Scotsman RS160, RS220 Owner’s Manual

RS160 and RS220

INTRODUCTION

This service manual is intended as a reference for

the installer, user, and service agent of this

Scotsman Refreshment Stand. It includes the

necessary information to install, start up, operate,

clean and maintain this unit.

TABLE OF CONTENTS

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FOR THE INSTALLER: Installation Of Loose

Shipped Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FOR THE INSTALLER: Tubing Installation . . . . . . . . . . . . . . . . . . . . . . . 4

FOR THE INSTALLER: Sealing of Cabinet . . . . . . . . . . . . . . . . . . . . . . . 5

FOR THE INSTALLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation: Scotsman CM Cuber . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation: Scotsman Slim Line Cuber . . . . . . . . . . . . . . . . . . . . . . . . . 8

SODA SYSTEM SCHEMATIC: 6 Valve Units . . . . . . . . . . . . . . . . . . . . . . 9

SODA SYSTEM SCHEMATIC: 8 Valve

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

HOW IT WORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INITIAL START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FOR THE OPERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CLEANING AND SANITIZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SANITIZING SYRUP SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SERVICE DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SERVICE DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ELECTRICAL SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

MOVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

REMOVAL & REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

This manual contains important information, read it before installation or operation.

Keep it for future reference.

It marks important safety information on a hazard

that might cause serious injury.

