gage to the

discharge access valve.

2. While the unit is in the freeze cycle, determine

the discharge pressure, it should be about 245

PSIG.

3. If needed, rotate the adjustment stem to

increase or decrease the pressure:

A. To increase discharge pressure (reduce water

flow) rotate the stem counter-clockwise.

B. To decrease the discharge pressure (increase

water flow) rotate the stem clockwise.

Remove the manifold when done. Note: The water

outlet temperature should be between 100-110

when the valve is properly set.

Thermostatic Expansion Valve:

The TXV is not adjustable, do not attempt to adjust

it.

How to Adjust the Amount of Water Purge

Adjustment is done by use of the control buttons

on the AutoIQ Controller. Examine the next section

to become familiar with the AutoIQ Controller

before beginning.

1. If the machine is on, push and hold the OFF

button for more than 3 seconds, then release it.

This switches the machine Off.

2. Push and hold the OFF button for more than 3

seconds (until all LEDs flash on) then release it.

3. Examine the green LEDs. They should have all

flashed once, then certain ones will have turned on

to indicate which purge level the machine is set at.

There are 5 levels of purge available:

1. Maximum Purge is when All 5 lights are

ON. Note: This setting may extend the harvest

cycle and reduce capacity.

2. Heavy Purge is when these 4 lights are ON:

Freeze, Harvest, Clean, Off .

3. Standard Purge (Factory setting) is when

these 3 lights are ON: Harvest, Clean, Off .

4. Moderate Purge is when these 2 lights are

ON: Clean, Off .

5. Minimum Purge is when this light is ON: Off

.

Adjust by pushing and releasing the Freeze button.

Pushing and releasing the Freeze button increases

the purge one level up to the maximum, then it

goes to the minimum.

4. The machine will automatically restart after 60

seconds of no switch inputs, or restart the machine

by pushing in and holding the Off button for more

than 3 seconds, then releasing it. The unit will then

be Off. From there the machine may be placed in a

freeze cycle by pushing and releasing the Freeze

button.

January 2003

Page 14

Page 15

How To Operate The AutoIQ Controller

R

The AutoIQ Controller is a microprocessor based

device that receives input from several sources

and switches various components on and off.

Its manual control is thru the use of the Push

Button Control Switches

1. Freeze Button. Pushing and releasing this

button starts or restarts the machine. The AutoIQ

Controller remembers what cycle it was last in and

returns to that cycle.

2. Harvest Button: Pushing and releasing this

button will cause the machine to go directly to a

Harvest Cycle. Can be done from Freeze or Off.

The machine will switch Off at the end of the

Harvest cycle.

3. Clean Button: Pushing and releasing this button

will cause the machine to only power the water

pump for circulation of ice machine cleaner. After

the ice machine cleaner has

circulated for about 10

minutes, a second push of this

button will switch on the

rinsing system to flush out the

dissolved scale and ice

machine cleaner.

4. Off Button: Pushing and

releasing this button will

switch the machine OFF at the

end of the next cycle. If the

button is pushed and HELD

for more than 3 seconds, the

unit will switch off immediately.

To Reset: First push and

release the Off button, then

push and release the Freeze

button.

LOW VOLTAGE IN/OUT

WATER VALVE

HOT GAS VALVE

CONTACTOR COIL

STACKING

FUTURE USE

RESERVOIR & DISCHARGE

LINE THERMISTORS

BIN CONTROL SENSOR

7

6

5

4

89

AIR COOLED FAN MOTO

INDICATOR LIGHTS:

SCE275

HI VOLTAGE IN/OUT

WATER PUMP

PUSH BUTTON

CONTROL SWITCHES

BIN FULL

FREEZE

BIN CONTROL SENSOR

RESERVOIR WATER

LEVEL SENSOR

FACTOR Y USE

3

2

1

January 2003

Page 15

HARVEST

CLEAN

OFF

ERROR LIGHTS:

WATER

REFRIGERATION

Page 16

SCE275

How The Electronic Cuber Works

Controller Inputs:

1. Reservoir water temperature. This is measured

by a thermistor located in the water pump outlet.

2. Discharge line temperature. This is measured by

a thermistor located on the compressor discharge

line.

3. Water level. This is measured by an infrared

sensor and float. The float rises and falls with the

water level, and switches the sensor on and off as

it moves.

4. Bin fill level. This is determined by a set of

electric eyes between the evaporators. Ice

eventually fills the bin and covers the cube

deflector to the point that ice is between the bin

controls (and the evaporators); after 20 seconds of

“blockage” the bin controls signal the controller that

no more ice is needed.

When ice is removed for use,

the ice between the

evaporators slides out into

the bin and the ice machine

automatically restarts.

5. Time. The controller measures and compares

how long it takes for various events to happen. It

stores that data for future reference.

Controller Outputs:

A. 24 volt:

1. LEDs

2. Inlet water valve

3. Hot Gas Valve

4. Contactor Coil

B. High Voltage

1. Water Pump

2. Air cooled Fan Motor

Note: A few cubes may

remain on the cube deflector,

this is normal.

If little ice is used, the ice

level will be high at the back

of the bin. As ice is used, the

ice will “level out” and fill the

bin more evenly.

When The Machines Fills Up To Its

Shut Off Point, Ice Will Be On The

Cube Deflector.

January 2003

Page 16

Page 17

Water System

SCE275

Water flows into the ice machine during the harvest

cycle thru the inlet water valve. The water valve will

NOT be open the complete length of the harvest

cycle. The water pump forces water to the top of

the evaporators, both in the Freeze and Harvest

cycles. Un-frozen water falls thru the cube

deflector and back into the reservoir.

