Page 1

Selection Guide

SmartX Mx4x-6xxx, Mx4x-7xxx

Series Actuators and Accessories

Applications

Direct-coupled SmartX Actuators are designed to accept twoposition, floating, or proportional control from a DDC system

or from a thermostat, for control of HVAC applications. The

actuators are designed to be used in both damper and valve

control applications. Typical applications include air handling

units, unit ventilators, fan coil units, VAV terminals, control

dampers, inlet guide vanes, and linked valve assemblies.

Use the following guide to select actuators for damper

applications. Refer to the Applicable Literature table for valve

literature.

Mx41-707x

Mx41-715x

Mx41-6043

Mx41-6083

Mx40-704x

Mx41-634x

Mx41-6153

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Mx40-717x

Page 2

Applicable Literature

Selection Guide

F-Number Description Audience

F-27211

F-27212

F-27213

F-27214

F-27215

F-26744

F-26745

F-26742

F-26748

F-26749

F-26644

F-26642

F-26645

F-27160

F-26750

F-27087

F-26752

F-27086

F-11080 Valve Selection Chart Water

F-11366 Valve Selection Chart Steam (two-way valves only)

F-13755 CA-28 Control Valve Sizing

F-26080 EN-205 Water System Guidelines

MF41-6043/MS41-6043 Series,

MF41-6083/ MS41-6083 Series Non-Spring Return Direct Coupled Actuator Installation Instructions

MF41-6153, MS41-6153 Non-Spring Return Direct Coupled

Actuator Installation Instructions

MF41-6043/MF41-6083 Series Non-Spring Return Rotary 24Vac

Three-Position Control Electronic Damper Actuators General

Instructions

MS41-6043/MS41-6083 Series Non-Spring Return Rotary 24Vac

Modulating Control 0…10Vdc Electronic Damper Actuators

General Instructions

MF41-6153/MS41-6153 Series Non-Spring Return Rotary Electronic Damper Actuators General Instructions

MF41-6343 SmartX Series Non-Spring Return Direct Coupled

Actuator General Instructions

MS41-634x SmartX Series Non-Spring Return Direct Coupled

Actuator General Instructions

MA40-717x SmartX Series Spring Return Direct Coupled Actuator General Instructions

MS40-717x SmartX Series Spring Return Direct Coupled Actuator General Instructions

MF40-7173 SmartX Series Spring Return Direct Coupled Actuator General instructions

MF4x-7xx3, MF4x-7xx3-50x Schneider Electric SmartX Series

Spring Return Direct Coupled Actuator General Instructions

MA4x-7xx3, MA4x-7xx3-50x, MA4x-7xxx, MA4x-7xxx-50x SmartX

Series Spring Return Direct Coupled Actuator General Instructions

MS4x-7xx3, MS4x-7xx3-50x SmartX Series Spring Return Direct

Coupled Actuator General Instructions

Mx4x-6xxx-220/-230 and Mx4x-7xxx-220 Actuator/Linkage Assemblies for 2-1/2”…6” Globe Valves General Instructions

MA4x-xxxx-2xx, MF4x-xxxx-2xx, MS4x-xxxx-2xx Series Actuator/

Linkage Assemblies for 1/2”…2” Globe Valves General Instructions

Vx-2x13-5xx-9-xx Series, VB-2x13-500-9-xx Series Ball Valve

Assemblies and Ball Valve Body/Linkage Assemblies Installation

Instructions

Vx-7000 and Vx-9000 Series, Mx4x-6xxx and Mx4x-7xxx Series,

Linked Globe Valve Assemblies and Actuator/Linkage Assemblies with SmartX Actuators Selection Guide

Vx-2x13-5xx-9-xx Series Ball Valve Assemblies and VB-2x13500-9-xx Series Ball Valve Body/Linkage Assemblies Selection

Guide.

Sales Personnel

Application Engineers.

Other details:

Installers

Service Personnel

Start-up Technicians

Installers

Service Personnel

Start-up Technicians

Purpose

All documents describe actuator

features, specifications, possible applications, and step-by-step mounting

instructions. Other details:

Also provides checkout instructions.

Globe Valves

Ball valves

Linked Globe Valve assemblies with

SmartX actuators.

Linked Ball Valve assemblies with

SmartX actuators.

Provides charts, equations, and

diagrams to assist in the configuration

of valve system applications. TOOL150, valve sizing slide rule may be

purchased separately.

Describes Schneider Electric approved water treatment practices.

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 3

Selection Guide

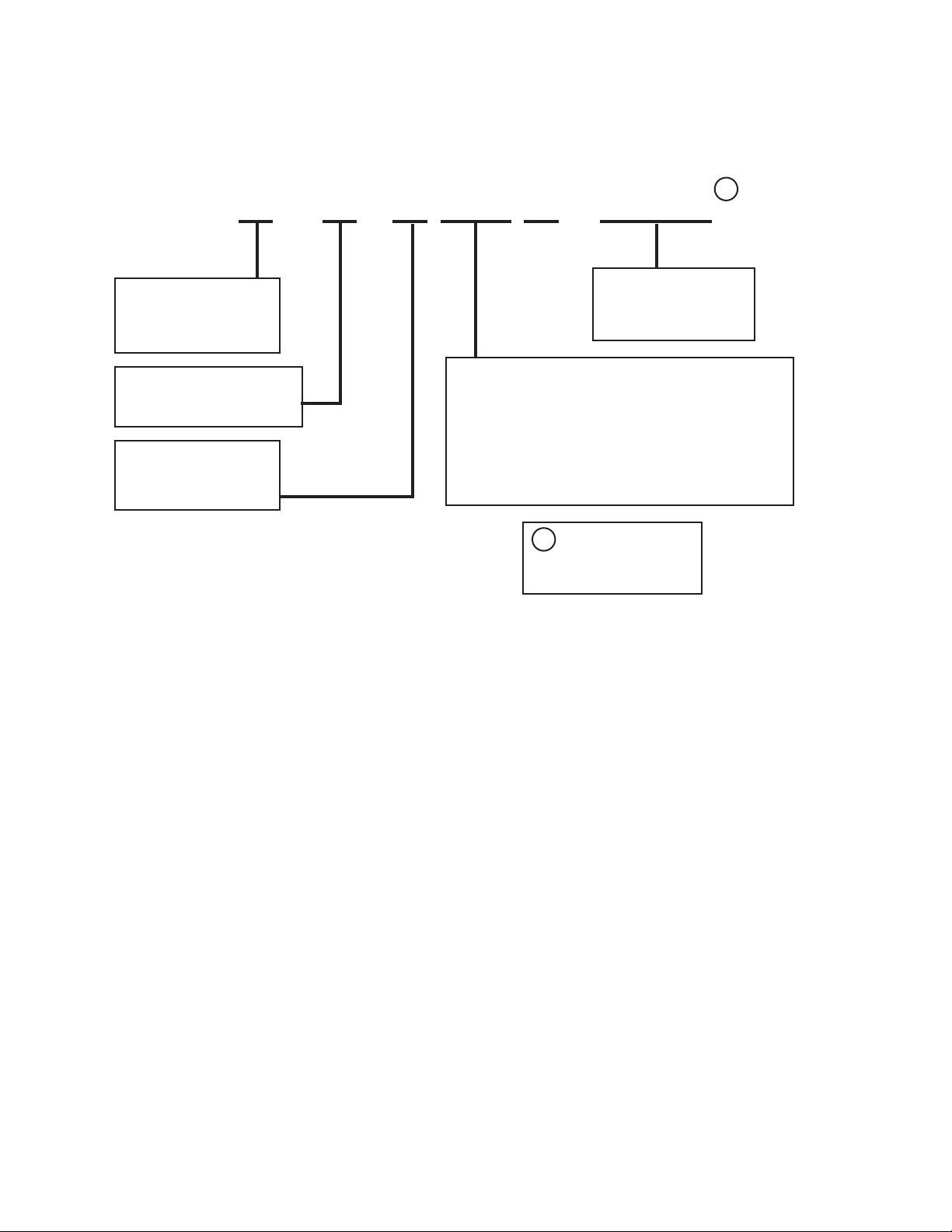

Actuator Part Numbering System

M X 4 X - X X X X - X X X

1

Control Signal Type

A = Two position

F = Floating

S = Propor tional

Rotation Positioning

0 = Non-Manual Override

1 = Manual Override

Spring Return Action

6 = Non-Spring Return

7 = Spring Return

Supply Voltage

0 = 120 Vac

1 = 230/240 Vac

3 = 24 Vac

Torque Rating

04 = Mx40 and MA41 models: 35 lb-in. (4 Nm)

MS41 and MF41 models: 44 lb-in. (5 N-m)

07 = 60 lb-in. (7 N-m)

08 = Mx40 and MA41 models: 70 lb-in (8 N-m)

MS41 and MF41 models: 88 lb.in (10 N-m)

15 = 133 lb-in. (15 N-m)

17 = 150 lb-in. (17 N-m)

34 = 300 lb.in (34 N-m)

Consult the Actuator

1

Selection Chart and

the Actuator Accessories

Chart for available models.

