Page 1

CME1202R & CME1402R

INTRODUCTION

To the owner or user: This service manual is

intended to provide you and the maintenance or

service technician with the information needed to

install, start up, clean, maintain and service this

ice system.

Table of Contents

FOR THE INSTALLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

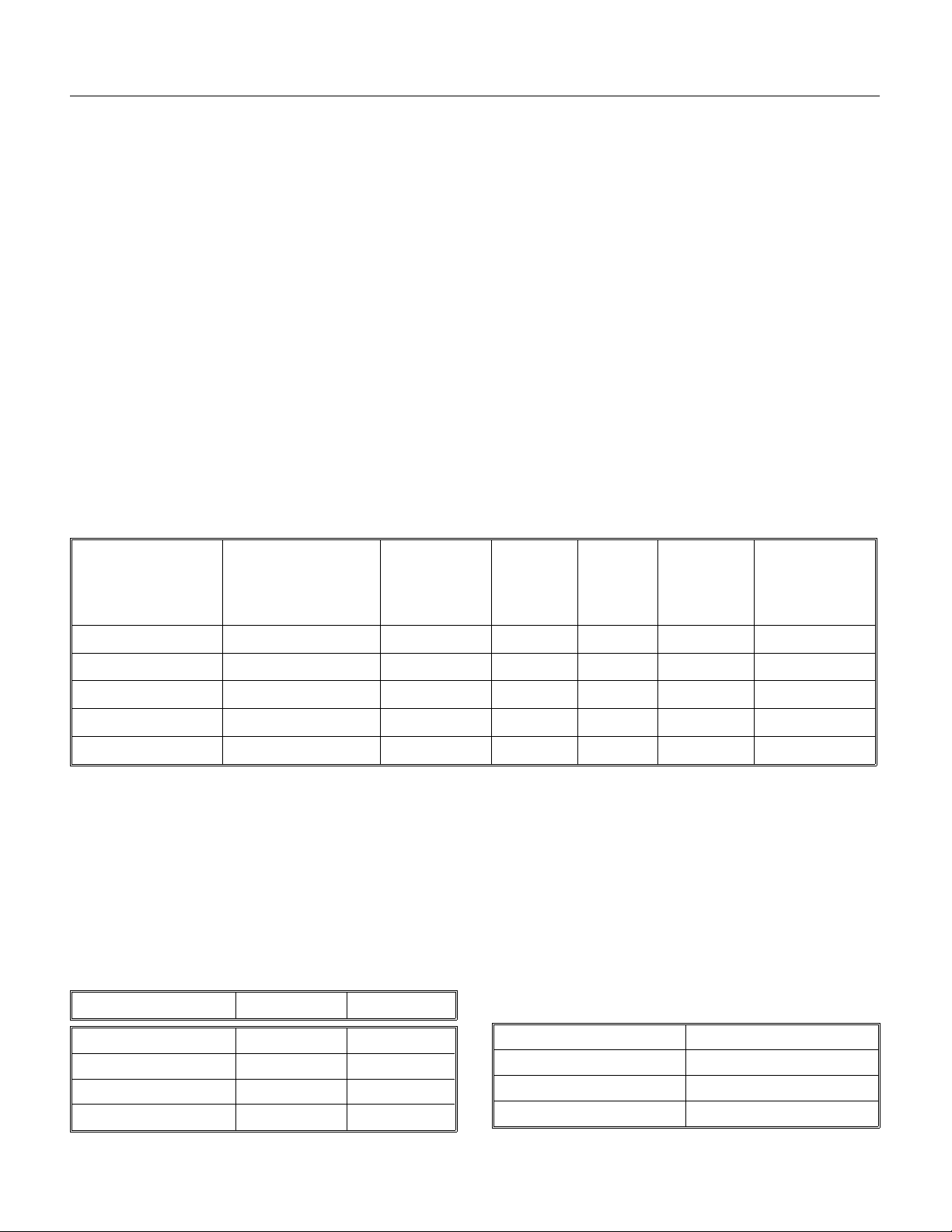

BACK VIEW OF CABINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

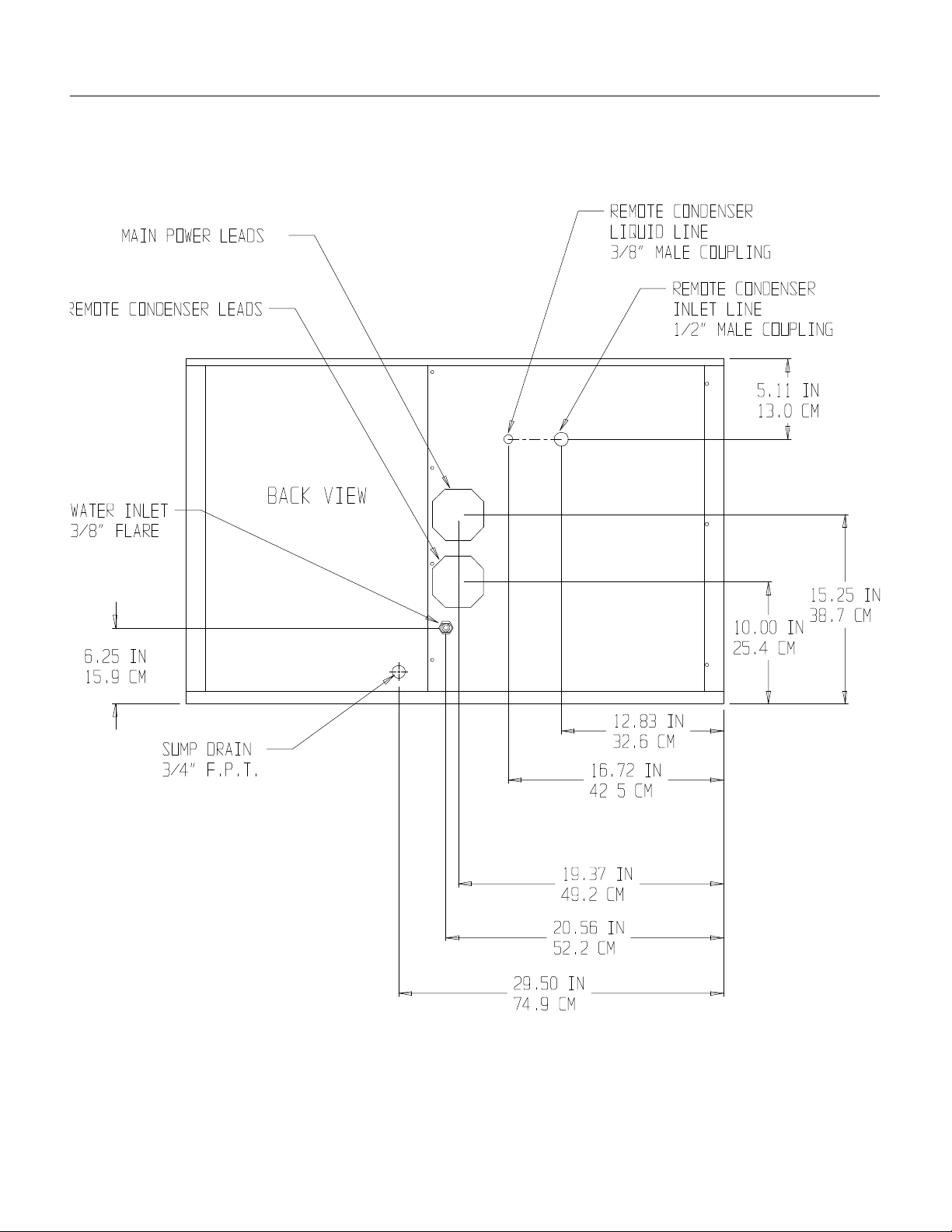

ERC401 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

FOR THE INSTALLER: Location & Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

FOR THE INSTALLER: Location & Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

FOR THE INSTALLER: Scotsman Remote Condenser . . . . . . . . . . . . . . . . . . . . . . page 7

FOR THE INSTALLER: Coupling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

FOR THE ELECTRICIAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

FOR THE PLUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

FINAL CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

INITIAL START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

FREEZING CYCLE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 14

HARVEST CYCLE - HOT GAS BYPASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

COMPONENT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

SYSTEM SPECIFICATIONS: CME1202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 21

SYSTEM SPECIFICATIONS: CME1402 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 22

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

SERVICE DIAGNOSIS: Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 24

SERVICE DIAGNOSIS: Electrical and/or Adjustments . . . . . . . . . . . . . . . . . . . . . . page 25

SERVICE DIAGNOSIS: Refrigeration and/or Mechanical . . . . . . . . . . . . . . . . . . . . . page 26

SERVICE DIAGNOSIS: Bin Ice Level Control . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

REMOVAL AND REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 28

REFRIGERATION SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

LIQUID CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 32

Parts Lists and Wiring Diagrams are located in

the center of this manual, printed on yellow

paper.

This manual was printed on recycled paper.

Keep this manual for future reference.

Note this symbol when it appears in the

manual. It indicates a potential hazard.

January 1995

Page 1

Page 2

CME1202R & CME1402R

FOR THE INSTALLER

These machines will fit the following Scotsman ice

storage bins:

•• BH900

•• BH1000 (with bin top KBT21)

••BH1360

and will stack onto the following ice mach ines:

••CME1402 or CME1202 (use KSCMS4 8)

••MCM1462 or CMS1402B or CMS1202B (with

stacking kit KSCMS48)

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performan ce . They mee t o r exce ed th e

standards of U.L. , N.S.F., and C.U.L.

Scotsman assu mes no liability or res ponsib ility of

any kind for pro ducts manufact ured by Scotsman

that have been altered in any way, including the

use of any parts and /or oth er comp on ents not

specifically approved by Scotsman.

Model Number Dimensi ons

(without bin)

W" x D" x H"

Basic

Electrical

A remo te cond ense r a nd prech arged tubing kit are

required to asse mble this ice syst em.

The normal finish for the machin e is ename l

sandalwood . An op tio na l st ainless ste el p anel kit

(SPKCMS48 ) can be fie ld inst alle d. It cont ain s a

stainless stee l top, lef t sid e panel, an overlay righ t

sid e panel , and front pa nels.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and designs are subject to change

without notice.

Minimum

Circuit

Ampacity*

Maximum

Fuse

Size+

Refrigerant

Charge**

R-404A

Condenser

Type

CME1402RE-3A

CME1402RE-32A

CME1202RE-3A

CME1202RE-32A

CME1202RE-6A

48 x 24

48 x 24

48 x 24

48 x 24

48 x 24

3

⁄8 x 271⁄2

3

⁄8 x 271⁄

3

⁄8 x 271⁄2

3

⁄8 x 271⁄

3

⁄8 x 271⁄

208-230/60/3 15.5 20 336 oz. Remote Air

208-230/60/1 22.9 30 336 oz. Remote Air

2

208-230/60/3 14.4 20 336 oz. Remote Air

208-230/60/1 20.9 30 336 oz. Remote Air

2

230/50/1 336 oz. Remote Air

2

* Minimum Circuit Ampacity is use d to determine wire size an d type per t he Natio nal Ele ctric Code.

+ Or HACR type circuit breakers.

** The unit is shipp ed with the ch arg e in th e rece ive r and, be gin nin g with May 199 6 prod uction, 11 2 o z in

the Scotsman ERC40 1 cond en ser. For re-cha rgin g purpo se s, se e th e table belo w.

Use Scotsman remote condenser RCE1401 or ERC401. Use precharged tubing kit RTE 25 (25’) or R TE4 0

(40").