As water is turned into ice, the water level

in the reservoir falls to the full cube

setting, and the Water Level

Sensor sends a signal to the

AutoIQ Controller to open

Water Inlet

the inlet water valve to refill

the reservoir. This happens

twice per freeze cycle.

The third time the water

level falls to the full cube

setting it indicates to the

AutoIQ Controller that it is

time to begin the Harvest

cycle. The air cooled fans

will shut off just before the

beginning of the Harvest

cycle.

Evaporator

During the Harvest cycle,

water again enters the water

reservoir, and overfills it to

rinse the reservoir of

accumulated minerals. It

does NOT overflow for a

fixed amount of time, but

for a time

determined by

the AutoIQ

Controller.

The water

pump will be

Water Inlet

Valve

Thermostatic

Expansion

Valve

off for a short

period of time at

the beginning of

harvest.

Refrigeration System:

The refrigeration system is similar to that of most

commercial cube ice machines. Heat is removed

from the water and discharged out the condenser

during the freeze cycle.

The evaporators are in series: As liquid refrigerant

passes thru the Thermostatic Expansion

Valve, it enters the bottom of the front

evaporator, and ice will form there first.

Refrigerant then flows out the top of the

front evaporator and enters at the

bottom of the back evaporator,

finally flowing out the top row

Water Level

Sensor

of the back

Water

Pump

compressor.

When cubes

need to be released

(Harvest) the Hot

Gas Bypass Valve is

opened and hot

discharge gas flows

directly from the

Reservoir

Drain

compressor to the

front evaporator

inlet. This warms

up the

Hot Gas

Valve

evaporators and the

surface of the ice

frozen to the

evaporator

surface melts. Ice

then falls into

Filter/Dryer

Compressor

evaporator

and back to

the

the bin.

Fan Motor

Condenser

January 2003

Page 17

Page 18

SCE275

Technicians Only: Freeze Cycle Operational Sequence

How The Electronic Cuber Works

This section is intended for the technician. It is not

necessary for the normal operation and

maintenance of the machine.

The AutoIQ Controller operates the ice machine by

monitoring several input measures and switching

various loads on and off.

Assuming the machine has been operational,

the Freeze cycle begins with the end of the

Harvest Cycle:

Reservoir is full

Condenser fan is OFF

Water Inlet Valve is OFF

Water Pump is ON

Compressor is ON

Hot Gas Valve is ON

AutoIQ Controller Operation, Beginning freeze:

1. Switches on the Freeze indicator light and shuts

off the hot gas valve.

2. Measures and stores the discharge temperature.

3. Starts the fan motors (air cooled only). Fan

control begins 4 minutes into the freeze cycle.

When the discharge temperature indicates that

cooler ambient conditions exist, the fan is cycled

on and off every 30 seconds until it is switched of

just before harvest.

If the discharge temperature exceeds the design

maximum, shuts the machine down on a

Refrigeration Error.

4. Checks for a “bin full" signal throughout the

cycle.

5. Measures the reservoir water temperature. If the

machine is operating correctly, the reservoir water

temperature will fall at a standard rate. The AutoIQ

Controller will be checking to see if the water

temperature fall matches that rate.

If not, it re-checks the discharge line temperature.

If too low, it Shuts Down on a Refrigeration Error. If

the discharge temperature is acceptable, the water

system is checked by shutting off the water pump

and determining if the water level goes up enough.

If it does not, it is assumed that there is a water

pump problem and the machine Shuts Down on a

Water Error.

If the water level does “measure up" the water

pump is restarted and the AutoIQ Controller then

measures how long it takes to lower the water

level. If the water level does not fall, the machine

Shuts Down on a Water Error.

6. Once per cycle the machine may shut off the

water pump. It only does this when the water

temperature reaches a preset minimum. The pump

will only be off for a few seconds. After the pump

restarts, the inlet water valve opens to refill the

reservoir.

7. When the water level falls to the pre-set limit, the

inlet water valve will open to refill the reservoir.

This happens 2 times every freeze cycle.

8. As the machine makes ice, the water level in the

reservoir will ultimately fall a third time to the

Harvest Level (when the top electric eye in the

water level sensor is disrupted by the adjustment

screw). At that point, the fan may be shut off and

the unit continues in a freeze cycle for a few more

seconds (0-60 depending upon discharge

temperature). Note: If the freeze cycle exceeds the

preset Maximum of 35 minutes, the AutoIQ

Controller will Shut Down on a Refrigeration Error.

9. The end of Freeze cycle will see the machine in

this state:

Water level = below harvest position

Condenser fans will be off

Water inlet valve will be off

Water pump will be ON

Compressor will be ON

Hot gas valve will be off

At this point Harvest begins and the AutoIQ

Controller switches the Harvest indicator light ON.

Note: If there is a power interruption, the AutoIQ

Controller will automatically restart the machine

with a process that begins with returning the

machine back to a normal state: water re-fills the

reservoir, the unit freezes for 30 seconds, and then

goes thru a 4 minute harvest. After harvest it

returns to a new Freeze cycle. While in this

electrical restart mode, the controllers Freeze light

will be blinking, even when it is in a Harvest cycle.

January 2003

Page 18

Page 19

Technicians Only: Harvest Cycle Operational Sequence

SCE275

Harvest

The (air cooled) fans are off.