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 4

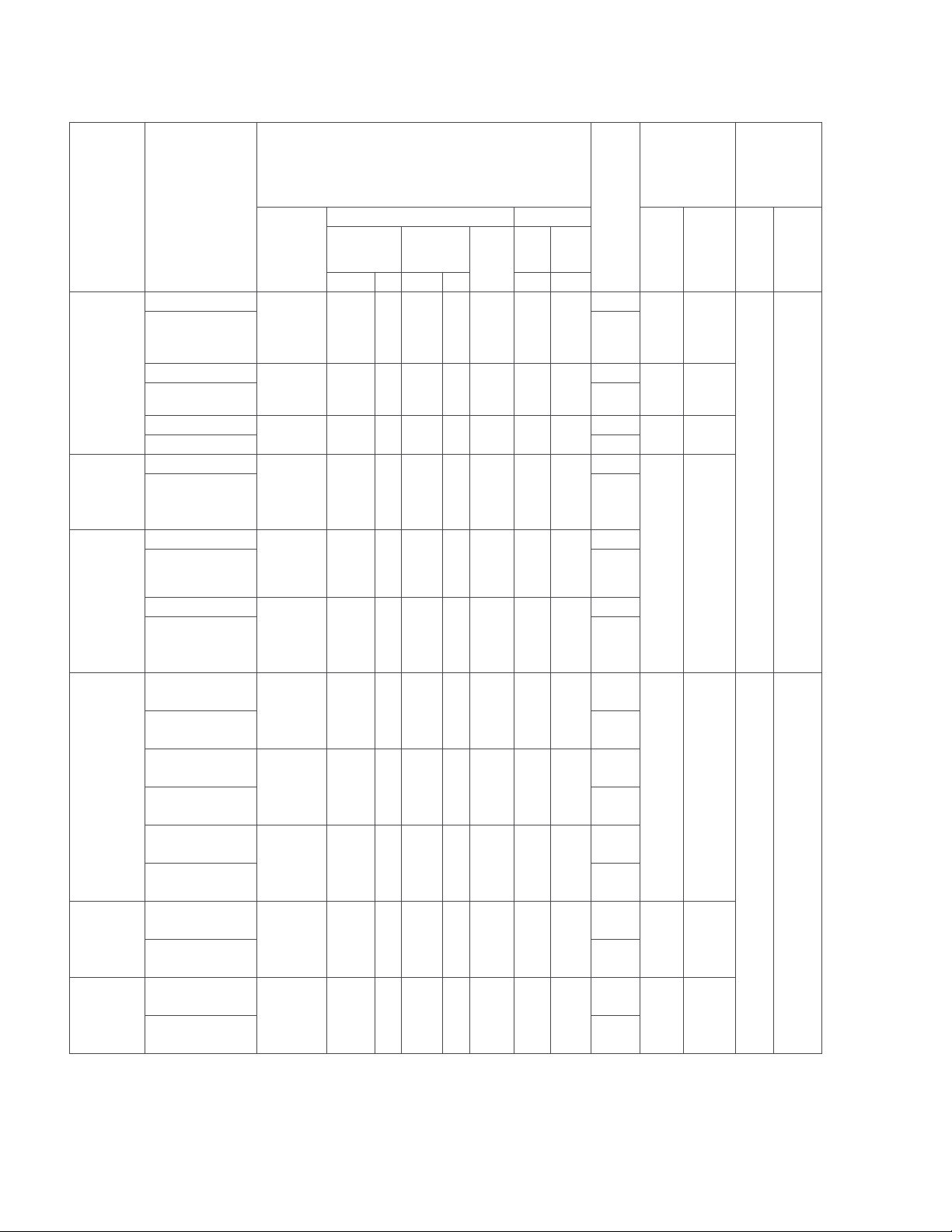

Table 1. Mx40-704x, Mx4x-707x, and Mx4x-715x

Selection Guide

Actuator

Type

Two-

Position

Floating

Proportional

Power Input

Part Numbers

Voltage

50 Hz 60 Hz

Running Holding

50

DC

Amps

Hz

60

Hz

VA W VA W W W

MA40-7043

MA40-7043-501 1

24 Vac ±

20%

22…30

4.4 2.9 4.4 2.9 0.11 0.8 0.8

Vdc

MA40-7040

MA40-7040-501 1

MA40-7041

MA40-7041-501 1

MF40-7043

MF40-7043-501

c

120 Vac ±

10%

230 Vac ±

10%

24 Vac ±

20%

22…30

6.4 3.8 4.3 3.4 — 1.6 1.2

5.8 4.1 4.6 3.9 — 1.5 1.2

5.9 4.4 5.9 4.4 0.17 2.9 2.9

Vdc

MS40-7043

MS40-7043-501

c

c

24 Vac ±

20%

22…30

5.6 4.2 5.6 4.2 0.15 2.4 2.4

Vdc

MS40-7043-MP

24 Vac

MS40-7043-MP5 1

22…30

Vdc

6.6 5.0 6.6 5.0 0.17 3.2 3.2

Approx. Timing

(sec.) @ 70 °F

(21 °C) with No

Switches

SPDT Auxiliary

-

<50 <26

<50 <26

b

<50 <26

b

-

b

1

-

<130 <25

b

1

-

b

Load

Powered

Spring

Return

Output

Torque

Rating

lb.-in. (N-m)

Max.

Min.

Stall

35

150

(4)

(17)

Two-

Position

Floating

Proportional

MA41-7073

MA41-7073-502

MA41-7070

d

MA41-7070-502

MA41-7071

d

MA41-7071-502

MF41-7073

d

MF41-7073-502

MS41-7073

d

MS41-7073-502

d

d

d

d

d

24 Vac ±

20%

22…30

Vdc

120 Vac ±

10%

230 Vac ±

10%

24 Vac ±

20%

22…30

Vdc

24 Vac ±

20%

22…30

Vdc

4.8 3.2 4.8 3.2 0.13 0.8 0.8

10.7 4.2 5.6 3.6 — 2.0 1.2

17.0 5.1 8.0 4.0 — 2.7 1.4

6.2 4.8 6.2 4.8 0.18 2.8 2.8

5.8 4.6 5.8 4.6 0.17 2.3 2.3

-

2

-

e

2

-

e

2

-

e

2

-

e

2

<80 <40

<195 <30

<195 <30

60

(7)

250

(28)

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 5

Selection Guide

Actuator

Part Numbers

Type

Voltage

50 Hz 60 Hz

VA W VA W W W

MA40-7153

MA41-7153

d

MA40-7153-502

MA41-7153-502

Two-Position

MA40-7150

MA41-7150

MA40-7150-502

d

MA41-7150-502

MA40-7151

MA41-7151

d

MA40-7151-502

MA41-7151-502

Floating

MF40-7153

MF41-7153

MF40-7153-502

d

MF41-7153-502

Proportional

MS40-7153

MS41-7153

MS40-7153-502

d

MS41-7153-502

a - De-rating required for spring return actuators at low temperatures.

b - One adjustable from 15…95° rotation (MIN…1 scale).

c - With plenum-rated cable.

d - Equipped with manual override.

e - One adjustable from 25°…85° rotation and one set to operate @ 5° fixed.

d

d

d

d

d

24 Vac ±

20%

22…30

Vdc

120 Vac ±

10%

230 Vac ±

10%

24 Vac ±

20%

22…30

Vdc

24 Vac ±

20%

22…30

Vdc

9.8 7.5 9.7 7.5 0.29 2.8 2.8

11.7 8.8 10.0 8.4 — 3.6 5.0

15.5 9.5 10.6 8.5 — 4.6 3.3

9.8 7.7 9.7 7.7 0.30 3.3 3.3

9.8 7.4 9.7 7.4 0.28 2.9 2.9

Power Input

Running Holding

50

DC

Amps

Hz

60

Hz

SPDT Auxiliary

No

Two

No

Two

No

Two

No

Two

No

Two

Switches

e

e

e

e

e

Approx. Timing

(sec.) @ 70 °F

(21 °C) with No

Load

Spring

Powered

Return

<190 <30

Output

Torque

Rating

lb.-in. (N-m)

Max.

Min.

Stall

133

350

(15)

(40)

Table 2. Mx40-717x Series Spring-Return Actuators

De-rating required for spring return actuators at low temperatures.

Power Input @ 50/60Hz

Part

Numbers

MA40-7173

Voltage

Running

Watts

Running Holding Min. Max. Stall

24 Vac ± 20% 5.3 7.4 5.1

22…30 Vdc 5.0 5.0 3.0

VA

MA40-7170 120 Vac ± 10% 6.2 8.4 6.6

MA40-7171 240 Vac ± 10% 6.5 9.8 8.5

MF40-7173

MS40-7173

24 Vac ± 20% 5.8 8.1 5.3

22…30 Vdc 5.7 5.7 3.6

24 Vac ± 20% 5.5 7.8 4.7

22…30 Vdc 5.0 5.6 2.5

MS40-7170 120 Vac ± 10% 6.4 8.5 5.2

SPDT

Auxiliary

Switches

No

Sec. @ 70 °F (21 °C)

with No Load

Spring

Powered

Return

162 72

147 65

MS40-7171 240 Vac ± 10% 7.2 10.8 9.0

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Approx. Timing in

Output Torque

Rating

lb.-in. (N-m)

150 (17) 545 (61.8)

Page 6

Table 3. Non-Spring Return Actuators

Selection Guide

Power Input @ 50/60Hz

Part Numbers

MF41-6043

MF41-6043-502

MF41-6043-510

MS41-6043

MS41-6043-502

MS41-6043-520

MS41-6043-522

MF41-6083

MF41-6083-502

MF41-6083-510

MS41-6083

MS41-6083-502

MS41-6083-520

MS41-6083-522

b

b

b

bc

b

b

b

bc

b

b

bc

be

bf

MF41-6153

MS41-6153 4.0 5.0 1.2 No

MF41-6343

MS41-6343

Voltage Watts

Running Holding

2.0 2.3 — No

2.0 2.3 — 2

2.0 2.3 — No

24 Vac +20/-15%

3.0 3.3 1.2 No

3.0 3.3 1.2 2

3.0 3.3 1.2 No

3.0 3.3 1.2 2

2.0 2.3 — No

2.0 2.3 — 2

2.0 2.3 — No

24 Vac +20/-15%

3.0 3.3 1.2 No

3.0 3.3 1.2 No

3.0 3.3 1.2 No

3.0 3.3 1.2 2

24 Vac +20/-15%

3.0 3.0 — No

24 Vac ± 20% 3.9 5.7 4.1

22…30 Vdc 4.1 4.1 3.0

24 Vac ± 20% 3.6 5.6 4.0

22…30 Vdc 3.4 3.4 2.2

VA

MS41-6340 120 Vac ±10% 4.7 7.5 6.2

SPDT

Auxiliary

Switches

No 162

No 148

Approximate

Timing in Seconds

@ 70 °F (21 °C)

a

with No Load

90 @ 60Hz

108 @ 50Hz

125 @ 60Hz

150 @ 50Hz

MS41-6341 240 Vac ±10% 5.0 9.0 8.1

b - Equipped with plenum-rated cable.

c - Equipped with two built-in auxiliary switches.

d - Equipped with 1k W feedback potentiometer.

e - Equipped with adjustable start/span.

f - Equipped with adjustable start/span and two auxiliary switches.

g - Minimum voltage at high temperatures: 24 Vac, +20%, -10% at 90…130 °F ambient.

h - Minimum voltage at high temperatures: 24 Vac, +20%, -5% (MF models) and 24 Vac, +20%, -10% (MS models) at 85…130 °F ambient.

a - Auxiliary switch ratings are as follows:

Actuator

Output Torque

Rating (Min.

lb.-in. (N-m)

44 (5)

g

88 (10)

h

133 (15)

300 (34)

Auxiliary Switch Ratings

Mx41-6043, Mx41-6083 Mx41-6153

AC Rating 24 Vac, 4 A resistive, 2 A inductive 24 Vac, 6 A resistive, 2 A inductive