June 1995

Page 1

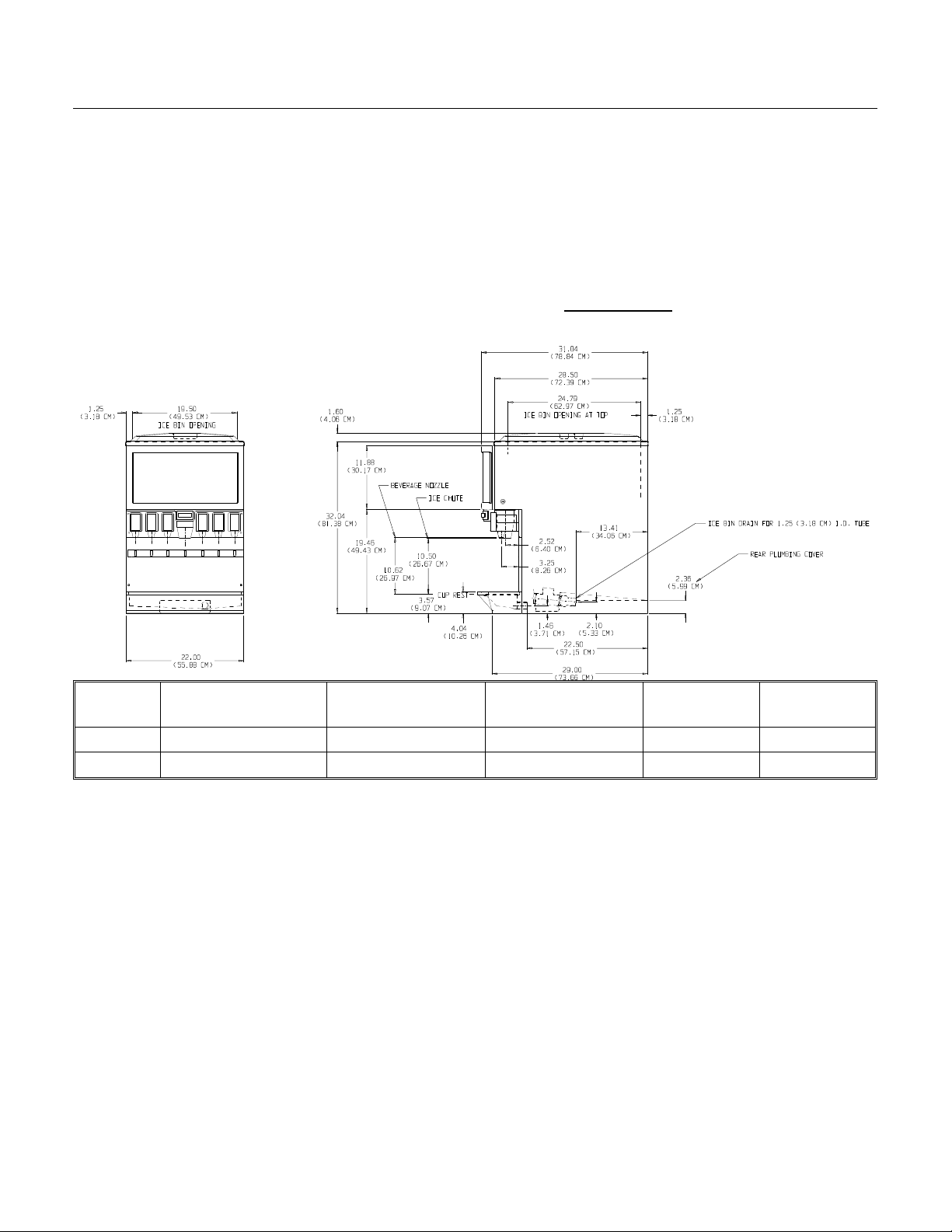

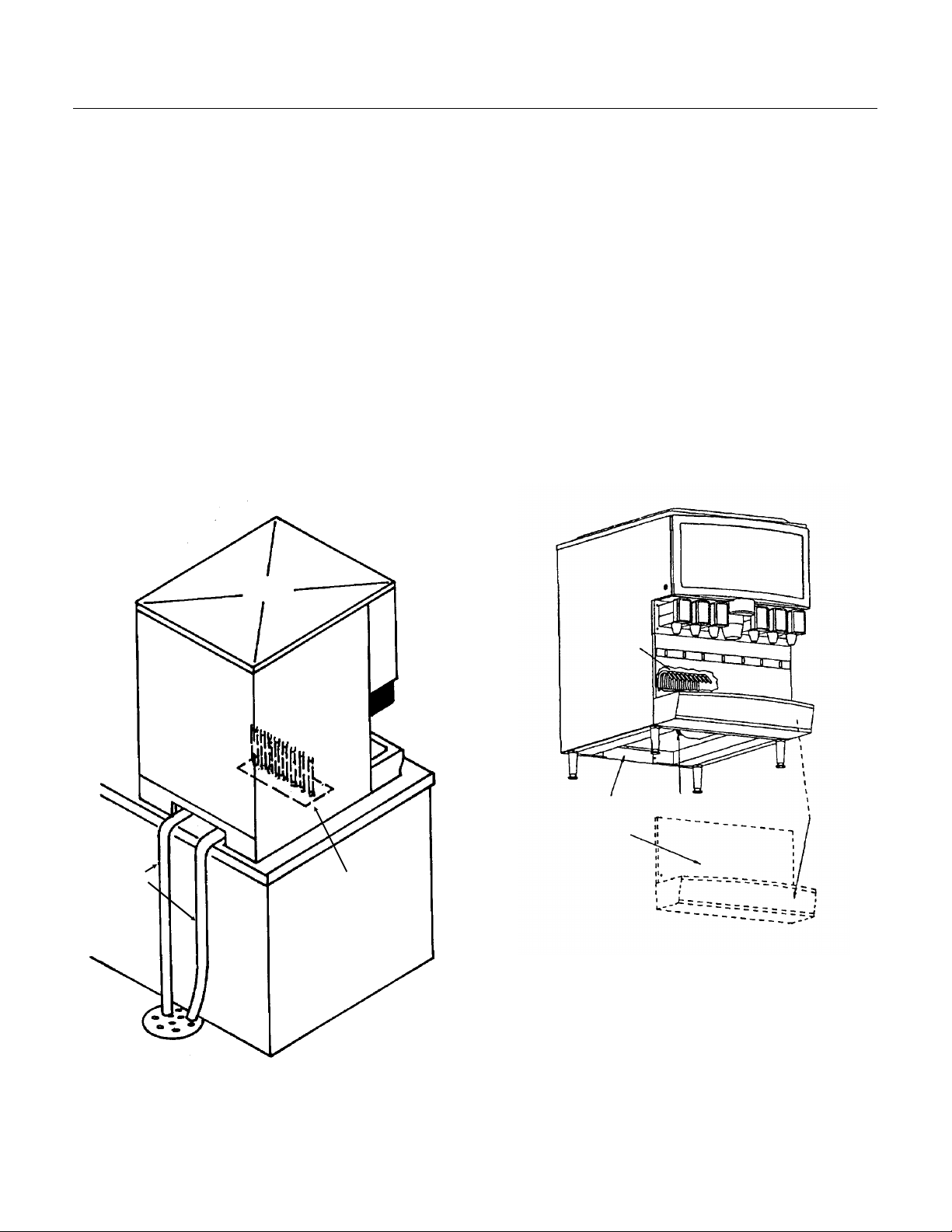

RS160 SHOWN,

RS220 SIMILAR

BUT 30" WIDE

RS160 and RS220

SPECIFICATIONS

The term “Refreshment Stand” means a machine

that stores ice in an insulated, sanitary container;

upon demand it dispenses that ice into a cup or

glass; it cools beverages using ice falling from the

hopper onto a cold plate at the base of the hopper;

and it dispenses beverages via post-mix or pre mix

valves. Some of the valves are not carbonated;

they may be changed to carbonated if desired.

Power to operate the valves may be shut off by a

key switch.*

* Premix is not electrically powered.

The RS requires additional equipment to be

functional:

An ice machine or source of sanitary ice; a

carbonator for post mix (and potable water); a

syrup delivery system, either pressurized syrup

cans or bag-in-a-box; and CO

must also be connected to a drain.

NOTE: This Refreshment Stand is designed to

dispense

will not work.

cubed ice only. Flaked or Nugget ice

. The dispenser

2

Base

Model

RS160 22" 160 lb. 115/60/1 2 amps 4’ with plug

RS220 30" 220 lb. 115/60/1 2 amps 4’ with plug

Rotor motor is 1/10 HP.

Options: Fast flow carbonator (100 G.P.H.). May be obtained as push button actuation for ice and soda or

lever actuation for ice & soda. Both are factory installed. Various brand standard or fast flow post-mix

valves are available (factory installed). Also available in premix with Booth Capre valves only (factory