The water valve opens and fills the reservoir to the

Full level.

The water pump shuts off, it will restart in less than

a minute.

The AutoIQ Controller checks how long it takes to

fill the reservoir and if it was too much time, the

machine Shuts Down on Water Error.

Note: The machine will automatically attempt to

restart after shutting down because of a lack of

water. The time between restarts is about 20

minutes.

The inlet water valve will stay on and open for a

predetermined fraction of the time it took to fill the

reservoir. This overflows and rinses the reservoir

water.

During the Harvest Cycle, ice will be falling from

the evaporators and between the bin control’s

electric eyes. The harvest cycle’s length is based

on the actual time from the start of the prior harvest

cycle until the last cube fell, plus an added amount

of time as a margin.

The maximum harvest cycle time allowed is 8

minutes. Harvest time is varied by the AutoIQ

Controller based on the prior harvest cycle’s

length.

Diagnostic Lights:

There are two diagnostic lights, one to indicate a

water problem, and the other to indicate a

refrigeration problem.

If a Diagnostic

Light:

Blinks once and

repeats

Blinks twice

and repeats

Blinks three

times and

repeats

Is On all the

time

Both On all the

time

Restarts:

The controller will attempt to restart the ice

machine after the first and second shut downs

because of a water or refrigeration error.

There will be a 50 minute interval between restarts.

Water Light Refrigeration

Light

Water pump did

not start

Lack of water

fill

not used High discharge

Water valve

leaking thru

rapidly

Check for thermistor set

unplugged or failed

Very long ice

harvest

No harvest of

ice

temperature

Check for low

discharge

temperature or

long freeze

cycle

If no cubes fall (or are sensed) by the end of

Maximum Harvest Time, the controller senses a

refrigeration error. If the next cycle also produces a

refrigeration error, the machine Shuts Down.

Note: The last Harvest cycle before shutting off

on Bin Full will be longer than normal (4-5

minutes).

During a harvest cycle, the water pump will shut off

when the bin sensors indicate that the bin is full.

Note: The machine will not restart for 4 minutes

after switching off on Bin Full, unless the freeze

button is pressed.

January 2003

There are two exceptions to this:

1. Lack of water. The controller will try to refill the

reservoir about every 20 minutes after shutting

down for lack of water.

2. Harvest errors: The controller must sense two

consecutive harvest errors in order to stop the

machine. The controller will try to operate the

machine two additional times before a manual

reset is needed.

Page 19

Page 20

SCE275

Sanitizing and Water System Cleaning

Cleaning Schedule:

Scrub the door and frame edges once a week

with soap and water.

Sanitize the bin interior once a month.

Clean the water system and air cooled

condenser a minimum of twice per year. If in an

area of high mineral concentration in the water

supply, clean water system 4 times a year.

This ice machine will perform at its best when kept

clean. There are three areas to keep clean: The

water system including the water reservoir,

distributors and evaporator surface; the bin

controls; and the air cooled condenser filter and

the condenser itself.

Water cooled units:

The water cooled condenser may, over time and

under certain water conditions, become internally

restricted by minerals. These will have to be

dissolved by acid or the condenser replaced. Only

a qualified service agent should attempt this type

of service.