Note: This refriger ati on sys tem may NOT be conne cte d to a condenser cir cui t that had been use d

in a R-12, R-22 or R-502 system. Doing so wil l voi d the refri ger ati on sys tem warra nty.

This ice system (exc ep t remote conden se r) is designe d to be installe d ind oors, in a controlle d env iro nme nt .

MINIMUM MAXIMUM

Air Temperatu re 500F. 1000F.

Water Temperature 40

0

F. 1000F.

Water Pressure 20 psi 80 psi

Voltage -5% +10%

Charging Table

Condense r Mo de l Total Syst em Charge

ERC401 448 oz

RCE1401 448 oz

MAC 7G 336 oz

June 1996

Page 2

Page 3

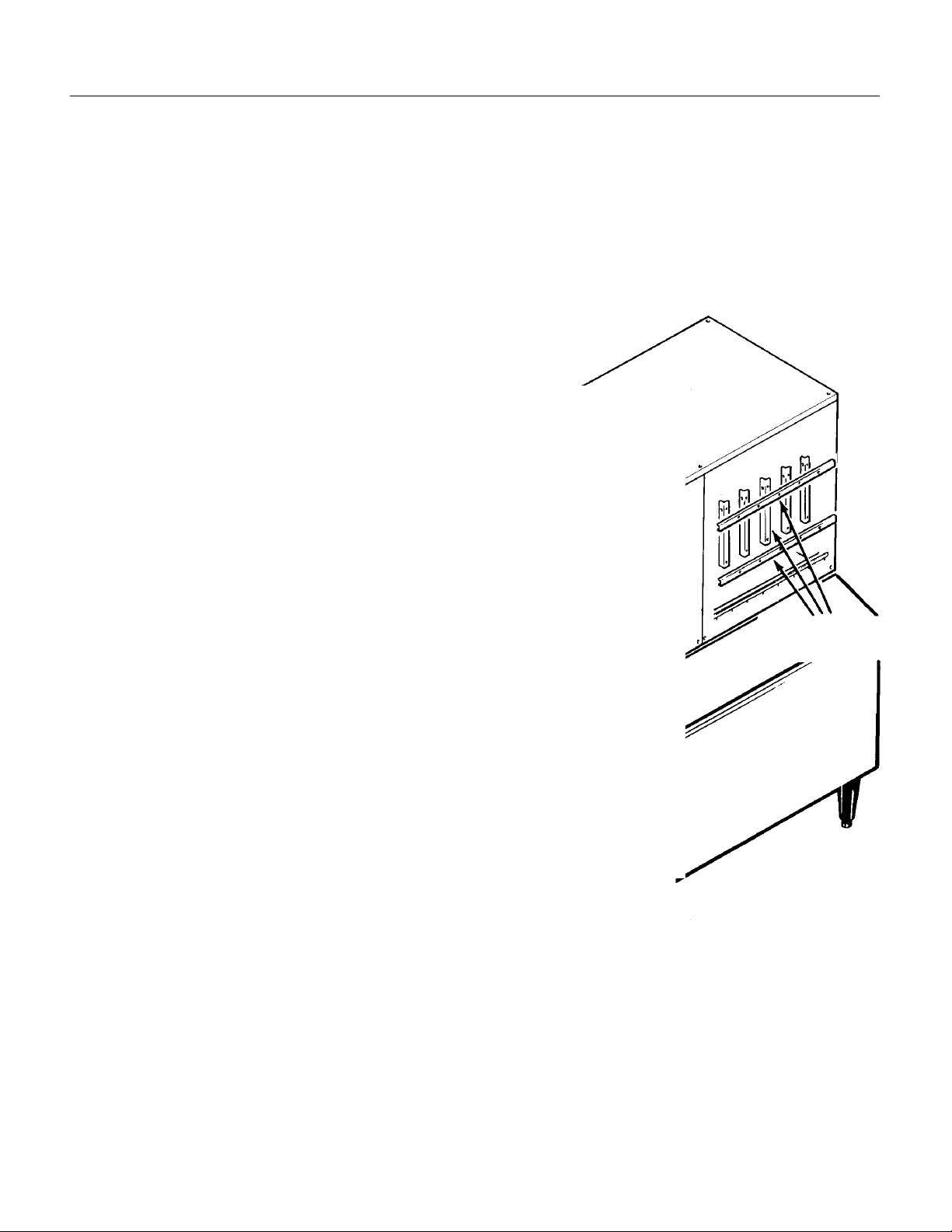

BACK VIEW OF CABINET

CME1202R & CME1402R

June 1996

Page 3

Page 4

CME1202R & CME1402R

ERC401 SPECIFICATI ONS

23 13⁄16"

7

⁄8"

19

ERC Dimensions

ABFG

3

43

⁄8"10

3

⁄

"21

4

3

⁄

"16

4

5

⁄

"

8

June 1996

Page 4

Page 5

CME1202R & CME1402R

FOR THE INSTALLER: Locat ion & Assem bly

Location:

Afte r u ncrat in g and inspe ction , th e unit i s re ady fo r

installat ion . It is important that the machine be

installed in a location where it has enough space

around it to be accessible for service . Try to avoid

hot, dirty and crowded locations. Be sure that the

location for the mach ine is wit hin the

environmental limitations.

Storage Bin:

Tip th e sto rag e bin on its back , usin g par ts of the

carton to prot ect the exterior finish. Inst all th e leg s

packed with the BH90 0. If stacking use a heav y

duty leg kit (KLP6).

1. Arrange for prope r elec tric, water and drain. See

instructio ns for the plumbe r and for the electrician.

2. After mounting the legs pos itio n the ice s to rag e

bin in the sele cte d loc at ion :

Note: Allo w eno ugh sp ac e to th e lef t and back t o

service the machine. Do NOT push the bin into

position, inst ea d, lif t it there . Push ing a bin may

damage th e le g s and leg mo unts.

ICE MACHINE AND BIN ASSEMBLY

Level the bin in bo th the fron t to rear and side to

side directio ns by adjust ing the leg levelers .

3. Inspect the bin top mounting gasket. It must be

flat, with no gaps, to pro vide a good wat er se al

when the cuber is insta lled on top of the bin.

Ice Maker:

Install the mod ula r cube r on top of the bin using

care to be sure a good se al is made betwee n th e

two cabinets. Use of a mechanic al lift is

recommended . Alig n the hole s in t he bott om re ar

of the cabine t to mate wi t h the two mo untin g holes

on the top rear of the bin.

Use bolts and straps found on the back of the ice

machine to secu re th e ice mac hin e to the bin.

When alignme nt and levelin g are comp let ed,

tighten the bolts to secure the mounting straps.

Remove the front panel, and remove the

evaporator shipping brackets and hardwa re .

Remote Condenser:

A new condenser coil designed for the machine’s

capacity MUST be used. Because of the possibilit y

of mineral oil contamination, coils and line sets

that had been connect ed to R-12 , R-50 2 or R-22

units MAY NOT BE CONNECTED TO THIS

SYSTEM. Doing so voids the refrig era tio n syst em

warranty.

June 1996

SHIPPING

BRACKETS

Page 5

Page 6

CME1202R & CME1402R

FOR THE INSTALLER: Locat ion & Assem bly

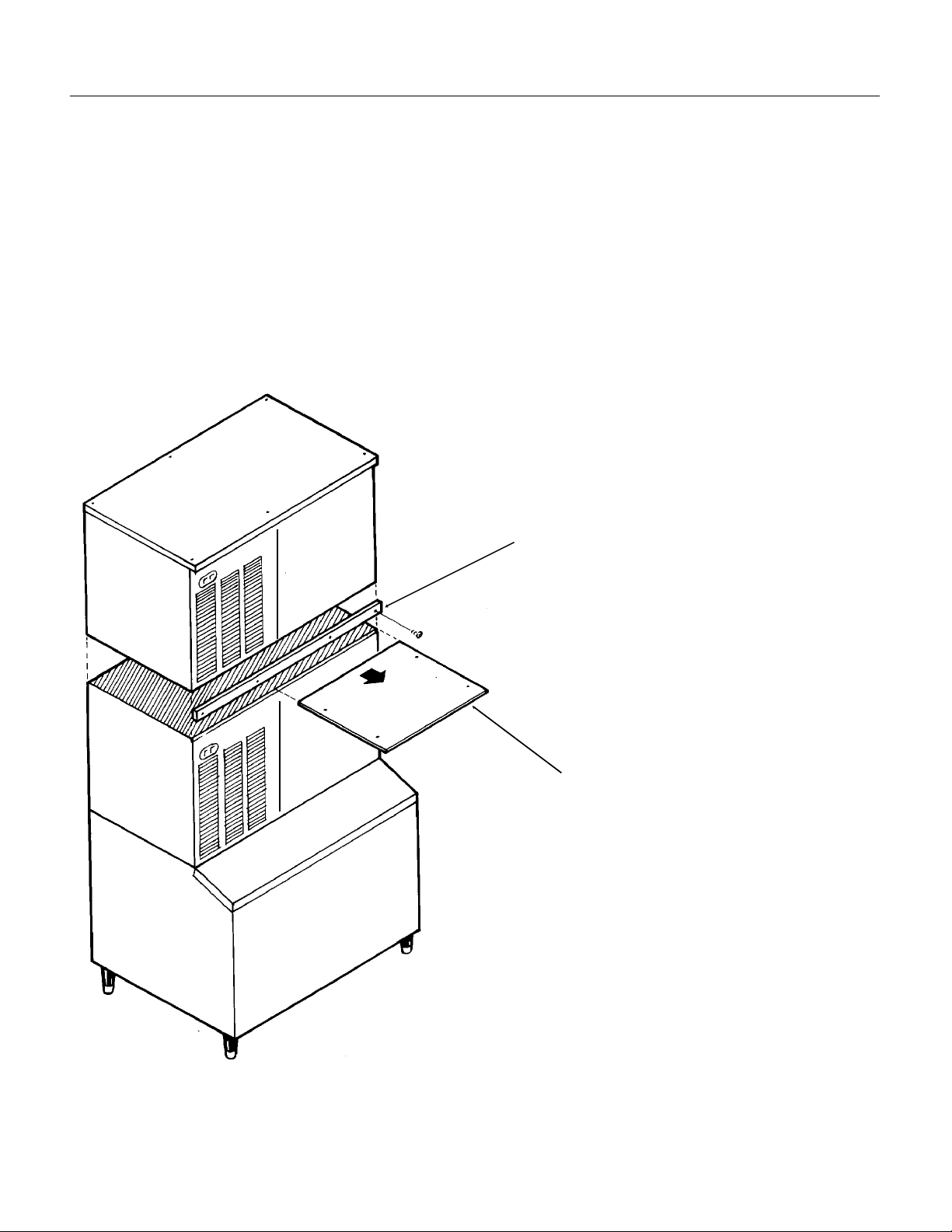

Stacking Instructions

A sta ckin g kit , KSCMS4 8, is require d to

interconne ct th e ice level co nt rols, seal the

freezing compartments, support the bin with heavy

duty legs, and retain the front panels.

Follow the installation instruc tions of the stackin g

kit, but in general:

Replace the orig ina l bin leg s wit h heav y duty leg s

(KLP6).

When stackin g two units, re move the top panel

and the evaporator cove r from th e lower ice make r.

STACKING

(The top removed from the lower ice make r will no

longer have any function.)

Add a strip of gasket (from the sta ckin g kit) to the

top edge of the bott om ice machines evap ora to r

compartment.