installed).

Cubed ice machines may be stacked onto the top of the dispenser with an adapter kit:

••RS160: Scotsman cubers SLE300, SLE400 or SLE400R use kit # KADUN2.

••RS220: Scotsman cubers CME250, CME256, CME500, CME506, CME650 OR CME656 use kit #

KADCM2.

Scotsman Drink Systems are designed and manufactured with the highest regard for safety and

performance. They meet or exceed the standards of U.L. and N.S.F.

Scotsman assumes no liability or responsibility of any kind for products manufactured by Scotsman that

have been altered in any way, including the use of any parts and/or other components not specifically

approved by Sc ot sman

Scotsman reserves the right to make design changes and/or improvements at any time. Specifications and

designs are subject to change without notice.

Width Total Ice Storage

Capacity

June 1995

Page 2

Basic Electrical Amperage Power Cord

Install Lever

In Slot

RS160 and RS220

FOR THE INSTALLER: Installation Of Loose Shipped Parts

Several components are packed inside the hopper:

••Drip tray and grill

••2 drain hoses

••Several hose clamps

••Several barbed hose fittings

••Fluorescent tube

••Lever (for lever models)

Remove them and set them aside for installation.

Ice lever/Ice Chute/Fluorescent Tube

1. Lift up and pull out to remove upper front panel.

2. Slide out ice chute mounting panel.

3. Insert the ice lever in to the valve panel through

the slot as shown.