DC Rating 12…30 Vdc, DC 2 A

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 7

Selection Guide

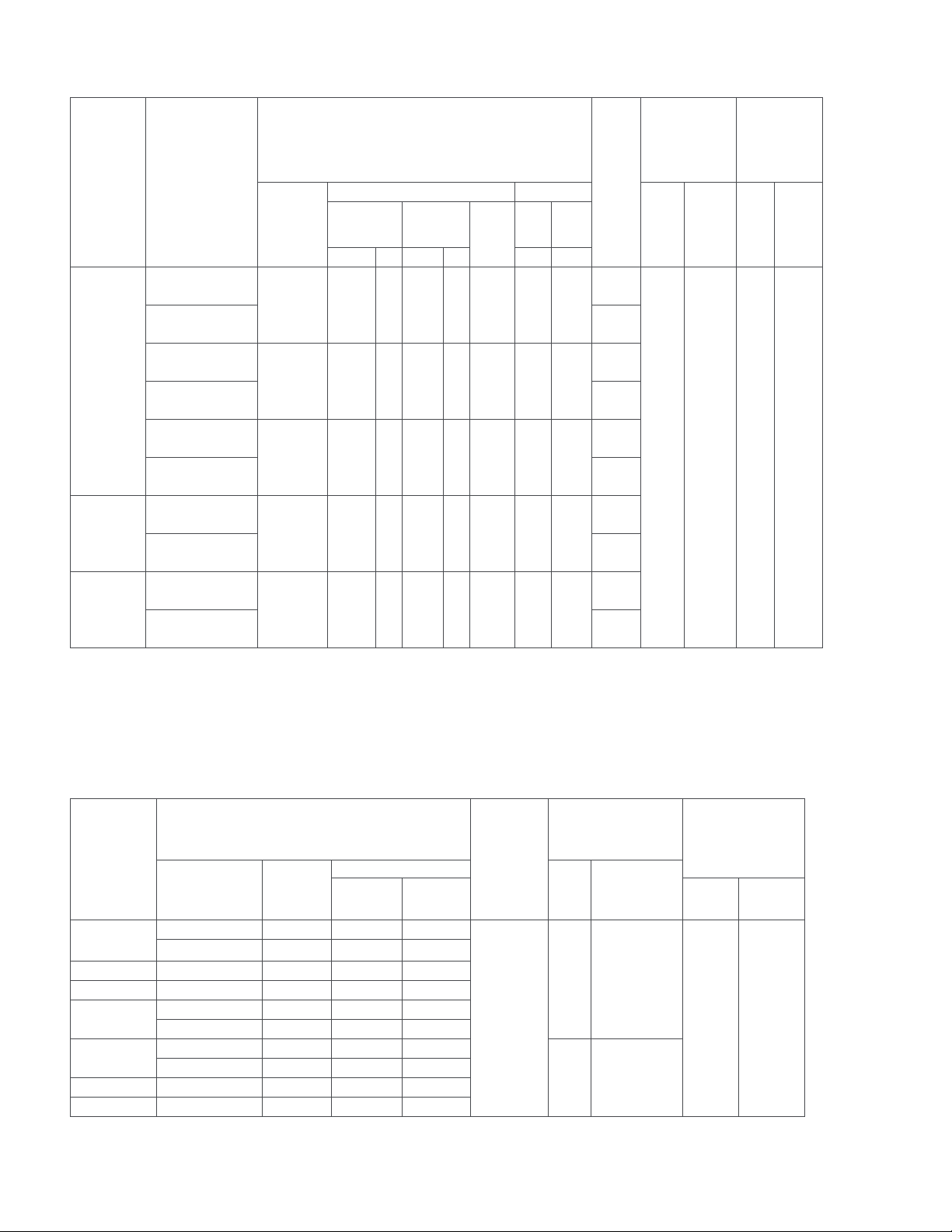

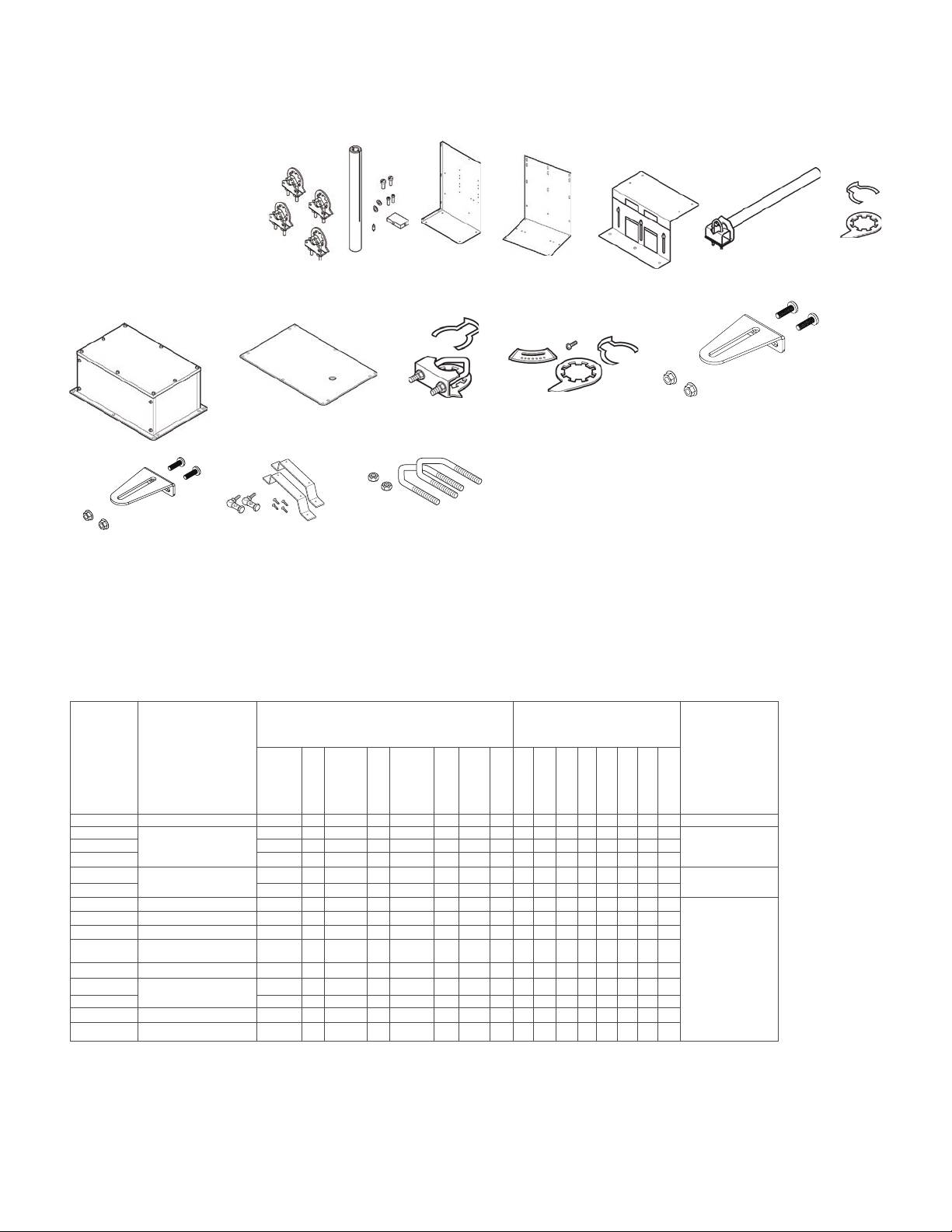

Actuator Accessories

AM-621

AM-675

AM-674

AM-693-R

Actuator Accessories Table

Spring Return Actuators

(Series [x] or individuals)

Par t

Numbers

Description

AM-688

AM-692

AM-671

AM-672

AM-673

AM-689

NEW Mx41-730x ACTUATORS ACCESSORIES

AM-708 500 ohm resistor for connection to 4 to 20 mA input signals

AM-801 Mx41-730x-xxx Actuator Crank Ar m Kit

AM-802 Mx41-730x-xxx Actuator Crank Ar m Kit with Actuator Mounting Bracket and Two

AM-803 9-3/4” damper Shaft Extension for 5/16” to 1” Diameter Round Shafts

AM-804 Jackshaft Linkage (requires AM-805 Suppor t Plate for Mx41-73xx Actuators)

AM-805 Suppor t Plate for Mx41-73xx Actuators

BEL-ZTH US Handheld Interface Module for Field Programming of the MS41-7303-xxx

Ball Joints

Models

AM-676

AM-690-R

AM-686

Non-Spring Return

Actuators

(Series [x] or individuals)

Installation

Instruction

MF40-7043

MA40-704x

AM-621 Round Shaft Extension X X X X X X X X -

abcd

AM-671

abcd

AM-672

c

AM-673

AM-674

AM-675 X X X X X X

AM-676 Shaft Extension X X X X X X X X X X

AM-686 Position Indicator X X X X

e

AM-687

AM-688

AM-689 Rotation Limiter X

i

AM-690-R

AM-691 X X X X

f

AM-692

gh

AM-693-R

a - AM-693 crank arm kit required.

b - Cannot be used with Mx41-634x or Mx40-717x series actuators.

c - Drill appropriate mounting holes where needed.

d - The large “C”-shaped clamps included in AM-693 crank arm kit are required for mounting the actuator. Drill appropriate mounting holes where needed.

e - For shafts to 1.05” diameter or 5/8” square.

f - For shafts to 3/4” and 1.05” diameter (with AM-690 and AM-691, respectively).

g - Use the self-tapping screws and flat washers provided in kit to mount actuator.

h - AM-692 V-bolt kit required. The AM-693-R damper linkage kit is used in conjunction with the AM-687 or AM-688 universal clamps to provide a mechanical linkage between the damper

actuator and the damper shaft when a direct coupling is not possible.

i - Used in conjunction with the AM-687 or AM-688 universal clamps for crankarm functionality in non-direct mounting applications.