Install the pane l retainin g bra cke t onto the botto m

ice machine befo re pla cin g th e upper unit on it.

Place additio na l gask et ont o the top ed ges of th e

bottom ice machin e.

Carefully lift the uncra ted top unit onto the botto m

one and align the two cab ine ts. Use of a

mechanical lift is recommended for this step.

At the back of the two ice mak ers, bolt the upper

ice maker cabin et to the lowe r ic e maker cab ine t

using the moun tin g st rap s and bolt s fro m the

hardware package.

Add the relay kit to int erco nnec t th e two ice

machine’ s bin contro l circ uit s.

STAINLESS STEEL PANEL

RETAINING BRACKET

June 1996

Page 6

EVAPORATO R COV ER

Page 7

CME1202R & CME1402R

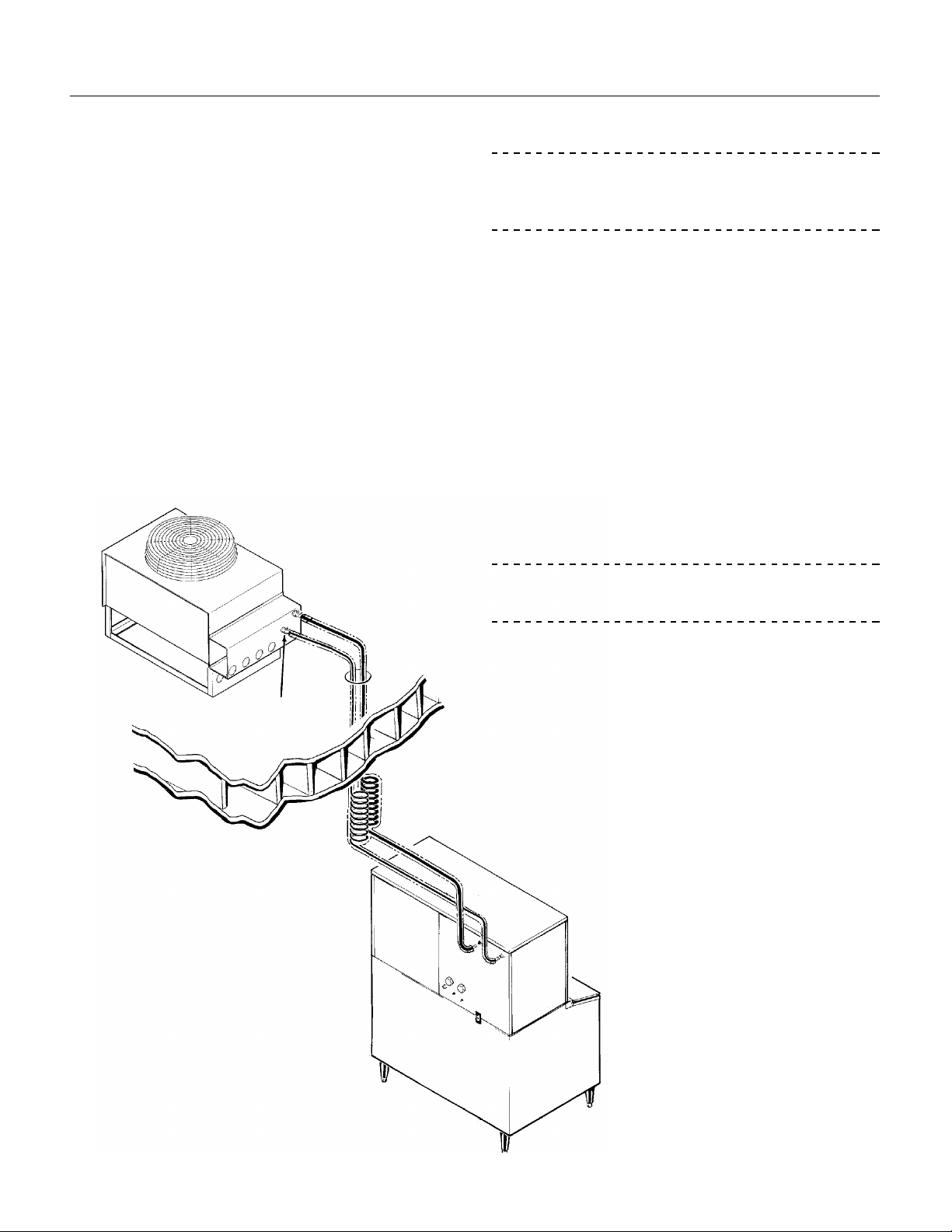

FOR THE INSTALLER: Scots man Remot e Condenser

Locate the condenser as near as possible to the

interior location of the ice maker.

Location of the condenser is limited by the specific

length of prec harge d ref rige ran t tu bin g supplied for

the application. The pre-charged tubing connects

the ice maker to the remot e co ndense r. The

condenser mus t be above the ice maker.

Select the be st av aila ble locat ion, protecting the

condenser from ext reme s of dirt , dust , and sun.

Meet all applicable bu ildin g codes.

Roof Attachment:

Install and atta ch th e remo te con dense r unit to the

roof of the build ing , us ing the meth ods and

practices of const ruct ion that co nform to the local

building code s, inc lud ing havin g a roofin g

contractor se cure the condense r to the roo f.

Precharged Line Routing

CAUTION

Do not connect prec harge d tubin g until all rou tin g

and forming of the tubin g is complet e. See the

coupling instructions for connecting instructions.

1. Each set of prech arg ed refrig era nt lines co nsis ts

of a 3/8 inch diameter liquid line, and a 1/2 inch

diameter discharge line. Both ends of each line

have quick connec t couplin gs , th e end withou t

access valves goes to the ic e make r.

Note: The openings in the buildin g ce iling or wall,

listed in the next step, are the minimum sizes

recommended for passin g the ref rige ran t line s

through .

2. Have the roofing contracto r cut a minimum hole

for the refrigerant lines of 1.75". Check local

codes, a separat e hole may be requ ired for the

electrical power to the condense r.

CAUTION

REFRIGERANT

CONNECTIONS

LOCATE CONDENSER

NO LOWER THAN ICE

MACHINE

DO NOT KINK OR CRIMP REFRI GE RANT

TUBING WHEN INSTA LLING IT.

3. Route the refrige rant lines throu gh the roof

opening.

Follow straight line routing whenever possible.

Any excess tubing MUST be reta ine d with in the

building.

4. Spiral any excess length of pre charge d tu bin g

inside the building. Use a horizontal spiral to

avoid any tra ps in the lines.

Note: Spiral nee d not be as

tight as illustrated.

5. Have the roofing contractor

seal the holes in th e roof pe r

local cod es .

TYPICAL

INSTALL AT ION

June 1996

Page 7

Page 8

CME1202R & CME1402R

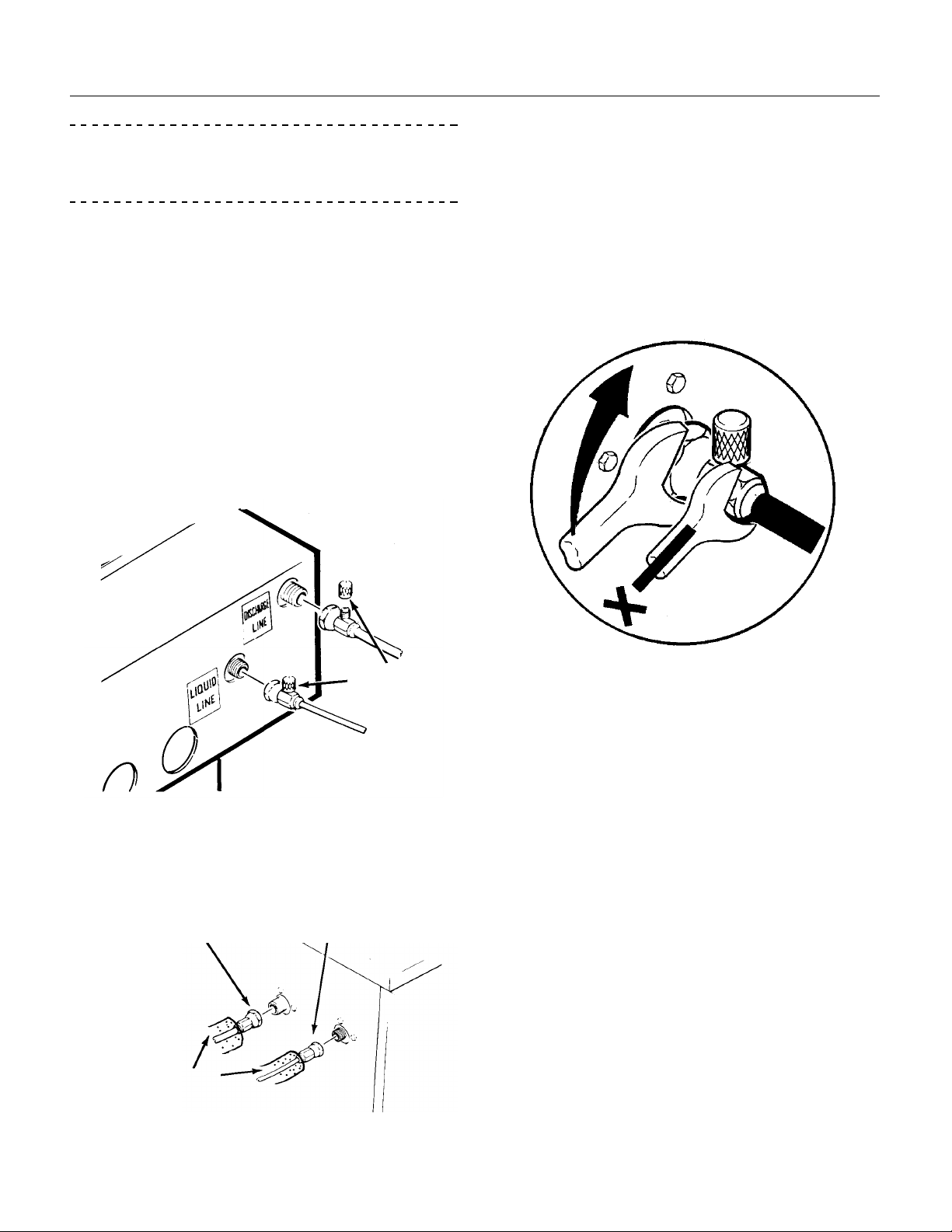

FOR THE INSTALLER: Coupling Ins truc tions

CAUTION

The couplin gs on the set s of pre ch arg ed lines are

self sealing when inst alle d pro pe rl y. Carefully

follow the instructions:

Initial Connec tions :

1. Remove the protector caps and plugs. Wipe the

seats and threaded surfaces with a clean cloth to

be certain that no fore ign matt er remains on them.

2. Lubricate the inside of the cou plin gs, especia l ly

the O-Rings with refrige rant oil.

••The 1/2 inch discharge line (schrader valve

end) goes to the remote condense r fitt ing

marked “discharge line”.

••The 3/8 inch liquid line (sch rad er valv e end)

goes to the remote con dense r fitt ing marke d

“liquid line”.

Final Connections :

3. Begin tighte ning the coup ling s tog et her by

hand, then using two wrench es (it is importa nt that

ONLY the nut on the precharged lines be turned,

the other parts of the coupling s must NO T be

allowed to turn or the proce ss will tear out the

diaphragms and they will be loose in the

refrigeration system) tighten the coupling until it

bottoms out or a definite increase in resistance is

felt.