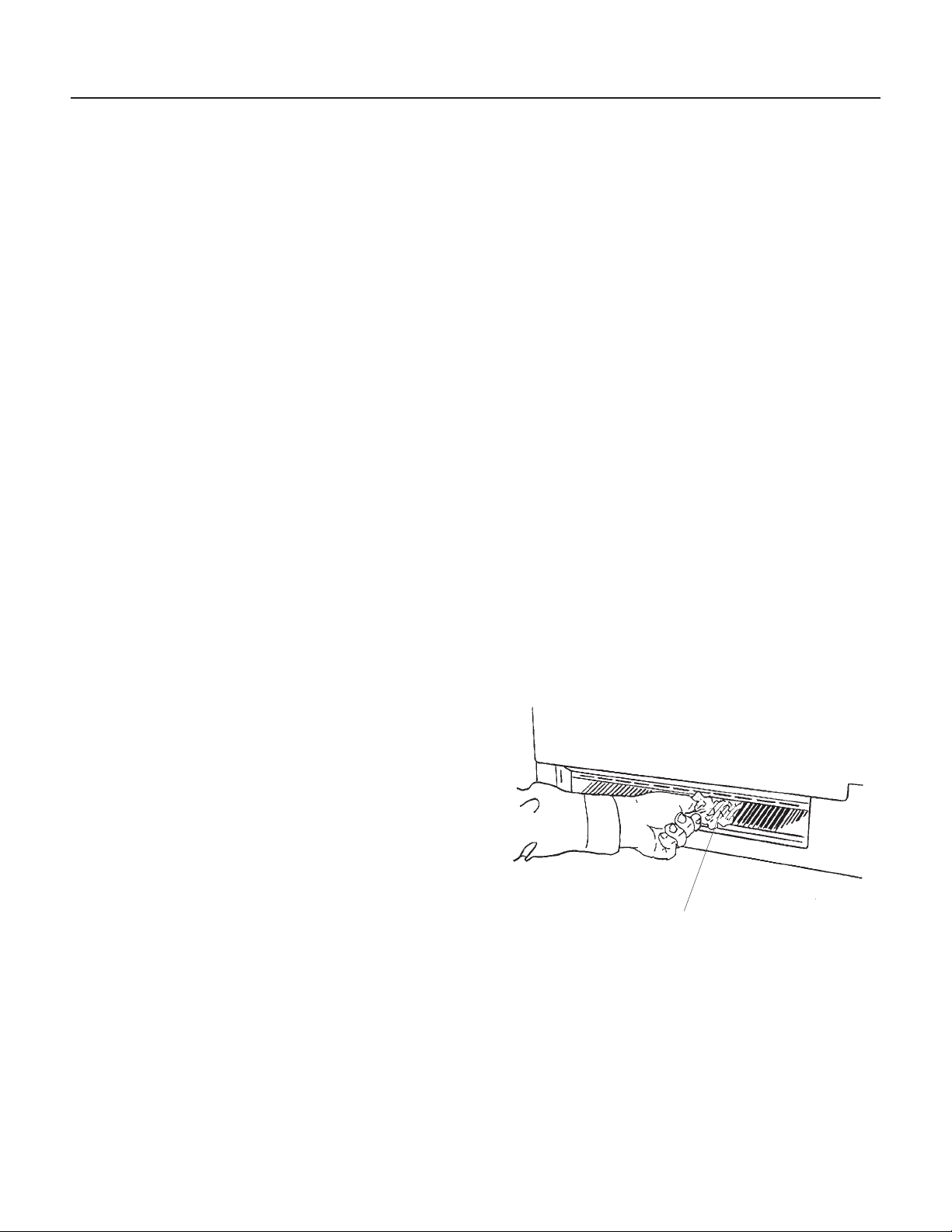

Air Filter (air cooled only):

The air filter is located in a slot between the

condenser fins and the condenser fans.

1. Remove the grill on the left front of the unit.

Grill Screws

Grill Removal

2. Locate the filter edge, it is between the

condenser fins and the fan motors.

3. Pull the filter to the left though the slot in the

front base of the ice machine.

4. Wash the surface of the filter off with cold water,

or, if torn or so dirty it can’t be cleaned, replace

with a new filter.

5. Return the filter to its installed position.

6. Replace the grill. Do not operate the unit without

the filter in place.

Note: If the unit has been operated without the filter

in place, the fins of the condenser will become

fouled with dirt, and must be cleaned.

If there is any doubt about dirt inside the fins of the

condenser, the cabinet should be removed and a

qualified service agent should clean the condenser.

January 2003

Page 20

Air Filter Removal

Page 21

Sanitizing and Cleaning In Place Cleaning of the Ice Machine Water System:

SCE275

1. Remove and discard all ice from the bin. If the

cleaning was pre-planned, the ice machine could

be switched off the night before to minimize waste.

2. Remove the left front grill.

3. Push and release the Harvest button (this

releases any ice that may be on the evaporators

and warms them up).

4. Wait for the machine finish the Harvest cycle the

machine will switch off). The Off light will be

blinking.

5. Push and release the Clean button. The Clean

indicator light will be blinking and the pump will

re-start.

6. Pour 8 ounces (235 ml) of Scotsman Ice

Machine Cleaner into the reservoir water (below

the evaporators).

7. After the ice machine cleaner has circulated for

10 minutes, push and release the Clean button.

Ice Machine Cleaner

contains acids. These

compounds may cause

burns.

If swallowed, DO NOT

induce vomiting. Give large

amounts of water or milk.

Call Physician immediately.

In case of external contact,

flush with water.

KEEP OUT OF THE

REACH OF CHILDREN.

Pouring Ice Machine Cleaner

into the Reservoir

Note: A possible sanitizing solution may be made

by mixing 1 ounce of liquid household bleach with

o

2 gallons of warm (95-115

F.) potable water.

10. Locate the two three-prong-head bolts holding

the hood to the bin and remove them.

11. Remove the hood from the ice machine.

12. Locate the evaporator cover and remove the

four thumb screws that hold it to the machine.

Remove the evaporator cover.

13. With rubber gloves and a clean cloth or spray

bottle, use the sanitizer solution to thoroughly

wash or spray all interior surfaces of the ice

storage bin, hood, knobs, and bin door with the

sanitizing solution. Wash the joint between the

hood and bin with the sanitizing solution. Also

wash or spray the evaporator cover, the inside

back wall of the freezing compartment, the top of

the water distributors, the exterior surface of the

reservoir, and the troughs with the sanitizing

solution.

14. Return the evaporator cover to its original

position and secure it with the original thumb

screws.

15. Return the hood to its normal position and

secure it to the machine with the original bolts.

16. Pull cube deflector out of the reservoir.

17. Push and release the Clean button again.

18. Pour 11 ml or 2.25 teaspoons of liquid

household bleach, or an amount of locally

approved sanitizer of sufficient strength to create a

sanitizing solution equal to 200 ppm of sodium

hypochlorite in .75 gallons (2.8 l), into the reservoir

water.

Cube Deflector

This starts the rinse process. The Clean indicator

light will be ON. Note: The rinse flushes any

residual cleaner out of the ice machine’s water

system.

8. Continue the rinsing process for 20 minutes,

then push the off button to switch the machine off.

Go thru steps 9-23 to sanitize the ice machine

water system or go to step 24 to finish the cleaning

process.

9. Mix 2 gallons of Sanitizer solution. Follow local

codes for Sanitizer.

November 2004

19. Thoroughly immerse the cube deflector in a

container of sanitizing solution.

20. After the sanitizing solution has circulated for

10 minutes, push and release the Clean button.

This starts the rinse process.

21. Continue the rinsing process for 20 minutes

then push the off button to switch the machine off.