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Mounting

Bracket

Weather

Shield &

Base

V-clamp X X X X

Replacement Universal

Clamp

Crank Arm Kit

V-bolt X X X X

Crank Arm Kit X X X X

X X X X X X

X X X X X X

X X X X X X

X X X X X X X X X X

MF4x-7073

MA4x-707x

MS40-7043

X X X X

X X X

X X X X

MS4x-7073

MA4x-715x

MF4x-7153

MS4x-7153

MF40-7173

MA40-717x

MF41-6043

MS40-717x

MF41-6083

MS41-6043

MF41-6153

MS41-6083

MF41-6343

MS41-6153

MS41-634x

F-25096

F-25097

F-25098

Page 8

AM-708

Selection Guide

AM-703

AM-704

AM-706

AM-712

AM-710, AM-717

AM-705

AM-709

AM-711

AM-715

AM-713

AM-714

AM-751

AM-726

AM-727

AM-728

AM-752

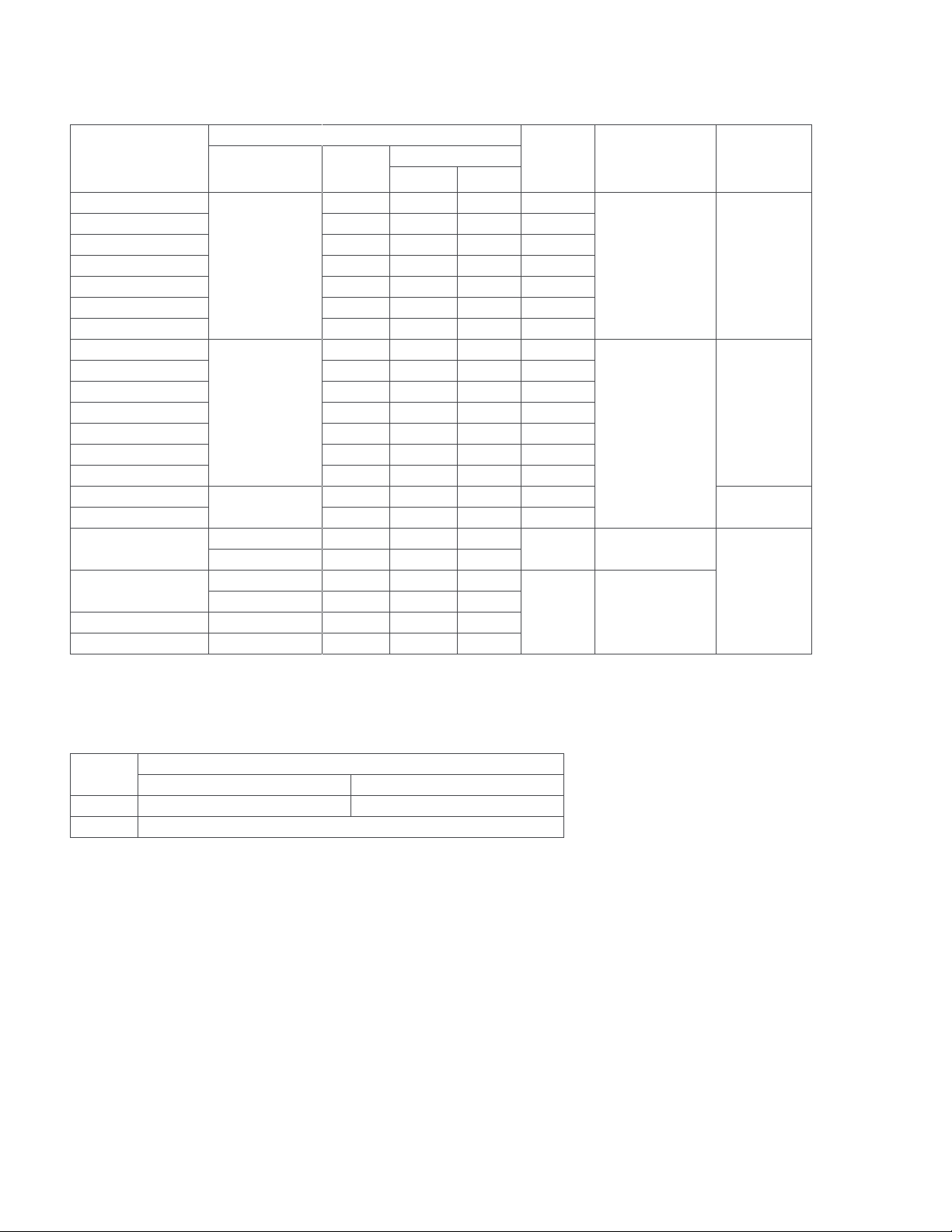

Actuator Accessories Table

Spring Return Actuators

(Series [x] or individuals)

Par t

Numbers

AM-703 Span Adjustment X X X X X X X

AM-704 Modulation Interface X X X X X X X

AM-705

AM-708

AM-709

a

AM-710

AM-711

AM-712 X X

AM-713 Bracket X X

AM-714 Weather Shield X X X X X X F-25097

AM-715

AM-717

AM-726

b

AM-728

AM-751

AM-752 X X X X

a - For shafts to 3/4” diameter round or up to 1/2” square.

b - Cannot be used when creating a linked valve/actuator assembly.

Description

MF40-7043

MA40-704x

Positioner

500W Resistor

Position Indicator

& Stroke Limiter

V-clamp X X

Crank Arm

Adaptor Kit

Crank Arm

Adaptor Kit

Replacement

Universal Clamp

Crank Arm Adaptor

Conduit Adaptor X X X X

Anti-rotation Bracket

X X

X X

X X F-26896

X X F-26896

MA4x-707x

MS40-7043

X X X X X X X X

X X X X X X

MF4x-7073x

MA4x-715x

MS4x-7073x

MF4x-7153x

MS4x-7153x

MF40-7173

MA40-717x

X X X X

Non-Spring Return Actuators

(Series [x] or individuals)

MF41-6043

MS40-7173

X X X X

MF41-6083

MS41-6043

MF41-6153

MS41-6083

MF41-6343

MS41-6153

MS41-634x

Instruction

Installation

F-26895

F-26895AM-706 X X X X X X X X

F-26896

F-26802AM-727 X X X X

F-26898

Document

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 9

Selection Guide

AM-735

AM-741

AM-753

AM-756

Actuator Accessories Table

Par t

Numbers

Description

AM-736

AM-758

Spring Return Actuators

(Series [x] or individuals)

AM-759

AM-754

AM-737

AM-760

AM-740

AM-761

& AM-762

Non-Spring Return Actuators

(Series [x] or individuals)

Instruction

Installation

Document

MF40-7043

MA40-704x

AM-735 Crank Arm Kit X X F-27246

AM-736

AM-737 Universal Crank Arm

AM-740 Replacement Kit X X F-27249

AM-741 Weather Shield X X X X X F-27250

AM-753

AM-754

AM-756 Metric Conduit Adaptor X X X X X X X X X X F-26899

AM-758

AM-760

AM-761

AM-762

TF-711-02

TF-713-02 X X X X —

TF-5521 Pipe Plug X X X X —

a - For Honeywell Floor Mount Mod Motor.

b - For shafts 3/4” round and 5/8” square.

c - For shafts 3/8”…1/2” round and square.

d - Only used on Mx41-707x-xxx, Mx41-715x-xxx.

Crank Arm Kit with

b

Mounting Clamp

c

Short “U” Mounting

Slotted “L” Mounting

7-inch Anti-Rotation

9-inch Anti-Rotation

Sealtight Conduit Con

Bracket

Bracket

Bracket

Bracket

Bracket

nector

a

X X F-26986

X X X X X X X X X X F-25098

-

MA4x-707x

MS40-7043

MF4x-7073x

MS4x-7073x

X X X X

X X X X

MA4x-715x

MF4x-7153x

MS4x-7153x

MF40-7173

MA40-717x

X X X X

X X X X

X X X X —

MF41-6043

MS40-7173

MF41-6083

MS41-6043

MF41-6153

MS41-6083

X X F-27247

X X F-27248

MF41-6343

MS41-6153

MS41-634x

F-26898

F-25096AM-759 Tall “U” Mounting Bracket X X X X

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 10

MF41-6043 and MS41-6043 Actuators

For non-spring return applications requiring floating or proportional modulation

control of dampers and valves in HVAC systems.

Features:

• Direct mount to round, square, or hexagonal damper shaft

• Rated at 44 lb-in. (5N-m) torque, minimum

• Does not require any limit switches

• Manual override allows positioning for installation and manual operation

• MF41-6043 provides floating point control (3-position)

• MS41-6043 provides proportional control compatible with 0…10Vdc

• 5-year warranty

Selection Guide

Actuator Specifications

Inputs

Control Signal

MF41-6043 Floating three-position control, 24Vac.

MS41-6043 Proportional, 0…10Vdc; input

resistance 100kW.

Power Requirements (see table) All 24Vac circuits are Class2.

Connections 3ft. (0.9m) long,

18AWG leads, plenum-rated.

Motor Type Synchronous

Outputs

Electrical

AC Rating 24Vac, 4A resistive, 2A inductive

DC Rating 12…30Vdc, DC 2A

Timing 90sec. at 60 Hz, 108sec. at 50 Hz

Mechanical

Output torque rating 44lb-in. (5N-m).

Stroke Normal angle of rotation is 90°,

limited to a maximum of 95°

Field adjustable to limit travel on

either end of stroke. Set

or 5° preload at the factory

Position indicator Adjustable pointer is provided

for position indication. See

the Note in “Switch Range.”

Output shaft setscrew

tightening torque 55…60lb-in. (6.3…6.8N-m)

Nominal Damper Area Actuator sizing should

Environment

Temperature Limits

Shipping and storage -40…158°F (-40…70°C) ambient

Operating -25…130°F (-32…55°C) ambient

Humidity 5…95% RH, non-condensing

Enclosure Rating NEMA Type 2

Agency Listings

UL UL-873, Underwriters Laboratories.

European Community EMC Directive (89/336/EEC).

cUL Canadian Standards C22.2 No. 24-93.

Accessories

AM-726 Rotary-to-Linear Bracket

AM-727 Rotary-to-Linear Crank Arm

AM-728 Conduit Adapter

AM-741 Weather Shield Kit

Part Numbers

MF41-6043 24 Vac +20/-15% 2.3 — 2.0

MS41-6043 24 Vac +20/-15% 3.3 1.2 3.0

Voltage

damper manufacturer’s specifications

Power Input @ 50/60Hz

be done in accordance with

Emissions (EN50081-1).

Immunity (EN50081-2).

Running VAHolding

VA

Watts

Figure-1 MF41-6043 and MS41-6043 Mounting Dimensions (mm)

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 11

Selection Guide

MF41-6083 and MS41-6083 Actuators

For non-spring return applications requiring floating or proportional modulation

control of dampers and valves in HVAC systems.

Features:

• Direct mount to round, square, or hexagonal damper shaft

• Rated at 88 lb-in. (10N-m) torque, minimum

• Does not require any limit switches

• Manual override allows positioning for installation and manual operation

• MF41-6083 provides floating point control (3-position)

• MS41-6083 provides proportional control compatible with 0…10Vdc

• Models available with: independently adjustable dual auxiliary switches;

adjustable start point (offset) and span

• 5-year warranty

Actuator Specifications

Inputs

Control Signal

MF41-6083 Floating three-position control, 24Vac

MS41-6083 Proportional, 0…10Vdc; input

resistance 100kW.

Control signal adjustment available with MS41-6083-520 and

MS41-6083-522

Start point (offset) Between 0 and 5Vdc (factory setting = 0Vdc)

Span 2…30Vdc

Power Requirements (see table) All 24Vac circuits are Class2

Connections 3ft. (0.9m) long, 18

AWG leads, plenum-rated.