TIGHTENING THE QUICK CONNECTS

SCHRADER

VALVES

••The 1/2 inch discharge line goes to the ice

maker fittin g mark ed “disch arg e line”.

••The 3/8 inch liquid line goes to the ice make r

fitting marked “liquid line.”

LIQUID LINEDISCHARGE LINE

INSULATION

4. Using a marker or pen, mark a line lengthwise

from the couplin g union nut to the bulkhea d. Then

tighten th e co up ling and ad dit ional 1/4 turn . As the

nut turns, the line will show when 1/4 turn is made.

5. After all connectio ns are ma de, and aft er t he

king valve has been open ed, ch eck the coupling s

for leaks.

June 1996

Page 8

Page 9

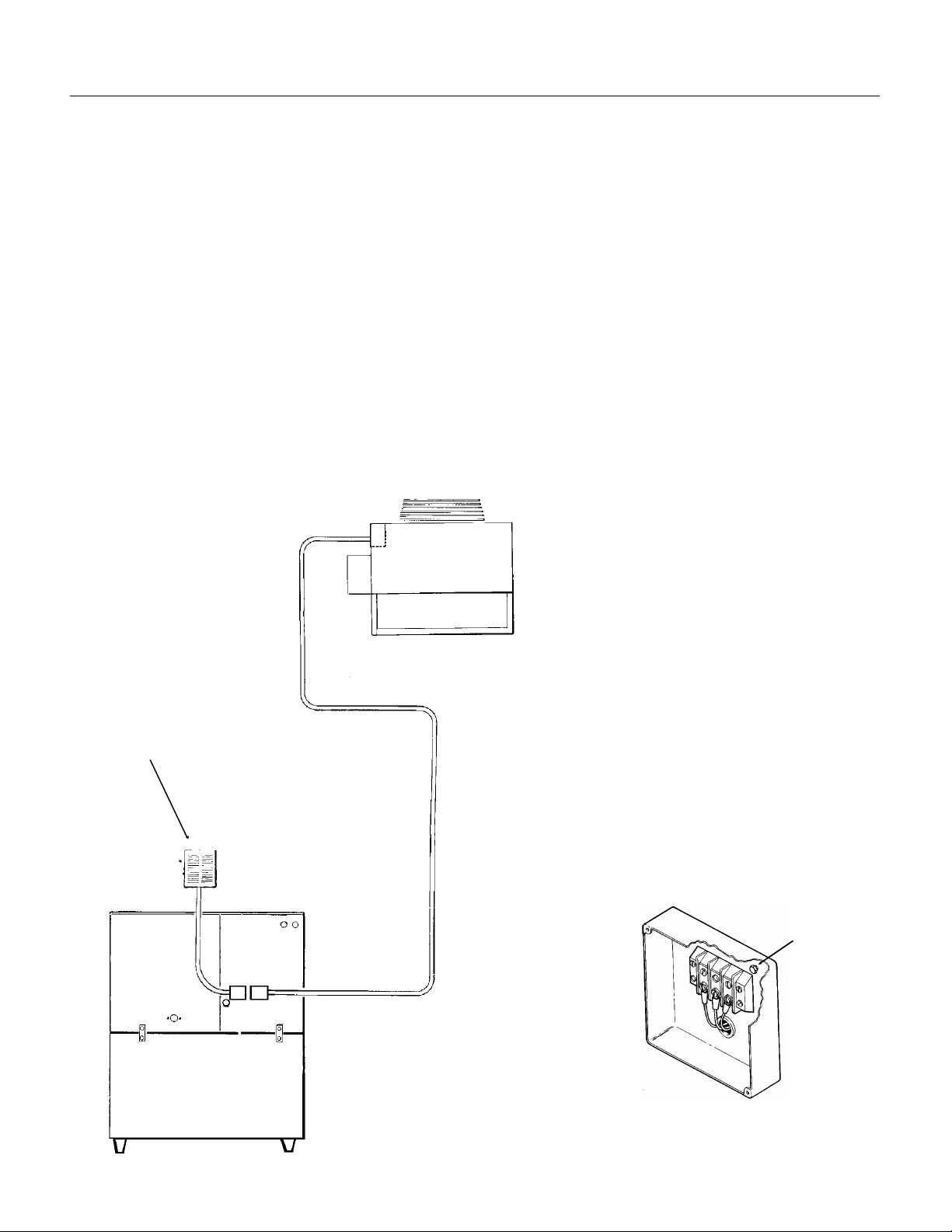

FOR THE ELECTRICIAN

DETAIL OF JUNCTION BOX, 3 PHASE SHOWN

CME1202R & CME1402R

See the ice machine namep lat e fo r curre nt

requirements to determine wire and fuse size to be

used for electrical hookup. When the cuber and

the remote conde nse r are co nnect ed , each must

be grounded to the other usin g the gro un d screw s

provided in the respe ct ive ju nction bo xes . The

cuber then requires a solid chassis to chassis

earth ground wire. See Wiring Diagram.

Be certain the cuber is connected to its own

electrical circuit and individ ually fus ed. Voltage

variation should no t exceed ten perce nt of the

nameplate rat ing , even under sta rtin g cond itio ns.

Low voltages can cause erratic ope rat ion and may

be responsible for seriou s dama ge to the ice

maker.

FOLLOW ALL APP LICABLE CO DES

ELECTRICAL CONNECTIONS

The Scotsma n remote con dense r is designe d to

be powered from the ice machin e. The re is a

separate electrical junctio n box at the back of the

ice maker for the remot e conden ser. Wire the

remote condense r to the ice maker in ac cord ance

with local and natio na l elect ric co de s. All ou tdoo r

wiring must be in rain proo f condu it.

Note: If connecting to another UL listed remote

condenser, follow the instuctions provided with that

product for electrical connect ions.

The condenser fan motor will run whenever the

compressor is running.

Electrical conn ection s are made at the rear of the

ice maker, inside the junction box.

All external wiring should conform to the national,

state and local electrical cod e require ments.

Usually an electrical permit and services of a

licensed electrician will be required .

HAND

DISCONNECT

SWITCH

POWE R

SUPPLY

INTERCONNECTING

WIRES

GROUND

SCREW

REMOTE CONNECTIO N

June 1996

Page 9

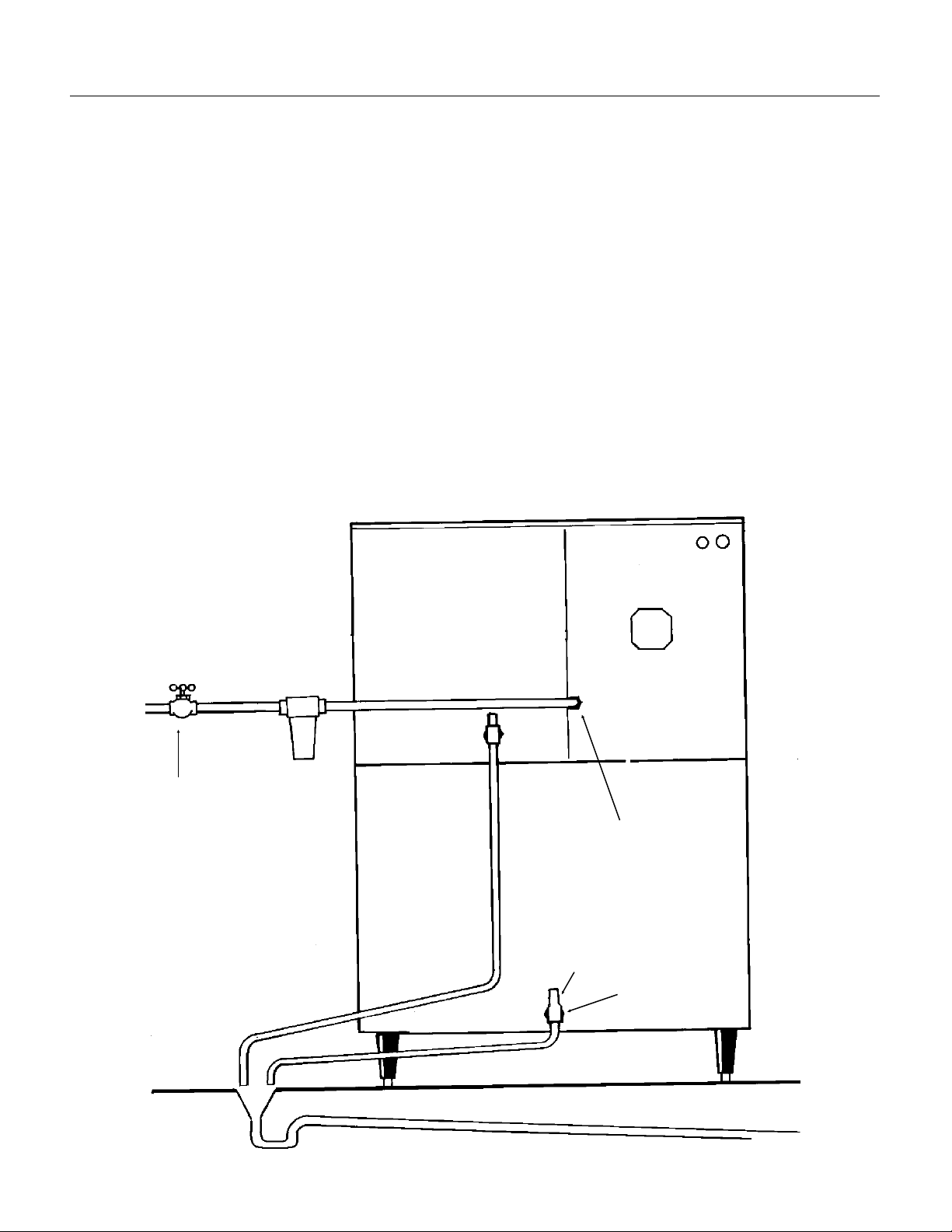

Page 10

HAND

SHUT OFF

VALVE

CME1202R & CME1402R

FOR THE PLUMBER

The recommended wat er supply line is a 3/8-inch

O.D. copper tubin g with a minimum opera tin g

pressure of 20 PSIG and a maximum of 80 PSIG.

Connect to cold wate r sup ply line with st anda rd

plumbing fit tin gs , with shut off valve insta lled in an

accessible plac e betwe en the wate r supply an d

the cuber. In some cases a plumber will be

required.

Water Limitations:

An ice machine is a food manuf act urin g pla nt , it

takes in a raw material, wate r, and turns it int o a

food product, ice. The purity of the water is very

important in obtaining pure ice and in maximizing

product life. It is generally bett er to filter the water,

although there is no one filter that will cure all

water prob lems. A good filt er co mbin ed with a

polyphosph at e fe eder gives about th e best overa l l

performance .

DRAIN

Connect ion s: A ll drain s are gravit y ty pe an d must

have a minimum of 1/4-inch fall per foot on

horizontal run s. The drain s to be insta lled to

conform with the local plu mbin g code. In stall a

vertical open ve nt on drain line high poin t to insure

good draining . The ideal drain receptac le is a

trapped and ven ted flo or dra in. Recommended bin

drain is 3/4 inch O.D. RIGI D tub ing and sho uld be

vented and run separately. Insulation for high

humidity areas is reco mmen ded.

The ice machine sump drain is 3/4" FPT. There

mus t be a ve nt at th i s con nect io n fo r p roper su m p

draining. Reco mmen ded dra in is 3/4 inch O.D.

RIGI D tu b in g and sh ou l d be run sep a ratel y.

Insulation for high humidity areas is

recommended .