4. Swing the ice lever through from right to left and

let it hang freely.

5. Twist the fluorescent tube into the sockets.

ICE CHUTE

MOUNTING

PANEL

ICE CHUTE

6. Replace ice chute mounting panel.

7. Insert clear ice chute into the panel and twist

clockwise 1/3 turn.

8. Replace the upper front panel.

RS160 TOP VIEW

(For Reference)

June 1995

Page 3

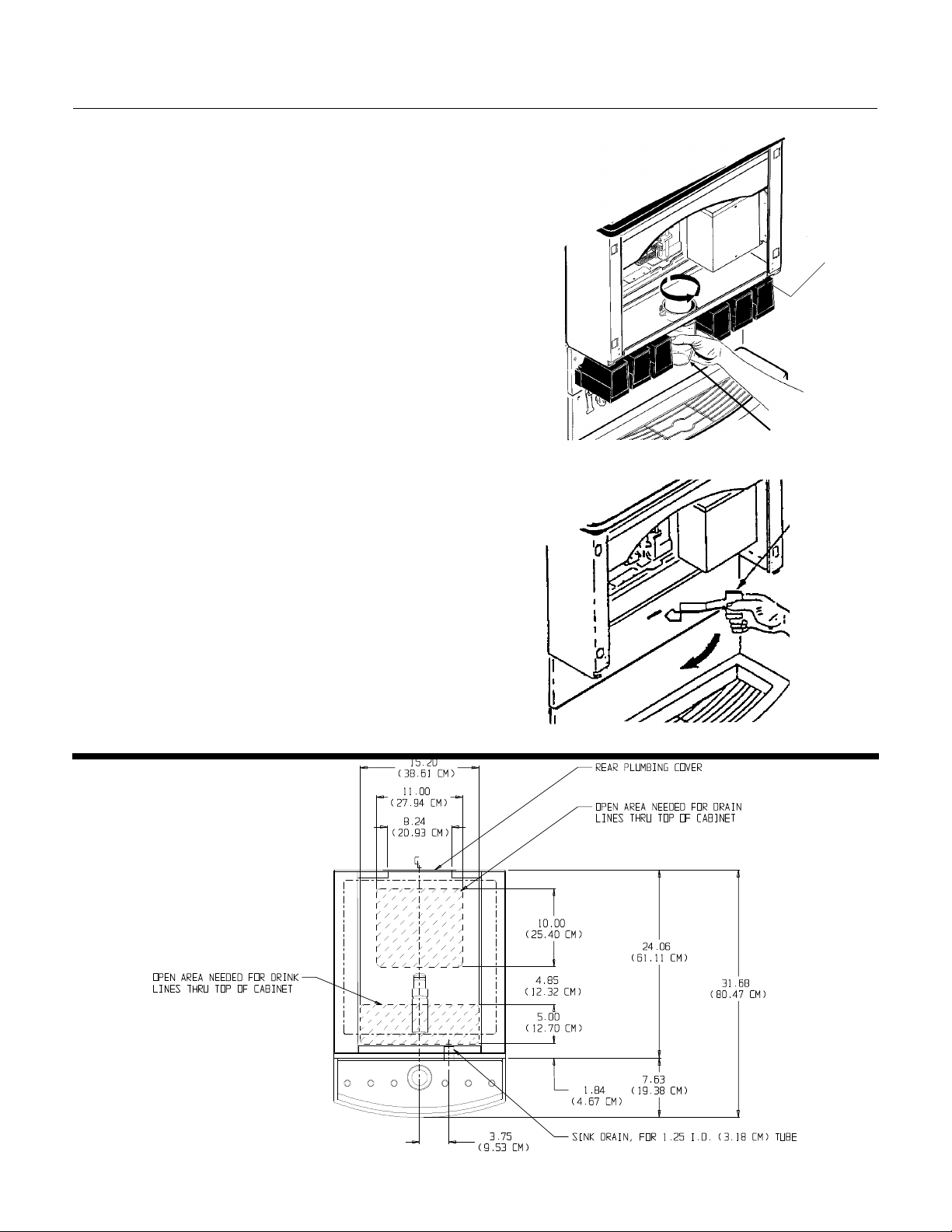

DRAIN

FITTING

MOUNTING TABS

RS160 and RS220

FOR THE INSTALLER: Tubing Installation

1. Locate the dispenser on the counter. Allow

vertical clearance above unit for the removal of the

cover, and for pouring ice into the hopper.