Motor Type Synchronous

Outputs

Electrical

Position output signal: Feedback potentiometer

available with MF41-6083-510 0…1000W < 10mA

Output voltage 0…10Vdc

Maximum output current 1mA

Dual auxiliary switches available with

MF41-6083-502, MS41-6083-502,

MF41-6083-522, and MS41-6083-522

AC Rating 24Vac, 4A resistive, 2A inductive

DC Rating 12…30Vdc, DC 2A

Switching hysteresis 2°

Switch Range

Switch A 0…90° range in 5° intervals

Recommended range usage 0…45°

Factory setting 5°

Switch B 0…90° range in 5° intervals

Recommended range usage 45…90°

Factory setting 85°

Timing 125sec. at 60Hz, 150sec. at 50Hz

Mechanical

Output torque rating 88lb-in. (10N-m)

Stroke Normal angle of rotation is 90°, limited to

Position indicator Adjustable pointer is provided for

Output shaft setscrew

tightening torque 55…60lb-in. (6.3…6.8N-m)

Nominal Damper Area Actuator sizing should be done in

Environment

Temperature Limits

Shipping and storage -40…158°F (-40…70°C) ambient

Operating -25…130°F (-32…55°C) ambient

Humidity 5…95% RH, non-condensing

Enclosure Rating NEMA Type 2

Agency Listings

UL UL-873, Underwriters Laboratories

European Community EMC Directive (89/336/EEC)

cUL Canadian Standards C22.2 No. 24-93

Accessories

AM-726 Rotary-to-Linear Bracket

AM-727 Rotary-to-Linear Crank Arm

AM-728 Conduit Adapter

AM-741 Weather Shield Kit

Part

Numbers

MF41-6083 24 Vac +20/-15% 2.3 — 2.0

MS41-6083 24 Vac +20/-15% 3.3 1.2 3.0

a maximum of 95°. Field adjustable to limit

Voltage

travel on either end of stroke. Set for 5°

See the Note in “Switch Range.”

accordance with damper manufacturer’s

Power Input @ 50/60Hz

Running VAHolding

preload at the factory

position indication.

Emissions (EN50081-1)

Immunity (EN50081-2)

VA

specifications

Watts

Figure 2. MF41-6083 and MS41-6083 Mounting Dimensions (mm)

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 12

MF41-6153 and MS41-6153 Actuators

For non-spring return applications requiring floating or proportional

modulation control of dampers and valves in HVAC systems.

Features:

• Direct mount to round or square damper shaft

• 133 lb-in (15 N-m) torque rating

• Does not require any limit switches

• Manual override to allow positioning for installation and manual operation

• MF41-6153 provides floating point control (drive open-hold-drive closed)

• MS41-6153 provides proportional control compatible with 0…10 Vdc or

0…20 mA dc

• 5-year warranty

Actuator Specifications

Inputs

Control Signal

MF41-6153 Three position

MS41-6153 Proportional, 0…10Vdc, input

resistance 100kW

Power Requirements (see table) All 24Vac circuits are Class2

Connections 3ft. (91 cm) long plenum-rated

cables, 18AWG color coded leads

Motor Type Synchronous

Outputs

Electrical

Timing Approx. 125sec. at 60Hz;

150sec. at 50Hz

Dual Auxiliary Switch Ratings

AC Rating 24Vac, AC6A resistive, AC2A inductive

DC Rating 12…30Vdc, DC 2A

Switch Ranges

Switch A 0°…90° with 5° intervals

Recommended Range Usage 0°…45°

Factory Setting 5°

Switch B 0°…90° with 5° intervals.

Recommended Range Usage 45°…90°

Factory Setting 85°

Switch Hysteresis 2°

Mechanical

Output torque rating 133 lb-in (15 N-m)

Stroke Angle of rotation is limited to

a nominal 90° (maximum 95°), field

adjustable to limit travel on either end

of stroke. Set for 5° preload at the factory

Position indicator Adjustable pointer is provided

for position indication

Damper Shaft Clamp Direct coupled using a through

hole output hub

Shaft Sizes 1/4” to 3/4” (6.4…20.5mm) diameter round

1/4”…1/2” (6.4…13mm) square

Minimum Shaft Length 3/4” (20mm)

Nominal Damper Area Actuator sizing should be done

in accordance with damper

manufacturer’s specifications

Weight 2.2lb (1kg)

Environmental

Temperature Limits

Shipping and storage -40…158°F (-40…70°C) ambient

Operating -25…130°F (32…55°C)

Humidity 5…95% RH, non-condensing

Locations NEMA1 (IECIP54)

Agency Listings (Actuator)

UL UL-873, Underwriters Laboratories

European Community EMC Directive (89/336/EEC)

cUL Canadian Standards C22.2 No. 24-93

Accessories

AM-735 Crank Arm Kit

AM-736 Crank Arm Kit with Bracket

AM-737 Universal Crank Arm for Honeywell Floor Mount Mod Motor

AM-740 Replacement Kit

AM-741 Weather Shield Kit

Part

Numbers

MF41-6153 24 Vac +20/-15% 3.0 — 3.0

MS41-6153 24 Vac +20/-15% 5.0 1.2 4.0

Figure3. MF41-6153 and MS41-6153 Mounting Dimensions (mm)

Voltage

Immunity (EN61000-6-2)

Emission (EN50081-1)

Power Input @ 50/60Hz

Running VAHolding

VA

Selection Guide

Watts

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 13

Selection Guide

MA40-704x, MF40-7043, and MS40-7043 Series Actuators

For spring return applications requiring floating, two-position, or proportional

modulation control of dampers and valves in HVAC systems.

Features:

• Direct mount to round or square damper shaft

• 35 lb-in (4 N-m) torque rating

• Overload protection throughout rotation

• Optional built-in auxiliary switches

• True mechanical clockwise or counterclockwise spring return operation for

reliable, positive close-off in airtight applications

• Visual position indicator

• Direct acting or reverse acting control mode available on proportional

models

• Rotation limiting available

• Rugged die-cast housing for NEMA 2/IP54 rating

• 5-year warranty

Stroke Rotation is limited to 95° ± 5° maximum,

Actuator Specifications

Inputs

Control Signal

MA40-704x and MA40-704x-501 On-off. SPST control contacts

or Triacs (500mA rated)

MF40-7043 and MF40-7043-501 Floating point control, 24 Vac

MS40-7043 and MS40-7043-501 Spring return, proportional,

2…10Vdc or 4to 20mA dc

with a 500W resistor

Power Requirements (see table) All 24Vac circuits are Class2

All circuits 30Vac and above are Class1

Connections

MA40-704x and MA40-704x-501 3ft. (91 cm) long, appliance cables,

1/2in. conduit connector.

For M20 Metric conduit, use

AM-756 adaptor.

MF40-7043 and MF40-7043-501,

MS40-7043 and MS40-7043-501 3ft. (91cm) long, plenum-rated

cables, 1/2 in. conduit connector.

For M20 Metric conduit, use

AM-756 adaptor.

Motor Type

Brush MA40-704x

Brushless DC MF40-7043, MS40-7043

Outputs

Electrical

Control Mode Switch provided for selection of direct

acting or reverse acting control mode

on proportional models

Timing Approximate timing for MA40-704x series is

50 seconds. Approximate timing for MF40-7043

series or M40-7043 series is 130 seconds

One auxiliary switch available with Mx40-7043-501 and MS40-7043MP5, SPDT 6A resistive @ 24 Vac, adjustable 0…95° (0…1 scale).

Switch meets VDE requirements for 6 (1.5)A, 24 Vac.

One auxiliary switch available with MA40-7040-501 or MA40-7041-501,

SPDT 6A resistive @ 250 Vac, adjustable 15…95° (MIN…1 scale).

Switch meets VDE requirements for 6 (1.5)A, 250 Vac.

Position Feedback Voltage “AO” 2…10Vdc (maximum 0.5mA)

output signal for position feedback

or operation of up to four slave actuators.

Mechanical

Output Torque Rating 35lb-in. (4N-m) minimum,

150lb-in. (17 N-m) maximum

Position Indicator Visual indicator, 0…1 (0is

Direction of Rotation CW or CCW rotation is

Damper Shaft Clamp Direct coupled using a

Damper Shaft Size Up to 5/8” in diameter and

Nominal Damper Area Actuator sizing should be done

Environment

Temperature Limits

Shipping and storage -40…160°F (-40…71°C) ambient.

Operating -22…140 °F (-30…60 °C)

Humidity 5…95% RH, non-condensing

Enclosure Rating NEMA 2 (IEC IP54)

Agency Listings

UL UL 873, Underwriters Laboratories

cUL Canadian Standards C22.2 No. 24

European Community EMC Directive (89/336/EEC)

Australia This product meets requirements to bear the

Authority under the Radiocommunications Act 1992

Part Numbers

MA40-7043 and

MA40-7043-501

MS40-7043 and

MS40-7043-501

MS40-7043-MP

MS40-7043-MP5

MF40-7043 and

MF40-7043-501

MA40-7040 and

MA40-7040-501

MA40-7041 and

MA40-7041-501

Voltage

50/60Hz

24 Vac ± 20%

22…30 Vdc

24 Vac ± 20%

22…30 Vdc

24 Vac ± 20%

22…30 Vdc

24 Vac ± 20%

22…30 Vdc

120 Vac ±

10%

230 Vac ±

10%

adjustable from 40…95 ° with a

mechanical stop

the spring-return position)

available through reversible mounting

through hole output hub

1/2” square. With AM-710, up to

3/4” in diameter and 1/2” square

in accordance with damper

manufacturer’s specifications

(File #9429 Category Temperature-Indicating

and Regulating Equipment)

Low Voltage Directive (72/23/EEC)

RSM Mark according to the terms

specified by the Communications

Running (Hz) Holding (Hz)

50 60

VA W VA W W W

4.4 2.9 4.4 2.9 0.11 0.8 0.8

5.6 4.2 5.6 4.2 0.15 2.4 2.4

6.6 5.0 6.6 5.0 0.17 3.2 3.2

5.9 4.4 5.9 4.4 0.17 2.9 2.9

6.4 3.8 4.3 3.4 — 1.6 1.2

5.8 4.1 4.6 3.9 — 1.5 1.2

DC

Amps

50 60

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 14

Selection Guide

Figure 4. Mx40-704x Series Mounting Dimensions (mm)

MA41-707X, MF41-7073, and MS41-7073 Series Actuators

For spring return applications requiring floating, two-position, or

proportional modulation control of dampers and valves in HVAC

systems.