POTABLE

WATER

SUPPLY

AIR GAP BETWEEN

DRAIN LINES AND

BUILDING DRAIN

SUMP DRAIN MUST

BE VENTED

3/4" FPT

OPTIONAL

FIL T ER

3/8" MALE FLARE

VENT

BIN

DRAIN

WATER SUPPLY AND DRAIN CONNECT ION

June 1996

Page 10

Page 11

FINAL CHECK LIST

OPTIONAL

FILTER

1. Is the cabinet in a roo m where ambie nt

temperatures are within the minimum and

maximum temperat ures spe cifie d?

2. Is there clearance at the left and back sides of

the cabinet for serv ice ac ces s?

3. Has water supply pressure bee n checke d to

insure a minimum of 20 PSIG and a maximum of

80 PSIG opera tin g pre ssure?

4. Is the cabinet level?

5. Check that any ship ping material has been

removed from inside the

cabinet.

6. Check that the reservoir is

properly secured to the bottom

of the evaporator plates.

7. Have all electrica l, wat er an d

drain conn ect ions been

properly made?

CME1202R & CME1402R

FINAL INSTAL L AT ION

8. Is the water supply line shut

off valve inst alle d and elect rical

wiring properly connected?

9. Check all refrigerant lines

and conduit lines, to guard

against vibration or rubbing and

possible failure .

10. Have the bin and cabinet

been wiped clean?

1 1 . Has the Manuf actu rers

Registration form been properly

filled out? Check for correct

model and serial numbers from

Serial nameplate, then mail to

the SCOTSMAN fac tor y.

12. Has the owner/u ser been

given the Service Manual and

instructe d how to op era te and

maintain the ice maker?

13. Has the owne r bee n given

the na m e and teleph on e

number of the authorized

SCOTSMAN Service Agency

serving him?

PRECHARGED

LINES

CONNECTED

LEVEL

ASSEMBLY

SUMP DRAIN

HAND SHUT

OFF VALVE

BIN DRAIN

June 1996

Page 11

Page 12

TIMER

CME1202R & CME1402R

INITIAL STA RT UP

Before Start Up:

1. Check that both the ICE-OFF-WASH rocker

switch and the COMPRESSOR ON-OFF toggle

switch are in the OFF position.

2. Switch on the electrical power. Electrical power

must be supplied to the ice machin e for 4 hour s

before start ing the compresso r for th e first time .

The crankcase heater will now heat the

compressor’s oil. The oil is warmed to evaporate

any refrige ran t that may hav e colle ct ed in it. If

there is refrigerant in the oil when the compressor

starts, the oil will foam and will not lubrica te the

compressor properly, shortening its life.

Do NOT start the compressor for the first time

unless the dome of the compressor is warm.

Start Up

1. Remove front panels by removin g scre ws at the

base and pulling out.

2. Remove two screws and the cont rol box cove r.

3. OPEN the water supply line shut off valve.

FRONT VIEW OF T IME R

ACTUATOR

BUTTON

CAM

FREEZE

PORTION

MICROSWI TCH

HARVEST

PORTI ON

4. Open the “king” valve on the receiv er.

5. Inside the control box is the shaft of the timer

and switch assembly. Rotate the shaft of the timer

clockwise until the ac tuator arm on t he microswitch

drops off outer cam int o cam slo t. See “Front Vie w

of Timer”.

6. Move the ICE-OFF-WASH to the ICE position.

7. Check the water fill cycle: For several minutes

the inlet water valve will be open and water will

flow into the reservoir. Near the end of the fill cycle

water should be drain ing thru the reserv oir dra in. If

at the end of the fill cycle the reservoir is not full,

rep ea t step 5.

Check that the sump covers are snapped in place.

Check that the wate r dist ribu to rs are pro per ly

seated at the top of the evaporators and that water

is flowing over all cube cells.

Note: Some water spray from the evaporators is

normal when the machine is new . The spray will

quit after a few cycles.

CONTROL BOX

CUBE SIZE

CONTROL

8. When the sump has filled, move the co mpre sso r

ON-OFF toggle switch, to the ON position.

ICE/OFF/WASH

BIN ICE LEVEL SWITC H

June 1996

Page 12

Page 13

INITIAL STA RT UP

CAMS

ADJUSTMENT

OF THE TIMER

9. Check operation of the freez ing cycle: Ice will

begin to form from the top of the evaporators

down. After t he first cycle, freezing time will ran ge

between 12 and 15 minutes. Longer time for

temperatures above 70

required whe n temperatures are below 70

Average co mple te cycle time is about 14 minutes.

10. After a n ice harvest, check Cube Size.

o

F. and shorter time

o

F.

CME1202R & CME1402R

CUBE SIZE DIAGRAM

JUST RIGHT

There is just enoug h water av ailable in the

reservoi r to ma ke one fu ll sized batch of cubes . A s

the water level drops, the water pump may pick up

some air at the end of the freezin g cyc le so so me

bubbles in the pump discharge hose at the end of

freeze is normal. If the water pump runs out of

water before th e end of free ze , th e cube size

control may be set too cold, or the water syst em

may be leaking water.

Compare cube size to the "Cube Size Diagra m "

To adjust the cube size, loca te cube size control in

the front of the cont rol box, and rot at e the

adjustment screw on e eight h of a turn:

••COUNTER Clockwise for SMALLER ice cubes

••Clockwise for LARGER ice cubes

Observe size of the ice in the next ice cube

harvest and repeat adjustme nt until correc t ice

cube is achieved.

11. Check Harvest Time. There must be eno ug h

time in harvest to defro st all the cubes bu t not an

excessive amount that will wast e capa city. The

length of the harvest cycle is determine d by the

timer cam positions.

If needed, adjust the harvest time so t here are

about 15 seconds of harve st time lef t afte r the last

cube has fallen from the evapora to rs.

Because harvest time varies with the wate r and air

temperat ure s at the ice mach ine , cold er air an d

water will result in faste r ice making but require

longer harvest cycles. Do NOT adjust harvest

time too short or the unit will not harvest all the

ice.

The harvest time is set by: loosening the set scre w

on the cam, ro tating the shaft to open or close the

distance bet wee n the hig h part of the cams, and re

tightening the set screw. More of an opening

between the cams hig h areas =more harv est time.

An adjust men t of the cube size may be needed

after the harvest time has be en changed, so check

the cube size again.

When the cubes are the correct size, they will be

connected toget her verti call y, and drop off in strips.

The batch weight wil l be about 13.5 to 14.5 lb.

Note: if the cubes at the bottom rows of some

evaporators are smaller than oth ers, the size di fferen ce

does not affect capacity or perf orman ce. However, the re

should be ice in all cells. If not, contact the Factory.

TOO SMALL

SET

SCREW

12. Check Bin Ice Level Control. When the unit is

in the harvest cyc le, place something solid against

the transducer so cke t (loca te d in the base to the

left of the evaporators). The machine will switc h off

at the END OF THE HARVEST CYCL E, and will

restart whe n the object is remov ed . The control

has a Full and a Partial positio n. At Full, the

machine will switch off when ice is 8" from the

transducer socke t. The control will not work on

bins taller than 8’. Note: Even when full the unit will

make a batch of ice if switched off and then on.

13. Replace all covers, panels and screws.

14. Fill out the Warra nty Reg istra tio n and

Customer Evalua tio n form. Ex plain to the user the

maintenanc e req uire men ts of the ice mach ine .

Info r m t he us e r o f the name an d te l ephone

number of the local SCO TSMA N Distribu to r or

service agency.

June 1996

Page 13

Page 14

RESERVOIR

CME1202R & CME1402R

FREEZING CYCLE OPERA TI ON

Water from th e sump ass embly is pumped to the

water distrib ut or syst em at the top of each

evaporator plate. From the water distributor the

water casca des by gra vity over all ce lls of the plate

and to the sump assembly be low.

At the beginning of t he freezing cycle, the electrical

circuit is complet ed to the compre sso r and the

water pump. The water pump operates

continu ously, through both the fre ez ing cycle an d

the harvest cyc le.

During the freez ing cycle, the hot gas solen oid

valve is CLOSE D and the wate r inlet solen oid

valve is CLOSED. When the ice cubes are partial ly

formed, the cube size control will sense the

temperature at whic h it is preset to CLOS E. This

will complete the electrical circuit to the timer. The

timer then controls th e remaind er of the free zin g

cycle. The timer will keep the ice make r opera tin g

in the freezing cycle fo r a sele cted length of time.

This will give the ice cubes time to fully form. after

that selected length of time, the timer will switch

the ice maker into the harve st cycle, through the

contacts of the timer assembly microswitch.

Low Temperature Freeze :

When the outside air te mpe rat ure is low, the Head

Pressure Reg ulato r will close of f the liqu id line to

the receiver, causing liqu id ref rige ran t to back up

into the condenser until th e head pressure builds

up to 240 PSIG. While this is occurring, the head

pressure regu lat or pa sse s disc ha rge gas int o the

receiver to keep the refrigerant flowing.

WATER DISTRIBUTION

INLET

WATER

VALVE

DRAIN

WATER SCHEMATIC

REFRIGERATION SCHEMATIC

June 1996

Page 14

Page 15

HARVEST CYCLE - HOT GAS BYPASS

RESERVOIR

CME1202R & CME1402R

When the timer switches the ice maker int o the

harvest cyc le, high press ure , hig h tempe rature gas

refrigeran t being disch arg ed from th e compre sso r

is diverted fro m the conde nse r thro ug h the hot ga s

solenoid valve into each evaporator plate. During

this cycle, the ref rige ran t bypa sse s the con dense r.

In the electrical circuit, both the compressor and

the water pump are operating and the hot gas

solenoid valve is energized and OPEN and the

water inlet so len oid valve is OPEN.

The finished ice cube s are rele ased from the side s

of each evaporator plate by the warming eff ec t of

the hot gas condensing in each evaporator plate

and the water casca ding over the ice cu bes. The

released ice cub es dro p int o the ice stora ge bin

below . At the end of the harvest cycle , the time r

cam will push the actuator arm to the microswitch

IN. If the ice level control is s till CLO SED, a whole

new cycle will begin. If the ice level control is

OPEN, the ice maker will begin to shut OFF.

Pump Down Cycle:

When the ice level contro l is open at the end of the

harvest cycle, power is removed fro m the liquid

line valve coil, and the pump down cycle begins.

The compressor will continu e to run until the pump

down control, sensing low side pre ssu re, opens at

15 PSIG.

WATER

DISTRIBUTION

INLET

WATER

VALVE

DRAIN

WATER SCHEMATIC

REFRIGERATION SCHEM ATI C

June 1996

Page 15

Page 16

CME1202R & CME1402R

COMPONENT DES CRIP TIO N

Cube Size Control

This reverse acting thermos ta t contro ls the length

of the freezing cycle. It is sensing the temperature

of the suction line. Whe n the suction line gets cold

enough, the cu be size con tro l closes (on

temperature fa ll) and starts the timer. A ch ange in

either ambient air or incoming water temperature

will affe ct the efficiency of the refriger ation system,

and this will vary the length of time it takes the

evaporator to reach the temperat ure at which the

cube size control is prese t to close . See CUBE

SIZE ADJUSTMENT BE FORE at tempt ing to adju st

the control.

Relay

The multi-function, three pole, double throw,

plug-in relay is insta lled direct ly int o a recept acle

on the printed circuit board in th e control b ox. The

relay funct ion s in pa rt to by-pa ss th e bin

thermost at cont rol to prev ent th e ice maker from

shutting OFF, when the bin thermostat opens

during the freezing cycle. The bypass action

serves to ensure full-s ized ice cubes with each

harvest cycle.