Note: If installing an ice cube machine on top,

check for proper total cabinet clearance, including

adapter kit.

The syrup and carbonated water connections need

to be made at the cold plate’s stub lines. The cold

plate stub lines are behind the splash panel.

Tubing routing to the cold plate is from either the

back of the unit, or through openings in the base.

A plumbing circuit schematic diagram is on the

back of the cabinet, refer to it for cold plate

connections.

2. Plan the routing of the tubing (drain and soda).

If the tubing will pass through the base, a hole

in the counter top must be made prior to

sealing the unit to the counter.

The tubing may also be routed through the back.

3. Connect the drain system. There are two drains

to connect: The sink (or drip tray) drain and the

cold plate drain. They must be routed separately.

The tubes may drain the unit through the back or

through the openings in the base.

Drip Tray/Grill

1. Remove splash panel from unit.

2. Connect the sink drain hose to the sink drain

fitting and secure it with a hose clamp. Route the

tube to the building drain. Follow all local plumbing

codes.

4. Hang the drip tray onto the metal tabs on the

base of the unit.

5. Replace the splash panel.

Note: If the cabinet has been sealed to the

countertop, add sealant around the sink and

counter top to provide a seal with a radius of 1/2".

Follow the sealant manufacturer’s instructions on

the package for working with the sealant, and

cleaning up.