22. Repeat steps 10-15.

23. Return the cube deflector to its original

position.

24. Push and release the Freeze button.

25. Return the front grills to their normal positions

and secure to the machine with the original

screws.

Page 21

Page 22

SCE275

Additional Maintenance

Water Distributors

It may become necessary to remove the water

distributors from the top of the evaporator and

clean (de-mineralize) them outside of the ice

machine.

1. Remove right front grill.

2. Push and release the OFF button.

3. Remove the machine’s hood & door.

4. Reach over the water distributors and pull the

hose off.

5. Push the two water distributors to the right until

the left end clears its retaining slot, then pull the

left end up.

6. Repeat for the back one.

Removal of Water Distributors

7. Examine the top of the evaporators. The Water

Distribution Channels must be free from mineral

build up. If build up is evident, scrub the channels

with Scotsman Ice Machine Cleaner and a plastic

bristle brush.

8. Examine the water distributors. Although they

are made of a material that is resistant to mineral

build up, some may be present. Soak or scrub the

distributors in or with a solution of Scotsman Ice

Machine Cleaner and warm potable water.

9. Return the water distributors to their normal

installed position.

9a. Snap the two distributors onto the water

manifold. Place them on the back evaporator, right

end first. Push the distributors far enough to the

right until the left end clears the retaining slot, then

release. Check that the distributors are seated

properly.

9b. Place the water hose onto the back water

distributors.

9c. Repeat for the front evaporator.

To Remove Scale From Bin Interior:

1. Mix a cleaning solution of 4 ounces of Ice

Machine Cleaner to 4 pints of hot (95

water.

2. Using rubber gloves, dip a nylon scouring pad

into the cleaning solution and scrub the scale off

the interior of the bin.

3. After the scale has been removed, rinse all

surfaces inside the bin with clean, potable water.

To Drain Reservoir Completely (if desired):

1. Remove front panel.

2. Push and hold the Off button.

3. Remove screw holding reservoir cover, pull inlet

tube out of reservoir cover, lift cover out of

machine.

4. Unplug water pump connection, remove ground

screw.

5. Remove float from float stem.

6. Unplug water level sensor.

0

F.-1100F. )

10. Reverse the above steps to reassemble.

The storage bin must be cleaned regularly to

maintain a sanitary environment. Once a week

cleaning of the door and door frame with soap and

water, a hot water rinse and an air dry is a basic

procedure. Scale that may form on the plastic liner

can be removed by scrubbing the surface with a

mixture of Scotsman Ice Machine Cleaner and hot

water. Remove any scale prior to cleaning.

January 2003

7. Lift pump and sensor out of the machine.

8. Pull up on standpipe to release water.

9. Reverse steps 2-8 to reassemble.

Note: Be certain that the float is fully re-seated on

the stem and the water pump bracket is positioned

properly on the base.

Make sure that the stand pipe is properly seated.

10. Push and release Freeze button.

11. Replace front panel.

Page 22

Page 23

Additional Maintenance

SCE275

Exterior Cabinet Cleaning:

The exterior cabinet may be cleaned by scrubbing

with soap and water. Do not use cleaners

containing petroleum products.

A nylon type brush may be used to scrub stubborn

deposits.

Additional Maintenance: Inlet Water Valve

Screen

The inlet water valve has a screen on its inlet side

to keep debris from flowing into the valve. In some

cases, this screen may become clogged or

restricted by debris build up. Check for the proper

water flow:

Flow rate is 1.25 G.P.M.

1. Remove hood.

2. Remove right front grill.

3. Obtain a measuring cup and a watch.

4. Pull the water discharge tube out of the reservoir

and place it in the cup.

5. Push and release the Harvest button.

To Check the Inlet Water Valve Screen.

1. Disconnect the electrical power.

2. Shut off the water supply.

3. Remove the hood and bin.

4. Unplug the electrical connection of the inlet

water valve.

5. Remove the screws holding the inlet water valve

to the cabinet.

Inlet Water

Valve

6. If working properly, the water valve will fill an 8

oz cup in about 3-4 seconds. Be prepared to push

the Off button. If it does not, the water valve inlet or

other water device is restricted.

Removal of Inlet

Water Valve

6. Remove outlet tube from inlet water valve.

7. Rotate inlet water valve from inlet fitting and

remove valve from machine.

8. Examine the inlet screen, if dirty, brush off

screen.

Note: Screen is not replaceable, and may only be

removed by taking off the covering bracket. The

bracket forms part of the inlet water system, and

must be water tight to the valve body, removal is

not recommended.

9. Reverse to reassemble.

January 2003

Page 23

Page 24

SCE275

Additional Maintenance: Bin Controls

The bin controls use a system of infrared emitting

and receiving components to sense the build up of

ice in the bin. They are located in between the

evaporators. They must be free of mineral build up

to function properly. To check:

1. Remove the right front grill.

2. Push and hold the off button until the machine

stops..

3. Remove the knobs holding the hood to the bin.

4. Remove the hood..

5. Remove the thumb screws holding the bin

control brackets.

Removal of Bin Controls

7. Examine the bottom of the brackets, there are

two sensors in each bracket, check that they are

clear of mineral build up. They may be wiped clean

with ice machine cleaner to assist in removal of the

build up. Use a toothbrush if necessary to remove

scale.

Be sure to drain the reservoir or go thru a Clean

cycle to remove residual cleaner.

Note: Do NOT use abrasive materials or cleaner

on the bin sensor lenses.