Timer - Ti me r & Swi tch As se mbly

The function of the time r beg ins whe n activa te d by

the cube size contro l. The outer su rfa ce , or la rge

diameter lobe of the timer cam, dete rmine s the

timer cycle for fin ish fre ez ing of the ice cube s,

while the inner surface , or sma ll diame ter lobe ,

determines the time cycle for the harvest cycle .

When the microswitch button is pushed in there is

power connected to the coil of the rela y, and the

unit is in the freeze cycle. When the microswit ch

button is released, the power to the relay is

stopped, and the unit goes into harvest. The

microswitch is actuated by a cam assembly

directly co nnected to the timer motor.

One complete rotation of the cam will take eight

minutes. Harvest is preset at three and one half

minutes, but is adjustable.

High Pressure Safe ty Control

This is a manual reset contro l that sh uts down the

ice maker, should the discharge pressure ever

reach 450 PSIG. Locate d below the co ntrol bo x.

Low Pressure Control (Pump Down)

CONTROL BOX

This pressure cont rol conn ects po wer to the

compresso r cont acto r coil. It s Cut In is 35 PSIG

and its Cut Out is 15 PSIG. Locate d below the

control box.

CUBE

SIZE

CONTROL

RELAY

TIMER &

SWITCH

June 1996

Hi Pressure

Reset, Push

to Reset

Page 16

Page 17

COMPONENT DES CRIP TIO N

Bin Level Control

CME1202R & CME1402R

This electronic control uses sound waves to

measure th e distan ce betwee n th e bott om of the

ice machine and th e top of the ic e in the bin . It is

designed to cont rol th e machine’s ice production to

maintain that distan ce.

The contro l is adjusta ble so that th e ice machin e

will maintain a certain height of ice. When set at

FULL it will not allow the machin e to fill the bin any

closer to the ice machine than about 8", and it will

not work if the distance to the bottom of the bin is

greater than 8 feet.

BIN ICE LEVEL

SELECTO R

SWITC H

ICE/OFF /WASH SWIT CH

Because it uses sou nd waves , a sligh t “ticking”

sound can be heard comin g from t he botto m of the

machine.

There are thre e parts to th e con t rol, the

transducer, the circuit board, and the ice level

control switch.

THE USER CAN SELECT THE

AMOUNT OF ICE TO BE

MAINTAINED IN THE BIN.

SOUND WAVES

June 1996

Page 17

FULL

PARTIAL

Page 18

WATER

DISTRIBUTO RS

CME1202R & CME1402R

COMPONENT DES CRIP TIO N

Water Inlet Solenoid Valve

The water inlet soleno id valv e fills the sump

assembly with water and exce ss wat er overflo w s

out the standp ipe and down the drain . Th is act ion

fills and rinses the sump during each harvest

cycle. The flow rat e is 1 g.p.m.

Water Distribution System

The water distribu tio n syst em ev enly sup plie s

water to all cells of the evapo rat or p lat es. The

water pump pumps water f rom the sump up the

vertical tygon tube to the tee. From the r e water is

channeled through the water manifold to the water

distributors, above each evaporator plate, and

from six holes with in each dis trib ut or, water flows

to the cells of each side of the evap ora to r plat es.

Gravity flow ret urn s th e unfro zen excess po rtio n of

water to the sump reserv oir fo r recircu lat ion .

Hot Gas Solenoid Valve

The hot gas solenoid valve functions only during

the harvest cyc le, to dive rt the hot discharge gas

from the compressor, by passing the condenser,

for direct flow in the evaporator plates to release

ice cubes fro m the ice cub e molds. The hot gas

solenoid valve is installed in a branch of the

discharge line. When the harvest cycle begins the

energize d soleno id co il lif ts th e valve stem within

the valve body, to cause the hot disch arg e gas to

be diverted to the evaporators.

SUMP STAND PIPE

OPTIONAL

WATER FILTE R

HAND

VALVE

PUMP

COMPONENT LOCATION

SUMP

DRAIN CAP

June 1996

Page 18

Page 19

CME1202R & CME1402R

CLEANING

A Scotsman Ice Syst em rep rese nt s a siza ble inves tme nt of time and money in any compa ny ’s bus ine ss. In

order to receive th e best retu rn for tha t inve st men t, it MUST receiv e period ic maintenance.

Maintenance and Cleaning should be scheduled at a minimum of twi ce per year.

CLEANING: ICE MAKER

1. Remove screws and the front panel.

2. Switch the compressor swit ch to OFF. Switch

the ICE-OFF-WASH rocke r switch to OFF.

3. Remove the control box cover, and rotate the

shaft of the timer and switch assembly

CLOCKWISE advanc ing to the freezin g cyc le.

(Beginning of the high er par t of the cam ag ain st

the microswitch).

4. Open the ice stora ge bin do or and dis card all

the ice.

5. Remove the hose cla mp, rubber cap and drain

all the water from the sump assembly into the bin.

Replace the rubber cap and hose clamp.

6. Mix 24 ounces of Scotsman Ice Machine

Cleaner with 2 gallons of warm (95

water.

7. Pour the clea nin g solu tio n into th e reservoir until

full.

8. Move the master switch to the W ASH po sit ion.

9. Let th e unit operate for 30 minutes.

During the wash cycle, if the mac hine run s out of

solution , mix 2 more ga llon s of solution per step 6,

refill the sump and continue the wash cycle for th e

remainder of the 30 minute s.

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Giv e

large amounts of wat er

or milk. Call Physician

immediately. In case of

external contact, flush

with water.

KEEP OUT OF THE

REACH OF CHILDREN.

0

F. - 1150F.)

10. Move the ICE-OFF-WASH switch to the OFF

(center) positio n.

11. Remove the cap and drain th e clea nin g

solution from th e sump. Rep lac e th e drain cap .

12. Rotate the shaft of the timer and switch

assembly CLO CKWIS E to the harv est pos itio n

(low part of the cam against microswitch). Move

the ICE-OFF-WAS H switch to the ICE position to

start the Harvest cycle.

If after completing this proce dure one or more

evaporator plates does not have a full flow of water

for each vertica l column of cube s, sh ut down the

operation and remo ve and clean all wate r

distributor manifolds. Reinstall the water distributor

manifolds.

Note: The ice making portion of the water system

should b e sanitized after cleaning by repeating

steps 2-12 and substitutin g a sanitizing solution for

the cleaning solution.

13. Move the compressor swit ch to the ON

position to start th e ice making proc ess .

CAUTION

DO NOT use ice produced from the cleani ng

solution. Be sure none remains in the bin.

14. Check the next ice cub e harves t to be certain

that the ice cubes are clear and the acid taste is

gone.

15. Add hot wat er to th e bin to melt t he ice.

16. Replace all pane ls.

June 1996

Page 19

Page 20

CME1202R & CME1402R

CLEANING

Remote Condenser

1. Shut off th e ice machine.

The fa n b lade can

cause personal injury.

Disconnect power

before beginning to

clea n con de ns e r.

2. Remove dirt and debris that migh t be under the

condenser.

3. Brush off the botto m of the co nden ser fin s. Do

not use a wire brush.

4. Check to see that the inside of the co nden ser is

clean; light sho uld be visible th rou gh the fins . If

not, clean the int ern al pa rts by vacuum, pressure

washer and/or coil cleaner.

Ice Storage Bin

The interior liner of the bin is in contac t with a food

grade prod uc t: ice. The sto rag e bin must be

cleaned regularly to maintain a sanitary

environme nt . Once a wee k clea ning of the door &

frame with soap and wat er, a hot water rinse and

and air dry is a basic procedure. Scale that may

form on the plastic liner of a bin may be removed

by scrubbing the surface of the line with a mixture

of Scotsman Ic e Mach ine Clean er and hot wat er.

Remove any scale prior to sanitizing .

Inlet Water Valve

The inlet side of th e water valve has a screen in it

to protect the int ern al comp on ents from debris th at

may be carried to the valve by the water. If the

screen becomes clogged, it must be cleaned off.

1. Shu t off the wate r supply .

2. Unplug electrical connector from the valve .

3. Dismount valve from cabinet.

4. Remove inlet connect ion from valv e.

5. Brush debris from

sceen.

6. Reverse st eps 1-4 to

reassemble .

To remove scale:

1. Mix a c lea ning solution of 4 ounces of Sc otsma n

Ice Machine Cleaner to 4 pints of hot (9 5

0

11 0

F.) water.

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of water

or milk. Call Physician

immediately. In case of

extern al contact, flush

with water.

KEEP OUT OF THE

REACH OF CHILDREN.

2. Remove all ice from the bin.

3. Using rubber gloves, dip a nylon sc ouring pad

into the cleaning solut ion , an d scrub th e scale off

of the liner.

4. After the scale has been removed, rinse all of

the surfaces inside the bin with clean, potab le

water.

To sanitize the bin and ice machine:

Follow local codes for f reque ncy of sanitizing . Use

an approved sanitizer and follow the directions and

warnings of that sanitiz er or use the follo wing

instructio ns for use of hous ehold blea ch, if it meet s

local cod es :

1. Remove all ice from the bin.

2. Mix a sanitizing solution of 1 ou nce of

household bleach to 2 gallons of water.

3. Using clean rubber glov es and a clean cloth,

wipe all interior surfa ces of the ice machin e and

ice storage bin with the sanitizing solution.

Immerse any small part s in the sanitizin g so lut ion

and wash the parts, flus hin g the solu tio n

thoroughly in, over and thro ugh all parts and

surfaces of the parts being clea ned.

0

F. to

SCREEN

4. Allow to air dr y.

INLET

WATER

VALVE

June 1996

Page 20

Page 21

CME1202R & CME1402R

SYSTEM SPECIFICATIONS: CME1202

The following numb ers are a guide line to field op era tio n There will b e some varia tion from unit to unit.

The numbers headin g the colu mns are: Cond enser air te mp. /Ca bin et air temp ./ Water temp.

0/70/55 90/90/70 110/90/80

Typical Cycle Time 16 - 17 minutes 17 - 18 minutes 19 - 20 minutes

Standard Harvest Time*

1

3

⁄2 minutes 3 1⁄2 minutes 3 1⁄2 minutes

Typical Freeze Cycle

Suction Pressu re, End of

Cycle

Typical Freeze Cycle

Discharge Pressure,

End of Cycle

Typical Harvest Cycle

Suction Pressu re, Peak

Typical Air Cooled

Harvest Cycle Discharge

Pressure, Min

* See page 13 for harvest time optimiza tio n ins tru ctio ns .

Typical Harvest Ice Wei g ht

36 PSIG 35 PSIG 39 PSIG

250 PSIG 260 PSIG 305 PSIG

78 PSIG 100 PSIG 125 PSIG

140 PSIG 185 -190 PSIG 225 PSIG

••13.5 t o 14 .5 lb.

Refrigerant Char ge:

••336 ounces of R-404A when connected to a MAC 7G condenser

••448 ounces of R-404A whe n co nnect ed to a RCE1401 co nd enser

••448 ounces of R-404 A when co nn ect ed to a ERC401 conde nse r.