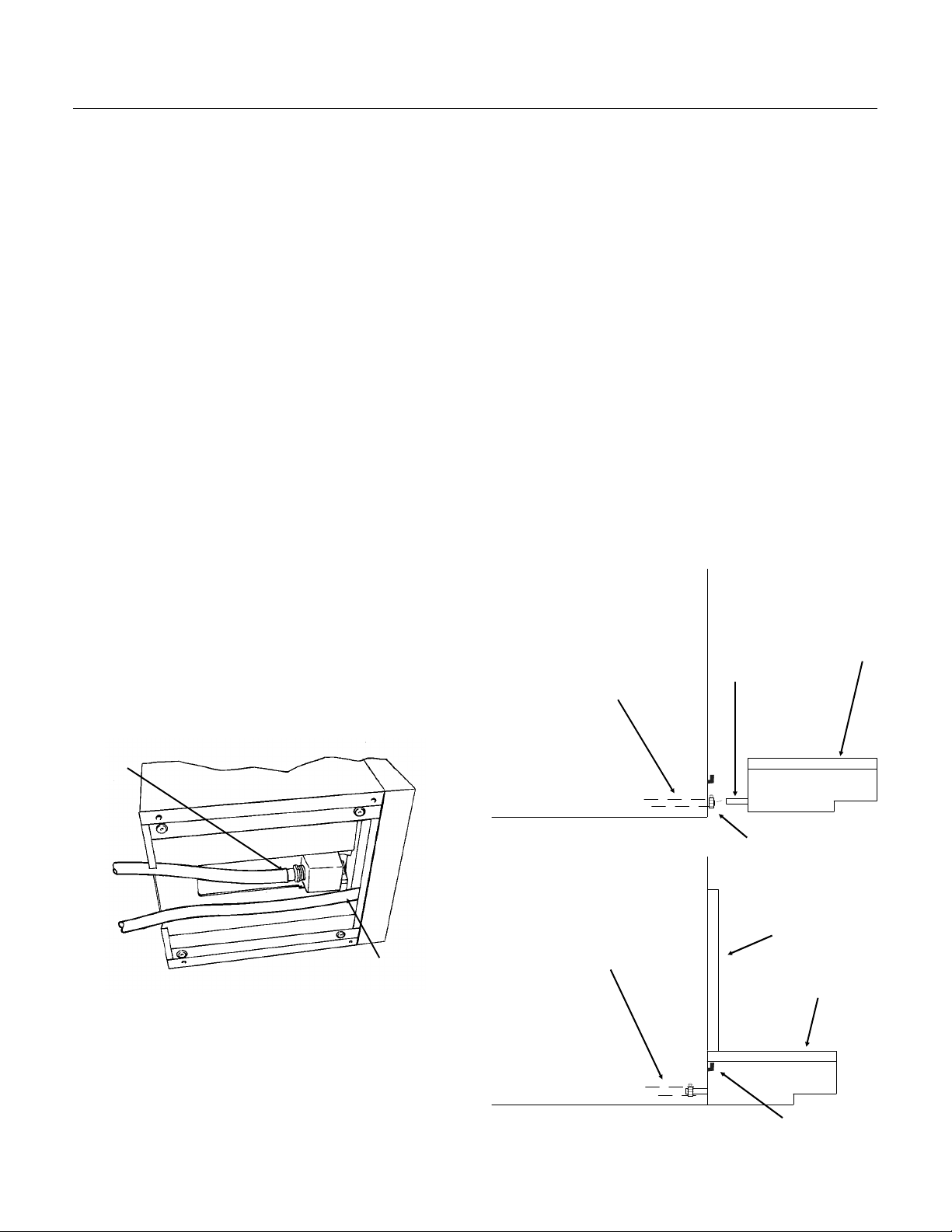

SIDE VIEW OF DRIP TRAY INSTALLATION

DRIP TRAY

The cold plate drain tube is the one with the foam

insulation on it. Tilt or lift the unit to expose the

bottom of the dispenser.

Cold Plate

Drain

Connection

Bottom View of

Dispenser

Sink Drain Connection

Connect the threaded drain fitting (packed loose in

the hopper) to the cold plate drain connection.

Connect the cold plate drain tube to this fitting,

route the hose to the building drain.

Install the sink drain after the machine has been

set in place.

DRAIN TUBING

HOSE

CLAMP

SPLASH

PANEL

DRAIN TUBING

DRIP TRAY

June 1995

Page 4

FOR THE INSTALLER: Sealing of Cabinet

In order to comply with National Sanitation

Foundation (NSF) requirements, this unit must be

either elevated above the counter top sufficiently to

provide space for cleaning under the unit or

sealed to the counter top.

Elevating the unit may be accomplished by using

the leg kit. Legs screw into threaded holes in the

base of the unit.

If the unit is to be sealed to the counter top, the

soda tubing installation should be planned such

that its connections may be finished after the unit

has been sealed to the counter.

Seal the unit by the use of room temperature

vulcanizing (RTV) rubber sealant such as General

Electric IS 808 Industrial Sealant, Dow Corning

731 or the equivalent.

With the unit located on the counter as desired:

A. Tilt or lift the unit to expose the bottom flanges

of the base frame.

RS160 and RS220

THE CABINET MUST BE

LEVELED LEFT TO RIGHT AND

FRONT TO BACK

USE LEGS OR

SEAL TO

COUNTERTOP

B. Apply the sealant to cover the bottom flanges of

the base frame.

C. Return the unit to the desired position on the

counter top.

D. Add sealant around the base frame and counter

top to provide a seal with a radius of 1/2". Follow

the sealant manufacturer’s instructions on the

package for working with the sealant, and cleaning

up.

E. Seal around all access holes in the counter top

with Permagum or Mortite caulk or an equivalent

material.

June 1995

Page 5

RS160 and RS220

FOR THE INSTALLER

1. If installing a carbonator, locate it nearby.

2. Route the drain lines to the building drain. Vent

the drain tubes if installing at the back of the

cabinet.