Features:

• Direct mount to round or square damper shaft

• 60 lb-in (7 N-m) torque rating

• Overload protection throughout rotation

• Optional built-in auxiliary switches

• Provides true mechanical clockwise or counterclockwise

spring return operation for reliable positive close-off in airtight

applications

• Visual position indication

• Direct acting or reverse acting control mode available on

proportional models

• Rotation limiting available

• Rugged die-cast housing for NEMA 2/IP54 rating

• Manual override

• 5-year warranty

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 15

Selection Guide

Actuator Specifications

Inputs

Control Signal

MA41-707x and MA41-707x-502 On-off. SPST control contacts

or Triacs (500 mA rated)

MF41-7073 and MF41-7073-502 Floating point control, 24 Vac

MS41-7073 and MS41-7073-502 Spring return, proportional,

2…10Vdc or 4…20mA dc

with a 500 W resistor

Power Requirements (see table). All 24Vac circuits are Class2. All

circuits 30 Vac and above are Class 1

Connections 3ft. (91 cm) long, appliance

cables, 1/2in. conduit connectors

For M20 Metric conduit, use AM-756 adaptor

Motor Type

Brush MA41-707x

Brushless DC MF41-7073, MS41-7073

Outputs

Electrical

Control Mode Switch provided for selection

of direct acting or reverse acting

control mode on proportional models

Timing: Approximate timing for MA41-707x

series is 80 seconds. Approximate

timing for MF41-7073 series or

MS41-7073 series is 195 seconds.

Two auxiliary switches available with Mx41-7071-502 or Mx41-7070502, SPDT 7A resistive @ 250 Vac, one fixed @ 5° and one adjustable

25…85°. Switch meets VDE requirements for 7 (2.5)A, 250 Vac.

Two auxiliary switches available with Mx41-7073-502, SPDT 7A resistive @ 24 Vac, one fixed @ 5° and one adjustable 25 to 85°. Switches

meet VDE requirements for 6 (1.5)A, 24 Vac.

Enclosure Rating NEMA 1

NEMA 2 (IEC IP54) with conduit

connector in the down position

Agency Listings

UL UL 873, Underwriters Laboratories

(File #9429 Category Temperature-Indicating

and Regulating Equipment)

cUL Canadian Standards C22.2 No. 24

European Community EMC Directive (89/336/EEC)

Low Voltage Directive (72/23/EEC)

Australia This product meets requirements to bear the RSM

Mark according to the terms specified

by the Communications Authority

under the Radiocommunications Act 1992

Part Numbers Voltage

MA41-7073 and

MA41-7073-502

MS41-7073 and

MS41-7073-502

MF41-7073 and

MF41-7073-502

MA41-7070 and

MA41-7070-502

MA41-7071 and

MA41-7071-502

50/60Hz

24 Vac ± 20%

22…30 Vdc

24 Vac ± 20%

22…30 Vdc

24 Vac ± 20%

22…30 Vdc

120 Vac ± 10% 10.7 4.2 5.6 3.6 — 2.0 1.2

230 Vac ± 10% 17.0 5.1 8.0 4.0 — 2.7 1.4

Running (Hz) Holding (Hz)

50 60 DC

VA W VA W W W

4.8 3.2 4.8 3.2 0.13 0.8 0.8

5.8 4.6 5.8 4.6 0.17 2.3 2.3

6.2 4.8 6.2 4.8 0.18 2.8 2.8

50 60

Amps

Position Feedback Voltage “AO” 2…10Vdc (maximum 0.5mA)

output signal for position

feedback or operation of up

to four slave actuators.

Mechanical

Output Torque Rating 60lb-in. (7N-m) minimum,

250 lb-in. (28 N-m) maximum

Stroke Rotation is limited to 95° ± 5° maximum,

adjustable from 30…95° with

AM-689 rotation limiter

Position Indicator Pointer and (-5…90°) scale are

provided for position indication (-5°is

the normal, or spring-return, position)

Direction of Rotation CW or CCW rotation is available

through reversible mounting

Damper Shaft Clamp Direct coupled using a through

hole output hub

Damper Shaft Size Up to 3/4” in diameter and

1/2” square. With AM-687, up to 1.05”

in diameter and 5/8” square

Nominal Damper Area Actuator sizing should be done

in accordance with damper

manufacturer’s specifications

Manual Override For Mx41-707x manual over ride

rotation is adjustable from -5°…85° by

using manual override crank

Environmental

Temperature Limits

Shipping and storage -40…160°F (-40…71°C) ambient

Operating -22…140 °F (-30…60 °C)

Humidity 5…95% RH, non-condensing

Figure 5. Mx41-707x Series Mounting Dimensions (mm)

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 16

Selection Guide

MA41-

715X, MF41-7153, and MS41-7153 Series Actuators

For spring return applications requiring floating, two-position, or

proportional modulation control of dampers and valves in HVAC

systems.

Features:

• Direct mount to round or square damper shaft

• 133 lb-in (15 N-m) torque rating

• Overload protection throughout rotation

• Optional built-in auxiliary switches

• True mechanical clockwise or counterclockwise spring return

operation for reliable positive close-off in airtight applications

• Visual position indicator

• Direct acting or reverse acting control mode available on

proportional models

• Rotation limiting available

• Rugged die-cast housings for NEMA 2/IP54

• Manual override

• 5-year warranty

Actuator Specifications

Inputs

Control Signal

MA41-715x and MA41-715x-502 On-off. SPST control

MF41-7153 and MF41-7153-502 Floating point control 24 Vac

MS41-7153 and MS41-7153-502 Propor tional, 2…10Vdc or

Power Requirements All 24Vac circuits are Class2

Connections 3ft. (91 cm) long, appliance

For M20 Metric conduit, use AM-756 adaptor

Motor Type

BrushlessDC MA41-715x, MF41-7153, MS41-7153

Outputs

Electrical

Control Mode Switch provided for selection of

Timing Approximate timing is 190 seconds

Two auxiliary switches available with MA41-7151-502 or MF41-7150502, SPDT 7A resistive @ 250 Vac, one fixed @ 5° and one adjustable

25…85°. Switch meets VDE requirements for 7 (2.5)A, 250 Vac.

Two auxiliary switches available with Mx41-7153-502, SPDT 7A resistive

@ 24 Vac, one fixed @ 5° and one adjustable 25…85°. Switches meet

VDE requirements for 6 (1.5)A, 24 Vac.

Position Feedback Voltage 2…10Vdc

Mechanical

Output Torque Rating 133lb-in(15N-m) minimum,

Stroke Rotation is limited to 95° ± 5°

Position Indicator Pointer and (-5…90°) scale are

Direction of Rotation CW or CCW rotation is

contacts or Triacs (500 mA rated)

4to20mA dc with a

500W resistor.

All circuits 30Vac and above are Class1

cable, 1/2in. conduit connectors

direct acting or reverse acting control

mode on proportional models

(maximum 0.5mA) output signal for

position feedback or operation of up

to four slave actuators

350 lb-in. (40 N-m) maximum

maximum, adjustable from

30…95° with AM-689 rotation limiter

provided for position indication (-5°

is the normal, or spring-return, position)

available through reversible mounting

Damper Shaft Clamp Direct coupled using a through

hole output hub.

Damper Shaft Size Up to 3/4” in diameter and

1/2” square. With AM-687, up to

1.05” in diameter and 5/8” square

Nominal Damper Area Actuator sizing should be

done in accordance with damper

manufacturer’s specifications.

Manual Override For Mx41-715x rotation is

adjustable from -5°…85° by using

manual override crank

Environmental

Temperature Limits

Shipping and storage -40…160°F (-40…71°C) ambient

Operating -22…140 °F (-30…60 °C)

Humidity 5…95% RH, non-condensing

Enclosure Rating NEMA 1. NEMA 2 (IEC IP54)

with conduit connector in the down position.

Agency Listings

UL UL 873, Underwriters Laboratories

(File #9429 Category Temperature-Indicating

and Regulating Equipment)

cUL Canadian Standards C22.2 No. 24

European Community EMC Directive (89/336/EEC)

Low Voltage Directive (72/23/EEC)

Australia This product meets requirements to bear the

RSM Mark according to the terms specified by

the Communications Authority under the

Radiocommunications Act 1992.

Part Numbers Voltage

MA41-7153 and

MA41-7153-502

MS41-7153 and

MS41-7153-502

MF41-7153 and

MF41-7153-502

MA41-7150 and

MA41-7150-502

MA41-7151 and

MA41-7151-502

50/60Hz

24 Vac ± 20%

22…30 Vdc

24 Vac ± 20%

22…30 Vdc

24 Vac ± 20%

22…30 Vdc

120 Vac ±

10%

230 Vac ±

10%

Running (Hz) Holding

50 60 DC

VA W VA W W W

9.8 7.5 9.7 7.5 0.29 2.8 2.8

9.8 7.4 9.7 7.4 0.28 2.9 2.9

9.8 7.7 9.7 7.7 0.30 3.3 3.3

11.7 8.8 10.0 8.4 — 3.6 5.0

15.5 9.5 10.6 8.5 — 4.6 3.3

(Hz)

50 60

Amps

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 17

Selection Guide

Figure 6. Mx41-715x Series Mounting Dimensions (mm)

MA40-717X, MF40-7173, and MS40-717x Series Actuators

For spring return applications requiring floating, two-position, or proportional

modulation control of dampers and valves in HVAC systems.

Features:

• Direct mount to round or square damper shaft

• 150 lb-in (17 N-m) torque rating

• Overload protection throughout rotation

• Oil immersed gear train provides continuous lubrication

• NEMA 4 housing (IEC IP56)

• Automatic current sensing motor control provides extended reliability and

repeatable timing

• Provides true mechanical clockwise or counterclockwise spring return

operation for reliable positive close-off in airtight applications

• MA40-717x models provide on-off control

• MF40-7173 models provide floating point control (drive open-hold-drive

closed)

• MS40-717x models provide proportional control compatible with 2…10 Vdc

or 4…20 mA dc with the addition of a 500 ohm resistor (not included)

• 5-year warranty

• Can be double mounted (gang mounting) to accommodate high torque

application requirements (2 to 4 actuators)

• MS40-717x models provide position feedback signal

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 18

Selection Guide

Actuator Specifications

Inputs

Control Signal

MA40-717x Two wire, SPST or Triacs

MF40-7173 SPDT floating control output,

Triacs (500 mA rated), or 2 SPST contacts

MS40-717x proportional, 2…10Vdc or 4…20mA dc

with the addition of a 500 ohm

resistor (not included).

Power Requirements (see table) All 24Vac and 22…30 Vdc circuits

are Class2. All circuits 30 Vac

and above are Class 1

Impedance 2…10 Vdc, 121KW. 4…20 mA dc,

500W (user supplied)

(MS40-717x models only)

Connections

Class 1:

Class 2 Power and Control: 24 inch (61 cm) long appliance

cables, 18AWG color coded leads.

1/2in. conduit connector.

For M20 Metric conduit, use AM-756 adaptor.

36 inch (91 cm) Long, 22 AWG color coded appliance cable pigtail

leads. 1/2in. conduit connector. For M20 Metric conduit, use AM-756

adaptor.