Typical Compressor Amp Dra w

Single phase

••5 minute s int o fre eze: 14 - 15 Harvest: 17 - 18

Three phase

••5 minutes into freeze : 8 - 9 Harvest: 10 - 10.8

High Pressure Cut Out

••High pressure saf et y, Man ua l rese t, cut out at 450 PSI G

Ice Level Control

••Maximum Range = 8 feet

••Partial Fill Setting: = 21" - 22" from the base of the ice machin e

Time r

••1 revolution takes 10 minute s (cha nged from 8 in June 1996)

Cube Size Control

••Cut In adjustable between 0

o

F. an d +250F.

June 1996

Page 21

Page 22

CME1202R & CME1402R

SYSTEM SPECIFICATIONS: CME1402

The following numbers are a guideline to fie ld opera tio n. There will be some variat ion from unit t o unit.

The numbers headin g the colu mns are: Cond enser air te mp. /Ca bin et air temp ./ Water temp.

0/70/55 90/90/70 110/90/80

Typical Cycle Time 15 - 17 minutes 16 - 17 minutes 18 - 19 minutes

Standard Harvest Time*

1

3

⁄2 minutes 3 1⁄2 minutes 3 1⁄2 minutes

Typical Freeze Cycle

Suction Pressu re, End of

Cycle

Typical Freeze Cycle

Discharge Pressure,

End of Cycle

Typical Harvest Cycle

Suction Pressu re, Peak

Typical Air Cooled

Harvest Cycle Discharge

Pressure, Min

* See page 13 for harvest time optimiza tio n ins tru ctio ns .

Typical Harvest Ice Wei g ht

35 PSIG 31-35 PSIG 36 PSIG

265 PSIG 270 PSIG 310 PSIG

80 PSIG 90-95 PSIG 110 PSIG

155 PSIG 180- 200 PSIG 235 PSIG

••13.5 t o 14 .5 lb.

Refrigerant Char ge:

•• 336 ounc es of R-404A when connected to a MAC 7G condenser

•• 448 ounces of R-404A whe n co nnect ed to a RCE140 1 cond enser

••448 ounces of R-404 A when co nn ect ed to a ERC401 conde nse r.

Typical Compressor Amp Dra w

Single phase

••5 minute s int o fre eze: 15 - 16 Harvest: 22 - 23

Three phase

••5 minutes into freeze : 9 - 10 Harvest: 13 - 14

High Pressure Cut Out

••High pressure saf et y, Man ua l rese t, cut out at 450 PSI G

Ice Level Control

••Maximum Range = 8 feet

••Partial Fill Setting = 21" - 22" from the base of the ice machine

Time r

••1 revolution takes 10 minute s (cha nged from 8 in June 1996)

Cube Size Control

••Cut In adjustable between 0

o

F. an d +250F.

June 1996

Page 22

Page 23

ADJUSTMENTS

CLOSE UP

VIEW OF TIMER

SWITCH

ACTUATOR

Electrical power

present in the control

box can cau se perso na l

injury.

Disconnect power

before beginning to

adjust timer.

Adjustment Of The Timer & Switch Assembl y

One complete revolu tio n of the cam on the timer

takes eight minu tes. The harves t time set at the

factory is three and a half minutes.

It. is importa nt that th e lengt h of the harve st cycle

allow enough time for all th e ice cube s to fall fro m

the evaporator . Too short of a time will cause the

evaporato r to fre eze up and stop ejecting ice into

the bin. Too much time wastes ic e making

capacity, energy and wa te r. Adjustment of th e

harvest cycle may require a corresponding

adjustment of the cube size contro l. Rot at ing the

shaft of the timer cam clockwise will allow puttin g

the machine int o eit her t he free zing cycle or

harvest cycle, as required in the cleaning

instructions.

CME1202R & CME1402R

MICROSWITCH

CAM

To Adjust The Timer & Sw itc h Ass em bly :

The length of the harvest cycle can be changed by

loosening the set screw on the cam, and then

rotating the shaft so that the opening between the

cams change. More of an opening between the

cams = more harvest time . The harv est time may

be reduced if not needed. This will yield more ice

per day.

ADJUSTING TIMER

TIMER

CAM

June 1996

Page 23

Page 24

CME1202R & CME1402R

SERVICE DIAGNOS IS: Wat er

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

No ice is made Inlet water valve will not open or

is dirty

No water being pump ed ove r

evapora to r s.

Water inlet valv e lea ks thru at

high rate

Cubes are not uniform in shape Water distribu to rs are dirty Clean water system

Long Freeze Cycle Inlet water valve leaks through Replace inlet water valve

See electrical/ad jus tme nt See electrica l/a djustme nt

Makes thick ice/freezes up Water inlet valve restrict ed Clean or replace valve

Low water pressure Check water filter or supply

Sump covers out of positio n Re-positio n sump cov ers

Cubes too larg e Inlet wate r valve leak s thro ug h Replace inlet wat er va lve

See electrical/ad jus tme nt See electrica l/a djustme nt

Low Capacity Incoming water very warm Check water temperature to

Lack of water See unit runs out of water

Unit runs out of water Reservoir leaks Repair leak

Inlet water valve restricted Clean or replace valve

Short harvest cycle Adjust timer

Water pressure too low Check sup ply

Clean inlet screen , check coil,

replace va lve if req uire d

Check pump motor, replace

pump if motor will not run.

No water in reservoir, check inlet

water valve , che ck res ervo ir for

leak.

Replace inle t wat er va lve

building

June 1996

Page 24

Page 25

CME1202R & CME1402R

SERVICE DIAGNOS IS : Elect ric al and/or Adjus t ment s

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

Machine does no t op era te No power Reconne ct powe r

High pressure control open Reset, check machine

High tempera tu re cut out open Hot gas valve leak s thru , replace

P. C. Board Op en Replace bo ard

Master switch open Test/replace

Timer contacts open Replace timer

Bin ice level control holding

mac hine off

Makes thick ice/freezes up Harvest Cycle too short Adjust timer for lon ger harv est

Low water pressure Check water filter or supply

Hot gas valve defect ive Replace hot ga s valv e

Sump covers out of positio n Re-positio n sump cov ers

Cubes too small Adjust cube size

Cube size contro l stuc k ope n Replace cu be size contro l

Runs, makes no ice Pump problem or water leak in

reservoir

Water inlet valv e eit her lets in no

water or leaks th rou gh

Timer stuck Replace timer

Relay does not energize; unit

stuck in harvest

Long freeze cyc le Water inlet valve leaks through Re pla ce inle t wat er va lve

Water tempe rat ure too high Advis e user

Cubes too smal l Cube size set wrong Adjust cube size

Cubes size contro l stu ck clos ed Repla ce cu be size contro l

Cubes too large Water inle t valv e lea ks throu gh Replace inle t wat er va lve an d

Compressor cycles on and off on

pump down contro l

Compressor will not run Low pressure con tro l will not close Check pump down control fo r

Unit cycles on and off anytime in

any cycle

Low refrigerant charge Locate leak, repair, replace drier,

Liquid line valve or drier restricte d Check and repla ce

TXV restricted Check and replace

Head pressure co nt rol valv e not

working (low condensing temp.)

Contactor coil op en Check/replace cont act or

Compressor wind ing s op en Check repla ce co mpre sso r

Loose con ne ct ion in PC boa rd Replace PC board

See page 27

cycle

Check water system and pump

Replace inle t wat er va lve

Replace rela y

adjust cube size control

evacuate and weigh in nameplate

charge.

Check/re place head pressure

control valve

proper operation

June 1996

Page 25

Page 26

CME1202R & CME1402R

SERVICE DIAGNOS IS: Refri geration and/or Mec hanic al

SYMPTOM POSSIBLE CAUSE PROBABLE FIX

Poor harvest Hot gas valve does not open Check for power to the coil, check

for not open ing , replace

Head pressure co nt rol valv e does

not maintain enou gh head

pressure.

Unit cycles off during freeze or

harvest

Low capacity High head pressu re, from dirt y

Unit shuts off befo re bin is full Bin Ice level co ntrol is set to

Compressor cycles on and off Low pressure control opening

Frost on compresso r Some frost will not hurt Do nothing

Hi temperature switch opens and

closes

condenser, fa ulty fan motor

Non condensabl e gas in the

system

Extreme ho t loca tio n Re loca te the cabinet

Overcharge of refrigerant Evacuate and weigh in nameplate

Hot gas valve leaks thru At the end of the freeze cycle

Liquid and discharge lines are in

contact with each other

“Partial ”

and closing

Compressor ov erh eats TXV not lettin g enough refrig era nt

TXV meters too much refrig erant Replace TXV

Replace he ad pres sure con tro l

valve.

Hot gas valve leak s thru , replace it

Clean condenser, rep air fa n

motor

Purge system, evacuate and

weigh in nameplate charge

charge

there should be frost on the

evaporator end of the hot gas

tubes, if not replace the hot gas

valve

Separate and insulate them

Move bin Ice level rocker switch

to “Full”.

Check low side pressure, liquid

line valve must open and low side

pressure raise ov er 35 PSIG

before pump down control will

close to run compressor

into evaporators, adjust or

replace TXV

Mechanical fault with

compresso r, rep lac e comp res sor

June 1996

Page 26

Page 27

CME1202R & CME1402R

SERVICE DIAGNOS IS: Bin Ice Level Control

CONDITION DETERMINE CAUSE PROBABLE CORRECTION

Ice Machine does not run, it

has power to it, the high

pressure c ontrol is closed,

the on/off switch is set to ON

(the compressor will n ot

operate until the liquid line

valve opens, but the pump

should be working if there is

no ice in th e bin).

Machine runs , make s ice,

switches on and off, but ice

level cannot be controlled.

Indicator light is out or

flickers, board may seem to

be off

A. Listen for a ticking sound from

transducer.

B. Remove front panel(s), twist

transducer 1/ 4 turn and pull out.

DO NOT UNPLUG with power

connected. Ex amine the

transducer, the inside must be

clean an d dr y.

C. Check powe r to bin level

control board.

D. Disconnect el ectri ca l power

and test ice machine circuit by

attaching a jumper wire between

bin thermostat posts on circuit

board part no. 12-1912-01 (the

circuit board with the timer on it).

Reconnect power.

E. Transducer or ice level board

assembly defectiv e.

Ice level switch may be defective.

On boards with a light, check by

moving switch & watching light.

Check connection to ice level swit ch Repair or replace harness to switch

If no noise, go to C. If there is a

noise, chec k for a ligh t on the board

(models built after 4/9 3). If there is a

light on, check relay contacts N.O.

and COM. The contacts should be

CLOS ED. If clo sed , go to D. If no t,

replace the board. If ligh t is off, or

prior model, go to B.

If the inside of the transducer (above

screen) was wet, replace it. Set bin

level to FULL and aim at an object

about 1-3 feet away. Machine

should restart, if not go to D.

Should be 12 volts from transformer,

if not replace transformer. If there is

power go to D.

If machine does not st art go back to

machine cir cuit. If machin e sta rt s ,

disconnec t electric al power, remove

jumper wire and reconnect electrical

power . The n go to E.

Replace tran sdu ce r. Se t bin level to

FULL and aim at an object about 1-3

feet away. Machine should restart. If

not , re place the board.

Replace ice level switch

PARTIAL

VIEW OF

CIRCUIT

BOARD

12-1912-01

TIMER

PLUG - IN

RELAY

BIN THERMOSTAT

June 1996

Page 27

Electrical S hock Hazard Can

Cause Personal Injury.

Disconnect Power Before

Servicing.

Bin Thermostat Posts at Line

V olt ag e.

POSTS MENTIONED IN

“B” ABOVE

Page 28

CME1202R & CME1402R

REMOVAL AND REP LACE ME NT

Cube Size Control

To remove the cube size con tro l:

Electrical Sh ock Hazard .

Electrical shock can

cause person al injury.