3. Locate electrical supply (for cord - 115v outlet).

The outlet must be properly grounded. The

circuit must be fused and no other electrical

appliance should be on the circuit.

ALL ELECTRICAL WIRING MUST CONFORM

TO NATIONAL AND LOCAL CODES

4. Remove splash panel.

Refer to the plumbing schematic on the back of

the cabinet (all stub lines are labeled) and:

Typical Installation

A. Connect carbonated water supply lines (field

supplied) from the remote carbonator to the

carbonated water stub line at the dispenser cold

plate.

B. Connect water supply lines (field supplied)

from building source to carbonator (filtered water

is recommended).

C. Connect water supply line(s) to the plain

water stub line(s) on the cold plate for use with

the non-carbonated valve.

NOTE: If ALL valves need carbonation, connect

an additional carbonated water line from the

carbonator to the plain water stub line on the

cold plate.

D. Connect syrup lines from the syrup supply to

the cold plate syrup stub lines.

Sink and

Cold Plate

Drain Tubes

Beverage &

Water Tubes

Cold

Plate

Stub

Lines

Back Plumbing

Cover Plate

Remove Splash

Panel and Sink

6. Connect primary CO

regulator to CO2 tank.

2

Secure secondary regulators to wall or other

stationary surface.

7. Connect CO

regulator and inlet of secondary regulators.

8. Connect CO

secondary regulators and syrup tanks. Or to syrup

pumps in the case of Bag-In-Box.