Thumb Screw

6. Lift the the bin control brackets up and out from

between the evaporators.

Bin Controls,

Clean Here

January 2003

Page 24

Page 25

SCE275

Technical Characteristics

Air Cooled 70oF. air and 50oF. water 90oF. air and 70oF. water

Typical Freeze Cycle Time 15 minutes 18 minutes

Typical Harvest Cycle Time 2 minutes 1.5 minutes

Typical Low Side Pressure, end of

freeze

Typical Discharge Pressure, end

of Freeze

Typical Low Side Pressure, peak

in Harvest

Typical Discharge pressure in

harvest

Water Cooled 70oF. air and 50oF. water 90oF. air and 70oF. water

Typical Freeze Cycle Time 15 minutes 16 minutes

Typical Harvest Cycle Time 2.5 minutes 2 minutes

Typical Low Side Pressure, end of

freeze

Typical Discharge Pressure, end

of Freeze

Typical Low Side Pressure, peak

in Harvest

Typical Discharge pressure in

harvest

24 PSIG 29 PSIG

235 PSIG 306 PSIG

130 PSIG 118 PSIG

270 PSIG 240 PSIG

24 PSIG 26 PSIG

245 PSIG 245 PSIG

90 PSIG 93 PSIG

175 PSIG 190 PSIG

Typical Harvest Ice Weight

2.8 to 3.2 lb.

Refrigerant Type / Charge

R-404A / 18 ounces air cooled

R-404A / 12 ounces water cooled.

Hi Pressure Cut Out - Automatic Reset (water cooled only)

400 PSIG Cut Out + or - 10 PSIG

300 PSIG Cut In + or - 10 PSIG

Typical Compressor Amp Draw

Freeze: begins at 6.9 declines to 4.1

Harvest: 7 - 7.3

Superheat

4-6oF. 10 minutes into freeze cycle. TXV is not adjustable.

Compressor

Tecumseh hermetic, capacitor start, capacitor run (A series).

January 2003

Page 25

Page 26

SCE275

Service Diagnosis

Proper service diagnosis begins with observation, comparing the complaint to the operation of the unit. Ice

machine service diagnosis should proceed from water, to electrical and then to refrigeration.

Problem or Symptom Possible Cause Probable Correction

Bin is full, ice in cube port Use some ice

Machine is off

Unit is off on a Water

Error

Power is off, check LEDs.

Transformer is open

Unit has been switched off

or has finished a Clean

cycle, Off Light is glowing

Unit has Shut Down Check for Refrigeration or Water Error

Water inlet valve

malfunction

Water pump malfunction

Water level sensor may

have failed.

Low discharge or long

freeze cycle

If all lights are out, check power supply, restore

power if off

If all lights are out and there is power, check

transformer output for 24 vac

Push and release Freeze button

Check water Light, if the Light blinks 2 times and

repeats, check the water inlet valve for proper

water flow.**

Check that pump hose is attached and if pump is

plugged in and working.

Check float stem, reset machine. If it will not

reset or gives another water error and everything

else is OK, replace the water level sensor.

Check refrigeration Light. If the Light is glowing,

there is a probable refrigeration problem or on

water cooled a water interruption

Check refrigeration Light. If the Light blinks once

and repeats, look for a harvest problem.** This

Harvest problem

Unit is off on a

Refrigeration Error

High Discharge Temp

Unit does not go into

harvest - exceeds

maximum freeze time

Unit runs and both

Error Lights are ON

Same, but 1 light is on Reservoir temp. wrong Check water temp and sensor.

* Machine may be reset by pushing and releasing the Off button, then pushing and releasing the Freeze

button. ** See following pages

Temperature sensors out

of range

also indicates that cubes were sensed by the bin

controls.

If the light blinks 2 times and repeats, check for a

harvest error - no cubes sensed.

Check refrigeration Light. If the Light blinks 3

times and then repeats, check for a reason for

high discharge temperatures - such as a bad fan

motor or very hot ambient.

Push and release Off button. Push and release

Freeze button. Check operation.

Push cube size float down and check operation.

Replace the temperature sensor set (water and

discharge).

January 2003

Page 26

Page 27

Service Diagnosis

Problem or Symptom Possible Cause Probable Correction

Check bin controls. The bin full light should be

off. If it is on or blinking the bin controls may be

dirty. Clean if dirty. The board and bin controls

may also need to be checked.

Push and release Off button. Push and release

Freeze button. Check machine operation. Check

if ice is made and harvests.

Unit is off because of a

“Harvest Problem”

Bin controls did not sense

ice falling, unit stayed in

harvest until the maximum

harvest time ran out.

SCE275

Cubes are too large

Cubes are too small

Low ice capacity

Unit does not shut off

Bin controls or AutoIQ

Controller may have failed.

Other components may

have failed

Cube size control float is

sticking.

Inlet water valve leaks thru Check inlet water valve

Unit not level Check levelness

Not enough water Check for leak in reservoir

Dirty condenser or filter Replace filters, clean condenser

Blockage of air flow

Low refrigerant charge

Bin control system may

have failed.

See “Unit does not shut off” below..

Check the next page

Check/clean

Remove anything from in front of the machine

that blocks the free flow of air.

Check system. If there is a low charge, find the

leak, recover the refrigerant, repair the leak,

replace the dryer, evacuate and weigh in the

nameplate charge.