Motor Type Brushless DC

Outputs

Electrical

Stroke Electronically limited to 92° ±1° (MS)

MF-MA Mechanically limited To 101° ±1°

Timing Approximate timing is 147 sec. (MS);

162 sec. for MF and MA models

Mechanical

Output Torque Rating 150lb-in. (17N-m) minimum, 545lb-in.

(61.8N-m) maximum

Position Indicator Pointer and scale are provided for

position indication (0°is the

normal, or spring-return, position)

Direction of Rotation CW or CCW rotation is available

through reversible mounting

Damper Shaft Clamp Direct coupled using a

through hole output hub.

Damper Shaft Size Up to 3/4” in diameter, 1/2” square.

With AM-687, up to 1.05” in

diameter and 5/8” square

Nominal Damper Area Actuator sizing should be done

in accordance with damper

manufacturer’s specifications

Environmental

Temperature Limits

Shipping and storage -40…160°F (-40…71°C) ambient

Operating -25…140°F (-32…60°C)

Humidity 5…95% RH, non-condensing

Locations NEMA 1 (IEC IP10)

NEMA 4 (IEC IP56) with customer

supplied water tight conduit connectors

Agency Listings

UL UL 873, Underwriters Laboratories

(File #9429 Category Temperature-Indicating

and Regulating Equipment).

European Community EMC Directive (2004/108/EC)

Low Voltage Directive (72/23/EEC)

cUL Canadian Standards C22.2 No. 24-93

Australia This product meets requirements

to bear the RSM Mark according to the

terms specified by the Communications

Authority under the Radiocommunications Act 1992

Part

Numbers

MA40-7173

MS40-7173

MF40-7173

MA40-7170 120 Vac ±10% 8.4 6.6 6.2

MS40-7170 120 Vac ±10% 8.5 5.2 6.4

MA40-7171 240 Vac ±10% 9.8 8.5 6.5

MS40-7171 240 Vac ±10% 10.8 9.0 7.2

Power Input @ 50/60Hz

Voltage Running VA Holding VA Watts

24 Vac ±20% 7.4 5.1 5.3

22…30 Vdc 5.0 3.0 5.0

24 Vac ±20% 7.8 4.7 5.5

22…30 Vdc 5.6 2.5 5.0

24 Vac ±20% 8.1 5.3 5.8

22…30 Vdc 5.7 3.6 5.7

Figure 7. Mx40-717x Series Mounting Dimensions (mm)

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 19

Selection Guide

MF41-6343 and MS41-634x Series Actuators

For non-spring return applications requiring floating or

proportional modulation control of dampers and valves in HVAC

systems.

Features:

• Direct mount to round or square damper shaft

• 300 lb-in (34 N-m) torque rating

• Overload protection throughout rotation

• Oil immersed gear train provides continuous lubrication

• NEMA 4 housing (IEC IP56)

• Manual override to allow positioning for installation and

manual operation

• Automatic current sensing motor control provides extended

reliability and repeatable timing

• MF41-6343 models provide floating point control (drive openhold-drive closed)

Nominal Damper Area Actuator sizing should be done in

• MS41-634x models provide proportional control compatible

with 2…10 Vdc or 4…20 mA dc with the addition of a 500

ohm resistor (not included)

• 5-year warranty

• Can be double-mounted (gang mounted) to accommodate

high torque application requirements (2 to 4 actuators)

• MS41-634x models provide position feedback signal

Manual Override Activated by the manual override crank

Environmental

Temperature Limits

Shipping and storage -40…160°F (-40…71°C) ambient.

Operating -25…140°F (-32…60°C)

Humidity 5…95% RH, non-condensing

Enclosure Ratings NEMA 1 (IEC IP10).

Actuator Specifications

Inputs

Control Signal

MF41-6343 SPDT floating control output,

Triacs (500 mA rated), or 2 SPST contacts

MS41-634x proportional, 2…10Vdc or 4…20mA dc

with the addition of a 500 ohm

resistor (not included).

Power Requirements (see table)

All 24Vac and 22…30 Vdc circuits are Class2.

All circuits 30 Vac and above are Class 1.

Connections

Class 1

Class 2 Power and Control 24 inch (61 cm) long appliance cables,

1/2in. conduit connector.

For M20 Metric conduit, use AM-756 adaptor

36 inch (91 cm) long, 22 AWG color coded appliance cable pigtail

leads. 1/2in. conduit connector. For M20 Metric conduit, use AM-756

adaptor.

Motor Type Brushless DC

Outputs

Electrical

Stroke Electronically limited to 92° ±1° (MS)

MF Mechanically limited To 101° ±1°

Timing Approximate timing is 148 sec. (MS)

and 162 sec. for MF models.

Mechanical

Output torque rating 300lb-in. (34N-m) minimum,

650lb-in. (73.7N-m) maximum

Position indicator Pointer and scale are provided

for position indication)

Direction of rotation CW or CCW rotation is available

through reversible mounting

Damper Shaft Clamp Direct coupled using a through

hole output hub

Damper Shaft Size 3/8”…1/2” round and 3/8”…1/2” square

With AM-754, up to 1.05” in diameter

and 5/8” square

Agency Listings

UL UL 873, Underwriters Laboratories

European Community EMC Directive (2004/108/EC)

cUL Canadian Standards C22.2 No. 24-93

Australia This product meets requirements to

Part Numbers Power Input @ 50/60Hz

MS41-6343 24 Vac ±20% 5.6 4.0 3.6

MS41-6340 120 Vac ±10% 7.5 6.2 4.7

MS41-6341 240 Vac ±10% 9.0 8.1 5.0

MF41-6343 24 Vac ±20% 5.7 4.1 3.9

accordance with damper

manufacturer’s specifications.

NEMA 4 (IEC IP56) with customer

supplied water tight conduit connectors.

(File #9429 Category Temperature-Indicating

and Regulating Equipment)

Low Voltage Directive (72/23/EEC)

bear the RSM Mark according to

the terms specified by the Communications

Authority under the Radiocommunications Act 1992.

Voltage Running VAHolding VAWatts

22…30 Vdc 3.4 2.2 3.4

22…30 Vdc 4.1 3.0 4.1

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 20

Figure 8. MX41-634X Series Mounting Dimensions

Selection Guide

Damper Actuator Cross Reference

The cross reference tables list Direct-Coupled Actuators which may replace obsolete SEC and Belimo devices, as well as older

TAC devices. The tables list two-position, floating, and proportional actuators. The devices to be replaced are listed alphanumerically in the left-hand column, with the suggested replacement in the center column. The replacement actuators in this list represent what we believe are equivalent units.

SEC to Current Actuators

SEC P/N Current P/N Description 2 F P

MA40-7041 230 Vac 35 lb-in. (4N-m) (2-position) X

MA40-7041-501 230 Vac 35 lb-in. (4N-m) w/aux switch (2-position) X

MA41-7071 230 Vac 60 lb-in. (7N-m) (2-position) w/manual override X

MA41-7071-502 230 Vac 60 lb-in. (7N-m) w/aux switch (2-position) w/manual override X

MA40-7170 120 Vac 150 lb-in. (17N-m) (17N-m) (2-position) X

MA40-7171 240 Vac 150 lb-in. (17N-m) (2-position) X

MA40-7173 24 Vac or 22…30 Vdc 150 lb-in. (17N-m) (2-position) X

MF41-7073 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) (floating) w/manual override X

MF41-7073-502 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) w/aux switch (floating) w/manual override X

—

MA-7101 MA40-7040 120 Vac 35 lb-in. (4N-m) (2-position) X

MA-7101-500 MA40-7040-501 120 Vac 35 lb-in. (4N-m) w/aux switch (2-position) X

MA-7103 MA40-7043 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) (2-position) X

MA-7103-500 MA40-7043-501 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) w/aux switch (2-position) X

MA-7201 MA41-7070 120 Vac 60 lb-in. (7N-m) (2-position) w/manual override X

MA-7201-500 MA41-7070-502 120 Vac 60 lb-in. (7N-m) w/aux switch (2-position) w/manual override X

MA-7203 MA41-7073 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) (2-position) w/manual override X

MA-7203-500 MA41-7073-502 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) w/aux switch (2-position) w/manual override X

MF41-7153 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) (floating) w/manual override X

MF41-7153-502 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) w/aux switch (floating) w/manual override X

MF40-7173 24 Vac or 22…30 Vdc 150 lb-in. (17N-m) (floating) X

MS41-7073-502 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) w/aux switch (proportional) w/manual override X

MS41-7153-502 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) w/aux switch (proportional) w/manual override X

MS40-7170 120 Vac 150 lb-in. (17N-m) (proportional) X

MS40-7171 240 Vac 150 lb-in. (17N-m) (proportional) X

MS40-7173 24 Vac or 22…30 Vdc 150 lb-in. (17N-m) (proportional) X

MS41-6340 120 Vac 300 lb-in. (34N-m) NSR (proportional) X

MS41-6341 240 Vac 300 lb-in. (34N-m) NSR (proportional) X

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Page 21

Selection Guide

SEC P/N Current P/N Description 2 F P

MA-7501 MA41-7150 120 Vac 133 lb-in. (15N-m) (2-position) w/manual override X

MA-7501-502 MA41-7150-502 120 Vac 133 lb-in. (15N-m) w/aux switch (2-position) w/manual override X

MA-7503 MA41-7153 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) (2-position) w/manual override X

MA-7503-502 MA41-7153-502 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) w/aux switch (2-position) w/manual override X

MA-7505 MA41-7151 230 Vac 133 lb-in. (15N-m) (2-position) w/manual override X

MA-7505-502 MA41-7151-502 230 Vac 133 lb-in. (15N-m) w/aux switch (2-position) w/manual override X

MF41-6043 24 Vac 35 lb-in. (4N-m) NSR (floating) X

MF-6103

MF-6203

MF-6633 MF41-6153 24 Vac 133 lb-in. (15N-m) spdt NSR (floating) X

MF-6733 MF41-6343 24 Vac or 33-30 Vdc 300 lb-in. (34N-m) spdt NSR (floating) X

MF-7103 MF40-7043 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) (floating) X

MF-7103-500 MF40-7043-501 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) w/aux switch (floating) X

MS-6103

MS-6233

MS-6633

MS-6733 MS41-6343 24 Vac or 22…30 Vdc 300 lb-in. (34N-m) 2-10 Vdc/4-20 mA dc NSR (proportional) X

MS-7103 MS40-7043 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) (proportional) X

MS-7103-500 MS40-7043-501 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) w/aux switch (proportional) X

MS-7203 MS41-7073 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) (proportional) w/manual override X

MS-7433 MS41-7153 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) (proportional) w/manual override X