Disconnect power

before begin ning to

service compon ents.

Water Distr ibutor Tubes And Manifold Tubes

To remove the water dis trib ut or tube and manif old

tube:

1. Remove the front panel.

2. Slide the water distributor tube to th e front about

1/8-inch alon g the top of the evap ora to r plat e, unti l

the water distrib ut or tube can be unsnapp ed from

the flexible no tch and lifted upward.

WATER DISTRI BUT OR

1. Remove front panel.

2. Remove cover fro m cont rol box.

3. Trace ca pilla ry tube, from the cube size contro l

to the refrigerant suction line.

NOTCH IN BACK OF

CONTROL BOX

CUBE SIZE

CONTROL

REPLACEMENT OF THE CUBE SIZE CONTRO L

3. Unsnap and disconnect water distribut or tubes

from the wate r ma nif old section . To replace t he

water distrib ut or tu bes and manif old tubes , reve rse

the removal proce du re. BE SURE the notch es in

the water manifold tubes properly engage the

alignment keys in the tee . BE SURE the wat er

distribut or tube is secure ly faste ne d at the notch at

both sides of the evaporator plate. Check identical

attachment f or the left water distributor tube and

notch; also, that th e distributor/manifold

connections at the top center of each evaporator

plate is snug against the top of the plate.

4. Remove the coiled capilla ry tub e bulb from the

tube well on the suction line .

5. Remove electrical lea ds fro m the cube size

control.

6. Remove screws and pull the capilla ry tub e

through the notch in the back of the control box.

Remove the cube size co ntrol. To replace the cub e

size control, reverse the removal procedure.

June 1996

Page 28

Page 29

REMOVAL AND REP LACE ME NT

CME1202R & CME1402R

Inlet Water Solenoid Valve Assembly

To remove the inlet wat er so lenoid valve assembly:

Electrical Shock Hazard.

Electrical shock can

cause personal injury.

Disconnect power

before beginning to

service components.

Water Pump

1. Remove front panel.

2. Unplug water pump ele ct rical co nnect ion .

3. Drain water res ervo i r.

4. Use corbin clamp plie rs t o loose n and slide

corbin clamps on hoses away from pump.

5. Remove screws reta inin g pump to bracket .

6. Pull pump out of ice machine .

7. Reverse to reassemble.

8. Replace front panel.

1. Shut OFF water supp ly to machin e.

2. Loosen and remove outle t wat er line from the

inlet water so lenoid valve asse mbly.

3. Remove screws and pull the water so len oid

valve out to gain acce ss.

INLET WATER

VALVE

REMOV A L OF TH E

INLET WATER VAL VE

8. Reconne c t electrical power.

Transducer

1. Disconnect electrical power BEFORE removing

transducer.

2. Remove the fro nt panel an d loca te the

transducer so cke t.

3. Twist inner portio n of tra nsduc er

counter-clockwise and push up gently.

4. Unplug transducer an d remove from the

machine.

5. Reverse st eps 1-4 to reas semb le.

4. Pull electrical cord fro m solen oid coil termina ls.

5. Remove inlet wat er fit tin g fro m the wate r

solenoid valve. To replace the inlet water valve

assembl y, reverse the removal pro ced ure s.

Bin Ice Level Control Circuit Boar d

1. Disconnect Electrical Power before removing

circuit board.

2. Remove front panel.

3. Remove control box cover.

4. Remove wires from circuit board co nnect ions.

5. Unlock circuit board fa st eners by twistin g 1/2

turn.

6. Pull circuit board of of f faste ner pos ts.

7. Reverse to reassemble, refer to wiring diagram

as ne eded .

June 1996

Page 29

Page 30

CME1202R & CME1402R

REMOVAL AND REP LACE ME NT

Thermostatic Expansion Valve

1. Before replacing this valve, be cert ain that th e

valve is the cause of the pro ble m, and canno t be

adju sted.

2. Remove the front panel.

3. Discharge and reco ver th e refrigerant.

4. Locate the TXV bulb (on the suction line),

remove the clamps an d bulb from the tube.

5. With the refrige rat ion syste m open, unsweat the

TXV from the tubing.

6. Place the new TXV in positio n.

7. Wrap the new TXV body with heat sin k mat eria l.

Do not get any moisture in the valve .

8. Carefully braze the valve to the tubing. Examine

the joints , if they loo k go od proce ed to the ne xt

step, if no t, re -do the m.

9. Install a new drye r, and braze it in place also.

10. Reattach the TXV bulb to the suc tio n line in th e

same place as the old one.

1 1 . Eva cuat e the syst em to 300 mic ron s.

12. Weigh or measure the nameplate charge into

the receiver.

13. If the ma ch ine has been of f on the bre ake r

there may be refrig erant trapped in the oil of the

compresso r, so do not restart until the compre sso r

has been warmed by the crankcase heater for 4

hours. If the compresso r was warm th rou ghout th e

replaceme nt proce ss, the ice mach ine may be

restarted with out wait ing to re-warm the

compresso r.

Hot Gas or Liquid Line Valve.

1. Before replacing this valve, be cert ain that th e

valve is the cause of the pro ble m.

2. Remove the front panel.

3. Discharge and reco ver th e refrigerant.

4. Unplug the coil of th e valv e.

5. With the refrige rat ion syste m open, unsweat the

valve from the tubing .

6. Place the new valve in posit ion .

7. Wrap the new valve bo dy with heat sink

material. Do no t get any moist ure in the valve.

8. Carefully braze the valve to the tubing. Examine

the joints , if they loo k go od proce ed to the ne xt

step, if no t, re -do the m.

9. Install a new drye r, and braze it in place also.

10. Plug the power cord back onto the coil.

1 1 . Eva cuat e the syst em to 300 mic ron s.

12. Weigh or measure the nameplate charge into

the receiver.

13. If the ma ch ine has been of f on the bre ake r

there may be refrig erant trapped in the oil of the

compresso r, so do not restart until the compre sso r

has been warmed by the crankcase heater for 4

hours. If the compresso r was warm th rou ghout th e

replaceme nt proce ss, the ice mach ine may be

restarted with out wait ing to re-warm the

compresso r.

June 1996

Page 30

Page 31

V APOR VAPOR

TEMP. PRESS. TEMP. PRESS .

(DEG F) (PSIG) DEG F) (PSIG)

-20 17 70 146

-18 18 72 150

-16 20 74 155

-14 21 76 161

-12 23 78 166

-10 24 80 171

-8 26 82 177

-6 28 84 182

-4 29 86 188

-2 31 88 194

0 33 90 200

2 35 92 206

4 37 94 212

6 39 96 219

8 41 98 225

10 43 100 232

12 46 102 239

14 48 104 246

16 50 106 253

18 53 108 260

20 55 110 268

22 58 112 275

24 60 114 283

26 63 116 291

28 66 118 299

30 69 120 307

32 72 122 316

34 75 124 324

36 78 126 333

38 81 128 342

40 85 130 351

42 88 132 360

44 91 134 370

46 95 136 379

48 99 138 389

50 102 140 399

52 106 142 409

54 110 144 420

56 114 146 430

58 118 148 441

60 123 150 452

62 127 152 464

64 132 154 475

66 136 156 487

68 141 158 499

REFRIGERAT ION SERVICE

CME1202R & CME1402R

This ice mac hine uses R-404A refrigerant and polyoles ter oil. Do NOT

use mineral oil in this refrig era tio n syste m.

••R-404A is a "Near Azeotrop e" so liqu id cha rgin g is required: See the

nex t page .

••Whe n the system is serviced, a special liquid line drier is required . It is

included with replacement compressors.

••R-404A is not compa tib le with minera l oil, so these ice machin es use

Polyoles ter oil. Po lyole st er oil ab sorb s wat er very easily . When one of

these refrige ration systems is opened for service, it must be re-se ale d

as soon as possible (15 minutes maximum).

••Special leak detec tio n equipment is required to loc ate small ref rige ran t

leaks. Usua lly a leak detec to r capable of dete ct ing a Halon gena ted

refrigerant or HFC-134A will work. Check with the leak detector

manufacturer if in do ubt.

Access Valves: To use the access valves :

••Remove the cap from the stem, use a 3/16" allen wrench to check

that the valve is CLOSED. The remove the core ca p.

••Close the valve and repla ce the caps when the job is finis hed.

The valve must be closed and the ca ps mus t be on or the valve

will leak.

General Information:

Work on the refrig era tio n syst em shou ld only be done when it is certa in

that the system needs repair.

••Refrain from checking refrigera tion pre ss ures without reason.

Visual insp ect ion of the wat er sys te m, observation of the ice

formatio n, amp dra w, volt age, and other tech nique s will lead to proper

diagnosis.

••If gauges must be used, don’t always che ck the high side pressure. If

the condenser is clean and seems to be operating correctly, it most

likely is.

••If gauges must be used, use very short hoses to minimize ref rige ran t

discharged into the air.

••Refrigeran t sh ould no t be added except as a way to determine the

proper opera tion of the product . If the syst em was low on refrig era nt ,

there is a leak, and it must be found and repaired.

••This system has a critical charge, it must be recharged with the

correct amount of refrigera nt as listed on the nameplate of the ice

machine, or performance will suffer.

•• Anytime th e refrigeration system has been opened , the drye r sho uld

be replace d. Note: Only a HFC type dryer can be used.

••When brazing the tubing connections to components such as the

TXV, the component must be protecte d by heat sink mate rial.

Recover, reclaim or recycle refrige ran t. The me th od chosen is up to

the service comp an y. Any refrigerant placed into a Sc otsman ice machine

must meet ARI sp ec 7 00-93 . Rec laim pro grams are available throu gh

most refrige ran t who lesa lers .

June 1996

Page 31

Pressure-Temperature Ch art for R-404A

Page 32

Access Valves

Note: There are no valve

cores in this valve.

CME1202R & CME1402R

LIQUID CHARGING

Instructions for R-404A

In preparatio n for c hargin g, the low side hose

should have a sight glass, and/ or a rest rict or

device (such as a "Charge Fas ter ") insta lled in it

for metering liquid into the low side of the system.

1. Af ter a thoro ugh evacuat ion to at least 200

microns, shut off the manif old valves an d switch

off the vacuum pu mp.

2. Place a drum of R-40 4A onto an electroni c

scale.

3. Attach the chargin g hose to the drum.

4. Open the valve on the drum and purge the

charging hose.

5. Zero out the scale.

6. Shut the low side acc ess valve at the ice

machine.

7. Open the discha rge manif old valve full op en.

8. Watch the scale , whe n the correct charge is

shown, shu t the man ifo ld va lve.

Note: If all of the charge will not "go in" the

discharge side:

A. Shut the discharge acce ss valv e at the ice

machine.

B. Switch the machine on.

C. Open the low side acces s valve at the ice

machine.

D. Open the low side manifo ld va lve and obse rve

the sight glass to be certa in that only gas is

flowing into the system.

E. Whe n th e p roper char ge is ind i cated on the

scale, shut off the manifold valve(s).

9. Shut off the valve on the refrig era nt drum.

10. Re-open the manifo ld va lves unt il all liquid has

flowed out of the hoses.

1 1 . Sh ut the low side ac ces s valve on the ice

machine.

12. Remove hoses from ice machine and repla ce

all caps.

Hose Connection Schematic for Liquid Charging

Allen

Wrench

Torque Stem to

6-8 ft. lb.

Torque Stem Cap to

8-12 ft. lb.

Torque

Core Cap to

7-12 ft. lb.

June 1996

Page 32

Loading...

Loading...