Check bin controls. Check bin full light, if off,

place something between the electric eyes. Note:

Hood must be on. Use a piece of duct tape about

4" long and position it by hand between the

evaporators. The bin full light should begin to

blink (after 20 seconds of continuous blockage it

will glow steadily). If not, check operation of

electric eyes by unplugging #4 and jumping out

the two pins on the controller. If the bin full light

blinks, replace the bin controls. If it does not

blink, replace the controller. Note: Leaving #4

unplugged and jumped for 20 seconds will shut

the machine down on a bin full. It will restart after

5 minutes or may be reset by pushing the Freeze

button.

January 2003

Page 27

Page 28

SCE275

Service Diagnosis

Problem or Symptom Possible Cause Probable Correction

Open motor windings, or

seized bearings, or blade

stuck against shroud

Fan motor(s) do not

turn.

No power to fan motors

Replace fan motor or free fan blade.

Fan motor unplugged, check for voltage at

controller. Controller cycles fan motors during

freeze. If no voltage to the fan motors at

controller during freeze, replace controller.

Pump motor does not

turn

Hot Gas Valve does

not open.

Hot Gas Valve leaks

thru (warm tube

temperatures on both

sides of valve during

freeze)

Water Inlet Valve does

not open

Open motor windings, or

seized bearings

No power to pump

Open solenoid coil. Replace hot gas valve

Stuck valve Replace hot gas valve

No power to coil in Harvest

Mechanical problem in

valve

Open solenoid coil Replace valve

Stuck valve Replace valve

No power to valve (early

part of harvest)

Replace pump

Check electrical connections. Check water level.

Switch the unit to Clean, the pump should then

have power to it. If not, replace the AutoIQ

Controller.

Check wire connections, if ok, replace AutoIQ

Controller

Replace valve

Check wire connections, if ok, replace AutoIQ

Controller

Water Inlet Valve does

not flow enough water

Water Inlet Valve

leaks thru

Compressor does not

work

Restriction in water supply Check water filters and/or inlet screen.

Mechanical problem in

valve

Unit in Clean cycle Push and release Freeze button.

Contactor coil open Replace contactor

Open starting components Check and replace

Open windings Check and replace compressor

Internal valve failure Replace compressor

January 2003

Page 28

Replace valve

Page 29

PTCR

SCE275

The “D” series and higher use a PTCR (Positive

Temperature Coefficient Resistor) in place of a

conventional start relay and start capacitor.

Power from the contactor connects to the PTCR and

to the Run Capacitor

A wire connects the other terminal of the PTCR to

the compressor’s start winding.

Another wire connects the run capacitor to the start

winding.

A parallel circuit connects power from the contactor

to the Run winding of the compressor.

A PTCR changes resistance sharply when its

temperature changes. When the PTCR is cold, it

connects full current to the compressor’s start

winding. After a very short time, the PTCR heats up

and shuts off the current flow. Under normal

conditions, the PTCR’s case is at about 180

At that temperature the PTCR has very high

resistance and will not allow current to flow. It must

cool down to about 120

through it again.

o

F. Before current will pas

o

F.

Diagnosis:

1. Disconnect electrical power.

2. Check if the PTCR is cool enough to handle safely.

If not, wait 5 minutes for it to cool off.

3. Disconnect both leads to the PTCR and measure

its resistance with an ohmmeter. If the PTCR reads

less than 22 ohms or more than 40 ohms, replace it.

January 2003

Page 29

Page 30

SCE275

Removal and Replacement: AutoIQ Controller

Begin by disconnecting the electrical power.

Electrical shock

hazard.

Electrical shock can

cause personal injury.

Disconnect power before

beginning to service

1. Remove 2 screws and the right front grill.

2. If the machine is operating, push and hold the

Off button until the machine switches off.

3. Unplug or disconnect electrical power.

4. Remove the one screw at the right end of the

AutoIQ Controller.

5. Pivot the controller up and away from its

mounting bracket.

6. Unplug all connecting wires.

7. Reverse steps 6-1 to replace the controller.

Electrical Box and Components

Below the bin on the left side of the chassis is a

sheet metal box containing the transformer,

compressor contactor, compressor relay, start

capacitor and run capacitor.

This box may only be accessed by removing the

hood and bin. After that:

1. Remove the cap screw securing the electrical

box to the ice machine chassis.

2. Pull the electrical box forward to release it from

the tab at the back of the box.

3. The box may now be placed in a horizontal

position for better service access.

Standpipe:

The overflow standpipe is located at the back of

the reservoir. The water pump and water level

sensor must be removed to get access to it.

The height of the standpipe is very important.

Measured from the top edge of the reservoir to the

very top of the standpipe, the distance should be:

27

"

3

32

January 2003

Page 30

Page 31

SCE275

Removal and Replacement: Water Pump, Water Level Sensor

Water Pump

The pump provides the force to move the water

from the reservoir to the freezing surface. The

pump does not need oil, but if it becomes noisy,

overheats, or will not pump it should be replaced.

Be certain to confirm electrical faults with a

voltmeter or ohmmeter before replacing the pump.

The pump should operate with the compressor.

Electrical shock hazard.

Electrical shock can

cause personal injury.

Disconnect power before

beginning to service

components.

1. Unplug or disconnect the electrical power.

2. Open the bin door and unscrew the knobs

holding the hood to the bin.

Water Level Sensor

1. Unplug or disconnect the electrical power.

2. Open the bin door and unscrew the knobs

holding the hood to the bin.

3. Pull the hood off the bin.

4. Remove ground wire from mounting screw.

5. Unplug water pump.

6. Unplug water level sensor.

7. Remove the 2 screws holding the reservoir

covers to the reservoir.