MF41-6043-502 24 Vac 35 lb-in. (4N-m) NSR (floating), w/two aux switches X

MF41-6043-510 24 Vac 35 lb-in. (4N-m) NSR (floating), feedback potentiometer X

MF41-6083 24 Vac 70 lb-in. (8N-m) spdt NSR (floating) X

MF41-6083-502 24 Vac 70 lb-in. (8N-m) NSR (floating), w/two aux switches X

MF41-6083-510 24 Vac 70 lb-in. (8N-m) NSR (floating), feedback potentiometer X

MS41-6043 24 Vac 35 lb-in. (4N-m) NSR (proportional) X

MS41-6043-502 24 Vac 35 lb-in. (4N-m) NSR (proportional), w/two aux switches X

MS41-6043-520 24 Vac 35 lb-in. (4N-m) NSR (proportional), adjustable start point (offset) and span X

MS41-6043-522 24 Vac 35 lb-in. (4N-m) NSR (proportional), w/two aux switches, adjustable start point (offset) and span X

MS41-6083 24 Vac 70 lb-in. (8N-m) 2-10 Vdc/4-20 mA dc NSR (proportional) X

MS41-6083-502 24 Vac 70 lb-in. (8N-m) NSR (proportional), w/two aux switches X

MS41-6083-520 24 Vac 70 lb-in. (8N-m) NSR (proportional), adjustable start point (offset) and span X

MS41-6083-522 24 Vac 70 lb-in. (8N-m) NSR (proportional), w/two aux switches, adjustable start point (offset) and span X

MS41-6153 24 Vac 133 lb-in. (15N-m) 2-10 Vdc/4-20 mA dc NSR (proportional) X

MS41-6153-502 24 Vac 133 lb-in. (15N-m) NSR (proportional), w/two aux switches X

TAC Old to Current Actuators

TAC Old Current Description 2 F P

MF40-6043 MF41-6043 24 Vac 35 lb-in. (4N-m) NSR (floating) X

MF40-6043-510 MF41-6043-510 24 Vac 35 lb-in. (4N-m) NSR (floating), feedback potentiometer X

MF40-6043-520 MF41-6043-520 24 Vac 35 lb-in. (4N-m) NSR (floating), adjustable start point (offset) and span X

MF40-6043-522 MF41-6043-522 24 Vac 35 lb-in. (4N-m) NSR (floating), w/ two aux. switches, adjustable start point (offset) & span X

MF40-6083 MF41-6083 24 Vac 70 lb-in. (8N-m) NSR (floating) X

MF40-6153 MF41-6153 24 Vac 133 lb-in. (15N-m) NSR (floating) X

MF40-6343 MF41-6343 24 Vac or 22…30 Vdc 300 lb-in. (34N-m) NSR (floating) X

MS40-6043 MS41-6043 24 Vac 35 lb-in. (4N-m) NSR (proportional) X

MS40-6043-510 MS41-6043-510 24 Vac 35 lb-in. (4N-m) NSR (proportional), feedback potentiometer X

MS40-6043-520 MS41-6043-520 24 Vac 35 lb-in. (4N-m) NSR (proportional), adjustable start point (offset) and span X

MS40-6043-522 MS41-6043-522 24 Vac 35 lb-in. (4N-m) NSR (proportional), w/ two aux. switches, adjustable start point (offset) & span X

MS40-6083 MS41-6083 24 Vac 70 lb-in. (8N-m) NSR (proportional) X

MS40-6153 MS41-6153 24 Vac 133 lb-in. (15N-m) NSR (proportional) X

MS40-6343 MS41-6343 24 Vac or 22…30 Vdc 300 lb-in. (34N-m) NSR (proportional) X

Belimo to Current Actuators

Belimo P/N Current P/N Description 2 F P

— MA40-7170 120 Vac 150 lb-in. (17N-m) (2-position) X

— MA40-7171 240 Vac 150 lb-in. (17N-m) (2-position) X

— MA40-7173 24 Vac or 22…30 Vdc 150 lb-in. (17N-m) (2-position) X

— MF40-7073 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) (floating) X

— MF41-7073 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) (floating) w/manual override X

— MF40-7073-502 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) w/aux switch (floating) X

— MF41-7073-502 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) w/aux switch (floating) w/manual override X

— MF40-7173 24 Vac or 22…30 Vdc 150 lb-in. (17N-m) (floating) X

© 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies. May, 2019 tc

Docume nt Number: F-26 646 -12

Page 22

Selection Guide

Belimo P/N Current P/N Description 2 F P

— MS41-7073-502 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) w/aux switch (proportional) w/manual override X

— MS40-7170 120 Vac 150 lb-in. (17N-m) (proportional) X

— MS40-7171 240 Vac 150 lb-in. (17N-m) (proportional) X

— MS40-7173 24 Vac or 22…30 Vdc 150 lb-in. (17N-m) (proportional) X

— MS41-6340 120 Vac 300 lb-in. (34N-m) NSR (proportional) X

— MS41-6341 240 Vac 300 lb-in. (34N-m) NSR (proportional) X

AF120

AF120-S

MA41-7150 120 Vac 133 lb-in. (15N-m) (2-position) w/manual override X

MA41-7150-502 120 Vac 133 lb-in. (15N-m) w/aux switch (2-position) w/manual override X

AF230 MA41-7151 230 Vac 133 lb-in. (15N-m) (2-position) w/manual override X

AF230-S MA41-7151-502 230 Vac 133 lb-in. (15N-m) w/aux switch (2-position) w/manual override X

AF24 MA41-7153 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) (2-position) w/manual override X

AF24-3 MF41-7153 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) (floating) w/manual override X

AF24-S MA41-7153-502 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) w/aux switch (2-position) w/manual override X

AF24-3-S MF41-7153-502 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) w/aux switch (floating) w/manual override X

AF24-SR MS41-7153 24 Vac or 22…30 Vdc 133 lb-in. (15N-m) (proportional) w/manual override X

AF24-SR-S MS41-7153-502 24 Vac or 22…30 Vdc, 133 lb-in. (15N-m) w/aux switch (proportional) w/manual override X

AFR24-SR

24 Vdc or 22…30 Vdc, 133 lb-in. (15N-m) (proportional) X

AFR24-3 24 Vdc or 22…30 Vdc, 133 lb-in. (15N-m) (floating) X

AFR24-3-S 24 Vdc or 22…30 Vdc, 133 lb-in. (15N-m) (floating) X

AFR120 120 Vac, 133 lb-in. (15N-m) (2-position) X

—

AFR120-S 120 Vac, 133 lb-in. (15N-m) (2-position), w/aux switch X

AFR24 24 Vac or 22…30 Vdc, 133 lb-in. (15N-m) (2-position) X

AFR24-S 24 Vac or 22…30 Vdc, 133 lb-in. (15N-m) (2-position), w/aux switch X

GM24 MF41-6343 24 Vac or 22…30 Vdc 300 lb-in. (34N-m) spdt NSR (floating) X

GM24-SR MS41-6343 24 Vac or 22…30 Vdc300 lb-in. (34N-m) 2…10 Vdc/4…20 mA dc NSR (proportional) X

LF120 MA40-7040 120 Vac 35 lb-in. (4N-m) (2-position) X

LF120-S MA40-7040-501 120 Vac 35 lb-in. (4N-m) w/aux switch (2-position) X

LF230 MA40-7041 230 Vac 35 lb-in. (4N-m) (2-position) X

LF230-S MA40-7041-501 230 Vac 35 lb-in. (4N-m) w/aux switch (2-position) X

LF24 MA40-7043 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) (2-position) X

LF24-3 MF40-7043 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) (floating) X

LF24-S MA40-7043-501 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) w/aux switch (2-position) X

LF24-3-S MF40-7043-501 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) w/aux switch (floating) X

LF24-SR MS40-7043

24 Vac or 22…30 Vdc 35 lb-in. (4N-m) (proportional) X

LF24-SR-S MS40-7043-501 24 Vac or 22…30 Vdc 35 lb-in. (4N-m) w/aux switch (proportional) X

LM24 MF41-6043 24 Vac 35 lb-in. (4N-m) NSR (floating) X

LM24-10P MF41-6043-510 24 Vac 35 lb-in. (4N-m) NSR (floating), feedback potentiometer X

LM24-S MF41-6043-502 24 Vac 35 lb-in. (4N-m) NSR (floating), w/two aux switches X

LM24-SR MS41-6043 24 Vac 35 lb-in. (4N-m) NSR (proportional) X

MS41-6043-520 24 Vac 35 lb-in. (4N-m) NSR (proportional), adjustable start point (offset) and span X

—

MS41-6043-522 24 Vac 35 lb-in. (4N-m) NSR (proportional), w/two aux switches, adjustable start point (offset) and span X

MS41-6043-502 24 Vac 35 lb-in. (4N-m) NSR (proportional), w/two aux switches X

NF120

120 Vac 60 lb-in. (7N-m) (2-position) X

NF120-S 120 Vac 60 lb-in. (7N-m) w/aux switch (2-position) X

NF230 230 Vac 60 lb-in. (7N-m) (2-position) X

NF230-S 230 Vac 60 lb-in. (7N-m) w/aux switch (2-position) X

—

NF24 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) (2-position) X

NF24-S 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) w/aux switch (2-position) X

NF24-SR 24 Vac or 22…30 Vdc 60 lb-in. (7N-m) (proportional) X

MF41-6083 24 Vac 70 lb-in. (8N-m) spdt NSR (floating) X

NM24

MF41-6083-502 24 Vac 70 lb-in. (8N-m) NSR (floating), w/two aux switches X

MF41-6083-510 24 Vac 70 lb-in. (8N-m) NSR (floating), feedback potentiometer X

MS41-6083 24 Vac 70 lb-in. (8N-m) 2…10 Vdc/4…20 mA dc NSR (proportional) X

NM24-SR

MS41-6083-502 24 Vac 70 lb-in. (8N-m) NSR (proportional), w/two aux switches X

MS41-6083-520 24 Vac 70 lb-in. (8N-m) NSR (proportional), adjustable start point (offset) and span X

MS41-6083-522 24 Vac 70 lb-in. (8N-m) NSR (proportional), w/two aux switches, adjustable start point (offset) and span X

SM24 MF41-6153 24 Vac 133 lb-in. (15N-m) spdt NSR (floating) X

SM24-SR

MS41-6153 24 Vac 133 lb-in. (15N-m) 2…10 Vdc/4…20 mA dc NSR (proportional) X

MS41-6153-502 24 Vac 133 lb-in. (15N-m) NSR (proportional), w/two aux switches X

May, 2019 tc © 2019 Schneider Ele ctric . All rig hts res erve d. All tradema rks are o wned by S chneid er Elect ric Industries SAS o r its af filia ted comp anies.

Document Number: F-2664 6-12

Loading...

Loading...