June 1995

Page 6

line between outlet of primary

2

lines between outlets of

2

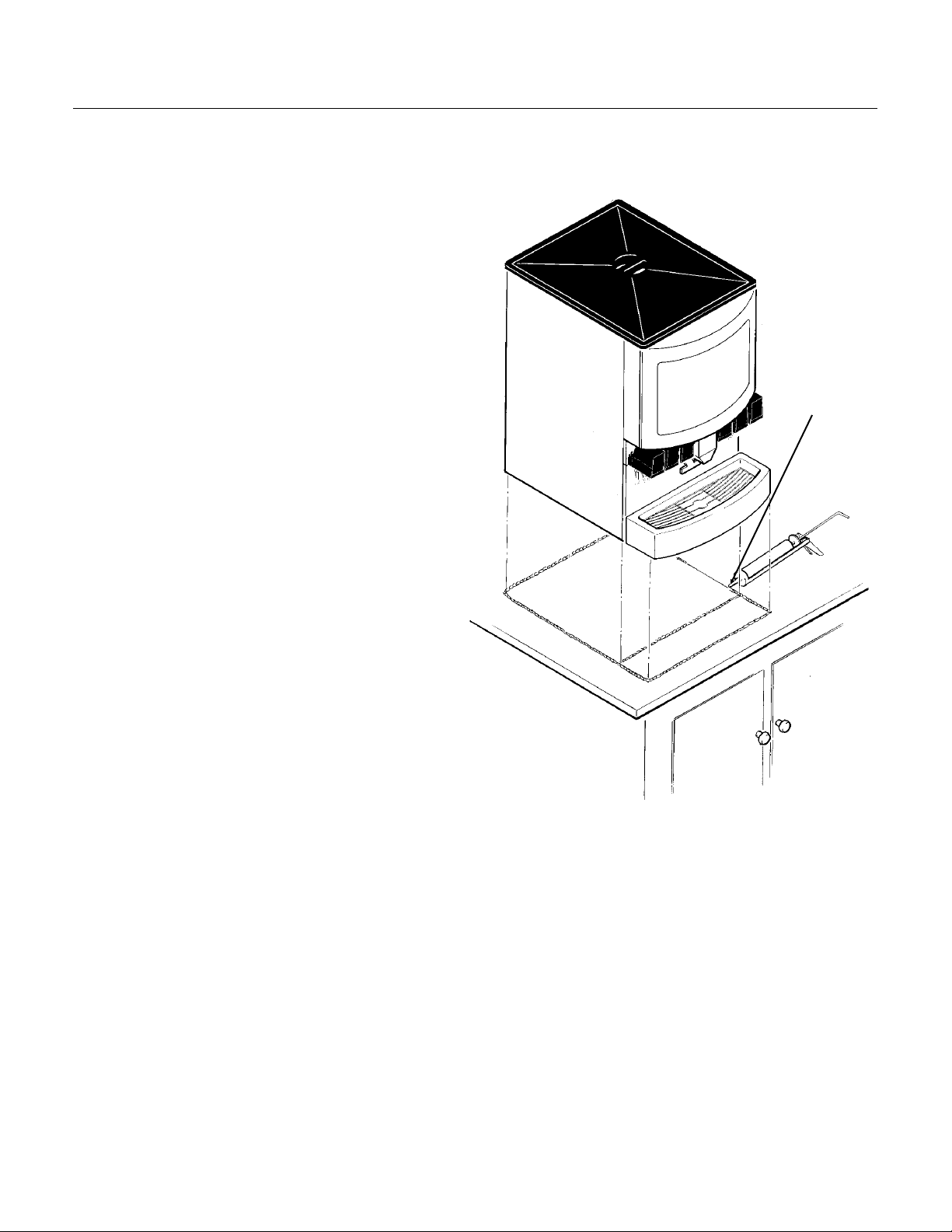

Installation: Scotsman CM Cuber

1. Make sure the counter the dispenser is placed

on is structurally able to hold the combined weight

of the dispenser, ice and ice machine.

2. Install the dispenser.

3. Remove the dispenser cover (save it - it will be

needed if the ice machine is removed).

4. Place stainless steel adapter sleeve onto the

top of the dispenser.

5. Using the tube of sealant from the kit, place a

bead of sealant onto the top edges of the area on

the adapter where the ice machine will go.

6. Place a bead of sealant onto the inside and

outside seams where the dispenser and adapter

meet.

7. Using a mechanical lift, hoist the ice machine

onto the dispenser, center left to right and align

flush to the back.

RS160 and RS220

8. Install a bin thermostat bracket assembly onto

the underside of the CM ice machine.

Note: Thermostat bracket only required by CM250,

CME250, CM500, CME500, CM650 or CME650.

9. Fasten together at the back of the machine

using bolts from the ice maker and mounting

straps from the kit.

10. Place the front cover plate onto the dispenser

in front of the ice machine.

June 1995

Page 7

RS160 and RS220

Installation: Scotsman Slim Line Cuber

Assembly:

The assembly of the ice machine onto the

dispenser requires two additional parts: an adapter

and a thermostat stand off kit.

1. Mark two spots on the inside left liner of the

dispenser: 2" down from the top, 4" from the back,

and 4" apart.

2. At the two marked spots, drill two 1/4" holes thru

the plastic liner only.

3. From the stand off kit, locate the stand offs and

plastic anchors. Thread the stand offs partially into

the plastic anchors.

4. Push the anchors/stand offs into the holes

5. Screw the stand offs all the way into the

anchors. Be sure that the holes in the stand offs

are horizontal.

6. Place a bead of silastic (from the kit) around the

stand offs.

7. From the adapter kit, place the stainless steel

adapter onto the top of the dispenser. Follow all

directions included with the kit.

8. After the ice machine has been placed on the

dispenser, remove the front panel and uncoil all of

the bin thermostat capillary tube.

9. Route the capillary tube thru the front hole in the

base of the ice machine, to the left side if the

dispenser towards the stand offs.

10. Route the end of capillary tube thru the

stand-offs, bend the tube around the stand offs so

that it does not fall off.

11. Check that the routing of the capillary tube is

away from the ice chute and up high enough near

the base of the ice machine.

June 1995

Page 8

Loading...

Loading...