8. Pull the water pump and water level sensor

assembly up and out of the reservoir.

10. Pull the float from the float stem.

11. From below the reservoir cover, push the

mounting tabs together to release the water level

sensor from the reservoir cover.

12. Reverse steps 11-1 to replace the water level

sensor.

3. Pull the hood off the bin.

4. Remove ground wire from mounting screw.

5. Unplug water pump.

6. Unplug water level sensor.

7. Remove the 2 screws holding the reservoir

covers to the reservoir.

8. Pull the water pump and

water level sensor assembly up

and out of the reservoir.

9. Remove the screws holding

the water pump to the two

reservoir covers, and the pump

is free to be replaced.

10. Reverse steps 9-1 to replace

the pump.

Water Pump

Water Level

Sensor

Mounting Plates

January 2003

Page 31

Page 32

SCE275

Removal and Replacement: Inlet Valve & Water Trough

Water Inlet Valve

The water inlet valve is located in the lower back of

the cabinet. The hood and bin must be removed to

gain access to this part.

The valve is directly connected to the incoming

water supply. With the water supply turned off, the

connection can be removed from the front of the

machine.

1. Go thru the steps on page to remove the hood

and bin.

2. Locate the inlet water valve. Pull the wire harness

off the terminals of the valve.

3. Remove the cover over the utility connections.

4. Use two wrenches and loosen the nut on the male

flare holding the water supply to the water inlet

connection. Remove the water supply line from the

water inlet valve.

5. Remove the two screws that hold the water inlet

valve to the cabinet.

6. Pull the water inlet valve out and remove the

discharge hose from the outlet of the valve.

Inlet Water

Valve

Cover Removed From

Utility Bracket

7. The valve may now be removed from the ice

machine.

8. Reverse steps 7-1 to replace the valve.

Water Trough

1. See the next page and remove the bin controls

first (steps 1-9).

2. Pull out the cube deflector.

3. Unsnap the trough from the evaporator pins and

rotate the front trough out of the machine.

4. Unsnap the trough from the evaporator pins and

rotate the back trough out of the machine.

5. Reverse to reassemble. Note: The troughs are

marked: FRONT TROUGH and BACK TROUGH.

Begin by hanging the troughs on the evaporator’s

front pins and then rotating the trough until it snaps

onto the back set of pins. Be certain that all 4 pins

are engaged on each trough.

View of Machine Without Bin or Hood

January 2003

Page 32

Page 33

Removal and Replacement: Bin Control Set

SCE275

Bin Controls

The bin controls are located in between the two

evaporators, one on the left and one on the right.

The hood must be removed to gain access to

them.

1. Remove the right front grill.

2. If the machine is making ice, push and release

the Harvest button.

3. After the ice has fallen off the evaporators, push

and hold the Off button until the machine stops.

4. Unplug the machine or disconnect the electrical

power.

5. Remove the two knobs holding the hood to the

bin.

6. Slide the bin forward to remove it from the ice

machine.

7. Locate the bin controls and brackets.

8. Remove the thumb screws holding the bin

controls to the evaporators.

Bin Control

Bin Controls May Have a Shield Over Them

Remove Mounting Bolt

Remove the Mounting Bolt First

9. Pull the bin controls up and out of the ice

machine.

10. Trace the wires back to the connectors, and

unplug them.

11. Reverse steps 10-1 to replace the bin controls.

Flange of

Bin Control

Note: They MUST be changed as a set.

The bin controls must be positioned so that the

flange of the bin control is behind the water trough.

Edge of

Water

Trough

January 2003

Page 33

Page 34

SCE275

Removal and Replacement: Thermistors

There is a thermistor to sense reservoir water

temperature and another to sense compressor

discharge temperatures. If the AutoIQ Controller

senses a fault with the thermistors, both diagnostic

indicator lights will be glowing continuously.

Electrical shock

hazard.

Electrical shock can

cause personal injury.

Disconnect power before

beginning to service

Disconnect electrical power before beginning.

1. Remove the grills from the front of the cabinet.

2. Push and hold the Off button to shut the

machine Off.

3. Remove the hood.

14. Insert the new thermistor into the discharge

hose. Do not allow the body of the thermistor to

contact the hose opposite of the mounting hole.

15. Secure thermistor with cable tie.

16. Plug thermistor into wire harness.

17. Return water pump and water level sensor to

its normal position. Reconnect power and ground

wires.

18. Return bin and hood to their normal positions.

19. Reconnect electrical power and push the

Freeze button to restart the machine.

20. Return the grills to their normal position.

4. Remove the bin.

5. Locate the thermistor attached to the discharge

line of the compressor. Remove the insulation

covering the thermistor and un-clip it from the

discharge line.

6. Unplug the thermistor from the wire harness by

AutoIQ Controller.

7. Plug the new set into the AutoIQ Controller.

8. Route the thermistor to the discharge tube of the

compressor and attach it to the discharge line in

the same place as the original.

9. Re-cover the thermistor with insulation.

10. At the upper left of the machine, un-plug the

water pump and water level sensor.

11. Lift up the water pump mounting plate and pull

the water hose off the water pump. Remove the

water pump and water level sensor and set aside.

12. Remove the water thermistor from the

discharge hose of the water pump.

13. Unplug the thermistor from the wire harness.

January 2003

Page 34

Page 35

Water Distributors

Water Distributors are a snap-fit on the top edge of the evaporators.